Patents

Literature

2934 results about "Expanded clay aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

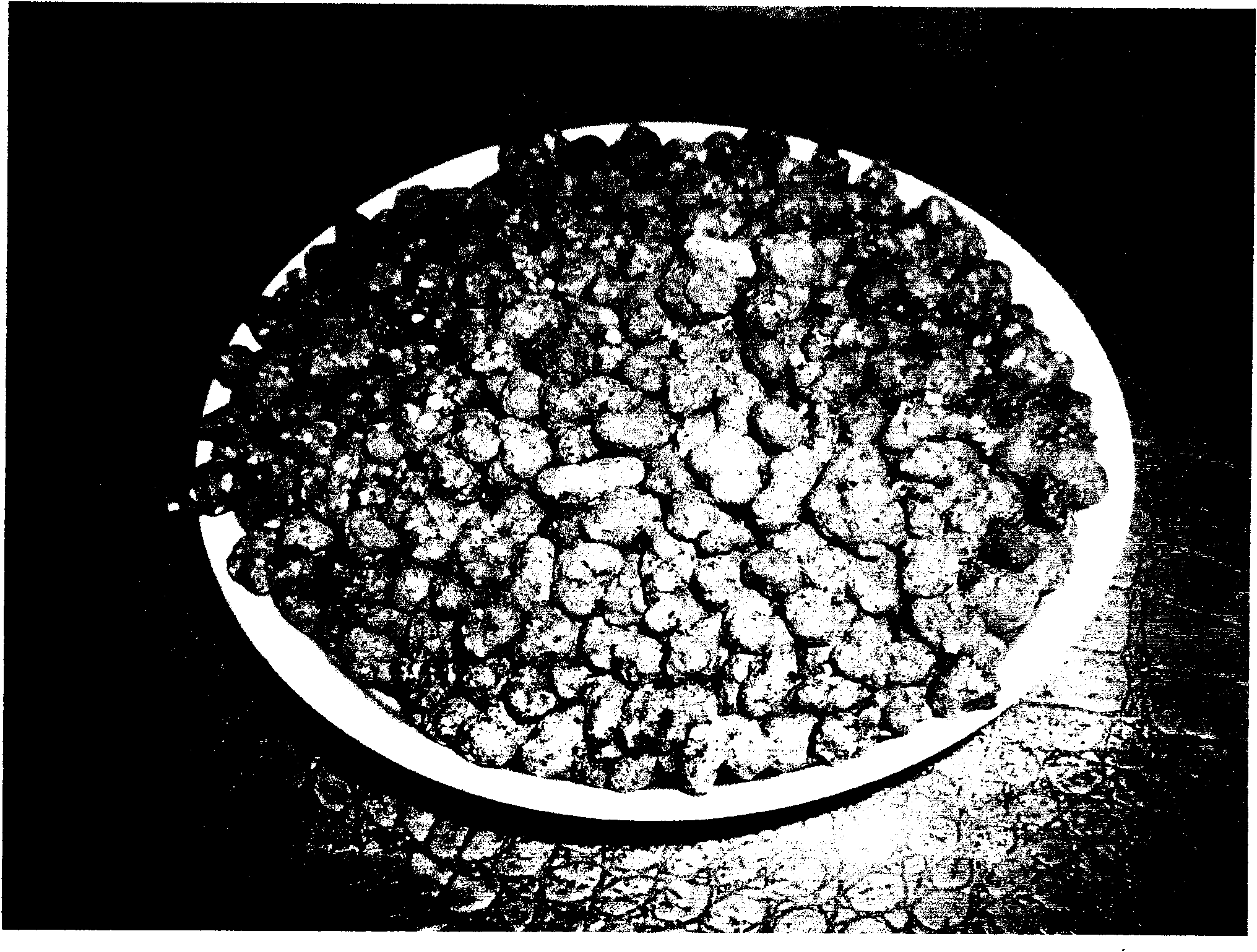

Lightweight expanded clay aggregate (LECA) or expanded clay (exclay) is a lightweight aggregate made by heating clay to around 1,200 °C (2,190 °F) in a rotary kiln. The yielding gases expand the clay by thousands of small bubbles forming during heating producing a honeycomb structure. LECA has an approximately round or potato shape due to circular movement in the kiln and is available in different sizes and densities. LECA is used to make lightweight concrete products and other uses.

Ceramsite water permeable brick and preparation method thereof

The invention provides a ceramsite water permeable brick, which comprises the following components by weight: 80-100 parts of ceramsite, 10-15 parts of silicon sand, 20-40 parts of cement, a setting accelerator accounting for 2-4% of the weight of the ceramsite, and a water reducing agent accounting for 2-4% of the weight of the ceramsite. According to the invention, silicon sand dust made ceramsite is combined with a small quantity of cement, the setting accelerator, the water reducing agent and a silicon sand fabric to manufacture the ceramsite water permeable brick. One the one hand, the water permeable brick has a beautiful appearance, and on the other hand it combines the lightweight and high strength characteristics of ceramsite. At the same time, ceramsite is round stone rather than polygonal, and usually the gap between round objects is larger than that between polygonal objects, so that the prepared water permeable brick has good permeability effect. The water permeable brick prepared by the method has compressive strength of greater than or equal to 30Mpa and a permeability coefficient of greater than or equal to 0.05cm / s, and the other properties of the brick meet the JCT945-2005 industrial standard.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

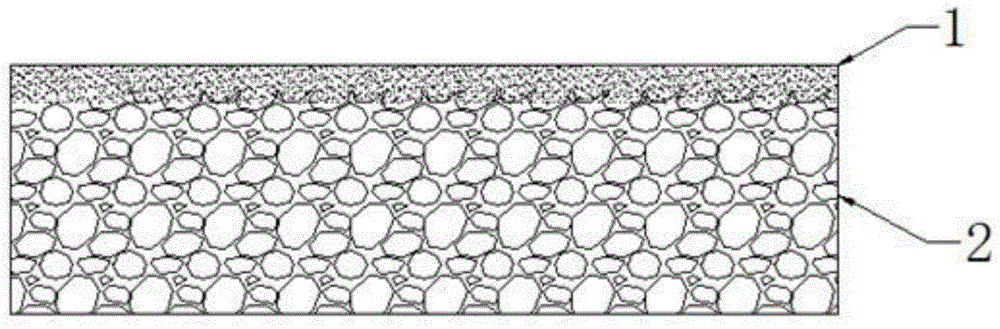

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

Spherical porous light haydite for treating waste water and its production method

InactiveCN1380137AHigh economic valueSolve the way outOther chemical processesSustainable biological treatmentPorosityEnvironmental resistance

The present invention relates to a kind of spherical porous loight-ceramsite produced by using industrial waste slag, steel-smelting rod mud and flyash as main raw material, using clay as binding agent, adding proper quantity of pore-forming agent and adopting high-temp., sintering process. Said invention also provides its production method, and said product can be specially used as filtration material for water treatment. Its product quality is as follows: specific surface area is 4-10 sq.m / g, average pore size is 50-250 micrometers, apparent density is 1.40-1.80 g / cu.cm and its voidage is 30-40%.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Biological adsorbing sightscene floative bed for treating water body as sightscene

InactiveCN1644533ARich in nutrientsImprove removal rateSustainable biological treatmentBiological water/sewage treatmentEutrophicationExpanded clay aggregate

An ecological absorptive landscape float bed for treating landscape water body achieves low cost and short treating period. Multiple holes are arranged on the float supporting basilar plate of float consists of light float materials, an ecological absorptive layer is arranged on the holes bottom by coated netting bag, the ecological absorptive layer contacts with landscape surface directly, high-efficient phosphorus absorptive material, ammonia nitrogen absorptive material and biological ceramic particles are filled, water-planting flowers, aquatic ornamental plants and commercial crops are planted on the ecological absorptive layer. It can improve nitrogen and phosphorus removing speed and capacity.

Owner:SHANGHAI JIAO TONG UNIV

Thermal-insulation loading recycled concrete

The invention relates to a concrete commonly used in building materials, and especially relates to a thermal-insulation loading recycled concrete. A technical problem to be solved is to provide a recycled concrete which is an integration of thermal insulation, loading, quake resisting, and energy saving and emission reduction. A technical scheme adopted is characterized in that a weight ratio (kg / m<3>) of a composite lightweight aggregate admixture: cement: recycled fine aggregate: sand: recycled coarse aggregate: cobblestone: ceramsite: coal ash: water: additives is (5-250):(200-800):(20-500):(5-800):(30-600):(5-1400):(50-800):(10-600):(50-500):(0.1-200); the composite lightweight aggregate admixture is a mixture of glazed hollow beads and an aerogel, and the weight part ratio of the glazed hollow beads to the aerogel is 1:(0.7-1.5); and the additives comprise the following components, by weight, 10-150 parts of silica fume, 4-40 parts of an air entraining agent, 5-30 parts of a foaming agent, 3-30 parts of a water reducing agent, 1-30 parts of a polypropylene fiber, and 10-150 parts of waste slag. The technical scheme is used for making the recycled concrete.

Owner:TAIYUAN UNIV OF TECH

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

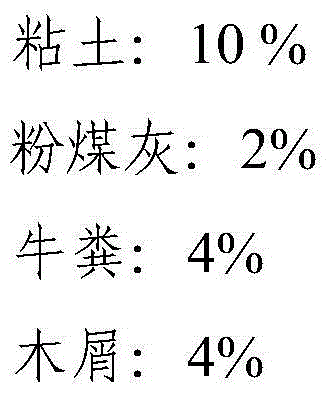

Baking-free gravel-shaped attapulgite fly ash ceramisites

InactiveCN102515631AImprove resource utilizationReduce land occupationSolid waste managementSodium BentoniteResource utilization

The invention discloses baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites. The main point of the technical scheme is that: the baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites comprise attapulgite clay tailing powder, fly ash, bentonite tailing powder, gravel ash and cement. The components of the baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites are subjected to mixing, pelletizing, curing, crushing, screening and packaging to obtain the baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites. The baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites have characteristics of particles with irregular shapes, and tiny gas holes in the internal, and are the building ceramisites with characteristics of high strength, low thermal conduction coefficient, good chemical stability, good durability, good thermal insulation, and good sound insulation. The fly ash and the tailings are comprehensively utilized to produce the baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites, such that the resource utilization rate is improved, the waste is changed into the treasure, the land occupation is reduced, and the environment is protected and purified. In addition, the baking-free gravel-shaped attapulgite attapulgite fly ash ceramisites are suitable for productions of concrete thermal insulation blocks, and thermal insulation and sound insulation materials.

Owner:许庆华

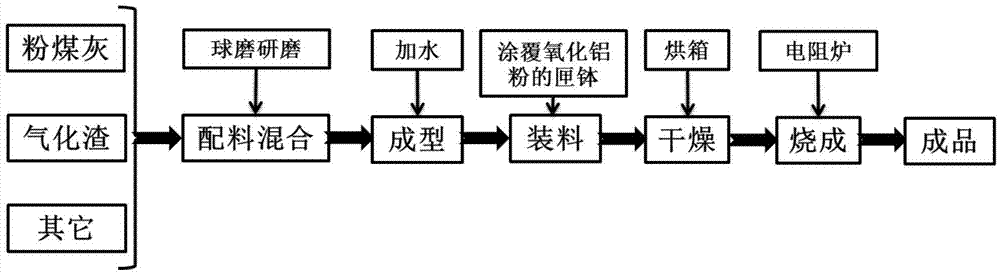

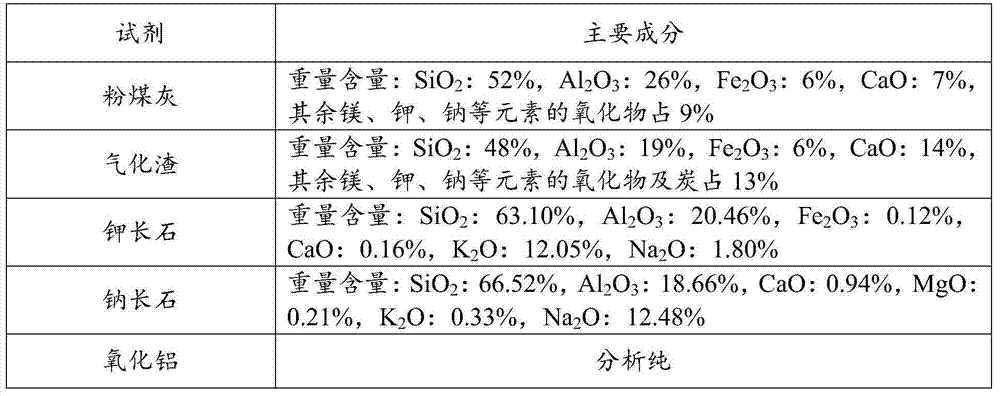

Lightweight ceramisite prepared from coal ashes and gasification slag as well as preparation method and application thereof

ActiveCN104774023ASignificant environmental benefitsImprove performanceSolid waste disposalCeramicwareSlagExpanded clay aggregate

The invention relates to the technical field of building materials, and in particular relates to lightweight ceramisite prepared from coal ashes and gasification slag as well as a preparation method and an application thereof. The lightweight ceramisite is prepared from the following raw materials with the following components in parts by weight: 100 parts of base materials comprising 40-90 parts of coal ashes, 10-30 parts of gasification slag, 0-20 parts of potassium feldspar and 0-20 parts of albite; and 0-4 parts of additional auxiliaries which are selected from one or two of semicoke or silicon carbide, wherein the coal ashes account for 40-90%, and the gasification slag particles account for 10-30%; and the sintering temperature is 1120-1200 DEG C, the energy consumption is reduced, the raw material distribution is relatively wide and the raw materials are easily available. The lightweight ceramisite has bulk density lower than or equal to 700 kg / m<3>, is smaller in weight, higher in strength, wider in raw material distribution and easier to obtain, and the barrel pressure strength can be higher than 10 MPa.

Owner:北京大学包头创新研究院

Method for preparing haydite from urban sewage plant sludge

InactiveCN101148346AHas a lightweightLight weightCeramic materials productionClaywaresChemical industryExpanded clay aggregate

The present invention discloses one kind of haydite produced with dewatered sludge, fly ash and clay as material and its production process, and belongs to the field of environment technology. The haydite is produced dewatered sludge, fly ash and clay as material, and through mixing and sintering at gradually raised temperature. It is yellow or brown spherical solid in the bulk specific weight of 650-750 kg / cu m, granular specific weight of 1050-1150 kg / cu m, water absorption of 5.80-10.8 %, and specific surface area of 2.29-5.56 sq m / g. The production process is simple and low in cost, and the haydite has light weight, high strength, small water absorption, great specific surface area and other features. The haydite has wide use in building, environment protection, metallurgy, chemical industry, and other industry.

Owner:SHANDONG UNIV

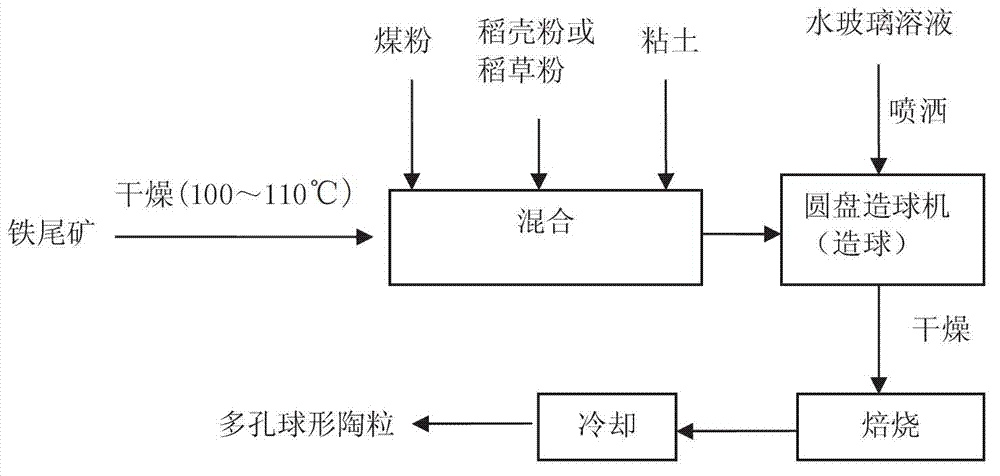

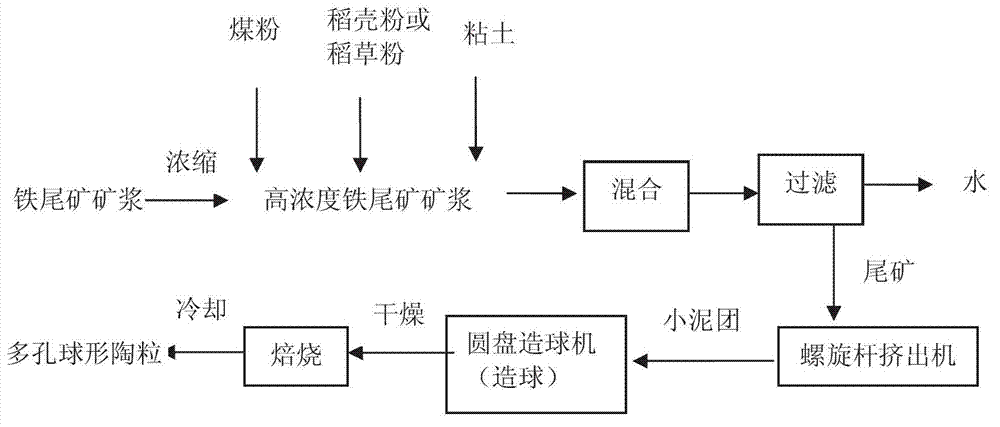

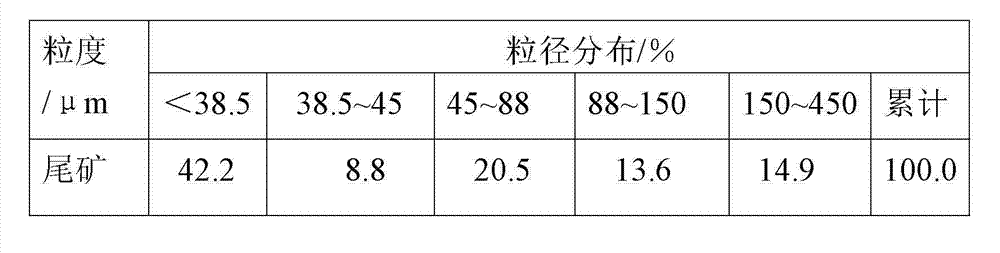

Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

ActiveCN102815965AReduce usageLow costCeramic materials productionCeramicwarePorosityThermal insulation

The invention discloses porous ceramsite made of low-silicon iron tailings and a preparation method of the porous ceramsite. The porous ceramsite is prepared from, by weight, 75-90 parts of low-silicon iron tailing powder or low-silicon iron tailing pulp, 5-20 parts of pore-forming agents and 1-8 parts of clay, wherein the SiO2 content in the low-silicon iron tailing powder or low-silicon iron tailing pulp is lower than 40%. The method includes: weighing and mixing the iron tailings, the pore-forming agents and the clay, and granulating the mixture into green balls; and after the green balls are dried, calcinating the dried green balls for 40-60min at the temperature of 1100-1180 DEG C, so that the ceramsite made of the iron tailings is obtained. By the method, the porous ceramsite conforming to architecture application and water treatment application can be prepared respectively. The ceramsite prepared by the method has the advantages of high strength and apparent porosity, low density, good thermal insulation property, high cost performance and the like, and can be used for preparing various light, sound-insulation and thermal-insulation materials or used as light building aggregate, water treatment biological carriers and the like.

Owner:武钢资源集团有限公司 +1

Method for preparing ceramsite catalyst for ozone catalytic oxidation

ActiveCN101185898AIncrease profitReduce dosageMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationExpanded clay aggregateCatalytic oxidation

The invention discloses a preparation method of haydite catalyst for catalytic ozonation. The method comprises the preparation of the haydite raw material nuclear, and the coating and the sintering process of the catalyst on the haydite raw material nuclear. The coating of the catalyst on the haydite raw material is used for crushing one or a plurality of the composite catalyst activity component(s) of MnO, MnO2, TiO2, CoO, Co3O4, Fe2O3, Fe4O3, and FeO into particles with the diameter of 0.1-1mm and being mixed with the raw materials produced by the haydites to produce 3-4mm haydites for coating catalyst. The haydite catalyst for catalytic ozonation is made. After mixture, the catalyst and the haydite raw material are loaded on the original haydite raw material nuclear with high adhesion strength, and meanwhile the once sintering molding guarantees the high utilization ratio of the catalyst, and the prepared haydite catalyst can be used repeatedly, thus reducing secondary pollution and operation cost of ozonation.

Owner:SOUTH CHINA UNIV OF TECH

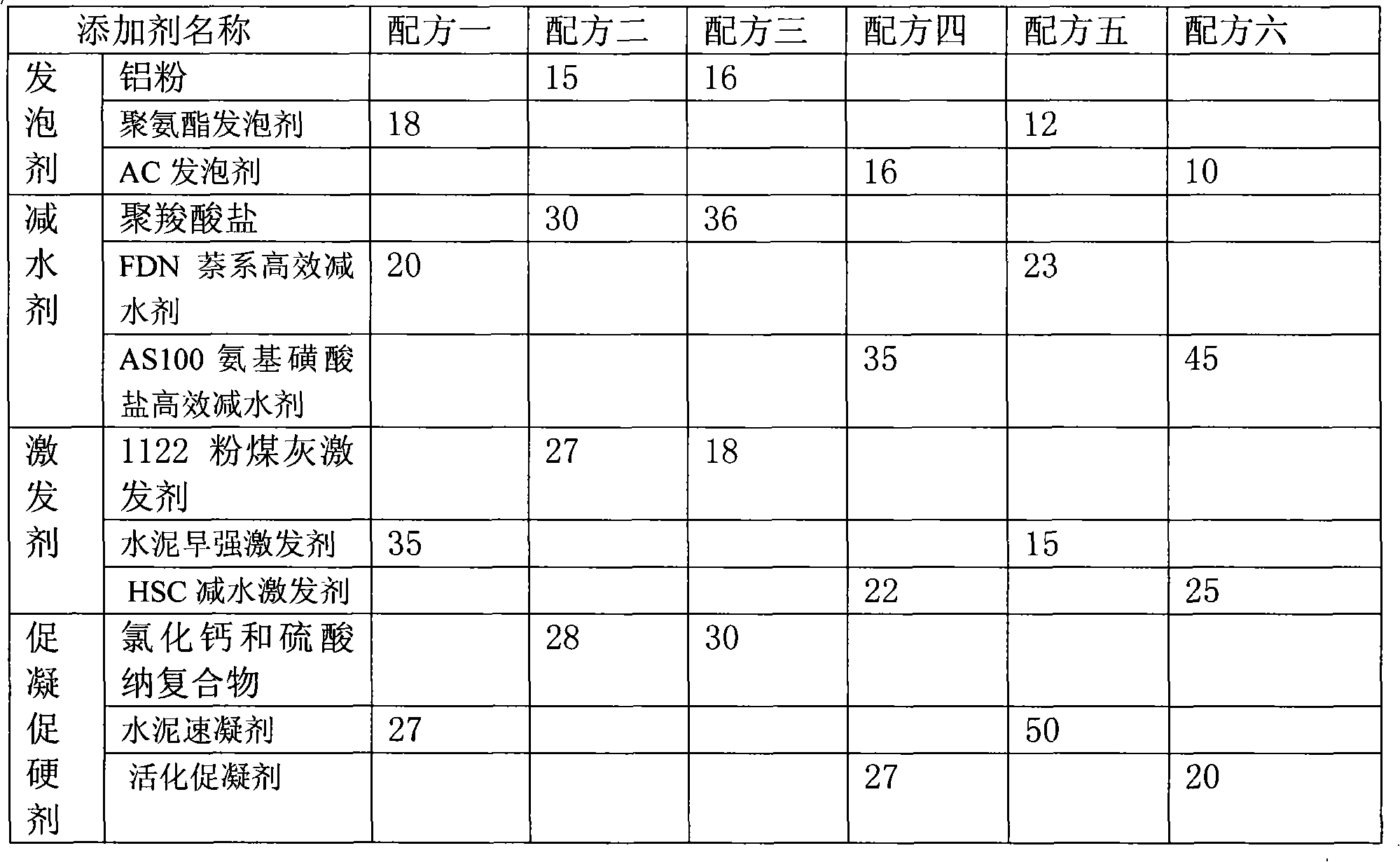

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

Municipal sludge expanded ceramsite and preparation method thereof

InactiveCN101618971ALow costSave resourcesCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention provides municipal sludge expanded ceramsite and a preparation method thereof. The municipal sludge expanded ceramsite is prepared from the following materials by mass percentage: 20% to 45% of municipal sludge, 50% to 70% of shale, tailings or clay, 1% to 5% of organic matter and 1% to 5% of iron powder, wherein, the tailings is one of pyrite tailings, gold tailings, lead-zinc tailings and aluminum tailings; and the organic matter is sawdust. The preparation method comprises the following steps: feeding the shale, tailings or clay into a crusher, and carrying out the screening treatment; adding and mixing the municipal sludge, the organic matter and the iron powder, feeding into an ageing silo and stirring; then, feeding into a granulating machine, granulating and calcinating in a rotary kiln; and finally, cooling and stacking the calcinated ceramsite by classification. By using a great amount of municipal sludge, the invention is resource-saving and environment-friendly; compared with the original cost, the overall cost of a building is reduced by 5% to 10%; and the prepared expanded ceramsite has the advantages of light weight, fire resistance, sound absorption, good heat insulating and preserving performance, simple process and low cost, so that the invention is suitable for industrialized production.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Porous phosphorus removing ceramic granules with function of slowly releasing alkali and preparation method thereof

ActiveCN101935195AImprove plasticityLarge specific surface areaSilicon compoundsWater/sewage treatment by sorptionFiberPorosity

The invention discloses porous phosphorus removing ceramic granules with a function of slowly releasing an alkali and a preparation method thereof. The prepared ceramic granules are an environmental material for efficiently removing phosphorus from municipal sewage and industrial wastewater. Based on the basic chemical properties of the phosphorus in water and a phosphorus removing mechanism by chemical absorption, the preparation method of the ceramic granules comprises the following steps of: mixing 20 to 40 mass percent of ordinary portland cement (42.5 level), 10 to 20 mass percent of bentonite, 10 to 20 mass percent of fly ash, 10 to 15 mass percent of calcium oxide, 15 to 25 mass percent of nitrocellulose, 14 to 30 mass percent of xonotlite fiber particle and 0.1 to 0.5 mass percent of pore-creating agent; adding water for stirring the mixture according to a water-solid ratio of 0.35 to 0.45; granulating the mixture into granules with required grain sizes; and after the granules are foamed and solidified, curing the granules by using high-temperature steam to obtain the ceramic granules. The method has the advantages of simple preparation process, readily available raw materials, low cost and wide application prospect in the field of the removing of the phosphorus in water bodies. The prepared ceramic granules have the characteristics of capacity of slowly releasing the alkalis, silicic and calcareous textures, porosity, capacity of continuously and efficiently absorbing and removing the phosphorus and suitability for phosphorus removing systems of the municipal sewage and the industrial wastewater.

Owner:郑俊 +1

Manufacturing method of ecological fire preventing and heat insulating building material

InactiveCN101618567AImprove insulation effectImprove insulation performanceMixing operation control apparatusCeramic shaping apparatusFiberExpanded clay aggregate

Owner:王建国

Sewage sludge shale ceramic particle and preparation method thereof

InactiveCN101186485AHigh strengthLow water absorptionCeramic materials productionClaywaresLand resourcesBrick

Sewage sludge shale ceramsite and a preparation method thereof are provided, which relates to the light energy-saving ceramsite of building materials and a preparation method thereof. The ceramsite of the invention consists of sewage sludge, shale and admixtures; the method of the invention uses the sewage sludge, the shale and the admixtures as raw materials; first, the shale is grinded into shale powder and then the sewage sludge, the shale and the admixtures are mixed and wedged to be granulated into round particles and then enter into a kiln; the products are obtained after going through drying, preheating, barking and being taken out of the kiln for cooling. The ceramsite employs the sewage sludge discharged directly from sewage treatment plants and the shale as major materials, which greatly saves land resource and partial shale mine resource and provides an extremely good way for the non-hazardous and reclaiming treatment of sewage sludge; the method of the invention is simple, energy-saving and resources-saving and the density rank of the ceramsite is 300-700. The ceramsite of the invention can be widely applied in lightweight aggregate bricks, lightweight aggregate sheet materials, lightweight aggregate concrete, etc. and can also be taken as the filter material of sewage treatment, the water-retaining agent in cultivation, etc.

Owner:重庆三益污泥处理有限公司 +1

Haydite autoclaved aerated concrete and production method

InactiveCN101497517AImprove featuresLight weightSolid waste managementCeramic shaping apparatusSlagExpanded clay aggregate

The invention discloses a ceramsite autoclaved aerated concrete and a production method. The concrete consists of ceramsite, coal ash, sand, quartz tailing powder or silicon slag, lime, cement, gypsum, aluminum powder or aluminum paste powder, and admixture. The production method comprises the steps of measuring raw materials, blending and stirring, pouring and feeding a die, generating gas by static electricity, mold stripping, autoclaving, mechanical cutting and the like. The concrete has precise dimension and good performance.

Building silt soil non-sintered ceramic aggregate and preparation method thereof

ActiveCN102617107ASimple technical processEasy accessSolid waste managementSolid componentEnvironmental resistance

The invention discloses a building silt soil non-sintered ceramic aggregate, which is characterized by comprising solid components and water, wherein every kilogram of solid components comprise the following components in percentage by weight: 60-80 percent of building silt soil, 2-5 percent of cement, 2-5 percent of quick lime, 2-5 percent of desulfurized gypsum, 2-7 percent of perlite, 2-8 percent of fly ash and 5-10 percent of water glass; and the amount of the water accounts for 45-60 percent of the total mass of the solid components. The invention also discloses a preparation method of the ceramic aggregate. The ceramic aggregate and the preparation method thereof have the characteristics of simple pretreatment of building silt soil, simple preparation process and capabilities of eliminating industrial wastes such as fly ash and desulfurized gypsum without large-sized calcining equipment and expanding the utilization approach of the solid waste material; and by adopting a non-sintering process, the ceramic aggregate and the preparation method thereof have the advantages of environmental protection effects such as energy conservation and low carbon compared with a roasting process.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

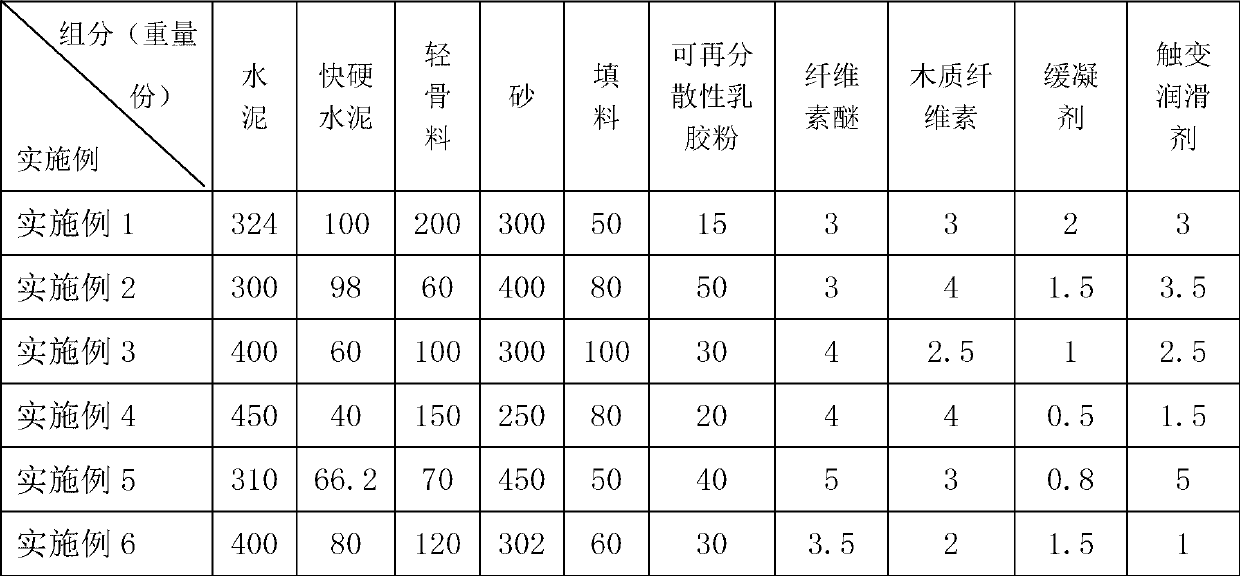

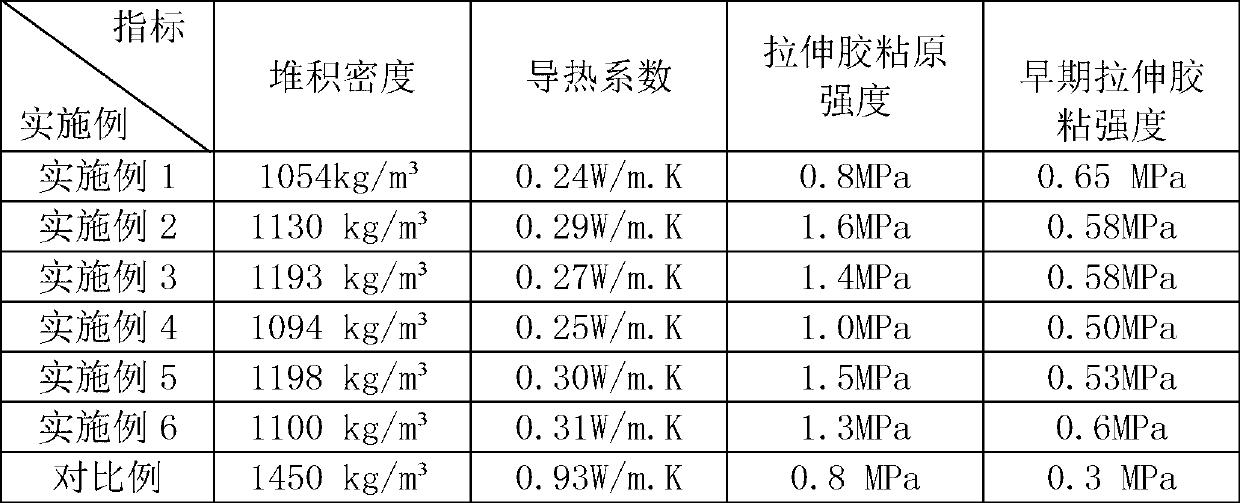

Binding mortar with light weight and high droop resistance and preparation and use methods

The invention provides binding mortar with light weight and high droop resistance, which consists of the following components in parts by weight: 300-450 parts of cement, 40-100 parts of rapid hardening cement, 60-200 parts of lightweight aggregate, 250-450 parts of sand, 50-100 parts of filling material, 15-50 parts of re-dispersible emulsion powder, 3-5 parts of cellulose ether, 2-4 parts of lignocellulose, 0.5-2 parts of retarder and 1-5 parts of thixotropic lubricant. The lightweight aggregates are glass microspheres, or hollow glass microspheres or ceramsite sand, of which the particle size is below 1.2mm and loose bulk density is below 0.8Kg / L. The invention has lower mortar density, good droop resistance, lower thermal conductivity and certain thermal insulation performance; the binding mortar can be hardened quickly, and the requirement of carrying out subsequent construction quickly is satisfied; the elastic modulus of the mortar is small, and deformation resistance is strong; and the mortar uses multiple polymer additives, and base materials have strong adaptability and strong binding performance.

Owner:深圳广田高科新材料有限公司

Siliceous mullite structure-insulating integrated composite brick and preparation method thereof

The invention discloses a siliceous mullite structure-insulating integrated composite brick and a preparation method thereof. The brick consists of a heavy working layer and a high-strength light insulating layer, wherein the main materials of the heavy working layer are dense bauxite and silicon carbide material, the aggregate of the high-strength light insulating layer is one or the mixture of alumina hollow balls, alumina-magnesia hollow balls, corundum hollow balls, hollow microspheres and light ceramisite, the heavy working layer and the light insulating layer are combined together by adopting vibratory pressing or mechanical pressing, and the length proportion between the heavy working layer and a light insulating layer is 1 to 5:2 to 1. The invention overcomes the defect of the abrasion-resistant siliceous mullite brick for rotary kilns, i.e. high coefficient of heat conductivity, and the defects of the light part of the conventional siliceous mullite composite brick, i.e. low strength and low refractoriness, and the structure-insulating integrated composite brick has the advantages of high abrasion resistance, high refractoriness, high structure strength and high insulating property.

Owner:浙江盛旺耐火材料股份有限公司

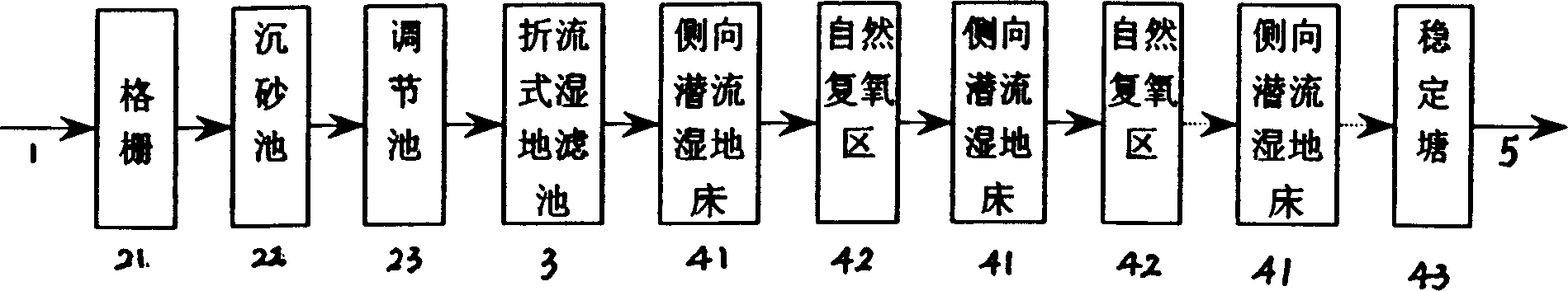

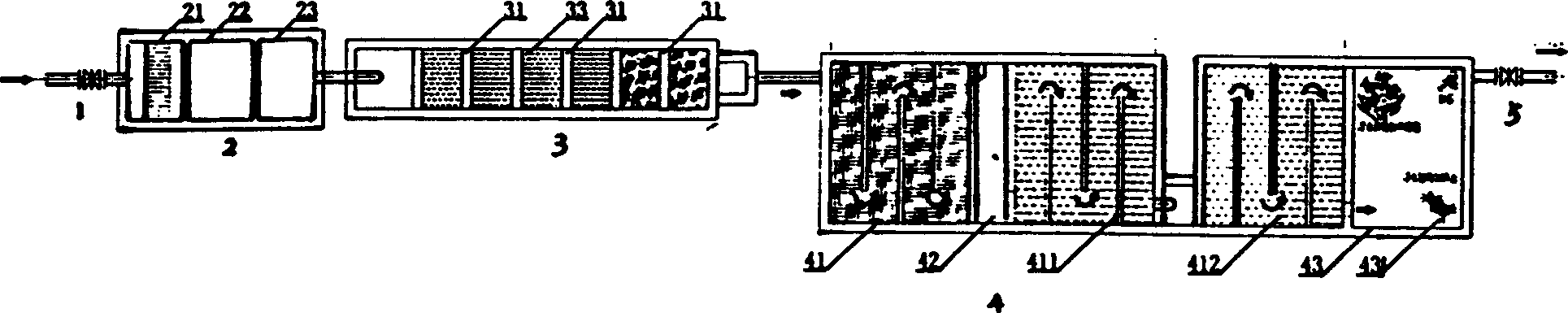

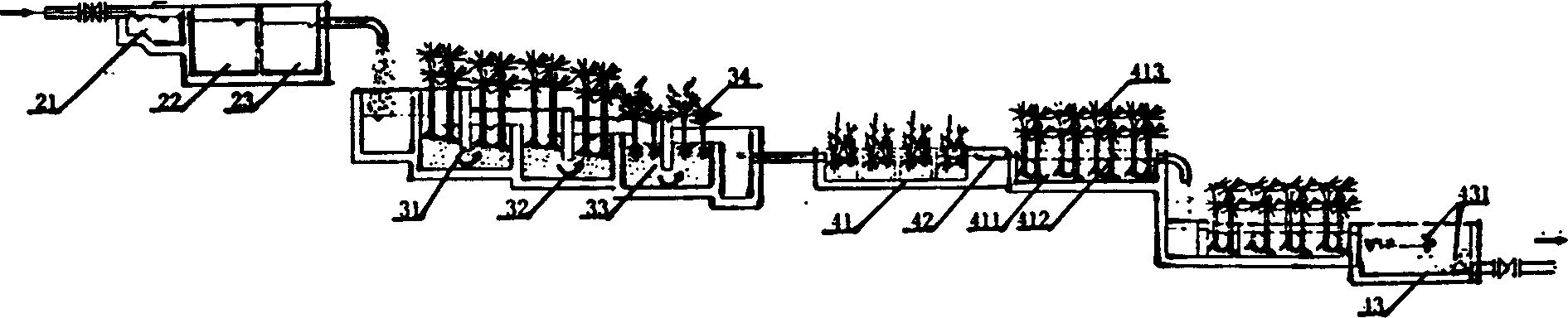

System and process for sawage treating with baffling wet land filtering tank and rateral underflow wet land bed

InactiveCN1693231AImprove biodegradabilityMake full use of interceptionTreatment using aerobic processesTreatment with aerobic and anaerobic processesWater flowExpanded clay aggregate

A system for treating sewage is composed of a pretreating construction, a deflection-type nunja filter pool group and a lateral underflow nunja bed group, which are arranged in gradient mode from high level to low level. Each filter pool contains a vertical retention wall, filler (haydite or zeolite) and aquatic plant. Said lateral underflow nunja bed group consists of multi-stage lateral underflow nunja bed, natural oxygen-aerating area and anaerobic stabilizing pond. Its method is also disclosed.

Owner:CHONGQING UNIV

Method for producing high-performance haydite from red mud

The invention discloses a method for producing high-performance haydite from red mud, which comprises the following steps: taking 40-70 parts by weight of Bayer-process red mud, 0-30 parts by weight of sintering-process red mud, 5-20 parts by weight of fly ash and 5-30 parts by weight of clay material on dry basis as raw materials; evenly mixing the raw materials with 5-20 parts by weight of water, and putting the mixture on a pelletization plate to carry out pelletization, thereby obtaining the haydite fresh pellets; sintering the haydite fresh pellets, of which the diameters are 0.5-20mm, in a rotary kiln or sintering machine at 1050-1200 DEG C for 15-60 minutes; and quenching the sintered haydite to obtain the high-performance haydite product, of which the density level is 600-900, the water absorptivity is lower than 12%, the cylindrical compressive strength is higher than 7.5MPa and the strength grade is higher than 50MPa. The invention can effectively and massively utilize red mud as the raw material to produce the high-performance haydite, has the advantages of simple manufacturing technique and high product quality, and changes wastes into valuable substances.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

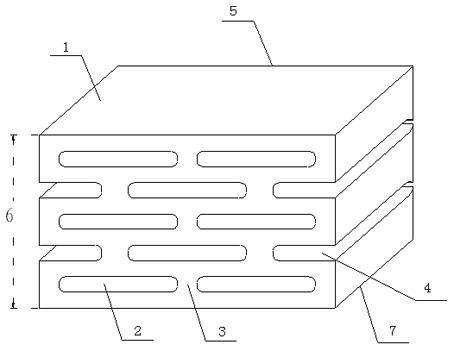

Light fly ash multi-row hole self-thermal insulation building block

InactiveCN102320799AIncrease thermal resistanceReduce usageClimate change adaptationPassive housesSlagAdhesive

The invention relates to a building material, and particularly relates to a light fly ash multi-row hole self-thermal insulation building block. The technical scheme is that: according to the light fly ash multi-row hole self-thermal insulation building block, through holes are uniformly distributed on a cuboid light fly ash building block. The light fly ash building block is prepared by adopting portland cement as a gelling material, adopting fly ash, crude ash, ceramsite or slag, pumice, perlite or vermiculite, sawdust, polyphenyl particles, building adhesives, humectants and additives as filling materials, diluting and dissolving the mixture with water, mixing, stirring, extruding, and curing; the cross sections of the through holes are rectangular, and the arrangement form of the through holes is multi-section, multi-layer, parallel, and interactive. With the combination of the structure of the multi-row hole self-thermal insulation building block and the light composite fly ash material, the performance of the building block such as heat preservation, light weight, thermal insulation, sound insulation, fire prevention, durability, and the like is greatly improved; traditional clay bricks, aerated blocks and traditional outer wall insulation methods are substituted; and national requirements for building energy saving are fully met.

Owner:王长河

Bamboo charcoal-based microelectrolysis porous ceramsite filler and preparing method thereof

ActiveCN104003483AReduce consumptionPromote micro-electrolysis effectWater/sewage treatmentPtru catalystIron powder

The invention provides bamboo charcoal-based microelectrolysis porous ceramsite filler and the preparing method thereof. According to the filler, iron serves as the anode, carbon serves as the cathode, and the cathode carbon is made from bamboo powder. According to the preparing process, activation and carbonization of bamboo powder are integrated, bamboo powder also plays a role in partial pore forming, the filler is of a porous honeycomb ball-shaped structure, the grain size is 1 mm - 15 mm, water absorption is 20% - 45%, and the specific surface area is 30 m<2> / g - 60 m<2> / g; iron powder, bamboo powder, clay, activating agents, catalysts, pore-forming agents and binding agents are mixed evenly to form a ball, the ball is placed in a muffle furnace to be roasted, nitrogen is introduced into the muffle furnace for protection, the temperature is increased to 150 DEG C - 250 DEG C, pre-activation and pre-carbonization are conducted for 30 min - 60 min, then the temperature is increased continuously to 500 DEG C - 800 DEG C, heat preservation is conducted for 1 h - 3 h, then the temperature is naturally reduced to the indoor temperature, and finally the bamboo charcoal-based microelectrolysis porous ceramsite filler is obtained. According to the bamboo charcoal-based microelectrolysis porous ceramsite filler and the preparing method thereof, raw materials are environmentally friendly and easy to obtain, the preparing technology is simple, the filler has a good effect in sewage treatment and is suitable for heavy metal and dye sewage treatment, and the problems such as poor recycling property of traditional filler can be solved.

Owner:FUZHOU UNIV

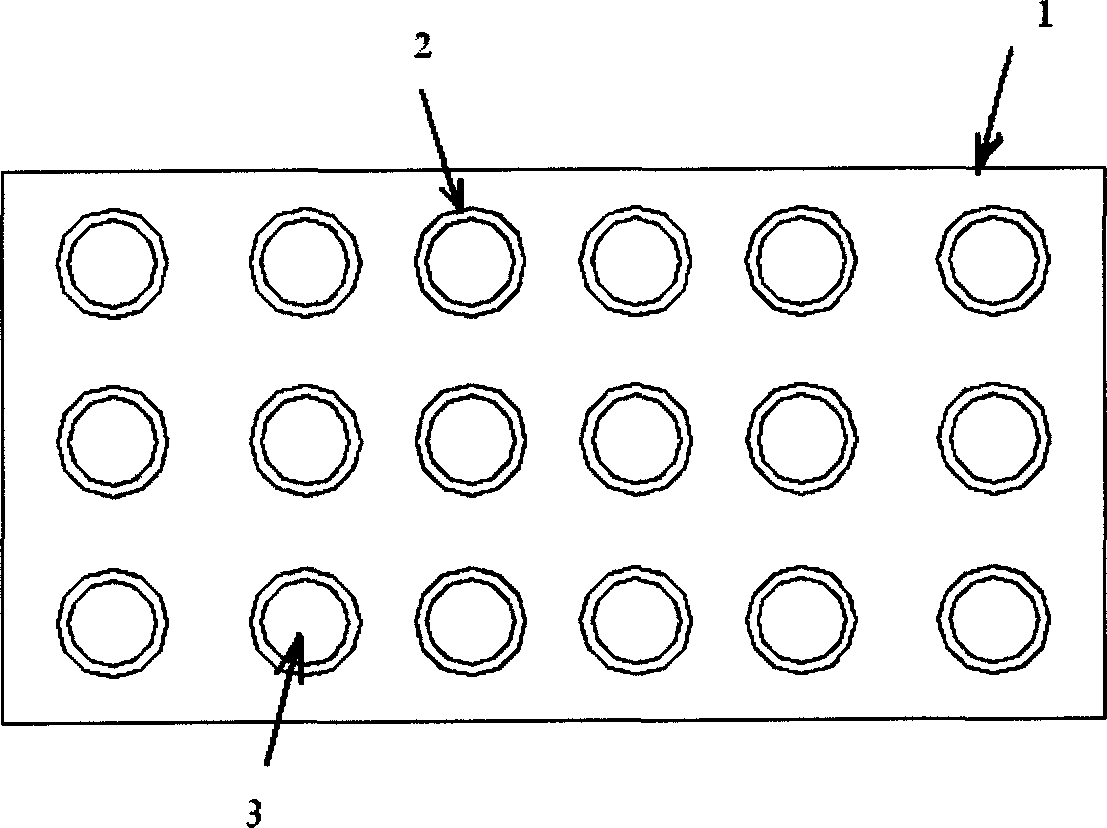

Baking-free type refuse burning flyash haydite and manufacturing method thereof

ActiveCN101357840ALow costNo need to worry about secondary pollutionSolid waste managementDry weightResource utilization

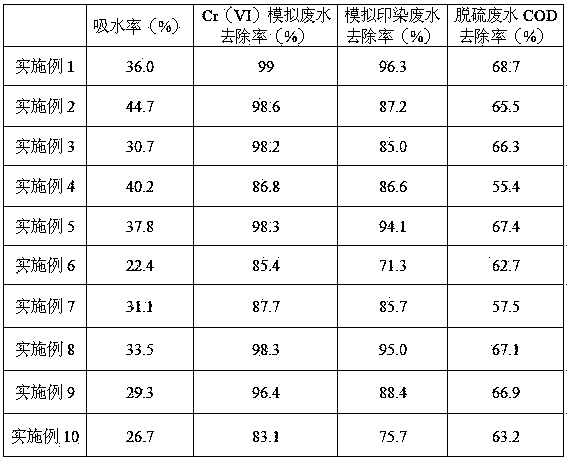

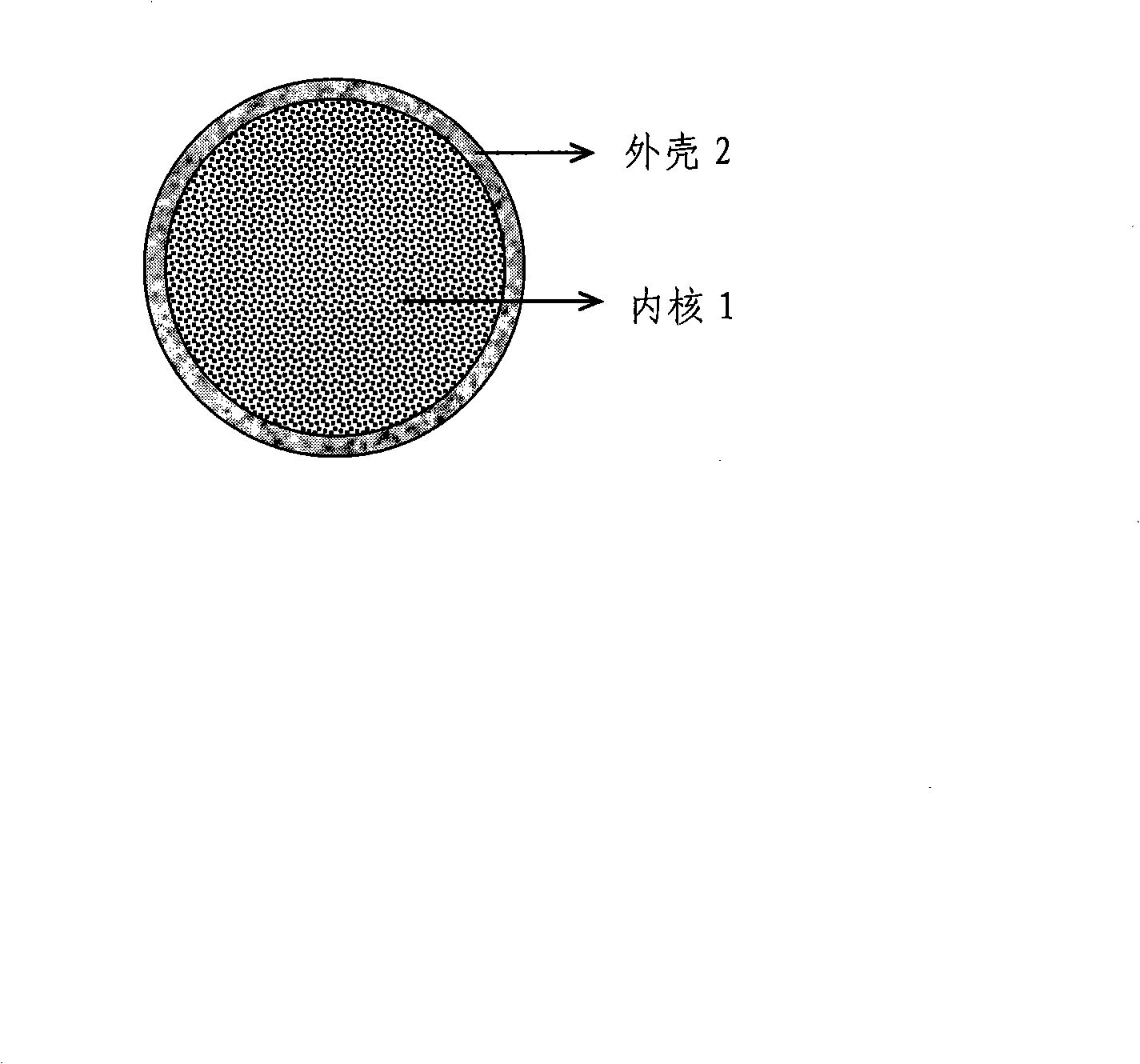

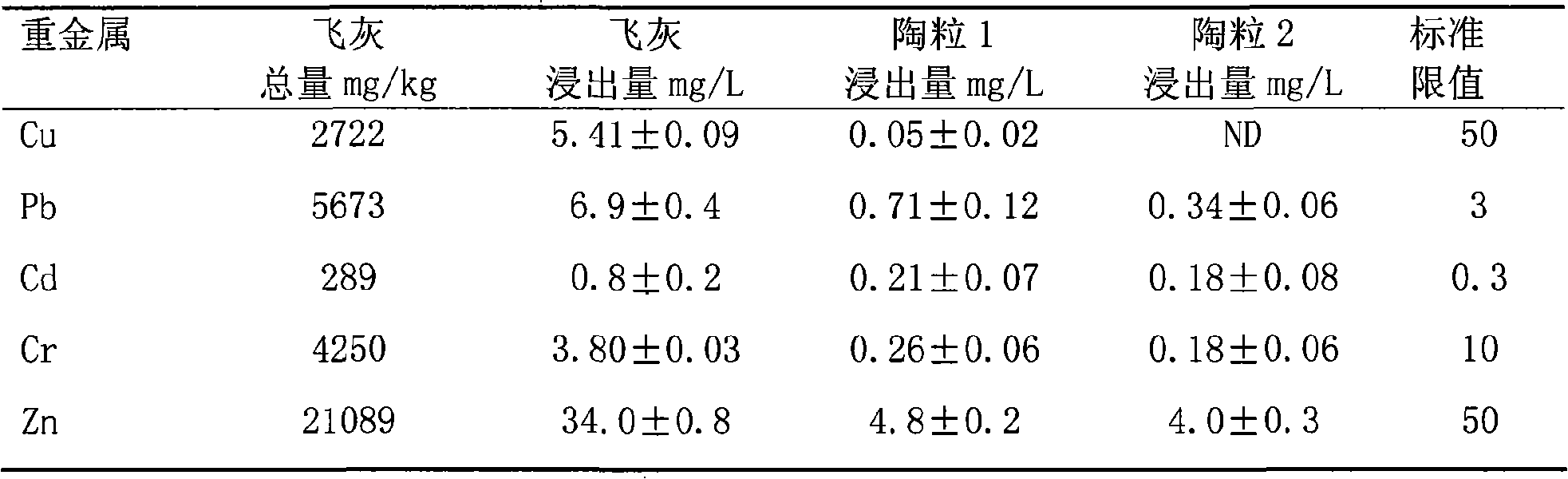

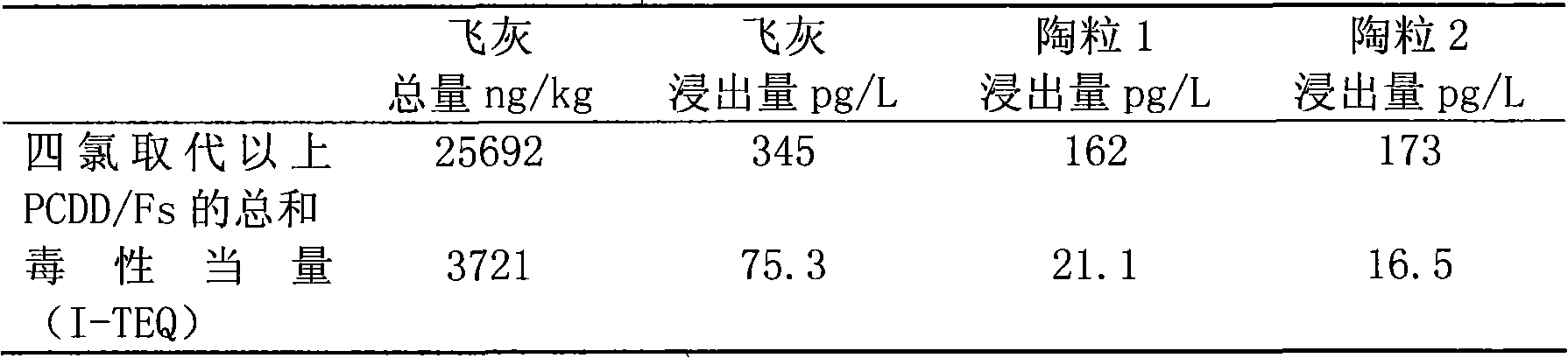

The invention provides a non-burned porcelain granule which adopts fly ash generated by waste incineration as the main raw material and a manufacturing method thereof; the non-burned porcelain granule comprises a spherical inner core 1 and a shell 2 attached outside; wherein, the components (dry weight) of the inner core 1 are as follows: 50 to 70 parts of fly ash generated by waste incineration, 25 to 50 parts of portland cement, 0 to 15 parts of coal ash and 0.2 to 0.5 part of heavy metal stabilized agent; the shell 2 adopts ordinary portland cement or lime. The method includes the following steps: firstly, the agent stabilization treatment is carried out on the fly ash generated by waste incineration; then the fly ash is mixed with the portland cement and coal ash to be granulated, thus manufacturing the inner core 1; finally, the inner core 1 is coated on the shell 2 in a pan granulator for natural curing. The method adopts the fly ash which is the dangerous waste as the raw material of the porcelain granule for resource utilization, realizes the harmlessness of the whole treatment process and has the advantages of economy, environmental protection and less investment of one-off equipment.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Baking-free gravel attapulgite building garbage ceramsite

InactiveCN102503281AUniform particle sizeImprove yieldSolid waste managementExpanded clay aggregateWaste material

The invention discloses baking-free gravel attapulgite building garbage ceramsite. The key point of the technical scheme is that the baking-free gravel attapulgite building garbage ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, building garbage powder, red bentonite powder, kieselguhr tailing powder and cement. The baking-free gravel attapulgite building garbage ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging.. The baking-free gravel attapulgite building garbage ceramsite is an irregularly-shaped granule and has a rough and hard surface light weight, high strength, high durability and a good heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the granule. The baking-free gravel attapulgite building garbage ceramsite is produced by utilizing the building garbage and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free gravel attapulgite building garbage ceramsite is suitable for producing concrete heat-preserving building blocks and heat-preserving and sound-insulating materials.

Owner:许庆华

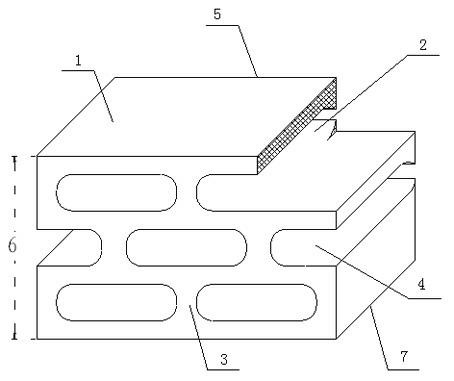

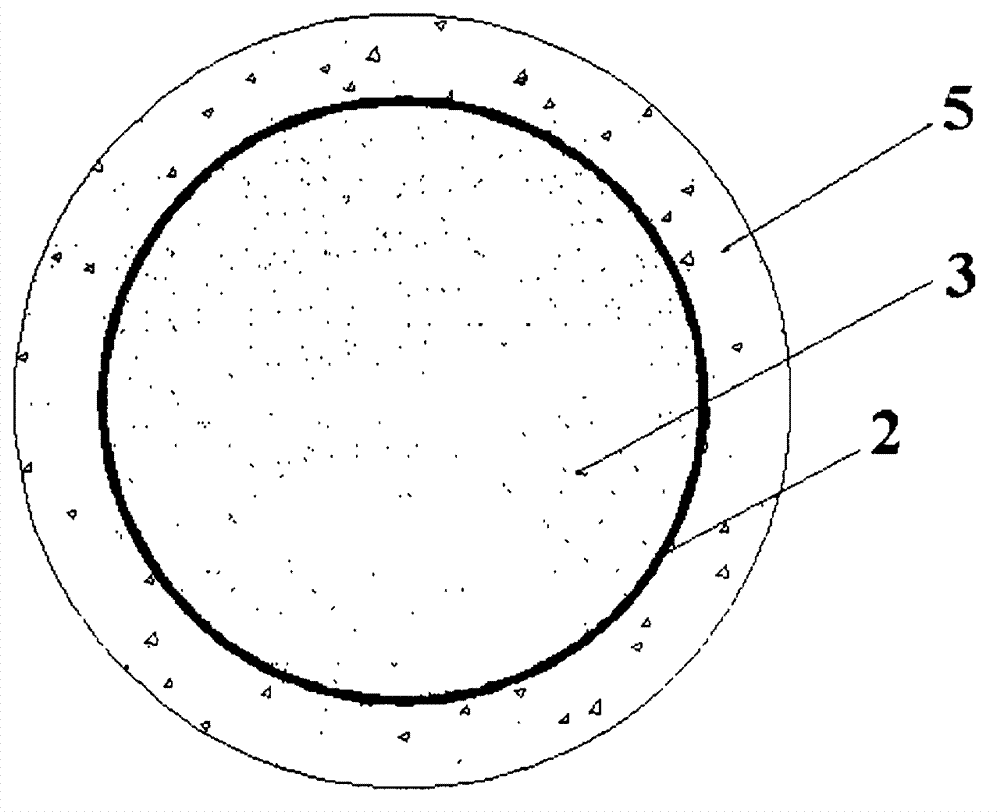

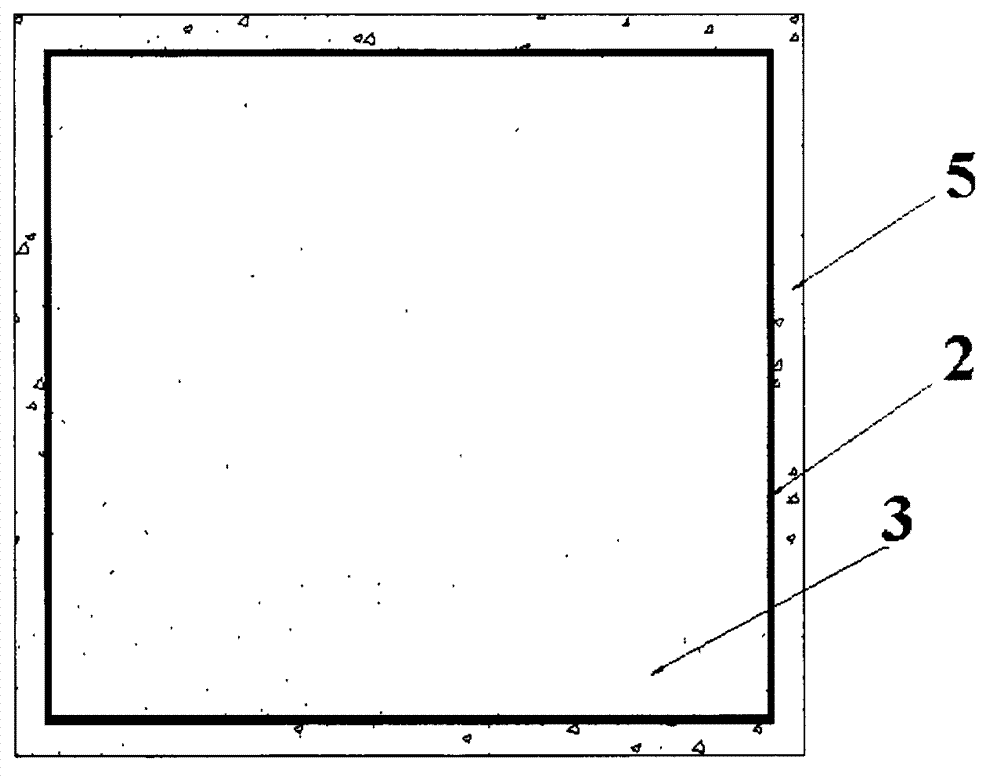

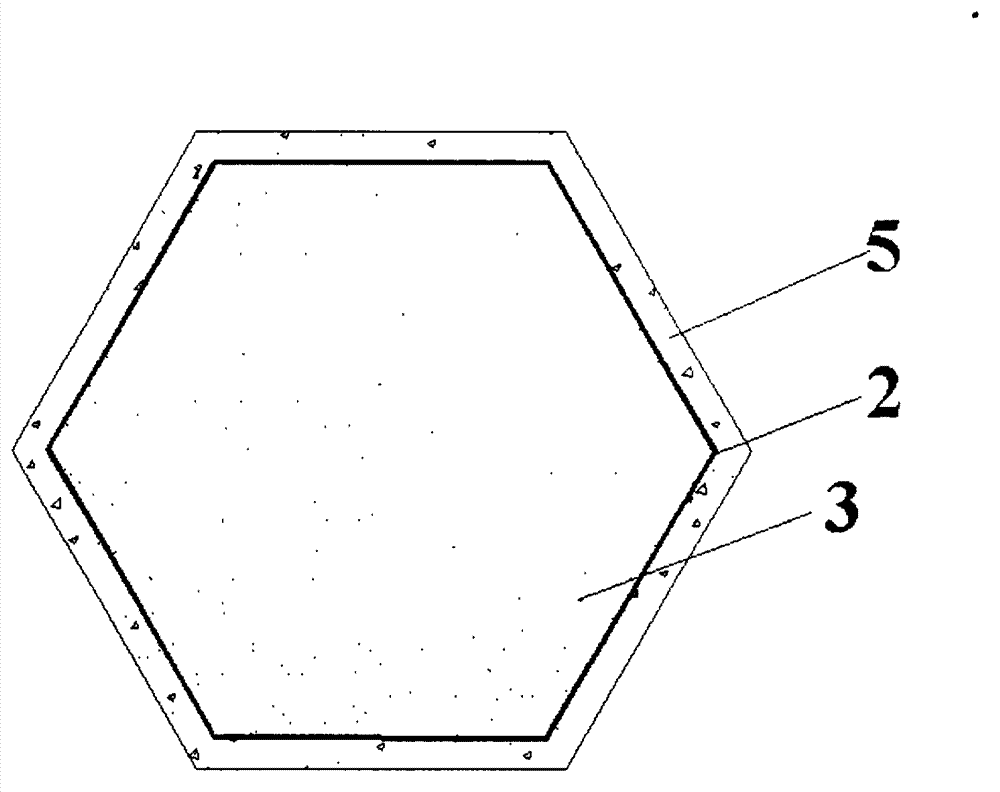

Steel tube foam concrete combined upright column and construction method thereof

InactiveCN103088964ASmall shrinkage deformationIncreased load-bearing capacityStrutsCeramicwareFoam concreteExpanded clay aggregate

The invention relates to a steel tube foam concrete combined upright column and a construction method of the steel tube foam concrete combined upright column. The steel tube foam concrete combined upright column comprises an upright column body, wherein the upright column body comprises steel tubes (2), foam concrete (3), reinforcing meshes (4) and outer wrapped concrete layers (5), wherein the foam concrete (3) is poured into the steel tubes (2); the reinforcing meshes (4) are arranged on the outer walls of the steel tubes; the steel tubes are connected by virtue of flange discs (6) and flange sockets (7); and a gasket (8) is arranged between each flange disc (6) and each flange socket (7). The foam concrete in the steel tube foam concrete combined upright column can adopt coal ash foam concrete or ceramsite foam concrete. The steel tube foam concrete combined upright column has a simple structure, and is high in shock resistance, high in carrying capability, good in economical performance and easy to construct, and suitable for main support columns and support parts of house structures, industrial building structures, recreational and athletic building structures and other structures.

Owner:HEFEI UNIV OF TECH

Special haydite for cultivating flowering plants

The invention relates to special haydite for cultivating flowering plants, belonging to life decoration appliances. The method of the haydite cultivation for the flowering plants is a novel cultivation method which rises in recent years, which is sanitary, environmental-friendly and beautiful, can be matched with elegant interior decoration, is simple and convenient in cultivation management and is popular with the people. The existing haydite in the market is divided into three types some of which has excessively high price, the low-cost substitute, i.e. building haydite is bad to phytostabilization due to low water absorption, light weight and smoothness, thereby being limited to indoor parts of foliage plant water planting and basin soil capping and having narrow usable range of outdoor cultivation. The haydite of the invention is developed and manufactured for indoor and outdoor flowering plant cultivation in elegant environments. The haydite has high water absorption up to 30-35%, suitable volume-weight and surface character, contains a plurality of nutrient elements, is beneficial to stabilization and growth of the plants, can be used separately, can be mixed with other matrixes to change performances in accordance with different proportions, and can be repeatedly used for years.

Owner:周良型

Preparation method of diatomite ceramic particles or ceramic plates

InactiveCN102093033AIncrease contentImprove adsorption capacityClaywaresExpanded clay aggregateVegetable fibers

The invention relates to a preparation method of diatomite ceramic particles or diatomite ceramic plates. The preparation method of the diatomite ceramic particles comprises the following steps: grinding diatomite, adding cosolvent, mineral powder and vegetable fiber powder to mix evenly and grind; and adding water to mix, shaking to obtain diatomite ceramic particles, and roasting to obtain the finished diatomite ceramic particles. The preparation method of the ceramic plates comprises the following steps: using evenly mixed powder to perform dry pressing with a pressure forming machine, or using mud with the water content of 15-25wt% to perform extrusion forming; and roasting to obtain the diatomite ceramic plates. The formed and dried diatomite ceramic plates or diatomite ceramic particles are soaked in slurry prepared from anatase titanium dioxide nanometer powder or metatitanic acid powder and then dried and roasted to obtain diatomite ceramic particles or diatomite ceramic plates with photochemical activity. In the invention, the low temperature sintering method is adopted to prepare the diatomite diatomite ceramic plates and ceramic particles which have high diatomite content and good adsorption property and water resistance and can be combined with various functional components on the surface. The diatomite ceramic products in the invention are convenient to use and have simple production technology and cheap and easy available raw materials.

Owner:JILIN UNIV +1

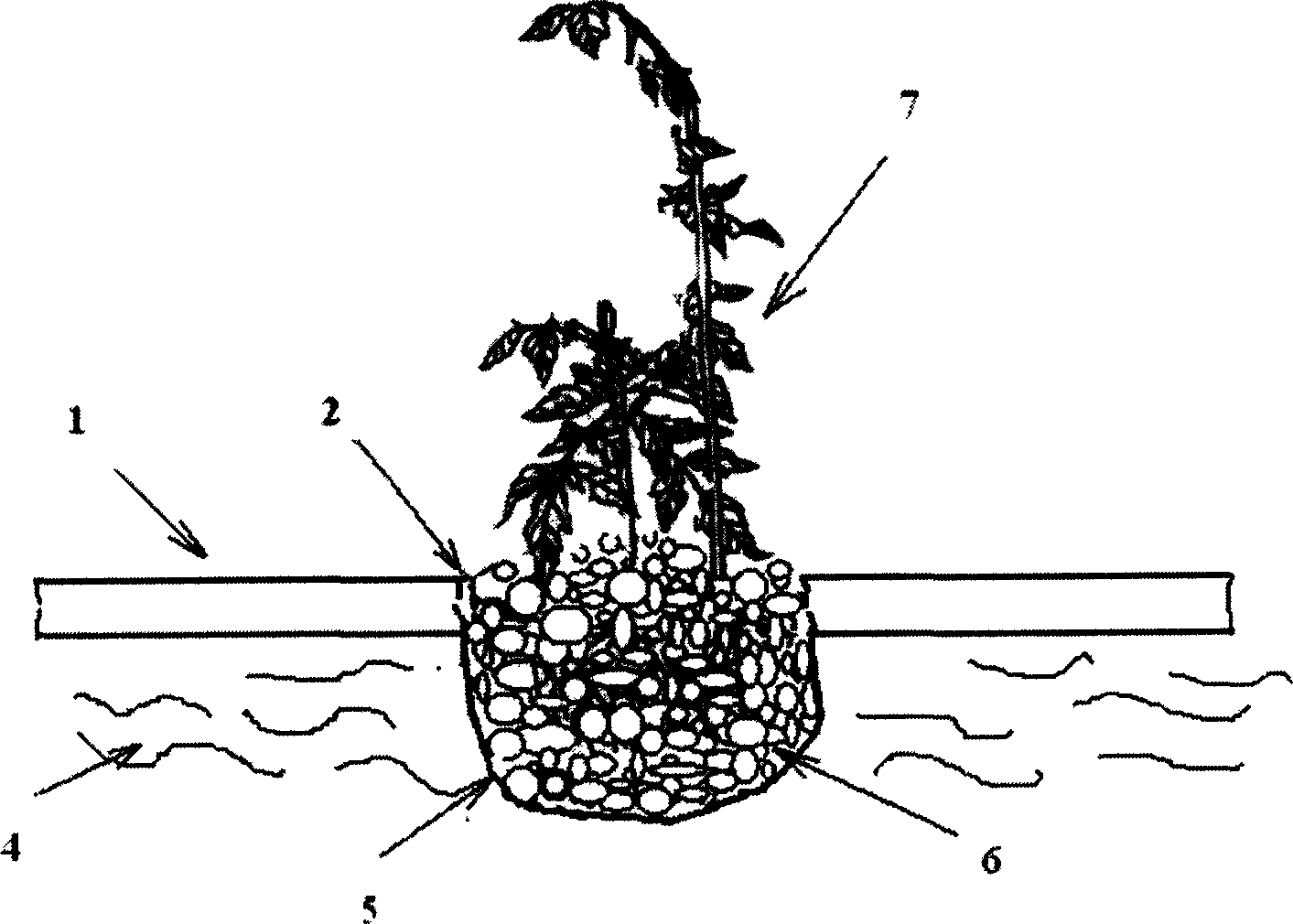

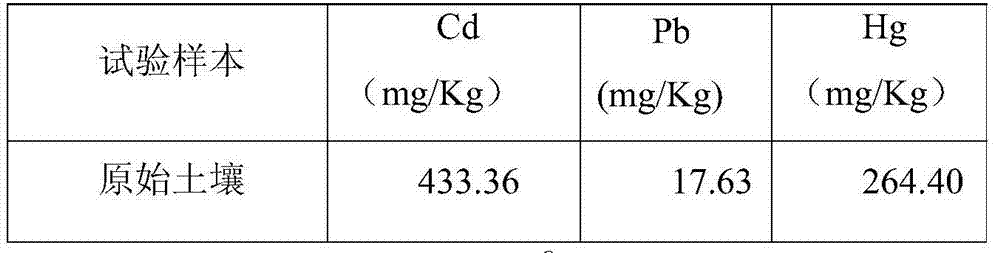

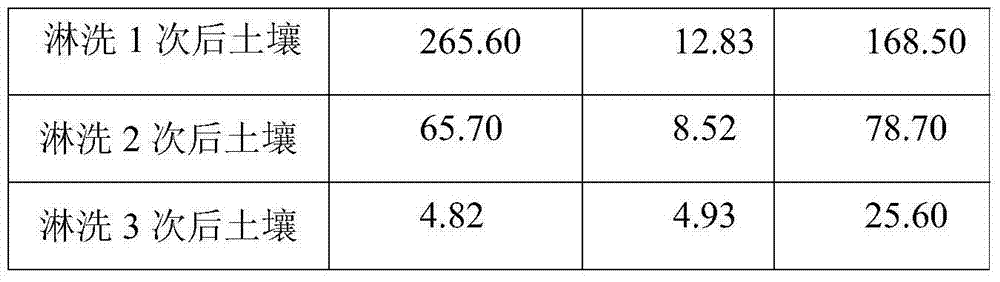

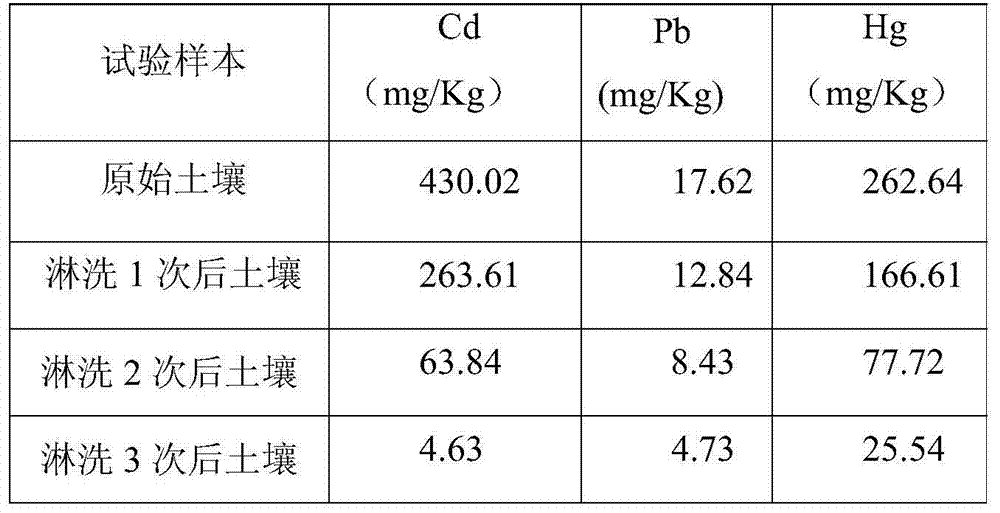

Two-level remediation method of heavy metal contaminated soil

ActiveCN103894395AQuality improvementEfficient removalOther chemical processesContaminated soil reclamationWater useClay minerals

The invention discloses a two-level remediation method of heavy metal contaminated soil. The method comprises the steps of breaking a heavy metal contaminated paddy field, irrigating the paddy field until a water logging layer on a soil layer is 10-15cm deep after breaking the 0.5-0.6m deep soil on the surface layer into soil lumps with sizes less than 2-3mm, adding a modified clay mineral adsorbent, mechanically stirring the adsorbent, standing for 6-8 hours, fishing out the adsorbent which floats on water and completes adsorption, and simultaneously discharging the supernatant, thus completing first-level remediation; then collecting adsorbed light ceramsites, eluting the ceramsites in a wastewater treatment plant, and then leaching 1-3 times by using pure water as an eluent, thus completing second-level remediation, wherein the amount of water used each time is 0.6-1 times the leachate added for the first time by volume. The method is simple to operate, is low in cost, has high removal efficiency, meets actual requirements, and has good popularization and application values.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com