Iron-carrying meso-porous silicon composite material as well as preparation method and application thereof

A silicon composite material and composite material technology, applied in the field of materials, can solve the problems of difficulty in recycling nano zero-valent iron particles, affecting the ability of dispersion and migration, large specific surface area of nano iron, etc., achieving low price, short drying time, increased The effect of dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

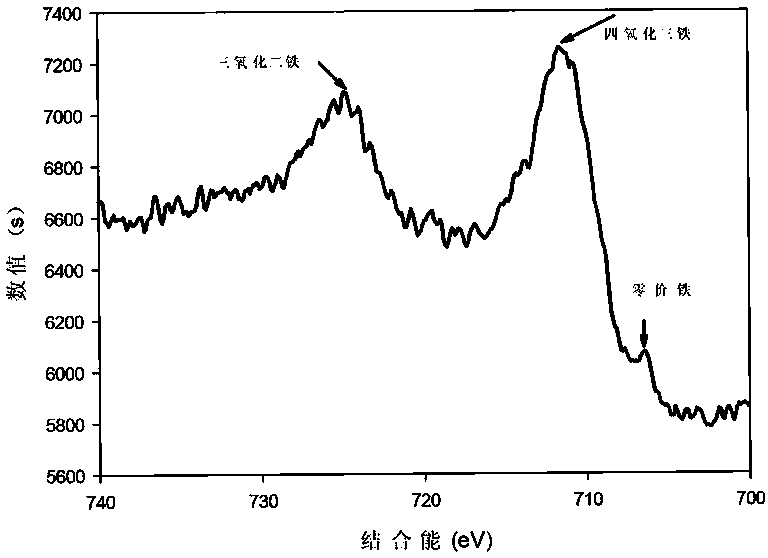

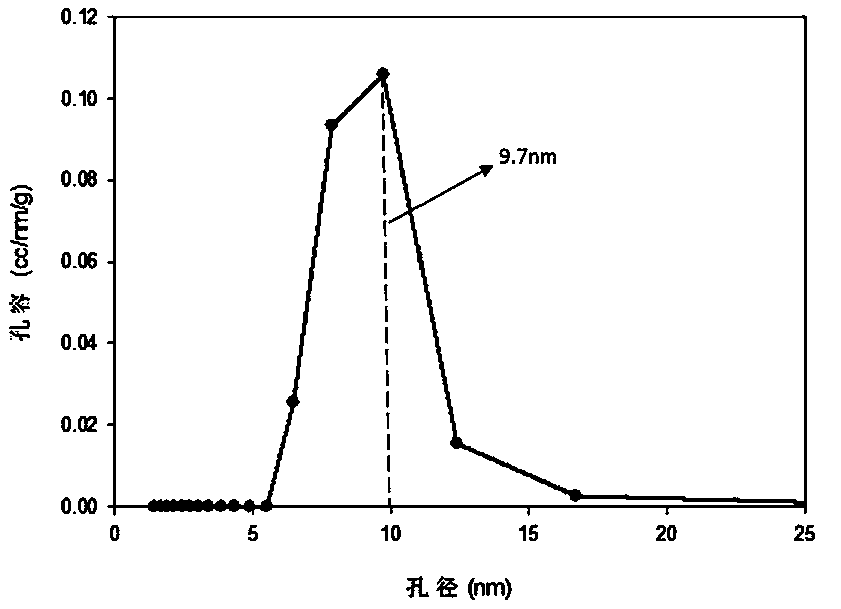

[0035] A preparation method of iron-loaded mesoporous silicon composite material:

[0036] (1) Preparation of mesoporous silicon SBA-15 carrier:

[0037] First, 4.0 g of block copolymer P123 was added to 160 mL of hydrochloric acid solution with a concentration of 1.54 mol / L, placed in a 35 °C water bath and stirred until dissolved, and then 8.6 g of tetraethyl orthosilicate (TEOs) was added dropwise to obtain a mixture . The aforementioned mixture was stirred at 35°C for 20 h, then transferred to a reaction kettle, and heated at 140°C for 24 h to obtain a white precipitate. Filter the white precipitate to collect the precipitate, air-dry the precipitate at room temperature, and obtain a white powder after drying; put the white powder obtained above into a box furnace, control the heating rate to 1°C / min, and heat up to 550°C in air for 4 h, to remove excess block copolymer P123, after the block copolymer P123 is removed, the mesoporous silicon SBA-15 carrier is obtained by ...

Embodiment 2

[0048] Take 80 ml of wastewater with a p-nitrophenol concentration of 400 mg / L, divide it into 8 groups on average, each group is 10 mL, and adjust the pH value of the solution to 2, 3, 4, 5, 6, 7, 8, and 9, respectively. To each group of wastewater, 50 mg of iron-loaded mesoporous silicon composite reduction material (experimental group) or mesoporous silicon material (control group) was added, and the temperature was 25 °C and the rotation speed was 150 rpm. After the reaction was completed, carry out solid-liquid separation with a 0.2 μm filter membrane, and measure the amount of unreduced p-nitrophenol in the filtrate using a UV-visible spectrophotometer. The experimental results are as follows: Figure 4 shown.

[0049] Depend on Figure 4 It can be seen that the reduction efficiency of the iron-loaded mesoporous silicon composite material of the present invention decreases slightly and then increases with the increase of the pH of the solution. When the pH of the soluti...

Embodiment 3

[0051] Prepare 30 groups of 10 mL p-nitrophenol-containing solutions, the initial concentrations of which are 200 mg / L, 400 mg / L, and 600 mg / L each in 10 parts, respectively add 50 mg of the iron-loaded mesoporous silicon composite prepared in Example 1 materials, at around 25°C and 150 rpm, for different concentrations of p-nitrophenol solutions (concentrations of p-nitrophenol solutions are 200 mg / L, 400 mg / L, 600 mg / L respectively) and the reaction time Samples were taken at 1 min, 2 min, 3 min, 5 min, 15 min, 30 min, 60 min, 90 min, 120 min, and 240 min, and the reaction solution was separated from the solid and liquid by a 0.2 μm filter membrane, and finally used The concentration of p-nitrophenol (PNP) solution after treatment was measured by ultraviolet-visible spectrophotometer.

[0052] The result is as Figure 5 shown by Figure 5 It can be seen that the iron-loaded mesoporous silicon composite material of the present invention has a good removal effect on p-nitrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com