Patents

Literature

262results about How to "Improves Strength and Toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

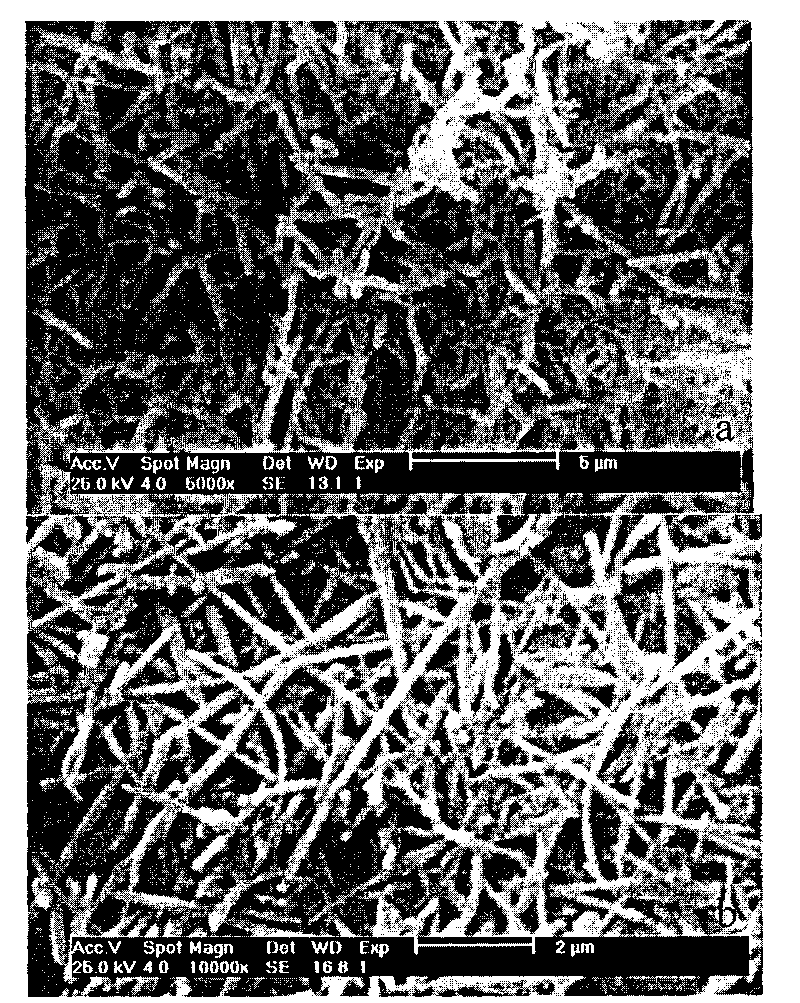

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

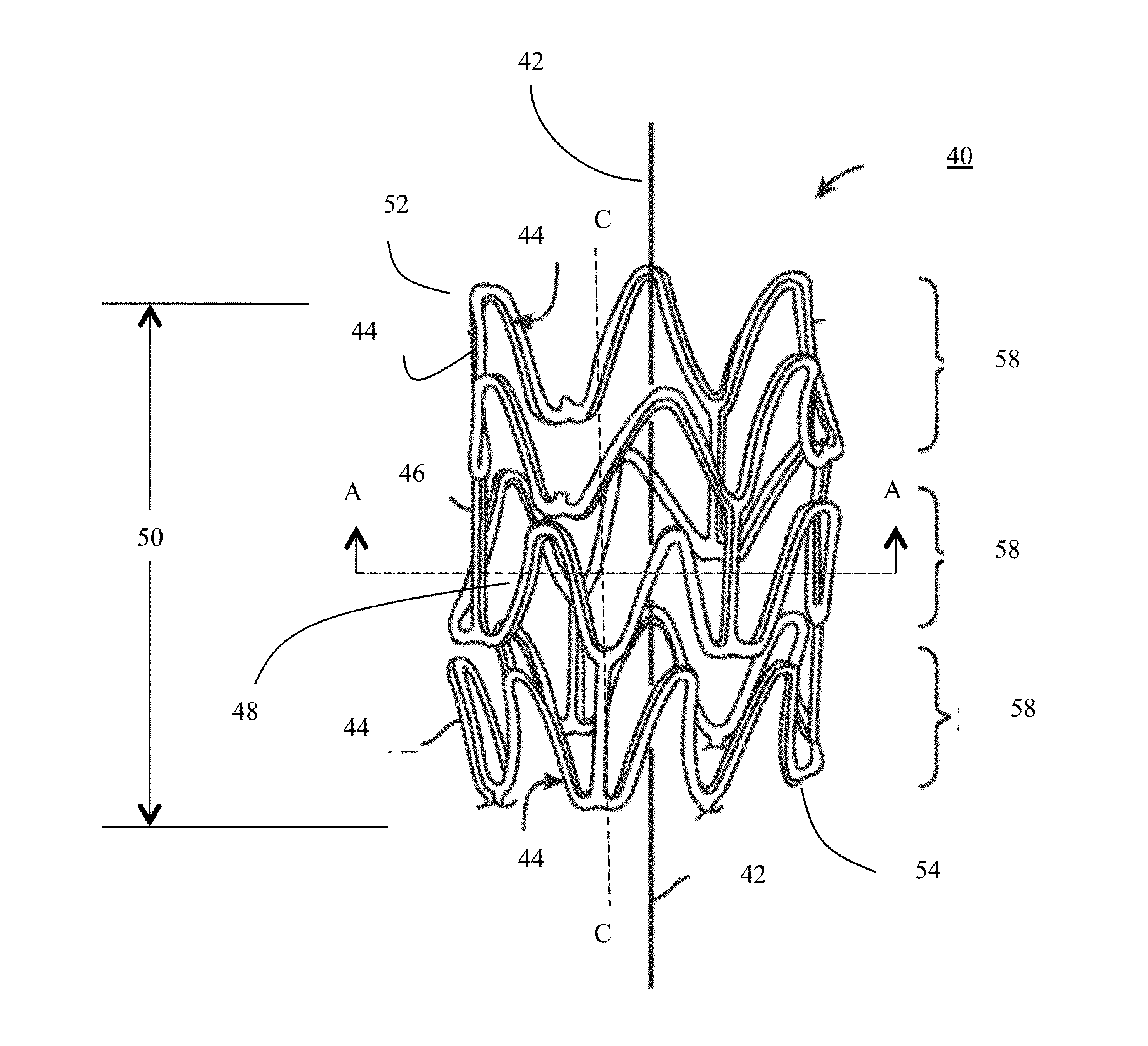

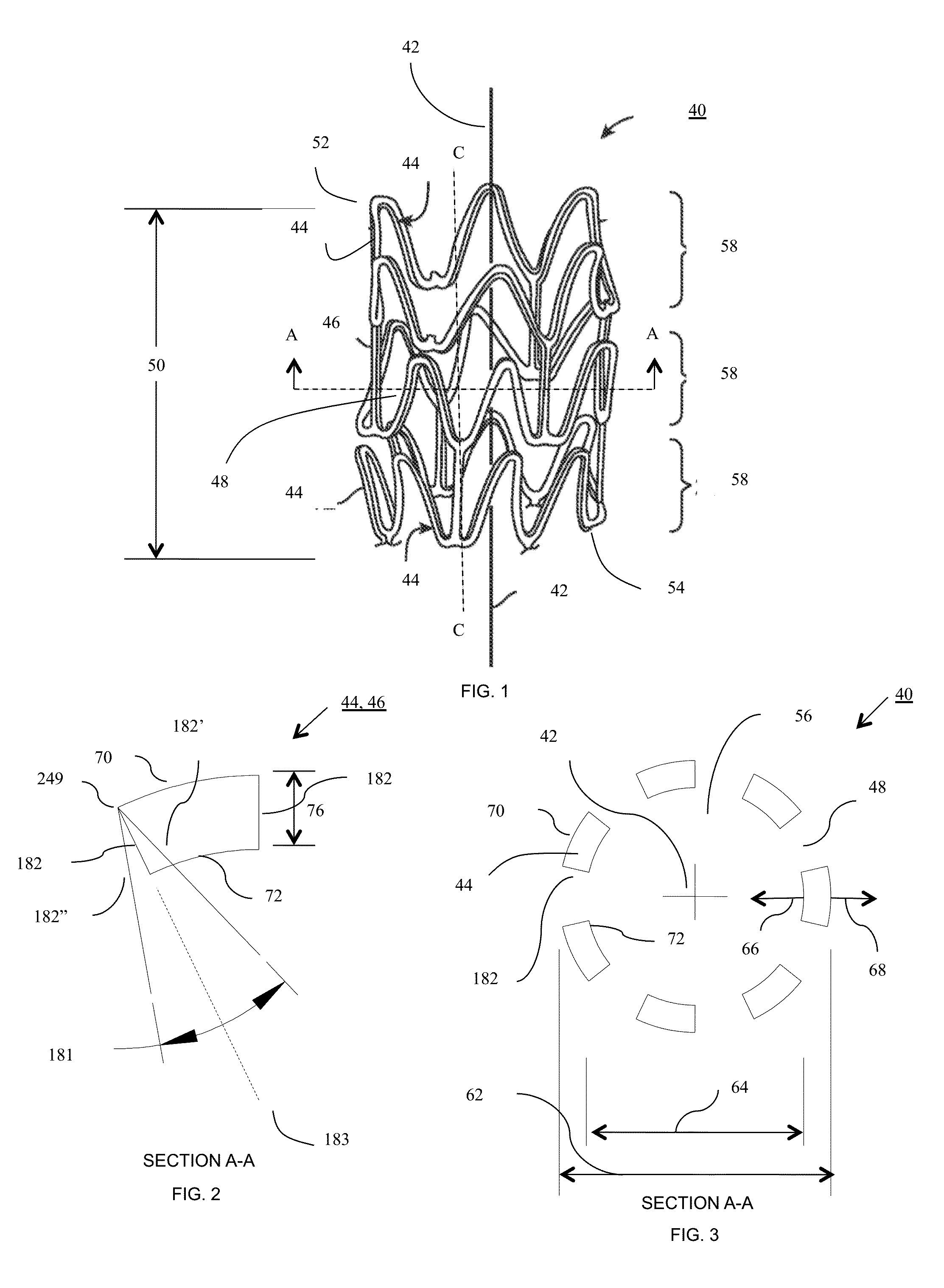

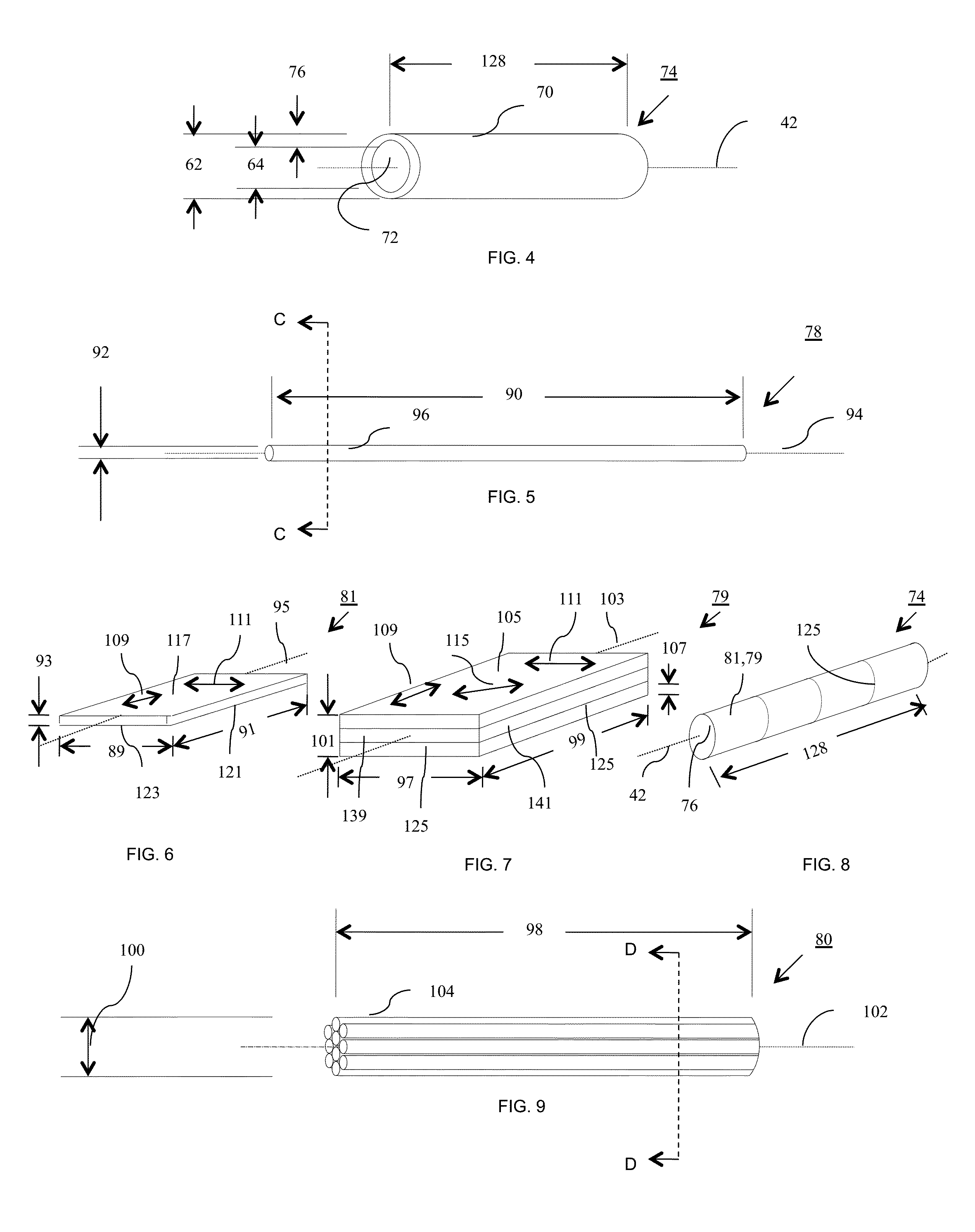

Bioresorbable Stent

ActiveUS20150306282A1Improve radial strengthMinimize luminal wall contact surface areaStentsSurgerySide effectPercent Diameter Stenosis

Disclosed herein is a high strength, bioresorbable wall thickness suitable for use in an endoprosthesis such as a stent that is produced by first forming a wall thickness by melt processing or solution processing one or more bioresorbable materials into a tubular shape; drawing the shape from shorter length to an optimum longer length and reducing the diameter from a larger diameter to a smaller diameter to orient the molecular chains of the material; fabricating a stent from the tube formed of the oriented material by cutting a strut pattern in its wall thickness; covering the stent's struts with at least one coating to delay degradation of the bioresorbable material; covering the stent's struts with one or more controlled release active ingredients to minimize the risk of restenosis or other side effects; crimping the stent onto a balloon catheter assembly; delivering the stent into an anatomical lumen via percutaneous methods to a treatment location; radially expanding the stent from a smaller size to a larger size at the treatment location wherein the stent temporarily supports the anatomical lumen; and removing the catheter from the lumen.

Owner:SCANLON JOHN JAMES +1

Preparation method of flexible binding agent-free self-support combination electrode

ActiveCN102945947ASimple methodImproves Strength and ToughnessCell electrodesThird phaseConductive materials

The invention relates to a preparation method of a flexible binding agent-free self-support combination electrode, comprising the following steps of: adding active electrode materials into flexible conductive material-containing even dispersion liquid according to specified proportion or generating electrode precursor materials of active electrode materials in the manner of proper reaction; sufficiently stirring, so that the active electrode materials are evenly dispersed among the active electrode materials or the surfaces of the active electrode materials; and adding third phase material-containing even dispersion liquid according to specified proportion, stirring, filtering, washing, and drying.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

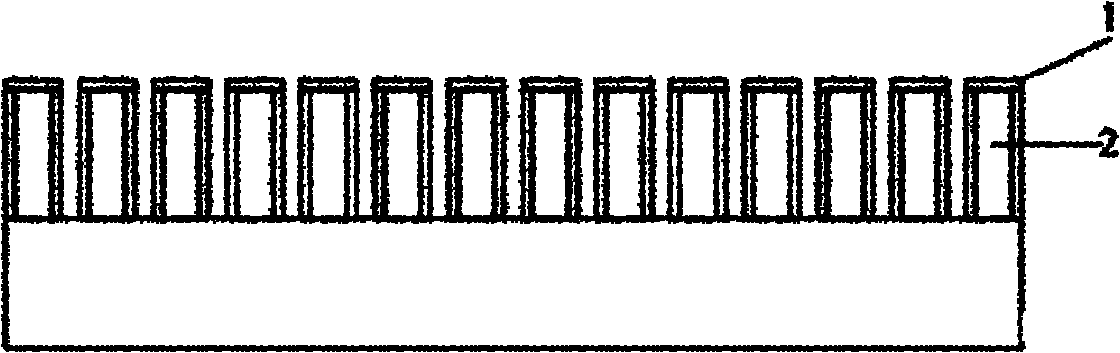

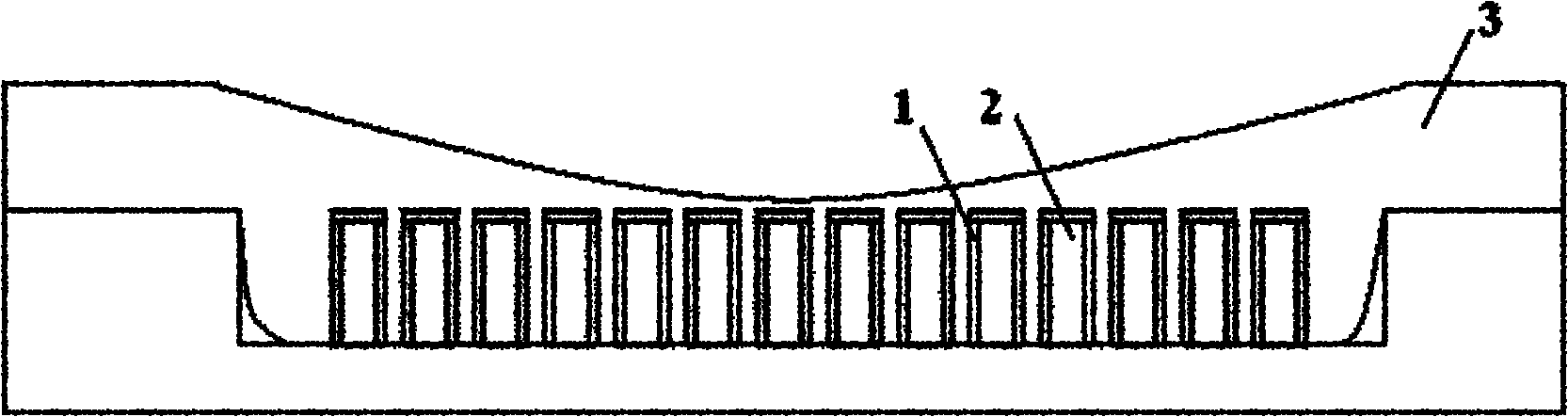

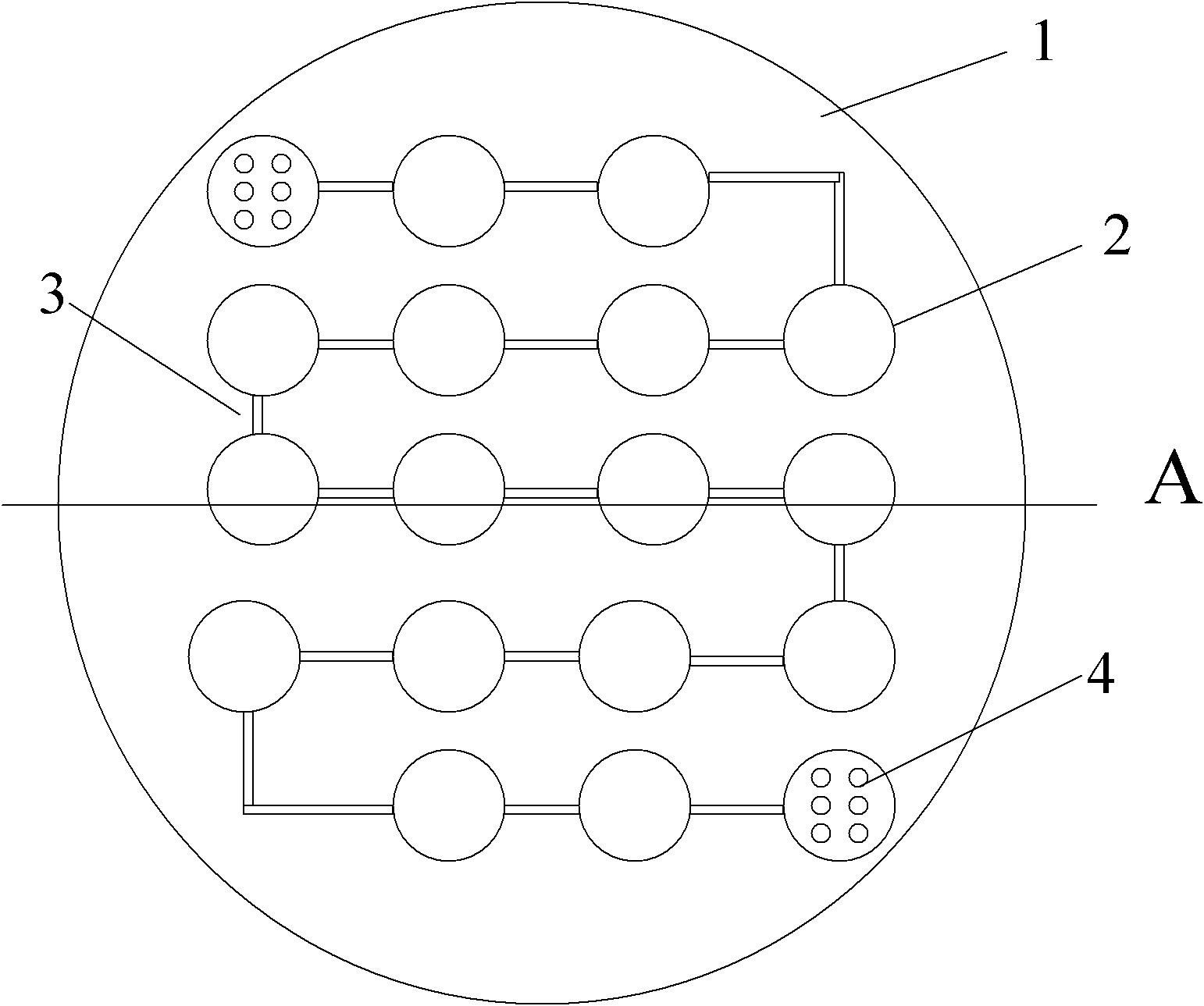

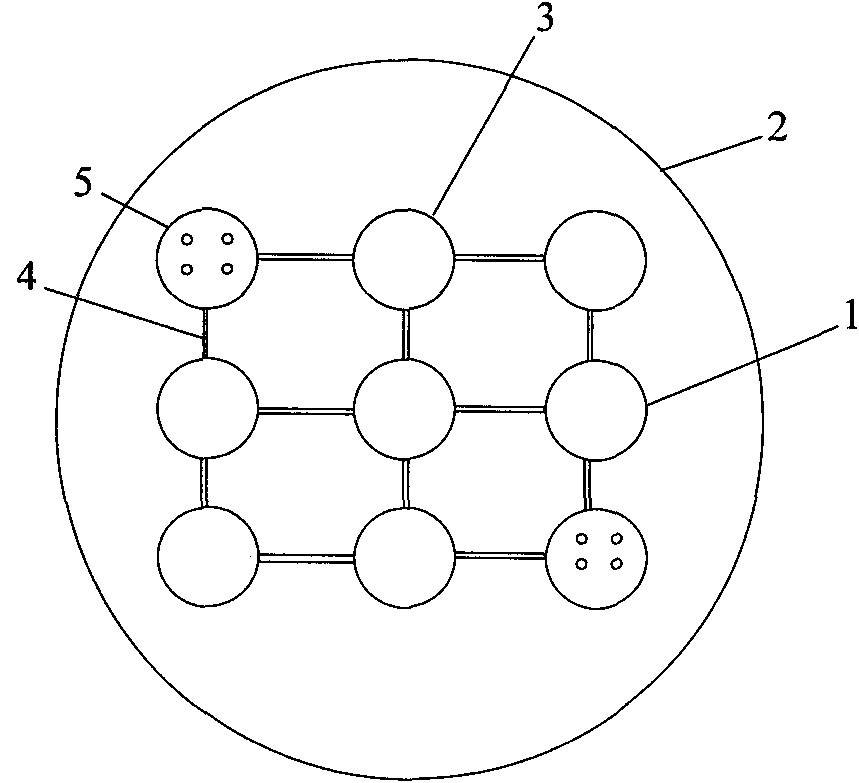

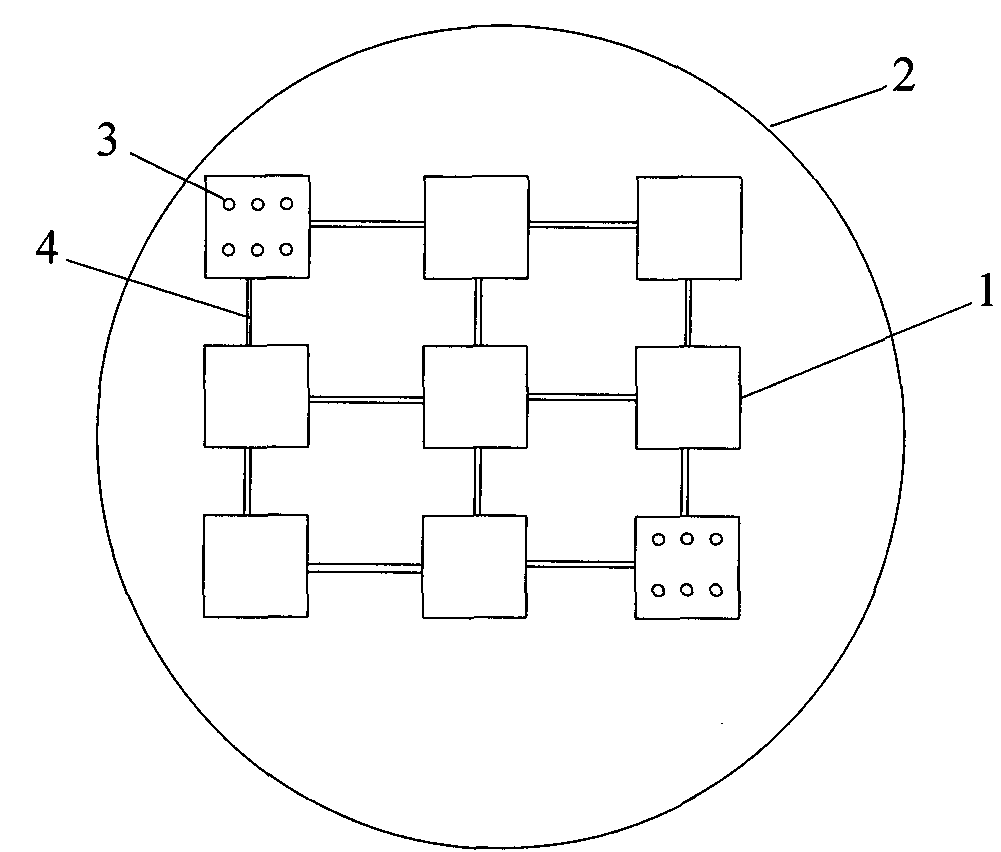

Preparation method for high-density interposer for microelectronic system-in-package

ActiveCN102070120AImprove reliabilitySmall coefficient of thermal expansionDecorative surface effectsChemical vapor deposition coatingThermal dilatationElectrical conductor

The invention discloses a preparation method for a high-density interposer for microelectronic system-in-package. The preparation method comprises the following steps of: 1, preparing a drectionally growing carbon nanotube bundle array, wherein the diameter of each carbon nanotube bundle is 0.5 to 30 microns, the gap of the carbon nanotube bundle is 0.8 to 100 microns, and the carbon nanotube bundle is 40 to 500 microns long; 2, depositing metal tungsten on the surface of the drectionally growing carbon nanotube bundle so as to form a conductor array; 3, melting borosilicate glass and compounding the melted borosilicate glass with the conductor array so as to form a compound body; and 4, grinding the upper surface and the lower surface of the formed compound body so as to expose the end of the carbon nanotube bundle deposited with the metal tungsten, and obtaining the high-density interposer for the system-in-package. The material adopted by the preparation method has low thermal expansivity and the process method is low in time consumption, so the prepared high-density interposer has the advantages of high density, high reliability and low cost.

Owner:SOUTHEAST UNIV

Aluminum alloy for high-pressure casting

The invention relates to aluminum alloy for high-pressure casting. The aluminum alloy for high-pressure casting comprises, by weight percentage, 4.5-7.5 % of silicon, 0.5-1.0 % of copper, 0.5-1.0 % of magnesium, 0.3-1.0 % of iron, 0.3-0.5 % of zinc, 0.3-0.5 % of manganese, 0.3-0.5 % of nickel, 0.13-0.15 % of strontium, 0.01-0.003 % of titanium, less than 0.003 % of boron, and lead as the rest. The aluminum alloy for high-pressure casting effectively improves the strength and tenacity of aluminum alloy, grains in the aluminum alloy microstructure are refined evenly, and the high-pressure casting performance of the aluminum alloy is effectively improved.

Owner:虞海香

Bone china and preparation method thereof

The invention provides bone china and a preparation method thereof and relates to chain forming products characterized by components. The bone china is sepiolite mineral nanofiber toughened bone china and comprises the following components in percentage by weight: bone powder 30-40%; Laiyang soil 9-15%; albite 15-20%; Datong soil 5-8%; Fangzi soil 5-10%; Longyan soil 15-20%; and sepiolite mineral nanofiber 2-8%. The preparation method comprises the following steps: treating sepiolite by a jet mill to obtain the sepiolite mineral nanofiber which is used as raw materials of blank materials by required weight percent; and preparing the raw material into the blank materials by adding water for ball-milling, sieving, deironing and aging and rotting; carrying out blank forming, drying and fettling on the blank materials to obtain a blank body; and then porcelainizing to prepare the sepiolite mineral nanofiber toughened bone china. The bone china has higher toughness, simple preparation process and low preparation cost.

Owner:HEBEI UNIV OF TECH

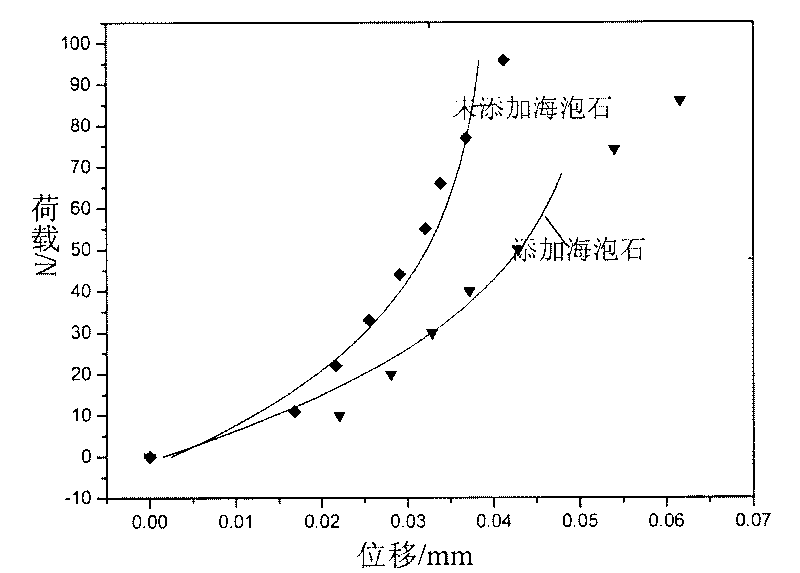

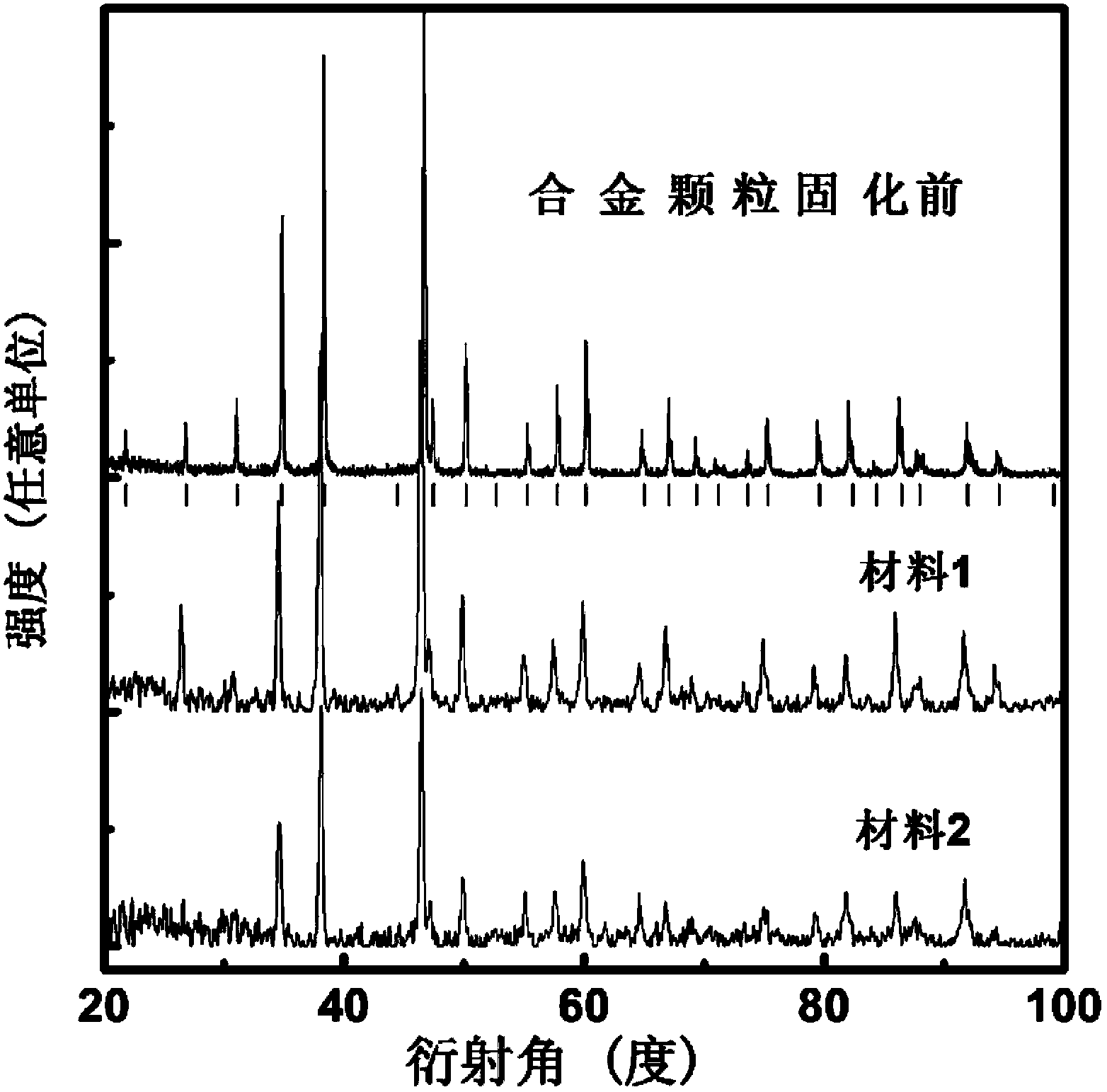

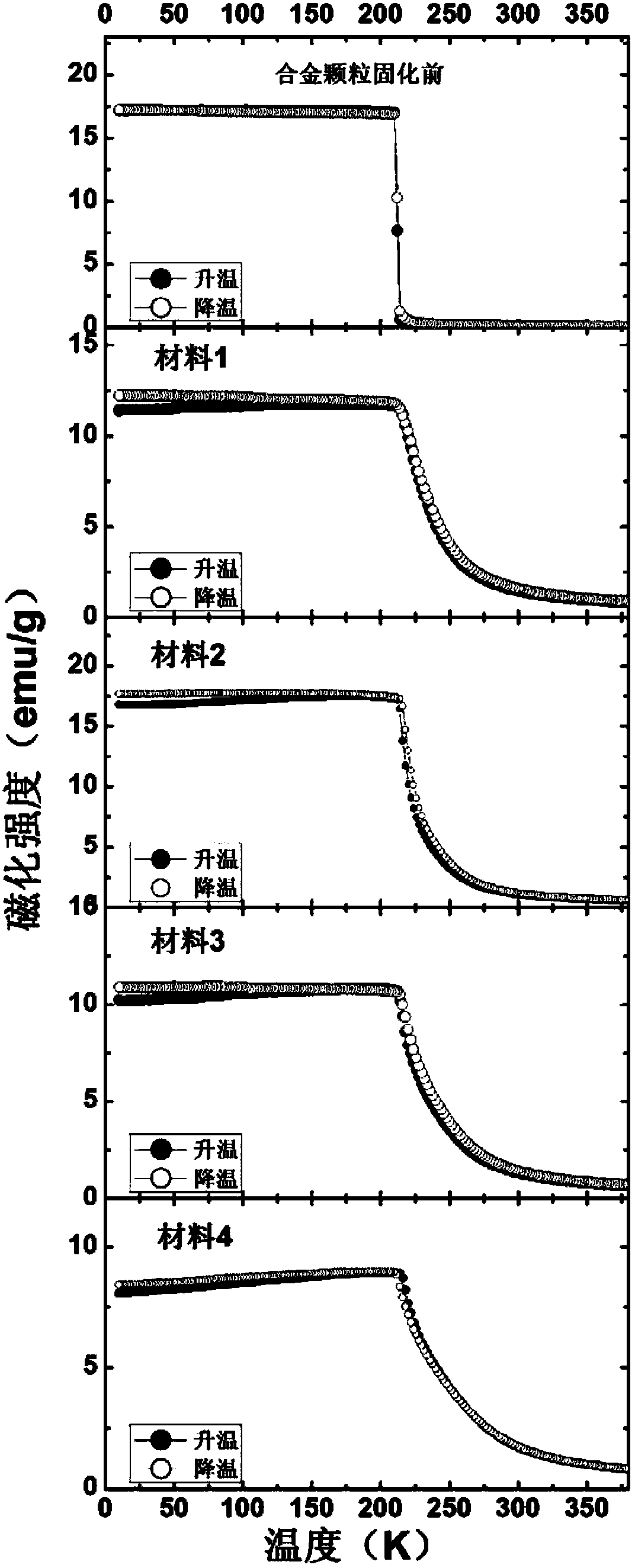

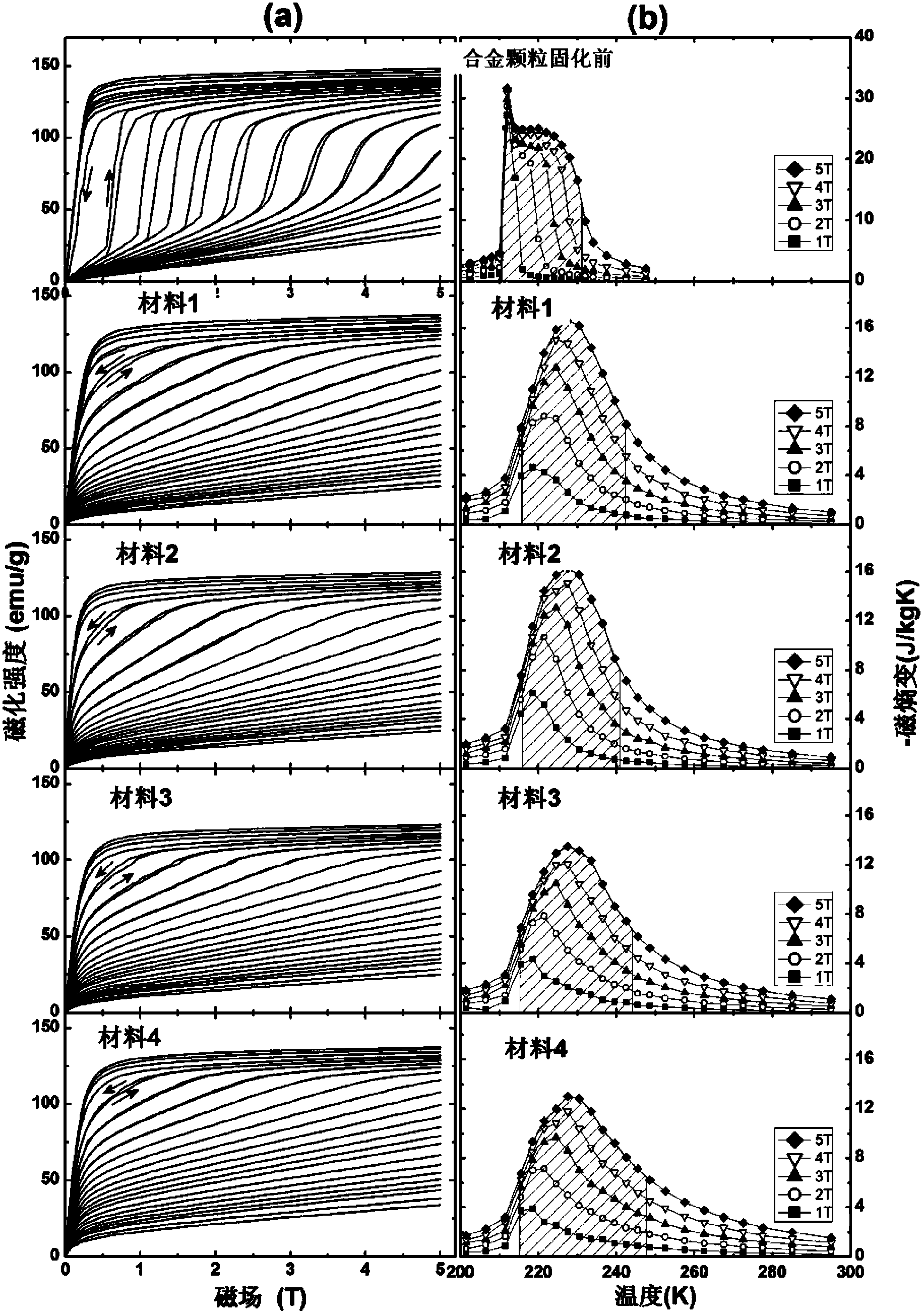

Thermoplastic molding adhesion magnetic refrigerant materials, preparation method and applications

ActiveCN103422014ALow priceImproves Strength and ToughnessMagnetic materialsThermoplasticHigh intensity

The invention provides magnetic refrigerant materials, a preparation method and applications. The materials comprise alloy particles with magnetocaloric effects and thermoplastic-type adhesion agents, wherein the particle size of the alloy particles is less than or equal to 200 microns; the alloy particles are adhered into block materials by the adhesion agents through thermoplastic molding; the alloy particles with magnetocaloric effects are La(Fe, Si)13-based materials with a NaZn13-type structure, the preference being La0.7Ce0.3Fe11.6Si1.4Cx, wherein x is more than or equal to 0.2 and less than or equal to 0.3. La(Fe, Si)13-based materials with magnetocaloric effects, high strength and good toughness are obtained through adhesion of adhesion agents and thermoplastic molding methods. The problem that materials with magnetocaloric effects are fragile is overcome. Though the range of magnetic entropy change and effective refrigerating capacity are declined compared to the range and the refrigerating capacity before adhesion, the range is still considerable. When the magnetocaloric materials prepared through the thermoplastic molding technology are compared to magnetocaloric materials prepared through the thermosetting molding technology, the toughness of the magnetocaloric materials prepared through the thermoplastic molding technology is enhanced greatly, the dependent variable corresponding to the maximum supporting pressure is increased greatly.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

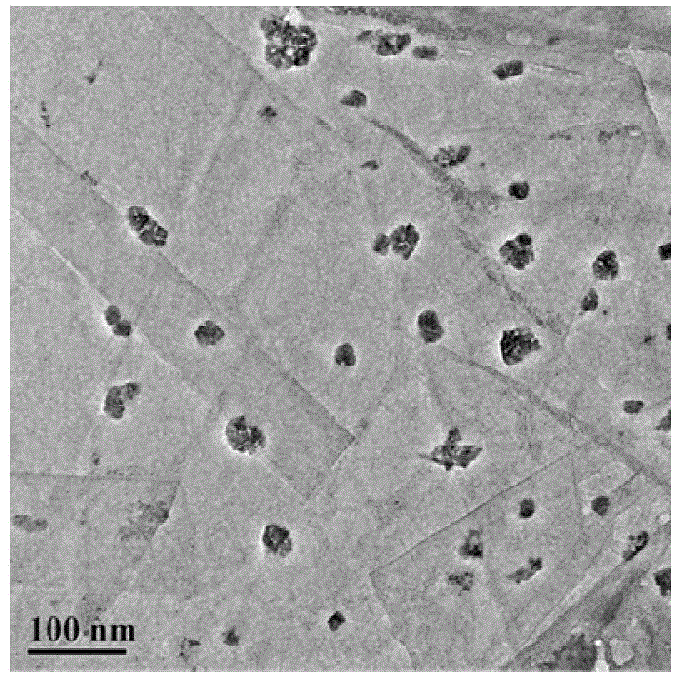

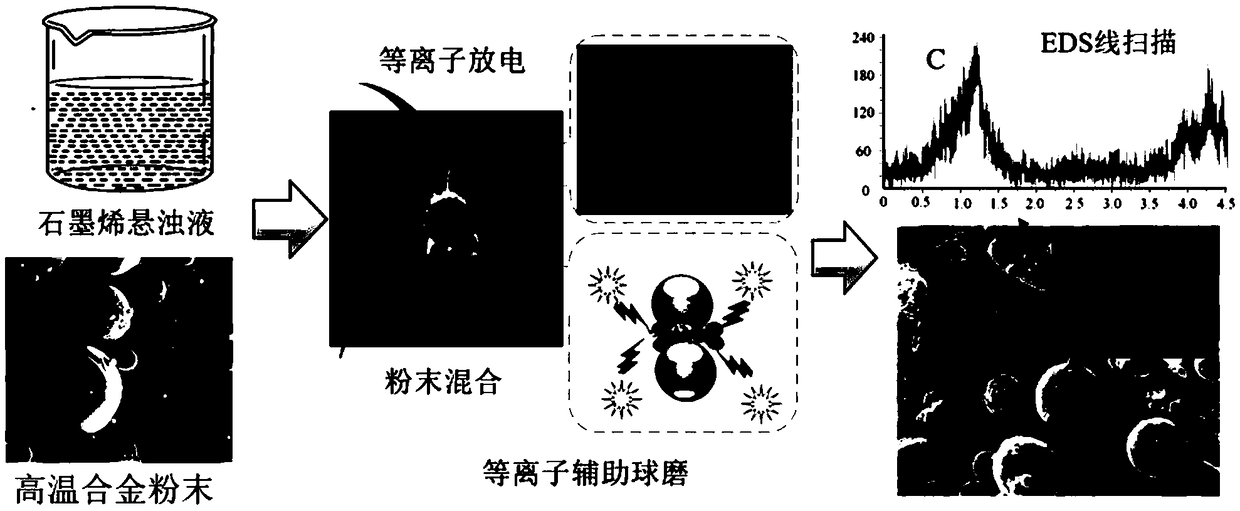

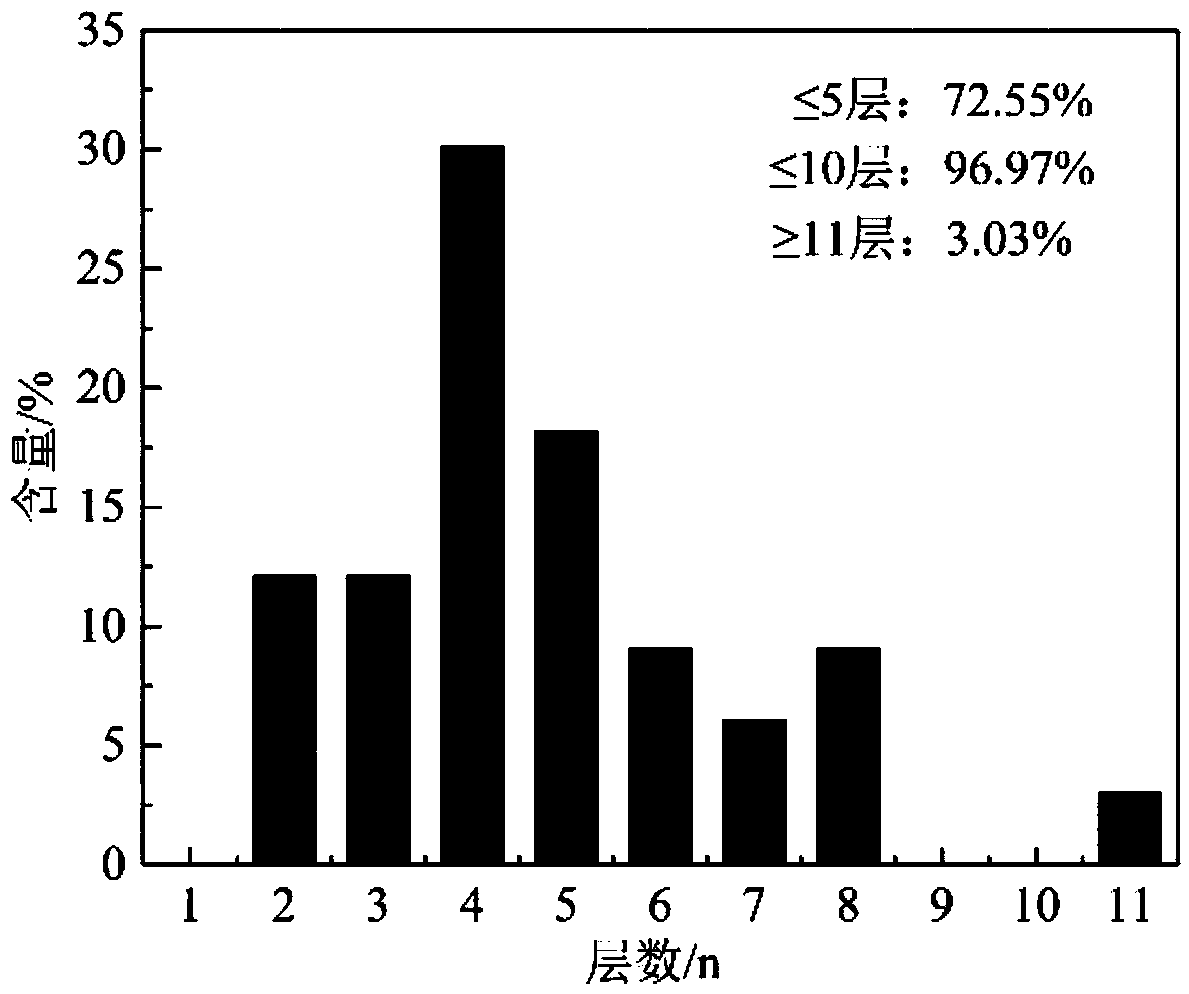

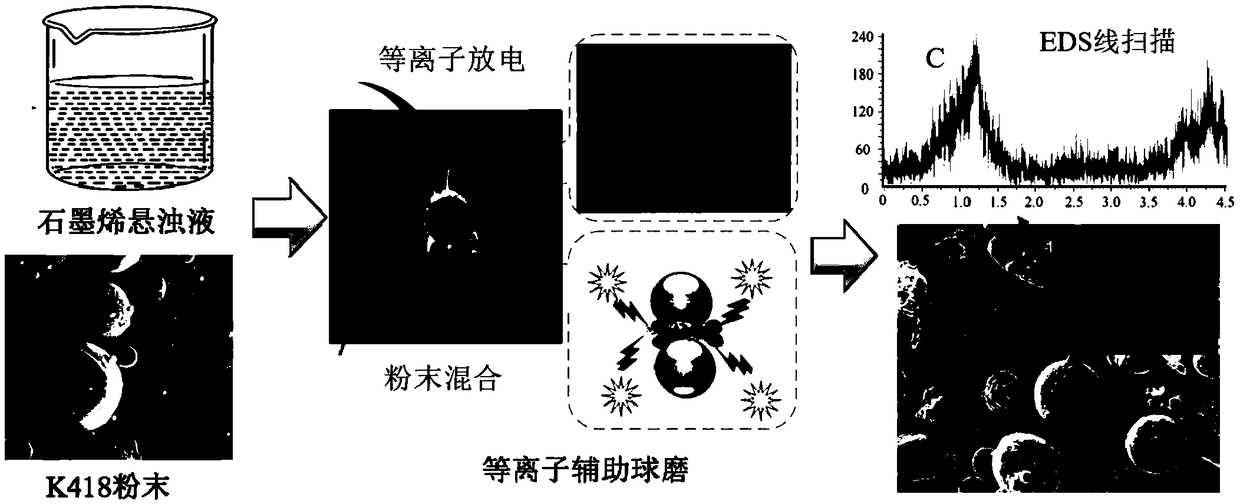

Preparation method of graphene alloy nanocomposite and SLM (Selective Laser Melting) forming process

InactiveCN109454240AImproves Strength and ToughnessReduced hot cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencyCvd grapheneInterfacial reaction

The invention discloses a preparation method of a graphene alloy nanocomposite and an SLM (Selective Laser Melting) forming process. According to the preparation method, turbid liquid is prepared through the ultrasonic vibration of anhydrous ethanol, so that the graphene is uniformly dispersed in the anhydrous ethanol, the graphene is uniformly dispersed, then after the graphene anhydrous ethanolturbid liquid is mixed with high-temperature alloy in proportion, the graphene and partial residue are distributed in the grain boundary and crystals by participating in the interfacial reaction, so that the strength and toughness of a formed part are improved, and the hot cracking tendency is reduced; the addition of graphene changes the organization form of the material; and in the SLM forming process, the graphene in the graphene high temperature alloy nanocomposite is used as a heterogeneous nucleating agent, and increases the nucleation rate in the solidification crystallization process.The graphene high temperature alloy nanocomposite is prepared by the dielectric barrier discharge plasma-assisted ball milling technique. The plasma enhances the activity of powder, so that columnar crystals preferentially growing change to isometric crystals, grains are refined and the performances are improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

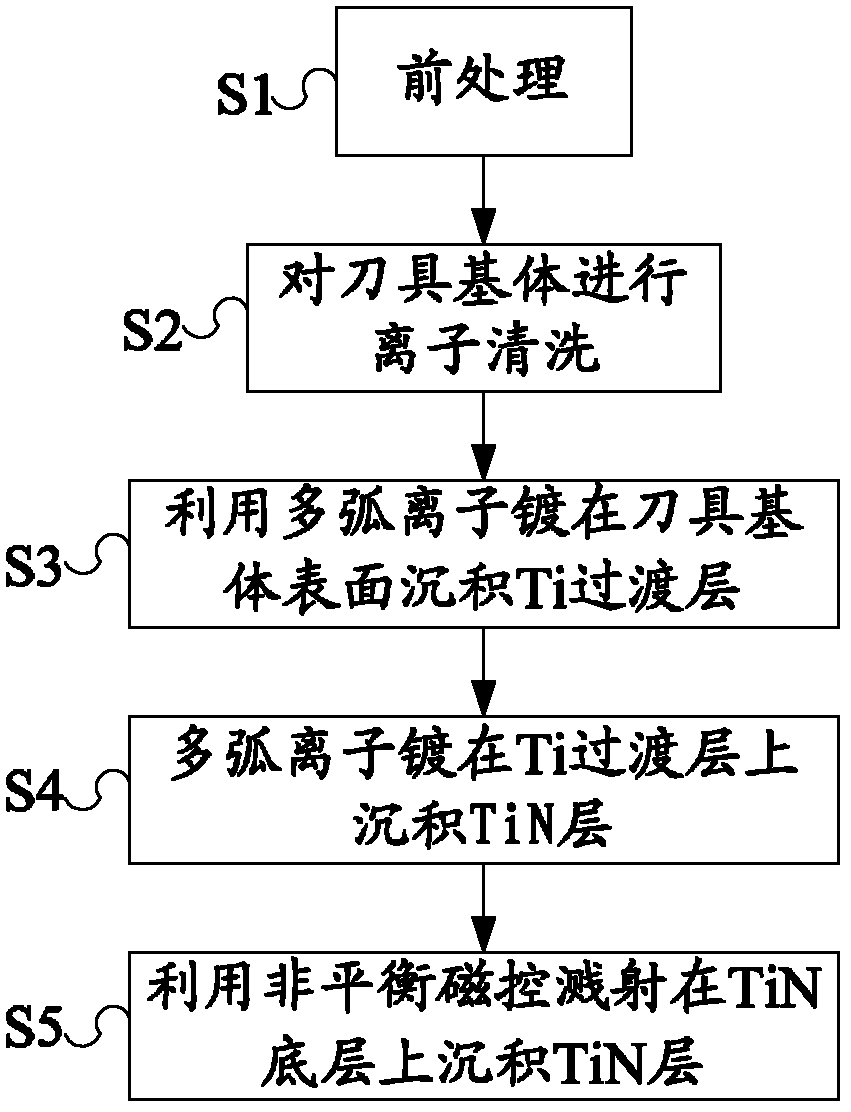

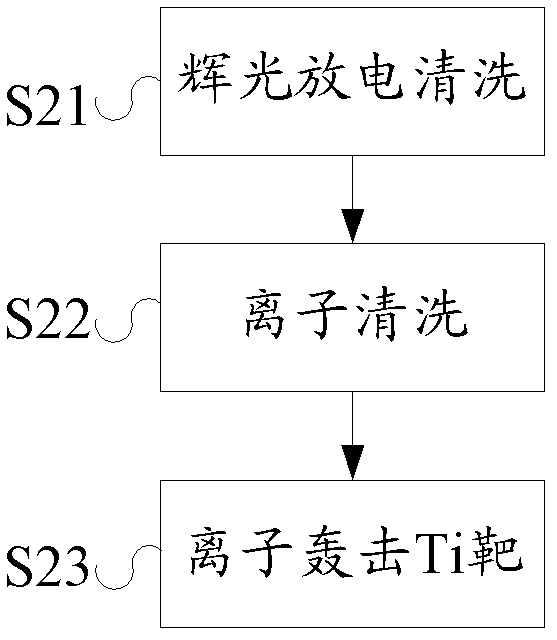

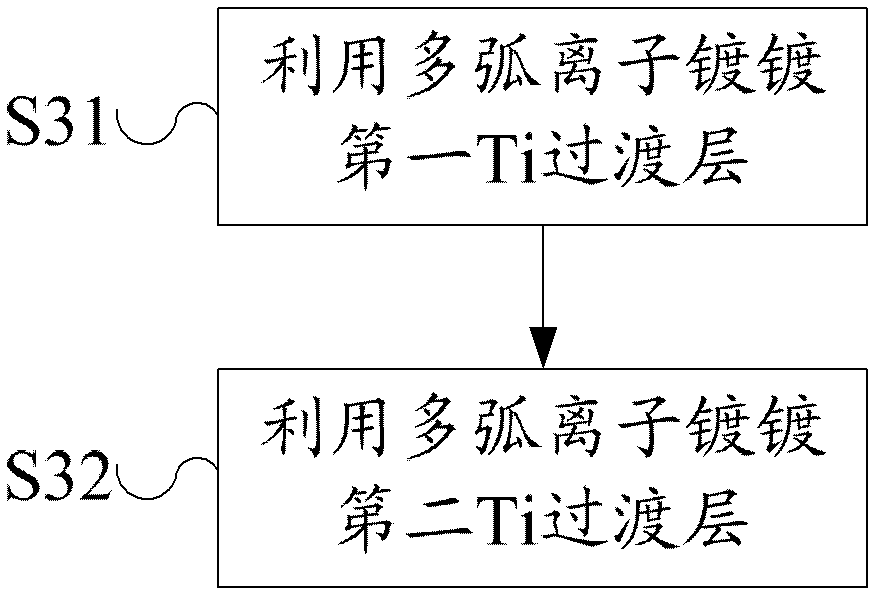

Machining method of wear-resistant cutters

ActiveCN102517546AImproves Strength and ToughnessGood impact and abrasion resistanceVacuum evaporation coatingSputtering coatingIonDuctility

The invention discloses a machining method of wear-resistant cutters, which includes steps of pretreating; cleaning bases of the cutters in an ionized manner; depositing a Ti transitional layer on the surface of the bases of the cutters by means of multi-arc ion plating; depositing a TiN bottom layer on the Ti transitional layer by means of multi-arc ion plating; and depositing a TiN layer on the TiN bottom layer by means of unbalanced magnetron sputtering. Since coating layers are prepared and deposited by means of multi-arc ion plating and unbalanced magnetron sputtering, strength and ductility of the coating layers can be improved evidently, impact resistance and wear resistance of the cutters are better and the service lives of the cutters in mechanical engineering devices are prolonged effectively.

Owner:SHANTUI CONSTR MASCH CO LTD

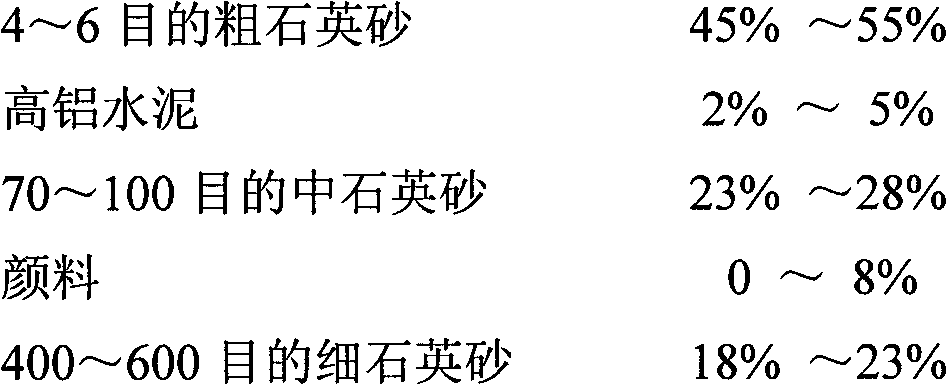

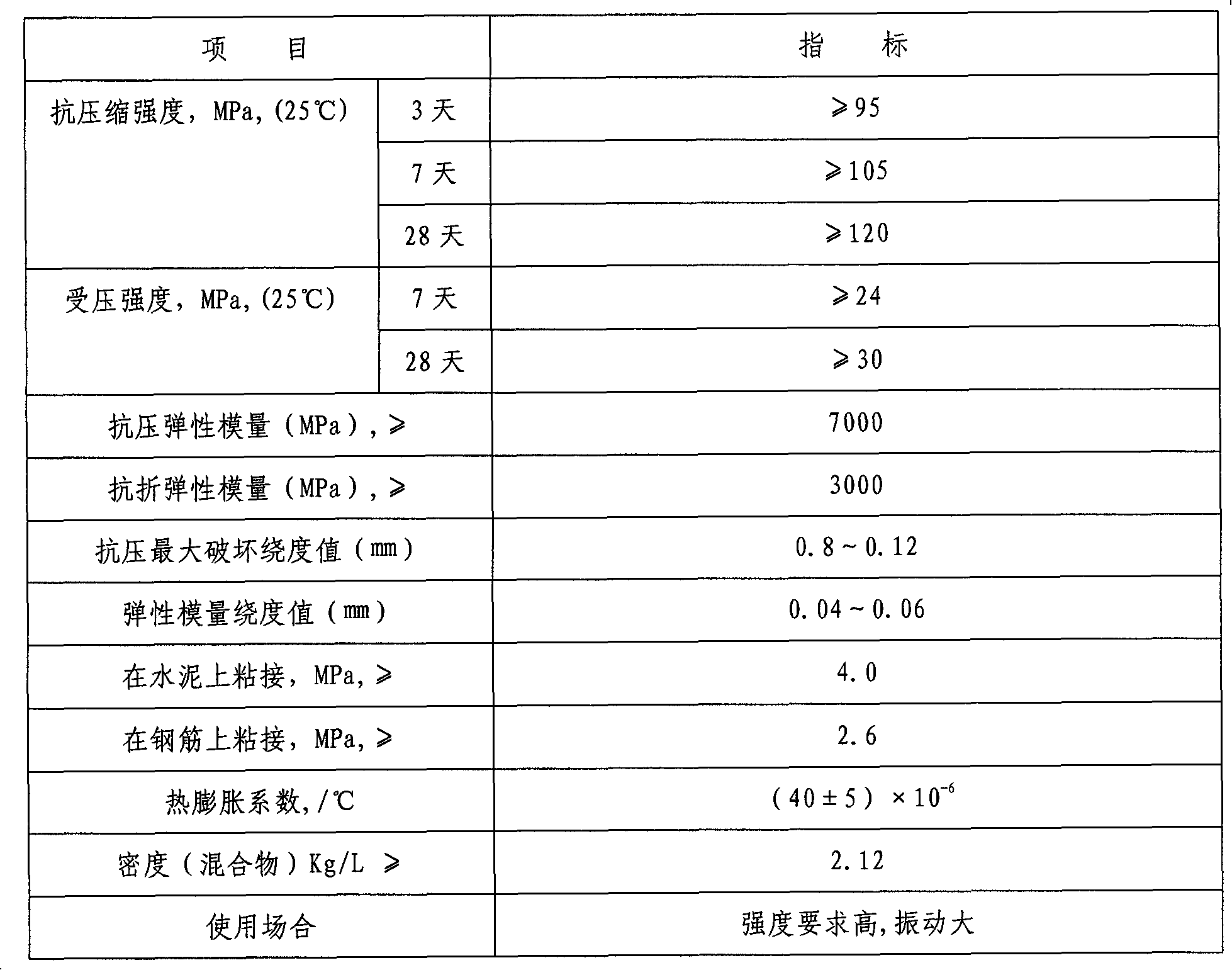

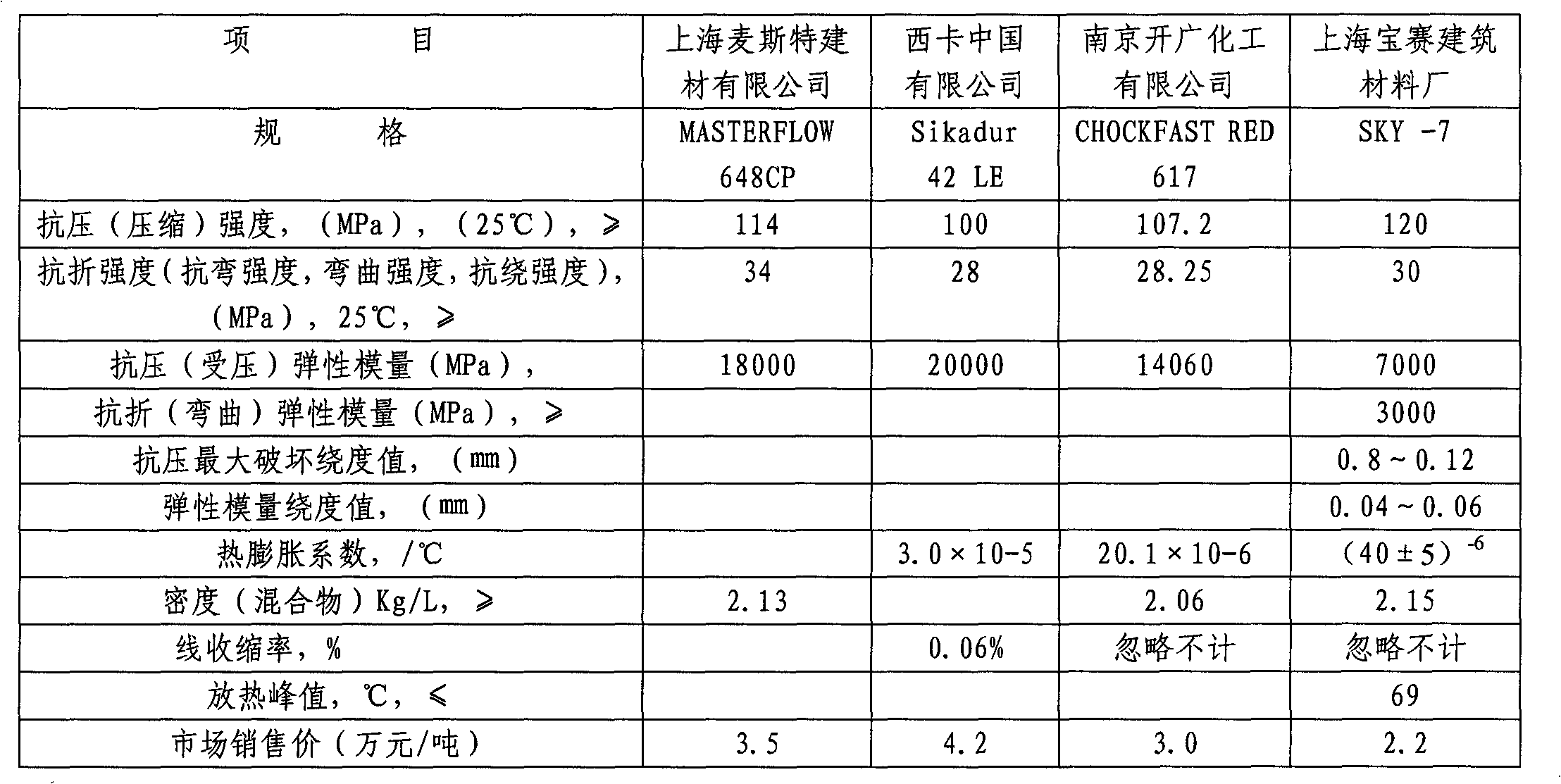

Polyurethane modified epoxy resin grouting material

The invention relates to a polyurethane modified epoxy resin grouting material. The grouting material is characterized in that: the grouting material comprises an adhesive and a solid material according to a weight ratio of 1:4-8, wherein the solid material comprises coarse quartz sand, high aluminum cement, middle quartz sand, a pigment and fine quartz sand; and the adhesive comprises a polyurethane modified epoxy resin, a curing agent, an epoxy-based reactive diluent, a leveling agent, a defoamer and a dispersant. Compared with grouting materials prepared with the prior art, the polyurethane modified epoxy resin grouting material provided by the invention allows the toughness and the strength of the grouting material to be improved, the impact and the shock of mobile equipment to the base to be effectively reduced, the service life of the equipment and the base to be prolonged, better water resistance and oil resistance to be possessed and the cost to be reduced by about 50%.

Owner:CHINA PETROLEUM & CHEM CORP +3

High-wet-strength wound dressing

InactiveCN103126806AImproves Strength and ToughnessGood for wound healingAdhesive dressingsAbsorbent padsChronic ulcersDiabetic ulcers

The invention relates to a high-wet-strength wound dressing. Specifically, the wound dressing is formed by three layers of structures, outer layer material is sol fiber, middle layer material is woven fabric or knitted fabric or other nonwoven fabric, and the three layers of structures are connected together in a physical or chemical mode. The wound dressing can be used for nursing wounds of chronic ulcers such as a vein blood stasis ulcer, a stress ulcer, a diabetic foot ulcer and other chronic ulcer wounds including cave type or depressed type or the like ulcer wounds.

Owner:FOSHAN UNITED MEDICAL TECH

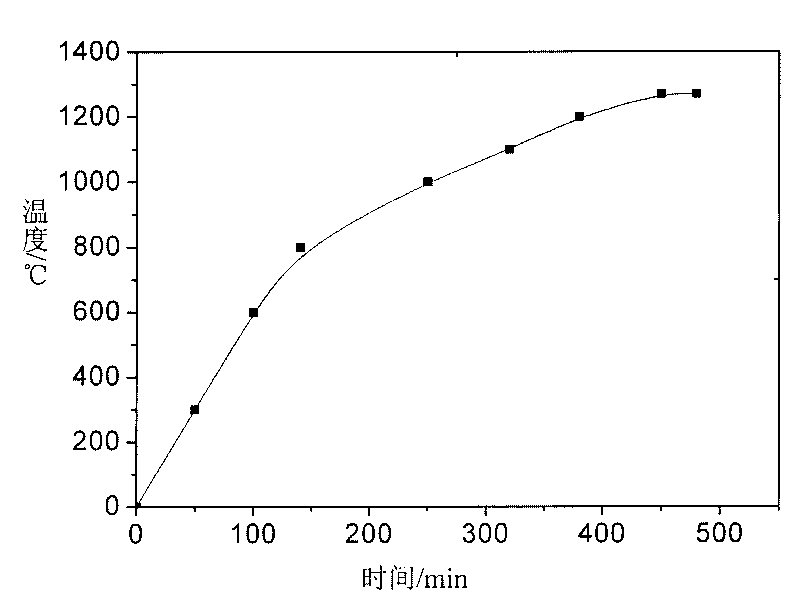

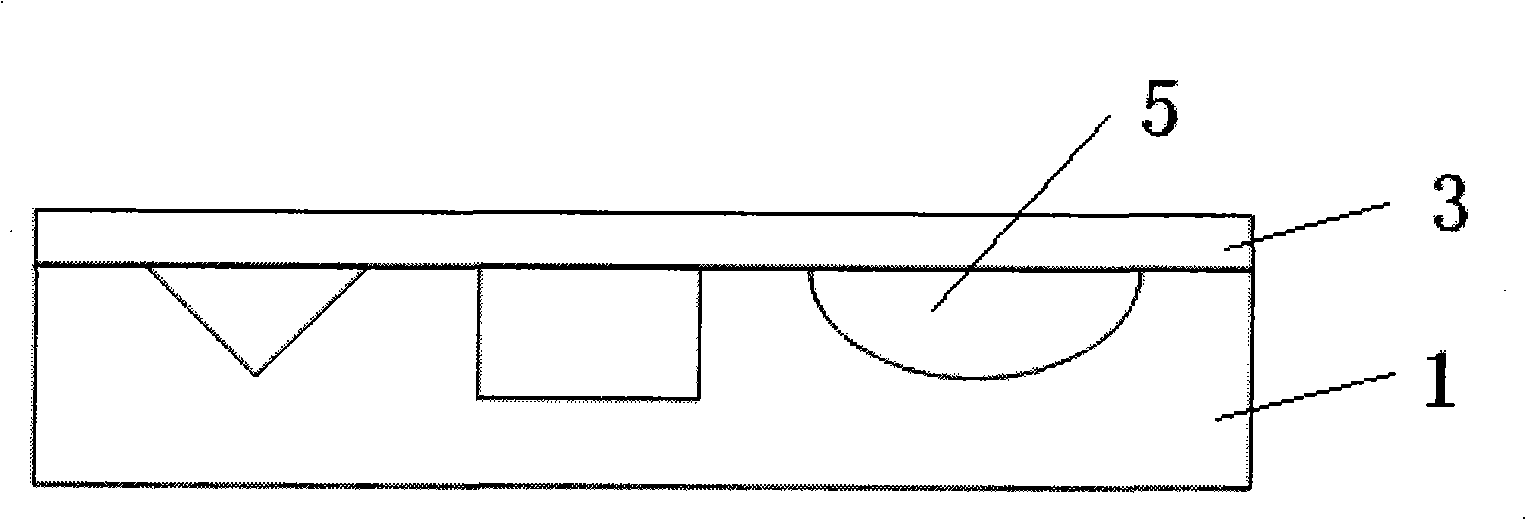

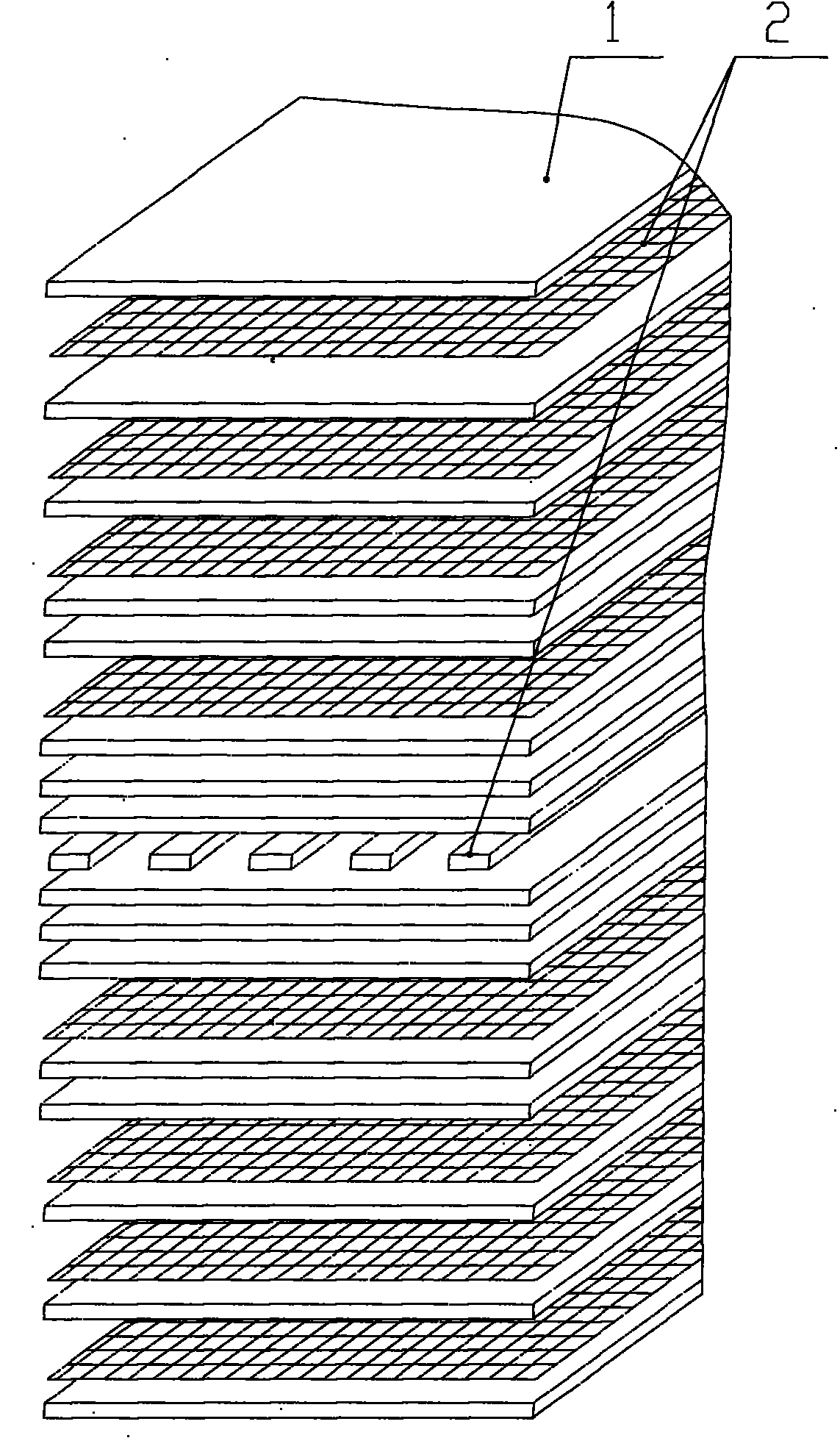

Method for manufacturing wafer-stage glass micro-cavity

InactiveCN101259951AReduce roughnessHigh bonding strengthPrecision positioning equipmentSoldering apparatusMetallurgyMachining process

The invention provides a fabrication method for a wafer-class glass micro-chamber, comprising the steps as follows: a first step: a special pattern is etched on a Si wafer to form a special pattern by a Si micro-machining process; a second step: the Si wafer and a Pyrex7740 glass wafer are bonded to each other under the atmosphere of less than 1Pa, thus leading the special pattern on the Pyrex7740 glass to form a sealing chamber body; a third step: the bonded wafers are heated to 810 to 890 DEG C under one atmosphere and the temperature is kept, the pressure different inside and outside the chamber leads the softened glass to form a structure corresponding to the micro-chamber pattern structure which is then cooled, and the wafer is annealed to eliminate the stress under normal pressure. The fabrication method of the wafer-class glass micro-chamber has the characteristics of simple process, precise forming, high depth-width-ratio of micro-chamber transmission, good surface characteristic of the micro-chamber, etc., can be widely applied to the fabrication of glass micro-chamber in an MEMS (micro-electron mechanical system), and belongs to wafer-class MEME fabrication process.

Owner:SOUTHEAST UNIV

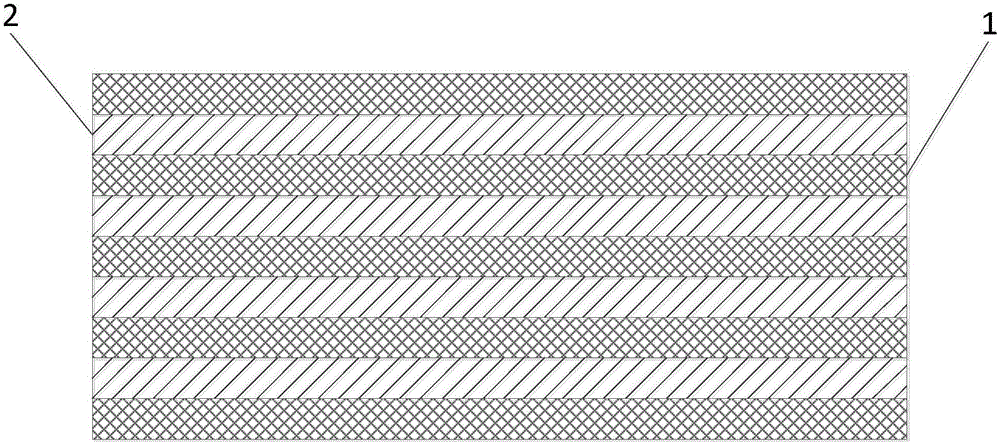

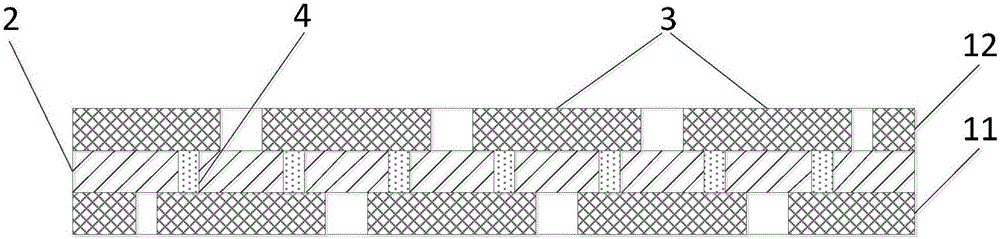

Metal wire and flexible display panel

InactiveCN106684115AImproves Strength and ToughnessStrong bending resistanceSolid-state devicesSemiconductor devicesSurface plateMetallurgy

The invention provides a metal wire. The problem of easy breaking of the metal wire is solved while the technical problems of complex preparation process, high production cost and the like in the prior art are also avoided. The invention also provides a flexible display panel; at least one metal layer is formed by the metal wire; the technical problems of instable display performance, low reliability, short service life and the like of the display panel are solved; the metal wire provided by the invention comprises sub wires and stress barrier materials which are arranged in a stacked manner alternatively; the sub wires and stress barrier materials are the same in extension directions, wherein the number of the sub wires is at least two; the flexible display panel provided by the invention comprises a substrate; an insulating layer and a metal layer are alternately arranged on the flexible substrate; and at least one metal layer is formed by the metal wire.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Pultrusion PU (polyurethane) resin composite material and preparation method thereof

The invention relates to the technical field of pultrusion PU (polyurethane) resin, in particular to a pultrusion PU resin composite material and a preparation method thereof. According to the pultrusion PU resin composite material, reinforced fibers and PU resin in a proper ratio are adopted, wherein the PU resin adopts aliphatic isocyanates to replace conventional aromatic isocyanates, further, primary hydroxyl polyether or primary hydroxyl polyester capable of improving mechanical strength of aliphatic PU and having a terminal group capable of reacting with isocyanates is added to form prepolymers, primary hydroxyl polyether or primary hydroxyl polyester having the terminal group capable of reacting with the isocyanates can improve the mechanical strength of aliphatic PU, and the aliphatic isocyanates have low probability of photooxidation, so that the service life of the composite material in wild and outdoor application is prolonged.

Owner:许劼

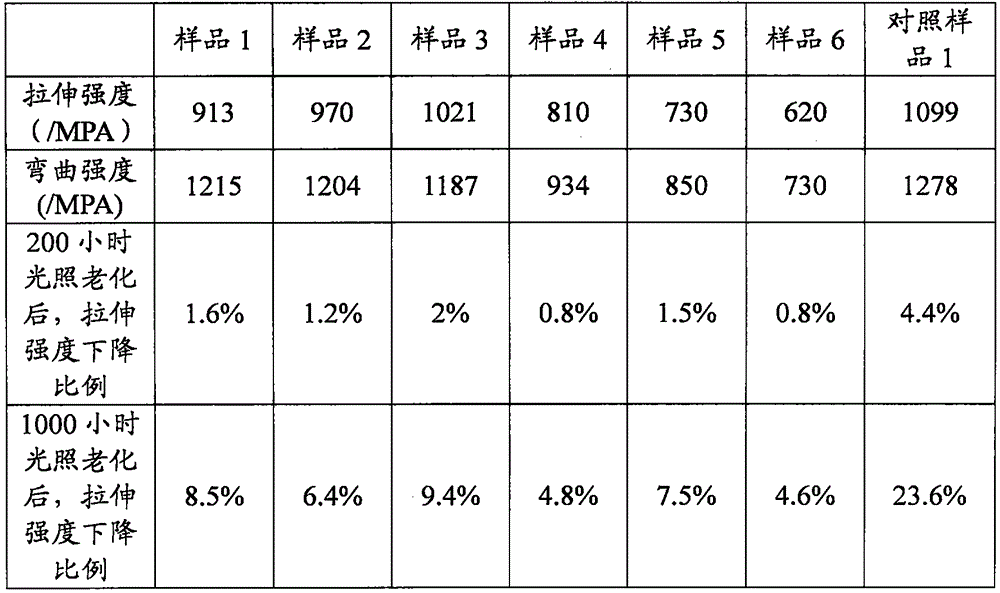

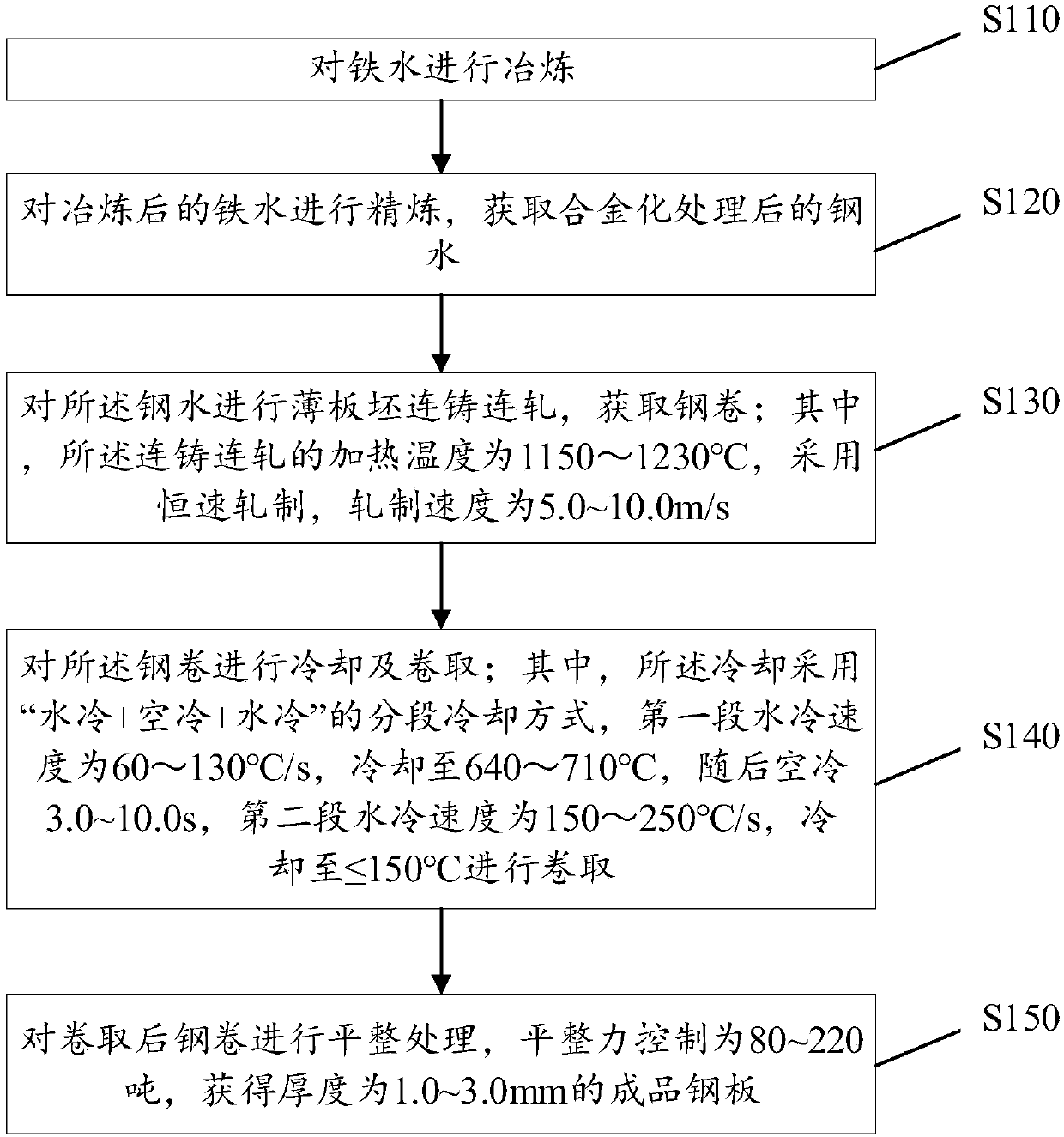

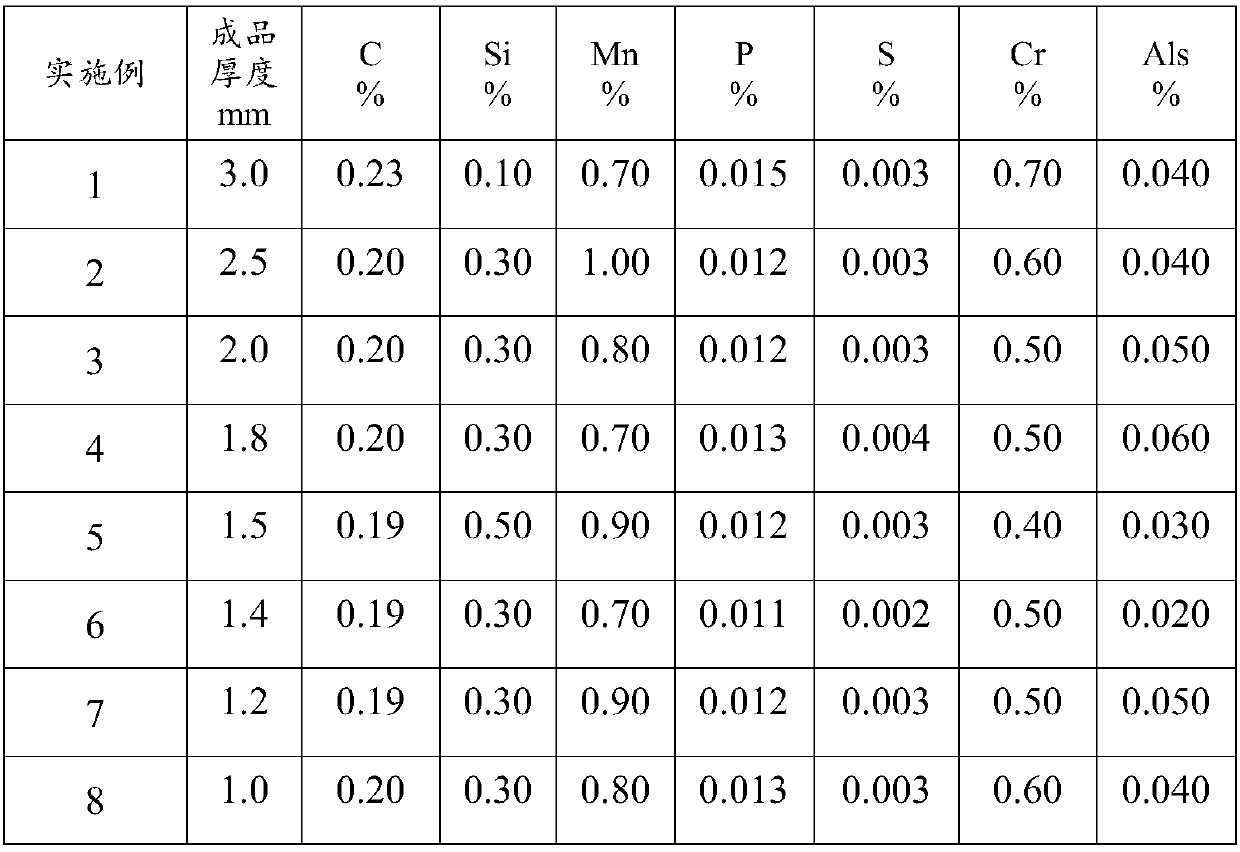

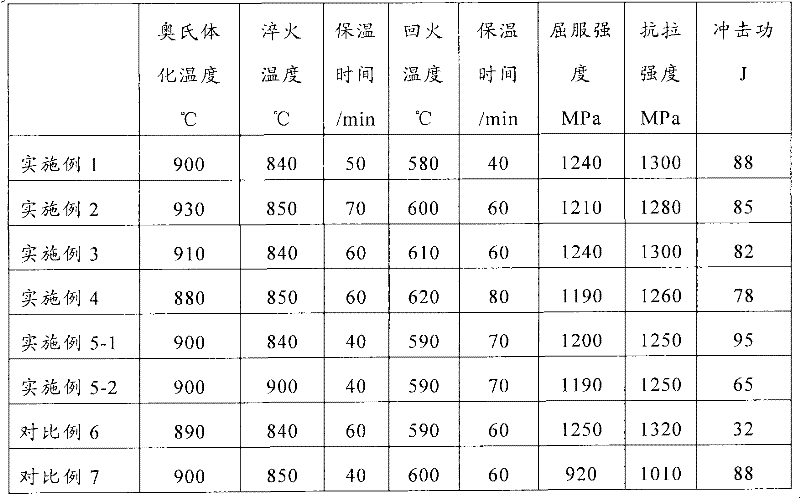

Thin-gauge 1180MPa-grade dual-phase steel and processing method thereof

InactiveCN107904509AHigh tensile strengthImproves Strength and ToughnessChemical compositionDual-phase steel

The invention discloses thin-gauge 1180MPa-grade dual-phase steel and a processing method thereof, and belongs to the technical field of steel rolling. The dual-phase steel comprises the following components in percentage by mass: 0.19%-0.23% of C, 0.10%-0.50% of Si, 0.60%-1.00% of Mn, not greater than 0.015% of P, not greater than 0.004% of S, 0.30%-0.70% of Cr, 0.020%-0.060% of Als, and the balance Fe and inevitable impurities. The dual-phase steel is produced through a continuous casting and rolling process for a sheet billet, and the processing method comprises the processes of smelting, refining, continuous casting and rolling for a sheet billet, cooling, coiling and leveling; and batch stable manufacturing for the thin-gauge 1180MPa-grade dual-phase steel with a thickness of 1.0-3.0mm is finally achieved, the production cost is lowered, and moreover, excellent comprehensive mechanical property is achieved, and the thin-gauge 1180MPa-grade dual-phase steel is capable of replacingcold-rolled dual-phase steel for manufacturing a vehicle body structural member of a passenger vehicle.

Owner:武汉钢铁有限公司

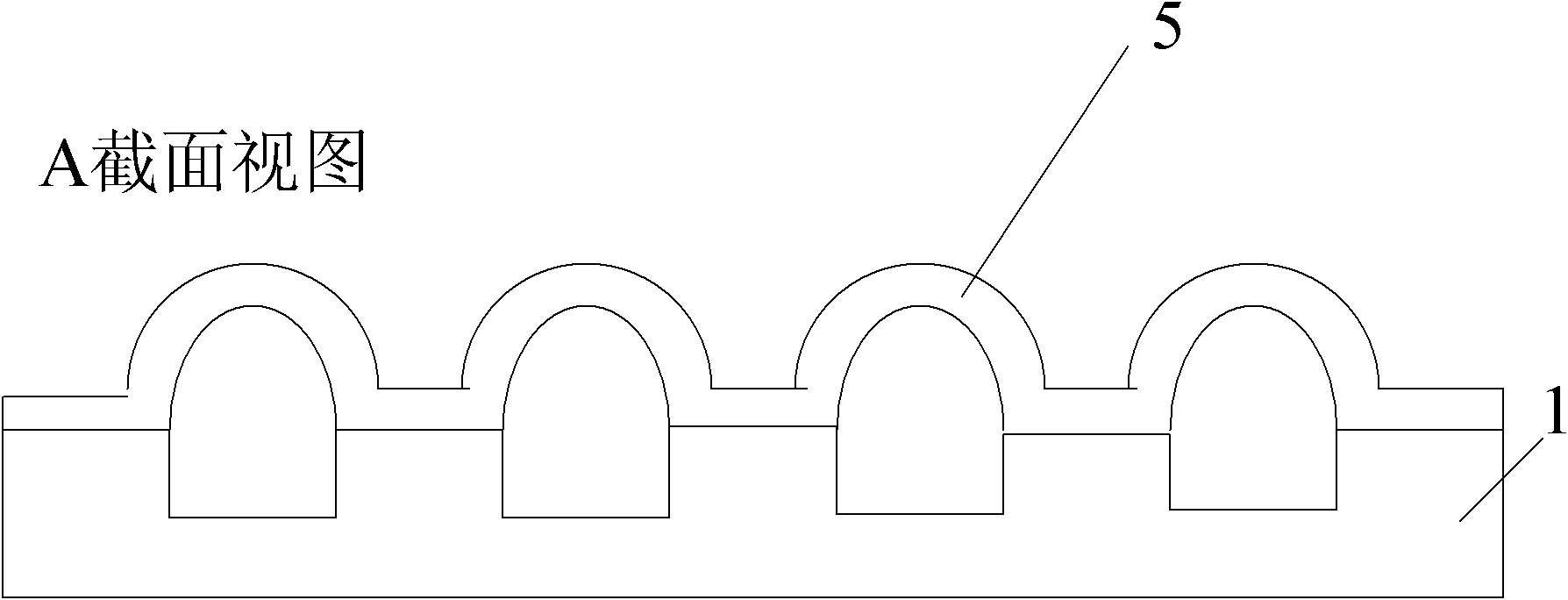

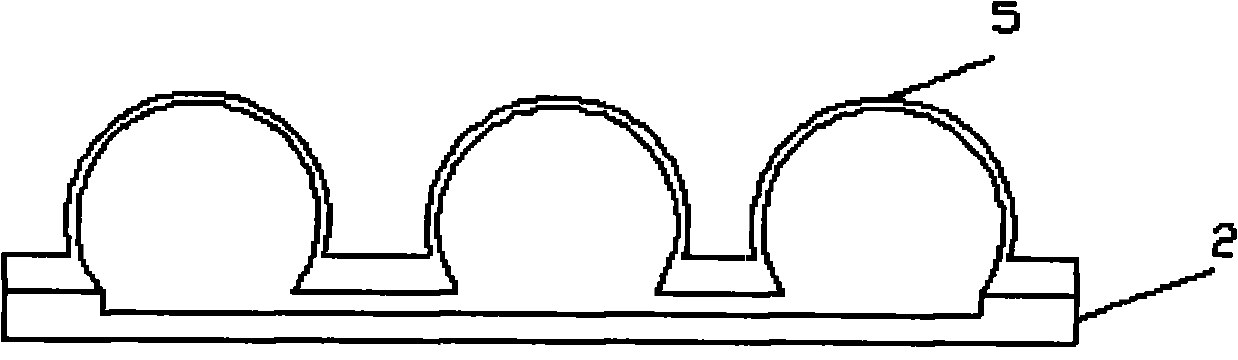

Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

ActiveCN102097545AReduce luminous attenuationImprove performanceSolid-state devicesSemiconductor devicesHeat resistanceSilica gel

The invention discloses a method for packaging a glass-silicon wafer-grade chiponboard (COB) of a light emitting diode (LED). The method comprises the following steps: 1, etching a silicon micro slot array with the micro slots communicated with each other through micro channels, and placing a proper amount of heat outgas agent in the micro slots; 2, performing anodic bonding on the Si wafer with patterns and the heat outgas agent and borosilicate glass wafer in air or in vacuum to form a sealed cavity; 3, heating and preserving heat to form a spherical glass micro cavity, cooling the cavity to normal temperature, annealing and removing silicon to obtain a wafer-grade glass micro cavity; 4, preparing a lead substrate; 5, mounting a chip and leading a wire; 6, carrying out wafer-grade bonding; and 7, filling silica gel to realize the wafer-grade packaging of the LED. By achieving the integration with the wafer-grade LED reflecting cup, the method reduces heat resistance and cost.

Owner:SOUTHEAST UNIV

Method for preparing polyurethane elastic fibers through mixed polyol

ActiveCN104790057AImproves Strength and ToughnessLow manufacturing costMonocomponent polyurethanes artificial filamentPrepolymerChemistry

The invention discloses a method for preparing polyurethane elastic fibers through mixed polyol. The method comprises the following steps: 1) mixing diethylene glycol phthalic anhydride polymer, polytetramethylene ether glycol and polyethylene glycol so as to form the mixed polyol, and adding diisocyanate into the mixed polyol to form a prepolymer; 2) dissolving the prepolymer into dimethylacetamide or dimethylformamide to react with monamine and furadiamine substances to generate a polyurethane urea stock solution, and adding an antioxidant, an anti-ultraviolet agent and a yellowing-resistant agent into the polyurethane urea stock solution, storing, curing and preparing into a spinning solution; 3) performing dry spinning so as to obtain polyurethane elastic fibers. The strength and toughness of the polyurethane elastic fibers prepared through the method are superior to other general products.

Owner:ZHEJIANG HUAFENG SPANDEX

Automobile sound insulation pad and preparation method thereof

InactiveCN104723983AImproves Strength and ToughnessLow mold shrinkageVehicle componentsFiber coatingAbsorption effect

The invention discloses an automobile sound insulation pad and a preparation method thereof. The sound insulation pad comprises a finish coat layer, a first sound insulation layer, a blend fiber mat, a second sound insulation layer and a honeycomb bottom layer which are arranged in sequence from top to bottom, the finish coat layer is made of PC / ABS alloy, the first sound insulation layer and the second sound insulation layer are both made of PP / PET composite short fiber, the inner wall of the honeycomb bottom layer is coated with an inorfil coating layer, the inorfil coating layer is a plant fiber coating layer, and the thickness of the plant fiber coating layer ranges from 20 mm to 35 mm. The automobile sound insulation pad obtained through the preparation method is low in weight, good in sound absorption effect, environment friendly and capable of being recycled and reused, can satisfy use requirements of customers well and conforms to the requirements of light weight, environment friendliness and comfort for modern automobiles.

Owner:CHONGQING TECH & BUSINESS INST

Glass fiber mat-reinforced silica aerogel and preparation method thereof

ActiveCN105906298AImproves Strength and ToughnessImprovement ingredientsWater solubleContinuous production

The invention discloses glass fiber mat-reinforced silica aerogel and a preparation method thereof. The glass fiber mat-reinforced silica aerogel comprises, by weight, 40-70 parts of a glass fiber mat, 4-30 parts of a silica aerogel solution, 2-10 parts of a modifier and 0.5-1 part of a water soluble phenol-formaldehyde resin solution. The preparation method comprises 1, sol solution preparation, 2, mixed solution preparation, 3, glass fiber cotton mat preparation, 4, glass fiber and mixed solution mixing, 5, aging and 6, aging. The glass fiber mat-reinforced silica aerogel improves silica aerogel toughness and strength, has flexible treatment aging and drying processes so that aerogel continuous production is realized, has excellent adsorbability, is soft and has good hydrophobicity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

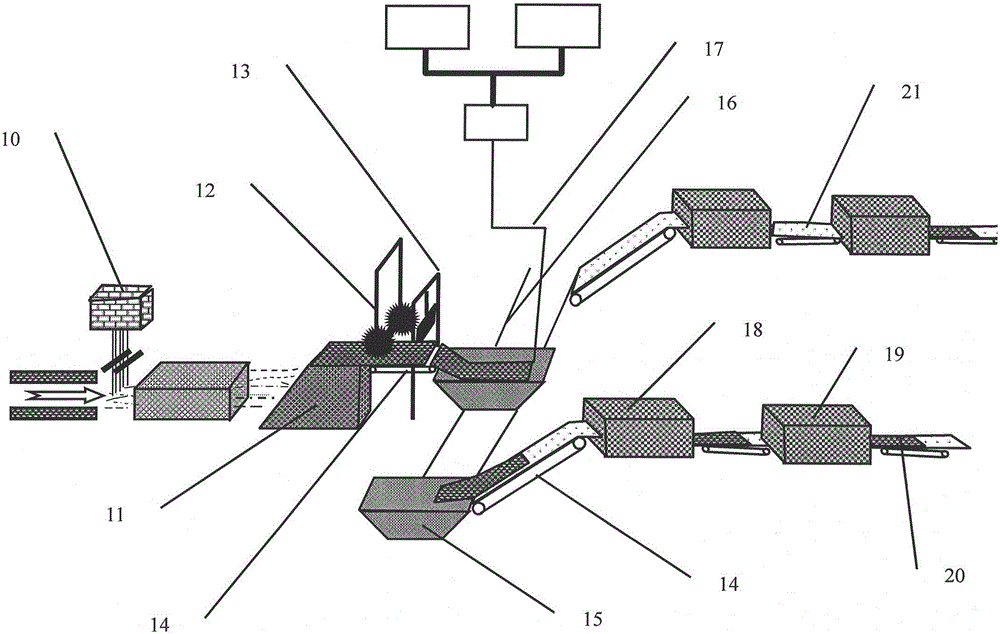

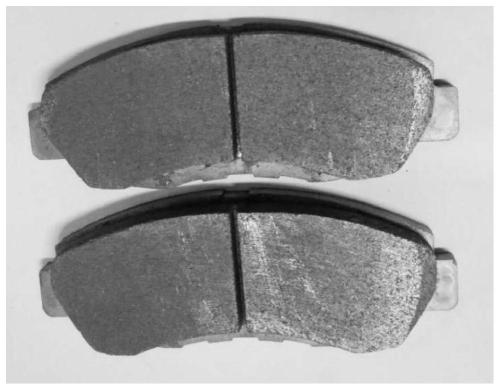

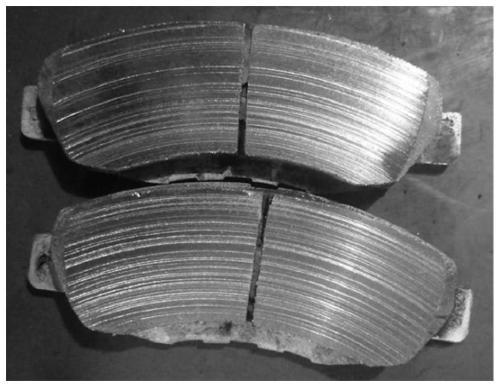

Copper-based friction material suitable for carbon ceramic brake disc and preparation method thereof

ActiveCN111286642AImprove high temperature strength and toughnessImproves Strength and ToughnessFerrosiliconFerrochrome

The invention relates to a copper-based friction material suitable for a carbon ceramic brake disc and a preparation method thereof. The friction material comprises the following components in percentage by mass: 52-60% of copper powder, 12-20% of iron powder, 2-4% of molybdenum disulfide powder, 5-9% of granular graphite powder, 3-6% of flake graphite powder, 1-4% of ferrochrome powder, 1-4% of ferrosilicon powder, 2-6% of ferroboron powder, 4-8% of ferromanganese powder, and 1-3% of ferrovanadium powder. The copper-based friction material is prepared by proportioning, mixing, pressing and pressure sintering. The copper-based friction material adopts prealloyed powder comprising ferrochrome, ferrosilicon, ferromanganese, ferroboron and ferrovanadium as a friction component, the good heatconductivity, high hardness and high toughness of the prealloyed powder are fully utilized, the heat conductivity of the friction material is further improved, the comprehensive mechanical property ofthe friction material is improved, higher friction coefficient and good wear resistance are obtained when the friction material is matched with the carbon ceramic brake disc, and the excellent braking effect is ensured.

Owner:CENT SOUTH UNIV

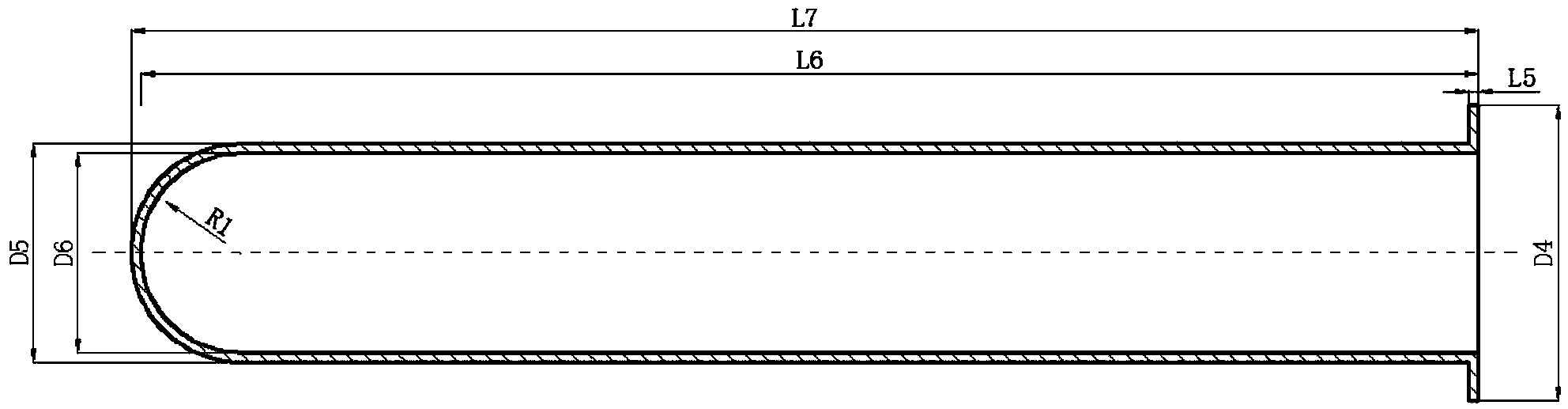

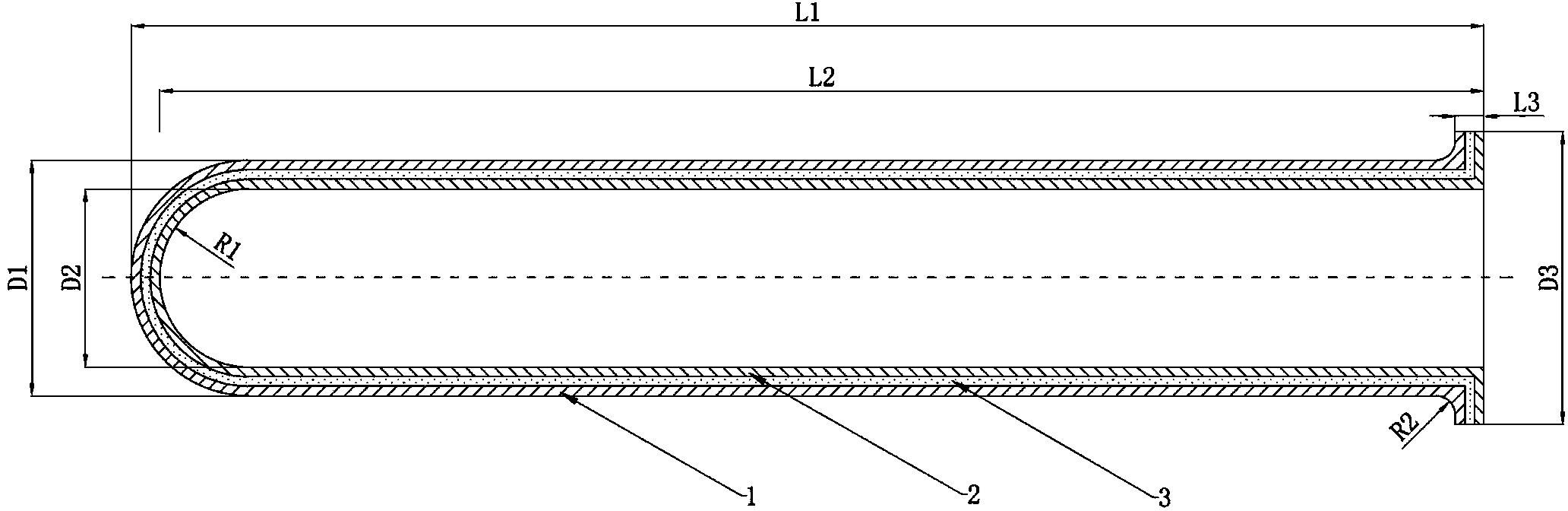

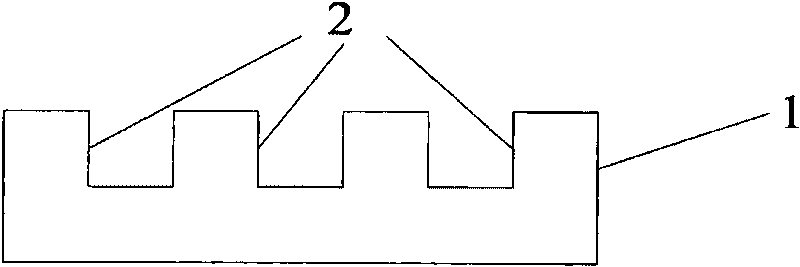

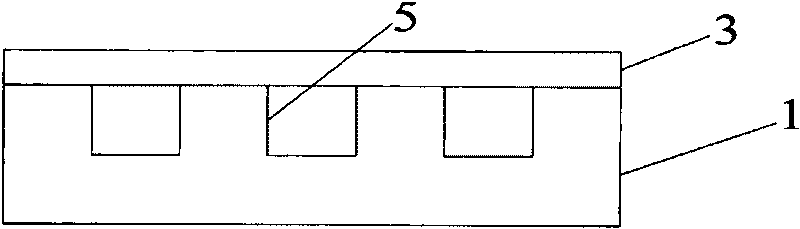

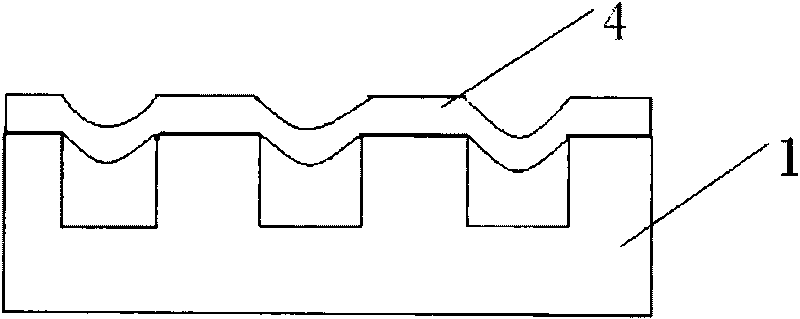

Inner heater protection tube made of silicon carbide ceramic composite material and preparation method thereof

The invention relates to an inner heater protection tube made of silicon carbide ceramic composite material and a preparation method thereof. The inner heater protection tube made of silicon carbide ceramic composite material comprises an outer silicon carbide layer, an inner silicon carbide layer and a carbon fiber reinforced layer; the outer silicon carbide layer is arranged on the outer surface of the carbon fiber reinforced layer, and the inner silicon carbide layer is arranged on the inner surface of the carbon fiber reinforced layer. The invention also relates to a preparation method of the inner heater protection tube made of silicon carbide ceramic composite material. The inner heater protection tube made of silicon carbide ceramic composite material prepared by the invention has high thermal conductivity, good thermal shock resistance, corrosion resistance, and long service life; when used in the metal smelting field, the inner heater protection tube of the invention can reduce the number and cost of equipment shutdown maintenance and replacement, significantly improve the production efficiency, and reduces the production cost.

Owner:山东宝纳新材料有限公司

Wear-resisting corrosion-resistant antibacterial aqueous coating

InactiveCN104403504AGood chemical resistanceImproves Strength and ToughnessShellac coatingsAntifouling/underwater paintsSodium carboxymethylcelluloseChemistry

The invention discloses a wear-resisting corrosion-resistant antibacterial aqueous coating which comprises the following raw materials in parts by weight: 50-55 parts of epoxy resin emulsion, 25-30 parts of acrylic emulsion, 20-28 parts of polystyrene emulsion, 10-15 parts of shell-lac tablet, 40-45 parts of natural latex, 3-6 parts of hydroxyethyl cellulose, 2-5 parts of carboxymethyl cellulose, 1-3 parts of fumed silica, 15-20 parts of styrene-butadiene thermoplastic elastomer, 10-15 parts of polyamide emulsion, 15-20 parts of sodium dodecylbenzene sulfonate, 10-15 parts of lauryl silver sulfate, 5-10 parts of nano-silver, 5-10 parts of titanium nitride, 5-10 parts of aluminum nitride, 10-15 parts of sepiolite powder, 10-15 parts of blast furnace slag powder, 2-4 parts of cerium oxide, 10-14 parts of a defoaming agent, 25-28 parts of a leveling agent, 2-4 parts of an aluminum-zirconium coupling agent TL-3, 3-4 parts of a filming cosolvent. 5-10 parts of a curing agent and 90-105 parts of water.

Owner:ANHUI JINDUN PAINT

Manufacture method of MEMS packaged glass microcavity with optical window

InactiveCN101700867AAvoid contactSimple methodPrecision positioning equipmentDecorative surface effectsSmooth surfaceClosed cavity

The invention discloses a manufacture method of an MEMS packaged glass microcavity with an optical window, which comprises the following steps of: firstly, etching a special microgroove pattern on a silicon wafer by using an Si micromachining process; secondly, bonding the silicon wafer etched with the microgroove and a Pyrex7740 glass wafer under an atmosphere pressure of 100Pa-30kPa to enable the Pyrex7740 glass wafer and the special pattern to form a closed cavity; and thirdly, heating the bonded wafer under high atmospheric pressure, preserving the temperature, enabling softened glass to protrude towards the closed cavity to form a spherical surface by using the difference of pressures inside and outside the cavity so as to form a microcavity structure corresponding to the microcavity pattern structure, cooling, annealing to eliminate the stress under normal pressure, wherein the spherical surface is not in contact with the bottom of the microgroove of the silicon wafer. The method is simple and is low in cost; in addition, an optical channel with a smooth surface is formed, and a smooth bonding surface is provided.

Owner:JIANGSU XINGSHA GLASS TECH +1

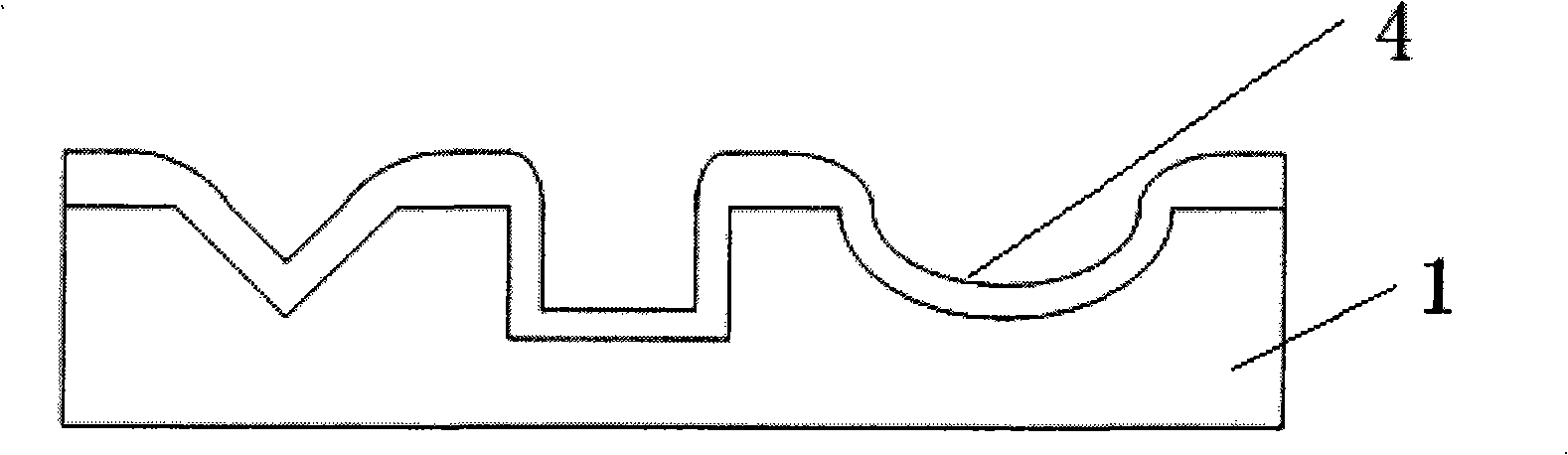

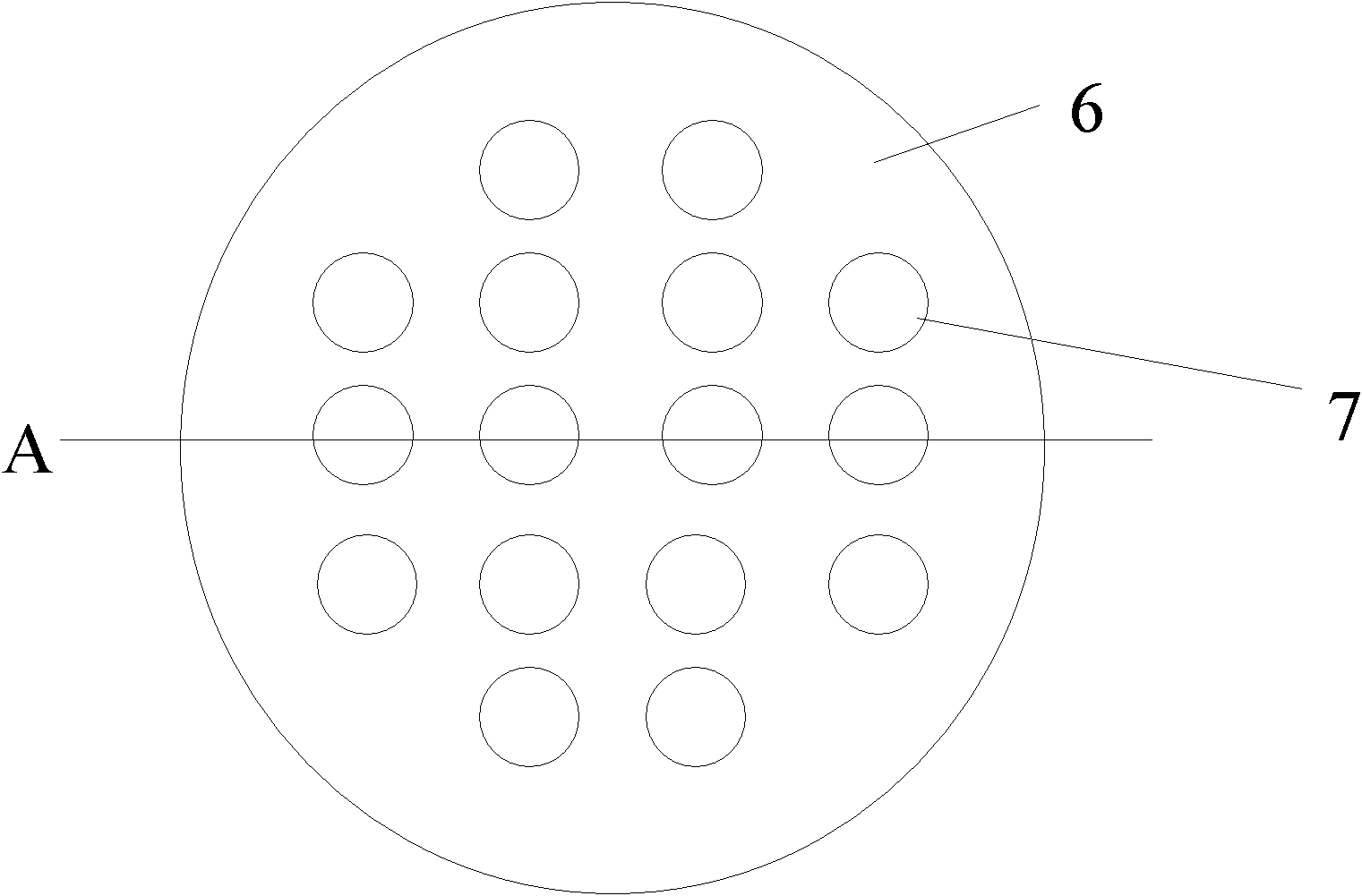

Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

ActiveCN101905859ANot easy to expandLow costPrecision positioning equipmentSoldering apparatusPhysical chemistrySilicon

The invention discloses a method for preparing a wafer-level uniform-dimension glass microcavity by positive pressure thermal forming. The method comprises the following steps of: etching an array consisting of microgrooves on a silicon wafer, and etching microchannels connecting the microgrooves, wherein the minimum groove width of the microgrooves is 5 times more than the runner width; and putting a proper amount of thermal outgassing agent into at least one microgroove, correspondingly bonding the plurality of microgrooves to form a sealed cavity by using a glass wafer, heating to soften the glass, making the thermal outgassing agent heated to release gases to generate positive pressure, acting the positive pressure on the softened glass corresponding to the plurality of microgrooves which are connected through the microchannels so as to form a spherical microcavity with uniform dimension, and cooling the microcavity. By connecting the same microgrooves through the microchannel, the inside air pressure of the microgrooves is substantially consistent, and the formed glass microcavity has uniform dimension. When the dimension of the microgrooves is far greater than that of the microchannel, the microchannels with smaller radius hardly expand due to higher additional pressure. Therefore, the glass corresponding to the microchannels can keep smooth.

Owner:SOUTHEAST UNIV

PVC (Polyvinyl Chloride) building template

InactiveCN101775897AImproves Strength and ToughnessImprove brittlenessForming/stuttering elementsCorrosionEnvironment effect

Owner:常州亚强塑胶有限公司

Large-scale non-quenched-and-tempered steel rolling equipment and rolling production method thereof

ActiveCN108246801AStable mechanical propertiesImproves Strength and ToughnessTemperature control deviceWork cooling devicesMicrostructurePrecipitation

The invention provides large-scale non-quenched-and-tempered steel rolling equipment and a rolling production method thereof. Through rolling with temperature control, the finish rolling temperature of large-scale non-quenched-and-tempered steel bars is controlled stably, low-temperature deformation is achieved, and grains are refined, so that plasticity and toughness are obviously improved whilethe high strength of large-scale non-quenched-and-tempered steel is ensured; and by intervening control cooling after rolling, precipitation strengthening, segregation strengthening and change of microstructure of micro alloying elements in large-scale non-quenched-and-tempered round steel are controlled, so that a stable metallographic structure and comprehensive mechanical properties are obtained. According to the rolling production method, the product surface quality is ensured, meanwhile, the defects that controlled rolling and controlled cooling cannot be achieved by a large-scale round steel production line; as for the large-scale non-quenched-and-tempered round steel obtained through the method, scratch on the surface of rolled pieces by a traditional water tank is avoided, oxidizedscale is controlled, and the surface quality of a rolled material is improved; and the mechanical property of the steel is stable, the requirements of controlled rolling and controlled cooling of thenon-quenched-and-tempered steel are met, and thus the mechanical property of the large-scale non-quenched-and-tempered steel is stabilized.

Owner:安徽钢研新材料科技有限公司

Steel for oil casing pipe, oil casing pipe and manufacturing methods thereof

InactiveCN102409241AGrain refinementImproves Strength and ToughnessDrilling rodsDrilling casingsSteel tubeQuenching

Owner:BAOSHAN IRON & STEEL CO LTD

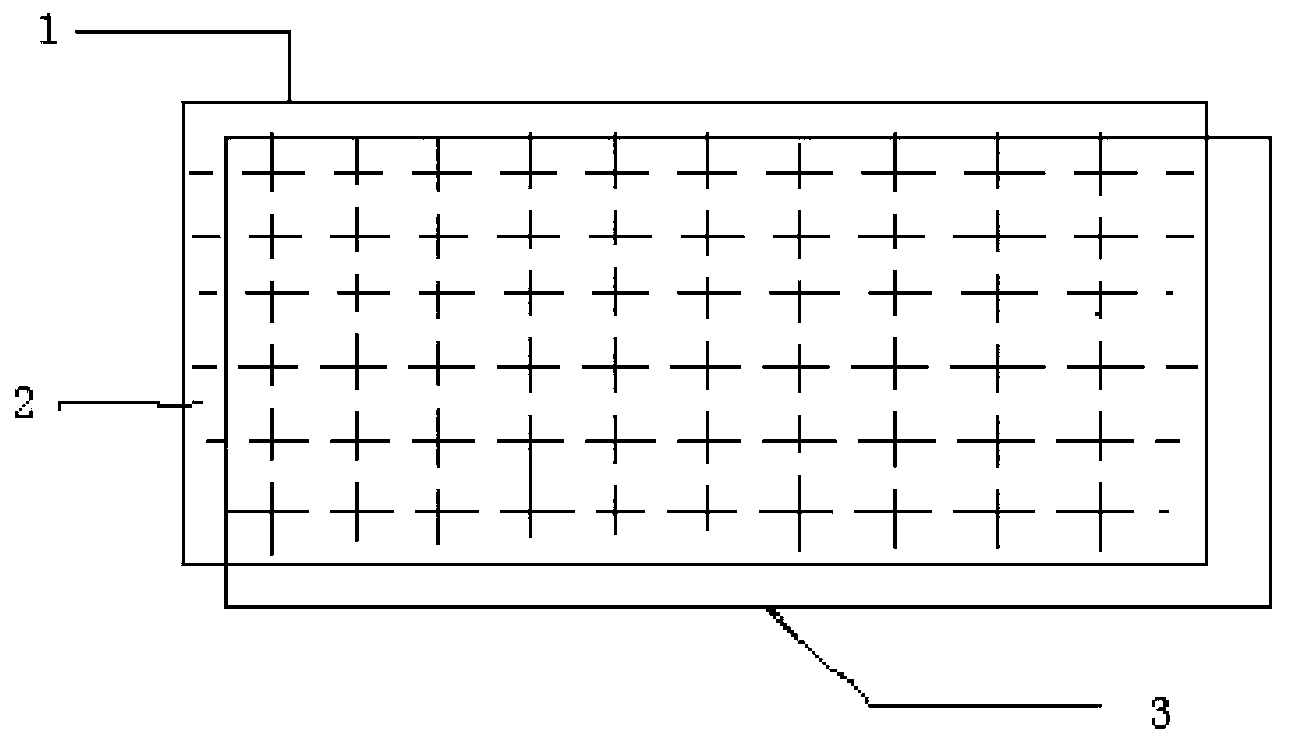

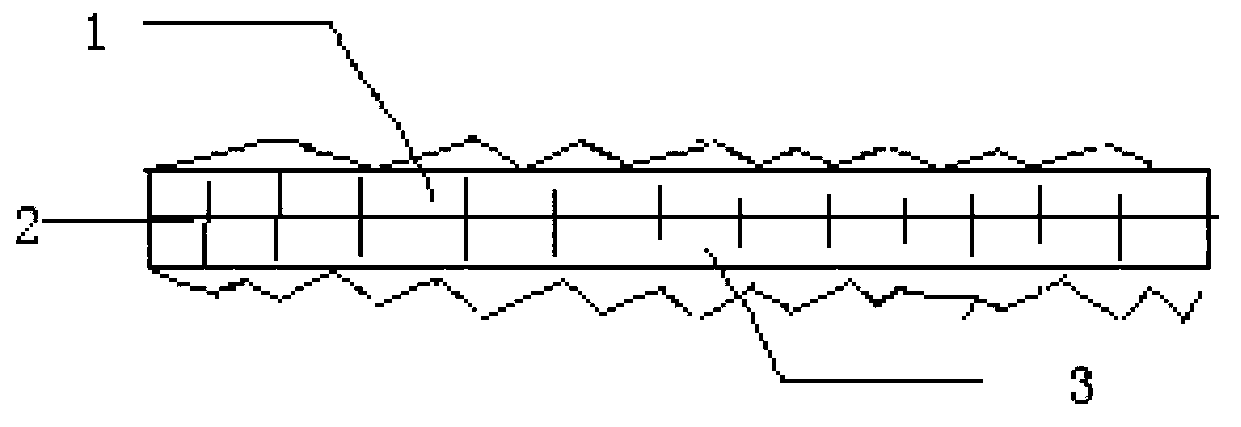

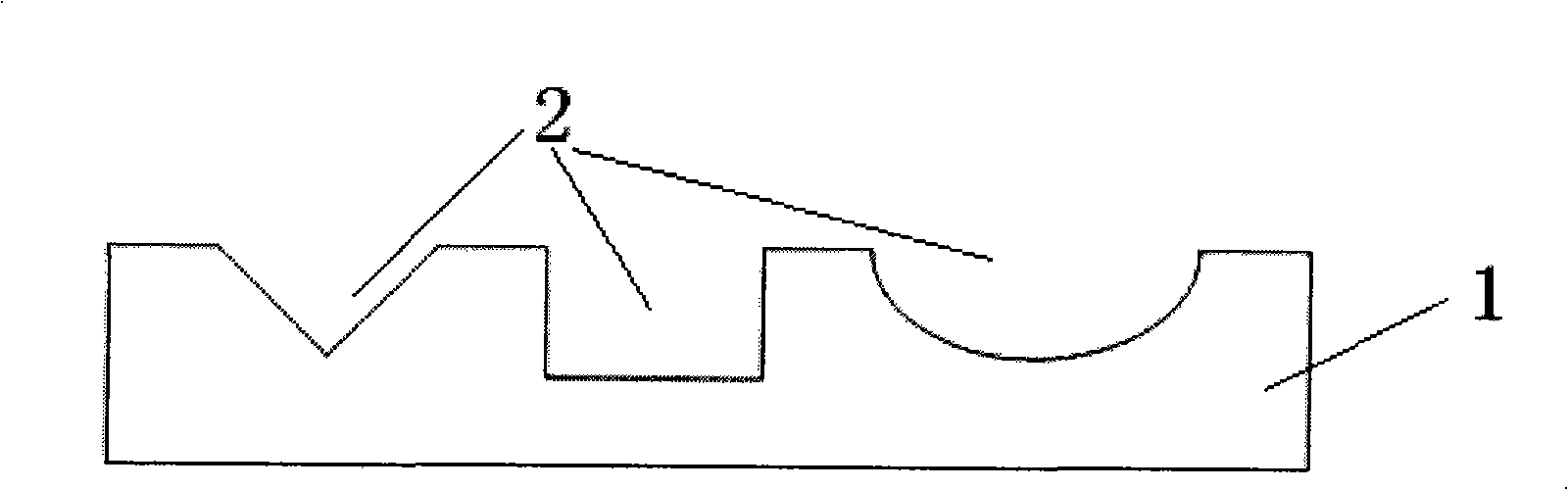

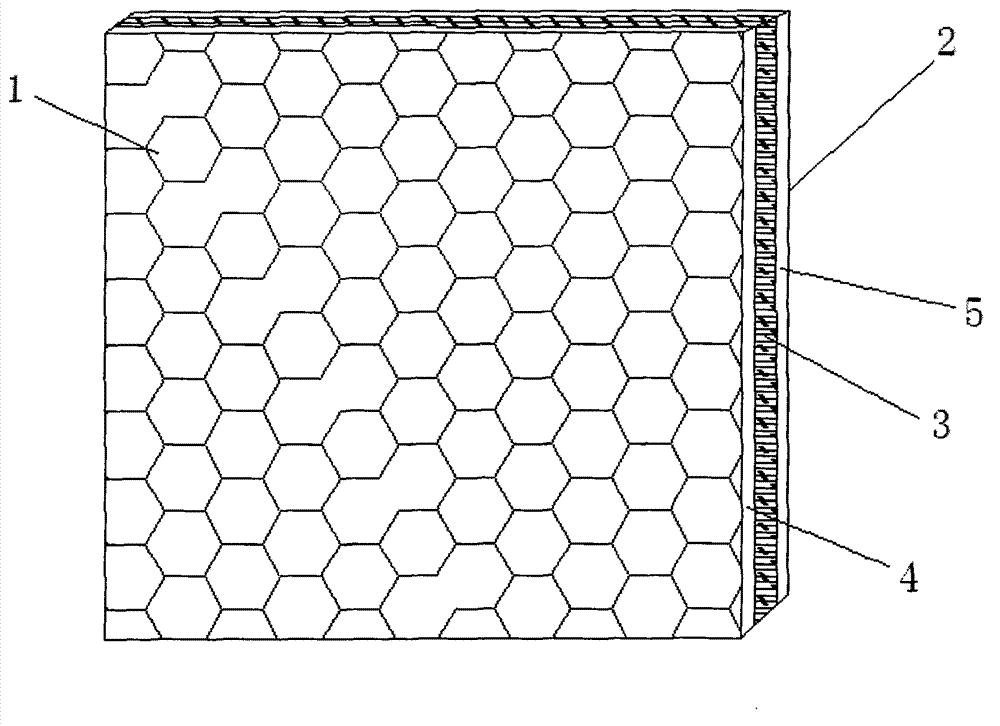

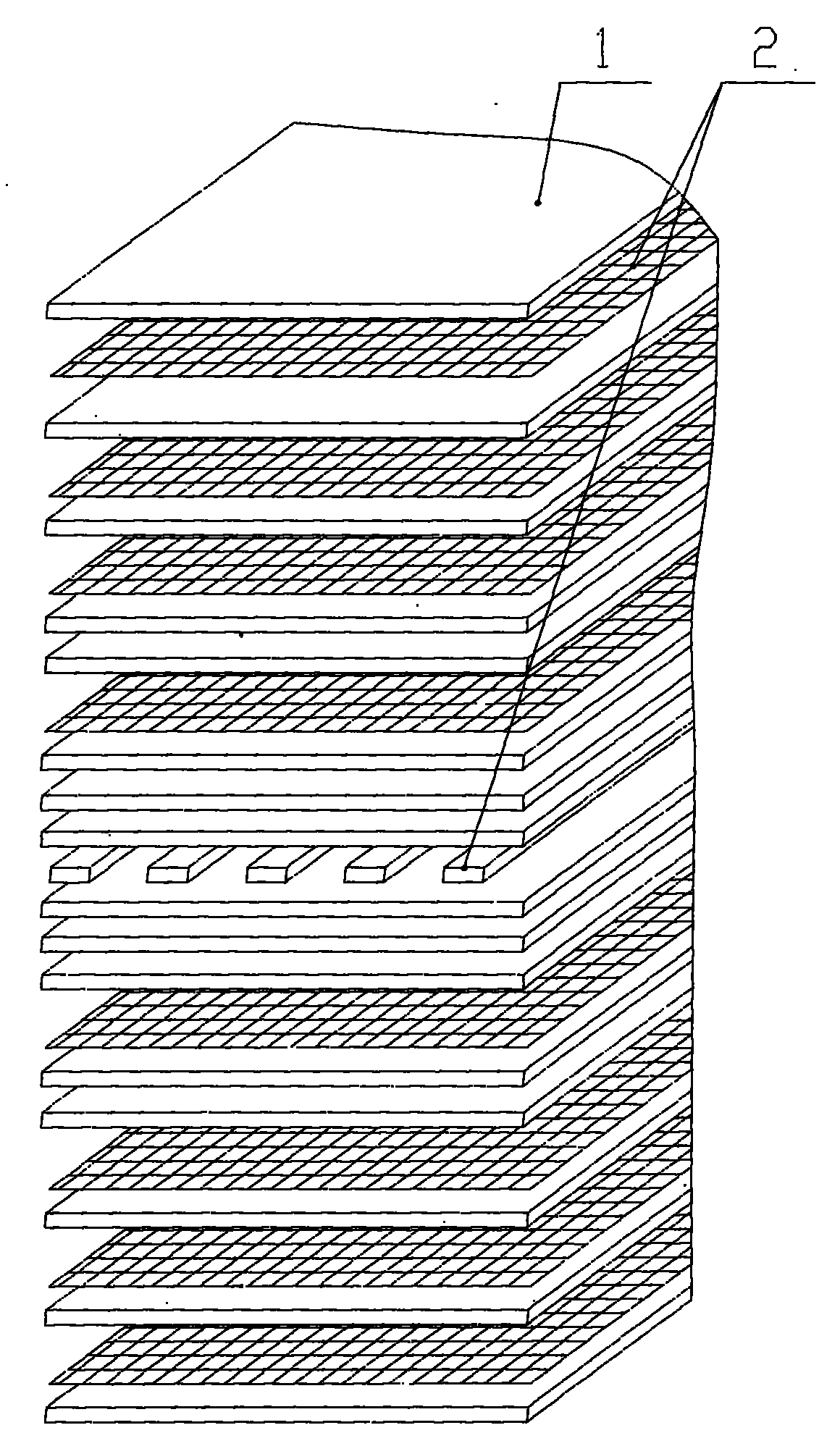

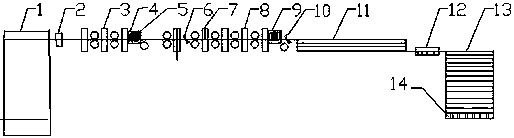

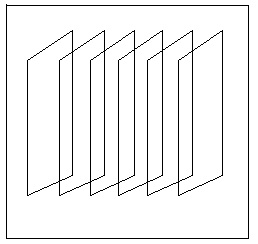

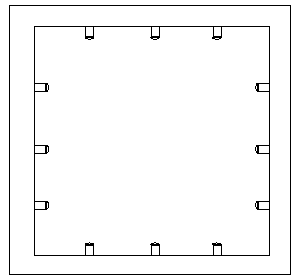

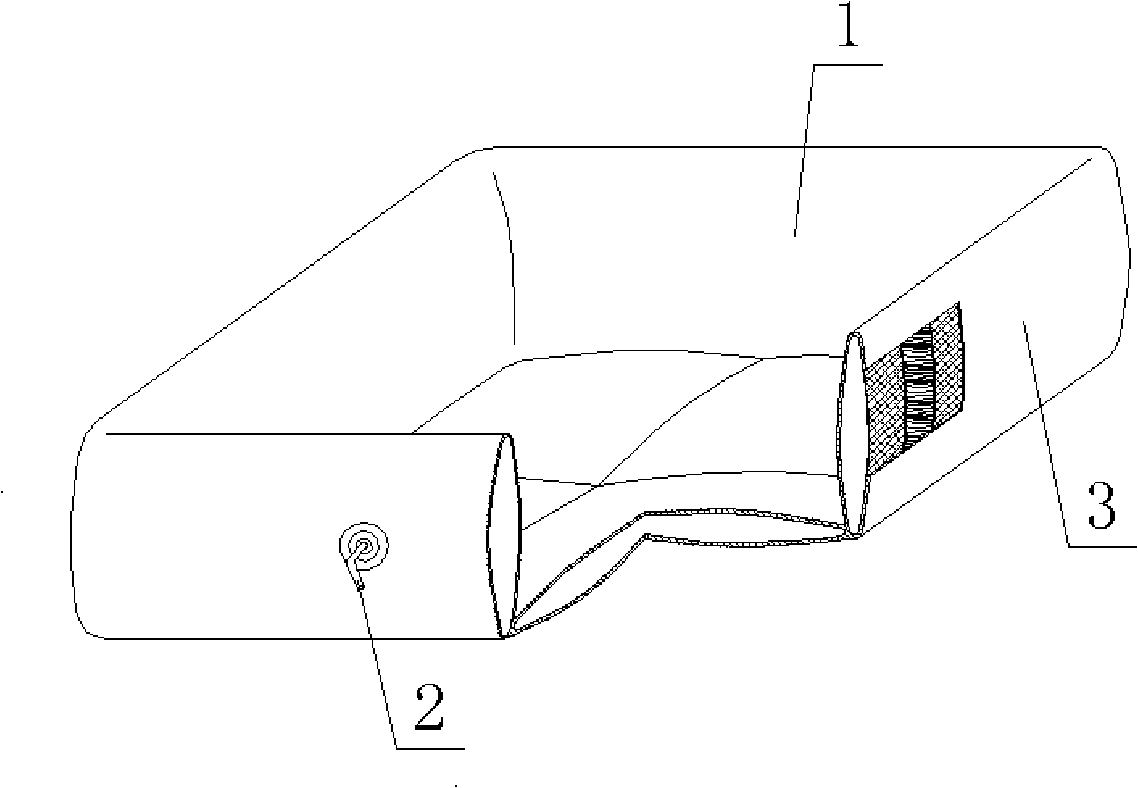

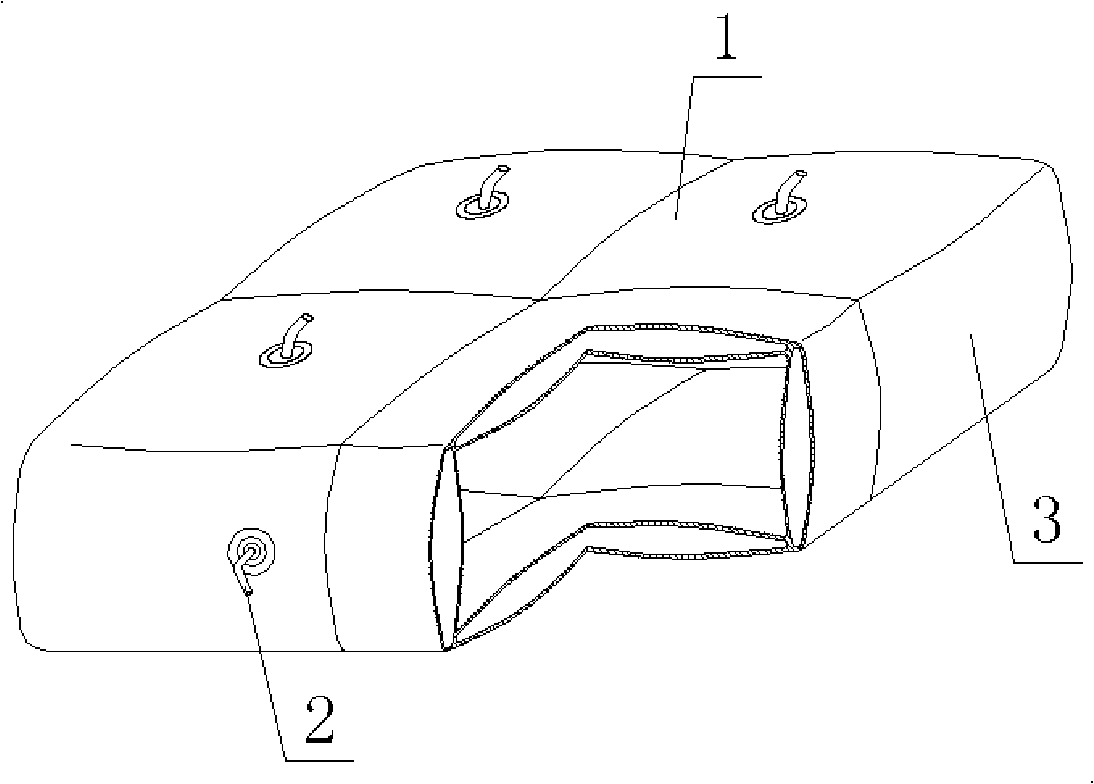

Inflating mould for concrete filling

InactiveCN101328763AHigh strengthImproves Strength and ToughnessForms/shuttering/falseworksSelf weightBuilding construction

The invention provides an inflation forming die used for concrete padding, comprising a flexible die wall (1) and an inflation plug-in module (2), wherein the flexible die wall (1) is closed to form a forming die. The invention is characterized in that the inflation plug-in module (2) is an inflation connector which can automatically close when a plug-in module is drawn out, and the flexible die wall (1) is provided with the inflation connector. Therefore, an inflation mandrel can be transported under a deflated state, and can be inflated and mounted at the construction field, thereby facilitating the transportation and greatly reducing the transportation cost; moreover, the inflation connector which is arranged on the forming die and can automatically close when the plug-in module is drawn out is advantageous to the prevention of gas leakage for the forming die on the position of the inflation connector; meanwhile, a padding component has the characteristics of light self-weight, low cost, good shakeproof performance, simple, convenient and quick production, convenient transportation and so on so as to achieve the aim of the invention, is applicable to a cast-in-situ concrete hollow floor, a cast-in-situ concrete roof, a cast-in-situ foundation slab, a cast-in-situ concrete wall body and a cast-in-situ concrete hollow bridge, in particular to a cast-in-situ concrete hollow flat slab.

Owner:湖南邱则有专利战略策划有限公司

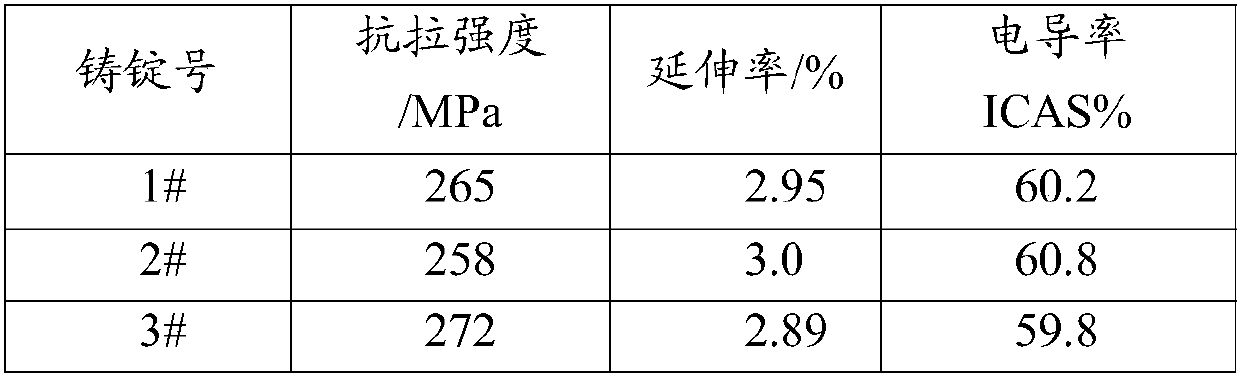

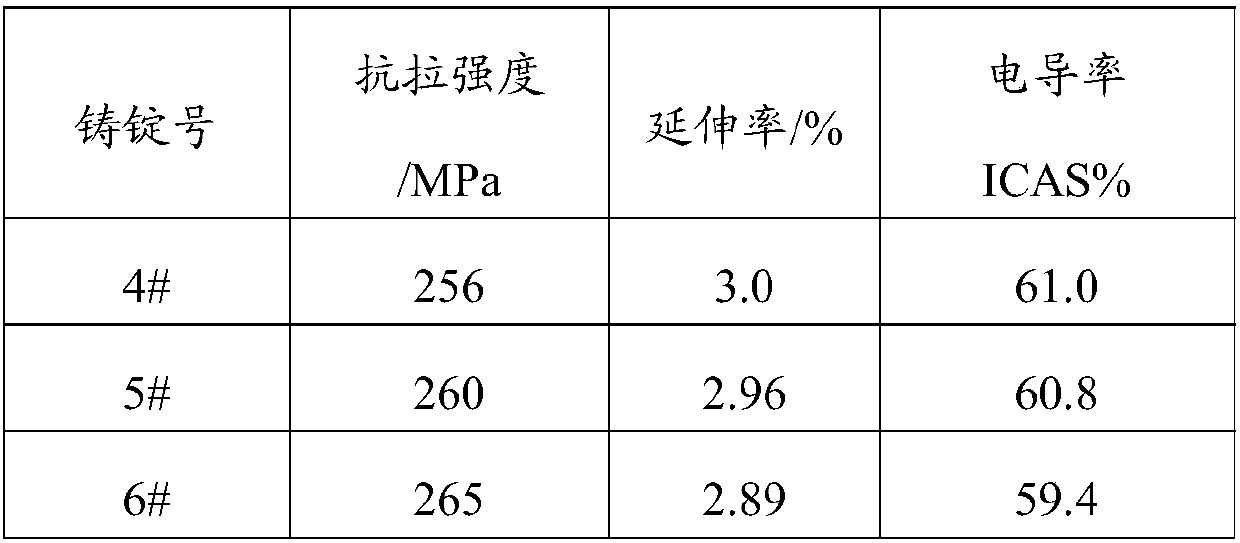

High-conductivity intermediate strength aluminum alloy and preparation method thereof

ActiveCN107675048AHigh strengthImproves Strength and ToughnessConductive materialMetal/alloy conductorsThree stageUltimate tensile strength

The invention discloses a high-conductivity intermediate strength aluminum alloy and a preparation method thereof. The aluminum alloy comprises, by weight percent, 0.35%-0.65% of Mg, 0.4%-1.0% of Zn,0.20%-0.40% of Cu, 0.30%-0.60% of Zr, 0.15%-0.35% of Er, 0.01%-0.06% of B, 0.1% or less of an impurity element of Si, 0.15% or less of Fe, 0.15% or less of other impurity elements, and the balance Al.The preparation process comprises the steps of raw material matching, raw material smelting, refining, pouring, three-stage homogenization treatment, compression deformation treatment, aging treatment and tensile deformation treatment. The preparation process of the high-conductivity intermediate strength aluminum alloy is simple and easy to practice. The aluminum alloy is good in mechanical performance and achieves high conductivity performance.

Owner:FOSHAN UNIVERSITY

Weld metal and welded structure having weld joints using the same

InactiveUS20120021246A1Promote formationHigh strengthArc welding apparatusFurnace typesHigh intensityToughness

To provide weld metal that has a high strength and toughness in the as-welded condition or in the annealed condition. The weld metal of the present invention contains by weight %, C: 0.04-0.15%, Si: 0.50% or less, Mn: 1.0-1.9%, Ni: 1.0-4.0%, Cr: 0.10-1.0%, Mo: 0.20 to 1.2%, Ti: 0.010-0.060%, Al: 0.030% or less, O: 0.15-0.060%, N: 0.010% or less, Fe and inevitable impurities as the remaining contents. The weld metal is further characterized by the fact that the ratio of Ti content (%) to Si content (%) i.e.,[compound type Ti] / [compound type Si] is more than 1.5, and the number A defined by the following formula is 0.50 or more, wherein A=[Ti] / ([O]−1.1×[Al]+0.05×[Si]).

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com