Patents

Literature

47results about How to "Reduce mercury levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing contaminants from fluid streams

InactiveUS20050155934A1Increase valueReduce carbon contentGas treatmentOther chemical processesPresent methodSorbent

A method and recyclable magnetic adsorbent are provided for removing contaminants from a fluid stream that has by-products. The method includes providing an adsorbent material that has incorporated at least one ferromagnetic material. Contacting the ferromagnetic adsorbent material to at least a portion of contaminated stream to adsorb the contaminant. The contaminated adsorbent is then separated from the by-products using a magnetic separation process. The adsorbent is recovered from the solid by-products and reusable in the present method.

Owner:CALGON CARBON

Method for removing contaminants from fluid streams

InactiveUS7429330B2Increase valueReduce carbon contentGas treatmentOther chemical processesPresent methodSorbent

A method and recyclable magnetic adsorbent are provided for removing contaminants from a fluid stream that has by-products. The method includes providing an adsorbent material that has incorporated at least one ferromagnetic material. Contacting the ferromagnetic adsorbent material to at least a portion of contaminated stream to adsorb the contaminant. The contaminated adsorbent is then separated from the by-products using a magnetic separation process. The adsorbent is recovered from the solid by-products and reusable in the present method.

Owner:CALGON CARBON

Mushroom cultivation substrate

InactiveCN102603403AReduced levels of cadmium and mercuryReduce contentFertilizer mixturesSucroseSaccharum

The invention relates to a mushroom cultivation substrate, which consists of solid materials and water. The mushroom cultivation substrate is characterized in that the solid materials comprise by weight 78-82% of broad-leaf tree sawdust, 14-20% of wheat bran, 0.8-1.2% of sucrose, 0.7-1.2% of gypsum powder, 0.8-1.5% of fused calcium-magnesium phosphate fertilizer, and 0.8-1.5% of a compound fertilizer, and that water in the mushroom cultivation substrate accounts for 58-62% of the total weight of the solid materials. According to the mushroom cultivation substrate, fused calcium-magnesium phosphate fertilizer and the compound fertilizer serving as mushroom heavy metal modifying agents are added in the conventional cultivation substrate of the mushroom, the addition amount of fused calcium-magnesium phosphate fertilizer and the compound fertilizer is within the range of 0.8-1.5%, so that the cadmium content in the mushroom is reduced by 18-39.6%, and the mercury content is reduced by 19.9-29%; moreover, the accumulation function of the heavy metals can be reduced to the largest degree, and the adverse effects on important agronomic characteristics such as mycelium spreading speed, yields and the like are avoided.

Owner:FUJIAN AGRI & FORESTRY UNIV

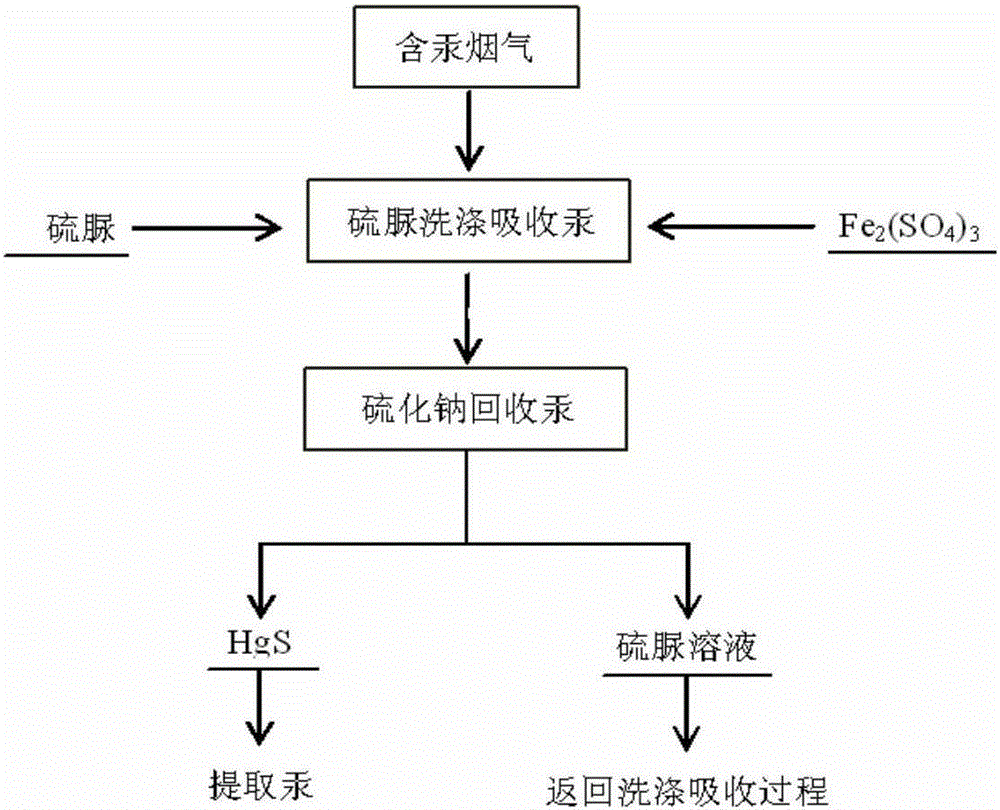

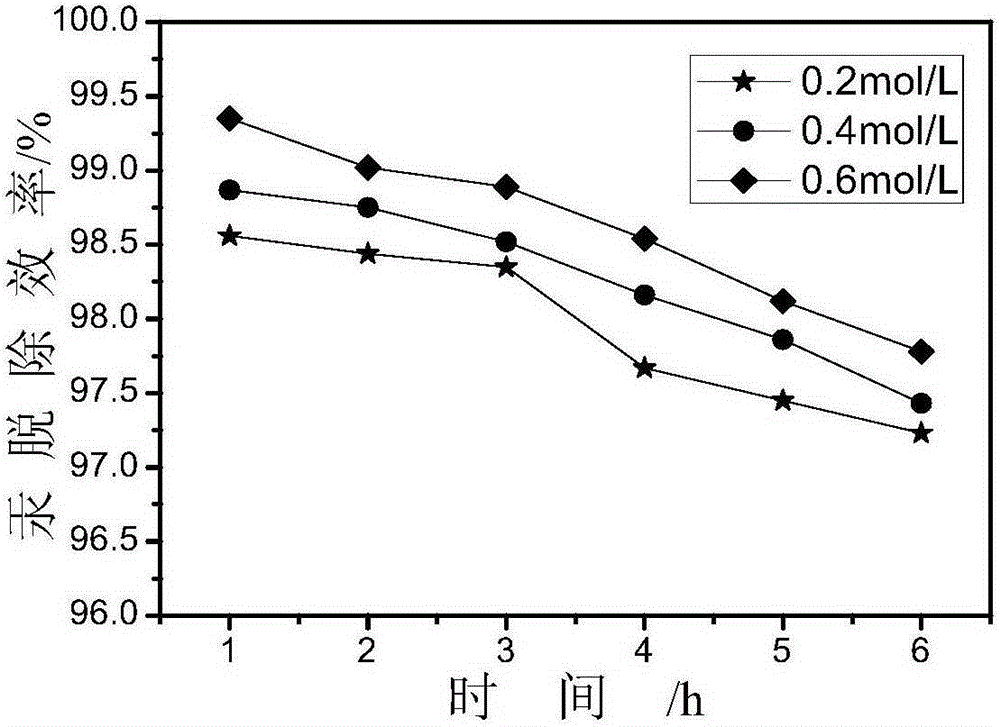

Washing liquid for eluting mercury in mercury-containing flue gas and method for recovering mercury form mercury-containing flue gas

ActiveCN105289261AEasy to precipitate and recoverImprove absorption efficiencyDispersed particle separationMercury compoundsRecovery methodThiourea

The invention disclose a washing liquid for eluting mercury in mercury-containing flue gas and a method for recovering mercury form mercury-containing flue gas. The washing liquid is a sulfuric acid solution containing thiourea and trivalent iron ions, and is especially suitable for removing mercury from smelting flue gas with a high content of sulfur dioxide. The mercury recovery method comprises the following steps: introducing mercury-containing flue gas into a washing reactor to fully contact the washing liquid, which flows in an opposite direction, wherein during the process the elemental mercury and oxidation-state mercury in the flue gas are purified and absorbed, then using a sulfurized salt precipitant to recover mercury form the washing liquid, and returning the washing liquid to the washing tower. The method can well remove mercury from flue gas, the recovery efficiency is high, and the comprehensive recovery rate of mercury from flue gas can reach 95% or more.

Owner:CENT SOUTH UNIV

Comprehensive processing method for waste mercury catalyst

InactiveCN105154676AEmission reductionHigh recovery rateProcess efficiency improvementDistillationComponents of crude oil

The invention relates to the technical field of comprehensive processing for waste mercury catalysts, in particular to a comprehensive processing method for a waste mercury catalyst. The waste mercury catalyst is mixed with quick lime and then boiled, so that effective ingredients of the waste mercury catalyst act with the quick lime, the purpose of curing the waste mercury catalyst is achieved, and the conversion efficiency of the waste mercury catalyst in the distillation process is improved; steam with mercury obtained after distillation is cooled to obtain steam residues, the steam residues act with a reactant, and mercury ingredients in the steam residues are precipitated greatly; and through ultrasonic processing coupled with centrifugal processing, the reactant and the steam residues can act more thoroughly, the rate of mercury recovery performed after mercury catalyst processing is improved, waste liquid emissions are reduced, environmental pollution is reduced, and the content of mercury discharged in the environment is reduced to 0.09-0.13%.

Owner:贵州蓝天固废处置有限公司

Treatment method of water polluted by mercury

ActiveCN104150634AReduce mercury levelsProcessing speedWater contaminantsMultistage water/sewage treatmentHydrogen SulfateP-tert-Butylphenol

The invention relates to the field of water treatment, and in particular relates to a treatment method of water polluted by mercury. The method comprises the following steps: (1) regulating the pH value of mercury-containing sewage to be 6-6.5, and adding sodium alcohol ether sulfate and sodium hypochlorite into the mercury-containing sewage, wherein the additive amount of sodium alcohol ether sulfate accounts for 1-2 times of the mass concentration of mercury in the sewage, and the additive amount of sodium hypochlorite accounts for 3-5 times of the mass concentration of mercury in the sewage; (2) regulating the pH value of the sewage to be 8-9, and then adding poly p-tert-butylphenol disulfide, ferrous sulfide and sodium hydrogen sulfate into the sewage under the conditions that the mass ratio of p-tert-butylphenol disulfide to ferrous sulfide to sodium hydrogen sulfate is (1-2) to (2-4) to 5, and the mass concentration of poly p-tert-butylphenol disulfide in the sewage is 1-5%; (3) then adding a flocculating agent, calcium oxide and alkylphenol polyoxyethylene into the sewage under the conditions that the mass ratio of the flocculating agent to calcium oxide to alkylphenol polyoxyethylene is 1 to 3 to 2, and the additive quantity of the flocculating agent is 0.1-0.3% of the quantity of the sewage; (4) standing the sewage for 3-5 days in a separation tank, and then performing solid-liquid separation; (5) adsorbing the separated sewage by adopting an activated carbon absorber, and then discharging the sewage.

Owner:ZHEJIANG OCEAN UNIV

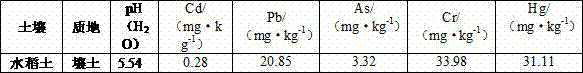

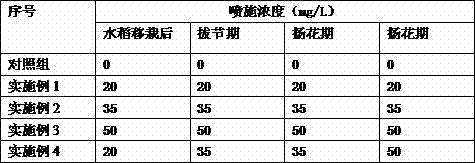

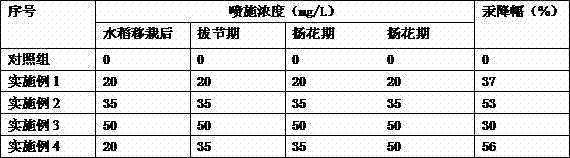

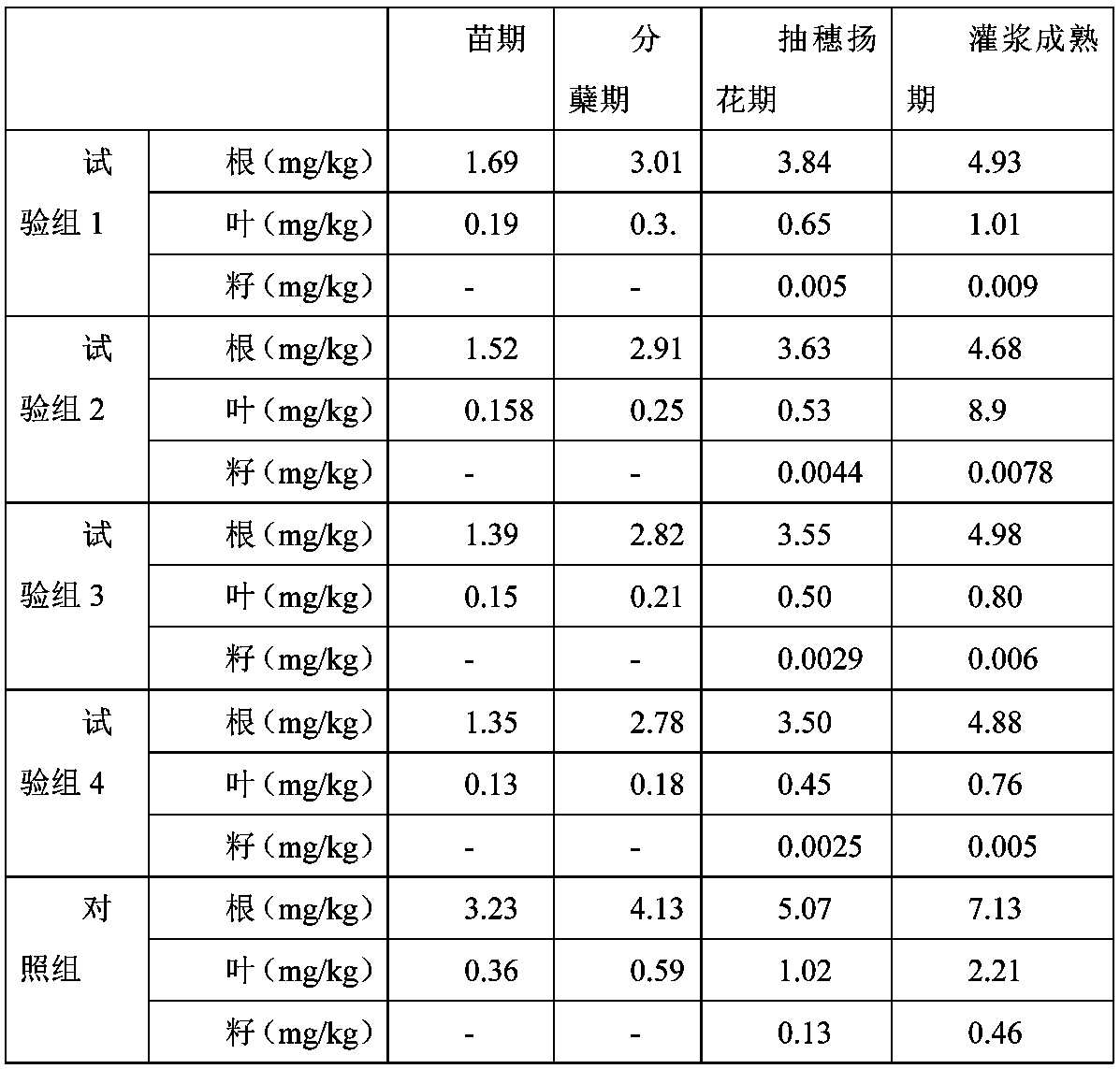

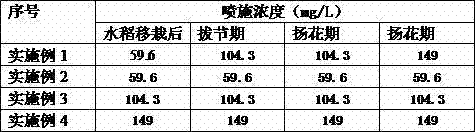

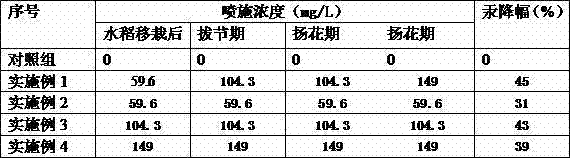

Method for controlling rice heavy metal mercury accumulation by salicylic acid

InactiveCN104221796AReduce the amount of applicationLow costFertilising methodsRice cultivationSalicylic acidAqueous solution

The invention discloses a method for controlling rice heavy metal mercury accumulation by salicylic acid. The method is characterized by sequentially comprising the following steps that (1) after the soil preparation, rice seedlings are transplanted; (2) the salicylic acid is prepared into a water solution with the concentration being 1 to 50mg / L, after 7 to 21 days of the rice transplanting, on the 1st to 7th days of the jointing period, the 1st to 7th days of the flowering period and the 7th to 21st days of the flowering period, the salicylic acid solution is sprayed on leaf surfaces by a sprayer, and 3L salicylic acid solution is uniformly sprayed in each region with the dimension being 3.5m*4.0m. Through the spraying of the salicylic acid solution with the proper concentration in each growth period of the rice, the mercury contents of the produced rice are respectively reduced by 30 percent to 60 percent, and in addition, a conventional agricultural method can be adopted for soil preparation, seedling culture, transplanting and field management in the rice production process.

Owner:CHINA JILIANG UNIV

Hazardous mercury-containing waste residue all-wet high-efficiency demercuration method

The invention discloses a hazardous mercury-containing waste residue all-wet high-efficiency demercuration method. The method comprises the steps of conducting oxidation treatment on hazardous mercury-containing waste residues through an acid persulfate solution, and adjusting the pH of the hazardous mercury-containing waste residues to 7 or more; and conducting leaching through a thiosulfate solution, conducting leaching through an organic acid and iodine salt mixed solution and conducting leaching through a sodium sulfide and sodium hydroxide mixed solution. By means of the method, mercury in multiple valence states in the hazardous mercury-containing waste residues can be efficiently leached; the mercury residual rate is low; the hazardous mercury-containing waste residues can be changed into general waste; the hazardous waste treatment cost is greatly reduced; and secondary pollution to the environment is avoided.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Environmentally friendly nuisanceless rice planting method

InactiveCN109089807AReduce mercury levelsGood effectRoot crop cultivationPlant protective coveringsRhizosphereRoot system

The invention discloses an environmentally friendly nuisanceless rice planting method. The environmentally friendly nuisanceless rice planting method is characterized by comprising the following steps: culturing photosynthetic bacteria, preparing a photosynthetic bacteria solution a, preparing a base solution, mixing the photosynthetic bacteria solution a with the base solution to obtain a photosynthetic bacteria solution b, soaking a rice seedling root system in the photosynthetic bacteria solution b for 12-14 h during transferring of rice; forming a photosynthetic bacteria rhizosphere film on a rice seedling rhizosphere, and then planting. Compared with the prior art, the environmentally friendly nuisanceless rice planting method has the beneficial effects that (1) a rhizosphere bacteriafilm is formed on the root of soil by improved photosynthetic bacteria, the roots of rice are protected, mercury is stopped from entering the roots of the rice, the content of mercury in rice seeds is reduced, compared with a traditional mercury spraying technology, the method is more remarkable in effect, the amount of application is small, and the ability of stopping the rice from adsorbing themercury is excellent; and (2) the environmentally friendly nuisanceless rice planting method is environmentally friendly, while the rice is effectively stopping from adsorbing the mercury, influenceto the original ecological system of the soil and the yield of a farmland is small, and abundance of microbial population of the soil can be promoted.

Owner:XINJIANG GUANGHEYUAN BIOTECH CO LTD

Method for remediating Hg-polluted soil of farmland through plant

InactiveCN106424105ASolve the problem of high levels of heavy metal mercuryReduce mercury levelsContaminated soil reclamationEuphorbia esulaSoil remediation

The invention provides a method for remediating Hg-polluted soil of a farmland through plant, and belongs to the technical field of farmland soil remediation and treatment. The method for remediating the Hg-polluted soil of the farmland through the plant comprises the following steps: 1) applying fertilizer to the Hg-polluted soil to improve the soil fertility; and 2) planting euphorbia esula in the improved soil. According to the method for remediating the Hg-polluted soil of the farmland through the plant, the soil fertility is improved; an enriching crop, namely, euphorbia esula, is planted to enrich the heavy metal Hg in the polluted farmland, so that the problem of excessively high metal mercury content of the farmland soil can be solved.

Owner:BEIJING GEOENVIRON ENG & TECH

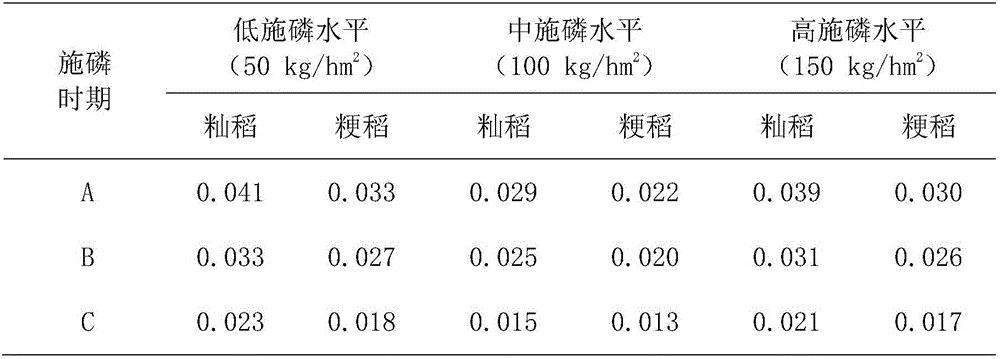

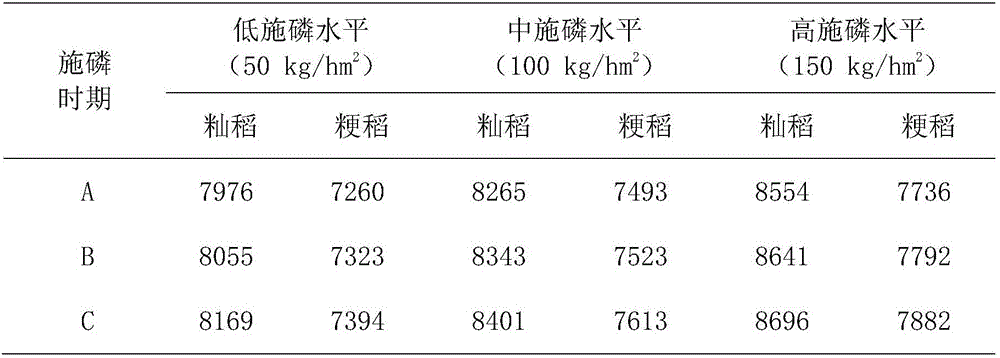

Method for applying phosphate fertilizer to reduce content of mercury in rice grains of heavy mercury polluted rice field

InactiveCN106358553AReduce mercury levelsEliminate health threatsFertilising methodsHectareJaponica rice

The invention relates to a method for applying a phosphate fertilizer to reduce the content of mercury in rice grains of a heavy mercury polluted rice field, belonging to the technical field of agricultural product heavy metal pollution prevention and treatment. The method is characterized by comprising the following steps: in the heavy mercury polluted rice field (the soil Hg concentration is 2mg / kg, which is 4 times the national limit standard), applying 100kg / hm<2> (at a middle phosphorus application level by an effective component P2O5) of the phosphate fertilizer for three times, namely, applying 1 / 2 of the total phosphatic fertilizer 3 days before rice transplanting, and applying 1 / 4 of the total phosphatic fertilizer 5 days before earing and 10 days after head sprouting respectively; throwing the phosphate fertilizer 3 days before rice transplanting, namely, uniformly throwing the phosphate fertilizer into the rice field; applying the phosphate fertilizer in a leaf surface spraying mode 5 days before earing and 10 days after head sprouting, dissolving a water-soluble phosphate fertilizer into water, and spraying 300L of water with the phosphate fertilizer to each hectare of the rice field. Compared with a common high-level one-time phosphate fertilizer application method used in practical rice production, the method has an application effect that the content of mercury in the rice grains can be greatly reduced (the content of the mercury in indica type rice is reduced by 61.54%, and the content of mercury in japonica rice is reduced by 56.67%), and the yield of rice is not greatly reduced.

Owner:CHANGZHOU UNIV

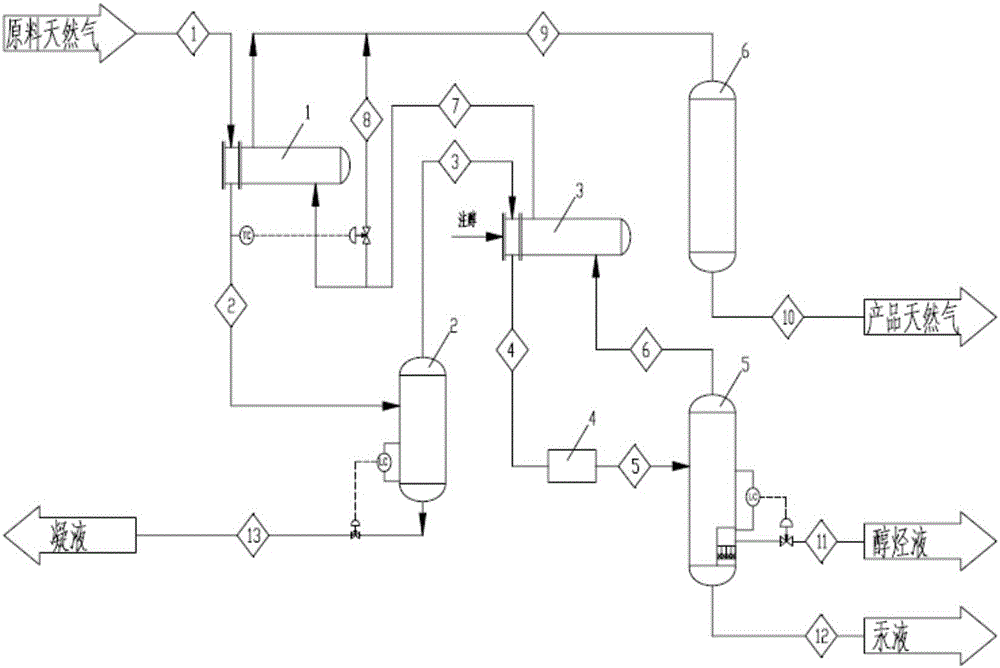

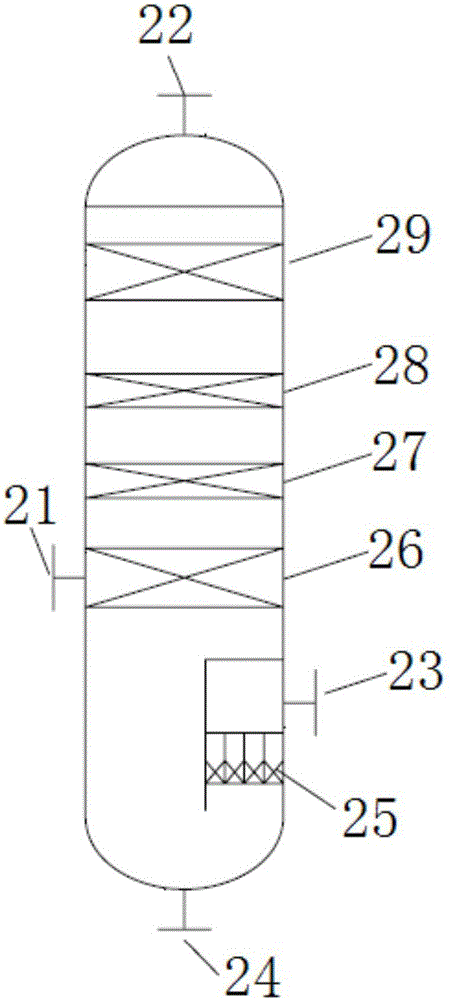

Natural gas demercuration device and method

ActiveCN105779055AEffective separation and removalEfficient separationGas treatmentGaseous fuelsAlcoholProcess engineering

The invention discloses a natural gas demercuration device and method. The device comprises a raw gas precooler, a raw gas separator, a raw gas aftercooler, a refrigerating facility, a low-temperature separator and the like which are connected in sequence. The natural gas demercuration device and method have the positive effects that an internal demercuration member is arranged by improving an internal structure of the low-temperature separator, such that an alcohol-hydrocarbon solution is extracted from the side surface instead of being extracted from the bottom by low-temperature separation, and low-temperature liquid mercury is discharged from the bottom of the low-temperature separator to be subjected to low-temperature demercuration, dehydration and dealkylation. Mercury, water and heavy hydrocarbons in raw gas are separated and removed effectively by the low-temperature separator through adopting a low-temperature separation, demercuration, dehydration and dealkylation system consisting of the raw gas precooler, the raw gas separator, the raw gas aftercooler, the refrigerating facility and the low-temperature separator.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method adopting sodium nitroprusside for controlling rice heavy metal mercury accumulation

ActiveCN104322336AReduce the amount of applicationLow costHorticulture methodsRice cultivationAqueous solutionLand preparation

The invention discloses a method adopting sodium nitroprusside for controlling rice heavy metal mercury accumulation. The method sequentially comprises the following steps that (1) after the soil preparation, rice seedlings are transplanted; (2) the sodium nitroprusside is prepared into a water solution with the concentration being 1 to 50mg / L, the sodium nitroprusside solution is sprayed onto leaves by a sprayer on 7th day to 21st day after the rice transplanting, 1st day to 7th day in the flowering stage and 7th day to 21st day in the flowering period, and 3L of the water solution is uniformly sprayed in each 3.5m*4.0m region. The sodium nitroprusside solution with the proper concentration is sprayed in each growth period of the rice, so the mercury content of the produced rice is respectively reduced by 30 percent to 50 percent, and in addition, in the rice production process, agricultural conventional methods are respectively adopted for land preparation, seedling culture, transplanting and field management.

Owner:CHINA JILIANG UNIV

Tin amalgam particle and preparing method and application thereof

The invention discloses a tin amalgam particle and a preparing method thereof. The preparing method includes steps of: (1) adding 71-90wt% of tin and 10-29wt% of mercury into a sealed container in atmosphere of inert gases, fusing tin and mercury by raising temperature, and evenly mixing to obtain an alloy solution; (2) in atmosphere of inert gases, preparing the alloy solution into alloy drops with diameters of 0.5-2.0 mm; and (3) indirectly cooling inert gas current through liquid and condensing the alloy drops by aid of the cooled inert gas current at temperature of -100 DEG C to -190 DEG C to obtain the tin amalgam particle. The invention further discloses application of the tin amalgam particle in low-temperature fluorescent lamps. The tin amalgam particle can effectively control mercury vapor pressure, enables the fluorescent lamps to reach optimum light effect, can replace liquid mercury, accurately controls the amount of mercury guided into the lamps, is low in mercury content, can save mercury resources to the maximum limit and achieves effect of energy conservation and emission reduction. The preparing process is simple, feasible and suitable for large-scale industrial production.

Owner:上海亚尔精密零件制造有限公司

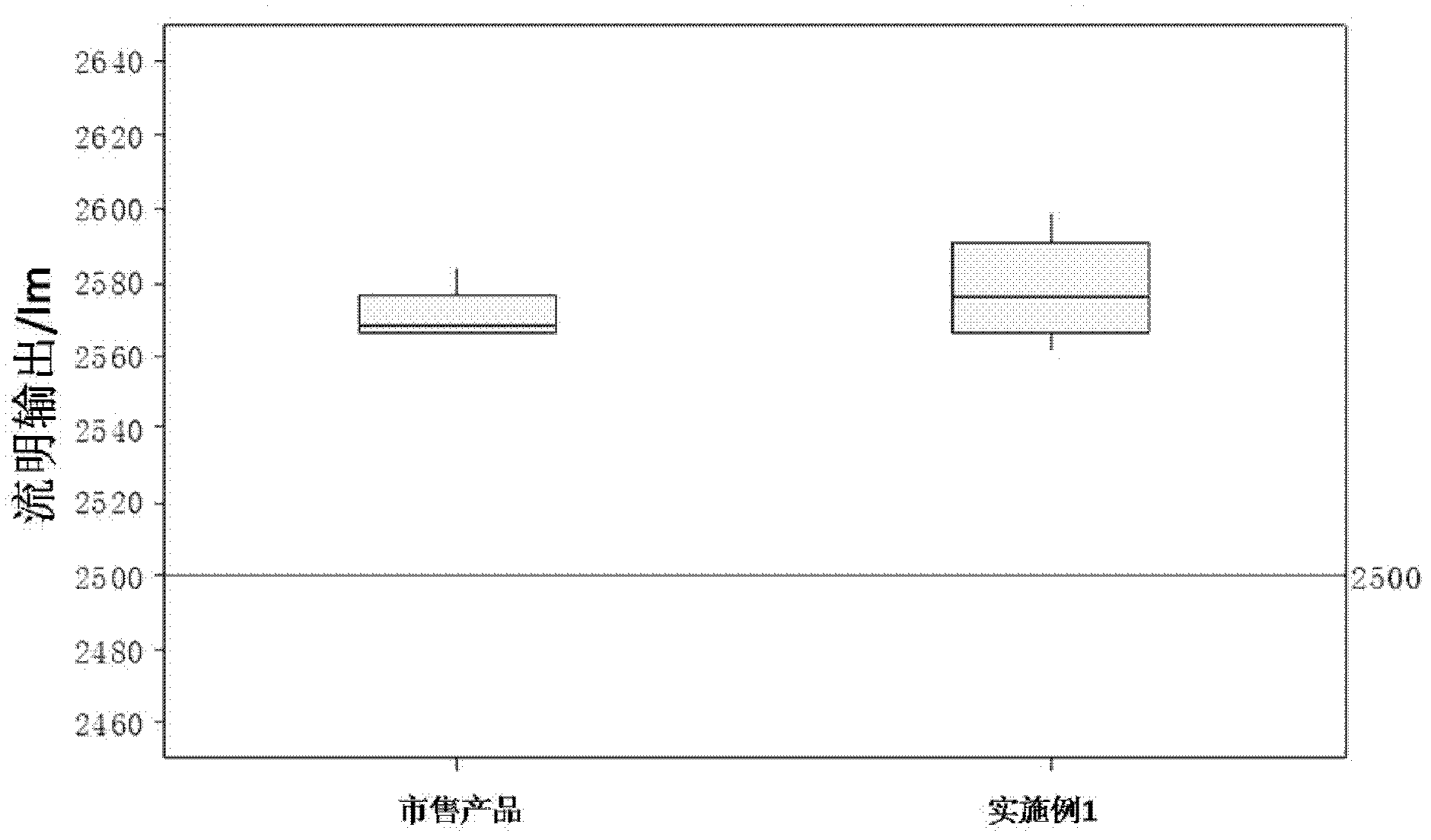

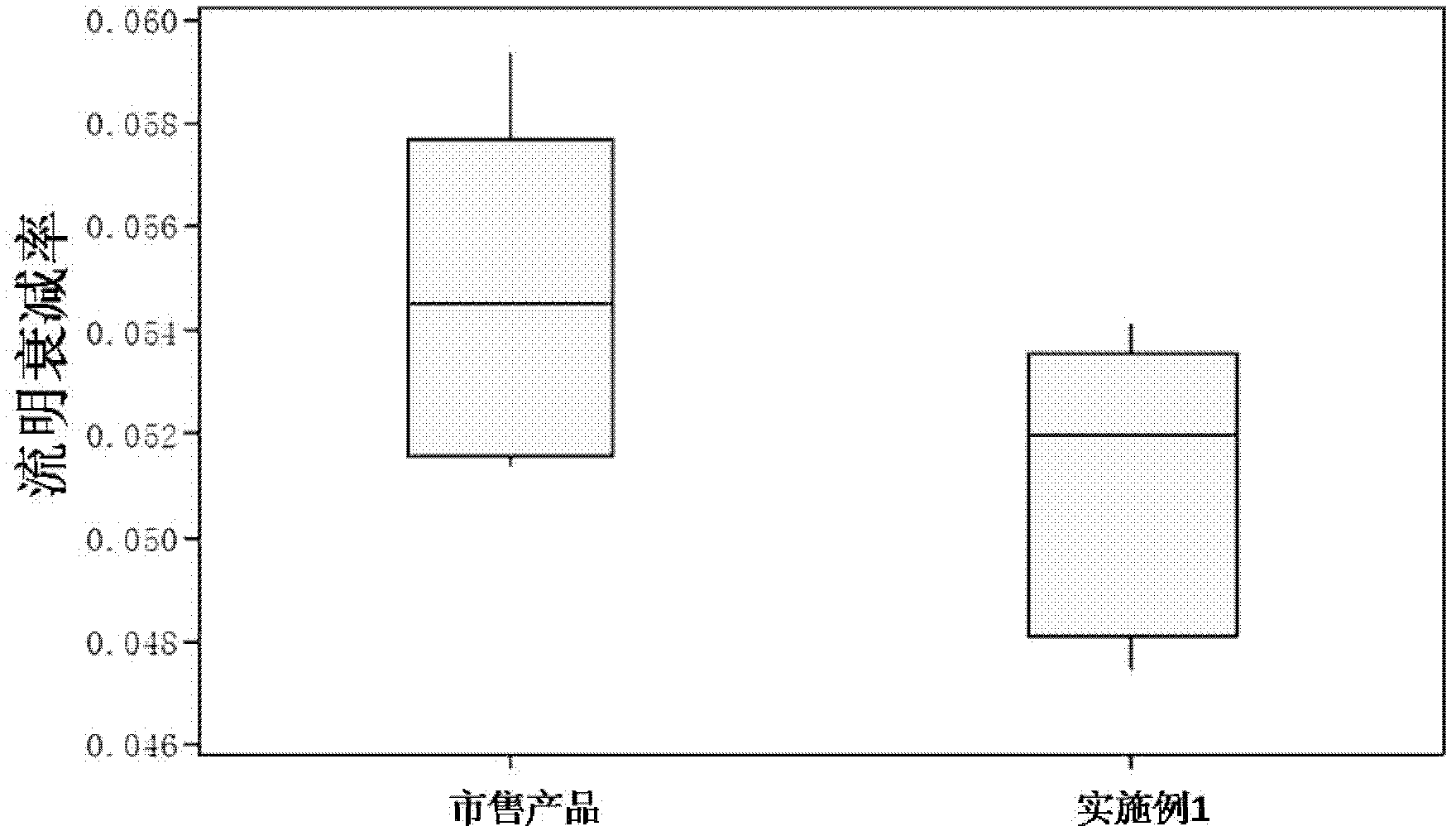

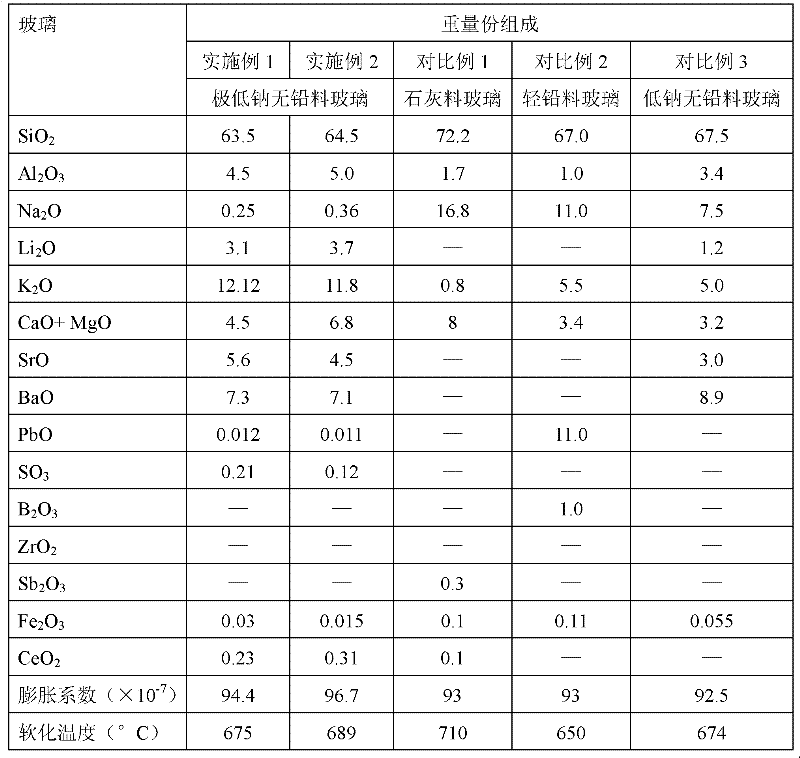

Ultra-low-sodium lead-free glass and applications thereof

InactiveCN102503124ARadiation suppressionMeet environmental protection requirementsGas discharge lamp detailsLumen maintenanceFluorescent lamp

The invention belongs to the technical field of the energy-saving light source material and relates to ultra-low-sodium lead-free glass and applications thereof. The sodium content of the ultra-low-sodium lead-free glass is below 0.5% and above 0.23%, thus the lumen maintenance of the lamp tube is extremely improved in the use process, the luminous decay of the lamp tube is minimized, the effect of extremely high lumen maintenance is realized without adopting protective film coating, the cost is saved and the coating difficulty of the fluorescent powder is reduced. The ultra-low-sodium lead-free glass does not contain As2O3 and Sb2O3; the content of PbO is extremely low, which is below 0.012%, thus the product belongs to lead-free glass; and the weight percent of CeO2 is not zero and the glass material meets the Rohs environmental protection standard. The ultra-low-sodium lead-free glass can be widely used to prepare various electronic luminous bodies such as fluorescent lamp tubes or energy saving lamp tubes.

Owner:SHANGHAI YAMING LIGHTING

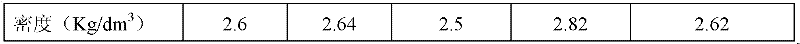

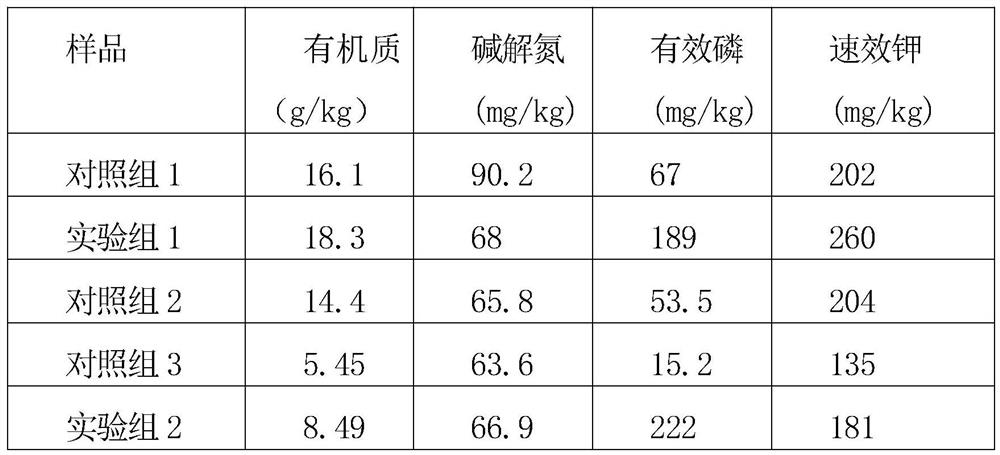

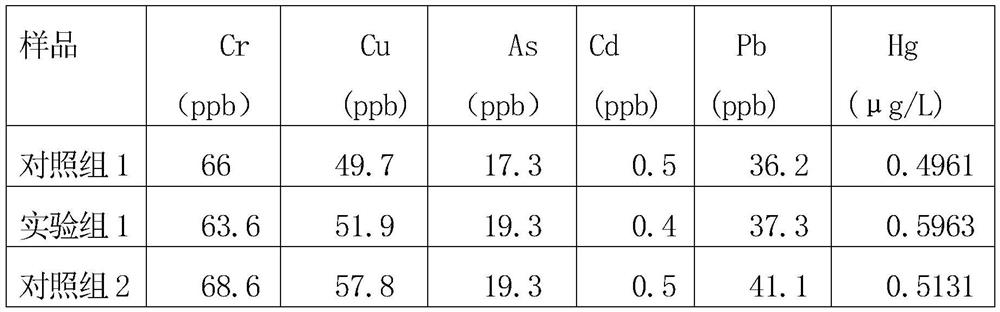

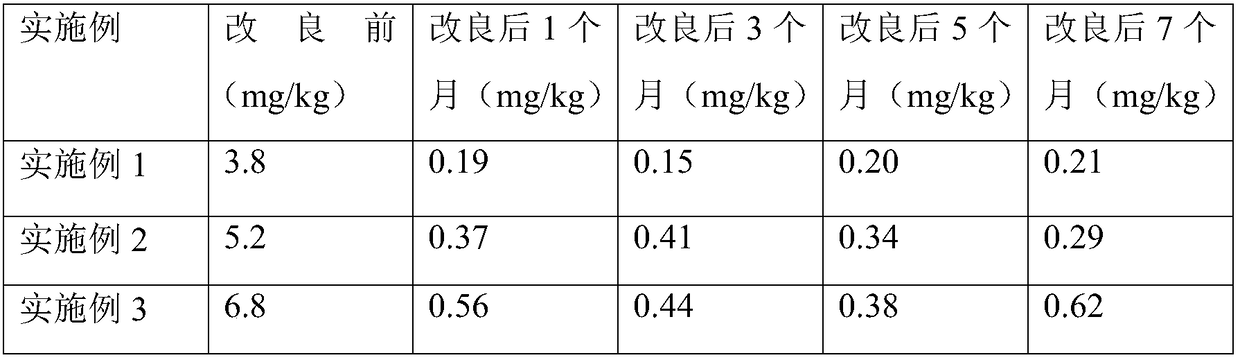

Soil conditioner and preparation method and application thereof

InactiveCN113265256ARegulate pHImprove the environmentAgriculture tools and machinesMagnesium fertilisersMonosodium glutamateCarbonization

The invention provides a soil conditioner and a preparation method and application thereof, and relates to the field of soil improvement. The soil conditioner comprises the following components in percentage by weight: 88%-95% of purified attapulgite, 3%-8% of fulvic acid, 1%-2% of nanoscale carbonized astragalus residue powder, 0.5%-1% of nanoscale modified cellulose powder and 0.5%-1% of monosodium glutamate tail liquid. The soil conditioner can effectively increase the content of organic matters, available phosphorus and available potassium in soil, increase the pH value of the soil and reduce the content of heavy metals chromium and cadmium in the soil, so that the soil structure is effectively improved, the crop growth is promoted, and the quality of agricultural products is improved.

Owner:LANZHOU UNIVERSITY +1

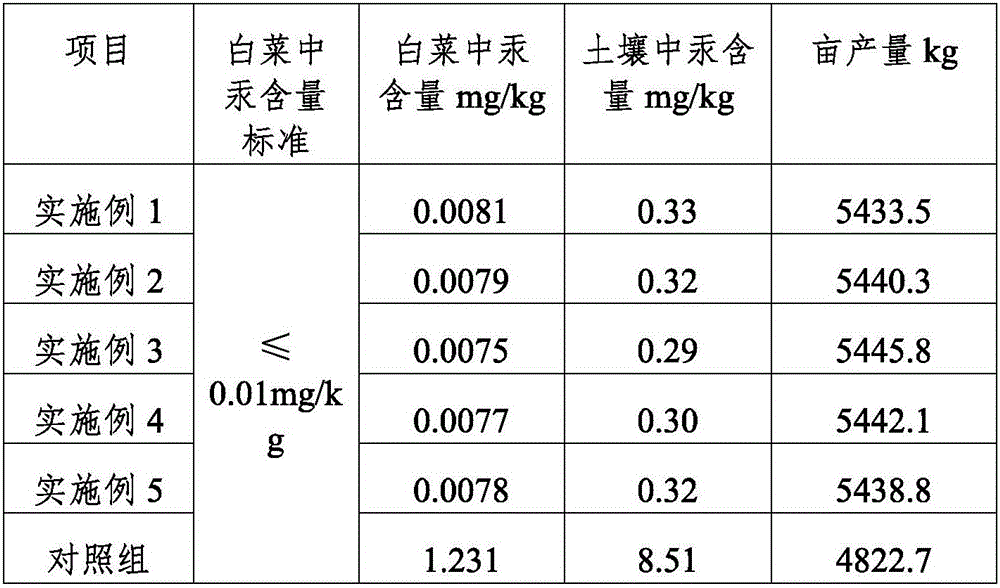

Fertilizer for mercury polluted soil

InactiveCN106748199AFull of nutritionGood restorativeCalcareous fertilisersOrganic phosphatic fertilisersSodium BentoniteSoil heavy metals

The invention relates to the technical field of fertilizers, in particular to a fertilizer for mercury polluted soil. The fertilizer comprises, by weight, 25-30 parts of urea, 15-20 parts of potassium sulfate, 25-30 parts of urea phosphate, 10-15 parts of calcium nitrate, 10-15 parts of calcium chloride, 8-13 parts of gypsum, 6-9 parts of sodium selenite, 4-7 parts of zinc sulfate, 3-5 parts of ammonium molybdate, 10-15 parts of Chinese medicine residues, 15-20 parts of plant extract, 15-20 parts of modified calcium hydroxide and 10-15 parts of modified bentonite. The fertilizer is rich in nutrients, the total nutrient content of nitrogen, phosphorus and potassium is larger than or equal to 58.9%, the rate of changing an effective state into an ineffective state serves as a soil restoration evaluation index, the conversion rate of mercury metal in the soil reaches 96.1% or more, take Chinese cabbages as an example, yield can be increased by 12.6-12.9%, and double benefits of high yield and soil heavy mental restoration are achieved.

Owner:BLESSING OF GUIZHOU ECOLOGICAL FERTILIZER CO LTD

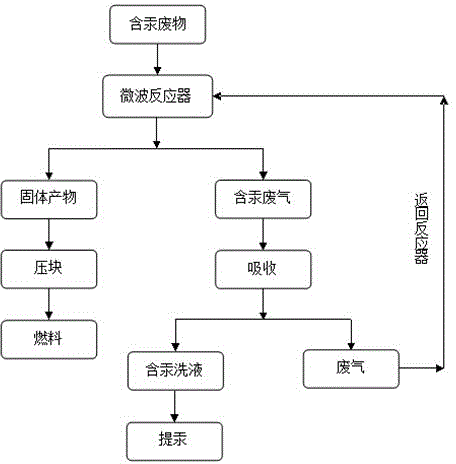

Mercury-containing waste recovery method

The invention relates to a mercury-containing waste recovery method and a device, and belongs to the technical field of mercury treatment. The method comprises steps of: putting mercury-containing wastes into a closed microwave reactor; regulating the power of the microwave reactor to 1-80kW; heating the mercury-containing wastes at the heating rate of 10-100 DEG C / min from the room temperature to 200-900 DEG C; then filling mercury-containing waste gas generated by the reaction into an eluting solution so as to extract mercury; finally, filling the waste gas after mercury extraction into the microwave reactor to circularly react for 3-30 minutes and then stopping the reaction; and taking solid products (mercury-containing wastes after mercury extraction reaction) from the microwave reactor, and briquetting the solid products to be used as fuel. The device comprises the microwave reactor, a gas absorption device and a circulation device, wherein the microwave reactor is sequentially communicated with the gas absorption device and the circulation device so as to form a circulation loop. The method is a novel, efficient, economic and practicable mercury removing technology, and 'zero emission and zero pollution' can be completely realized.

Owner:KUNMING UNIV OF SCI & TECH

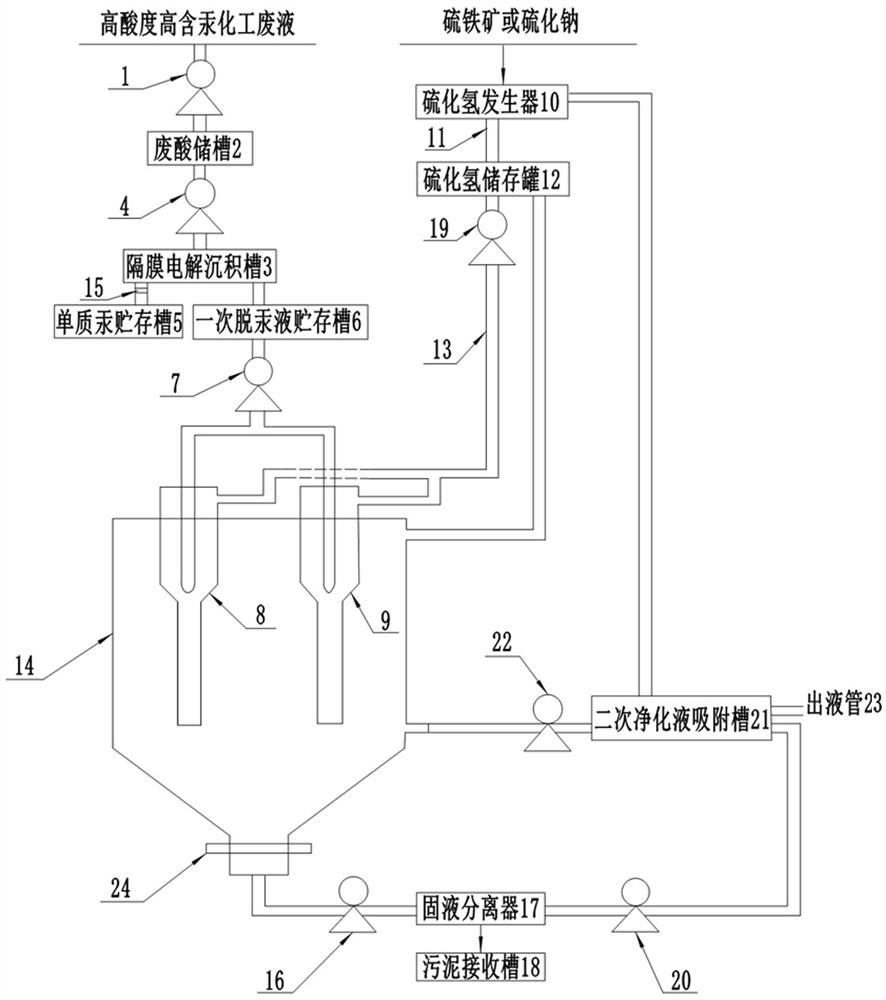

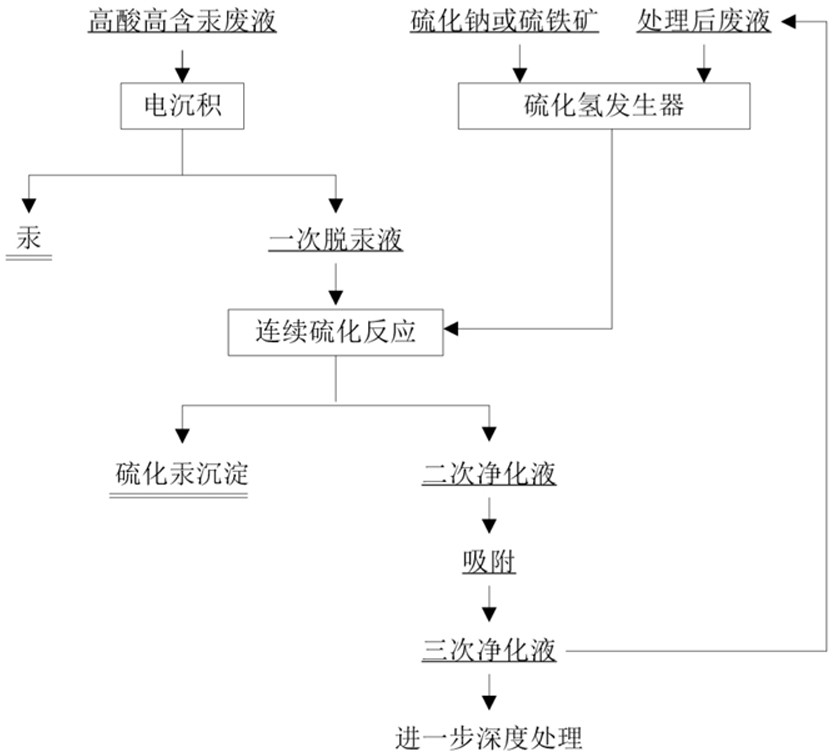

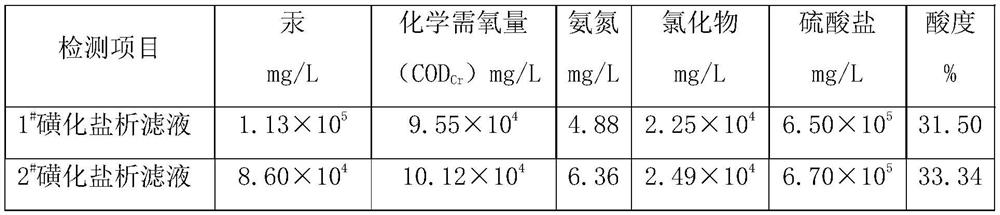

Method and device for jointly removing mercury from high-acidity chemical mercury-containing waste acid liquid

PendingCN111762927AContinuous and efficient removalGuaranteed deep purificationWater contaminantsWater/sewage treatmentSorbentMercury sulfide

The invention discloses a method and device for jointly removing mercury from high-acidity chemical mercury-containing waste acid liquid, and belongs to the field of mercury treatment. The device consists of a diaphragm electro-deposition unit, a continuous vulcanization mercury removal unit and an adsorption mercury removal unit which are connected in sequence and can realize continuous and efficient removal of the mercury in any form in the high-acidity mercury-containing waste acid liquid. According to the method disclosed by the invention, the mercury in the high-acidity mercury-containingwaste acid liquid can be continuously and rapidly removed by utilizing a diaphragm electrolytic deposition method-continuous vulcanization method-adsorbent mercury removal method combined process technology, so that the mercury is precipitated and removed in the form of metal mercury and mercury sulfide, and the mercury can be recycled after being collected; the electrolytic deposition method issmall in occupied area, environmentally friendly and free of pollution; organic mercury and inorganic mercury are precipitated out in the form of metal mercury finally, so that the mercury content ofthe high-acidity waste liquid can be effectively reduced; hydrogen sulfide gas produced by the continuous vulcanization method is hermetically circulated in a system with no pollution brought about; and the adsorbent mercury removal method can ensure deep purification of the waste liquid, which is more beneficial to the comprehensive utilization of the purified acid liquid.

Owner:唐山周行科技发展有限公司

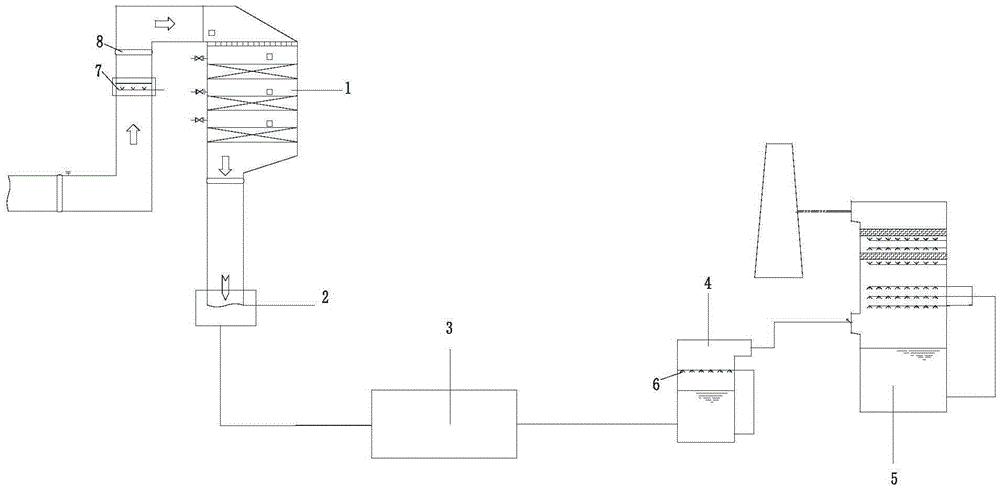

Mercury curing and removing method for coal-fired power plant and device thereof

InactiveCN105381698AAchieve removalAvoid enteringDispersed particle separationSolubilityAir preheater

The invention discloses a mercury curing and removing method for a coal-fired power plant. The method comprises the following steps of treating a flue gas by an air preheater after the flue gas is subjected to denitration treatment; conducting electrostatic dust-removal treatment on the treated flue gas, and removing divalent mercury in a sulfide solution; and desulfurizing the flue gas which is subjected to demercuration treatment, and emitting the flue gas. According to the method, the divalent mercury in the flue gas is collected in a mercury collector before the flue gas which is subjected to dust removal by a dust collector enters a desulfurization tower, so that the divalent mercury in the flue gas is prevented from entering desulfurization gypsum, and the mercury content in the desulfurization gypsum is greatly reduced; hazardous waste treatment is carried out intensively after mercury in the collector is enriched, the gypsum quality is prevented from being influenced by the fact that the divalent mercury enters the desulfurization gypsum of the desulfurization system, and the problem of secondary pollution caused by mercury release is avoided at the same time; the mercury collector is arranged before desulfurization, the temperature of the flue gas at the desulfurization inlet can be reduced, and the desulfurization efficiency can be improved; and mercury collected in a mercury collection reactor can be intensively subjected to hazardous waste treatment, so that mercury removal can be truly realized.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

A composite microbial agent and a preparation method and application thereof

InactiveCN109182227ARegulate metabolic balanceEfficient and stable pollutionFungiBacteriaFusarium oxysporumMicroorganism

The invention provides a composite microbial agent and a preparation method and application thereof, wherein the composite microbial agent comprises Saccharomyces cerevisiae, Fusarium oxysporum, Alternaria tenuiflora and Pseudomonas putida. The invention combines Saccharomyces cerevisiae, Fusarium oxysporum, Alternaria tenuiflora and Pseudomonas putida to synergize the four strains, regulate the metabolic balance among the bacteria, make the compound bacterium highly effective and stable to pollute the mercury in the soil, and reduce the mercury content in the plant.

Owner:泽明环境发展有限公司 +1

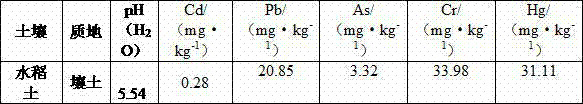

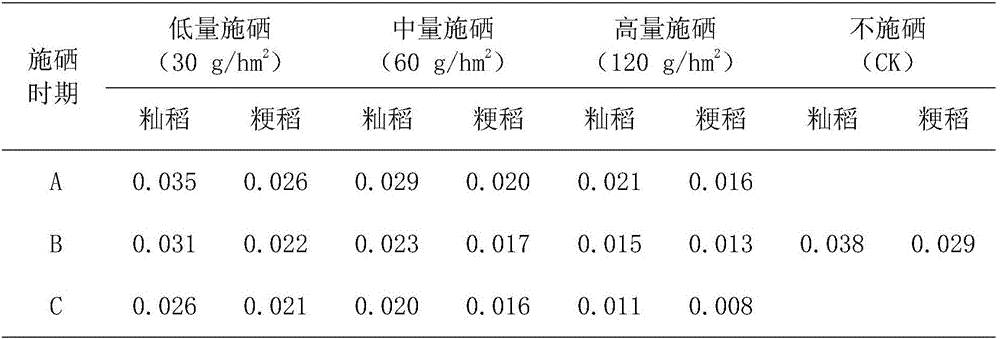

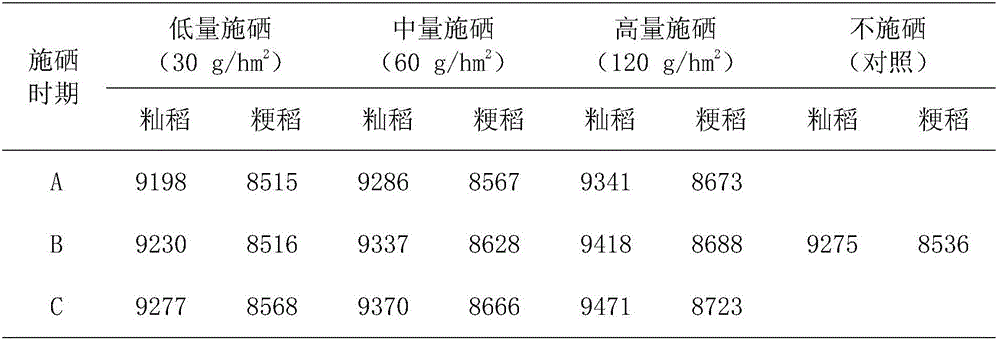

Selenium application method for reducing mercury content of rice grains in rice field with severe mercury contamination

InactiveCN106612833AReduce mercury levelsYield was not significantly affectedFertilising methodsWater solubleJaponica rice

The invention relates to a selenium application method for reducing mercury content of rice grains in a rice field with severe mercury contamination and belongs to the technical field of controlling heavy metal contamination in agricultural products. The method is characterized by applying selenium three times under total application amount of 120 g / hm<2> (high application amount) to a rice field with severe mercury contamination (having soil Hg concentration of 2 mg / kg, four times the national limit standard), to be specific, applying 1 / 2 of total selenium 20 days after rice transplanting, applying 1 / 4 of the total selenium 5 days before heading, and applying 1 / 4 of the total selenium 10 days after heading. Compared with common selenium-free application in actual rice production, the method provides a great decrease in the mercury content of rice grains (71.05% for Indica rice, and 72.41% for Japonica rice).

Owner:CHANGZHOU UNIV

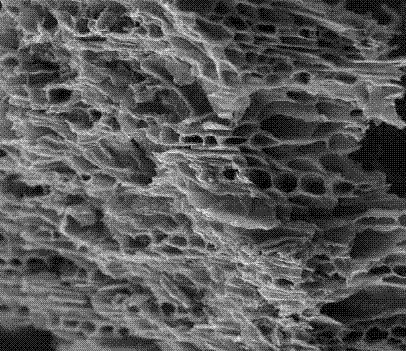

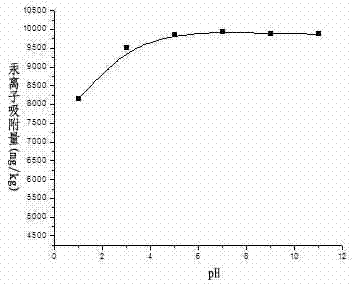

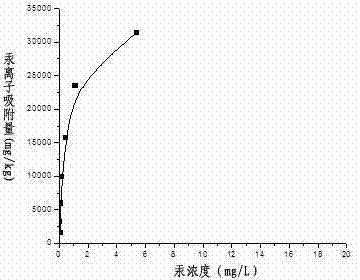

Method for adsorbing mercury ions in wastewater by carbon granules prepared by chicken manure

InactiveCN104492377AWell-developed pore structureReduce mercury levelsOther chemical processesWater contaminantsIonEnvironmental chemistry

The invention relates to a method for adsorbing mercury ions in wastewater by carbon granules prepared by chicken manure. The method comprises the following steps: acquiring fourth carbonized granules by the steps I-IV, adjusting the pH value of mercury-containing wastewater to be 8, adding 50g of mixture of poly-tert-butylphenoldisulfide, ferrous sulfide and sodium hydrogen sulfate with the mass ratio of 1:2:4 into one liter of mercury-containing wastewater, mixing for 1h, adjusting the pH value of mercury-containing wastewater to be 6.5, adding with 50g of mixture of polyoxyethylene fatty alcohol sodium sulfate and sodium hypochlorite into one liter of mercury-containing wastewater, mixing for 2h, filtering, adjusting the pH value of mercury-containing wastewater to be 5-6.3, and adding 12.5g of the fourth carbonized granules into one liter of the treated mercury-containing wastewater, and mixing at 120r per minute for 8h.

Owner:QINGDAO AGRI UNIV

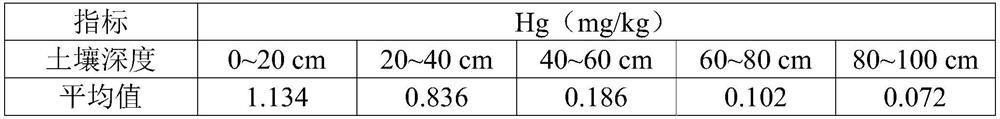

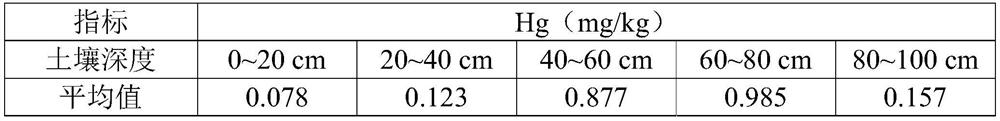

Layered replacement repair method for mercury-polluted farmland

ActiveCN112404112AReduce the level of mercury pollutionAvoid secondary pollutionContaminated soil reclamationPollutantEnvironmental chemistry

The invention discloses a layered replacement repair method for mercury-polluted farmland. The method comprises the following steps: respectively shoveling out and stacking shallow-layer polluted soiland deep-layer clean soil through an excavator bucket, backfilling shallow-layer polluted soil subjected to curing treatment to a deep-layer position for tamping, and backfilling the original deep-layer clean soil on the cured shallow-layer polluted soil, thereby achieving layered replacement of the shallow-layer polluted soil and the deep-layer clean soil. The mercury content of the repaired surface soil reaches the standard, the content of mercury pollution of the shallow soil is effectively reduced, secondary pollution of the soil is avoided, and the quantity of pollutants is reduced to the maximum extent; the land utilization rate is increased, and the normal agricultural production requirement is met; and the safety of agricultural products is guaranteed, and the risk that agricultural products exceed standards to human health is avoided.

Owner:广州草木蕃环境科技有限公司 +1

A kind of treatment method of mercury polluted water

ActiveCN104150634BReduce mercury levelsProcessing speedWater contaminantsMultistage water/sewage treatmentHydrogen SulfateP-tert-Butylphenol

The invention relates to the field of water treatment, and in particular relates to a treatment method of water polluted by mercury. The method comprises the following steps: (1) regulating the pH value of mercury-containing sewage to be 6-6.5, and adding sodium alcohol ether sulfate and sodium hypochlorite into the mercury-containing sewage, wherein the additive amount of sodium alcohol ether sulfate accounts for 1-2 times of the mass concentration of mercury in the sewage, and the additive amount of sodium hypochlorite accounts for 3-5 times of the mass concentration of mercury in the sewage; (2) regulating the pH value of the sewage to be 8-9, and then adding poly p-tert-butylphenol disulfide, ferrous sulfide and sodium hydrogen sulfate into the sewage under the conditions that the mass ratio of p-tert-butylphenol disulfide to ferrous sulfide to sodium hydrogen sulfate is (1-2) to (2-4) to 5, and the mass concentration of poly p-tert-butylphenol disulfide in the sewage is 1-5%; (3) then adding a flocculating agent, calcium oxide and alkylphenol polyoxyethylene into the sewage under the conditions that the mass ratio of the flocculating agent to calcium oxide to alkylphenol polyoxyethylene is 1 to 3 to 2, and the additive quantity of the flocculating agent is 0.1-0.3% of the quantity of the sewage; (4) standing the sewage for 3-5 days in a separation tank, and then performing solid-liquid separation; (5) adsorbing the separated sewage by adopting an activated carbon absorber, and then discharging the sewage.

Owner:ZHEJIANG OCEAN UNIV

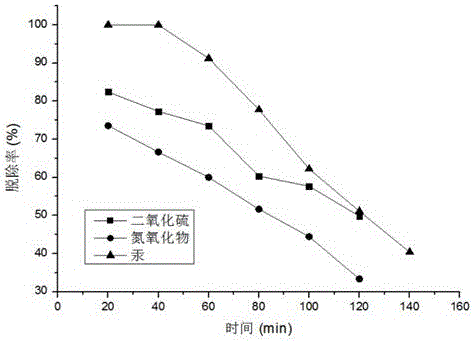

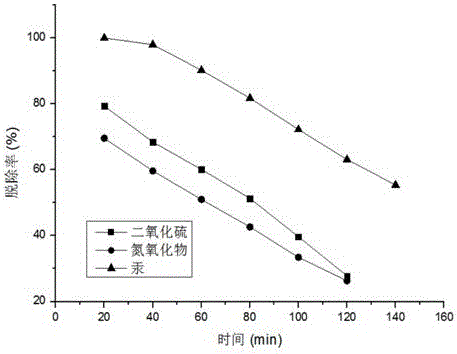

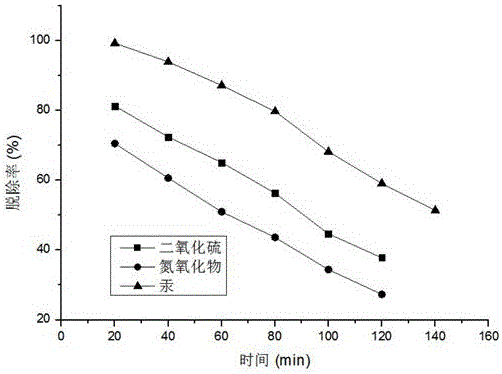

Method for wet removal of sulfur and mercury components in flue gas containing mercury and sulfur by urea phosphate

InactiveCN106731795AAvoid the tendency to drop rapidly in pHPromote catalytic oxidationGas treatmentDispersed particle separationActivated carbonPyrolusite

The invention relates to the technical field of purification treatment of flue gases, in particular to a method for wet removal of sulfur and mercury components in flue gas containing mercury and sulfur by urea phosphate. The method comprises the following steps: researching removal of the sulfur and mercury components in the flue gas containing the mercury and the sulfur; adding the urea phosphate for removing, adsorbing with activated carbon and then carrying out spraying treatment by adopting a sulfur and mercury removing agent prepared from the urea phosphate and pyrolusite. Therefore, liquid subjected to sulfur removal and mercury removal can be used for producing fertilizer, further the efficiency of the sulfur removal and the mercury removal for the flue gas containing the sulfur and the mercury is improved, added values of the sulfur removal and the mercury removal are also increased, and the cost of the sulfur removal and the mercury removal for the flue gas is reduced.

Owner:YINYU MINERALS WUCHUAN AUTONOMOUS COUNTY

Method for treating non-ferrous metal smelting off-gas through copper smelting fume

ActiveCN105797559ASolve pollutionEasy to removeGas treatmentDispersed particle separationResource utilizationEmission standard

The invention discloses a method for treating non-ferrous metal smelting off-gas through copper smelting fume and belongs to the field of wet desulfurization, denitrification and demercuration industrial waste gas treatment. Absorption liquid is formed by mixing the copper smelting fume and water, the non-ferrous metal smelting off-gas reacts with the absorption liquid in a full contact mode, through the catalytic oxidation effect of Cu2+ and other transition metal ions contained in the copper smelting fume, nitric oxide, sulfur oxide and mercury in the off-gas are absorbed, and SO2, NOx and Hg in the off-gas are far lower than the national emission standard. The fume in copper smelting off-gas is directly utilized, no raw material needs to be newly added, the resource utilization rate is high, investment is low, no secondary pollutants are generated, and obvious social and economic benefits are achieved.

Owner:KUNMING UNIV OF SCI & TECH

A kind of waste mercury catalyst comprehensive treatment method

InactiveCN105154676BHigh recovery rateEmission reductionProcess efficiency improvementDistillationComponents of crude oil

The invention relates to the technical field of comprehensive processing for waste mercury catalysts, in particular to a comprehensive processing method for a waste mercury catalyst. The waste mercury catalyst is mixed with quick lime and then boiled, so that effective ingredients of the waste mercury catalyst act with the quick lime, the purpose of curing the waste mercury catalyst is achieved, and the conversion efficiency of the waste mercury catalyst in the distillation process is improved; steam with mercury obtained after distillation is cooled to obtain steam residues, the steam residues act with a reactant, and mercury ingredients in the steam residues are precipitated greatly; and through ultrasonic processing coupled with centrifugal processing, the reactant and the steam residues can act more thoroughly, the rate of mercury recovery performed after mercury catalyst processing is improved, waste liquid emissions are reduced, environmental pollution is reduced, and the content of mercury discharged in the environment is reduced to 0.09-0.13%.

Owner:贵州蓝天固废处置有限公司

Comprehensive remediation method for mercury-polluted rice soil

InactiveCN108817073AReduce mercury levelsReduce governance costsContaminated soil reclamationTreatment effectCationic exchange

The invention discloses a comprehensive remediation method for mercury-polluted rice soil. The method comprises steps of adjusting a soil PH value, adsorbing by a cation exchange resin, planting a mercury hyperaccumulation plant and utilizing a microorganism waste material. The method is capable of comprehensively using soil remediation measures of a physical adsorption method, a phytoremediationmethod, a microbial remediation method and the like, and remarkably reducing mercury content in the mercury-polluted rice soil, has the characteristics of low treatment cost, short period, high mercury removal efficiency and no secondary pollution, has the advantages of low work management strength, stable treatment effect and high performance, is suitable for improvement of a large area of the heavy metal polluted soil, and has extensive application prospect.

Owner:YIELEAD RICE IND

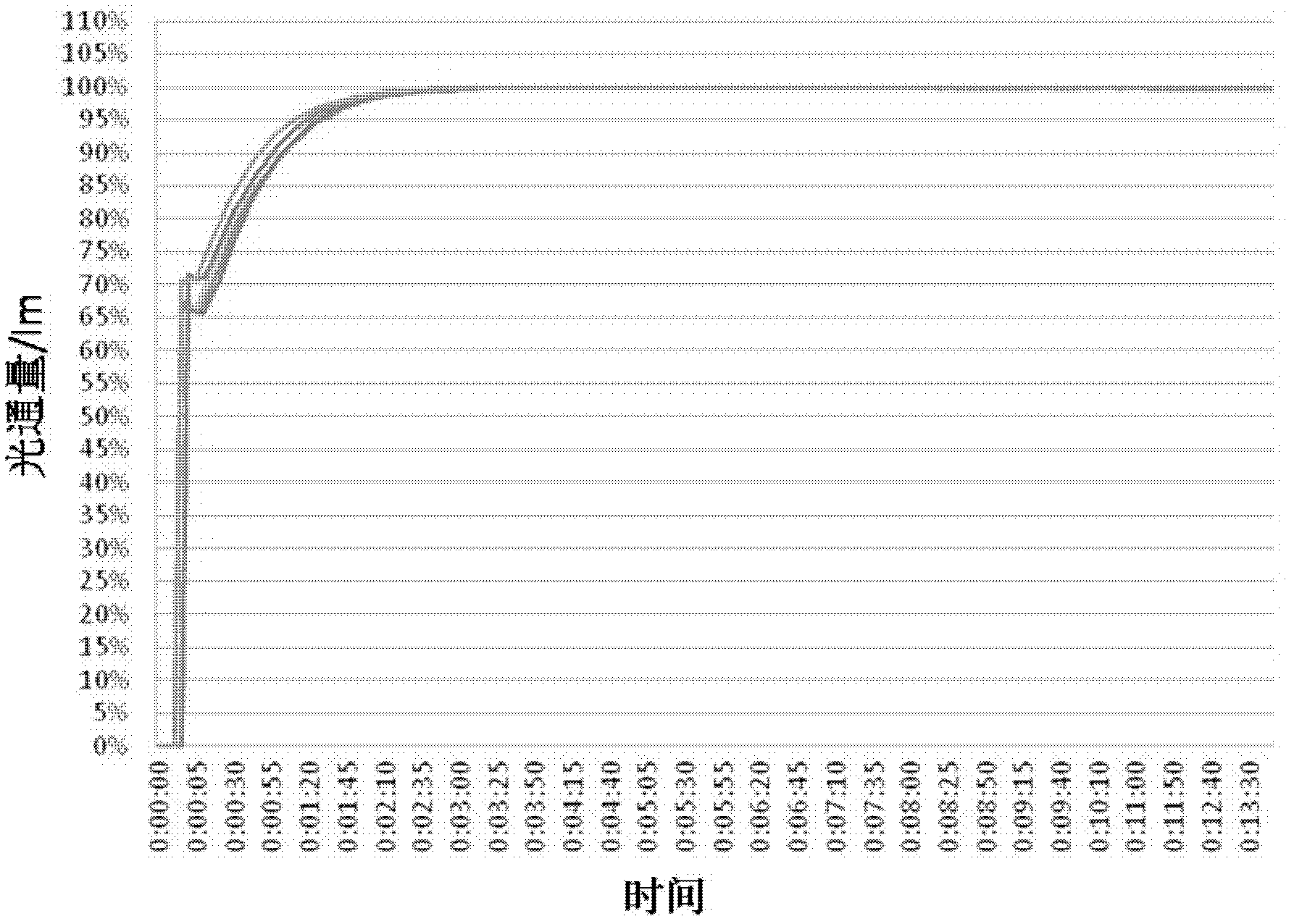

Manufacture process for trap lamp tube

InactiveCN102543625BImprove light outputReduce mercury levelsTube/lamp vessel fillingThermionic cathode manufactureEngineeringMercury-vapor lamp

The invention discloses a manufacture process for a trap lamp tube, which includes the steps: 1) preparing materials for cutting, washing and baking a tube; 2) preparing powder and powdering; 3) checking and baking the powdered tube; 4) bending the tube, bending a leg, cutting a leg tube and processing a tube shape; 5) powdering and inserting an electrode for primary packaging; 6) exhausting, testing mercury, expelling mercury and inserting another electrode for secondary packaging; 7) aging and cleaning the tube; and 8) tinning. The manufacture process is characterized in that mercury in mercury testing and expelling is solid mercury instead of liquid mercury, and cylindrical nickel cups are used as the electrodes of the lamp tube to replace traditional tungsten filaments. By the aid of the solid mercury replacing the liquid mercury, light-emitting efficiency of the lamp tube is improved, residual mercury content in the lamp tube is reduced, and environmental pollution is reduced. The cylindrical nickel cup electrodes replacing the tungsten filament electrodes enable the temperature on the surface of the lamp tube to be low when the lamp tube is in operation, so that the service life of the lamp tube is prolonged, and the lamp tube can be prevented from generating dark spaces and pollution due to heating of the tungsten filaments. Additionally, trapping effect of the whole trap lamp tube is further improved by the aid of proportioning ratio of trapping powder and the process.

Owner:NINGBO JIANGDONG CHENGCHUANG IND PROD DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com