Patents

Literature

196results about How to "Good technical and economic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

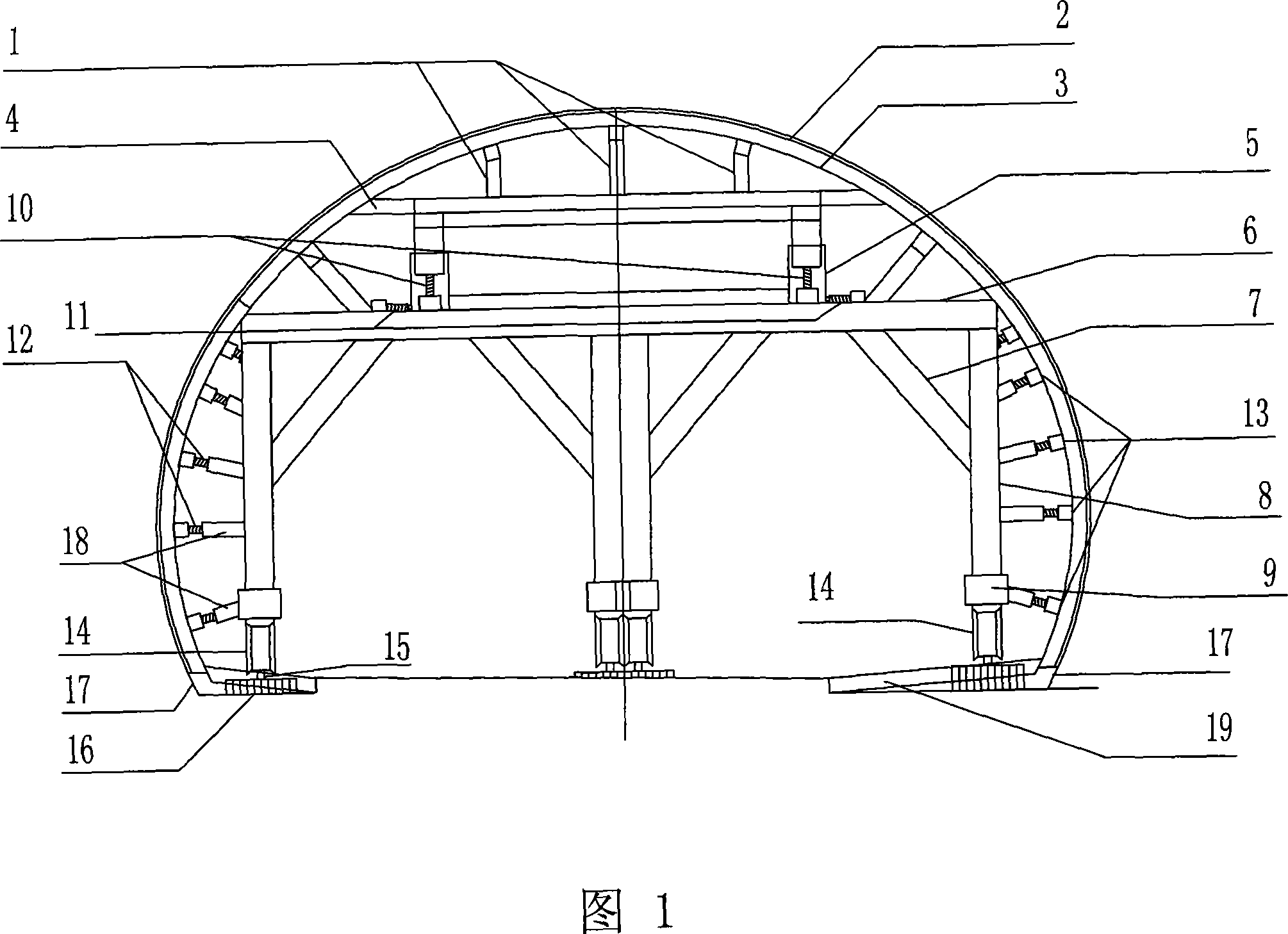

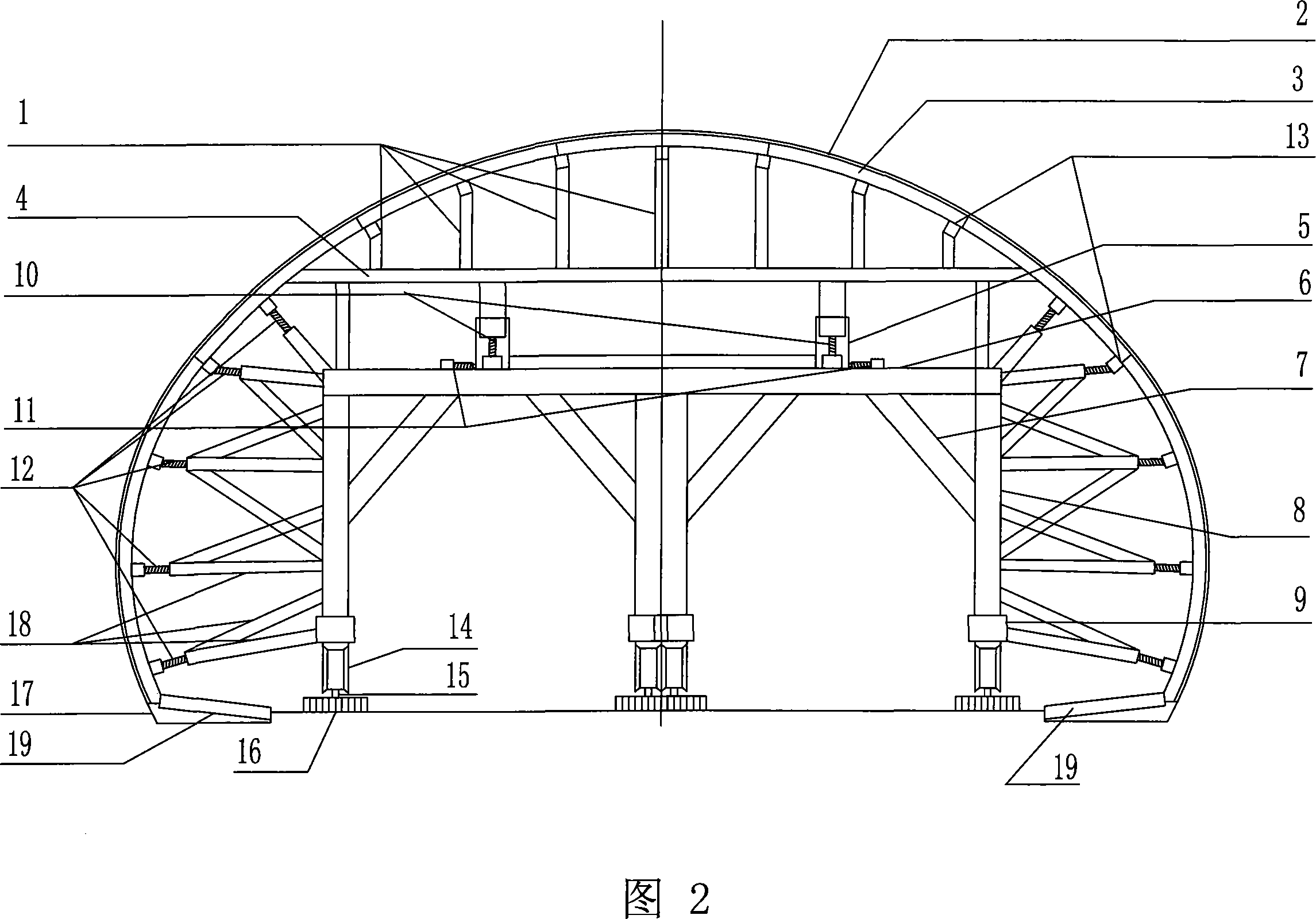

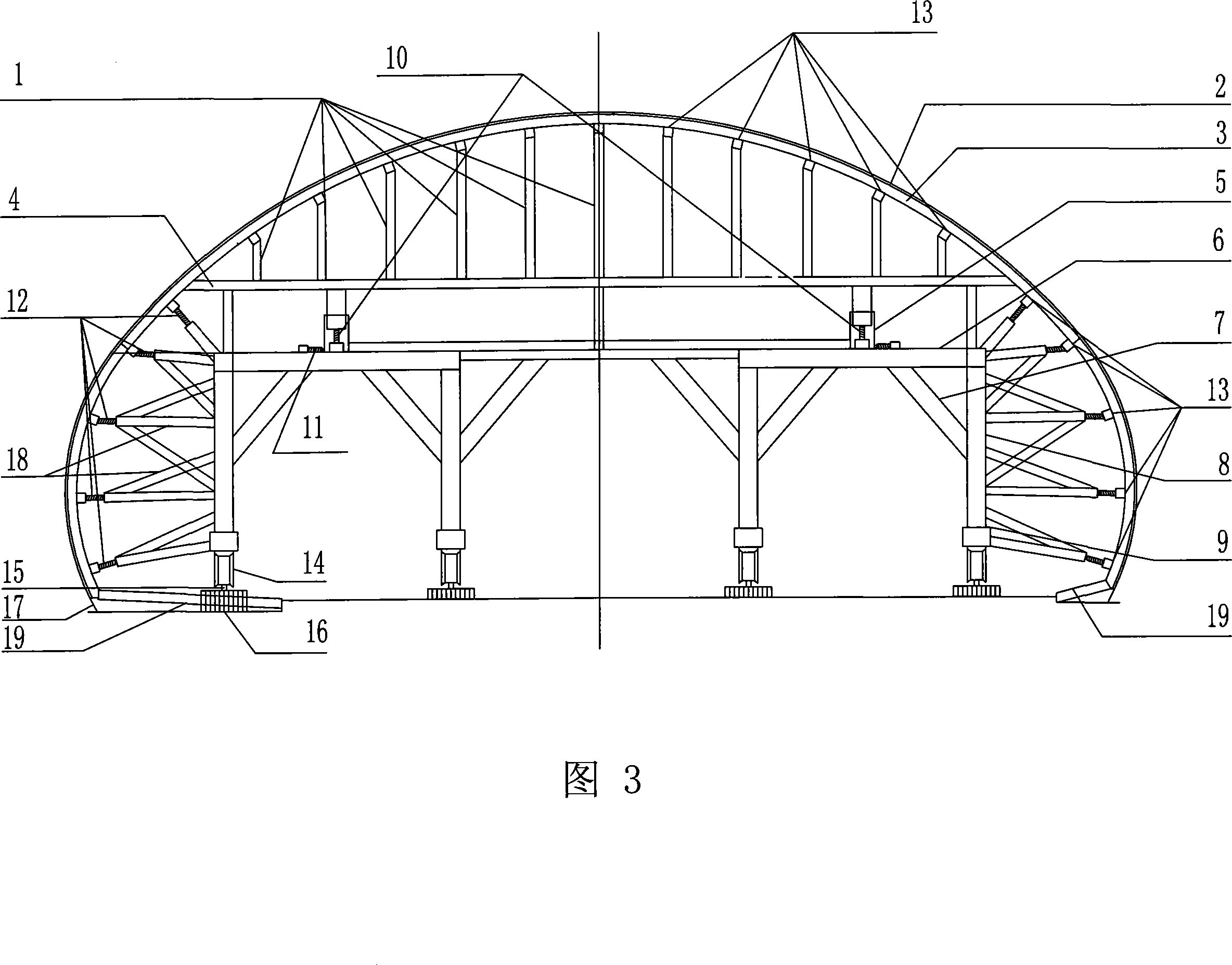

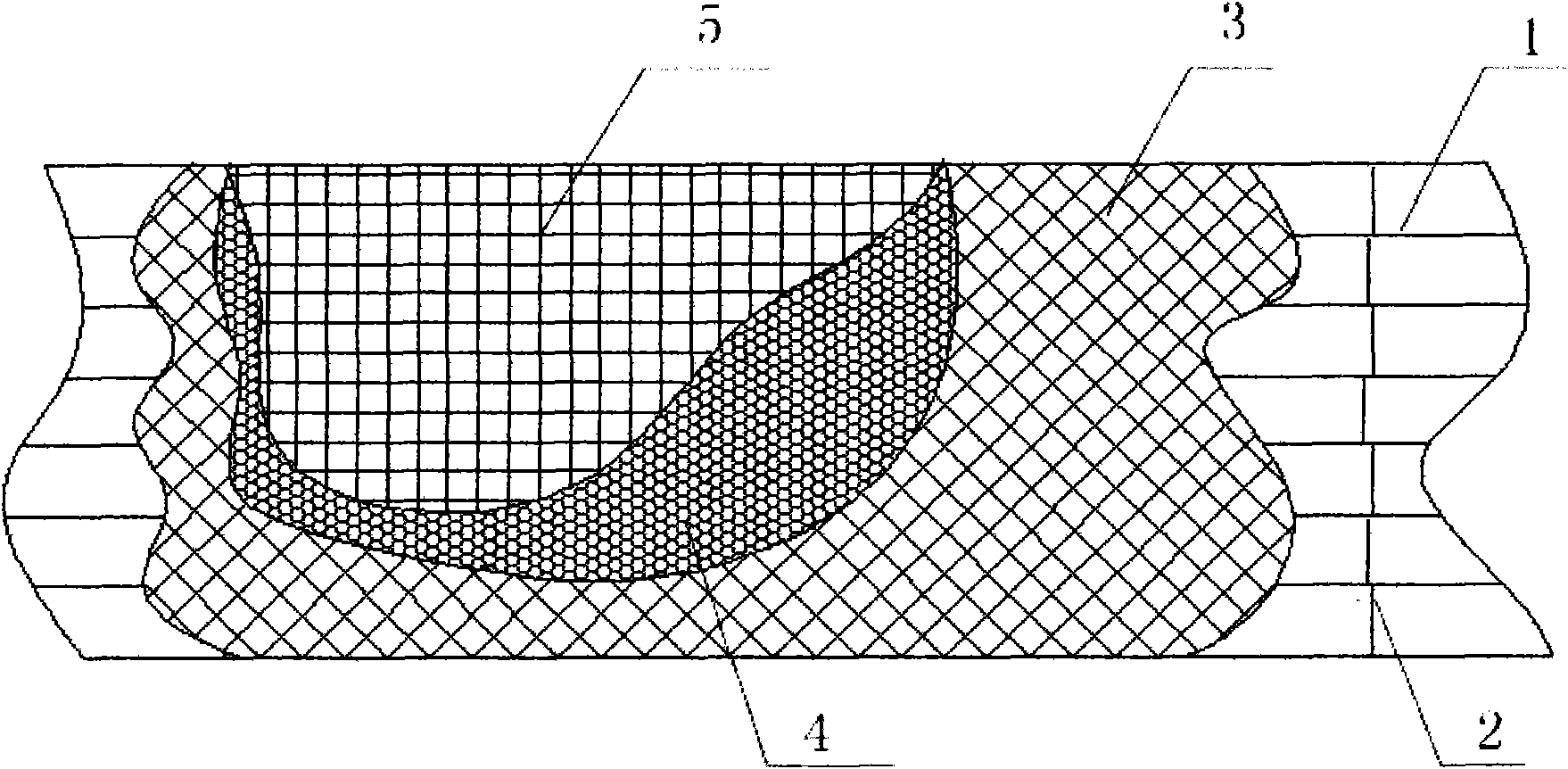

Construction method for large section and multiple sections tunnel lining

ActiveCN101230785AImprove construction progressQuick disassemblyUnderground chambersTunnel liningAssembly lineConstruction management

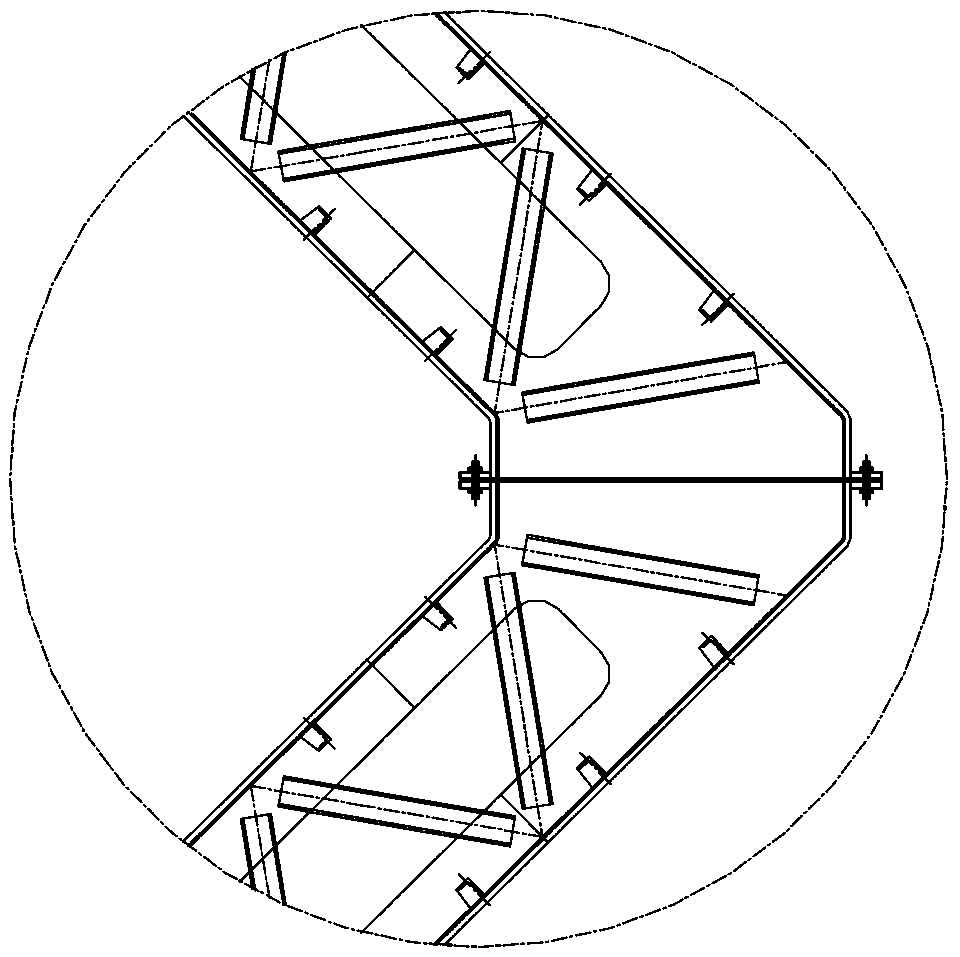

The invention discloses a large cross-section and multiple cross-section tunnel lining construction method. Combined type lining trolleys are chosen to carry through the trolley assembly lining to the cross-section, and adding a gantry mounting on the basis of a normal trolley single gantry mounting can form an assembled and detachable lining trolley. Steel molding plates, road wheels, main gantry mountings, etc. are listed in unchanged components in the process of the assembly trolleys with different cross-sections, and lateral adjusting driving screws, upper platform chord members, upper platform upright posts, lining steel arches, etc. are listed in adjustable components. In the process of the construction from one cross-section to another cross-section, the unchanged components do not change, and only the changeable components are carried through the refitting and assembly. The construction method has the characteristics of fast construction progress, low cost, easy control of site construction management, etc., can save a great deal of manpower, physical resources and financial resources and obtain good technical economic effect, and has the remarkable economic, social and environmental benefits; the invention is especially adapted to the large cross-section and multiple cross-section type lining construction of tunnels and underground constructions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

A biologic organic fertilizer, and preparation method

InactiveCN1872803APromote growthImprove the ecological environmentBio-organic fraction processingClimate change adaptationOil processingPotassium

This invention relates to a method for manufacturing bioorganic fertilizer. The bioorganic fertilizer is manufactured by: mixing sugar industry waste, breeding industry waste, oil-processing waste, phosphoric fertilizer, trace element fertilizer and silicon fertilizer, and performing aerobic fermentation and post fermentation. The effective components of the bioorganic fertilizer are: organic matters (greater than or equal to 30%), N, P and K (greater than or equal to 8%), beneficial microorganisms (greater than or equal to 200,000,000 / g), active silicone (greater than or equal to 5%), magnetic components (0.25%), and Fe, Zn and Mo (0.5-1%). The bioorganic fertilizer has abundant raw material sources, and is environmentally friendly.

Owner:成官文

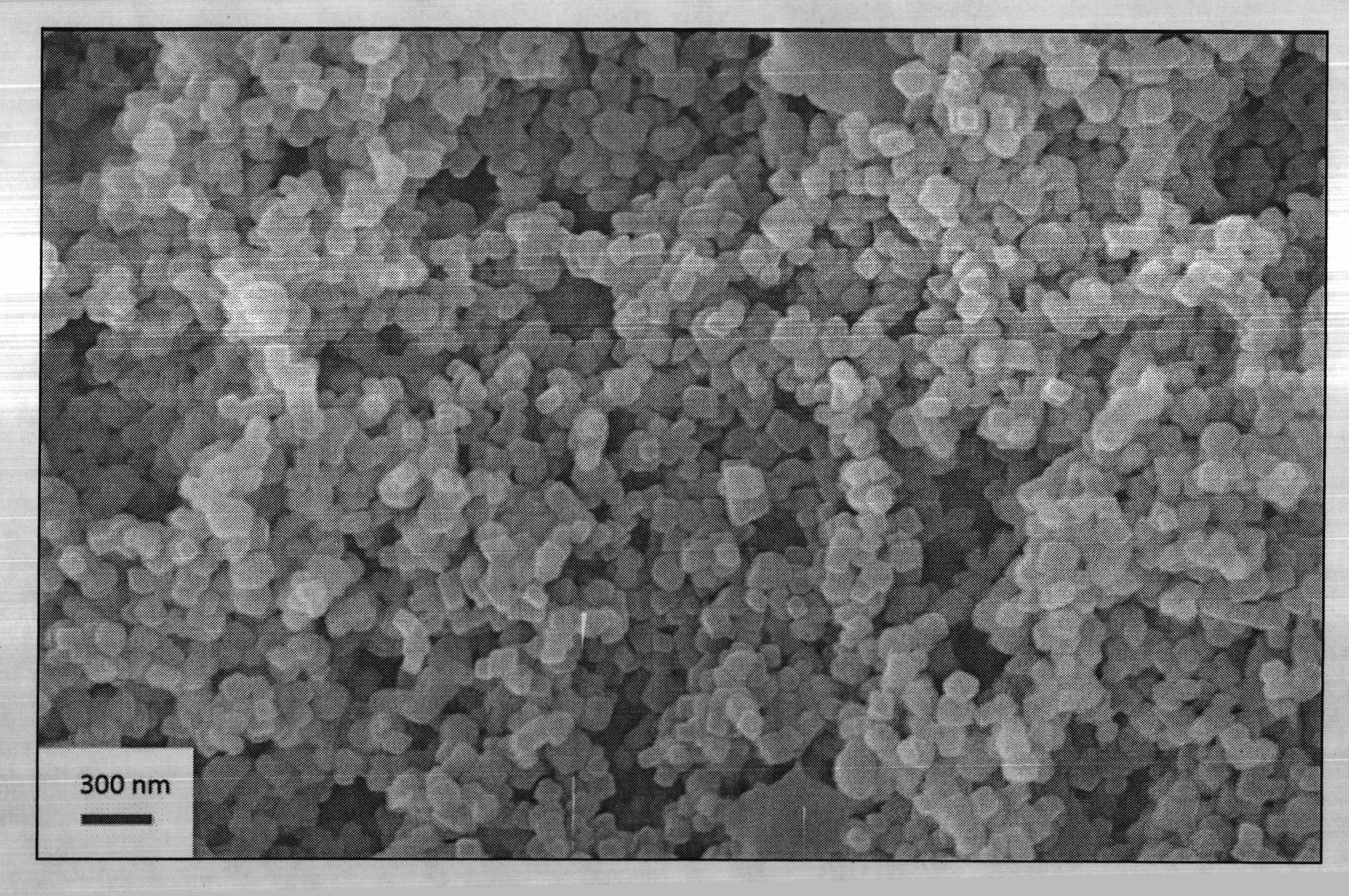

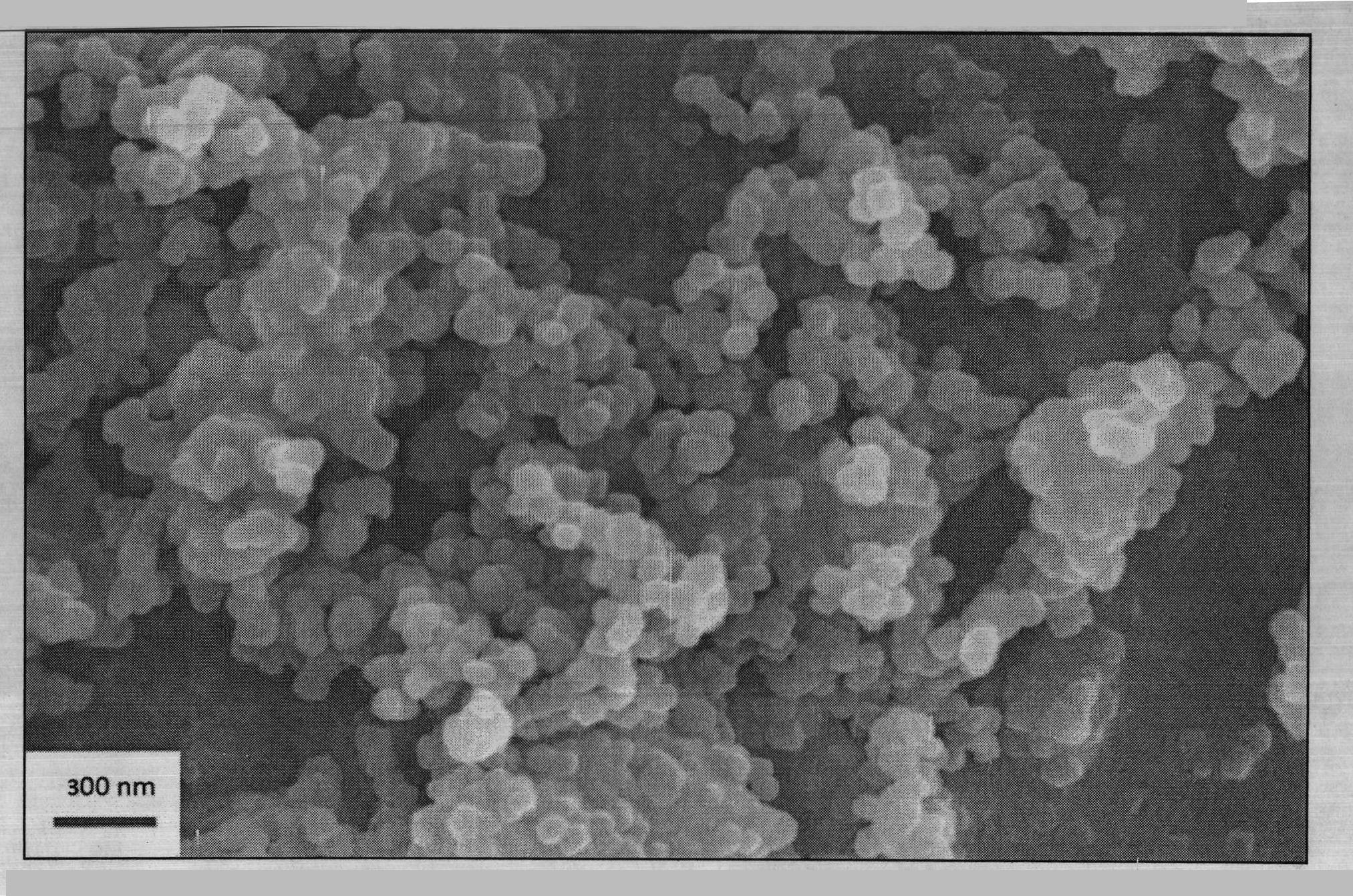

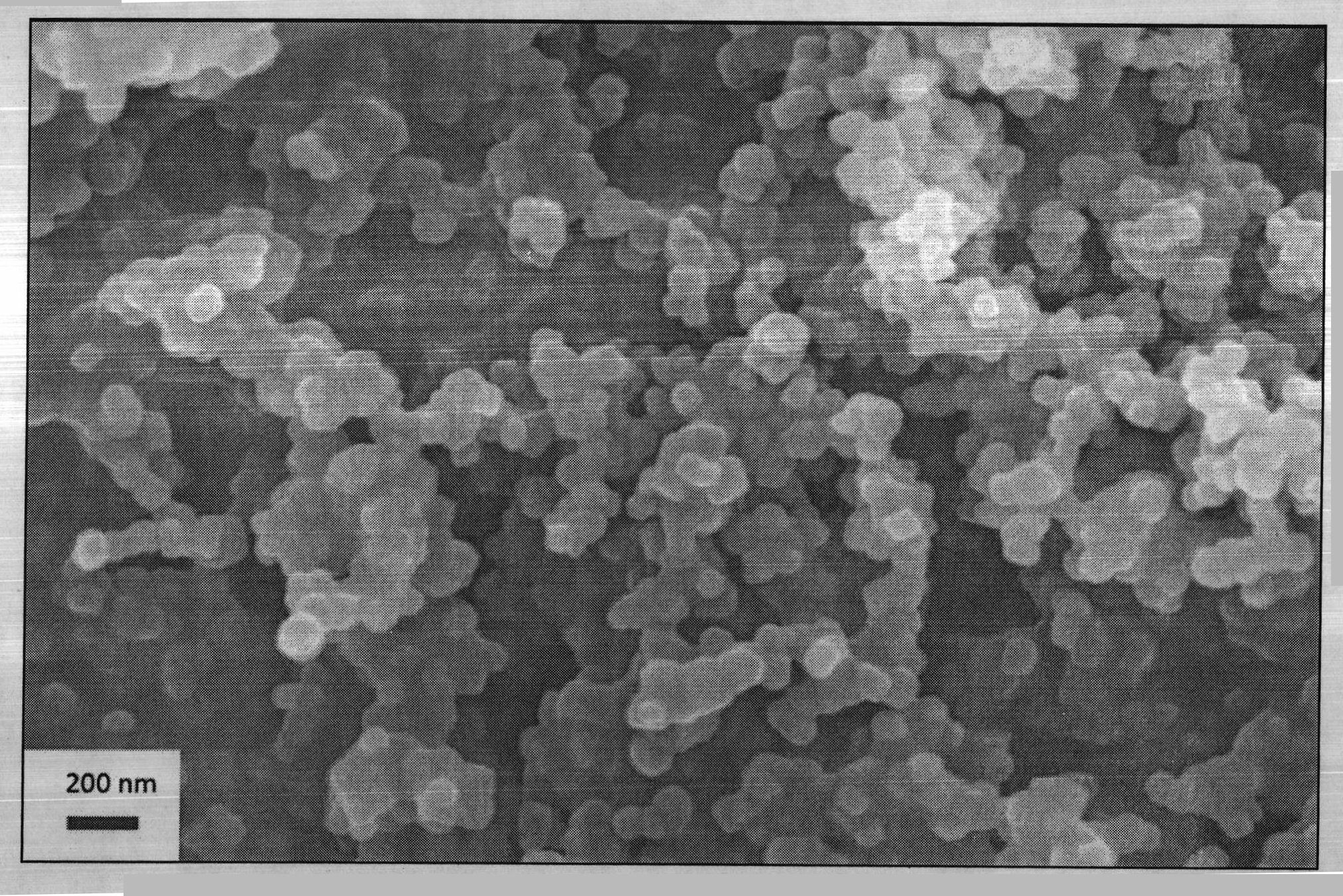

Surface modification method for nano calcium carbonate

ActiveCN102174275AOvercome the disadvantage of being difficult to disperseGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface modification method for nano calcium carbonate, which is characterized by comprising the following steps of: adding inorganic alkali into nano calcium carbonate slurry, uniformly stirring, heating the slurry, adding fatty acid and performing surface modification. The method comprises the following specific steps of: adding a certain amount of nano calcium carbonate slurry into a reaction kettle, adding 0.00004 to 0.00040mol of inorganic alkali into 1g of CaCO3, and uniformly stirring; heating to the temperature of between 75.0 and 90.0 DEG C, adding 0.00005 to 0.00035mol of fatty acid or fatty acid salt into 1g of nano calcium carbonate (CaCO3) slurry, reacting, and continuously stirring for 30 to 120 minutes; and after surface modification reaction is finished, cooling, filtering, washing, drying and grinding the slurry to obtain the nano calcium carbonate subjected to surface modification. The method is simple and practicable, a modifier can form a uniform and complete coating layer on the surface of the nano calcium carbonate, and the modified product has a good application effect in polymer such as silicone sealant, polyvinyl chloride (PVC) paste resin and the like.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

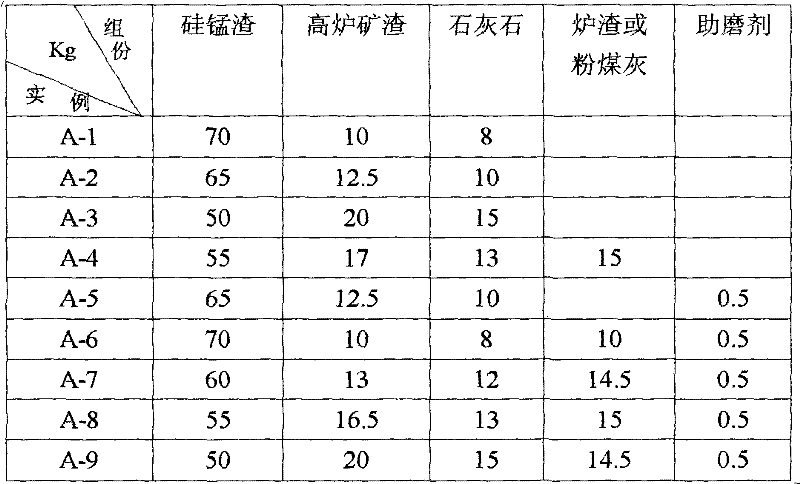

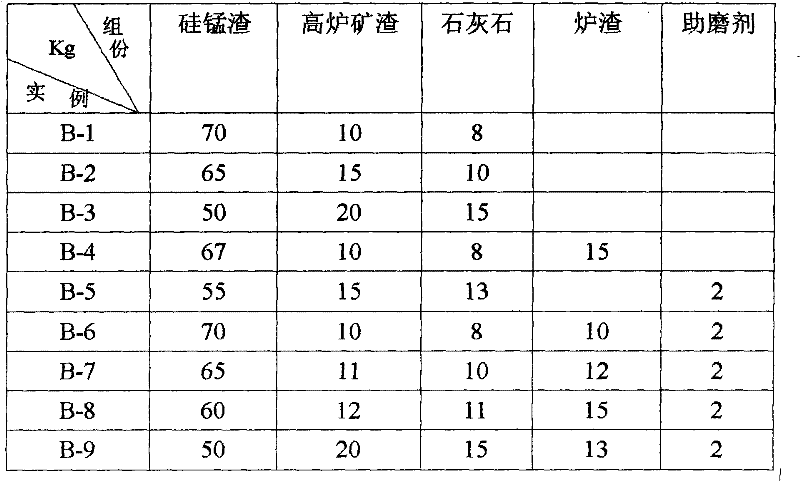

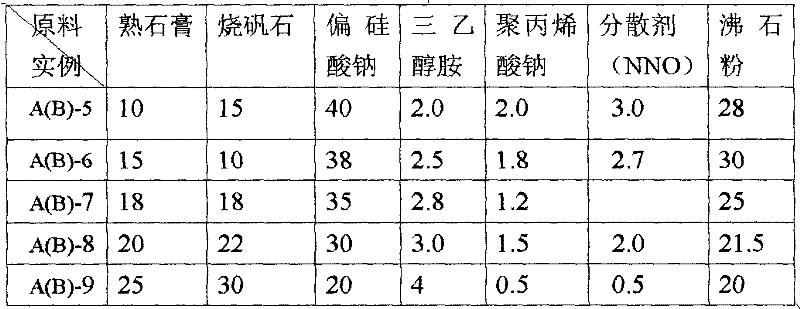

Composite admixture for cement or high-performance concrete and preparation method thereof

InactiveCN102180612ASave resourcesGood social benefitsSolid waste managementIndustrial wasteHigh performance concrete

A composite admixture for cement or high-performance concrete and a preparation method thereof. The admixture comprises silicon manganese slag, slag, limestone, furnace slag or fly ash, and grinding aids, and the mass ratios are: 50-70 of silicon-manganese slag, 10-20 of slag, 8-15 of limestone, 10-15 of furnace slag or fly ash, and 0.5 or 2 of grinding aids. The preparation method comprises: adding the raw materials according to the ratios into a ball mill, grinding till the grinding fineness meets that the Blaine specific surface area is not less than 400 m2 / kg or 450 m2 / kg so as to obtain the silicon manganese slag-based composite admixture for cement or high-performance concrete. The preparation of the admixture can use a large amount of industrial waste residues - silicon manganese slag discharged from the production of silicomanganese alloy, and the admixture is prepared with a proper amount of slag, limestone, furnace slag or fly ash, and a small amount of grinding aids, which has remarkable economic effect, and outstanding social benefits and environmental benefits.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Coal-minin method of high-dipping thick seam

InactiveCN1657745AImprove ventilationReduce air volumeUnderground miningTunnel/mines ventillationEconomic benefitsEngineering

The invention discloses a method for coal mining to the greatly oblique coal layer, comprising two steps: designing the method and back producing technique, placing slit flexible shielding support in the coal layer of 8-10m and deciding return airway and cutting point; the back producing technique includes enlarging airway, installing support, put down support and desinence of working face, etc. The method has simple operational steps as well as remarkable economic benefit.

Owner:KAILUAN GRP

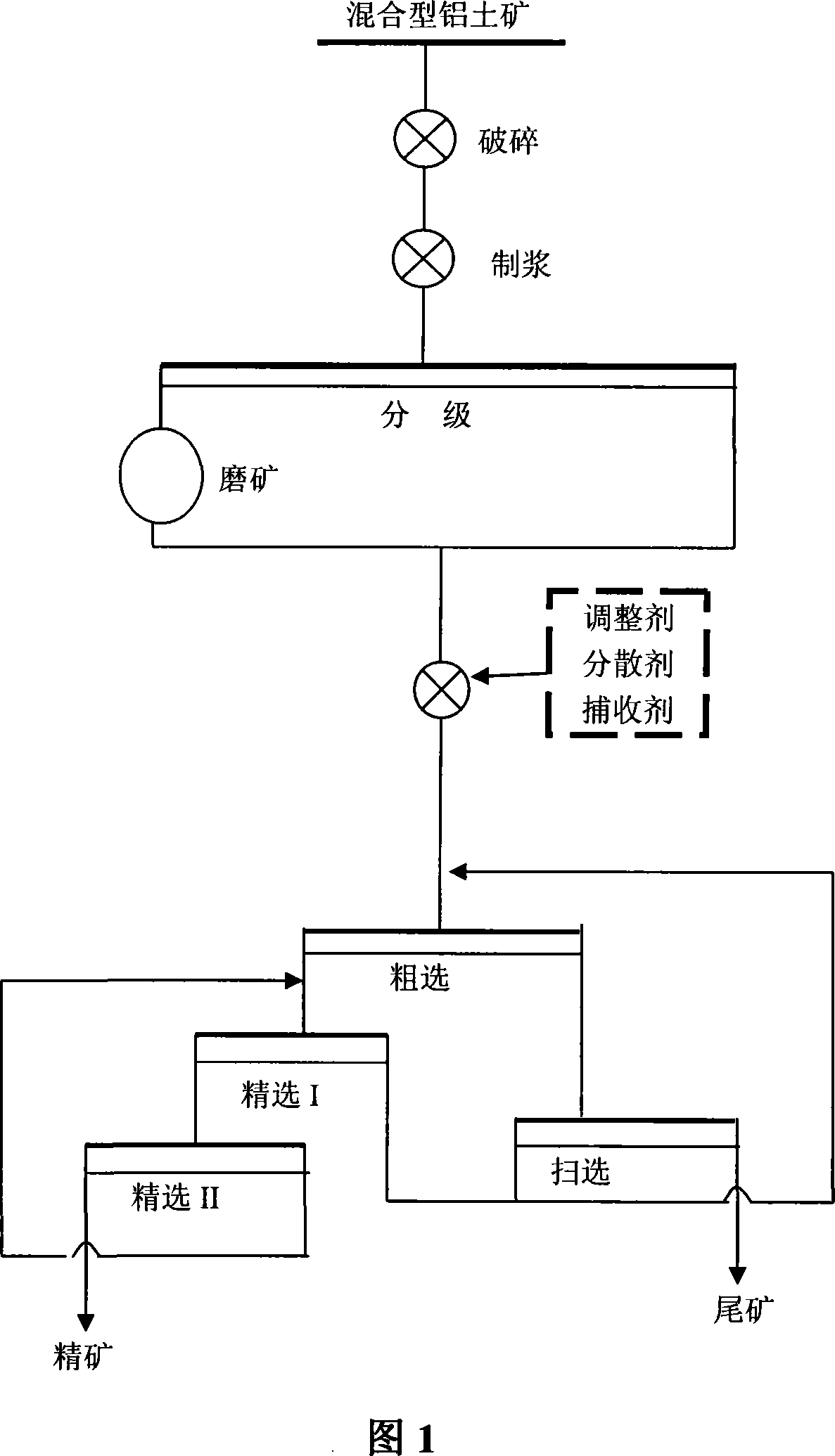

Method for ore dressing and desilicating mixed type bauxite

ActiveCN101176859ASolve the problem of beneficiation and desiliconizationSimple technical processFlotationWet separationHybrid typeSlurry

The invention relates to a mill run desiliconizing method for the mixed alumyte, in particular to a mill run desiliconizing method for the mixed alumyte with the gibbsite. The invention is characterized in that: smashing the mixed alumyte, adding the water to make slurry and make the ore smash, abstracting the coarse fraction mineral and the fine fraction mineral in the products by means of a screen separation craft or a grade craft, fine grinding the coarse fraction mineral which is abstracted, then mixing the milling grinding products and the fine fraction mineral which is abstracted by means of the screen separation craft or the grade craft, and carrying through a floatation. After the invention is carried into execution, the mill run desiliconization of the mixed alumyte with the gibbsite in middle or low grade is realized; the invention has a higher coefficient of recovery under the condition of guaranteeing A / S ratio of the ore concentrate. The invention has the advantages of simple and steady technological process, strong operability, capability of enlarging the resource supply of alumyte and providing a technical support for economy when the alumyte resources are needed, and important economic meaning and a social meaning for the sustainable development of the alumina industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

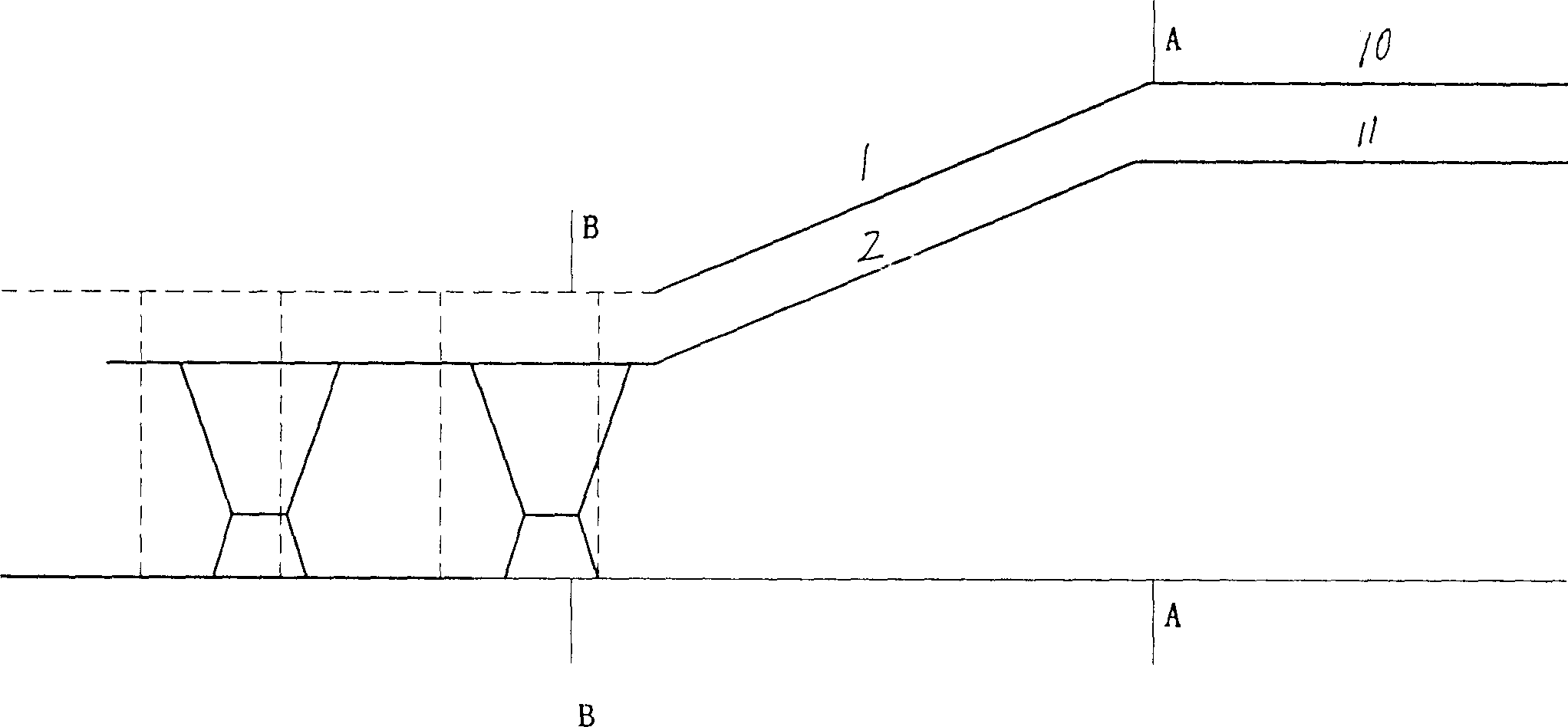

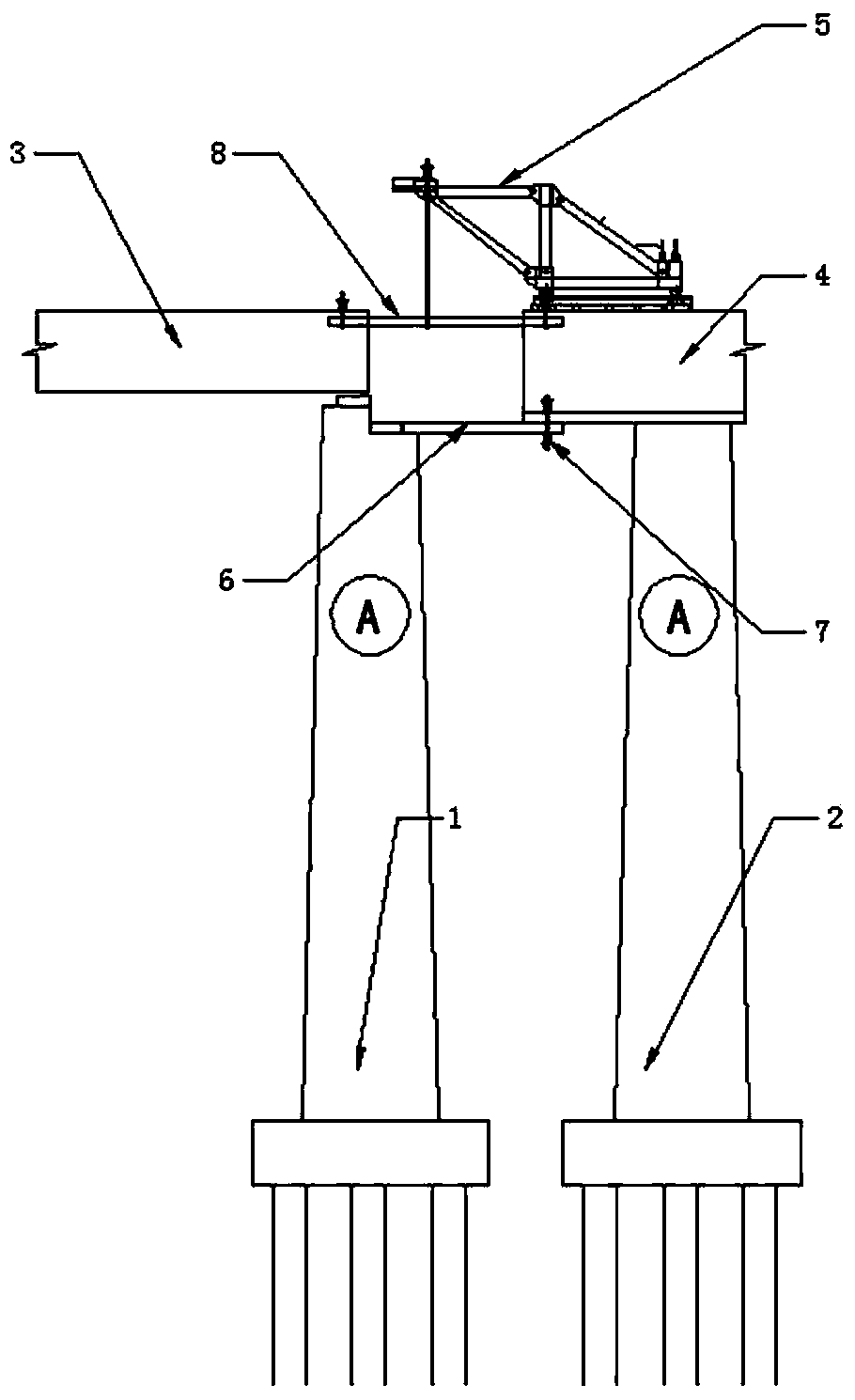

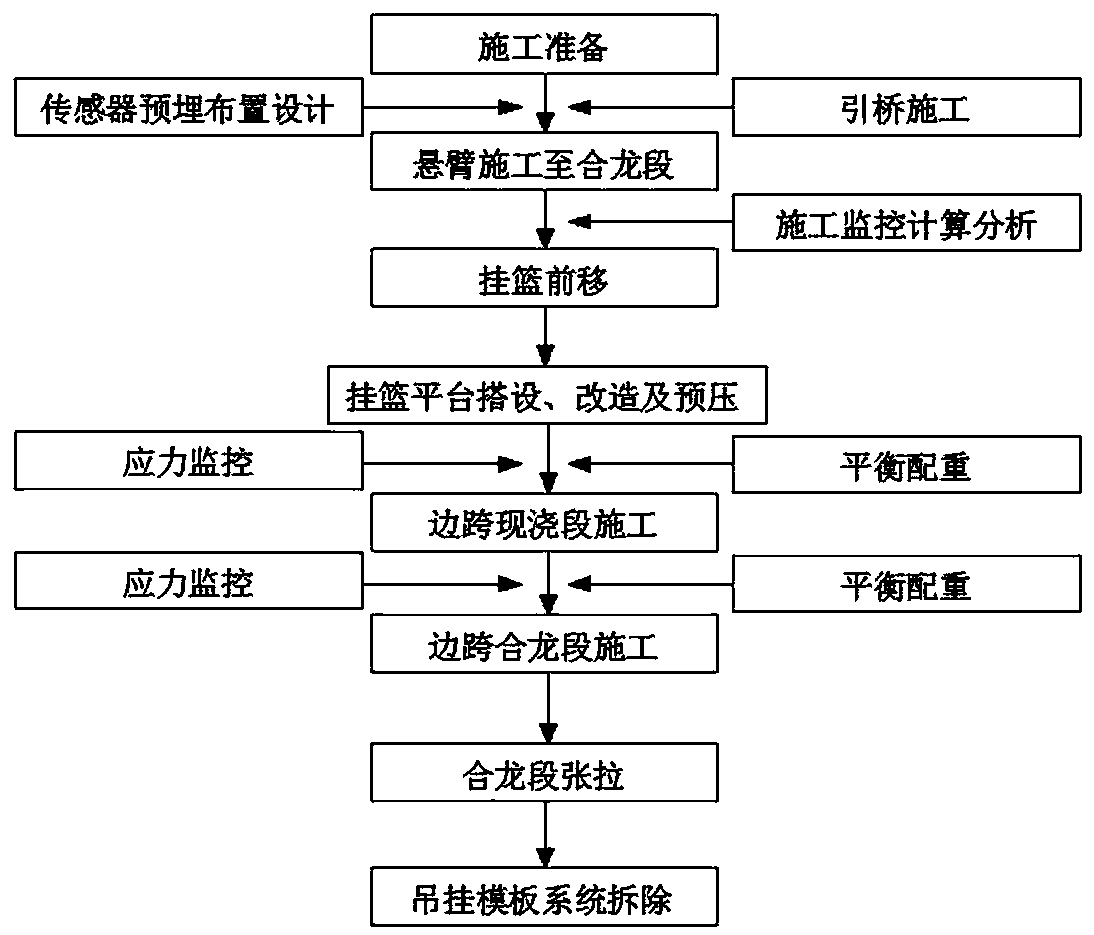

High pier continuous beam side span cast-in-place section and closed section integrated construction system and construction method

PendingCN109944170ASolve the erection problemAvoid constructionBridge erection/assemblyContinuous beamHanging basket

The invention relates to the technical field of building construction, in particular to a high pier continuous beam side span cast-in-place section and closure section integrated construction system and construction method, the construction method comprises the following steps of: construction preparation; construction monitoring calculation analysis; cantilever construction to the closure sectionand bridge approach construction; basket forward movement and basket platform reconstruction; pre-pressing; side span cast-in-place section construction; side span cast-in-place section construction;side span closure section construction; side span closure section tensioning; and lifting platform system dismantling. Compared with a prior method, the method effectively solves the problem of highpier support erection, avoids a large number of support erection construction, adopts the stress of the hanging system of the hanging basket, has simple construction technology, reduces the use amountof materials, reduces the use of large-scale hoisting equipment, has the obvious advantages of cost saving, construction period saving, better technical economy and the like aiming at the work of possibly prior support treatment and the like, avoids the prior construction support erection, avoids the work of a large number of basic treatment and the like, and has obvious construction period saving.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

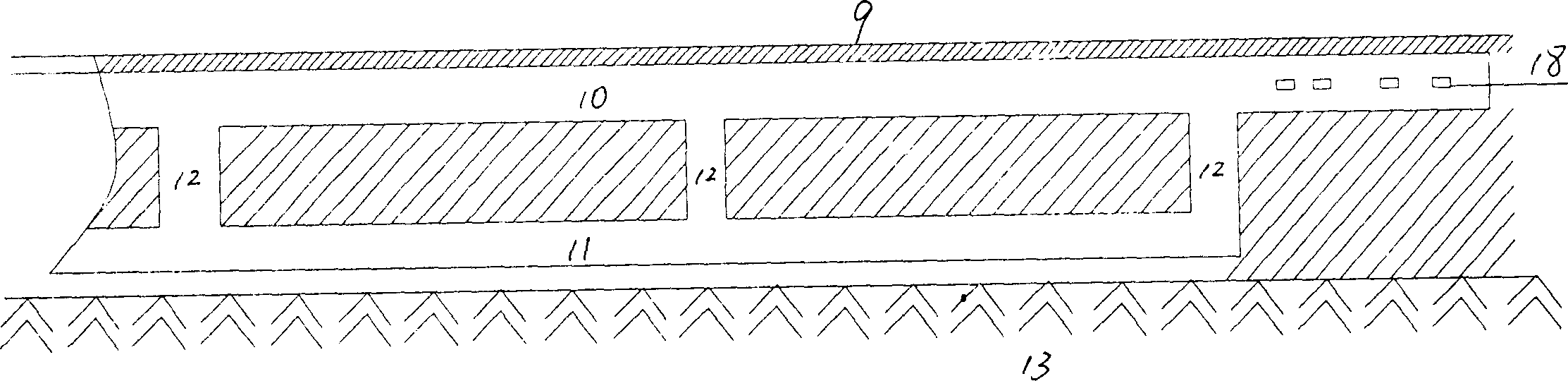

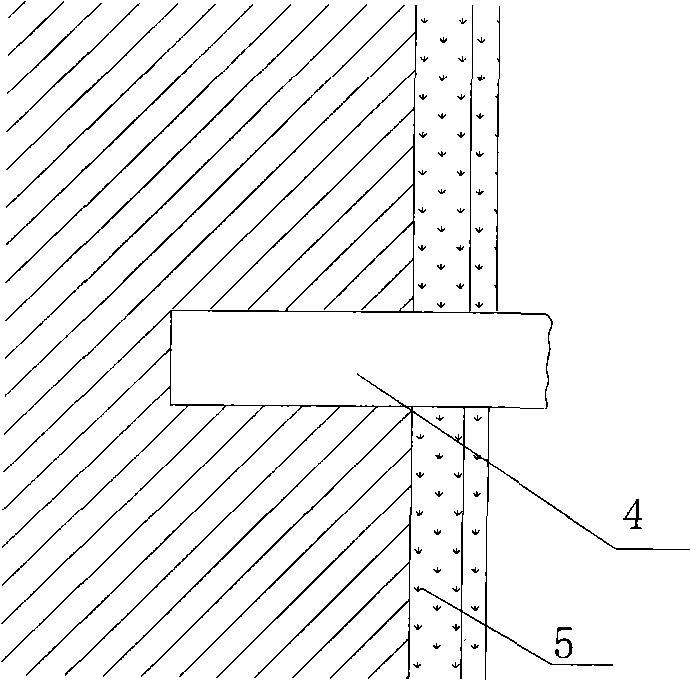

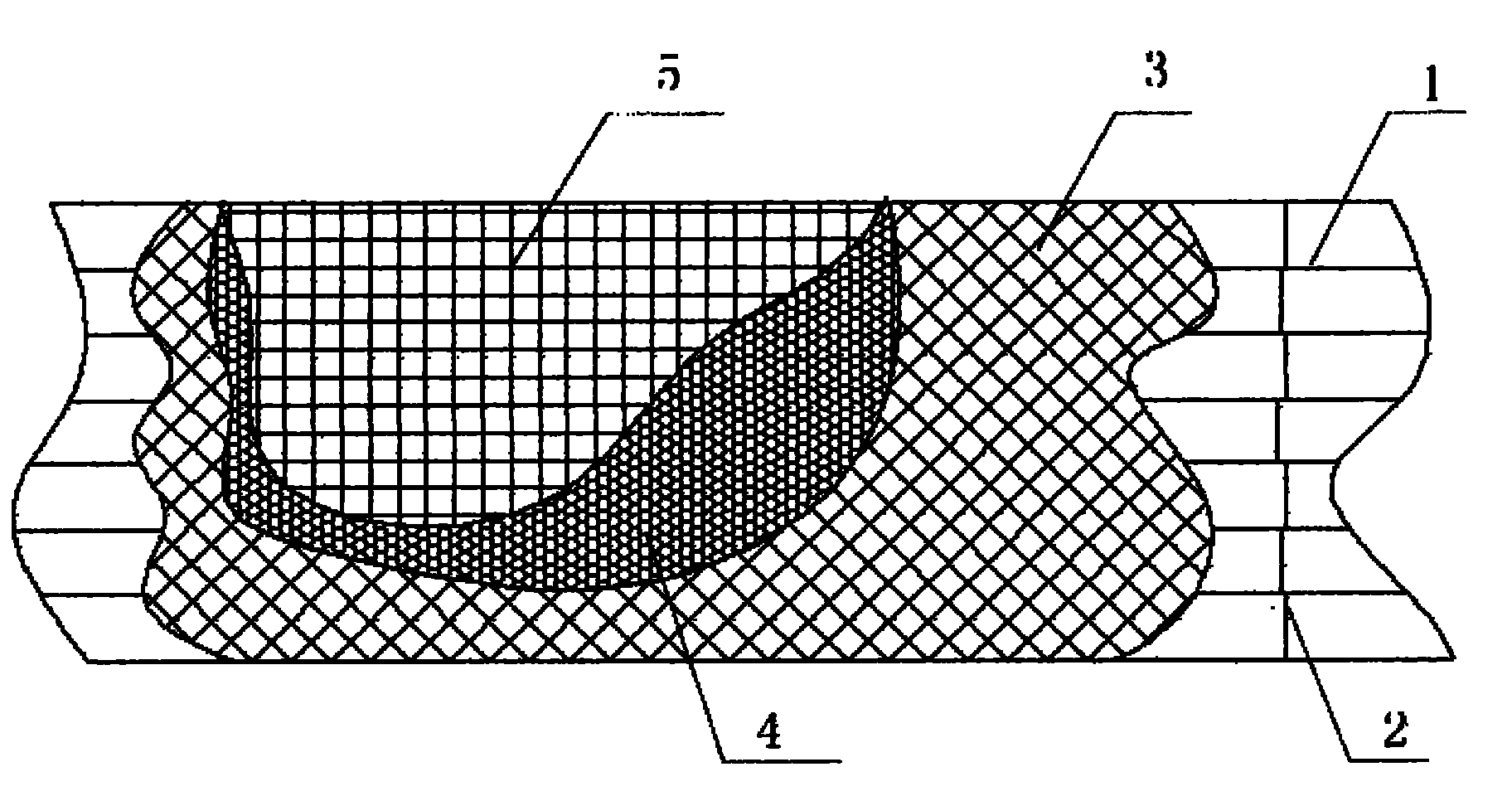

Blast furnace pressing-in grouting and lining-making construction method

InactiveCN101289698AGuarantee normal productionImprove maintenance efficiencyBlast furnace componentsBlast furnace detailsSlurryMaterials science

A blast furnace pressing-in grouting lining making construction method comprises the following: a first step of drilling grouting holes (2) in a furnace casing (5) of the damaged part of the blast furnace, inserting a grouting short pipe (4) with a valve (9) into each hole, and then welding the grouting short pipe (4) and the furnace casing (5) together; a second step of butting the output pipe of a pulp press and the grouting short pipe with the valve (9) on the furnace casing together; a third step of pressing stirred slurry (12) into the blast furnace through the pulp press, after reaching the preset slurry amount, the pulp press stopping pressing, opening the feedback valve of the pulp press, and then disassembling an output pipe (8) of the pulp press from the grouting short pipe (4) after closing the valve (9) of the grouting short pipe (4); a fourth step of circulating the second step until grouting is finished for all grouting holes. The blast furnace pressing-in grouting lining making construction method not only improves the efficiency and quality of blast furnace maintenance but also achieves good maintenance effect under both the delay status of the blast furnace and the non-delay status of the blast furnace.

Owner:WUHAN HONGCHENG METALLURGICAL MATERIAL

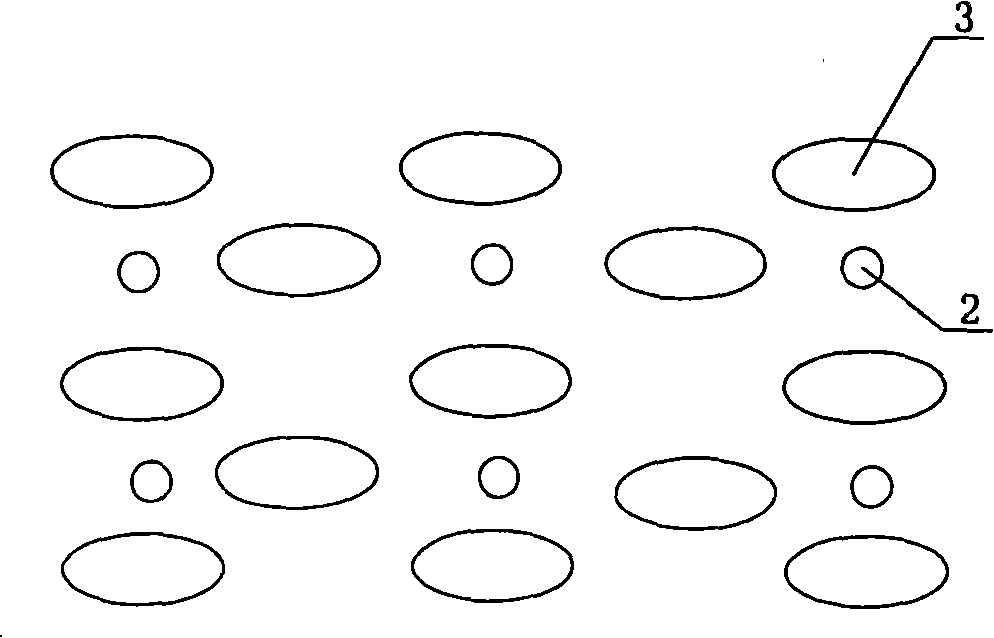

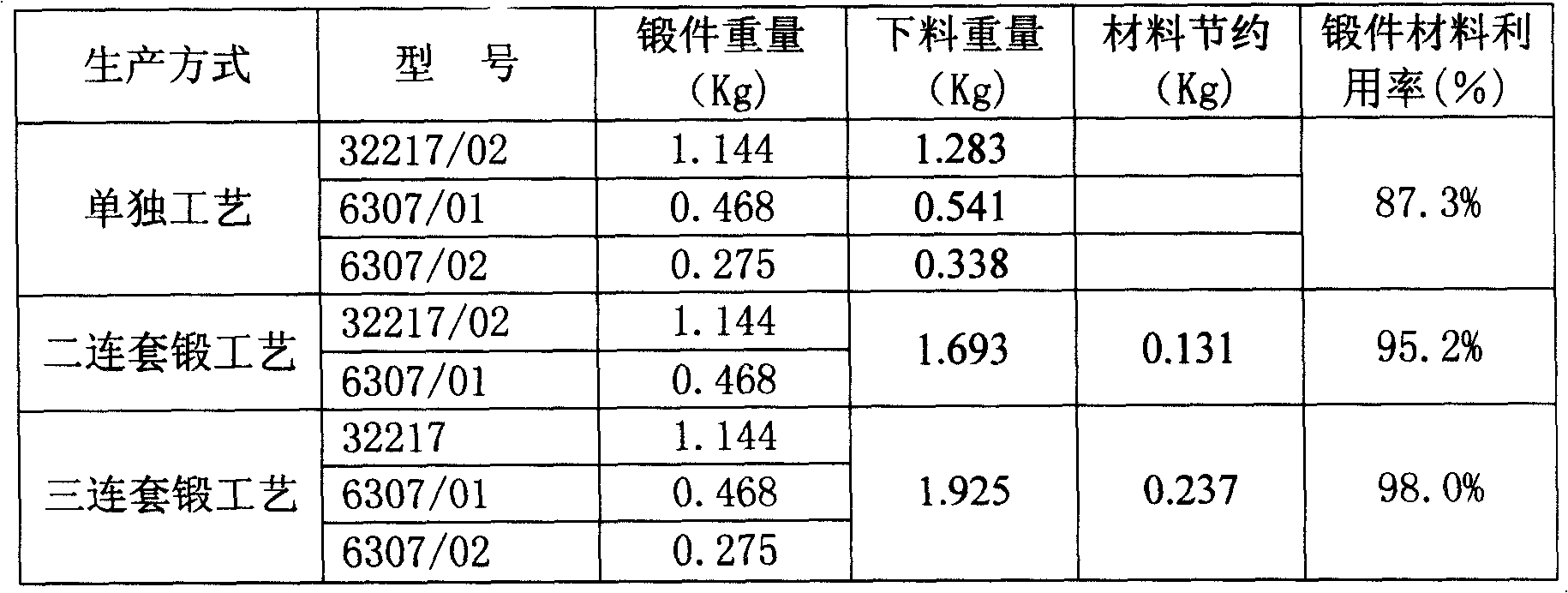

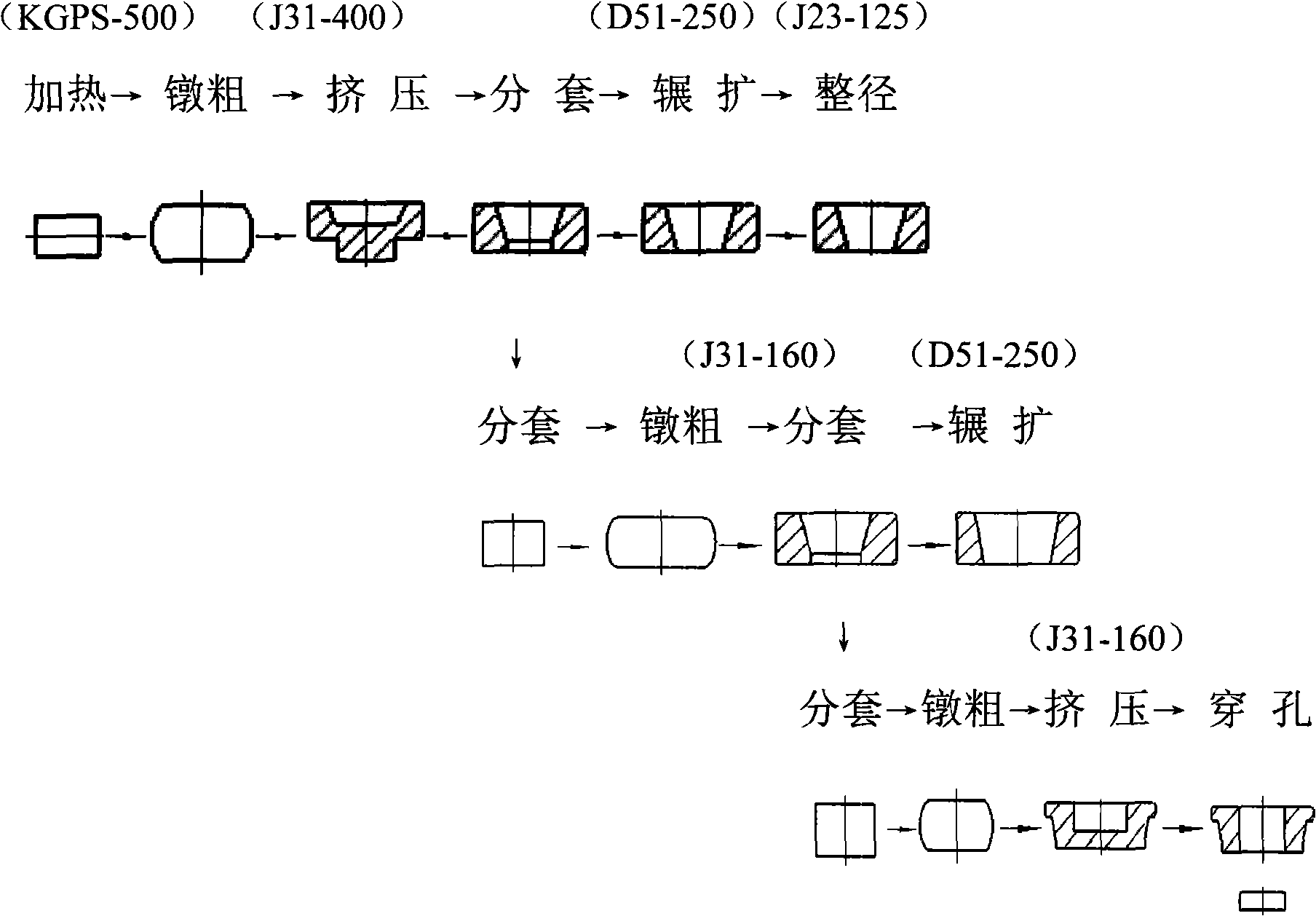

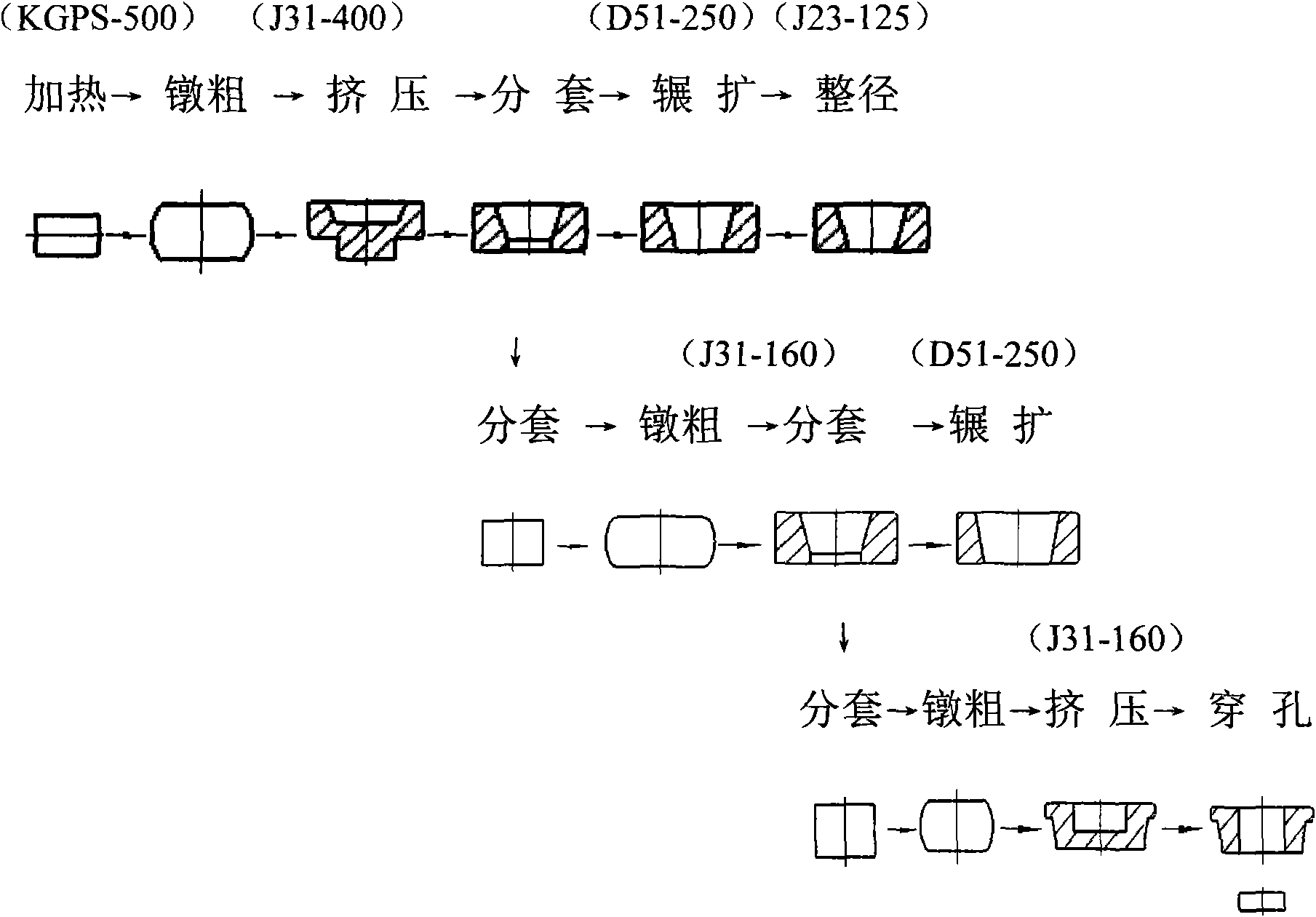

Annular bearing forging triple-package forging technology

The invention relates to an annular bearing forging triple-package forging technology belonging to the technical field of bearing forging and mainly solving the problem of lower stock utilization in the traditional annular bearing single and double-package forging technology. The technology is mainly characterized in that: (1) a steel section with the weight of 1.500-2.700kg and the diameter of 55-70 is heated to forging temperature, divided into two parts, i.e., an annular big bloom and an annular medium-small bloom, after the processes of upsetting and package separation; (2) the annular big bloom is made into a big annular bearing forge by the processes of ring rolling, restricking and cooling; (3) the annular medium-small bloom is separated into two parts, i.e., an annular medium bloom and an annular small bloom, after the processes of upsetting and package separation; (4) the annular medium bloom is made into a medium annular bearing forge by to the processes of ring rolling and cooling; and (5) the annular small bloom is made into a small annular bearing forge by the processes of ring rooling, extrusion, punching and cooling. The invention mainly adopts a novel technology of punching-expanding horizontal package separation and the annular bearing forging triple-package forging technology, thereby realizing the simultaneous production of annular bearing forgings in big, medium and small sizes.

Owner:李金国 +1

Method for preparing Mg-Li alloy by vacuum synchronous thermal reduction

The invention relates to a method for preparing an Mg-Li alloy by vacuum synchronous thermal reduction, belonging to the novel technical field of preparing magnesium alloy materials. The process course comprises the following steps of: preparing reactants according to stoichiometry of reduction reaction; pulverizing solid reactants and uniformly mixing; pressing the reactant powder into blocks and placing the blocks into a reduction tank, and carrying out thermal reduction reaction at the vacuum degree of 1-20Pa and the temperature of 950-1,500 DEG C; collecting alloy steam generated by reaction; and condensing the alloy steam to obtain an Mg-Li alloy in a condensed state. In the invention, the oxides of metals Mg and Li or a precursor of the oxides are utilized as raw materials, the synchronous reduction of the metals Mg and Li is realized through vacuum thermal reduction to prepare the Mg-Li alloy directly. The alloy preparation process has short route, wide sources of the raw materials, high material utilization rate, favorable economy and manufacturability, high efficiency and energy saving.

Owner:CHONGQING UNIV

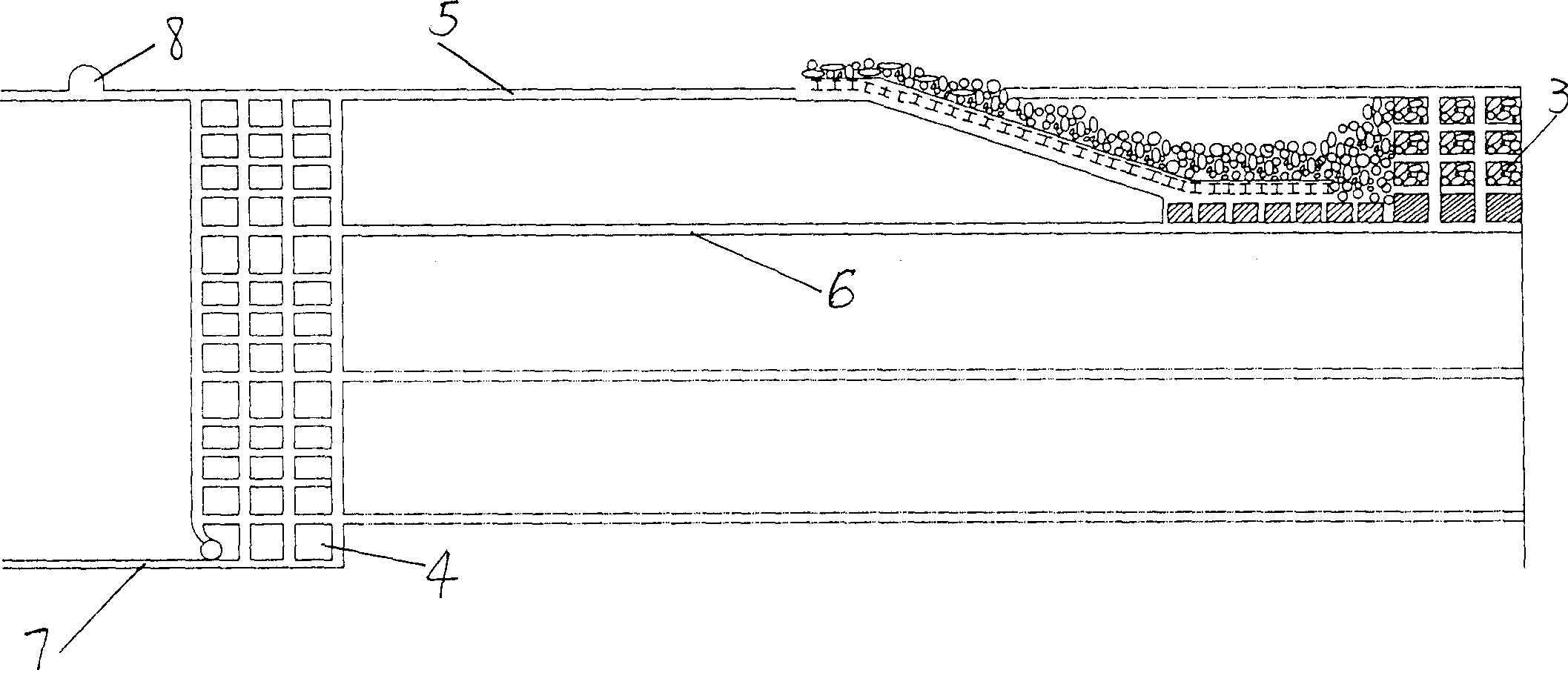

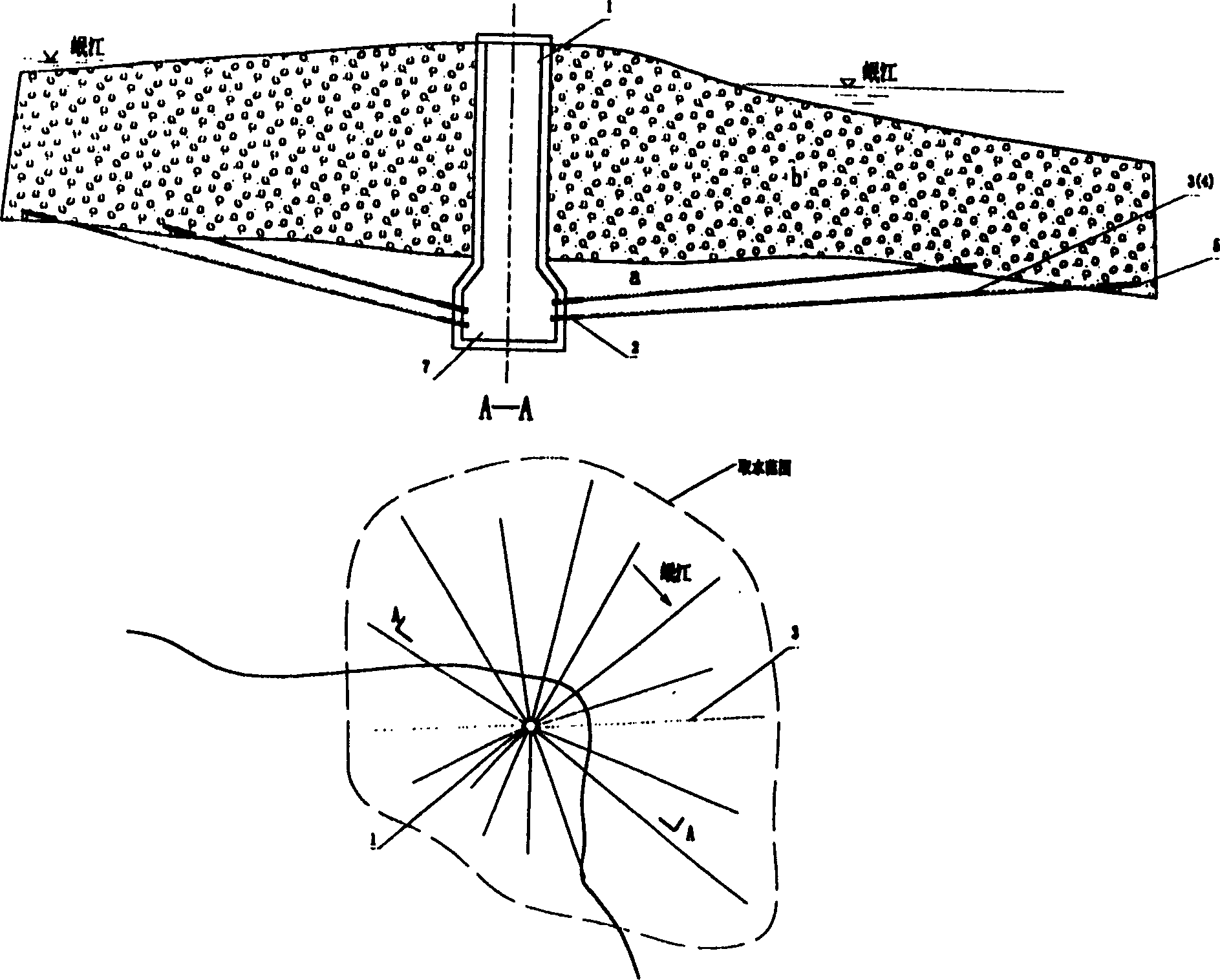

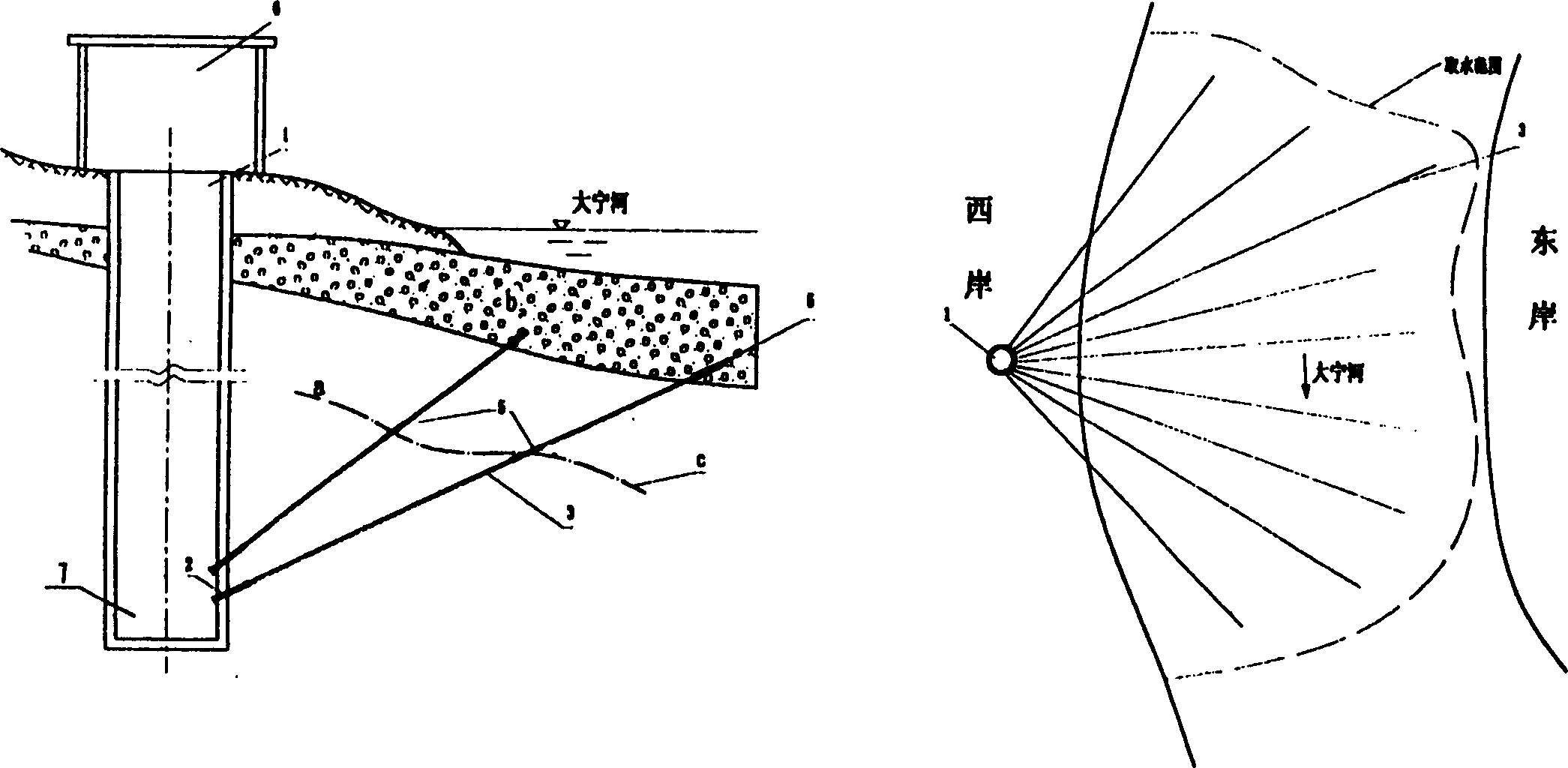

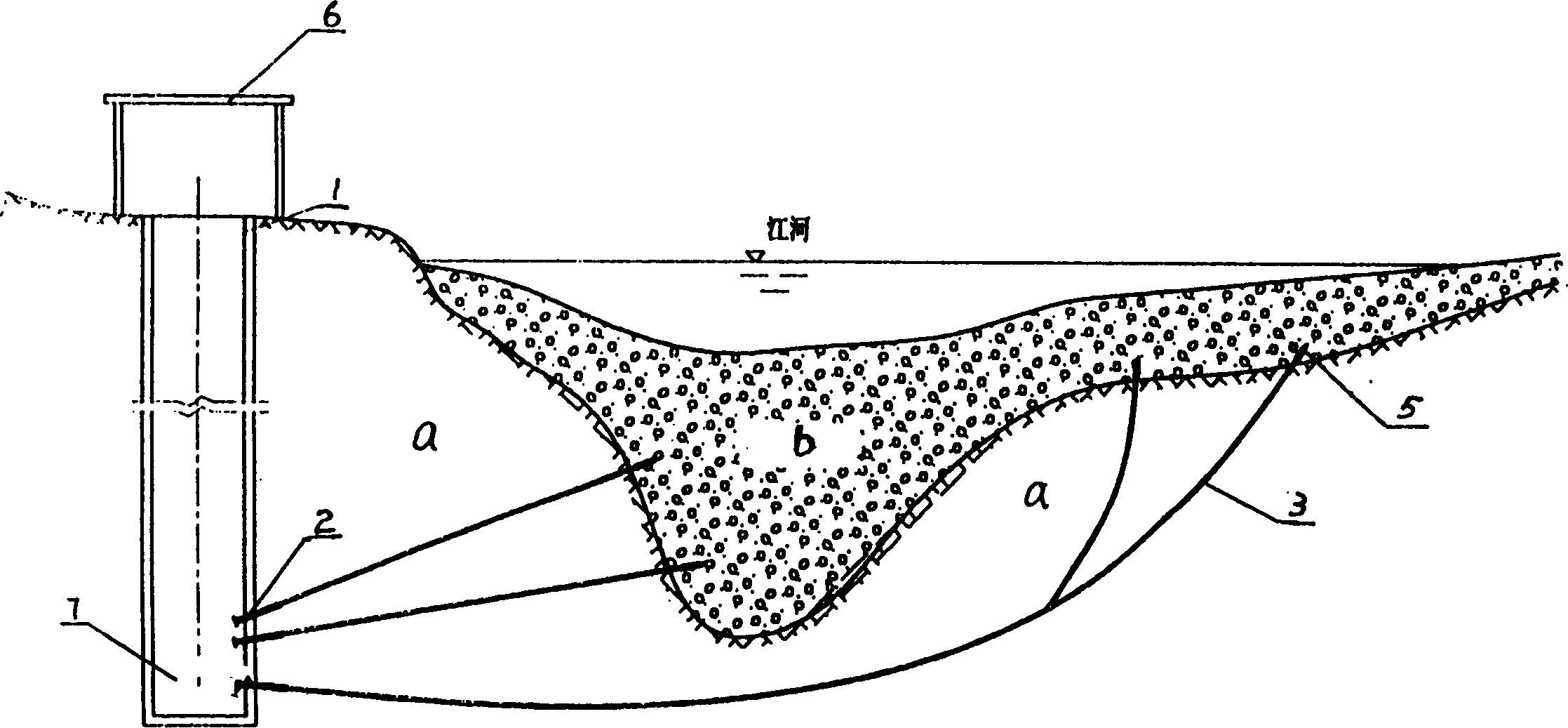

Percolation water intaking method of new engineering structure

ActiveCN1474000ALow level of construction safety guaranteeAvoid safety hazardsWater/sewage treatmentPumping plantsEcological environmentEnvironmental geology

The present invention relates to underground water taking and collecting method, and is new engineering structure for taking percolation water. The present invention features that the collecting well is embedded into base rock stratum for at least 5 m, controlled directional percolation holes are drilled into grit stratum under the base rock stratum around the well, and filters are set in the hole parts corresponding to the water bearing stratums. The said engineering structure makes the taken underground water need no further processing in the water producing system, and has the merits of both radiation well and natural filtering bed percolation well, including simple engineering structure, being safe and reliable, no damage to ecological environment, etc.

Owner:重庆泓源渗滤取水科技有限公司

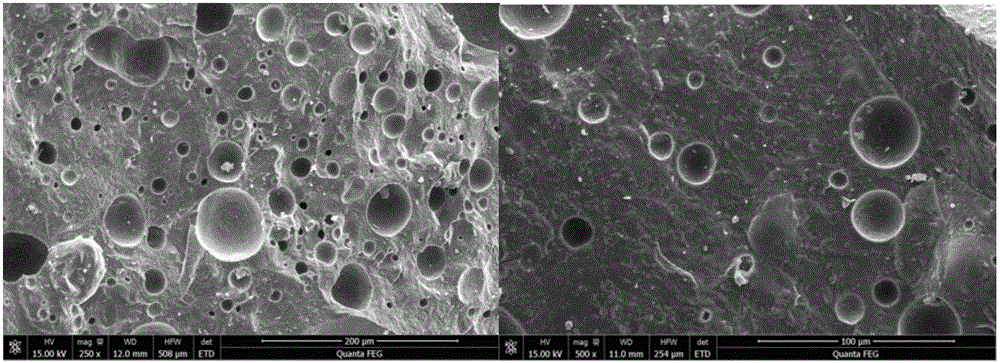

Production method of ecologic permeable ceramic bricks

The invention provides a production method of ecologic permeable ceramic bricks. The method comprises the following steps: 1, taking 5-10% of construction waste micro-powder, 5-15% of construction waste fine aggregates, 30-45% of construction waste coarse aggregates, 15-20% of dried sludge, 15-40% of modified mud, 0.075-0.2% of alum and 0.5-1% of borax; and 2, uniformly mixing, molding a test block under a molding pressure of 10-20Mpa through adopting a pressure molding process, naturally drying after molding, heating to 300-350DEG C at a rate of 2-3DEG C / min, keeping the temperature at 300-350DEG C for 2.5-3.5h, heating to 1050-1150DEG C at a rate of 3-8DEG C / min, sintering for 3-4h, and cooling. The method has the advantages of high waste utilization rate and effective solving of the contradiction between mechanical performances and the water permeability.

Owner:WUHAN UNIV OF TECH

Method for producing molten iron with high-phosphorus and low-iron refractory iron ore

InactiveCN101643806AEfficient desulfurizationImprove reducibilityFluidised-bed furnacesIronstoneHigh energy

The invention provides a method for producing molten iron with high-phosphorus and low-iron refractory iron ore, comprising the following steps: taking high-phosphorus and low-iron refractory iron oreas raw material; taking wood coal as reducing agent; oxidizing roasting; directly reducing; magnetically separating and separating; melting and separating; dephosphorizing molten iron; and obtainingthe low-phosphorus molten iron. The method can process the extremely refractory iron ore with high P content, high S content, high SiO2 content and low iron level, has high ore iron recovery rate, completely solves the difficulties of the high-phosphorus and low-iron refractory iron ore such as ore selecting and smelting, removing coke, and eliminating high-energy consumption and high-pollution technical process such as ore selecting, sintering, palletizing, coking, etc. Phosphorus-containing slag can realize resource comprehensive utilization. A great number of experiments and semi-industrialproduction demonstrate that the technical economic effect of the method is remarkable and effectively solves the current problem of ore resources supply-demand contradiction in China.

Owner:KUNMING IRON & STEEL HLDG CO LTD

Method for mineral dressing and silicon removal of bauxite

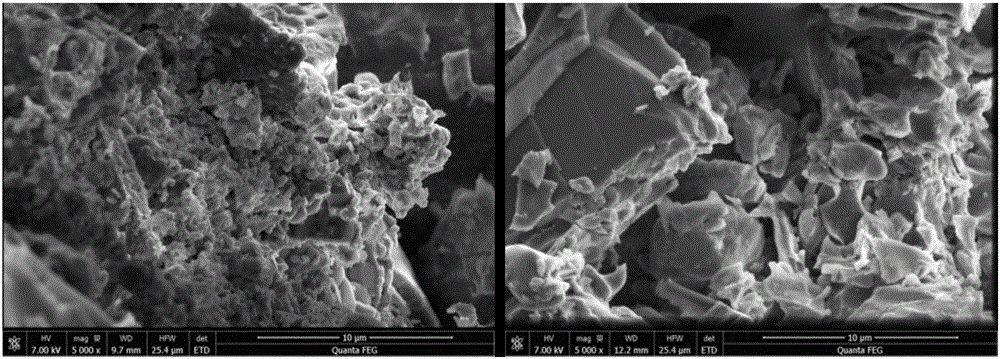

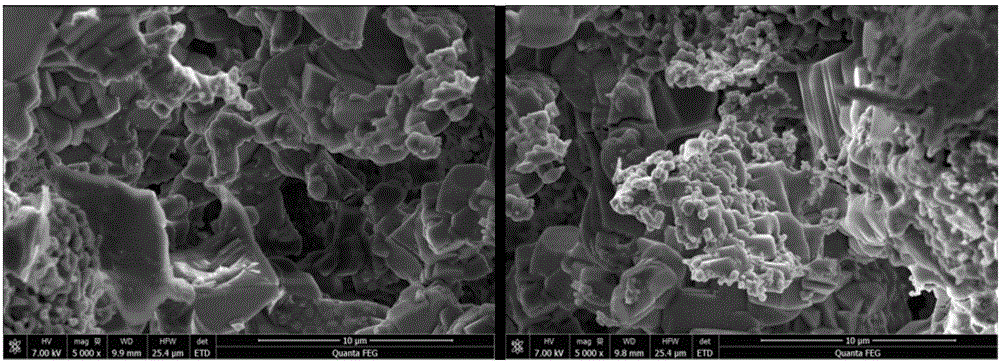

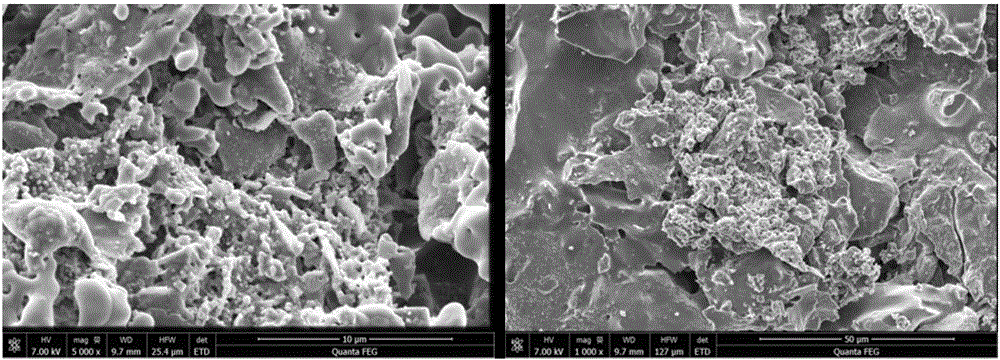

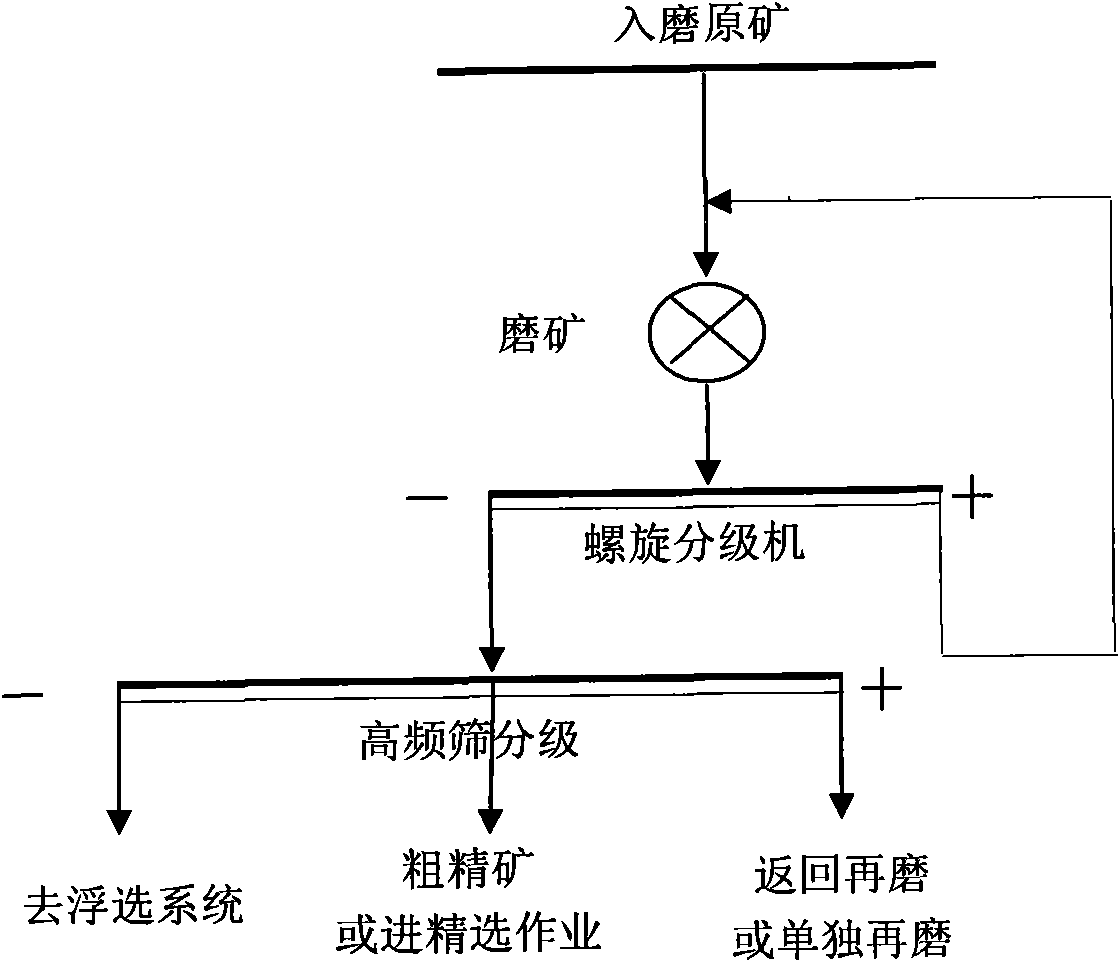

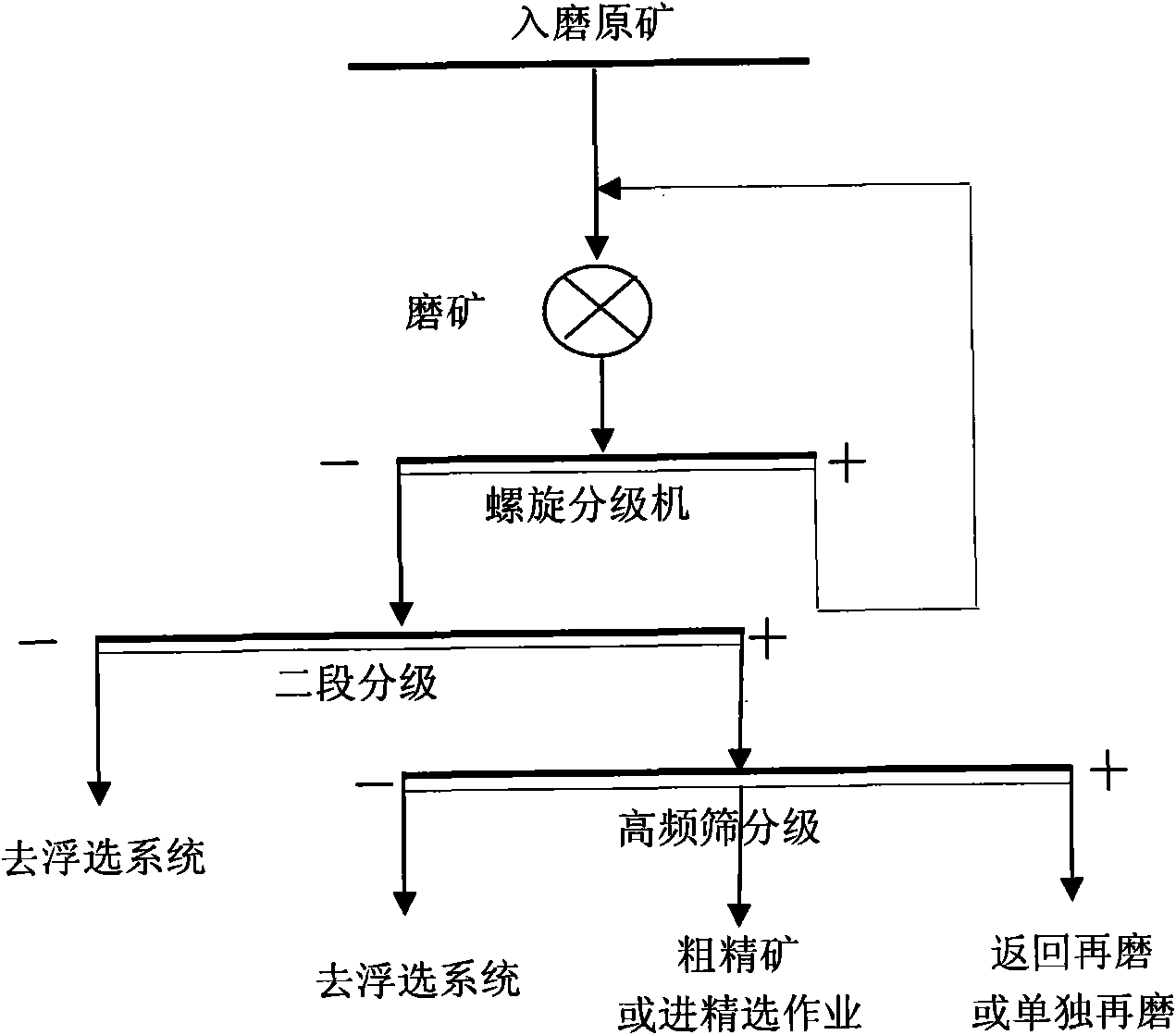

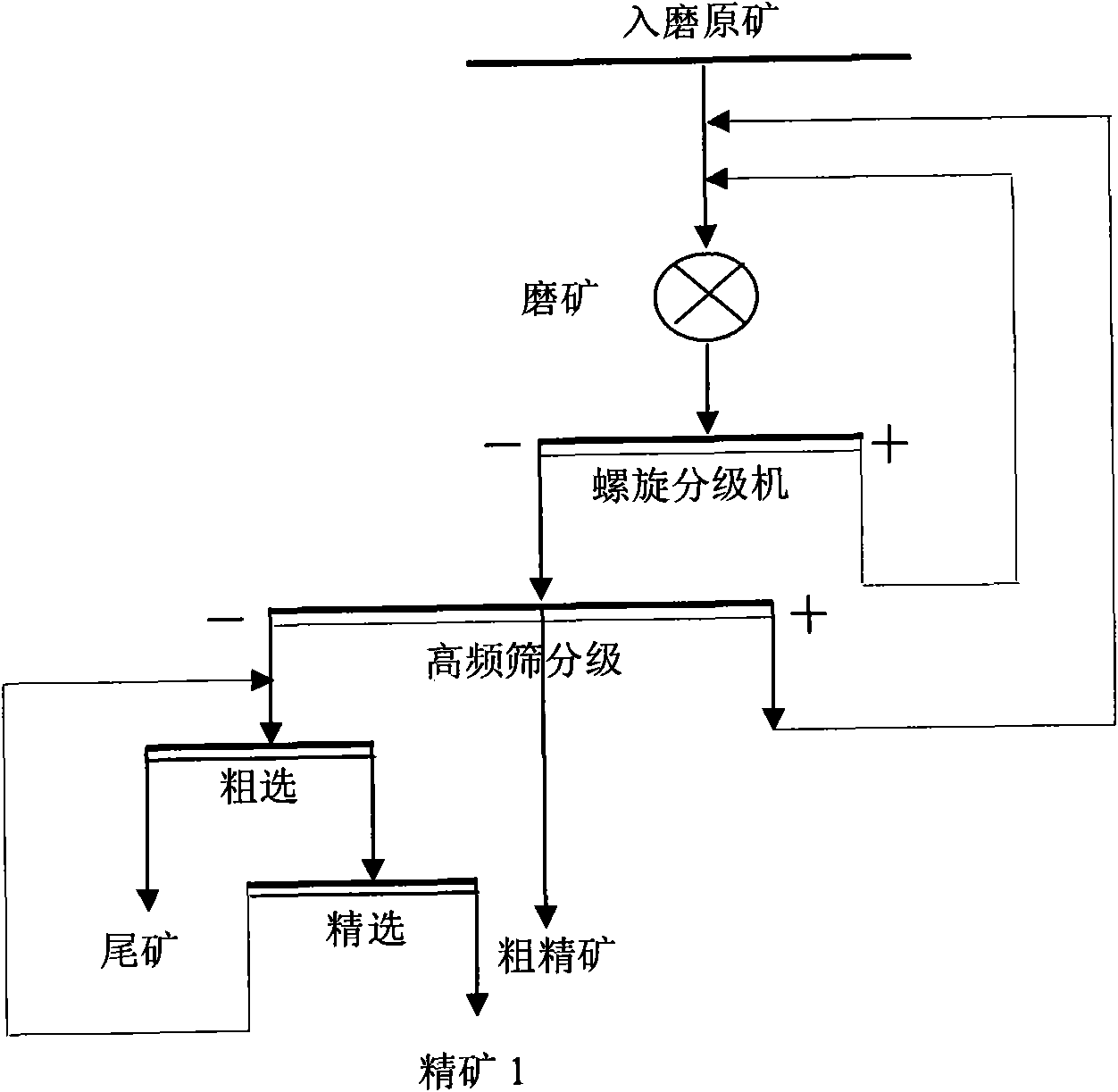

InactiveCN101850297ASimple technical processGood technical and economic effectFlotationWet separationDiasporeLarge size

The invention provides a method for mineral dressing and silicon removal of bauxite, and particularly relates to a method for mineral dressing and silicon removal of diaspore type bauxite. The method comprises an ore-grinding grading process and a flotation silicon removal process, and is characterized in that: the product of ore grinding is graded for two or three times, wherein a double-layer high-frequency vibrating screen is used at the last time of grading; and among three products obtained by grading of the double-layer high-frequency vibrating screen, large-size grains are reground and re-dressed, medium-size grains are used as rough concentrates or enter the flotation system for concentration, and small-size grains enter the flotation system for flotation silicon removal. The method has the advantages of effectively solving the technical problem that the grinding machine is high in energy consumption and low in treating capacity, the problem that the grain size of the flotation materials is small and other problems, better performing flotation silicon removal of bauxite, obtaining bauxite concentrates with qualified grade, along with good process technique and economic indexes.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

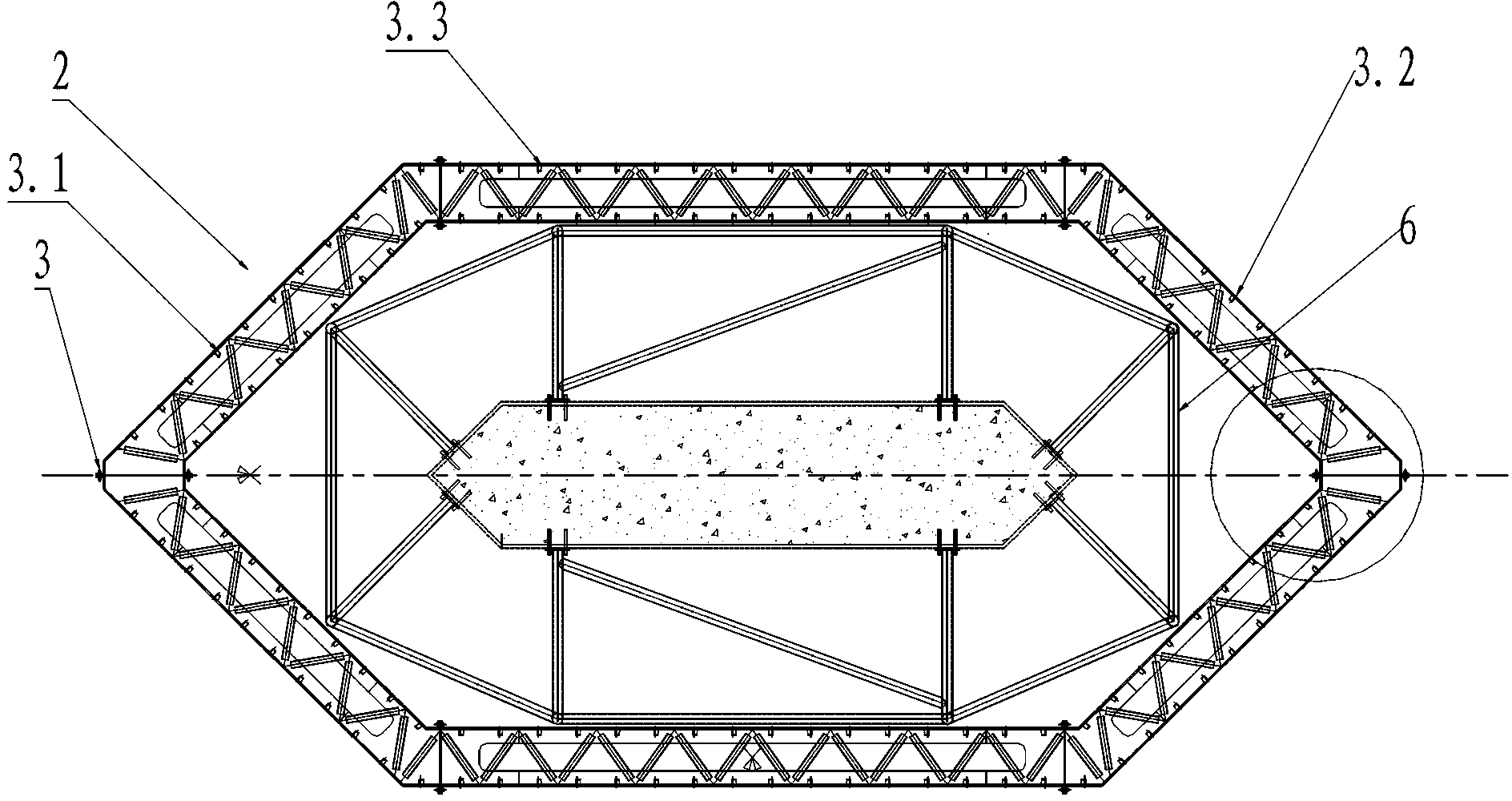

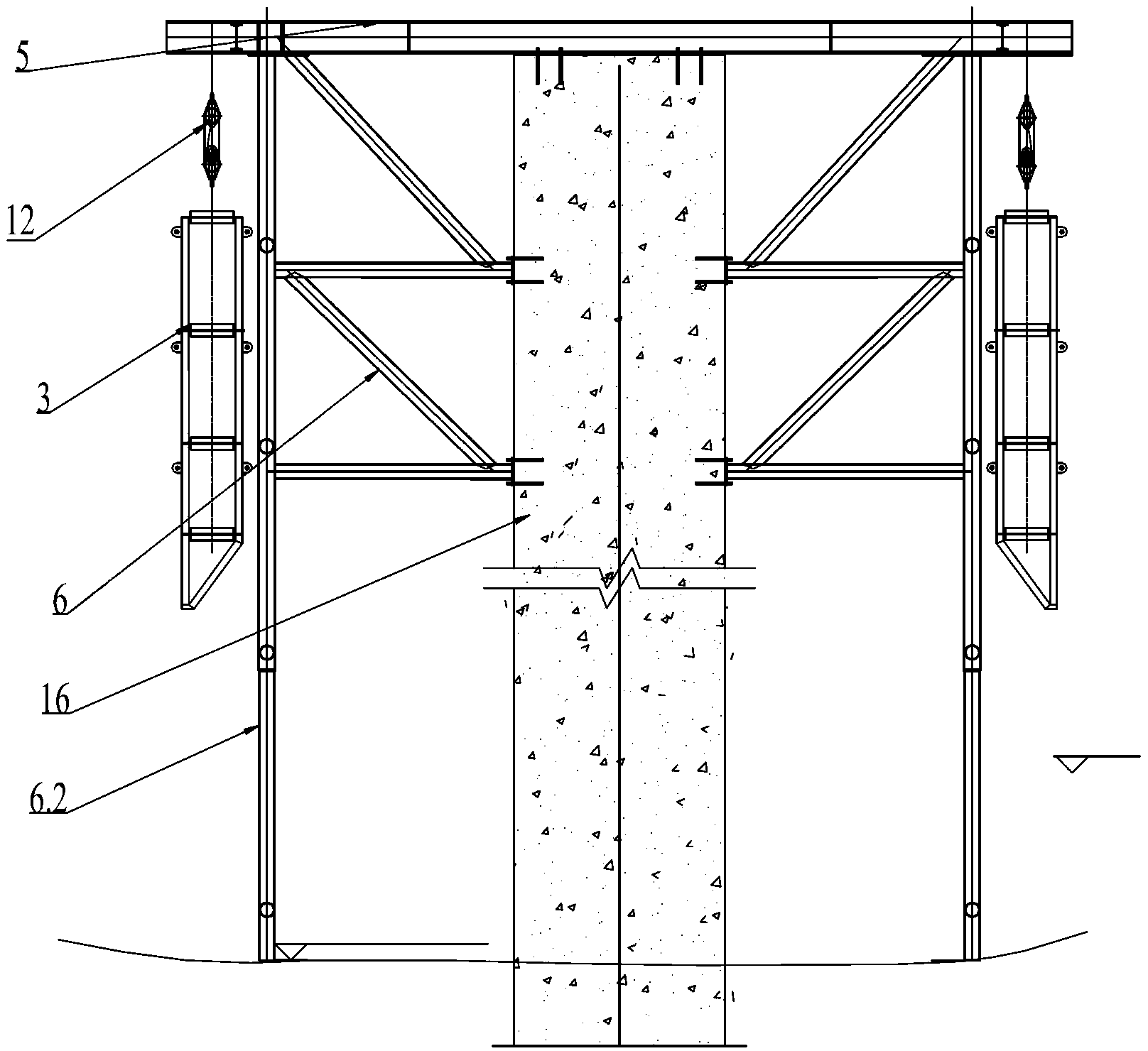

Method for installing steel cofferdam by the aid of pier supporting frame

The invention discloses a method for installing a steel cofferdam by the aid of a pier supporting frame. The method comprises that a lifting frame and a guide frame are installed on a pier, the steel cofferdam is divided into a plurality of steel cofferdam sections according to actual conditions, and each of the steel cofferdam sections is divided into a plurality of steel cofferdam units with chamfer angles. During construction, the lifting frame which is located at the top of the pier or on one side of the pier and is used for lifting the steel cofferdam is installed firstly, the guide frame which is located on one side of the pier and can be used for guiding and positioning the underwater steel cofferdam is installed, finally, steel cofferdam units are lifted horizontally and then adjusted to be vertical, and the steel cofferdam having a self-balancing capability can be formed through lifting and assembly of sections and units by the aid of the lifting frame and the guide frame in such a sequence that upstream steel cofferdam units and downstream steel cofferdam units are installed and then steel cofferdam units in the middle are installed. The method can effectively solve the problems of assembly, positioning and sinking of the steel cofferdam in a narrow and small space on the condition that no large lifting device is provided, and the method has the advantages of being good in adaptability, simple in structure, convenient to manufacture, good in operability, safe, reliable, good in economical efficiency, good in application prospect and the like.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Method for coupling MTO process with front-end depropanization process of naphtha and propane pyrolysis

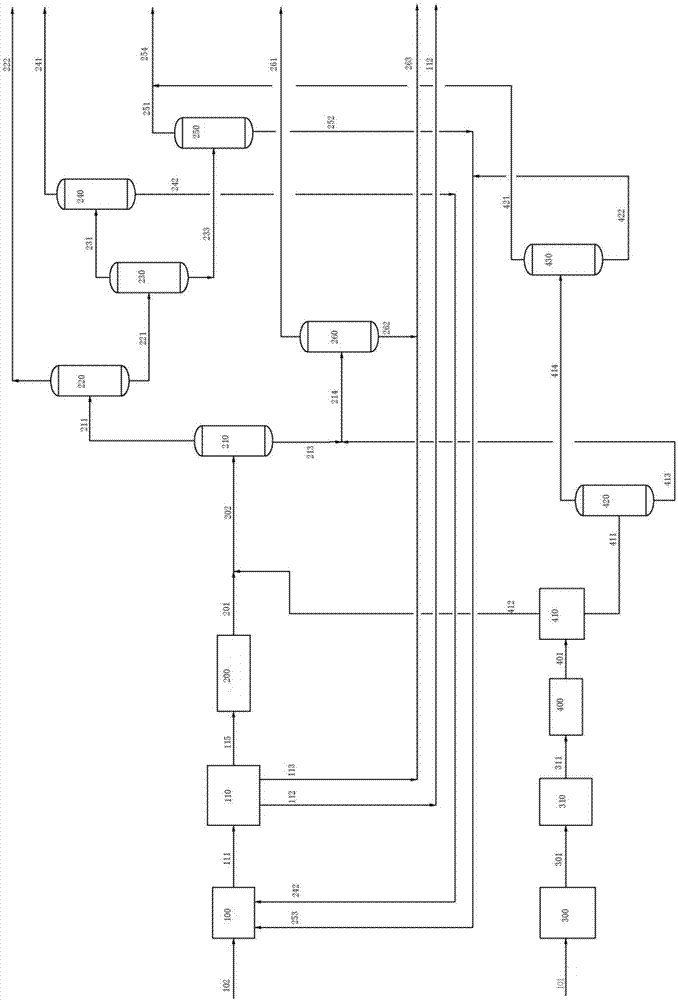

InactiveCN107056568AGood technical and economic effectSavingsDistillation purification/separationHydrocarbon from oxygen organic compoundsChemistryPyrolysis

The invention relates to a method for coupling an MTO process with the front-end depropanization process of naphtha and propane pyrolysis and mainly solves the problems that the existing coupling technology is high in pyrolysis raw material cost, low in propylene yield, long in MTO device separation flow and high in equipment engineering investment. The method has the advantages that the MTO process is coupled with the front-end depropanization process under the premise that the total yield of ethylene is unchanged and by the aid of the existing separation equipment of an ethylene device, methanol and propane are used to replace most of naphtha, the yield of the propylene is increased by 38500-190200 tons / year, the use amount of the naphtha is reduced by 2095200-3842300 tons / year, product and raw material costs are saved by 1.267-2.932 billion yuan per year, the problems above are well solved, and the method is applicable to the production of low-carbon olefin.

Owner:SINOPEC SHANGHAI ENG +1

Process and system for recycling high-chloride high-concentration non-degradable organic wastewater

InactiveCN105948150AShort processReasonable processOther chemical processesWater/sewage treatment by heatingHigh concentrationCombustion chamber

The invention provides a process and system for recycling high-chloride high-organic-matter wastewater; according to the process, in a set of system, an inorganic salt suitable for a snow melting agent is produced through a high-temperature cyclic oxidation process; organic matter self heat quantity is depended, an auxiliary heat source is externally added, and an organic matter is decomposed with low cost; at the same time, a high-temperature secondary combustion room is designed, and dioxin is decomposed; wastewater is subjected to atomized quenching concentration by using high temperature flue gas, and hazardous waste recycling treatment is realized with low cost; the process is especially suitable for organic wastewater containing sodium chloride, calcium chloride, magnesium chloride and other high-chloride salts, but also can be used for recycling disposal of other high-salt high-concentration organic wastewater, and has great economic and social benefits.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

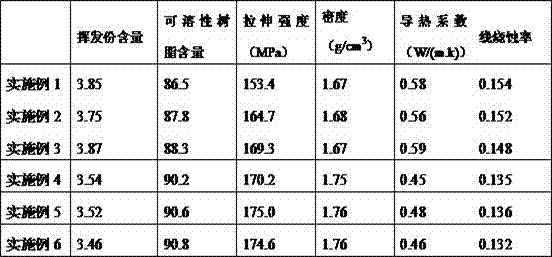

Ultrafine silicon carbide high silica fiber reinforced phenolic heat resistant composite material and preparation method thereof

ActiveCN107189339ASimple molding processImprove production and processing efficiencyFiberIndustrial equipment

Relating to the technical field of heat resistant composite materials, the invention discloses an ultrafine silicon carbide high silica fiber reinforced phenolic heat resistant composite material. The composite material comprises the following raw materials by weight: ammonia phenolic resin, glass fiber, superfine aluminum hydroxide, mica, silicon carbide, a silane coupling agent, calcium stearate and silicon nitride, etc. The composite material provided by the invention has good molding processability, a formed part has a smooth surface and high production and processing efficiency, and the product has high comprehensive yield. Artificial weather modification rocket projectile parts made from the material have excellent heat resistant and ablation resistant properties, and can meet the heat resistant and ablation resistant performance requirements of rocket projectile engine parts. The preparation method of the ultrafine silicon carbide high silica fiber reinforced phenolic heat resistant composite material provided by the invention can be completed by general industrial equipment, has low requirement for equipment complexity, and has the advantages of easy operation, stable process and high production efficiency, thus being suitable for large-scale industrial production.

Owner:SHANDONG NORTH MODERN CHEM IND

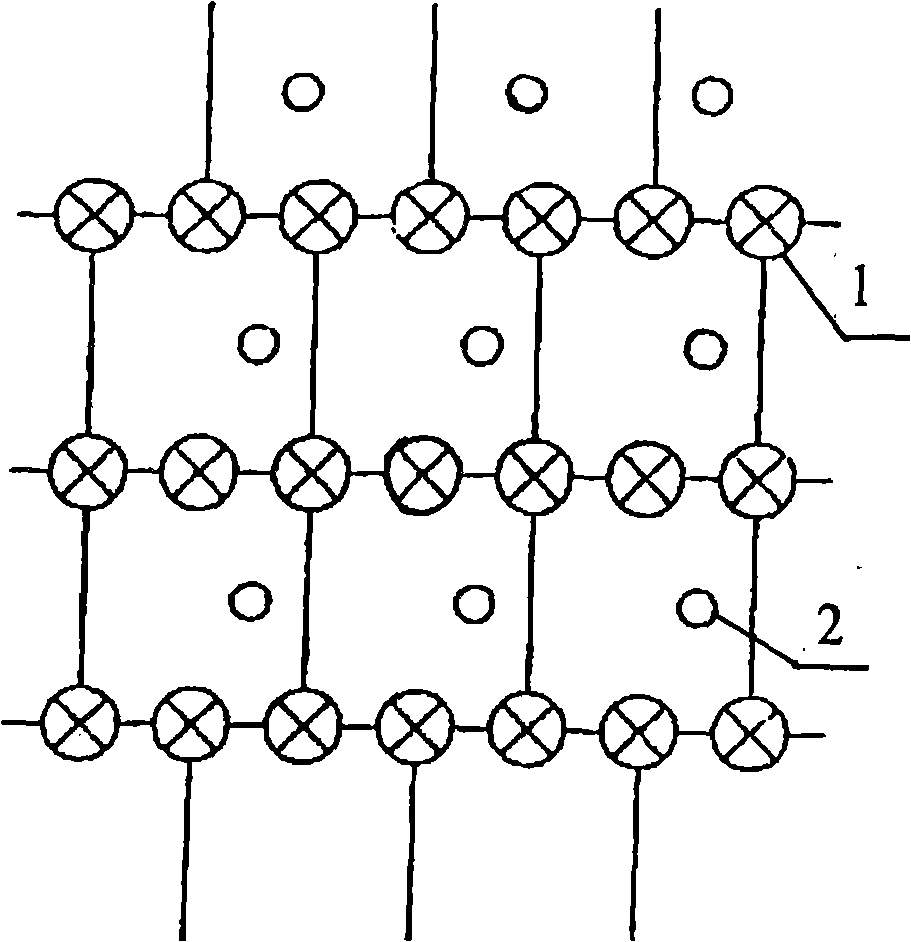

Construction method of thin shell with thin-shell structure

ActiveCN101832028AEasy to controlSimple construction methodBuilding material handlingShotcreteThin shells

The invention discloses a construction method of a thin shell with a thin-shell structure and relates to a reinforced concrete construction method of a thin shell with a thin-shell structure. Aiming to reduce the workload of producing, mounting and stripping a framework, the construction method comprises the following construction steps of: (1) hanging and paving a combined body of a concrete gridded attached carrier for deposing and pouring and reinforcing ribs on a prestress cable net, binding the attached carrier, the reinforcing ribs and the cable net by using the reinforcing ribs with a concrete bearing structure; and carrying out spraying and concreting to generate a form shell of the formwork for pouring concrete; and (2) carrying out spraying concreting on the generated form shell to finish the construction of the thin shell with the thin shell structure. The construction method is simple, can save a large amount of labor force and physical resources and has favorable comprehensive technical and economic performances.

Owner:CHINA CHEM ENG SECOND CONSTR

Method for preparing haydite by sintering sludge at low temperature

InactiveCN105016710AGood technical and economic effectIncrease profitCeramic materials productionClaywaresHydrogenPhosphate

The invention belongs to the types of building materials, and provides a method for preparing haydite by sintering sludge at low temperature. The method comprises the following steps of: 1) taking the following components in percentage by weight: 40%-45% of dewatered sludge, 40%-45% of high-alkali calcareous shale, 12%-18% of barium residues, 0.5%-0.8% of aluminum dihydrogen phosphate and 0.5%-1% of borax; and 2) uniformly mixing all the taken components so as to obtain a mixture, pressing and molding the mixture in balling molds by a static pressure molding method so as to obtain haydite, wherein the molding pressure is 8Mpa-12Mpa, after the haydite is molded, drying the molded haydite under the environment of 60-100 DEG C, preheating the dried haydite, raising temperature, sintering the preheated haydite, and slowly reducing temperature so as to obtain finished products. The method disclosed by the invention has the advantages of having a better solid waste utilization effect, having a good energy saving effect, and having a higher emission reduction effect; in conclusion, favorable economic effects are realized.

Owner:WUHAN UNIV OF TECH

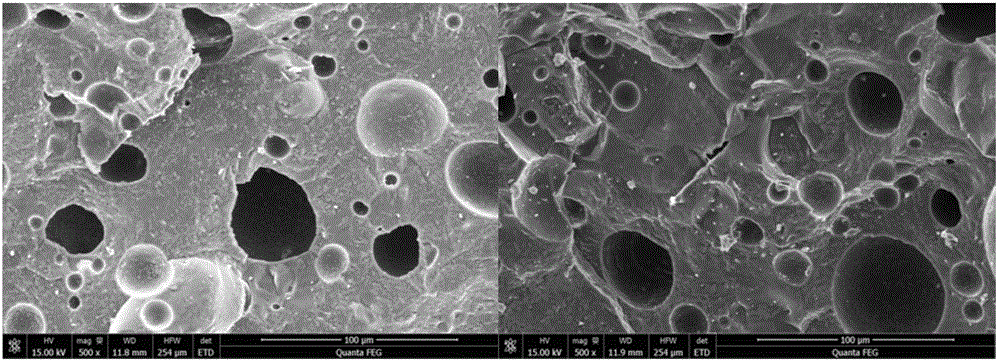

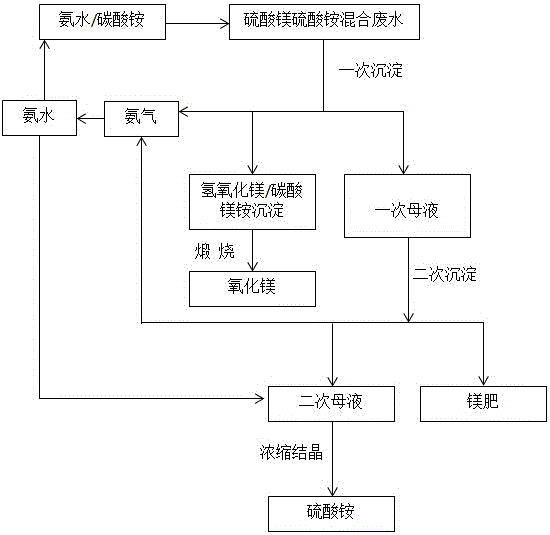

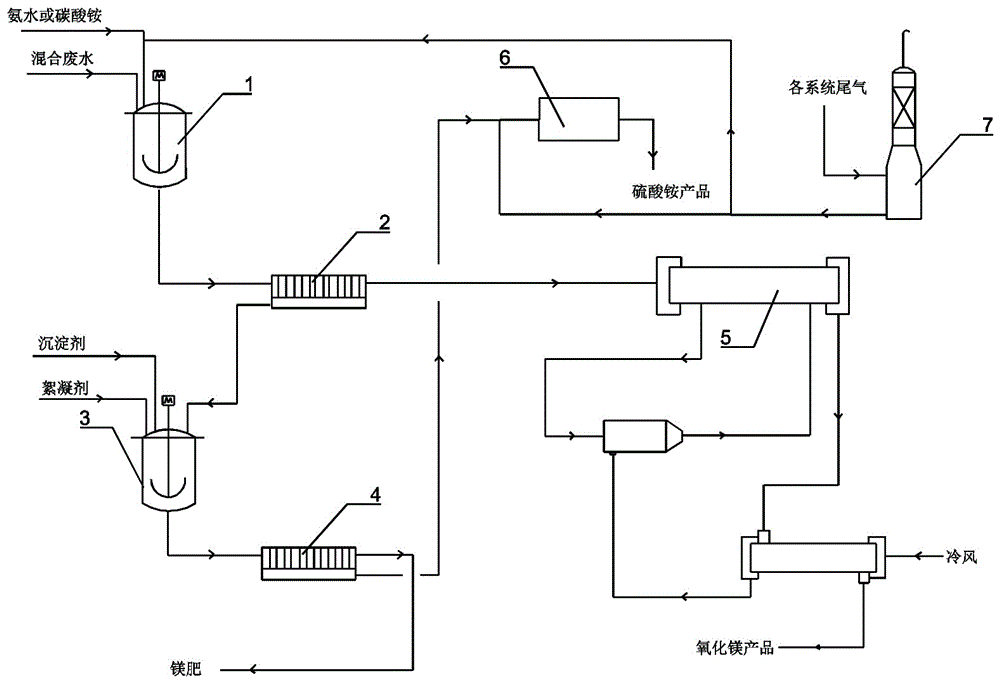

Process and system of recycling magnesium sulfate and ammonium sulfate mixed wastewater

InactiveCN106830247ARealize resource utilizationAchieving zero emissionsMagnesium fertilisersTreatment involving filtrationWastewaterMagnesium ion

The invention belongs to the technical field of wastewater recycling and particularly relates to a process and system of recycling magnesium sulfate and ammonium sulfate mixed wastewater. The process of recycling magnesium sulfate and ammonium sulfate mixed wastewater avoids the characteristic that ammonium sulfate and magnesium sulfate which are mutually dissolvable and co-crystallize are difficult to separate; magnesium ions are separated by means of segmental precipitation in order to produce high-quality magnesia and ammonium sulfate products and a byproduct, trace magnesium fertilizer; the components in the wastewater are recycled at low cost, the treatment cost of wastewater is reduced greatly, and zero emission of wastewater and waste residue is achieved; the invention also designs a system to implement the process; the system is reasonable in design and easy to industrially implement.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

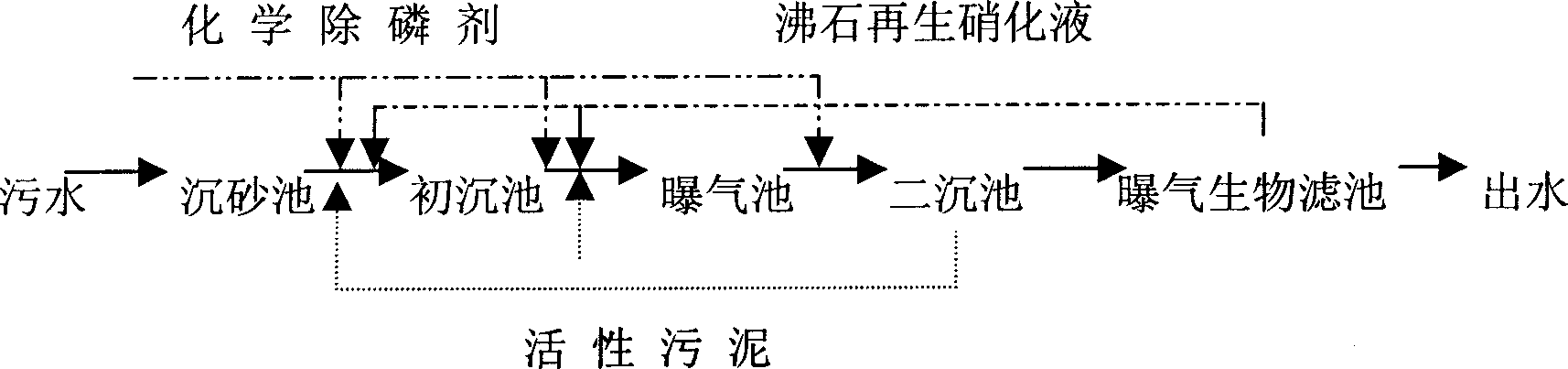

Process for removing nitrogen and phosphor using traditional waste water treatment process

InactiveCN1715218AMaintain processing powerSimple technologyMultistage water/sewage treatmentSustainable biological treatmentSettlingSewage

The traditional waste water treating process with added denitriding and dephosphorizing functions includes: throwing chemical dephosphorizing agent in the last section of settling pit, water outlet of the primary settling tank, or the aerobic section and outlet of the aerobic pond, and refluxing 30-60 % of active sludge and partial residual sludge to the primary settling tank to make traditional waste water treating process possess dephosphorizing function; connecting serially aerobic zeolite biofitering pond to the last section of the second settling pond to eliminate ammonia nitrogen with zeolite and chemical and biological synergistic regeneration to maintain the stable adsorption capacity of zeolite. The present invention is suitable for upgrading waste water treating yard, and has low cost.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

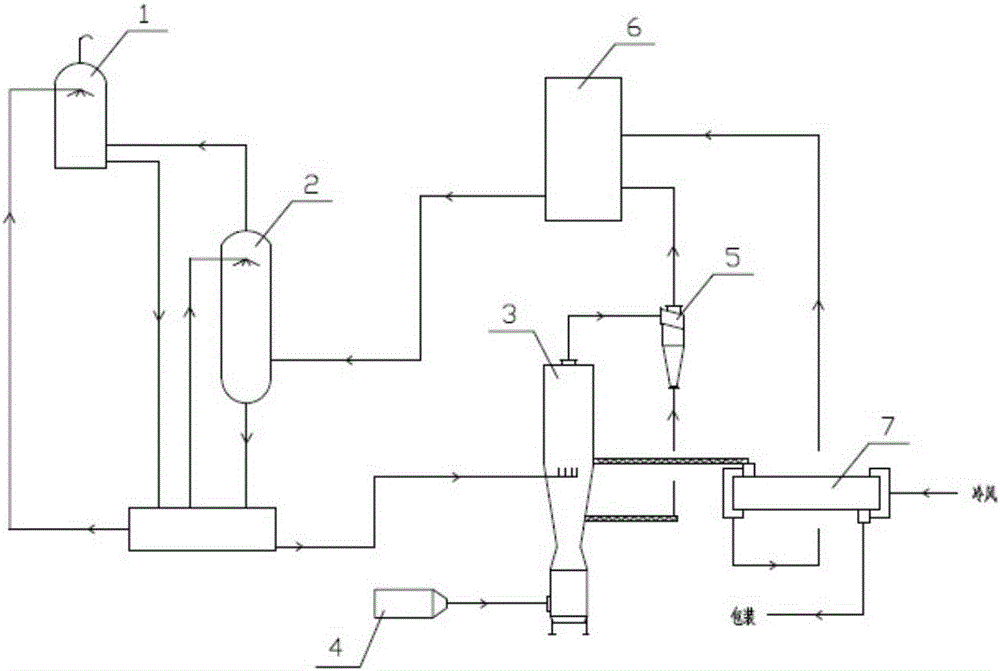

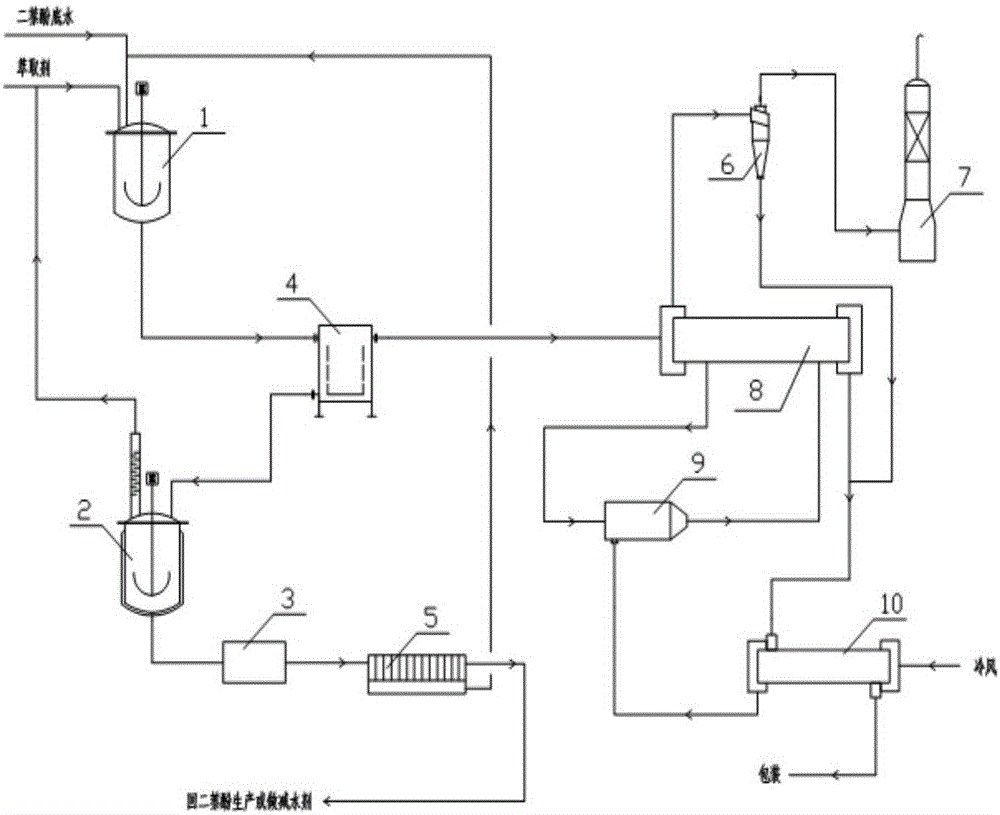

2-naphthol high-salt and high-concentration organic matter wastewater recycling process and system

ActiveCN105967415AEase of industrial implementationGood technical and economic effectOrganic chemistryOrganic compound preparationHigh concentrationSulfite salt

The invention discloses a 2-naphthol high-salt and high-concentration organic matter wastewater recycling process and system; an extraction crystallization process is designed for recovery naphthalenesulfonate for reuse production; organic compounds are oxidized at high temperature for producing anhydrous sodium sulfate for sale, tail gas is absorbed for producing sodium sulfite for circular use in 2-naphthol production; all components of 2-naphthol wastewater are recycled with low cost, zero emission of pollutants is realized, and the method is a currently reasonable recycling process for the 2-naphthol high-salt and high-concentration organic wastewater, and at the same time, the system for realizing the process is designed. The process and the system have popularization value for recycling disposal of the high-organic-matter wastewater, and have great economic and social effects.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

Method for producing high-purity sodium sulfite and sodium sulfate by desulfurizing coal-fired flue gas through alkaline method

ActiveCN103961995AReduce desulfurization burdenSimple processDispersed particle separationAlkali metal sulfite preparationSulfite saltFlue gas

The invention discloses a method for producing high-purity sodium sulfite and sodium sulfate by desulfurizing coal-fired flue gas through an alkaline method. A two-stage desulfurization process is adopted; first-stage desulfurization refers to coarse desulfurization in which sulfate is left in first-stage desulfurizing liquid, sodium sulfate is produced, and most of sulfur dioxide in flue gas enters second-stage desulfurization; the second-stage desulfurization refers to main desulfurization in which flue gas can be exhausted up to standard, and the desulfurizing liquid can be directly concentrated and crystalized to produce high-purity sodium sulfite. The method has the advantages of being simple in process and easy to implement; sulfur dioxide in low-concentration flue gas is recycled by adopting the two-stage desulfurization process, so that secondary pollution caused by desulfurization and zero emission are eliminated completely; 95-percent high-purity sodium sulfate and 95-percent high-purity sodium sulfite are produced by using sulfur dioxide flue gas, and sodium sulfite accounts for 90-95 percent, so that the conventional treatment way of pure resource consumption is changed, the desulfurization burdens of enterprises are relieved greatly, and even desulfurization is turned into value-added production, thus remarkable technical and economical effects are achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

Integrally-poured building house construction method

InactiveCN110331781AImprove construction qualityImprove construction efficiencyBuilding constructionsArchitectural engineeringBuilding construction

Owner:曹恒

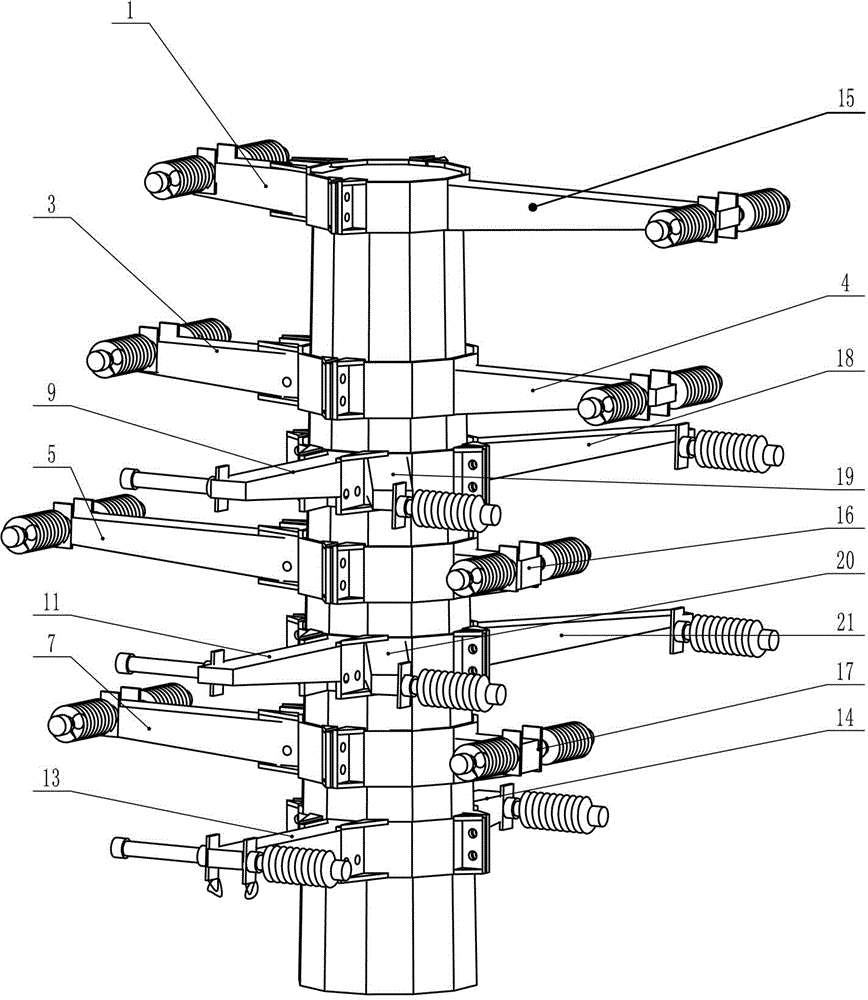

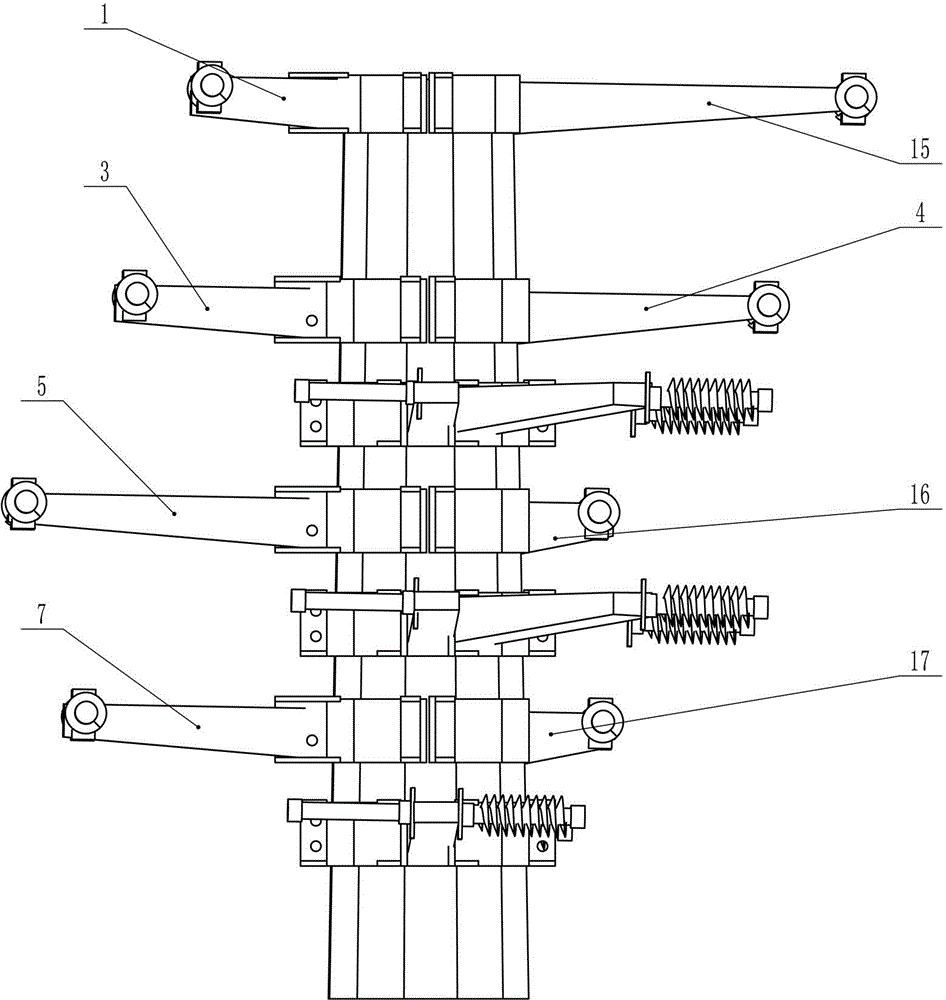

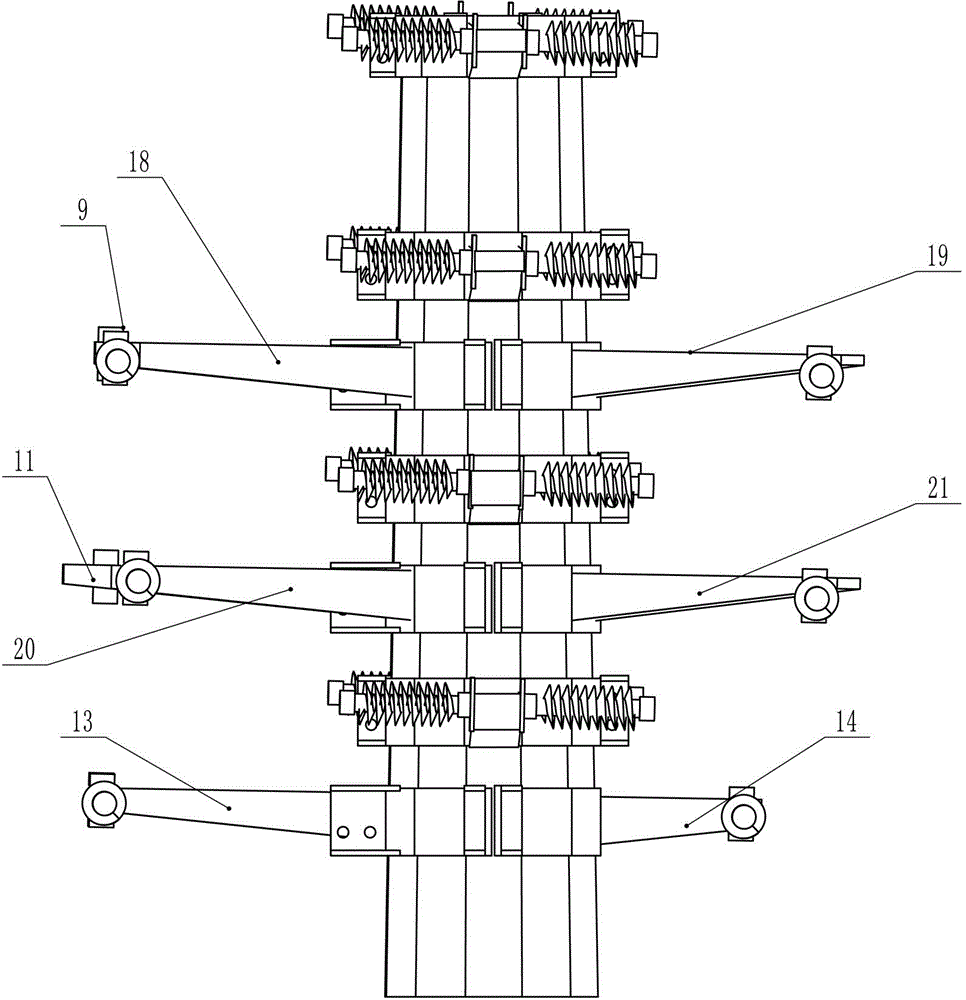

T-joint steel pipe pole with special-shape crossarms

The invention discloses a T-joint steel pipe pole with special-shape crossarms. The T-joint steel pipe pole comprises top crossarms, upper crossarms, middle crossarms, lower crossarms, T-joint poles, a pole tower body, crossarm insulators, wind-yaw-resistant insulators and movable crossarm hoops. The crossarms and the T-joint poles are mounted on the pole tower body and are spatially designed layer by layer to form certain included angles. The crossarm insulators and the wind-yaw-resistant insulators are mounted at ends of the crossarms. Two pairs of hoop lead crossarms are arranged above and below section points of upper lead crossarms and middle lead crossarms in the lateral direction of newly added T-joint poles respectively, and movement and angle adjustment of the T-joint poles are facilitated. The length and the rotation angles of the crossarms are calculated according to electrical distance gap of the T-joint tower. The problem that electrical safety distance is spatially insufficient for circuits during T-joint is solved by the newly added T-joint poles, and the T-joint steel pipe pole has the advantages of simplicity in mounting, excellent single-pole indicators, high economic efficiency of synthesis technique and the like, and is worthy of popularization and application in construction of high-voltage alternating-current two-circuit T-joint lines or long-term T-joint pole reservation.

Owner:WENZHOU ELECTRIC POWER DESIGN +1

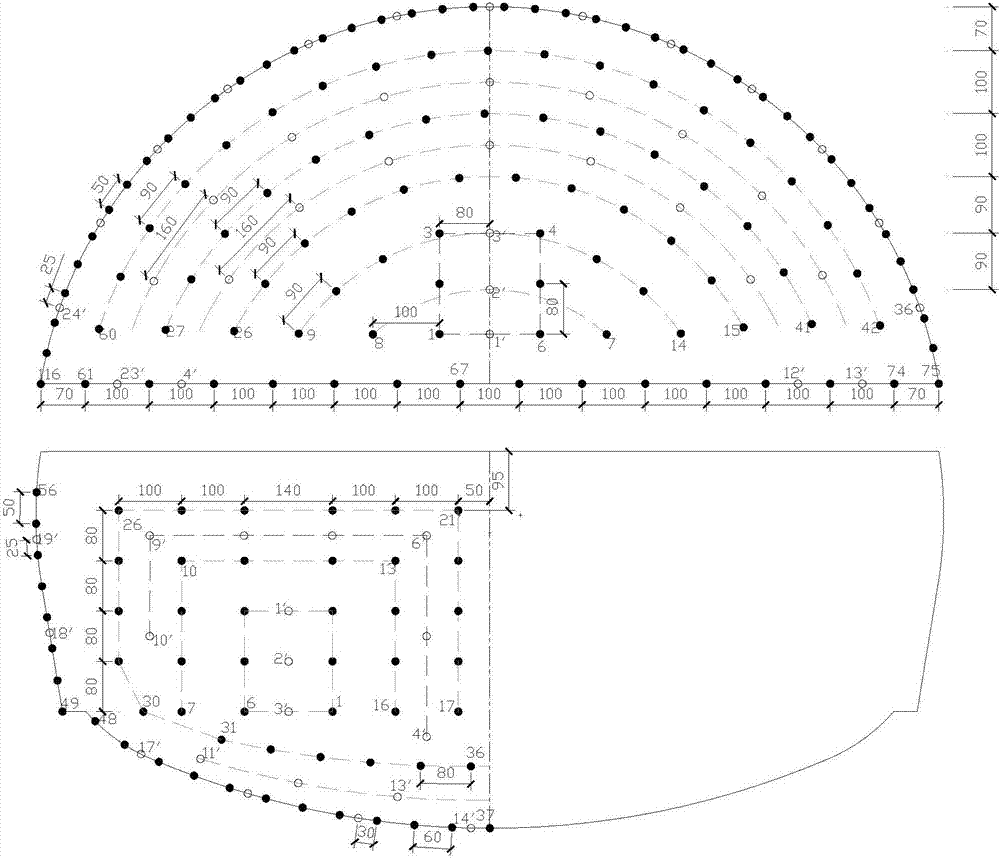

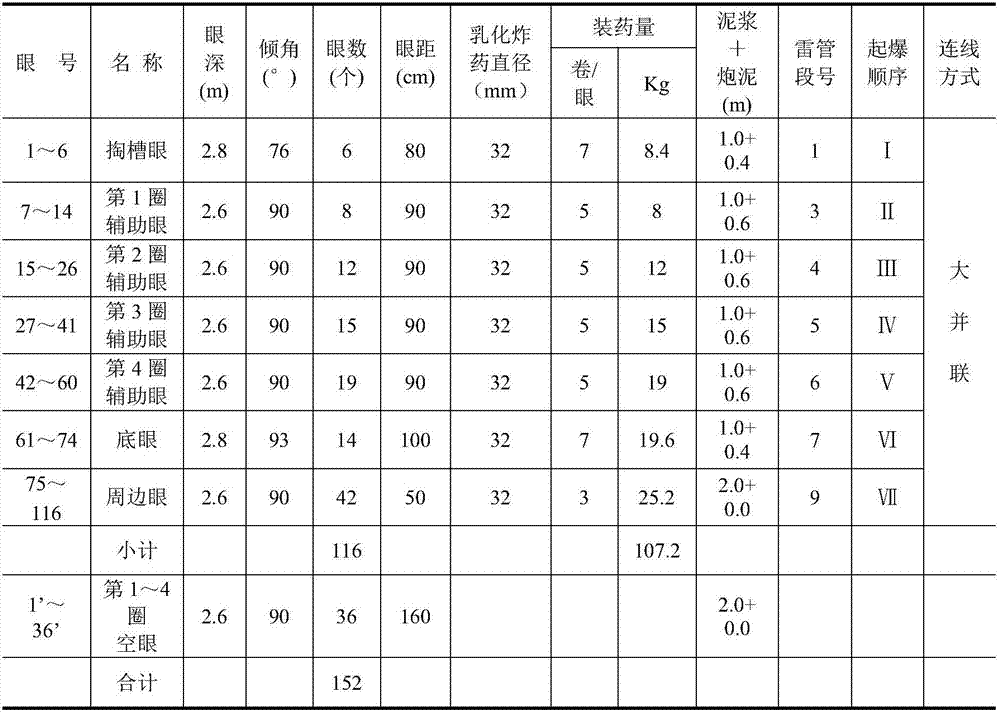

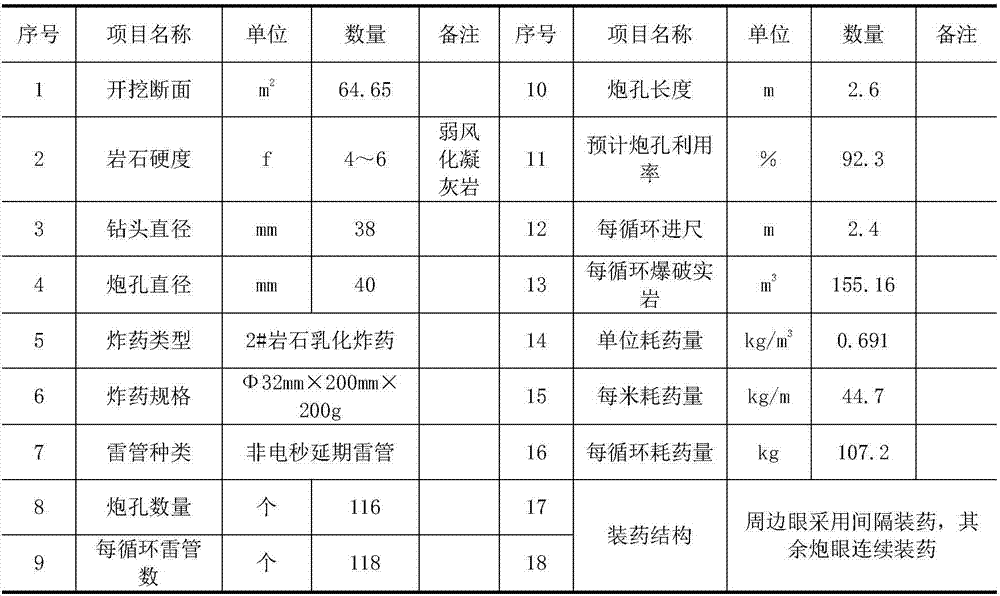

Tunnel empty-hole mud vibration-reduction-control blasting method capable of reducing vibration and noise

The invention relates to a tunnel empty-hole mud vibration-reduction-control blasting method capable of reducing vibration and noise. According to the method, hole drilling is positioned according to a drilling and blasting arrangement diagram; before powder charging, high-pressure air is used for sweeping holes, rock emulsion explosives and non-electric second-delay detonators are respectively selected, the powder charging holes are charged with powder according to a vibration reduction blasting parameter design list, the periphery holes are charged with the powder at intervals, the rest of the blastholes are continuously charged with the powder, the powder are charged to the bottoms of the holes, tamping is used for plugging the holes in place, and the empty holes are filled with plastic bags with mud; and the detonators are connected in place according to requirements, equipment and persons are all evacuated outside the safe distance, and detonation is carried out after the equipment and the persons are confirmed to be safe. The method has the advantages that the hole bottom blasting force can be enhanced, the blasting footage can be increased, particularly, reflection, refraction and absorption of the blasting shock waves can be strengthened, the process of shock wave->attenuating->stress wave->attenuating->seismic wave can be accelerated, the blasting vibration and noise can be greatly reduced, the blasting vibration speed is detected to be lees than 5cm / s, the phenomenon that people are disturbed can be greatly reduced, and the good technical economic effect can be obtained.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

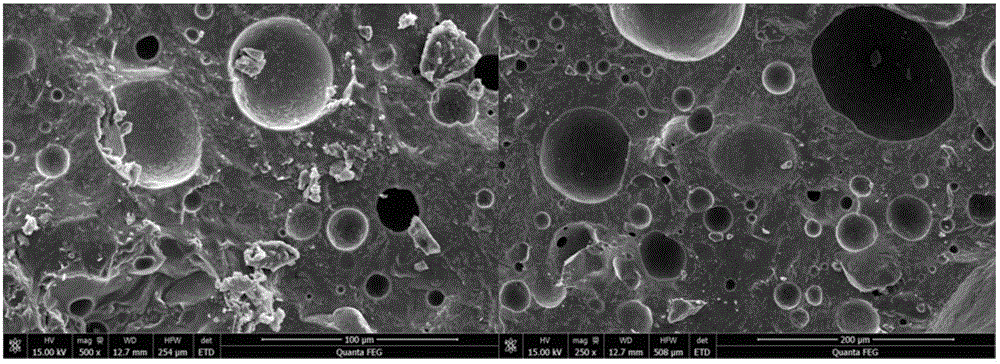

Method for preparing light porous ceramsite from municipal sewage sludge

InactiveCN107188601ASimple systemGood technical and economic effectCeramic materials productionCeramicwareAir atmosphereResource utilization

The invention provides a method for preparing light porous ceramsite from municipal sewage sludge. The method comprises the following steps that 1, the light porous ceramsite is prepared from, by weight, 70-80% of municipal sludge, 15-25% of coal gangue powder, 1-5% of carborundum powder and 2-10% of calcium phosphate; 2, all the components are mixed to be uniform, then, a pressing molding method is adopted for molding, the molding pressure is 5-15 Mpa, the mixture is dried in the air atmosphere under the temperature of 100-120 DEG C for 40 min after being molded, and placed into a sintering furnace, the temperature is slowly increased to 120-600 DEG C for 80 min, and then, the temperature continues to be increased at the speed of 5-10 DEG C / min to about 1,060 DEG C to obtain the light porous ceramsite can be obtained. According to the finished ceramiste, the water absorptivity is not larger than 10%, the stacking density range is not larger than 500 kg / m<3>, and the cylinder compressive strength is not smaller than 0.4 MPa. The technical index can reach the standard of GBT 17431.1-2010 'lightweight aggregate and a testing method thereof'. The method is suitable for ceramsite for buildings. Waste can be turned into wealth, environment pollution is improved, and therefore the suitable high-valued outlet is provided for sludge disposal and resource utilization, and remarkable economic benefits and social benefits are achieved.

Owner:新岛世纪(北京)新型材料技术有限公司 +5

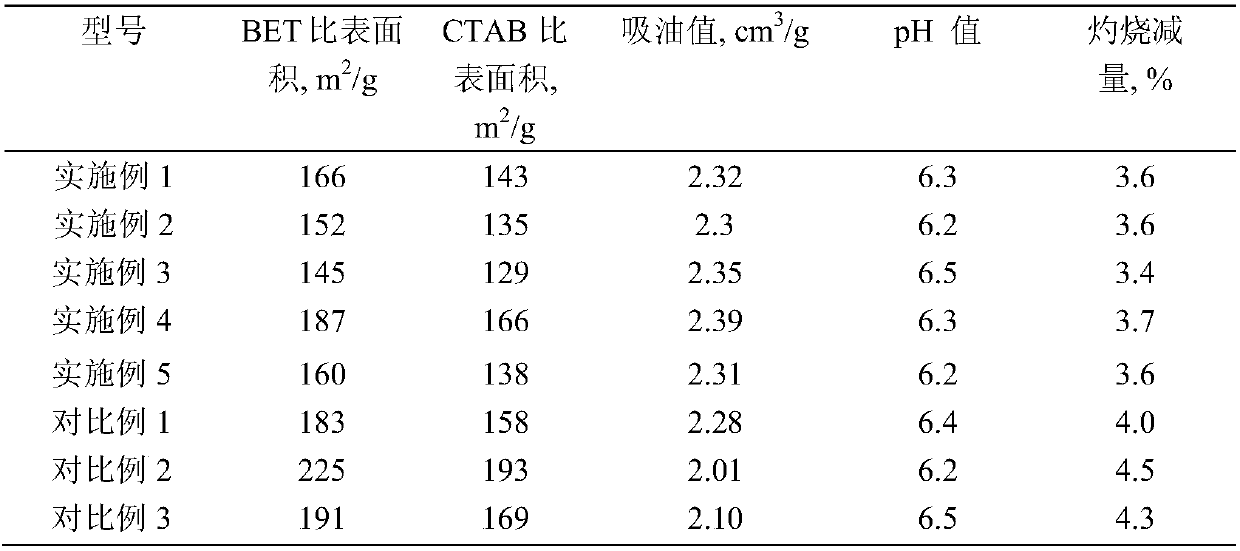

White carbon black capable of improving processing performance of rubber and preparation method of white carbon black

ActiveCN107697922AReduced mechanical propertiesEasy to processSilicon compoundsReaction temperatureReaction system

The invention provides white carbon black capable of improving the processing performance of rubber and a preparation method of the white carbon black. The preparation method comprises the following steps: (1) heating water, adding water glass, and mixing the water with the water glass to obtain a reaction base solution, wherein the temperature in the whole process does not change; (2) adding acidand water glass into the reaction base solution for mixing and reaction, wherein the reaction temperature and the concentration of the water glass are constant, and are equal to the reaction temperature and the concentration of the water glass in the reaction bottom solution; (3) adjusting the pH of a reaction system; (4) adding acid and water glass for mixing and reaction, wherein the pH of thereaction system is 7.0 to 10.0 and is constant, and the reaction temperature is constant and is equal to that of the reaction base solution; (5) adding acid to adjust the pH till the pH is equal to the pH of aging reaction and the temperature is constant and equal to that of the reaction base solution; (6) carrying out aging reaction on white carbon black suspension under a condition that the temperature is equal to that of the reaction base solution, and then carrying out solid-liquid separation to obtain the white carbon black. The white carbon black provided by the invention can improve theprocessing performance of the rubber on the basis of not reducing the mechanical property of the rubber.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Magnesium alloy compositely forming method

InactiveCN101214600AReliable workmanshipEasy to operateExtrusion control devicesEnergy consumptionMagnesium alloy

A magnesium alloy compound forming method belongs to the processing field of magnesium alloy which is characterized in that the invention heats a cast acquired by a casting method for 350 to 425 DEG C and simultaneously heats an extruding die to 232 to 425 DEG C and then maintains temperature for 25 to 120mins; then extrudes a performing extruding proximate matter with a two-dimensional characteristic of the cast by an extruding speed of 1.2 to 12m / min; cutting a mould pressing blank material with a same volume as the cast, heats the mould pressing blank to 290to 400 degrees and maintains the temperature for 25 to 120mins after a die is heated to 232 to 400 degrees, finally carries through one-time mould pressing by a deformation speed of 2 to 200mm / s to acquire a final product. The magnesium alloy cast produced by the invention can meet not only meet the requirement for shape of the product, but also improve the comprehensive performance of the magnesium alloy cast and can simultaneously lead the comprehensive performance of the product to be more uniformly. The invention has the advantages of reliable technical quality, high efficiency, little energy consumption, high quality and high technical yield. The invention is suitable for batch productions on the structural component products with extruding and mould pressing characteristics.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com