Patents

Literature

57results about How to "Low grade requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

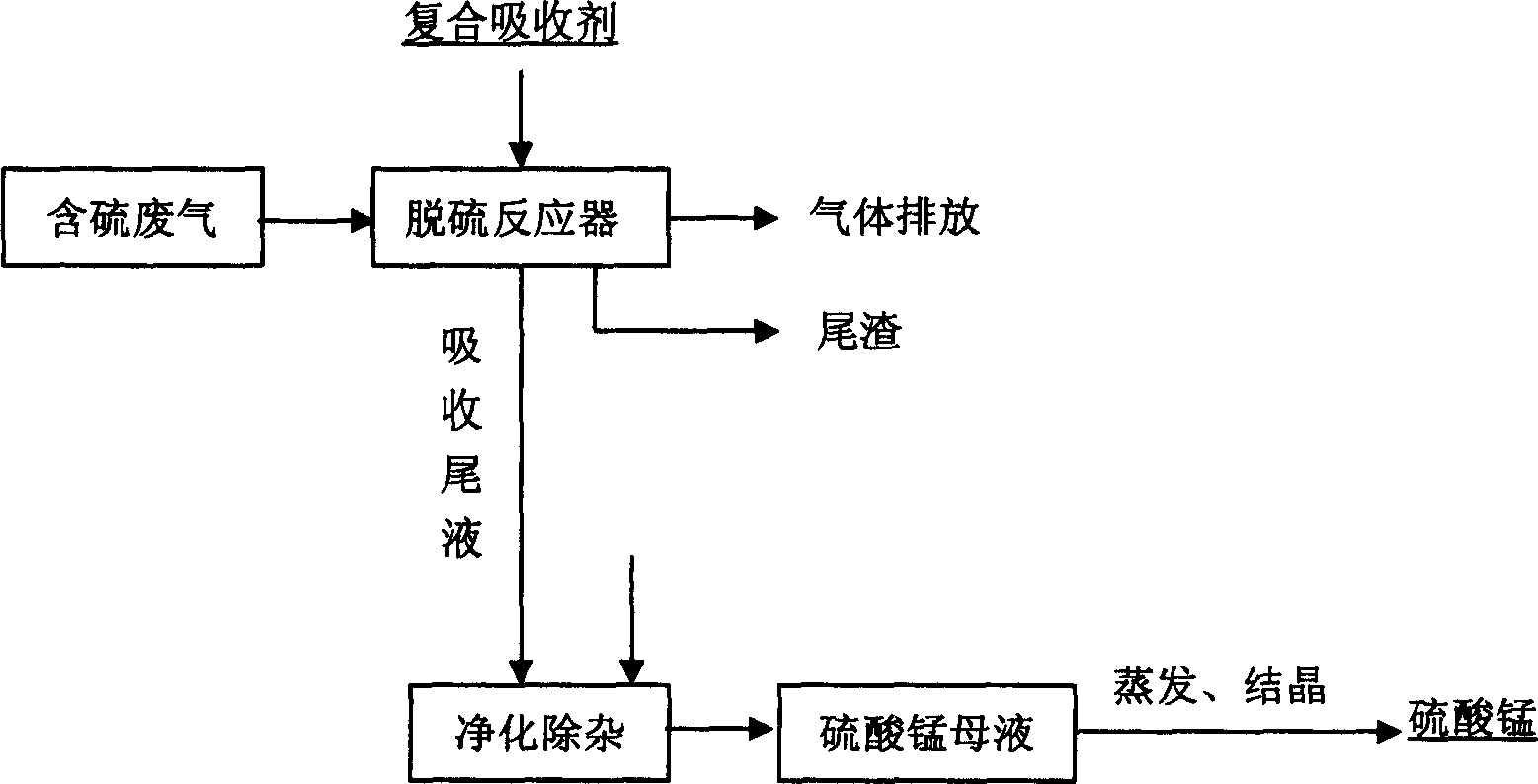

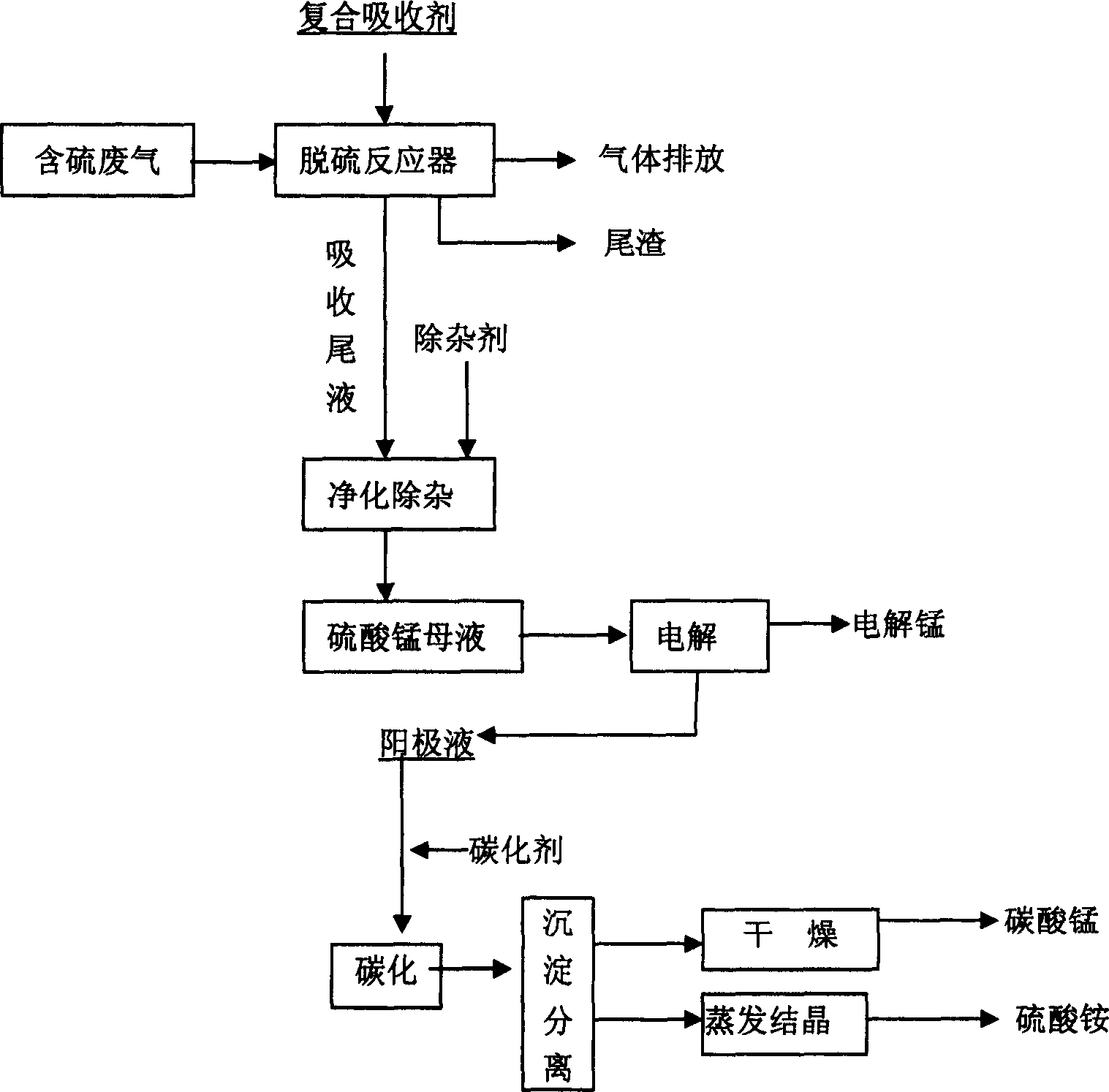

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

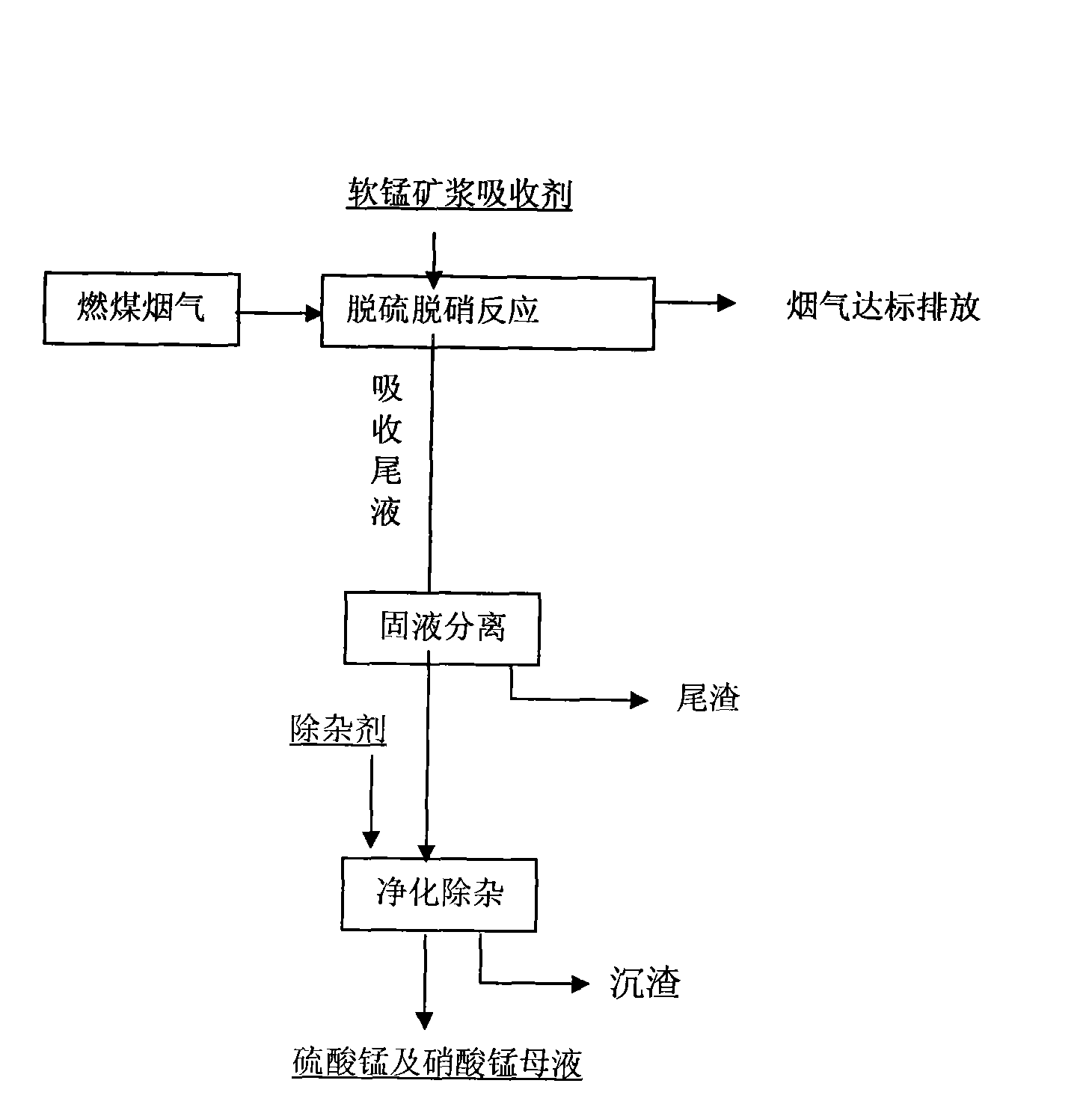

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

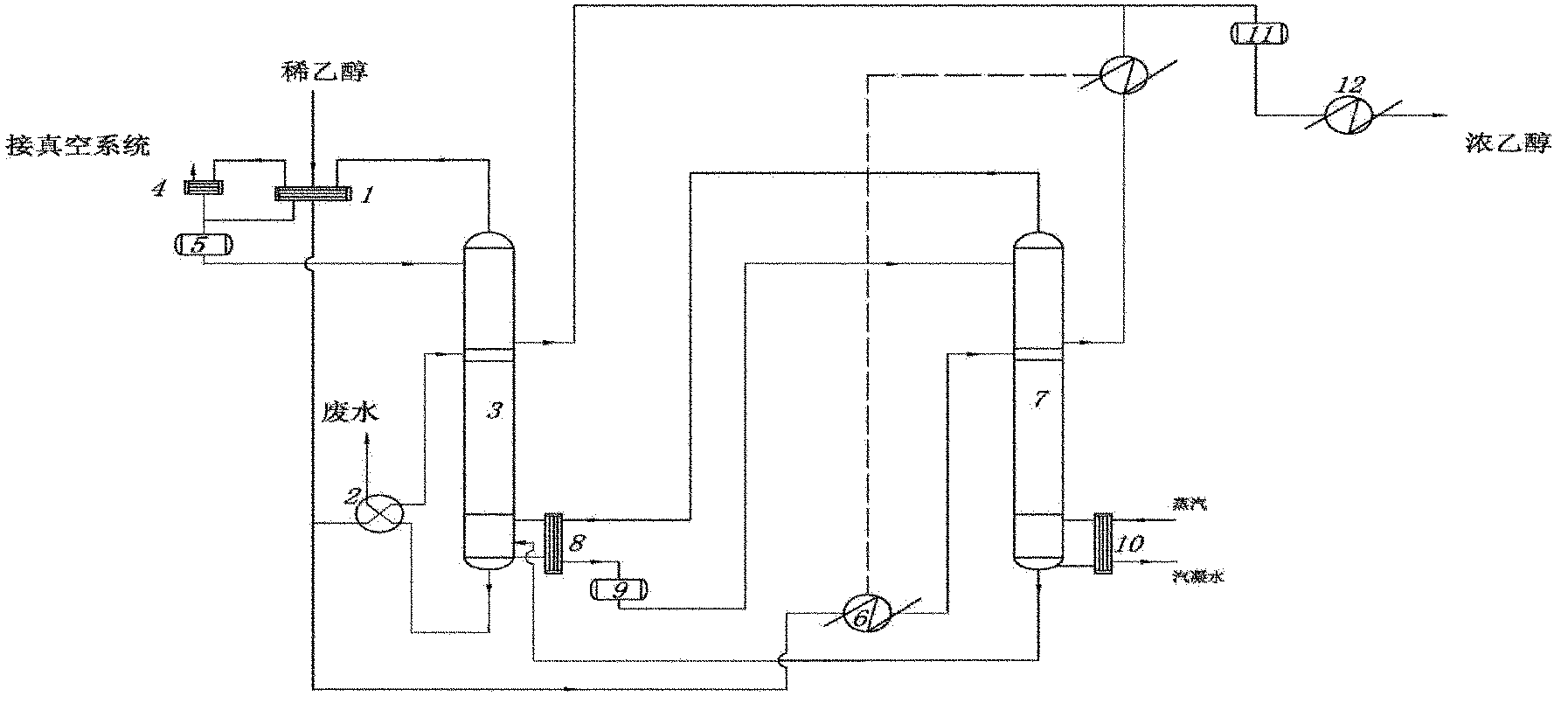

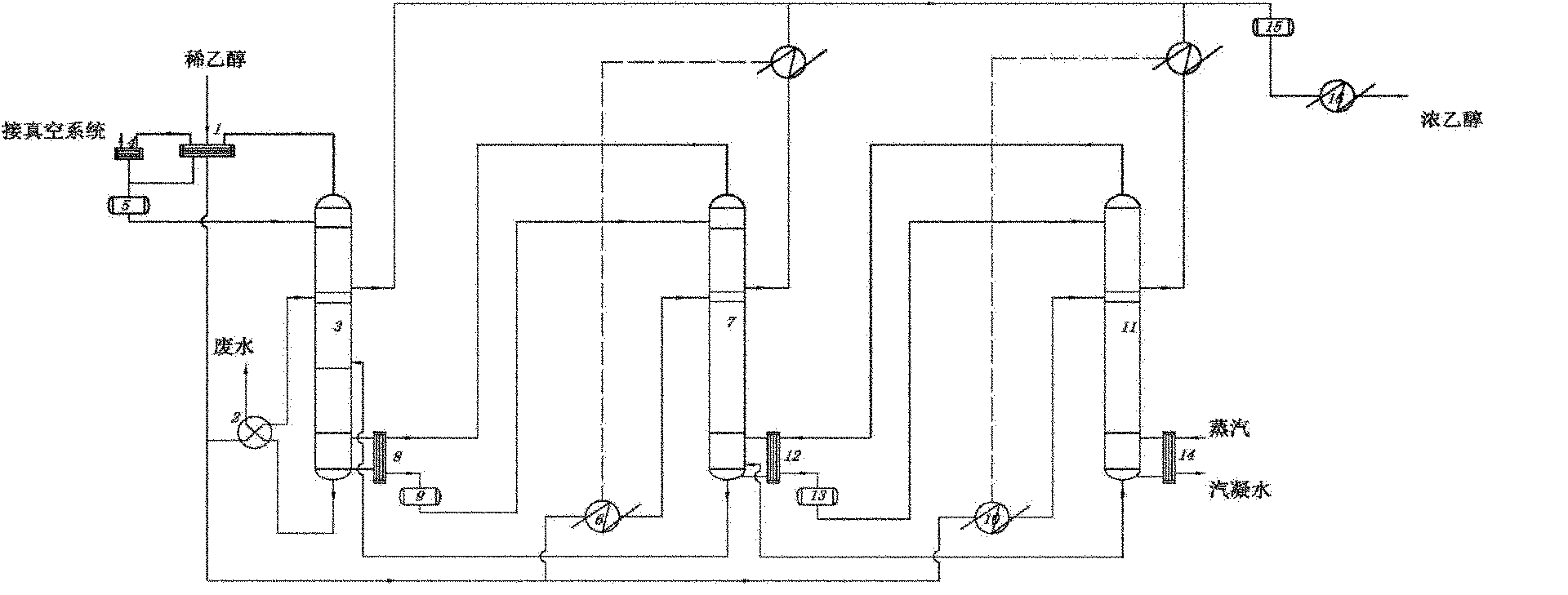

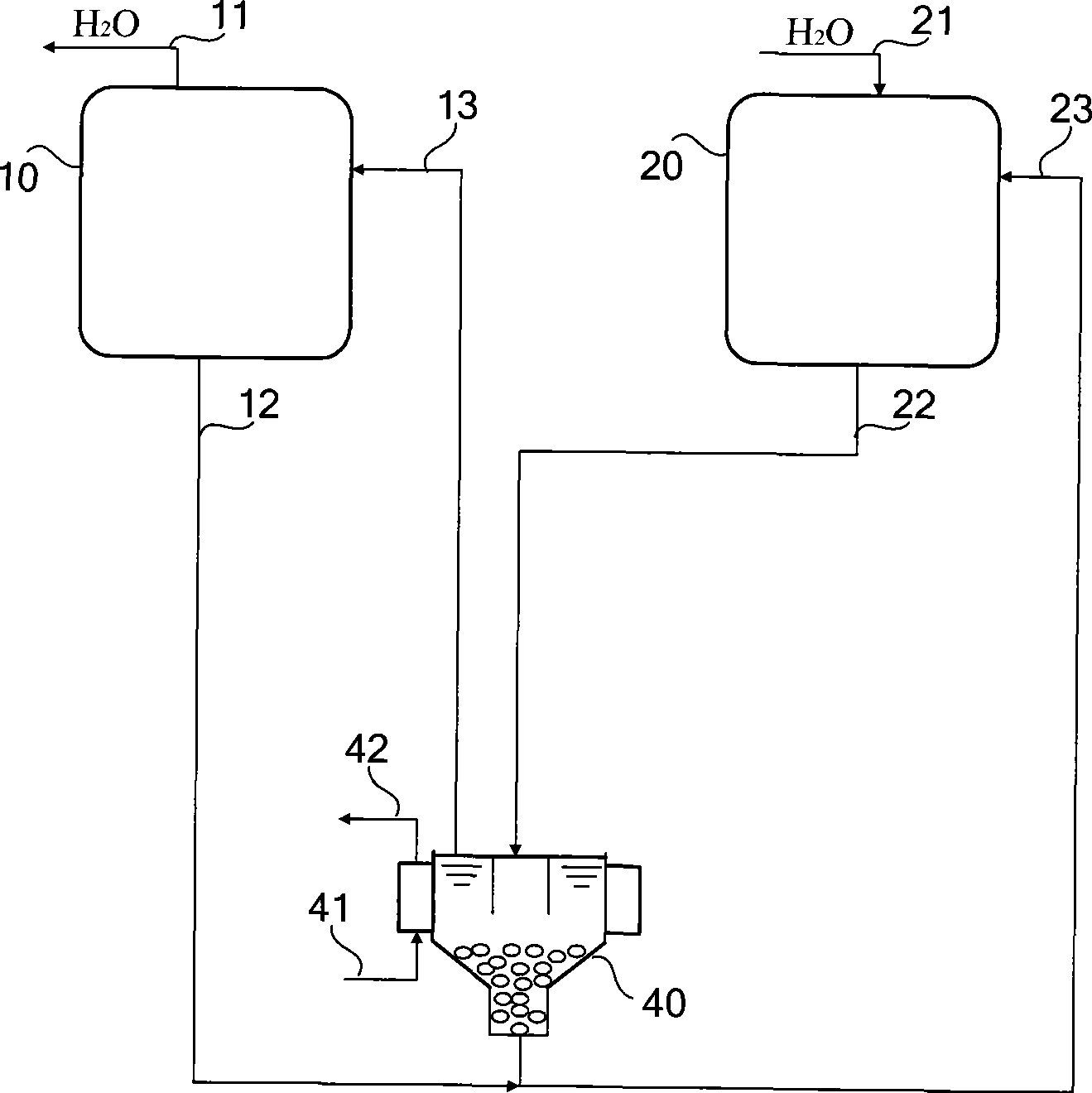

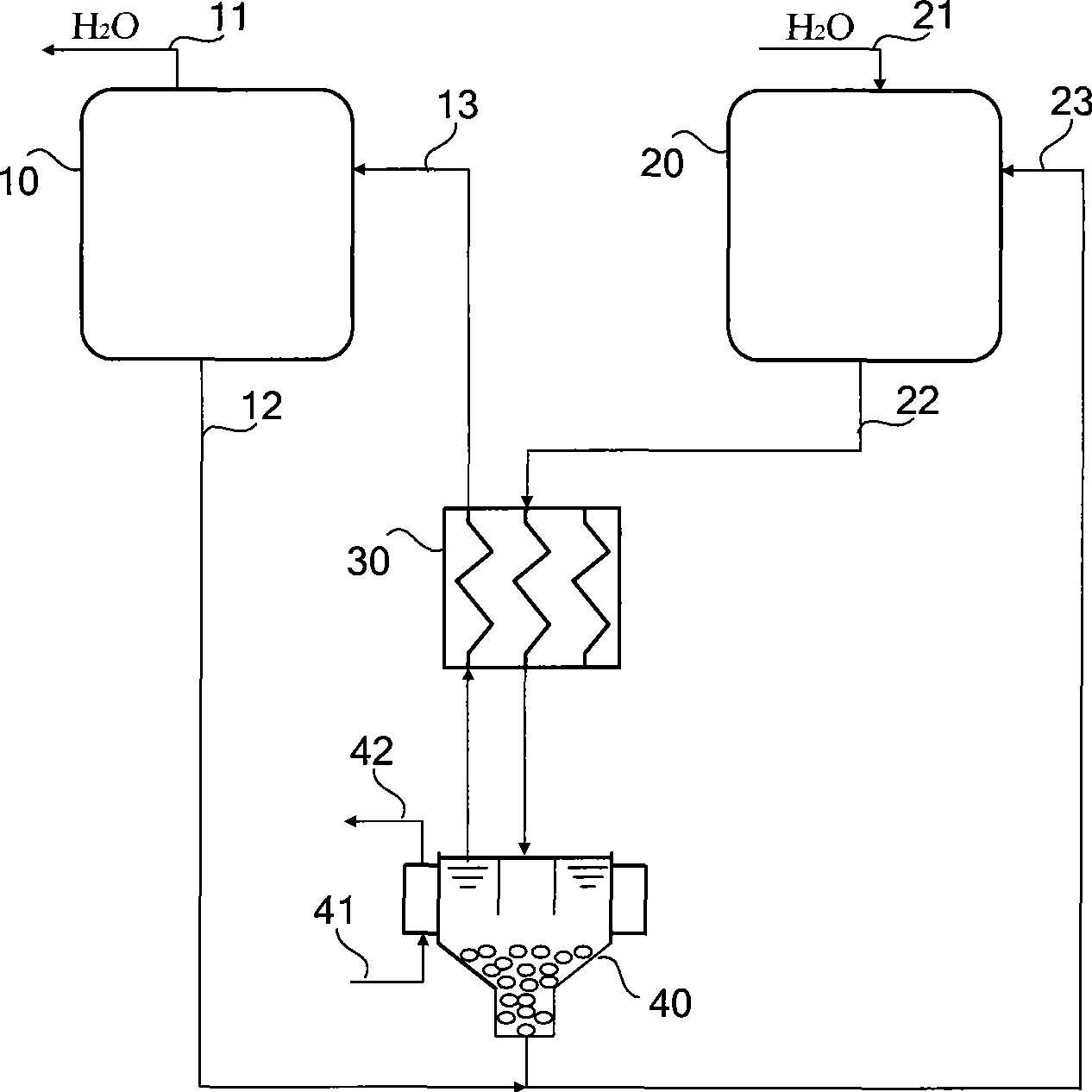

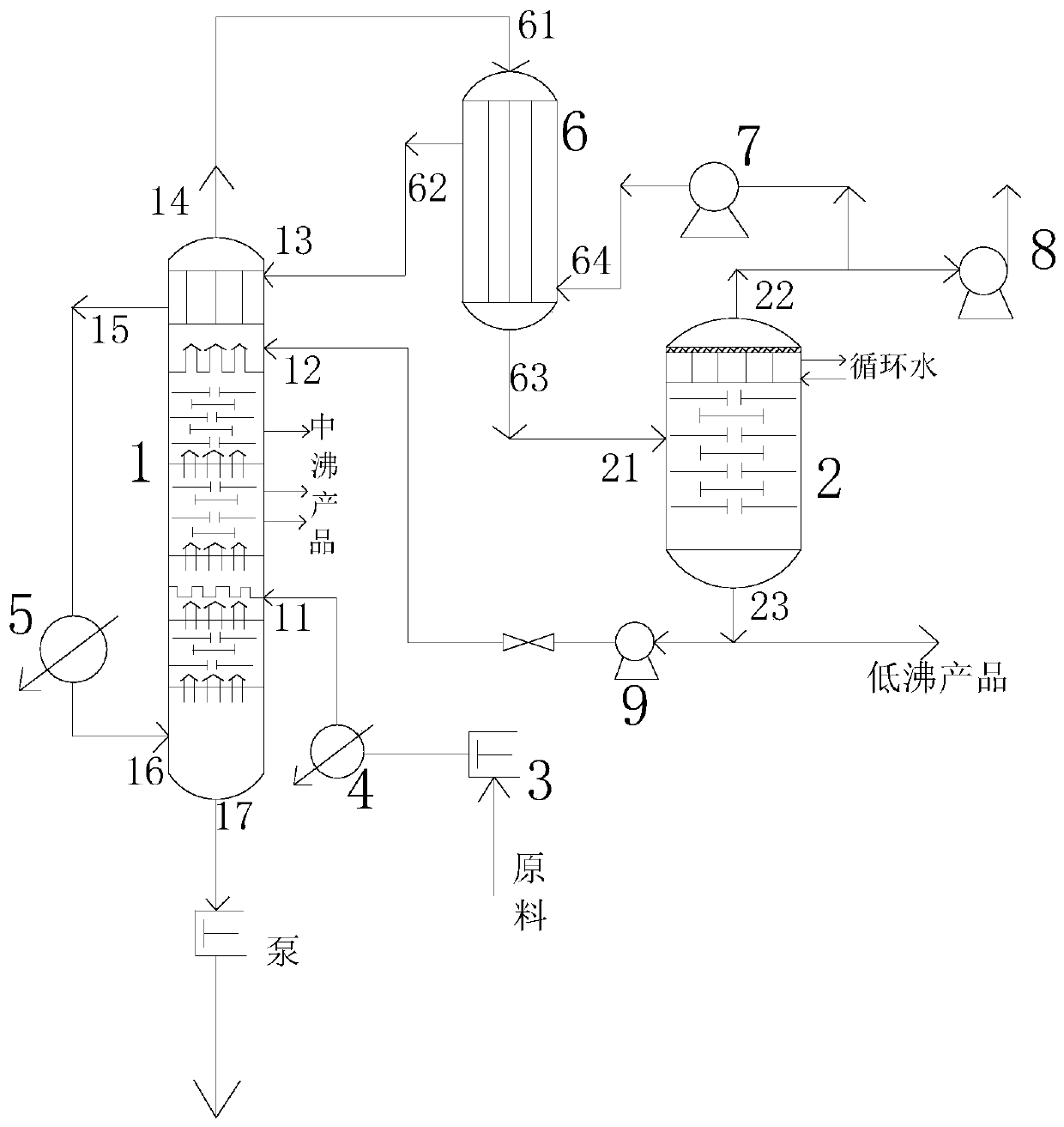

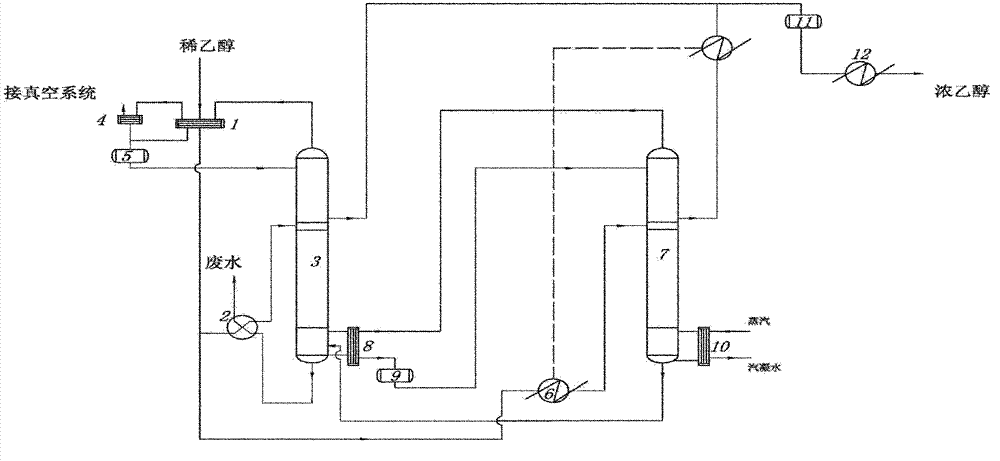

Low-pressure ethanol recovery device and method with triple effect rectification

ActiveCN102091429AReduce energy consumptionReduce lossesOrganic compound preparationHydroxy compound preparationRecovery methodReboiler

The invention discloses a low-pressure ethanol recovery device and method with triple effect rectification. The low-pressure ethanol recovery device with triple effect rectification comprises a first rectifying tower, a second rectifying tower, a third rectifying tower, a rectifying tower reboiler, a rectifying tower feed preheater, a condenser, a return tank, a dilute ethanol feed preheater, a temporary finished product storage tank and a finished product cooler. In the ethanol recovery method with triple effect rectification, by controlling the recovery of the finished ethanol in the second rectifying tower, the content of ethanol in tower bottom wastewater of the second rectifying tower is 5wt%-30wt%, the temperature of the tower bottom wastewater is 100-120 DEG C, and the working pressure of the third rectifying tower is 250-400kPa. The invention adopts the low-pressure triple effect rectification technique and reduces energy loss in the technical process, thus greatly reducing the energy consumption; and the operating pressure and temperature of the third rectifying tower are greatly reduced, and the requirements on the high temperature resistant and corrosion resistant properties of equipment are reduced, thereby reducing the equipment investment and the maintenance cost.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

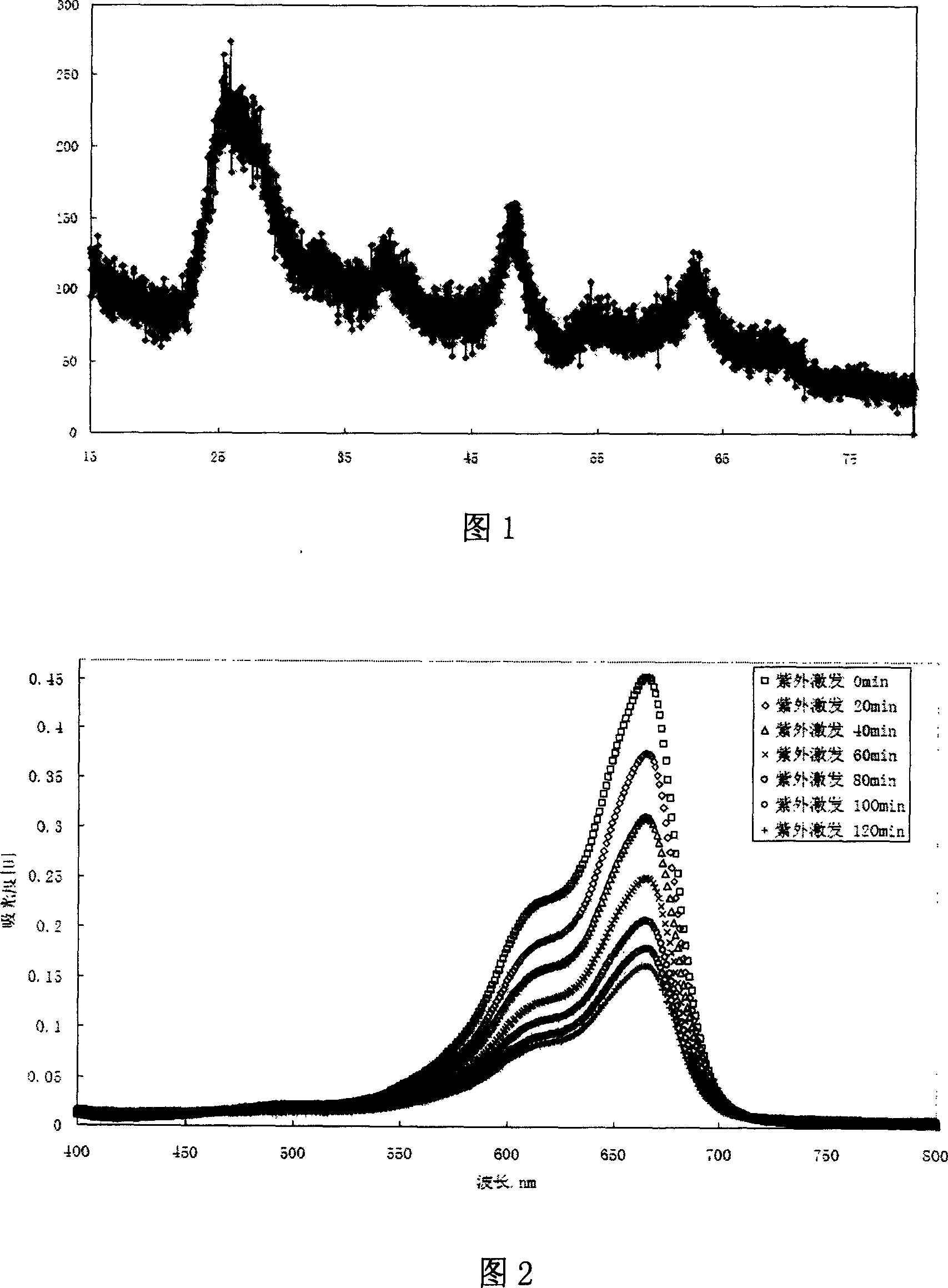

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

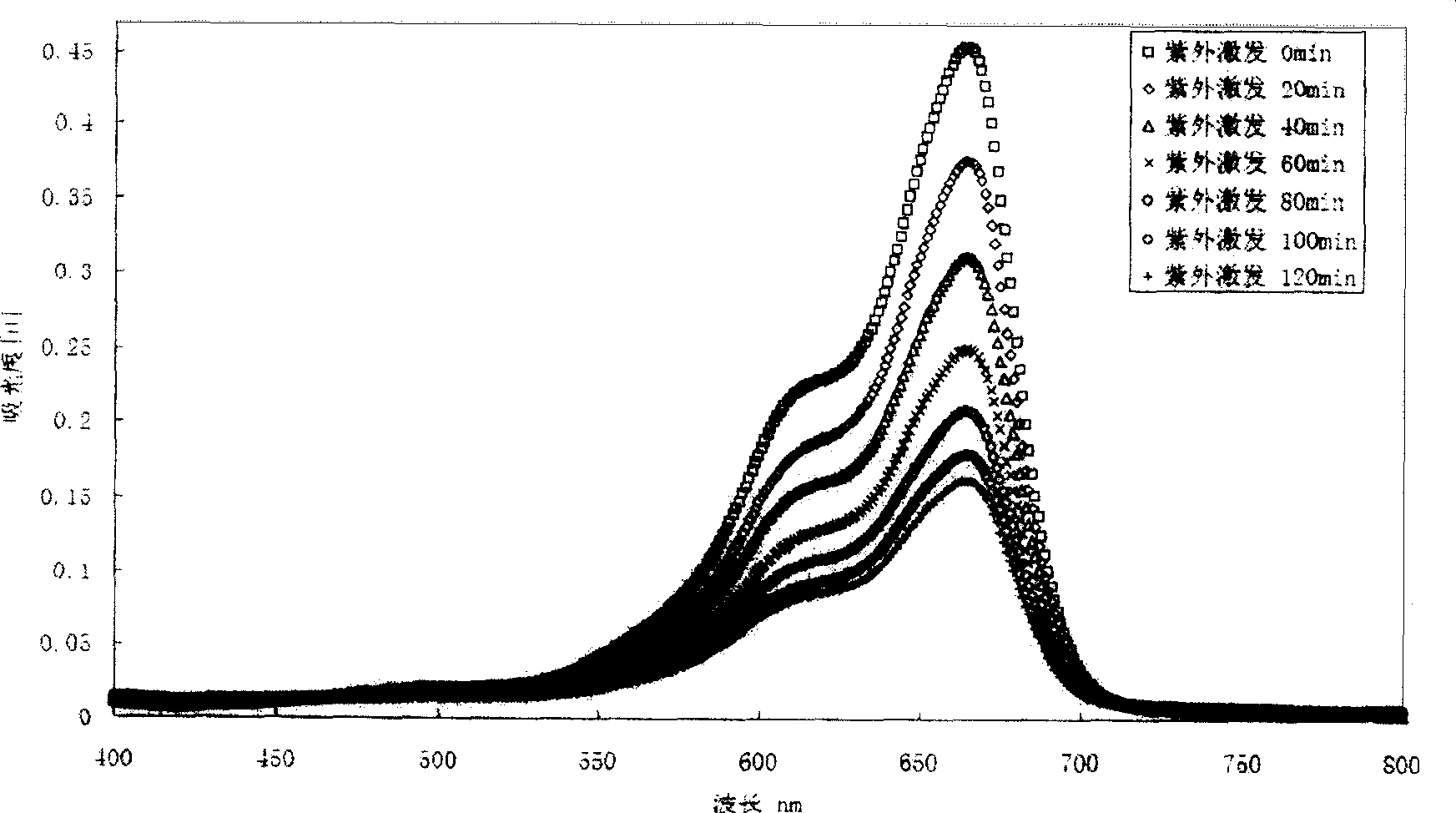

InactiveCN1935669AImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

The invention belongs to an organic metal oxide-TiO2 photocatalyst preparing process, especially relating a synthesizing method of low temperature-crystallizing nanometer TiO powder and sol with high catalytic activity. And it obtains n-titanic acid deposit by making alkali neutralization and dilution hydrolyzation or heating hydrolyzation on titanic solution, and implements synthesizing related system nano crystal materials with normal-pressure and low-temperature liquid phases by such a processing process of re-dispersing the deposit by oxydol. And it largely reduces the cost of raw materials and avoids using titanium tetrachloride with strong corrosivity, reducing equipment requirements.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

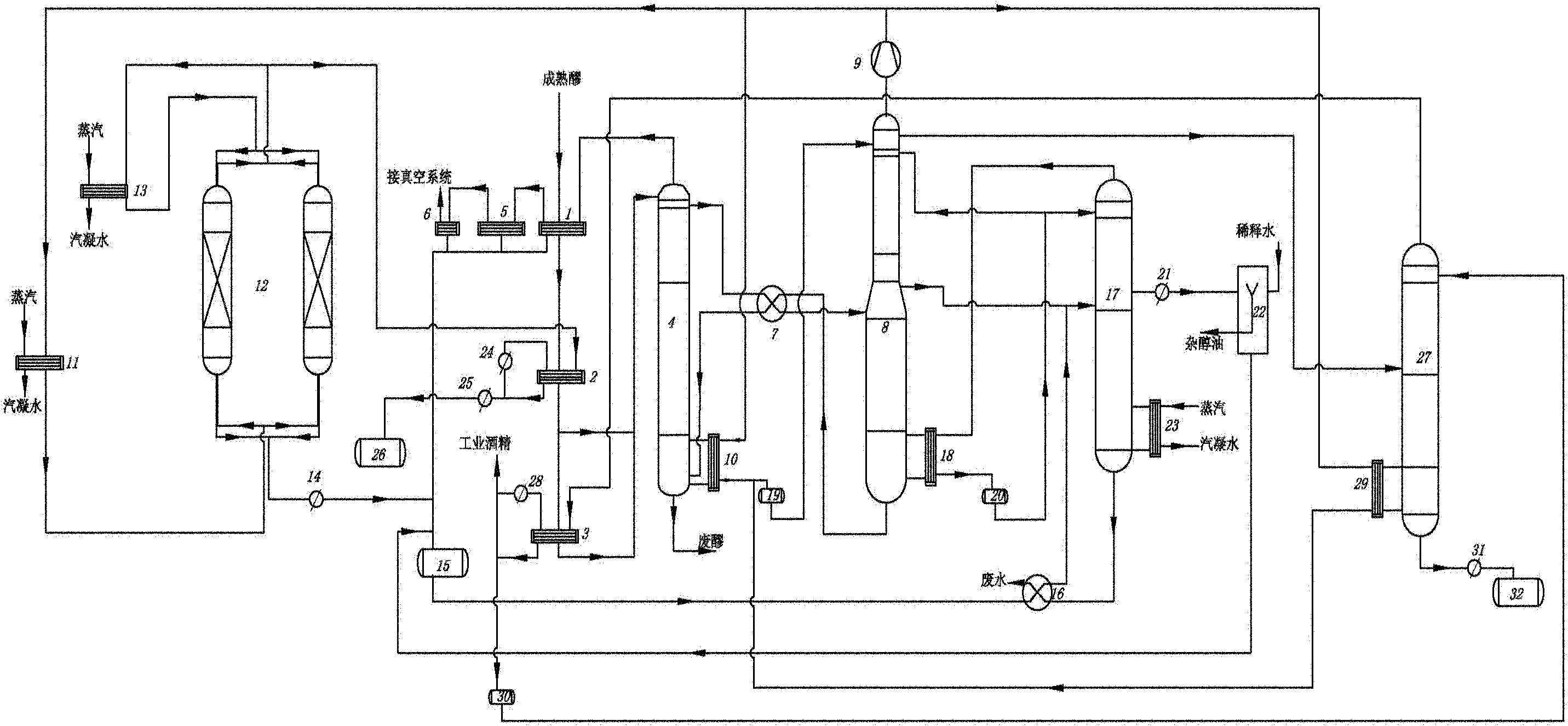

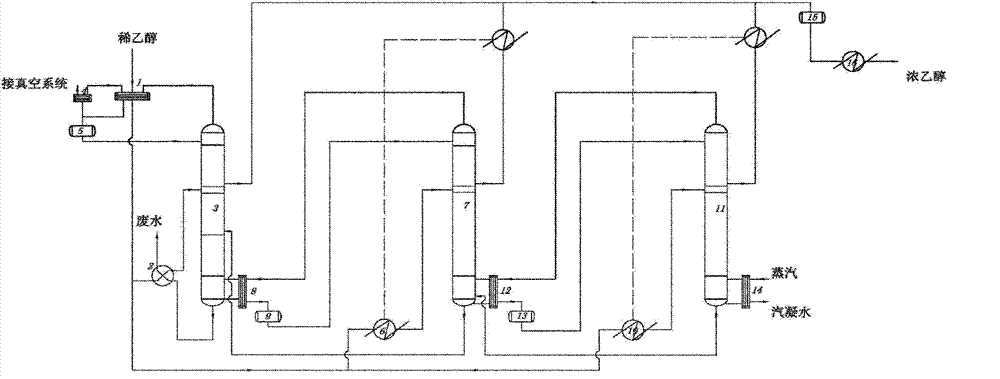

Distillation dehydration device and process for co-producing ethanol fuels and custom grade edible alcohols

ActiveCN102040471ALow operating pressureLess investmentOrganic compound preparationHydroxy compound separation/purificationDesorptionDistillation

The invention discloses a distillation dehydration device and a distillation dehydration process for co-producing ethanol fuels and custom grade edible alcohols. The device comprises a molecular sieve adsorption / desorption tower, a coarse fractionating tower, an assembled tower, a rectifying tower, a methanol tower and mash pre-heaters, wherein the wine steam of the assembled tower, after compressed by an ethanol steam compressor, is used as the heat sources and raw material wine steams of the coarse fractionating tower and the methanol tower; the wine steam of the rectifying tower is used asthe heat source of the assembled tower; and the wine steam of the coarse fractionating tower, the anhydrous alcohol steam and the wine steam of the methanol tower are respectively used as the heat sources of the first, second and third mash pre-heaters. The device can simultaneously produce ethanol fuels and custom gradeedible alcohols, and can separately produce ethanol fuels or custom grade edible alcohols. The device and the process of the invention have the advantages that, because a multi-effect energy coupling mode is adopted, compared with an original process, the energy consumption ofthe process of the invention is greatly reduced, and the steam consumption of the ethanol fuel per metric ton is reduced to 1.1 to 1.5 t / t, compared with the steam consumption of 1.5 to 2.0 t / t in the original process, the steam consumption is down by 25 to 35 percent without consuming high-grade steams (more than 0.7 MPag); and the steam consumption of the custom grade edible alcohol per metric ton is reduced to 1.2 to 1.4 t / t, compared with the steam consumption of 1.9 to 2.5 t / t in the original process, the steam consumption is down by 35 to 50 percent.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

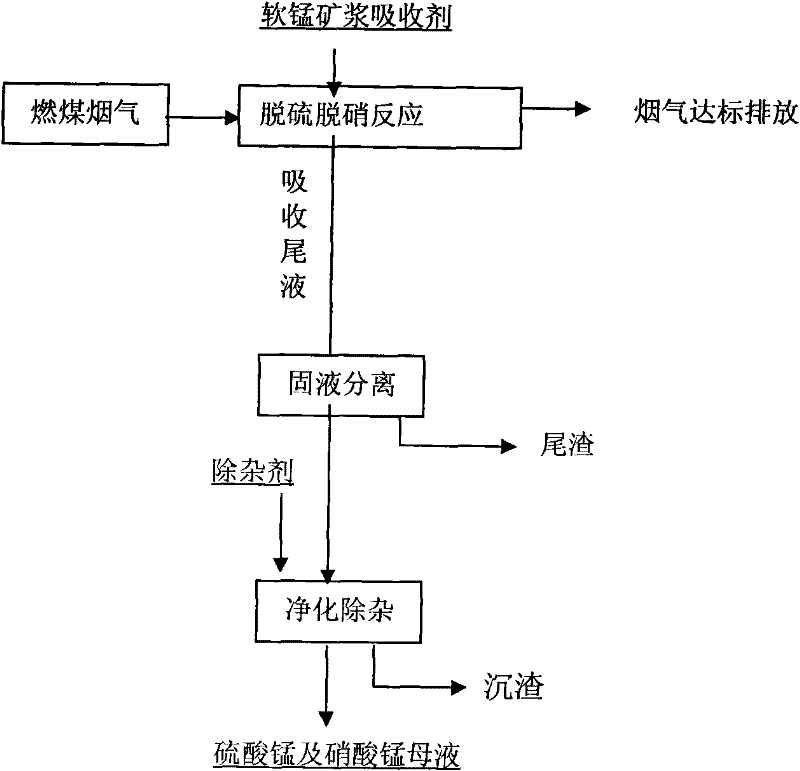

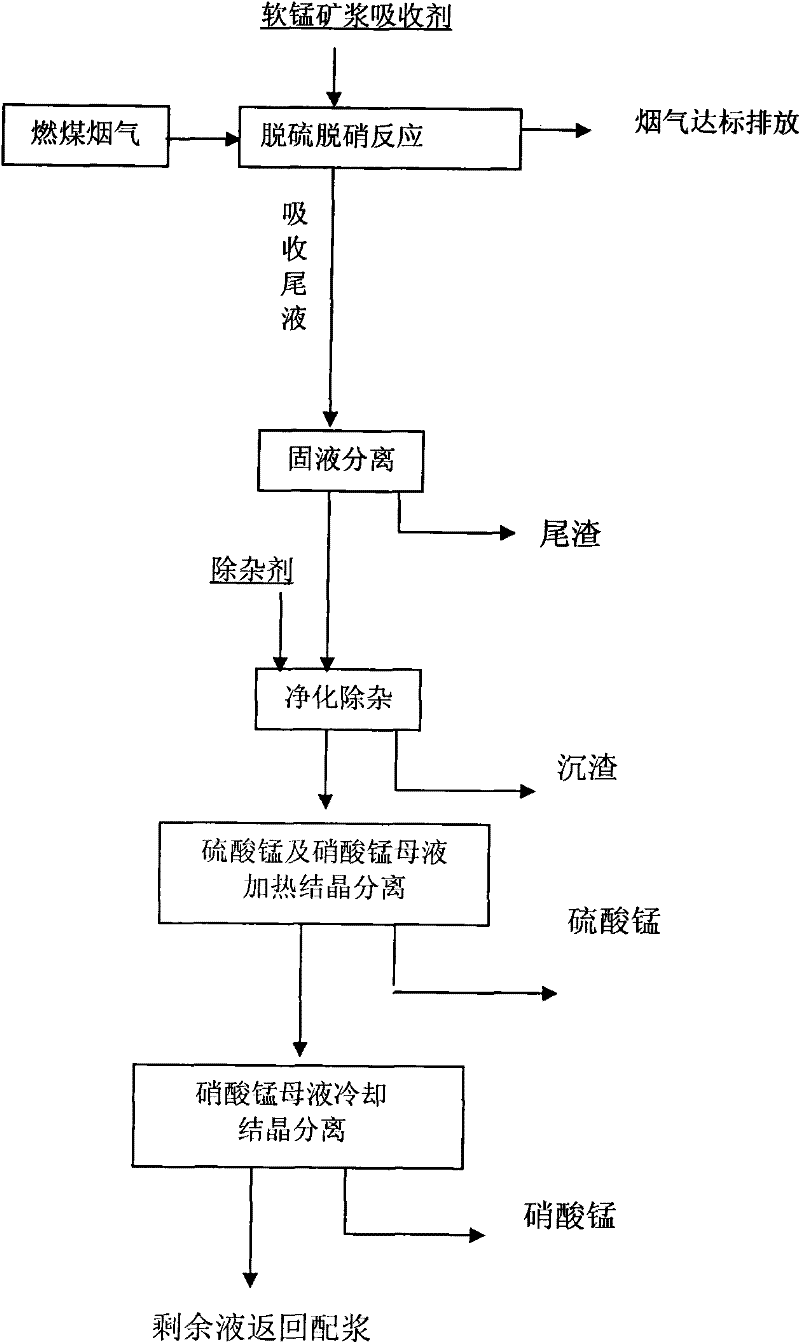

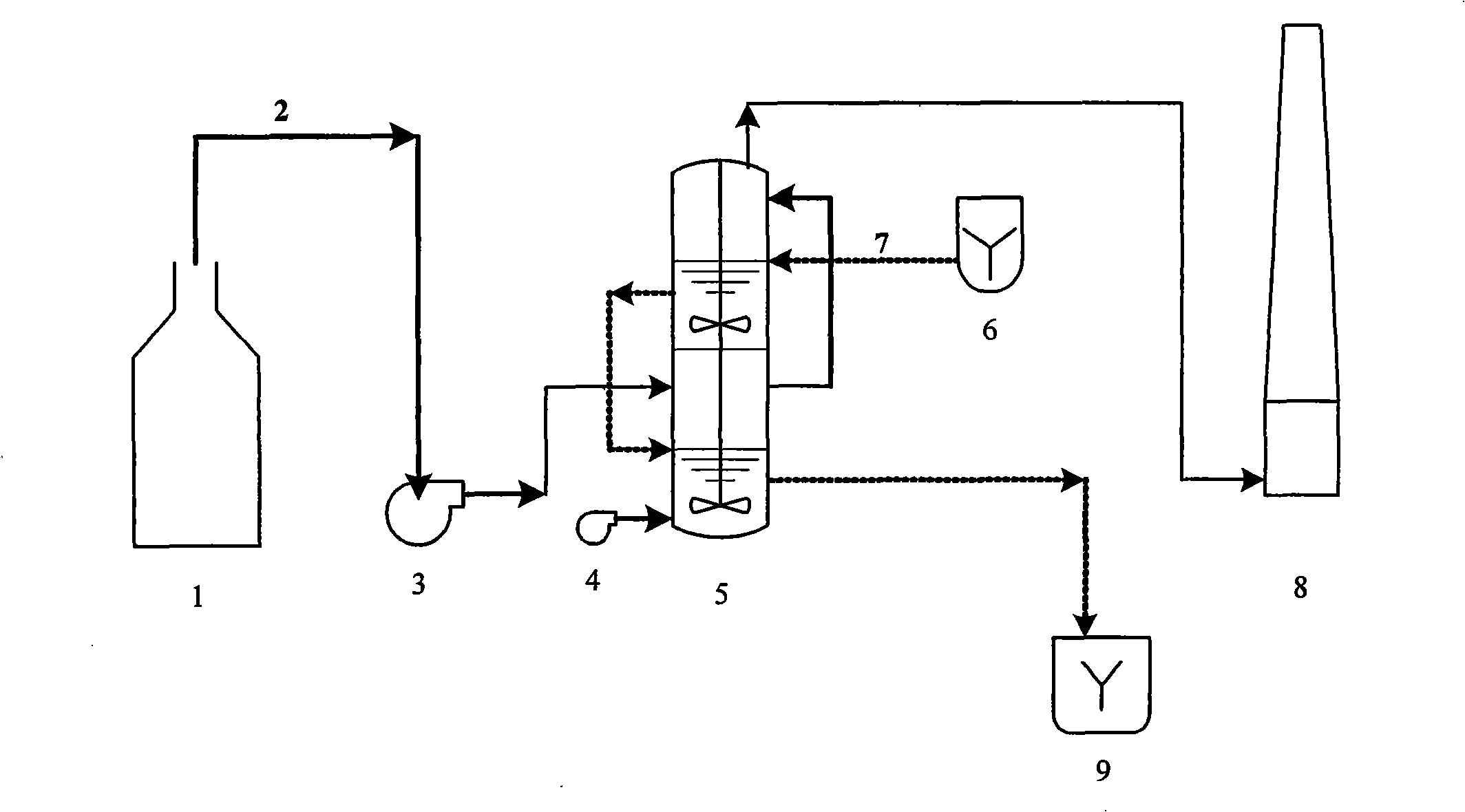

Synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation

ActiveCN101574617ARich reservesLow priceDispersed particle separationProcess efficiency improvementSolubilityPyrolusite

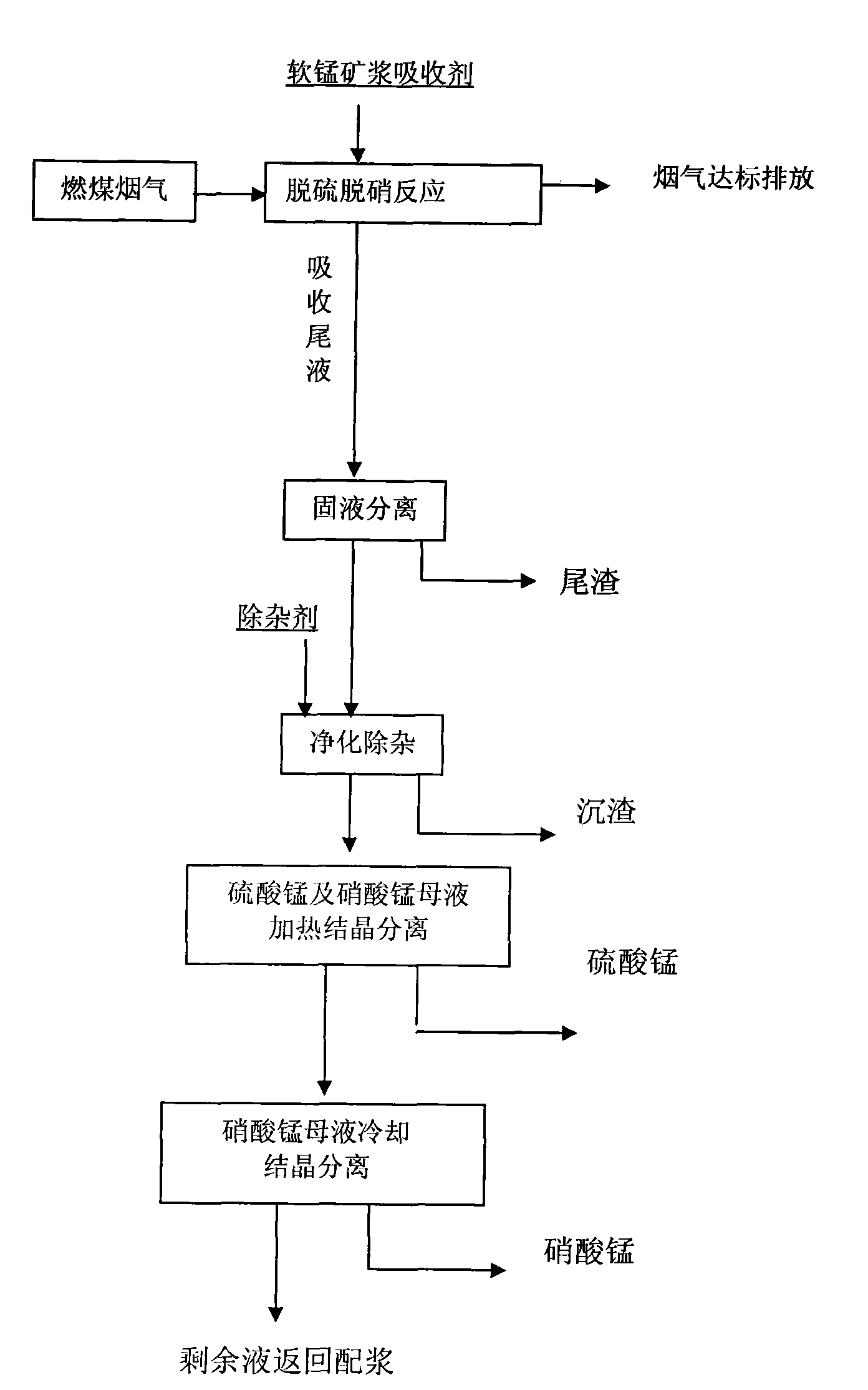

The invention discloses a synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation. The method mainly comprises the following steps: pyrolusite, water and metal-chelator are prepared into pulp which is taken as an absorbing agent; sulfur dioxide and nitrogen oxides in the flue gas are synchronously absorbed and removed by the absorbing agent; the flue gas is discharged when the purification reaches a standard; the primary product of the mixed mother solution of manganese sulfate and manganese nitrate is obtained after absorbing tail solution is purified; and by utilizing the different solubility of manganese sulfate and manganese nitrate at same temperature, the mixed mother solution is heated firstly to cause the manganese sulfate therein to be crystallized and separated, next, the left mother solution is cooled to cause the manganese nitrate therein to be crystallized and separated, and the left solution is returned to preparation pulp for recycling. No waster water is discharged in the whole process, thereby achieving the purposes of controlling waste by waste, recycling sulfur resources and improving the comprehensive utilization value of pyrolusite. The method is characterized by high desulphrization and denitration efficiency and manganese utilization rate, little secondary pollution, obvious economic benefit and the like.

Owner:SICHUAN UNIV

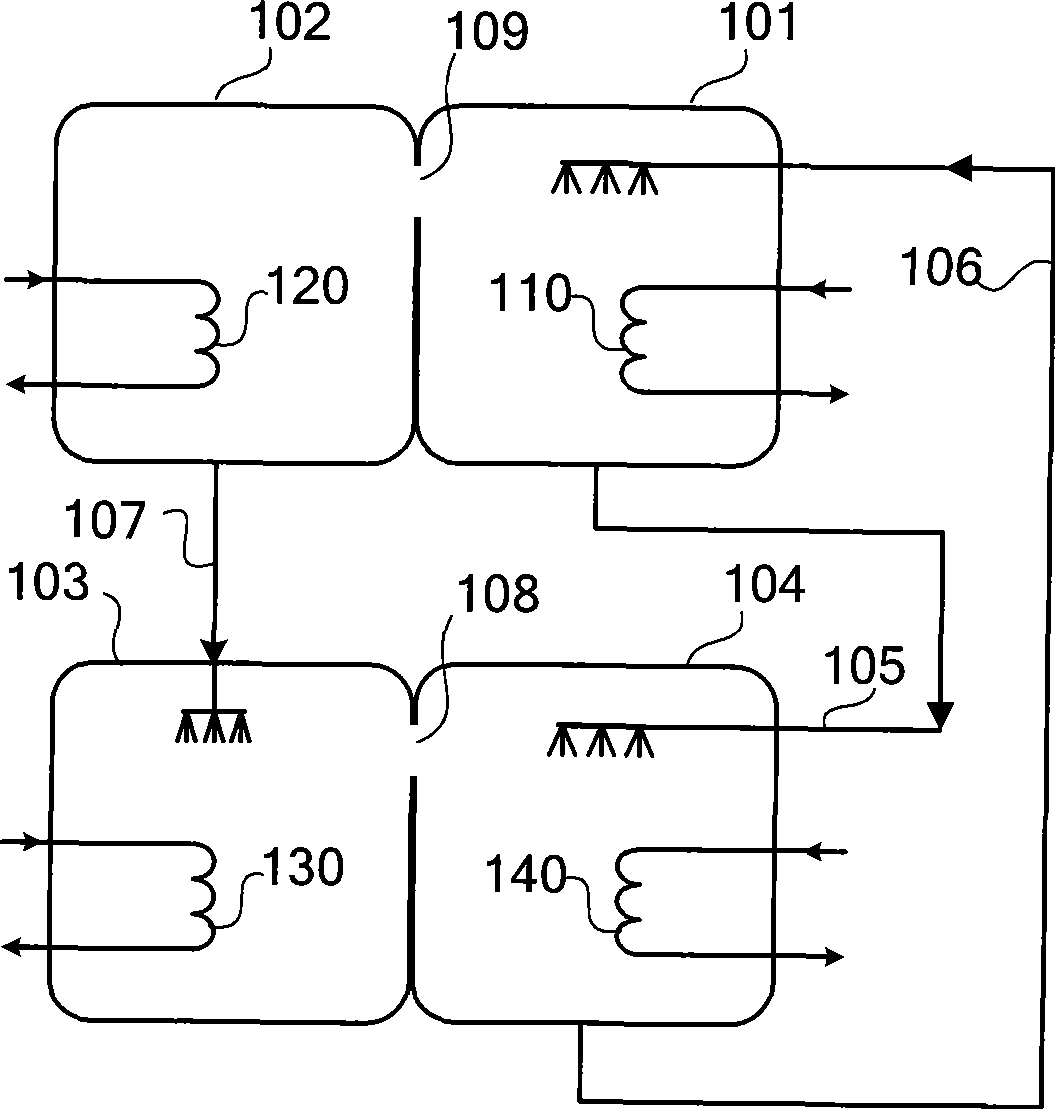

Compression-absorption-diffusion combined refrigerating plant and its refrigeration cycle method

InactiveCN101344345AImprove efficiencyRelieve pressureRefrigeration machinesEngineeringRefrigeration plant

The invention provides a compression-absorption-diffusion composite refrigeration device and a refrigeration circulation method which adopts the device, while the device and the method belong to the technical field of refrigeration devices. The device is coupled in a series connected way by an absorption refrigeration system, a compression refrigeration system and a diffusion refrigeration system and is composed of a common heat exchange device, a throttling device and a refrigeration working medium; and the device comprises a liquid storage device, a solution pump, a generator, a rectifier, a first-stage condenser, a second-stage condenser, a compressor, a throttle valve, an evaporator and an absorber. Ammonia vapor completes first pressure increase in the diffusion refrigeration system and the absorption refrigeration system and enters the compressor through a pipeline after entering the first-stage condenser for completing second pressure increase, after that, the ammonia vapor enters the second-stage condenser to be cooled to liquid ammonia, the liquid ammonia enters the evaporator through the throttle valve, the evaporation and the refrigeration are carried out under the role of a diffusing agent of the evaporator, the liquid ammonia is further mixed with the diffusing agent to enter the absorber, ammonia in the absorber is absorbed, and the diffusing agent is returned back to the evaporator along the pipeline. The device of the invention is applicable to small-scale low-grade waste heat refrigeration occasions.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

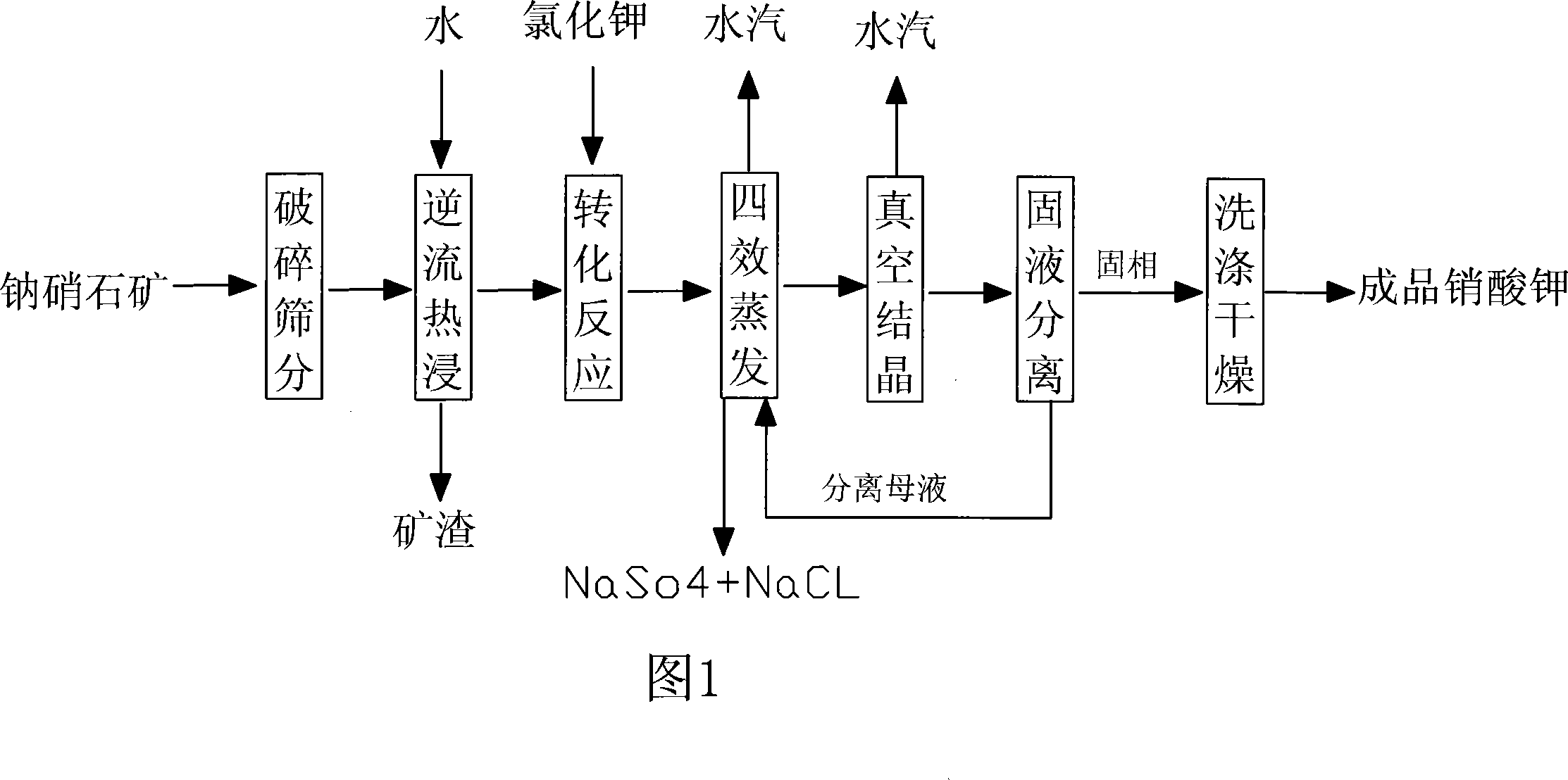

Method for producing potassium nitrate by chilisaltpeter ore transformation process

InactiveCN101177287ASimple processLess investmentAlkali metal nitrate preparationCoal miningThree level

The invention provides a transformation method for preparing potassium nitrate via nitratite, which adopts the technology steps that the ore is crushed until the grinding diameter is below 2cm, and multilevel counterflow heat immersed making the content of NaNO3 equal and more than 450g / l; potassium chlorate is added for heat transformation; four-effect evaporation is applied for brine evaporation and saline miner degree after degree, making the content of KNO3 equal and more than 800g / l; finished product potassium nitrate is obtained through three level vacuum cold crystallization, centrifugal detach and then drying. The nitrate recovery yield of the invention is above 75%, the potassium recovery yield is above 85%. The invention has the advantages of simplifying the technological process, saving investment cost, having high power-efficiency utilization ratio, and being suitable for low grade soda-nitre mine coal mining.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

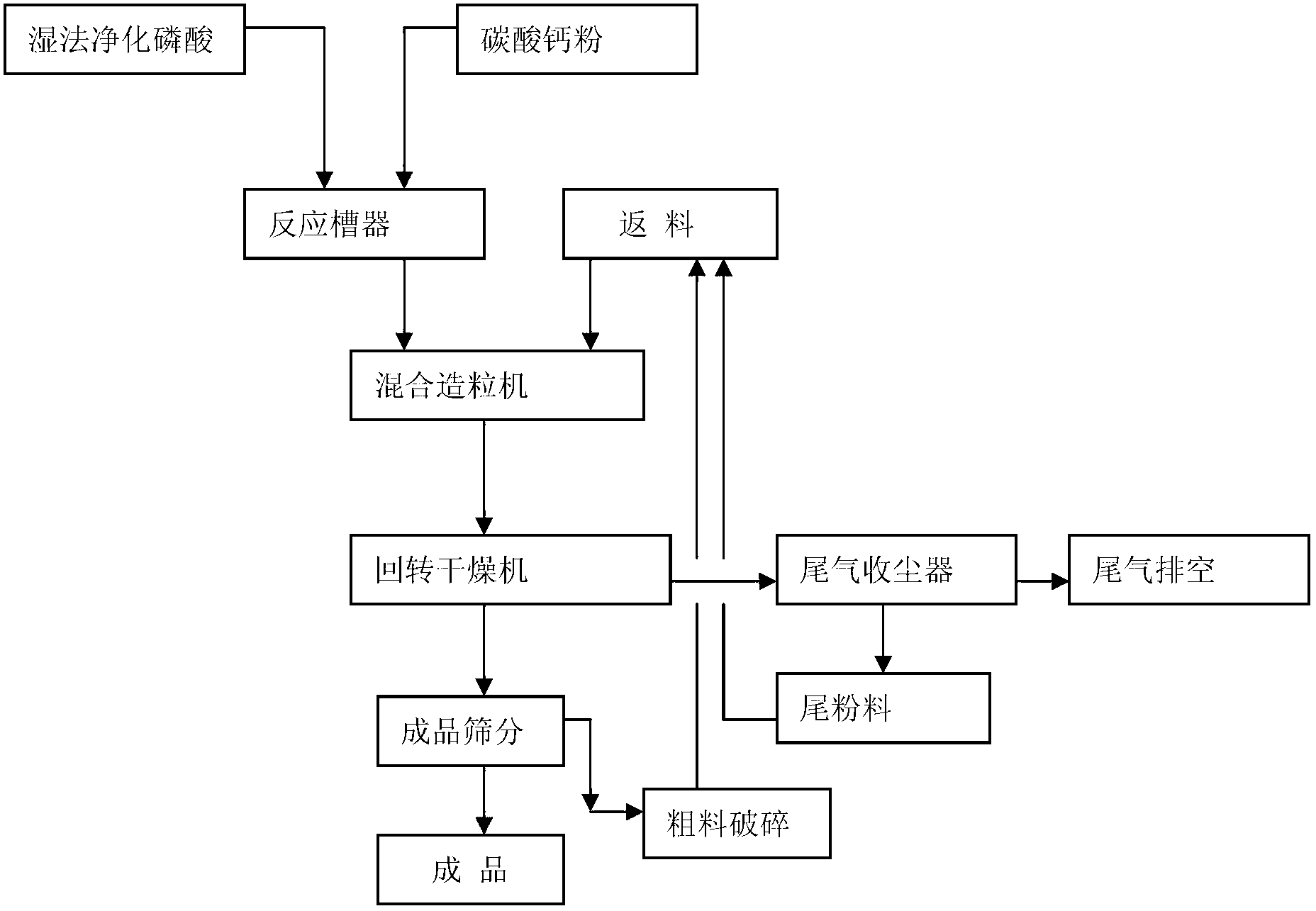

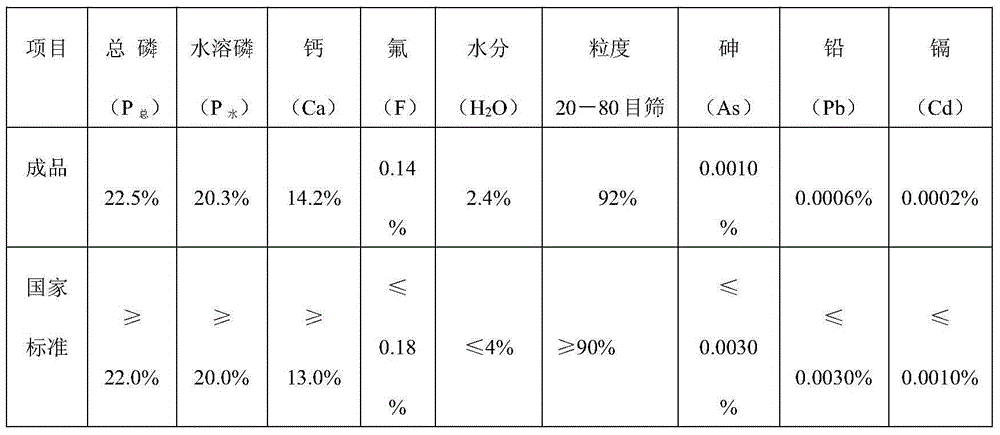

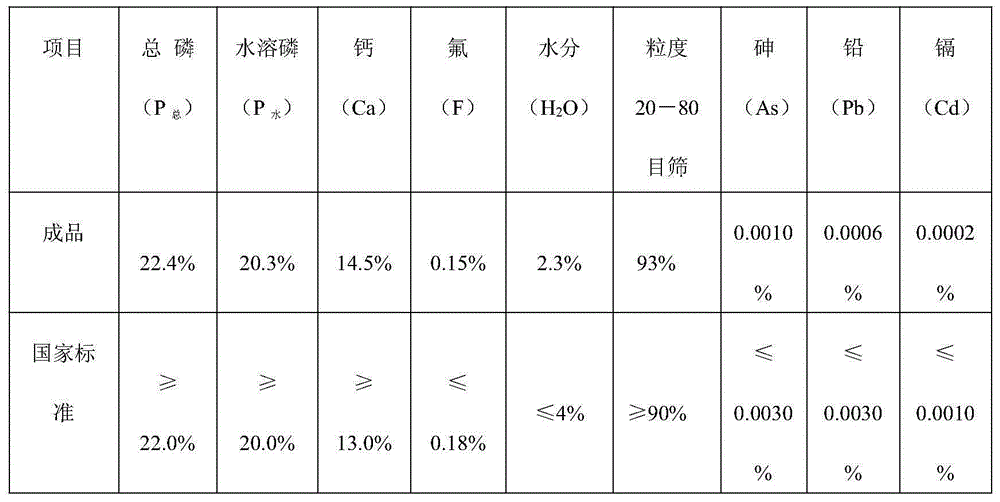

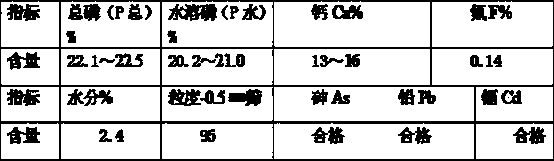

Production method of feed-grade granular calcium hydrogen phosphate III-type product

ActiveCN102701171ALow grade requirementsHigh biological potencyAnimal feeding stuffPhosphorus compoundsPhosphoric acidMonocalcium phosphate

The invention relates to a production method of a feed-grade granular calcium hydrogen phosphate III-type product, which comprises the following steps of: mixing strong phosphoric acid with 30-50 wt% of phosphorus pentoxide and a calcium-containing compound according to the Ca / P ratio of 0.75-0.85 in a reactor at high rotating speed greater than and equal to 450 RPM for reaction, continuously feeding produced mixed slurry containing calcium hydrogen phosphate and monocalcium phosphate together with a return material into a mixing granulator for granulation, and feeding a produced feed-grade granular calcium hydrogen phosphate III-type moisture semi-finished product into a drying machine for drying; and screening a dried finished product output by the drying machine to obtain the calcium hydrogen phosphate III-type product, and crushing tailings remained after screening and returning the crushed tailings to the mixing and granulation steps as the return material. With the production method, the feed-grade granular calcium hydrogen phosphate III-type product is directly synthesized in one-step reaction, the production method has low grade requirement for raw materials, short production process flow and high phosphorus utilization rate, and no white fertilizer or waste water is produced; and the granular product does not cake and has good flowability, and the biological value of animals is high.

Owner:SINOCHEM YUNLONG

Magnesium phosphate cement

The invention discloses a magnesium phosphate cement, which is prepared from the following ingredients in parts by mass: 45-75 parts of magnesium oxide mixture, 15-50 parts of dihydric phosphate and 2-10 parts of retarder, wherein the magnesium oxide mixture comprises calcined dolomite dust. A preparation method of the calcined dolomite dust comprises the following steps: after smashed dolomite and silicon-containing ingredients are evenly mixed, calcining at the temperature of 1100-1800DEG C; and then, grinding a calcined product to obtain the calcined dolomite dust. Compared with traditionalmagnesium phosphate cement, the magnesium phosphate cement prepared by the method has the advantages that performance is similar and color is white, meanwhile, the selection range of a magnesium oxide raw material in the magnesium phosphate cement is enlarged, the cost of the magnesium phosphate cement is obviously lowered, and therefore, the magnesium phosphate cement has a good market prospect.

Owner:CHONGQING UNIV

Production method for feed grade particulate calcium dihydrogen phosphate

InactiveCN105217592ALow grade requirementsIncrease profitPhosphorus compoundsParticulatesPhosphoric acid

The present invention relates to a production method for feed grade particulate calcium dihydrogen phosphate The method comprises the following steps of: step 1. purifying wet process phosphoric acid with a mass concentration of phosphorus pentoxide at 40-45 wt% to a feed-grade level standard; step 2. grinding natural calcium carbonate ore to fine powder, wherein the fine powder with the fineness which is 100 meshes is greater than 90%; and a concentration of CaCO3 in natural calcium carbonate fine powder is greater than 95 wt%; step 3. in accordance with a Ca / P ratio in the range of 0.56-0.65, performing a proportion measurement reaction, producing a semifinished product of calcium dihydrogen phosphate, adding feed grade particulate calcium dihydrogen phosphate revert into the semifinished product, wherein an index thereof accrods with a GB22549-2008 standard; step 4. drying, wherein during drying, hot air inlet temperature is 300-600 DEG C, drying device outlet temperature is 80-110 DEG C, and moisture content of a finished product after drying is 1-4 wt%; and step 5. performing granulation and sieving on the finished product obtained in the step 4, sending a finished product of particulate calcium dihydrogen phosphate at 20-80 mesh to a packaging process and perform packaging to obtain a final product, wherein a material larger than 20 meshes is ground and used as a revert together with the finished product that is smaller than 80 meshes.

Owner:SINOCHEM YUNLONG

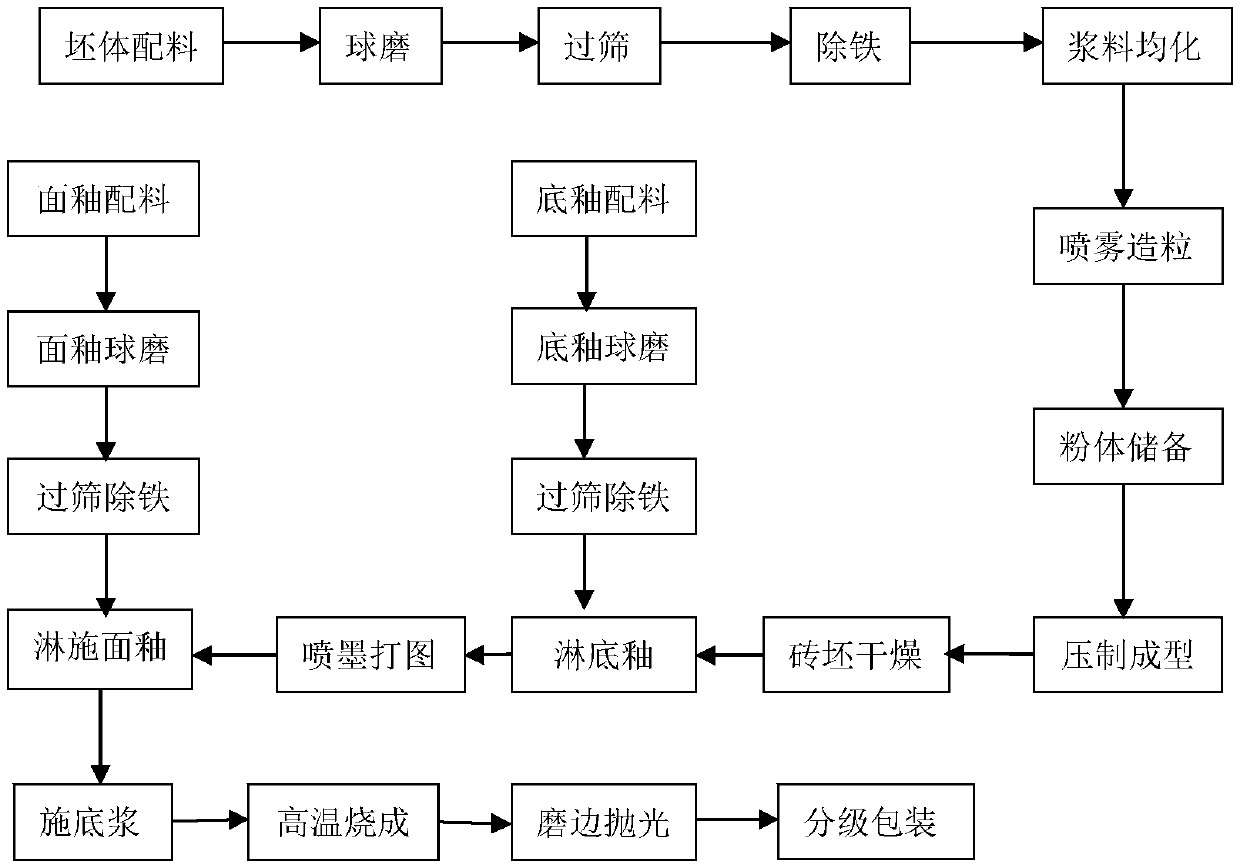

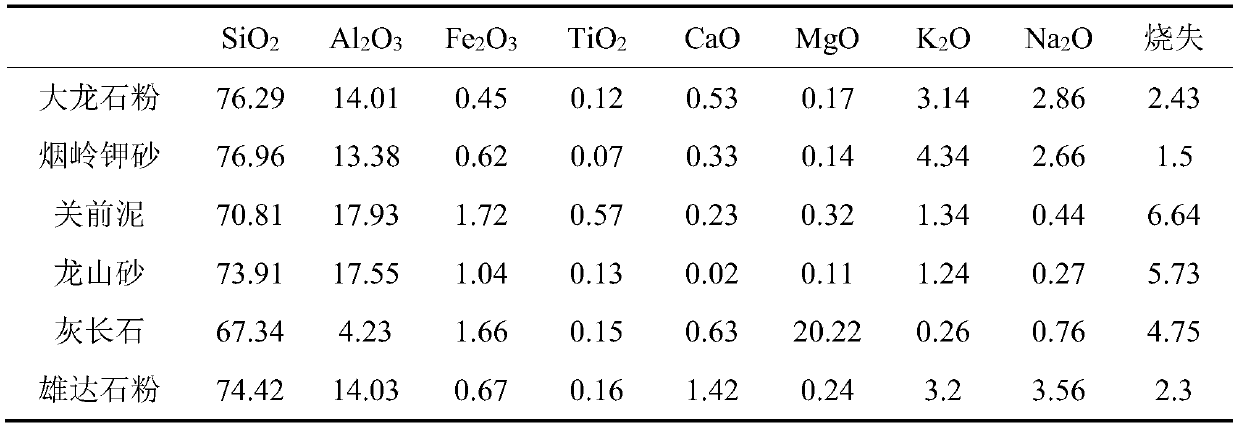

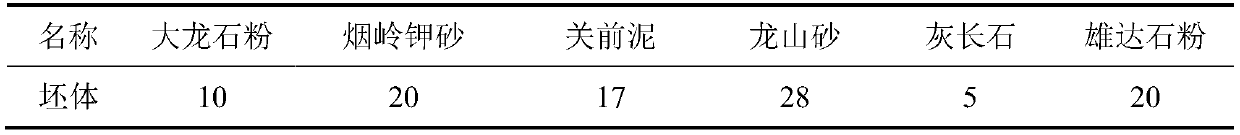

High-silica porcelain rustic tile and production method thereof

InactiveCN109942288AThe appearance quality is not lowResolving conflicts that are difficult to obtainPotassiumHigh silica

The invention discloses a high-silica porcelain rustic tile and a production method thereof. A green body is prepared from, by weight, 10% of Dalong stone powder, 20% of Yanling potassium sand, 17% ofGuanqian mud, 28% of Longshan sand, 5% of grey feldspar and 20% of Xiongda stone powder, the added ingredients account for, by weight, 1.5-2.5% of the raw materials, the one-step firing temperature is 1202 DEG C, and the firing period is 60-65 minutes. Through optimization of a green body formula and optimization of a corresponding glaze formula, the high-quality rustic tile with the product appearance quality, the product interior quality and the product using performance being not lower than those of the tile produced by using an existing high-aluminum green body formula is obtained by combining a firing technology, and the contradiction that due to special requirements, the raw materials are difficult to obtain is solved.

Owner:GUANGDONG HONGYU NEW MATERIALS CO LTD

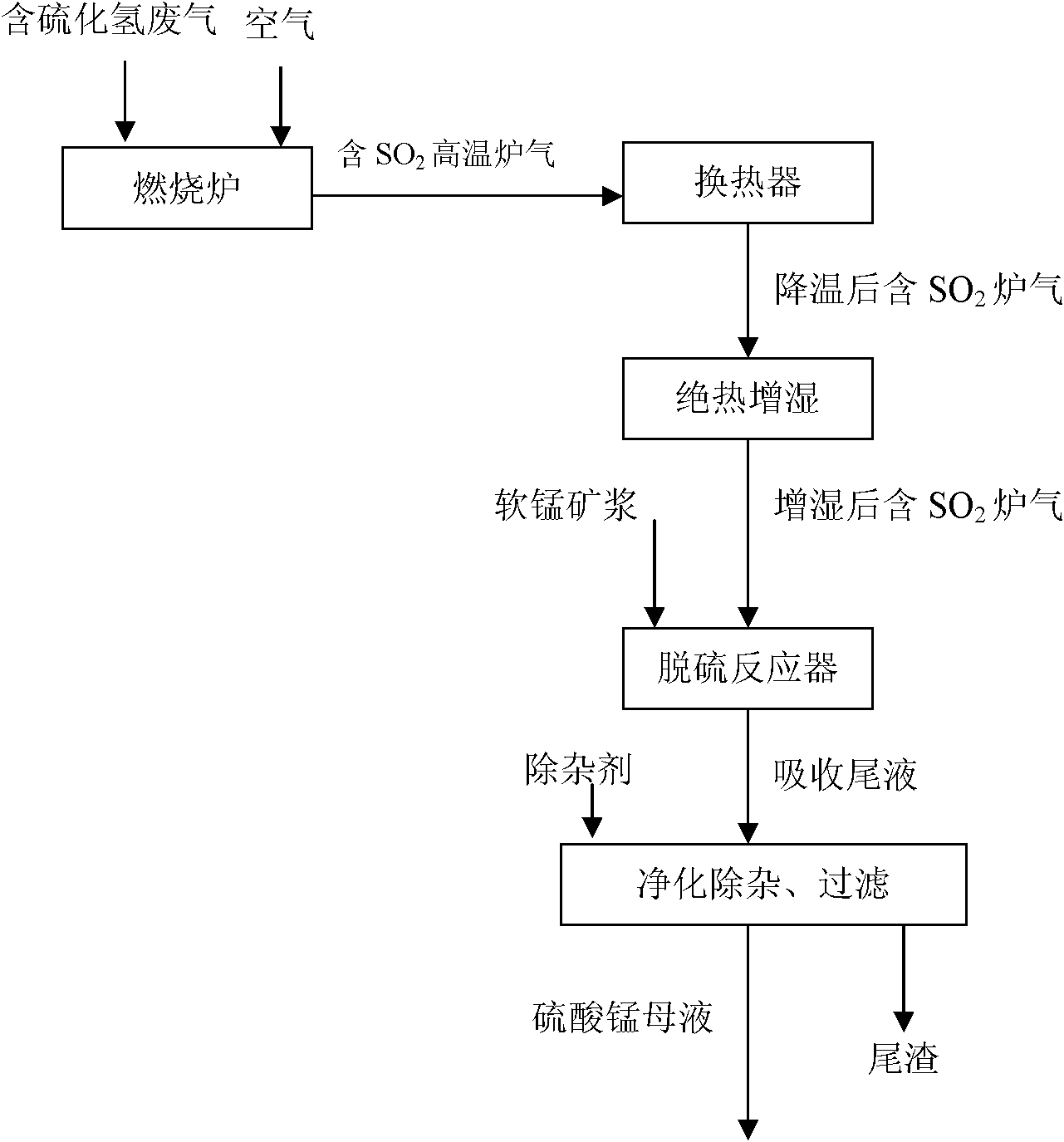

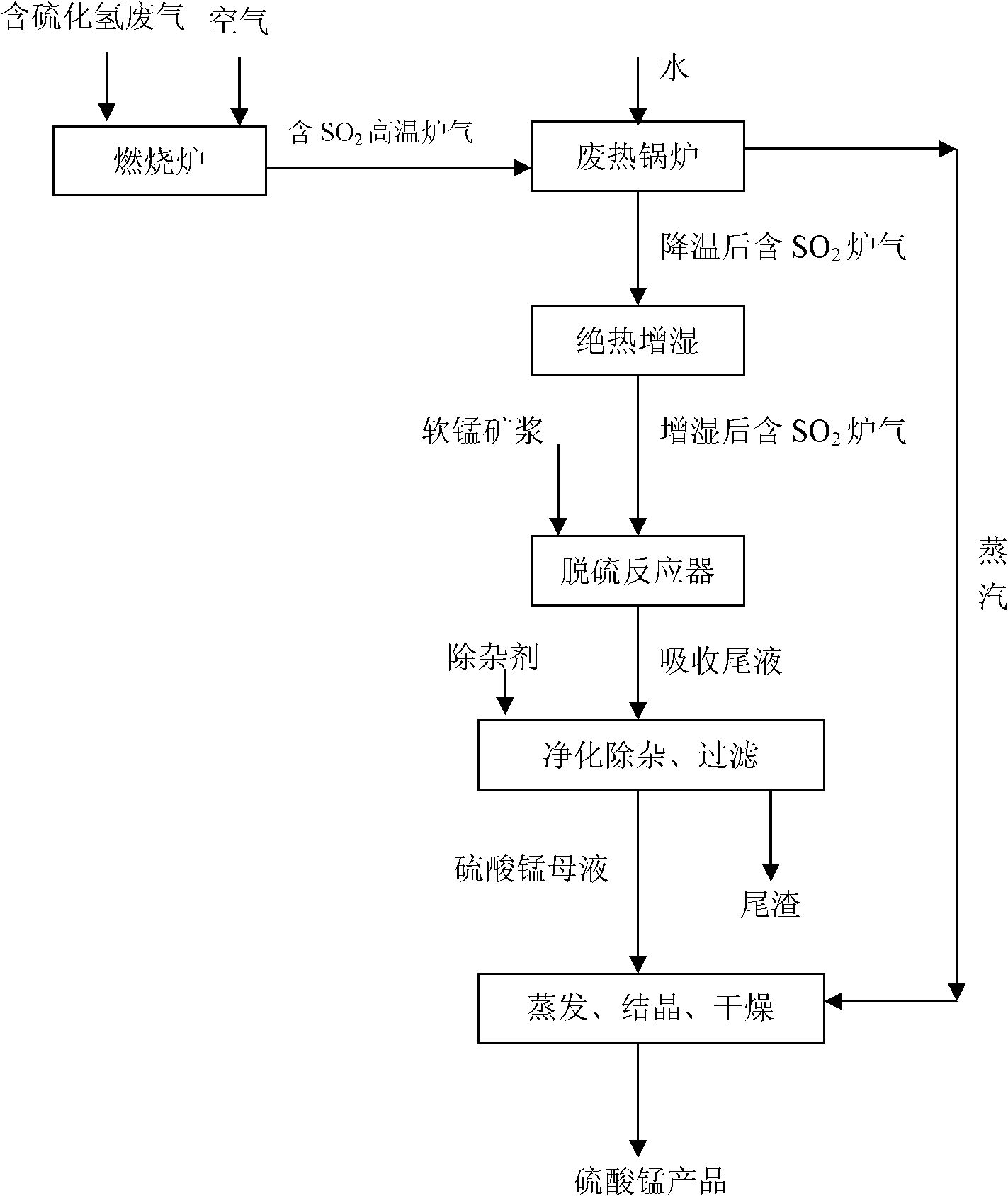

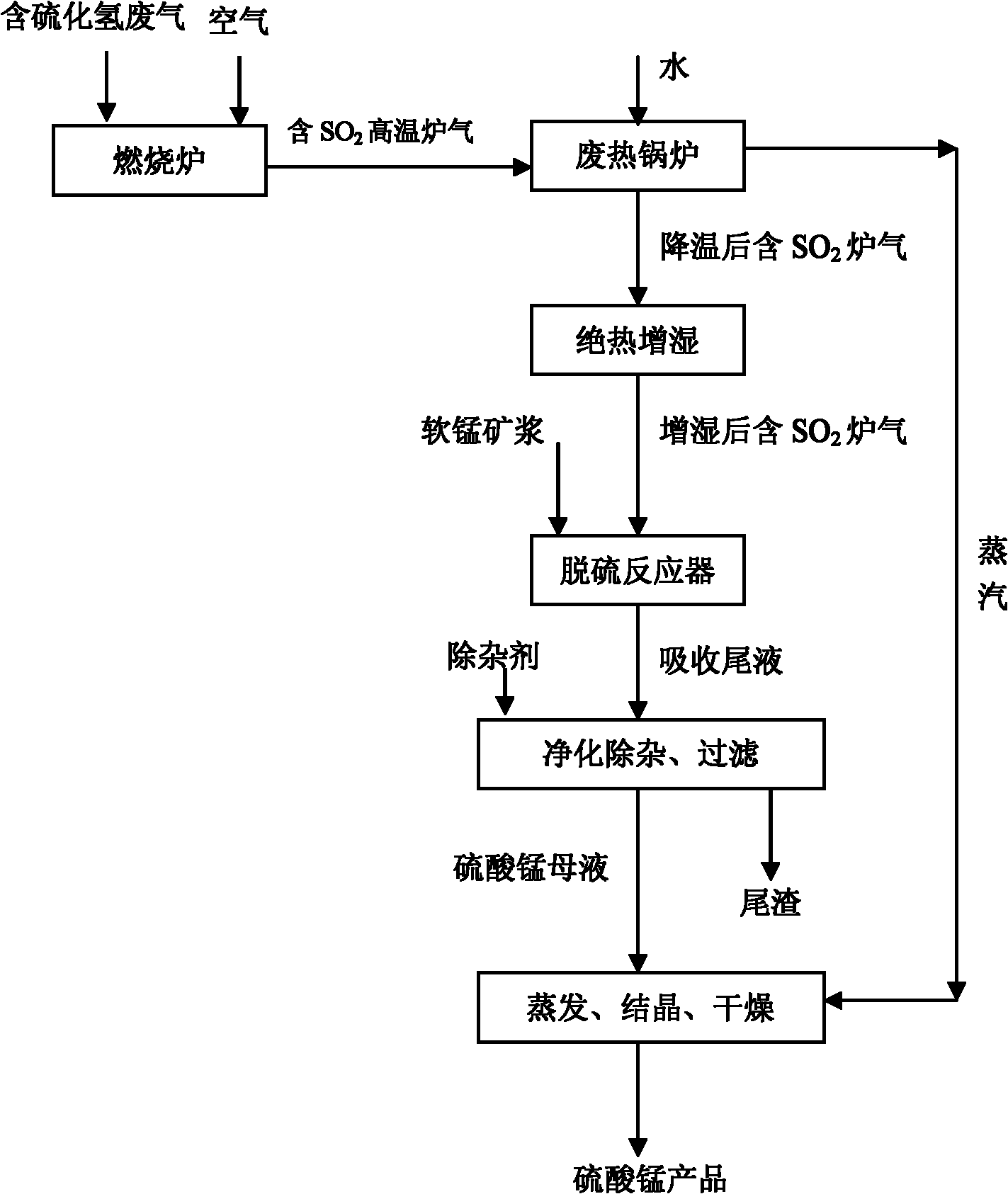

Method for removing hydrogen sulfide from industrial gas in recycling way

ActiveCN101979130ATo achieve complementary useRich reservesDispersed particle separationEnergy inputIndustrial gasPyrolusite

The invention discloses a method for removing hydrogen sulfide from an industrial gas in a recycling way. The method mainly comprises the following steps of: feeding the hydrogen sulfide-containing industrial gas and air into a burning furnace to burn at the temperature of between 600 and 1,200 DEG C so as to obtain sulfur dioxide-containing high-temperature furnace gas; cooling the sulfur dioxide-containing high-temperature furnace gas to not more than 80 DEG C and humidifying; feeding the humidified and cooled sulfur dioxide-containing furnace gas into a pyrolusite pulp absorption system todirectly contact the furnace gas with the pyrolusite pulp for absorption reaction so as to generate manganese sulfate-containing absorption tail solution; performing full absorption reaction and solid-liquid separation, wherein the obtained liquid phase is manganese sulfate-containing aqueous solution; and adding an impurity removing agent to react and then performing solid-liquid separation, wherein the obtained liquid phase is solution of manganese sulfate which is further processed. By implementing the method, the hydrogen sulfide can be removed and recovered from the industrial gas in a recycling way, the pollution of the hydrogen sulfide to atmosphere is reduced and controlled, the comprehensive utilization added value of the pyrolusite is improved, and meanwhile, the method has the characteristics of high sulfur-removing effect, high manganese utilization rate and light secondary pollution.

Owner:SICHUAN UNIV

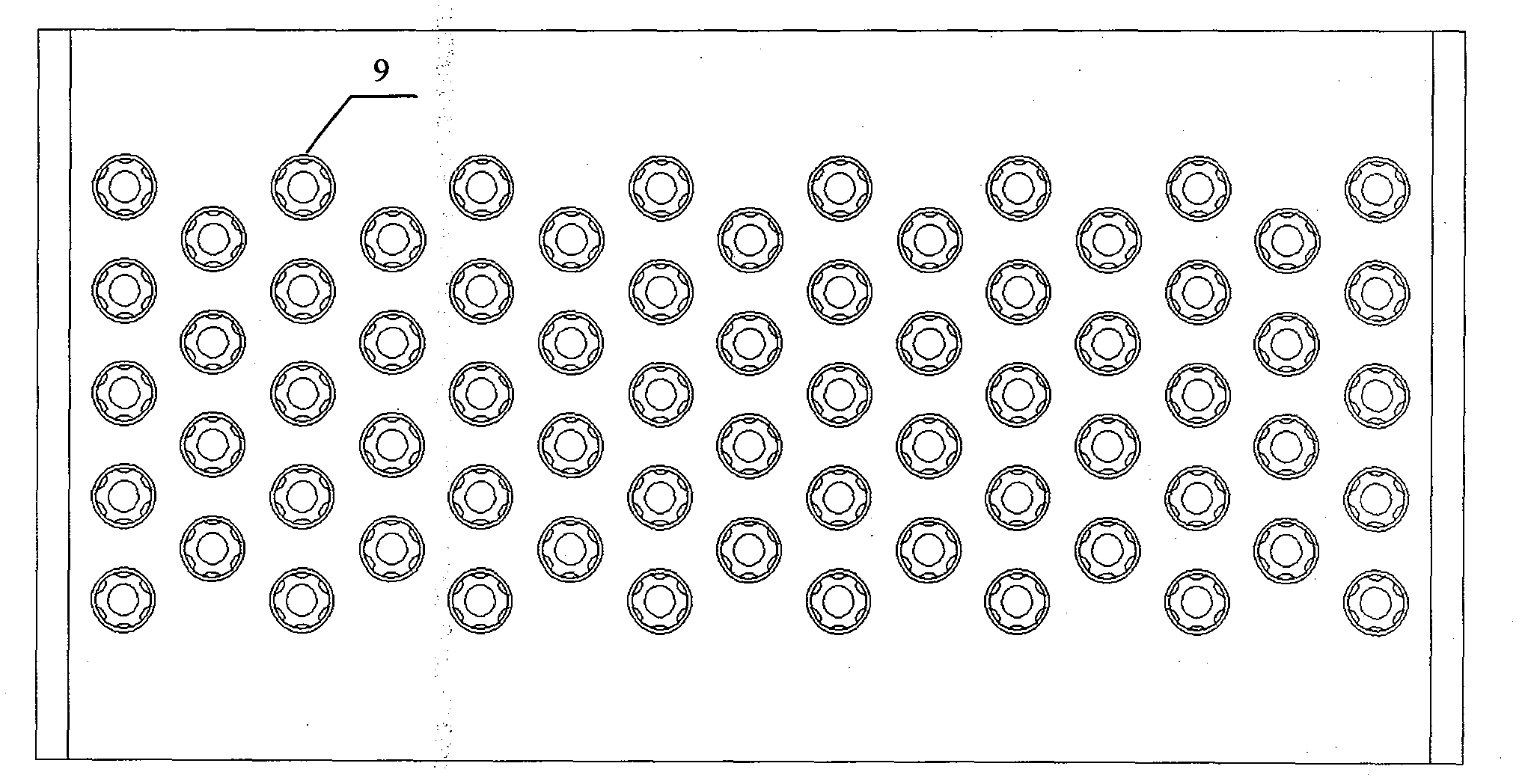

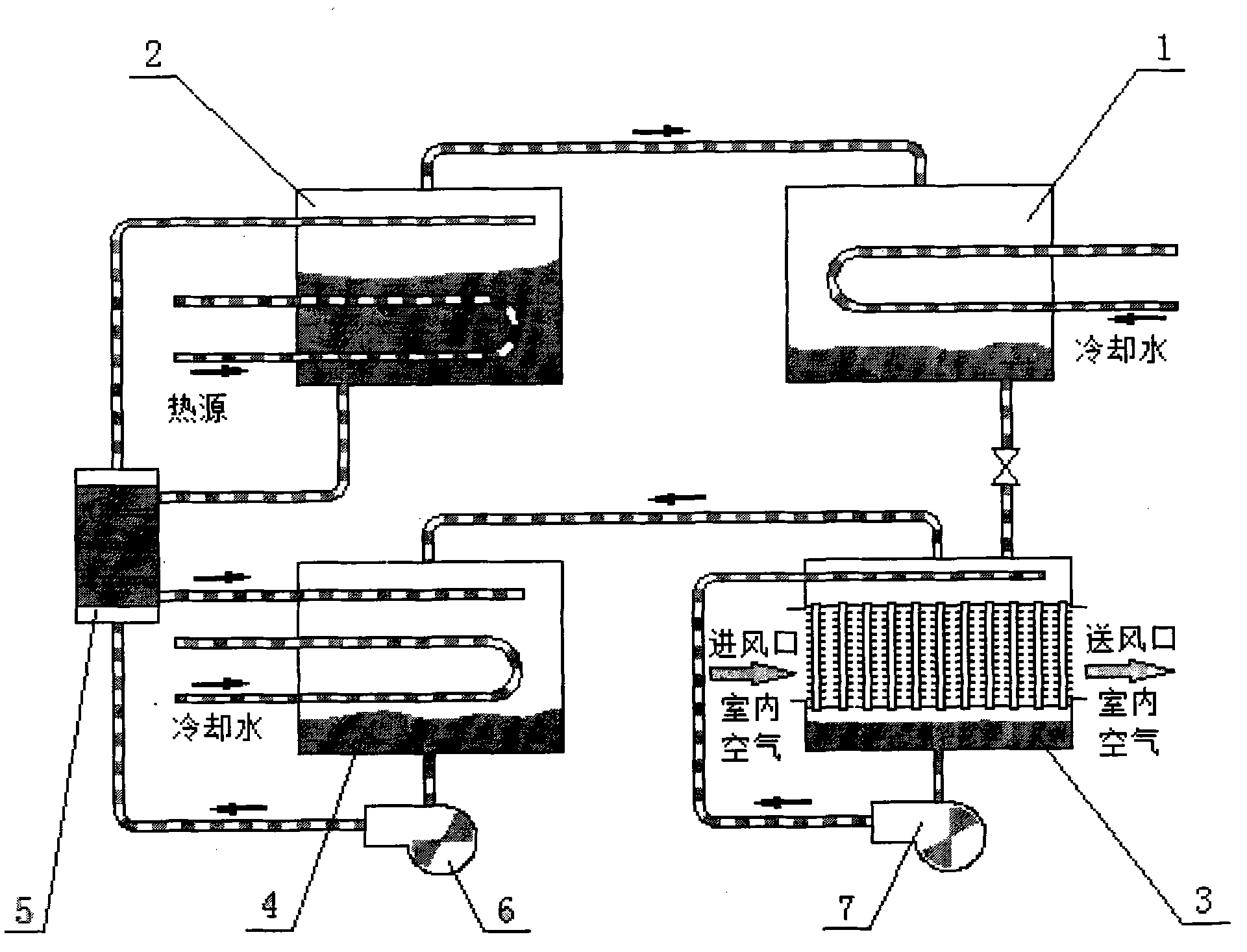

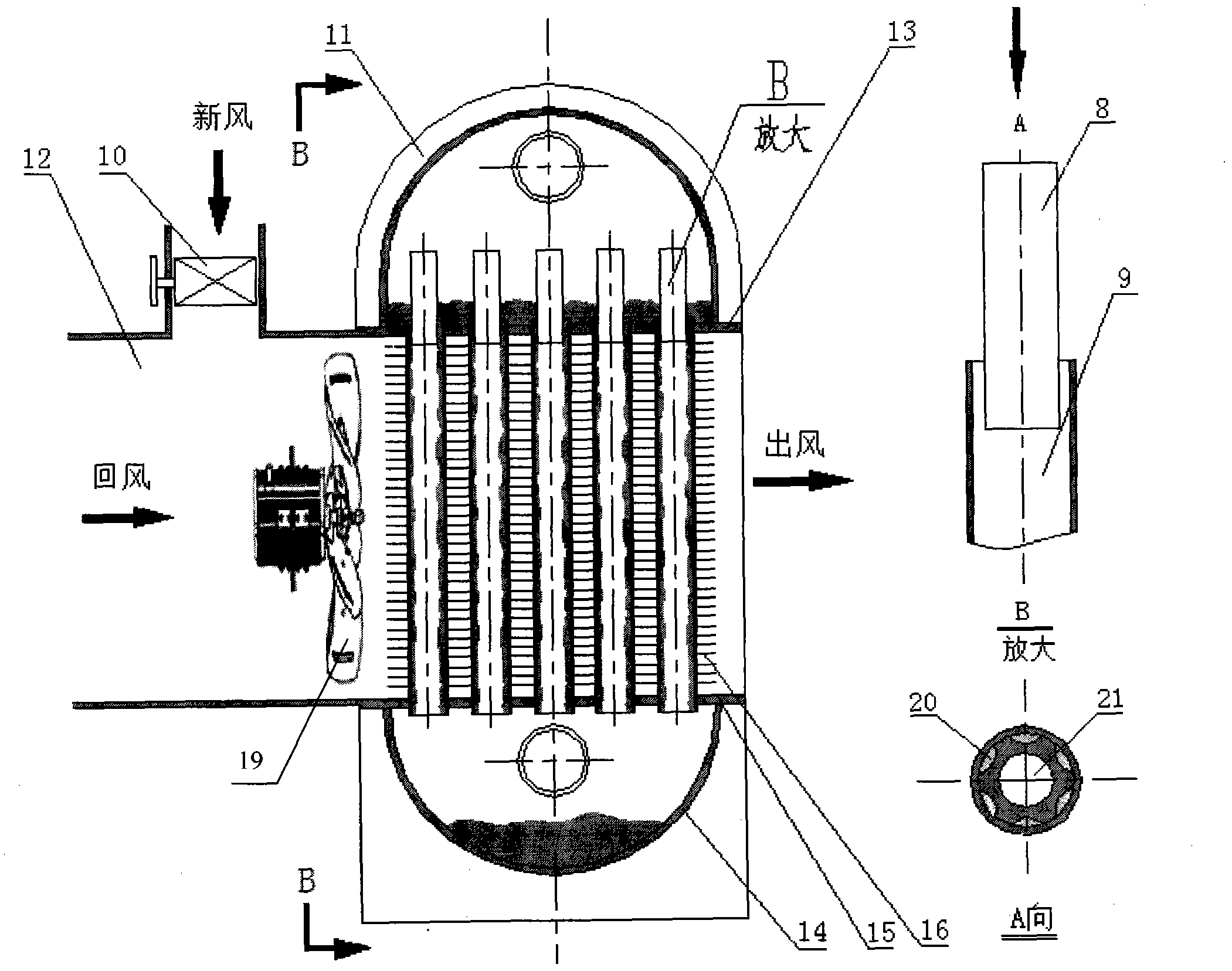

Lithium bromide absorption type water chilling unit for direct cooling type cold-blast air evaporator

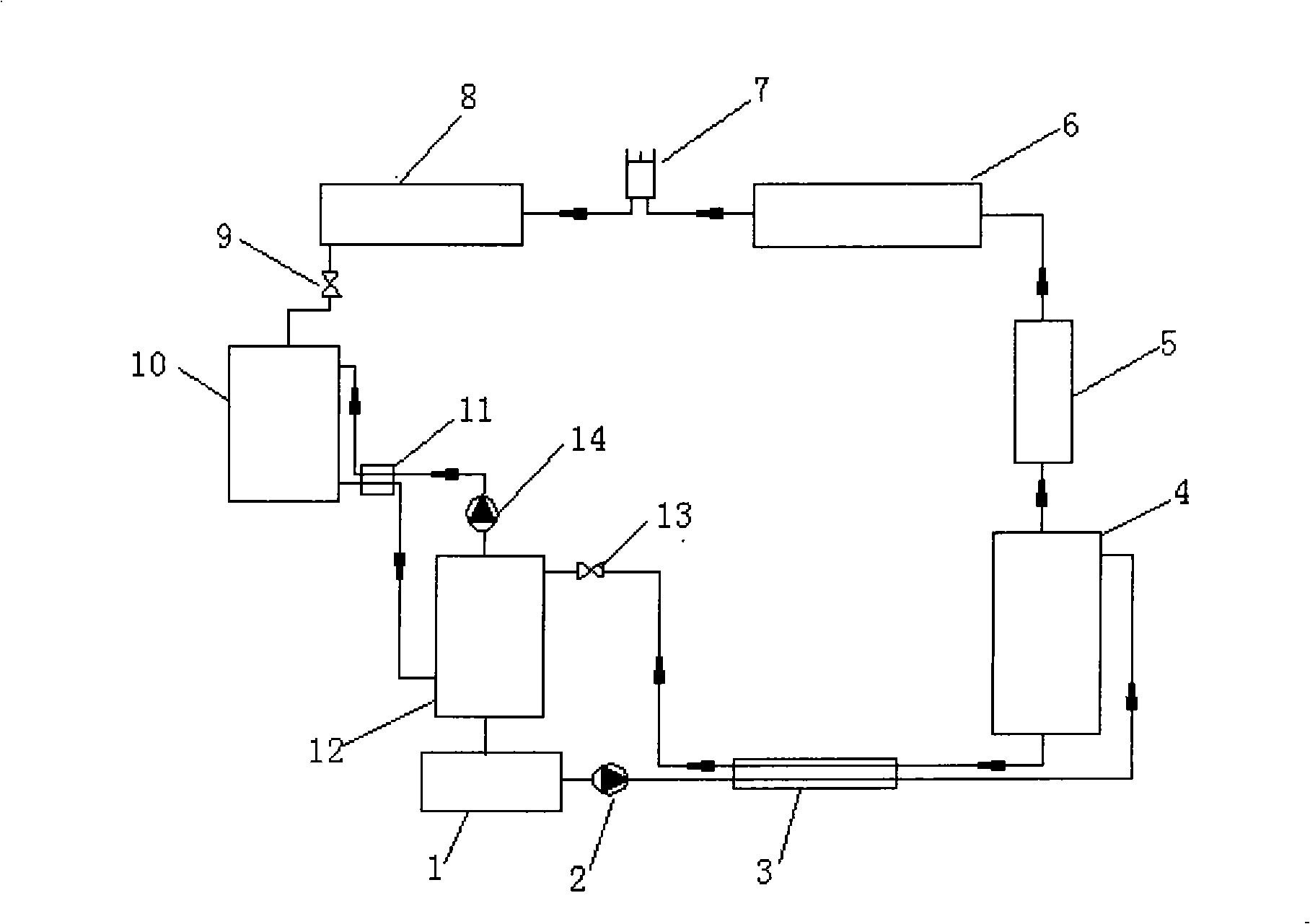

InactiveCN102147135ARaise the evaporation temperatureIncrease temperatureEvaporators/condensersAir conditioning systemsLithium bromideEngineering

The invention discloses a lithium bromide absorption type water chilling unit for a direct cooling type cold-blast air evaporator, which comprises a lithium bromide absorption type water chilling unit and a refrigerant circulator and a lithium bromide solution circulator thereof, wherein the lithium bromide absorption water chilling unit comprises a condenser 1, a generator 2, a direct cooling type cold-blast air evaporator 3, an absorber 4, a solution heat exchanger 5, a solution pump 6 and a refrigerant pump 7, and the water chilling unit is directly connected with an air conditioner air system. The lithium bromide absorption water chilling unit is characterized in that the direct cooling type cold-blast air evaporator 3 is a vacuum closed cylinder consisting of air-cooled heat transfer pipe sets 9, and air is cooled in an air-cooled manner. By adopting the invention, the contradiction between unit performance and heat source grade in the traditional lithium bromide absorption water chilling technology is eliminated, the unit performance parameter is improved, and advantages are created for continuous application of solar refrigerating air conditioners and comprehensive utilization of low-temperature waste heat and exhaust heat.

Owner:王红斌 +3

Method for preparing beryllium oxide or high-purity beryllium oxide from beryllium containing solution

ActiveCN103818937ALow grade requirementsImprove qualityBeryllium oxides/hydroxidesO-Phosphoric AcidAlcohol

The invention relates to the technical field of beryllium oxide preparation, and refers to a method for preparing beryllium oxide or high-purity beryllium oxide from a beryllium containing solution. The method comprises the following steps of: 1, weighing and mixing a phosphoric acid extractant, alcohol and sulfonated kerosene in a volume ratio of 10: 10: 75 to 25: 15: 90, then preparing to be an extractant. The method disclosed by the invention is simple and flexible to operate, convenient to realize continuity. The method has low requirements in beryllium containing ore grade and can treat the beryllium containing waste liquid of any concentration. In comparison with the prior art, the recovery rate of beryllium oxide, the back extraction ratio and the one-time precipitation rate of hydrolysis BeO are higher and the quality of beryllium oxide or high-purity beryllium oxide can be effectively guaranteed, so that high-quality beryllium oxide or high-purity beryllium oxide can be obtained. In the process of production, acid waste liquids are mainly produced, and the acid waste liquids can be discharged after a neutralizing treatment is carried out, the waste residue and exhausted air emissions are less, therefore the method is an environment-friendly technology.

Owner:XINJIANG RES INST OF NON FERROUS METALS

Method for producing feed-grade monocalcium phosphate by dry method

InactiveCN104016327AReduce moisture contentLow grade requirementsPhosphorus compoundsWastewaterPhosphoric acid

The invention relates to a production method of feed-grade monocalcium phosphate. The production method of feed-grade monocalcium phosphate comprises the following steps: firstly, purifying phosphoric acid by wet process with the concentration of 45-60wt% in percentage by mass of phosphorus pentoxide to the feed grade standard; secondly, grinding natural calcium carbonate mine into fine powder, wherein the content of CaCO3 in the natural calcium carbonate fine powder reaches 95wt% above; thirdly, carrying out matching and metering reaction on phosphoric acid and the natural calcium carbonate fine powder according to the range of Ca / P=0.56-0.65, and adding feed-grade monocalcium phosphate returning charge; fourthly, feeding the resultant in the step 3 into a curing storeroom, and curing for 72 hours above; drying the cured materials, and drying a finished product until the water content is 1-4wt%; and sixthly, crushing and screening the dried product to obtain the feed-grade monocalcium phosphate product conforming to the GB22549-2008 standard. According to the production method disclosed by the invention, other production technological defects are overcome, the feed-grade monocalcium phosphate product is synthesized by one step; the raw material grade requirement is low; the technological process is short; white fertilizers and waste water are not generated.

Owner:SINOCHEM YUNLONG

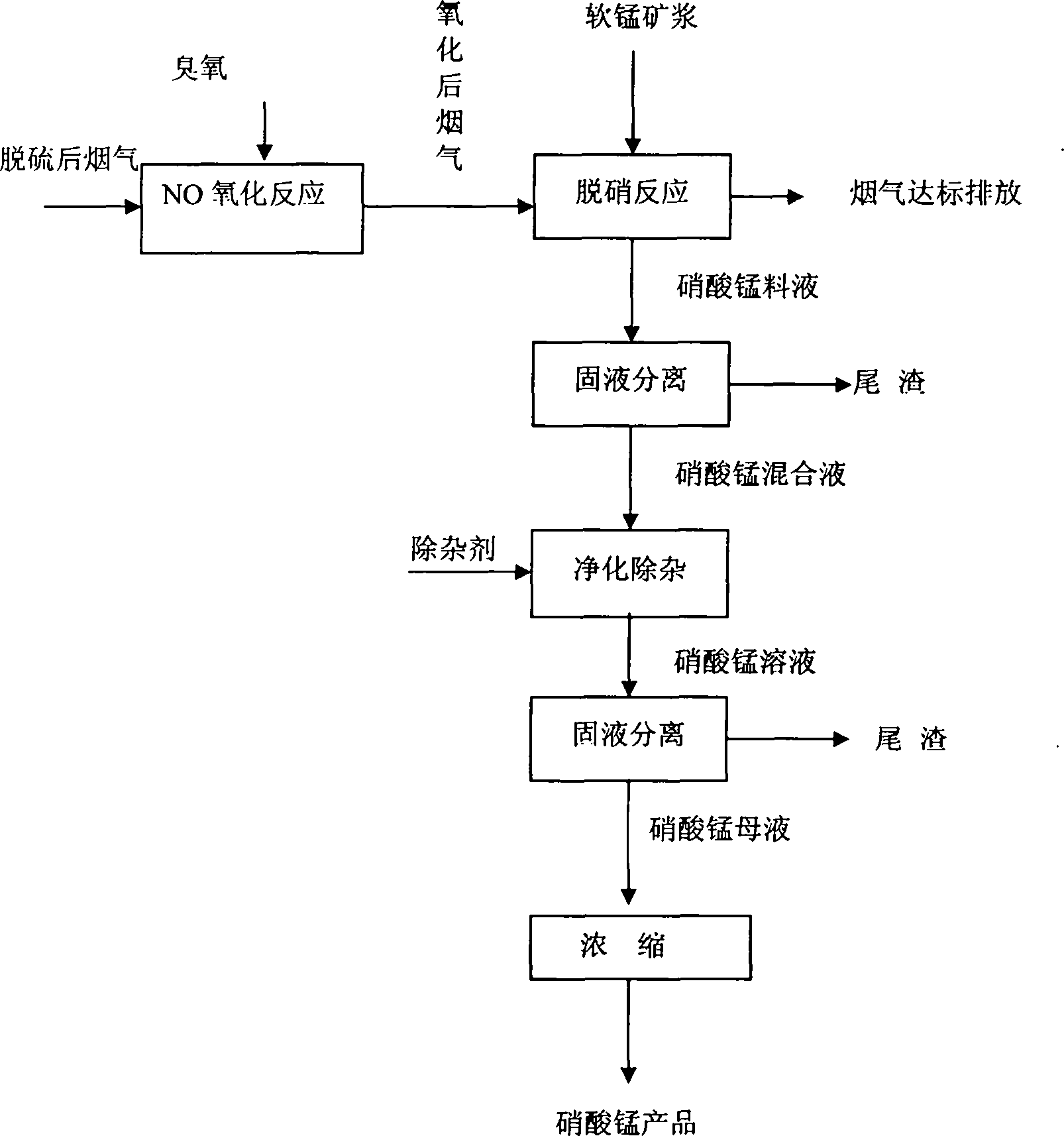

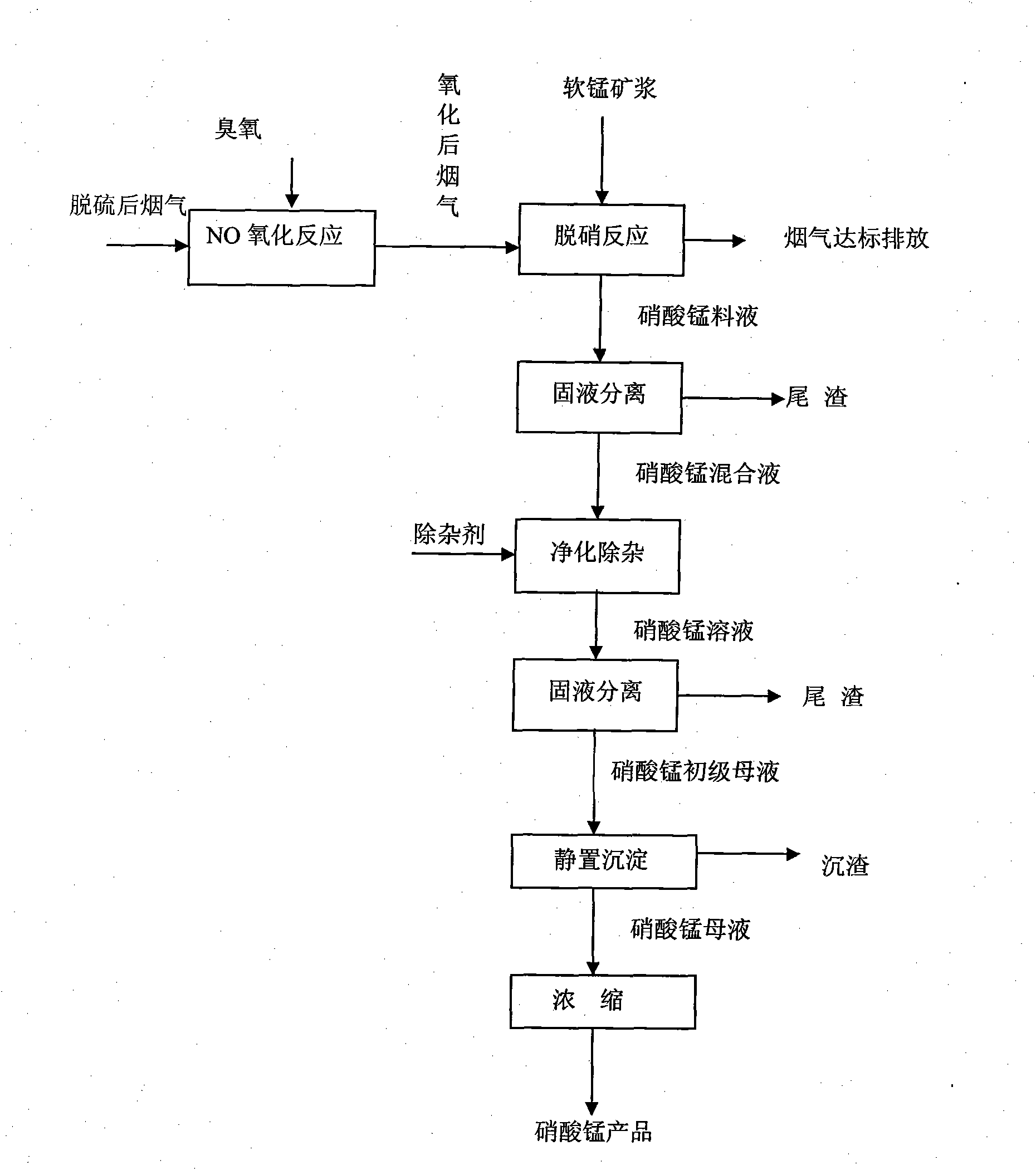

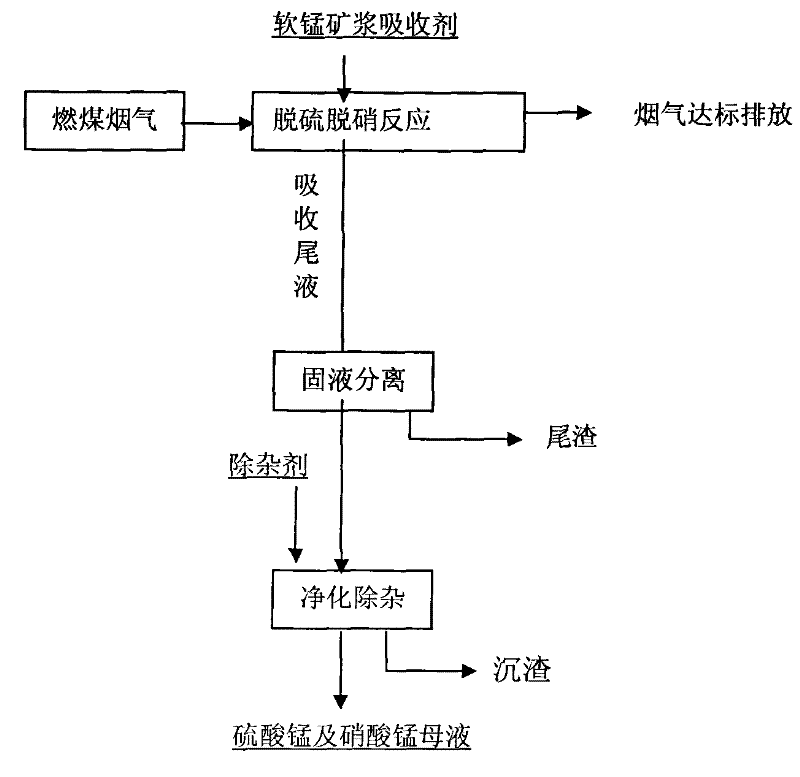

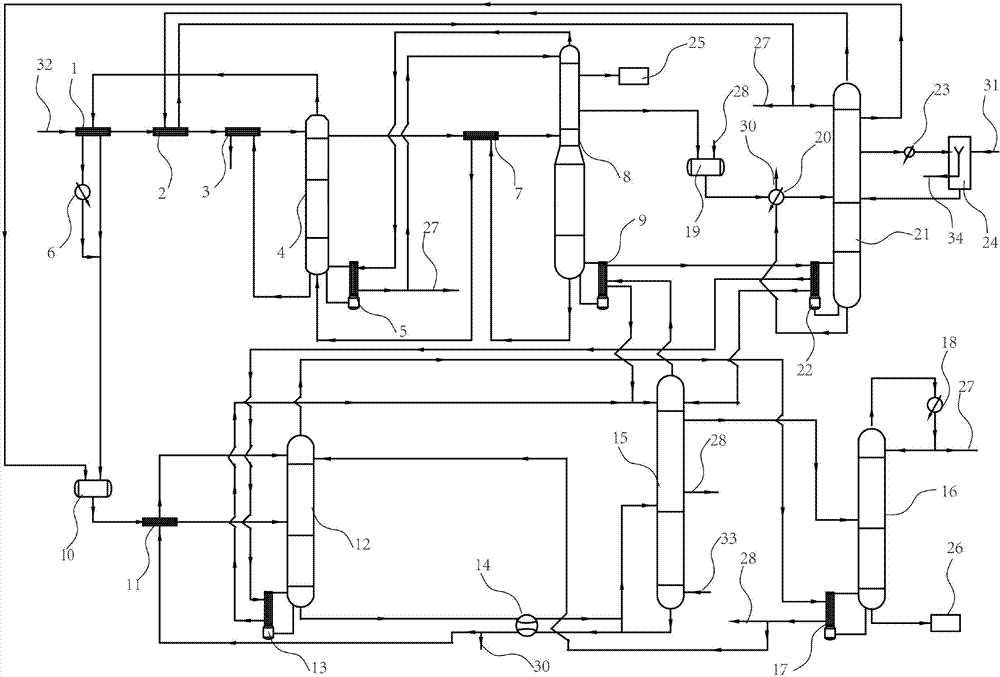

Coal-fired flue gas pyrolusite pulp recycling denitration method

InactiveCN101972588AImprove oxidation efficiencyQuick responseDispersed particle separationManganese nitratesPyrolusiteImpurity

The invention discloses a coal-fired flue gas pyrolusite pulp recycling denitration method, which mainly comprises the following steps of: injecting ozone into desulfurized coal-fired flue gas, and oxidizing NO in the coal-fired flue gas into water-soluble NO2; taking ore pulp prepared from water and low-grade pyrolusite as an absorbent so as to make the pyrolusite pulp and the coal-fired flue gas directly contacted to carry out an absorption and denitration reaction; removing NOX in the flue gas, purifying the coal-fired flue gas to meet the standard for discharging, performing solid-liquid separation on the reacted ore pulp to prepare mixed solution of manganese nitrate; and purifying and removing impurities from the mixed solution of manganese nitrate so as to prepare mother liquor of manganese nitrate, and heating and concentrating the mother liquor of manganese nitrate to prepare industrial products comprising 50 percent of manganese nitrate. Wastewater is not discharged in the whole technical process, so the aims of treating exhaust gas through the low-grade pyrolusite and recycling and preparing manganese nitrate with economic value are fulfilled. The method has the characteristics of high denitration rate, high manganese utilization rate, obvious economic benefit and the like, and is environment-friendly.

Owner:SICHUAN UNIV

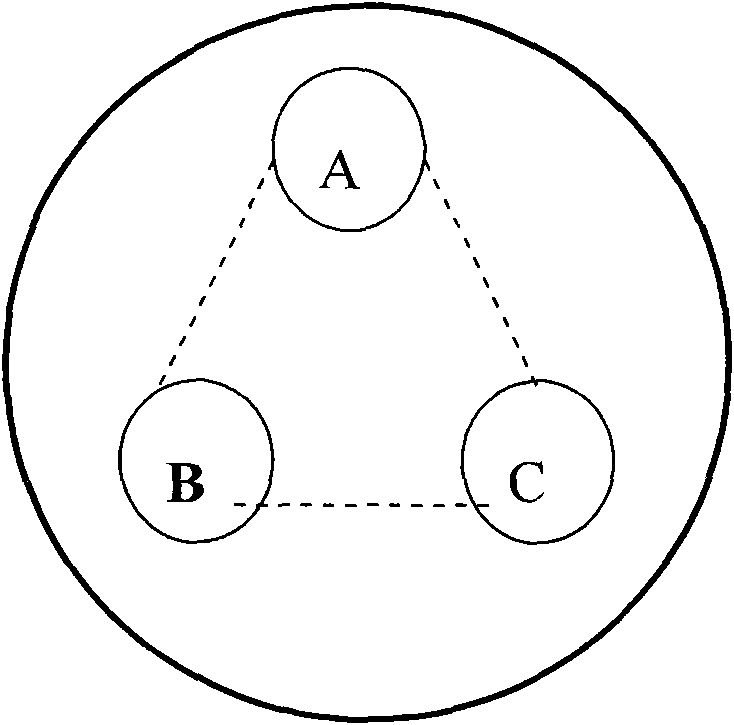

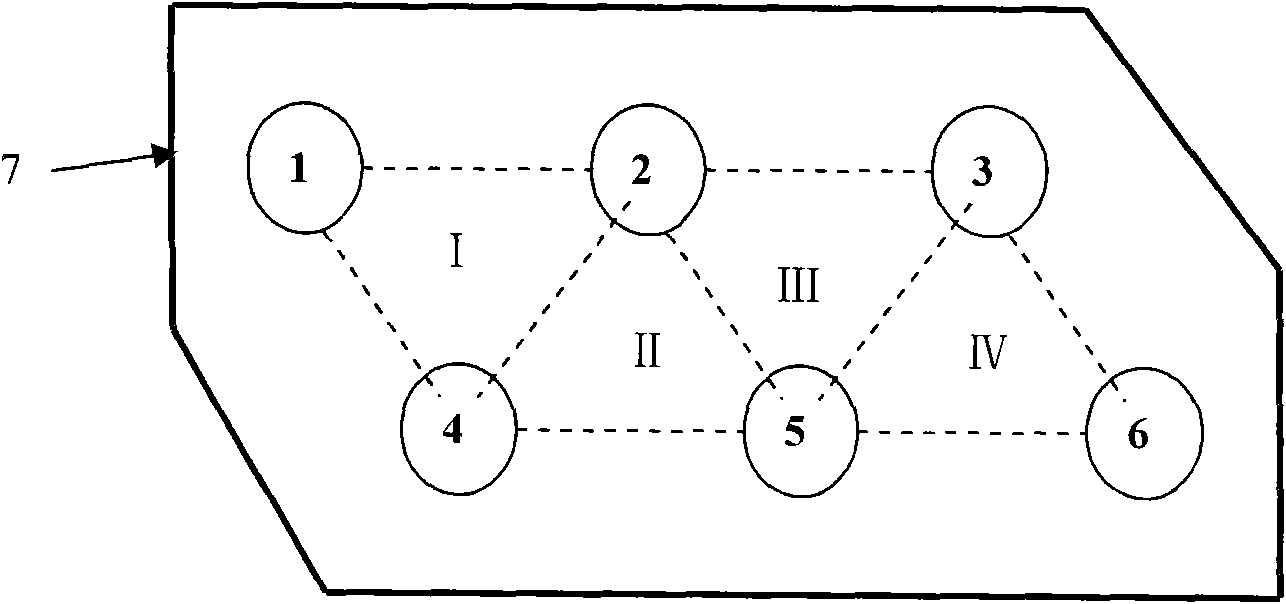

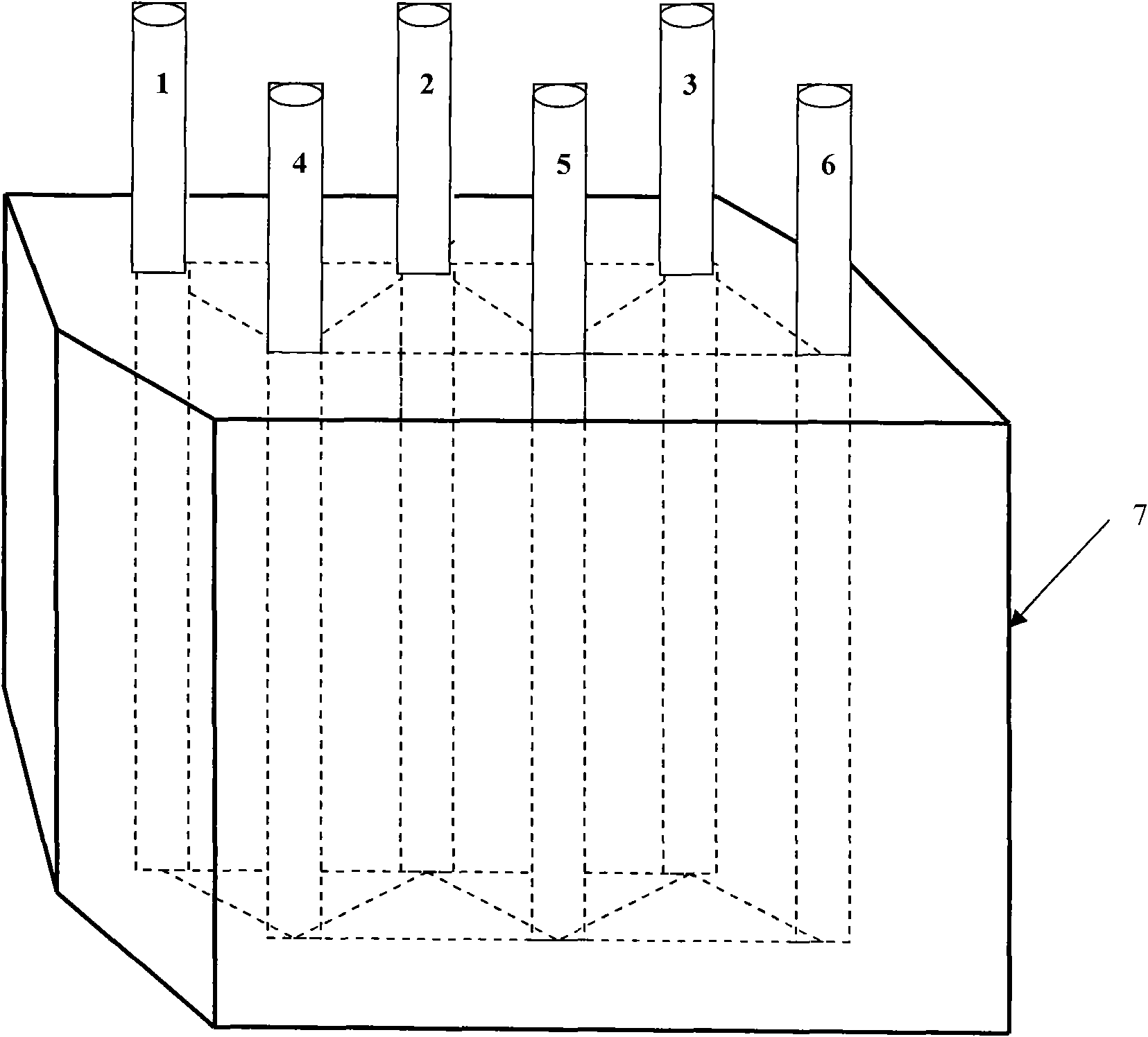

Six phase electrode electric melting furnace

InactiveCN101619928AImproved arc stabilityReduce burning lossCrucible furnacesElectric heating for furnacesFurnace temperatureIsoetes triquetra

The invention provides a six phase electrode electric melting furnace, relating to an electric melting magnesium smelting device, solving the problems of slow temperature rise of furnace temperature, high energy consumption and low yield which exist in current three phase electrode electric melting furnace. In the six phase electrode electric melting furnace, the furnace body is a six-prism body; the six phase electrode is inserted and arranged in the furnace body; the first electrode, the second electrode and the third electrode are arranged in a row with uniform spacing; the fourth electrode, the fifth electrode and the sixth electrode are arranged in a row with uniform spacing; the two rows of electrodes as a whole form a parallelogram; four equilateral triangle hot zones are respectively formed by the first, second, fourth electrodes, the second, fourth, fifth electrodes, the second, third, fifth electrodes, and the third, fifth, sixth electrodes. In the smelting process, the six phase electrode electric melting furnace forms four triangle hot zones, thus achieving concentrated heat, rapid heating of magnesium stones, steady reaction, dramatic lowering of electricity consumption, high speed of temperature rise of furnace temperature which can reach 3500 DEG C, uniform and stable product quality, energy saving and consumption lowering, high yield and good benefit.

Owner:大石桥市金益特种镁质材料厂

Simultaneous desulfurization and denitrification method for resource utilization of coal-fired flue gas pyrolusite slurry

ActiveCN101574617BRich reservesLow priceDispersed particle separationProcess efficiency improvementSolubilityPyrolusite

The invention discloses a synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation. The method mainly comprises the following steps: pyrolusite, water and metal-chelator are prepared into pulp which is taken as an absorbing agent; sulfur dioxide and nitrogen oxides in the flue gas are synchronously absorbed and removed by the absorbing agent; the flue gas is discharged when the purification reaches a standard; the primary product of the mixed mother solution of manganese sulfate and manganese nitrate is obtained after absorbing tail solution is purified; and by utilizing the different solubility of manganese sulfate and manganese nitrate at same temperature, the mixed mother solution is heated firstly to cause the manganese sulfate therein to be crystallized and separated, next, the left mother solution is cooled to cause the manganese nitrate therein to be crystallized and separated, and the left solution is returned to preparation pulp for recycling. No waster water is discharged in the whole process, thereby achieving the purposes of controlling waste by waste, recycling sulfur resources and improving the comprehensive utilization value of pyrolusite. The method is characterized by high desulphrization and denitration efficiency and manganese utilization rate, little secondary pollution, obvious economic benefit and the like.

Owner:SICHUAN UNIV

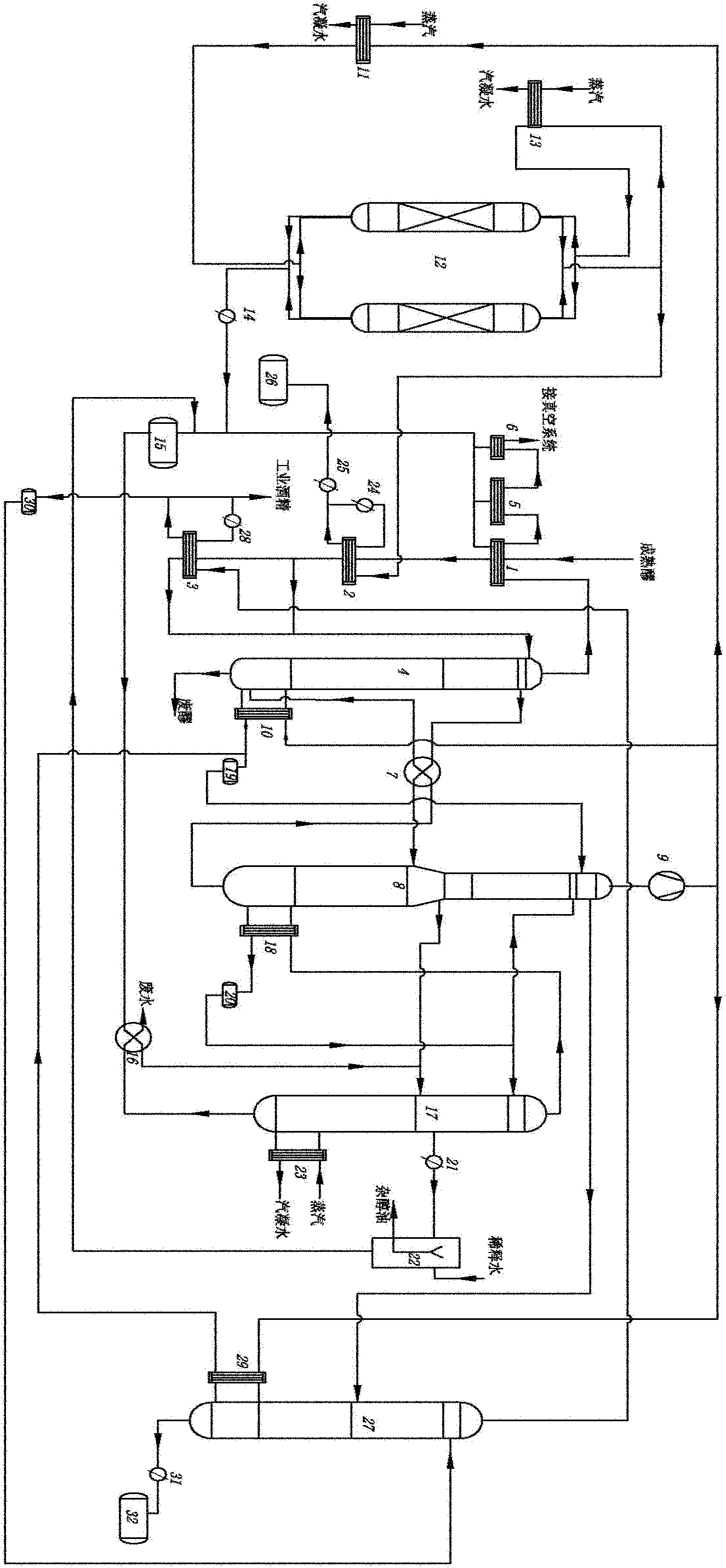

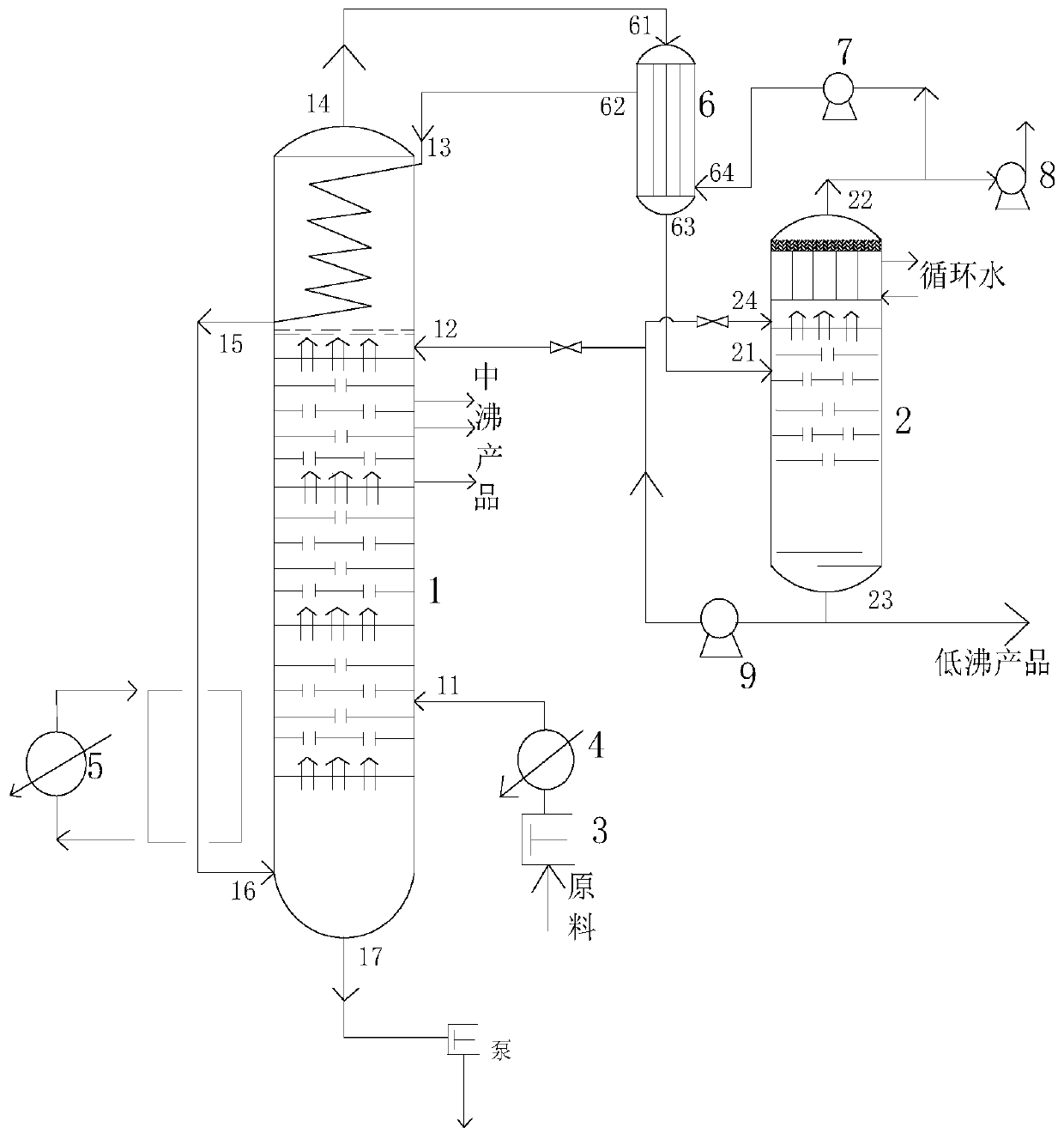

Common and superior edible alcohol co-production distillation energy-saving device and energy-saving process thereof

ActiveCN104232455AReduce consumptionReduce energy consumptionAlcoholic beverage preparationAlcoholDistillation

The invention discloses a common and superior edible alcohol co-production distillation energy-saving device and an energy-saving process thereof. The common and superior edible alcohol co-production distillation energy-saving device comprises a coarse distillation tower, a combined tower, a water scrubbing tower, a rectification tower, a methanol tower and a mash preheating device, wherein the mash preheating device, the coarse distillation tower and the combined tower are sequentially communicated with one another; the rectification tower, the water scrubbing tower and the methanol tower are sequentially communicated with one another; the mash preheating device is further communicated with the water scrubbing tower; the mash preheating device is communicated with a mature fermented mash feeding pipeline; the combined tower is provided with a common alcohol outlet, and the methanol tower is provided with a superior alcohol outlet. The common and superior edible alcohol co-production distillation energy-saving device provided by the invention can ensure flexible adjustment between common edible alcohol and superior edible alcohol, can rapidly meet market demands, and lowers steam consumption and water consumption of a whole set of distillation system.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Absorbent solution circulating system and method

InactiveCN101482340ALow grade requirementsRaise the gradeHeat pumpsClimate change adaptationAbsorption heat pumpCrystallization

The invention relates to an absorbent solution circulating system and a method. The absorbent solution consists of absorbent and working substance; and the absorbent solution circulating system comprises a generator, an absorber, an absorbent crystallizer and an automatic absorbent solution heat exchanger. The absorbent crystallizer is used for cooling absorbent solution from the generator and / or absorbent solution from the absorber to form crystallized absorbent solution and absorbent crystals, the crystallized absorbent solution is delivered to the generator, and the absorbent crystals are delivered to the absorber; and the automatic absorbent solution heat exchanger is used for exchanging heat with the crystallized absorbent solution and / or absorbent crystals with the absorbent solution from the generator and / or the absorbent solution from the absorber. The system can achieve circulation of the absorbent solution between the generator and the absorber in the circulation of an absorption heat pump, so as to improve grade of cold or heat outwards output by the circulation of the absorption heat pump and efficiency.

Owner:苏庆泉

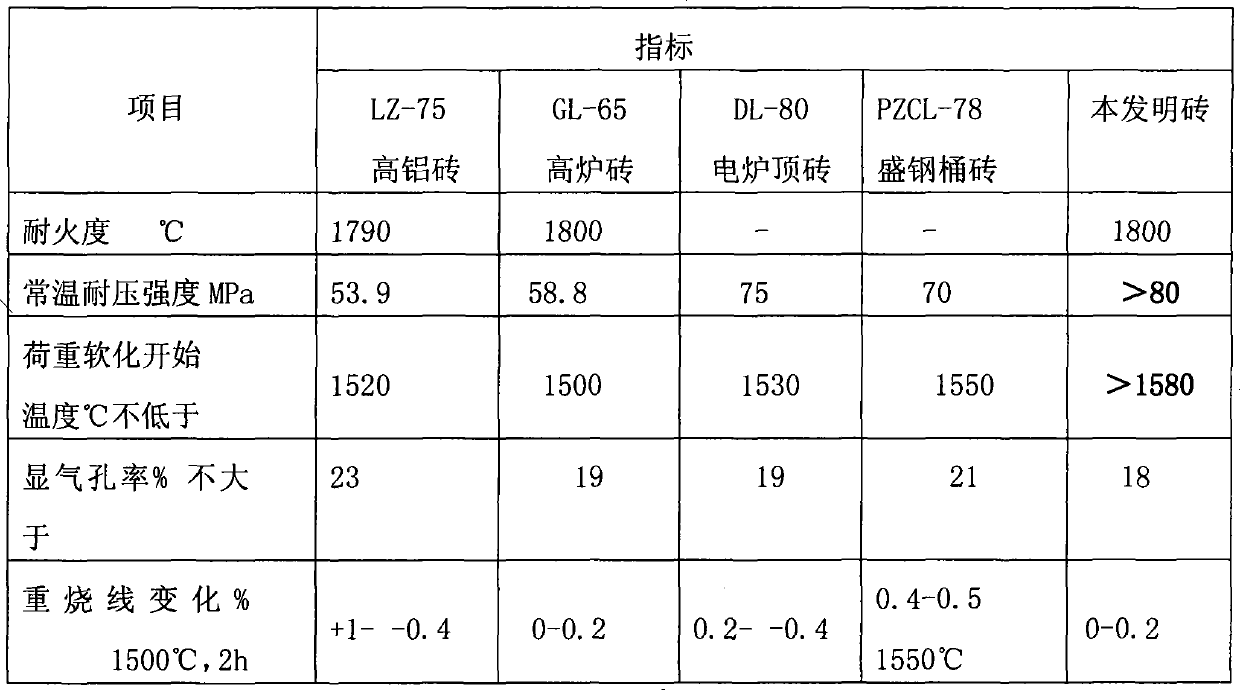

Low-temperature burning high-aluminum refractory brick and preparation method thereof

The present invention provides a low-temperature braking high-aluminum refractory brick and the preparing method thereof, and the invention is characterized in that the refractory brick is prepared by the following main raw material and bonding agent; wherein: the main material comprises the raw material with the following weight proportion: wherein the bauxite chamotte with granularity 3-0.088mmfor 50-70%, bauxite chamotte with granularity less than 0.088 for 7-20%, emery with granularity less than 0.088 for 5-20%, dry powder shaped pyrophyllite for 2-10%, and dry powder shaped refractory clay for 5-20%; and the adding amount of the bonding agent is 10-20% of the weight of the raw material. The high-alumina brick is obtained using the low ore grade bauxite chamotte with low temperature 1250-1350 DEG C, and the high-quality refractory brick has the advantages of: ordinary-temperature compressive strength above 80MPa, and the load softening staring temperature above 1580 DEG C.

Owner:巩义市金岭耐火材料有限公司

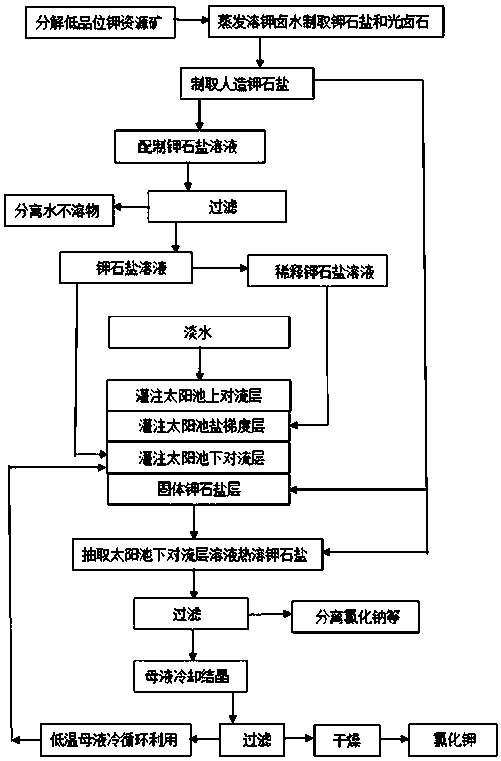

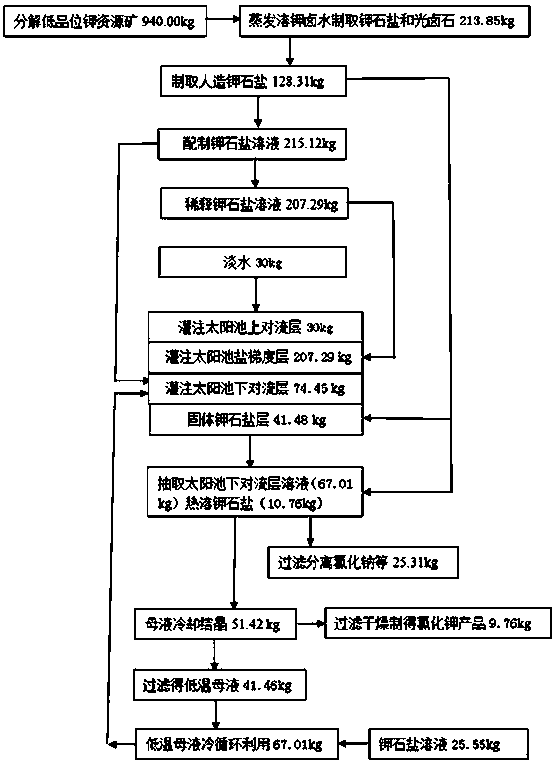

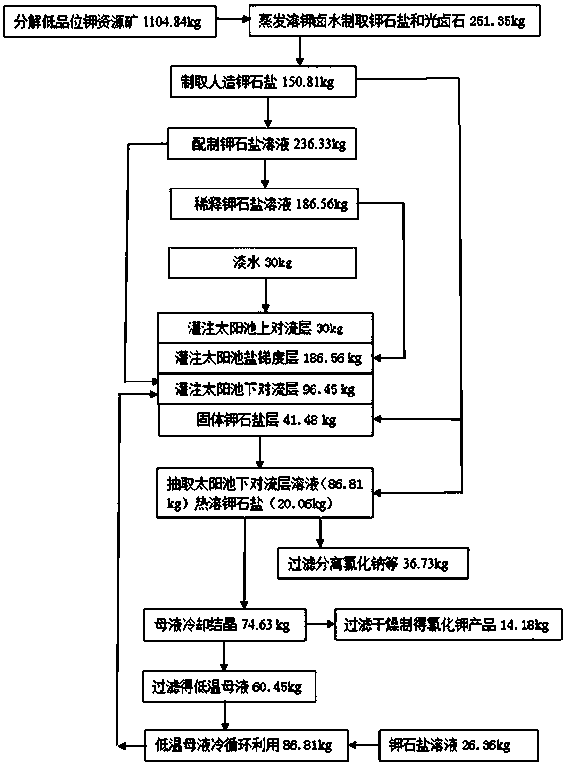

Method for preparing potassium chloride from low-grade potassium resource ore at low energy consumption

InactiveCN110734078AOptimize heat storage performanceIncreased Potassium DissolutionAlkali metal chloridesChloride potassiumMother liquor

The invention discloses a method for preparing potassium chloride from low-grade potassium resource ore at low energy consumption, and relates to the technical field of inorganic salt. The method comprises following steps: 1, decomposing low-grade potassium resource ore; 2, evaporating potassium dissolved brine to prepare sylvine and carnallite; 3, preparing artificial sylvine; 4, preparing a sylvine solution; 5, diluting the sylvine solution; 6, building a solar pond; 7, horizontally filling the solar pond layer by layer; 8, running the solar pond; 9, hot melting sylvine; 10, filtering; 11, cooling and crystallizing; and 12, low-temperature mother liquor recycling. The method has the beneficial effects that the energy consumption is low, the cost is saved, utilization of low-grade potassium resources is improved, the solubility of potassium chloride is improved, and the energy consumption in the recycling process of the low-grade potassium resources is reduced.

Owner:QINGHAI UNIVERSITY

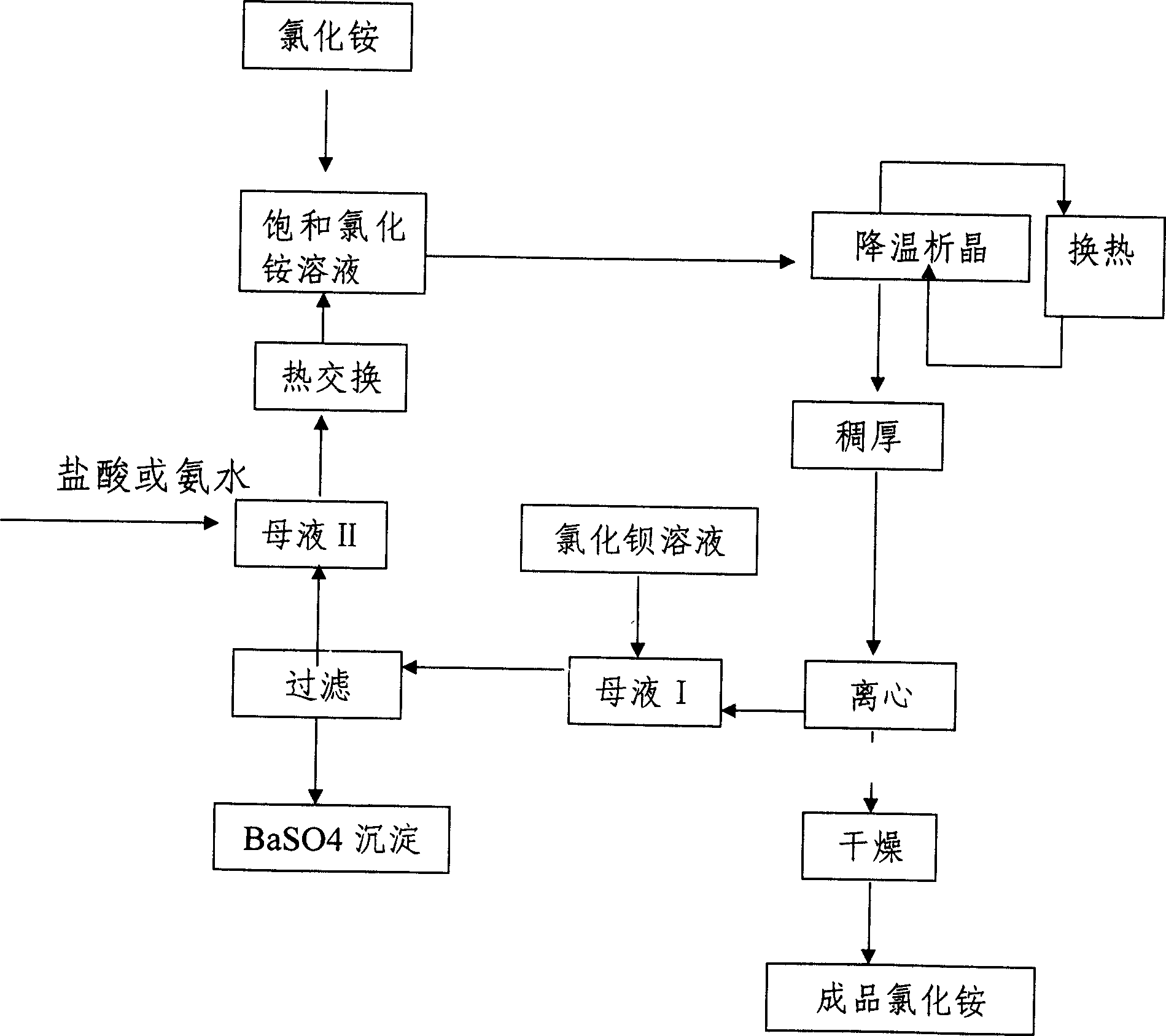

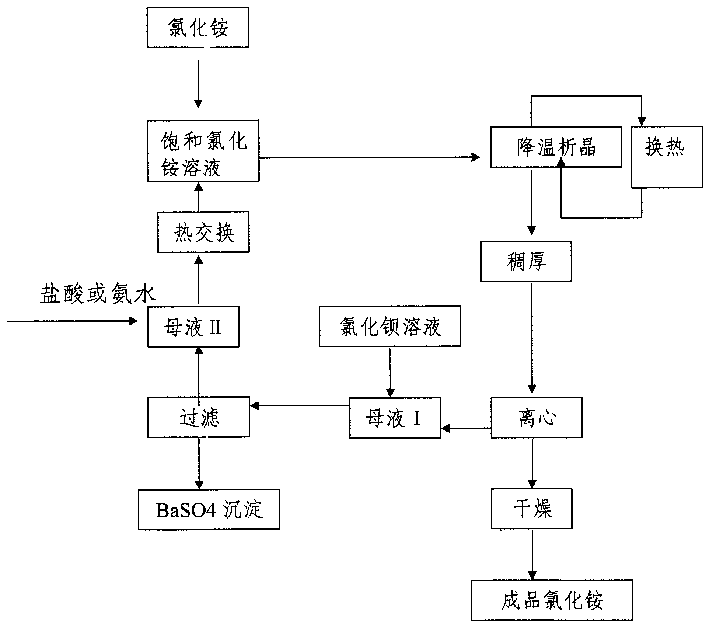

Method for qualifying industrial ammonium chloride products

InactiveCN1197772CImprove product qualityLow grade requirementsAmmonium halidesBarium dichlorideChloride

A method for improving the quality of industrial ammonium chloride products, the steps are as follows: (1) first dissolve ammonium chloride into a saturated solution of ammonium chloride with water at 40-70°C or an unsaturated ammonium chloride solution; (2) then Cool the saturated solution of ammonium chloride to 10-25°C, and precipitate ammonium chloride crystals; (3) pass the ammonium chloride crystallization liquid through a thickener to increase the solid-liquid ratio, then enter the centrifuge for dehydration, and dry to obtain the finished ammonium chloride (4) in the mother liquor I that gets rid of when centrifuge dehydration again, add the not excessive barium chloride solution relative to the sulfate radical in mother liquor I, filter after generating the barium sulfate precipitation, obtain the mother liquor II after filtering, mix mother liquor II After heating up to 40-70°C, it is used to dissolve ammonium chloride and recycled. Compared with prior art, utilize the sulfate radical ion SO in the finished product ammonium chloride that the inventive method obtains 4 2- The content is low, generally below 0.02%. It is a superior product of industrial grade ammonium chloride, suitable for use in batteries and electric chromium.

Owner:JIANGSU DEBANG CHEMICAL INDUSTRY GROUP CO LTD

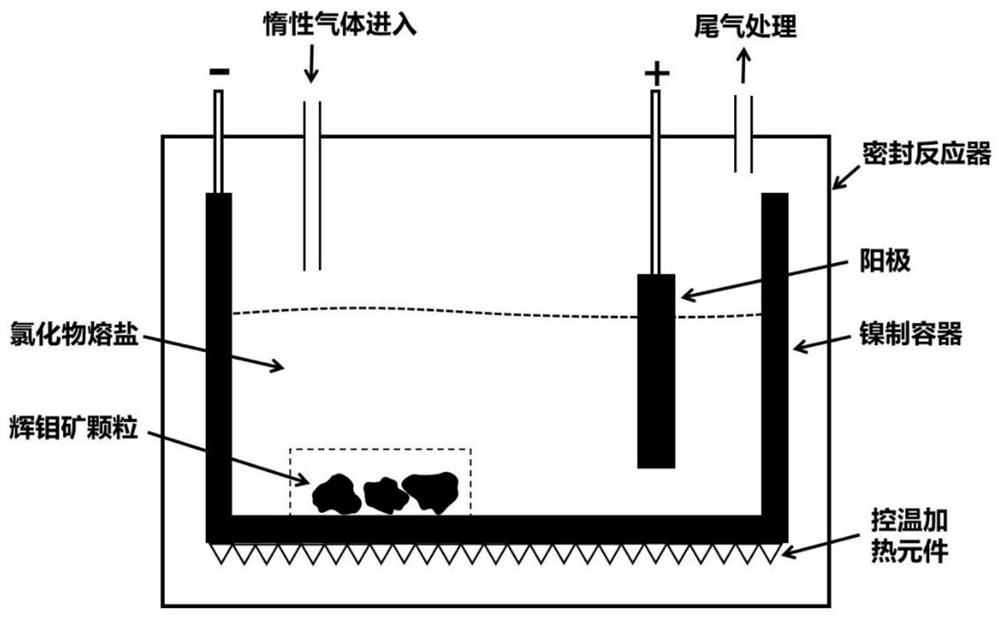

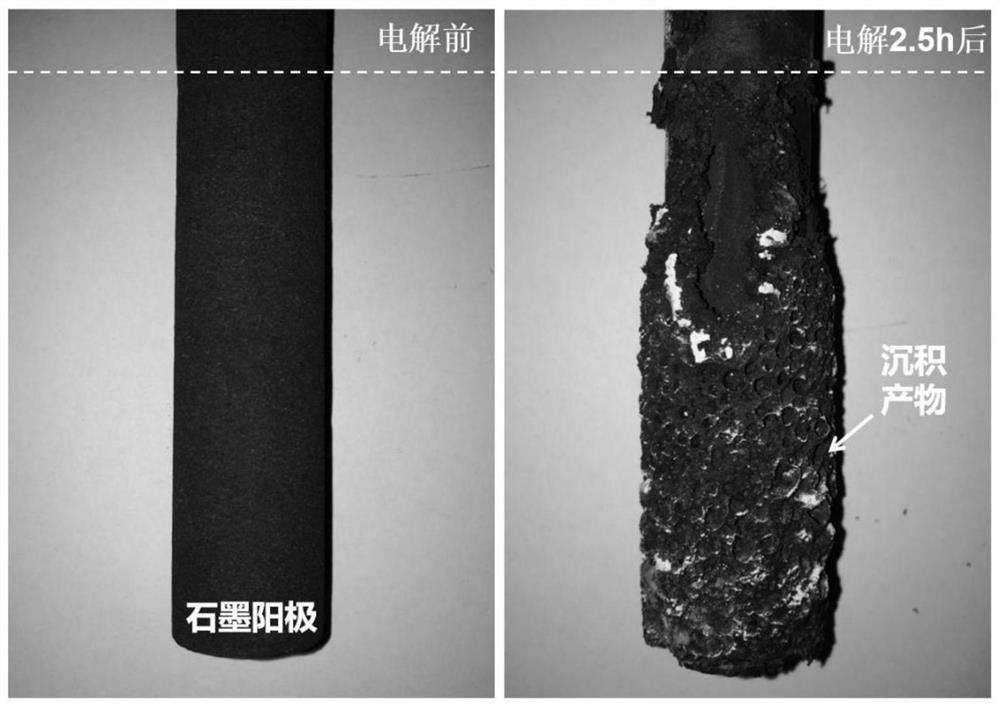

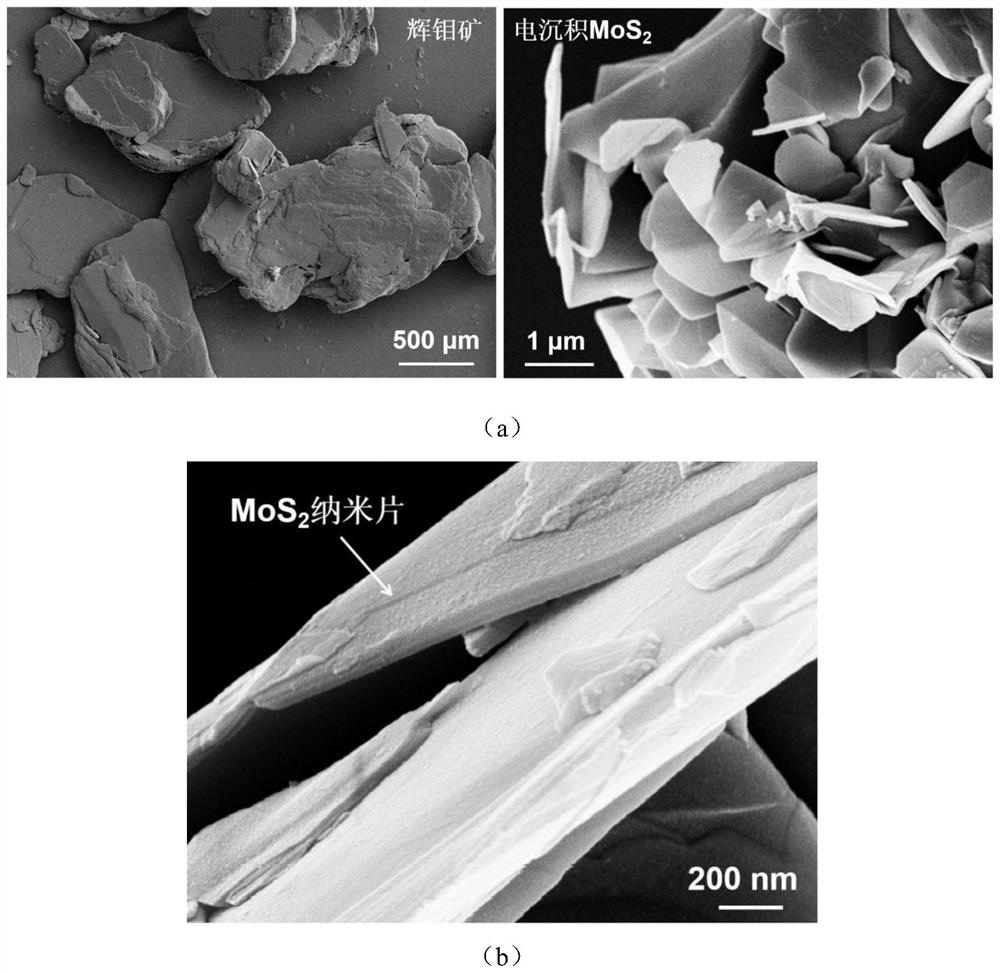

Electrochemical method for preparing high-purity molybdenum disulfide nanosheet from molybdenite

ActiveCN112899704AHigh purityImprove electrochemical stabilityElectrolysis componentsSecondary cellsElectrolysisElectrical battery

The invention discloses an electrochemical method for preparing a high-purity molybdenum disulfide nanosheet from molybdenite. The purity of the obtained molybdenum disulfide nanosheet reaches 99.0% or above, and the average thickness of the nanosheet is only 10-30 nm. The method comprises the following preparation steps: (1) putting alkali metal chlorate into a nickel reaction container, melting at high temperature, and then reducing the temperature of molten salt to a reaction temperature; (2) adding molybdenite into a nickel container and immersing themolybdenite in molten salt by taking the nickel container as a cathode and the molten salt as electrolyte, and mounting an anode for electrolysis; and (3) after the electrolysis is finished, taking out the anode, cooling to room temperature in an inert atmosphere, collecting anode surface sediments, and washing and drying to obtain the high-purity molybdenum disulfide powder. The method is simple to operate, clean in process and low in preparation cost; and the obtained molybdenum disulfide nanosheet is stable in property, and shows relatively high lithium storage performance and electrochemical stability when being used as a lithium ion battery negative electrode material.

Owner:WUHAN UNIV

Energy-saving carrier gas stripping system and stripping process

PendingCN111450561AAchieve enrichment separationReduce heatEnergy recuperation in distillationVacuum distillation separationGas heaterEngineering

The invention belongs to the technical field of stripping separation, and relates to an energy-saving carrier gas stripping system and stripping process. The energy-saving carrier gas stripping systemcomprises a gas stripping tower, a separation tank, a raw material heater, a carrier gas heater and a gas circulation heat exchanger, wherein a heat exchange and mass transfer section is arranged atthe inner top of the gas stripping tower, and the gas stripping tower, the gas circulation heat exchanger and the heat exchange and mass transfer section sequentially communicate with each other through pipelines; the gas circulation heat exchanger, the separation tank and the gas stripping tower sequentially communicate with each other through pipelines; the raw material heater communicates withthe gas stripping tower; the heat exchange and mass transfer section, the carrier gas heater and the gas stripping tower are sequentially communicate with each other through pipelines; and the heat exchange and mass transfer section comprises a heat exchange tube and a filler, and the heat exchange tube is a tubular heat exchange tube or a coiled tube type heat exchange tube. According to the invention, separation temperature is low, different carrier gas heating modes are adopted for heat exchange and mass transfer, enrichment and separation of one or more substances are achieved through stripping and rectification, separation effect is good, heat of the system is recycled, heat consumption and cold consumption of separation are reduced, and energy consumption is saved by 30%-50%.

Owner:陕西聚能新创煤化科技有限公司

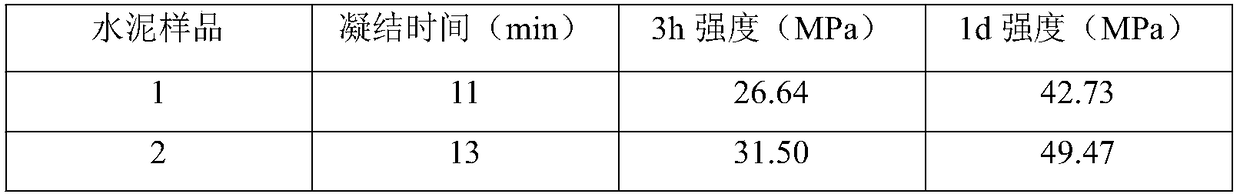

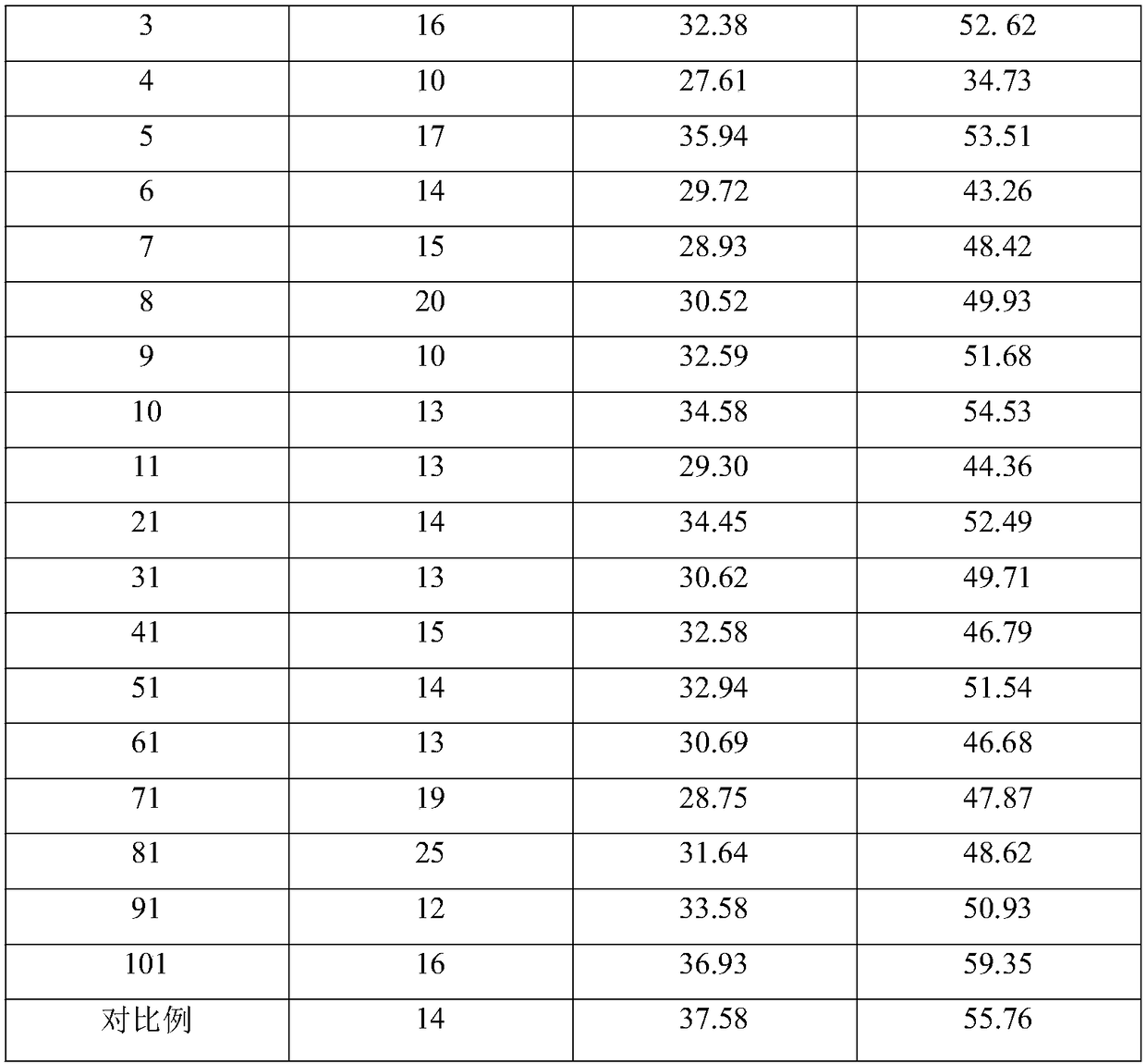

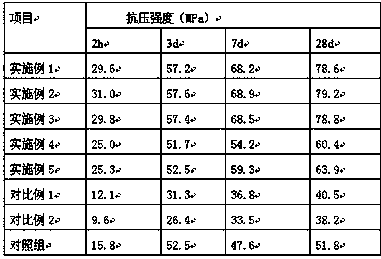

Method for reducing preparation cost of sulphoaluminate cement

InactiveCN111499233AReduce manufacturing costImprove microstructureCement productionAluminateCompressive resistance

The invention relates to the technical field of preparation of novel building materials, and discloses a method for reducing the preparation cost of sulphoaluminate cement. The method performs modification of fly ash, and the obtained modified fly ash is used as a bauxite substitute for preparing sulphoaluminate cement clinker; rare earth is used for activating hydration activity of mineral substances in the coal ash so as to provide early hydration strength for cement, and the stability of later activity is maintained; the method has a fast hydration speed, stimulates activity, exerts later strength, improves the microstructure of the sulphoaluminate cement slurry, inhibits the later strength from collapsing, is very beneficial to the performance development of sulphoaluminate cement, andreduces the production cost of cement. The prepared sulphoaluminate cement has the 3-day compressive strength of 56 MPa or above and the 28-day compressive strength of 78 MPa or above, fly ash is effectively utilized, and the cost is reduced.

Owner:肥西县创玺建材科技有限公司

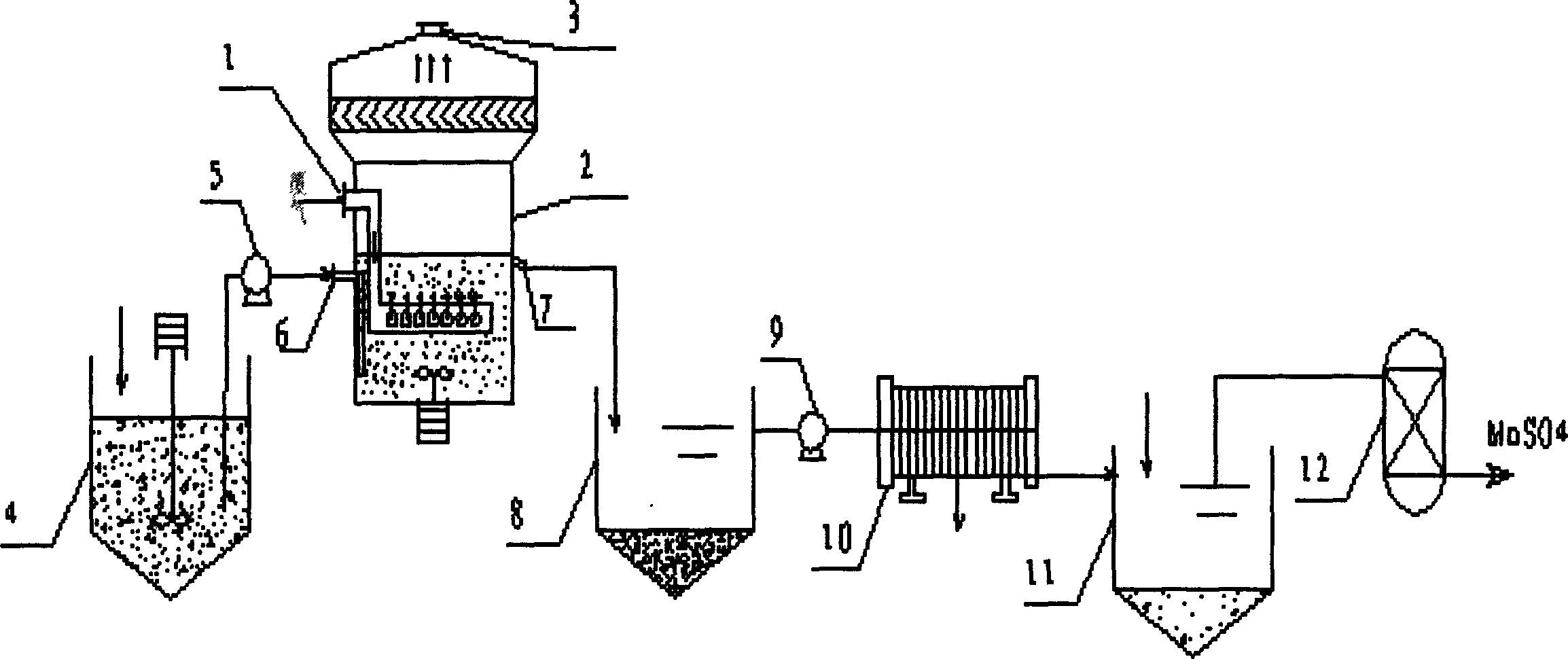

Method for preparing manganese sulfate solution by using sulphur dioxide gas leach manganese dioxide ore

The invention discloses a method for preparing a manganese sulphate solution by leaching pyrolusite with sulfur dioxide gas. The method mainly comprises: pyrolusite and water are prepared into pyrolusite slurry with a liquid to solid ratio of between 5:1 and 1:1; the slurry, the sulfur dioxide gas and oxygen are continuously passed into a reactor provided with two stages of absorbing and leachingreaction chambers which are arranged and connected serially up and down; and absorbing and leaching reactions are carried out in the two absorbing and leaching reaction chambers sequentially at normal temperature, wherein each stage of absorbing and leaching reaction chamber is provided with a stirrer of no less than 5 kW for each cubic meter, the mass flow of the slurry is determined by the stoichiometric ratio of manganese dioxide required by the mass flow of the sulfur dioxide, and the amount of the added oxygen is determined by the pH values of reaction systems in the absorbing and leaching reaction chambers. Another invention applied by the applicant of the invention discloses a reactor for use in pyrolusite leaching. The reactor realizes stable and continuous production, achieves high sulfur and manganese resources recovery rate, meets tail gas exhaust standards and can effectively suppress the generation of MnS2O6 at the same time.

Owner:成都合众新能源科技有限公司

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

InactiveCN100484880CImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing beryllium oxide or high-purity beryllium oxide from beryllium-containing solution

ActiveCN103818937BLow grade requirementsImprove qualityBeryllium oxides/hydroxidesO-Phosphoric AcidAlcohol

The present invention relates to the technical field of producing beryllium oxide, which is a method for producing beryllium oxide or high-purity beryllium oxide from a beryllium-containing solution. Phosphoric acid extractant in volume ratio: alcohol: sulfonated kerosene is 10:10:75 to 25:15:90 Weigh and mix together to configure the extractant. The operation of the invention is simple and flexible, and it is convenient to realize continuous operation. The invention has low requirements on the grade of beryllium-containing ore. Able to process any concentration of beryllium-containing waste liquid, the method of the present invention Recycling than existing technology beryllium oxide Recovery rate, Stripping rate and hydrolysis BeO The primary precipitation rate is higher, which can effectively guarantee the quality of beryllium oxide or high-purity beryllium oxide, and then Get High Quality Beryllium Oxide or High Purity Beryllium Oxide , in the production process, the present invention mainly produces acid waste liquid, which can be discharged after neutralization treatment, and the amount of waste residue and waste gas is less, which is a green and environmental protection process.

Owner:XINJIANG RES INST OF NON FERROUS METALS

Low-pressure ethanol recovery device and method with triple effect rectification

ActiveCN102091429BReduce energy consumptionReduce lossesOrganic compound preparationHydroxy compound preparationRecovery methodReboiler

The invention discloses a low-pressure ethanol recovery device and method with triple effect rectification. The low-pressure ethanol recovery device with triple effect rectification comprises a first rectifying tower, a second rectifying tower, a third rectifying tower, a rectifying tower reboiler, a rectifying tower feed preheater, a condenser, a return tank, a dilute ethanol feed preheater, a temporary finished product storage tank and a finished product cooler. In the ethanol recovery method with triple effect rectification, by controlling the recovery of the finished ethanol in the secondrectifying tower, the content of ethanol in tower bottom wastewater of the second rectifying tower is 5wt%-30wt%, the temperature of the tower bottom wastewater is 100-120 DEG C, and the working pressure of the third rectifying tower is 250-400kPa. The invention adopts the low-pressure triple effect rectification technique and reduces energy loss in the technical process, thus greatly reducing the energy consumption; and the operating pressure and temperature of the third rectifying tower are greatly reduced, and the requirements on the high temperature resistant and corrosion resistant properties of equipment are reduced, thereby reducing the equipment investment and the maintenance cost.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com