Patents

Literature

59results about How to "Control ingredient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of thermally-reduced graphene oxide/nano carbon fiber composite electrode for full-vanadium flow battery

InactiveCN104332640ALarge specific surface areaIncrease the reaction areaCell electrodesFiberCarbon fibers

The invention relates to the field of battery manufacturing and energy source storage and particularly provides a preparation method of a thermally-reduced graphene oxide / nano carbon fiber composite electrode for a full-vanadium flow battery. The preparation method comprises the following steps: firstly, preparing a spinning solution for an experiment; secondly, uniformly mixing graphite oxide powder and the spinning solution; stripping the graphite oxide powder into graphene oxide by using an ultrasonic manner; preparing a nano fiber membrane by adopting an electrostatic spinning method; and then pre-oxidizing the nano fiber membrane in the air and carbonizing in an inert atmosphere pipe type furnace to obtain the needed thermally-reduced graphene oxide / nano carbon fiber composite electrode. According to the full-vanadium flow battery composite electrode prepared by the method, the diameter of carbon fibers is a nano scale; and the carbon fibers are compounded with thermally-reduced graphene oxide and the roughness of the fibers is greatly increased, so that the specific surface area of the electrode is two orders of magnitudes higher than that of a traditionally-used electrode material. Meanwhile, the high-activity thermally-reduced graphene oxide is adopted so that the electrochemical activity of the electrode is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for combination electrode for all-vanadium redox flow battery

InactiveCN104241661AImprove electrochemical activityImprove energy efficiencySucessive textile treatmentsCell electrodesCarbon fibersCharge discharge

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method of a bismuth-base catalyst / carbon nanofiber combination electrode for an all-vanadium redox flow battery. Firstly, spinning solution required for an experiment is prepared and then bismuth salt and the spinning solution are uniformly mixed. According to an electrostatic spinning method, a required nanofiber film is prepared and then the nanofiber film is pre-oxidized in the air and is carbonized in an inert atmosphere tube furnace so as to obtain the required bismuth-base electrocatalyst / carbon nanofiber combination electrode. After the obtained electrode material is cleaned and dried, testing of related electrochemical performance representation and charge-discharge properties can be carried out on the electrode material. The carbon fiber diameter, which is prepared according to the preparation method, is in the nano class; compared with a specific surface area of a conventionally used electrode material, the specific surface area of the bismuth-base catalyst / carbon nanofiber combination electrode is greatly increased. Moreover, the carbon nanofibers are compounded with a high-activity bismuth-base electrocatalyst, and thus, electrochemical activity of the electrode can be greatly improved, so that energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

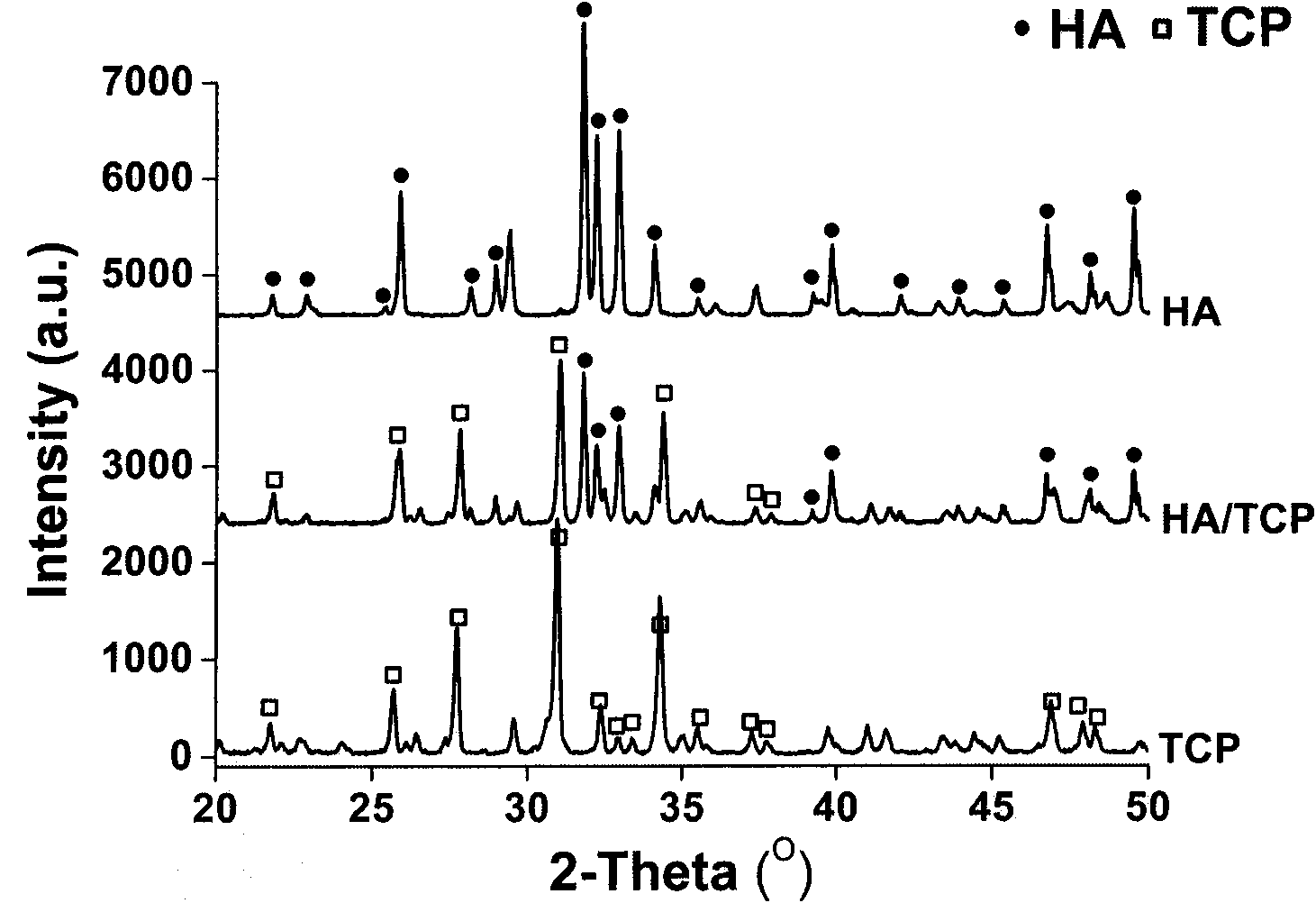

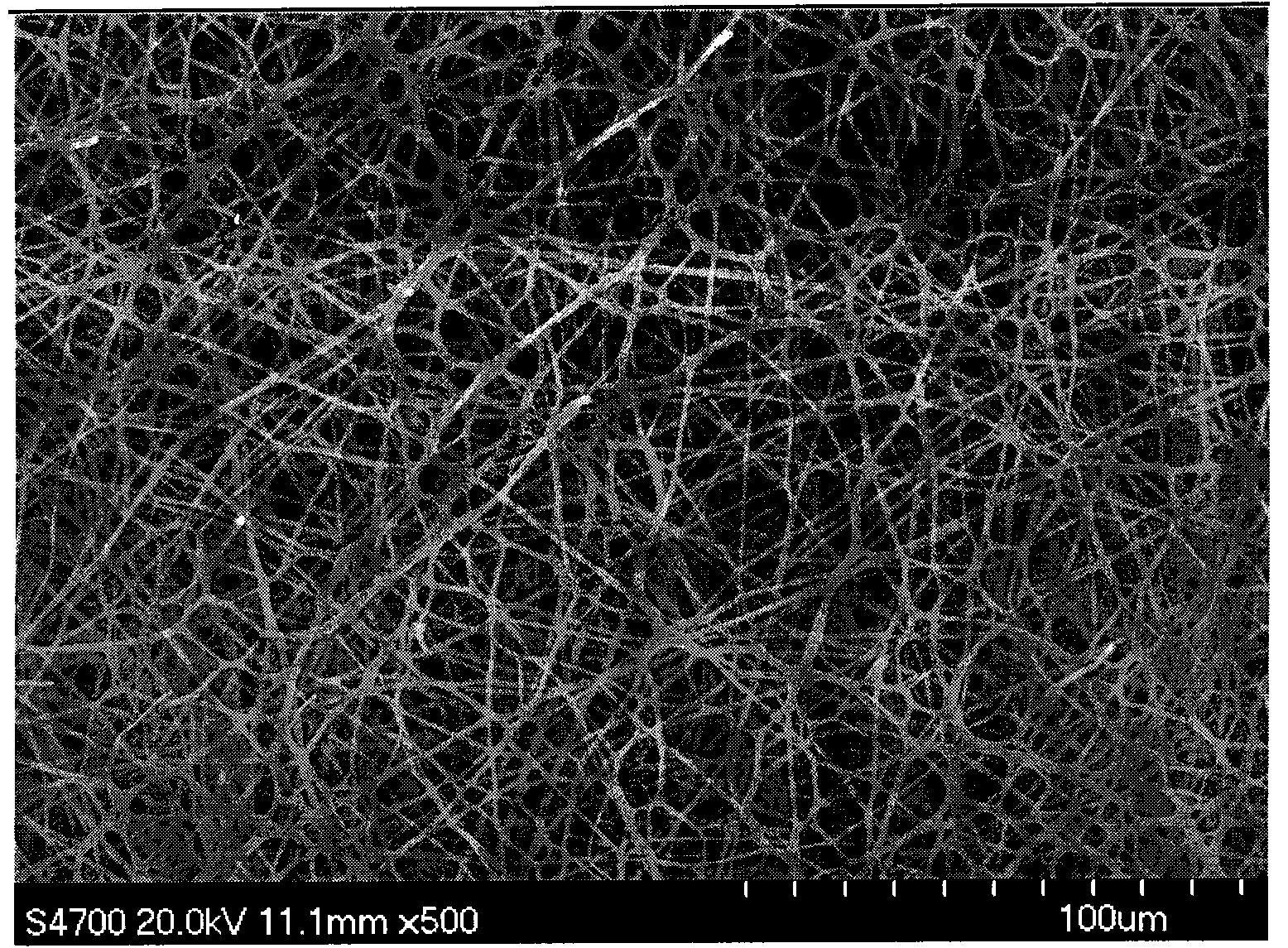

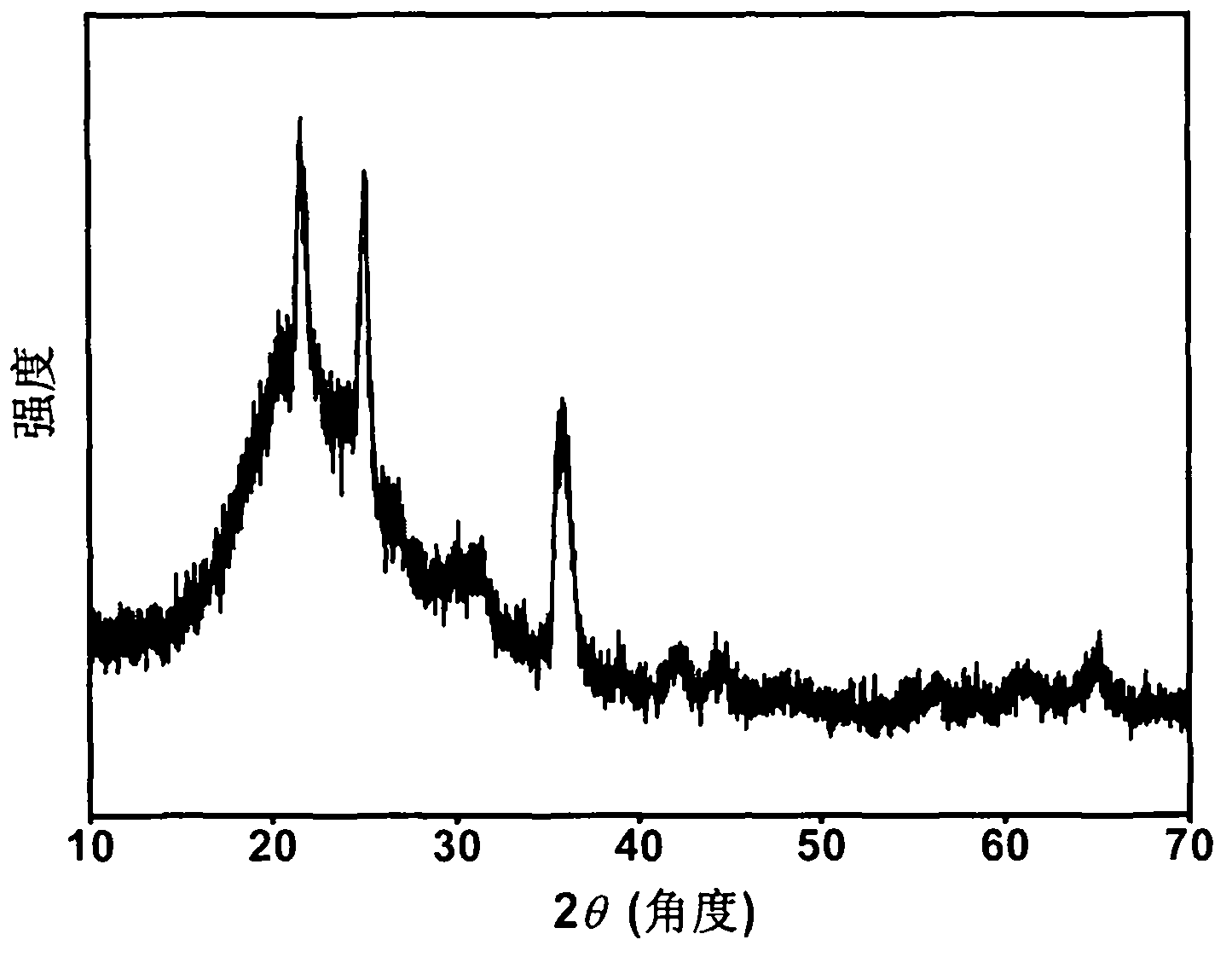

Biomimetic calcium phosphate fiber composite bracket material and preparation method thereof

The invention provides a biomimetic calcium phosphate fiber composite bracket material and a preparation method thereof. The bracket material has similar component and structure as natural reticulated bone and consists of nanometer / micron calcium phosphate fiber substrate and biological polymer coating on the surface, wherein the calcium phosphate fiber is lapped on each other to form a three-dimensional reticulated bone structure, the porosity is not lower than 80% and thickness of the polymer coating is from 100 to 1000 nm. The preparation method comprises the following steps of: dripping solution containing calcium ions into hydrolyzed phosphate solution; adjusting the PH value of the phosphate solution between 1 and 10 and the calcium-phosphorus ratio between 1.0 and 1.6; aging at low temperature to obtain precursor collosol and adding polymer spinning improver into the collosol to perform electrostatic spinning to obtain continuous three-dimensional nanometer / micron fiber; post-processing for shaping, sintering at high temperature, soaking and drying to obtain the biomimetic calcium phosphate fiber composite bracket material.

Owner:BEIJING UNIV OF CHEM TECH

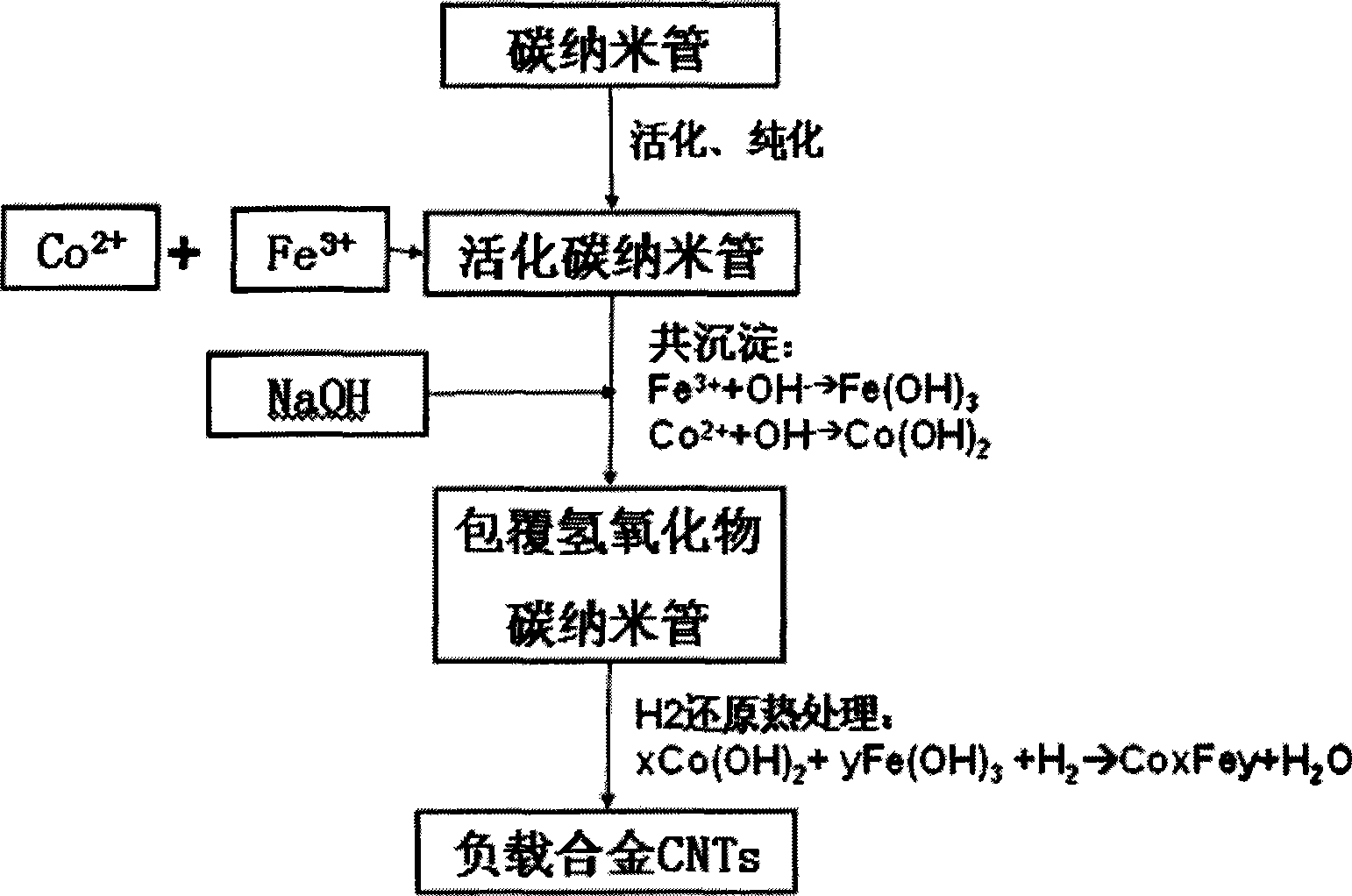

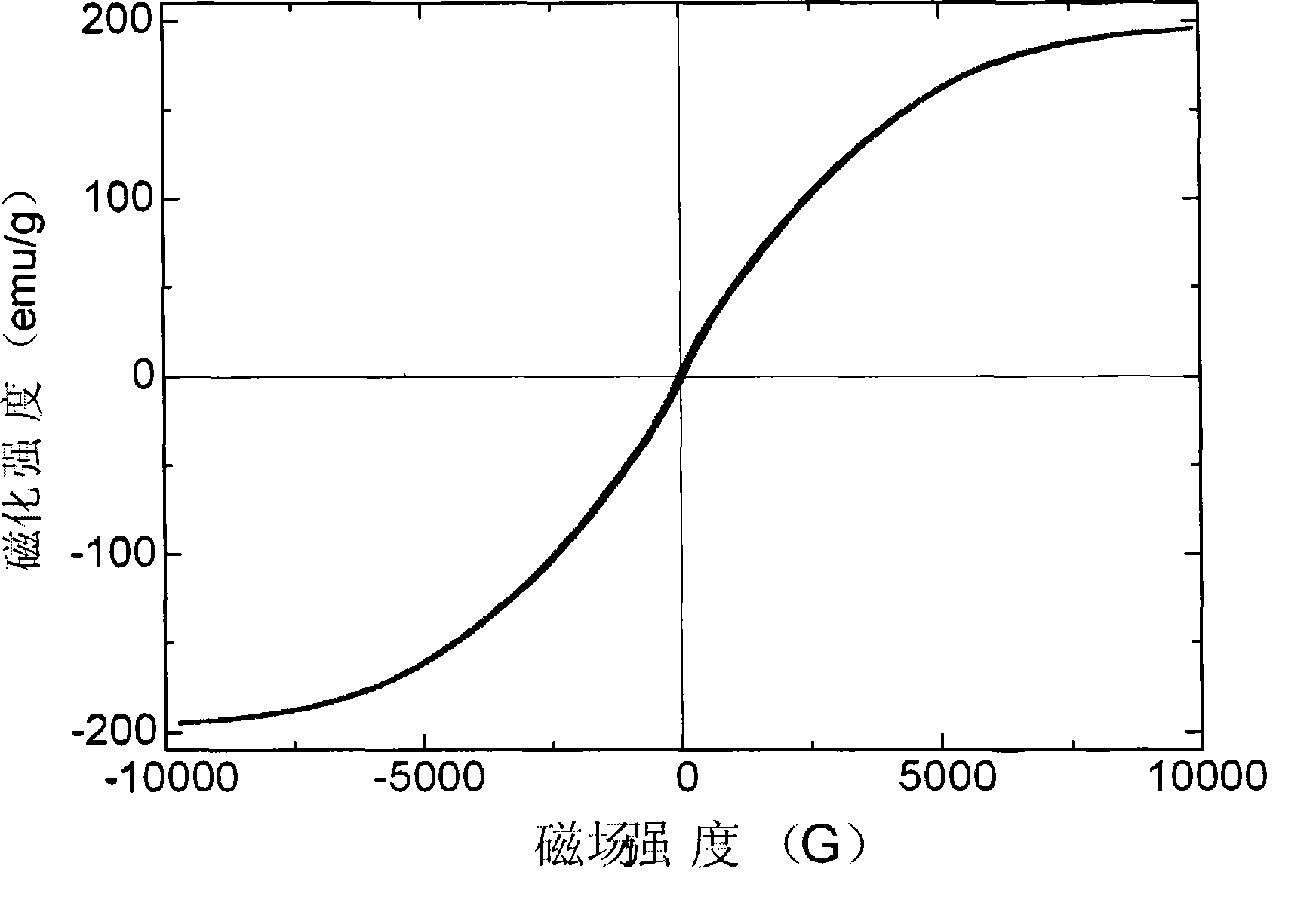

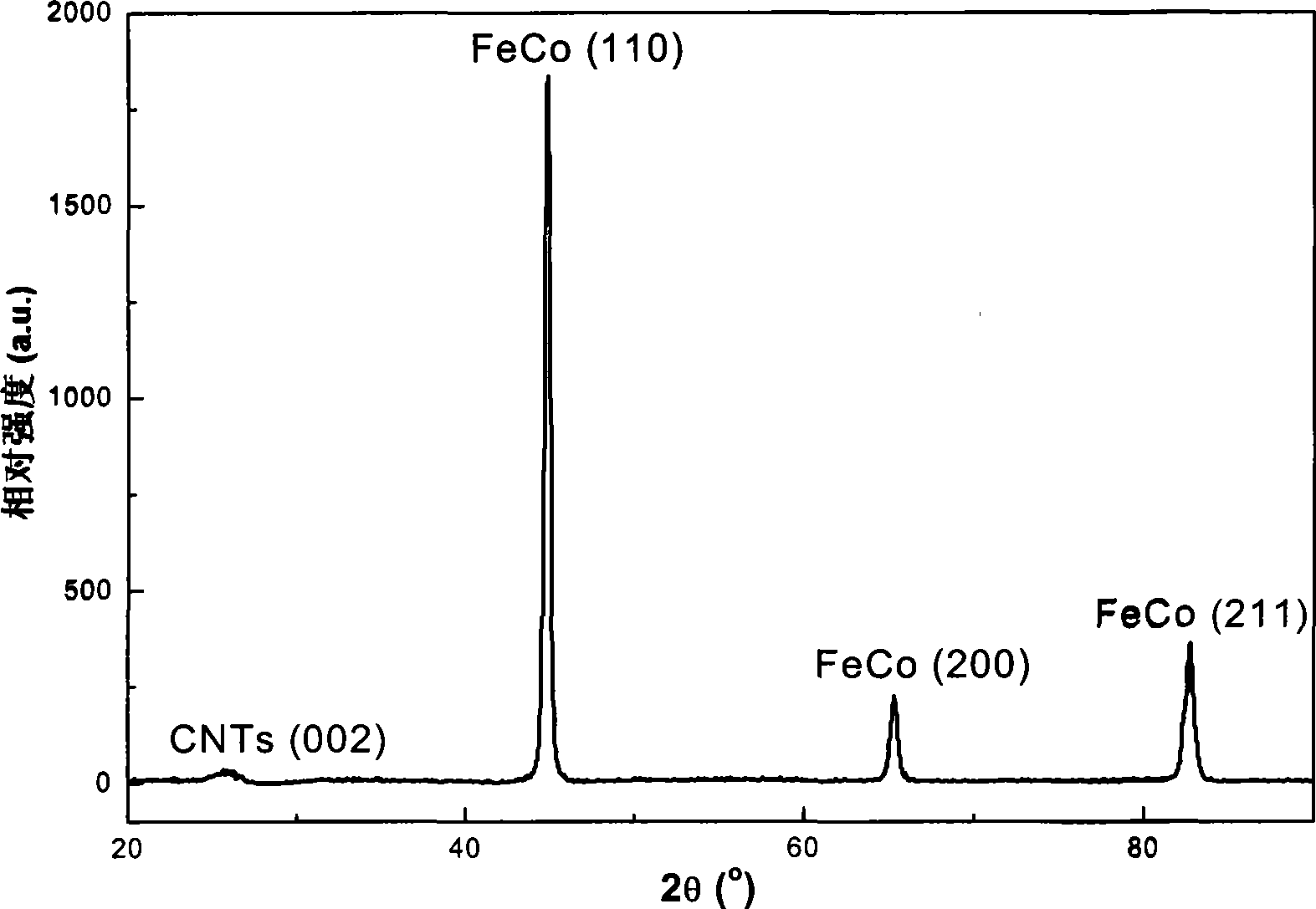

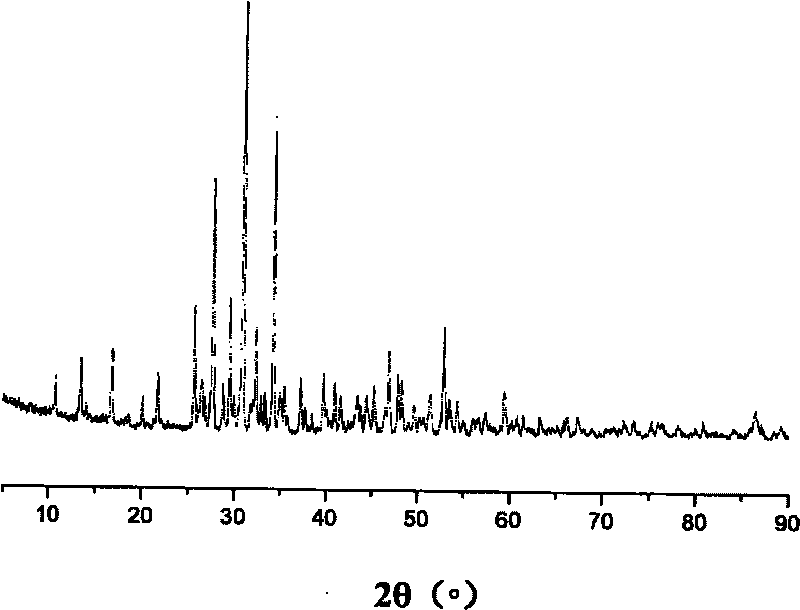

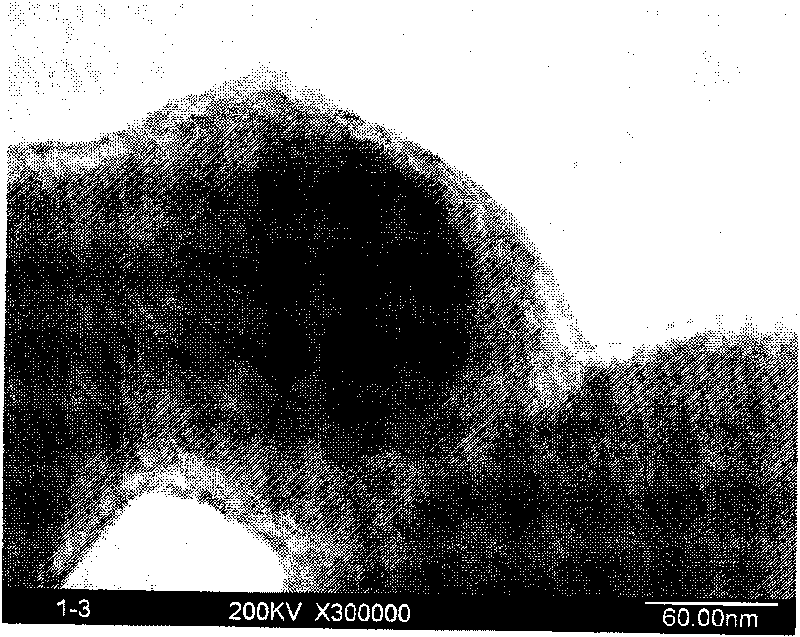

Preparation of surface load magnetic alloy particle carbon nano-tube composite material

InactiveCN101503579AGood electromagnetic performanceCrystallization intactOther chemical processesPigment physical treatmentCarbon nanotubeCrystallinity

The invention discloses a preparation method for carbon nano tube surface loaded magnetic alloy nano particle composite material, which belongs to the field of electromagnetic wave absorbing material preparation. The preparation method comprises the following steps: after purifying and activating a carbon nano tube, evenly dispersing the carbon nano tube to chloride salt solution of iron, cobalt and nickel, slowing adding an alkali solution dropwise into the solution in the fierce agitation process, and regulating the pH value of the solution and making iron ions, cobalt ions and nickel ions be coprecipitated onto the surface of the carbon nano pipe in the form of hydroxide according to the alloy proportion set when the solution is prepared; taking out a deposit by centrifugation or filtering; and after drying the deposit, carrying out the heat treatment of the deposit in the reducing atmosphere to obtain the carbon nano tube composite material loaded with magnetic alloy particles. The preparation method adopts a simple process. As no impurity element is introduced into the preparation process, the obtained magnetic alloy particles have high degree of crystallinity and excellent magnetic properties. In addition, the method has easy regulation of the alloy components. The composite material prepared by the method is significantly applied in the fields of electromagnetic interference resistance, stealth, microwave darkrooms, and the like.

Owner:TSINGHUA UNIV

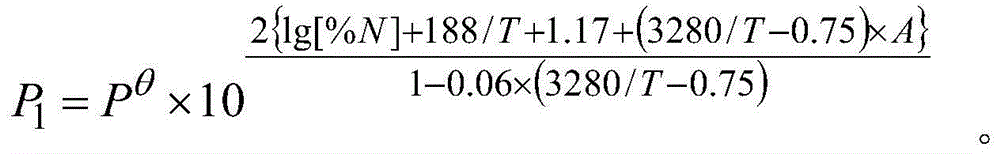

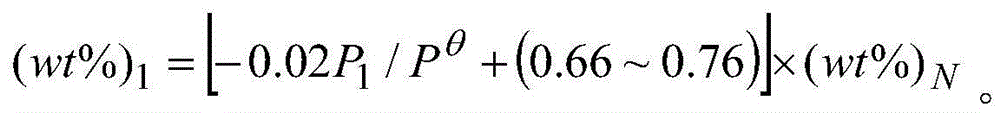

Method for pressurized induction smelting of high nitrogen stainless steel through pressure control in stages

ActiveCN104862609AControl ingredientSolve the problem of nitrogen poresElectric furnaceSteelmakingThermal insulation

The present invention discloses a method for pressurized induction smelting of high nitrogen stainless steel through pressure control in stages, and belongs to the technical field of high nitrogen stainless steel smelting. The high nitrogen stainless steel smelted by the method comprises less than or equal to 0.2% of C, 12-23% of Mn, 15-24% of Cr, less than or equal to 1% of Si, 0-4.5% of Mo, 0.7-2% of N, 0-4.5% of Ni, and the balance of Fe. The method specifically comprises: preparing materials and determining pressurization parameters in stages; loading the materials; vacuumizing to achieve 10 Pa, and then carrying out electrifying heating; filling nitrogen gas with a purity of more than or equal to 99.99% to achieve smelting pressure after the raw material is subjected to steelmaking, alloying, and carrying out thermal insulation for 10-15 min; and filling high purity nitrogen gas until achieving a casting pressure, and then casting. According to the present invention, the nitridized alloy addition amount is optimized and the smelting pressure and the casting pressure are reasonably controlled, such that the problems of serious nitrogen segregation, nitrogen precipitation, nitrogen gas pore formation and the like during the high nitrogen stainless steel solidification process are effectively solved.

Owner:NORTHEASTERN UNIV

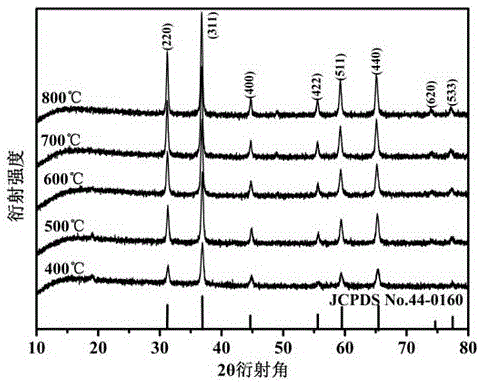

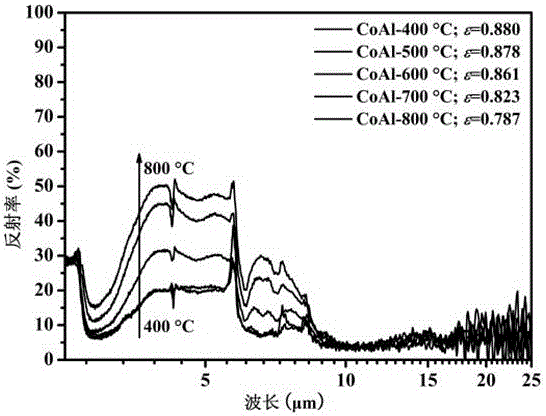

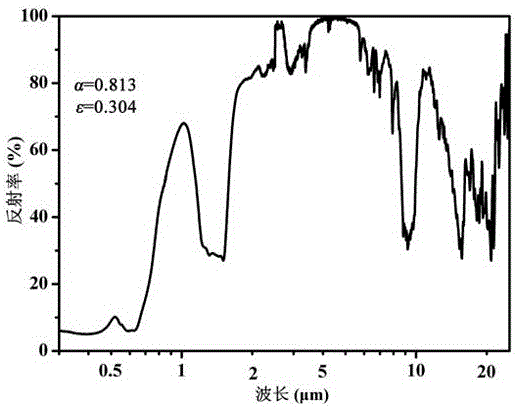

Synthesis of cobalt aluminum spinel blue nano ceramic pigment and application in preparation of solar energy light-absorbing coating

InactiveCN106830917AImprove uniformityImprove stabilityPigmenting treatmentRadiation-absorbing paintsSolventMaterials science

The invention discloses synthesis of a CoAl2O4 spinel blue ceramic pigment, a transition metal cobalt salt and a metal aluminum salt are dissolved in distilled water to obtain a starting solution; a chelating agent and esterification agent mixed water solution is dripped into the starting solution, and a sol-gel precursor is obtained by stirring and heating; the pH of the sol-gel precursor is adjusted to 6-7, the sol-gel precursor is hydrolyzed by continuous stirring and heating to form a sol solution; a solvent in the sol solution is evaporated to obtain a dry gel, the dry gel is ignited by absolute ethanol, by full self-propagating combustion of the dry gel, a combustion product is obtained, and the CoAl2O4 spinel blue ceramic pigment is obtained by heat treatment of the combustion product at 400 to 800 DEG C. The blue ceramic pigment, an organic binder and an organic solvent are mixed and sprayed onto a metal substrate after ball milling dispersion to obtain a CoAl2O4 spinel blue ceramic solar energy light-absorbing coating, and application of a colorful absorbing coating in solar energy outdoor buildings can be realized.

Owner:STATE GRID HUNAN ELECTRIC COMPANY DISASTER PREVENTION & REDUCTION CENT +1

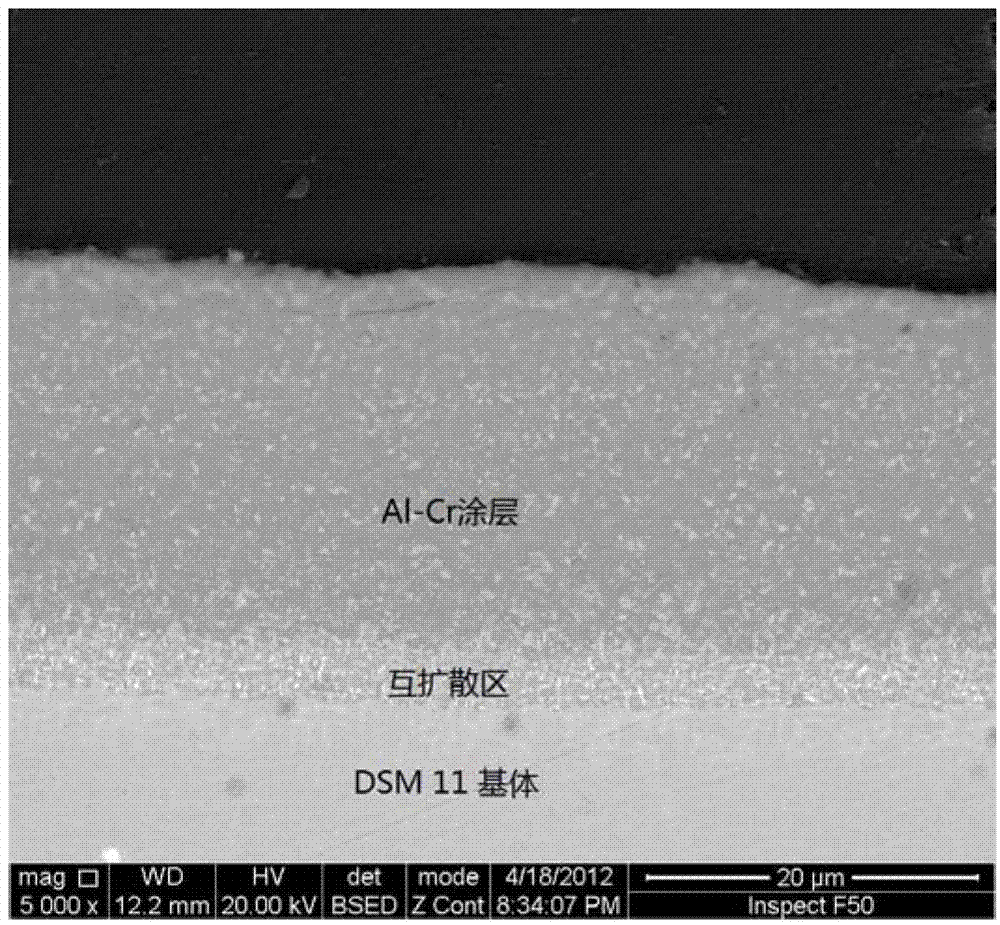

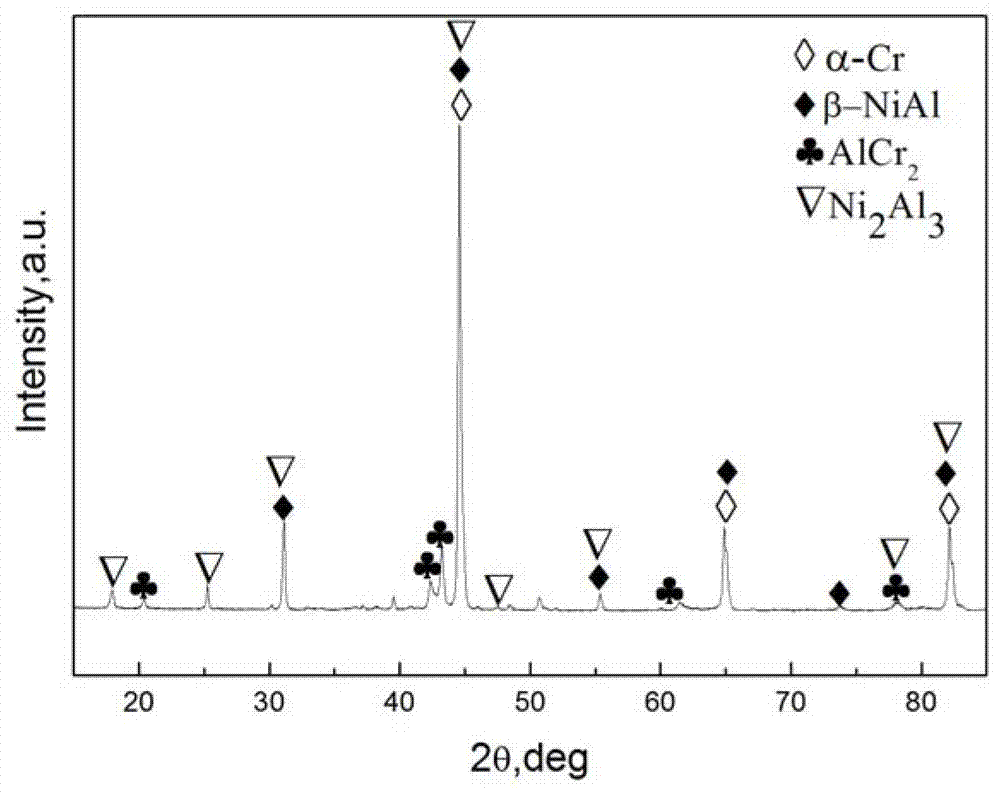

Preparation method for Al-Cr coating on nickel-based superalloy

InactiveCN103590002AExtended service lifeImprove antioxidant capacityVacuum evaporation coatingSputtering coatingPre treatmentMaterials science

The invention discloses a preparation method for an Al-Cr coating on a nickel-based superalloy, which belongs to the technical field of high temperature protection coatings. The method comprises the following steps: pretreating a superalloy matrix; depositing a Cr layer on the surface of the cleaned superalloy by using arc ion plating; and finally, carrying out alumetizing through powder embedding so as to obtain the Al-Cr coating on the superalloy. The preparation method for the Al-Cr coating on the nickel-based superalloy has the advantages of good process repeatability, easy realization of industrial production and the like; the prepared coating has a compact structure, high bonding strength on the matrix and controllable components, the storage phase of Al and the content of Cr in the coating are effectively increased, so antioxidation and anti-thermal etching performance of the raising are improved, and the service life of the coating is effectively prolonged. The coating prepared by the preparation method is applicable to protection of the nickel-based superalloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

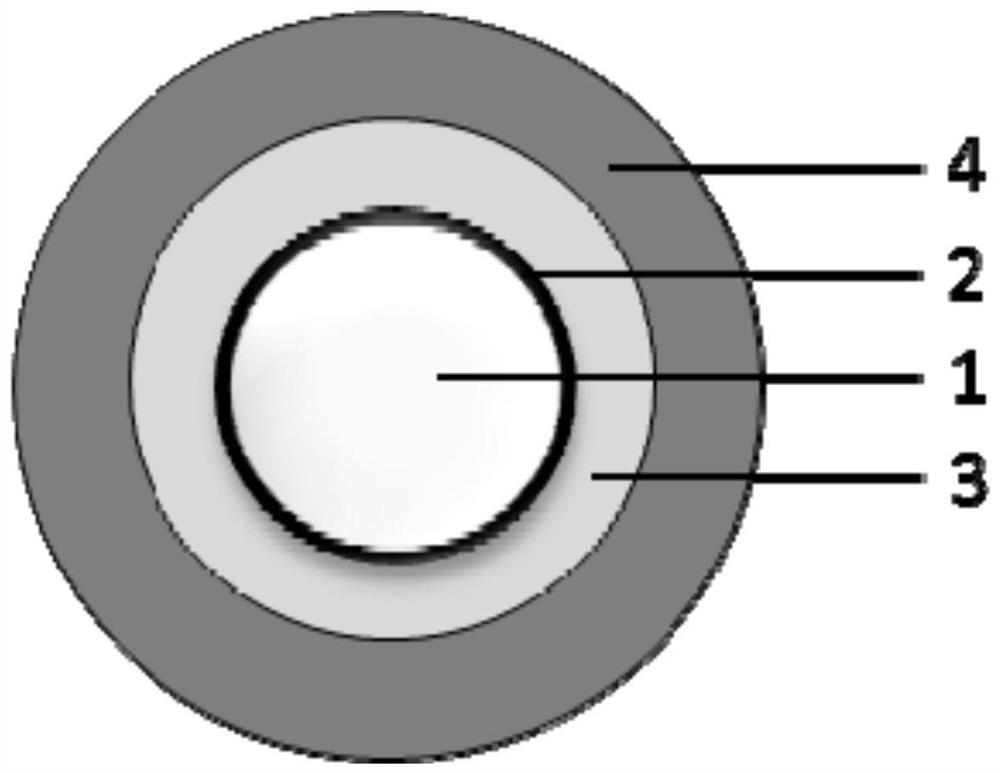

Ferroferric oxide/calcium phosphate nuclear shell structure nano particle and preparation method thereof

The invention discloses a preparation method of a ferroferric oxide / calcium phosphate nuclear shell structure nano particle. The ferroferric oxide used as a nuclear structure is prepared by using a coprecipitation method, and magnetofluid with favorable dispersibility in water can be prepared by modifying the surface of the ferroferric oxide. A mixed solution with the molar ratio of calcium salt and phosphate of 1.0-1.6 is prepared, and the pH value of the solution is adjusted to be 1-10, and the solution is aged at low temperature to form precursor sol. The magnetofluid is uniformly dispersed into the sol to obtain the ferroferric oxide / calcium phosphate nuclear shell structure composite nano particle in the processes of drying and high-temperature sintering. The particle diameter of the composite nano particle is between 80nm and 120nm, wherein the particle diameter of the ferroferric oxide is between 8nm and 60nm. The composite particle is used for a cell regulation and bone repair project under the action of a magnetic field.

Owner:BEIJING UNIV OF CHEM TECH

Mg-Gd-Y-Zr magnesium alloy refining flux and producing method thereof

The invention provides an Mg-Gd-Y-Zr magnesium alloy refining flux and a production method thereof. The chemical components of the flux are mixed according to the following mass percentages: potassium chloride of ranging from 30 to 50 percent, barium chloride of ranging from 5 to 20 percent, sodium chloride of ranging from 2 to 10 percent, calcium chloride of ranging from 10 to 20 percent, calcium fluoride of ranging from 2 to 8 percent, cryolite of ranging from 1 to 5 percent, gadolinium compound of ranging from 3 to 8 percent, yttrium compound of ranging from 3 to 8 percent, and zirconium compound of ranging from 2 to 8 percent, wherein, the gadolinium compound is gadolinium chloride, gadolinium carbonate or gadolinium fluoride, the yttrium compound is yttrium chloride, yttrium carbonate or yttrium fluoride, the zirconium compound is zirconium tetrachloride or potassium zirconium fluoride. The flux has good melting point, viscosity, wettability and the slag removing performance which is improved greatly. Because the flux does not contain magnesium chloride or react with the lanthanon such as gadolinium and yttrium, the chemical reaction loss of the lanthanon in the refining process is not caused, thereby being particularly suitable for the refining purifying process of the Mg-Gd-Y-Zr magnesium alloy and improving the refining effect of the magnesium fused mass.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of nano graphite powder/carbon nanofiber composite electrode for all-vanadium redox flow battery

InactiveCN104319405AIncrease roughnessImprove electrochemical activityCell electrodesCarbon fibersCarbon nanofiber

The invention relates to the field of battery manufacturing and energy source storage, in particular to a preparation method of a nano graphite powder / carbon nanofiber composite electrode for an all-vanadium redox flow battery. Firstly, a spinning solution required by an experiment is prepared, and then nano graphite powder with different particle sizes and the spinning solution are uniformly mixed. By an electrospinning technology, a required nanofiber membrane is prepared, and then is pre-oxidized in the air and is carbonized in an inert atmosphere tubular atmosphere furnace to obtain a required nano graphite powder / carbon nanofiber composite electrode. According to the all-vanadium redox flow battery composite electrode prepared by the method provided by the invention, the carbon fiber diameter is at the nanoscale, and the carbon fiber is compounded with nano graphite powder with high electrical conductivity, so that the roughness of the fiber is substantially increased, and thus the specific surface area of the electrode is two orders of magnitude larger than that of the conventionally used electrode material. Meanwhile, the high-activity nano graphite powder enables the electrochemical activity of the electrode to be improved, so that the energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing Ti-Si-N film by adjusting gas partial pressure of magnetic controlled sputtering reaction

InactiveCN1804113AControl ingredientControl mechanical propertiesVacuum evaporation coatingSputtering coatingSputteringProduct gas

The preparation method for Ti-Si-N film comprises: using dc reaction magnetron sputtering with Ti-Si embedded target and N2-Ar mixed atmosphere; setting the effective sputtering area and total gas pressure; changing the N2 partial pressure within 0.002-0.04Pa. This invention is practical to control film intergradient, micro-tissue and mechanical performance by just changing one gas.

Owner:SHANGHAI JIAO TONG UNIV

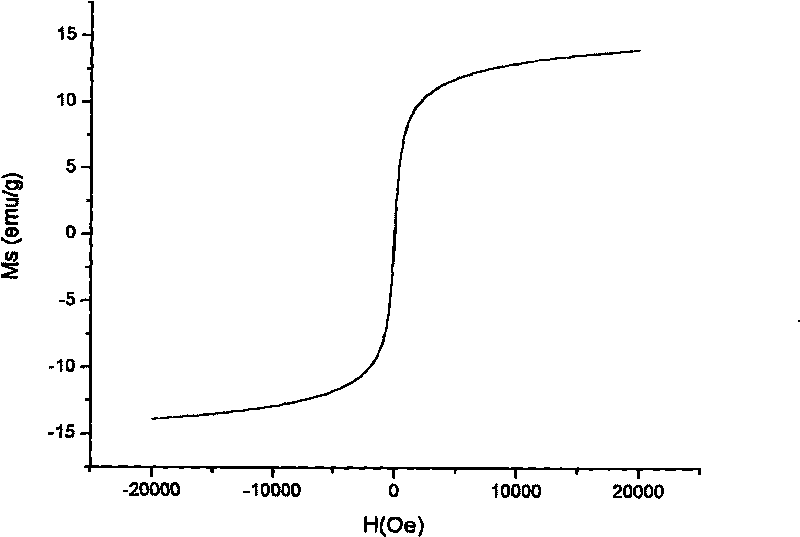

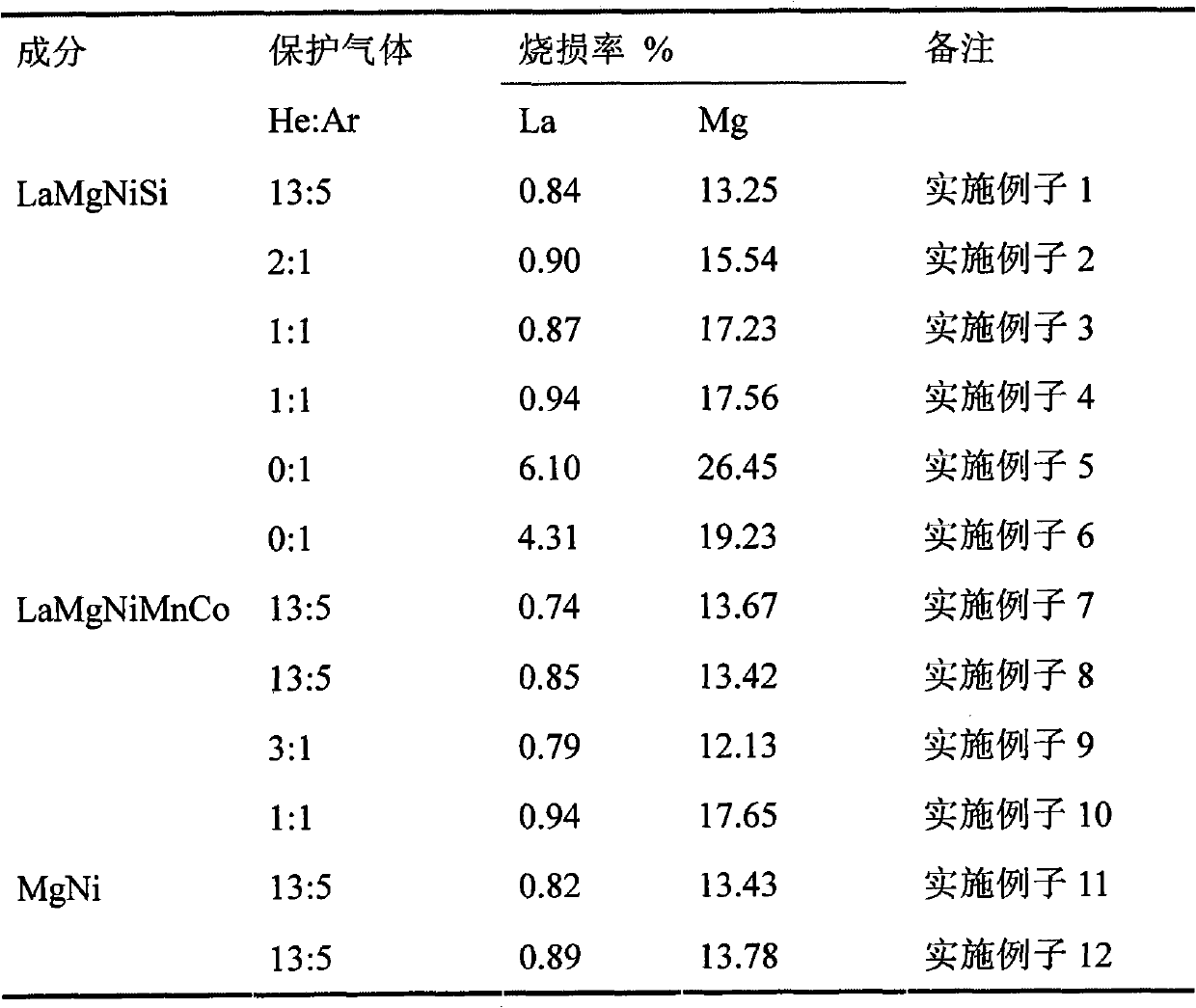

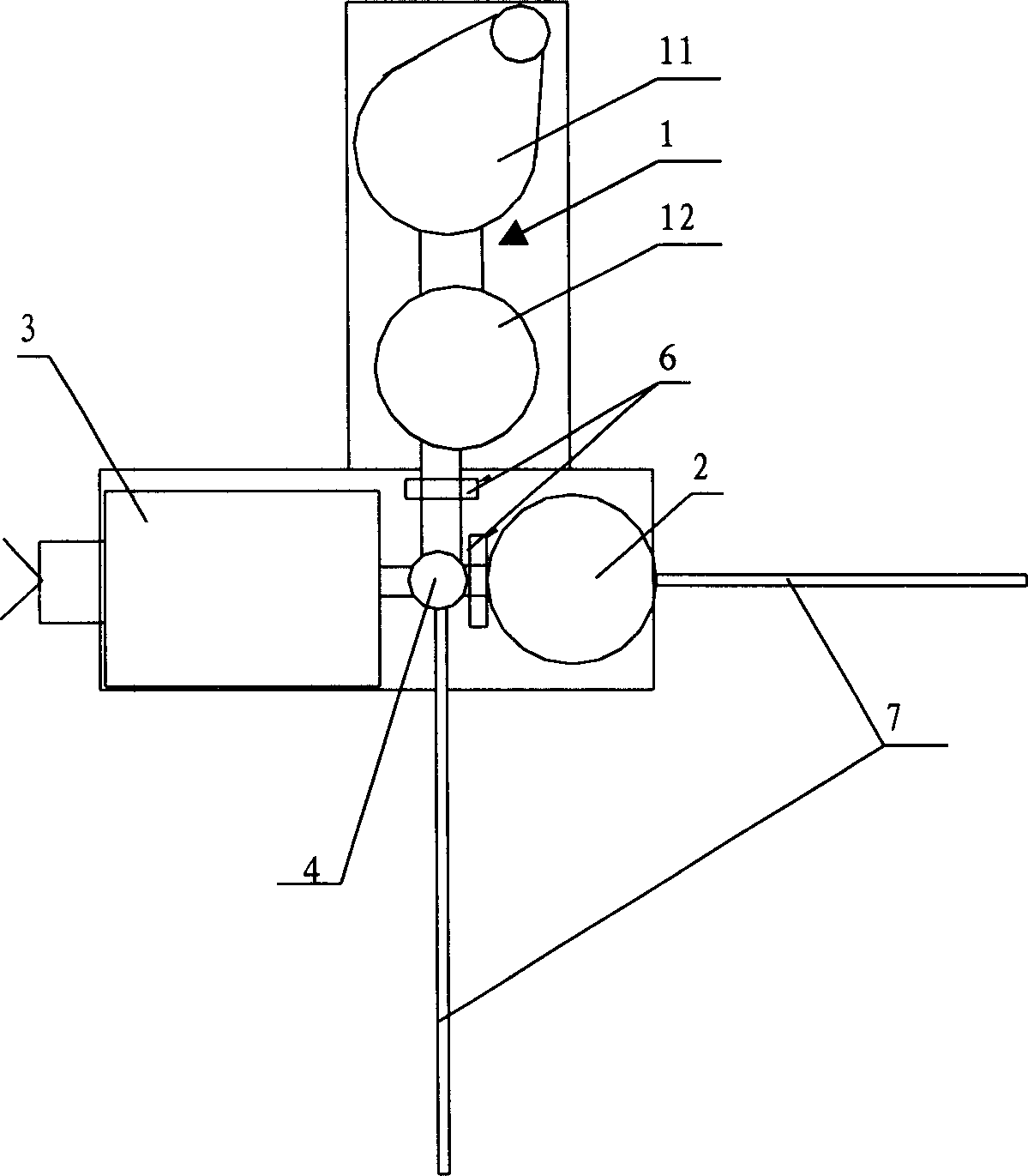

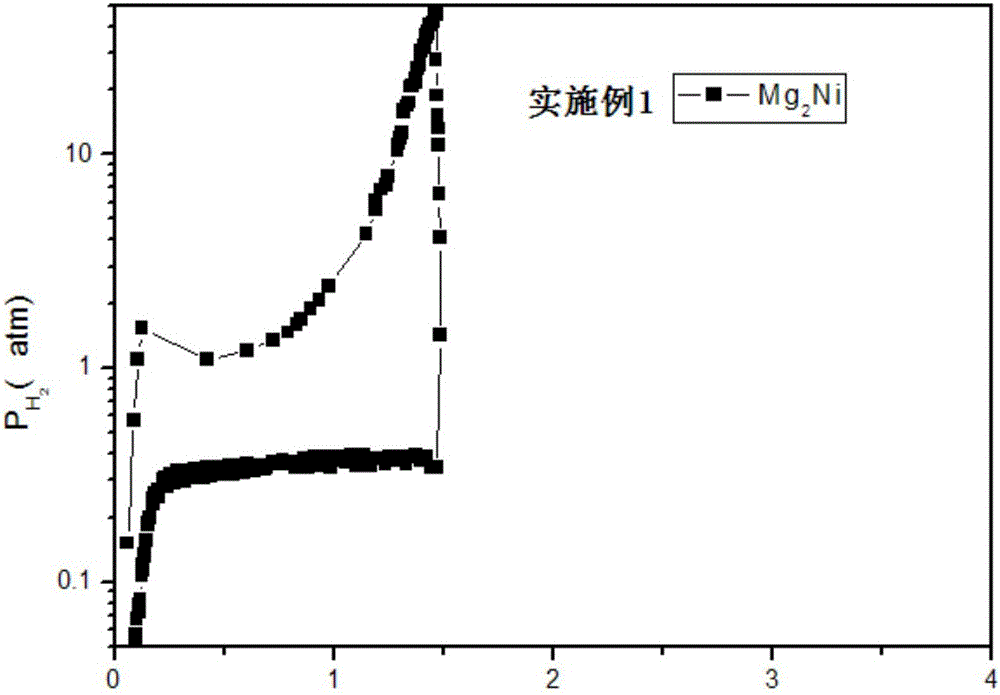

Preparation method of Mg-contained hydrogen storage alloy

The invention belongs to the technical field of functional metal alloy materials and relates to a smelting method applicable to La-Mg-Ni series and Mg2Ni type hydrogen storage alloys, which comprises the following concrete steps of: weighing the components of the La-Mg-Ni series hydrogen storage alloy as ABy according to a stoichiometric proportion, wherein the A is LaxMg1-x, the B is Niy-zCz, and the C is Mn, Fe, Mo, Co, Al, Ti, Si, V, Cr, Cu, Zn, Zr, Nb, W, Hf, Ta, B, P or / and Sn, La, Mg and Ni, adding into a crucible of a medium-frequency induction smelting furnace, and placing on a feeding device in the furnace after carrying out surface processing on Mg blocks; carrying out vacuum pumping until the vacuum degree is 10-2 Pa, introducing He and Ar protective gases mixed according to a certain proportion until the air pressure in the furnace reaches 0.01-0.1MPa, regulating the power range to be 15-35kW, and controlling the temperature at 600-1300 DEG C until metals are molten; and stopping electrifying for 1-10 minutes, adding the Mg into the crucible through the feeding device in the furnace, regulating the power range to be 15-35kW, controlling the temperature at 600-1300 DEG C and casting after smelting for 1-10 minutes. The process has simple operation, good controllability, stable components of the prepared hydrogen storage alloy and lower cost and can realize low-cost and large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of tungsten-based catalyst/nano carbon fiber composite electrode for full-vanadium flow battery

InactiveCN104332638ALarge specific surface areaIncrease the reaction areaCell electrodesFiberCarbon fibers

The invention relates to the field of battery manufacturing and energy source storage and particularly provides a preparation method of a tungsten-based catalyst / nano carbon fiber composite electrode for a full-vanadium flow battery. The preparation method comprises the following steps: preparing a spinning solution for an experiment; uniformly mixing a tungsten salt with the spinning solution; preparing a nano fiber membrane by adopting an electrostatic spinning method; and pre-oxidizing the nano fiber membrane in air and carbonizing in an inert atmosphere pipe type furnace to obtain the needed tungsten-based catalyst / nano carbon fiber composite electrode. After the obtained electrode material is washed and dried, related electrochemical performance characterization and charging and discharging performance tests can be carried out on the electrode material. According to the prepared tungsten-based catalyst / nano carbon fiber composite electrode for the full-vanadium flow battery, the diameter of carbon fibers is nano-grade; and compared with a traditionally-used electrode material, the specific surface area is greatly enlarged. Nano carbon fibers are compounded with a high-activity tungsten-based catalyst, and the electrochemical activity of an electrode is greatly improved, so that the energy efficiency of the full-vanadium flow battery is extremely improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

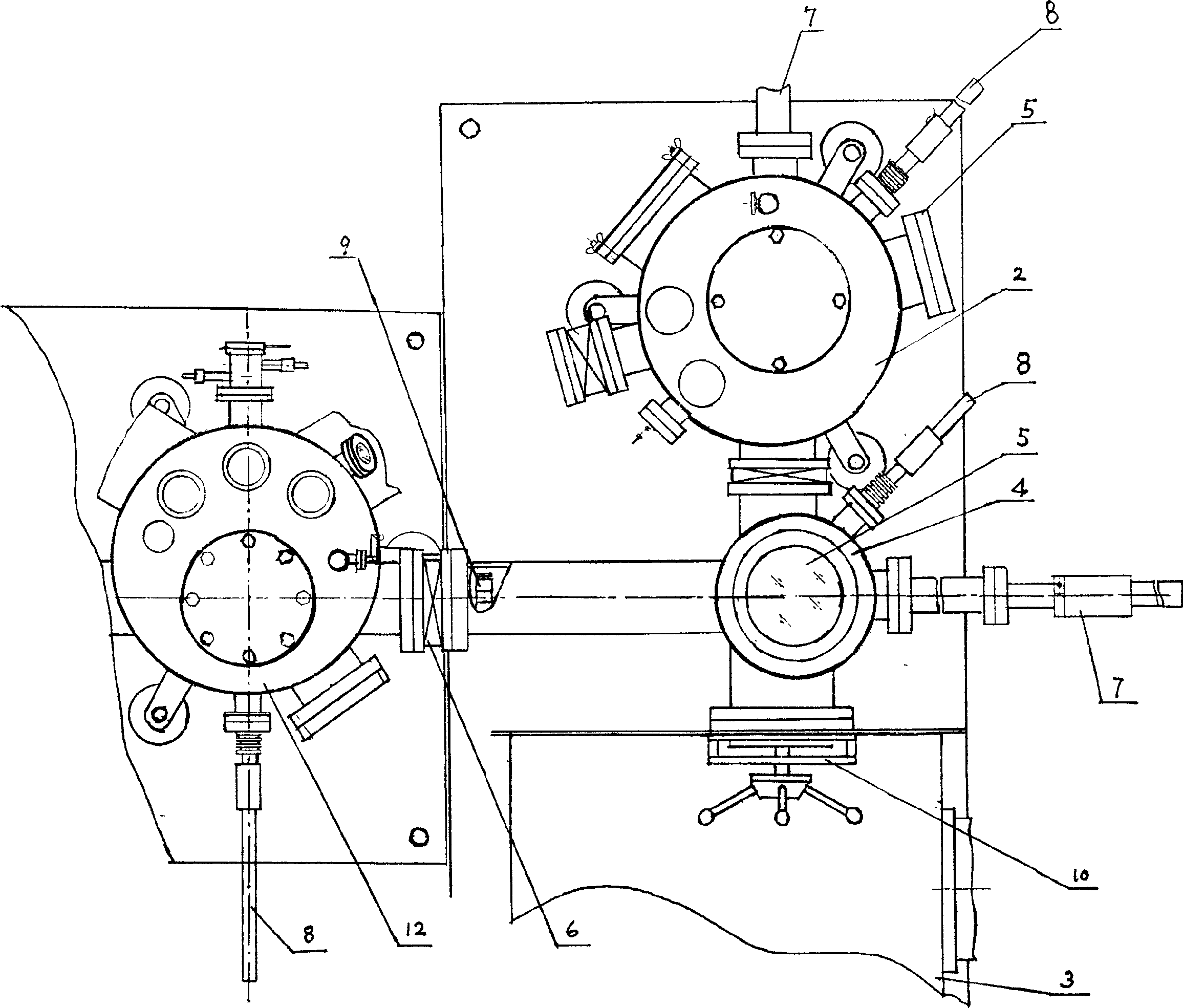

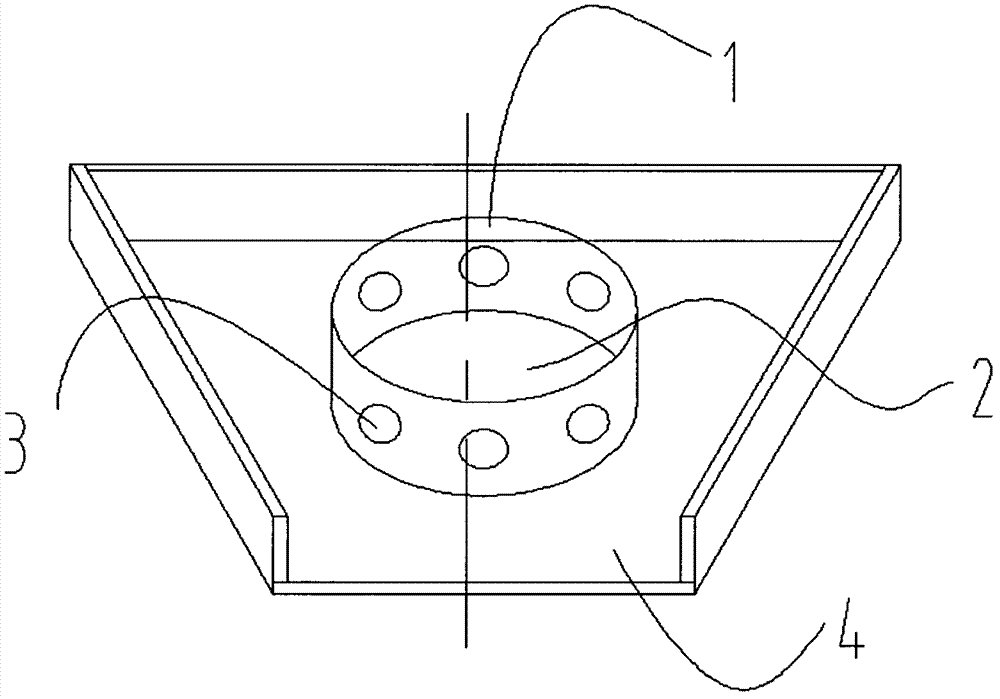

Gas-phase deposition coating and vacuum heat-treatment on-line combined composite coating equipment

InactiveCN1428455AImprove cleanlinessSolve pollutionVacuum evaporation coatingSputtering coatingGas phaseManipulator

The present invention relates to a gas-phase deposition film-plating and vacuum heat treatment on-line combined composite deposition equipment, including deposition chamber, heat treatment chamber, glove box and transition chamber. The transition chamber is made into a stainless steel cylindrical structure, and is set between the deposition chamber, heat treatment chamber and glove box and is connected with the deposition chamber, heat treatment chamber and glove box by means of stainless steel pipeline, and on the stainless steel pipeline a stainless steel high vacuum insertion plate valve is set. Said transition chamber also is equipped with upper cover with observation window, and its side wall is equipped with a transfer bar and a robot, its heat treatment chamber also is equipped with an observation window.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Alloy cored wire for deeply desulfurization of steel bucket finery and its preparation method

The invention discloses a core-spun yarn and preparing method of steel drum finer deep desulfuration, which comprises the following parts: blending 3-12 wt percent passivation magnesium residual Fe powder or adjusted CaO-CaF2 premelting ground-slag agent or adjusted CaO-BaO-CaF2 premelting ground-slag agent; covering through 0.20-0.30 mm thickness thin steel to produce Mg-Fe core-spun yarn, or Mg-CaO-CaF2 core-spun yarn or Mg-CaO-BaO-CaF2 core-spun yarn. The invention reduces the cost, which possesses excellent desulfuration effect to control steel liquid ingredient.

Owner:WUHAN UNIV OF SCI & TECH

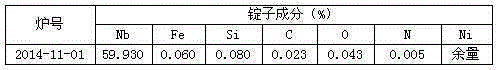

Preparation method of nickel niobium alloy

InactiveCN104988341AControl ingredientGuaranteed quality characteristicsMedium frequencyNiobium alloy

The invention discloses a preparation method of a nickel niobium alloy, and relates to a preparation method for producing an intermediate alloy of a titanium alloy. The preparation method is characterized in that high purity nickel and high purity niobium are used as raw materials in the preparation process of the nickel niobium alloy; and the nickel niobium alloy is obtained by smelting through a medium-frequency vacuum induction furnace. Compared with the prior art, the preparation method has the following benefits: (1) the alloy smelting method effectively controls the alloy components, eliminates the influence of the aluminum element on the alloy performance, and guarantees the alloy quality characteristics; (2) the components are stable; the intermediate alloy is produced with the metal oxide as the raw material by using the metallothermics; the alloy is weak in uniformity, higher in segregation degree and bad in compactness; and the produced alloy is stable in uniformity and excellent in compactness; and (3) the alloy smelting method effectively eliminates the influence of the aluminum element on the alloy components, solves the defects of easy alloy segregation and weak compactness, improves the alloy quality, is convenient for the titanium alloy production and operation, and is convenient for the titanium alloy preparation.

Owner:CHENGDE TIANDA VANADIUM IND

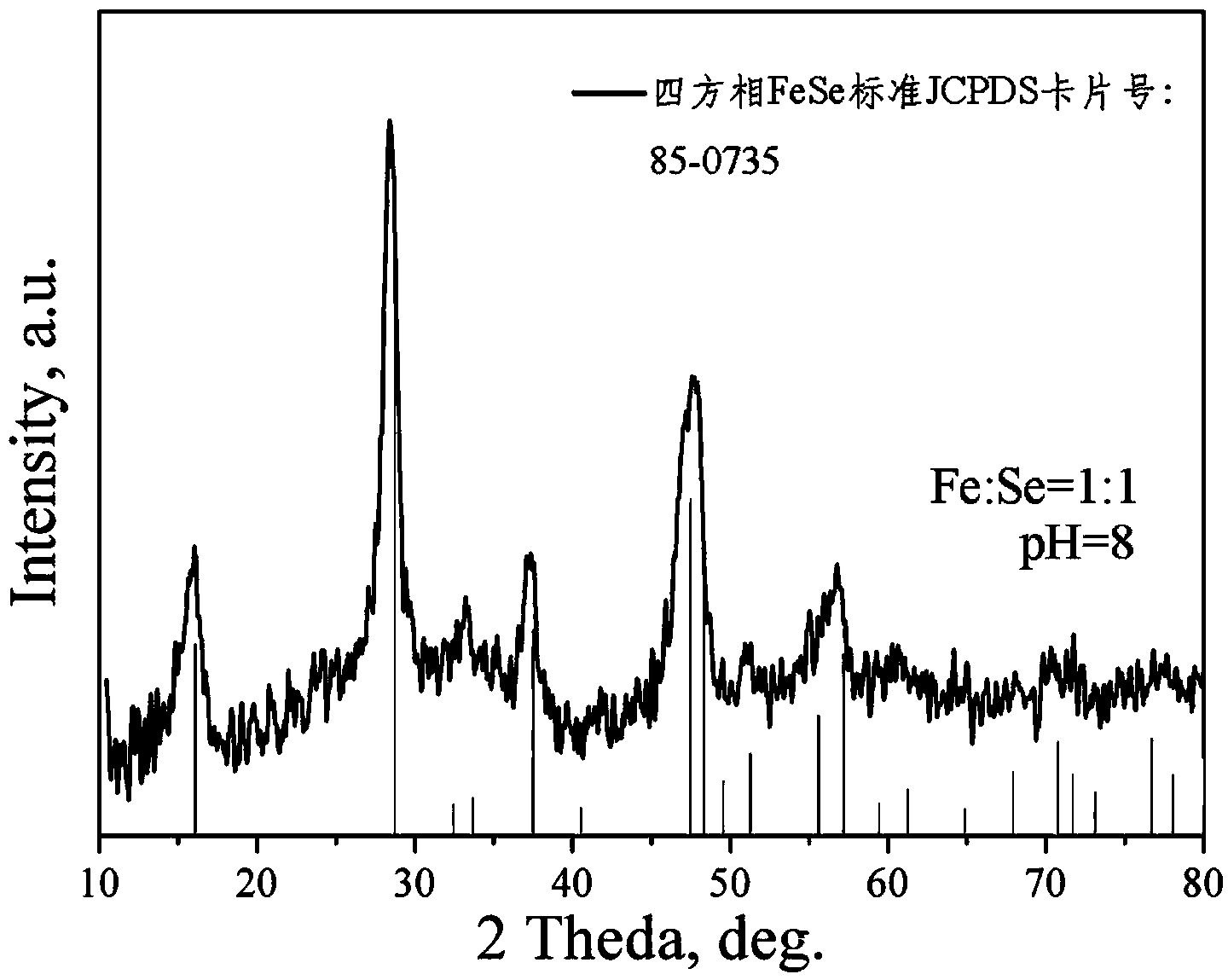

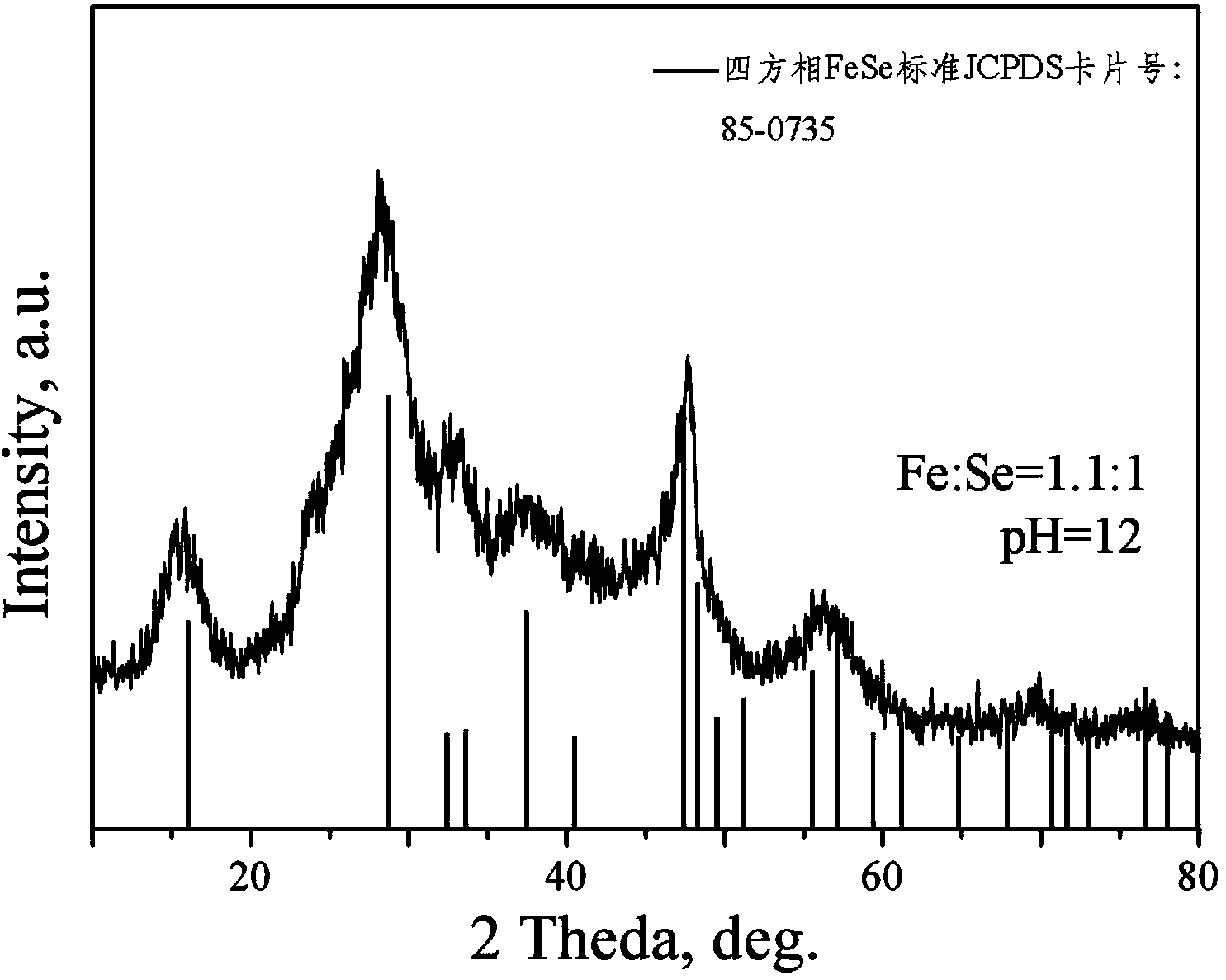

Preparation method of FeSe nano powder

ActiveCN103663391AReduce pollutionThe process is simple and easy to controlMaterial nanotechnologyBinary selenium/tellurium compoundsFerrous saltsParticle-size distribution

The invention provides a preparation method of FeSe nano powder. The method comprises the following steps: 1, adding Se powder to an alkali liquor according to a certain molar ratio and agitating for dissolving, so as to obtain a solution A; 2, adding NaBH4 powder to the solution A according to a certain molar ratio and agitating for dissolving, so as to obtain a solution B; 3, adding a ferrous salt to the solution B according to a certain molar ratio in a glove box full of inert gases and agitating, so as to obtain a solution C; 4, adjusting the pH value of the solution C, and then orderly settling, filtering, washing and drying, so as to obtain the FeSe nano powder. The preparation method of the FeSe nano powder is simple and easy-to-control in preparation technology, short in technological process, strong in repeatability and applicable to industrial large-scale production. The FeSe prepared by the preparation method is tetragonal nanoscale powder, the chemical components and particle size distribution are even, and the requirements of subsequent application can be met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

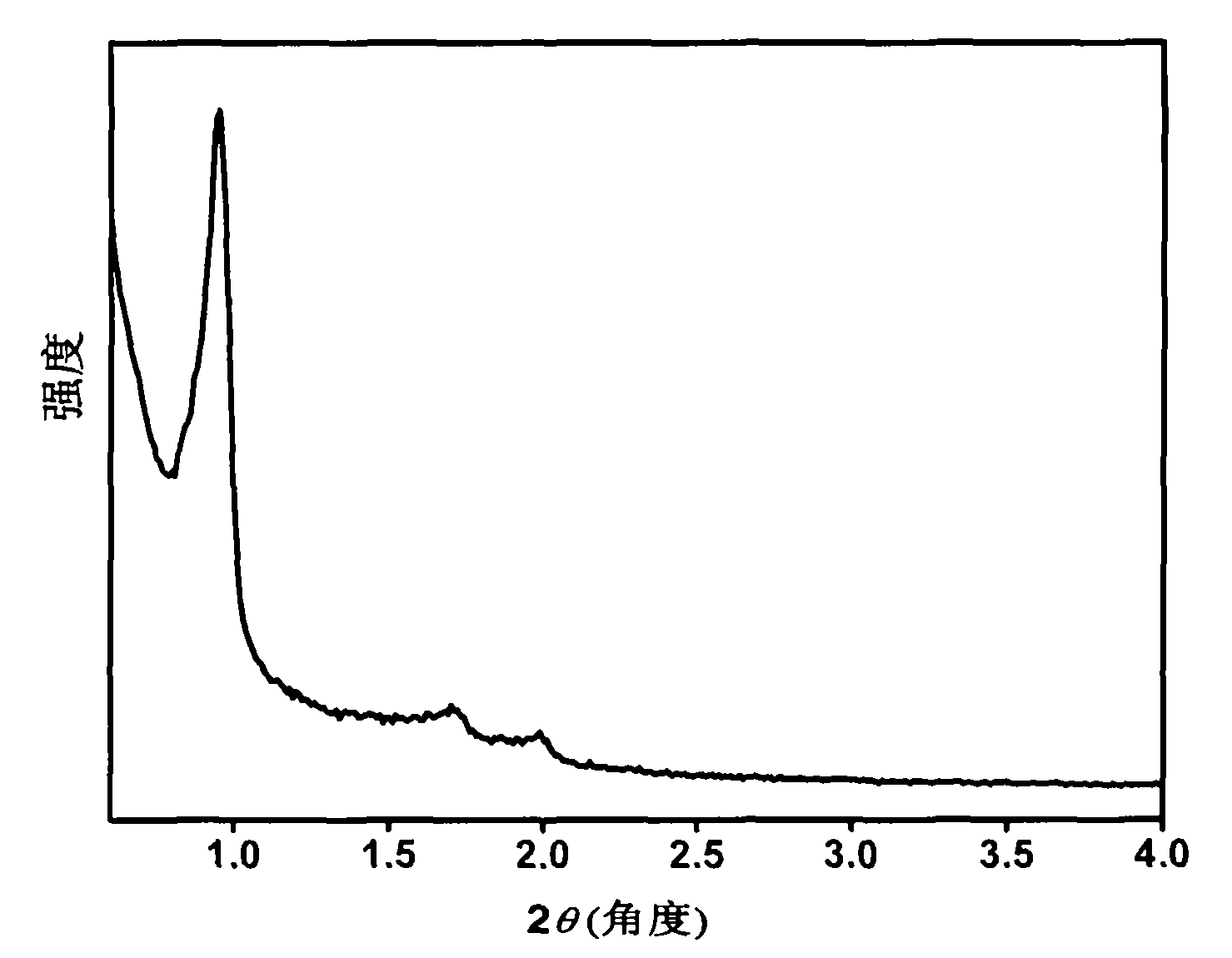

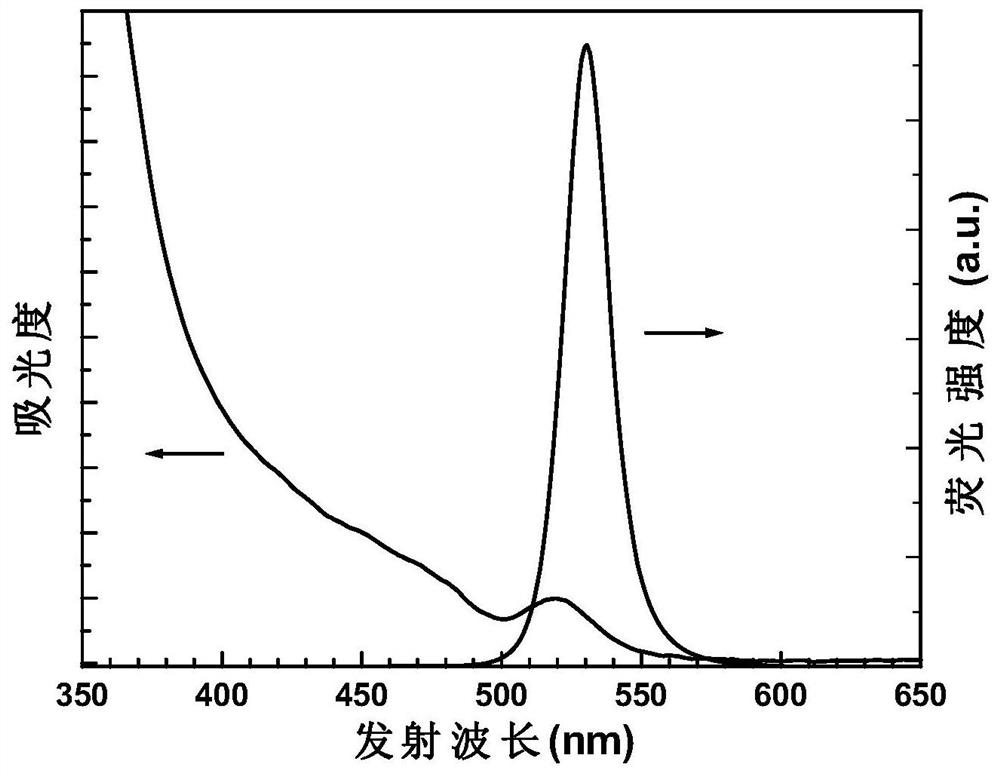

Crystallized mesoporous zinc silicate/silicon oxide composite powder and preparation method thereof

InactiveCN103232043AThe reaction raw materials are simpleLow costSilicon oxidesInorganic saltsRoom temperature

The invention discloses crystallized mesoporous zinc silicate / silicon oxide composite powder and a preparation method thereof. The composite powder is of a two-dimensional hexagonal mesoporous structure and the mesoporous wall is composed of crystalline zinc silicate and amorphous silicon oxide. The preparation method comprises the following steps of firstly preparing mesoporous silicon oxide and dissolving the inorganic salt of zinc in ethanol to prepare a zinc salt solution; adding the mesoporous silicon oxide in the zinc salt solution according to compositions of the prepared powder, wherein the molar ratio of the mesoporous silicon oxide to the zinc salt is 2-25; uniformly dispersing the mesoporous silicon oxide into the zinc salt solution through fully stirring; and in the meantime, continuing stirring at room temperature, volatilizing the ethanol to obtain powder and obtaining the crystallized mesoporous zinc silicate / silicon oxide composite powder via vacuum drying and calcination. The preparation method is simple and convenient in operation; and the prepared mesoporous zinc silicate / silicon oxide composite powder is high in order degree, large in pore size and specific surface area, high in crystallinity and good in stability.

Owner:INNER MONGOLIA UNIVERSITY

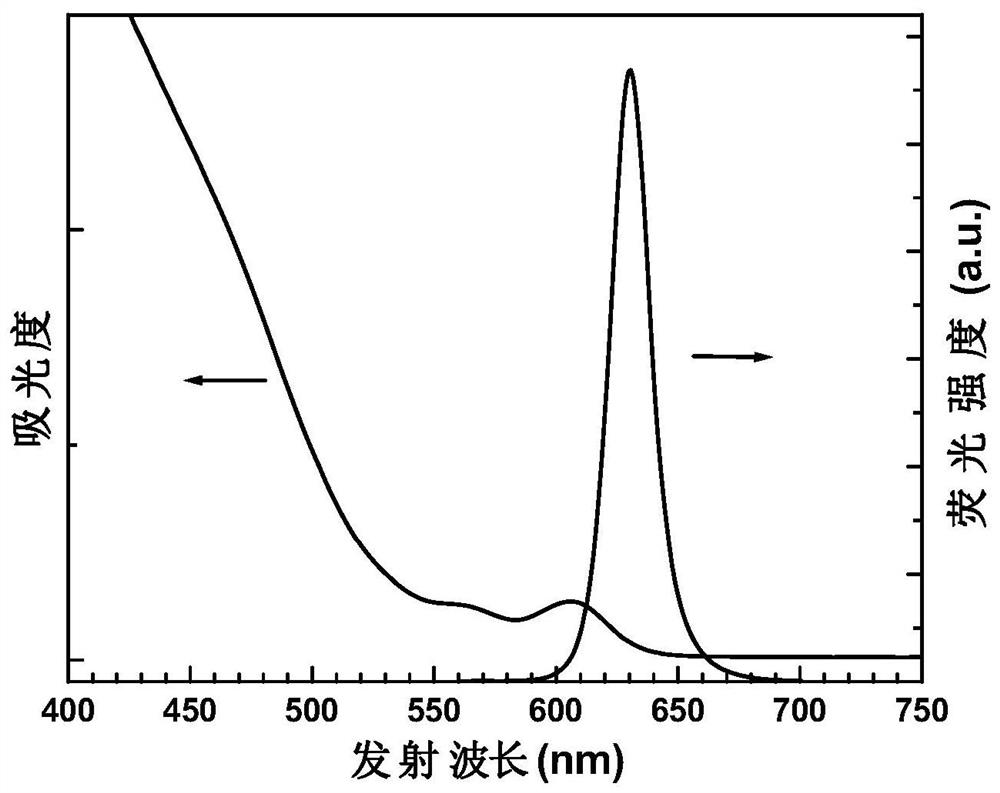

Quantum dots and preparation method thereof

ActiveCN112680214AImprove injection abilityImprove injection balanceLuminescent compositionsQuantum efficiencyQuantum dot

The invention discloses a preparation method of quantum dots, wherein the preparation method comprises the steps: preparing ZnCdSe seed crystals, growing a ZnSe transition layer on the ZnCdSe seed crystals, and sequentially coating the ZnSe transition layer with a ZnSe shell layer and a ZnS shell layer. The invention also discloses the quantum dots prepared by the preparation method. Through the arrangement of the ZnSe transition layer, the relationship between a core and the shell layers is consolidated, the transition between the core and each shell layer is effectively controlled, and the defects between crystal lattices are reduced; the formation of other seed crystals in the quantum dots is inhibited through fatty acid so as to control the components, size and uniformity of the seed crystals of the quantum dots, anions are supplemented to carry out growth nucleation of the seed crystals, a quantum dot core structure with the ZnSe transition layer on the surface is formed, and then epitaxial growth of the ZnSe shell layer and the ZnS shell layer are sequentially carried out; lattice stress between components of the mixed crystal structure core and lattice stress between the core and the shell are reduced, and the prepared quantum dots are adjustable in peak position in visible light, narrow in half-peak width and high in quantum efficiency.

Owner:CHINA BEIJING BEIDA JUBANG SCI & TECH CO LTD +1

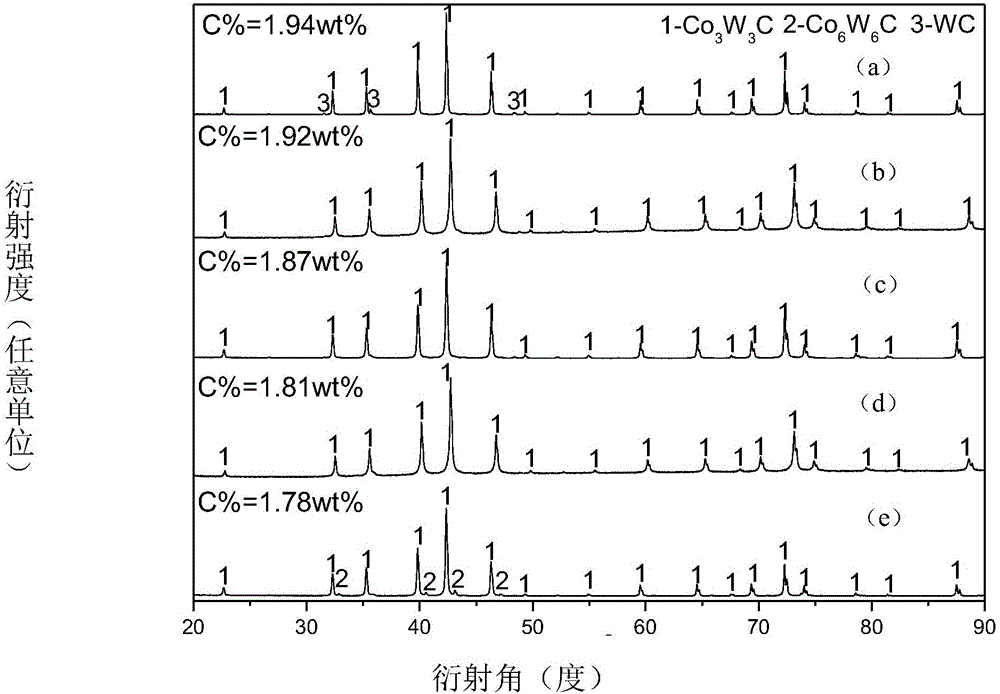

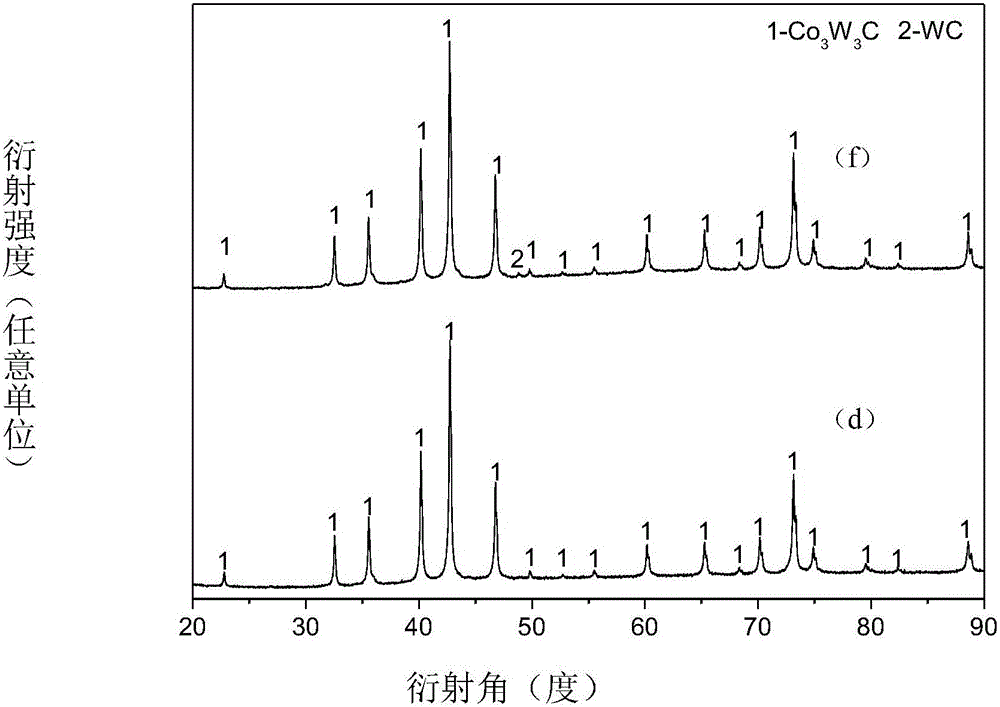

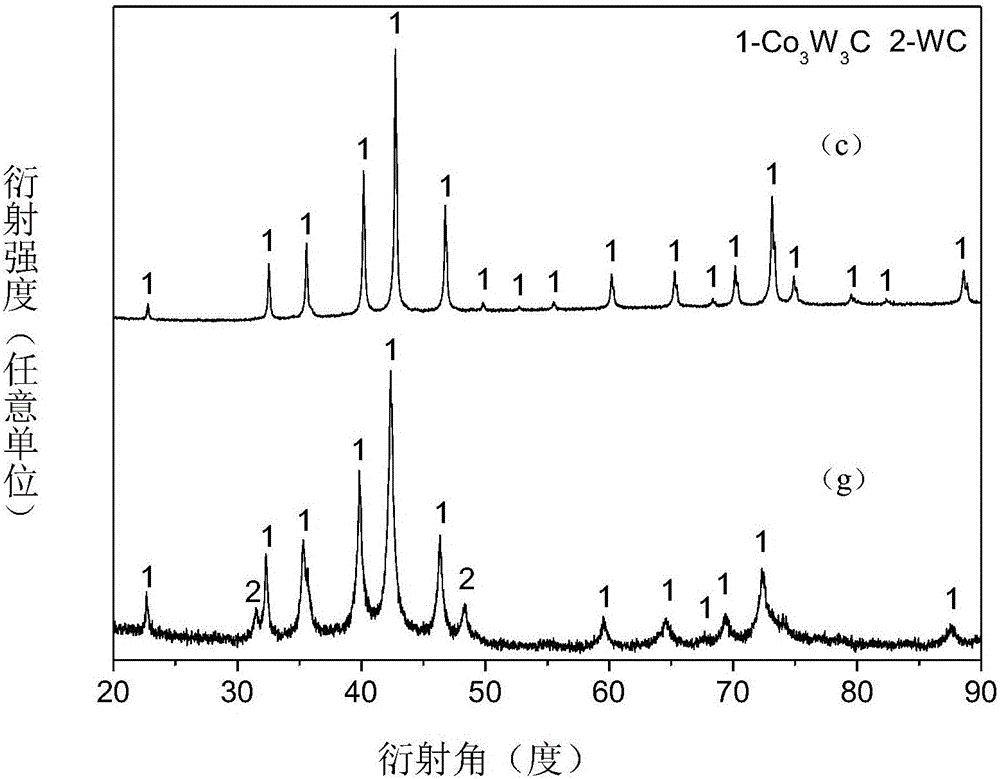

Preparation method of pure single-phase ternary carbide Co3W3C

The invention provides a preparation method of pure single-phase ternary carbide Co3W3C and belongs to the field of hard alloy material preparation. Cobalt powder, tungsten powder and carbon powder serve as raw materials and are blended and subjected to intermittent ball milling together with hard alloy balls of different diameters and absolute ethyl alcohol, then cold pressing and a chemical reaction are conducted, and a green body containing the pure single-phase ternary carbide Co3W3C powder is obtained; then intermittent ball milling and crushing are conducted, sieving with a 400-600-mesh mesh screen is conducted, and the Co3W3C powder which is pure in physical phase and uniform in granularity is obtained; the Co3W3C powder is arranged in a die, subjected to cold pressing and forming, placed into a discharging plasma sintering equipment for sintering and cooled to the room temperature, and a Co3W3C block material containing a single physical phase can be obtained. A product obtained through the method is a pure single-phase substance.

Owner:BEIJING UNIV OF TECH

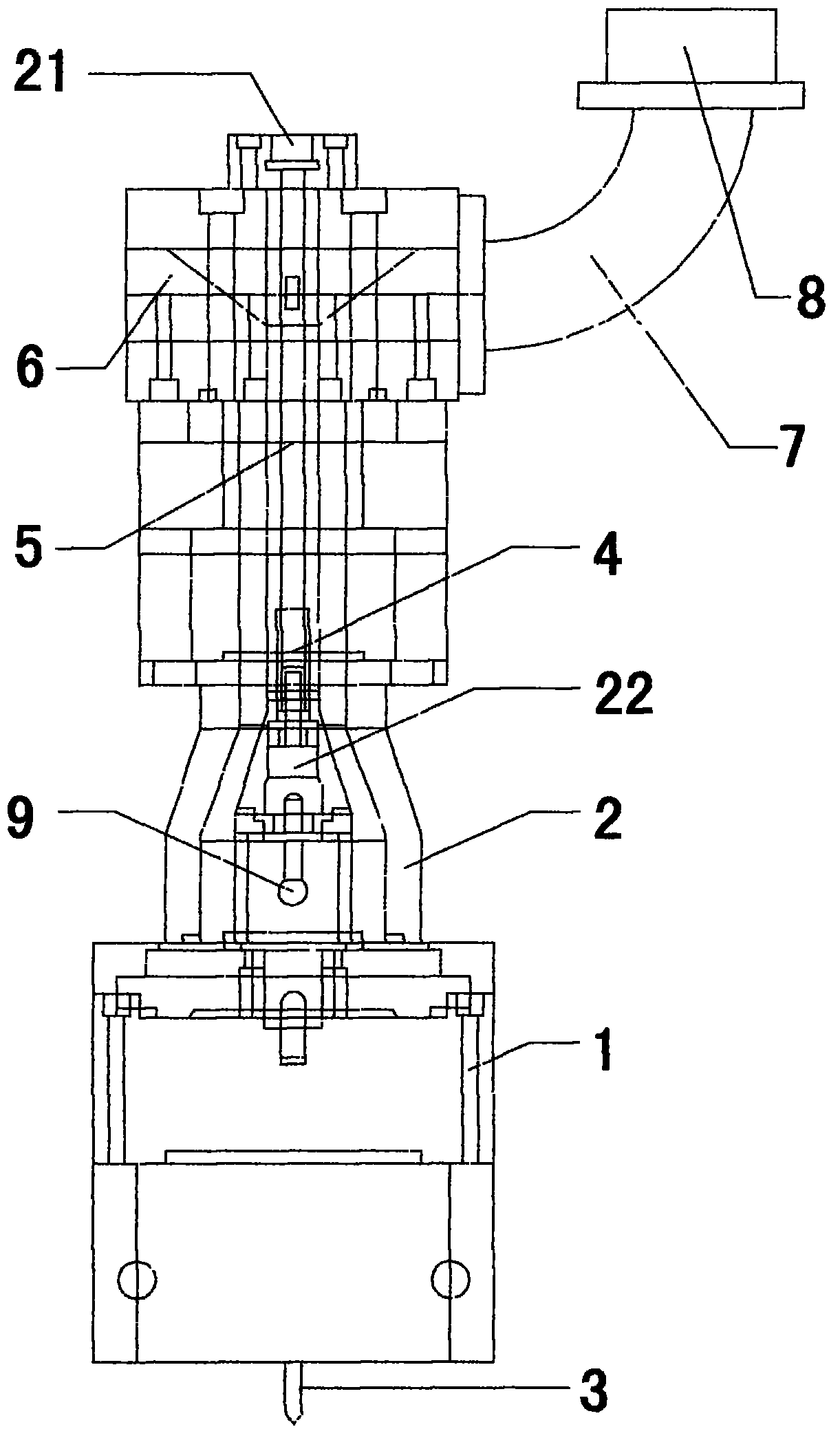

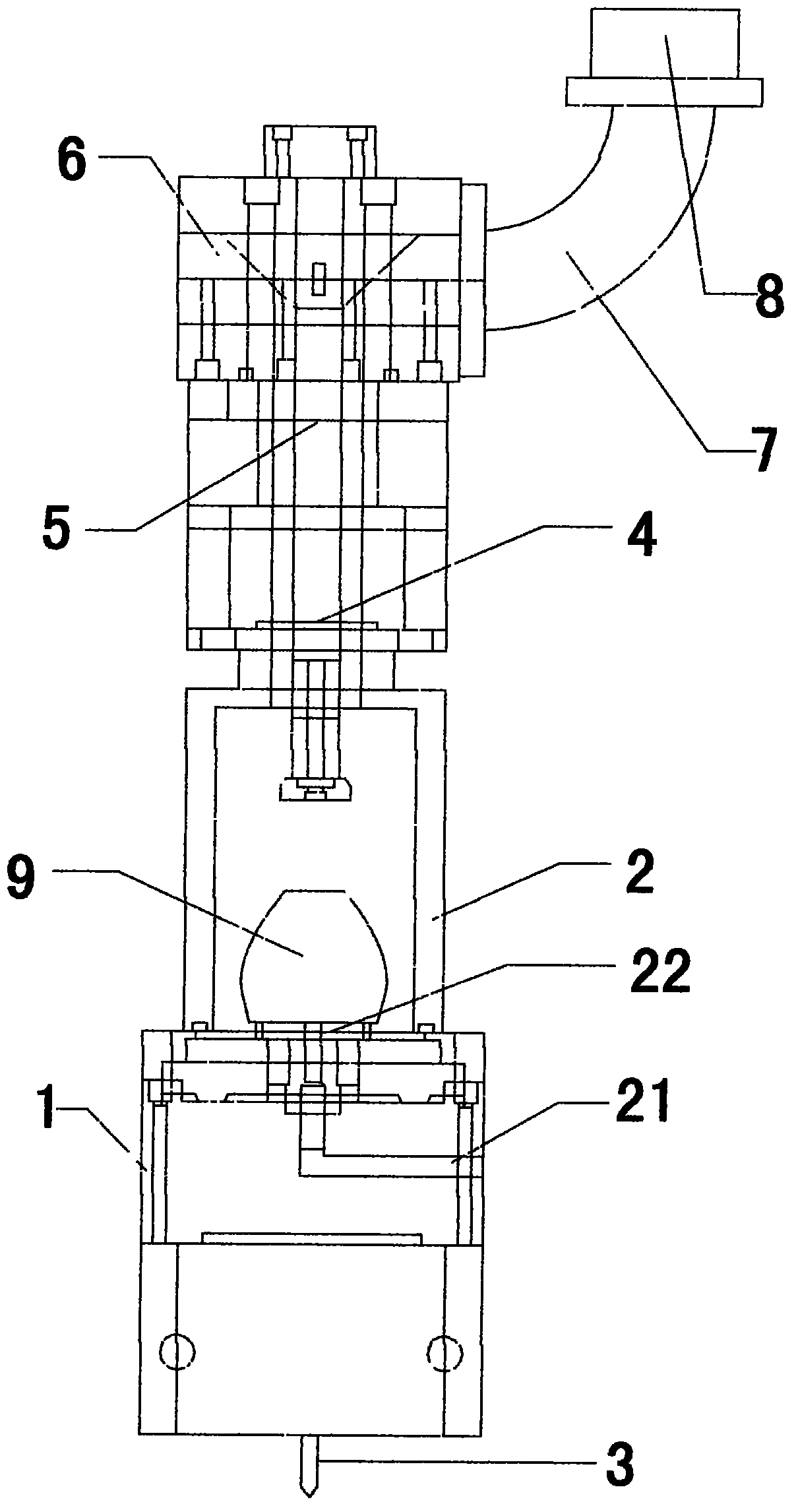

Method and equipment for forming optical films on workpiece

ActiveCN104233235AProcess equipment is compactImprove deposition efficiencyChemical vapor deposition coatingPulse microwaveEngineering

The invention relates to a method and equipment for forming optical films with various functions on a workpiece. A pulse plasma chemical vapor deposition method is adopted as the method. The method comprises the following steps that a, the workpiece is fixedly arranged in a sealed microwave cover, and the sealed microwave cover is vacuumized; b, oxygen is led into the sealed microwave cover, pulse microwaves are guided into the sealed microwave cover, and reaction is carried out for a certain time; c, gas containing film-forming component elements is led into the sealed microwave cover, the oxygen is continued to be led into the sealed microwave cover, the pulse microwaves are continued to be guided into the sealed microwave cover, reaction is carried out for a certain time, then, the gas is stopped from being led into the sealed microwave cover, and the pulse microwaves are stopped from being guided into the sealed microwave cover. The pulse plasma chemical vapor deposition method has the high deposition efficiency, the whole process only needs few minutes, and therefore the production efficiency is quite high; plasmas of the oxygen perform plasma cleaning and surface activation treatment on the surface of the workpiece before film forming, and therefore film adhesion is greatly improved; therefore, the product quality is improved.

Owner:HUIZHOU OBOLAND OPTOELECTRONICS TECH

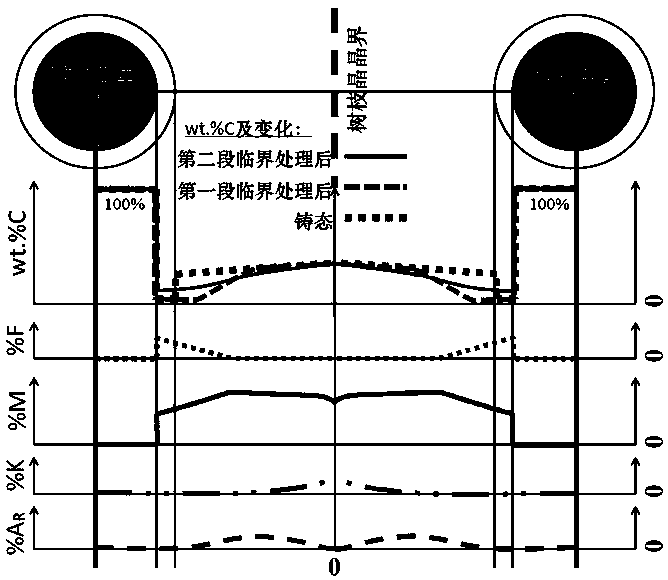

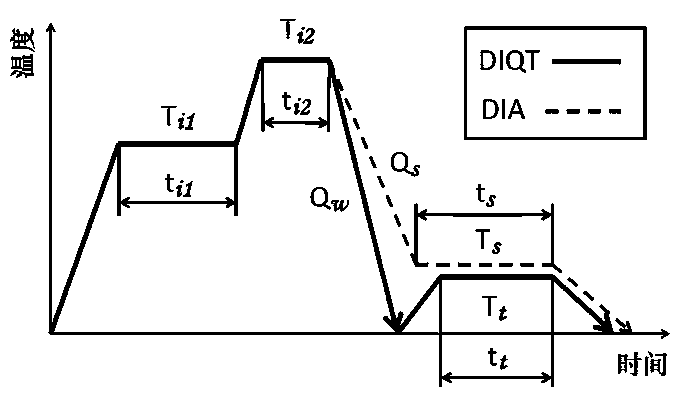

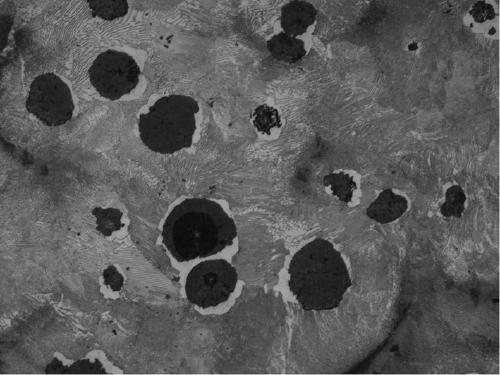

Heat treatment method capable of effectively improving hardness of spheroidal graphite cast iron

The invention belongs to the heat treatment technology or the technical field of spheroidal graphite cast iron structural material machining. The low dual critical temperature is adopted for carryingout austenitizing and quenching and low temperature tempering. Particularly, the first critical temperature is the eutectoid transition point A1, heat preservation is carried out under the first critical temperature or the close temperature, and a spheroidal graphite cast iron matrix is in transition to the hypoeutectoid component from the eutectoid component; the second critical temperature is the austenitizing temperature A3 point of hypoeutectoid steel, heat preservation is carried out under the austenitizing temperature A3 point or the close temperature, the matrix is mainly characterizedas hypoeutectoid steel insufficiency austenitizing, after quenching, after quenching, at the interface from the edge of spheroidal graphite to dendrite, the gradient control structure with the dendrite as the unit is obtained, and is a little non-converted ferritic toughening subcritical quenching structure and comprises eutectoid steel and nearly eutectoid steel fine martensite and not completelydissolved carbide, low tempering reduces quenching stress, and the matrix is toughened; and the advantages of being high in process yield, excellent in wear resistance, capable of reducing energy consumption, friendly to the environment, simple, easy to operate and the like are achieved.

Owner:CHANGCHUN UNIV OF TECH

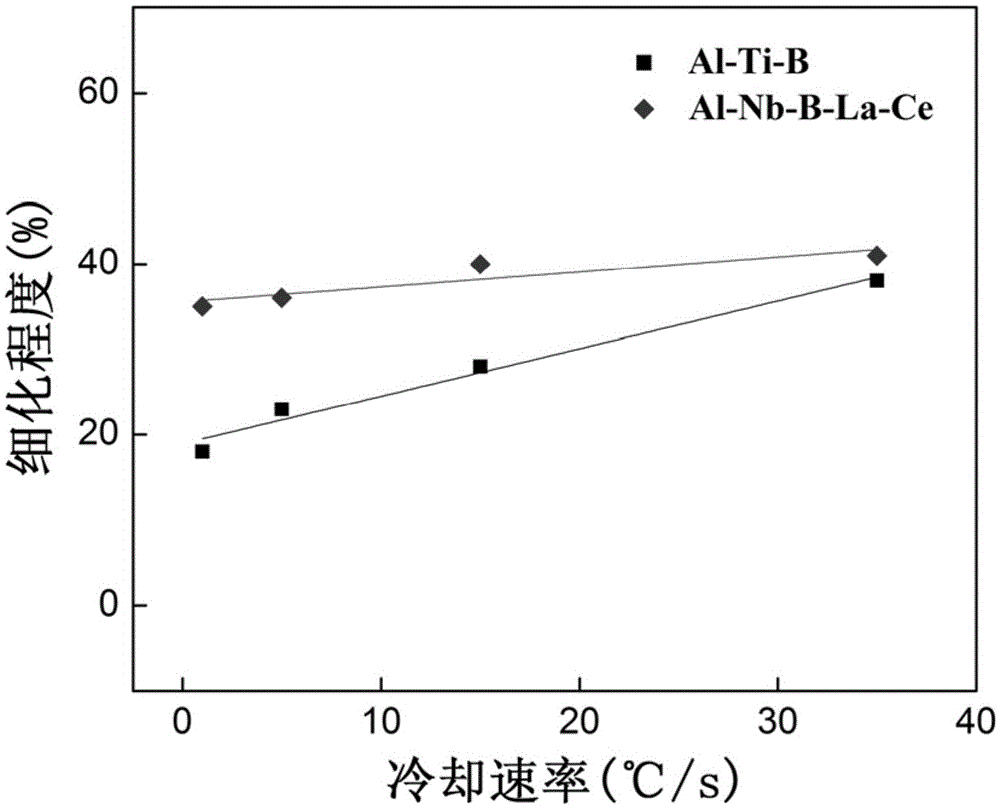

Low-cooling-rate-sensitivity high-nucleation-ability AlNbBRE grain refiner for cast aluminum alloy and preparation method thereof

The invention discloses a low-cooling-rate-sensitivity high-nucleation-ability grain refiner for cast aluminum alloy and a preparation method thereof. The grain refiner comprises Al-xNb-yB-zRE, wherein x is higher than 0.01wt% and not higher than 6wt%, y is higher than 0.01wt% and not higher than 3wt%, z is higher than 0.01wt% and not higher than 1wt%, and the balance Al; RE is one or more of La, Ce, Nd, Er, Gd, Y, Yb and Sc. Meanwhile, the invention discloses the smelting method for preparing the grain refiner, and the preparation technological process is simple. The grain refiner is used for carrying out grain refining on the cast aluminum-silicon alloy, the refining effect is superior, the cooling-rate sensitivity on the refining effects of casting portions in complex shapes and different thicknesses, namely the portions with different cooling rates is low, the mechanical performance of the refined alloy is remarkably improved, and the difference of performance between the portions with the different cooling rates is remarkably lowered.

Owner:BEIHANG UNIV

Method for refining grains in aluminum alloy smelting process

InactiveCN111004938AReduce energy consumptionSolve the overheating of molten aluminumDrossSmelting process

The invention relates to a method for refining grains in an aluminum alloy smelting process. The method comprises that a cold material with a smelting furnace tonnage of 20-40% is added into a smelting furnace, and then an electrolytic aluminum liquid with a smelting furnace tonnage of 55-75% and a temperature of not lower than 850 DEG C is added; after the electrolytic aluminum liquid is added, the liquid level is not stirred, the temperature is not increased, and when the temperature is reduced to less than 660 DEG C and a semi-solidified state is achieved, the temperature is increased again; when the temperature is increased to 740-760 DEG C, the chemical components of an alloy liquid are adjusted by adding an intermediate alloy and a metal element, wherein the intermediate alloy and the metal element are refined in a gas strengthening body manner in a refining tank filled with nitrogen or argon to obtain a refining agent, the refining agent is sprayed into the electrolytic aluminumliquid, the electrolytic aluminum liquid is continuously refined for 20-30 min, and the dross on the surface of the aluminum liquid is scraped out after refining is completed; and finally the aluminum alloy is obtained through continuous casting. The method is simple in process, good in grain refinement effect and stable in product quality.

Owner:YUNNAN RUNXIN ALUMINUM

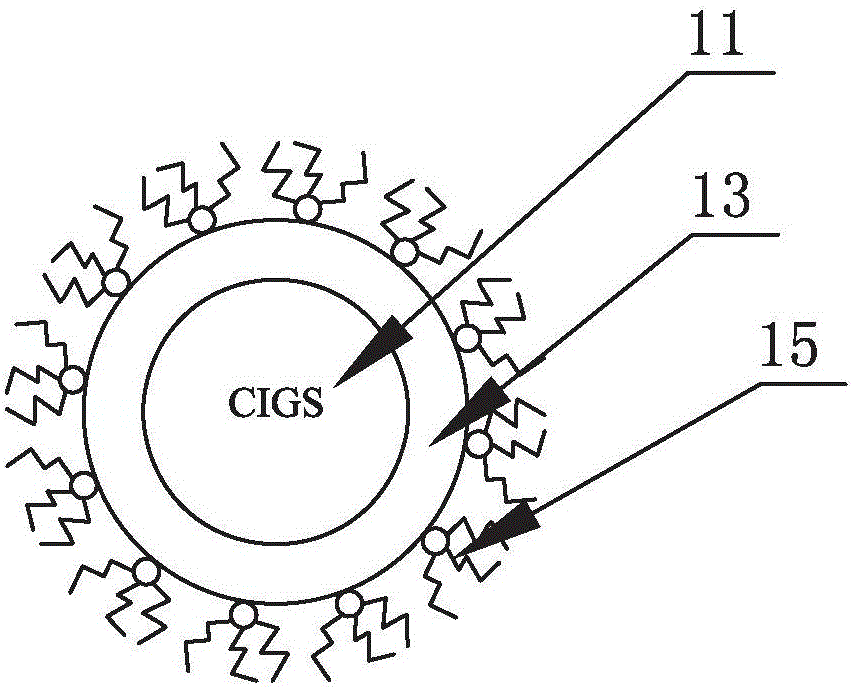

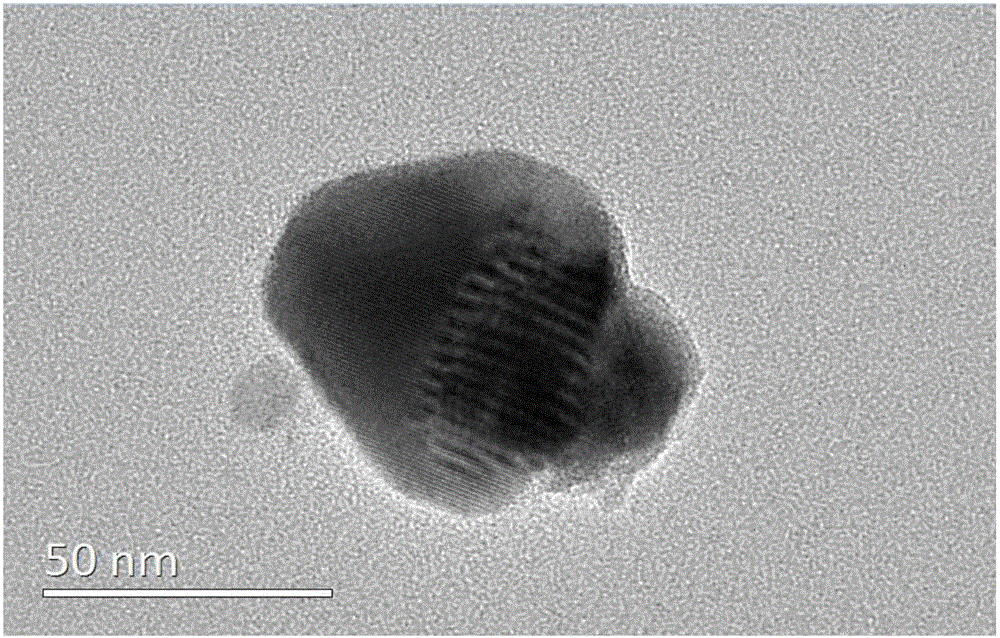

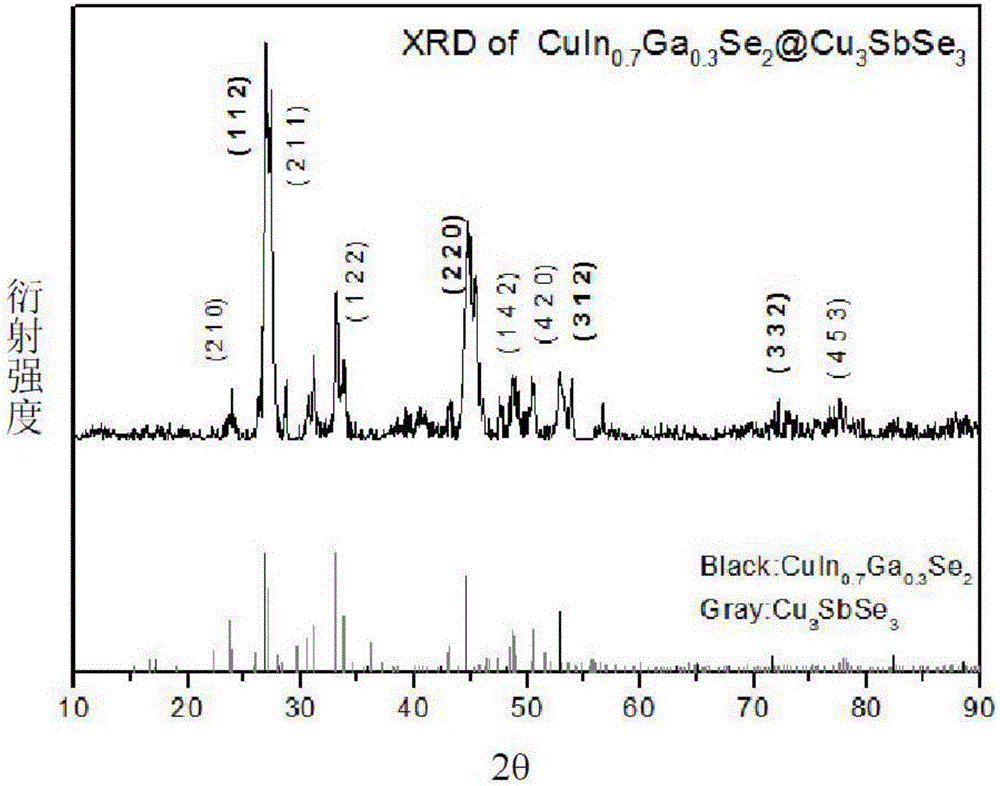

Copper-indium-gallium-selenium and copper-stibium-selenium composite nanomaterial and synthetic method therefor, and thin film battery

ActiveCN105845760AImprove electrical performanceHigh crystallinityMaterial nanotechnologyPhotovoltaic energy generationIndiumCopper

The invention relates to a synthetic method for a copper-indium-gallium-selenium and copper-stibium-selenium composite nanomaterial. The synthetic method comprises the following steps of providing a selenium precursor solution, a copper-indium-gallium-selenium precursor solution and a copper-stibium precursor solution, wherein the total molar weight of the selenium element in the three kinds of precursor liquid is 1.5-3 times of that of the copper element; enabling the selenium precursor solution and the copper-stibium precursor solution to be injected into the copper-indium-gallium-selenium precursor solution, heating to 100-300 DEG C; and taking a long-chain alkene compound as a chelating agent to synthesize the copper-indium-gallium-selenium and copper-stibium-selenium composite nanomaterial. The invention also relates to the copper-indium-gallium-selenium and copper-stibium-selenium composite nanomaterial synthesized by the method, and a thin film battery applying the copper-indium-gallium-selenium and copper-stibium-selenium composite nanomaterial.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

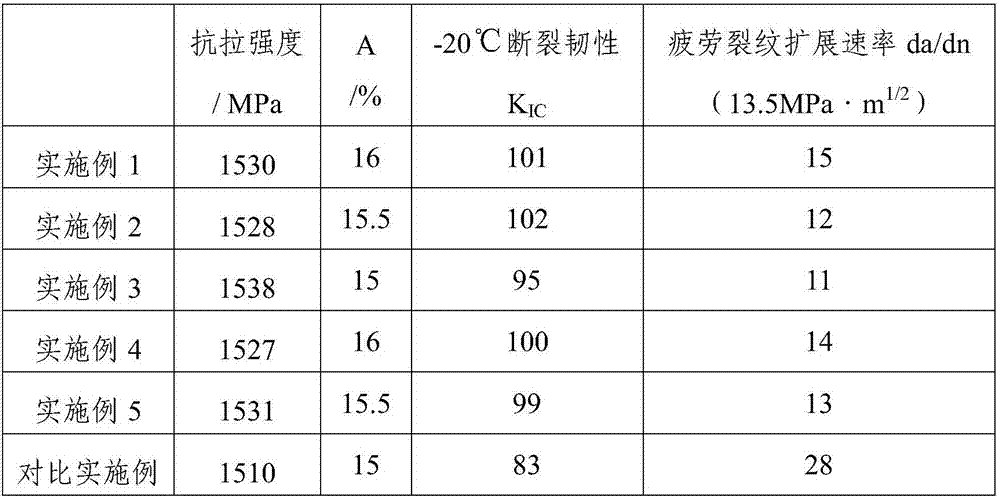

Production method capable of reducing fatigue crack growth rate of bainite steel rail

The invention discloses a production method capable of reducing the fatigue crack growth rate of a bainite steel rail. The production method specifically comprises the steps as follows: during smelting and deoxidation, the slag basicity of refining slag is controlled in the range of 1.8-2.3, and slag inclusions are controlled in the plastic range of anorthite; the temperature of a continuous casting tundish is 10-20 DEG C higher than the liquidus, and the pulling rate is controlled to range from 0.3 m / min to 0.5 m / min; a casting blank is obtained with a liquid core reduction technology, and the equiaxial crystal ratio of the casting blank is controlled to be higher than 95%. The composition and the size of the inclusions are controlled with the technology, tiny total-equiaxial crystal continuous casting is formed, the center segregation is reduced, in the later period, the bainite steel rail produced finally with the heating technology, the proper cooling technology and the heat treatment technology is higher in strength than a bainite steel rail prepared with a conventional smelting method, the fracture toughness KIC at subzero 20 DEG C is up to 102 MPa*m<1 / 2>, and for the fatigue crack growth rate, when deltak is equal to 13.5 MPa*m<1 / 2>, da / dn is as low as 11 m / Gc.

Owner:武汉钢铁有限公司

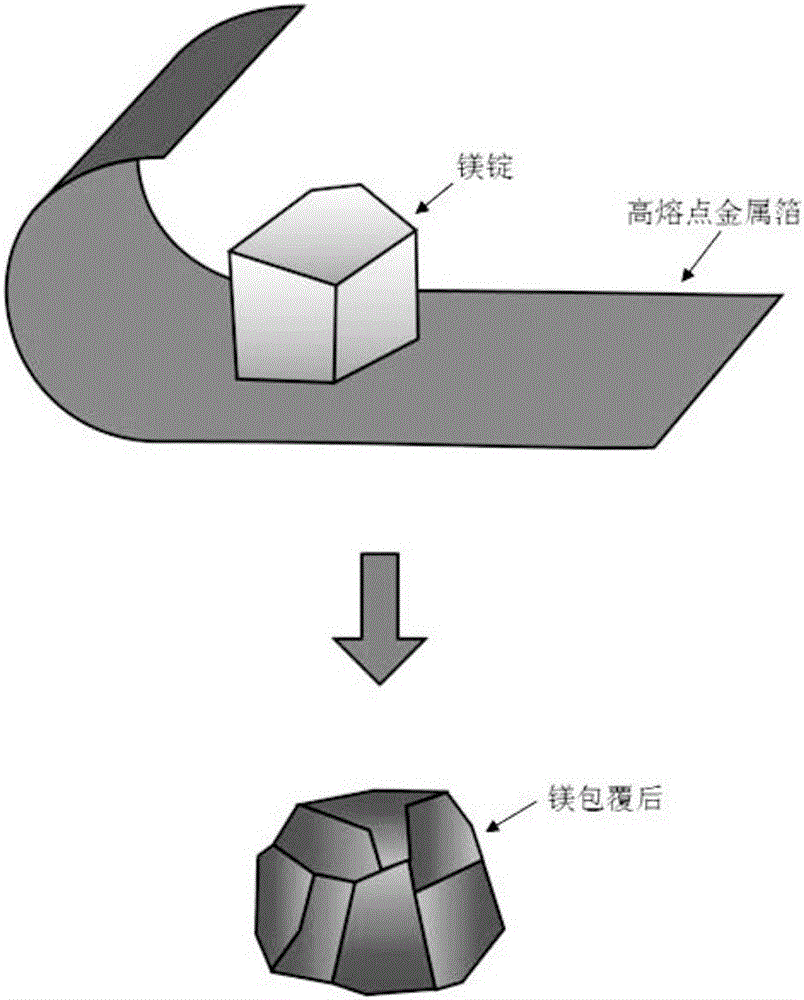

Controllable magnesium-containing hydrogen storage alloy preparation method

The invention discloses a controllable magnesium-containing hydrogen storage alloy preparation method.The method is characterized by including material preparation of a magnesium-containing hydrogen storage alloy, magnesium coating and induction smelting.The controllable magnesium-containing hydrogen storage alloy preparation method solves the problem of addition in smelting of high-melting metals and low-melting metals such as magnesium in the hydrogen storage alloy, and is especially effective in control of volatilization and burning loss of magnesium.Due to combination of magnesium coating and induction smelting, burning loss of magnesium is quite slow and controllable, alloy element absorption rate is greatly increased, uniformity and accuracy of chemical components are guaranteed, and a preparation process and equipment requirements are simplified relatively.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

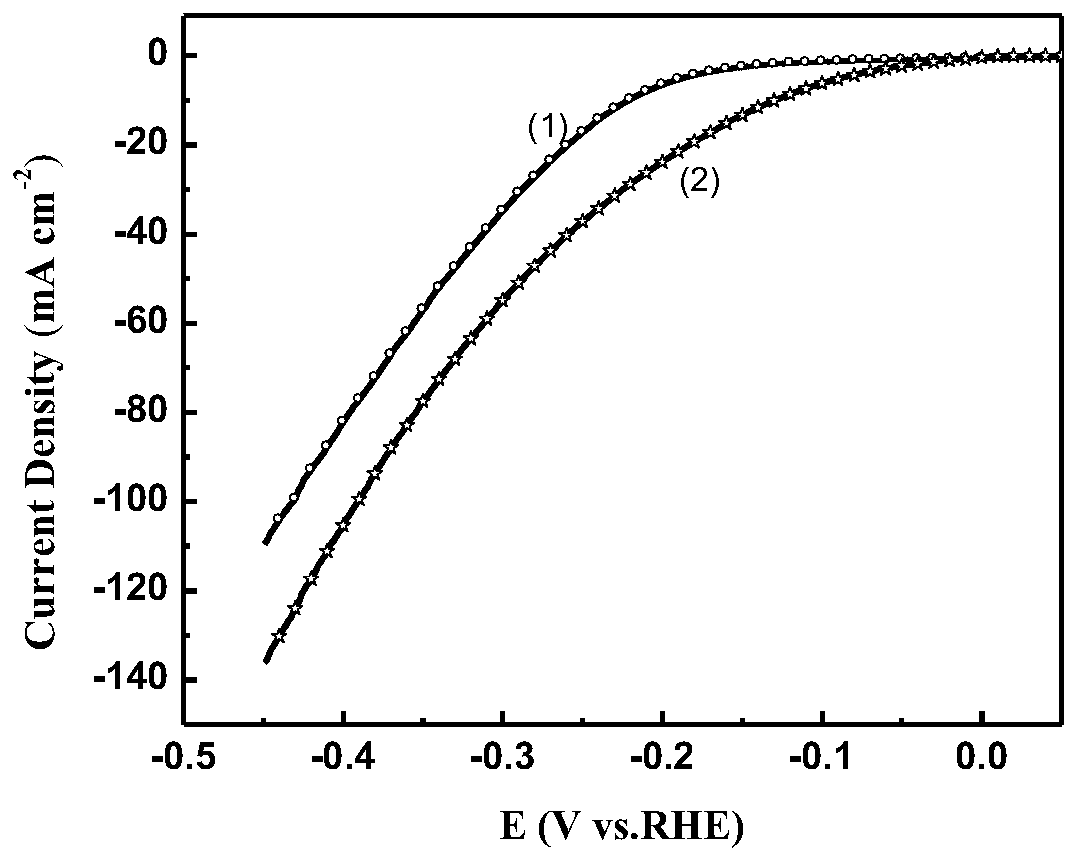

Nickel or nickel alloy porous material with directional holes, preparation method thereof and application thereof in a hydrogen evolution electrode

PendingCN110714140AEasy to implementLow costTransportation and packagingMetal-working apparatusAlloy elementDirectional solidification

The invention discloses a nickel or nickel alloy porous material with directional holes, a preparation method thereof and application thereof in a hydrogen evolution electrode. The method comprises the steps that water-based nickel or mixed slurry containing nickel and alloy element powder is injected into a mold, the water-based slurry is directionally solidified and formed through a freezing temperature field, an obtained cold blank is frozen and dried to remove ice crystals, then a binder is removed in a hydrogen atmosphere, and the nickel or nickel alloy porous material is prepared throughhigh-temperature sintering. Preparation of nickel-based alloys with different components can be achieved by controlling the powder components in the slurry, and the porosity, the hole diameter and the microstructure of the alloys can be finely adjusted and controlled through the solid phase content and the freezing condition. The nickel or nickel alloy porous material has the advantages that theprocess is simple, the raw material source is wide, and the nickel-based alloy porous material with the different components and high porosity and high air permeability can be prepared. The prepared porous material is beneficial to release of hydrogen in the water electrolysis process, the hydrogen evolution overpotential can be reduced, the electrolysis efficiency can be improved, and the nickelor nickel alloy porous material has application potential in the field of water electrolysis hydrogen evolution.

Owner:CENT SOUTH UNIV

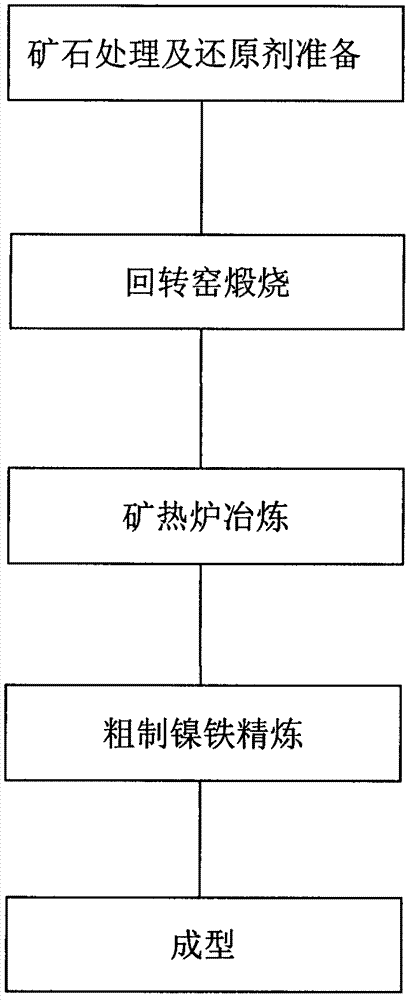

Nickel steel bean production method

InactiveCN103088254AControl ingredientControl shapeRotary drum furnacesSteelmakingChemical composition

The invention discloses a nickel steel bean production method, and belongs to the technical field of steelmaking. Chemical components of the nickel steel bean comprise: 20% of Ni, 0.15-0.3% of Si, 0.1% of C, 0.03% of S, 0.03% of P, and the balance of Fe. The nickel steel bean has an irregular bean shape. Production steps comprise: treating ore, preparing a reduction agent, carrying out calcination in a rotation kiln, smelting in a submerged arc furnace, carrying out refinement on the crudely-prepared ferronickel, forming, adopting laterite-nickel ore as a raw material, and adopting a nickel steel bean forming device and a cooling water tank to rapid form, wherein the nickel steel bean forming device can be statically fixed, and further can horizontally rotate, and a water temperature of the cooling water tank is controlled to a certain temperature range. According to the present invention, the components of the nickel steel bean can be accurately controlled, such that the Ni content is about 20%, and the Si content and the S content are low; the side surface outlet size of the nickel steel bean forming device can be adjusted so as to adjust the size of the nickel steel bean; the nickel steel bean has characteristics of small size and light weight; and the temperature of the cooling water tank is controlled so as to control the shape of the nickel steel bean shape.

Owner:SHANGHAI ZHONGHE METAL PROCESSING

Detection method for capsule capable of strengthening body resistance against hepatitis B

ActiveCN104792917AShort peak timeEasy to separateComponent separationSalvianolic acid BAdditive ingredient

The invention discloses a detection method for a capsule capable of strengthening body resistance against hepatitis B. The detection method comprises a thin-layer chromatography qualitative identification item and a content determination item, wherein the thin-layer chromatography qualitative identification item comprises identification of polygonum multiflorum, identification of polygonum cuspidatum and macleaya cordata, identification of cyrtomium fortune, and identification of flatstem milkvetch seed and crotalaria mucronata in the preparation; the content determination item comprises determining the content of salvianolic acid B which is a characteristic ingredient of salvia miltiorrhiza in the preparation. The detection method disclosed by the invention effectively controls the mixture of macleaya cordata and crotalaria mucronata in the capsule capable of strengthening body resistance against hepatitis B, meanwhile effectively controls the ingredients and the content of the capsule capable of strengthening body resistance against hepatitis B, and enables the medicine to be safer and more effective.

Owner:九寨沟天然药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com