Metal-organic frame-derived ferroferric oxide@carbon/reduced graphene oxide nano composite wave-absorbing material and preparation method thereof

A ferric tetroxide, organic framework technology, applied in chemical instruments and methods, other chemical processes, magnetic field/electric field shielding, etc., can solve the problems of narrow effective absorption bandwidth, high filling, difficult to achieve multi-frequency bands, etc., to achieve enhanced attenuation The effect of loss capacity, strong absorption and easy adjustment of wave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

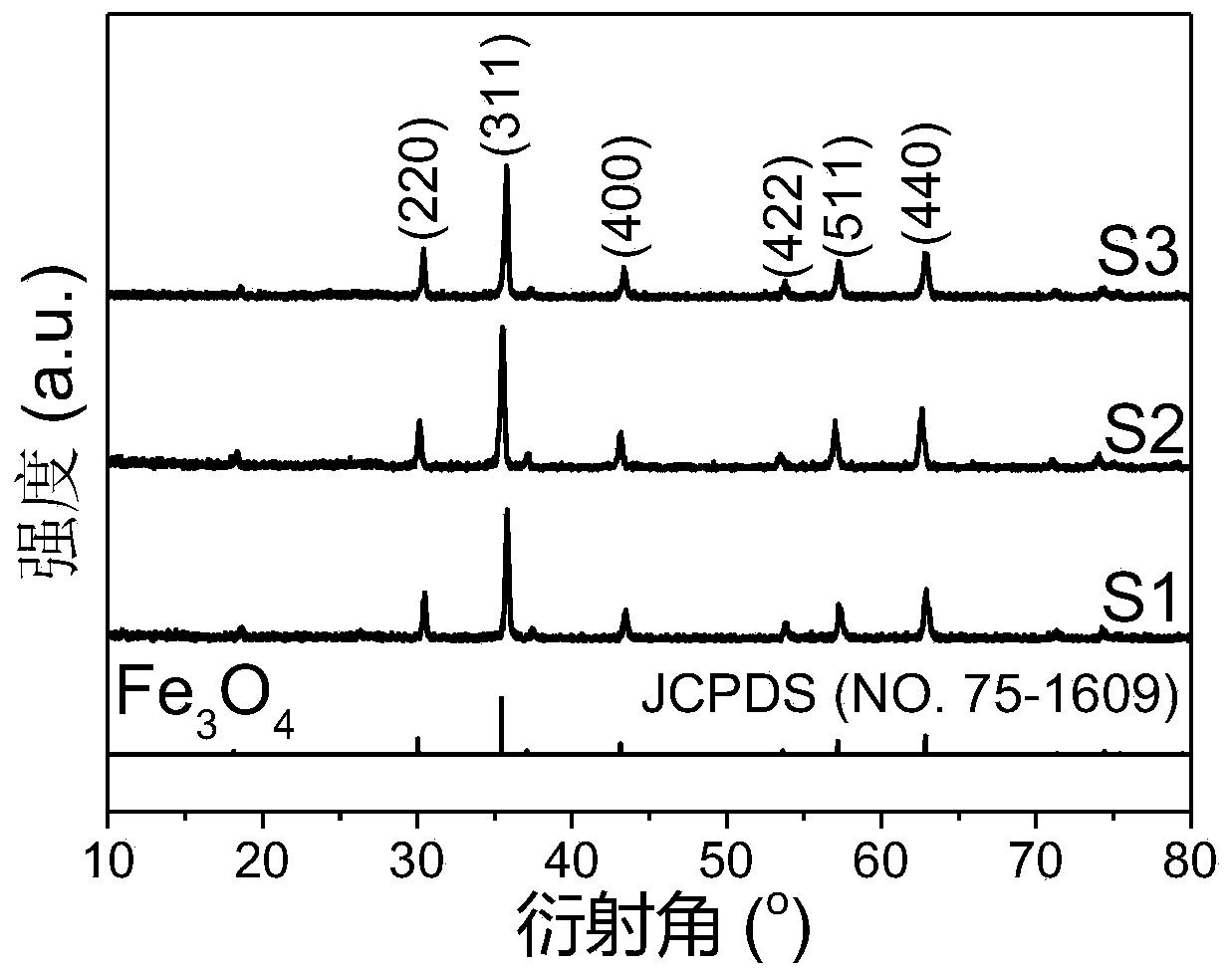

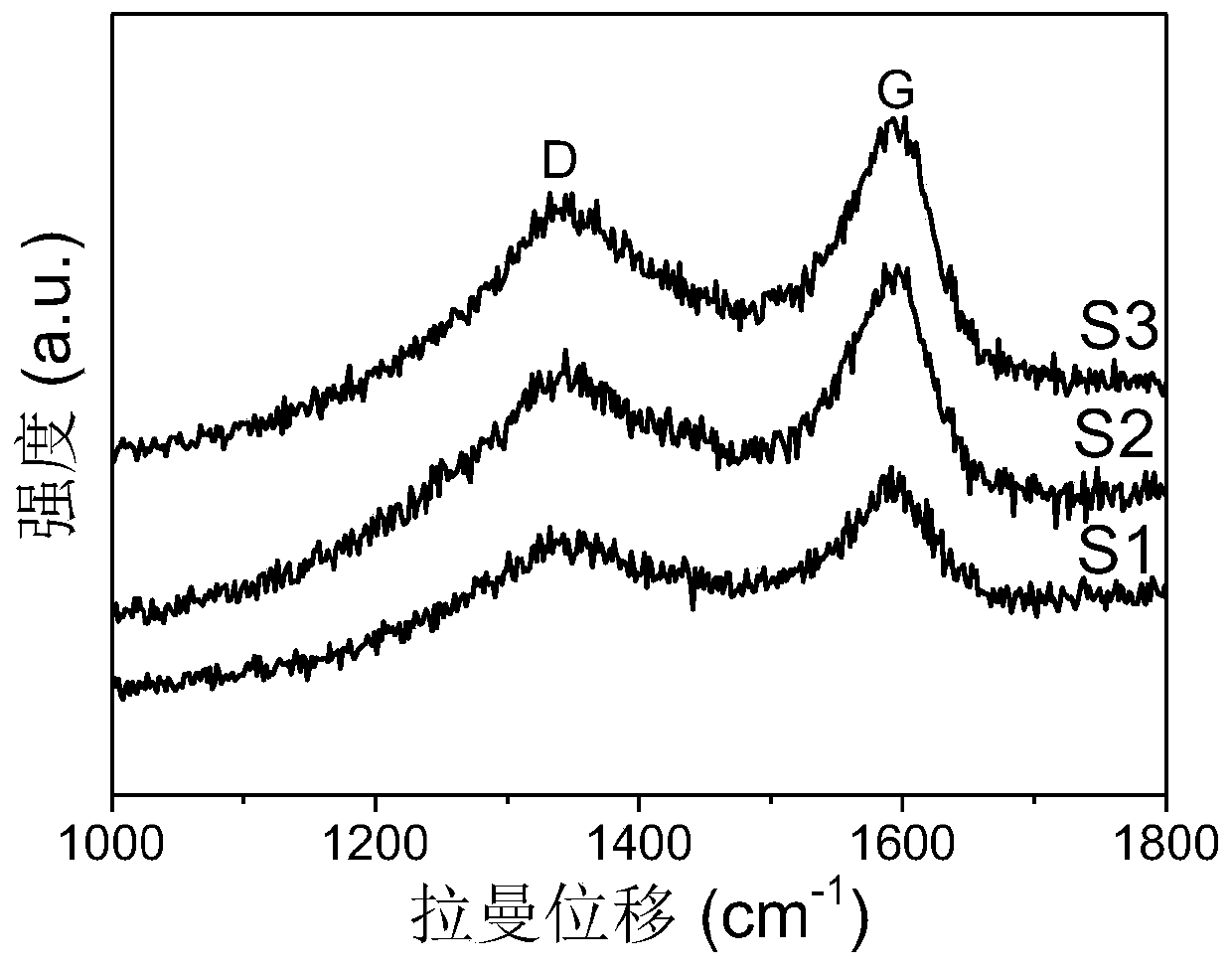

Embodiment 1

[0028] (1) Take a 150mL beaker, add 80mL N,N-dimethylformamide (DMF), weigh 20 mg of graphite oxide and add; ultrasonically disperse for 15 minutes, stir vigorously for 30 minutes, and obtain a uniform GO / DMF dispersion.

[0029] (2) Weigh 1.990g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Quickly add to the GO / DMF dispersion, stir vigorously for 10 minutes, weigh out 1.222g of terephthalic acid (H 2 BDC) Add the dispersion, mix and stir for 30min, add GO / DMF / Fe 3+ / H 2 The BDC dispersion was transferred to an autoclave lined with polytetrafluoroethylene, and reacted at 110°C for 24 hours in an electric heating blast drying oven.

[0030] (3) After the solvothermal reaction is completed, the precipitate is collected by repeated centrifugation and washing with DMF and absolute ethanol for several times, and the precipitate is collected, placed in a vacuum drying oven, and dried at 55°C for 12 hours.

[0031] (4) Carry out high-temperature pyrolysis of the dried precipitate in a tube f...

Embodiment 2

[0034] (1) Take a 150mL beaker, add 80mL N,N-dimethylformamide (DMF), weigh 40 mg of graphite oxide and add; ultrasonically disperse for 15min, stir vigorously for 30min to obtain a uniform GO / DMF dispersion.

[0035] (2) Weigh 1.990g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Quickly add to the GO / DMF dispersion, stir vigorously for 10 minutes, weigh out 1.222g of terephthalic acid (H 2 BDC) Add the dispersion, mix and stir for 30min, add GO / DMF / Fe 3+ / H 2 The BDC dispersion was transferred to an autoclave lined with polytetrafluoroethylene, and reacted at 110°C for 24 hours in an electric heating blast drying oven.

[0036] (3) After the solvothermal reaction is completed, the precipitate is collected by repeated centrifugation and washing with DMF and absolute ethanol for several times, and the precipitate is collected, placed in a vacuum drying oven, and dried at 55°C for 12 hours.

[0037] (4) Carry out high-temperature pyrolysis of the dried precipitate in a tube furnace under...

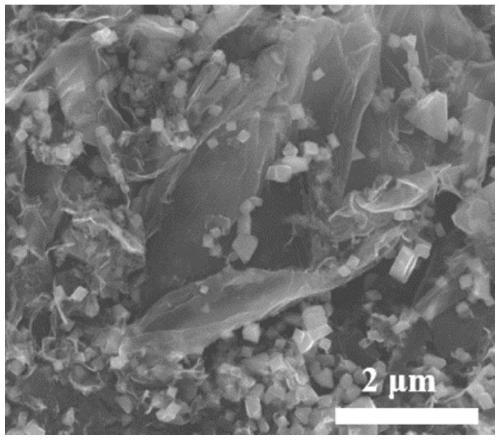

Embodiment 3

[0040] (1) Take a 150 mL beaker, add 80 mL of N,N-dimethylformamide (DMF), weigh 80 mg of graphite oxide and add; ultrasonically disperse for 15 minutes, and vigorously stir for 30 minutes to obtain a uniform GO / DMF dispersion.

[0041] (2) Weigh 1.990g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Quickly add to the GO / DMF dispersion, stir vigorously for 10 minutes, weigh out 1.222g of terephthalic acid (H 2 BDC) Add the dispersion, mix and stir for 30min, add GO / DMF / Fe 3+ / H 2 The BDC dispersion was transferred to an autoclave lined with polytetrafluoroethylene, and reacted at 110°C for 24 hours in an electric heating blast drying oven.

[0042] (3) After the solvothermal reaction is completed, the precipitate is collected by repeated centrifugation and washing with DMF and absolute ethanol for several times, and the precipitate is collected, placed in a vacuum drying oven, and dried at 55°C for 12 hours.

[0043] (4) Carry out high-temperature pyrolysis of the dried precipitate in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com