Patents

Literature

187 results about "Mercury pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercury pollution also harms wildlife and ecosystems. Mercury occurs naturally in the earth’s crust, but human activities, such as mining and fossil fuel combustion, have led to widespread global mercury pollution.

Bacterium for reducing mercury pollution in seawater and application thereof

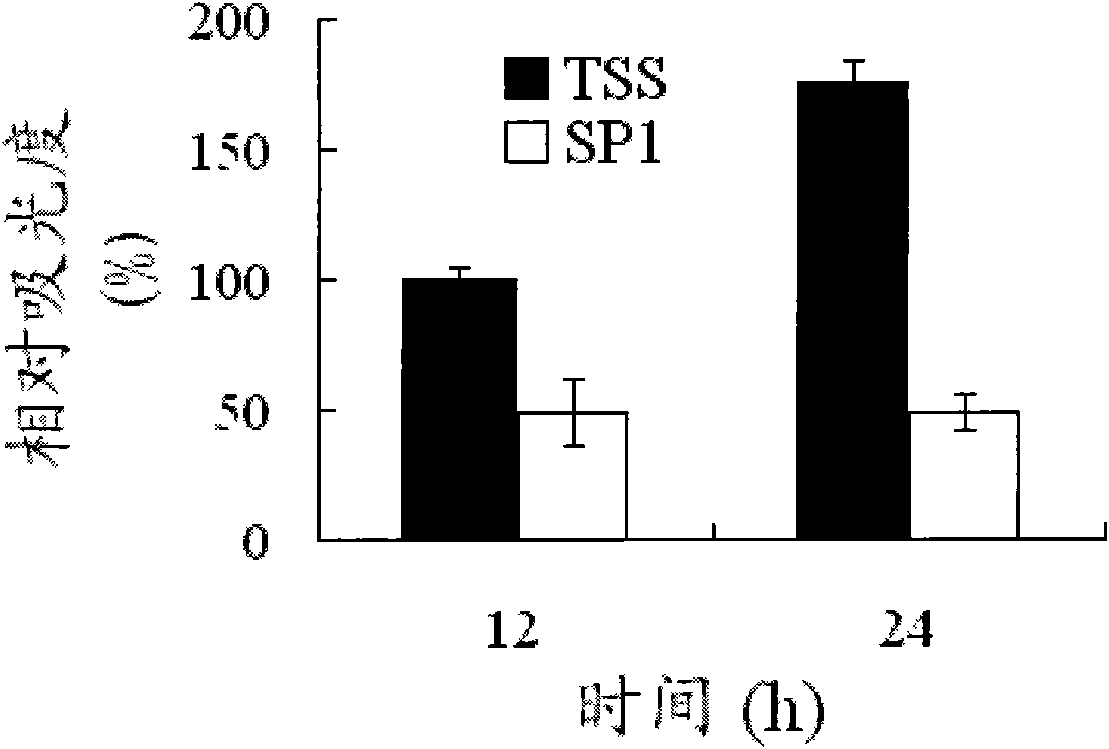

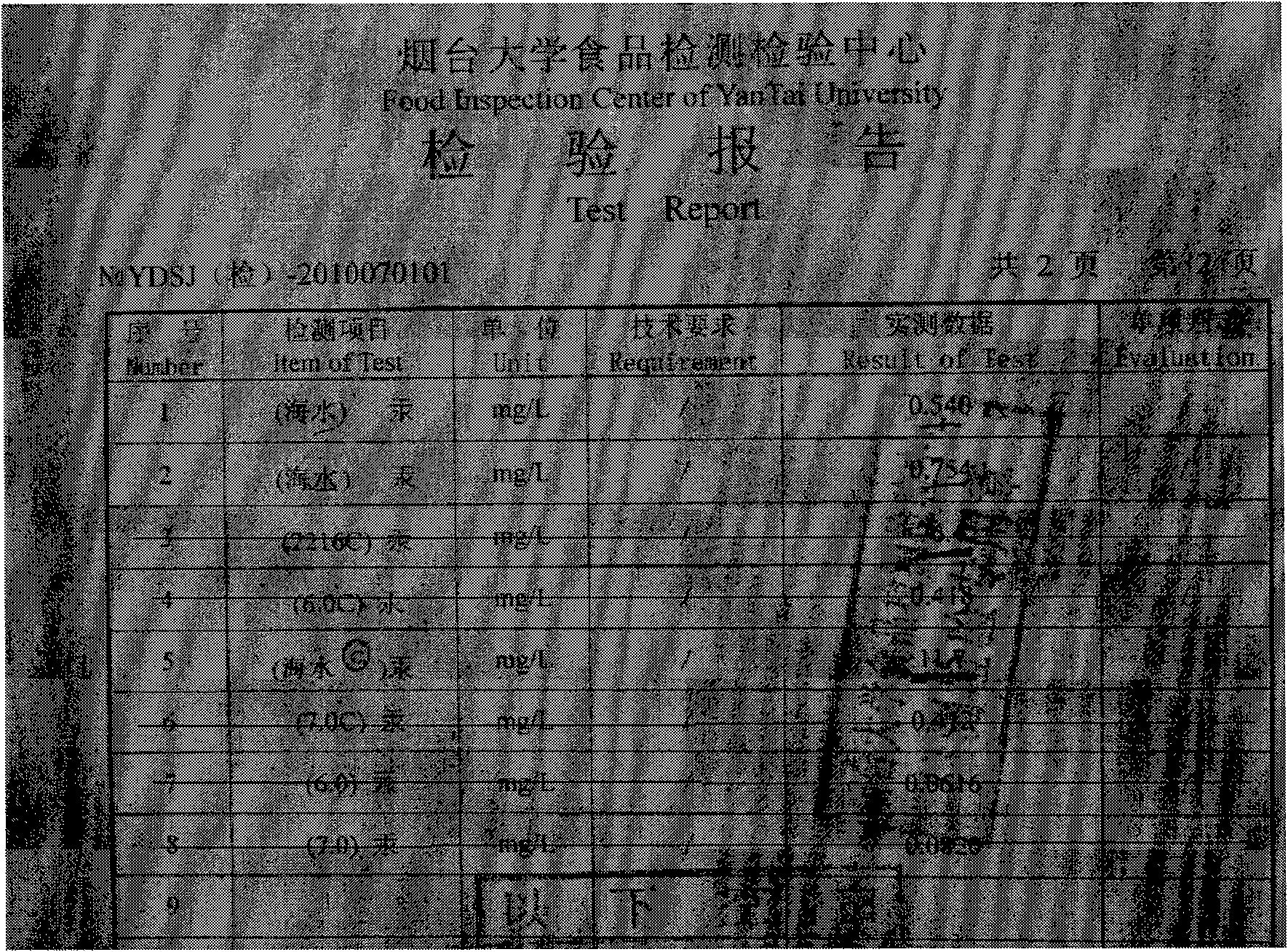

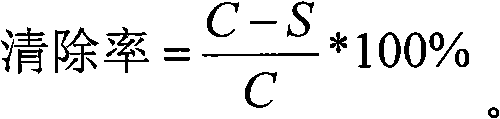

The invention, relating to the field of environmental improvement by using environmental microorganism, particularly discloses a bacterium for reducing mercury pollution in seawater and an application thereof. The bacterium for reducing mercury pollution in seawater is Pseudomonasputida SP1, preserved in China General Microbiological Culture Collection Center (CGMCC) on Jun.1,2010 under the preservation number of CGMCC No.3887. The bacterium Pseudomonasputida SP1 can remove mercury from seawater. The use of the bacterial strain SP1 in removing mercury pollution from seawater has the advantages of high efficiency, low nutritional requirement, simple operation, high safety and the like. Compared with other processes, the cost of treating mercury pollution in seawater is greatly reduced, andthe efficiency of treating mercury pollution in seawater is raised.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Method for preparing chloroethylene by catalytic reforming

InactiveCN101817723ASolve the problem of high temperature energy consumptionSolve pollutionPhysical/chemical process catalystsHalogenated hydrocarbon preparationCatalytic reformingActivated carbon

The invention discloses a method for preparing chloroethylene by catalytic reforming, which relates to a method for preparing the chloroethylene. The method comprises: a step of preparing a catalyst by using active carbon as a carrier, in which a barium salt is used as a catalyst, the active carbon is used as the catalyst carrier, and the barium salt is dissolved in water, absorbed by the active carbon and dried to obtain the catalyst carried by the active carbon; and a step of synthesizing the chloroethylene, in which acetylene gas and dichloroethane vapour are mixed and introduced to a reactor containing the catalyst carried by the active carbon to react, the reaction effluent is cooled to room temperature, unreacted dichloroethane is condensed to be separated out, and the remaining gas is compressed and frozen to give liquid chloroethylene. In the invention, a mercury free catalyst is adopted, the mercury pollution of the chloroethylene production industry is eliminated, and the reaction is performed spontaneously with little energy consumption.

Owner:ZHONGKE YIGONG SHANGHAI CHEM TECH CO LTD

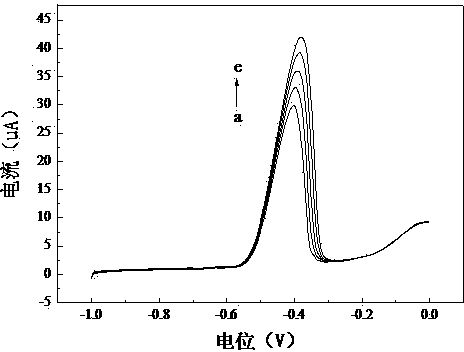

Method for quickly detecting lead and cadmium by adopting scanning anodic stripping voltammetry

InactiveCN103592356AImprove stabilityGuaranteed stabilityMaterial electrochemical variablesRelative standard deviationMercury pollution

The invention discloses a method for quickly detecting lead and cadmium by adopting scanning anodic stripping voltammetry. The method comprises the following steps: a sample to be tested is prepared; lead or cadmium standard liquid is prepared; a three-electrode system consisting of glassy carbon electrodes plated with mercury films, platinum wire counter electrodes and Ag / AgCl reference electrodes is assembled; parameters are set and the scanning anodic stripping voltammetry is adopted to respectively implement parallel determination for current values between working electrodes and reference electrodes of each standard liquid solution until the relative standard deviation of readings is not more than 5%; lead and cadmium heavy metals of the sample are measured through detecting the current values between the working electrodes and the reference electrodes; a working station automatically calculates to obtain detecting results through automatically searching peaks to determine each curve peak area. The detecting method has the advantages of high sensitivity, good accuracy, reduction of mercury pollution, high electrode stability and good reproducibility, and can be applied to the detection of the heavy metals of lead and cadmium with conventional trace and ultratrace.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

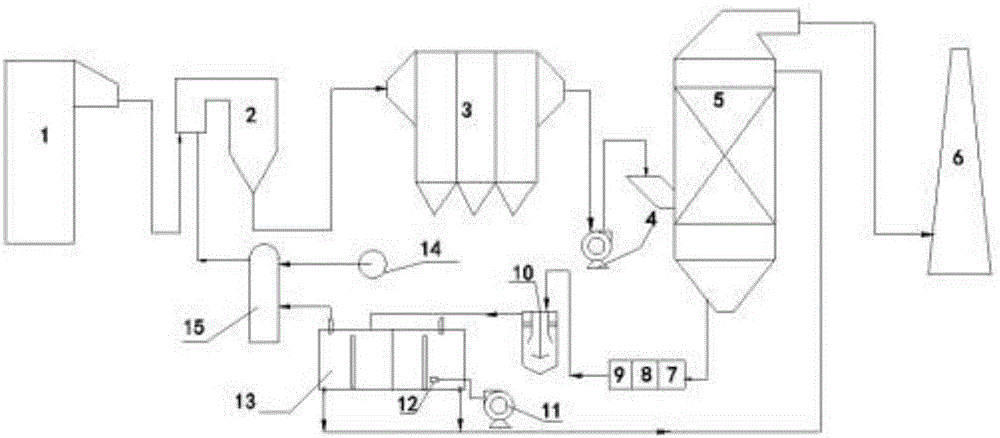

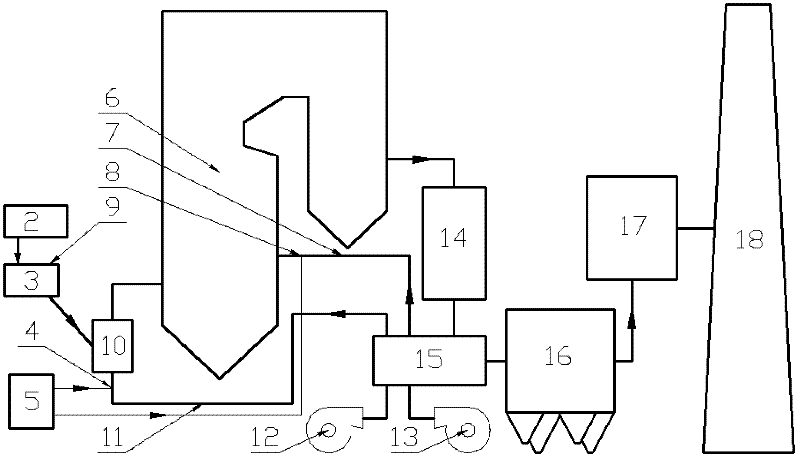

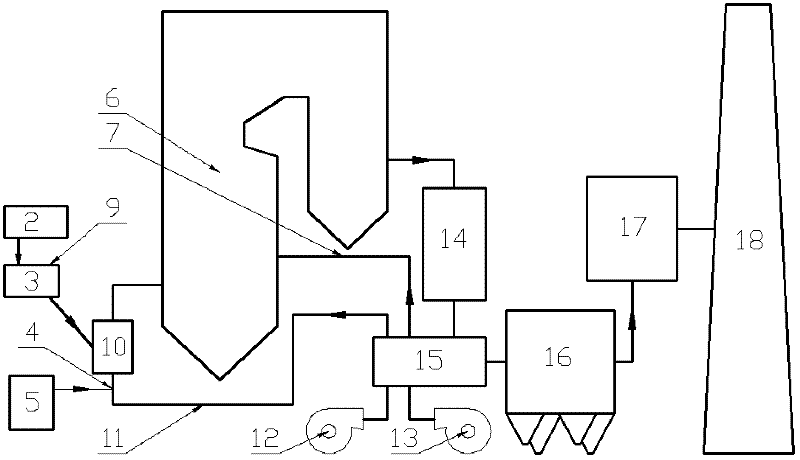

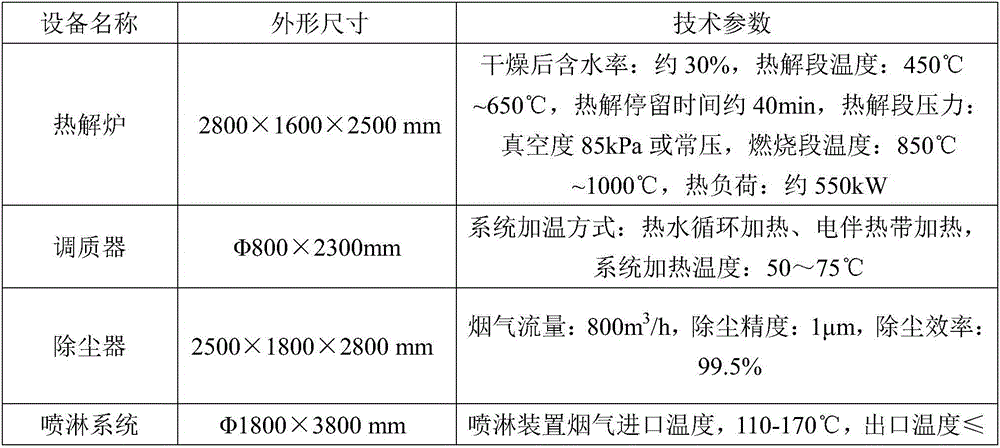

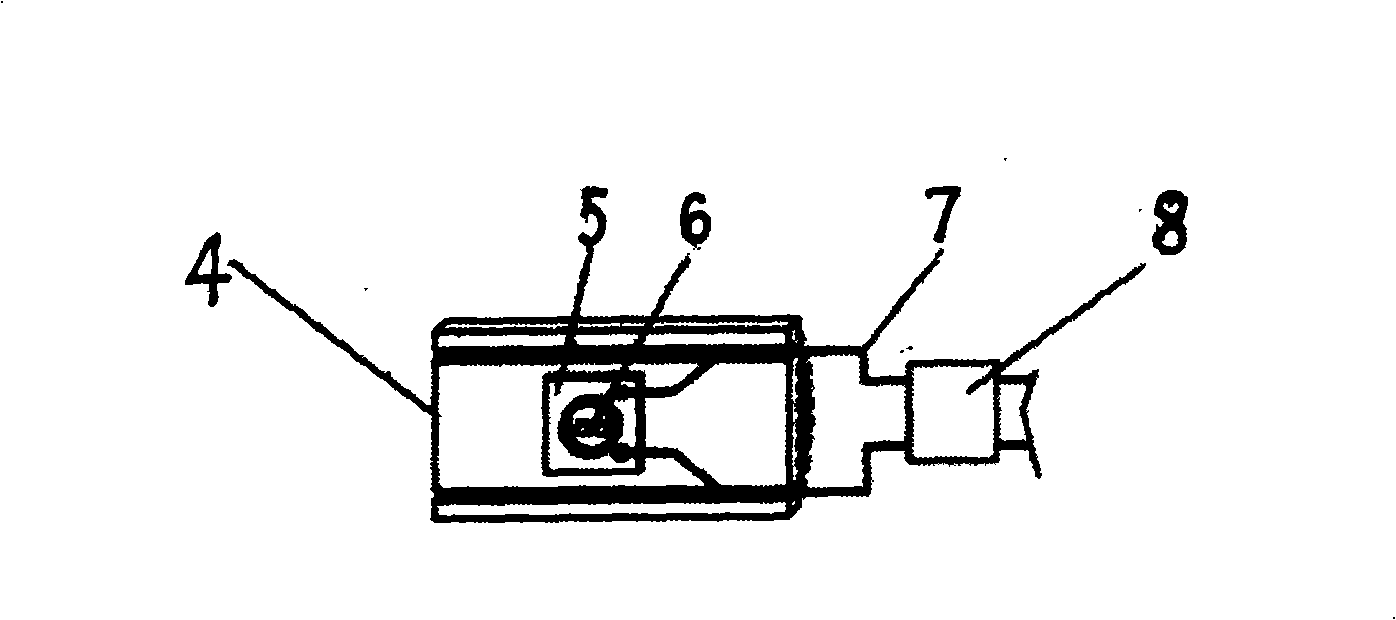

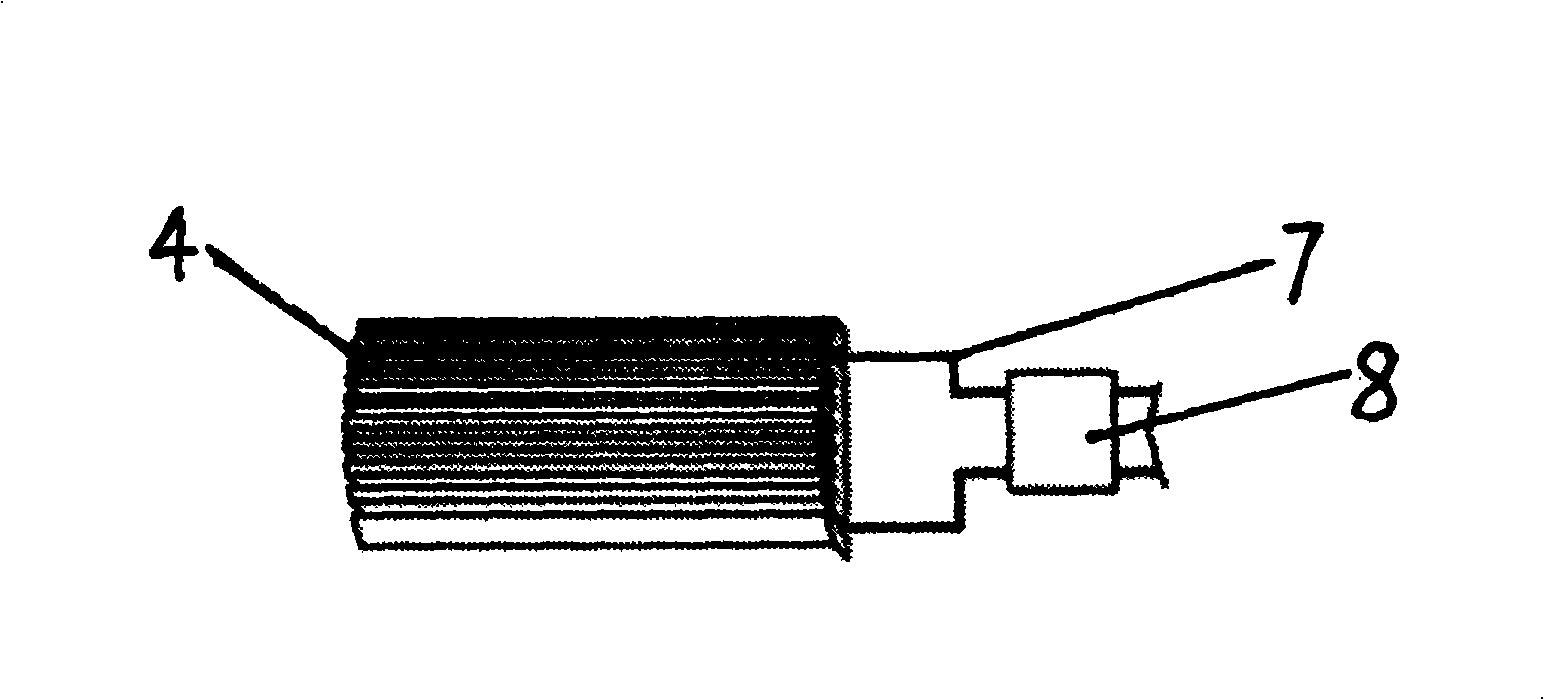

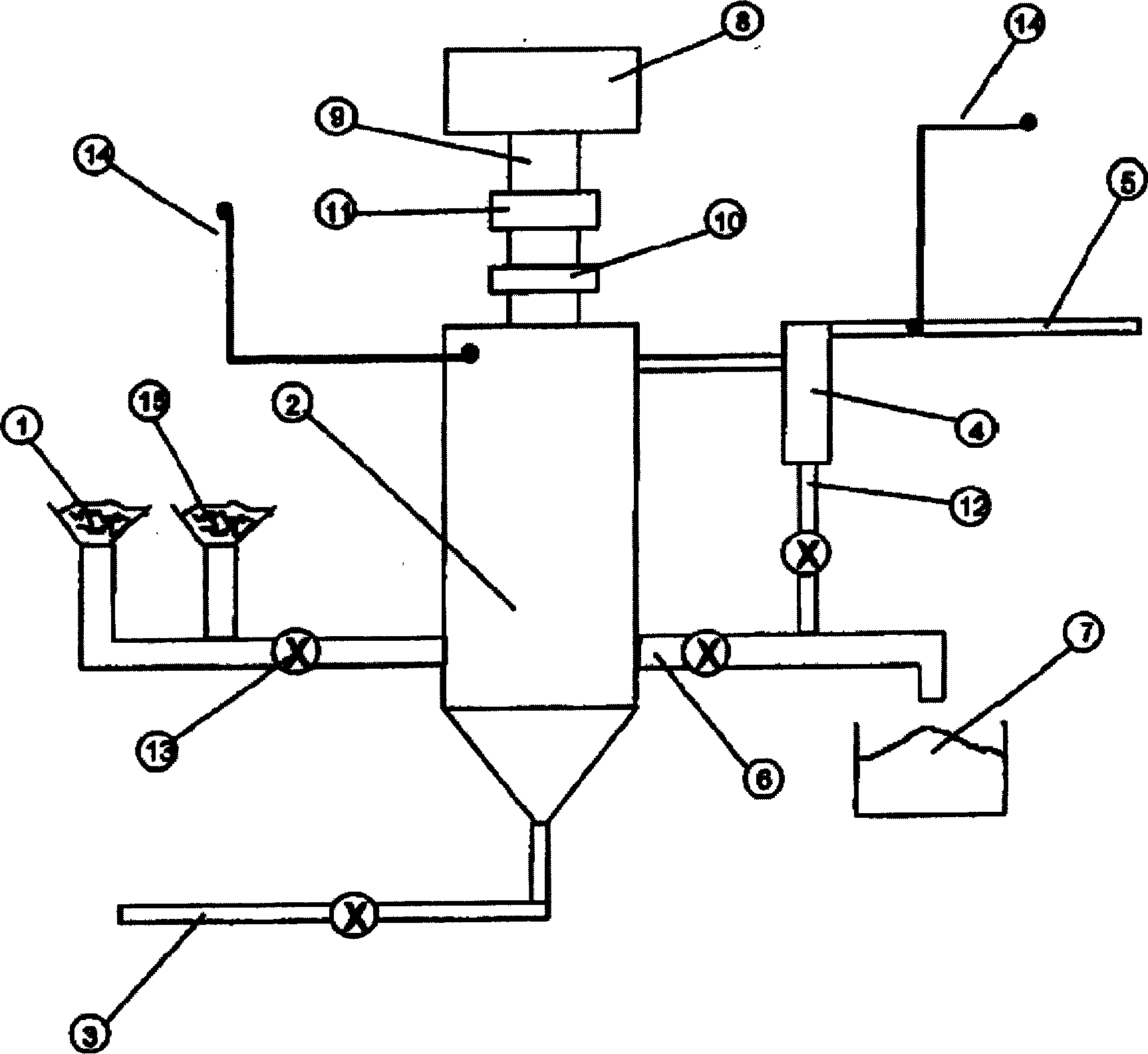

Repairing method and device for mercury-polluted soil by using low-temperature pyrolysis treatment

InactiveCN103056157ASmall physical and chemical propertiesLess damage to natural fertilityContaminated soil reclamationSoil sciencePollution soil

The invention discloses a repairing method and device for mercury-polluted soil by using low-temperature pyrolysis treatment. The repairing method for the mercury-polluted soil comprises the following steps: crashing excavated mercury-polluted soil and drying the excavated mercury-polluted soil with air, wherein the soil moisture content is less than or equal to 10%; and secondly, putting the soil dried with the air into a pyrolysis device, wherein the original temperature of the pyrolysis device is 250 DEG C, heating within 30 minutes to be at a temperature within 400 DEG C, and condensing and recycling mercury steam evaporated in the soil through a gas recycling device. The invention provides the method and the device for properly repairing and recycling mercury. The method for repairing the mercury-polluted soil by using a low-temperature pyrolysis treatment repairing technology and separating pollutants from the soil by using a physical heating method is adopted, so that not only can the soil cultivation capability be kept, but also can realize the purpose of absolutely removing the mercury from the polluted soil. Clean soil and organic matters can be properly added in the treated soil, so that the agriculture production can be rapidly repaired, and the operation cost is low.

Owner:GUIZHOU ACAD OF ENVIRONMENTAL SCI & DESIGNING

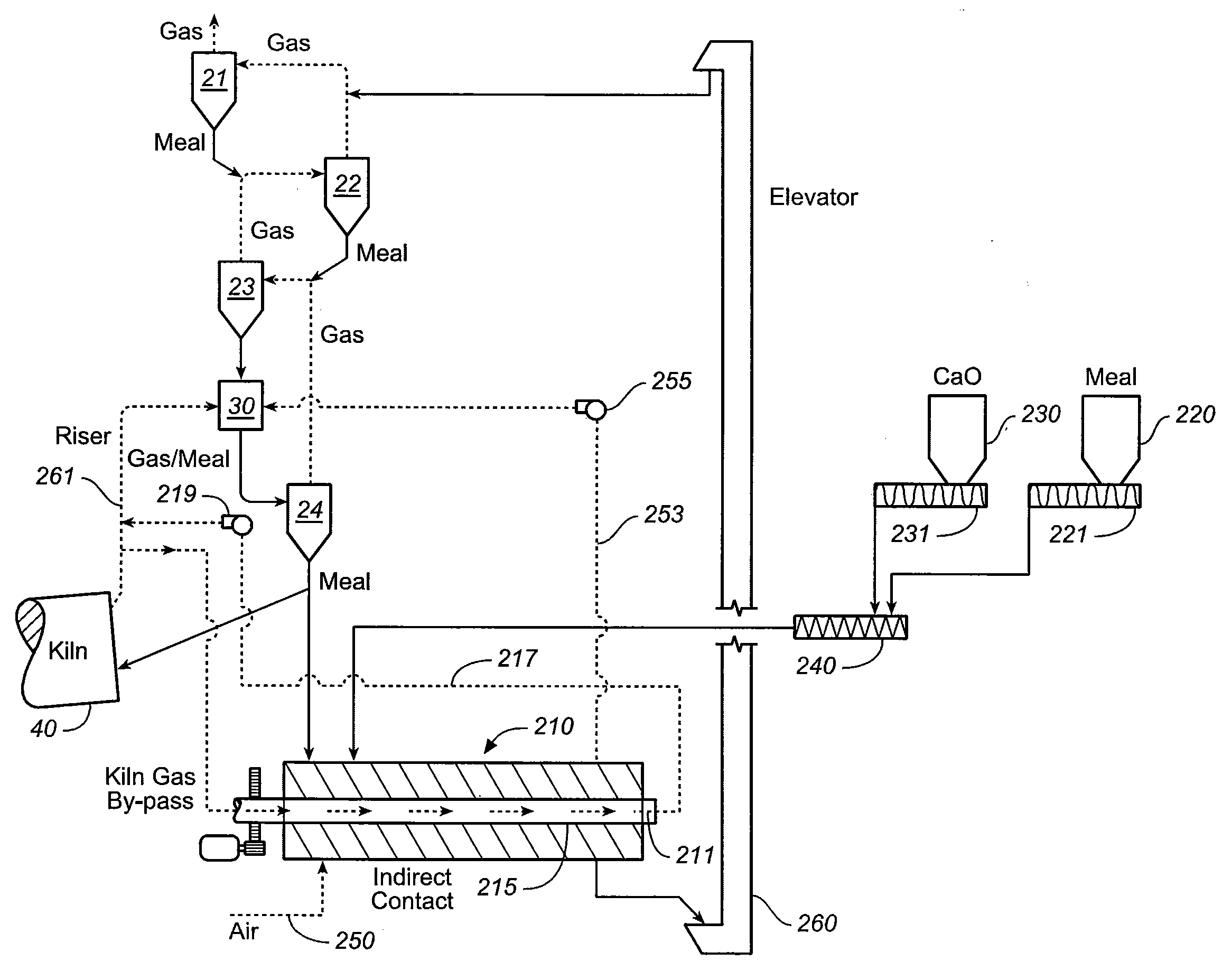

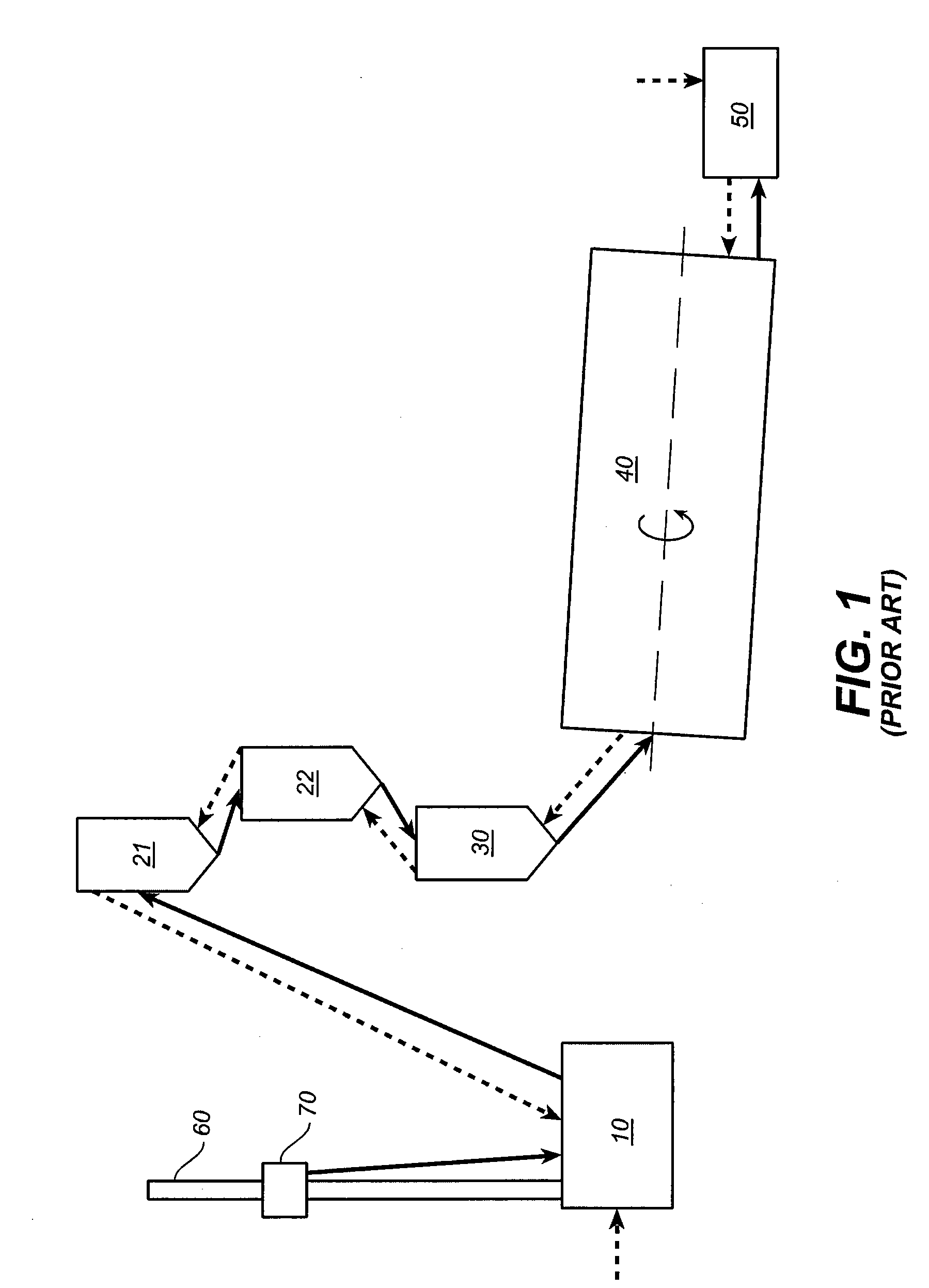

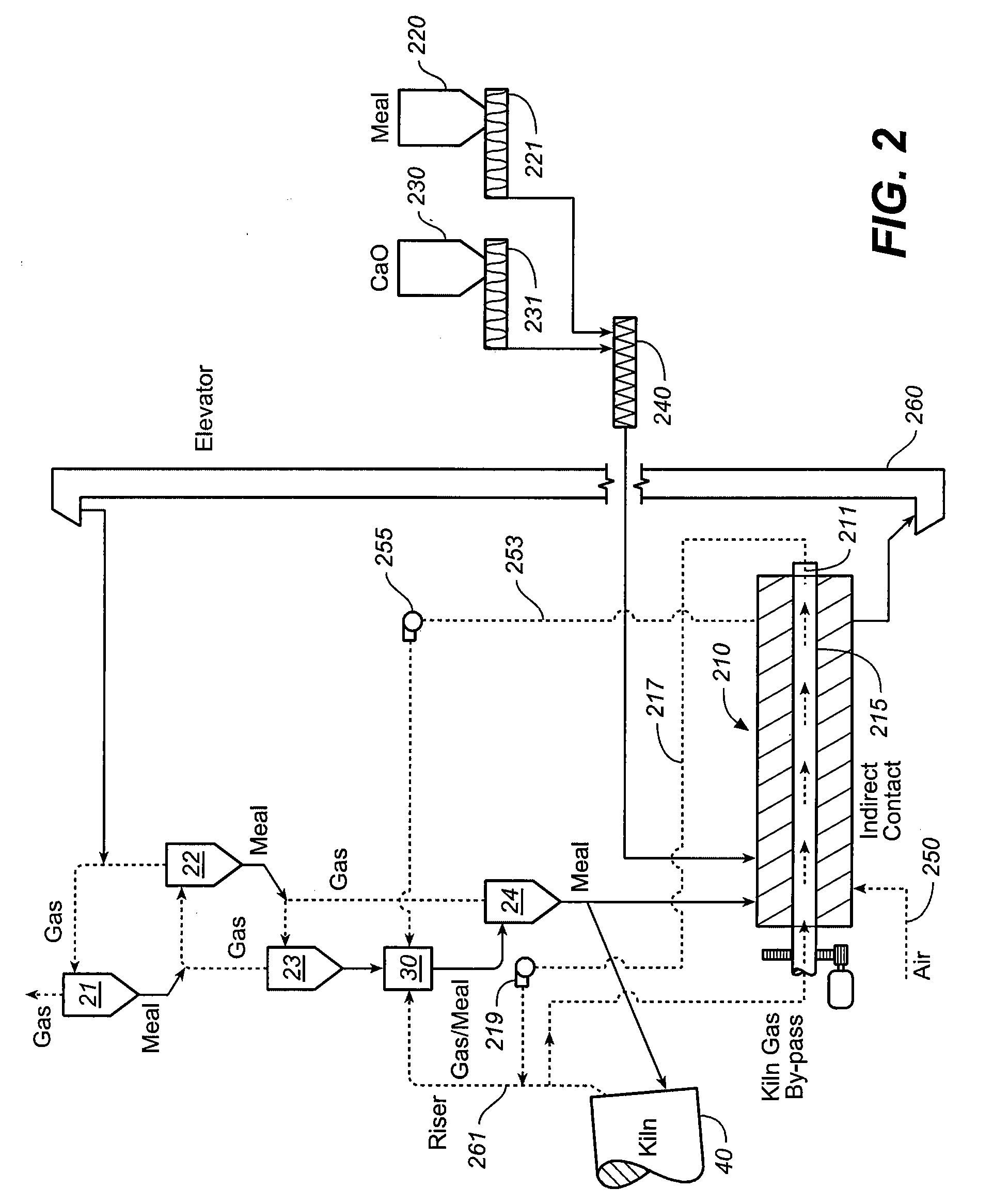

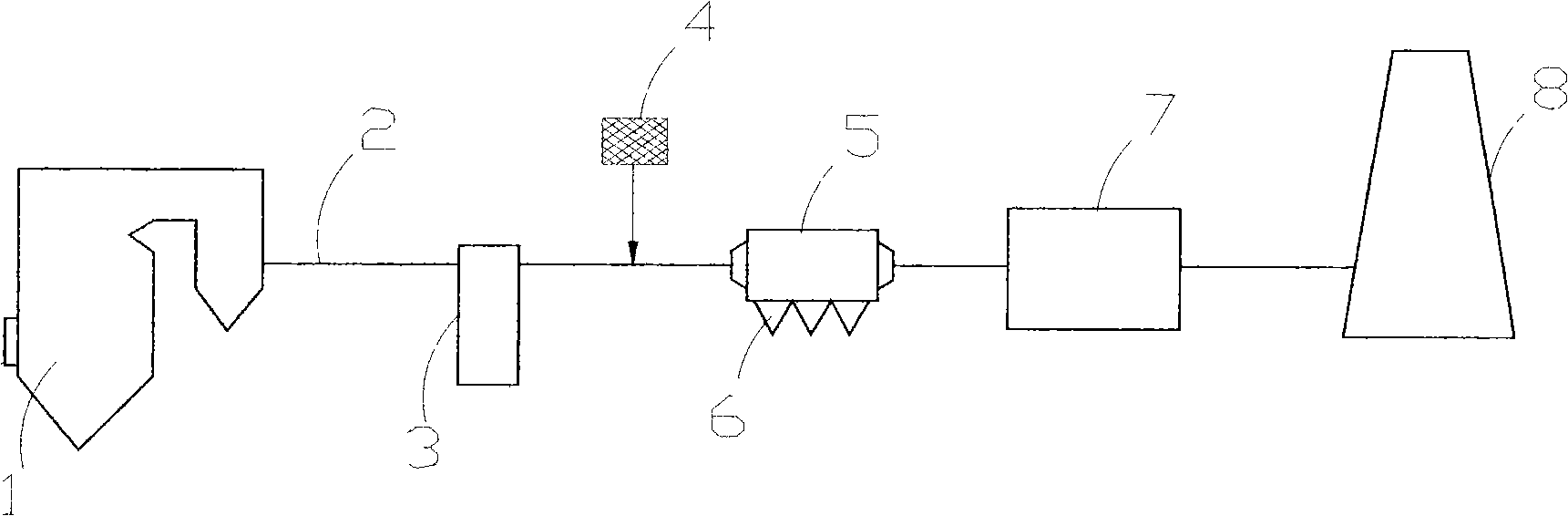

Apparatus and method for controlling mercury pollution from a cement plant

ActiveUS20100000406A1Emission reductionGas treatmentIsotope separationAtmospheric airMercury pollution

A method and apparatus for reducing discharges into the atmosphere of mercury pollutants associated with dry process, precalciner cement manufacturing is shown. Raw feed meal used in cement production is heated in a special heating chamber to drive off volatile mercury pollutants, such as elemental mercury and mercury oxides. Preferably, the feed meal is heated to a temperature of at least 175° C. The gases that are driven off flow are then cooled to condense the mercury pollutants causing them to be adsorbed on carbon particles injected into the gas flow. The carbon particles containing the condensed mercury pollutants are then filtered out of gas flow, for example, using a fabric filter. The gas flow may be burned to destroy other volatile pollutants such as hydrocarbons and / or ammonia.

Owner:ENVIROCARE INT +1

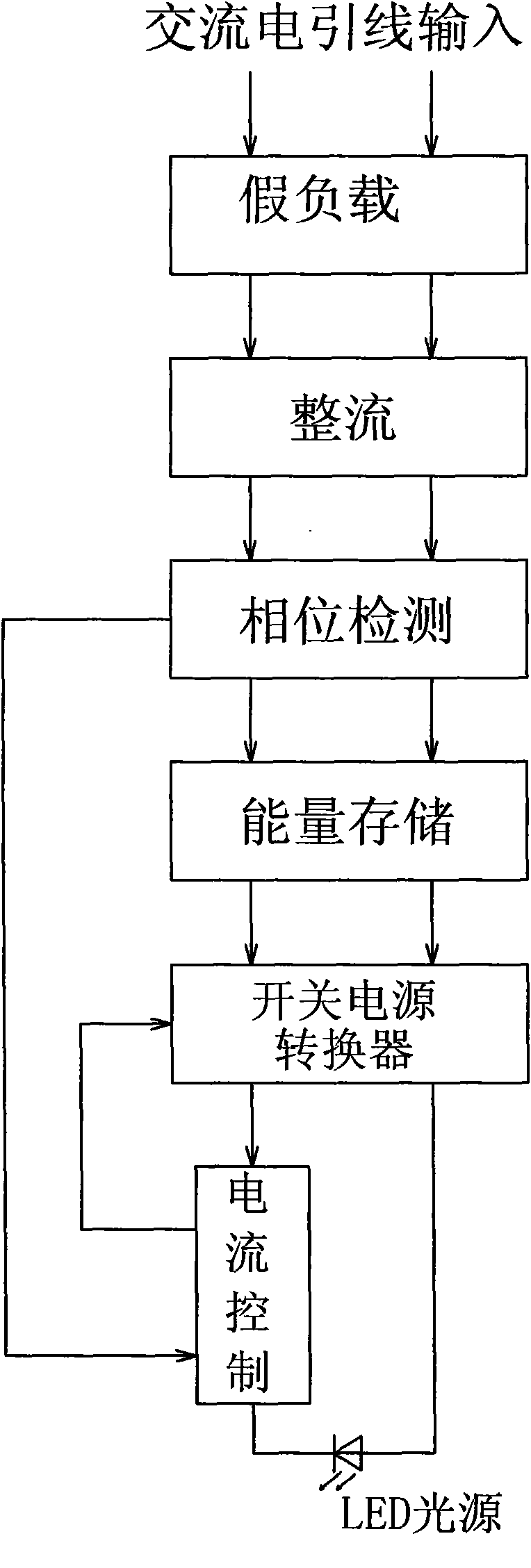

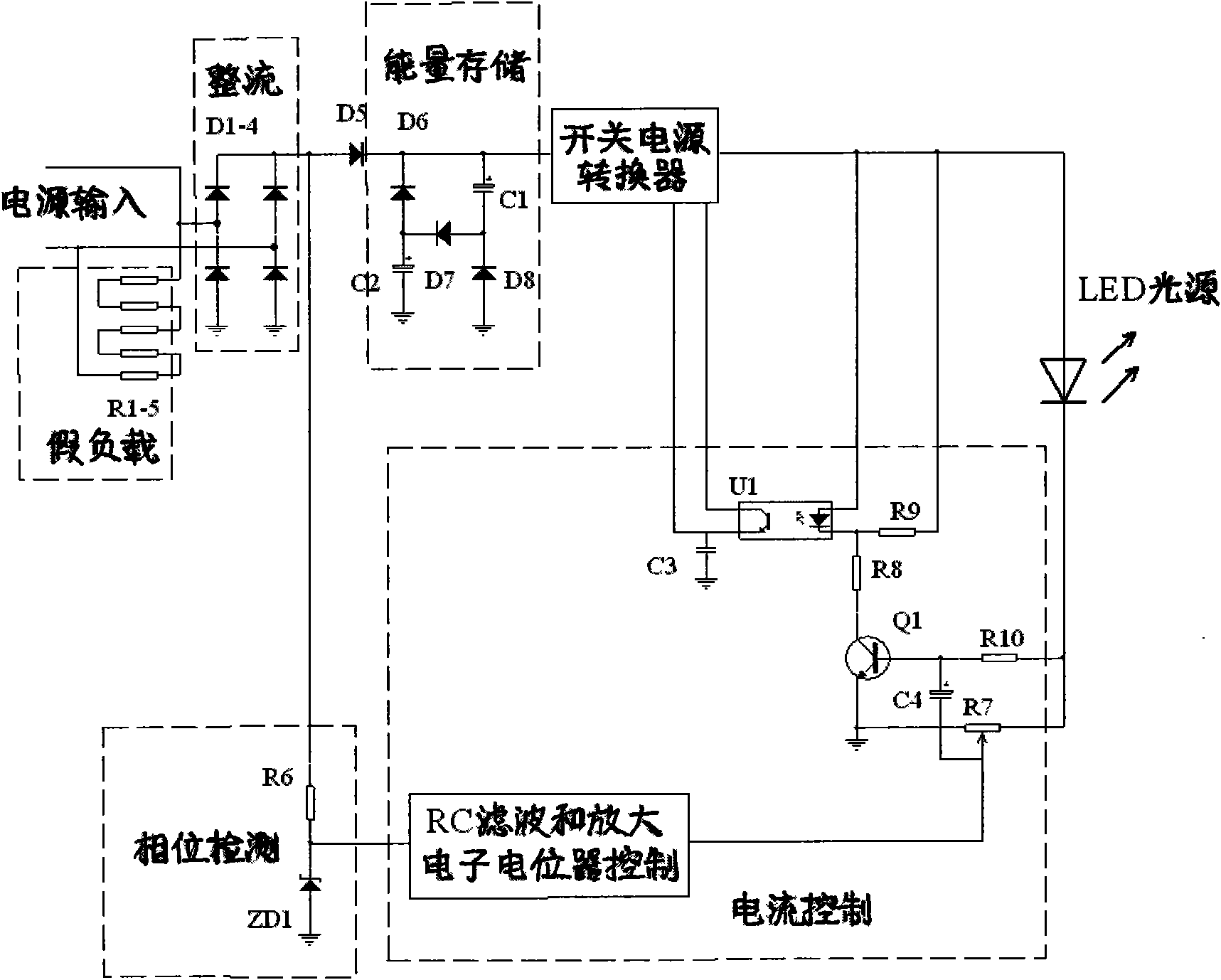

Dimming method applicable to traditional dimmers and LED dimmable drive power

InactiveCN101646288AShock-resistantSolution to short lifeElectrical apparatusElectric light circuit arrangementEngineeringShock resistance

The invention relates to a dimming method applicable to traditional dimmers and an LED dimmable drive power. The method comprises the following steps: converting PWM signals determined by the phase ofthe angle of flow into DC signals through a phase test circuit after being filtered by a RC circuit, and magnifying the signals to control the changes of the resistance value of a constant-current sampling resistor so as to regulate the magnitude of the LED current. The invention can regulate the brightness of an LED bulb by the traditional dimmer, so that people can conveniently change the traditional incandescent bulb lamp into the LED bulb lamp with the ideal stepless dimming function. The LED has the characteristics of long service life, no mercury pollution or ultraviolet pollution, highlight efficiency, shock resistance, energy saving and the like, and belongs to a new generation of green light sources. Therefore, the invention has the advantages of favorable dimming effect (1-100%of continuous stepless dimming), soft light color, environmental protection and energy saving.

Owner:GUANGZHOU BODI LIGHTING & ELECTRICAL MFG CO LTD

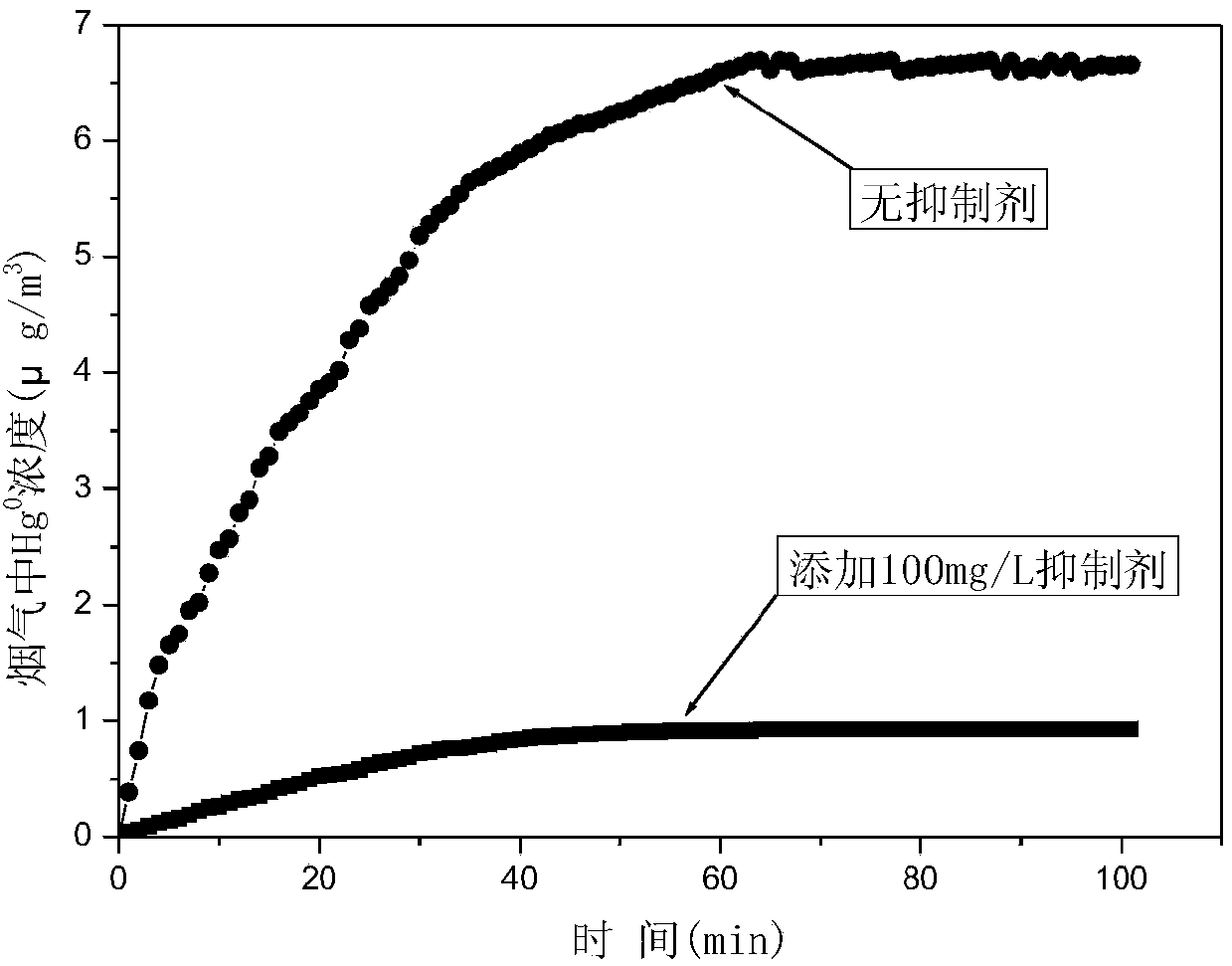

Mercury re-releasing inhibitor in wet flue gas desulfurization slurry and application method thereof

InactiveCN103736387AAvoid wastingEffective combinationDispersed particle separationSlurryMercury pollution

The invention discloses the technical field of flue gas demercuration method, and in particular to a mercury re-releasing inhibitor in wet flue gas desulfurization slurry and application method thereof. The inhibitor disclosed by the invention comprises the following components by weight percent: 25 to 45 percent of thiosulfate and 55 to 75 percent of sodium sulfide. The additive is added into the desulfurization slurry to inhibit the release of mercury; the adding amount of the additive is 100ml / L to 600mg / L. The inhibitor can react with Hg<2+> in the slurry well by utilizing the synergistic effect of thiosulfate and sodium sulfide to form stable HgS sediment; the sediment and desulfurization gypsum enter a solid phase together and are separated and removed. Meanwhile, the inhibitor disclosed by the invention is suitable for being added under the operating conditions of a wet desulfurization system, so that the waste of the additive is reduced. By the inhibitor, the re-release of the mercury in the limestone-gypsum wet flue gas desulfurization slurry can be inhibited effectively, the demercuration efficiency of a limestone-gypsum wet flue gas desulfurization system can be improved, and the problem of mercury pollution caused by coal-fired flue gas emissions can be solved effectively.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

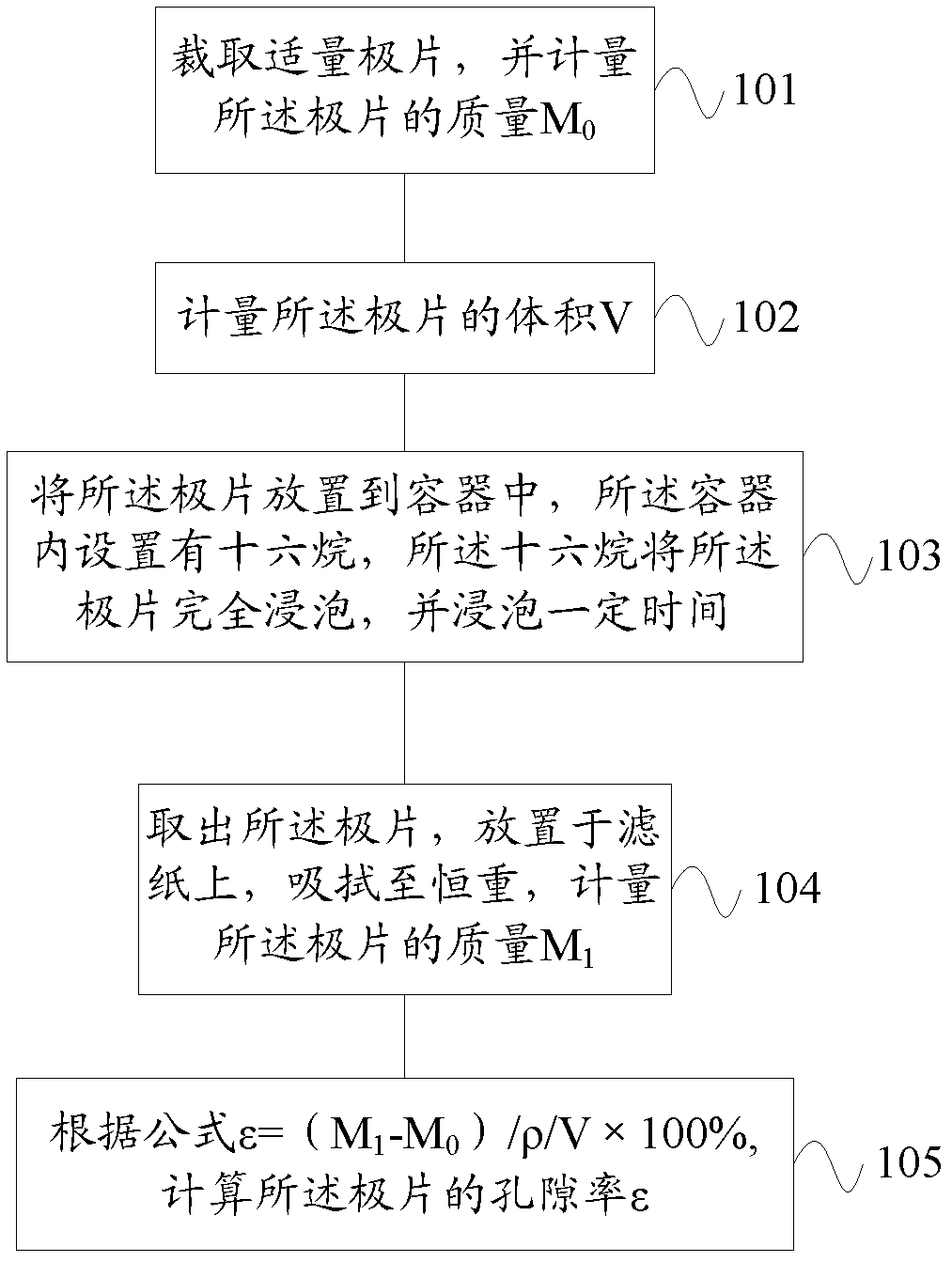

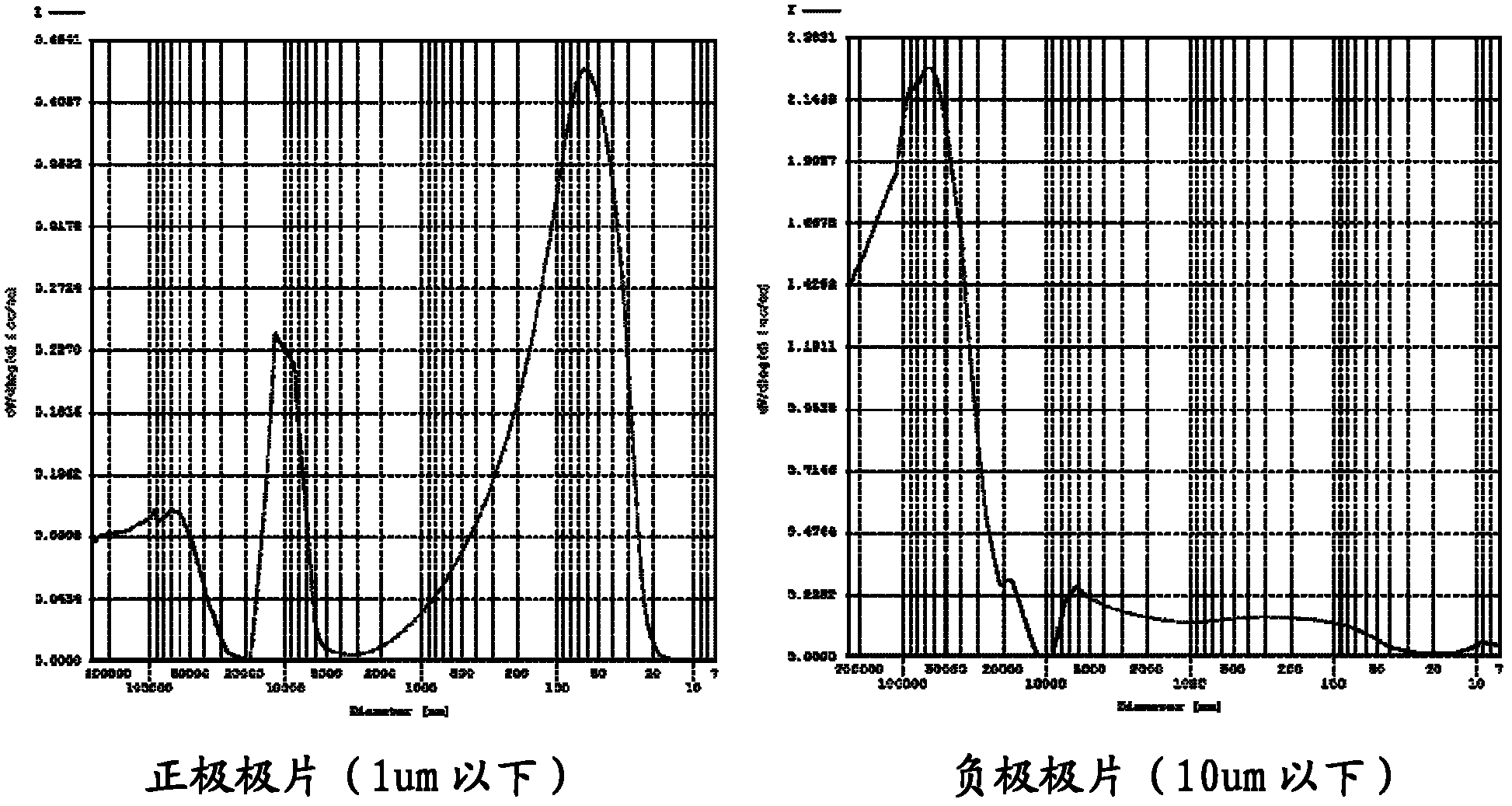

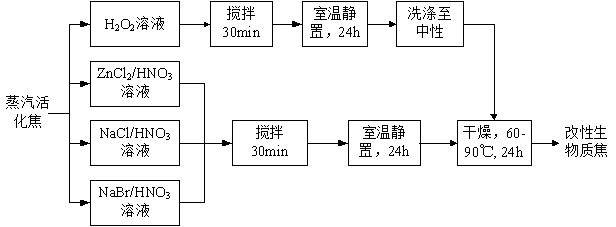

Method of testing porosity of pole piece

ActiveCN103134744AReduce pollutionReduce potential harmPermeability/surface area analysisWeighing by absorbing componentPorosityTest efficiency

The invention discloses a method of testing porosity of a pole piece. The method comprises that a certain pole piece is cut and taken, the mass M0 of the pole piece is weighed, the size V of the pole piece is measured, the pole piece is placed in a container, cetane is arranged in the container, the pole piece is completely soaked in the cetane for a certain time, the pole piece is taken out and placed on a filter paper, the pole piece is absorbed and wiped to constant weight, the mass M1 of the pole piece is weighed, and the porosity epsilon of the pole piece is calculated according to a formula epsilon=(M1-M0) / rho / V*100%. The method of testing the porosity of the pole piece needs not the complex and difficult operating process of mercury injection apparatus, and reduces measuring cost, in addition, mercury pollution and potential hazard on operation staff are reduced, meanwhile the processing work on waste mercury is reduced, and testing efficiency is improved.

Owner:TIANJIN ENERGIES

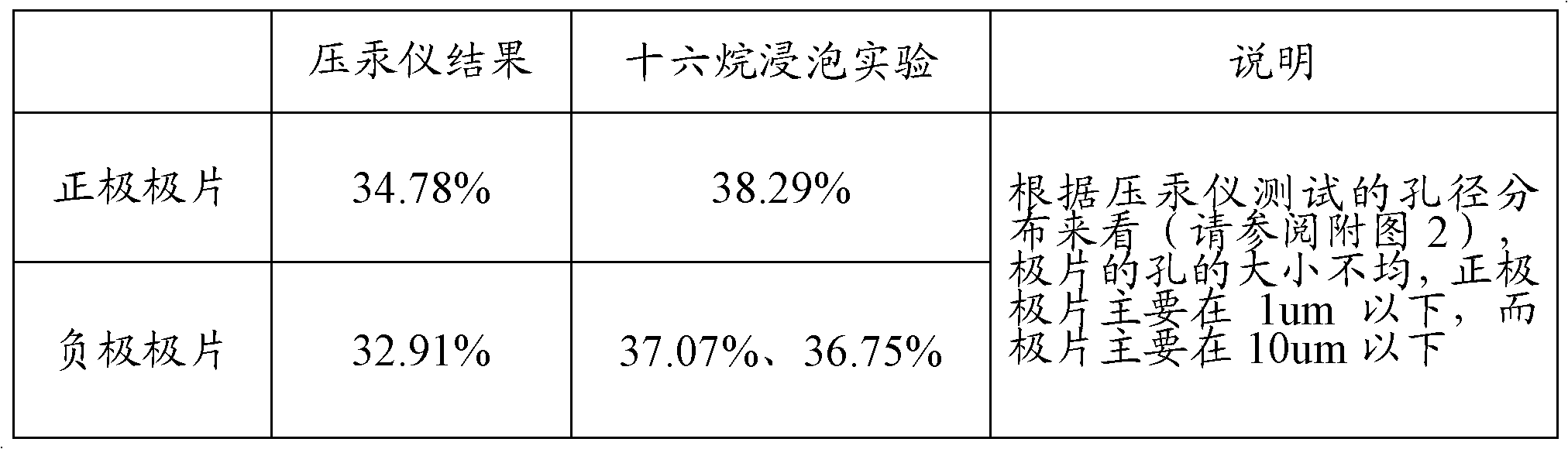

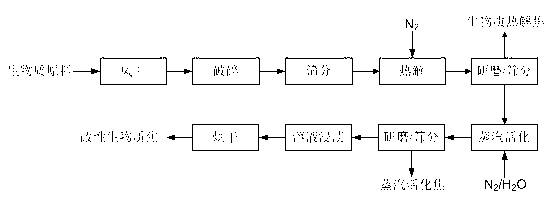

Biomass carbon-based flue gas demercuration adsorbent and preparation method thereof

InactiveCN103252212AControl pollution dischargeRealize the double effect of protectionOther chemical processesDispersed particle separationMercury pollutionNitrogen gas

The invention discloses a biomass carbon-based flue gas demercuration adsorbent and a preparation method thereof. Based on comprehensive utilization of biomass resources and control of flue gas mercury pollutants, the emission of flue gas mercury is controlled by using modified biomass tar as the adsorbent. The biomass carbon-based flue gas demercuration adsorbent with a developed pore structure and abundant surface functional groups is prepared through treating processes of pyrogenic decomposition (at 400-800 DEG C in a nitrogen atmosphere) and steam activation (at an activation temperature of 800 DEG C with an N2-to-H2O mole ratio of 1: 1) of biomass raw material, modified reagent (H2O2, ZnCl2, NaCl or NaBr) solution dipping, and the like; and the biomass carbon-based flue gas demercuration adsorbent has the characteristics of wide adsorbent raw material source, simple preparation process, low cost, high demercuration efficiency and the like, and is suitable for coal-fired power plants and management of flue gas mercury emission in the fields of waste incineration and the like. The carbon-based flue gas demercuration adsorbent is prepared by adopting biomass, so that the emission reduction of mercury pollution can be realized, and the renewable resource of biomass can be utilized efficiently in a large scale; and the biomass carbon-based flue gas demercuration adsorbent has obvious economic benefit, environmental benefit and social benefit.

Owner:NANJING NORMAL UNIVERSITY

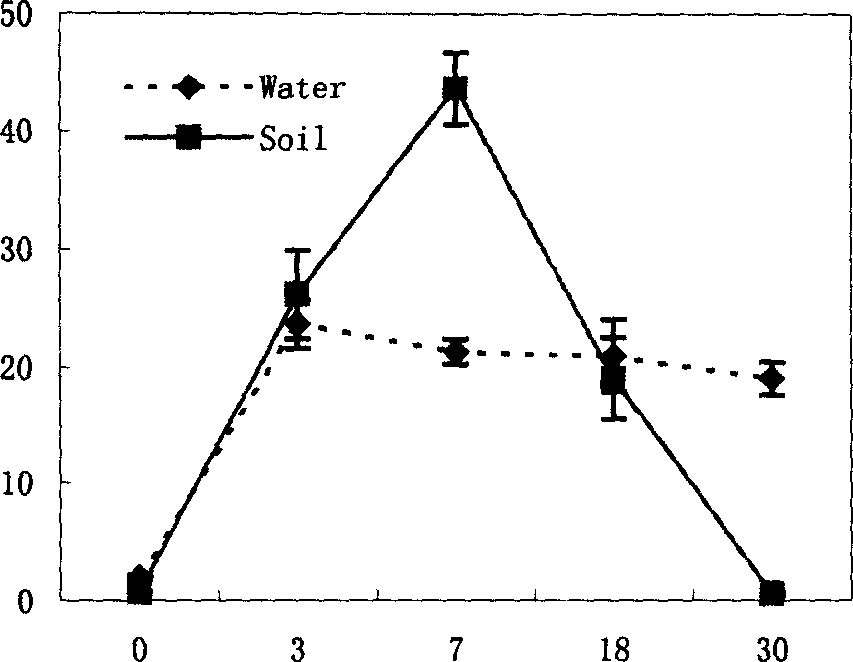

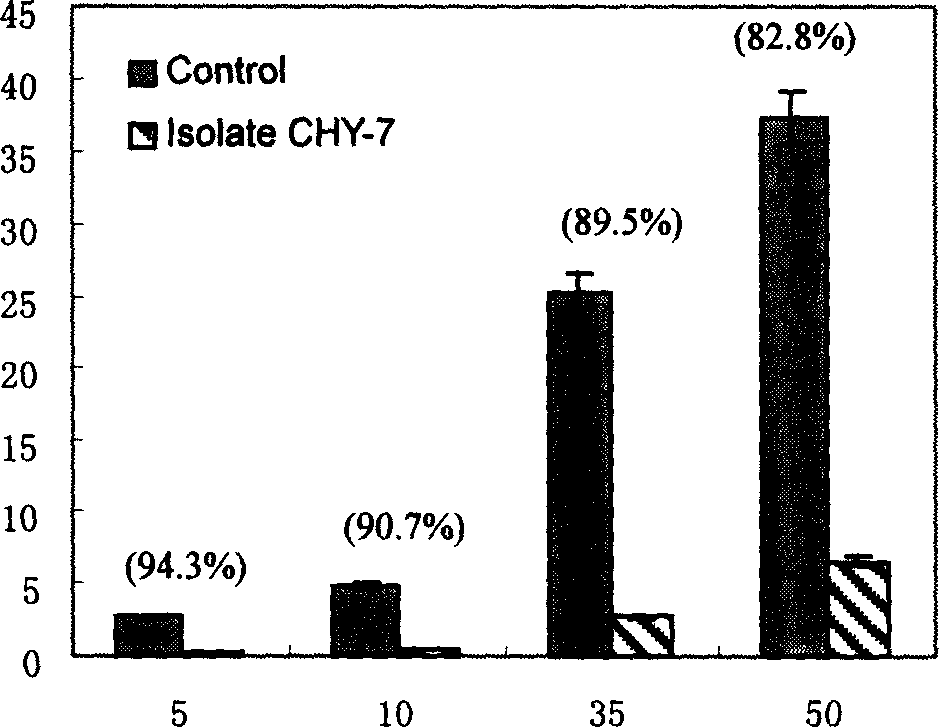

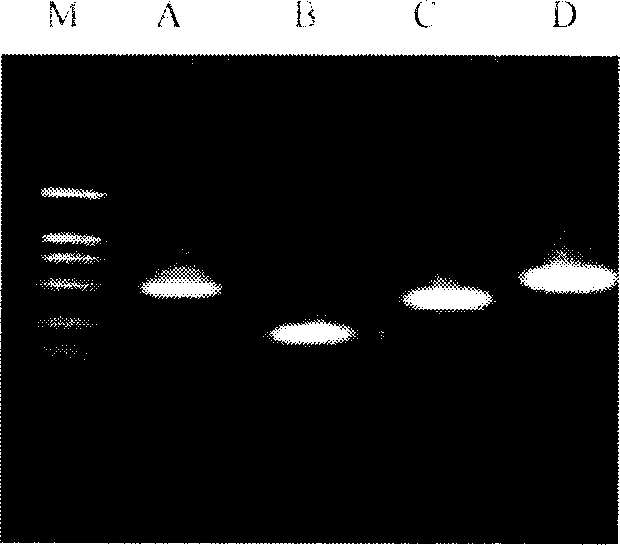

High anti-mercury offensive smell pseudomonas strain CHY-7 and use in treating mercury pollution

InactiveCN1683518AStrong ability to survive in natureStrong ability to reduce ionic mercuryBacteriaContaminated soil reclamationBacteroidesEcological environment

The present invention belongs to the field of environment tackling with microbes. The strain is pseudomonasputida CHY-7 separated from mercury contaminated soil and preserved in Chinese typical culture preserving center. Pseudomonasputida CHY-7 is suitable for culture in neutral, weak acid or weak alkaline culture medium at normal temperature, and may grow in water or soil. Pseudomonasputida CHY-7 is aerobic Gram-negativre bacterium and has size of (2.0-4.0)x(0.7-1.1) micron and no spore generated. It forms yellowish colony with smooth raised edge and can generate fluorescence in chromogenesis culture medium. It has high effect of reducing ionic mercury into volatile mercury element and may be applied widely in tackling mercury contaminated environment.

Owner:FUJIAN MEDICAL UNIV

Mercury-free synthetic method of chloroethylene

ActiveCN102911007ATackling Mercury PollutionPlay the role of saving energy and reducing consumptionPreparation by hydrogen halide split-offPreparation by halogen halide additionMercury pollutionEthane Dichloride

The invention relates to a mercury-free synthetic method of chloroethylene and relates to chloroethylene. The method includes at least one of hydrogen chloride or dichloroethane steam and acetylene are used as raw materials to be mixed to obtain mixed raw material gases; the mixed raw material gases are pre-heated and fed into a pipe reactor loaded with catalytic agents for reaction; the flowing speeds of the mixed raw material gases are controlled, and the pressure of a reaction system is adjusted so that the conversion rate of at least one of the mixed raw material gases reaches above 80%; andthe reaction product which is obtained from the third step is compressed, frozen, separated and rectified to obtain a chloroethylene monomer which meets polymerization requirements. According to the mercury-free synthetic method, the problem of mercury pollution in chloroethylene industry can be solved, and byproduct steam can be produced so that energy saving and consumption actions can be achieved. Simultaneously, by means of a pipe type cooling system, hot spot temperatures of a catalysis bed can be controlled in a smaller range so that long-term sable work of the catalytic agent is facilitated. The mercury-free synthetic method is capable of achieving comprehensive utilization of energy.

Owner:ZHONGKE YIGONG SHANGHAI CHEM TECH CO LTD

Method and system for treating high-chlorine desulfurization waste water by electrolytic method and performing flue gas mercury pollution control

InactiveCN106630027ACutting costsReduced corrosion resistanceGas treatmentWater contaminantsElectrolysisMercury pollution

The invention discloses a method and a system for treating high-chlorine desulfurization waste water by an electrolytic method and performing flue gas mercury pollution control, and belongs to the technical field of waste water treatment. The method comprises the following steps: (1) pretreating the high-chlorine desulfurization waste water; (2) pumping the pretreated desulfurization waste water into an electrolysis device to perform electrolysis; (3) purifying chlorine generated by electrolysis and then introducing the purified chlorine into a chlorine liquefier to perform liquefied storage for future use; (4) carrying the stored chlorine by compressed air to be introduced into an SCR inlet flue of a coal-fired power plant boiler; and (5) refluxing the obtained desalted water into a wet scrubber. By the method, high-chlorine desulfurization waste water treatment and flue gas mercury pollution control are integrated, so the aim of treating the desulfurization waste water is fulfilled and the mercury in coal-fired flue gas is controlled.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

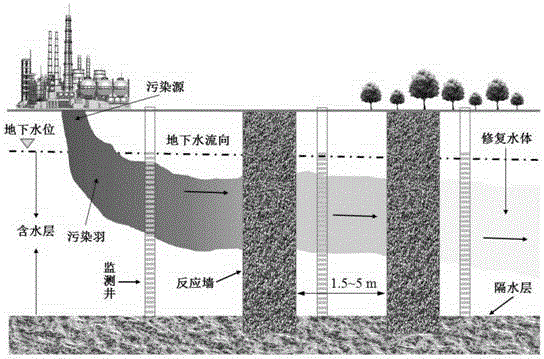

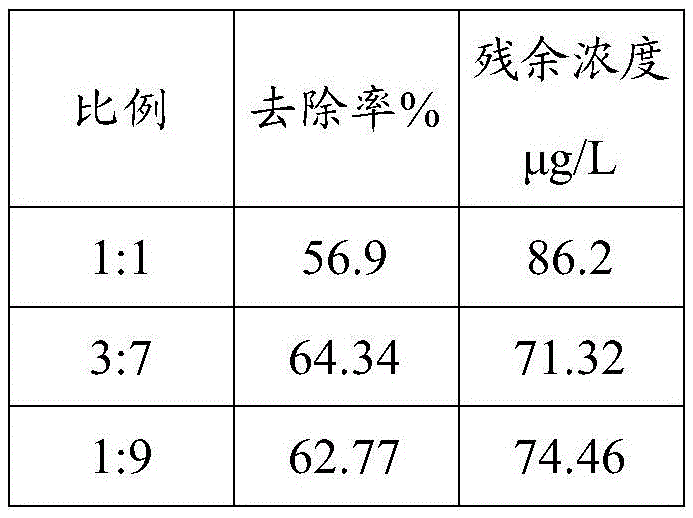

Method for in-situ remediation of mercury pollution in underground water with magnetite and bauxite slag

ActiveCN105668680AEfficient removalImprove stabilitySpecific water treatment objectivesWater contaminantsIn situ remediationDesorption

Disclosed is a method for in-situ remediation of mercury pollution in underground water with magnetite and bauxite slag.The method includes: crushing and sieving natural magnetite slag and natural bauxite slag for standby application; excavating a trench in the lower reach of the underground water pollution plume in the direction vertical to the underground flow, putting uniformly mixed permeable reactive barrier filling materials into the trench, and performing even compaction to obtain a permeable reactive barrier.The magnetite and bauxite can effectively remove mercury in underground water, and meanwhile, acidic mercury-polluted underground water tends to be neutral in pH value after flowing through the reactive barrier.Using the underground water for desorption of active materials loaded with mercury, the results show that the magnetite and bauxite mixture has good stability and safety as the mercury remediation material, and cannot cause secondary pollution to the underground water.By adding a certain proportion of sand, on the premise that usage of the active materials is not increased, thickness of the barrier body can be increased, hydraulic retention time is prolonged, and more construction expense of the PRB (permeable reactive barrier) is saved.

Owner:中科华鲁土壤修复工程有限公司

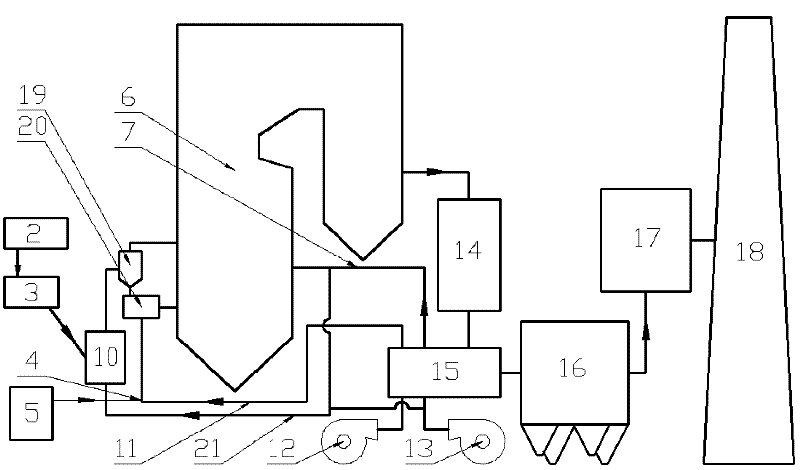

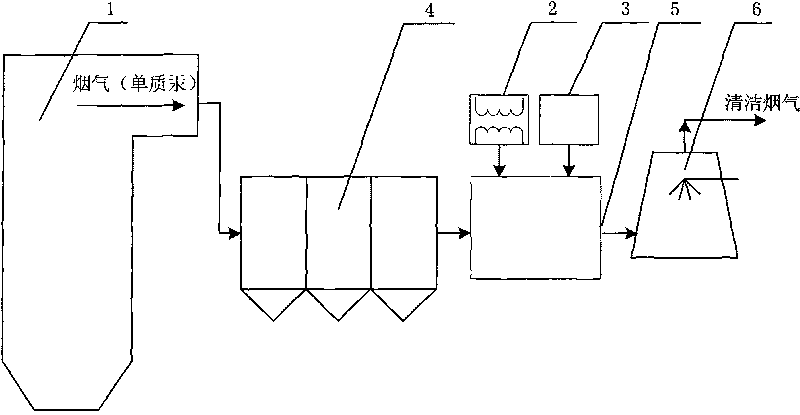

Method and system for efficiently controlling mercury pollution of coal-fired power plant at low cost

InactiveCN102343200ARaise the ratioImprove mercury removal efficiencyDispersed particle separationAir preheaterControl system

The invention discloses a method and system for efficiently controlling mercury pollution of a coal-fired power plant at low cost. The system comprises a primary hot air duct, a secondary hot air duct and a liquid storing tank, wherein the primary hot air duct and the secondary hot air duct are communicated with an air preheater and a hearth; a coal conveying system is communicated with a coal grinding system through a coal feeder; the liquid storing tank is filled with a halide additive solution; and the liquid storing tank is communicated with at least one of the coal conveying system, the coal feeder, the primary hot air duct and the secondary hot air duct. According to the system, the halide additive solution enters a boiler body and participates in a combustion reaction, the oxidation of the mercury in flue gas is promoted and the ratio of mercury oxide in the flue gas is increased, so that the synergetic demercuration effect of flue gas purifying equipment such as denitration equipment, desulfurization equipment, dedusting equipment and the like in a tail flue of a boiler is improved, and the mercury content of flue gas in a chimney is greatly lowered. A mercury pollutant control system has the advantages of small investment and low running cost while the mercury pollutant emission level of the coal-fired power plant can meet stricter environmental standard requirements.

Owner:HUANENG CLEAN ENERGY RES INST

High-stability composite mercury catalyst for hydrochlorination of acetylene

InactiveCN102085485AHigh catalytic activityReduce dosagePhysical/chemical process catalystsPreparation by halogen halide additionManganeseGadolinium

The invention discloses a high-stability composite mercury catalyst for hydrochlorination of acetylene. The catalyst comprises the following components: 100 parts of active carbon serving as a carrier, 1-15 parts of mercuric chloride serving as a main catalytic component and 1-10 parts of auxiliary component, wherein the auxiliary component is one of chlorides of cobalt, manganese and gadolinium or a mixture of multiple of the chlorides, or one of chlorides of bismuth, cadmium and copper or a mixture of multiple of the chlorides. According to the invention, the problems of the current mercuric chloride catalyst that the mercury consumption during production is excessively large and the environmental pollution is serious are solved. The activity of the composite mercury catalyst disclosed by the invention is improved by 5-50% compared with that of the pure mercuric chloride catalyst, the utilization efficiency of the catalyst can be effectively improved, the production cost is lowered, and the mercury pollution is reduced.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

Agent for absorbing fire coal flue gas mercury pollutant and preparation and use thereof

ActiveCN101301603AConvenient sourceAchieve combinatorial optimizationOther chemical processesDispersed particle separationSpecific adsorptionSorbent

The present invention discloses an adsorbent for mercury pollution in coom smoke gas, a modified adsorbent thereof, and the preparation and application thereof. By employing the dewatered sludge from the city sewage processing factory as material, the adsorbent for mercury pollution in coom smoke gas is obtained after steps of dipping in chemical medicament, stirring and placing, pyrolysis and charring, and washing and drying. Furthermore, the modified adsorbent obtained by filtering modified element in the surface of the adsorbent can enhance the specific adsorption and the adsorption capability of the mercury of the material, and reduce the used amount of the absorption material. The adsorbent, the modified adsorbent and the compound prepared by the present invention can be used in treatment of the mercury pollution in coom smoke gas in different general operating manners. The adsorbent and the modified adsorbent prepared by the present invention have convenient material source, low production cost, facility application, and remarkable circumstance and economy benefit.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Passivator for restraining mercury pollution of vegetable soil

InactiveCN102703090AReduce available mercury contentCause secondary pollutionAgriculture tools and machinesOrganic fertilisersCalcium hydroxideMercury pollution

The invention discloses a passivator for restraining mercury pollution of vegetable soil, which comprises the following components in parts by weight: 3-15% of hydroxyapatite, 5-20% of algin and 5-20% of calcium hydroxide. By application of the soil mercury passivator which is mainly prepared from algin, hydroxyapatite and calcium hydroxide, the available mercury of vegetable soil of which the full mercury content is 0.5mg / kg is reduced by more than 50% within a 60-day culture period; and the passivator not only has the function of reducing and passivating mercury in soil, but also has the function of improving soil. The passivator is convenient to operate, low in cost, short in treatment period, capable of effectively reducing the available mercury content of soil and easy to popularize and hardly causes secondary pollution to soil environment.

Owner:JIMEI UNIV

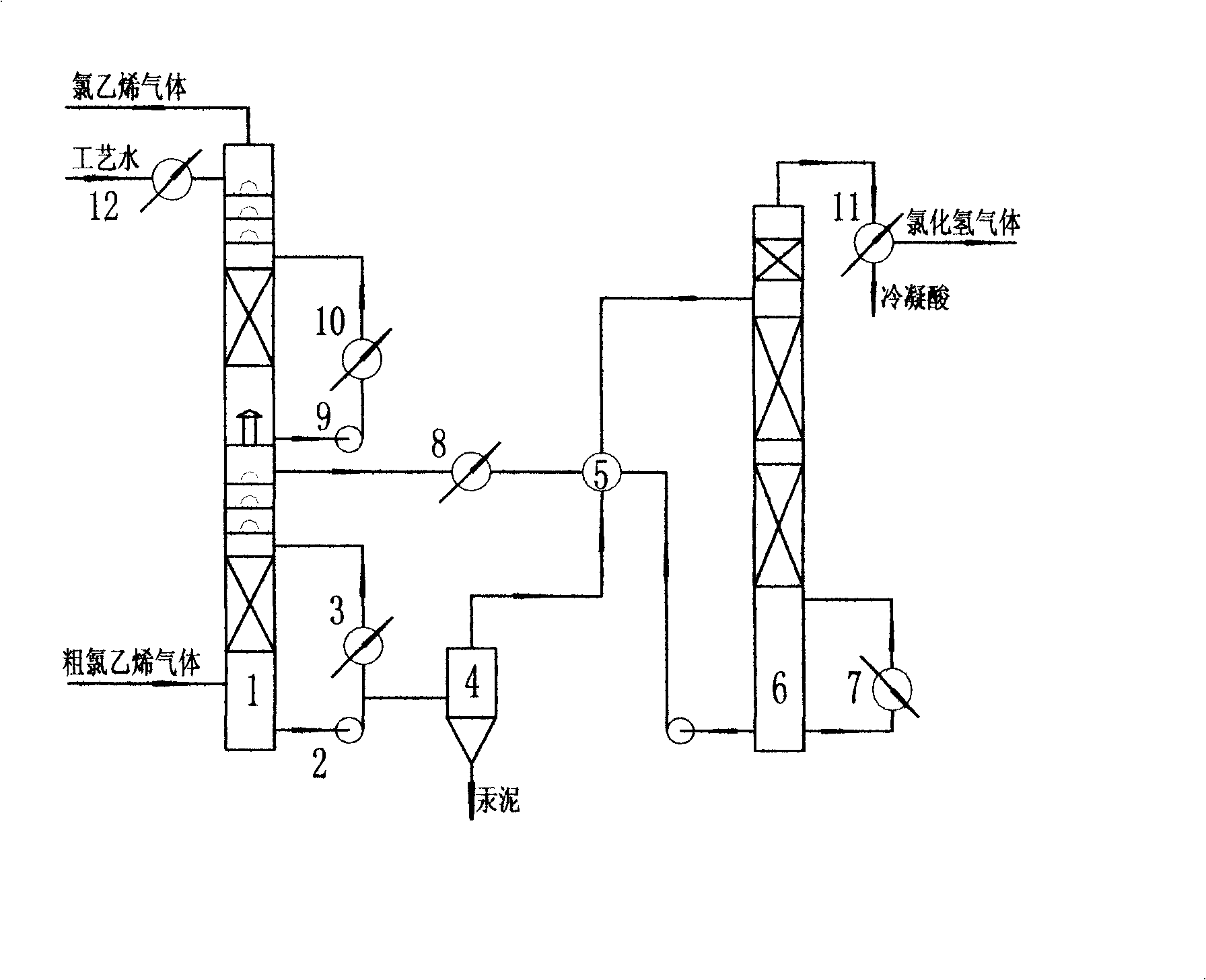

Method for realizing hydrochloric acid closed cycle and precluding mercury pollution in polychloroethylene production

InactiveCN101348534AMeet the purification process requirementsAchieve recyclingDesorptionPolyvinyl chloride

The invention discloses a method for realizing a closed circuit of hydrogen hydride and hydrochloric acid in the polyvinyl chloride production to eliminate mercury pollution. The method is capable of maintaining the water balance of a hydrogen chloride absorption and desorption system to avoid hydrochloric acid containing mercury from being expelled from the system. The hydrogen chloride absorption process which is a process of low temperature absorption by section respectively adopts cycling hydrochloric acid and process water to wash process gas containing the hydrogen chloride. The desorption is carried out through single-section tower type desorption indirect heating; and the desorbed hydrogen chloride returns to a vinyl chloride synthesization system, and the thin hydrochloric acid returns to an absorption system. Therefore, the consumption of the hydrogen chloride can be reduced, the acidic water pollution caused by the hydrogen chloride can be avoided, and the environmental pollution caused by the mercury can be eliminated. Mercury-free condensed hydrochloric acid produced by a condenser arranged at a gas outlet of a desorption tower can be sold as byproduct hydrochloric acid.

Owner:王凯勋

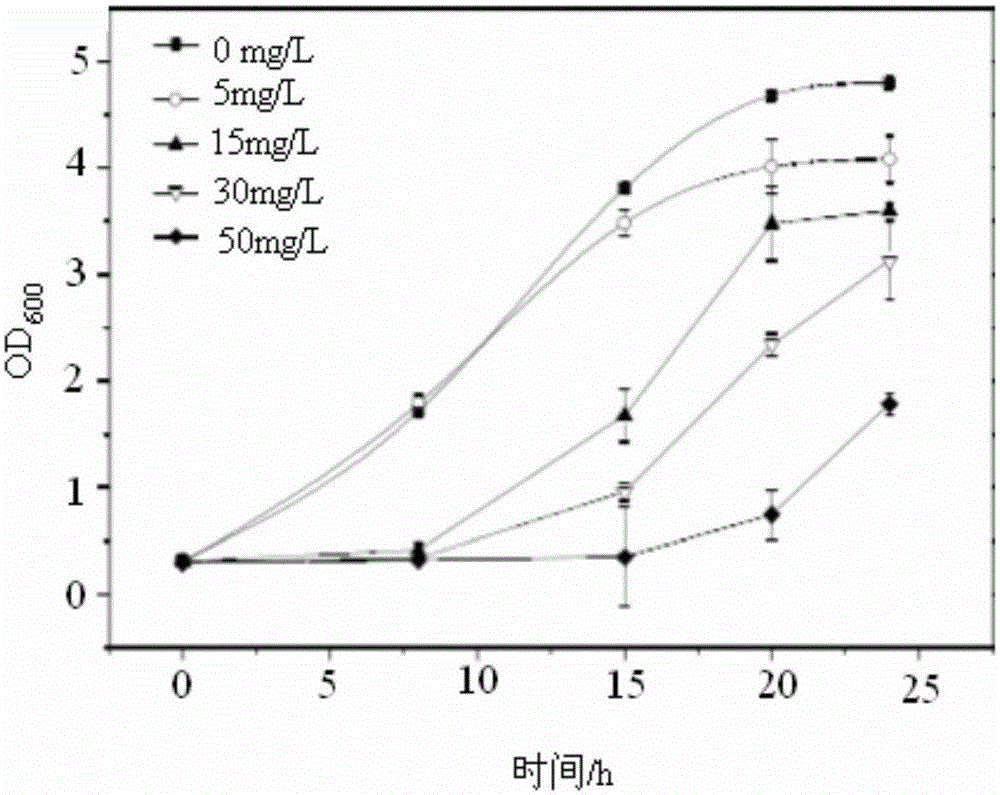

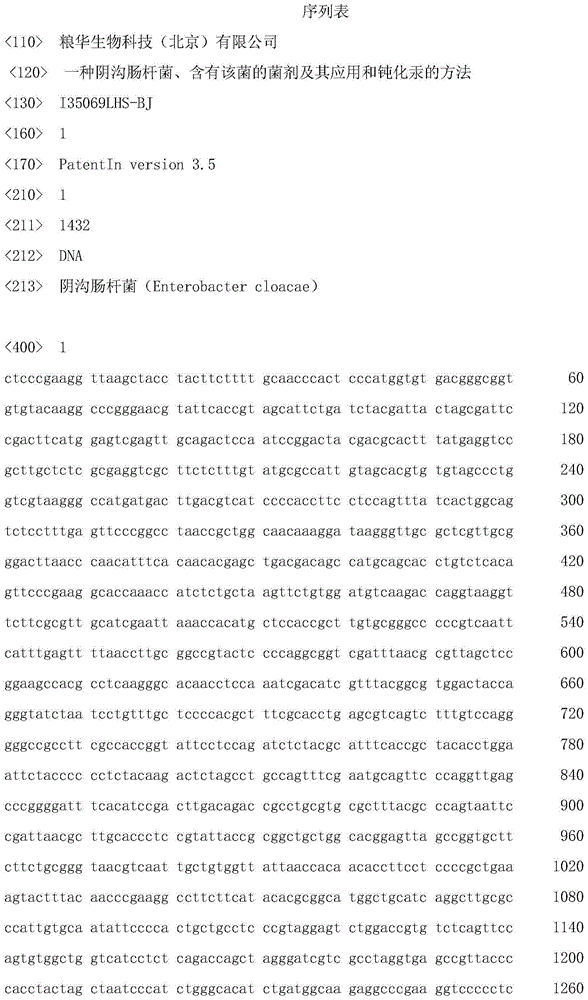

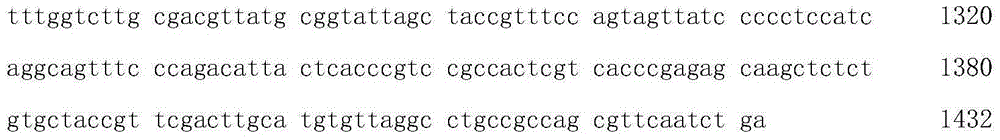

Enterobacter cloacae, microbial inoculum containing enterobacter cloacae, use of microbial inoculum and method for passivation of mercury

InactiveCN106497809APassivation fastReduced bioavailabilityBacteriaWater contaminantsHigh concentrationEnterobacter cloacae

The invention relates to the technical field of bioremediation of heavy metal mercury pollution and discloses enterobacter cloacae, a microbial inoculum containing the enterobacter cloacae, a use of the microbial inoculum and a method for passivation of mercury. The enterobacter cloacae has an accession number of CGMCC NO: 10850. The method for passivation of mercury comprises contacting the enterobacter cloacae having the accession number of CGMCC NO: 10850 and / or the microbial inoculum containing the enterobacter cloacae having the accession number of CGMCC NO: 10850 with a mercury-polluted sample so that mercury in the mercury-polluted sample is passivated. The enterobacter cloacae has high degradation ability to mercury, has a degradation rate of 85.5%, can tolerate high concentration mercury pollution, is easy to operate and can play an important role in bioremediation of mercury-polluted soil or mercury-containing wastewater.

Owner:粮华生物科技(北京)有限公司

Structured non-mercuric catalyst, and preparation method and application thereof

InactiveCN103170354ASolve two major problems in productionMove out quicklyPhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonActive component

The invention discloses a structured non-mercuric catalyst. The structured non-mercuric catalyst is composed of 80-99.9wt% of a carrier, 0.01-10wt% of an active component and 0-19.99wt% of an assistant; and the carrier is composed of 60-95wt% of silicon carbide foam and 5-40wt% of active carbon, and the active carbon is adhered to the silicon carbide foam. The structured non-mercuric catalyst has a high catalytic activity when the catalyst is used in an acetylene hydrochlorinating reaction for preparing chloroethylene. The structured non-mercuric catalyst solves a mercury pollution problem, and utilizes the good heat conduction property of the silicon carbide foam to rapidly remove heat in order to avoid the temperature runway of a bed, so the production capacity and the product quality are improved. The invention also discloses a preparation method of the structured non-mercuric catalyst. The preparation method comprises the following steps: dissolving the active component and the assistant in water to prepare a solution, immersing the carrier in the solution at 60-80DEG C for 1-3h, and drying to obtain the structured non-mercuric catalyst. The preparation method has the advantages of simplicity, strong operability and good controllability.

Owner:ZHEJIANG UNIV

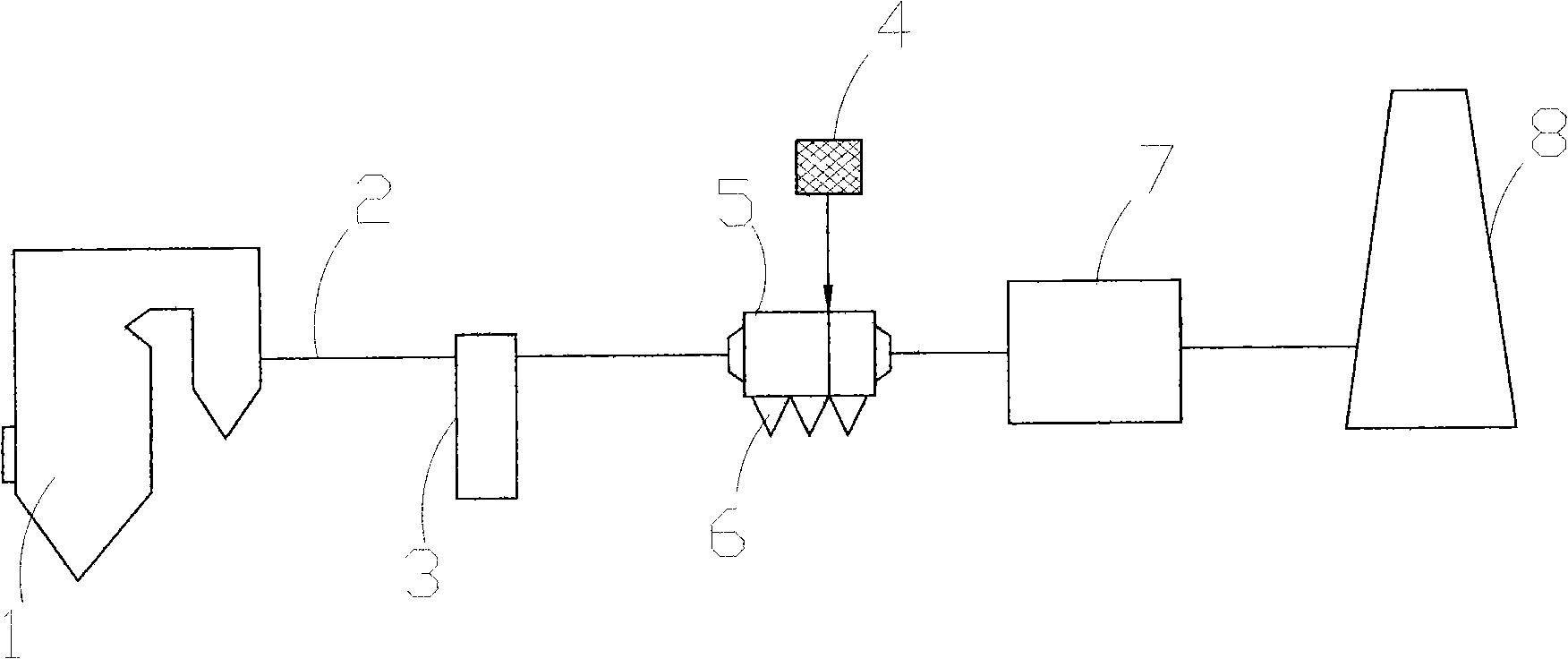

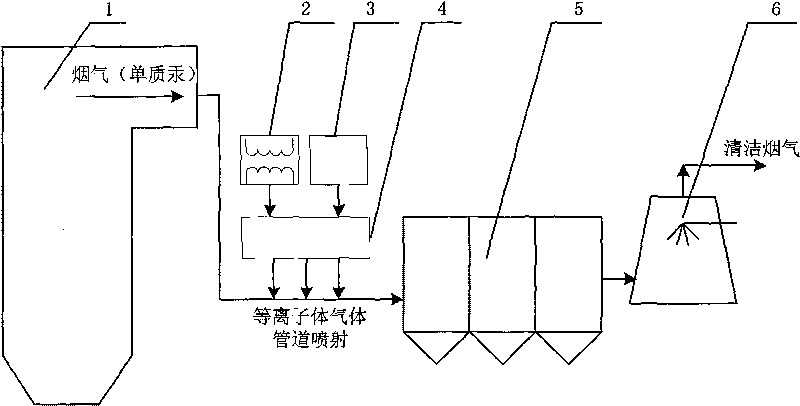

Oxidizing method for removing gaseous elemental mercury in boiler fume

InactiveCN101703875AFull control of gaseous zero-valent mercurySimple production processDispersed particle separationMercury pollutionElemental mercury

Owner:NANJING NORMAL UNIVERSITY

Mercury-containing sludge heat treatment method

ActiveCN106007297AFully harmlessFull utilization of resourcesCombination devicesSludge treatment by de-watering/drying/thickeningSludgeMercury pollution

The invention discloses a mercury-containing sludge heat treatment method which is characterized by treating mercury-containing sludge with moisture content of over 90% sequentially by a sludge conditioning device with a heating function, a dehydrator, a screw conveyer, a pyrolysis unit, a dust remover, a spraying condensation device, a coalescer and a tail gas treatment device, wherein treatment of the pyrolysis unit sequentially comprises drying treatment, pyrolysis treatment and combustion treatment. The mercury-containing sludge is firstly pre-treated; the pre-treated sludge is fed into the pyrolysis unit; after the sludge is subjected to pyrolysis combustion, formed pyrolysis gas circularly enters a drying section to be utilized; mercury and compounds thereof in the sludge are all changed into mercury vapor; then the mercury vapor is charged into a dust removal unit and a condensation unit to recover liquid mercury. According to the mercury-containing sludge heat treatment method disclosed by the invention, a pyrolysis technology is adopted to carry out harmless treatment on the sludge; heat energy is recycled; sludge treatment energy consumption is reduced; mercury pollution is prevented; moreover, byproducts with a certain value are produced; the mercury-containing sludge heat treatment method not only has economic benefits, but also has social benefits.

Owner:SOUTHWEST PETROLEUM UNIV +1

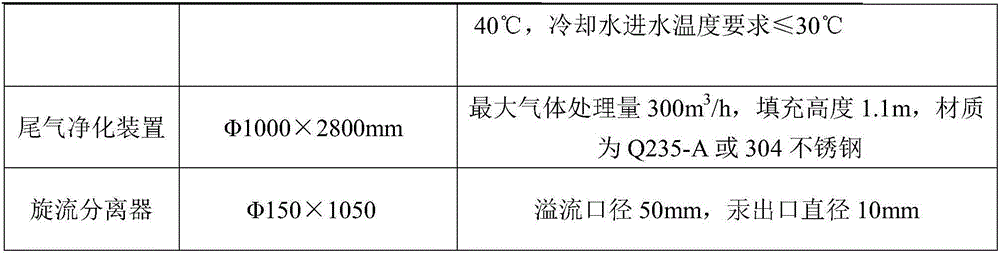

Disposal clinical thermometer and manufacturing method therefor

InactiveCN101118187ASolve pollutionEquilibrium Vacuum ShrinkageThermometers using material expansion/contactionEngineeringMercury pollution

The present invention relates to a disposable clinical thermometer and the manufacture method. The temperature is measured and the measured temperature is stabilized by a liquid drainage method, a temperature sensing bulb is a cavity body, colored simethicone temperature sensing liquid and a sodium chloride chip are arranged in the temperature sensing bulb, colorless transparent glycerin assistant fluid or glycerin assistant fluid with obvious color difference with the colored temperature sensing liquid is filled in a capillary pipe, when the temperature is measured, temperature sensing liquid is heated and caused to expand, emitted upwards, raised along the capillary pipe, and the assistant fluid is emitted to the valve body of a temperature locating device. After the temperature is measured, a piston is pressed down, the assistant fluid is emitted to an assistant fluid storehouse through a fluid emission slot, the piston is pressed down and the fluid emission slot is closed, the piston is locked, and simultaneously the chip sodium chloride generates gas in the vacuum state to fill up the space caused by the rise and location of the temperature sensing liquid. The present invention has the advantages that the nontoxic temperature sensing liquid replaces mercury, thus solving the problem of mercury pollution. The measured body temperature is not changed under the influence of the outside temperature, and the disposable operation does not cause cross infection.

Owner:宋显荣

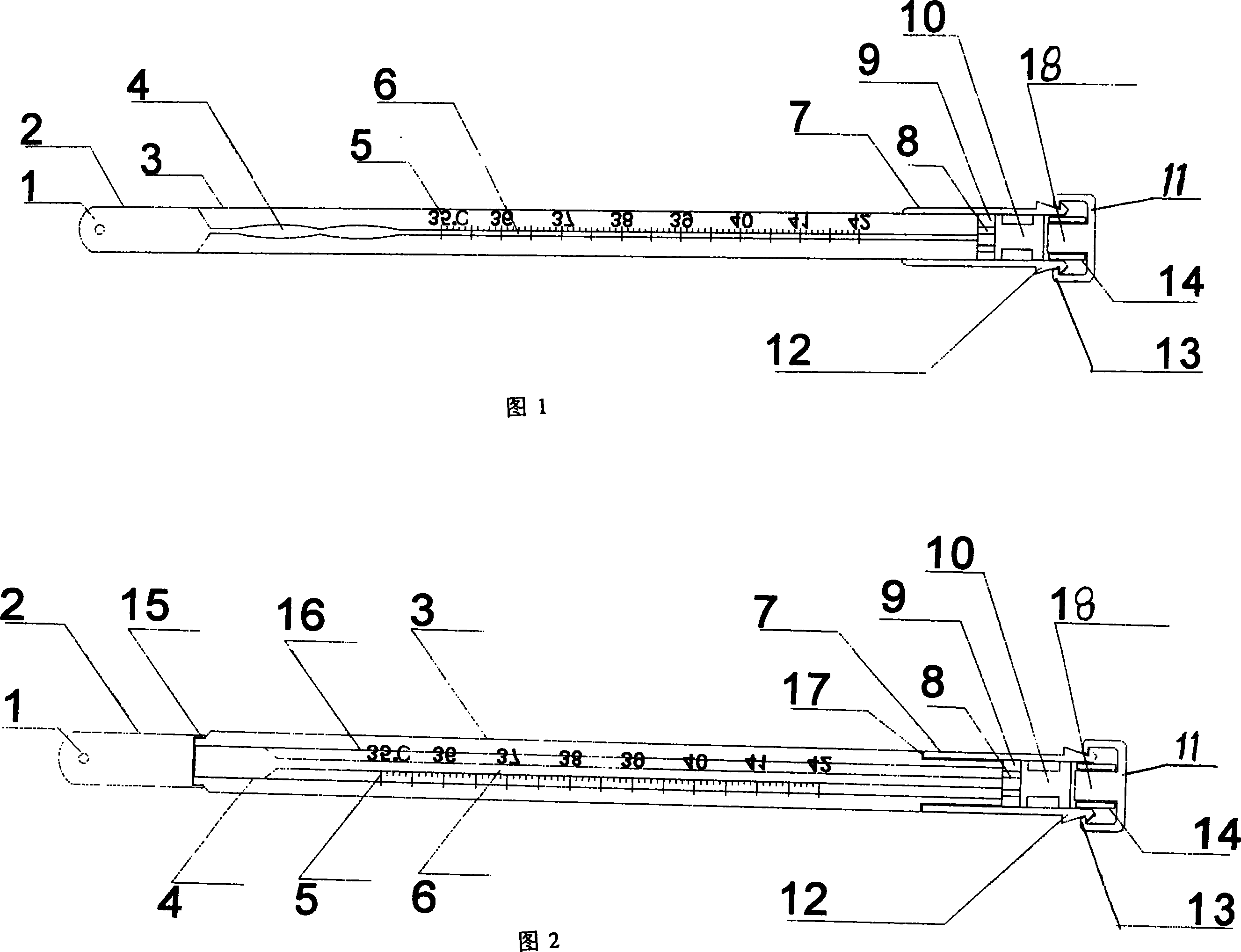

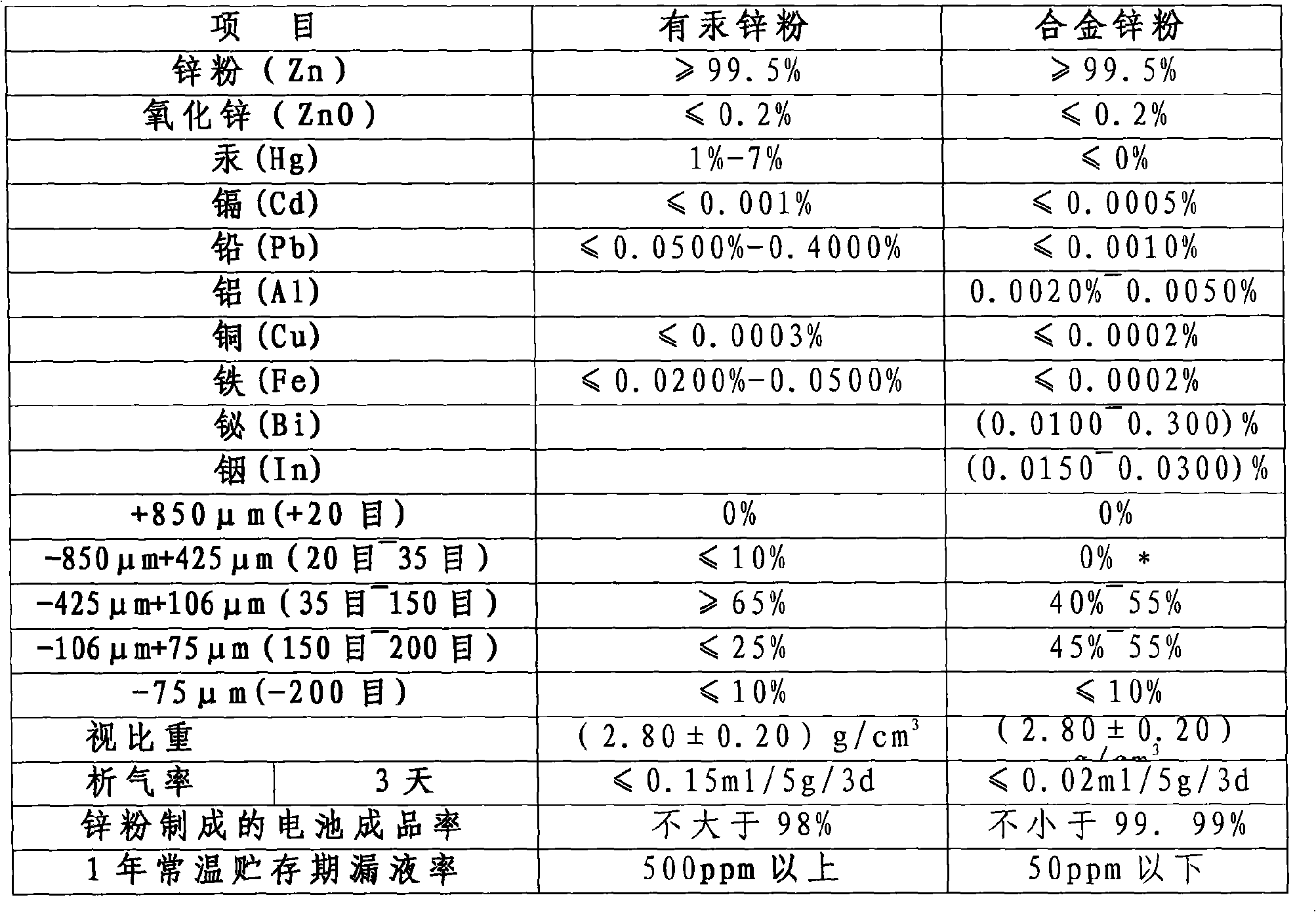

Preparation method of alloy zinc dust special for mercury-free batteries

The invention relates to a preparation method of zinc alloy powder special for Hg-free battery. The preparatin method of the invention includes the following steps: cleaned and dried high-purity zinc ingots and additional elements of high-purity powder of indium, bismuth and aluminum are put into a main frequency induction furnace and heated up to the temperature of 460 DEG C; the raw materials are melted, evenly mixed, and then poured into a heat preserving leaking package which is heated to 550DEG C for heat preservation; the zinc alloy solution is pulverized into powder by purified and compressed air jet in a pulverized settlement cylinder, then settled and condensed into solid particles in a double-layer pulverized settlement cylinder which is communicated with cooling water; a multi-layer rotating vibrating screen is used for screening and then the zinc powder with qualified granulation is put into a V-shaped mixer for even mixing; the zinc powder is packaged for oxidation prevention after being checked as qualified. The powder of the invention is totally consistent with the quality standard of Hg-free zinc alloy powder and is environmental protection due to no mercury pollution; the adopted pulverization method by compressed air jet has the advantages of simple process, convenient operation, low cost, low labor intensity and small occupied production area; the zinc alloy powder with indium, bismuth and aluminum added without environmental pollution can obviously reduce the amount of hydrogen evolution of the cathode.

Owner:潮州正龙电池工业有限公司

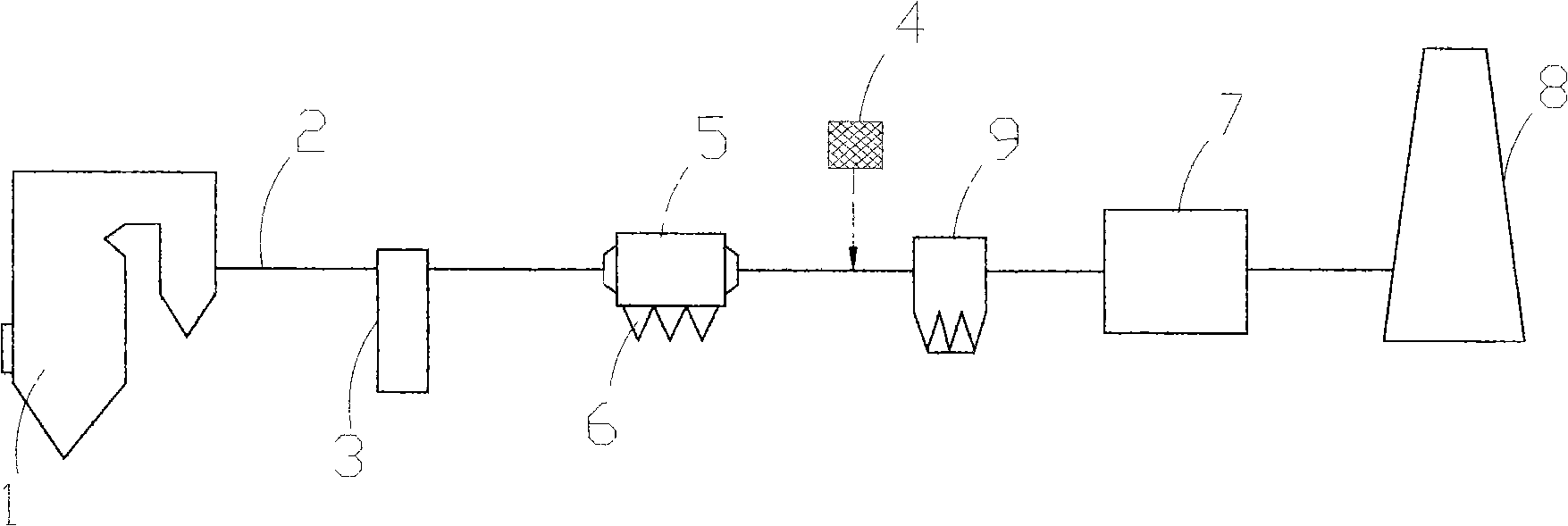

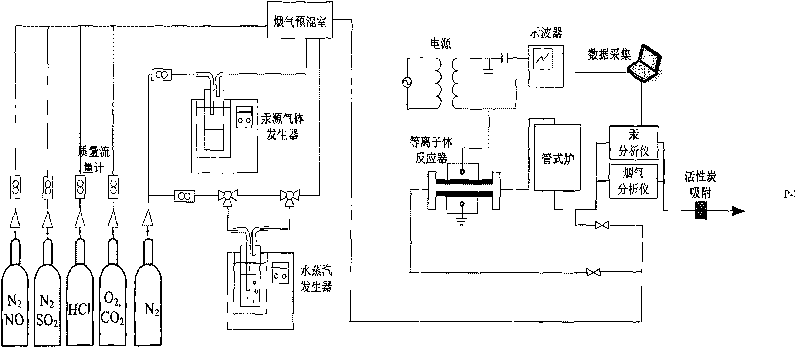

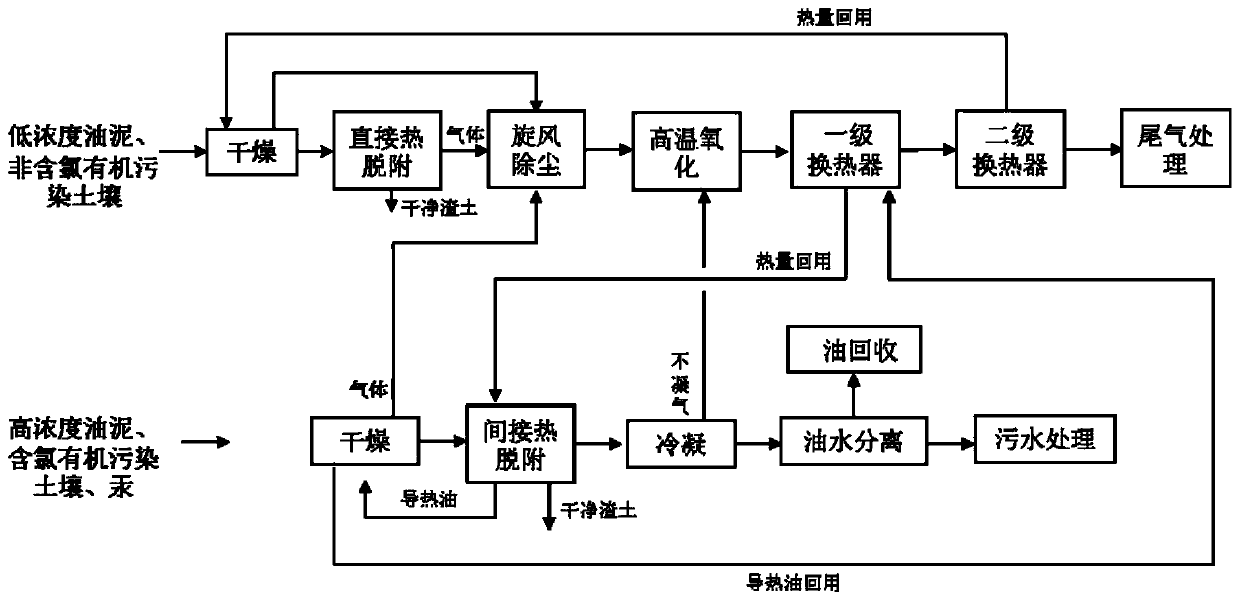

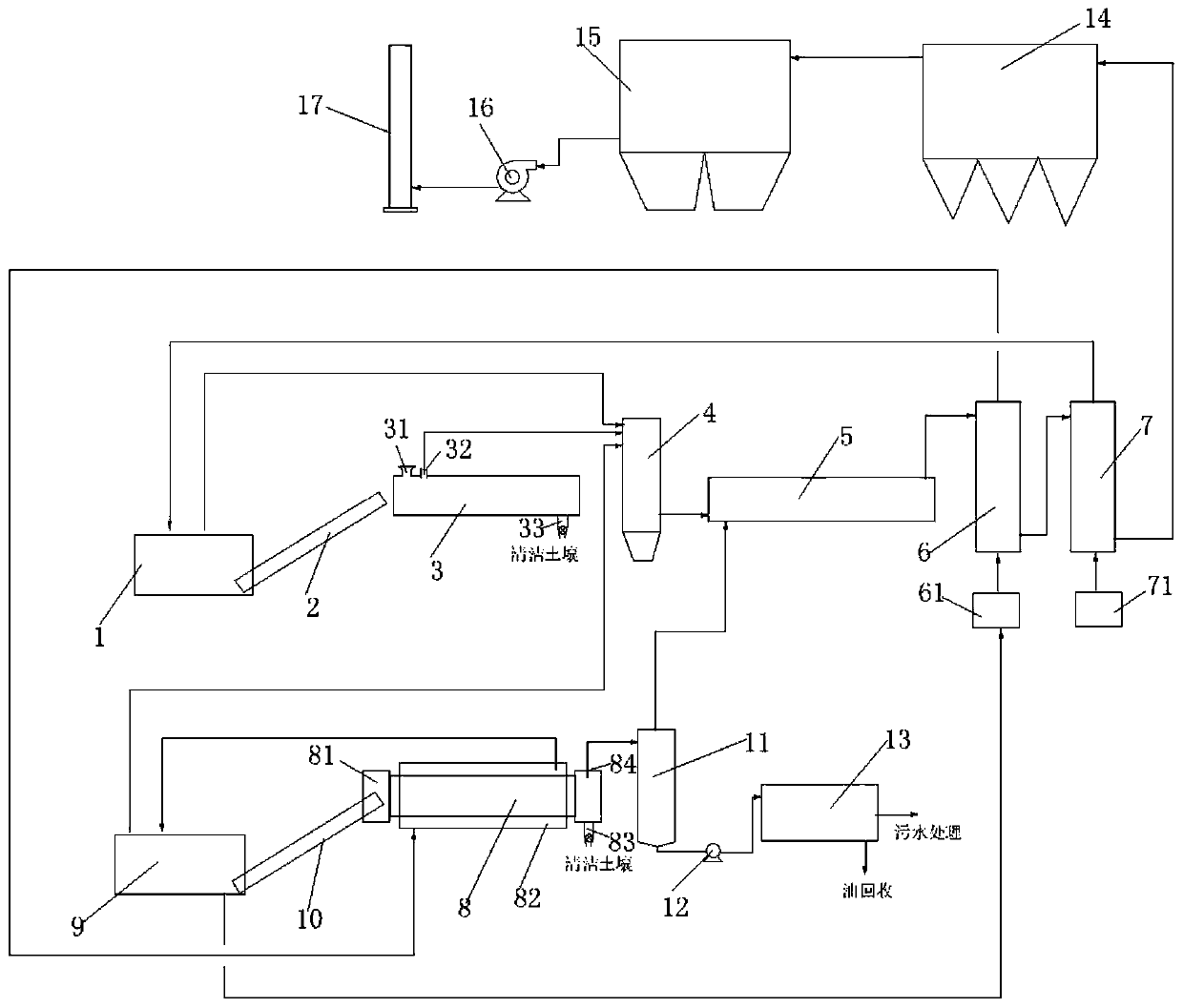

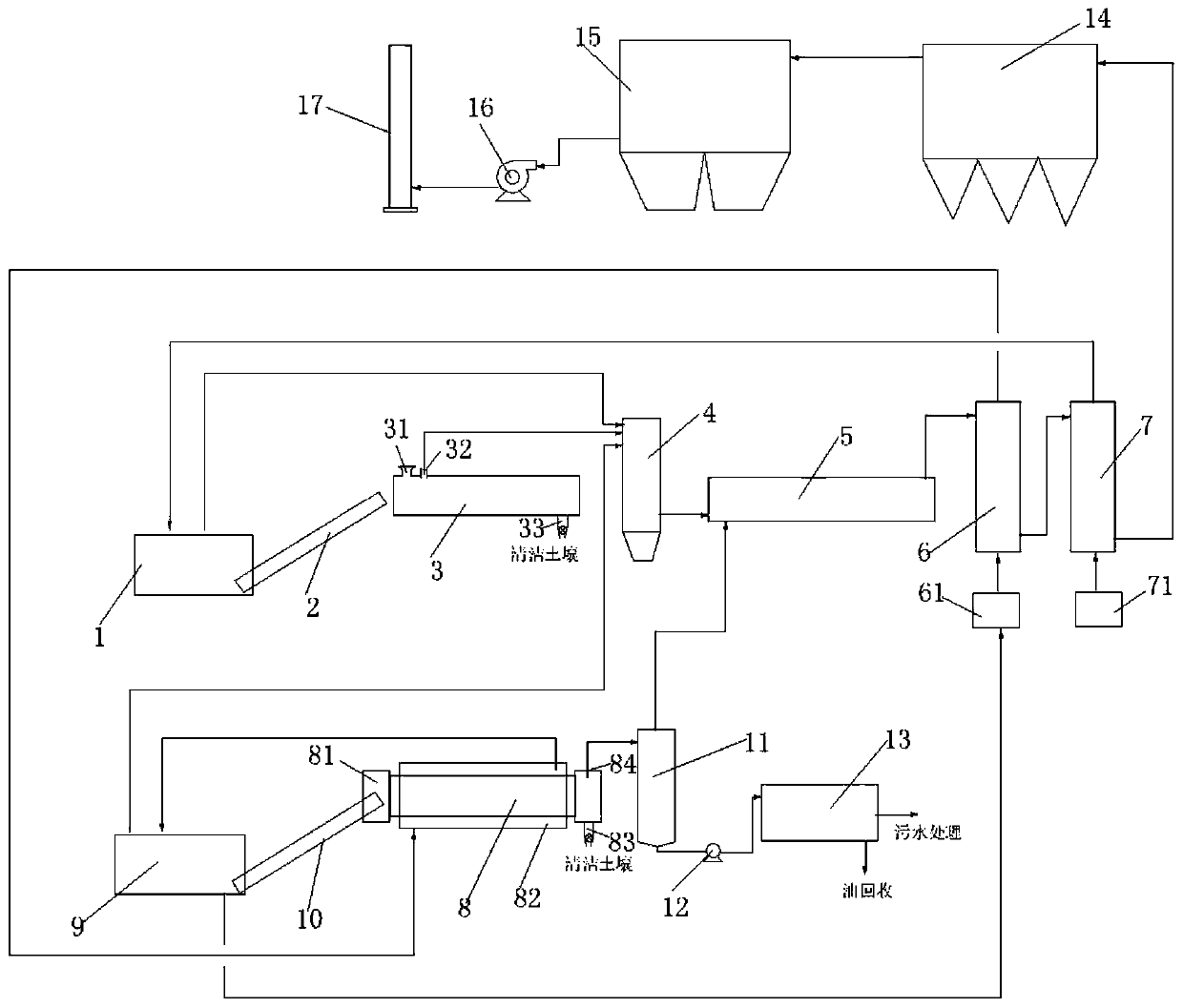

Thermal desorption combined utilization and waste heat recycling method and system adopted by method

PendingCN111174619AAvoid generatingImprove processing efficiencyHeat storage plantsContaminated soil reclamationOil sludgeMercury pollution

The invention discloses a thermal desorption combined utilization and waste heat recycling method and a system adopted by the method. The method comprises the following steps of (1) carrying out drying and directly thermal desorption treatment on low-concentration oil sludge or chlorine-free organic polluted soil, and carrying out cyclone dust removal treatment on generated waste gas; (2) carryingout drying and indirect thermal desorption treatment on high-concentration oil sludge or chlorine-containing organic polluted soil or mercury polluted soil, and sequentially carrying out condensationand oil-water separation treatment on the generated waste gas; and (3) carrying out high-temperature oxidation, two-stage heat exchange cooling treatment and tail gas treatment on the waste gas in the step (1) and the non-condensable gas in the step (2), and then discharging. The system consists of a directly-heated thermal desorption system, an indirectly-heated thermal desorption system and a tail gas purification and waste heat recycling system; pollutants are treated in a classified mode, the treatment amount is large, the treatment efficiency is high, and safety and environment friendliness are achieved; and generated waste heat is recycled to the maximum extent, energy is saved, consumption is reduced, resource recovery is achieved while pollution treatment is achieved, and sustainable development is facilitated.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

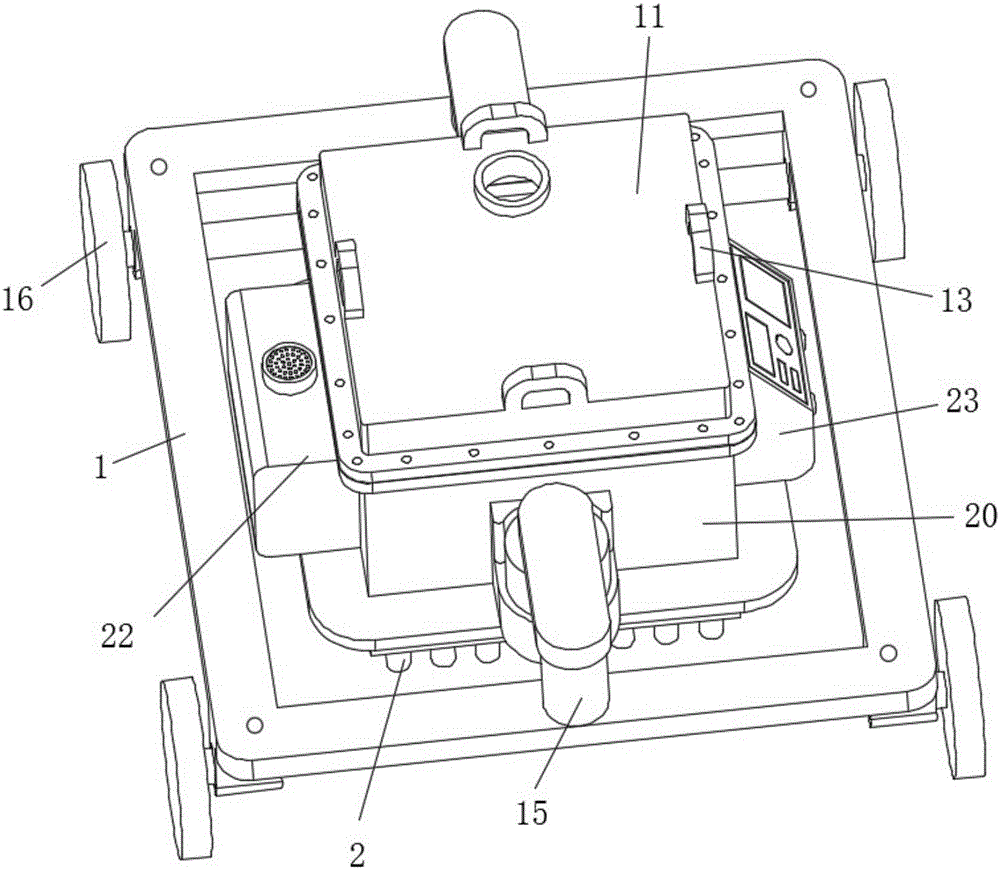

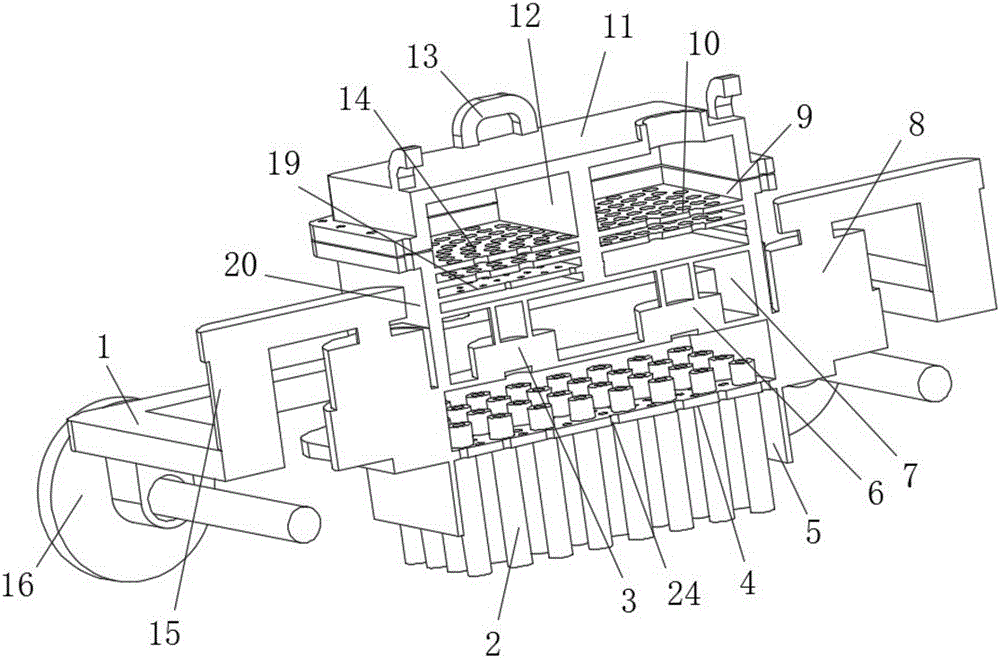

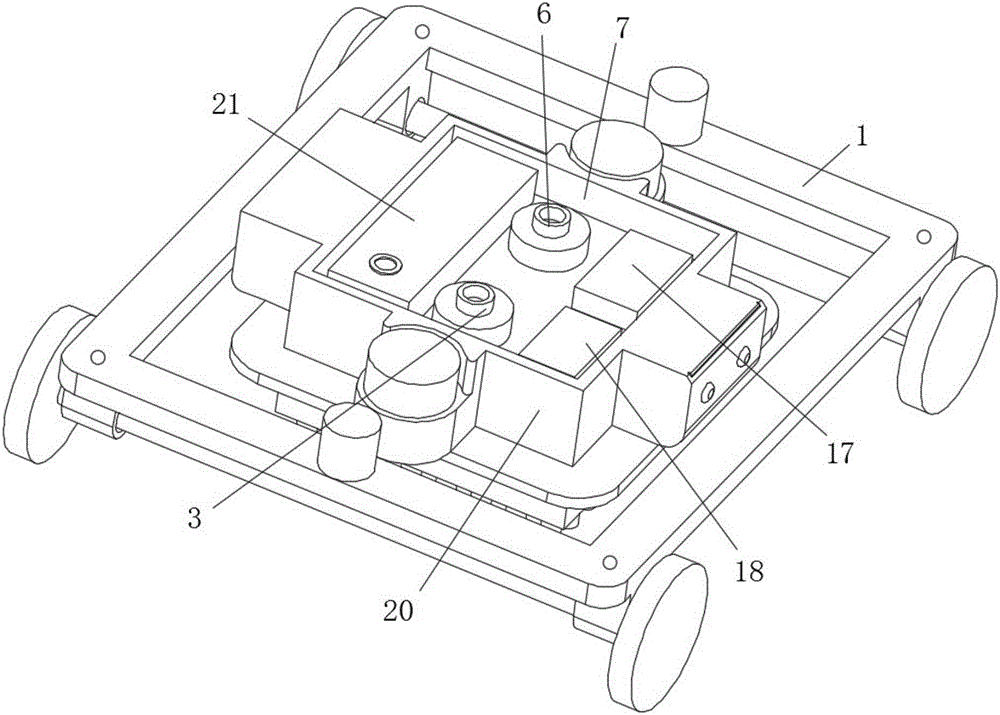

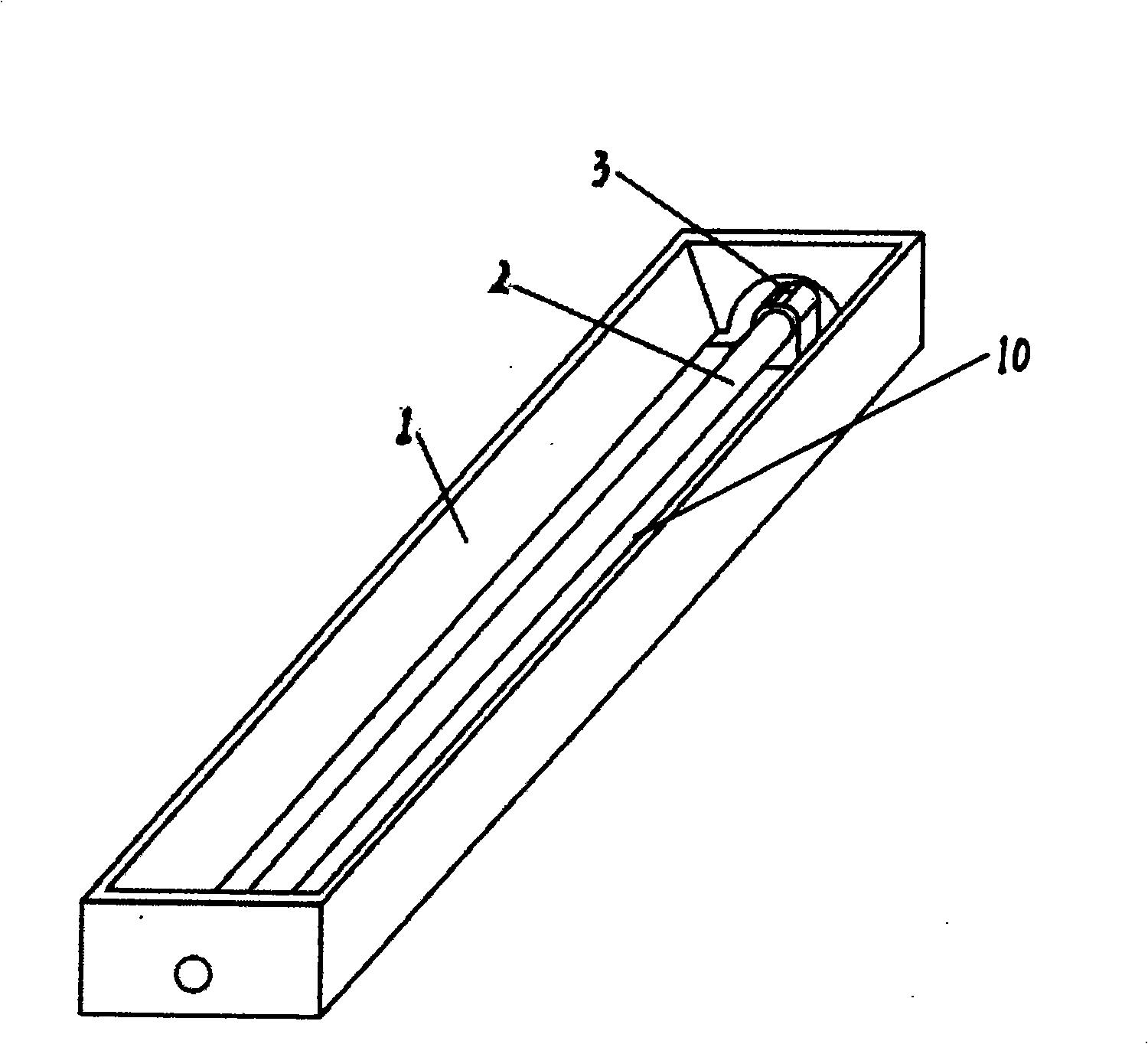

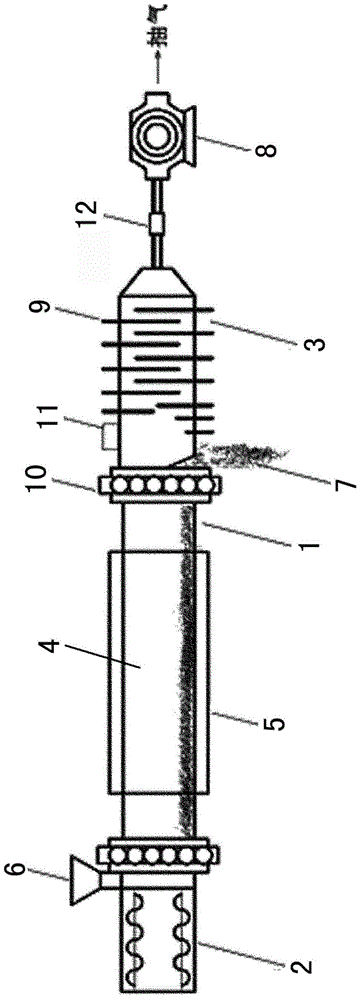

Integral in-situ mercury pollution repair device and repair method thereof

ActiveCN106424108AEasy to replaceFew stepsContaminated soil reclamationSustainable biological treatmentMiniaturizationEngineering

The invention discloses an integral in-situ mercury pollution repair device and a repair method thereof. The device comprises a frame and a box; rollers are mounted at the lower end of the frame; connecting columns are respectively arranged at the front and back two ends of the frame; the upper end of the box is screwed with an end cover; a pull ring is arranged on the end cover; an isolation plate is arranged at the lower end of the box; a mounting plate is arranged in the isolation plate; and insertion pipes are uniformly mounted on the mounting plate. The device has no need to carry soil in use, can repair mercury ion-polluted soil in situ, saves unnecessary steps, realizes miniaturization, can conveniently replace a porous resin absorbing plate, can renewedly extract and recycle mercury elements therein to prevent reflowing into water and soil, protects the soil to the greatest extent, and is higher in practical value.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

Optical wand -type LED lighting source

InactiveCN101334134AExtended service lifeUniform lightMechanical apparatusLight source combinationsSocial benefitsLight guide

The invention relates to a light stick type LED lighting source. The prior filament lamp or the fluorescent tube used for illumination has the defects that the power consumption is huge, the service life is short, the lighting time is long, the mercury pollution is easy to be caused during the manufacturing process, and the light ray lack the softness and the evenness. The light stick type LED lighting source is composed of a LED light source, a high-efficiency light guiding stick, a reflecting film, a directional reflecting cover and an outer casing, wherein the LED light source and PCB board are arranged on one or two side faces of the geometrical body formed by the high-efficiency light guiding stick, a V shaped light reflecting slot is arranged on the upper surface of the high-efficiency light guiding stick, the reflecting film is positioned on the upper surface of the high-efficiency light guiding stick, the directional reflecting cover is positioned on the front face of the high-efficiency light guiding stick, and the invention can be a single pipe or a multi-pipe light stick type LED lighting source. The light stick type LED lighting source has the advantages of energy saving, environmental protection and long service life; as one of the future light sources which are most interested in by the people, the direct aim of the LED lighting source is to replace the filament lamp or the fluorescent tube, thereby the LED lighting source has a good economic benefit and social benefit.

Owner:WAI CHI OPTO TECH (SHENZHEN) LTD

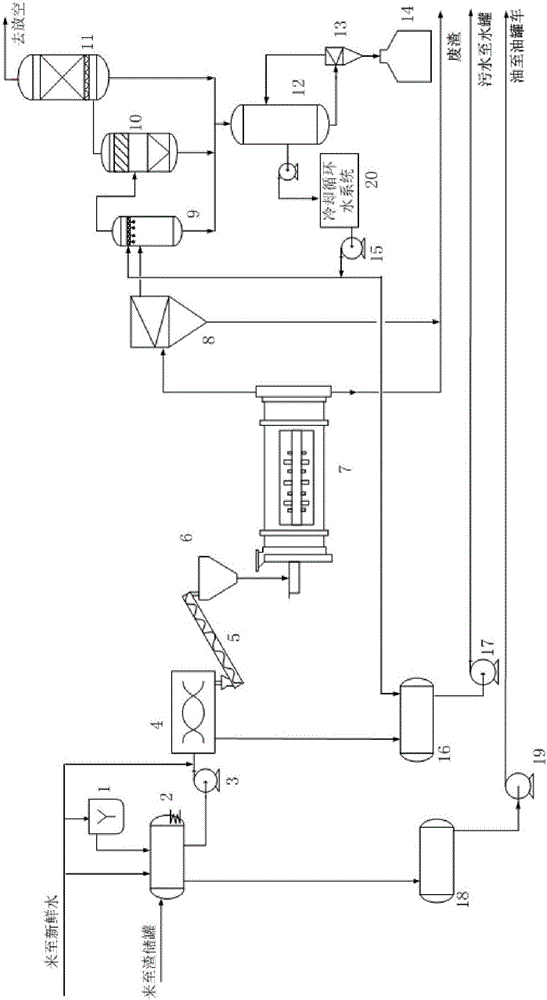

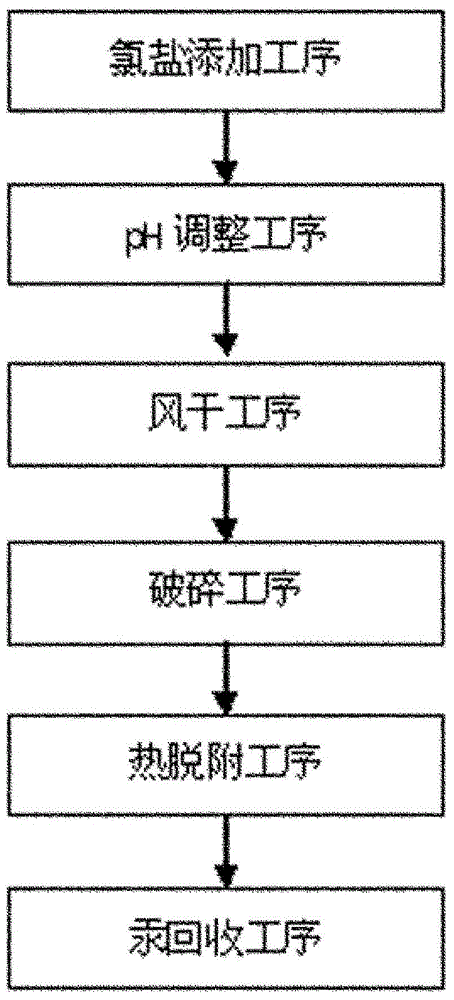

Mercury pollution soil thermal desorption and mercury recovery method and integrated equipment

InactiveCN105032915AHigh broad spectrumSimple processContaminated soil reclamationRecovery methodSlurry

Disclosed is a mercury pollution soil thermal desorption and mercury recovery method. The method comprises the steps that 1, chlorine salt is added, wherein after mercury pollution soil is broken and levigated, the chlorine salt is added, water is added for sufficient stirring to obtain slurry; according to the additive amount of the chlorine salt, the molar concentration of hydrolyzed chloride ions is higher than that of mercury in soil; 2, pH is adjusted, wherein the pH of the slurry is adjusted by means of an acid water solution to range from 6.5 to 7.5; 3, air drying is performed, wherein the slurry is naturally dried; 4, breaking is performed, wherein the naturally-dried slurry is broken, 5-mesh undersize fine soil is used as soil to be processed for follow-up processing; 5, thermal desorption is performed, wherein thermal desorption is performed on soil to be processed at the temperature of 150 DEG C to 300 DEG C, mercury is recycled under natural cooling, and soil obtained after thermal absorption is used for other purposes; and 6, mercury is recycled, wherein a mercury-contained compound obtained after thermal desorption is performed is recycled at room temperature. The invention further discloses integrated equipment for implementing the mercury pollution soil thermal desorption and mercury recovery method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for removing mercury from mercury pollution materials

InactiveCN1846884ACompact and effective equipmentReduce mercury levelsSolid waste disposalMicrowave methodMercury pollution

The microwave method of reducing mercury content in mercury contaminated material includes the following steps: 1. setting the mercury contaminated material inside one microwave reactor; 2. providing airflow to the microwave reactor to stir the mercury contaminated material; and 3.exposing the mercury contaminated material to microwave radiation to raise the temperature to over 357 deg.c, so as to produce vapor containing mercury and the treated material. The said method may be also used to reduce contents of mercury and carbon simultaneously, and some no-carbon material may be used in the reactor.

Owner:HENDERIKS HLDG

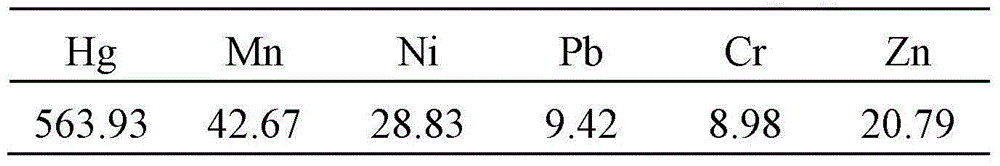

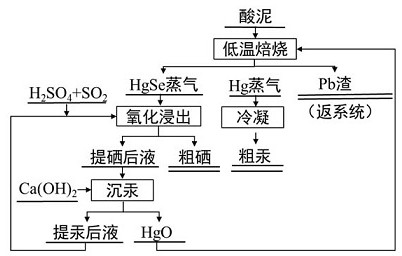

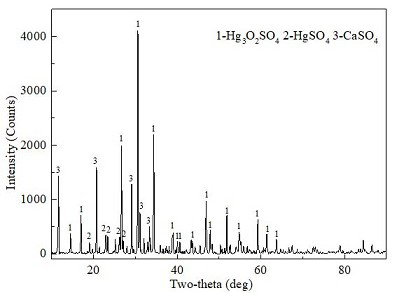

Comprehensive recovery method for valuable metals in lead-zinc smelting acid mud

PendingCN113088694AHigh puritySimple processProcess efficiency improvementElemental selenium/telluriumEnvironmental engineeringMercury pollution

The invention relates to a comprehensive recovery method for valuable metals in lead-zinc smelting acid mud, and belongs to the technical field of hazardous waste resource development and utilization. The method is mainly divided into two steps according to the form of a mercury-containing phase, the mercury-containing phase easy to treat is directly subjected to pyrogenic roasting and volatilization recovery, the selenium-containing and mercury-containing phase difficult to treat is converted into the phase easy to treat through wet leaching, and then the easy-to-treat phase is further treated and recycled; and mercury in the acid mud is recovered in the form of elemental mercury, selenium is recovered in the form of crude selenium, and the lead and silver residues are returned to a Isa furnace for smelting and recovery. According to the method, deep removal and separation of mercury and selenium and efficient recovery of lead, silver, selenium and mercury can be achieved, the recovery rate of mercury and selenium can reach 96% or above, the recovery rate of lead and silver can reach 99%, high-valued utilization of the acid mud can be achieved through the technology, the problem of mercury pollution in production is well solved, the acid mud treatment process is closed, and direct contact with people is avoided in the production process, so that the production safety is ensured, and good popularization and application prospects are achieved.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com