Methanol gasoline cosolvent

A methanol gasoline and co-solvent technology, applied in the gasoline field, can solve the problems of poor cold start effect, poor co-solvent effect, insufficient combustion, etc., and achieve the effects of lowering the service temperature, promoting the dispersion performance, and reducing the service performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

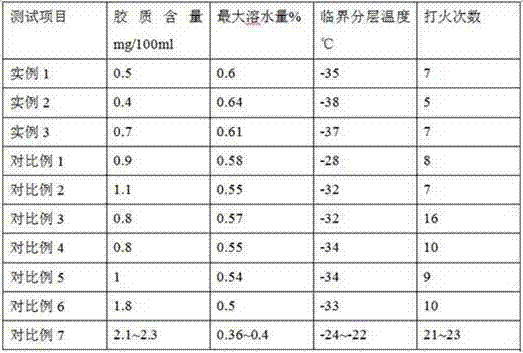

Examples

preparation example Construction

[0016] The preparation method of adding liquid comprises the steps:

[0017] (1) According to the mass ratio of 1:3:4~6, take beeswax, peeled grapes and water and put them into a grinder for 50 minutes at 800r / min, collect the crushed mixture, and take 70~80 parts by weight Crush the mixture, 40~45 parts of yeast extract, 15~20 parts of fatty acid methyl ester, 13~15 parts of lysine and 3~5 parts of sodium chloride, mix well, sterilize and get the nutrient solution;

[0018] (2) According to the mass ratio of 6:1, put the nutrient solution and bacterial powder into the fermentation tank, set the temperature at 32~40℃, stir and ferment at 150r / min for 2~4 days, collect the fermentation mixture, centrifuge and collect supernatant;

[0019] (3) Ultrasonic vibration of the supernatant and mixed solvent at a volume ratio of 1:3, standing for stratification, removing the water phase, distilling the remaining liquid, recovering the mixed solution, collecting the residue, and distill...

Embodiment 1

[0025] The preparation method of adding liquid comprises the steps:

[0026] (1) According to the mass ratio of 1:3:4, take beeswax, peeled grapes and water and put them into a pulverizer for 50 minutes at 800r / min, collect the pulverized mixture, and take 70 parts of the pulverized mixture, 40 parts by weight 1 part of yeast extract, 15 parts of fatty acid methyl ester, 13 parts of lysine and 3 parts of sodium chloride, mix well, sterilize, and obtain the nutrient solution;

[0027] (2) According to the mass ratio of 6:1, put the nutrient solution and bacterial powder into the fermentation tank, set the temperature at 32°C, stir and ferment at 150r / min for 2 days, collect the fermentation mixture, centrifuge and collect the supernatant;

[0028] (3) Ultrasonic vibration of the supernatant and mixed solvent at a volume ratio of 1:3, standing for stratification, removing the water phase, distilling the remaining liquid, recovering the mixed solution, collecting the residue, and...

Embodiment 2

[0034] The preparation method of adding liquid comprises the steps:

[0035] (1) According to the mass ratio of 1:3:6, take beeswax, peeled grapes and water and put them into a pulverizer for 50 minutes at 800r / min, collect the pulverized mixture, and take 80 parts of the pulverized mixture, 45 parts by weight 1 part of yeast extract, 20 parts of fatty acid methyl ester, 15 parts of lysine and 5 parts of sodium chloride, mix well, sterilize, and obtain the nutrient solution;

[0036] (2) According to the mass ratio of 6:1, put the nutrient solution and bacterial powder into the fermentation tank, set the temperature at 40°C, stir and ferment at 150r / min for 4 days, collect the fermentation mixture, centrifuge and collect the supernatant;

[0037] (3) Ultrasonic vibration of the supernatant and mixed solvent at a volume ratio of 1:3, standing for stratification, removing the water phase, distilling the remaining liquid, recovering the mixed solution, collecting the residue, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com