Preparation method of single crystal high Al component AlxGa1-xN ternary alloy nanorod

A ternary alloy and nanorod technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of spontaneous phase separation, unsuitable for commercial development, high cost, etc., to achieve the suppression of phase separation, Simple preparation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

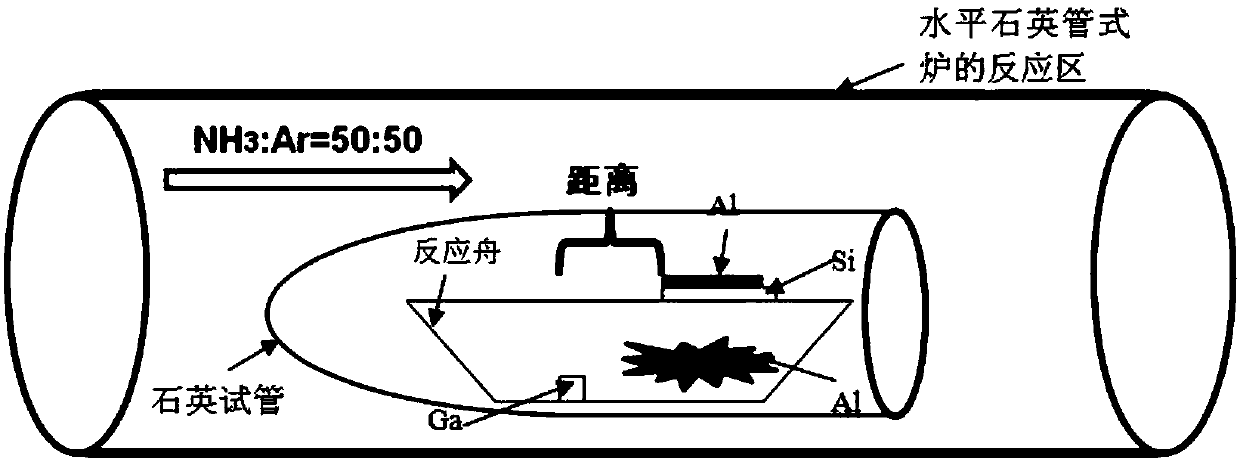

[0051] A single crystal high Al composition Al x Ga 1-x The preparation method of N ternary alloy nanorods comprises the following steps:

[0052] Step 1, pre-deposition thin layer of aluminum powder

[0053] (1) Ultrasonic treatment is carried out to the silicon substrate with deionized water, and after cleaning, the silicon substrate after ultrasonic is obtained;

[0054] Add aluminum powder with a purity of 99.999 and an average particle size of 5 μm into ethanol, and perform ultrasonic vibration for 20 minutes. When the aluminum powder is uniformly dispersed, the ultrasonically mixed aluminum powder is obtained;

[0055] (2) Put the ultrasonicated silicon substrate into the ultrasonicated aluminum powder mixture, and air-dry naturally to obtain a silicon substrate with a thin layer of aluminum powder deposited; the deposition thickness of the thin layer of aluminum powder is 0.5 mm.

[0056] Step 2, preparation preparation

Embodiment 2

[0070] A single crystal high Al composition Al x Ga 1-x The preparation method of N ternary alloy nanorods is the same as in Example 1, the difference is that step 4, heating

[0071] (1) Under the protection of argon, the reaction system is heated with a heating rate of 30°C / min. When the furnace temperature of the reaction system reaches the set temperature of 950°C, the argon flow rate is adjusted to 50 sccm, and at the same time, the flow rate is Be the ammonia gas of 50 sccm, after keeping 2h, stop heating;

[0072] (2) Cooling with the furnace, when the temperature drops to 700°C, turn off the flow of ammonia gas, continue to feed argon to ensure the argon atmosphere, and cool to room temperature with the furnace;

[0073] (3) After complete cooling, take out the reaction device, and the off-white substance deposited on the surface of the thin-layer aluminum powder silicon substrate is Al x Ga 1-x N ternary alloy nanorods.

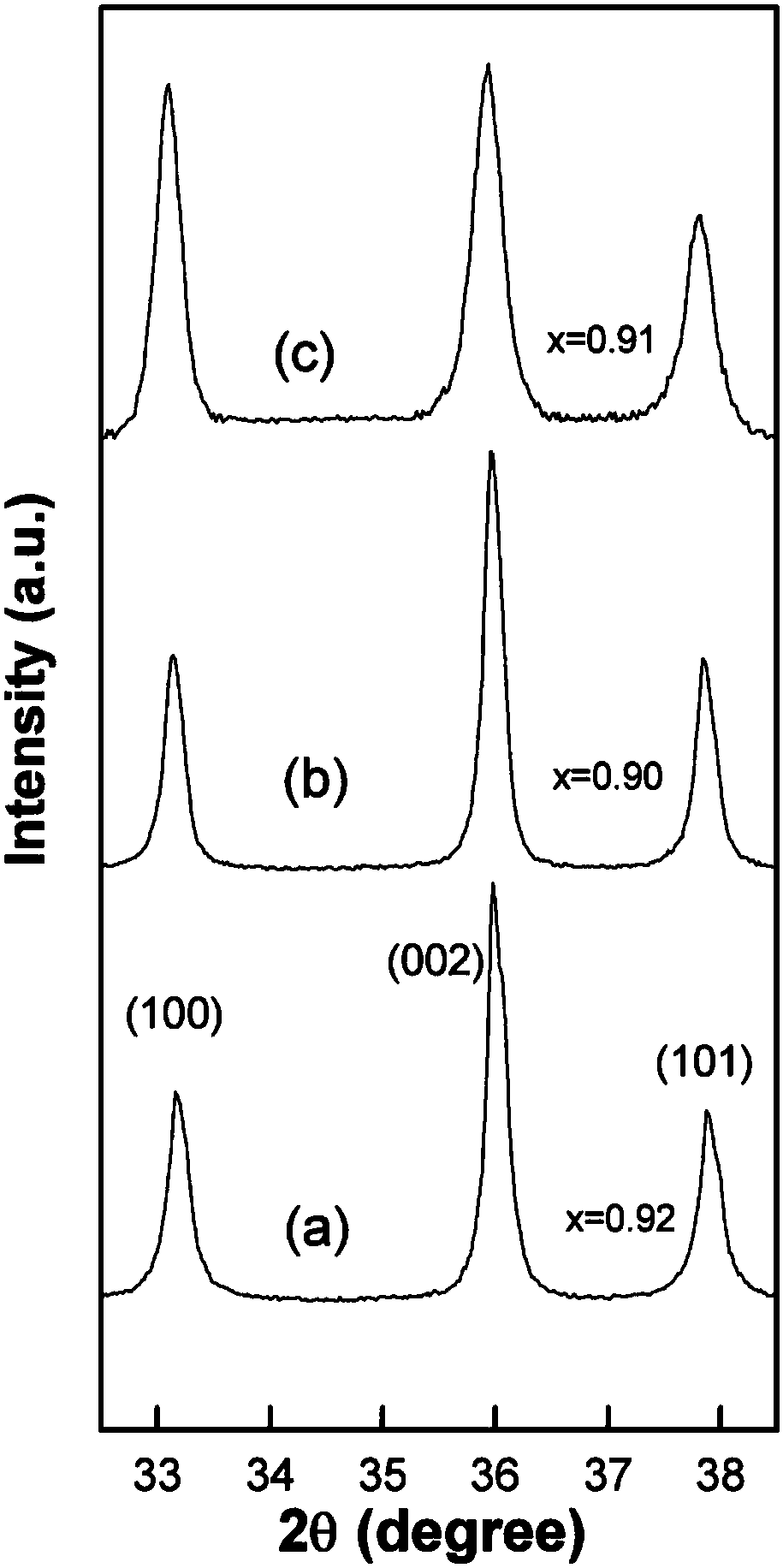

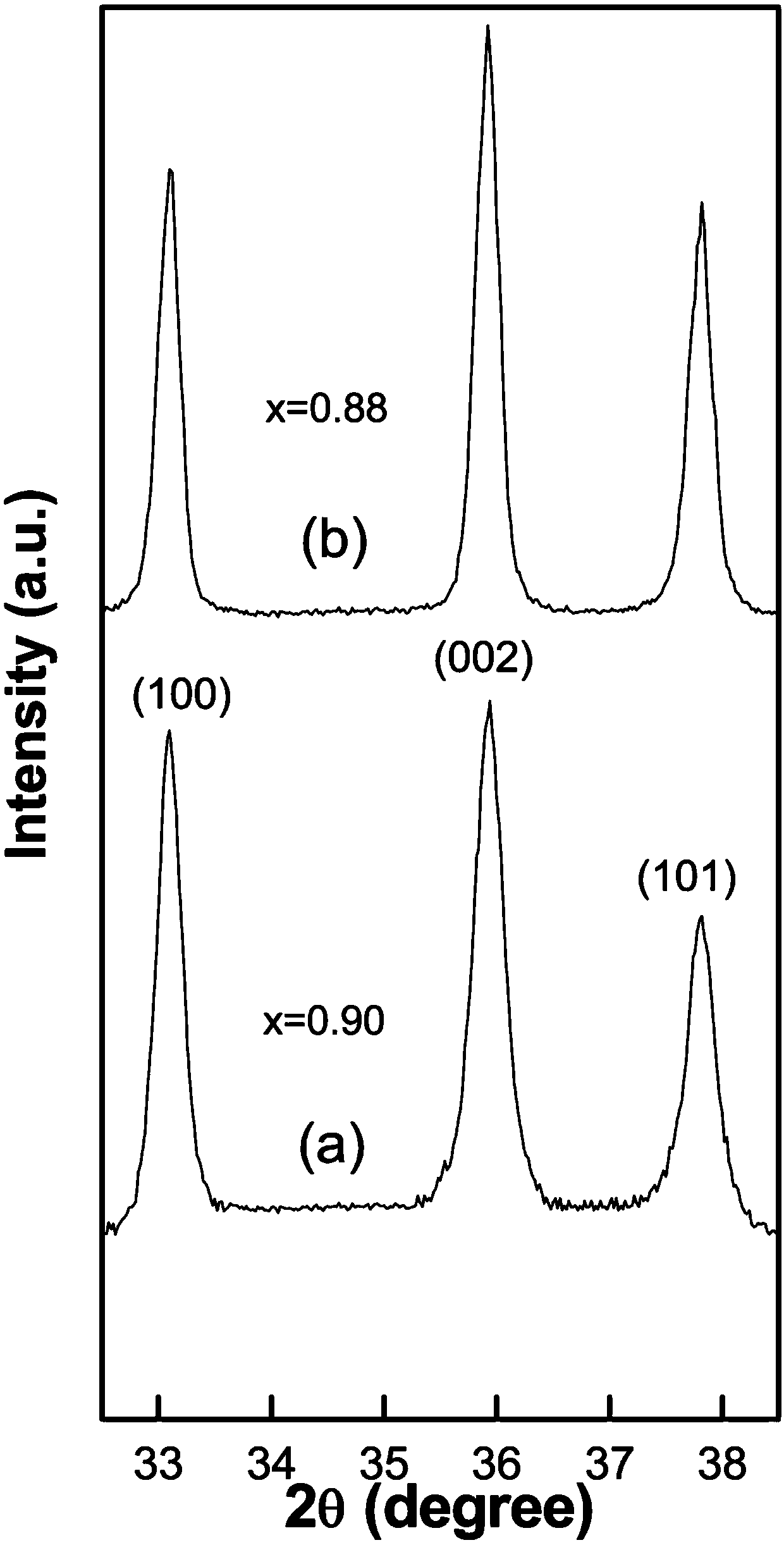

[0074] Prepared Al x Ga 1-x N ternary a...

Embodiment 3

[0076] A single crystal high Al composition Al x Ga 1-x The preparation method of N ternary alloy nanorods is the same as in Example 1, the difference is that,

[0077] Step 4, heating

[0078] (1) Under the protection of argon, the reaction system is heated at a rate of 30°C / min. When the furnace temperature of the reaction system reaches the set temperature of 1000°C, the argon flow rate is adjusted to 50 sccm, and at the same time, the flow rate is Be the ammonia gas of 50 sccm, after keeping 2h, stop heating;

[0079] (2) Cooling with the furnace, when the temperature drops to 700°C, turn off the flow of ammonia gas, continue to feed argon to ensure the argon atmosphere, and cool to room temperature with the furnace;

[0080] (3) After complete cooling, take out the reaction device, and the off-white substance deposited on the surface of the thin-layer aluminum powder silicon substrate is Al x Ga 1-x N ternary alloy nanorods.

[0081] Prepared Al x Ga 1-x N ternary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com