Patents

Literature

3004results about "Alkali metal chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water desalination process and apparatus

ActiveUS20060060532A1Electrolysis componentsGeneral water supply conservationSolubilityWater desalination

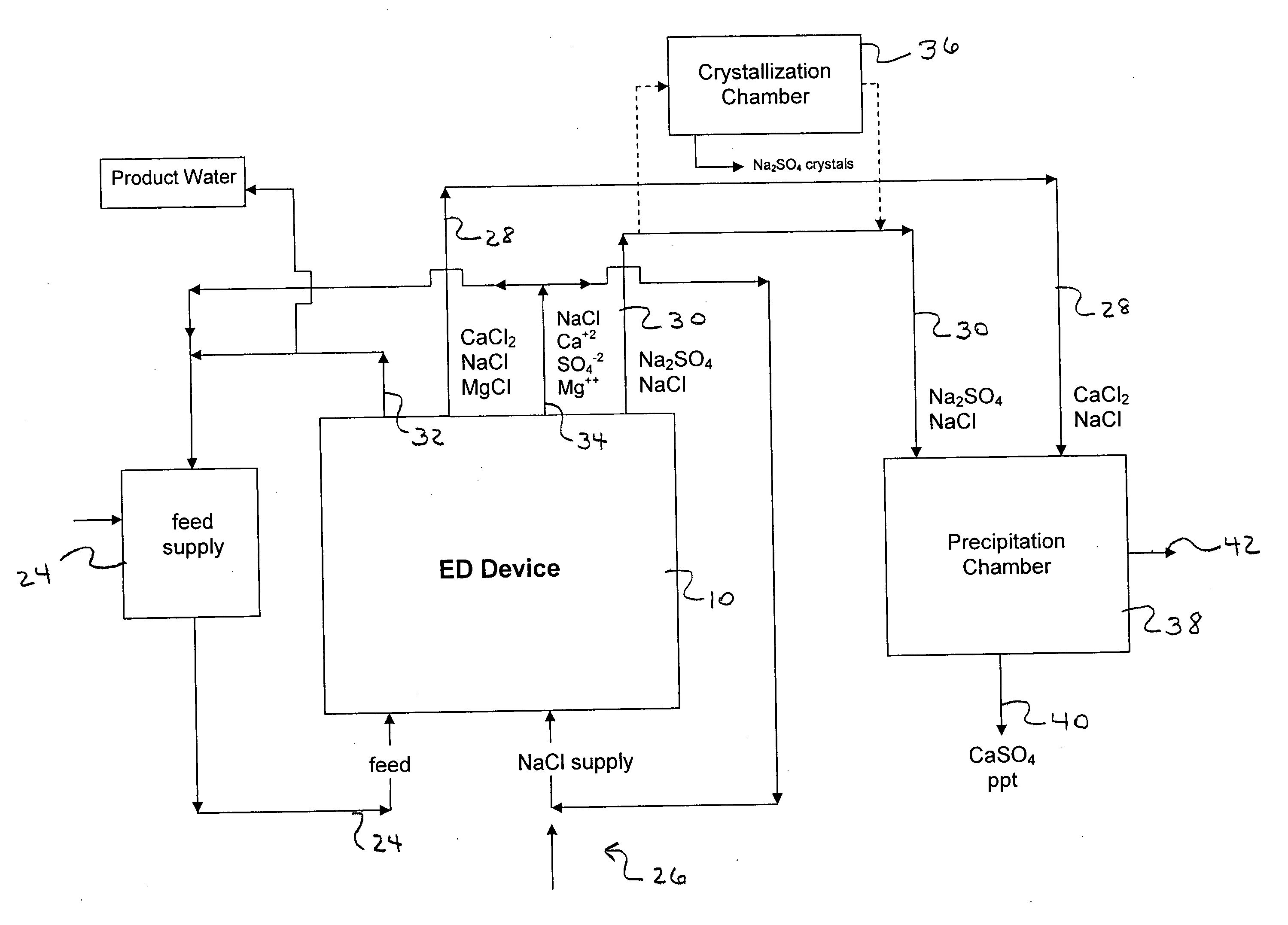

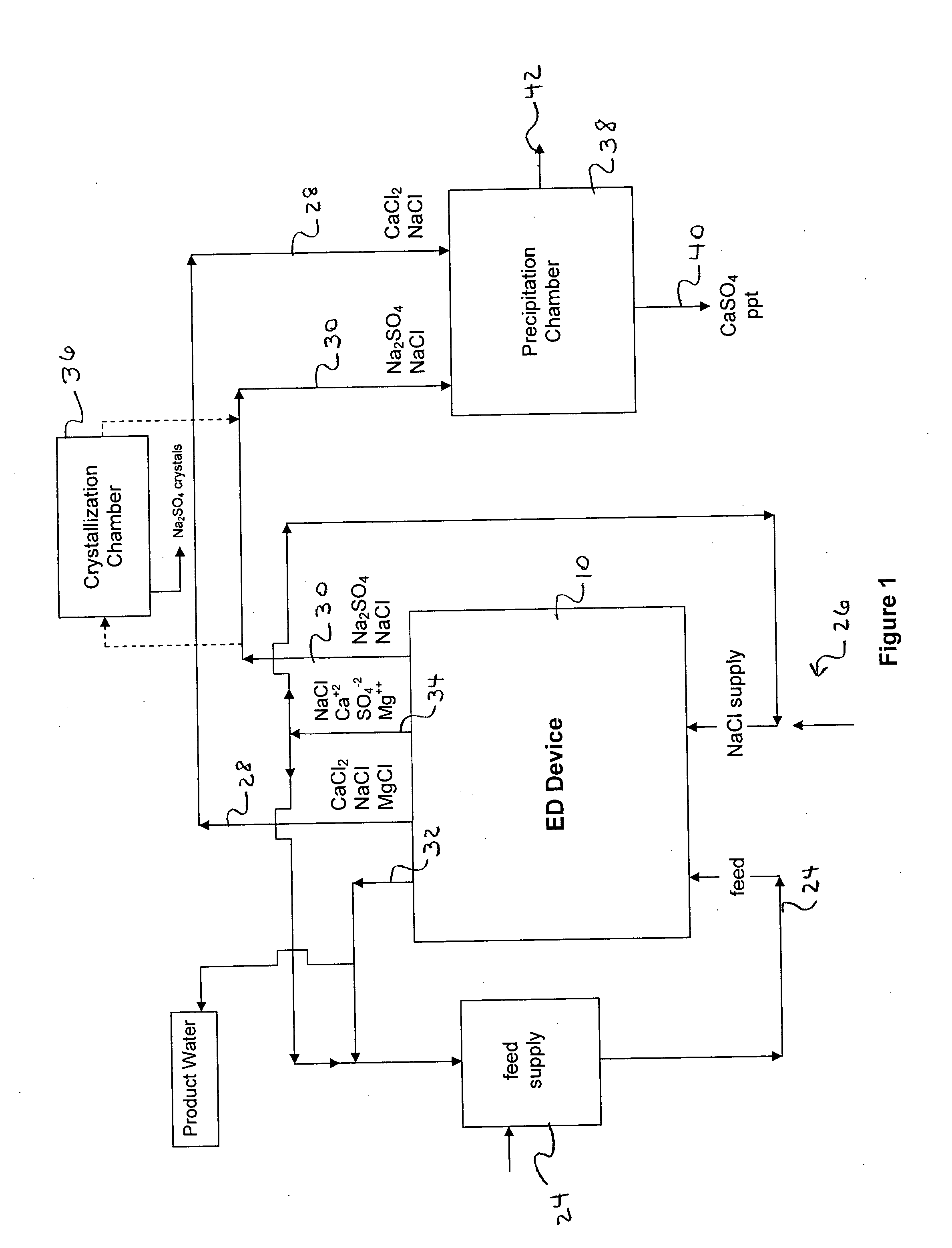

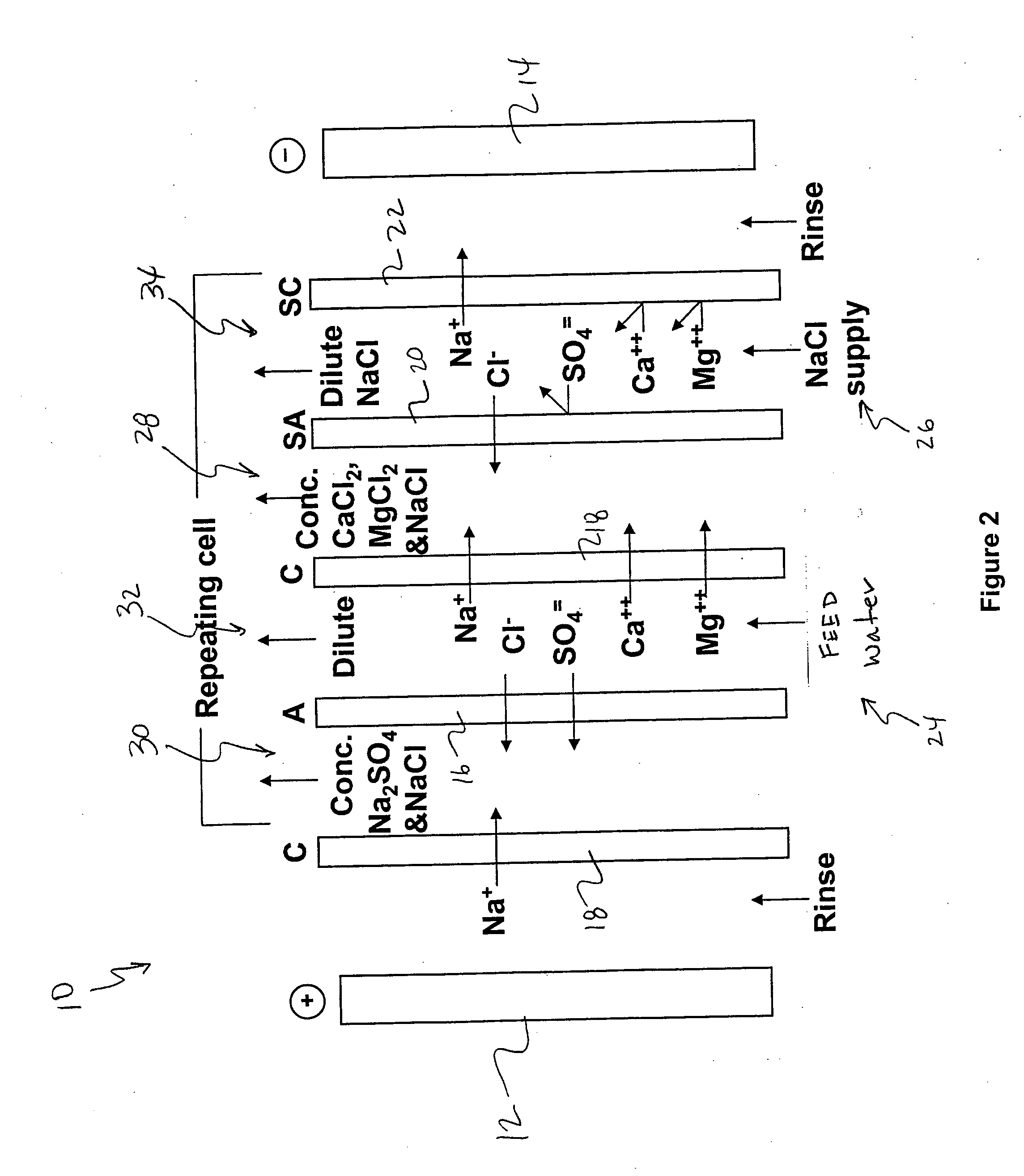

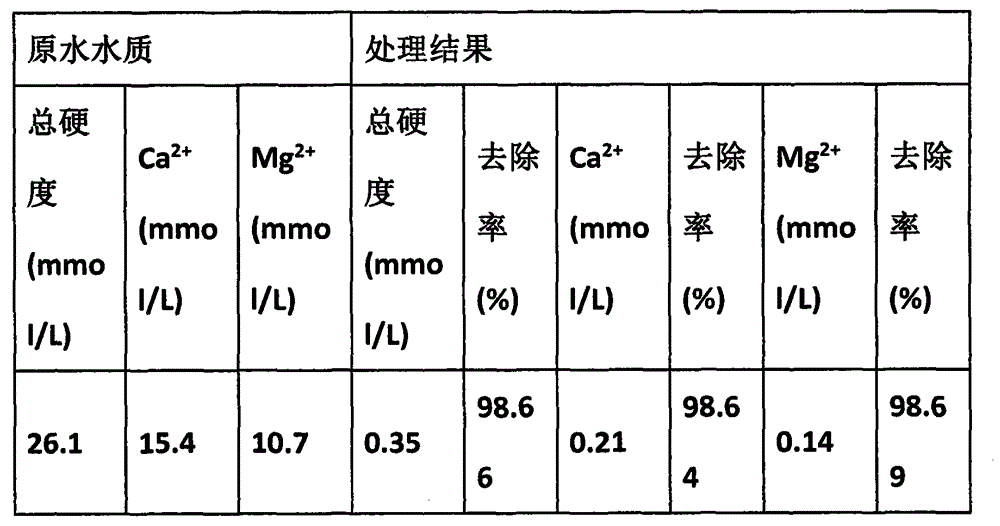

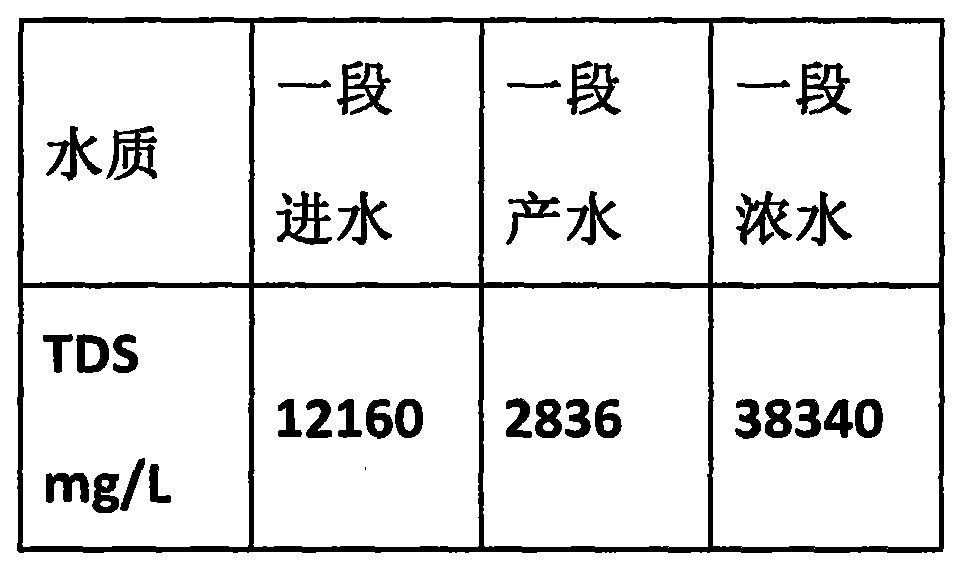

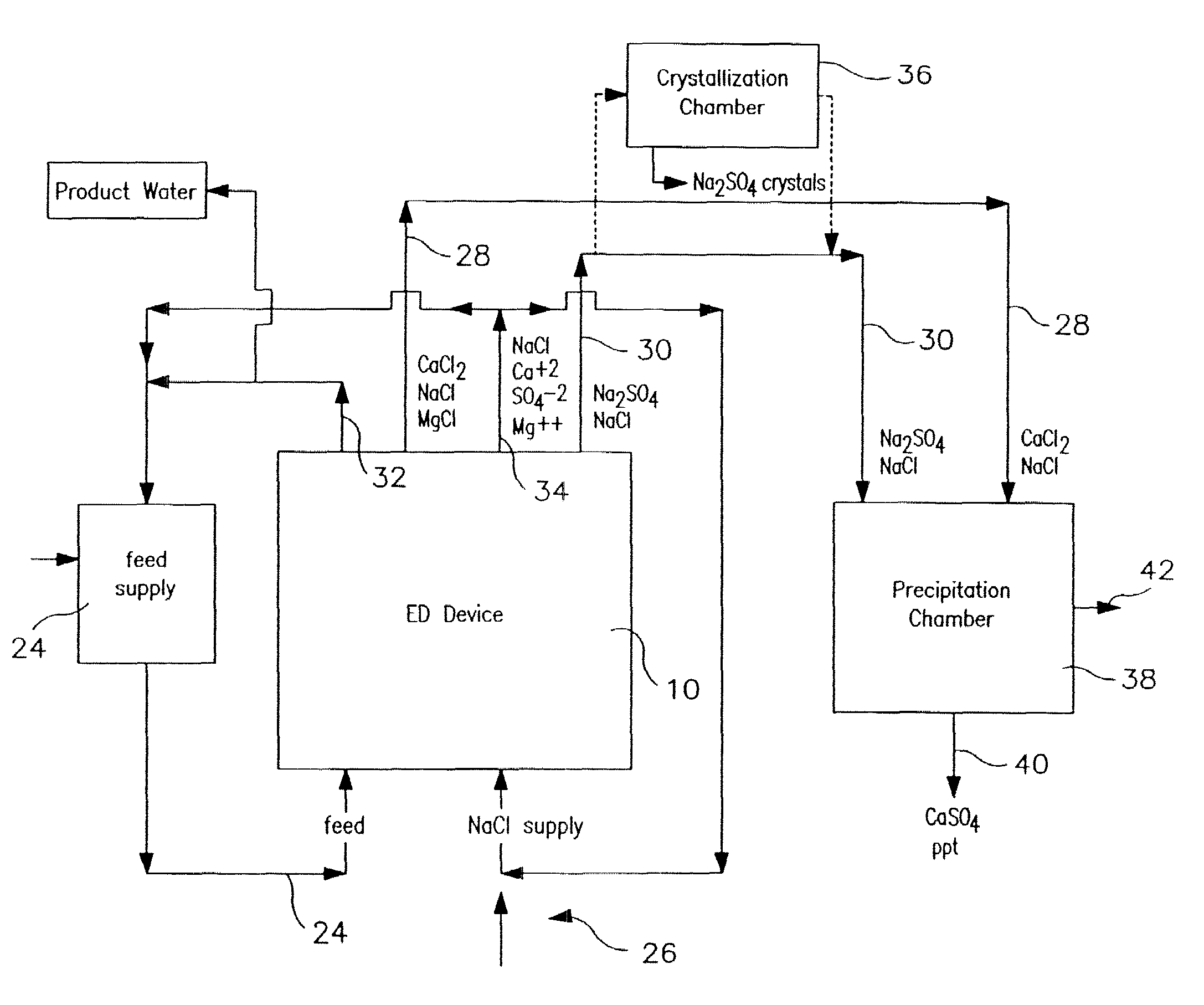

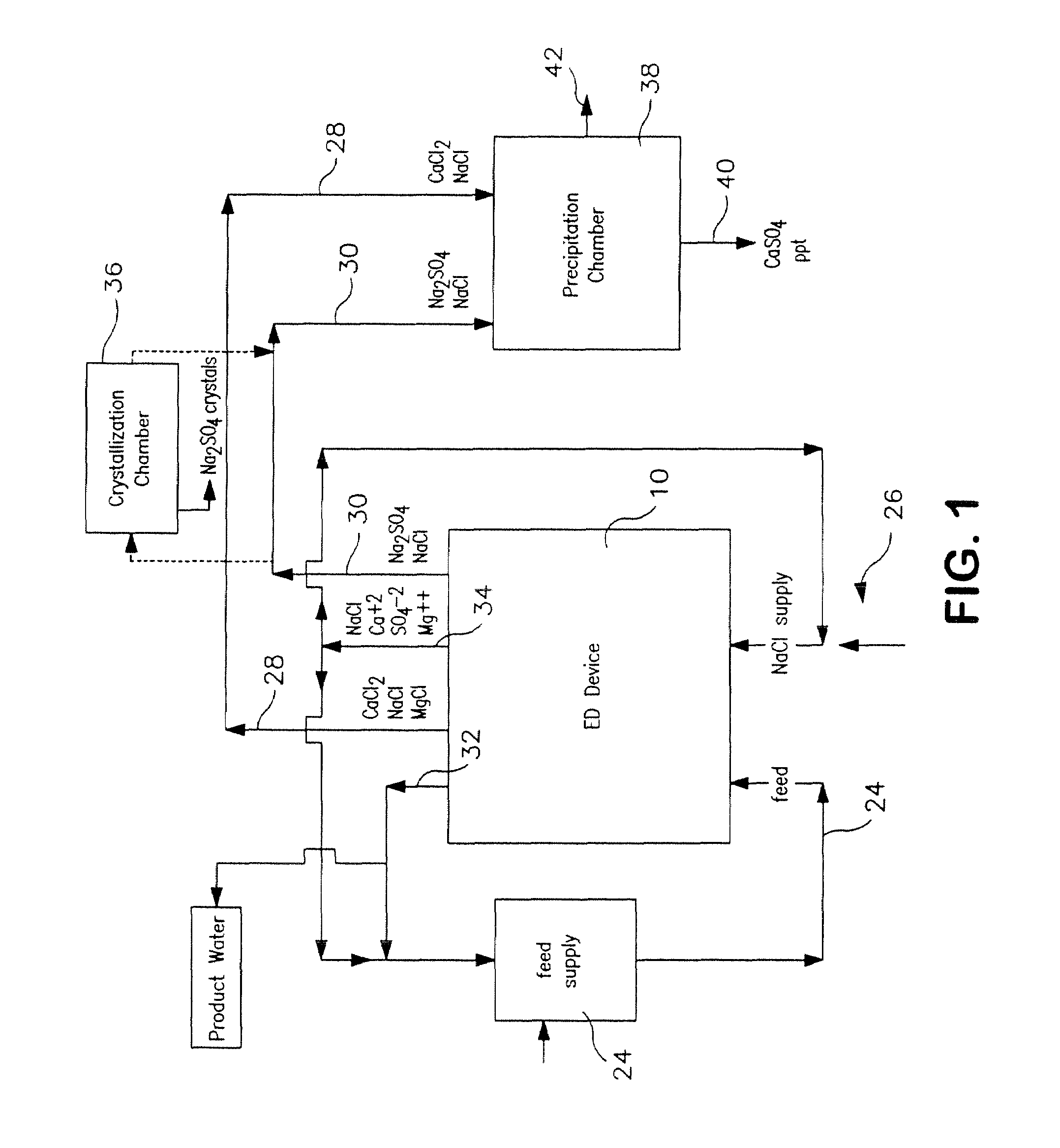

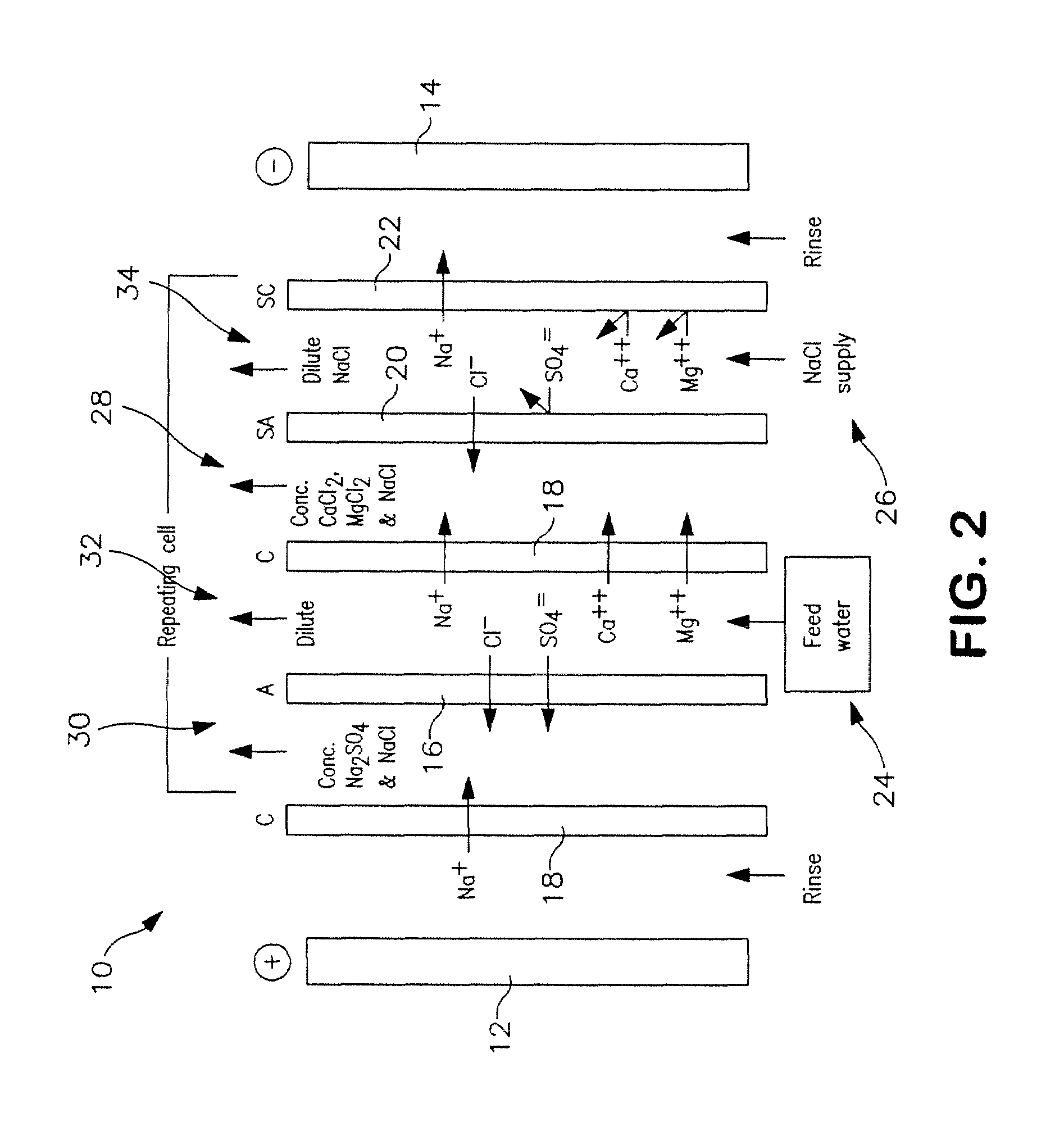

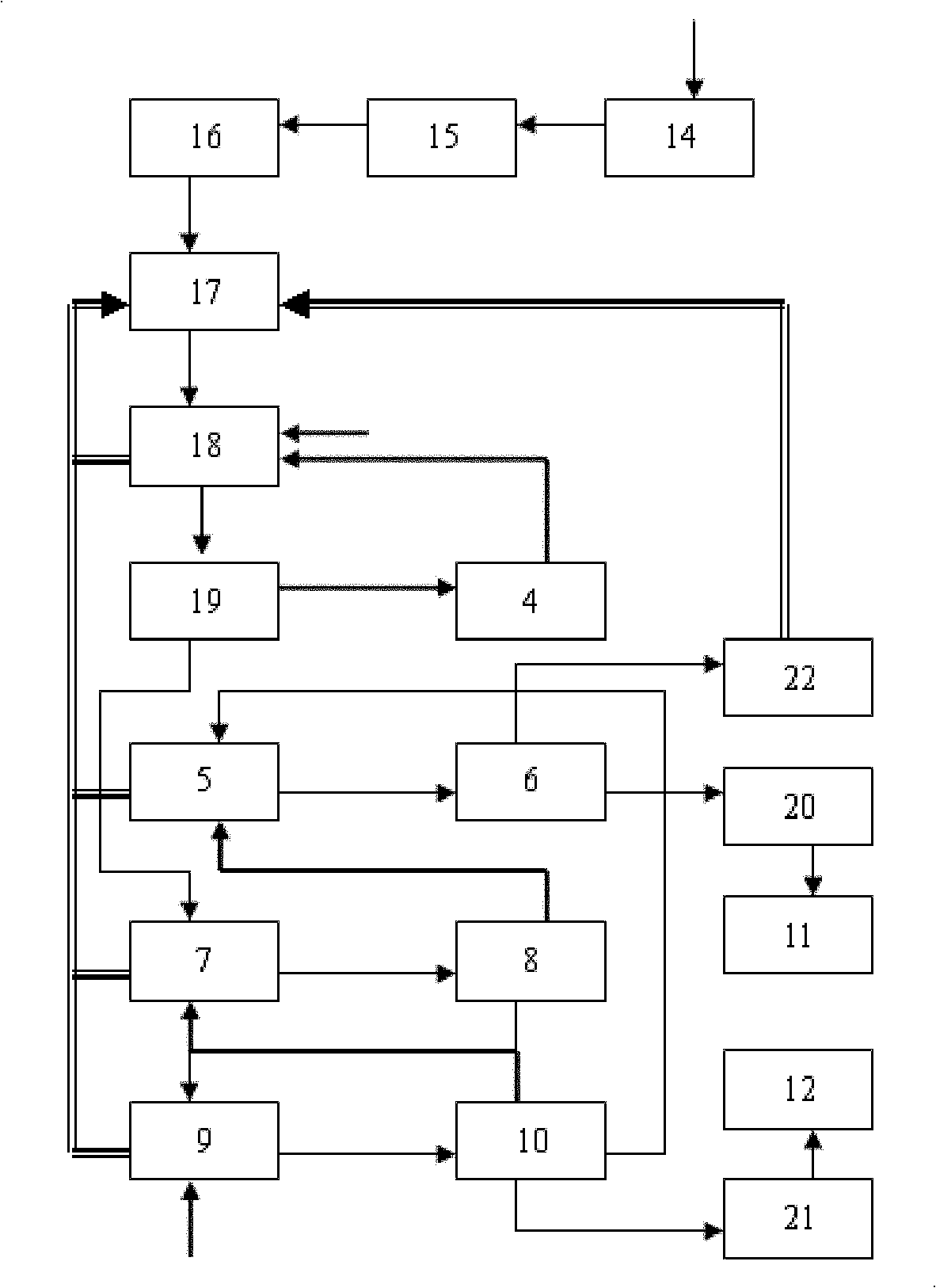

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

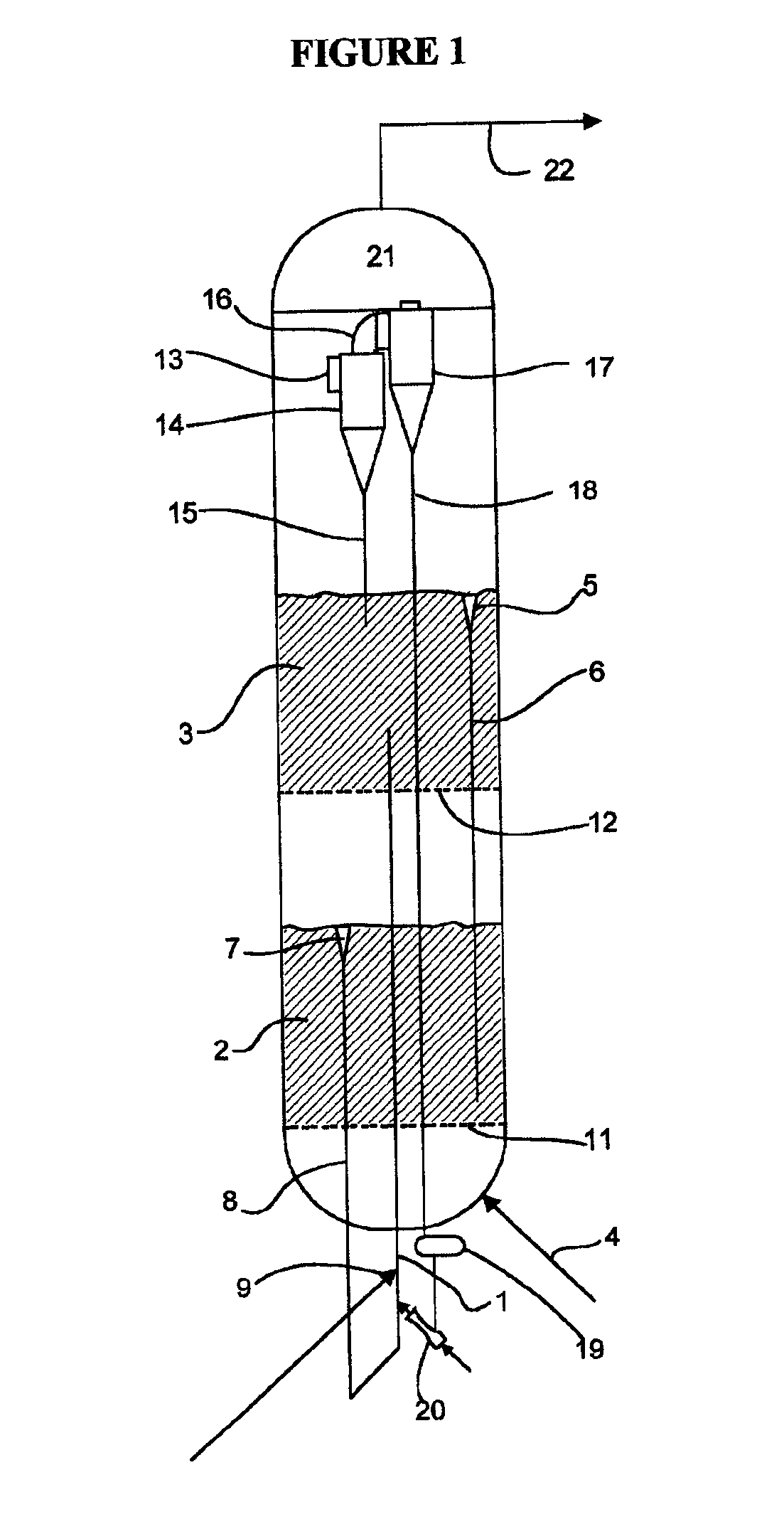

Conversion of petroleum residua to methane

InactiveUS6955695B2Eliminate needReduce usageThermal non-catalytic crackingElectrolysis componentsParticulatesGas phase

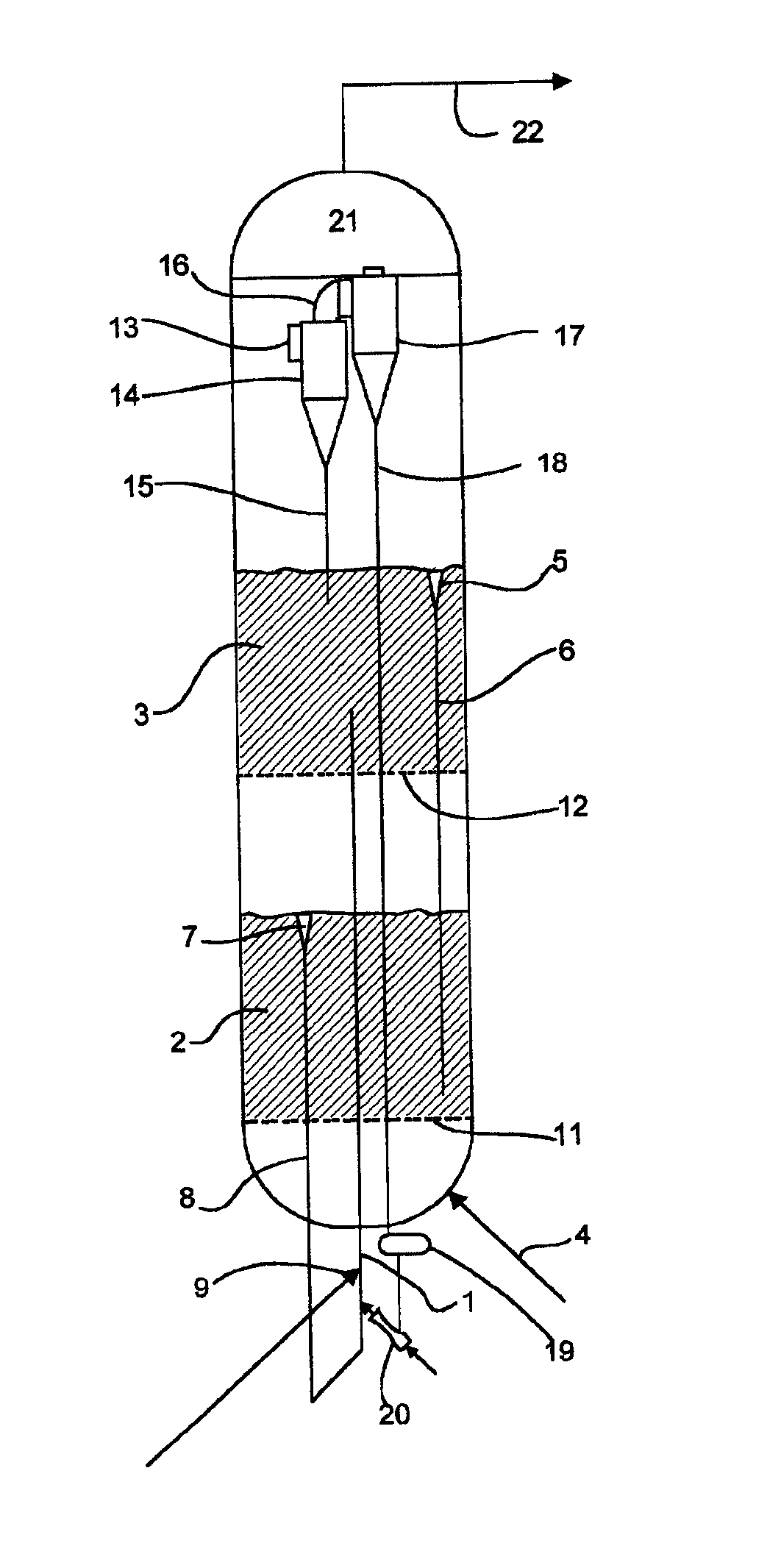

This invention discloses improvements on previous inventions for catalytic conversion of coal and steam to methane. The disclosed improvements permit conversion of petroleum residua or heavy crude petroleum to methane and carbon dioxide such that nearly all of the heating value of the converted hydrocarbons is recovered as heating value of the product methane. The liquid feed is distributed over a fluidized solid particulate catalyst containing alkali metal and carbon as petroleum coke at elevated temperature and pressure from the lower stage and transported to the upper stage of a two-stage reactor. Particulate solids containing carbon and alkali metal are circulated between the two stages. Superheated steam and recycled hydrogen and carbon monoxide are fed to the lower stage, fluidizing the particulate solids and gasifying some of the carbon. The gas phase from the lower stage passes through the upper stage, completing the reaction of the gas phase.

Owner:PETRO2020

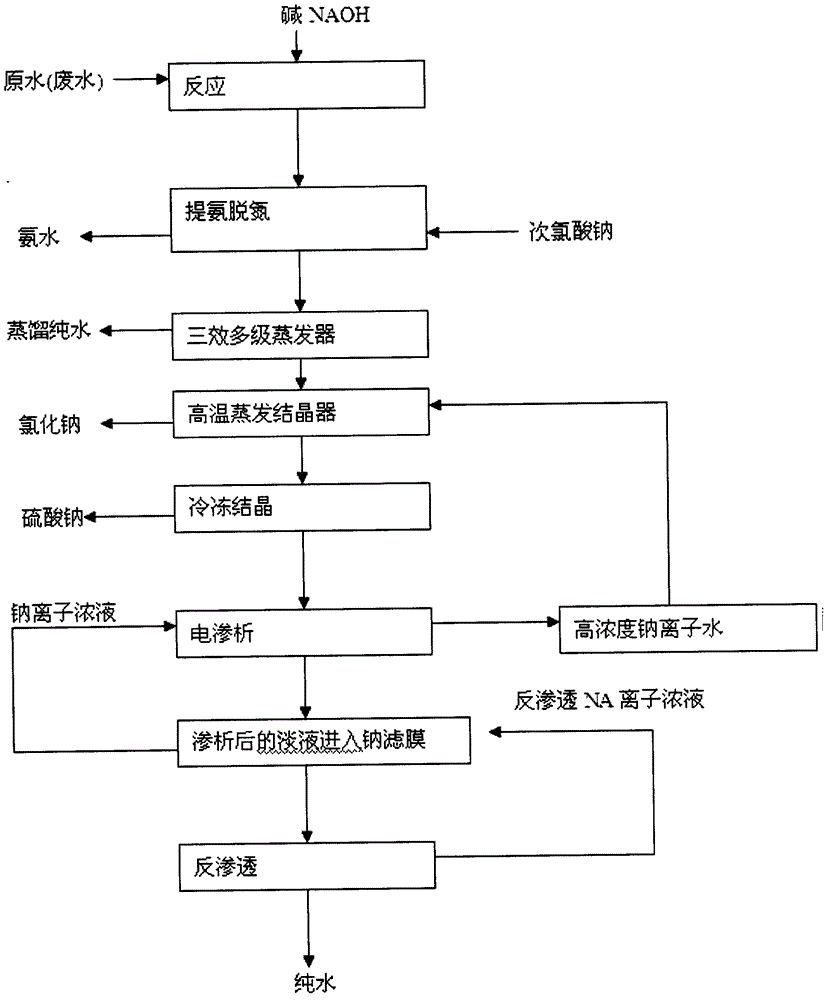

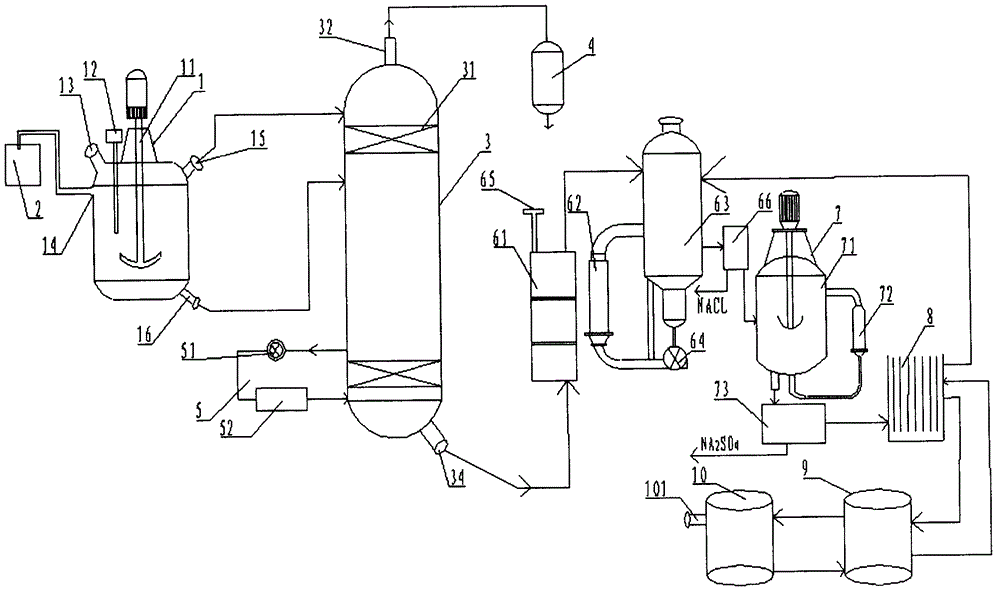

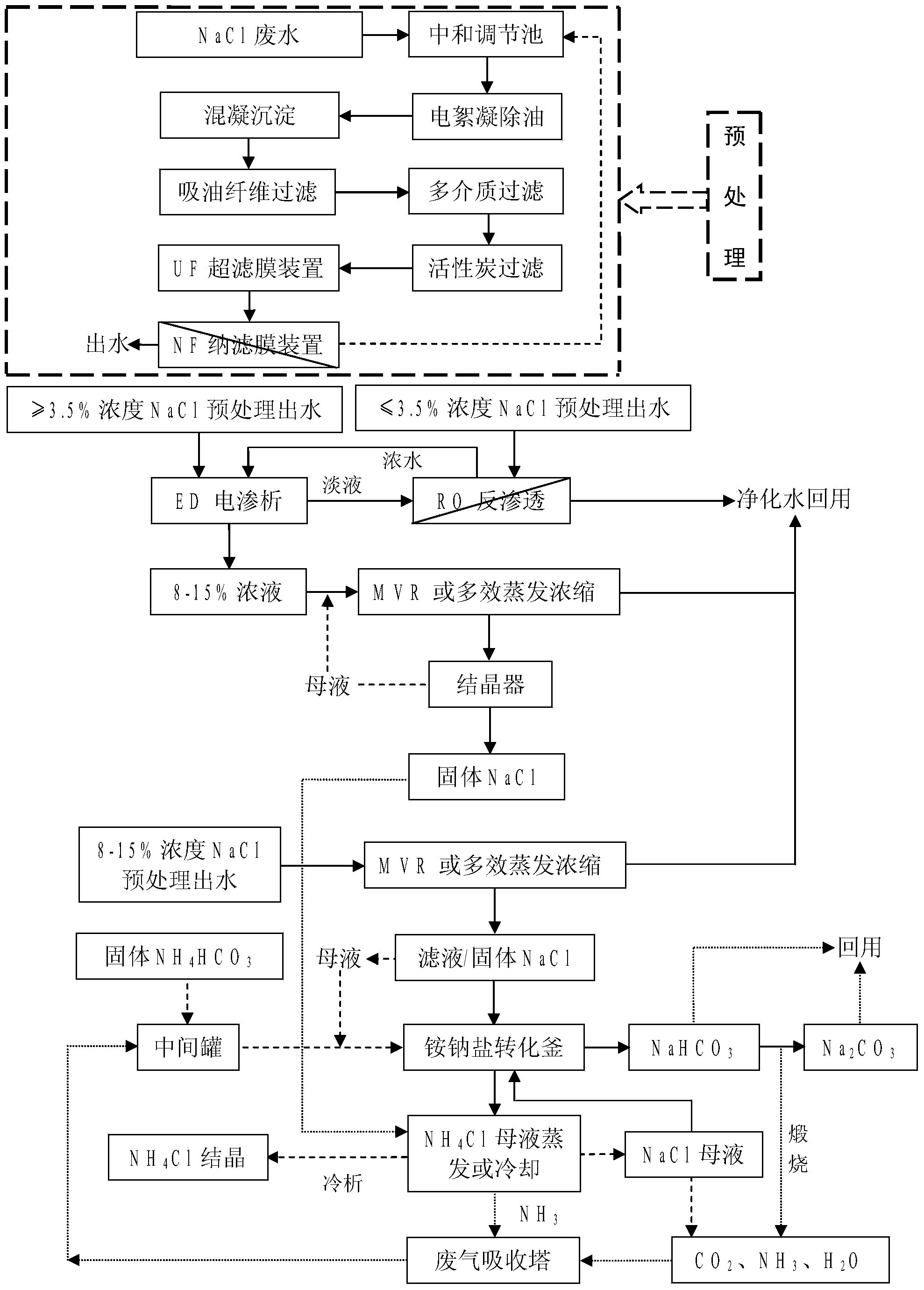

Method and device for utilizing sewage containing ammonia and sodium

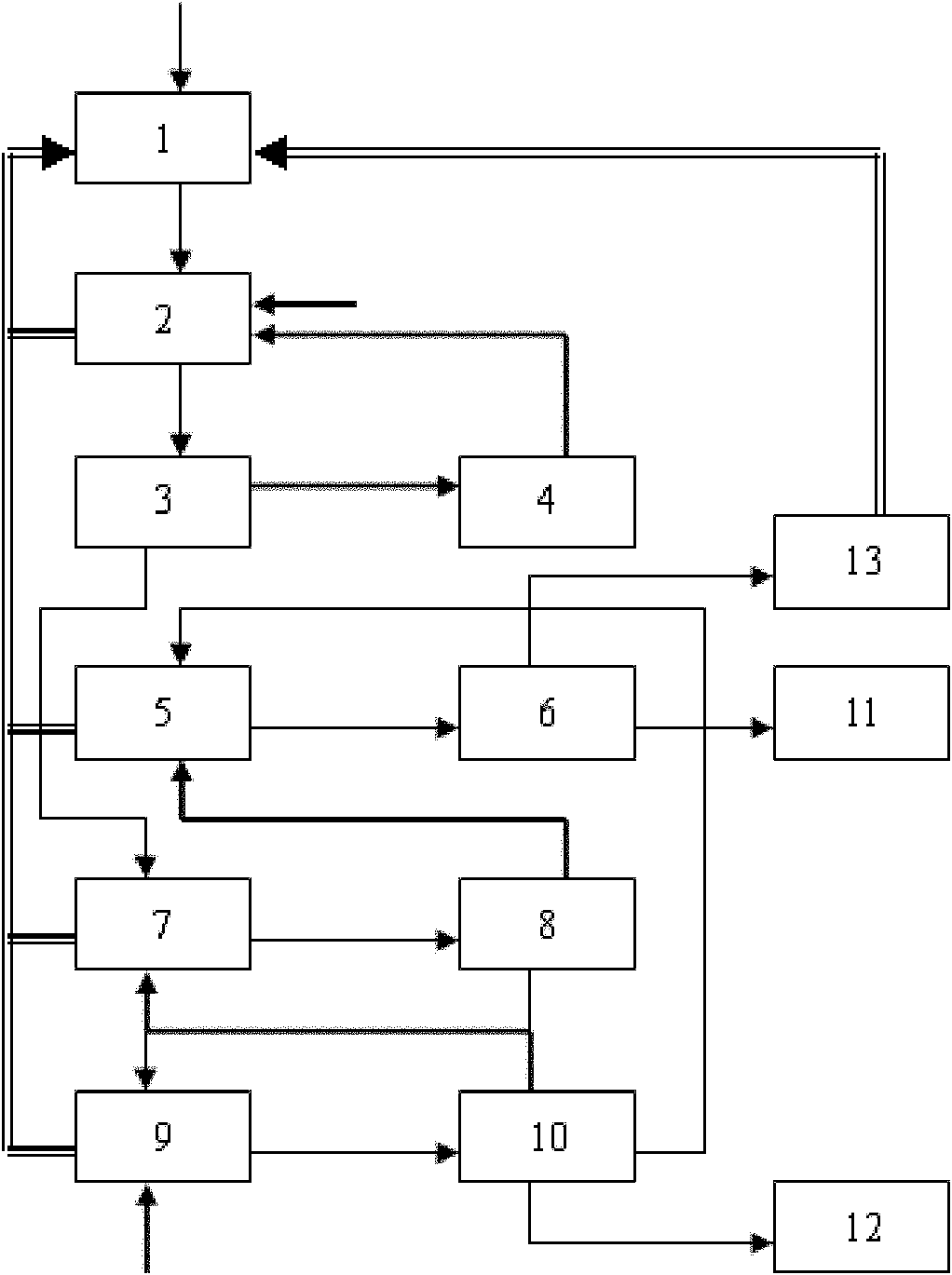

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

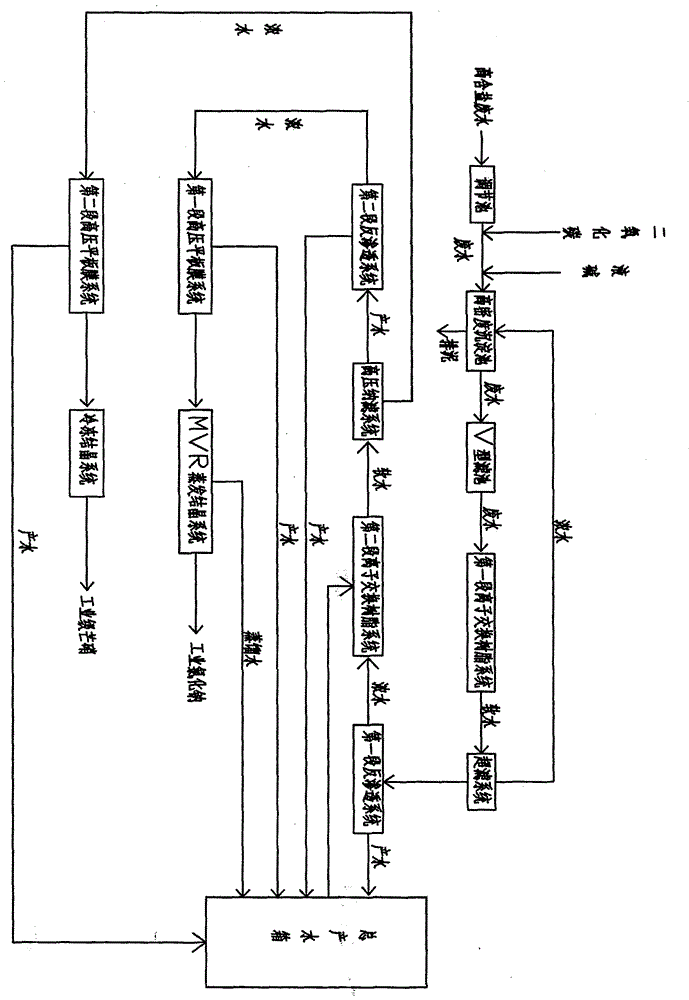

Treatment method of high saline wastewater

ActiveCN104692574ATake advantage of the combinationAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentSocial benefitsFiltration

The invention discloses a treatment method of high saline wastewater, and relates to the treatment technology. The method comprises the following steps: preparing high saline wastewater, regulating in a regulating pond, chemically pre-treating in a settling pond, filtering in a V-shaped filter pond, the first section ion exchange softening, ultrafiltering in an ultrafiltration system, reverse osmosis treating through a first section reverse osmosis system, the second ion exchange softening, nano-filtering through a high-pressure nano-filtration system, nano-filtering to produce water, reverse osmosis treating through a second section reverse osmosis system, concentrating through a first section high-pressure flat film system, MVR evaporating and crystallizing to obtain the industrial level sodium chloride; nano-filtering to concentrate water, concentrating through a second section high pressure flat film system, freezing and crystallizing to obtain the industrial level mirabilite. The ultra-filtration, the nano-filtration, the reverse osmosis and high-pressure flat film methods are reasonably coupled to combine with the MVR crystallization and freezing crystallization to treat the high saline wastewater, the defect of single technology is overcome, the combination advantage is developed, the problems of efficiently and economically treating and recycling the high saline wastewater can be solved, and the treatment method has obvious economic benefit and social benefit.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Water desalination process and apparatus

ActiveUS7459088B2Electrolysis componentsGeneral water supply conservationWater desalinationSolubility

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

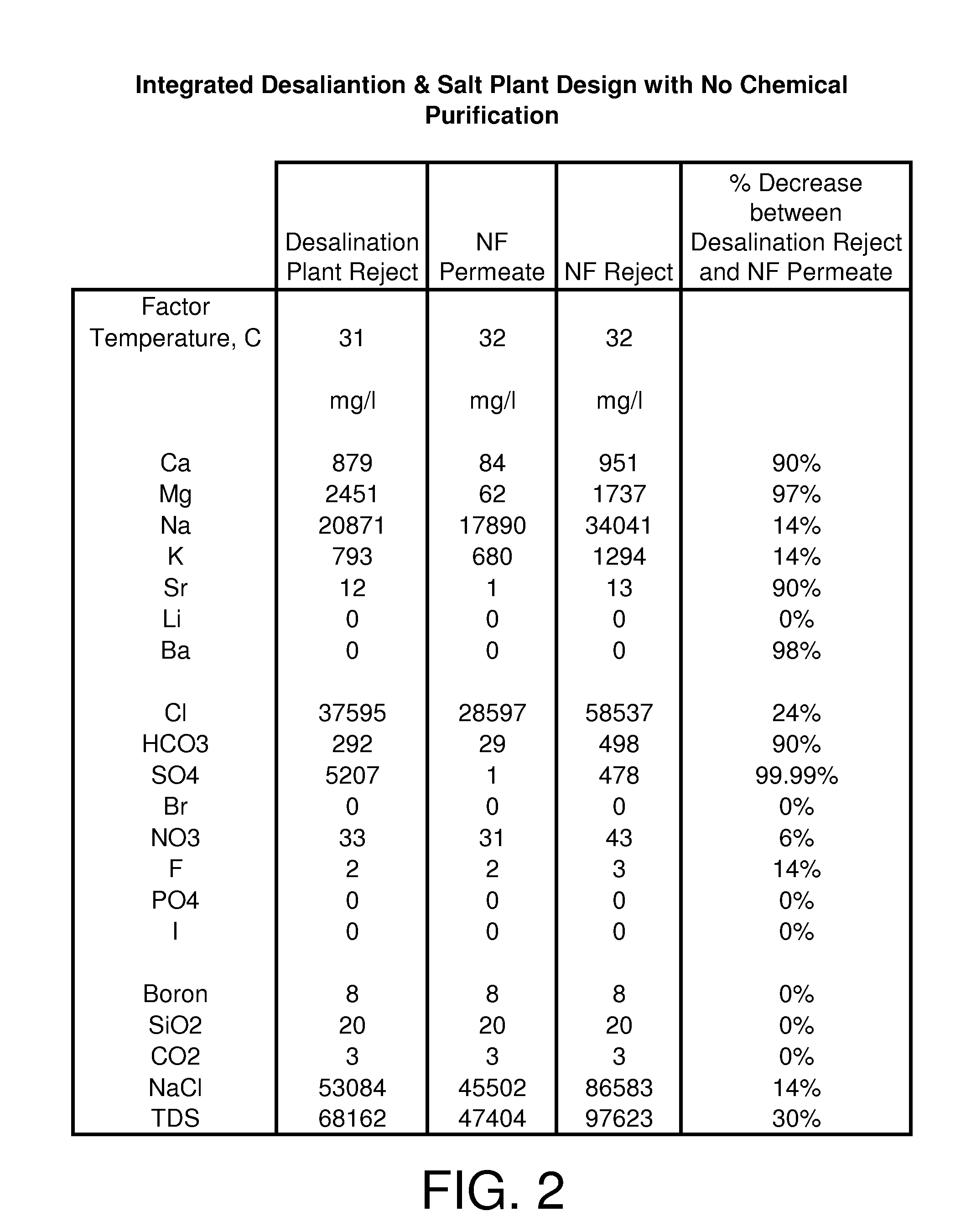

Water desalination plant and system for the production of pure water and salt

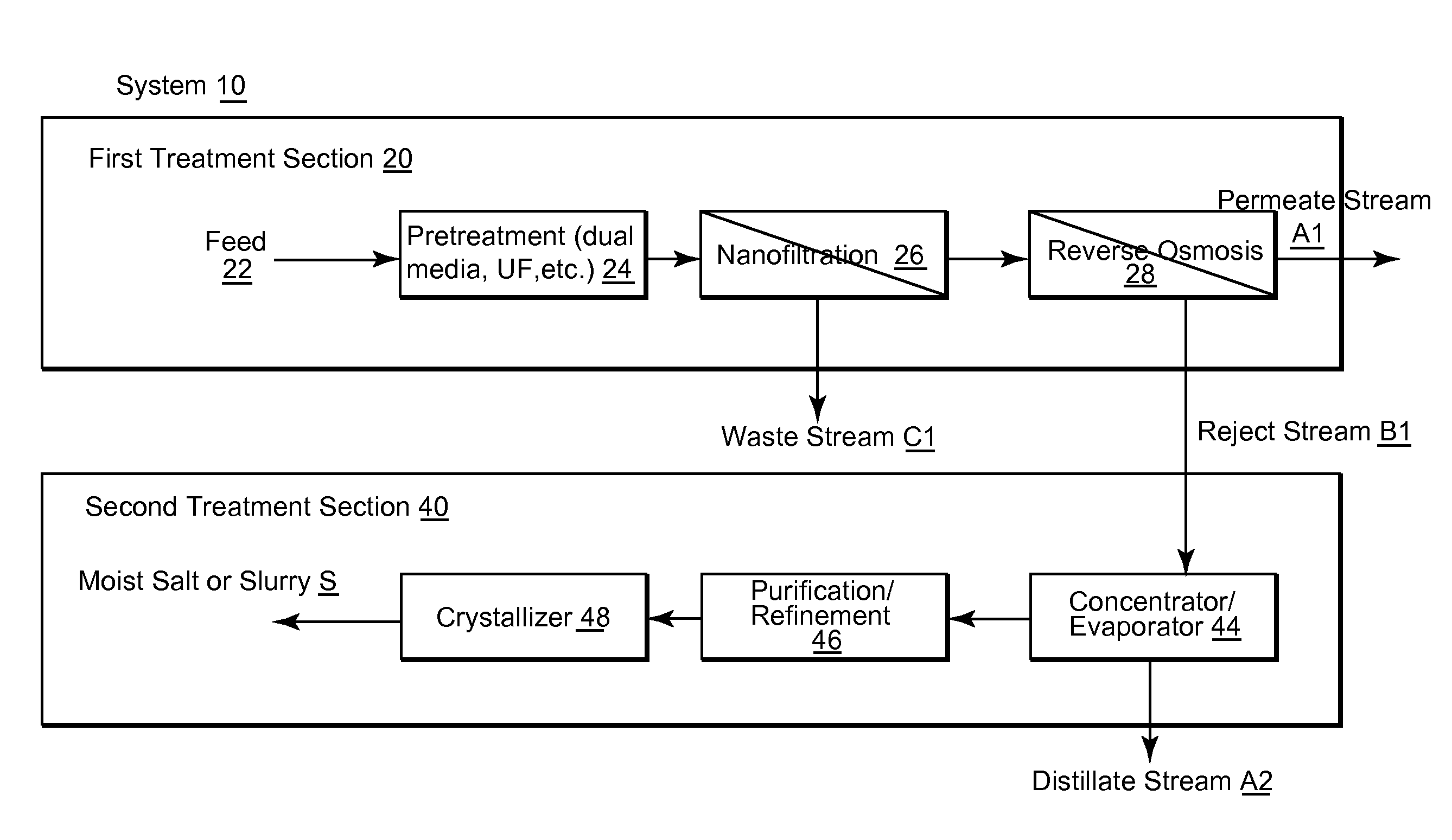

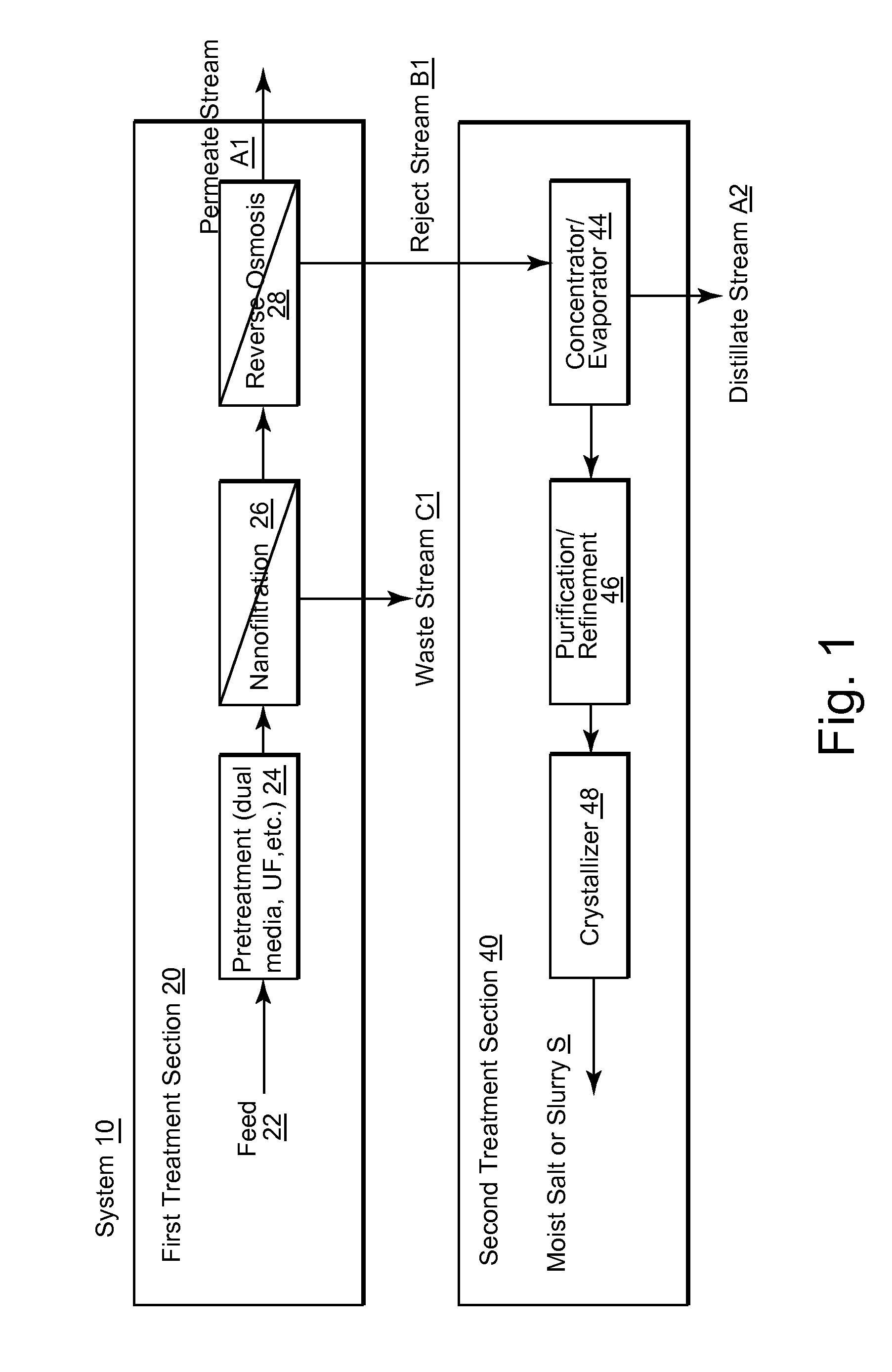

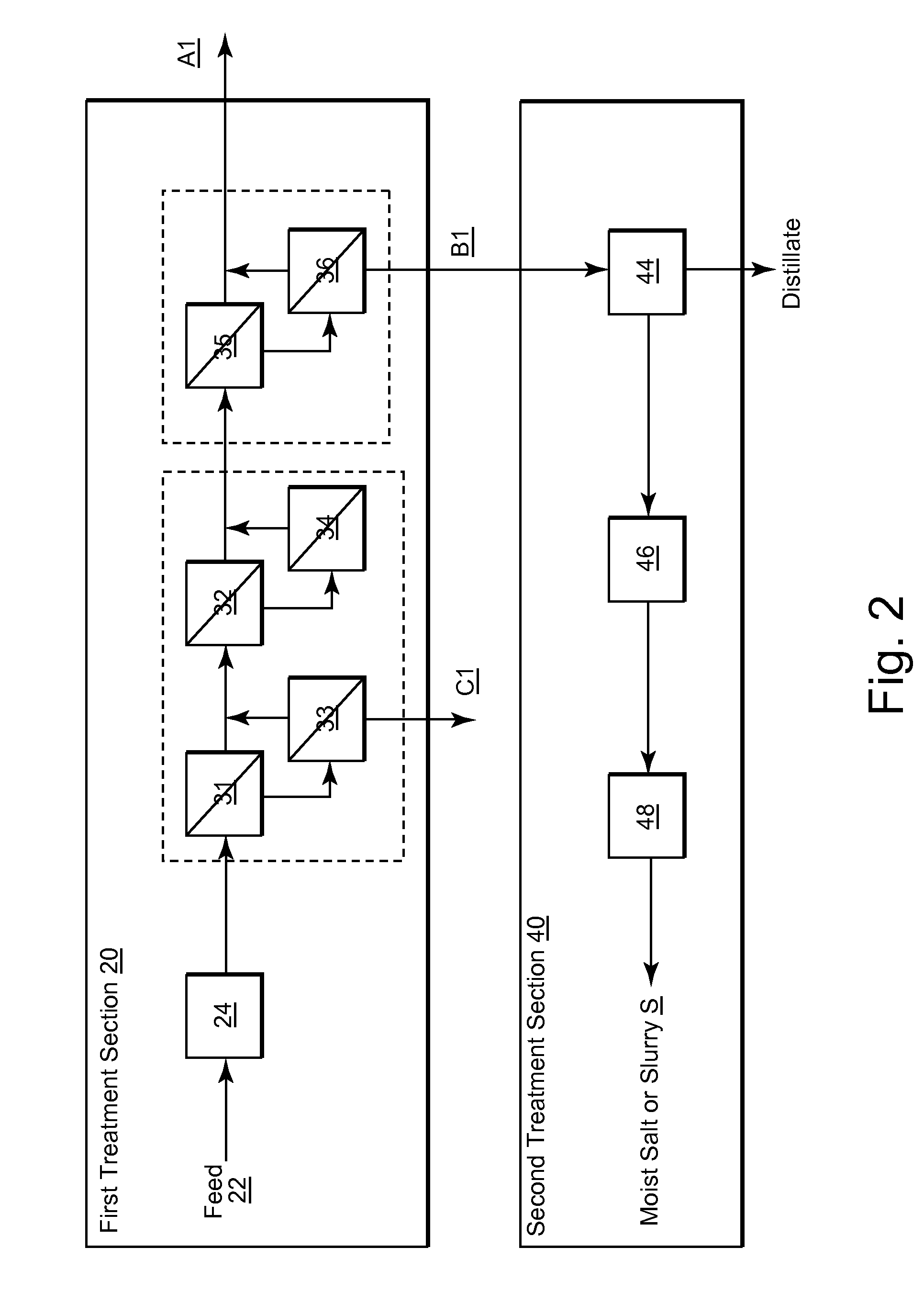

InactiveUS20120160753A1Enhanced commercial NaCl productionGeneral water supply conservationSeawater treatmentSaline waterWater desalination

A desalination plant for treating a sea water or brackish water feed is provided. The desalination plant includes a first treatment section to effectively remove scaling species, the first treatment section including nanofiltration section, the nanofiltration section including at least two stages and at least two passes; and a reverse osmosis section that operates at high recovery to produce a purified permeate stream and a selectively NaCl salt-enriched reject stream as a saline output.

Owner:VORA NISHITH +4

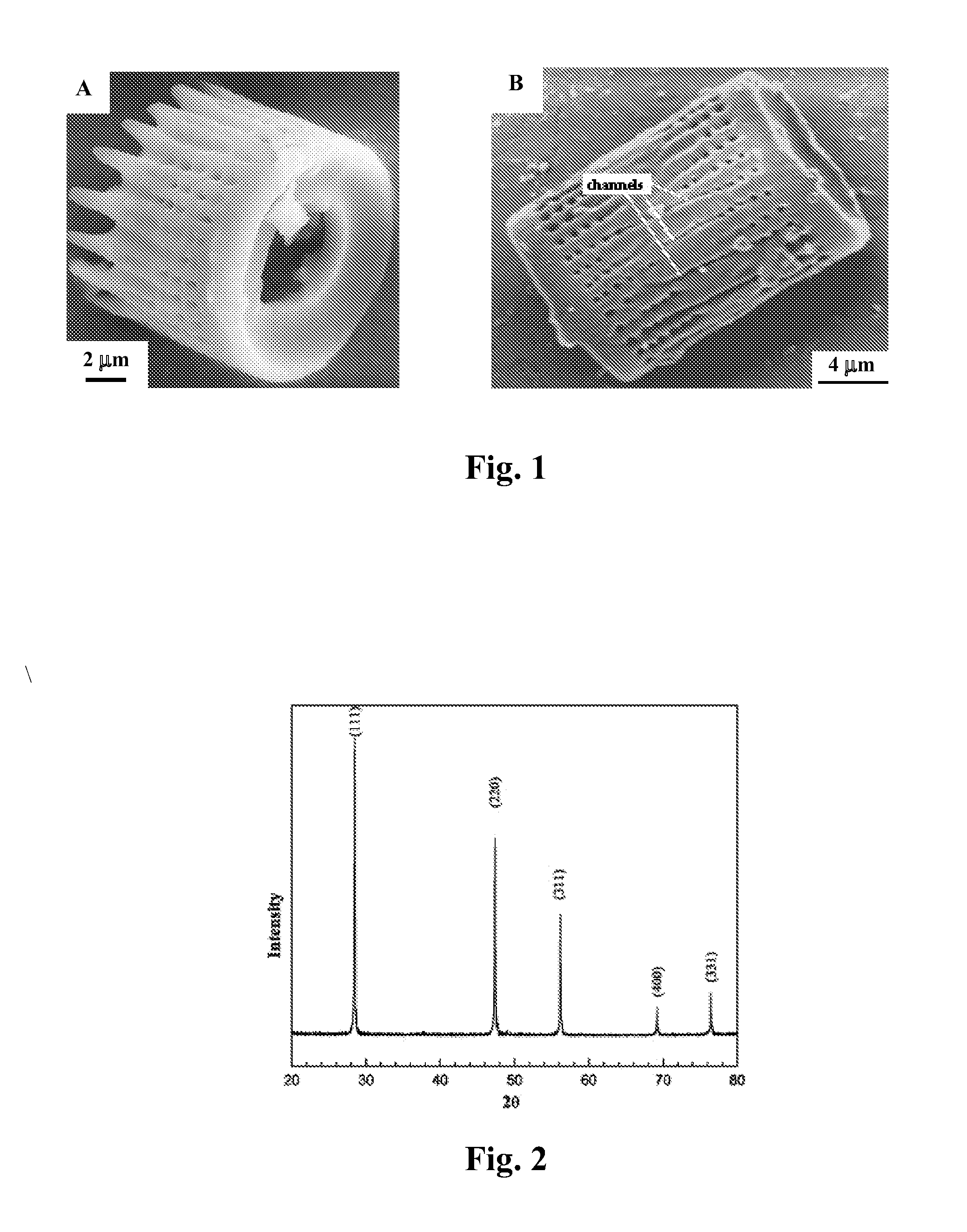

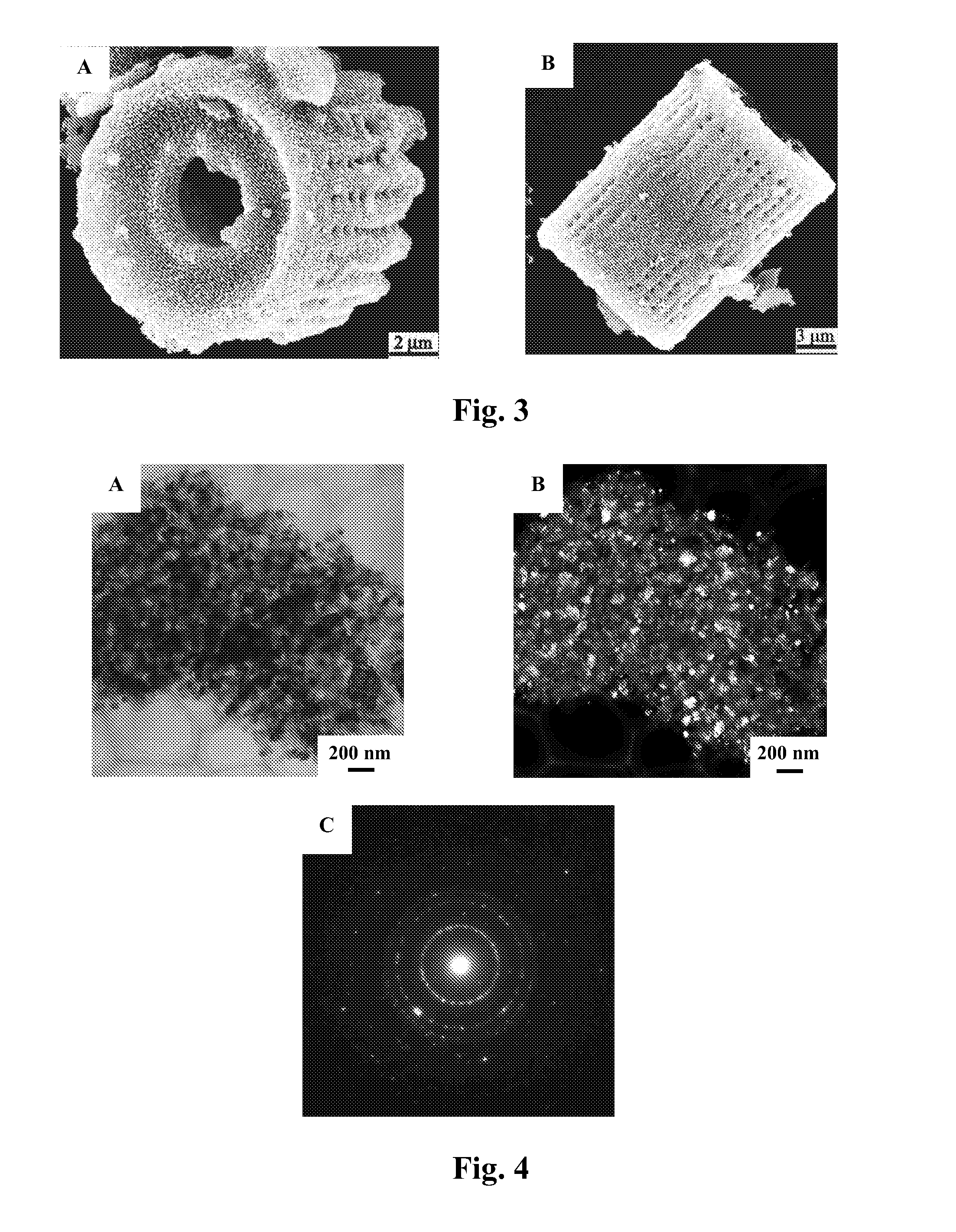

Methods of fabricating nanoscale-to-microscale structures

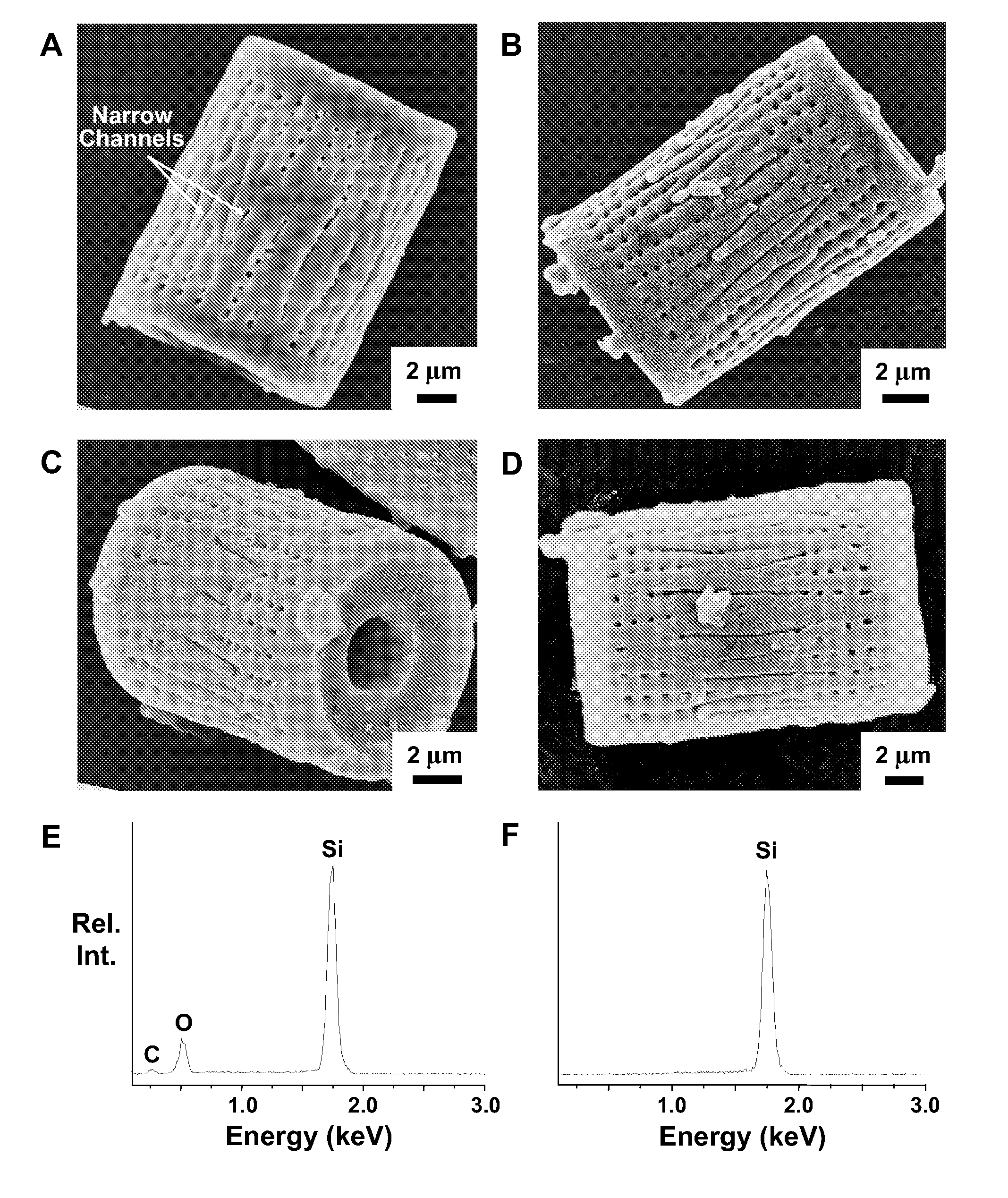

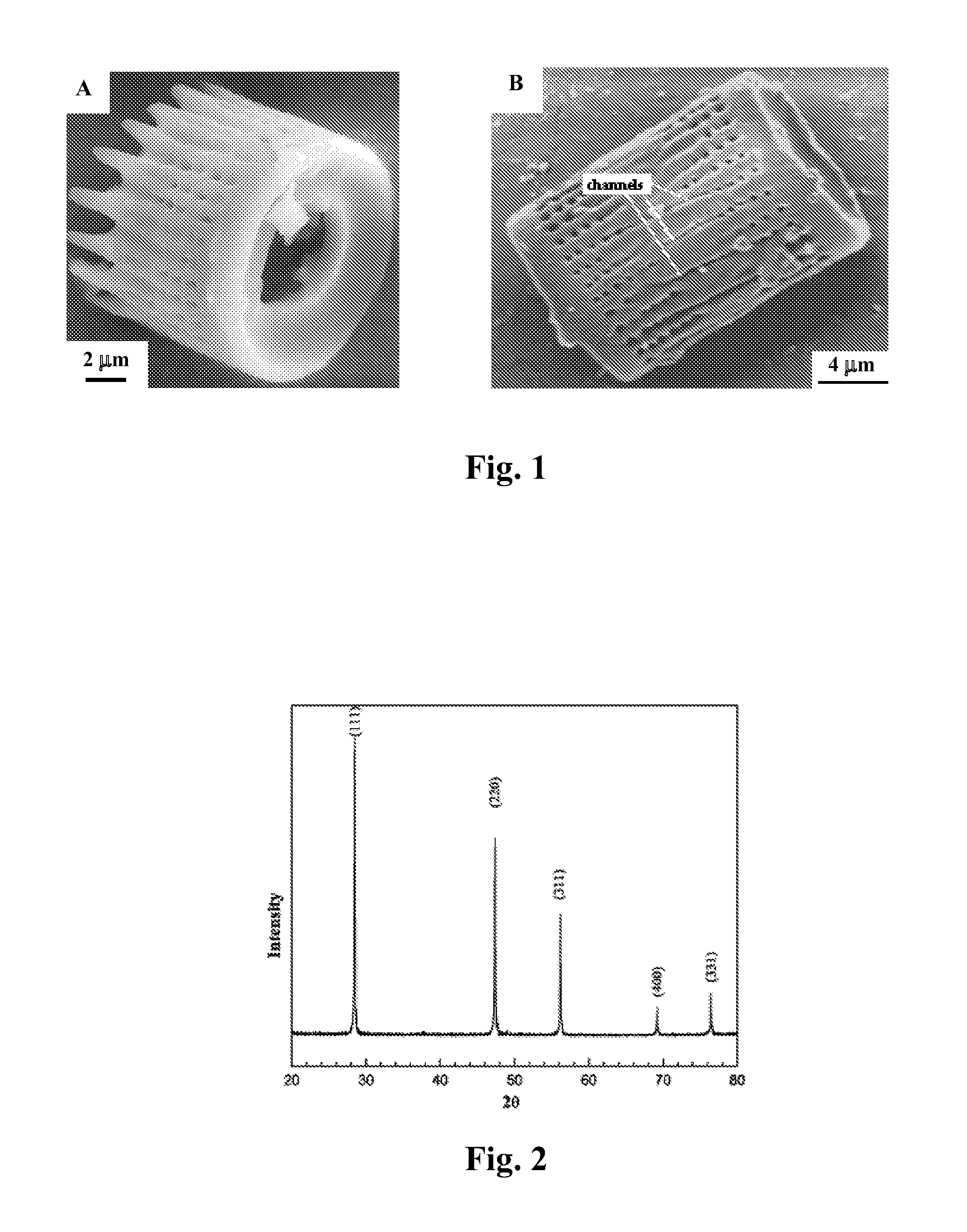

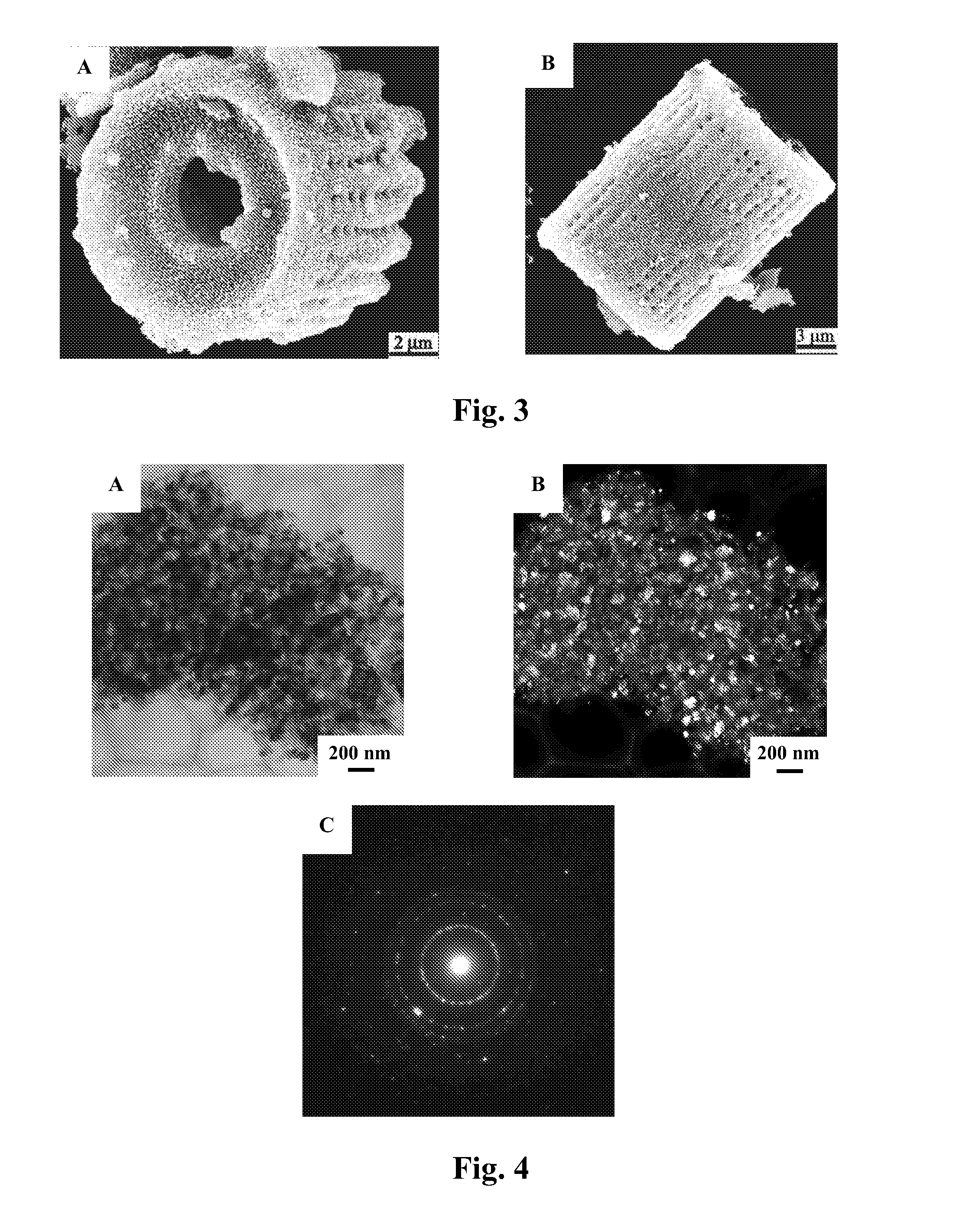

InactiveUS20080038170A1Attractive and optical propertyAttractive mechanical propertySilicaMixing methodsChemical compositionChemical reaction

Methods for the production of shaped nanoscale-to-microscale structures, wherein a nanoscale-to-microscale template is provided having an original chemical composition and an original shape, and the nanoscale-to-microscale template subjected to a chemical reaction, so as to partially or completely convert the nanoscale-to-microscale template into the shaped nanoscale-to-microscale structure having a chemical composition different than the original chemical composition and having substantially the same shape as the original shape, being a scaled version of the original shape. The shaped nanoscale-to-microscale structure formed comprises an element (such as silicon), a metallic alloy (such as a silicon alloy), or a non-oxide compound (such as silicon carbide or silicon nitride).

Owner:GEORGIA TECH RES CORP

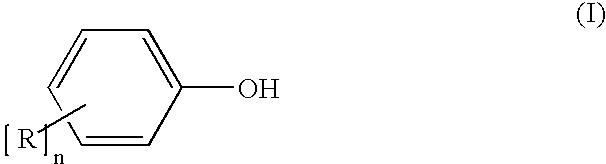

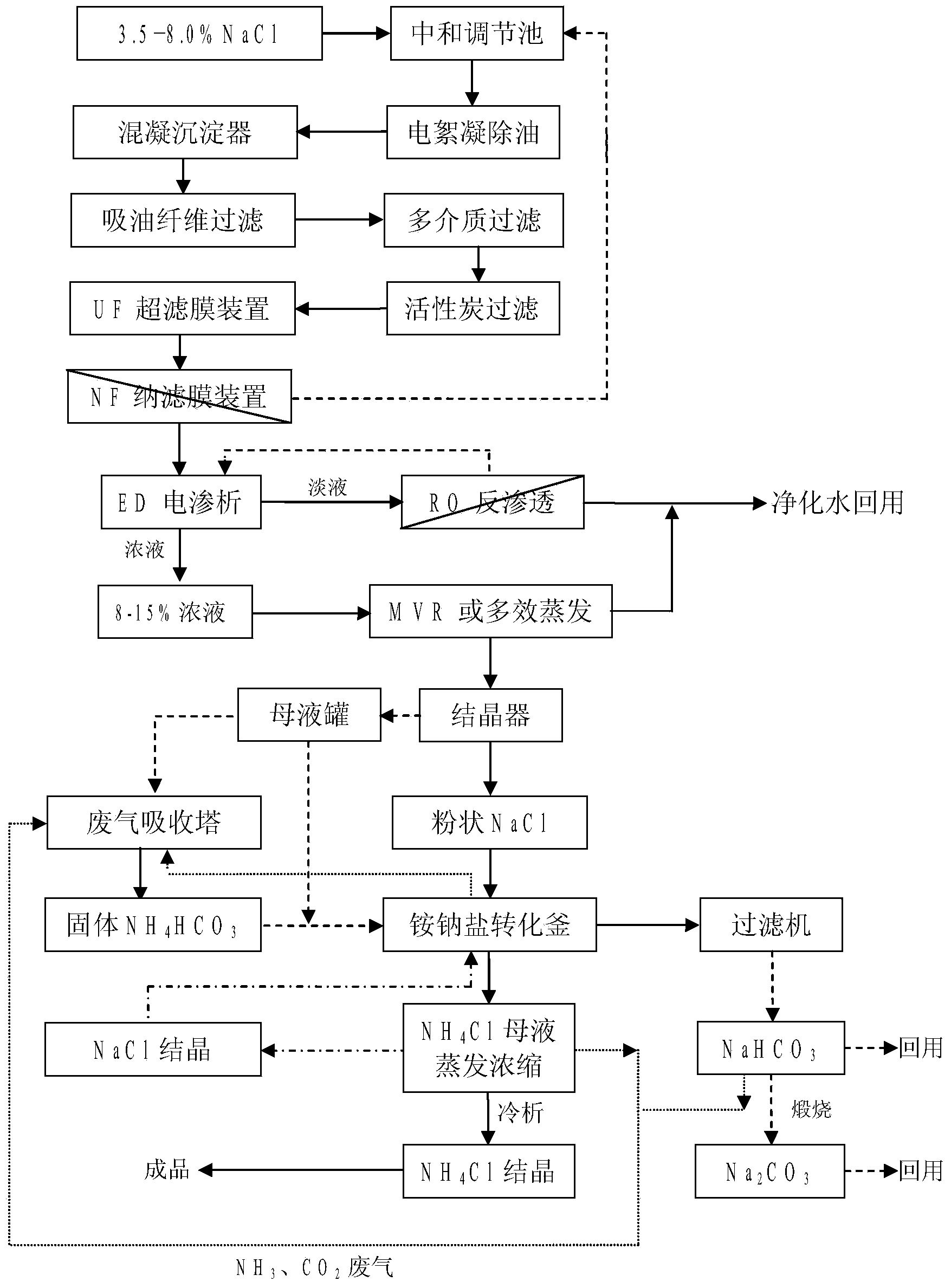

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

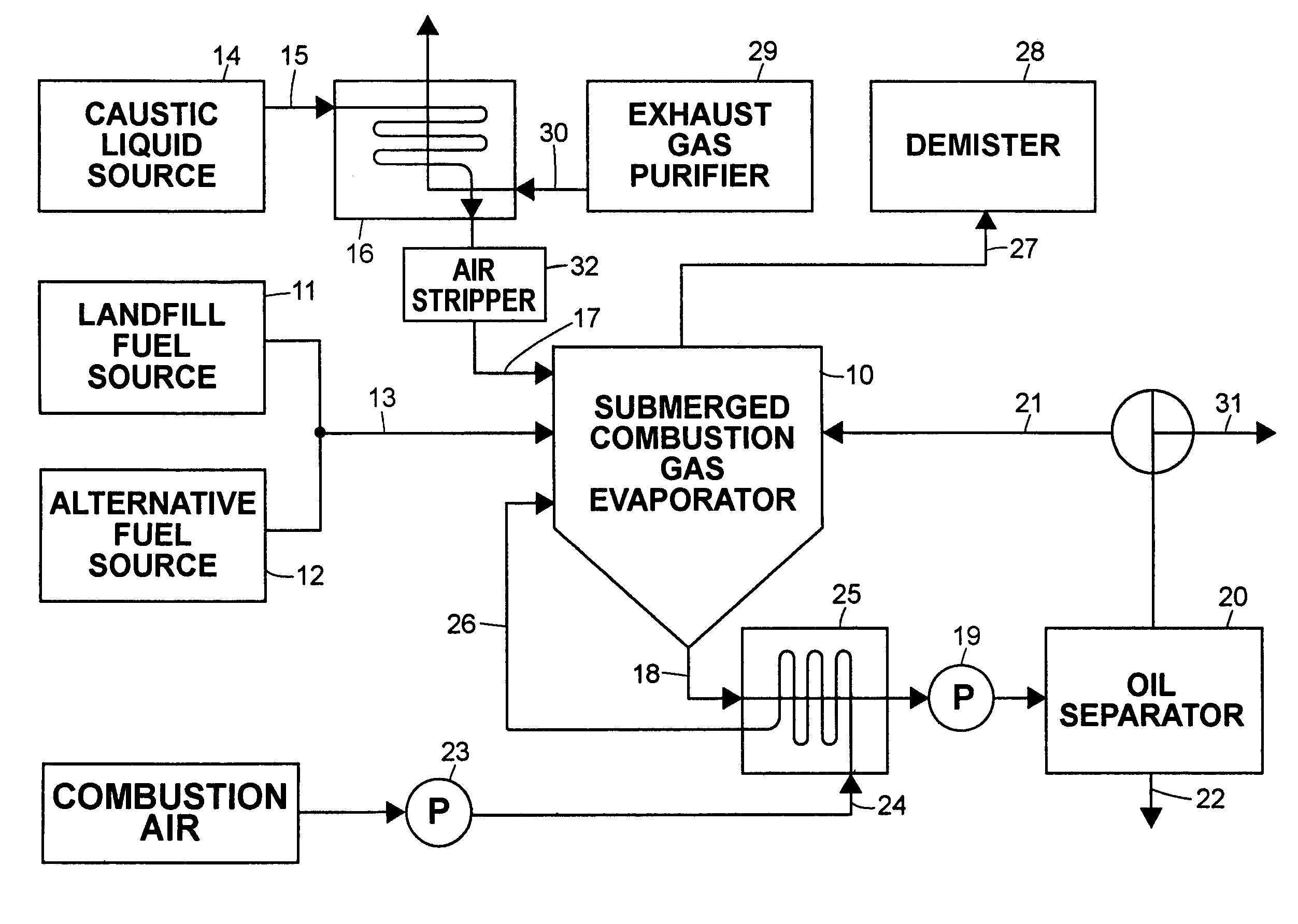

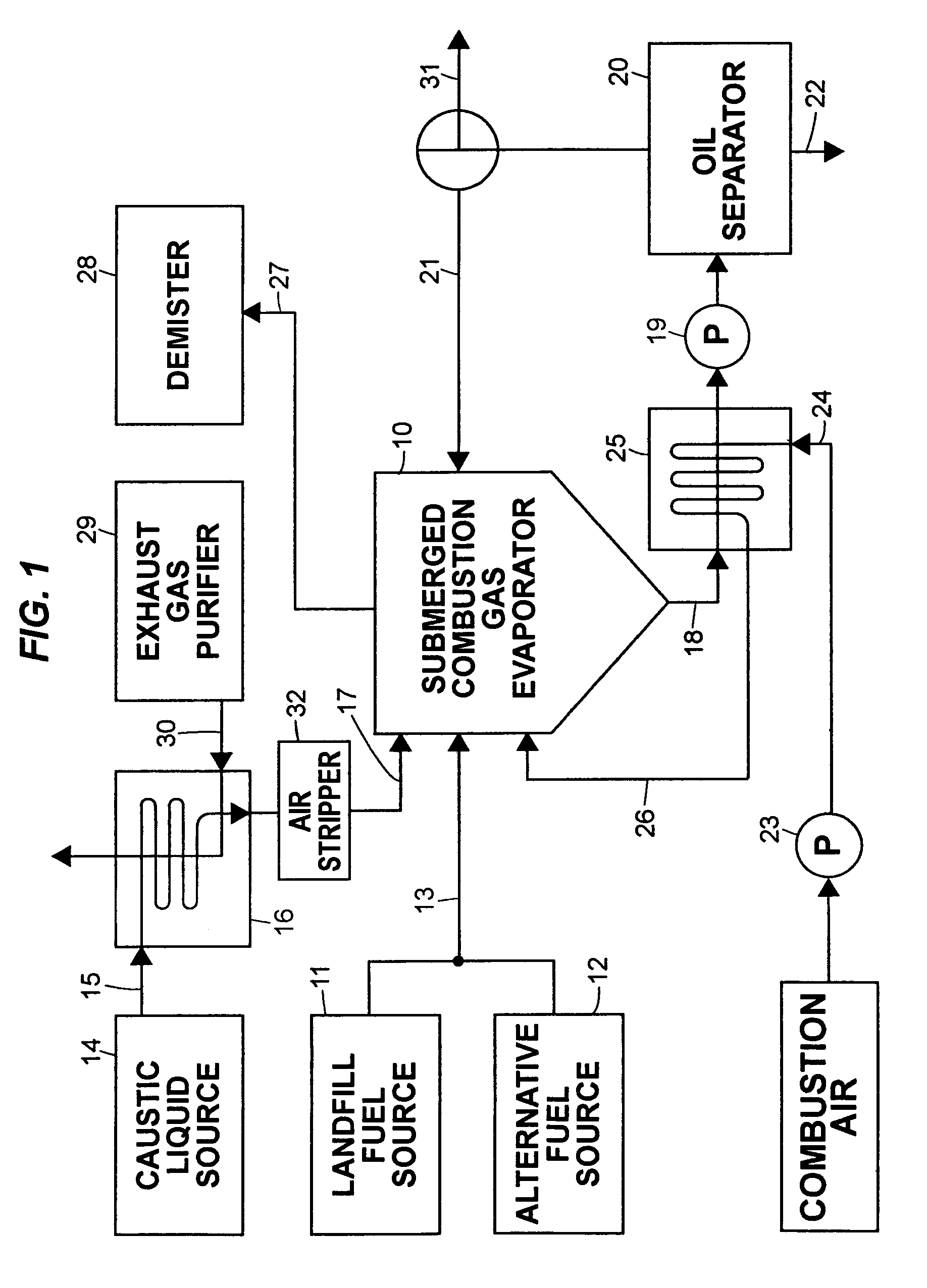

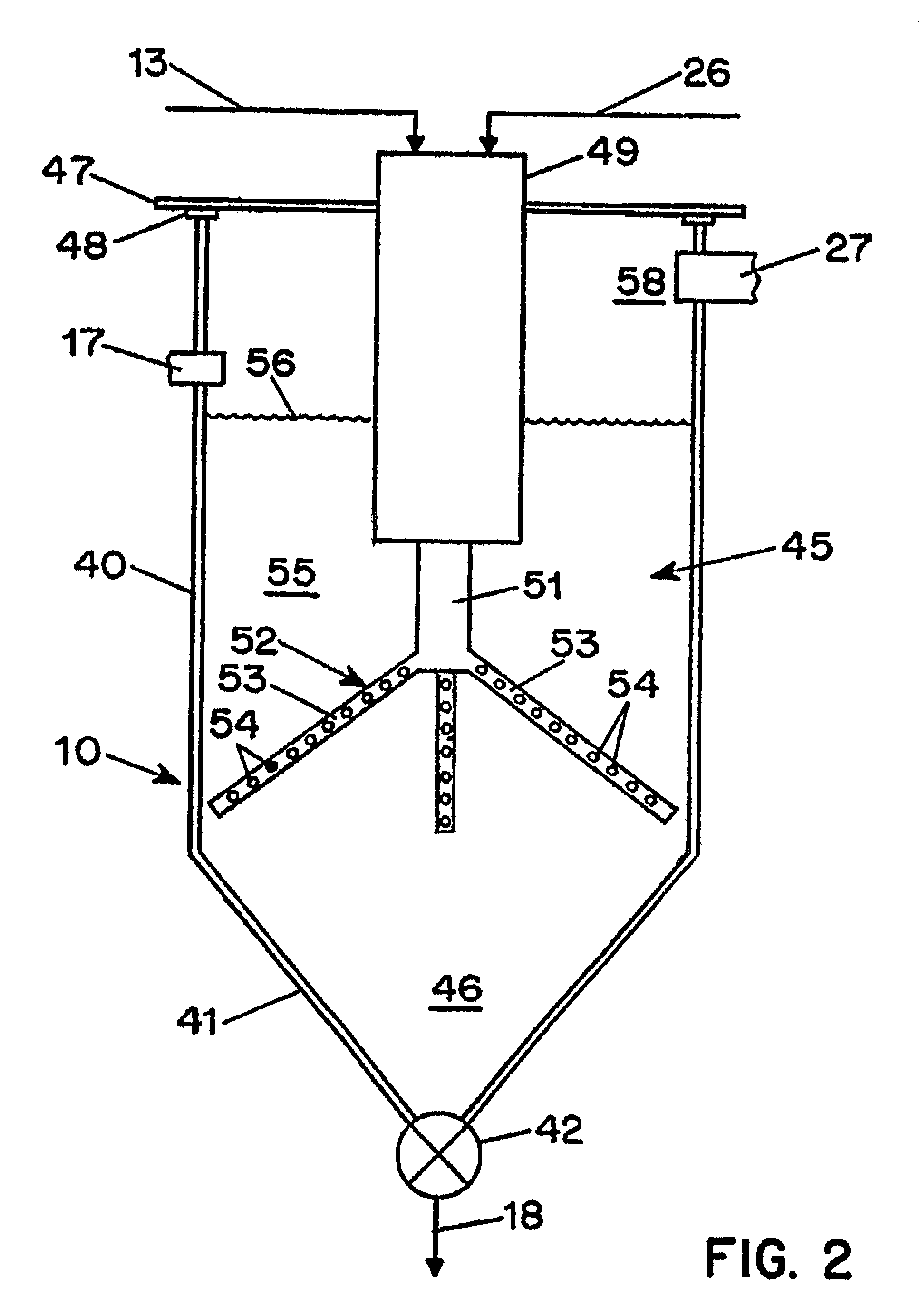

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

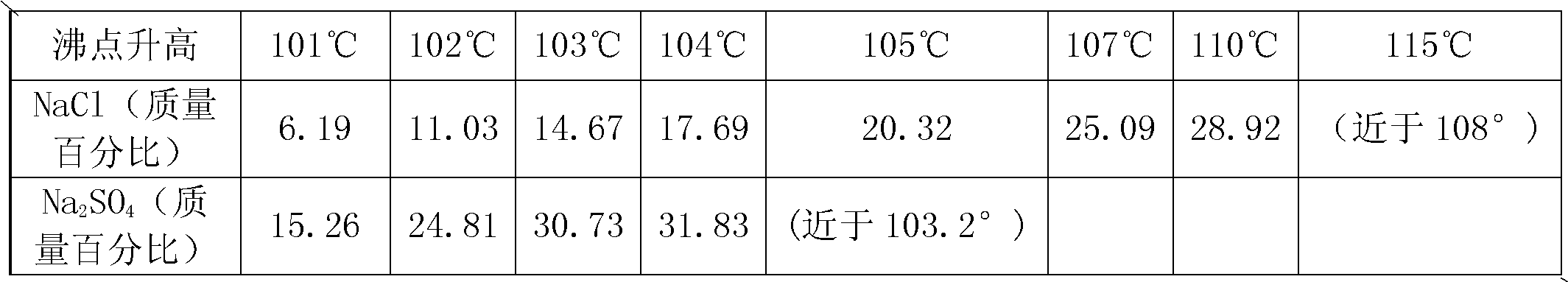

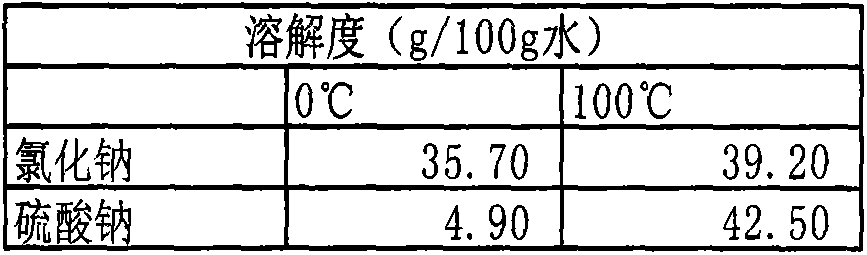

Application of MVR (mechanical vapor recompression) crystallizing evaporator in sodium sulfate and sodium chloride separation technology

InactiveCN103172088AImprove thermal efficiencyReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal chloridesPhysical chemistryExhaust fumes

The invention discloses an industrial application of an MVR (mechanical vapor recompression) crystallizing evaporator technology in the production of sodium sulfate and sodium chloride in Huaian, Jiangsu, and relates to an improvement of a salt and sodium sulfate coproduction evaporation technology, belonging to the technical field of chemical three-waste treatment and utilization, and in particular to an application of an MVR crystallizing evaporator in a sodium sulfate and sodium chloride separation technology. The application is mainly technically characterized in that sodium sulfate liquid is concentrated by the MVR crystallizing evaporator, the sodium sulfate is produced at high temperature, and the sodium chloride is produced at low temperature. According to the invention, the mechanical re-compressed vapor is evaporated, concentrated and crystallized at 90-100 DEG C to obtain sodium sulfate, and the re-compressed vapor at a low temperature of 55 DEG C is concentrated and crystallized to obtain sodium chloride. According to the invention, the application of the MVR technology to the concentration of sodium sulfate liquid is realized, the sodium sulfate is produced at high temperature, and sodium chloride is produced at low temperature. The application disclosed by the invention is an environmental protection project which saves energy, reduces emission and avoids waste gas, waste water and waste residue.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

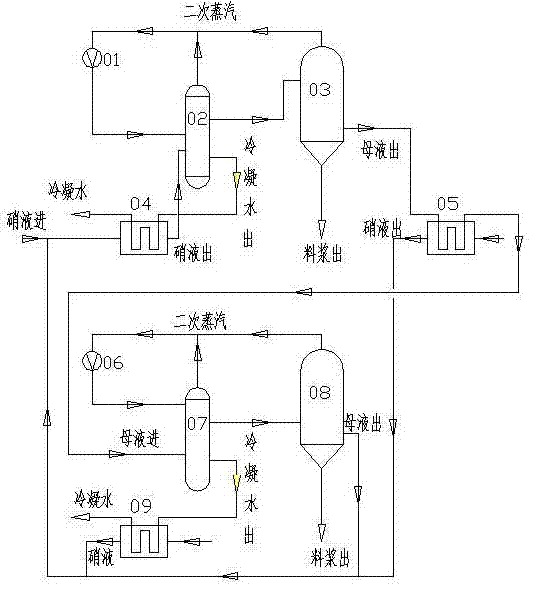

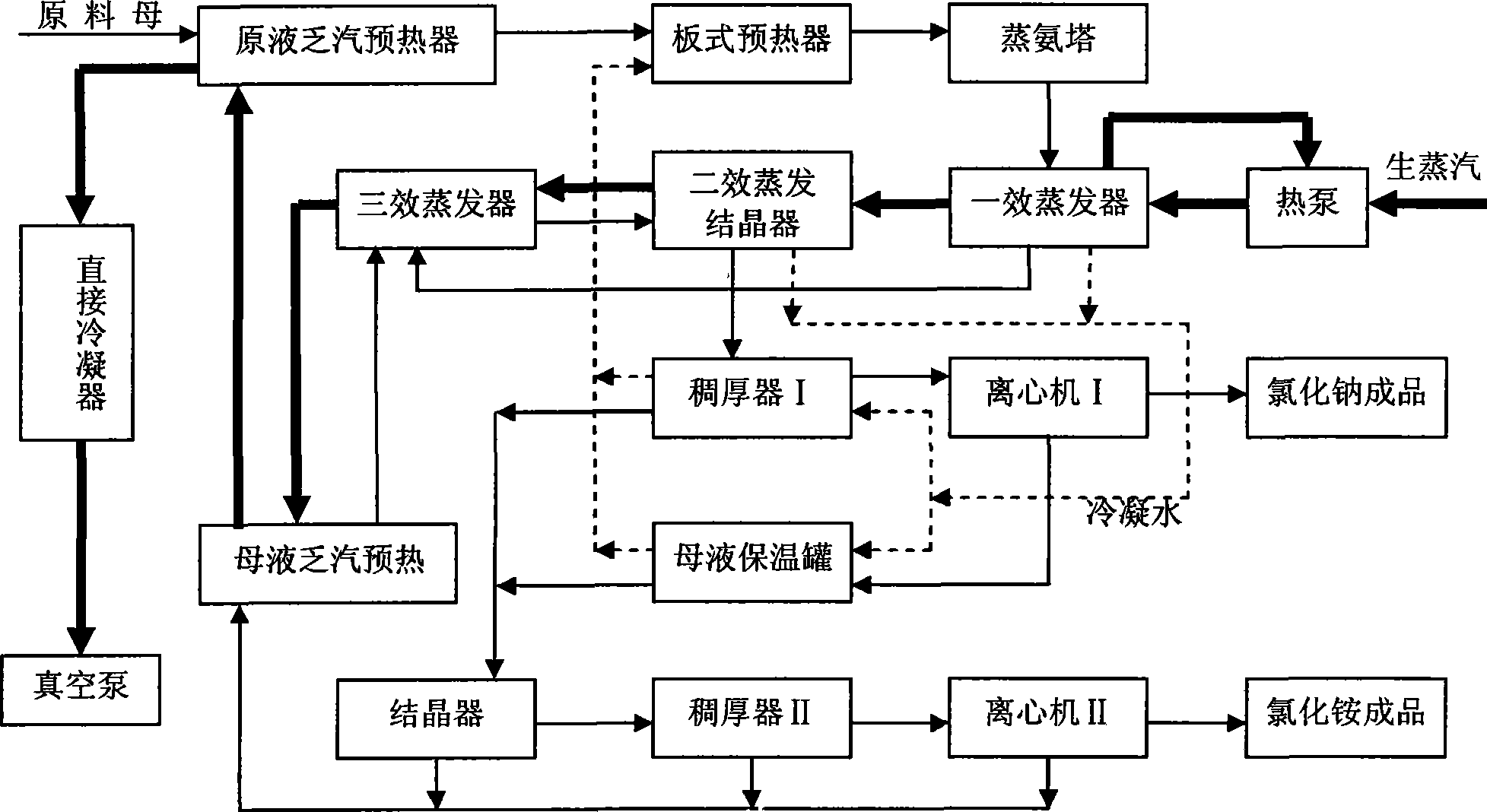

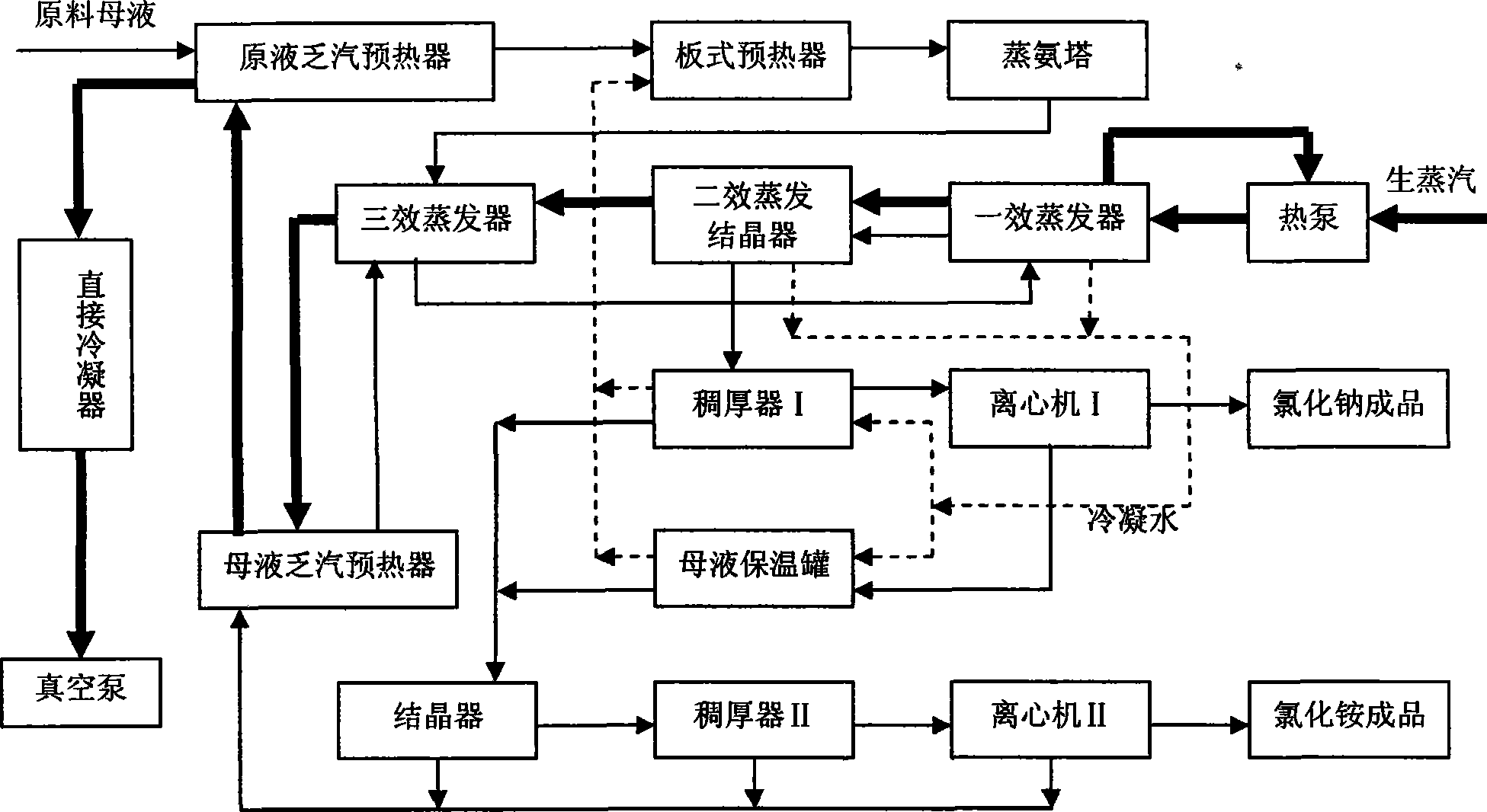

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

Recovery of common salt and marine chemicals from brine

InactiveUS20030080066A1High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

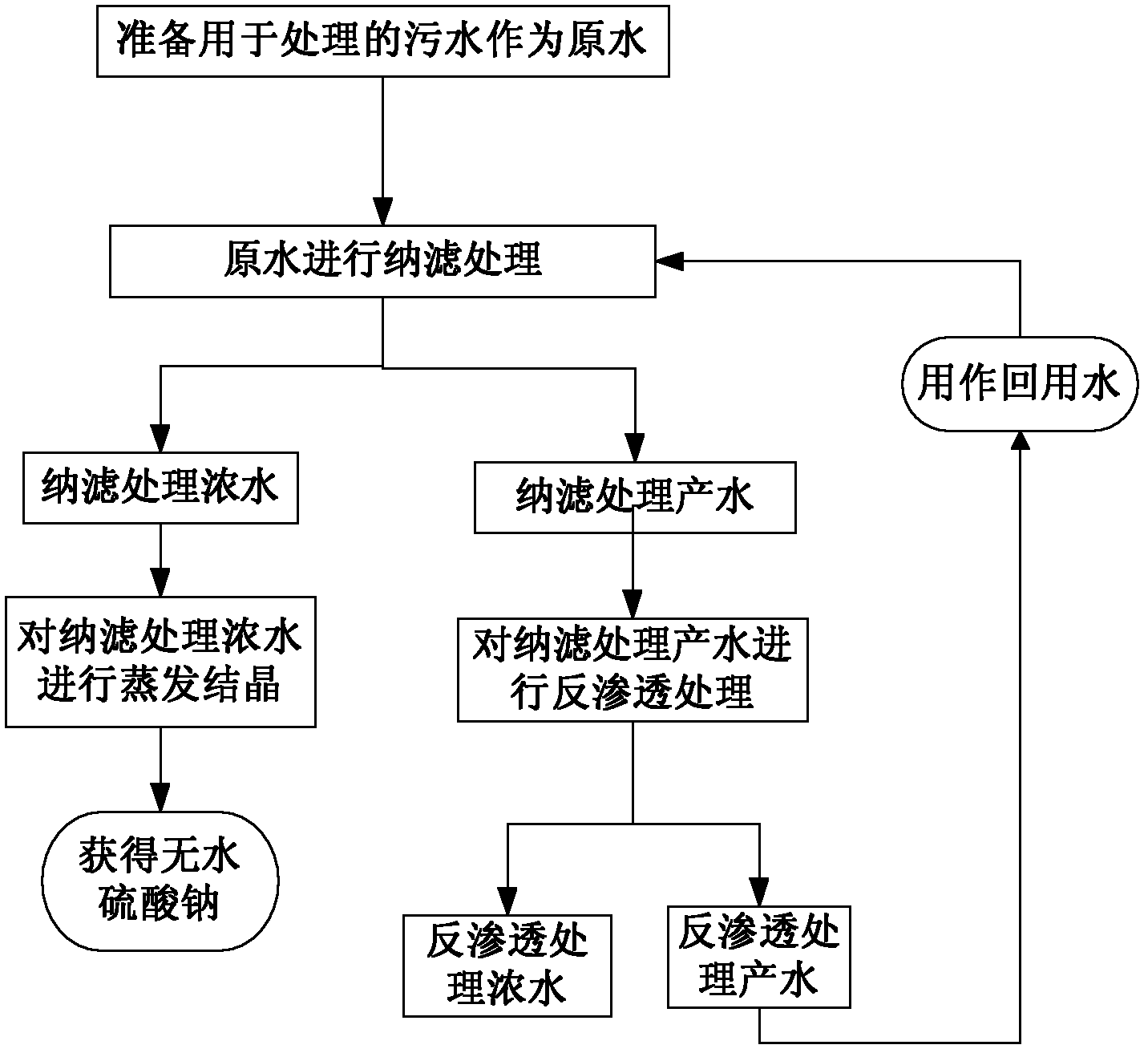

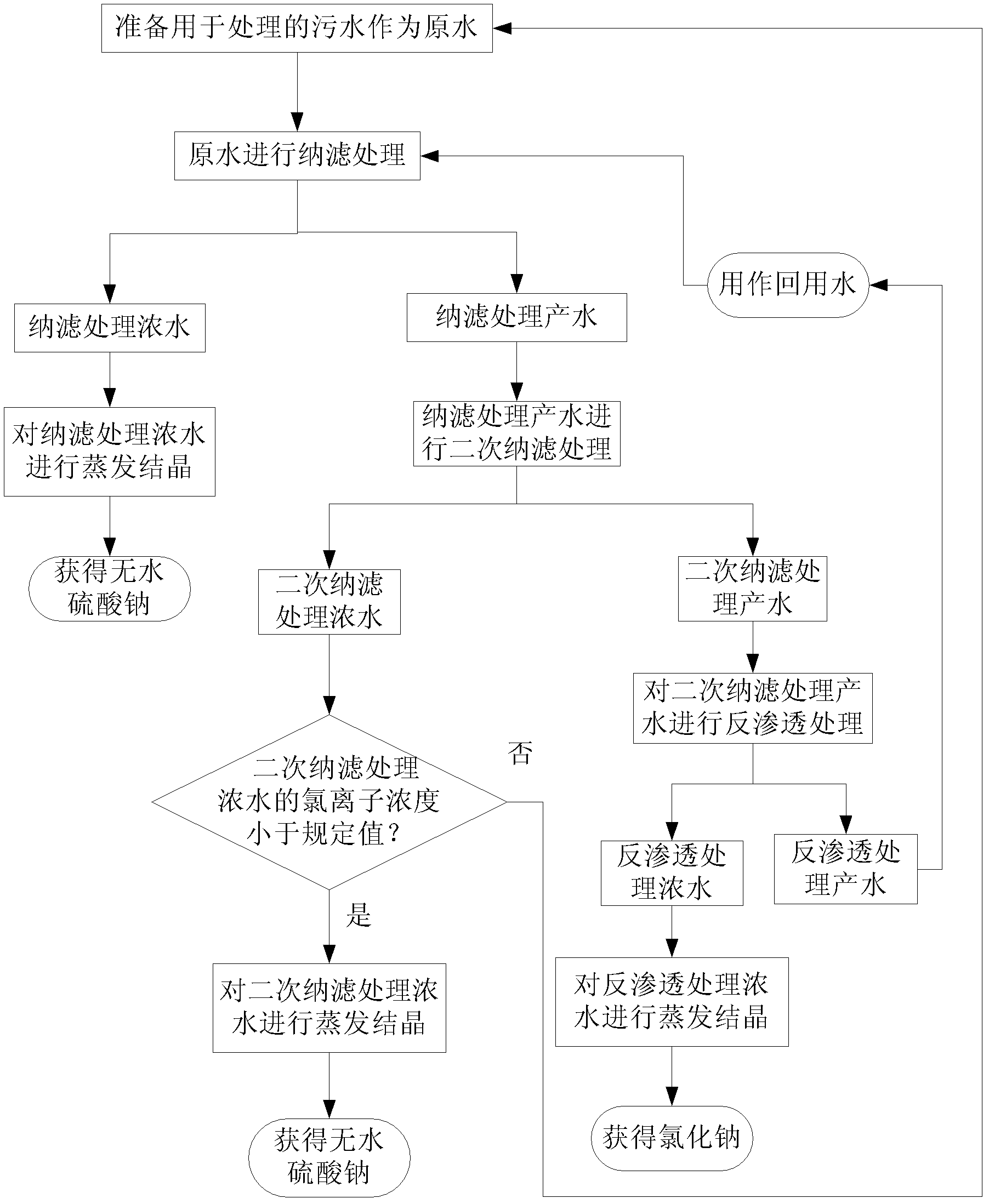

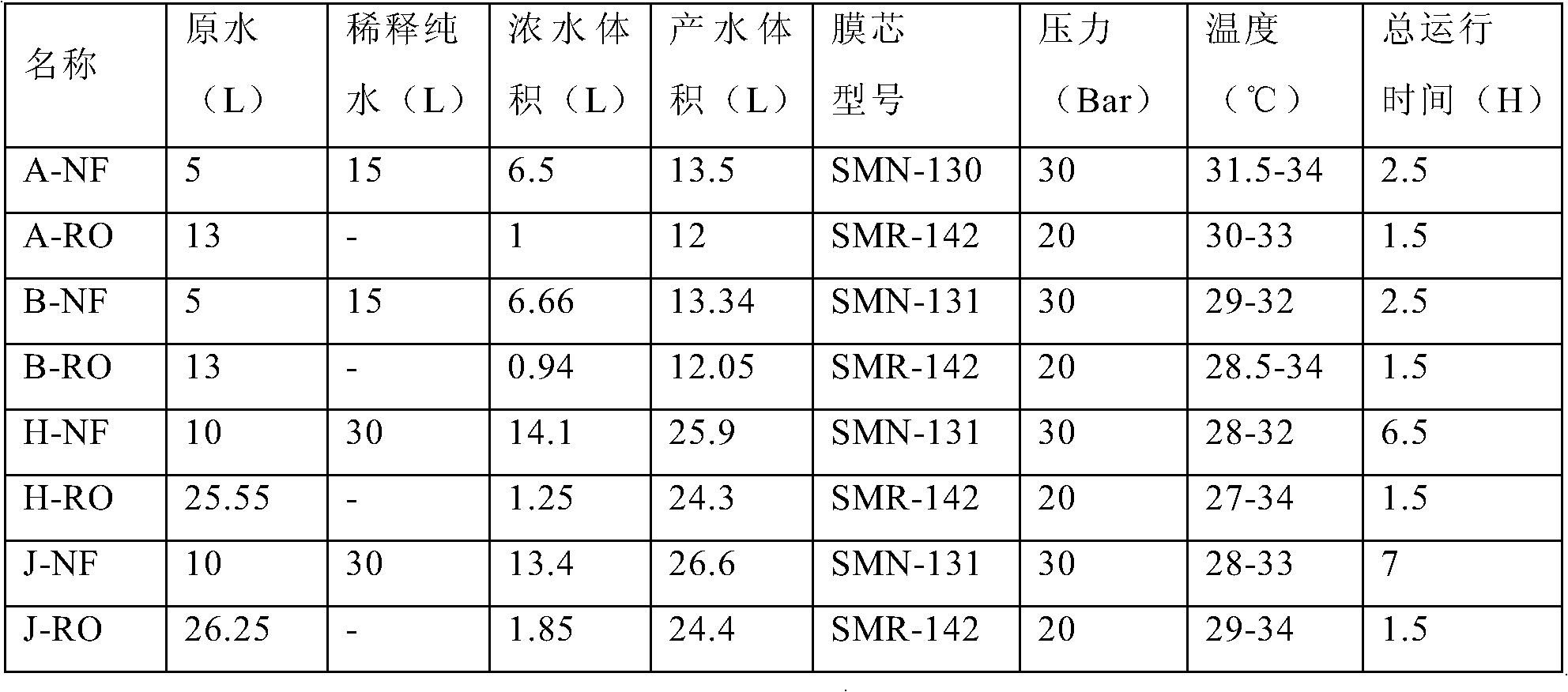

Treating method for sewage containing sodium sulfate and sodium chloride

ActiveCN102616891AEfficient separationNo pollution in the processWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentReverse osmosisSewage

The invention provides a treating method for sewage containing sodium sulfate and sodium chloride. The method comprises a step of preparing sewage to be treated as raw water and a step of carrying out nanofiltration on the raw water. The method may also comprise a step of carrying out evaporative crystallization on concentrated water obtained after nanofiltration so as to obtain anhydrous sodium sulfate. The method may further comprise a step of carrying out reverse osmosis treatment on yielded water obtained after nanofiltration and using yielded water obtained after reverse osmosis treatment as diluting water in nanofiltration of the raw water. The method may also comprise a step of carrying out secondary nanofiltration on yielded water obtained after nanofiltration so as to obtain concentrated water and yielded water obtained after secondary nanofiltration, a step of carrying out reverse osmosis treatment on yielded water obtained after secondary nanofiltration and carrying out evaporative crystallization on concentrated water obtained after reverse osmosis treatment so as to obtain sodium chloride, a step of using yielded water obtained after reverse osmosis treatment as diluting water in nanofiltration of the raw water, and a step of carrying out evaporative crystallization on concentrated water obtained after secondary nanofiltration in the sequence of concentration so as to obtain anhydrous sodium sulfate or subjecting the concentrated water together with next batch of raw water to nanofiltration again . The method provided in the invention can be used for separating and purifying anhydrous sodium sulfate and sodium chloride and for purifying sewage.

Owner:昆明先导新材料科技有限责任公司

Methods of fabricating nanoscale-to-microscale structures

InactiveUS7615206B2Attractive electronic and optical propertyAttractive mechanical propertySilicaMixing methodsChemical reactionChemical composition

Methods for the production of shaped nanoscale-to-microscale structures, wherein a nanoscale-to-microscale template is provided having an original chemical composition and an original shape, and the nanoscale-to-microscale template subjected to a chemical reaction, so as to partially or completely convert the nanoscale-to-microscale template into the shaped nanoscale-to-microscale structure having a chemical composition different than the original chemical composition and having substantially the same shape as the original shape, being a scaled version of the original shape. The shaped nanoscale-to-microscale structure formed comprises an element (such as silicon), a metallic alloy (such as a silicon alloy), or a non-oxide compound (such as silicon carbide or silicon nitride).

Owner:GEORGIA TECH RES CORP

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

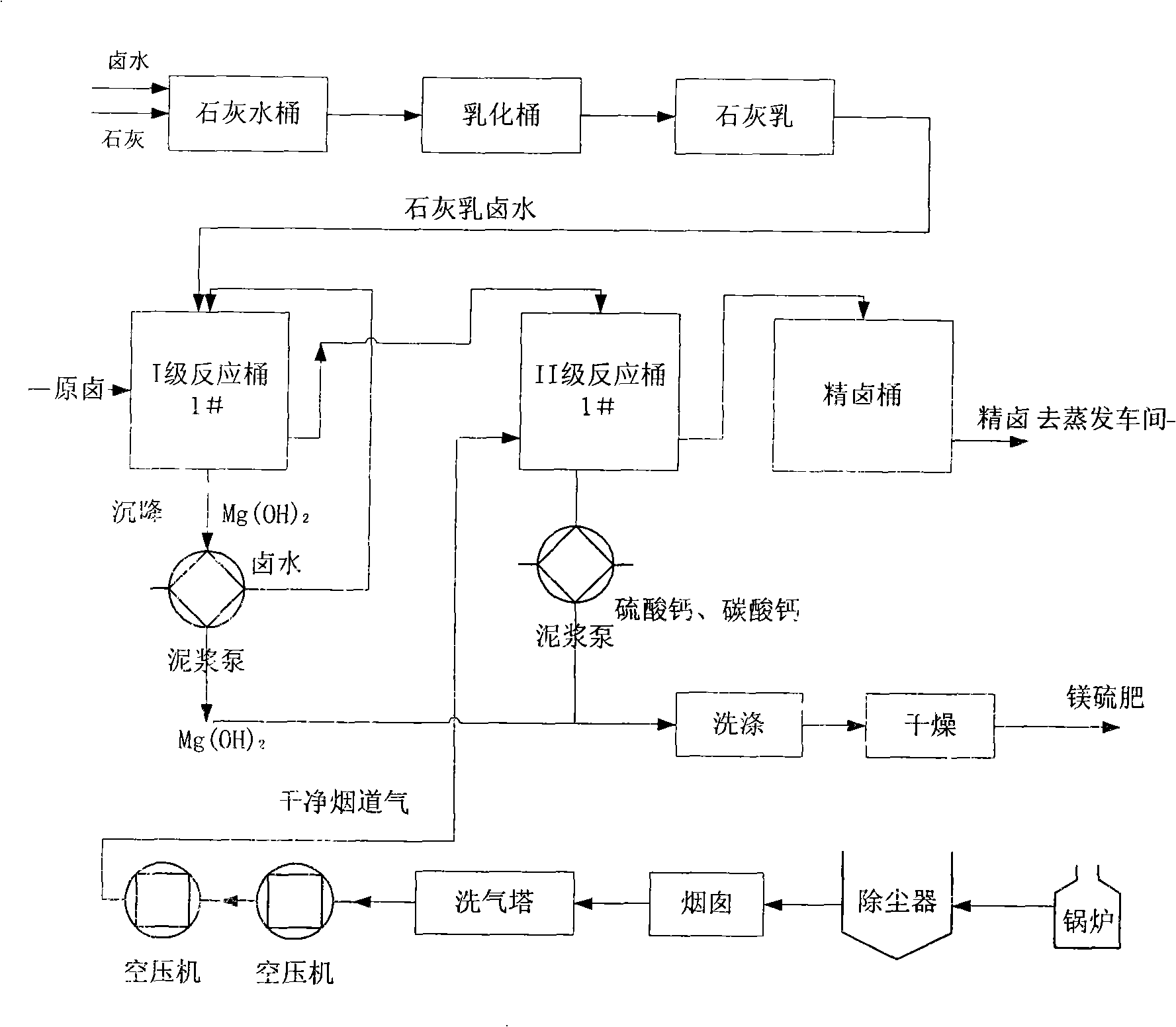

Technological process for purifying bittern

InactiveCN101289200AReduce purification costsImprove purification qualityAlkali metal chloridesSlurryCalcium carbonate precipitation

The invention provides a brine purification technical method which comprises that: a first step is that limewater is added into brine so that reaction happens to calcium hydroxide in the limewater and magnesian ion in the brine to generate magnesium hydrate sedimentation, the magnesian ion in the brine is removed, excessive calcium hydroxide is used for causticizing the sodium sulfate in the brine into sodium hydroxide; a second step is that flue gas is put into the brine after the magnesian ion is removed for carrying out reaction between carbon dioxide in the flue gas and the sodium hydroxide causticized in the brine to generate sodium carbonate which reacts with calcium ion in the brine to generate calcium carbonate sedimentation, the calcium ion in the brine is removed; a third step is that slurry produced in the first step and the second step is collected; and a fourth step is that refined brine after being treated by the first step and the second step is recycled. The technical method can reduce the pollution to environment, can save energy, and can reduce the consumption of raw brine and the purification cost of the brine at the same time, thereby conforming to the requirements of the strategy of sustainable development.

Owner:CHINA NATIONAL SALT INDUSTRY CORPORATION +1

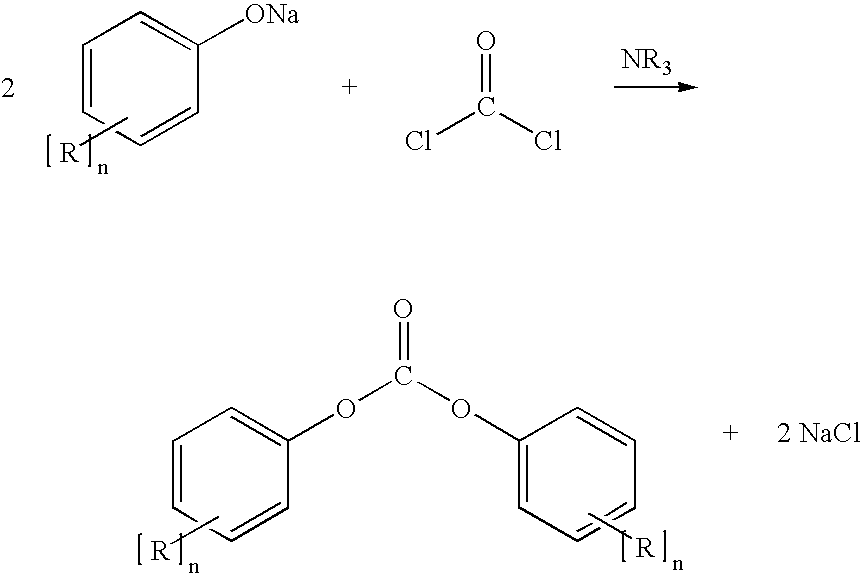

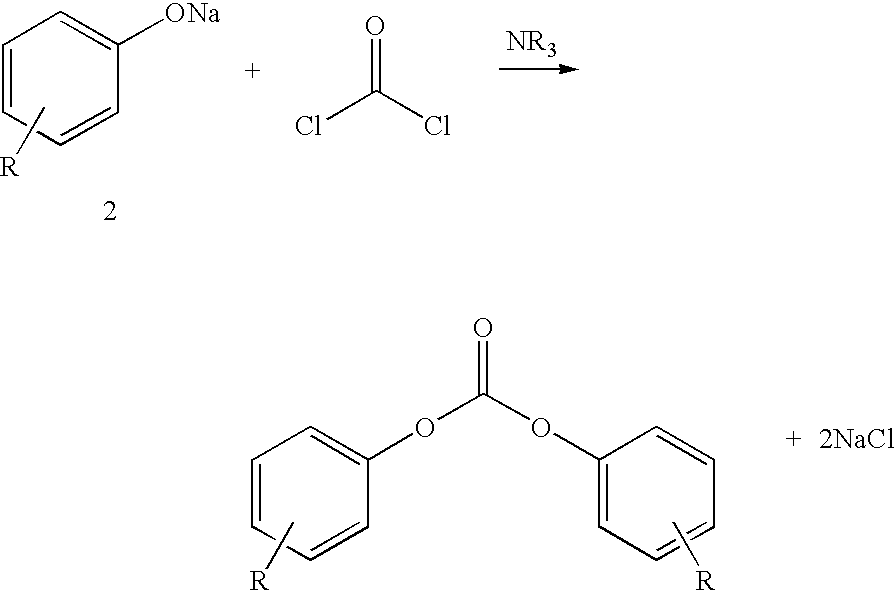

Process for the production of diaryl carbonates and treatment of alkalichloride solutions resulting therefrom

Processes comprising: (a) reacting phosgene and a monohydroxyl aryl compound in the presence of a suitable catalyst to form a diaryl carbonate and a solution comprising an alkali chloride; (b) separating the diaryl carbonate from the solution; (c) adjusting the pH of the solution to a value of less than or equal to 8 to form a pH-adjusted solution; (d) treating the pH-adjusted solution with an adsorbent to form a treated solution; (e) subjecting at least a portion of the treated solution to electrochemical oxidation to form chlorine and an alkali hydroxide solution; and (f) recycling at least a portion of one or both of the chlorine and the alkali hydroxide solution.

Owner:BAYER MATERIALSCIENCE AG

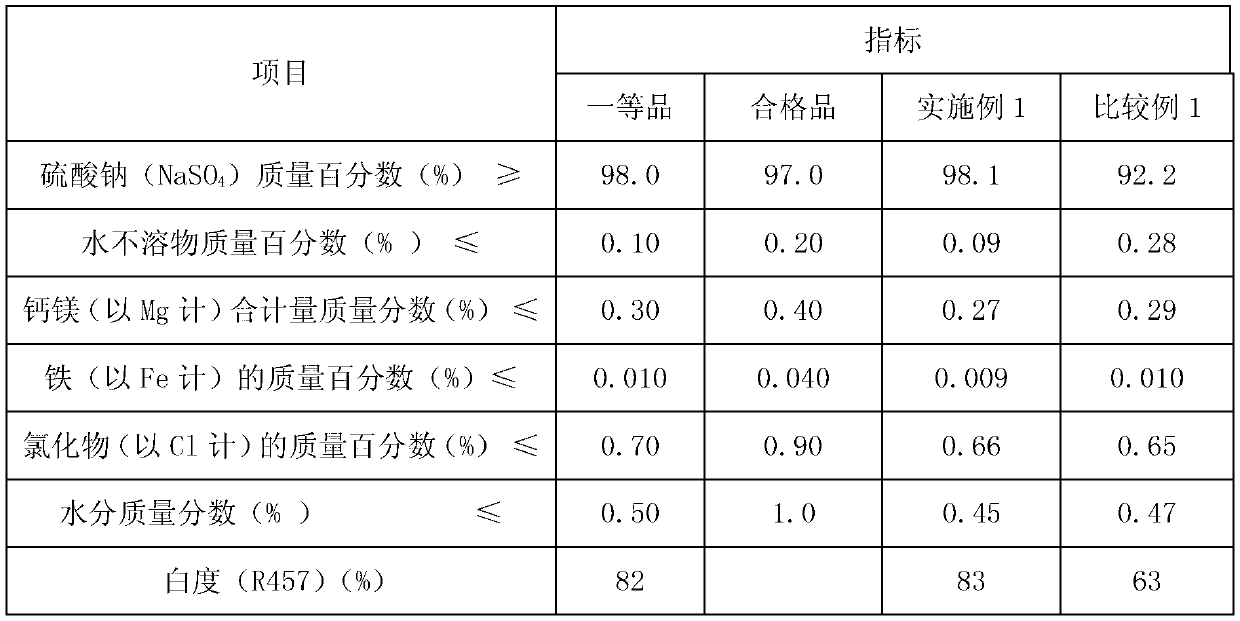

Chemical industrial waste salt refining process

ActiveCN104649495AImprove qualityRealize resource regenerationMultistage water/sewage treatmentAlkali metal chloridesTunnel kilnEvaporation

The invention relates to a chemical industrial waste salt refining process which comprises the following steps: pretreating high salt wastewater generated in the production process of aminobenzene ether and p-nitrophenol so as to adjust the pH value, adsorbing by using activated carbon, kieselguhr or macroporous resin, removing organisms and organic salts in the wastewater, reducing the COD of the wastewater, neutralizing the high salt wastewater, performing multi-effect evaporation or mechanical recompression so as to evaporate and crystallize, and centrifuging a solid salt; performing high-temperature calcination on the centrifuged solid salt in a rotary kiln or a tunnel kiln, thereby decomposing and oxidizing the organisms at a high temperature, further thoroughly combusting the tail gas generated through calcination in a heat accumulation type tail gas combustion furnace, preheating and recycling the tail gas, performing spraying absorption, dissolving the calcinated salt with water so as to prepare a saturated solution, filtering by using a precise filter, directly supplying the filtrate to ionic membrane caustic soda for use, or performing multi-effect evaporation or mechanical recompression on the filtered saturated salt water so as to evaporate, crystallize and purify, and performing centrifugation, thereby obtaining high-quality solid sodium chloride.

Owner:JIANGSU ZHONGDAN GROUP

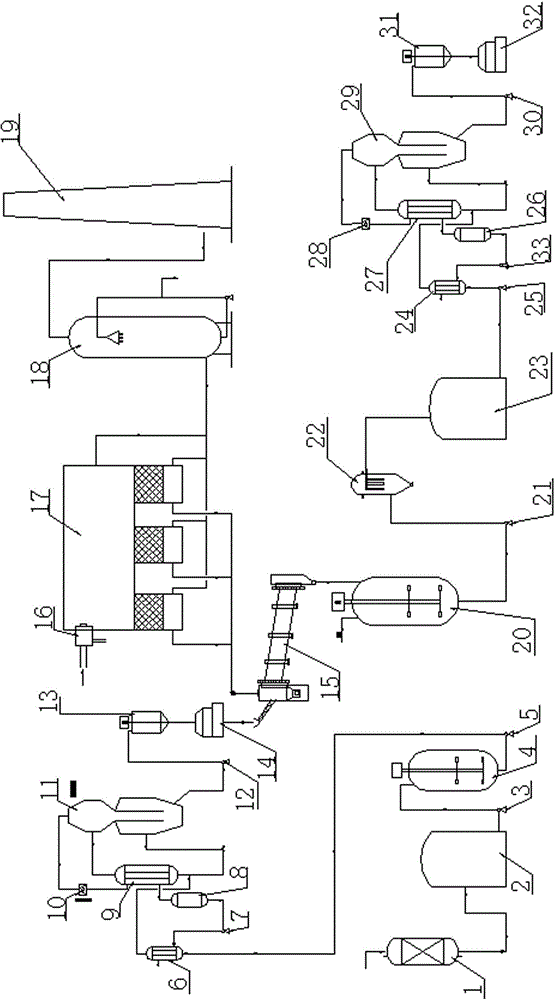

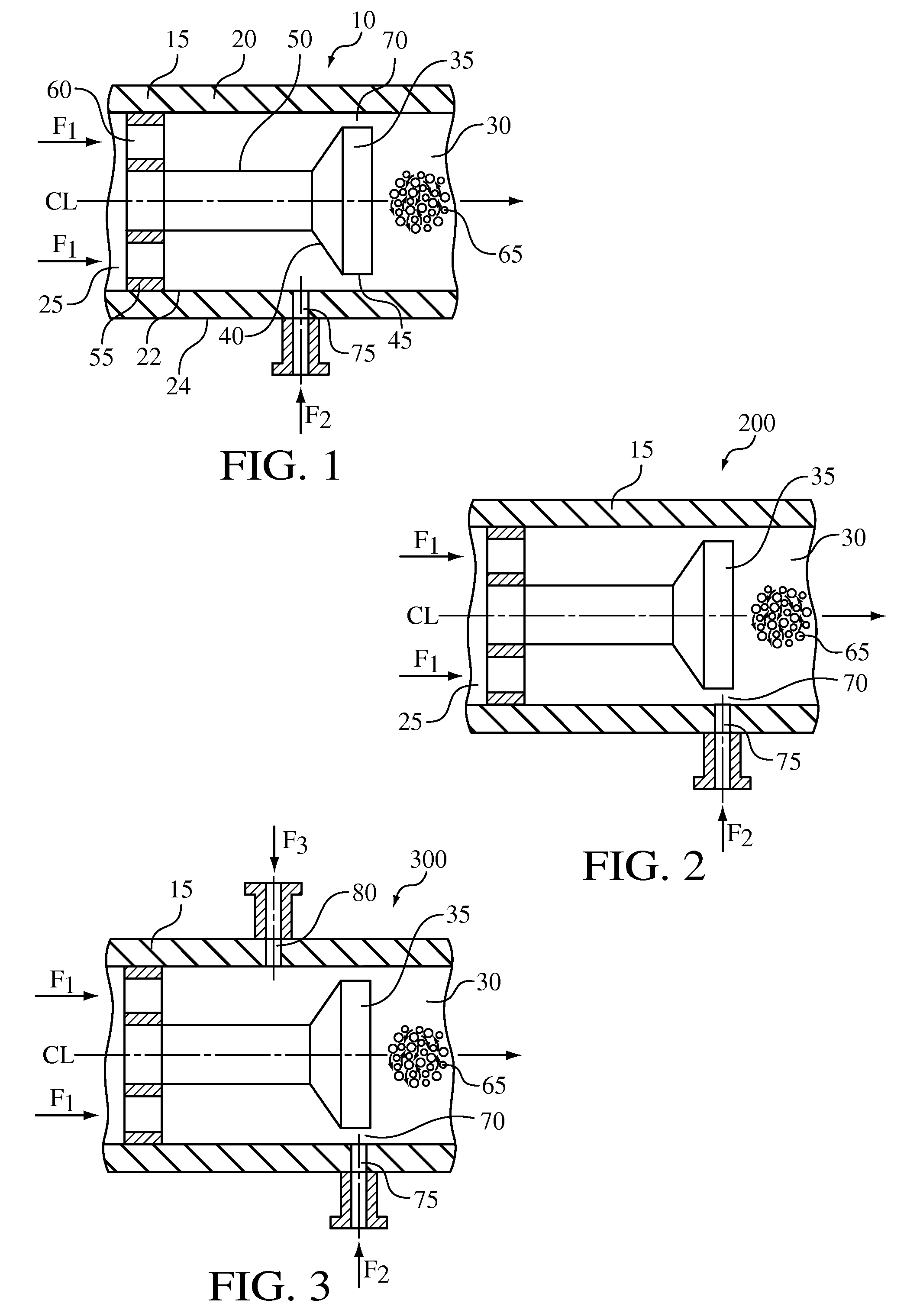

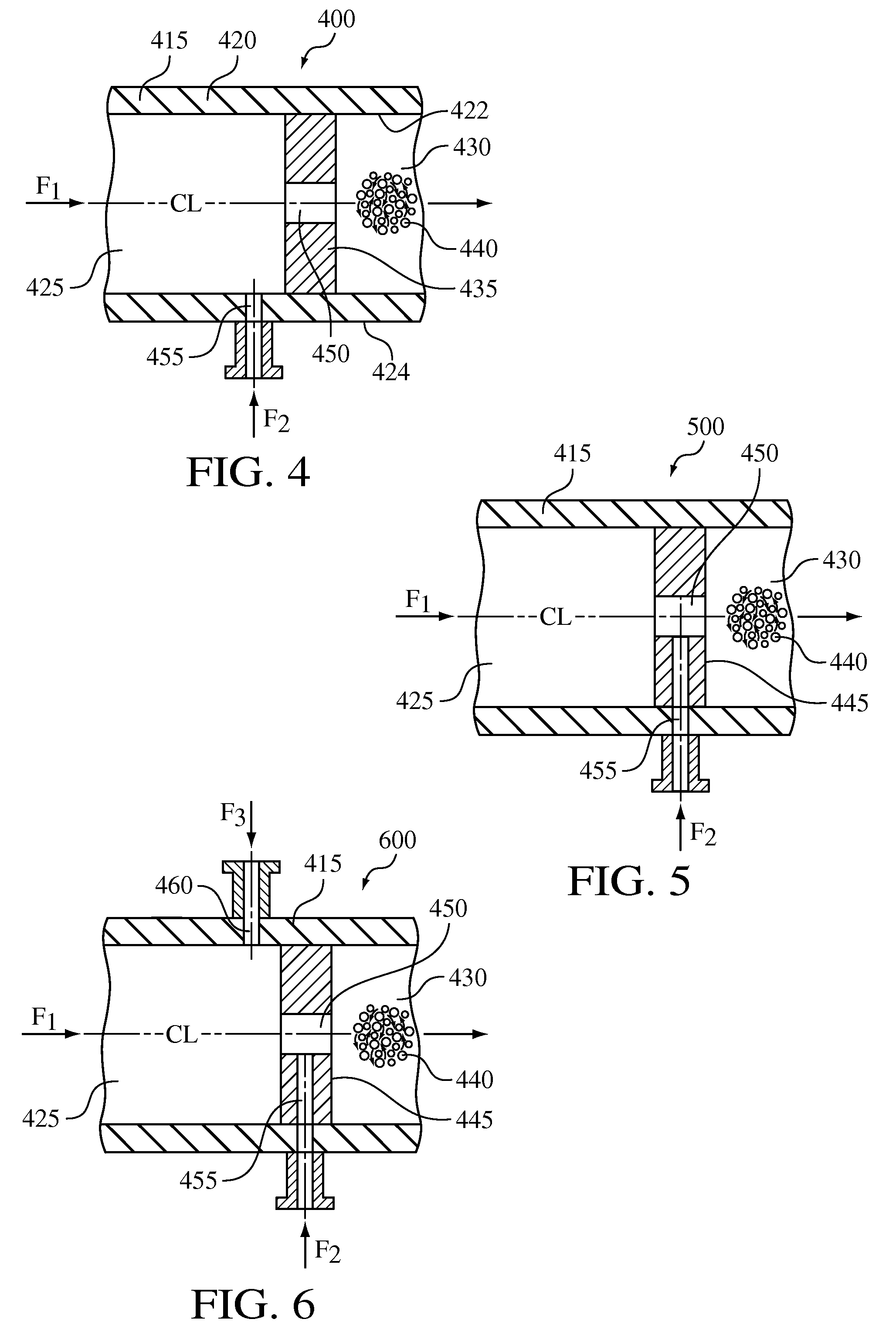

Hydrodynamic cavitation crystallization device and process

InactiveUS20080194868A1Polycrystalline material growthFrom normal temperature solutionsAnti solventCavitation

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals. The compound to be crystallized can be, for example, an active pharmaceutical ingredient.

Owner:CAVITECH HLDG

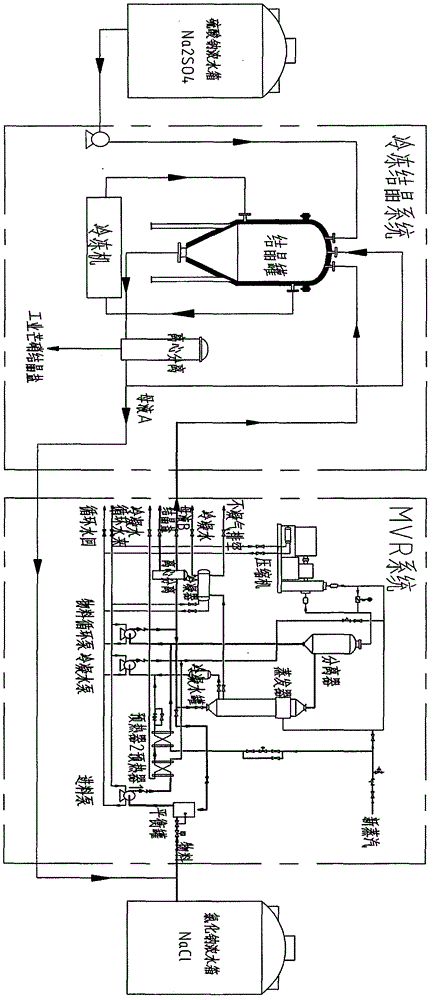

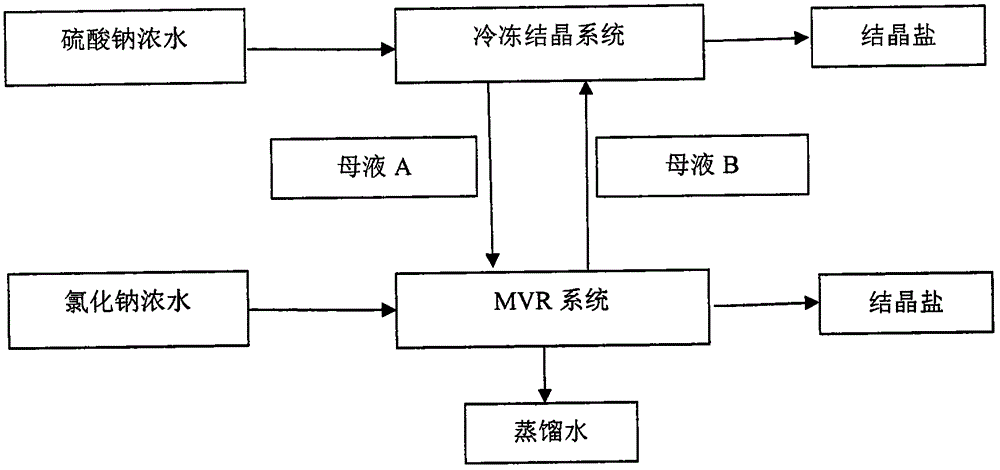

Crystallization treatment method and device of high salt wastewater

ActiveCN104692575AHigh energy consumptionHigh operating costsAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentResource utilizationWastewater

The invention relates to a crystallization treatment method and device of high salt wastewater and belongs to the technical field of water treatment. The method is characterized in that after sodium sulfate concentrated water is treated by a freezing crystallization system, generated mother liquor A enters into an MVR system for evaporative crystallization; after sodium chloride concentrated water is treated by the MVR system, generated mother liquor B enters into a freezing crystallization system for freezing crystallization, and the mother liquor can be treated in a circulation overlapping manner; a drain outlet of the MVR system of the device is connected with a liquid inlet of a crystallization tank in the freezing crystallization system through a pipeline and the drain outlet of the freezing crystallization system is connected with a liquid inlet pipe of the MVR evaporative crystallization system. The method has the advantages that the mother liquor is treated by a freezing crystallization technology and an MVR evaporation crystallization technology in a circulation overlapping manner, so that the problems of zero emission and resource utilization are solved, and therefore, the energy consumption is effectively reduced and the operating cost is lowered.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

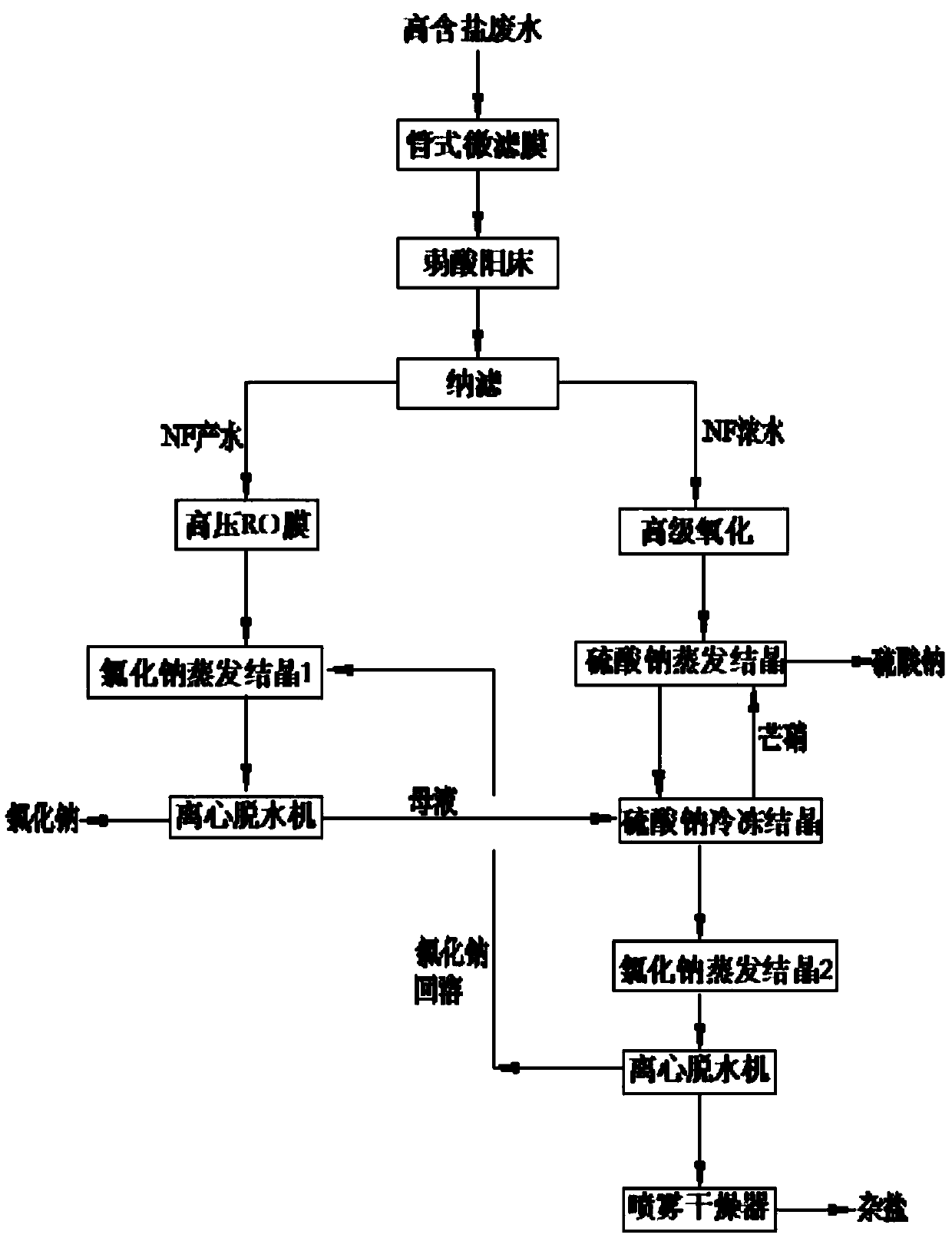

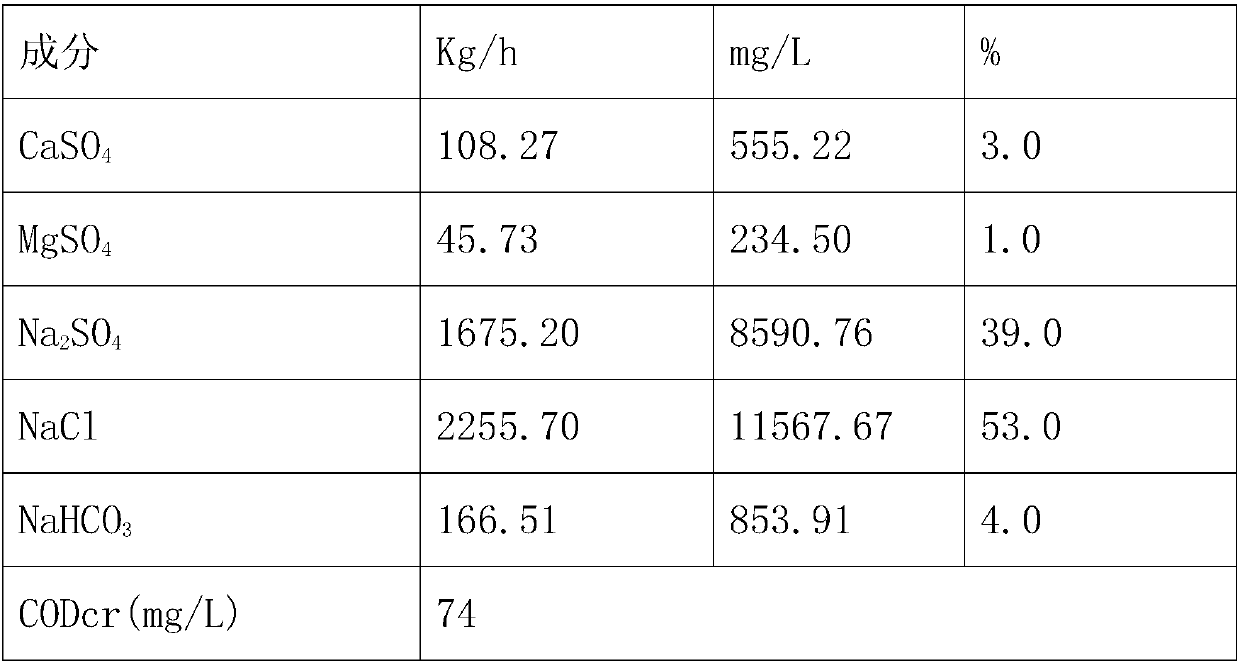

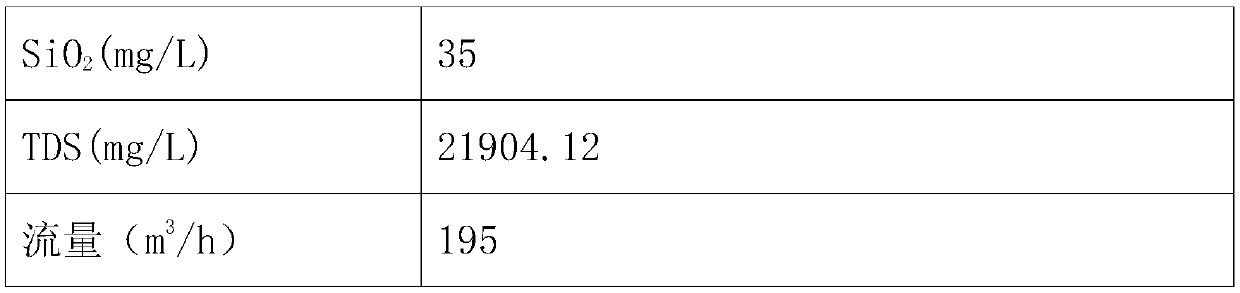

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

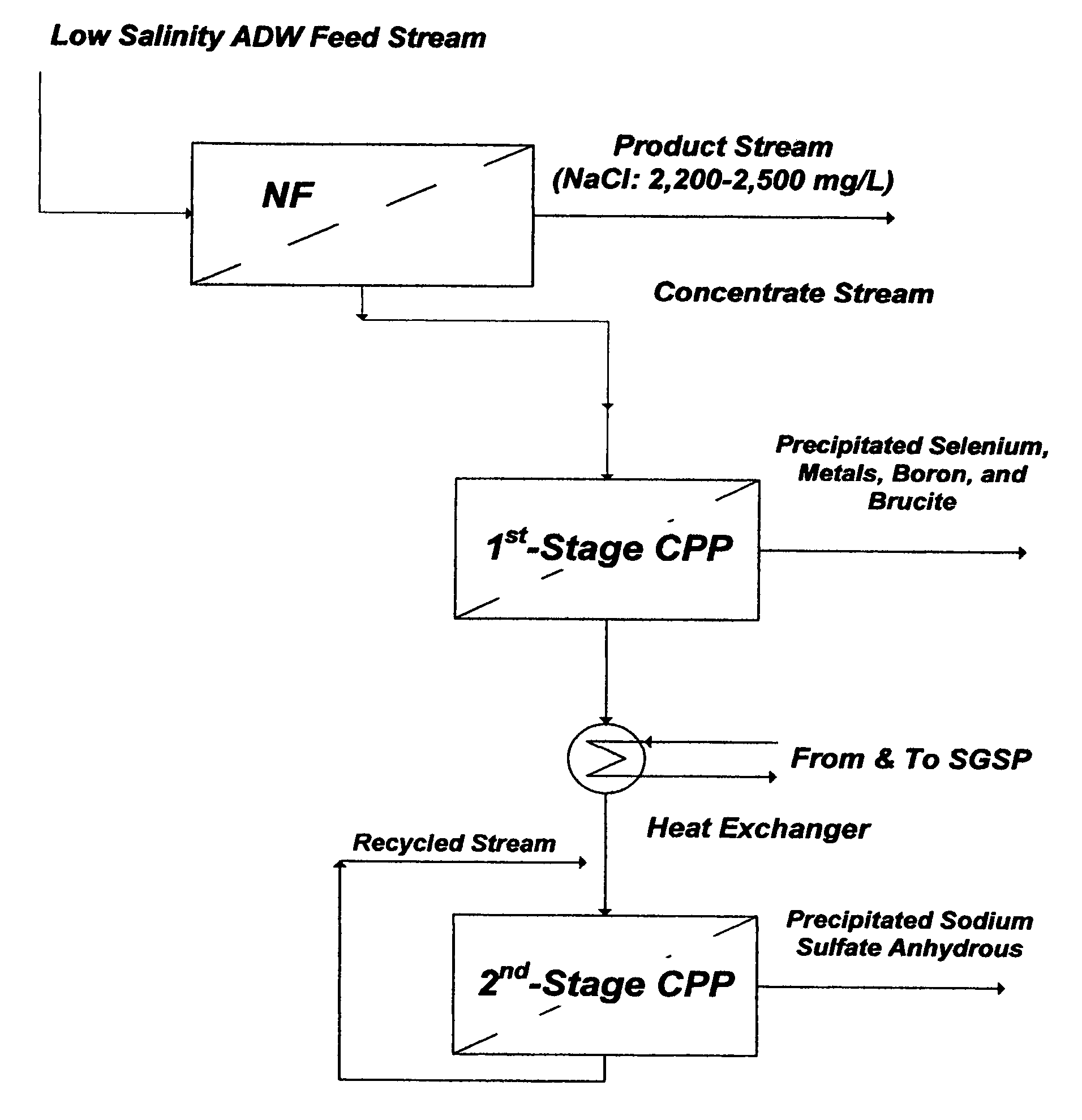

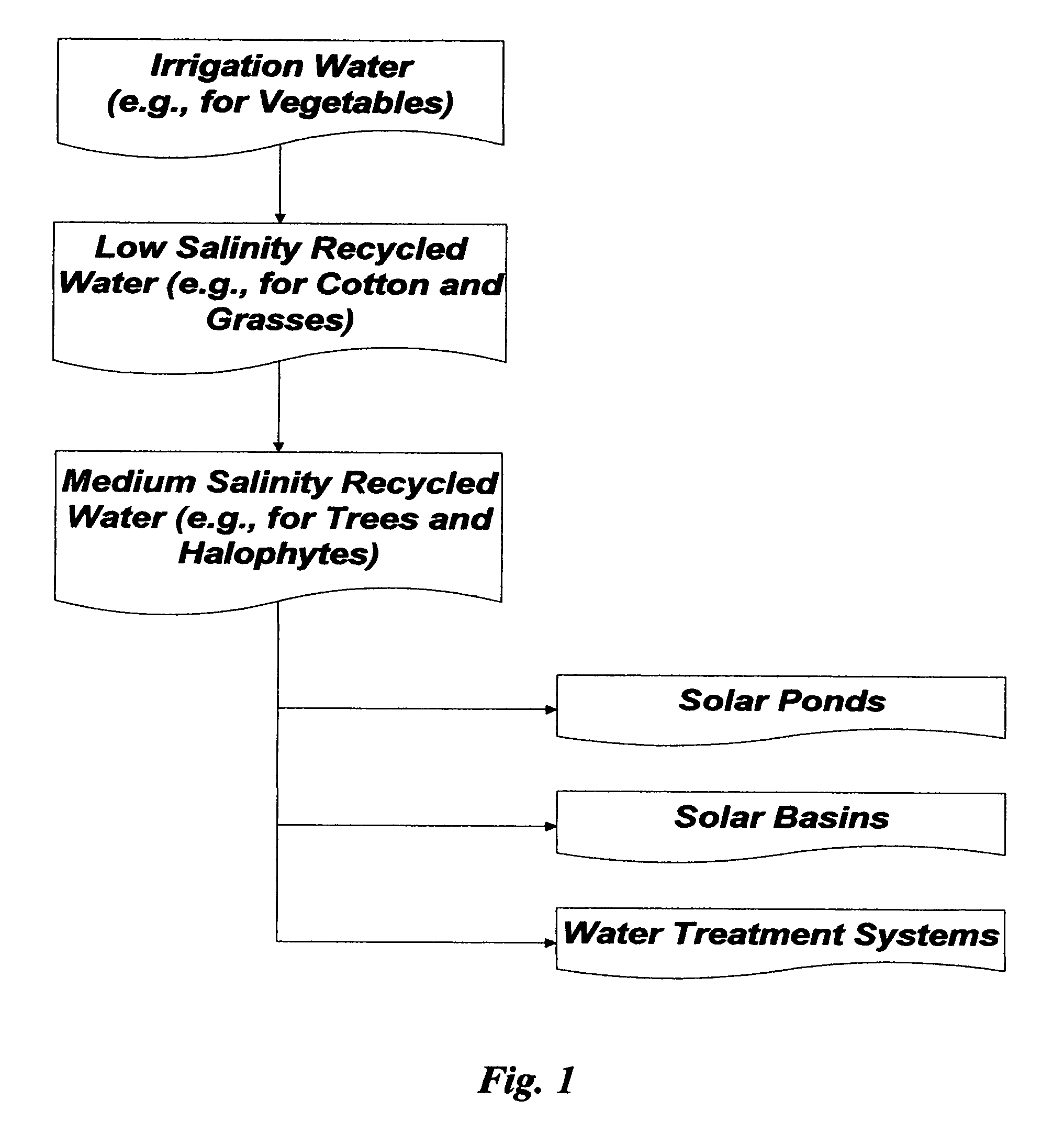

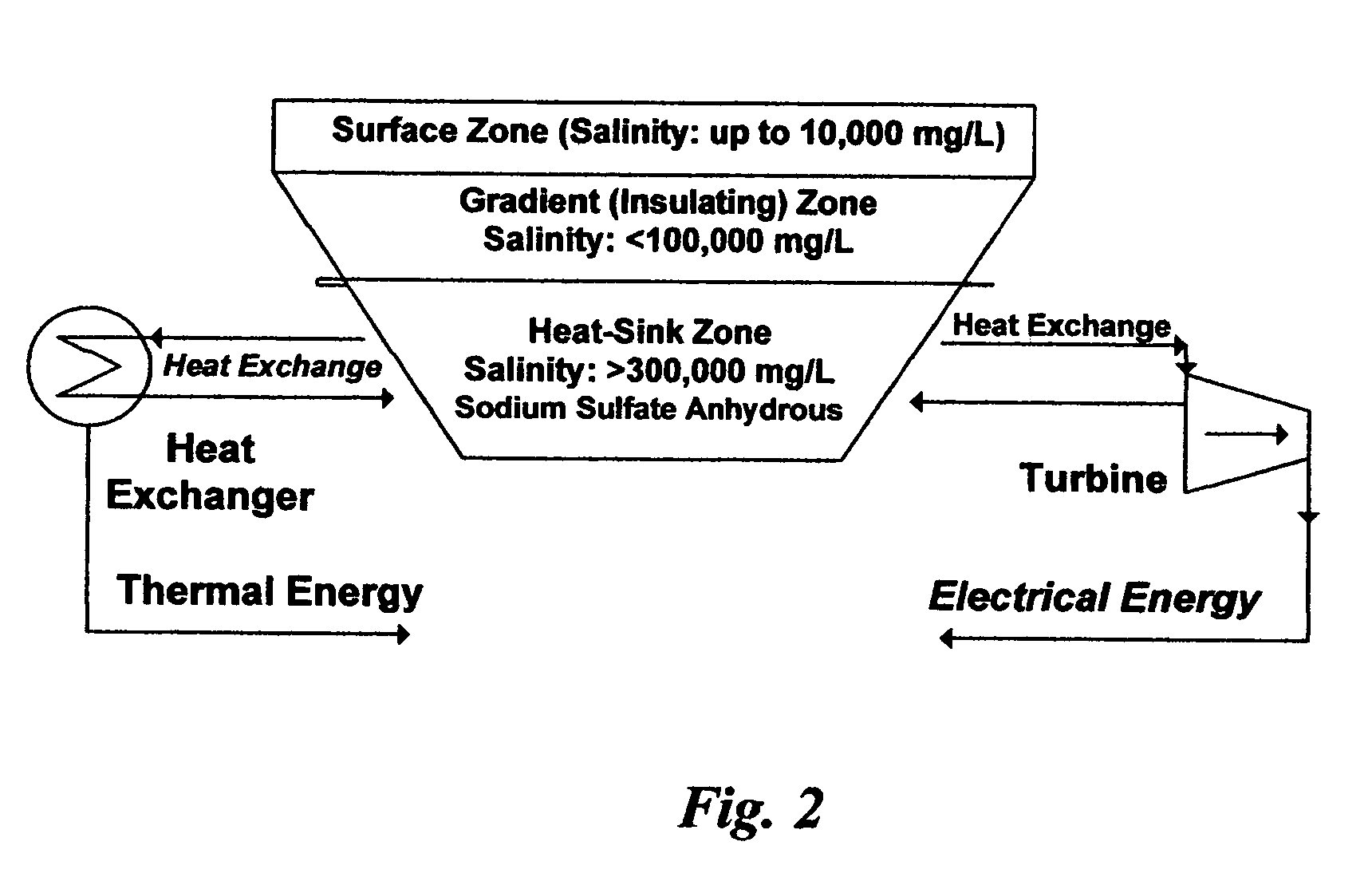

Methods for treating agricultural drainage water and the like

InactiveUS7501065B1Avoid pollutionSolar heating energyGeneral water supply conservationSulfateWater quality

Zero discharge processing methods for the treatment of agricultural drainage water (ADW) are disclosed. The disclosed methods are capable of meeting the three critical issues in treating ADW: (1) selective removal of sulfate scale-prone species and toxic species; (2) production of usable water that at least meets irrigation water quality; and (3) recovery of sodium sulfate and sodium chloride as valuable commodities.

Owner:BADER MANSOUR S

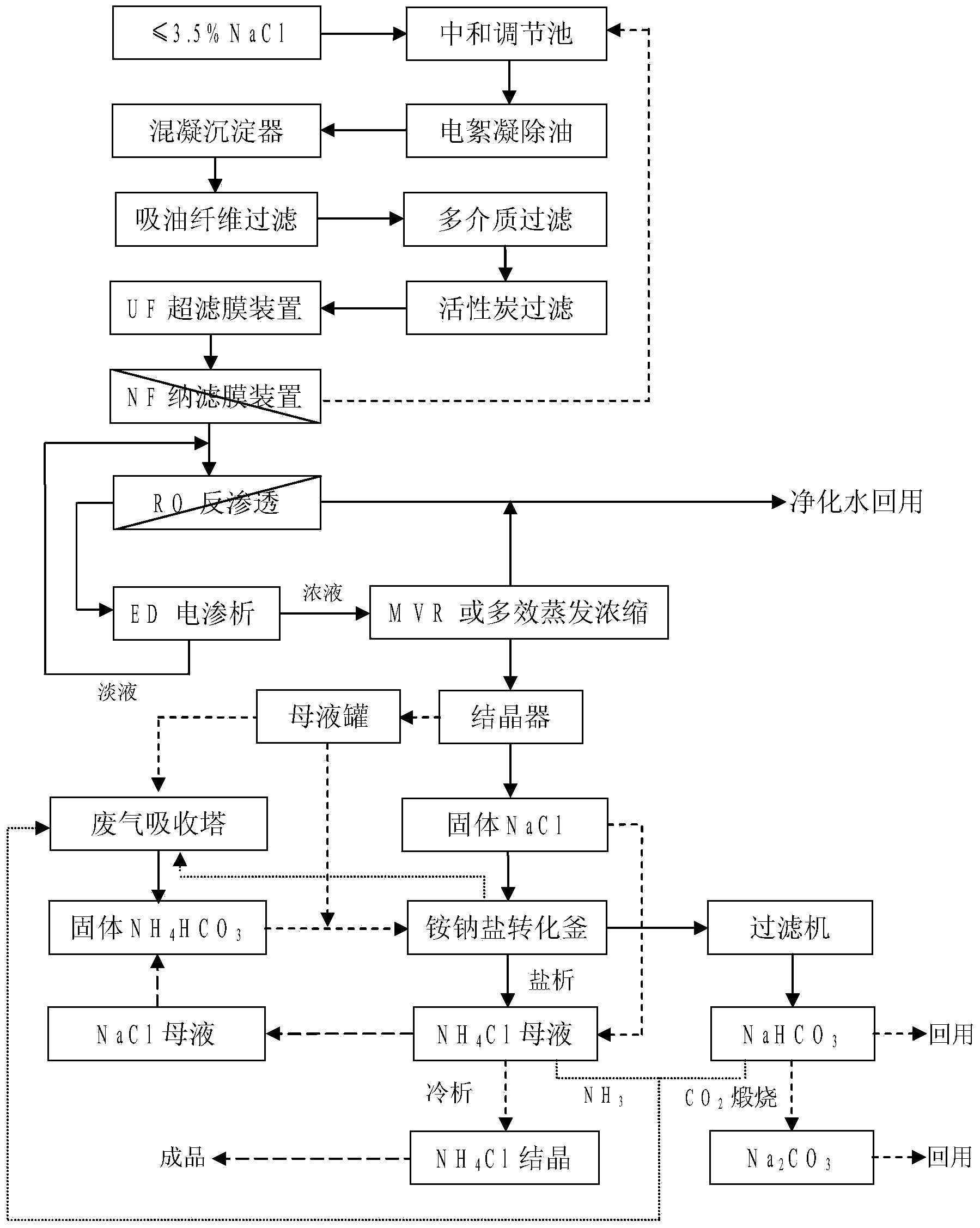

Combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth

InactiveCN103449653AImprove environmental protection measuresAvoid volatile lossGeneral water supply conservationMultistage water/sewage treatmentSodium bicarbonateUltrafiltration

The invention relates to a combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth. According to the method, a series of desalination and concentration treatments such as deoiling, neutralizing, homogenizing, aeration, flocculation, ultrafiltration, nanofiltration, reverse osmosis, electroosmosis and MVR (mitral valve replacement) concentration are carried out on the wastewater, so that recyclable purified water is obtained; ammonium bicarbonate is added into the sodium chloride extracted from the wastewater, so that the sodium salt can be converted and regenerated into sodium bicarbonate, sodium carbonate and ammonium chloride products for dressing and smelting of the rare earth. According to the method, the recovery rate of the wastewater is high, the effluent quality is stable, the conversion rate of the sodium salt is high, and no three wastes are discharged; production equipment is compact, simple to operate, and easy to realize automation control; the problem that the sodium chloride-containing wastewater and other similar industrial wastewater generated in dressing and smelting of rare earth are difficult to recycle is solved.

Owner:YANSHAN UNIV

Method for separating magnesium from lithium and extracting lithium from brine

InactiveCN101538057ASolve the difficult technical problems of filtrationSimple technical processMultistage water/sewage treatmentSolution crystallizationFiltrationHigh energy

The invention provides a method for separating magnesium from lithium and extracting the lithium from high magnesium-lithium ratio brine (brine from a saline lake, from underground and from an oil-gas field). The method comprises: sodium salt and potassium and magnesium mixed salt are separated from the brine by evaporation of a saltpan; after boron extraction, sodium hydroxide is used for precipitating Mg<2+> from obtained old brine, and crystallized Mg(OH)2 is obtained by modification and precipitation condition control; filtration and separation are carried out to remove the Mg(OH)2 to realize separation of magnesium and lithium; after filtered mother solution is vaporized and concentrated for 2-4 times, Na2SO4 and NaCl are separated by crystallization, and pure caustic soda can be added to form lithium carbonate from lithium; or the operation of further evaporation is carried out until Na2SO4 and NaCl are separated by multiple times of natural evaporation or forced evaporation concentration and multiple times of cooling crystallization; the operations of evaporation and concentration are carried out until LiCl saturation, and LiCl products can be prepared after the operation of cooling crystallization is carried out. Compared with the prior art for separating the magnesium from the lithium and extracting the lithium from the brine, the method obtains the crystallized Mg(OH)2 by modification and precipitation condition control, solves the existing technical problem of hard filtration of Mg(OH)2, solves the defects of high energy consumption, complex process and high cost of the existing calcination method, and solves the fundamental defects of low Li<2+> recovery ratio and complex technical process of the traditional precipitation method. The Li<2+> recovery ratio ranges from 85-93%, Mg<2+> removal ratio is more than 99.5%, and the method solves the problem of extracting Li<+> and Mg<2+> from high-magnesium and low-lithium brine with Mg<2+> / Li<+>>=20 mass ratio.

Owner:钟辉

Process for production of diaryl carbonate

The invention relates to a process for production of diaryl carbonate combined with the electrolysis of the resultant alkali metal chloride-containing process wastewater. The process according to the invention makes possible, inter alia, improved utilization in electrolysis of the alkali metal chloride-containing solution obtained in the production of diaryl carbonate.

Owner:BAYER MATERIALSCIENCE AG

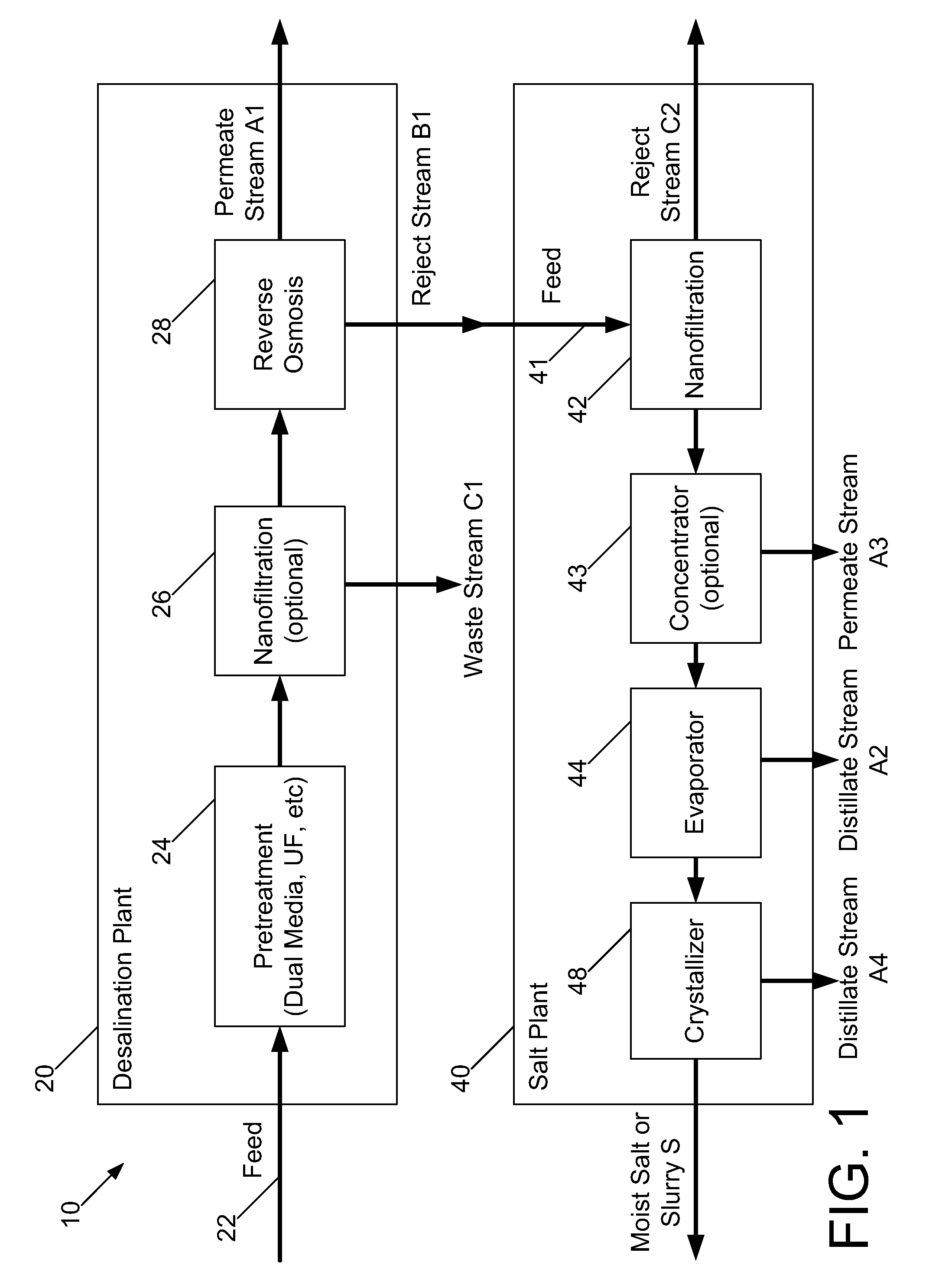

Seawater desalination plant and production of high purity salt

The present invention discloses an integrated desalination and salt plant for the production of a salt or slurry product of high purity. The reject stream from the desalination plant is used as the feed stream for the salt plant. The salt plant feed stream is filtered to effectively remove sulfate, which prevents scale formation in the salt plant equipment. The filtering may also reduce the level of calcium, magnesium, bicarbonate, or other components of the feed which may also prevent scale formation in the salt plant equipment. The salt plant produces a high purity salt product without the use of chemical purification.

Owner:BL TECH INC

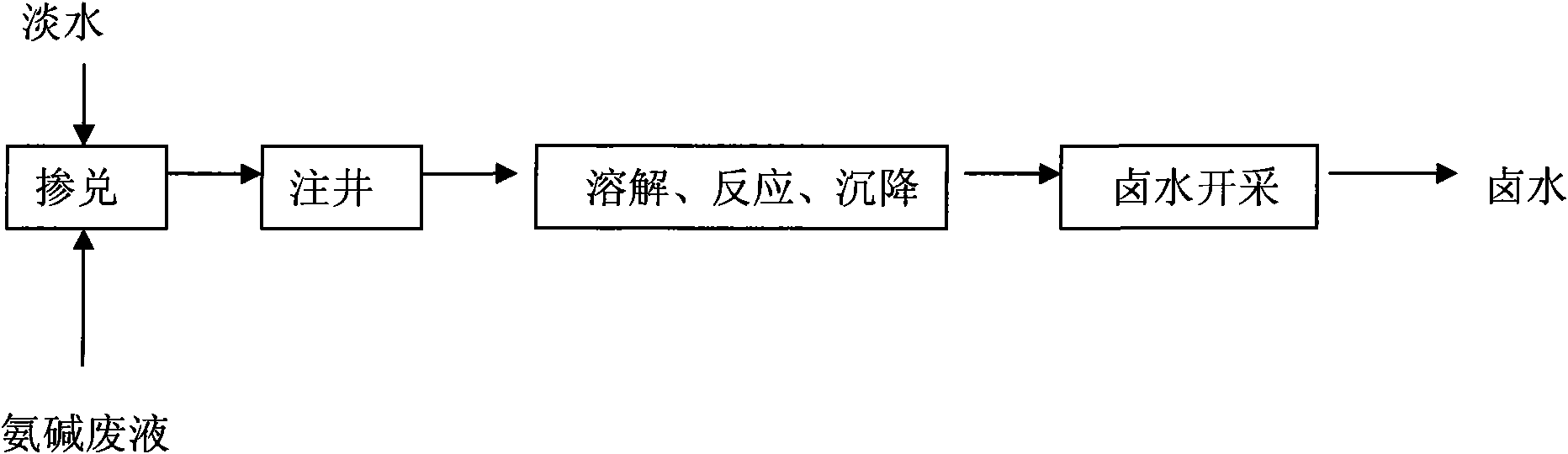

Resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of sodium sulfate type salt mine

ActiveCN101629484AAchieve reuseImprove protectionFluid removalAlkali metal chloridesChemical industrySulfate

The invention discloses a resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of a sodium sulfate type salt mine, which comprises the following steps: injecting waste ammonium alkali liquid under the salt mine instead of fresh water directly or after being added with fresh water, dissolving rock salt to from mine brine, and extracting the mine brine after natural sedimentation. In the invention, the waste ammonium alkali liquid is used for the sodium sulfate type salt mine, the waste ammonium alkali liquid is injected under the salt mine for brine extraction directly or after being added with water to obtain high-quality brine with low sodium sulfate content, thereby not only the sodium sulfate content in the brine is reduced, but also NaCl in the waste ammonium alkali liquid is recycled, the resource recycling of the waste ammonium alkali is achieved, and the emission of wastes is reduced. The prepared brine can be used in vacuum salt manufacturing, brine alkali manufacturing, mine brine air-cured salt manufacturing and other chemical industries.

Owner:江苏省制盐工业研究所有限公司 +1

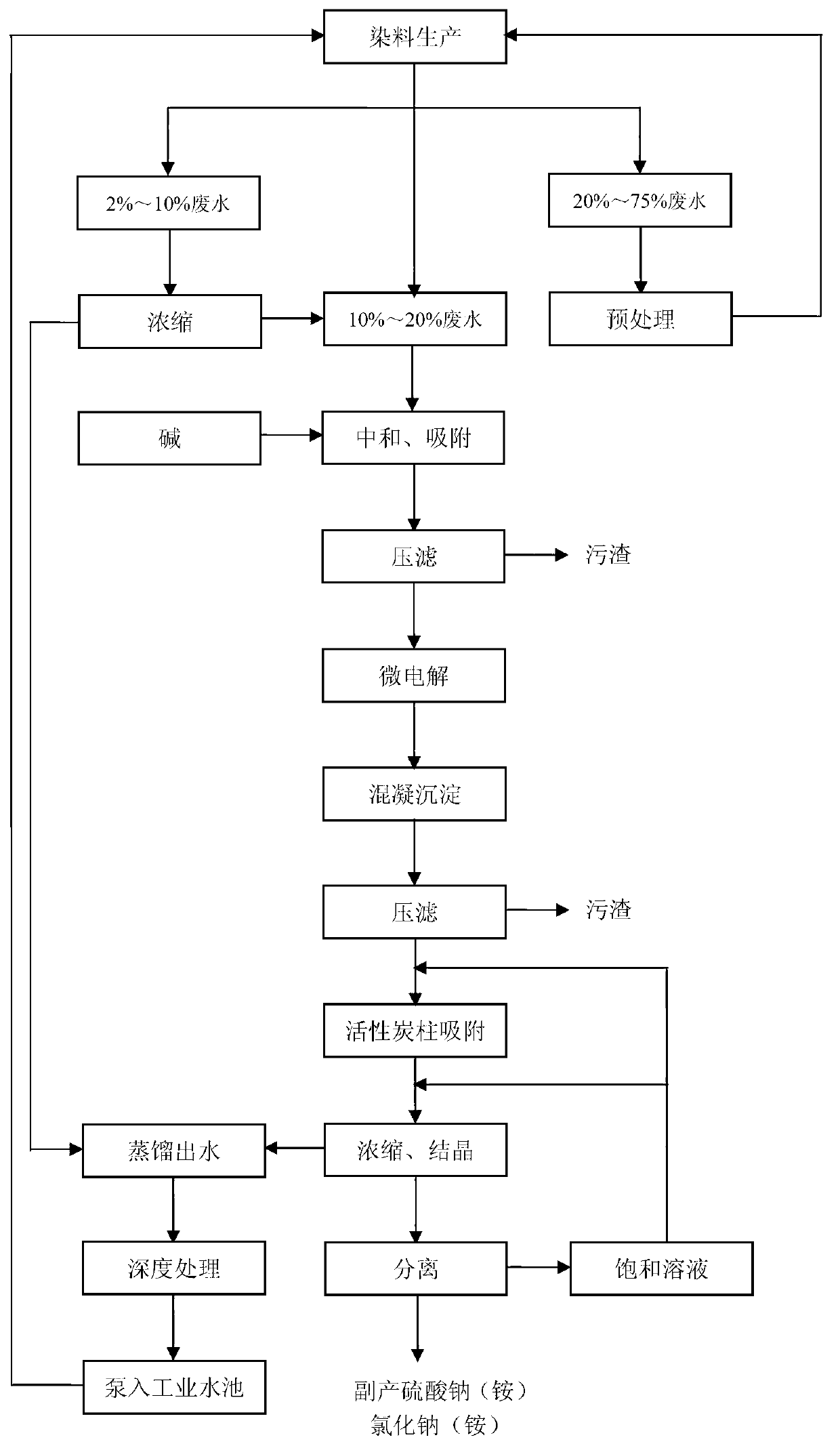

Dye acidic waste water treatment method and device

ActiveCN103130370AWide pH rangeLow costAmmonium sulfatesMultistage water/sewage treatmentAutomatic controlWater discharge

The invention relates to a dye acidic waste water treatment method and device. The method comprises steps as follows: separately collected dye waste acid is subjected to distilling concentration, neutralization, adsorption, micro-electrolysis, coagulative precipitation, activated carbon column adsorption, concentrating crystallization and separation through an automatic control system to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride; and the distilled water is subjected to advanced treatment to reach the industrial reuse water standard, enters an industrial water storage tank, and is circulated to the dye production procedure. The method and device are especially suitable for industries generating abundant waste sulfuric acid and waste hydrochloric acid, such as production of dyes, titanium white and the like. The abundant waste sulfuric acid and waste hydrochloric acid generated in the production process can be utilized to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride, thereby recycling acidic waste water, and changing wastes into valuable substances; and meanwhile, the distilled water can be circulated into industrial production after advanced treatment, thereby reducing the waste water discharge.

Owner:ZHEJIANG DIBANG CHEM

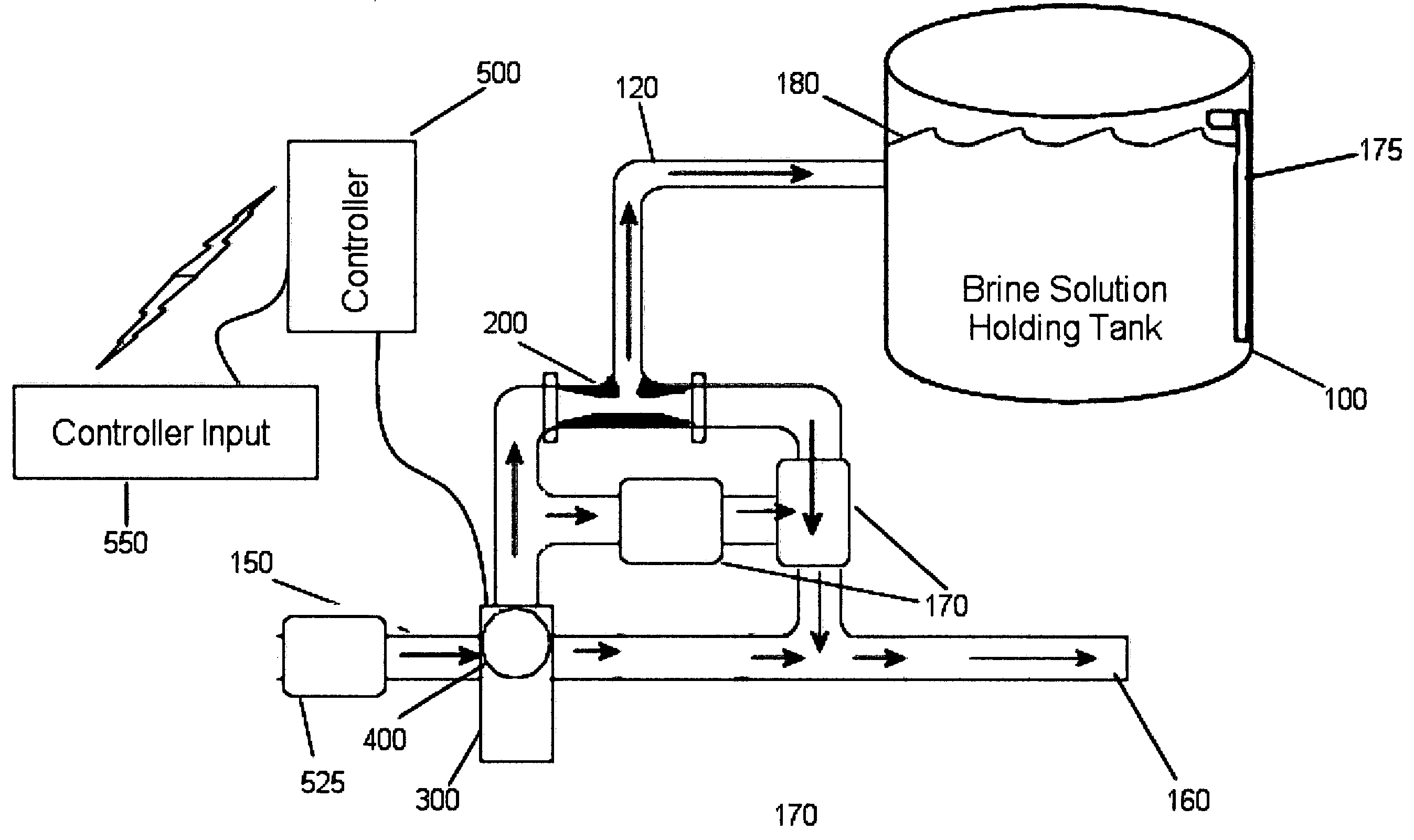

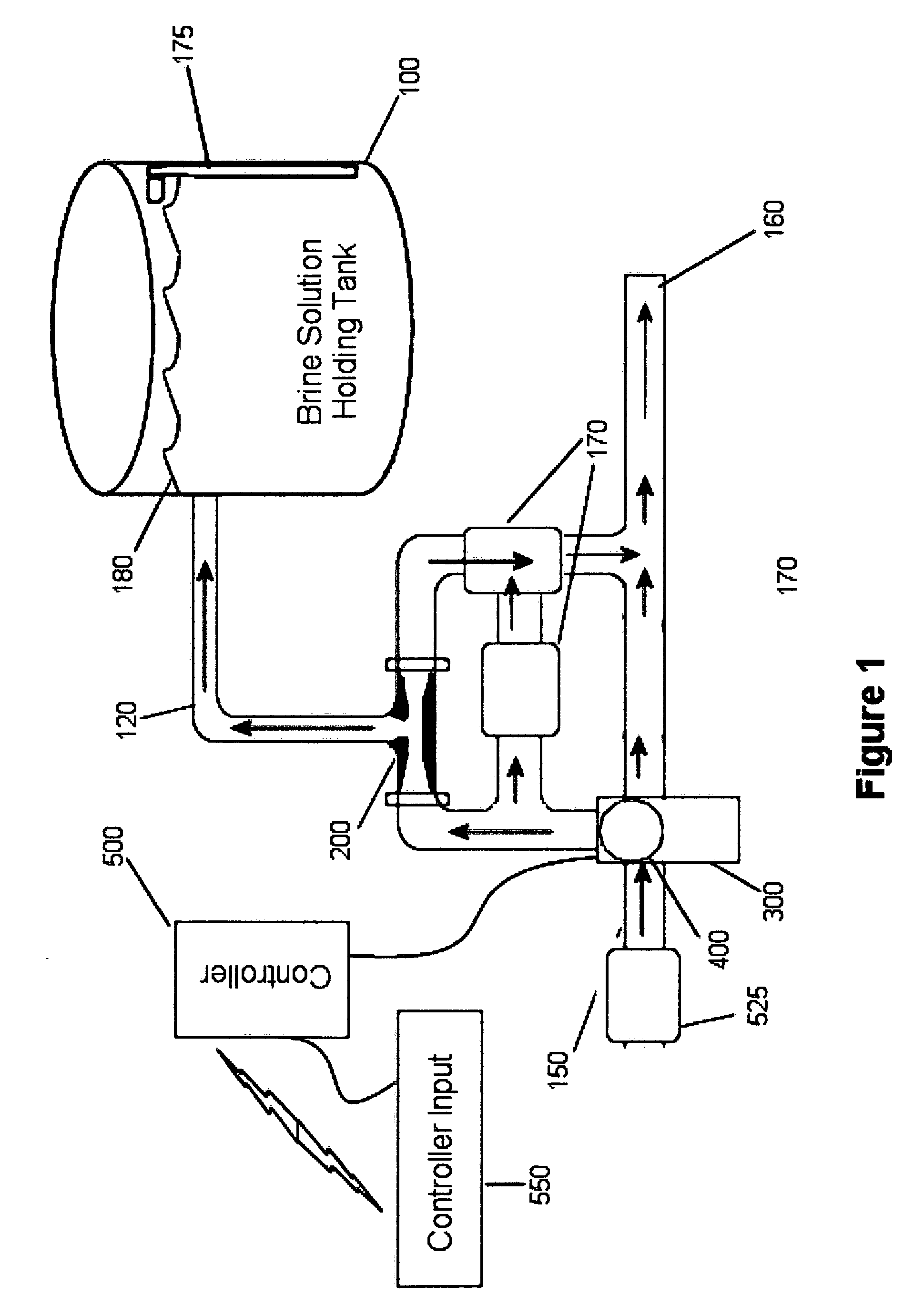

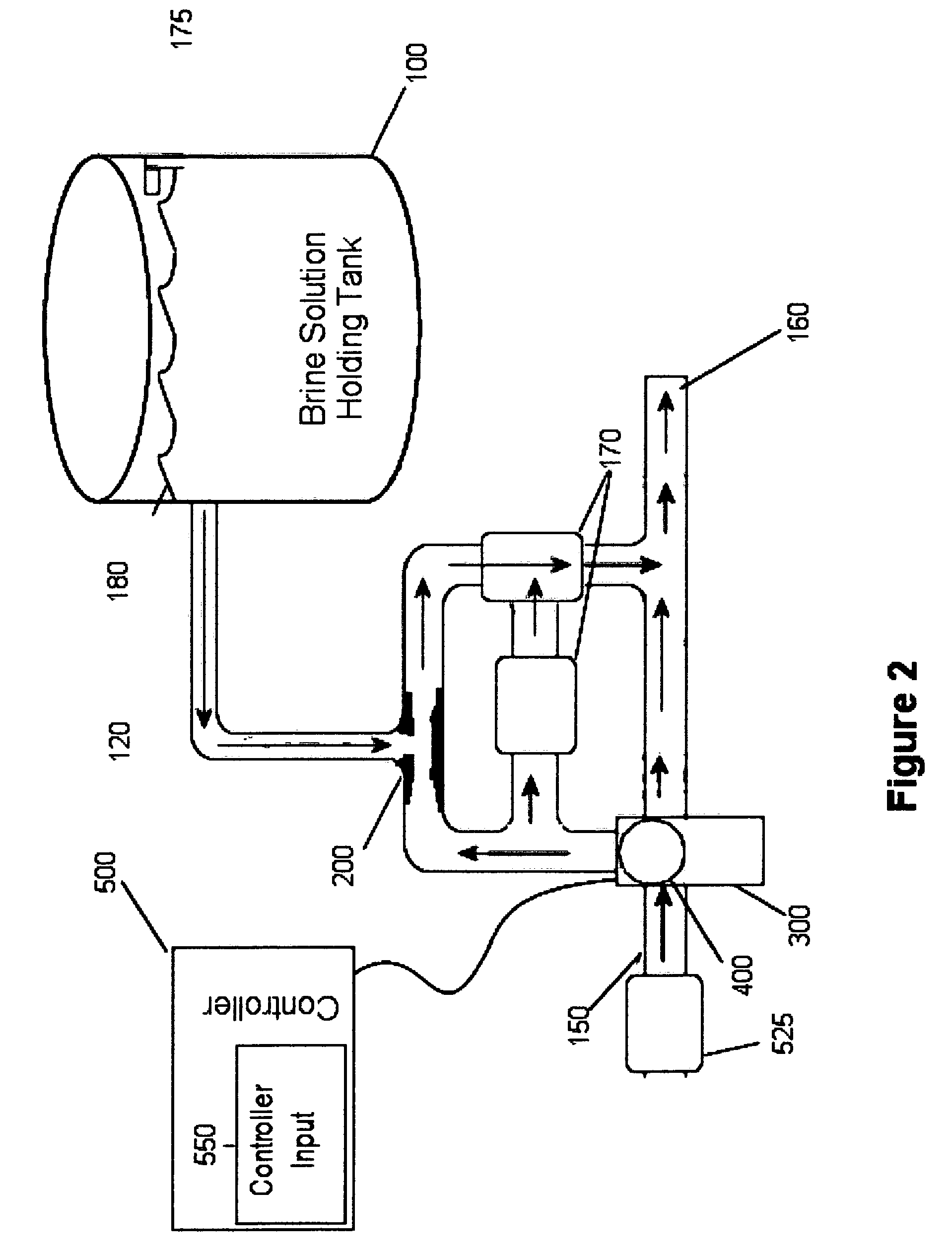

Salt dispensing system

ActiveUS20070207053A1Water treatment parameter controlSolid sorbent liquid separationWater sourceSalt water

An automated salt dispensing system operating in conjunction with an at least one salt chlorine generator with a controller, an at least one water supply pipe with an at least one inflow and an at least one outflow, an at least one water diversion pipe, an at least one actuator in communication with the controller and controlling a control valve, said control valve being coupled to said at least one water supply and said at least one diversion pipe and diverting water into said water diversion pipe. The invention further includes an at least one brine solution holding tank; and an at least one pressure differential device, wherein the at least one brine solution holding tank is coupled to said at least one pressure differential device and the controller signals the actuator and the control valve diverts water from the water supply pipe into the water diversion pipe and the at least pressure differential device draws brine solution from an at least one brine solution holding tank into the water supply line.

Owner:PENTAIR WATER POOL & SPA INC

Popular searches

Volume/mass flow measurement Scale removal and water softening Force measurement Isotope separation Sedimentation separation Reverse osmosis Water/sewage treatment by flocculation/precipitation Water/sewage treatment by oxidation Calcium/strontium/barium sulfates Water/sewage treatment by magnetic/electric fields

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com