Patents

Literature

1211results about How to "Nothing produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

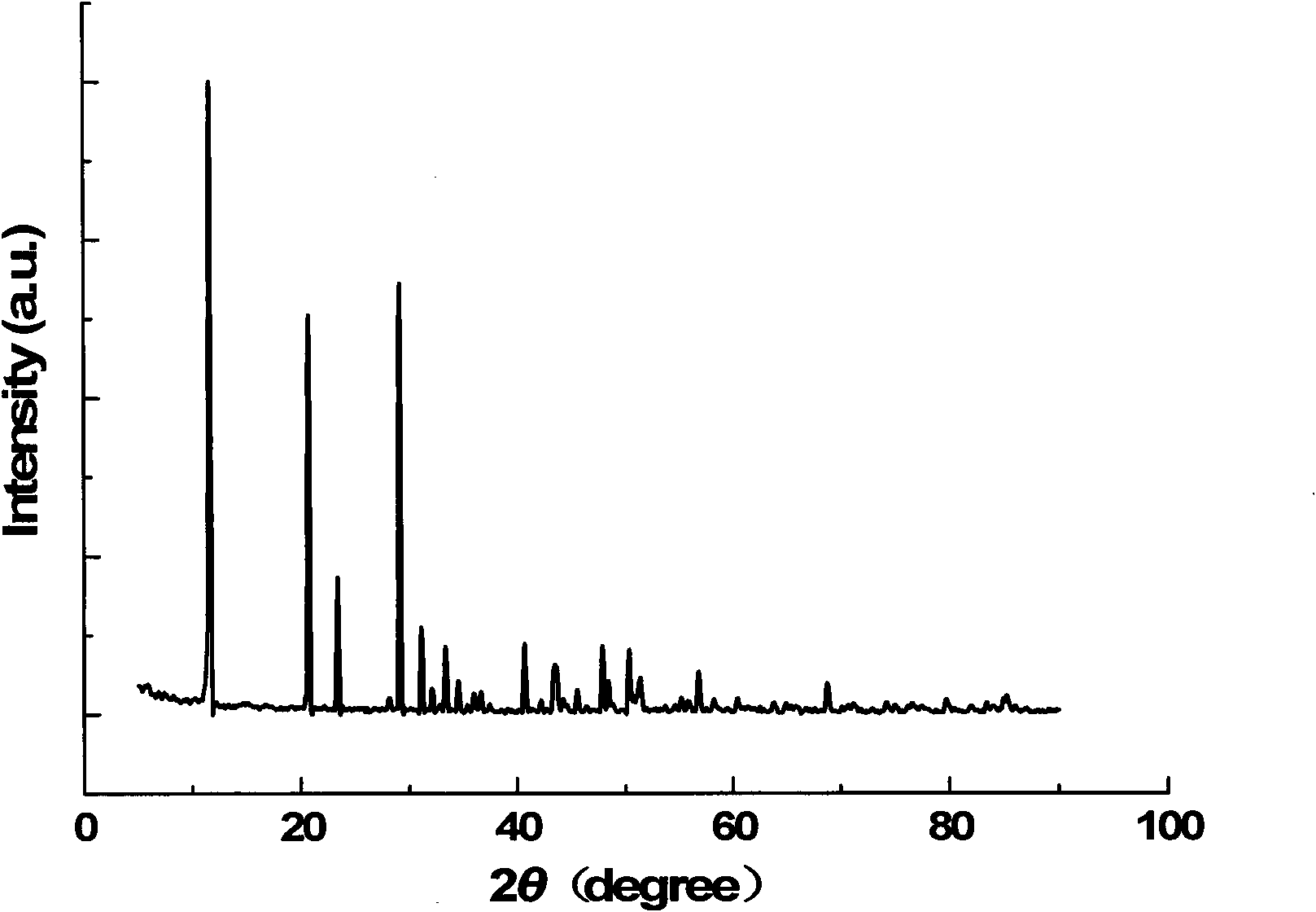

Preparation and application method of optical catalysed environment protection type coating

The invention provides a preparation and application method for photocatalysis environmental protection type painting, which relates to construction painting, especially provides a preparation and application method for photocatalysis function painting, which includes steps: mixing titanium-containing organic, water, chelating agent and hydrolysis inhibitor to prepare nano anatase type titanium dioxide water sol; adding metal, oxide or impure titanium dioxide photocatalyst into the titanium dioxide water sol and stirring equably. Using method is coating inorganic isolated layer firstly and coating the photocatalysis painting after drying. Advantages of the invention are: the prepared painting and using technique can be widely used for inner and outer wall surface of building and is harmless to bottom ainting, photocatalysis efficiency is high, cost is low, bonding is firm, transparency is good, preparation is simple, and usage is easy.

Owner:YUNNAN UNIV +1

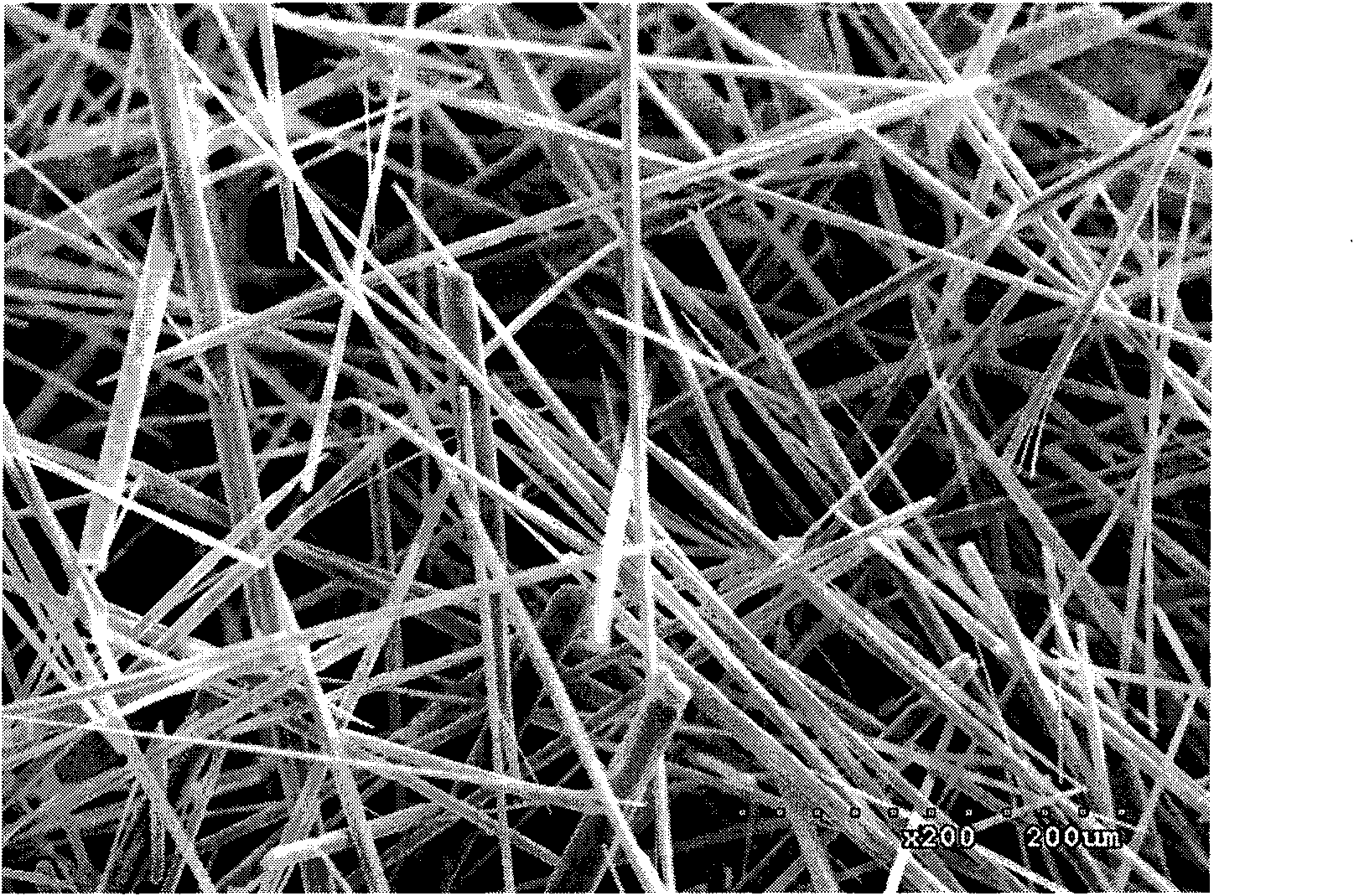

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

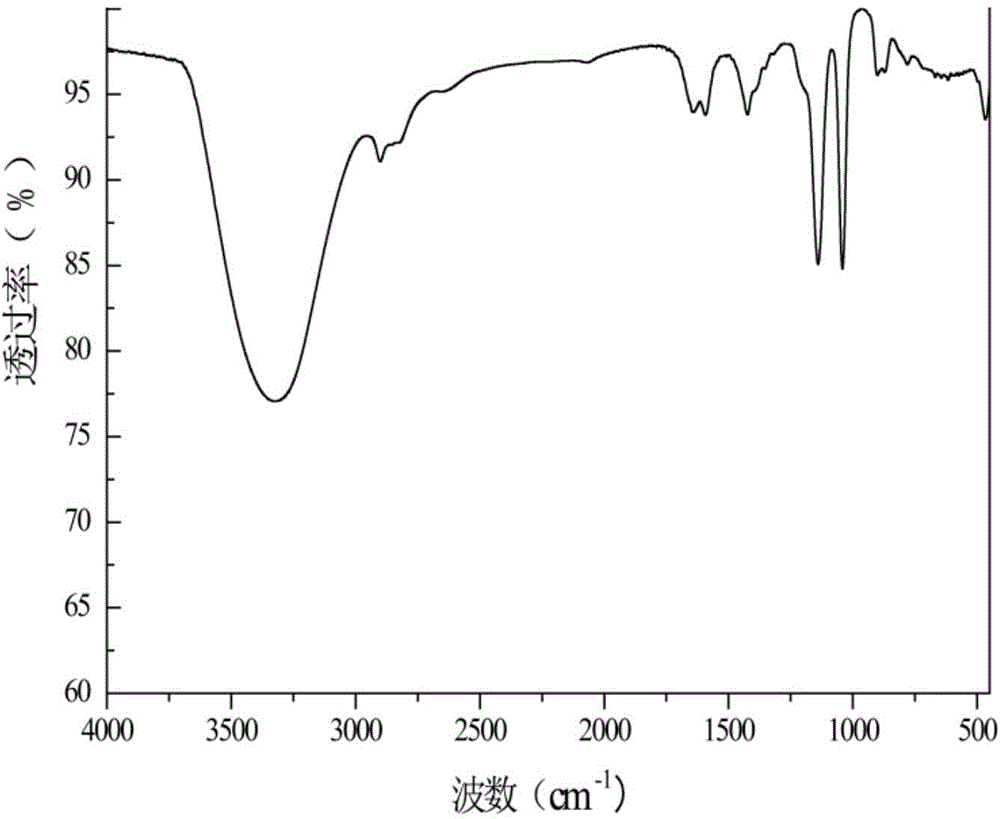

Hybridization hydrogel flat membrane for water filtration and preparation method thereof

InactiveCN103170250ANothing producedHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkSolubility

The invention discloses a hybridization hydrogel flat membrane for water filtration and a preparation method thereof. Irreversible deposition of macromolecules, colloids, electrolytes and the like is easy to occur on the surface of the membrane or inside the membrane because of hydrophobicity of a membrane filtration material, and thus causes membrane pollution, resulting in that the membrane flux is reduced continuously and the membrane separation process can not be normally implemented. The invention discloses the hybridization hydrogel flat membrane for water filtration. The flat membrane takes sodium alga acid as a macromolecule skeleton, acrylamide and a ramification of the acrylamide as a polymerization monomer to be added with a chemical crosslinking agent and an ionic crosslinked agent, and a water-solubility compound as a pore-foaming agent, and then a high-strength high-tenacity double cross-linked network hydrogel is formed in a polymerization manner, the pore-foaming agent is eluted so as to obtain the flat membrane which is used for water filtration, and the hybridization hydrogel flat membrane high hydrophily and good anti-fouling performance. The preparation method provided by the invention has the advantages that the process is simple, the cost is low, a waste solvent is not generated, and the obtained hydrogel flat membrane has good application prospect in easily-polluted membrane separation fields such as oil-water separation, protein separation and microorganism filtration.

Owner:TIANJIN POLYTECHNIC UNIV

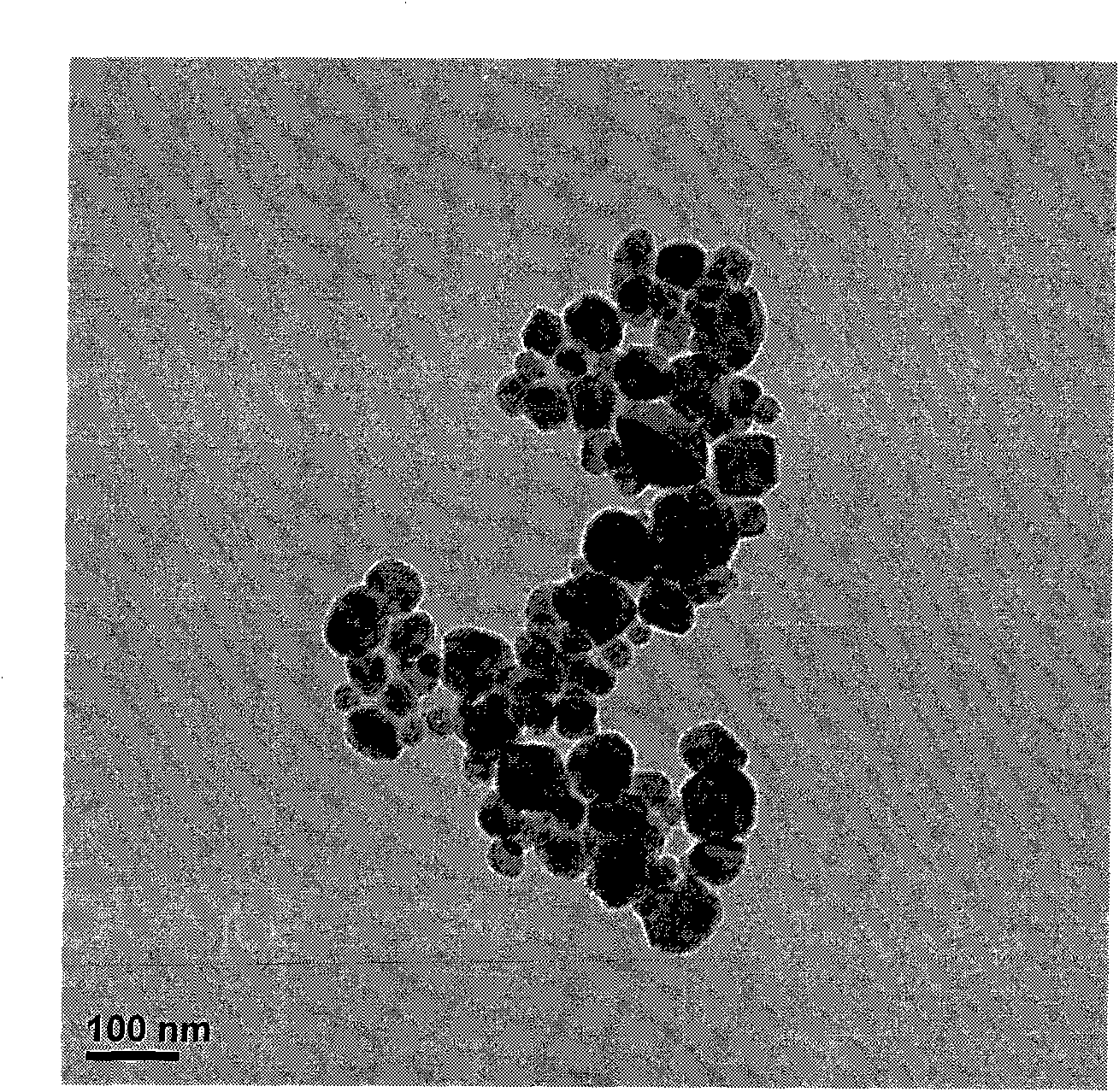

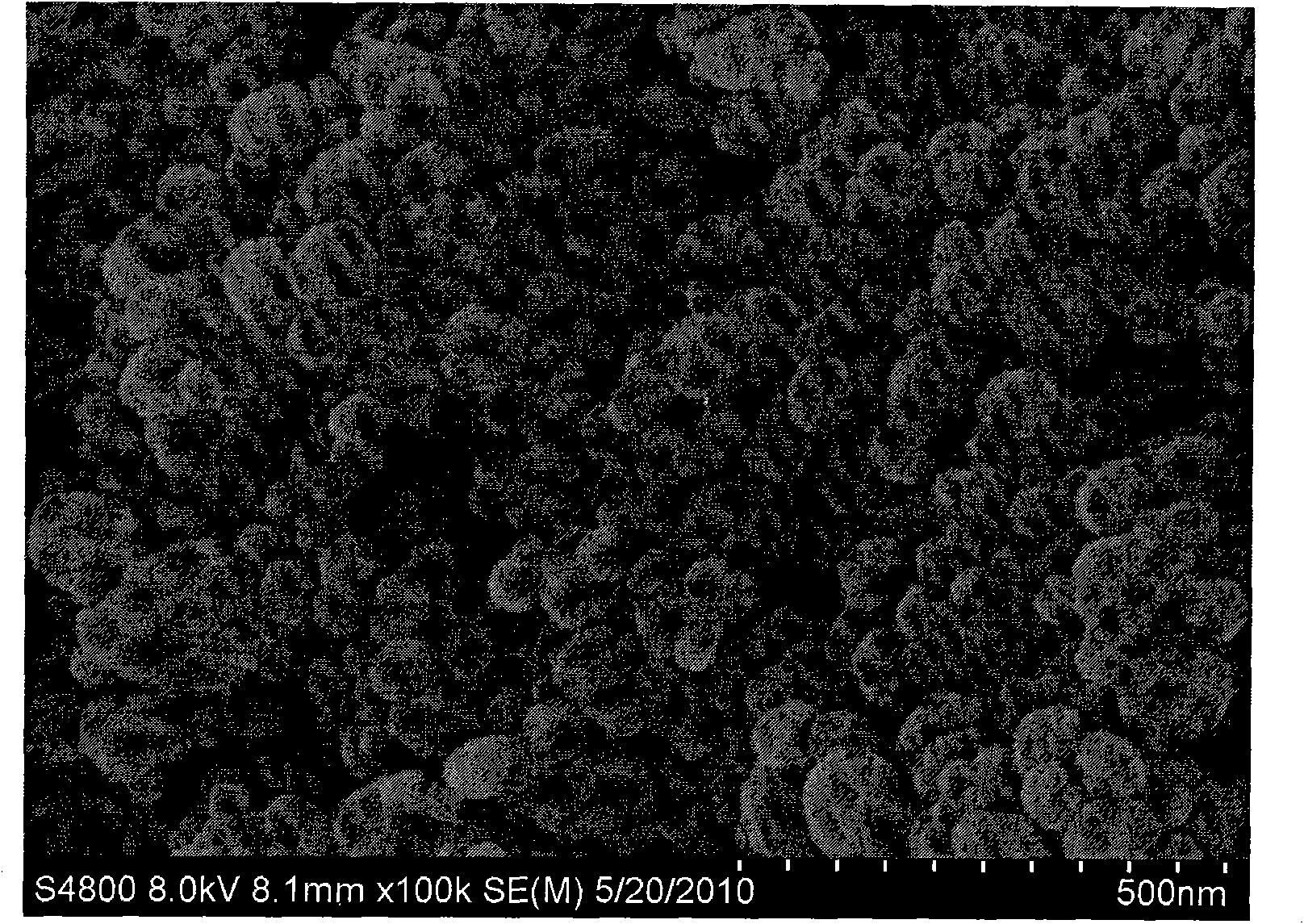

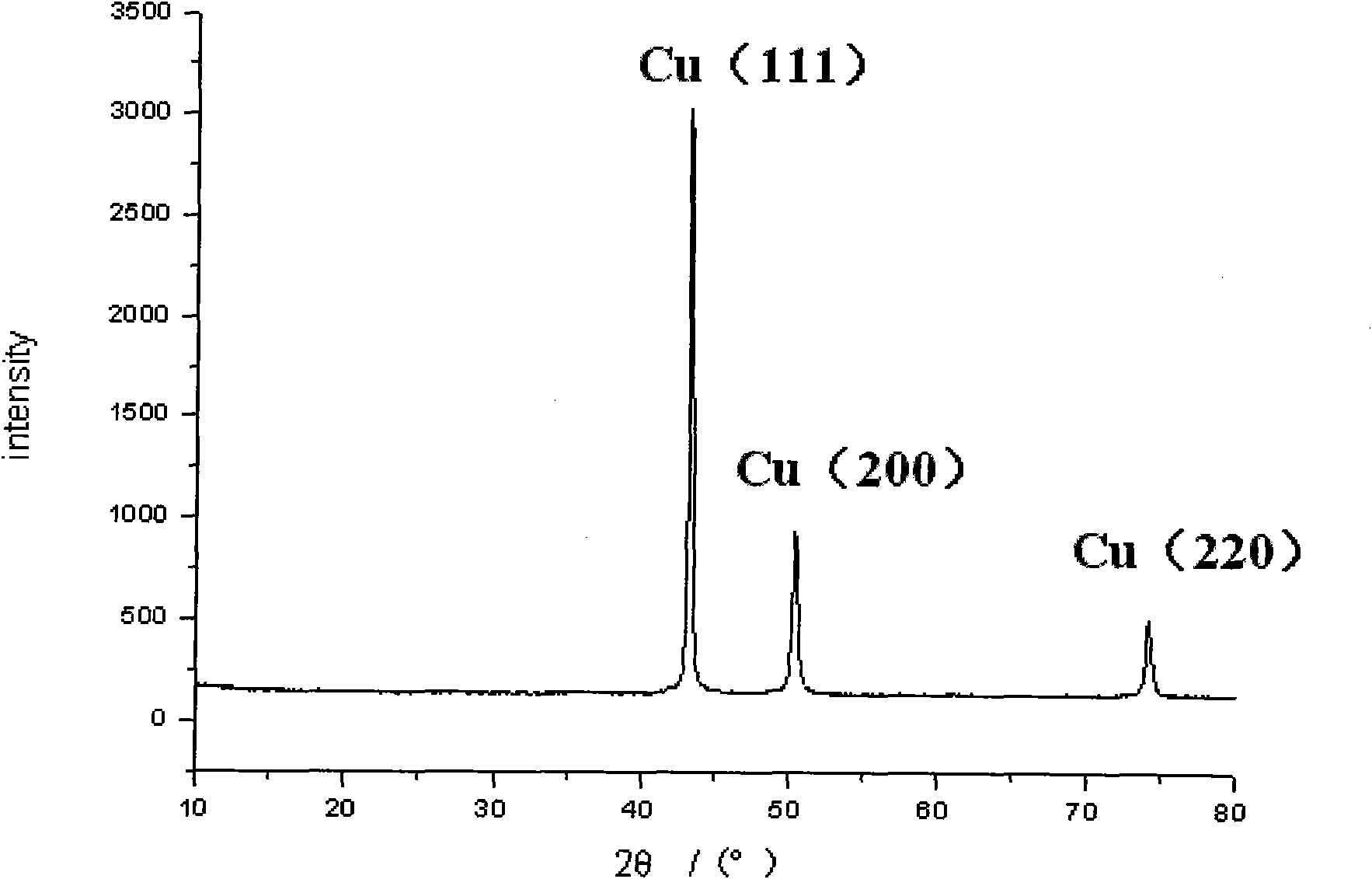

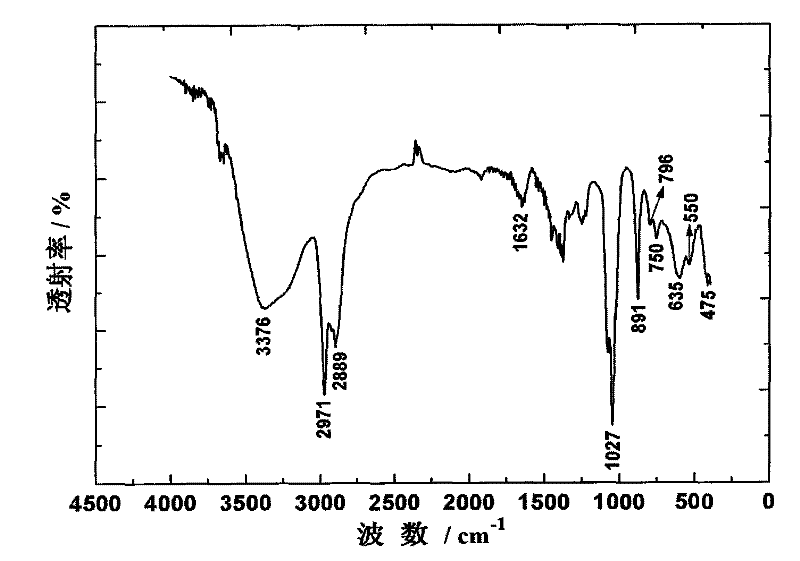

Method for preparing nano copper conductive ink

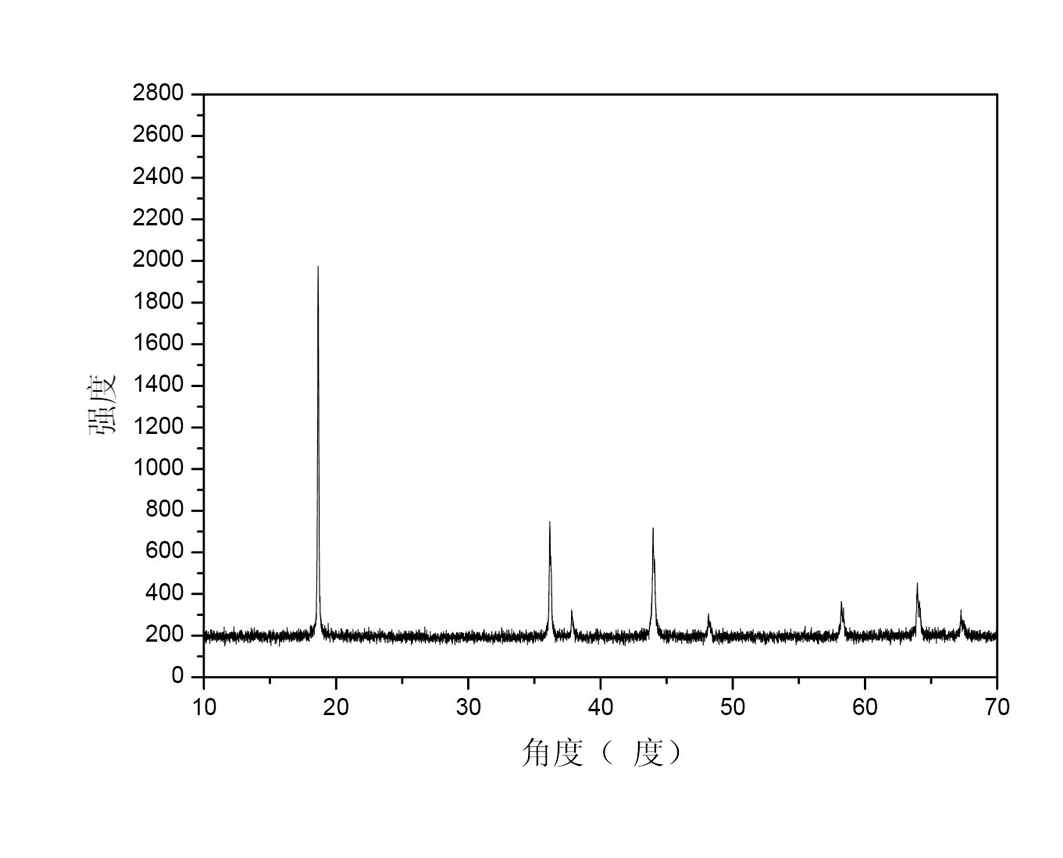

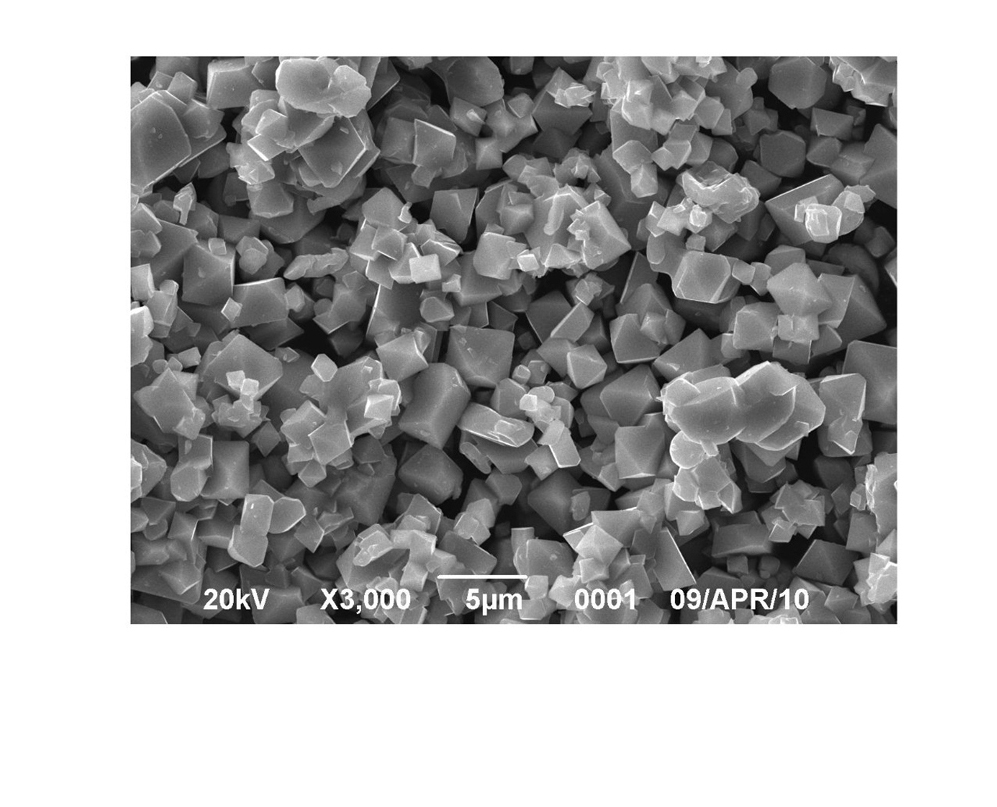

ActiveCN101880493AGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH ofthe solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing light oil from supercritical water modified vacuum residuum

InactiveCN101077980ANothing producedTo achieve the purpose of purifying oilThermal non-catalytic crackingChemistryNitrogen

The process of preparing light oil with vacuum residue includes the following steps: feeding vacuum residue and water into one high pressure reactor with stirrer, heating to 380-460 deg.c in the presence of gaseous medium, maintaining for 24-60 min, and cooling to obtain light oil. Or, the process includes the following steps: feeding vacuum residue and water into one static tubular reactor with gaseous medium, setting the reactor inside a molten salt furnace at 420-460 deg.c, maintaining for 5-120 min, quenching in one water tank, taking out the liquid phase oil part from the reactor, washing the reactor with n-heptane, and merging to obtain the light oil. The process of preparing light oil with vacuum residue has also effects of desulfurizing, and eliminating nitrogen and metal, and produces no waste gas.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalysts for solid base for producing biodiesel

InactiveCN101041130AImprove performanceNothing producedCatalyst carriersPreparation by ester-hydroxy reactionAlkaline earth metalTransesterification

The invention discloses a solid base catalyst for preparing bio-diesel, characterized in that porous material with the same cubage is dipped in alkali metal or alkaline earth metal soluble salt solution and transition metal element or thulium soluble salt solution, whose weight proportion is that porous material: alkali metal or alkaline earth metal soluble salt: transition metal element of thulium soluble salt is 1: 0.02-1: 0.001-0.2; it is dried, baked, rubbed and screened to be obtained. The invention is provided with good catalytic performance, easy treatment after transesterification, no waste liquid generated and easy separation. It can be used repeatedly and it is easy to be used in industry.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

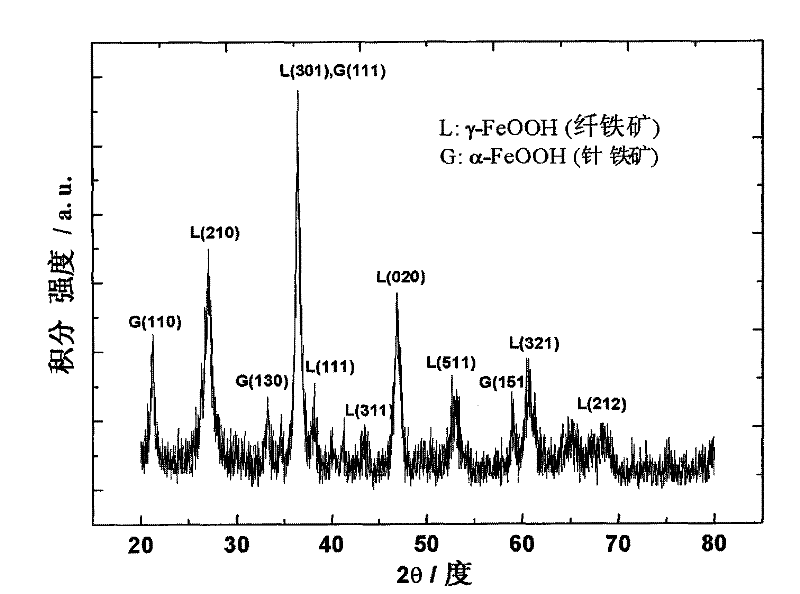

Preparation method of supported FeOOH catalyst, and electro-Fenton waste water treatment system

ActiveCN102218319AEasy to separateNothing producedMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationSludgeWater processing

The invention discloses a preparation method of a supported FeOOH catalyst, and an electro-Fenton waste water treatment system. The invention belongs to the technical field of waste water processing. The invention is characterized in that active carbon is utilized as a carrier and ferrous sulphate is utilized as a precursor; through dipping, ethylene diamine tetraacetic acid and ammoniacal undergo an oxidation reduction reaction with active carbon and ferrous sulphate in the presence of oxygen to produce active carbon supported objects and then the active carbon supported objects are washed by deionized water and then are placed in a vacuum oven to be dried at a temperature of 40 to 50 DEG C for 10 to 12 hours to form a supported FeOOH catalyst; active components of the supported FeOOH catalyst comprise alpha-FeOOH and gamma-FeOOH; and under an applied electric field, an out-phase electro-Fenton oxidation system is composed of the supported FeOOH catalyst and hydrogen peroxide and canremove efficiently organic pollutants in waste water. The invention has effects and advantages that an out-phase catalyst can be separated from waste water easily and recycled, and an out-phase electro-Fenton oxidation system can operate in a neutral medium without need of PH adjustment and generation of chemical sludge.

Owner:DALIAN UNIV OF TECH

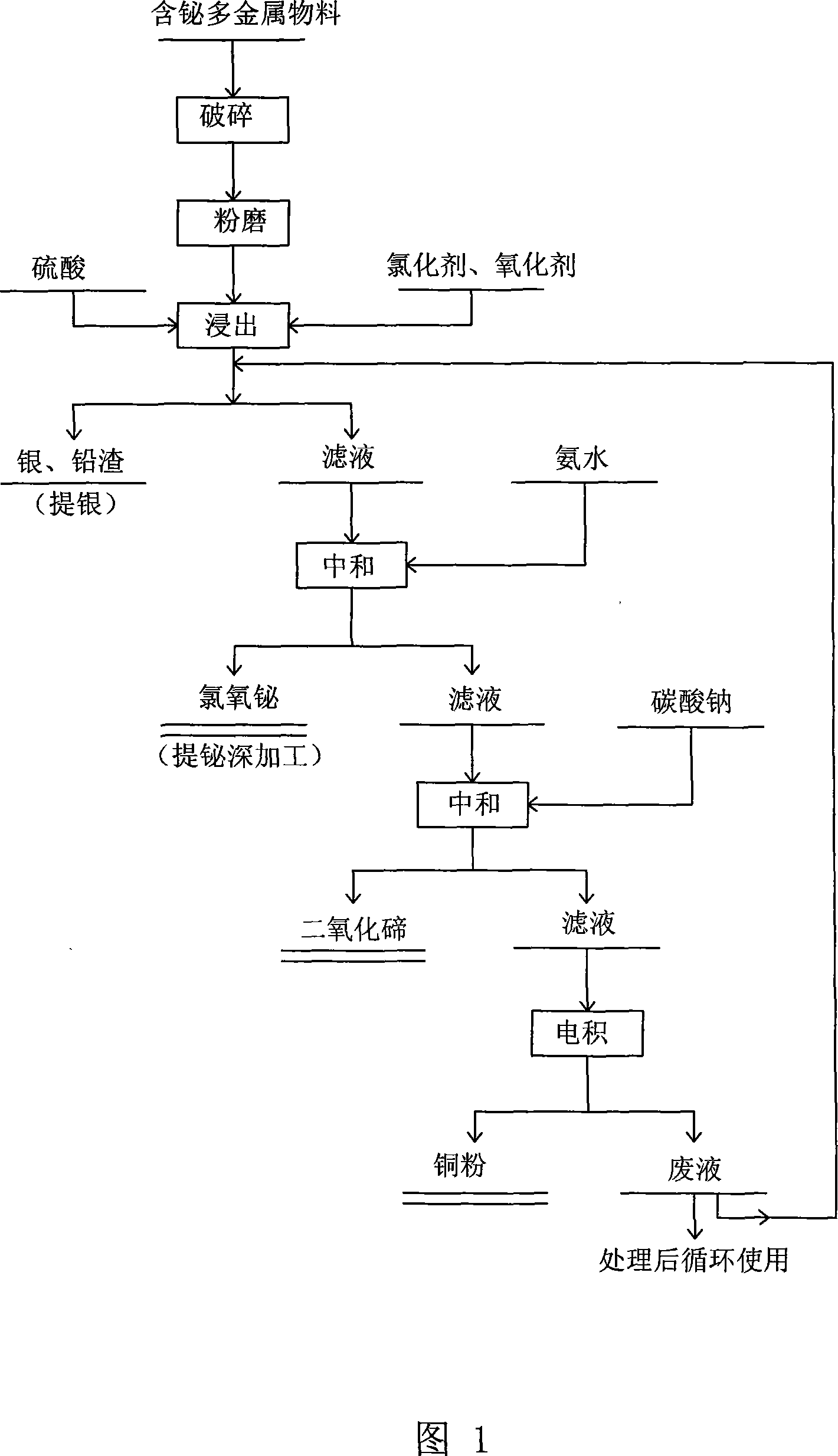

Comprehensive extraction of valent metal from bismuth-containing polymetallic material

InactiveCN101029353AHigh recovery rateImprove product added valuePhotography auxillary processesProcess efficiency improvementSesquioxideTe element

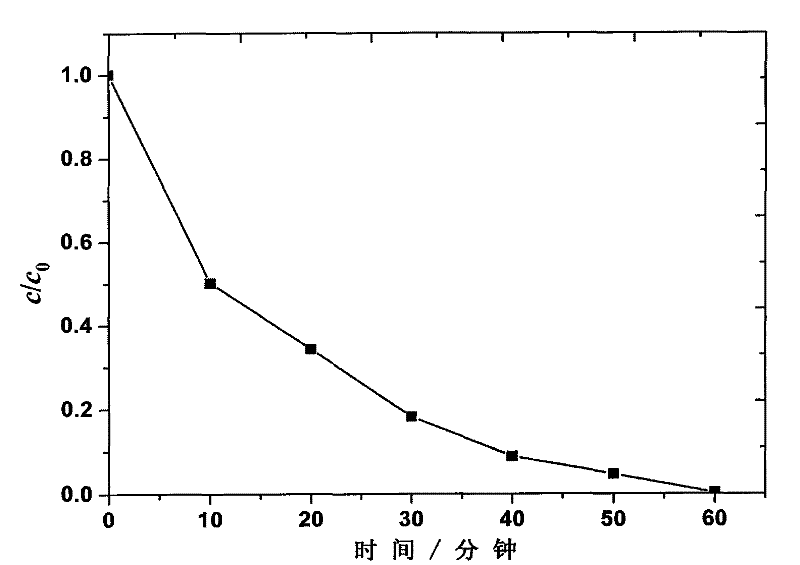

A method for extracting metal from bismuth-contained multi-metal material is carried out by leaching out copper and tellurium from bismuth-contained multi-metal by sulfuric acid, adding into chlorinating agent and oxidant to leach out metal bismuth, extracting silver from leaching-out slag with AgCl, PbSO4 and PbC12, adding ammonia water into leaching-out liquid, adjusting pH value to 1.5 to obtain bismuth oxychloride slag with 70% bismuth content, smelting into coarse bismuth by firing method or machining to obtain high-purity bismuth sesquioxide, adjusting pH value to 4.5 by Na2CO3, depositing tellurium to obtain tellurium dioxide and copper-contained solution, and electrically depositing to obtain copper powder with copper-contained content90%. It adopts wetting and firing metallurgical technology, has higher metal recovery rate and excellent leaching-out separation effect and effluent circulating utilization and no environmental pollution.

Owner:HUNAN JINWANG BISMUTH

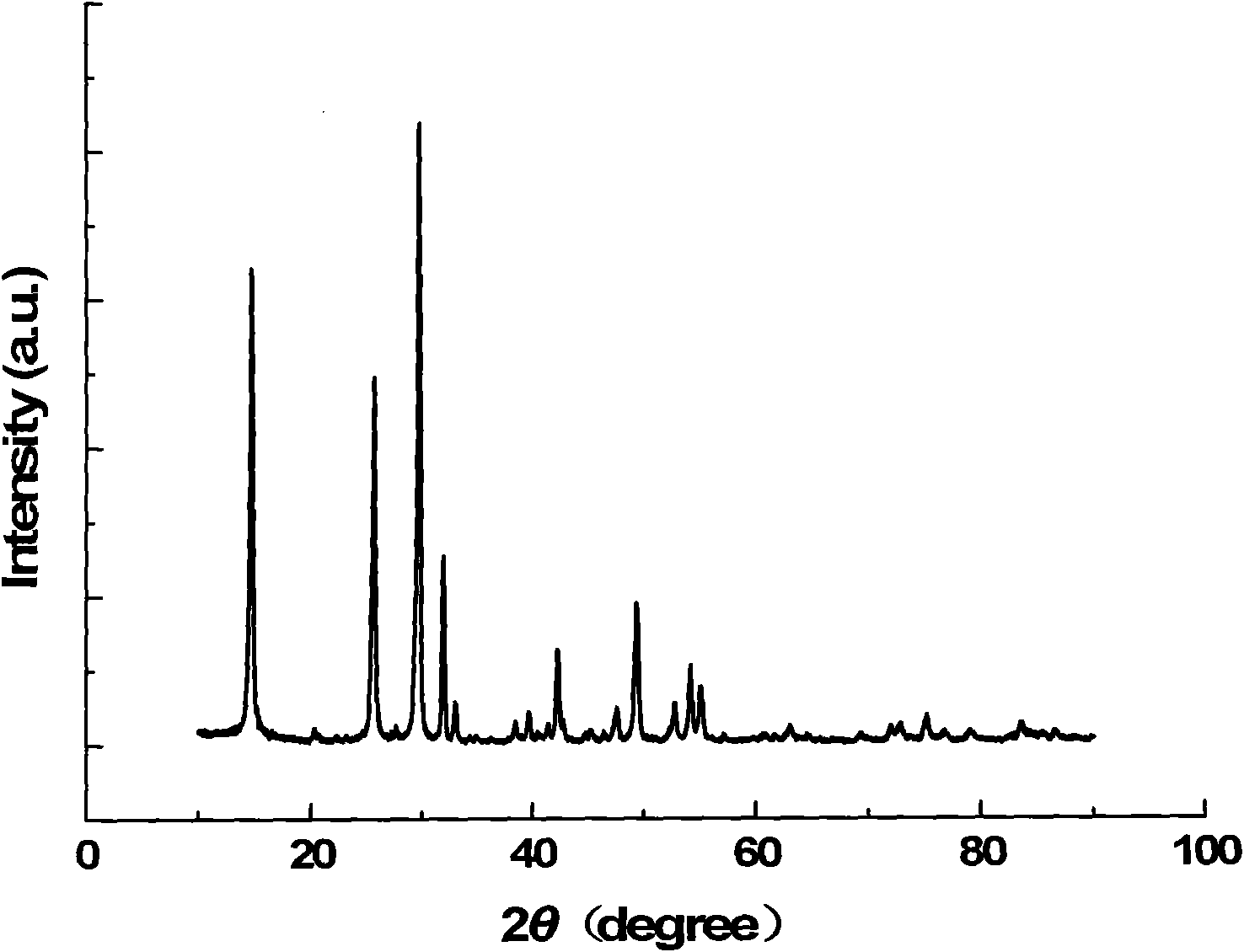

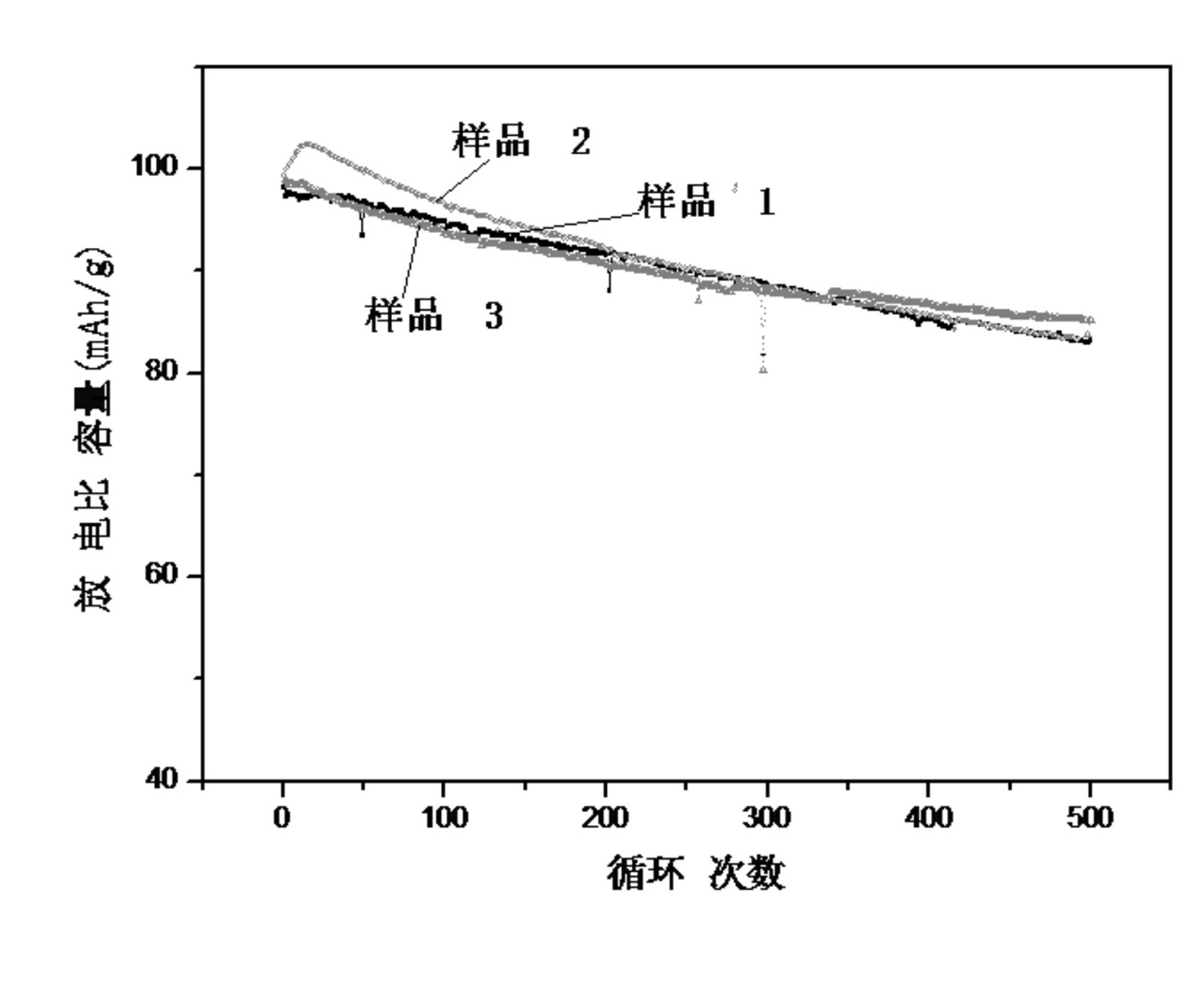

Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

InactiveCN101964416AUniform bulkGood crystallizationCell electrodesSecondary cellsElectrical batteryManganate

The invention relates to a preparation technology of a battery anode material and a related automobile battery and particularly discloses a preparation method of lithium ion battery anode material lithium manganate. The method comprises the following steps: using lithium source, Mn3O4 and nanoscale doping metal additive as raw materials for proportioning, then presintering Mn3O4 or the Mn3O4 processed by ball milling, mixing the presintered Mn3O4 with the mixture of lithium source and metal additive; performing the first sintering and second sintering to the mixed raw material; and finally classifying and screening the sintering product to obtain the spinel lithium manganate product with the required grain size. The invention also discloses an automobile lithium ion battery which is assembled by using the spinel lithium manganate prepared by the method of the invention as anode and using graphite as cathode. The preparation method of the invention has simple operation and environmental friend; and the prepared lithium manganate product has excellent product performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

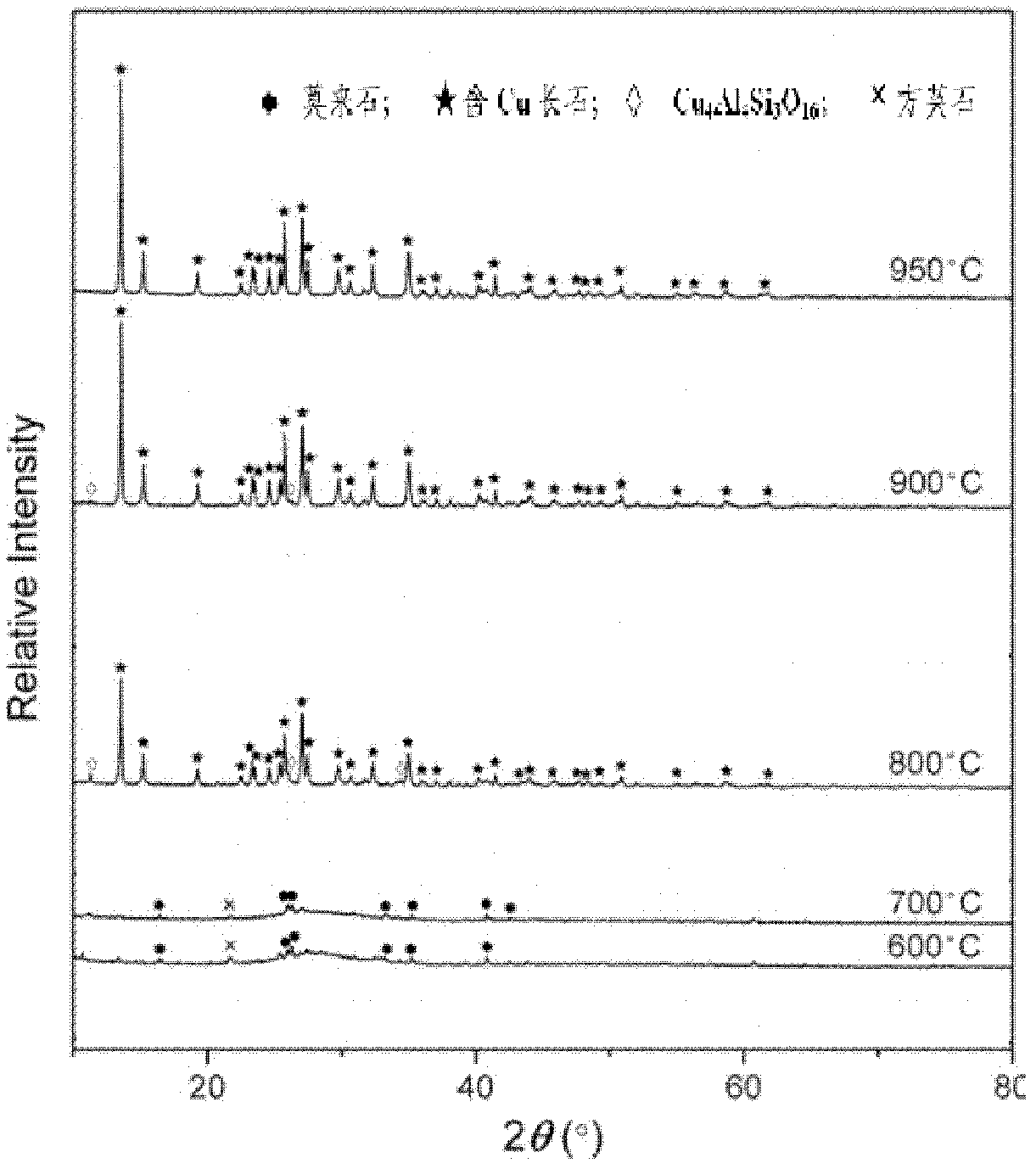

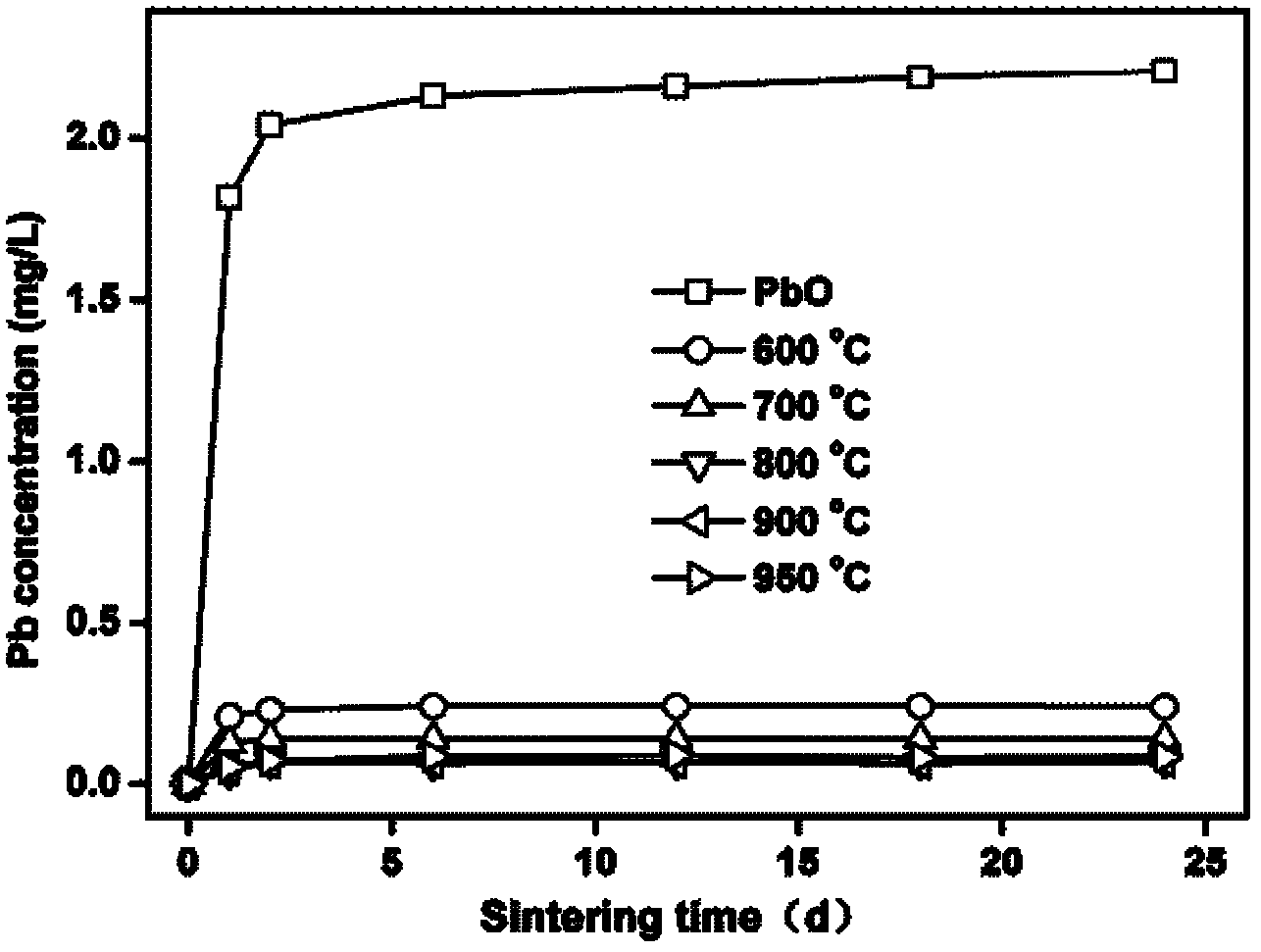

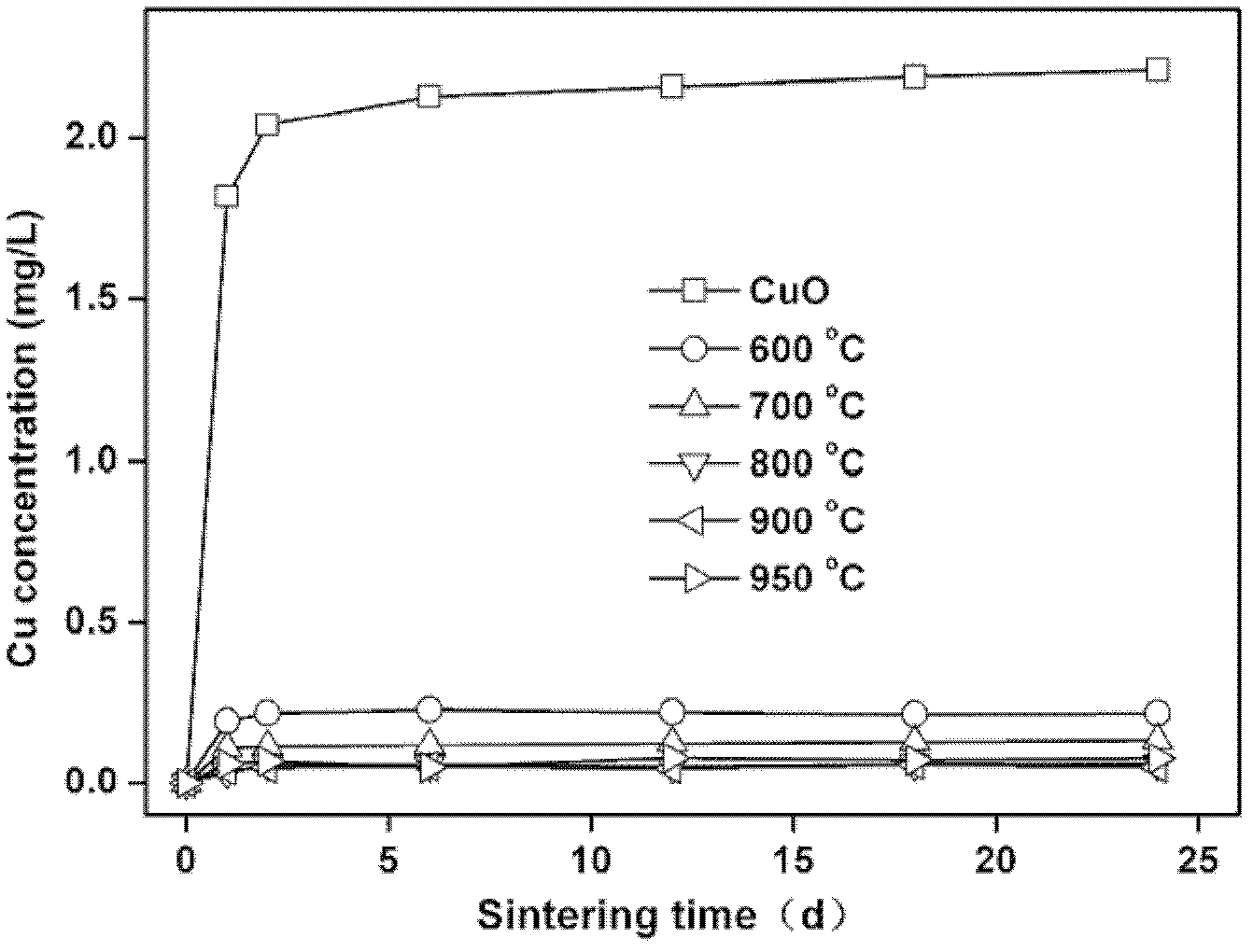

Clay-based heavy metal thermal curing agent and its method for curing heaving metal

ActiveCN102657925ANothing producedEasy to handleContaminated soil reclamationOrganic fertilisersMass ratioStone dust

The invention discloses a clay-based heavy metal thermal curing agent and its method for curing heavy metal. The clay-based heavy metal thermal curing agent comprises, by weight, 40-60% of clay, 5-15% of iron oxide, 20-30% of fly ash and 15-25% of stone flour. The method provided by the invention comprises the following steps of: uniformly mixing the clay-based heavy metal thermal curing agent and a heavy metal pollutant according to the mass ratio of 1: 5-10: 1, carrying out extrusion moulding on the mixed sample at the pressure of 300-1000Mpa, and sintering the molded sample at the temperature of more than 800 DEG C for 2-5 h to obtain a recycled material. According to the invention, heavy metal is coalesced by absorption of clay to heavy metal; fly ash and stone flour are used to fully mix heavy metal with the clay-based heavy metal thermal curing agent during the mixing process; iron oxide and alumina components in the clay-based heavy metal thermal curing agent react with heavy metal at the temperature of more than 800 DEG C for high-temperature fusion glass transition so as to form a spinel structure; and heavy metal in the form of spinel and feldspar crystal structural components is fixed in the heavy metal thermal curing agent to form the recycled material.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

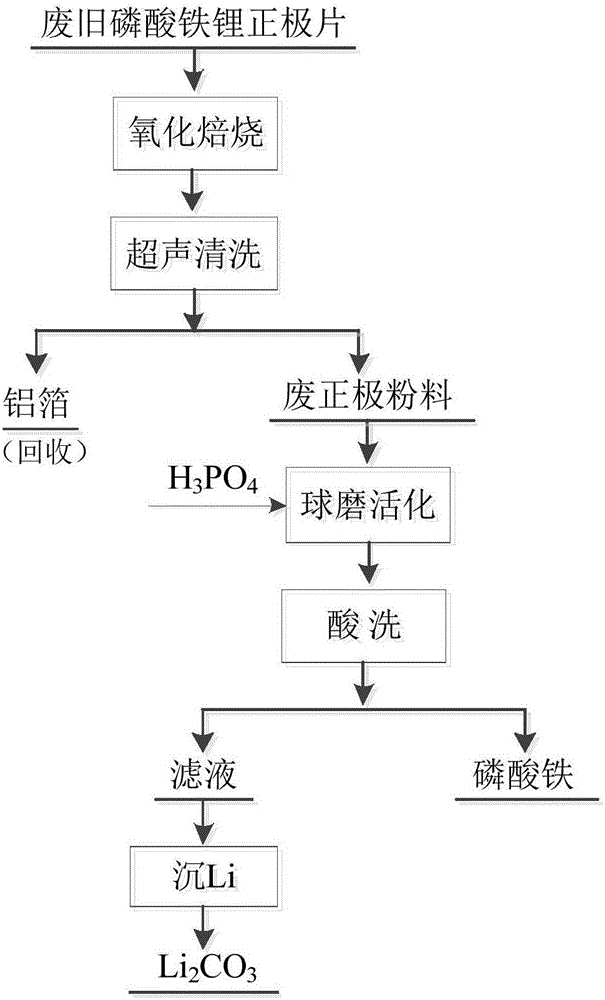

Method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste

ActiveCN106450547AAdaptableNothing producedWaste accumulators reclaimingBattery recyclingPhosphoric acidIndustrial scale

The invention discloses a method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste. The method comprises the following specific steps: (I) oxidizing roasting; (II) carrying out pole piece cleaning; (III) adding phosphoric acid and performing ball-milling activation; (IV) performing acid pickling to separate FePO4; and (V) precipitating lithium of the filtrate to obtain a target object Li2CO3. The method disclosed by the invention has the following advantages: the P, Fe and Li resources in the lithium iron phosphate waste can be fully utilized to prepare iron phosphate and lithium carbonate products with high added value, no waste of Fe is generated, the resource recycling rate is high, the technological process is short, the reaction system is simple, a few raw materials are consumed, the cost is low, the product value is high, and the method is very suitable for industrial scale production.

Owner:JINGMEN GEM NEW MATERIAL

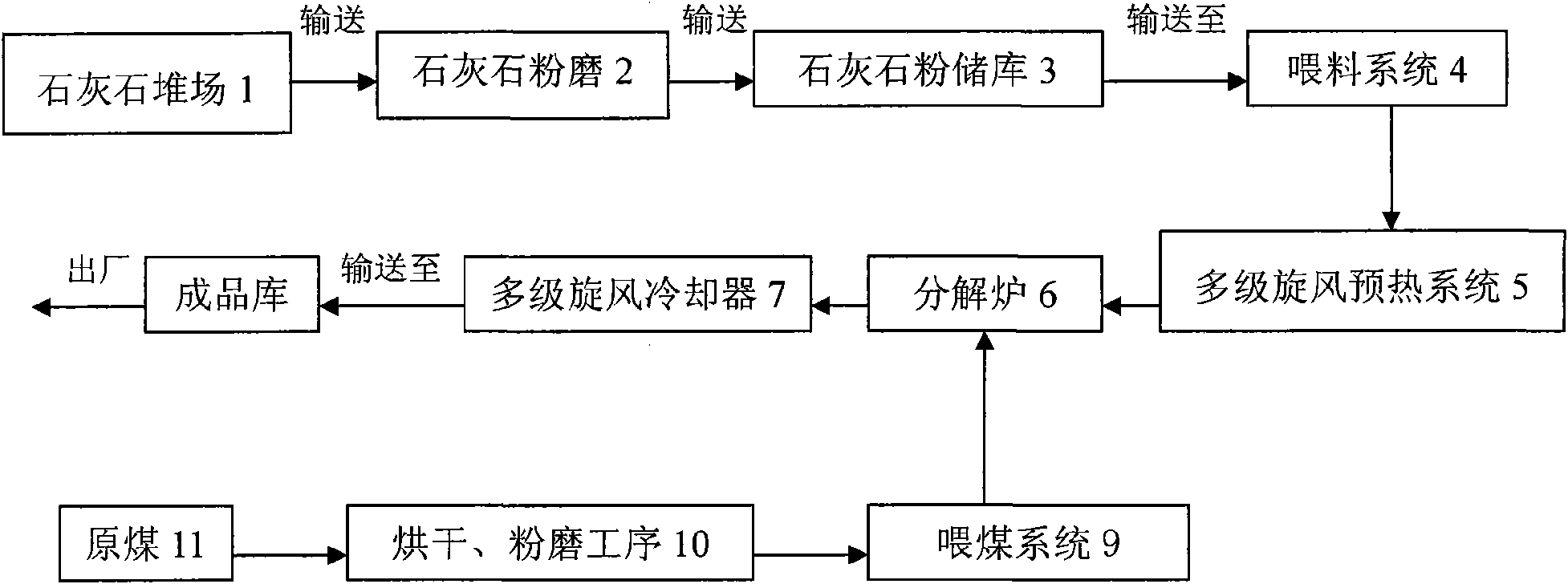

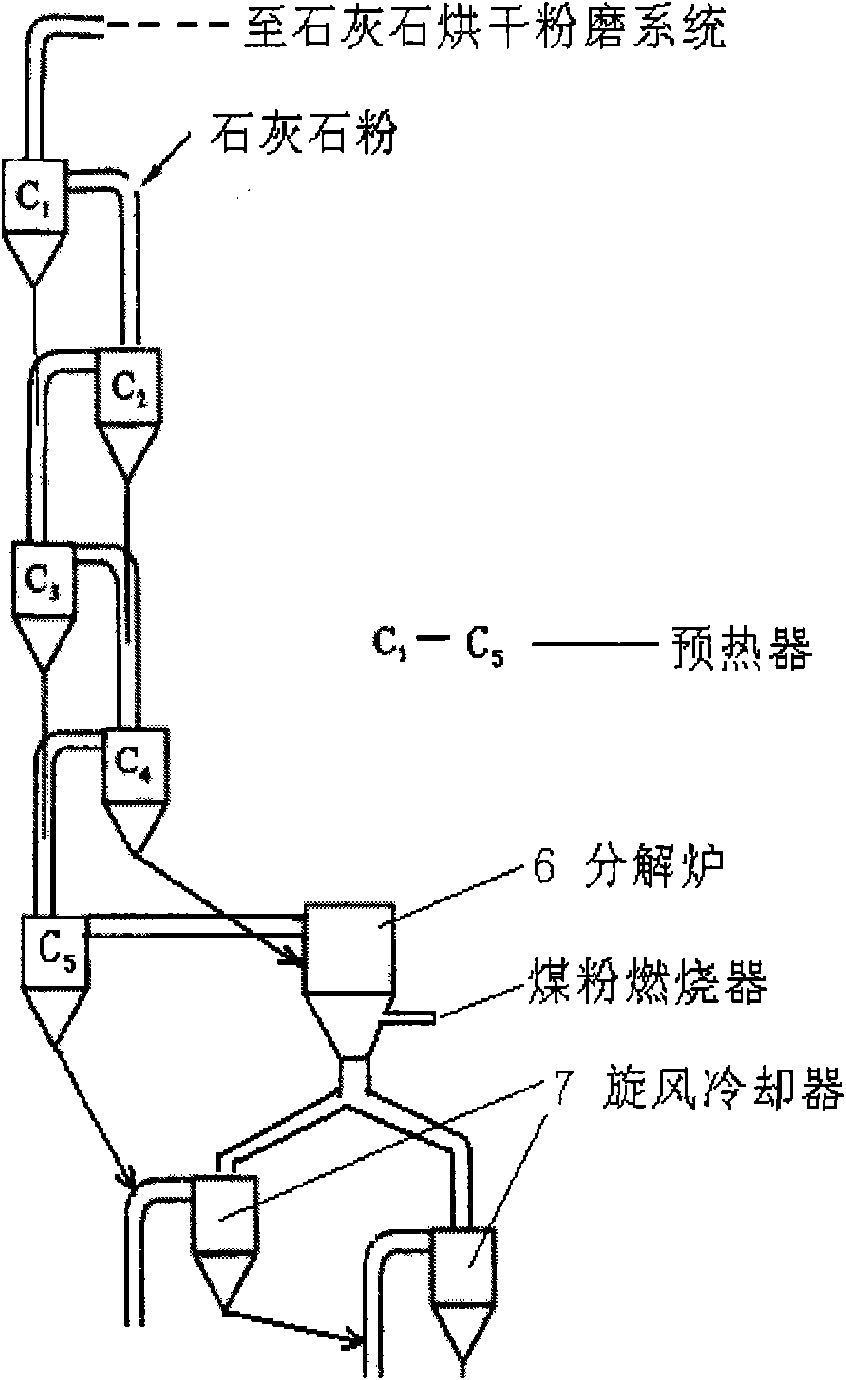

Calcination process of active lime

The invention discloses a calcination process of active lime. The calcination process adopts a preheating-suspension calcination device comprising a multi-stage cyclone preheating system, a decomposing furnace and a multi-stage cyclone cooler. The calcination process is characterized in that limestone powder which is broken and homogenized into blocks is ground into fine powder, the fine powder is placed in a storage tank for homogenization, then preheated by the multi-stage cyclone preheating system and sent to the decomposing furnace for calcination, thereby preparing the active lime, and the active lime is further cooled by the multi-stage cyclone cooler for obtaining the active lime; wherein the main control temperature of the decomposing furnace is 850-950 DEG C; and the calcination time is 3-5 seconds. The calcination process utilizes the preheating-suspension calcination reaction method for calcining the active lime, and fuel can use low-grade fuel-biluminous coal. Compared with the traditional process, the calcination time is short, the effective utilization rate of the lime product is high, the product quality is stable, the energy consumption is low, and a production region has no environmental pollution; meanwhile, the calcined active lime is the fine powder, the use is very convenient, and the range of applications is broader in comparison with the active lime calcined by the traditional process, thereby being conductive to promotion and implementation.

Owner:BEIJING LIULIHE CEMENT

Phosphorus-nitrogen synergistic flame-retardant polyalcohol and preparation method thereof

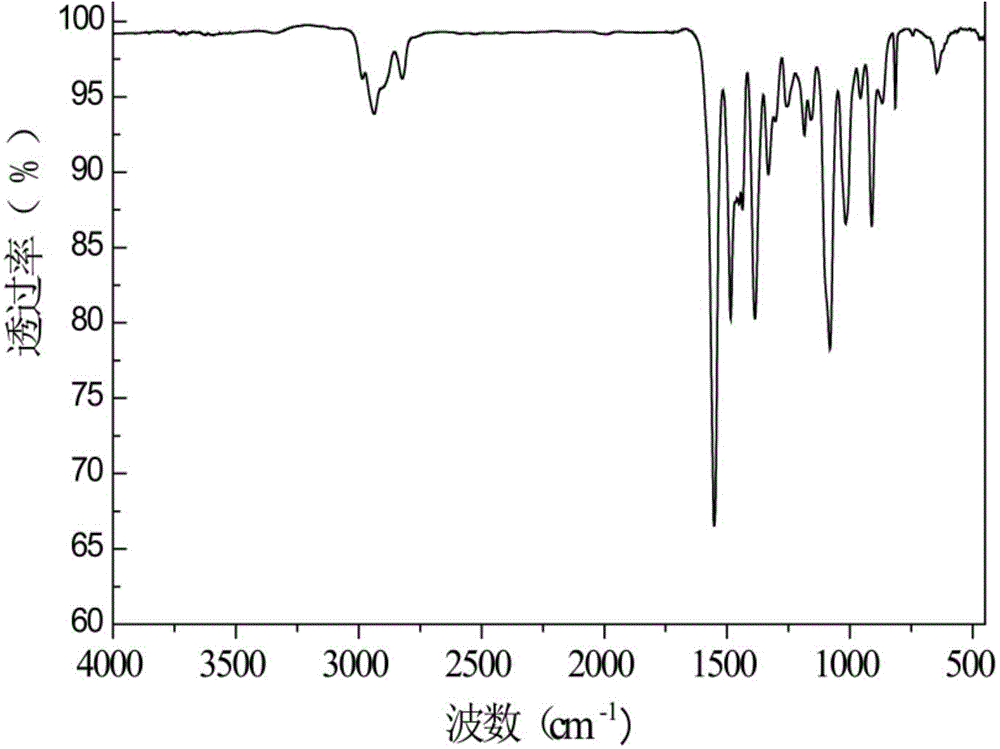

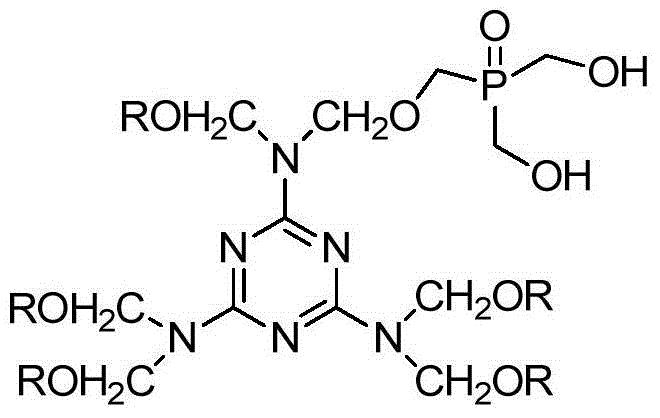

InactiveCN103980313AEfficient Flame RetardancyAvoid the weakness of easy hydrolysisGroup 5/15 element organic compoundsDistillationPhosphine oxide

The invention discloses phosphorus-nitrogen synergistic flame-retardant polyalcohol and a preparation method thereof, relating to the synthesis of flame-retardant polyalcohol. The preparation method of the phosphorus-nitrogen synergistic flame-retardant polyalcohol comprises the following steps: 1) with quaternary phosphorus salt as a raw material, adding alkali and stirring for reacting, filtering and separating the salt generated by reacting, then oxidizing with a hydrogen peroxide solution, and performing reduced-pressure distillation for removing moisture to obtain tris(hydroxymethyl)phosphine oxide; 2) performing an ether exchange reaction between hexakis(methoxymethyl)melamine and the tris(hydroxymethyl)phosphine oxide obtained in the step 1) at 50-100 DEG C in the presence of an acid catalyst, and reducing pressure for removing small-molecular methanol to obtain the phosphorus-nitrogen synergistic flame-retardant polyalcohol. The prepared phosphorus-nitrogen synergistic flame-retardant polyalcohol is formed by connecting phosphorus elements through phosphorus-carbon bonds, and the weakness that the phosphorus-carbon bonds (phosphorus-ester bonds) are hydrolyzed easily is avoided, thus the phosphorus-nitrogen synergistic flame-retardant polyalcohol has the characteristic of relatively high hydrolysis resistance.

Owner:XIAMEN UNIV

Method for preparing electronic-grade tetramethylammonium hydroxide (TMAH)

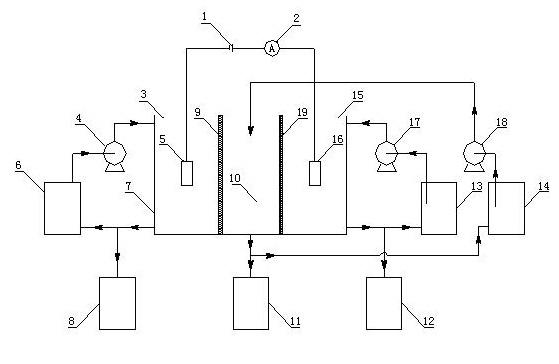

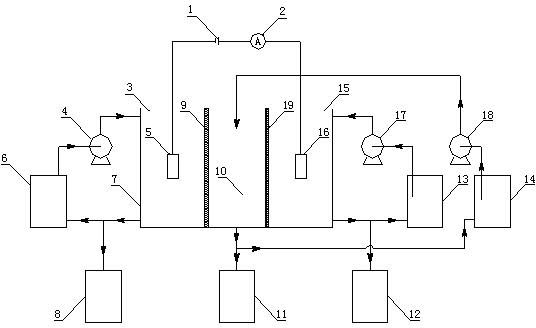

InactiveCN102206832ASimple processImprove current efficiencyElectrolysis componentsElectrolytic organic productionTetramethylammonium hydroxideBuffer tank

The invention discloses a method for preparing electronic-grade tetramethylammonium hydroxide (TMAH), belonging to the field of electrochemistry. In the method, tetramethylammonium bicarbonate is used as a raw material for electrolysis, a dual-film electrolyzer is used for preparing the electronic-grade TMAH, and the whole electrolyzer implements cyclic stirring of the electrolyte in the electrolytic process in an external cycle mode. The electrolytic conditions are as follows: the cathode tank uses a 0.2-0.5 mol / L TMAH solution; the buffer tank uses a 1.0-3.0 mol / L TMAHCO3 solution; the anode tank uses a 0.2-0.6 mol / L Na2SO4 solution; the temperature for electrolysis is 40-60 DEG C; and the current density is 400-1000 A / m<2>. The invention has the advantages of simple technological process, low raw material cost, high product yield (the content of metallic ions in the product is lower than 4ppm, achieving the standard for electronic-grade TMAH), high electrolytic-current efficiency (up to 80-90%), environmental protection, no pollution and high production safety.

Owner:ZHENGZHOU UNIV

Inorganic micro/nanoparticle/polymer composite building thermal-insulation aerogel material and preparation method thereof

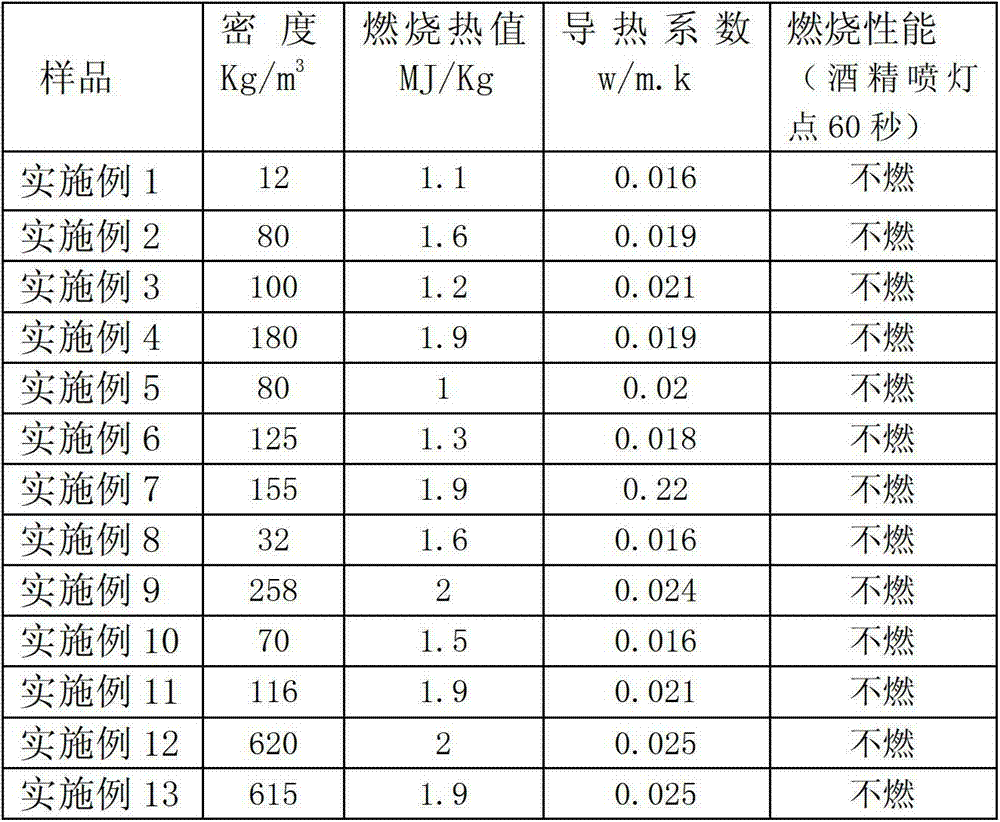

The invention discloses an inorganic micro / nanoparticle / polymer composite building thermal-insulation aerogel material which is compounded from the following components in parts by weight: 0.5-50 parts of inorganic micro / nanoparticle, 0.1-5 parts of polymer, 0-10 parts of crosslinkable polymer, 0.5-20 parts of reinforcing fiber, 0.1-5 parts of defoaming agent and 100 parts of water. The density of the material is 12-620 Kg / m<3>, the heat conductivity coefficient is 0.016-0.025 w / m.k, and the combustion heat value is 1.1-2.0 MJ / Kg. The invention also provides a preparation method of the aerogel material. The aerogel material disclosed by the invention has the advantages of low density, light weight, favorable mechanical strength and low heat conductivity coefficient, and is beneficial to energy saving and consumption reduction. The combustion heat value is lower than 2.0 MJ / Kg, and thus, the aerogel material satisfies the flame-retardant requirements for Grade-A building thermal-insulation materials. The aerogel material is an ideal building flame-retardant thermal-insulation material, and can be widely used in external-wall thermal-insulation occasions.

Owner:SICHUAN UNIV

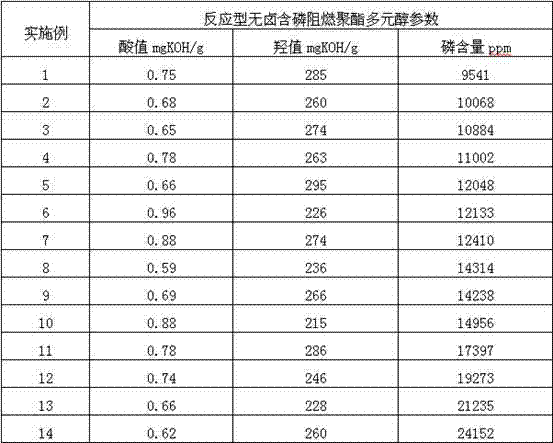

Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

The invention discloses a preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol. The preparation method is characterized by comprising following steps: taking binary acid, dihydric alcohol, halogen-free phosphorous copolymer fire retardant and catalyst to be put into a reaction kettle, stirring and warming up, filling nitrogen to empty, reacting for 2 to 8h when the temperature reaches 125 to 155 DEG C, then warming up to 180 DEG C, vacuumizing to ensure the air pressure to be 100 to 5000 Pa, controlling reaction temperature to be 180 to 245 DEG C, after reacting for 2 to 4h, sampling at an interval of 10 to 40 min to test acid value, stopping heating when the acid value is reduced below 2 mgKOH / g, and stirring for cooling so as to obtain the reaction type halogen-free phosphorous flame retardant polyester polyol. The reaction type halogen-free phosphorous flame retardant polyester polyol is applied to synthesis of rigid or soft polyurethane foamed plastic, and the prepared polyurethane foamed plastic has excellent flame retardant property, and the limit oxygen index can be up to more than 32%.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

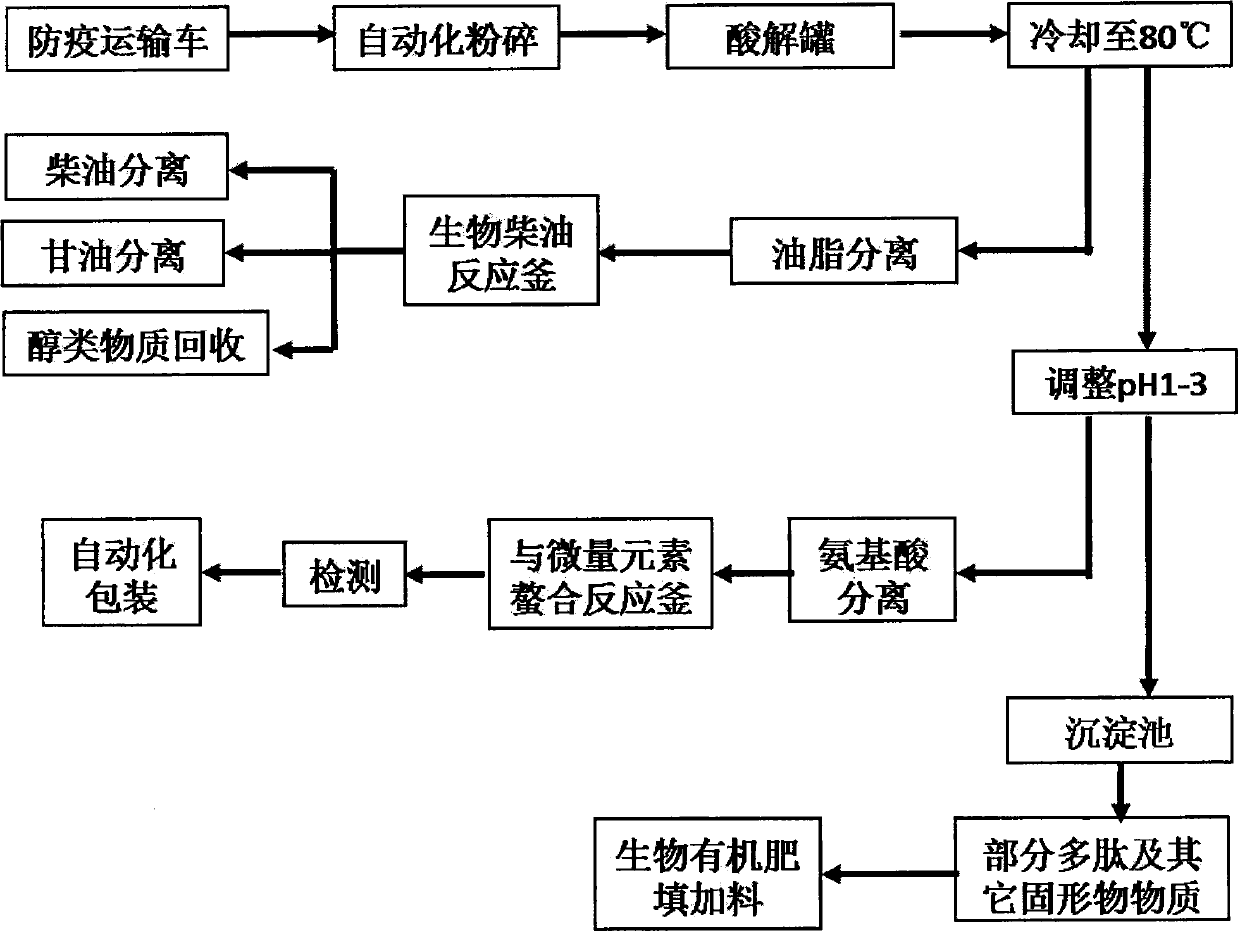

Zero-pollution innocent treatment and high-additional value recycling process for dead beasts and birds

ActiveCN104190694ANothing producedNo pollutionSolid waste disposalClimate change adaptationFertilizerChemistry

The invention relates to a zero-pollution innocent treatment and high-additional value recycling process for dead beasts and birds and belongs to an intensive agriculture production technology. The process comprises the following steps: performing innocent treatment on the dead beasts and birds by utilizing a closed container, automatically grinding the dead beasts and birds, automatically transferring all solids and liquid into a closed hydrolysis tank, hydrolyzing under the conditions of the initial acid concentration c (1 / 2H2SO4) of 3-5mol / L, the temperature of 80-100 DEG C and 1-2 atmospheric pressures for 2-5 hours, and separating the upper grease used for biodiesel production when the temperature of hydrolysate is reduced to 80 DEG C below; and regulating the pH value of the hydrolysate to 1-3, and performing primary or secondary sedimentation to collect an amino acid solution used for amino acid fertilizer production by adopting a natural sedimentation method. According to the process, leaked liquid and volatile gas are avoided in the implementation process, new environmental pollution is avoided, the products are agricultural production necessities, the zero-pollution innocent treatment and high-additional value recycling for dead beasts and birds can be realized, and sustainable development of intensive animal husbandry is guaranteed.

Owner:NANJING AGRICULTURAL UNIVERSITY

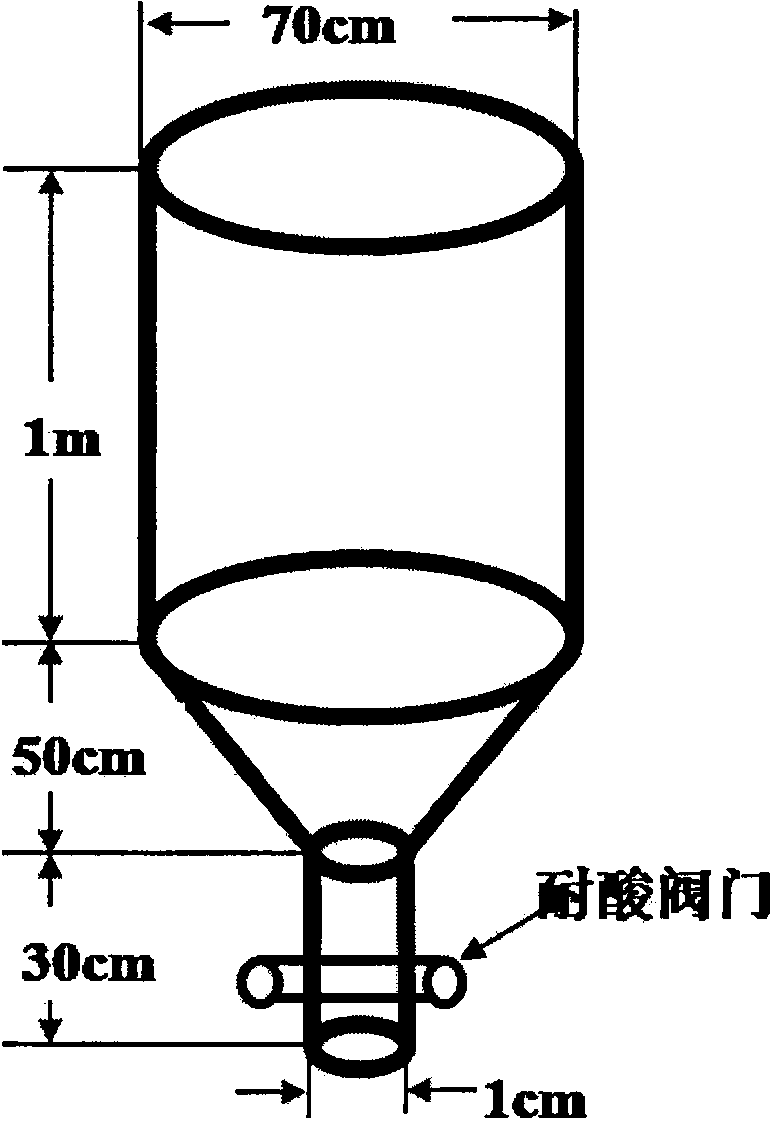

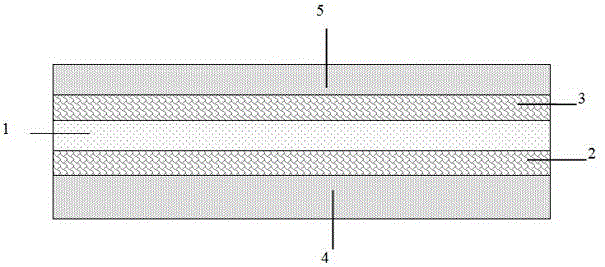

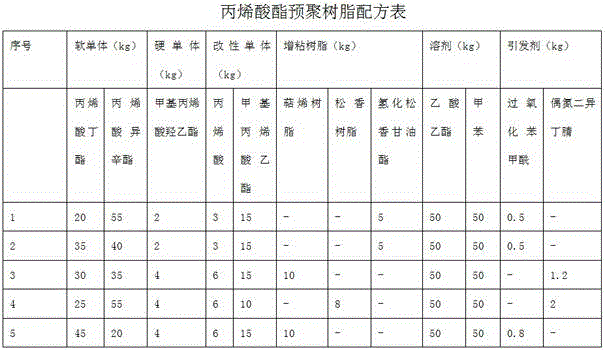

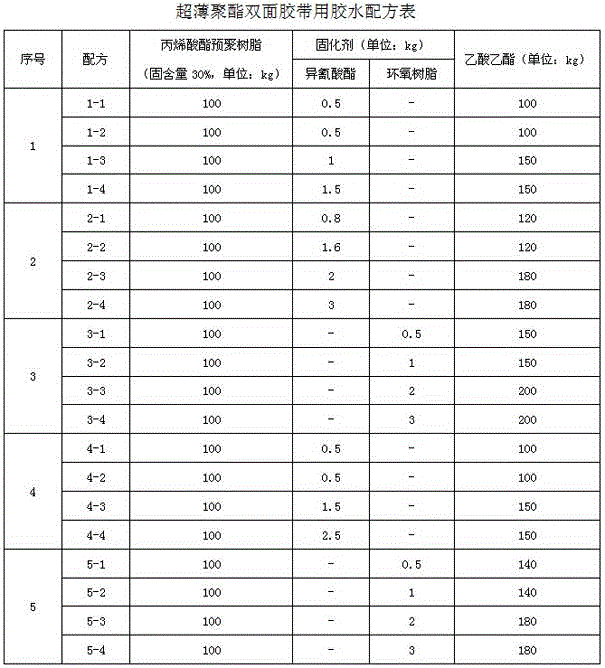

Ultra-thin polyester double-sided adhesive tape, glue thereof, and preparation method thereof

ActiveCN104152077AHigh bonding strengthImprove cohesionFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention discloses an ultra-thin polyester double-sided adhesive tape comprising a polyester thin film layer and two glue layers formed by glue coated on front and back sides of the polyester thin film. The thickness of the polyester thin film is 0.001-0.0012mm. The thickness of the glue layer is 0.002mm. Therefore, the thickness of the double-sided adhesive tape is only 0.005mm, such that electronic product development trends of thin and light can be satisfied. The total thickness of adhesive is 0.004mm, such that the tape has ultra-low thermal resistance, and heat generated by electrical components can be conducted in time. Therefore, electrical component damage caused by long-term working under high temperature is avoided. Also, the invention discloses a formula for the glue used in the ultra-thin polyester double-sided adhesive tape. The glue comprises the raw materials of, by weight, 100 parts of acrylate prepolymer resin, 0.5-3 parts of a curing agent, and 100-200 parts of ethyl acetate. With the glue, a single side thickness is 0.002mm, and high adhesive performance can be provided.

Owner:四川羽玺新材料股份有限公司

Leaf fertilizer containing amino acid and its preparation method

InactiveCN1911869AFull of nutritionPromote activationOrganic fertilisersFertilizer mixturesPhosphateCopper sulfate

The present invention relates to fertilizer preparing technology, and is especially one kind of foliage fertilizer containing amino acid and with fast acting and its preparation process. The foliage fertilizer includes potassium dihydrogen phosphate 2-4 weight portions, copper sulfate 0.3-0.6 weight portions, ferrous sulfat 0.4-0.8 weight portions, magnesium sulfate 0.4-0.8 weight portions, zinc sulfate 0.3-0.6 weight portions, borax 0.4-0.8 weight portions, manganese sulfate 0.2-0.4 weight portions, calcium sulfate 0.2-0.4 weight portions, urea 2-4 weight portions, honey 0.1-0.3 weight portions, milk 0.5-1.0 weight portions, water soluble vitamins electrolyte 0.02-0.04 weight portions, amino acid 0.5-1.5 weight portions, fish liver oil 0.02-0.04 weight portions, vitamins B 0.04-0.12 weight portions. The foliage fertilizer has rich nutrients and pH 5.5-6.5 after being diluted, is suitable for foliage absorption and may be used to replace root applying organic fertilizer.

Owner:陈俊茂

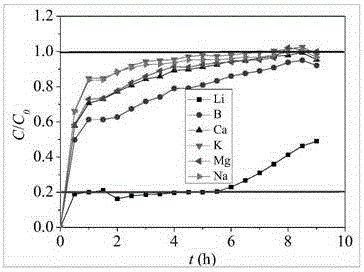

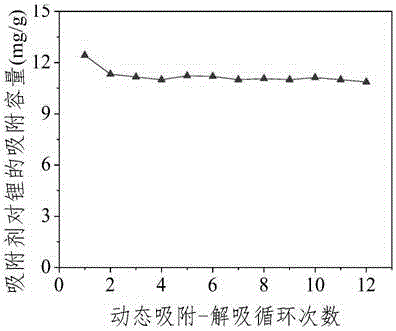

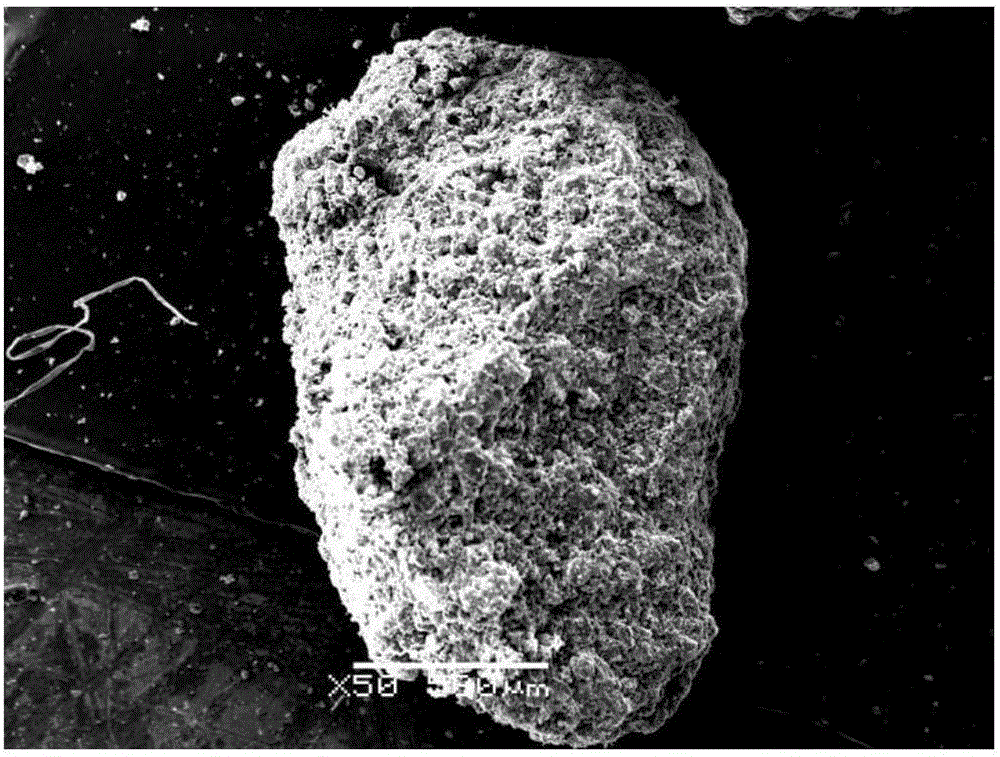

Microporous aluminum-salt lithium adsorbent, preparation method therefor, filler and lithium ion enriching method

ActiveCN106076243AOvercome the problem of high dissolution rateControl areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

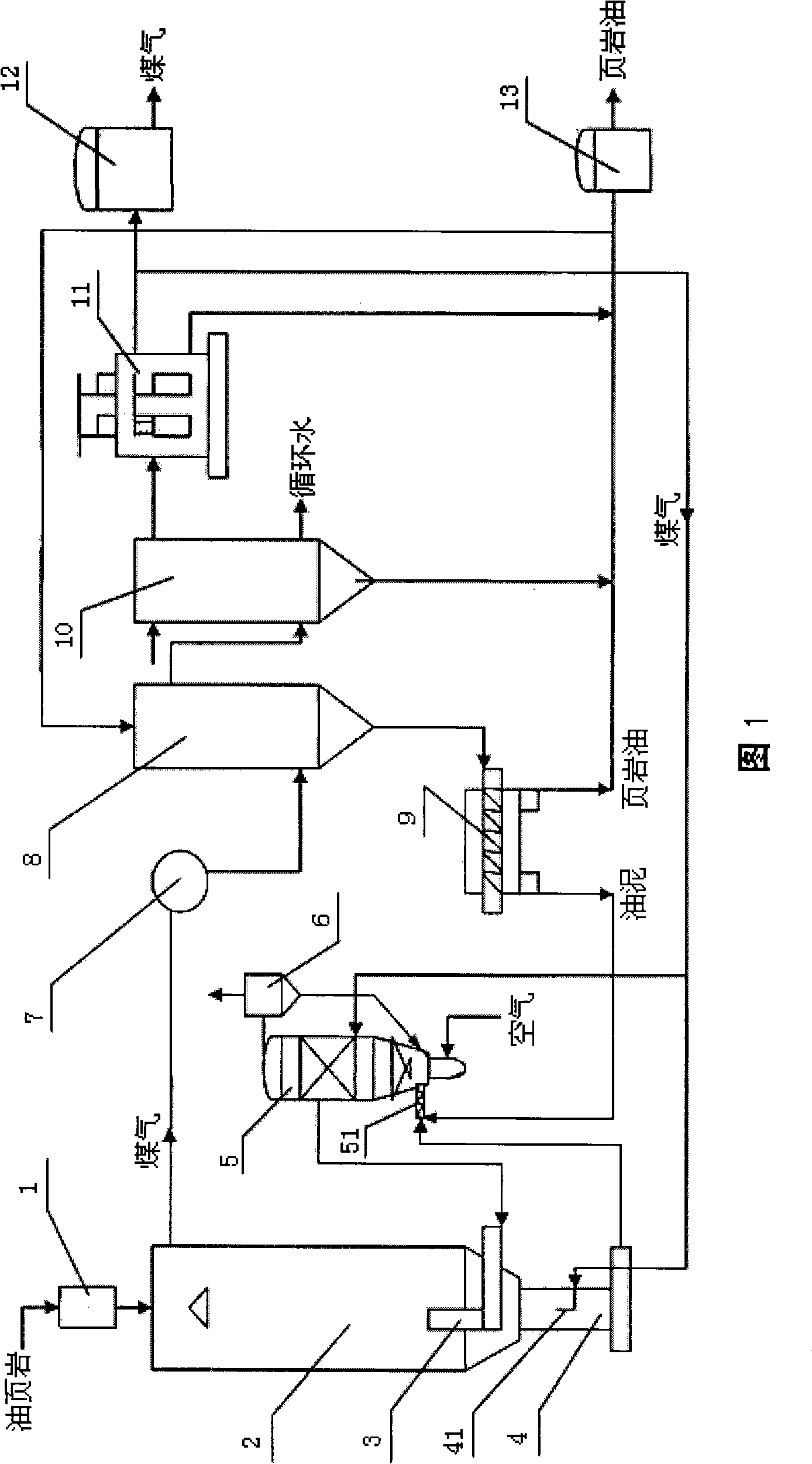

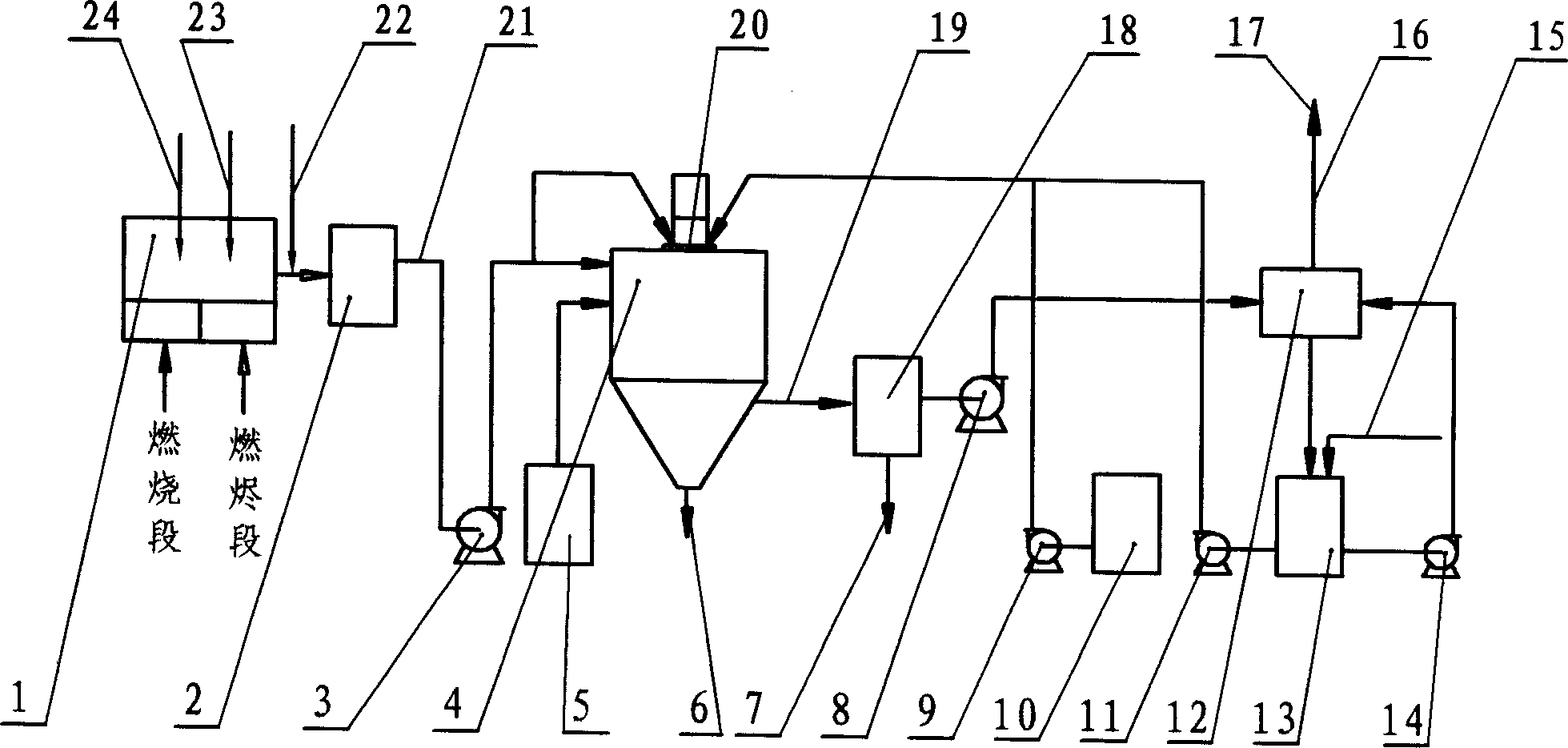

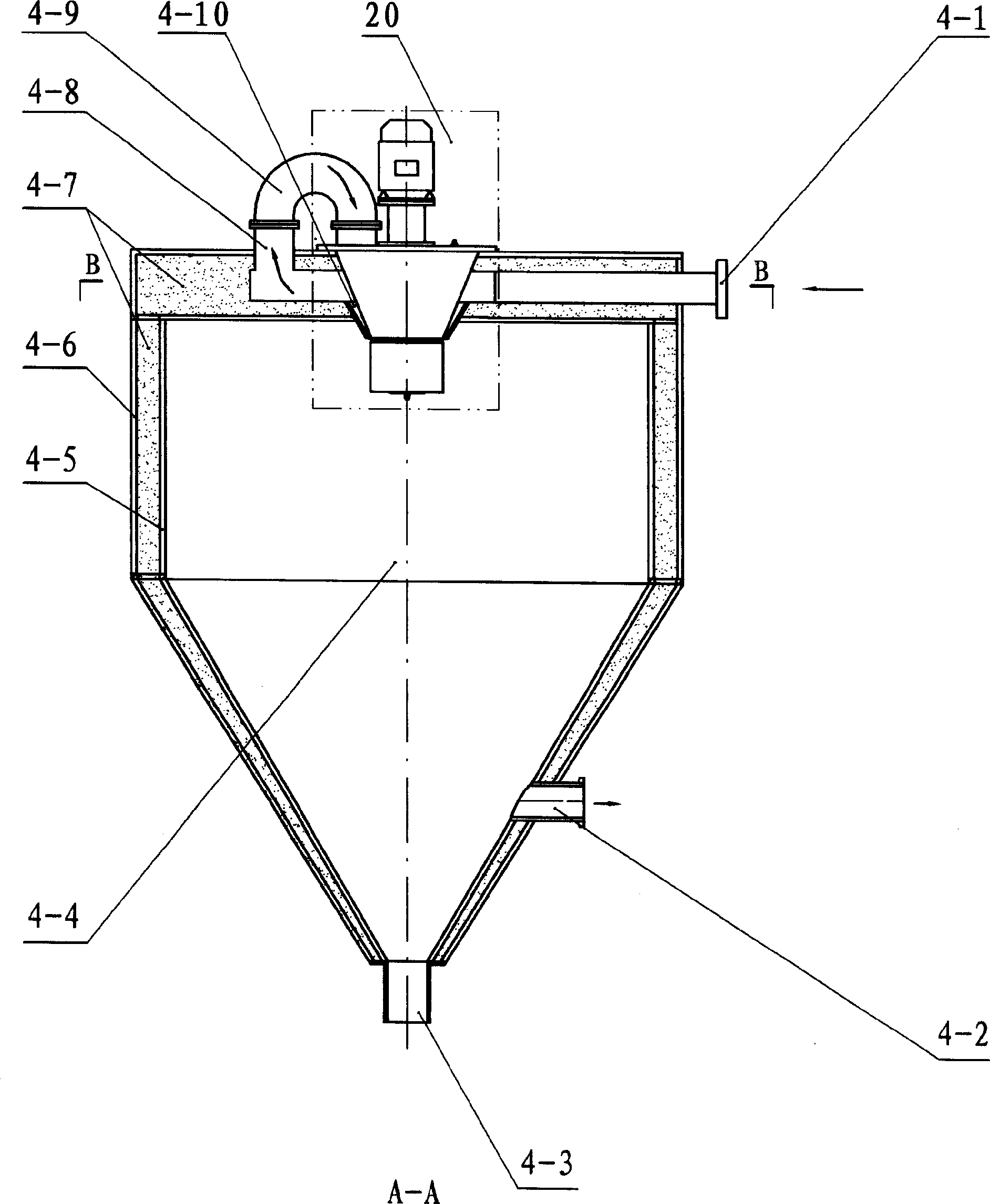

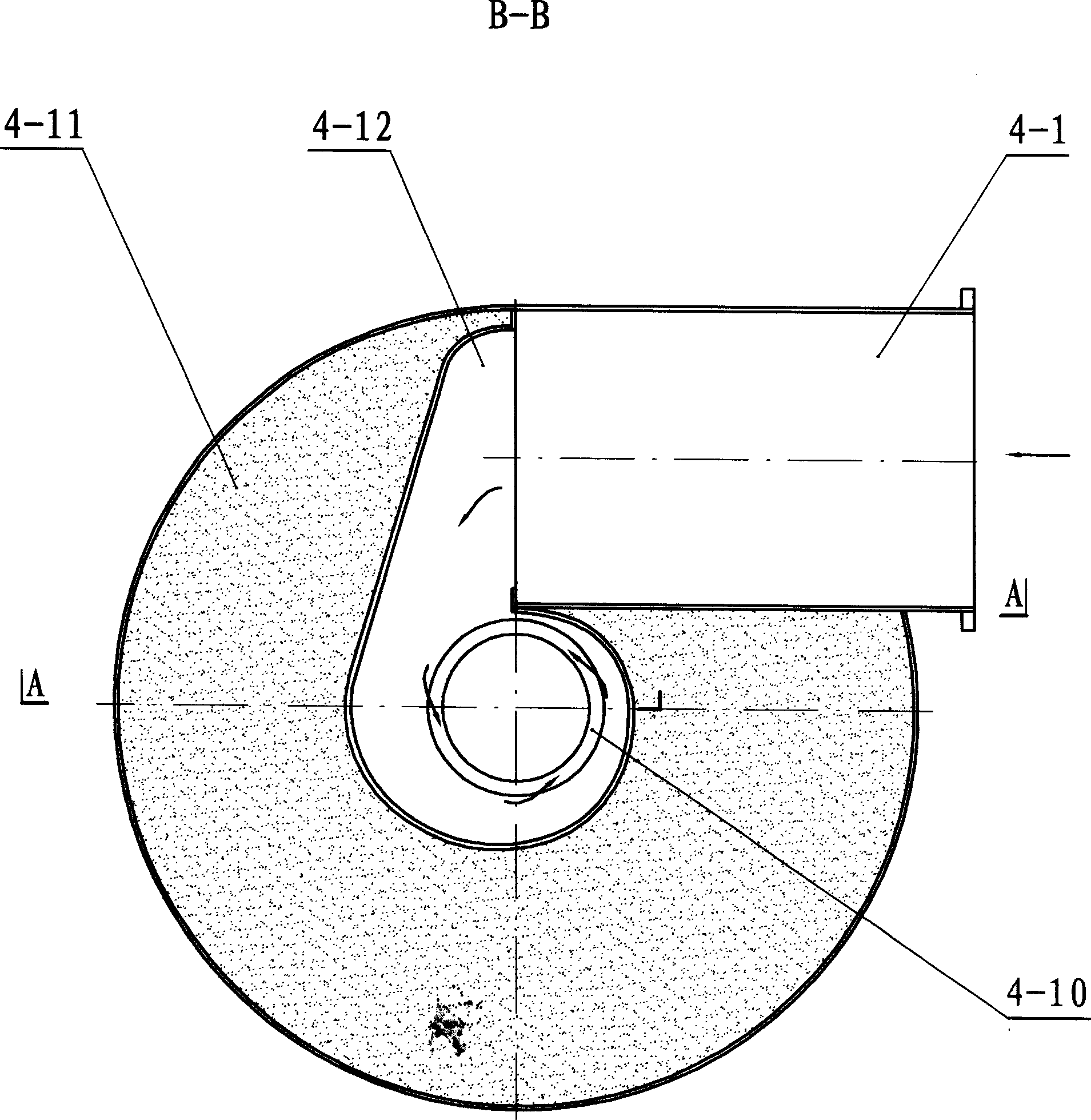

Full cycle dry distillation process and system for producing shale oil from oil shale (coal)

InactiveCN101280201AHigh calorific valueAchieve separationSpecial form destructive distillationDistillationOil sludge

The invention provides a full cycle dry distillation process and a system which use oil shale (coal) to produce shale oil; the technological process includes that the distillation of the oil shale is processed in an oil shale distillation system which is composed of an oil shale input storage tank, a non-oxygen coal-gas heating retort and a semi-coke discharge device to generate pyrogenous coal gas and the semi-coke; the pyrogenous coal gas is separated and purified by a pyrogenous coal gas multi-stage purifying system composed of a coal gas collecting pipe, an oil-washing tower, an intercooling tower and an electrical oil trap; the obtained coal gas is preheated by a coal gas preheating system composed of a fluidized bed combustion furnace, a spiral feeder and a duster collector and then is fed into the non-oxygen coal-gas heating retort for the dry distillation of the oil shale; the oil product separated from the oil-washing tower, the intercooling tower and the electrical oil trap is purified and collected through an oil product purifying and collecting system so that the shale oil product is obtained; the semi-coke and the sludge generated during the dry distillation and purification process are used as the materials for the preheating of the coal gas. The dry distillation process in the invention can effectively realize the functions of dry distillation, dust separation and combusting the semi-coke and sludge generated during the process of dry distillation for the preheating of the coal gas; thereby, the sources is utilized sufficiently and the environmental protection requirement is fulfilled.

Owner:ZHUHAI TOP ENERGY TECH

Method for recovering lithium and transition elements in waste lithium battery positive material by liquid phase method

InactiveCN110331290ANothing producedAchieve recyclingWaste accumulators reclaimingProcess efficiency improvementLithiumIon exchange

The invention discloses a method for recovering lithium and transition elements in waste lithium battery positive material by a liquid phase method. The method comprises the following steps that (1) the waste lithium battery is subjected to discharging treatment, the disassembled waste lithium battery is placed in a negative pressure environment for drying, and a dried positive plate for removingelectrolyte is obtained; (2) the dried positive plate is putted into low eutectic solvent, and active substances in the positive plate is dissolved in a high-temperature environment to obtain the reaction solution; (3) the reaction solution obtained in step (2) is filtered, washed, a filter cake is dried, collecting fluid, binder agent and conductive agent are obtained, the reducing agent is addedinto obtained filtrate, adjusting the obtained filtrate to be alkaline, and metal ions in the filtrate are reduced and precipitated; and (4) the filtrate containing precipitate in step (3) is filtered after the reduction reaction, the filter cake is dried and the transition elements are obtained, and the lithium element is obtained by means of extraction, precipitation, ion exchange and the like.The method is high in selectivity, high in leaching rate, simple to operate, low in cost, low in energy consumption, safe and environment-friendly.

Owner:CENT SOUTH UNIV

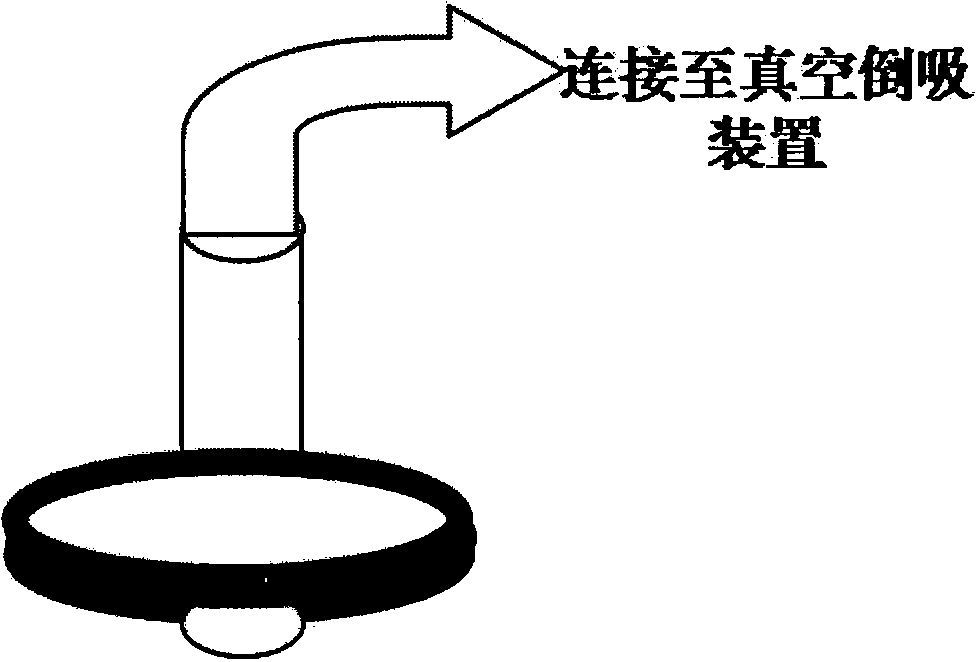

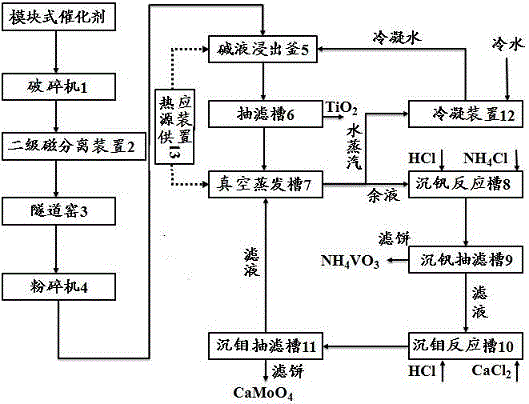

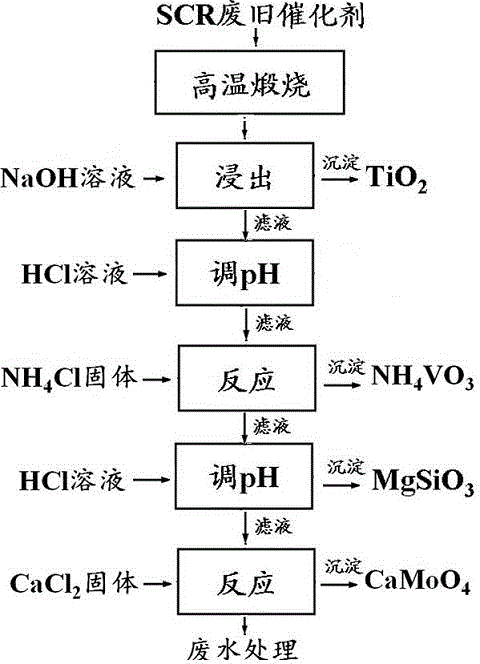

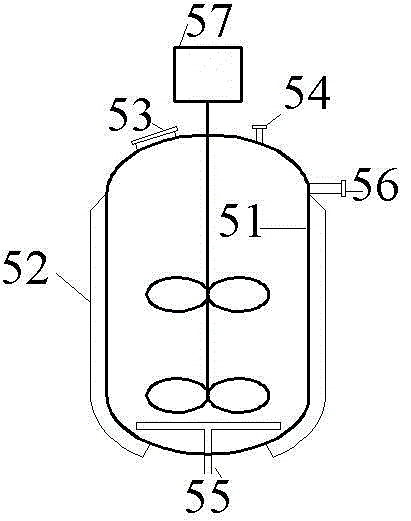

Continuous recovery device and continuous recovery process of vanadium, molybdenum and titanium in SCR (selective catalytic reduction) waste catalyst

The invention discloses a continuous recovery device and a continuous recovery process of vanadium, molybdenum and titanium in an SCR (selective catalytic reduction) waste catalyst, wherein a crusher is connected with a secondary magnetic separation device, the secondary magnetic separation device is connected with a tunnel kiln, the tunnel kiln is connected with a smasher, the smasher is connected with an alkaline leaching kettle, the alkaline leaching kettle is connected with a suction filtration groove, the suction filtration groove is connected with a vacuum evaporation tank, the vacuum evaporation tank is connected with a vanadium sedimentation reaction tank, and the vanadium sedimentation reaction tank is connected with a molybdenum sedimentation suction filtration groove; the alkaline leaching kettle is clamped outside the reaction kettle, a top overflow opening is positioned in the upper side of the jacket, a charging opening and a filling opening are positioned in the upper part of the reaction kettle, and the filling opening is guided to the middle part of the reaction kettle by virtue of a guide pipe. According to the continuous device disclosed by the invention, the production efficiency is effectively improved, thereby facilitating subsequent automatic and continuous production. A flat plate type flue gas denitrification catalyst is continuously recovered, infiltrating water is recycled, and the water yield is greatly saved.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

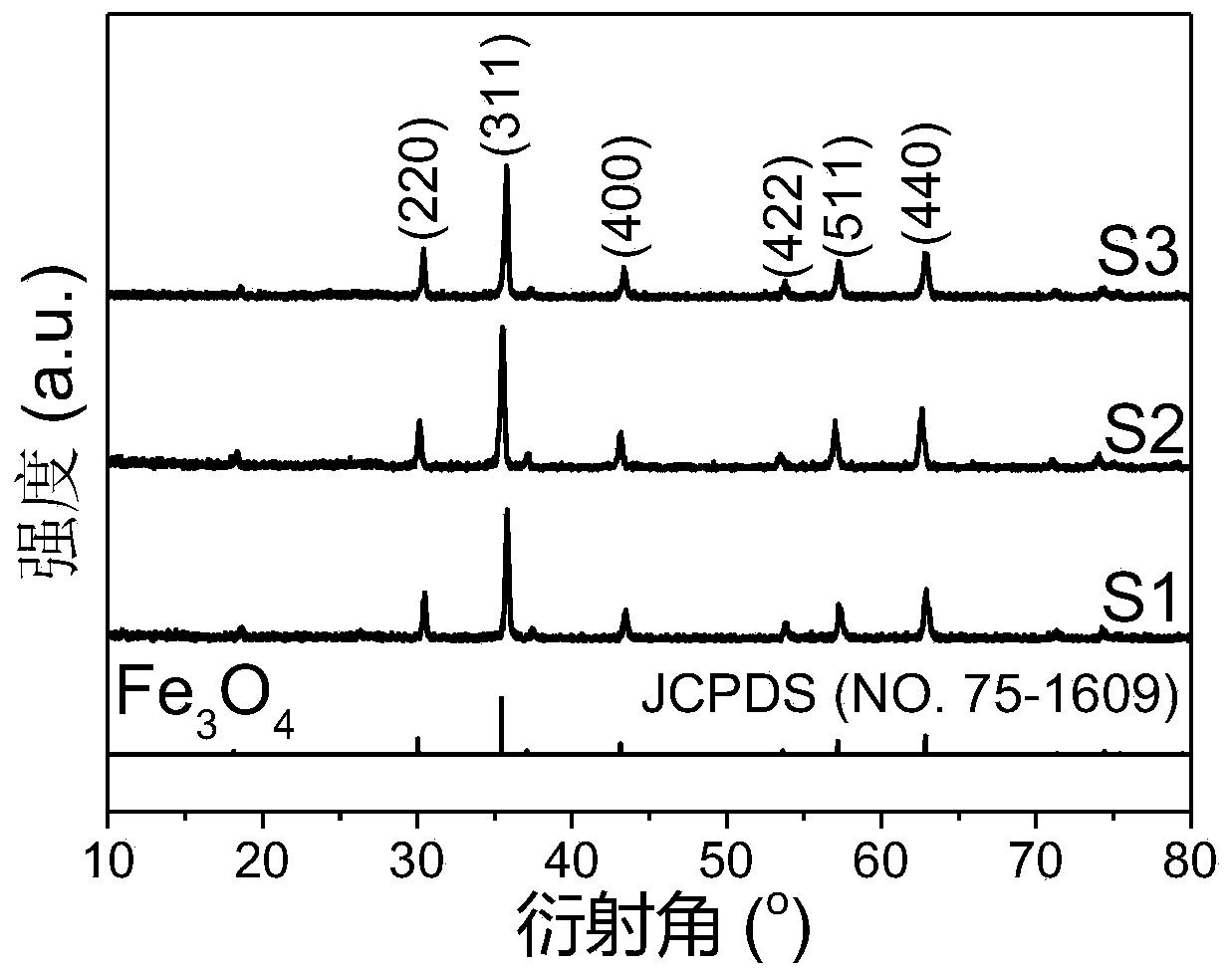

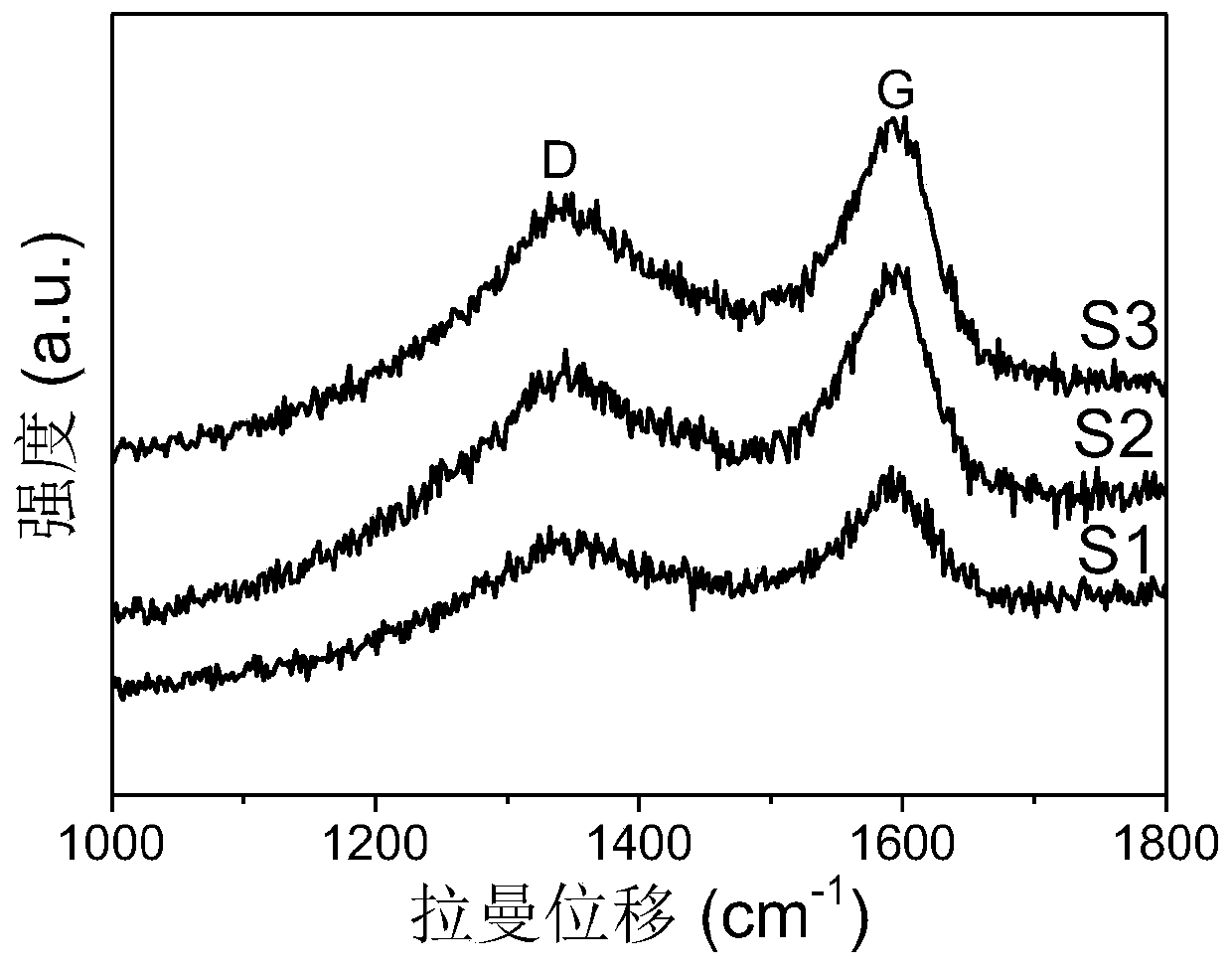

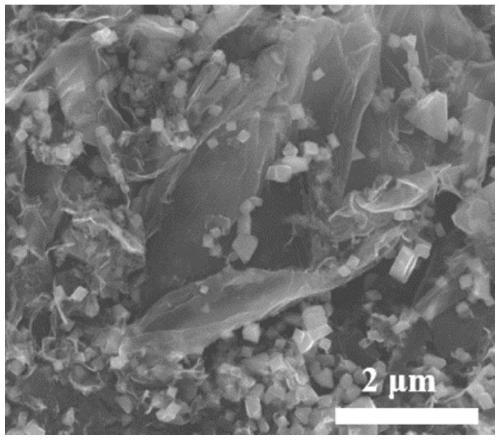

Metal-organic frame-derived ferroferric oxide@carbon/reduced graphene oxide nano composite wave-absorbing material and preparation method thereof

ActiveCN110012656ASimple and fast operationNothing producedOther chemical processesMagnetic/electric field screeningEnvironmental resistanceN dimethylformamide

The invention discloses a ferroferric oxide@carbon / reduced graphene oxide nano composite wave-absorbing material and a preparation method thereof. By using graphene oxide as a template, ferric chloride hexahydrate as a metal salt, terephthalic acid as an organic ligand, and N,N-dimethylformamide as a solvent, the ferroferric oxide@carbon / reduced graphene oxide nano composite material is prepared by a solvothermal-high temperature pyrolysis two-step method. The preparation method is environmentally friendly, generates no toxic by-products, and has a simple preparation process. The prepared nanocomposite material has a good microwave absorption capacity, a wide absorption frequency band, a low thickness, light weight and a low filling ratio, can absorb electromagnetic waves in different wavelength bands by adjusting the addition amount of graphene oxide in a precursor and the thickness of a coating layer, and has an important application value in the field of electromagnetic absorptionand electromagnetic shielding.

Owner:ANHUI UNIV OF SCI & TECH

Mixed enzyme production process by solid fermentation of fruits and vegetables and microorganisms

InactiveCN104839638ARetain enzyme activityRetain non-enzyme active ingredientsFood preparationEnvironmental resistanceMicroorganism

The present invention discloses a mixed enzyme production process by solid fermentation of fruits and vegetables and microorganisms and the production process includes the following steps: step one, washing and cleaning fresh fruits and vegetables; step two, juicing the cleaned fruits and vegetables using a juice extractor and obtaining the fruit and vegetable juice and the fruit and vegetable residue; step three, adding water content adjusting raw materials according to different water content of the obtained fruit and vegetable residue to adjust the water content of the fruit and vegetable residue, and mixing the above materials evenly to obtain a base material; step four, putting the step three obtained base material into a fermentation bottle to conduct sterilization; step five, cooling the sterilized fruit and vegetable base material to room temperature, and inoculating microorganism liquid strains to conduct solid fermentation; and step six, after the end of solid fermentation, blending the obtained fruit and vegetable juice into the solid fermented materials, conducting low temperature drying, and thereby obtaining the fruit and vegetable and microorganism mixed enzymes containing both fruit and vegetable enzymes and microbial enzymes. The mixed enzymes can not only fully preserve the enzyme activity of fruits and vegetables, but also obtain the enzyme ingredients of microorganisms, and in addition, the production process can also achieve the full advantage of the entire fruits and vegetables, does not produce any waste, and is ecological and environmental protective.

Owner:杭州德润全健康产业发展有限公司

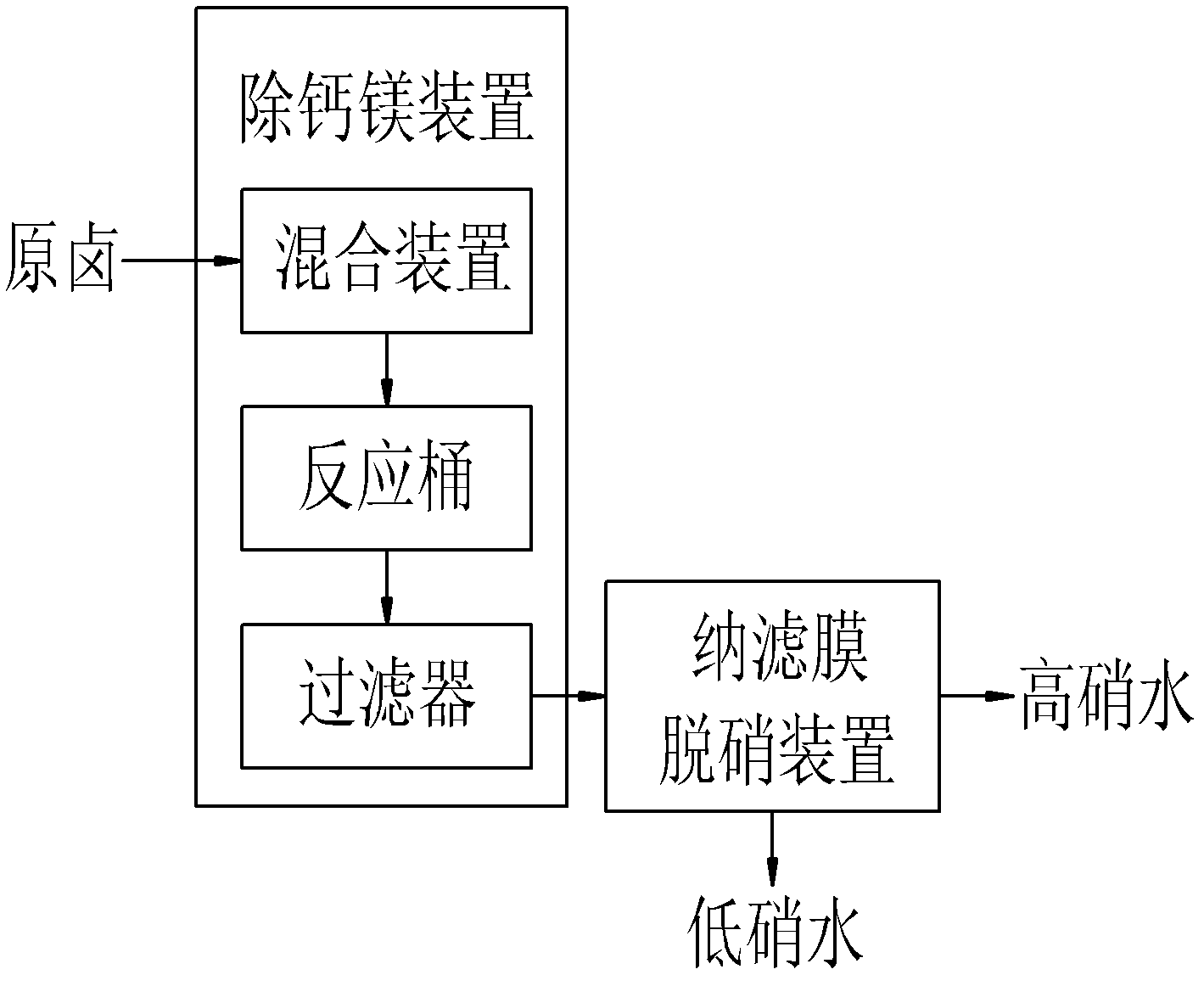

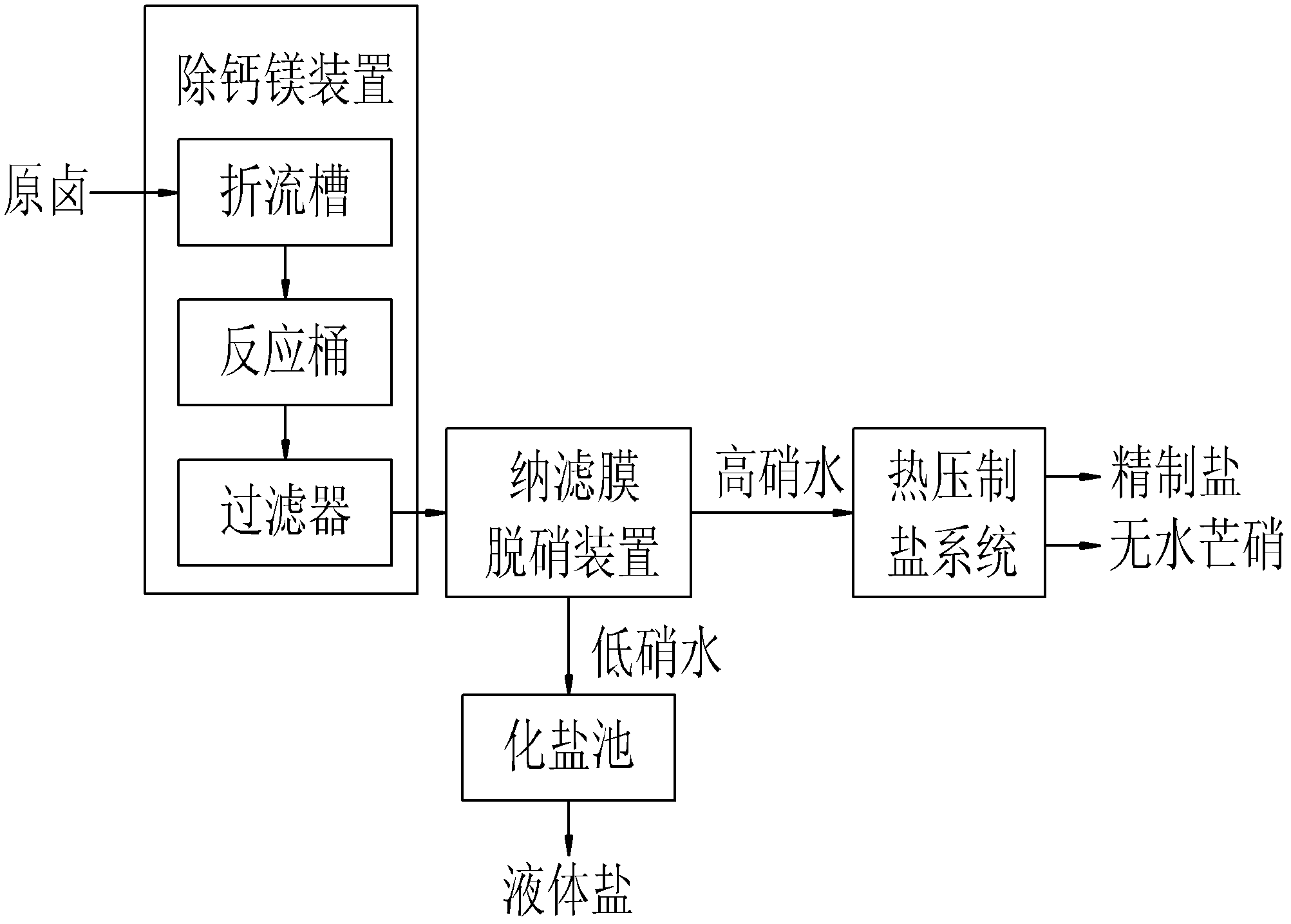

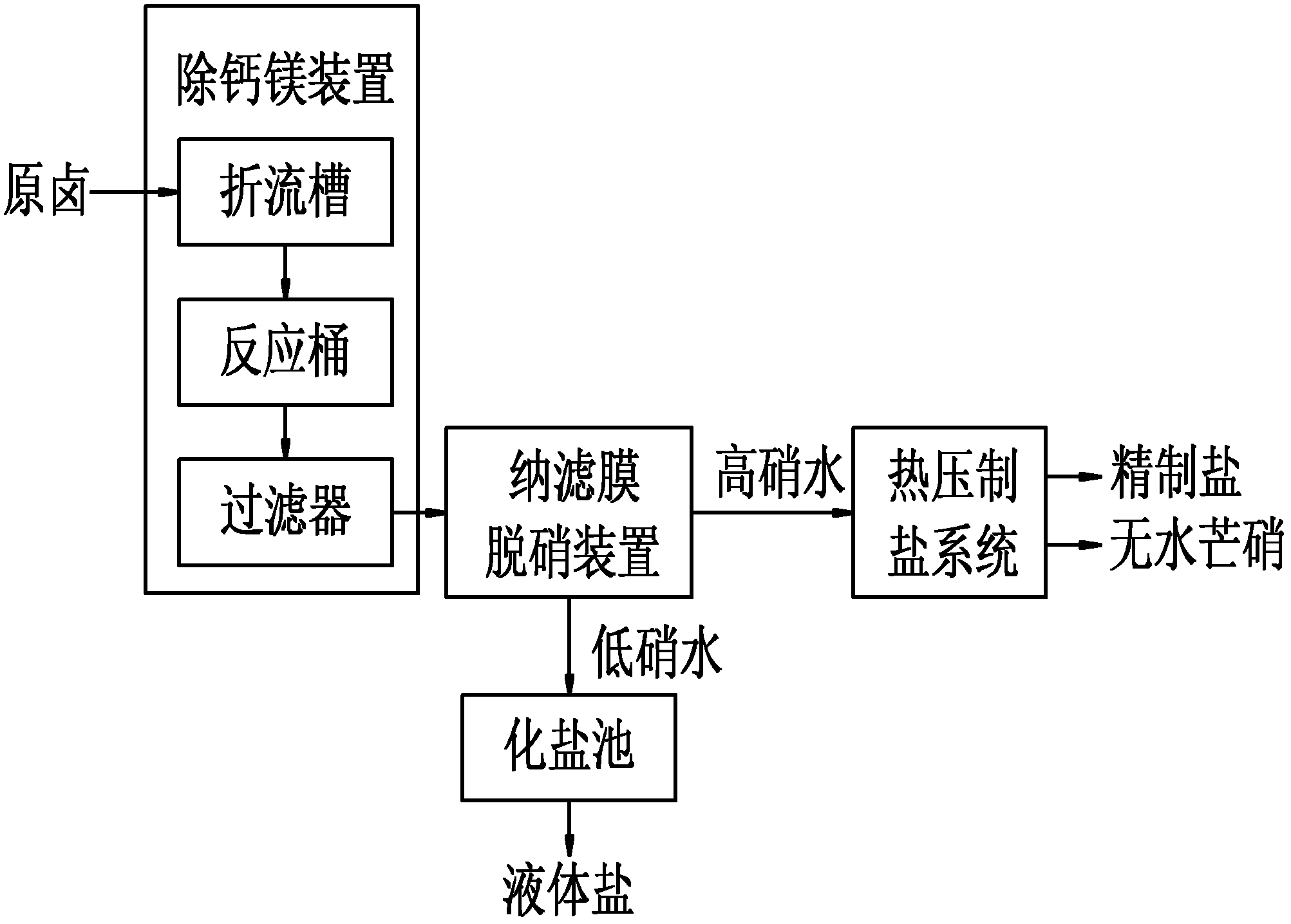

Original halogen denitration production process and production equipment

InactiveCN102432037AReduce energy consumptionReduce production energy consumptionAlkali metal chloridesAlkali metal sulfites/sulfatesFiltration membraneHalogen

The invention relates to an original halogen denitration production process and original halogen denitration production equipment. The process comprises the following steps of: 1, removing calcium ions and / or magnesium ions from original halogen extracted by a water solution method; 2, removing sulfate ions from the original halogen of which the calcium ions and / or the magnesium ions are removed by using a nano-filtration membrane denitration device; and 3, collecting high aqueous glauber salt and low aqueous glauber salt which are produced by the nano-filtration membrane denitration device respectively. In the invention, the nano-filtration membrane denitration device is used for denitrating the original halogen and can only be used for denitrating light salt brine generally in the prior art; the produced liquid salt reaches a standard of first-time salt brine, and the SO4<2-> content is less than 4g / l required by the requirement of the first-time salt brine and can be controlled to be less than 3g / l; the high aqueous glauber salt subjected to nano-filtration membrane denitration is used for preparing salt through hot press, and the energy consumption of the nano-filtration membrane denitration is about 20 percent less than that of multiple-effect vacuum evaporation; and the liquid salt has lower production energy consumption, salt slurry is not generated in the denitration method, and the denitration method is more environment-friendly compared with a chemical method.

Owner:CHINASALT JINTAN

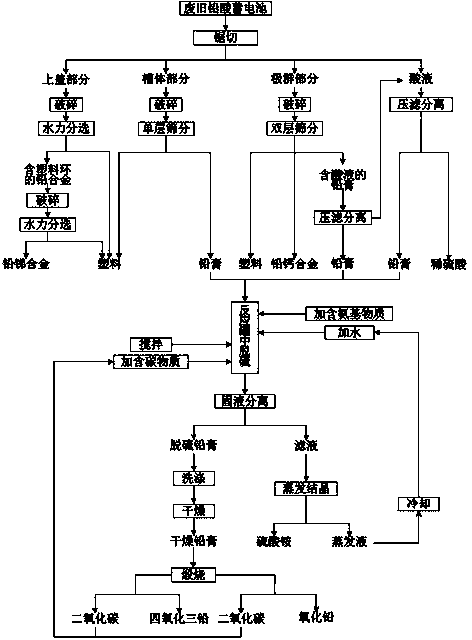

Method for recycling used lead-acid batteries in full circulation mode

InactiveCN103794834AAchieve separationGuaranteed normal processingMetal sawing devicesWaste accumulators reclaimingLEAD TETROXIDELead oxide

The invention relates to a method for recycling used lead-acid batteries in a full circulation mode. According to the technical scheme, a band sawing machine for cutting the used lead-acid batteries is used for sawing and cutting a used lead-acid battery into an upper cover, a groove body, an electrode set and acid liquid, and the upper cover, the groove body, the electrode set and the acid liquid are respectively processed to obtain lead-antimony alloy, plastic, lead plaster, lead-calcium alloy and dilute sulphuric acid. Then, the lead plaster is added into a reaction tank, amidogen-contained substances are added to the lead plaster, stirring is conducted, desulfurization is conducted after carbon-contained substances are added, solid-liquid separation is conducted, and therefore desulfurated lead plaster and filter liquid are obtained. Then, the filter liquid is evaporated and crystallized to obtain ammonium sulfate, and liquid evaporated in the evaporation and crystallization process is cooled to the room temperature and recycled. The washed desulfurated lead plaster is dried, and the dried desulfurated lead plaster is roasted at the temperature larger than 400 DEG C and smaller than or equal to 500 DEG C or at the temperature larger than 500 DEG C and smaller than or equal to 650 DEG C to obtain lead tetroxide or lead oxide. The method has the advantages of being simple in process, low in recycling cost, high in recycling rate, high in product purity and environmentally friendly.

Owner:襄阳远锐资源工程技术有限公司 +1

Smoke desucfuration denitrification dedust process and device

A process for desulfurizing, denitrifying and dusting the fume includes such steps as regulating the air supply of industrial furnace to decrease the generation of NOx, reversely spraying ammonia into combustion box, introducing oxygen to back smoke chamber, removing dust, reaction in centrifugally spraying drying tower to generate ammonium sulfate, separating, and washing in supergravitational washer. Its apparatus is composed of cyclone duster, draught fan, centrifugal spraying drying tower, oxygen generator, supergravitational washer and cyclone separator. Its advantages are high effect, low cost and no secondary pollution.

Owner:重庆正和生物能源有限公司

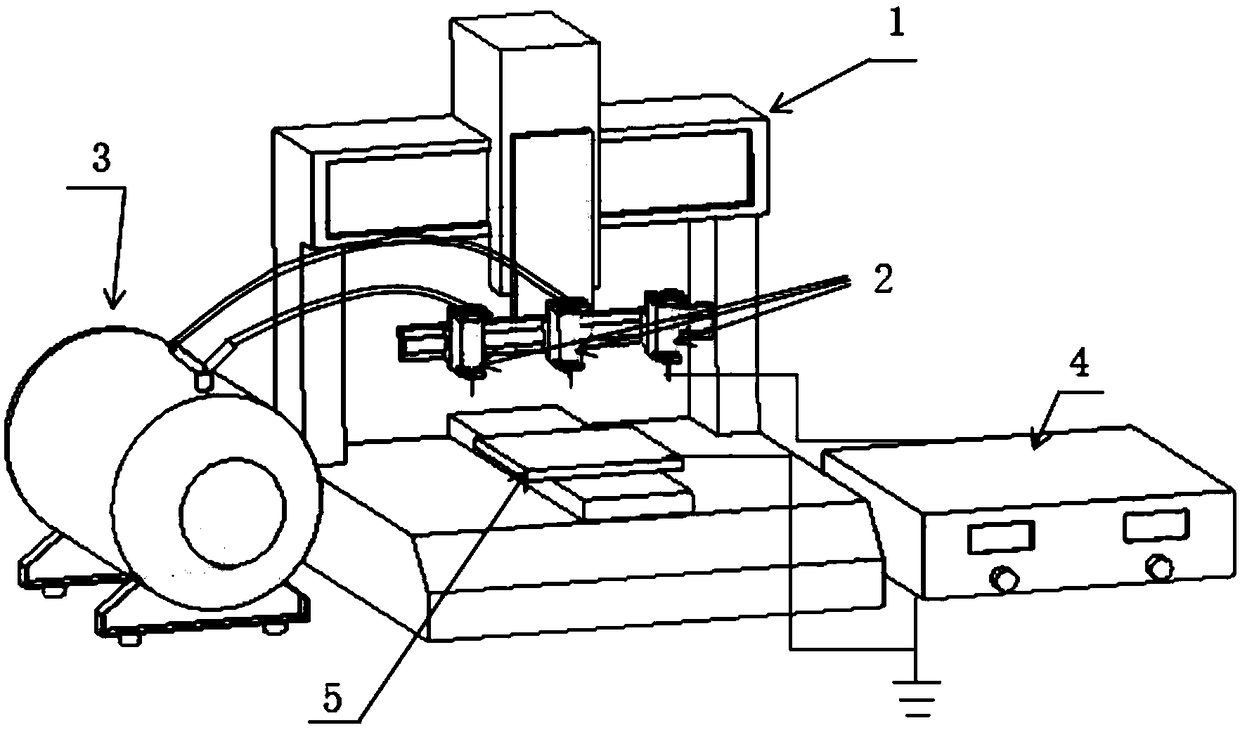

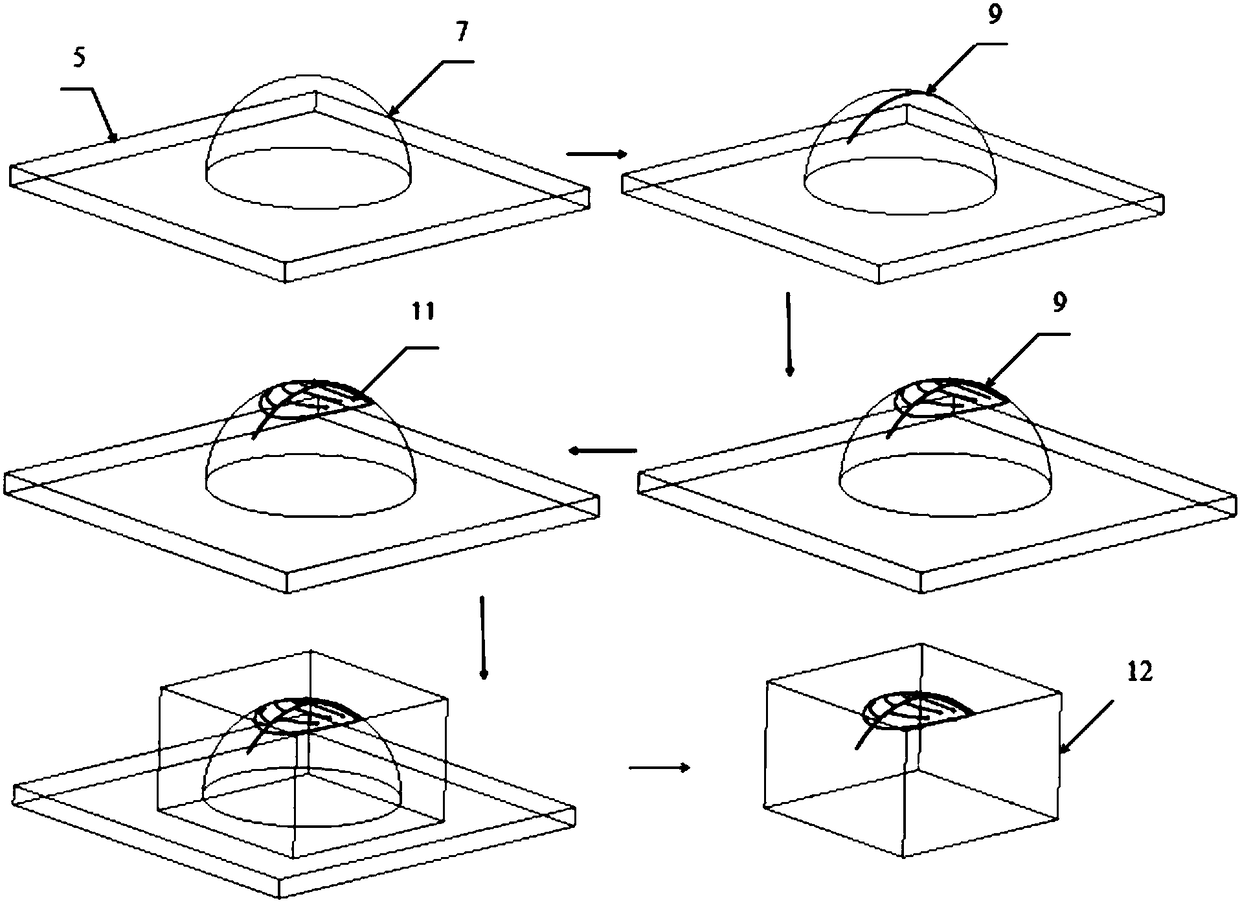

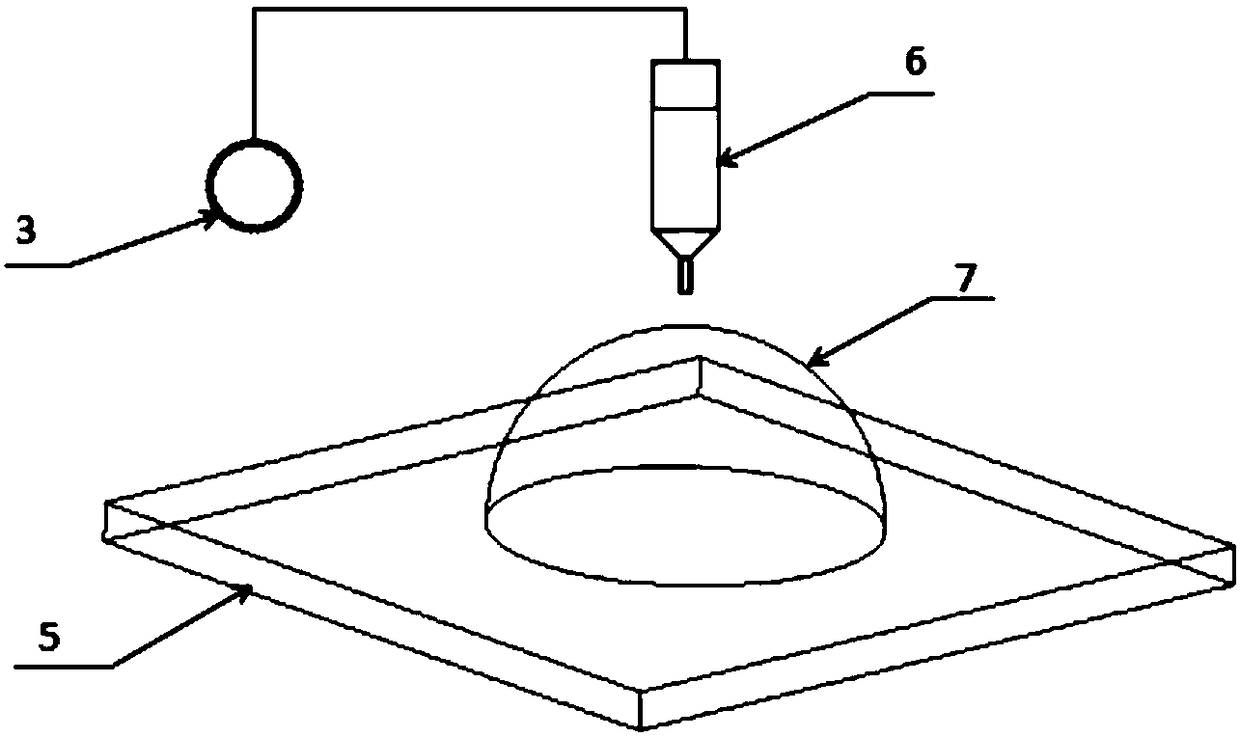

System and method for constructing a three-dimensional multi-scale vascularized stent

ActiveCN109124821AAchieve preparationGood removal effectAdditive manufacturing apparatusBlood vesselsManufacturing technologyHazardous substance

The invention discloses a system and method for constructing a three-dimensional multi-scale vascularized stent. The system comprises a 3D printer, a medical syringe, an air compressor and a high-voltage electric power. The method adopts a biological 3D printing technology combined with electrohydrodynamics direct writing to manufacture a stent containing a three-dimensional multi-scale vascularized network channel by a composite method of increasing and decreasing material manufacturing technology. As that three-dimensional shape of the sacrificial template require by the invention is imparted by the shape of the prin gelatin hemisphere, no harmful substances are generated in the whole process and the material is easy to obtain. By means of the printability of gelatin, Plannick F127 and PCL, three-dimensional and multi-scale vascularized stents can be fabricated, which solves the problem that three-dimensional and multi-scale vascularized stent network can not be obtained by biological 3D printing alone. It is of great significance to solve the vascularization problem of human tissue repair in clinical medicine.

Owner:SHANGHAI UNIV

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com