Patents

Literature

44results about How to "The reaction raw materials are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green synthetic method of controllable superfine metal oxide/carbon nano tube composite material

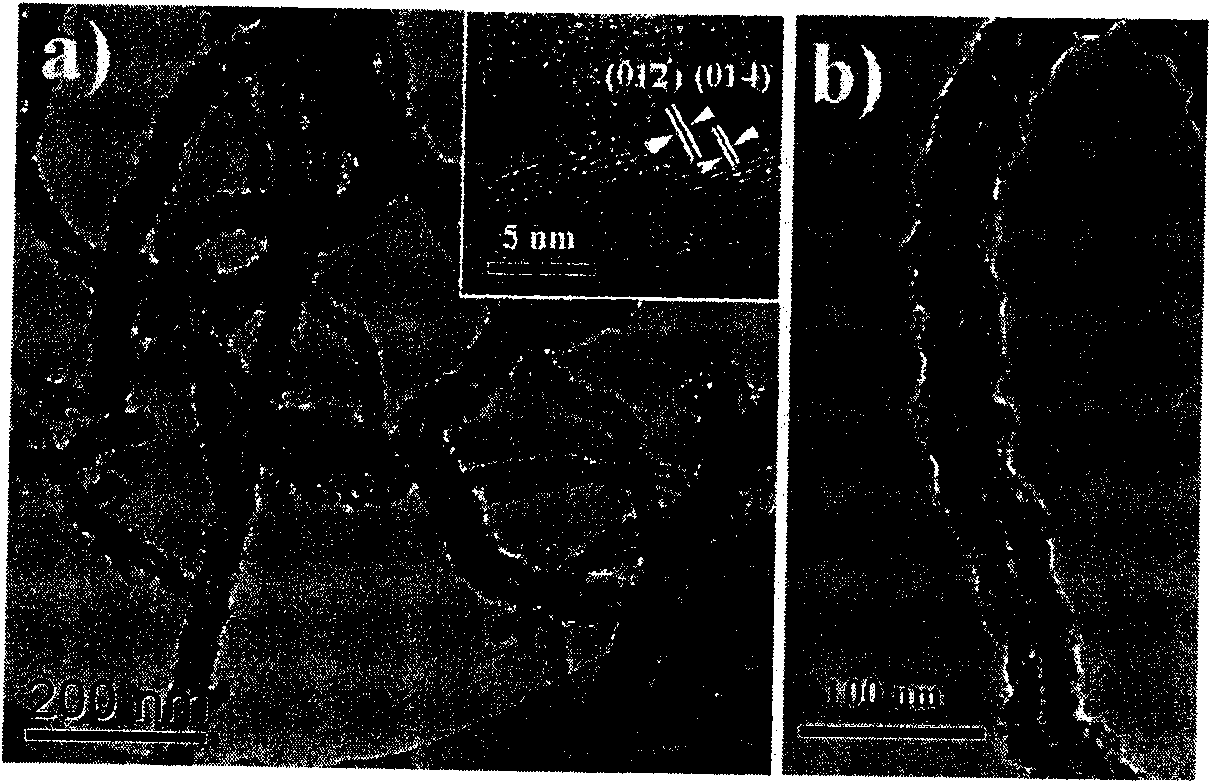

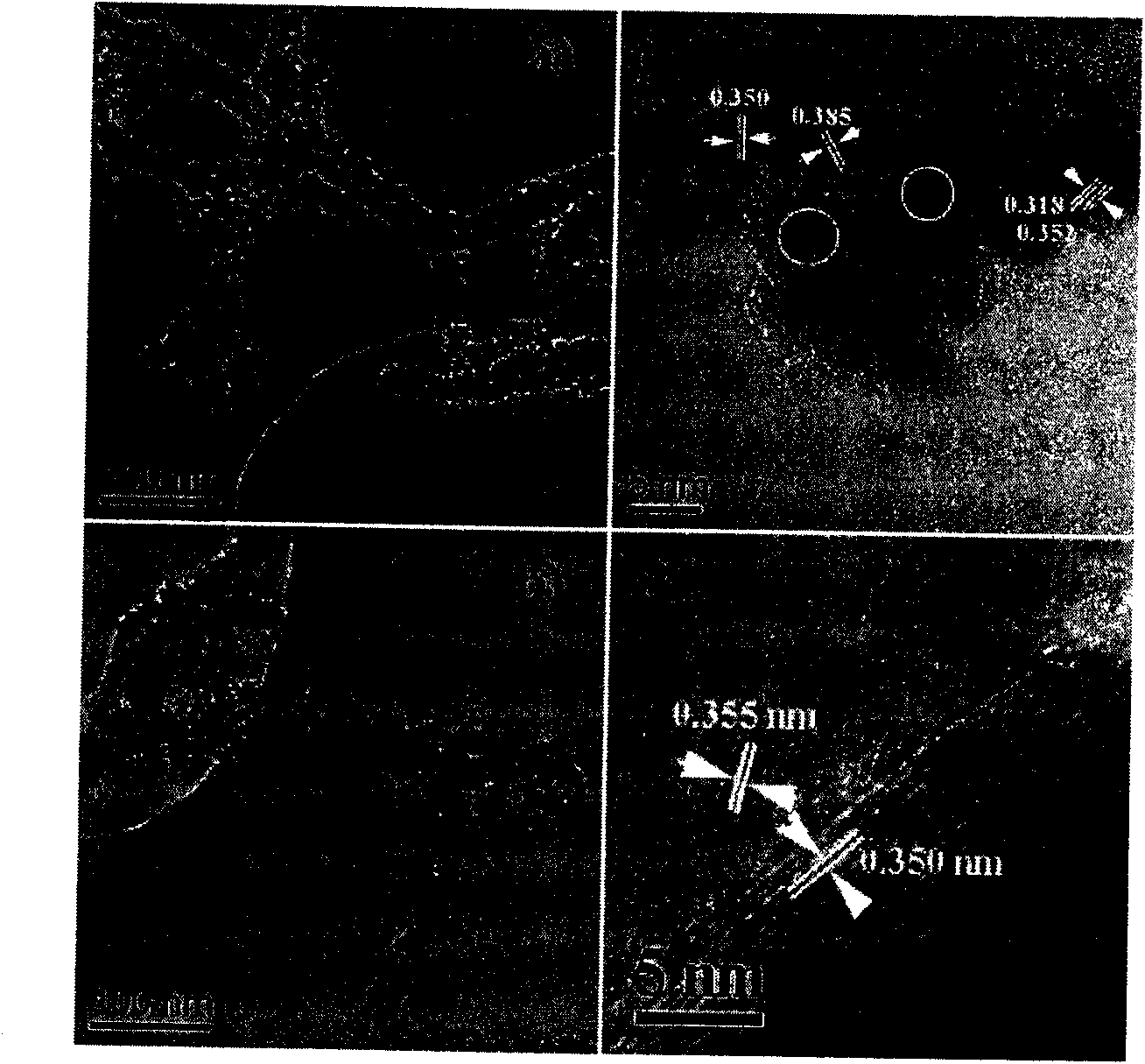

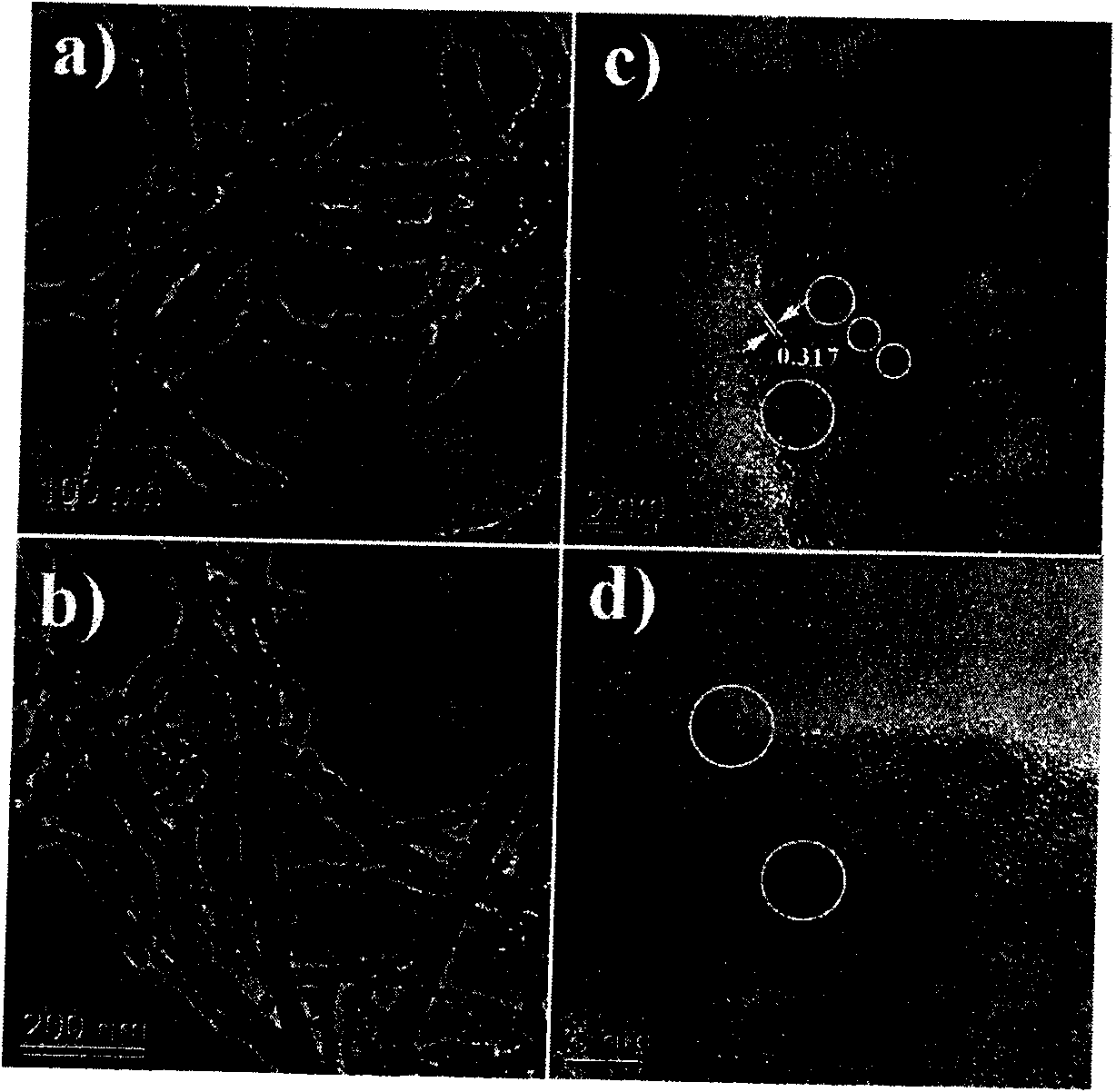

InactiveCN102040189AUniform and stable fixed loadLarge specific surface areaCatalyst carriersIndividual molecule manipulationCarbon nanotubeActive phase

The invention discloses a green synthetic method suitable for preparing a controllable superfine metal oxide / carbon nano tube composite material, relating to the field of nano science and catalytic composite materials. An active phase comprises multifunctional oxides of TiO2, ZrO2 and Fe2O3. The synthetic method comprises the following steps of: pretreating corresponding metal salts of TiOCl2, ZrOCl2 and Fe(NO3)3 in a DMF(Dimethyl Formamide) solution to form a precursor; adding phenol as a surfactant in the precursor; adding a multi-wall carbon nano tube treated with a proper amount of acid; carrying out slow hydrolytic polymerization and depositing under the condition of heating to form a TiO2 / CNT (Carbon Nano Tube), ZrO2 / CNT and Fe2O3 / CNT / composite material. The method has general applicability to realizing that multifunctional nano metal oxides which are convenient to obtain through hydrolysis are compounded with carbon tubes with hydrophobe surfaces; and the obtained nano composite material is possibly applied to various catalytic fields.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

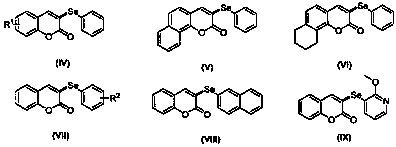

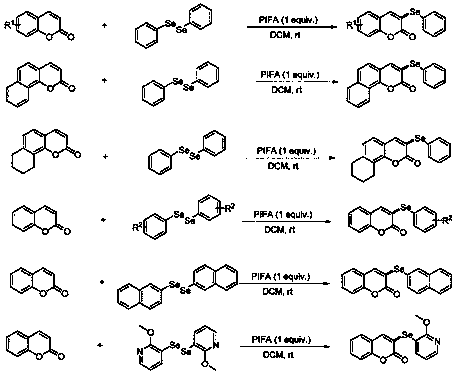

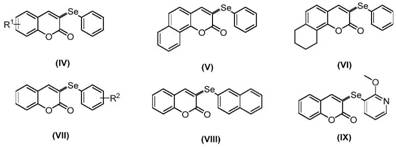

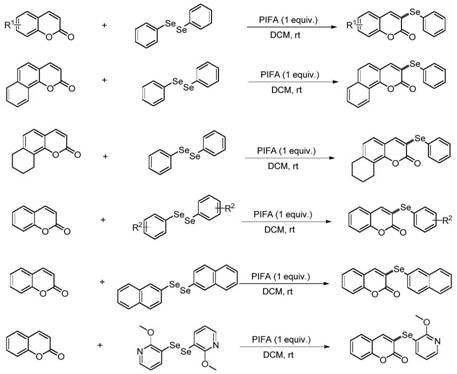

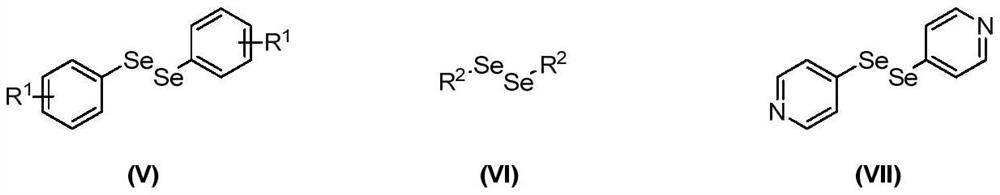

Preparation method of 3-selenocoumarin compound

The invention discloses a preparation method of a 3-selenocoumarin compound, which comprises the following steps: in a DCM solvent, synthesizing to obtain the 3-selenocoumarin compound at room temperature by using PIFA as an oxidant and using a coumarin compound and a selenide compound as substrates. According to the method, the reaction raw materials are cheap and easy to obtain, the preparationmethod is simple, PIFA is used as an oxidizing agent, the reaction cost is low, the reaction time is short, the yield is high, the operation is simple, and the method is suitable for synthesizing different types of 3-selenocoumarin compounds. The method disclosed by the invention can be used for synthesizing a series of 3-selenocoumarin compounds, and the synthesized product can be used as an intermediate compound for further constructing a complex active compound; meanwhile, the compound has great drug activity potential.

Owner:WENZHOU MEDICAL UNIV

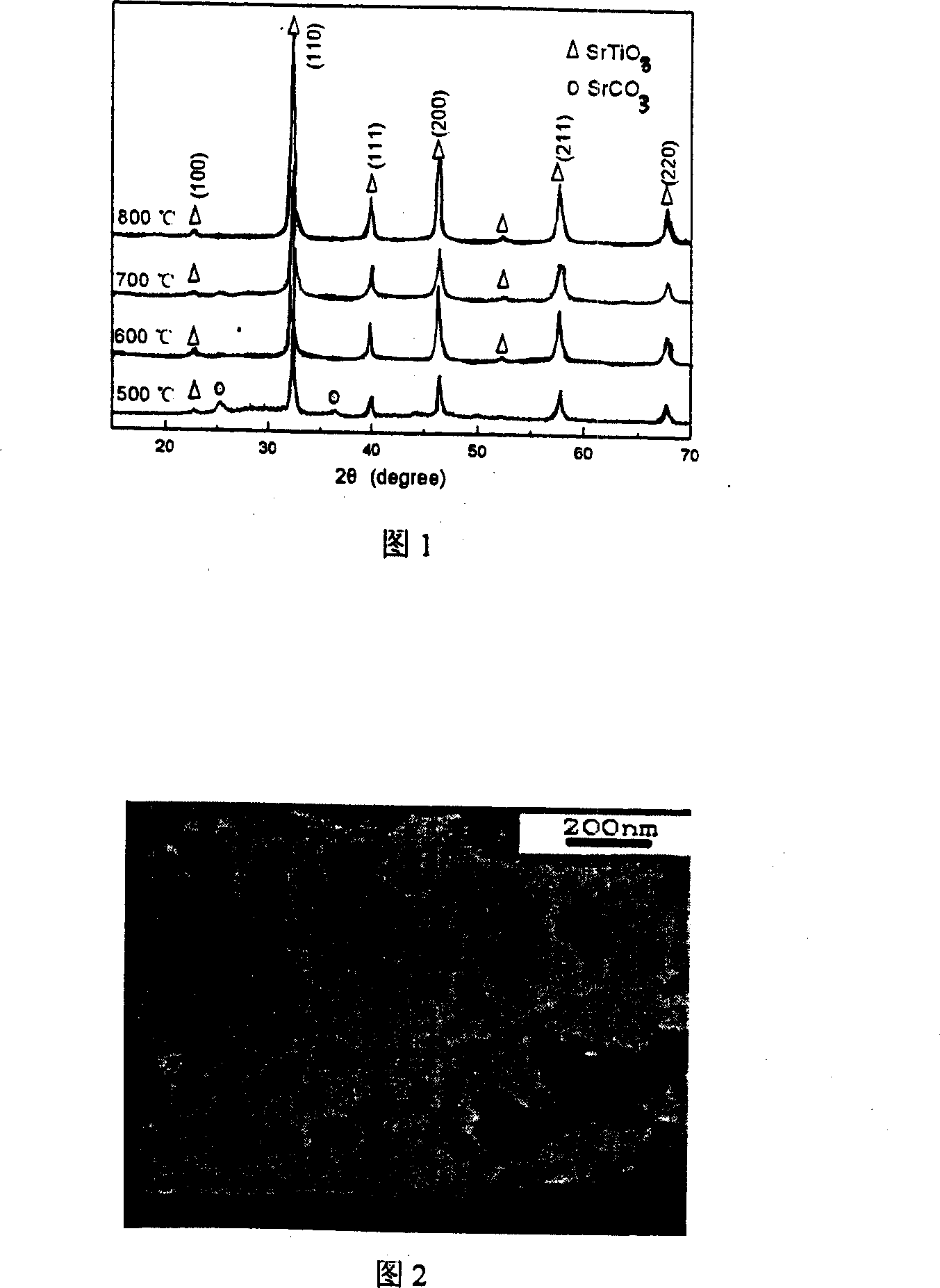

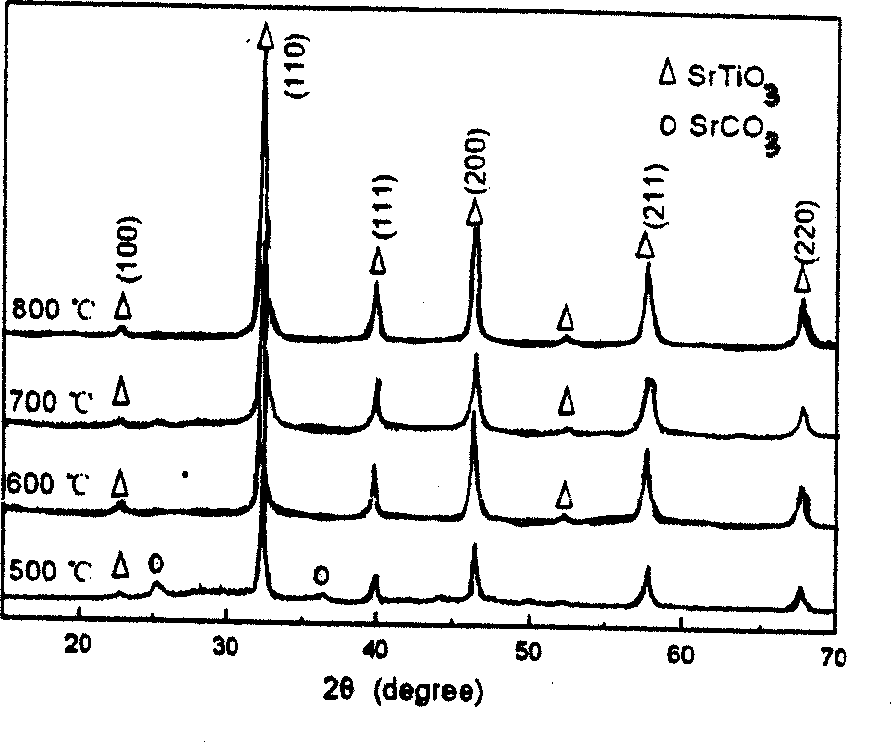

Method for preparing nano strontium titanate by lactic acid adjuvant process

InactiveCN101117290AEasy to getThe reaction raw materials are simpleFrom gel statePolycrystalline material growthStrontium titanateStrontium carbonate

The invention relates to a preparation method of nanometer strontium titanate with lactic acid aid. The invention takes strontium salt and butyl titanate as materials, lactic acid as solvent and inhibitor, and takes a small amount of water to promote hydrolyzing. The procedures of the invention are as follows: Firstly, strontium titanate is dissolved in the lactic acid, and then is added with the solvent of the butyl titanate slowly with violent stirring, and is kept still, thus homogeneous and transparent gel is obtained. The gel is calcineed at a high temperature, thus nanometer strontium titanate power is obtained. The composition components of the invention are less, can be got easily and are environment friendly without pollution. The lactic acid acts as the solvent of the strontium salt and as the inhibitor of the butyl titanate, and can well control the sol-gel process; therefore, the productive rate of the nanometer strontium titanate power prepared by the method is increased. The invention needs only 80 ml of gel for to make 0.1 mol of SrTiO3r. The proposal has a wide application and is suitable for the preparations of nanometer barium titanate and nanometer barium strontium titanate, etc.

Owner:XI AN JIAOTONG UNIV

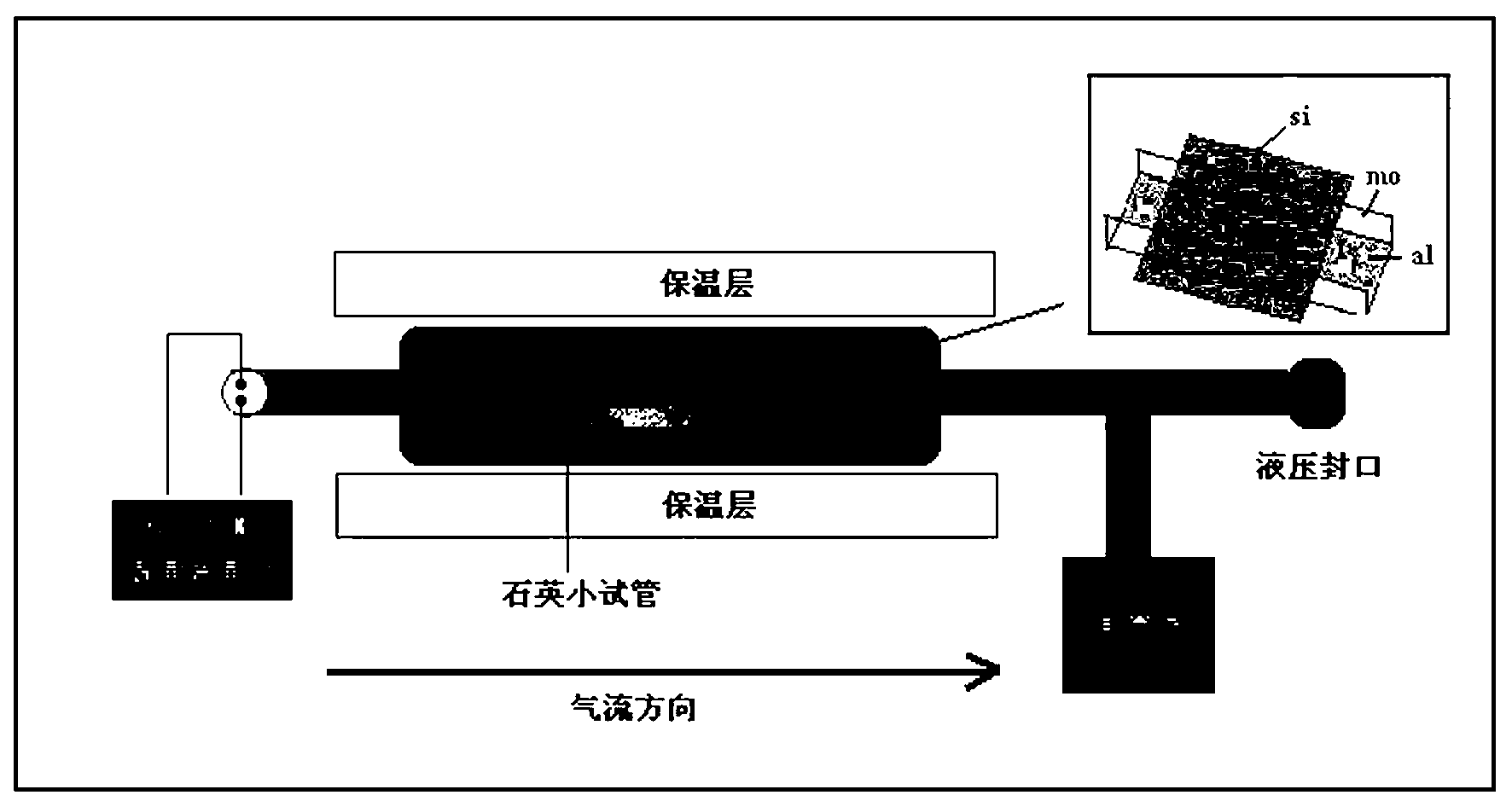

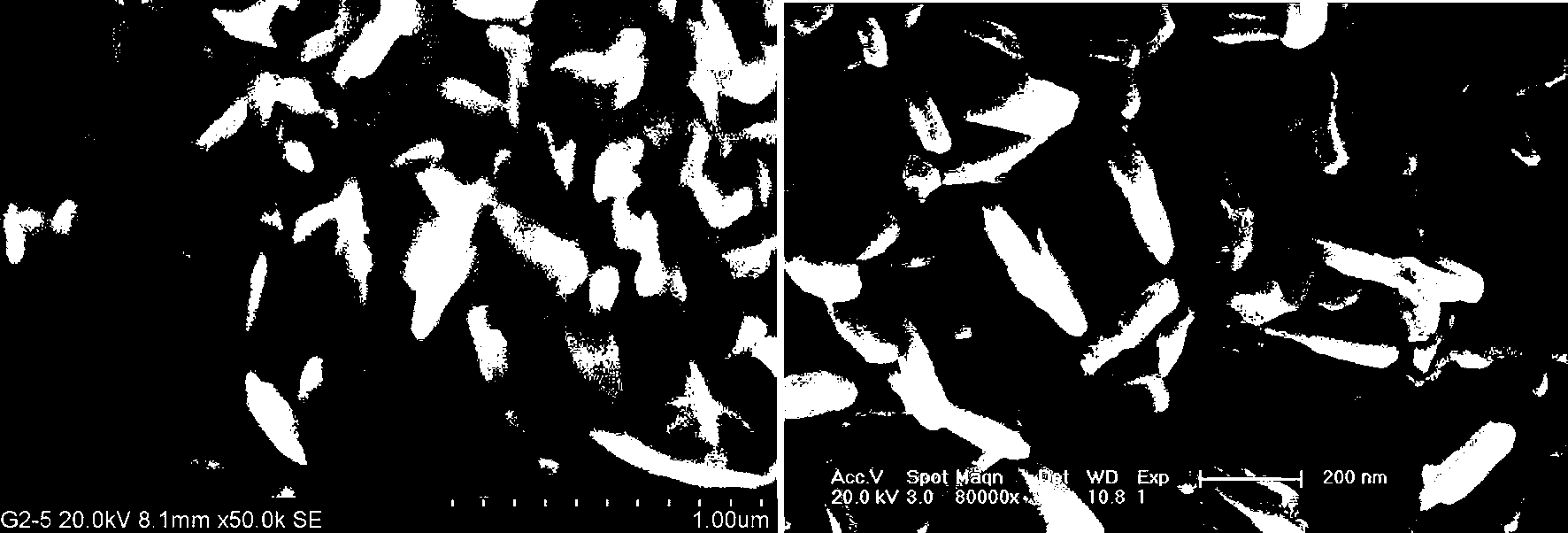

Preparation method of monocrystalline AlN nanocones and nanosheets

InactiveCN103160929AIncrease the vapor pressure concentrationThe reaction raw materials are simplePolycrystalline material growthFrom chemically reactive gasesAl powderGas phase

The invention discloses a method for preparing monocrystalline AlN nanosheets and nanocones through a gas-phase transmission method, which is realized through the following process steps: depositing raw material Al powder into a molybdenum boat, depositing a thin aluminum powder layer on a silicon chip, and inverting the silicon chip used as a growth substrate in the molybdenum boat and above an aluminum source; placing the molybdenum boat into a small quartz test tube which is 150 mm in length and 20 mm in diameter, and placing the test tube in a reaction area of a horizontal tube furnace; closing the system, and starting to vacuumize; when the vacuum degree of the system is lower than 5 Pa, introducing argon gas, and performing gas washing on the reaction system; and introducing argon gas and ammonia gas, changing the introduction manners of the ammonia gas and the argon gas, and reacting at 900 DEG C and 850 DEG C to respectively obtain monocrystalline wurtzite structure AlN nanosheets and nanocones. The invention realizes the growth of AlN nanosheets and nanocones by directly reacting commercial aluminum powder and ammonia gas in the absence of any catalyst in a moderate-temperature area (850-900 DEG C) for the first time. The method has the characteristics of simple process, good repetitiveness, low production cost and the like, and is easy to popularize.

Owner:SHENYANG LIGONG UNIV

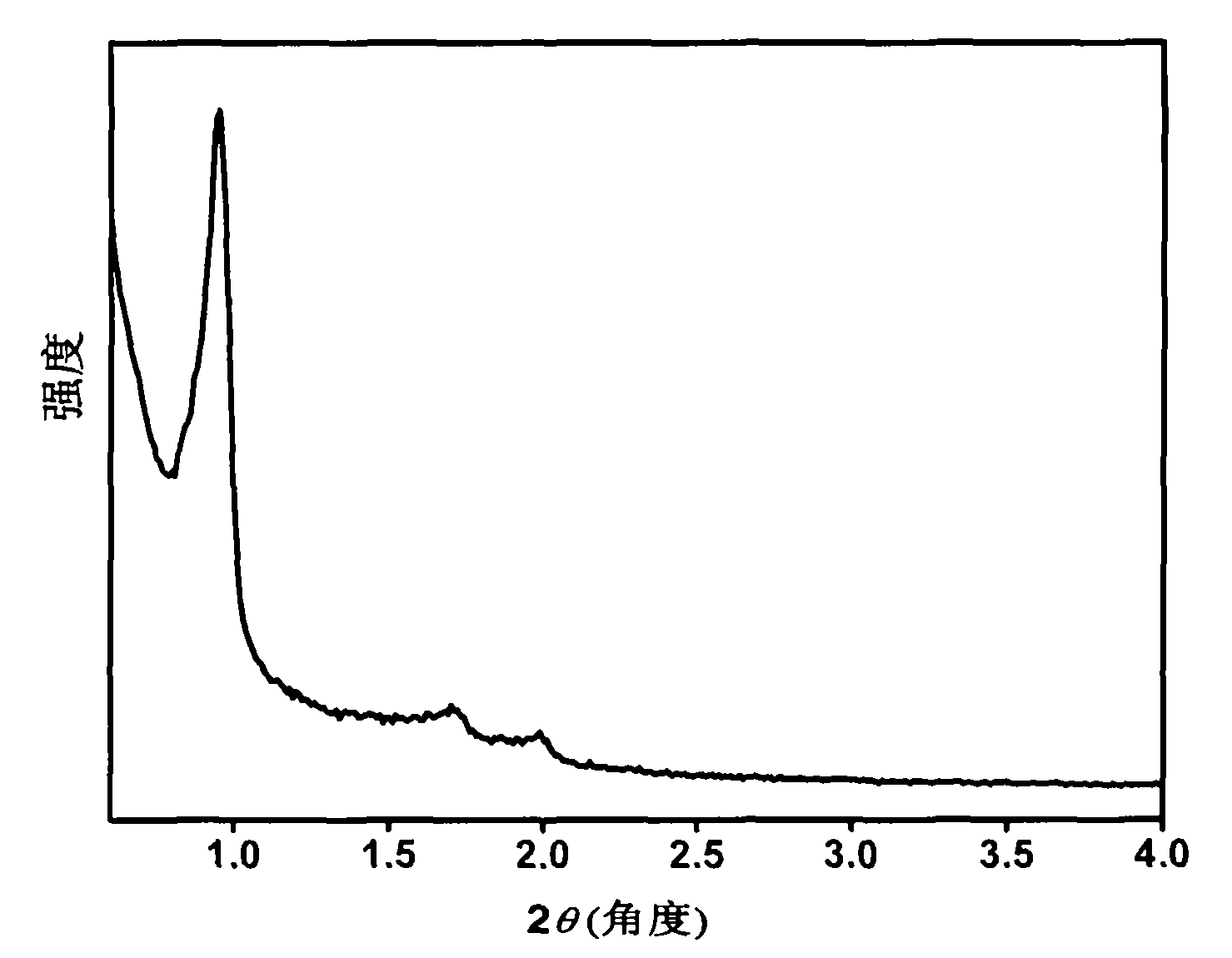

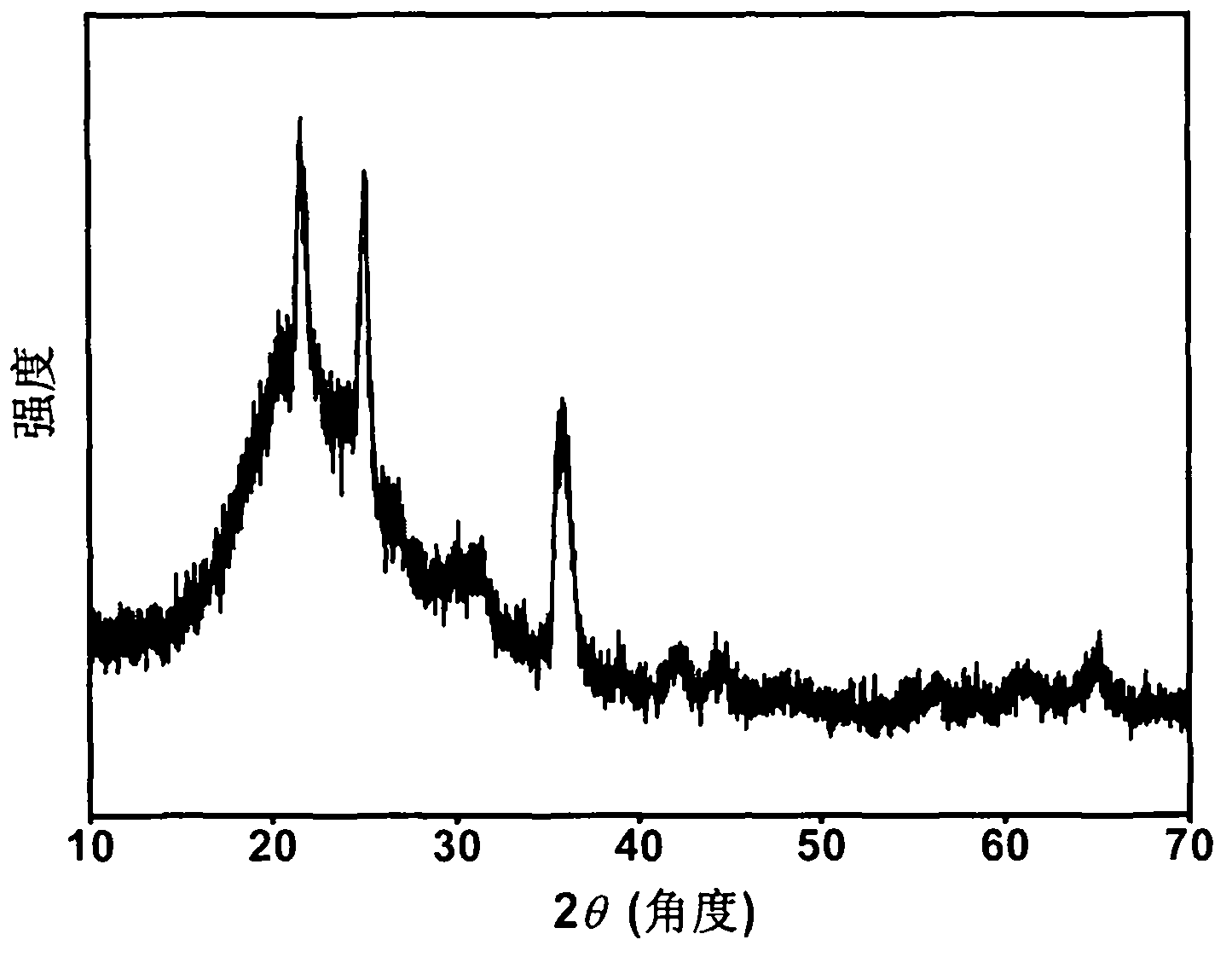

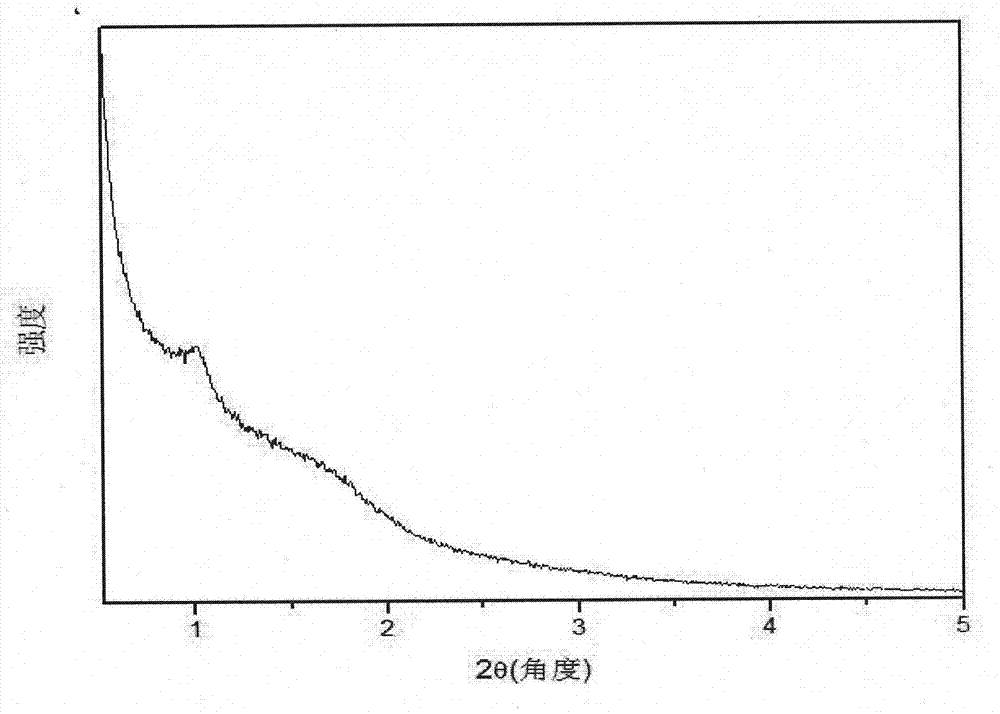

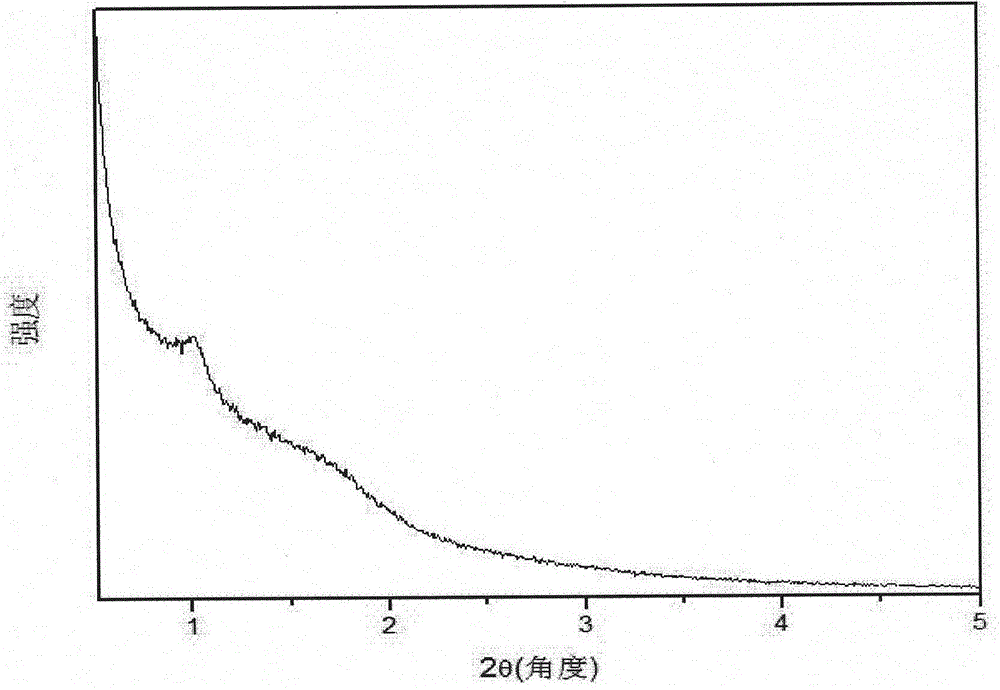

Crystallized mesoporous zinc silicate/silicon oxide composite powder and preparation method thereof

InactiveCN103232043AThe reaction raw materials are simpleLow costSilicon oxidesInorganic saltsRoom temperature

The invention discloses crystallized mesoporous zinc silicate / silicon oxide composite powder and a preparation method thereof. The composite powder is of a two-dimensional hexagonal mesoporous structure and the mesoporous wall is composed of crystalline zinc silicate and amorphous silicon oxide. The preparation method comprises the following steps of firstly preparing mesoporous silicon oxide and dissolving the inorganic salt of zinc in ethanol to prepare a zinc salt solution; adding the mesoporous silicon oxide in the zinc salt solution according to compositions of the prepared powder, wherein the molar ratio of the mesoporous silicon oxide to the zinc salt is 2-25; uniformly dispersing the mesoporous silicon oxide into the zinc salt solution through fully stirring; and in the meantime, continuing stirring at room temperature, volatilizing the ethanol to obtain powder and obtaining the crystallized mesoporous zinc silicate / silicon oxide composite powder via vacuum drying and calcination. The preparation method is simple and convenient in operation; and the prepared mesoporous zinc silicate / silicon oxide composite powder is high in order degree, large in pore size and specific surface area, high in crystallinity and good in stability.

Owner:INNER MONGOLIA UNIVERSITY

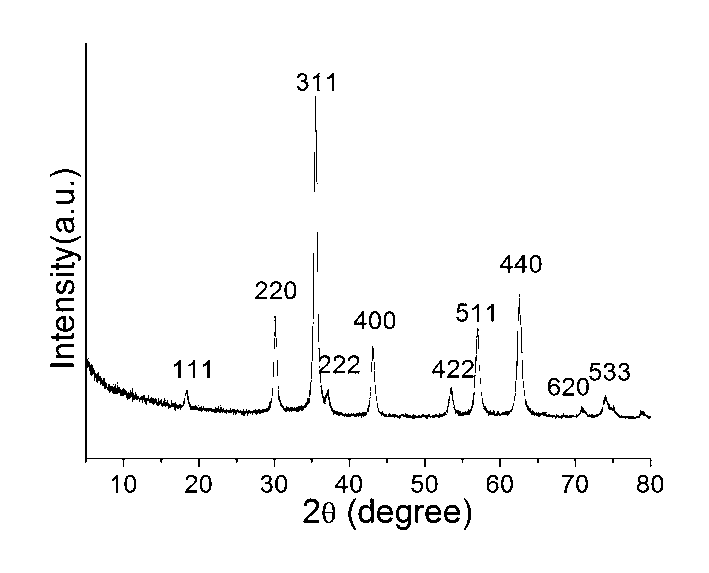

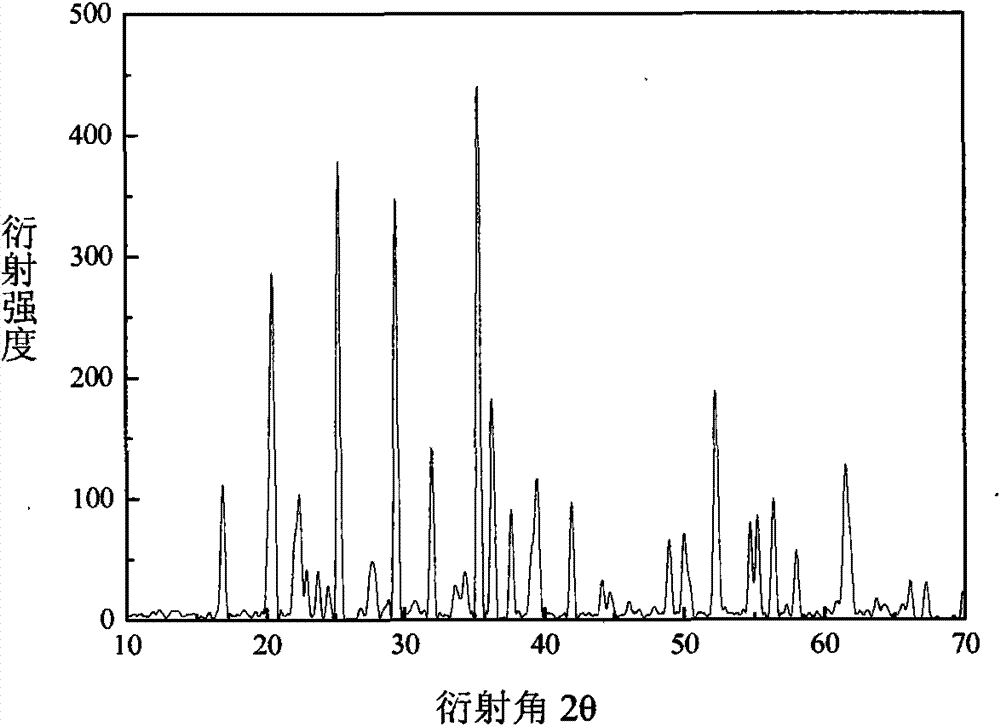

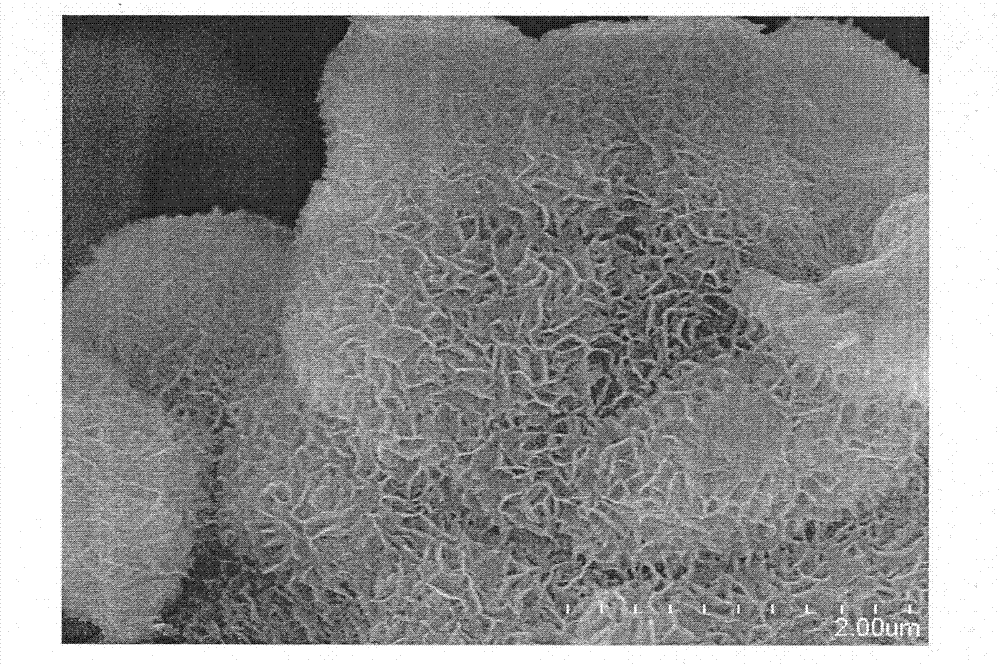

Preparation method of spherical ferrite

InactiveCN102850056AThe reaction raw materials are simpleReaction raw materials are cheap and easy to obtainZinc ferriteFerrite powder

The invention provides a preparation method of spherical magnetic ferrite (zinc ferrite, magnesium ferrite and manganese ferrite) by taking ethanol amine as a precipitator in a solvothermal method. The preparation method is characterized by comprising the steps of: taking ferric trichloride and an ethylene glycol solution of chloride as a reaction solution as well as the ethanol amine as a precipitator; stirring at the room temperature and evenly mixing to form a liquid phase reaction solution; transferring the liquid phase reaction solution into a reaction kettle, and carrying out hydrothermal reaction at 180-250 DEG C; and after the reaction, separating, washing and drying the product to obtain the corresponding ferrite powder. The method has the characteristics of being low in price of raw materials, simple in technology, convenient in operation, controllable in morphology, etc.

Owner:LUDONG UNIVERSITY

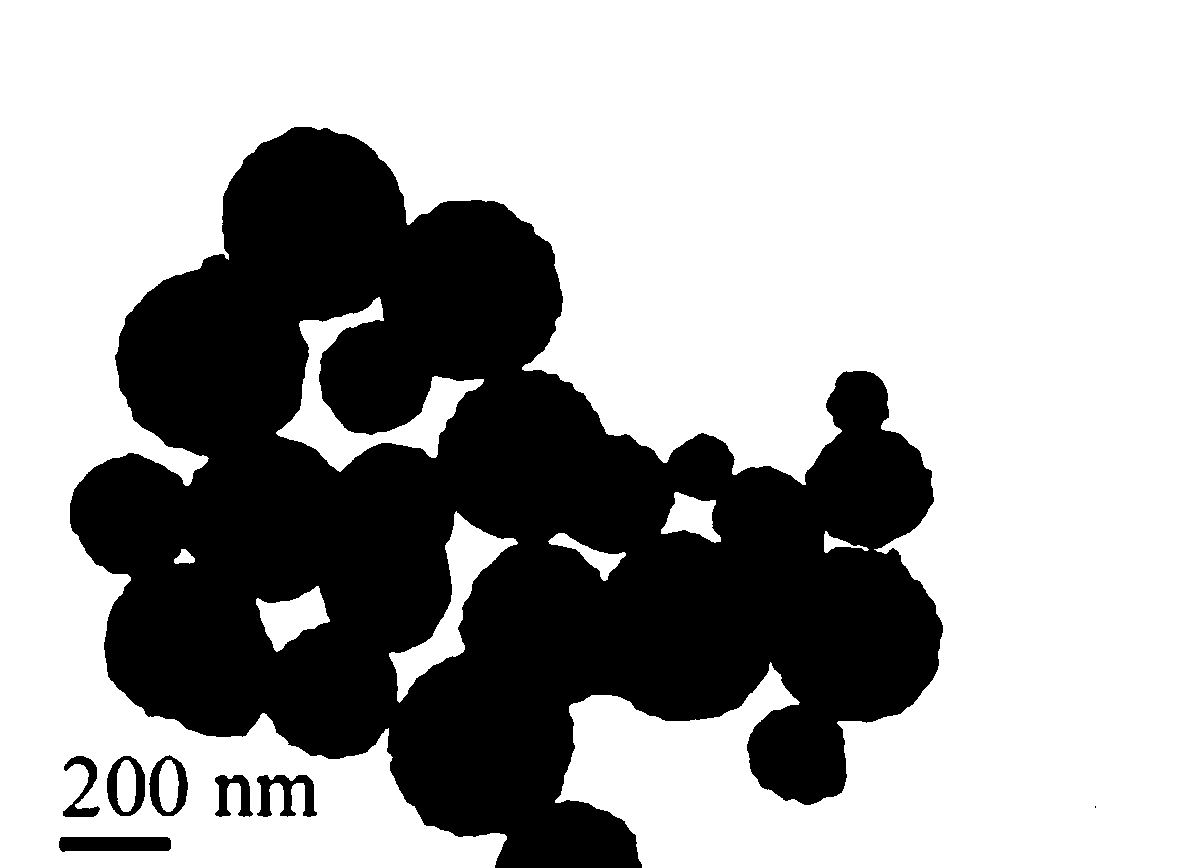

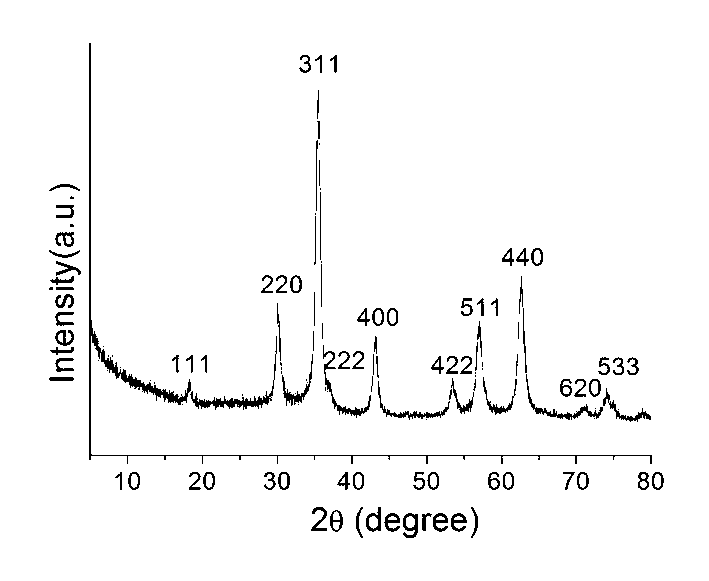

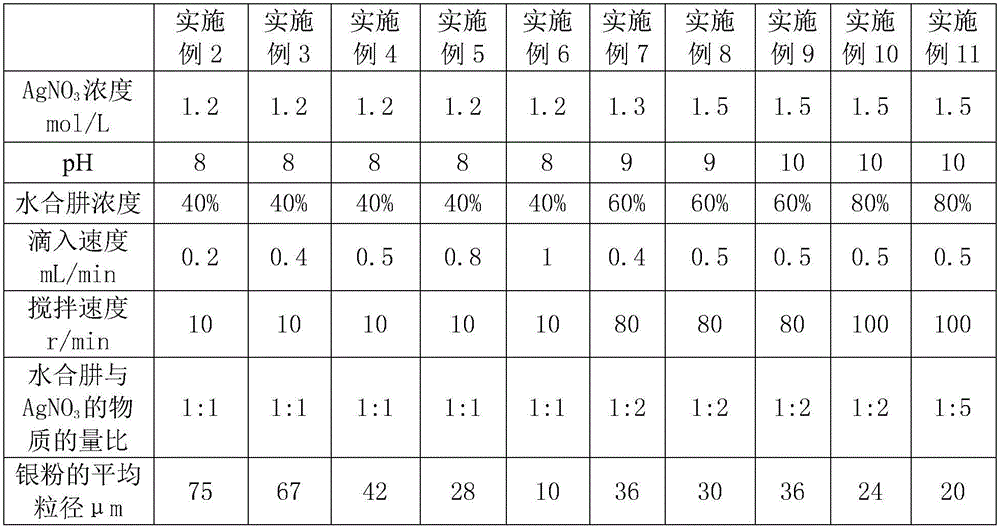

Ultra-pure silver powder preparation method capable of controlling particle size

The invention relates to an ultra-pure silver powder preparation method capable of controlling the particle size. The preparation method comprises the steps of (1) preparing a silver nitrate solution, wherein the concentration of silver nitrate in the solution is 1.2 to 1.5 mol / L; (2) adding aqueous ammonia into the silver nitrate solution prepared in the step (1), and adjusting the pH to be 8 to 9; (3) dripping a hydrazine hydrate aqueous solution with the concentration of 40% to 80% into the silver nitrate solution in the step (2) at the speed of 0.1 to 1 mL / min, so as to obtain silver powder slurry; and (4) filtering the silver powder slurry obtained in the step (3), washing the filtered silver powder slurry with deionized water for three times, and drying wet silver powder obtained after filtration under nitrogen protection to obtain silver powder. According to the preparation method, during the preparation process of ultra-pure silver powder, any protective agent and dispersing agent are not added in the reaction system, and organic matter residues are avoided; and when hydrazine hydrate is used for reducing silver nitrate, the reaction speed of silver nitrate reduction through hydrazine hydrate is accurately controlled through accurately controlling the flow of the hydrazine hydrate aqueous solution, so that the particle size of the ultra-pure silver powder is accurately controlled.

Owner:LIYANG LIFANG PRECIOUS METALS MATERIAL CO LTD

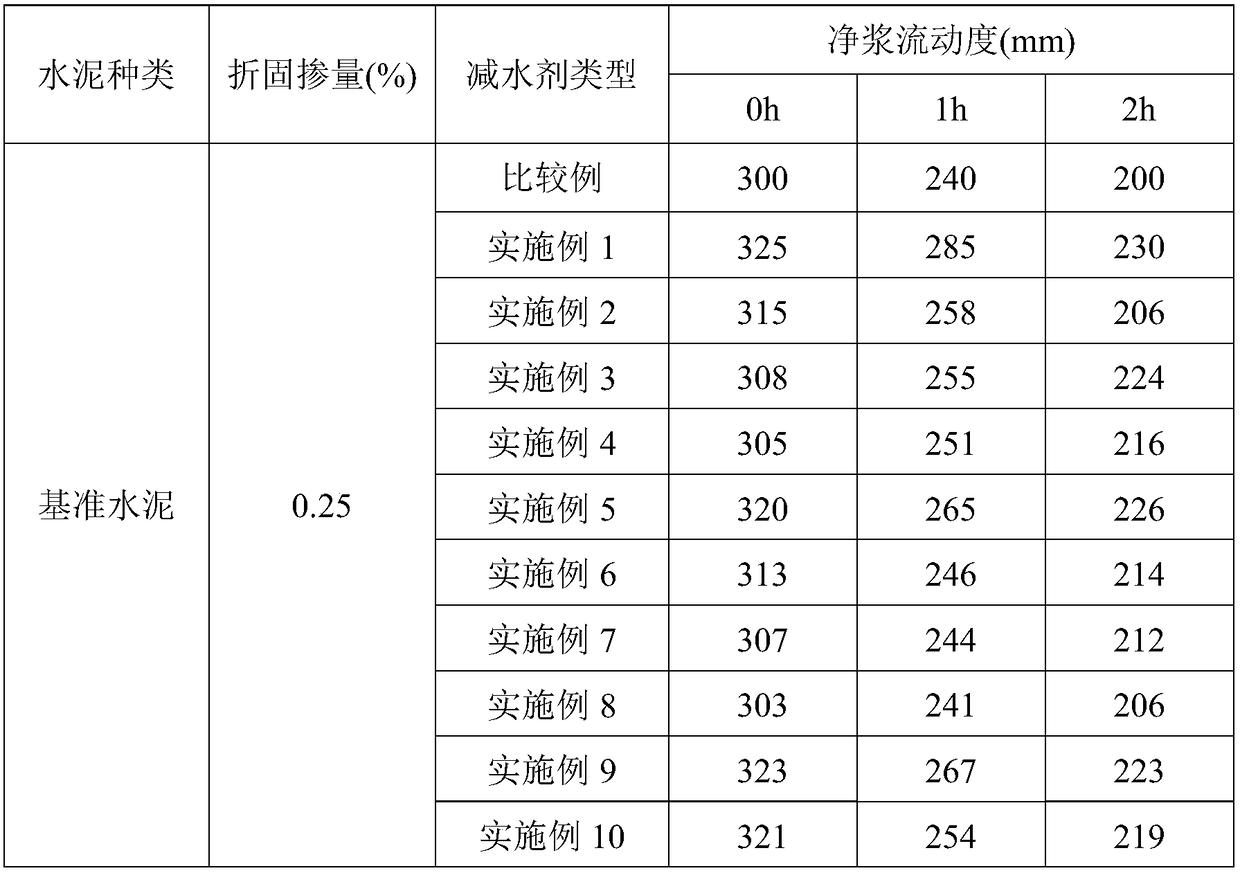

Method for preparing slump-retaining polycarboxylate water reducer by silylation of amino polyether end groups

The invention relates to a method for preparing a slump loss-resistant type polycarboxylic acid water reducer by silanizing a terminal group of amino polyether. The method provided by the invention takes an amino polyether type compound, a silane coupling agent, an unsaturated carboxylic acid type monomer and the like as main reaction raw materials and a polycarboxylic acid water reducer is prepared through firstly hydrolyzing, substituting, then carrying out condensation, and finally copolymerizing; the method comprises the following steps: firstly hydrolyzing by a halogenated silane coupling agent; then taking the silane coupling agent and the amino polyether type compound to be subjected to substitution reaction; carrying out the condensation on a substituted product and a vinyl silane coupling agent hydrolyzed product; taking a condensed product and unsaturated polyoxyethylene ether, a molecular weight regulator and the unsaturated carboxylic acid type monomer to be subjected to free-radical copolymerization reaction under the action of an initiator to prepare the polycarboxylic acid water reducer with a plurality of branched silane modified polyether side chains. The method provided by the invention has the advantages of simple and easy-to-control process, low cost, energy saving and high efficiency, environmental protection and no pollution; dual modification of the side chains of a main chain of a polycarboxylic acid molecule is successfully realized and more excellent water reduction and slump loss resistance performance, which is better than that of a common polycarboxylic acid water reducer, is represented.

Owner:中铁一局集团工业贸易有限公司

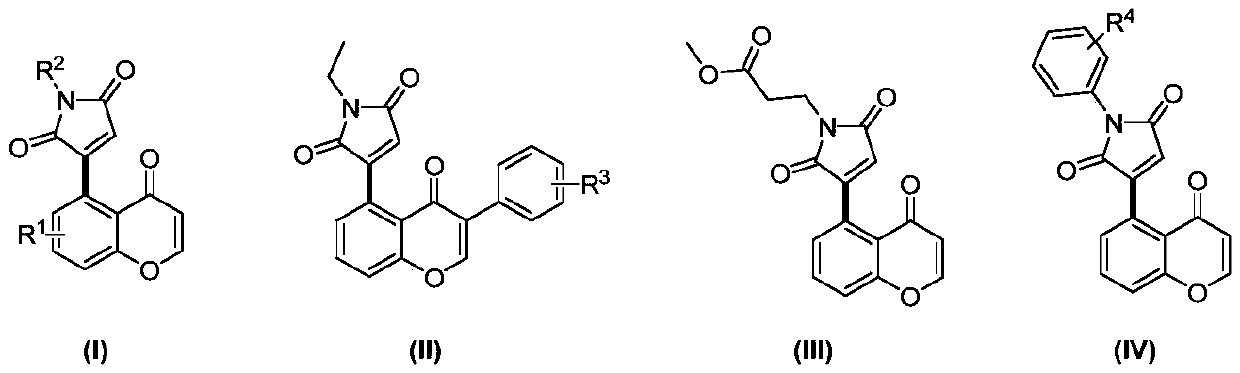

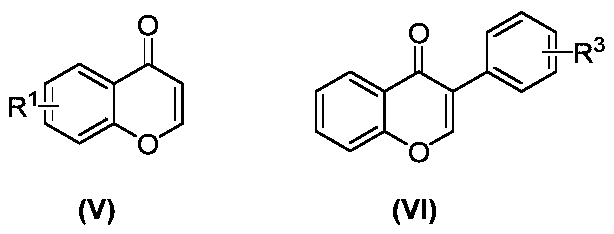

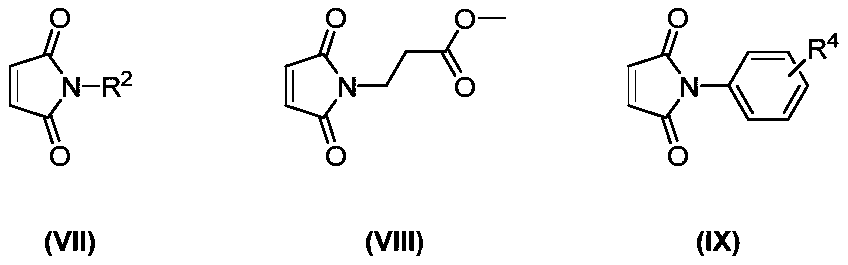

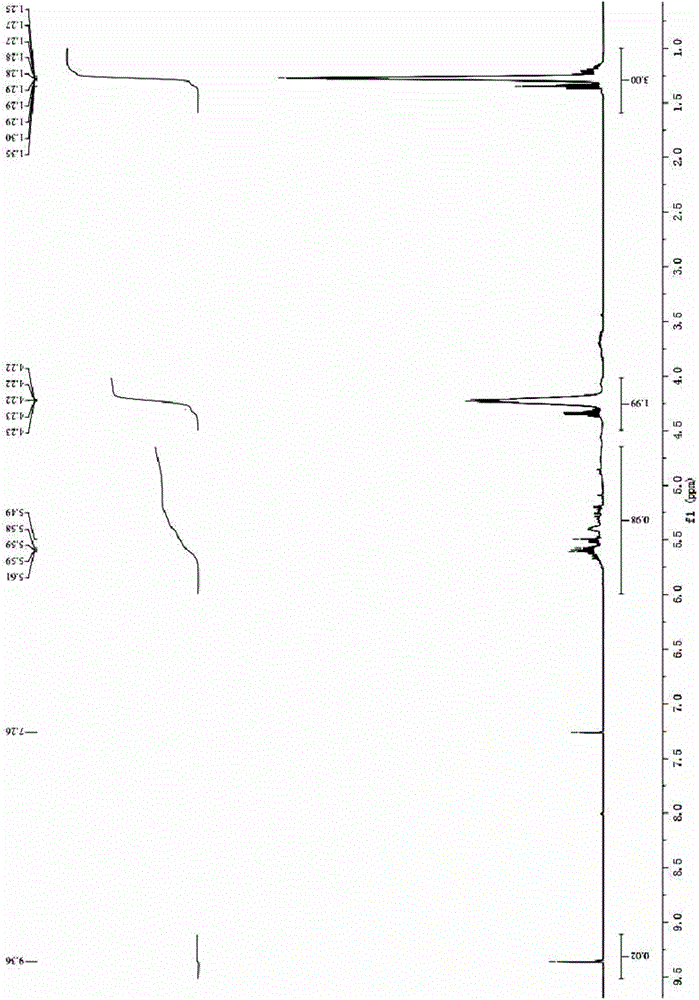

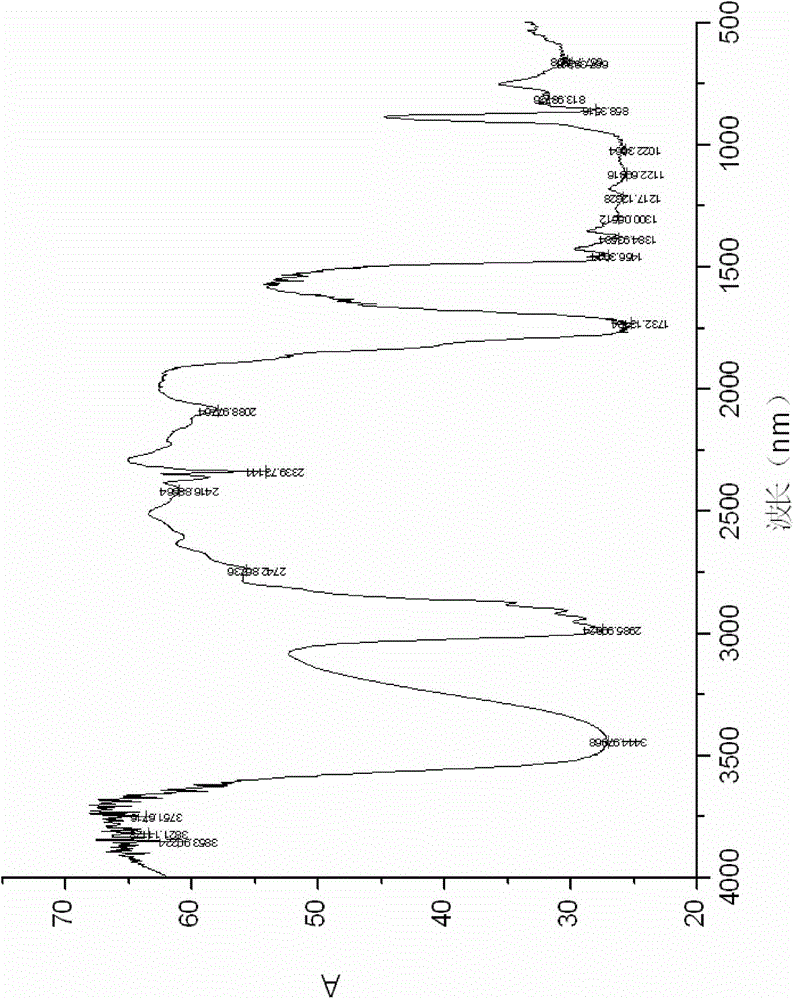

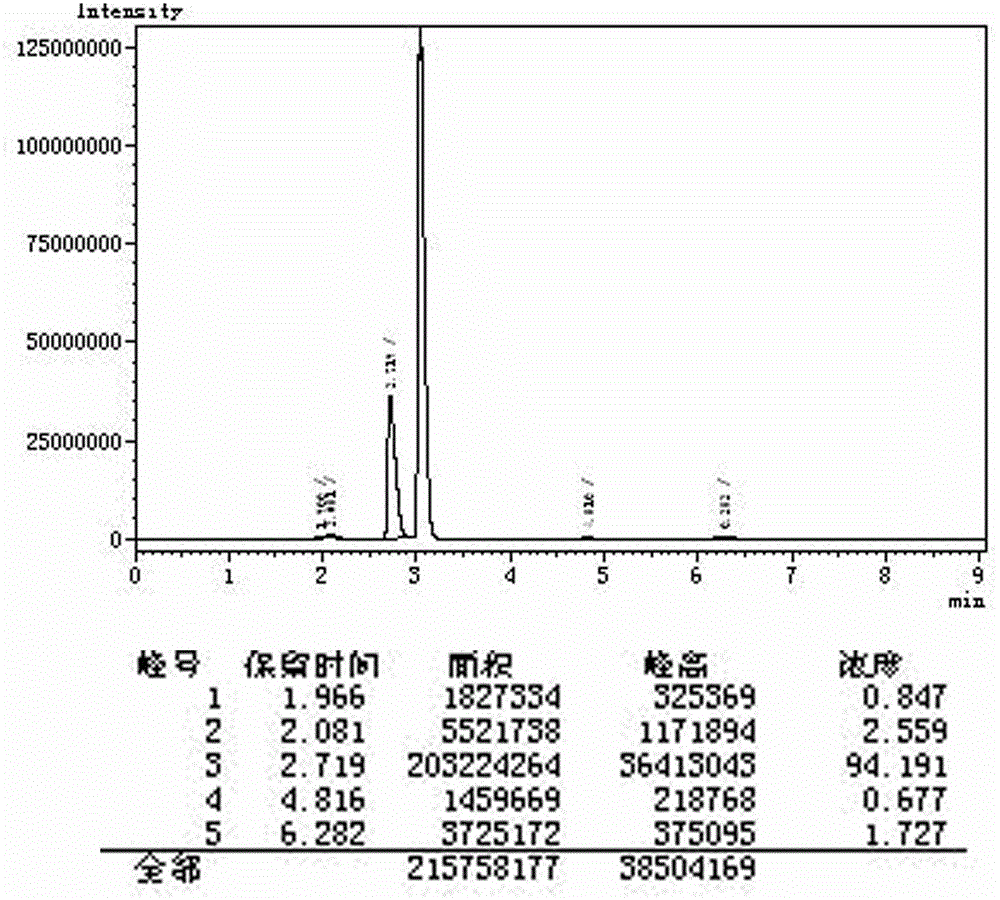

Preparation method of 5-maleimide chromone compound

ActiveCN110590751AReaction raw materials are cheap and easy to obtainInexpensive and easy to operateOrganic chemistryRutheniumP-Cymene

The invention discloses a preparation method of a 5-maleimide chromone compound. The preparation method comprises the steps that in a DCE solvent, [Ru(p-cymene)Cl2]2 and AgNTf2 are used as catalysts,silver acetate serves as an additive, a maleimide compound and a chromone compound are taken as substrates, and the 5-maleimide chromone compound is synthesized. According to the preparation method ofthe 5-maleimide chromone compound, the reaction raw materials are low in cost and easy to obtain, the preparation method is simple, ruthenium is used as a catalyst, the reaction cost is low, the reaction time is short, the yield is high, operation is easy, and the preparation method is suitable for synthesis of different types of 5-maleimide chromone compounds. The preparation method can be usedfor synthesizing a series of 5-maleimide chromone compounds, and synthesized products can serve as intermediate compound, and can also be used for further constructing complex active compounds; and meanwhile, the compounds have great medicine activity potential.

Owner:WENZHOU MEDICAL UNIV

Synthetic method of glyoxylic ester

InactiveCN105272849AHigh gas contentHigh yieldOrganic compound preparationCarboxylic acid esters preparationGlyoxylic acidPtru catalyst

The invention relates to the field of chemical engineering, especially to a synthetic method of glyoxylic ester. According to the synthetic method, glyoxalic acid and alcohol undergo an esterification reaction under catalysis of a catalyst in the presence of a water-carrying agent so as to obtain glyoxylic ester. The catalyst is acid, and the water-carrying agent is hydrocarbon. By the synthetic method, yield of a route product is high, content of a gas phase is high, and side reaction is few. There is no need to use heavy metal or other oxidizing agent. The reaction process is safer, and environmental pollution is avoided. Reaction materials are simple and easily available and are common technological raw materials. By the synthetic scheme, synthesis of glyoxylic ester can be industrialized. The synthetic method has cost advantage. Cost of glyoxylic ester is greatly reduced. The synthetic method provides conditions for slathering glyoxylic ester at the industrial level. In addition, quality of the product is better than quality of a commercially available reagent, and gas phase content of the product is far higher than gas phase content 92% of a commercially available reagent.

Owner:HENAN NEWLAND PHARMA

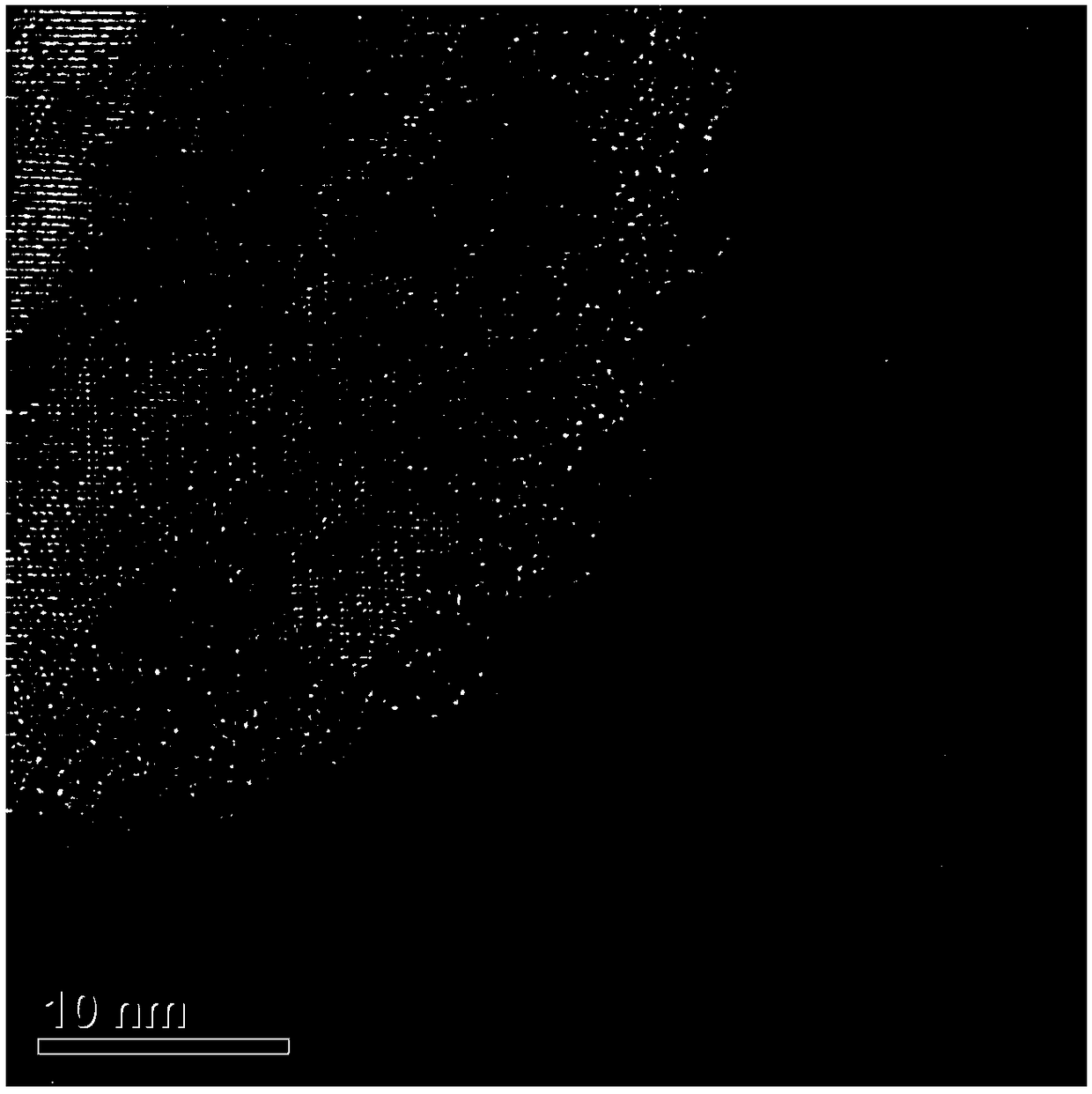

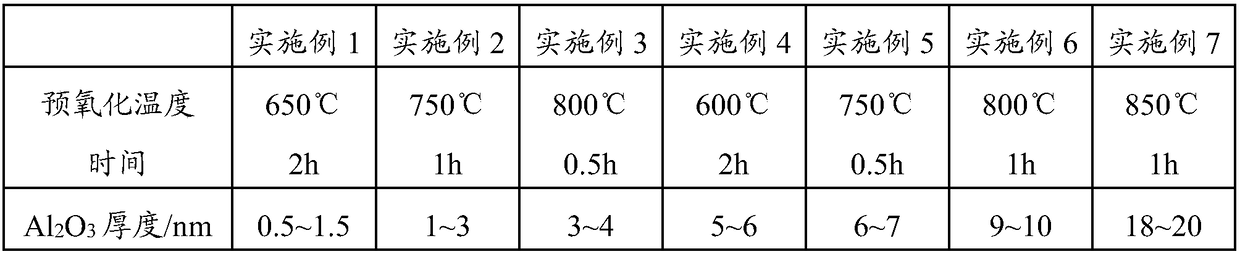

A kind of preparation method of aluminum oxide coated silicon negative electrode material

ActiveCN105958023BHigh capacity retentionLow costCell electrodesSecondary cellsOrganic reactionOxygen

The invention provides a preparation method of an aluminum oxide coated silicon cathode material. The preparation method comprises the following steps: (A) in an oxygen-containing atmosphere, carrying out heat treatment of 500-1000 DEG C on nanometer silicon powder to obtain preoxidized nanometer silicon; (B) mixing the preoxidized nanometer silicon with aluminum powder and tin powder, and carrying out heat treatment of 400-900 DEG C to obtain an intermediate; and (C) treating the intermediate with acid or an oxidant to obtain the aluminum oxide coated silicon cathode material. In the preparation method, the thickness of an aluminum oxide coating layer can be controlled by adjusting the technological conditions of nanometer silicon preoxidization; the reaction raw materials are simple, flammable and combustible organic reactants and complex vacuum systems do not need to be used in the preparation process, the operation process is simple and practicable, the practicability degree is high, and the cost is low. The silicon substrate cathode material prepared and obtained by the preparation method has more stable surface structure in the lithium deembedding and embedding process, and is high in capacity retention ratio, high in cycling stability and high in performance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

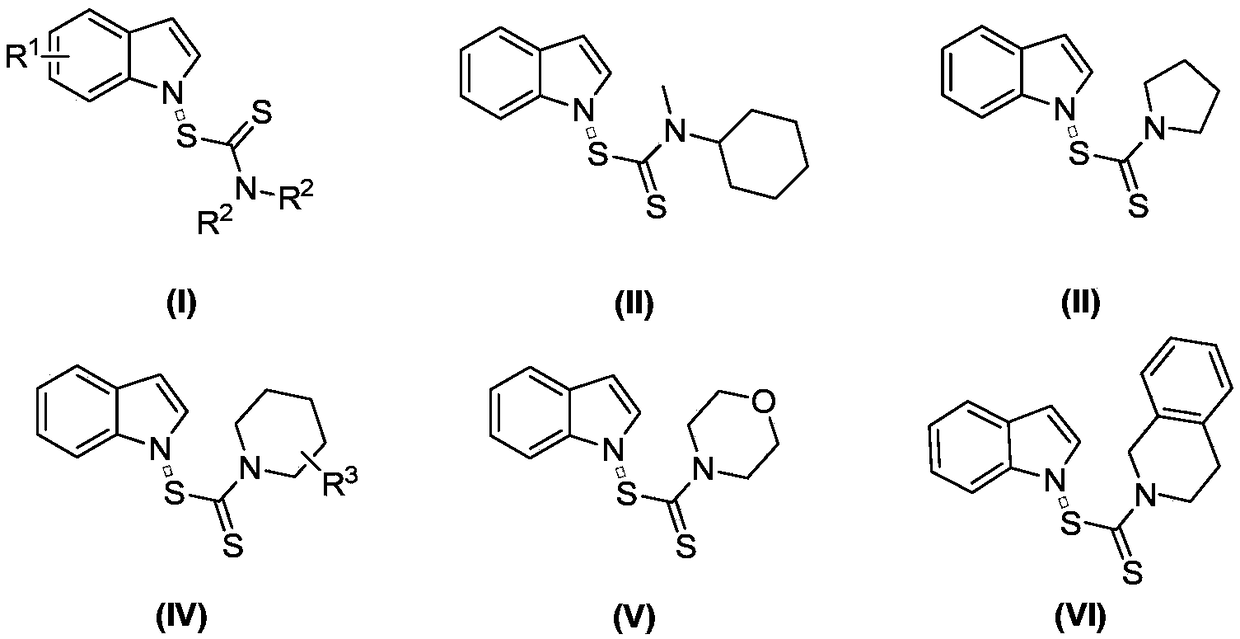

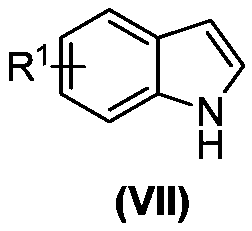

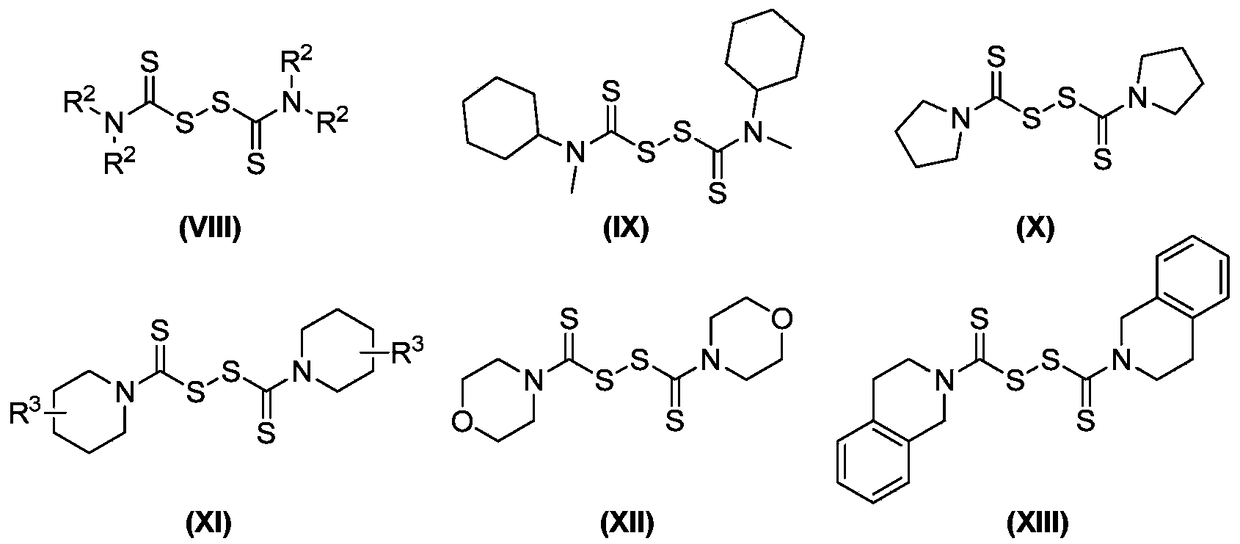

Preparation method of N-dithiocarbamate indole compound

The invention discloses a preparation method of an N-dithiocarbamate indole compound. The preparation method of the N-dithiocarbamate indole compound comprises the step of using potassium tert-butoxide as alkali and an indole compound and a thiuram compound as a substrate to synthesize the N-dithiocarbamate indole compound in DCE or a methylbenzene solvent. According to the preparation method of the N-dithiocarbamate indole compound, the N-dithiocarbamate indole compound is synthesized for the first time by chemically and selectively forming an N-S bond. The preparation method of the N-dithiocarbamate indole compound, disclosed by the invention, has the advantages that reaction raw materials are cheap and easy to obtain; the preparation method is simple; by using the potassium tert-butoxide as the alkali to perform a reaction at room temperature, the reaction time is short, the yield is high and the operation is simple; and the method is suitable for synthesis of different types of N-dithiocarbamate indole compounds. The preparation method of the N-dithiocarbamate indole compound can be used for synthesizing a series of N-dithiocarbamate indole compounds, the synthesized product can be used as an intermediate compound for further constructing complex active compounds; and meanwhile, the compound has great drug activity potential.

Owner:WENZHOU MEDICAL UNIV

Degradable transparent conductive film and production method thereof

InactiveCN101996697AImprove performanceHigh strengthConductive layers on insulating-supportsCable/conductor manufactureAluminium chlorideTransparent conducting film

The invention relates to a degradable transparent conductive film which consists of a carrier film and a conductive film. The innovation point is characterized in that the carrier film is a degradable polyethylene carrier film; and the conductive film is an aluminum oxide transparent conductive film which is evaporated on the surface of the degradable polyethylene carrier film in vacuum. A production method of the degradable transparent conductive film comprises the following steps of: preparing the degradable polyethylene carrier film by using polyethylene and a photosensitive catalyst; preparing the aluminum oxide transparent conductive film by aluminum chloride used as a raw material and evaporating the degradable polyethylene carrier film and the aluminum oxide transparent conductive film in vacuum to prepare the degradable transparent conductive film. In the invention, the transparent conductive film has the prominent advantages of degradation and no pollution, and the production method of the transparent conductive film is simple and easy to operate, and has the advantages of low cost, energy-saving and environment protection.

Owner:TIANJIN JINSHENGYU PLASTIC PROD SCI & TECH CO LTD

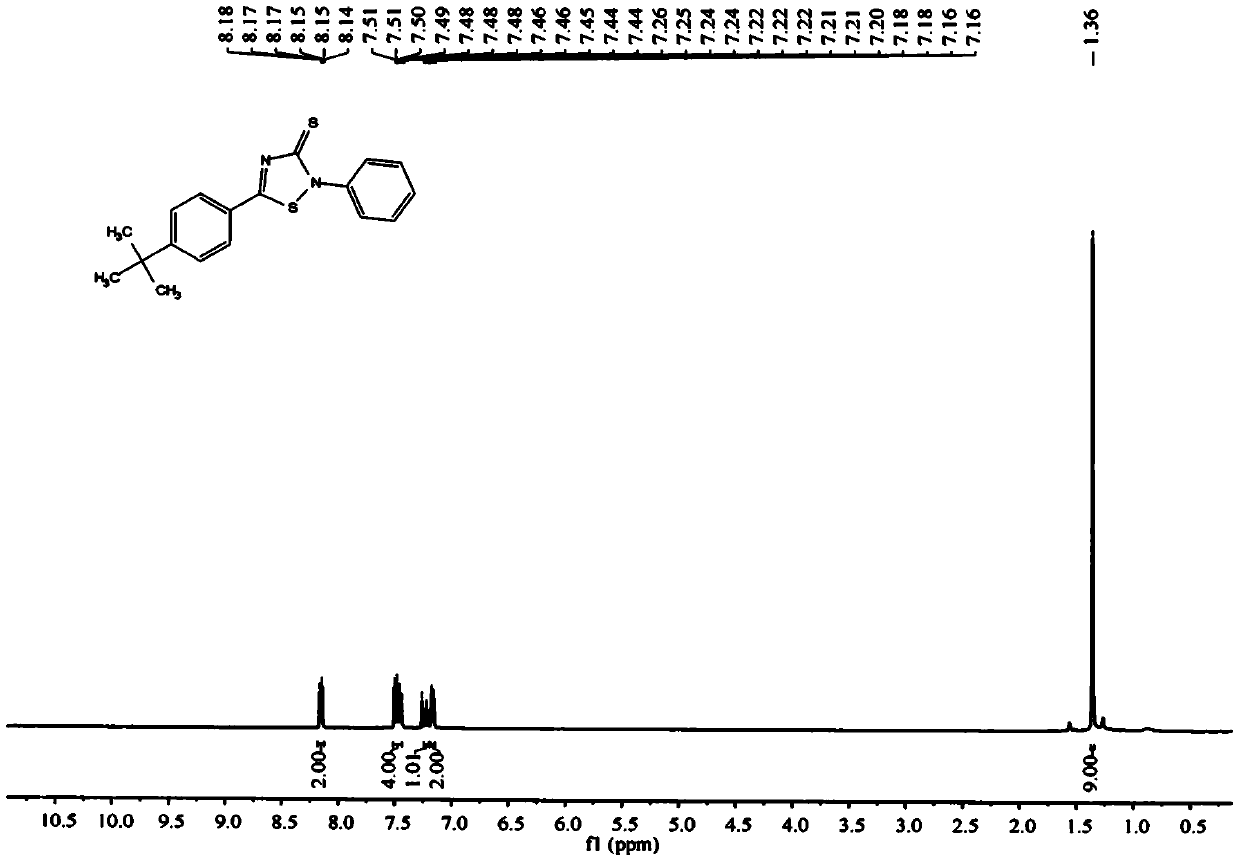

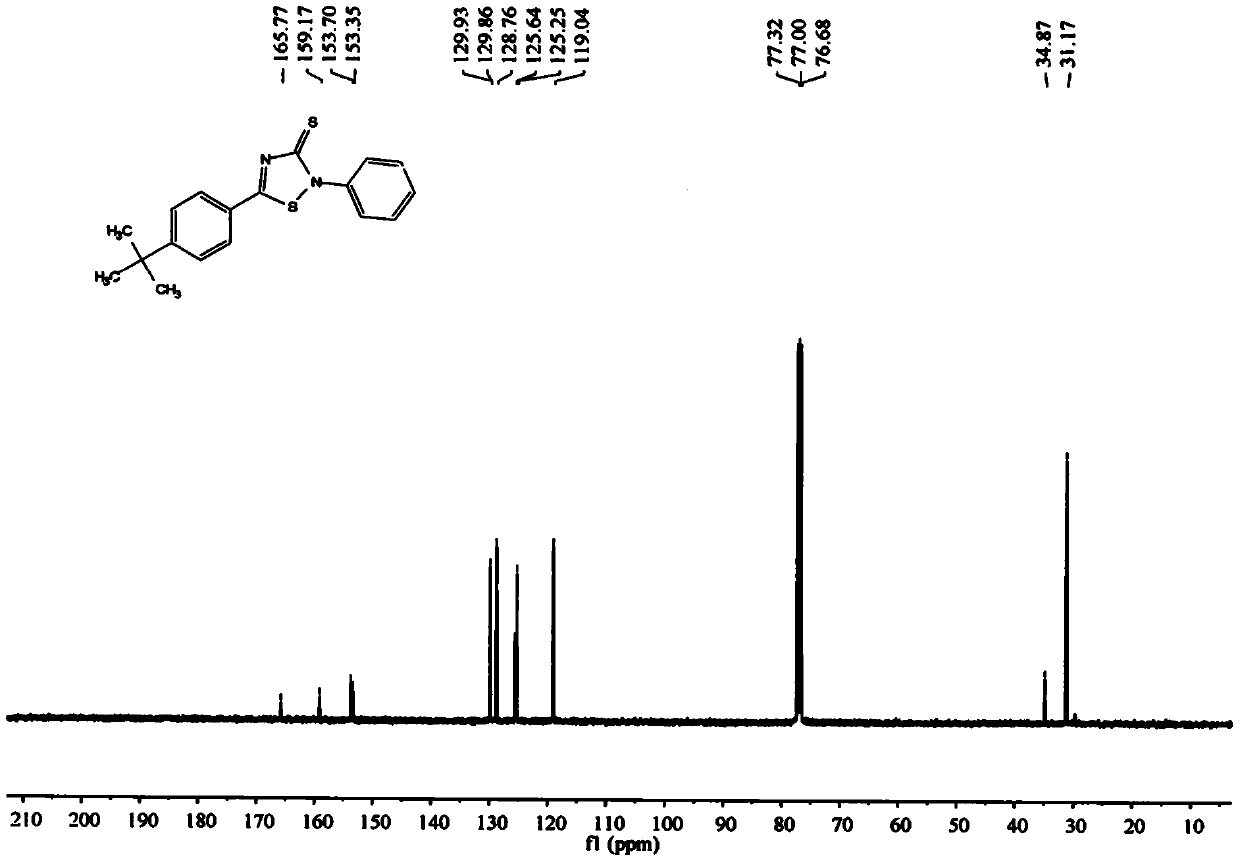

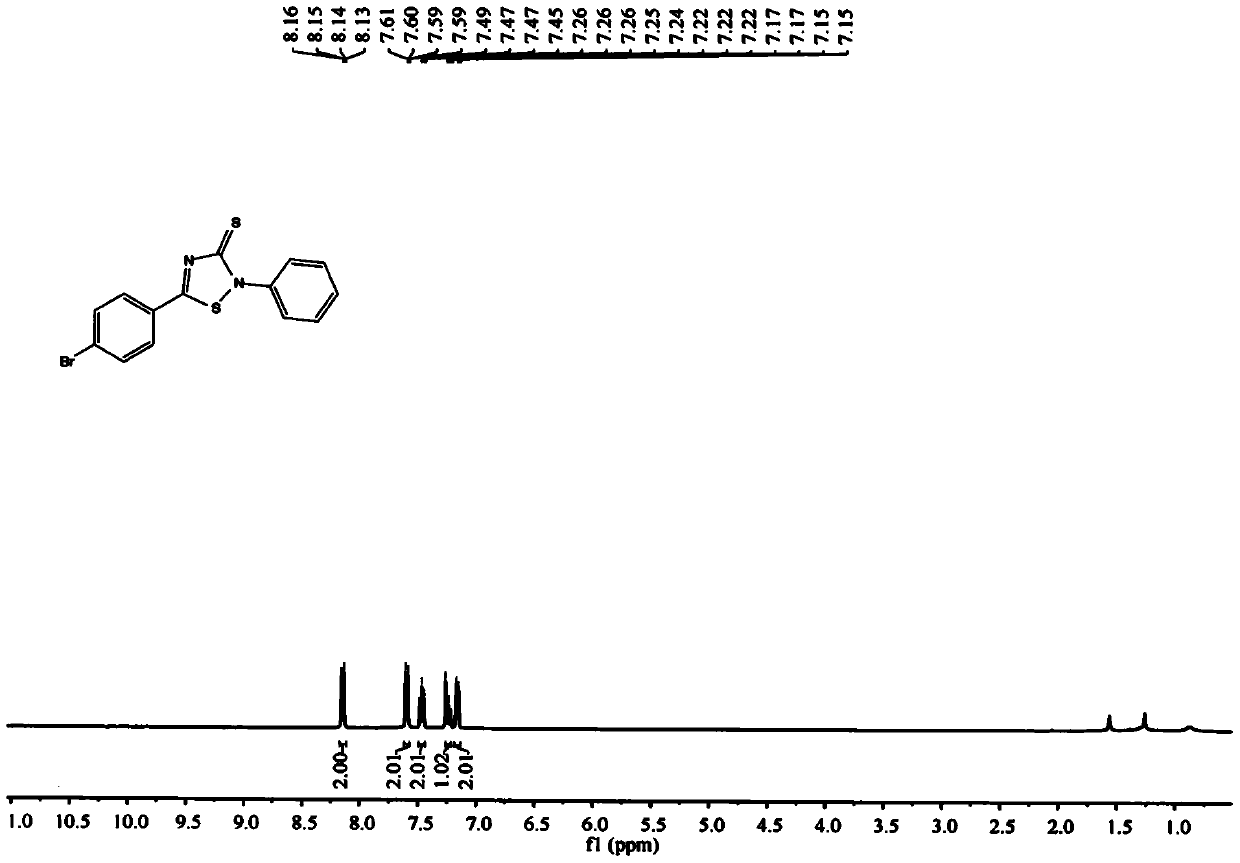

2,5-disubstituted-1,2,4 thiadiazole-3 (2H)-thione, derivatives and synthesis method thereof

PendingCN110204508AWide variety of sourcesReaction raw materials are cheap and easy to obtainOrganic chemistrySynthesis methodsThioketone

The invention mainly relates to a synthesis method of 2,5-disubstituted-1,2,4 thiadiazole-3 (2H)-thione and derivatives thereof. The 2,5-disubstituted-1,2,4 thiadiazole-3 (2H)-thione and the derivatives thereof are prepared from oxime lipid compounds, phenyl isothiocyanate compounds and elemental sulfur by a one-pot method under the promotion of an alkali in an oxygen atmosphere. The product withstable molecular structure and excellent chemical properties and the additional products thereof are prepared. The method does not need transition metal catalysis, and provides a new path for the synthesis of the 2,5-disubstituted-1,2,4 thiadiazole-3 (2H)-thioketone compounds. The method has the characteristics of simple reaction system, mild reaction conditions, less reaction equipment, simple and convenient experimental operation, medium and partial yield and the like.

Owner:XIANGTAN UNIV

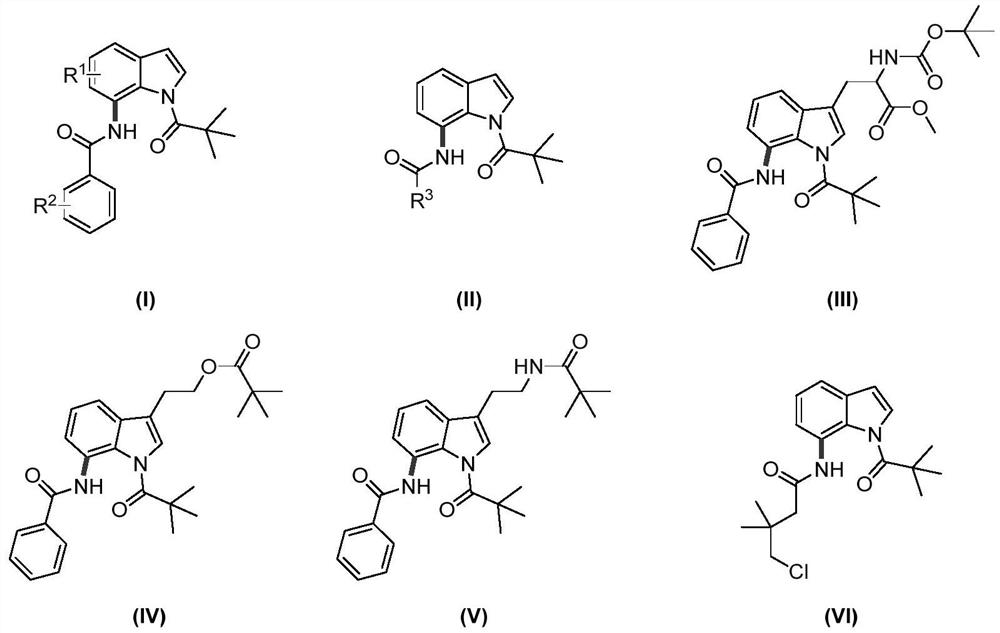

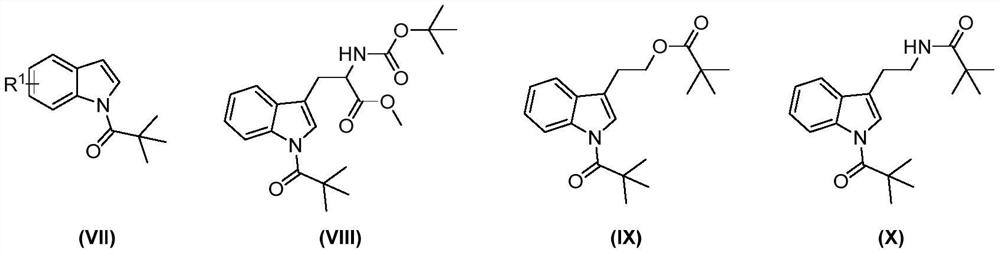

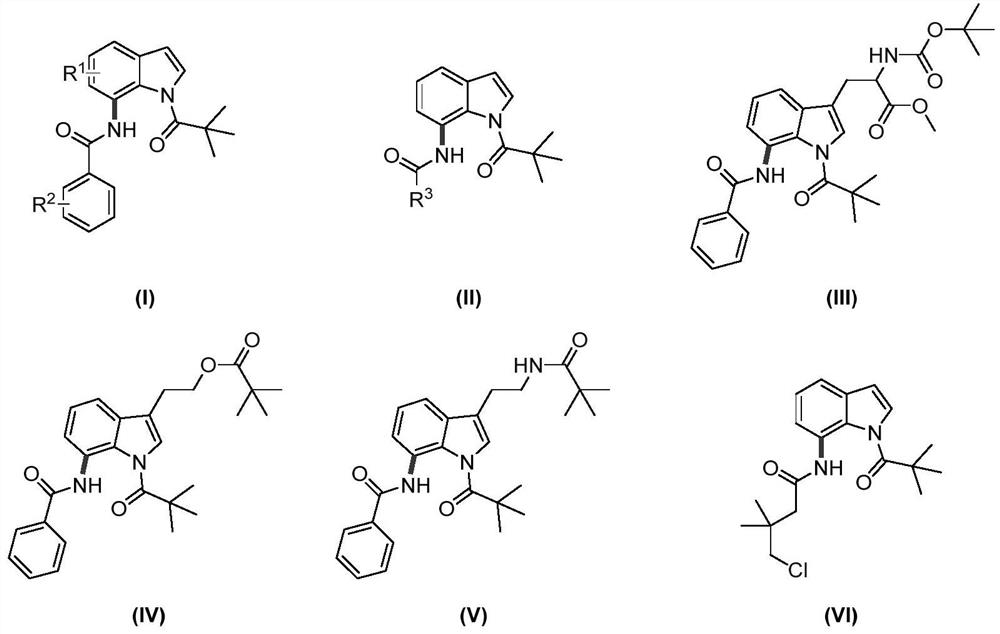

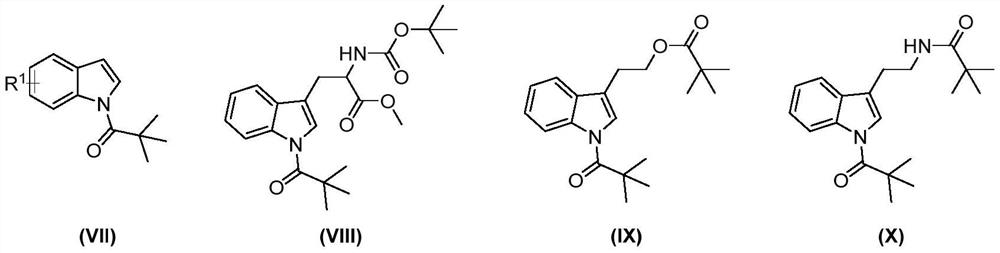

Preparation method of 7-amide indole compound

ActiveCN111892528AReaction raw materials are cheap and easy to obtainInexpensive and easy to operateOrganic chemistryPivalic acidPtru catalyst

The invention discloses a preparation method of a 7-amide indole compound. The method comprises the following steps of: in an HFIP solvent, synthesizing the 7-amide indole compound at room temperatureby using [Ru (p-cymene) Cl2] 2 and AgSbF6 as catalysts, using pivalic acid as an additive and using an indole compound and an oxazolone compound as substrates. The reaction raw materials are cheap and easy to obtain; the preparation method is simple; ruthenium is used as the catalyst, so that the reaction cost is low, the yield is high, the operation is simple; and the method is suitable for synthesizing different types of 7-amide indole compounds. The method disclosed by the invention can be used for synthesizing a series of 7-amide indole compounds, and the synthesized product can be used as an intermediate compound for further constructing a complex active compound; and meanwhile, the compound has great drug activity potential.

Owner:WENZHOU MEDICAL UNIV

Water-soluble monascus red pigment and method for preparing same

InactiveCN108707346AGood light and heat stabilityReaction raw materials are readily availableNatural dyesOrganic solventSodium Glutamate

The invention discloses a water-soluble monascus red pigment and a method for preparing the same. The method includes adding 3-5 kg of purified water into every 1 kg of monascus red pigment powder todilute the monascus red pigment powder, uniformly stirring the monascus red pigment powder and the purified water to obtain liquid, adding L-sodium glutamate or L-sodium aspartate or mixtures of the L-sodium glutamate and the L-sodium aspartate at optional proportions into the liquid, ultrasonically stirring the liquid, the L-sodium glutamate or the L-sodium aspartate or the mixtures, keeping thetemperature of 40-70 DEG C unchanged and carrying out reaction for 3-8 h. The preferable proportion of the L-sodium glutamate and the L-sodium aspartate in the mixtures is 1:1, 50-80 g of the mixturesof the L-sodium glutamate and the L-sodium aspartate are added into the liquid with every 1 kg of the monascus red pigment powder, the preferable usage of the mixtures is 65 g, the preferable temperature to be kept is 55 DEG C, and the preferable reaction time is 5 h. The water-soluble monascus red pigment and the method have the advantages that the method includes simple processes, chemicals such as acid, alkali and organic solvents are omitted, and the water-soluble monascus red pigment and the method are low in production cost and suitable for industrial production; the water-soluble monascus red pigment which is a product is high in purity and wide in application.

Owner:ZAOZHUANG UNIV

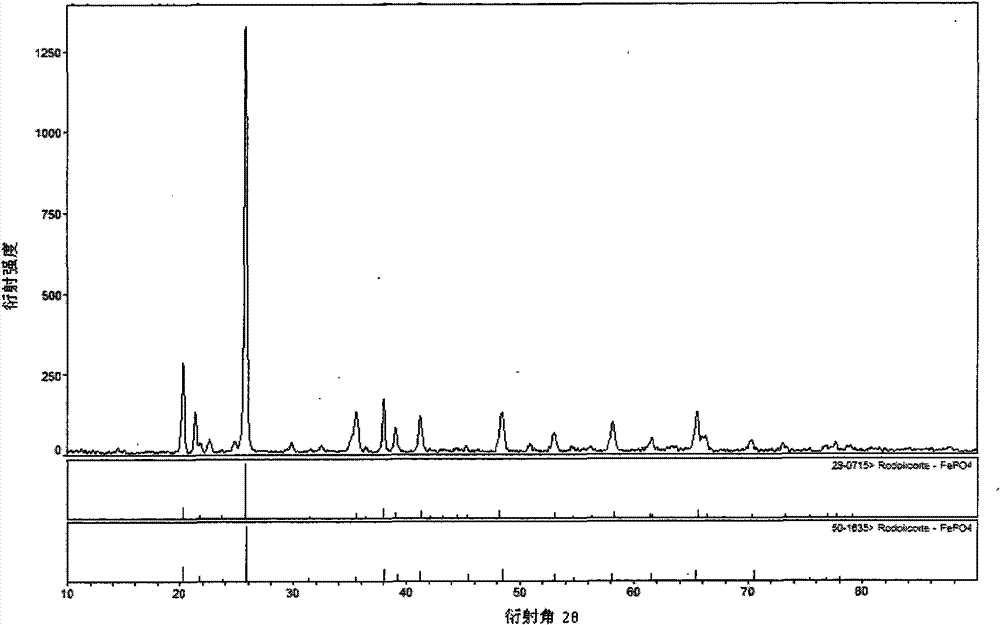

Method for preparing FexPO4 by electrolyzing ferrophosphorus

InactiveCN102051629BOvercome the problem of difficult ratioEliminate consumptionElectrodesChemical industryElectrolysis

Owner:SICHUAN UNIV

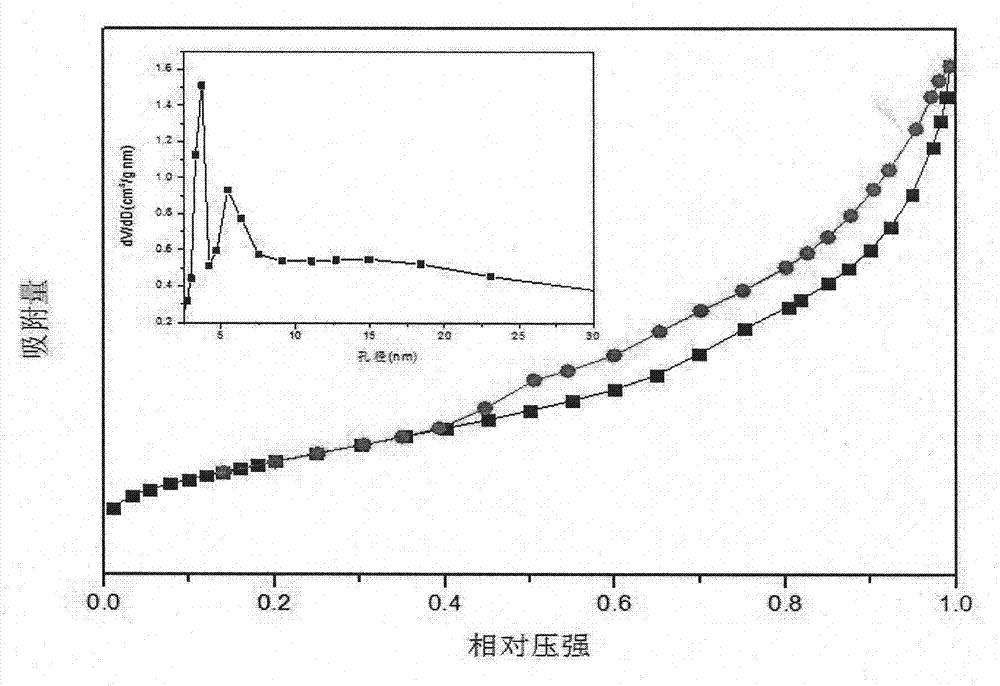

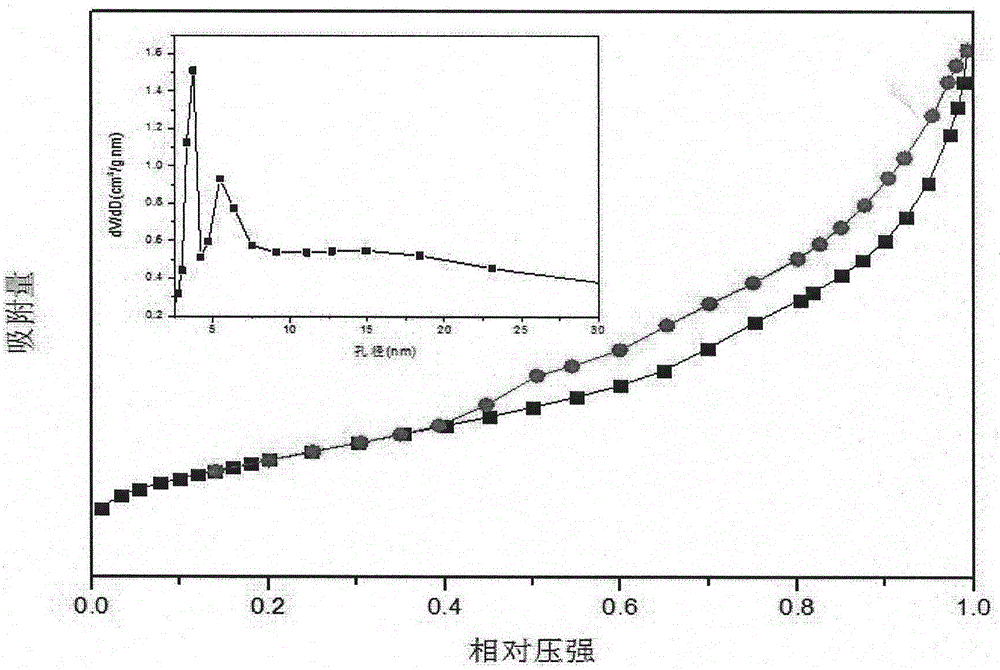

Crystallized mesoporous magnesium silicate powder and preparation method thereof

InactiveCN104495861AThe reaction raw materials are simpleLow costMagnesium silicatesSynthetic magnesium silicateMesoporous silica

The invention discloses crystallized mesoporous magnesium silicate (3MgO.4SiO2.2H2O) powder and a preparation method thereof. The crystallized mesoporous magnesium silicate (3MgO.4SiO2.2H2O) powder is of a two-dimensional hexagonal mesoporous structure, and a mesopore wall is composed of crystalline-state magnesium silicate. The preparation method of the crystallized mesoporous magnesium silicate powder comprises the following steps: by taking C-filled mesoporous silica SBA-15(C@SBA-15) as an auxiliary template and silicon source, MgCl2.6H2O as a magnesium source, and NH4Cl, NH3.H2O and deionzed water as reaction mediums, carrying out hydrothermal reaction at a certain temperature for a certain period of time, so that mesoporous magnesium silicate is obtained, wherein in a hydrothermal reaction process, SiO2 in C@SBA-15 is taken as reactant to participate in reaction, C in C@SBA-15 can be used for supporting the mesopore wall, magnesium silicate generated by reaction coats the surface of C to form a shell layer, and the magnesium silicate shell layer is taken as the mesopore wall; carrying out high-temperature calcining on the hydrothermal reaction product for removing C to form a mesoporous passage so as to finally obtain the crystallized mesoporous magnesium silicate powder. The prepared mesoporous magnesium silicate powder has high degree of order, large aperture and specific surface area, high crystallinity and good stability.

Owner:INNER MONGOLIA UNIVERSITY

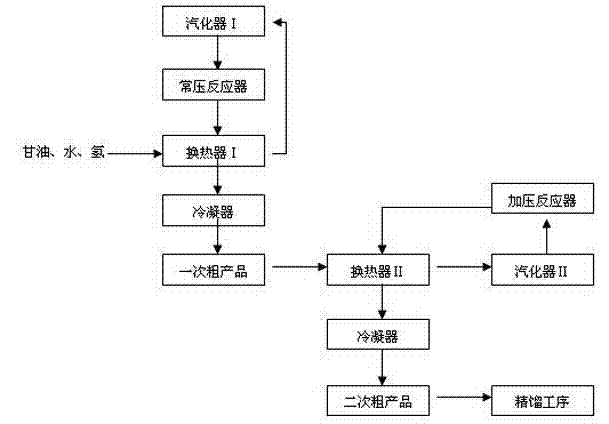

Process for preparing 1,2-propylene glycol from biological glycerol through low-temperature and low-pressure hydrogenation

InactiveCN102399131AAvoid design difficultiesLow investment costOrganic compound preparationHydroxy compound preparationPtru catalystReaction temperature

The invention discloses a new process for preparing 1,2-propylene glycol from biological glycerol through low-temperature and low-pressure hydrogenation. In the method, the biologically prepared glycerol is used as a raw material, Cu-SiO2 catalyst is adopted, and the 1,2-propylene glycol is catalytically prepared under extremely mild reaction conditions in two hydrogenation steps, wherein during reaction of the first step, the glycerol is dehydrated under the action of the catalyst to generate an intermediate product acetol; and during the reaction of the second step, the acetol is hydrogenated under the action of the catalyst to generate the 1,2-propylene glycol. The process has the advantages of easiness and convenience in reaction process, easiness in operation, high controllability, low reaction temperature, low reaction pressure, high target product yield and the like.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

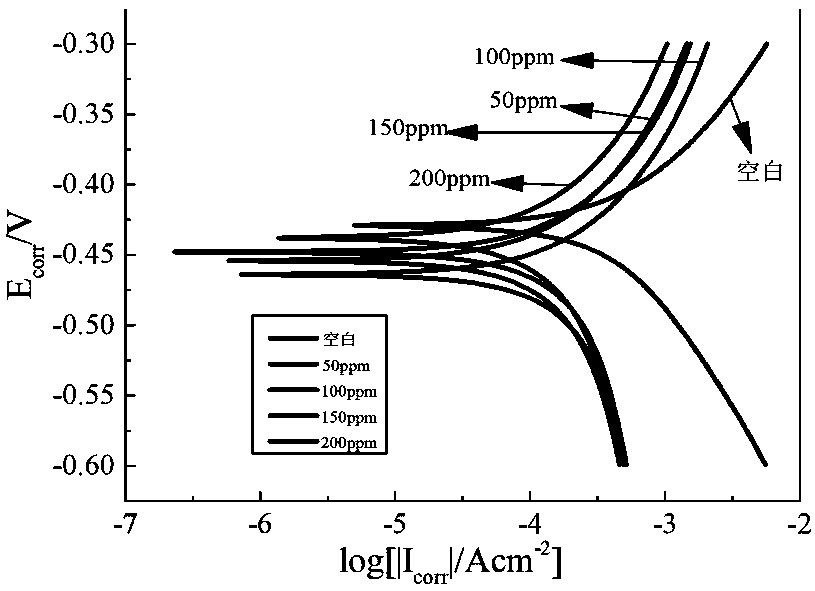

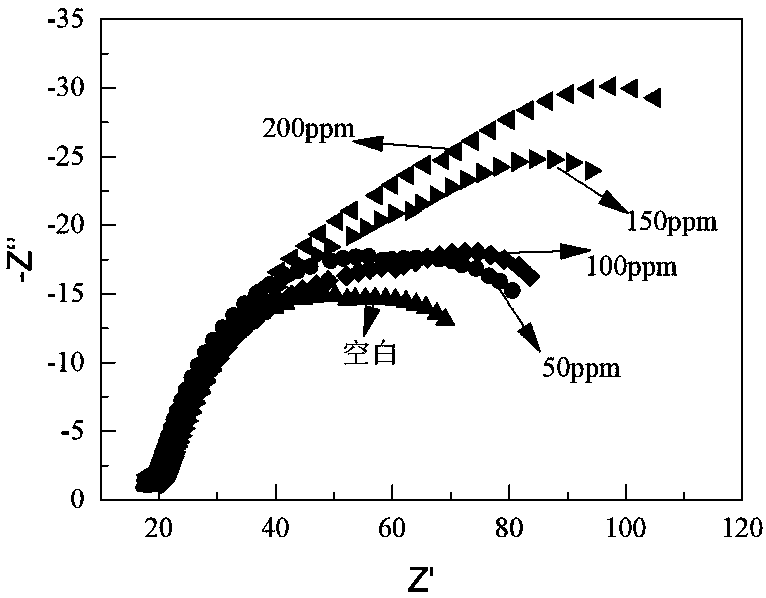

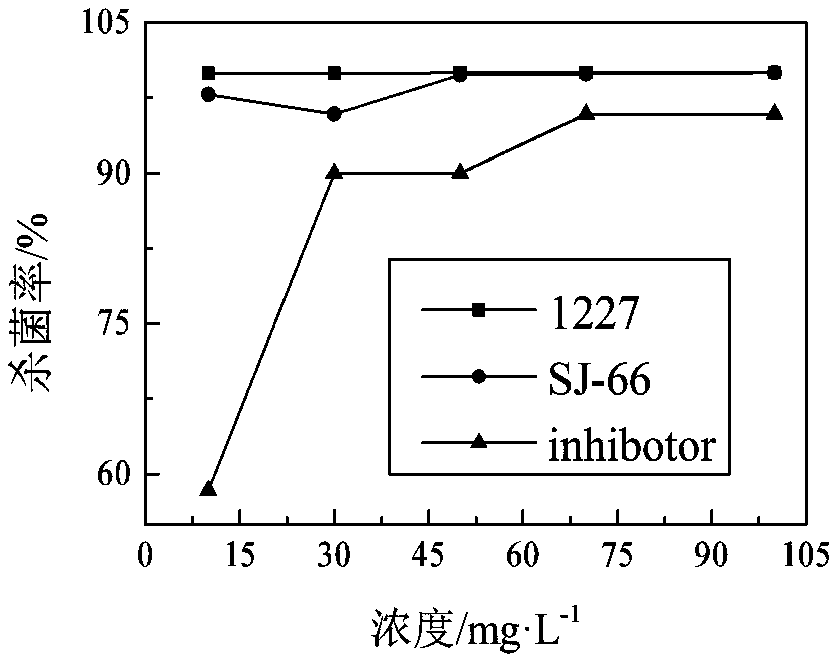

Mannich base quaternary ammonium salt compound as well as preparation method and application thereof

InactiveCN108383740AReduce the inconvenience of compoundingReduce corrosionBiocideOrganic chemistrySteel pipelinePetroleum

The invention provides a Mannich base quaternary ammonium salt compound; the invention also provides a preparation method of the Mannich base quaternary ammonium salt compound; and the invention alsoprovides an application of the Mannich base quaternary ammonium salt compound in corrosion and sterilization of steel pipelines in oil exploitation. The Mannich base quaternary ammonium salt compoundprovided by the invention can reduce inconvenience of compounding of a plurality of corrosion inhibitors and bactericides, has excellent corrosion inhibition performance and certain bactericidal ability when being used as a bactericidal corrosion inhibitor; and the compound has a simple synthetic method, mild reaction conditions, low costs and wide sources of raw materials, and can reduce costs toa certain extent.

Owner:YANGTZE UNIVERSITY

Method for preparing nano strontium titanate by lactic acid adjuvant process

InactiveCN100462332CEasy to getThe reaction raw materials are simpleFrom gel statePolycrystalline material growthStrontium titanateStrontium carbonate

The invention relates to a preparation method of nanometer strontium titanate with lactic acid aid. The invention takes strontium salt and butyl titanate as materials, lactic acid as solvent and inhibitor, and takes a small amount of water to promote hydrolyzing. The procedures of the invention are as follows: Firstly, strontium titanate is dissolved in the lactic acid, and then is added with the solvent of the butyl titanate slowly with violent stirring, and is kept still, thus homogeneous and transparent gel is obtained. The gel is calcineed at a high temperature, thus nanometer strontium titanate power is obtained. The composition components of the invention are less, can be got easily and are environment friendly without pollution. The lactic acid acts as the solvent of the strontium salt and as the inhibitor of the butyl titanate, and can well control the sol-gel process; therefore, the productive rate of the nanometer strontium titanate power prepared by the method is increased. The invention needs only 80 ml of gel for to make 0.1 mol of SrTiO3r. The proposal has a wide application and is suitable for the preparations of nanometer barium titanate and nanometer barium strontium titanate, etc.

Owner:XI AN JIAOTONG UNIV

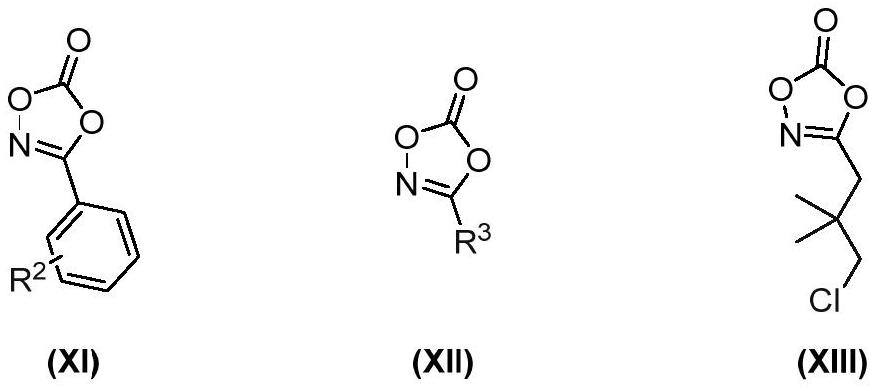

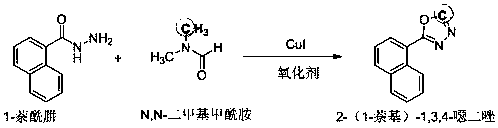

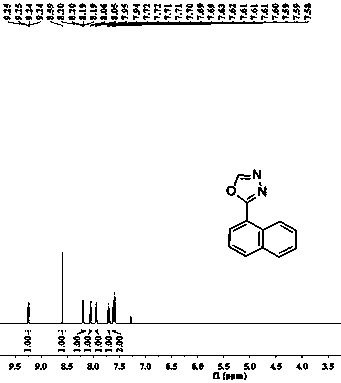

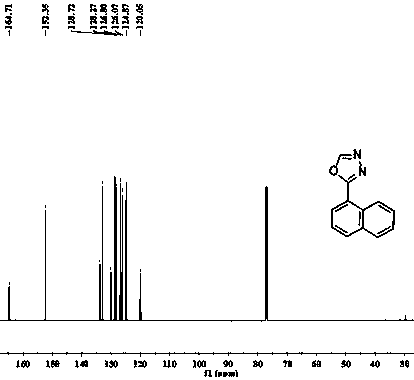

Method for constructing 2-(1-naphthyl)-1,3,4-oxadiazole by one step through DMF as carbon source

InactiveCN109232462AMild reaction conditionsThe reaction raw materials are simpleOrganic chemistryCarbon sourceOxadiazole

The invention discloses a method for constructing 2-(1-naphthyl)-1,3,4-oxadiazole by one step through DMF(N,N-dimethylformamide) as a carbon source. The method is characterized in that 1-naphthhydrazide is used as a reaction raw material, DMF(N,N-dimethylformamide) is used as the carbon source, a carbon cyclization reaction is carried out, and thus 2-(1-naphthyl)-1,3,4-oxadiazole is constructed byone step. According to the method provided by the invention, the synthesis means is novel, the reaction condition is mild, and the development requirement of green chemistry is met.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

A kind of preparation method of 7-amide indole compound

ActiveCN111892528BReaction raw materials are cheap and easy to obtainInexpensive and easy to operateOrganic chemistryPivalic acidPtru catalyst

The invention discloses a preparation method of 7-amide indole compounds, comprising: using [Ru(p-cymene)Cl in HFIP solvent 2 ] 2 and AgSbF 6 As a catalyst, pivalic acid as an additive, with indole compounds and oxazolone compounds as substrates, 7-amide indole compounds were synthesized at room temperature. The reaction raw material of the invention is cheap and easy to obtain, the preparation method is simple, and ruthenium is used as a catalyst, the reaction cost is low, the yield is high, the operation is simple, and it is suitable for the synthesis of different types of 7-amide indole compounds. The method of the invention can be used to synthesize a series of 7-amidoindole compounds, and the synthesized products can not only be used as intermediate compounds, but also be used to further construct complex active compounds; meanwhile, the compounds have great potential for drug activity.

Owner:WENZHOU MEDICAL UNIV

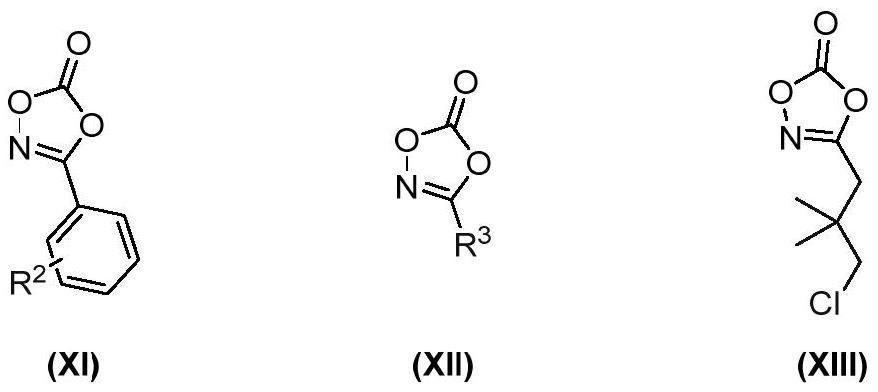

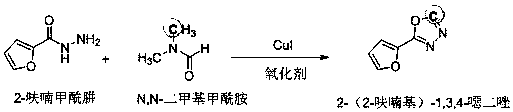

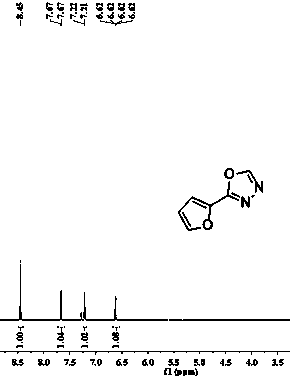

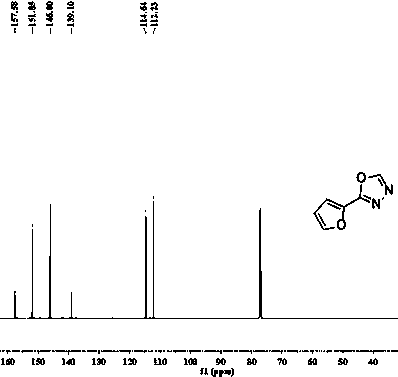

Method for building 2-(2-furyl)-1,3,4-oxadiazole in one step from DMF as carbon source

InactiveCN109206418AMild reaction conditionsThe reaction raw materials are simpleOrganic chemistryDimethyl formamideCarbon source

The invention discloses a method for building 2-(2-furyl)-1,3,4-oxadiazole in one step from DMF (N,N-dimethyl formamide) as a carbon source. The method is characterized in that 2-furoyl hydrazide is taken as a raw material, and the DMF is taken as carbon source to build the 2-(2-furyl)-1,3,4-oxadiazole in one step through a carbon cyclization reaction. The method has the advantages of novel synthesis means and mild reaction conditions, and meets the development requirement of green chemistry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

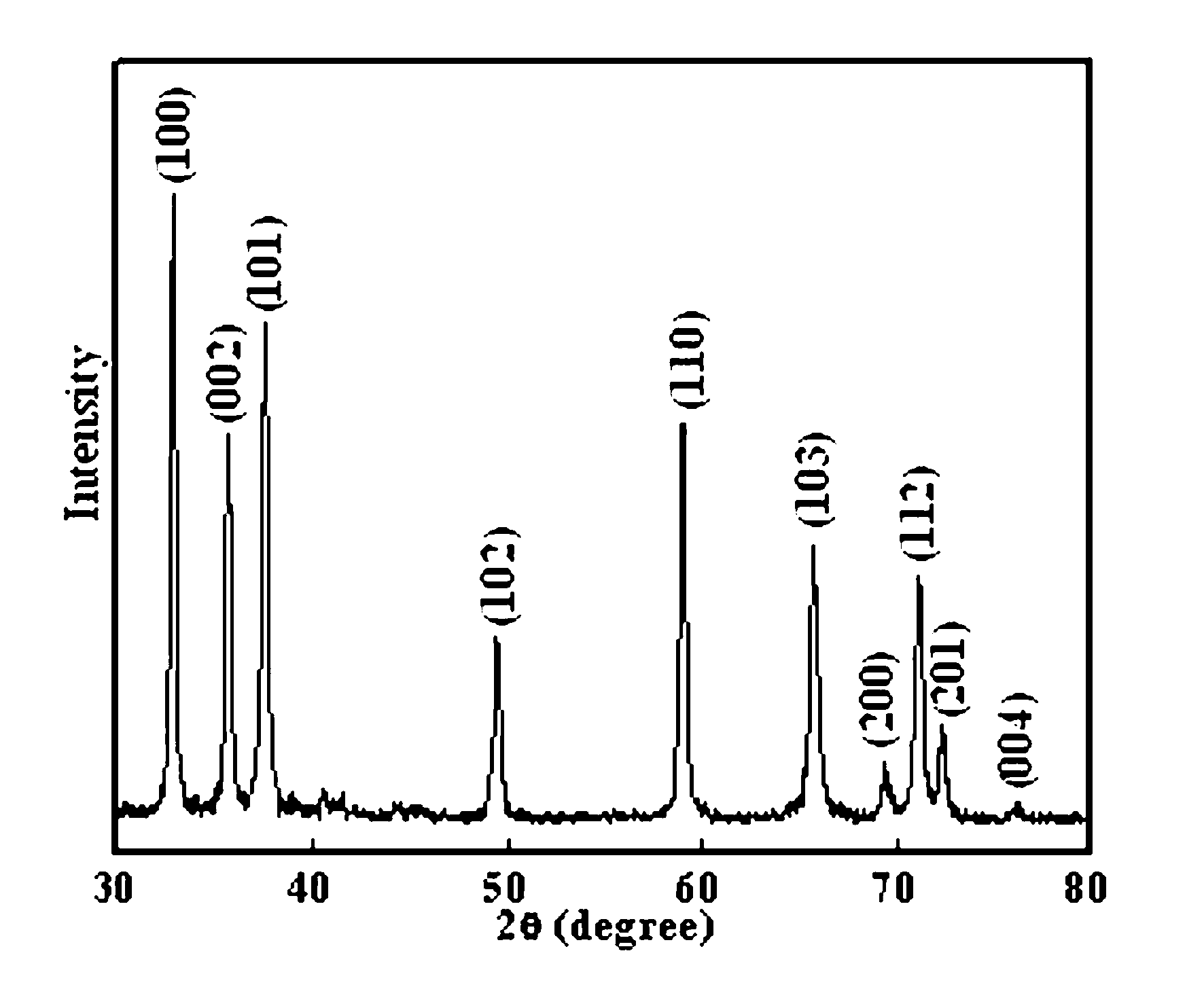

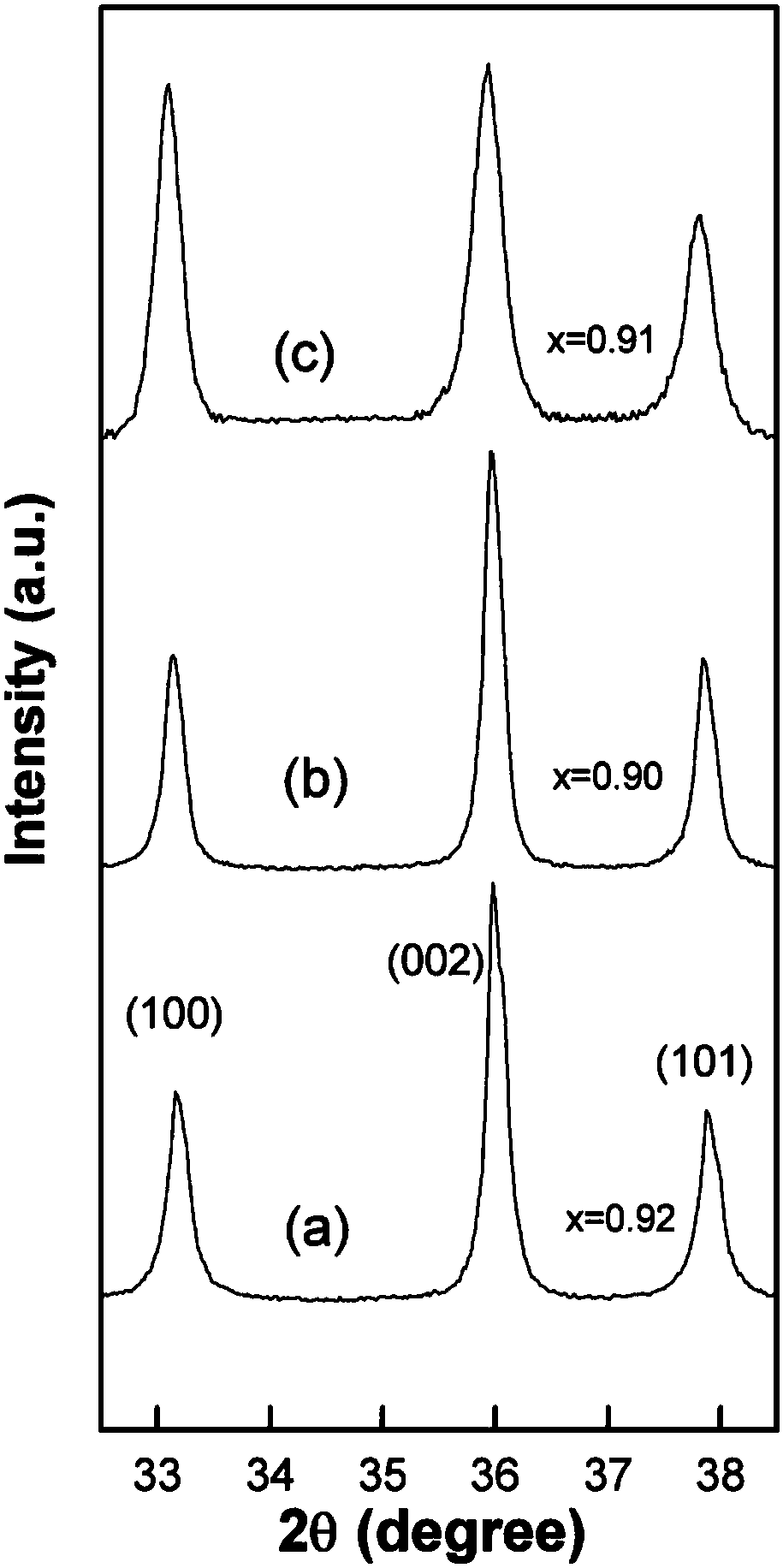

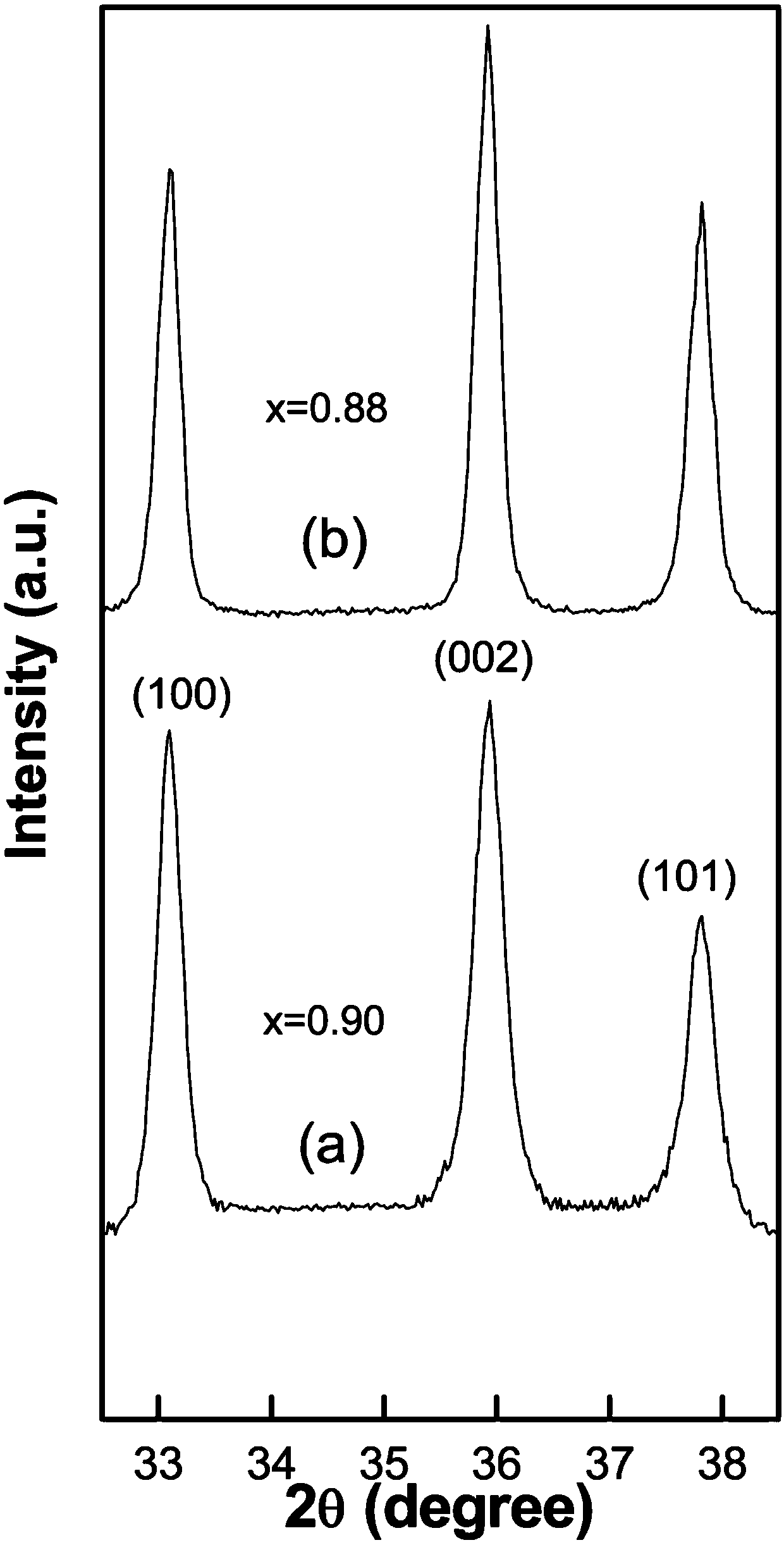

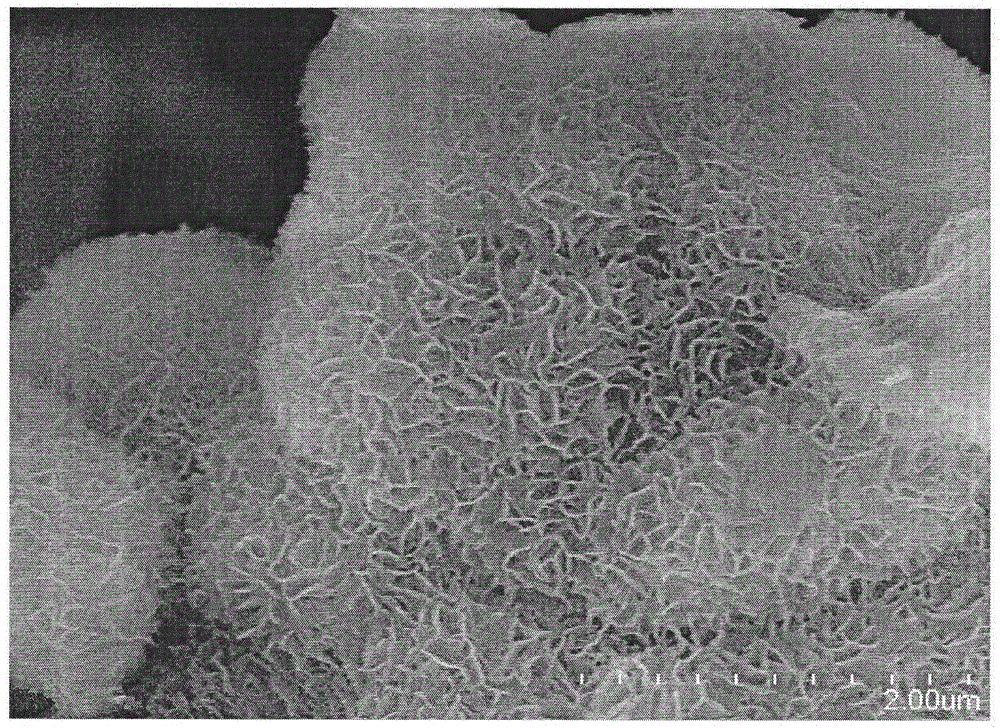

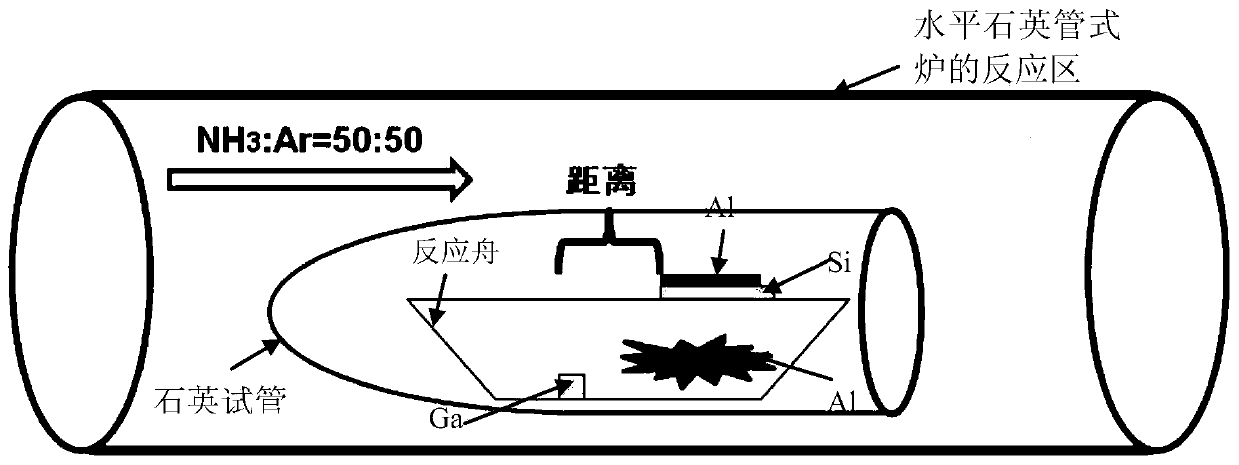

Preparation method of single crystal high Al composition alxga1-xn ternary alloy nanorods

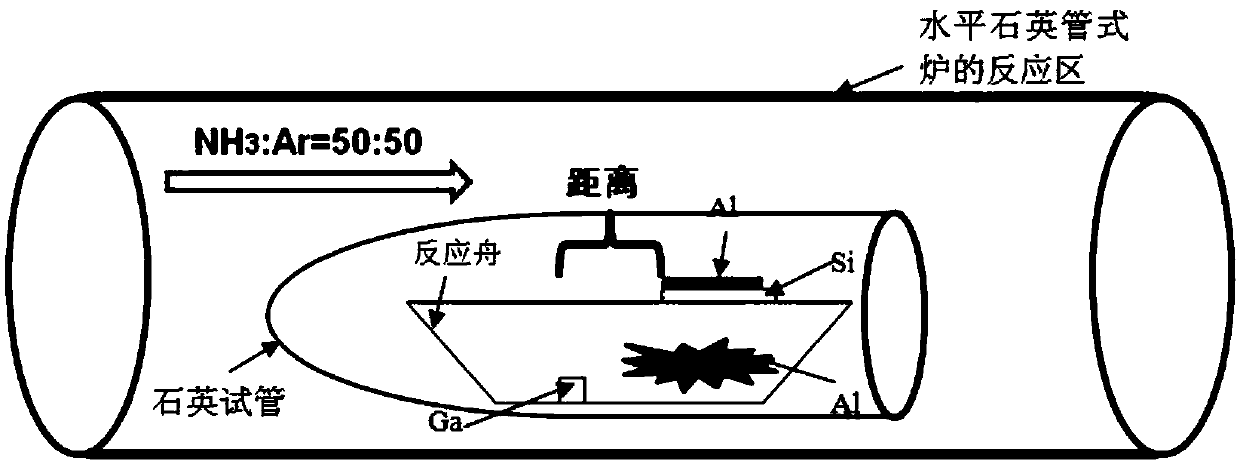

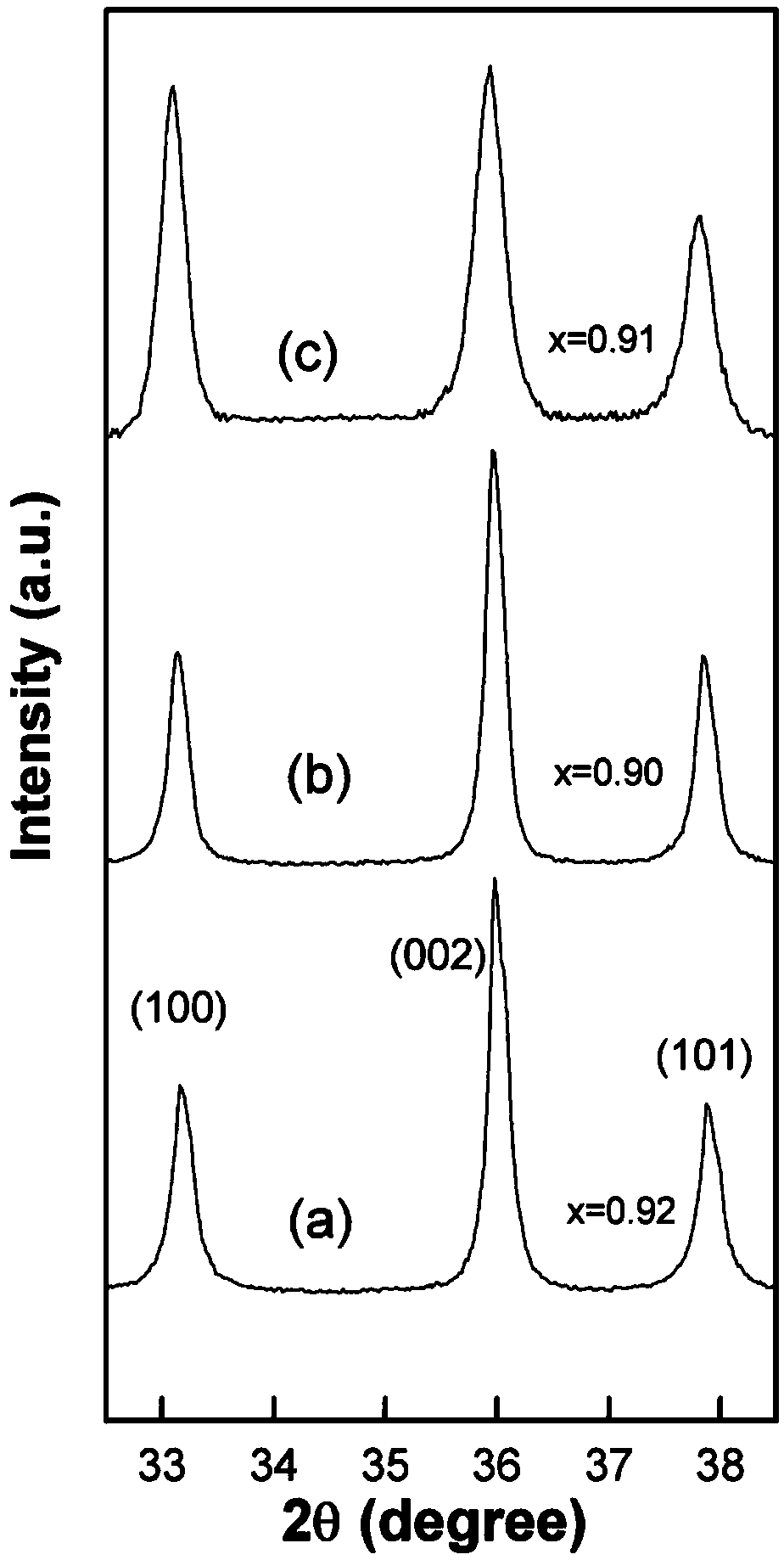

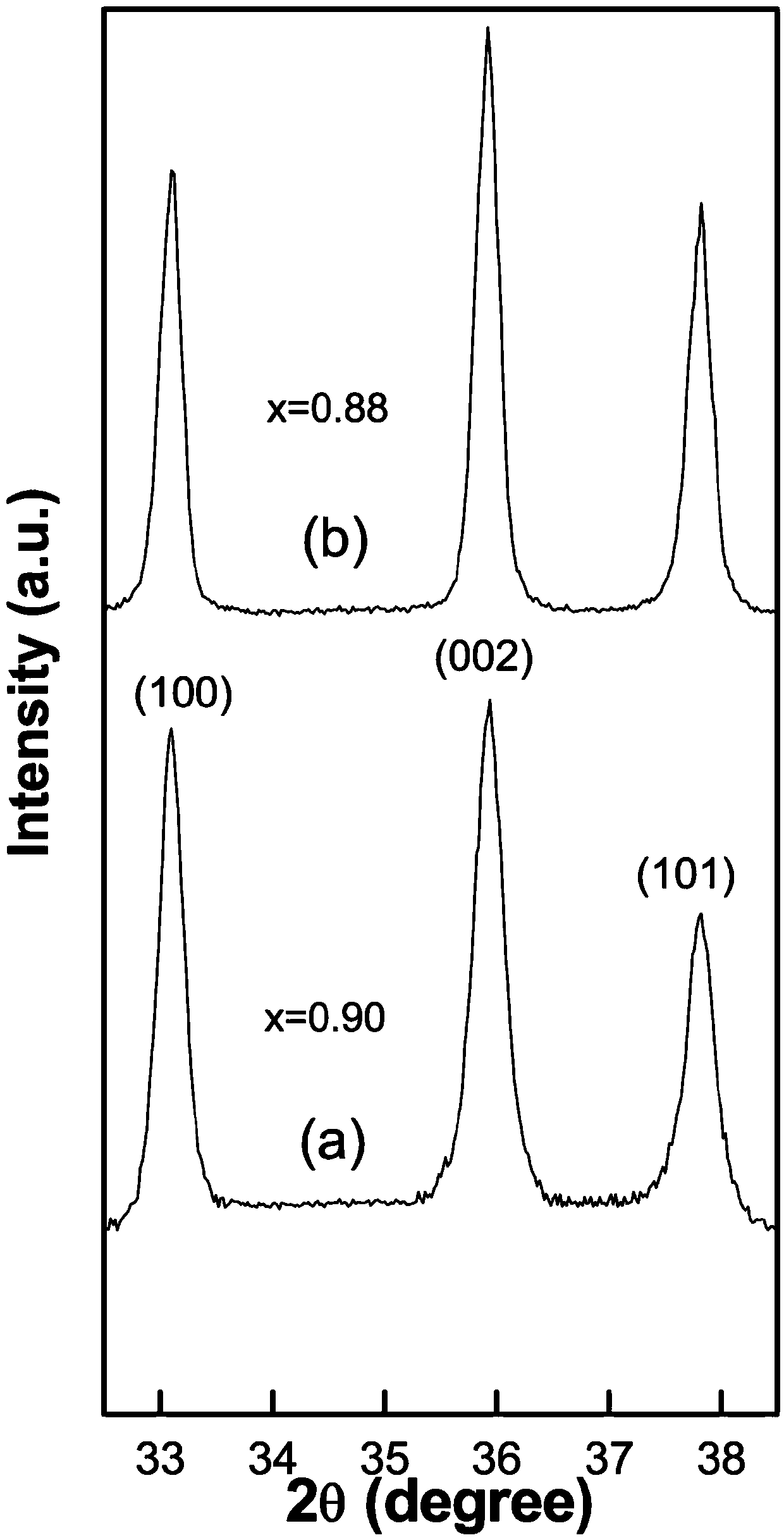

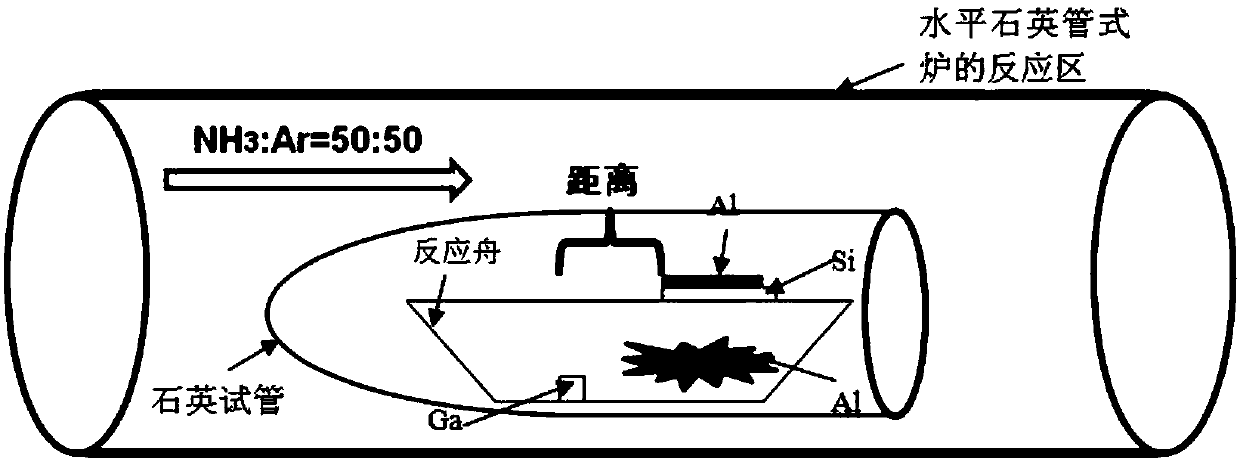

ActiveCN107699951BPromote growthEpitaxial growth achievedPolycrystalline material growthFrom chemically reactive gasesAl powderVacuum pumping

The invention relates to a preparation method of a single crystal high Al component AlxGa1-xN ternary alloy nanorod. The method includes: firstly preparing a silicon substrate with deposited thin layer aluminum powder having a deposition thickness of 0.5-1.0mm, then spreading metal Al powder flatly at one end of a reaction boat, placing the silicon substrate above the powder, dripping Ga liquid tothe other end of the reaction boat, putting a reaction device into a quartz test tube with one opening end, performing sealing and vacuum pumping; when the vacuum degree is less than or equal to 5Pa,introducing argon to fill the whole atmosphere with argon, then adjusting the argon flow rate, conducting heating to 900-1000DEG C, adjusting the argon flow rate to 40-60sccm, at the same time, introducing ammonia with the same flow rate to argon, keeping the state for 1-3h, and conducting furnace cooling, thus obtaining the high Al component single crystal AlxGa1-xN ternary alloy nanorod, wherein the adjustable range x of the Al component is less than or equal to 0.92 and greater than or equal to 0.88. The method has the advantages of simple process, good reproducibility, no phase separation, low production cost, no adding of any catalyst and template, and is easy for industrial popularization and application.

Owner:SHENYANG LIGONG UNIV

Preparation method of single crystal high Al component AlxGa1-xN ternary alloy nanorod

ActiveCN107699951AInhibition of phase separationThe reaction raw materials are simplePolycrystalline material growthFrom chemically reactive gasesArgon flowAluminium

The invention relates to a preparation method of a single crystal high Al component AlxGa1-xN ternary alloy nanorod. The method includes: firstly preparing a silicon substrate with deposited thin layer aluminum powder having a deposition thickness of 0.5-1.0mm, then spreading metal Al powder flatly at one end of a reaction boat, placing the silicon substrate above the powder, dripping Ga liquid tothe other end of the reaction boat, putting a reaction device into a quartz test tube with one opening end, performing sealing and vacuum pumping; when the vacuum degree is less than or equal to 5Pa,introducing argon to fill the whole atmosphere with argon, then adjusting the argon flow rate, conducting heating to 900-1000DEG C, adjusting the argon flow rate to 40-60sccm, at the same time, introducing ammonia with the same flow rate to argon, keeping the state for 1-3h, and conducting furnace cooling, thus obtaining the high Al component single crystal AlxGa1-xN ternary alloy nanorod, wherein the adjustable range x of the Al component is less than or equal to 0.92 and greater than or equal to 0.88. The method has the advantages of simple process, good reproducibility, no phase separation, low production cost, no adding of any catalyst and template, and is easy for industrial popularization and application.

Owner:SHENYANG LIGONG UNIV

Crystallized mesoporous magnesium silicate powder and preparation method thereof

InactiveCN104495861BThe reaction raw materials are simpleLow costMagnesium silicatesSynthetic magnesium silicateMesoporous silica

The invention discloses crystallized mesoporous magnesium silicate (3MgO.4SiO2.2H2O) powder and a preparation method thereof. The crystallized mesoporous magnesium silicate (3MgO.4SiO2.2H2O) powder is of a two-dimensional hexagonal mesoporous structure, and a mesopore wall is composed of crystalline-state magnesium silicate. The preparation method of the crystallized mesoporous magnesium silicate powder comprises the following steps: by taking C-filled mesoporous silica SBA-15(C@SBA-15) as an auxiliary template and silicon source, MgCl2.6H2O as a magnesium source, and NH4Cl, NH3.H2O and deionzed water as reaction mediums, carrying out hydrothermal reaction at a certain temperature for a certain period of time, so that mesoporous magnesium silicate is obtained, wherein in a hydrothermal reaction process, SiO2 in C@SBA-15 is taken as reactant to participate in reaction, C in C@SBA-15 can be used for supporting the mesopore wall, magnesium silicate generated by reaction coats the surface of C to form a shell layer, and the magnesium silicate shell layer is taken as the mesopore wall; carrying out high-temperature calcining on the hydrothermal reaction product for removing C to form a mesoporous passage so as to finally obtain the crystallized mesoporous magnesium silicate powder. The prepared mesoporous magnesium silicate powder has high degree of order, large aperture and specific surface area, high crystallinity and good stability.

Owner:INNER MONGOLIA UNIVERSITY

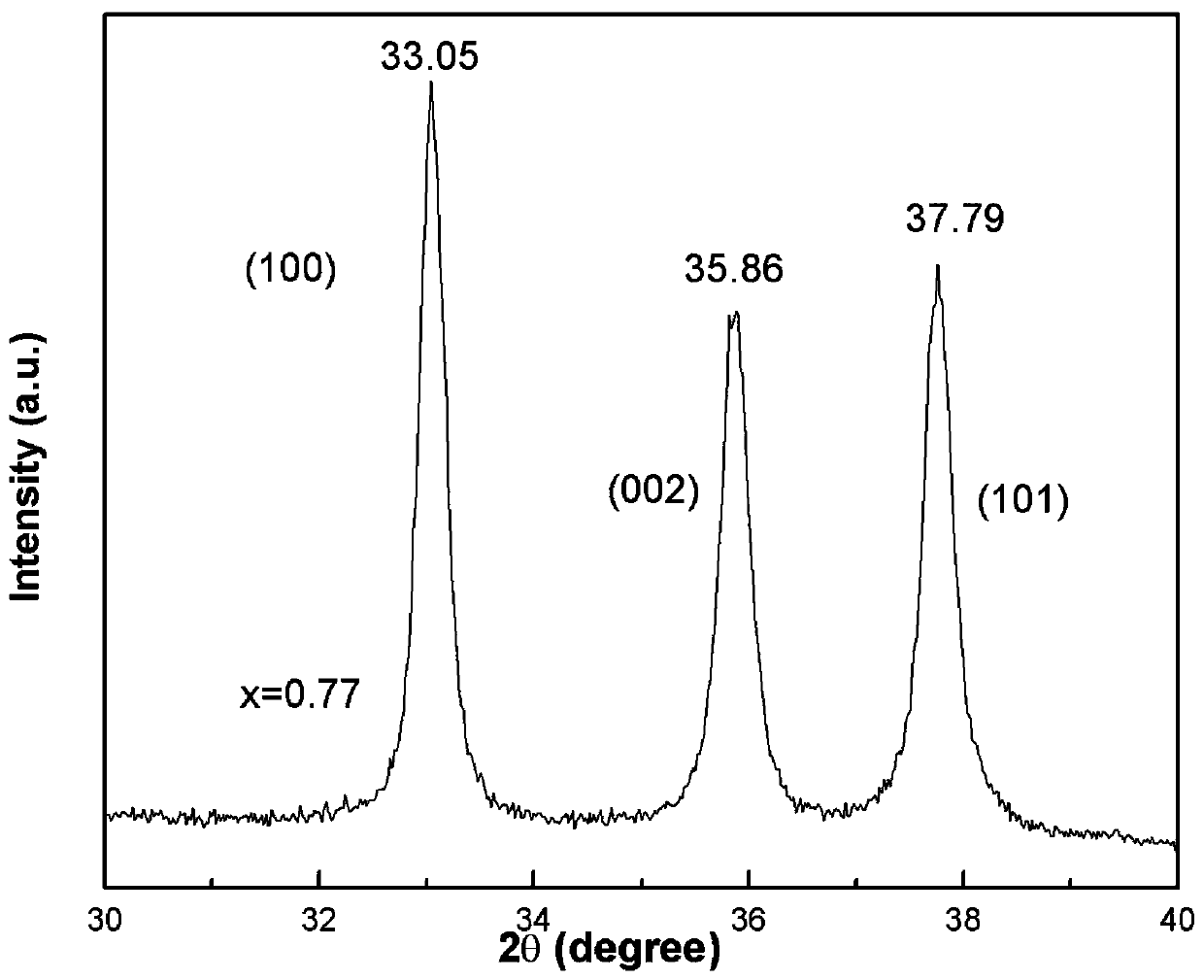

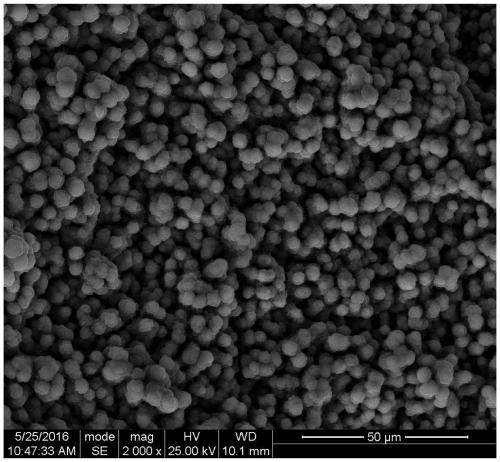

Alxga1-xn ternary alloy microcrystalline ball with high al composition and preparation method thereof

ActiveCN107740189BPromote growthEpitaxial growth achievedPolycrystalline material growthFrom chemically reactive gasesReaction temperatureMaterials science

The invention discloses a high-Al component AlxGa(1-x)N ternary alloy microcrystal sphere and a preparation method thereof and belongs to the technical field of semiconductor alloy material preparation. The microcrystal sphere is an AlxGa(1-x)N ternary alloy crystal of different wurtzite structures of an A1 component, the adjustable range x of the Al component is greater than or equal to 0.77 andless than 1, and the average diameter of the microcrystal sphere is 5.0 [mu]m. The preparation method of the microcrystal sphere comprises the following steps: by taking metal aluminum powder, metal gallium and an ammonia gas as reaction raw materials, vacuuming, introducing argon with the flow of 300-700 sccm, 10-15 minutes later, adjusting the flow of the argon to 40-60sccm, at the same time introducing an ammonia gas of the flow identical to that of the argon, heating to reaction temperature of 950-1000 DEG C within 1-3 hours, and performing vapor deposition method growth, thereby obtainingthe high-Al component AlxGa(1-x)N ternary alloy microcrystal sphere. The method is simple in process, good in repeatability, free of phase separation, low in production cost, free of catalyst or template and easy in industrial popularization and application.

Owner:SHENYANG LIGONG UNIV

A kind of preparation method of 3-selenocoumarin compound

ActiveCN110483460BReaction raw materials are cheap and easy to obtainInexpensive and easy to operateOrganic chemistryBiochemical engineeringCombinatorial chemistry

The invention discloses a preparation method of 3-selenocoumarin compounds, comprising: using PIFA as an oxidant in a DCM solvent, using coumarin compounds and selenoether compounds as substrates, and synthesizing at room temperature 3‑Selenocoumarins. The invention has cheap and easy-to-obtain reaction raw materials, simple preparation method, uses PIFA as an oxidant, has low reaction cost, short reaction time, high yield and simple operation, and is suitable for the synthesis of different types of 3-selenocoumarin compounds. The method of the invention can be used to synthesize a series of 3-selenocoumarin compounds, and the synthesized products can not only be used as intermediate compounds, but also be used to further construct complex active compounds; meanwhile, the compounds have great potential for drug activity.

Owner:WENZHOU MEDICAL UNIV

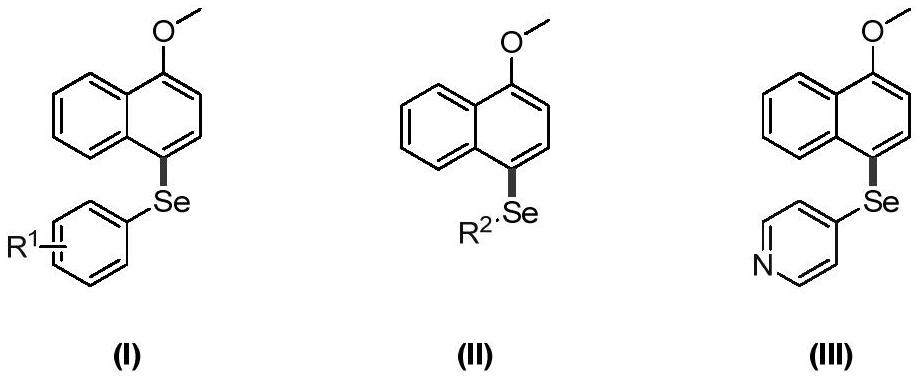

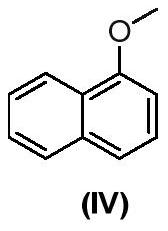

Preparation method of 4-selenomethoxynaphthalene

PendingCN113788774AReaction raw materials are cheap and easy to obtainInexpensive and easy preparation methodOrganic chemistryBiochemical engineeringCombinatorial chemistry

The invention discloses a preparation method of a 4-selenomethoxynaphthalene compound, which comprises the following step: in a DCM solvent, synthesizing the 4-selenomethoxynaphthalene at room temperature by using PIFA as an oxidizing agent and 1-methoxynaphthalene and a diselenide compound as substrates. The reaction raw materials are cheap and easy to obtain, the preparation method is simple, the PIFA serves as the oxidizing agent, the reaction cost is low, the reaction time is short, the yield is high, operation is easy, and the method is suitable for synthesis of different types of 4-selenomethoxynaphthalene compounds. The method disclosed by the invention can be used for synthesizing a series of 4-selenomethoxynaphthalene, and the synthesized product not only can be used as an intermediate compound, but also can be used for further constructing a complex active compound; and meanwhile, the compound has great pharmaceutical activity potential.

Owner:WENZHOU MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com