Patents

Literature

364results about "Eutectoid materials demixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

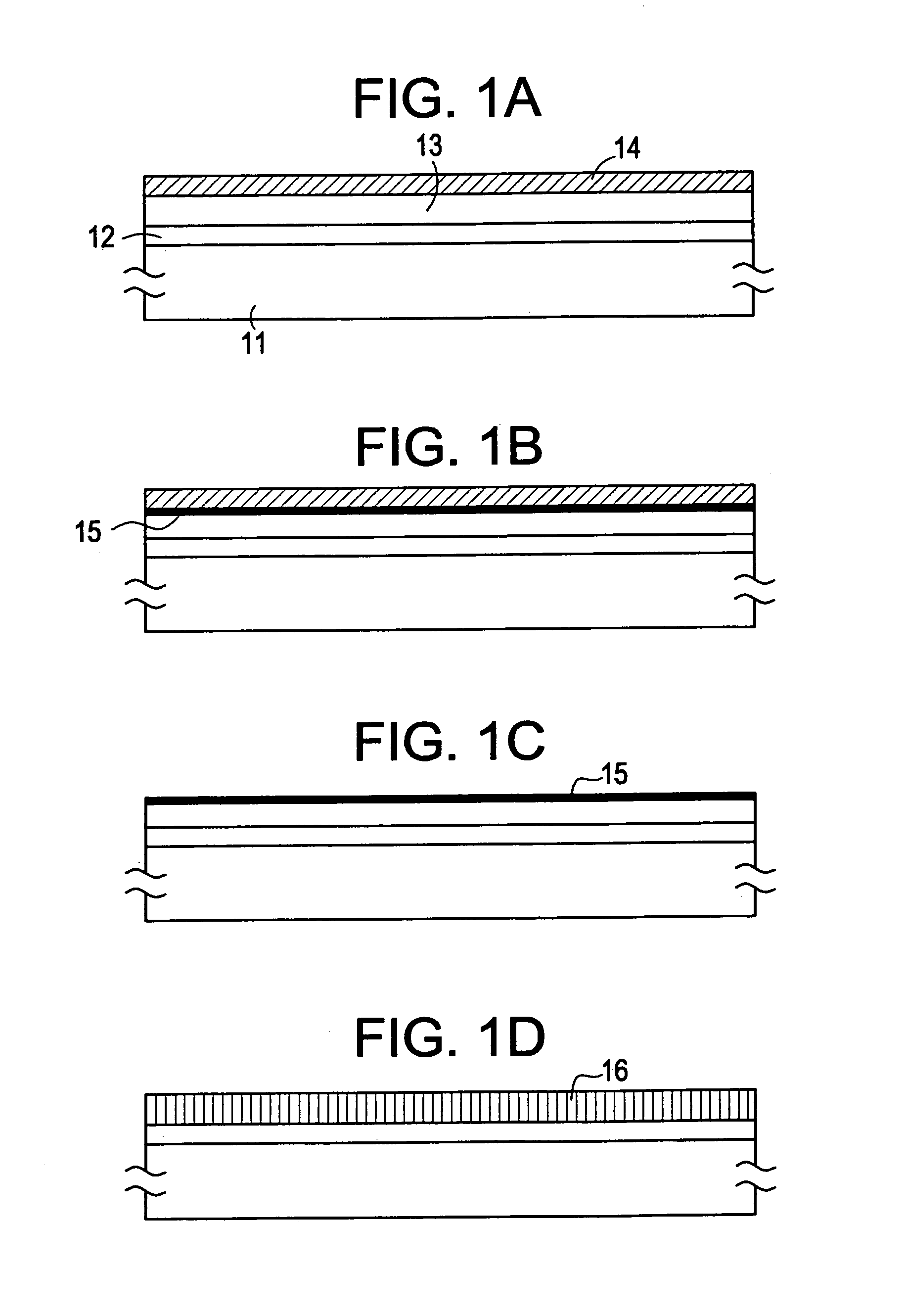

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS20090152506A1Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventDevice material

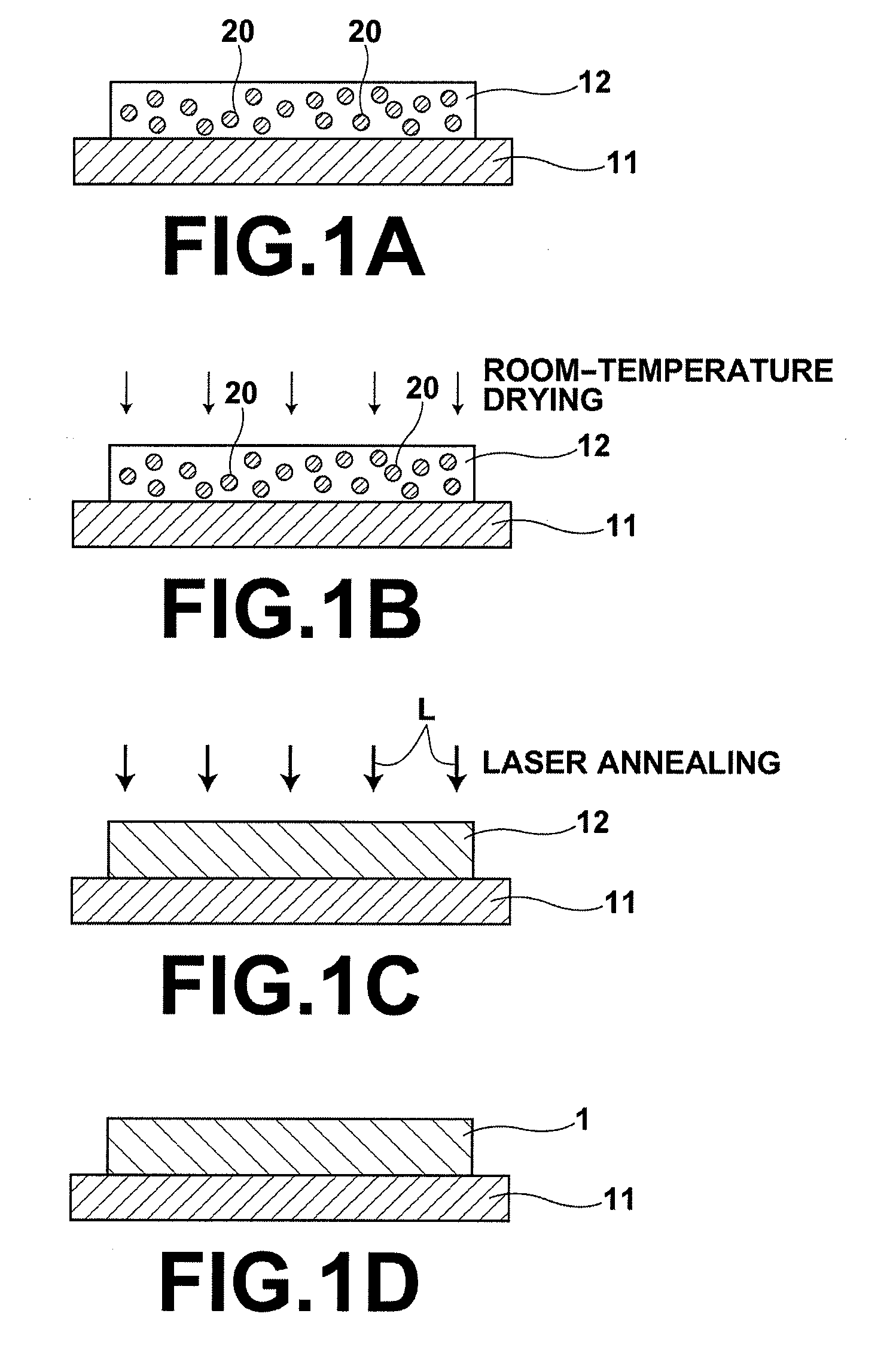

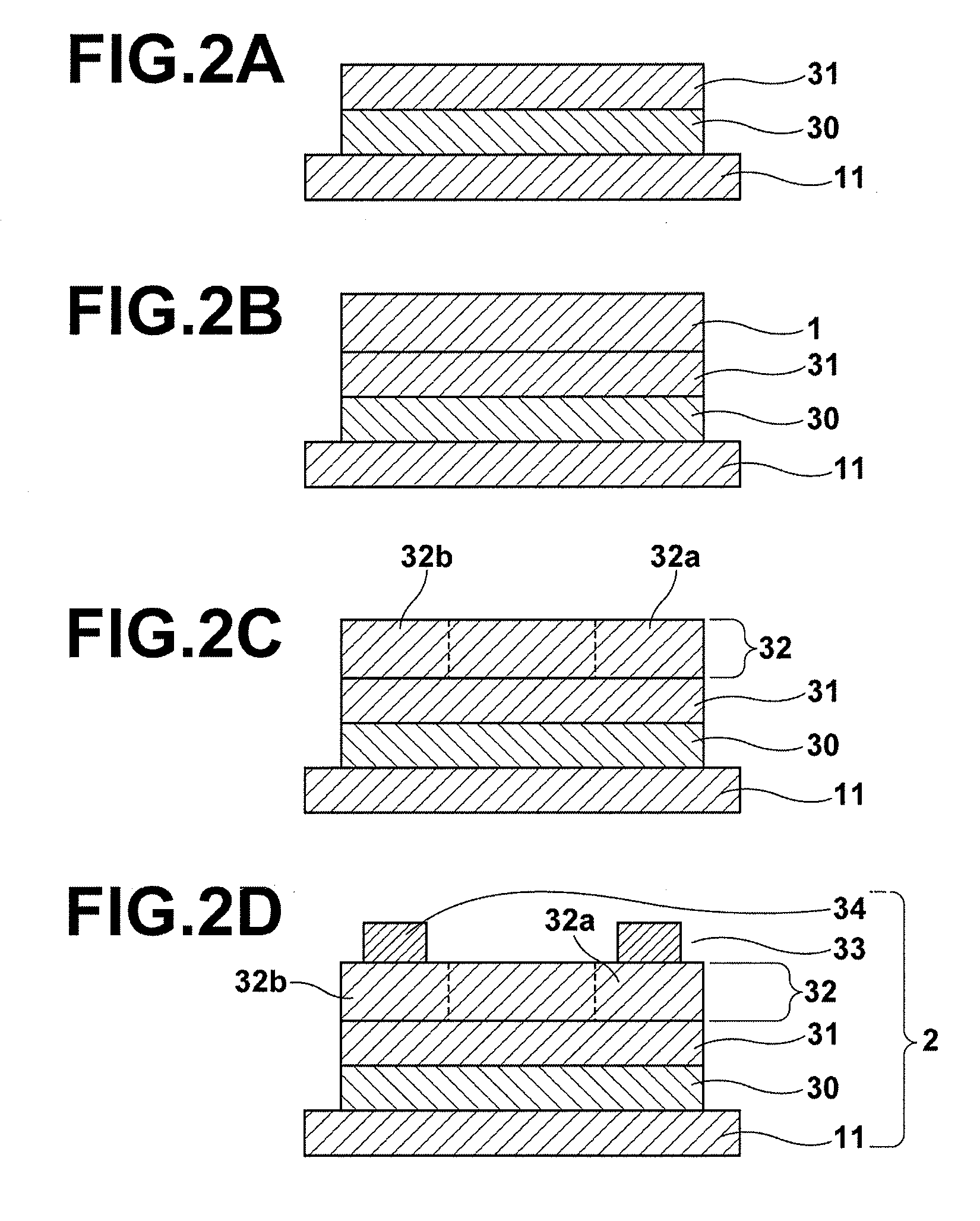

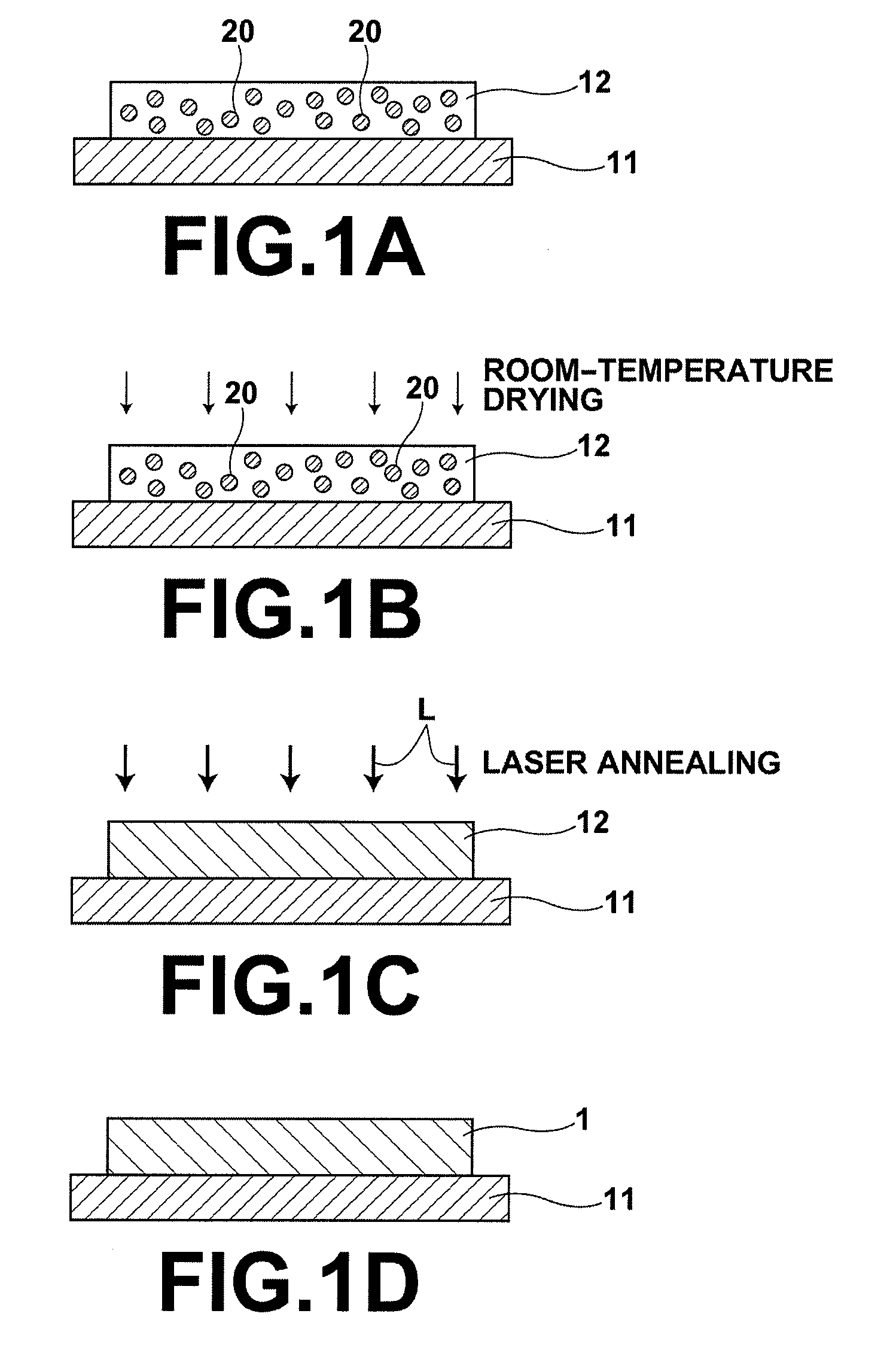

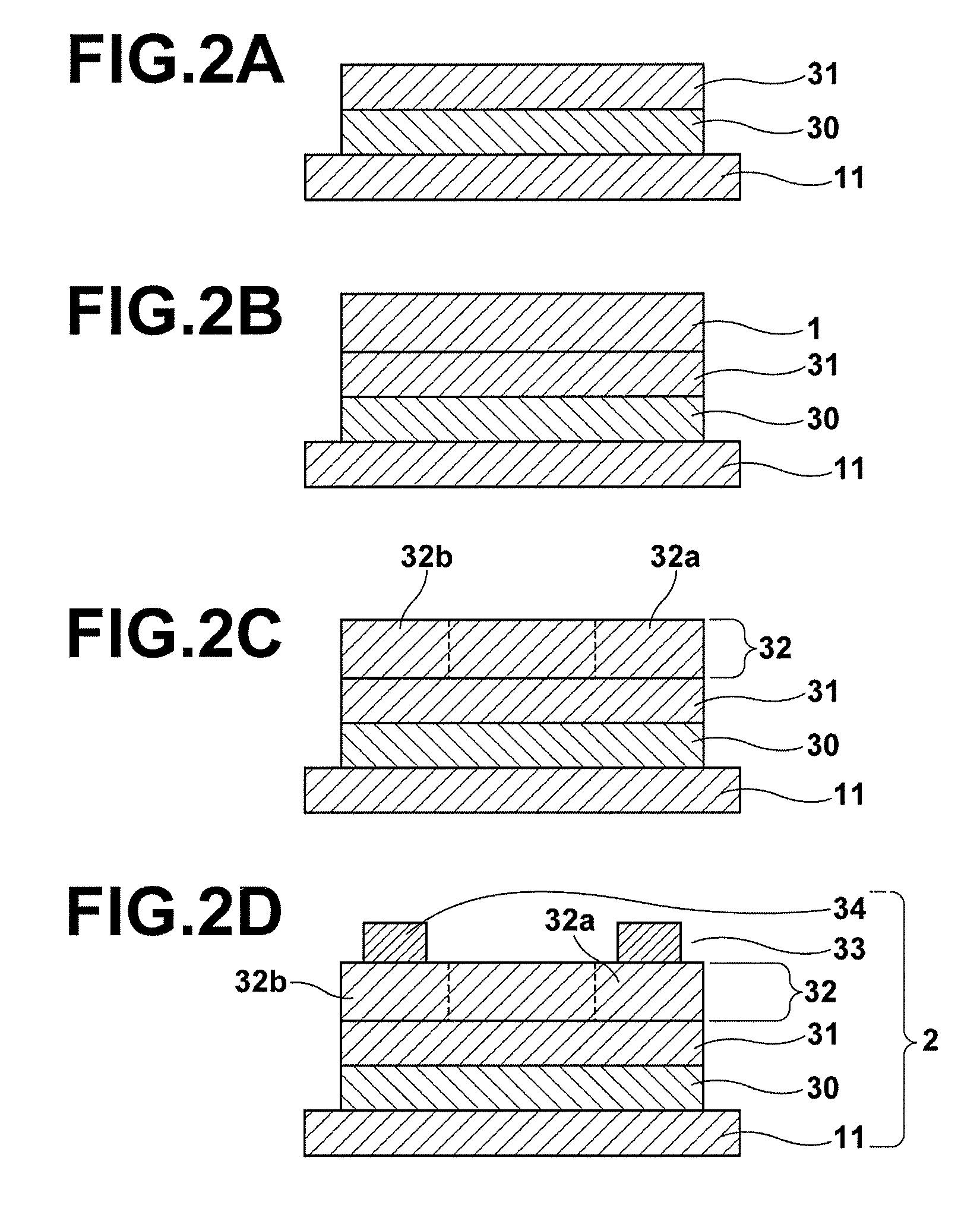

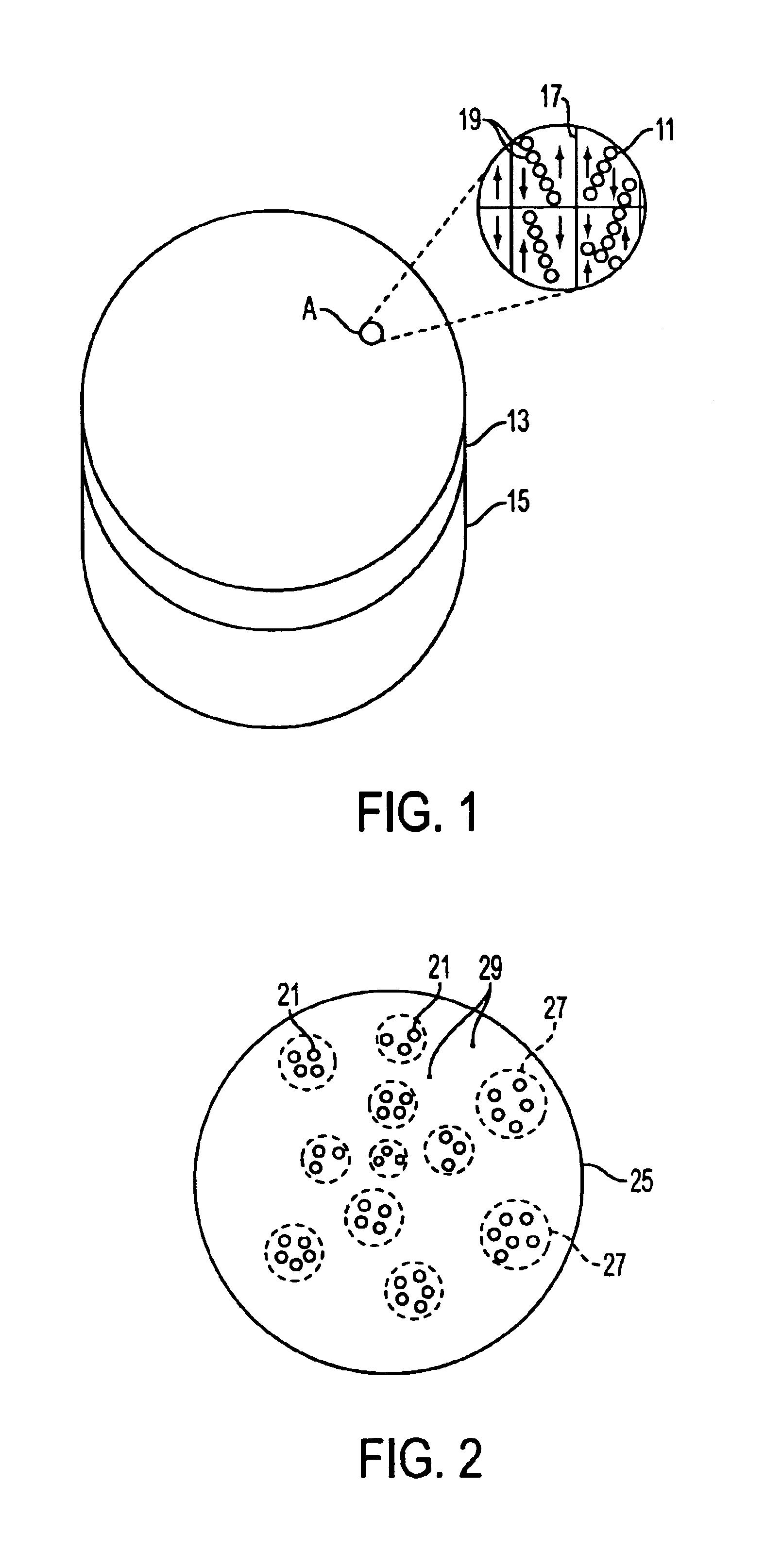

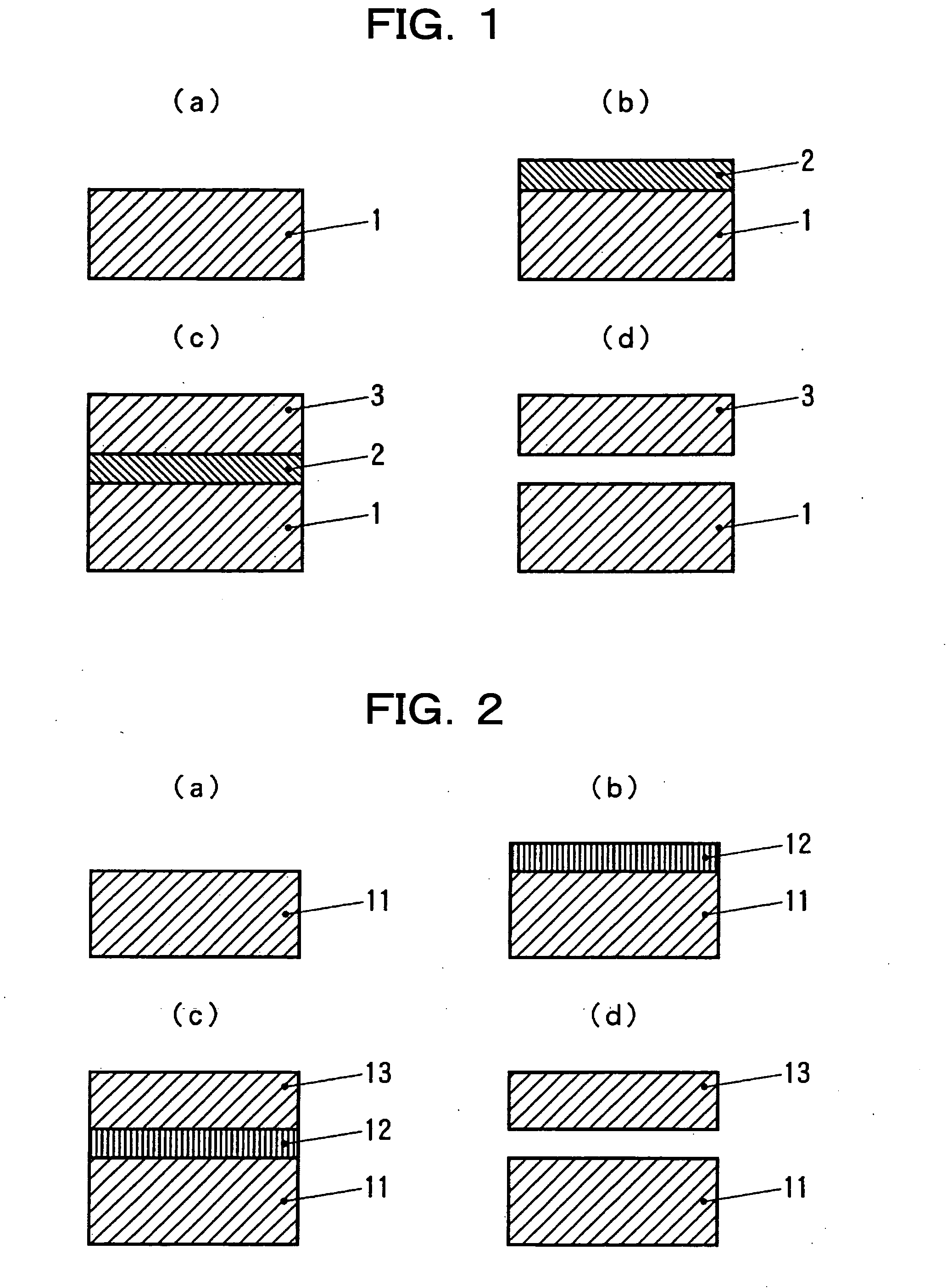

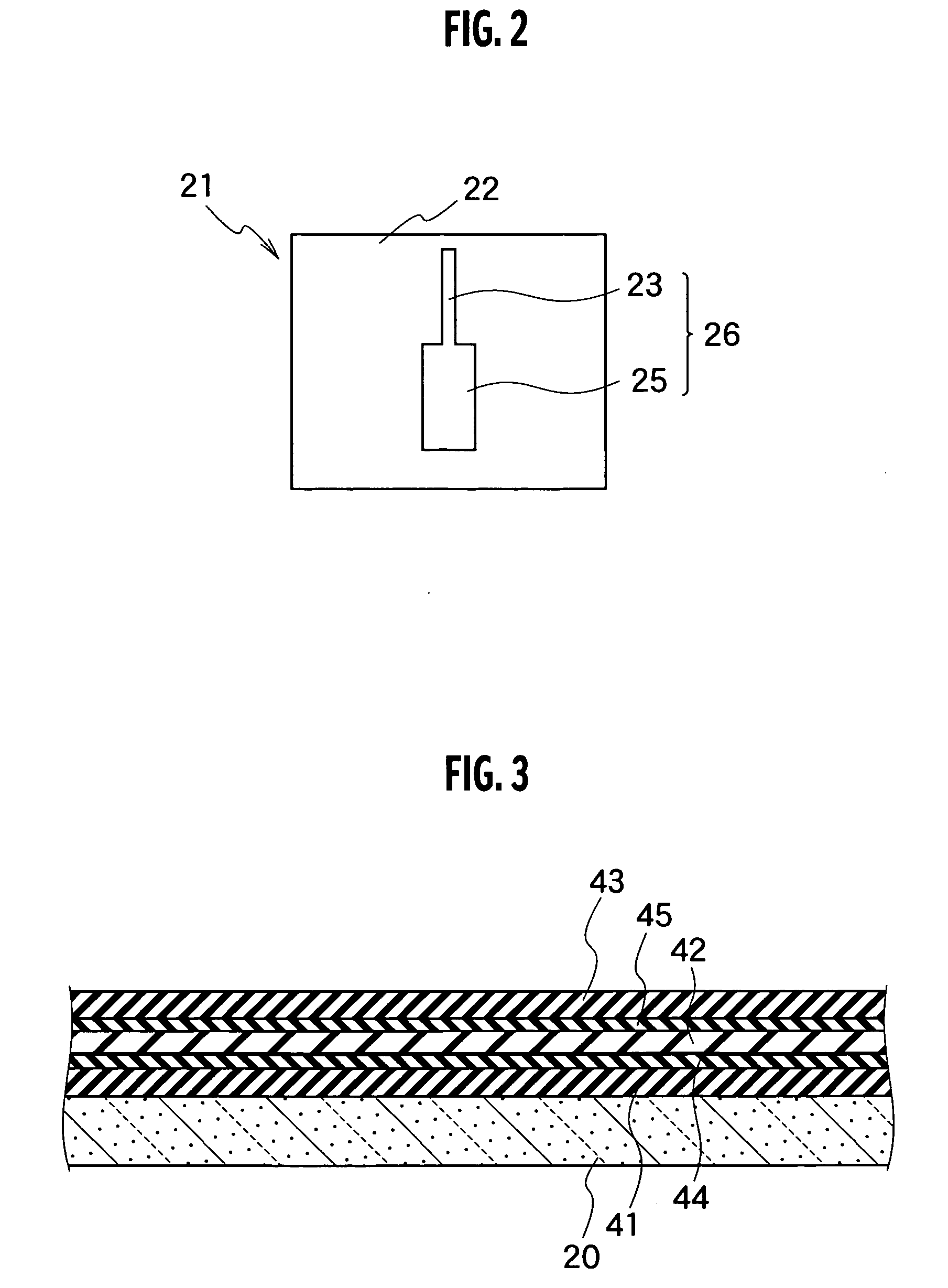

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS8202365B2Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventCrystal structure

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

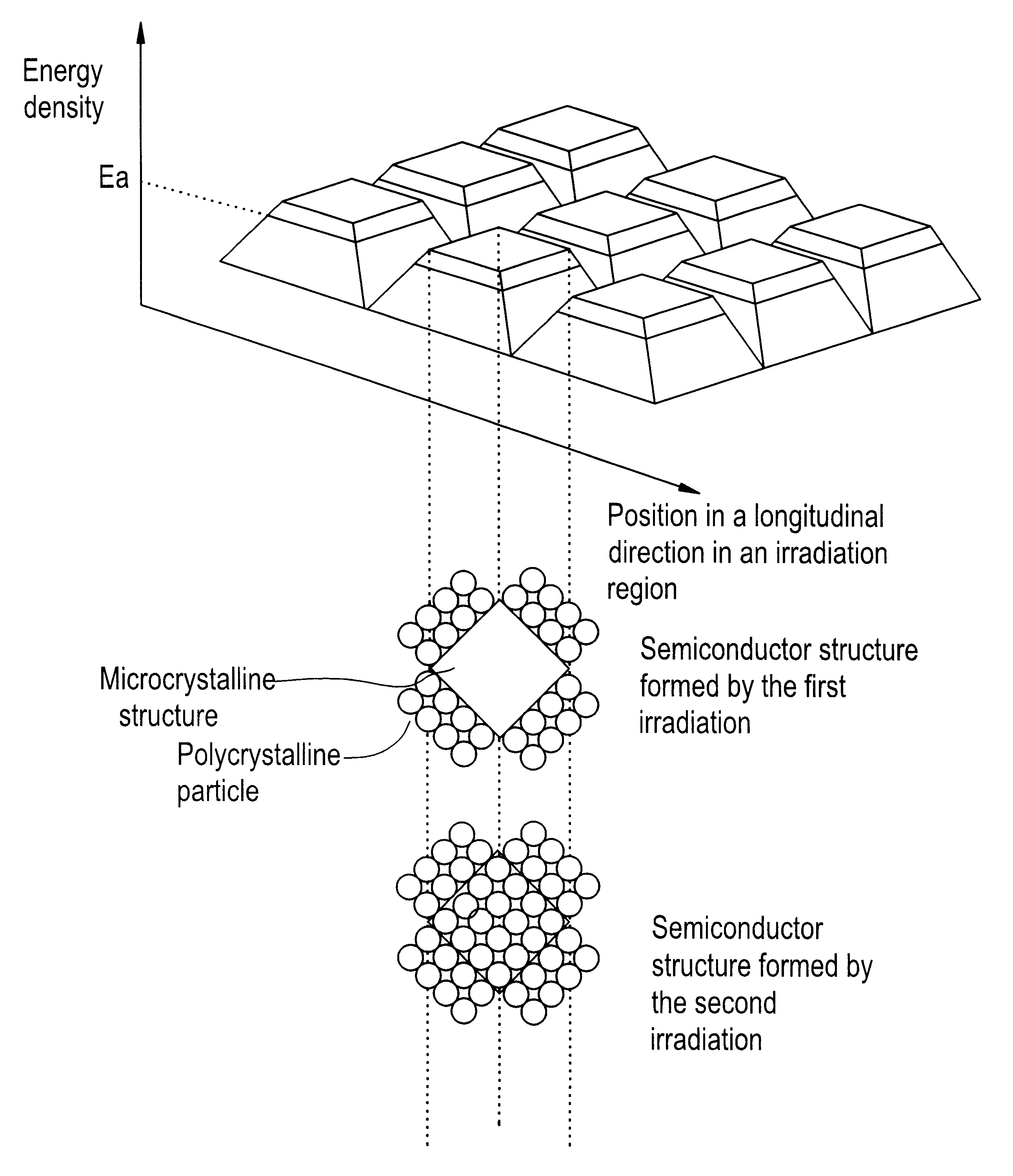

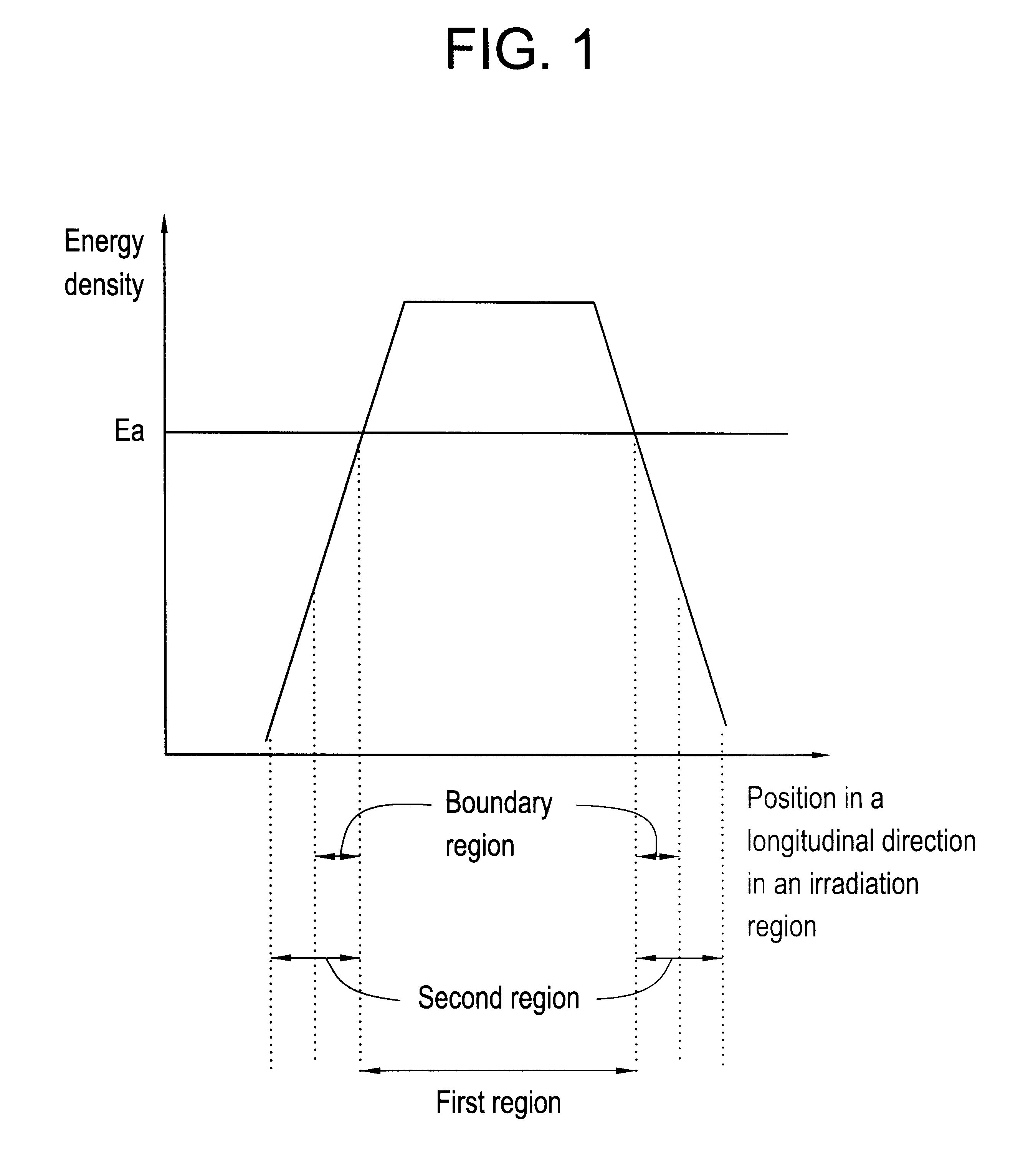

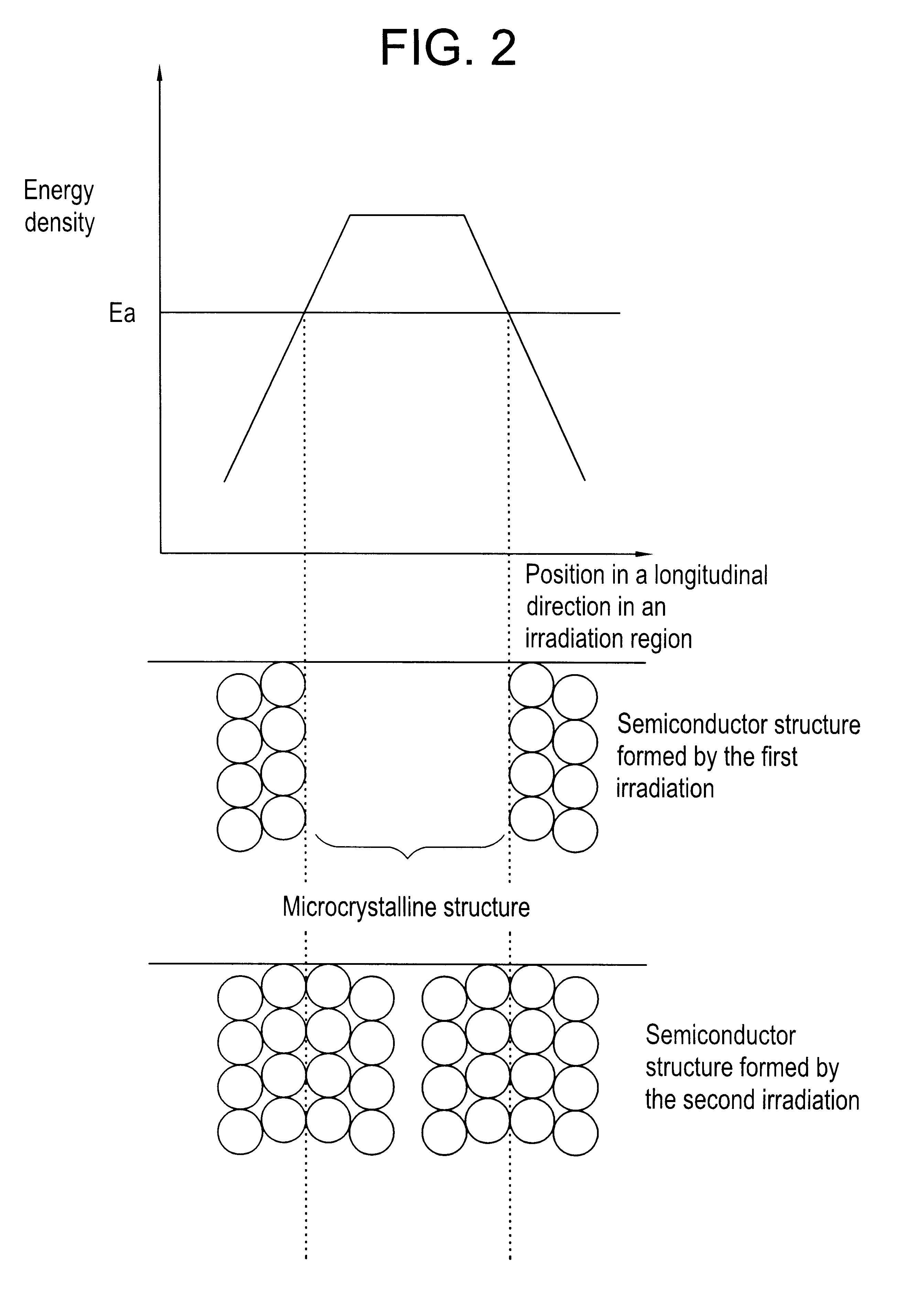

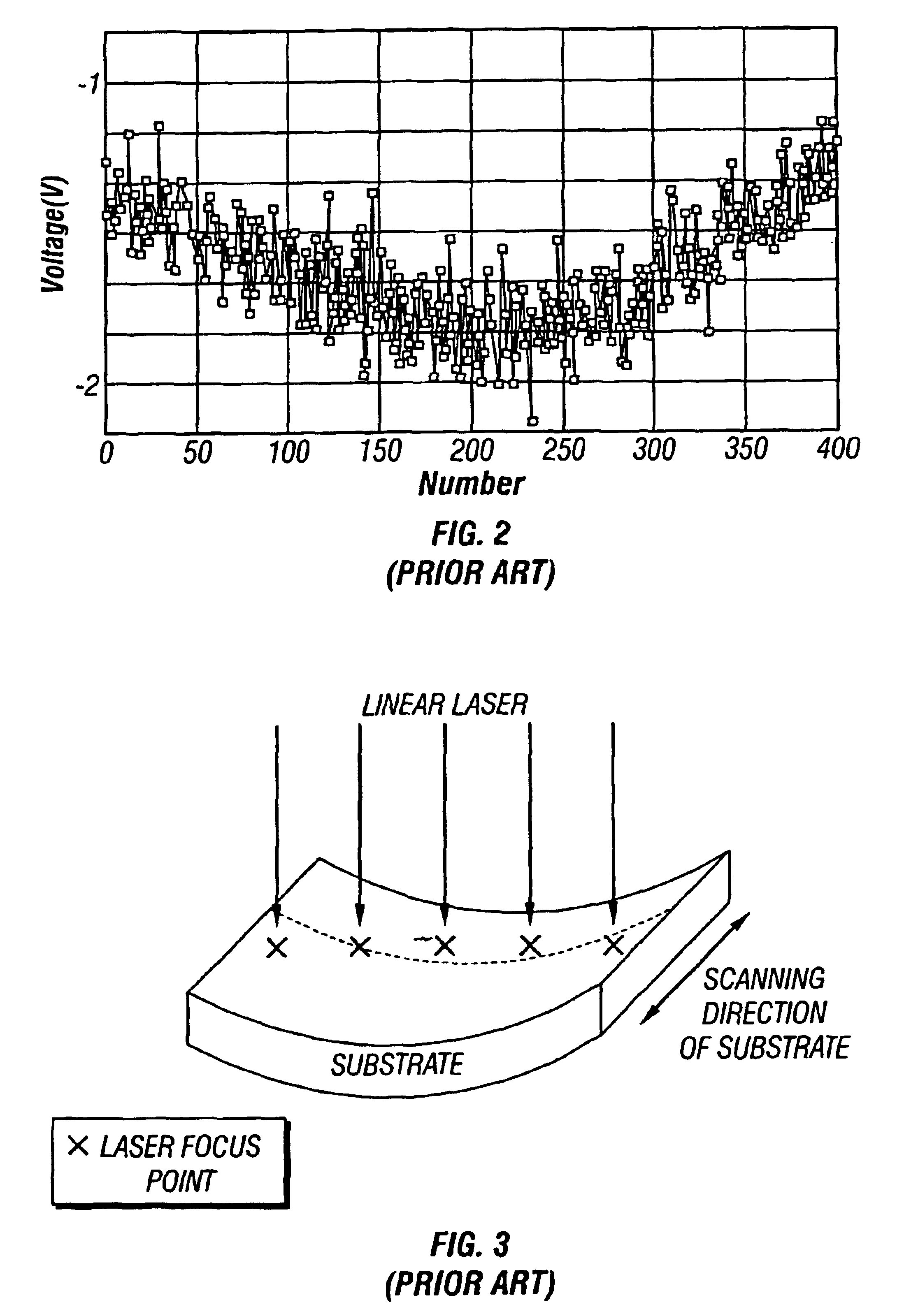

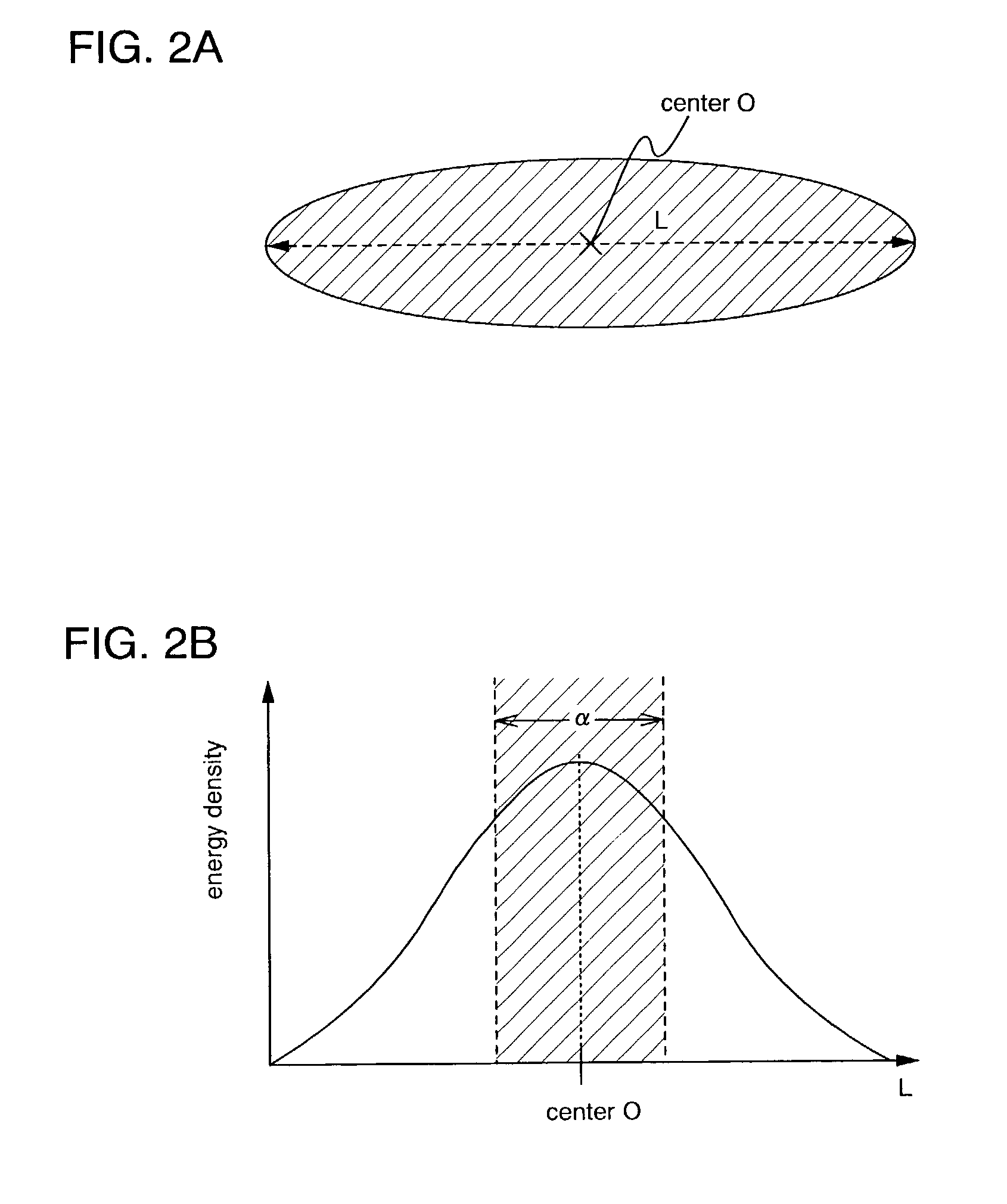

Laser irradiation process

A pulse laser beam having a rectangular irradiation region is irradiated on the same point in a non-single crystal semiconductor film multiple times. The pulse laser beam has an energy profile in a longitudinal direction in the beam irradiation region as follows: (a) there are the first region having an energy density of Ea or higher and the second regions on both sides of the first region having an energy density of less than Ea, and (b) an energy density slope has an absolute value of 20 to 300 J / cm3 in a boundary region extending to 1 mum from the boundary line between the first and the second regions.

Owner:GOLD CHARM LTD

Single crystalline graphene sheet and process of preparing the same

A single-crystal graphene sheet includes a polycyclic aromatic molecule wherein a plurality of carbon atoms are covalently bound to each other, the single-crystal graphene sheet comprising between about 1 layer to about 300 layers; and wherein a peak ratio of a Raman D band intensity to a Raman G band intensity is equal to or less than 0.2. Also described is a method for preparing a single-crystal graphene sheet, the method includes forming a catalyst layer, which includes a single-crystal graphitizing metal catalyst sheet; disposing a carbonaceous material on the catalyst layer; and heat-treating the catalyst layer and the carbonaceous material in at least one of an inert atmosphere and a reducing atmosphere. Also described is a transparent electrode including a single-crystal graphene sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

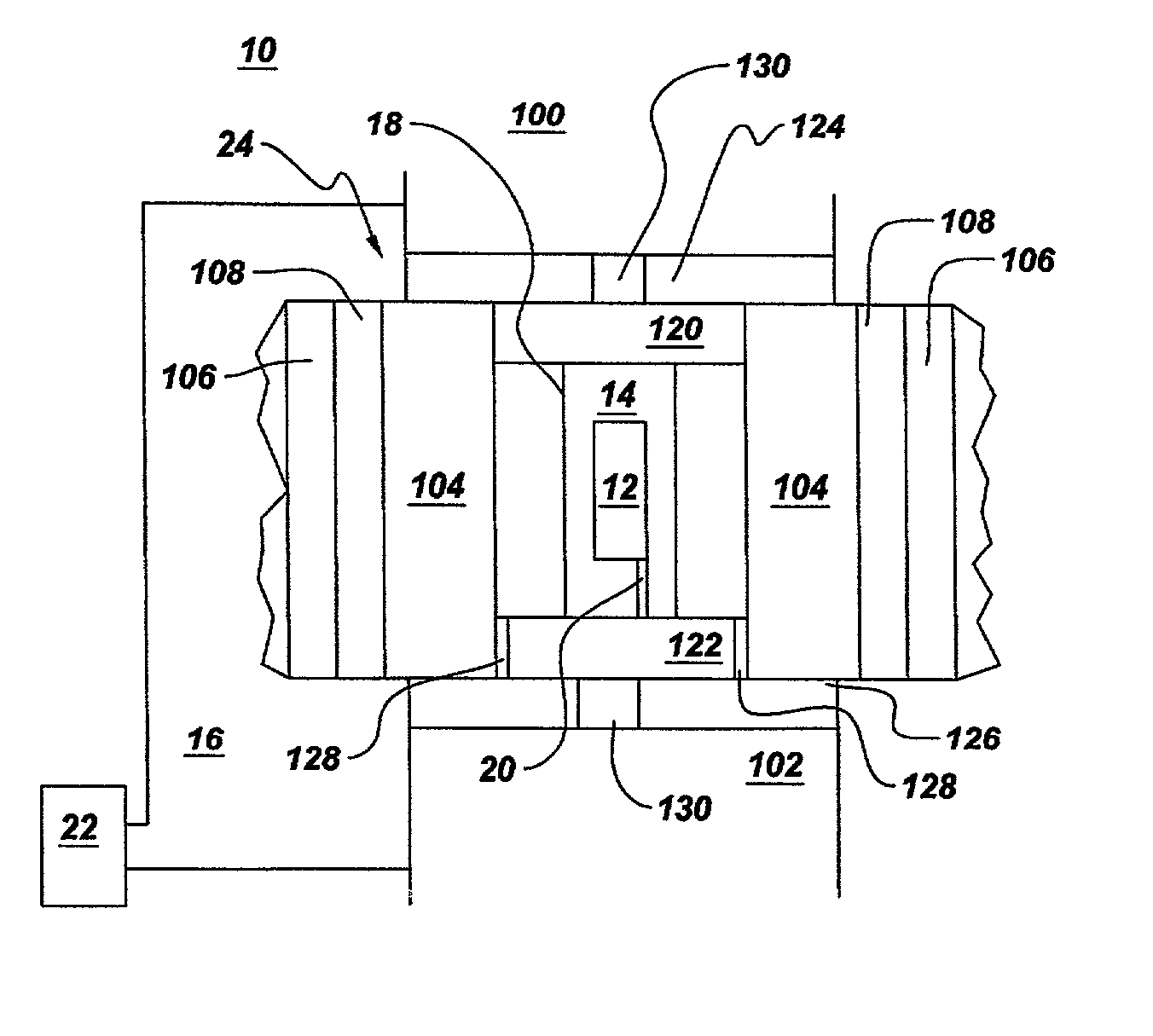

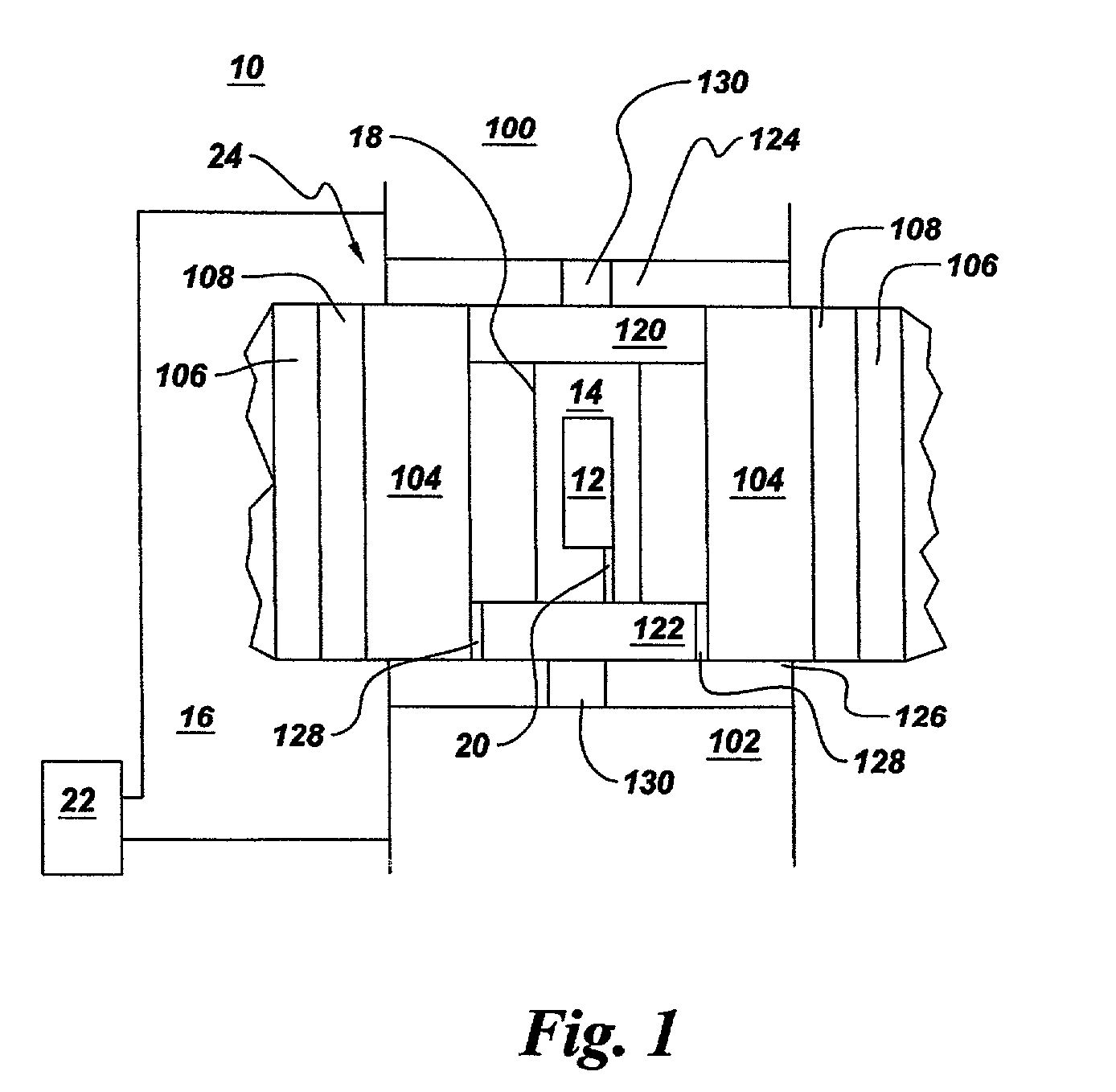

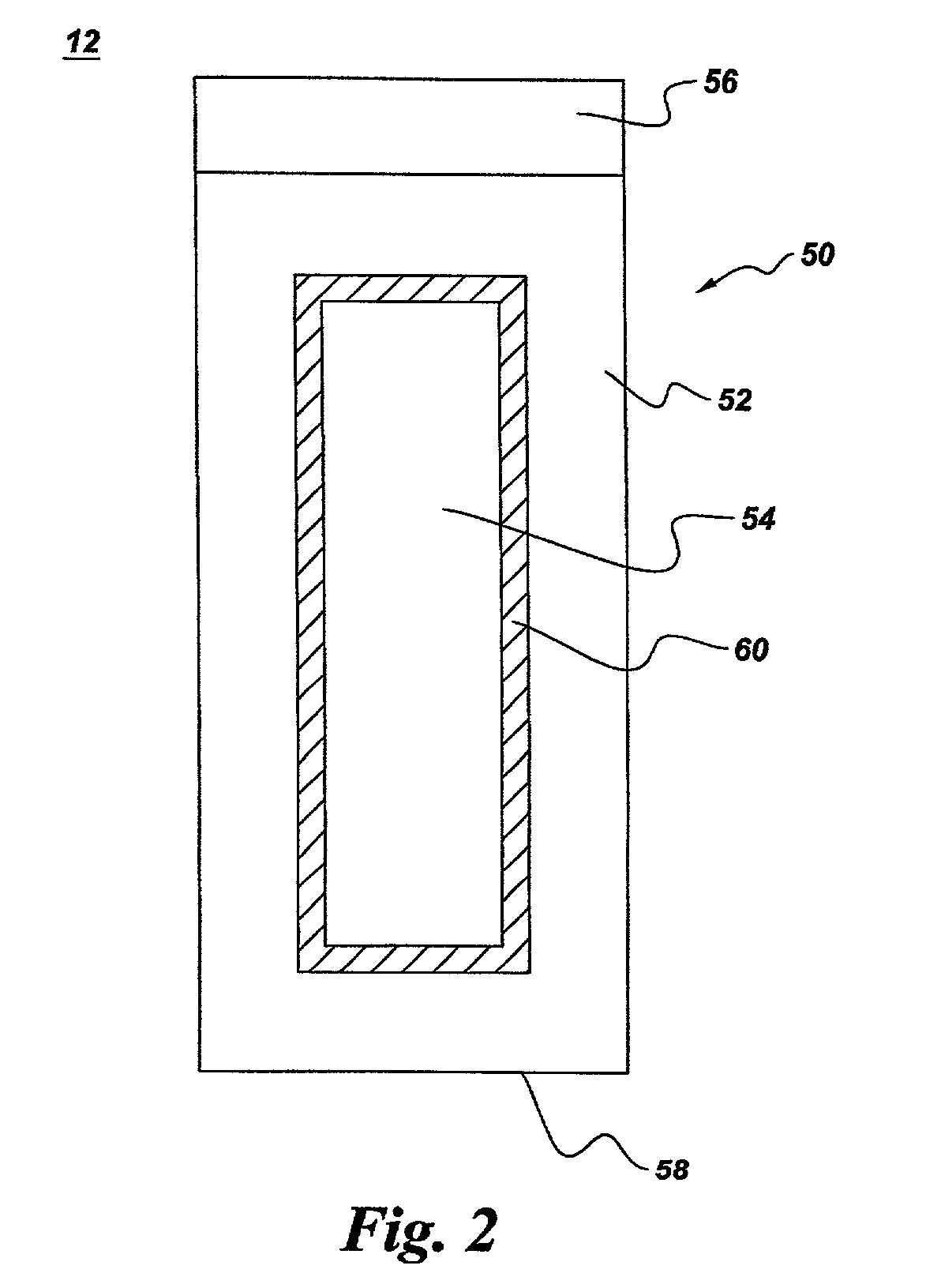

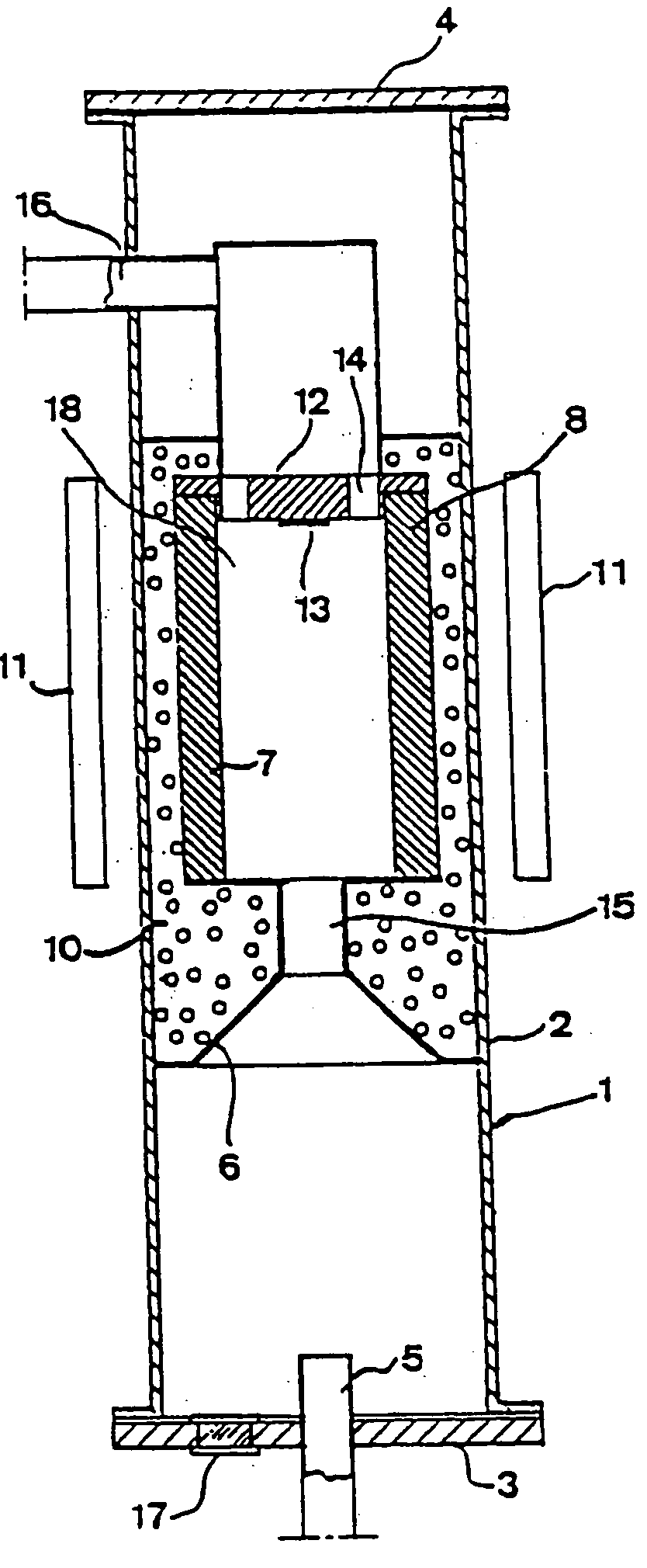

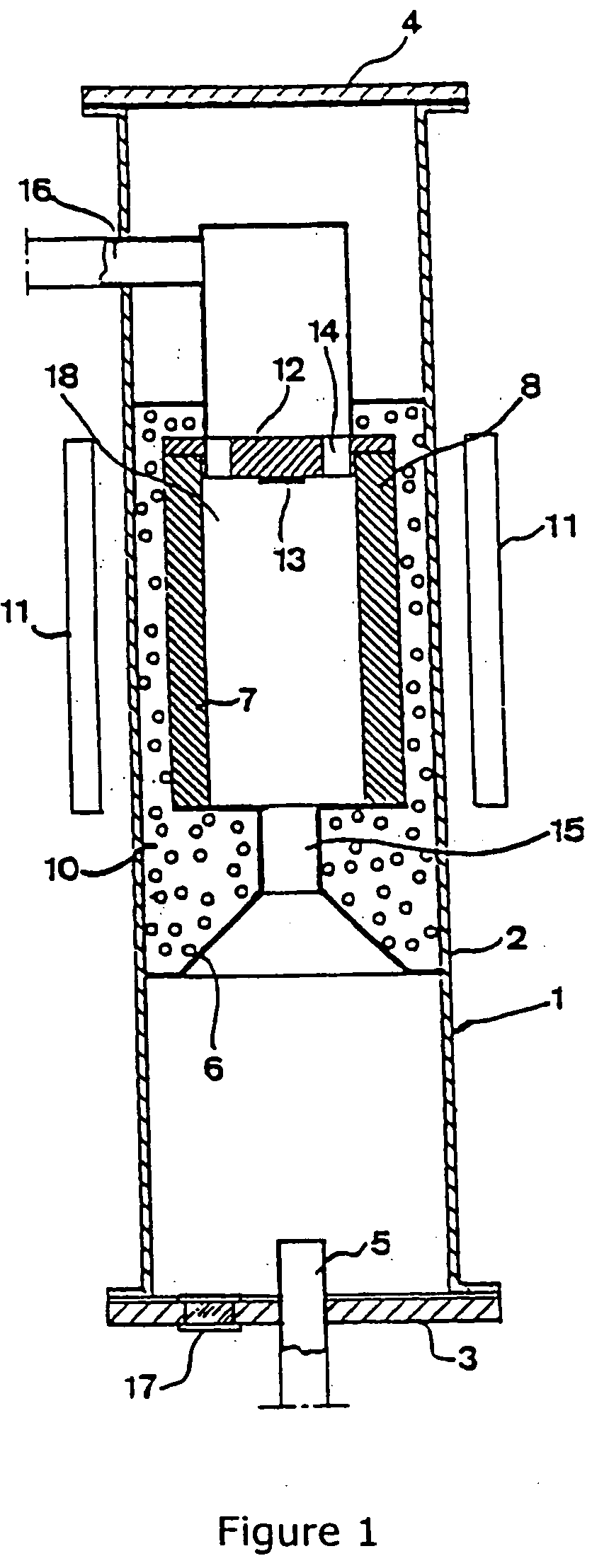

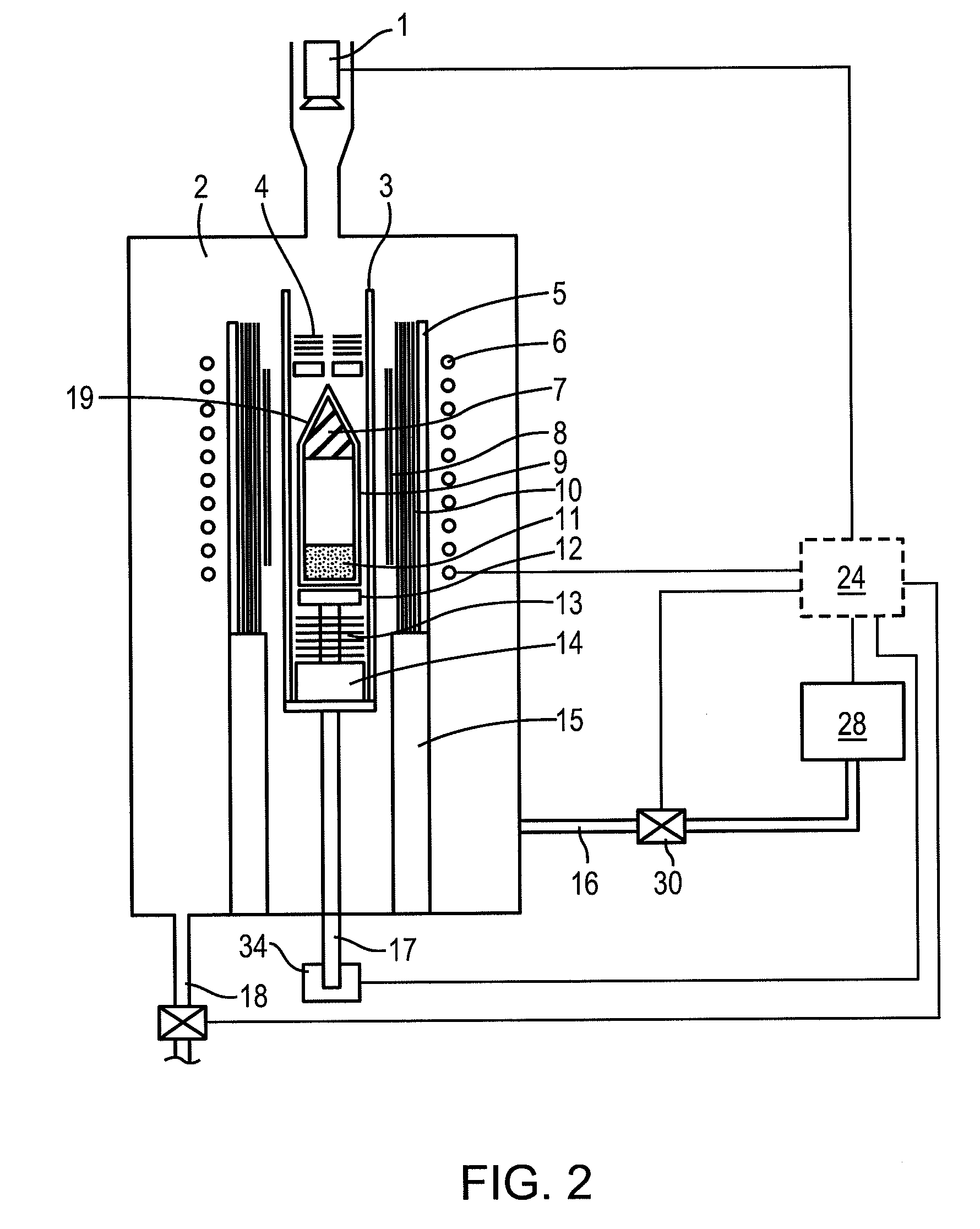

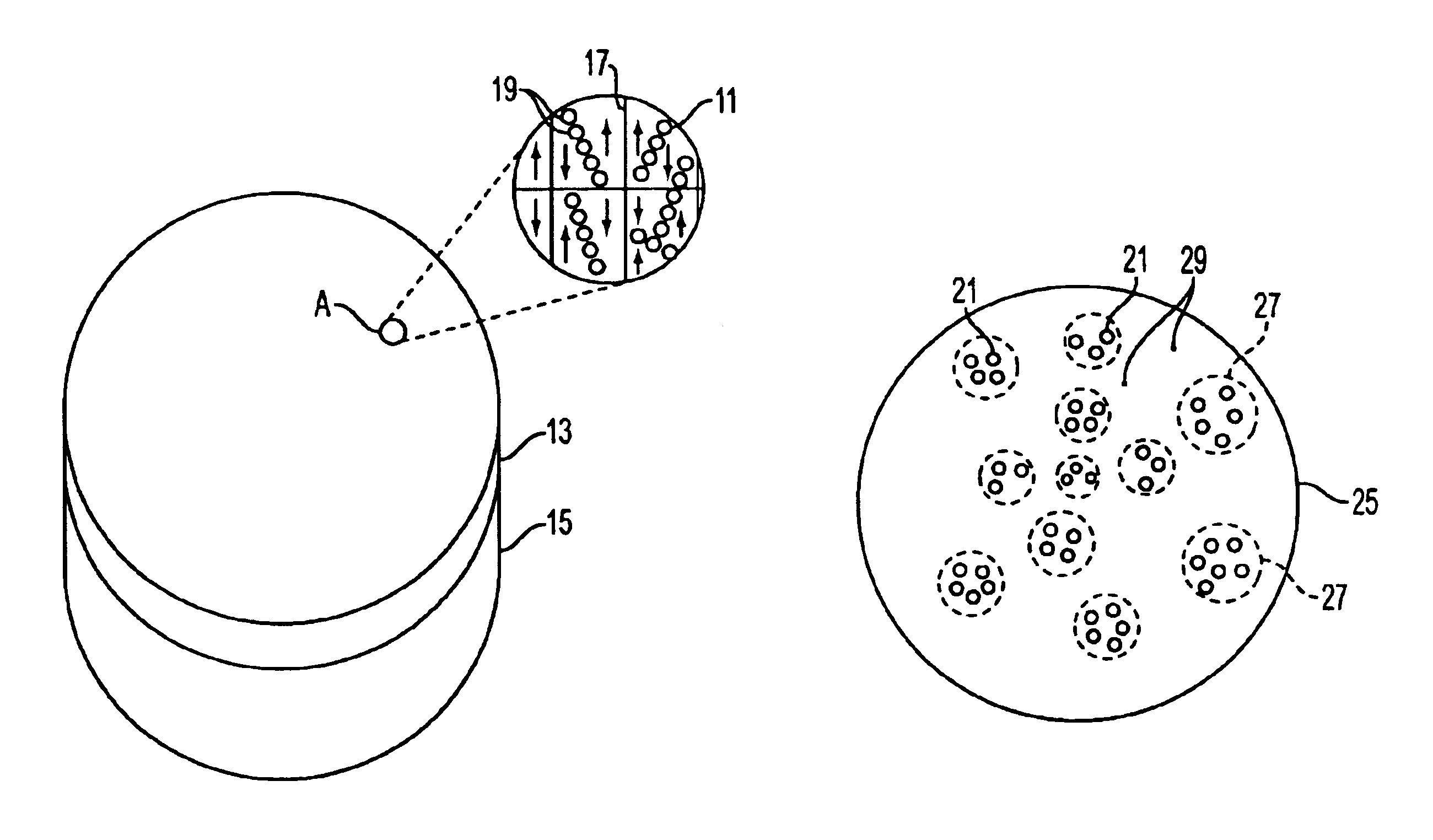

Pressure vessel

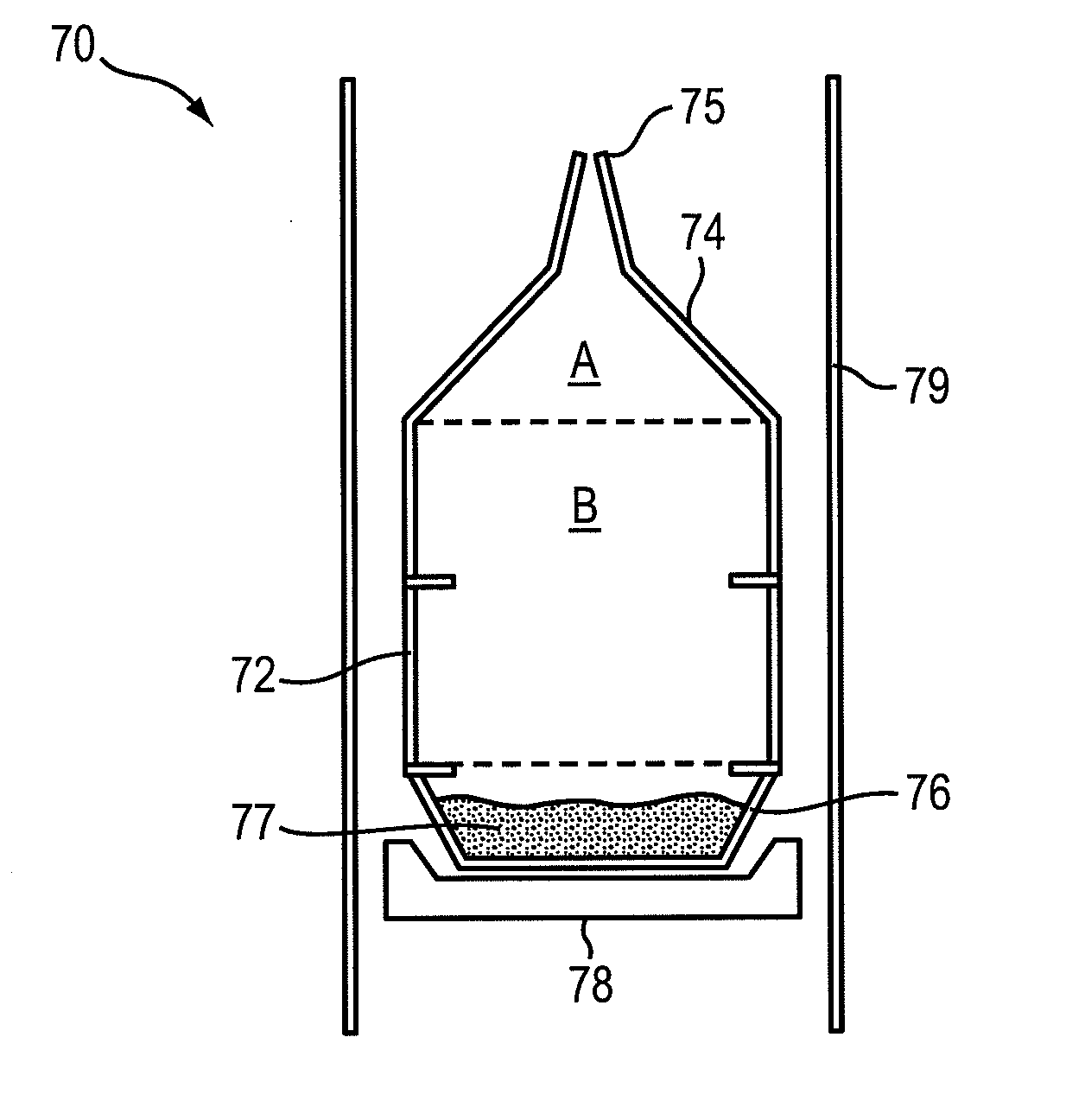

InactiveUS20030140845A1Prevent escapeAvoid creatingFrom gel statePolycrystalline material growthTemperature controlPressure transmission

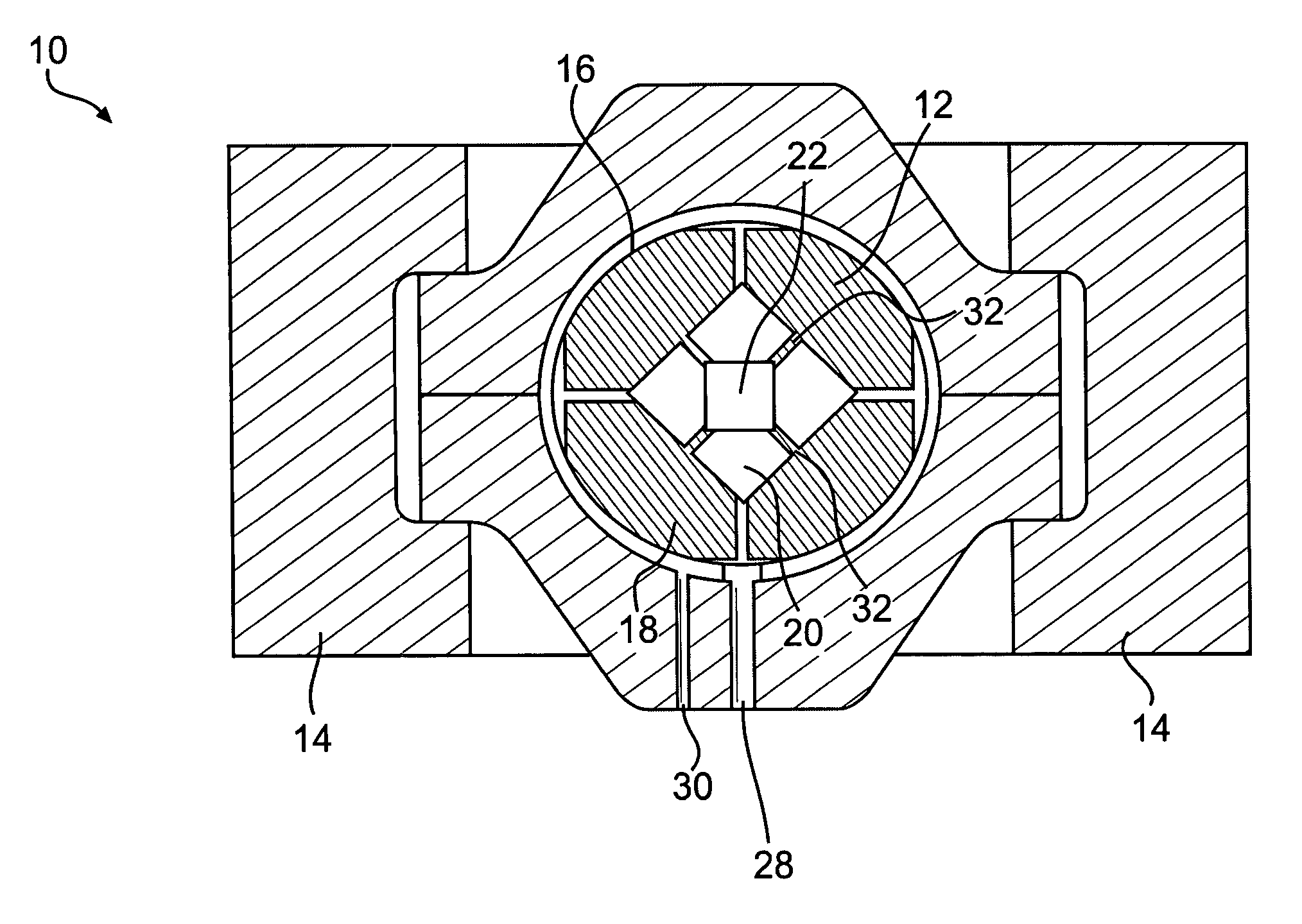

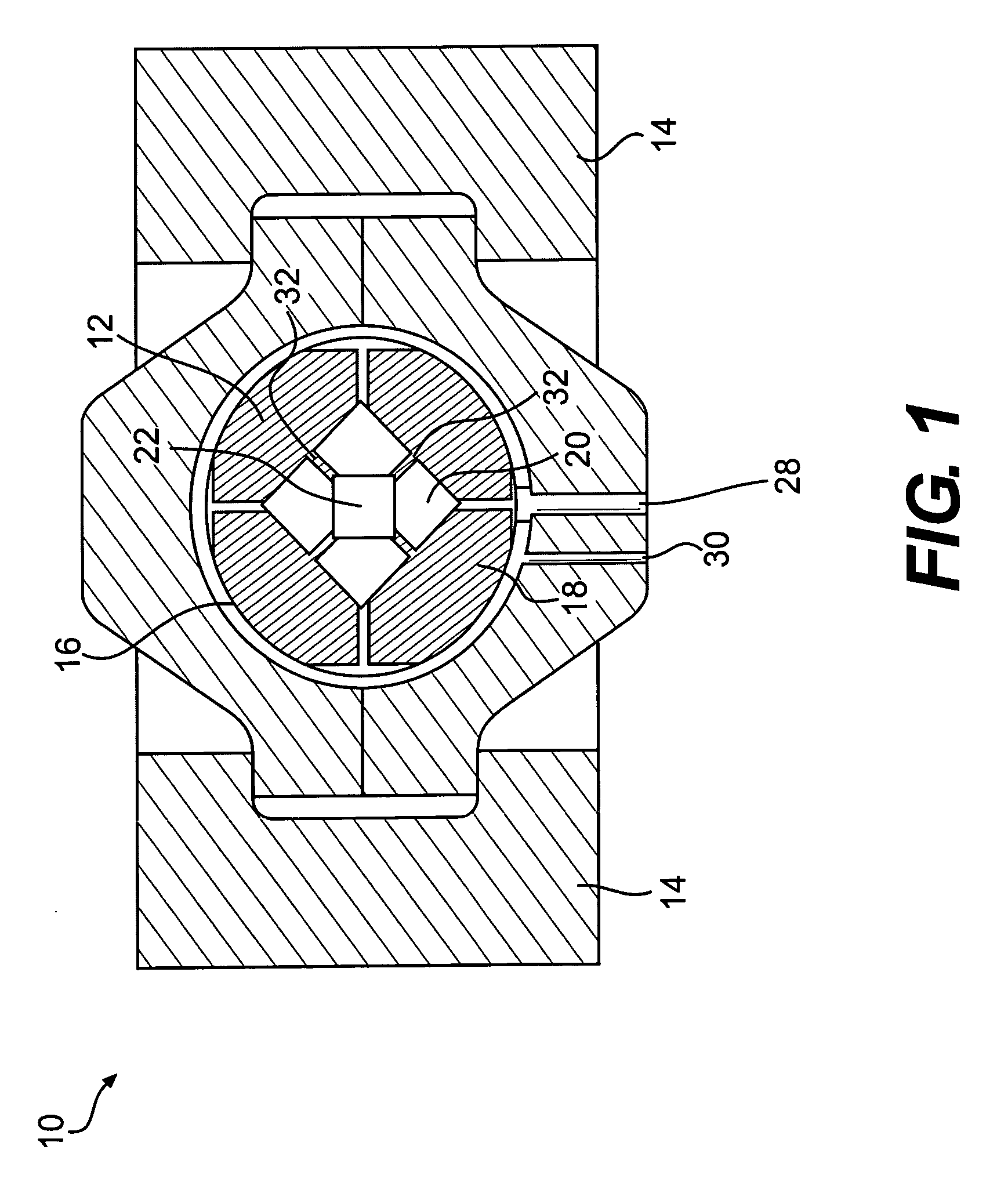

A pressure vessel for processing at least one material in a supercritical fluid. The pressure vessel includes a self-pressurizing capsule for containing at least one material and the supercritical fluid in a substantially air-free environment, a pressure transmission medium surrounding the capsule for maintaining an outer pressure on the capsule, at least one heating element insertable in the pressure transmission medium such that the heating element surrounds the capsule, a temperature measurement means for measuring a temperature of the capsule, a temperature controller for controlling the temperature and providing power to the heating element, a restraint to contain and hold in place the capsule, the pressure transmission medium, and the heating element, and at least one seal between the restraint and the pressure transmission medium for preventing escape of the pressure transmission medium. Methods of using the pressure vessel, processing a material at high temperature and high pressure in the presence of a supercritical fluid within the capsule are also described.

Owner:SORAA

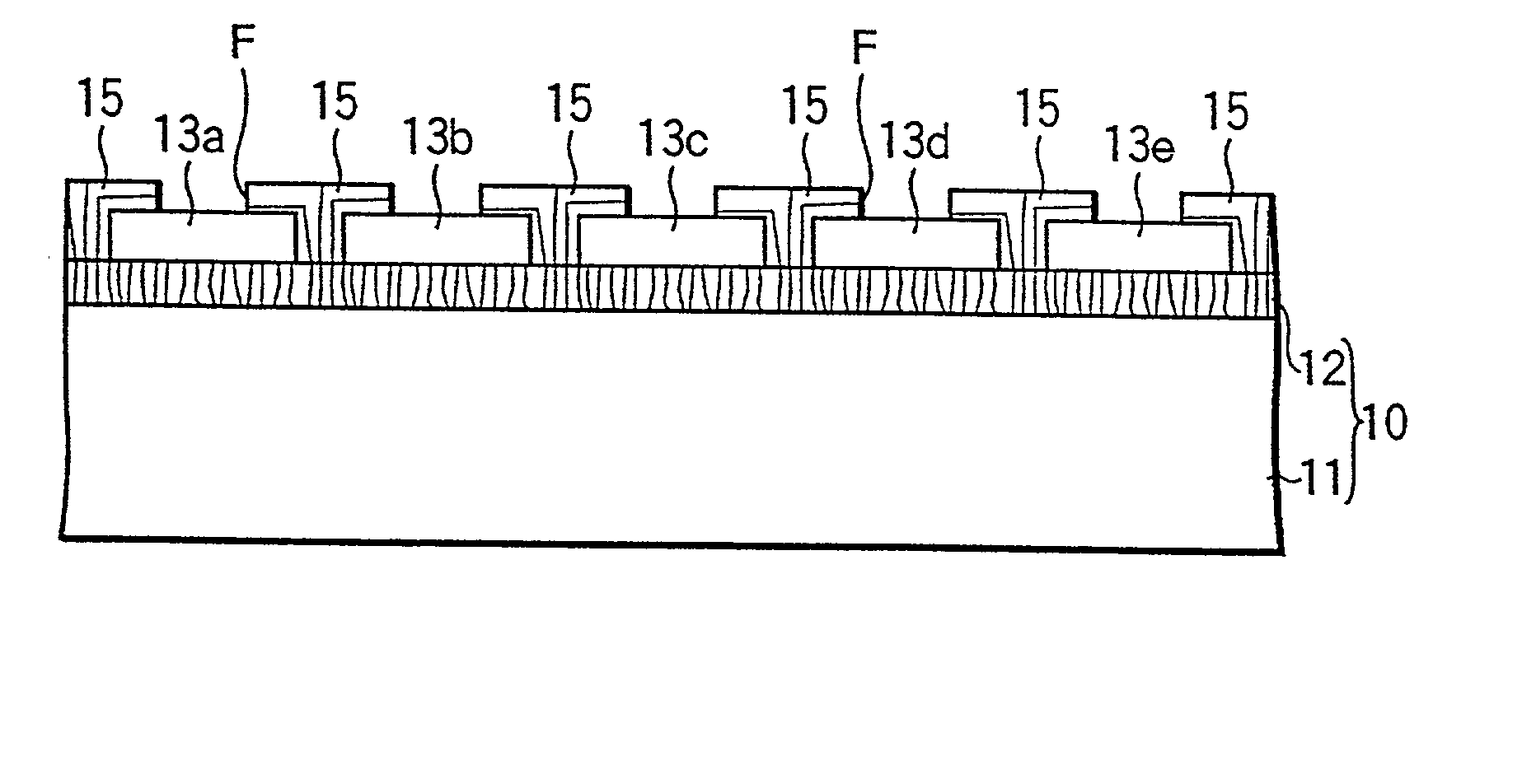

Nitride semiconductor growth method, nitride semiconductor substrate, and nitride semiconductor device

InactiveUS20020046693A1From gel statePolycrystalline material growthCrystallographic defectNitride semiconductors

A method of growing a nitride semiconductor crystal which has very few crystal defects and can be used as a substrate is disclosed. This invention includes the step of forming a first selective growth mask on a support member including a dissimilar substrate having a major surface and made of a material different from a nitride semiconductor, the first selective growth mask having a plurality of first windows for selectively exposing the upper surface of the support member, and the step of growing nitride semiconductor portions from the upper surface, of the support member, which is exposed from the windows, by using a gaseous Group 3 element source and a gaseous nitrogen source, until the nitride semiconductor portions grown in the adjacent windows combine with each other on the upper surface of the selective growth mask.

Owner:NICHIA CORP

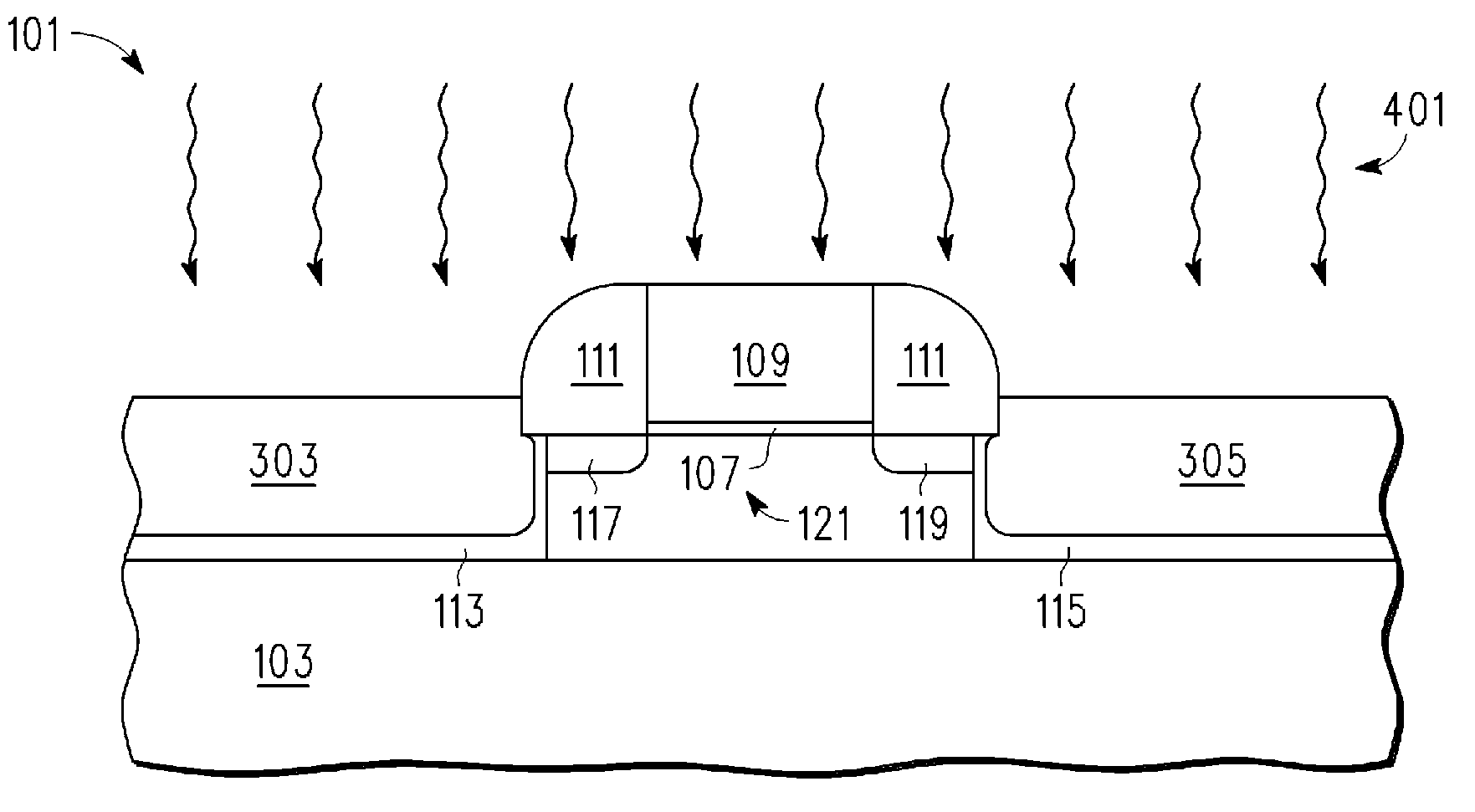

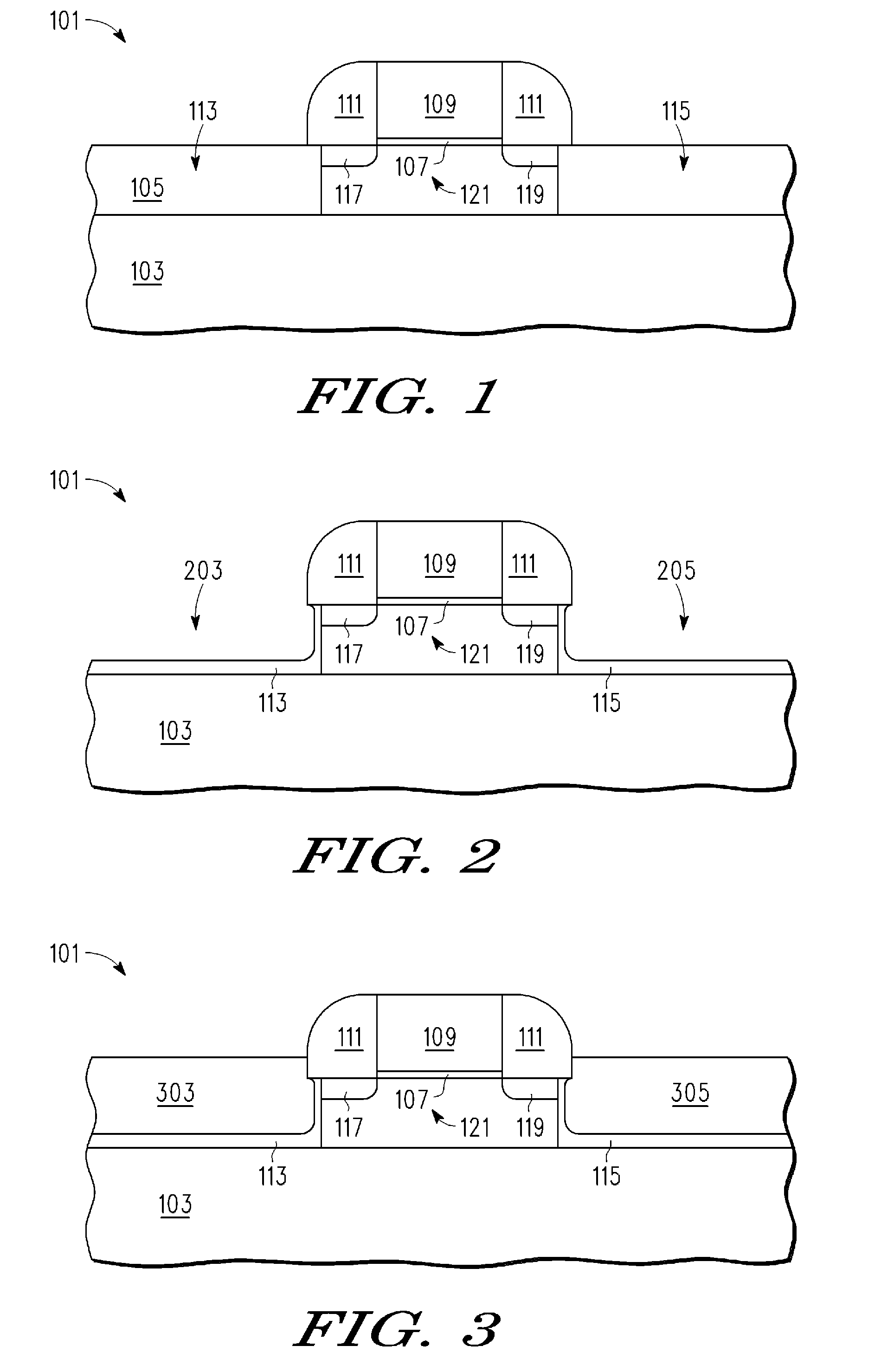

Anneal of epitaxial layer in a semiconductor device

InactiveUS7416605B2From gel statePolycrystalline material growthCharge carrier mobilityDegree Celsius

An anneal of an epitaxially grown crystalline semiconductor layer comprising a combination of group-IV elements. The layer contains at least one of the group of carbon and tin. The layer of epitaxially grown material is annealed at a temperature substantially in a range of 1,000 to 1,400 degrees Celsius for a period not to exceed 100 milliseconds within 10% of the peak temperature. The anneal is performed for example with a laser anneal or a flash lamp anneal. The limited-time anneal may improve carrier mobility of a transistor.

Owner:NORTH STAR INNOVATIONS

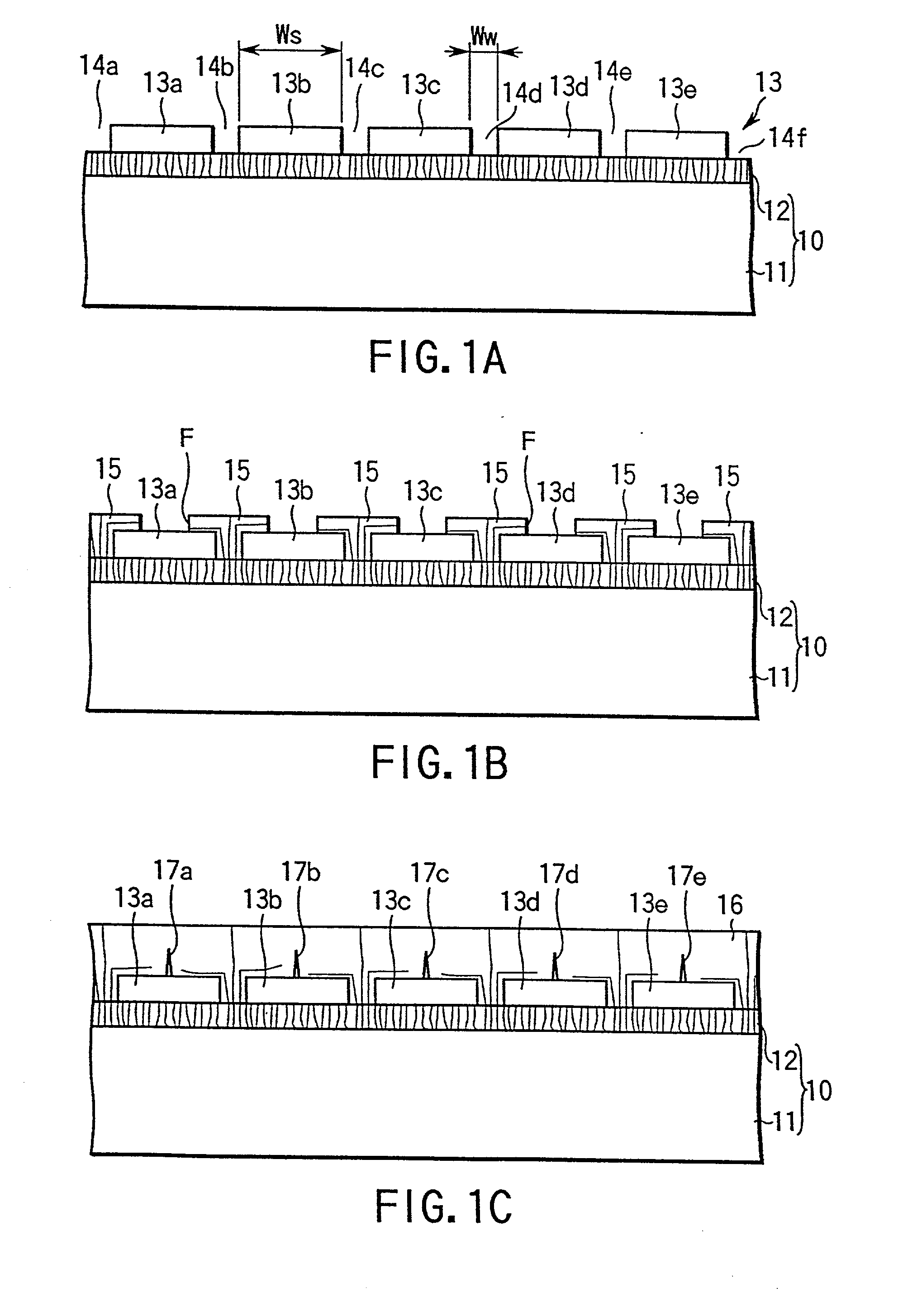

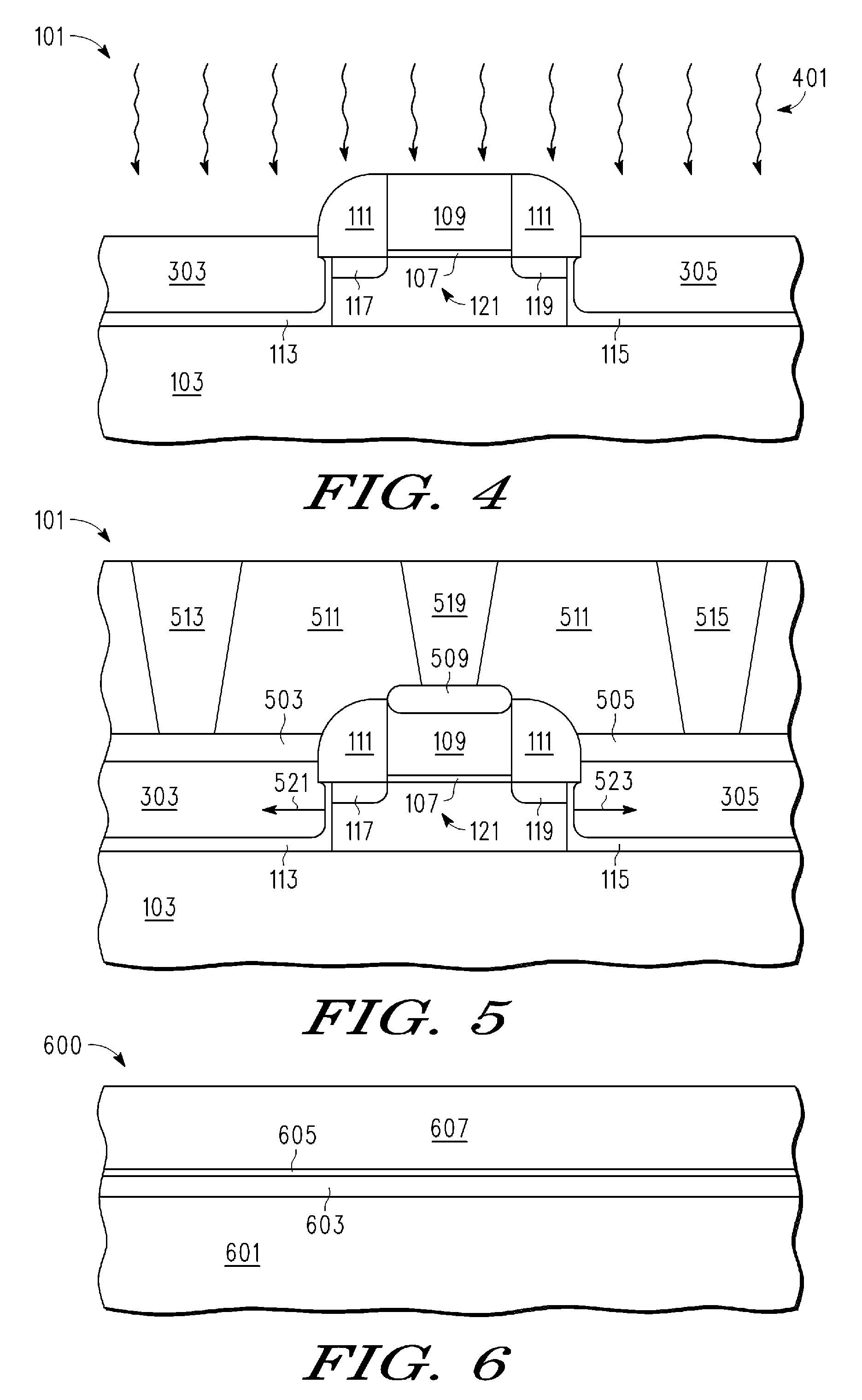

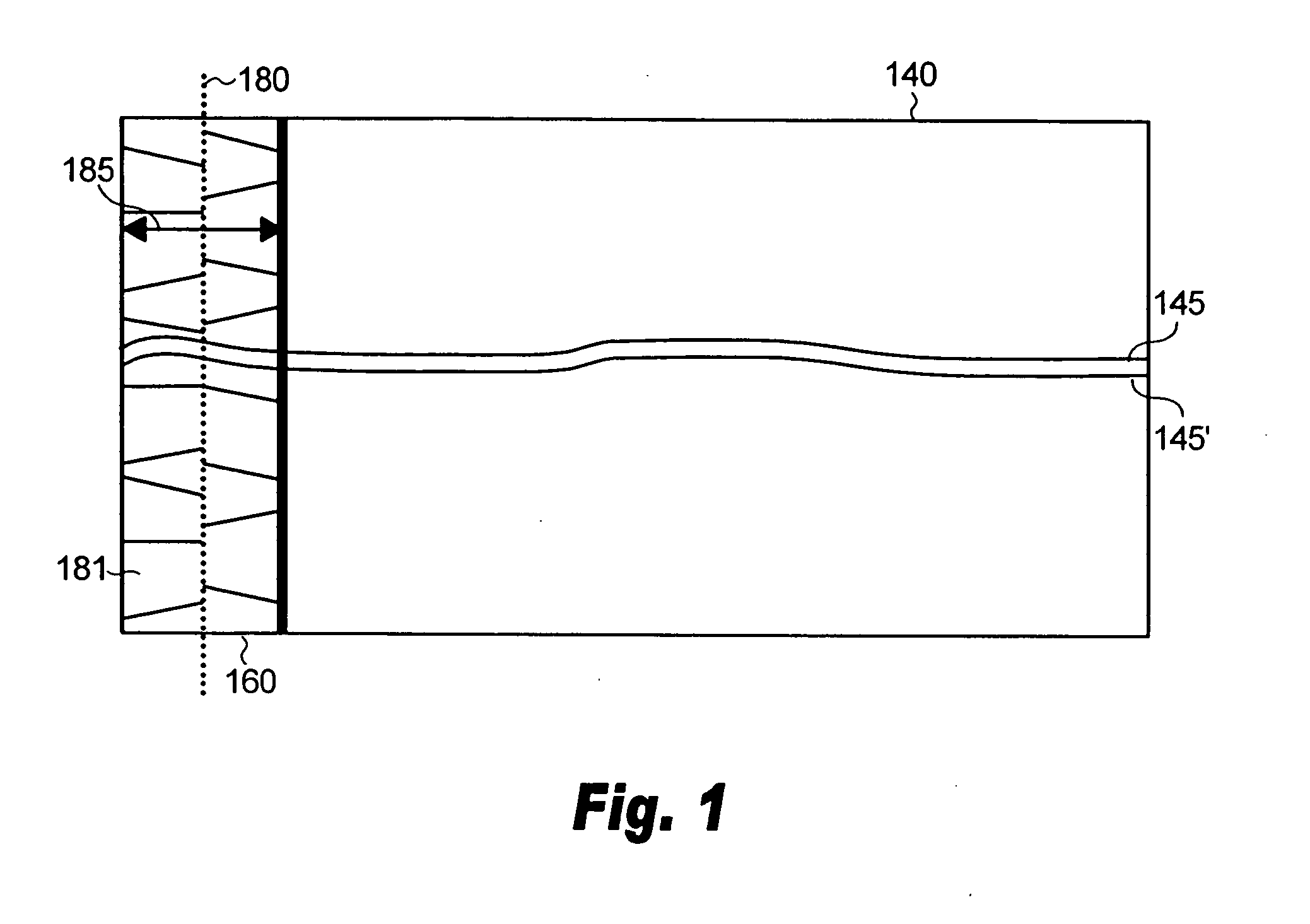

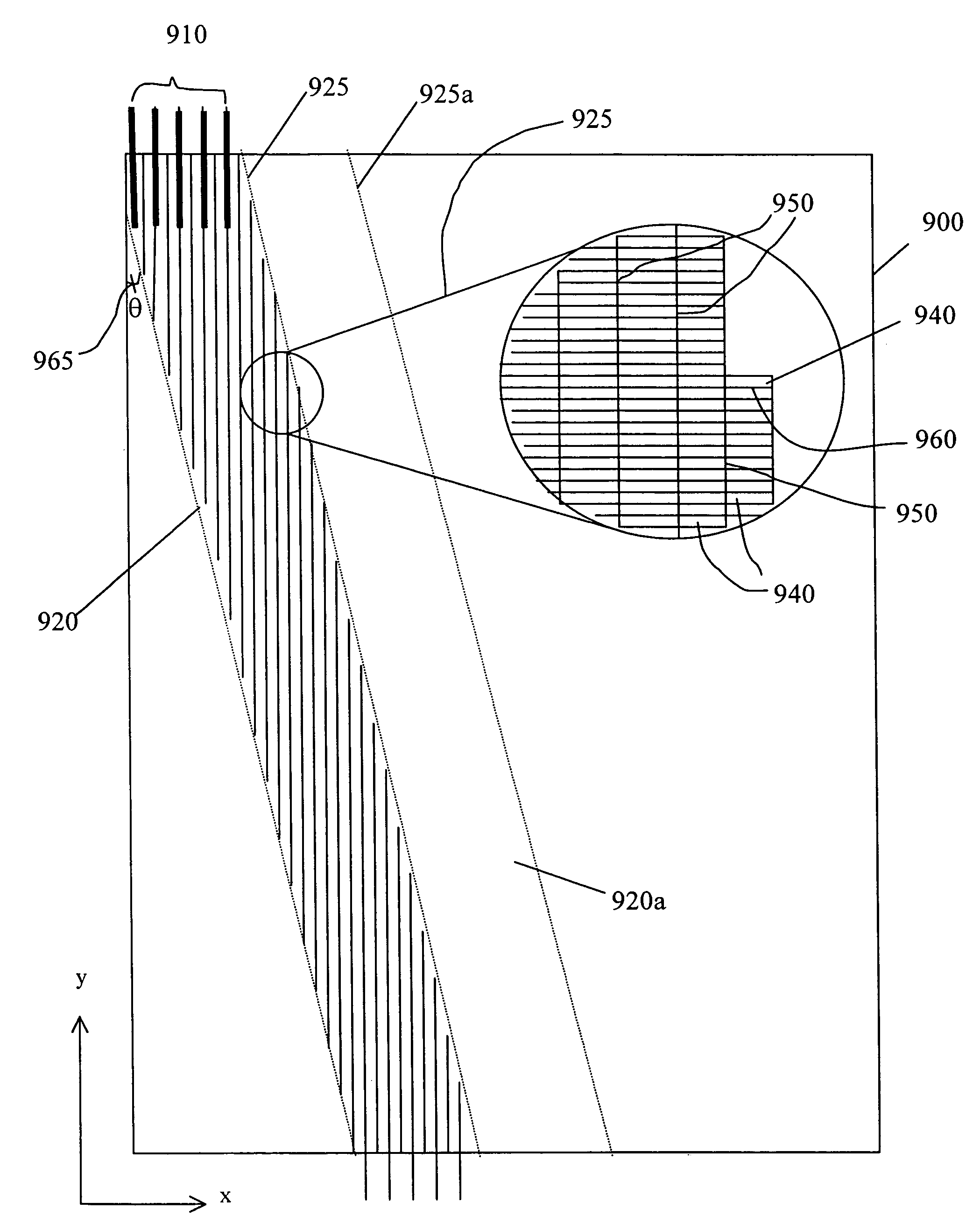

Line scan sequential lateral solidification of thin films

ActiveUS20060254500A1Improve uniformityReduce sharpnessFrom gel statePolycrystalline material growthOptoelectronicsNucleation

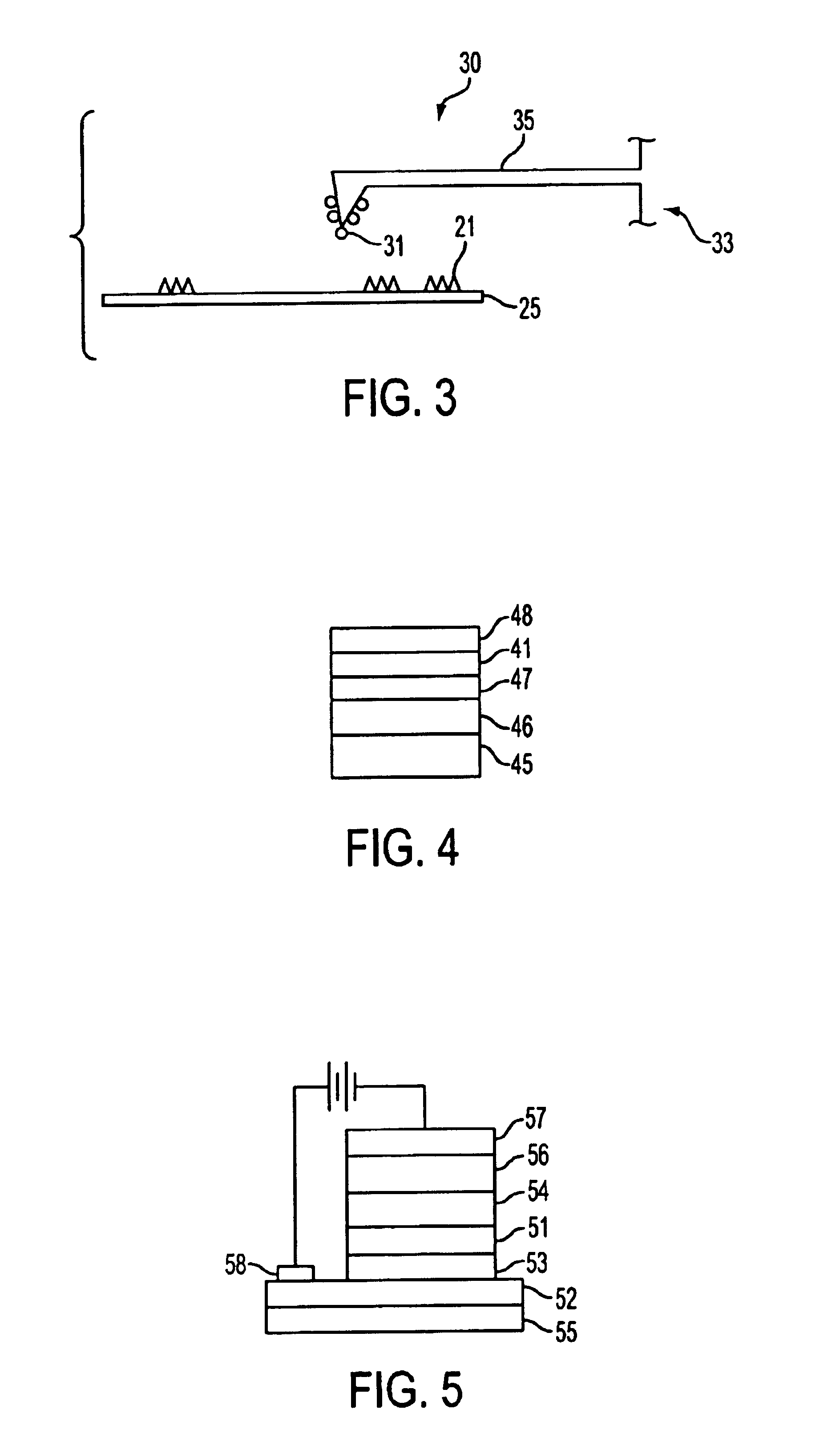

A polycrystalline film is prepared by (a) providing a substrate having a thin film disposed thereon, said film capable of laser-induced melting, (b) generating a sequence of laser pulses having a fluence that is sufficient to melt the film throughout its thickness in an irradiated region, each pulse forming a line beam having a predetermined length and width, said width sufficient to prevent nucleation of solids in a portion of the thin film that is irradiated by the laser pulse, (c) irradiating a first region of the film with a first laser pulse to form a first molten zone, said first molten zone demonstrating a variation in width along its length to thereby define a maximum width (Wmax) and a minimum width (Wmin), wherein the first molten zone crystallizes upon cooling to form one or more laterally grown crystals, (d) laterally moving the film in the direction of lateral growth a distance that is greater than about one-half Wmax and less than Wmin; and (e) irradiating a second region of the film with a second laser pulse to form a second molten zone having a shape that is substantially the same as the shape of the first molten zone, wherein the second molten zone crystallizes upon cooling to form one or more laterally grown crystals that are elongations of the one or more crystals in the first region.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

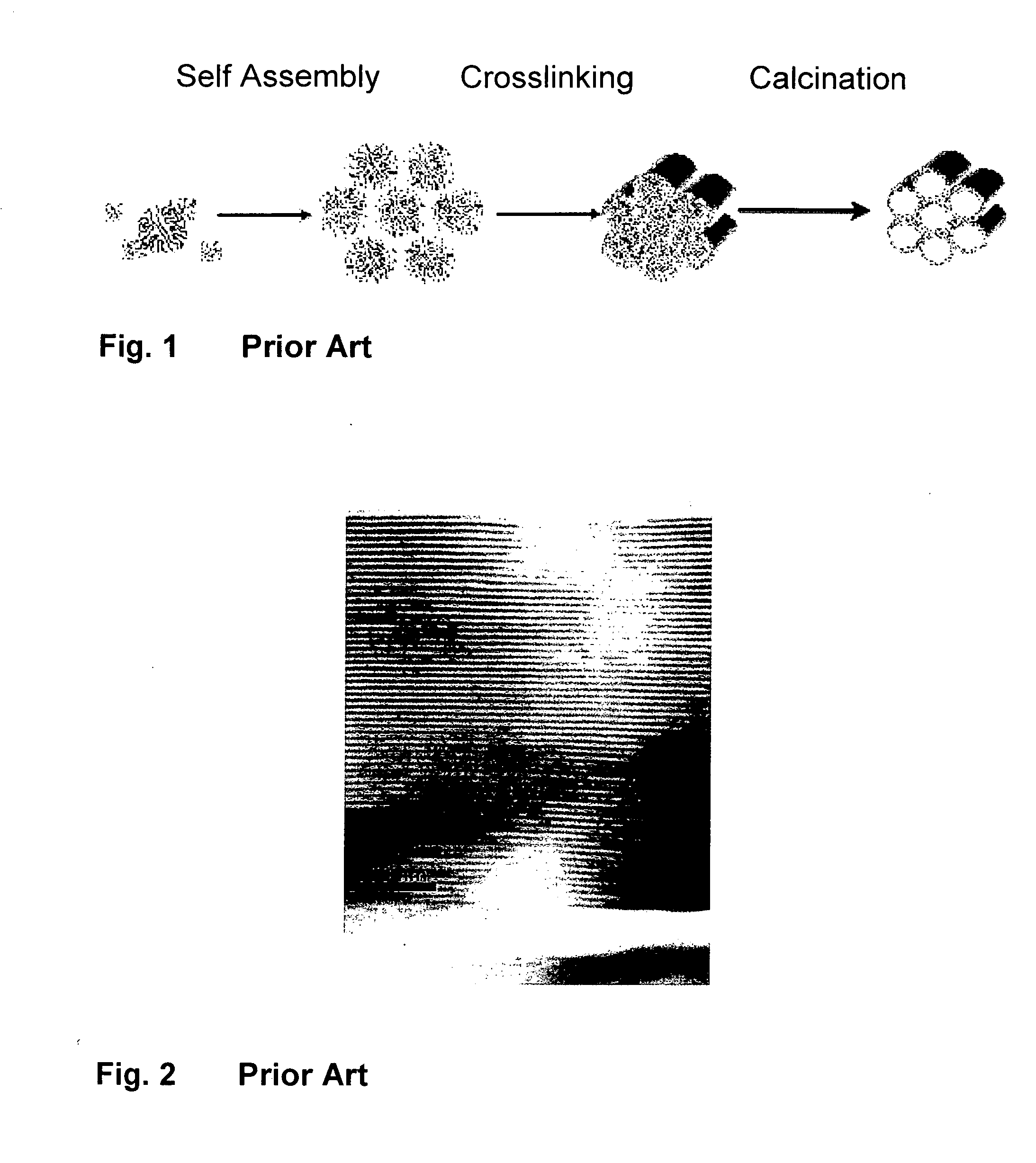

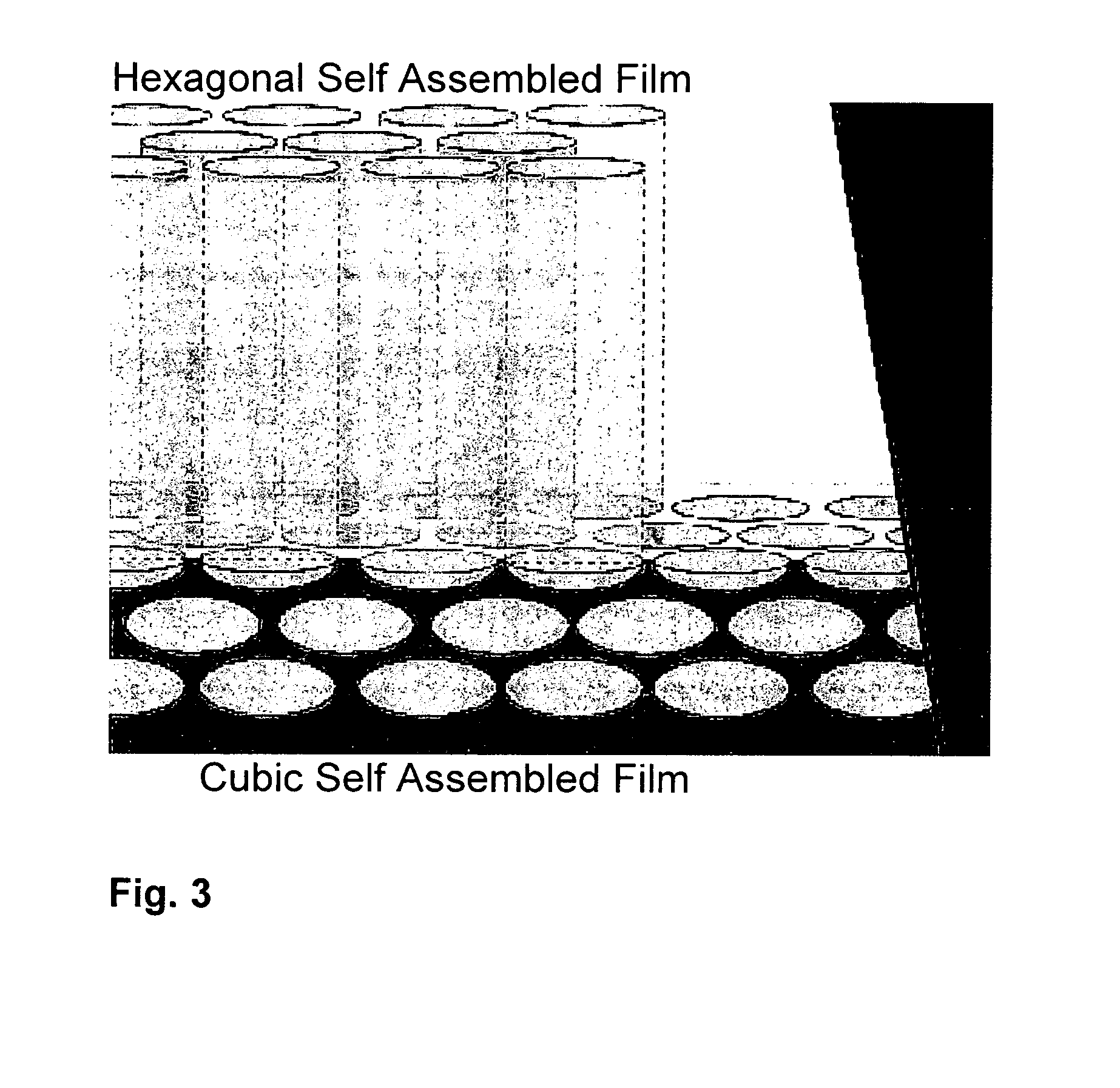

Ordered vertically oriented porous inorganic films produced through solution processing

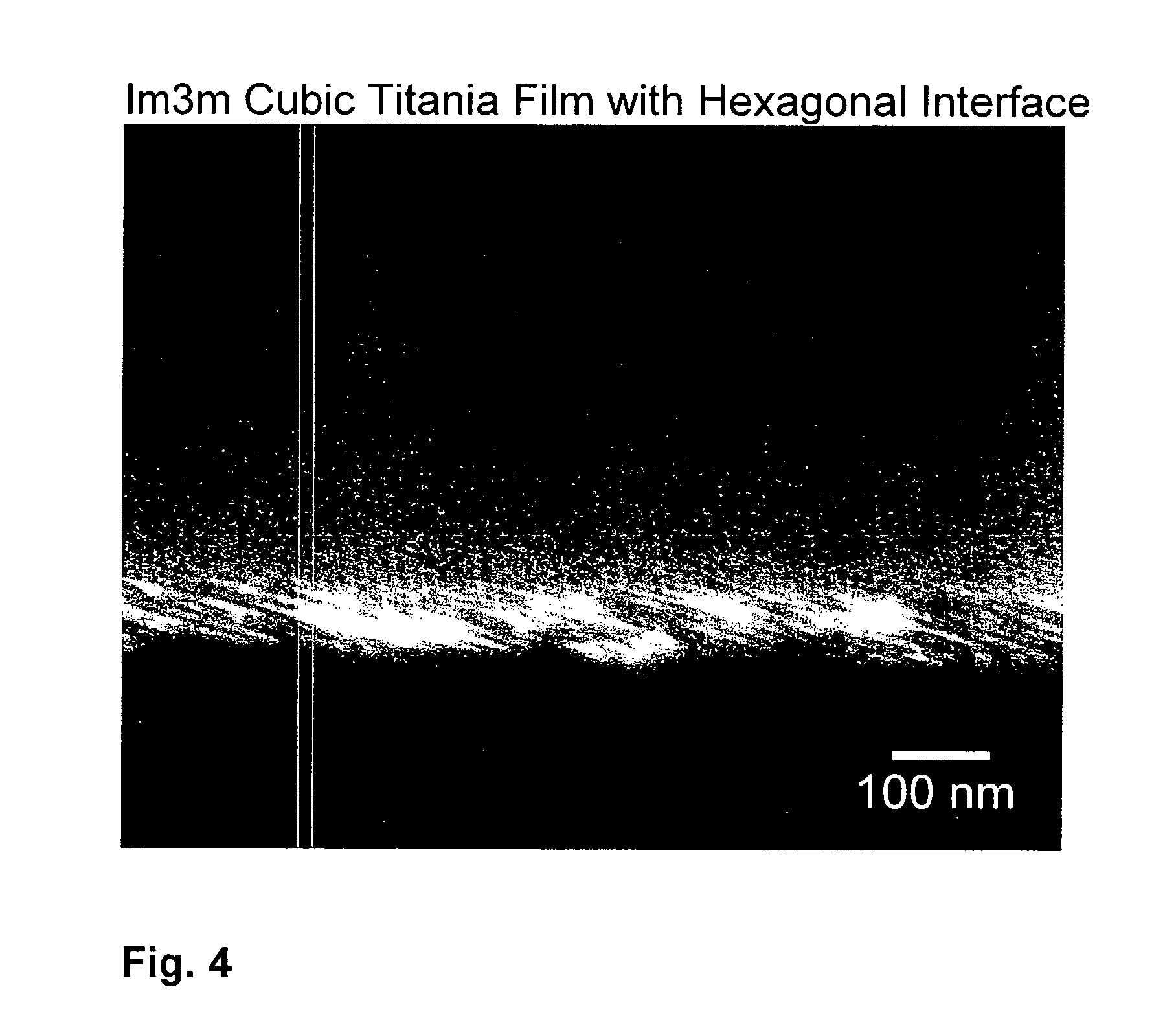

InactiveUS20060278158A1Easy to produceFrom gel statePhotosensitive materialsPatterned substrateSelf-assembly

Porous films with straight pores oriented normal to the plane of the films are produced through solution processing techniques. The production takes advantage of inorganic-surfactant or inorganic-polymer co-assembly and a patterned substrate. The patterned substrate, which is also produced via solution phase self-assembly, forces vertical orientation in a hexagonal cylinder system with no practical limits in substrate size or type. This provides a route to vertically oriented inorganic pores with a pitch ranging from 3 nm to over 15 nm and pore sizes ranging from 2 nm to over 12 nm. The size is tuned by choice the choice of organic templating agents and the deposition conditions. The pores can be produced with or without a capping layer which can be used to seal the nanopores.

Owner:RGT UNIV OF CALIFORNIA

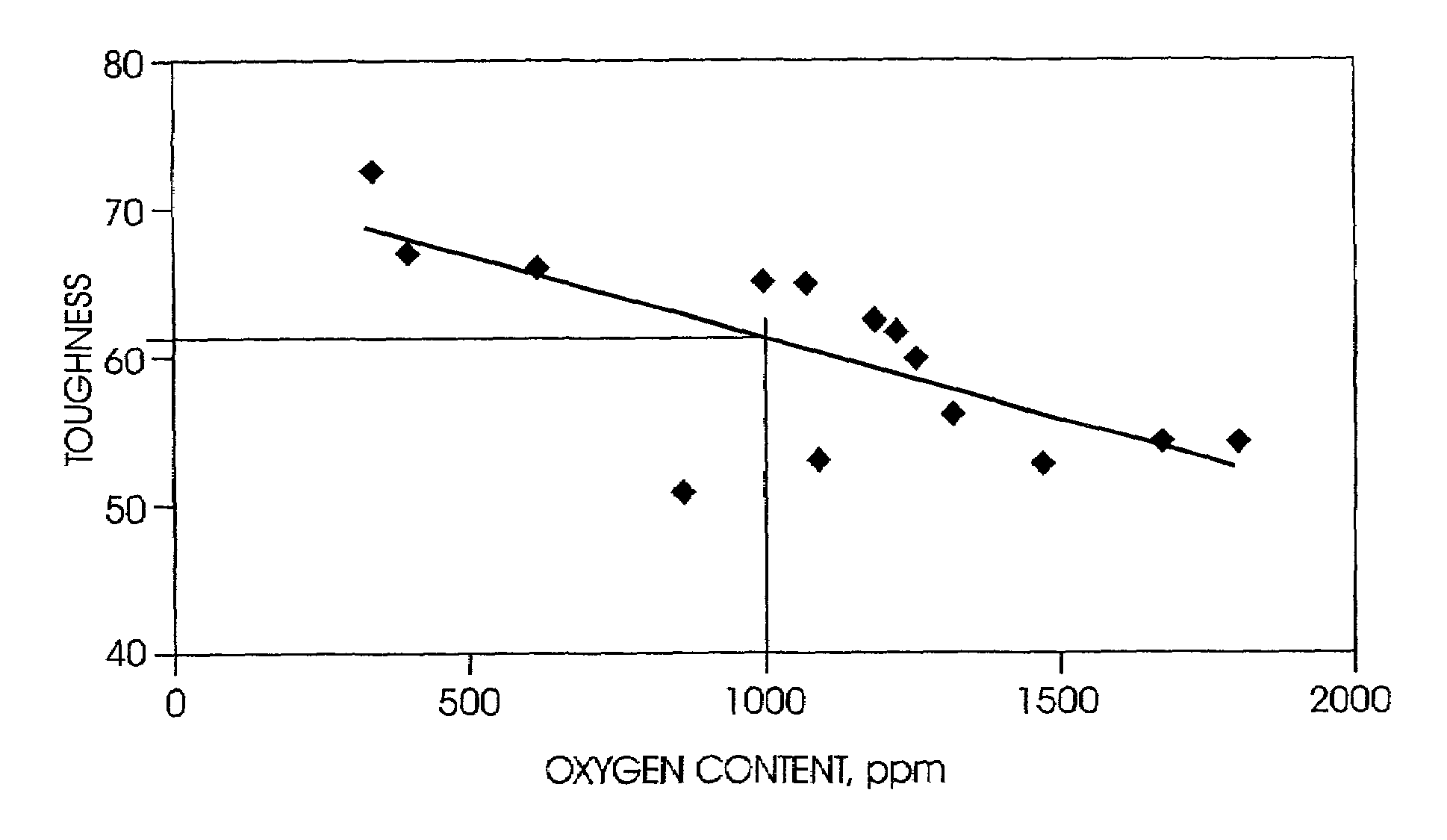

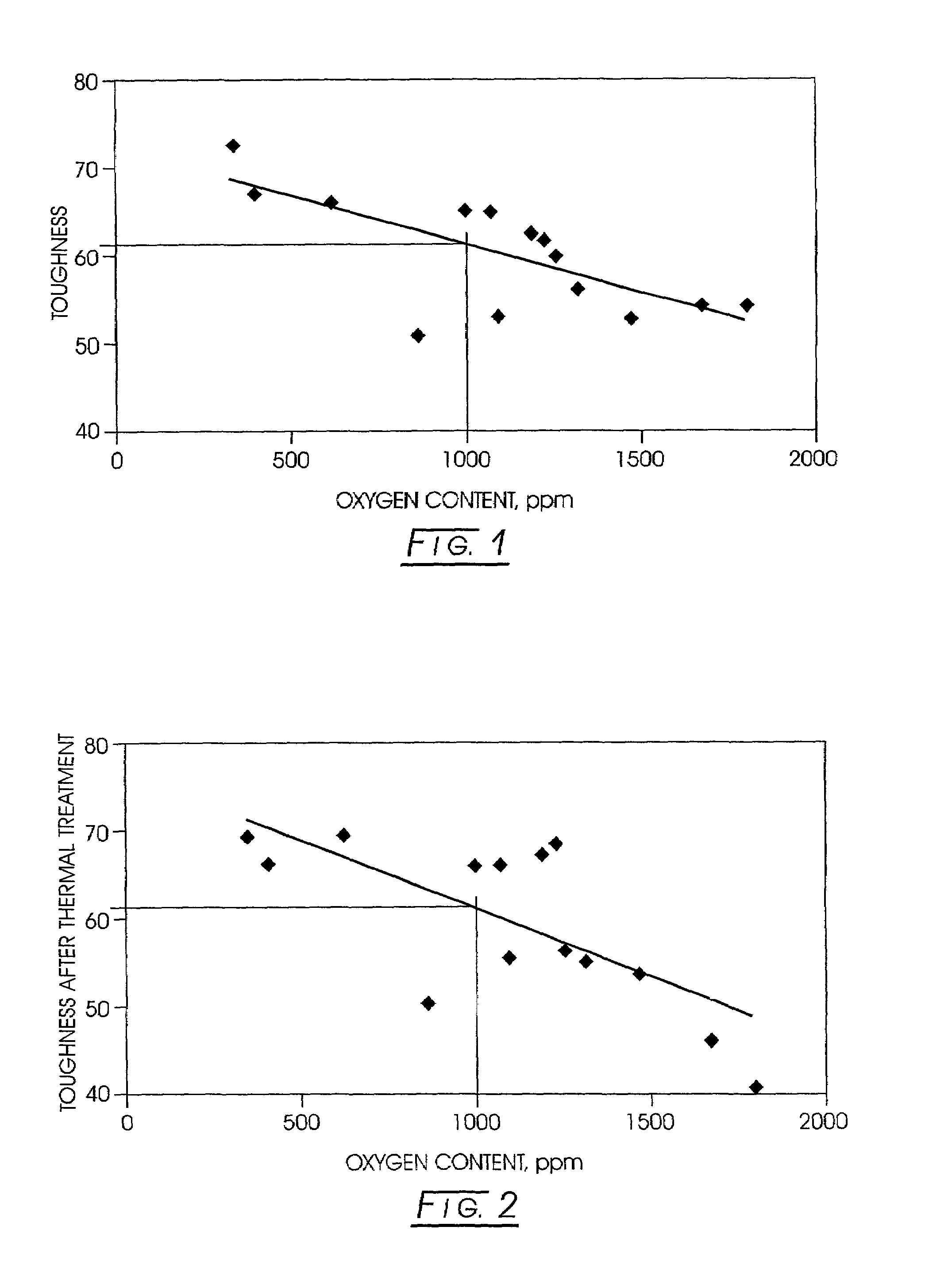

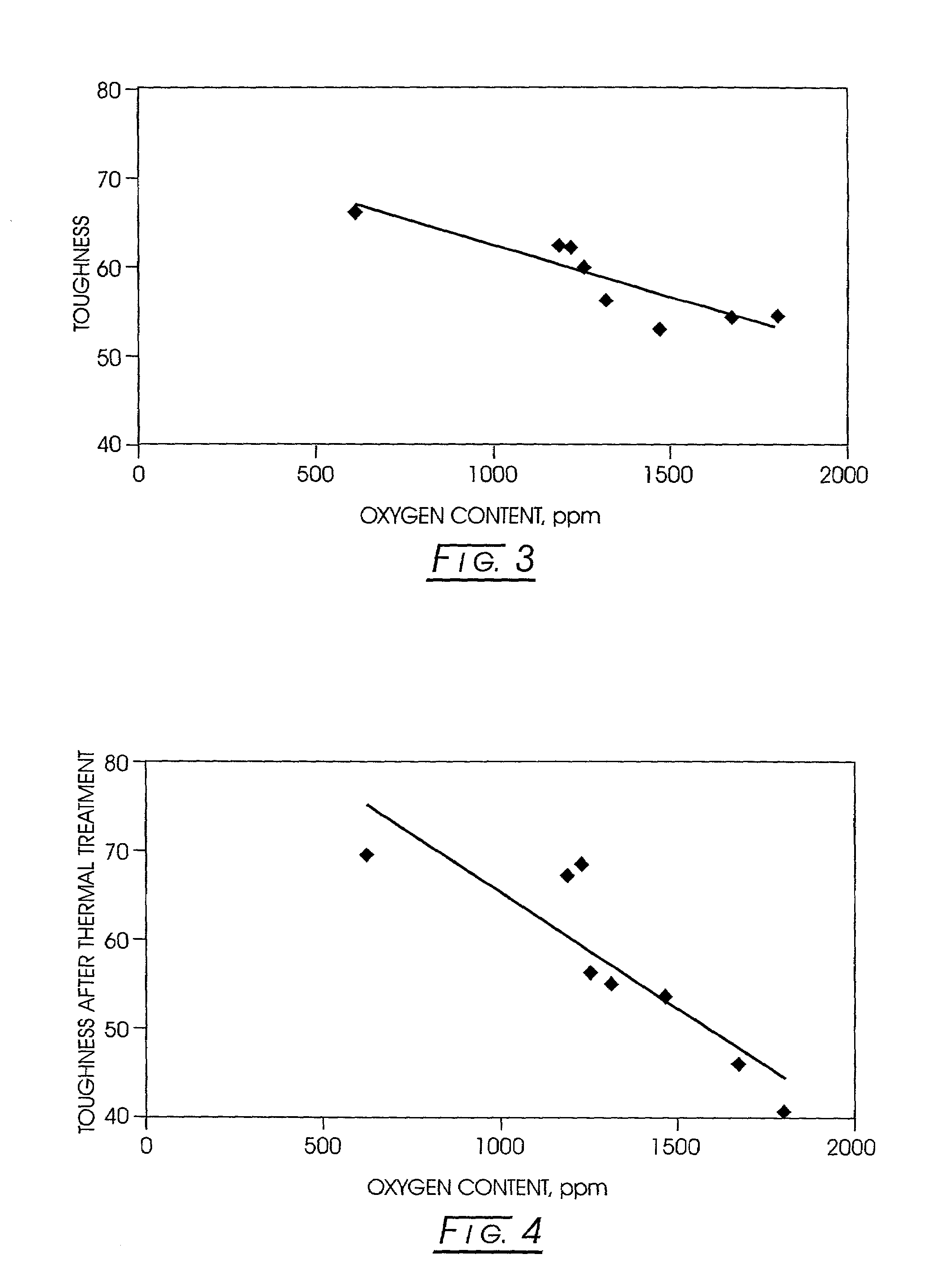

Low oxygen cubic boron nitride and its production

InactiveUS7001577B2Increased toughness indexImprove toughnessFrom gel statePolycrystalline material growthBoron nitrideHigh pressure

A method for improving the toughness of a CBN product made by a high temperature / high pressure (HP / HT) process commences by forming a blend of an oxygen getter and CBN product-forming feedstock. The blend is subjected to a CBN high temperature / high pressure (HP / HT) process for forming a CBN product. The amount of oxygen getter in the blend is sufficient to improve the toughness of the CBN product. The resulting CBN product desirably has an oxygen content of less than about 300 ppm. Oxygen getters include Al, Si, and Ti. The HP / HT process is conducted in the absence or presence of catalytic materials.

Owner:DIAMOND INNOVATIONS INC

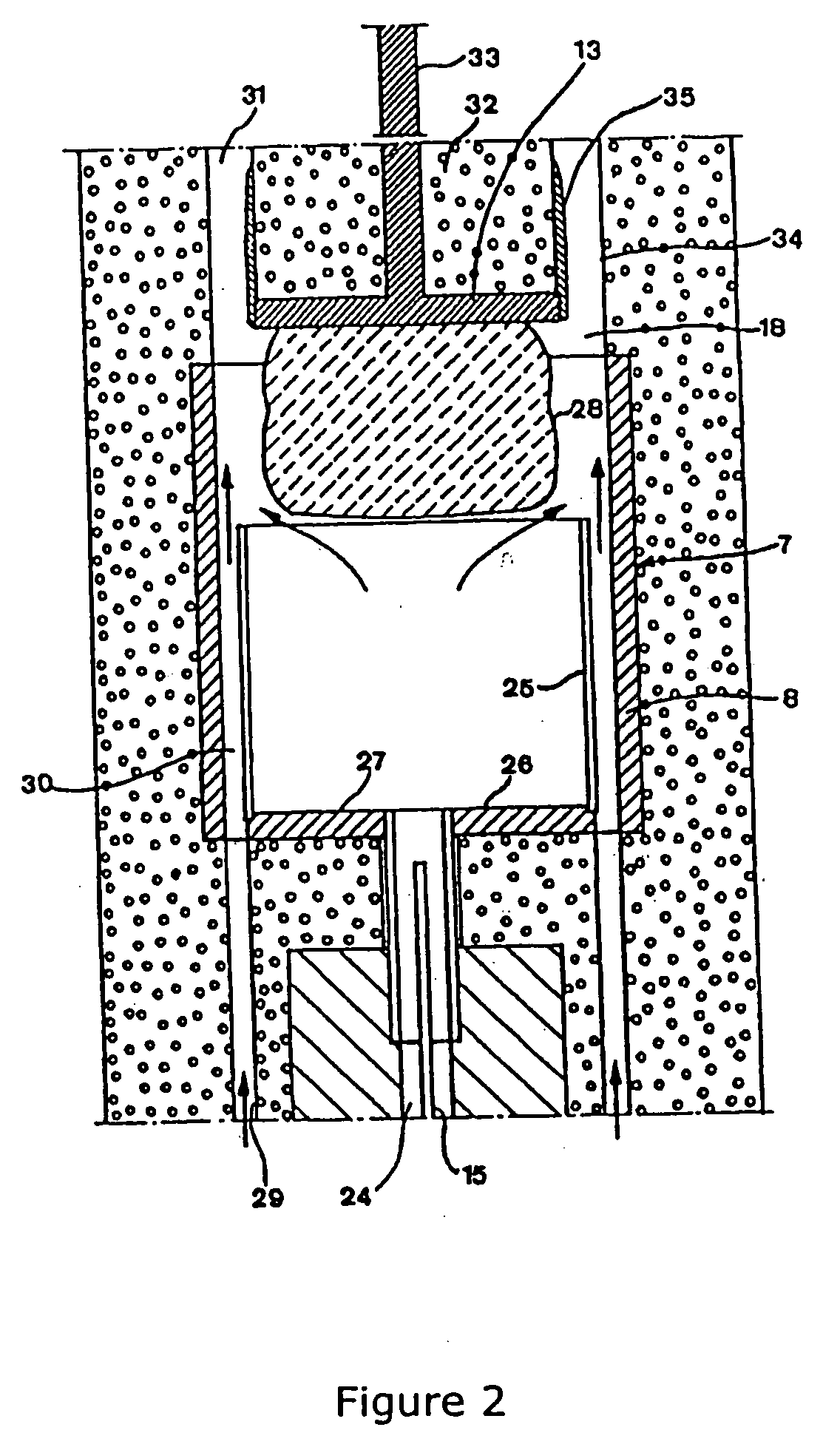

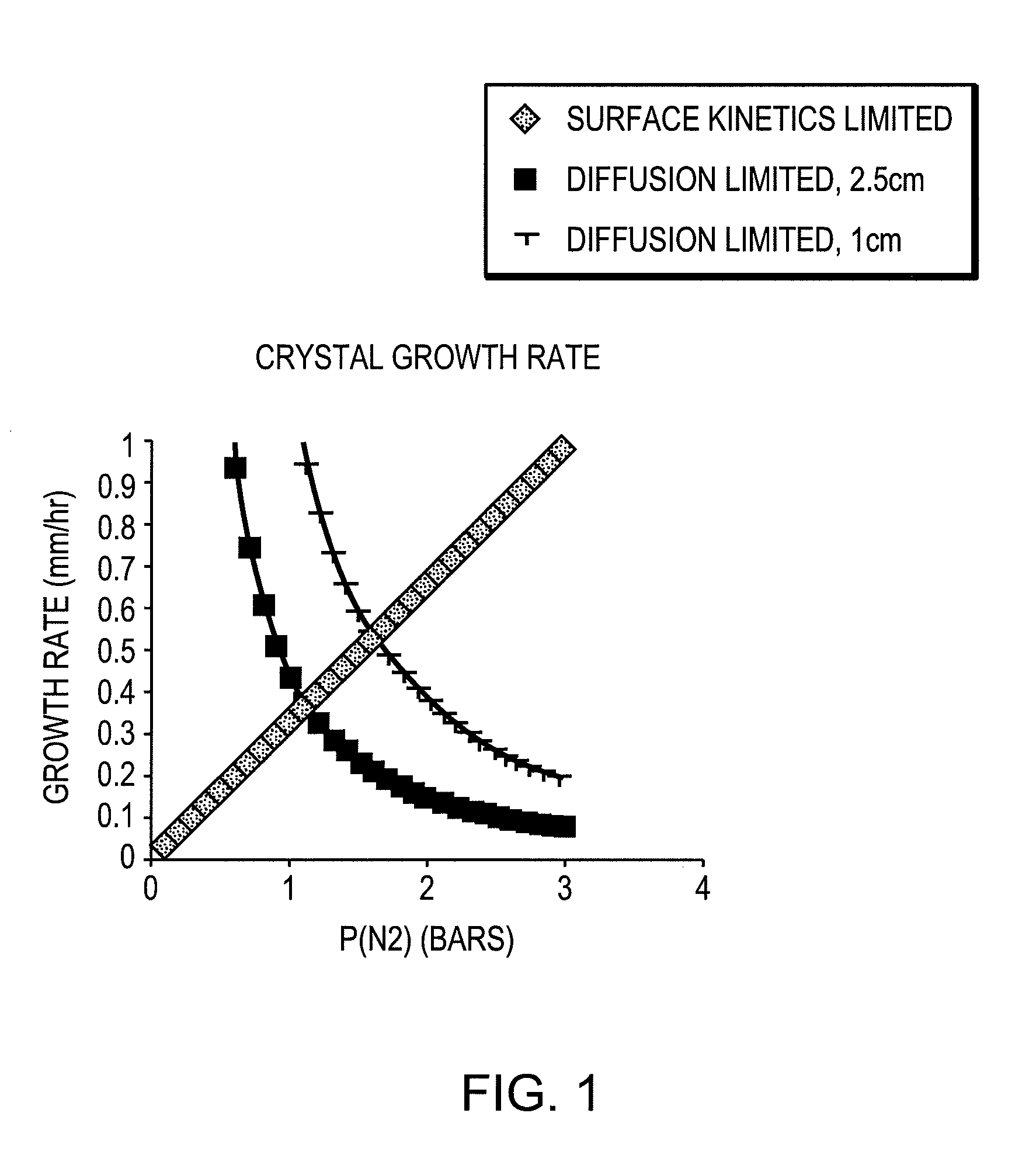

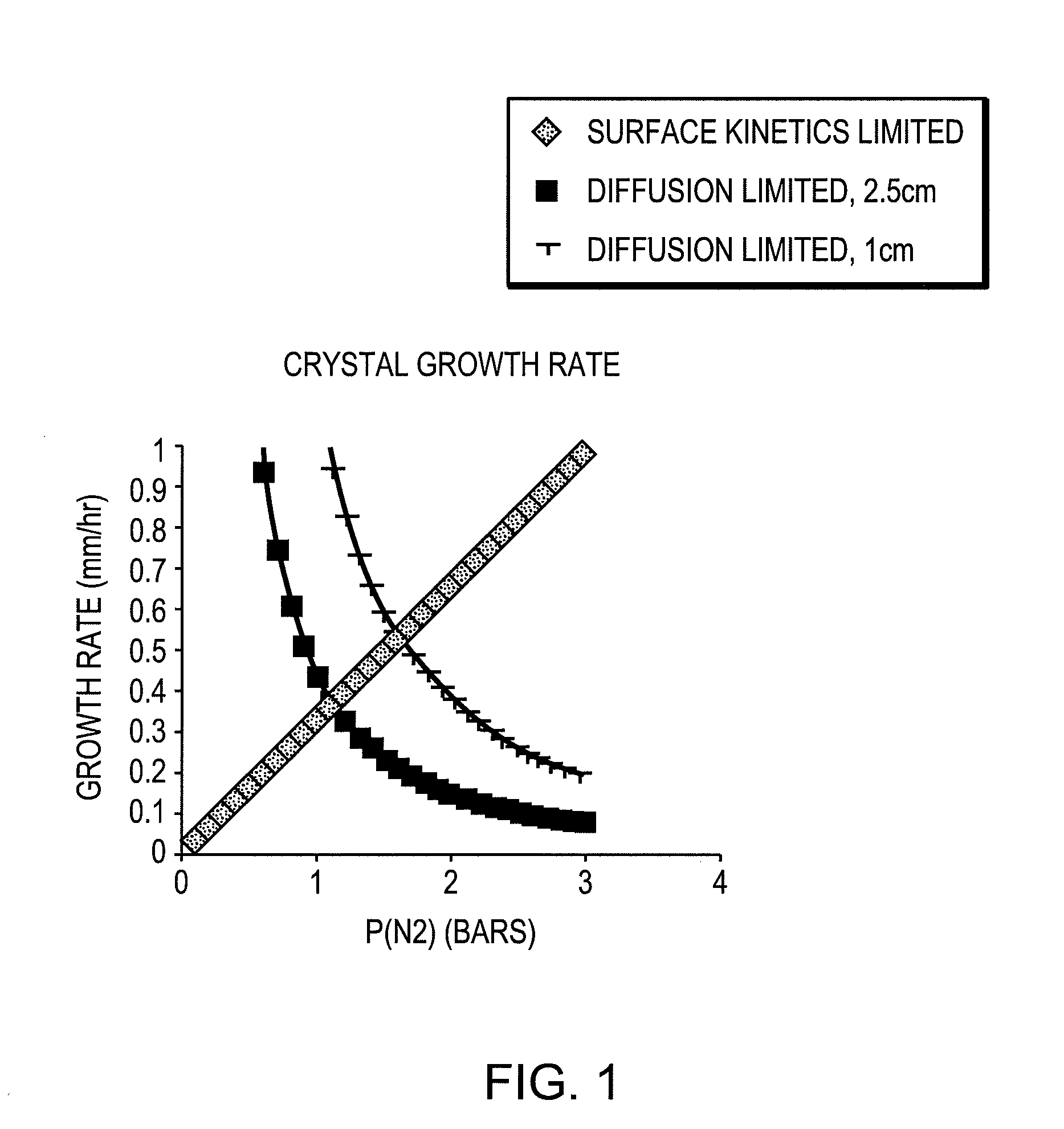

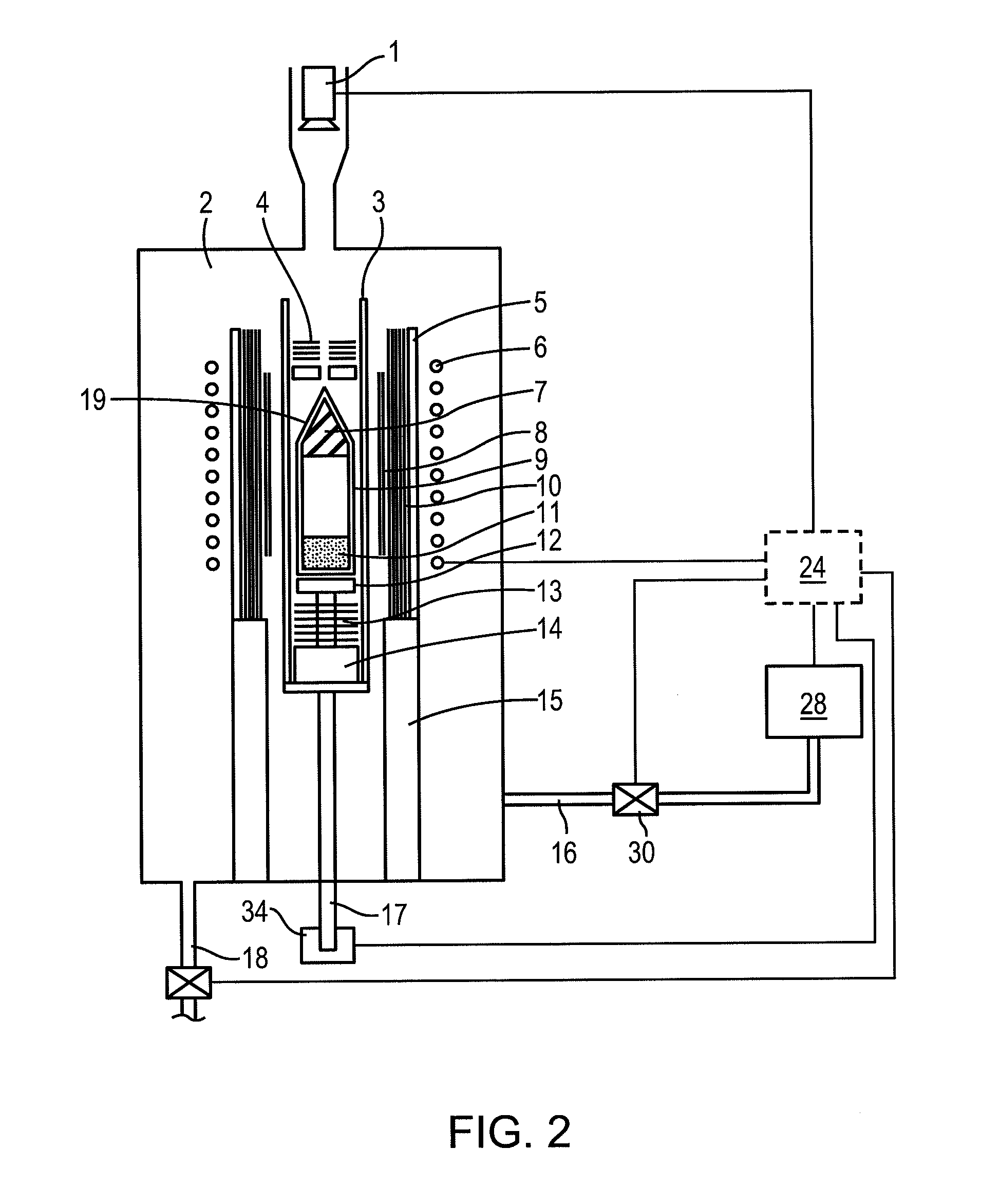

Device and method for producing single crystals by vapor deposition

ActiveUS20050000406A1Down and eliminate formationPreventing structural defect generationFrom gel statePolycrystalline material growthGas phaseSingle crystal

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL

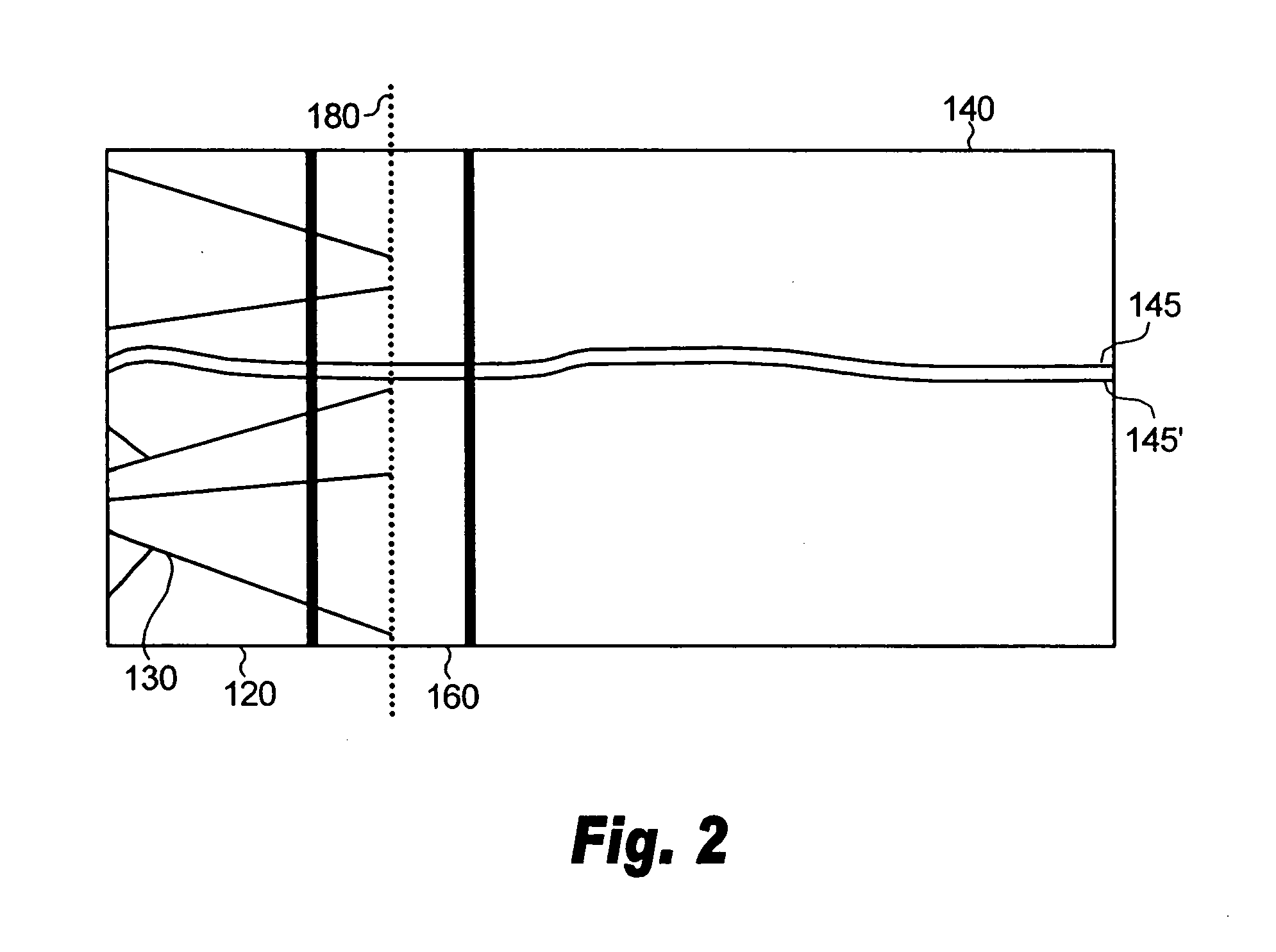

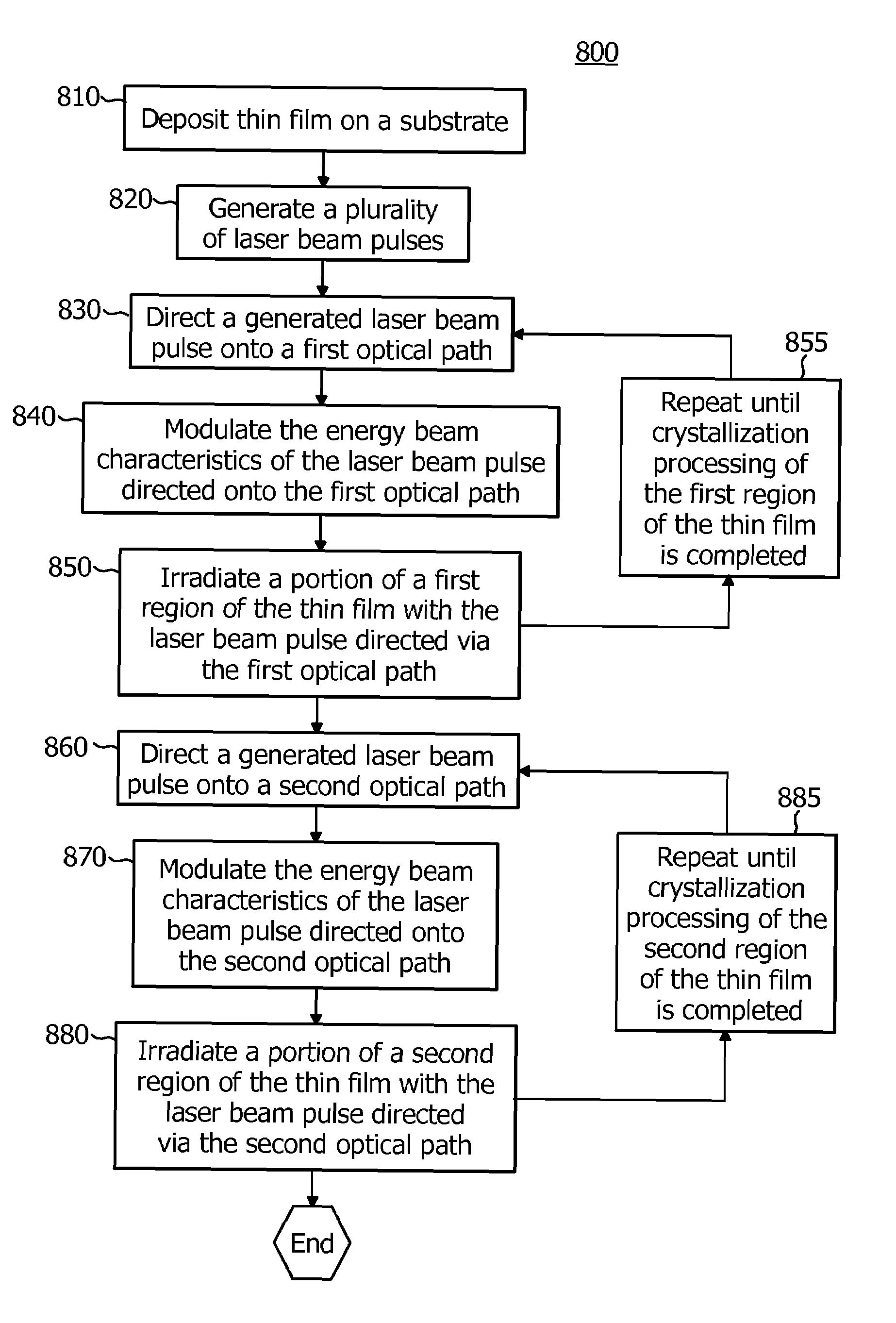

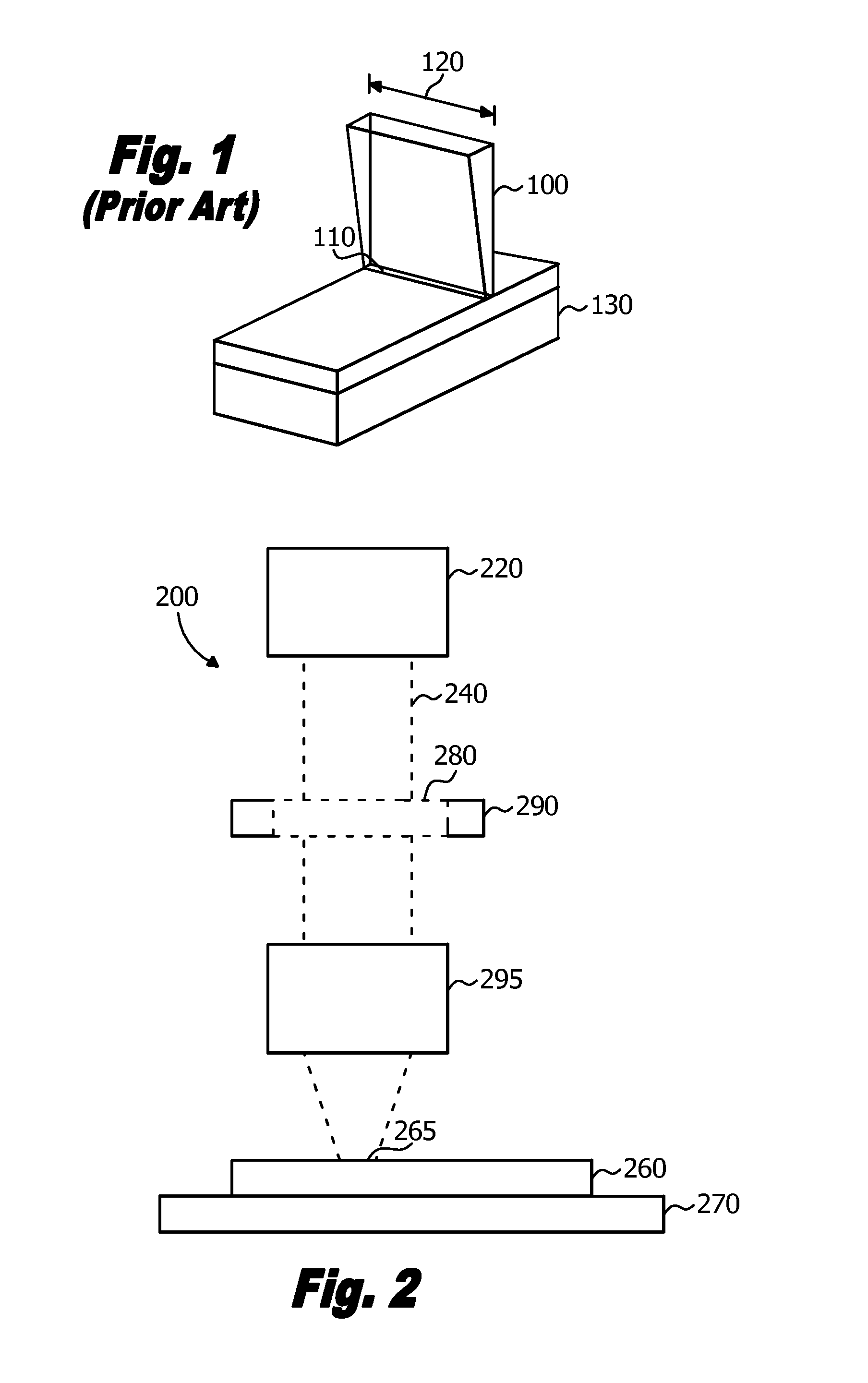

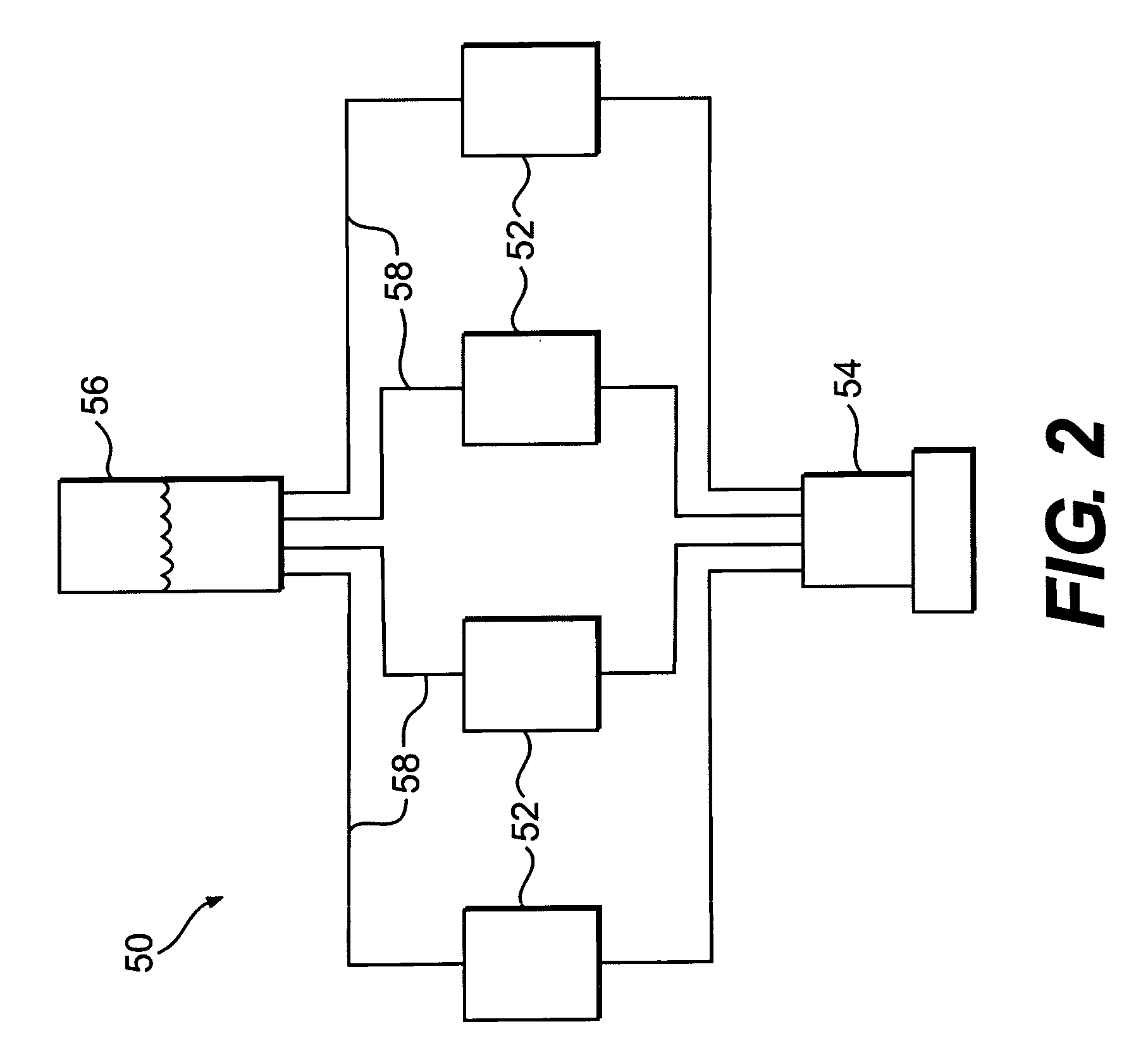

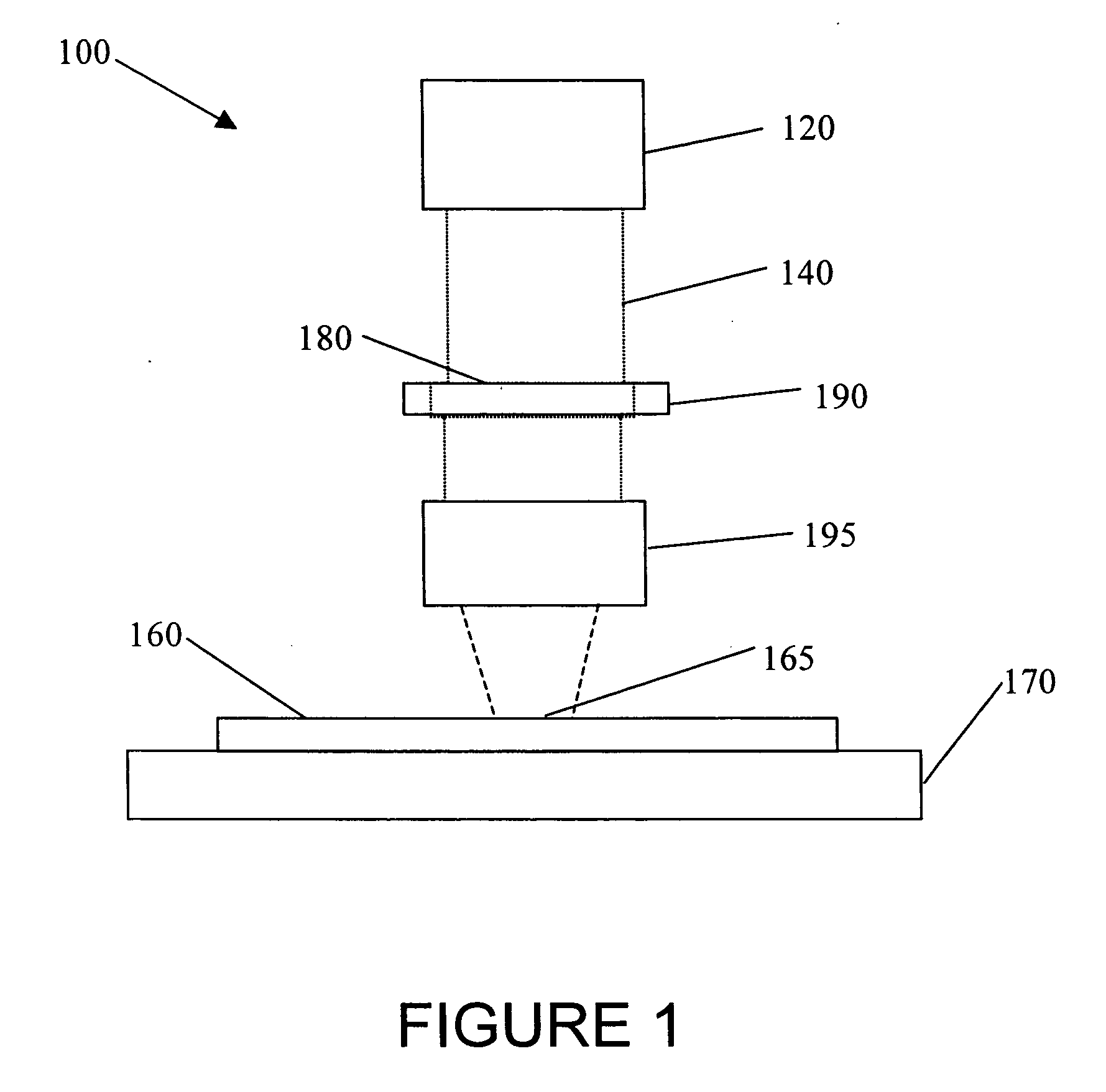

Systems and methods for inducing crystallization of thin films using multiple optical paths

InactiveUS7318866B2Promote crystallizationReduce the amount requiredAfter-treatment apparatusFrom gel stateLight beamBeam steering

The present invention is directed to systems and methods for irradiating regions of a thin film sample(s) with laser beam pulses having different energy beam characteristics that are generated and delivered via different optical paths. Exemplary methods include the steps of generating a plurality of laser beam pulses having energy beam characteristics, directing a generated laser beam pulse onto a first optical path, modulating the energy beam characteristics of the first optical path-directed laser beam pulse, irradiating at least a portion of a first region of the thin film with the first optical path-directed laser beam pulse to induce crystallization of the portion of the first region, directing a generated laser beam pulse onto a second optical path, modulating the energy beam characteristics of the second optical path-directed laser beam pulse, wherein the energy beam characteristics of the second optical path-directed laser beam pulse is different from the energy beam characteristics of the first optical path-directed laser beam pulse, and irradiating at least a portion of a second region of the thin film with the second optical path-directed laser beam pulse to induce crystallization of the portion of the second region. An exemplary system includes a first optical path, a second optical path, a beam steering element for directing laser beam pulses onto the first optical path and the second optical path; and a handling stage for controlling the position of a thin film relative to the laser beam pulses being directed via the first and second optical paths.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

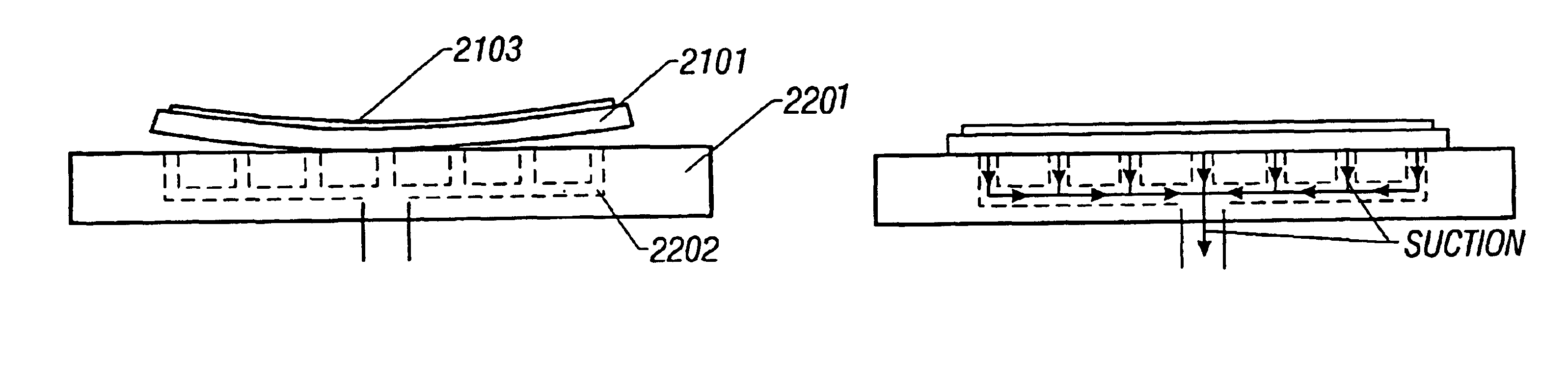

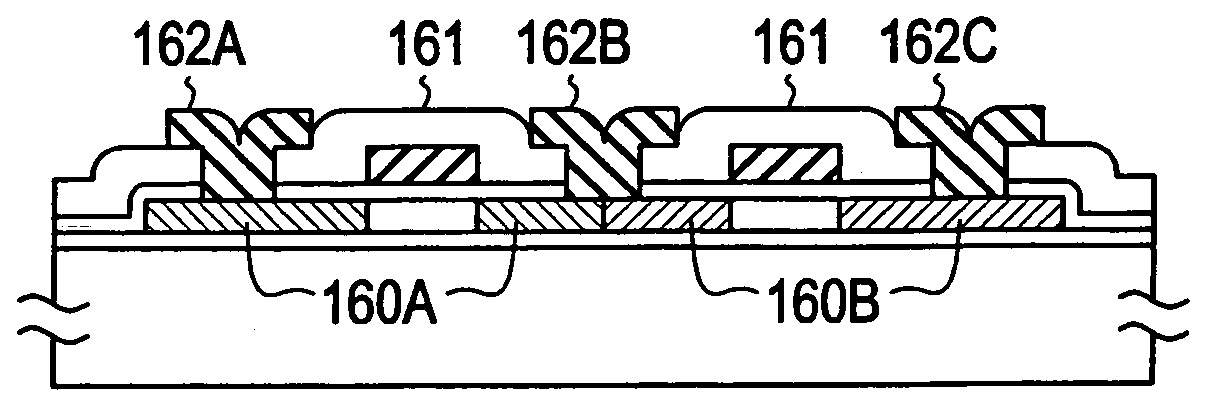

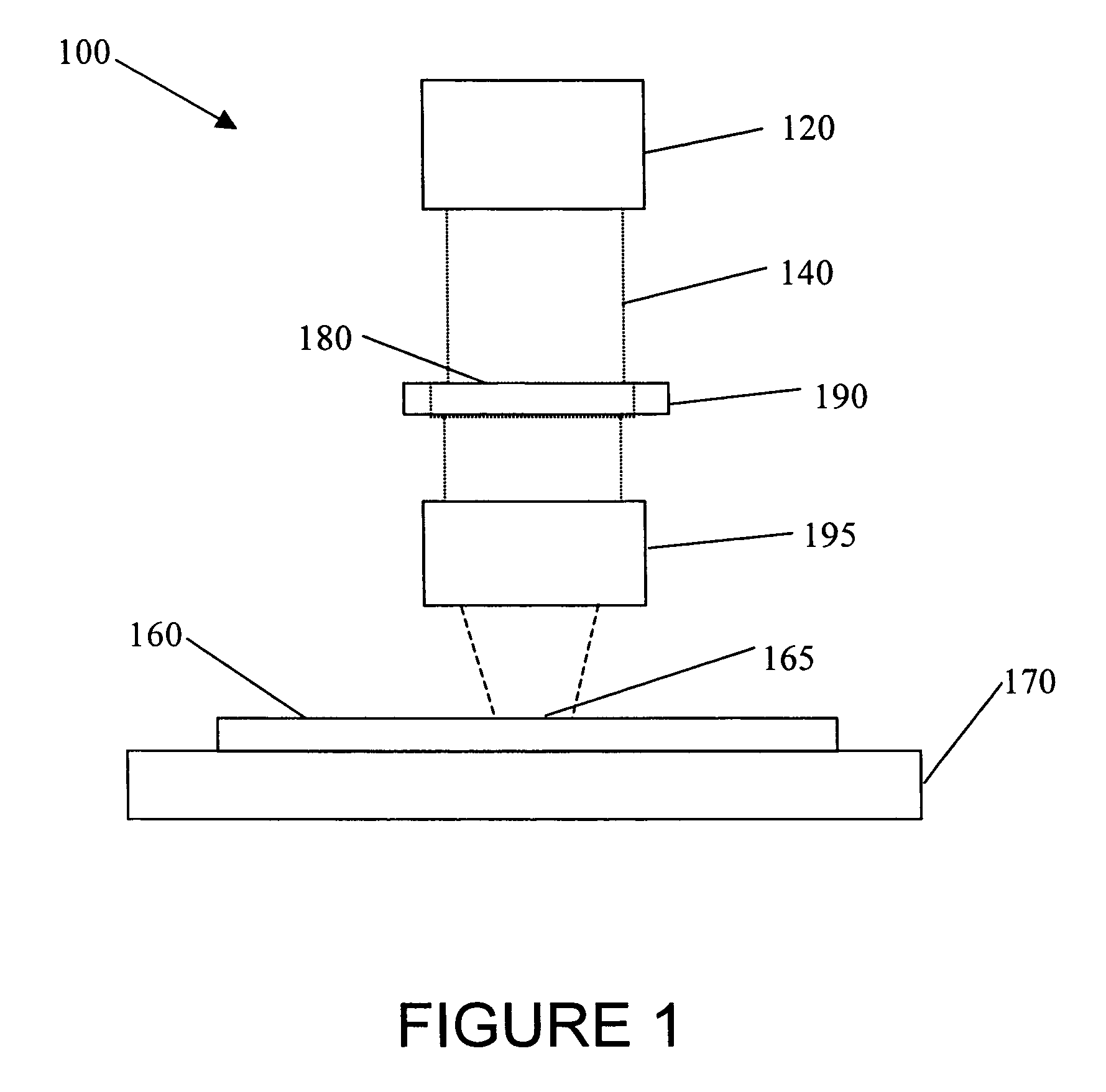

Method and apparatus for producing semiconductor device

InactiveUS6902616B1Correct warpingGood effectFrom gel statePolycrystalline material growthLiquid-crystal displayCrystallinity

A liquid crystal display device is manufactured by first forming a crystalline semiconductor film 2103, of silicon for example, over an insulating substrate 2101, such as glass. The substrate is warped in the process. The warpage is corrected by suction against a stage 2201. The film crystallinity is enhanced by scanning with a linear laser beam.

Owner:SEMICON ENERGY LAB CO LTD

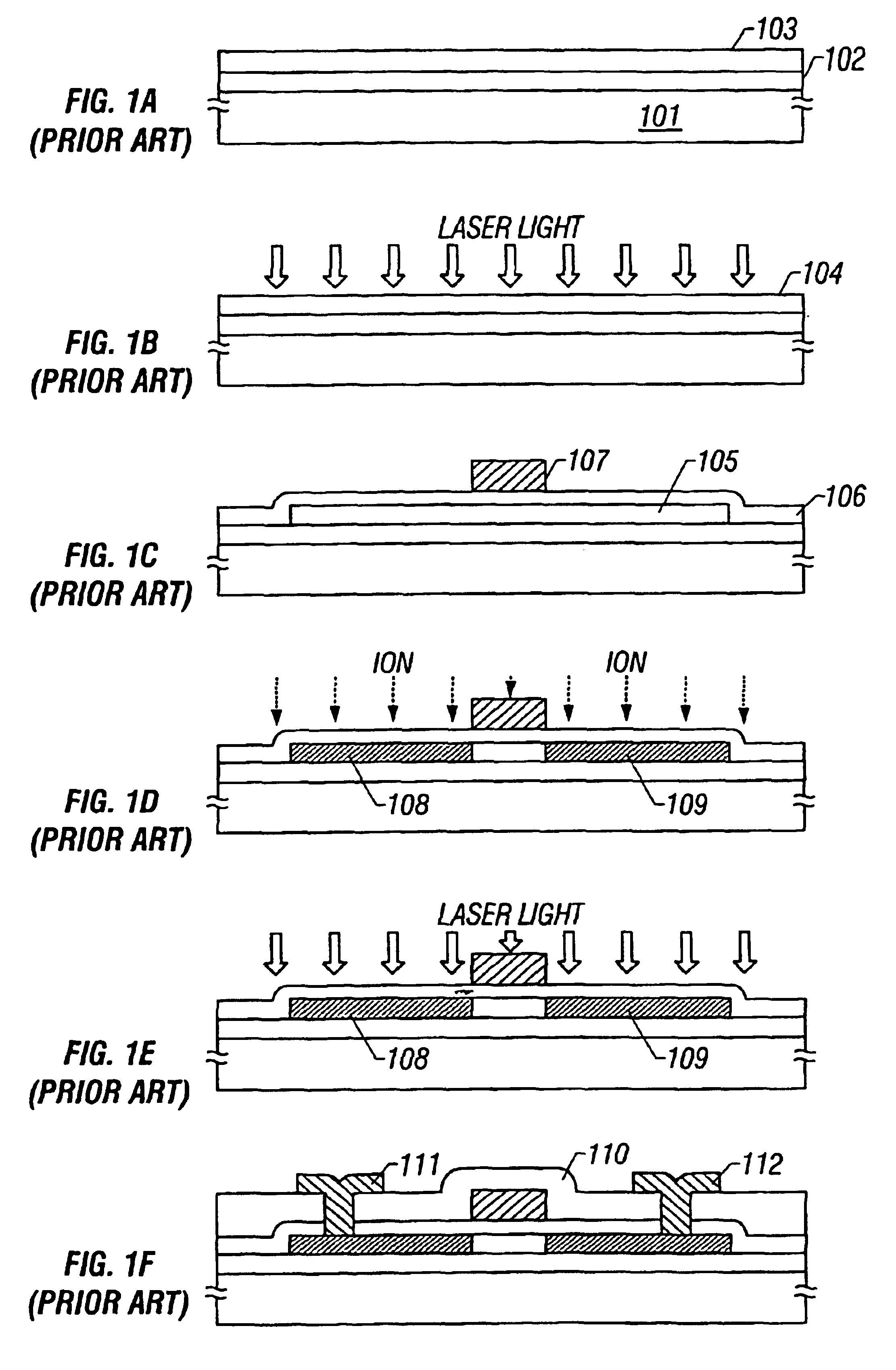

Semiconductor, semiconductor device, and method for fabricating the same

InactiveUS6997985B1Improve continuityImprove solubilityTransistorFrom gel stateGlass transition pointCobalt

Method of fabricating semiconductor devices such as thin-film transistors by annealing a substantially amorphous silicon film at a temperature either lower than normal crystallization temperature of amorphous silicon or lower than the glass transition point of the substrate so as to crystallize the silicon film. Islands, stripes, lines, or dots of nickel, iron, cobalt, or platinum, silicide, acetate, or nitrate of nickel, iron, cobalt, or platinum, film containing various salts, particles, or clusters containing at least one of nickel, iron, cobalt, and platinum are used as starting materials for crystallization. These materials are formed on or under the amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

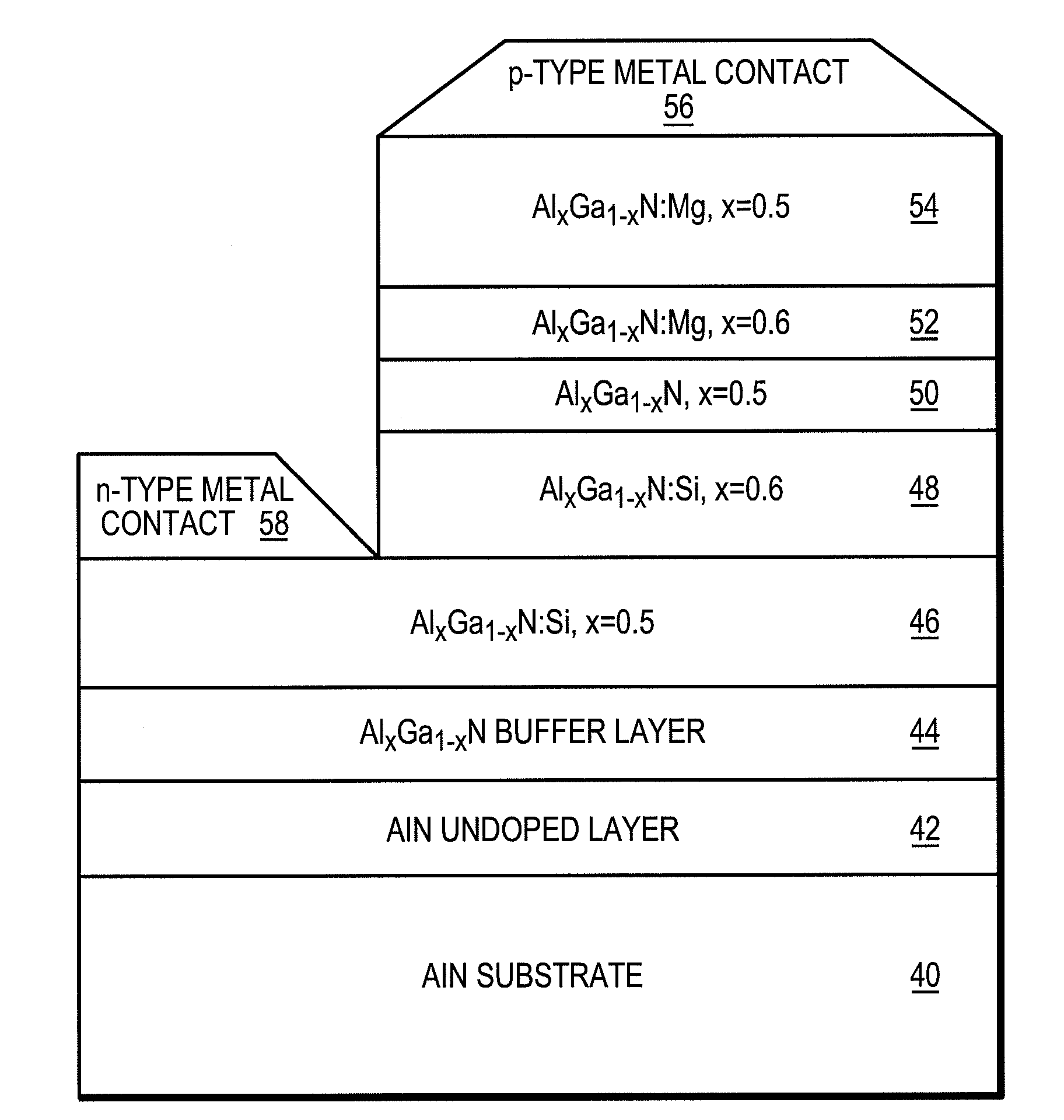

Nitride semiconductor heterostructures and related methods

InactiveUS20090283028A1Easy to manufactureGood chemical compatibilityFrom gel statePolycrystalline material growthSemiconductor structureSemiconductor heterostructures

Semiconductor structures and devices based thereon include an aluminum nitride single-crystal substrate and at least one layer epitaxially grown thereover. The epitaxial layer may comprise at least one of AlN, GaN, InN, or any binary or tertiary alloy combination thereof, and have an average dislocation density within the semiconductor heterostructure is less than about 106 cm−2.

Owner:CRYSTAL

Passivated nanoparticles, method of fabrication thereof, and devices incorporating nanoparticles

A plurality of semiconductor nanoparticles having an elementally passivated surface are provided. These nanoparticles are capable of being suspended in water without substantial agglomeration and substantial precipitation on container surfaces for at least 30 days. The method of making the semiconductor nanoparticles includes reacting at least a first reactant and a second reactant in a solution to form the semiconductor nanoparticles in the solution. A first reactant provides a passivating element which binds to dangling bonds on a surface of the nanoparticles to passivate the surface of the nanoparticles. The nanoparticle size can be tuned by etching the nanoparticles located in the solution to a desired size.

Owner:RENESSELAER POLYTECHNIC INST

System and high pressure, high temperature apparatus for producing synthetic diamonds

An apparatus for growing a synthetic diamond comprises a growth chamber, at least one manifold allowing access to the growth chamber, and a plurality of safety clamps positioned on opposite sides of the growth chamber; wherein the growth chamber and the plurality of safety clamps are comprised of a material having a tensile strength of about 120,000-200,000 psi, a yield strength of about 100,000-160,000 psi, an elongation of about 10-20%, an area reduction of about 40-50%, an impact strength of about 30-40 ft-lbs, and a hardness greater than 320 BHN.

Owner:THE GEMESIS CORP

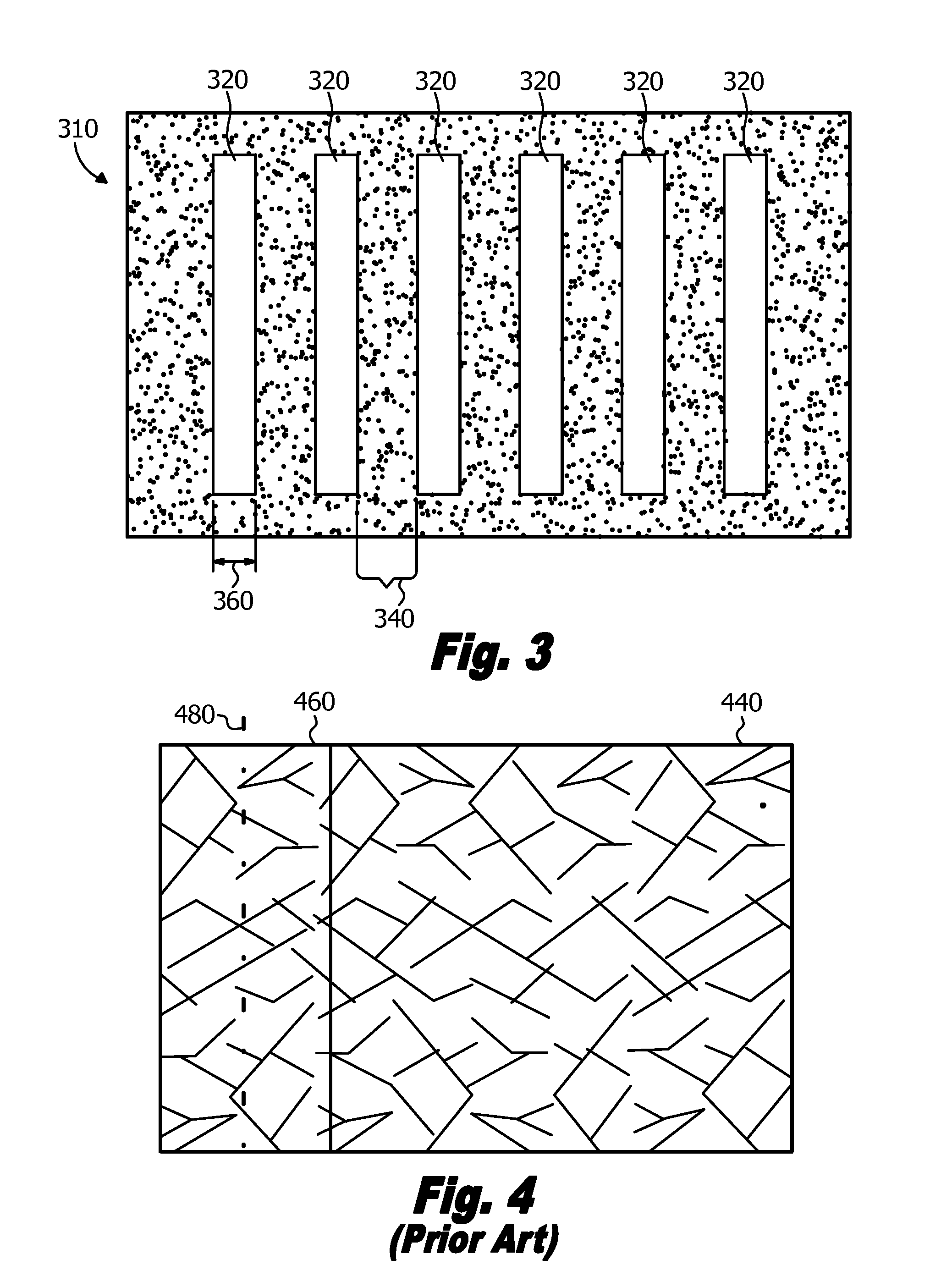

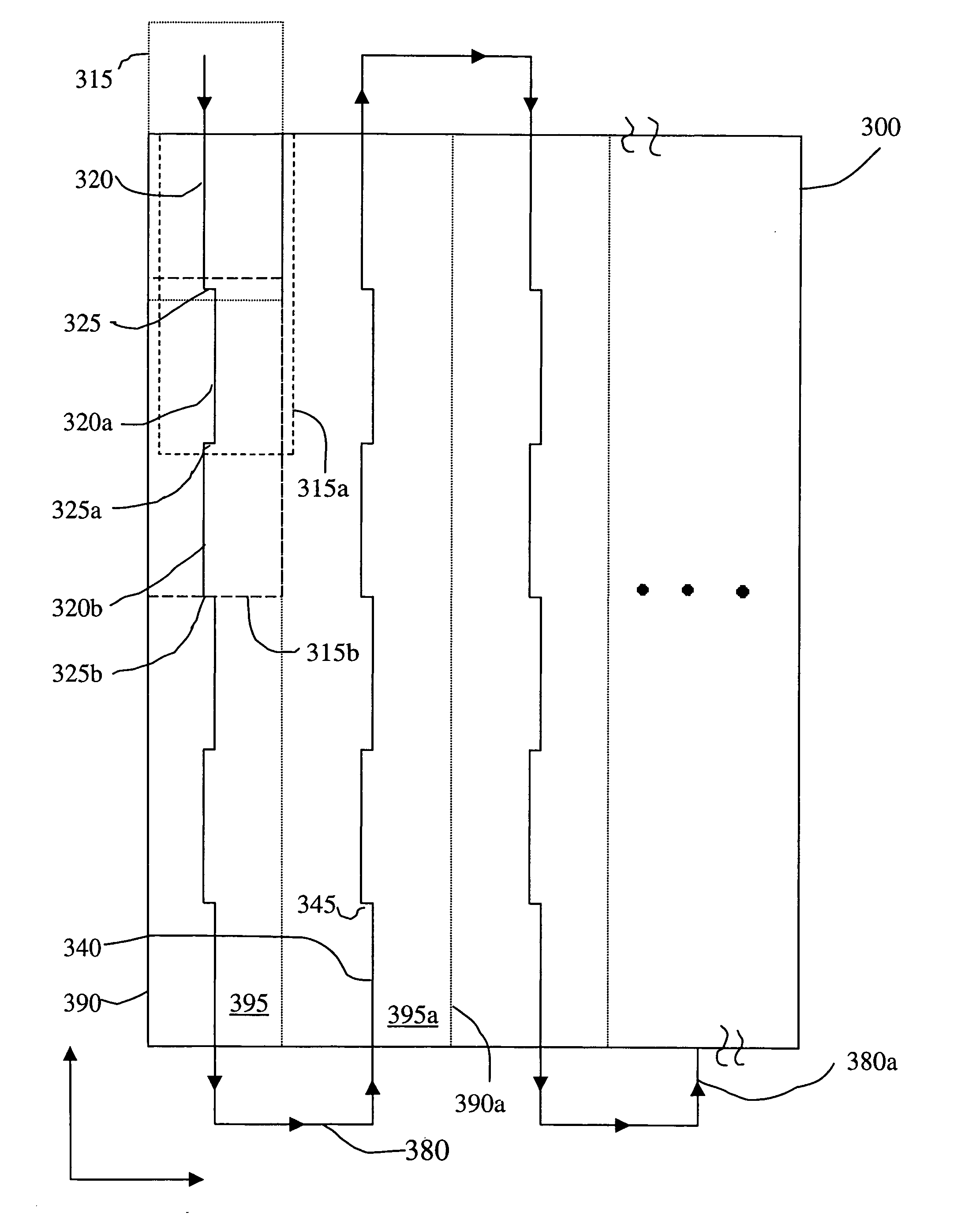

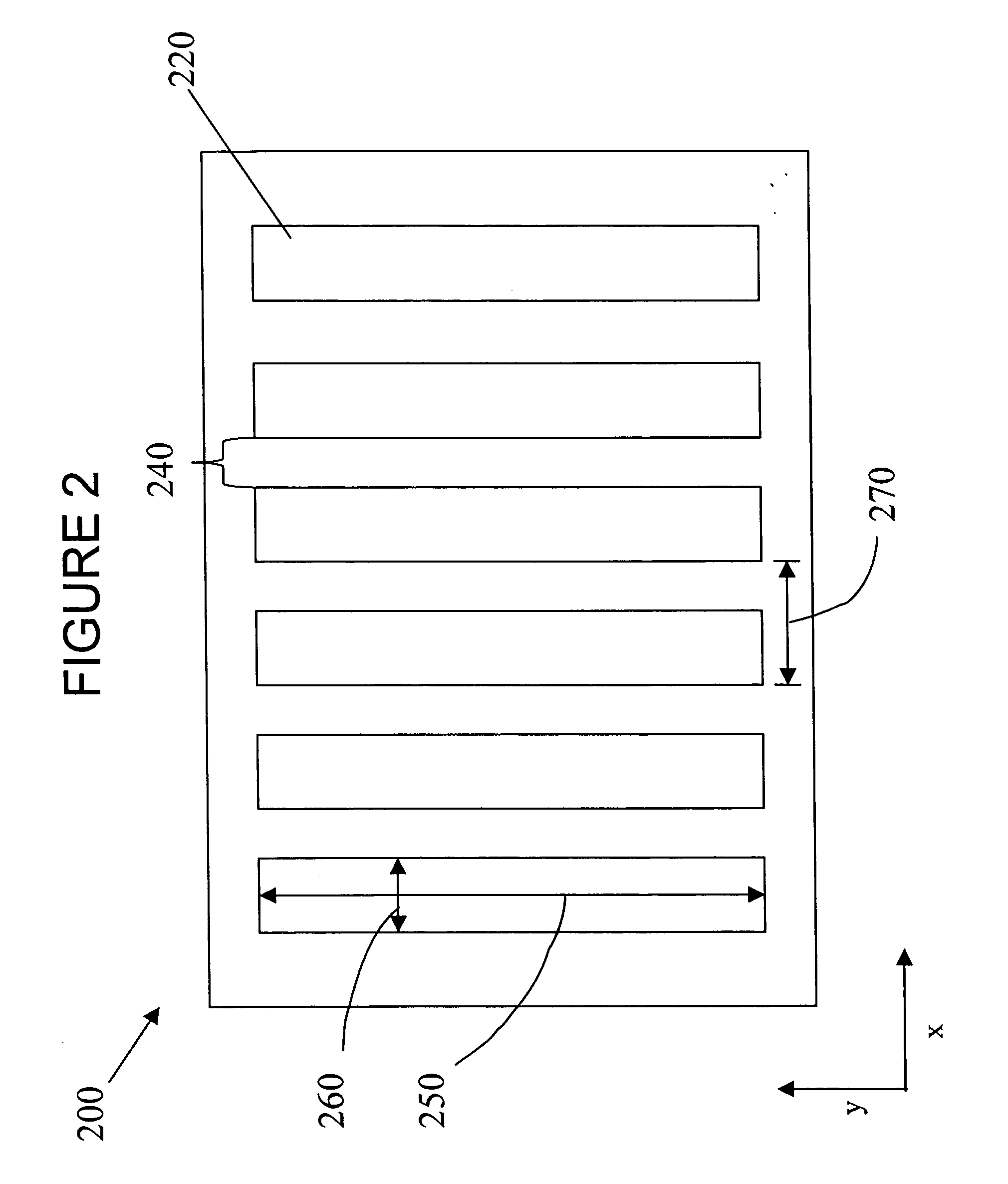

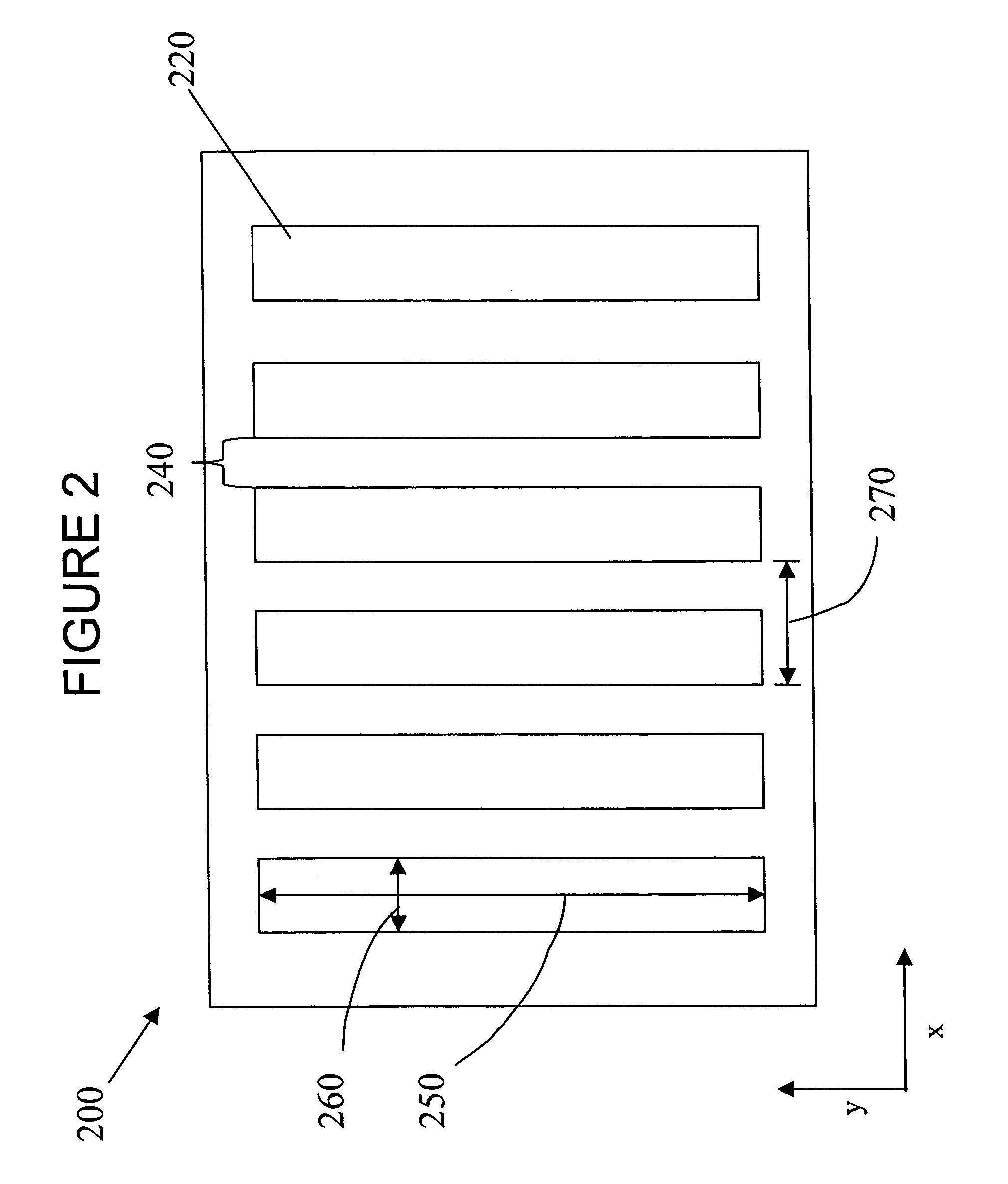

Single scan irradiation for crystallization of thin films

InactiveUS20050235903A1Improve propertiesSimple processFrom gel stateFrom solid stateLight beamOptoelectronics

A method of processing a polycrystalline film on a substrate includes generating a plurality of laser beam pulses, positioning the film on a support capable of movement in at least one direction, directing the plurality of laser beam pulses through a mask to generate patterned laser beams; each of said beams having a length l′, a width w′ and a spacing between adjacent beams d′, irradiating a region of the film with the patterned beams, said beams having an intensity that is sufficient to melt an irradiated portion of the film to induce crystallization of the irradiated portion of the film, wherein the film region is irradiated n times; and after irradiation of each film portion, translating either the film or the mask, or both, a distance in the x- and y-directions, where the distance of translation in the y-direction is in the range of about 1′ / n-δ, where δ is a value selected to form overlapping the beamlets from the one irradiation step to the next, and where the distance of translation in the x-direction is selected such that the film is moved a distance of about λ′ after n irradiations, where λ′=w′+d′.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Single scan irradiation for crystallization of thin films

InactiveUS7311778B2Improve propertiesSimple processFrom gel stateFrom solid stateLight beamOptoelectronics

A method of processing a polycrystalline film on a substrate includes generating a plurality of laser beam pulses, positioning the film on a support capable of movement in at least one direction, directing the plurality of laser beam pulses through a mask to generate patterned laser beams; each of said beams having a length l′, a width w′ and a spacing between adjacent beams d′, irradiating a region of the film with the patterned beams, said beams having an intensity that is sufficient to melt an irradiated portion of the film to induce crystallization of the irradiated portion of the film, wherein the film region is irradiated n times; and after irradiation of each film portion, translating either the film or the mask, or both, a distance in the x- and y-directions, where the distance of translation in the y-direction is in the range of about 1′ / n-δ, where δ is a value selected to form overlapping the beamlets from the one irradiation step to the next, and where the distance of translation in the x-direction is selected such that the film is moved a distance of about λ′ after n irradiations, where λ′=w′+d′.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

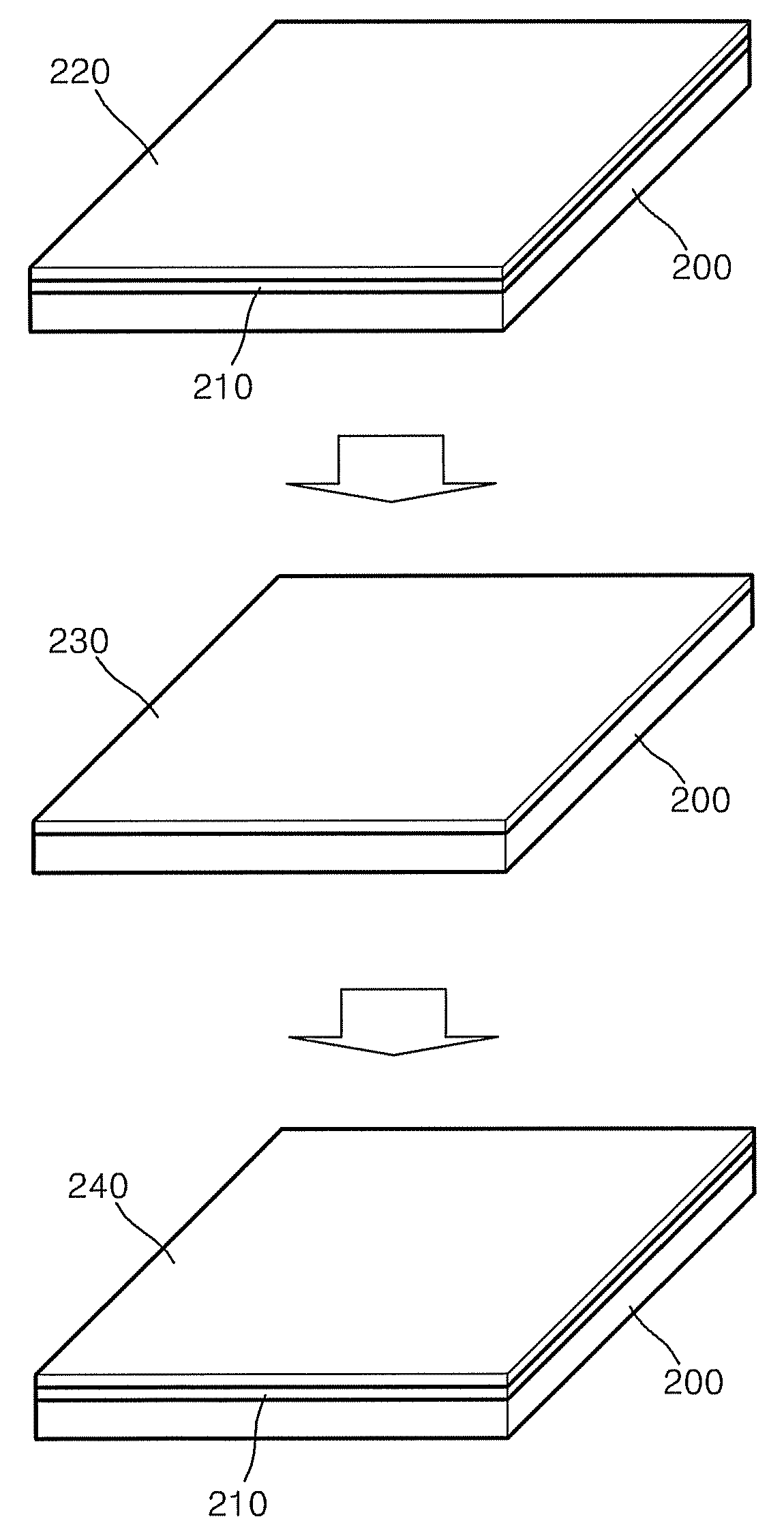

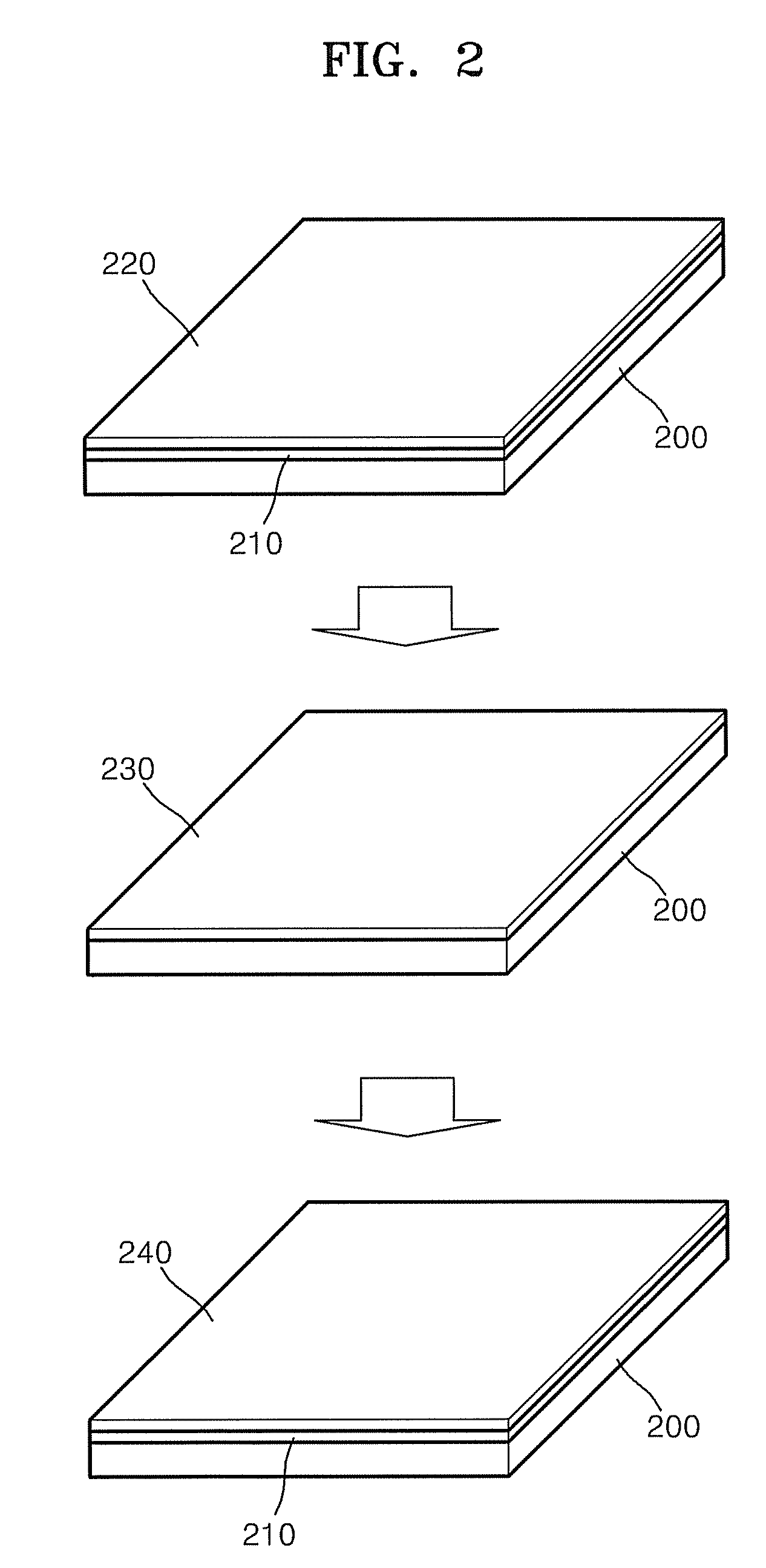

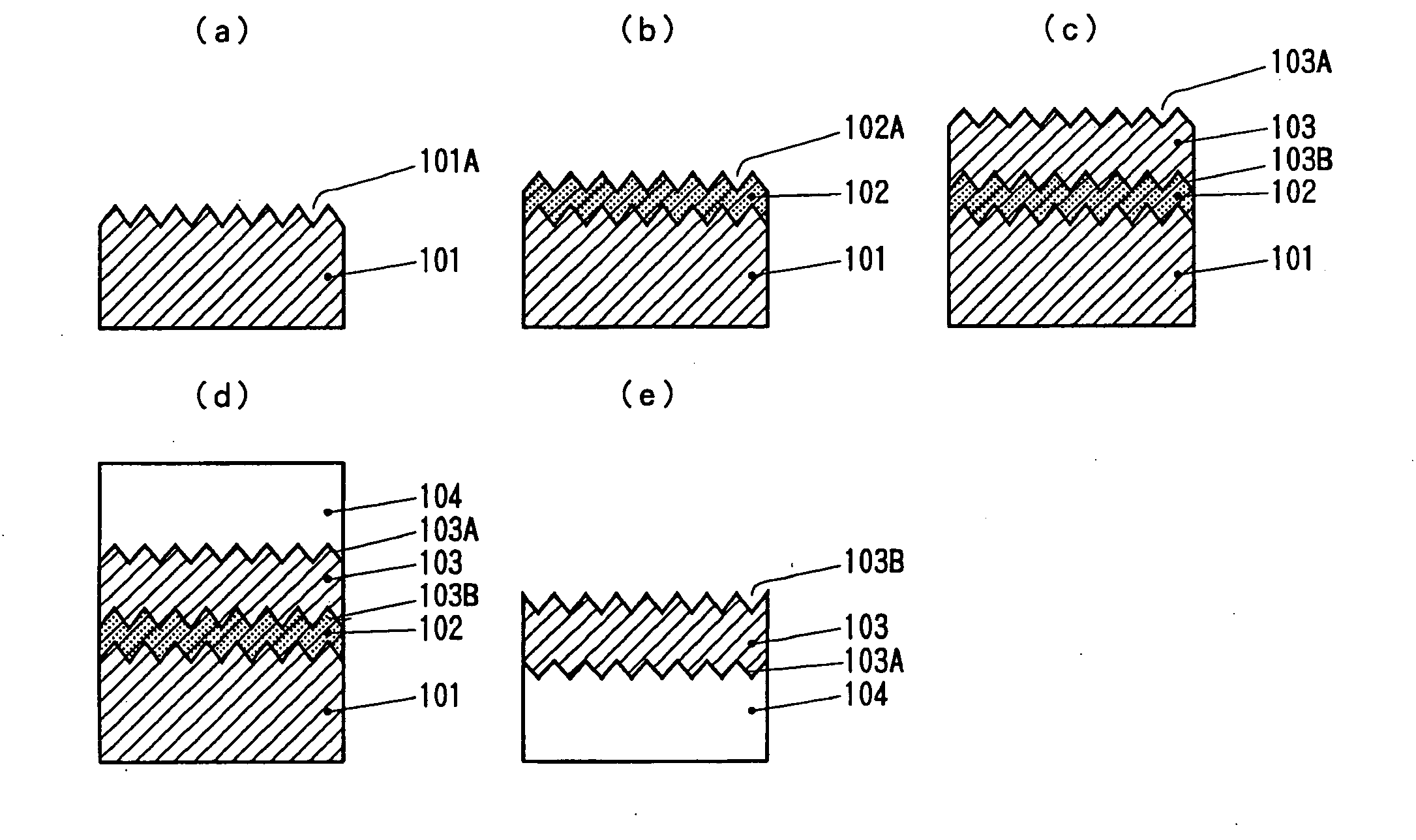

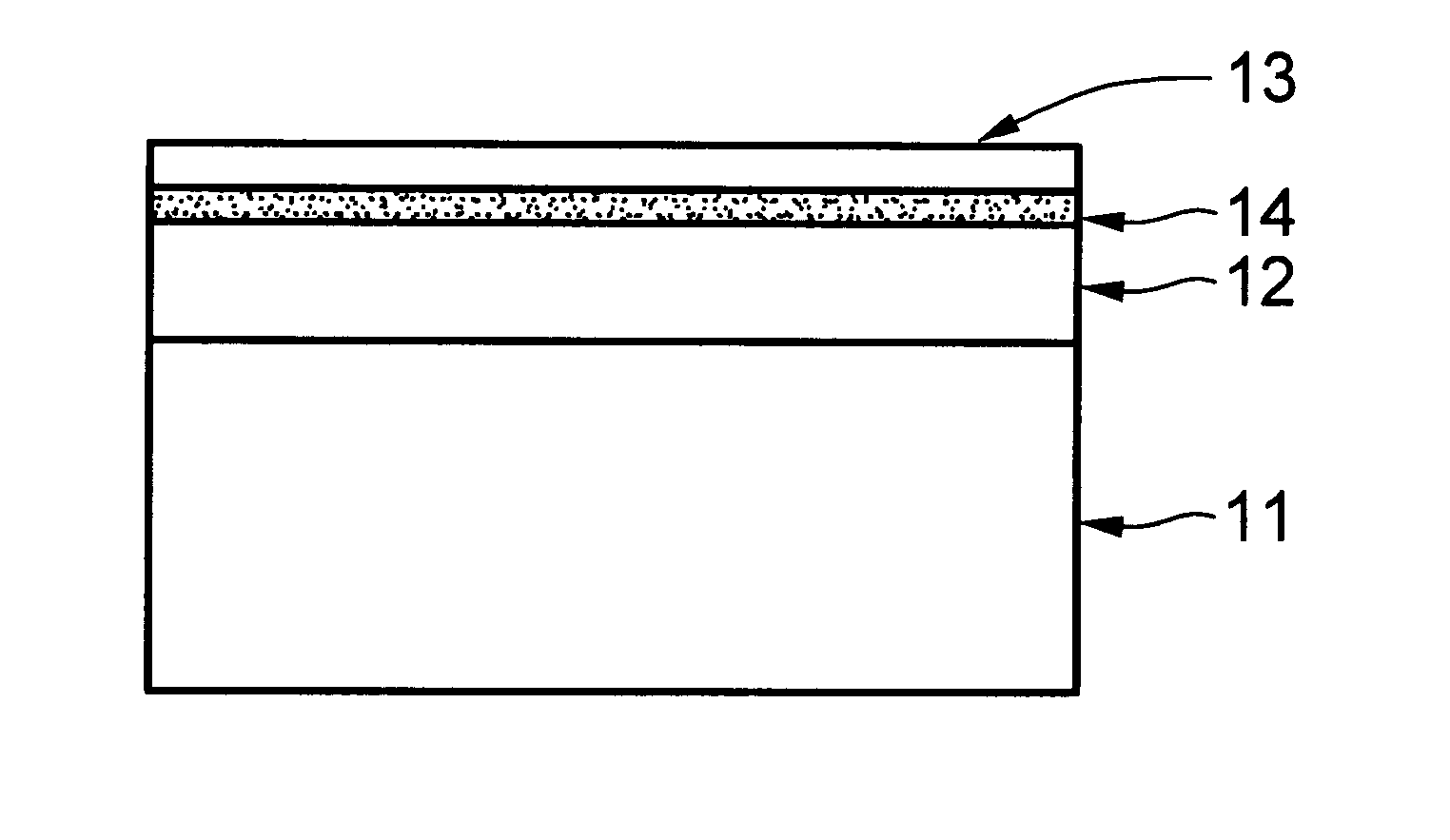

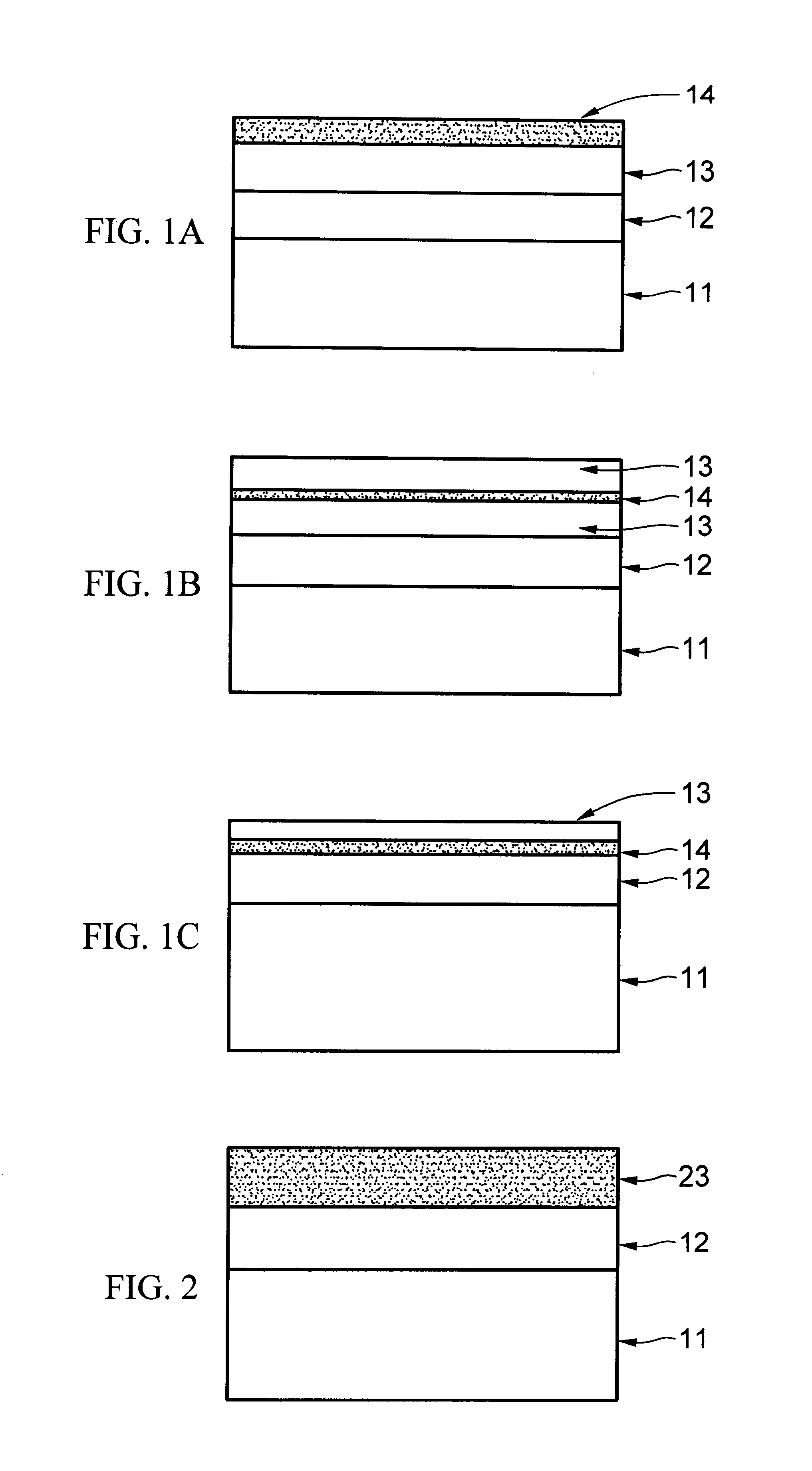

Process for Producing Monocrystal Thin Film and Monocrystal Thin Film Device

The present invention provides a method for manufacturing a monocrystalline film and a device formed by the above method, and according to the method mentioned above, lift-off of the monocrystalline silicon film is preferably performed and a high-purity monocrystalline silicon film can be obtained. A monocrystalline silicon substrate (template Si substrate) 201 is prepared, and on this monocrystalline silicon substrate 201, an epitaxial sacrificial layer 202 is formed. Subsequently, on this sacrificial layer 202, a monocrystalline silicon thin film 203 is rapidly epitaxially-grown using a RVD method, followed by etching of the sacrificial layer 202, whereby a monocrystalline silicon thin film 204 used as a photovoltaic layer of solar cells is formed.

Owner:JAPAN SCI & TECH CORP

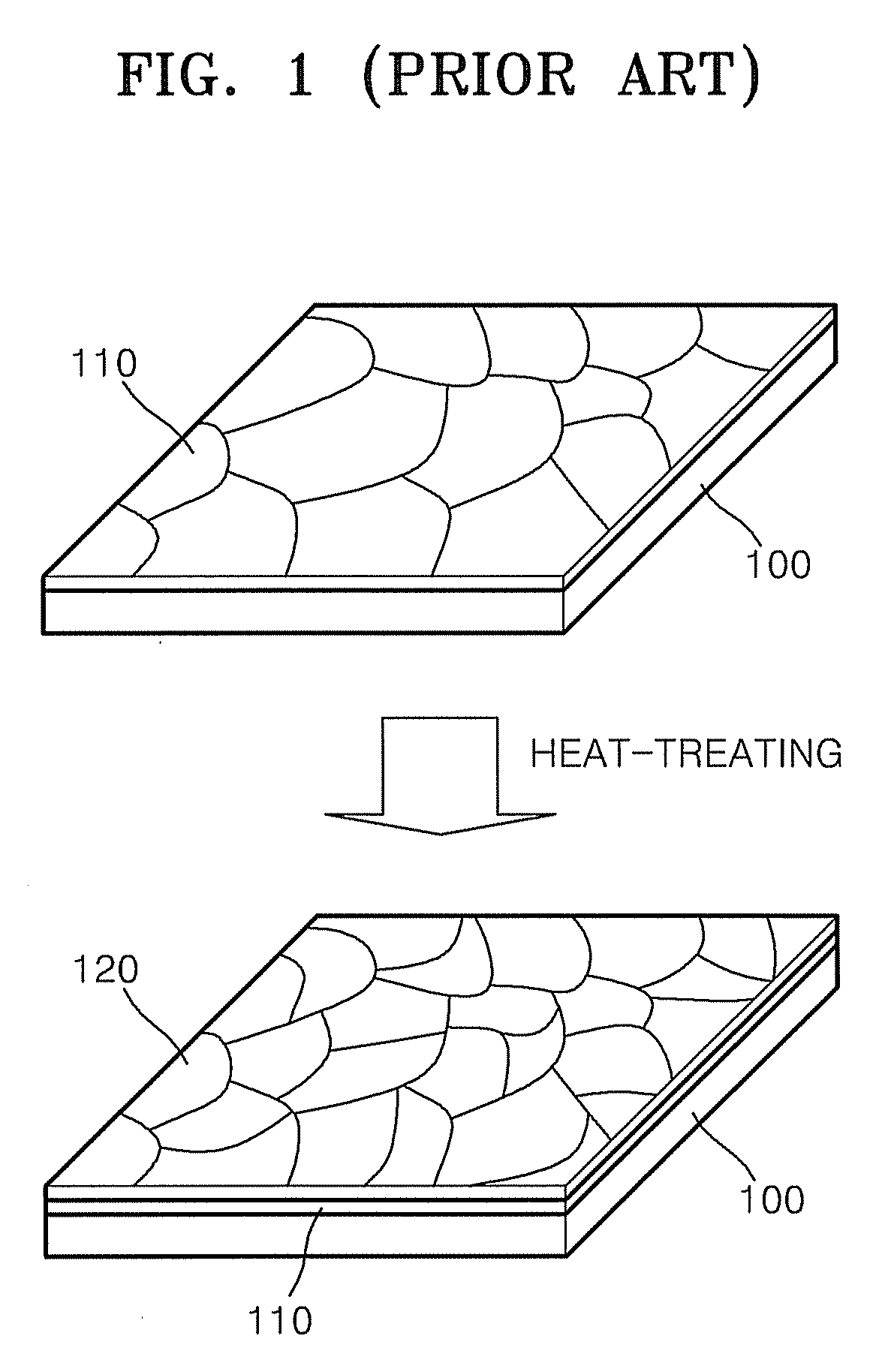

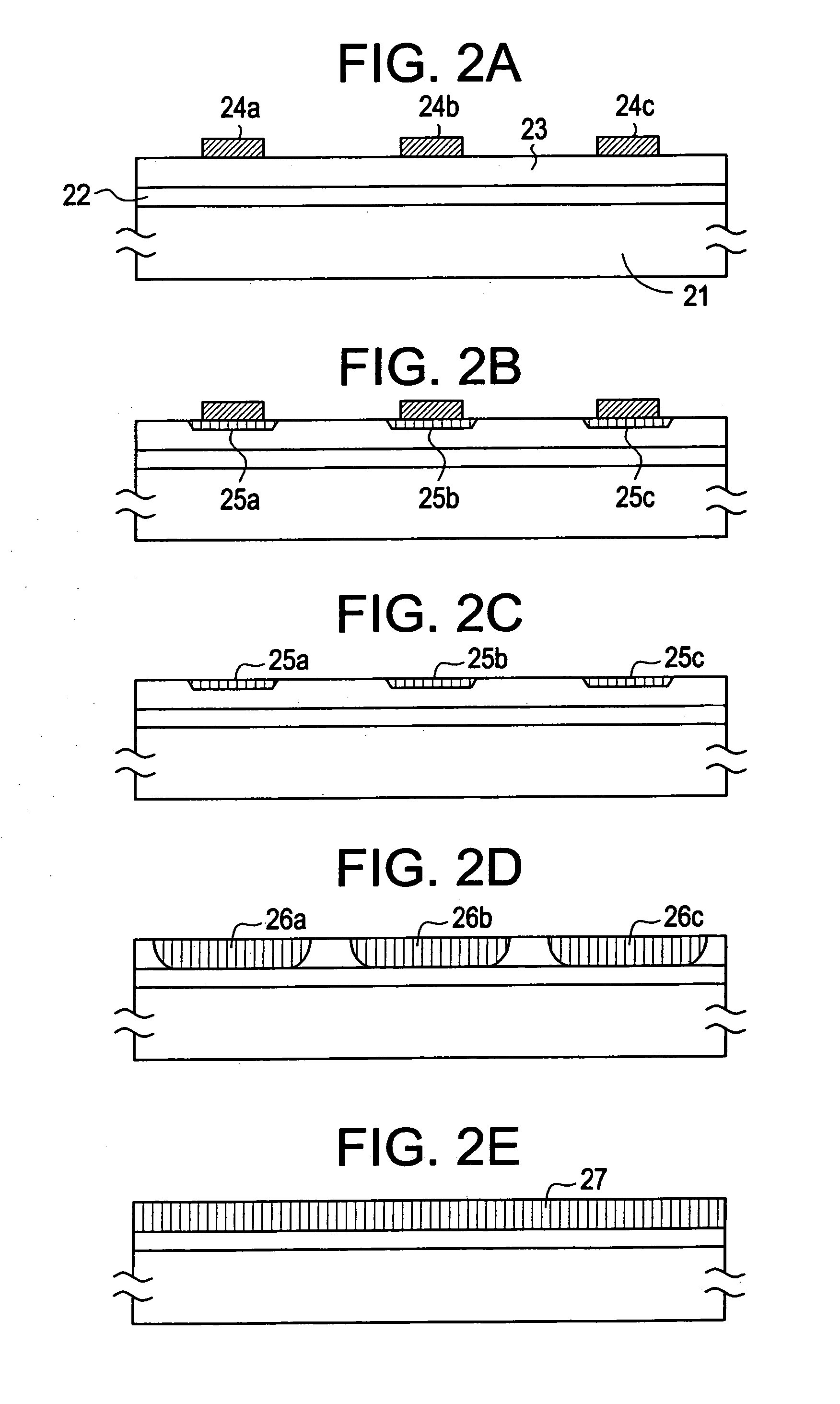

Method for crystallizing amorphous layer

InactiveUS6241817B1Avoid layeringLower crystallization temperatureFrom gel statePolycrystalline material growthPalladiumHeat treated

A method for crystallizing an amorphous layer into a polycrystalline layer. The method uses a substrate under the amorphous layer and a nickel film on the amorphous layer, which are subjected to a heat treatment. The nickel film is formed by a coating step that uses a nickel-containing solution. Alternatively, a nickel and gold, or a nickel and palladium, solution can be used. The method eliminates contamination with metal in the polycrystalline silicon layer and reduces its growth temperature.

Owner:LG DISPLAY CO LTD

Nitride semiconductor heterostructures and related methods

InactiveUS7638346B2Easy to manufactureReduce dislocationFrom gel statePolycrystalline material growthSemiconductor structureSemiconductor heterostructures

Owner:CRYSTAL

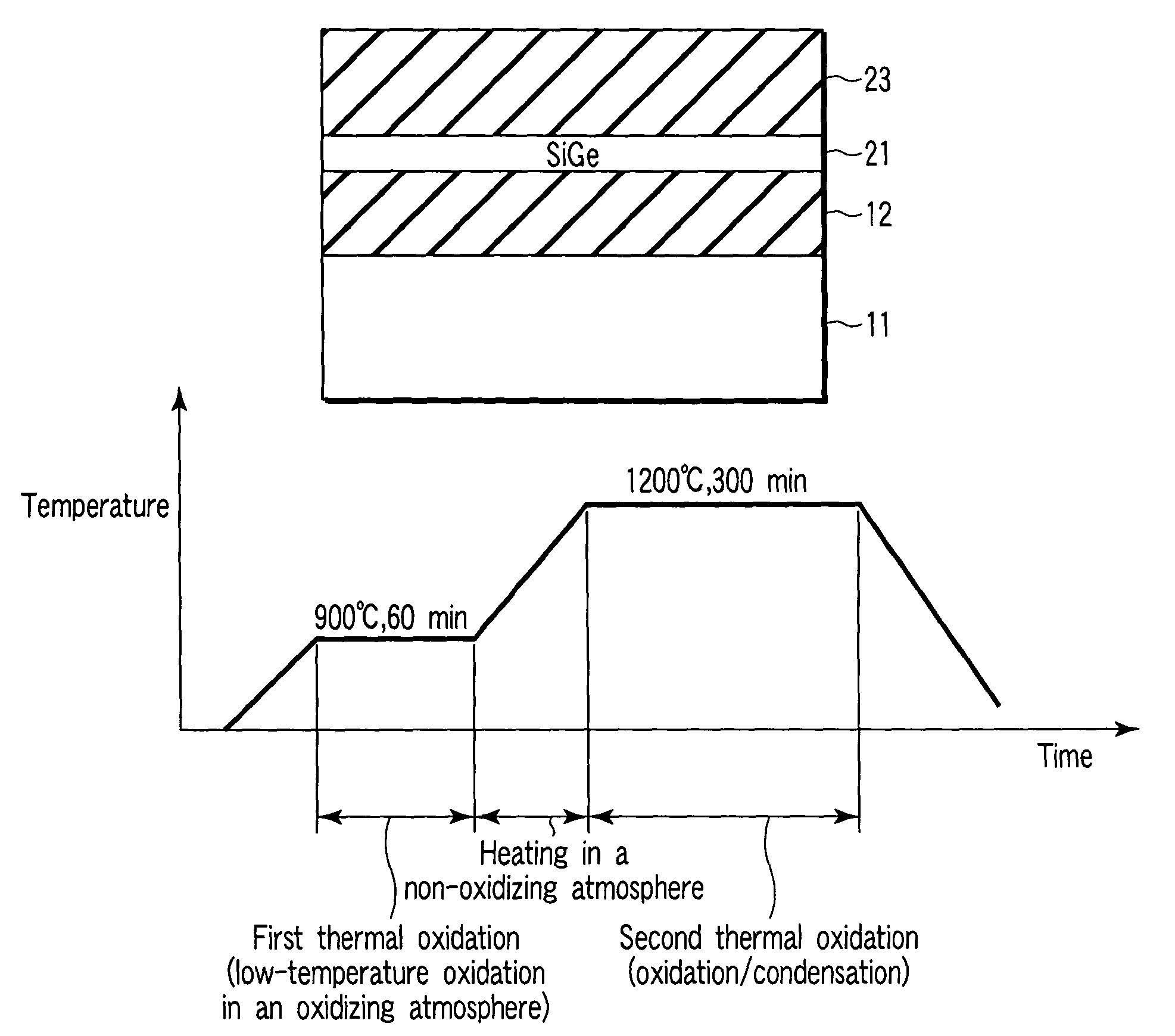

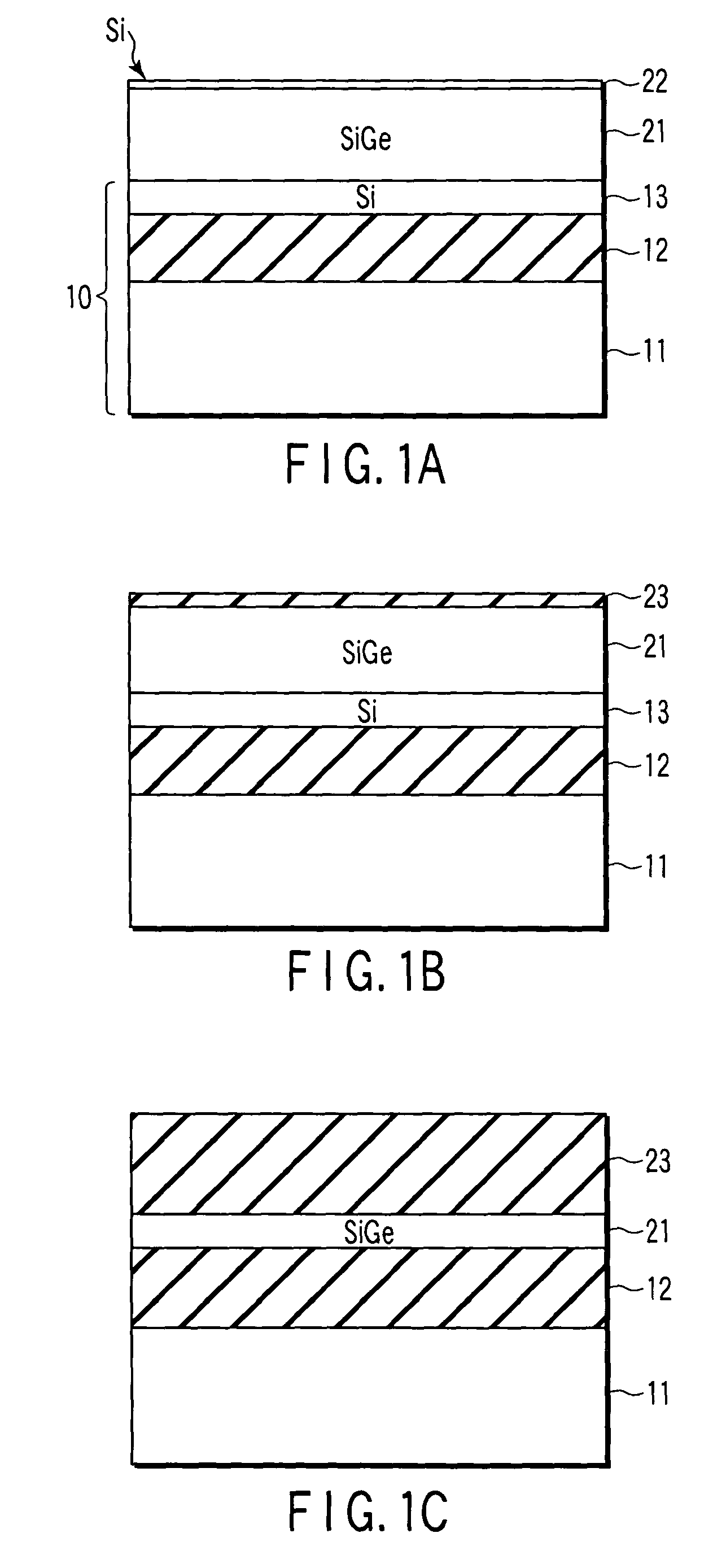

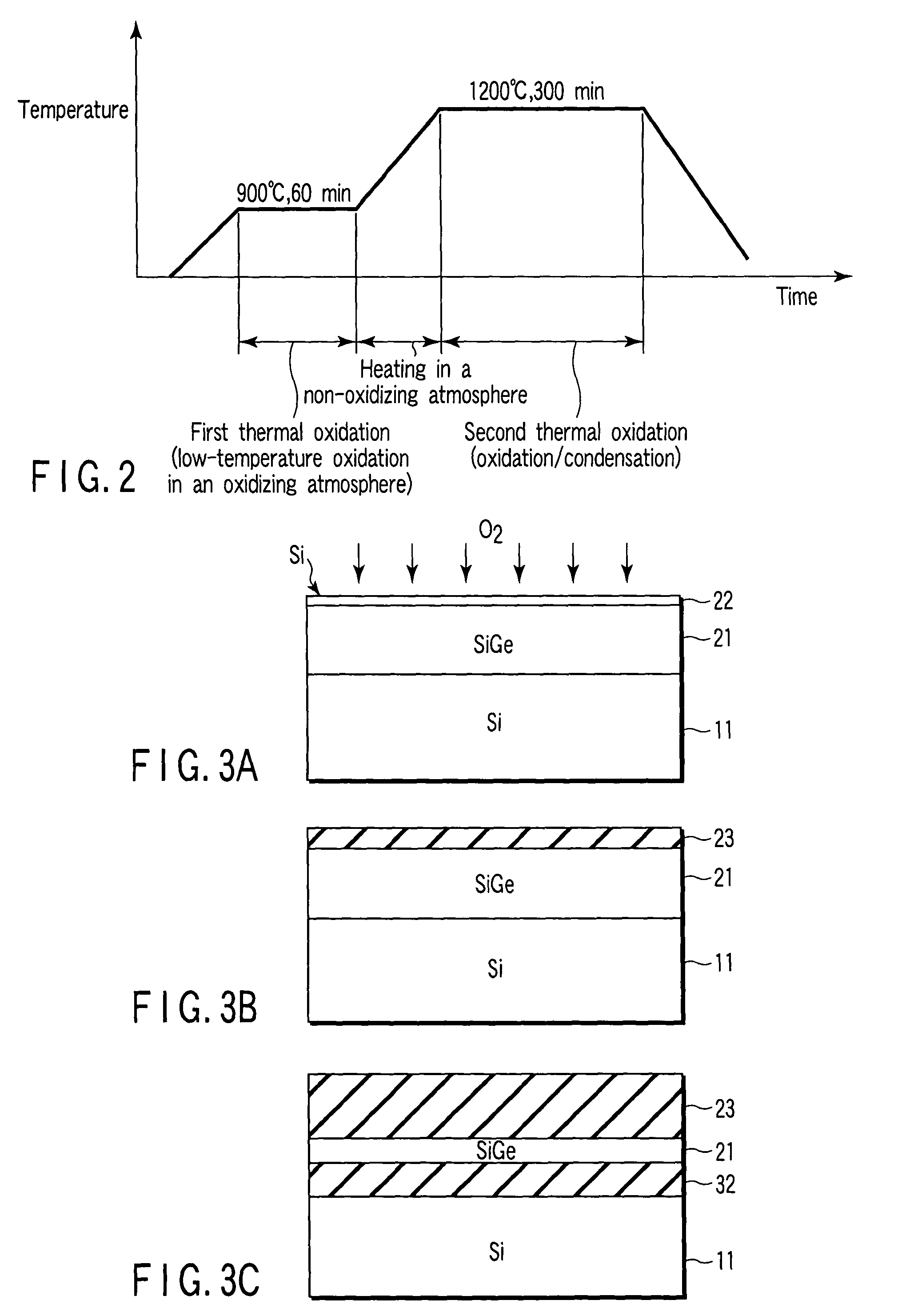

Semiconductor device and method of manufacturing the same

A method of manufacturing a semiconductor device. In the method, a substrate is prepared, which includes a buried oxide film and a SiGe layer formed on the buried oxide film. Then, heat treatment is performed on the substrate at a temperature equal to or lower than a first temperature, to form a protective oxide film on a surface of the SiGe layer. Next, the substrate having the protective oxide film is heated in a non-oxidizing atmosphere to a second temperature higher than the first temperature. Further, heat treatment is performed on the substrate thus heated, in an oxidizing atmosphere at a temperature equal to or higher than the second temperature, to form oxide the SiGe layer, make the SiGe layer thinner and increasing Ge concentration in the SiGe layer, thus forming a SiGe layer having the increased Ge concentration.

Owner:LAPIS SEMICON CO LTD +1

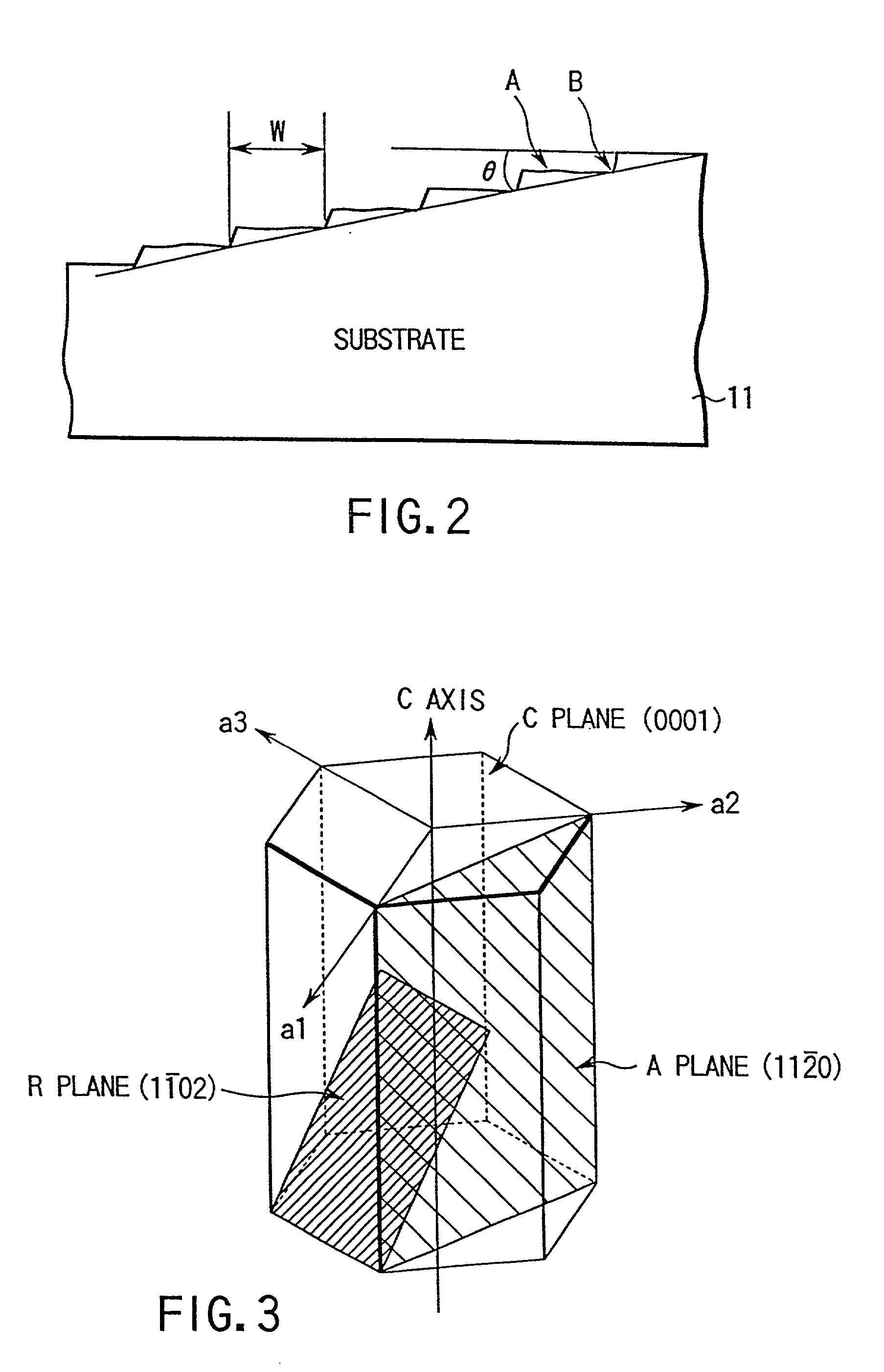

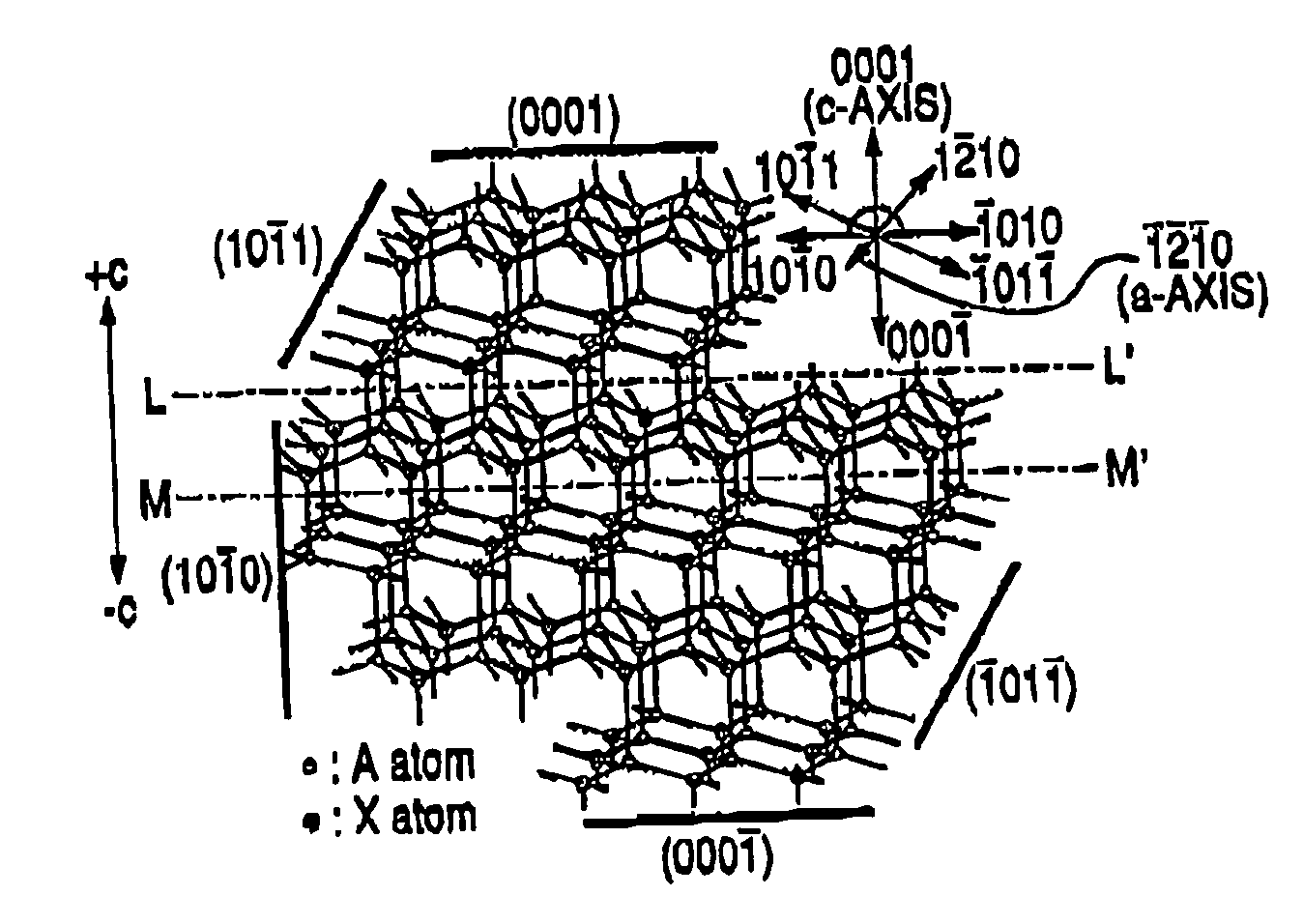

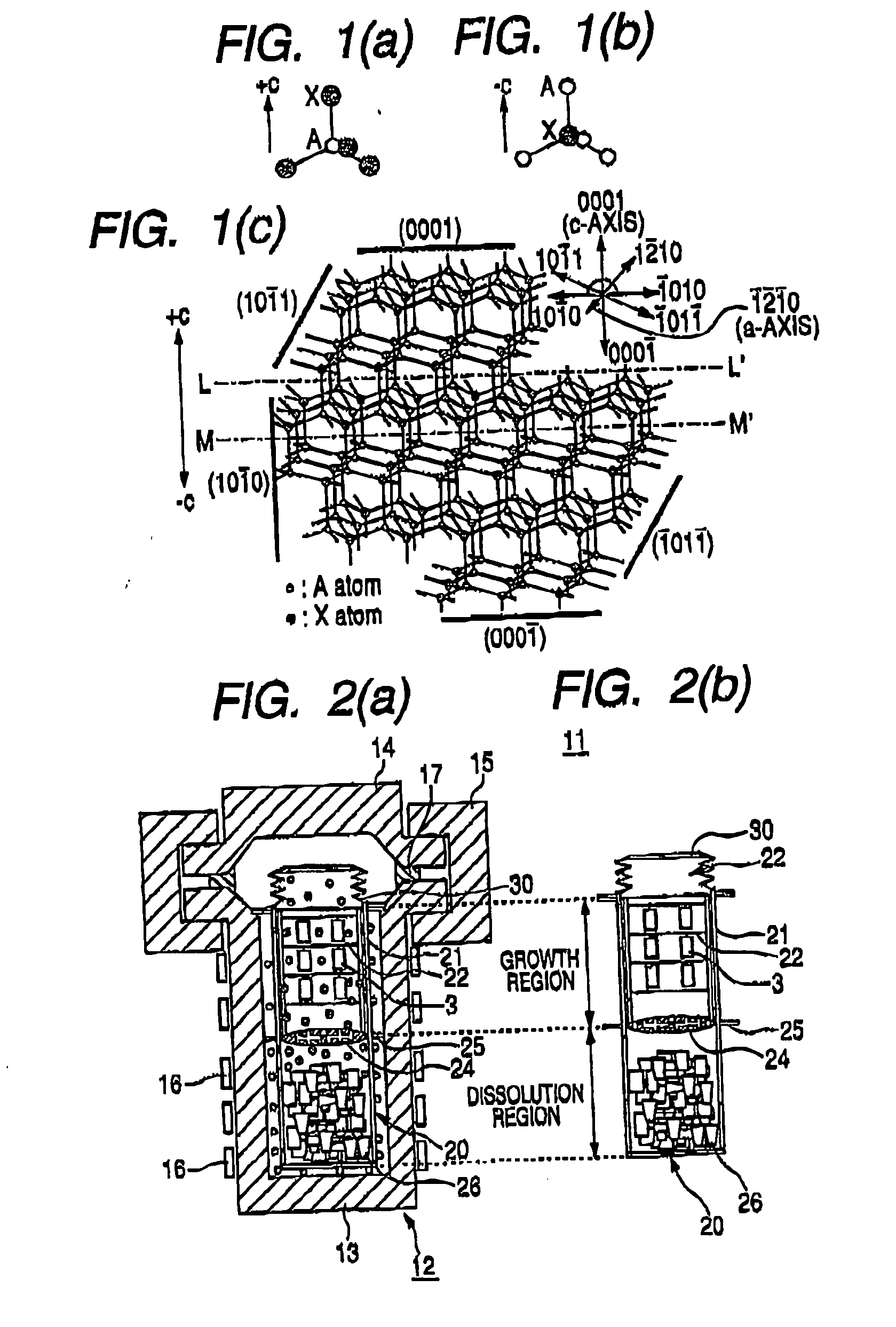

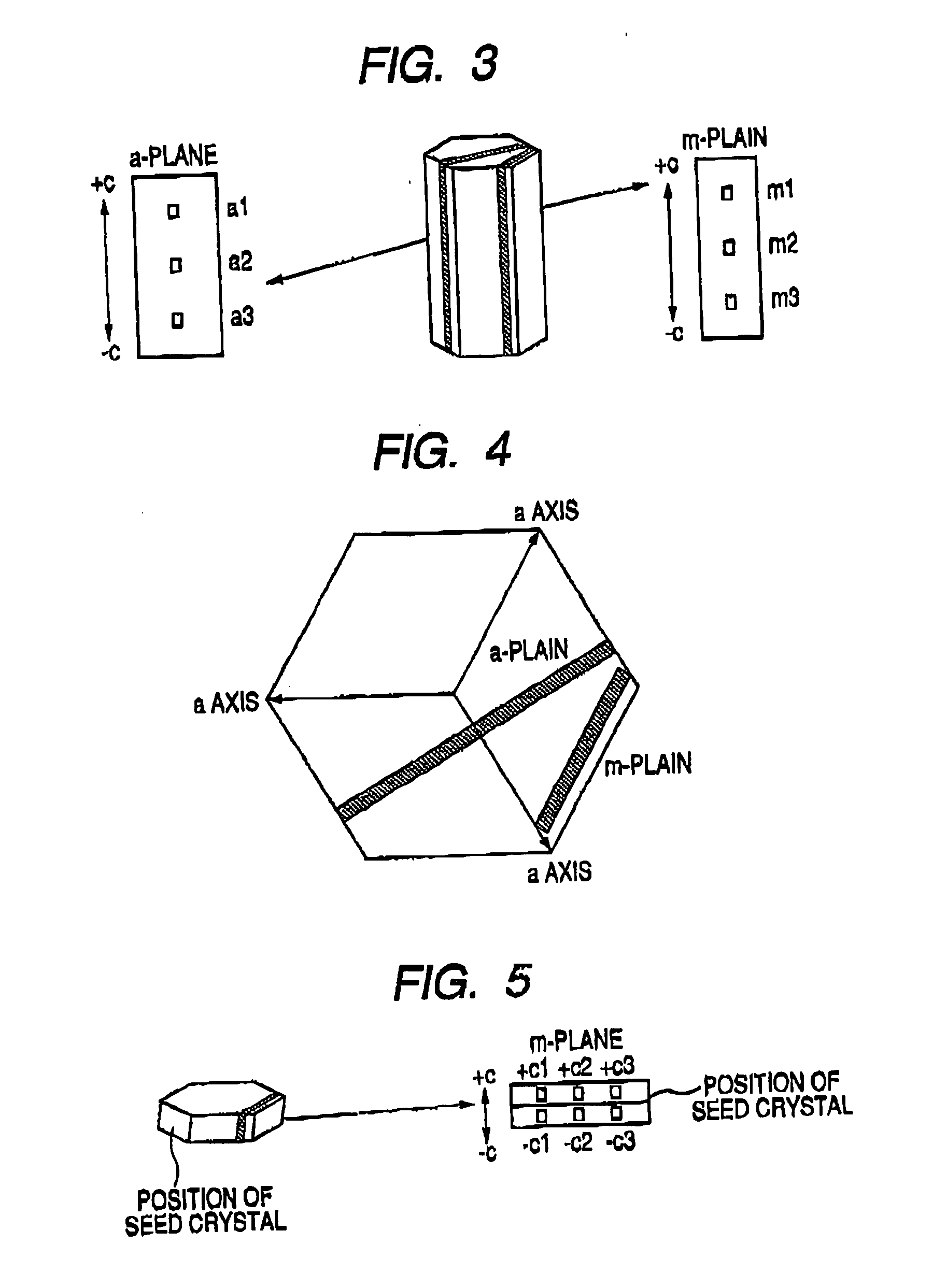

Hexagonal Wurtzite Type Single Crystal, Process For Producing The Same, And Hexagonal Wurtzite Type Single Crystal Substrate

InactiveUS20080056984A1Low impurity concentrationExcellent in uniformity of impurity concentrationFrom gel statePolycrystalline material growthSingle crystal substrateElectronegativity

Provided is a single crystal with a hexagonal wurtzite structure which is useful as a substrate for various devices and has high purity and is uniform. The single crystal with a hexagonal wurtzite structures which is obtained by a crystal growth on at least an m-plane of a columnar seed crystal and represented by AX (A representing an electropositive element and X representing an electronegative element) is characterized in that a variation in the concentration of a metal other than the electropositive element A and having a concentration of 0.1 to 50 ppm is within 100%.

Owner:MITSUBISHI CHEM CORP +1

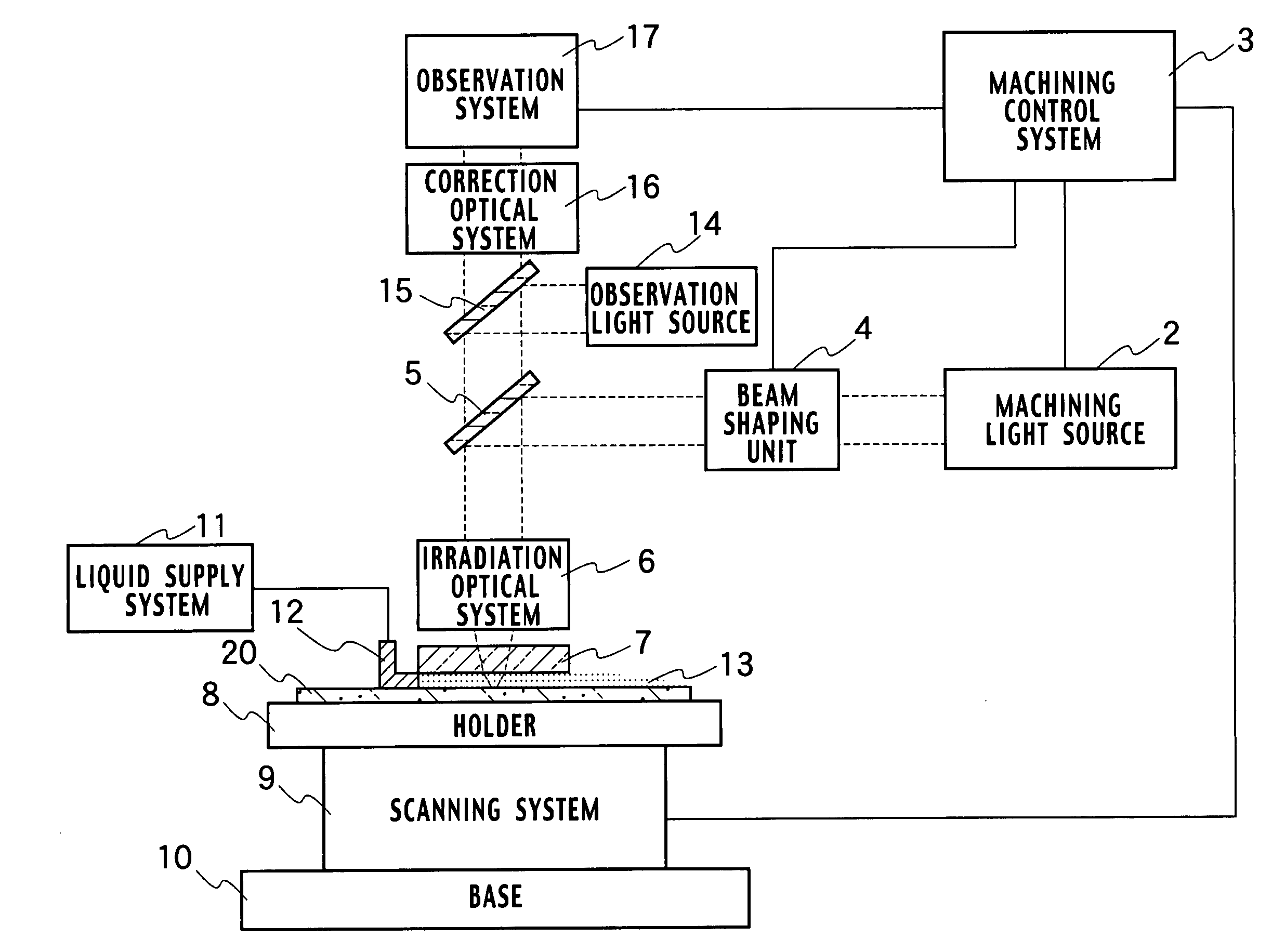

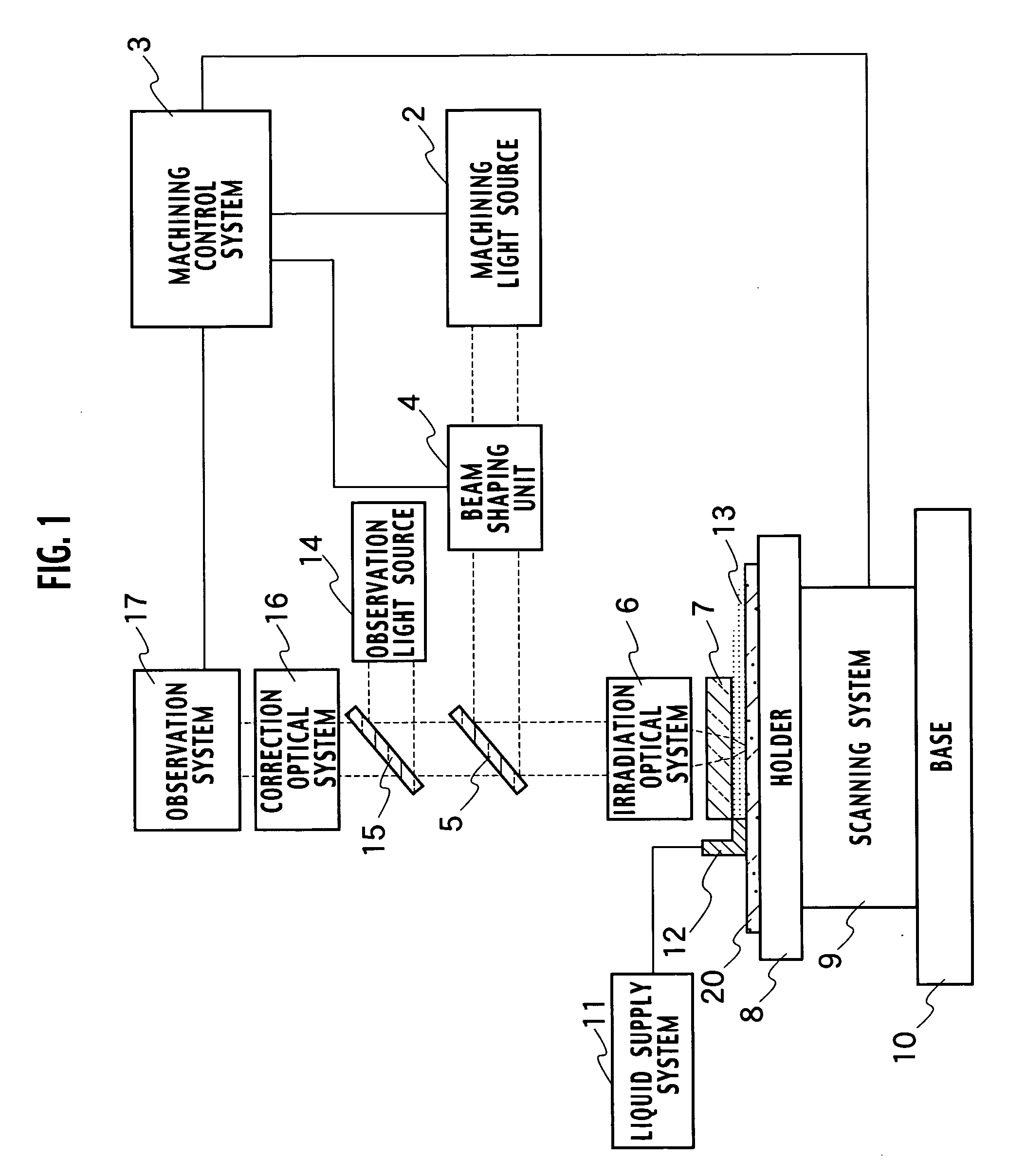

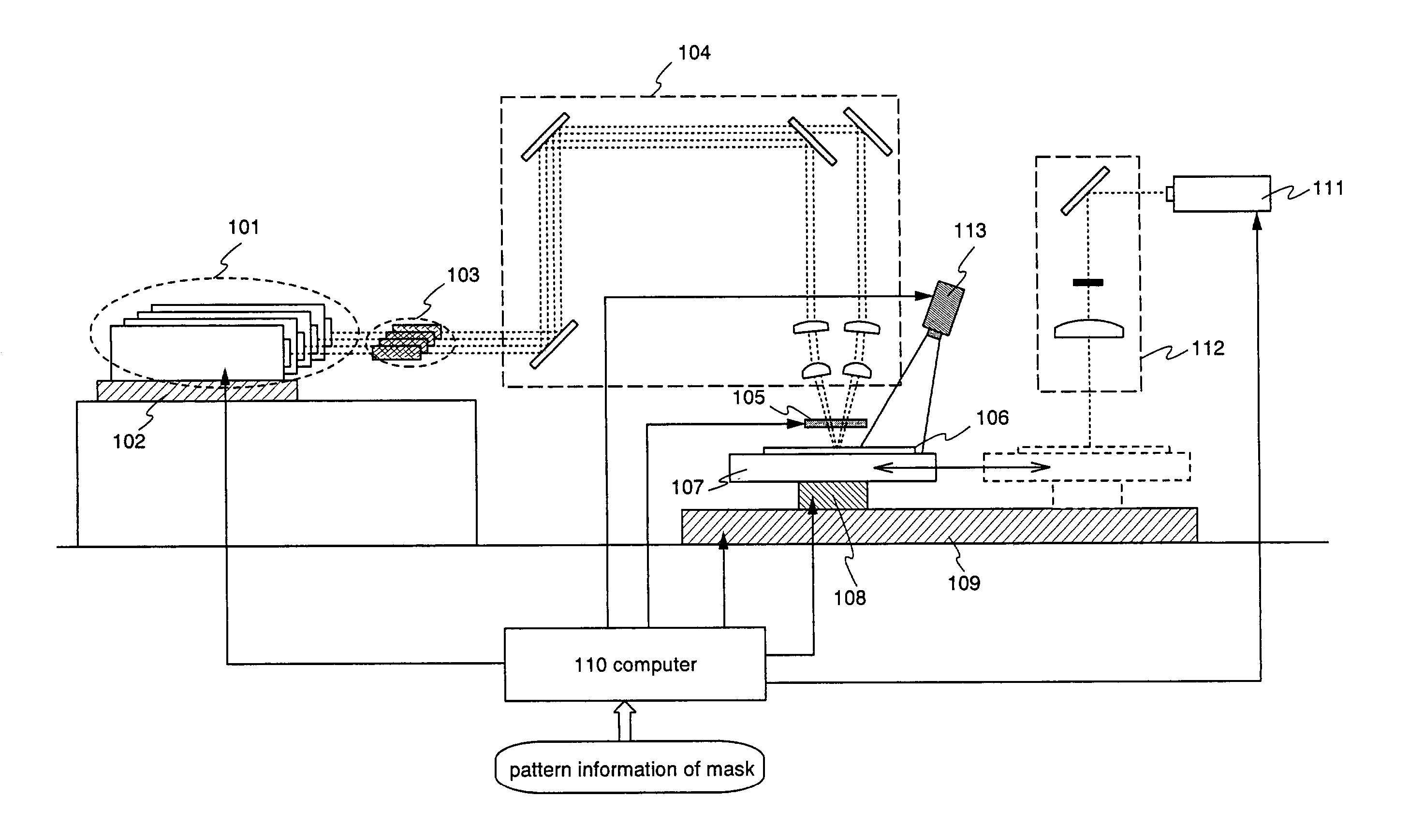

Apparatus for laser beam machining, machining mask, method for laser beam machining, method for manufacturing a semiconductor device and semiconductor device

InactiveUS20050045090A1High bonding strengthFrom gel statePolycrystalline material growthDevice materialOptical axis

An apparatus for laser beam machining includes a scanning system configured to move an object in a scanning direction from a first edge of the object to another edge of the object; a beam shaping unit configured to convert a laser beam to an asymmetrical machining laser beam in the scanning direction on a plane orthogonal to an optical axis of the laser beam; and an irradiation optical system configured to irradiate the machining laser beam emitted from the beam shaping unit onto the object.

Owner:KK TOSHIBA

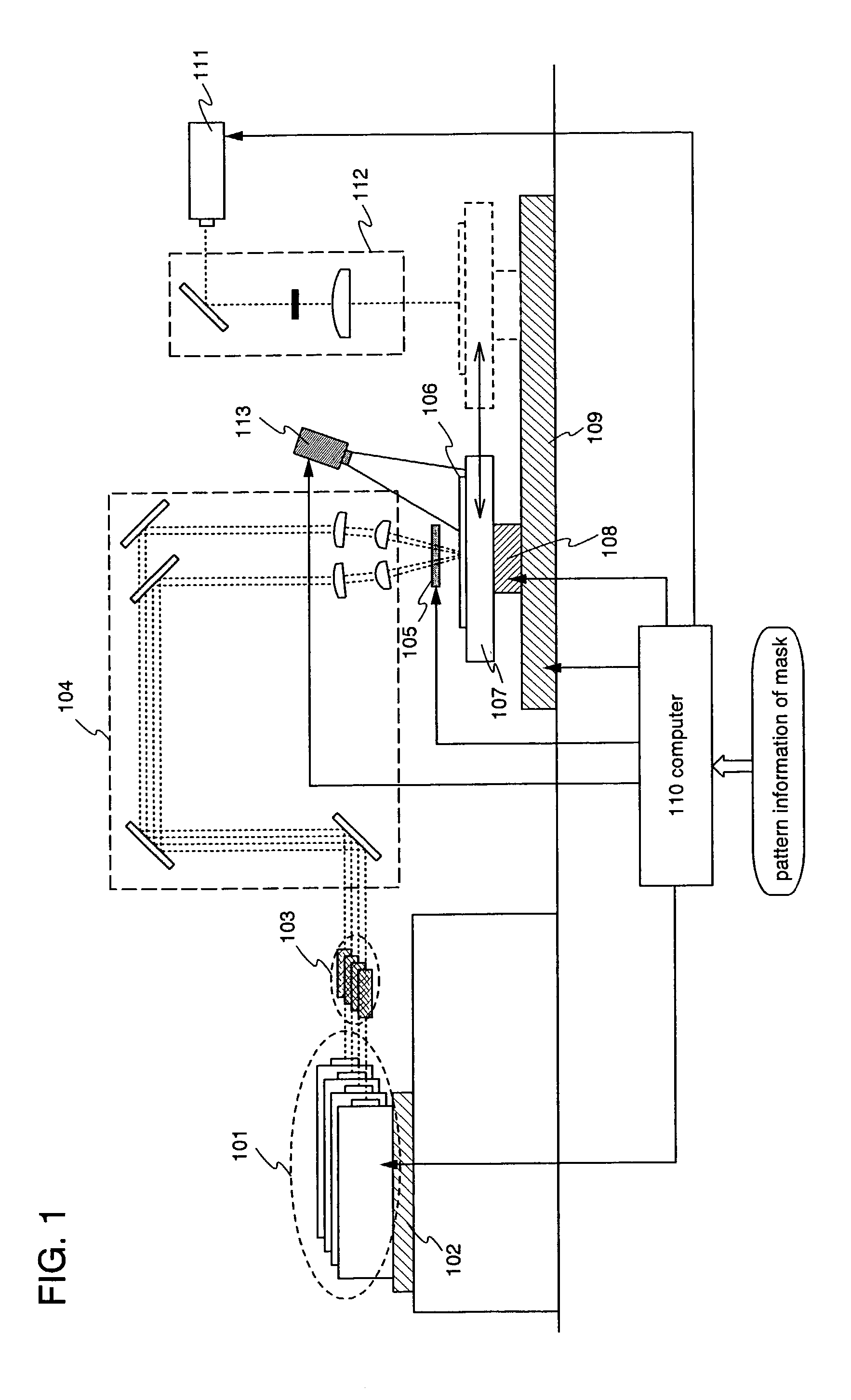

Laser irradiation apparatus

InactiveUS7105048B2High crystallinityImprove mobilityFrom gel stateFrom solid stateLight beamLaser scanning

Each region, which should be left on a substrate after patterning, of a semiconductor film is grasped in accordance with a mask. Then, each region to be scanned with laser light is determined so that at least the region to be obtained through the patterning is crystallized, and a beam spot is made to hit the region to be scanned, thereby partially crystallizing the semiconductor film. Each portion with low output energy of the beam spot is shielded by a slit. In the present invention, the laser light is not scanned and irradiated onto the entire surface of the semiconductor film but is scanned such that at least each indispensable portion is crystallized to a minimum. With the construction described above, it becomes possible to save time taken to irradiate the laser light onto each portion to be removed through the patterning after the crystallization of the semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

Single crystal SiC and a method of producing the same

InactiveUS6053973AEasily eliminate mismatchStably and efficiently obtainFrom gel statePolycrystalline material growthPorous carbonSurface roughness

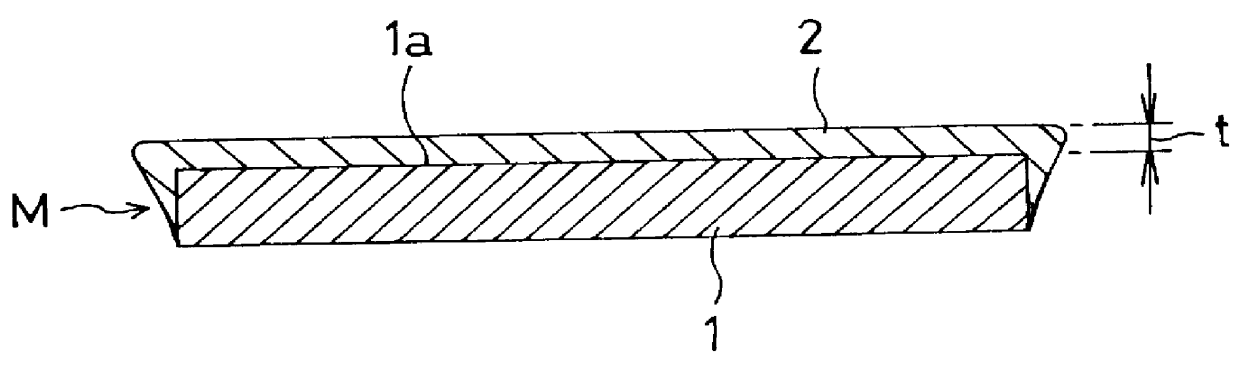

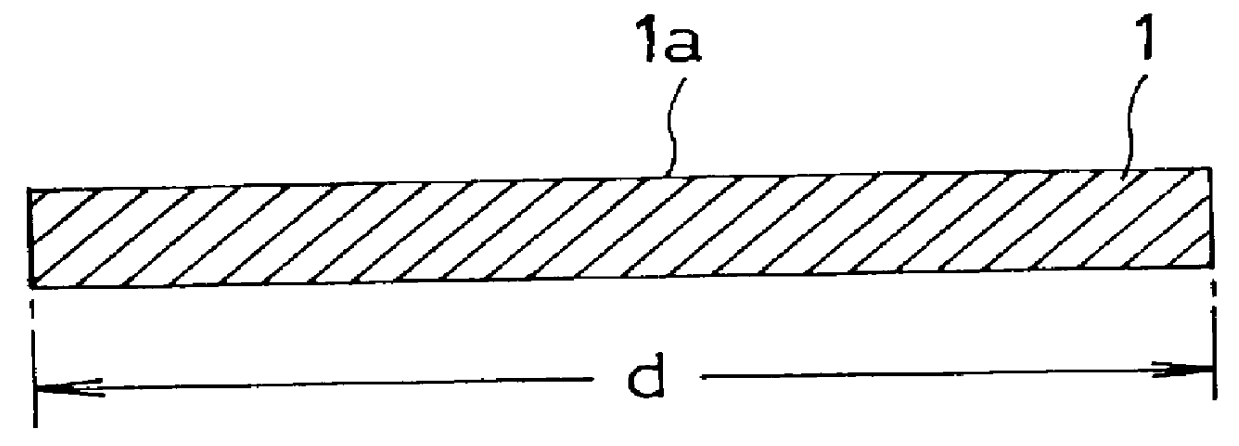

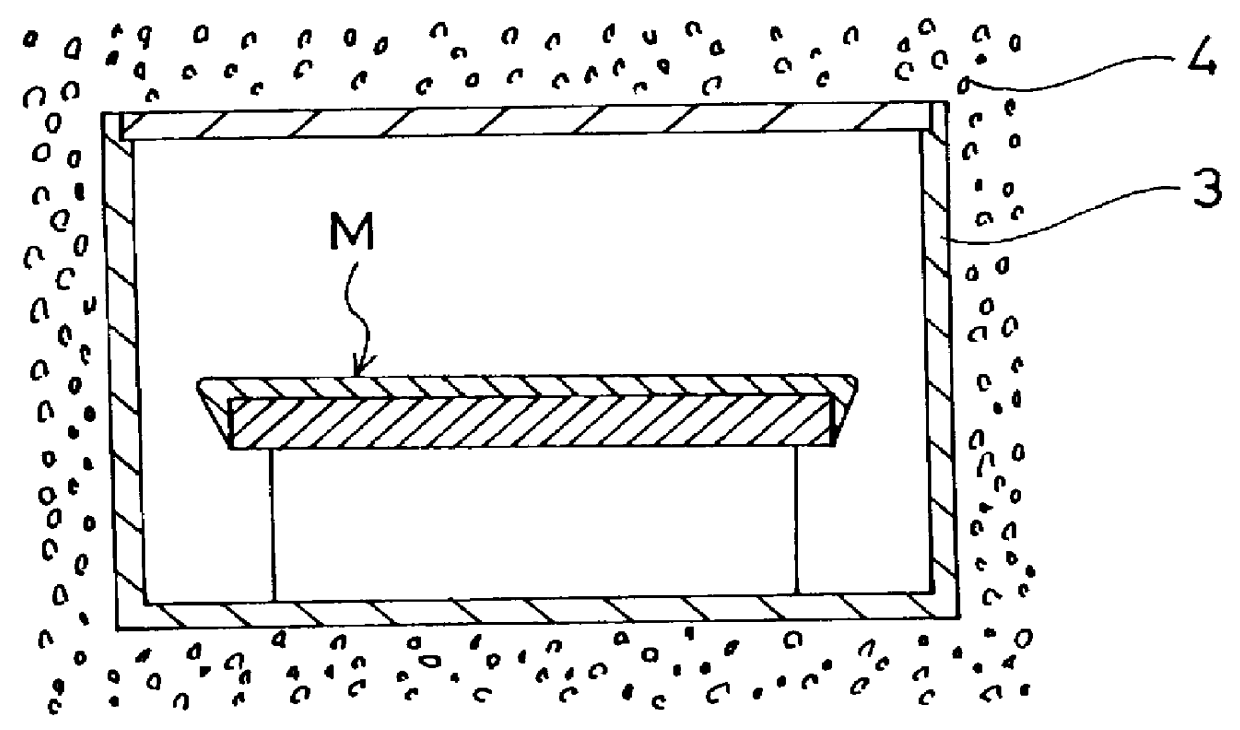

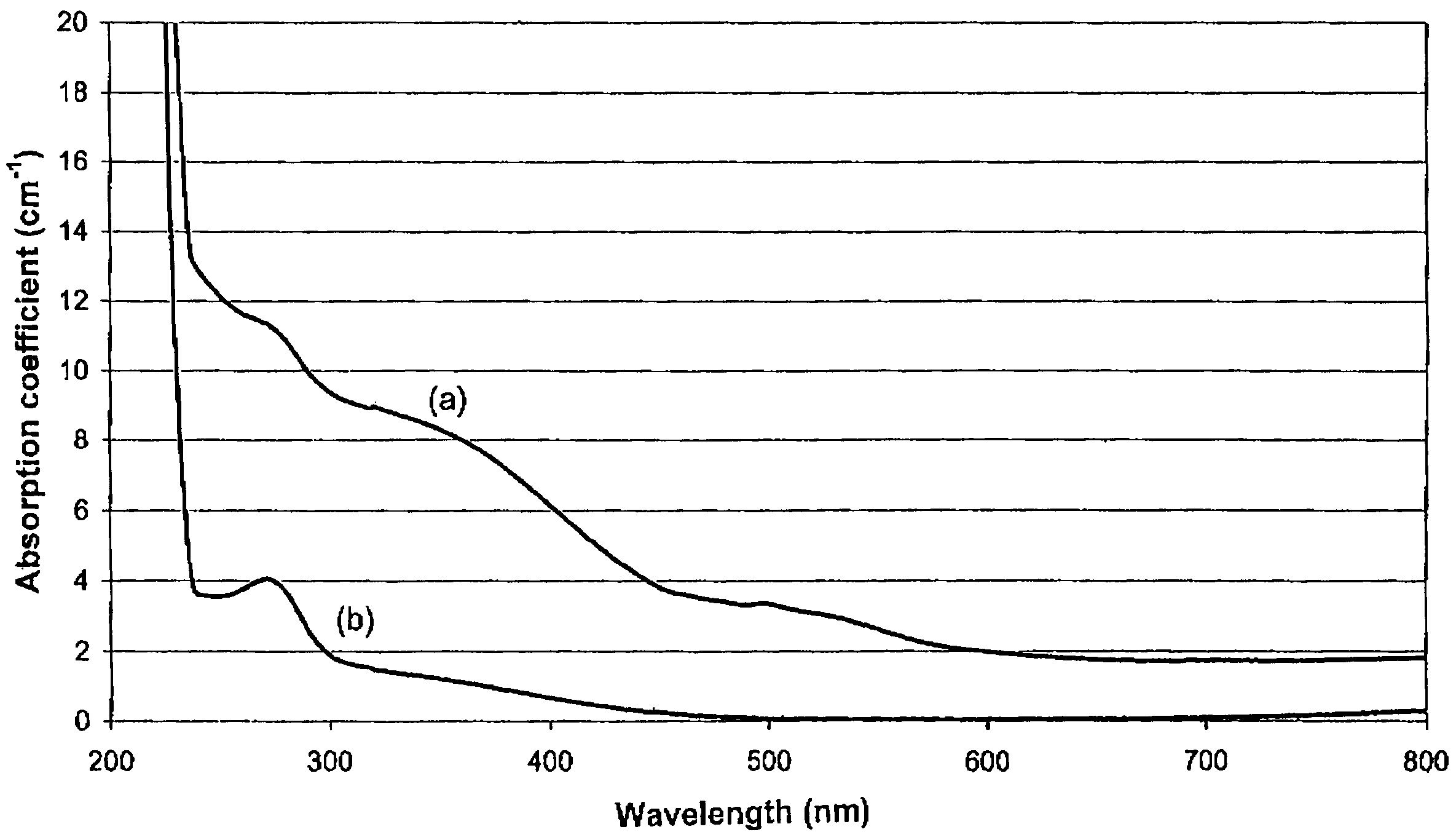

The surface 1a of a single crystal alpha -SiC substrate 1 is adjusted so as to have a surface roughness equal to or lower than 2,000 angstroms RMS, and preferably equal to or lower than 1,000 angstroms RMS. On the surface 1a of the single crystal alpha -SiC substrate 1, a polycrystalline alpha -SiC film 2 is grown by thermal CVD to form a complex is placed in a porous carbon container and the carbon container is covered with alpha -SiC powder. The complex is subjected to a heat treatment at a temperature equal to or higher than a film growing temperature, i.e., in the range of 1,900 to 2,400 DEG C. in an argon gas flow, whereby single crystal alpha -SiC is integrally grown on the single crystal alpha -SiC substrate 1 by crystal growth and recrystallization of the polycrystalline alpha -SiC film 2. It is possible to stably and efficiently produce single crystal SiC of a large size which has a high quality and in which any crystal nucleus is not generated.

Owner:NISSIN ELECTRIC CO LTD

Colored diamond

ActiveUS7172655B2Simple to achieve pressureEasy accessFrom gel stateUltra-high pressure processesSingle crystalMaterials science

A method of producing a single crystal CVD diamond of a desired color which includes the steps of providing single crystal CVD diamond which is colored and heat treating the diamond under conditions suitable to produce the desired color. Colors which may be produced are, for example, in the pink-green range.

Owner:ELEMENT SIX TECH LTD

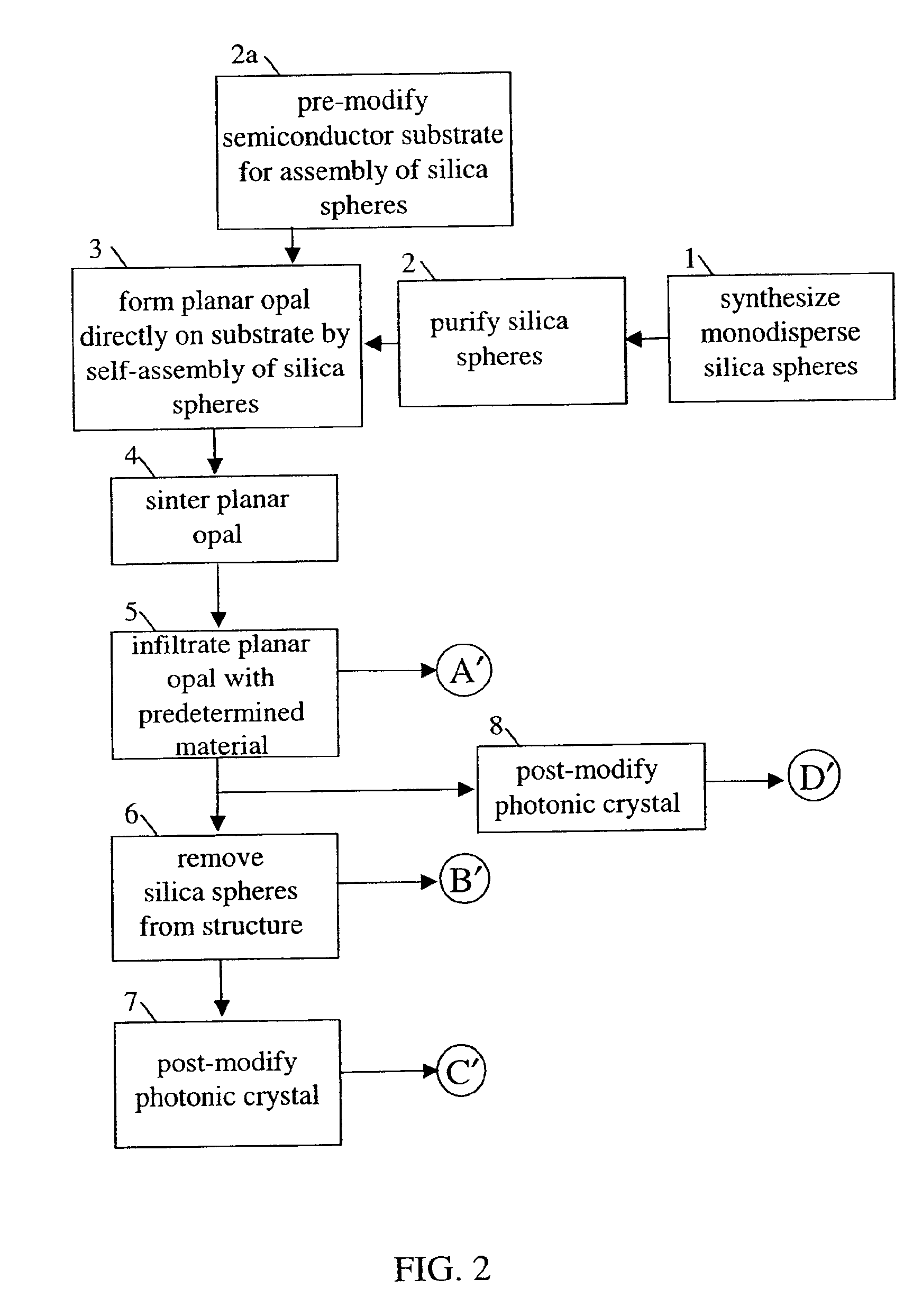

Self-assembled photonic crystals and methods for manufacturing same

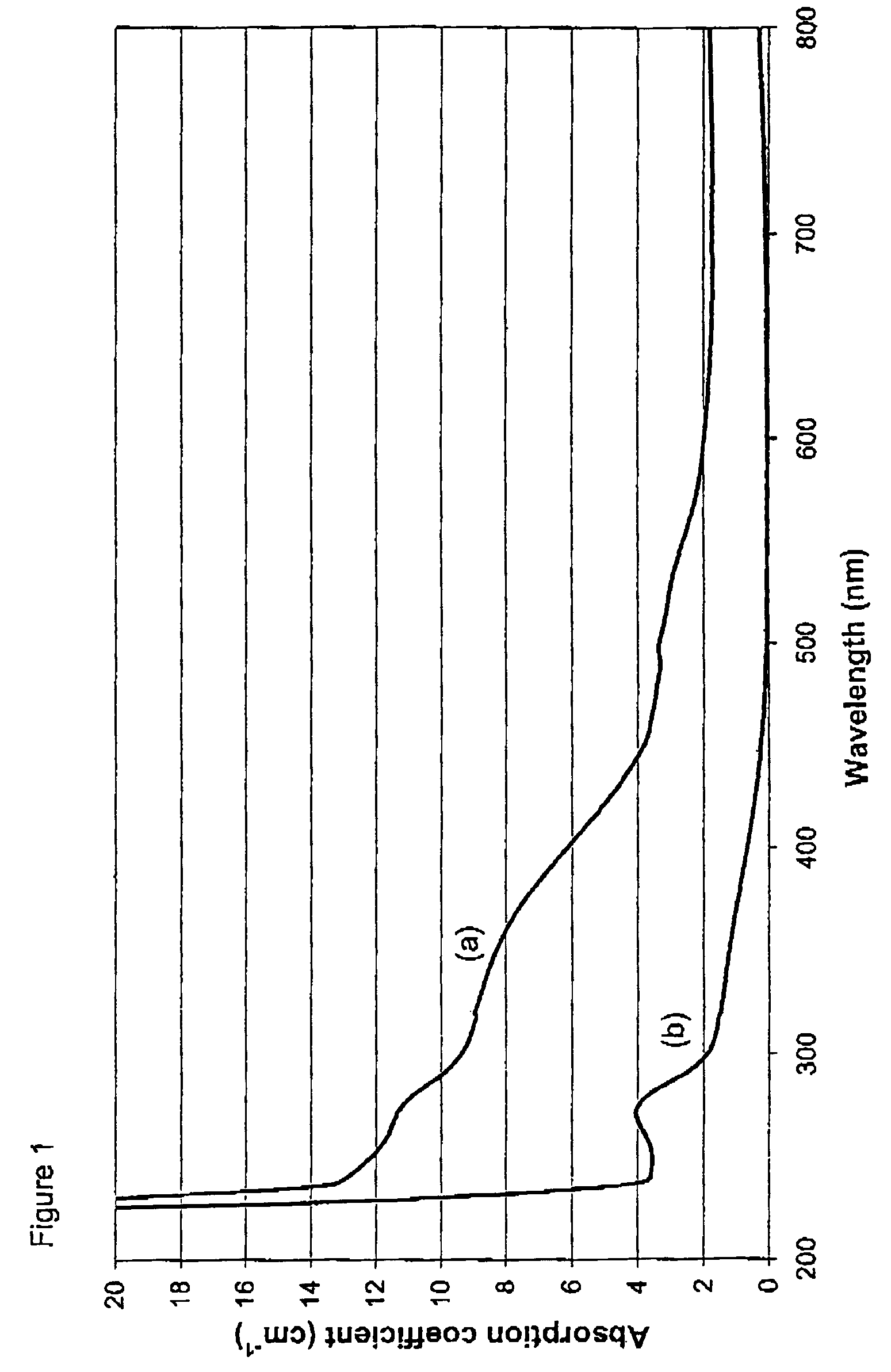

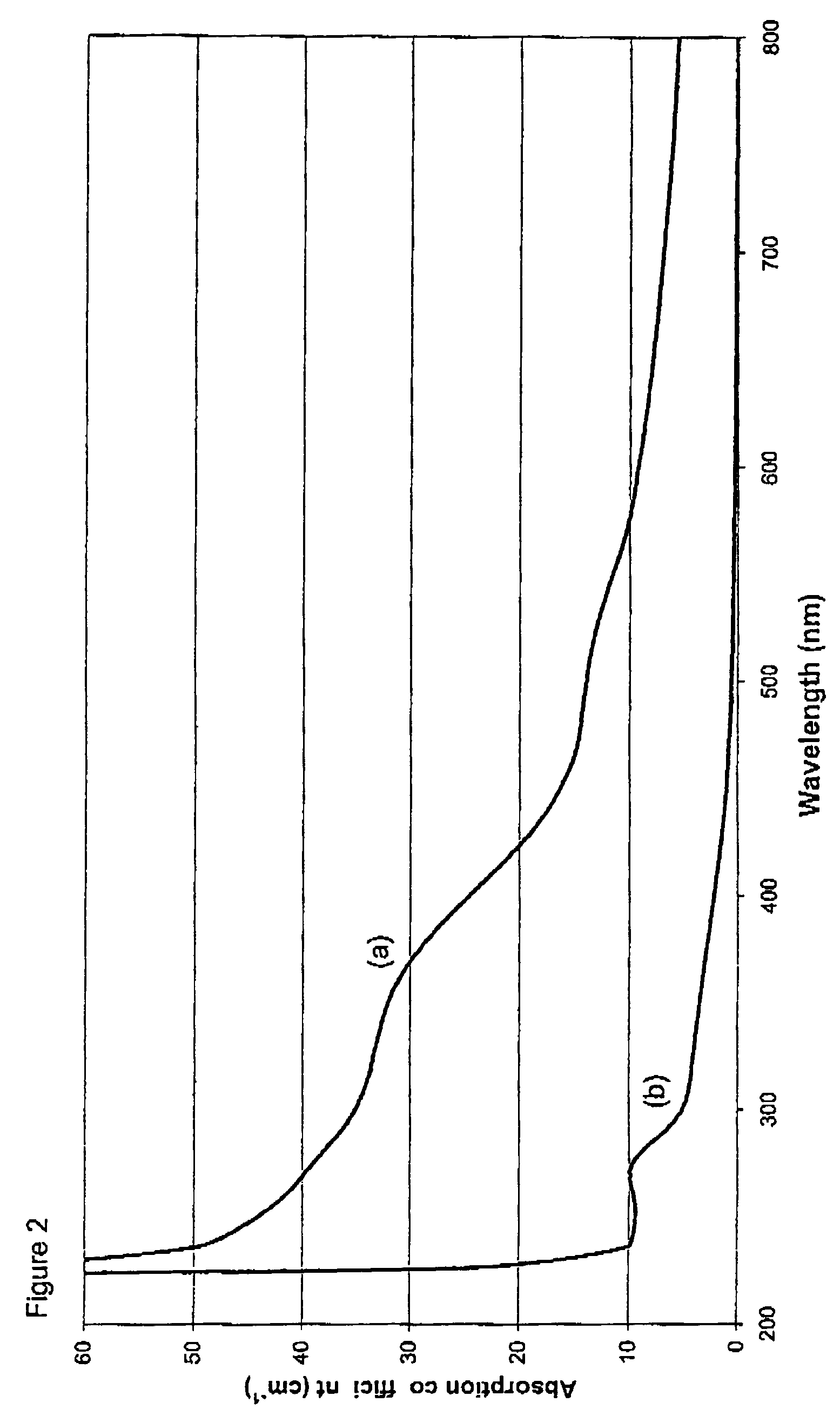

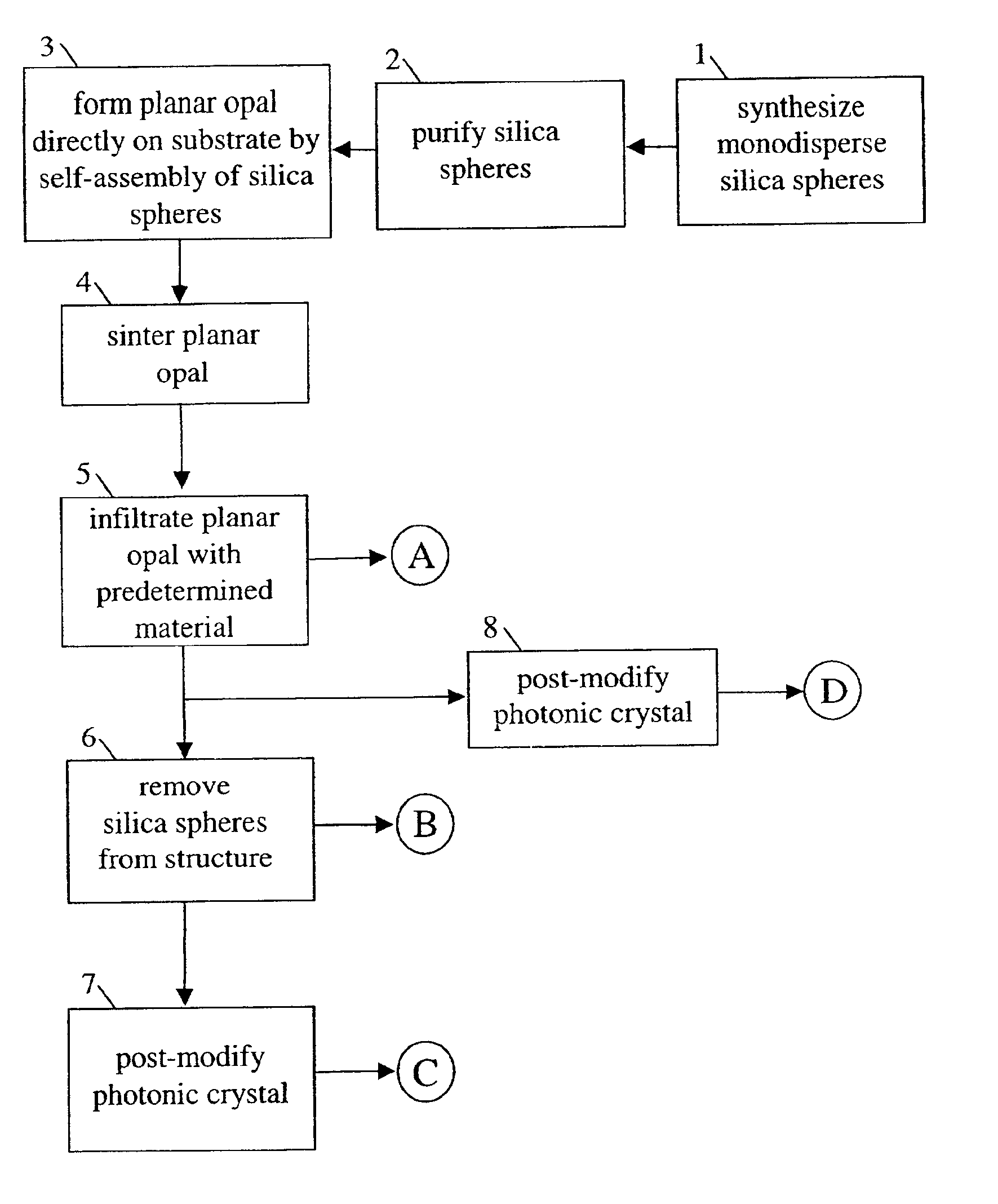

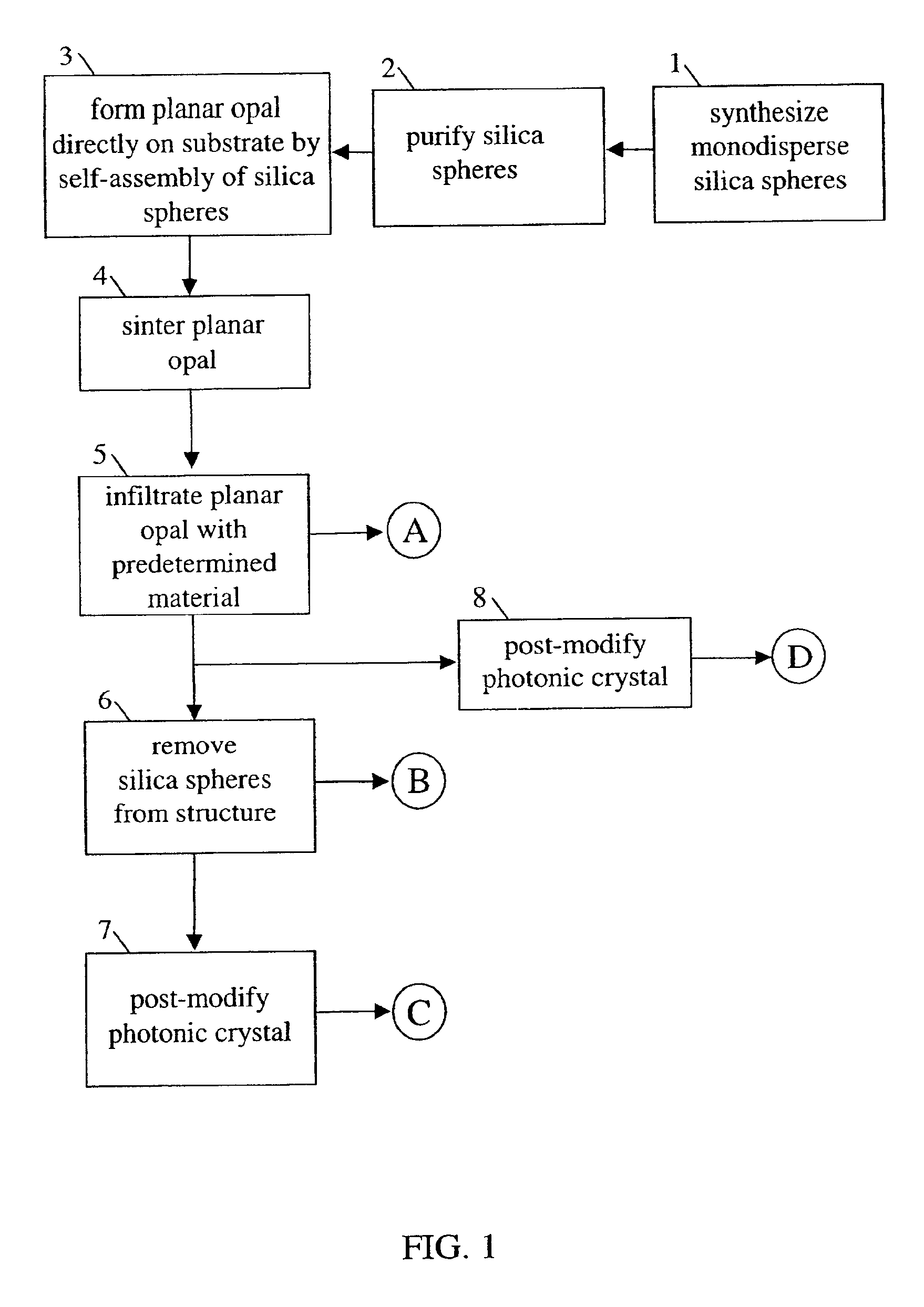

InactiveUS6858079B2Well formedImprove assembly strengthFrom gel stateMaterial nanotechnologyPhotonic crystalGlobular shaped

Self-assembled photonic crystals, including large sphere planar opals, infiltrated planar opals and inverted planar opals, as well as methods for manufacturing same are provided. Large sphere planar opals are manufactured according to a method comprising the steps of: synthesizing monodisperse silica spheres, wherein each of the silica spheres has a diameter greater than or equal to about 400 nanometers; purifying the silica spheres; and self-assembling the silica spheres into a plurality of ordered, planar layers on a substrate. Infiltrated planar opals may also be manufactured by further processing the large sphere planar opal by sintering the planar opal and infiltrating the planar opal with a predetermined material. Inverted planar opals may further be manufactured by removing the silica spheres from the infiltrated planar opal. Various modifications to the substrate and planar opal are also provided to enhance the properties of these photonic crystals.

Owner:NEC CORP

Process For Producing Aluminum Nitride Crystal And Aluminum Nitride Crystal Obtained Thereby

InactiveUS20080008642A1Mild production conditionsQuality improvementFrom gel statePolycrystalline material growthIndiumAlkaline earth metal

The present invention provides a method for producing aluminum nitride crystals under mild pressure and temperature conditions. In the production method of aluminum nitride crystals, aluminum nitride crystals are formed and grown in the presence of nitrogen-containing gas by allowing aluminum and the nitrogen to react with each other in a flux containing the following component (A) and component (B), or a flux containing the following component (B). (A) At least one element selected from the group consisting of the alkali metal and the alkaline-earth metal. (B) At least one element selected from the group consisting of tin (Sn), gallium (Ga), indium (In), bismuth (Bi) and mercury (Hg).

Owner:OSAKA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com