Patents

Literature

384results about How to "Promotes hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

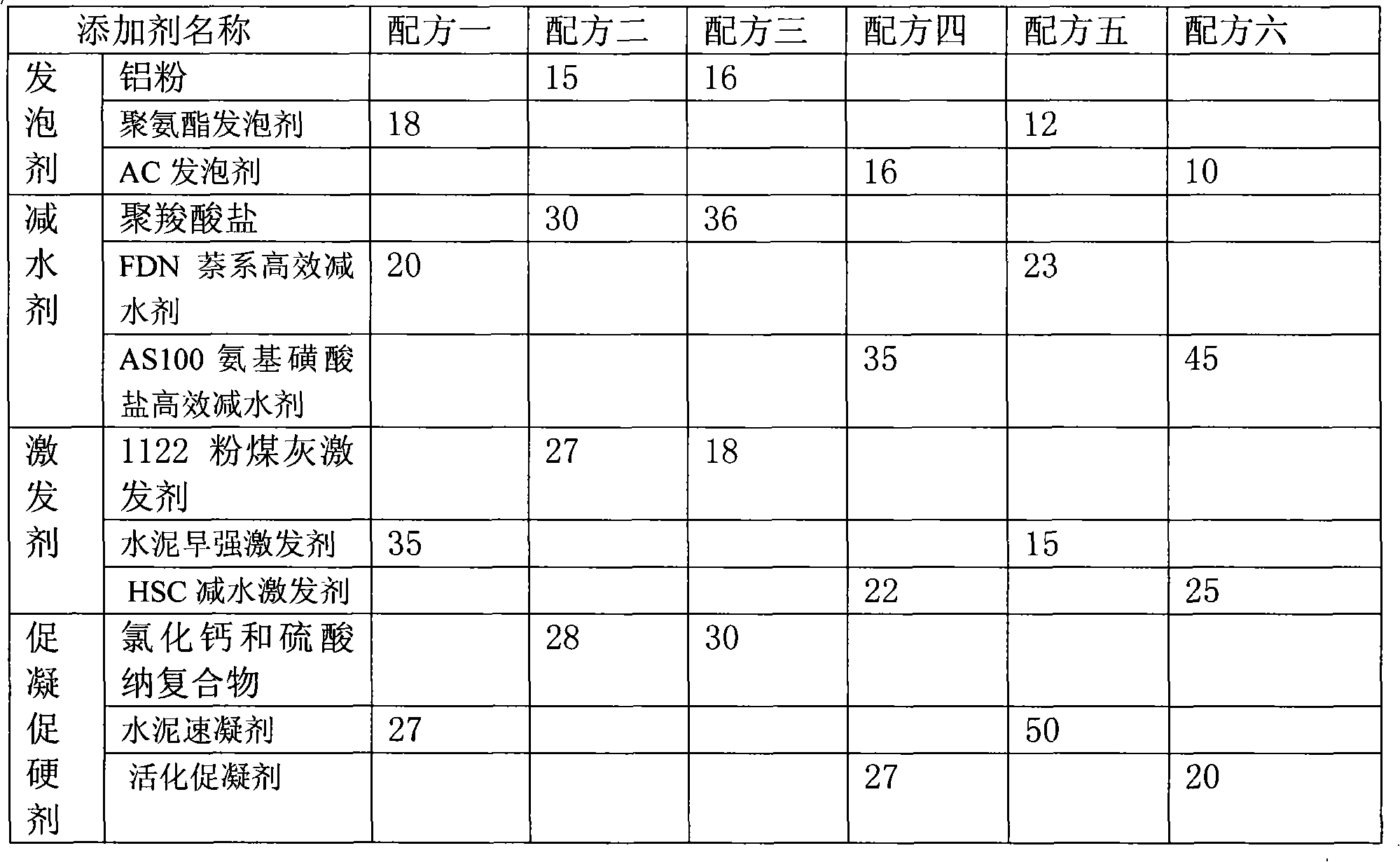

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

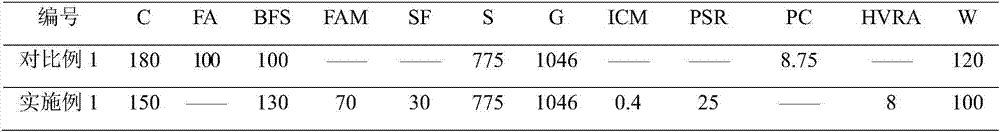

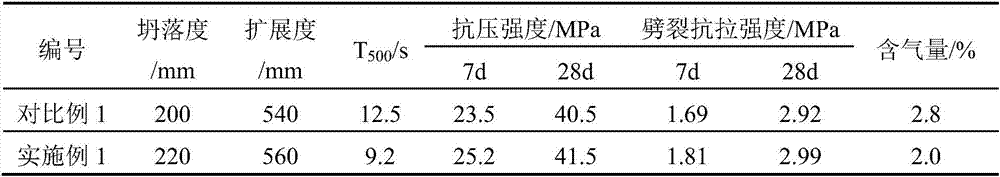

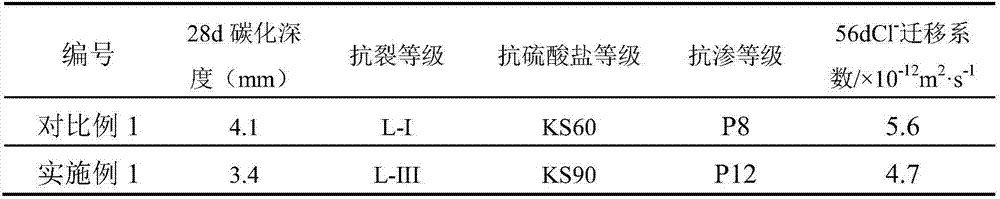

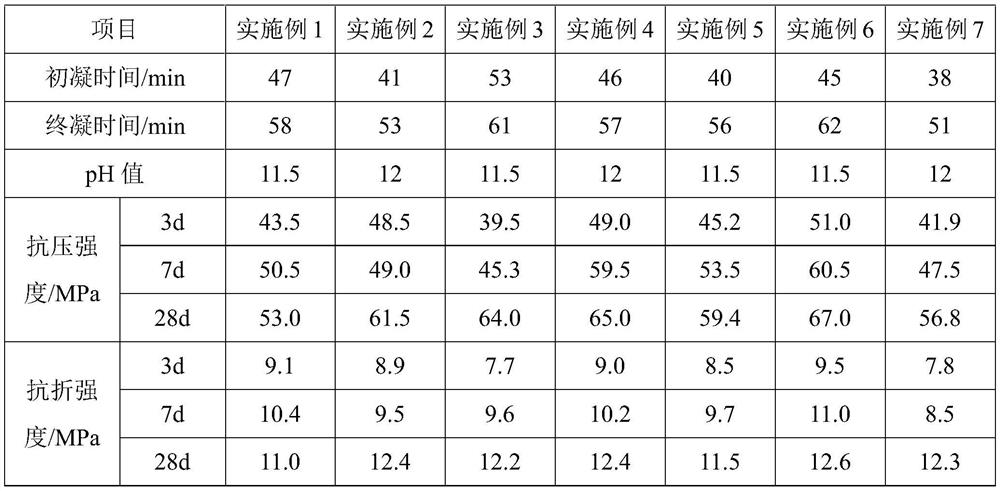

Ground limestone powder full-manufactured sand high-strength recycled self-compacting concrete and application thereof

ActiveCN104724989AHigh strengthImprove workabilitySolid waste managementSuperplasticizerUltimate tensile strength

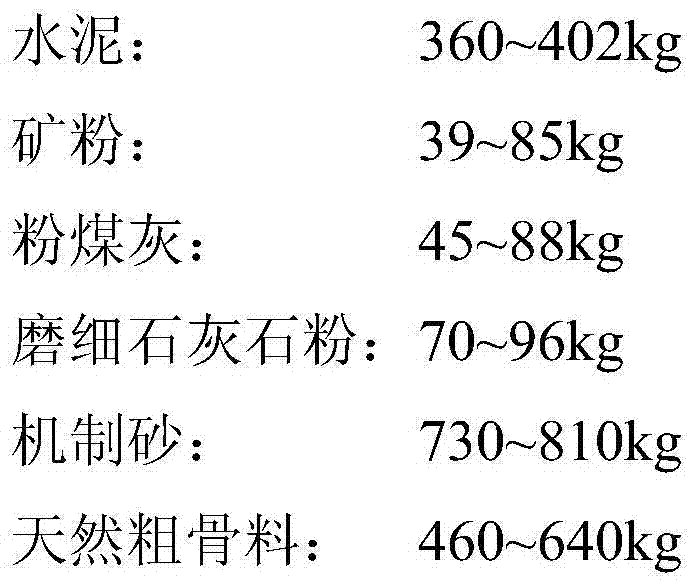

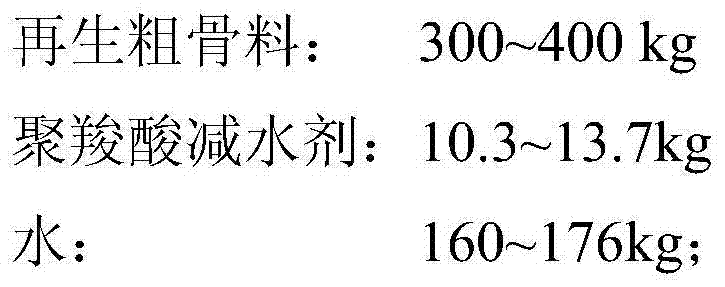

The invention discloses ground limestone powder full-manufactured sand high-strength recycled self-compacting concrete and application thereof. Per cubic meter of concrete contains 360-402kg of cement, 39-85kg of mineral powder, 45-88kg of fly ash, 70-96kg of ground limestone powder, 730-810kg of manufactured sand, 460-640kg of natural coarse aggregate, 300-400kg of recycled coarse aggregate, 10.3-13.7kg of polycarboxylate superplasticizer and 160-176kg of water. According to the full-manufactured sand high-strength recycled aggregate self-compacting concrete prepared from three additives including the ground limestone powder, the fly ash and the mineral powder, the fine aggregate is totally manufactured sand, and 31-46% of recycled coarse aggregate is added to the coarse aggregate, so that an effective path is provided for reducing exploitation and utilization of natural sand and sufficiently recycling concrete wastes, and a technical reference is provided for preparing the ground limestone powder full-manufactured sand self-compacting concrete.

Owner:华润水泥技术研发(广西)有限公司

Sea sand anti-corrosion marine concrete and preparation method thereof

The invention discloses sea sand anti-corrosion marine concrete. By adjusting the proportion of binding materials, cement, mineral powder, silicon ash and fly ash micro-spheres are uniformly distributed, and adsorption of corrosive ions is increased by hydration reaction of high-aluminum minerals and chemical curing of Cl- ions in sea sand. Transmission paths of the Cl- ions in the sea sand and the corrosive ions in a marine environment can be effectively inhibited by pore structure adjustment and corrosive ion transmission inhibitors, and reinforcing steel corrosion is decreased. Micro-expansion and water retention components in internal maintenance materials can effectively avoid cracking of the inside of the concrete due to excessive shrinkage under the moisture coupling action of a marine environment, and the working performance and the compactness of the concrete can be improved by special ball effects of ultra-dispersed shrinkage additives and the fly ash micro-spheres. The sea sand anti-corrosion marine concrete can effectively solve the problem of river sand resource shortage, resource application of the sea sand is realized, and the sea sand anti-corrosion marine concrete more effectively serves a severe marine environment and has an important engineering application value.

Owner:HAINAN RUIZE NEW BUILDING MATERIAL +2

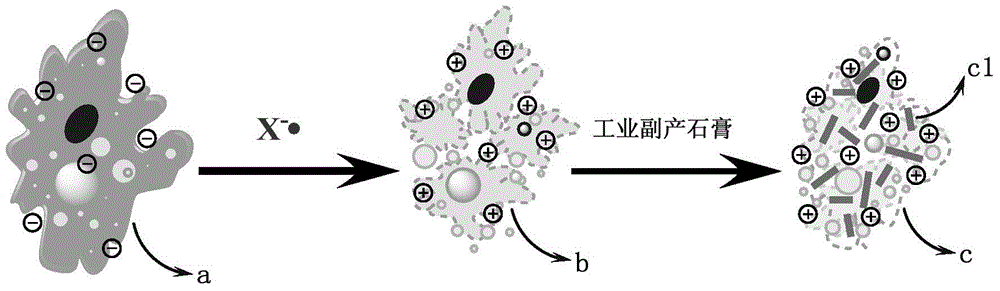

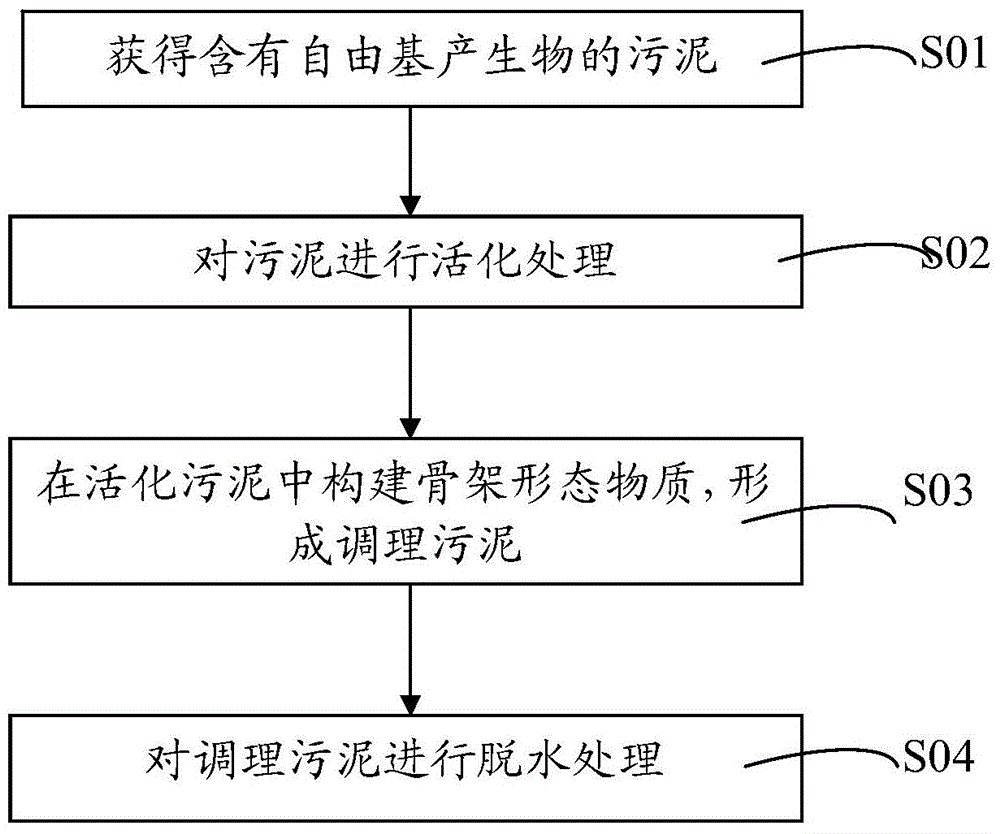

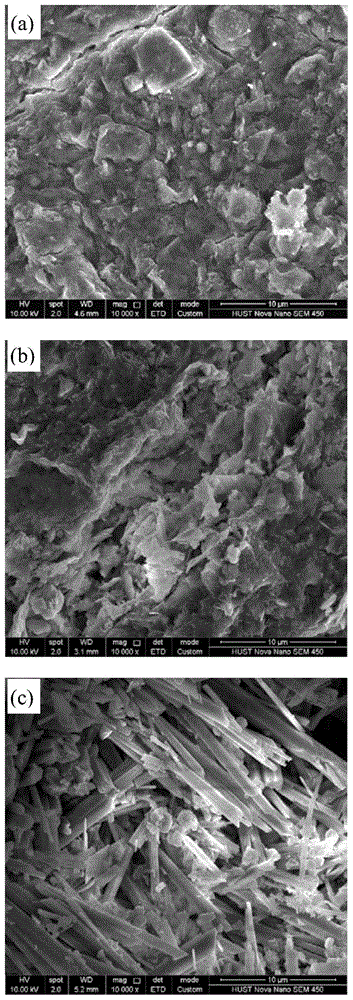

Compound conditioning and deep dewatering method of sludge

ActiveCN104649533AGood conditionSimple processSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationHydration reactionPorosity

The invention provides a sludge deep dewatering method. The sludge deep dewatering method comprises the following steps: obtaining sludge containing a free radical generating substance; adding an activator to the sludge containing the free radical generating substance for activation, thereby obtaining the activated sludge; adding industrial byproduct gypsum to the activated sludge for mixing treatment, thereby forming conditioned sludge containing a new skeleton form substance; and performing dewatering treatment on the conditioned sludge. According to the sludge deep dewatering method, zero-valent iron or nano zero-valent iron is taken as the activator to react with the free radical generating substance to generate active free radicals, and therefore, the extracellular polymeric substance of the sludge can be effectively damaged and the filtering property of the sludge can be improved on one hand, and on the other hand, ions after the activation reaction is completed are capable of directly promoting the industrial byproduct gypsum to perform a hydration reaction, and the new substance morphology of the skeleton form can be controlled; the skeleton structure is capable of remarkably increasing the porosity of the sludge, and therefore, the deep dewatering of the sludge is realized.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

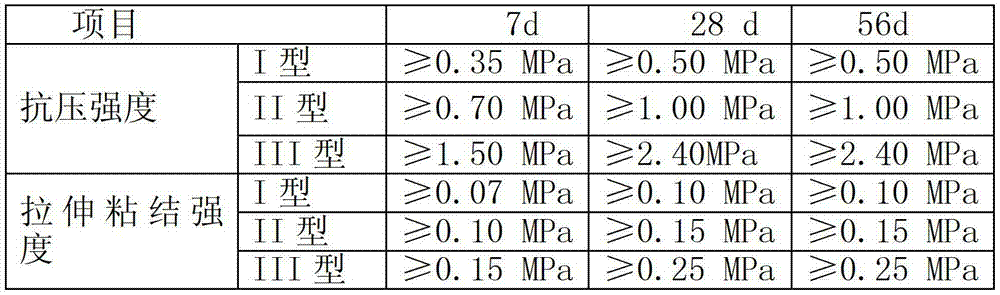

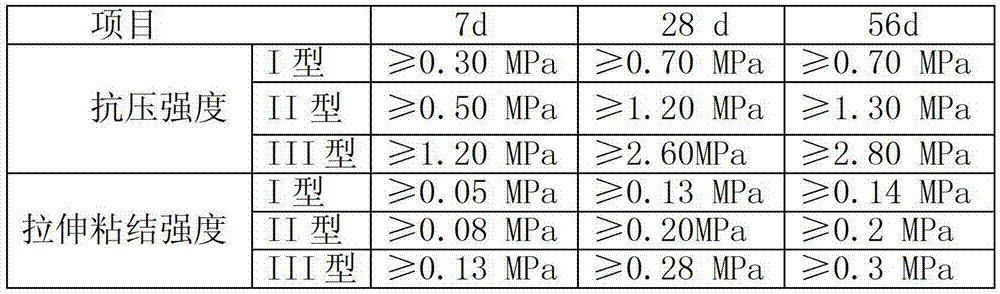

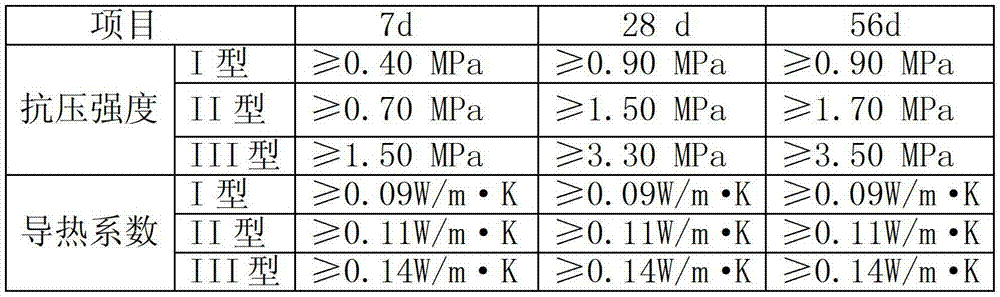

Insulation system with polycrystalline insulation mortar

ActiveCN101851958AEnhanced Penetration Grip InsufficientHigh compressive strengthClimate change adaptationHeat proofingHydroxypropylmethyl celluloseSodium silicate

The invention discloses an insulation system with polycrystalline insulation mortar, which belongs to the technical field of the building material. The insulation system comprises interface mortar, insulation mortar and waterproofing mortar, wherein the insulation mortar comprises the following components: cement, redispersable latex powder, cold water type polyvinyl alcohol, hydroxypropyl-methylcellulose ether, air entraining agents, sodium silicate, inorganic retarder and polystyrene particles. Compared with the prior art, the invention has the following advantages of: 1, solving the problem that the bonding strength of the inorganic cementitious material for penetration is not sufficient, and significantly improving the bonding strength and the compressive strength of the whole insulation system; 2, improving the construction property of the material and the insulation effect of the system; 3, improving the construction property and enhancing the long-term strength of the product;4, improving the waterproofing function of the system, and changing the rigidity of various kinds of polycrystalline mortar into softness, thereby improving the impact resistance, bending resistance,tensile strength, shrinkage resistance and other strain capacities of the insulation system; and 5. improving the bending resistance and the tensile strength of the material and the physical anti-cracking performance of the system.

Owner:HAIDA CONSTR GRP

Method for producing silicate product by using molybdenum tailings and hydrothermal method

InactiveCN101456704AImprove product qualityReduce energy consumptionSolid waste managementCeramicwareSoil conservationWaste recycling

The invention discloses a method for manufacturing a silicate product under hydrothermal condition of molybdenum tailings. The silicate product comprises an autoclaved aerated concrete building block or a slab, a steamed silicate brick, an autoclaved sand lime brick and a calcium silicate slab. The method for manufacturing the silicate product comprises the following steps: evenly mixing raw materials such as the molybdenum tailings, lime, gypsum and the like according to a proportion, shaping the mixture, and then producing the silicate product such as the aerated concrete building block, the brick, the slab and the like under the hydrothermal condition of vapor pressing or steaming, wherein the vapor pressing is carried out for 4 to 10 hours at a constant temperature of between 175 and 210 DEG C, and the steam pressure is 1.0 to 1.3MPa; and the steaming is carried out for 24 to 48 hours at a constant temperature of between 70 and 100 DEG C. The method uses the molybdenum tailings to change waste into valuable. The silicate product has the advantages of high strength, soil conservation, energy conservation, environmental protection, waste recycling and the like, and has remarkable economic benefit and social benefit.

Owner:SOUTH CHINA UNIV OF TECH

Steel scoria tail mud composite slag micro mist agglutination material

InactiveCN101492261APromote sustainable economic developmentEliminate slag damageSolid waste managementSlagBall mill

The invention relates to a cementing material of steel slag tailings and composite slag micro powder, which comprises the composite slag micro powder and the steel slag tailings, and the weight ratio of the composite slag micro powder to the steel slag tailings is between 1 to 1 and 1 to 3; the specific surface area of the composite slag micro powder is larger than 350 m / kg, the composite slag micro powder comprises a combined material and the slag micro powder, wherein the combined material accounts for 8 to 35 percent of the composite slag micro powder by weight, and the slag micro powder accounts for 65 to 92 percent of the composite slag micro powder by weight; and the combined material comprises gypsum. The cementing material has the advantages that: 1, the method is an effective method utilizing large amount of waste slag; 2, the raw material of the composite slag micro powder has wide source; 3, the steel slag tailings are natural-grade tailings after steel slag wet-type ball milling magnetic separation particles are toughened, and the settled tailings do not need to be dried and are directly used as an auxiliary material; and 4, the steel slag tailings account for large proportion, and can fully utilize waste slag resources.

Owner:武钢集团有限公司

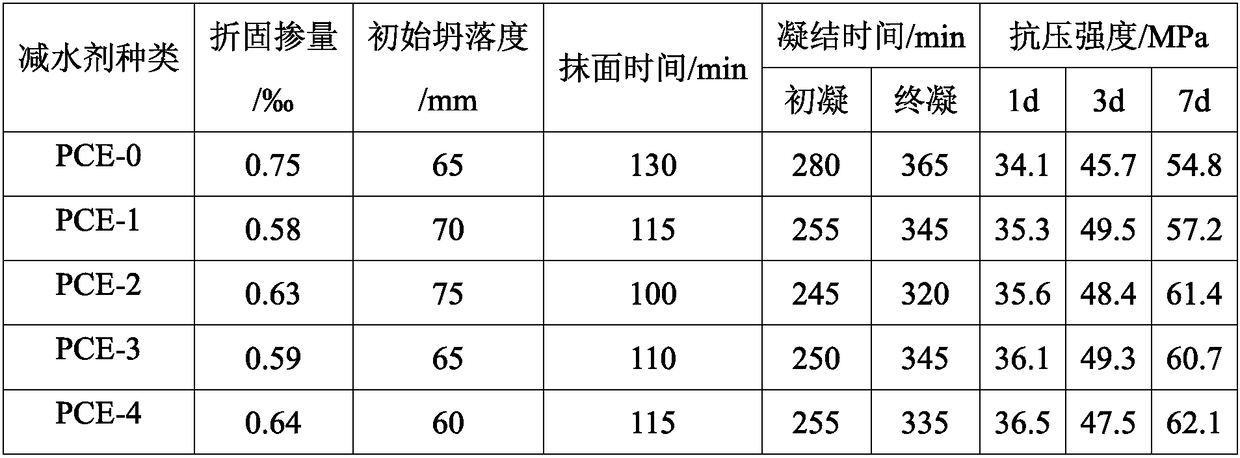

Rapid-hardened super-early strength polycarboxylate water reducer and preparation method thereof

The invention discloses a rapid-hardened super-early strength polycarboxylate water reducer and a preparation method thereof. According to the rapid-hardened super-early strength polycarboxylate waterreducer disclosed by the invention, by using a molecular cutting technique, molecular structures of main chain groups, side chain groups and the like are designed, a polyether monomer of a super-highmolecular weight is adopted as an active large monomer, a structure with a long side chain and a short main chain is formed by molecular chains, a small monomer of self-made unsaturated alcohol aminoester and small monomers such as ethyl methacrylate with N groups and triallylamine are introduced, and solution polymerization is carried out at a low temperature. The synthesized polycarboxylate water reducer has an outstanding function of promoting cement hydration reactions, can be applied to steam-curing concrete, low-temperature environment concrete and concrete with a requirement of demolding in advance, is capable of remarkably shortening the plastering and primary curing time of a molded plate, has a remarkable early strength effect, and is capable of accelerating the construction progress of concrete and increasing the transfer rate of mold plates.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Polycrystal inorganic lightweight aggregate thermal insulation mortar

InactiveCN103172314AImprove the defect of insufficient penetration gripImprove adhesionThermal insulationEther

The invention discloses a polycrystal inorganic lightweight aggregate thermal insulation mortar. The polycrystal inorganic lightweight aggregate thermal insulation mortar comprises cement, redispersible latex powder, hydroxymethyl propyl cellulose ether,air entraining agent, organosilicone water repellent, closed perlite or glass beads. 98% of the thermal insulation mortar is an inorganic incombustible material; the thermal insulation mortar has integrative functions of heat insulation, decoration, fire retardance, water retardance, climatic change resistance and the like; moreover, the process is simple and easy to operate; quality problems caused by construction technique can be reduced; the development cost is lowered; and large-range promotion and application are promoted.

Owner:HAIDA CONSTR GRP

Admixture for vegetation-form ecological concrete and compounding method thereof

The invention discloses an admixture for vegetation-form ecological concrete and a compounding method thereof, which relate to the technical field of cement concrete admixtures. The admixture is compounded by, by weight, calcium carbonate 5-10 parts, silica powder 40-50 parts, lignosulfonic acid 5-8 parts, sodium nitrite early strength agent 1-3 parts, hydroxy carboxylic acid high-efficiency water reducing agent 1-3 parts, polyacrylamide water-retaining agent 0.3-0.4 part and dodecyl sodium sulfate air entraining agent 0.01-0.02 part. The admixture compounded by the components is added into the vegetation-form ecological concrete so that the admixture can improve the mechanical strength and durability of the concrete, controls and ensures water permeability, porosity, homogeneity and the like of the concrete, and improves chemical resistance, potential of hydrogen, biocompatibility and other functions of the inside and the surface of the concrete.

Owner:NANTONG INST OF TECH

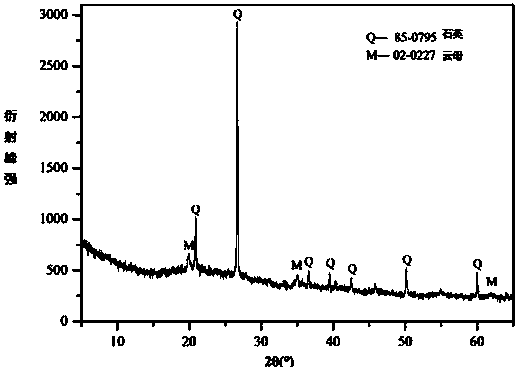

Method for manufacturing silicate product by ceramic waste hydrothermal process

InactiveCN101255037AHigh strengthGood performanceSolid waste managementCeramic particleHigh intensity

The invention discloses a method for preparing silicate products under the hydrothermal conditions of ceramic wastes. The silicate products mainly refers to autoclaved aerated concrete blocks or plates, autoclaved sand-lime bricks, autoclaved silicate pipe pile prefabricated parts and autoclaved silicate bricks. The method includes: evenly mixing waste ceramic particles and powder with raw materials such as lime and gypsum in proportion; preparing silicate products such as aerated concrete blocks, bricks, plates and prefabricated parts under autoclaved or steam curing hydrothermal condition. The autoclave is for 4-10 hours at a constant temperature of 175-210 DEG C and under the vapor pressure of 1.0-1.3 Mpa; steam curing is to steam cure 24-48 hours at a constant temperature of 70-100 DEG C. The invention makes good use of the waste of ceramics generated in the process. The silicate products has advantages of high intensity, saved soil and energy, environmental friendliness and waste-utilization and has remarkable economic benefit and social effect.

Owner:SOUTH CHINA UNIV OF TECH

Insulation system with polycrystalline anti-cracking and waterproofing mortar

InactiveCN101851960AImprove the defect of insufficient penetration gripImprove adhesionHeat proofingInsulation systemReducing agent

The invention discloses an insulation system with polycrystalline anti-cracking and waterproofing mortar, which belongs to the technical field of the building material. The insulation system comprises interface mortar, insulation mortar and waterproofing mortar, wherein the waterproofing mortar comprises the following components: cement, sand, redispersable latex powder, hydroxypropyl-methyl cellulose ether, inorganic water reducing agent, organosilicon waterproofing agent, sodium silicate and inorganic retarder. Compared with the prior art, the invention has the following advantages of: 1, solving the problem that the bonding strength of the inorganic cementitious material for penetration is not sufficient, and significantly improving the bonding strength and the compressive strength of the whole insulation system; 2, improving the construction property of the material and the insulation effect of the system; 3, improving the construction property and enhancing the long-term strength of the product; 4, improving the waterproofing function of the system, and changing the rigidity of various kinds of polycrystalline mortar into softness, thereby improving the impact resistance, bending resistance, tensile strength, shrinkage resistance and other strain capacities of the insulation system; and 5. improving the bending resistance and the tensile strength of the material and the physical anti-cracking performance of the system.

Owner:HAIDA CONSTR GRP

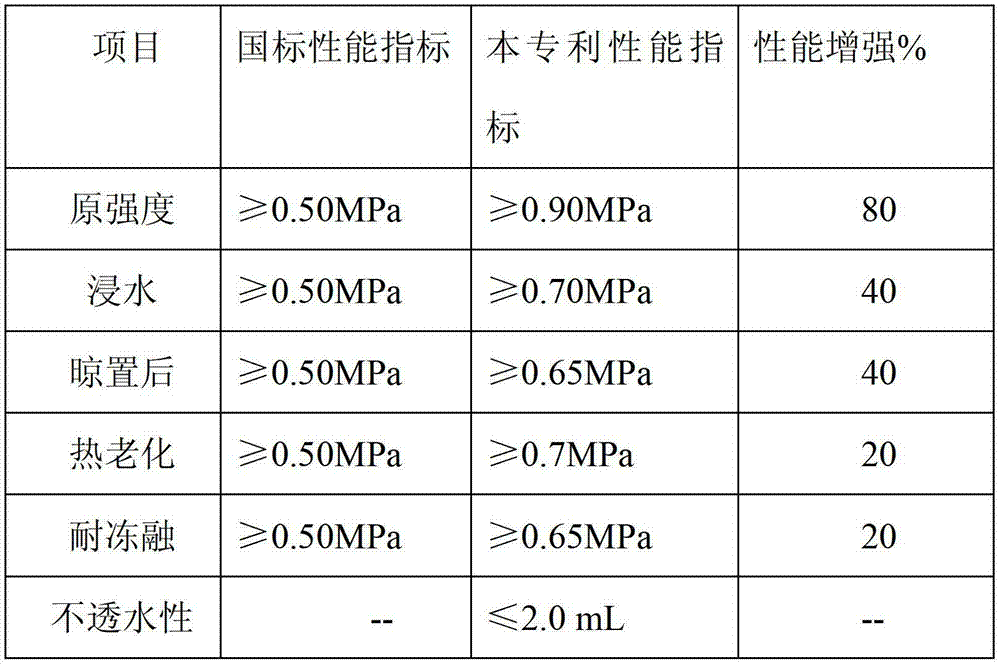

Green rapid-hardening early-strength magnesium phosphate-based healant and preparation method thereof

ActiveCN104909709AImprove compactnessHigh impermeability levelSolid waste managementSilica fumeMagnesium orthophosphate

The invention discloses a green rapid-hardening early-strength magnesium phosphate-based healant and a preparation method thereof. The green rapid-hardening early-strength magnesium phosphate-based healant is composed of a material A and a material B; the material A is prepared via mixing of a phosphate, borax, a toughening ingredient, an accelerating component, a water retention ingredient, a water reducing ingredient, and a grinding aid dispersing agent; and the B material is prepared via mixing of magnesium oxide, flyash, silica fume, ground steel slag, chromium iron tailing slag powder, anhydrite, an expanding agent, and a grinding aid dispersing agent. According to the preparation method, industrial supplementary cementious materials (flyash, silica fume, and ground steel slag) are added into cement, so that cement fluidity and early strength are improved; industrial chromium iron tailing slag powder is added into the green rapid-hardening early-strength magnesium phosphate-based healant as a filling material, so that it is beneficial for cement hydration reaction, set cement compaction rate is increased, and at the same time heavy metal waste solidification is realized. The green rapid-hardening early-strength magnesium phosphate-based healant is capable of achieving balance between magnesium phosphate cement setting time and high early strength, and solving problems that shrinking percentage is large and bonding strength is low.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Inorganic cured foam material for surface leaking stoppage of shallow buried coal seam mining area and preparation method of inorganic cured foam material

InactiveCN103396154APromotes hydrationImprove foam production efficiencySolid waste managementCeramicwareFiberCopper oxide

The invention discloses an inorganic cured foam material for surface leaking stoppage of a shallow buried coal seam mining area and a preparation method of the inorganic cured foam material, which belong to the inorganic cured foam material and the preparation method thereof. The leaking-stoppage cured foam comprises water, coal ash, slaked lime, cement, ox horn powder, aluminum powder, copper oxide, polyphosphoric acid, aluminum hydroxide, hydroxypropyl methyl cellulose and steel fiber. The preparation method of the inorganic cured foam material comprises the following steps of: firstly, adding the coal ash, the cement, the hydroxypropyl methyl cellulose, the steel fiber and the slaked lime in water to form a coal ash substrate serous fluid; secondly, adding the ox horn powder into a little water for stirring to form prefabricated mucus, and sufficiently stirring the coal ash substrate serious fluid and the prefabricated mucus to form a mixed solution; thirdly, adding an inorganic adhesive system into the mixed solution and sufficiently stirring to form a mixed adhesive solution; and finally, adding the aluminum powder for sufficiently stirring uniformly, foaming the serious fluid by utilizing an organic self-foaming system, and preparing the inorganic cured foam material for surface leaking stoppage of the shallow buried coal seam mining area. According to the invention, the seam infiltration capacity is strong, the compressive strength is large, the high temperature resistance and the heat insulation performance are good, and the substrate is purely inorganic and pollution-free.

Owner:CHINA UNIV OF MINING & TECH +1

Early strength cement grout with low dehydration ratio for grouting

InactiveCN101628800AGuaranteed suspension stabilityImprove resistance to water dilutionSlurrySuspending Agents

The invention discloses early strength cement grout with low dehydration ratio for grouting. The stable early strength cement grout for pre-grouting of coal mineshaft surface comprises the following components in part by weight: 100 parts of silicate cement, 80-120 parts of water, 10-40 parts of suspending agent, 1 part of inorganic sodium salt and 0.03-0.1 part of organic alcohol early strength agent. The cement grout utilizes physical and chemical functions of composite admixture, improves the suspending stability of the cement grout and the early compression strength of a concretion body, improves the flow deformation feature and the movable shearing force of the grout and realizes controllable grout diffusion distance.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Polycrystal flexible tile joint mixture

InactiveCN103172332AImprove the lack of penetration and gripHigh compressive strengthHydroxypropylmethyl celluloseAluminium

The invention discloses a polycrystal flexible tile joint mixture. The polycrystal flexible tile joint mixture comprises cement, bauxite cement, quartz sand, redispersible latex powder, organosilicone water repellent, hydroxymethyl propyl cellulose ether, coarse whiting and bentonite. The polycrystal flexible tile joint mixture has high bonding strength, has microdilatancy function, can effectively resist production of shrinkage cracks in construction, and prevents leakage.

Owner:HAIDA CONSTR GRP

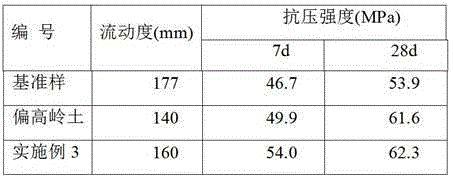

High-activity modified metakaolin-based mineral admixture for concrete and preparation method for mineral admixture

The invention relates to a high-activity modified metakaolin-based mineral admixture for concrete and a preparation method for the mineral admixture. The high-activity modified metakaolin-based mineral admixture for the concrete is prepared by mixing metakaolin and a composite modifying agent according to the mass ratio of 200:1 to 20:1, wherein the composite modifying agent is prepared by mixing 50 to 85 mass percent of stearic acid, 8 to 25 mass percent of calcium stearate and 7 to 25 mass percent of dimethyl silicone oil based on 100 mass percent. The high-activity modified metakaolin-based mineral admixture for the concrete and the preparation method for the mineral admixture have the advantages that 1) the early strength of the concrete can be remarkably strengthened; 2) the working performance of the concrete can be remarkably improved; 3) the osmosis resistance of the concrete can be improved; and 4) the mineral admixture is highly adapted to various kinds of cement and concrete additives.

Owner:WUHAN UNIV OF TECH +2

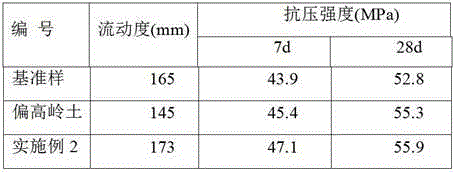

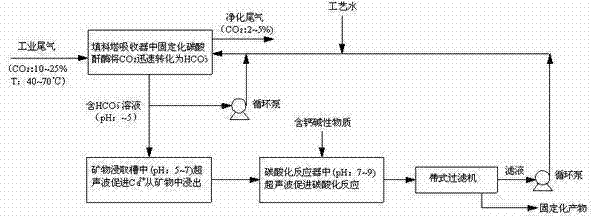

Method and device for immobilizing CO2 by enhancing mineral carbonation

InactiveCN102343199AFast catalytic reaction ratePromotes hydrationDispersed particle separationUltrasound - actionSlurry

The invention discloses a method and device for immobilizing CO2 in industrial tail gas by enhancing mineral carbonation. The device comprises a packed column absorber, a mineral leaching tank, a carbonation reactor and a belt type filter. The method comprises the steps of: enabling the industrial tail gas containing CO2 to enter the packed column absorber filled with immobilization carbonic anhydrase, rapidly transforming the CO2 into HCO3<-> under the catalysis action of the carbonic anhydrase; with a weak acidic solution containing the HCO3<-> as a mineral leaching agent, effectively leaching calcium ions from minerals in the mineral leaching tank under the action of ultrasonic waves to form a slurry enriching Ca<2+>; introducing the slurry enriching Ca<2+> into the carbonation reactor, adding a calcium-containing alkali material, regulating the pH of the slurry to be 7-9 to ensure that the HCO3<-> is transformed into CO3<2->, and generating a carbonation reaction with the Ca<2+> leached from the minerals to generate CaCO3. The invention can promote the CO2 to be rapidly transformed into the HCO3<->, can promote the calcium ions to be leached from the minerals and the carbonation reaction, and further realizes that the CO2 in the industrial tail gas is immobilized through direct carbonation under normal pressure.

Owner:SOUTHEAST UNIV

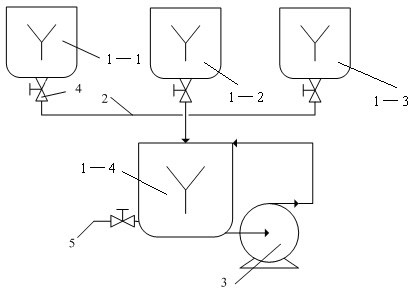

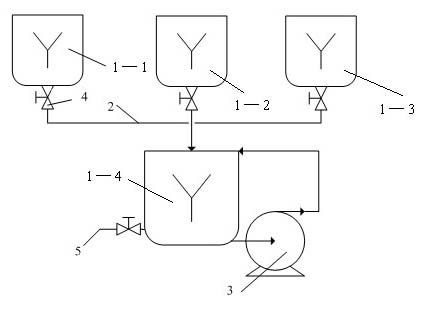

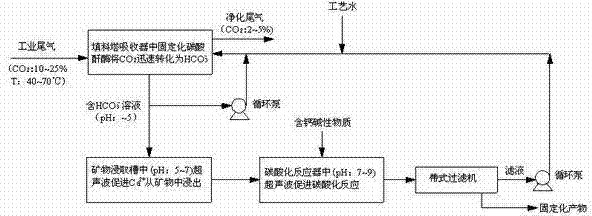

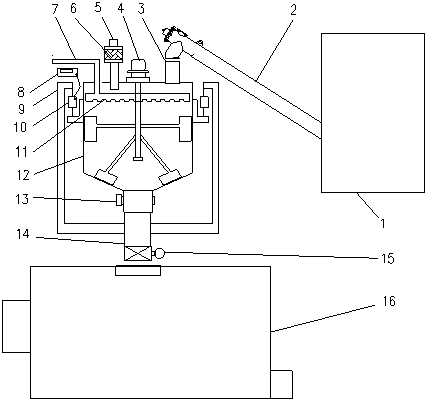

Dust-free concrete production device and production process of dust-free concrete

The invention provides a dust-free concrete production device which comprises a water supply system, a slurry blender, a concrete blender, a weight sensor and a blender bracket, wherein a blending mechanism, a dust filtering device, an air outlet, a powder material input opening, a water inlet and a material discharge opening are arranged on the slurry blender; the dust filtering device covers at the air outlet of the slurry blender; a dust absorbing material is arranged in the dust filtering device; a weight display device is connected with the weight sensor; the slurry blender is hung on the blender bracket through the weight sensor; the concrete blender is arranged below or at the remote end of the slurry blender; after being blended, the slurry is conveyed to the concrete blender from the material discharge opening to be blended into concrete continuously. The slurry blender is provided with the dust filtering device, so that the phenomenon of dust over-flow during the production process is solved thoroughly, and the environment in the machining field is improved; the ingredients of the slurry are weighed and measured accurately; the working efficiency in concrete blending is improved; and the slurry blender blends the slurry more uniformly, thereby being beneficial for the improvement of the quality of the concrete.

Owner:徐州永腾建材有限公司

Curing agent in concrete and preparation method and use method thereof

The invention discloses a curing agent in concrete, which comprises the following components: hydroxyl starch, starch grafted hydroxyethyl methacrylate, methyl cellulose, polyacrylamide, lignin sulfonate and aqua is preferred, wherein alcohol can be also added in as co-solvent. The curing agent in concrete has small admixture amount, is convenient to use, has very strong water absorbing and conserving capability in the concrete and blocks the water in the concrete from being evaporated externally; and even if the concrete is not cured by the water (moisture) from the outside environment after being cast, gelled material can have good hydration reaction, thereby greatly improving the strength of the concrete, reducing dryness and shrinkage, and preventing cracking.

Owner:广西红墙新材料有限公司

Polycrystal flexible tile binder

The invention discloses a polycrystal flexible tile binder. The polycrystal flexible tile binder comprises cement, quartz sand, redispersible latex powder, organosilicone water repellent, hydroxymethyl propyl cellulose ether, sodium silicate, slag powder and coarse whiting. The polycrystal flexible tile binder has the advantages of small plasticity, good construction performance, ageing resistance, permeability resistance, waterproofness, internal stress resistance, acid and alkaline corrosion resistance and the like.

Owner:HAIDA CONSTR GRP

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

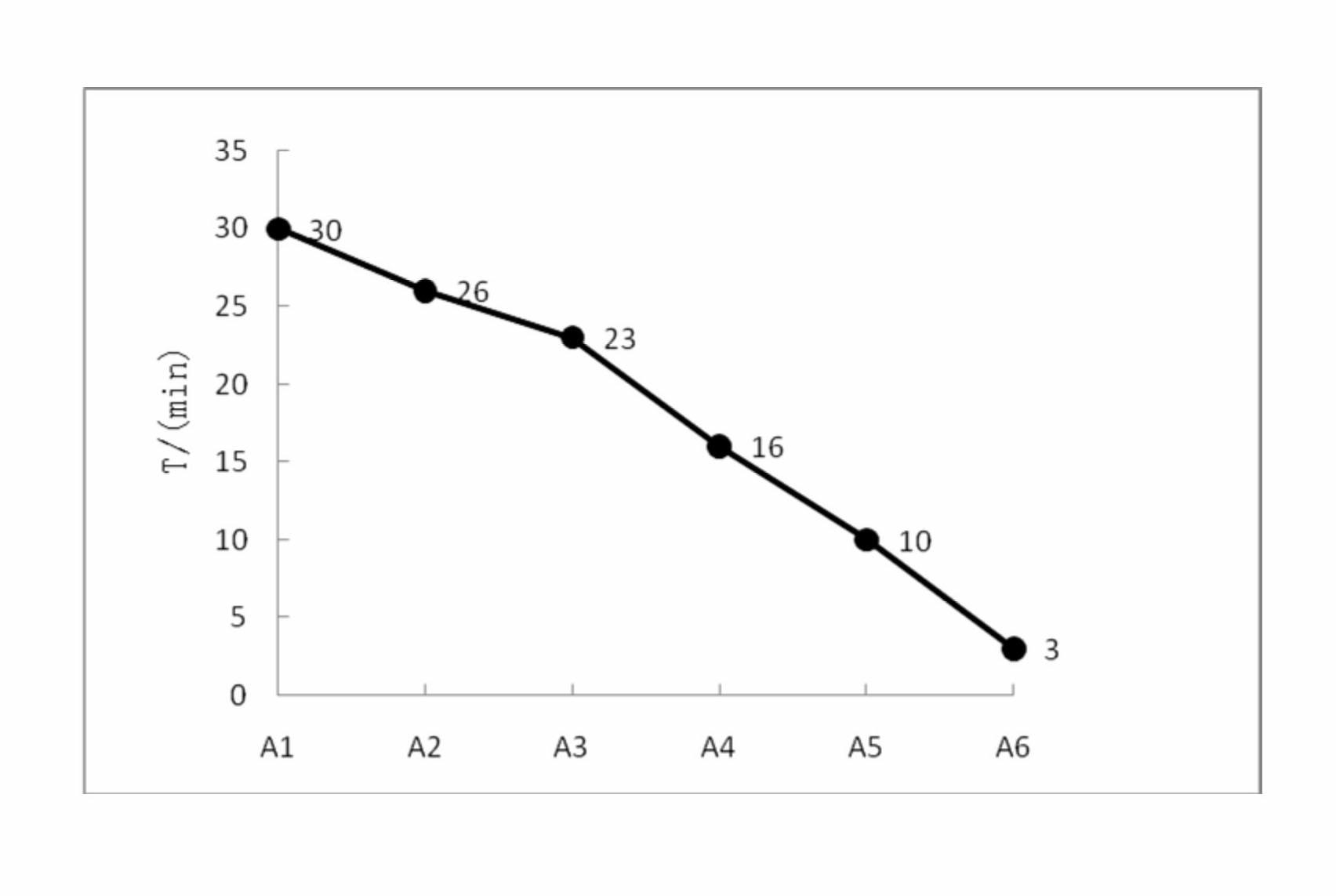

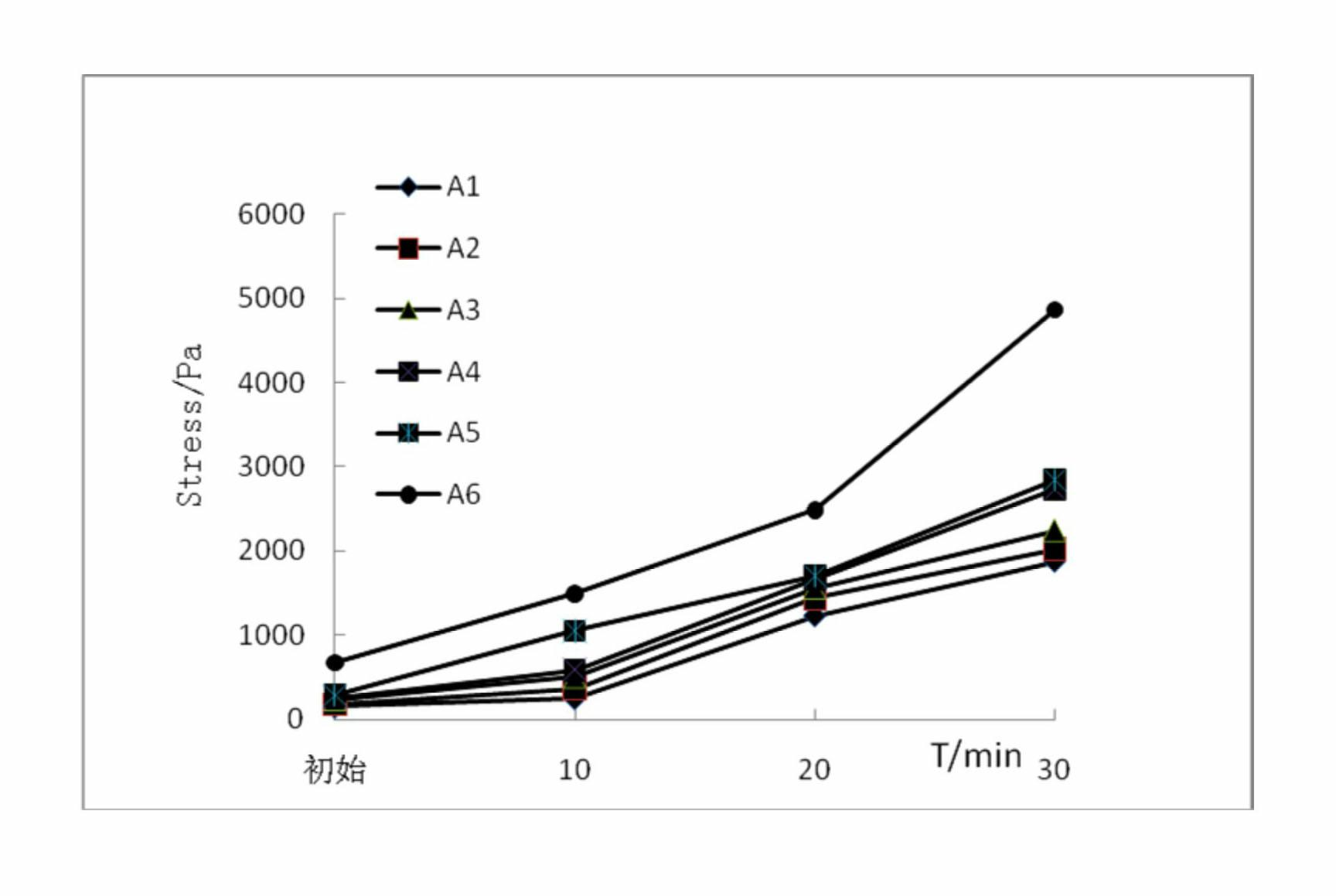

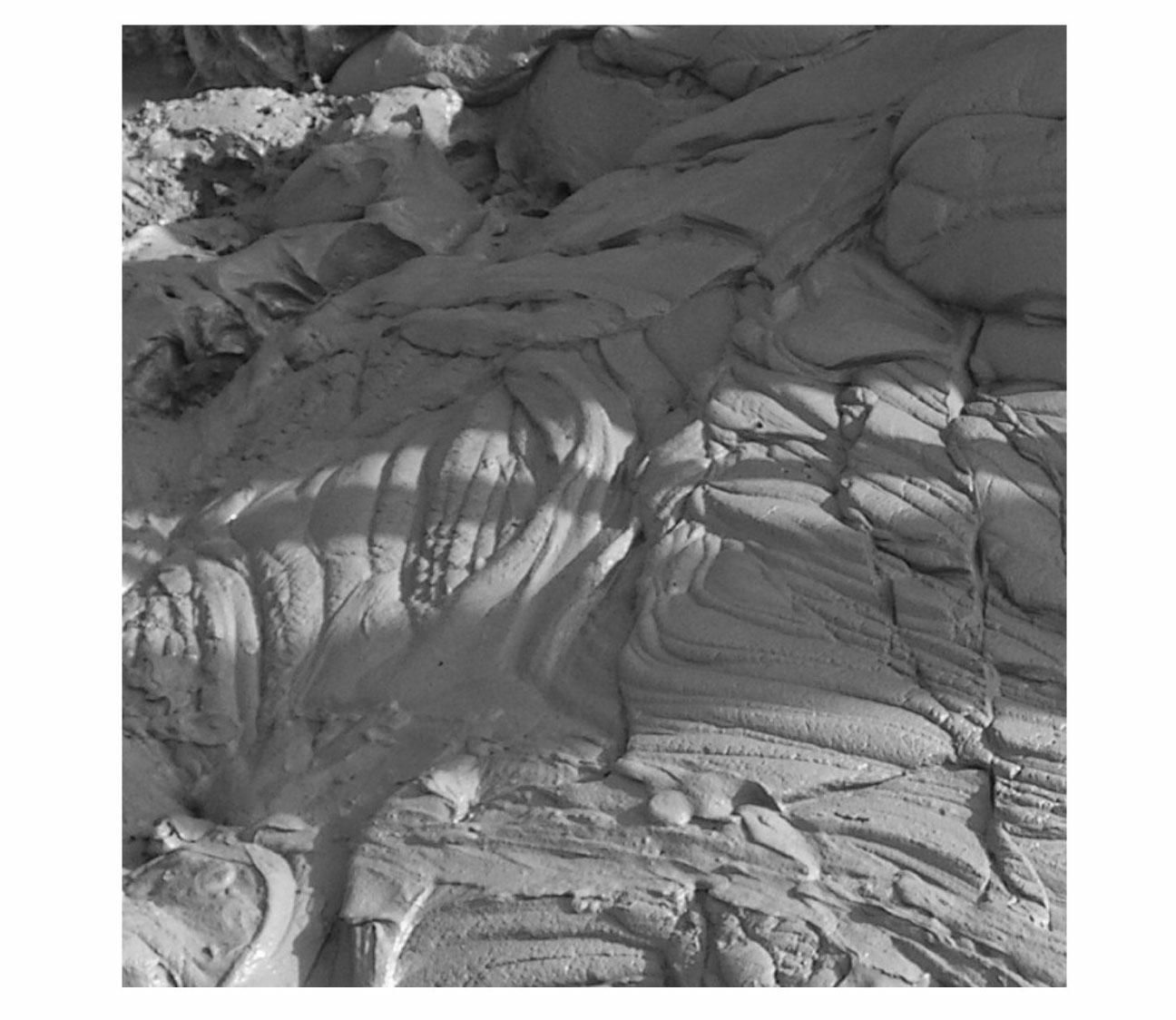

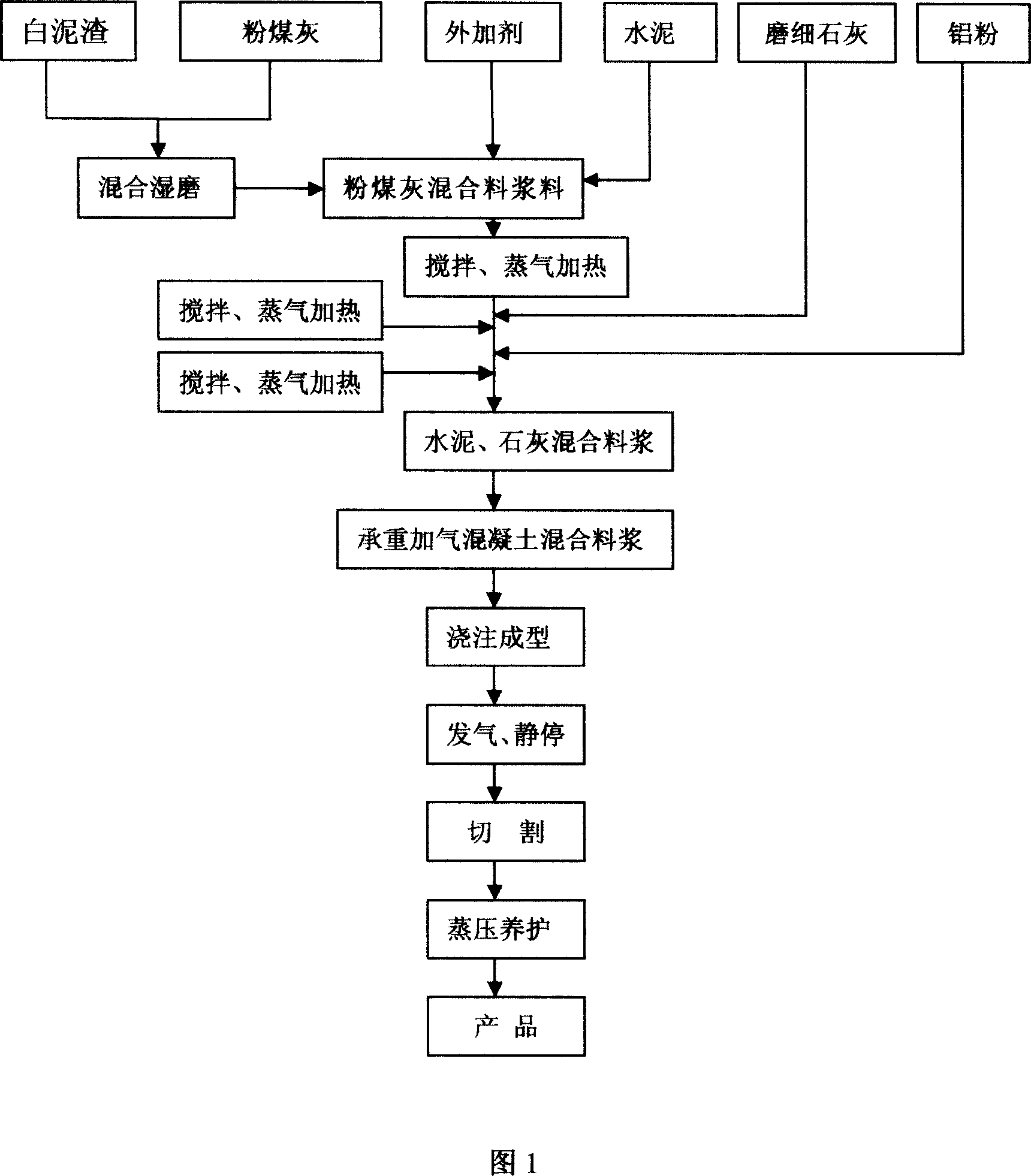

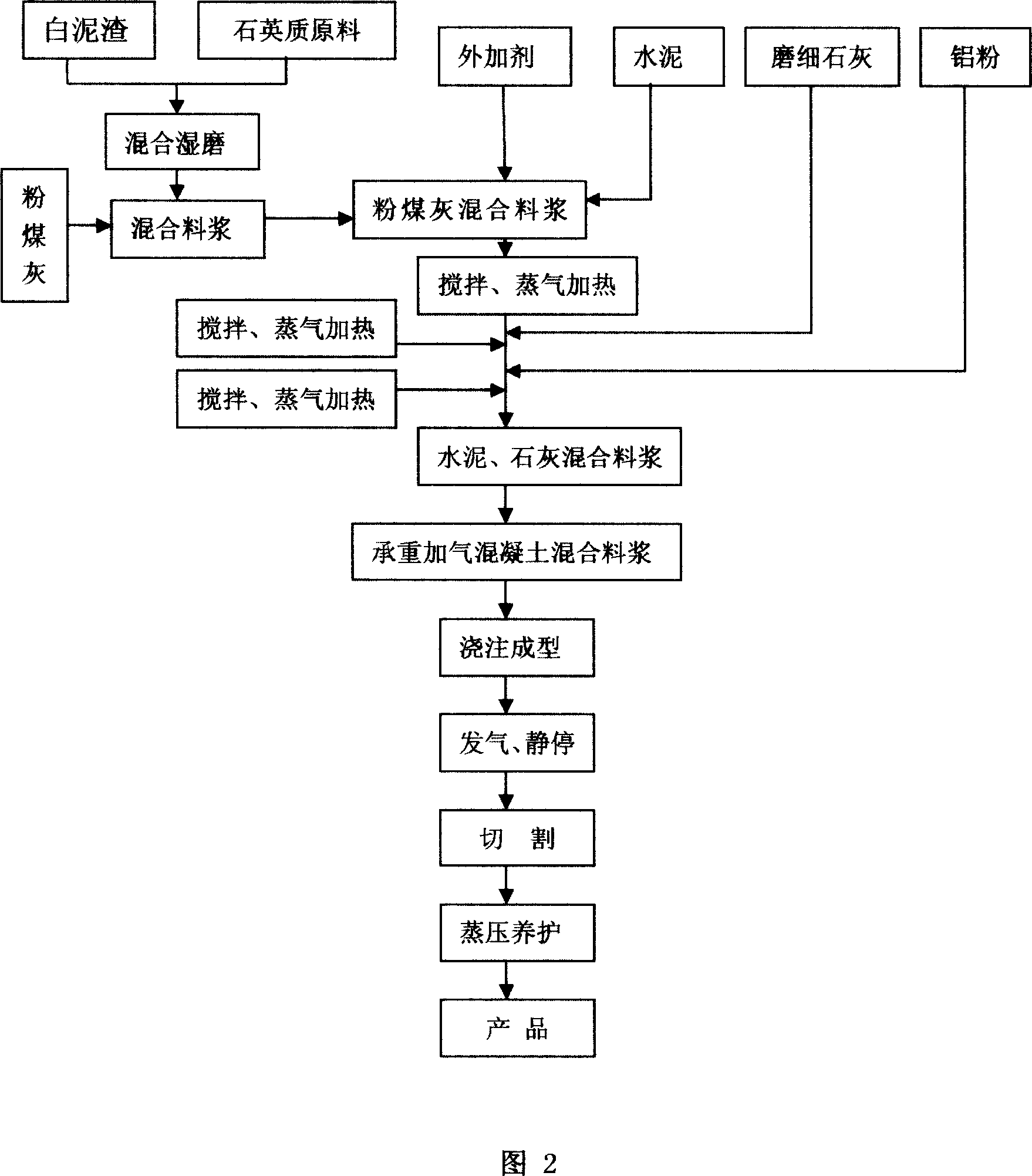

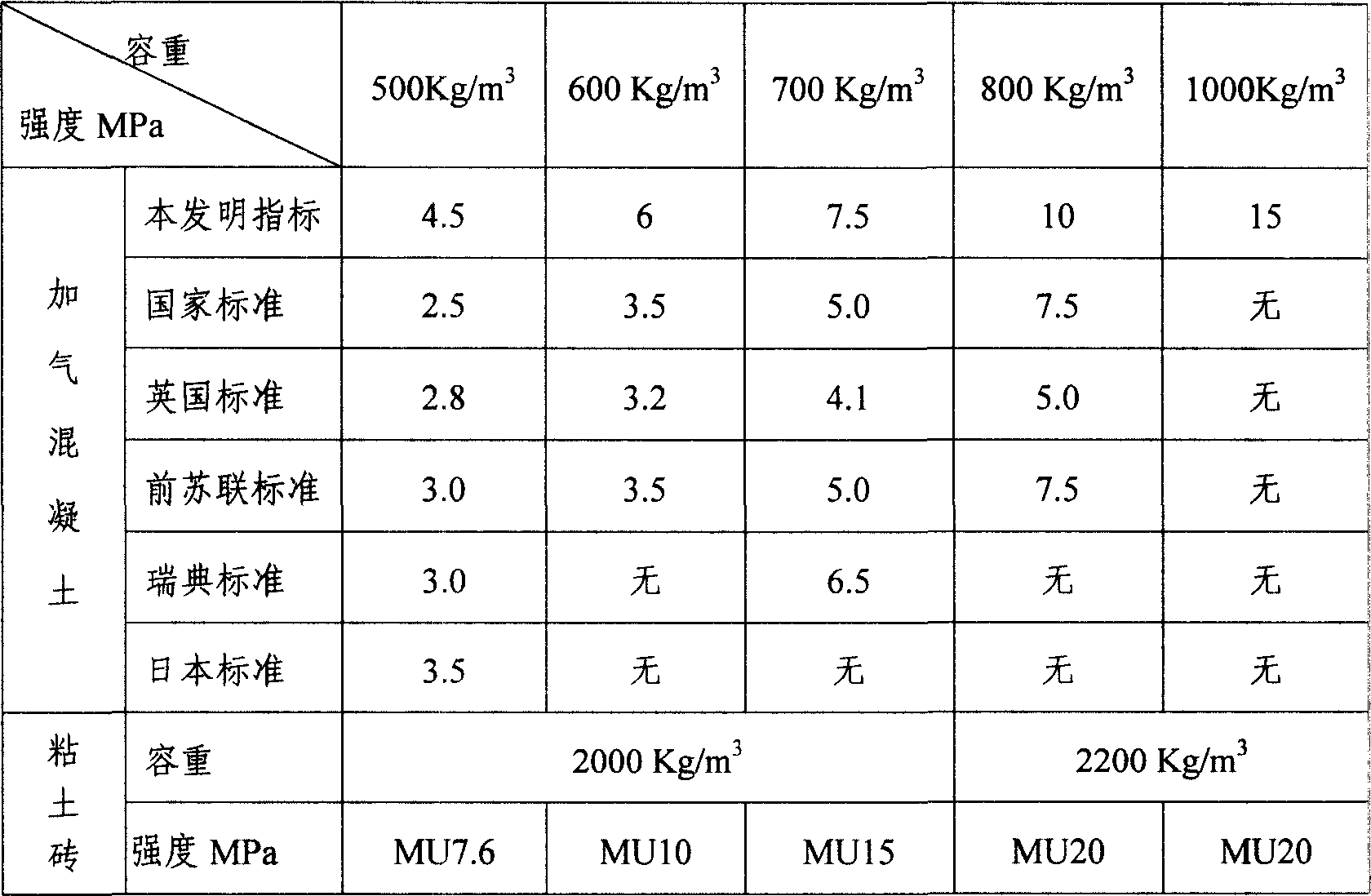

Method for preparing bearing steam-pressing aero-concrete using chemical clay-slag

InactiveCN1954983AImprove finenessPromotes hydrationSolid waste managementMixing operation control apparatusCalcium hydroxideSlag

A process for preparing the load-bearing aerated concrete from the chemical white mud dregs (calcium carbide dregs and epoxy propane tailing dregs) includes such steps as mixing the white mud dregs with silicon material, wet grinding, adding additive and cement, stirring, steam heating, adding lime powder, stirring, steam heating, adding aluminum powder, stirring, steam heating, moulding, laying aside while aerating, and cutting.

Owner:NANJING UNIV OF SCI & TECH

Method for producing high-iron sulphoaluminate cement by using red mud and aluminum ash

The invention relates to the technical field of special cement, in particular to a method for producing high-iron sulphoaluminate cement by utilizing red mud and aluminum ash. The method for producingthe high-iron sulphoaluminate cement by utilizing the red mud and the aluminum ash comprises the following steps: mixing carbide slag and waste sulfuric acid, reacting, and drying to obtain calcium sulfate-containing waste residues; mixing red mud, secondary aluminum ash, waste cathode carbon blocks, calcium sulfate-containing waste residues and / or waste gypsum, adopting limestone as a correctionmaterial, grinding and drying to obtain a cement raw material, and calcining the cement raw material to obtain cement clinker; mixing the modified red mud and the waste gypsum to obtain a mixture A;mixing the modified red mud, waste gypsum and limestone to obtain a mixture B; and mixing the cement clinker with the mixture A or the mixture B, and grinding to obtain the high-iron sulphoaluminate cement. Waste sulfuric acid is treated and utilized while industrial solid waste is utilized, and the produced high-iron sulphoaluminate cement is high in strength, free of heavy metal dissolution andlow in cost.

Owner:淄博海慧工程设计咨询有限公司

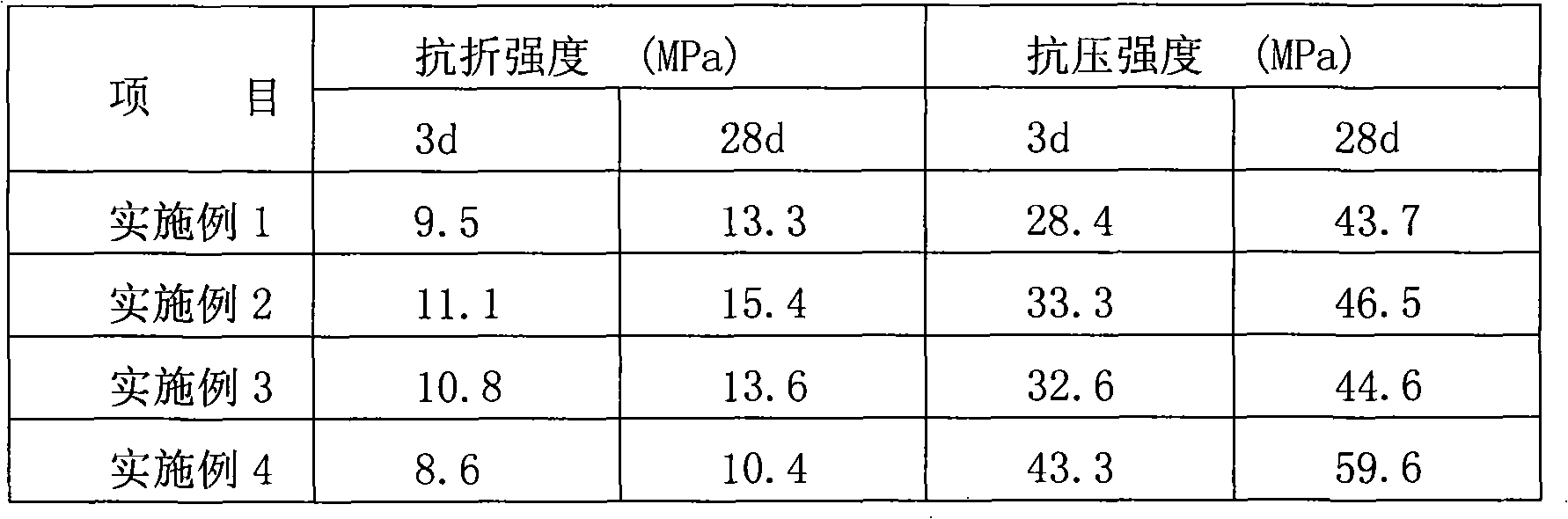

Sludge autoclaved brick and preparation method thereof

The invention discloses a sludge autoclaved brick. The sludge autoclaved brick comprises the following raw material components in parts by weight: 20-60 parts of sludge dehydrated mud cakes, 11-25 parts of first fly ash, 0-10 parts of carbide slag or first lime, 22-39 parts of furnace slag and 1-6 parts of a reinforcing agent, wherein the sludge dehydrated mud cakes comprise the following raw material components in parts by weight: 33-66 parts of sludge, 15-33 parts of second fly ash, 15-33 parts of second lime and 1-5 parts of a coagulating agent. The autoclaved brick is prepared from industrial wastes as main raw materials, and is low in energy consumption, non-sintered, safe, healthy and stable for a long time. The invention also discloses a preparation method of the sludge autoclaved brick. According to the preparation method, the sludge water content is controlled in a mode of conditioning at first and then dehydrating to form the sludge dehydrated mud cakes, and the fly ash and the like are added to perform hydration reaction. The autoclaved brick prepared by the method can meet performance requirements of a standard brick, and the production process is simple, low in energy consumption and environment-friendly.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

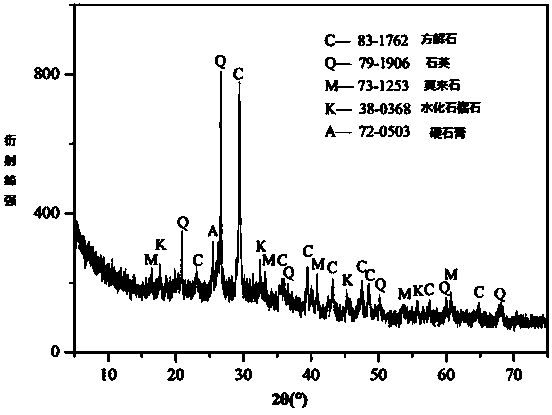

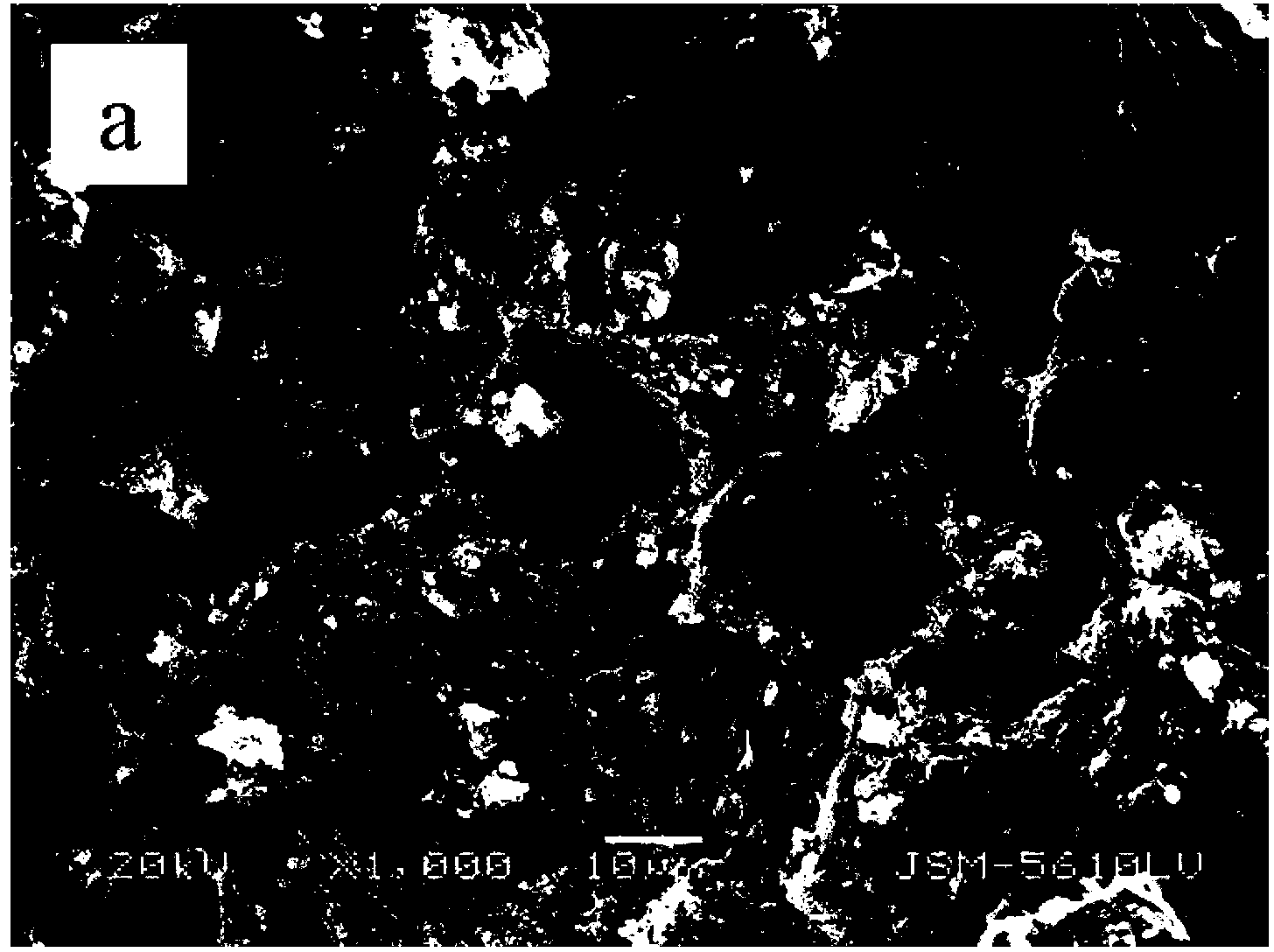

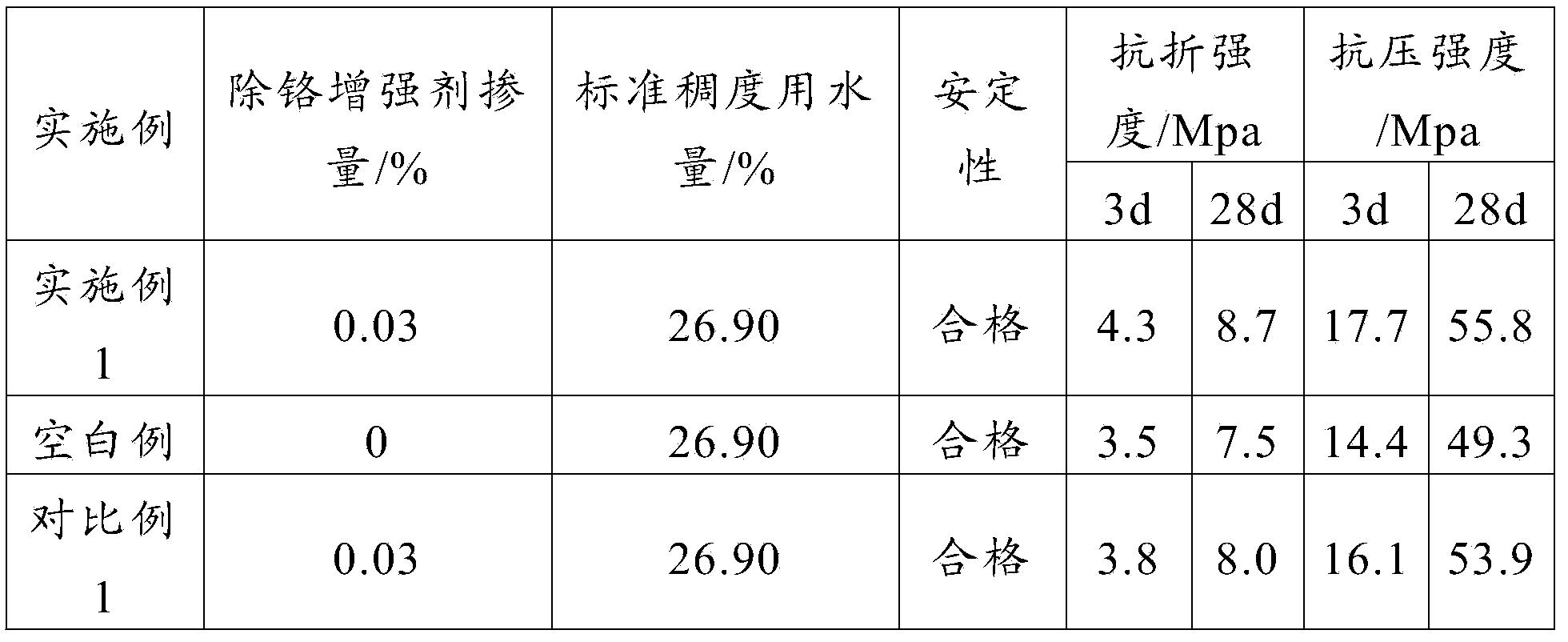

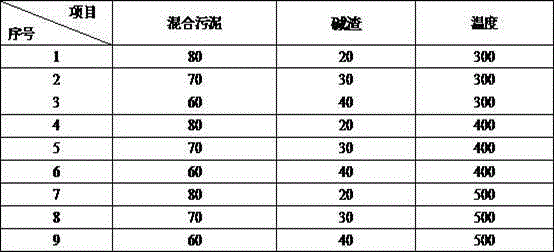

Chromium removal enhancer and preparation method thereof

The invention provides a method for preparing a chromium removal enhancer. The method comprises the following steps: (a) calcining kaolin, mixing the calcined kaolin and an acid solution, performing suction filtration, and washing and drying the obtained solid; (b) mixing the kaolin obtained in the step (a) and an mixed solution, and reacting to obtain the chromium removal enhancer, wherein the mixed solution is a mixed solution of a reducing agent, an antioxidant, an enhancer and water. According to the chromium removal enhancer prepared by the invention, the kaolin is taken as a raw material, the reducing agent, the antioxidant and the enhancer are mixed with the modified kaolin, and the chromium removal enhancer is obtained after the reaction. According to the chromium removal enhancer prepared by the invention, due to dual effects of adsorption and reduction, hexavalent chromium in cement is effectively removed, and physical properties of the cement are improved. The invention also provides the chromium removal enhancer prepared according to the method.

Owner:SHANDONG HONGYI TECH

Method for producing cement cementing material through industrial waste residue sludge

ActiveCN104016601AImprove water demand performanceImprove early and late strengthClinker productionSludgeHigh activity

The invention relates to a method for producing a cement cementing material (called cementing material for short) through industrial waste residue sludge. According to the method, sludge and alkali residues which are completely discharged after the sewage of the biologicalization, printing and dyeing and the like of a sewage treatment plant is treated are treated into the cementing material by virtue of the steps of pelleting, low-temperature calcination and the like after being mixed in a certain proportion, a right amount of gypsum powder is added to be ground into the cementing material, the cementing material can be coagulated and hardened in air and water, and the hydraulic cementing material with high activity can be directly used for the construction of dam building engineering, underwater building engineering, road building engineering, bridge building engineering, civil building engineering and the like; a small amount of other materials can also be added to be ground into a high-standard sludge cementing material. The method disclosed by the invention can be used for effectively overcoming the defects of the traditional treatment modes of stacking, backfilling, incineration and the like which extremely easily cause secondary pollution, and also overcoming the defects of increased energy consumption, reduced production efficiency, and the like caused by directly roasting high-temperature cement clinker, is a very good treatment method which has the advantages of low energy consumption, advancement and reasonability in process and no secondary pollution, can be used for obviously enhancing the quality and property of abrasion resistance and the like of cement and reducing the cost of the cement, is beneficial to environmental conservation, can be used for producing the sludge and the alkali residues into the cementing material, and the like.

Owner:江苏启坤循环经济产业技术开发有限公司

Lightweight high-strength ceramsite concrete as well as preparation method and application thereof

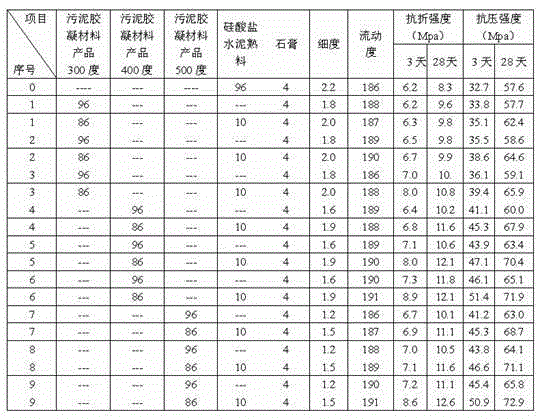

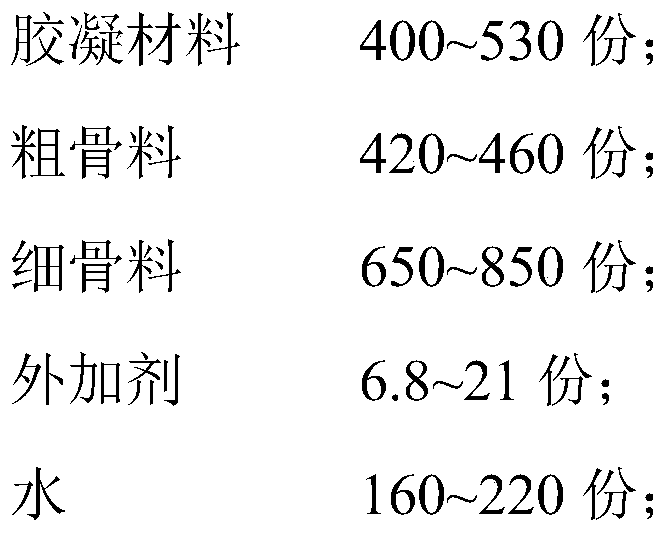

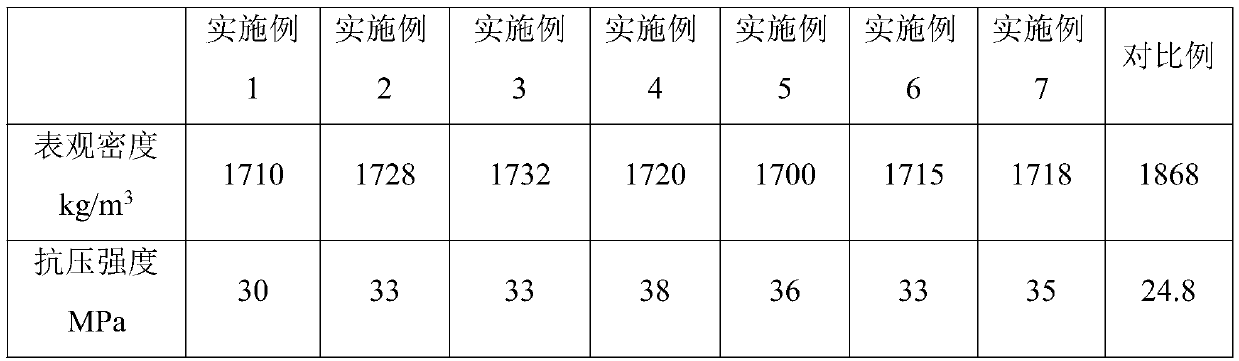

The invention relates to lightweight high-strength ceramsite concrete as well as a preparation method and application thereof, and relates to the field of building materials. The ceramsite concrete iscomposed of the following components in parts by weight: 400 to 530 parts of a cementing material, 420 to 460 parts of coarse aggregate, 650 to 850 parts of fine aggregate, 6.8 to 21 parts of admixtures, and 160 to 220 parts of water, wherein the coarse aggregate is fly ash ceramsite, the fine aggregate is composed of furnace slag and sand, and the admixtures include a polycarboxylic acid water reducing agent and an enhancing agent. The method uses ultra-fine modified fly ash, cement and activated silicon micropowder as the cementing material, the furnace slag and the river sand as the fine aggregate, and the fly ash ceramsite as the coarse aggregate to prepare the lightweight high-strength prefabricated component, and effectively solves the problem of ceramsite concrete layering due to asmall ceramsite density, and the prepared ceramsite concrete has high strength, is convenient for actual construction operation, and effectively uses solid waste, thereby facilitating environmental protection.

Owner:HEFEI UNIV OF TECH +1

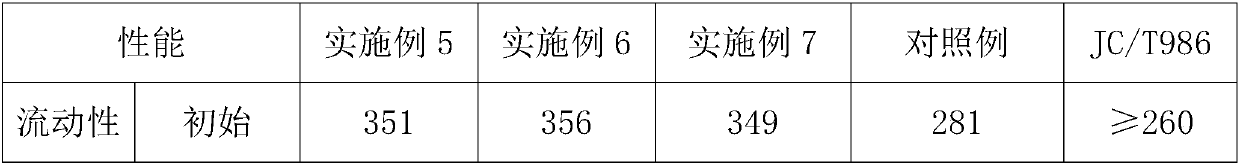

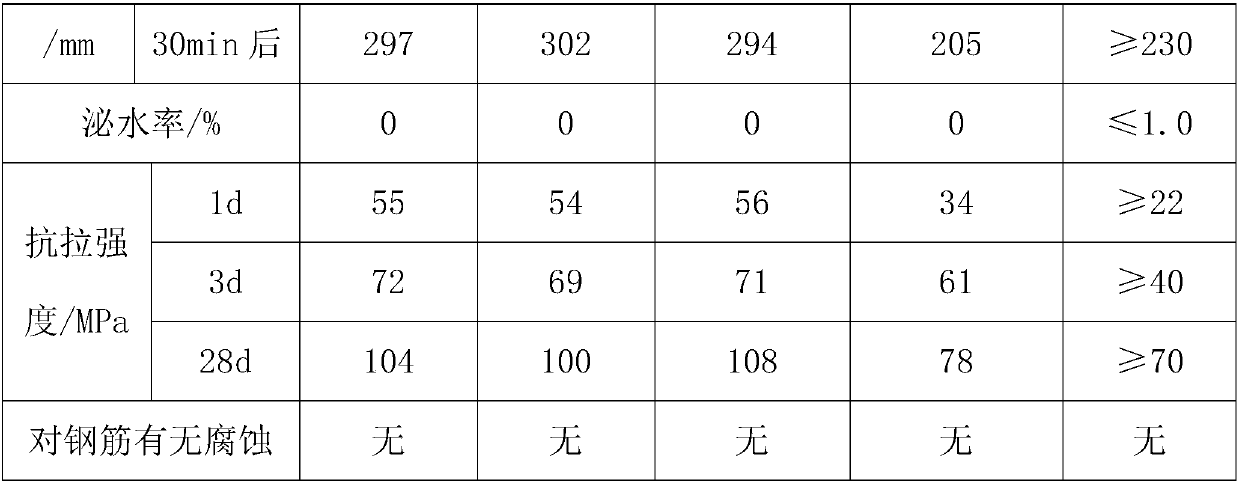

Grouting material for assembly type building reinforcement connection sleeve

InactiveCN107686314AGood water retentionIncreased compressive and flexural strength of mortarRebarPliability

The invention discloses a grouting material for an assembly type building reinforcement connection sleeve. The grouting material is prepared from the following raw materials in percentage by weight: 45-60% of cement, 30-45% of fine aggregates, 1-2% of an enhancer, 0.05-0.1% of a de-foaming agent, 7-10% of a phosphogypsum composite expanding agent, 0.5-0.8% of a polycarboxylic acid water reducer, 0.05-0.09% of a retarder, and 0.08-0.2% of an early strength agent, wherein the phosphogypsum composite expanding agent is a mixture of modified phosphogypsum, phosphorus slag micro powder and wollastonite. According to the grouting material disclosed by the invention, continuously graded fine sand and quartz sand are used as fine aggregates to match with the cement for use, the fine aggregates andthe cement are reasonably proportioned, and the phosphogypsum composite expanding agent is added, so that cement paste is very compact after being hardened; the grouting material is greatly improvedin strength, is matched with the enhancer, the retarder, the polycarboxylic acid water reducer and the early strength agent for use, so that mortar has good water-retaining property, plasticity and flexibility; and tensile bonding strength as well as mortar and brickwork tensile bonding strength are obviously improved, comprehensive properties are good, and using requirements of an assembly type building are met.

Owner:无为县严桥双龙建材厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com