Patents

Literature

64results about How to "Improve dispersion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based expandable fireproof steel structure coating and preparation method

ActiveCN103045037AStrong weather resistanceImprove dispersion performanceFireproof paintsAcid polymer adhesivesEmulsionBiomass

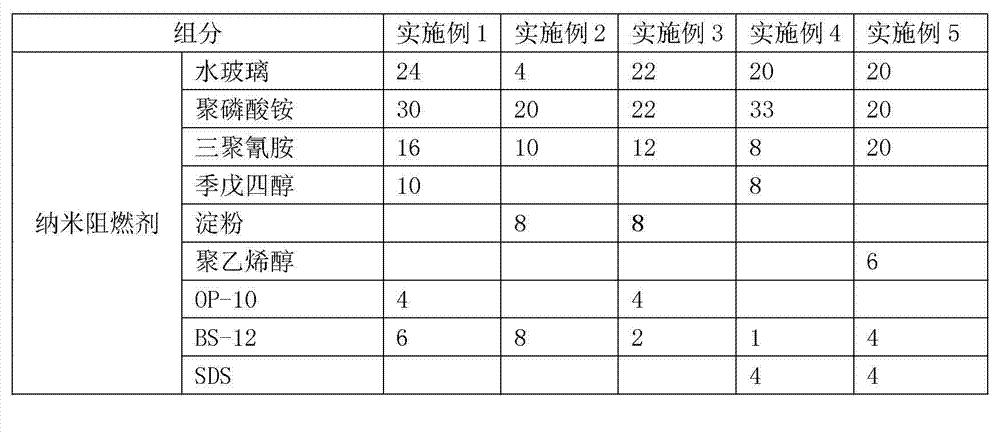

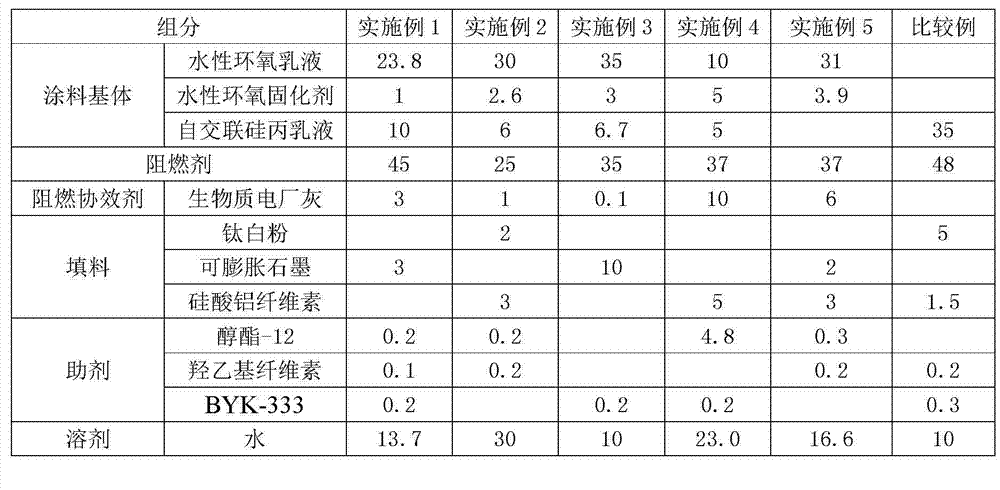

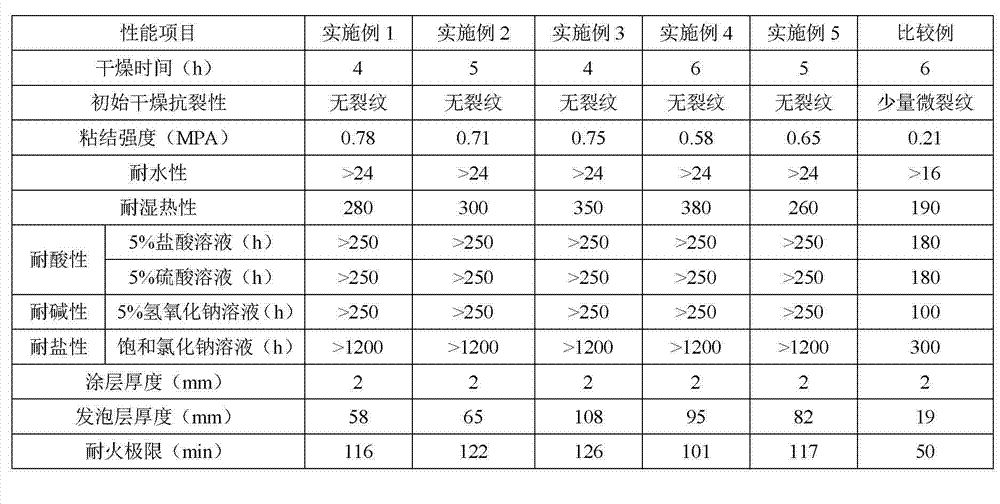

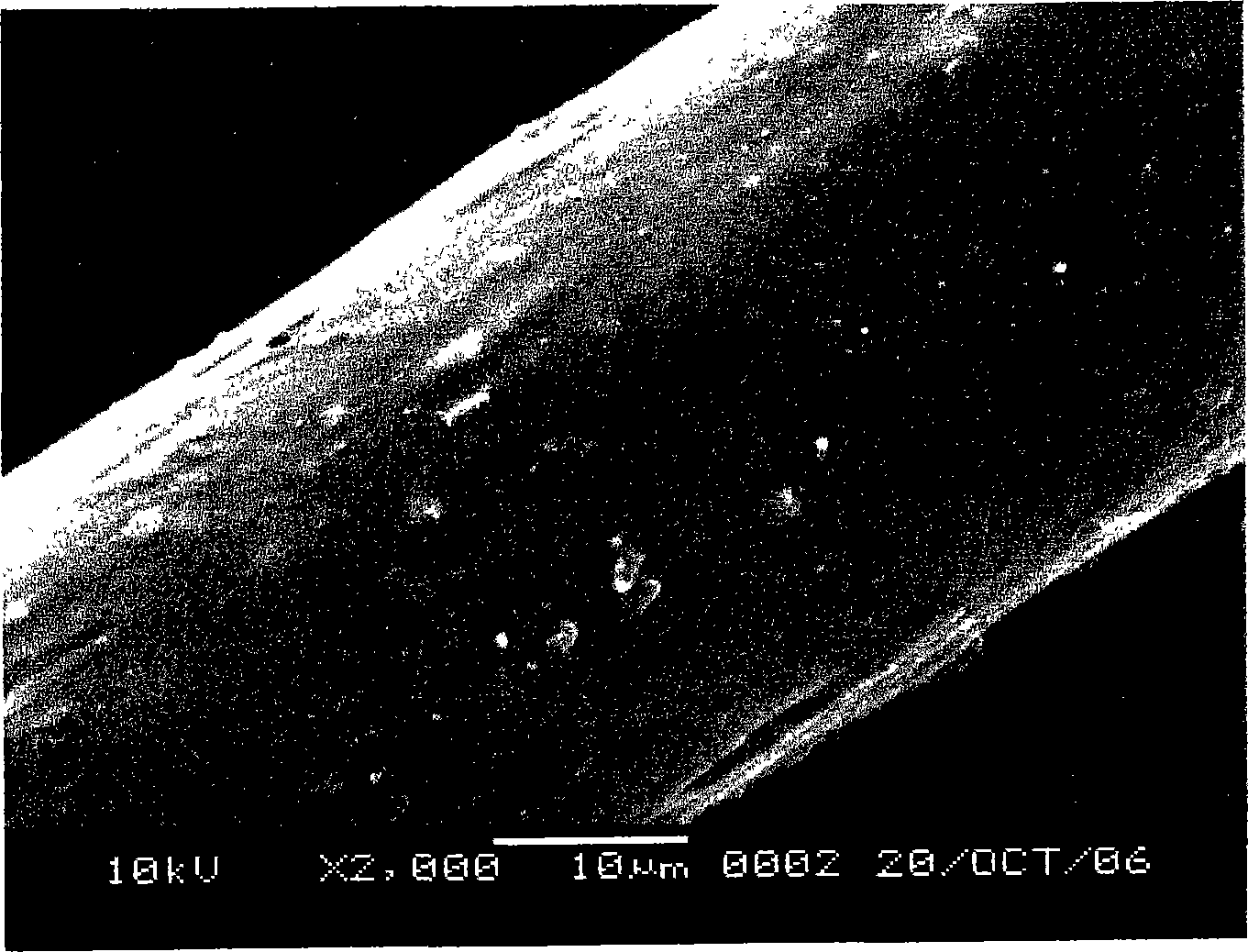

The invention relates to a water-based expandable fireproof steel structure coating and a preparation method thereof. The water-based expandable fireproof steel structure coating comprises the following components in mass percentage: 20-45% of coating matrix, 25-45% of nano-flame retardant, 0.1-10% of flame-retardant synergist, 1-10% of filler, 0.2-5% of auxiliary agent and 5-30% of water. The preparation method of the water-based expandable fireproof steel structure coating comprises the following steps: firstly, preparing the nano-flame retardant; secondly, adding a water-based epoxy emulsion, a water-based epoxy curing agent and a self-crosslinking silicone acrylic emulsion in the coating matrix into a stirring barrel, and stirring uniformly; thirdly, adding the nano-flame retardant, the flame-retardant synergist, the filler, the auxiliary agent and water, stirring for 10-30 minutes, adding a mixture into a ball grinding mil, grinding, checking whether the fineness of the coating meets a requirement, and if so, stopping grinding; fourthly, filtering the mixture with a filter screen, and separating grinding balls from the coating; and finally, filling the coating into a specified jar, discharging and barreling. The water-based expandable fireproof steel structure coating has a high expansion rate, has the fire endurance as long as 120 minutes and the coating thickens of 2 mm; and the water-based expandable fireproof steel structure coating is simple in preparation method, disposes solid wastes in the field of biomass power generation, is low in cost and wide in application and has significant economic and social benefits.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Method for preparing polypropylene composite parent material containing inorganic material for use on polypropylene fibers

A preparation method of inorganic-material-containing polypropylene composite master batch which is used in polypropylene fiber: composing polypropylene, inorganic material, additive A, B, C, D, E, specifically, the inorganic material is one or the compound of kaolin, calcium carbonate and montmorillonite with submicron-, micron- and nano-scales; the additive A is dispersant, B is lubricant, C is antioxidant, D is heat stabilizer, E is modifier; additive F is also added, which is coupling agent. As the coupling agent is added in compound by the method of the present invention, and the compatible effect of various components, there is a good compatibility between inorganic material and polypropylene resin with submicron-, micron- and nano-scales, and the dispersive property, the rheological property and the crystallization property are improved, and the spinnability is increased. The polypropylene composite master batch prepared by this method, can be used as a kind of low-cost composite master batch; being even mixed with fiber grade polypropylene according to proportions, the qualified polypropylene fiber can be produced.

Owner:JIAXING HENGSHENG POLYMER MATERIAL SCI TECH

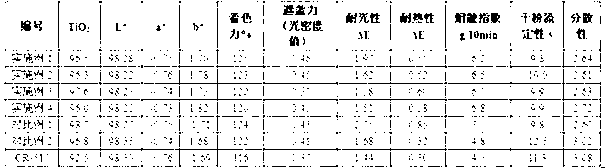

Preparation method of special type titanium dioxide pigment for plastic color master batch

InactiveCN103013184AImprove dispersion performanceIncreased photochemical activity of shielded titanium dioxidePigment treatment with organosilicon compoundsPigment physical treatmentAluminium saltsOrganosilicon

The invention provides a preparation method of a special type titanium dioxide pigment for a plastic color master batch, comprising the following steps of: preparing a titanium dioxide primary product into titanium dioxide slurry; adjusting a pH (Potential of Hydrogen) value by using an alkaline solution; adding phosphate or phosphoric acid, dispersing and carrying out grinding treatment; heating and raising the temperature; adding an acidic aluminum salt compound or an alkaline aluminum salt compound; meanwhile, adding inorganic acid or inorganic alkali and maintaining the pH value of the slurry; curing to form a first layer of a hydrated alumina covering layer on the surface of a titanium dioxide particle; continuously adding the inorganic acid or the inorganic alkali, adjusting the pH value and curing; washing by using de-ionized water and filtering; adding modified polysiloxane into a filtering cake; dispersing at a high speed to form a second layer of an organic silicon covering layer on the hydrated alumina covering layer; and drying and carrying out air-powder treatment to obtain the special type titanium dioxide pigment for the plastic color master batch. The preparation method disclosed by the invention has the advantages that the combination property is good; the dry powder mobility, the dispersity, the covering capability, the machining plasticization performance, the light resistance and the heat resistance achieve the level of special titanium dioxide for an international color master batch; and the application prospect is wide.

Owner:中信钛业股份有限公司

Preparation method of titanium dioxide pigment

InactiveCN104194410AImproved light resistance and weather resistanceImprove dispersion performancePigment treatment with non-polymer organic compoundsBoehmitePhosphoric acid

The invention belongs to the field of titanium dioxide production, particularly relates to a preparation method of a titanium dioxide pigment, and aims at solving the technical problem of providing a preparation method of a titanium dioxide pigment which is high in weather fastness and relatively friendly to environment. In order to solve the technical problem, according to the technical scheme, the preparation method comprises the following steps: firstly, carrying out silica coating on a silica primary product; then carrying out aluminum phosphate coating; and finally, carrying out alkaline coating on aluminum oxide to form a boehmite type aluminum oxide coating. According to the invention, coating is carried out by adopting the method, so that the light resistance and the weather fastness of the product are improved, and meanwhile, the dispersing performance of the product is also improved. According to the method, the addition of the phosphoric acid is relatively low, the generated free phosphoric acid is little, so resource waste is avoided, and the method is relatively friendly to environment.

Owner:PANGANG GROUP TITANIUM INDAL

Preparation method of crude terephthalic acid hydrogenation catalyst

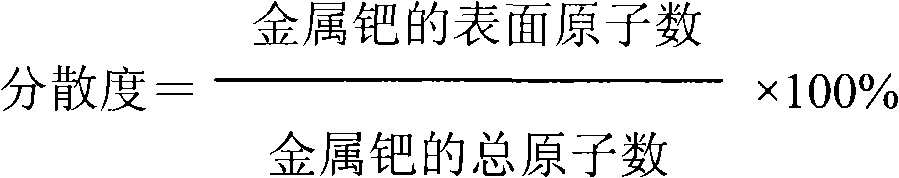

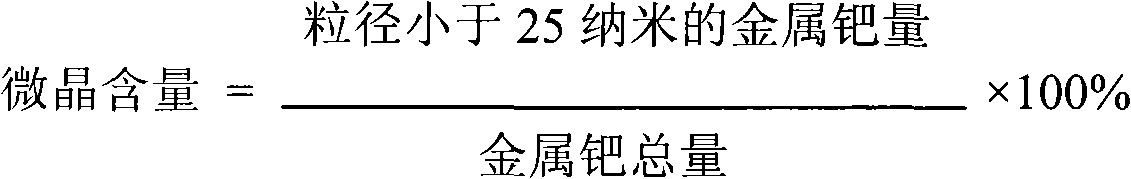

ActiveCN101767004AImprove dispersion performanceGood dispersionOrganic compound preparationCarboxylic compound preparationCrystalliteActive carbon

The invention relates to a preparation method of a crude terephthalic acid hydrogenation catalyst, mainly solving the problems that metal Pd in the catalyst has poor dispersion and low crystallite content in the prior art. Through the technical scheme comprising the following steps of: pre-impregnating an active carbon carrier with organic acid and organic acidic salt, filtering and drying the active carbon carrier, loading an active component of the metal Pd, finally adding a reducing agent for reducing and washing to obtain a finished catalyst, the invention better solves the problems and can be applied to the industrial production of hydrorefining crude terephthalic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

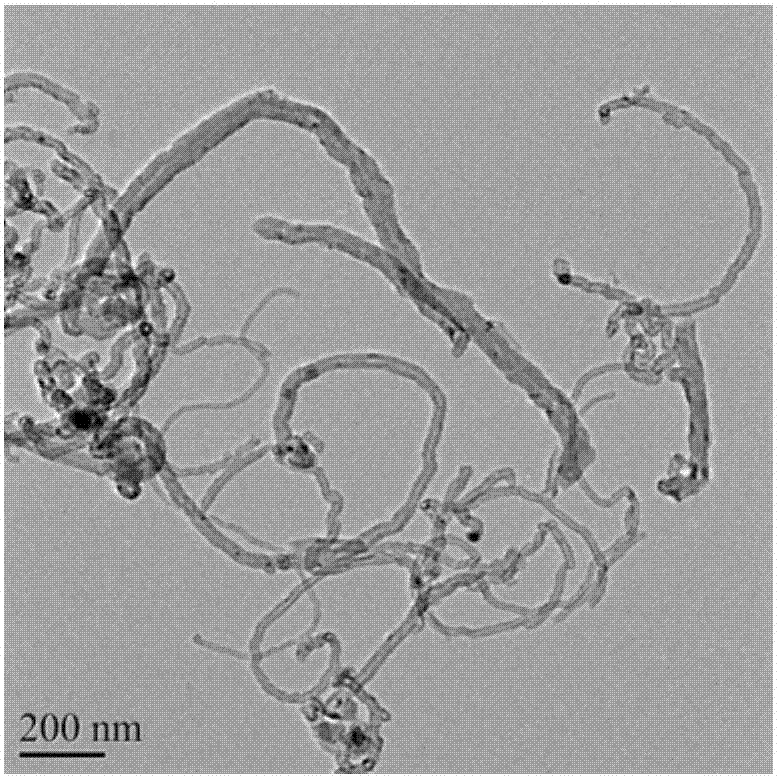

Preparation method of polymer/graphene/carbon nanometer tube composite material

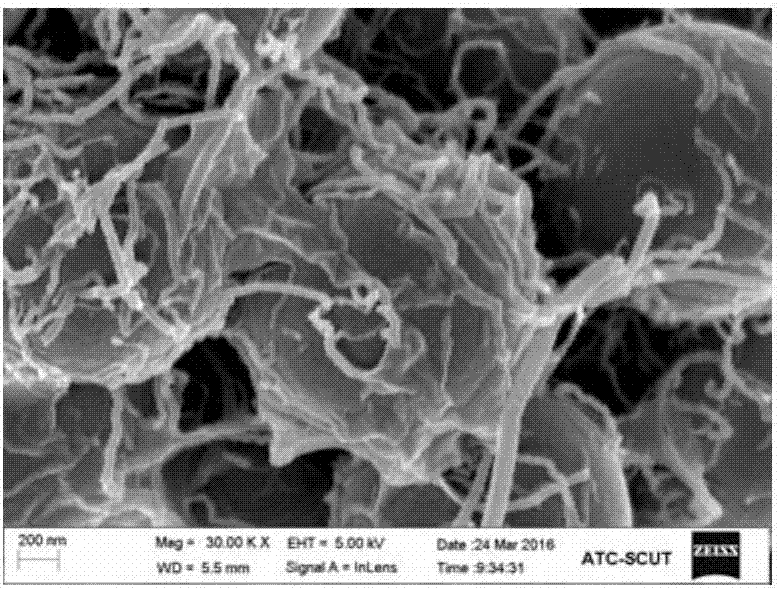

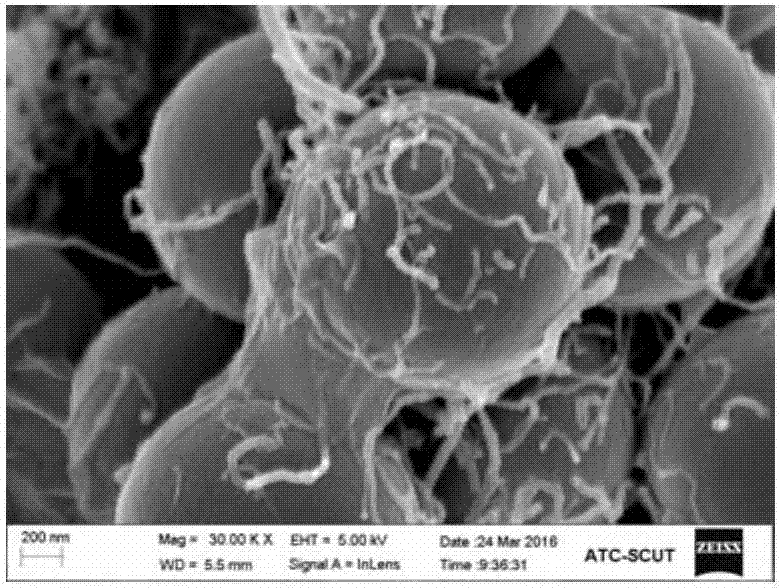

InactiveCN107325421AInhibition of agglomerationImprove dispersion performanceHeat-exchange elementsCvd grapheneCarbon nanotube

The invention discloses a preparation method of a polymer / graphene / carbon nanometer tube composite material. The method comprises the following steps of respectively performing preparation in an acid water solution under the ultrasonic effect to obtain uniformly dispersed polystyrene microspheres, graphene and carbon nanometer tube suspension solutions; then, uniformly mixing the three kinds of prepared suspension solutions; giving opposite charges to the three kinds of suspension solutions through regulating and controlling the pH value of the mixed solution. Through the static mutual effect, the graphene and the carbon nanometer tubes are uniformly coated on the surface of the polystyrene microspheres to obtain polystyrene / graphene / carbon nanometer tube three-ingredient hybrids; finally, a polystyrene composite material with a three-dimensional graphene-carbon nanometer tube hybrid network is obtained through a hot pressing forming process. The obtained polystyrene / graphene / carbon nanometer tube three-ingredient hybrids can mutually inhibit the respective agglomeration behaviors; the graphene and the carbon nanometer tubes are promoted to build the three-dimensional hybrid network in the polymer substrates; a great number of conductive paths are formed. Under the condition of low filling consumption, the excellent conduction performance of the composite material can be obviously realized.

Owner:广州中谱检测技术服务有限公司

Polyurethane microcapsule dispersing agent preparation method and product thereof

ActiveCN106582463AImprove dispersion performanceImprove storage stabilityMicroballoon preparationMicrocapsule preparationPrepolymerIsocyanate

The invention provides a polyurethane microcapsule dispersing agent preparation method and a product thereof. The preparation method comprises the following steps that excessive polyisocyanate and hydrophilic surfactant with a hydroxyl group is subjected to tetramethylethylenediamine catalytic reaction for 2-4 h at the temperature of 65-90 DEG C, and a polyurethane prepolymer is generated; the temperature of polyurethane prepolymer is lowered to be 25-40 DEG C, the polyurethane prepolymer is stirred and mixed with core materials to be uniform, and an oil phase is formed; the oil phase is added into a polyvinyl alcohol aqueous solution, homogeneous emulsification is conducted, and an O / W type emulsion is prepared; at the temperature ranging from 40 DEG C to 60 DEG C, a polyamine aqueous solution is slowly and dropwise added into the O / W type emulsion, after dripping is completed, heat preservation and curing are conducted for 1-2 h, and a polyurethane microcapsule dispersing agent is obtained. The polyurethane microcapsule dispersing agent has the excellent storage stability, dilution stability, centrifugal stability and acid and alkali resistant stability, harmful ingredients such as APEO, formaldehyde and aniline are not contained, and environmental protection is achieved; the polyurethane microcapsule dispersing agent preparation method and the product thereof have a wide application prospect and potential market value.

Owner:TAICANG BAONI IND CO LTD

Production method of superfine modified ground calcium carbonate by wet grinding

ActiveCN102977642AImprove affinityImprove dispersion performanceCalcium/strontium/barium compoundsPigment treatment with macromolecular organic compoundsWet grindingCalcium carbonate

The invention provides a production method of superfine modified ground calcium carbonate by wet grinding, comprising the following steps: (1) preparing ground calcium carbonate slurry; (2) preparing water-soluble surface modifier; (3) preparing the superfine modified ground calcium carbonate. In the production method, excellent water-soluble surface modifier is added in the water-soluble surface modifier, and the wet grinding method is used for producing the superfine modified ground calcium carbonate, thus, the affinity of the ground calcium carbonate particles to the organic superpolymer is enhanced, the dispersing performance of the ground calcium carbonate in the superpolymer is improved, and the prepared superfine modified ground calcium carbonate is excellent in affinity to the superpolymer, high in dispersing performance in the superpolymer and excellent in compatibility to the superpolymer and the auxiliary materials. By taking the superfine modified ground calcium carbonate produced by the production method as filler, the filling volume of the ground calcium carbonate in the products can be increased, and the performance of the products can be improved.

Owner:东南新材料股份有限公司

Hyperbranched polyester and synthetic method thereof, and thermoplastic resin composition and preparation method thereof

InactiveCN110256660AImprove dispersion performanceImprove the decline in toughnessChemistryInorganic filler

The invention discloses a hyperbranched polyester and a thermoplastic resin composition. The thermoplastic resin composition comprises, by weight, 60-85 parts of thermoplastic resin and 1-12 parts of the hyperbranched polyester, wherein capping groups containing vinyl groups account for 3% to 100% of the total number of the end groups of the hyperbranched polyester. The hyperbranched polyester containing vinyl end groups can enhance the toughness of thermoplastic resin. Moreover, if a nano-inorganic filler is added, the hyperbranched polyester can improve the dispersibility of the nano-inorganic filler in the thermoplastic resin composition and insulate the direct contact of a large amount of the nano-inorganic filler with the thermoplastic resin, thereby overcoming the problem of decrease in toughness caused by the addition of the nano-inorganic filler.

Owner:WUHAN JINFA TECH CO LTD +1

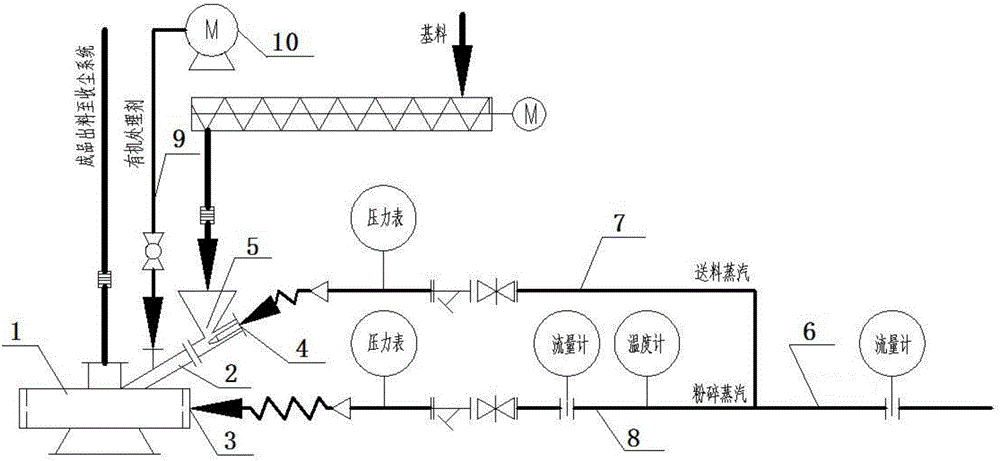

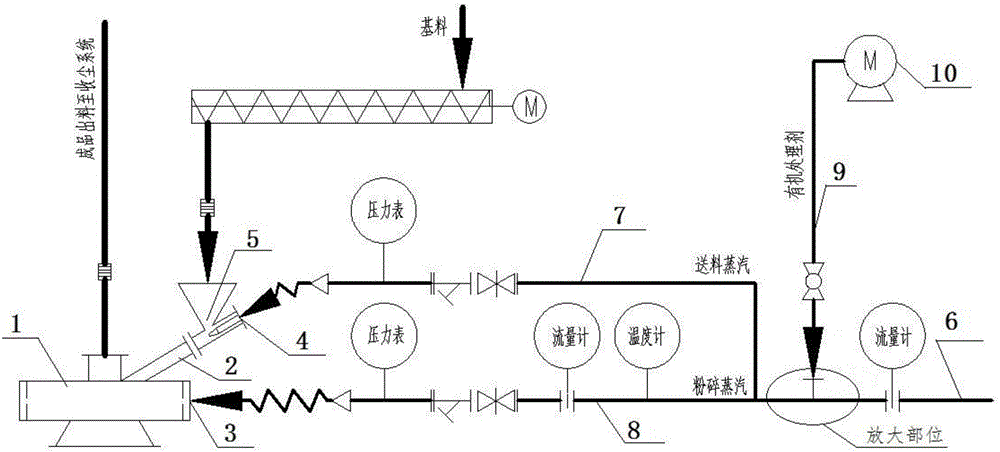

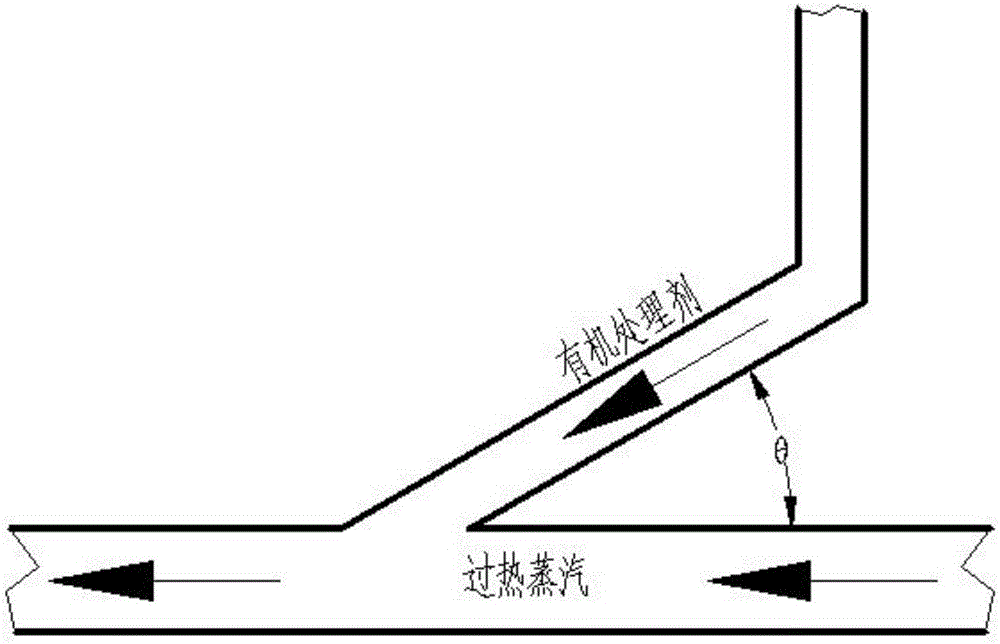

Titanium dioxide airflow crushing method and apparatus

ActiveCN106497146AImprove dispersion performanceFull contact with the materialGrain treatmentsPigment treatment with macromolecular organic compoundsGastric tube feedingTitanium dioxide

The invention relates to a titanium dioxide post-treatment technology, and concretely discloses a titanium dioxide airflow crushing method. The method comprises the following steps: 1, sending crude titanium dioxide into a post-treatment process in order to produce a base material; 2, preheating an airflow crushing device; 3, conveying the base material into the airflow crusher, and adding a metered amount of an organic treatment agent into an organic treatment agent feeding tube arranged on a superheated steam pipeline; and 4, collecting a product after normal discharging of a dust collecting system. The invention also discloses a titanium dioxide airflow crushing apparatus. The organic treatment agent feeding tube is arranged on the superheated steam pipeline to realize premixing of the organic treatment agent and superheated steam. The method and the apparatus have the following advantages: 1, the uniform mixing degree of the organic treatment agent and the material in the airflow crushing process is improved, and the dispersion performance of the titanium dioxide is effectively improved; and 2, the method is simple to enforce, and is easy to promote.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Preparation method for polyvinyl chloride resin used for flame-retardant cable

The invention relates to a formula and a production technology of polyvinyl chloride resin used for a flame-retardant cable. A suspending polymerization method is adopted and comprises the following steps: adding a vinyl chloride monomer, a stabilizing agent, a dispersing agent, a novel fire retardant, a chain extender, auxiliaries and de-ionized water into a polymerization kettle; cold stirring for 30 minutes; reacting for 5-6.5 hours at 50-60 DEG C; and after reducing pressure for 0.1 MPa, adding a terminator, thereby obtaining a water suspending solution of the polyvinyl chloride resin for the flame-retardant cable. The unreacted vinyl chloride monomer is removed, and centrifugal drying is performed, thereby obtaining an end product. The polyvinyl chloride resin used for the flame-retardant cable produced according to the production technology has the advantages that the form of grains in the product is regular, the plasticizing property is excellent, the mobility of flux is high, the additional fire retardant is unnecessary in the formula of the product, and the flame retardation of a material is obviously promoted. The product is mainly applied to the material with high demand on flame retardation, such as electric wires and cables, and the like.

Owner:XINJIANG TIANYE GRP

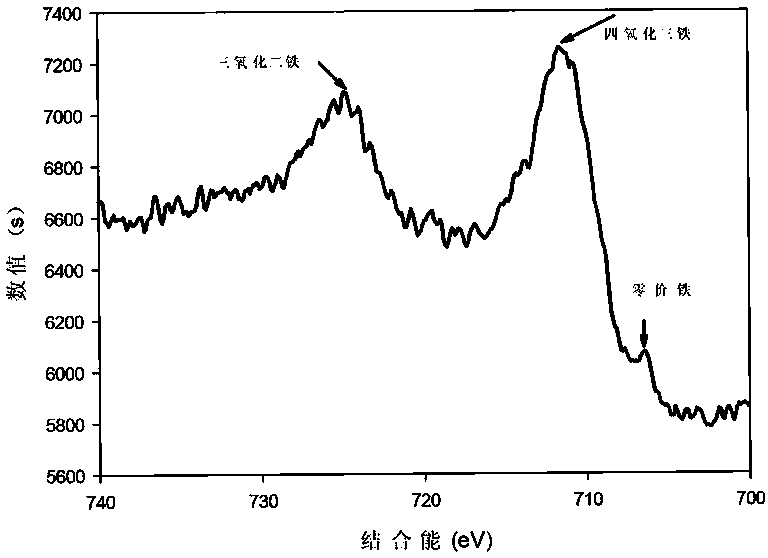

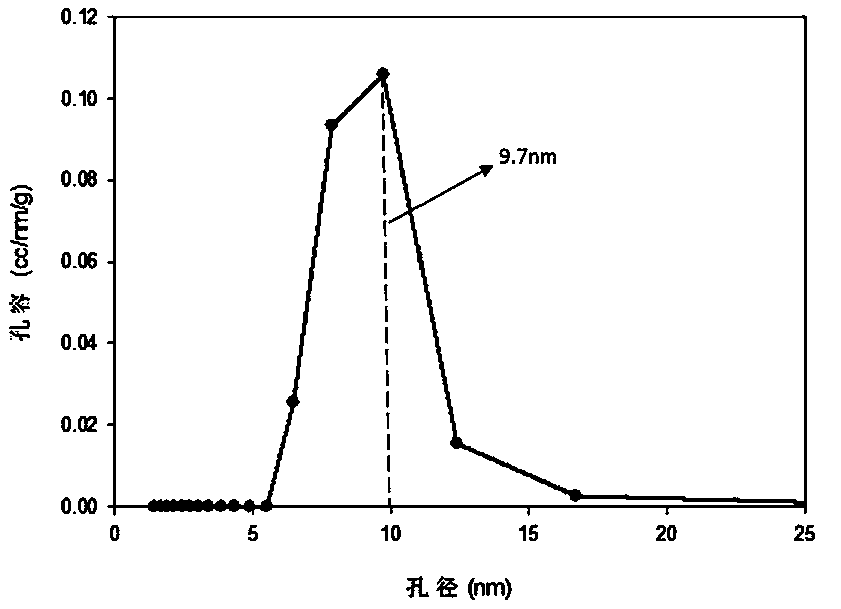

Iron-carrying meso-porous silicon composite material as well as preparation method and application thereof

InactiveCN104211126AImprove dispersion performanceShort drying timeWater contaminantsIron compoundsOxidation resistantPentane

The invention discloses an iron-carrying meso-porous silicon composite material as well as a preparation method and application thereof. The iron-carrying meso-porous silicon composite material is prepared by adopting the preparation method comprising the following steps: suspending meso-porous silicon in n-pentane, slowly introducing an iron source under magnetic stirring to obtain a ferric oxide meso-porous silicon composite material; after drying the ferric oxide meso-porous silicon composite material at a temperature of 50-70 DEG C, suspending in the n-pentane, under the atmosphere of an inert gas, dropwise adding a sodium borohydride solution, completely reducing ferric oxide to generate zero-valent iron so that the making of the iron-carrying meso-porous silicon is completed. The iron-carrying meso-porous silicon composite material is prepared by adopting a dual-solvent dipping method, can be applied to removal of organisms of nitrophenol organic matters in a water body, has the advantages of strong reducing property, high reaction rate, extremely short balance time, excellent oxidation resistance, and the like, and is high in removal rate and short in treatment time.

Owner:HUNAN UNIV

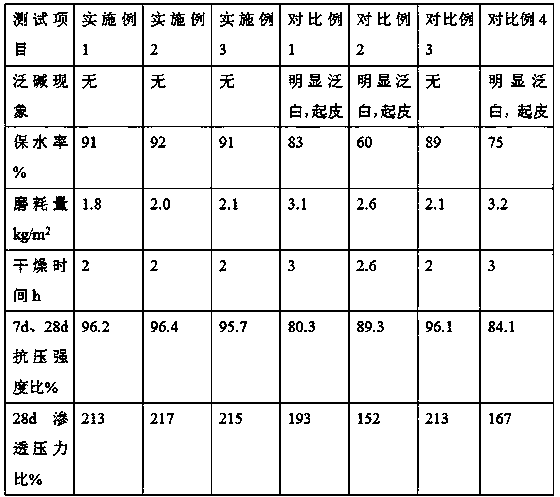

Concrete curing compound and preparation method thereof

InactiveCN108752043AImprove dispersion performanceImprove adsorption performanceDiamineBuilding material

The invention belongs to the field of building materials, and specifically relates to a concrete curing compound and a preparation method thereof. According to the concrete curing compound and the preparation method thereof, sepiolite, nanosilicon dioxide and nanotitanium dioxide are used as raw materials; through ball grinding mixing and acidification and sulfonation treatment of concentrated sulfuric acid, the dispersing performance of particles is improved; in addition, by use of the natures that the sepiolite is softened in water and is high in permeability, the sepiolite is remodified under the atmosphere of sodium hydroxide and under the environment of ferrous ions and ferric ions; by deposition of ferrous iron and iron, the adsorption performance of the particles is improved, so that pores are combined and filled with the particles more easily, and the anti-seepage performance is improved; then, succinic acid and ethidene diamine are used as raw materials, and ions are used as aguide agent, so that an organic complex is formed; through combination of the organic complex and calcium ions and blocking of capillaries inside concrete, the whiskering phenomenon is effectively prevented.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

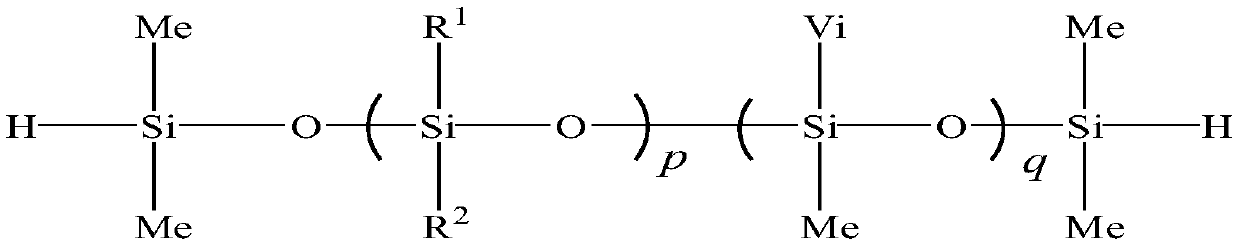

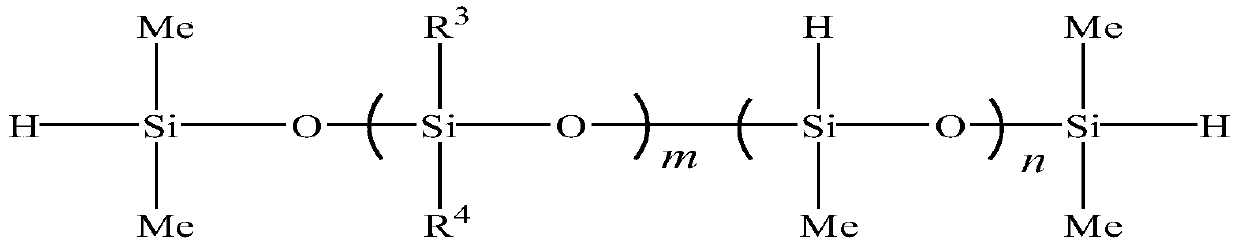

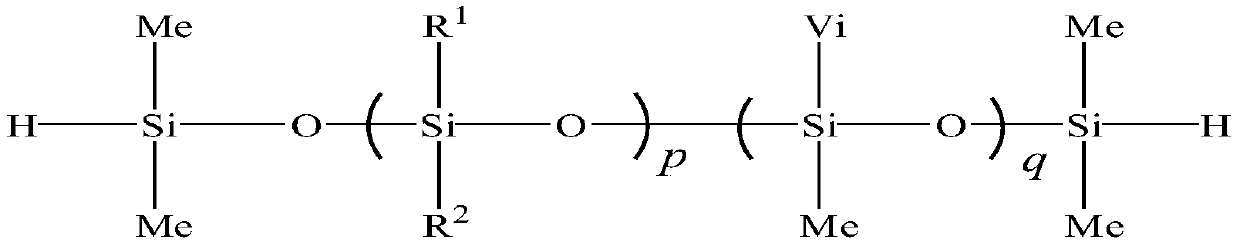

Silicone composition

ActiveCN110283322AImprove dispersion performanceExcellent defoaming performanceDefoamerOrganosilicon

The invention provides a silicone composition and a preparation method thereof. A hydrogen-containing polysiloxane reacts with an unsaturated polyether, and the obtained reaction product and a dimethylhydro-terminated vinyl polysiloxane undergo a hydrosilylation reaction and alkali treatment. The crosslinking viscosity is effectively controlled by the hydrogen-containing polysiloxane to form a dynamic crosslinked polymer having a spatial structure, and the addition of the unsaturated polyether improves the dispersing property of the silicone composition. The silicone composition can be used as a main body to prepare an organopolysiloxane defoamer, has a good defoaming performance in a high-temperature strong alkaline system, and has the advantages of good dispersibility, difficulty in agglomeration and precipitation, improvement of the foam suppression performance, and enhancement of the application performance in the later stage in the use process.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

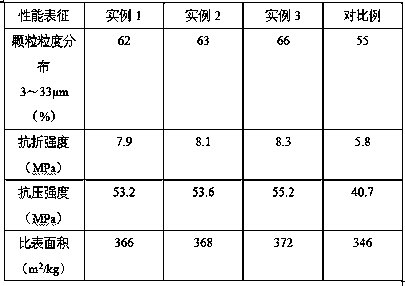

Preparation method of organic silicon modified high-molecular cement grinding aid

The invention relates to a preparation method of an organic silicon modified high-molecular cement grinding aid, and belongs to the technical field of cement production. According to the preparation method, sodium lignin sulfonate containing a large number of functional groups is introduced into diethanol amine, then a reaction with modified silicone oil is carried out for preparing an organic silicon modified high-molecular polymer. The organic silicon modified high-molecular polymer has long polyether side chains, and short chains contain a plurality of functional groups of Si-O bonds, hydroxyl groups, carboxyl groups and the like, so that the high-molecular polymer can be easily adsorbed on the surfaces of cement particles, an effect of particle dispersion is exerted, an effect of preventing the healing of cracked interfaces is achieved, the free energy of the surfaces of the cement particles can be effectively reduced, a larger steric hindrance effect can be achieved for the long polyether side chains, the dispersion property of the cement particles is further enhanced, and an effect of accelerating the crack propagation can be exerted. Energy generated in cement production areapplied to crushing the cement particles more, so that the particles are more uniform and fine, and thereby the goals of improving the cement powed grinding efficiency and reducing the energy consumption of the cement are realized.

Owner:胡果青

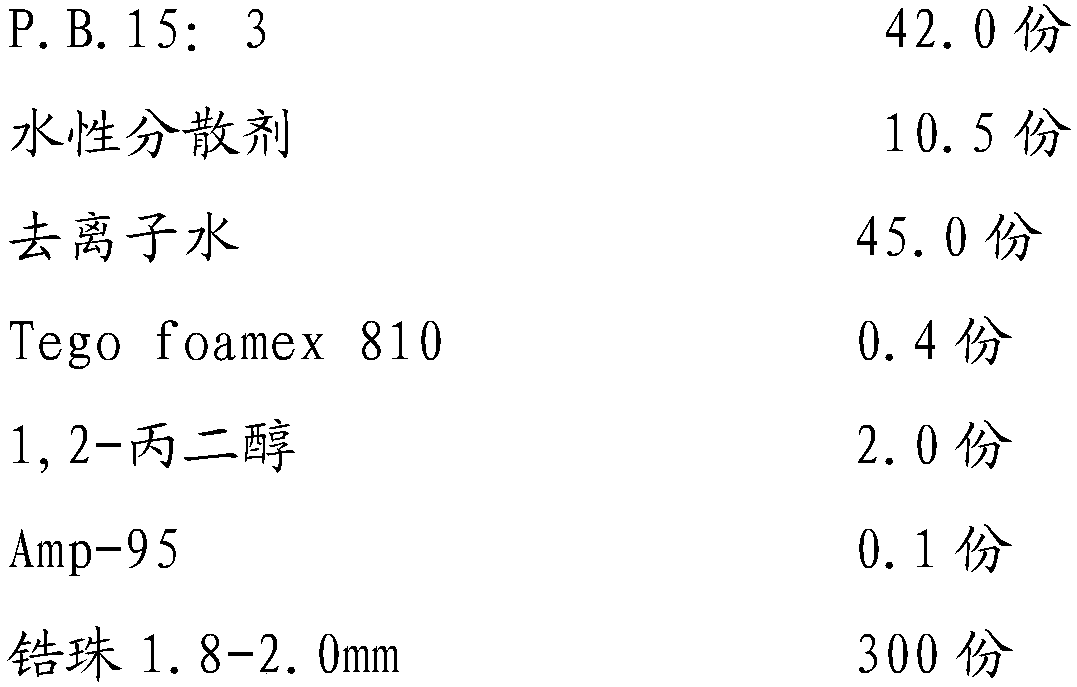

Plasma display screen barrier slurry and preparation method thereof

InactiveCN102074436AImprove dispersion performanceImproved leveling and thixotropyVessels or leading-in conductors manufactureSolid cathode detailsOrganic solventAluminium oxide

The invention relates to barrier slurry, in particular to plasma display screen barrier slurry and a preparation method thereof. The plasma display screen barrier slurry comprises 60 to 75 percent of glass powder and 25 to 40 percent of organic carrier, wherein the glass powder comprises 25 to 35 percent of diboron trioxide (B2O3), 20 to 30 percent of barium oxide (BaO), 5 to 10 percent of phosphorus pentoxide (P2O5), 0 to 20 percent of zinc oxide (ZnO), 0 to 20 percent of aluminum oxide (AL2O3) and 0 to 15 percent of copper oxide (CuO), ceric oxide (CeO2), lithium oxide (Li2O) or sodium oxide; and the organic carrier comprises 3.0 to 15 percent of polymer, 76 to 95 percent of organic solvent, 1.5 to 16 percent of film-forming auxiliary agent and 0.1 to 0.9 percent of gas-phase method silicon dioxide (SiO2) powder. By the plasma display screen barrier slurry and the preparation method thereof, dispersing property of the glass power is improved; levelling property and thixotropic property of the barrier slurry are improved; the defects of sinking, bubbling and the like of the barrier slurry subjected to coating and sintering are overcome; the manufacturing process is simple; the finished product ratio is high; and mass production is performed easily.

Owner:SICHUAN COC DISPLAY DEVICES

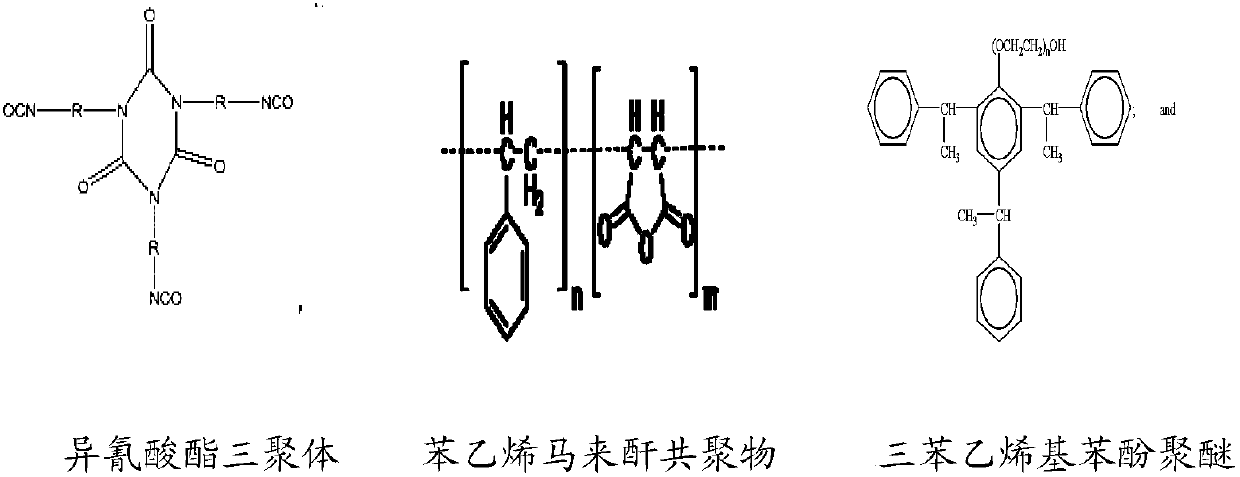

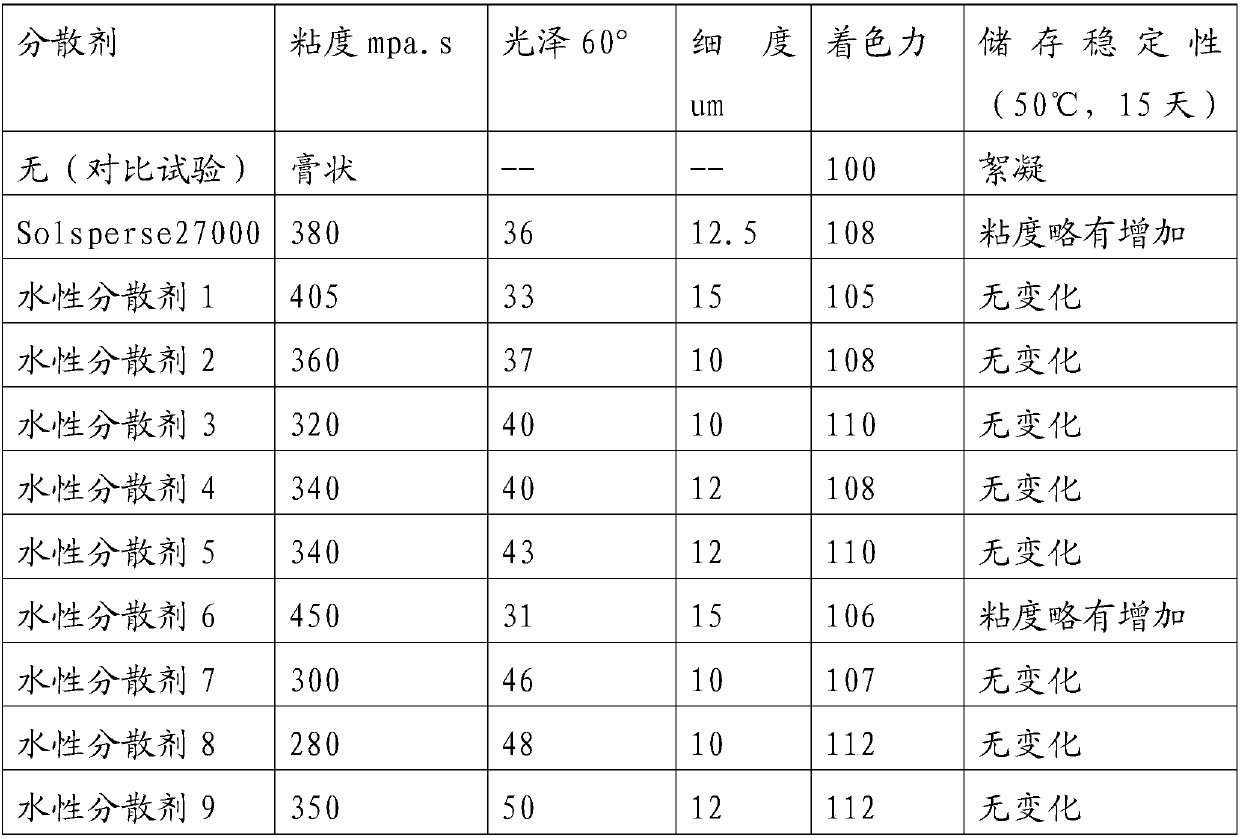

Novel aqueous dispersant and preparation method thereof, and application of novel aqueous dispersant to dispersion containing solid particles

InactiveCN107715787AImprove dispersion performanceReduce pollutionTransportation and packagingMixingCeramicPrinting ink

The invention discloses a novel aqueous dispersant and a preparation method thereof, and application of the novel aqueous dispersant to dispersion containing solid particles, belonging to the field ofdispersants. The novel aqueous dispersant contains a solvation chain compatible with an aqueous solvent and an anchoring group with affinity to dispersed solid particles. The solvation chain and theanchoring group are conjugated via a covalent bond. The novel aqueous dispersant is applied to dispersion containing solid particles of organic pigment, inorganic pigment, filler, graphene or metal powder. The dispersion is liquid dispersion or solid dispersion such as printing ink, paint, plastics, color paste, pesticides, and jet ink for ceramics. The novel aqueous dispersant provided by the invention is capable of improving the dispersion stability of solid particles in an aqueous medium or enhancing the application performance of a disperse system, and can reduce pollution of volatile organic solvents in the disperse system to environment.

Owner:WINBOS NEW MATERIALS

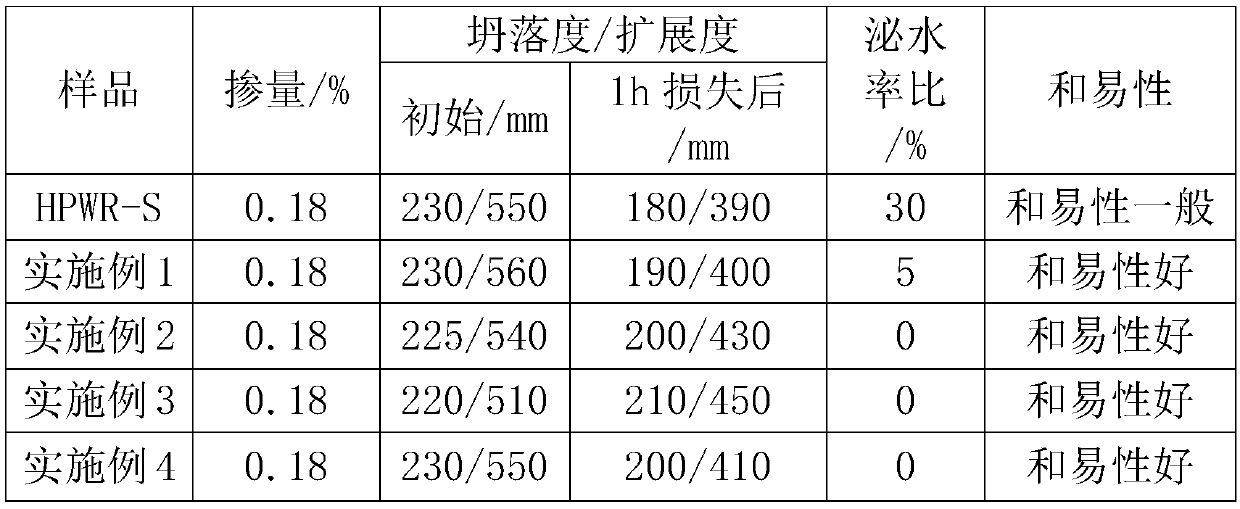

Preparation method of high water retention type polycarboxylate superplasticizer

The invention discloses a preparation method of a high water retention type polycarboxylate superplasticizer. The method comprises the steps as follows: firstly, acrylic acid is mixed with other unsaturated acid, unsaturated acid ester and unsaturated acid anhydride, an oxidizing agent is added, a mixed solution of an unsaturated monomer, a chain transfer agent, a reducing agent and water is dropwise added at a certain temperature, a certain quantity of free radical quencher is added after a copolymerization reaction, a main chain copolymer intermediate is obtained, then, a certain amount of cheap glucose, ethylene glycol monomethyl ether and a catalyst are added for esterification grafting, and finally, the high water retention type polycarboxylate superplasticizer is prepared through neutralization. By molecular structure design, a synthesis method using first polymerization and then grafting esterification is adopted, polyhydroxyl glucose with excellent water retention performance is introduced for grafting esterification, the method is high in grafting plasticity, high in copolymerization degree and low in double bond damage rate, and the prepared polycarboxylate superplasticizer has the characteristics of excellent water retention performance, high dispersity, low cost, excellent slump loss resistance and retarding functions and the like.

Owner:ZHEJIANG KZJ NEW MATERIALS CO LTD

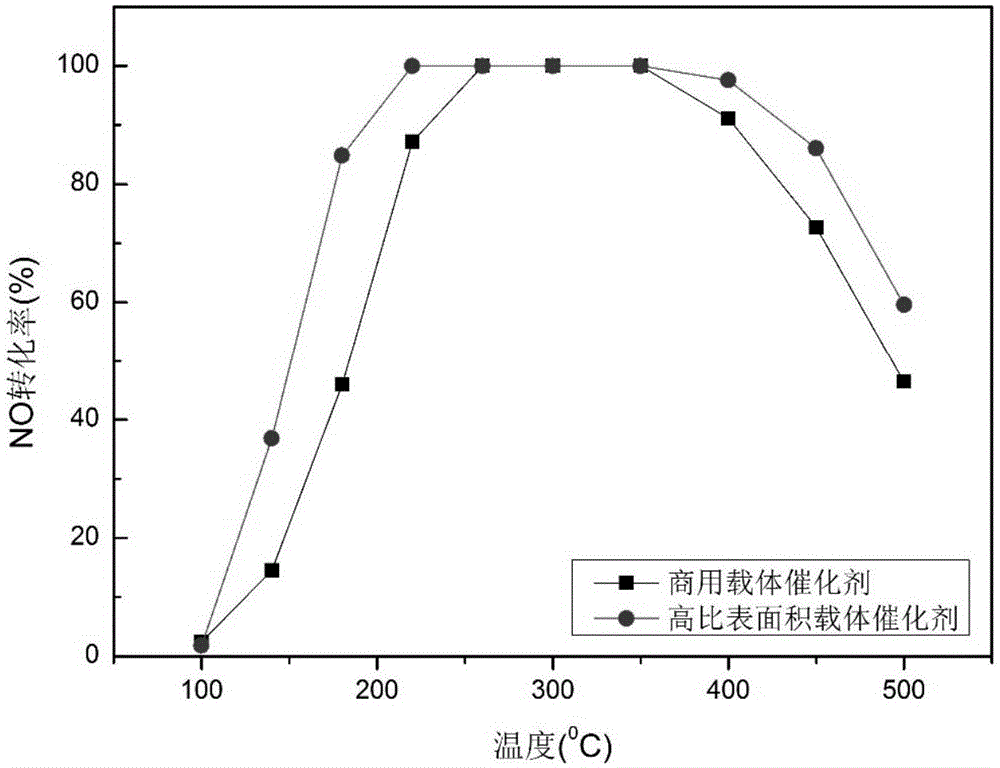

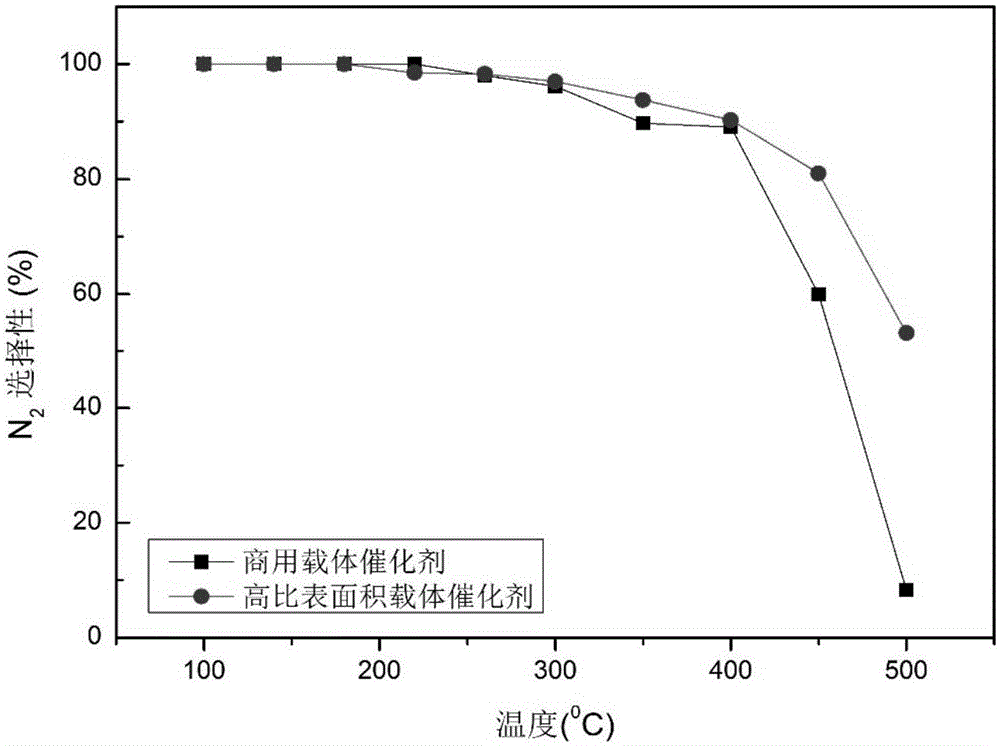

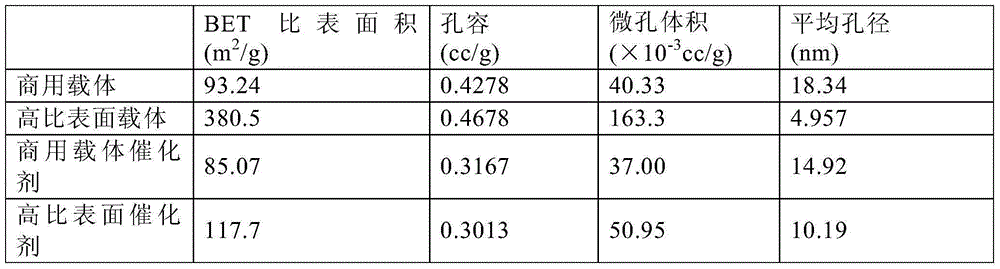

High-specific-surface denitration catalyst and preparation and application thereof

InactiveCN105126813AImprove nitrogen oxide conversionImprove dispersion performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsExhaust gasChemistry

The invention belongs to the field of air pollution control, and particularly relates to a high-specific-surface denitration catalyst and preparation and application thereof. The catalyst is applied to the field of purification of NOx in fixed-source smoke. A high-specific-surface carrier is adopted for the catalyst, ammonium metavanadate serves as an active component raw material, and the active component and the carrier are compounded; specifically, an ultrasonic immersing method is adopted for preparation, and a special heat treatment mode is adopted for sintering; the catalyst can achieve denitration with high efficiency (above 80%) at 200-450 DEG C under experiment conditions and further has high nitrogen selectivity (above 80%). The catalyst has good catalytic activity and can be applied to purification of NOx in fixed-source smoke denitration tail gas.

Owner:TSINGHUA UNIV

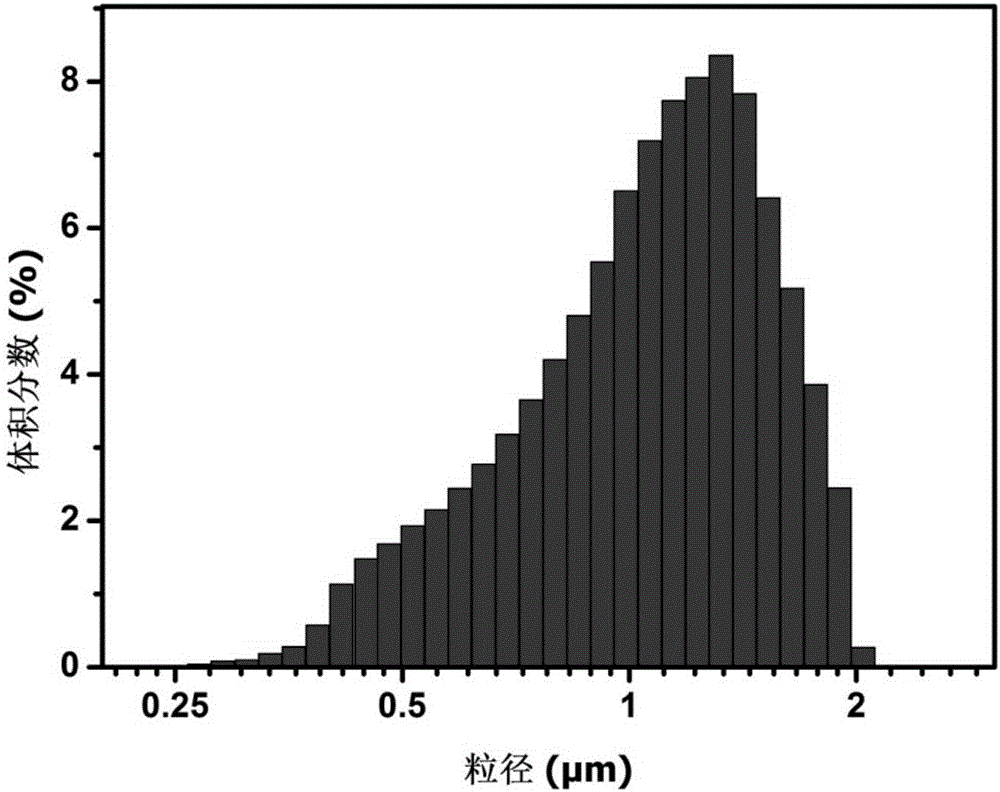

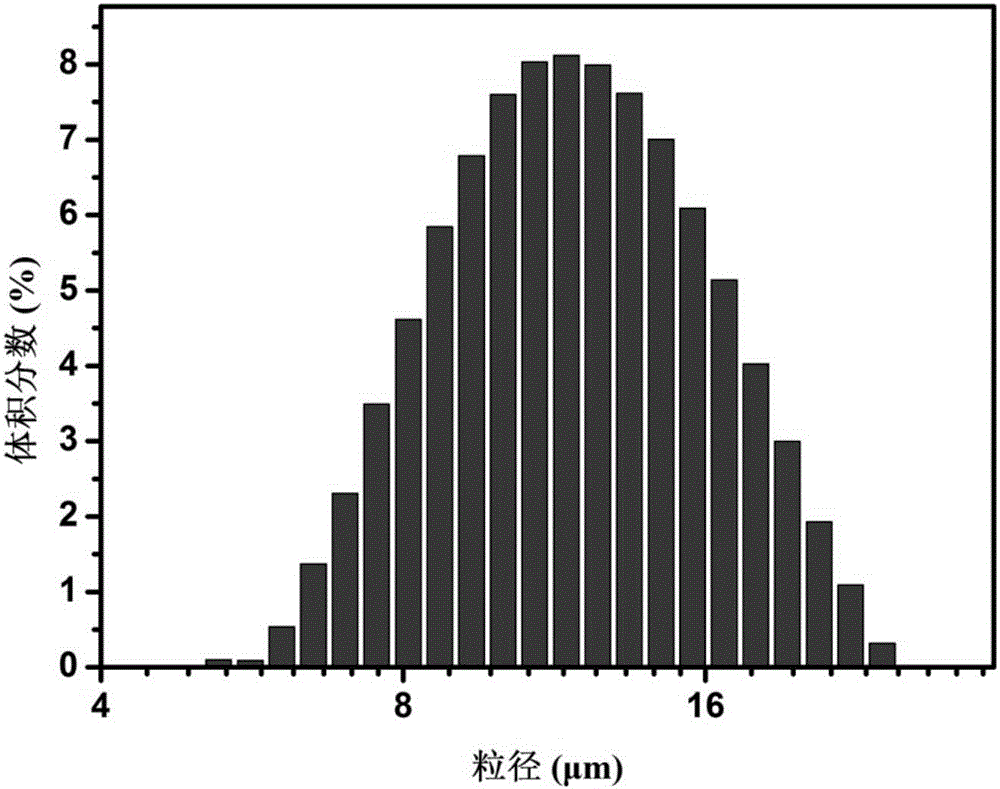

Compound immune magnetic beads for separation and purification of hepatic stellate cells and preparation method of compound immune magnetic beads

The invention relates to the technical field of cell separation and purification materials and particularly relates to compound immune magnetic beads for separation and purification of hepatic stellate cells and a preparation method of the compound immune magnetic beads. The compound immune magnetic beads are prepared by grafting antibodies on magnetic bead granules of which the granule sizes are50-1500nm, wherein the antibodies include CD11b and CD146 antibodies, and the inner cores of the magnetic bead granules are Fe3O4 micro-spheres including carboxylated graphene layers, modified chitosan layers and sodium alginate layers from inside to outside. The antibodies are grafted on the magnetic bead granules to obtain the compound immune magnetic beads; the magnetic bead granules contain more carboxyl functional groups, have good dispersion properties in solutions and can not aggregate easily; the antibodies have a higher grafting ratio on the magnetic bead granules and have higher binding stability; and the compound immune magnetic beads can be used for separation and purification of hepatic stellate cells so as to obtain hepatic stellate cells with higher purity and better activity.

Owner:ARMY MEDICAL UNIV

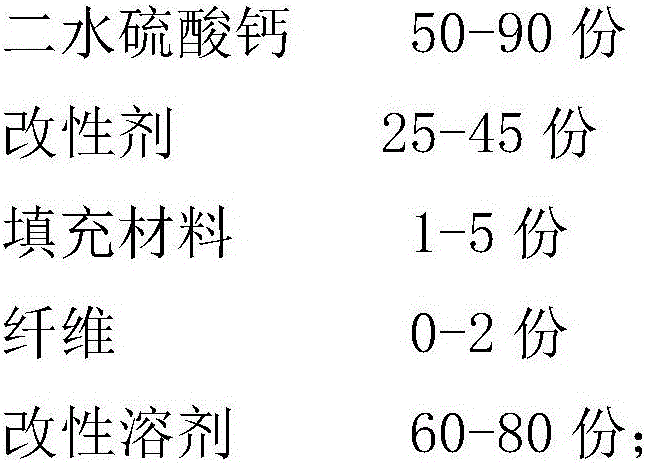

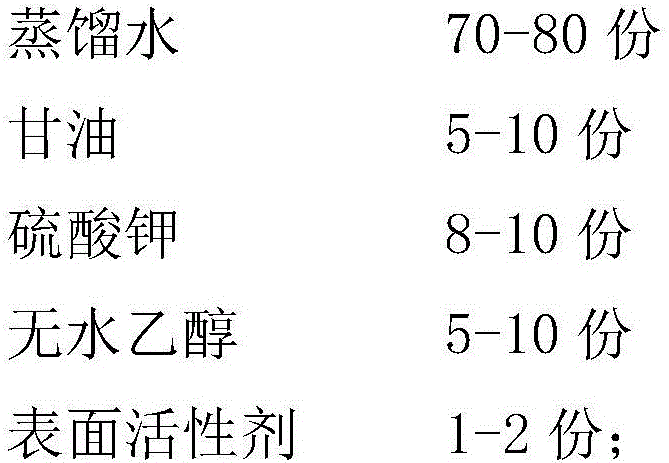

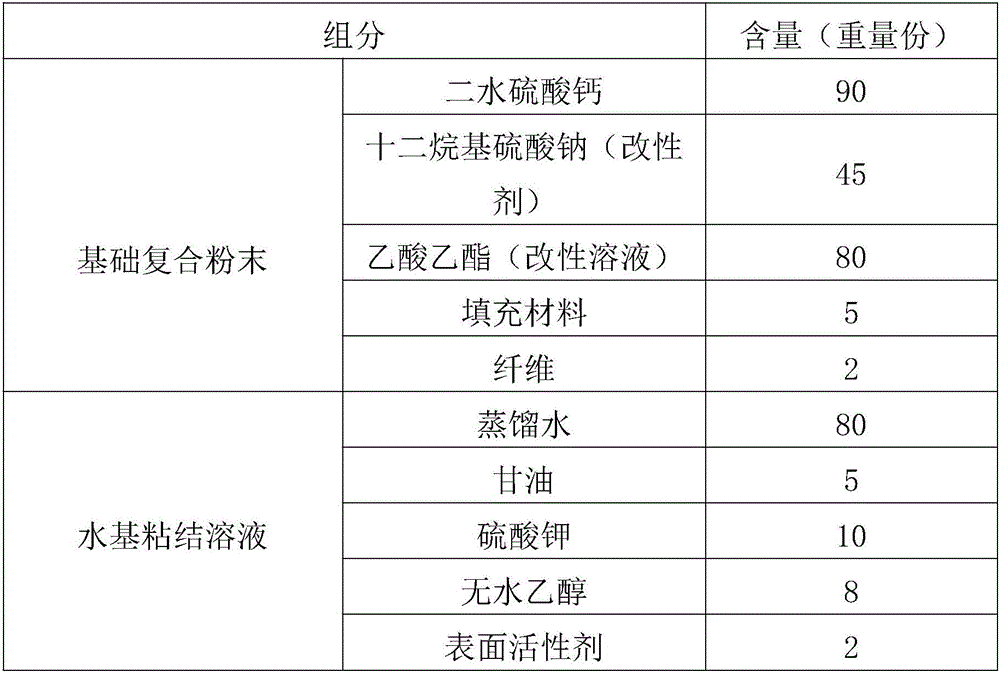

Three-dimensional printing material based on modification of gypsum base powder

InactiveCN106278087AFast hardeningImprove dispersion performanceAdditive manufacturing apparatusSolventGypsum

The invention discloses a three-dimensional printing material based on modification of gypsum base powder. Basic composite powder comprises the following components in parts by weight: 50-90 parts of calcium sulphate dihydrate, 25-45 parts of a modifying agent, 1-5 parts of a filling material, 0-2 parts of fibers, and 60-80 parts of a modified solvent. A water-based bonding solution comprises 70-80 parts of distilled water, 5-10 parts of glycerin, 8-10 parts of potassium sulphate, 5-10 parts of absolute alcohol and 1-2 parts of a surfactant. According to the three-dimensional printing material disclosed by the invention, a three-dimensional shaping principle is combined, and the gypsum base powder is modified, so that the hardening speed of gypsum powder is increased, and the rapid shaping requirements of the printing material are met.

Owner:SUZHOU BC TECH

Preparation method of calcium hydroxide/graphene nano composite material

InactiveCN109368678AImprove dispersion performanceUniform particle distributionCarbon compoundsCalcium/strontium/barium oxides/hydroxidesBatch productionCalcium hydroxide

The invention provides a preparation method of a calcium hydroxide / graphene nano composite material. The preparation method comprises the following steps: adding graphene powder and sodium chlorate into concentrated sulphuric acid, and stirring in an ice bath state; modifying the surface of the graphene with an oxygen containing group, and adding calcium chloride into functionalized graphene dispersion liquid; uniformly mixing and then heating to 60 to 90 DEG C, and dropwise adding a sodium hydroxide solution into the solution at the speed of 0.5 to 2mL / min; after dropwise adding is finished,continuously insulating for 30 to 60 minutes, centrifugally washing and then carrying out vacuum drying; heating at 40 DEG C in the protective atmosphere for 0.5 to 2 hours to obtain calcium hydroxide / graphene nano composite material powder. According to the method disclosed by the invention, calcium hydroxide nanoparticles are generated on the surface of the graphene in situ and are uniformly distributed; reaction conditions are mild. The preparation method has the advantages of simplicity in preparation, low cost and easiness in industrial batch production.

Owner:YANCHENG TEACHERS UNIV

Ship cabin sterilizing anti-corrosion anti-wear paint and preparation method thereof

InactiveCN104861751AStrong adhesionImprove dispersion performanceAntifouling/underwater paintsPaints with biocidesWaxChemistry

The invention discloses a ship cabin sterilizing anti-corrosion anti-wear paint which is characterized in that the paint is prepared from the raw materials of, by weight, 13-16 parts of E-52 epoxy resin, 13-19 parts of vinegar chloride resin, 1-2 parts of dibutyl maleate, 3-5 parts of xylylenediamine trimer, 1-2 parts of 2-amino-2-methyl-1-propanol, 1-2 parts of methyl butyl aluminum phosphinate, 2-4 parts of nitrocellulose, 3-5 parts of wood wax oil, 2-3 parts of polyether-modified silicone, 14-17 parts of modified bitumen, 4-7 parts of modified waste clay sand, 10-13 parts of dimethylacetamide, 3-5 parts of xylene, 3-5 parts of turpentine, 4-6 parts of glass flakes, 10-13 parts of propylene glycol monomethyl ether acetate, 0.3-0.7 parts of cocamidopropyl betaine, 2-3 parts of trans-cinnamic aldehyde, and 3-4 parts of eucalyptus oil. The paint provided by the invention has excellent adhesion, wear resistance, aging resistance and corrosion resistance, such that the requirements on paint are satisfied. With the added modified waste resin sand, the dispersion property of the paint is improved, and corrosion resistance and weather resistance of the paint are enhanced. The paint provided by the invention is environment-friendly and healthy, and does not harm human health.

Owner:TIANCHANG JULONG TRAVEL PAINT

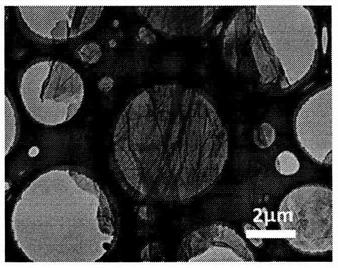

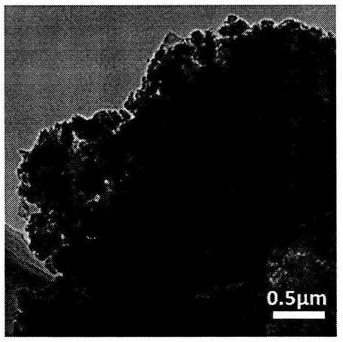

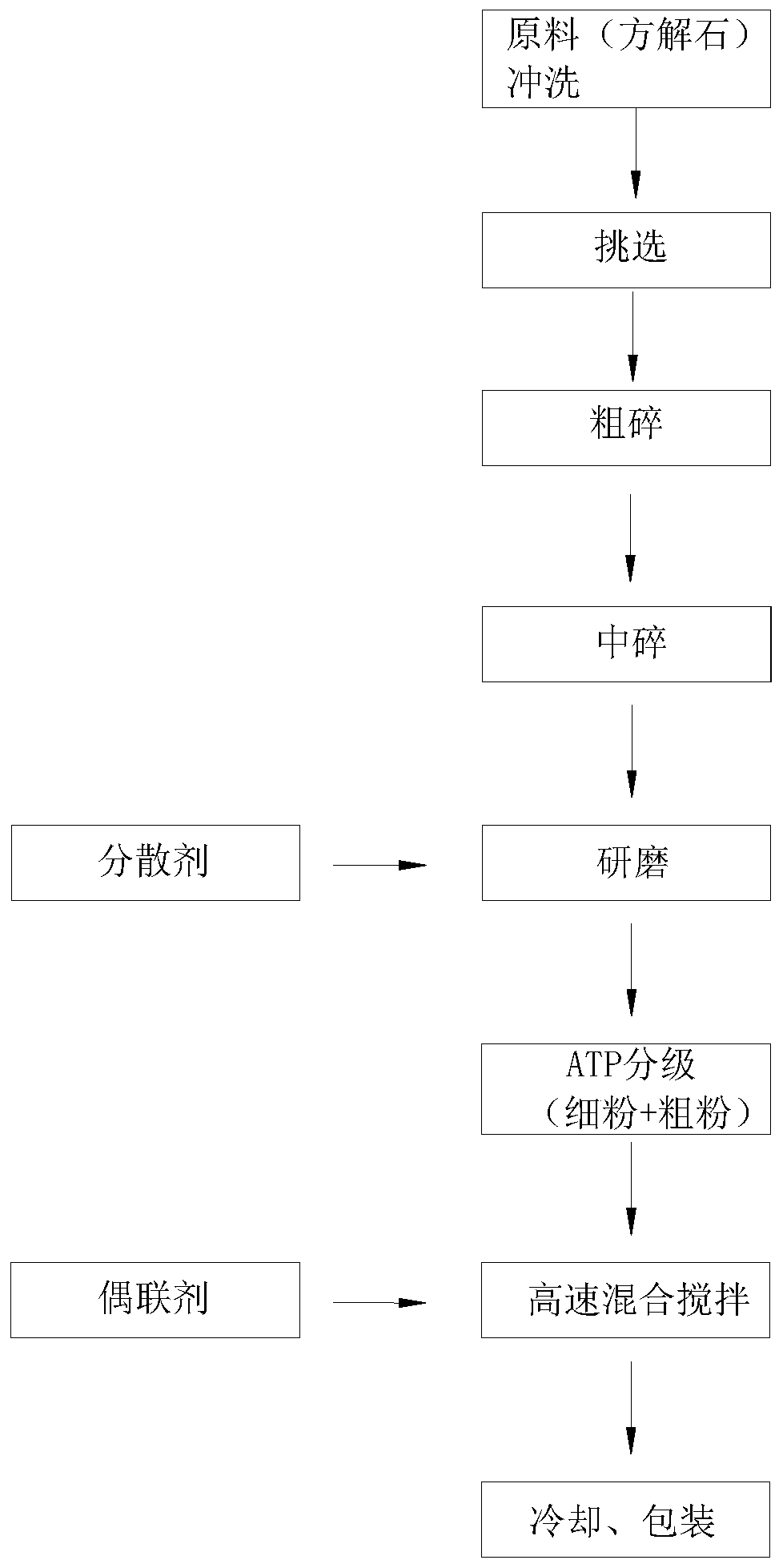

Nanoscale activated calcium carbonate and processing method thereof

InactiveCN110358328AImprove dispersion performanceShorten grinding timeMaterial nanotechnologyPigment physical treatmentCalciteCalcium carbonate

The invention discloses nanoscale activated calcium carbonate. The nanoscale activated calcium carbonate comprises calcite, a dispersant and a coupling agent; a mass part ratio of the calcium carbonate to the dispersant in a grinding process is 100:(0.2-5); and a mass part ratio of the dried nanometer calcium carbonate to the coupling agent in a high-speed mixing and stirring process is 100:(0.5-8). The method reduces the surface polarity of the nanometer calcium carbonate, so the surface of the nanometer calcium carbonate has strong oleophilic and hydrophobic properties, the dispersion property is improved, the dispersibility of the nanometer calcium carbonate in the composite material and the compatibility of the nanometer calcium carbonate with an organic high polymer are improved, andthe nanoscale activated calcium carbonate is obtained. The invention also discloses a processing method of the nanoscale activated calcium carbonate. The processing method comprises the following steps: 1, raw material washing; 2, choosing; 3, coarse crushing; 4, intermediate crushing; 5, addition of the dispersant, and grinding; 6, ATP grading (fine powder + coarse powder); 7, addition of the coupling agent, and high-speed mixing and stirring; and 8, cooling and packaging. The processing method adopting dry process modification has the advantages of low production cost, and suitableness for large-scale industrial production.

Owner:良德纳米粉体创新科技(安徽)有限公司

Quaternary phosphonium insulation board material and preparation method thereof

The invention discloses a quaternary phosphonium insulation board material, which is composed of the following raw materials (by weight): 10-13 parts of hollow glass beads, 10-15 parts of methyl cellulose, 7-8 parts of 2-mercaptobenzothiazole, 10-14 parts of allyltriphenylphosphonium bromide, 0.01-0.012 part of an initiator, 180-220 parts of styrene, 5-7 parts of ammonium persulfate, 30-40 parts of tetrabutyl titanate, 0.7-1 part of sp-8, and 7-12 parts of an ac foaming agent. With titanium sol introduced, mechanical properties of sheet plate products can be effectively improved, and a good synergistic antibacterial effect can be achieved when blended with quaternary phosphonium salt. Thereby, comprehensive quality of the finished product material is improved.

Owner:安徽省绩溪县华宇防火滤料有限公司

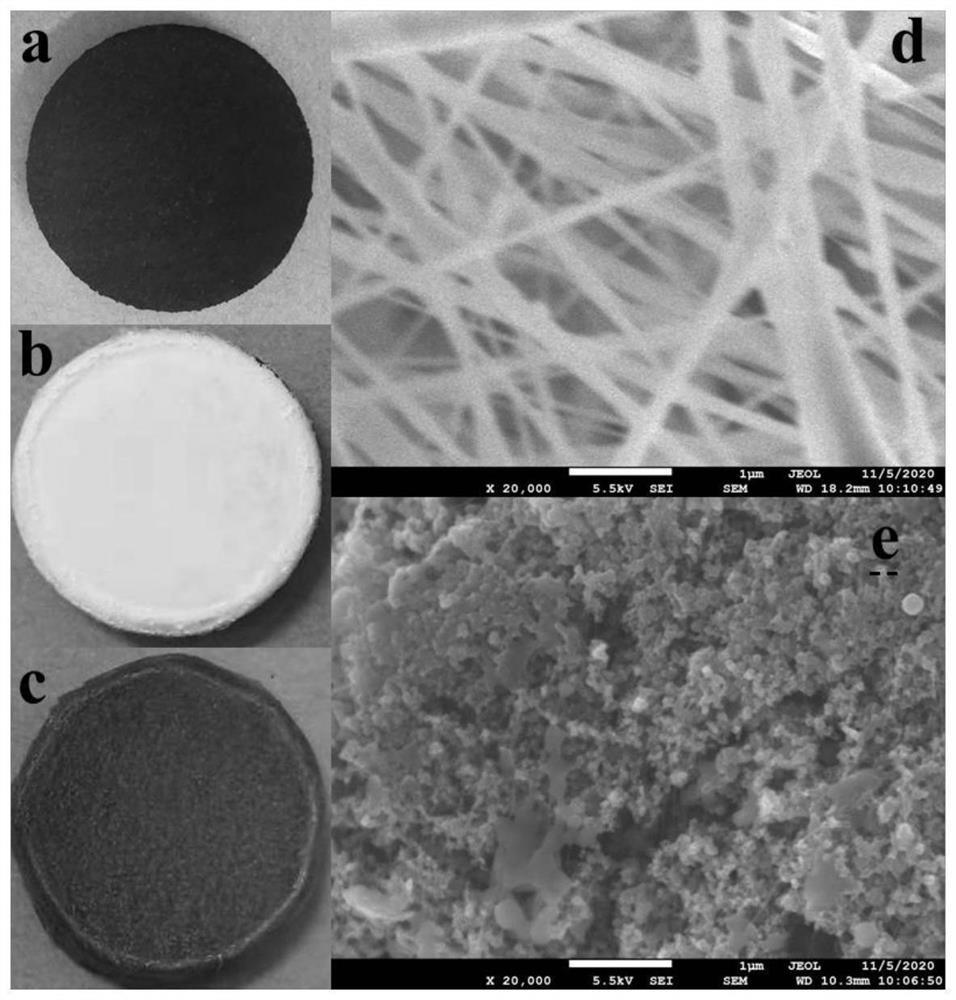

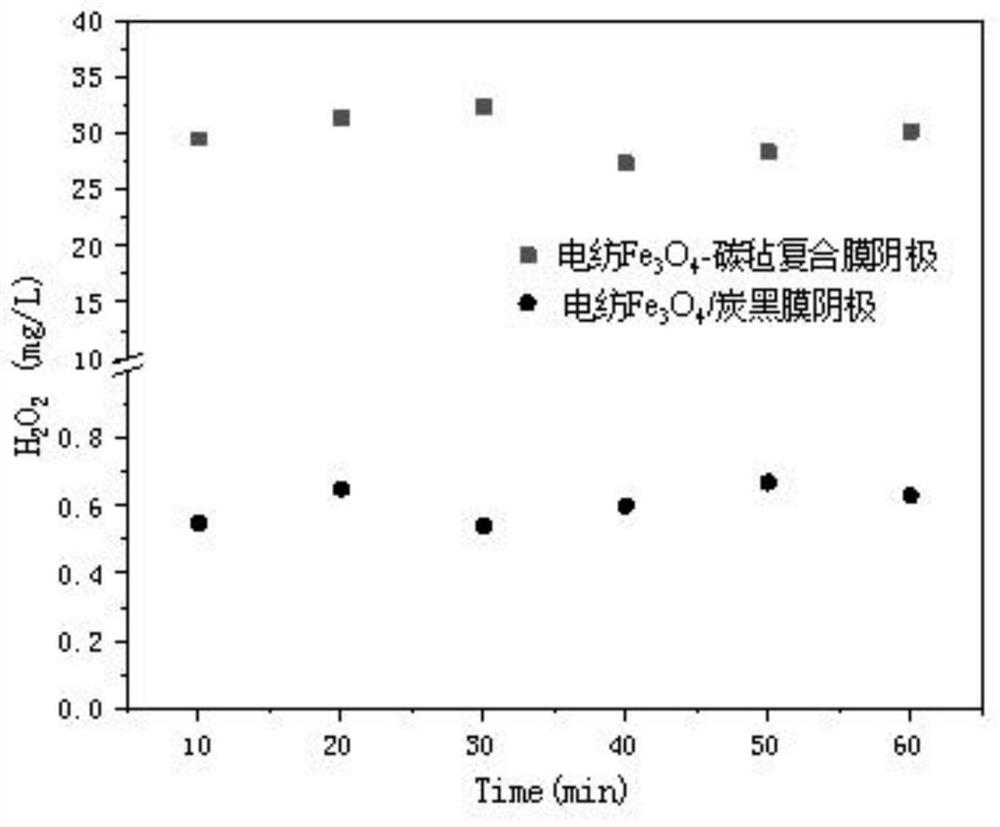

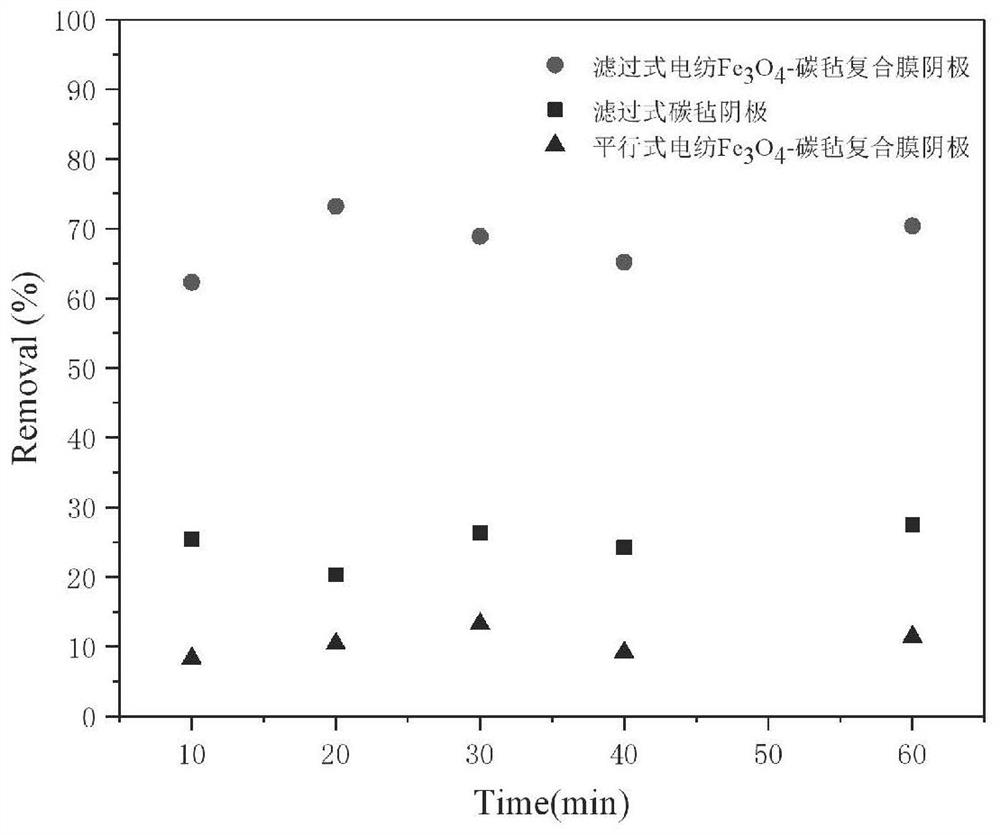

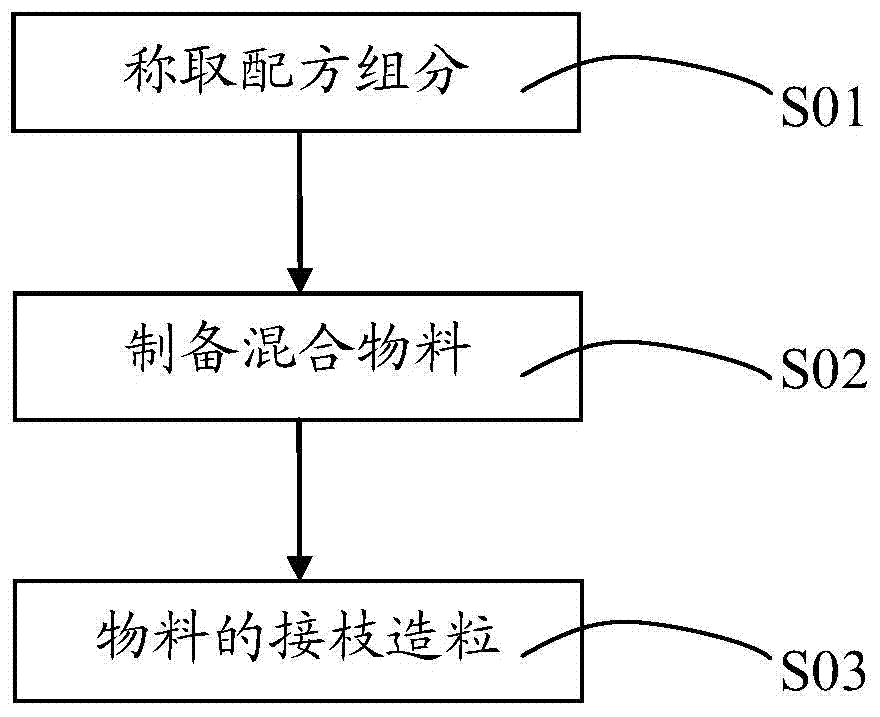

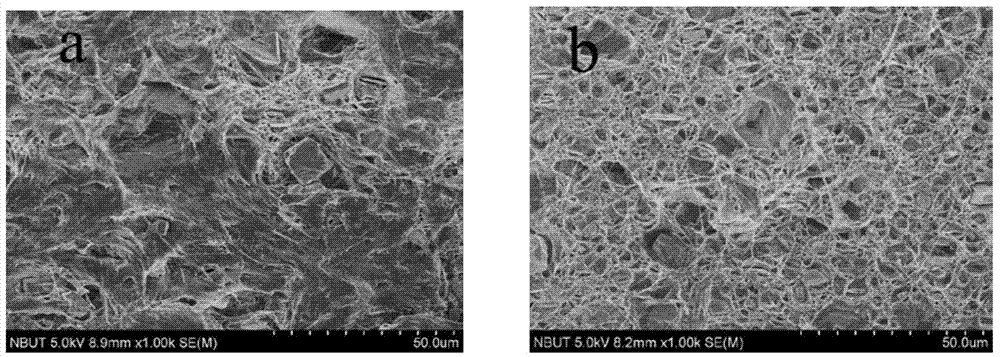

Preparation method and application method of electro-Fenton composite membrane cathode

ActiveCN112803030AAvoid reunionImprove dispersion performanceCell electrodesWater/sewage treatment by electrochemical methodsChemistryCatalytic membrane

The invention relates to a preparation method and an application method of an electro-Fenton composite membrane cathode, and the method comprises the following steps: uniformly dispersing nano-particles of a heterogeneous iron-containing catalyst in an electrostatic spinning solution, and collecting electrostatic fibers on a conductive carbon material carrier capable of producing hydrogen peroxide by adopting an electrostatic spinning technology, enabling the nano-particles to form an electrospinning catalytic membrane along with the electrostatic fiber generation process and loading the nano-particles on the carrier. According to the preparation method, the yield of hydrogen peroxide can be remarkably improved, especially in the electrostatic fiber generation process, a carbon felt which is modified by graphene and carbon black and has good conductivity is adopted as a fiber receiving device, hydrogen peroxide is efficiently generated in situ on the interface of the modified carbon felt, and .OH is generated in situ on the nano-particle catalysis interface. The yield of hydrogen peroxide is greatly improved, and the micro-pollutants enriched on the surface of the membrane cathode are efficiently catalyzed, so that the efficient removal of the micro-pollutants is realized.

Owner:HEBEI UNIV OF TECH

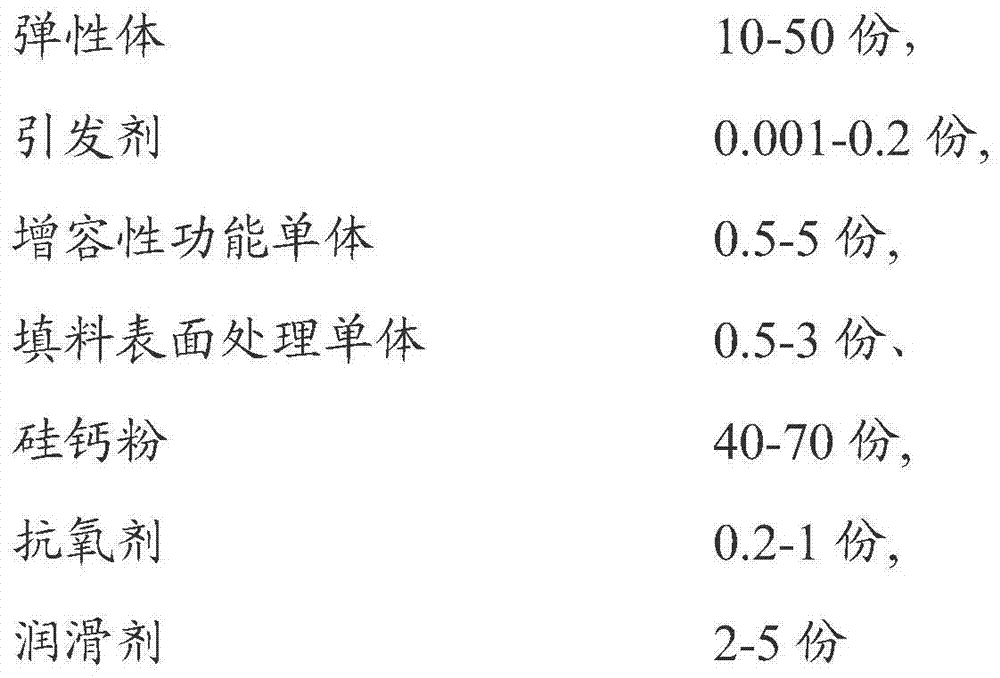

Reinforcing and toughening filling master batch with compatibilization performance and preparation method therefor

ActiveCN103709574AImproves Strength and ToughnessImprove dispersion performanceFunctional monomerSurface finishing

The invention belongs to the technical field of high-molecular materials, and provides a reinforcing and toughening filling master batch with a compatibilization performance and a preparation method therefor. The master batch comprises the following ingredients, by weight, 10-50 parts of an elastomer, 0.001-0.2 part of an initiator, 0.5-5 parts of a compatibilization functional monomer, 0.5-3 parts of a filling material surface treatment monomer, 40-70 parts of silicon calcium powder, 0.2-1 part of an anti-oxidant and 2-5 parts of a lubricant. The filling master batch has good reinforcing and toughening performances, and has an excellent compatibilization performance. The preparation method is advantaged by simple flows, reasonable and controllable technology conditions, simple processing technology and low cost, and is suitable for industrial production.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

Ultra-black large-melt-index high-dispersity black master batch special for direct spun fine-denier filaments

InactiveCN110903611ADispersion performance of super black melt fingerImprove dispersion performancePigment addition to spinning solutionPolyesterCarbon black

The invention discloses an ultra-black large-melt-index high-dispersity black master batch special for direct spun fine-denier filaments. The ultra-black large-melt-index high-dispersity black masterbatch is composed of the following components by weight: 25-30 parts of ultra-black carbon black, 74-67 parts of a polyester carrier and 1-3 parts of a dispersing agent. The black master batch provided by the invention is special for direct spun fine-denier filaments, and has ultra black, large melt index, and high dispersity performance.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

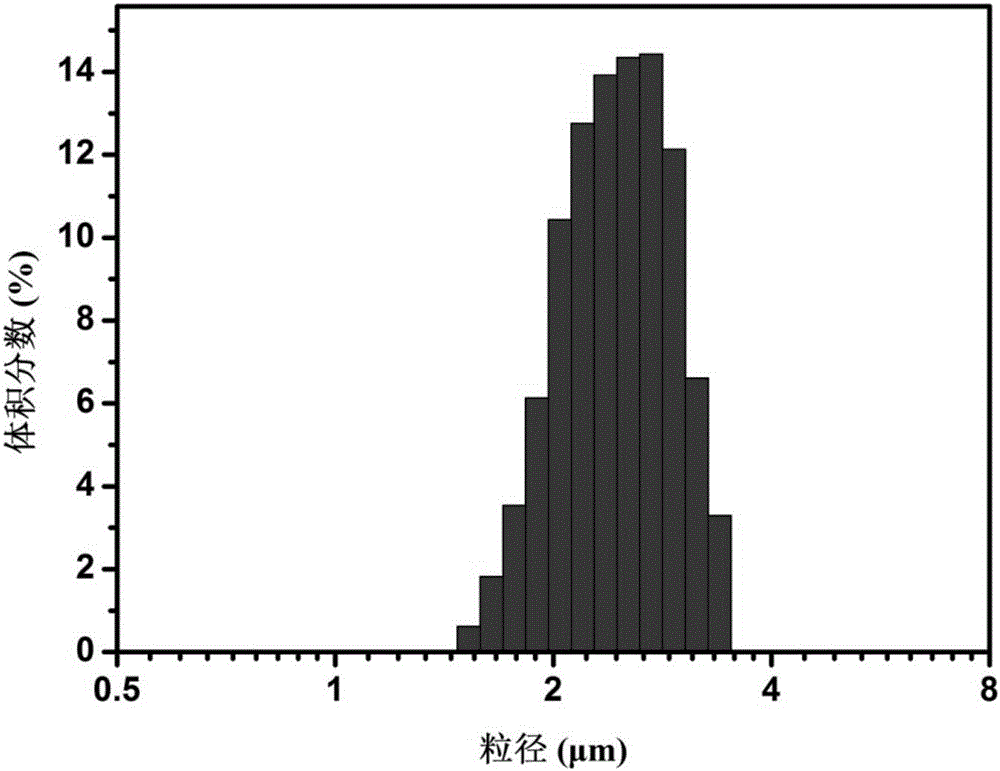

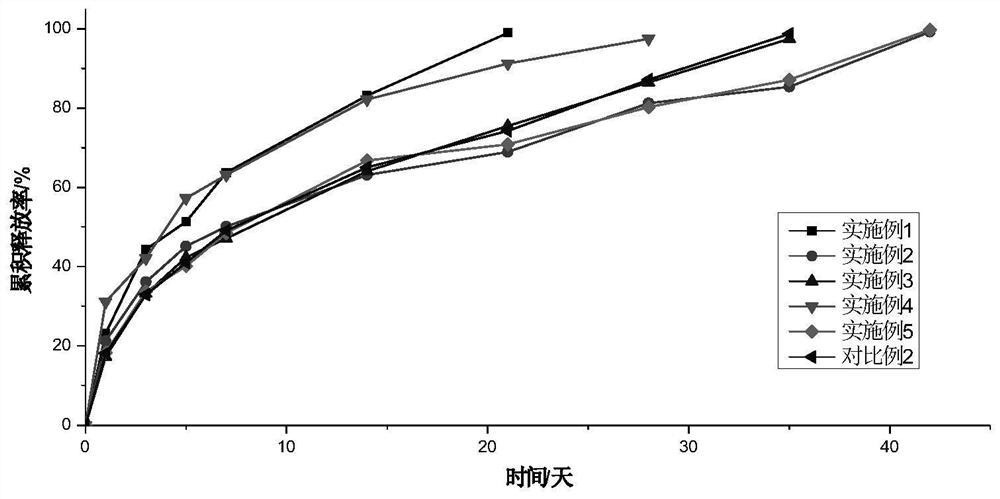

Microsphere-based stent as well as preparation method and application thereof

PendingCN112494728AImprove dispersion performanceStrong drug release abilityAdditive manufacturing apparatusTissue regenerationPolyesterBiomedical engineering

The invention discloses a microsphere-based stent as well as a preparation method and application thereof, the microsphere-based stent comprises a drug-loaded microsphere and a dispersing agent coating the surface of the drug-loaded microsphere, the drug-loaded microsphere comprises a polymer microsphere and a drug loaded in the polymer microsphere, the polymer microsphere is made of degradable polyester, and the dispersing agent is a hydrophilic high polymer material. According to the invention, the dispersing agent is used for coating the surfaces of the drug-loaded microspheres, the dispersing performance of the drug-loaded microspheres in the binder can be improved on the premise that the cohesiveness of the drug-loaded microspheres is not remarkably reduced, certain flowability can bekept before curing after the drug-loaded microspheres are subsequently mixed with the binder, which is conducive to subsequent 3D printing, and has good application prospects in tissue repair and regeneration materials.

Owner:GUANGDONG PROV MEDICAL INSTR INST

Preparation method of building adhesive

InactiveCN111100594AAvoid hollowingImprove dispersion performanceCyclodextrin adhesivesPolyureas/polyurethane adhesivesDivalent metalSurface bonding

The invention belongs to the field of adhesive manufacturing, and particularly relates to a preparation method of a building adhesive. According to the invention, waste straw is used as a raw materialto prepare the building adhesive. The building adhesive is a water-based adhesive, the tackifying cyclodextrin is cyclodextrin cationized by glycidyl chloride trimethylammonium, and the cationic cyclodextrin can coat cement in mortar in a colloid form in water, so that the bonding strength is improved, and the hollowing phenomenon of the adhesive is avoided; carboxymethylation is performed on lignin; the dispersion performance of cyclodextrin is favorably improved, and the carboxymethylated lignin has an obvious complexing effect on divalent metal salt ions, so that salting-out can be avoidedwhile the bonding strength is improved, the carboxymethylated lignin can increase the average molecular weight of the cyclodextrin and can improve the deposition density of the cyclodextrin during construction surface bonding, the polyvinyl formal enhances the flexibility and pressure resistance of an adhesive film after the adhesive is cured, the flexibility and bonding strength of the adhesiveare improved, and the adhesive has a wide application prospect.

Owner:罗桂富

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com