Patents

Literature

282 results about "2-Naphthol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Naphthol, or β-naphthol, is a fluorescent colorless (or occasionally yellow) crystalline solid with the formula C₁₀H₇OH. It is an isomer of 1-naphthol, differing by the location of the hydroxyl group on the naphthalene ring. The naphthols are naphthalene homologues of phenol, but more reactive. Both isomers are soluble in simple alcohols, ethers, and chloroform. 2-Naphthol is a widely used intermediate for the production of dyes and other compounds.

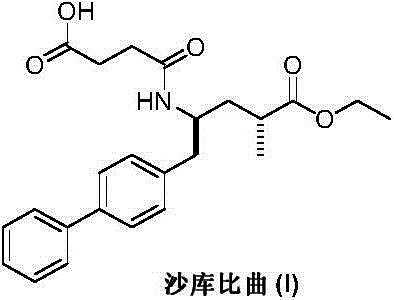

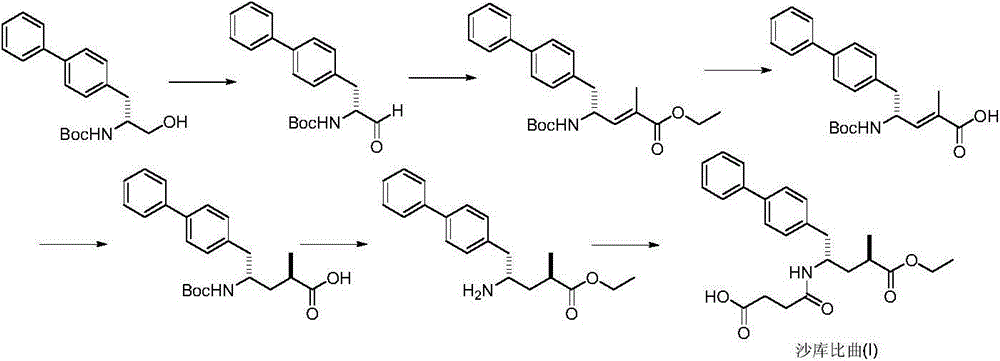

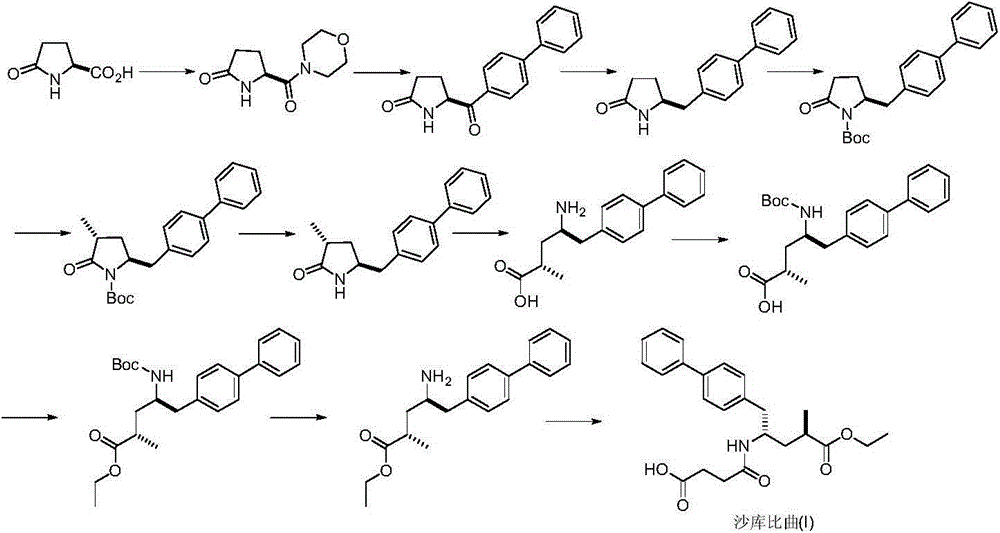

Preparation method of sacubitril

ActiveCN104557600AEase of industrial productionRaw materials are easy to getOrganic compound preparationCarboxylic acid amide separation/purificationSacubitril2-Naphthol

The invention discloses a preparation method of one of components of a novel antihypertensive drug LCZ696, namely, sacubitril (sacubitril, AHU-377, I). The method comprises the following preparation steps: carrying out cyclization, addition, debenzylation, ring opening, esterification, amidation and the like on a chiral induciton reagent (S)-1-(alpha-aminobenzyl)-2-naphthol (S-betti Base) and 2R-methyl-4-oxo-butyric acid to prepare the sacubitril (I). The preparation method is available in raw materials, concise in process, economic and environmentally friendly, and is suitable for industrial production.

Owner:广州博览咨询服务有限公司

Selective oxidative light catalyst and preparing method thereof

InactiveCN1552524AShort lifeLower reaction costOrganic-compounds/hydrides/coordination-complexes catalystsPhotocatalytic reactionBipyridine

A photocatalyst for selective oxidization is prepared from the inorganic carrier including NaX and NaY molecular sieves, ZSM-5 molecular sieve, mesopore molecular sieve, SO2, and Al2O3, the transition metal ions chosen from Fe, Mn, Ni and Co and the organic ligand chosen from alpha, alpha'-bipyridine, 1-(2-pyridineazo)-2-naphthol (PAN), schiff base, etc through complexing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

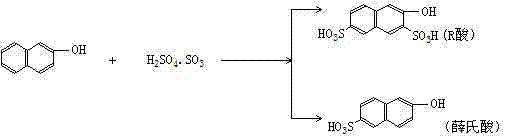

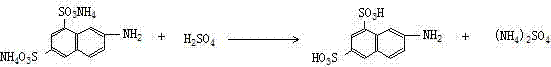

Process for preparing amino G acid

The invention relates to a process for preparing amino G acid, which belongs to the technical field of amino K acid production process. The process comprises the steps of sulfonating, salting out by ammoniacal liquor, treating G salt mother liquor, ammoniating G salt ammonium base sulfite, treating dehydrated liquid and the like, ammonium base sulfite is employed as a catalyst for replacing ammonium bisulfite, so that the pressure generated during ammonification process can be effectively reduced, the reaction time can be shortened, and the product yield and content can be increased. The method is characterized in that two streams of waste water are respectively treated, 2-naphthol is hydrolyzed and recovered by G salt mother liquor, neutralized for reaching the standard, and then exhausted; ammonium sulfate-rich effluent is used for producing fertilizer, and the zero discharge is realized. The unit consumption of the raw material 2-naphthol is decreased from 0.75 ton / ton in a traditional process to less than 0.64 ton / ton when the problem of waste water treatment is solved, so that the production cost is reduced, the production safety coefficient is high and no harmful gas is discharged. The process of the invention solves the problems that two streams of waste water are generated during the present production process, the difficulty of waste water treatment is large, the production cost is high and the large harm on environment is caused.

Owner:湖北鑫慧化工有限公司

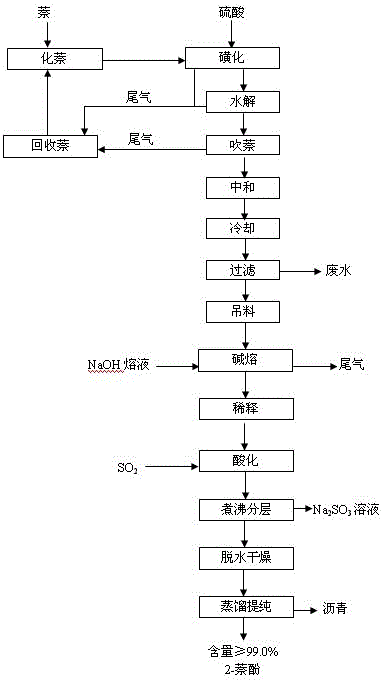

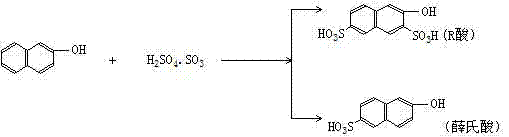

Preparation method of joint production of alpha maphthol and beta naphthol

InactiveCN1513824AAdd stepsLow yieldOrganic chemistryOrganic compound preparation2-Naphthol1-Naphthol

A process for preparing the 1-naphthol and 2-naphthol simultaneously includes sulfonating naphthalene by concentrated sulfuric acid, filtering to obtain alpha-naphthalenesulfonic acid and acidic mother liquid, dripping the mother liquid in fused naphthalene, high-temp sulfonating, hydrolyzing, blowing naphthalene to obtain high-purity beta-naphthalenesulfonic acid solution, respectively neutralizing the alpha-naphthalenesulfonic acid and beta-nephthalenesulfonic acid solution, alkali fusing, acidifying to obtain said two products, and dissolving beta-naphthalenesulfonic acid in sulfuric acid. Its advantages are high output rate and low pollution.

Owner:江苏华达化工集团有限公司

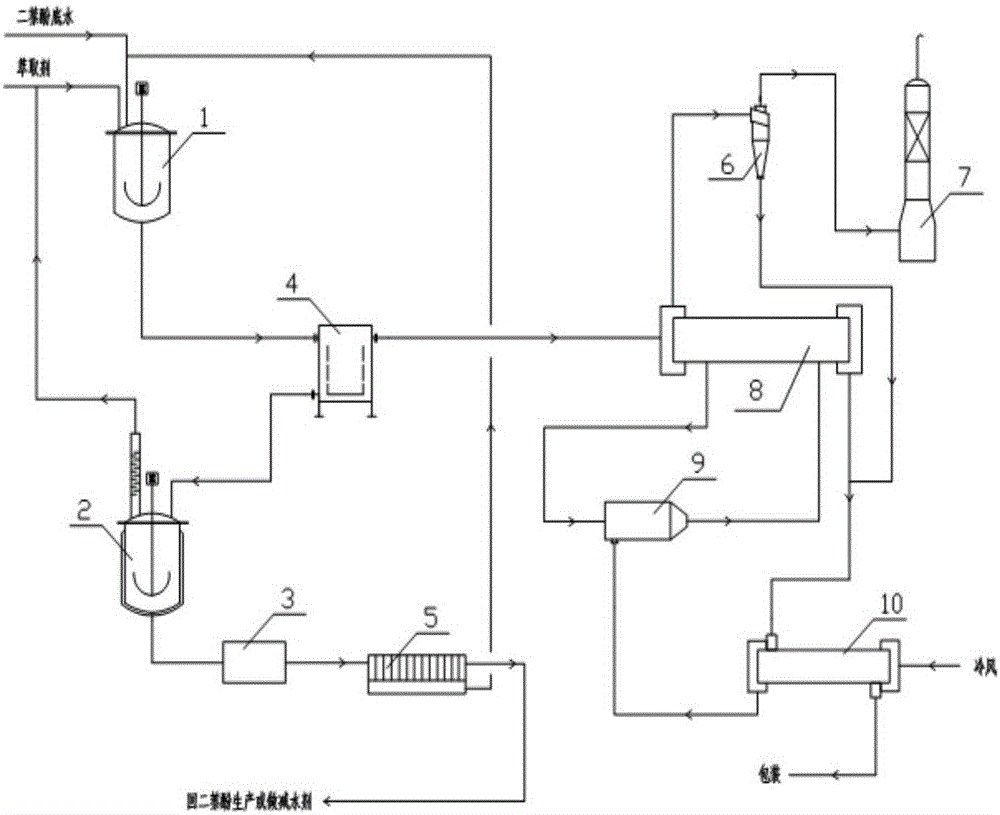

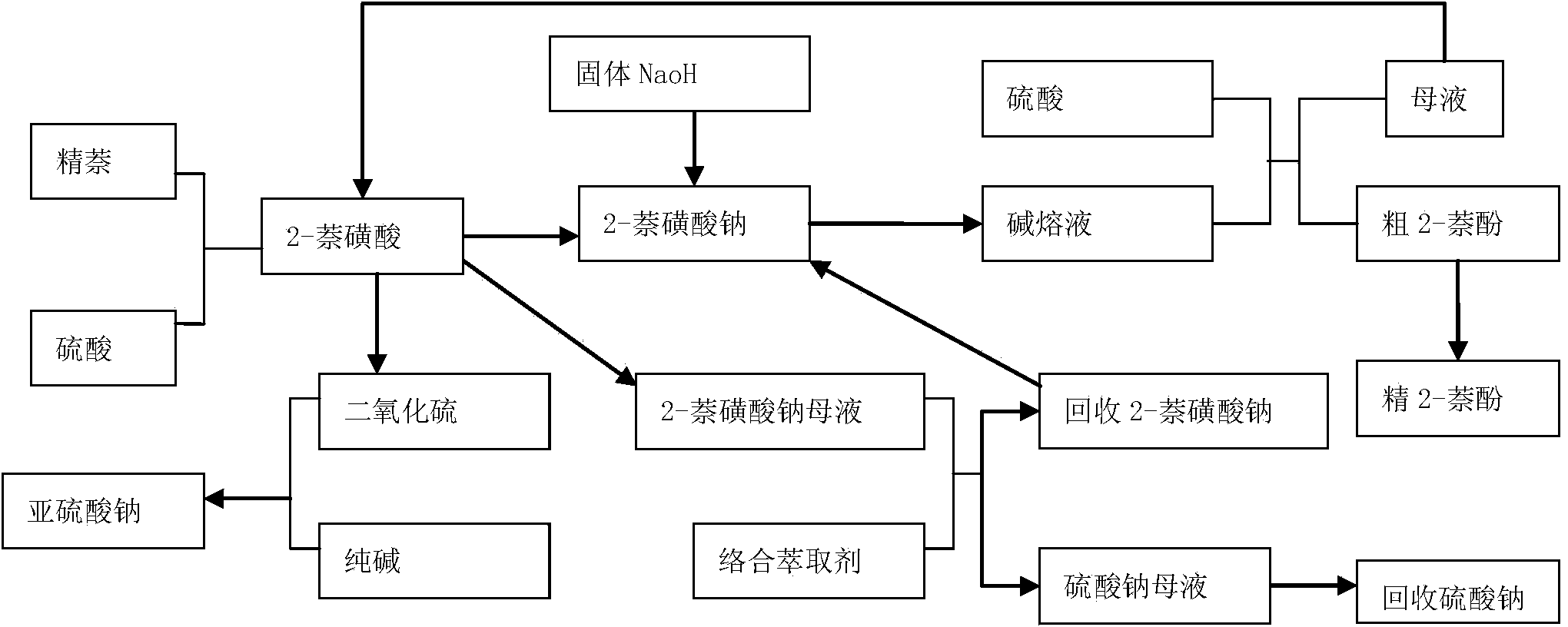

Environment-friendly production process of 2-naphthol

ActiveCN103626637AHigh yieldMeet the needs of industrial productionOrganic chemistryOrganic compound preparationEnvironmental resistanceSulfite salt

The invention relates to an environment-friendly production process of 2-naphthol. The environment-friendly production process of the 2-naphthol comprises the following steps: adding refined naphthalene into a sulfonation kettle, adding concentrated sulfuric acid, heating and performing sulfonation reaction, neutralizing a mixture by using alkali after the reaction is finished, crystallizing, filtering, drying, performing alkali fusion and diluting; neutralizing the diluted alkali fused sulfonation liquid by using sulfuric acid at 70 to 80 DEG C, controlling the pH to be 4 to 7, standing and layering, and separating out crude 2-naphthol; washing, dehydrating and rectifying the separated crude 2-naphthol to obtain refined 2-naphthol; and removing alkali from the separated waste liquid, neutralizing to serve as alkaline liquid, absorbing sulfur dioxide generated by neutralization by using a sodium carbonate aqueous solution to produce sodium sulfite, adjusting the pH value of the waste liquid after 2-sodium naphthalene sulfonate is separated to be 2+ / -1, performing three-stage extraction by using an extracting agent, performing reverse extraction on the extracting liquid by using dilute alkali, diluting sulfonated liquid by using the reverse extraction liquid, oxidizing the water phase by using a Fenton reagent or KMnO4, decoloring by using active carbon, and recovering sodium sulfate by a mechanical vapor recompression (MVR) concentration technology. By the process provided by the invention, no waste water is discharged basically and the production cost is reduced.

Owner:青岛奥盖克化工股份有限公司

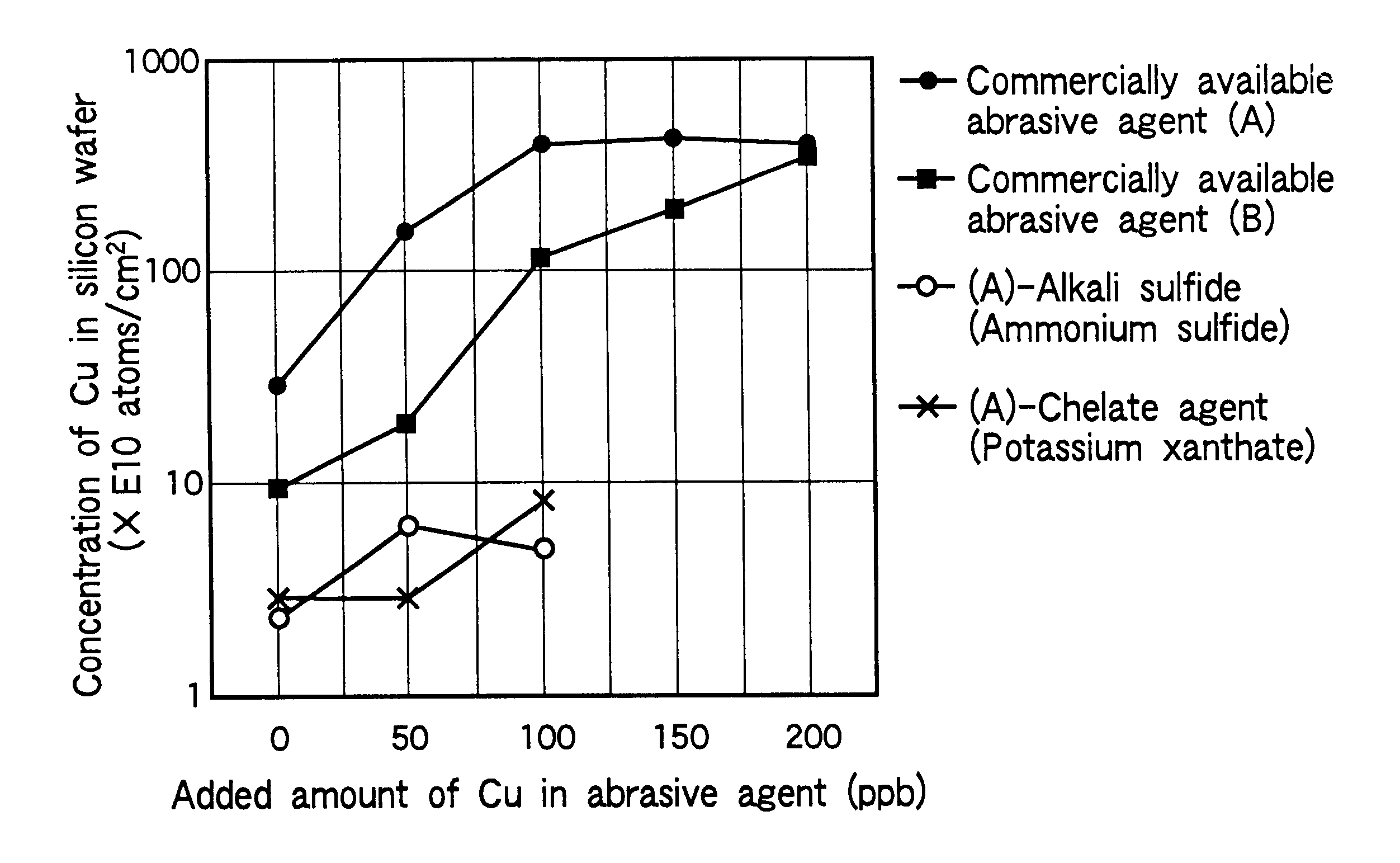

Method of polishing silicon wafer

InactiveUS6383060B2Polishing machinesRevolution surface grinding machinesAdditive ingredient2-Naphthol

Mirror-polishing of a silicon wafer is conducted using an abrasive agent which contains silica as a principal ingredient, and either one of the ingredients set forth at (1) and (2):(1) an ingredient which is selected from alkali sulfide, alkali hydrogensulfide, and the mixture thereof; and(2) a chelate agent which contains at least alpha-benzoinoxime, diethyldithiocarbamic acid, cupferron, xanthogenic acid, neocupferron, beryllon II, beta-quinolinol, 1,1,1-trifluoro-3(2-thenoyl)acetone, dimethylglyoxime, and 1-(2-pyridylazo)-2-naphthol.

Owner:SUMITOMO MITSUBISHI SILICON CORP

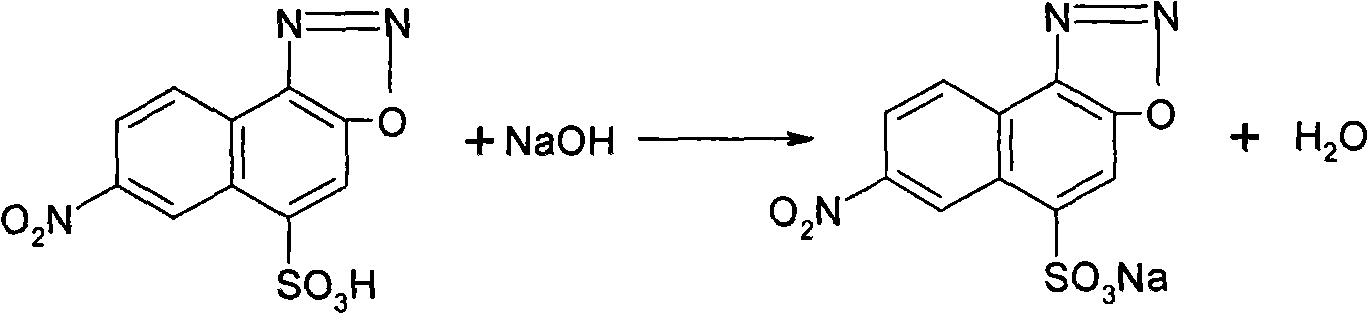

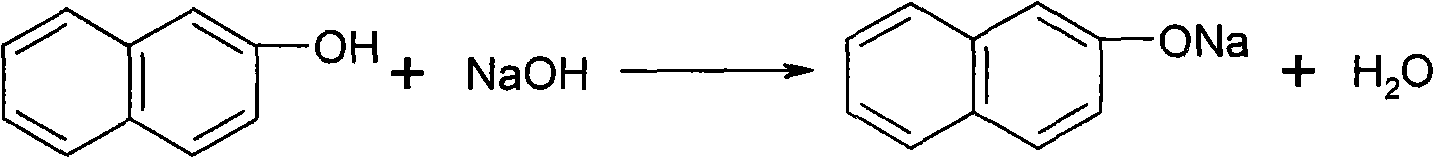

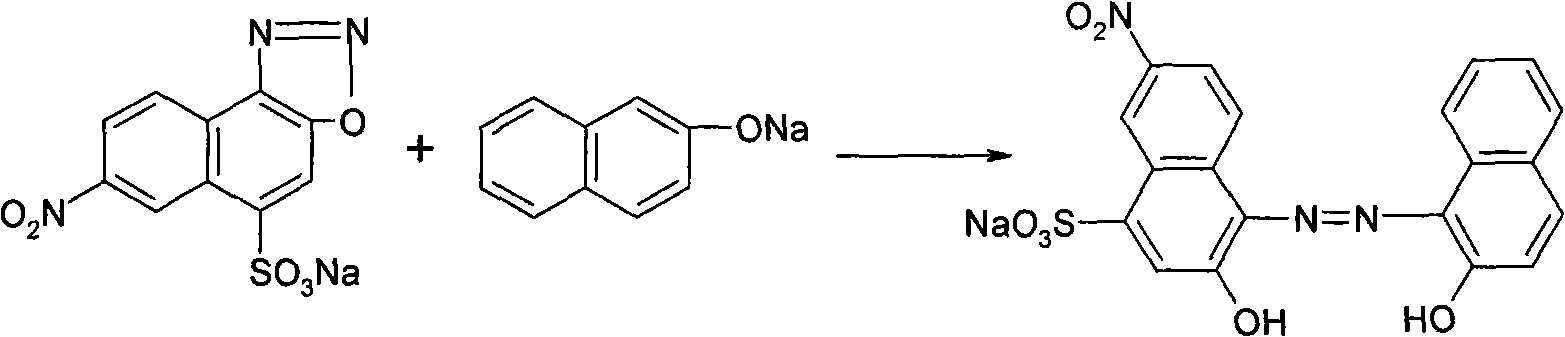

Method for preparing acid black 172

InactiveCN101538414AReduce viscosityIncrease concentrationDyeing processComplex metal azo dyesSodium bicarbonateDissolution

The invention relates to a method for preparing acid black 172. The method comprises the following steps that: (1) 6-nitro-1 and 2-diazoxynaphthalene-4-sulfonic acid are put into a dissolution tank, added with water for dissolution, added with a sodium hydroxide solution and stirred. (2) 2-naphthol is put into the dissolution tank, added with water for dissolution, added with the sodium hydroxide solution, stirred, heated, added with a dispersant and aliphatic diol or ether and stirred again; (3) a prepared 2-naphthol solution is rapidly put into and coupled with a solution with 6-nitro-1 and 2-diazoxynaphthalene-4-sulfonic acid so as to obtain coupled liquid; and (4) the coupled liquid is added with formic acid, ammonium bicarbonate or sodium bicarbonate and basic chromium sulfate, heated to be between 100 and 102 DEG C, thermally insulated and stirred so as to obtain an acid black 172 serous finished product. The method for preparing acid black 172 has the advantages of simple production process, scientific reasonable control on reaction conditions, short production cycle of produces, high yield, good quality, friction resistance, obviously raised fastness of resisting rinse and sunshine, obviously reduced side reaction and impurities, low production cost, high production efficiency and better environment-friendly property.

Owner:TIANJIN SANHUAN CHEM

Prepn of chiral compounds S-(+)-and R-(-)-1-(alpha-aminobenzyl)-2-naphthol

A preparation method for S-(+)-1-(alpha-aminobenzyl)-2-naphthol or R-(-)-1-(alpha-aminobenzyl)-2-naphthol mainly includes the following steps: A. under room temp., racemized (minus or plus)-1-(alpha-aminobenzyl)-2-naphthol is added with acetone and mixed, L-(+)-tartaric acid is added, mixing is continued until white solid is completely deposited, and then it is filtered to obtain S-(+)-1-(alpha-aminobenzyl)-2-naphthol and complex substance S-L-2 solid of L-(+)-tartaric acid; B. the obtained two components in step A are mixed and analyzed in sodium carbonate solution, and extracted with ethyl ether. The merged liquid extracts after being concentrated have the residual liquid obtained and stood still under low-temp., and the high-optical purity crystal of S-(+)-1-(alpha-aminobenzyl)-2-naphthol (S-1) is precipitated.

Owner:NANJING UNIV

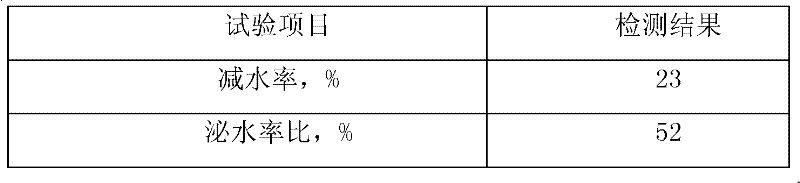

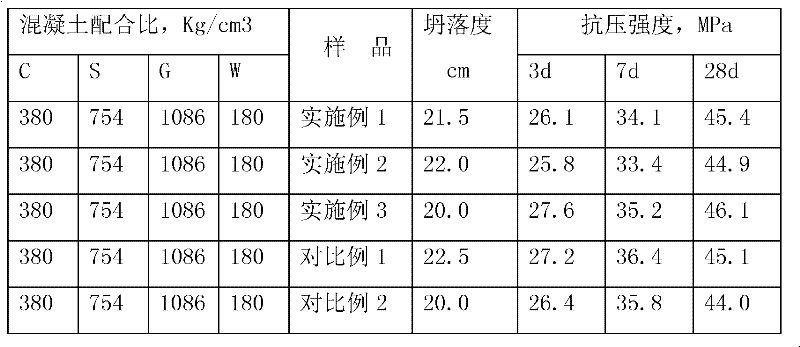

Preparation method for synthetizing high efficiency water reducing agent by 2-naphthol waste water

The invention relates to a preparation method for synthetizing a high efficiency water reducing agent by 2-naphthol waste water. The invention belongs to the technical field of concrete water reducing agents. According to the preparation method for synthetizing the high efficiency water reducing agent by the 2-naphthol waste water, the proportion of crude naphthalene to concentrated sulfuric acid to naphthol waste water to formaldehyde is (1:0.8)-(1.0:0.1)-(0.9:0.5)-0.8. The preparation method for synthetizing the high efficiency water reducing agent by the 2-naphthol waste water comprises the following process flows of: 1-, sulfonating: heating to melt crude naphthalene, adding the concentrated sulfuric acid when the temperature rises to 130-160 DEG C, and reacting for 2-2.5 hours at the temperature of 160-165 DEG C; 2-, hydrolyzing: cooling reactants to 90-110 DEG C, adding naphthol waste liquor and hydrolyzing for 0.5-1 hour; 3-, condensation: dropwise adding the formaldehyde at the temperature of 95-115 DEG C and reacting for 3-6 hours; and (4) neutralizing: adding liquid caustic soda to neutralize a condensation compound to regulate a pH value to be 7-9 to obtain a water reducing agent product. The preparation method for synthetizing the high efficiency water reducing agent by the 2-naphthol waste water has the advantages that the production process is simple, the operation is convenient, the process control is easy, waste is turned into wealth, and thereby, secondary emission cannot be generated, and the economic value and the social benefit are high and the like.

Owner:天津市飞龙砼外加剂有限公司

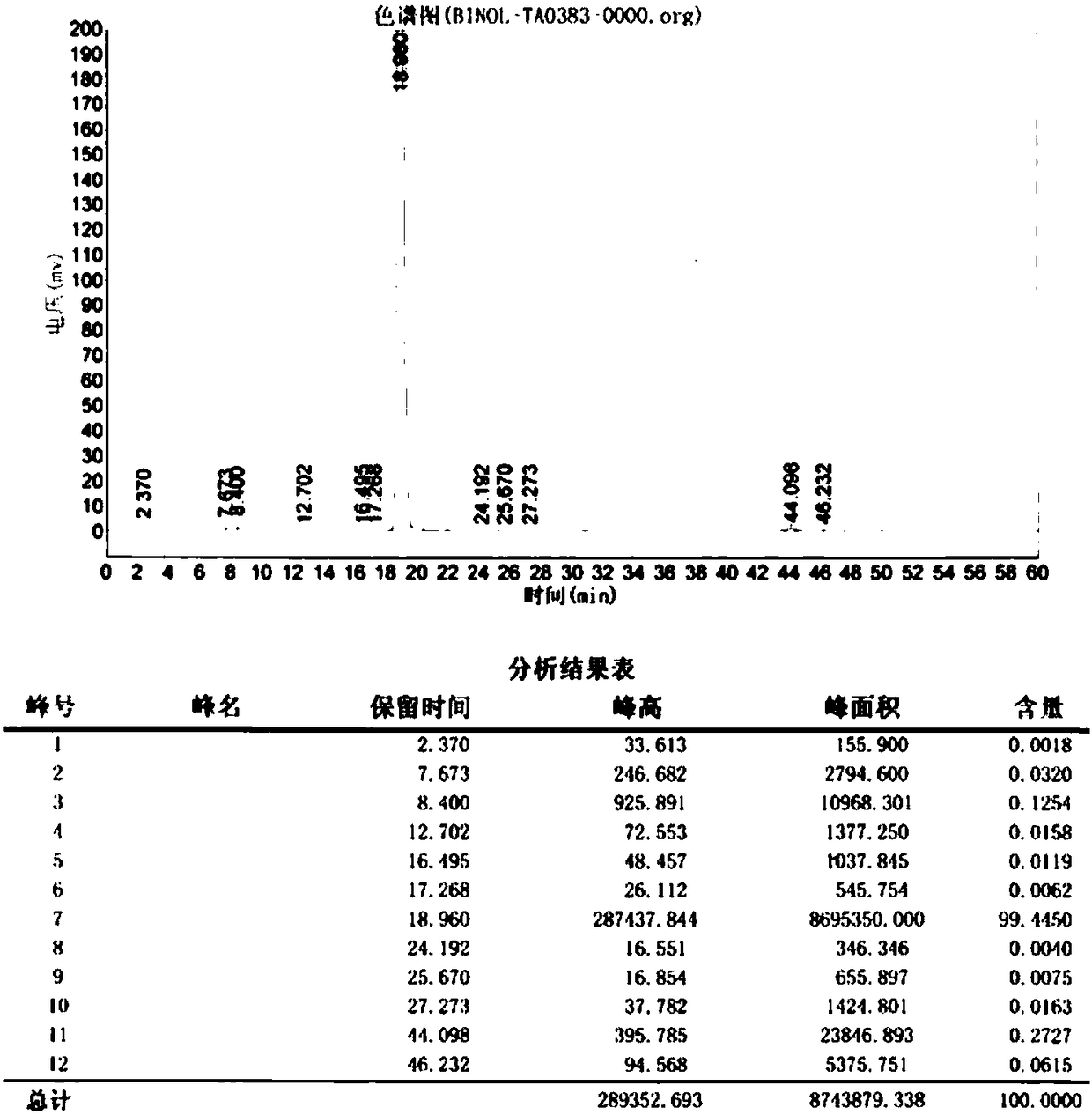

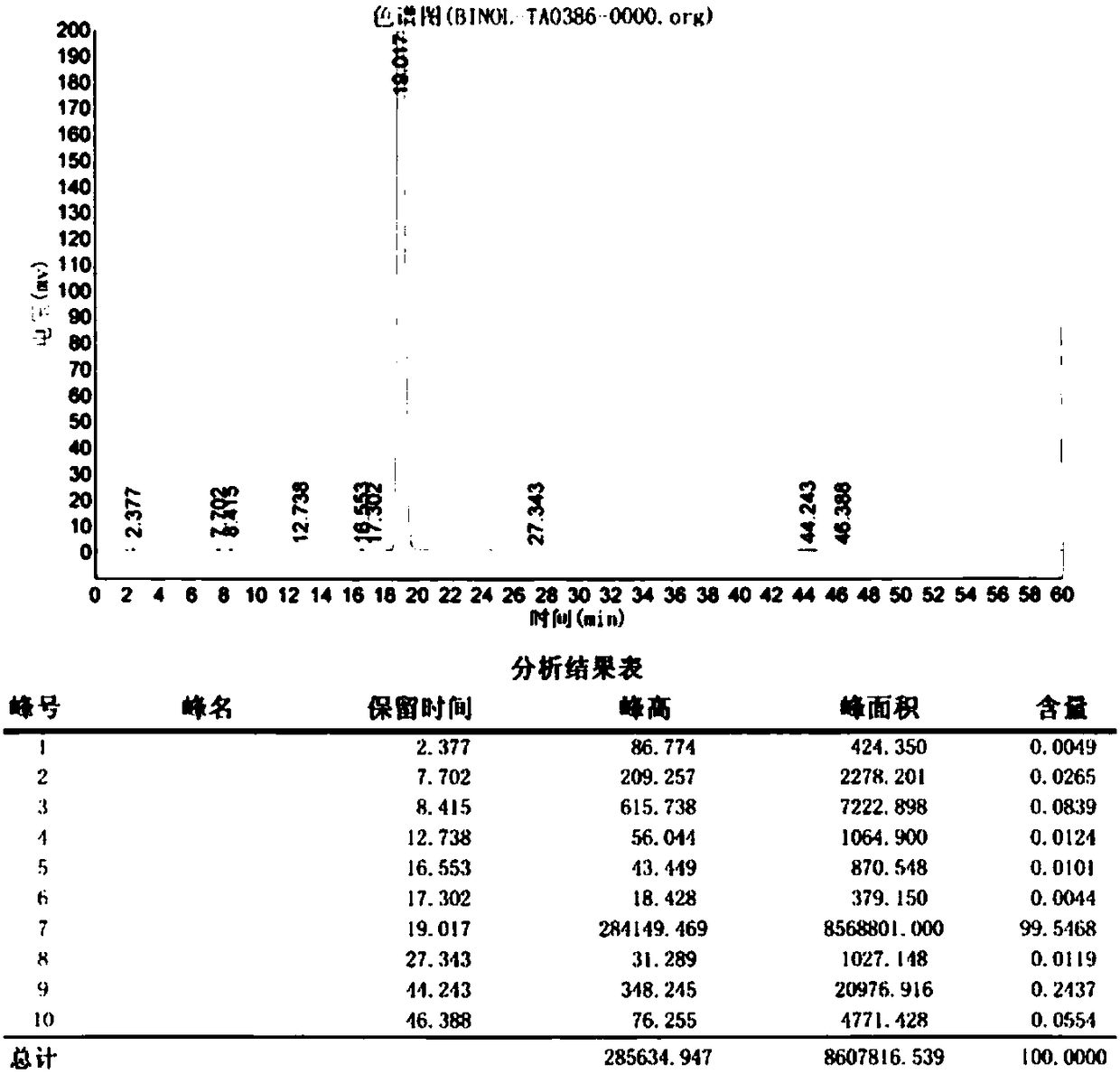

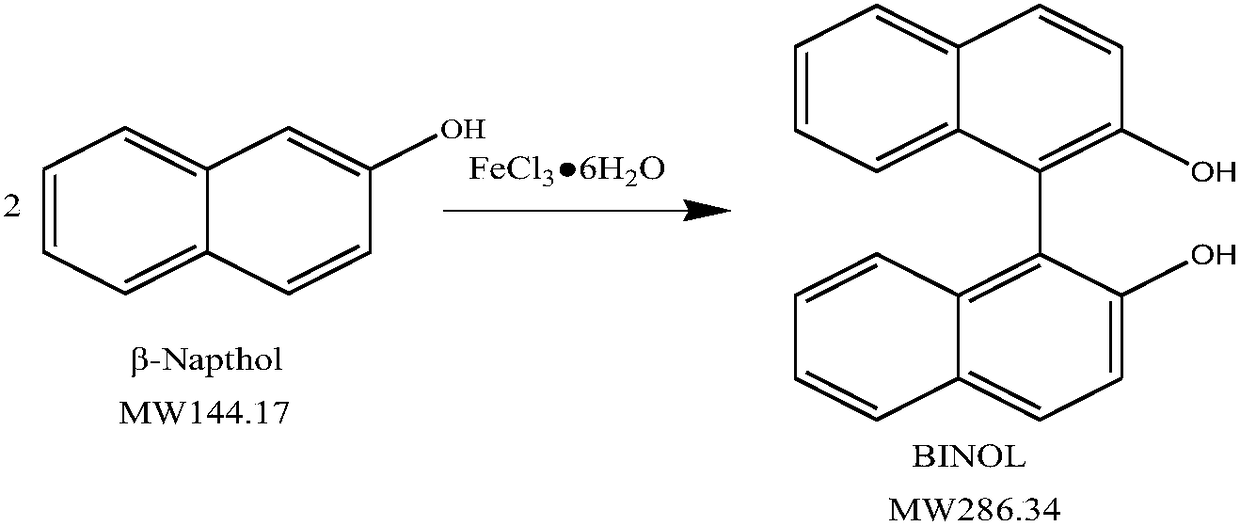

Method for preparing electronic 2,2'-binaphthol

InactiveCN108083985AUniform responseEasy to operateOrganic chemistryOrganic compound preparationWater insoluble2-Naphthol

The invention discloses a method for preparing electronic 2,2'-binaphthol. The method comprises the following steps: under the action of a phase transfer catalyst and / or a surfactant, enabling 2-naphthol to react with a ferric trichloride solution and hydrogen peroxide, and finally performing reaction treatment with a water insoluble organic solvent, thereby obtaining an electron-grade product, namely 2,2'-binaphthol. Compared with the prior art, the method has the advantages that (1) the method has the advantages of a small amount of wastes of a solid-phase method and reaction balance, easiness in operation and low equipment requirements of a liquid-phase method; (2) the reaction efficiency is high, and a small amount of ferric chloride is used; (3) a product yield is high, and the highest product yield is up to 95%; (4) the product purity is improved, and electron-grade high requirements of electronic chemicals on raw materials are met; (5) a good production environment can be made,the working intensity is low, a small amount of wastewater is generated, and wastewater with ferrous ions can be oxidized and recycled.

Owner:YWK CHEM TAICANG

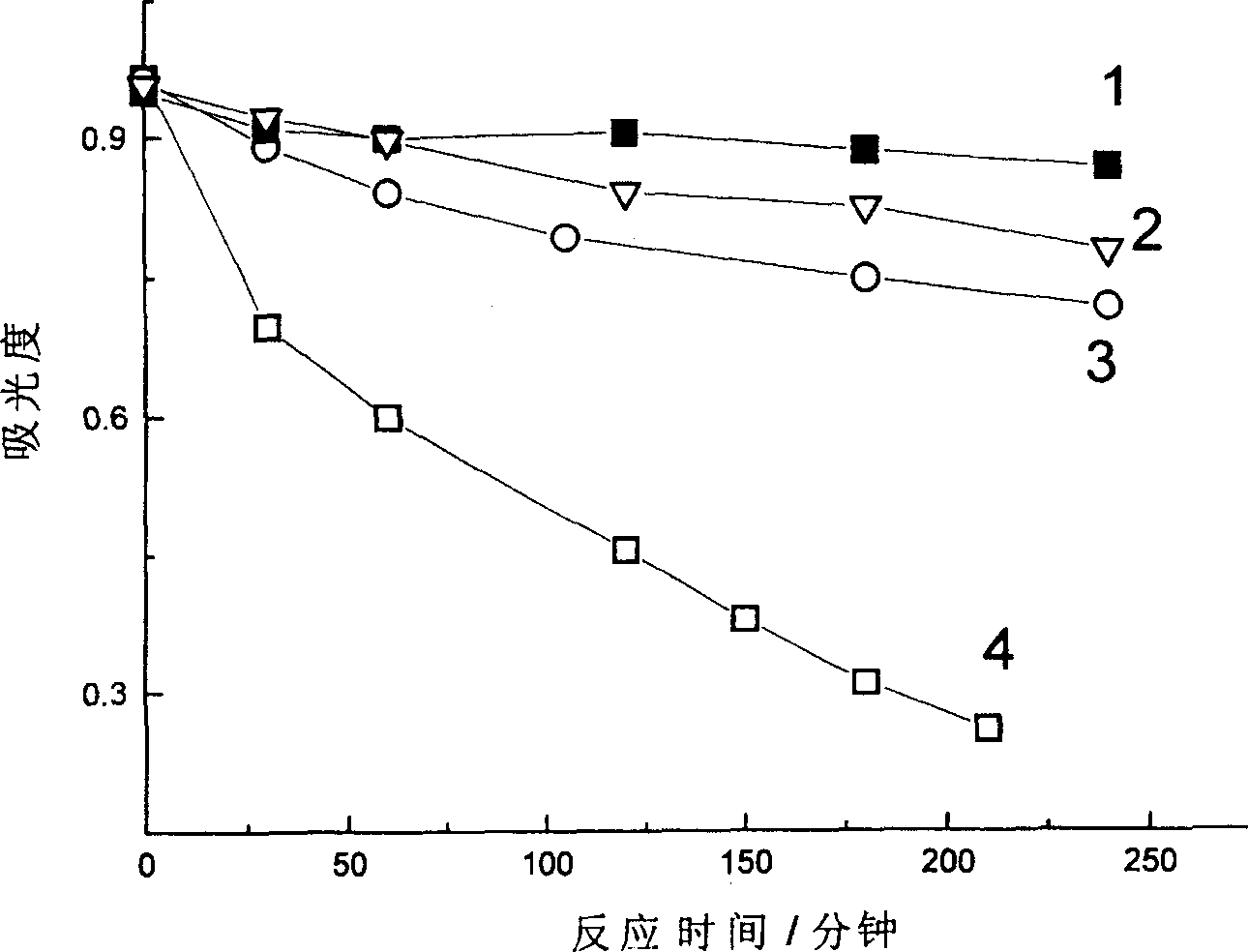

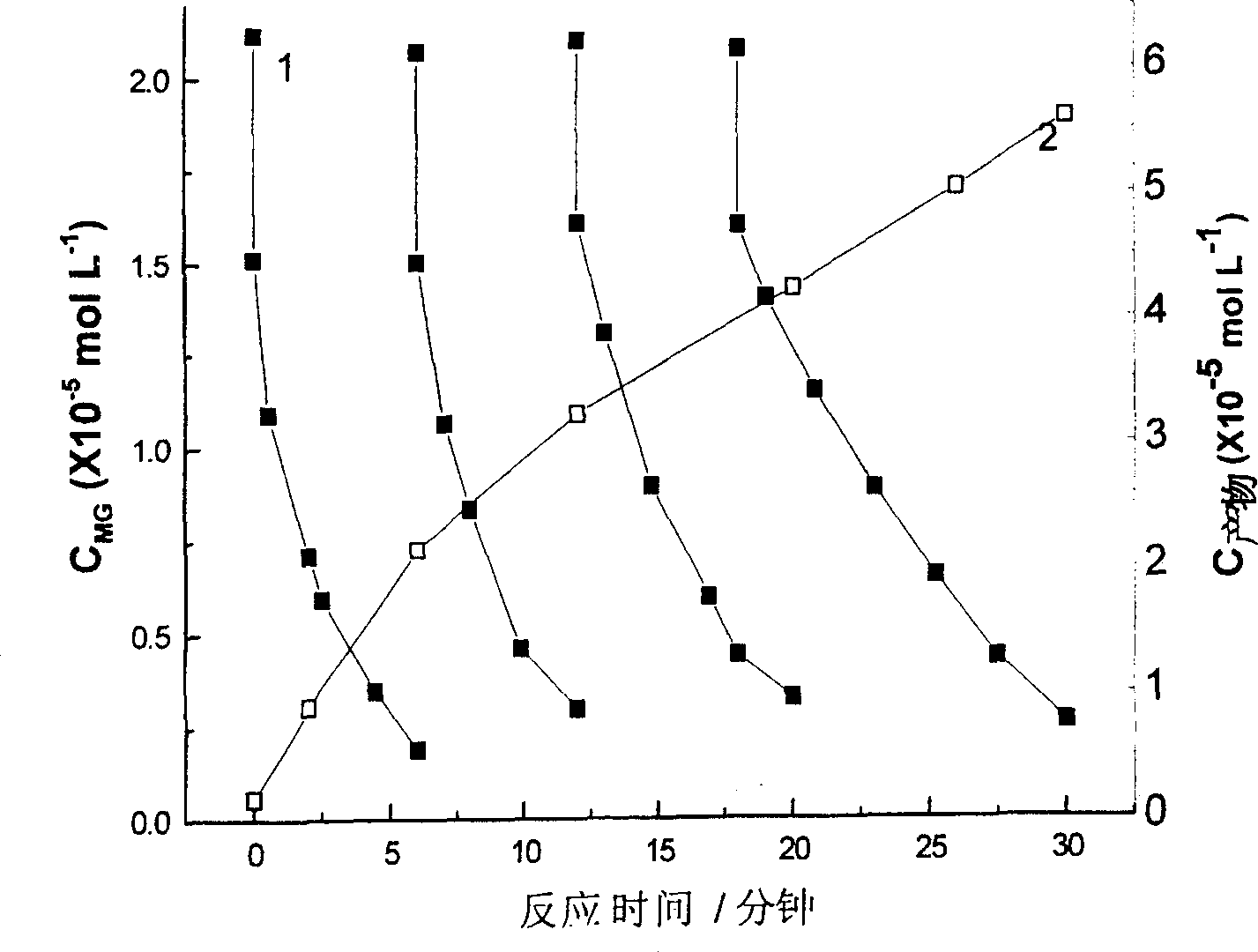

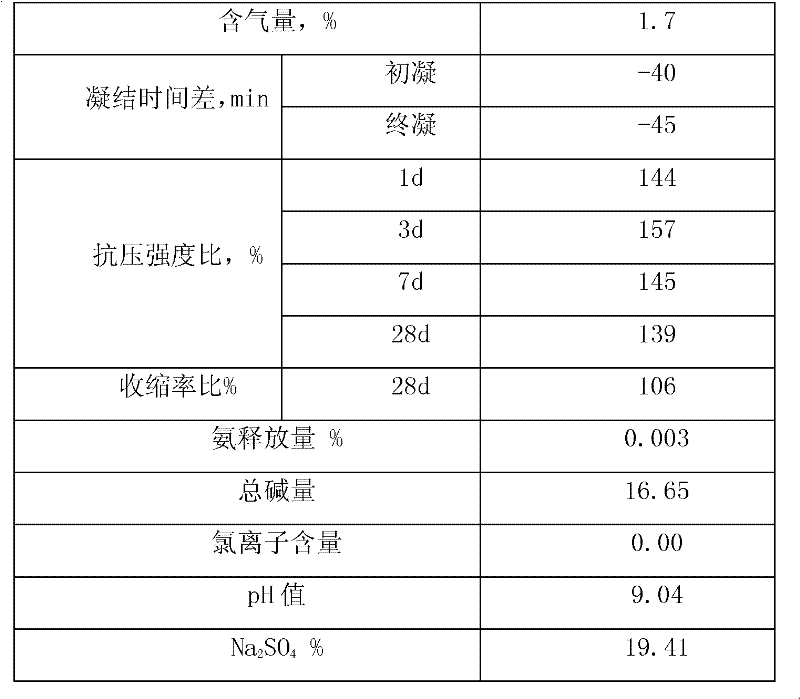

Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative

ActiveCN104072471AIncrease acidityHigh catalytic activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationReaction temperature

The invention discloses a green preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative and belongs to the technical field of chemical material preparation. According to the preparation method, in preparation reaction, the molar ratio of aromatic aldehyde to 2-naphthol is 1 to 2; the molar weight of the catalyst is 3-5 % of aromatic aldehyde; the reaction temperature is 110 DEG C; the reaction time is 10-30 min; the preparation method comprises the following steps: after reaction, water is added for cooling; a great amount of solid materials are precipitated; the solid materials are grinded and stand still and then are subjected to suction filtration; the obtained filter residues are water-washed and dried and then an aqueous solution with 95% of ethyl alcohol is adopted for recrystallization; the pure 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative is obtained after vacuum drying. Compared with other preparation methods using acidic ionic liquid as the catalyst, the preparation method has the advantages that the catalyst activity is good, the losses in recycling are less, the biological degradation is easy to realize, the whole preparation process is simple, convenient and economic and the industrialized mass production is facilitated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

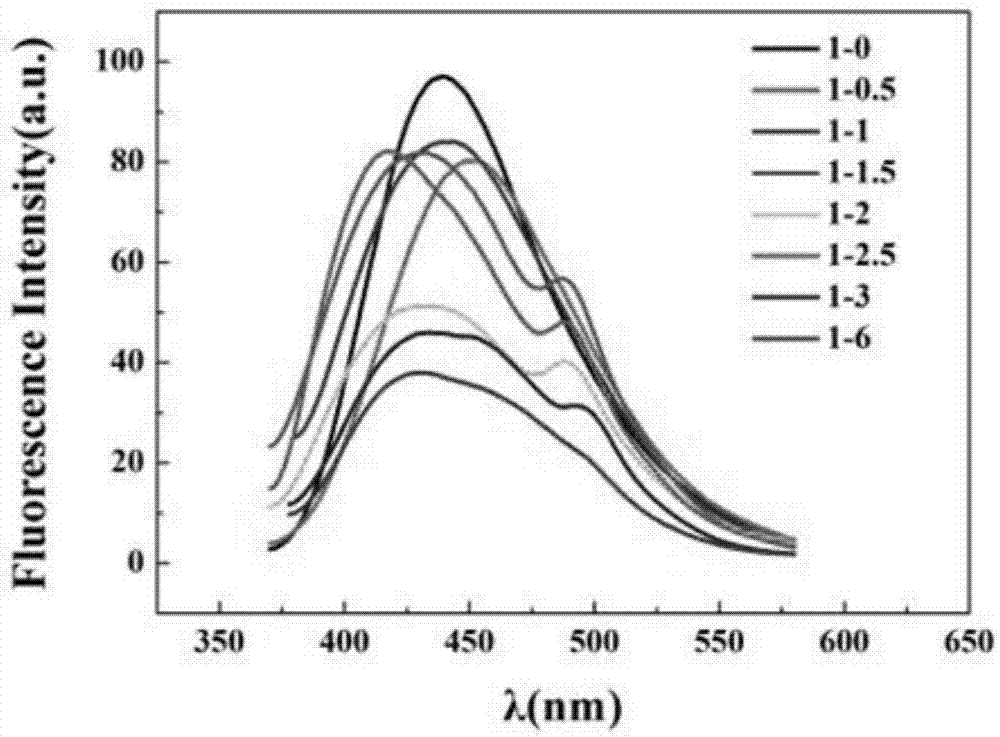

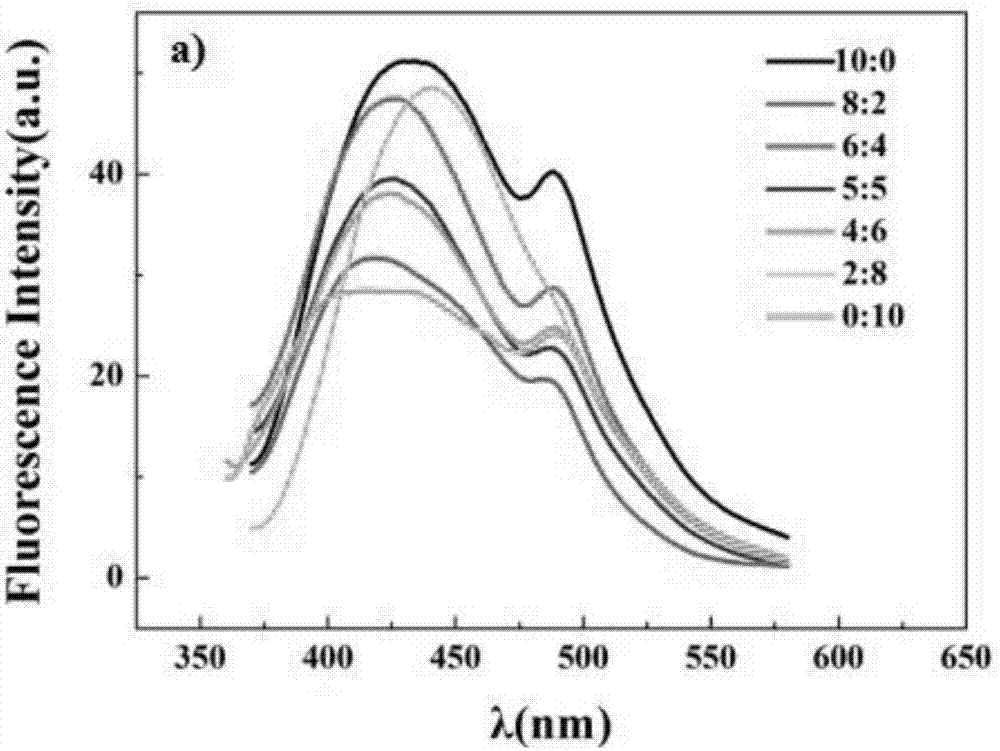

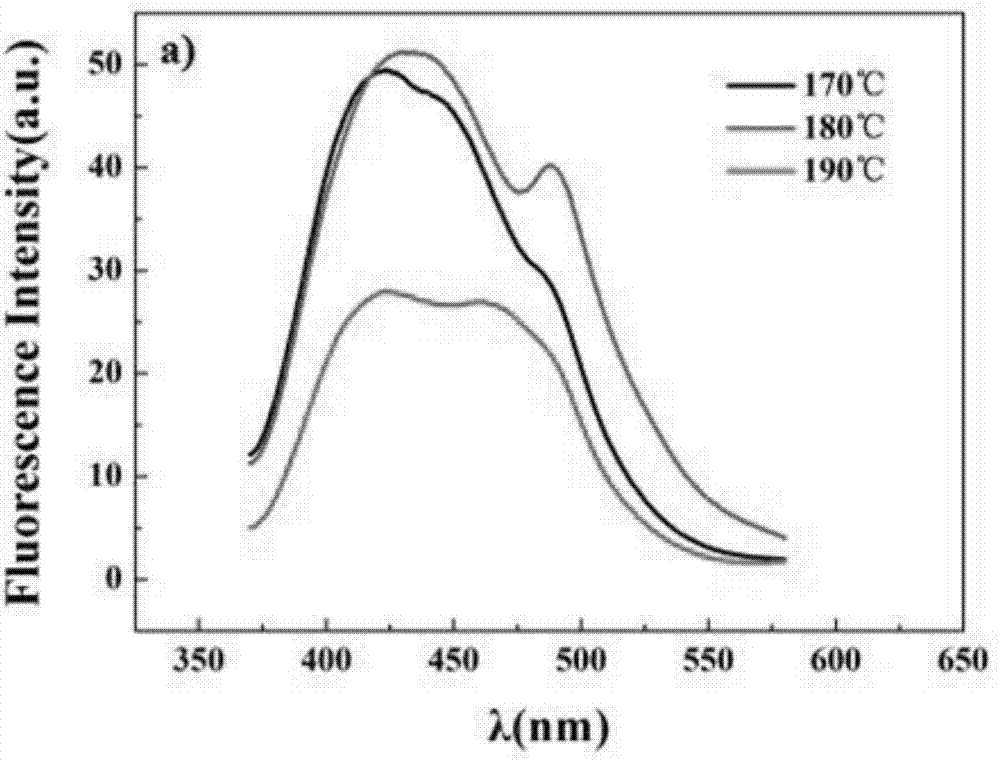

Preparation method for dual-emitting fluorescence carbon spot

InactiveCN107573930ARaw materials are cheap and easy to getEasy to operateNano-carbonFluorescence/phosphorescenceReaction temperature2-Naphthol

The invention discloses a method for quickly and conveniently preparing a dual-emitting carbon spot. The method comprises the following steps: step (1) weighing 1-(2-pyridine azo)-2-naphthol and copper chloride dihydrate in the mole ratio of 1:(1-3), adding absolute ethyl alcohol and water in the volume ratio of (10-0):(0-10) and ultrasonically dissolving, thereby acquiring a mixed solution; step(2) transferring the mixed solution into an airtight reactor for heating and reacting, wherein the reaction temperature is 170 DEG C-190 DEG C and the reaction time is 3-5h; and step (3) naturally cooling the reaction system to room temperature, performing silicagel column chromatography, removing a solvent and performing vacuum drying, thereby acquiring the carbon spot. The carbon spot prepared by the method has fluorescence emission at 426nm and 488nm wavelength under the excitation of 350nm light; the carbon spot is capable of detecting Fe<3+> according to specific dual signals of fluorescence peaks at the two wavelengths; the method is wide in linear range and low in limit of detection.

Owner:SOUTHWEST UNIVERSITY

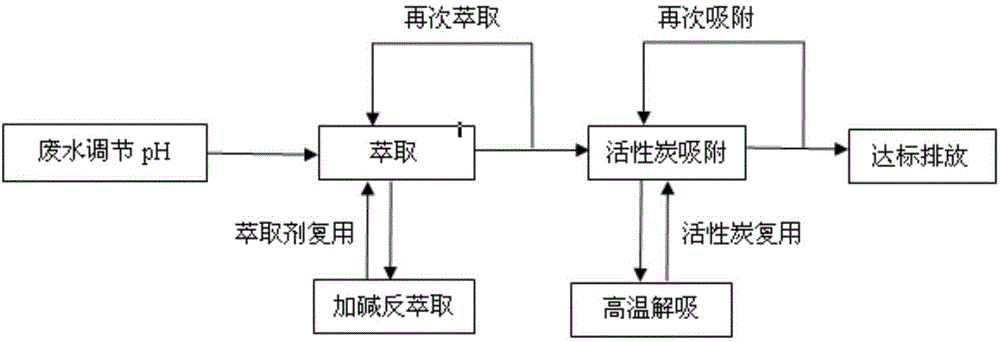

Method for treating wastewater generated in production of 2-naphthol

InactiveCN104591452AImprove processing efficiencyEasy to operateSpecific water treatment objectivesMultistage water/sewage treatmentActivated carbonWastewater

The invention discloses a method for treating wastewater generated in the production of 2-naphthol. The method comprises the following steps: (1) adding an extracting agent into acidified wastewater generated in production of 2-naphthol, uniformly stirring, extracting, after the extraction is completed, standing for layering to obtain an oil-phase extract and a water-phase raffinate; and (2) adding activated carbon to the raffinate for adsorption, after the adsorption is completed, separating to remove activated carbon to obtain purified wastewater. By combining extraction and activated carbon adsorption, the method has the advantages of high treatment efficiency, mild condition and the like and is simple to operate and easy to control, and furthermore, the extracting agent and activated carbon can be repeatedly used so that the cost is reduced and the naphthalene sulfonate in the wastewater can also be used as a resource for recycling.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

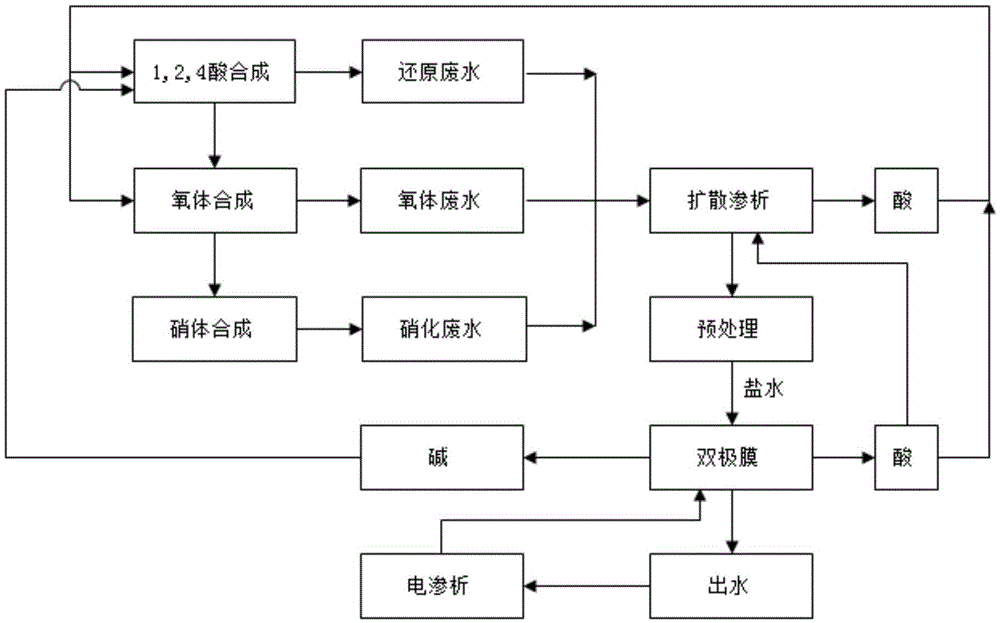

Improved 6-nitro-1-diazo-2-naphthol-4-sulphonic acid production process

ActiveCN105566176ASolve processing problemsLow input costOrganic chemistryOrganic compound preparationDialysis membranesFlocculation

The invention discloses an improved 6-nitro-1-diazo-2-naphthol-4-sulphonic acid (hereinafter referred to as 6nitro) production process. The process includes preparation of 1,2,4 acid, preparation of 1-diazo-2-naphthol-4-sulphonic acid and preparation of 6-nitro-1-diazo-2-naphthol-4-sulphonic acid and particularly includes steps: step 1, treating 6nitro wastewater through a diffusion dialysis membrane to recover acid and obtain diffusion dialysis treatment fluid; step 2, treating the diffusion dialysis treatment fluid to obtain treatment fluid by at least one of means of neutralization and sedimentation, microelectrolysis, Fenton oxidation, flocculation, wet oxidation, adsorption and extraction; step 3, treating the treatment fluid obtained at the step 2 by bipolar membrane electrodialysis to obtain an acid solution and an alkaline solution for recycling in 6nitro production process. By introduction of diffusion dialysis and bipolar membrane electrodialysis to the 6nitro production process, acid recovery is realized while acid and alkali input cost is reduced.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Method for producing high purity 2-hydroxy-3-naphthoic acid

ActiveCN102816063AEasy to handleImprove stabilityCarboxylic compound separation/purificationDistillationCarbonization

Disclosed is a method for producing a high purity 2-hydroxy-3-naphthoic acid. The method includes a 2-naphthol measuring tank, a caustic soda liquid storage tank, a caustic soda liquid measuring tank, a salt forming reaction vessel, carbon dioxide, a carbonization kettle, a resin separation, a resin solid waste, a dilute sulfuric acid, a neutralization, a filter pressing, a filter cake distillation, a 8% sodium hydroxide, a resin adsorption, an acid eduction, a sewage treatment workshop, a centrifugal dewatering, a pneumatic drying and finishing of a high purity 2-hydroxy-3-naphthoic acid product. The caustic soda liquid storage tank is downwards connected to the caustic soda liquid measuring tank, the caustic soda liquid measuring tank is connected to the salt forming reaction vessel, the salt forming reaction vessel is downwards connected to the carbonization kettle, simultaneously the carbon dioxide is connected to the carbonization kettle, 2-naphthol generated by reaction in the carbonization kettle and 2-naphthol obtained by the filter cake distillation are connected to the 2-naphthol measuring tank, the carbonization kettle is downwards connected to the resin separation, and simultaneously the resin separation is upwards connected to an ethyl naphthol feed liquid and the dilute sulfuric acid and downwards connected to the neutralization and the resin solid waste. According to the method, the whole process is simple, the operation and the usage are convenient, the stability is good, and the reliability is high.

Owner:山东世纪阳光科技有限公司

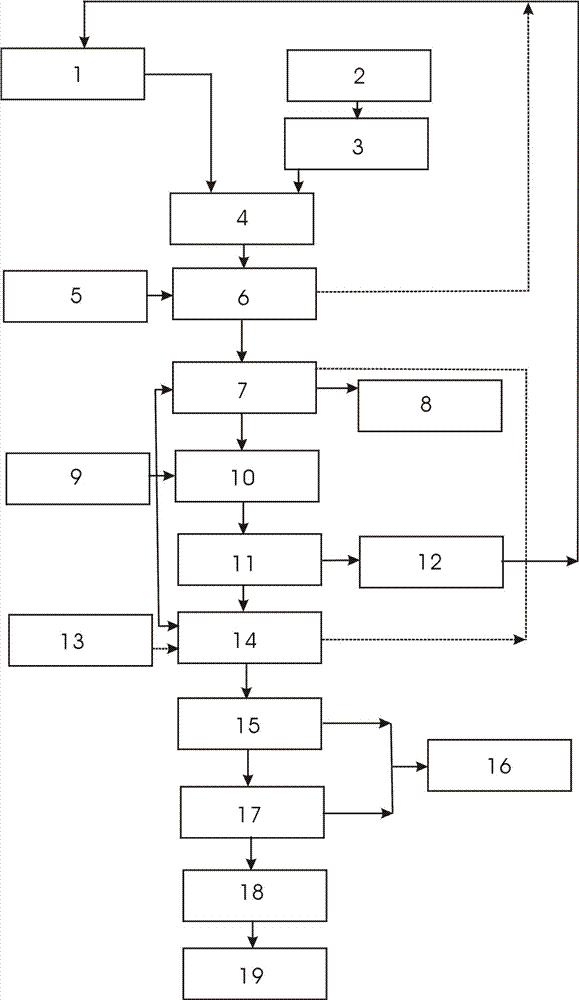

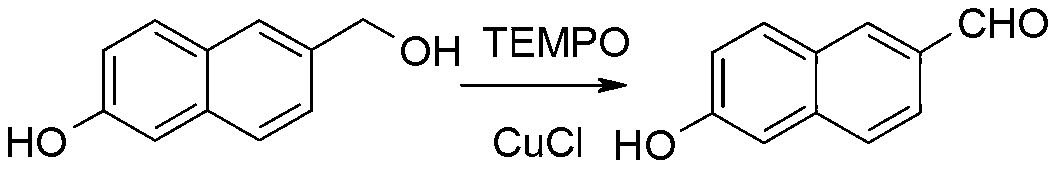

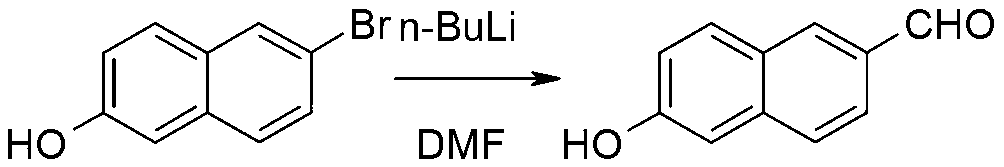

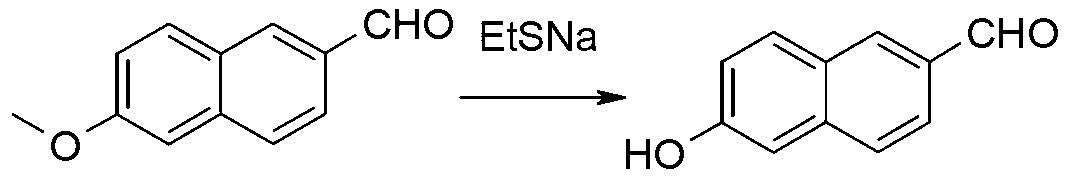

Synthetic method of 6-hydroxy-2-naphthaldehyde

InactiveCN103214358AIndustrial amplification is matureSimple reaction conditionsOrganic compound preparationCarbonyl compound preparationLithium chlorideGrignard reagent

The invention discloses a synthetic method of 6-hydroxy-2-naphthaldehyde, which comprises the following steps: A. beta-naphthol and bromine are reacted for generating 1, 6-dibromo-2-naphthol; then 1, 6-dibromo-2-naphthol and a reducing agent are reacted for obtaining 6-bromine-2-naphthol; B. 6-bromine-2-naphthol and a methyl esterification reagent are reacted for obtaining 6-bromine-2-naphthyl methyl ether; C. 6-bromine-2-naphthyl methyl ether and magnesium are reacted in a Grignard reaction solvent for generating a Grignard reagent; and then the Grignard reagent and N,N-dimethyl formamide are reacted for obtaining 6-methoxy-2-naphthaldehyde; D. 6-methoxy-2-naphthaldehyde and a demethylating reagent lithium chloride are dissolved in a high boiling point aprotic polar solvent for reaction, thereby obtaining a 6-hydroxy-2-naphthaldehyde. Cheap and easily obtained beta-naphthol is used as raw material according to the invention, and after bromination, reduction, methylation, Grignard, demethylating and other reactions, 6-hydroxy-2-naphthaldehyde is obtained; the invention has good advantages of industrial amplification maturation, simple reaction condition and low cost, and the demethylating yield reaches up to 91% and the overall yield reaches up to 62.8%.

Owner:SHANGHAI RECORD PHARM CO LTD

Method for cooperatively producing 1-naphthol and 2-naphthol from naphthalene sulfonation product by virtue of direct alkali fusion

ActiveCN104693009AAlkali fusion reaction goes wellReduce contentOrganic chemistryOrganic compound preparationMolten state2-Naphthol

The invention discloses a method for cooperatively producing 1-naphthol and 2-naphthol from a naphthalene sulfonation product by virtue of direct alkali fusion. The method comprises the following steps: performing multiple sulfonation reactions on naphthalene and concentrated sulfuric acid, directly performing an alkali fusion reaction on the obtained liquid sulfonation product and sodium hydroxide in a molten state, and then diluting, acidifying, boiling for layering, dehydrating and drying, rectifying and separating, thereby obtaining high-purity 1-naphthol and 2-naphthol simultaneously. The steps of hydrolyzing, naphthalene blowing, neutralization, cooling and crystallization and filtration of sulfonation products, and feeding for performing alkali fusion on a water-containing filter cake at a normal temperature in the existing process are avoided; no filtration wastewater difficult to treat is not generated anymore, the energy source and the resources are saved, the yield is increased and the operating environment is improved; as a result, the problems of three-waste treatment during naphthol production are thoroughly solved from the production process.

Owner:肖刚学

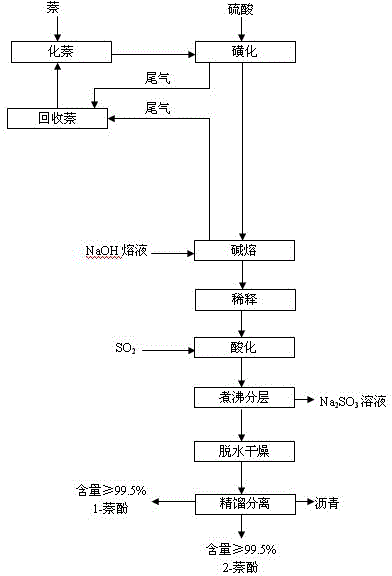

Preparation method of 1-amino-2-naphthol-4-sulfonic acid

InactiveCN101811998AAdd lessLow costOrganic compound preparationSulfonic acid preparation2-NaphtholPhenol

The invention provides a preparation method of 1-amino-2-naphthol-4-sulfonic acid. 2-naphthol is fully dissolved in NaOH aqueous solution which is added with dispersant and has the concentration of 5 to 10 percent into phenol sodium salt, and the weight of the added dispersant is 0.05 to 5 percent of that of 2- naphthol; 34 percent of concentrated hydrochloric acid is dripped into the solution, and the pH is controlled to be 6 to 7; 2-naphthol crystal particles are acid out; NaNO2 aqueous solution is added into 2-naphthol suspension, and the use amount of sodium nitrite is 50 to 55 percent of the weight of 2- naphthol; and then 34 percent of concentrated hydrochloric acid is added in, and the use amount of the concentrated hydrochloric acid is 65 to 75 percent of the weight of 2-naphthol; and nitrosation is carried out, the nitrosation temperature is 0 to 5DEG C, and the reaction time is 2 to 6h. By adding effective dispersant in a nitrosation stage, the preparation method of the 1-amino-2-naphthol-4-sulfonic acid can significantly improve the yield of the 1-amino-2-naphthol-4-sulfonic acid, has little addition of the dispersant, does not need to add extra equipment, reduces the cost of the 1-amino-2-naphthol-4-sulfonic acid, is easy for industrialization, and has very good economic benefit.

Owner:TIANJIN UNIV

2-naphthol high-salt and high-concentration organic matter wastewater recycling process and system

ActiveCN105967415AEase of industrial implementationGood technical and economic effectOrganic chemistryOrganic compound preparationHigh concentrationSulfite salt

The invention discloses a 2-naphthol high-salt and high-concentration organic matter wastewater recycling process and system; an extraction crystallization process is designed for recovery naphthalenesulfonate for reuse production; organic compounds are oxidized at high temperature for producing anhydrous sodium sulfate for sale, tail gas is absorbed for producing sodium sulfite for circular use in 2-naphthol production; all components of 2-naphthol wastewater are recycled with low cost, zero emission of pollutants is realized, and the method is a currently reasonable recycling process for the 2-naphthol high-salt and high-concentration organic wastewater, and at the same time, the system for realizing the process is designed. The process and the system have popularization value for recycling disposal of the high-organic-matter wastewater, and have great economic and social effects.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

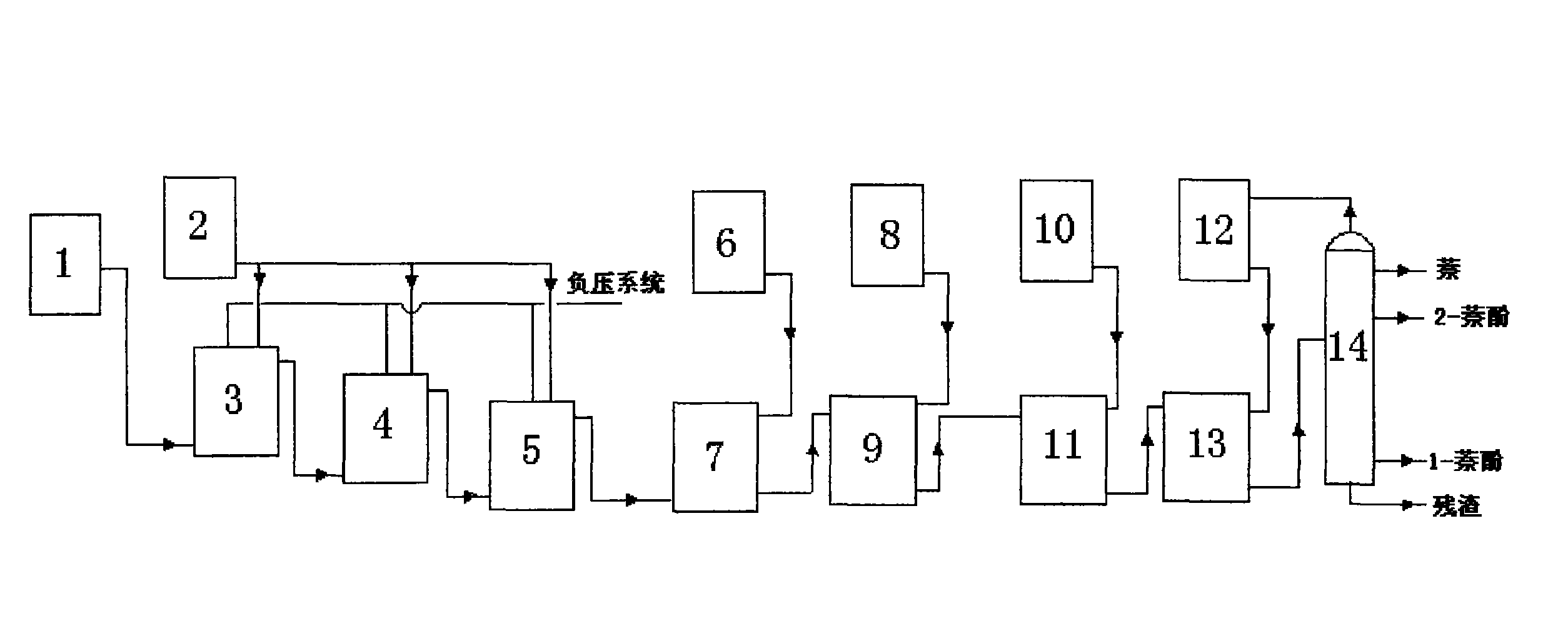

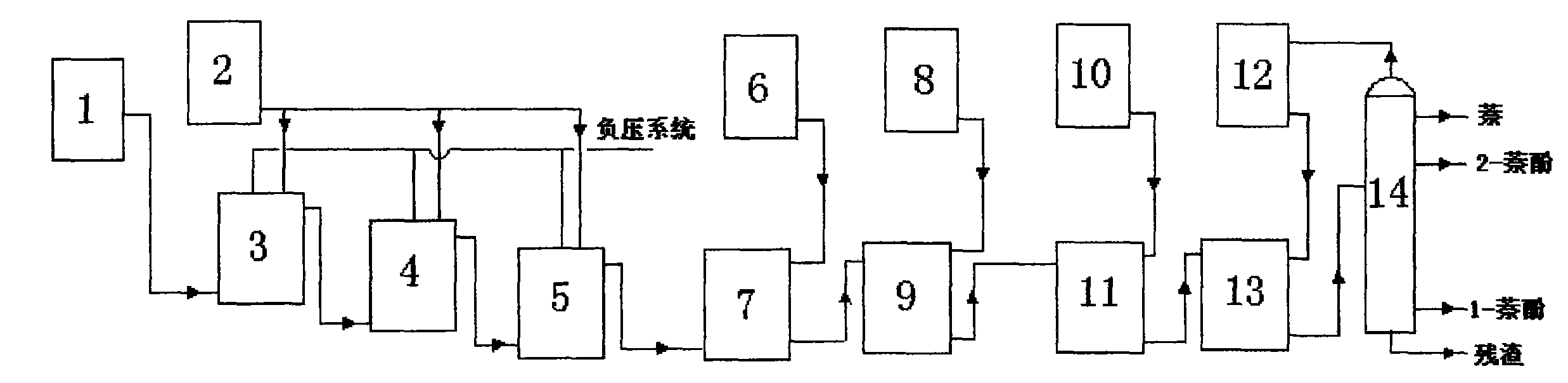

Novel process for efficiently and continuously synthesizing 2-naphthol

ActiveCN101781172AHigh synthesis efficiencyMany steps in the separation processOrganic chemistryOrganic compound preparationMelting tank2-Naphthol

The invention discloses a novel process for efficiently and continuously synthesizing 2-naphthol, which comprises the following steps of: (A) putting refined naphthol from a naphthol-melting tank (1) into a prime kettle of a sulfonation reaction kettle, respectively putting sulphuric acid into various levels of the sulfonation reaction kettle from a sulphuric acid-weighting tank (2) for a sulfonation reaction for 2-6h and reducing the pressure of the sulfonation reaction kettle so as to remove water generated by the reaction; (B) guiding a sulfonated product in the step (A) into a neutralizing tank (7), directly neutralizing with diluted alkali, keeping impurities in the sulfonation reaction, primarily evaporating to dewater and directly guiding into an alkali melting pot (9) for an alkali-melting reaction; (C) acidifying an alkali-melting reaction product in an acidifying tank (11) and extracting 2-naphthol and 1-naphthol from the alkali-melting reaction product in an extracting tower (13) with an extracting agent; and (D) rectifying an organic phase after extracting the naphthol in a rectification tower to recycle the extracting agent and rectifying and separating the 2-naphthol, the 1-naphthol and naphthol without participating the reaction. The invention adopts continuous reaction process design, has simple and convenient process, stable performance and high yield, overcomes the detects of intermittent operation, low synthesis effect, multiple steps for separating 2-naphthol from other impurities, low separation efficiency and much three-waste generation in a sulfonation alkali-melting 2-naphthol synthesis process of the prior art, realizes continuous process, greatly reduces three-waste emission, lessens wastewater by 20 percent than that of the traditional process, greatly improves the 2-naphthol synthesis efficiency and obtains the 1-naphthol as a byproduct.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Method for determining content of zinc in mung beans by using cloud point extraction-atomic spectrum method

InactiveCN103499537AHigh sensitivityImprove accuracyPreparing sample for investigationColor/spectral properties measurementsRelative standard deviationAlkylphenol

The invention provides a method for determining the content of zinc in mung beans by using a cloud point extraction-atomic spectrum method. The method is characterized by being comprising the flowing steps: pretreating mung bean samples by cold digestion and heating digestion through long-time soaking, combining 1-(2-pyridine azo)-2 naphthol (PAN) ethanol solution as a complexing agent with zinc to form a stable hydrophobic ionic associate after digestion, adding alkylphenol and ethylene oxide condensation compound to obtain a non-ionic surface active agent, extracting to obtain the non-ionic surface active agent organic phase, and determining the content of the zinc in the non-ionic surface active agent organic phase by using a flame atomic absorption spectrometry after dissolving and diluting of nitric acid and ethanol. The method solves the problems that a traditional method has low sensitivity to microelements and can be easily interfered by co-existing ions by using the flame atomic absorption spectrometry, and has the advantages of accuracy, reliability, high recovery rate, low relative standard deviation, high enrichment coefficient, rapidness and convenience.

Owner:SUZHOU GUOHUAN ENVIRONMENT DETECTION

Sulfonation and alkali fusion optimized production process for 2- naphthol

InactiveCN104016835ANo generationSimple processOrganic compound preparationSulfonic acid preparationSalting outWastewater

The invention relates to a sulfonation and alkali fusion optimized production process for 2-naphthol, and belongs to the field of organic chemical industry. By taking refined naphthalene as a material, 2-naphthol is prepared through processes such as sulfonating by 98% sulfuric acid, salting-out, alkali-fusing, acidifying, distilling, and the like. Defects of sulfonating, hydrolyzing and naphthalene-blowing, neutralizing, cold-separating, drying, alkali-fusing, acidifying and distilling in the convention process are overcome, the process is optimized, process flow is shortened, production cost is lowered, and no wastewater is produced; besides, the sulfonation and alkali fusion optimized production process for 2-naphthol has positive meaning for environment protection, and is especially applicable to production and usage of 2-naphthol.

Owner:湖北鑫慧化工有限公司

Combination treatment method of 2-naphthol production wastewater

ActiveCN102603101AAchieve recyclingRealize resource utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a combination treatment method of 2-naphthol production wastewater, belonging to the technical field of wastewater treatment. The method comprises the steps of: respectively treating the 2-naphthol production wastewater through complexing extraction and liquid membrane separation technologies to ensure that the wastewater is easily subjected to biochemical treatment; and respectively carrying out alkali washing and demulsification on a load extraction agent and a load emulsion to ensure that the extraction agent and a liquid membrane oil phase are regenerated, wherein a concentrated solution contains high-concentration sodium phenolate and sodium naphthalene sulphonic and can be reused in production sections. The treatment method of the 2-naphthol production wastewater has the advantages that the COD (Chemical Oxygen Demand) in the wastewater is reduced from about 100000mg / L to about 3000mg / L; nonbiodegradable organic pollutants in the wastewater are greatly decreased; the biodegradability of the wastewater is increased; reduction and resource utilization of the pollutants in the 2-naphthol production wastewater can be realized at the same time; and a certain economic benefit is provided.

Owner:中国中化股份有限公司 +2

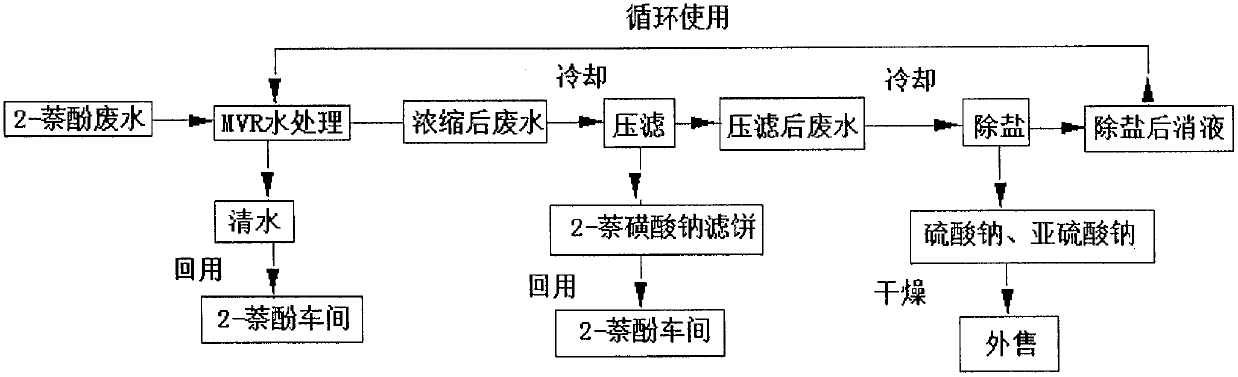

2-naphthol wastewater processing technology

InactiveCN105366746AEfficient removalSimple processWater contaminantsAlkali metal sulfite preparationSolubilitySulfite salt

A disclosed 2-naphthol wastewater processing technology comprises adjusting the pH value of wastewater to be neutral, then enabling wastewater to enter MVR water processing operation and performing evaporation concentration, and returning clear water obtained after evaporation condensation to a workshop for reutilization; cooling wastewater subjected to concentration, crystallizing to precipitate sodium 2-naphthalenesulfonate, then performing separation, enabling the obtained filtrate to enter refrigeration desalting operation and performing cooling reprocessing, crystallizing to precipitate inorganic salts, performing separation on the crystal-containing concentrate to obtain the inorganic salts, and drying; and enabling the clear liquid subjected to refrigeration desalting to enter the MVR water processing operation and performing cyclic concentration. The processing technology performs cooling crystallization separation on wastewater at different temperature by utilizing the principle that the solubility difference of organic salts and inorganic salts is large in wastewater at different temperature, thereby effectively removing sodium 2-naphthalenesulfonate, sodium sulfite and sodium sulfate in wastewater. The processing technology is simple, employed equipment is less, energy consumption is less, cost is low and processing efficiency is improved.

Owner:TANGSHAN BAOXIANG CHEM PROD CO LTD

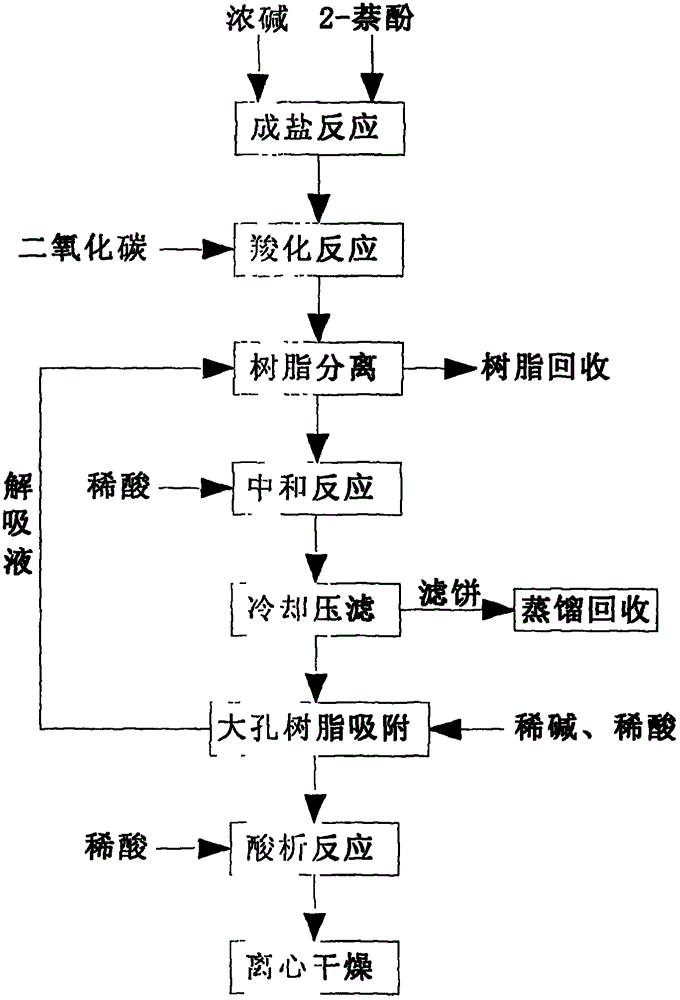

Method of improving content of 2-hydroxy-3-naphthoic acid produced in gas-solid phase method

InactiveCN104447302AAchieve recyclingReduce consumptionPreparation from carboxylic acid saltsOrganic compound preparationDesorption2-Naphthol

The invention discloses a method of improving content of 2-hydroxy-3-naphthoic acid produced in a gas-solid phase method; the method comprises the steps: performing a salt forming reaction to concentrated alkaline and 2-naphthol, performing a carboxylation reaction with carbon dioxide and then obtaining the finished 2-hydroxy-3-naphthoic acid after a series of steps of resin separation, neutralization reaction, cooling and filter pressing, resin absorption, acidification reaction and centrifugal drying. A resin absorption procedure is added between the filter pressing procedure and the acidification procedure, so that the residual 2-naphthol in the filtrate after the filter pressing can be removed and the content of 2-hydroxy-3-naphthoic acid is greatly increased; meanwhile, the concentrated solution produced after the desorption of absorbed saturated resin is recovered, the 2-naphthol and the 2-hydroxy-3-naphthoic acid are obtained and the recovery of the 2-naphthol is realized; meanwhile, the source consumption is reduced. The method is simple, is simple and convenient in operation, good in stability and high reliability.

Owner:TANGSHAN CITY FENGNAN DISTRICT JIAYUE CHEM PROD

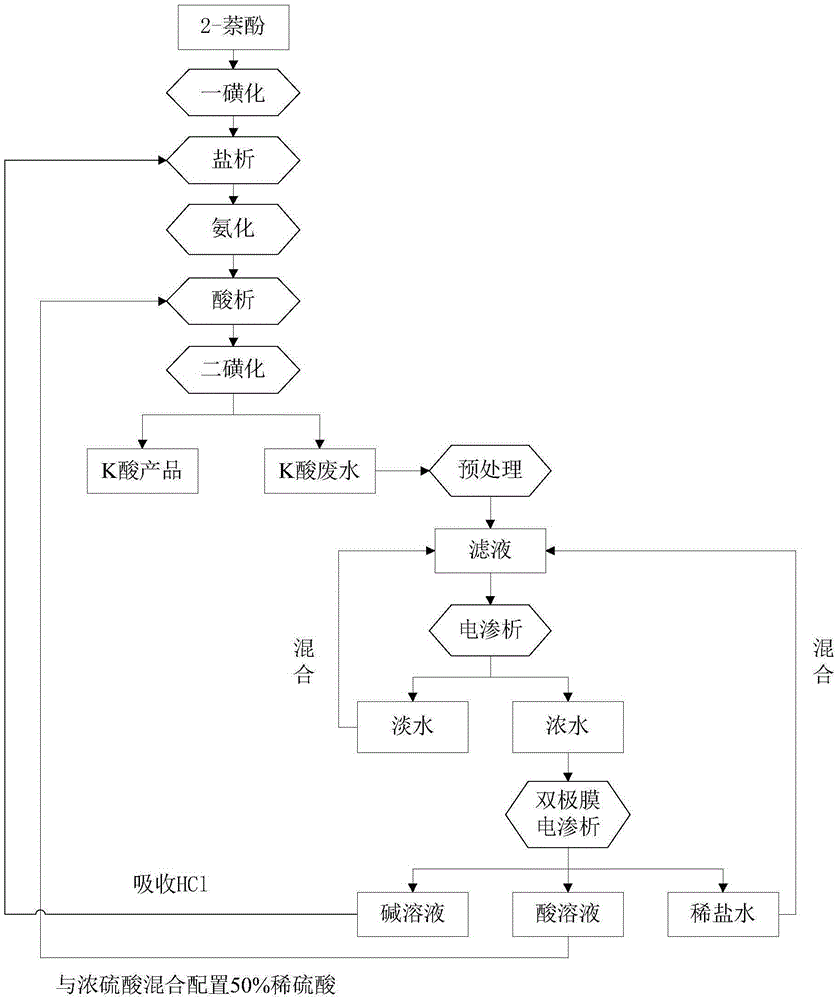

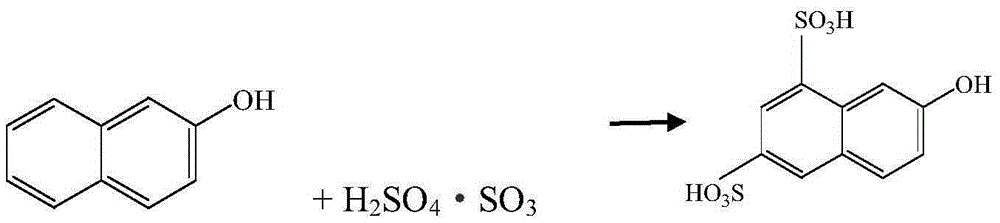

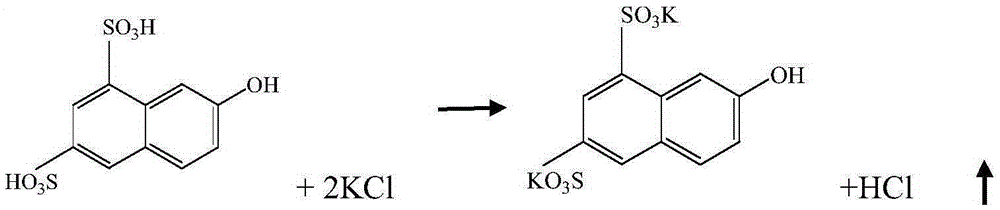

Improved K acid synthesis technology

InactiveCN105347579AAchieve sustainable developmentSimple processWater treatment compoundsMultistage water/sewage treatmentPotassium hydroxide2-Naphthol

The invention discloses an improved K acid synthesis technology. Through primary sulfonation, salting-out, ammonification, acidification and secondary sulfonation, a K acid product and K acid waste water are prepared from 2-naphthol. The K acid waste water treatment process comprises 1, pre-treatment: pre-treating K acid waste water to remove organic impurities of the waste water and to obtain a filtrate, 2, electroosmosis concentration: carrying out common electroosmosis concentration on the pretreated filtrate to obtain concentrated water and fresh water, 3, bipolar membrane desalination: carrying out bipolar membrane electroosmosis on the concentrated water obtained by the step 2 to obtain a sulfuric acid solution, a potassium hydroxide solution and dilute brine, recycling the sulfuric acid solution and the potassium hydroxide solution in the K acid synthesis process and / or the step 1, returning the dilute brine into an electroosmosis device and carrying out re-condensation. The improved K acid synthesis technology realizes standard discharge of waste water produced by the K acid synthesis technology, utilizes an effective resource in waste water by the bipolar membrane electroosmosis technology, realizes use in the technology and reduces a K acid synthesis cost.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Method for treating and resourcefully utilizing dye intermediate such as 2-naphthol production wastewater

ActiveCN106865851ASolving difficult-to-governance problemsReduce processing costsOrganic compound preparationWater contaminantsHigh concentrationEvaporation

The invention relates to a method for treating and resourcefully utilizing dye intermediate production wastewater. The dye intermediate production wastewater includes neutralized wastewater generated in a neutralizing work procedure. The method comprises the steps: (1) MVR evaporation and concentration: adjusting pH of the neutralized wastewater to 7.5 to 9 and performing MVR evaporation and concentration to obtain evaporation and concentration clean water and high-salinity high-concentration concentrated wastewater, wherein the evaporation and concentration clean water is reused for production; (2) oxidation and drying of an atomizing and oxidizing tower: oxidizing and drying the high-salinity high-concentration concentrated wastewater obtained in the step (1) through the atomizing and oxidizing tower, enabling organisms to be oxidized, decomposed and removed at high temperature and atomizing and granulating salt to obtain sodium sulfate. The wastewater treatment method disclosed by the invention is simple, can completely solve the problem that dye intermediate wastewater is difficult to treat, can remarkably reduce treatment cost, greatly utilizes resources and reduces environmental pollution.

Owner:内蒙古美力坚科技化工有限公司

Textile sizing agent and preparation method thereof

ActiveCN106480728AYarn performance is stableHigh strengthAbrasion resistant fibresYarnDiphenylmethane

The invention relates to textile a sizing agent and a preparation method thereof. The textile sizing agent comprises, by mass percentage, 82-88% of main materials and 12-18% of auxiliaries. The main materials comprise nano silicon dioxide modified starch, pea starch, phosphate starch, acrylic acid, butyl acrylate, acrylamide, sodium sulfamate, diphenylmethane and protein amino acid. The auxiliaries comprise methyl alcohol, 2-naphthol, monochloroacetic acid and NaOH. The preparation method of the textile sizing includes the steps that firstly, the main materials are prepared; secondly, the main materials and the auxiliaries are evenly mixed to obtain the textile sizing agent. When the textile sizing agent is used for sizing, textiles can be subjected to sizing in the temperature range of 25-28 DEG C; after sizing, yarn is stable in performance, and strength and wear resistance are enhanced.

Owner:江苏品源知识产权运营有限公司

Acidic bifunctional ionic liquid catalysis method for synthesis of benzoxanthene derivative

The invention discloses an acidic bifunctional ionic liquid catalysis method for synthesis of benzoxanthene derivatives. The key points of the technical scheme provided by the invention are as below: the acidic bifunctional ionic liquid catalysis method for synthesis of the benzoxanthene derivative employ aromatic aldehyde and 2-naphthol as raw materials and employs the acidic bifunctional ionic liquid comprising cation containing hydrogen bond donor and Bronsted acidic anion as the catalyst, and the raw materials and the catalyst are heated to 110-125 DEG C at atmospheric pressure to synthesize the benzoxanthene derivative. The invention adopts the bifunctional acidic ionic liquid as the catalyst; the materials have wide sources and are simple for preparation and low in cost; the catalyst has low dosage, high catalytic activity, and can be recycled; and the reaction process can be performed under solvent-free conditions to avoid the use of organic solvents, so as to achieve environmental and economical double benefits. The method for the synthesis of the benzoxanthene derivatives is efficient, environmentally friendly, and conducive to large-scale industrial production.

Owner:HENAN NORMAL UNIV

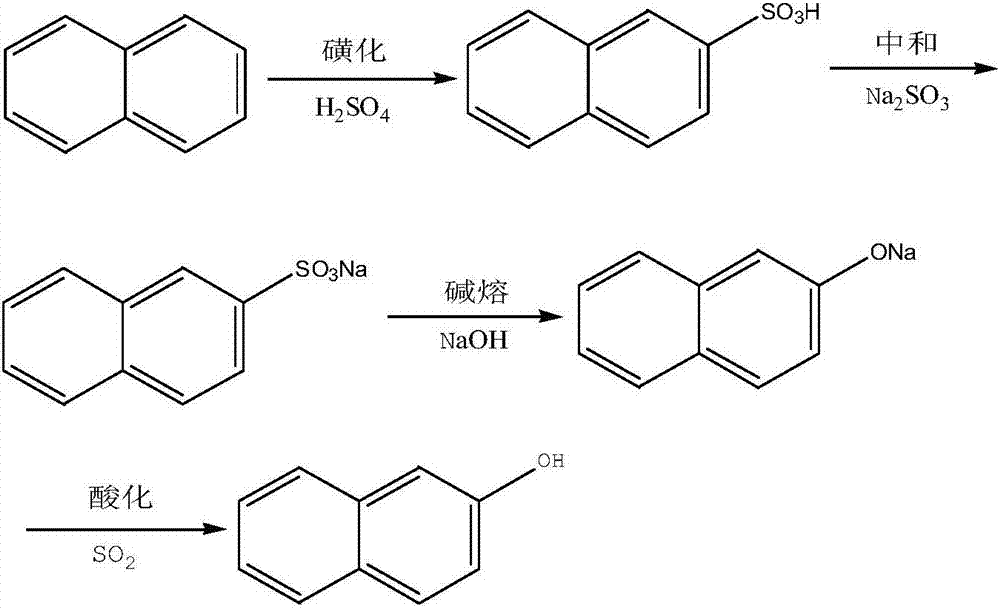

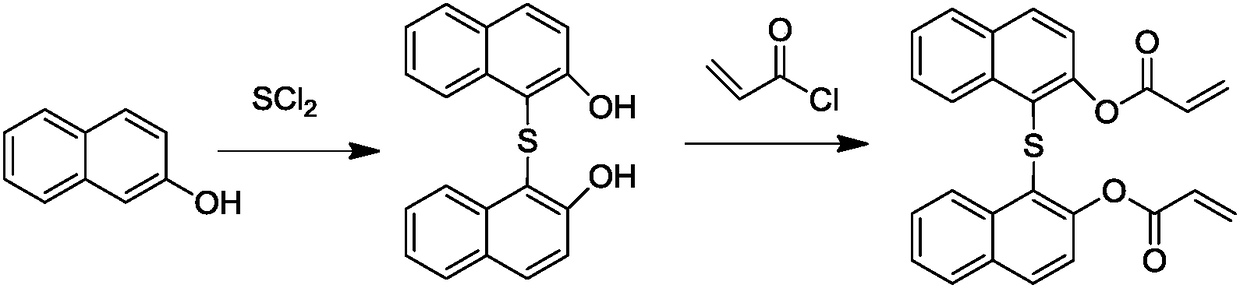

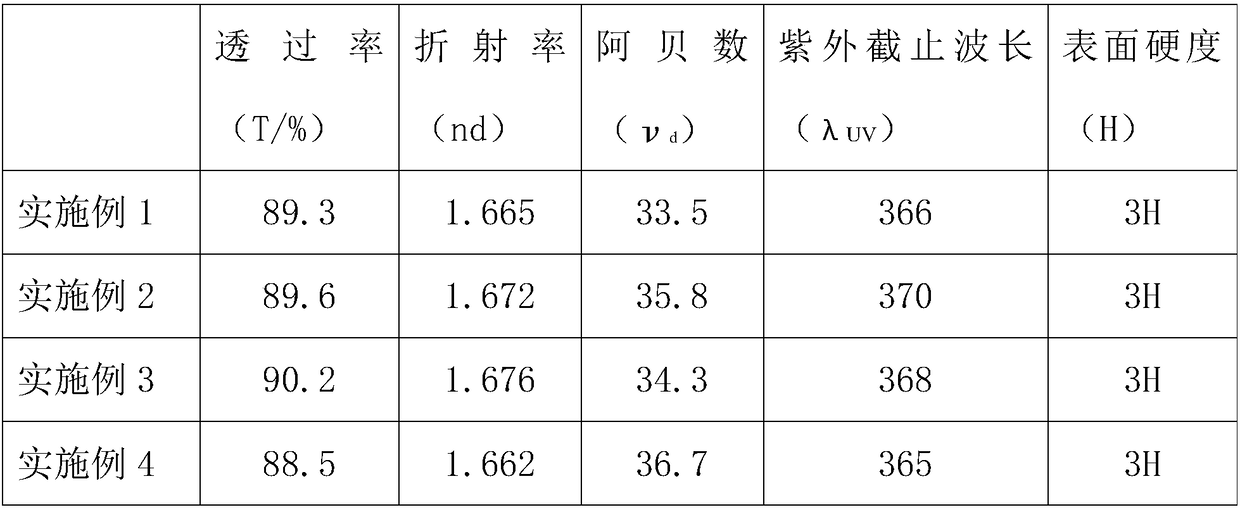

Preparation method of high refractive index sulfur-containing optical copolymerized resin

The invention discloses a preparation method of high refractive index sulfur-containing optical copolymerized resin. The preparation method comprises the following steps: stirring 2-naphthol and sulfur dichloride to react to obtain 1,1'-sulfobis(2-naphthol); adding the 1,1'-sulfobis(2-naphthol) into excessive triethylamine for quaternization, then dropwise adding acryloyl chloride, and stirring and reacting to obtain 2,2'-bis(2-acroloyloxyl)-1,1'-sulfobinaphthyl; and copolymerizing the 2,2'-bis(2-acroloyloxyl)-1,1'-sulfobinaphthyl, methyl methacrylate and styrene in a condition that azodiisobutyronitrile serves as an initiator, and heating and curing the mixture to obtain the high refractive index sulfur-containing optical copolymerized resin. By introducing a sulfur-containing monomer rich in electronic conjugated structural units with great molar refrangibility into a synthesized monomer of the optical copolymerized resin, the refractive index of the copolymerized resin is improved and the monomer is copolymerized with methyl methacrylate and styrene to prepare transparent resin.

Owner:望江县天长光学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative](https://images-eureka.patsnap.com/patent_img/a77cc210-9e65-45f0-9a6b-289b81579e2b/HDA0000541776600000011.PNG)

![Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative](https://images-eureka.patsnap.com/patent_img/a77cc210-9e65-45f0-9a6b-289b81579e2b/HDA0000541776600000012.PNG)

![Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative Green catalysis preparation method for 14-aryl group-14 H-dibenzo [a, j] xanthene type derivative](https://images-eureka.patsnap.com/patent_img/a77cc210-9e65-45f0-9a6b-289b81579e2b/HDA0000541776600000021.PNG)