Coal-fired flue gas pyrolusite pulp recycling denitration method

A technology of coal-burning flue gas and pyrolusite, which is applied in chemical instruments and methods, separation methods, manganese nitrate, etc., can solve the problems of difficult steel smelting industry, high production costs, and heavy environmental pollution. Secondary pollution, abundant reserves, and high oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

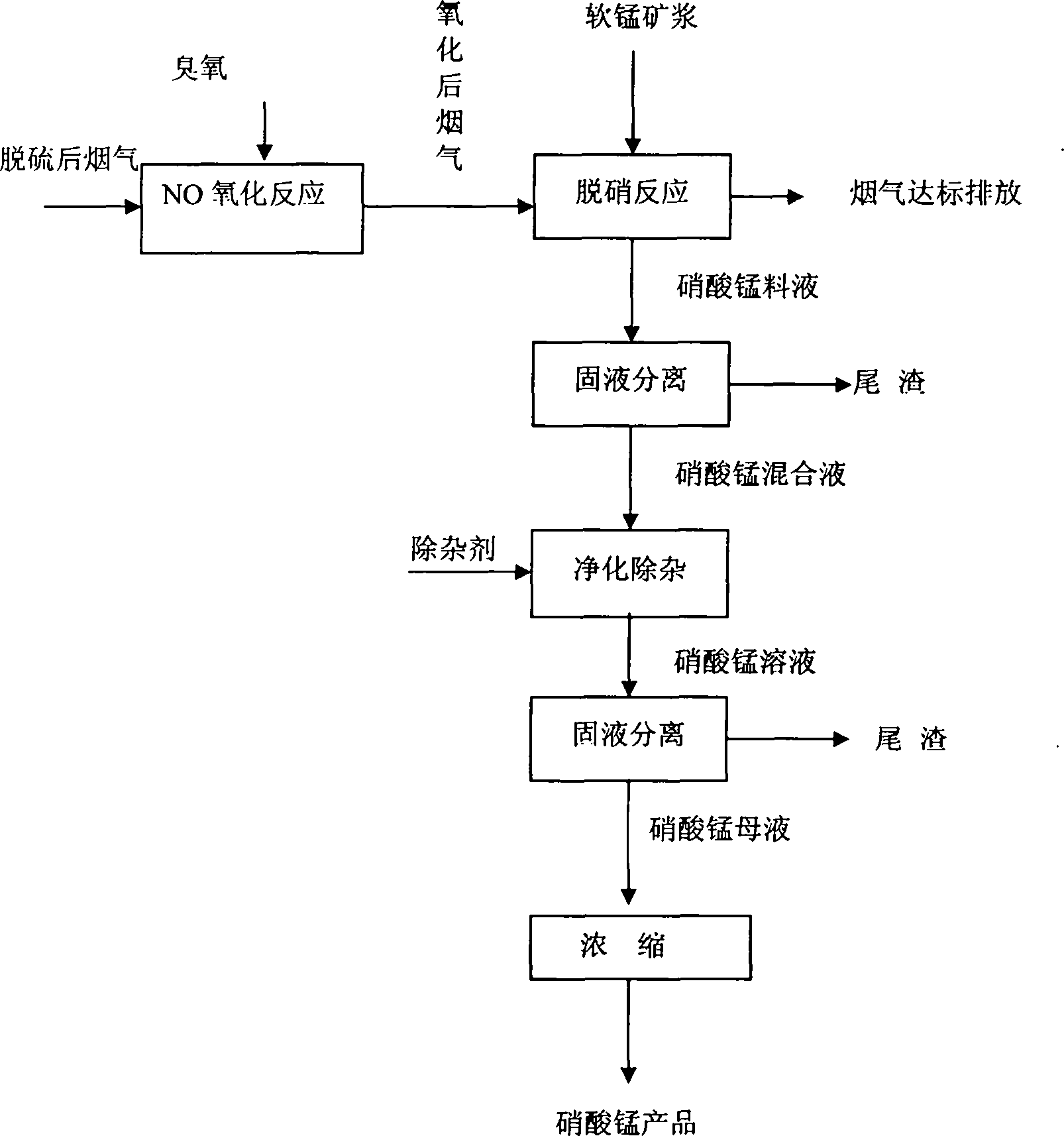

[0026] Take the treatment of a coal-fired boiler with a scale of 35t / h as an example. The amount of exhaust gas to be treated is 60000Nm 3 / h, NO in exhaust gas X The content is 1000mg / m 3 , the process flow of this embodiment is as follows figure 1 shown. Firstly, the pyrolusite powder and water not more than 100 meshes are prepared into a slurry with a liquid-solid mass ratio of 3:1 in a slurry tank equipped with an agitator, and the slurry is driven into the removal reactor through a slurry pump, and after desulfurization In the flue according to O 3 The / NO molar ratio is 1:1 and the ozone is injected, and the oxidation time is ≥0.5S. The oxidized flue gas enters the removal reactor, and then enters the pulp to be absorbed by the gas dispersion device. NO in flue gas X Absorption reaction with pyrolusite pulp absorbent to remove NO in exhaust gas X Absorption and removal, NOX The gas after the removal reaches the standard is discharged from the gas outlet of the re...

Embodiment 2

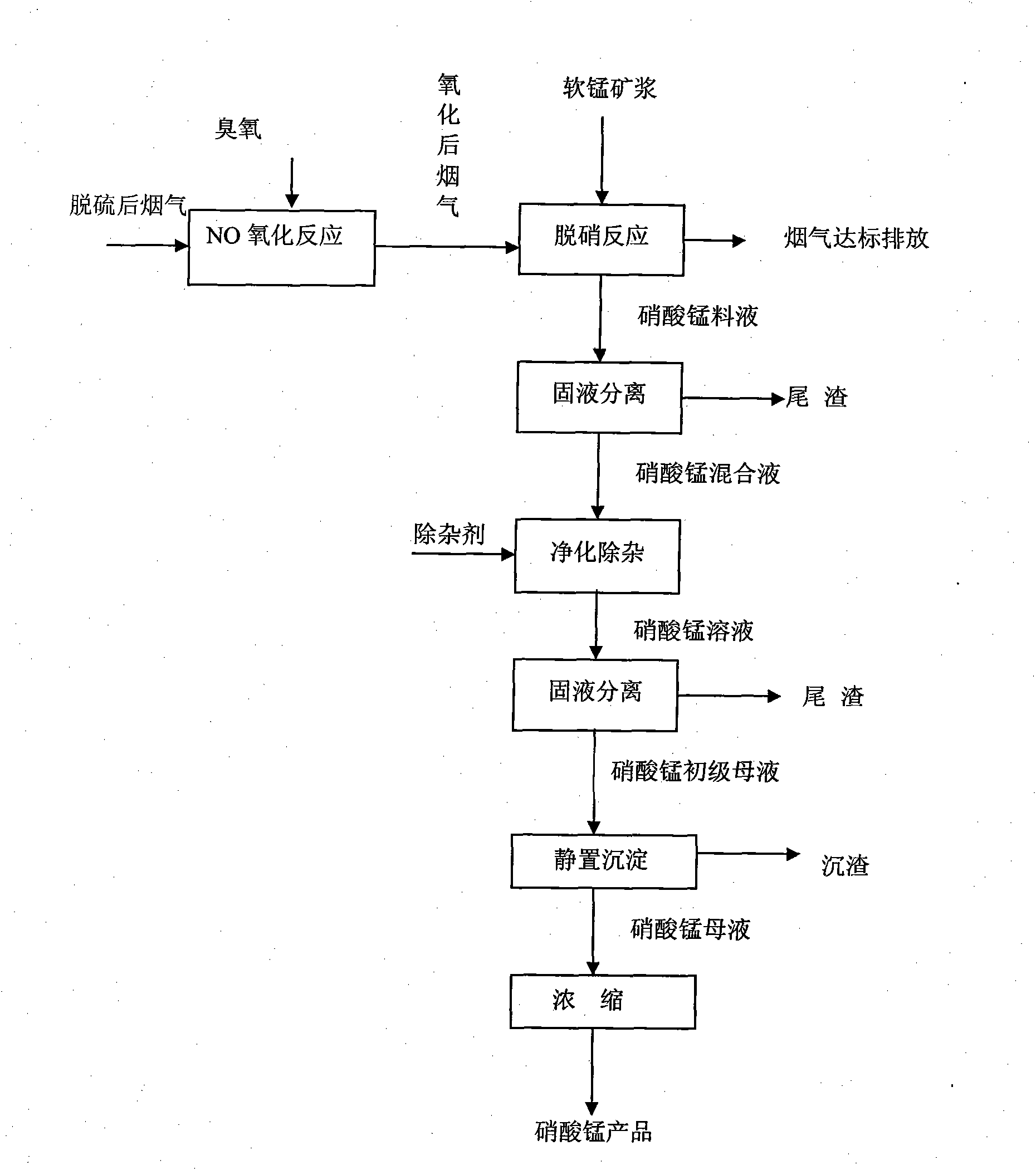

[0028] This example is basically the same as Example 1, except that the manganese nitrate solution is added to the impurity removal agent for solid-liquid separation after the impurity removal reaction, and the separated liquid phase is not directly sent to the concentration reactor for heating and concentration to produce Manganese nitrate products, but first static precipitation, after sufficient precipitation and purification treatment, sent to the concentration reactor for heating and concentration to produce manganese nitrate products, the produced manganese nitrate products have higher purity. The technological process of this embodiment is as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com