Patents

Literature

65results about How to "High waste rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-quality recycled fine aggregates by utilizing waste concrete

InactiveCN102010144ALow water absorptionReduce the water demand ratio of mortarSolid waste managementResource protectionSingle stage

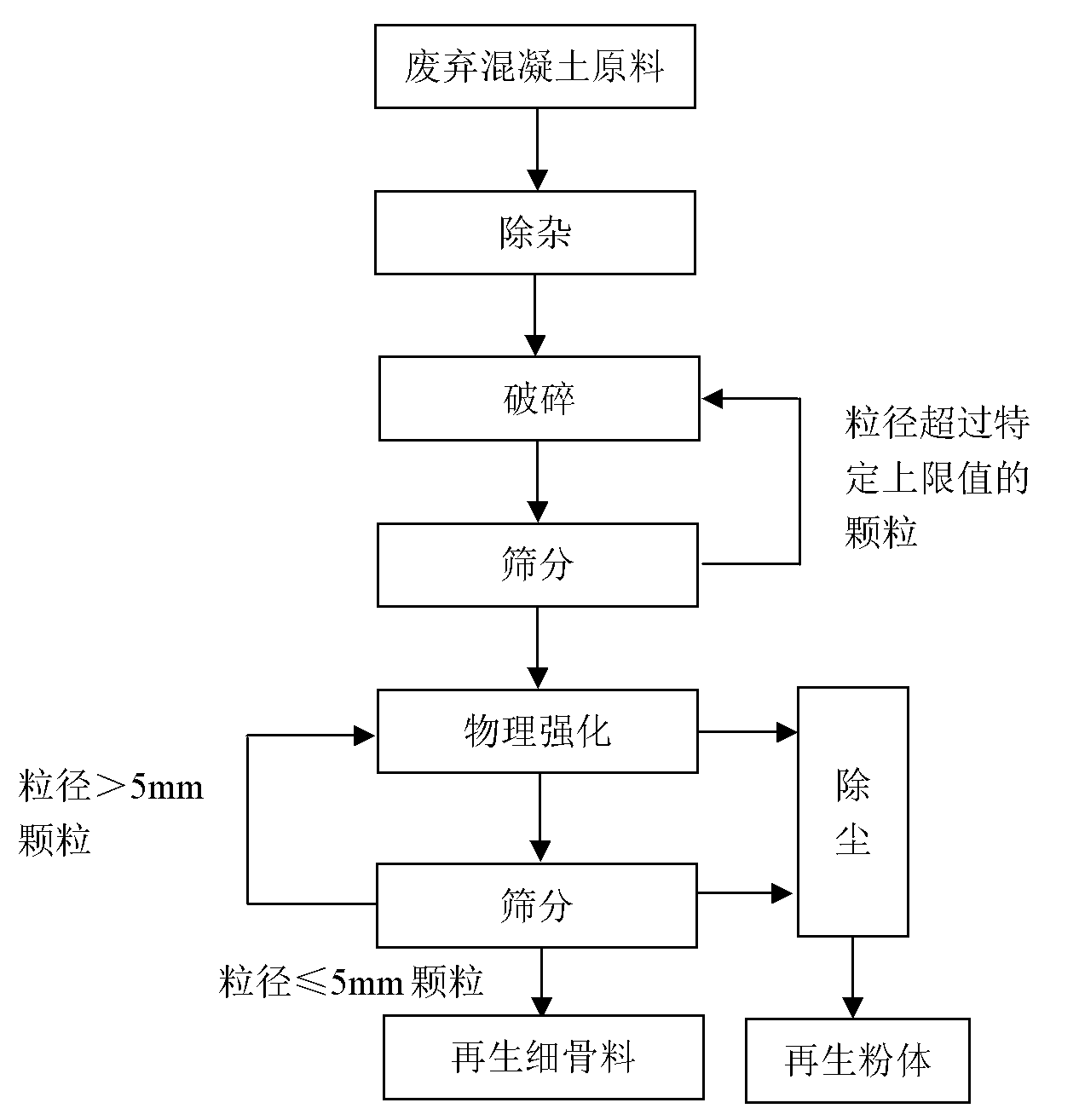

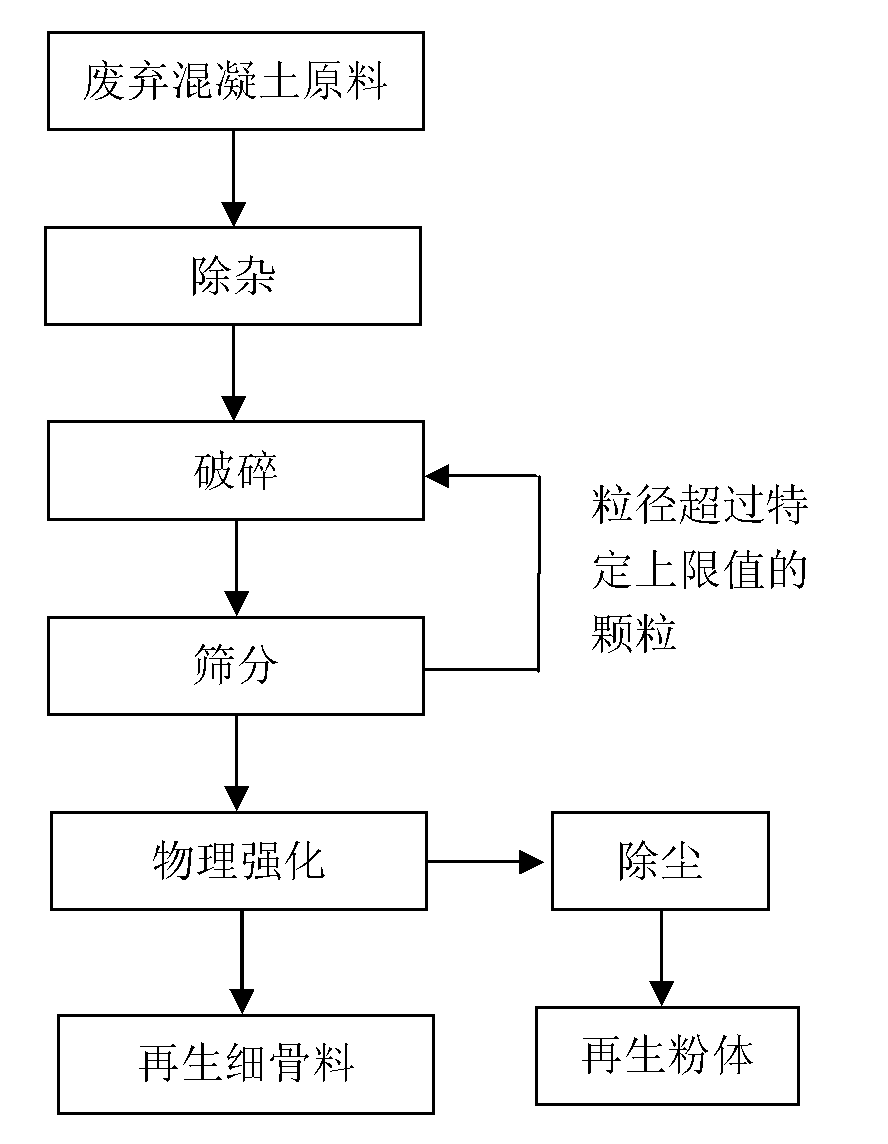

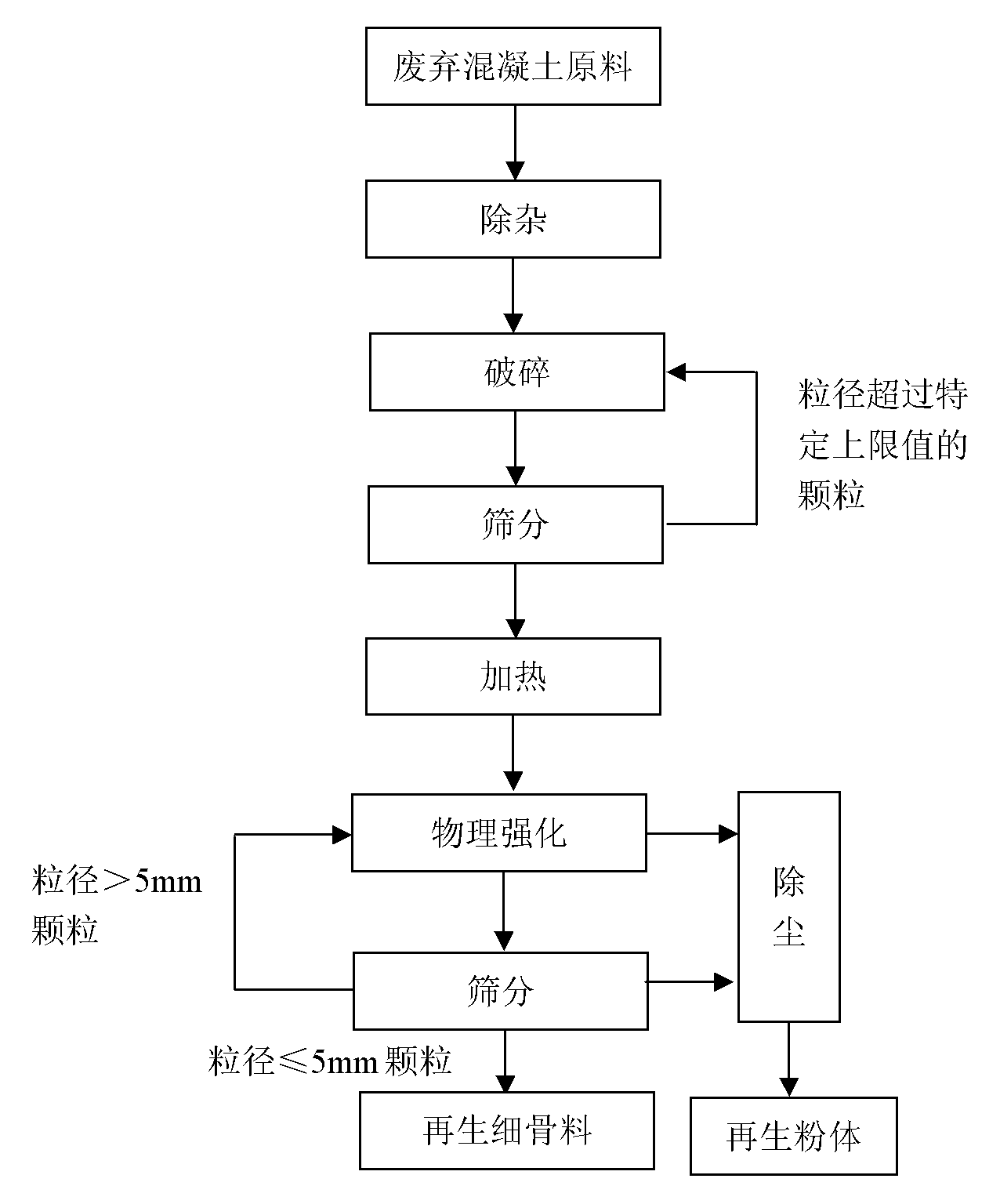

The invention belongs to the field of building materials and relates to a method for preparing recycled fine aggregates with waste concrete as a raw material. The method comprises the following steps: collecting waste concrete and utilizing crushing equipment to crush the concrete to aggregate particles with maximum size being not beyond 5-10mm through single-stage crushing or multi-stage crushing; utilizing strengthening equipment to remove the mortar and cement paste adhering to the surfaces of the aggregate particles, eliminate the protruding edges of the aggregate particles and ensure the appearances of the aggregate particles to be smooth to realize strengthening treatment of the aggregate particles and removing dust in the strengthening treatment process; and screening the strengthened aggregate particles and removing dust in the screening process, thus obtaining the particles with size being not beyond 5mm, namely the finished products. The method has strong applicability and high waste utilization rate, provides a feasible new way for recycling various waste concrete and has great significance in environment protection and resource protection and even sustainable social development.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

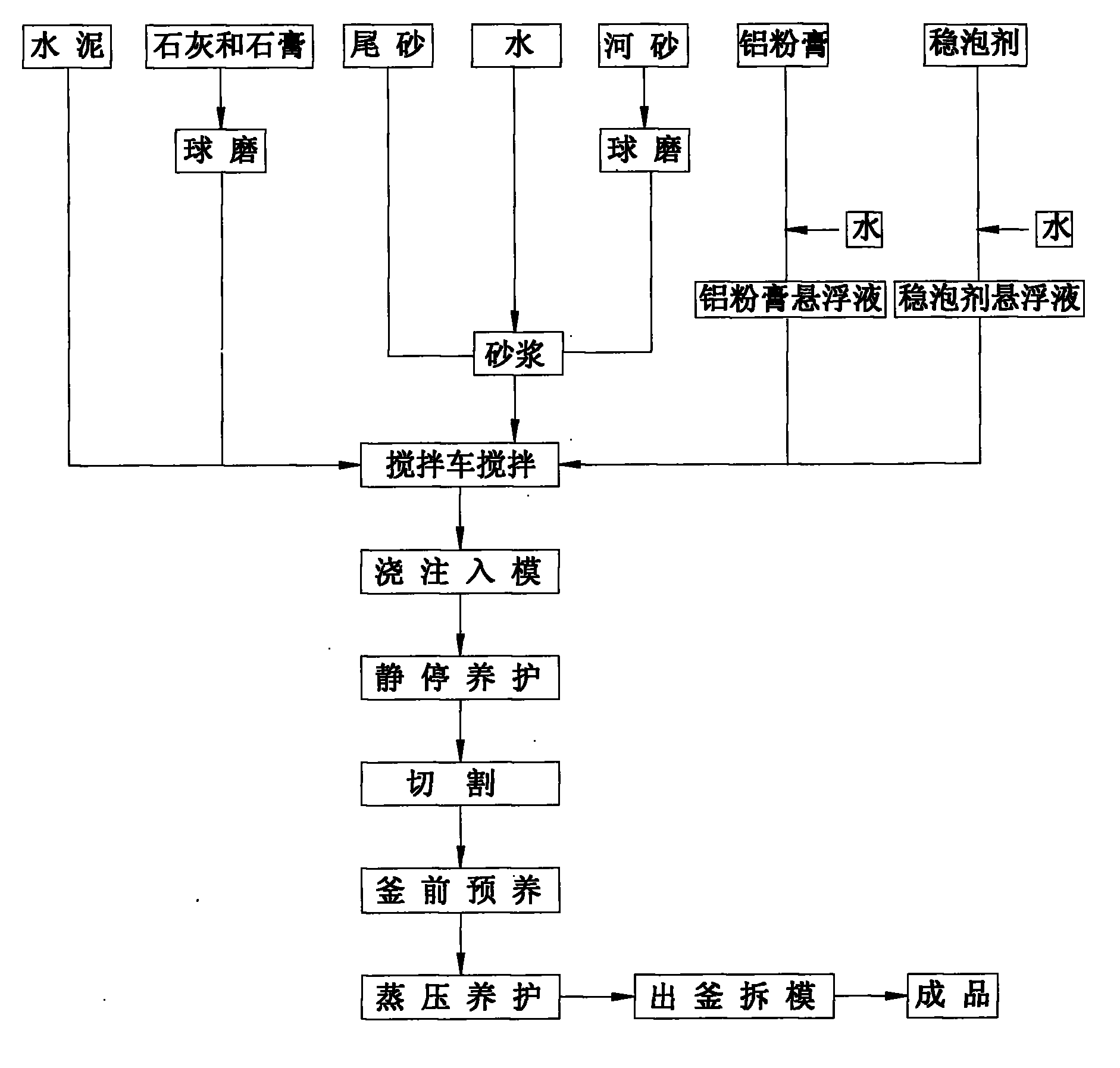

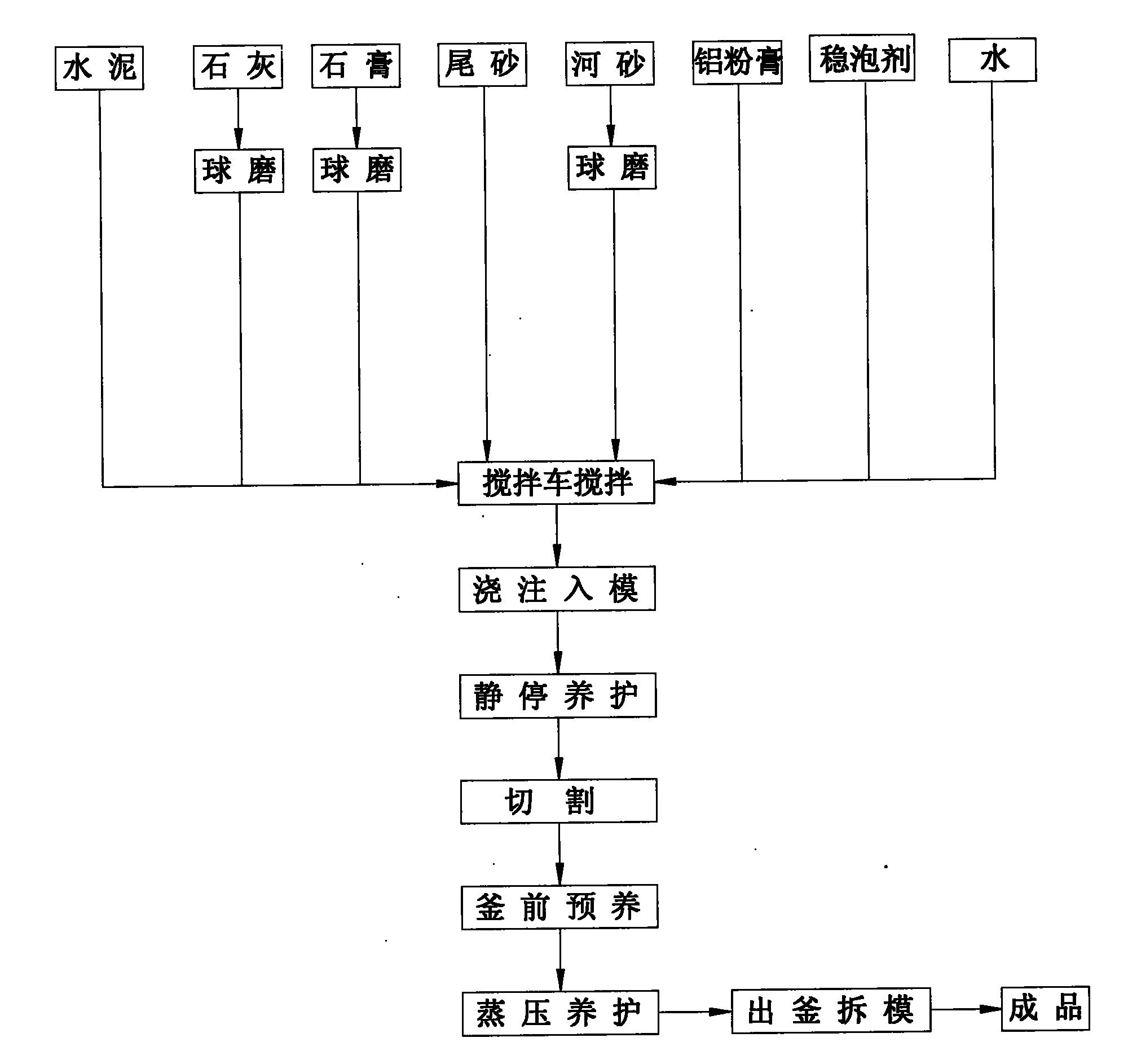

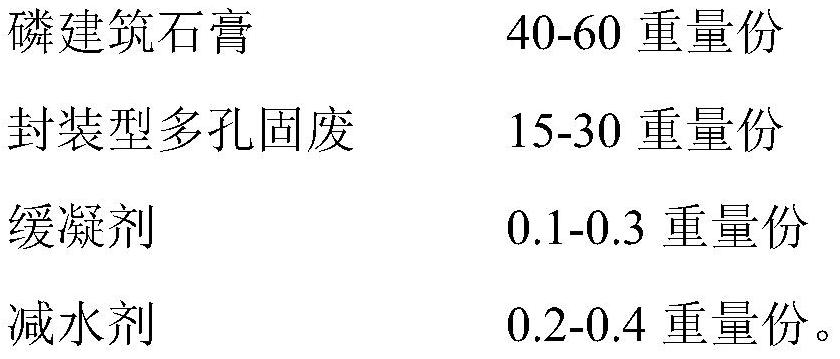

Light-weight block prepared by taking 'phosphorus solid waste' as raw material and preparation method of light-weight block

The invention relates to a light-weight block prepared by taking 'phosphorus solid waste' as a raw material and a preparation method of the light-weight block. The light-weight block and the method solve the problems of complicated technology, high energy consumption, long production period, low production cost and low waste utilization rate of the existing light-weight block preparation. The light-weight block is prepared by taking 55-65 parts of phosphorus tailing, 10-15 parts of carbide slag, 10-20 parts of salic active mineral admixture, 2-3 parts of phosphogypsum, 6-8 parts of cement and 3-5 parts of additive as raw materials, and carrying out crushing, wet ball milling, stirring, forming, gas forming, trimming, and steam pressing. The block is simple to construct, has a high waste utilization rate, can effectively stimulate potential activity of phosphorus tailings, saves energy, reduces consumption, and is environmentally friendly, low in production cost, low in cost, and outstanding in performance, and the raw materials are not required to be pre-dried, and are easy to obtain.

Owner:HUBEI UNIV OF TECH

Bayer process red mud and gangue porous sintered brick and production method thereof

InactiveCN103030372ARegular appearance qualityNo deformationCeramic materials productionCeramicwareTunnel kilnBrick

The invention discloses a Bayer process red mud and gangue porous sintered brick and a production method thereof. The porous sintered brick is prepared from the following raw materials: 60 to 75 parts of Bayer process red mud; 25 to 35 parts of gangue; 2 to 6 parts of tailings or wastes in chemical plants; and 0.5 to 3 parts of pore-forming agent. The preparation method of the brick comprises the following steps: after dehydrating the Bayer process red mud, mixing and uniformly stirring the Bayer process red mud and other ground raw materials, aging for 1 to 3 days, and adding water to stir aged powder in a stirring machine so as to obtain mud; carrying out extrusion forming on the mud under the extrusion pressure of 1.5 to 2.5MPa by adopting a stiff-plastic process so as to obtain a semi-finished product which accords with the specified dimension and the specified shape; and drying a mold brick and sintering the mold brick in a tunnel kiln to obtain the Bayer process red mud and gangue porous sintered brick. The product reaches the national strength standard of the sintered bricks. In the technology, the total use amount of industrial wastes is close to 100 percent; a large number of farmlands are saved; land resources are effectively protected; and the Bayer process red mud and gangue porous sintered brick and the production method thereof accord with the national policies of saving energy and reducing emission and have obvious environmental benefits, social benefits and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

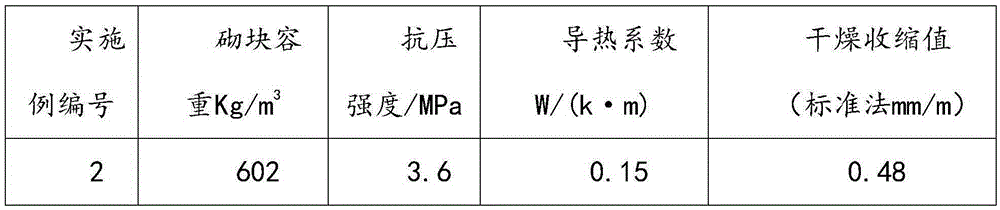

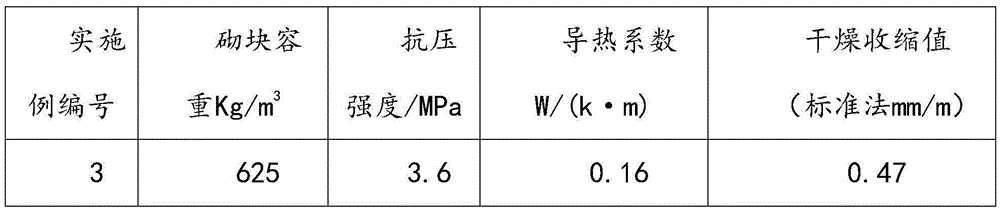

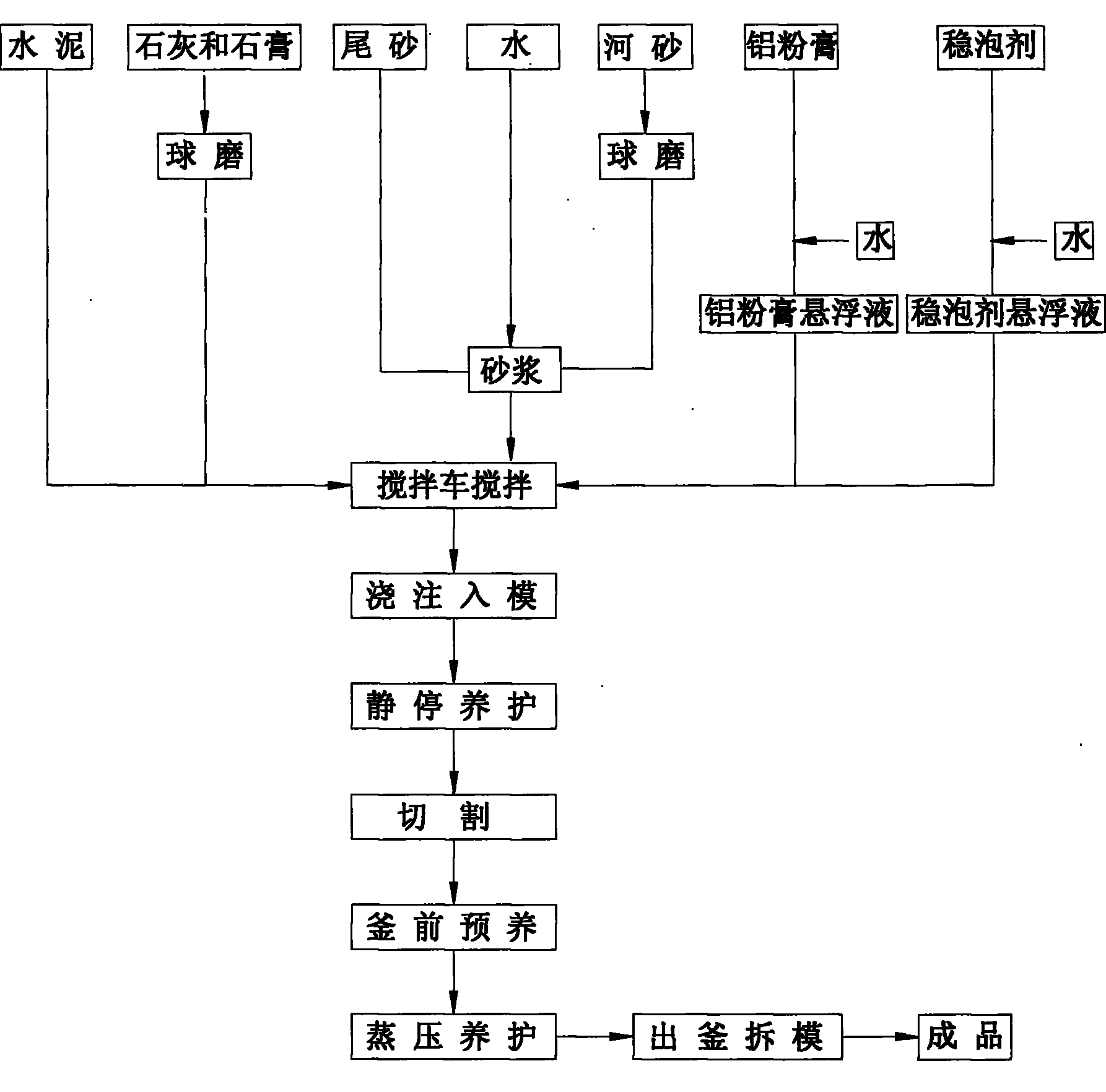

Pyrite beneficiation tailing autoclaved aerated concrete block and production process thereof

InactiveCN101786839ALight weightWith thermal insulationSolid waste managementCeramicwareForming gasSteam pressure

The invention discloses a pyrite beneficiation tailing autoclaved aerated concrete block, which is prepared from raw materials in part by weight: 10-75 pyrite beneficiation tailing, 0-75 river sand or sea sand or deposit sand, 15-24 lime, 5-10 cement, 1.0-2.0 plaster, 0.05-0.10 aluminum powder plaster and 0.05-0.10 foam stabilizer. The pyrite beneficiation tailing autoclaved aerated concrete block has the characteristics of light weight, heat preservation, heat insulation, sound insulation, high strength, fire prevention, moth prevention and the like, as well as good earthquake resisting performance and processing performance and favorability for mechanical construction and is an green and energy-saving and environment-friendly building material. The invention also discloses a production process of the concrete block, which comprises the following steps: taking various raw materials according to the stoichiometric ratio; preparing slurry from the raw materials; and injecting the slurry into a die by pouring, forming gas, standing and curing, cutting and stacking, carrying out heat-moisture procuring before an autoclave, entering the slurry for steam pressure curing and demoulding after discharging the autoclave; and obtaining pyrite beneficiation tailing autoclaved aerated concrete. The process has the advantages of remarkable energy-saving effect, low production cost and high clean production degree.

Owner:GUANGDONG BUILDING MATERIAL RES INST

Production method of ecologic permeable ceramic bricks

The invention provides a production method of ecologic permeable ceramic bricks. The method comprises the following steps: 1, taking 5-10% of construction waste micro-powder, 5-15% of construction waste fine aggregates, 30-45% of construction waste coarse aggregates, 15-20% of dried sludge, 15-40% of modified mud, 0.075-0.2% of alum and 0.5-1% of borax; and 2, uniformly mixing, molding a test block under a molding pressure of 10-20Mpa through adopting a pressure molding process, naturally drying after molding, heating to 300-350DEG C at a rate of 2-3DEG C / min, keeping the temperature at 300-350DEG C for 2.5-3.5h, heating to 1050-1150DEG C at a rate of 3-8DEG C / min, sintering for 3-4h, and cooling. The method has the advantages of high waste utilization rate and effective solving of the contradiction between mechanical performances and the water permeability.

Owner:WUHAN UNIV OF TECH

High-activity crystal seed for concrete production and preparation method thereof

InactiveCN101830660AImprove burnabilityLower firing temperatureSolid waste managementSolid waste disposalSlagSeed crystal

Owner:EAST CHINA JIAOTONG UNIVERSITY

Autoclaved brick prepared by utilizing stone coal vanadium extraction tailings as main raw material and preparation method thereof

ActiveCN103288407ASolve the difficulty of usingHigh strengthSolid waste managementBrickPulverized fuel ash

The invention relates to an autoclaved brick prepared by utilizing stone coal vanadium extraction tailings as a main raw material and a preparation method thereof. The technical scheme comprises the steps of adding water into 50-75wt% of pretreatment vanadium extraction tailings, 10-30wt% of pulverized fuel ash and 10-25wt% of slaked lime as raw materials, wherein the content of water accounts for 12-18wt% of the raw materials, stirring uniformly, pressing to form and standing for 12h; and putting the unburned brick after standing into an autoclave to autoclaved cure for 5-8h, naturally cooling and discharging the brick from the autoclaved so as to obtain an autoclaved brick prepared by utilizing the stone coal vanadium extraction tailings as the main raw material, wherein the pretreatment vanadium extraction tailings is obtained through drying the vanadium extraction tailings until the water content is less than 2wt%, crushing the vanadium extraction tailings until the grain size is less than 3mm and standing for 2 days; the autoclaved curing temperature is 180-200 DEG C, and the autoclaved curing pressure is 1.15-1.25MPa. The method has the characteristics of high waste utilization ratio, high production efficiency and low cost, and the autoclaved brick prepared by utilizing the stone coal vanadium extraction tailings as the main raw material has high strength and excellent durability.

Owner:WUHAN UNIV OF TECH

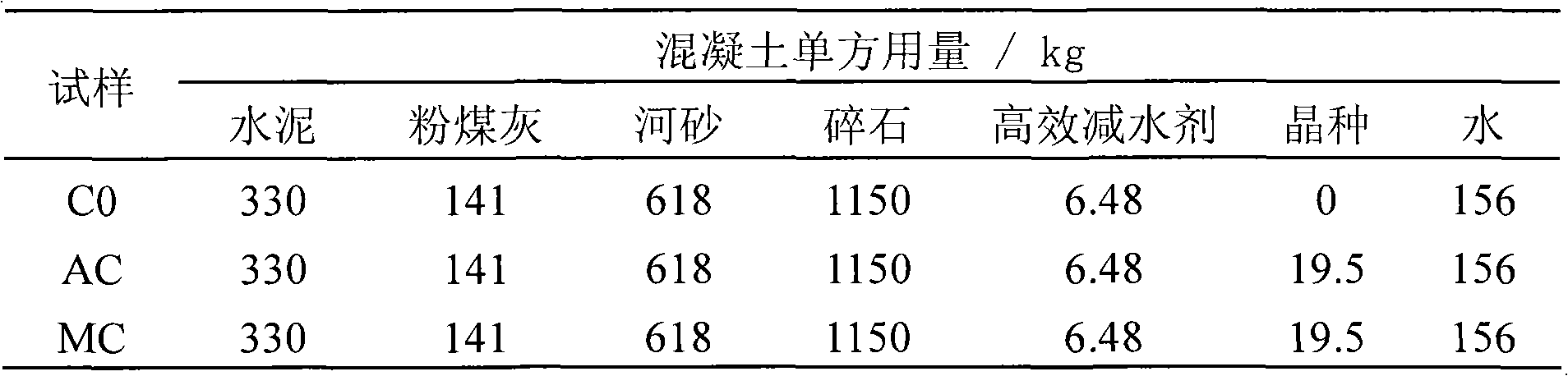

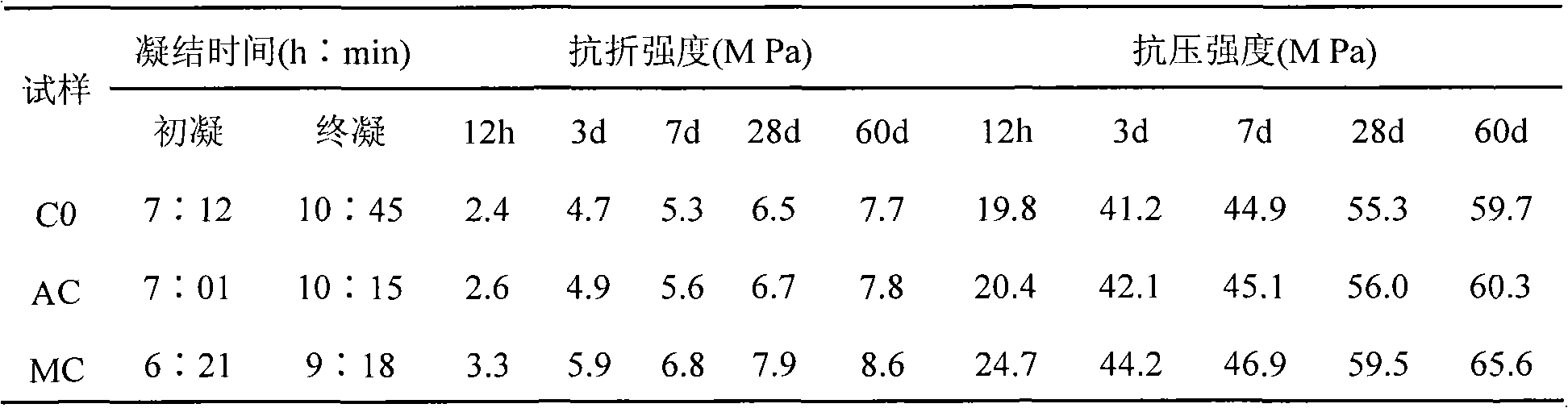

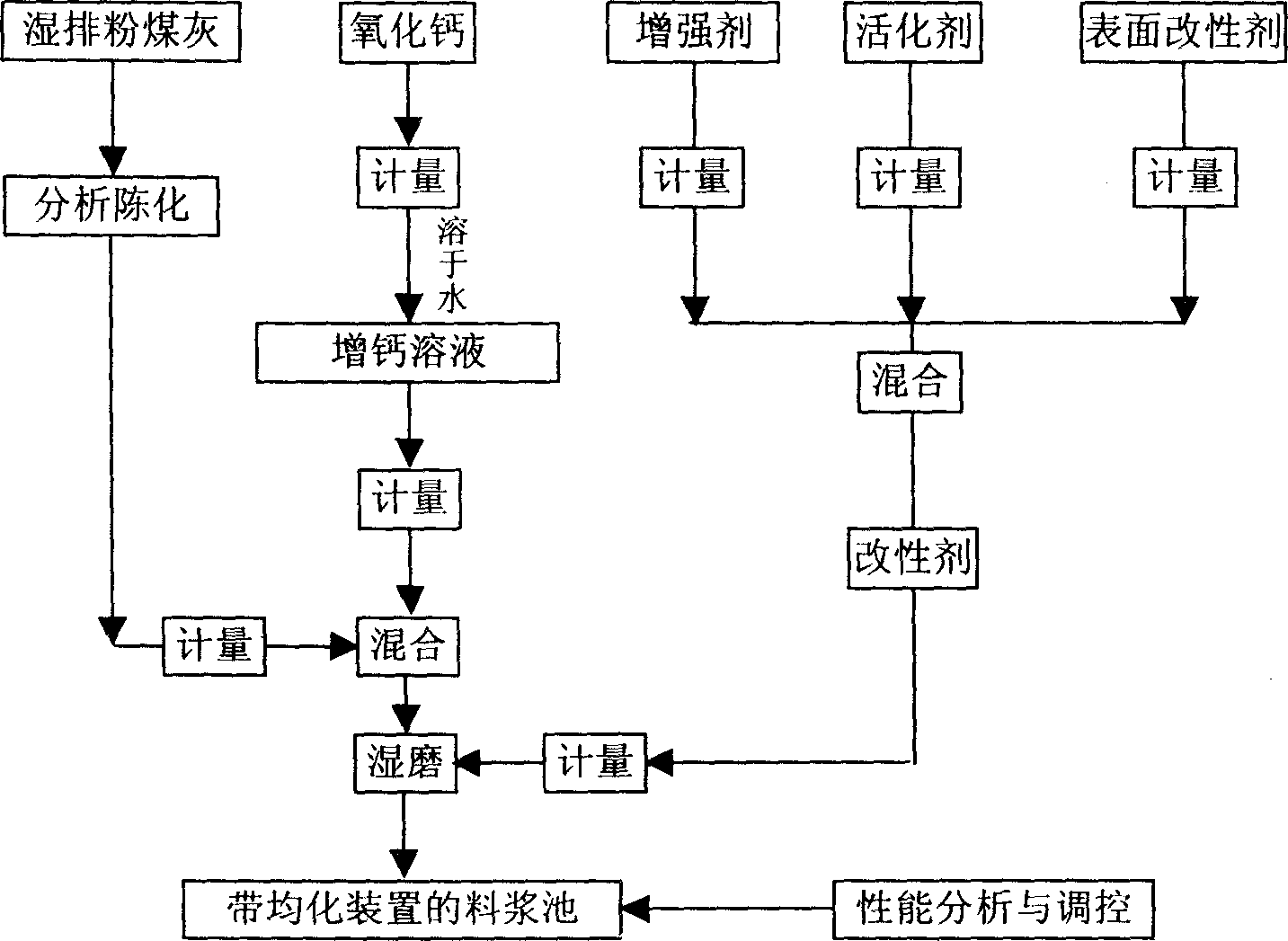

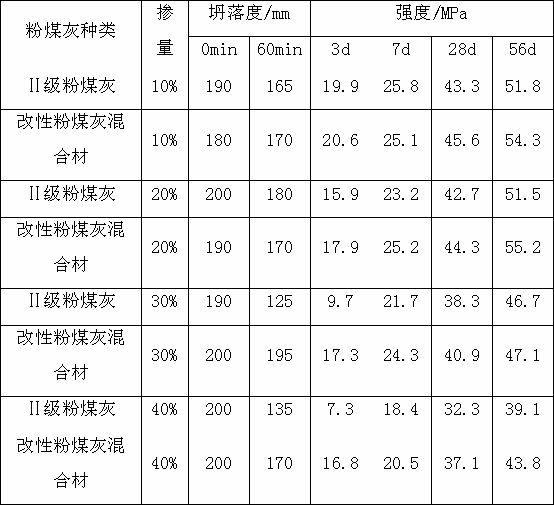

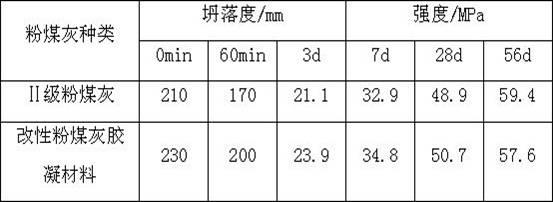

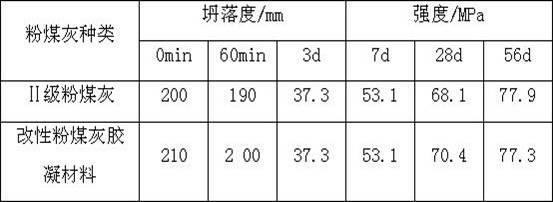

High-activity admixture slurry made of wet fly-ash and method for preparing same

The invention discloses high-active doping slurry and preparing method, which comprises the following parts: 55-65 percent wet-discharge coal ash, 30-44 percent calcium-increasing solution and 1-5 percent modifier, wherein the calcium-increasing solution is calcium hydroxide solution; the modifier is composed of 10-30 percent reinforcer, 20-40 percent surface modifier and 30-50 percent activist.

Owner:WUHAN UNIV OF TECH

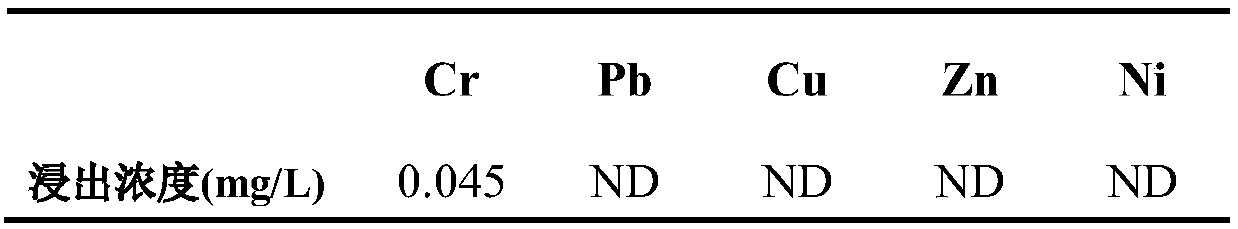

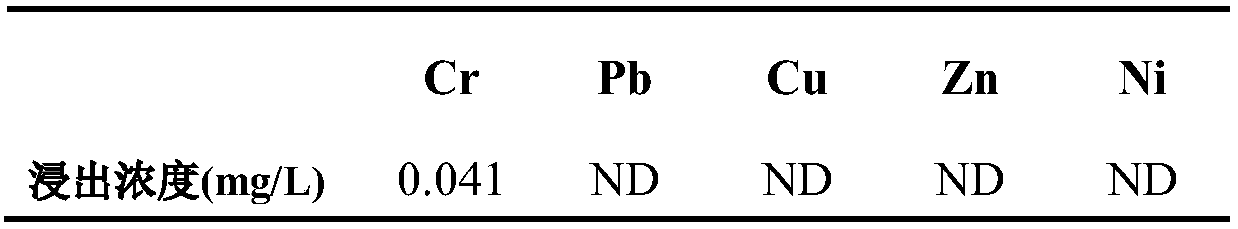

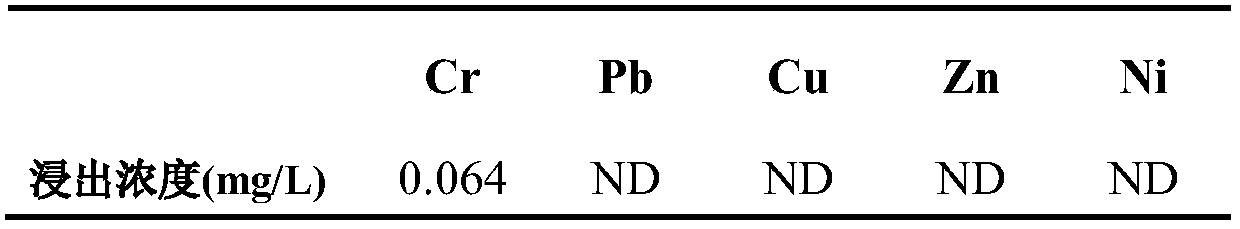

Process for preparing baking-free ecological brick from garbage burning fly ash

The invention relates to a process for preparing a baking-free ecological brick from garbage burning fly ash. The method comprises the following steps: 10-40 parts by weight of the garbage burning fly ash is grinded, sieved and placed in a container, 5-15 parts by weight of sodium hydroxide and 20-40 parts by weight of water are added, mixing is carried out, and a reaction is carried out; 50-90 parts by weight of ordinary portland cement is added with stirring, and a mixed material is obtained; the material is injected into an ecological brick die for vibration compaction; after grouting, the die is placed in a constant temperature constant humidity climate box for maintenance, and the die is removed; after the die is removed, a brick body is placed in a water maintainer for maintenance, and the ecological brick is obtained. The process has the advantages of low operation cost, short disposal period, low secondary pollution, high waste utilization rate, effective stabilization of toxic substances in the garbage burning fly ash, and low toxicity leaching rate of the product; the prepared ecological brick does not need baking, and has the advantages of simple process and high efficiency.

Owner:NANJING UNIV OF TECH

Coagulated stone brick and holllow building block

The present invention relates to a building wall body material-coagulating stone brick and hollow block. Its raw material composition includes 11-28% of coagulating stone, 26-40% of coal slag, 32-43% of tails sand and the rest is water. The coagulating stone is a new type building material, and can be used as a substitute for cement.

Owner:张玉成 +2

Lightweight gypsum board for absorbing electromagnetic radiation and preparation method thereof

The invention relates to a lightweight gypsum board for absorbing electromagnetic radiation and a preparation method thereof. The lightweight gypsum board comprises the following raw material components in parts by mass: 30-50 parts of building phosphogypsum, 15-30 parts of a steel slag micro powder, 10-40 parts of copper slag, 2-8 parts of carbon fibers, 0.1-0.3 part of a retarder, 0.1-0.3 part of a water reducing agent and 0-0.1 part of an air entraining agent. According to the lightweight gypsum board disclosed by the invention, the absorption of electromagnetic waves is realized by utilizing ferroelectric and other substances in the copper slag. In addition, the dielectric constant of the material is changed by utilizing the carbon fibers, and the electromagnetic wave absorption ability of the gypsum board is further improved. After the electromagnetic wave passes through the gypsum board, the intensity of the electromagnetic wave is obviously decreased, and the breaking strength and impact strength of the electromagnetic wav are increased. The prepared lightweight gypsum board has a high waste utilization rate and excellent electromagnetic wave absorption property at 1.5-5.4GHz, and various properties meet the GBT23451-2009 General Technical Requirements of Light Weight Panel used for Building Partition.

Owner:WUHAN UNIV OF TECH

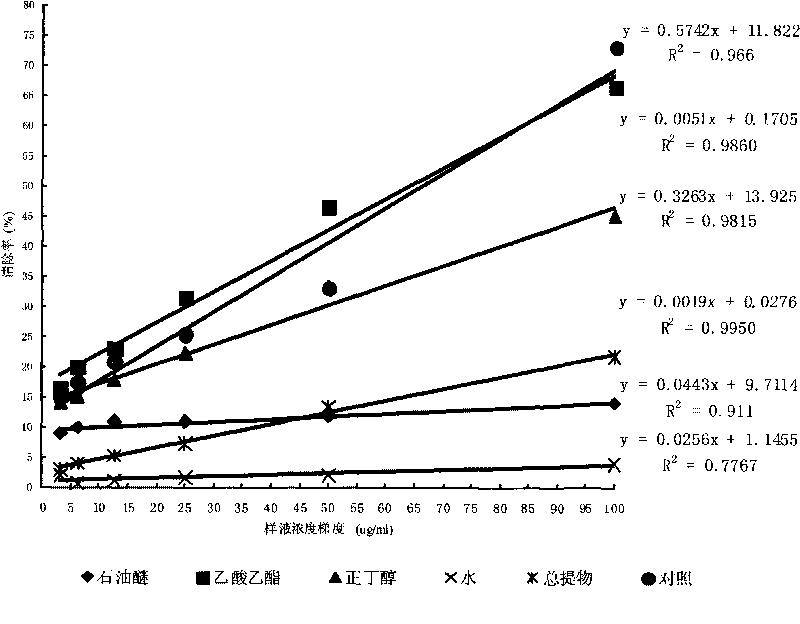

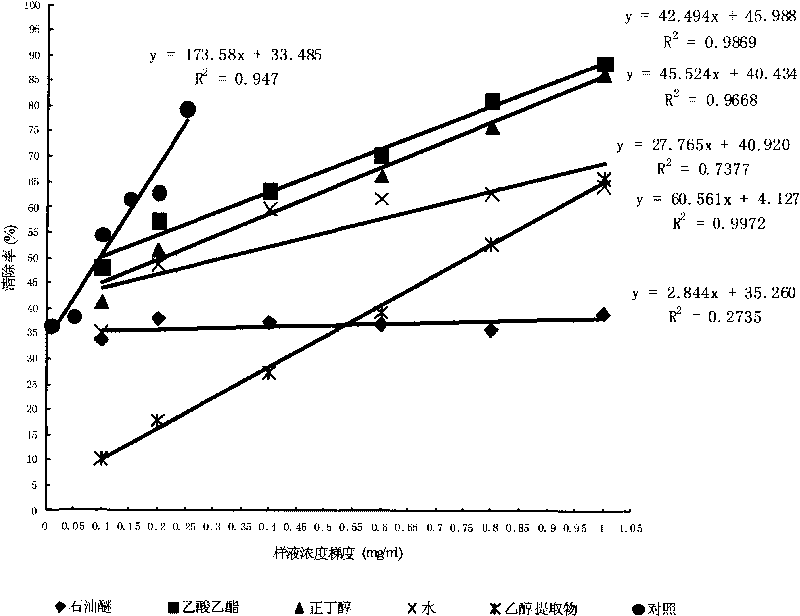

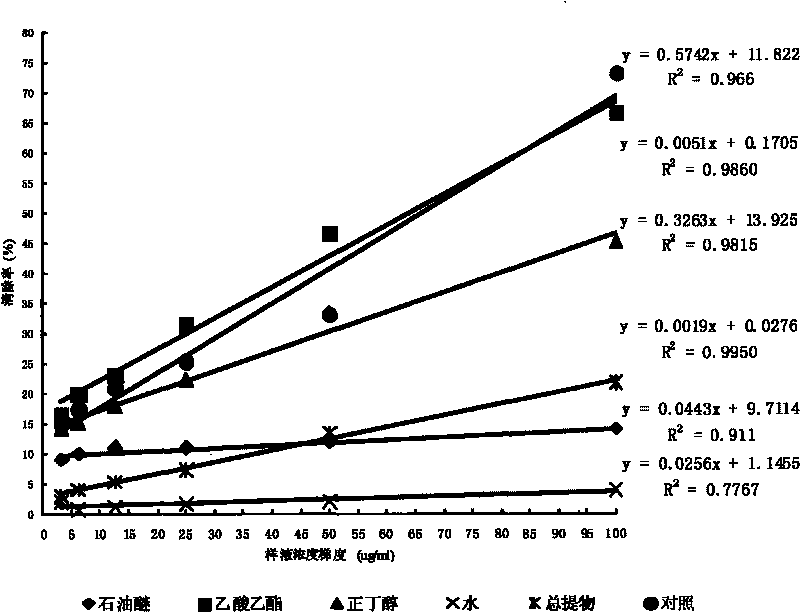

Extract of carica papaya L. seeds produced in Hainan, preparation method and application thereof

InactiveCN101731578AExtracts are all naturalNo side effectsCosmetic preparationsToilet preparationsSide effectRise over thermal

The invention discloses an extract of carica papaya L. seeds, which is prepared by the following steps: dissolving the carica papaya L. seeds into ethanol and lixiviating the carica papaya L. seeds at the room temperature, rotationally steaming the filtered solution till the ethanol is evaporated to obtain a coarse extract of the carica papaya L. seeds, dissolving the coarse extract into water, then extracting the coarse extract by using an organic solvent, and concentrating the extract to obtain the extract of the carica papaya L. seeds. The invention also discloses a preparation method for the extract and application thereof. The extract is pure natural, has no toxic or side effect, has stability to illumination and metal ions (calcium, iron and zinc), and is suitable for acid conditions; the anti-oxidation activity of the extract is enhanced along with the rise of the temperature at the temperature of below 100 DEG C; the production method has the advantages of readily available raw materials, high waste utilization rate and low cost; and the prepared product can be widely used in the field of food, medicament, cosmetics, veterinary medicament, feed and the like.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

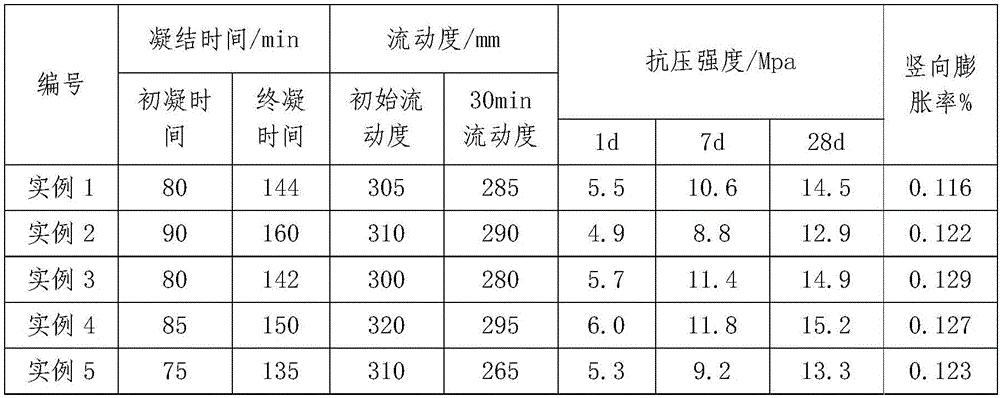

Phosphorus-based grouting filling material suitable for old goaf treatment

The invention discloses a phosphorus-based grouting filling material suitable for old goaf treatment. The phosphorus-based grouting filling material is prepared through the following steps: uniformly mixing, by weight, 40-60 parts of phosphorus slag powder, 30-40 parts of fly ash, 6-10 parts of an active activator and 3-8 parts of an expanding agent, adding the above obtained mixture, 0.5-1.5 parts by weight of a water reducer, 0.5-1 part by weight of a water retaining agent and 30-50 parts by weight of water to a stirring pool, uniformly stirring, adding 100-200 parts by weight of phosphorus tailings, and uniformly stirring. The phosphorus-based grouting filling material has the advantages of fast strength development, high filling efficiency, no shrinkage, and suitableness for long-distance pumping, the initial setting time is not smaller than 70min, the final setting time is not greater than 200min, the initial fluidity is not smaller than 300mm, the 30min fluidity retention value is not smaller than 260mm, the 1d compressive strength is not smaller than 4.9MPa, the 7d comprehensive strength is not smaller than 8.8MPa, the 28d compressive strength is not smaller than 12.9MPa, and the vertical expansion rate is not smaller than 0.1%.

Owner:HUBEI UNIV OF TECH

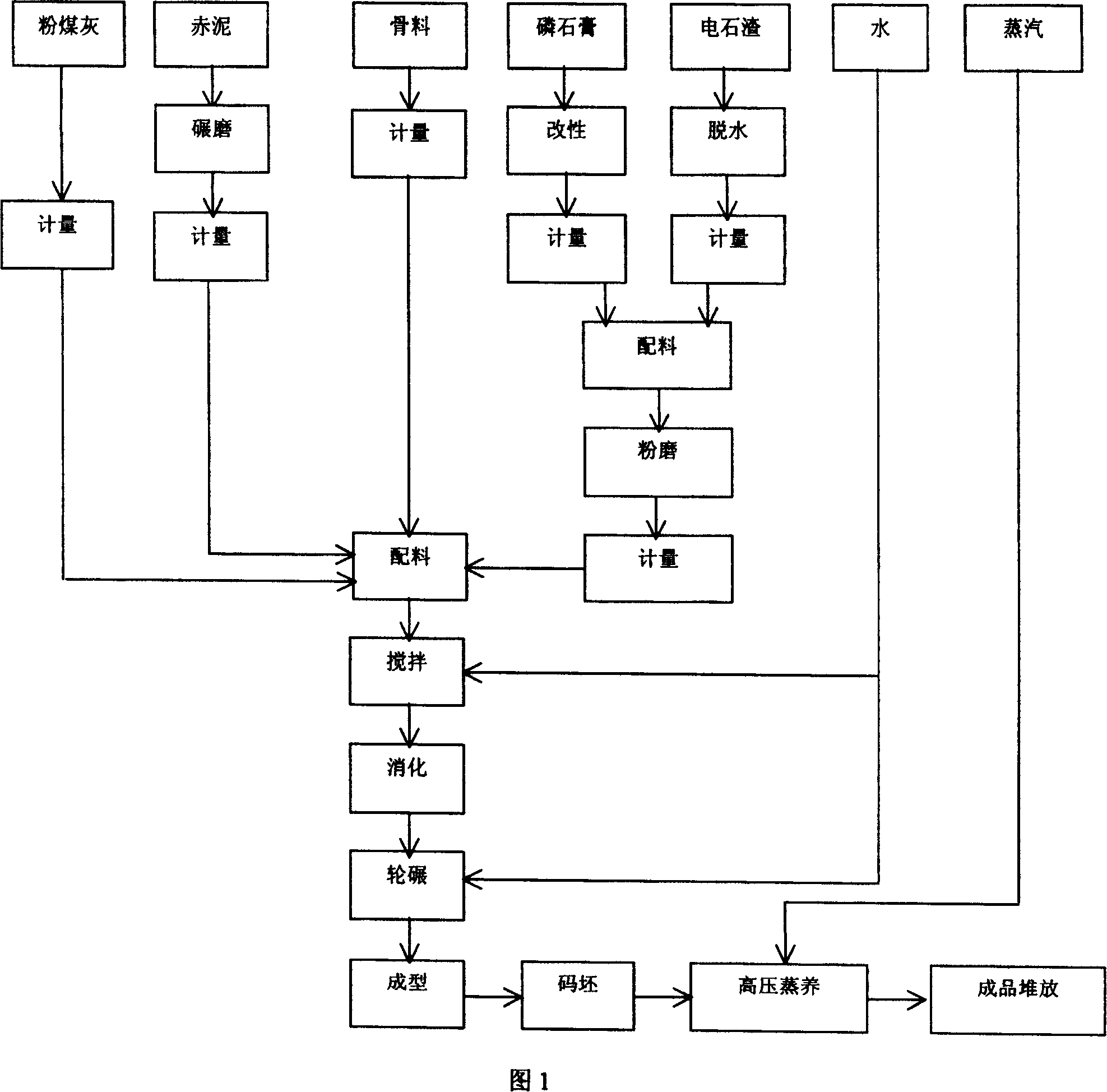

Red mud autoclaved brick and preparation method thereof

The invention relates to a kind of stream-pressed bricks by utilizing red mud as the raw material, the constituents of the raw material include (by weight percent): red mud 25-40%, coal ash 10-30%, aggregate 35-55%, carbide slag 8-14% and modified phosphogypsum 2-5%.

Owner:WUHAN UNIV OF TECH

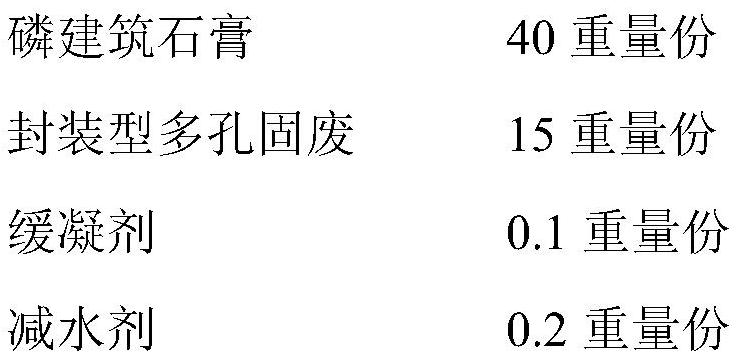

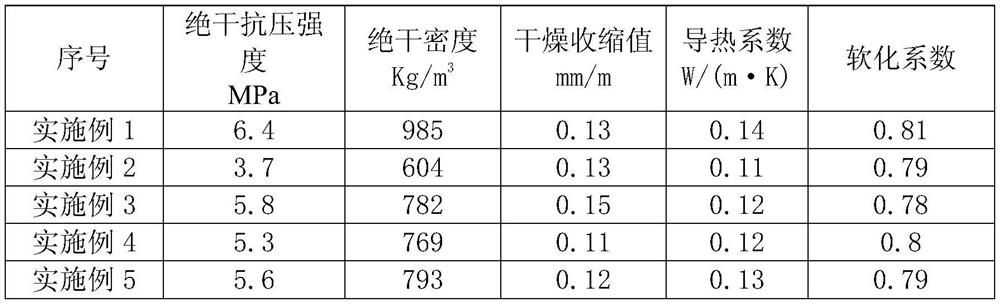

Phosphogypsum light-weight sheet material prepared from barium dreg and preparation method thereof

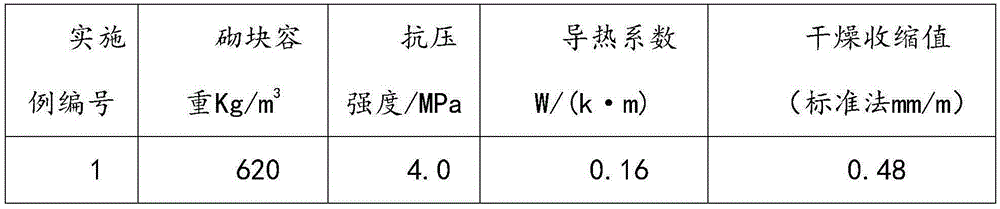

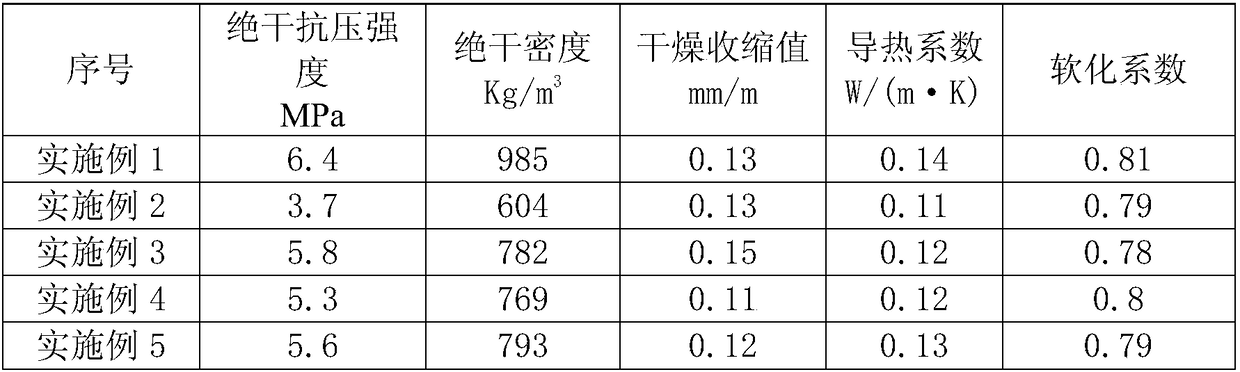

The invention relates to a phosphogypsum light-weight sheet material prepared from barium dreg and a preparation method thereof. The phosphogypsum light-weight sheet material is prepared from the following raw material components in parts by mass: 10 to 20 parts of the barium dreg, 4 to 10 parts of phosphogypsum dihydrate, 60 to 80 parts of phosphorous hemihydrate gypsum, 5 to 15 parts of metakaolin, 1 to 3 parts of carbide slag, 0.5 to 1.2 parts of light aggregate, 0 to 0.1 part of set retarder, 0.1 to 0.3 part of water reducing agent and 0 to 0.1 part of water-retaining agent. The phosphogypsum light-weight sheet material prepared from the barium dreg, provided by the invention, has the advantages of light weight and heat insulation; the volume weight is adjustable in a range of 600 to 1,000Kg / m<3> and the thermal conductivity coefficient is lower than 0.15W / (m*K); the phosphogypsum light-weight sheet material has no obvious layering and cracking and the problem that a traditional cement sheet material is cracked by shrinkage can be effectively overcome by utilizing a micro-expansion property of gypsum hydration; each performance of the prepared light-weight sheet material can meet standards of General Technical Requirements of Light Weight Panel used for Building Partition Wall JGT169-2016.

Owner:WUHAN UNIV OF TECH

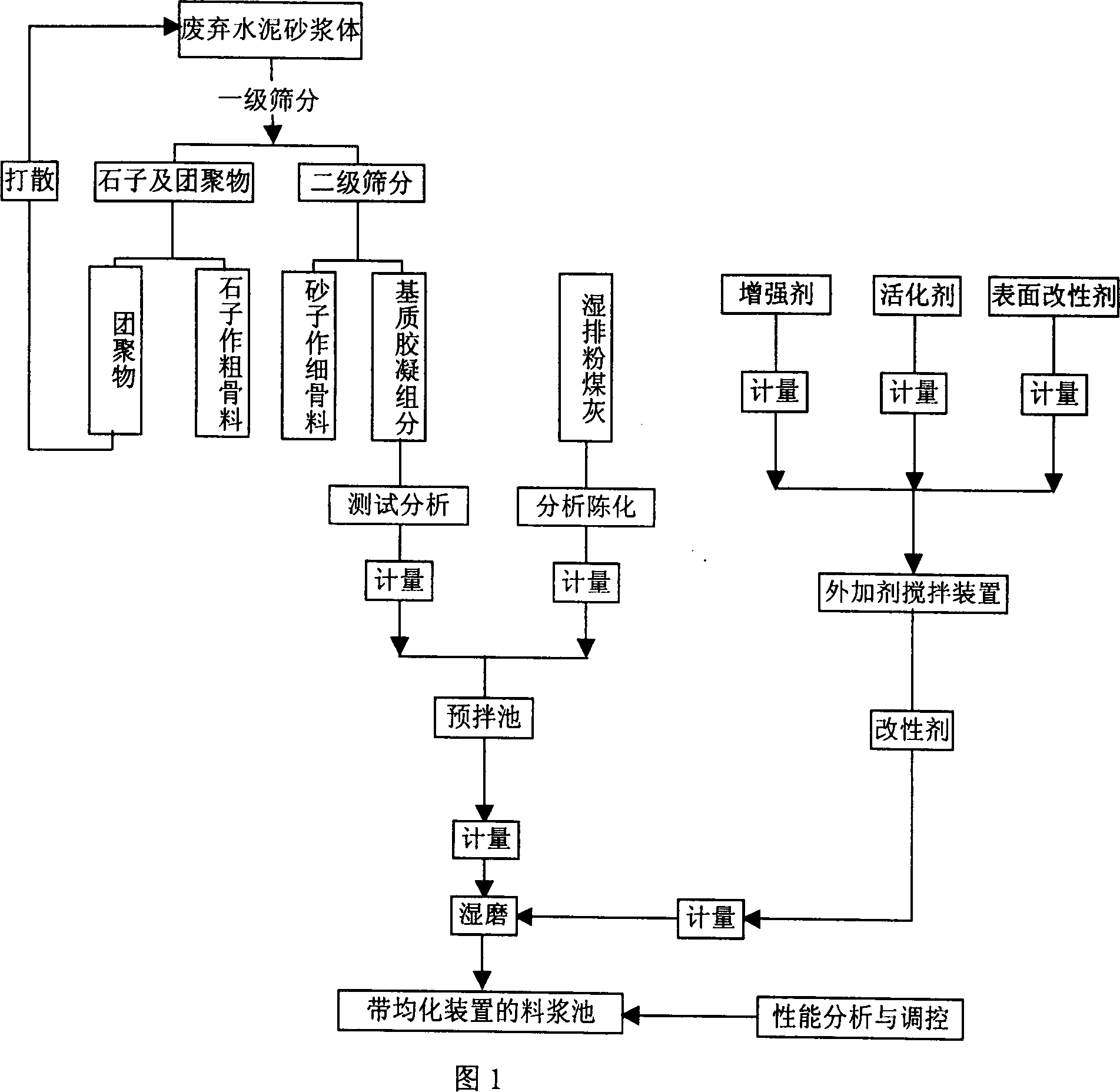

High activity mixture slurry with several mineral components and its prepn process

The present invention relates to one kind of high activity mixture slurry with several mineral components and its preparation process. The high activity mixture slurry is prepared with waste cement slurry as cementing component 40-60 weight portions, wet fly ash accounting in solid 40-60 weight portions, modifier 1-5 weight portions and water 80-100 weight portions, and through wet grinding. The modifier consists of reinforcing agent 10-30 wt%, surface modifier 20-40 wt% and activator 30-50 wt%. The present invention has two kinds of waste utilized and possesses the features of simple production process, low cost, high activity, capacity of compounding high quality concrete, etc.

Owner:WUHAN UNIV OF TECH

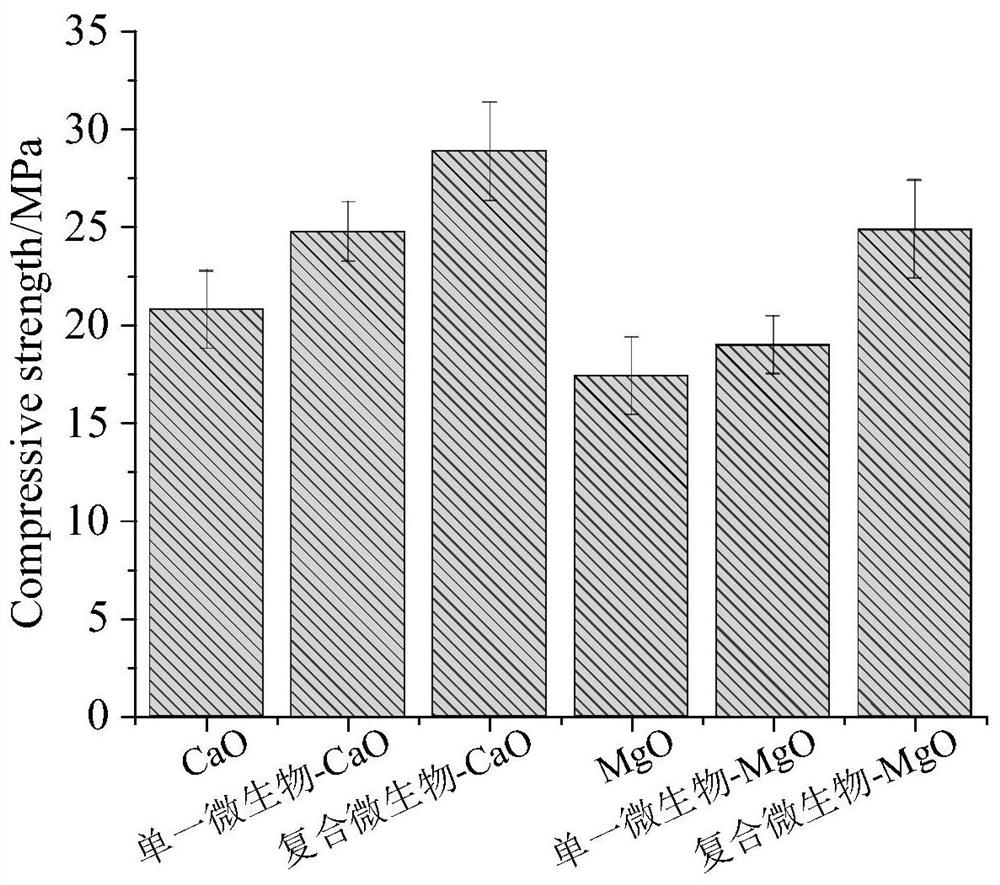

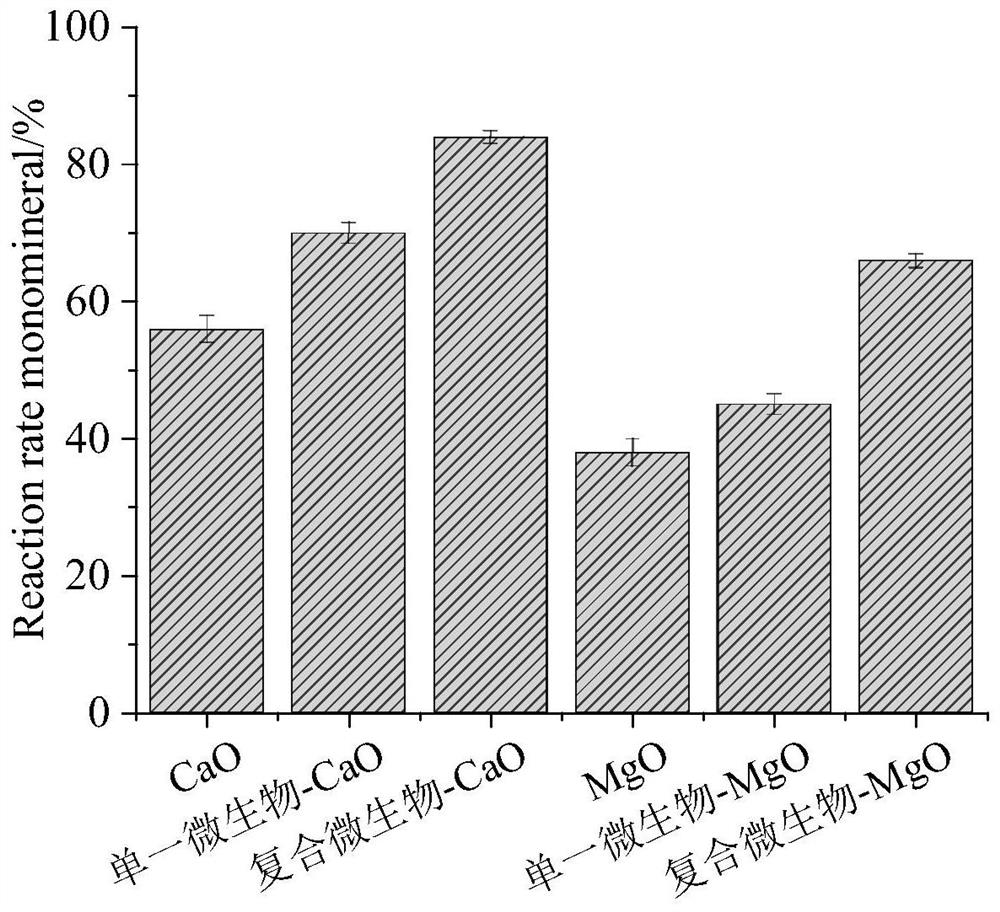

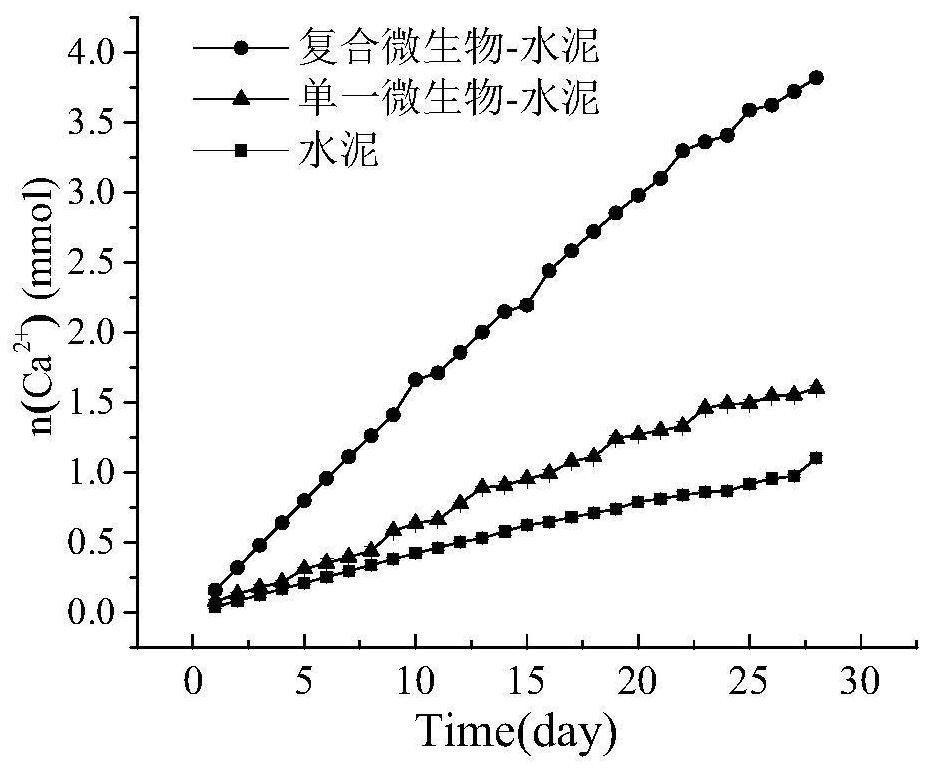

Method for preparing building material by complex microorganism mineralization

The invention discloses a method for preparing a building material by complex microorganism mineralization. The method comprises the steps of cultivating microorganism l strains with the acid production function and microbial strains with the mineralization sediment function, and obtaining a microorganism additive; mixing the microorganism additive, mineral powder and water to be evenly stirred toobtain complex microorganism slurry; and carrying out curing forming on the complex microorganism slurry to obtain a complex microorganism building material product. Calcium magnesium mineral use rates in materials like industrial solid waste, waste concrete, cement and the like can be sufficiently used, more stable carbonate mineralization is formed, the material phase mineralization strength isimproved, and the strength and the volume stability of the building material product with complex microorganisms can be improved.

Owner:SOUTHEAST UNIV

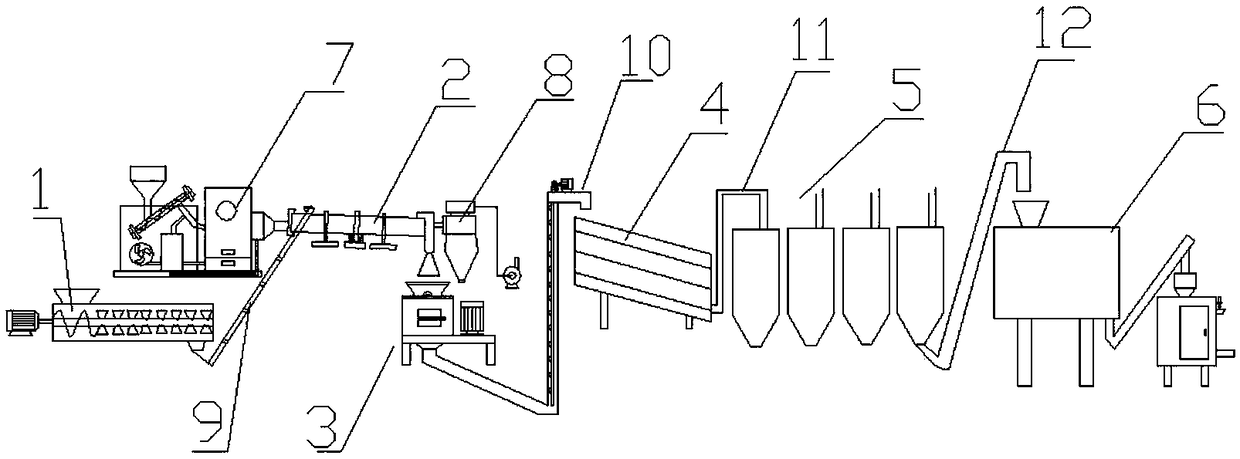

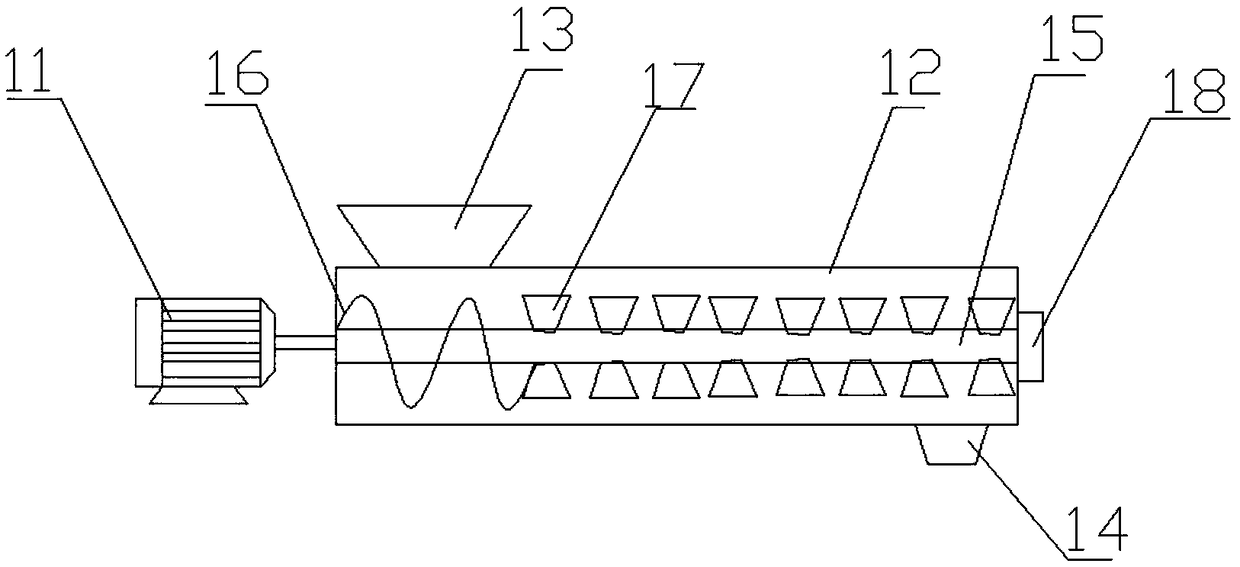

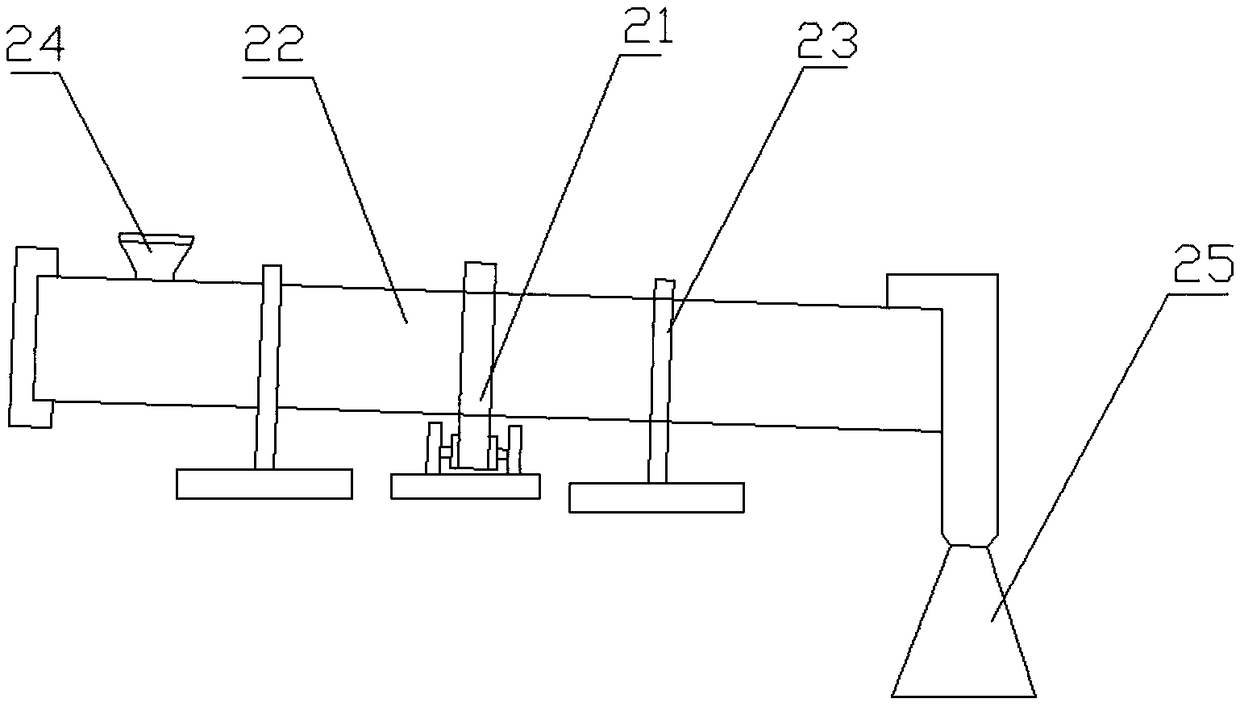

Production line and process for recycling waste granite powder

InactiveCN108772173A100% utilizationAvoid secondary pollutionSievingScreeningProduction linePulp and paper industry

Owner:杭州一诺再生资源利用有限公司

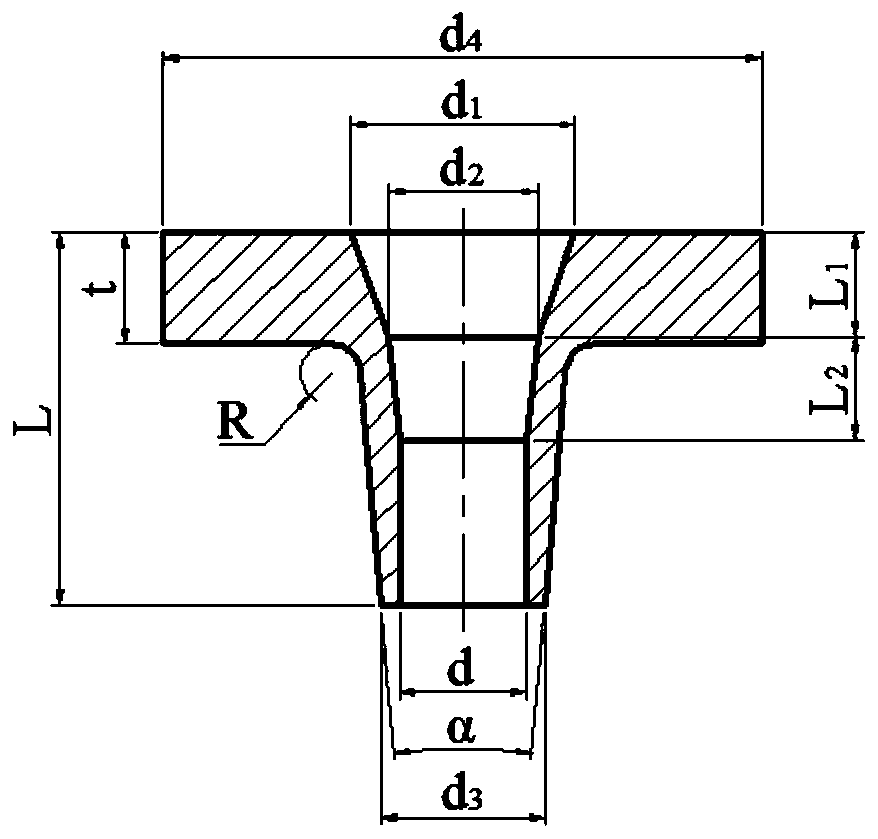

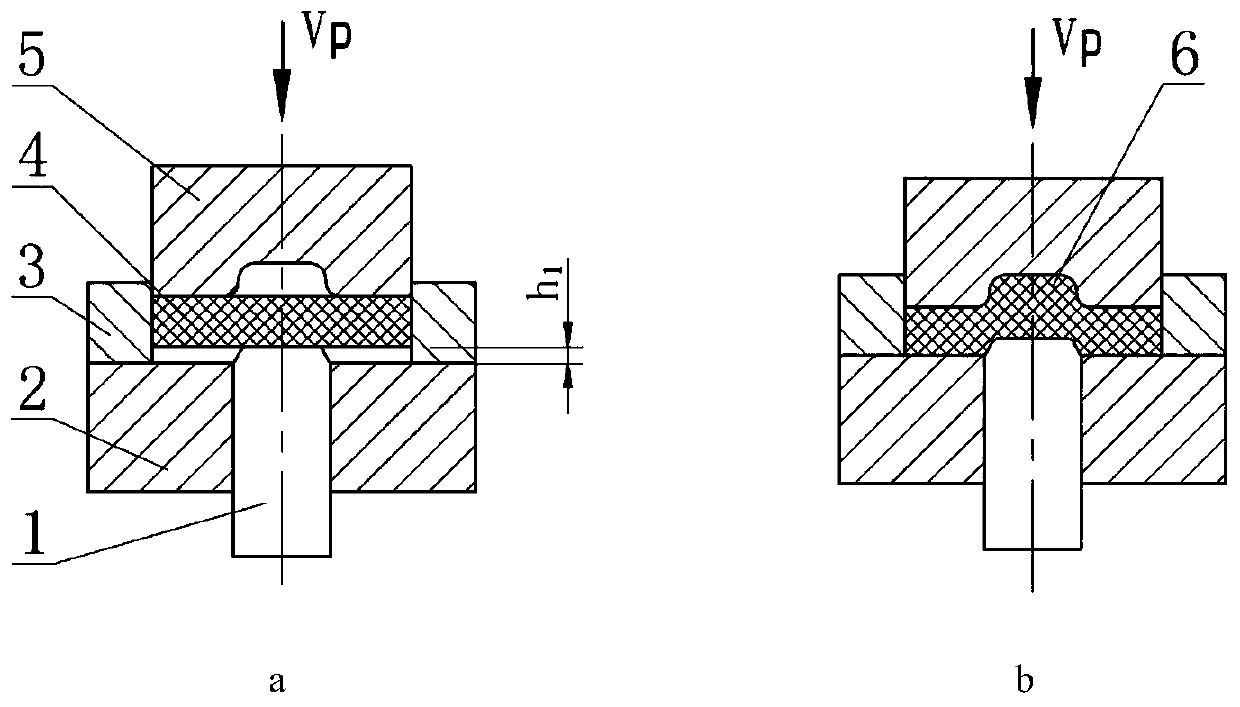

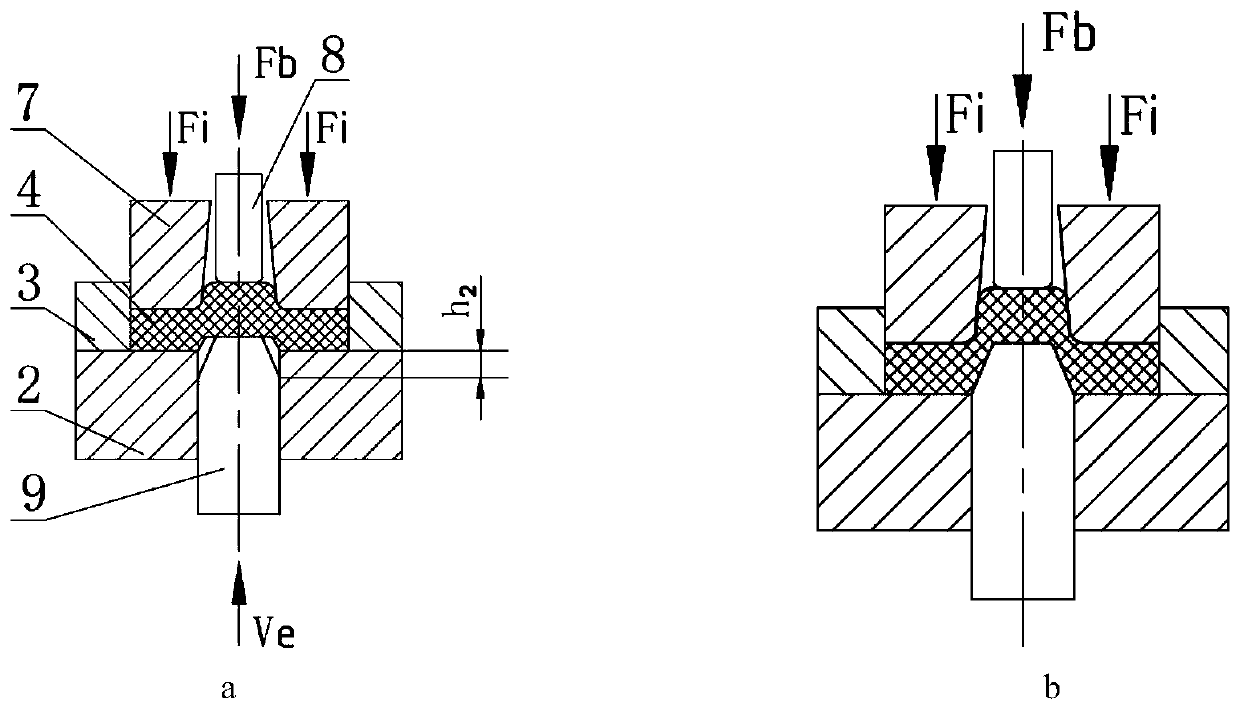

Conical-spout bushing plate integral punching extrusion compound forming die and forming method

The invention provides a conical-spout bushing plate integral punching extrusion compound forming die and a forming method. The conical-spout bushing plate integral punching extrusion compound formingdie comprises a female die, an embedded sleeve, a first extrusion female die, a second extrusion female die, an extrusion male die, a first stamping male die, a second stamping male die, a third stamping male die and a fourth stamping male die. Each die is replaced and used in different technological stages respectively. The forming method comprises the steps that a regular metal plate is placedin a die cavity formed in a press machine, a technology with extrusion and stamping combined is adopted and a baseplate and a discharge spout are integrally formed, and a blank is in a strong three-way compressive stress state, and generation of cracks in the forming process is avoided. The conical-spout bushing plate integral punching extrusion compound forming die and the forming method are characterized in that the forming precision is high, the machining process is simple, and production efficiency is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

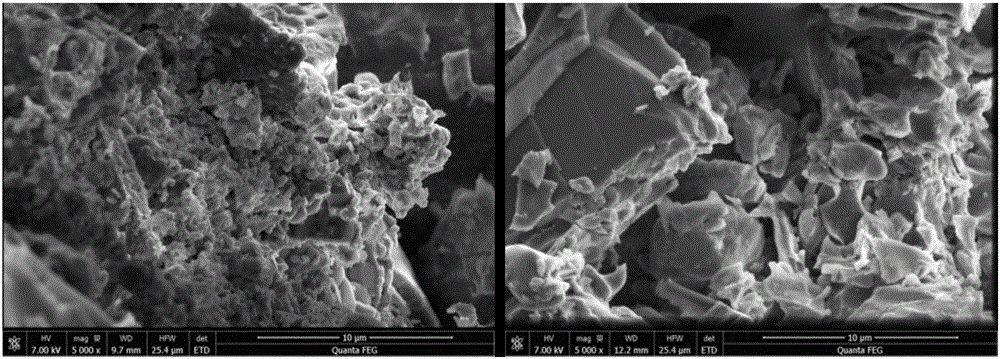

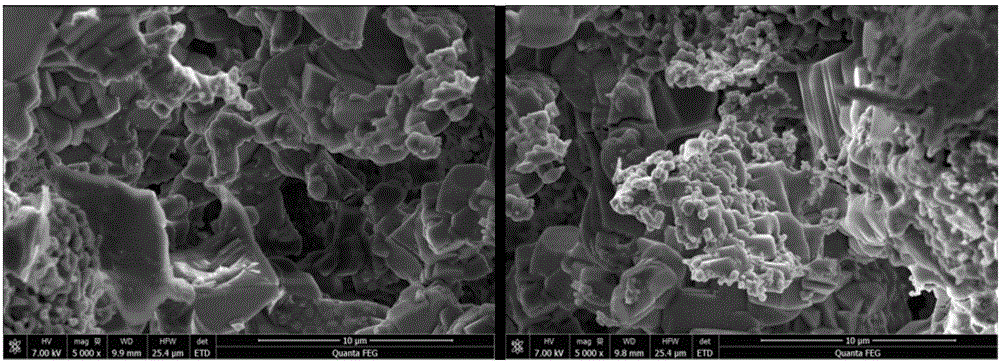

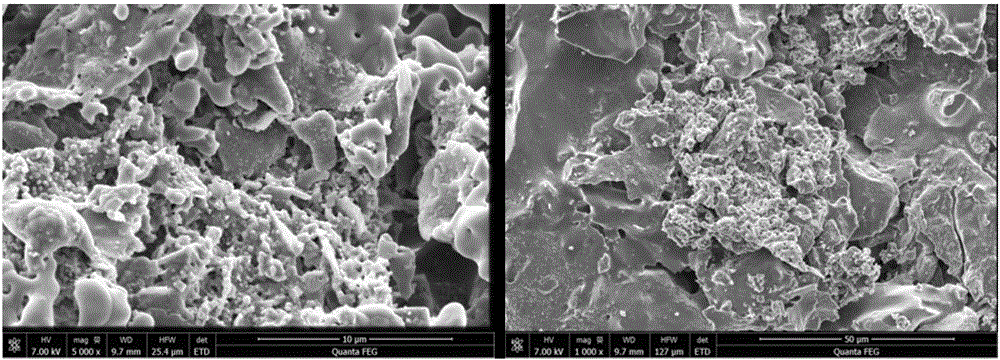

Preparation method of mineral admixture slurry for high-performance prefabricated component

The invention relates to a preparation method of mineral admixture slurry for a high-performance prefabricated component. The preparation method comprises the following steps: taking wet-discharged fly ash with the mass water content of 25 to 35 percent, ageing for 48 hours and mixing 30 to 40 percent of a reinforcing agent with 60 to 70 percent of a surfactant to obtain a modifier; mixing the wet-discharged fly ash with the solid content of 65 to 75 percent, quartz tailing sand with the solid content of 22 to 34 percent, 1 to 3 percent of the modifier, and 80 to 100 percent of water, carrying out wet grinding until the specific surface area is 1500m<2> / kg or above and the average diameters of particles are smaller than 1[mu]m, and obtaining the mineral admixture slurry with a daily active index of 130. According to the preparation method disclosed by the invention, the fly ash and the quartz tailing sand are utilized as raw materials so as to benefit environmental protection; when the high-performance prefabricated component is produced, the cement content can be reduced; when the prefabricated component is subjected to high pressure steam curing, the wet-discharged fly ash is thermally excited to generate crystals such as hydration products, hydrated calcium silicate and ettringite; the crystals can replace part of cementing materials; after the quartz tailing sand is thermally excited, the activity is enhanced, and the strength of the prefabricated component is effectively improved.

Owner:HUBEI UNIV OF TECH

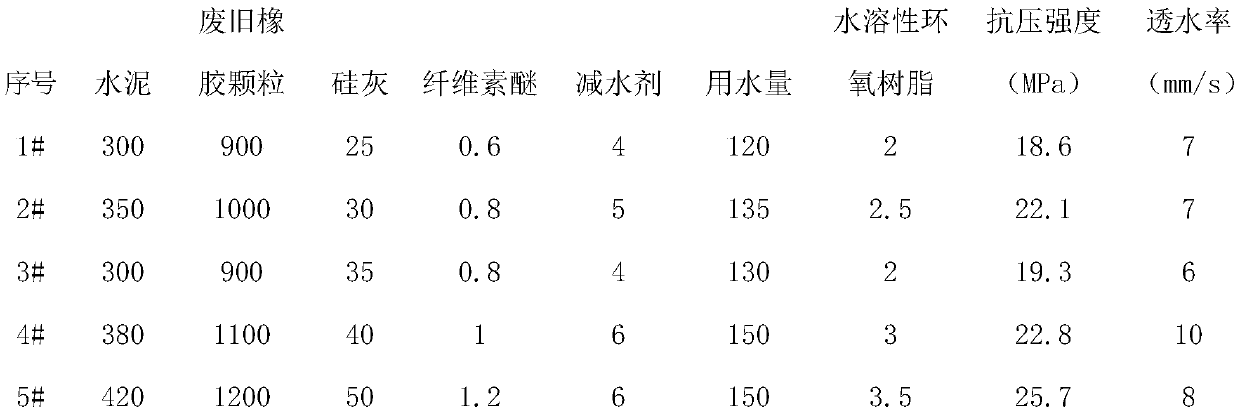

Light permeable flexible rubber pavement brick and preparation method thereof

ActiveCN110668746AGood flexibilityHigh waste rateSolid waste managementCeramicwareSilica fumePolymer chemistry

The invention provides a light permeable flexible rubber pavement brick and a preparation method thereof. The raw materials and the weight parts thereof are as follows: 900-1200 parts of waste rubberparticles, 300-420 parts of cement, 25-50 parts of silica fume, 0.6-1.2 parts of cellulose ether, 4-6 parts of a water reducing agent, 2-3.5 parts of water soluble epoxy resin and 120-150 parts of water. The method is as follows: mixing the cement, silica fume and cellulose ether evenly in proportion, then adding the waste rubber particles, and continuing stirring to make the mixture even; mixing80% of the water and 100% of the water reducing agent and stirring evenly, and then adding into the solid mixture to be mixing evenly; pouring 100% of the water-soluble epoxy resin into the remaining20% water, then adding into the mixture, stirring and mixing; loading into a mold, and performing static pressure molding; curing and demoulding. The pavement brick has high compressive strength, highwater permeability, light dead weight, flexibility and comfort, and good noise reduction and sound absorption performance.

Owner:FUJIAN BUILDING ENG QUALITY INSPECTION CENT +1

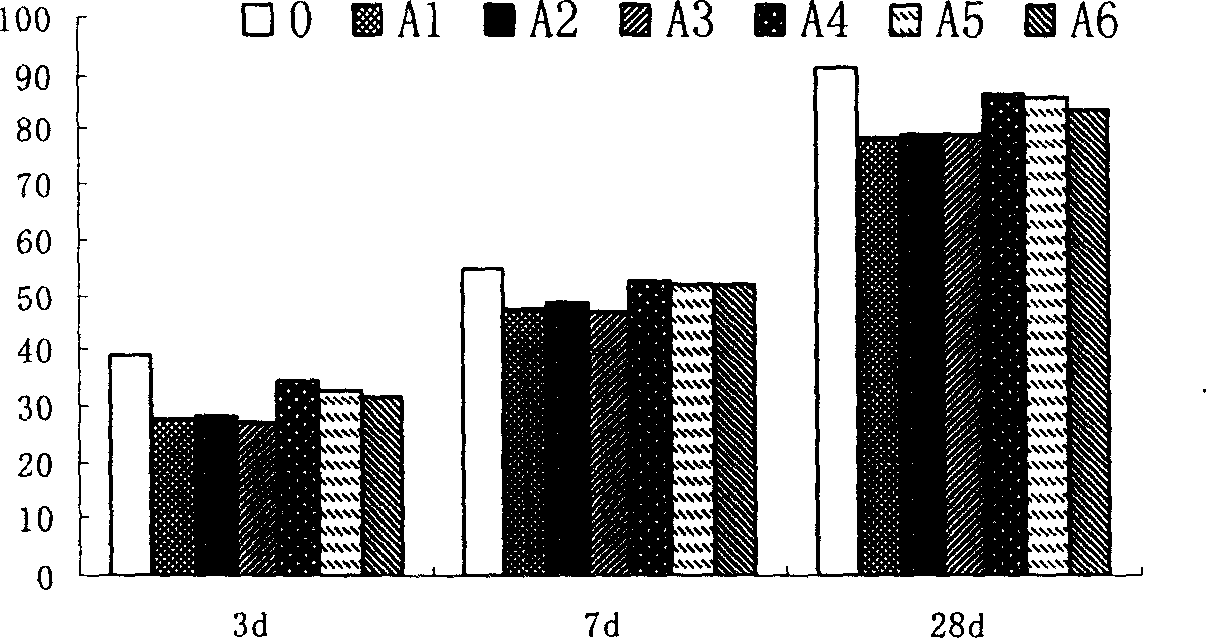

Low grade fly ash mixed slurry used for concrete and preparation method thereof

InactiveCN102633474AImprove the environmentPromote hydrationSolid waste disposalLower gradeLow graded

The invention discloses a low grade fly ash mixed slurry used for concrete. The mixed slurry is prepared by wet grinding the following components by mass percent: 35-55% of low grade fly ash, 9-16% of industrial residue, 1-4% of modifying agent and 35-45% of mixing plant recycled water; and the mixing plant recycled water contains the quality of the water in the low grade fly ash. The invention also discloses a preparation method of the low grade fly ash mixed slurry used for the concrete. The invention provides a low grade fly ash mixed slurry used for the concrete and a preparation method, wherein the mixed slurry is high in activity, low in cost and high in waste utilization rate.

Owner:XIAMEN TIANRUN JINLONG BUILDING MATERIAL

Phosphorus-based salt mine goaf filler prepared from ardealite solidification salt waste

InactiveCN105777036AHigh viscosityAvoid geological disastersSolid waste managementPlasticizerSalt-wasting

The invention belongs to the technical field of fillers, and particularly relates to a phosphorus-based salt mine goaf filler prepared from ardealite solidification salt waste. The phosphorus-based salt mine goaf filler is prepared from the following components in parts by weight: 10-30 parts of ardealite, 70-85 parts of salt waste, 0-0.2 part of a retarder, and 0-0.4 part of a plasticizer. The phosphorus-based salt mine goaf filler disclosed by the invention has the benefits that the waste utilization rate is high, and phosphatizing waste and salinizing waste are used as main raw materials, so that the preparation cost is low; the coagulation time can be adjusted, and the retarder is used for adjusting the coagulation time of the filler, so that enough filling time can be obtained; the stickiness is adjustable, and the plasticizer is used for improving the stickiness of the filler, so that the requirement of a filling technology is met.

Owner:WUHAN UNIV OF TECH

Ceramic tile polishing mud construction waste-based filling material and preparation method thereof

Owner:ZIBO HUANYI RESOURCE INTEGRATION UTILIZATION CO LTD

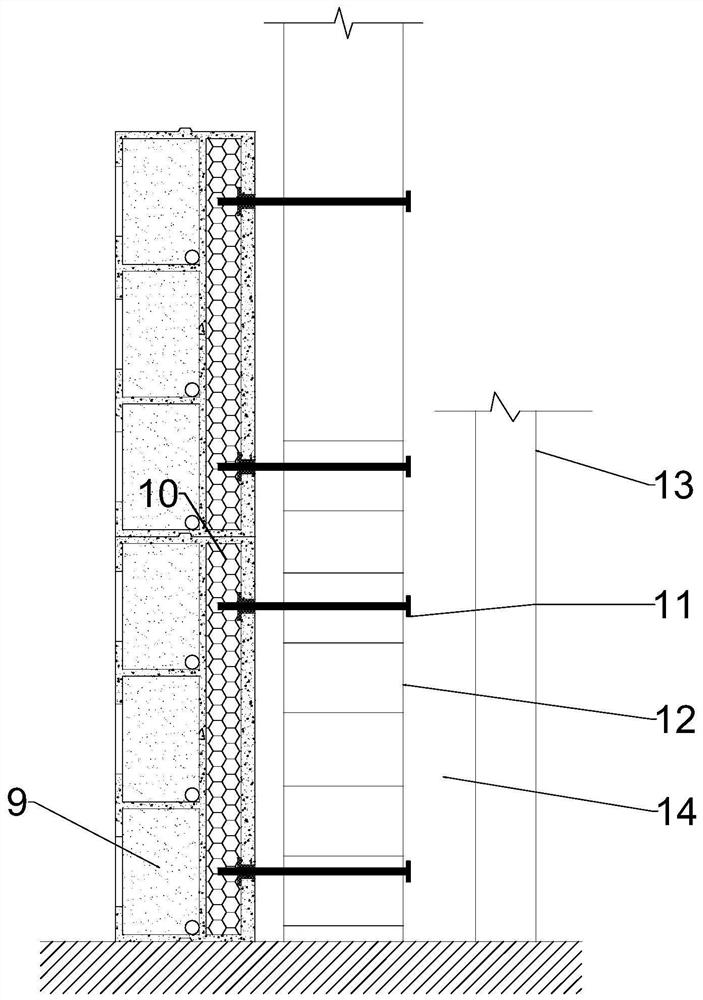

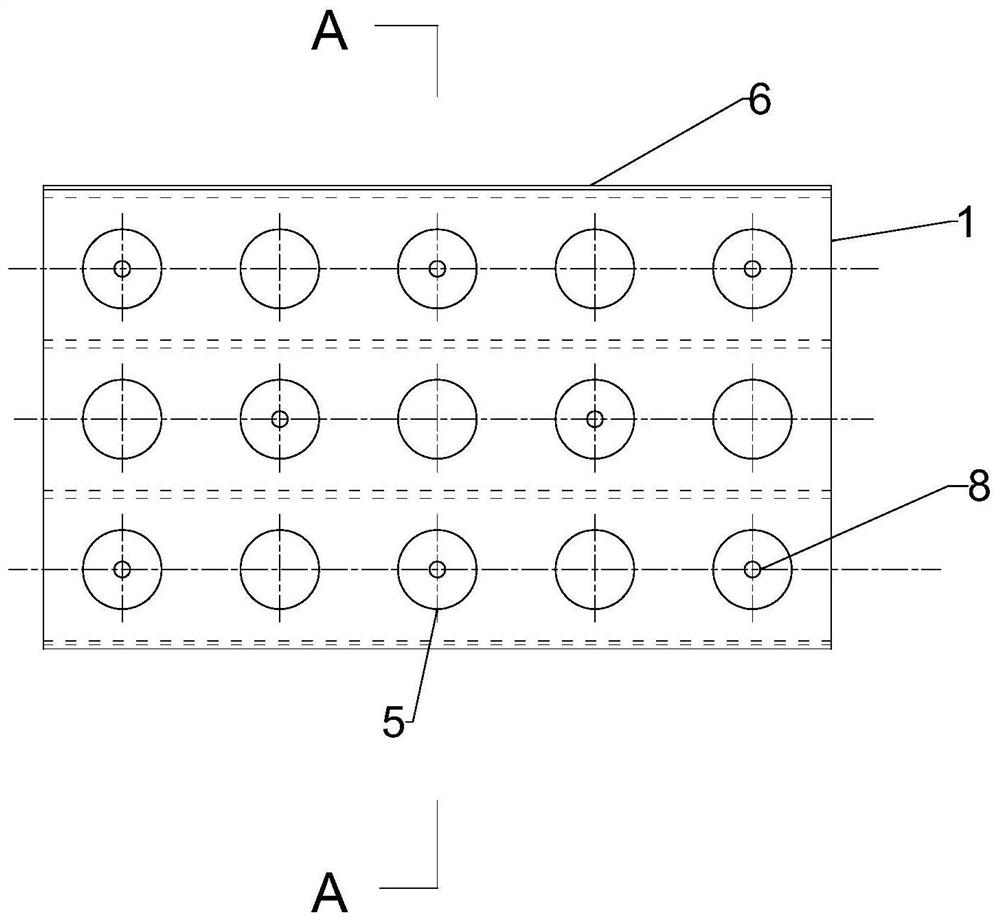

Non-dismantling formwork with planting and heat preservation functions and preparation method

InactiveCN112554356AHigh waste rateImprove water resistanceWallsClimate change adaptationAgricultural scienceWater source

The invention discloses a non-dismantling formwork with planting and heat preservation functions and a preparation method. The non-dismantling formwork comprises a plurality of formwork units of the same structure, wherein the multiple formwork units are spliced through rabbets, each formwork unit comprises a bottom plate arranged at the lower part and a plurality of planting cavities formed in the bottom plate, the interiors of the bottom plates are of hollow structures, heat preservation layers are arranged in cavities, the planting cavities are provided with planting openings, a drip irrigation water pipe is arranged in each planting cavity, the drip irrigation water pipe is connected with an external water source, and the bottom plate is connected with a mounting wall surface. According to the non-dismantling formwork, grouting and extrusion integrated forming is adopted, the formwork is formed by assembling the multiple formwork units, installation and greening of the building wall surface can be rapidly and efficiently achieved, the formwork units can be repeatedly used, resource consumption and product cost are greatly reduced, waterproof, energy-saving, heat-insulating, planting and greening functions are integrated, the whole system is made of inorganic materials, and the service life of an existing planting system is greatly prolonged.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

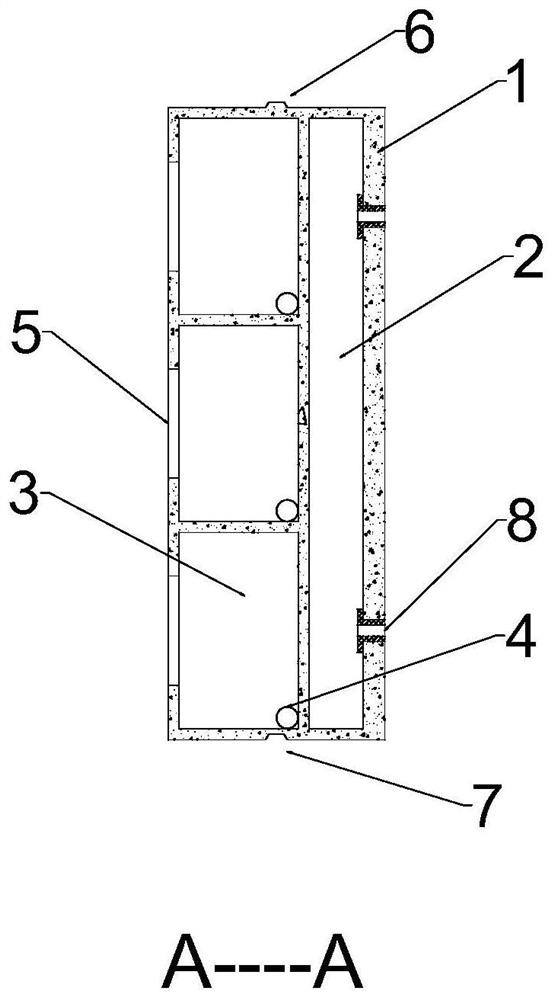

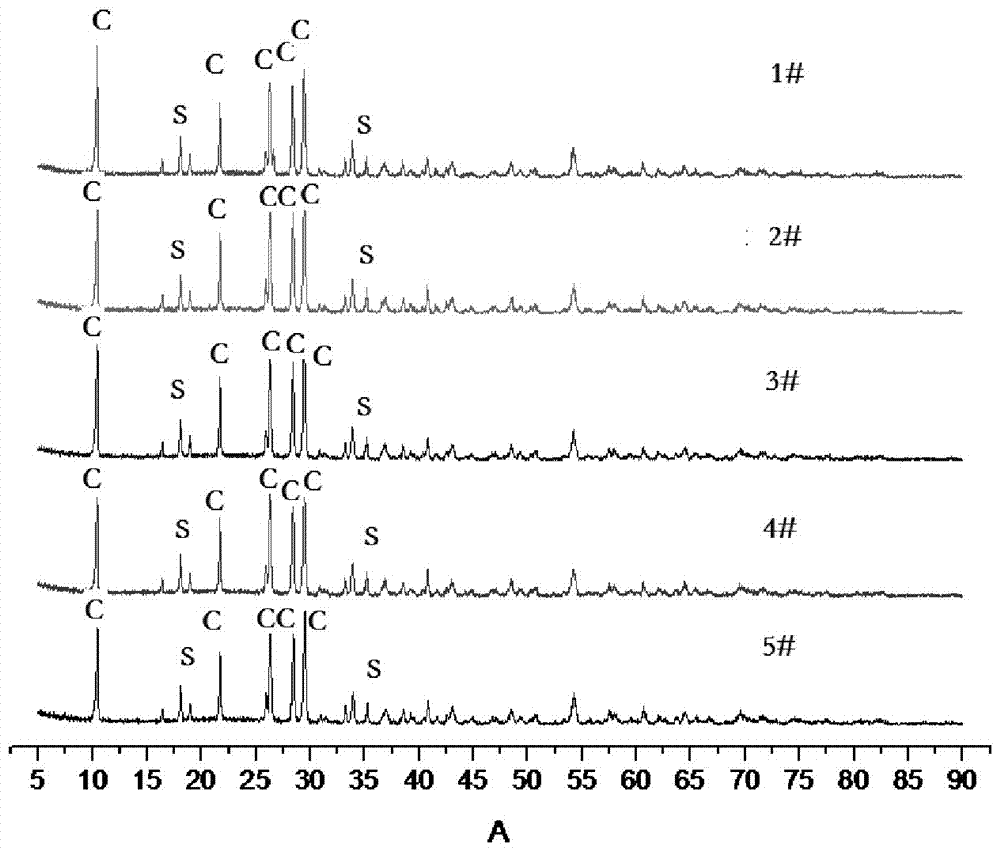

Cordierite-spinel multiphase material and synthesis process thereof

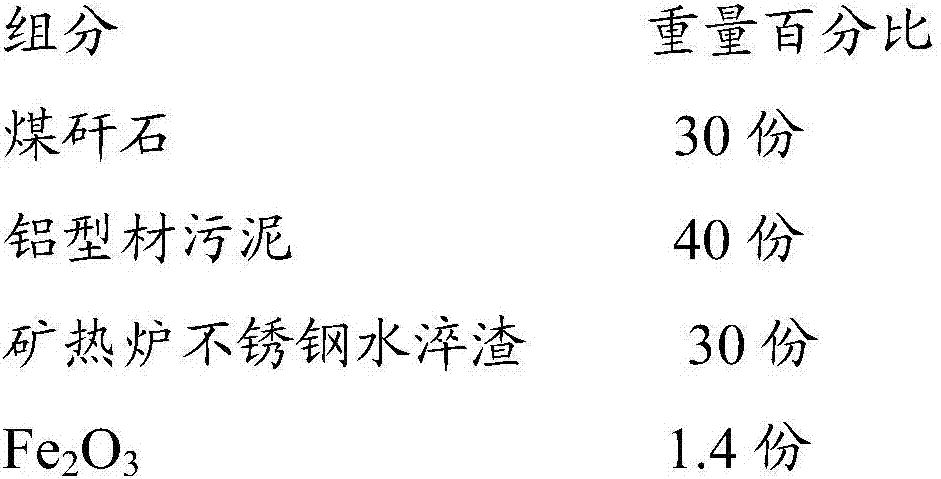

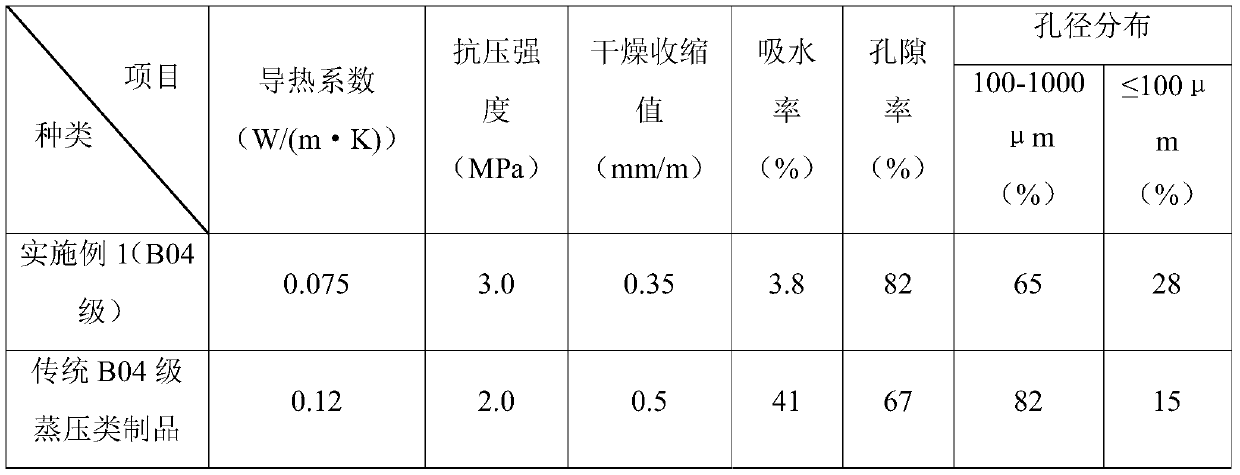

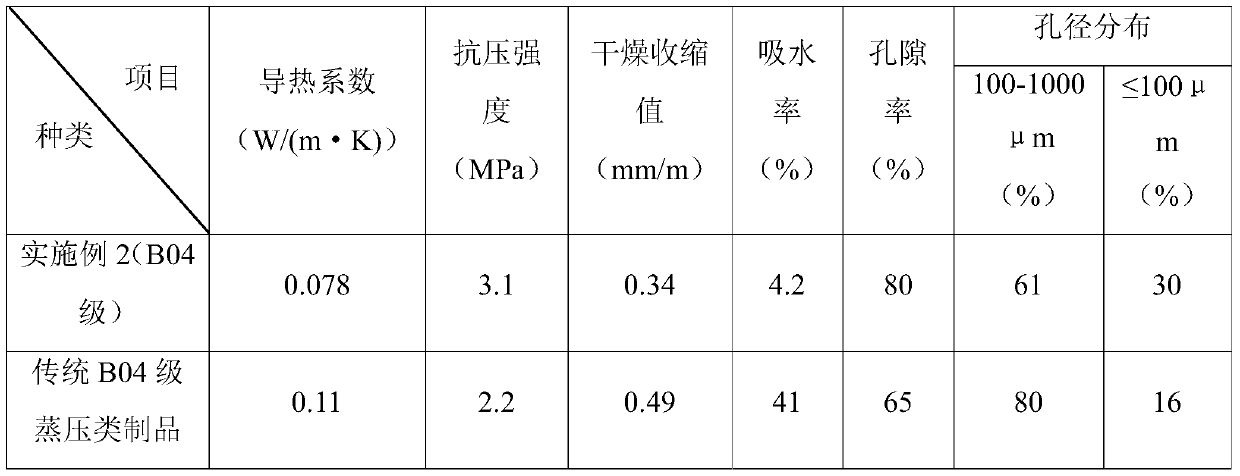

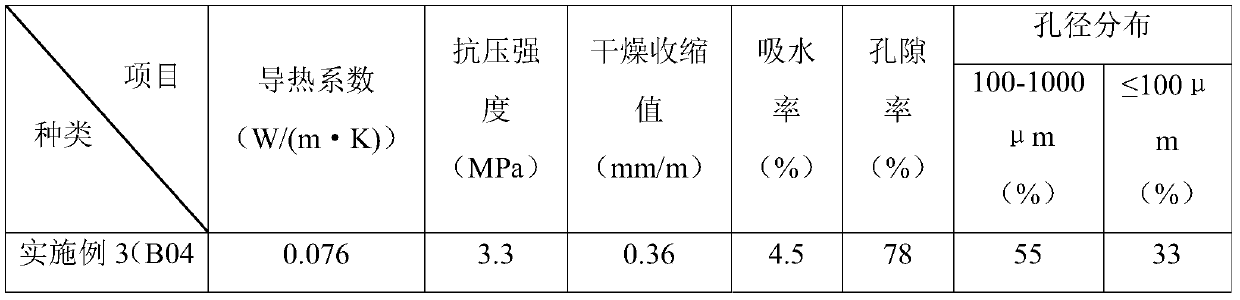

The invention provides a cordierite-spinel multiphase material and a synthesis process thereof. The cordierite-spinel multiphase material is prepared from, by weight, 30-40 parts of coal gangue, 35-45 parts of aluminum profile factory sludge, 15-35 parts of stainless steel electric furnace water quenching slag and 0.8-1.8 parts of Fe2O3 powder. The synthesis process includes the steps that the coal gangue, the aluminum profile factory sludge and the stainless steel electric furnace water quenching slag are respectively subjected to drying, powder grinding, screening, mixing, continuous pulverizing, the Fe2O3 powder is added, and stirring is performed to obtain dry powder; 15-20 g of water is added to per 100 g of dry powder, distilled water is added, stirring and pressure molding is performed, firing is performed in air atmosphere at the temperature of 1300-1350 DEG C for 3-5 hours, and natural cooling is performed. The cordierite-spinel multiphase material has the advantage of being high in purity, high waste utilization rate, low in production cost and high in conversion rate.

Owner:福建省建筑科学研究院有限责任公司

Ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material as well as preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material as well as a preparation method thereof. The ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material is prepared from a siliceous component, a calcareous component, a coagulated component, a gas-forming component, a gas-guiding component, a hydrophobic component and water; the siliceous component is prepared from modified ceramic tile polishing mud, kieselguhr and modified fluorogypsum; and the calcareous component is prepared from quicklime and modified carbide slag. According to the thermal insulation material provided by the invention, the waste utilization rate is high, the ceramic tile polishing mud, the fluorgypsum and the carbide slag can be resourcefully utilized, in the product structure, the porosity is high, the aperture is small and uniform, macro holes and micro holes coexist, the heat conductivity coefficient is low, the mechanical property is high, the water absorption rate is low, and therefore, the thermal insulation material can be widely applied tocivil buildings and industrial buildings in thermal insulation.

Owner:SHANDONG ZIJIAN GRP

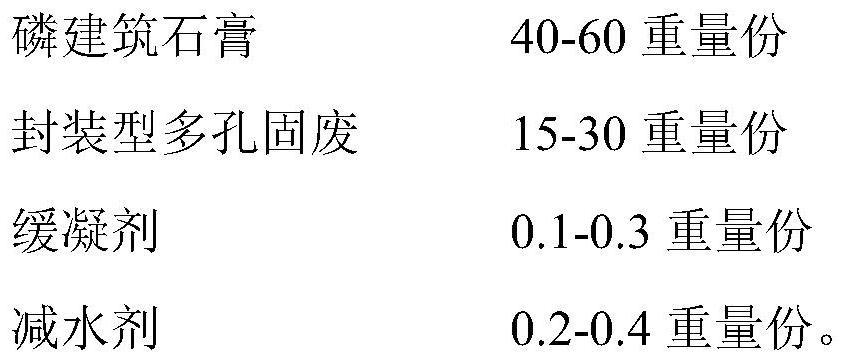

Light gypsum board capable of preventing neutron radiation and preparation method thereof

ActiveCN113149703AHigh waste rateGood stabilitySolid waste managementCeramicwarePhysicsMethacrylate methyl

The invention relates to a light gypsum board capable of preventing neutron radiation, the gypsum board contains 19%-55% by mass of packaged porous solid waste, the packaged porous solid waste adsorbs a boric acid solution with the concentration of 0.2%-0.7%, and polymethyl methacrylate with the boron content of 0.5%-1% is used for packaging. The light gypsum board capable of preventing neutron radiation has good moderation and absorption effects on neutrons, is high in waste utilization rate, environmentally friendly, light in weight, capable of adjusting humidity and high in functionality, and various properties of the light gypsum board meet the requirements of GBT23451-2009 Lightweight Partition Board Standards for Building.

Owner:HUBEI UNIV OF TECH

A kind of phosphogypsum light board prepared by using barium slag and its preparation method

The invention relates to a phosphogypsum light-weight sheet material prepared from barium dreg and a preparation method thereof. The phosphogypsum light-weight sheet material is prepared from the following raw material components in parts by mass: 10 to 20 parts of the barium dreg, 4 to 10 parts of phosphogypsum dihydrate, 60 to 80 parts of phosphorous hemihydrate gypsum, 5 to 15 parts of metakaolin, 1 to 3 parts of carbide slag, 0.5 to 1.2 parts of light aggregate, 0 to 0.1 part of set retarder, 0.1 to 0.3 part of water reducing agent and 0 to 0.1 part of water-retaining agent. The phosphogypsum light-weight sheet material prepared from the barium dreg, provided by the invention, has the advantages of light weight and heat insulation; the volume weight is adjustable in a range of 600 to 1,000Kg / m<3> and the thermal conductivity coefficient is lower than 0.15W / (m*K); the phosphogypsum light-weight sheet material has no obvious layering and cracking and the problem that a traditional cement sheet material is cracked by shrinkage can be effectively overcome by utilizing a micro-expansion property of gypsum hydration; each performance of the prepared light-weight sheet material can meet standards of General Technical Requirements of Light Weight Panel used for Building Partition Wall JGT169-2016.

Owner:WUHAN UNIV OF TECH

A process for preparing ultra-light filler from waste incineration fly ash

ActiveCN106187268BLow running costShort disposal cycleCeramic materials productionCeramicwareWater bathsRoom temperature

The invention relates to a technology for preparing an ultra-light filler from solid waste incineration fly ash. The solid waste incineration fly ash serves as the raw material, shale or pulverized fuel ash serves as the auxiliary material, wood dust or straw or rice hull serves as a pore-forming agent, a small amount of compound heavy metal stabilizer is doped, all the materials are mixed according to certain proportions, and the ultra-light filler which is small in heavy metal leaching rate is prepared through the steps of water adding stirring, water-bath reacting, granulating, drying and sintering. Firing of the filler adopts a rapid sintering schedule without a preheating stage, that is to say, material pellets are suddenly heated to sintering temperature from room temperature, and uniform temperature increasing and the preheating process are not conducted midway. The technology is short in consumed time and high in efficiency, and the prepared filler is light, porous and high in strength. Compared with a conventional solid waste incineration fly ash treatment and disposal way, the technology has the advantages of being low in operation cost, short in disposal period, less in secondary pollution, high in waste utilization rate and the like.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com