Pultrusion PU (polyurethane) resin composite material and preparation method thereof

A polyurethane resin and composite material technology, which is applied in the field of polyurethane resin for pultrusion, can solve the problems of slow curing speed, poor mechanical properties of unsaturated polyester, and decreased strength, so as to improve wetting ability, strength and toughness, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

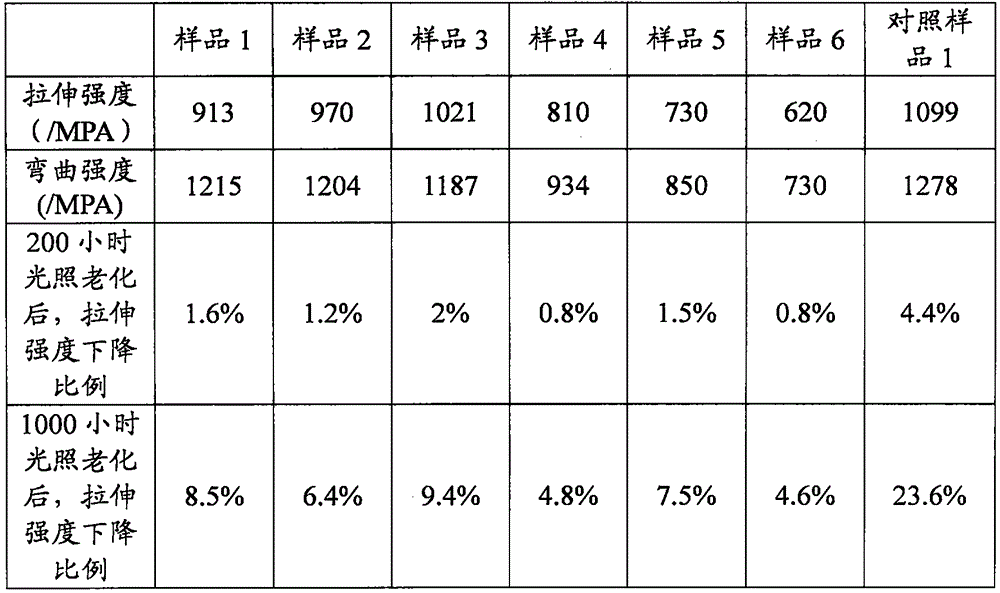

Examples

preparation example Construction

[0066] The present invention also relates to the preparation method of the composite material of above-mentioned polyurethane resin for pultrusion, comprising the following steps:

[0067] The aliphatic isocyanate with a weight fraction of 60%-100% and the primary hydroxyl polyether or primary hydroxyl polyester with a weight fraction of 0%-40% that can improve the mechanical strength of aliphatic polyurethane and have end groups that can react with isocyanates Formation of isocyanate prepolymers;

[0068] Polymerization of isocyanate prepolymers to form composites of polyurethane resins for pultrusion.

[0069] Preferably, said polymerizing the isocyanate prepolymer to form a composite material of polyurethane resin for pultrusion includes:

[0070] Put the isocyanate prepolymer in the barrel of the injection machine A;

[0071] 80-100 parts by weight of polyols, 0-10 parts by weight of chain extenders, 0.1-1 parts by weight of catalysts, 0.1-2 parts by weight of hydroxyaci...

Embodiment 1

[0076]Black material: prepolymer formed by IPDI and PTMG1000 (PTMG1000, converted into liquid at 60°C, dehydrated under high temperature and reduced pressure at 110°C, cooled to 60°C, added IPDI, kept stirring at 75°C for 80 minutes), wherein the weight ratio of IPDI and PTMG1000 is 110:20, NCO% is about 30%, put the black material in the A barrel. White material: DMN-60050 parts, DMN-45048 parts, glycerin 2 parts, after high temperature 110 ℃ vacuum dehydration cooling treatment, add catalyst UL-290.3 parts, Bicat-80.05 parts, Bicatz0.1 parts, 1 part of lactic acid (Dehydration treatment at low temperature at 50°C), 2 parts of molecular sieve, 2 parts of internal release agent Q2-51862, 0.5 part of paraffin powder, 1.5 parts of nano-titanium dioxide, 3.5 parts of nano-calcium carbonate, put the white material in B barrel and mix well. Mix the components in the A barrel and the B barrel with a weight ratio of 150:100 and inject them into the injection box through the glue inje...

Embodiment 2

[0078] Black material: prepolymer formed by IPDI and 7201A (7201A is transformed into liquid at 60°C, dehydrated at 110°C, cooled to 75°C, added with IPDI, kept at 75°C and stirred for 2 hours), wherein the weight ratio of IPDI to 7201A is 110 : 40, NCO% is about 26%, and the black material is placed in the A barrel. White material: DMN-60050 parts, DMN-45048 parts, 2 parts of glycerin, after high temperature 110 ℃ vacuum dehydration cooling treatment, add catalyst UL-290.5 parts, Bicat-80.05 parts, Bicatz0.1 parts, 1 part of lactic acid (low temperature 50°C dehydration treatment), 2 parts of molecular sieve, 3 parts of internal release agent INT-1948MCH, 0.5 parts of paraffin powder, 1.5 parts of nano-titanium dioxide, 3.5 parts of nano-calcium carbonate, put the white material in the B barrel and mix well. Mix the components in the A barrel and the B barrel with a weight ratio of 170:100 through the glue injection machine and inject it into the glue injection box, and impre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com