Environment-friendly production process of 2-naphthol

A production process and a naphthol technology, which are applied in the field of 2-naphthol environmental protection production process, can solve the problems of high risk of use, high waste water treatment cost, secondary pollution and the like, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

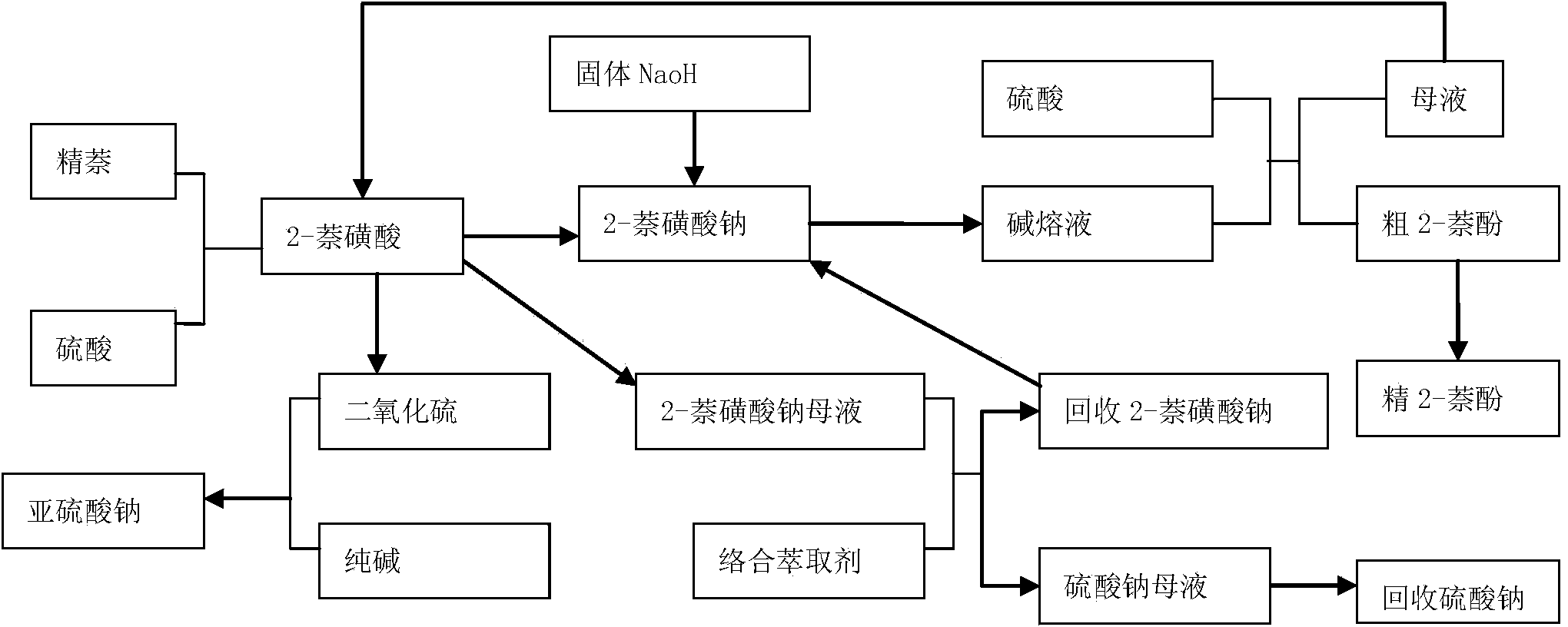

Image

Examples

Embodiment 1

[0016] Add 1170 parts by weight of refined naphthalene to the sulfonation kettle, heat to 120°C, add 1100 parts by weight of 98% concentrated sulfuric acid, heat up to 160°C for sulfonation, and use the waste sodium sulfite aqueous solution after separating the crude 2-naphthol Neutralize, then neutralize with dilute alkali, crystallize, filter, dry, alkali melt, dilute, then neutralize with sulfuric acid at 70°C-80°C until the phenolphthalein is colorless, stand and separate the crude 2- Naphthol, then washed with water, dehydrated, rectified, and sliced to obtain about 1000 parts by weight of 2-naphthol, the separated waste liquid goes to the alkali in step (1) and is used as lye, and the sulfur dioxide produced in neutralization is used with a soda ash aqueous solution Absorb sulfur dioxide to produce sodium sulfite.

Embodiment 2

[0018] Add 1170 parts by weight of refined naphthalene to the sulfonation kettle, heat to 120°C, add 1100 parts by weight of 98% concentrated sulfuric acid, and heat up to 160°C for sulfonation. The spent sodium sulfite aqueous solution is neutralized, alkali neutralized, crystallized, filtered, dried, alkali melted, diluted, and then neutralized with sulfuric acid at 70°C-80°C until the phenolphthalein is colorless, and the crude 2 -Naphthol, then washed with water, dehydrated, rectified, and sliced to obtain about 1000 parts by weight of 2-naphthol, and the separated wastewater was adjusted to a pH of about 2 with sulfuric acid, according to the ratio of extractant:wastewater=1:3 (volume) Carry out three-stage extraction, (extractant volume ratio N 235 : 200 # Solvent oil=1:4), the extract is back-extracted with 5%-10% sodium hydroxide, and the back-extraction is used to dilute the sulfonation solution, which can increase the yield of 2-naphthol by 2%-3%. After being oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com