Mercury-containing waste recovery method

A recovery method and waste technology, applied in the field of mercury treatment, can solve problems such as mercury instability, environmental secondary pollution, low thermodynamic stability, etc., and achieve the effects of uniform heating, high thermal efficiency, and excellent wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

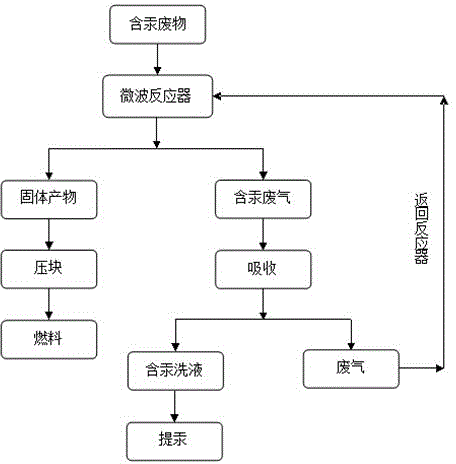

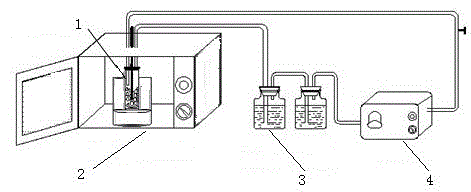

[0027] Implementation mode one: if figure 1 As shown, the recycling method of the mercury-containing waste in this embodiment includes: the mercury-containing waste material (containing mercury μg / m 3 The waste activated carbon containing 150mg / kg of mercury obtained by the flue gas treated by activated carbon injection technology) is placed in a closed microwave reactor, the power of the microwave reactor is adjusted to 1kW, and then the mercury-containing waste material is heated at a rate of 10°C / min From room temperature to 500°C, then pass the mercury-containing waste gas generated by the reaction (the flow rate of the waste gas generated by the cycle reaction is maintained at 600 mL / min) into the washing liquid (the composition of the washing liquid is a mixture of potassium permanganate and sulfuric acid , wherein the concentration of potassium permanganate is 1wt%, the concentration of sulfuric acid is 5wt%; the solid-liquid ratio of the mercury-containing waste materi...

Embodiment approach 2

[0029] Embodiment 2: The recycling method of the mercury-containing waste in this embodiment includes: making the mercury-containing waste material (containing mercury 15 μg / m 3 The waste activated carbon containing 80mg / kg of mercury obtained by the flue gas treated by activated carbon injection technology) is placed in a closed microwave reactor, the power of the microwave reactor is adjusted to 80 kW, and then the mercury-containing waste material is heated up at 900 ℃ / min The rate is increased from room temperature to 900°C, and then the mercury-containing waste gas generated by the reaction (the flow rate of the waste gas generated by the cycle reaction is maintained at 1000 mL / min) is passed into the washing liquid (the composition of the washing liquid is a mixture of potassium permanganate and sulfuric acid liquid, wherein the concentration of potassium permanganate is 3wt%, the concentration of sulfuric acid is 30wt%; the solid-liquid ratio of mercury-containing waste ...

Embodiment approach 3

[0031] Embodiment three: the recovery method of the mercury-containing waste of this embodiment comprises: the mercury-containing waste material (containing mercury 5 μ g / m 3The waste activated carbon containing 100mg / kg of mercury obtained by the flue gas treated by activated carbon injection technology) is placed in a closed microwave reactor, the power of the microwave reactor is adjusted to 60 kW, and then the mercury-containing waste material is heated up at 100°C / min The rate is increased from room temperature to 200°C, and then the mercury-containing waste gas generated by the reaction (the flow rate of the waste gas generated by the cycle reaction is maintained at 200 mL / min) is passed into the washing liquid (the composition of the washing liquid is a mixture of potassium permanganate and sulfuric acid liquid, wherein the concentration of potassium permanganate is 6wt%, the concentration of sulfuric acid is 10wt%; the solid-liquid ratio of mercury-containing waste mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com