Patents

Literature

808results about "Clinker production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

Process and a plant for the production of Portland cement clinker

InactiveUS6908507B2Emission reductionReduce carbon dioxide emissionsGas treatmentDispersed particle separationCalcium in biologyHydrogen

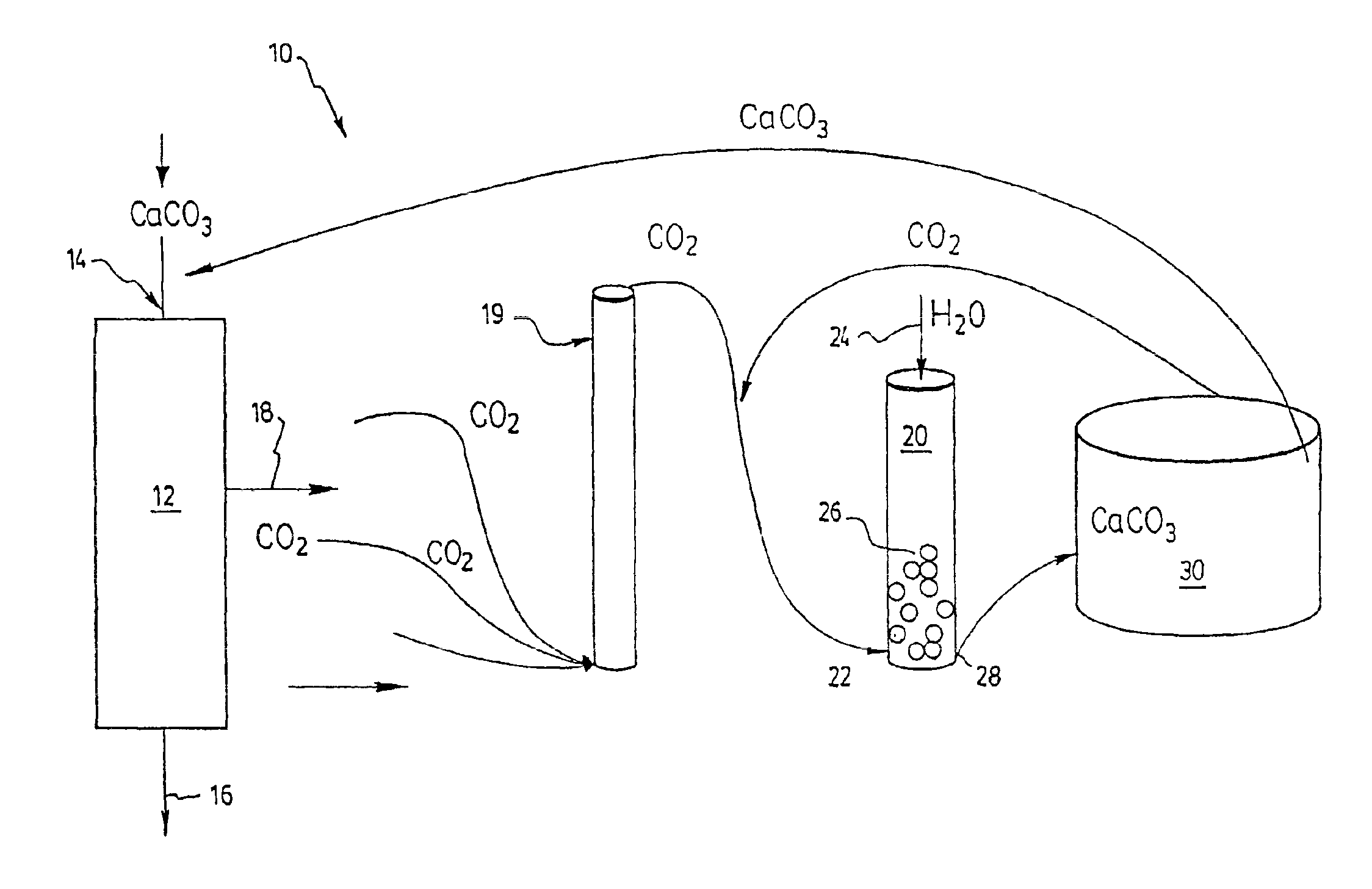

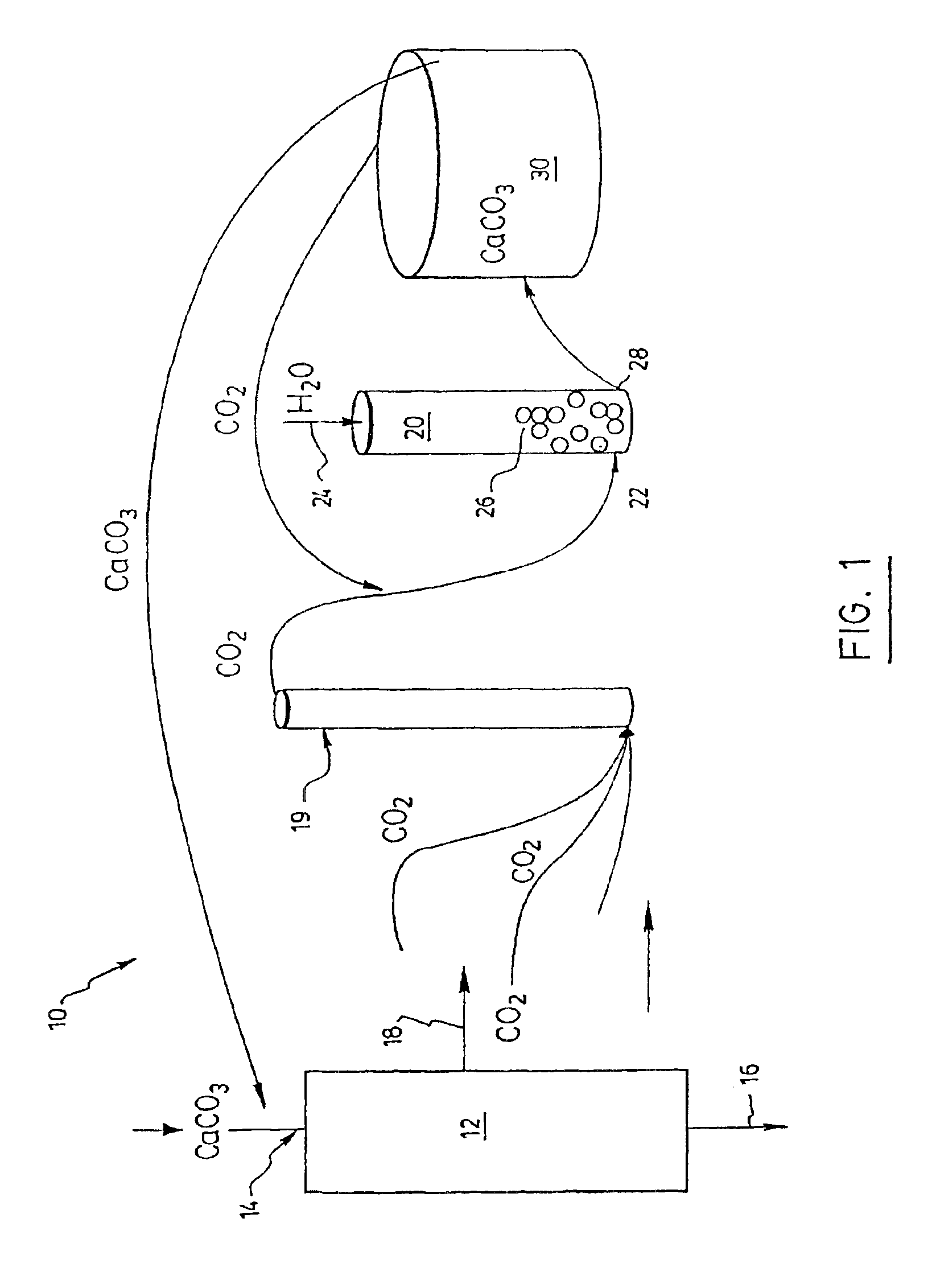

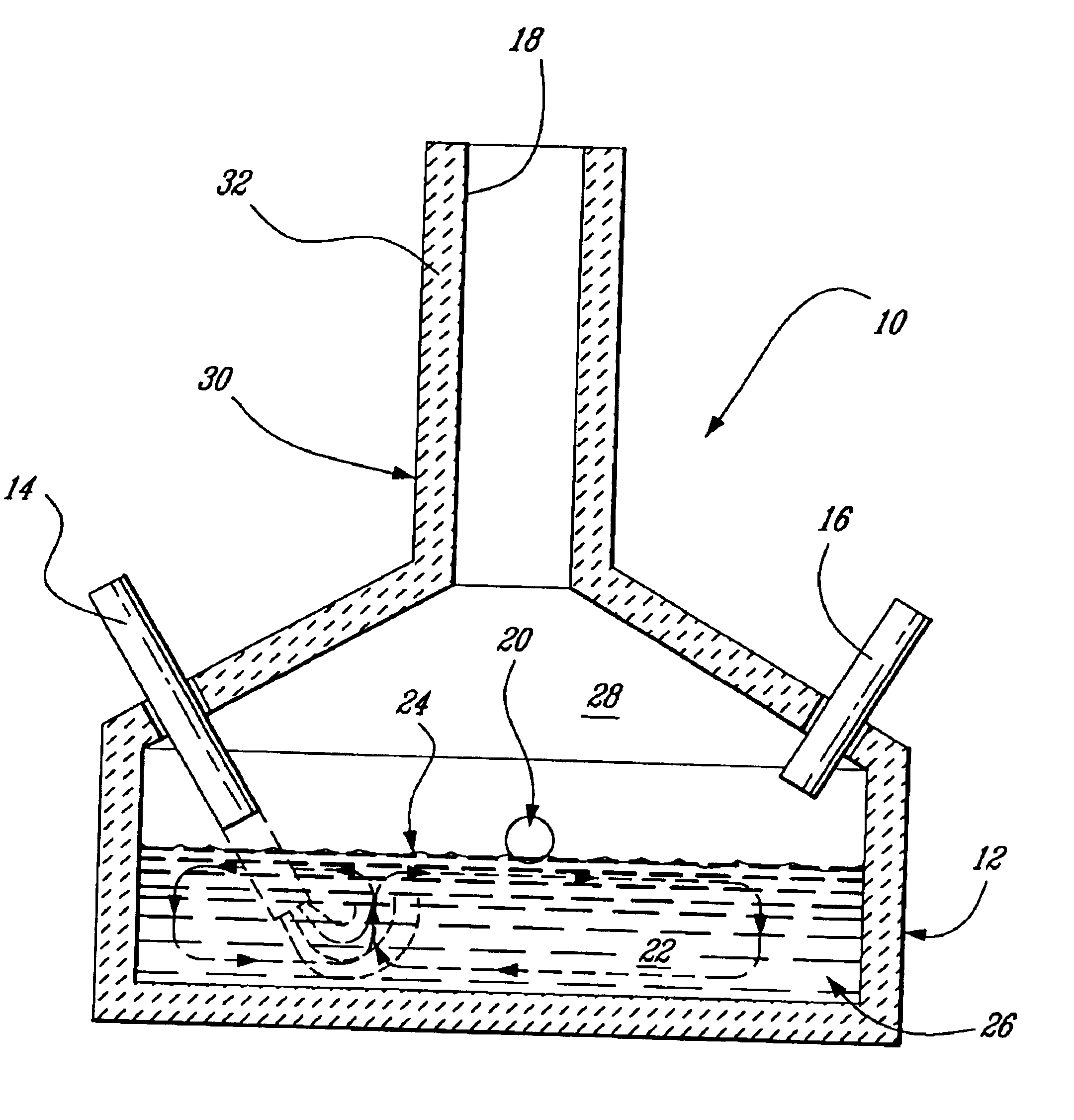

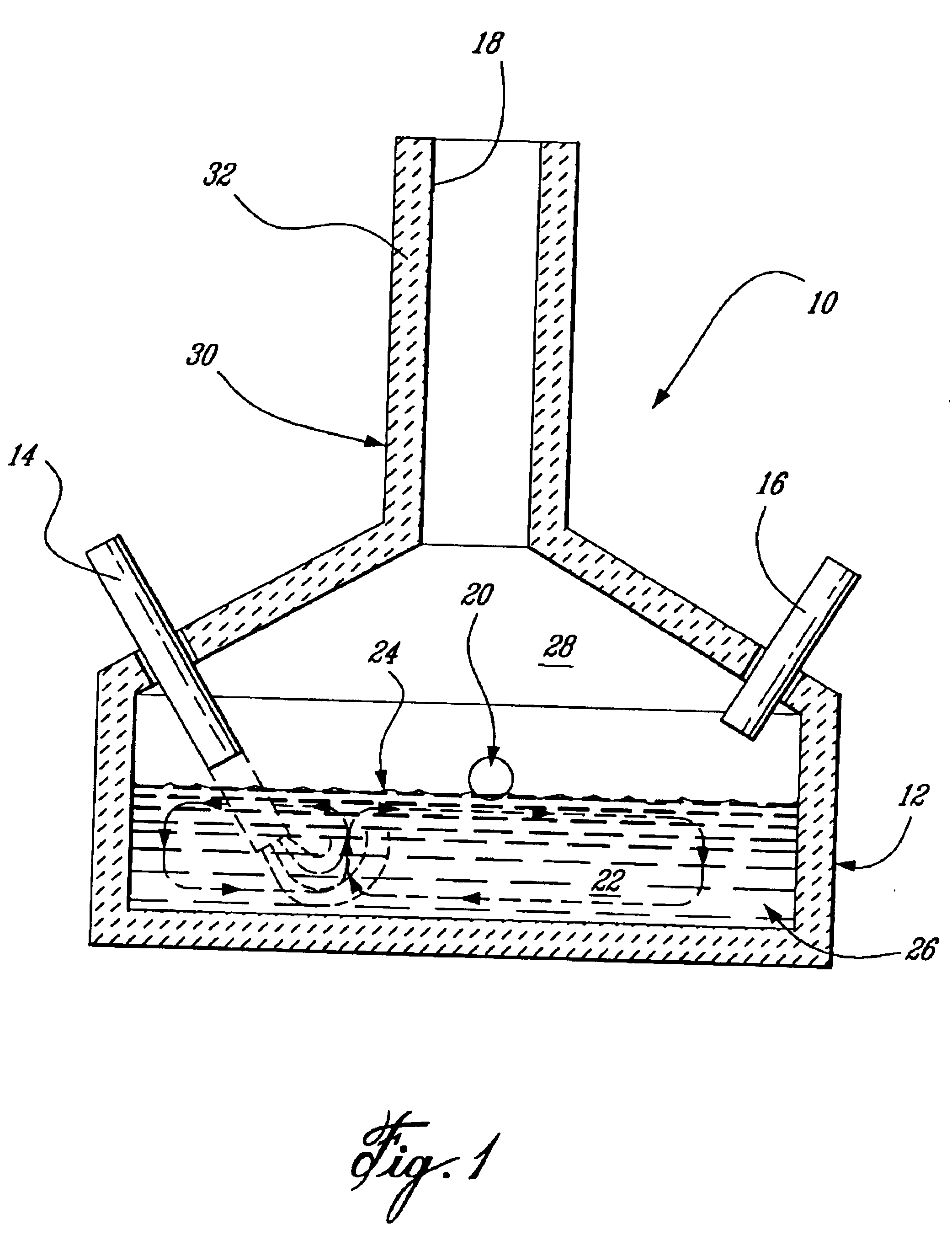

A process is disclosed for producing cement clinker, comprising the steps of: a) providing a mixture of ground calcareous materials and ground argillaceous materials; b) heating the mixture of step a) to a temperature sufficient to calcine and fuse the ground materials to form the cement clinker, and thereby producing an exhaust gas containing CO2; c) catalysing the hydration of at least a portion of the CO2 contained in the exhaust gas and producing a solution containing bicarbonate ions and hydrogen ions; and d) adding to the solution obtained in step c) metal ions, and adjusting the pH of the solution to precipitate a carbonate or said metal. Preferably, the metal ions are Ca++ obtained from the dissolution of a material selected from the group consisting of CaCl2, cement kiln dust and sea salts and the carbonate is CaCO3 which is advantageously recycled into the process by adding the CaCO3 to the mixture of step a). A cement plant for performing this process is also disclosed.

Owner:CO2 SOLUTION

Use of high carbon coal ash

InactiveUS6755905B2Avoid insufficient heatingReduce flowCharge manipulationHandling discharged materialSlagHigh carbon

A synthetic slag is produced by a high temperature combustion reaction between coal ash having a high carbon content, and a source of lime such as cement kiln dust. The carbon content of the coal ash is oxidized by oxygen gas, which typically is derived from air or an air / oxygen combination in an exothermic reaction and the heat generated is exploited in the melting process. In this way the gaseous products will typically comprise nitrogen, unreacted oxygen and carbon dioxide, and heat energy can be readily recovered from the hot off gas products evolving during the combustion reaction. The synthetic slag may be pelletized and employed as lightweight mineral aggregate or milled to cement fineness to provide slag cement.

Owner:LAFARGE CANADA INC

Method of Manufacturing Carbon-Rich Product and Co-Products

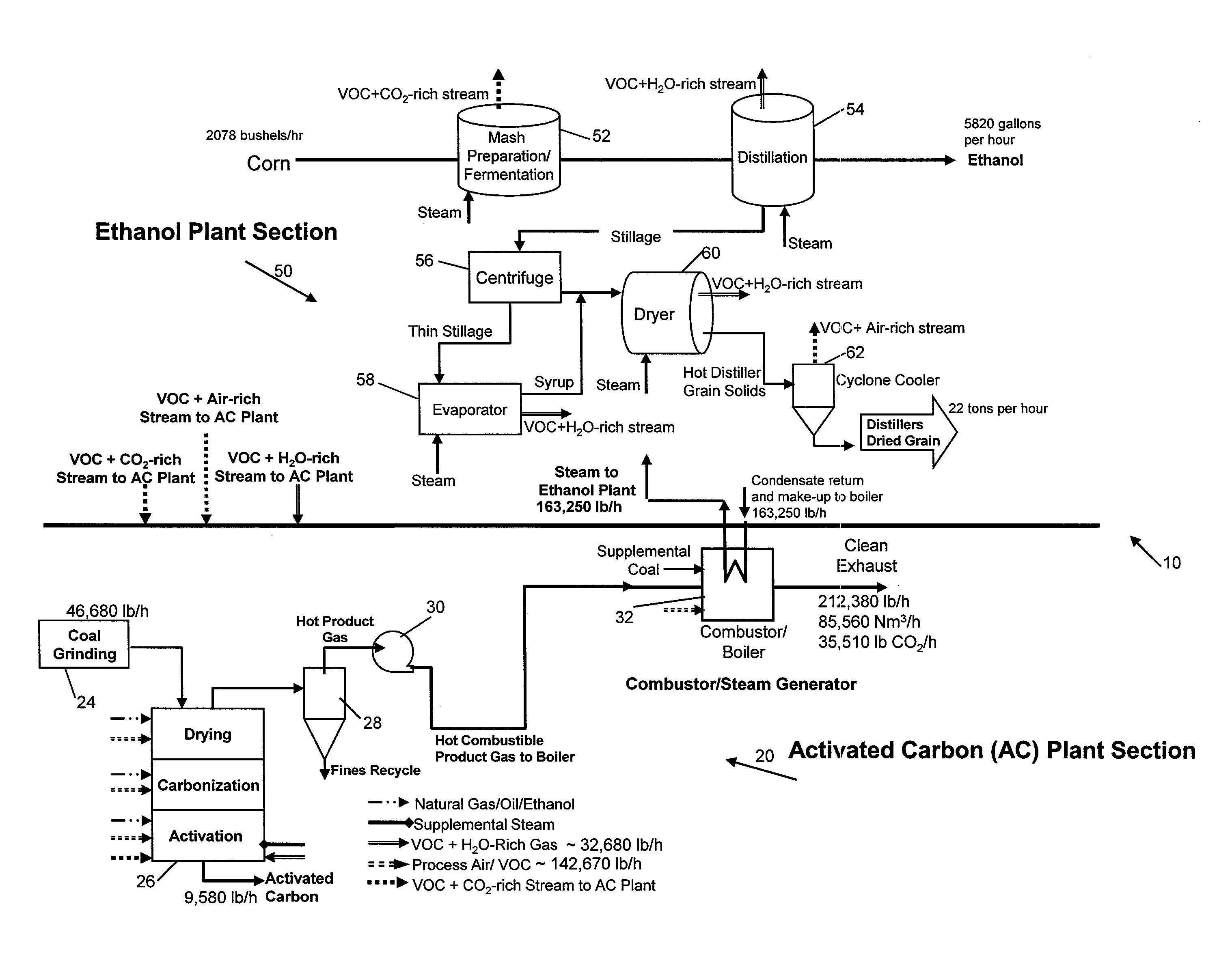

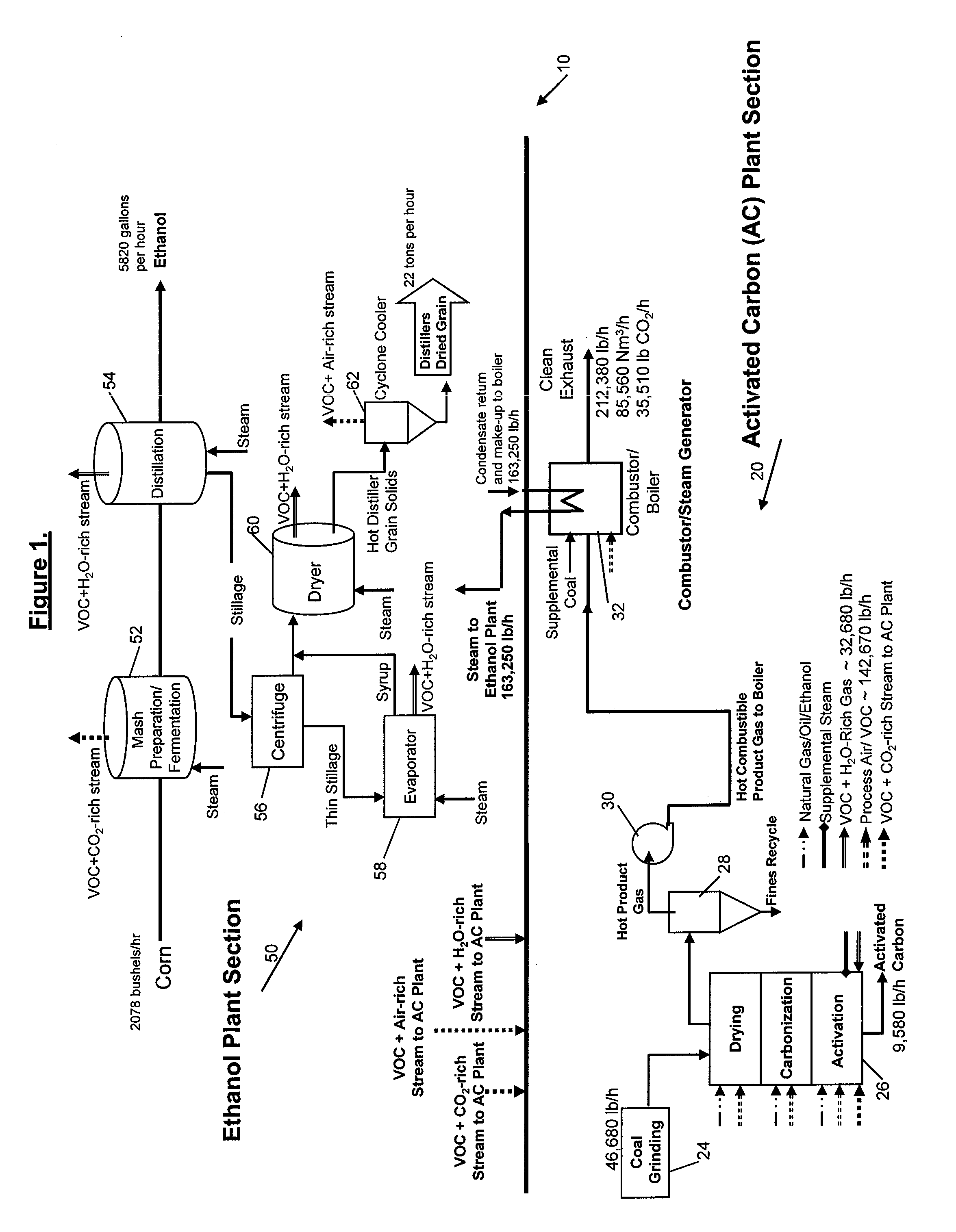

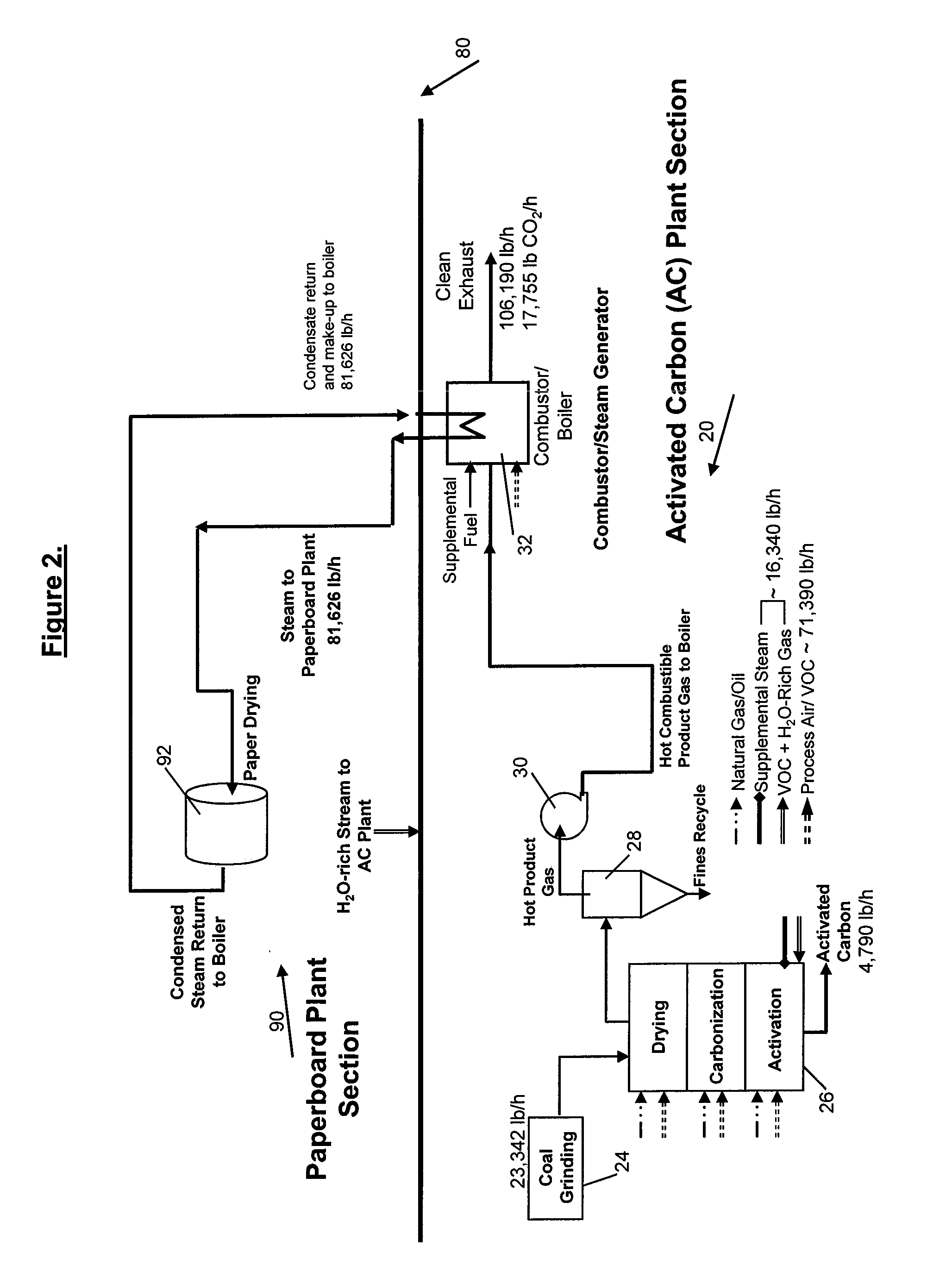

ActiveUS20100178624A1Simple and cost-effectiveImprove efficiencyBioreactor/fermenter combinationsGaseous fuel feeder/distributionWater vaporHigh carbon

A method in which a parent hydrocarbon-rich material is processed so as to produce both a carbon-rich solid material that has a higher carbon to hydrogen ratio than that of the parent material and a carbon-deficient combustible gas that has a lower carbon to hydrogen ratio than the parent material. In the process, the material is activated by exposing it to a hot gas stream having elevated levels of one or both of carbon dioxide and water vapor. The combustible gas is combusted to produce heat. At least about 80% of the heat is used in one or more endothermic steps that include drying coal or biomass.

Owner:SRINIVASACHAR SRIVATS

Non-sodium chloride environment-friendly type coal-saving combustion adjuvant special for cement

InactiveCN101475864AReduce contentReduce consumptionSolid fuelsClinker productionChromium CompoundsAdjuvant

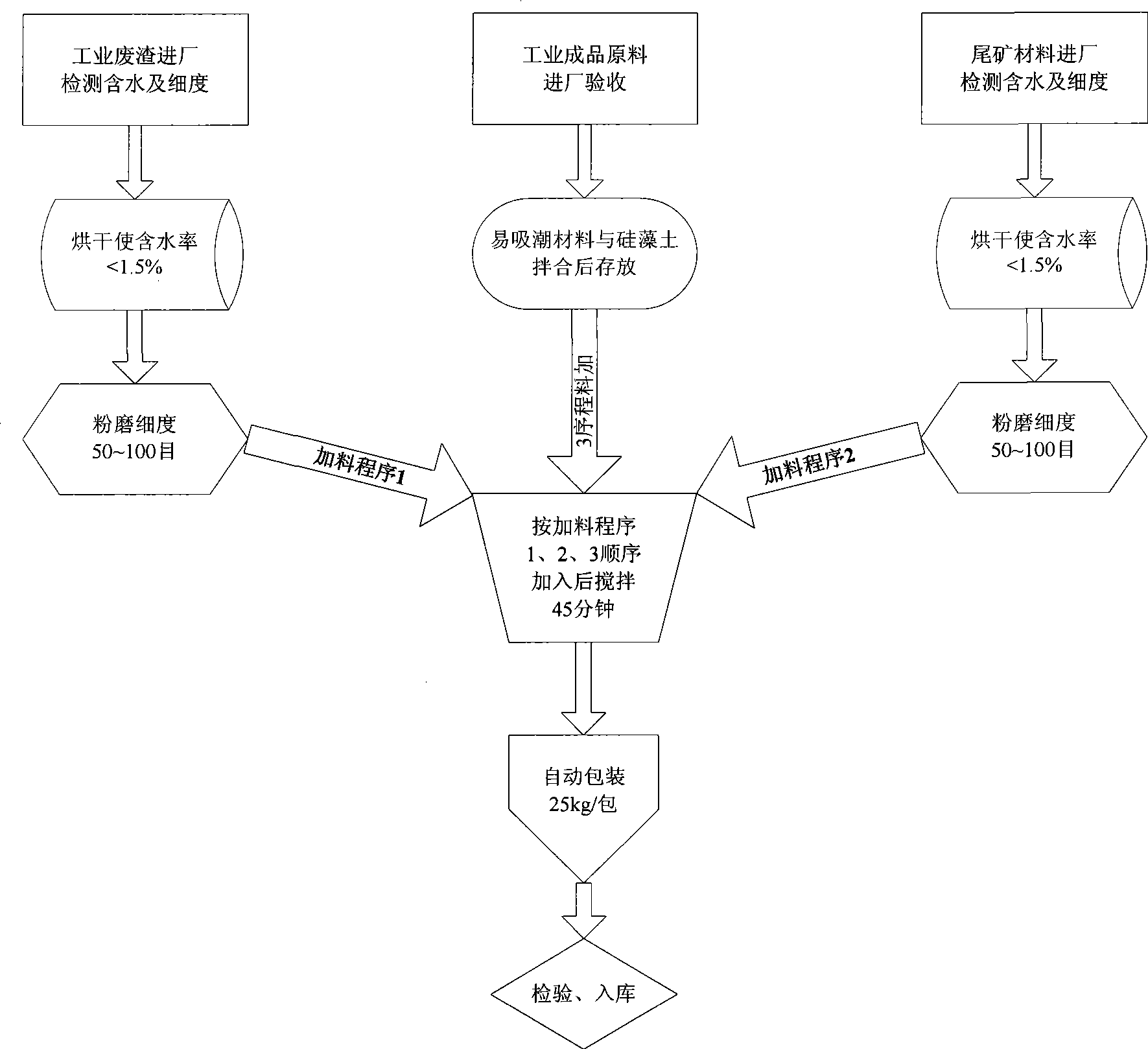

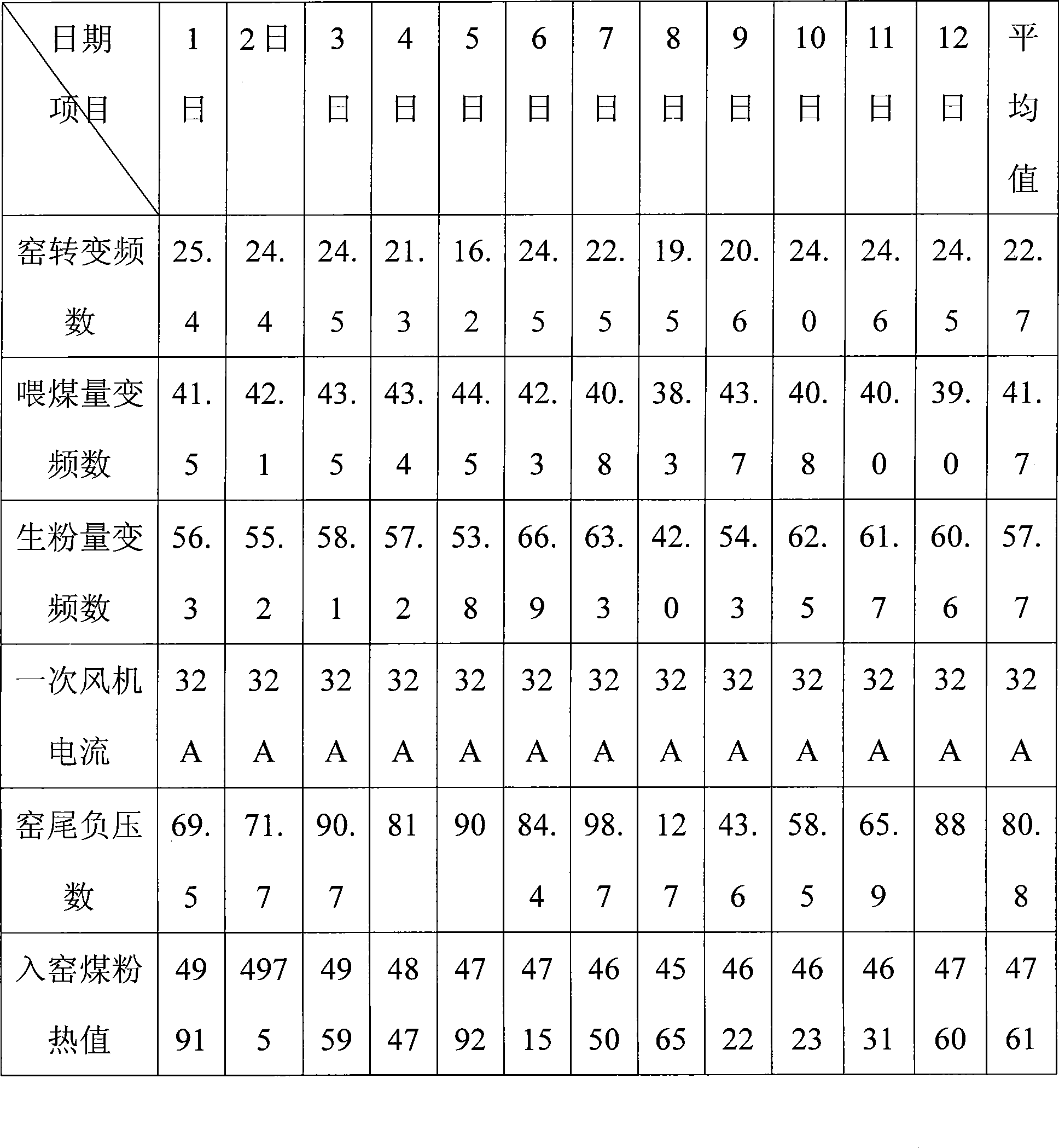

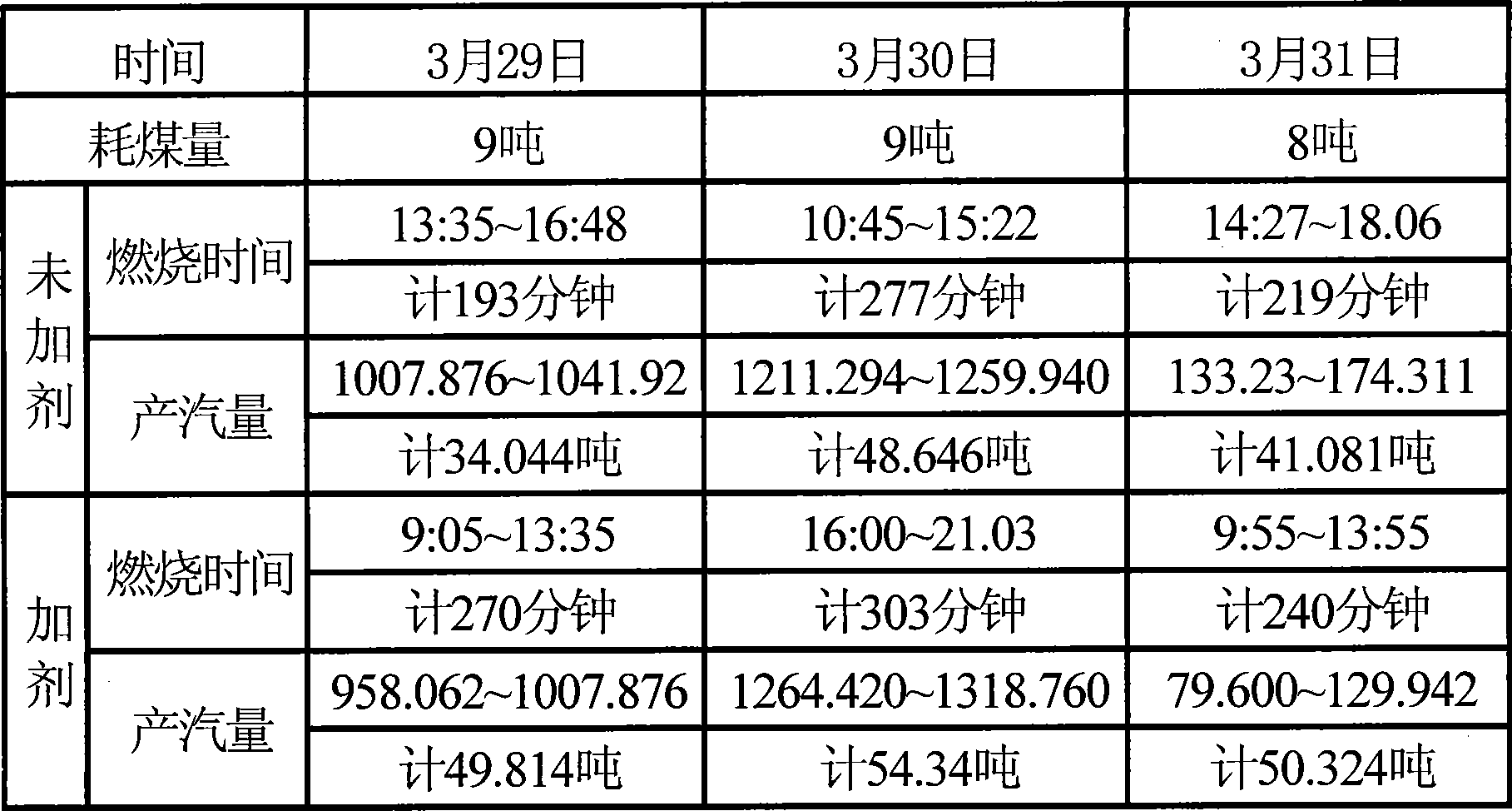

The invention discloses a sodium chloride-free environment-friendly coal-saving combustion improver special for cement, which aims to solve the technical problem of eliminating the damage of sodium chloride to furnaces, kiln bodies and the atmosphere. The combustion improver consists of an industrial grade finished product raw material, industrial residue, and a tailing material, and contains a barium compound, boride, carbonate, a chromium compound, fluoride, a magnesium compound, a manganese compound, nitride, a molybdenum compound II, a zirconium compound, industrial residue or tailings of rare earth, oxide and dicyclopentadienyl iron. Compared with the prior art, the combustion improver completely cancels the sodium chloride, furthest reduces the content of Cl<-> in ingredients, eliminates the damage of the sodium chloride to the furnaces, the kiln bodies and the atmosphere, reduces the damage of causing acid rain to the atmosphere, increases a plurality of metal acids, oxygen compounds and rare earth minerals, contains waste residue, ensures that the combustion is controllably performed, improves combustion environment, improves the combustion efficiency of fire coal, reduces energy consumption, prolongs the service life of equipment, and protects the environment.

Owner:深圳市伯益科技有限公司

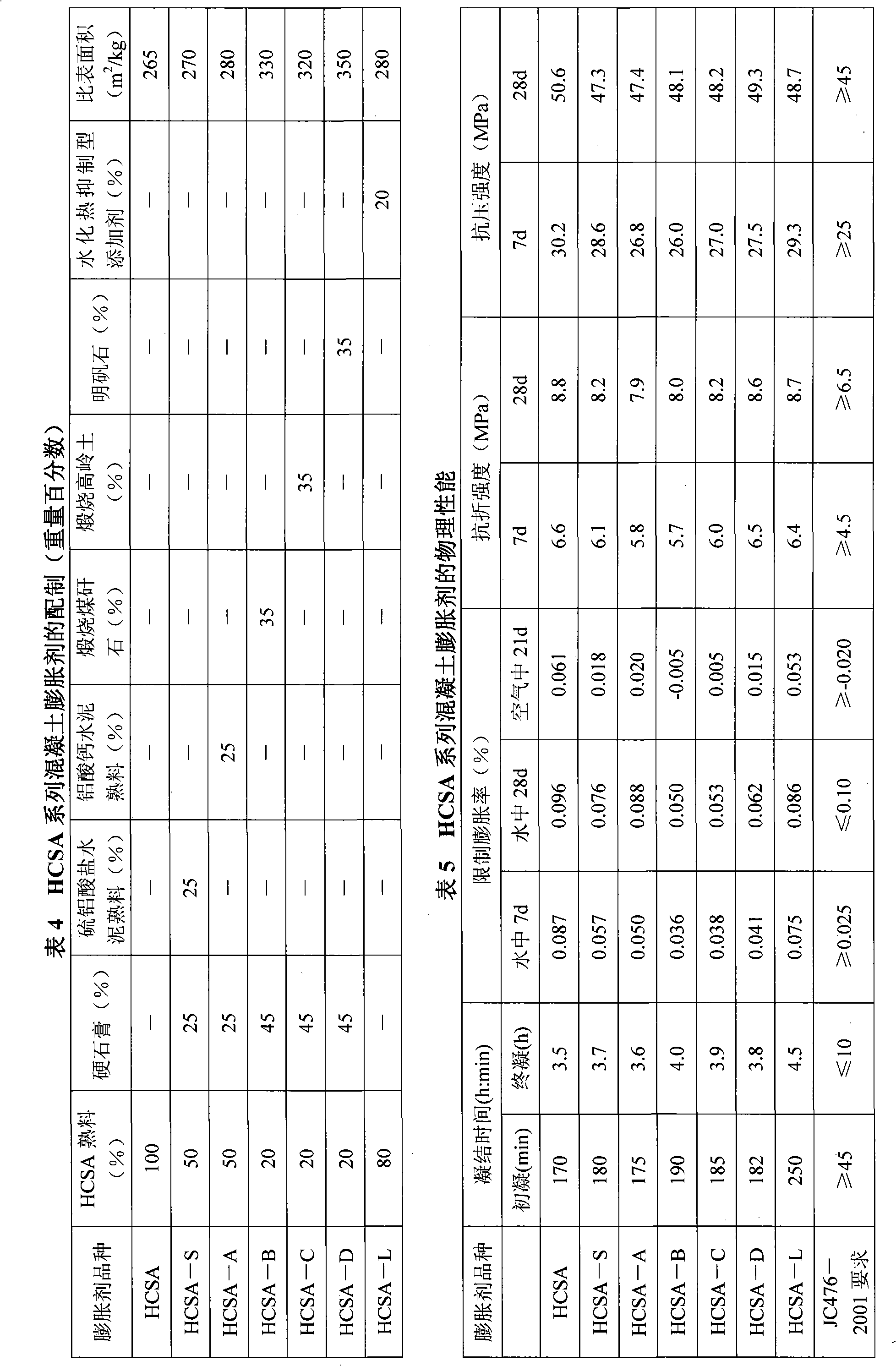

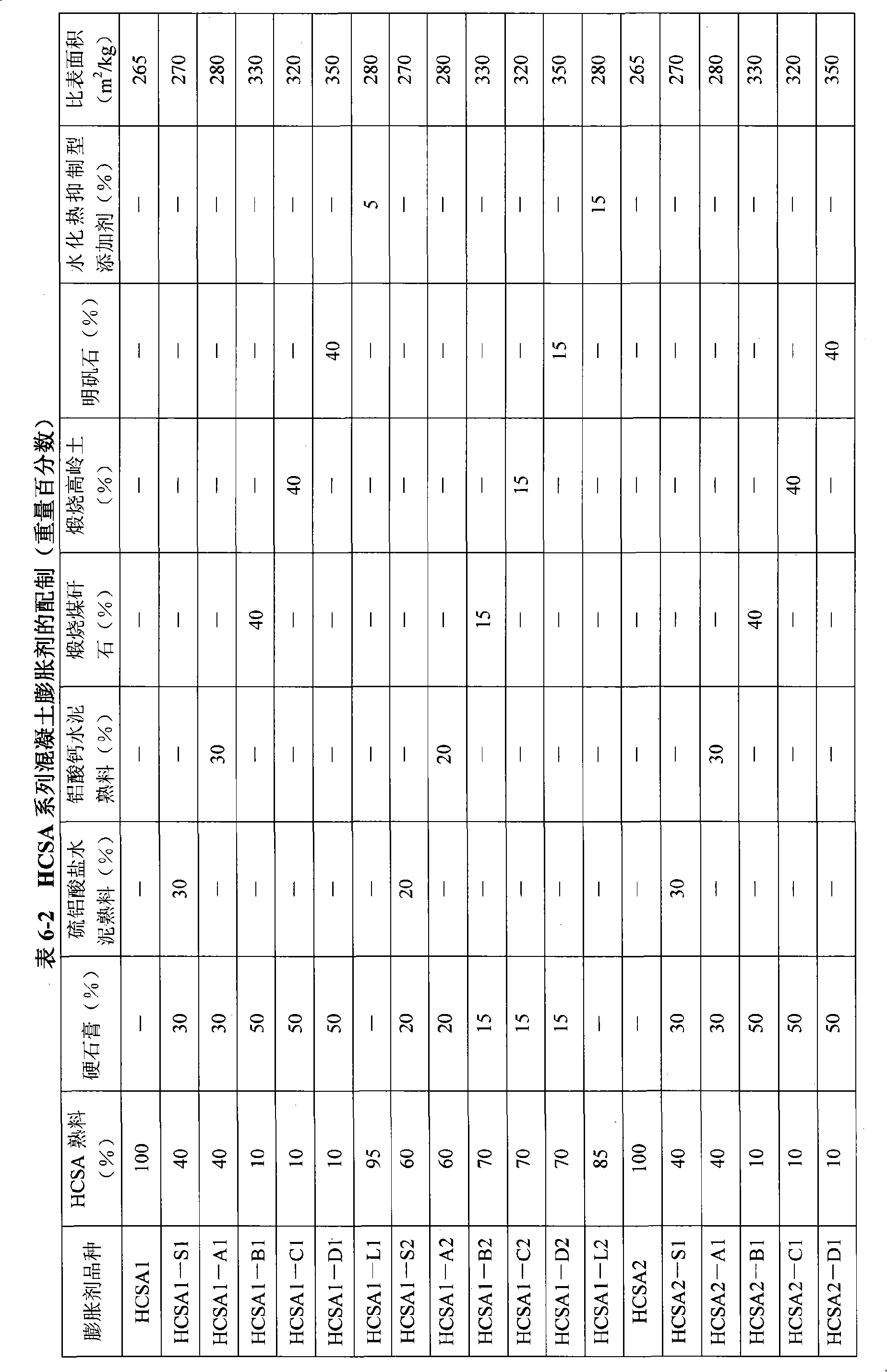

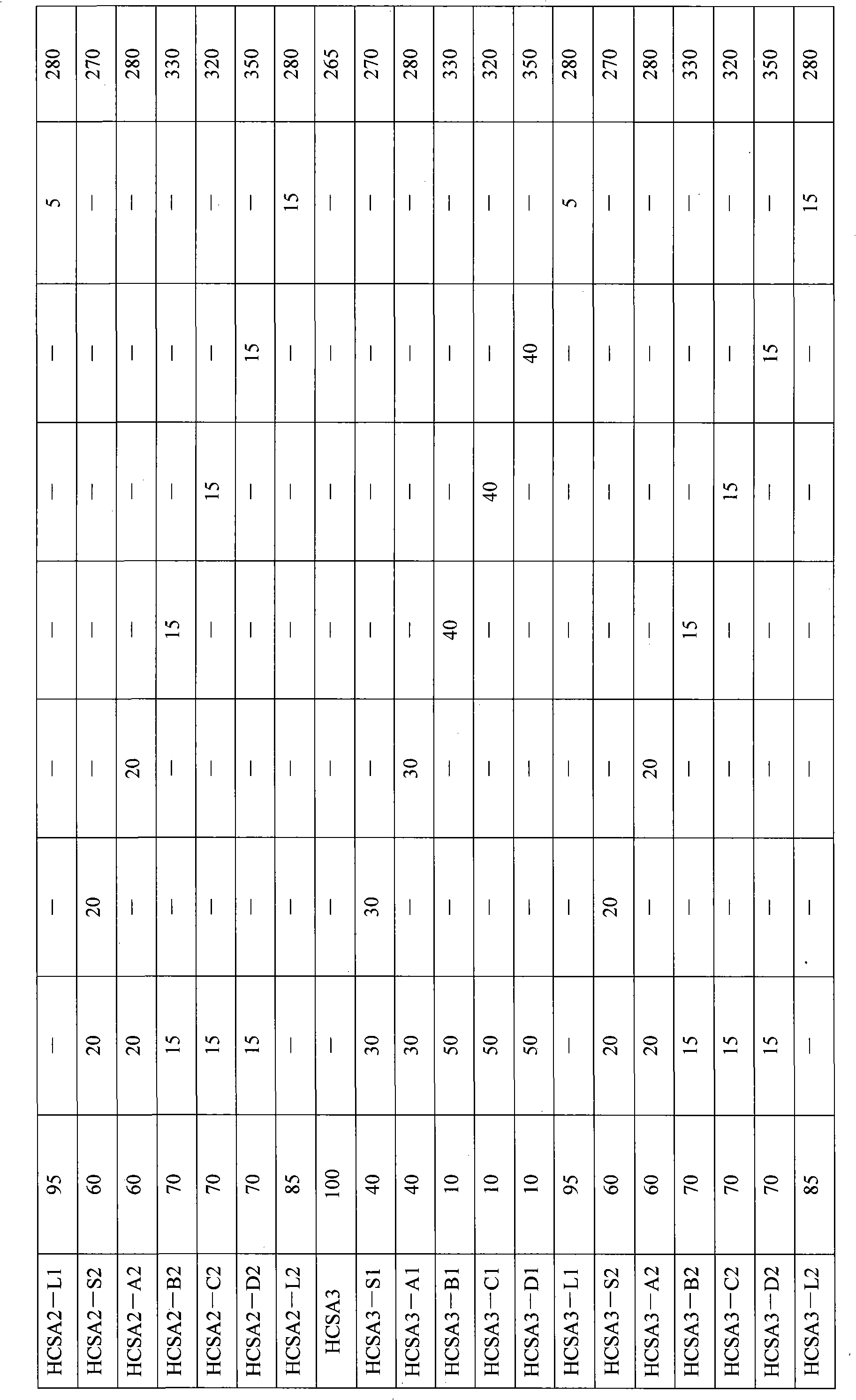

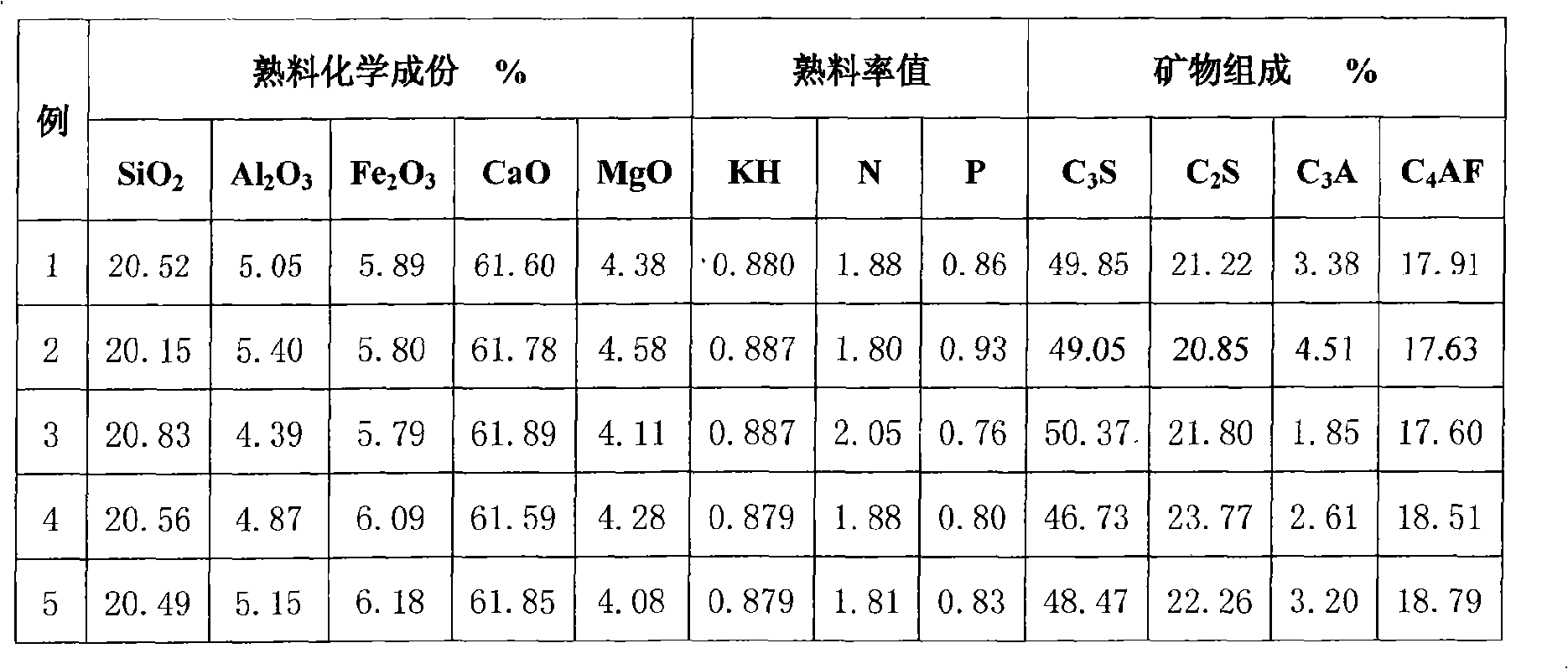

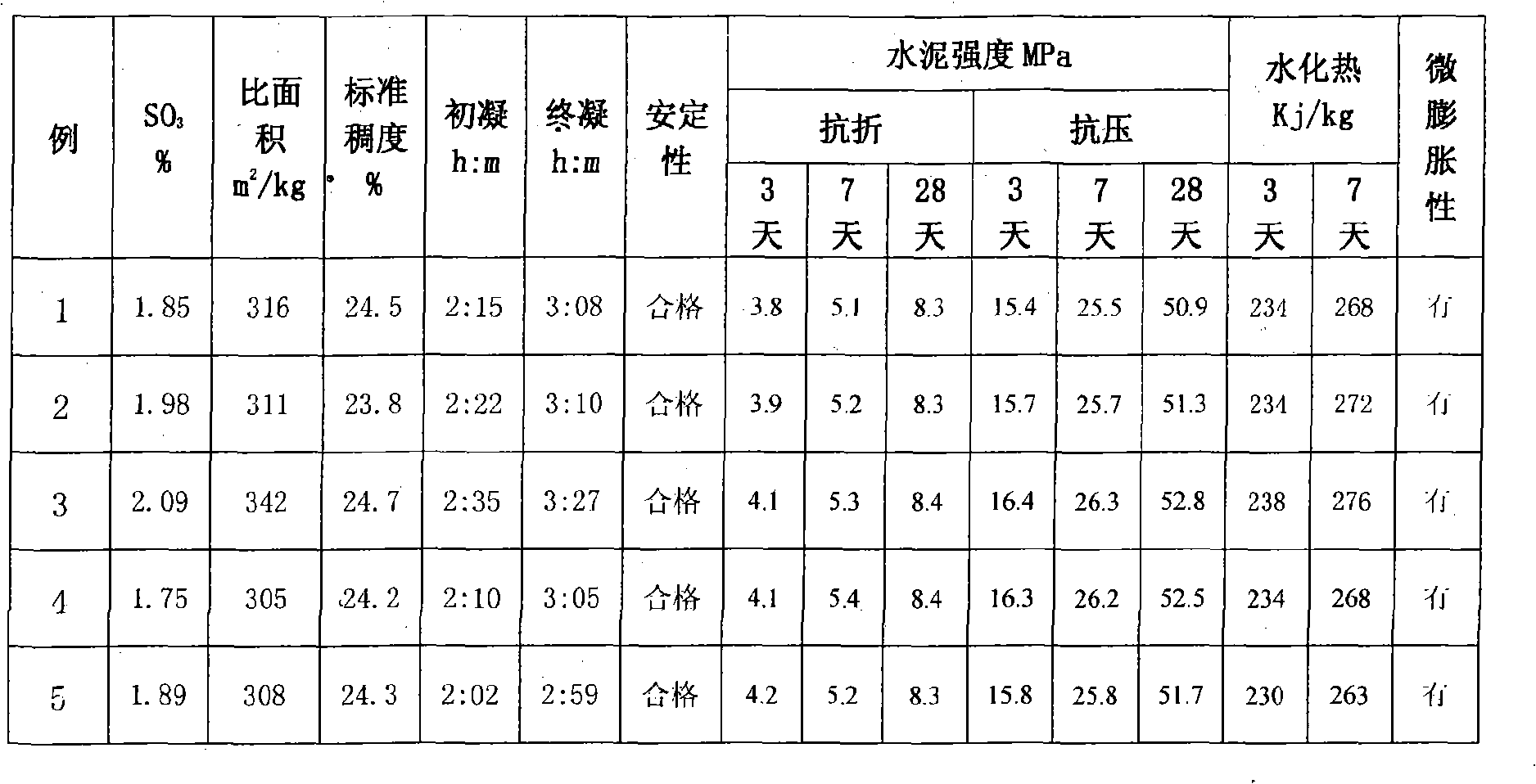

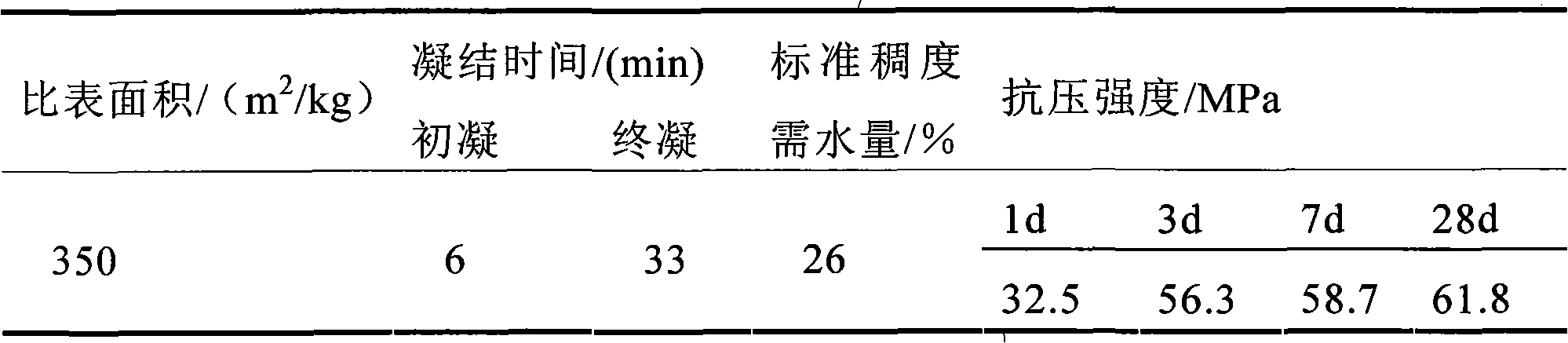

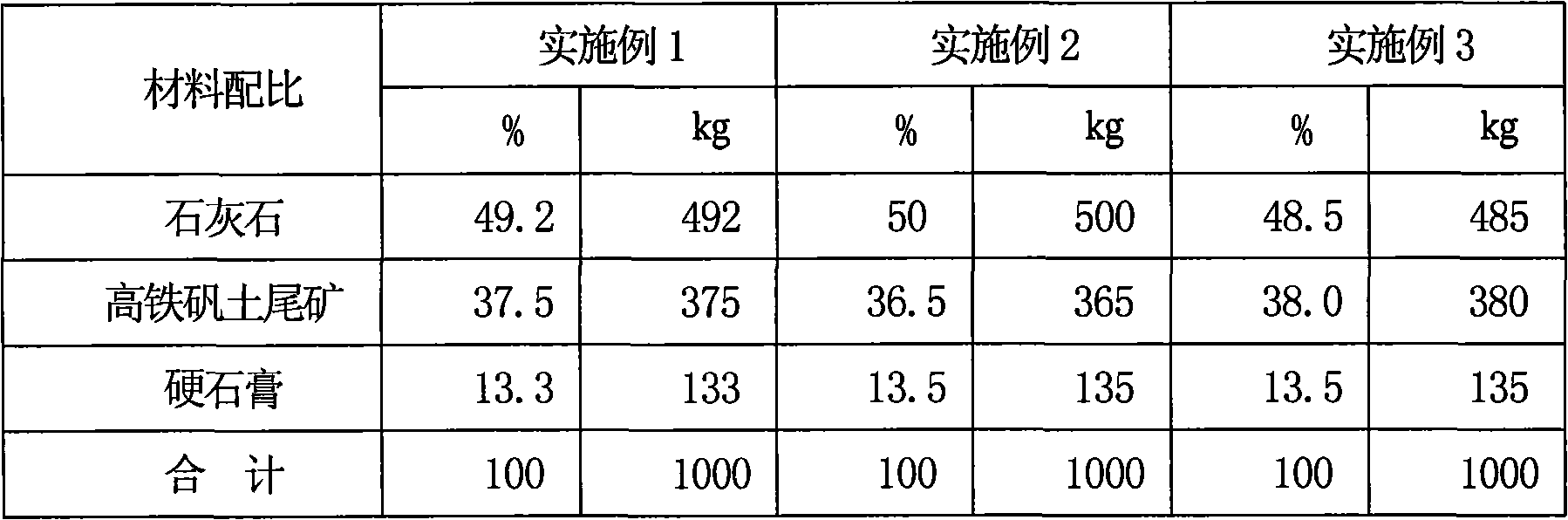

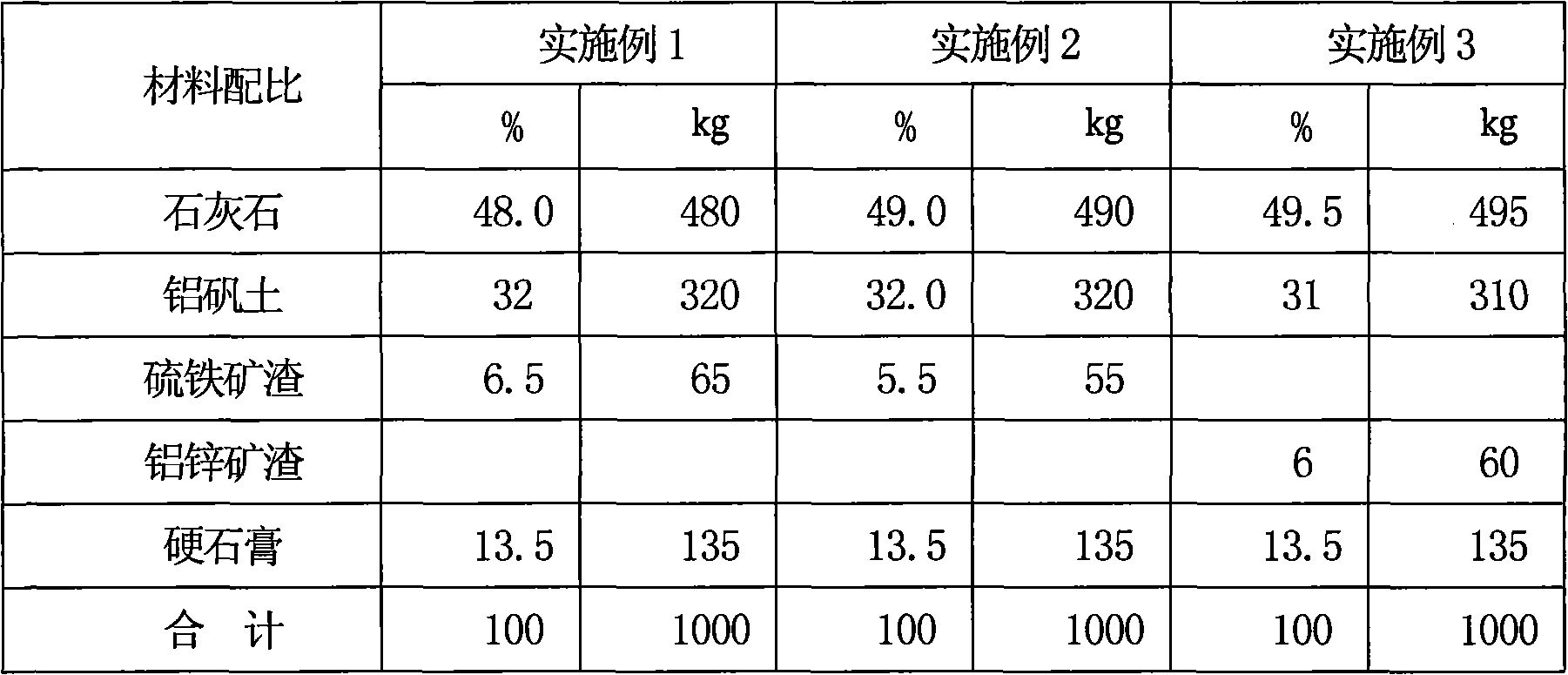

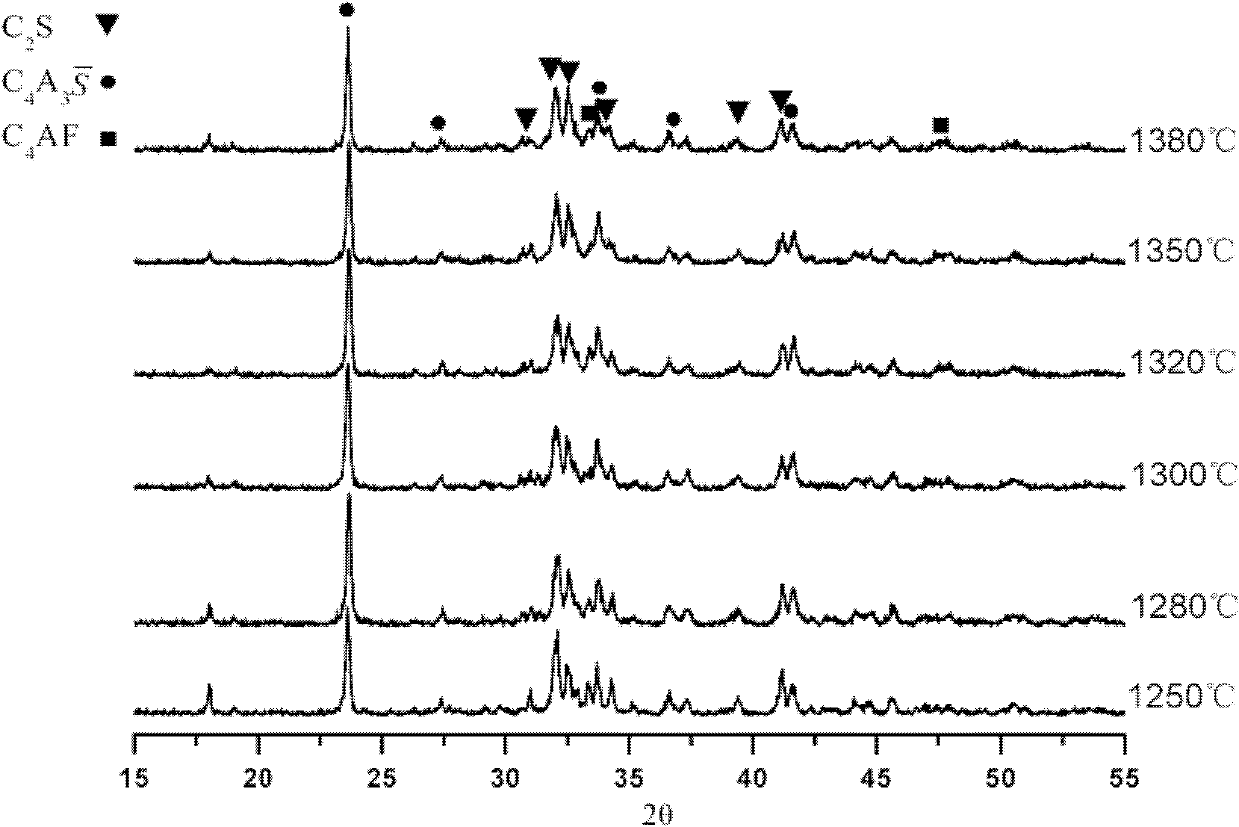

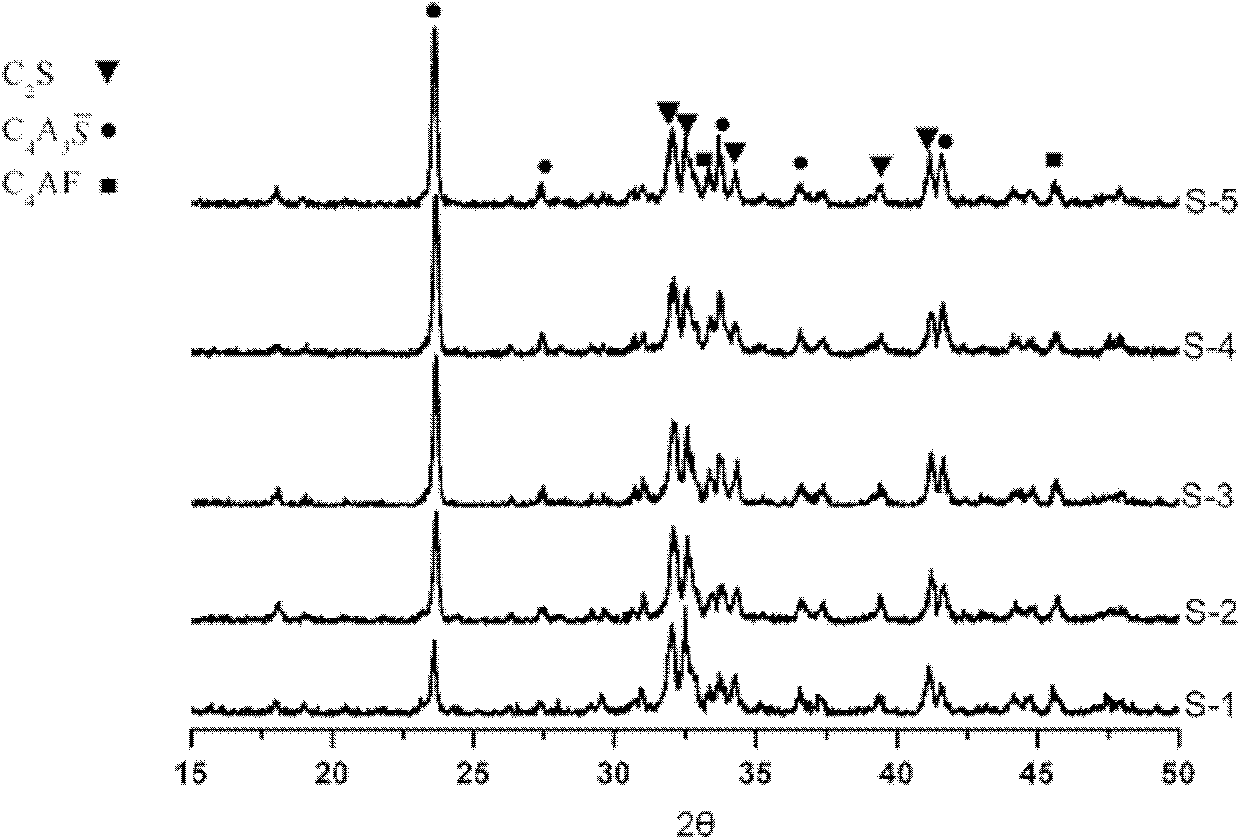

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

Use of organic waste/mineral by-product mixtures in cement manufacturing processes

InactiveUS20050066860A1Reduce nitrogen oxide (NOx) emissionNitrogen compoundsDispersed particle separationNitrogen oxidesCement manufacturing

The use of organic waste / mineral by-product mixtures as raw materials in the manufacture of cement clinker; as alternative or supplemental fuel sources for heating a kiln used in a cement clinker manufacturing process; and, to reduce nitrogen oxide (NOx) emissions generated during cement manufacturing processes are disclosed.

Owner:N VIRO INT

Novel red-mud-based grouting material and preparation method thereof

InactiveCN103896503ALow grade requirementsHigh strengthClinker productionRed mudUltimate tensile strength

The invention discloses a novel red-mud-based grouting material and a preparation method thereof. The grouting material comprises the following components in percentage by weight: 70-80% of red mud, 20-30% of a mineral admixture, and an additionally-admixed composite alkali activator of which the modulus is 1.2-1.6, and the appropriate admixing amount is 8-12%. The novel red-mud-based grouting material prepared by using the red mud and the mineral admixture has good liquidity and relatively high early strength, can be used for reducing the influence on the environment by reasonably adopting industrial waste residues, and is simple in ingredients and low in manufacturing cost.

Owner:焦作丁豪科技股份有限公司

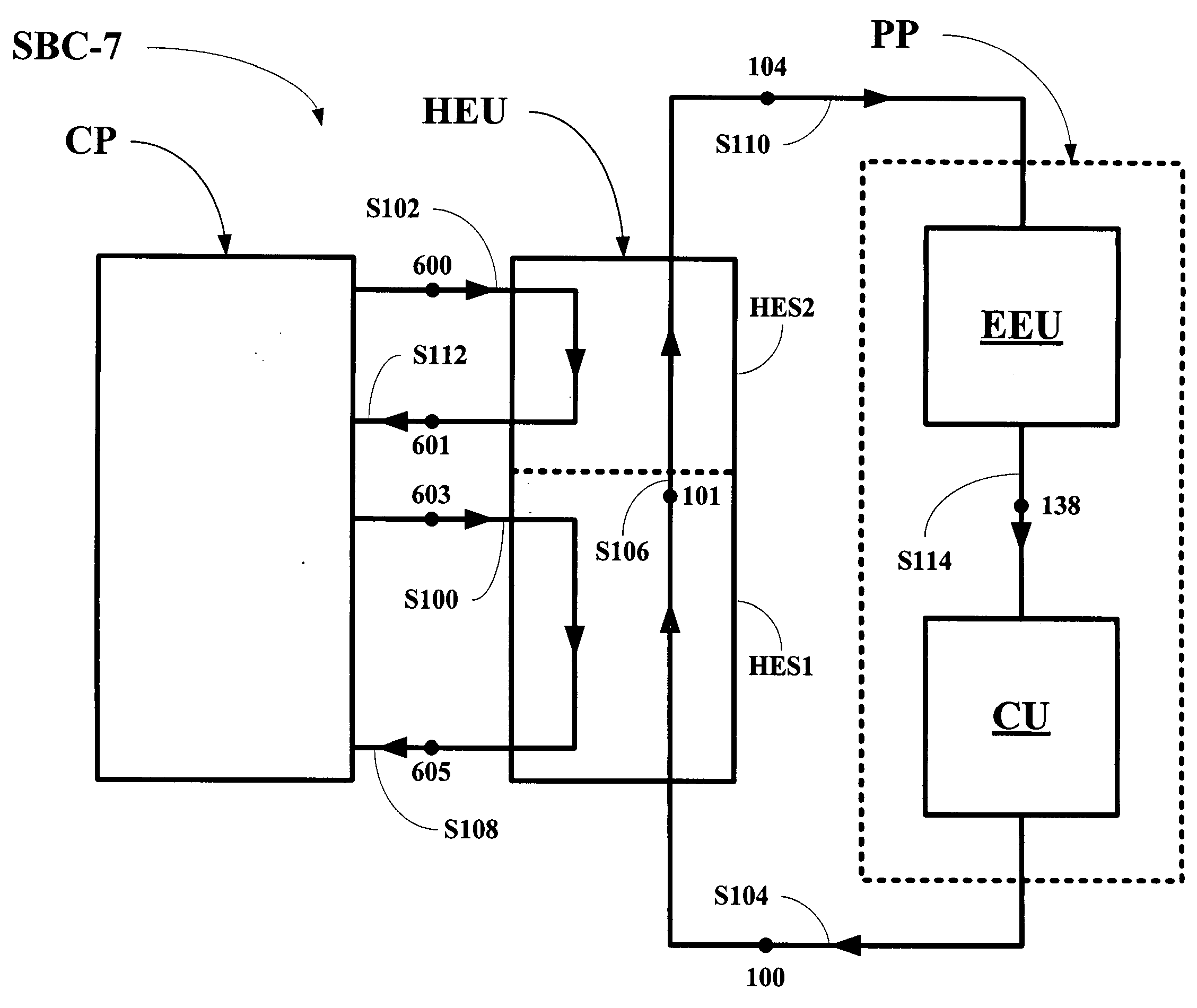

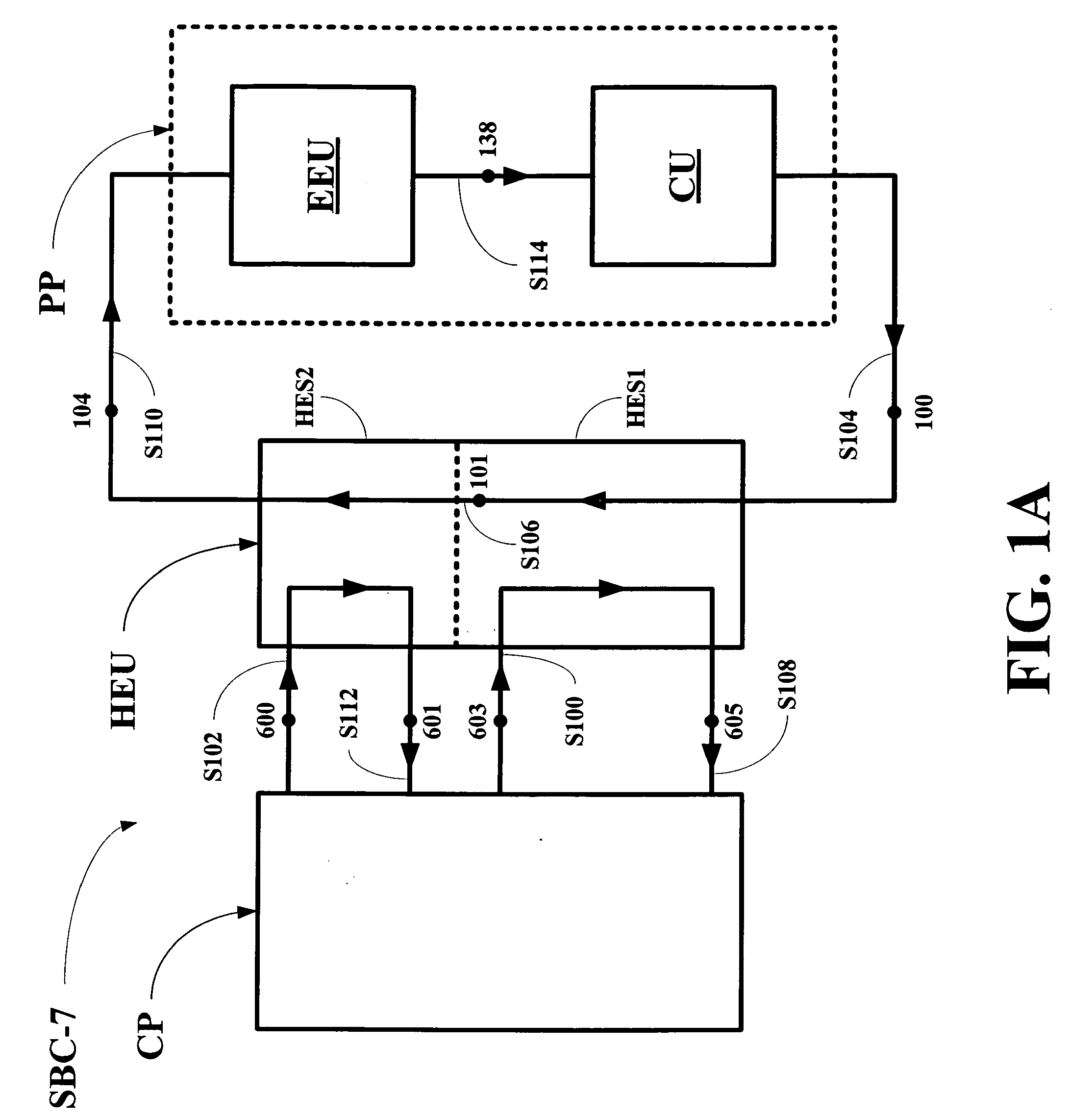

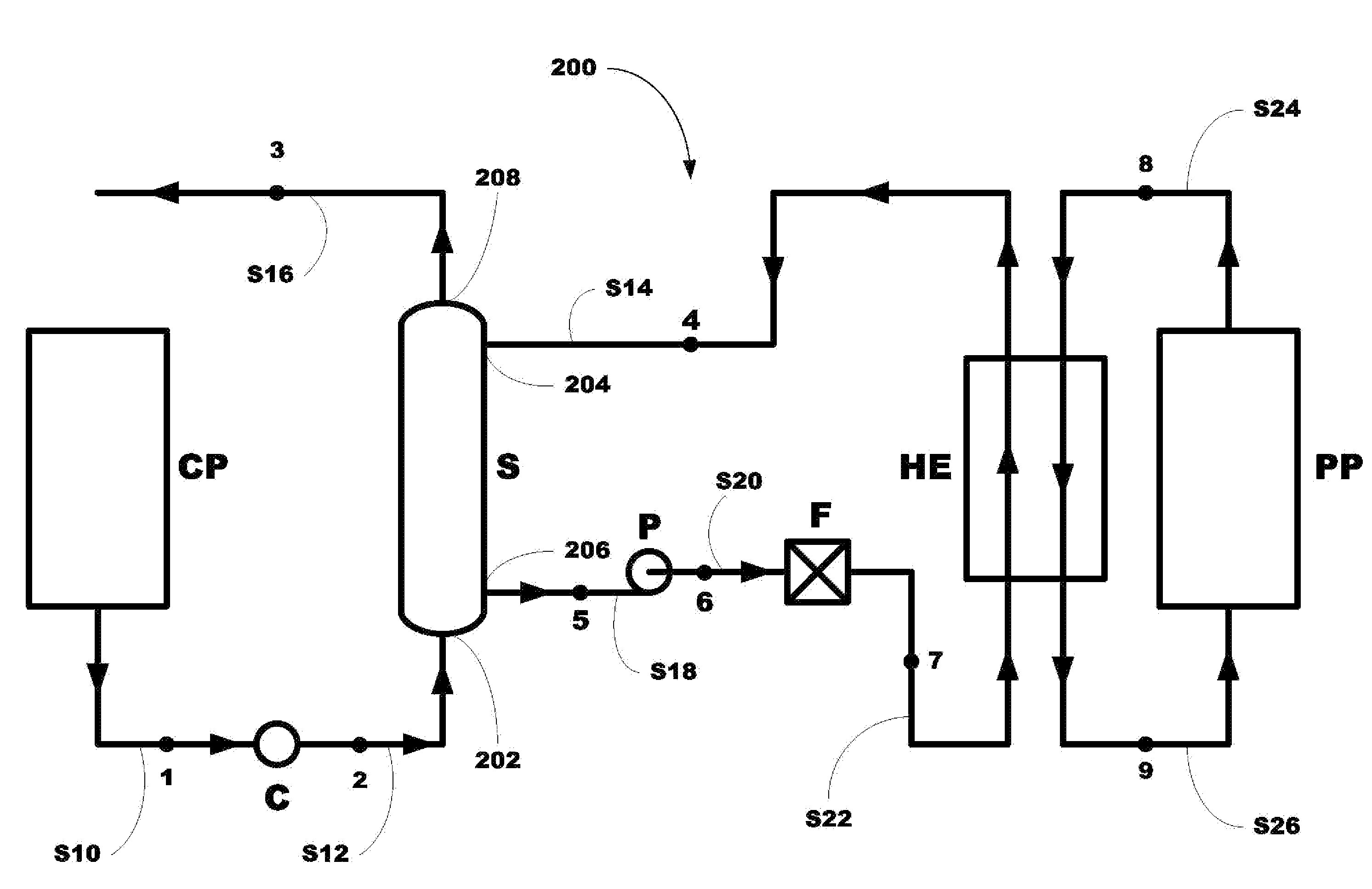

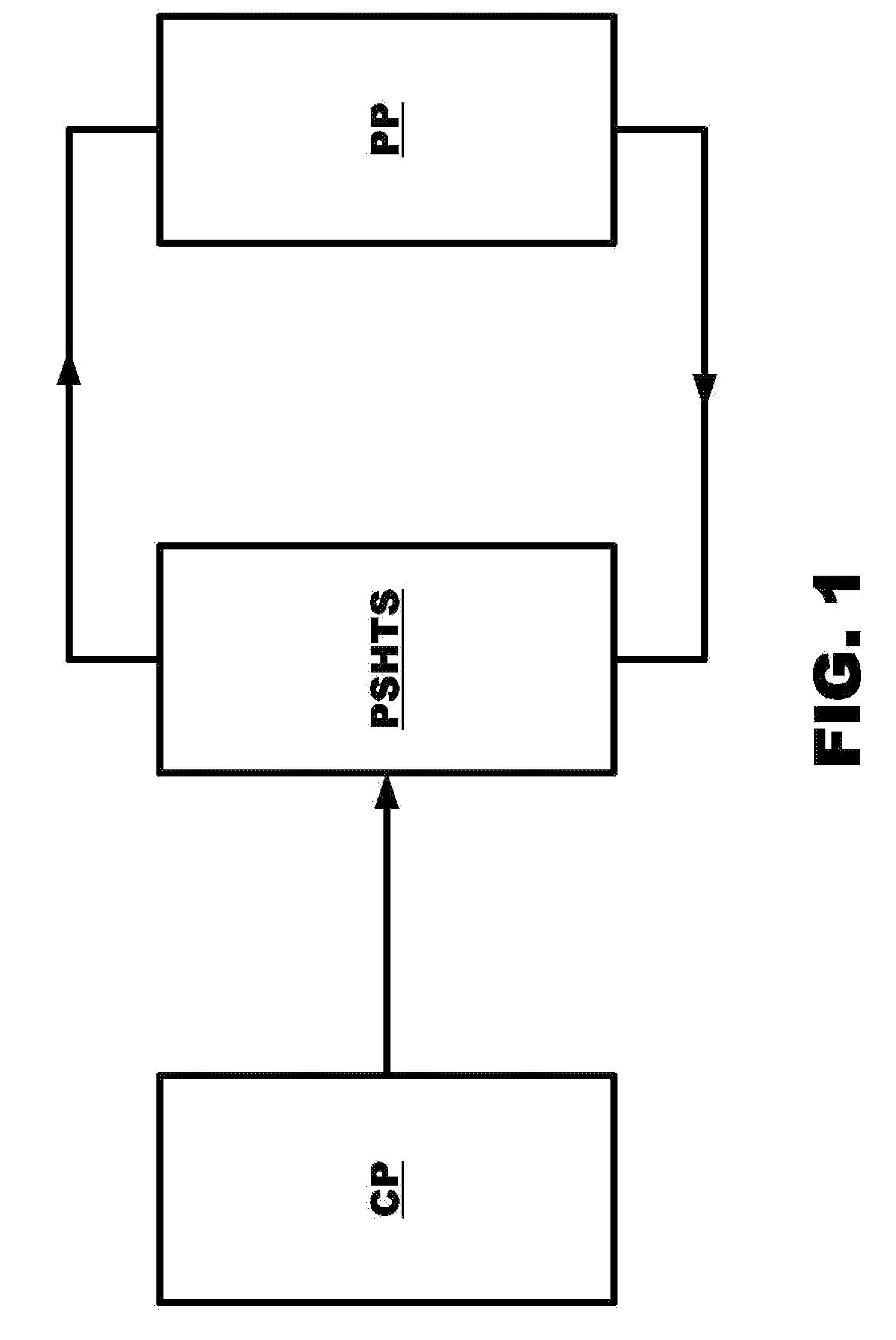

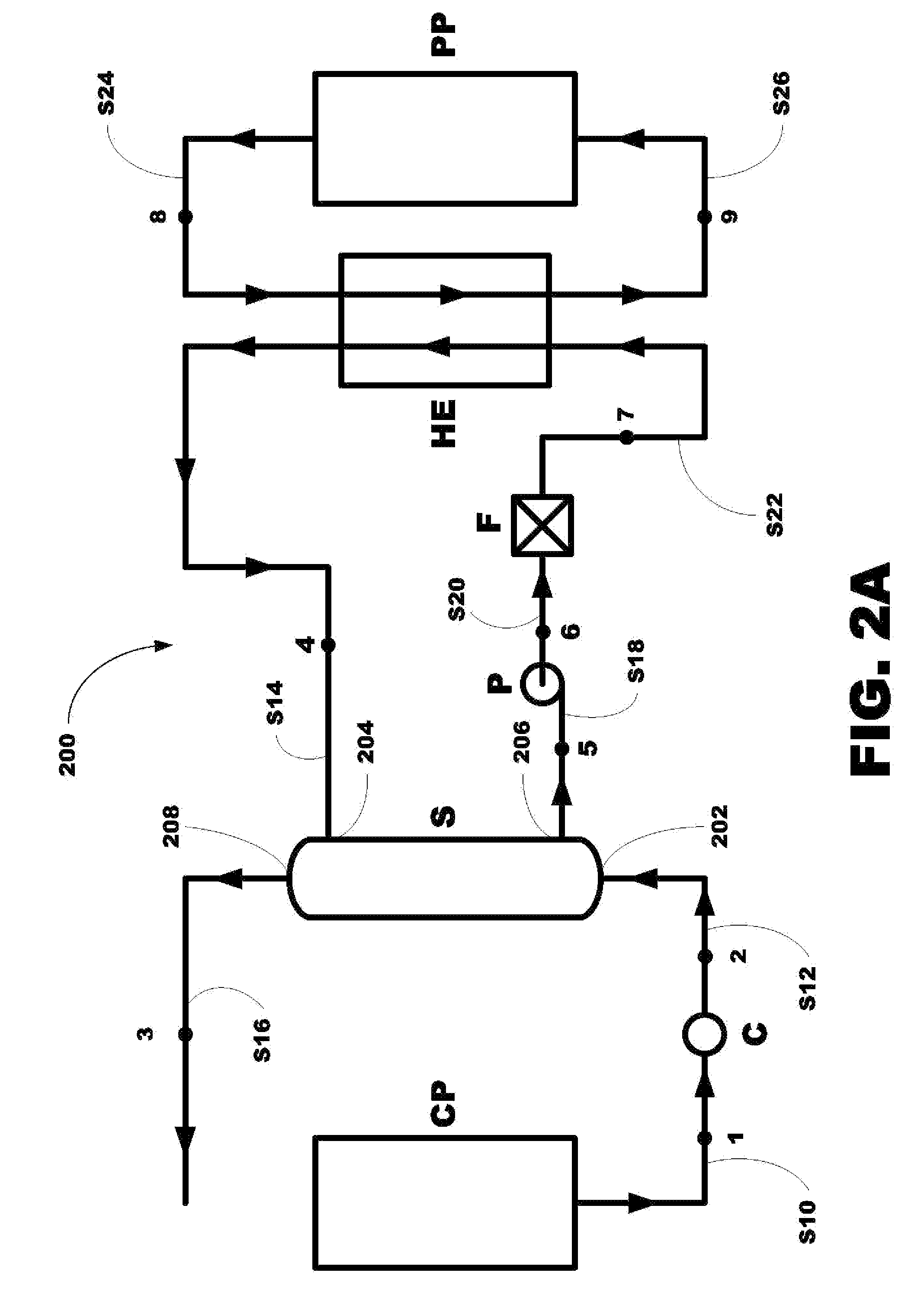

Method and system for converting waste heat from cement plant into a usable form of energy

Methods and systems for converting waste heat from cement plant into a usable form of energy are disclosed. The methods and systems make use of two heat source streams from the cement plant, a hot air stream and a flue gas stream, to fully vaporize and superheat a working fluid stream, which is then used to convert a portion of its heat to a usable form of energy. The methods and systems utilize sequential heat exchanges stages to heat the working fluid stream, first with the hot air stream or from a first heat transfer fluid stream heated by the hot air stream and second with the flue gas stream from a second heat transfer fluid stream heated by the hot air stream.

Owner:KALINA POWER LTD +1

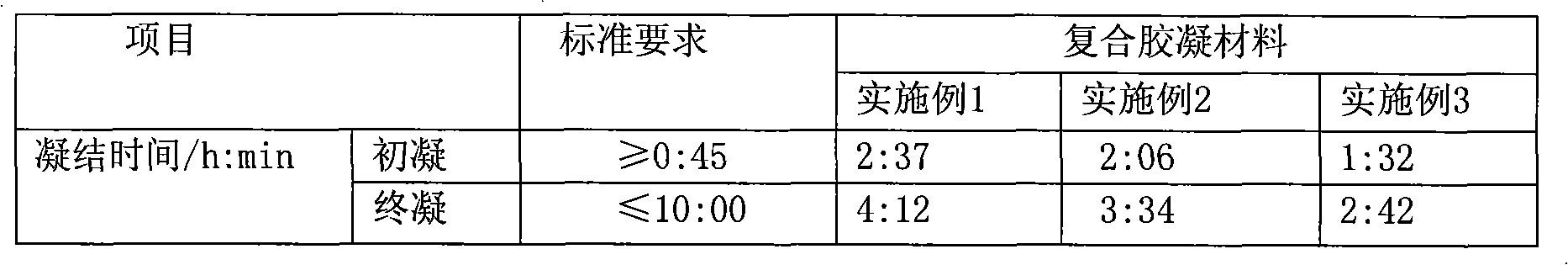

Composite gel material and preparation method thereof

InactiveCN102633461AEffective blockageIncrease macro strengthSolid waste managementClinker productionSlagBiological activation

The invention relates to a composite gel material and a preparation method thereof, and belongs to building materials. The composite gel material comprises the following raw materials in percentage by weight: 28-55% of blast furnace slag powder, 0-18% of steel slag powder, 22-45% of coal ash, 5-15% of desulfurization gypsum and 6-10% of composite solid activator. The preparation method comprises the following steps of: sequentially adding the materials into a grinding machine and grinding for 20-60 minutes until the specific surface area is more than or equal to 300m<2> / kg; and fully mixing the materials with the steel slag powder which is ground until the specific surface area is more than 400m<2> / kg to obtain the composite gel material, or respectively grinding the materials and then uniformly mixing. The composite gel material has the advantages of availability of materials, high alkalinity, stability in air, outstanding activation effect, high industrial waste utilization rate, low cost, simple process and the like, and can be used as 325R-425 composite concrete or used as a gel material in concrete engineering and during concrete product manufacturing.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

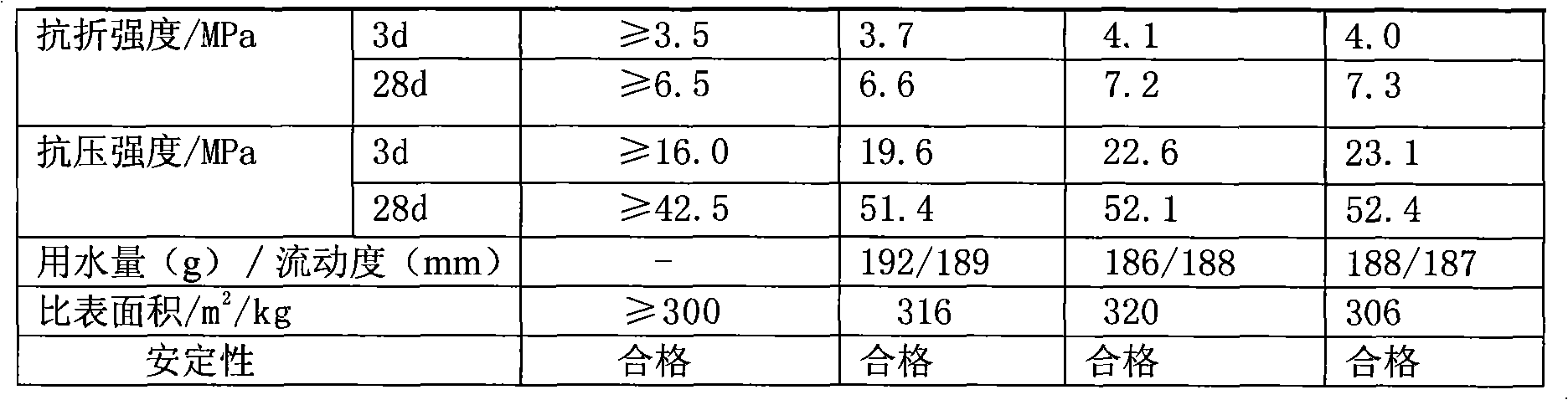

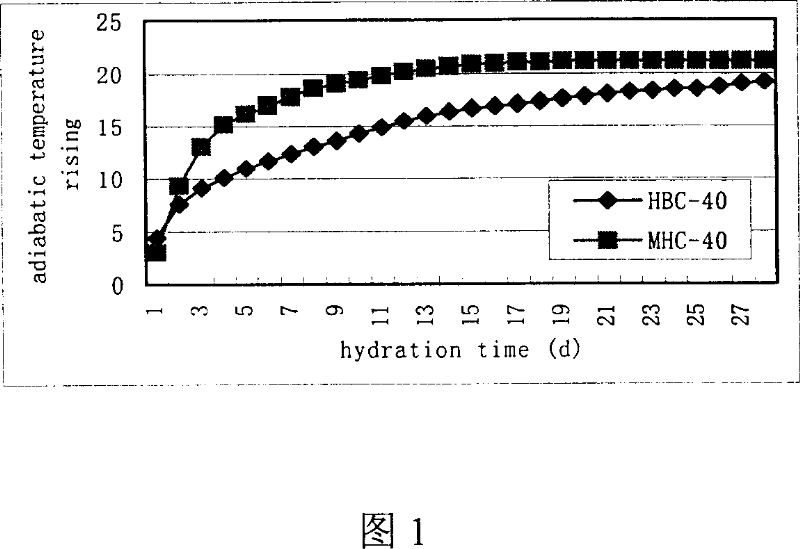

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

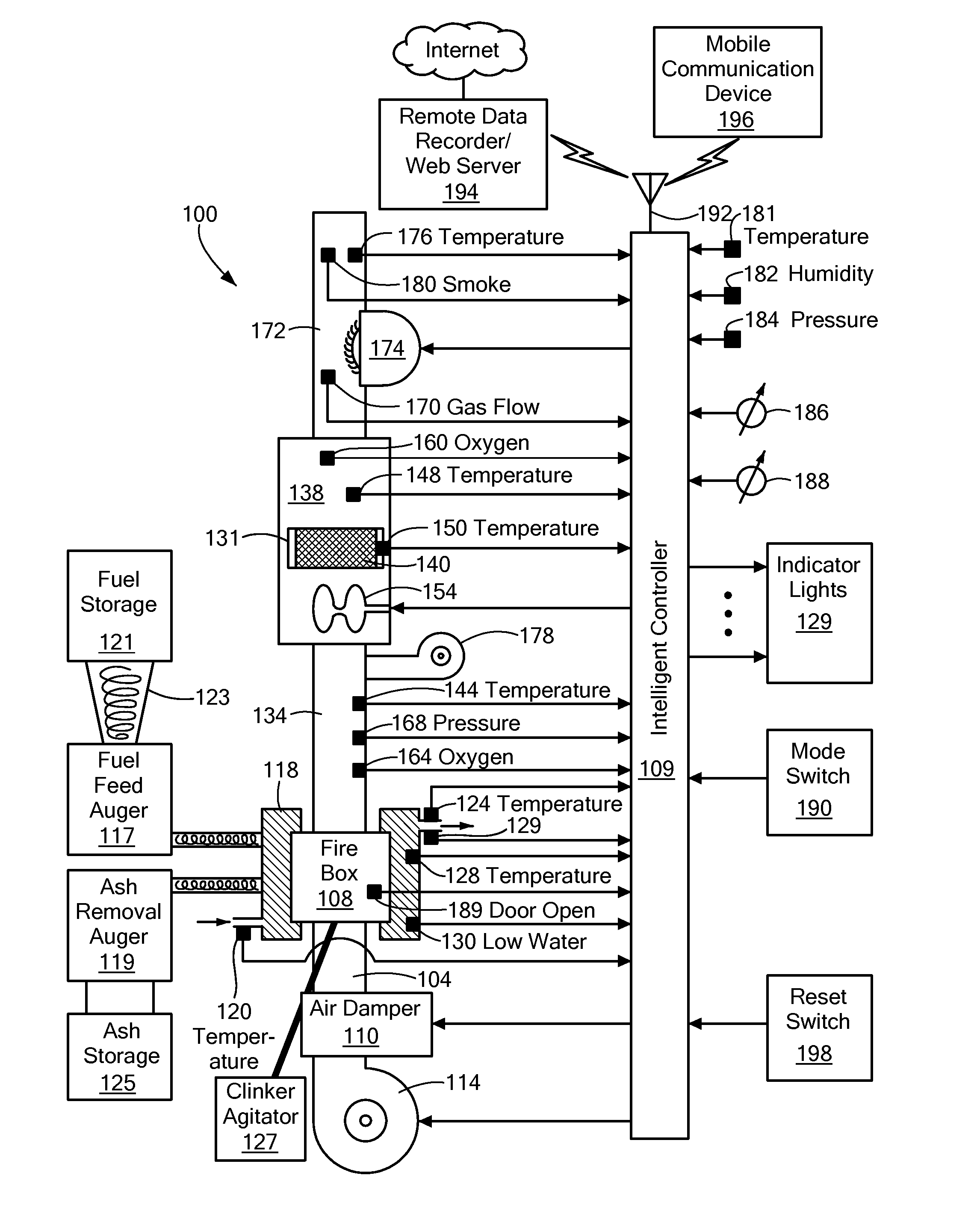

Fuel Feed and Air Feed Controller for Biofuel-Fired Furnace

A microprocessor-based controller manages delivery of BTUs or power by determining an amount of thermal heat or power needed through sensors and, in response, controls a batch or continuous feed of biofuel fuel and / or air to a biofuel furnace. The controller controls the fuel and air required to operate the furnace efficiently.

Owner:BIOMASS CONTROLS PBC

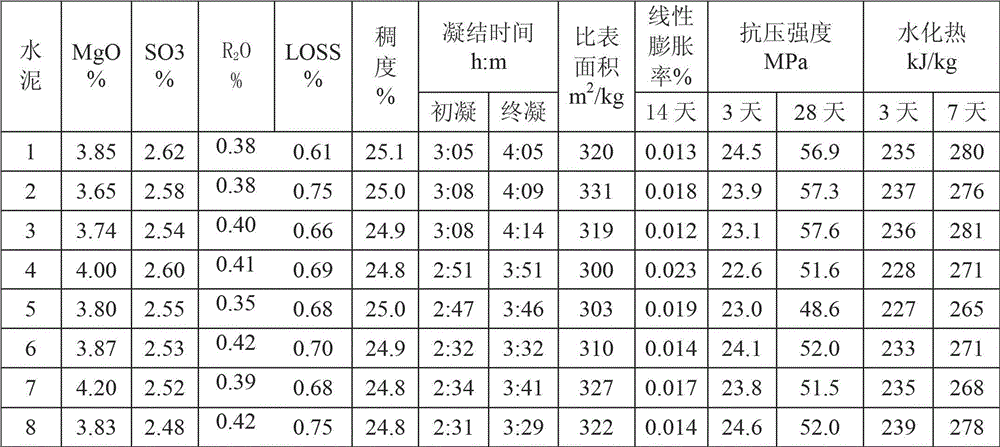

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

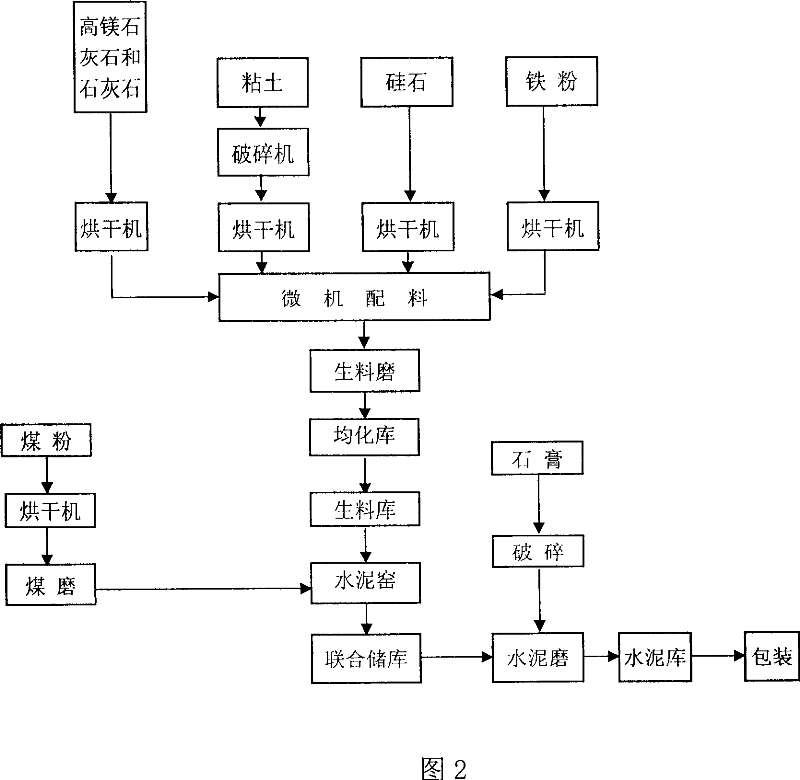

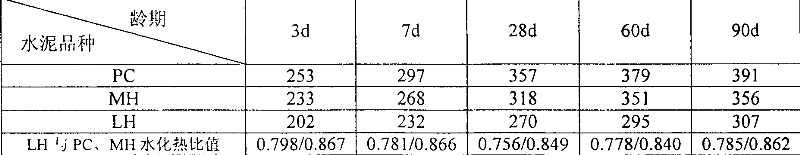

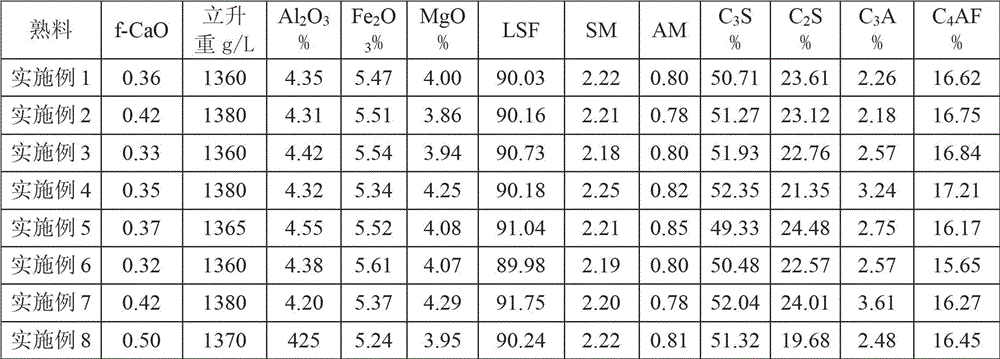

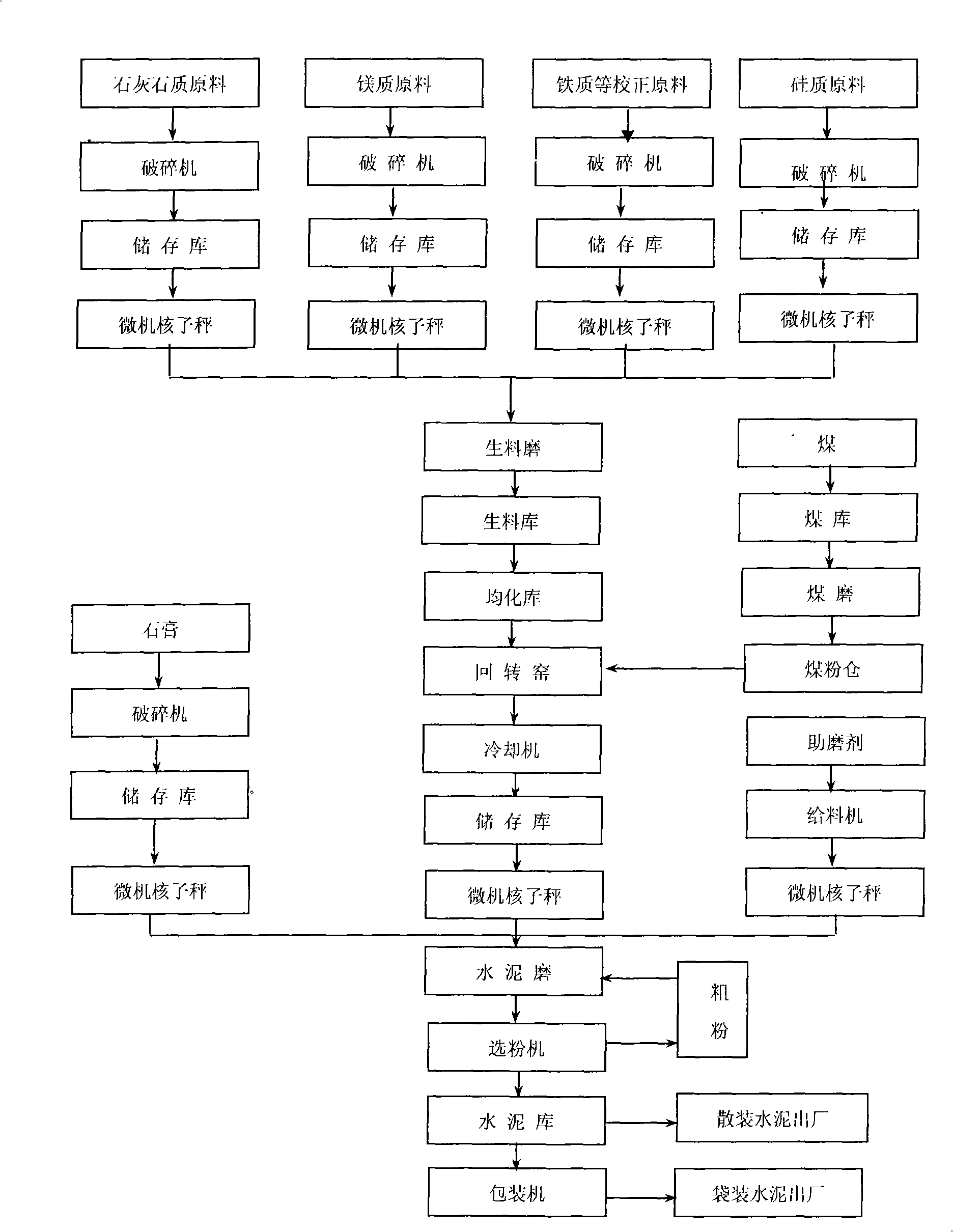

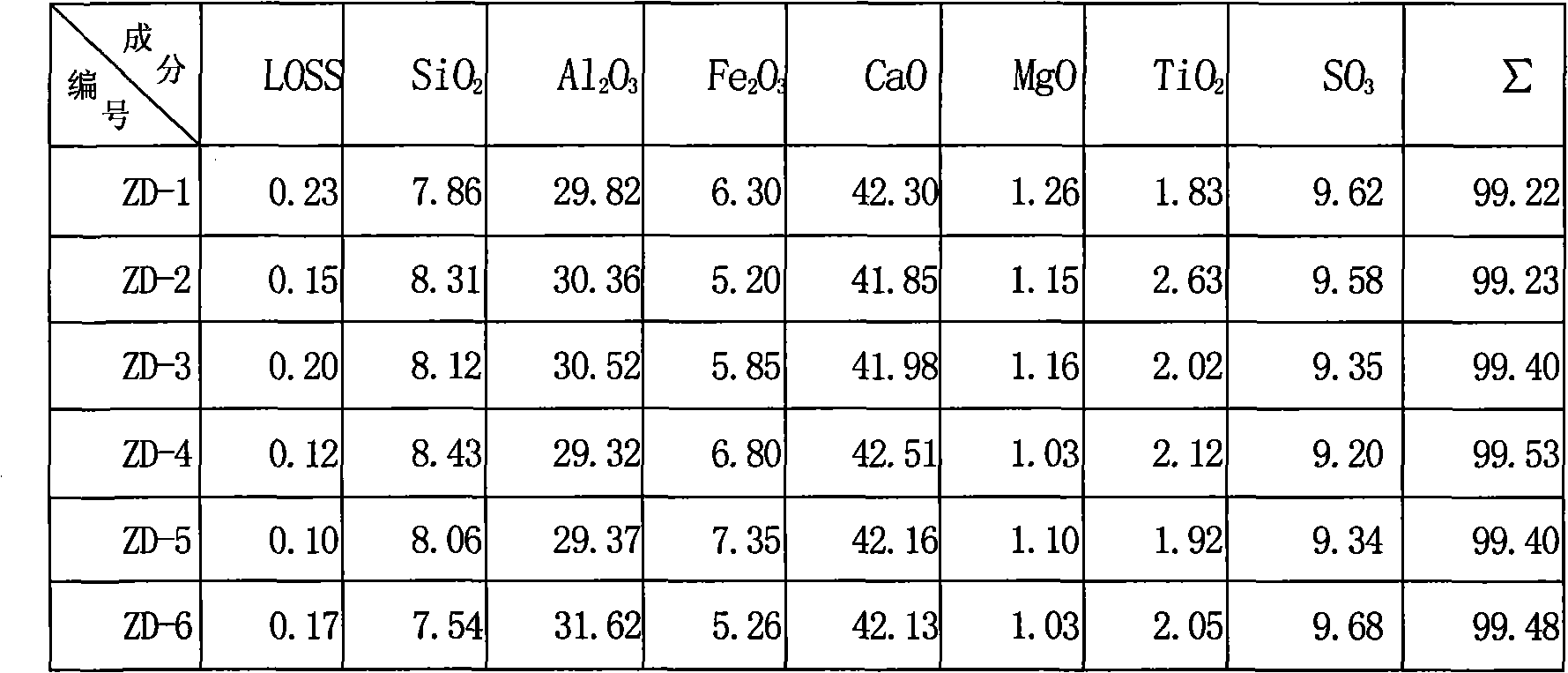

High-magnesium moderate-heat portland cement and production method thereof

InactiveCN101353231AReduce water demandThe micro-expansion property hasClinker productionHigh magnesiumPortland cement

The invention relates to a high-magnesium moderate heat portland cement, which is characterized in that (1) the contents of MgO and SO3 in the cement are 3.0-6.5% and 1.4-2.2% respectively; (2) the weight percentages of the mineral composition for grinding cement clinker are 35-55% of C3S, 15-35% of C2S, 1-6% of C3A and 10-25% of C4AF; and the content of MgO in the cement clinker is 3.0-6.5%; (3) in the raw materials for calcining the clinker, the contents of MgO, CaO and Fe2O3 are respectively controlled at a certain value within the ranges of 2.5-3.8%, 38.0-42.0% and 3.5-4.5%, and the variation ranges thereof are respectively controlled within plus or minus 0.10%, plus or minus 0.20% and plus or minus 0.15%. The production method of the cement mainly comprises three procedures of raw material milling, clinker calcining and cement grinding, namely, 'two grinding and one calcining'. The concrete made from the cement is characterized by good fluidity, low water requirement, moderate cement heat, high later strength, good durability, microdilatancy performance, and the like; compared with the conventional portland cement and moderate heat portland cement, the high-magnesium moderate heat portland cement is more favorable for realizing high performance of the concrete.

Owner:湖南石门特种水泥有限公司

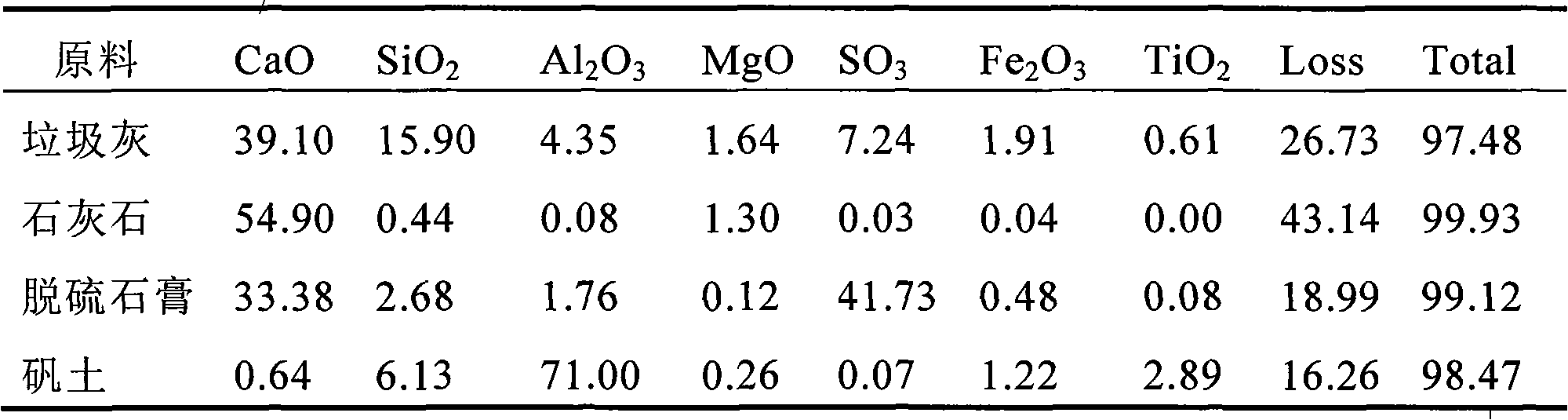

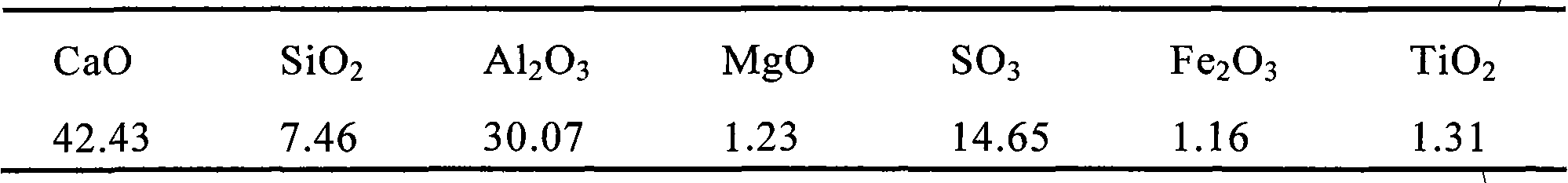

Method for preparing quick-hardened cement-based adhesive by utilizing refuse-incinerated fly ash

InactiveCN101921548ALighten the serious burdenReduce processing costsSolid waste managementInorganic adhesivesFiberAdhesive

The invention relates to a method for preparing a quick-hardened cement-based adhesive by utilizing refuse-incinerated fly ash, comprising the following steps of: (1) calcination of sulphoaluminate cement: raising the temperature of a sulphoaluminate cement raw material to 1,200-1,250 DEG C in the temperature rise speed of 20-30 DEG C / min, then preserving the temperature for 1-2h to form a sulphoaluminate cement clinker, and mixing the sulphoaluminate cement clinker with anhydrous gypsum to obtain the sulphoaluminate cement; and (2) preparation of the quick-hardened cement-based adhesive: blending the sulphoaluminate cement, quartz sand, pulverized fuel ash, hydroxypropyl methyl cellulose, re-dispersible rubber powder and fibers to obtain the quick-hardened cement-based adhesive. Comparedwith the prior art, the method can ensure the performance of the product and also can reduce serious environmental burden and processing cost which are caused by not utilizing the fly ash, desulfurized gypsum and the like.

Owner:TONGJI UNIV

Method and apparatus for the utilization of waste heat from gaseous heat sources carrying substantial quantities of dust

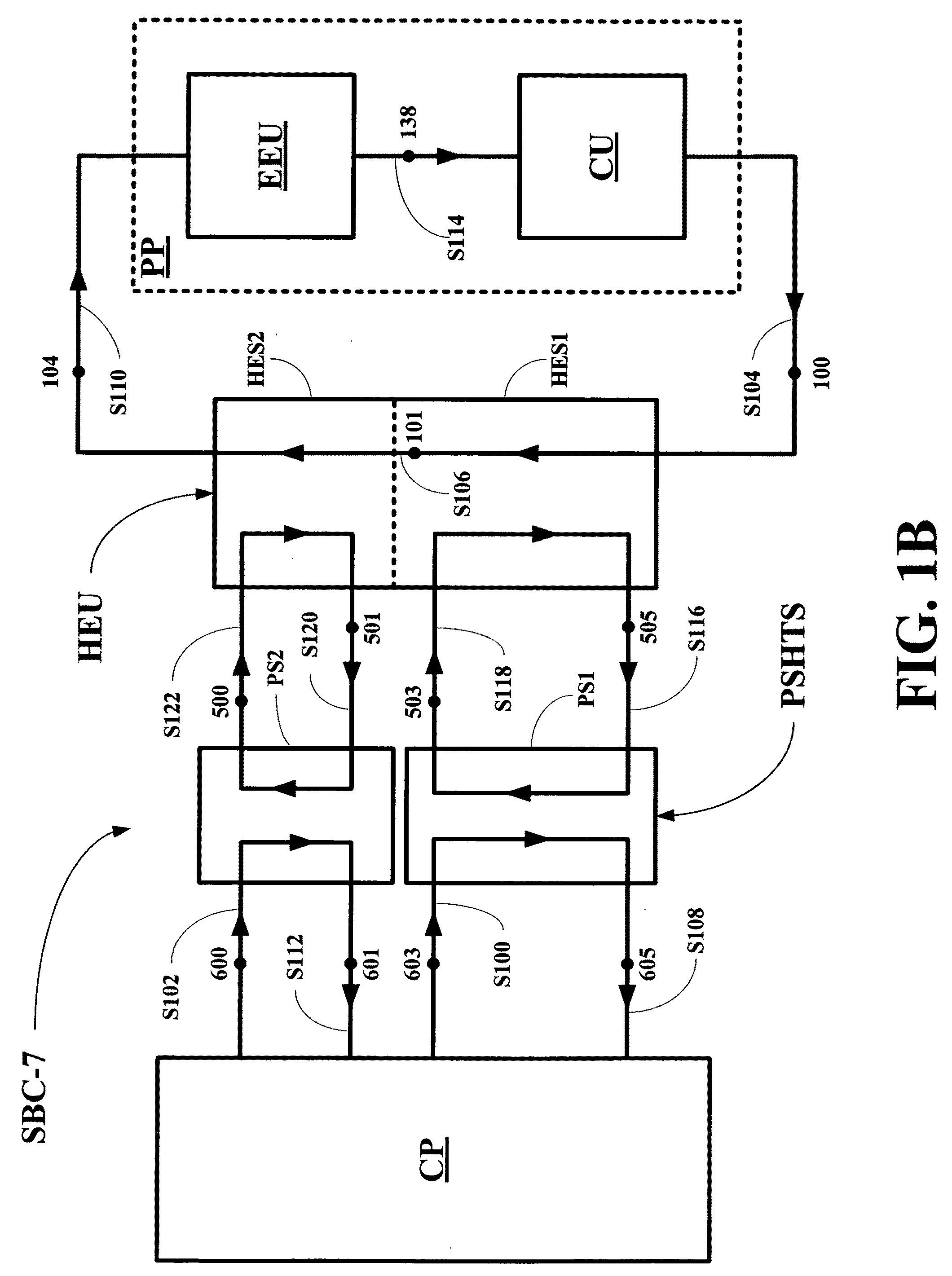

An apparatus, system and method for transferring heat from a hot flue gas stream from a cement plant including large particles and dust to a working fluid of a power plant via a high temperature heat transfer fluid without exposing all or most of the equipment to the erosive force of the particles and dust is disclosed where the apparatus includes a cement plant, a particle separation and heat transfer system and a power plant

Owner:KALINA POWER LTD

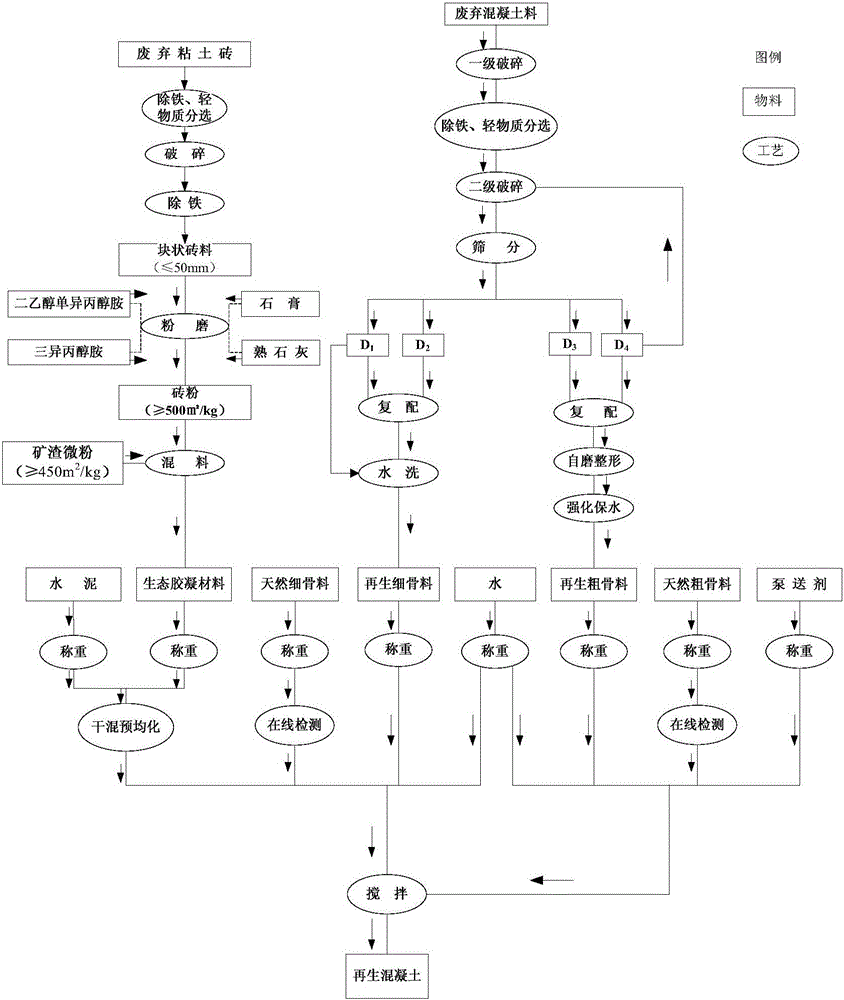

Production technology of ecological concrete

InactiveCN105948545AEfficient use ofAchieve recyclingSolid waste managementClinker productionSlurryUltimate tensile strength

The invention discloses a production technology of ecological concrete. The production technology comprises the steps of preparing an ecological cementing material by using construction waste clay bricks, and preparing recycled aggregate by using construction waste concrete; uniformly mixing cement and the ecological cementing material, then adding part of water, natural fine aggregate and recycled fine aggregate, stirring to form slurry, then adding natural coarse aggregate, recycled coarse aggregate, the rest water and a pumping aid, and stirring to prepare C30-C40 strength grade ecological concrete. By adopting the production technology of the ecological concrete, provided by the invention, useful components of construction waste are effectively used, the waste is turned into wealth, resources are saved, and the recycling of the construction waste resources is realized; the prepared ecological concrete is comparative with normal concrete in performance, is low in production cost, and can be largely applied to general construction engineering.

Owner:GANSU DELONG ECOLOGICAL BUILDING MATERIAL CO LTD

Modified low-alkalinity sulphoaluminate cement

InactiveCN101671133ASimple production processEasy qualitySolid waste managementClinker productionCrack resistanceCarbonization

The invention discloses modified low-alkalinity sulphoaluminate cement, which is a hydraulic cementing material prepared by the following steps: forging raw materials including proper elements to obtain 55-70% of clinker which takes anhydrous calcium sulphoaluminate (C3A3S), dicalcium silicate (C2S) and tetracalcium aluminoferrite (C4AF) as main mineral elements, using 5-10% of lithium residues asa modifier, adding a proper amount of 8-15% of anhydrite, 15-20% of mixing material and 0.05-0.2% of adjusting setting agents, and grinding to prepare the cement. The invention has the advantages ofsimple preparation technique, easily guaranteed quality, industrial waste residue recycle, low energy consumption, low cost, environment protection, good performances of low alkalinity, early and highstrength, microdilatancy, cracking resistance, freezing resistance, impermeability, anti-carbonization, abrasion resistance, flushing resistance, good adhering capability, adjustable primary time offinal setting, good slurry fluidity, good coherence in water and wide application range.

Owner:YONGZHOU ZHONGDA SPECIAL CEMENT

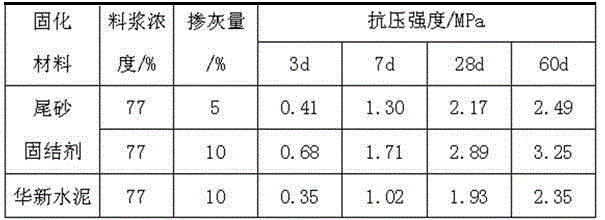

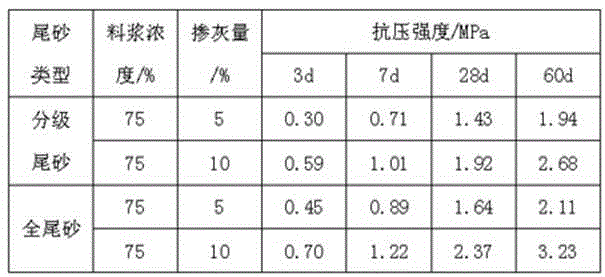

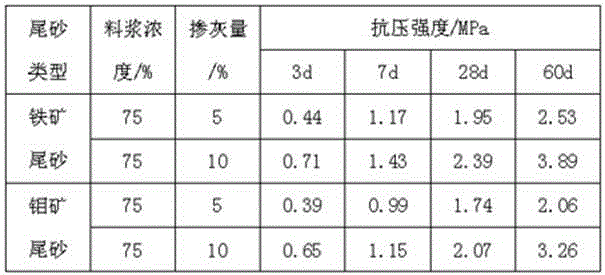

Clinker-free compound-type tailing consolidating agent as well as preparation and application for same

InactiveCN103145354ARealize resource utilizationIncrease profitClinker productionCinker content reductionSlagEngineering

The invention relates to a clinker-free compound-type tailing consolidating agent as well as a preparation and an application for the same, wherein the clinker-free compound-type tailing consolidating agent comprises the following components in percentage by weight: 55-72% of blast furnace water-quenched slag, 20-35% of desulfurization ash, and 2-15% of compound excitant. Via the clinker-free compound-type tailing consolidating agent disclosed by the invention, a new way is opened up for comprehensive utilization for the industrial solid wastes aforementioned, the cemented filling cost of tailing is reduced, and the purpose of treating wastes by using wastes is realized, thus obtaining remarkable, economic, social and environmental benefits.

Owner:HENAN AGRICULTURAL UNIVERSITY

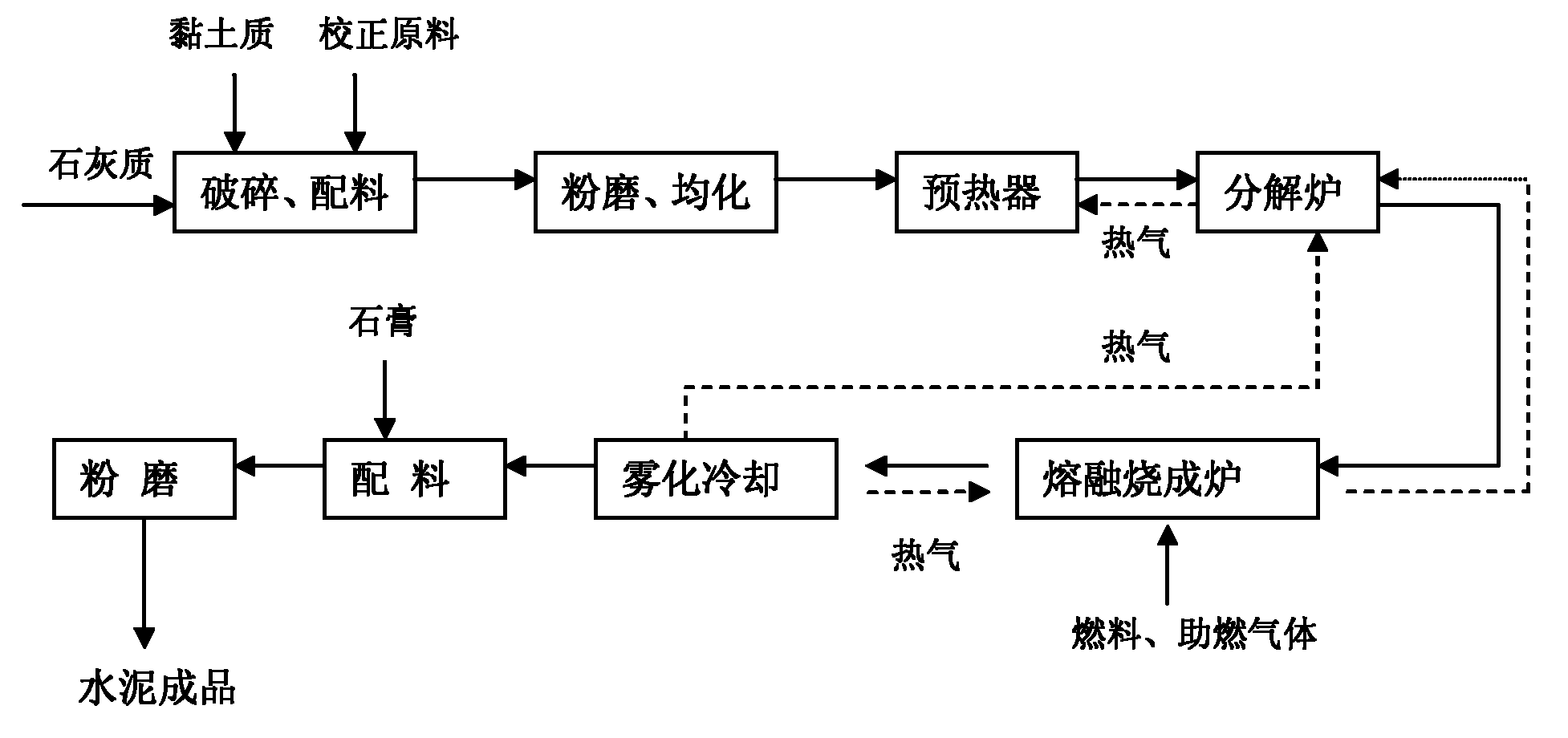

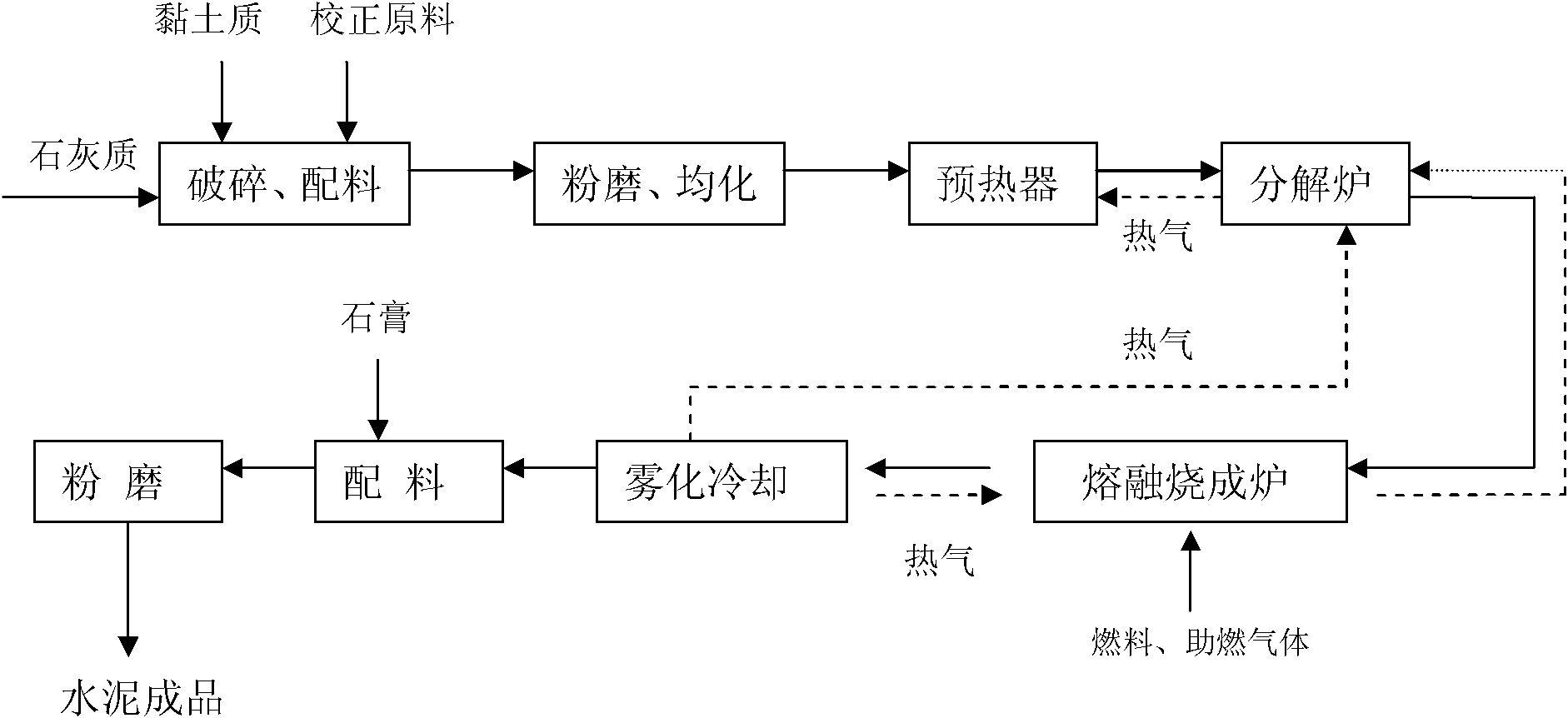

Cement production method

ActiveCN101811838AIncreased mass and heat transfer ratesIncrease production capacityClinker productionMelting tankCombustion

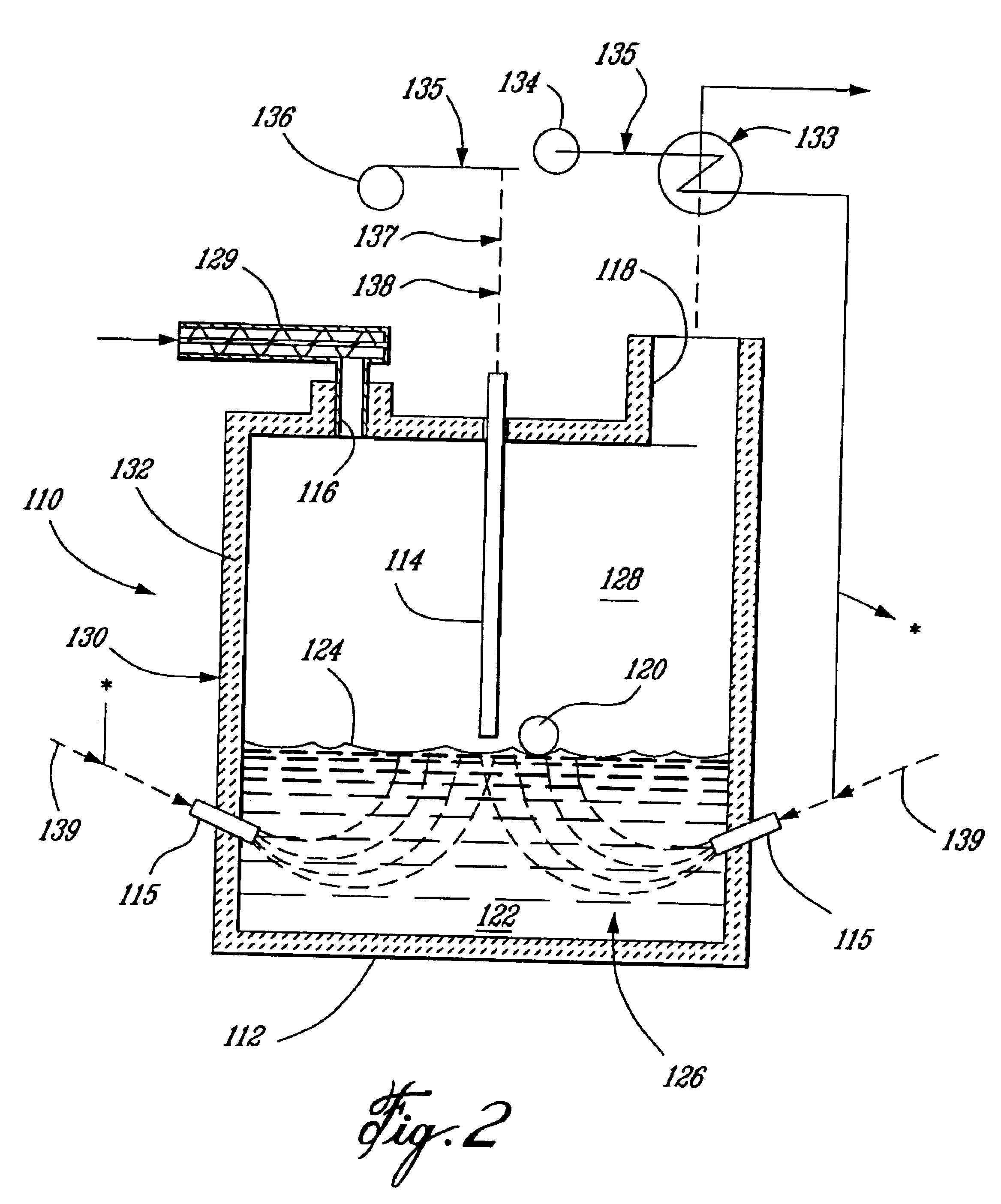

The invention relates to a novel cement production method and belongs to the technical field of cement production. The invention aims at solving the technical problem of reducing the energy consumption in the cement production process. The cement production method is characterized in that after being pre-heated and pre-decomposed, a cement raw meal is placed into a high-temperature molten pool at 1350DEG C to 1650DEG C to be transformed into molten mass; fuel and combustion-supporting gas are sprayed in through a spray gun which is immersed into the molten mass to provide energy; cement melting and sintering reaction is carried out; and the sintered molten clinker is cooled, proportioned and grinded continuously, thus producing the finished cement. The method adopts the full molten liquid phase reaction, the mass and heat transfer rate is greatly enhanced, the reaction time is short, and the transformation rate is high, thus enhancing the production capacity and saving a large amount of energy consumption.

Owner:GUIZHOU CHANHEN CHEM CO LTD

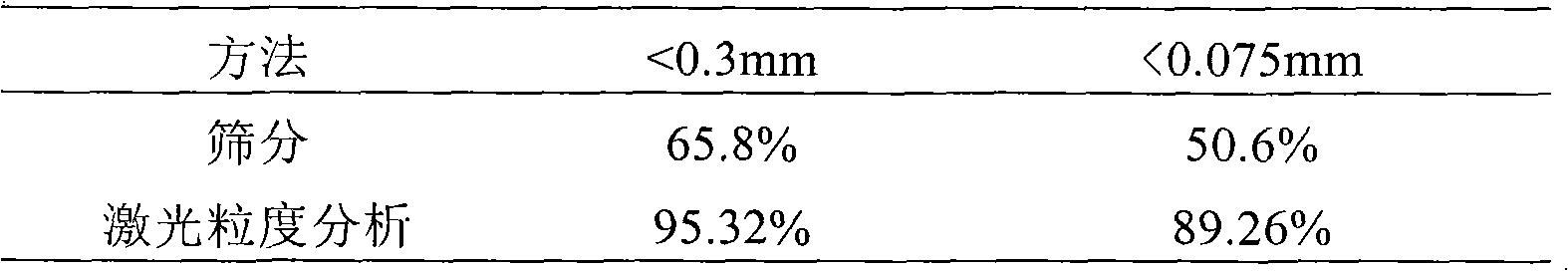

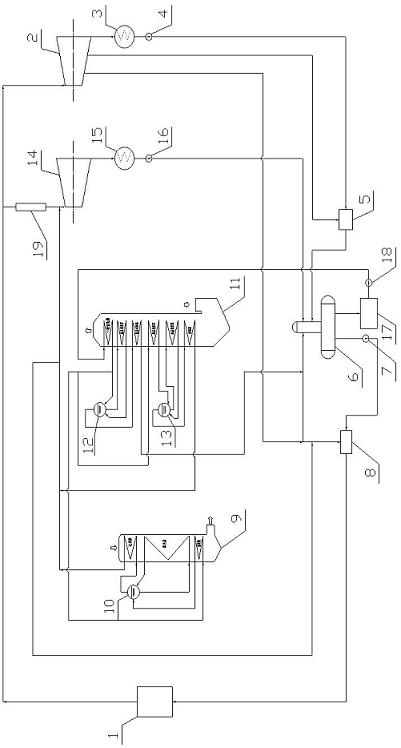

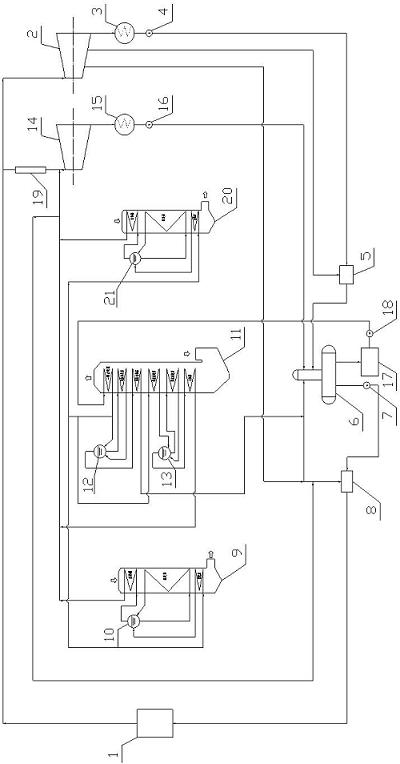

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

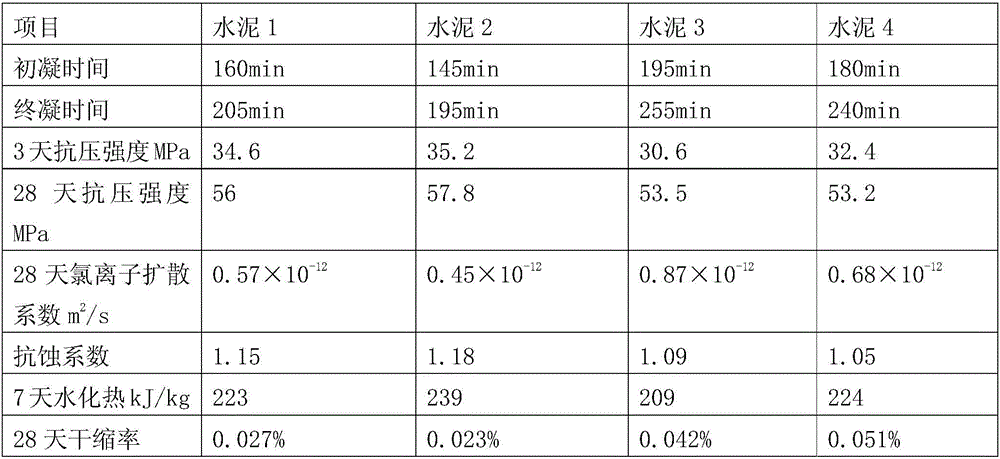

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

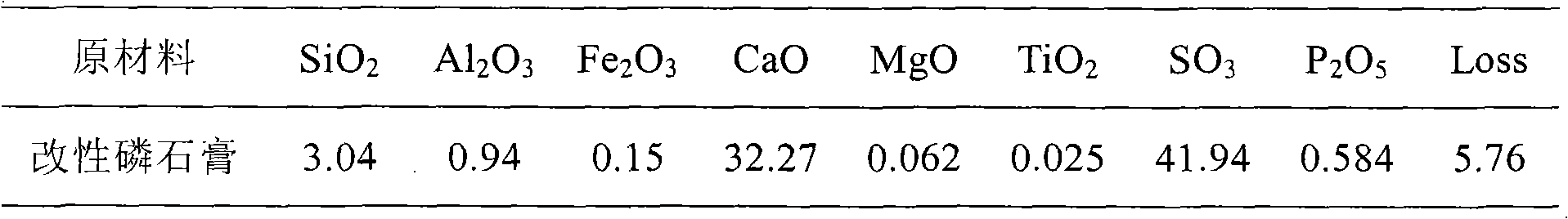

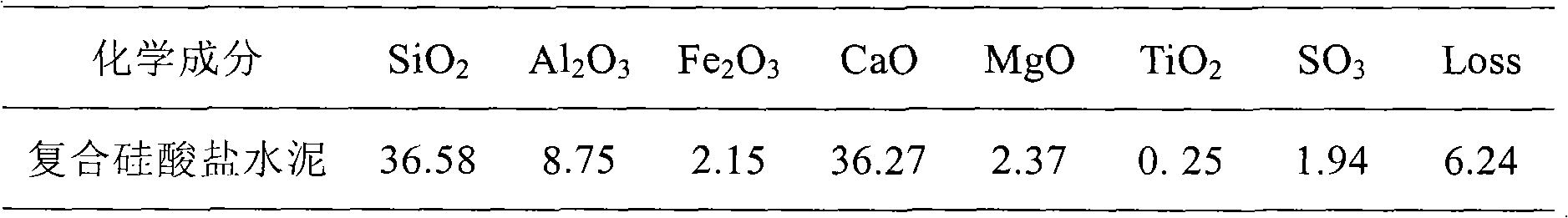

Composite portland cement and preparation method thereof

The invention relates to composite portland cement, which mainly comprises the following raw materials by weight percent: 20% to 30% of construction waste micropowder, 15% to 25% of lead and zinc mine tailings, 10% to 15% of mineral admixture, 3% to 5% of modified phosphogypsum and 40% to 50% of cement clinker. The preparation method of the composite portland cement comprises the preparation of modified phosphogypsum, the preparation of construction waste micropowder, the preparation of activator, the preparation of mineral admixture and the preparation of final products. The invention has great significance for the efficient use, energy saving and environment protection of construction waste and industrial waste, and the composite portland cement has the advantages of low cost and higherstrength.

Owner:WUHAN UNIV OF TECH

Raw materials combustion adjuvant

Disclosed is a slurry sintering agent which is prepared by using oxidizing agent as the main raw material, and one or more selected from mineralization agent, seed crystal, grinding aid or packing material as the compatible auxiliary raw materials. The sintering agent can reduce deacidized material in the clinker aggregate and improve the sintering quality of the clinker aggregate.

Owner:尹小林

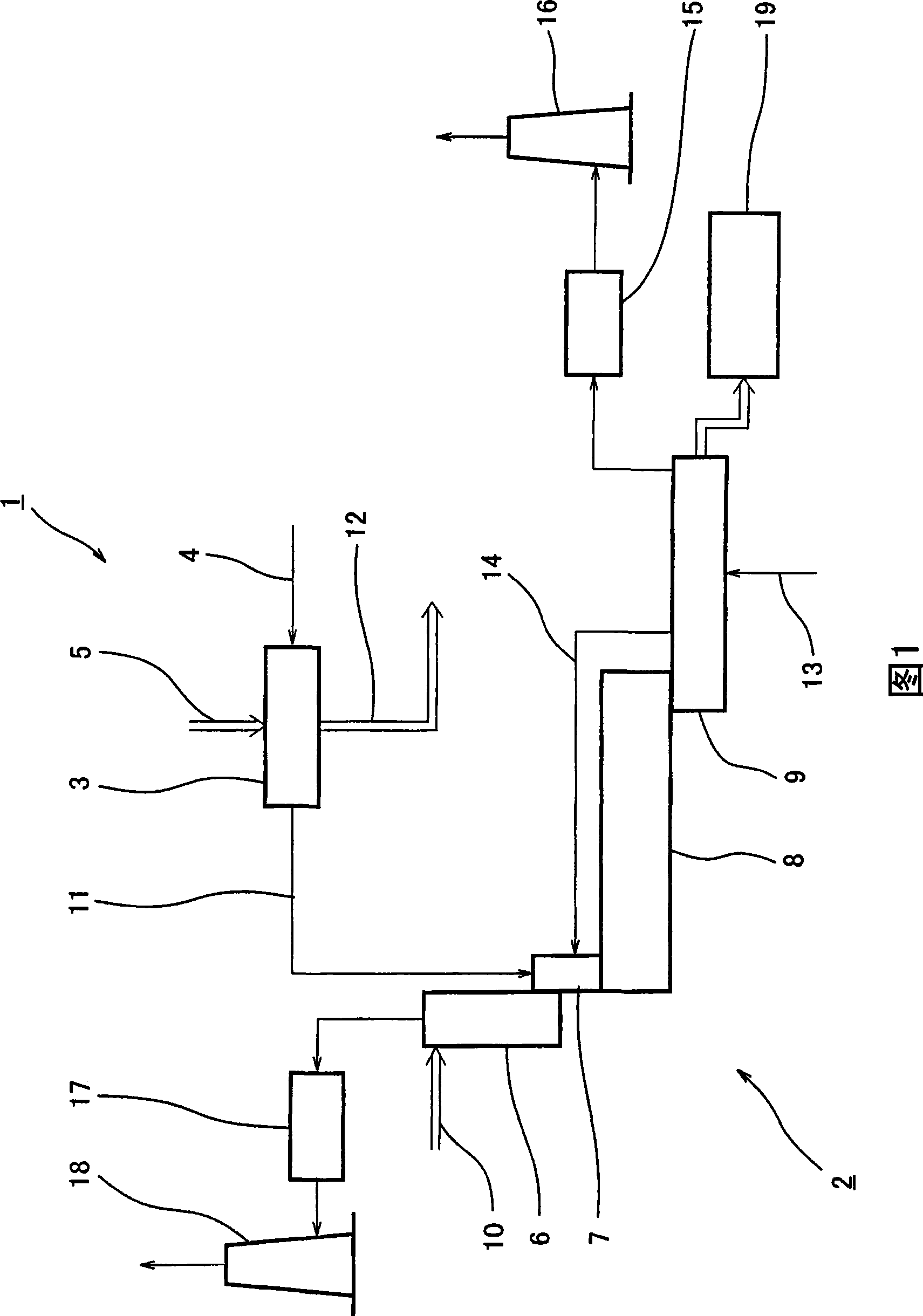

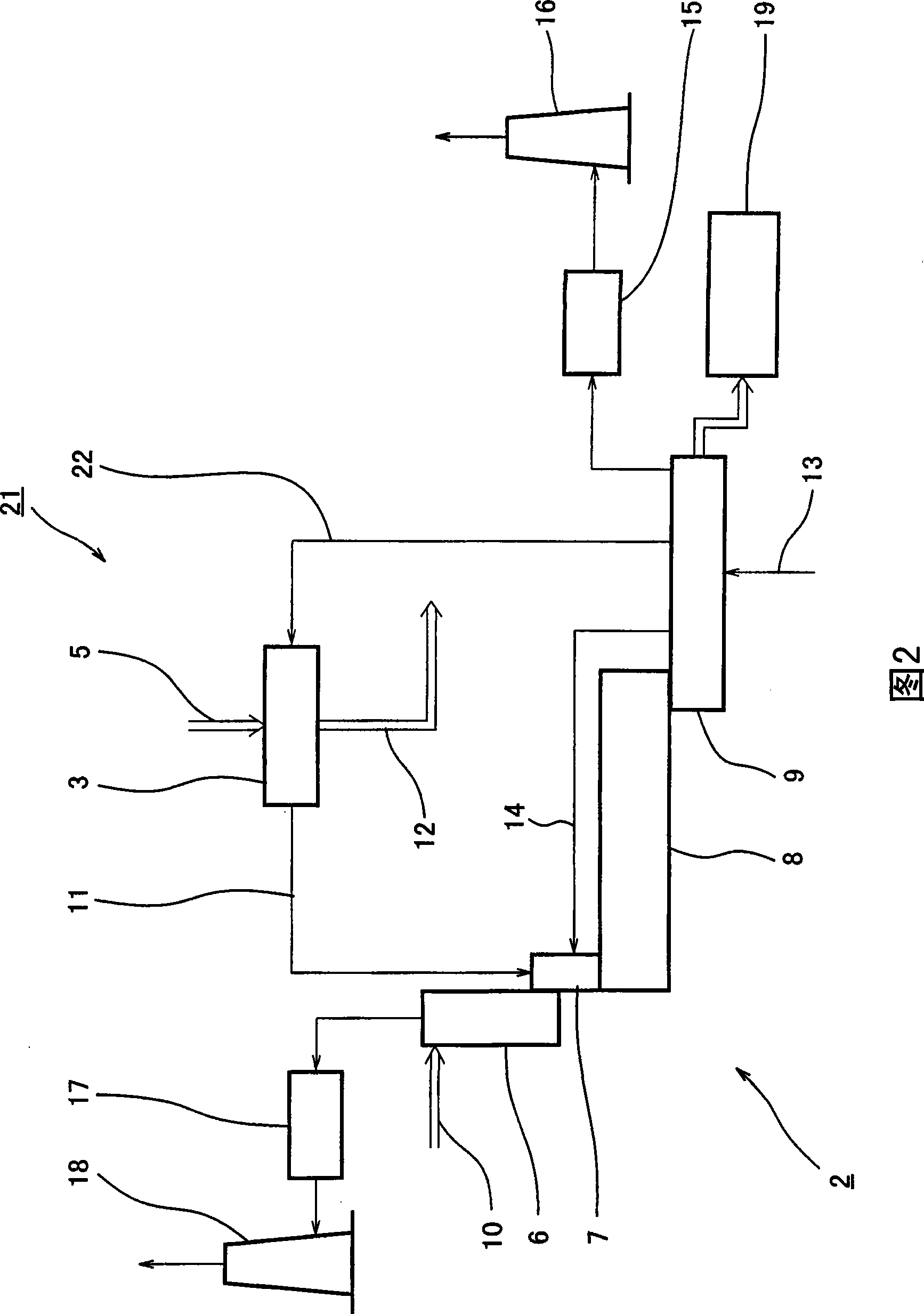

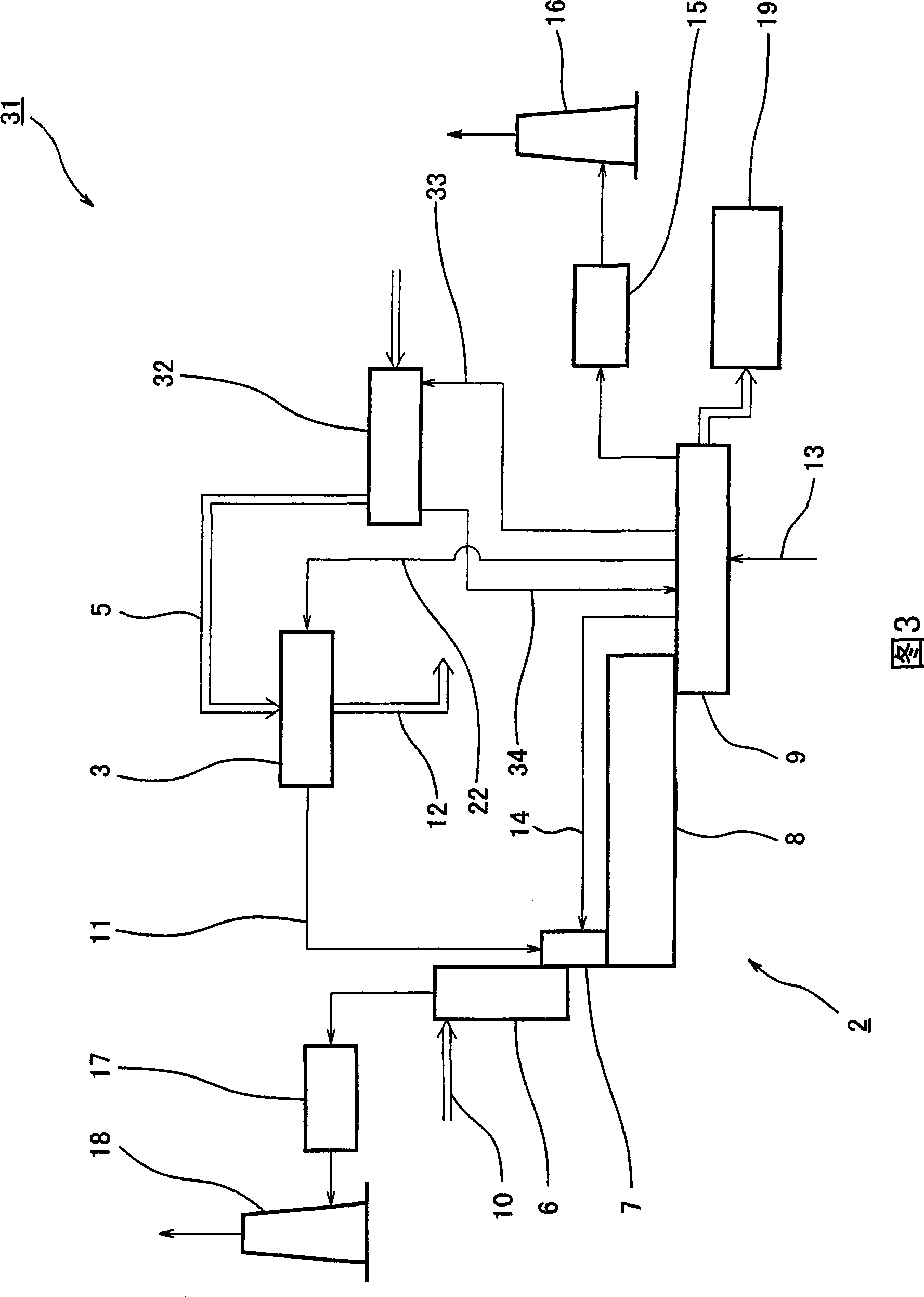

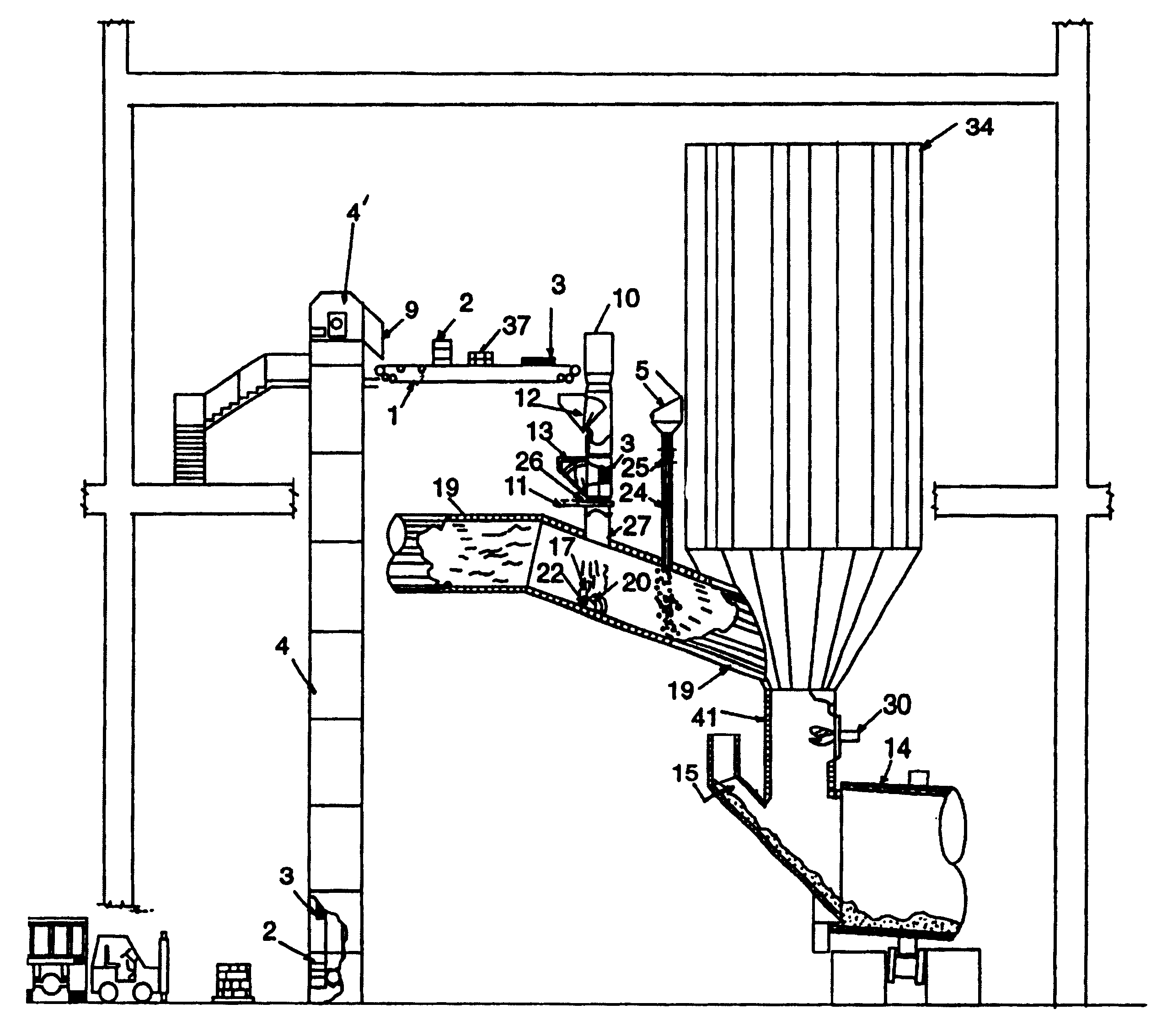

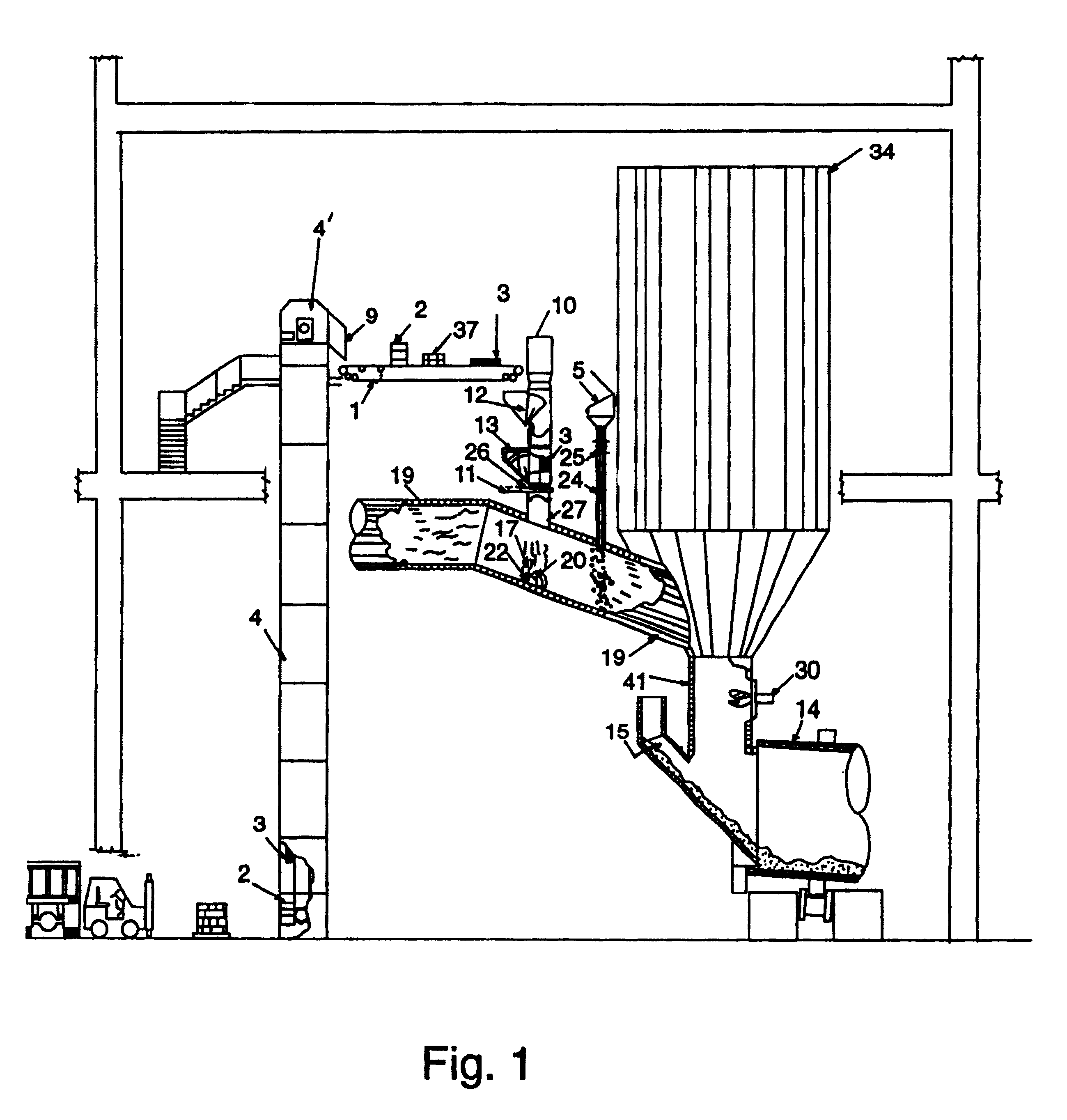

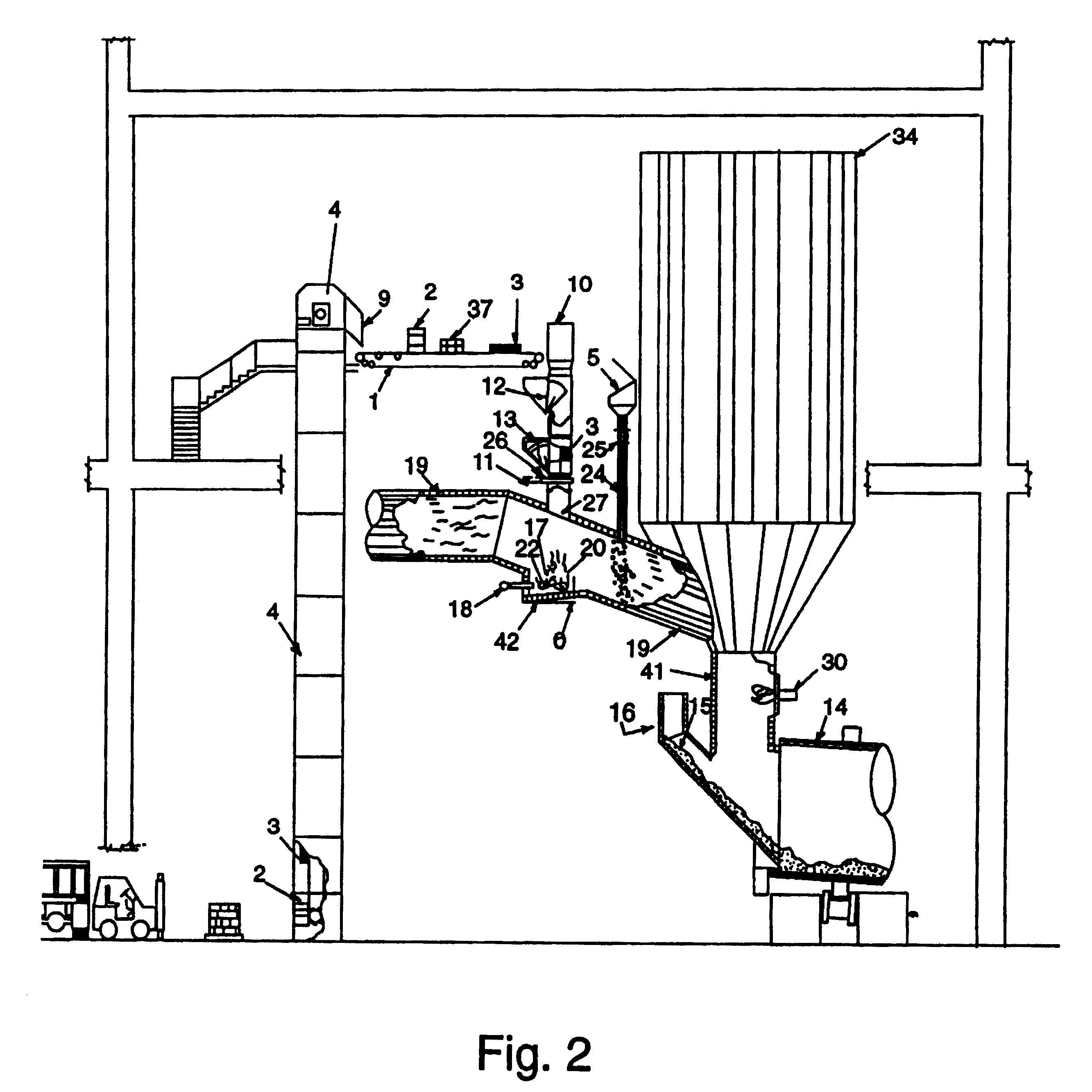

Apparatus and method for processing wastes

InactiveCN101434461AEfficient use ofLow costClinker productionSpecial form destructive distillationWaste processingProcess engineering

The invention provides waste processing equipment which is expected for improving utilization of heat energy and lowering equipment cost by means of a cement manufacturing process. The method for solving the problems is the waste processing equipment of the invention which is provided with a gasifier (3) for heating the waste and enabling the waste to generate thermal decomposition gas, a preheater (6) for preheating cement stone of cement manufacturing complete plant (2), a calcinator (7), a welding furnace (8), and a clinker cooler (9), and a gas delivery passage (11) for delivering particle-shaped carbon and ash and pyrolytic eumatolytic gas generated from the gasifier (3) to at least one of the calcinator (7) and the welding furnace (8).

Owner:KAWASAKI HEAVY IND LTD +3

Method and apparatus for recovering energy from wastes by combustion in industrial furnaces

InactiveUS6470812B1Efficient energy recoveryEffective recoveryBranding equipmentMechanical apparatusWastewaterAtmospheric pollution

Method and apparatus to recover energy from waste by means of combustion of such waste in industrial furnaces, particularly of the rotary type, that has an external calciner, feeding such waste into the tertiary air duct of the calciner and burning the waste inside the duct itself, to efficiently make use of the energy produced by such combustion, as a contribution of the total cost of fuel necessary to operate the industrial furnace. The method and apparatus permit the elimination of hazardous wastes that are efficiently disassociated when burned sufficiently to produce effluents that are typically non-toxic, producing greatly reduced or even no atmospheric pollution nor environmental damage.

Owner:CEMEX DE C V

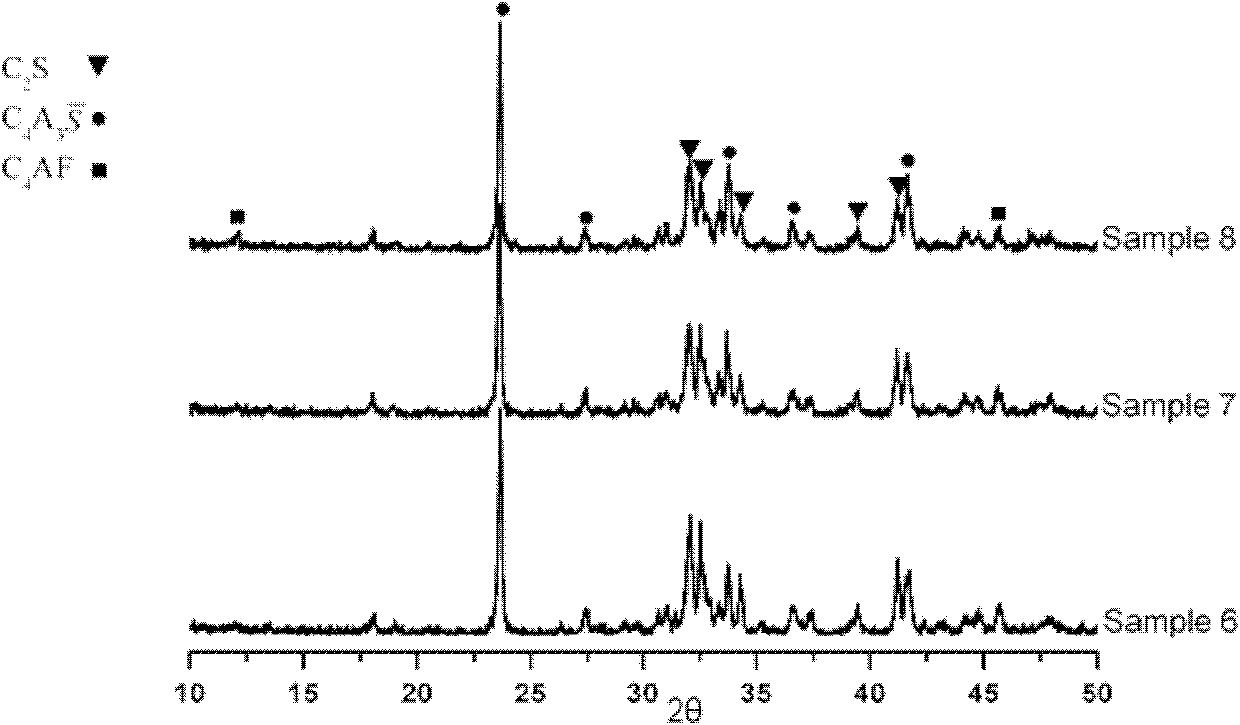

Low-energy-consumption and low-emission cement and preparation method and application thereof

InactiveCN102249576AImprove performanceWith the advantages of energy saving and emission reductionClinker productionCoesiteResource consumption

The invention discloses low-energy-consumption and low-emission cement and a preparation method and application thereof. Cement clinker mainly comprises the following minerals in parts by weight: 35-65 parts of C2S, 20-50 parts C4A3S and 5-15 parts of C4AF. A corresponding green stock consists of the following components in parts by weight: 30-60 parts of CaO, 25-35 parts of SiO, 5-35 parts of Al2O3, 1-6 parts of SO3 and 1-10 parts of Fe2O3. The cement clinker is a product which is prepared by calcining limestone, alumina and clay or sandstone and gypsum serving as raw materials at the temperature between 1,280 DEG C and 1,300 DEG C for 45-70 minutes by combining the advantages of low calcium content, low-temperature baking and high later strength of a belite mineral, low-temperature baking and high later strength of anhydrous calcium sulphoaluminate, and the like. The cement product has the advantages of excellent performance, low energy and resource consumption and low carbon dioxide emission, can play an important role in the field of construction, and has a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

Coal-fired power generation and waste heat power generation coupling system for private station of cement kiln

ActiveCN102080582AReduce non-adjusted steam extractionImprove stabilityEnergy industryIncreasing energy efficiencyEngineeringDeaerator

The invention discloses a coal-fired power generation and waste heat power generation coupling system for a private station of a cement kiln, comprising a coal-fired boiler, a kiln head waste heat boiler, a kiln tail waste heat boiler, a kiln head steam pocket, a kiln tail steam pocket, a condensing steam turbine, a condensate pump, a heater, a deaerator, a water feeding pump and related auxiliary devices, wherein the kiln head waste heat boiler utilizes a dual-pressure system; a primary economizer of the low-pressure system is used as a public economizer for the waste heat power generation; the high-pressure steam and the steam generated by the kiln tail waste heat boiler are collected to the main steam pipeline of the waste heat power generation system; one path of the main steam pipeline is connected with a steam turbine of the waste heat power generation system while the other path thereof is connected with non-adjustable extraction steam of a coal-fired steam turbine; one path ofthe main steam pipeline of the coal-fired unit is connected with the coal-fired steam turbine while the other path thereof is connected with the waste heat steam turbine. In the invention, the coal-fired power generation is rationally coupled with waste heat power generation system so that the problem that the stability of the waste heat power generation system of the cement kiln is low is solved, and the whole thermal circulating efficiency of the private station can be largely increased.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

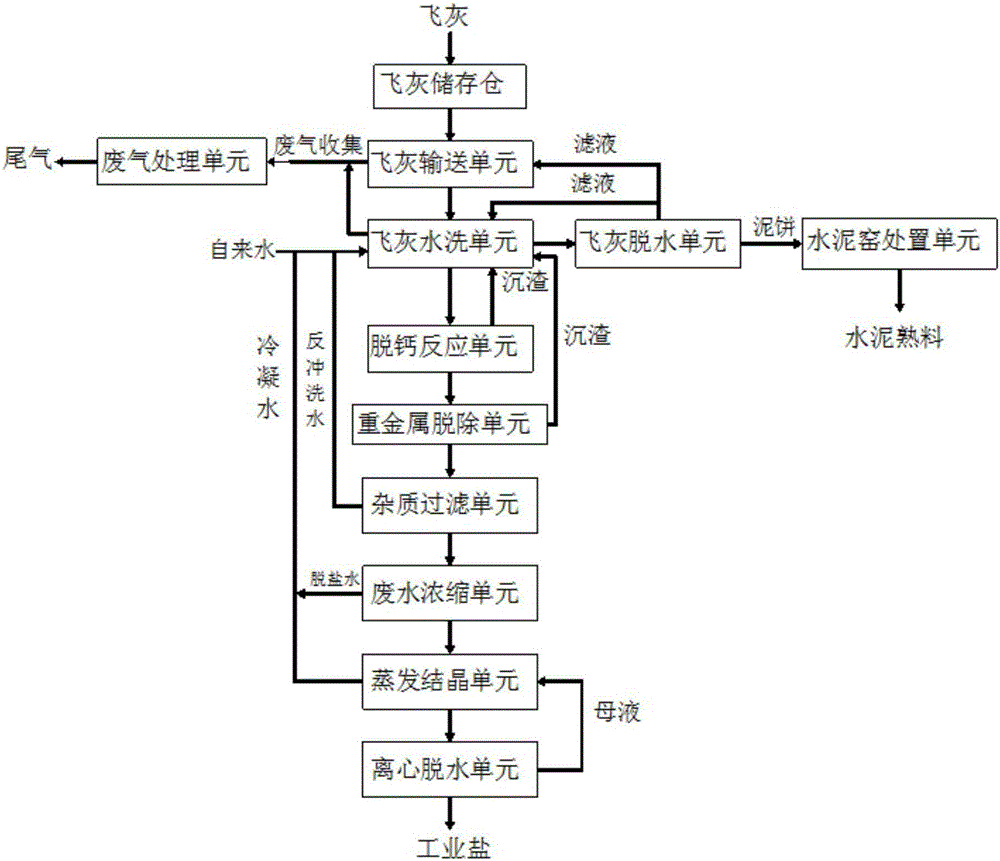

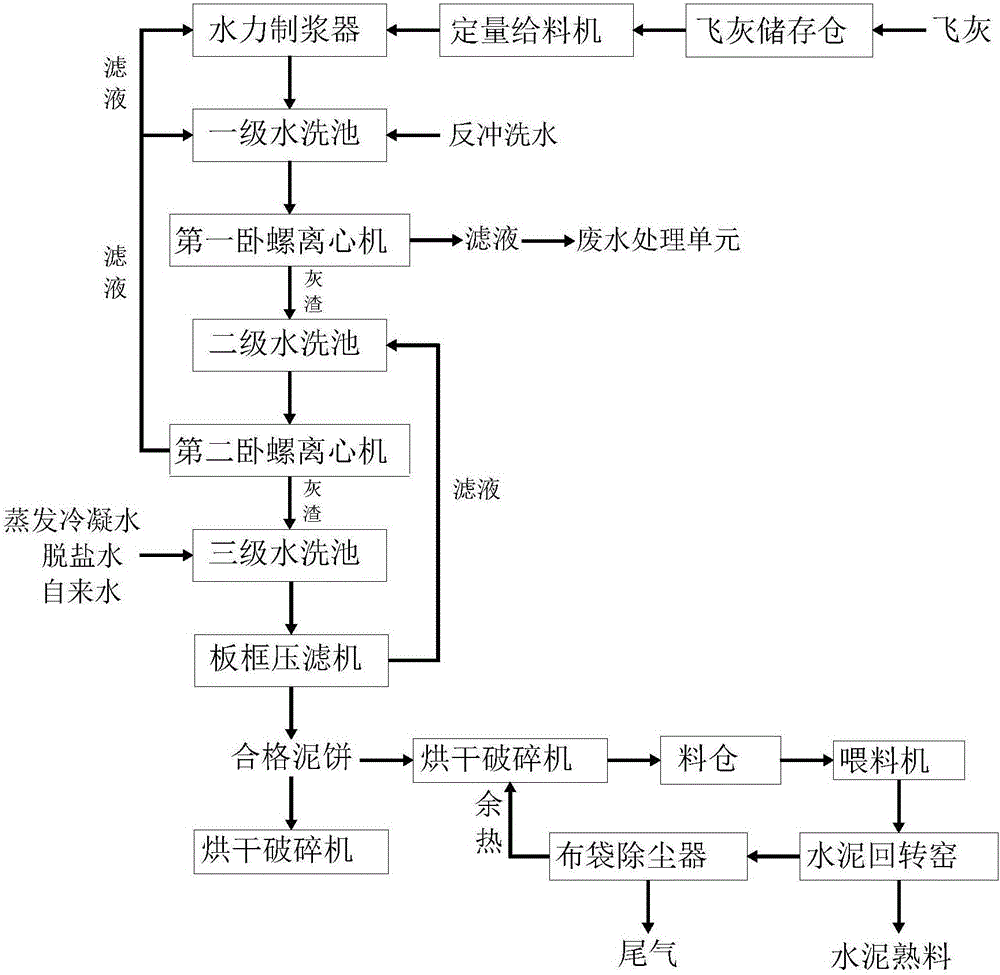

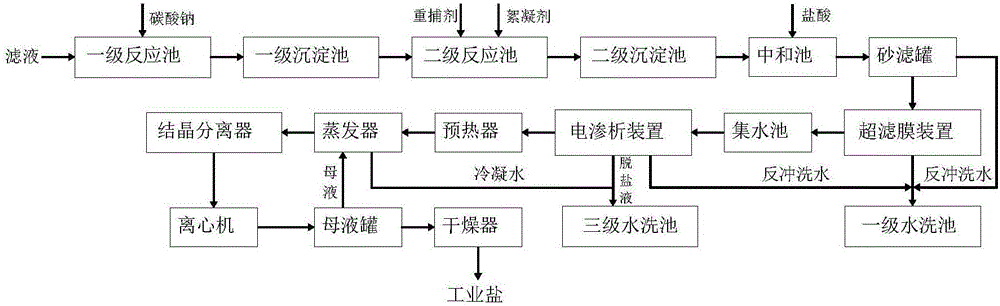

Water-washing pretreatment and cement kiln cooperated recycling disposal system for garbage fly ash

PendingCN106746124ATechnical Issues to Mitigate DisruptionWater/sewage treatment by centrifugal separationTreatment involving filtrationCement kilnCalcination

The invention belongs to the technical field of treatment and disposal of solid wastes and particularly relates to a water-washing pretreatment and cement kiln cooperated recycling disposal system for garbage fly ash. The system comprises a fly ash conveying unit, a fly ash treatment system, a wastewater treatment system and a cement kiln treatment unit which communicate with one another sequentially; the fly ash conveying unit is used for conveying the fly ash to the fly ash treatment system; the fly ash treatment system is used for removing chloride ions and heavy metals from the fly ash; the wastewater treatment system is used for treating fly ash washing wastewater so as to enable the treated fly ash washing wastewater to reach the standards and recycle the wastewater, and meanwhile, extracting industrial salts with application value from the wastewater; and the cement kiln treatment unit is used for carrying out high-temperature calcination on the treated fly ash so as to decompose harmful ingredients such as dioxin and stable heavy metals in the fly ash, and meanwhile, generating clinker for manufacturing cement. The technical problem in the prior art that the chloride ions and the heavy metals in the fly ash will cause damage to a cement kiln when the fly ash serves as a production raw material for the cement is solved.

Owner:浙江万银节能环保科技有限公司

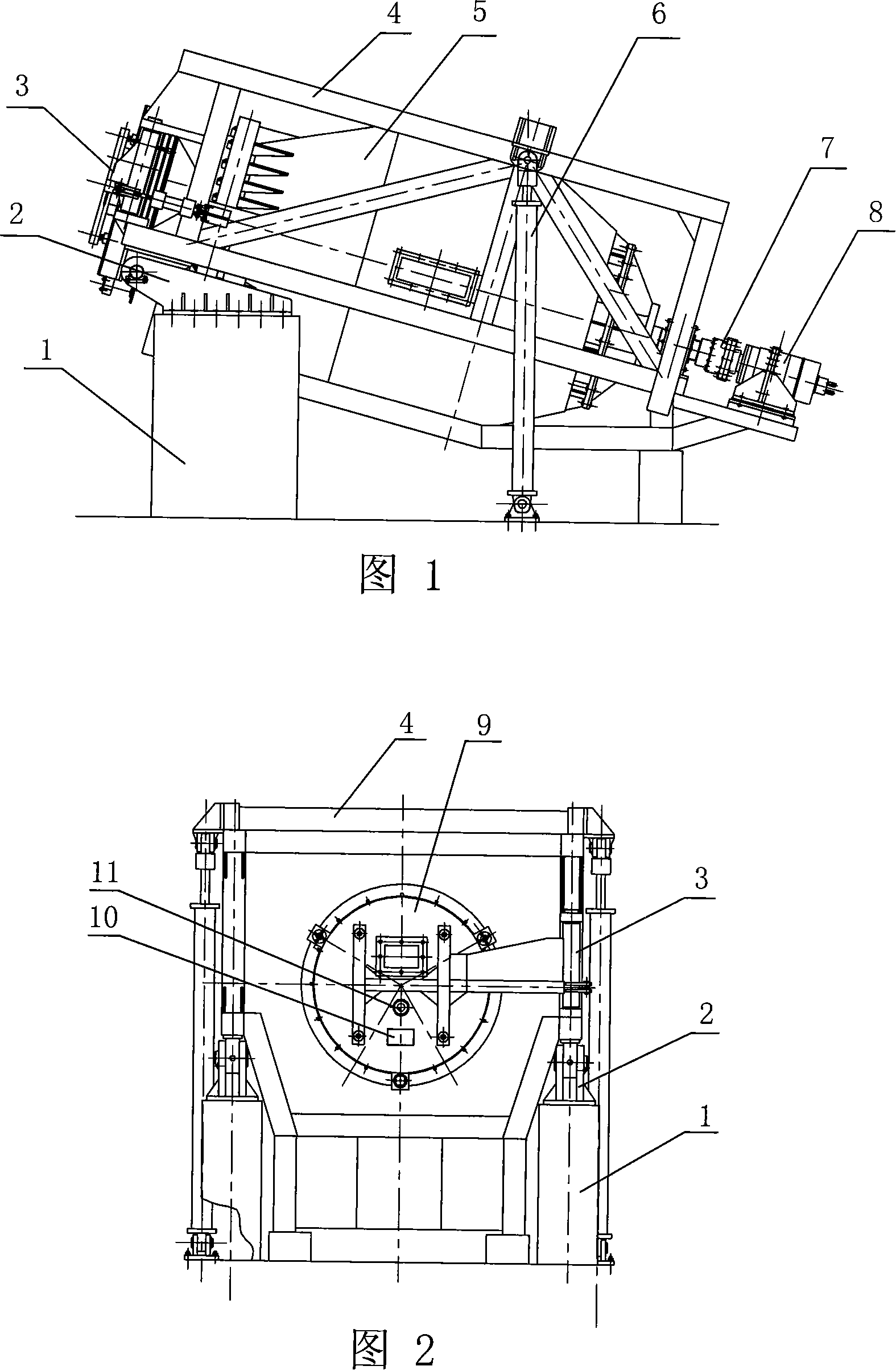

Tiltable rotary secondary aluminum smelting furnace

InactiveCN101131304AImprove performanceIncrease production capacityRotary drum furnacesClinker productionCombustorRotary furnace

This invention relates to a tilting rotary secondary aluminum smelting furnace. It includes roller type rotary furnace body, which is supported on the steel support. The anterior end of rotary furnace is arranged in the sleeve. The anterior end face of the rotary furnace has round furnace opening. The posterior end of rotary furnace connects to power device. The steel support corresponding to the rotary furnace posterior end parts connects to lifting cylinder. The steel support corresponding to the rotary furnace anterior end part connects to supporting shaft. There is round furnace door corresponding to the round furnace opening. There is sealing ring between the round furnace opening and door. The round furnace door is arranged on the roll-over shaft and connects to controlling oil cylinder. The round furnace door has fuel gas combustor and waste air discharging opening. The structure is simple. This invention is convenient. It has low energy dissipation and high producing efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com