Light fly ash multi-row hole self-thermal insulation building block

A technology of self-insulating blocks and fly ash, which is applied in the field of building materials, can solve problems such as fire prevention and durability hazards, energy consumption, waste of resources, etc., and achieve the goal of reducing the amount of raw materials used, reducing its own weight, and improving the insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

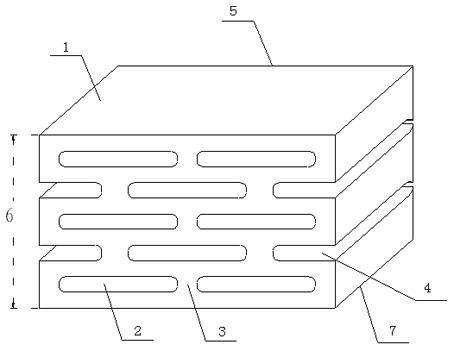

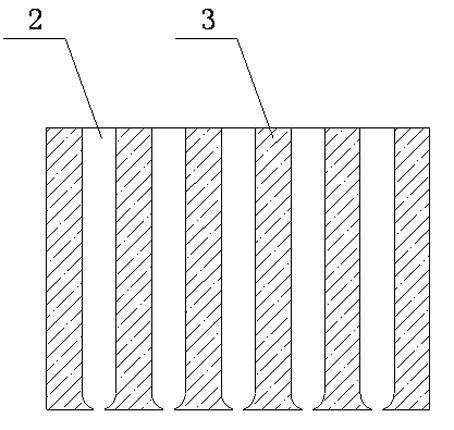

[0013] Embodiment 1, the main block size (length×width×height) of the block (brick): 390mm×260mm×190mm. Refer to attached figure 1 and 2 , the block 1 has five rows of through-holes, of which the first, third and fifth rows of through-holes are two (or called two sections) complete through-holes 2 spaced apart from the same horizontal line (arranged; the second and fourth rows of through-holes It is composed of a complete through hole 2 plus semi-open holes 4 on the left and right sides (that is, 1 / 2 of the complete through hole) arranged at intervals with horizontal lines; the through hole is a flat cuboid, its front and rear ends are connected, and the rear end opening adopts an arc shape Shrinkage cavity structure; there is an interval 3 between the through holes, and the inner wall of the through hole is arc-shaped.

[0014] The weight ratio of each component of the lightweight fly ash block is: Portland cement 20%; fly ash 35%; coarse ash 20%; ceramsite or slag 5%; perl...

Embodiment 2

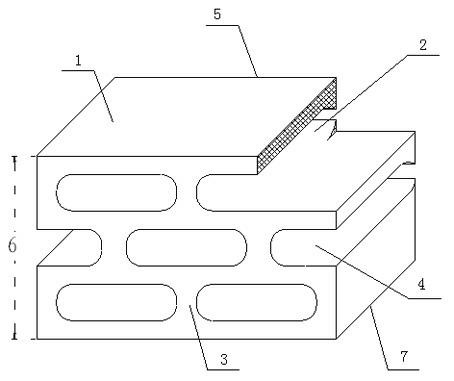

[0015] Embodiment 2, the main block size (length×width×height) of the block (brick): 390mm×240mm×190mm. The block 1 (brick) three-row hole block (brick) ( image 3 ); the through-holes on the block are set as two complete through-holes 2 in the first row, one complete through-hole 2 plus half-open holes 4 at both ends (that is, 1 / 2 of the complete through-holes) in the second row, and the third Line up two holes. The through holes are flat cuboids, the front and rear ends are connected, and the rear opening adopts an arc-shaped shrinkage cavity structure; there is an interval 3 between the through holes, and the inner wall of the through holes is arc-shaped.

[0016] The weight ratio of each component of the lightweight fly ash block is: Portland cement 10%; fly ash 32%; coarse ash 30%; ceramsite or slag, pumice 20%; perlite or vermiculite 0.5% ; sawdust 1%; waste polyphenylene particles (new products are better) 0.5%; 107 construction adhesive 0.05%; GP concrete humectant 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com