Patents

Literature

574results about How to "Improve fire and flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Ceramicized silicon rubber, preparation method and application

ActiveCN102964836AEasy to processReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsCouplingOrganic group

The invention relates to a ceramicized silicon rubber, which comprises 1)60-100 parts of silicon rubber, wherein a general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 2)20-100 parts of silicon dioxide; 3)1-20 parts of silicone oil, wherein the general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 4)0.1-10 parts of coupling agent and 5)20-120 parts of ceramicized powder. The above raw materials are mixed in a kneader and then vacuumized, the ceramicized powder and the coupling agent are added in the kneader and then uniformly mixed to form the bulk ceramicized rubber, and the ceramicized rubber is performed roll mixing and filtered to obtain the ceramicized silicon rubber. The ceramicized silicon rubber has the advantages that the processing is easy, the production cost is low, the ceramicized silicon rubber can be performed ablation to a ceramic shell, and can protect the burned objects from damaging.

Owner:常州市沃科科技有限公司

Flame-retardant ceramic composite material and preparation method thereof

ActiveCN103601954AEasy to processReduce manufacturing costRubber insulatorsInsulated cablesCeramic compositePolyolefin

The invention discloses a flame-retardant ceramic composite material which comprises the following components in parts by weight: 100 parts of polyolefin, 0-100 parts of silicone rubber, 1-100 parts of silica, 0-30 parts of silicone oil, 0.00001-10 parts of platinum complex or platinum compound calculated based on platinum, 0-10 parts of coupling agent, 0-100 parts of flame retardant, 1-250 parts of porcelain powder, 0-10 parts of antioxidant, and 0.01-10 parts of vulcanizing agent. The materials are mixed in a kneading machine, the materials are added into the kneading machine through vacuumizing and then uniformly mixed so as to obtain bulk ceramic rubber, and after being cooled, the cooled rubber is subjected to open milling by adding the vulcanizing agent so as to obtain the flame-retardant ceramic composite material. The flame-retardant ceramic composite material disclosed by the invention is easy to process and low in production cost, and can be ablated into a ceramic shell so as to protect a burnt object from being damaged. Because a platinum complex or a platinum compound is added in the flame-retardant ceramic composite material disclosed by the invention, the sintering temperature of the flame-retardant ceramic composite material can be reduced, the reaction speed of preparation can be increased, the production efficiency is improved, and the production cost is lowered.

Owner:SHANGHAI KETER POLYMER MATERIAL

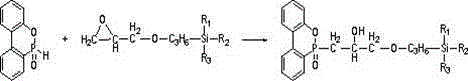

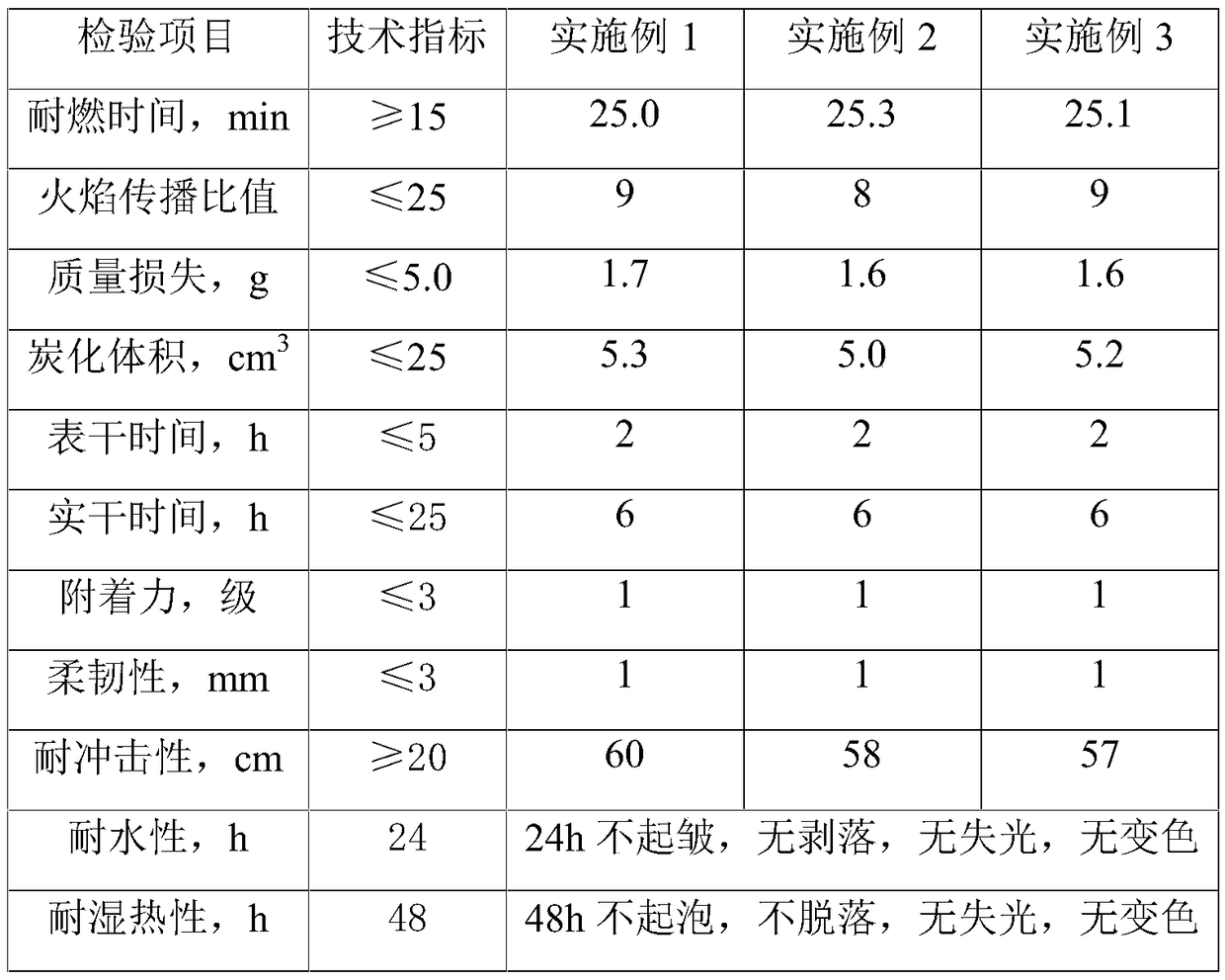

Aqueous ultrathin expansion-type fireproof coating for steel structure and preparation method thereof

ActiveCN104130671AImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsPolymer sciencePentaerythritol

The invention discloses an aqueous ultrathin expansion-type fireproof coating for a steel structure and a preparation method thereof, and belongs to the technical field of fireproof coatings. The aqueous ultrathin expansion-type fireproof coating comprises, by mass, 10-35 parts of a modified aqueous epoxy emulsion, 1-8 parts of a curing agent, 5-15 parts of a styrene-acrylic emulsion or a silicone-acrylic emulsion, 10-20 parts of ammonium polyphosphate, 6-12 parts of melamine, 8-16 parts of pentaerythritol, 5-15 parts of a fire retardant, 5-15 parts of a pigment and a filling material, 2-8 parts of an assistant and 15-35 parts of water. The aqueous ultrathin expansion-type fireproof coating has the characteristics of low raw material cost, simple preparation process and environmental friendliness.

Owner:沈阳泰丰化工有限公司

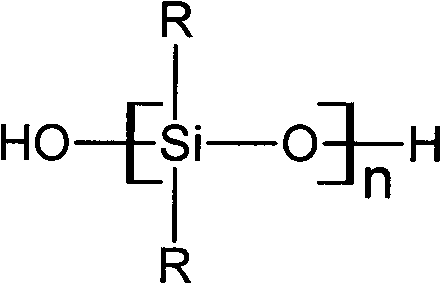

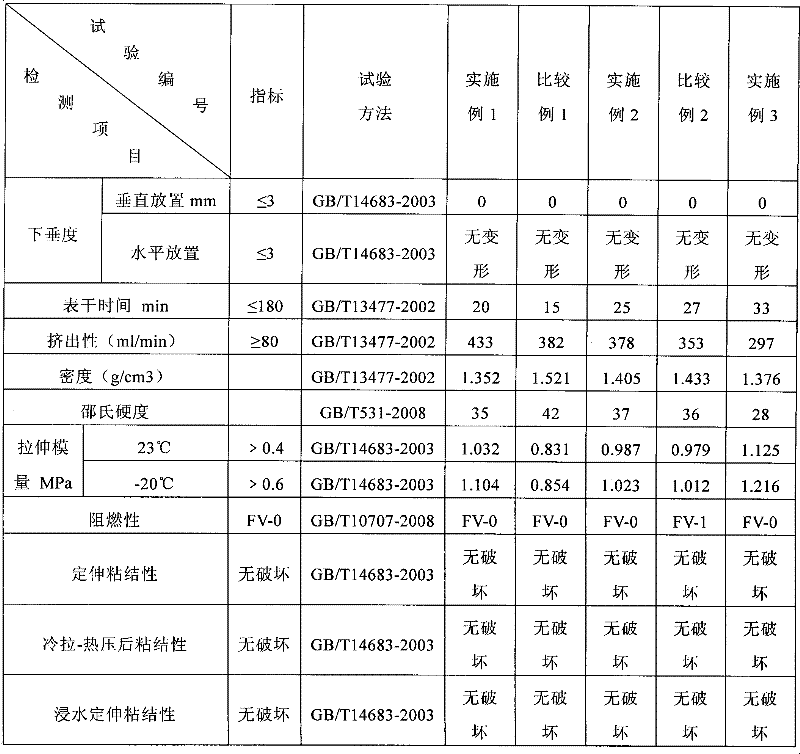

Silicone fireproof sealant for construction and preparation method thereof

InactiveCN101747859ALess corrosiveHigh flame retardant efficiencyNon-macromolecular adhesive additivesOther chemical processesRoom temperatureNitrogen

The invention discloses a silicone fireproof sealant for construction and a preparation method thereof. The preparation comprises the steps of adding alpha, omega-dihydroxy polysiloxane, a filler, an inorganic flame retardant and a nitrogen system flame retardant into a kneading machine, carrying out dehydration at the temperature of 100-180 DEG C and the vacuum degree of 0.06-0.1MPa for 0.5-4 hours, cooling, and then preparing a base material. The base material, polydimethylsiloxane, an inorganic pigment, a crosslinking agent, a silane coupling agent and a catalyst are added into a planetary mixer at the room temperature, keeping the vacuum degree at 0.06-0.1MPa, stirring at the speed of 20-80 r / min, carrying out reaction under stirring for 0.5-6 hours, and preparing the silicone fireproof sealant for construction with no pollution to the base material, flame retardance and excellent adhesion and storage stability. The inorganic flame retardant and the nitrogen system flame retardant are in synergistic flame retardance, and the silicone fireproof sealant can effectively reduce the adding amount of the inorganic flame retardant and greatly improve the mechanical processing performance of a product under the situation of achieving the equivalent flame retardant grade FV-0.

Owner:浙江凌志新材料有限公司

Preparation method of organic-inorganic composite capsule wall energy-storage microcapsule

ActiveCN103769021AImprove thermal stabilityHigh mechanical strengthHeat-exchange elementsMicroballoon preparationFiltrationOil phase

The invention discloses a preparation method of an organic-inorganic composite capsule wall energy-storage microcapsule. The method is as below: mixing an organic phase change material and a surface active agent, heating with stirring to obtain an even oil phase material; adding silica-containing silica sol and ethyl orthosilicate in a mass ratio of 1:1-10:1 into deionized water to prepare a water phase material; then adding an oil phase material into the water phase material, and uniformly dispersing into an emulsion; then adding polyisocyanate and a crosslinking agent, maintaining the original temperature and stirring speed, so as to obtain the microcapsule with the organic-inorganic composite capsule wall; and finally, conducting vacuum filtration, washing and drying on the obtained liquid substance to obtain the product. The phase change energy-storage microcapsule obtained by the method can be used in several fields such as building energy saving and insulation of pipeline storage tank, and the capsule wall of the microcapsule has the advantages of organic material and inorganic material and longer cycle of usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

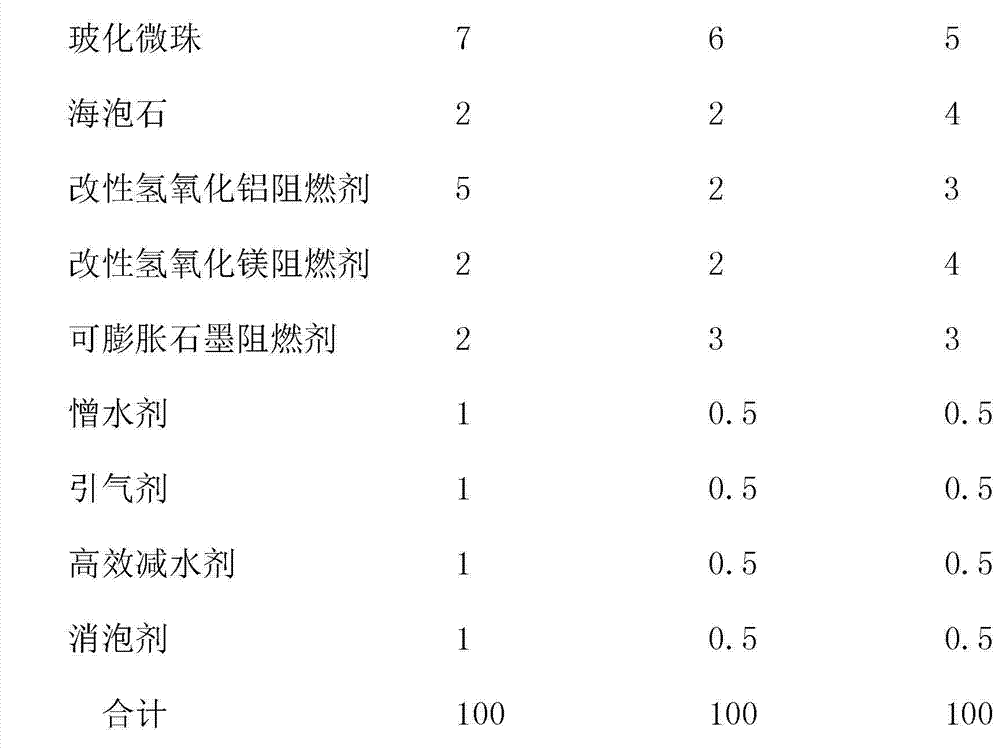

Thin fire-resistant/flame-retardant paint for tunnel and preparation method thereof

The invention relates to thin fire-resistant / flame-retardant paint for a tunnel and a preparation method thereof. The paint is prepared from the following raw materials in percentage by weight: 40-50% of silicate cement, 5-10% of high-alumina cement, 1-5% of fly ash, 1-5% of redispersible rubber powder, 1-5% of aluminum silicate fiber, 5-10% of expanded perlite, 5-10% of vermiculite, 5-10% of hollow glass microsphere, 5-10% of vitrified microsphere, 1-5% of sepiolite, 1-5% of modified aluminum hydroxide flame retardant, 1-5% of modified magnesium hydroxide flame retardant, 1-5% of expandable graphite flame retardant, 0.5-1% of air entraining agent, 0.5-1% of water reducing agent, 0.5-1% of water repelling agent and 0.5-1% of defoaming agent. The paint provided by the invention has excellent bonding strength, high fire resistance, low heat conductivity and remarkable sound absorption and noise reduction effect, further has favorable moisture resistance, water resistance and durability, and effectively reduces the coating thickness, saves the resources and lowers the construction difficulty on the premise of meeting Chinese standards and related specifications.

Owner:BAOJI TIEJUN CHEM ENG ANTI CORROSION INSTALLATION

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

Fireproof flame-retardant polyurethane external wall thermal-insulation system material

InactiveCN101851993AImprove fire and flame retardant performanceImprove heat resistanceFireproof paintsCovering/liningsFoaming agentPolyol

The invention relates to a fireproof flame-retardant polyurethane external wall thermal-insulation system material, which is characterized by comprising a moistureproof primer paint, a flame-retardant rigid polyurethane foam material, an interface agent, anti-crack mortar, a fireproof coating and a decorating coating which are arranged sequentially from inside to outside, wherein the flame-retardant rigid polyurethane foam material consists of an component A and a component B; the component A is prepared by mixing 80 to 50 parts by weight of phosphorous flame-retardant polyether polyol, 20 to 50 parts by weight of heterocyclic amine polyether polyol, 2 parts by weight of organic silicon foam stabilizer, 2 parts by weight of dimethylethanolamine catalyst, 1 part by weight of dibutyltin dilaurate catalyst, 20 to 50 parts by weight of flame retardant and 20 to 40 parts by weight of fluoro dichloroethane; the component B is a flame-retardant polyisocyanates curing agent; in the using process, the component A and the component B are mixed and foamed and an isocyanate index is between 1.05 and 1.10. The fireproof flame-retardant polyurethane external wall thermal-insulation system material of the invention has the advantage of having higher fireproof flame-retardant property.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD

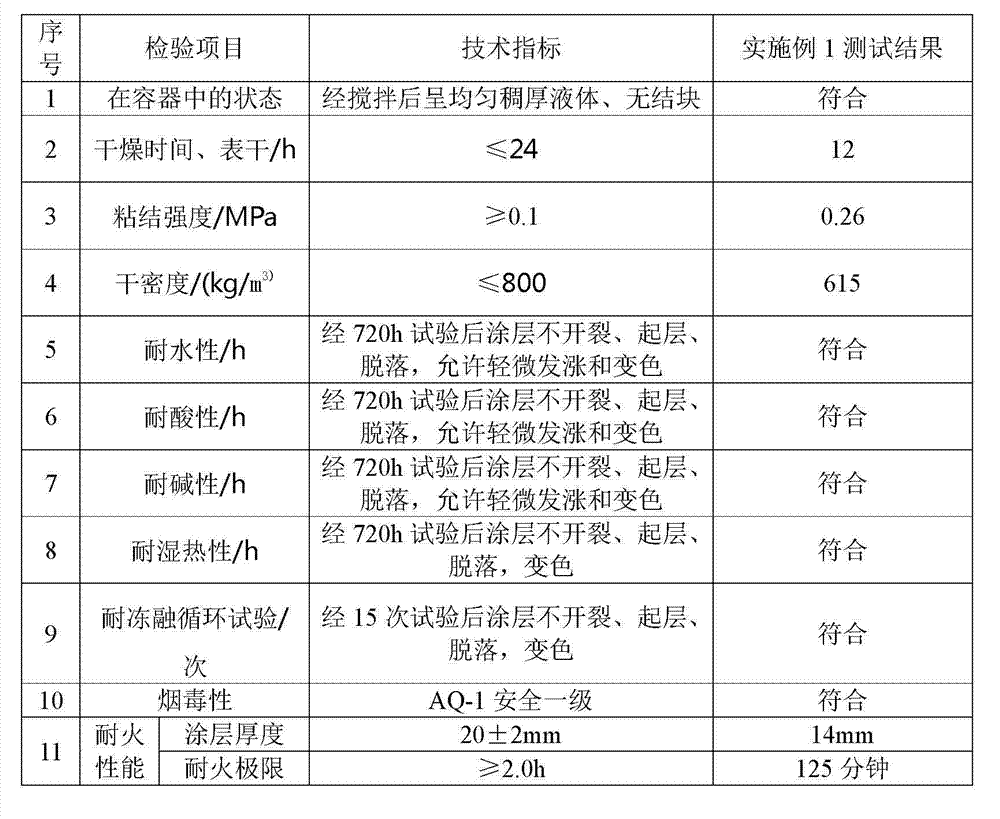

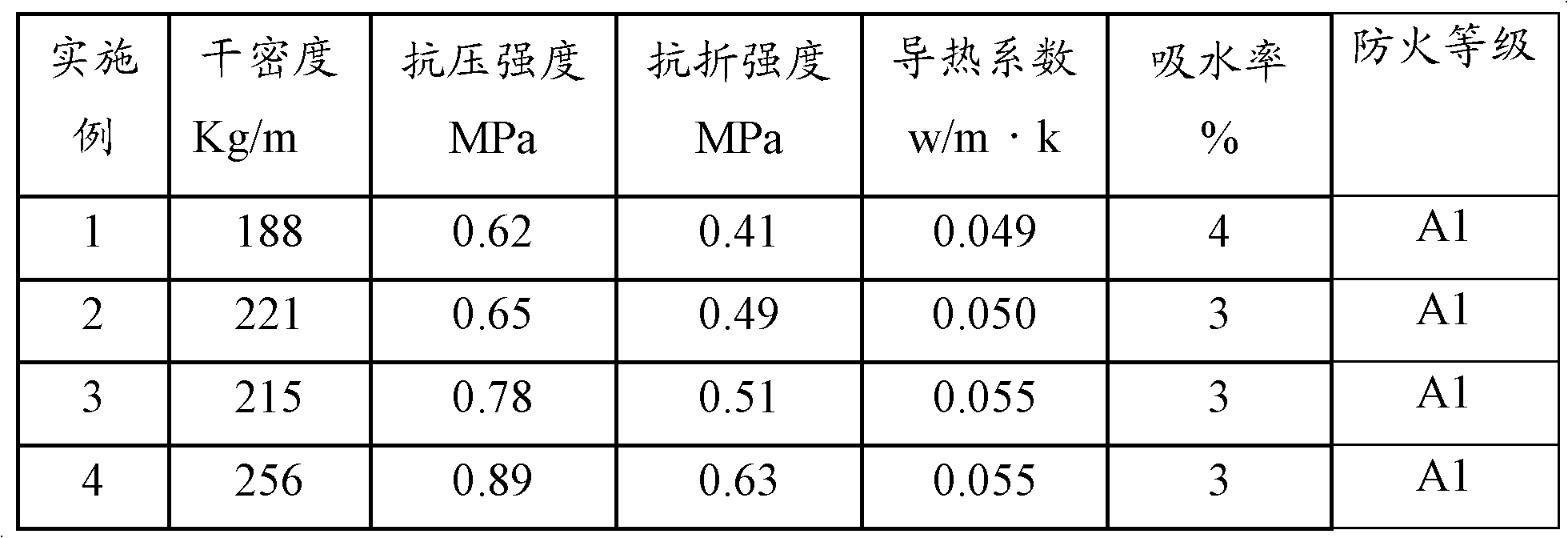

Inorganic fireproof door core material plate

ActiveCN102371613AImprove fire and flame retardant performanceImprove insulation effectCeramic shaping apparatusCeramicwareFoaming agentCombustion

The invention relates to an inorganic fireproof door core material plate, which is formed by forming a mixture from polypropylene fibre, flyash, nano or sub-nano SiO2, mixing the mixture with MgSO4 aqueous solution, AB glue, AB type glue additive, cement foaming assistant agent, cement foaming agent and carbon dioxide gas and curing. The inorganic fireproof door core material plate is very good in fireproof flame retardant property and very good in thermal insulation property. Furthermore, the inorganic fireproof door core material plate is high in intensity; and the combustion property is upto national A1-level standard.

Owner:CHONGQING YUWANTONG NEW MATERIAL TECH

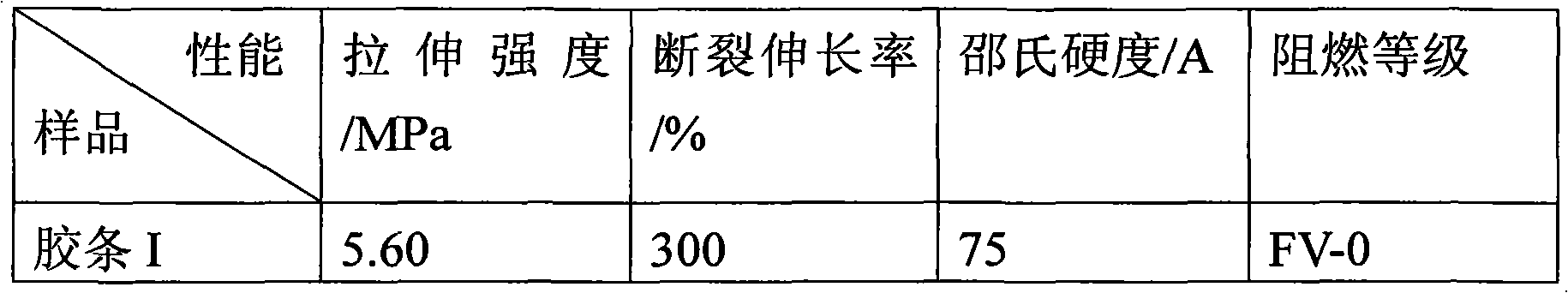

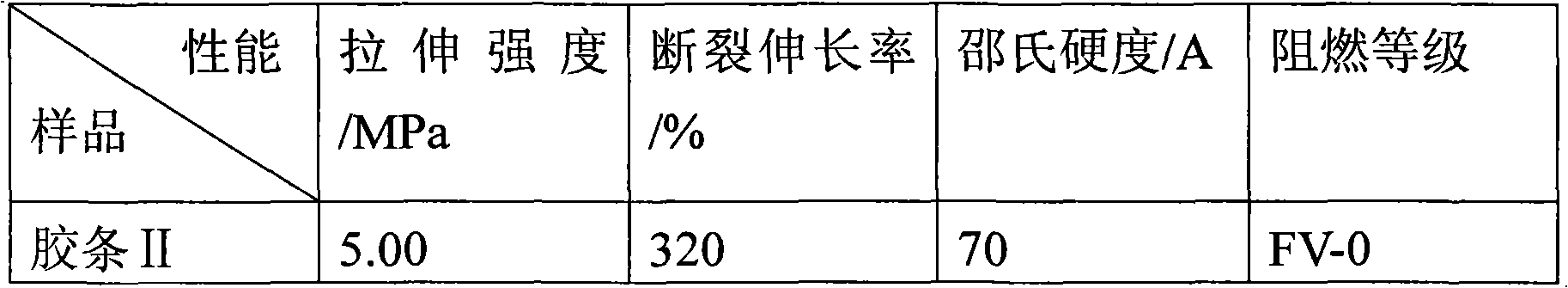

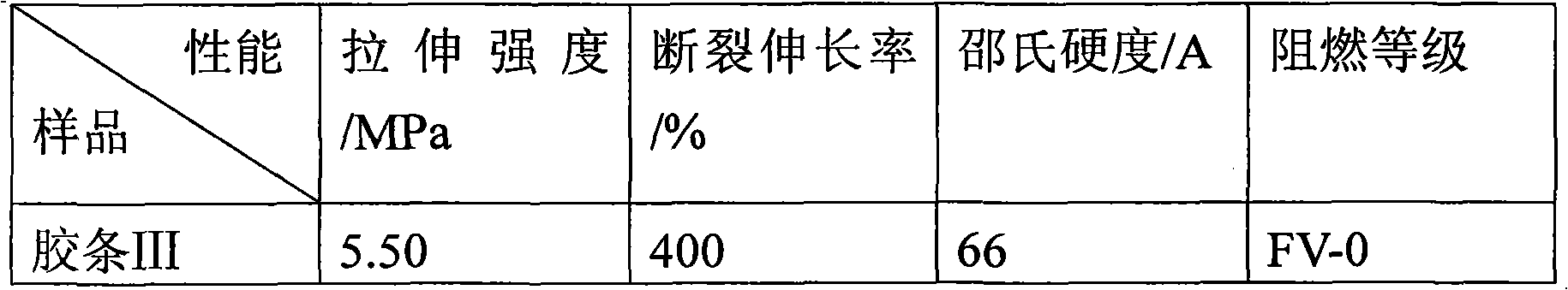

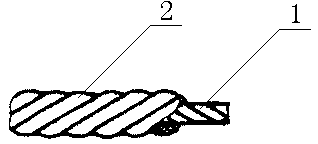

Flame-retardant high-temperature vulcanized silicone rubber strips for doors and windows of buildings and preparation method thereof

The invention discloses flame-retardant high-temperature vulcanized silicone rubber strips for doors and windows of buildings and a preparation method thereof. The method comprises the following steps: adding methyl vinyl silicone rubber, an inorganic flame retardant, fillers and a structural control agent into a kneading machine, dehydrating the mixture at the temperature of between 100 and 180 DEG C and the vacuum degree of between -0.06 and -0.10 MPa for 0.5 to 4 hours, and then cooling the mixture to produce compound rubber; thinning and milling masterbatch rubber, a vulcanizing agent and the compound rubber for 3 to 5 times at room temperature on a mill; cutting thinned compound rubber sheet into rubber strips with the width of between 4 and 6 centimeters and feeding the rubber strips to a screw extruder to extrude the rubber strips; and vulcanizing and forming the rubber strips through a high-temperature drying channel and finally performing a secondary vulcanization in a drying box to produce the flame-retardant high-temperature vulcanized silicone rubber strips for the doors and the windows of the buildings. The flame-retardant high-temperature vulcanized silicone rubber strips for the doors and the windows of the buildings overcome the defects of low hardness and difficult installation of common silicone rubber strips, have high flame-retardant performance and wide range of use temperature, and can be used under bad weather conditions.

Owner:浙江凌志新材料有限公司

Organic-inorganic composite nanometer heat-insulating fire-retardant coating and preparation method thereof

ActiveCN104177965AImprove adhesionImprove anti-corrosion performanceFireproof paintsEpoxy resin coatingsEpoxyOrganic film

The invention discloses an organic-inorganic composite nanometer heat-insulating fire-retardant coating and a preparation method thereof. The organic-inorganic composite nanometer heat-insulating fire-retardant coating is prepared by mixing organic film-forming substance acrylic ester emulsions or styrene-acrylate emulsions, epoxide resin, organic intumescent fire-retardant system pentaerythritol, melamine and ammonium polyphosphate with inorganic fire retardant nanometer aluminum hydroxide, nanometer magnesium hydroxide, filler nanometer titanium dioxide, ceramic hollow microspheres, glass hollow microspheres and a part of auxiliary agents. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention not only has excellent facing property and fire-retardant property, but also achieves reflection effect on solar radiation and certain heat-insulating and heat-preserving property on a substrate, also has good adhesivity, mechanical property and hydrophobic effect, can be formed through spray coating or brush coating before being solidified, and is a novel water-based multifunctional fire-retardant material. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention can not only be used as a general building wall body fire-retardant coating, but also be suitable for the fire prevention of building and ornament materials, heat-insulating materials, steel structure supports, beam columns, metal roofs and the like.

Owner:山西省建筑科学研究院集团有限公司

Ceramic fire-resistant and flame-retardant silicone rubber and preparation method thereof

InactiveCN106398231AImprove fire and flame retardant performanceImprove performancePolymer scienceSilanes

The invention relates to the technical field of silicone rubber, and particularly relates to a ceramic fire-resistant and flame-retardant silicone rubber and a preparation method thereof. The ceramic fire-resistant and flame-retardant silicone rubber is composed of a component A and a component B in a weight ratio of 0.8-1.2: 1. The component A comprises the following raw materials in weight part: 60-140 parts of silicone rubber A, 35-45 parts of reinforcing agent, 60-100 parts of filler A, 11.4-17.2 parts of silane auxiliary agent A, 0.15-0.25 part of lubricant A, 0.1-0.3 part of flame retardant, and 0.5-1.5 parts of vulcanizing agent. The component B comprises the following raw materials in weight part: 60-140 parts of silicone rubber B, 230-290 parts of filler B, 3-6 parts of silane auxiliary agent B, and 0.2-0.4 part of lubricant B. According to the technical scheme of the invention, the ceramic fire-resistant and flame-retardant silicone rubber is good in fire-resistant and flame-retardant property, and excellent in comprehensive performance.

Owner:东莞市朗晟材料科技有限公司

Flame-retardant composite yarns and production method for same

The invention discloses flame-retardant composite yarns and a production method for the same. The flame-retardant composite yarns are characterized in that polyester filament yarns are adopted for central fibers, wherein the outer surfaces of the central fibers are wrapped with wrapping fibers in a winding way; aramid short fibers made from polyisophthaloyl metaphenylene diamine fibers are adopted as the wrapping fibers; the flame-retardant composite yarns are formed by a fully-automatic bobbin winder, a high-speed doubling winder and a two-for-one twisting procedure. According to the flame-retardant composite yarns and the production method for the same, the strength of the composite yarns is greatly strengthened, the advantages of high flame retardance of the aramid short fibers and high tenacity of the polyester filament yarns are effectively integrated, and the composite yarns are suitable for high-speed sewing and is high in sewing processing efficiency; in addition, special garments made from the composite yarns wear comfortable, the sewing requirements of special garments and equipment used in high-temperature working environments can be met, and the composite yarns can be widely used for the sewing of firefighting, electric welding, fireproof and high-temperature resistant fabrics as well as fireproof inorganic roller shutters, fireproof and high-temperature resistant gloves, fireproof gilts and fireproof and high-temperature resistant sealing rings, have good fireproof and flame-retardant effects, and are wide in application range.

Owner:JIHUA 3506 TEXTILE & APPL

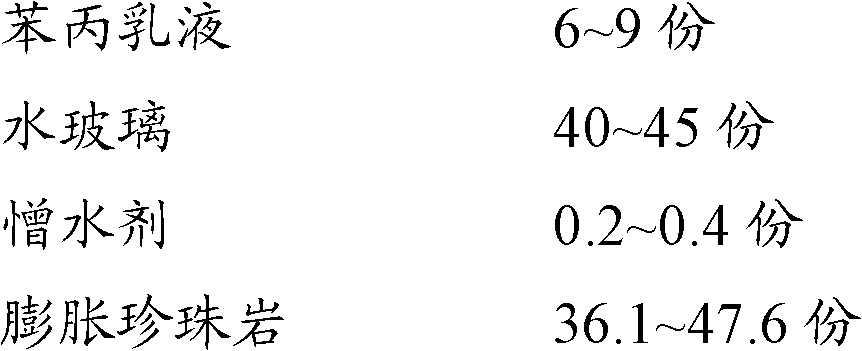

Modified expanded perlite insulation board and preparation method thereof

InactiveCN102584166AImprove insulation effectImprove mechanical propertiesEmulsionThermal insulation

The invention provides a modified expanded perlite insulation board and a preparation method thereof. The insulation board is prepared from 6-9 parts of distilled water, 0.2-0.5 part of mildew preventive, 6-9 parts of styrene-acrylic emulsion, 40-45 parts of water glass, 0.2-0.4 part of hydrophobic agent and 36.1-46.7 parts of expanded perlite. The preparation method comprises the following steps of: (1) mixing and stirring evenly the 6-9 parts of distilled water, the 0.2-0.5 part of mildew preventive and the 6-9 parts of styrene-acrylic emulsion; (2) under the condition of stirring, adding the 40-45 parts of water glass to a mixture obtained in step (1) slowly and mixing and stirring evenly; (3) adding the 0.2-0.4 part of organosilicon hydrophobic agent and the 36.1-46.7 parts of expanded perlite to a mixture obtained in step (2), mixing and stirring evenly and pressing the obtained mixture into plates; and (4) drying and cooling the plates obtained in the step (3) and then packaging and putting the plates in a storage. By adopting the method, the modified expanded perlite insulation board with good thermal insulation performance, water-proof performance, mechanical property and fire-retardant performance can be prepared.

Owner:深圳市嘉达节能环保科技有限公司

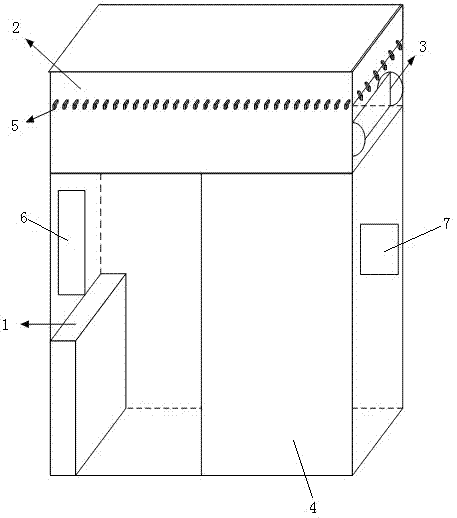

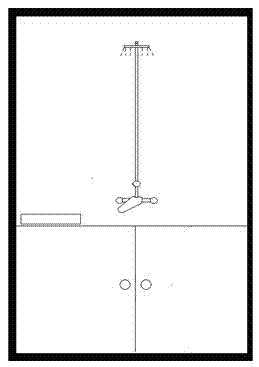

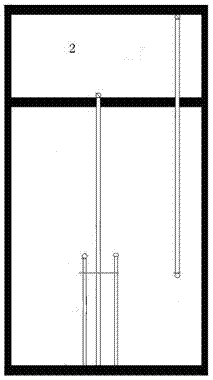

Multifunctional fire disaster refuge cabin for high-rise buildings

InactiveCN103111028AEasy to operateImprove fire and flame retardant performanceBreathing protectionFire retardantOxygen supply

The invention relates to a multifunctional fire disaster refuge cabin for high-rise buildings. The multifunctional fire disaster refuge cabin for the high-rise buildings comprises a cuboid cabin body. The shell of the cuboid cabin body is composed of steel materials with ultrathin intumescent fire retardant coating coated. The inner layer of the cuboid cabin body is composed of metal plate materials. An interlayer composed of fire retardant and thermal insulation materials is between the shell and the inner layer. A cabin door composed of a common door and a fire prevention door or a cabin window composed of a common window and a fire prevention window is placed in the front of the cuboid cabin body. An oxygen supply system, an emergency power supply, a pipeline, a lighting lamp and a refuge cabin environment monitoring system are placed inside the cuboid cabin body, wherein the refuge cabin environment monitoring system timely monitors environment inside and outside the cabin. A ventilating system and a spaying system are placed on the top of the cuboid cabin body. The multifunctional fire disaster refuge cabin for the high-rise buildings is simple in equipment operation, good in fire retardant effect, fast in reaction speed, high in surviving rate, long in survival time, strong in self-rescue ability, low in manufacturing cost, and easy to produce, accords with requirement of national lifesaving equipment, is high in safety, large in market of equipment requirement and wide in application range.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

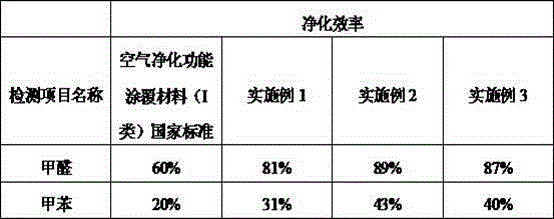

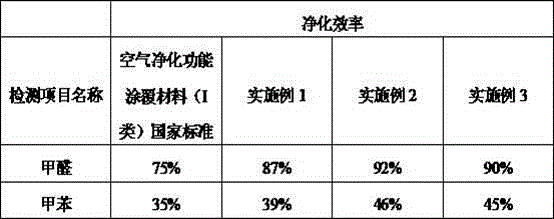

Diatom ooze wall material capable of efficiently purifying air or resisting against bacteria or automatically humidifying and preparation method of diatom ooze wall material

ActiveCN104446283AImprove adsorption capacityAutomatically adjust humidityDecompositionHazardous substance

The invention discloses a diatom ooze wall material capable of efficiently purifying air or resisting against bacteria or automatically humidifying and a preparation method of the diatom ooze wall material. The diatom ooze wall material is prepared from the following raw materials in parts by weight: 30-50 parts of kieselguhr, 10-20 parts of sepiolite powder, 1-3 parts of heavy calcium powder, 5-15 parts of calcium hydroxide, 1-3 parts of quick lime, 5-15 parts of quartz sand, 15-25 parts of wollastonite powder, 1-5 parts of hydroxypropyl methyl cellulose, 2-5 parts of EVA flexible rubber powder, 1-3 parts of a titanium dioxide mesoporous molecular sieve, 1-5 parts of nano-zinc oxide and 1-3 parts of an organic silicon defoamer. The diatom ooze wall material prepared by the method has the effects of high in harmful substance adsorption and decomposition capacities, high antibacterial ability, environmental protection, no pollution, automatic humidification, temperature resistance, fireproof property and simple preparation process.

Owner:内蒙古东盛硅藻土科技创新产业园有限公司 +1

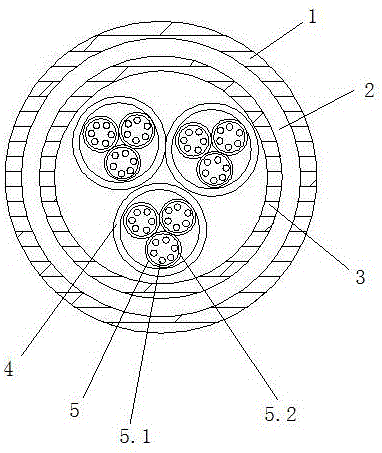

Flame-retardant cable and preparation method therefor

ActiveCN105957613AImprove fire and flame retardant performanceStable structureInsulated cablesInsulated conductorsTetrafluoroethyleneElectrical conductor

The invention relates to the processing technical field of cables, and specifically to a flame-retardant cable. The flame-retardant cable comprises multiple insulating wire core groups, shielding layers, a reinforcement layer, a high-temperature-resistant layer and a protection layer, wherein each insulating wire core layer is formed by multiple insulating wire cores in a stranded manner; each insulating wire core comprises a conductor and a high-temperature insulating layer which coats the exterior of the corresponding conductor; each shielding layer is wound around the periphery of each insulating wire core layer; the peripheries of the shielding layers are packaged by the reinforcement layer; the high-temperature-resistant layer is arranged on the outer surface of the reinforcement layer; the outer surface of the reinforcement layer is coated with the protection layer; and each high-temperature insulating layer is an ethylene-tetrafluoroethylene copolymer layer. The invention also provides a preparation method for the flame-retardant cable. The prepared flame-retardant cable provided by the invention is simple to manufacture, convenient to operate, and relatively good in the fireproof and flame-retardant performance; and meanwhile, the cable is resistant to high temperature and bending, tensile, high in flexibility, and wearproof, and has a quite good protection effect on oxygen, high-energy radiation and harmful metal aging.

Owner:ANHUI AICS SCI & TECH GROUP

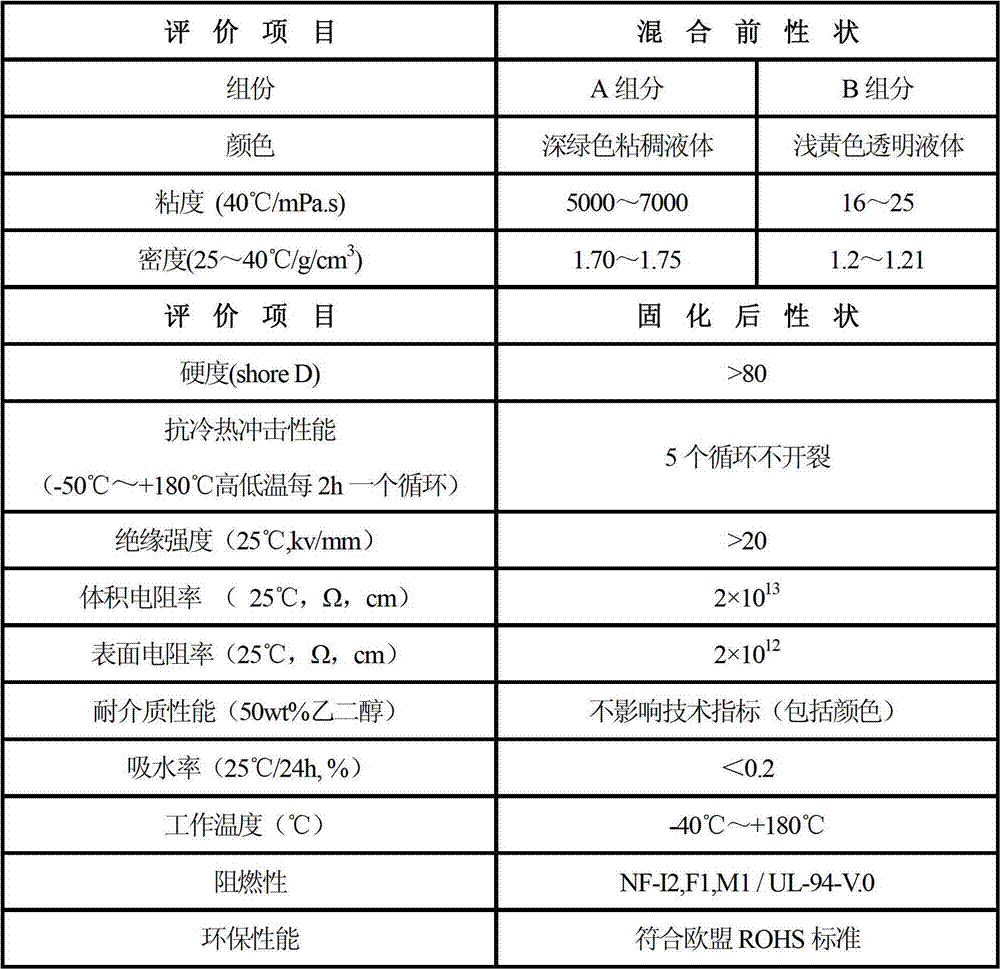

Flame-retardant encapsulating material and preparation method thereof

The invention relates to the field of encapsulation of electronic component, in particular relates to a flame-retardant encapsulating material applicable to electronic and electric product and a preparation method of the flame-retardant encapsulating material, solving the problems of the prior art that the fire-proofing and flame retardant performance is poor, and relatively high flame-retardant rating cannot be obtained. The material comprises a component A and a component B; in percentage by weight, the component A comprises base stock bisphenol-A epoxy resin, fire retardant, diluent diethylene glycol dibenzoate, flexibilizer dioctyl phthalate, pigment, organic silicon defoaming agent and filler silica micropowder; the component B comprises curing agent phthalic anhydride or methyl tetrahydrophthalic anhydride, curing agent eleostearate anhydride, and accelerator 2, 4, 6-tri(dimethylamino methyl) phenol; before the flame-retardant encapsulating material is used, the component A is pre-heated in an oven and then uniformly agitated in an up-to-bottom way; and the component A and the component B are uniformly mixed, so as to obtain flame-retardant encapsulating material; and then the encapsulating can be carried out. The flame-retardant encapsulating material provided by the invention is mainly applicable to insulating packaging of various electronic components such as power engine, rail transit, war industry, spaceflight, car and power.

Owner:大连宝津科技发展有限公司 +1

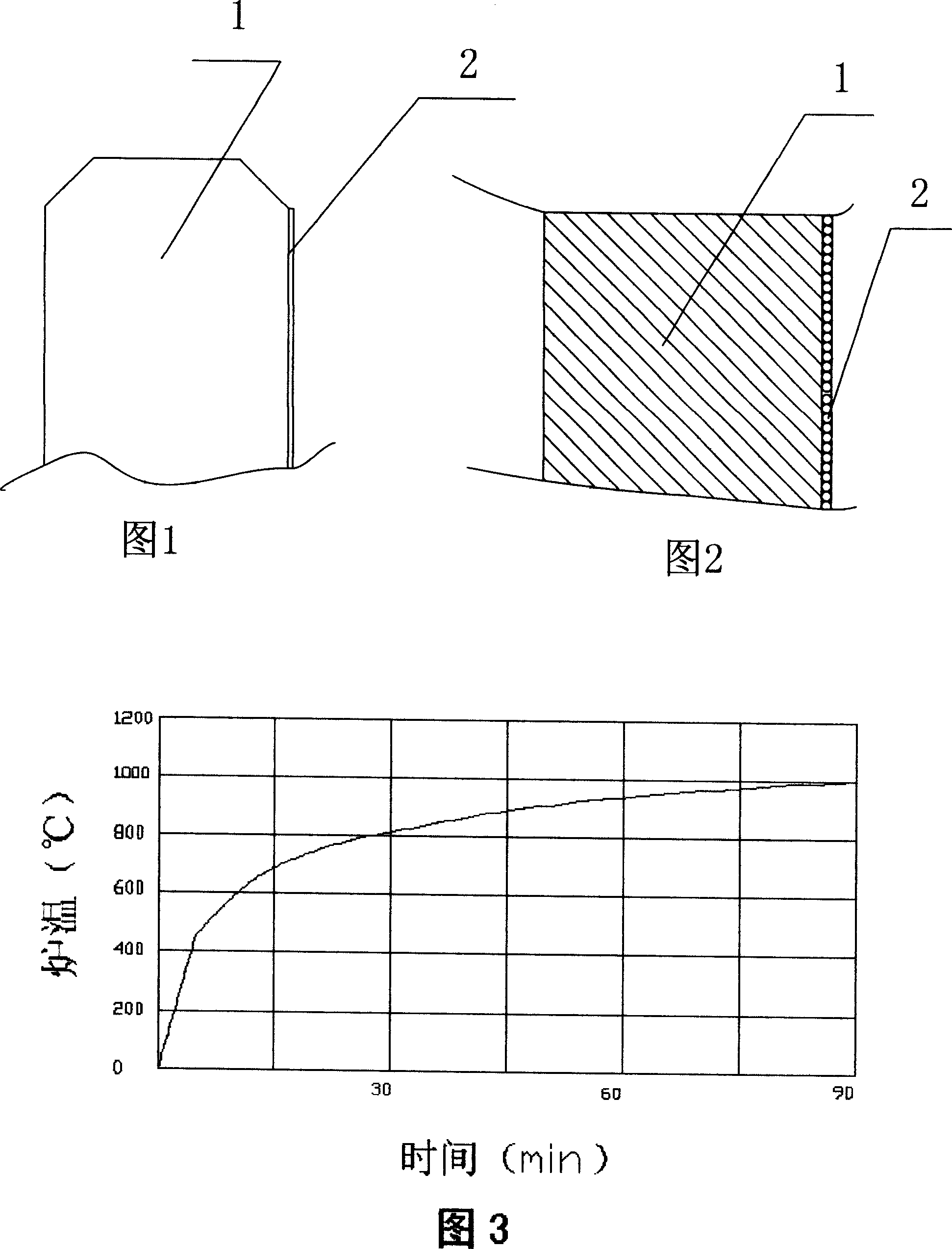

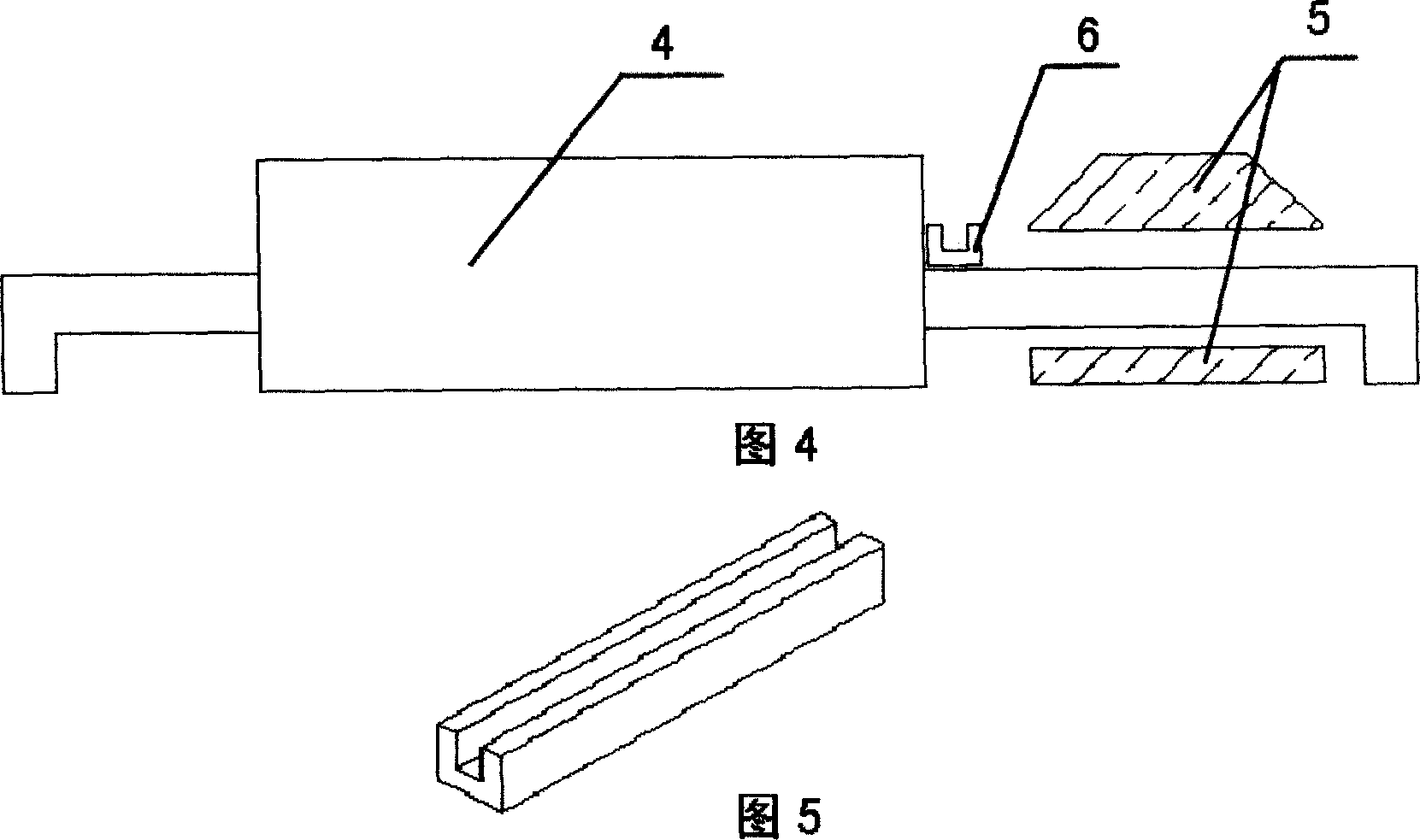

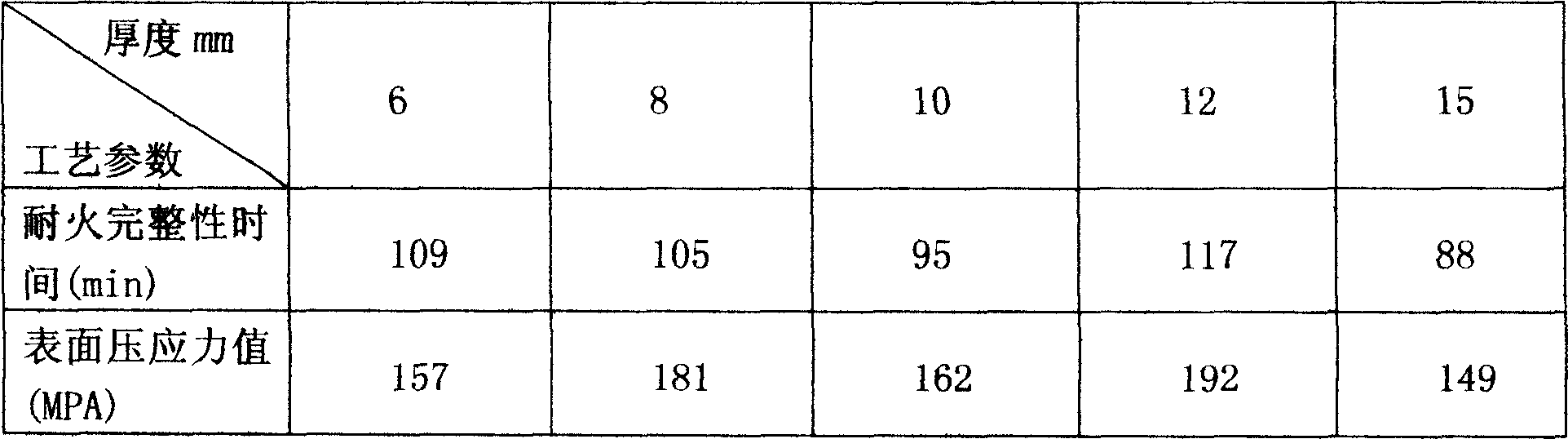

Method for producing fire-resisting glass and dedicated production equipment

ActiveCN101092286AAccelerates the ion exchange reaction processWon't peel off easilyGlass tempering apparatusGratingHeat resistance

This invention discloses method and specific apparatus for producing fireproof glass. The apparatus comprises: an upper stage plate, a furnace, a cooling wind grating and a lower stage plate. A baffle is set between the heating furnace and the cooling wind grating. The method comprises: (1) spray-coating a cesium / potassium salt solution onto glass at normal temperature; (2) naturally wind-drying the spray-coated glass at normal temperature, placing in a 680-725 deg.C tempering furnace, rapidly heating, cooling, circulating the glass between the heating furnace and the cooling wind grating by a roll so that the heating and cooling temperature is uniform, and unloading to obtain fireproof glass. The cesium / potassium salt solution comprises: cesium salt 0.8-1.2%, potassium salt 38-41%, acetone 40-45%, formic acid 8-13%, and Swiss-78 6-8%. The fireproof glass has such advantages as high heat resistance, low specific gravity, high light permeability, no yellowing, and no air bubbles.

Owner:新福兴玻璃工业集团有限公司

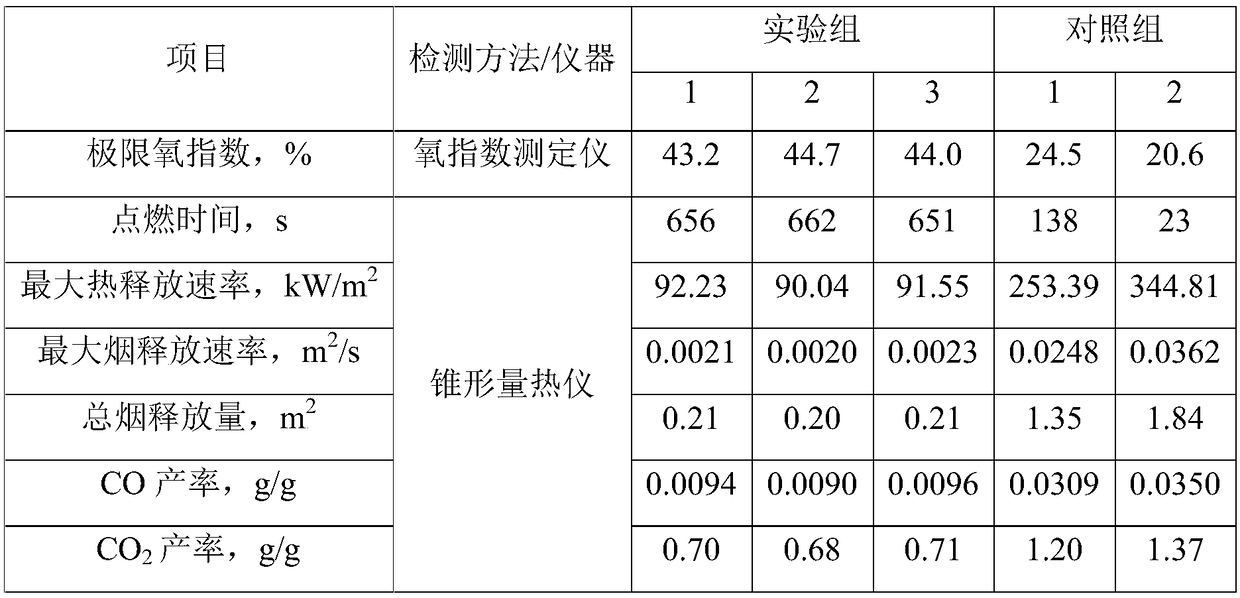

Expansive waterborne fireproof and flame-retardant coating for wood material and preparation method of expansive waterborne fireproof and flame-retardant coating

The invention relates to an expansive waterborne fireproof and flame-retardant coating for a wood material and a preparation method of the expansive waterborne fireproof and flame-retardant coating. The coating comprises water and the following components in parts by weight: 200 parts of melamine-modified urea resin emulsion, 110-120 parts of ethylene-vinyl acetate copolymer emulsion, 20-24 partsof boric acid, 36-38 parts of ammonium polyphosphate, 20-24 parts of guanylurea phosphate, 36-40 parts of pentaerythritol, 30-34 parts of melamine, 1.0-1.4 parts of sulfonated carbon, 3.6-4.0 parts ofzinc borate, 2.0-2.4 parts of ammonium octamolybdate, 16-20 parts of coating auxiliaries and 0-44 parts of pigment and filler. When heated, the expansive waterborne fireproof and flame-retardant coating is capable of greatly retarding the combustion of the wood material so as to prevent fire spreading; and the expansive waterborne fireproof and flame-retardant coating has good smoke inhibiting property and is capable of delaying the smoke generation time, reducing the release amount of smoke and the generation of poisonous gases and providing more safety time and space for escape and rescue of personnel under the condition of a fire hazard.

Owner:湘诚新材料科技有限公司

Polyurethane sponge and processing method thereof

InactiveCN106957408AWith flame retardant functionGood flame retardant functionDiethyl phosphateHalogen

The invention discloses polyurethane sponge and a processing method thereof. Polyether polyol with a flame retardant function is directly added to a material A, and a diethyl ethylphosphonate fire retardant is selectively added to a material B, so that the polyurethane sponge does not contain halogen, is low in viscosity and very stable in a two-component system of the material A and the material B, and a product is endowed with good fireproof and flame-retardant properties while the process is simple. The product is endowed with good mildew-proof and antibacterial effects through an antibacterial agent and a mildew preventive added to the material B; and through addition of nanoscale inorganic material tourmaline powder, the product has the function of lastingly emitting anions. The production technology and the formula are relatively simple on the premise that all performance indexes reach the expected requirements; the production process and the formula are relatively simple; the processes such as heating or refrigerating do not need to be specifically carried out in the production process and foaming and curing in a natural state can be carried out; the production success rate of sample post-detection is very high; the produced polyurethane sponge has obvious fireproof and flame-retardant functions, antibacterial and anti-mildew functions and continuous anion release function, and is beneficial to improvement of the competitiveness of the product.

Owner:东莞恒生高分子科技有限公司

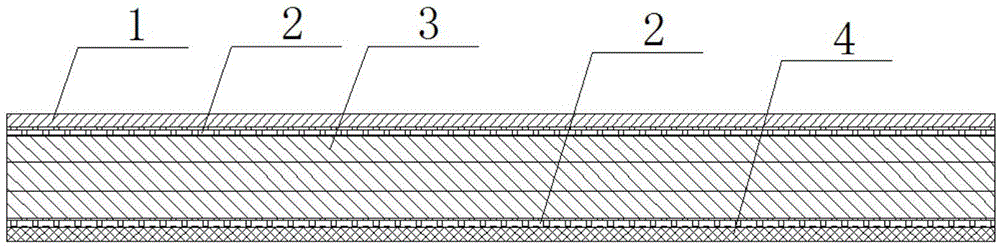

Fireproof marine-grade plywood

ActiveCN105643731AImprove fire and flame retardant performanceGood weather resistanceOther plywood/veneer working apparatusWood treatment detailsSolid woodGlass fiber

The invention relates to the technical field of composite artificial boards and discloses fireproof marine-grade plywood. The fireproof marine-grade plywood comprises a flame-retardant veneer, high-strength glass fiber meshes, flame-retardant solid wood core veneers and a flame-retardant bottom board, wherein the flame-retardant veneer is arranged on the uppermost layer, the flame-retardant bottom board is arranged on the bottommost layer, and one layer of high-strength glass fiber mesh, the three layers of flame-retardant solid wood core veneers and one layer of high-strength glass fiber mesh are sequentially arranged between the flame-retardant veneer and the flame-retardant bottom board from top to bottom; the layers are bonded through modified macromolecular WBP flame-retardant and waterproof glue. The fireproof marine-grade plywood has the functions of being resistant to fire, inflaming, water, moisture, insects and ants and absorbing sounds and shock, saves the energy, protects the environment and is high in strength.

Owner:GUANGZHOU YING ERAN FIRE MATERIAL CO LTD

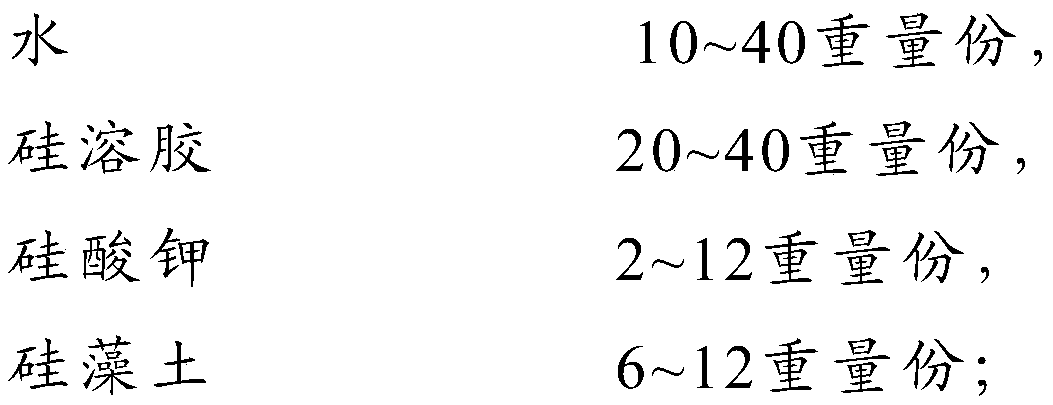

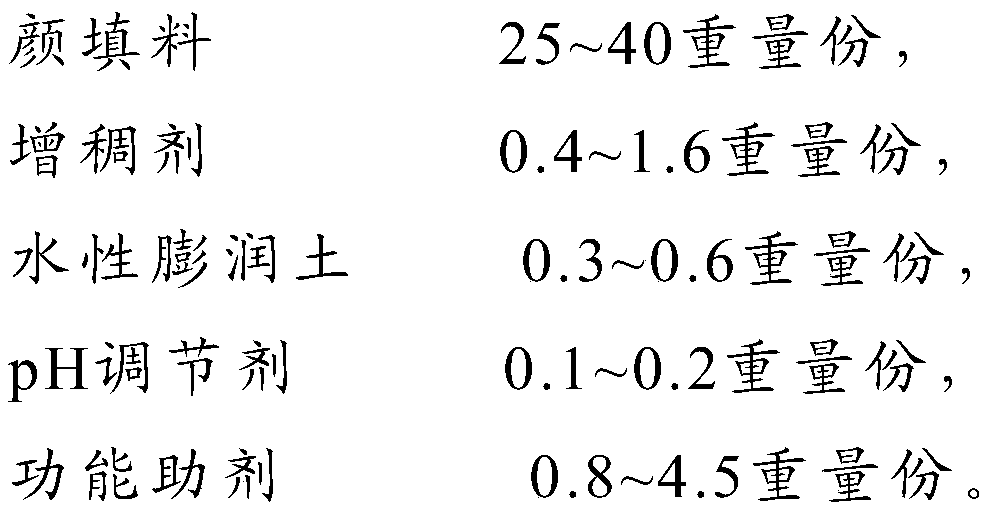

Aqueous interior wall coating taking inorganic material as film forming substance and preparation method thereof

InactiveCN109777162ANo smellNon-irritatingFireproof paintsAntifouling/underwater paintsSodium BentoniteSilica gel

The invention discloses an aqueous interior wall coating taking an inorganic material as a film forming substance and a preparation method thereof. The coating is prepared from the following raw materials: water, a silica sol and potassium silicate, wherein the content of silicon dioxide in the silica gel is 25-30%. The particle sizes of the silicon dioxide particles are 8-10 nm, and the pH valueof the silica sol is 8-11; the content of silicon dioxide (SiO2%) in potassium silicate is greater than or equal to 18.0, and the modulus is between 3.75 and 4.15; the coating also comprises a stabilizer and a silane coupling agent and also comprises pigments and filler, a thickener, aqueous bentonite, a pH regulator and a functional auxiliary agent. According to the aqueous interior wall coating,an organic emulsion is replaced by inorganic potassium silicate and the silica sol as the film forming substance, and the raw materials are directly drawn from the nature and are rich in source, non-toxic, peculiar smell-free and non-irritant. Meanwhile, the inorganic interior wall coating which is alkaline can inhibit growth of bacteria and algae, so that the wall space is kept clean and has a good ventilating property. The wall body is kept dry, and the condition that the coating of the wall space is mildewy, is bulged and falls off as a result of dampness is prevented.

Owner:赵曦轮 +1

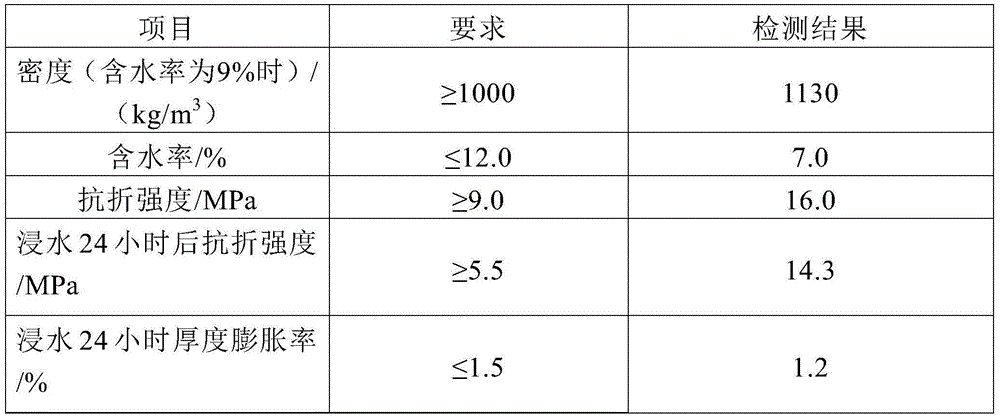

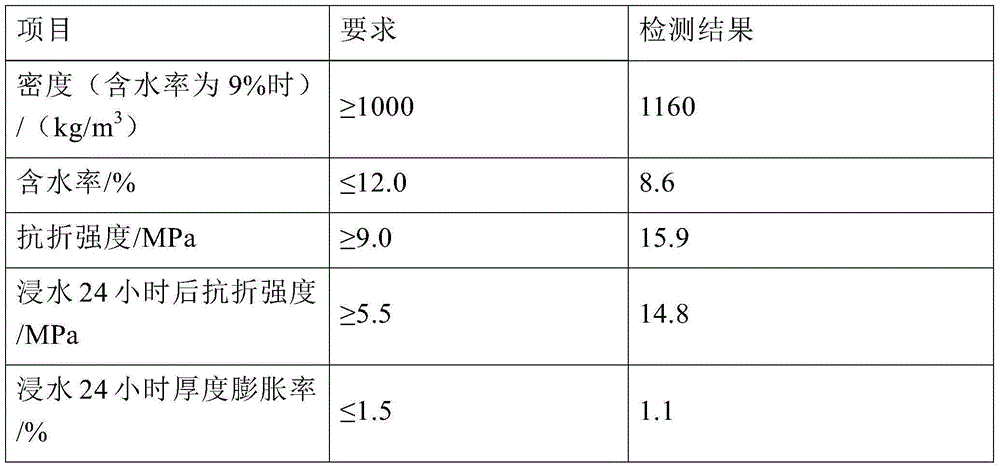

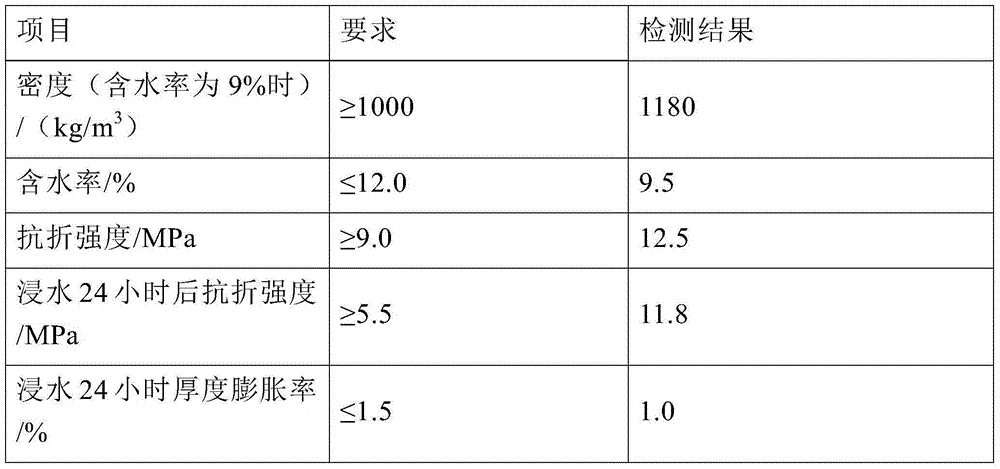

Steam curing-free high-strength cement-wood chip plate and preparation method thereof

ActiveCN105130333AHigh strengthGood fire resistanceSolid waste managementGlass/slag layered productsThermal insulationWater content

The invention discloses a steam curing-free high-strength cement-wood chip plate and a preparation method thereof. The steam curing-free high-strength cement-wood chip plate comprises, by weight, 60-100 parts of cement, 20-60 parts of an active admixture, 10-12 parts of wood chips, 0.8-1.2 parts of thermal insulation aggregate, 7-9 parts of ceramsite, 0.3-0.5 parts of short fibers, 0.3-0.5 parts of an auxiliary agent and 45-50 parts of water. The preparation method comprises mixing cement, the active admixture, short fibers, water and the auxiliary agent to obtain a uniform mixture, adding wood chips, thermal insulation aggregate and ceramsite into the mixture, carrying out stirring to obtain a uniform mixture, laying a net, carrying out rolling flattening, then carrying out molding, loading a vehicle with plate blanks, transporting the plate blanks into a primary curing kiln, carrying out demolding, carrying out stacking, carrying out secondary curing, and naturally drying the plates so that water content is in a range of 5-10%. The steam curing-free high-strength cement-wood chip plate has excellent integrated physical properties and completely satisfies the national industry standard JC / T 411-2007 of cement-wood chip plate.

Owner:ZHUO DA NEW MATERIAL TECH GRP

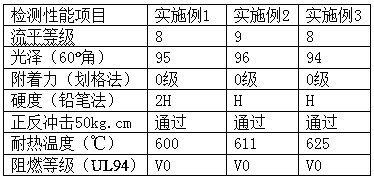

High-temperature-resistant flame-retardant powder paint and production method thereof

InactiveCN110643280AImprove stabilityImprove insulation performanceFireproof paintsPowdery paintsEpoxyPowder coating

The invention discloses high-temperature-resistant flame-retardant powder paint and a production method thereof. The powder paint is produced from the following raw materials in parts by weight: 30-60parts of organic silicon resin, 30-60 parts of epoxy resin, 3.4-6.8 parts of modified dicyandiamide, 0.2-0.4 part of dimethylimidazole, 10-20 parts of silica powder, 10-20 parts of mica powder, 0.3-0.6 part of a sand textured agent, 30-60 parts of a flame retardant and 1.2-2.4 parts of carbon black. A film, which is formed after the produced powder paint is subjected to spraying and curing, has excellent high-temperature-resistant performance, fireproof performance and flame-retardant performance in the premise that the mechanical performance, including the levelling performance and the anti-impact performance, of the film is not affected; and according to the powder paint, the production method is simple, and industrial production can be conducted.

Owner:广西南宁维一防腐科技有限公司

Flame-retardant water-based polyurethane paint

InactiveCN105505180AHigh glossHigh hardnessFireproof paintsPolyurea/polyurethane coatingsWater basedHeat resistance

The invention discloses flame-retardant water-based polyurethane paint which is prepared from 85-88 parts of modified polyurethane resin, 12-15 parts of resol resin, 7-10 parts of waterborne acrylic resin, 3-6 parts of bentonite, 15-18 parts of zeolite powder, 13-16 parts of diatomite, 12-15 parts of talcum powder, 2-4 parts of a thickening agent, 3-5 parts of a flatting agent, 1-2 parts of a defoaming agent, 1-2 parts of an anti-corrosion agent and 2-3 parts of pigment. The flame-retardant water-based polyurethane paint has excellent heat resistance, fireproof performance and flame retardancy, excellent in water resistance, high in adhesive force, high in hardness and high in drying speed.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

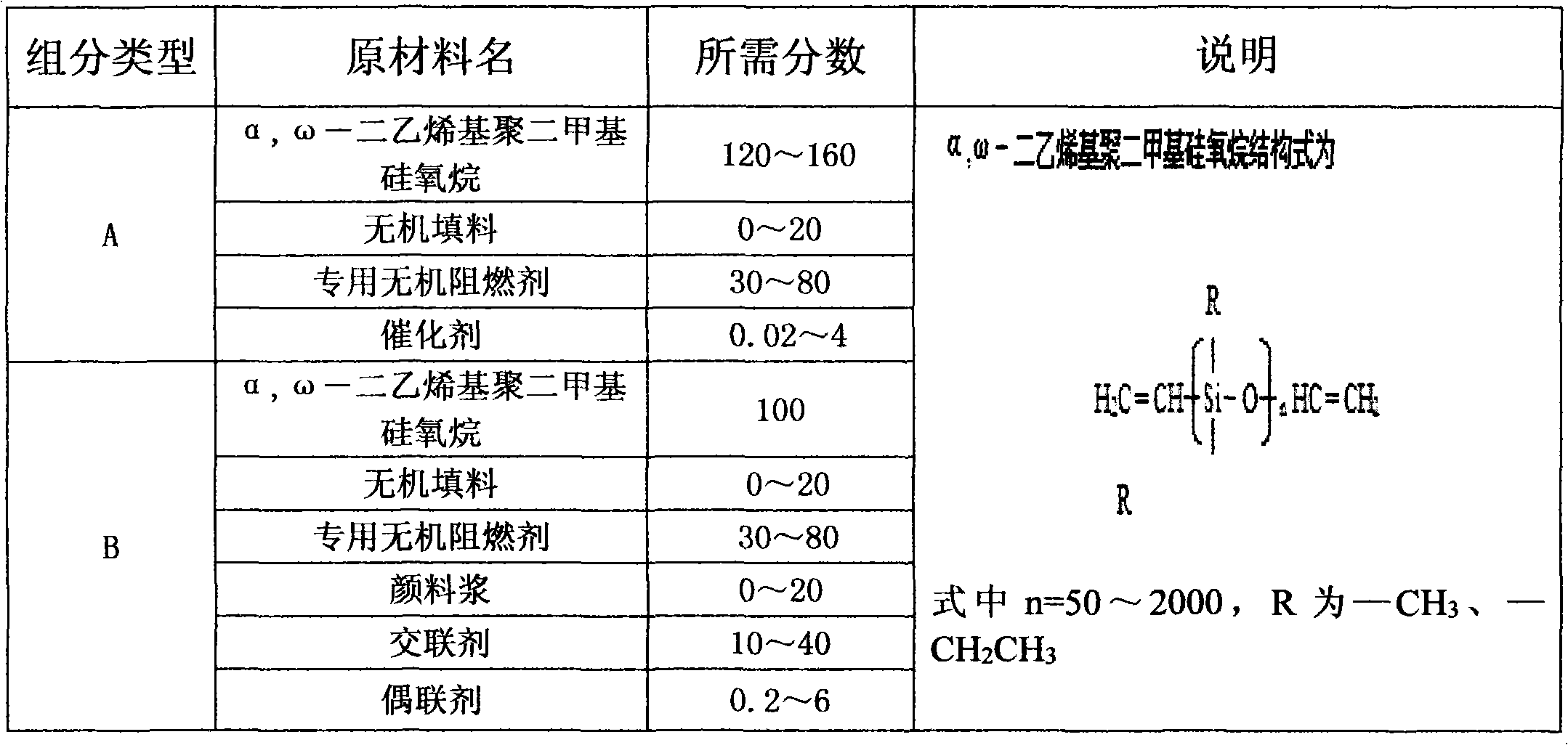

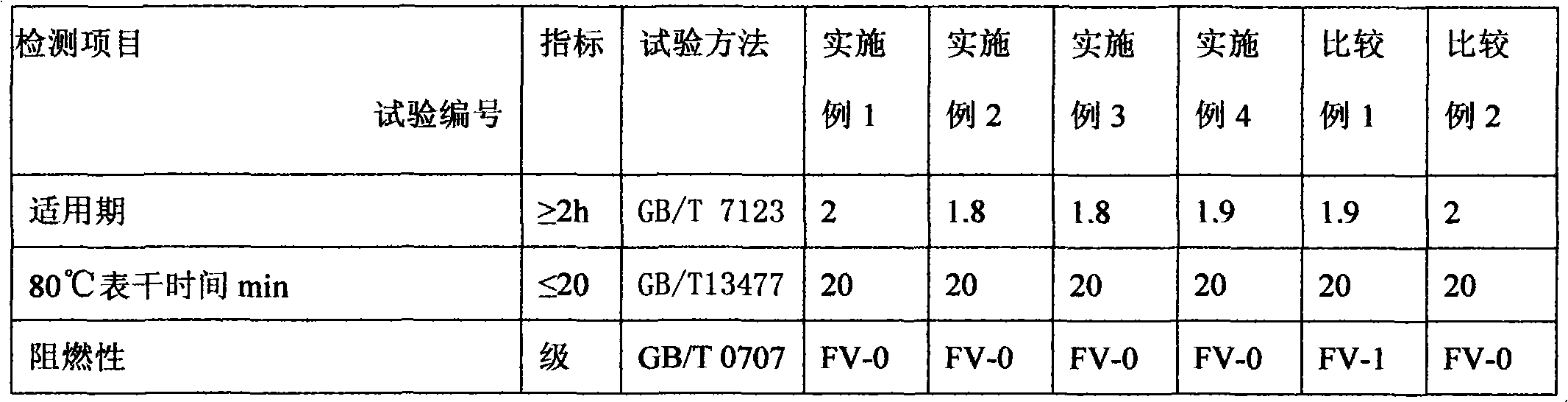

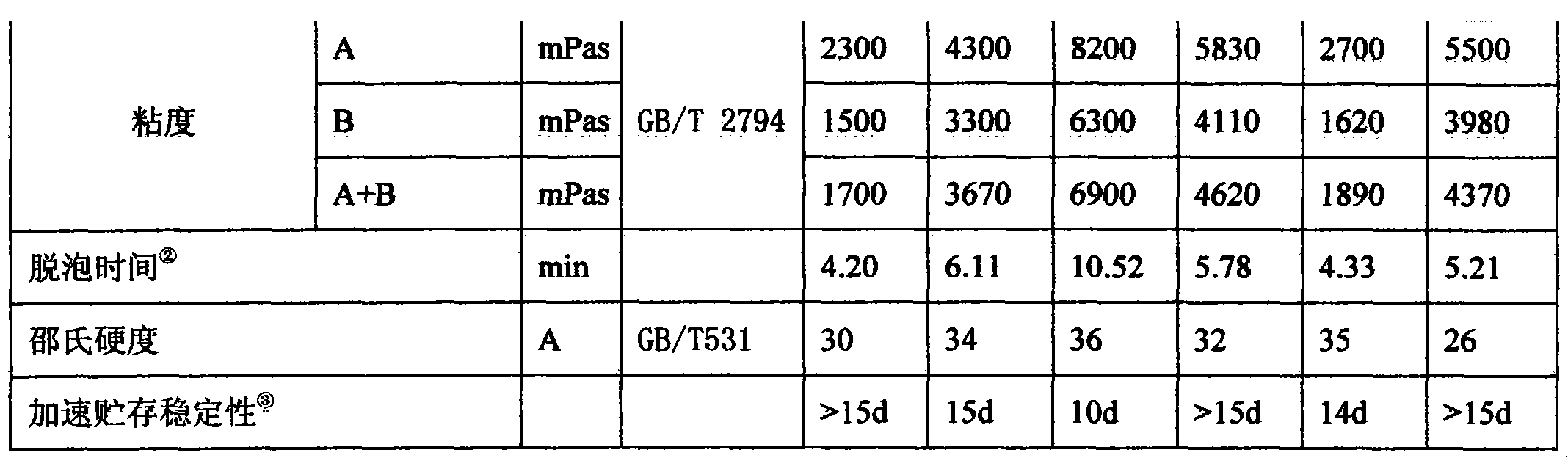

Additional organosilicon fireproof pouring sealant for electronics and preparation method thereof

InactiveCN102399445ANo pollution in the processNo low toxicityOther chemical processesSealantPollution

The invention discloses an additional organosilicon fireproof pouring sealant for electronics and a preparation method thereof. The preparation method comprises the following steps that alpha, ohm-divinylpolydimethylsiloxane as a base material, a special inorganic fire retardant as a fire retardant, an appropriate amount of an inorganic filling material as an improvement agent, and appropriate amounts of a cross-linking agent, a coupling agent and a catalyst are respectively prepared into a component A and a component B; the component A and the component B undergo a heating sulfuration addition reaction to produce the additional organosilicon fireproof pouring sealant for electronics, wherein the additional organosilicon fireproof pouring sealant for electronics does not produce pollution on a base material, and has excellent flame resistance, waterproof properties and dustproof properties. Through utilization of the special inorganic fire retardant, when a flame retardation grade reaches a level FV-0, storage properties of the additional organosilicon fireproof pouring sealant for electronics is improved, and deaeration properties and fluidity of the additional organosilicon fireproof pouring sealant for electronics are greatly improved in use. The component A and the component B compose the additional organosilicon fireproof pouring sealant for electronics, wherein the additional organosilicon fireproof pouring sealant for electronics does not produce pollution on a base material, and has stable flame resistance and storage properties and excellent operationality, and a high flame retardation grade reaching the level FV-0. Through the inorganic fire retardant which is adopted by the preparation method and is subjected to special treatment, an addition proportion, finished product storage stability and used product fluidity are effectively improved.

Owner:SHANGHAI YOUNAI ORGANOSILICON MATERIAL

Preparation method of fireproof flame-retardant interfacial agent for exterior insulation phenol formaldehyde foam board of outer wall

The invention discloses a preparation method of a fireproof flame-retardant interfacial agent for an exterior insulation phenol formaldehyde foam board of an outer wall. The preparation method comprises a raw material proportioning and producing process. The fireproof flame-retardant interfacial agent is prepared by using a flame-retardant system with a vinyl acetate-ethylene copolymerization emulsion as base stock, ammonium polyphosphate as a dehydration catalyst, pentaerythritol as a carbonizing agent and melamine as a foaming agent and adding other auxiliaries. The phenol formaldehyde foam board disclosed by the invention is safe, environment-friendly, non-toxic and tasteless; a layer of interface with favorable flexibility and bonding force and excellent fireproof and flame-retardant property is formed on the surface of the phenol formaldehyde foam board, so that the toughness of the surface is increased, the bonding strength between the surface and a bonding and plastering material is improved and the functions of preventing the phenol formaldehyde foam board from pulverizing and slagging off is achieved; and therefore the using effect of the phenol formaldehyde foam board in the external insulation of the outer wall can be remarkably improved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com