Ammoxidation catalyst for diesel engine exhaust gas purification system and preparation method thereof

A tail gas purification and ammonia oxidation technology, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of high selectivity, and achieve the effects of simple preparation method, reduced ammonia slip, and high N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

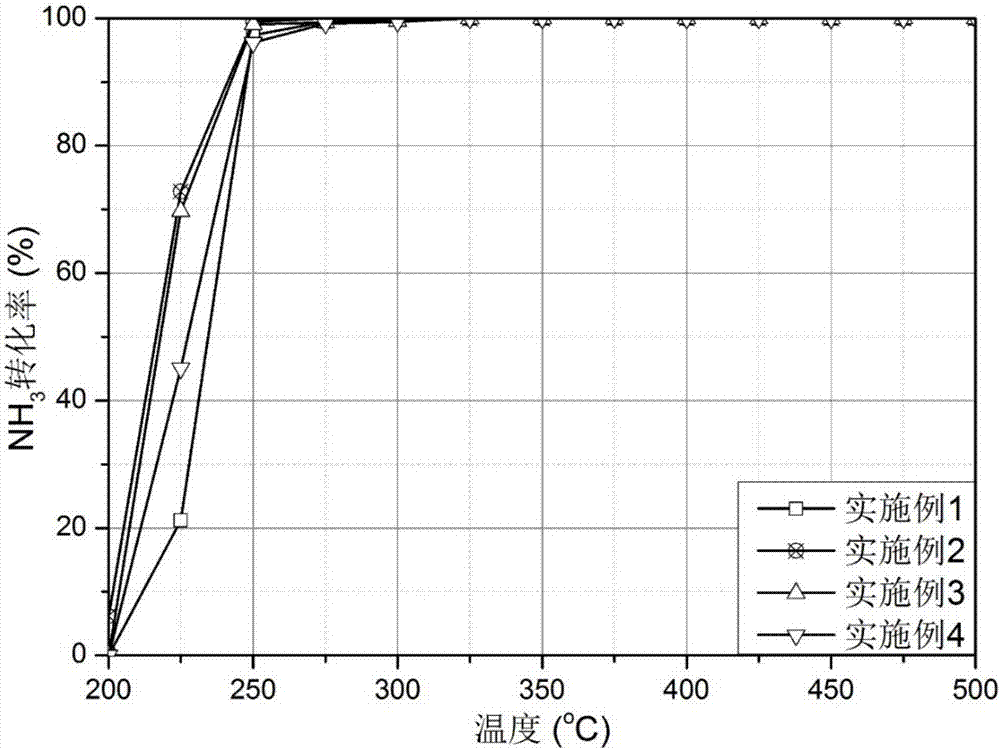

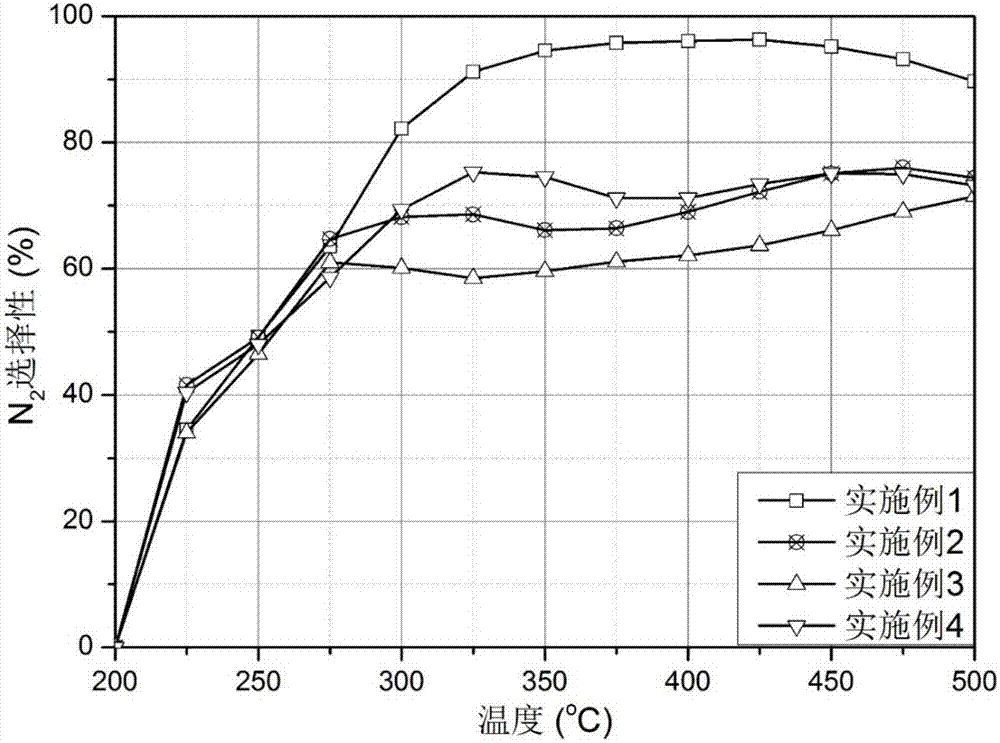

Embodiment 1

[0030] The catalyst is composed of a carrier and a coating. The coating is loaded with noble metal platinum. The coating amount is 120g / L, and the loading amount of noble metal platinum is 0.15g / L. The catalyst carrier is a cordierite ceramic carrier with a volume of 1.236L. The pore density is 400 mesh / square inch; the coating contains cerium-zirconium-aluminum composite oxide and β molecular sieve.

[0031] The ammonia oxidation catalyst used for diesel engine exhaust purification system comprises the following steps:

[0032] (1) Preparation of composite oxide cerium-zirconium-aluminum: first prepare the cerium-aluminum composite oxide according to the mass ratio of cerium oxide and alumina at 1:9, and then press the cerium-aluminum composite oxide Preparation of cerium-zirconium-aluminum composite oxide by impregnation method; prepare zirconyl nitrate solution according to the saturated adsorption capacity of cerium-aluminum composite oxide, impregnate, then stand for 12h,...

Embodiment 2

[0038]The specific preparation method and activity test are basically the same as in Example 1, except that titanyl sulfate is used instead of zirconyl nitrate to prepare the titanium-cerium-aluminum composite oxide. In the titanium-cerium-aluminum composite oxide, the mass ratio of titanium oxide to cerium-aluminum composite oxide is 1:7.

Embodiment 3

[0040] The specific preparation method and activity test are basically the same as in Example 1, except that the composite oxide is a cerium-silicon-aluminum composite oxide. The cerium-silicon-aluminum composite oxide is prepared by impregnating the silicon-aluminum composite oxide with a cerium nitrate solution. In the silicon-aluminum composite oxide, the mass ratio of silicon oxide to aluminum oxide is 1:19. In the cerium-silicon-aluminum composite oxide, the mass ratio of cerium oxide to silicon-aluminum composite oxide is 1:9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com