Zero-pollution innocent treatment and high-additional value recycling process for dead beasts and birds

A technology for harmless treatment of sick and dead livestock and poultry, applied in climate change adaptation, solid waste removal, etc., can solve the problems of loss of biological resources, low economic benefits, high cost, etc., achieve simple and easy treatment process, and reduce production costs , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

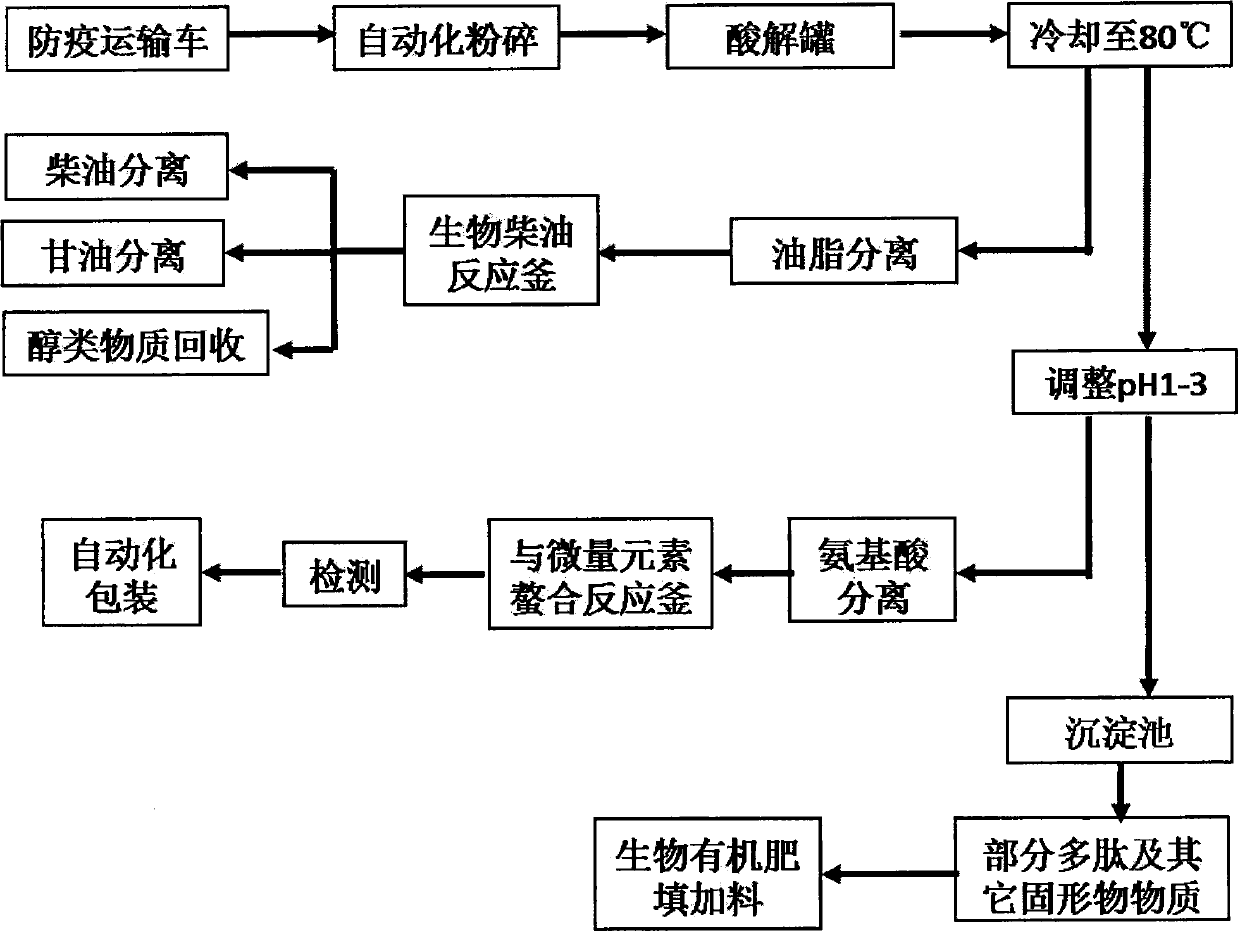

[0028] (1) Process route

[0029] For the process route of zero-pollution treatment of sick and dead livestock and poultry animals and high value-added resource utilization, see figure 1 The process technology of the present invention lies in that from the automatic crushing of sick and dead livestock and poultry animals to the production of biodiesel, glycerin and amino acid products, there is no waste gas, waste water and waste discharge, and the products are necessary for agricultural production, which truly realizes zero pollution and harmless treatment and high Value-added resource utilization.

[0030] (2) Technical points

[0031] 1. Automatic crushing technology

[0032] In the technical process of the present invention, the sealed pulverizer is placed on the hydrolysis tank and fixed. After the sick and dead livestock and poultry animals are transported back by the epidemic prevention vehicle, they are put into a fully sealed coarse pulverizer, and the sick and dead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com