Patents

Literature

388results about How to "Lower crystallization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

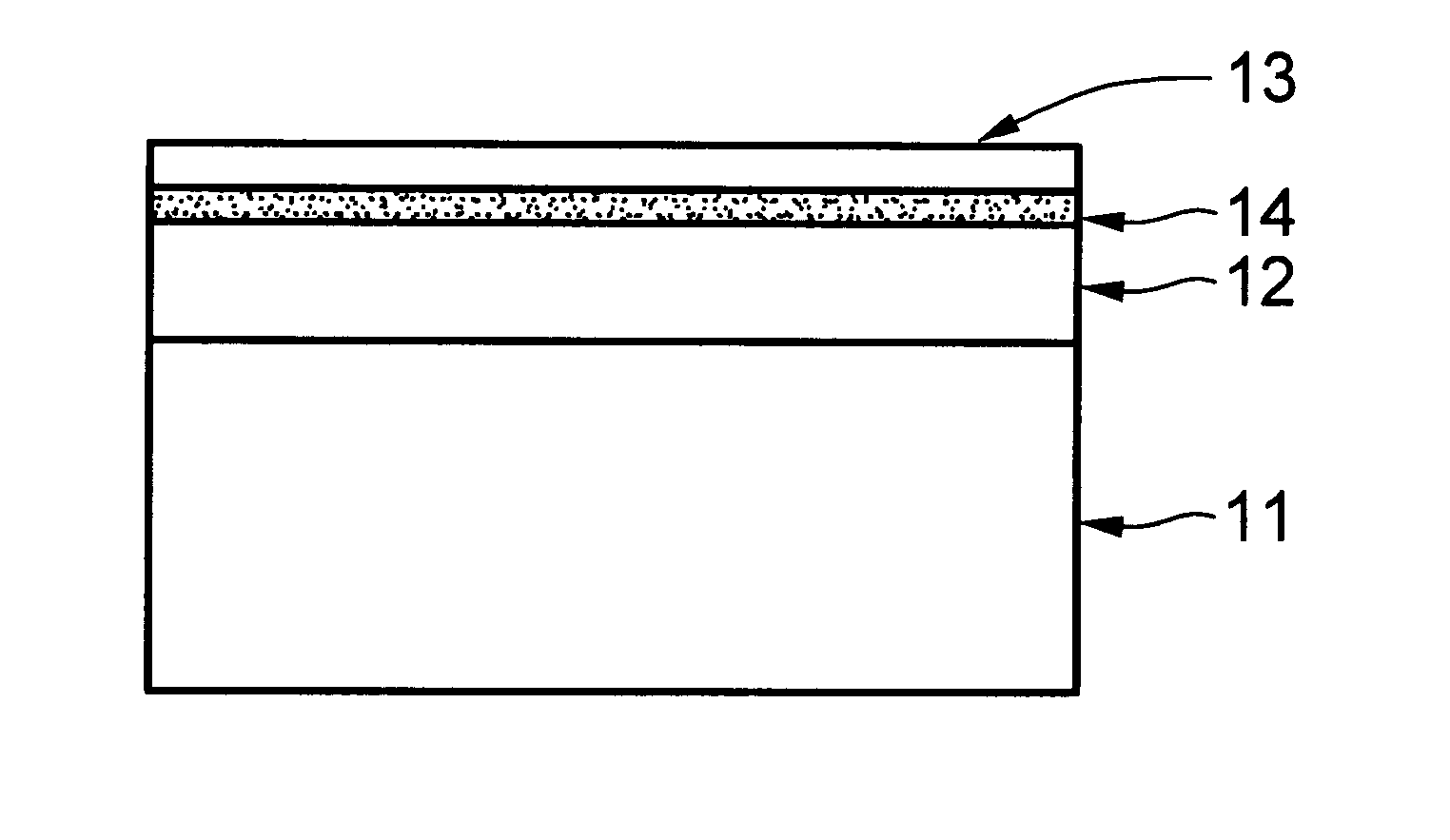

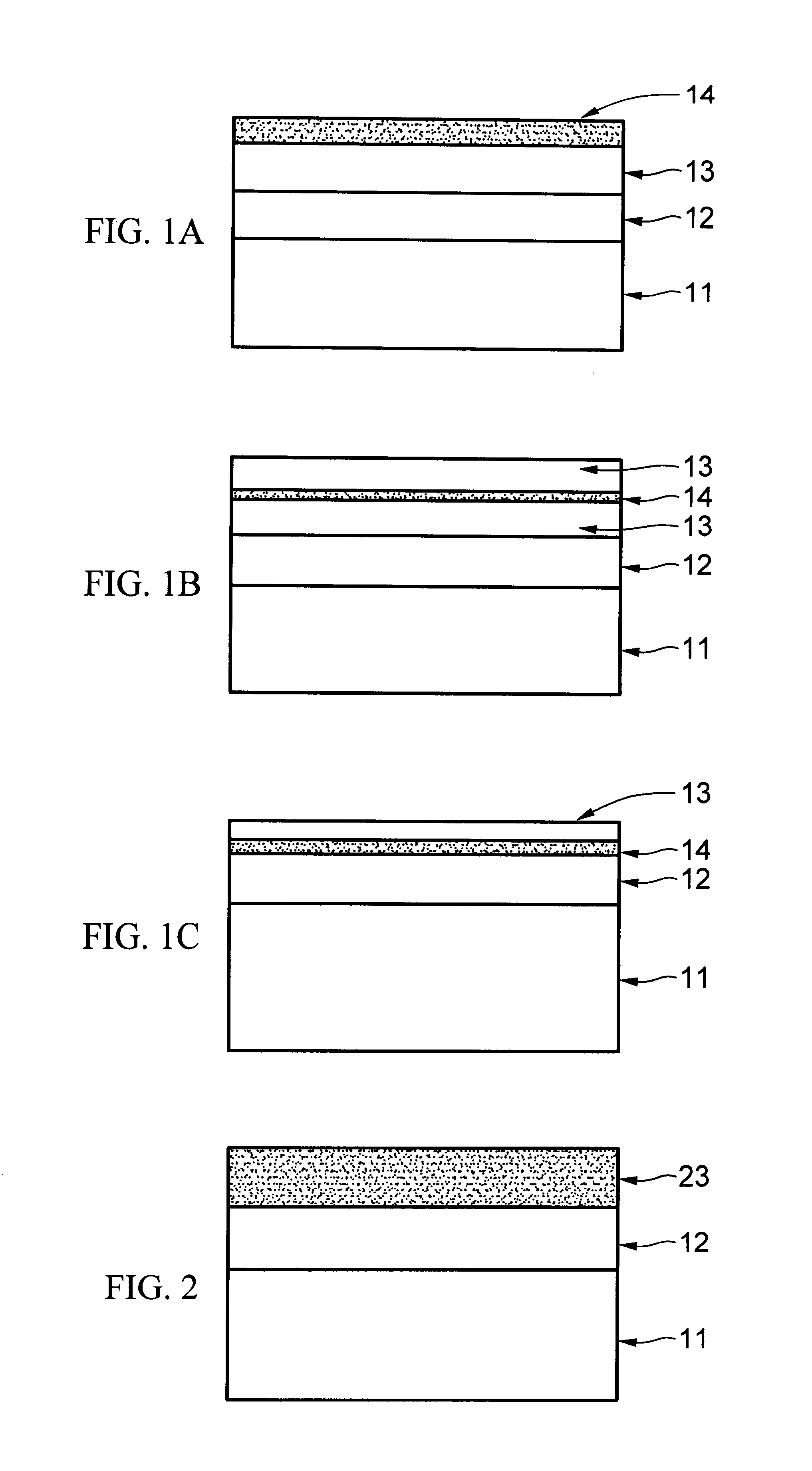

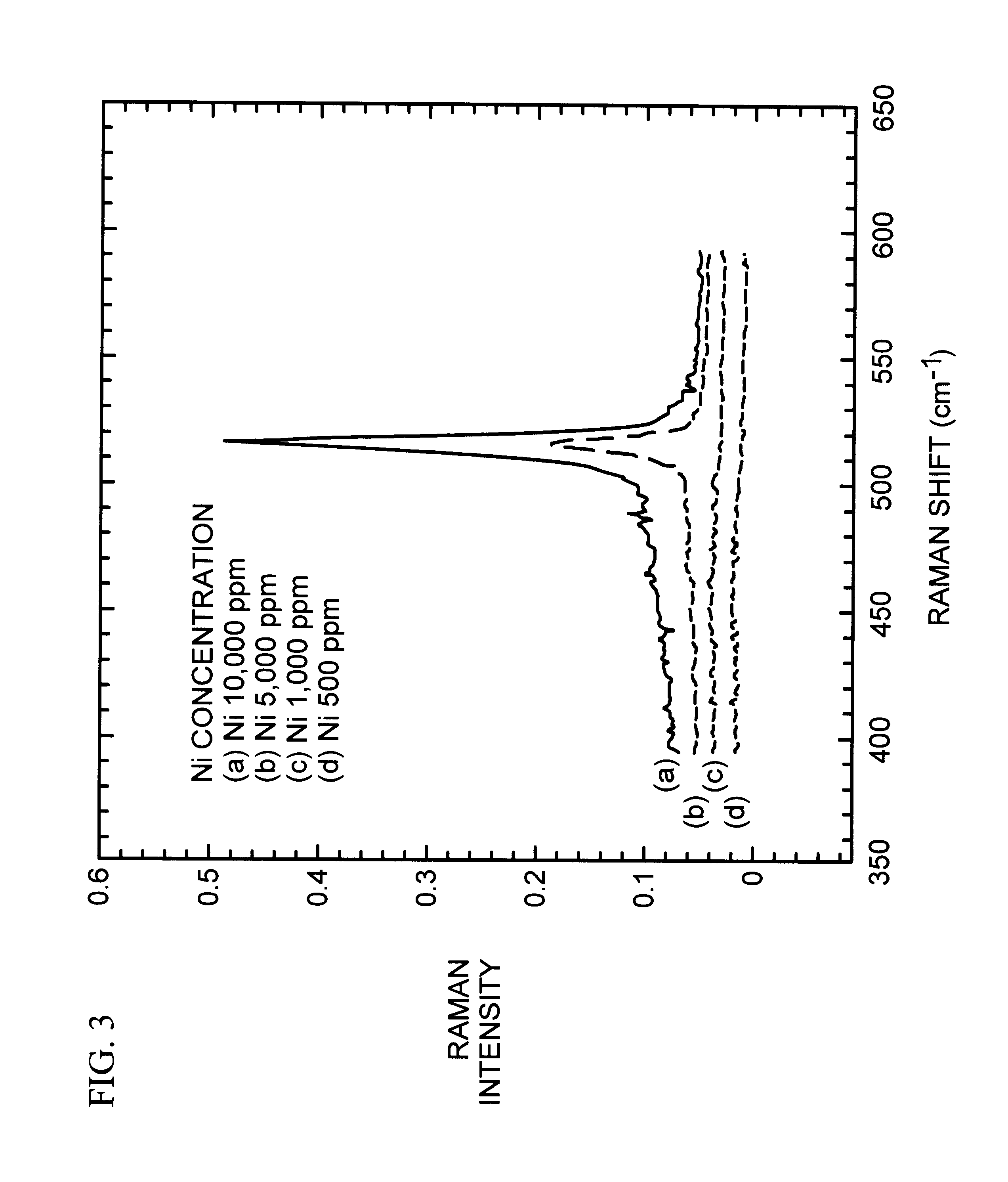

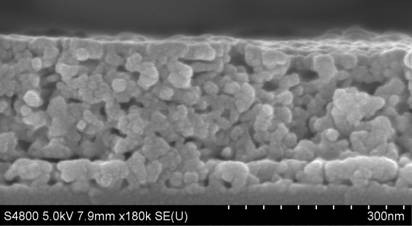

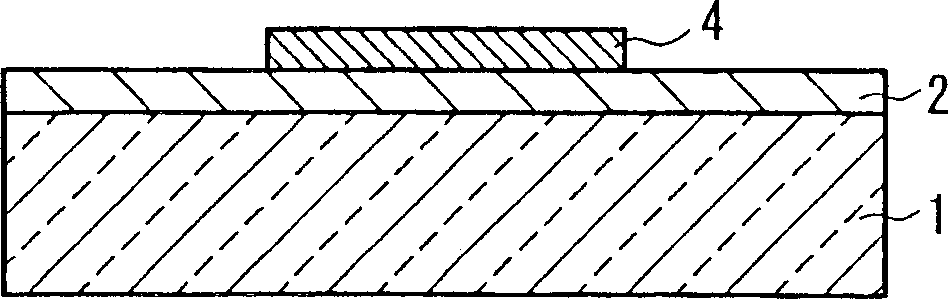

Method for crystallizing amorphous layer

InactiveUS6241817B1Avoid layeringLower crystallization temperatureFrom gel statePolycrystalline material growthPalladiumHeat treated

A method for crystallizing an amorphous layer into a polycrystalline layer. The method uses a substrate under the amorphous layer and a nickel film on the amorphous layer, which are subjected to a heat treatment. The nickel film is formed by a coating step that uses a nickel-containing solution. Alternatively, a nickel and gold, or a nickel and palladium, solution can be used. The method eliminates contamination with metal in the polycrystalline silicon layer and reduces its growth temperature.

Owner:LG DISPLAY CO LTD

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

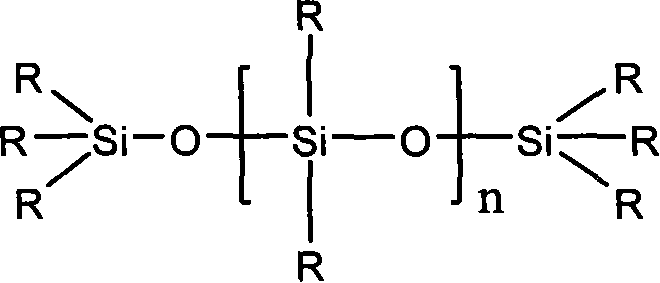

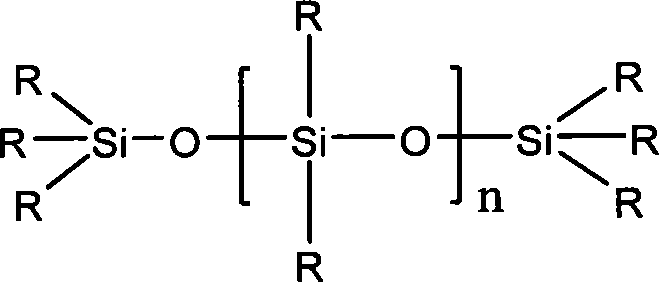

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

Process for preparing anatase type TiO2 sol

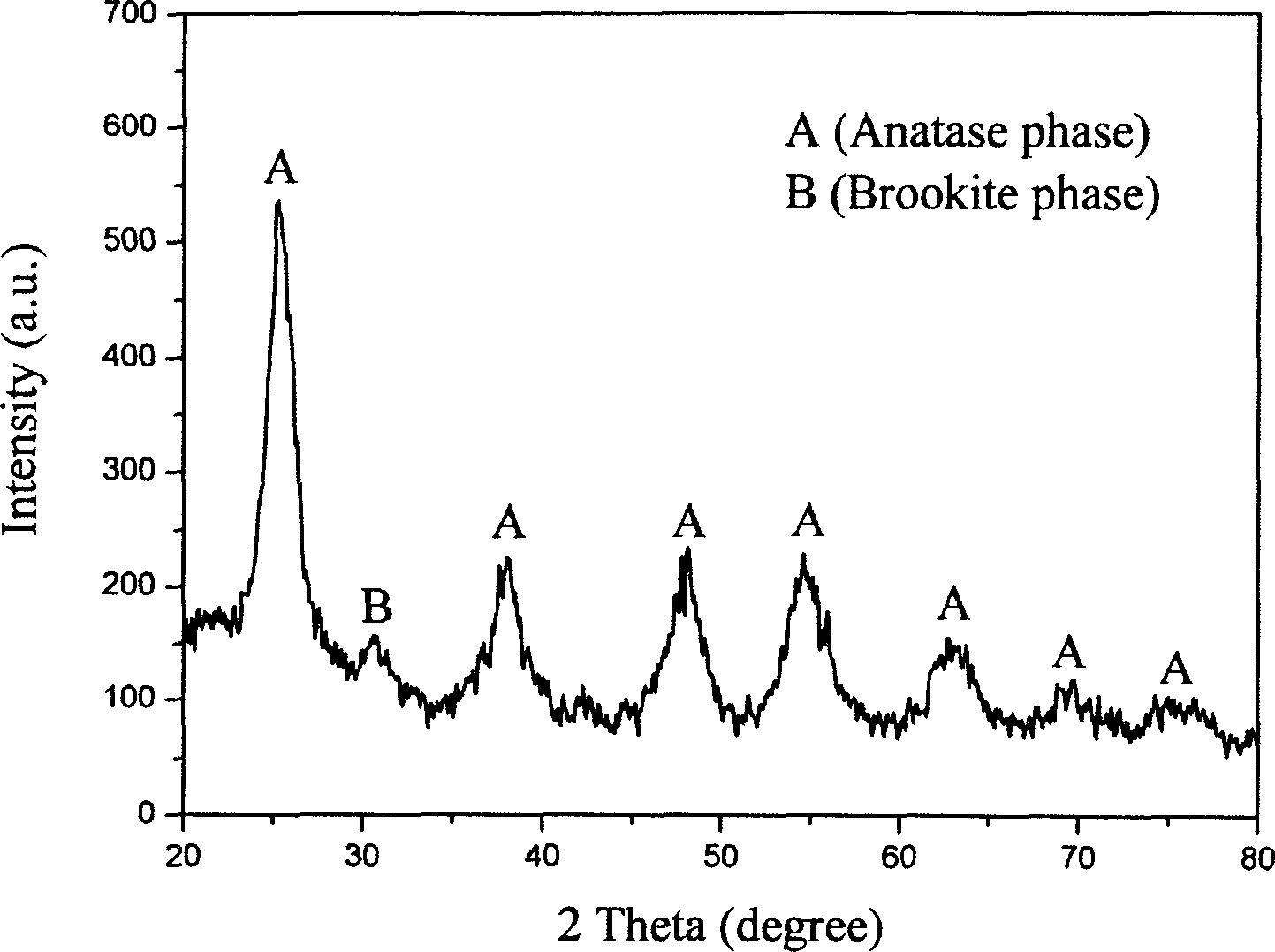

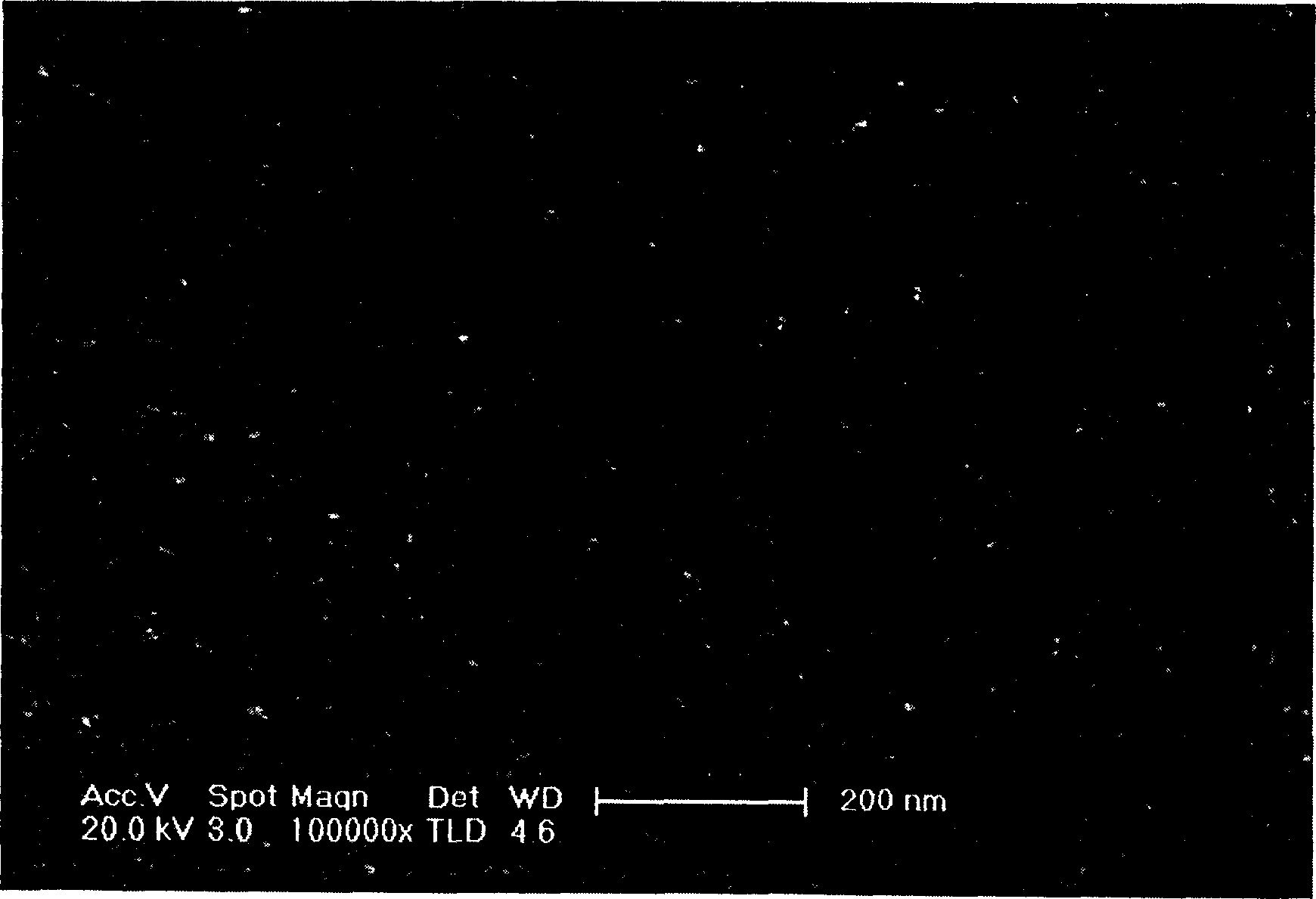

InactiveCN1699181AReduce energy consumptionImprove bindingPhysical/chemical process catalystsTitanium dioxideAlcoholDecomposition

The invention discloses a process for preparing anatase type TiO2 sol which comprises preparing alcoholic solution of titanium compounds from titanium compounds and alcohols by the mol ratio of 1:1.42-12, agitating and dropping the alcoholic solution of titanium compounds into the water solution of acid with pH=1.0-4.0 for hydrolytic decomposition, the mol ratio of titanium compounds and water in the aqueous solution of acids being 1:76-151, inversing flow for 6-48 hours at 65-85 deg. C, evaporating the obtained sol at 50-55 deg. C to remove the alcohols, thus obtaining octahedrite type titanium dioxide collosol.

Owner:SOUTHEAST UNIV

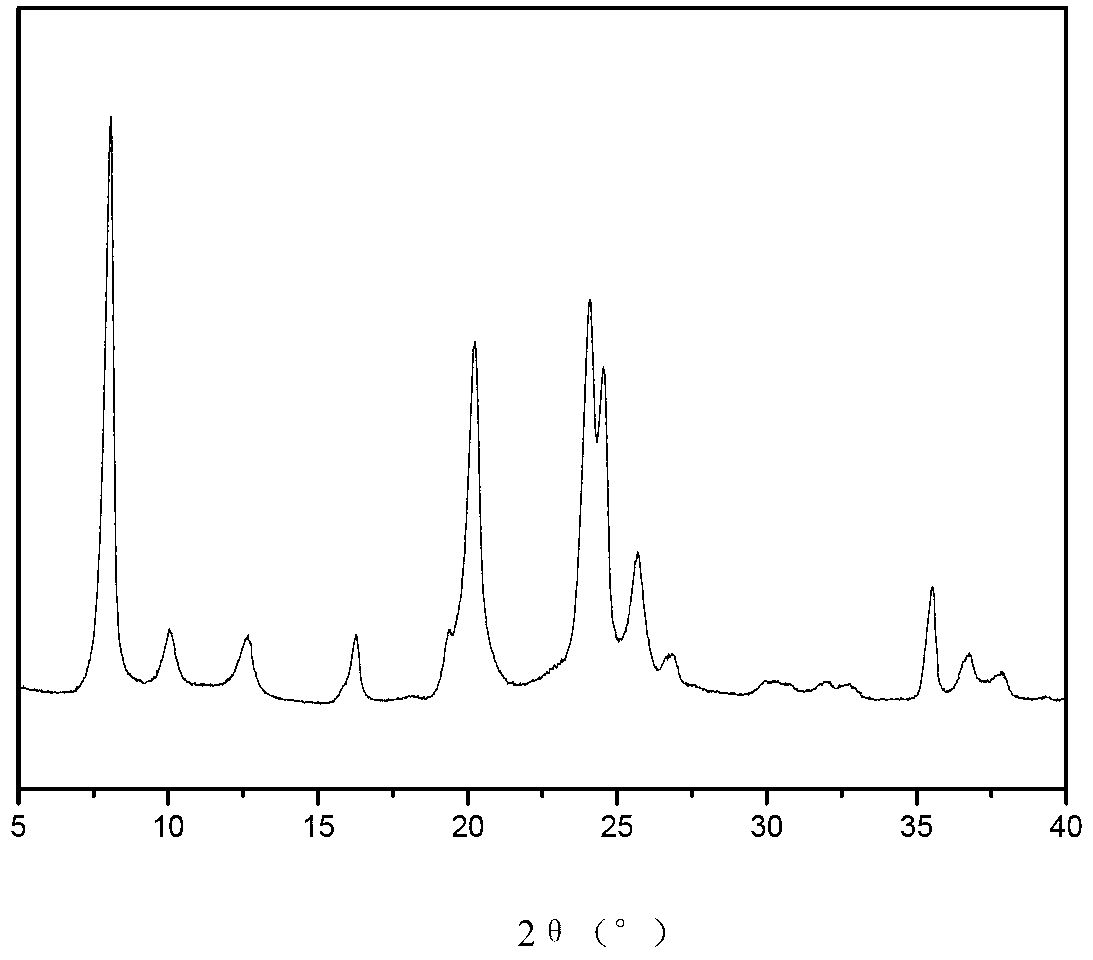

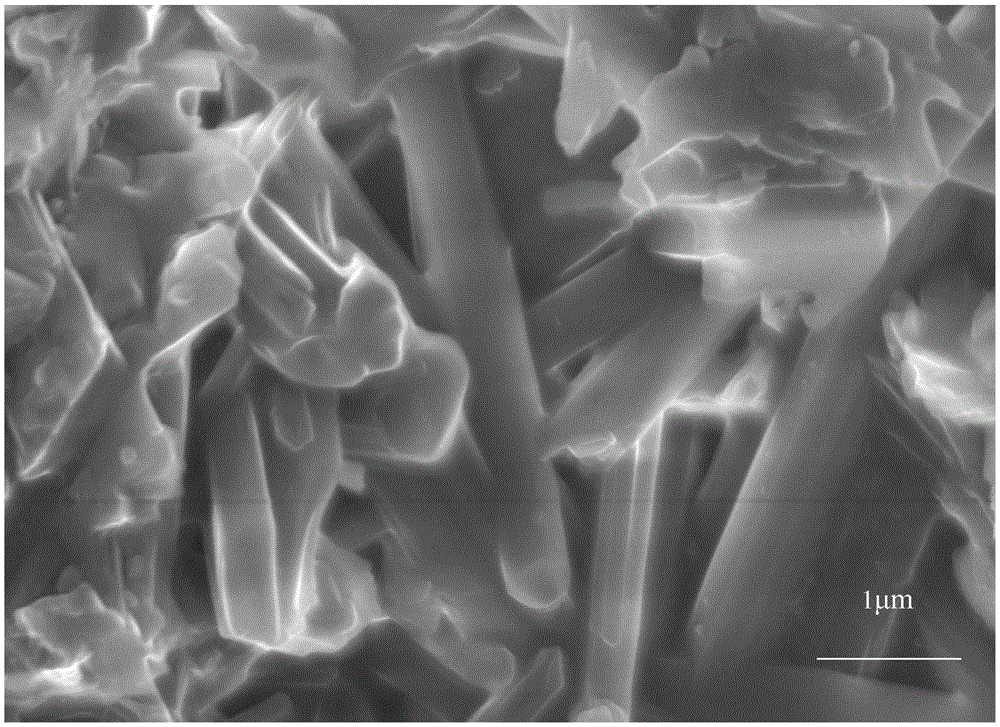

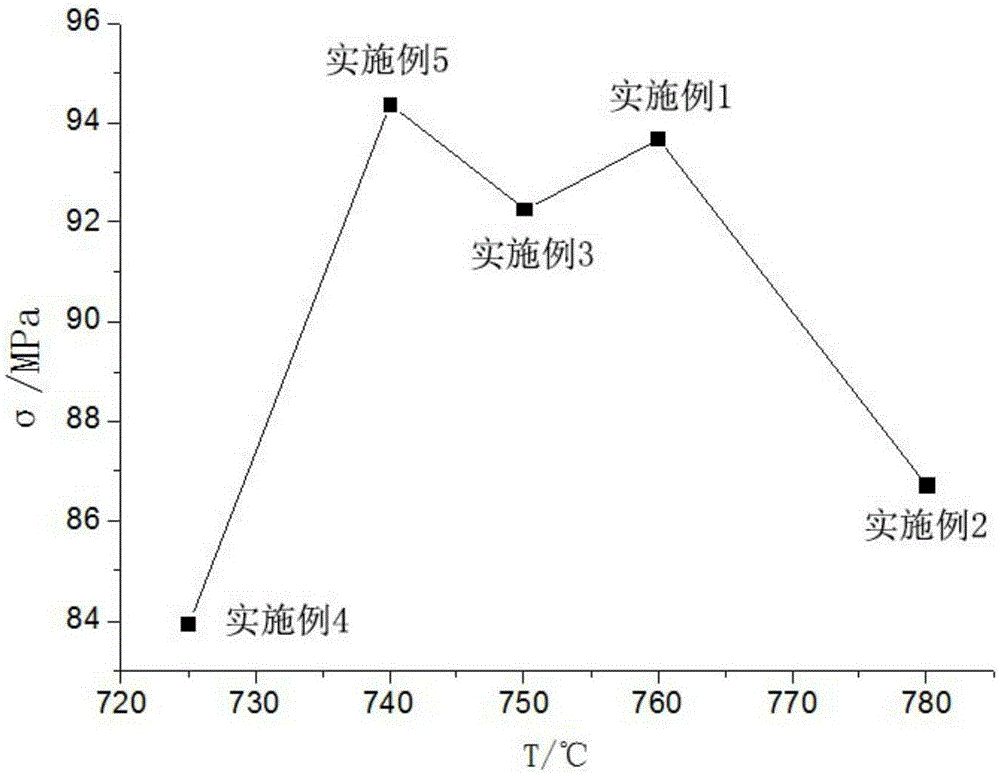

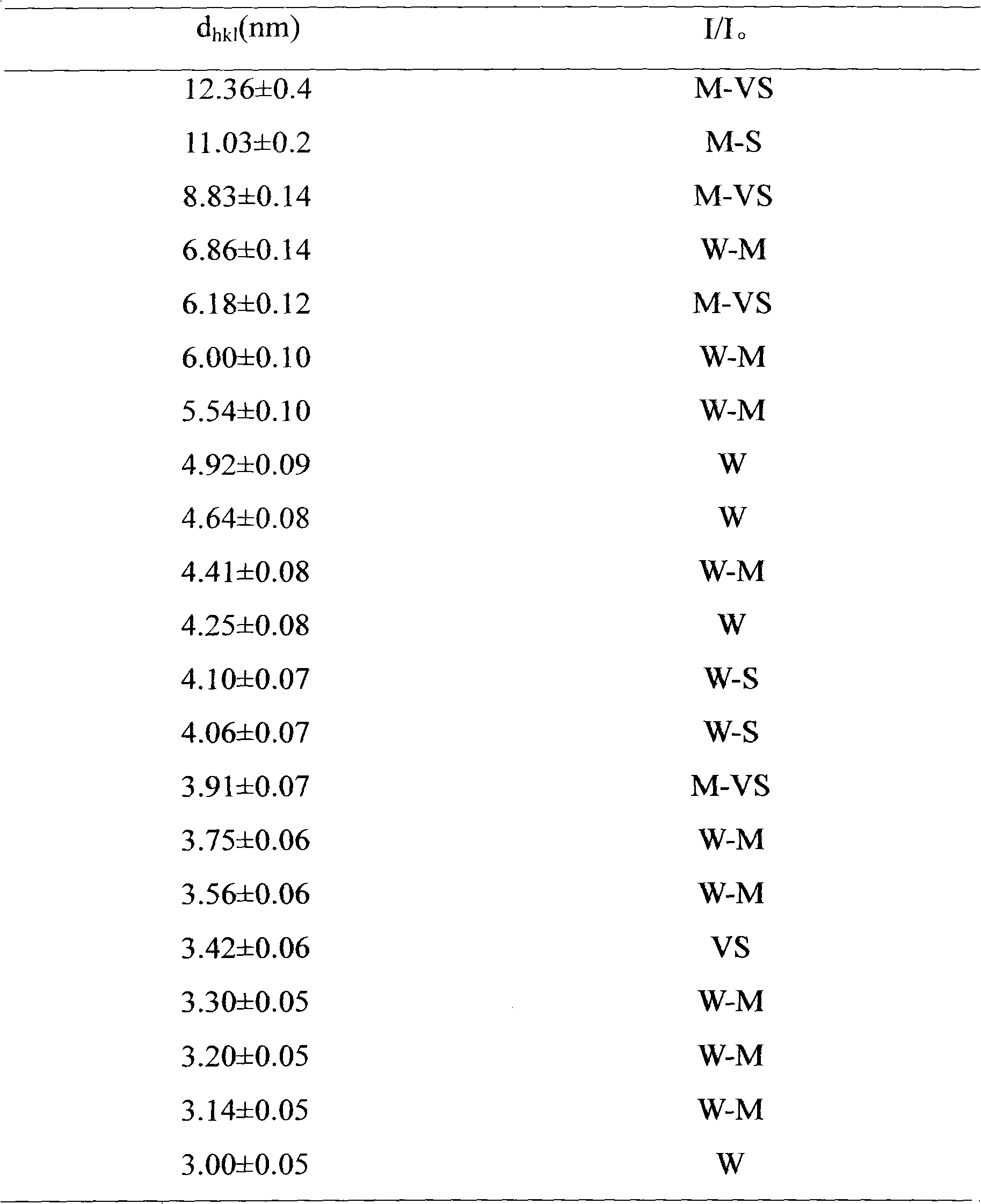

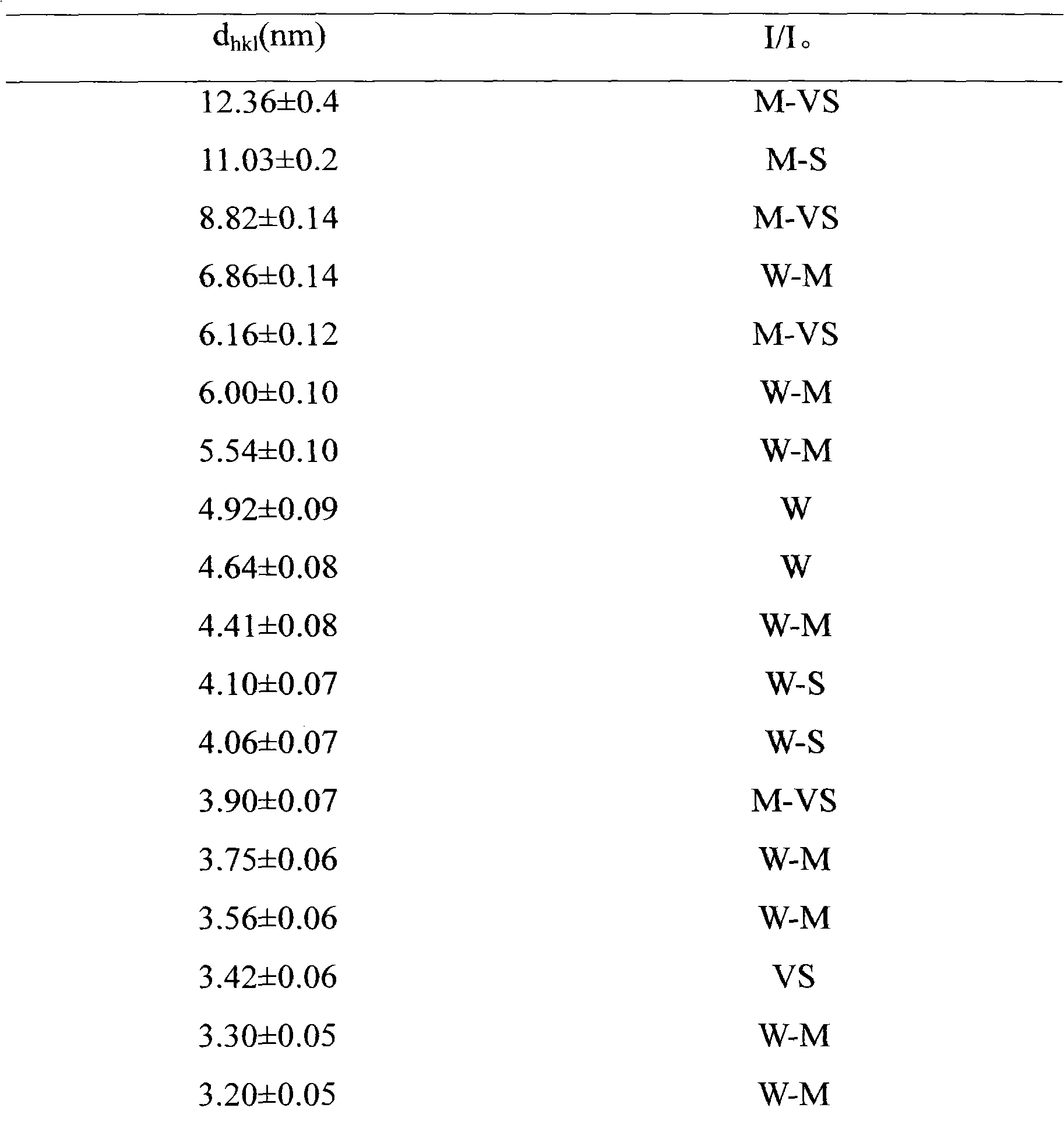

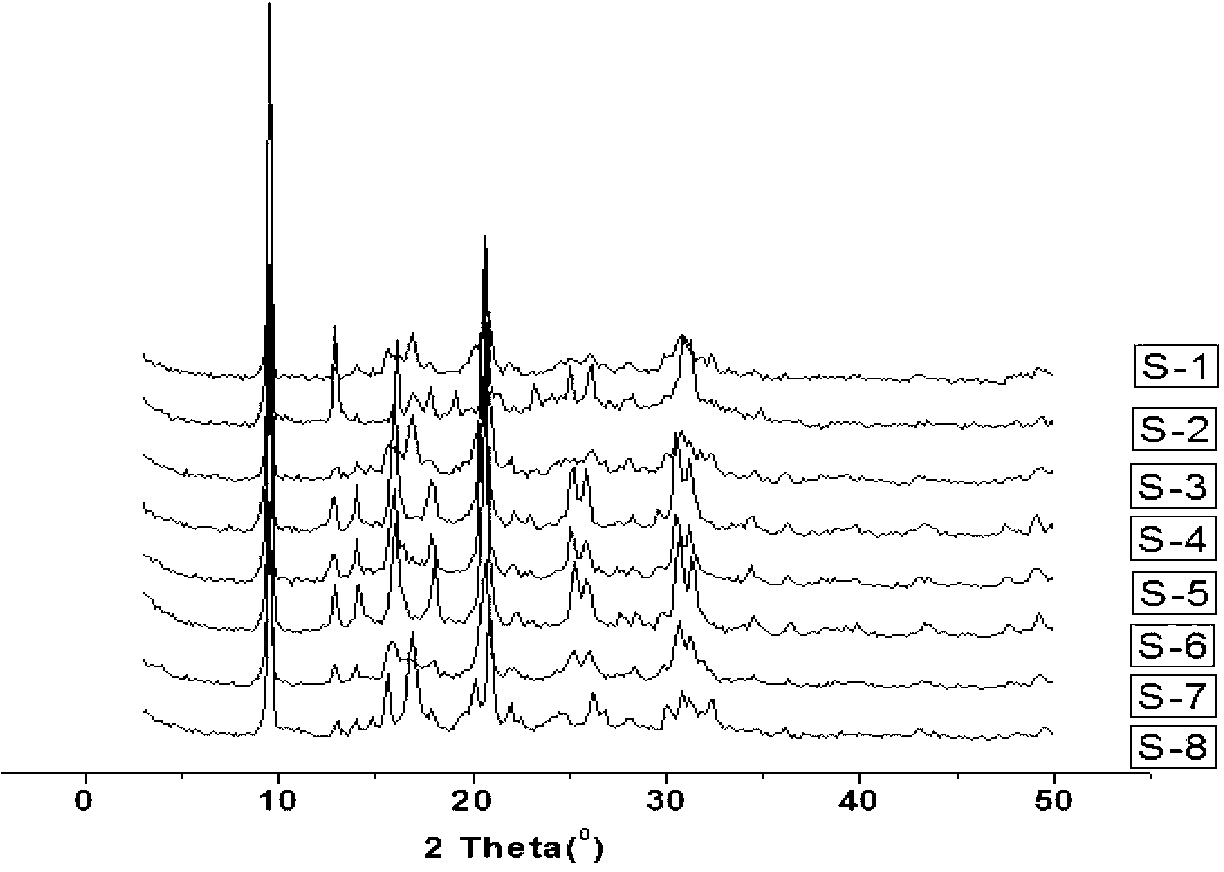

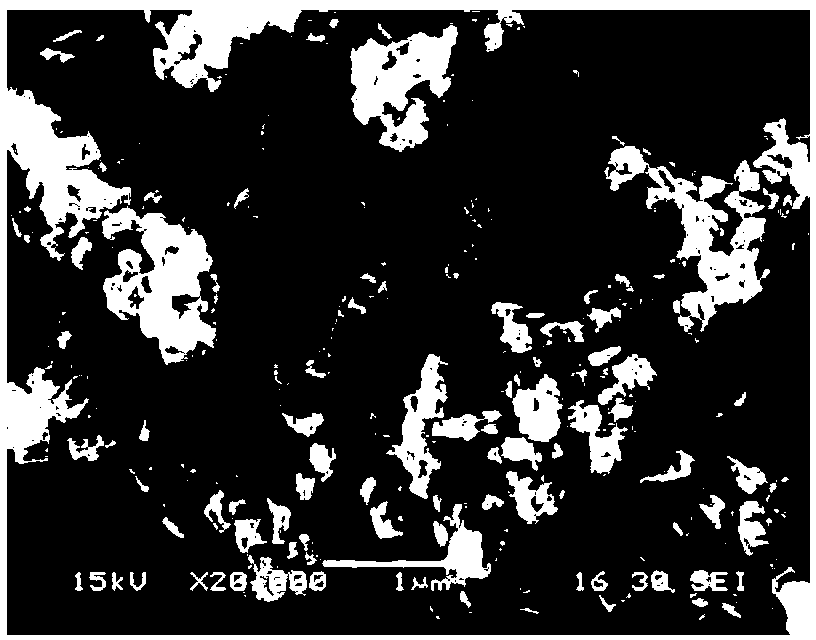

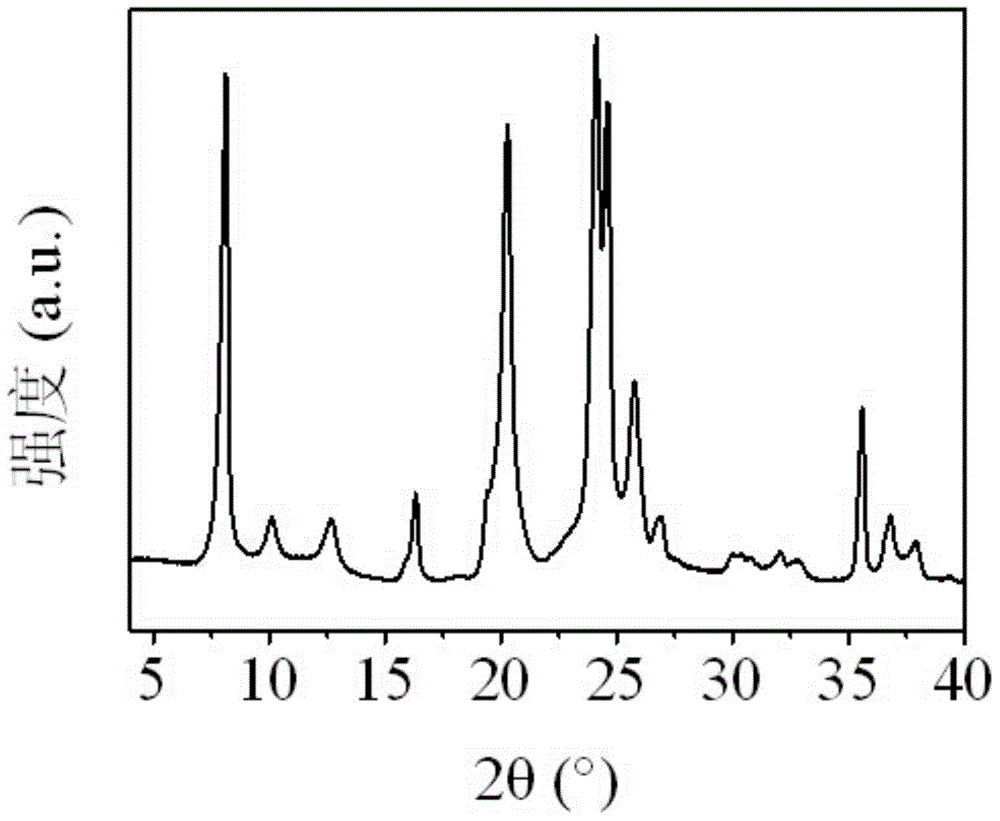

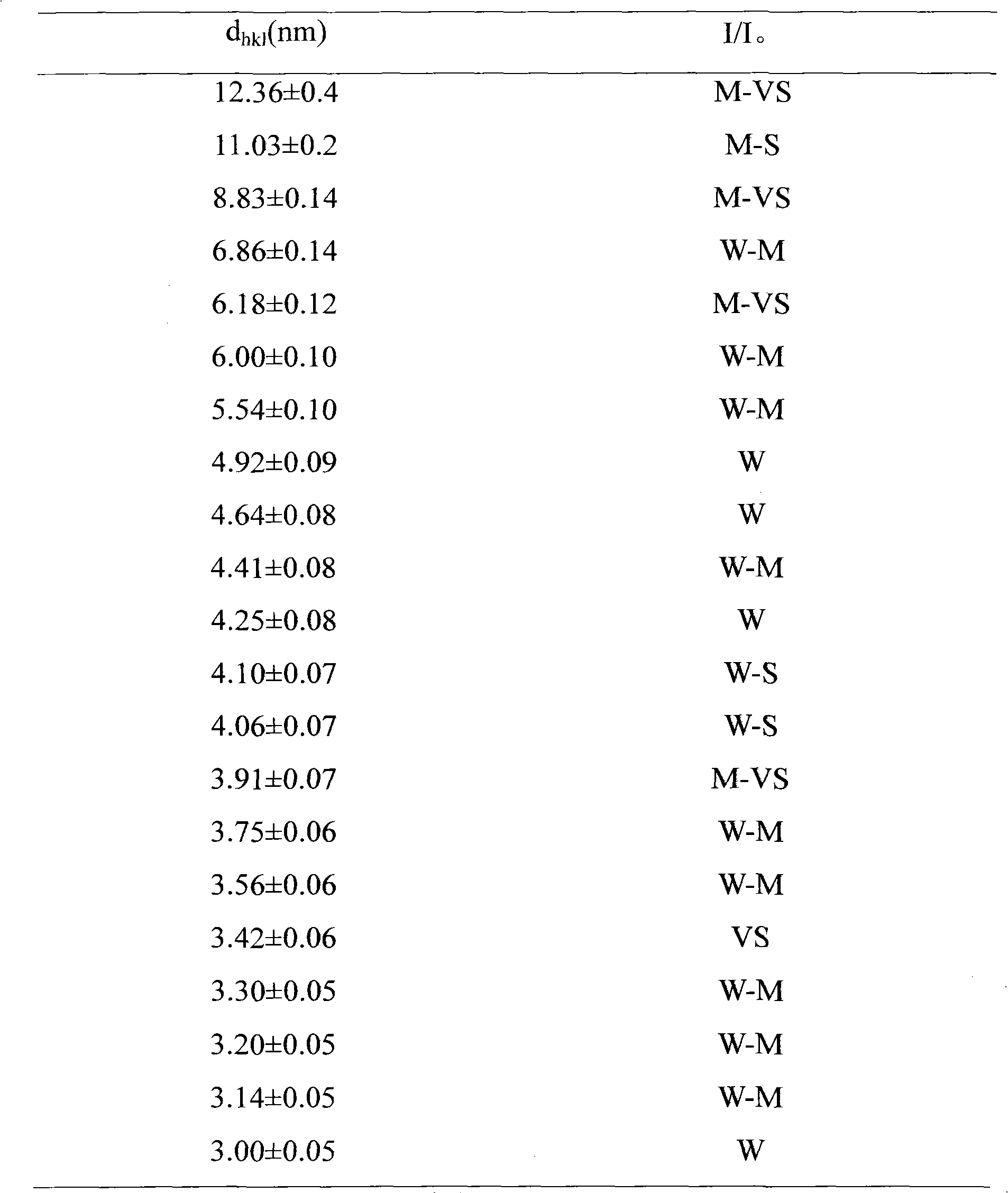

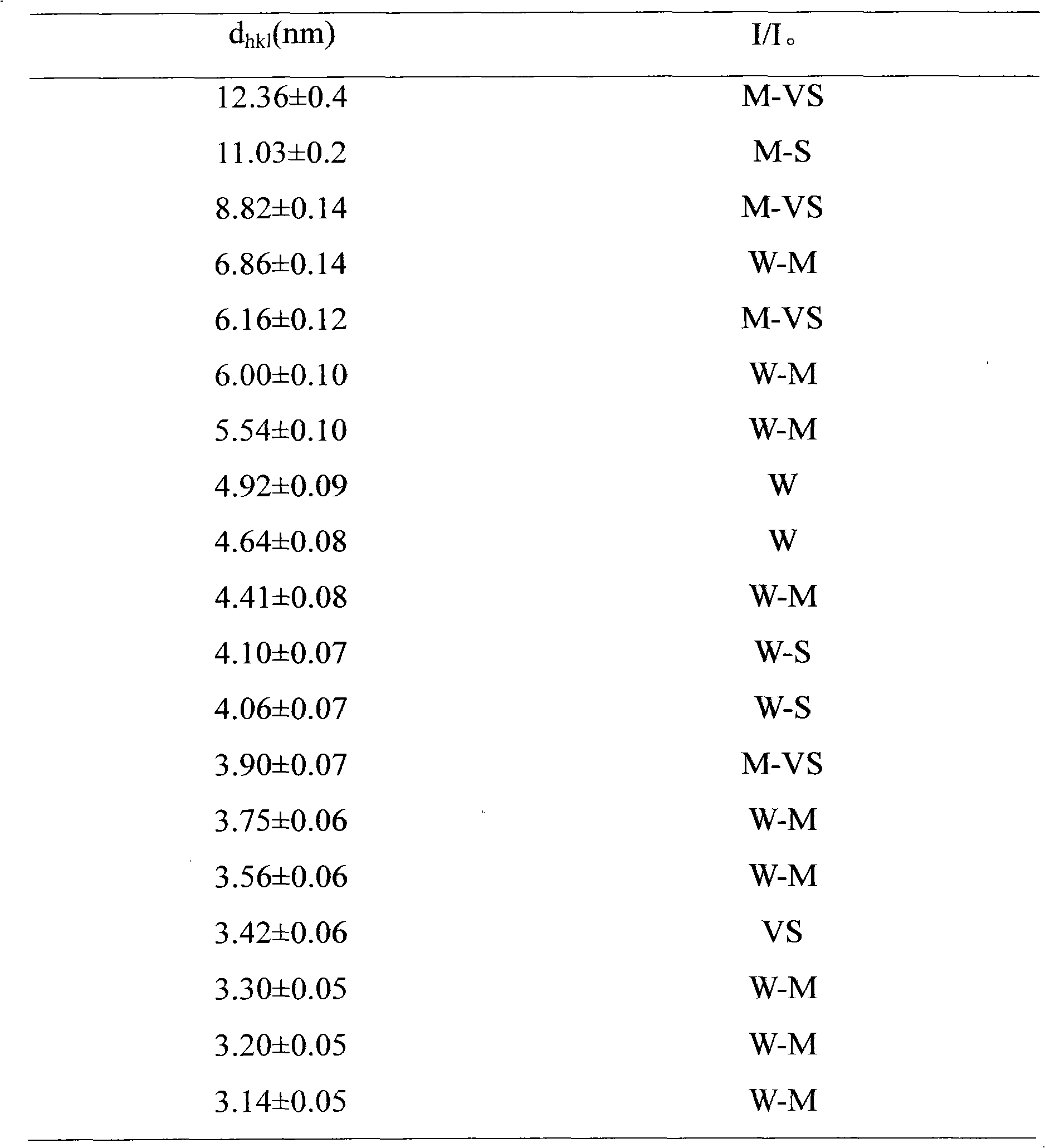

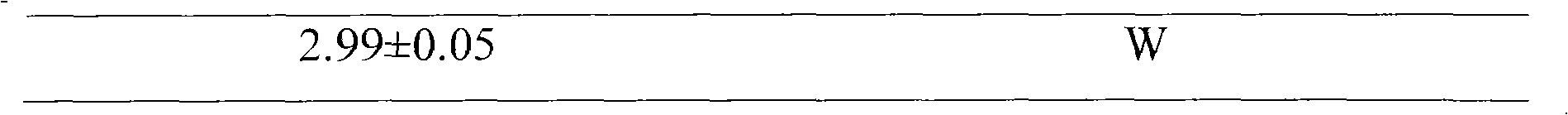

Method for preparing ZSM-22 molecular sieve by using seed crystal synthesis method

ActiveCN103101924AShorten crystallization timeLow crystallization temperatureCrystalline aluminosilicate zeolitesMolecular sieveAluminium salts

The invention relates to a preparation method of a molecular sieve, and provides a method for preparing ZSM-22 molecular sieve by using a seed crystal synthesis method. The method comprises the following steps of: uniformly mixing deionized water with aluminum sulfate; adding alkali sources into a mixture; adding tetraethoxysilane under stirring; continuously stirring until the solution is uniform to form silicon-aluminum gel; adding ZSM-22 molecular sieve crystal seed to stir; putting the mixture into a reaction kettle for crystallization reaction; and filtering and drying a product to obtain ZSM-22 molecular sieve raw powder. By using the preparation method, the application of organic template agent is eliminated, the crystallization time is shortened, the crystallization temperature is reduced, and the industrial application is facilitated; the product keeps good crystallization degree and purity and high catalytic reaction activity; the unnecessary loss during production is reduced; the product has a potential application value on some important catalytic reaction; and inorganic raw materials used in production is environmentally-friendly and low in cost.

Owner:ZHEJIANG JIRUITONG NEW MATERIAL CO LTD

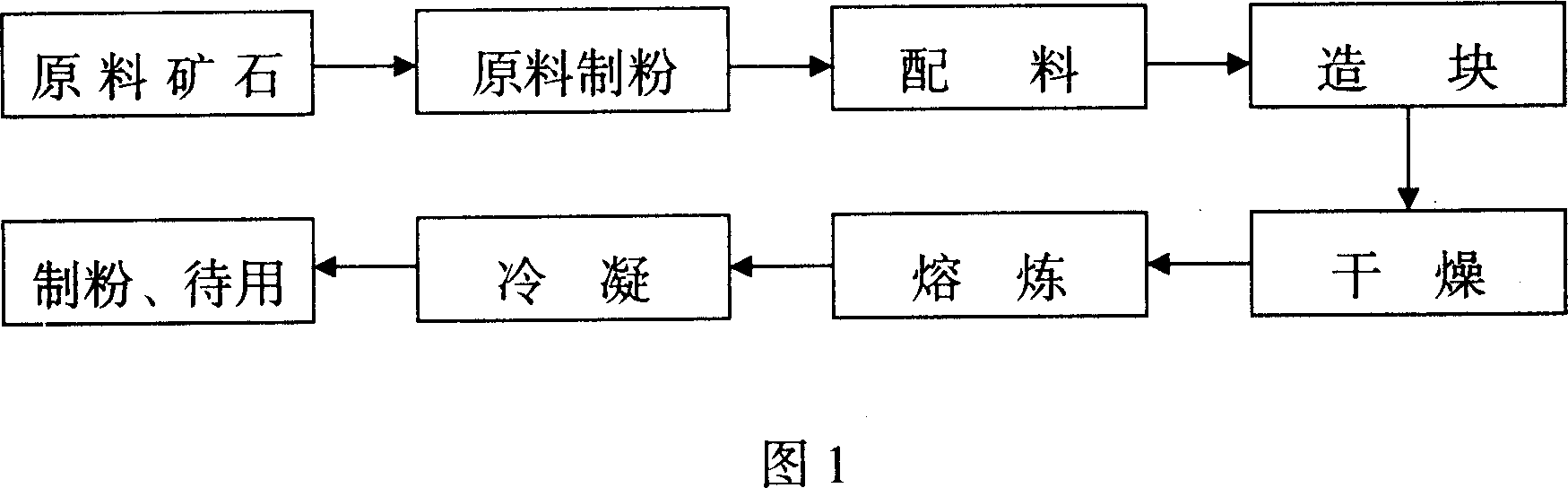

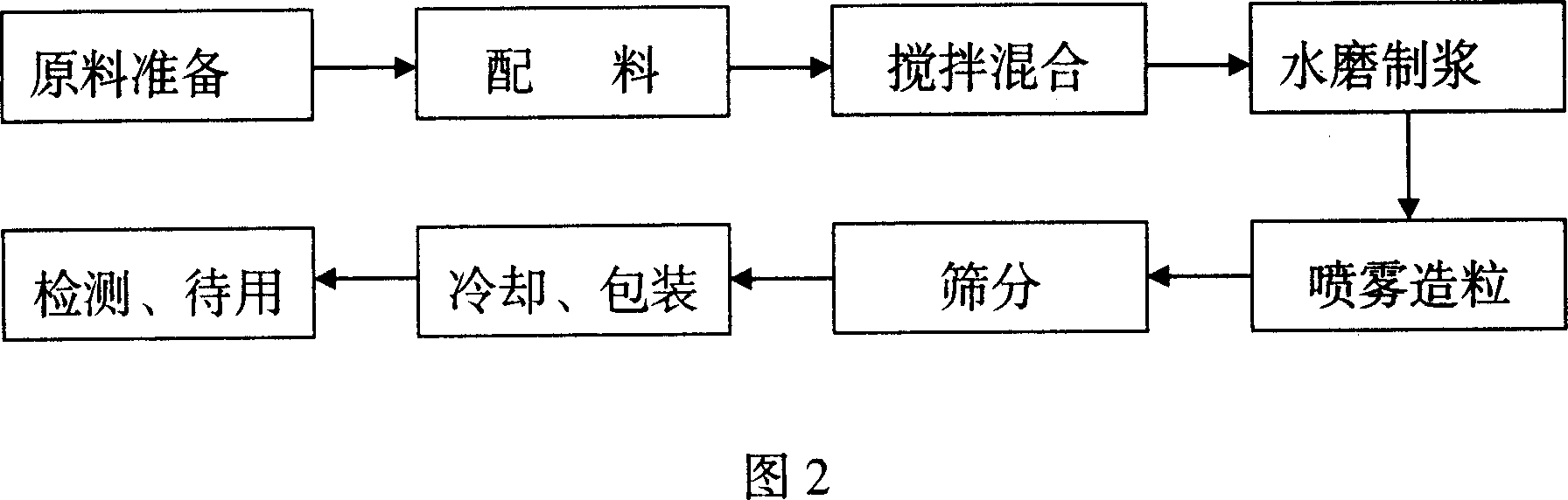

Low-carbon steel protecting slag for continuous casting of sheet billet and preparing method thereof

InactiveCN1927502ALower crystallization temperatureImprove melting uniformityProcess efficiency improvementChemical compositionSlag

The invention relates to a method for preparing low-carbon steel protective slag used to casting sheet blank. Wherein, it is characterized in that: the chemical component mass percentages of said protective slag are SiO2 at 28-32, CaO at 29-33, Al2O3 at 3-5, MgO at 1-3, Fe2O3<=3, F at 7-9, Na2O+K2O at 9-12, Li2O<=2.0, C at 7-9, and adhesive at 1-3; said protective slag is alkali one whose alkali R is higher then 1 and R=CaO / SiO2. The invention can realize low crystallize temperature, high solidify temperature and high crystallize ratio, to meet the casting demand of FTSC sheet blank.

Owner:HEBEI IRON AND STEEL

Crystallizer protecting cinder for continuous casting of crack sensitive steel and its prepn process

InactiveCN1974062AReduce crystallization rateLower crystallization temperatureProcess efficiency improvementManganese(II) carbonateWollastonite

The present invention provides one kind of crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process. The protecting cinder is compounded with wollastonite, limestone, quartz sand, fluorite, industrial soda, manganese carbonate and carbon material. Chemically, it consists of CaO 28-42 wt%, SiO2 26-40 wt%, CaF2 10-20 wt%, Na2O 4-10 wt%, MnO2 2-8 wt%, Al2O3 0-6 wt%, and C 2-10 wt%, and has the weight ratio between CaO and SiO 2in 1.0-1.2. The crystallizer protecting cinder can reduce the heat transfer, maintain the crystallization rate and the crystallization temperature of protecting cinder, reduce longitudinal cracks in the surface of cast billet, and raise continuous casting efficiency and quality.

Owner:CHONGQING UNIV

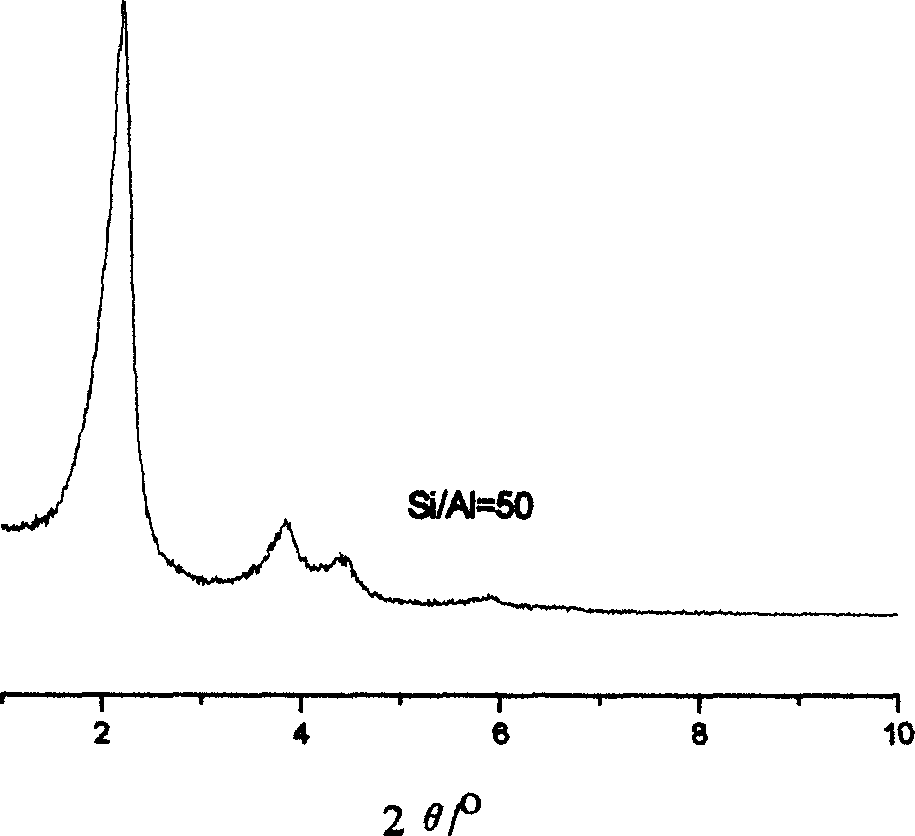

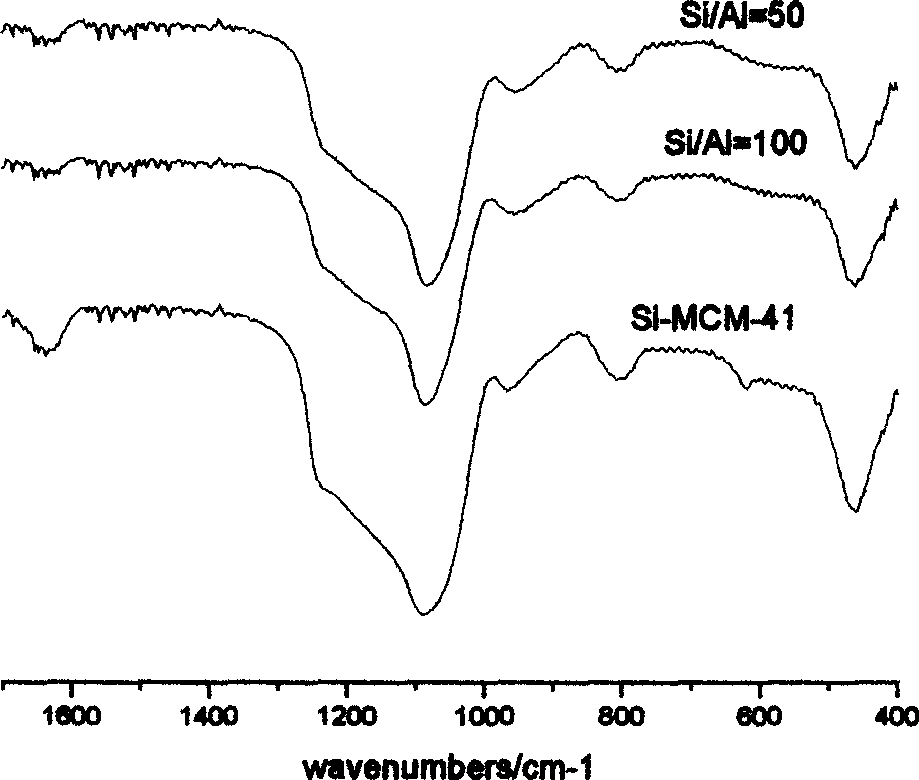

Process of preparing mesoporous molecular sieve with ionic liquid as template agent

InactiveCN1609164AEasy to makeLower crystallization temperatureCoke quenchingCrystallization temperatureMCM-41

The present invention is process of preparing Al-MCM-41 mesoporous molecular sieve with ionic liquid as template agent. The ionic liquid is 1-palmityl-3-methylimidazole bromide, and the material includes sodium silicate, aluminum sulfate, sulfuric acid and water. The preparation process of Al-MCM-41 mesoporous molecular sieve includes the steps of: preparing template agent, preparing the reaction mixture, hydrothermal crystallization, filtering, water washing, drying and roasting. The present invention has the advantages of simple process and low crystallization temperature.

Owner:EAST CHINA NORMAL UNIV

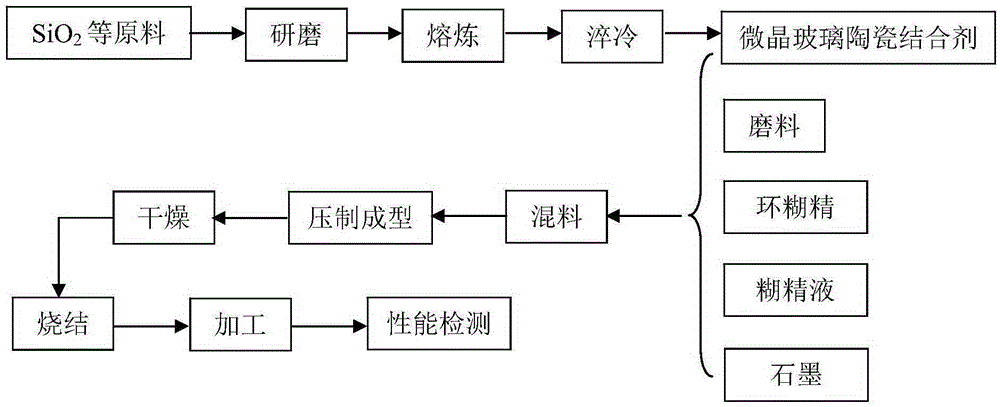

Microcrystalline glass ceramic binding agent, preparing method thereof, SG grinding wheel and preparing method thereof

ActiveCN105252435ASmall coefficient of thermal expansionLow crystallization temperatureAbrasion apparatusGrinding devicesTO-18Materials science

The invention discloses a microcrystalline glass ceramic binding agent, a preparing method thereof, an SG grinding wheel and a preparing method thereof. The binding agent is prepared from, by weight percentage, 40% to 65% of SiO2, 6% to 20% of Al2O3, 5% to 18% of Na2O, 0.5% to 5% of CaO, 3% to 10% of K2O, 8% to 35% of B2O3, 0.5% to 2% of MgO and 2% to 6% of TiO2. The microcrystalline glass ceramic binding agent is formed by reasonably selecting the raw materials, the scientific ratio is adopted, the binding agent has the beneficial effects of being low in thermal expansion coefficient and crystallization temperature and high in strength accordingly, the microcrystalline glass ceramic binding agent is suitable for being used as a binding agent of the SG grinding wheel, the firing temperature of the SG grinding wheel is greatly reduced, and the firing time of the SG grinding wheel is greatly shortened; and meanwhile the work efficiency and the machining accuracy of the SG grinding wheel are improved, grinding heat is reduced, and the service life of the grinding wheel is prolonged.

Owner:白鸽磨料磨具有限公司

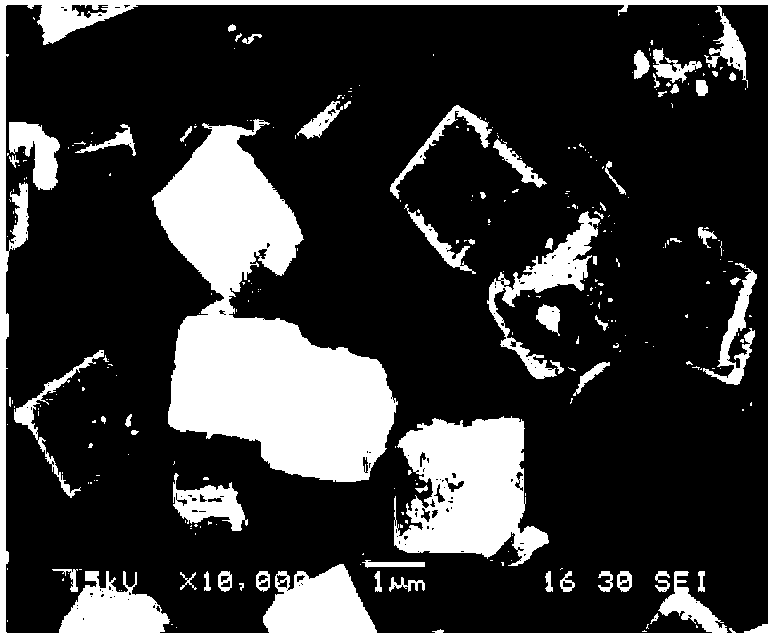

Method for synthesizing MCM-22 molecular sieve

InactiveCN102040228ALower crystallization temperatureShort crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveBenzene

The invention relates to a method for synthesizing MCM-22 molecular sieve. The method comprises the following steps of: preparing gel consisting of a silicon source, an aluminum source, an organic template agent, halogen compounds, alkali and water; then crystallizing the gel; and performing the traditional steps of filtering, washing, drying and roasting so as to obtain product of the MCM-22 molecular sieve, wherein the organic template agent can be dimethyleneimine, and also can be a mixed template agent composed of the dimethyleneimine and one or more than one of hydrocarbon, organic amine, alcohol and ketone. Compared with the prior art, the method has the advantages of low crystallization temperature, short crystallization time, high yield coefficient of product, high product quality and the like. The MCM-22 molecular sieve produced according to the invention has excellent catalytic performances of catalytic cracking, olefin alkylating, benzene alkylating and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for depositing vanadium dioxide thin film on glass under low temperature

InactiveCN101265036ALower crystallization temperatureLow deposition temperatureSeed crystalVanadium dioxide

Based on the crystal heteroepitaxial growth principle, the invention provides a low-temperature preparation method of depositing a vanadium dioxide film on a glass substrate without changing the quality (thermochromatism) of the vanadium dioxide film. Using glass as substrate, the method comprises the following steps: 1) cleaning and pre-treating the glass substrate; 2) depositing a vanadium dioxide diffusion barrier layer on the glass substrate; 3) depositing a zinc oxide seed crystal layer on the vanadium dioxide diffusion barrier layer; and 4) depositing a vanadium dioxide thermochromic layer on the zinc oxide seed crystal layer. The vanadium dioxide thermochromic layer has low crystallization temperature and lattice constant matched with vanadium dioxide, and is particularly suitable for the heteroepitaxial growth of the vanadium dioxide film. Therefore, the invention can efficiently reduce the deposition temperature of vanadium dioxide film, simplify the process of producing intelligent vanadium dioxide glass, minimize cost and energy consumption, and greatly reduce the difficulty in industrialization of intelligent vanadium dioxide glass.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

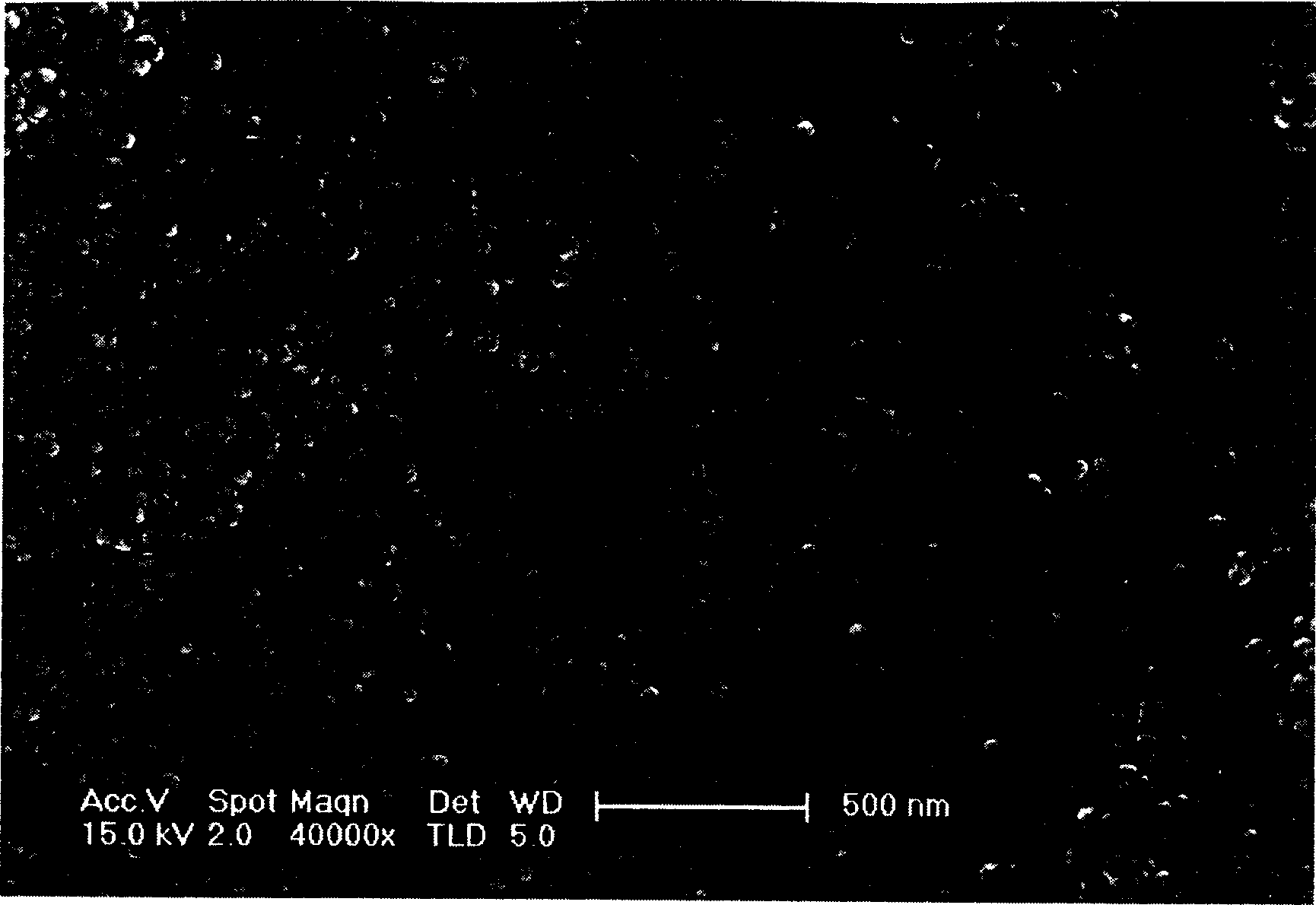

Synthesis method of low-silicon nano SAPO-34 molecular sieve

ActiveCN103130241AShorten the timeLower crystallization temperatureMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesSynthesis methodsHigh pressure

The invention relates to a synthesis method of a low-silicon nano SAPO-34 molecular sieve, which comprises the following steps: sequentially mixing a silicon source, an aluminum source, a template agent R, deionized water and a phosphorus source to obtain a gel mixture; placing the gel mixture in a stainless steel high-pressure reaction kettle of which the liner is made of polytetrafluoroethylene, sealing, putting into a drying oven, and performing primary traditional hydrothermal crystallization; adding a dispersant agent S into the primary traditional hydrothermal crystallization solution, stirring for 0.5-4 hours, transferring into the reaction kettle of which the liner is made of polytetrafluoroethylene, sealing, putting into a microwave reactor, and performing secondary microwave hydrothermal crystallization; and washing, drying, and roasting to obtain the nano SAPO-34 molecular sieve. Compared with the prior art, the invention greatly lowers the crystallization temperature and shortens the time of the whole synthesis process. The nano molecular sieve can be widely used for conversion, separation and absorption of hydrocarbons, and especially has the advantages of high conversion rate, high low-carbon alkene selectivity, low carbon deposition rate, long reaction life and the like in the process of preparing alkene from methanol.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

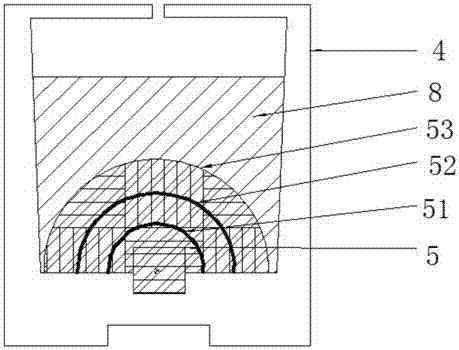

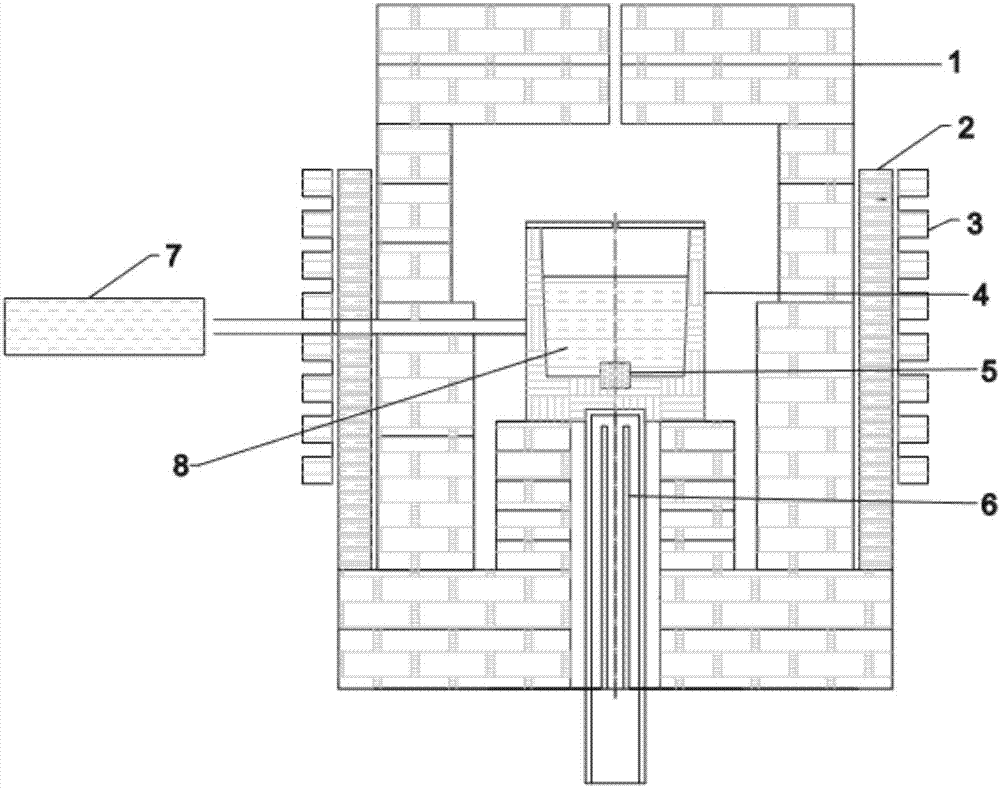

Growth equipment and growth method for large-size gallium oxide monocrystalline

InactiveCN107541776AReduce volatilityReduce decompositionPolycrystalline material growthUnder a protective fluidBrickCopper electrode

The invention relates to a piece of growth equipment and a growth method for large-size gallium oxide monocrystalline. The equipment comprises the following components: a zirconia insulating brick (1), a quartz cylinder (2), a water cooling copper electrode (3), an iraurita crucible (4), a heat exchanger (6), and an infrared thermometer (7). The method comprises the following steps: the iraurita crucible (4) is placed in the crystal growth furnace cavity formed by the zirconia insulating brick (1), the outside of the zirconia insulating brick (1) is provided with the quartz cylinder (2) and the water cooling copper electrode (3) in order, the heat exchanger (6) is placed at the bottom of the iraurita crucible (4), the infrared thermometer (7) is connected to the iraurita crucible (4), andthe iraurita crucible (4) contains a gallium oxide solution (8) and seed crystal (5). Compared with the prior art, heat exchange method is used for growing crystal, the efficiency is improved, and production cost is reduced; at the same time, grown crystal has the advantages of excellent quality, little stress, low dislocation density, good crystal perfection and optical homogeneity, improved utilization rate of the gallium oxide material, and simplified processing operation.

Owner:TONGJI UNIV

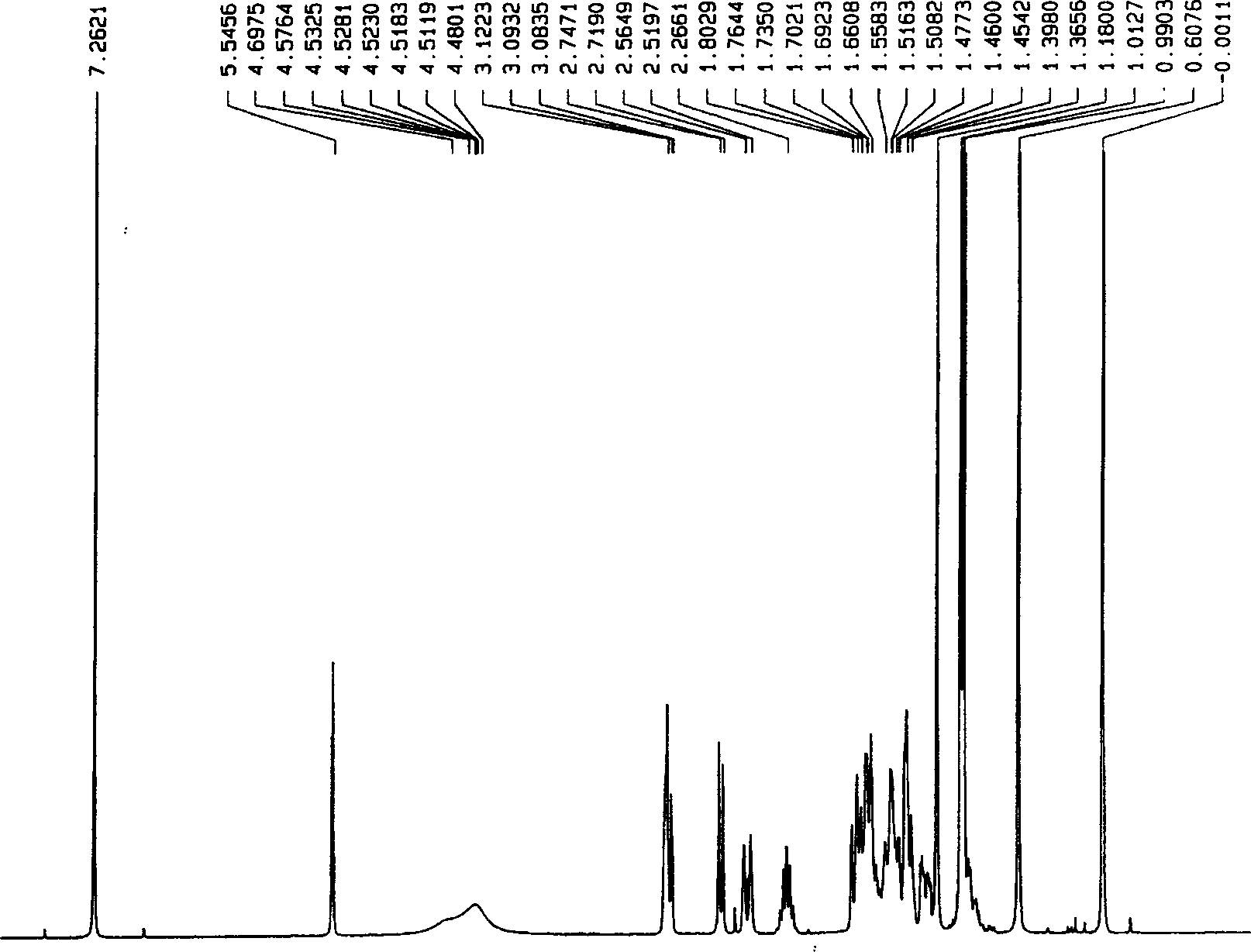

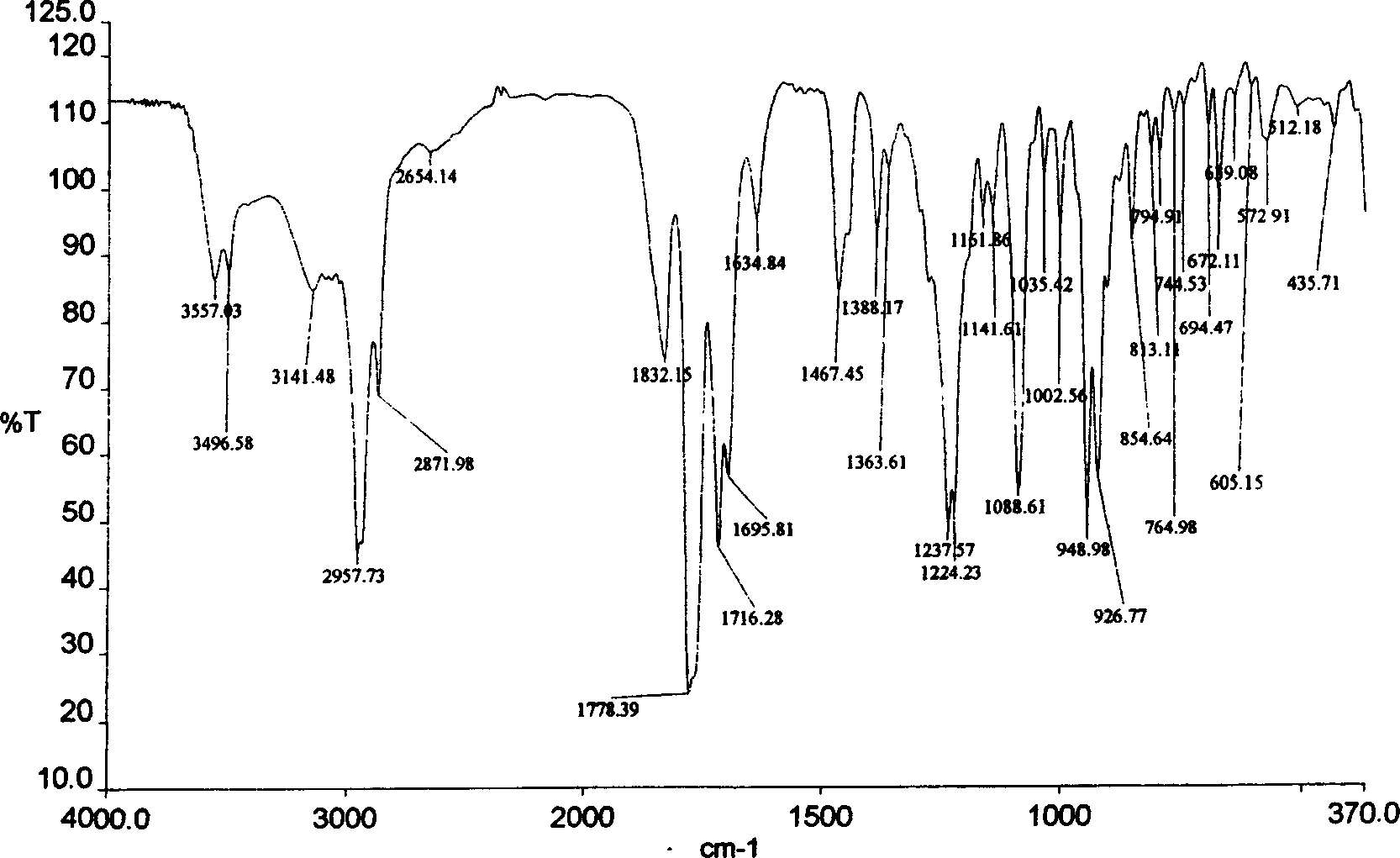

Modified butanediol ester poly succinic acid and synthetic method

InactiveCN1796435AImproved crystallization behaviorSlow crystallization ratePolymer scienceSynthesis methods

This invention relates to a cyclic compound, especially poly (butylenes succinate) modified by copolymerization with maleopimaric anhydride and its synthesis method. Succinic acid, 1,4-butanediol are mixed at a mole ratio of 1:1~4, and 4~20g maleopimaric imine dicarboxylic ester oligomers are added per 163g succinic acid / 1,4-butanediol mixture. The system is stirred at a temperature of 160~200 deg.C in the presence of inert gas, and cadmium acetate, zincum acetate, stibium oxide, butyl titanate or their optional combinations are added as catalysts at a mass fraction of 0.1~3% for a polymerization at a temperature of 230~280 deg.C and a pressure of 5~10Pa to produce modified poly(butylenes succinate) with a following structure. Such an environmentally friendly polymer performs a good elongation rate at break, impact-resistance strength and bending strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

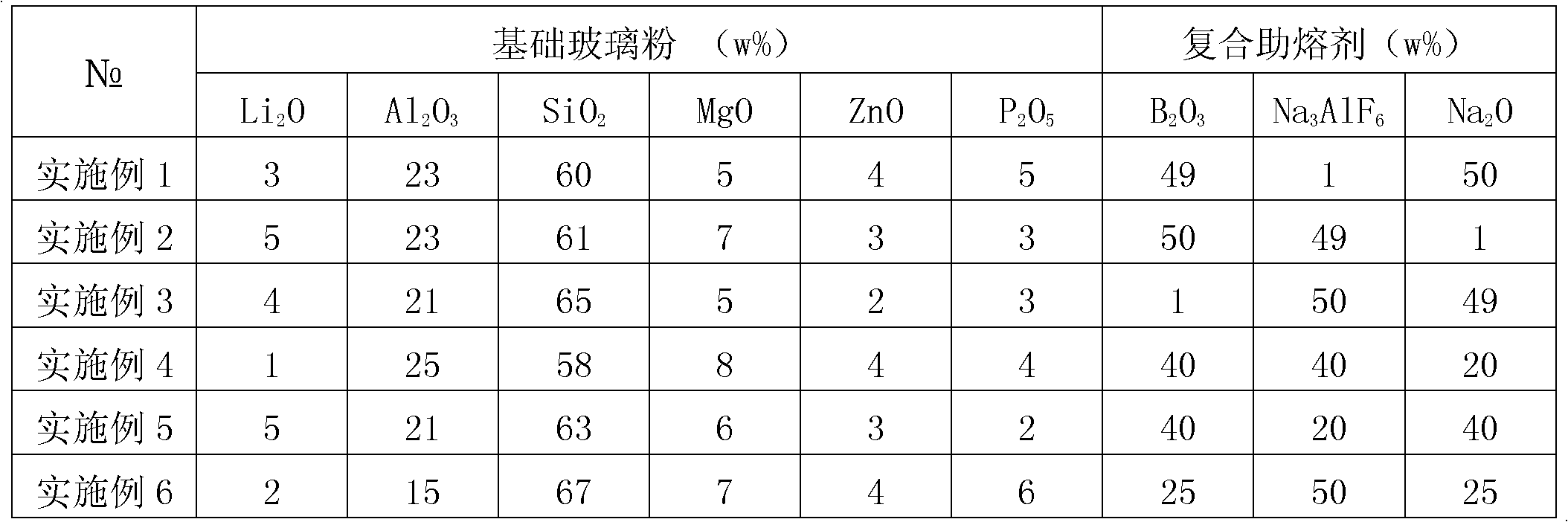

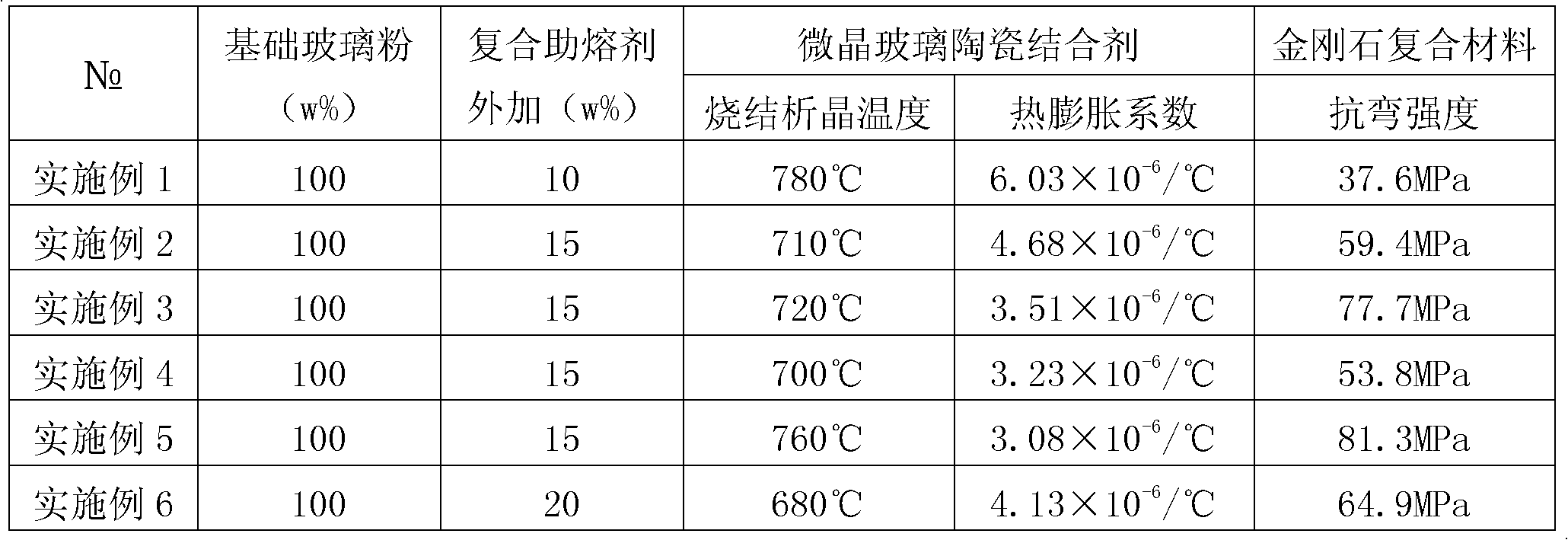

Microcrystal glass ceramic bond for diamond composite materials

InactiveCN102531400ASmall coefficient of thermal expansionLower crystallization temperatureThermal expansionUltimate tensile strength

The invention discloses a microcrystal glass ceramic bond for diamond composite materials. The microcrystal glass ceramic bond is characterized in that 10 to 20 percent by weight of composite cosolvent is added in base glass powder in order to decrease the crystallizing temperature. The components of the base glass powder and the contents of the components in percentage by weight are as follows: 1 to 5 percent of Li2O, 15 to 27 percent of Al2O3, 55 to 70 percent of SiO2, 2 to 10 percent of MgO, 3 to 8 percent of ZnO and 2 to 6 percent of P2O5. The components of the composite cosolvent and the percentages by weight of the components are as follows: 1 to 45 percent of B2O3, 1 to 55 percent of Na3AlF6 and 1 to 60 percent of Na2O. The microcrystal glass ceramic bond with low thermal expansion coefficient, low crystallizing temperature and high strength, which is provided by the invention and is suitable for diamond composite materials, enhances the performance of diamond composite materials.

Owner:TIANJIN UNIV

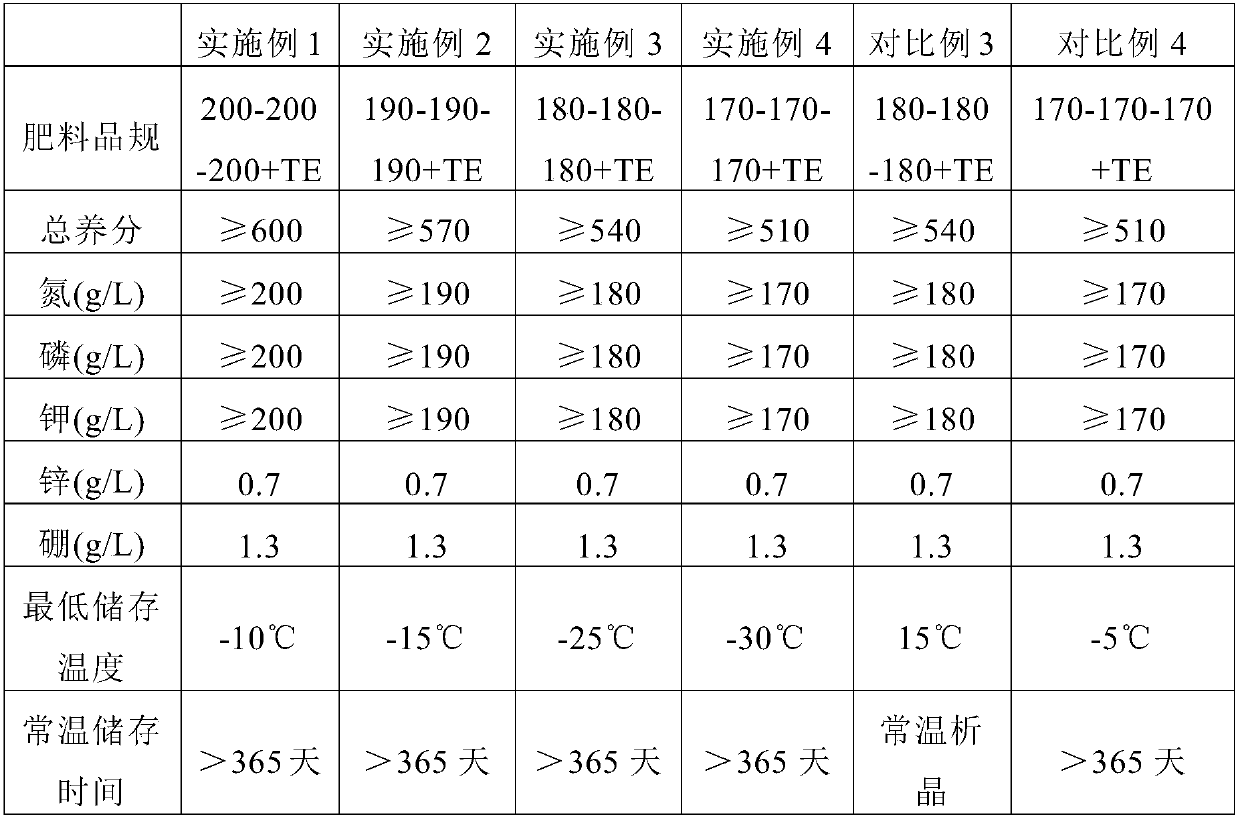

Balanced macroelement clear liquid fertilizer

InactiveCN109627087ALower crystallization temperatureIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCrystallization temperatureWater soluble

The invention provides a balanced macroelement clear liquid fertilizer and a preparation method thereof. The clear liquid fertilizer comprises a urea-formaldehyde nitrogen solution, a water-soluble phosphate fertilizer and a water-soluble potassic fertilizer, wherein the urea-formaldehyde nitrogen solution comprises urea, methylol urea, methylene urea and triazinone compounds. Therefore, the urea-formaldehyde nitrogen solution is taken as a basic nitrogen fertilizer raw material to be mixed with the water-soluble phosphate fertilizer and the water-soluble potassic fertilizer so as to obtain the clear liquid fertilizer containing macroelements, wherein the methylol urea, methylene urea and triazinone compounds in the clear liquid fertilizer can stably provide sustained-release nitrogen after being absorbed by plants, thereby increasing the utilization rate of a nitrogen fertilizer and enhancing the fertilizer efficiency; the crystallization temperature of the clear liquid fertilizer canbe as low as 10 DEG C or even as low as 30 DEG C or below, thereby further expanding the safe application area of the clear liquid fertilizer; the preparation cost is lower, and the cost performanceis high; the long-term storage stability is good, and precipitates do not appear easily.

Owner:SINOCHEM AGRI LINYI R&D CENT CO LTD

Low temperature deposition method of hypovanadic oxide thin film on glass

InactiveCN101280413ALow deposition temperatureReduce difficultyVacuum evaporation coatingSputtering coatingVanadium dioxideLow temperature deposition

The invention provides a low temperature deposition method of vanadium dioxide thin film on a glass substrate by utilizing a principle of template induction function for the crystal growth. Glass is taken as a substrate, and the low temperature deposition method comprises the steps in sequence that firstly, the glass substrate is cleaned and pre-heated; secondly, a silicon dioxide diffusing blocked layer is prepared; thirdly, a metal oxide buffer layer is prepared; fourthly, a vanadium dioxide thermal color layer is prepared. The material of the metal oxide buffer layer adopted by the invention is transparent in the visible light area and has low crystallization temperature, the crystal shape of the material can be well matched with the vanadium dioxide, and the template induction function can be generated during the growing process of the vanadium dioxide thin film, therefore, the deposition temperature of the vanadium dioxide thin film can be greatly reduced. The preparing process of the vanadium dioxide intelligent glass is simplified, the cost is reduced, the energy consumption is saved, and the difficulty of the industrialization process of the vanadium dioxide intelligent glass is greatly reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

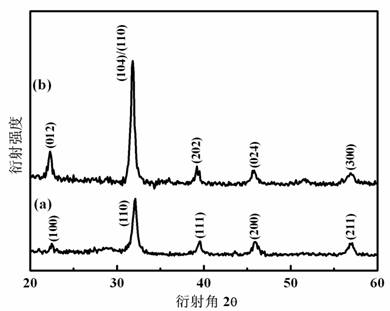

Method for synthesizing and preparing ZSM-22 molecular sieve under conditions of no organic template and no crystal seed

InactiveCN104671252AReduce usageAvoid pollutionCrystalline aluminosilicate zeolitesMolecular sieveAluminium sulfate

The invention relates to the field of preparation of molecular sieves, and aims to provide a method for synthesizing and preparing a ZSM-22 molecular sieve under the conditions of no organic template and no crystal seed. The method comprises the following steps: uniformly mixing deionized water and an alkali source, adding aluminum sulfate, adding a silicon source under stirring conditions, continuing stirring to form a silica-alumina gel, and carrying out crystallizing reaction on the obtained silica-alumina gel in a reaction kettle; after the reaction finishes, obtaining the product, carrying out vacuum filtration on the product, and drying to obtain the ZSM-22 molecular sieve raw powder. The method thoroughly avoids the use of the organic template agent, and lowers the crystallizing temperature on the premise that the crystallizing time is not obviously changed, thereby reducing the unnecessary energy consumption and environmental pollution in the production process. More importantly, the method has very high silicon raw material utilization ratio and high yield, thereby greatly saving the production cost and being beneficial to application in other industrial fields.

Owner:ZHEJIANG UNIV

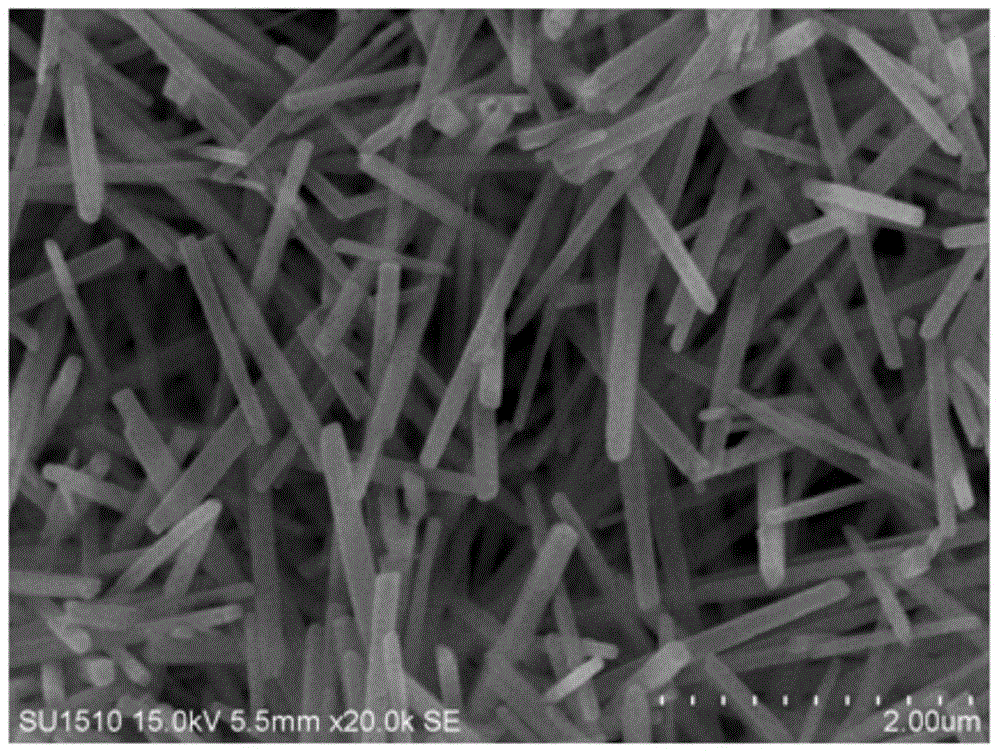

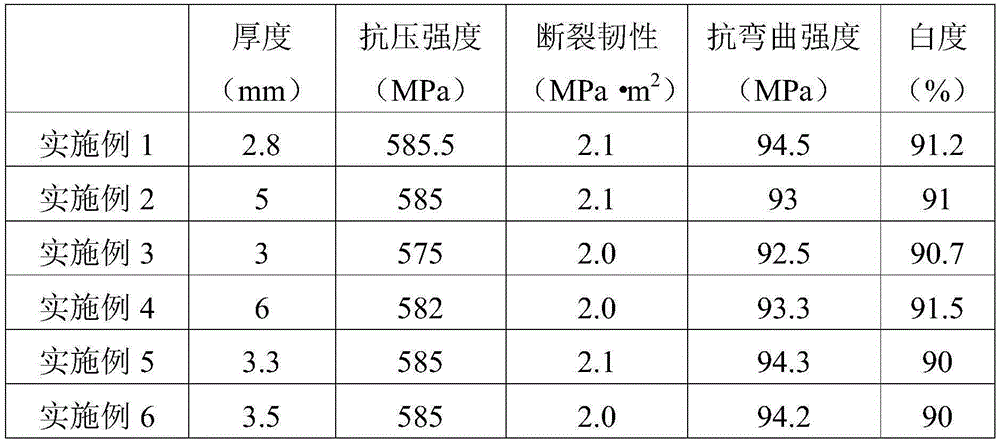

Preparation technology for glass ceramics sheet

ActiveCN105271642AImprove bending abilitySolve technical problems that are easily deformedGlass rolling apparatusFlexural strengthNucleation

The invention discloses a preparation technology for a glass ceramics sheet. The preparation technology includes the steps that 1, SiO2, Al2O3, K2O, Na2O, CaO, MgO, F and a clarifying agent are weighed to obtain batch; 2, the batch is added into a melting furnace, the melting temperature is controlled to be 1510 DEG C-1520 DEG C, and the melted batch is clarified on the stirring condition to generate glass melt; 3, the glass melt enters a three-roll roller press to be rolled and calendered to form a glass plate; 4, the glass plate enters a roller kiln, and a glass ceramics sheet is obtained through primary nucleation, intensified nucleation and crystallization; 5, annealing, cooling, polishing and trimming are carried out on the obtained glass ceramics sheet to obtain the glass ceramics sheet product. The thickness of the glass ceramics sheet prepared through the preparation process according to the component content is 2-10 mm, the technical effect of bending resistance of the sheet in the production technical process is achieved, bending resistance and compressive strength are high, industrialization of the glass ceramics sheet is achieved, and market promotion is easy.

Owner:JIANGXI XINFENG MICROCRYSTALLINE JADE CO LTD

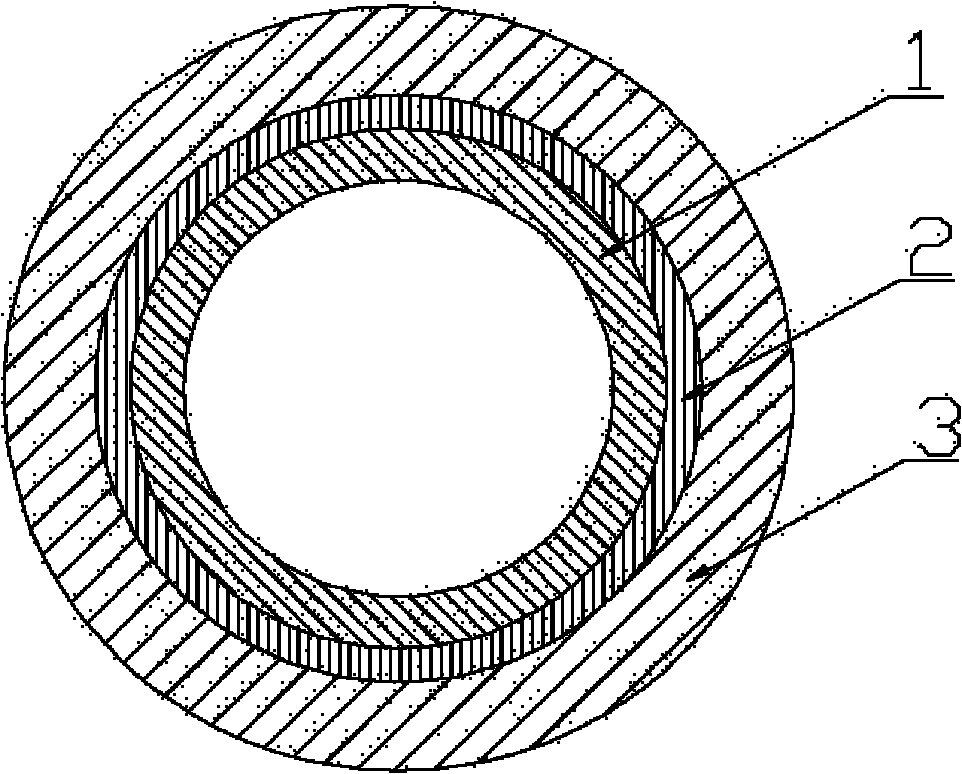

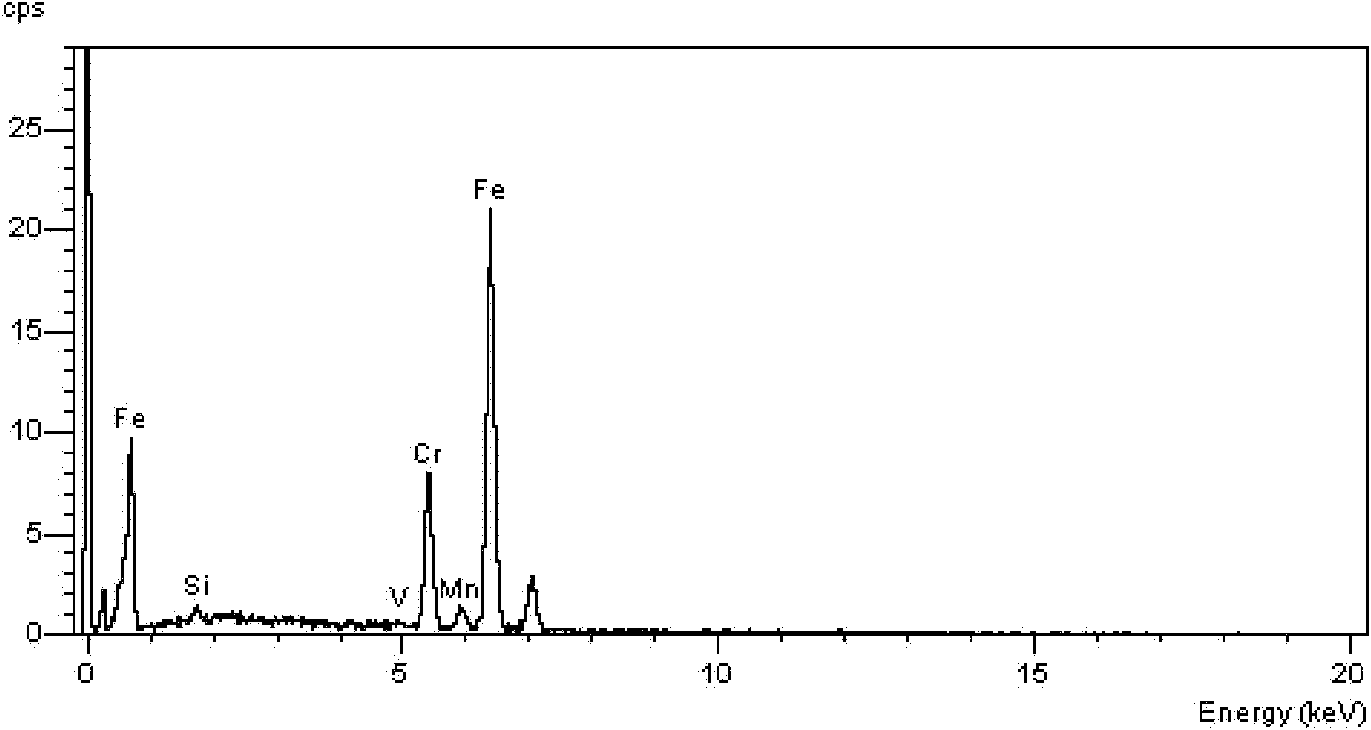

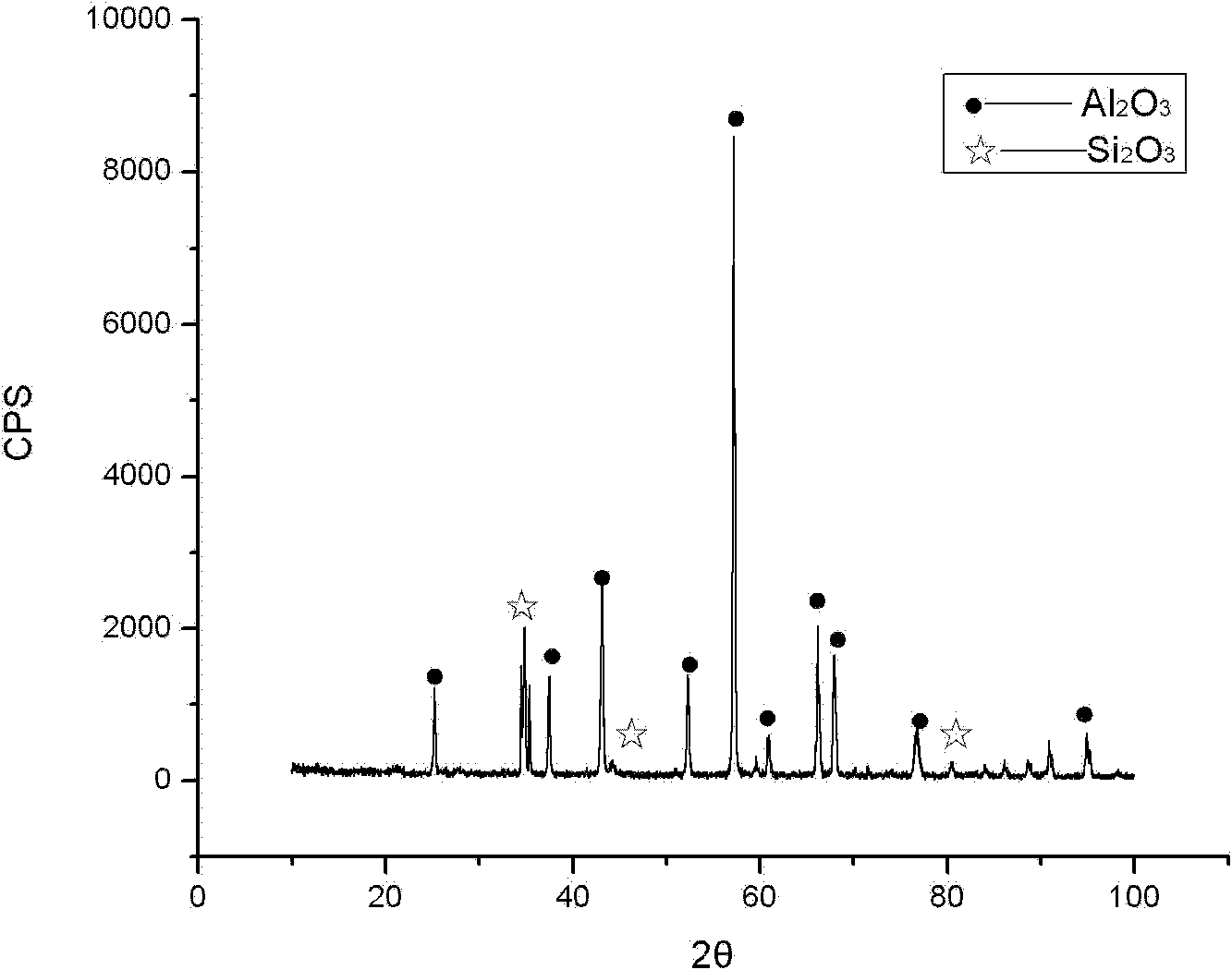

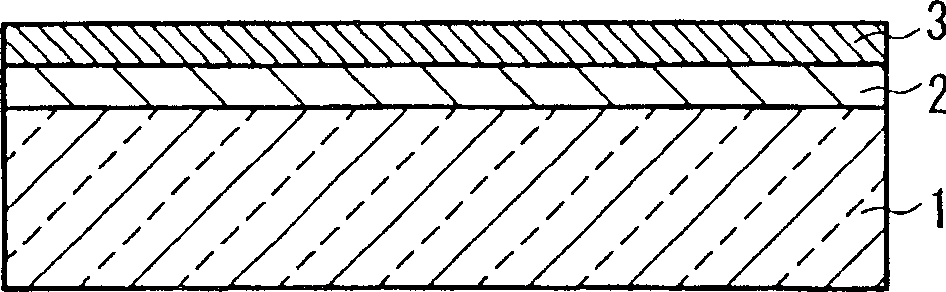

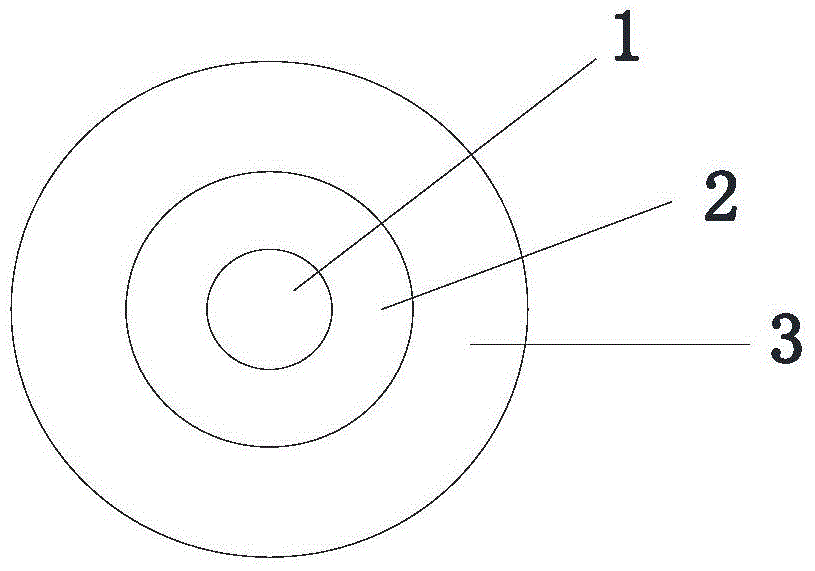

Method for preparing SHS ceramic liner metal tube from iron-based wastes

The invention relates to a method for preparing an SHS ceramic liner metal tube from iron-based wastes and discloses a method for manufacturing a corrosion-resistant and wear-resistant ceramic liner metal tube. The technical scheme is that: the treated iron-based wastes and Al powder are proportioned, mixed and sintered through an SHS centrifugal thermit reaction; an iron alloy layer and a ceramic layer are formed on an inner wall of the metal tube under the action of centrifugal force; and the prepared metal tube has the sandwich structural characteristic, namely the ceramic layer 1, the iron alloy layer 2 and a metal tube substrate layer 3 are formed from the interior to the exterior in turn. The method for preparing the SHS ceramic liner metal tube solves the problem that the conventional ceramic liner metal tube has over-high manufacturing cost and ceramic surface quality defect, and improves the wear resistance and corrosion resistance of the tube. The prepared metal tube can be widely applied to conveying powder, slurry and tailings in metallurgy, mines, electric power, coal and other industries.

Owner:UNIV OF SCI & TECH BEIJING

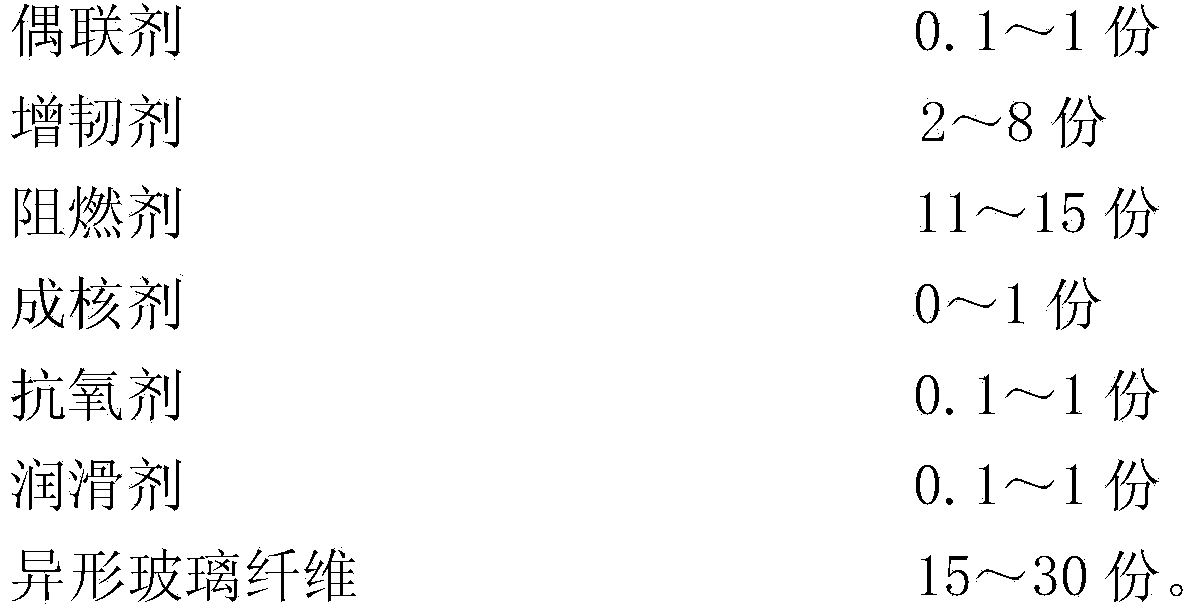

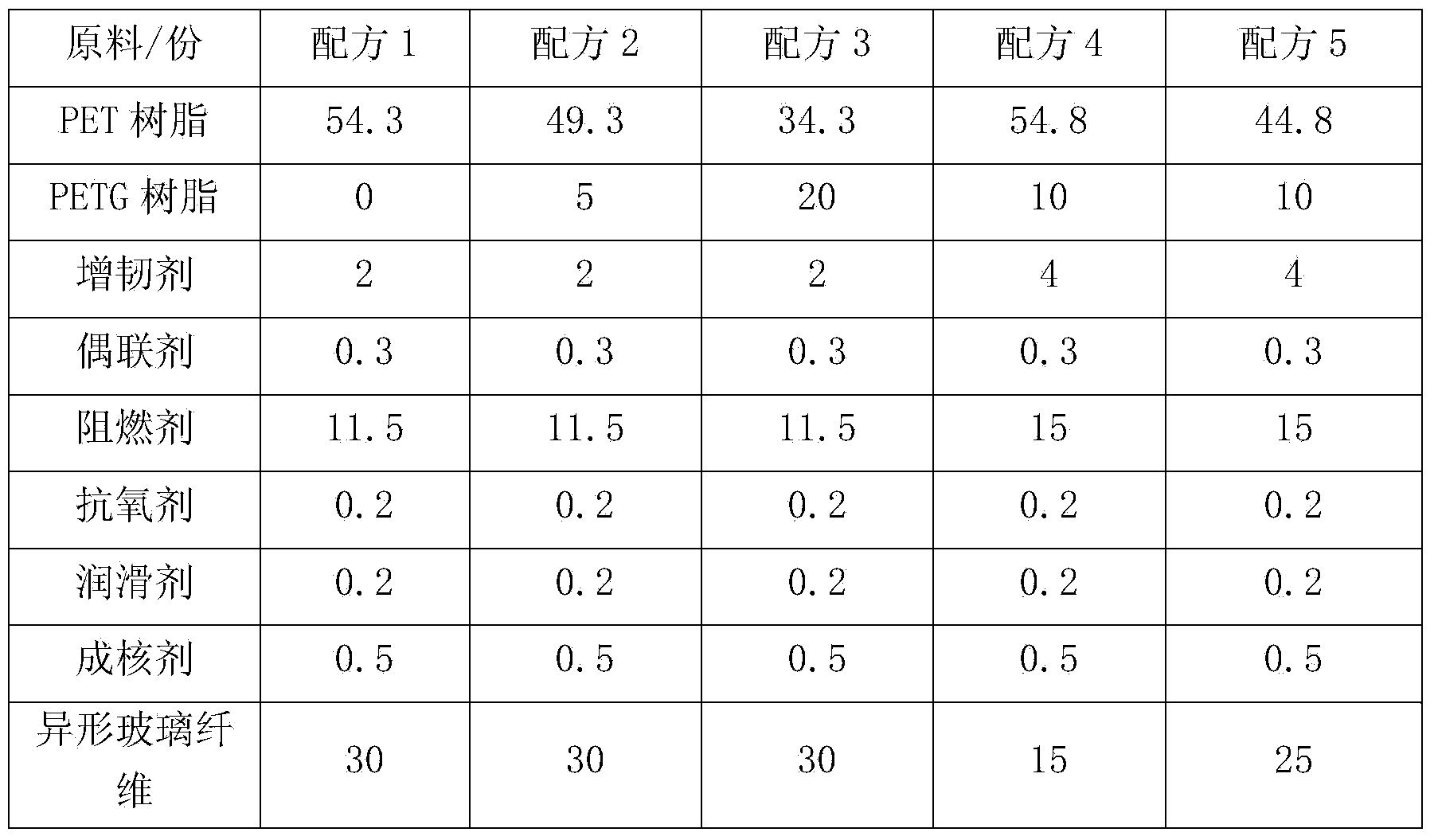

Low-fiber-emergence low-warping high-tenacity flame-retardant PET/PETG composite material and preparation method

The invention discloses a low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material and a preparation method, and relates to the field of high polymer materials. The composite material is prepared by mixing 30-50 parts of PET resin, 5-20 parts of PETG resin, 0.1-1 part of a coupling agent, 2-8 parts of a flexibilizer, 11-15 parts of a fire retardant, 0-1 part of a nucleating agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricating agent, adding 15-30 parts of irregular-shaped glass fibers during the extrusion process of a twin-screw extruder, extruding, and pelletizing to obtain. The preparation method of the low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material disclosed by the invention utilizes the characteristic that the PETG resin is well compatible with the PET resin; the addition of the flame-retardant system PETG, the flexibilizer and the nucleating agent greatly improves the processing performance, the surface performance and the impact performance of the composite material, while influencing the other performances a little; meanwhile, the addition of the PETG and the irregular-shaped glass fibers reduces the crystallization temperature and the crystallization rate of the material, and lowers the warping degree.

Owner:古道尔工程塑胶(深圳)有限公司

Synthetic method of MCM-22 (Multiple Chip Module 22) molecular sieve

ActiveCN102040229ALower crystallization temperatureShort crystallization timeCrystalline aluminosilicate zeolitesKetoneAlkylation

The invention relates to a preparation method of an MCM-22 (Multiple Chip Module 22) molecular sieve, which comprises the following steps of: firstly preparing a structure directing agent, and uniformly mixing the structure directing agent with a silicon source, an aluminum source, a boron source or an iron source, an organic template agent and water into glue, wherein the organic template agent can be dimethyleneimine and can also be a mixed template agent comprising the dimethyleneimine and one or more of hydrocarbons, organic amine, alcohols and ketones; and then synthesizing an MCM-22 molecular sieve material through the silicon source, the aluminum source, alkali, the organic template agent and the structure directing agent, carrying out hydrothermal crystallization and obtaining an MCM-22 molecular sieve product through conventional processes of filtering, washing, drying and roasting. The method disclosed by the invention has the main characteristic that the structure directing agent is added into gel, and compared with the prior art, the method disclosed by the invention has the advantages of low crystallization temperature, short crystallization time, high product yield, high product quality and the like. The MCM-22 molecular sieve product disclosed by the invention has excellent catalytic performances, such as catalytic cracking, olefin and benzene alkylation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

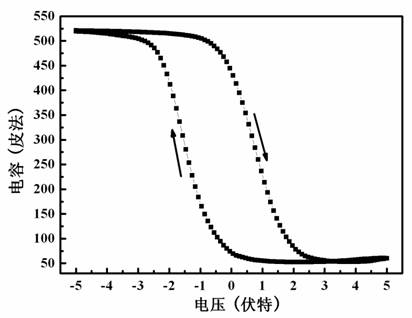

Bismuth ferrite base film layer stacked structure capacitor and preparation method thereof

InactiveCN102222672AGood lattice matchingImprove insulation performanceSolid-state devicesSemiconductor/solid-state device manufacturingBarium strontium titanateLanthanide

The invention discloses a bismuth ferrite base film layer stacked structure capacitor and a preparation method thereof, wherein the capacitor comprises a bottom electrode, a substrate, a buffer layer, a ferroelectric film layer and a metal point electrode in sequence from the bottom to top; the buffer layer is a manganese-doped barium strontium titanate film, the chemical formula is Ba0.6Sr0.4Ti(1-x)MnxO3, x is the mole equivalent of element manganese, and x is equal to 0.005-0.05; and the ferroelectric film layer is a bismuth ferrite base film, the chemical formula is Bi(1-y)LnyFeO3, wherein Ln is one of lanthanide, y is the mole equivalent of lanthanide, and y is equal to 0.01-0.2. The preparation method is simple, and the obtained capacitor is a storage cell of a ferro-electric field effect transistor; and the capacitor overcomes the defects that the bismuth ferrite base film capacitor on ordinary silicon substrate has the defects of poor interface performance and high working voltage, and has good energy storage performance.

Owner:UNIV OF JINAN

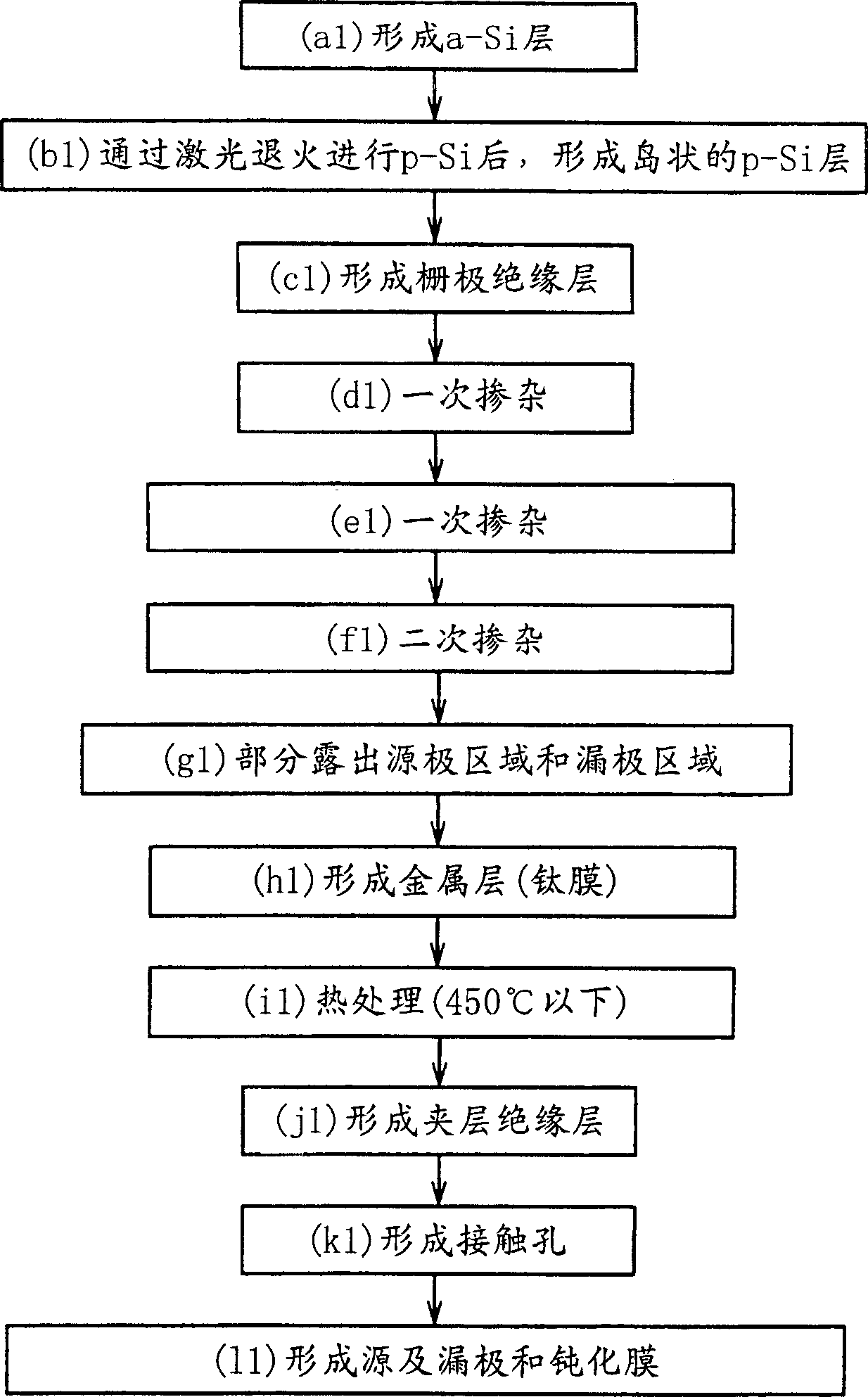

Thin film transistor and its producing method

InactiveCN1388591ALower crystallization temperatureTransistorStatic indicating devicesEngineeringSilicon based

The invention provides a method for carrying out a heat treatment required during the manufacture of a thin film transistor (TFT) at relatively low temperatures. In this method, in a heating step in which at least a portion of a silicon-based semiconductor layer is crystallized, a silicide is formed in a source region and a drain region in the semiconductor layer. A TFT according to the invention includes a silicon-based semiconductor layer having a channel region, a source region and a drain region being so disposed as to sandwich the channel region, a source electrode electrically connected to the source region, a drain electrode electrically connected to the drain region, and a gate electrode insulated from the source electrode and the drain electrode, and the source region and the drain region contains a silicide.

Owner:PANASONIC CORP

Low-temperature-resistant and abrasion-resistant cable

InactiveCN105038257AChanging the crystallization temperatureLower crystallization temperatureRubber insulatorsInsulated cablesPhosphorous acidMelamine phosphate

The invention discloses a low-temperature-resistant and abrasion-resistant cable. The low-temperature-resistant and abrasion-resistant cable comprises a conductive cable core, an inner protective cover and an outer protective cover. The conductive cable core is wrapped by the inner protective cover, and the inner protective cover is wrapped by the outer protective cover. The outer protective cover comprises polymethylvinylphenylsiloxane gum, hydrogenated butadiene-acrylonitrile rubber, solution polymerized styrene-butadiene rubber, methyl fluorine silicone oil, epoxidized soybean oil, dioctyl nylon acid ester, fumed silica, micro gelating capsule red phosphorus, melamine phosphate, dicumyl peroxide, vinyltriethoxysilane, zinc oxide, Ca / Zn compound stabilizer, TX-1 type rare-earth stabilizer, magnesium stearate, antioxygen 1076, phosphorous acid trioctyl ester and silicone powder. The low-temperature-resistant and abrasion-resistant cable is good in low temperature resistance and high in tenacity and abrasion resistance.

Owner:ANHUI RUIKAN SCI CABLE

Poly (arylene sulfide) and production process thereof

InactiveUS20070093642A1Improved melt stabilityHigh whitenessNatural resin processMolten stateShear rate

A poly(arylene sulfide) having properties that a melt viscosity is 1 to 3,000 Pa·s as measured under conditions of a temperature of 310° C. and a shear rate of 1,216 sec−1, a pH is 7.0 to 12.0 as measured in a mixed solvent of water / acetone (volume ratio=2 / 1), a crystallization temperature is at most 220° C. as measured in the course of lowing the temperature of the polymer at a rate of 10° C. / min from a molten state, and a whiteness degree is at least 70 as measured in the form of a melt molded or formed product, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

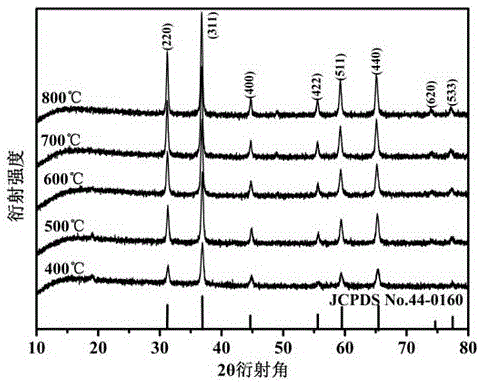

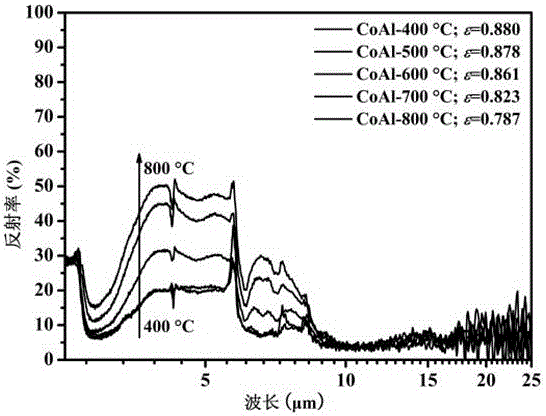

Synthesis of cobalt aluminum spinel blue nano ceramic pigment and application in preparation of solar energy light-absorbing coating

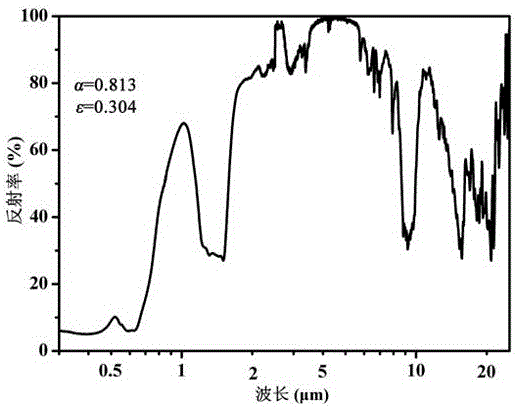

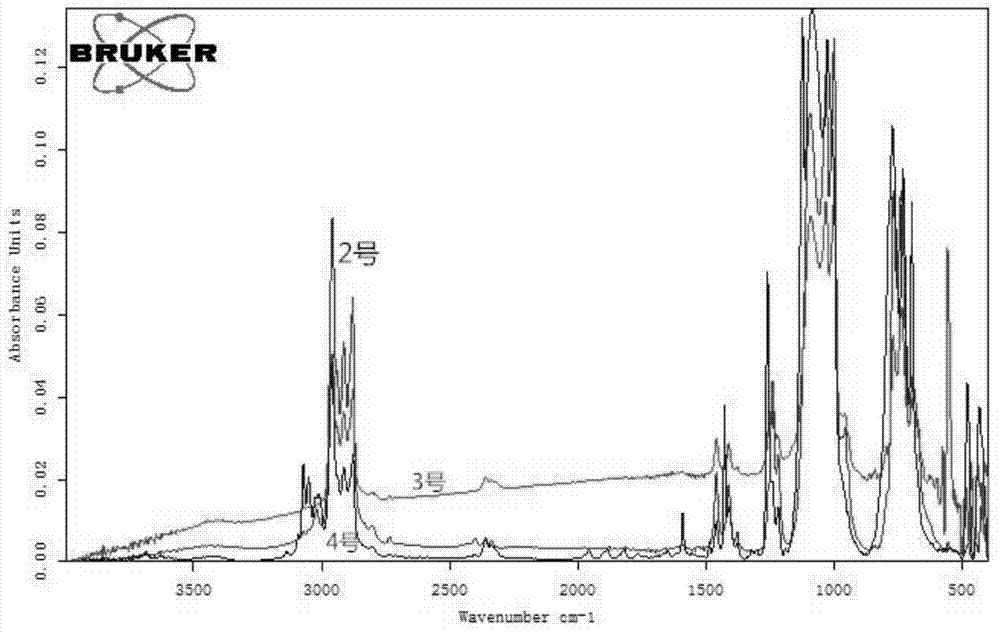

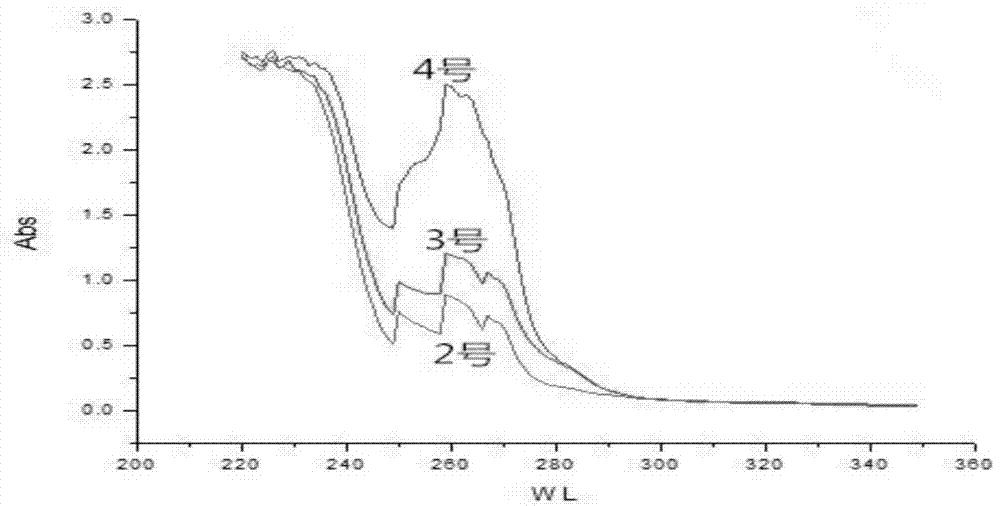

InactiveCN106830917AImprove uniformityImprove stabilityPigmenting treatmentRadiation-absorbing paintsSolventMaterials science

The invention discloses synthesis of a CoAl2O4 spinel blue ceramic pigment, a transition metal cobalt salt and a metal aluminum salt are dissolved in distilled water to obtain a starting solution; a chelating agent and esterification agent mixed water solution is dripped into the starting solution, and a sol-gel precursor is obtained by stirring and heating; the pH of the sol-gel precursor is adjusted to 6-7, the sol-gel precursor is hydrolyzed by continuous stirring and heating to form a sol solution; a solvent in the sol solution is evaporated to obtain a dry gel, the dry gel is ignited by absolute ethanol, by full self-propagating combustion of the dry gel, a combustion product is obtained, and the CoAl2O4 spinel blue ceramic pigment is obtained by heat treatment of the combustion product at 400 to 800 DEG C. The blue ceramic pigment, an organic binder and an organic solvent are mixed and sprayed onto a metal substrate after ball milling dispersion to obtain a CoAl2O4 spinel blue ceramic solar energy light-absorbing coating, and application of a colorful absorbing coating in solar energy outdoor buildings can be realized.

Owner:STATE GRID HUNAN ELECTRIC COMPANY DISASTER PREVENTION & REDUCTION CENT +1

Method for preparing solid bee honey

The invention discloses a method for preparing solid honey and relates to a method for preparing food, in particular to a preparation method for hardening honey. The method mainly comprises the steps of material selection, mixing and crystallization. The steps in detail are as follows: a. a material is selected, in which exquisite honey with small crystallization nucleus is selected as a crystallization revulsant; b. at a temperature of between 50 and 55 DEG C, honey is condensed till Be is between 39 and 45 degrees or the water content is between 14 and 25 percent and is cooled; c. when the temperature is cooled to 40 DEG C, the exquisite honey selected in the step a is added into the honey obtained in the step b; and d. the honey is stirred and is continuously cooled to a temperature of between 10 and 14 DEG C; the humidity of air is controlled less than or equal to 58 percent; and the honey is recrystallized to obtain the solid honey. The method has a simple process, easy control of the process course and low crystallization temperature, well protects the effective nutritive compositions of the honey, does not need to add minor ingredients additionally to realize the solidification of the liquid honey, ensures the original flavor and nutrition of the honey to the maximum and brings great convenience for people to store, carry and eat the honey.

Owner:陈建祥

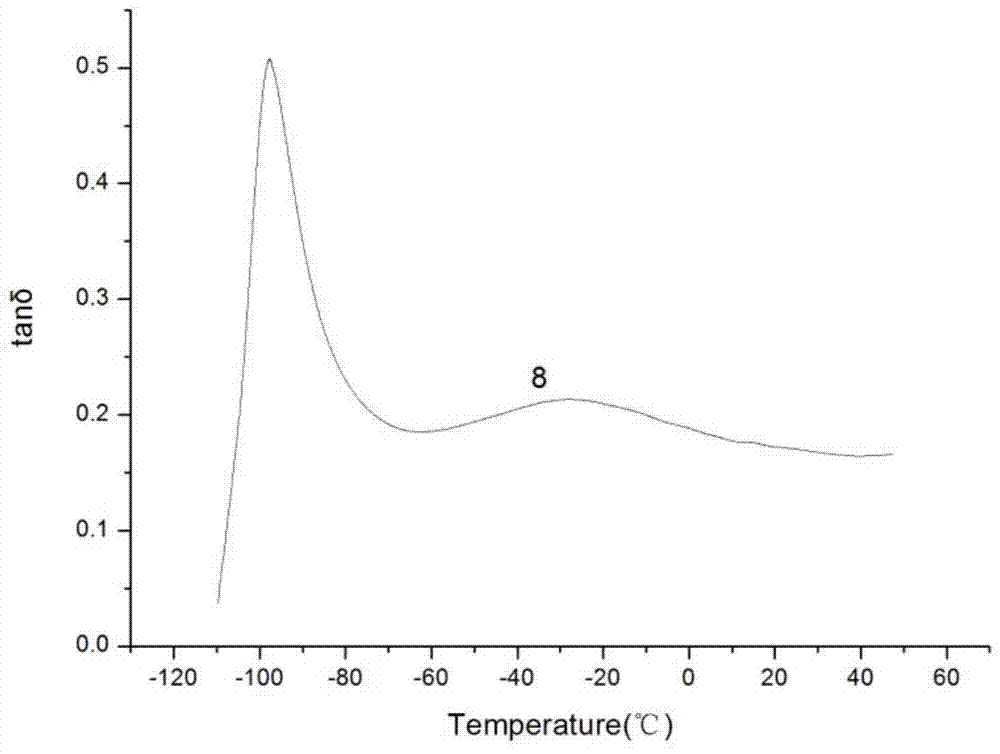

Damping silicon rubber with relatively small temperature effect and preparation method thereof

The invention relates to damping silicon rubber with a relatively small temperature effect and a preparation method thereof. The crude rubber of the damping silicon rubber is characterized in that a main chain of the crude rubber of the silicon rubber consists of methyl phenyl silicone chain elements, diethyl silicone chain elements, dimethyl silicone chain elements and methyl ethylene silicone chain elements with different content; the molecular weight of the crude rubber is more than 400 thousands; the crude rubber is prepared by copolymerizing methyl phenyl cyclosiloxane, diethyl cyclosiloxane, dimethyl cyclosiloxane and methyl ethylene cyclosiloxane in the presence of initiators of polypropylene oxide and the like. The crude rubber with the structure has good damping property in a relatively wide temperature range after being vulcanized, the dynamic loss factor and the modulus hardly change along with temperature changes, and the damping silicon rubber belongs to the field of organic silicon high polymer.

Owner:SHANDONG UNIV

Poly(arylene sulfide) and production process thereof

InactiveUS7655748B2High whitenessExcellent melt formabilityNatural resin processMolten stateShear rate

A poly(arylene sulfide) having properties that a melt viscosity is 1 to 3,000 Pa·s as measured under conditions of a temperature of 310° C. and a shear rate of 1,216 sec−1, a pH is 7.0 to 12.0 as measured in a mixed solvent of water / acetone (volume ratio=2 / 1), a crystallization temperature is at most 220° C. as measured in the course of lowing the temperature of the polymer at a rate of 10° C. / min from a molten state, and a whiteness degree is at least 70 as measured in the form of a melt molded or formed product, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com