Synthesis of cobalt aluminum spinel blue nano ceramic pigment and application in preparation of solar energy light-absorbing coating

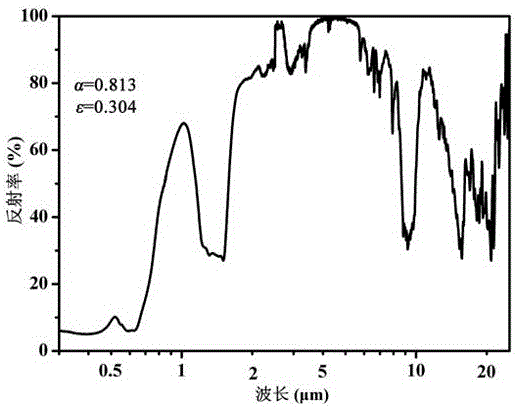

A spinel-type, nano-ceramic technology, used in fibrous fillers, radiation-absorbing coatings, etc., can solve the problems of poor moisture resistance of coatings, good temperature resistance of coatings, and high cost, and achieves lower crystallization temperature, The effect of improving production conditions and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

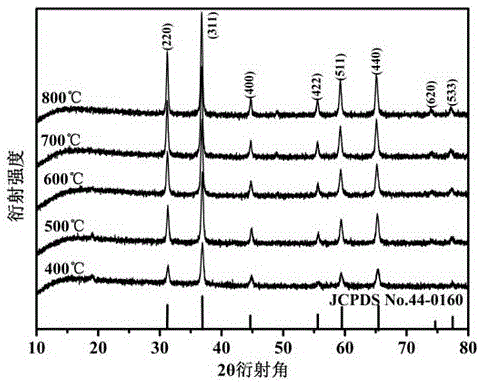

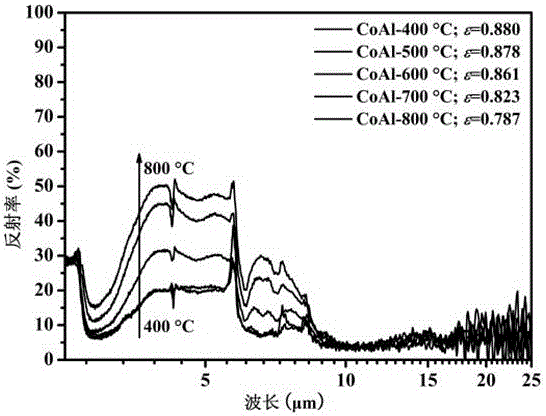

[0032] (1) CoAl 2 o 4 Synthesis of spinel-type blue nano-ceramic pigments

[0033] Add 0.2 mol of cobalt nitrate hexahydrate and 0.4 mol of aluminum nitrate nonahydrate into 400 ml of water respectively, stir magnetically at room temperature, and obtain the initial A solution after the metal salt is completely dissolved. Add 0.6 mol citric acid and 0.6 mol polyethylene glycol 400 into 200 ml of water, and obtain solution B after complete dissolution; slowly add solution B to the initial solution A, stir and heat to 35~40 °C to obtain Sol-gel precursor; adjust the sol-gel precursor to a pH value of 6~7 with 0.1 mol / L ammonia water under stirring; continue stirring at 35~40°C to make it hydrolyze to form a sol solution; Evaporate the solvent of the sol solution at 120~130 ℃ to obtain the xerogel; use a few drops of absolute ethanol to ignite the xerogel in the air, so that the xerogel will form a gray self-propagating powder through self-propagating combustion; finally The gr...

Embodiment 2

[0039] (1) CoAl 2 o 4 Synthesis of spinel-type blue nano-ceramic pigments

[0040] Add 0.1 mol cobalt chloride hexahydrate and 0.2 mol aluminum chloride to 200 ml water respectively, stir magnetically at room temperature, and obtain the initial A solution after the metal salt is completely dissolved; add 0.4 mol ethylenediaminetetraacetic acid and 0.6 mol Add polyethylene glycol 400 into 200 ml of water, and obtain solution B after complete dissolution; then slowly add solution B to the initial solution A, stir and heat to 35-40 °C to obtain a sol-gel precursor; Under stirring, use 0.1 mol / L ammonia water to adjust the sol-gel precursor to a pH value of 6~7; continue stirring at 35~40 °C to make it hydrolyze to form a sol solution; put the sol solution at 120~130 °C Evaporate the solvent under certain conditions to obtain the xerogel; use a few drops of absolute ethanol to ignite the xerogel in the air, so that the xerogel will form a dark gray self-propagating powder throug...

Embodiment 3

[0044] (1) CoAl 2 o 4 Synthesis of spinel-type blue nano-ceramic pigments

[0045] Add 0.1 mol of cobalt sulfate heptahydrate and 0.2 mol of ammonium aluminum sulfate dodecahydrate to 700 ml of water respectively, stir magnetically at room temperature, and obtain the starting A solution after the metal salt is completely dissolved. Add 0.4 mol citric acid and 0.4 mol polyethylene glycol 400 into 200 ml of water, and obtain solution B after complete dissolution; slowly add solution B to the initial solution A, stir and heat to 35~40 °C to obtain Sol-gel precursor; adjust the sol-gel precursor to a pH value of 6~7 with 0.1 mol / L ammonia water under stirring; continue stirring at 35~40°C to make it hydrolyze to form a sol solution; Evaporate the solvent of the sol solution at 120~130 ℃ to obtain the xerogel; use a few drops of absolute ethanol to ignite the xerogel in the air, so that the xerogel will form a gray self-propagating powder through self-propagating combustion; fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com