Patents

Literature

688results about "Alkali metal sulfite/sulfate purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing sodium sulfate and sodium chloride in Na2SO4-NaCl-H2O system

InactiveCN1944256AIncrease profitReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal halide purificationInorganic saltsSeparation technology

The process of producing sodium sulfate and sodium chloride in a Na2SO4-NaCl-H2O system belongs to the field of mixed inorganic solution evaporating separation technology. Mixed solution of sodium sulfate and sodium chloride as material is first evaporated and then separated to obtain sodium sulfate, sodium chloride and evaporated mother liquor; the evaporated mother liquor is low temperature evaporated and separated to obtain sodium chloride and salt-making mother liquor; and the salt-making mother liquor is evaporated and separated to obtain sodium sulfate and saltpeter-making mother liquor. The present invention has the features of high main and side product quality, high material adaptability, low cost, low cost, no waste draining, etc.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

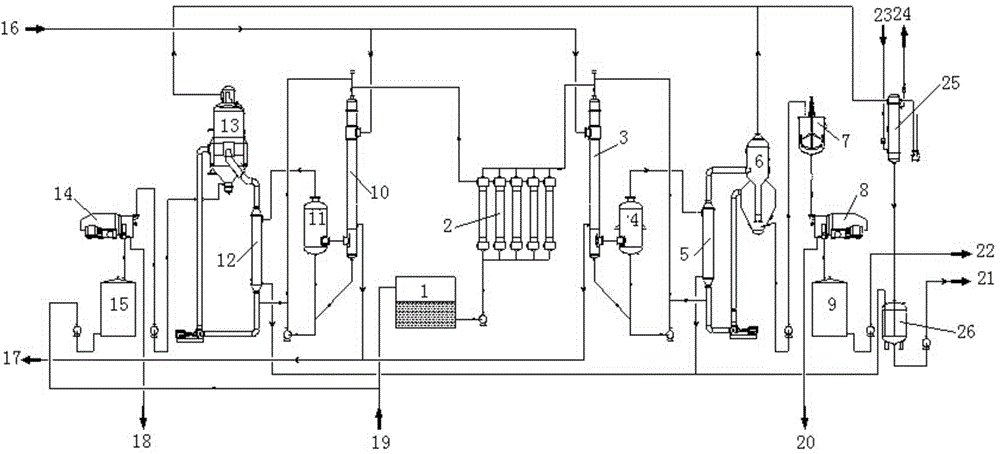

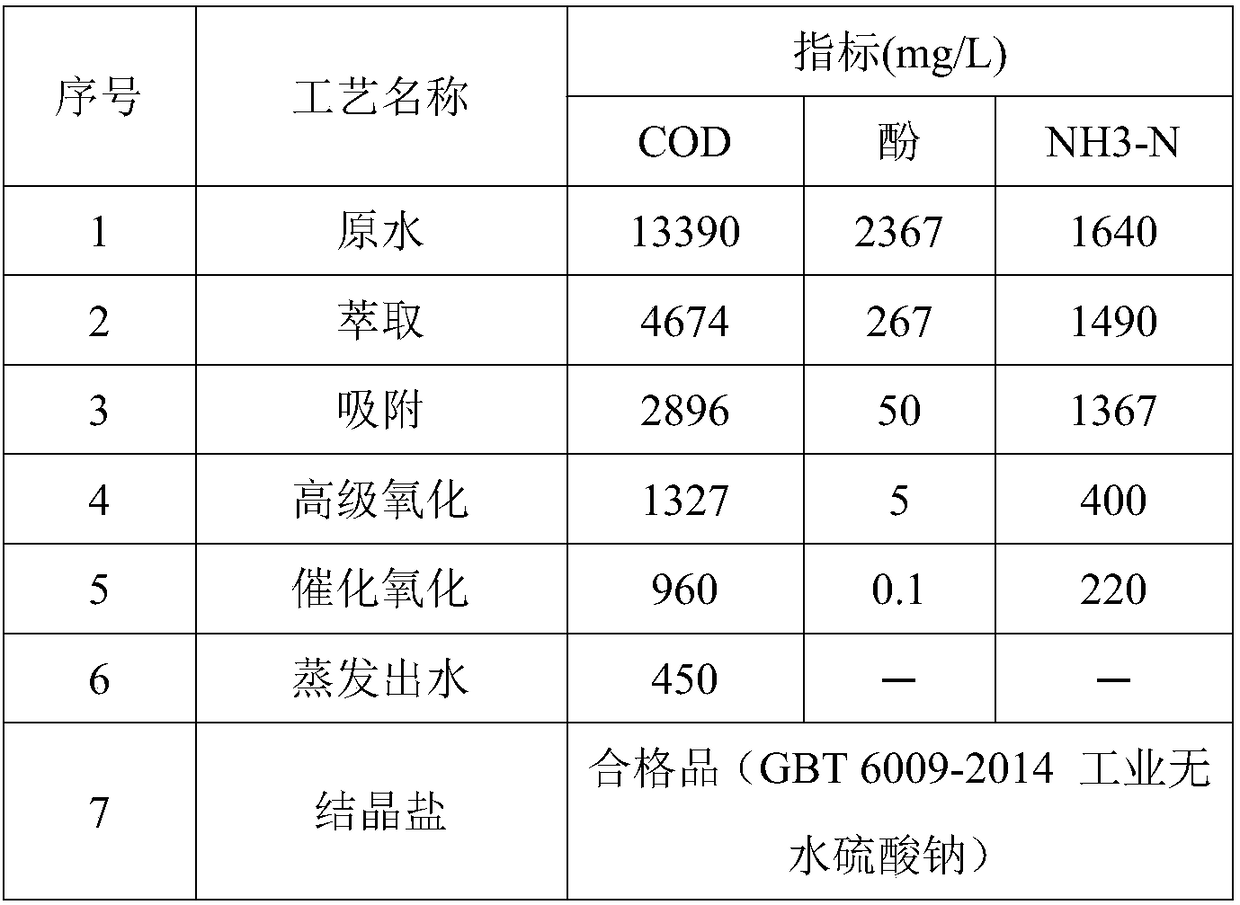

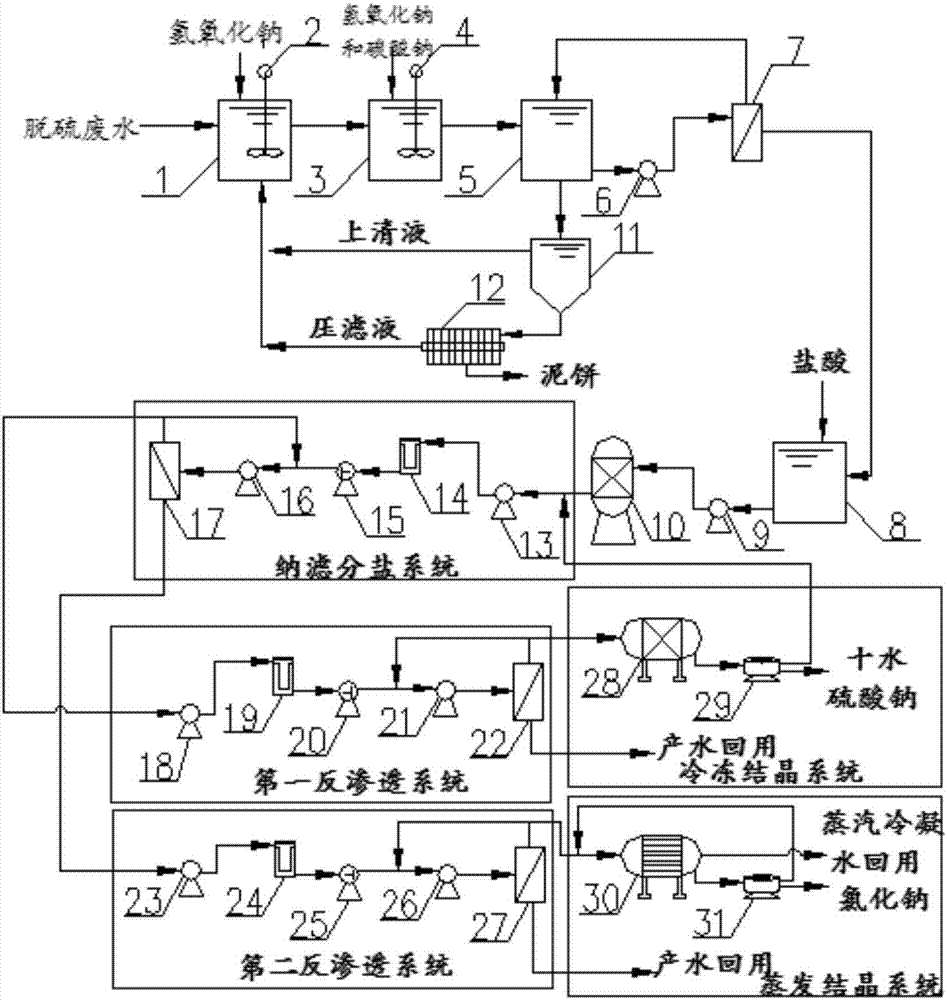

Treatment method of high saline wastewater

ActiveCN104692574ATake advantage of the combinationAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentSocial benefitsFiltration

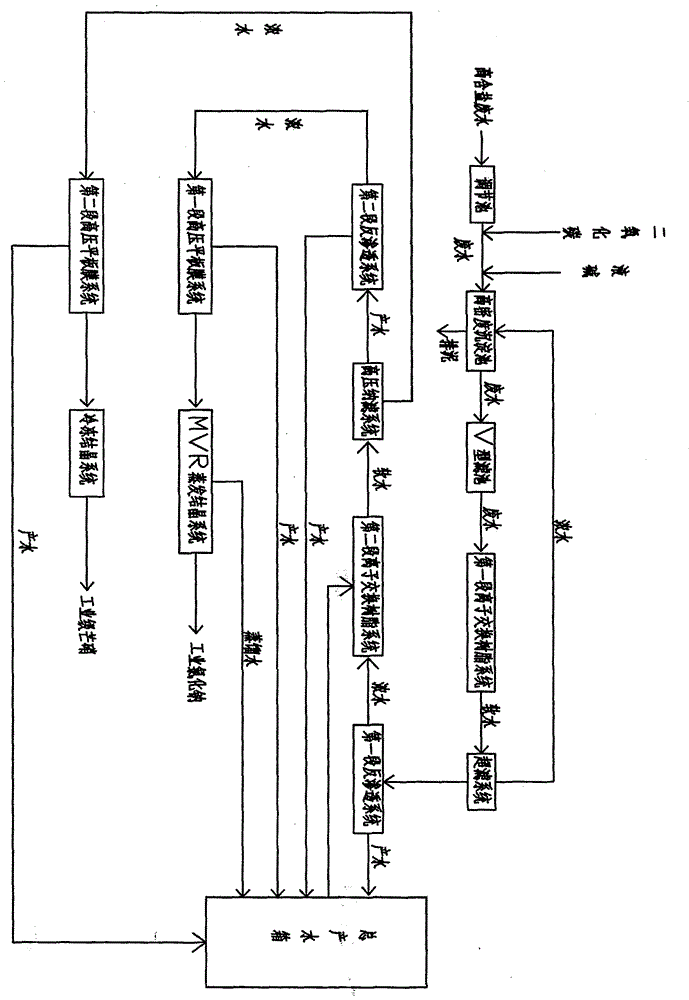

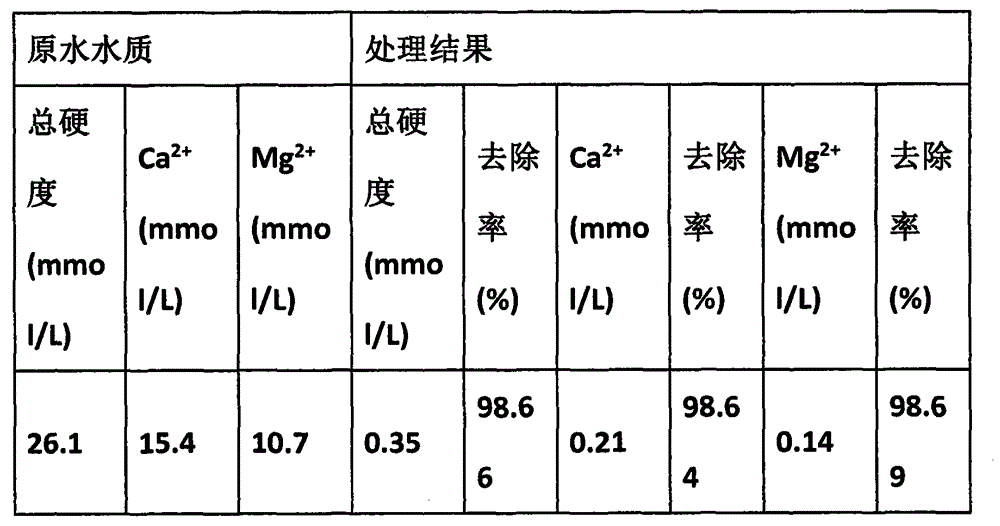

The invention discloses a treatment method of high saline wastewater, and relates to the treatment technology. The method comprises the following steps: preparing high saline wastewater, regulating in a regulating pond, chemically pre-treating in a settling pond, filtering in a V-shaped filter pond, the first section ion exchange softening, ultrafiltering in an ultrafiltration system, reverse osmosis treating through a first section reverse osmosis system, the second ion exchange softening, nano-filtering through a high-pressure nano-filtration system, nano-filtering to produce water, reverse osmosis treating through a second section reverse osmosis system, concentrating through a first section high-pressure flat film system, MVR evaporating and crystallizing to obtain the industrial level sodium chloride; nano-filtering to concentrate water, concentrating through a second section high pressure flat film system, freezing and crystallizing to obtain the industrial level mirabilite. The ultra-filtration, the nano-filtration, the reverse osmosis and high-pressure flat film methods are reasonably coupled to combine with the MVR crystallization and freezing crystallization to treat the high saline wastewater, the defect of single technology is overcome, the combination advantage is developed, the problems of efficiently and economically treating and recycling the high saline wastewater can be solved, and the treatment method has obvious economic benefit and social benefit.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Application of MVR (mechanical vapor recompression) crystallizing evaporator in sodium sulfate and sodium chloride separation technology

InactiveCN103172088AImprove thermal efficiencyReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal chloridesPhysical chemistryExhaust fumes

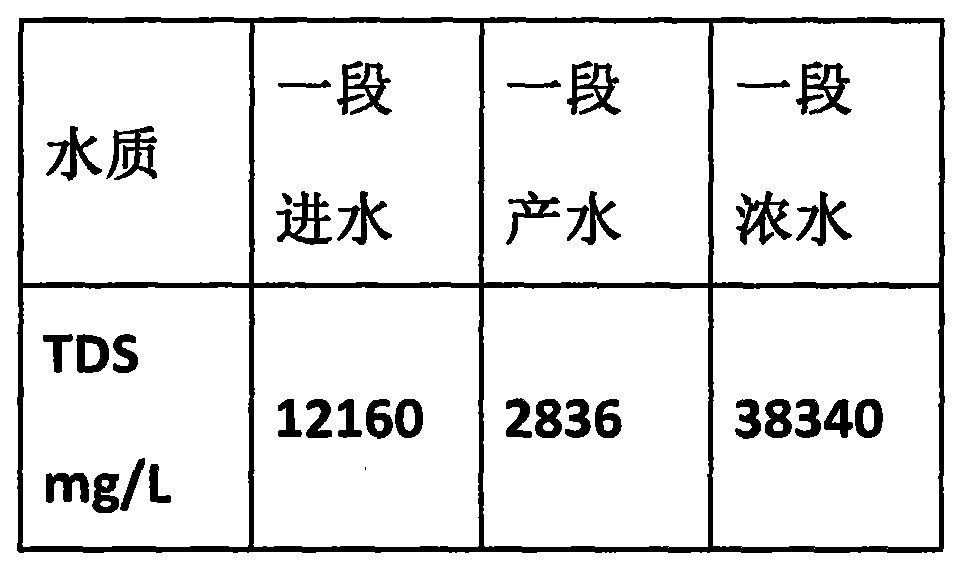

The invention discloses an industrial application of an MVR (mechanical vapor recompression) crystallizing evaporator technology in the production of sodium sulfate and sodium chloride in Huaian, Jiangsu, and relates to an improvement of a salt and sodium sulfate coproduction evaporation technology, belonging to the technical field of chemical three-waste treatment and utilization, and in particular to an application of an MVR crystallizing evaporator in a sodium sulfate and sodium chloride separation technology. The application is mainly technically characterized in that sodium sulfate liquid is concentrated by the MVR crystallizing evaporator, the sodium sulfate is produced at high temperature, and the sodium chloride is produced at low temperature. According to the invention, the mechanical re-compressed vapor is evaporated, concentrated and crystallized at 90-100 DEG C to obtain sodium sulfate, and the re-compressed vapor at a low temperature of 55 DEG C is concentrated and crystallized to obtain sodium chloride. According to the invention, the application of the MVR technology to the concentration of sodium sulfate liquid is realized, the sodium sulfate is produced at high temperature, and sodium chloride is produced at low temperature. The application disclosed by the invention is an environmental protection project which saves energy, reduces emission and avoids waste gas, waste water and waste residue.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

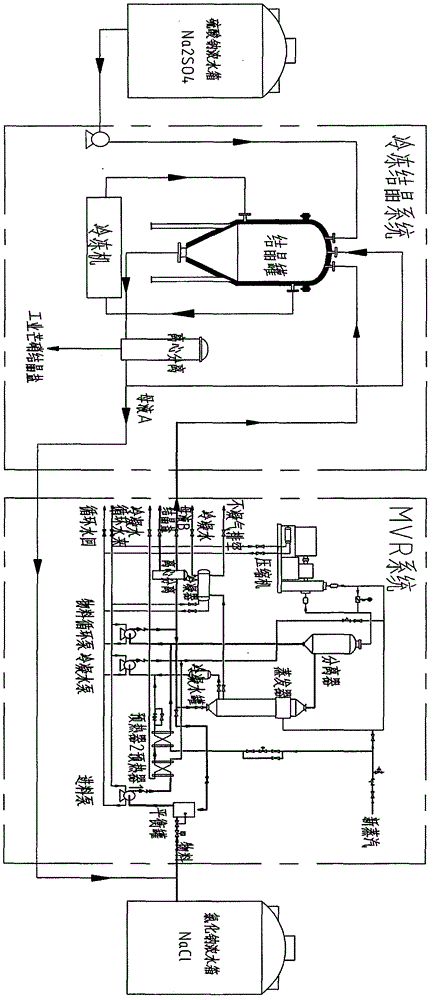

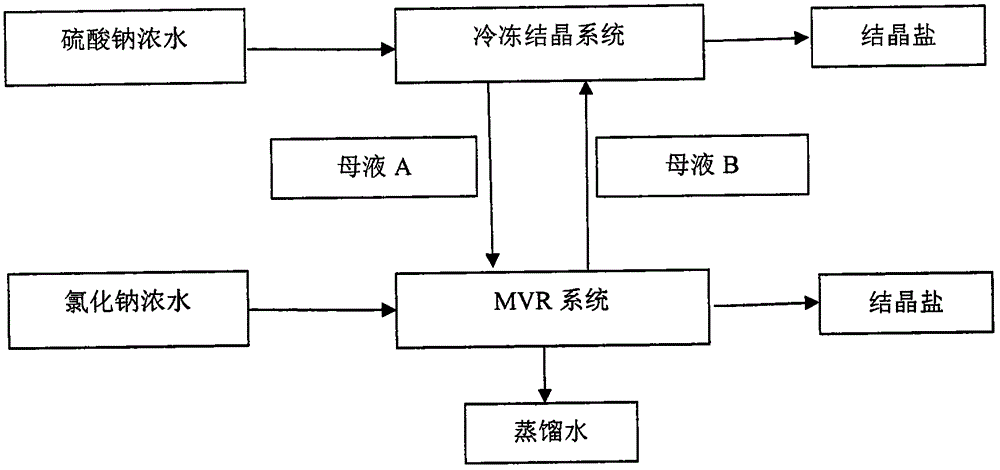

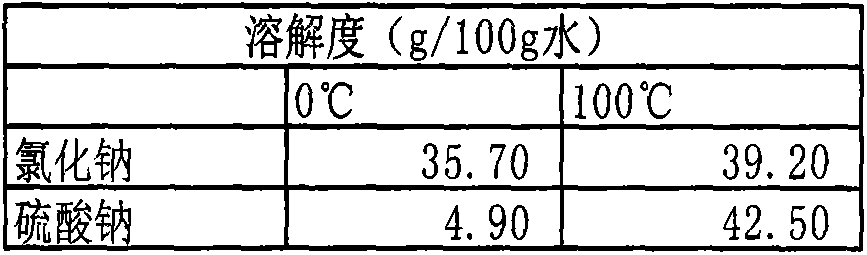

Crystallization treatment method and device of high salt wastewater

ActiveCN104692575AHigh energy consumptionHigh operating costsAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentResource utilizationWastewater

The invention relates to a crystallization treatment method and device of high salt wastewater and belongs to the technical field of water treatment. The method is characterized in that after sodium sulfate concentrated water is treated by a freezing crystallization system, generated mother liquor A enters into an MVR system for evaporative crystallization; after sodium chloride concentrated water is treated by the MVR system, generated mother liquor B enters into a freezing crystallization system for freezing crystallization, and the mother liquor can be treated in a circulation overlapping manner; a drain outlet of the MVR system of the device is connected with a liquid inlet of a crystallization tank in the freezing crystallization system through a pipeline and the drain outlet of the freezing crystallization system is connected with a liquid inlet pipe of the MVR evaporative crystallization system. The method has the advantages that the mother liquor is treated by a freezing crystallization technology and an MVR evaporation crystallization technology in a circulation overlapping manner, so that the problems of zero emission and resource utilization are solved, and therefore, the energy consumption is effectively reduced and the operating cost is lowered.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

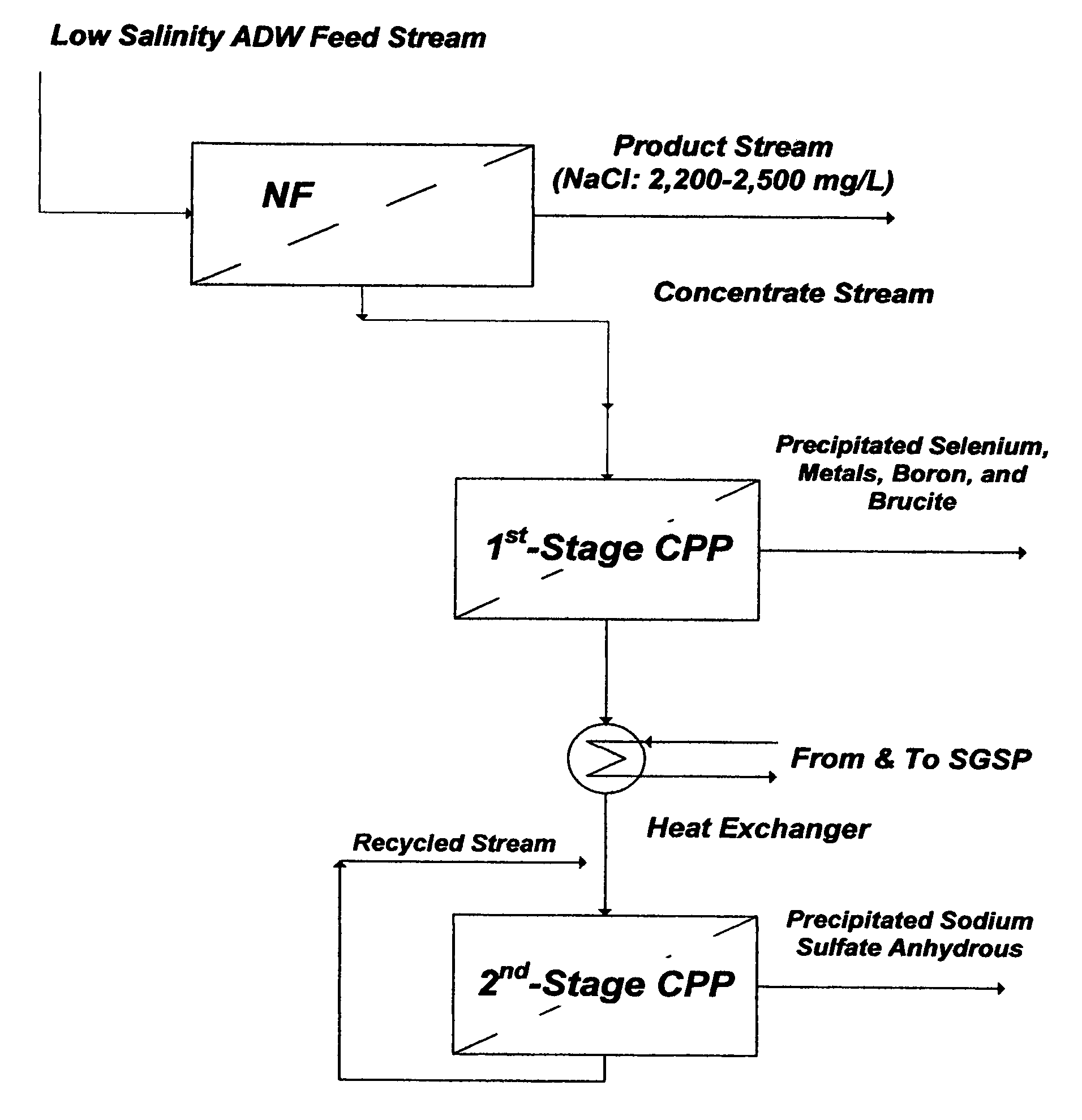

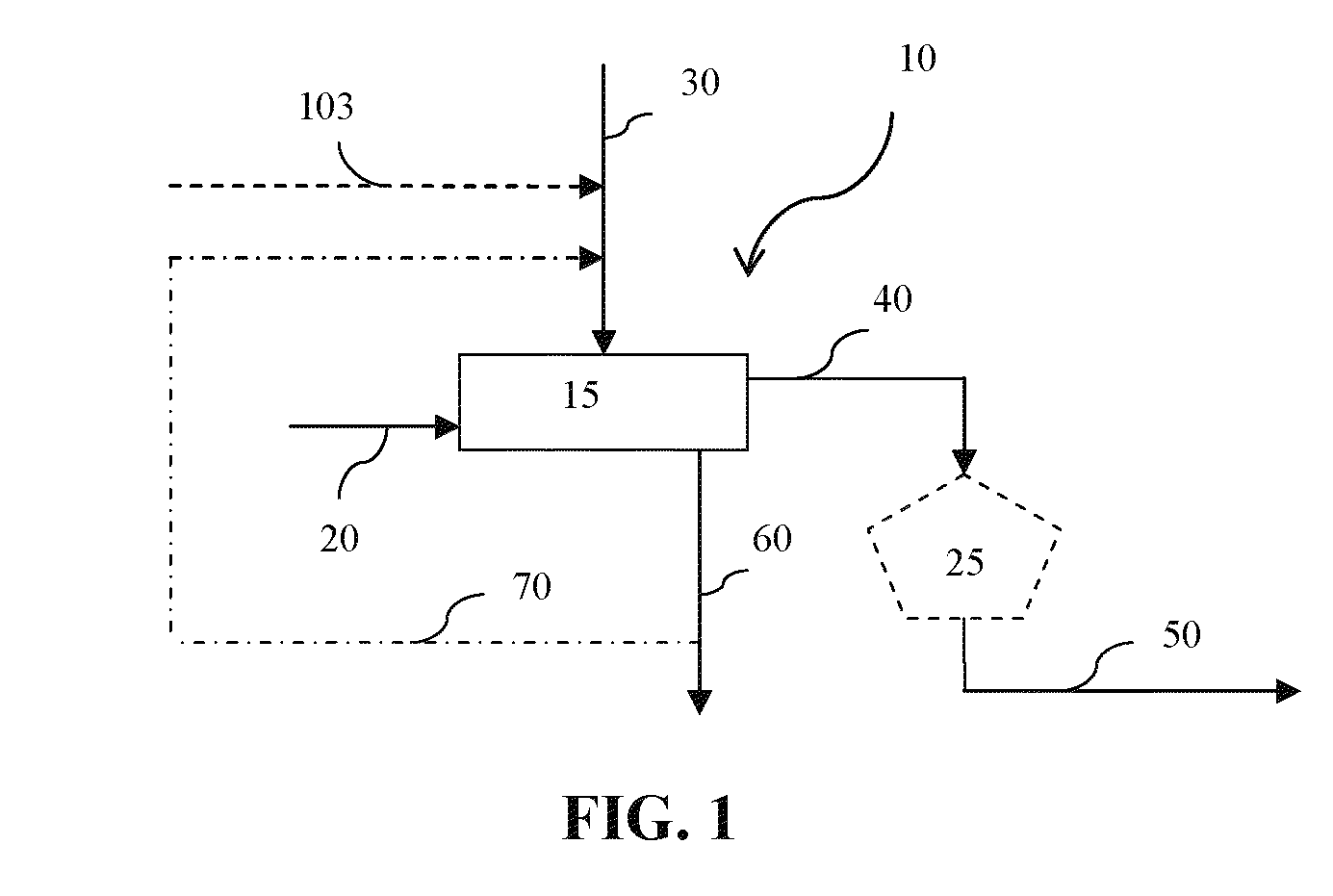

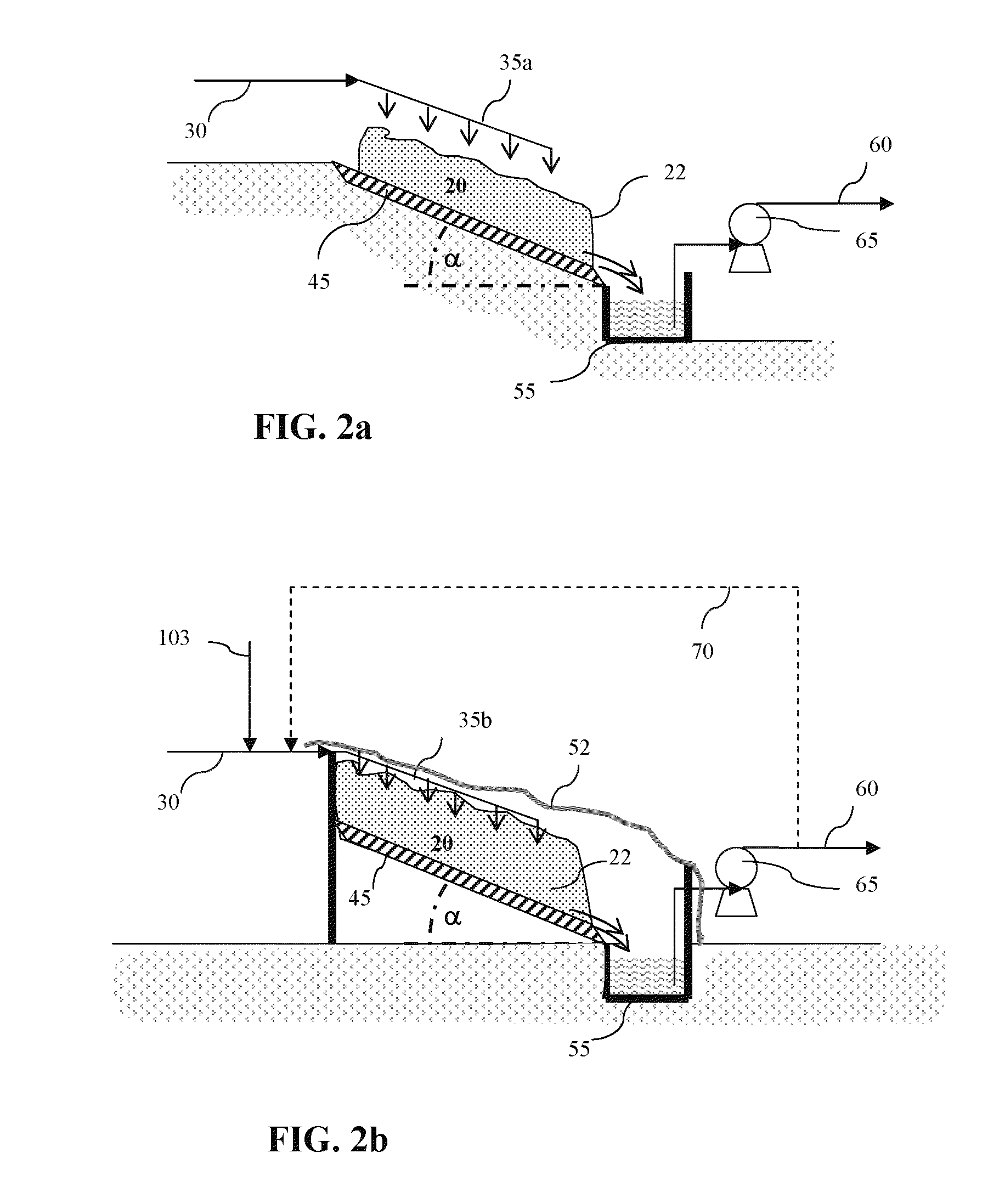

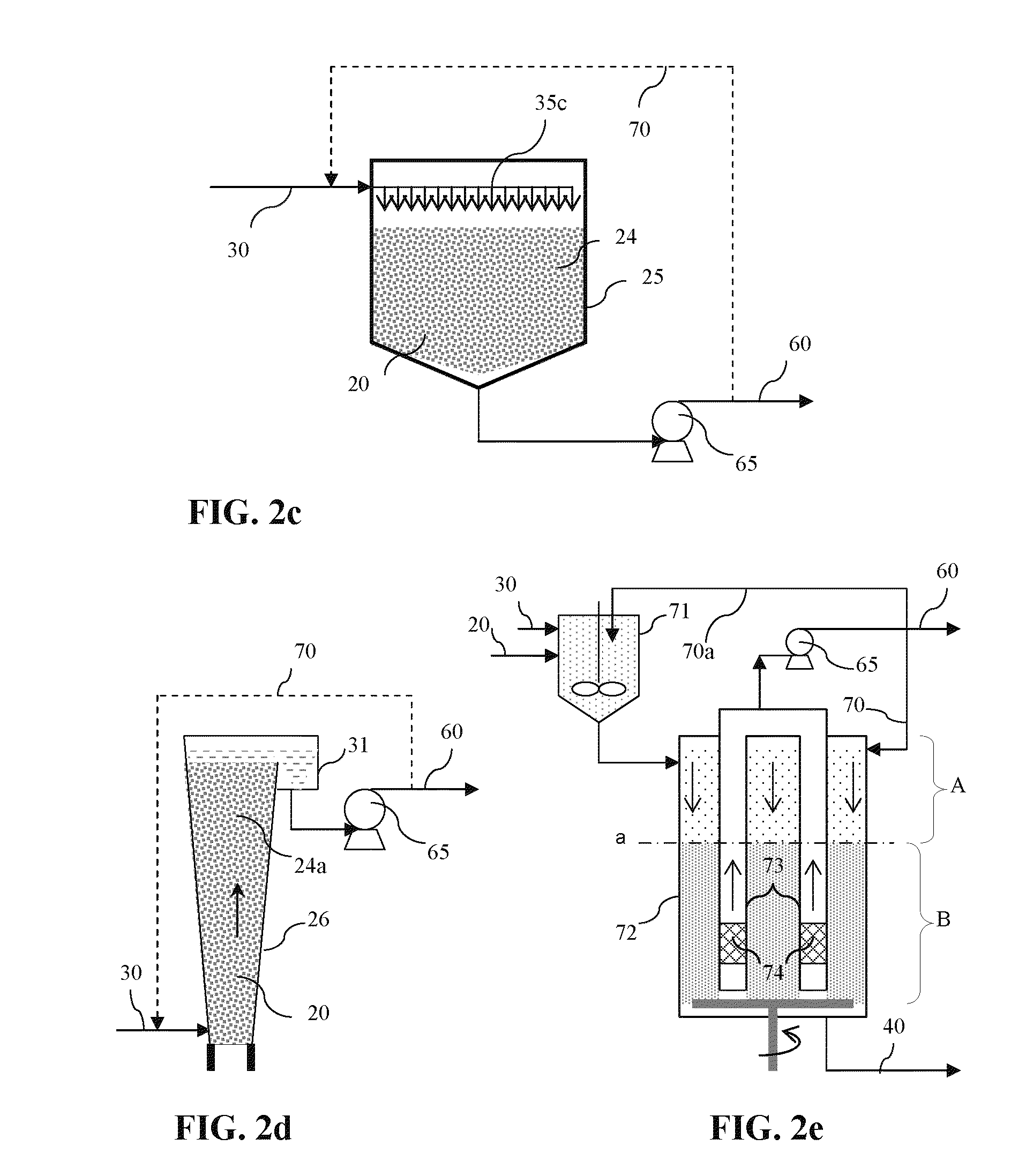

Methods for treating agricultural drainage water and the like

InactiveUS7501065B1Avoid pollutionSolar heating energyGeneral water supply conservationSulfateWater quality

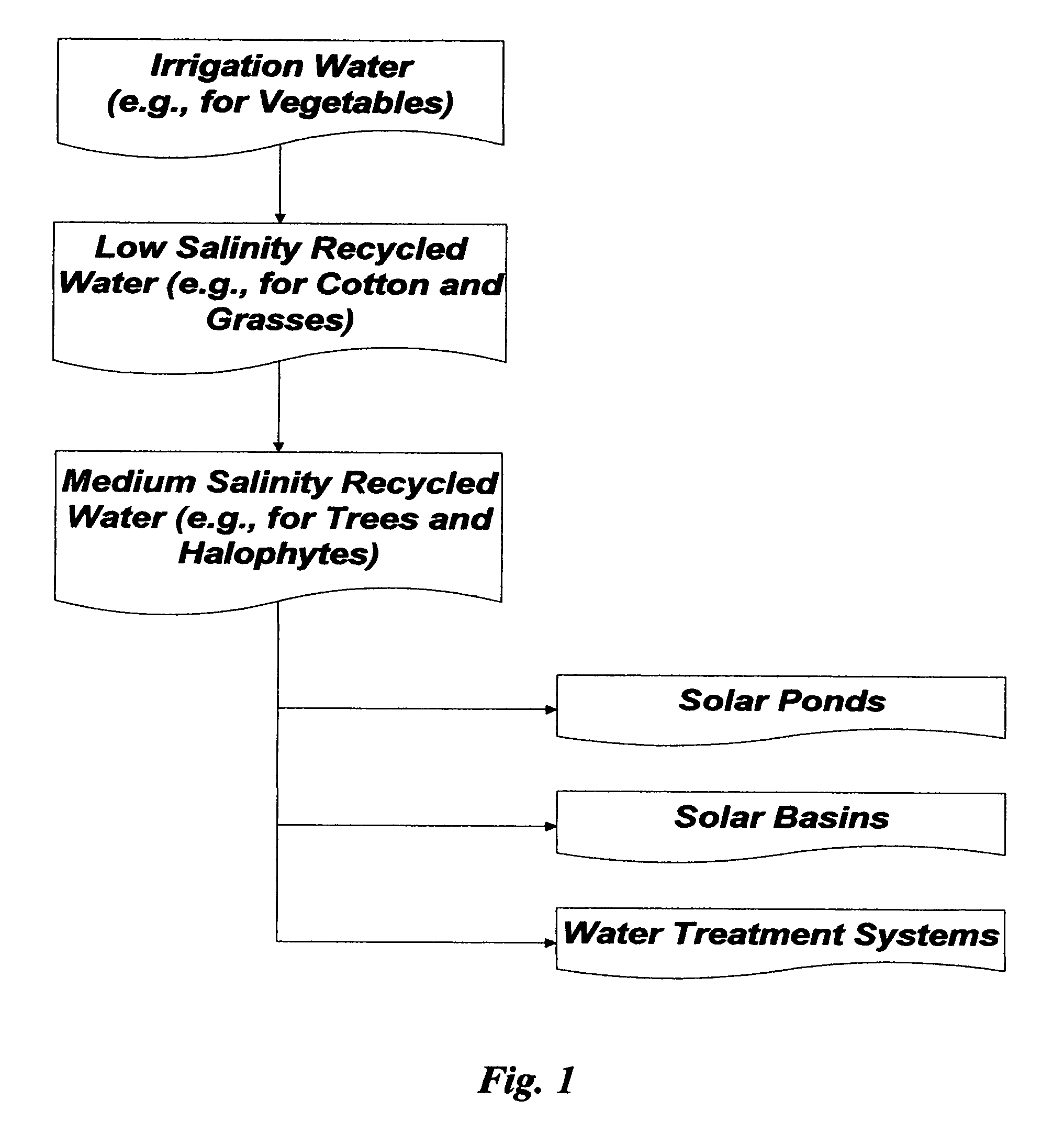

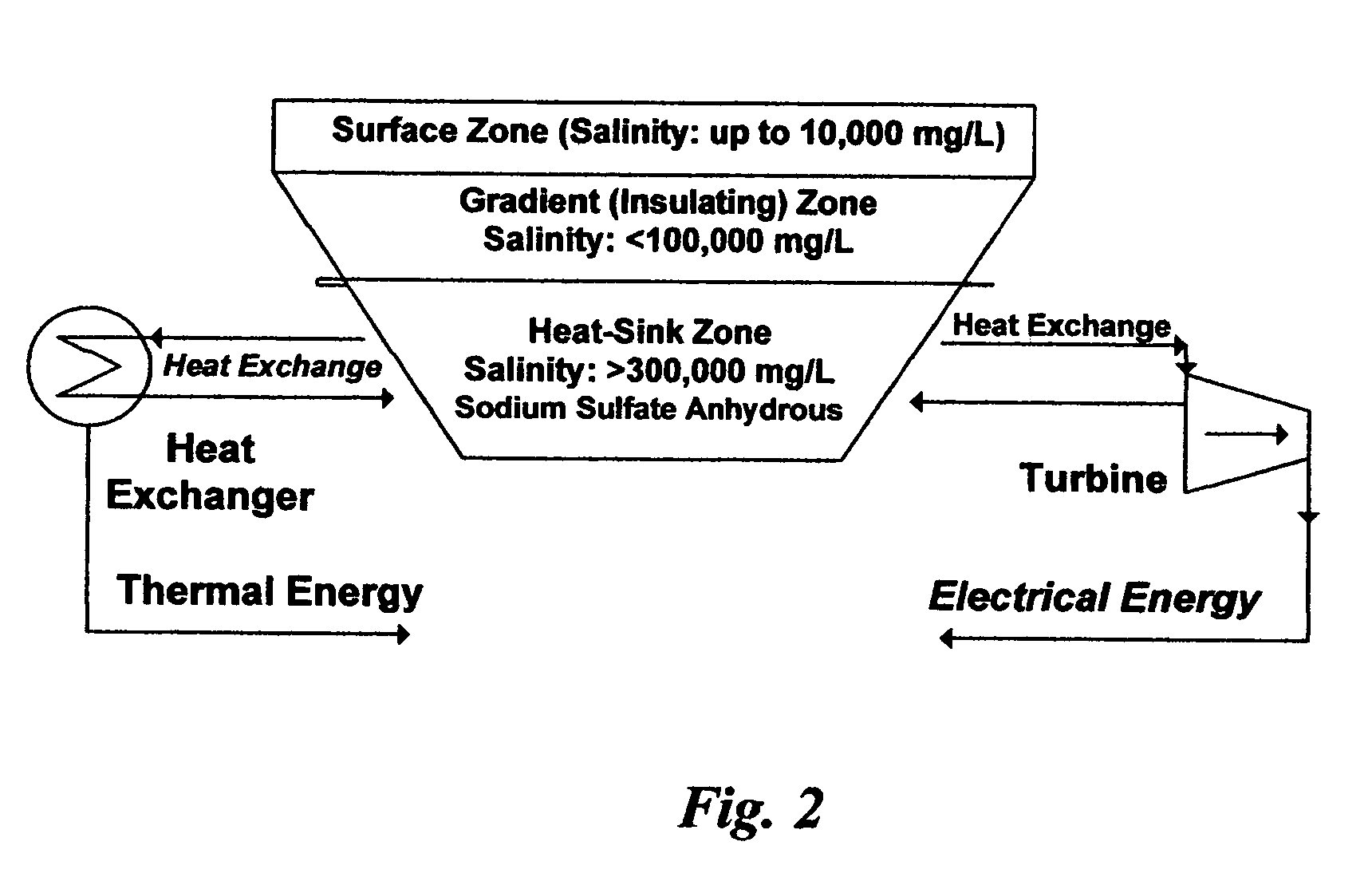

Zero discharge processing methods for the treatment of agricultural drainage water (ADW) are disclosed. The disclosed methods are capable of meeting the three critical issues in treating ADW: (1) selective removal of sulfate scale-prone species and toxic species; (2) production of usable water that at least meets irrigation water quality; and (3) recovery of sodium sulfate and sodium chloride as valuable commodities.

Owner:BADER MANSOUR S

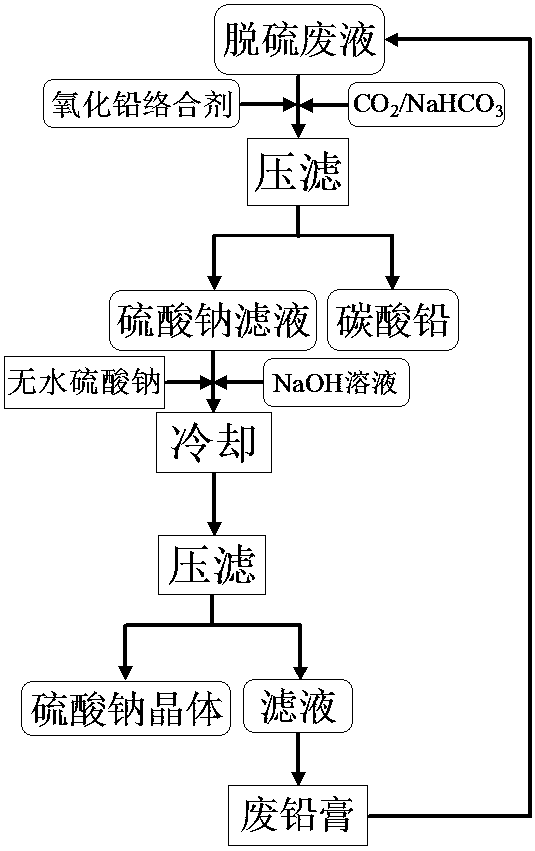

Method of recovering sodium sulfate from lead-bearing desulfurized waste liquid

ActiveCN103771459AStrong complexing abilityEliminate secondary pollutionAlkali metal sulfite/sulfate purificationLead carbonateLead oxide

The invention discloses a method of recovering sodium sulfate from a lead-bearing desulfurized waste liquid. The method is characterized by comprising the following steps: after adding a complexing agent into the lead plaster-bearing desulfurized waste liquid, forming a lead carbonate precipitate of lead complex ions in the liquor by adopting carbon dioxide or sodium hydrogen carbonate, and then carrying out solid-liquid separation to obtain a sodium sulfate filtrate and the lead carbonate precipitate; adding anhydrous sodium sulfate and sodium hydroxide into the sodium sulfate filtrate obtained by separating lead carbonate, and cooling at low temperature to separate out sodium sulfate crystals; and returning the filtrate without the sodium sulfate crystals again for desulfurization of lead oxide-bearing wastes.

Owner:BEIJING UNIV OF CHEM TECH

Process of treating and reusing effluent from 1-amino-8-naphthol-3, 6-disulfonic acid production

InactiveCN101066824ARealize recycling of resourcesNot affected by the adsorption effectOrganic chemistryTreatment using aerobic processesResource recoveryOrganic matter

The present invention is process of treating effluent from the production of dye intermediate 1-amino-8-naphthol-3, 6-disulfonic acid and recovering resource. The process includes: distilling pre-treatment of the effluent; adsorbing 1-amino-8-naphthol-3, 6-disulfonic acid, intermediate product and other organic matter from the effluent with macroporous weak alkaline resin ND900 in serially connected three column; neutralizing the adsorbed columns treated water with alkali and decompression distilling; and final aerobic biochemical treatment for the water to reach exhaust standard. The process can reduce CODcr in the effluent from 16,700 mg / l to below 100 mg / l. The used resin may be desorbed with NaOH+H2O desorbing agent for reuse, and the desorbed liquid may be distilled for recovery.

Owner:NANKAI UNIV

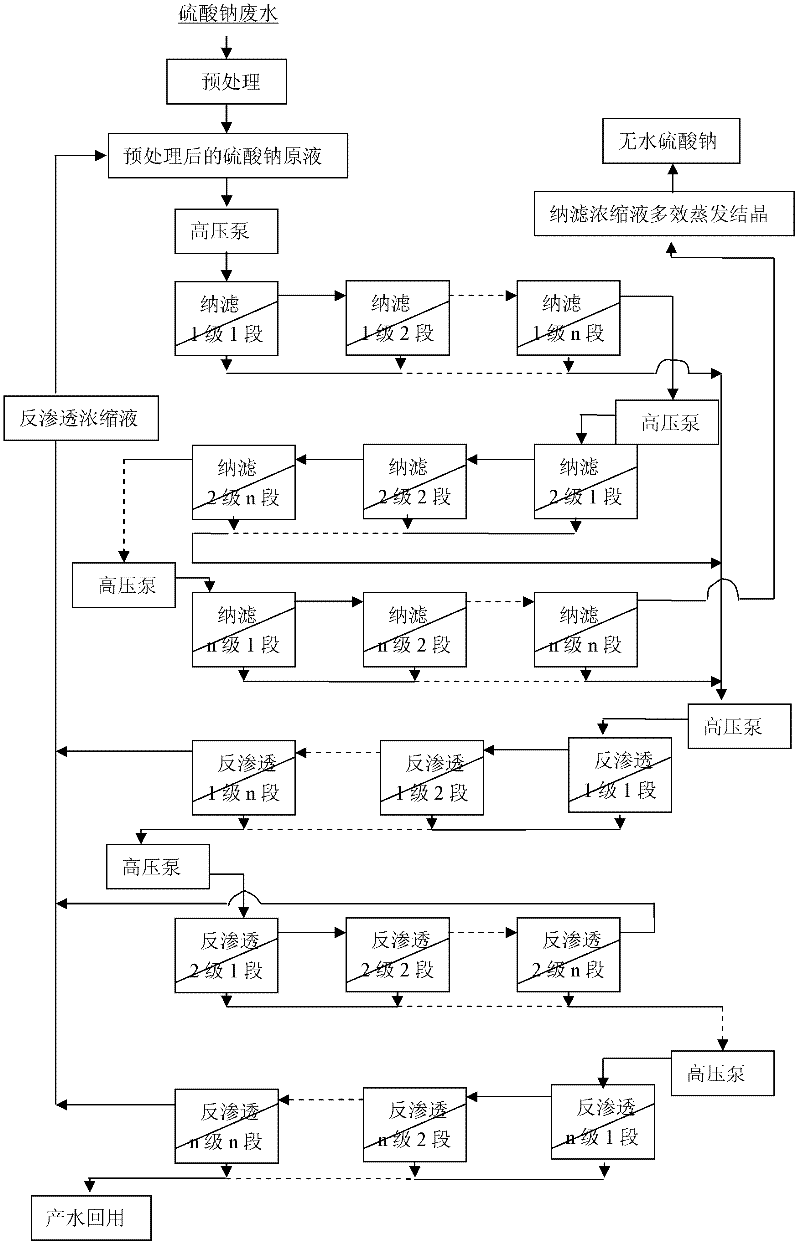

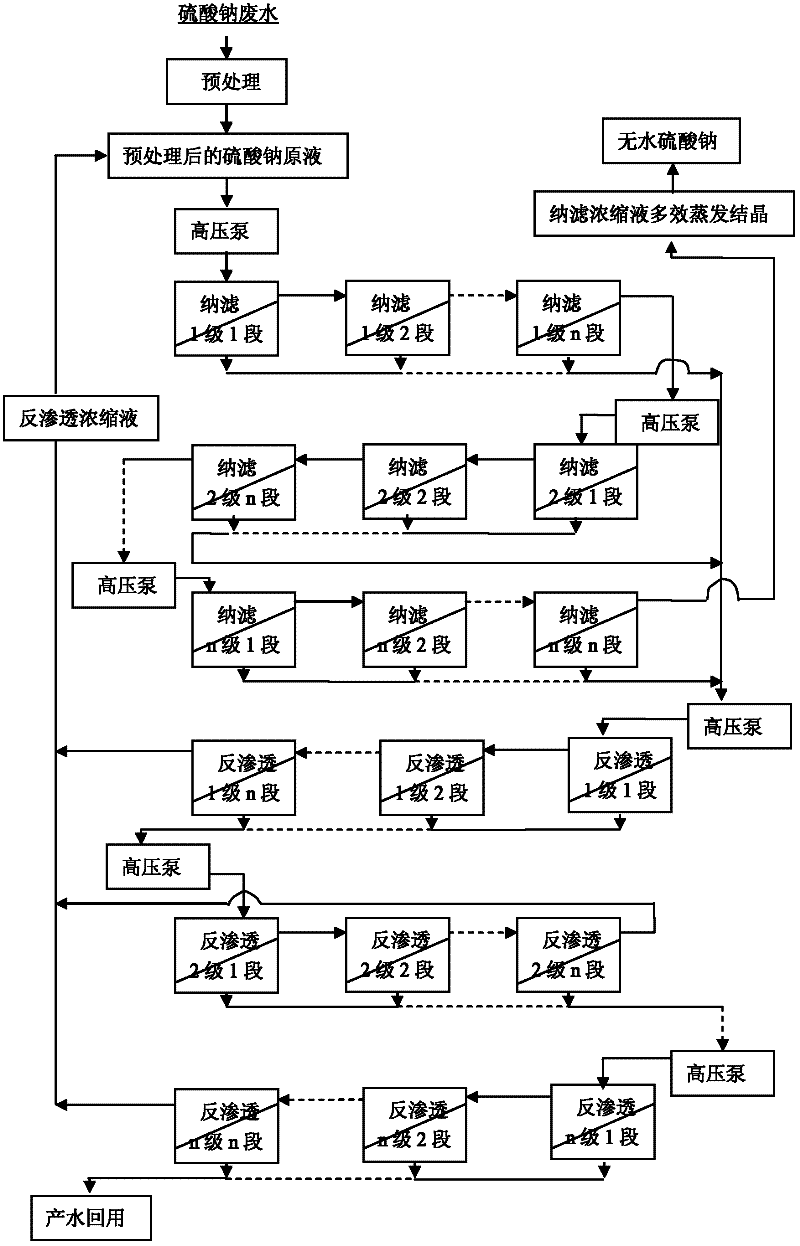

Process for treating sodium sulfate wastewater by using nanofiltration-reverse osmosis combined membrane

InactiveCN102491452AAchieving zero emissionsSmall footprintAlkali metal sulfite/sulfate purificationWater/sewage treatment bu osmosis/dialysisEvaporationReverse osmosis plant

The present invention relates to a process for treating sodium sulfate wastewater by using a nanofiltration-reverse osmosis combined membrane. According to the process, the pretreated sodium sulfate wastewater is conveyed to a nanofiltration membrane stack through a high pressure pump, and the nanofiltered concentrated solution is subjected to multiple effect evaporation crystallization to obtain an anhydrous sodium sulfate product and condensed water, wherein the condensed water is recycled; the nanofiltered producing water is conveyed to a reverse osmosis membrane stack through the high pressure pump, the resulting concentrated solution returns to the pretreated sodium sulfate stock solution to carry out the secondary nanofiltration, and the reverse osmosis producing water is recycled, wherein the concentrated solution is subjected to the reverse osmosis membrane stack. Compared to other pollution control technologies, the process of the present invention has the following advantages that: the equipment is compact, and the land occupation is small; no morphological and chemical influence is generated to the treated object; the process is a continuous process, and the automatic and uninterrupted operating can be achieved; the process has characteristics of low energy consumption, no phase change, no temperature change, easy control and simple operation; the process can be directly circulated on the site; the sodium sulfate is subjected to concentration, evaporation crystallization, and recovery utilization in the absence of chemical and physical changes, such that the zero discharge of the sodium sulfate wastewater is achieved; the reverse osmosis producing water is adopted as the process pure water to use so as to save a large amount of the process water.

Owner:JILIN JIEN NICKEL IND +1

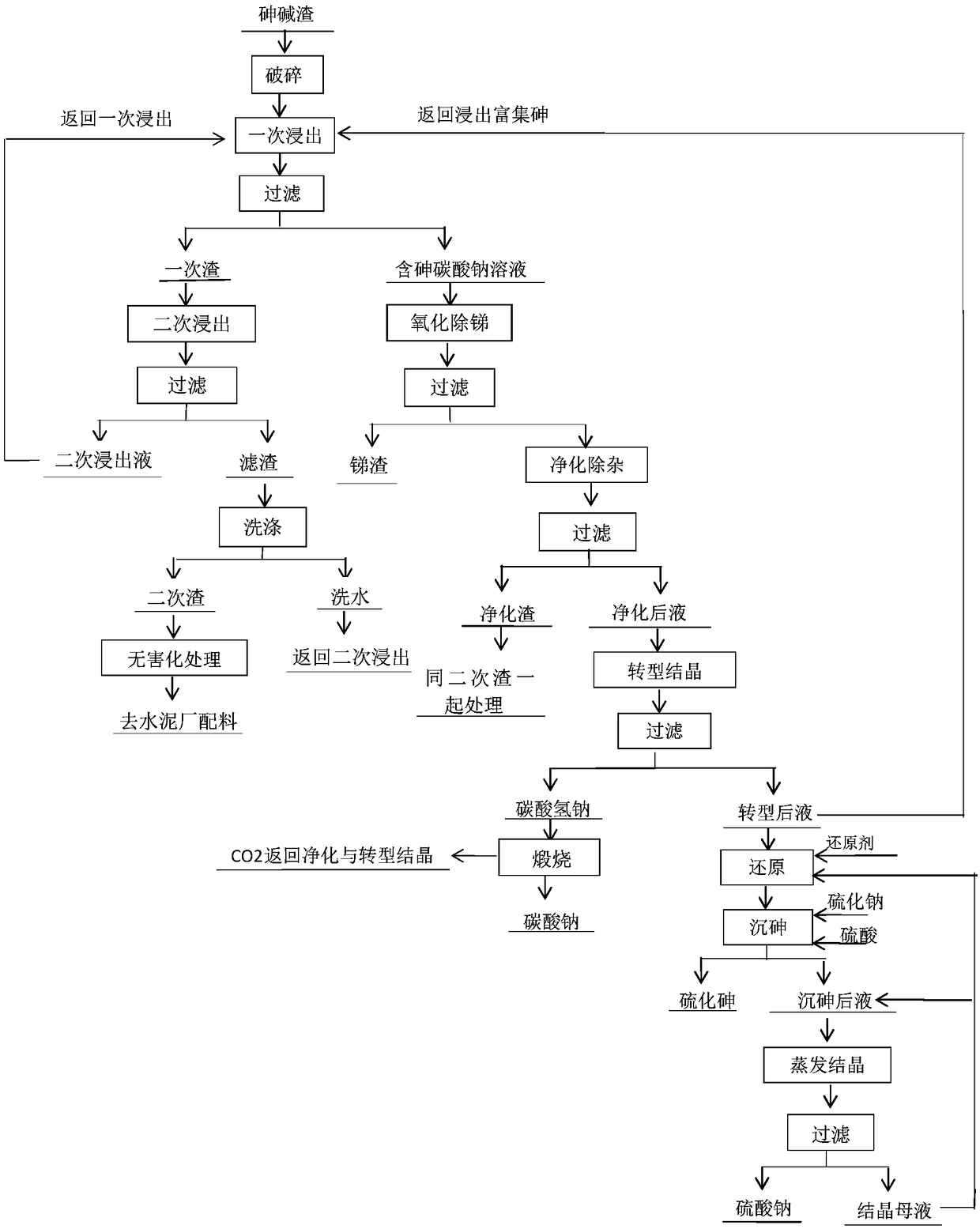

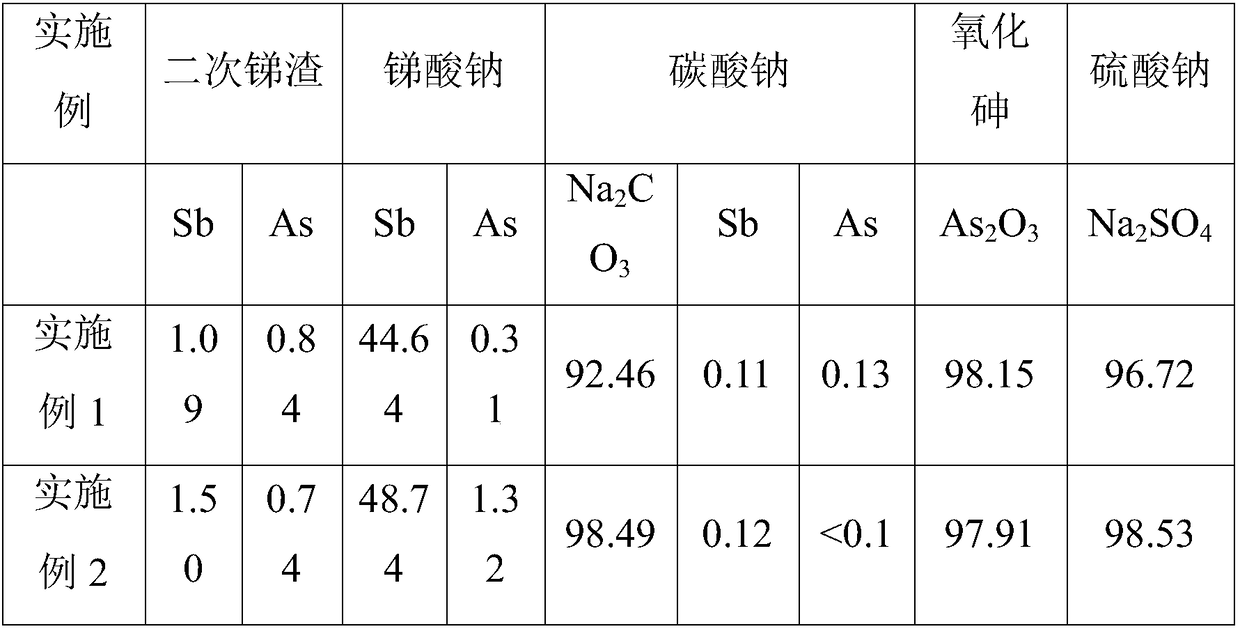

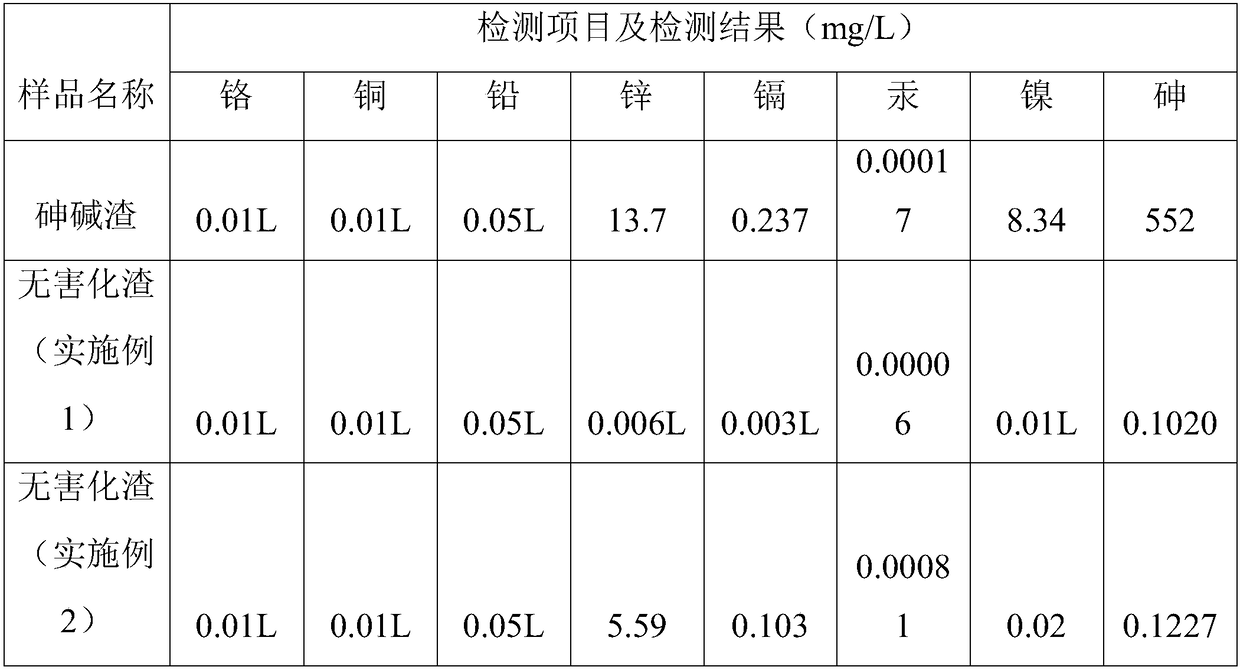

Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

PendingCN108441642ARealize green and clean cycle productionHigh recovery rateSolid waste disposalAlkali metal sulfite/sulfate purificationWastewaterImpurity

The invention belongs to the field of antimony smelting arsenic alkali residue treatment and particularly discloses a wet-method recycling and harmless treatment process for antimony smelting arsenicalkali residue. The process adopts a whole-wet-method treatment process and mainly comprises the eight working procedures of breaking, dissolving for leaching, oxidation for antimony outlet, purification for impurity removing, transition for crystallizing, reduction for arsenic sinking, evaporative crystallization and secondary residue harmless treatment. Recycling and harmless treatment of the arsenic alkali residue, zero emission of waste residue and waste water and up-to-standard discharge of exhaust gas are thoroughly achieved, the long-term plagued arsenic alkali residue environmental pollution problem in the antimony smelting industry in China is thoroughly solved, and the environmental risk caused by stacking the arsenic alkali residue is eliminated; and meanwhile, separation, enrichment and effective recovering of valuable elements are achieved.

Owner:CHENZHOU YANGTAO CHEM

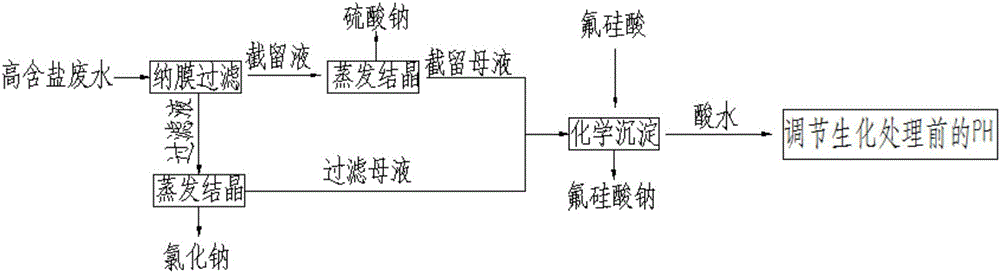

Recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN105110536AReduce processing costsRealize resource utilizationWater/sewage treatment by centrifugal separationWater contaminantsAcid waterWastewater

The invention discloses a recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate and belongs to the field of wastewater treatment. The method comprises: filtering wastewater through a nanofiltration membrane; performing evaporative crystallization on filtrate through the nanofiltration membrane to obtain sodium chloride and filtered mother liquor; performing evaporative crystallization on retained liquor which does not pass through the nanofiltration membrane to obtain sodium sulfate and retained mother liquor; mixing the filtered mother liquor with the retained mother liquor to obtain a mixture and adding fluosilicic acid into the mixture; and stirring sufficiently the mixture to obtain sodium fluosilicate by filtering. Filtered acid water is used in pH value adjustment of a system before biochemical treatment.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

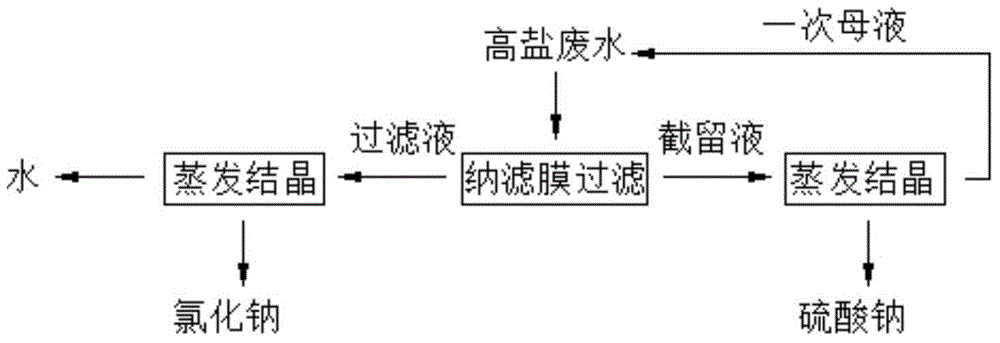

Method for recycling high-salt waste water containing sodium chloride and sodium sulfate

InactiveCN104961285AHigh purityMeet quality requirementsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentIndustrial waste waterNanofiltration

The invention discloses a method for recycling high-salt waste water containing sodium chloride and sodium sulfate, and belongs to the field of industrial waste water treatment. The method comprises the steps of filtering by a nanofiltration membrane, evaporating and crystallizing filtrate penetrating through the nanofiltration membrane to obtain sodium chloride, evaporating and crystallizing trapped fluid which cannot penetrate through the nanofiltration membrane to obtain sodium sulfate, returning a primary mother solution to the system, and mixing the primary mother solution with raw materials to be continuously recycled. By adopting the method, sodium sulfate and sodium chloride in the high-salt waste water can be effectively recycled, a purpose of treating the high-salt waste water can be realized, and the current environmental-protection demand can be satisfied, waste can be converted into treasure, the recycling of salts can be realized, and the benefit of factories can be increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

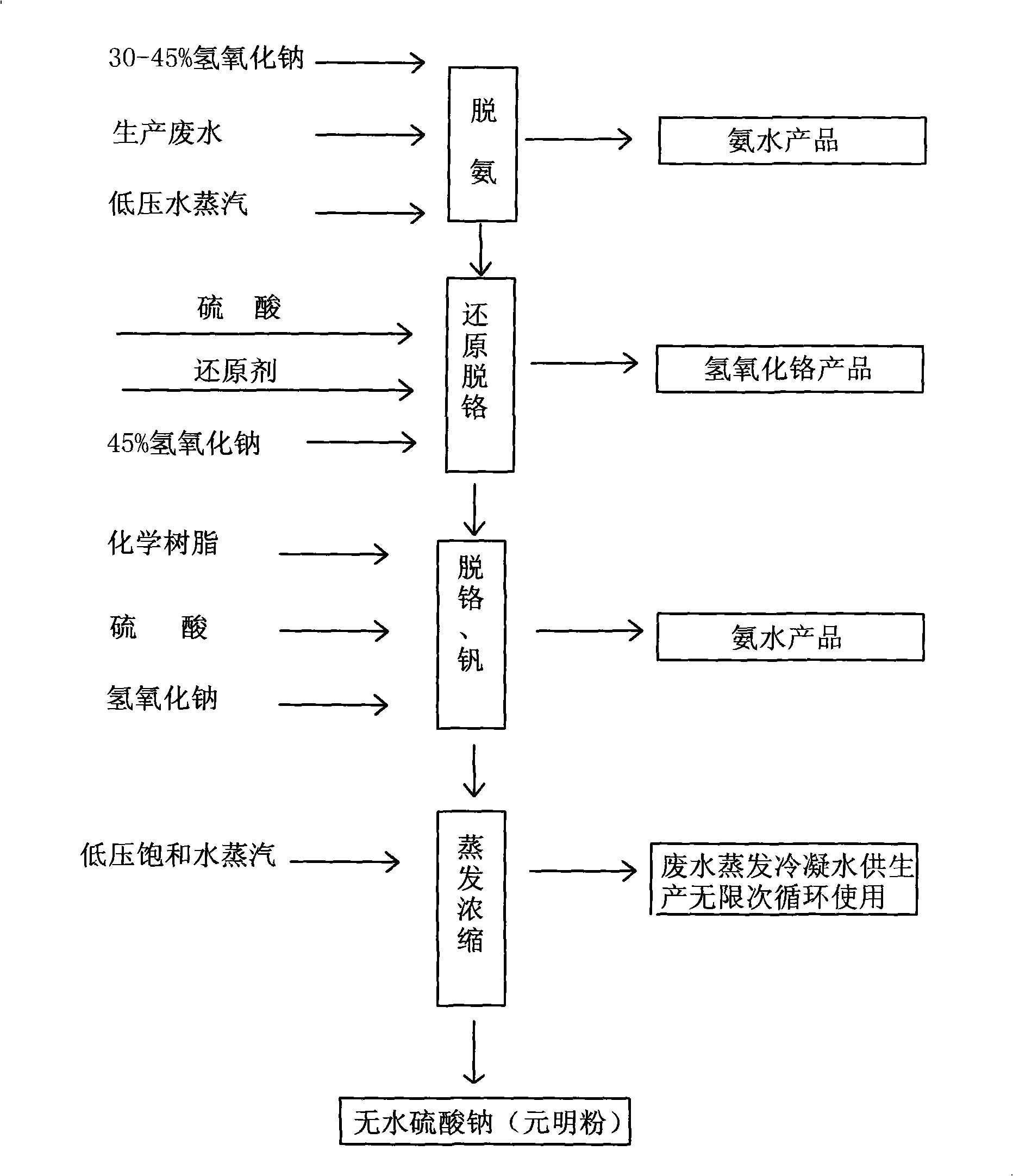

Method for treating wastewater containing ammonia, vanadium, chrome and sodium sulfate

ActiveCN101525189AProduce environmental effectWater contaminantsWater/sewage treatment by ion-exchangeSal ammoniacWastewater

The invention provides a method for treating wastewater containing ammonia, vanadium, chrome and sodium sulfate. The method comprises the following steps: step 1, deaminating to prepare ammonia; step 2, extracting chromic hydroxide; step 3, absorbing the vanadium and the chrome with resin columns; and step 4, extracting anhydrous sodium sulfate. The method can separate the ammonia, the vanadium, the chrome and the anhydrous sodium sulfate from the wastewater containing the ammonia, the vanadium, the chrome and the sodium sulfate to purify and recycle the wastewater, realize zero emission and generate environmental protection effect, thereby being suitable for extracting usable substances from the wastewater containing the ammonia, the vanadium, the chrome and the sodium sulfate while purifying and recycling the water.

Owner:辽宁虹京实业有限公司

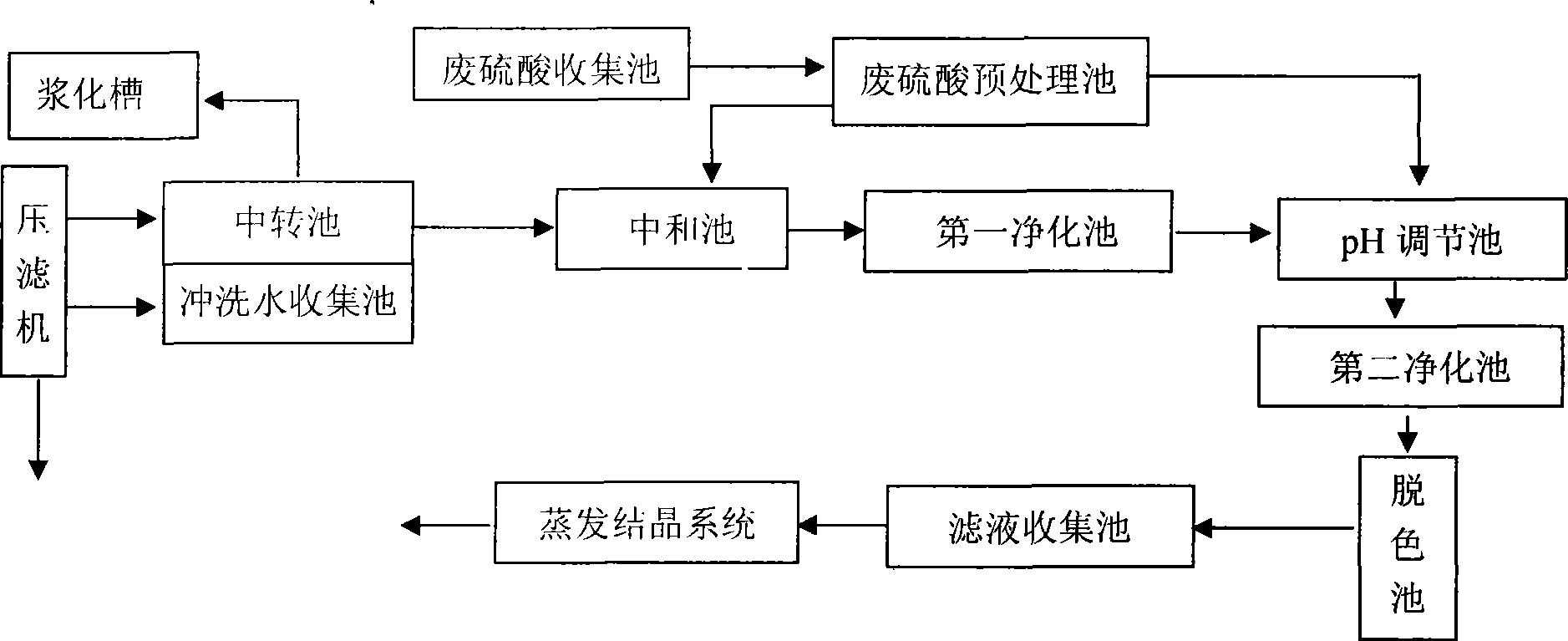

Method and device for recycling anhydrous sodium sulfate from desulfurization lead plaster filter liquor

ActiveCN101244831AEvaporative crystallizationGuaranteed Concentration RequirementsSulfate/bisulfate preparationAlkali metal sulfite/sulfate purificationFiltrationResource recovery

The invention relates to a method of recycling anhydrous sulfate sodium from de-sulfurized lead paste filtration, belonging to a resource recovery and utilization process, which avoids the disadvantages that waste sulfate is used and low concentration sulfate sodium is emitted into the environment. The method of the invention comprises: desulfurized lead paste filtration collection, sodium carbonate neutralization, first time heavy metal removal, filtration PH value adjustment, second-time heavy metal removal, decolorizing step, and vaporization and crystallization step; the device comprises a transfer tank, a neutralization tank, a first-stage purifying tank, a PH adjusting tank, a second-stage purifying tank, a decolorization tank, a filtration collection tank and a vaporization crystallization system; the waste sulfate collection tank is connected with a waste sulfate pre-processing tank, the waste sulfate pre-processing tank is respectively connected with the neutralization tank and the PH adjusting tank. The invention can directly recycle anhydrous sulfate sodium, the waste sulfate is used to neutralize the carbonate sodium remained in the filtration; the heavy metal ions and other ions in the filtration are removed according to two steps, so that the grade of obtained anhydrous sulfate sodium is equal to or larger than industrial grade.

Owner:HUAZHONG UNIV OF SCI & TECH

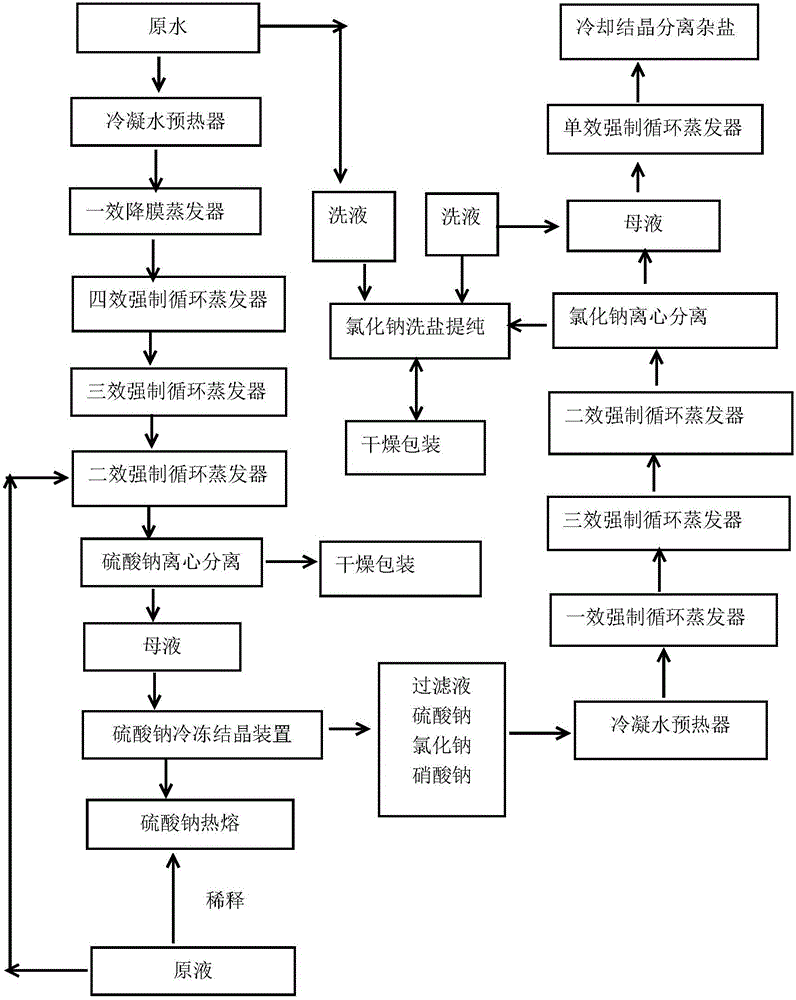

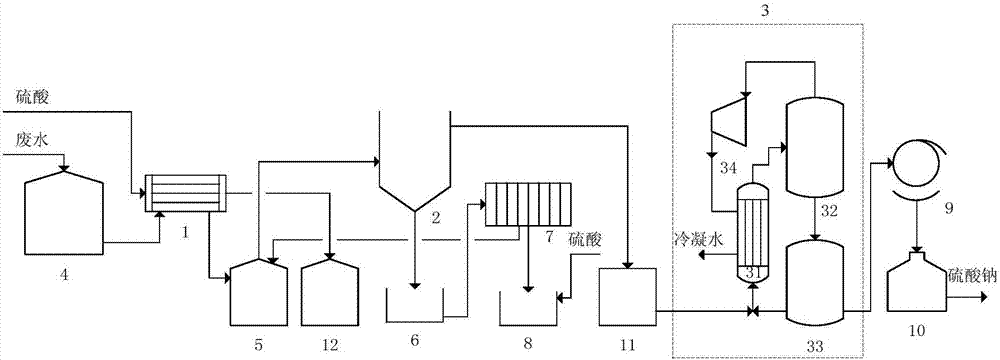

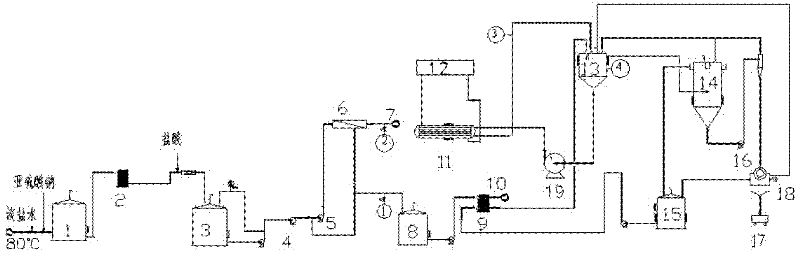

Desulfurization wastewater concentration, evaporation, crystallization and salt separation process

ActiveCN106007133AEfficient separationDissolution inhibitionWater/sewage treatment by centrifugal separationWater contaminantsWastewaterSingle effect

The invention discloses a desulfurization wastewater concentration, evaporation, crystallization, and salt separation process. The process comprises the steps as follows: introducing raw water into a quadruple-effect counter-flow forced circulation evaporator, treating sodium sulfate through evaporating, concentrating and crystalizing, separating sodium sulfate first, and freezing separated mother liquor, wherein most of sodium sulfate in the mother liquor is successfully separated; introducing the frozen mother liquor into a triple-effect evaporator after preheating, evaporating, concentrating and crystalizing sodium chloride, wherein the obtained crystal salt is used as an industrial raw material; introducing the mother liquor produced by a sodium chloride evaporator into a single-effect evaporator to obtain an abraum salt crystal. The process successfully separates the sodium sulfate in the desulfurization wastewater, and the sodium chloride is treated through evaporating, concentrating and crystalizing, the obtained sodium chloride crystal salt is used as the industrial raw material, the mother liquor produced by the sodium chloride evaporator enters the single-effect evaporator to obtain the abraum salt crystal, so that the sodium sulfate and the sodium chloride are effectively separated.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

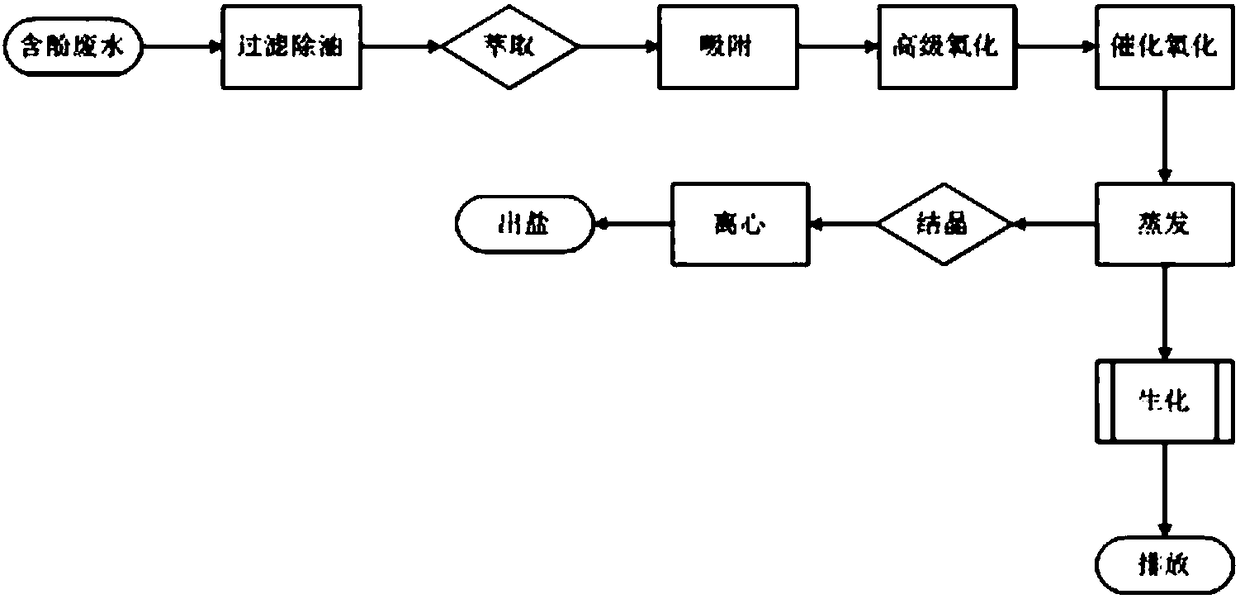

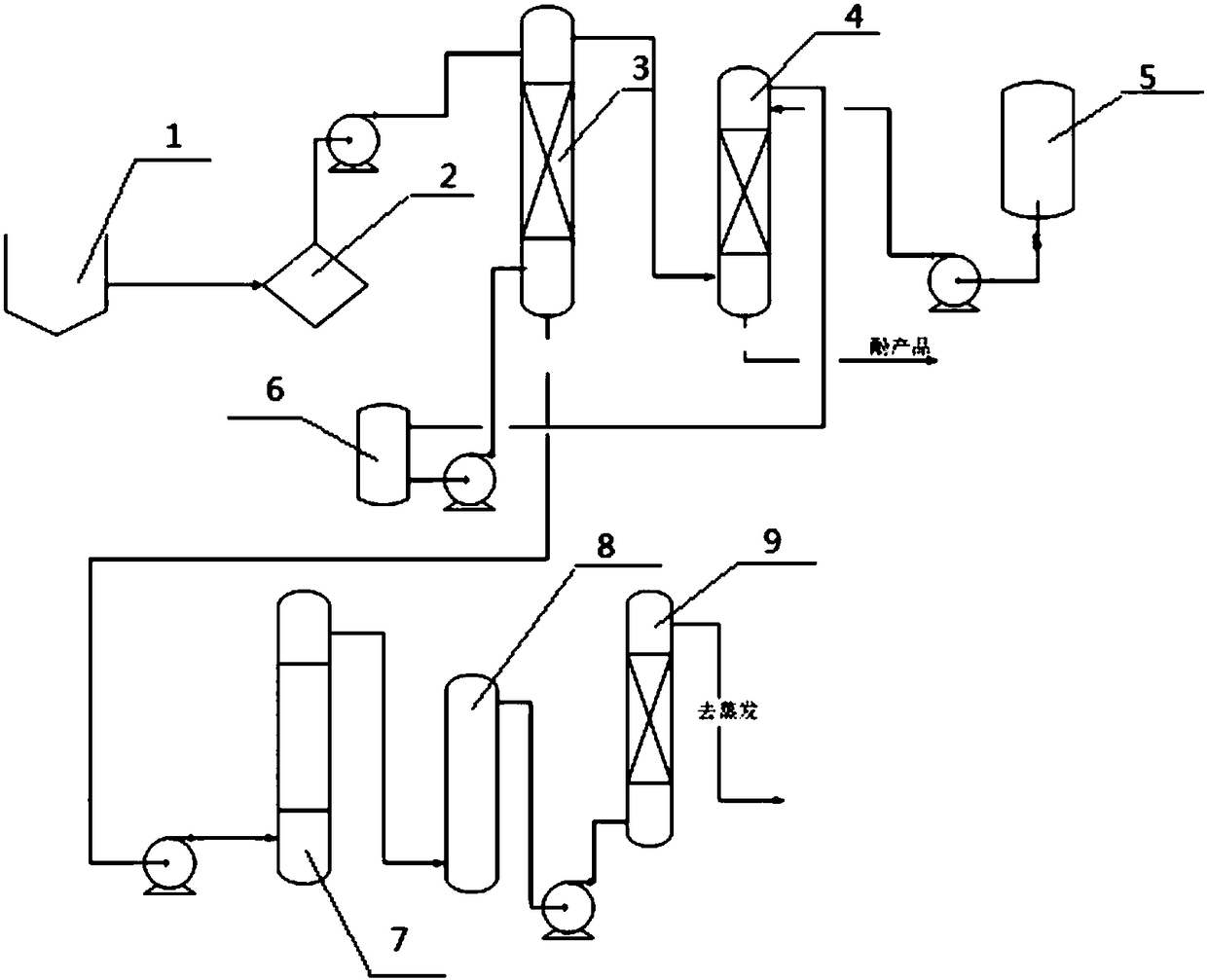

Process and device for treating phenol-containing wastewater

PendingCN108191140AEfficient removalGuaranteed efficiencyWater/sewage treatment by centrifugal separationWater contaminantsPhenol adsorptionFiltration

The invention discloses a process and device for treating phenol-containing wastewater. The process comprises the steps: carrying out oil removal by filtration, extraction and separation, phenol adsorption and advanced oxidation, delivering adsorbed wastewater into a first fixed bed reactor, adding 0.05-0.2% (volume) of hydrogen peroxide, and carrying out an oxidation reaction under the action ofa solid catalyst bed layer; delivering the wastewater subjected to advanced oxidation into a second fixed bed reactor, adding 0.002-0.01% (volume ratio) of ozone, and carrying out a catalytic oxidation reaction under the action of the solid catalyst bed layer; and sequentially carrying out evaporation, cooling crystallization, centrifugal separation and desalting treatment on the wastewater subjected to catalytic oxidation to obtain an industrial-grade sodium sulfate product. By using the process, the wastewater treatment efficiency is increased, the industrial-grade sodium sulfate product isobtained, the use amounts of adsorption resin, hydrogen peroxide, sodium hydroxide and the like are reduced, and the environment pollution is reduced.

Owner:JIANGSU HUDA CHEM TECH CO LTD

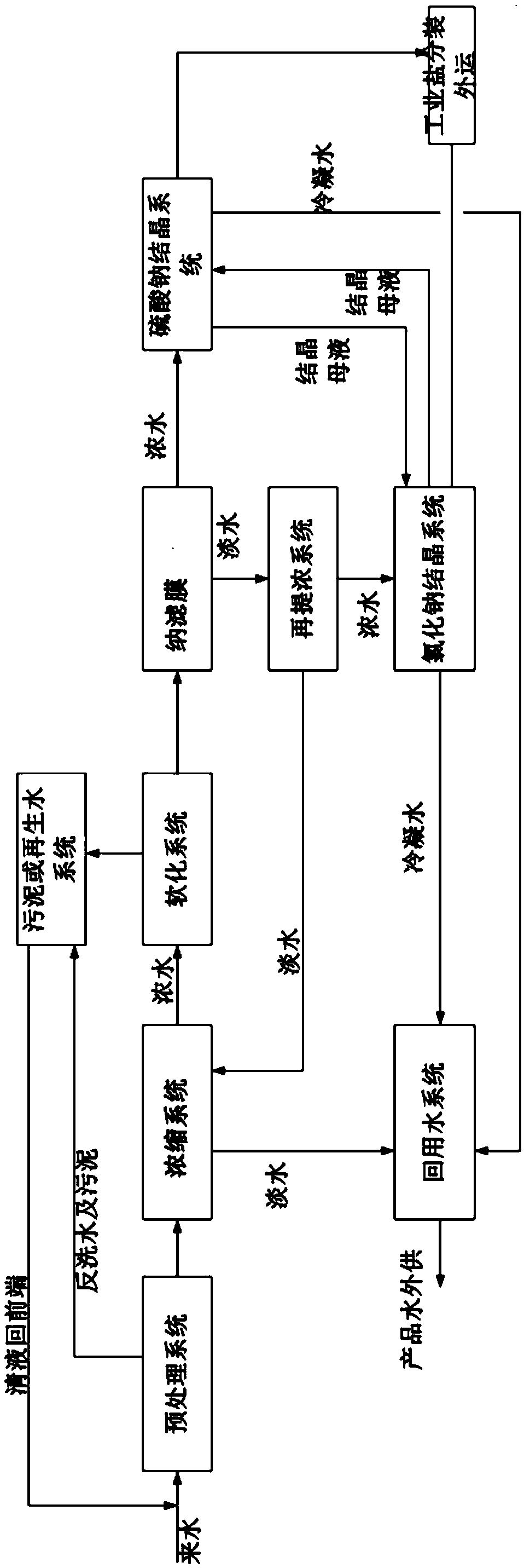

Nanofiltration membrane blending based high salinity wastewater zero discharge processing method and device

PendingCN108623104AWide adaptabilityAchieving zero emissionsScale removal and water softeningTreatment involving filtrationWater dischargeConcentration ratio

The invention relates to a nanofiltration membrane blending based high salinity wastewater zero discharge processing method, and a device. The nanofiltration membrane blending based high salinity wastewater zero discharge processing method mainly comprises following steps: high salinity wastewater is delivered through a pretreatment system for impurity removing, salt extraction concentration, andsoftening; softened concentrated water is introduced into a nanofiltration blending system for blending of the concentrations of monovalent and divalent salts, so that the monovalent salt to divalentsalt concentration ratio is controlled to be 0.01 to 0.1; concentrated water discharged from the nanofiltration blending system is introduced into a sodium sulfate crystallization system for processing so as to obtain divalent salt products capable of satisfying industrial salt requirements and a sodium chloride-containing mother liquor; an obtained nanofiltration blending system penetrating fluidis delivered through an extraction concentration system, and is introduced into a sodium chloride crystallization system so as to obtain sodium chloride salt products and a sodium sulfate-containingmother liquor; the sodium chloride crystallization mother liquor is subjected to impurity removing, and is introduced into the sodium sulfate crystallization system; the sodium sulfate crystallizationmother liquor is subjected to impurity removing, and is introduced into the sodium chloride crystallization system. The nanofiltration membrane blending based high salinity wastewater zero dischargeprocessing method is capable of realizing wastewater zero discharge, and stabilizing salinity fluctuation in the crystallization systems.

Owner:NANJING UNIV OF TECH +1

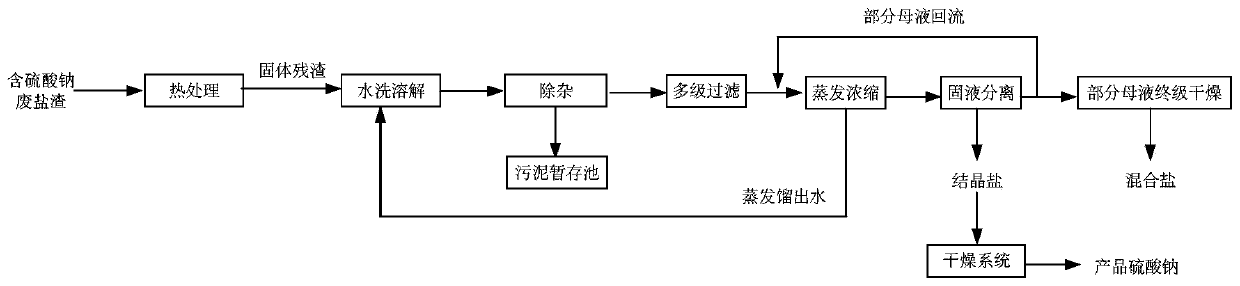

Method for recovering sodium sulfate by utilizing sodium sulfate containing waste salt residue

InactiveCN109704369AReduce pollutionGuaranteed uptimeAlkali metal sulfite/sulfate purificationFiltrationEvaporation

The invention discloses a method for recovering sodium sulfate by utilizing sodium sulfate containing waste salt residue. According to the invention, a combined process of heat treatment, dissolutionand water-washing, multistage purification and impurity removal, and thermal evaporation concentration and crystallization is adopted to treat waste salt residue with a main component of sodium sulfate. Through heat treatment, organic components in the sodium sulfate containing waste salt residue are completely degraded and decomposed under the condition of a high temperature; through dissolutionand water-washing treatment, waste salt components in the sodium sulfate containing waste salt residue are completely dissolved, and residual carbon black residue is removed through solid-liquid separation; through purification and impurity removal treatment, impurity components like metal ions in a salt solution are removed by adoption of technologies like chemical precipitation and filtration; and through thermal evaporation concentration and crystallization treatment, a clean salt solution is treated by adoption of a steam heating evaporation technology to obtain a sodium sulfate product. In the whole process, harmless treatment and resourceful utilization of the sodium sulfate containing waste salt residue are realized; the sodium sulfate product produced by using the process providedby the invention reaches the standards (GB / T6009-2014) of an industrial-grade anhydrous sodium sulfate product; economic benefits are improved; and environmental pollution is avoided.

Owner:ZHEJIANG SHENLIAN ENVIRONMENTAL PROTECTION GRP CO LTD

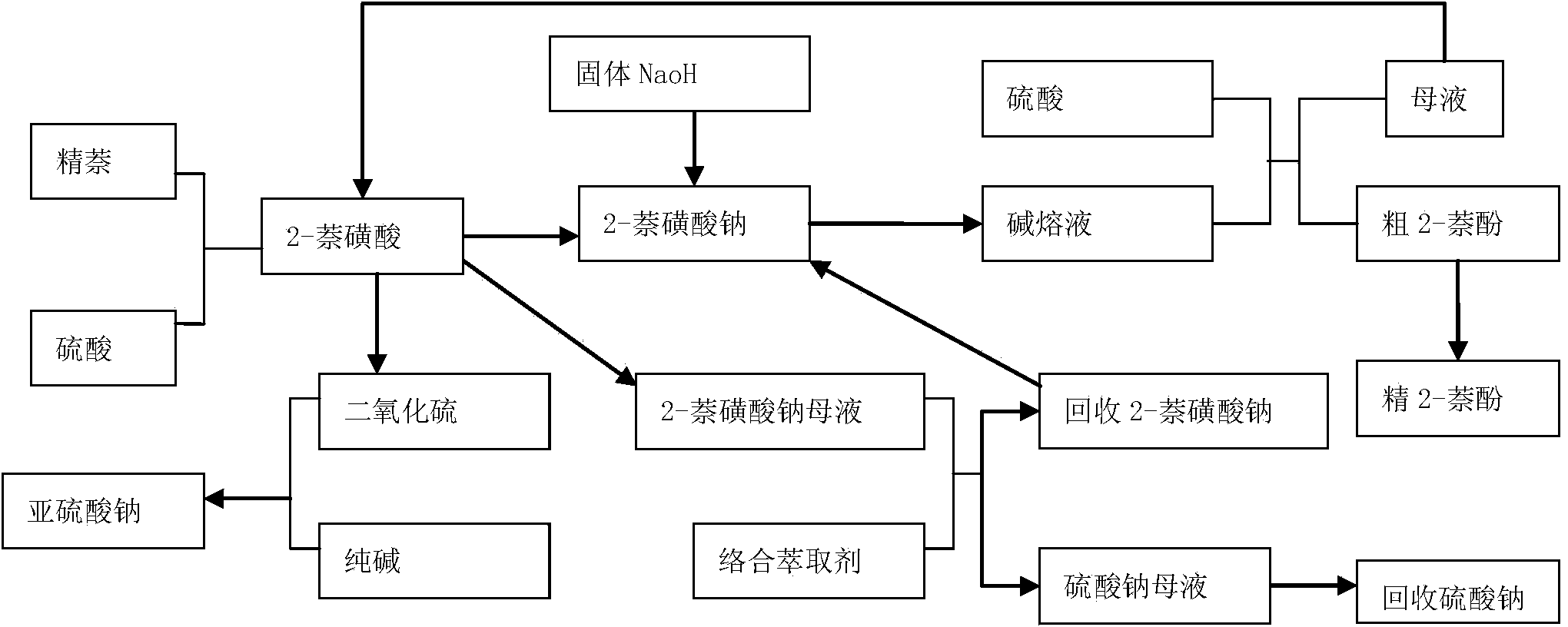

Environment-friendly production process of 2-naphthol

ActiveCN103626637AHigh yieldMeet the needs of industrial productionOrganic chemistryOrganic compound preparationEnvironmental resistanceSulfite salt

The invention relates to an environment-friendly production process of 2-naphthol. The environment-friendly production process of the 2-naphthol comprises the following steps: adding refined naphthalene into a sulfonation kettle, adding concentrated sulfuric acid, heating and performing sulfonation reaction, neutralizing a mixture by using alkali after the reaction is finished, crystallizing, filtering, drying, performing alkali fusion and diluting; neutralizing the diluted alkali fused sulfonation liquid by using sulfuric acid at 70 to 80 DEG C, controlling the pH to be 4 to 7, standing and layering, and separating out crude 2-naphthol; washing, dehydrating and rectifying the separated crude 2-naphthol to obtain refined 2-naphthol; and removing alkali from the separated waste liquid, neutralizing to serve as alkaline liquid, absorbing sulfur dioxide generated by neutralization by using a sodium carbonate aqueous solution to produce sodium sulfite, adjusting the pH value of the waste liquid after 2-sodium naphthalene sulfonate is separated to be 2+ / -1, performing three-stage extraction by using an extracting agent, performing reverse extraction on the extracting liquid by using dilute alkali, diluting sulfonated liquid by using the reverse extraction liquid, oxidizing the water phase by using a Fenton reagent or KMnO4, decoloring by using active carbon, and recovering sodium sulfate by a mechanical vapor recompression (MVR) concentration technology. By the process provided by the invention, no waste water is discharged basically and the production cost is reduced.

Owner:青岛奥盖克化工股份有限公司

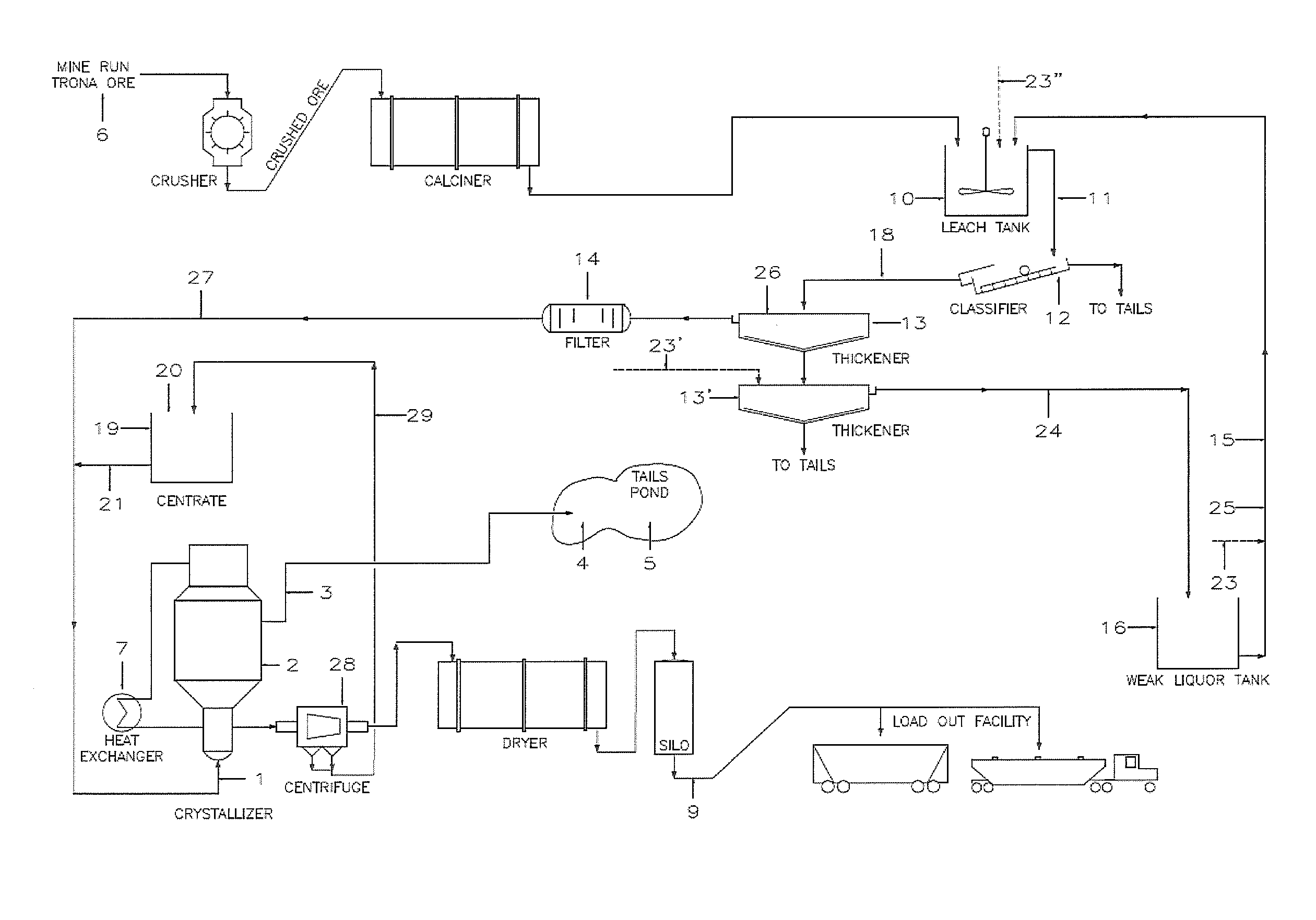

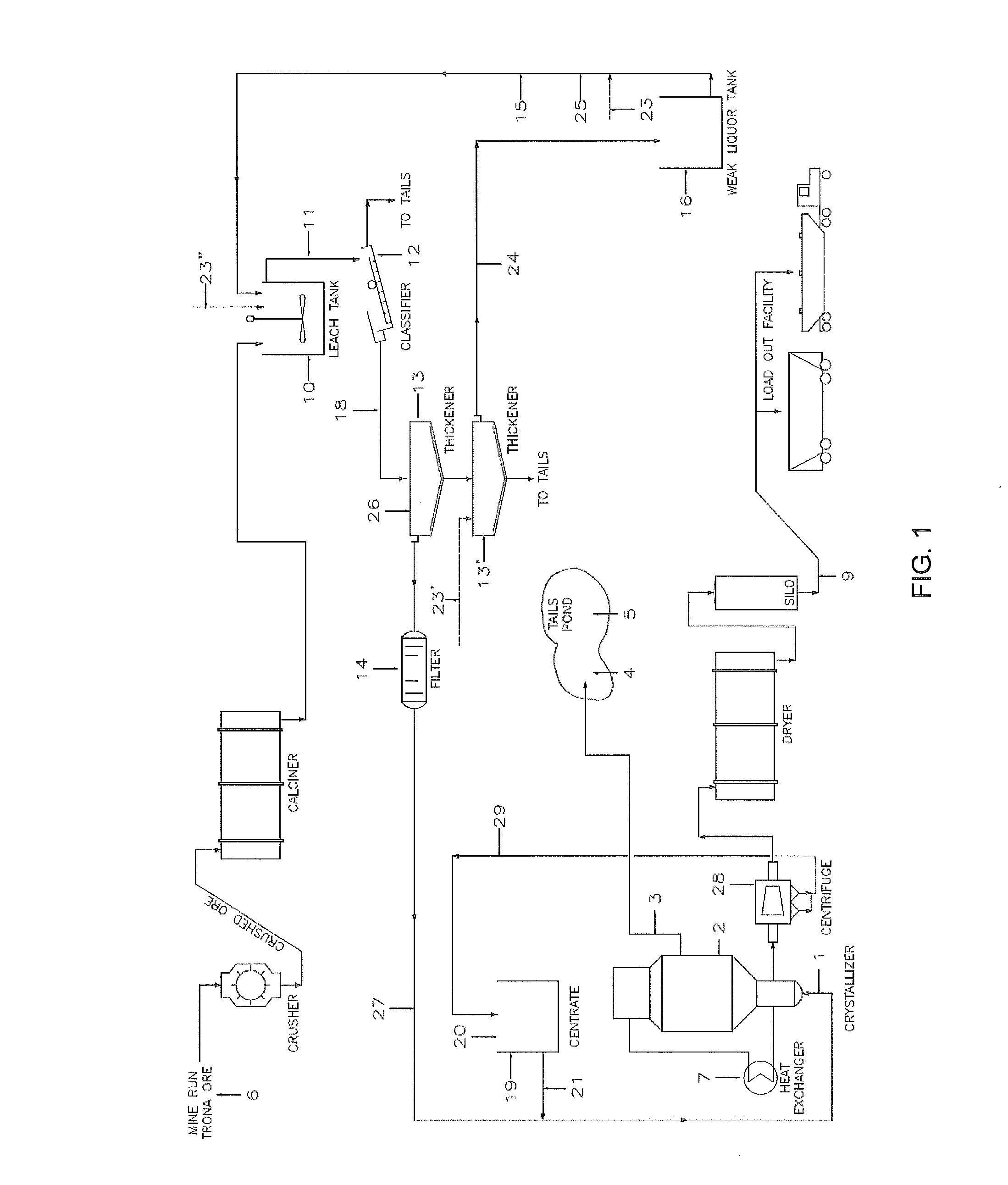

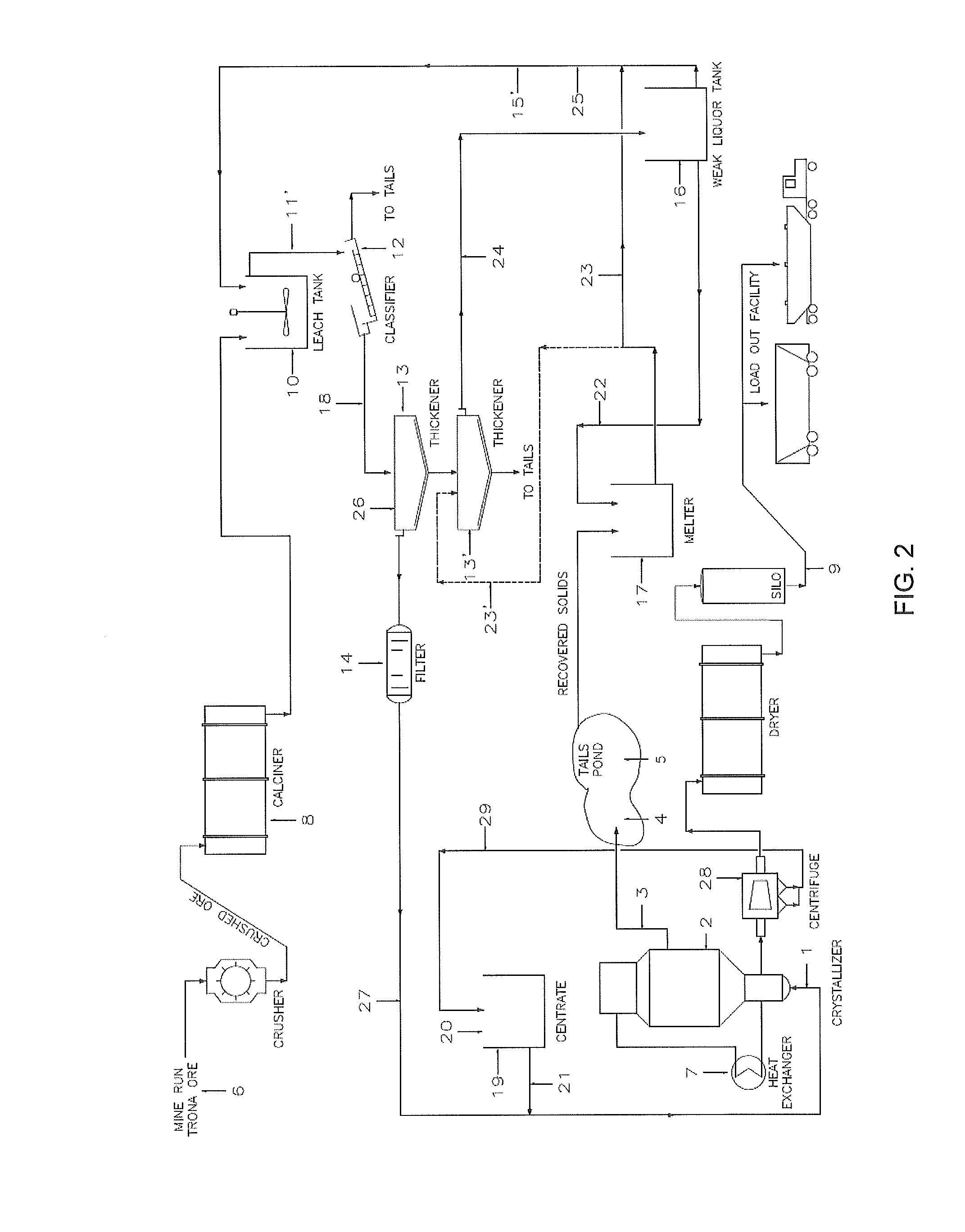

Impurities removal from waste solids in the production of soda ash, sodium bicarbonate and/or other derivatives

ActiveUS20110274599A1Low impurity contentIncrease valueBicarbonate preparationSolvent extractionSodium bicarbonateDissolution

A method for removing impurities from a waste solid to provide at least a portion of a suitable crystallizer feed to a process for making crystalline sodium carbonate, bicarbonate, and / or other derivatives. The method comprises: contacting the waste solid with a leach solution to dissolve at least one impurity and dissolving the resulting leached residue. Leaching may include heap percolation. The leach solution may comprise a crystallizer purge liquor, a process waste effluent, a mine water, or mixtures thereof. The method may further comprise adding a magnesium compound to the resulting leached residue during or after its dissolution to remove another impurity. The waste solid preferably comprises a pond solid containing such impurities. The pond solid may be recovered from a pond receiving crystallizer purge liquor(s) and / or other process waste effluent(s). The pond solid may contain sodium carbonate, any hydrate thereof, sodium bicarbonate, and / or sodium sesquicarbonate. The impurities to be removed may comprise sodium chloride, sodium sulfate, silicates, and / or organics.

Owner:SOLVAY CHEM INC

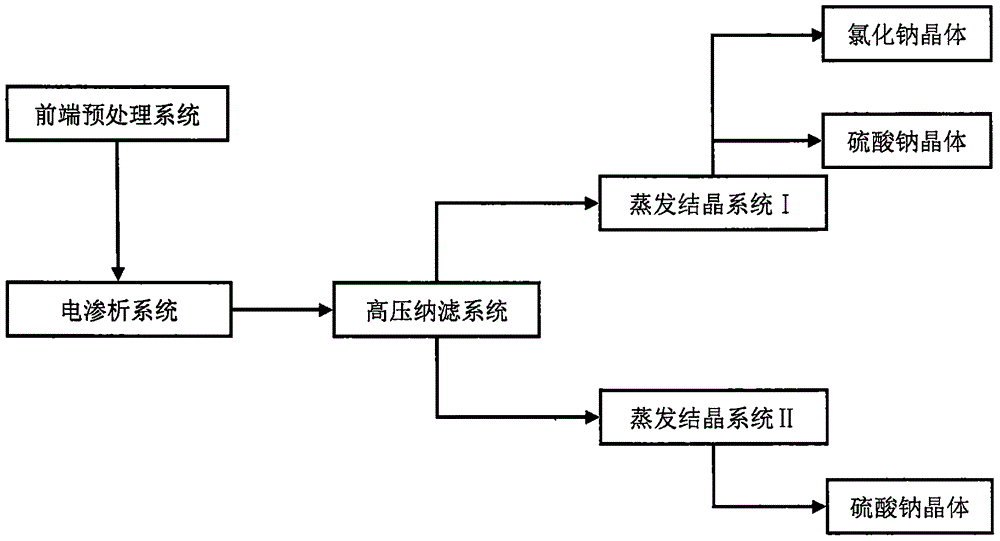

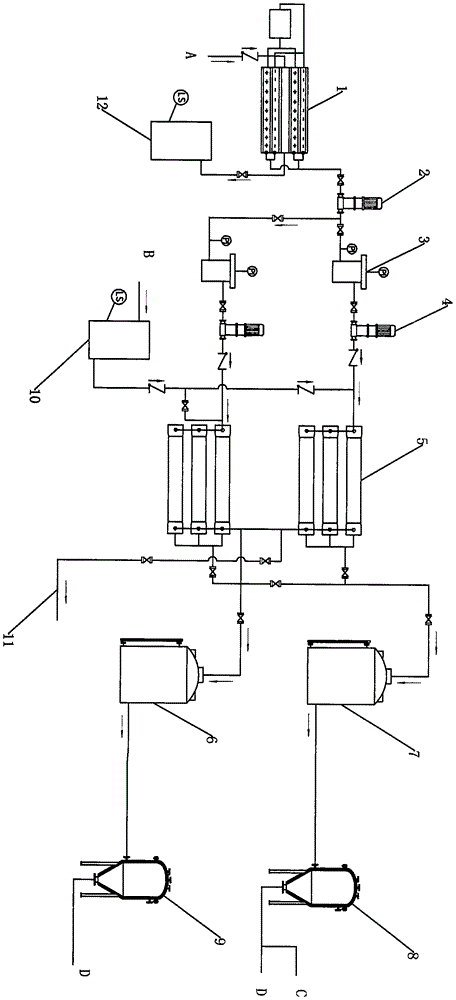

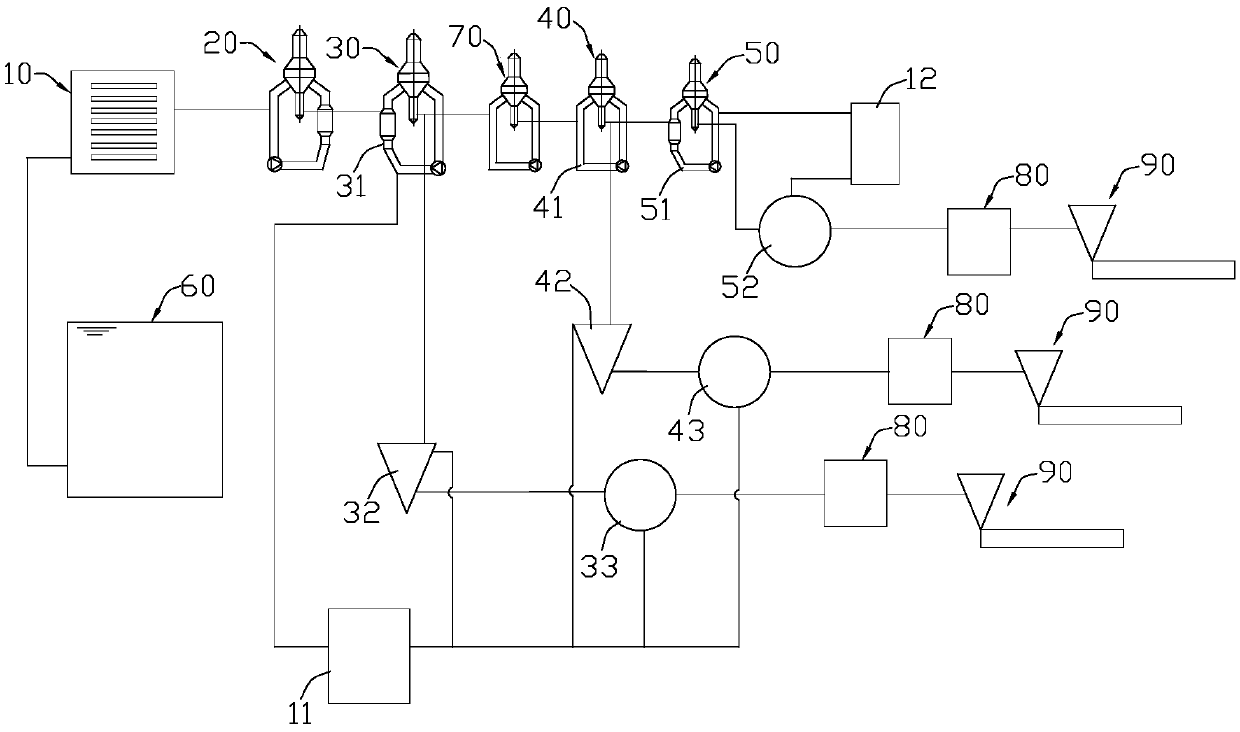

High-salt-content industrial wastewater electrodialysis-high pressure nanofiltration combined salt separation system

InactiveCN105692993AIncrease or decrease quantitySolve the problem that mixed salt cannot be usedAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentHigh pressureCell separation

The invention relates to a high-salt-content industrial wastewater electrodialysis-high pressure nanofiltration combined salt separation system and technique, belonging to a water treatment technique. The technique comprises the following steps: high-salt-content wastewater treated by a front end pretreatment system is supplied to an electrodialysis system and concentrated by the electrodialysis system to obtain high-salt-content concentrated water; the high-salt-content concentrated water is directly sent into a high pressure nanofiltration system by a charging pump, and separated by a high pressure nanofiltration membrane assembly in the high-pressure nanofiltration system into sodium chloride concentrated water and sodium sulfate concentrated water; the sodium chloride concentrated water directly enters a subsequent evaporative crystallizing system I, thereby finally obtaining industrial-grade sodium chloride; and the sodium sulfate concentrated water directly enters a subsequent evaporative crystallizing system II, thereby finally obtaining the industrial-grade sodium sulfate. The system and technique are simple to operate, and have the characteristics of stable operation, high salt separation efficiency and the like. Compared with the existing salt separation technique, the technique provided by the invention implements salt separation on ultrahigh-salt-content water, can achieve the effect of high-efficiency salt separation, and greatly lowers the energy consumption and operating cost.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

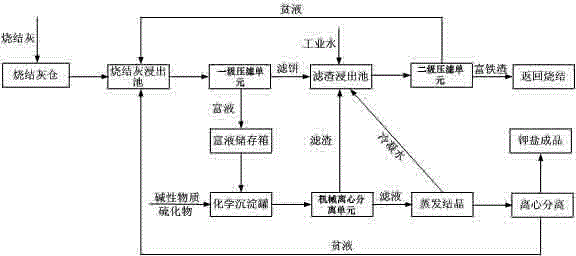

Method and equipment for extracting potassium salt from sintering machine head electroprecipitating dust in metallurgical industry

InactiveCN104609443ASolve the current situation of shortageSolve the problem that alkali metal enrichment can have adverse effectsAlkali metal sulfite/sulfate purificationAlkali metal halide purificationFiltrationLiquid storage tank

The invention relates to a method and equipment for extracting potassium salt from sintering machine head electroprecipitating dust in the metallurgical industry. The method comprises the following steps of stirring and leaching, chemical precipitation, mechanical centrifugation, and evaporation and crystallization. The equipment comprises a sintering dust leaching pool which is sequentially connected with a primary pressure-filtration unit, a rich liquid storage tank, a chemical precipitation tank, a mechanical centrifugation unit, and an evaporation and crystallization unit. According to the method disclosed by the invention, electroprecipitating dust is directly leached by using industrial water to leach potassium salt; the chemical method enables impurity metal ions in the leachate to rapidly and stably form a precipitate, and the product purity is higher; the solution after precipitation is efficiently separated by mechanical centrifugation; the filter residue is secondarily leached by adding the industrial water and the condensed water returned by the evaporation and crystallization unit, and the barren solution generated by the secondary pressure-filtration and centrifugation unit is returned as a sintering ash leachate, thus ensuring furthest extraction for the potassium salt in the sintering ash, and ensuring the reasonable allocation of the leachate of the whole system, without wastewater drainage. The equipment disclosed by the invention is simple in structure, economic and reliable, and capable of obtaining a high-purity potassium salt product after evaporation and crystallization, and drying.

Owner:中钢集团天澄环保科技股份有限公司

Method for producing reagent grade sodium sulfate by using white carbon black mother solution

InactiveCN102320629ALow impurity contentImprove qualityAlkali metal sulfite/sulfate purificationCelluloseEvaporation

The invention discloses a method for producing reagent grade sodium sulfate by using a white carbon black mother solution. The method comprises the following steps of: 1) removing a little amount of solid residue such as white carbon black and the like in the white carbon black mother solution by using a mixed cellulose micropore filtration membrane with thickness phi of less than or equal to 0.15 micron, and preliminarily purifying the white carbon black mother solution into a sodium sulfate solution; 2) treating the sodium sulfate solution obtained in the step 1) by using chelating resin toobtain a 5 to 6 percent pure sodium sulfate solution; 3) performing electrodialytic concentration on the 5 to 6 percent pure sodium sulfate solution obtained in the step 2) to obtain a 15 to 25 percent pure sodium sulfate solution; and 4) performing multi-effect evaporation on the 15 to 25 percent pure sodium sulfate solution obtained in the step 3) to obtain crystal, separating the crystal by using a centrifuge, drying the separated crystal at the temperature of 120 DEG C, and thus obtaining a finished product. The sodium sulfate product prepared by the method has the characteristics of low impurity content, high quality, low moisture content and the like, and is a high reagent grade sodium sulfate product.

Owner:福建海能新材料有限公司

Removal of impurities in the production of crystalline sodium carbonate, bicarbonate, or sulfite

ActiveUS20100226840A1Reduce contentGood physical propertiesCrystallization separationAlkali metal sulfite/sulfate purificationSodium bicarbonateDicarbonate

A magnesium treatment for removing water-soluble impurities in a process for making crystalline sodium carbonate, bicarbonate, or sulfite. A waste comprising such impurities is treated with a magnesium compound to form water-insoluble matter which is removed to form a purified solution. The treatment may be performed on a solution which contains the waste and optionally dissolved calcined trona. The purified solution may be used as a feedstock to form crystalline soda ash, and / or used as a reactant to produce crystalline sodium sulfite or bicarbonate via reaction with SO2 or CO2. In preferred embodiments, the waste may comprise a purge or weak liquor, a reclaimed solid, or combinations thereof. The water-soluble impurities may be silicates and / or foam-causing impurities, and the waste may contain sodium bicarbonate, sodium sesquicarbonate, and / or one or more sodium carbonate hydrates, such as decahydrate.

Owner:SOLVAY CHEM INC

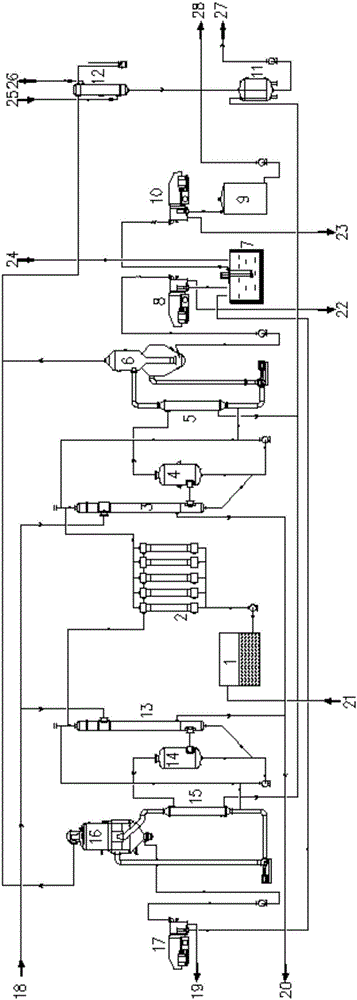

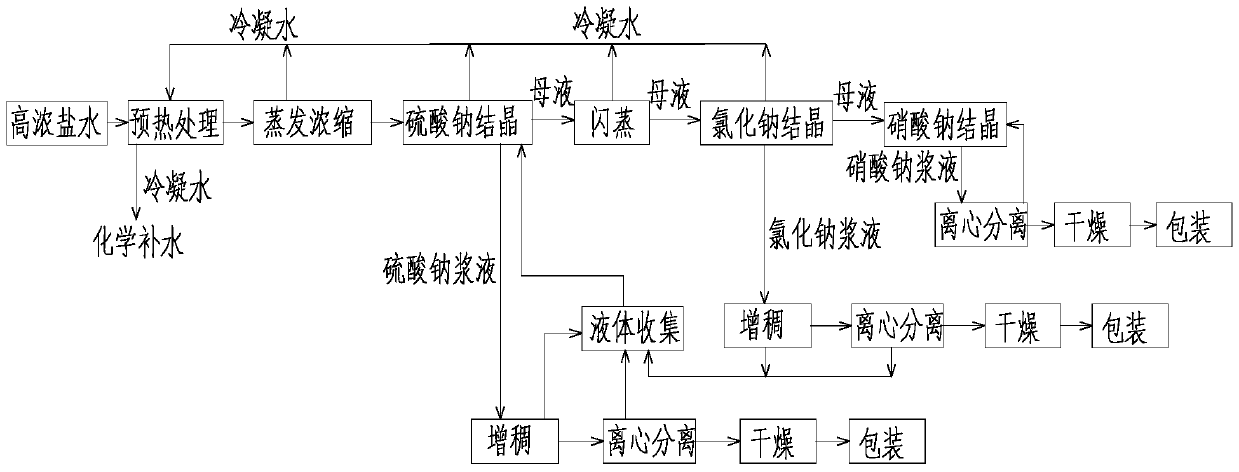

Treatment method and device for coal chemical industry high-concentration brine

ActiveCN105502438AAchieving zero emissionsRealize comprehensive utilizationAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationHigh concentrationResource utilization

The invention discloses a treatment method and device for coal chemical industry high-concentration brine. The treatment method for the coal chemical industry high-concentration brine includes the following steps that 1, preheating and evaporating concentration are conducted on the coal chemical industry high-concentration brine in sequence; 2, sodium sulfate crystallization is carried out on the high-concentration brine concentrated in an evaporation mode to obtain sodium sulfate slurry and mother liquor, and the sodium sulfate slurry is thickened, treated in a crystal growth mode and centrifugally separated to obtain sodium sulfate crystal; 3, sodium chloride crystallization is carried out on the mother liquor obtained in the step 2 to obtain sodium chloride slurry and mother liquor, and the sodium chloride slurry is thickened, treated in a crystal growth mode and centrifugally separated to obtain sodium chloride crystal; 4, sodium nitrate crystallization is carried out on the mother liquor obtained in the step 3 to obtain sodium nitrate slurry and mother liquor, and the sodium nitrate slurry is centrifugally separated to obtain sodium nitrate crystal. Zero emission of the coal chemical industry high-concentration brine and resource utilization of crystalline salt are achieved.

Owner:深圳能源资源综合开发有限公司

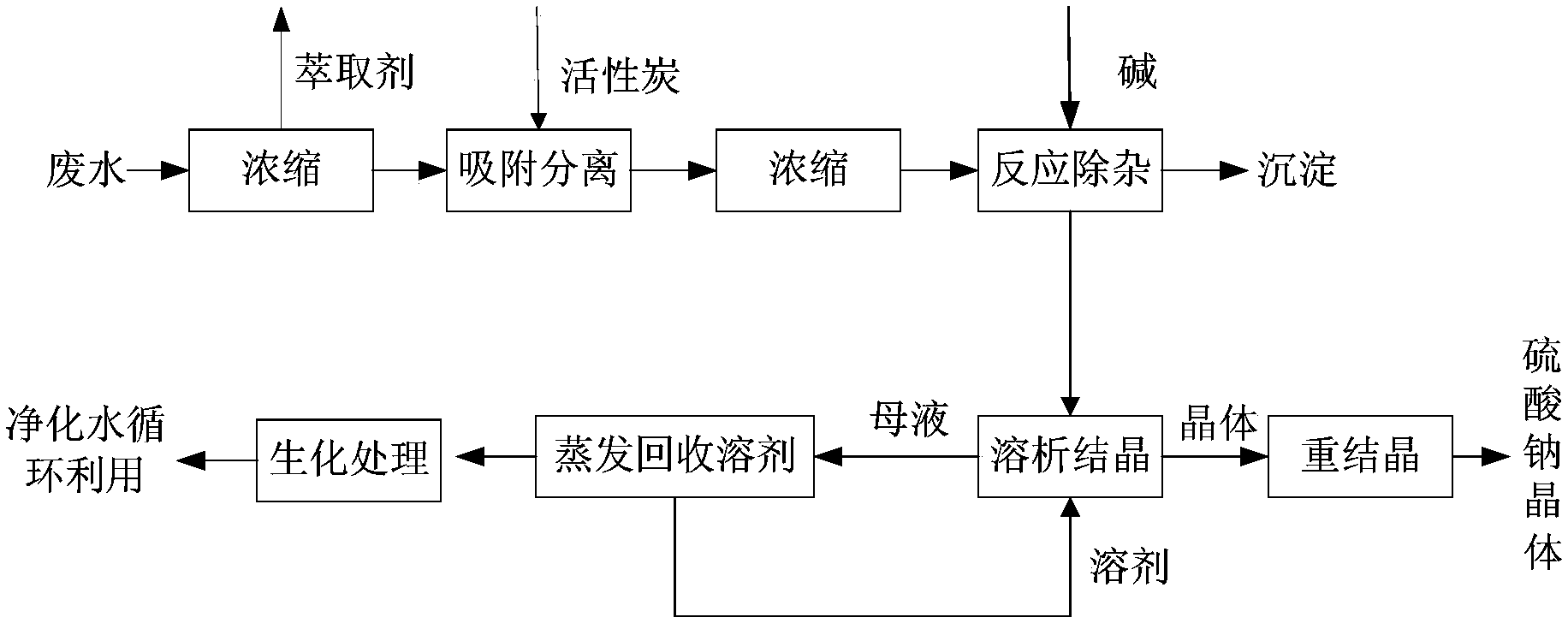

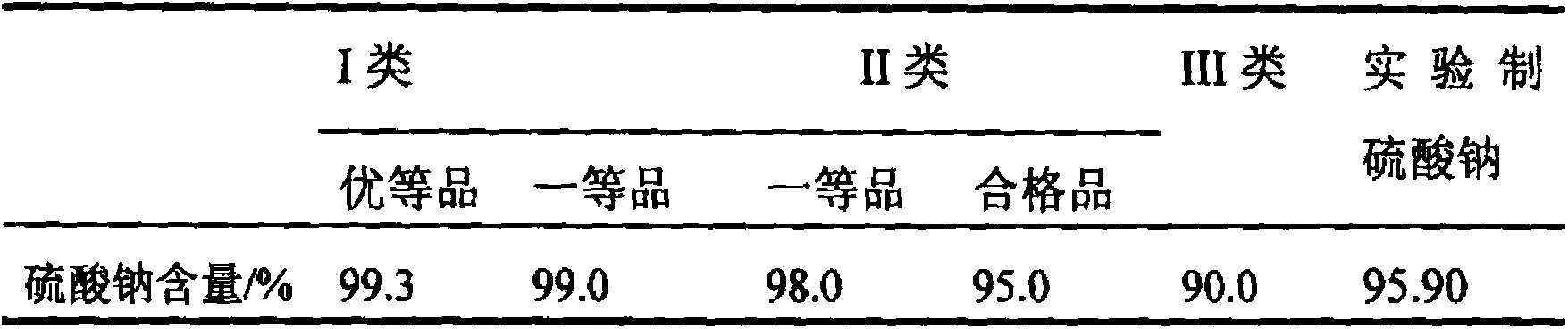

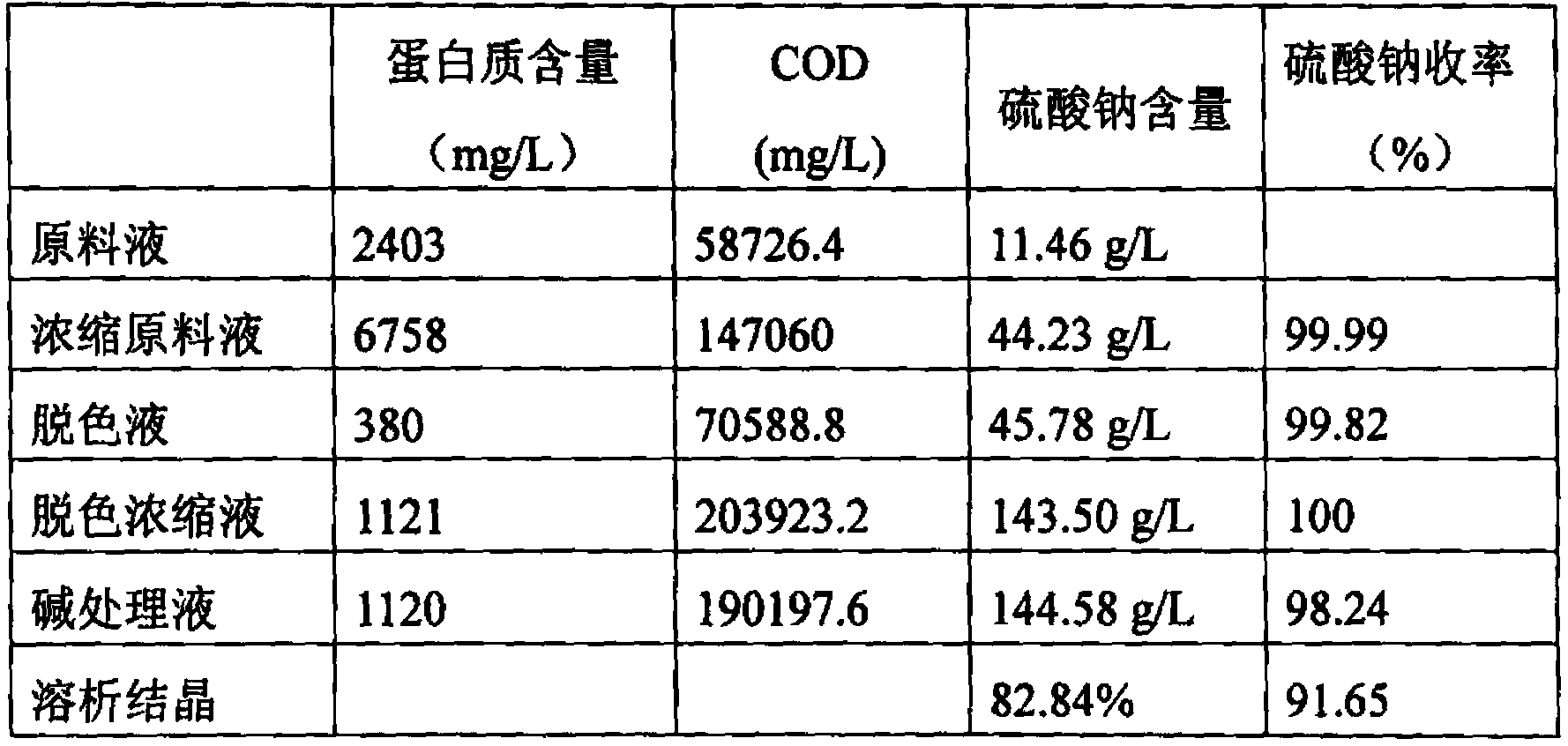

Method for purifying penicillin production waste liquid and recycling sodium sulfate

ActiveCN103979730AReduce the difficulty of governanceReduce governance costsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentActivated carbonChemistry

The invention relates to a method for purifying a penicillin production waste liquid and recycling sodium sulfate. The method comprises the following steps: firstly, primarily evaporating the penicillin production waste liquid; concentrating a raw material liquid in desorbing residual solvents in the waste liquid; adding activated carbon into the primarily concentrated raw material liquid, wherein the liquid phase obtained from separation is a destaining solution of which a part of organisms are removed; continuously evaporating the destaining solution to obtain a concentrated destaining solution; adding alkali into the concentrated destaining solution, reacting to remove the impurities, filtering and precipitating, wherein an obtained liquid is an alkali treated liquid; adding a dilution agent for dilution crystallization into the alkali treated liquid, performing solid-liquid separation, and recrystalizing the solid, thereby obtaining high-purity sodium sulfate crystal; feeding a liquid into a solvent recycling tower for recycling the dilution agent, and feeding a tower kettle liquid to a biochemical pool for treatment. Compared with the prior art, organisms such as protein and pigment in the penicillin production waste liquid are reduced, at the same time sodium sulfate is recycled, then circulation application of sodium sulfate and water is achieved, the treatment difficulty and cost of the penicillin production waste liquid are remarkably alleviated and lowered, and great economic and environment benefits are achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

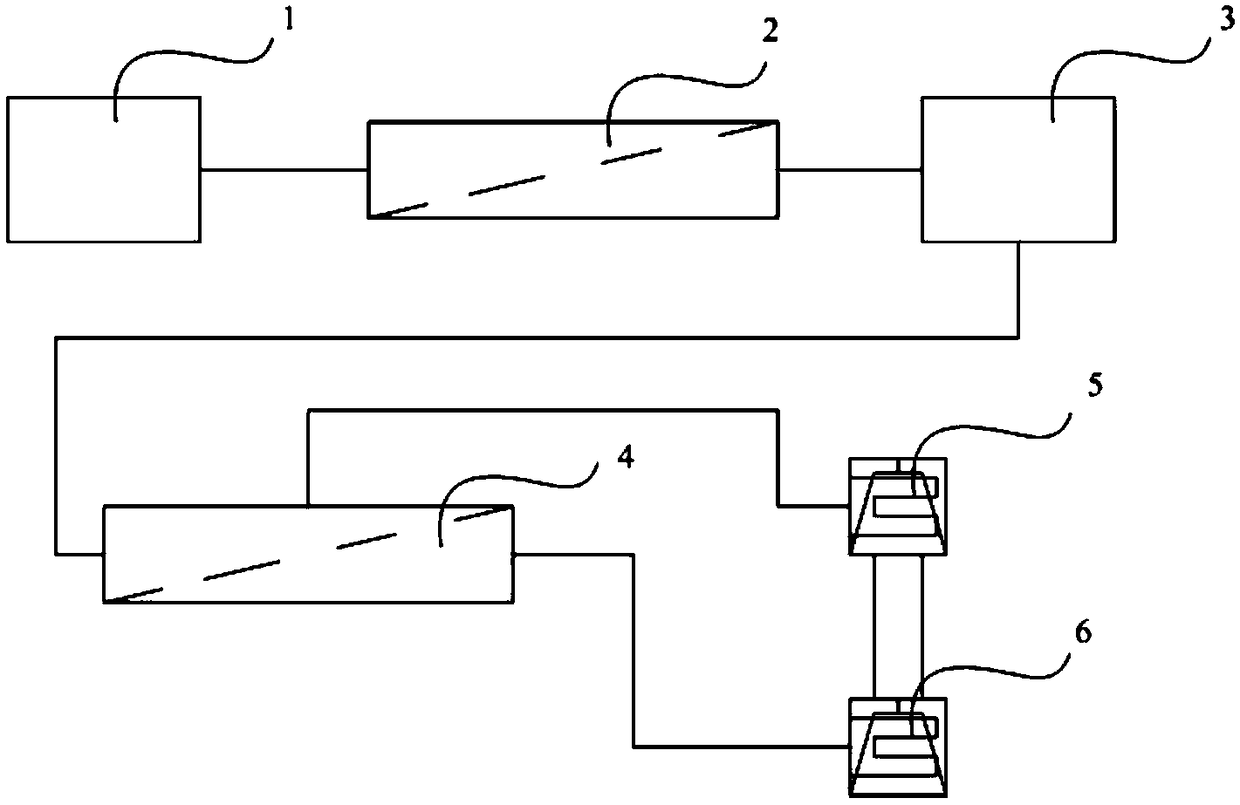

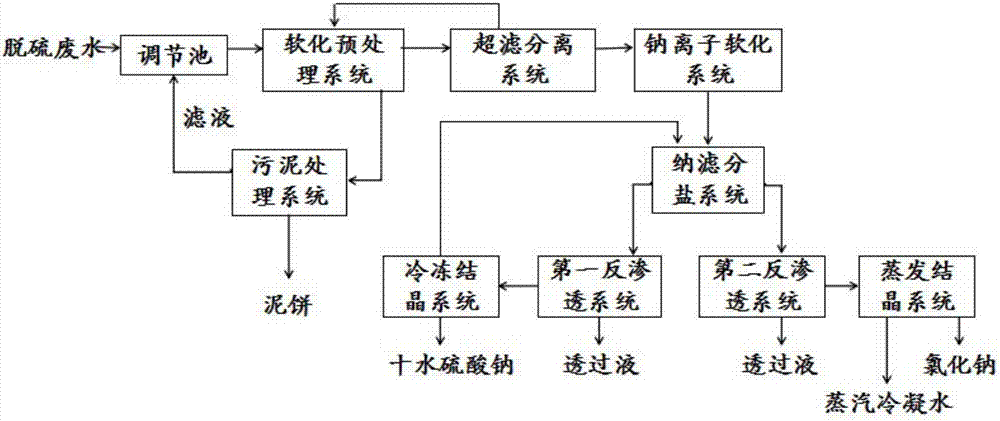

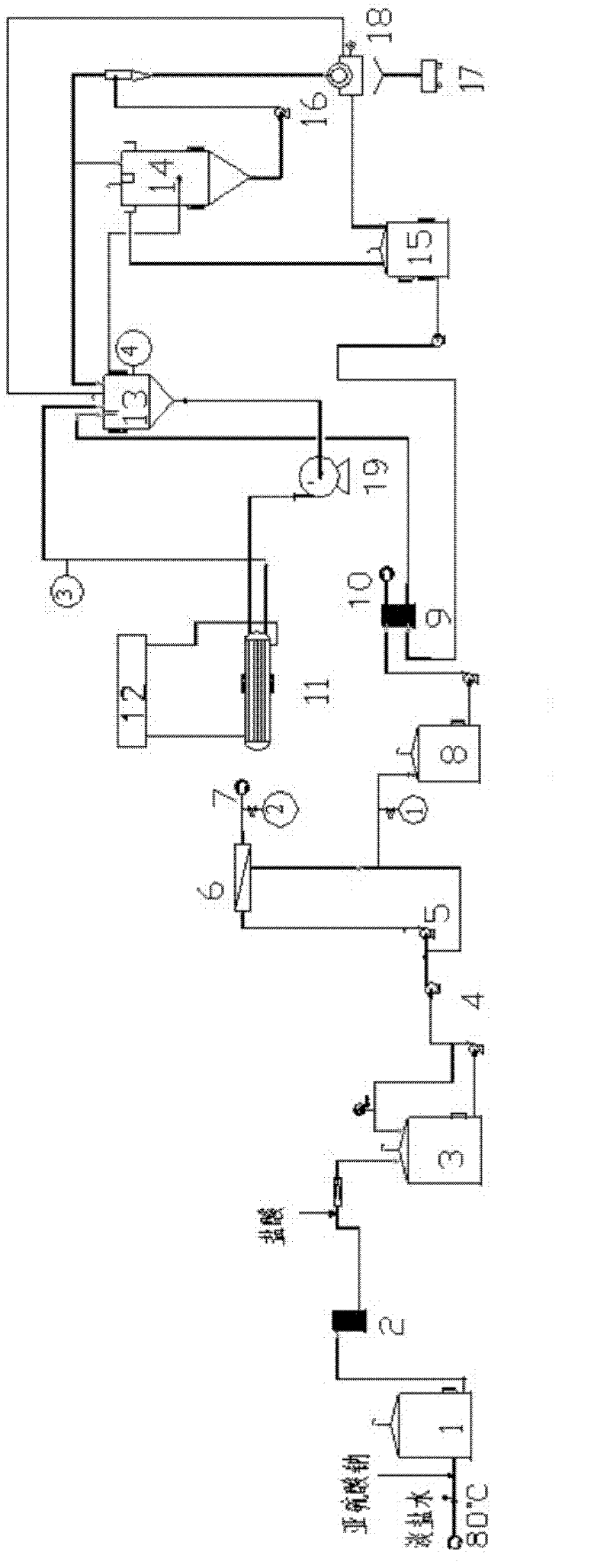

Method and device of quality-orientated crystallization treatment on desulfurization waste water

PendingCN106946395AReduce hardnessRealize resource utilizationSludge treatment by de-watering/drying/thickeningTreatment involving filtrationSeparation technologyPhysical chemistry

The invention relates to a method and a device of quality-orientated crystallization treatment on desulfurization waste water. The invention effectively integrates a desulfurization waste water softening pretreatment technology, a membrane separation technology and a crystallization technology, carries out softening pretreatment on the desulfurization waste water to lower the hardness of the desulfurization waste water firstly, then carries out salt separation treatment and concentration treatment on the desulfurization waste water subjected to softening pretreatment by adopting the membrane separation technology to separate sodium sulfate and sodium chloride in the desulfurization waste water and utilizes the sodium sulfate in the waste water recovered by utilizing cooling crystallization and evaporative crystallization treatment to prepare sodium sulfate decahydrate crystals with purity larger than or equal to 98 percent and sodium chloride crystals with purity larger than or equal to 94 percent at the same time finally to realize zero-pollution emission of the desulfurization waste water. By adopting the method and the device, the technical problems that if the desulfurization waste water is directly evaporated, the energy consumption is high, equipment is liable in scaling, and mixed salts obtained by evaporation are difficultly recycled are solved, the cost is saved, the resource utilization of the desulfurization waste water to the maximum is realized, and comprehensive recycling of the desulfurization waste water is truly realized.

Owner:BEIJING TDR ENVIRON TECH CO LTD

Production process of lithium hydroxide

ActiveCN104724729AHigh purityImprove qualityAlkali metal sulfite/sulfate purificationAlkali metal oxides/hydroxidesHigh concentrationSeparation technology

The invention discloses a production process of lithium hydroxide. According to the production process of lithium hydroxide, the crystallization mother liquor with high-concentration sodium sulfate and lithium hydroxide is used as the raw material, wherein the crystallization mother liquor with high-concentration sodium sulfate and lithium hydroxide is obtained after crystallization precipitation of sodium sulfate decahydrate in the production process of lithium hydroxide by the lithium sulfate method. Lithium hydroxide is prepared by the following steps: step A, introducing the crystallization mother liquor into a membrane separation system, wherein concentrated sodium sulfate solution is the intercept liquid and lithium hydroxide solution is the permeate liquid; step B, cooling (or cooling after further concentration) the sodium sulfate solution obtained in the step A, separating the sodium sulfate solution by centrifugation and drying the centrifuged sodium sulfate solution, so that crystal of sodium sulfate decahydrate is obtained; step C, concentrating the lithium hydroxide solution obtained in the step A by a steamer and further concentrating the concentrated lithium hydroxide solution in a crystallizing tank, then cooling, crystallizing and separating the concentrated lithium hydroxide solution by centrifugation and drying the centrifuged lithium hydroxide solution to obtain crystal of lithium hydroxide monohydrate. According to the production process, sodium sulfate and lithium hydroxide are effectively separated by the membrane separation technology, so that the purity of the lithium hydroxide solution is improved; thus, the quality of the lithium hydroxide product is effectively improved and production efficiency of the lithium hydroxide product is raised while the production cost is reduced.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

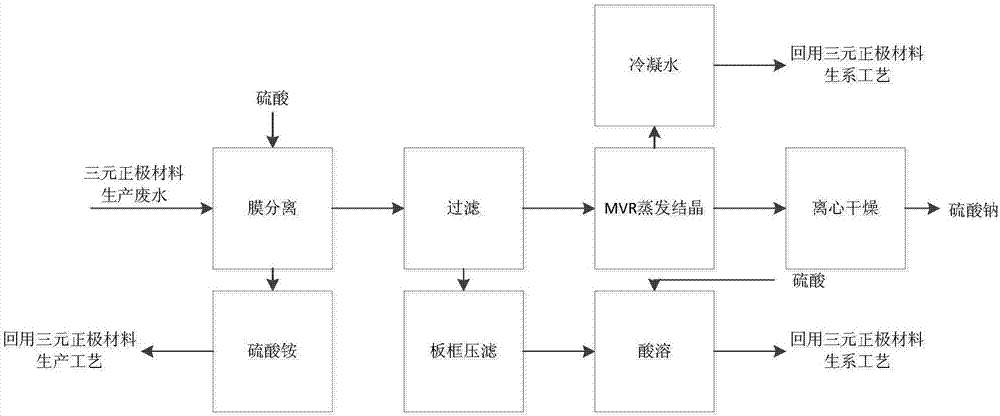

Treatment method and treatment system for ternary positive electrode material production wastewater

PendingCN106957124AHigh recovery rateSimple methodTreatment involving filtrationAlkali metal sulfite/sulfate purificationFiltrationSodium sulfate

The invention relates to a treatment method and treatment system for ternary positive electrode material production wastewater. According to the treatment method, a technological process of combining film separation, solid-liquid separation and evaporative crystallization is adopted for the first time: firstly, a sulfuric acid solution is taken as an absorbent and ammonia nitrogen in the wastewater is converted into ammonium sulfate by adopting film separation to achieve deamination; since the pH at an earlier stage is alkaline, a lot of metals in the wastewater are broken after deamination and form sediments together with alkali, and heavy metal sediments in the solution are filtered and removed; and supernate is subjected to evaporative crystallization to obtain sodium sulfate after filtration. According to the treatment method, ternary positive electrode material production wastewater is subjected to advanced treatment and reuse, so that the problem of treatment of the ternary positive electrode material production wastewater is effectively solved, ammonia, heavy metal and sodium sulfate resources in the wastewater are recovered, the water recovery rate is high and zero emission is achieved.

Owner:池州西恩新材料科技有限公司

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

Production method for increasing nitrate removal capacity by membrane method

ActiveCN102417193AImprove denitrification effectGuaranteed control effectAlkali metal sulfite/sulfate purificationAlkali metal chloridesSodium sulfateSodium hydroxide

The invention relates to a production method for increasing nitrate removal capacity by a membrane method. Light brine from a brine electrolytic dechlorination working section is subjected to pretreatment, and then, enters a membrane device for filtering sodium sulfate; outlet water of the membrane device for filtering the sodium sulfate is divided into two parts; one part which is nitrate-poor brine with a concentration being lower than 3 g / l enters a primary brine device of a sodium hydroxide device for salt dissolving; the other part which is nitrate-rich brine with a concentration being higher than 45 g / l enters a refrigeration denitration unit, temperature is once decreased to -7 to -8 DEG C, and the temperature is readjusted to 1 to -3 DEG C so as to separate out Glauber's salt crystals; the Glauber's salt crystals enter a centrifuge so as to produce Glauber's salt products; and mother liquor is returned for repeated use. With the adoption of the production method provided by the invention, the content of rich nitrate is increased through refiltering the nitrate-rich brine under the conditions of existing nitrate removal device by the membrane method, and more Glauber's saltcrystals are correspondingly separated out under the condition of using the same flow of nitrate-rich brine, so that the production capacity of the nitrate removal device by the membrane method is increased, and brine with a qualified sulfate indicator is ensured to be obtained.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com