Production method of ecologic permeable ceramic bricks

A technology of ecological ceramics and permeable bricks, which is applied in the field of building materials to achieve the effects of increasing the utilization rate and usage, improving mechanical properties, and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

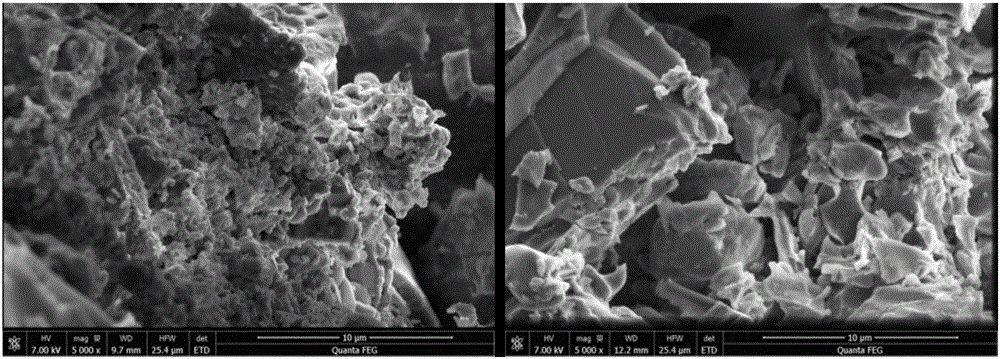

[0028] A method for preparing ecological ceramic permeable bricks by using waste concrete, dried sludge and modified sludge. Its components and contents (weight) are: dried sludge 15%, modified sludge 19%, construction waste micropowder 10% %, construction waste fine aggregate 10%, construction waste coarse aggregate 45%, alum 0.2%, borax 1%. The preparation process is as follows: various raw materials are pretreated according to the requirements, measured separately, mixed evenly according to the proportion, and then formed into a test block by pressure molding method. The temperature was raised to 300°C at a rate of °C / min, kept at 300°C for 3 hours, then raised to 1050°C at a rate of 5°C / min, and cooled after sintering for 3 hours. The sintered strength reaches 32.7Mpa, the water permeability coefficient is 0.0421cm / s, and the wear-resistant grinding pit length is 28.4cm. The microscopic scan is as follows figure 1 shown.

Embodiment 2

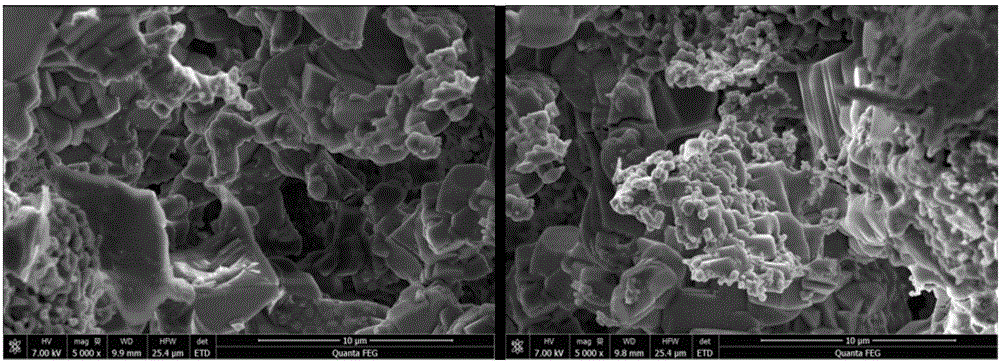

[0030] A method for preparing ecological ceramic permeable bricks by using waste concrete, dried sludge and modified sludge. Its components and contents (weight) are: 20% of dried sludge, 29% of modified sludge, and 5% of construction waste powder %, construction waste fine aggregate 10%, construction waste coarse aggregate 35%, alum 0.15%, borax 1%, the preparation process is: the various raw materials are pretreated according to the requirements, measured separately, mixed according to the proportion, and then press-molded The test block is formed by the method, the forming pressure is 20Mpa, after forming, it is dried naturally for 48 hours and then dried in the environment of 100 ℃, and the temperature is raised to 300 ℃ at the speed of 2 ℃ / min, after the constant temperature is 3 hours at 350 ℃, and then the temperature is 4 ℃ / min The temperature was raised to 1100°C at a certain speed, and the temperature was lowered after sintering for 3 hours. The sintered strength rea...

Embodiment 3

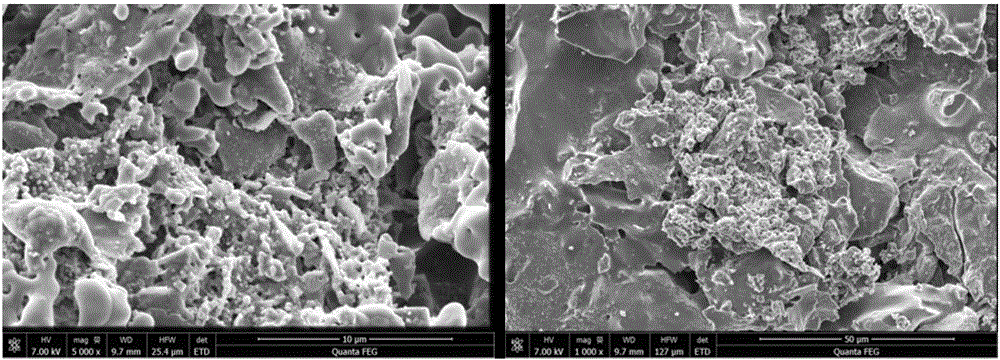

[0032] A method for preparing ecological ceramic permeable bricks by using waste concrete, dried sludge and modified sludge. Its components and contents (weight) are: 20% of dried sludge, 24% of modified sludge, and 5% of construction waste powder %, construction waste fine aggregate 5%, construction waste coarse aggregate 45%, alum 0.1%, borax 1%. The preparation process is as follows: various raw materials are pretreated according to the requirements, measured separately, mixed evenly according to the proportion, and then formed into a test block by pressure molding. Raise the temperature to 300°C at a rate of ℃ / min, keep the temperature at 320°C for 3 hours, then raise the temperature to 1150°C at a rate of 6°C / min, and cool down with the furnace after sintering for 3 hours. The sintered strength reaches 39.6Mpa, the water permeability coefficient is 0.0386cm / s, and the wear-resistant grinding pit length is 25.6cm. The microscopic scan is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com