Chemical industrial waste salt refining process

An industrial waste salt and process technology, applied in alkali metal chlorides, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high energy consumption, non-recyclable, incomplete incineration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

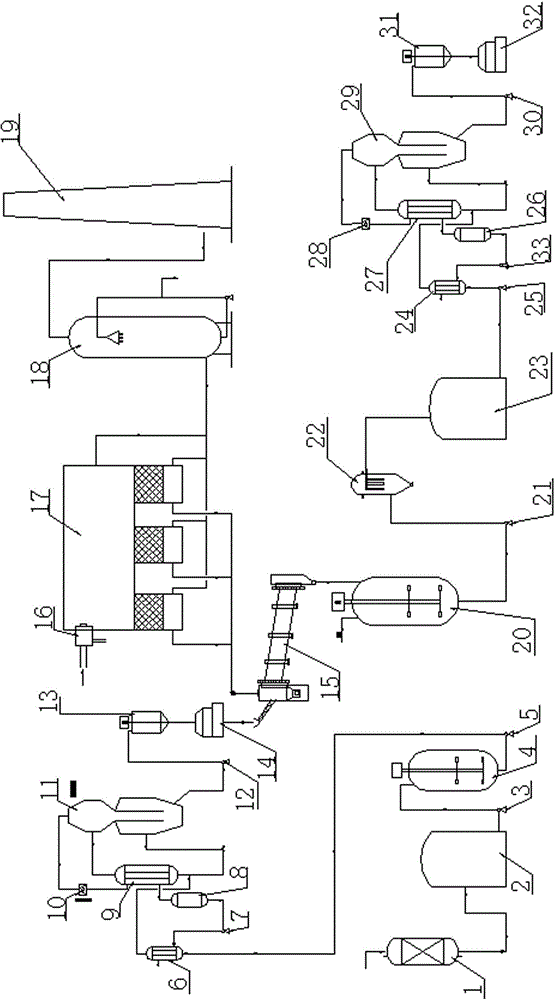

Image

Examples

Embodiment 1

[0018] Add ethanol, p-nitrochlorobenzene, and phase transfer catalyst into the reaction kettle, add 50-75% NaOH solution dropwise, and react at 60-65°C. After the reaction is finished, dilute with heated water, so that the salt in the lower layer is dissolved in water and reach the saturated concentration of sodium chloride, then stand still and separate layers. Remove the reaction product in the upper layer and the waste brine in the lower layer, add hydrochloric acid to adjust the pH value, so that the pH value is 1-3, remove tar and azo through activated carbon adsorption, and then remove p-nitrophenol by adsorption on macroporous resin, and remove the p-nitrophenol after adsorption The brine was adjusted to neutral with NaOH. Evaporate and crystallize through MVR, centrifuge to obtain solid salt, and then calcine the solid salt in a rotary kiln at a temperature of 400-750°C for 2-3 hours. The calcined salt is cooled and packaged for sale. The sodium chloride content in th...

Embodiment 2

[0020] Melt the solid o-nitrochlorobenzene into a liquid, put it into the reaction kettle, add ethanol and a phase transfer catalyst, add 75% liquid NaOH dropwise at 55-60 °C, after the reaction is completed, wash it with hot water, and let it stand Layering, adjust the salt-containing mother liquor to PH = 7, remove tar and azo through activated carbon adsorption, evaporate and crystallize the mother liquor through MVR, and centrifuge to obtain solid salt, and then calcinate the solid salt at a temperature of 400-750°C in a rotary kiln for 3 -4 hours, the calcined salt is made into a saturated solution, filtered through a precision filter, evaporated and crystallized by MVR, and centrifuged to obtain solid salt, which is packaged for sale after drying. The sodium chloride content in the salt was 95.5%, and the recovery rate reached 97%.

Embodiment 3

[0022]Add ethanol, p-nitrochlorobenzene, and phase transfer catalyst into the reaction kettle, add 50-75% NaOH solution dropwise, and react at 60-65°C. After the reaction is finished, dilute with heated water, so that the salt in the lower layer is dissolved in water and reach the saturated concentration of sodium chloride, then stand still and separate layers. Remove the reaction product in the upper layer and the waste brine in the lower layer, add hydrochloric acid to adjust the pH value, so that the pH value is 1-3, remove tar and azo through activated carbon adsorption, and then remove p-nitrophenol by adsorption on macroporous resin, and remove the p-nitrophenol after adsorption The brine was adjusted to neutral with NaOH. Evaporated and crystallized by MVR, centrifuged to obtain solid salt, and then calcined the solid salt in a rotary kiln at a temperature of 400-750°C for 2-3 hours, the calcined salt was made into a saturated solution, filtered through a precision filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com