Patents

Literature

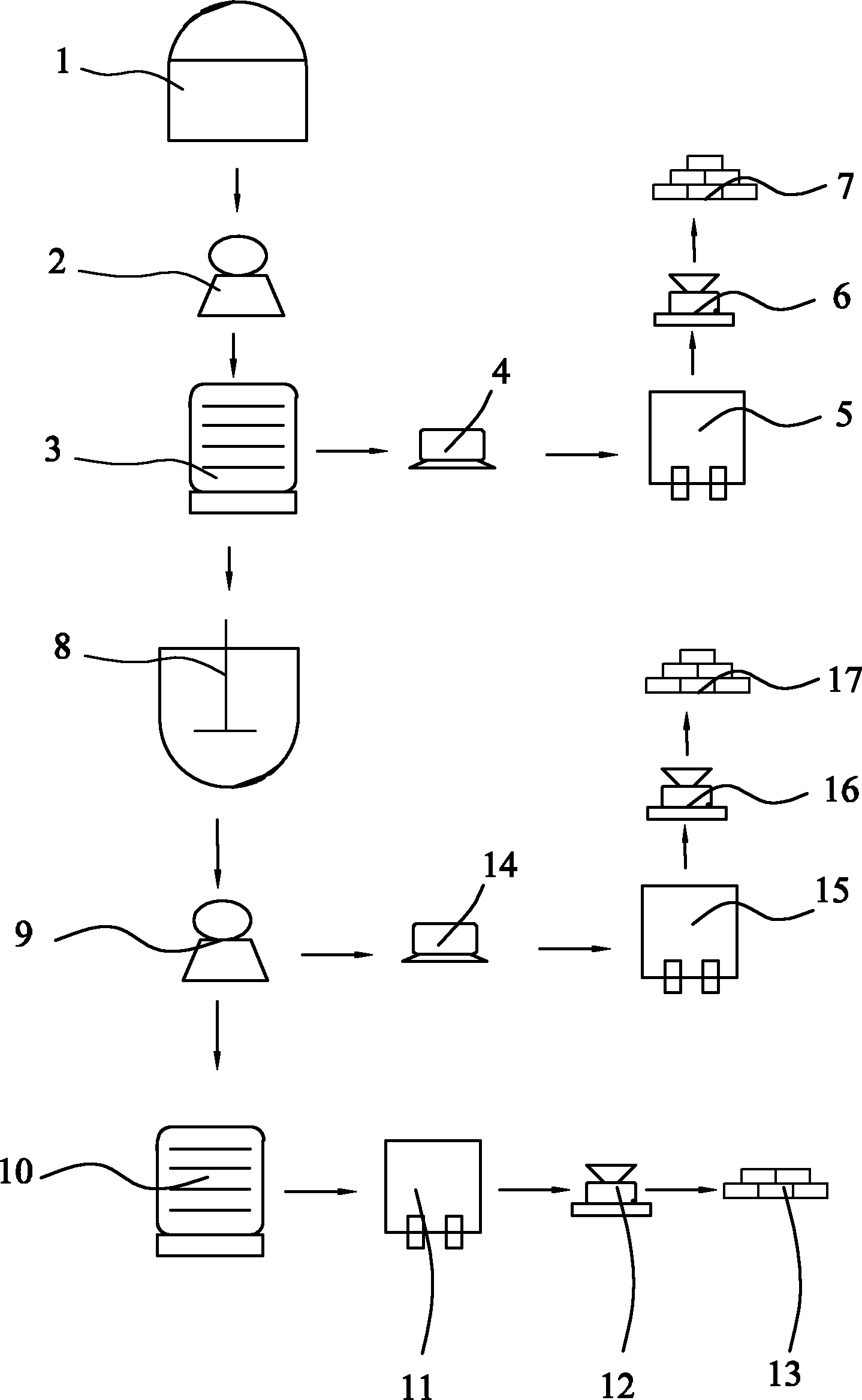

61results about "Manganese nitrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

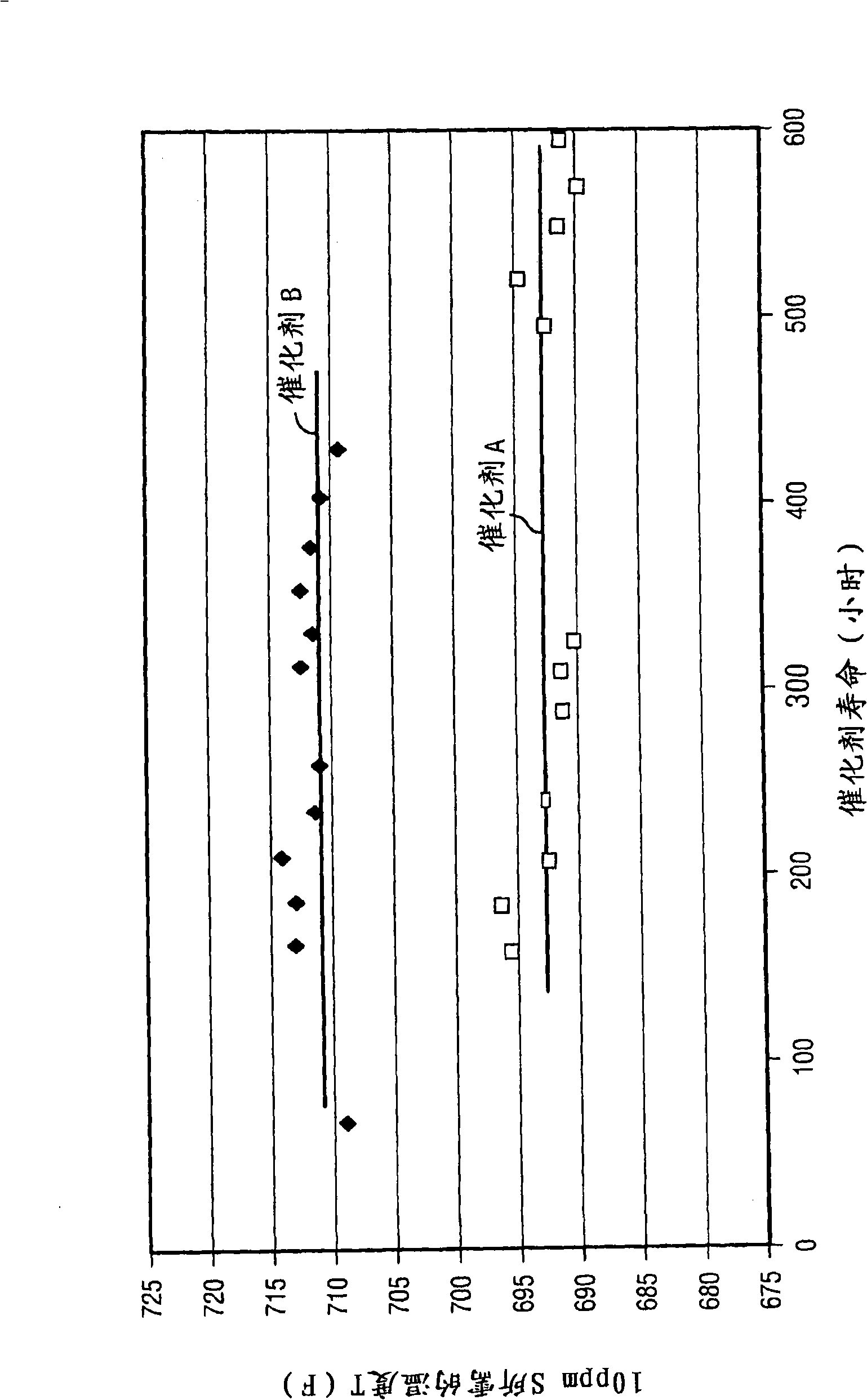

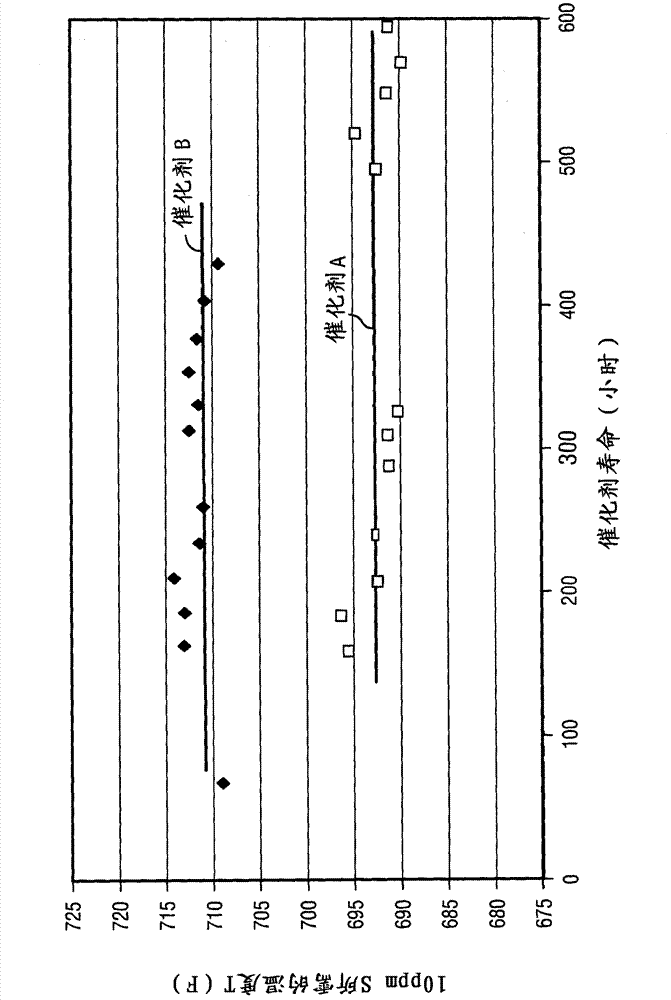

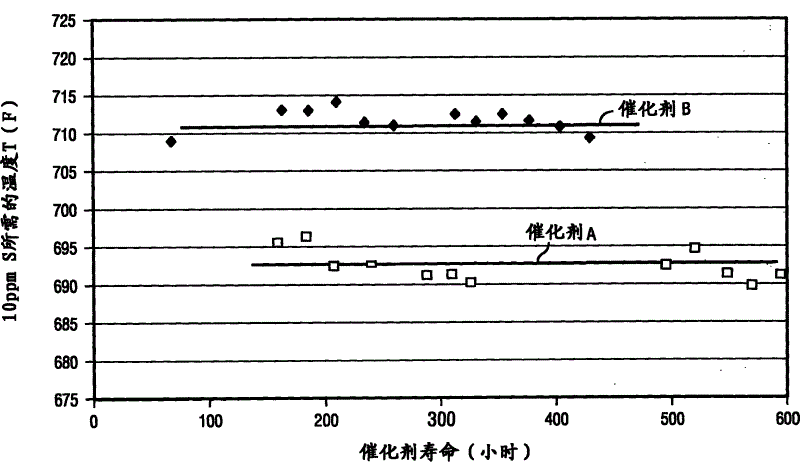

A catalyst and process for the manufacture of ultra-low sulfur distillate product

InactiveCN101516500ACatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationHydrodesulfurization

The invention describes a catalyst and process useful in the hydrodesulfurization of a distillate feedstock to manufacture a low-sulfur distillate product. The catalyst comprises a calcined mixture of inorganic oxide material, a high concentration of a molybdenum component, and a high concentration of a Group VIII metal component. The mixture that is calcined to form the calcined mixture comprises molybdenum trioxide, a Group VIII metal compound, and an inorganic oxide material. The catalyst is made by mixing the aforementioned starting materials and forming therefrom an agglomerate that is calcined to yield the calcined mixture that may be used as the catalyst or catalyst precursor.

Owner:SHELL INT RES MAATSCHAPPIJ BV

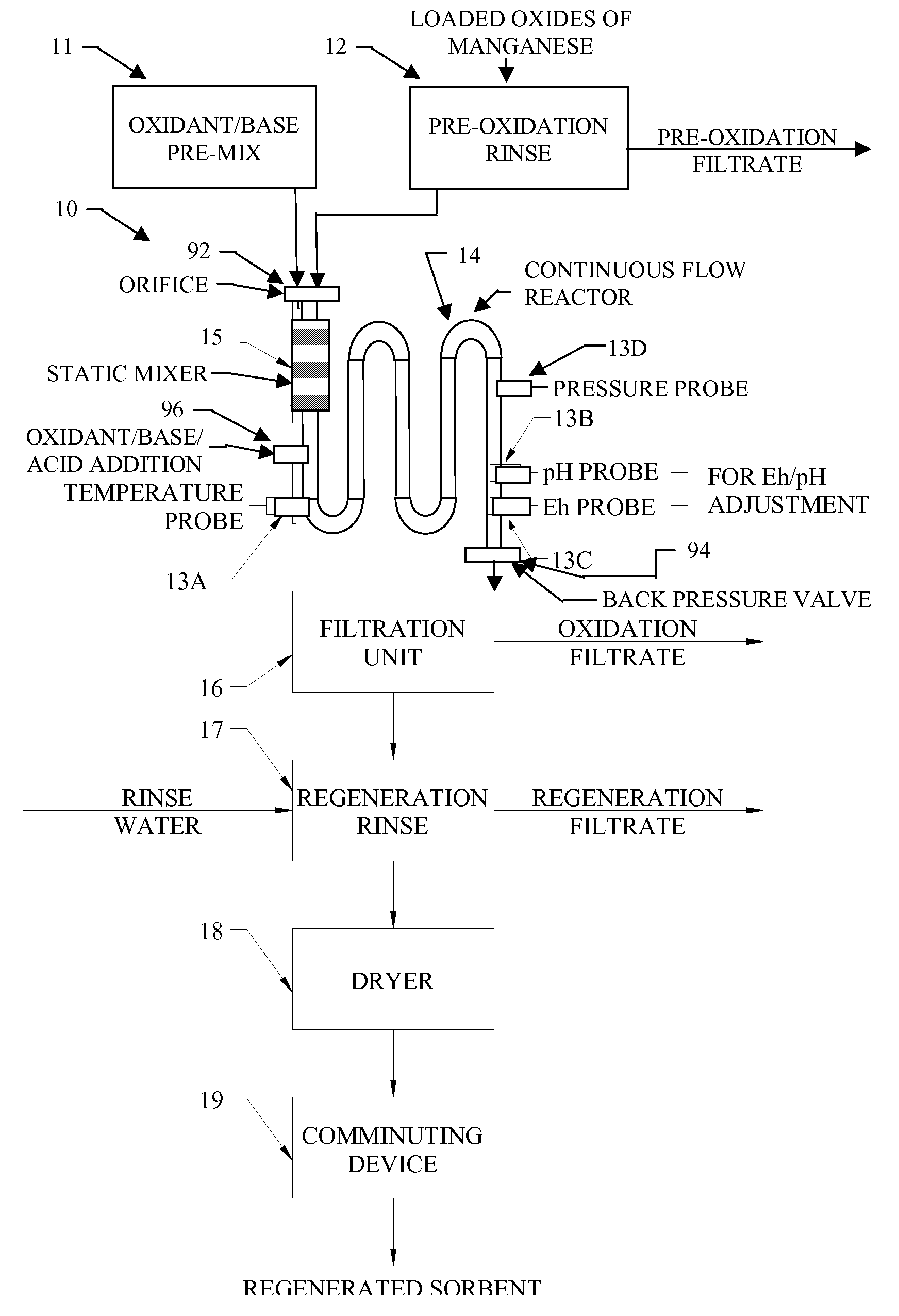

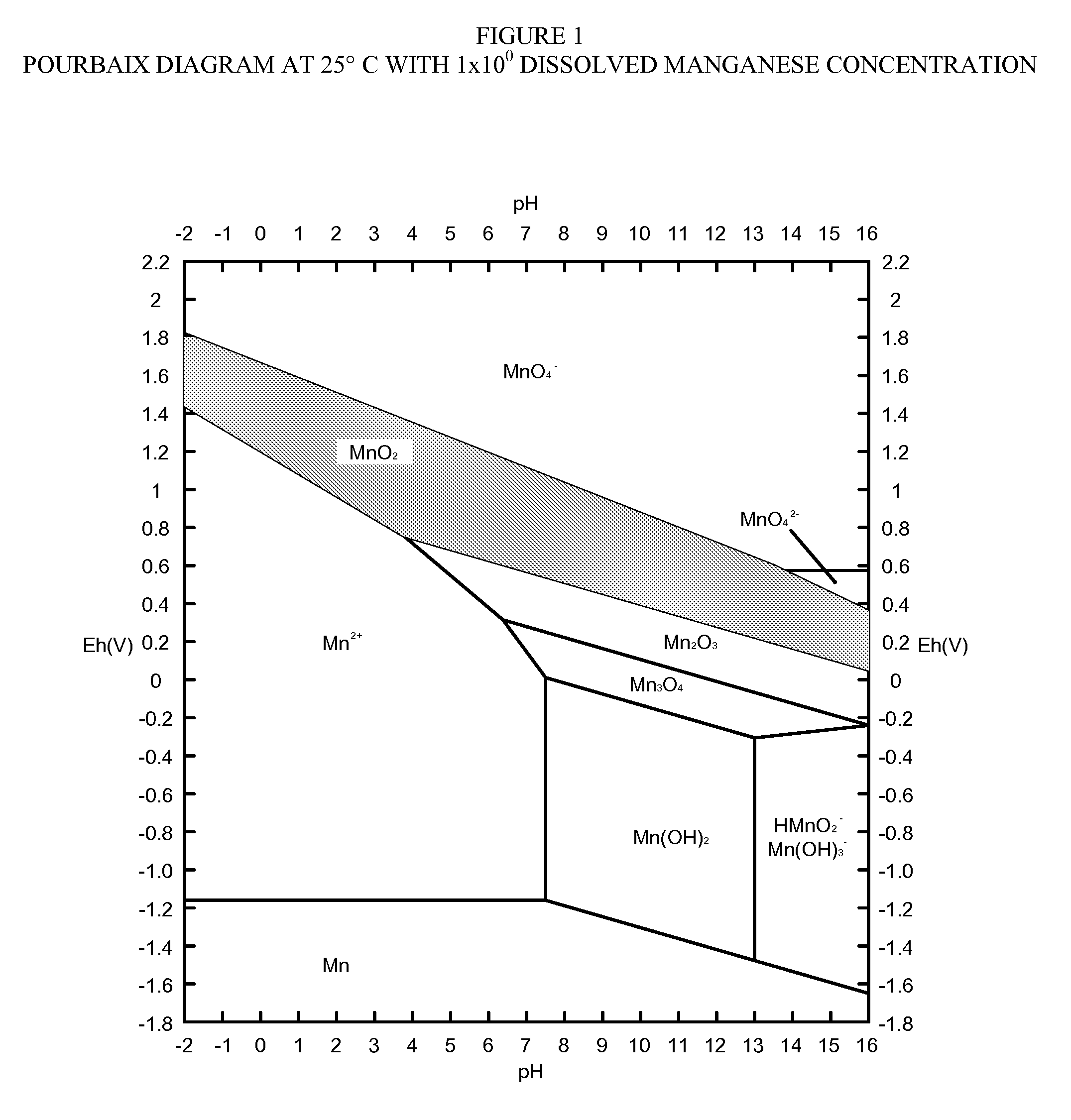

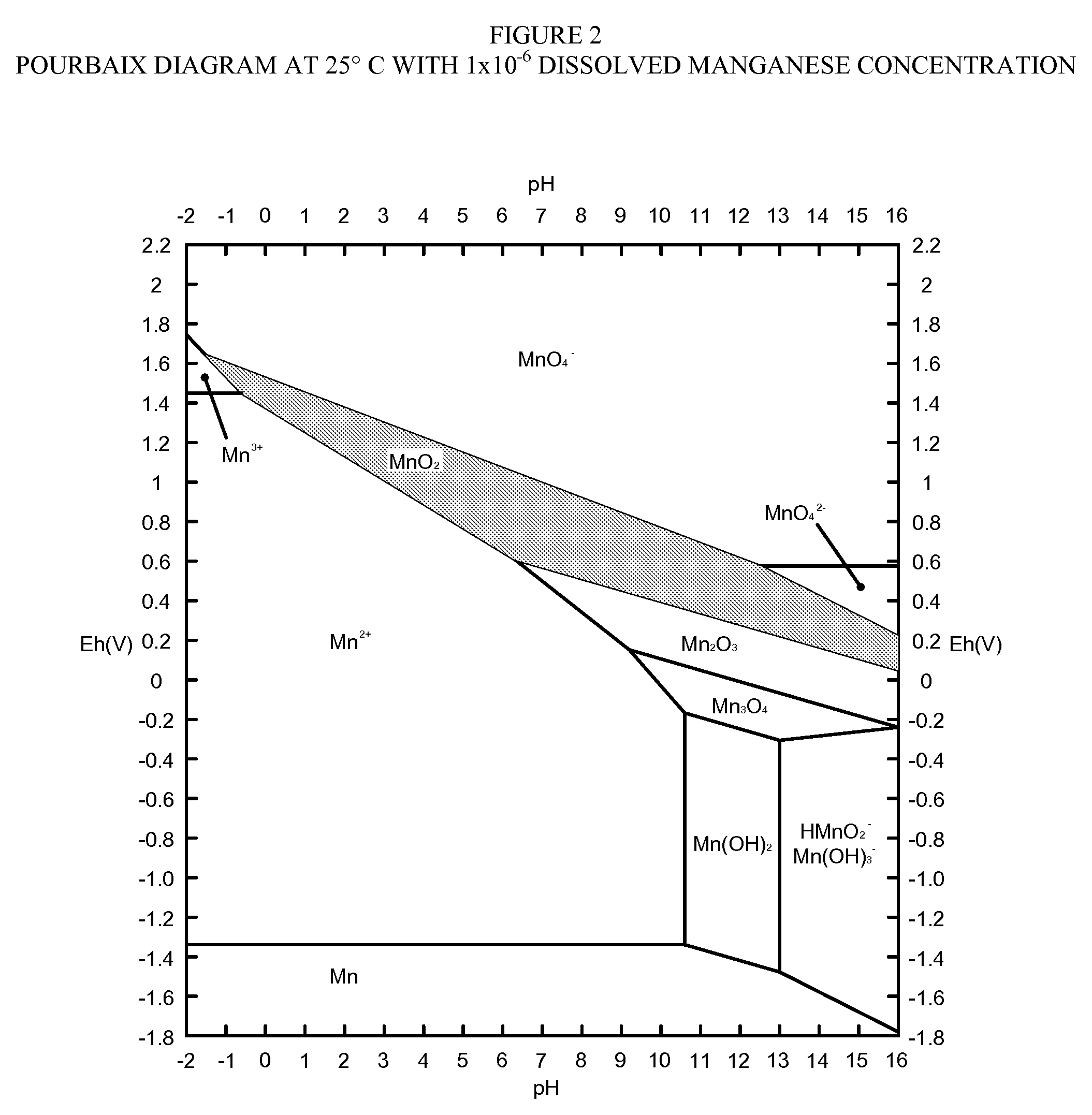

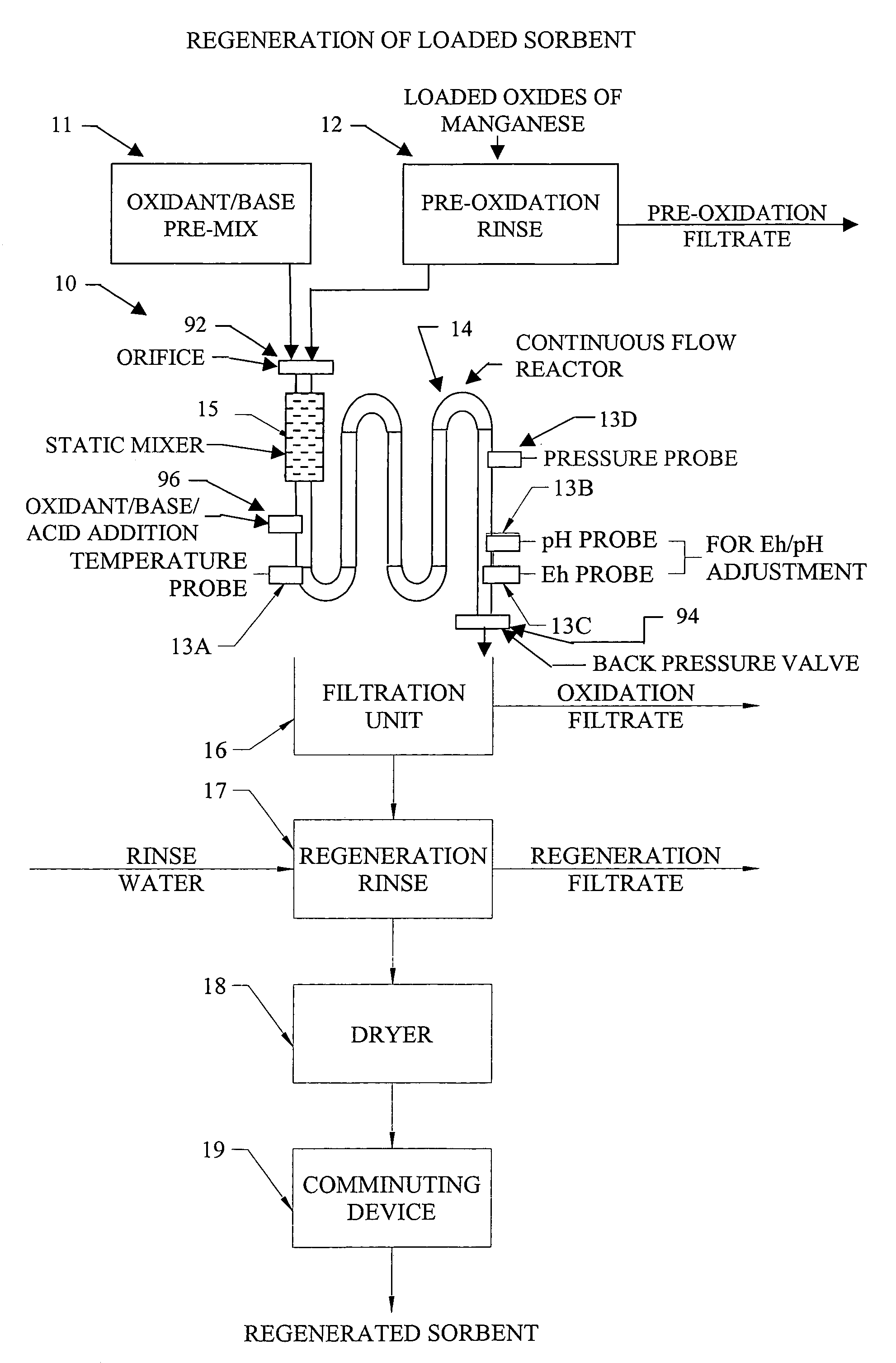

Oxides of Manganese Processed in Continuous Flow Reactors

InactiveUS20080317650A1Adapt quicklyOther chemical processesRecovering materialsSorbentOxidation state

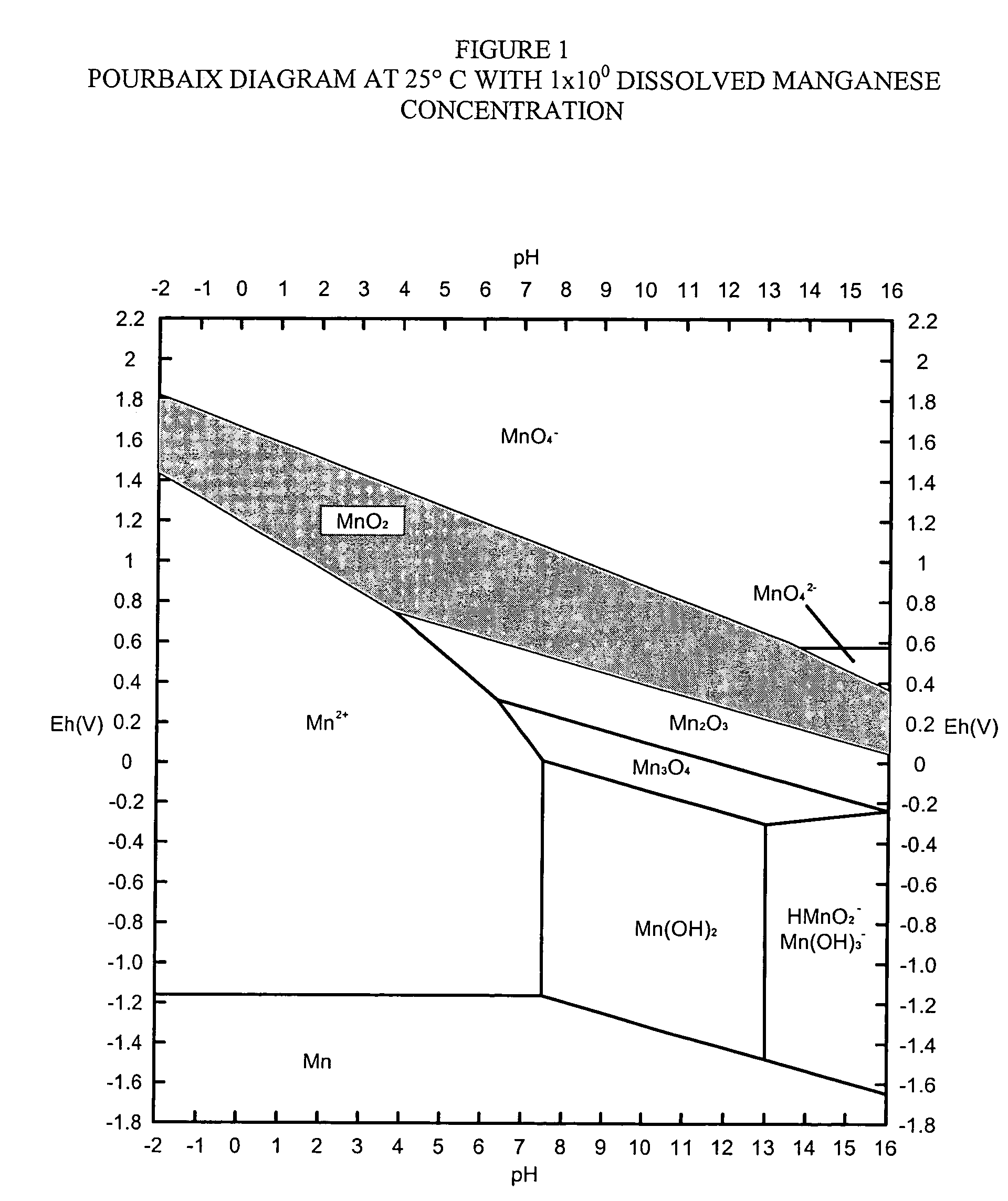

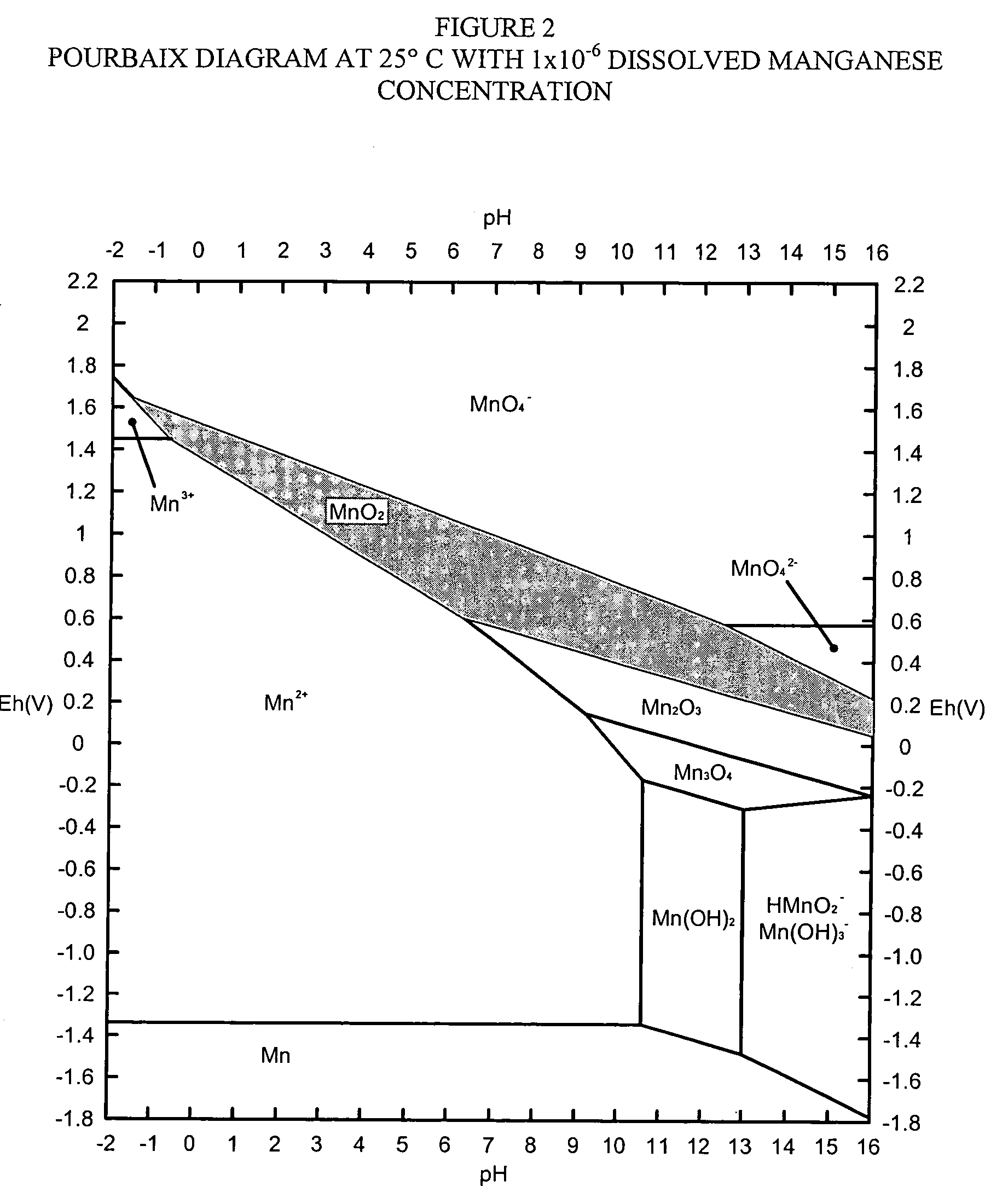

Methods and systems for regenerating and pretreating oxides of manganese and precipitation of oxides of manganese from manganese salt solutions. Oxides of manganese, a slurry containing oxides of manganese or manganese salt solutions are mixed with heated aqueous oxidizing solutions and processed in a continuous process reactor. Temperature, pressure, Eh value, and pH value of the mixed solution are monitored and adjusted so as to maintain solution conditions within the MnO2 stability area during processing. This results in regenerated, pretreated and precipitated oxides of manganese having high or increased pollutant loading capacities and / or oxidation states. Oxides of manganese thus produced are, amongst other uses; suitable for use as a sorbent for capturing or removing target pollutants from industrial gas streams. Filtrate process streams containing useful and recoverable value present as spectator ions may be further processed to produce useful and marketable by-products.

Owner:BOREN RICHARD M +1

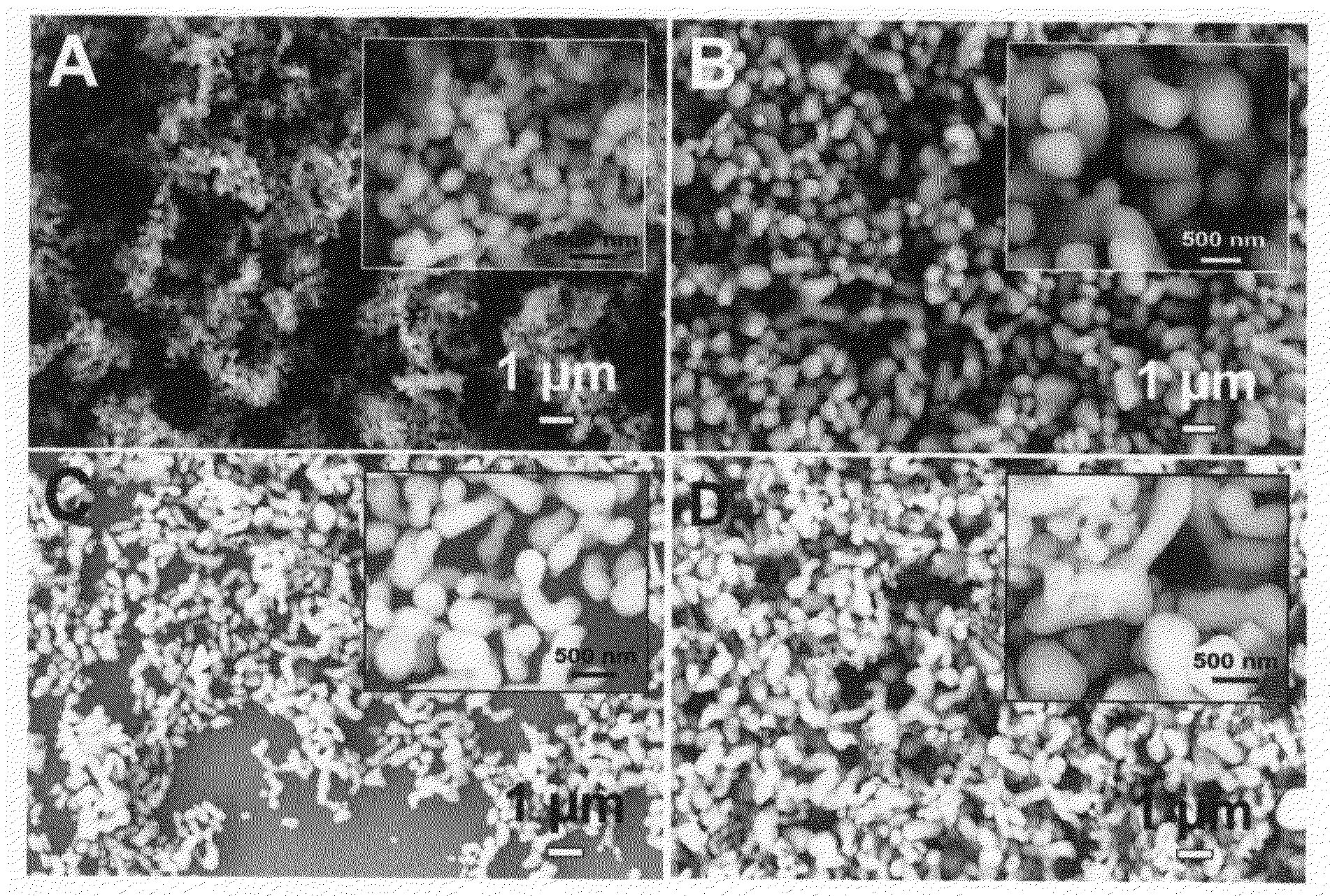

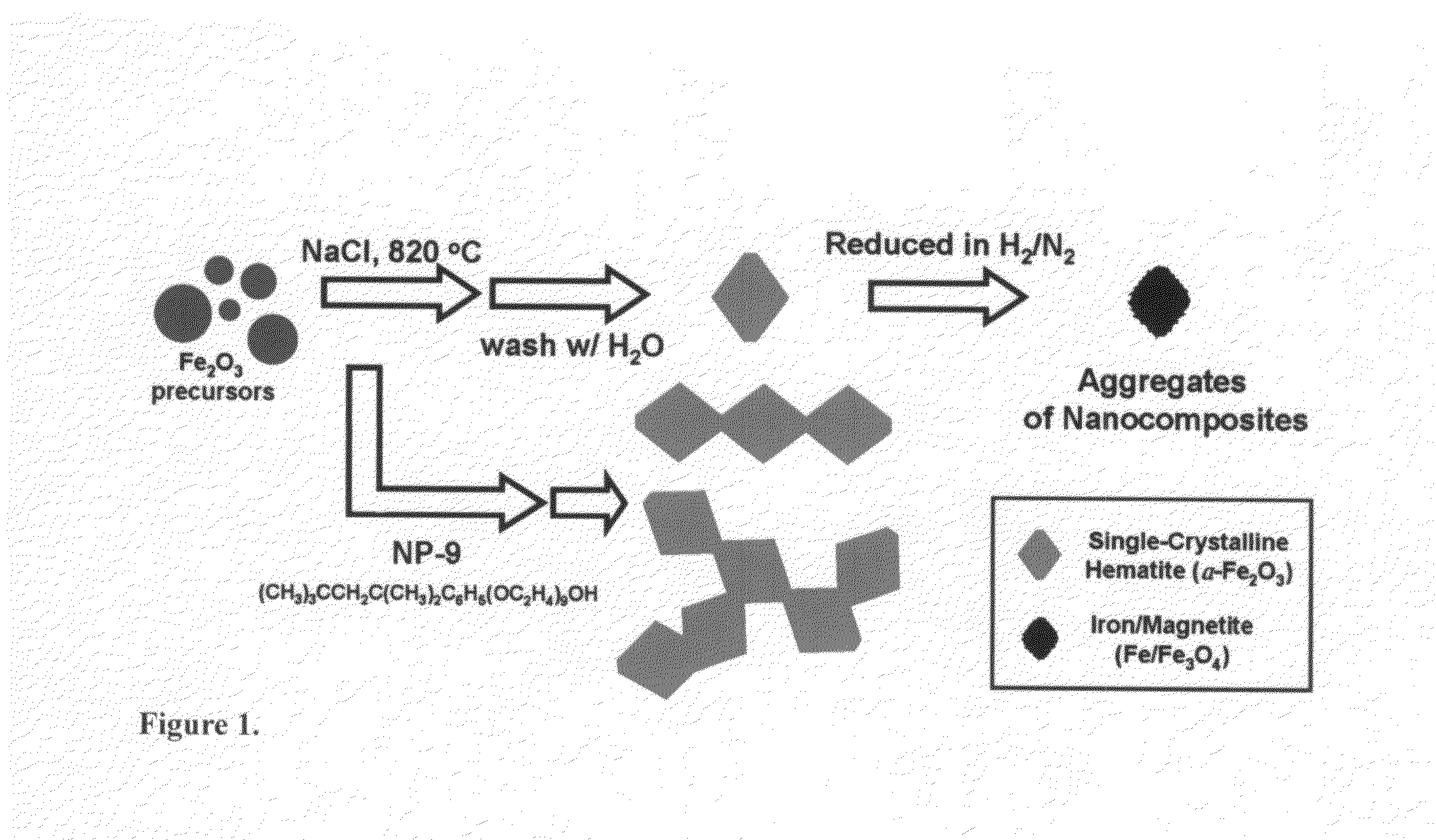

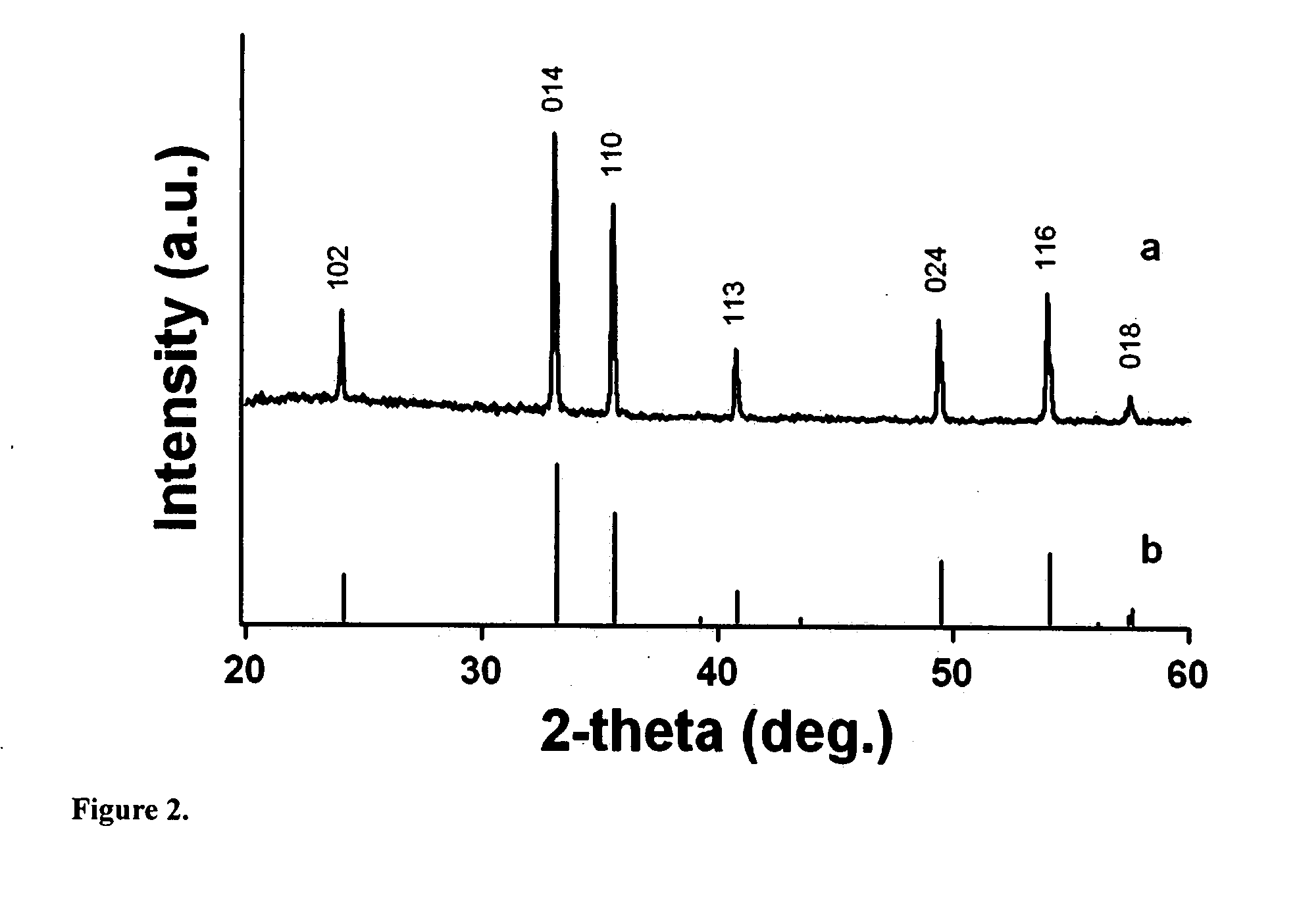

Single-crystalline hematite rhombohedra and magnetic nanocomposites of iron and magnetite and methods of making same

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method for preparing surface modified IIB metal oxide hydrogenation catalyst

ActiveCN1765512AImprove performanceHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsState of artHigh activity

The invention relates to a method for preparing a hydrogenation catalyst which can change the property of the surface of IIB group metallic oxide. The invention adds the zinc via immersion method, and the carrier is avoided high temperature sintering process after the immersion with zinc solution and dried, and before loading the hydrogenation active metal. Compared to present technique, the invention avoids the high temperature process after adding zinc element and before adding hydrogenation metal, to decrease the reciprocity between the zinc and carrier, which avails the regulation on the reciprocity between hydrogenation metal and carrier. In addition, the inventive method has simple process, lower power consumption, easy operation and lower producing cost. The invention can be used in the reaction of hydrogenation refining, and hydrogenation cracking of hydrocarbon, which has higher activity and selectivity than present catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

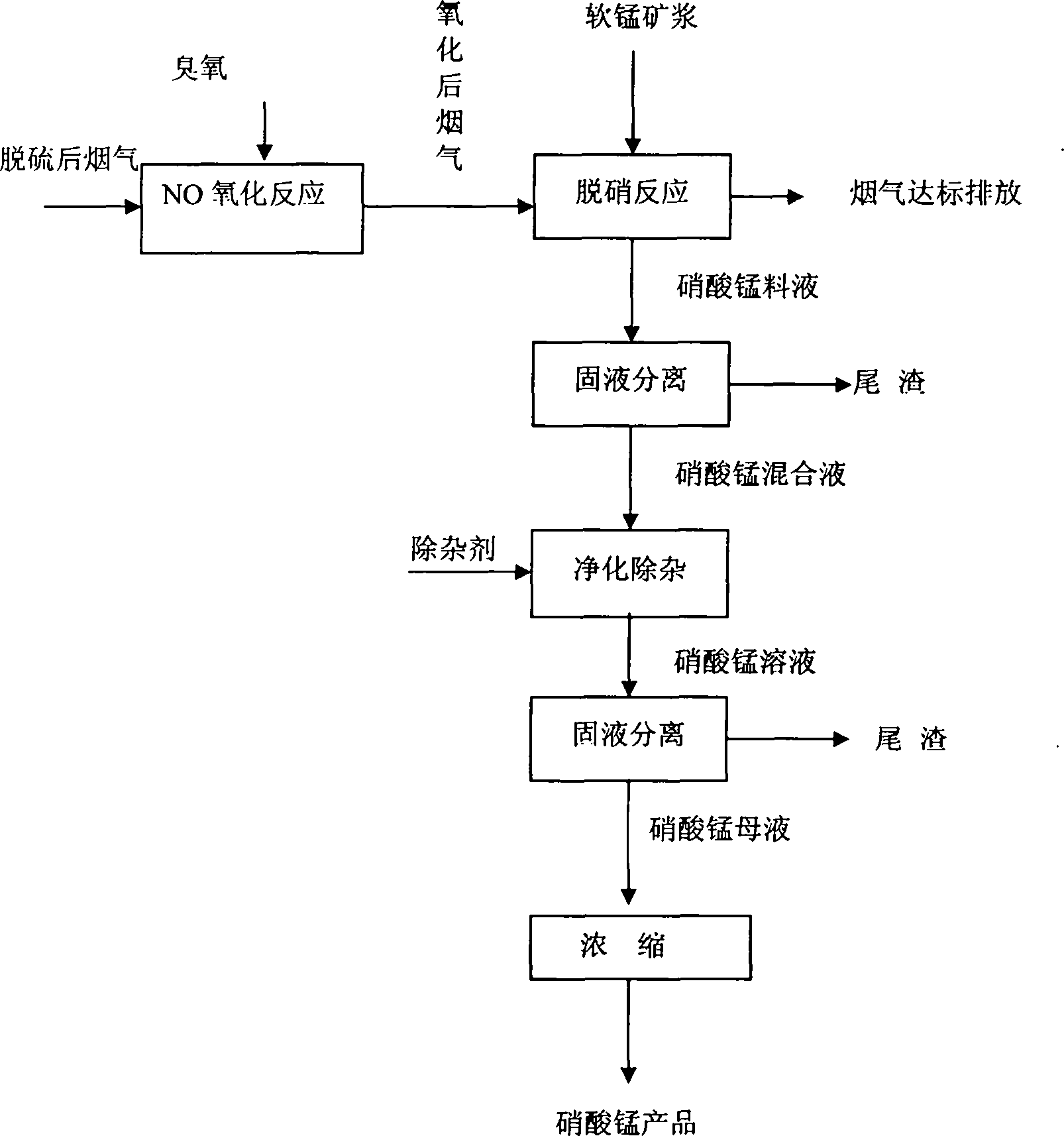

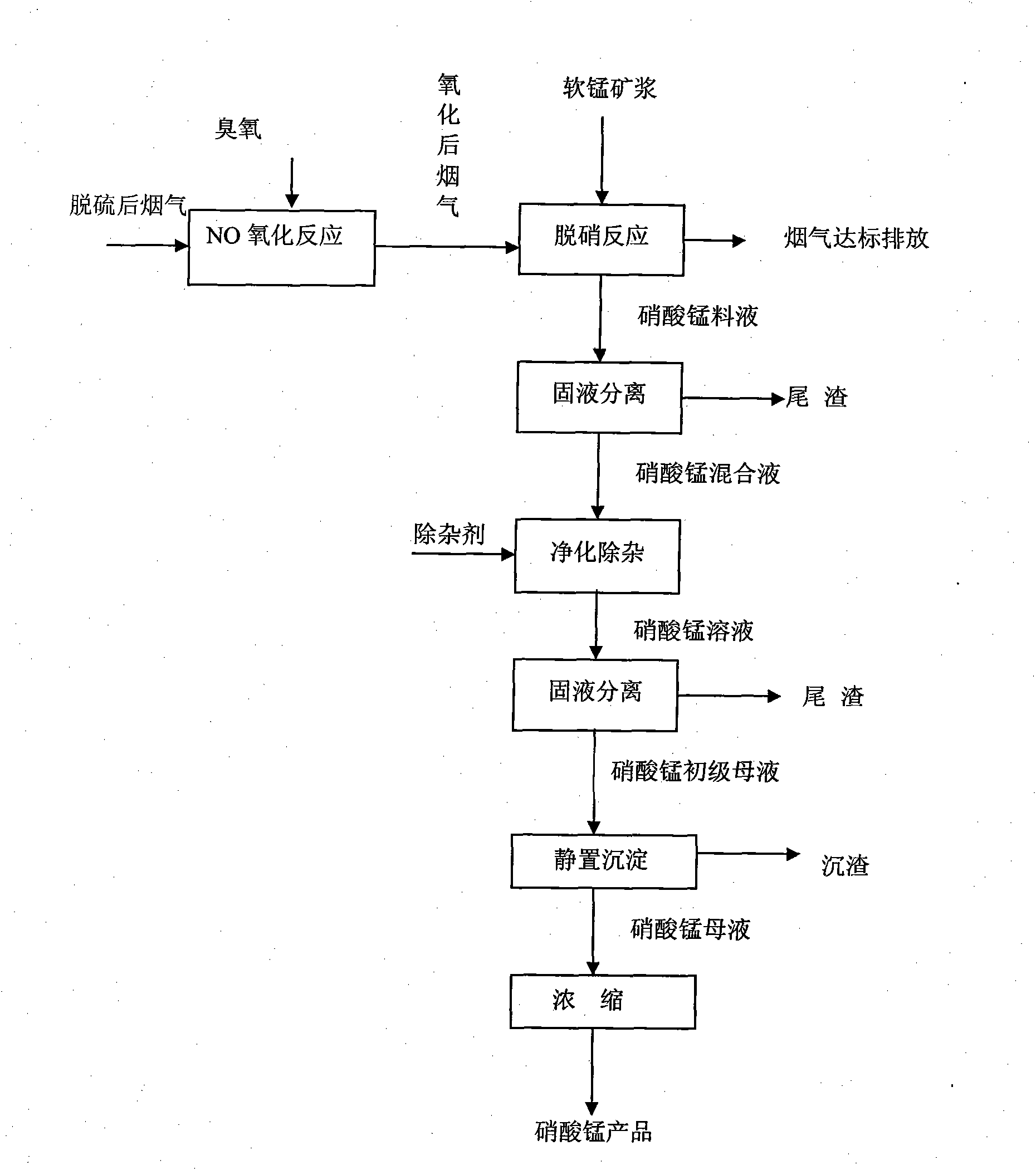

Coal-fired flue gas pyrolusite pulp recycling denitration method

InactiveCN101972588AImprove oxidation efficiencyQuick responseDispersed particle separationManganese nitratesPyrolusiteImpurity

The invention discloses a coal-fired flue gas pyrolusite pulp recycling denitration method, which mainly comprises the following steps of: injecting ozone into desulfurized coal-fired flue gas, and oxidizing NO in the coal-fired flue gas into water-soluble NO2; taking ore pulp prepared from water and low-grade pyrolusite as an absorbent so as to make the pyrolusite pulp and the coal-fired flue gas directly contacted to carry out an absorption and denitration reaction; removing NOX in the flue gas, purifying the coal-fired flue gas to meet the standard for discharging, performing solid-liquid separation on the reacted ore pulp to prepare mixed solution of manganese nitrate; and purifying and removing impurities from the mixed solution of manganese nitrate so as to prepare mother liquor of manganese nitrate, and heating and concentrating the mother liquor of manganese nitrate to prepare industrial products comprising 50 percent of manganese nitrate. Wastewater is not discharged in the whole technical process, so the aims of treating exhaust gas through the low-grade pyrolusite and recycling and preparing manganese nitrate with economic value are fulfilled. The method has the characteristics of high denitration rate, high manganese utilization rate, obvious economic benefit and the like, and is environment-friendly.

Owner:SICHUAN UNIV

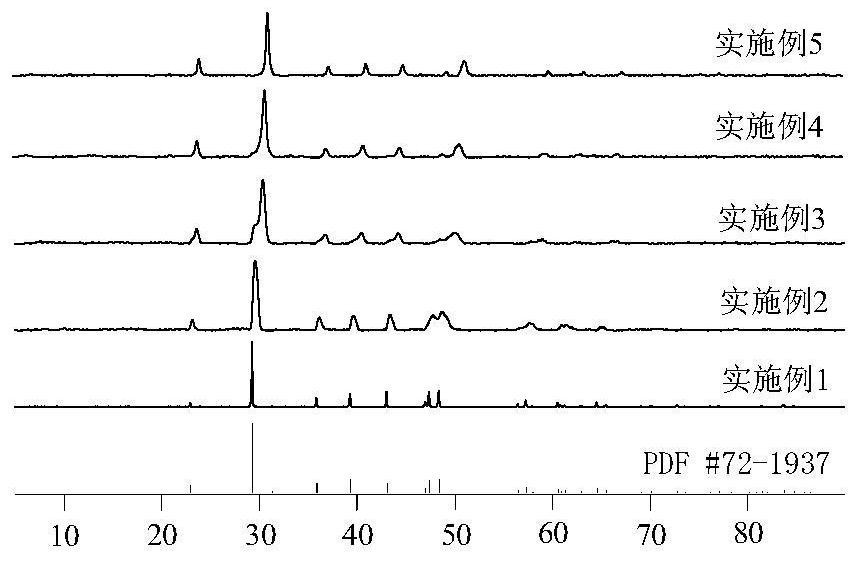

Preparation method and application of calcite-rhodochrosite solid solution

PendingCN112174180AAchieve long-term stabilityLow costCalcium/strontium/barium carbonatesCalcium/strontium/barium nitratesPhysical chemistryCrystallinity

The invention discloses a method for synthesizing calcite-rhodochrosite mixed crystal solid solution by a precipitation method. The method comprises the steps of obtaining calcite-rhodochrosite mixedcrystal solid solution with high crystallinity and good stability by using an ammonium bicarbonate preparation solution as a base solution and then adding anhydrous calcium nitrate and manganous nitrate in different molar ratios into the ammonium bicarbonate solution. Finally, a proper quantity of calcite-rhodochrosite solid solution is dissolved in three different solutions at the temperature of25 DEG C, and the rules of migration, transformation and enrichment of manganese in the environment are mastered. Compared with calcite-rhodochrosite synthesized through a traditional precipitation method, the calcite-rhodochrosite series solid solution synthesized through the method has the advantages of being low in cost, easy to control, capable of achieving long-term stable storage of manganese in the environment and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for producing bivalent manganous salt

InactiveCN107324395AReduce energy consumptionReduce pollutionOrganic compound preparationCarboxylic acid salt preparationManganeseChemical products

The present invention proposes a method for producing divalent manganese salt, which includes the following operations: mixing raw materials containing manganese dioxide, acidic aqueous solution and hydrogen peroxide, controlling the pH value of the reaction mixture to be no greater than 6.4, and generating divalent manganese salt after stirring ; Wherein, the acidic aqueous solution is an aqueous solution containing one or more of sulfuric acid, hydrochloric acid, nitric acid, acetic acid or citric acid. The invention provides a method with low energy consumption and low pollution, which converts manganese dioxide into divalent manganese salt, or removes manganese dioxide as impurities from raw materials. In the present invention, hydrogen peroxide, as a common chemical product, is cheap, produces water and oxygen after the reaction is completed, has no pollution, and does not bring impurities into the solution. According to specific needs, one or more aqueous solutions of sulfuric acid, hydrochloric acid, nitric acid, acetic acid or citric acid can be used to generate different manganese salts, so the product has good adaptability and high purity.

Owner:彭权刚 +2

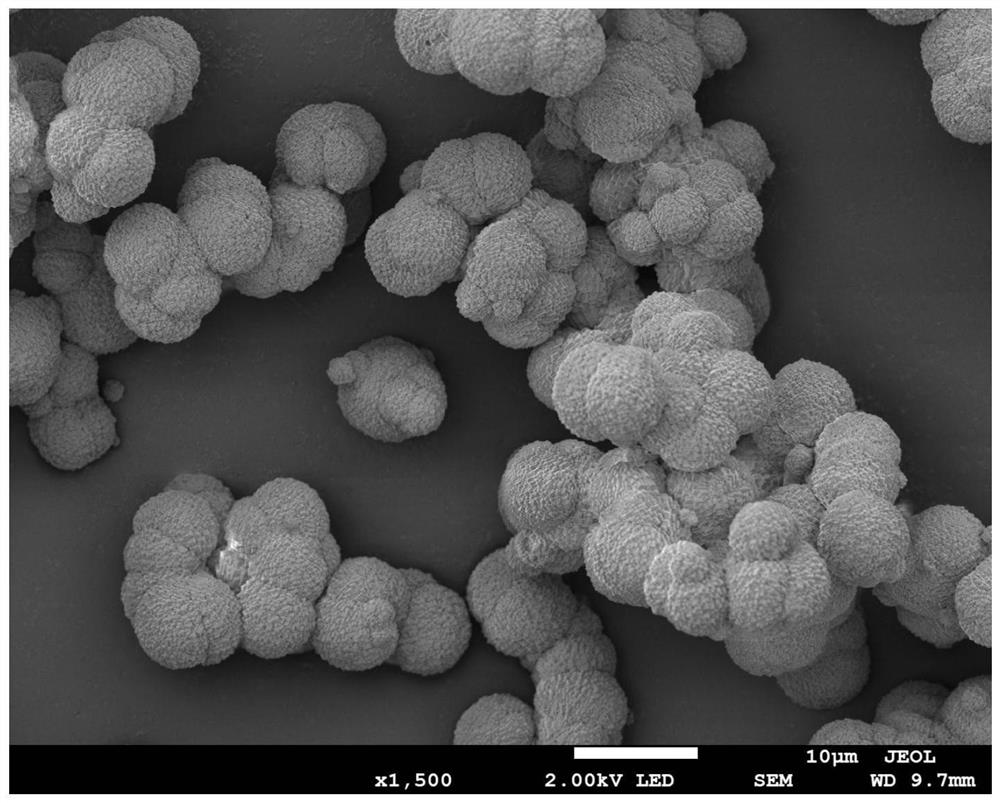

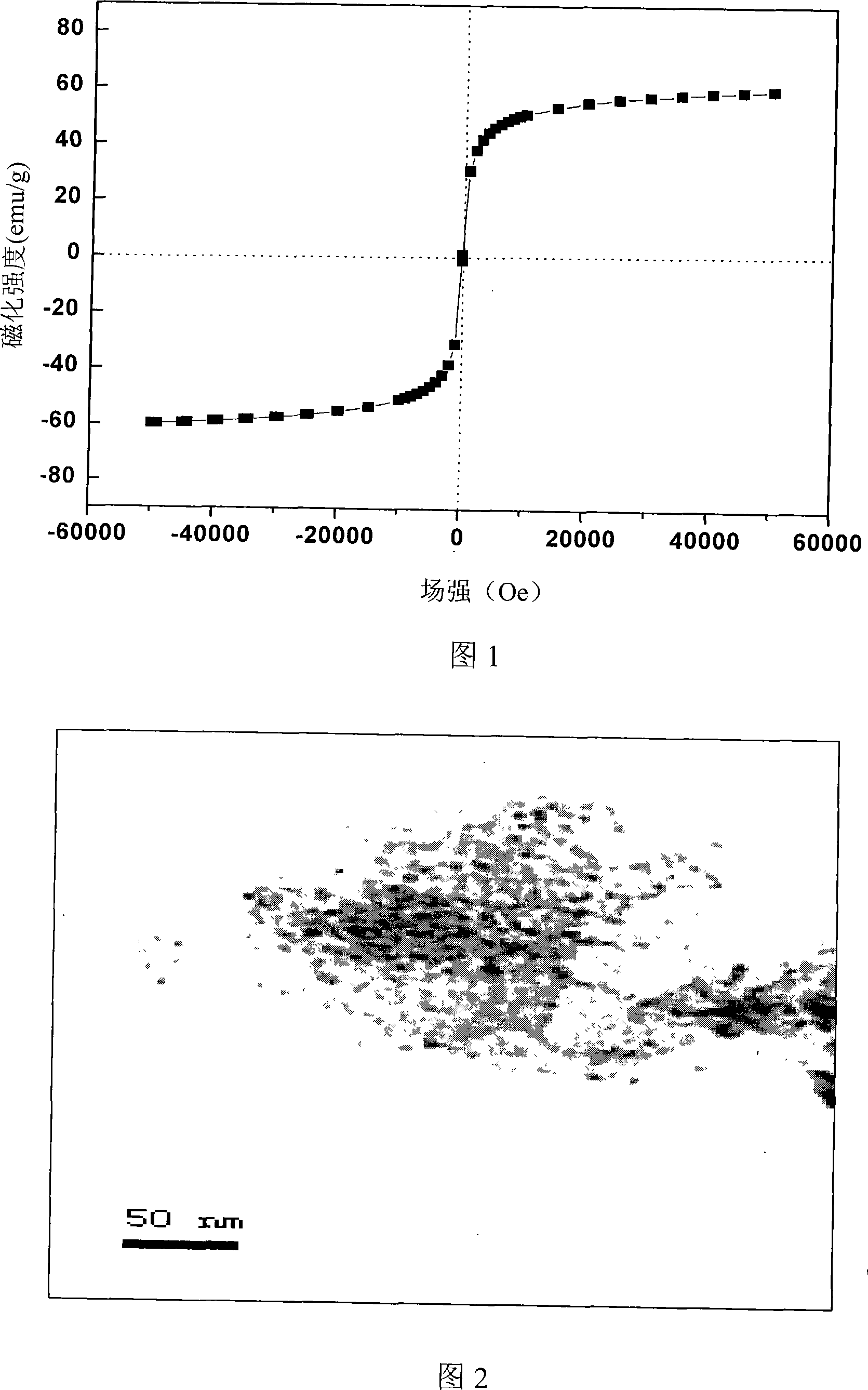

Method for preparing water-based Fe3O4 magnetic fluid

InactiveCN101209860AImprove stabilityPollutedMagnetic liquidsManganese nitratesSolubilityWater based

The invention discloses a preparation method of water-based Fe3O4 magnetic fluid, which relates to a preparation method of water-based nano magnetic fluid with superparamagnetism. The invention solves the problem that the current magnetic fluid contains organic matter and has poor organism compatibility. The steps of the invention are that: FeCl3 and FeCl2 are dissolved in deionized water and pH value is adjusted; the mixture is heated in oil bathe at the temperature of 120-180 DEG C, NaOH is dripped in under the protection of inert gas and the mixture is insulated and mixed for 0.5-2.5h; deionized water cleaning and ultrasonic dispersion are carried out, permanent magnet is put into the solution to ensure the solution does not contain chloride and is neutral; the solution is subject to centrifugation after being dispersed by ultrasound; the solution is stirred, concentrated and refluxed at the speed of 300r / min for 3-6h at the temperature of 100-160 DEG C and under the protection of inert gas. The viscosity of the water-based Fe3O4 magnetic fluid prepared by the invention is less than 10mpa.s, particle size is between 3 and 10nm, saturation magnetization is more than 60emu / g and the water-based Fe3O4 magnetic fluid has superparamagnetism, good stability and water solubility, and the material is non-toxic and cheap. The method is simple, easy and suitable for industrial production.

Owner:HARBIN NORMAL UNIVERSITY

Oxides of manganese processed in continuous flow reactors

InactiveUS7419637B2Rapid and adaptive processingAdapt quicklyCombination devicesComponent separationSorbentOxidation state

Methods and systems for regenerating and pretreating oxides of manganese and precipitation of oxides of manganese from manganese salt solutions. Oxides of manganese, a slurry containing oxides of manganese or manganese salt solutions are mixed with heated aqueous oxidizing solutions and processed in a continuous process reactor. Temperature, pressure, Eh value, and pH value of the mixed solution are monitored and adjusted so as to maintain solution conditions within the MnO2 stability area during processing. This results in regenerated, pretreated and precipitated oxides of manganese having high or increased pollutant loading capacities and / or oxidation states. Oxides of manganese thus produced are, amongst other uses; suitable for use as a sorbent for capturing or removing target pollutants from industrial gas streams. Filtrate process streams containing useful and recoverable value present as spectator ions may be further processed to produce useful and marketable by-products.

Owner:ENVIROSCRUB TECH CORP

Oxidizing method for nitrite ions in desulfurization and denitrification waste liquid

InactiveCN107973323AAvoid secondary pollutionLow costMagnesium nitratesCalcium/strontium/barium nitratesNitrite ionUltraviolet lights

The invention provides an oxidizing method for nitrite ions in desulfurization and denitrification waste liquid. The oxidizing method comprises the following steps of firstly carrying out solid-liquidseparation and deep dedusting on the desulfurization and denitrification waste liquid, then adjusting the pH value of the solution to be in the suitable range for oxidation treatment, completely oxidizing nitrites in the waste liquid into nitrates through a manner of combining an oxidizing agent and ultraviolet light to produce free radical, and finally obtaining a nitrate product. The oxidizingmethod provided by the invention has the beneficial effects that the operation is simple and convenient, the cost is low, the oxidizing efficiency is high, the problem of secondary pollution easily caused by the nitrite waste liquid is solved, and the recycling of all nitrogen elements in the waste liquid is realized, so that the application prospect is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

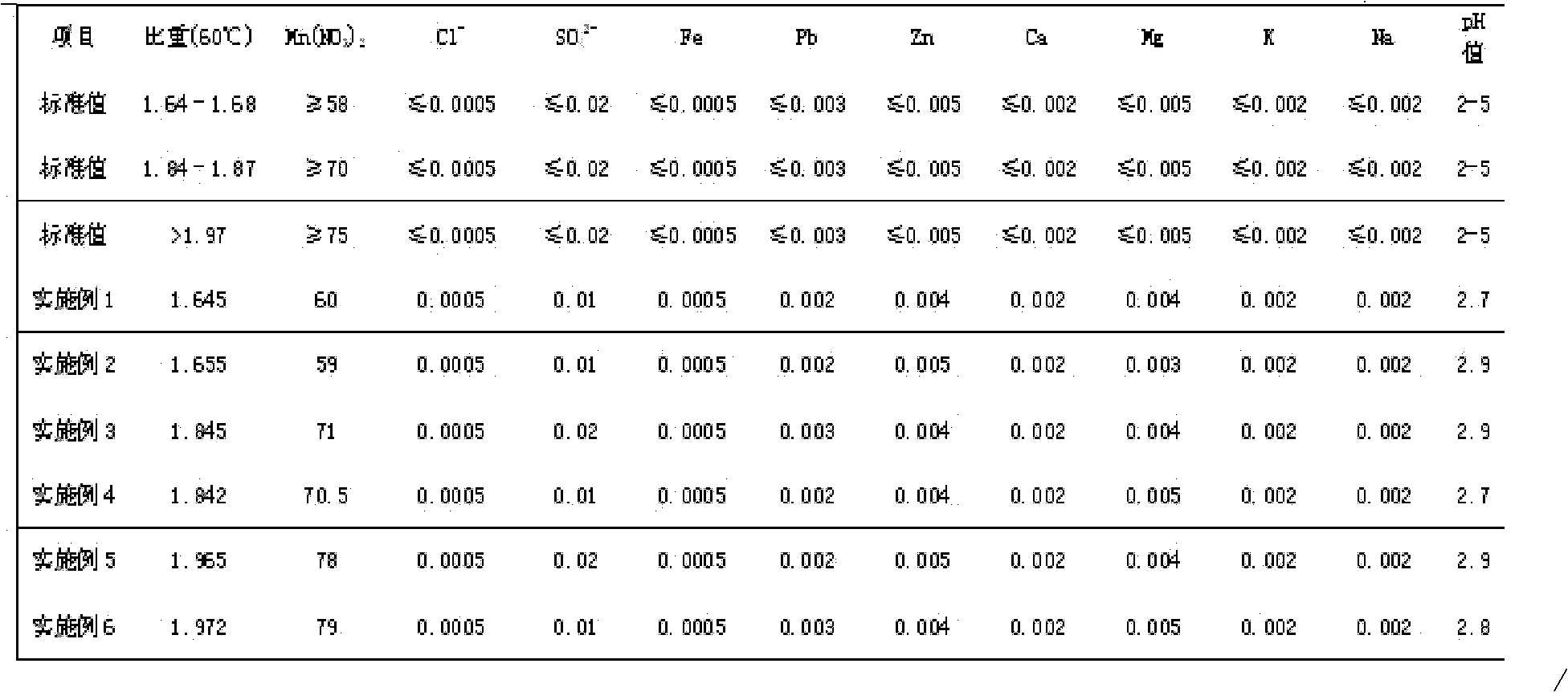

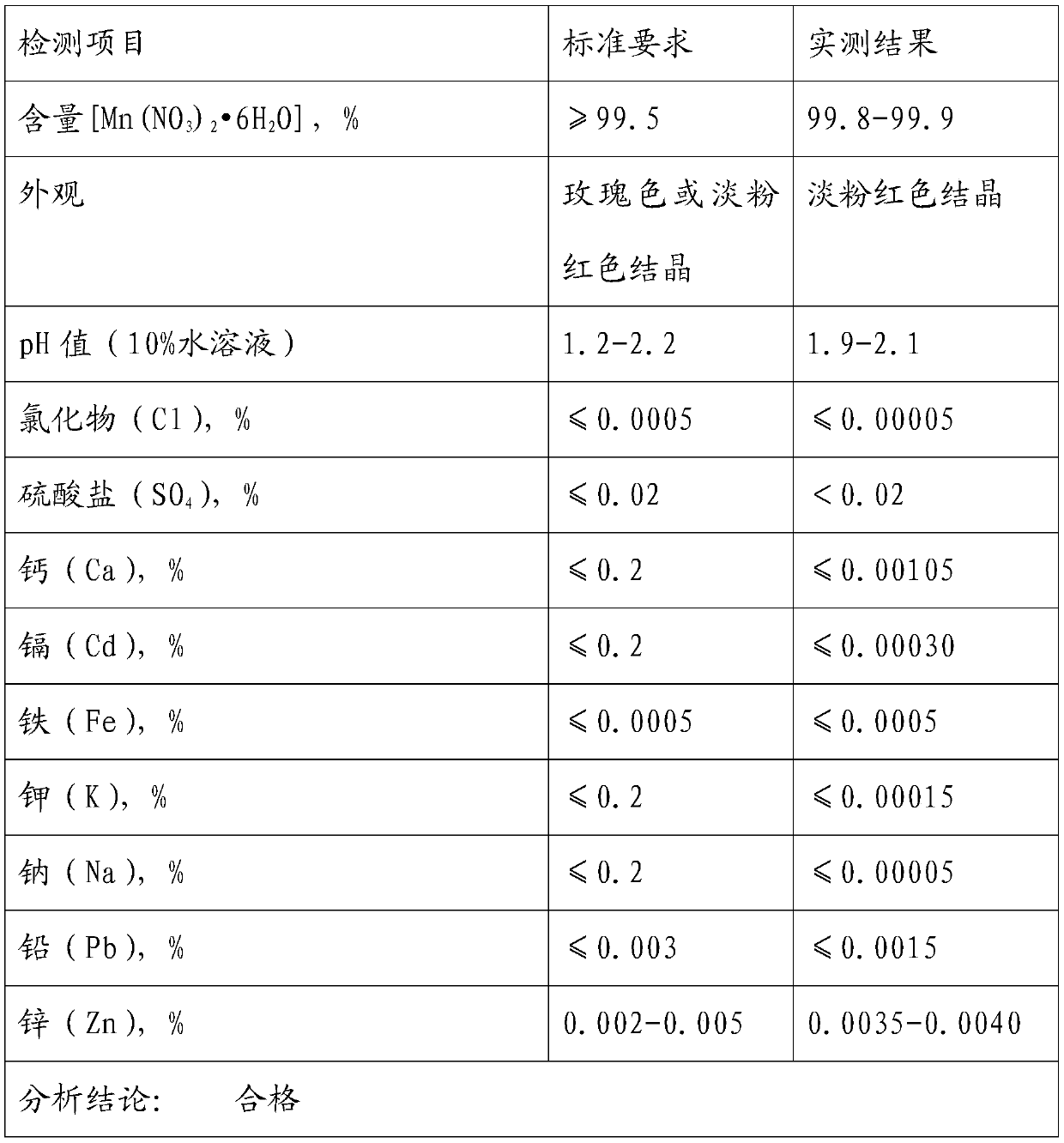

Preparation method of electronic grade manganous nitrate for tantalum capacitor

The invention relates to a preparation method of electronic grade manganous nitrate for a tantalum capacitor, which includes a. adding crushed and washed manganese metal into nitric acid, stirring the mixture while adding the manganese metal till the manganese metal is completely dissolved and then statically placing the mixture for 10 to 40 minutes; b. conducting coarse filtering on the solution, adjusting the pH value of the solution to be 2 to 4 through nitric acid; and c. heating the solution receiving acid adjustment in vacuum mode to condense the solution to the required ratio, adjusting the pH value of the solution through nitric acid to be 2-5, cooling the solution and conducting fine filtering on the solution to obtain a manganous nitrate solution product. The preparation method can be used for preparing liquid manganous nitrate products in batch in industrial mode to achieve using standard of electronic grade products for the tantalum capacitor. Manganese dioxide produced by the electronic grade manganous nitrate is high in purity, good in crystal structure, good in chemical activity, even and compact in layer, small in particle, firm in adhesion, small in resistivity, low in using unit consumption and low in content of chemical impurities such as iron, calcium, lead, potassium and magnesium, thereby being suitable for serving as high-purity catalyst, oxidant, adsorbent and the like.

Owner:NINGXIA ORIENT TANTALUM IND

Method for preparing surface modified IIB metal oxide hydrogenation catalyst

ActiveCN100364668CImprove performanceHigh activityCatalyst activation/preparationManganese sulfatesState of artHigh activity

The invention relates to a method for preparing a hydrogenation catalyst which can change the property of the surface of IIB group metallic oxide. The invention adds the zinc via immersion method, and the carrier is avoided high temperature sintering process after the immersion with zinc solution and dried, and before loading the hydrogenation active metal. Compared to present technique, the invention avoids the high temperature process after adding zinc element and before adding hydrogenation metal, to decrease the reciprocity between the zinc and carrier, which avails the regulation on the reciprocity between hydrogenation metal and carrier. In addition, the inventive method has simple process, lower power consumption, easy operation and lower producing cost. The invention can be used in the reaction of hydrogenation refining, and hydrogenation cracking of hydrocarbon, which has higher activity and selectivity than present catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst and process for the manufacture of ultra-low sulfur distillate product

ActiveCN102698769ACatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationSulfur

Described is a catalyst and process useful in the hydrodesulfurization of a distillate feedstock to manufacture a low-sulfur distillate product. The catalyst comprises a calcined mixture of inorganic oxide material, a high concentration of a molybdenum component, and a high concentration of a Group VIII metal component. The mixture that is calcined to form the calcined mixture comprises molybdenum trioxide, a Group VIII metal compound, and an inorganic oxide material. The catalyst is made by mixing the aforementioned starting materials and forming therefrom an agglomerate that is calcined to yield the calcined mixture that may be used as the catalyst or catalyst precursor.

Owner:SHELL INT RES MAATSCHAPPIJ BV

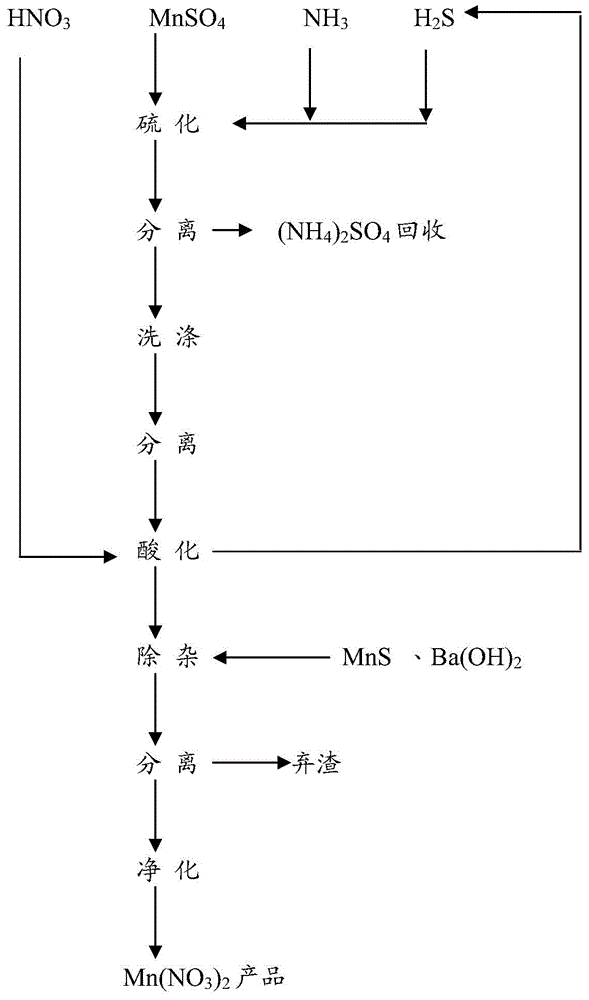

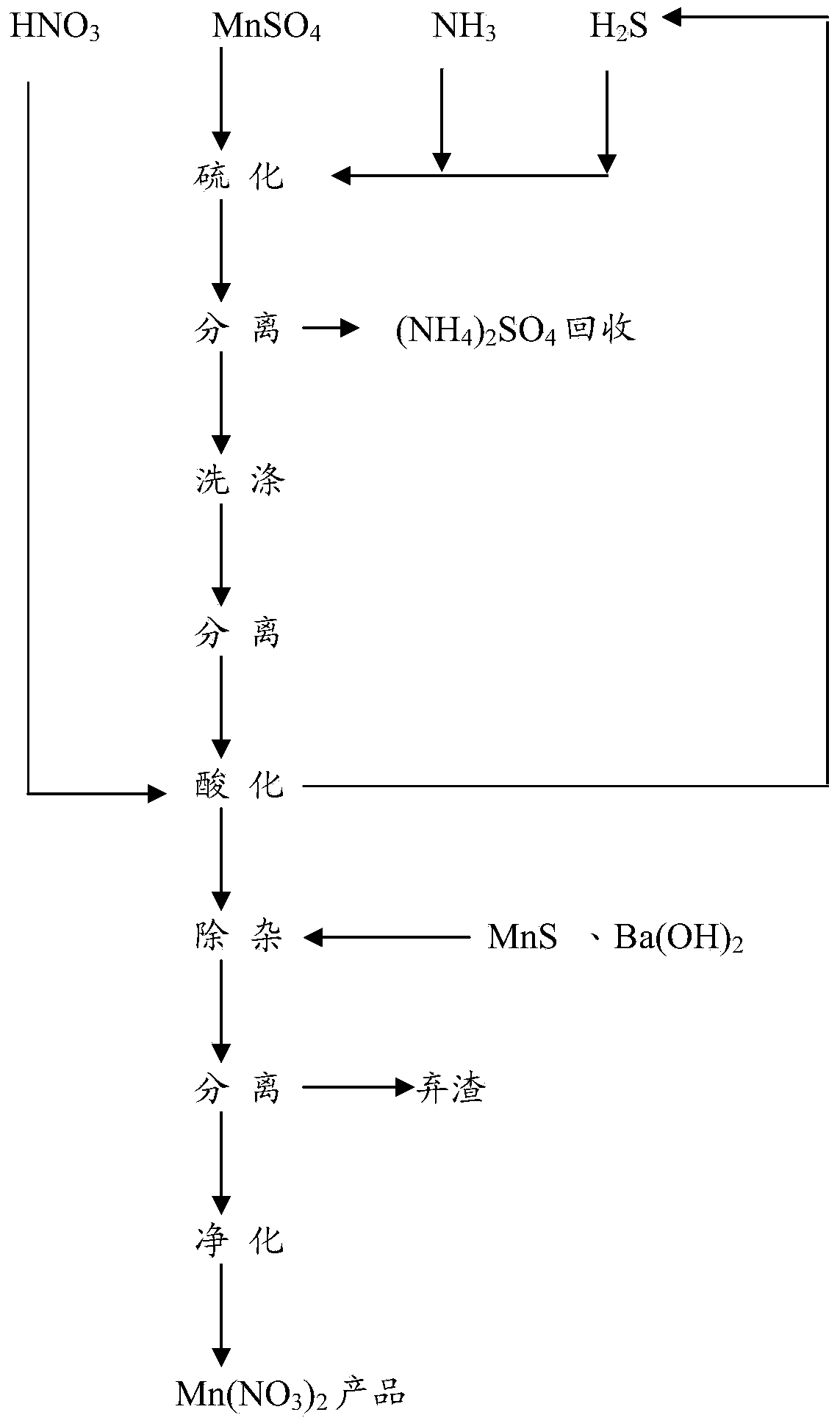

High-purity manganese nitrate and its preparation method

The invention provides a high-purity manganous nitrate and a preparation method thereof. The method comprises the following steps: (1) sulfuration, adding the mixed gas containing ammonia gas and hydrogen sulfide into a manganese sulfate solution of 150-300g / L to conduct a sulfuration reaction until the concentration of Mn<2+> in the solution is less than 500ppm, then stopping the reaction, conducting solid-liquid separation, and then washing an obtained manganese sulfate filter cake for later use; (2) acidification, adding nitric acid into the manganese sulfate filter cake obtained in the sulfuration step (1) at the nitrogen atmosphere, keeping the temperature of a reaction system to be less than 50 DEG C, and using hydrogen sulfide produced in a nitrogen displacement reaction in the reaction process; stirring, reacting until the pH value is 3.5-4.0, stopping adding acid, then conducting solid-liquid separation, and the obtained filtrate is a manganous nitrate product. The preparation method adopts a manganese sulfide-nitric acid process route to obtain the high-purity manganous nitrate product with low content of heavy metals, and the process cost is lowered.

Owner:GUIZHOU REDSTAR DEVING

High-purity manganous nitrate and preparation method thereof

The invention provides a high-purity manganous nitrate and a preparation method thereof. The method comprises the following steps: (1) sulfuration, adding the mixed gas containing ammonia gas and hydrogen sulfide into a manganese sulfate solution of 150-300g / L to conduct a sulfuration reaction until the concentration of Mn<2+> in the solution is less than 500ppm, then stopping the reaction, conducting solid-liquid separation, and then washing an obtained manganese sulfate filter cake for later use; (2) acidification, adding nitric acid into the manganese sulfate filter cake obtained in the sulfuration step (1) at the nitrogen atmosphere, keeping the temperature of a reaction system to be less than 50 DEG C, and using hydrogen sulfide produced in a nitrogen displacement reaction in the reaction process; stirring, reacting until the pH value is 3.5-4.0, stopping adding acid, then conducting solid-liquid separation, and the obtained filtrate is a manganous nitrate product. The preparation method adopts a manganese sulfide-nitric acid process route to obtain the high-purity manganous nitrate product with low content of heavy metals, and the process cost is lowered.

Owner:GUIZHOU REDSTAR DEVING

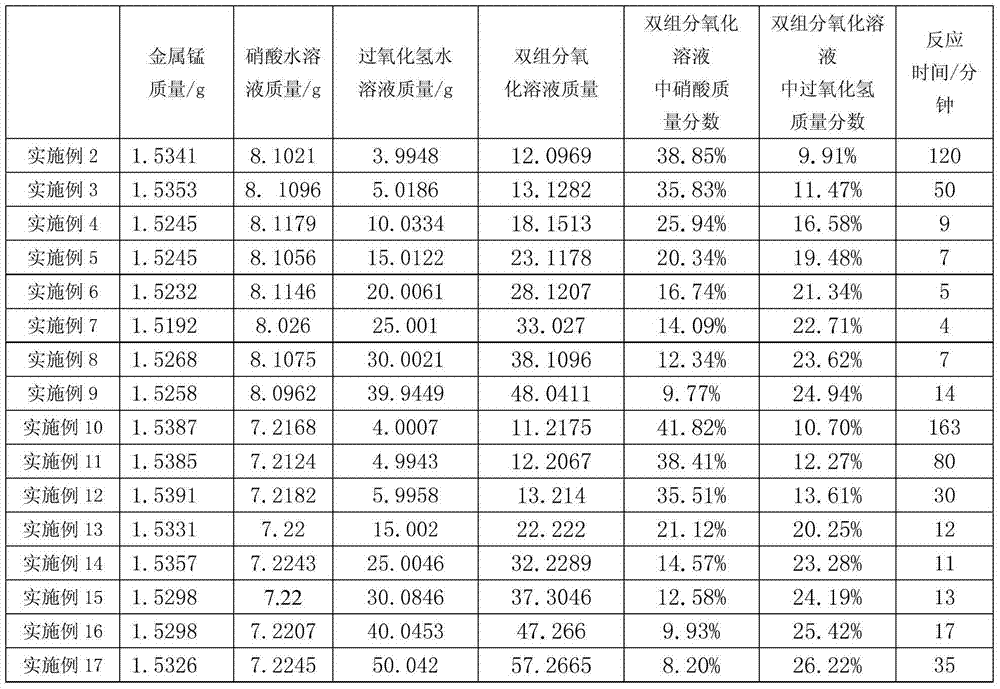

Preparing method for manganese nitrate solution

InactiveCN104229897AIncrease reaction rateReduce manufacturing costManganese nitratesReaction rateRates reactions

The embodiment of the invention discloses a preparing method for a manganese nitrate solution. The method comprises the following steps: mixing a nitrate solution and a hydrogen peroxide solution to obtain a double-component oxidizing solution; reacting after mixing the metallic manganese with the double-component oxidizing solution to obtain the manganese nitrate solution. According to the invention, after the double-component oxidizing solution is obtained through mixing the nitrate solution and the hydrogen peroxide solution, the manganese nitrate solution is obtained through the reaction of the obtained double-component oxidized solution with the metallic manganese. Compared with the method in the prior art that the manganese nitrate solution is obtained through the direct reaction of a nitrate solution with the metallic manganese, the preparing method provided by the utility model has the advantages that the reaction rate of the preparing method is obviously improved; besides, as reaction can be carried out by adopting nitrate with relatively lower concentration, and the production cost is reduced.

Owner:BEIJING JINGJINGXING TECH CO LTD

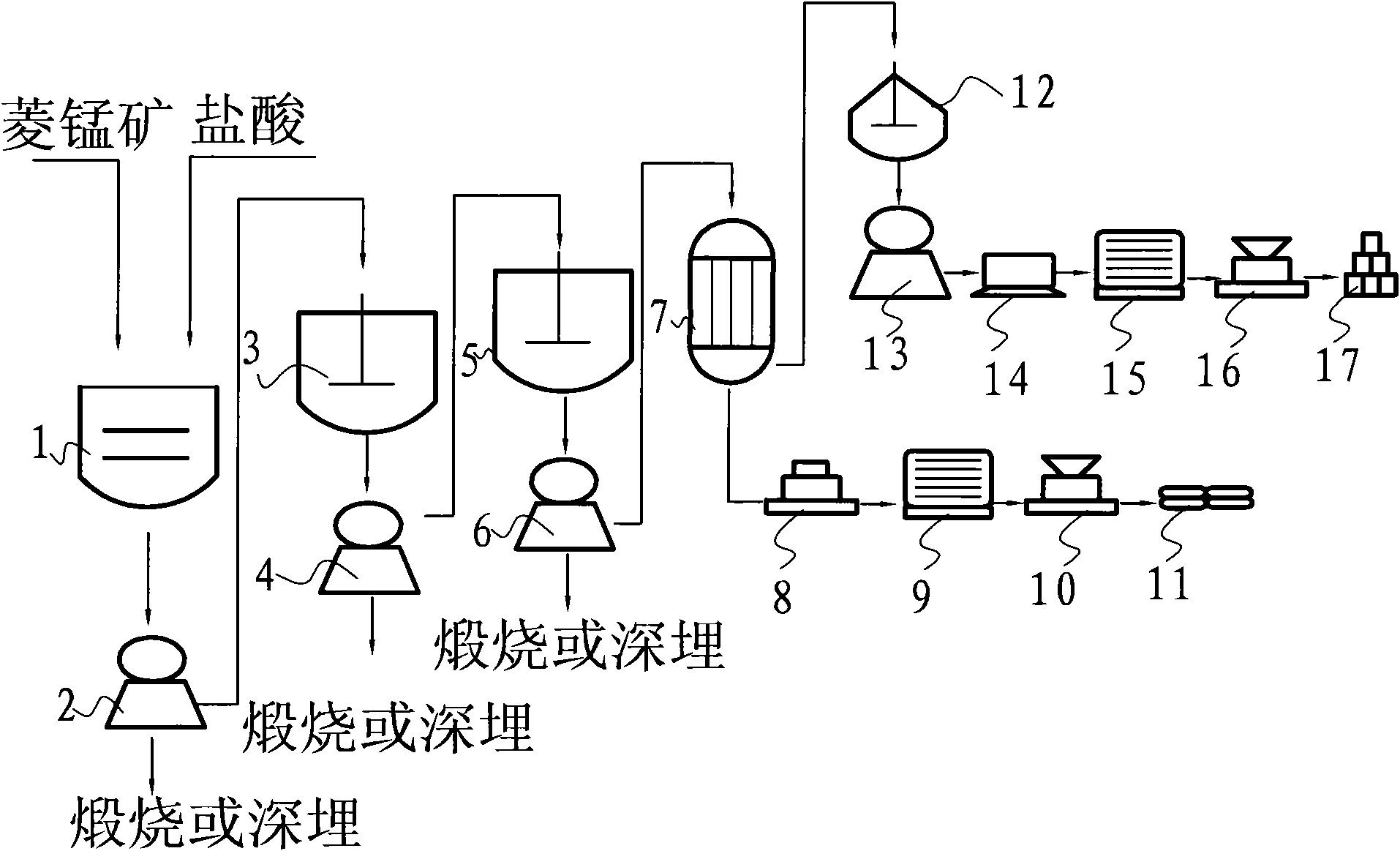

Method for preparing high-purity manganese nitrate and co-generating gypsum by using waste sulfuric acid treated by rhodochrosite

The invention belongs to the technical field of the treatment and the utilization of chemical three wastes, in particular to a method for generating high-purity manganese nitrate and co-generating gypsum by using waste sulfuric acid treated by rhodochrosite. The invention has the main technical scheme that the method comprises the following steps of: treating waste sulfuric acid generated by producing titanium pigmen by fully utilizing the rhodochrosite; crushing the rhodochrosite and extracting manganese contained in the rhodochrosite with hydrochloric acid; making an extracting liquid react with the waste sulfuric acid generated by producing the titanium pigment; and carrying out comprehensive reaction by using nitric acid. On the one hand, the wastes are changed into the valuables and the waste sulfuric acid is converted into manganese nitrate with high economic value while the pollution to the environment is treated; and on the other hand, the gypsum is co-generated while the manganese nitrate is produced. The invention has the advantages of low production cost, high profit, high market demand and simple process and production equipment; and the method is a comparatively practical treatment and utilization method; and the considerable economic values can be created, chemical waste residues are eliminated and the pollution to the environment is governed.

Owner:王嘉兴

Method for producing high-purity manganese nitrate

The invention discloses a method for producing high-purity manganese nitrate. The method comprises the following steps: step 1, carrying out a synthetic reaction in a quartz glass device by taking industrial nitric acid and electrolytic manganese metal as raw materials; step 2, adding a proper amount of an amino-carboxyl chelating agent into the synthetic reaction solution, continuously stirring,and then standing and precipitating; step 3, filtering the solution, concentrating, cooling and crystallizing; and step 4, after the crystallization is completed, carrying out dehydration treatment toobtain primary crystals, and carrying out recrystallization treatment on the primary crystals to obtain the product. Metal ion impurities in the product are removed by using the amino-carboxyl chelating agent; the content of metal impurities in the manganese nitrate product meets the high-standard requirements of customers, and meanwhile, the influence of the aminocarboxylic chelating agent serving as an impurity can be completely ignored due to the extremely small addition amount of the amino-carboxyl chelating agent, so that the technical defect that high-purity manganese nitrate cannot beproduced at low cost in the prior art is overcome.

Owner:成都市科隆化学品有限公司

Method for preparing manganous nitrate solution

InactiveCN103754940AImprove leaching rateSmall surplusManganese nitratesPyrolusitePhysical chemistry

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and reed powder into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

Method for preparing manganous nitrate solution

InactiveCN103754946BImprove leaching rateSmall surplusManganese nitratesPyrolusiteEnvironmental engineering

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and napier grass powder into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIV

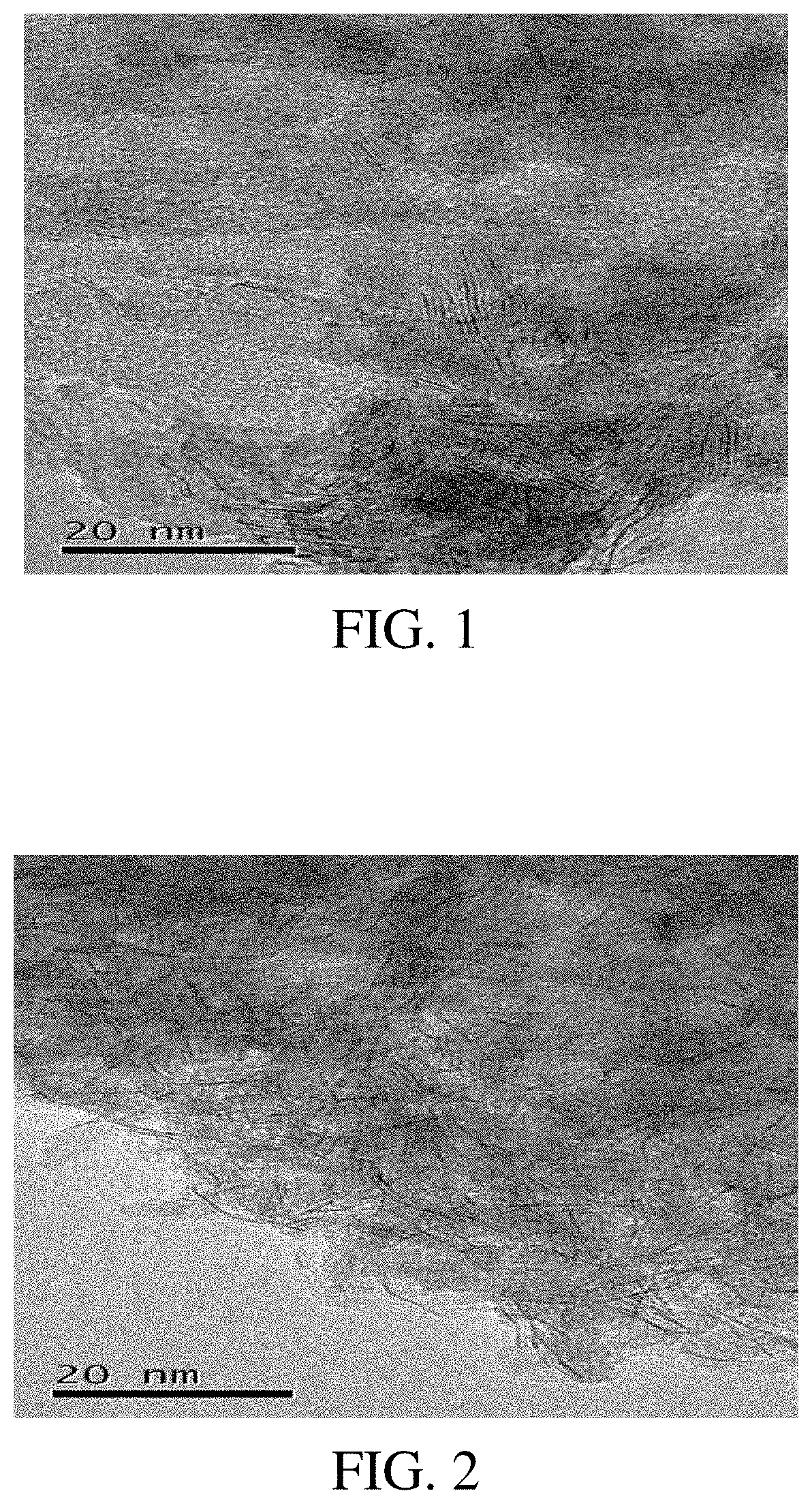

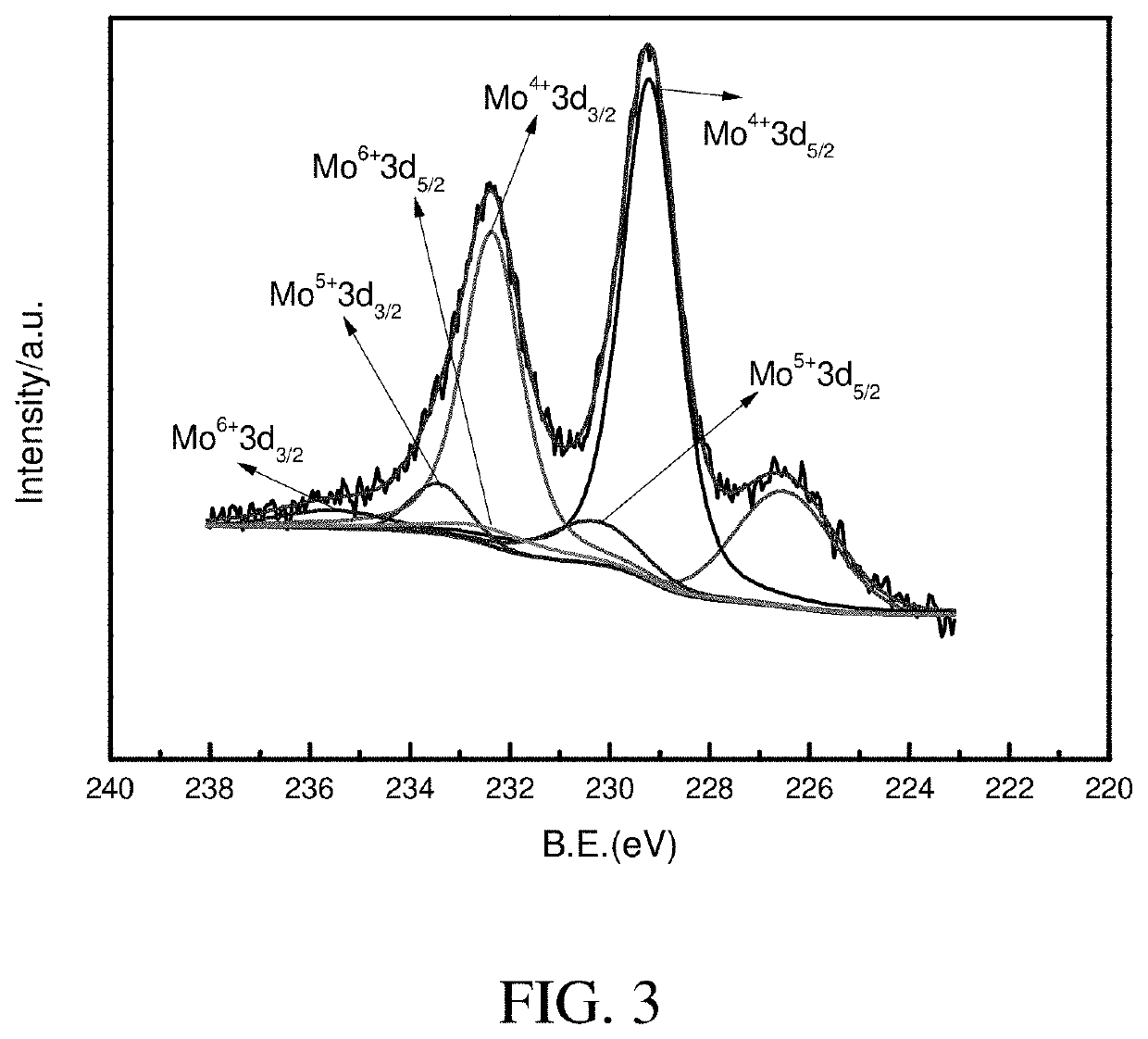

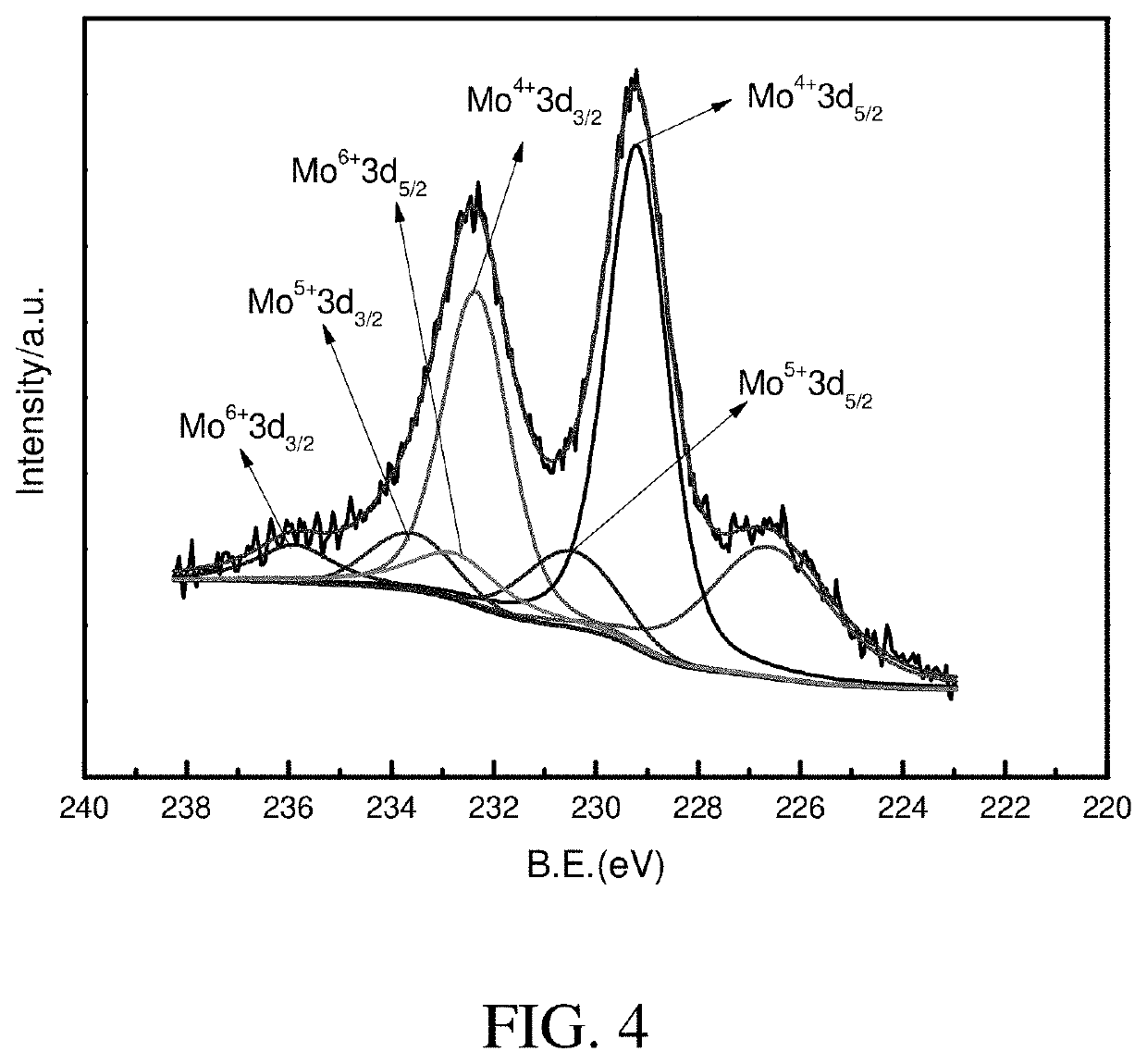

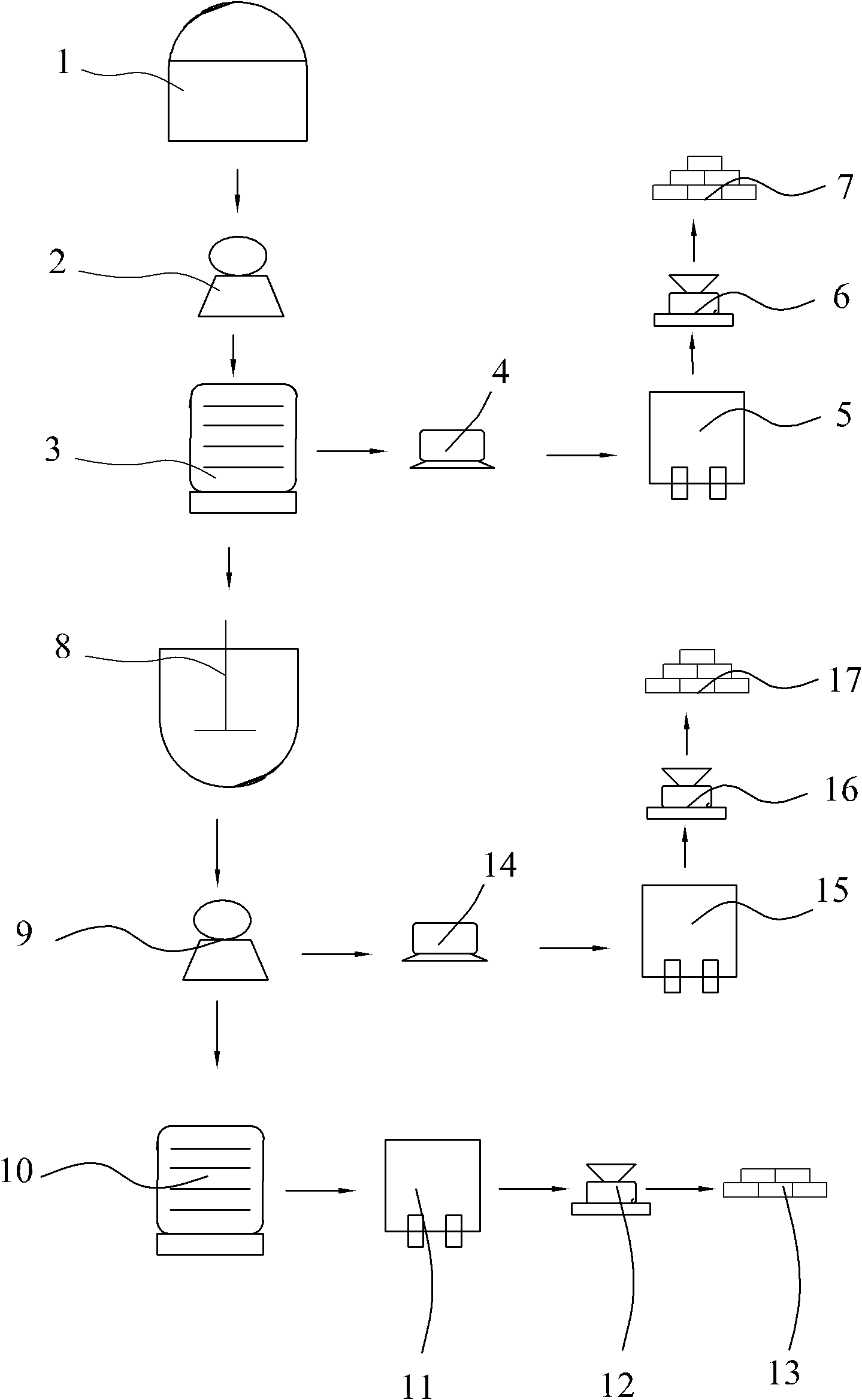

Hydrogenation catalyst, preparation process thereof and use thereof

PendingUS20220362751A1Easier to be sulfurizedHarder to be sulfurizedMolybdeum compoundsHeterogenous catalyst chemical elementsPtru catalystSulfidation

A hydrogenation catalyst contains a hydrogenation catalyst carrier and an active hydrogenation component. The active hydrogenation component includescompriscs a Group VIB metal sulfide and a Group VIII metal compound, and the molar proportion of a substance of the Group VIII metal compound that interacts with the Group VIB metal sulfide to the total amount of the Group VIII metal compound is 60-100%. The hydrogenation catalyst has a higher active metal sulfurizing degree and a higher number of type II active centers, and can be applied to the hydrogenation treatment process of oil products such as distillate oils and residual oils

Owner:CHINA PETROCHEMICAL CORP +1

Method for reducing molybdenum impurity in manganese nitrate by organic solvent extraction process

The invention relates to a method for reducing molybdenum impurity in manganese nitrate by an organic solvent extraction process. The method comprises the following steps: heating unqualified manganese nitrate by using tetrachloroethylene, performing refluxing for dissolving to prepare a tetrachloroethylene solution of manganese nitrate, naturally filtering the obtained solution by a filter paper,recovering the tetrachloroethylene solvent, for cycle use, by using a distillation device, and carrying out cooling crystallization on residues obtained after the distillation in order to obtain qualified manganese nitrate. The manganese nitrate and molybdenum nitrate have different solubilities in tetrachloroethylene, so the manganese nitrate and molybdenum nitrate are conveniently separated byusing the tetrachloroethylene as the solvent, thereby the method has the advantages of simple process, easiness in operation, stable product quality, recycling of the solvent tetrachloroethylene, andresource saving; the method also has the advantages of no discharge of a waste liquid in the preparation process, small consumption of the raw material, great reduction of the production cost, high economic benefit and friendliness to the environment; and the manganese nitrate obtained by the method is an analytically pure reagent, and can be widely used in fields of electronics, chemicals, electroplating and catalyst manufacturing.

Owner:张珍华

Method for preparing manganous nitrate solution

InactiveCN103754951BImprove leaching rateSmall surplusManganese nitratesPyrolusiteEnvironmental engineering

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and wood sawdust into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIV

Method for preparing manganous nitrate solution

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and rice bran into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIV

Method for preparing manganous nitrate solution

InactiveCN103754940BImprove leaching rateSmall surplusManganese nitratesPyrolusitePhysical chemistry

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and reed powder into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIV

Method for preparing manganous nitrate solution

InactiveCN103754948BImprove leaching rateSmall surplusManganese nitratesPyrolusiteEnvironmental engineering

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and bamboo sawdust into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIV

Method for preparing manganous nitrate solution

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder with the particle size being not greater than 180 meshes and high-concentration organic wastewater which does not contain benzene-ring substances into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

Method for preparing manganous nitrate solution

InactiveCN103754946AImprove leaching rateSmall surplusManganese nitratesPyrolusiteEnvironmental engineering

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and napier grass powder into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

Method for preparing manganese sulfate, manganese nitrate and calcium sulfate

InactiveCN102249333ANo secondary pollutionEasy to operateCalcium/strontium/barium sulfatesManganese sulfatesManganeseImpurity

The invention provides a method for preparing manganese sulfate, manganese nitrate and calcium sulfate, and the method comprises: grinding manganosite into coarse powder, soaking the coarse powder in a waste liquid generated in titanium white production utilizing a sulfuric acid method at the temperature of 60-80 DEG C for 8-10 hours, carrying out suction-filtering to obtain a clarified filtrate, and adding manganese hydroxide to remove impurities and obtain a pure manganese sulfate solution; distilling the pure manganese sulfate solution while decompressing to obtain a manganese sulfate saturated solution, cooling and precipitating manganese sulfate crystals containing crystal water, then drying and crushing to obtain a manganese sulfate crystal product; reacting the pure manganese sulfate solution with a calcium nitrate solution under stirring, filtering the reaction product to obtain a calcium sulfate filter cake and a manganese nitrate filtrate, distilling the manganese nitrate filtrate while decompressing to obtain a manganese nitrate supersaturated solution, cooling and crystallizing to obtain manganese nitrate crystals, drying and crushing to obtain a manganese nitrate powder product; and washing the calcium sulfate filter cake, drying and crushing to obtain a calcium sulfate dihydrate product.

Owner:王莉

Method for preparing manganous nitrate solution

The invention discloses a method for preparing a manganous nitrate solution. The method comprises the steps of adding pyrolusite powder and rice straw powder into a reaction kettle which is resistant to pressure and the corrosion of nitric acid, adding a mixed solution prepared from nitric acid and manganous nitrate, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com