Steam curing-free high-strength cement-wood chip plate and preparation method thereof

A technology of cement sawdust and steam curing, which is applied in chemical instruments and methods, layered products of hydraulic substances, sustainable waste treatment, etc. Good water resistance, sound insulation and heat preservation performance, good fire resistance and flame retardancy, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the above-mentioned preparation method of the steam-free high-strength cement sawdust board, which method comprises: 1) after mixing cement, active admixture, short fiber, water and additives uniformly, adding wood chips, thermal insulation aggregate and Ceramsite, after being evenly stirred, it will be formed after laying and rolling. The mesh cloth is made of alkali-resistant glass fiber mesh cloth; The humidity is 50%-60%, and the curing time is 20-24 hours; (3) After demolding, the palletizing enters the second curing, the curing temperature is 30°C-35°C, the relative humidity is 85%-95%, and the curing time is 40-48h; 4 ) Dry the board naturally to make the moisture content reach 5% to 10%.

[0033] The steam-free high-strength cement sawdust board of the present invention can be widely used as non-load-bearing interior and exterior wall panels, ceilings, roof panels, partition walls, etc. of various buildings, and has high stren...

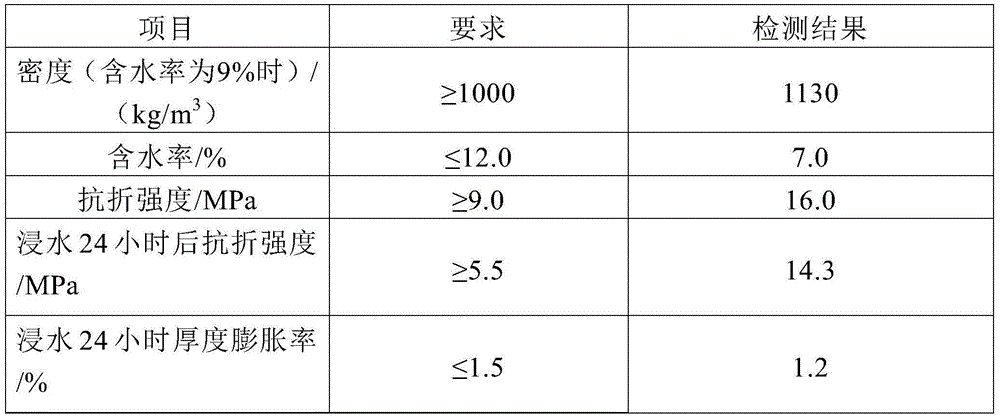

Embodiment 1

[0036] 1) Weigh the following components: 100kg of 42.5 grade ordinary Portland cement, 12.5kg of I grade fly ash, 8.5kg of micro silica fume, 11kg of poplar wood chips with a particle diameter of 60 mesh and a moisture content of 12%, and a particle diameter of 20 mesh, bulk density 80kg / m 3 Vitrified microbeads 1kg, particle size 3cm shale ceramsite 8kg, length 6mm polypropylene fiber 0.3kg, sodium silicate 0.1kg, calcium formate 0.03kg, sodium metaaluminate 0.05kg, 40,000 viscosity hydroxypropyl Methyl cellulose ether 0.1kg, liquid polycarboxylate superplasticizer 0.16kg, calcium stearate 0.02kg, vinyl acetate-ethylene copolymer redispersible latex powder 0.01kg, water 50kg; sodium silicate, calcium formate , sodium metaaluminate, water retaining agent, water reducing agent, water repellent and polymer as additives;

[0037] 2) Mix cement, fly ash, microsilica fume, short fiber, water and additives evenly, then add sawdust, thermal insulation aggregate and ceramsite, mix e...

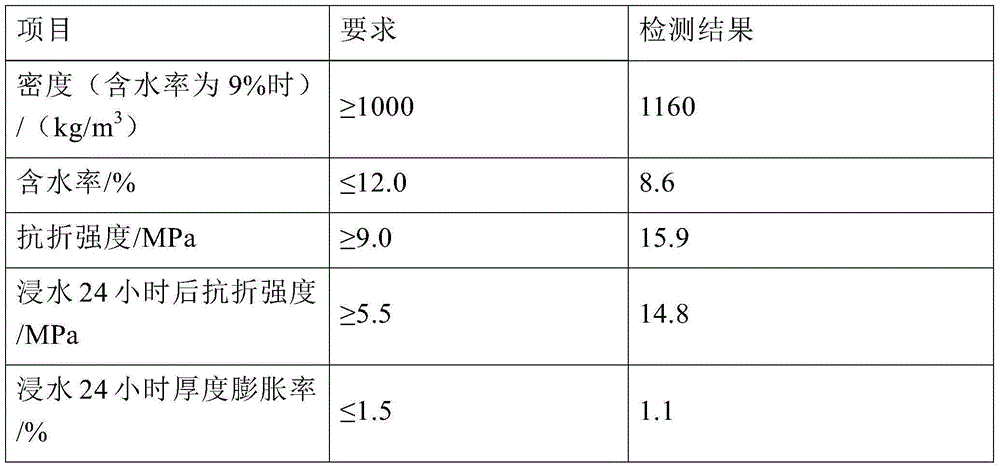

Embodiment 2

[0045] 1) Weigh the following components: 80kg of 52.5 grade ordinary Portland cement, 32.5kg of II grade fly ash, 8.5kg of microsilica fume, 11kg of apricot wood chips with a particle diameter of 80 mesh and a moisture content of 13%, and a particle diameter of 30 mesh, bulk density 100kg / m 3 1kg of perlite, 8kg of shale ceramsite with a particle size of 5cm, 0.45kg of polyvinyl alcohol fiber with a length of 8mm, 0.01kg of sodium silicate, 0.03kg of calcium formate, 0.05kg of sodium metaaluminate, and 0.1kg of starch ether with a viscosity of 60,000 , liquid polycarboxylate superplasticizer 0.16kg, zinc stearate 0.02kg, styrene-butadiene emulsion 0.01kg, water 50kg; including sodium silicate, calcium formate, sodium metaaluminate, water retaining agent, water reducing agent, water repellent Agents and polymers as additives;

[0046] 2) Mix cement, fly ash, microsilica fume, short fiber, water and additives evenly, then add sawdust, thermal insulation aggregate and ceramsite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com