High activity mixture slurry with several mineral components and its prepn process

A multi-mineral and admixture technology, applied in the field of building materials, can solve the problems of high-efficiency utilization of waste cement paste, no systematic research reports, low utilization rate of wet-drained fly ash, low water resistance requirements, etc., to reduce one time Sexual resource utilization, significant socio-economic and environmental benefits, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

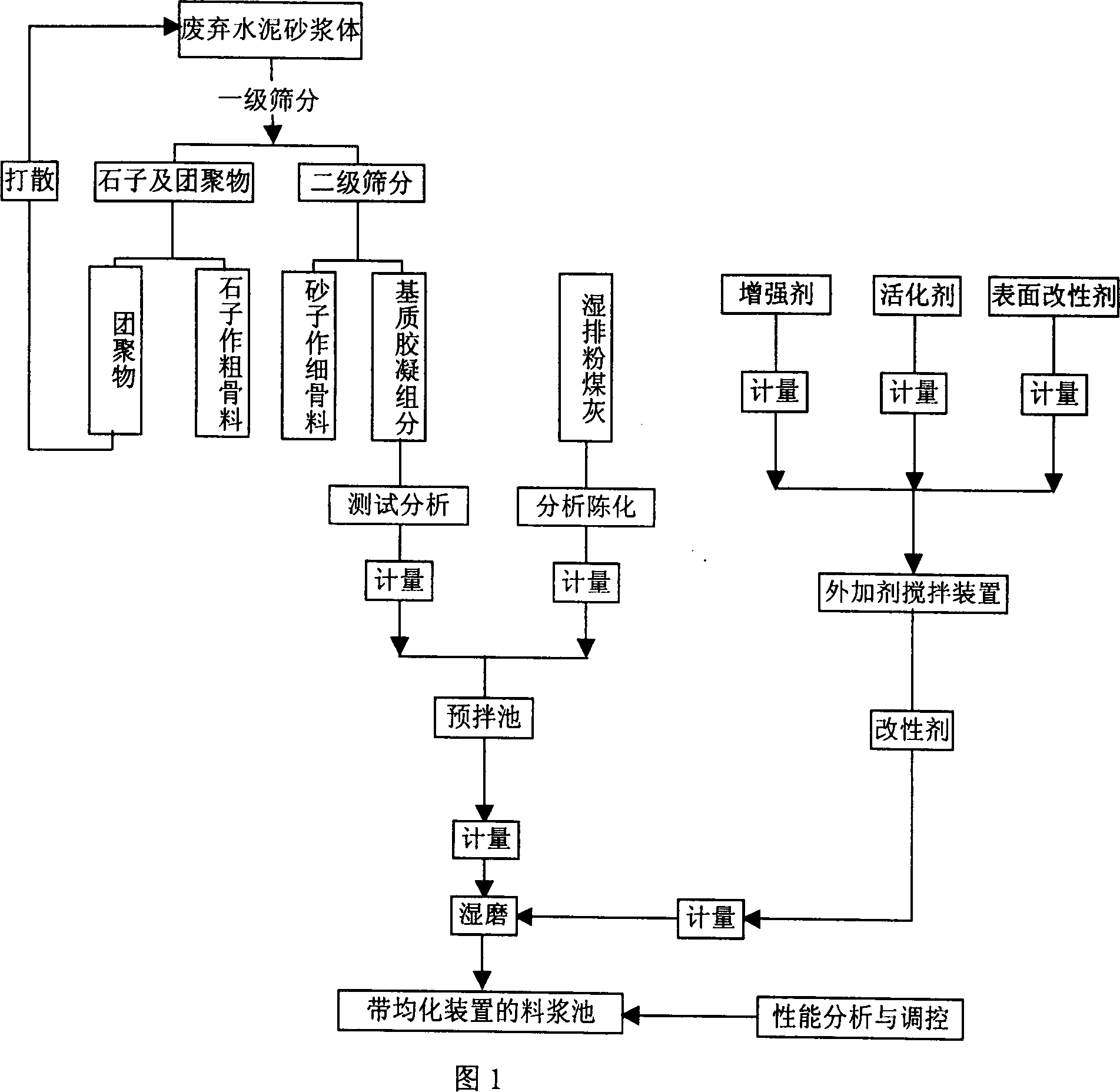

[0027] Embodiment 1: as shown in Figure 1, a kind of highly active multi-mineral component admixture slurry preparation method, it comprises the steps:

[0028] 1) Selection of raw materials: a. Select waste cement paste, measure the actual water content and sand content of the waste cement paste, separate the sand and stone through effective screening, and age the matrix gelling components for future use; The water content of the waste cement slurry is 30-40%, the content of free calcium oxide is ≤2.5%, the content of sulfur trioxide is ≤3%, and the sand content is ≤10%; the Blaine specific surface area is 300-400m 2 / Kg;

[0029] b. Select the wet-discharged fly ash, measure the actual moisture content and carbon content of the wet-discharged fly ash, and age it for later use; the moisture content of the wet-discharged fly ash is 25-35%, and the content of free calcium oxide is ≤2.5%. Sulfur trioxide content ≤ 3%, carbon content ≤ 12%; Blaine specific surface area is 350-40...

Embodiment 2

[0040] A preparation method for highly active mineral admixture slurry, which comprises the steps of:

[0041]1) Selection of raw materials: a. Select waste cement paste, measure the actual water content and sand content of the waste cement paste, separate the sand and stone through effective screening, and age the matrix gelling components for future use; The water content of the waste cement slurry is 30-40%, the content of free calcium oxide is ≤2.5%, the content of sulfur trioxide is ≤3%, and the sand content is ≤10%; the Blaine specific surface area is 300-400m 2 / Kg;

[0042] b. Select the wet-discharged fly ash, measure the actual moisture content and carbon content of the wet-discharged fly ash, and age it for later use; the moisture content of the wet-discharged fly ash is 25-35%, and the content of free calcium oxide is ≤2.5%. Sulfur trioxide content ≤ 3%, carbon content ≤ 12%; Blaine specific surface area is 350-400m 2 / Kg;

[0043] 2) Modifier preparation: accor...

Embodiment 3

[0046] A kind of preparation method of high activity wet row fly ash admixture slurry, it comprises the steps:

[0047] 1) Selection of raw materials: a. Select waste cement paste, measure the actual water content and sand content of the waste cement paste, separate the sand and stone through effective screening, and age the matrix gelling components for future use; The water content of the waste cement slurry is 30-40%, the content of free calcium oxide is ≤2.5%, the content of sulfur trioxide is ≤3%, and the sand content is ≤10%; the Blaine specific surface area is 300-400m 2 / Kg;

[0048] b. Select the wet-discharged fly ash, measure the actual moisture content and carbon content of the wet-discharged fly ash, and age it for later use; the moisture content of the wet-discharged fly ash is 25-35%, and the content of free calcium oxide is ≤2.5%. Sulfur trioxide content ≤ 3%, carbon content ≤ 12%; Blaine specific surface area is 350-400m 2 / Kg;

[0049] 2) Modifier preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com