Method for producing cement cementing material through industrial waste residue sludge

A technology of industrial waste slag and cement glue, which is applied in cement production, clinker production, etc., can solve the problems of low cost reduction, low production efficiency, and increased energy consumption, and achieves low cost, improved early and late strength, and Improve the effect of low early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

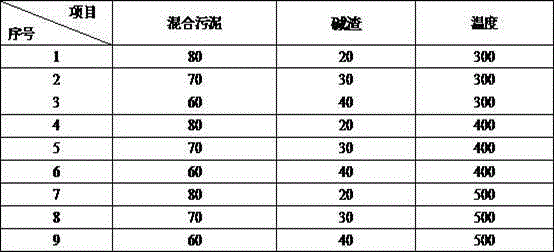

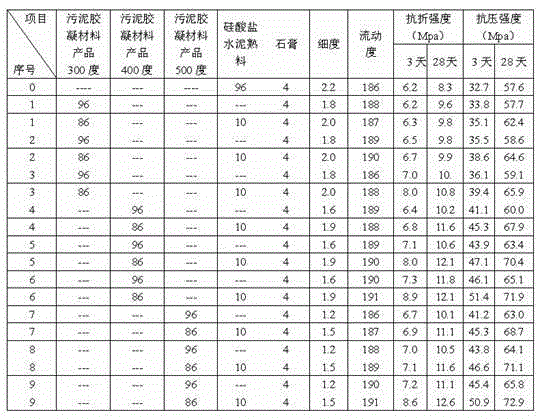

Examples

example 2

[0018] Example 2: The sludge is calculated as 70% by weight percentage, and the alkali slag is calculated as 30% by weight percentage;

example 3

[0019] Example 3: The sludge is calculated as 60% by weight percentage, and the alkali slag is calculated as 40% by weight percentage:

[0020] C) Forming into balls: put the mixture into the mixing molding machine, add an appropriate amount of water while stirring, stir and mix evenly, and then process the mixture into a ball with a diameter of 5-10mm that is uniformly dispersed, without agglomeration or dust. Material balls, stacked and dried for later use;

[0021] D) Drying and roasting: The material balls are sent into the drying rotary kiln, and they are rotated and roasted at 300-500°C for 30-50 minutes to leave the kiln, and the cement clinker made of sludge is obtained.

[0022] The optimum roasting temperature in the above-mentioned drying rotary kiln is 400±50°C.

[0023] For the kiln body mentioned above, if the drying rotary kiln is selected, it can be heated and roasted in the middle of the kiln body. After roasting, the temperature hot air will automatically go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com