Binding mortar with light weight and high droop resistance and preparation and use methods

A technology of bonding mortar and high resistance, applied in the field of mortar, can solve the problems of lack of thermal insulation effect, single function, delayed construction time, etc., and achieve good anti-sagging performance, improve indoor environment, and reduce building energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

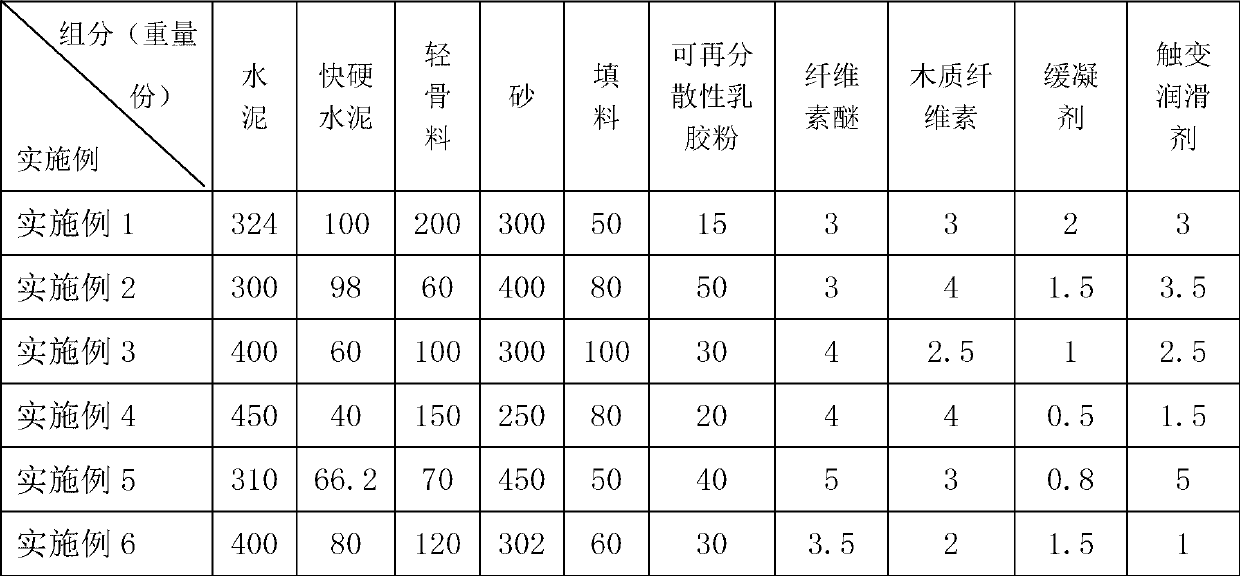

[0045] The parts by weight of the components of the lightweight high-sag-resistant bonding mortar used in this example are shown in Table 1, wherein the cement used is P.Ⅱ52.5R Portland cement, and the rapid hardening cement used is CA50 aluminate For cement, the lightweight aggregate used is ceramsite sand with a particle size of less than 1.2mm and a loose bulk density of less than 0.8Kg / L. The sand used is quartz sand with a particle size of 40-70 mesh, and the filler used is a particle size of 200. -400 mesh double fly powder, the redispersible latex powder used is vinyl acetate and ethylene copolymer powder (Vac / E), the cellulose ether used is hydroxypropyl methyl cellulose ether with a viscosity of 40,000, and the used The fiber length of lignocellulose is 600 μm, the retarder used is L(+)-tartaric acid produced by Changzhou Tianmao Chemical Engineering Co., Ltd., and the thixotropic lubricant used is 602 thixotropic lubricant produced by Lockwood Company.

[0046] Mix t...

Embodiment 2

[0052] The parts by weight of the components of the lightweight high-sag-resistant bonding mortar used in this example are shown in Table 1, wherein the cement used is P.Ⅱ52.5R Portland cement, and the rapid-hardening cement used is 42.5 rapid-hardening sulfur For aluminate cement, the lightweight aggregate used is vitrified microbeads with a particle size below 1.2mm and a loose bulk density below 0.8Kg / L, the sand used is quartz sand with a particle size of 40-70 mesh, and the filler used It is a secondary fly ash with a particle size of 200-400 mesh. The redispersible latex powder used is vinyl acetate and ethylene copolymer powder (Vac / E), and the cellulose ether used is 40,000 viscosity hydroxyethyl Methyl cellulose ether, the fiber length of used lignocellulose is 1000 μm, used retarder is the L(+)-tartaric acid that Changzhou Tianmao Chemical Engineering Co., Ltd. produces, and used thixotropic lubricant is produced by Lockwood Company The 602 thixotropic lubricant.

...

Embodiment 3

[0057] The parts by weight of the components of the lightweight high-sag-resistant bonding mortar used in this example are shown in Table 1, wherein the cement used is P.Ⅱ52.5R Portland cement, and the rapid hardening cement used is CA50 aluminate For cement, the lightweight aggregate used is hollow glass microspheres with a particle size of 0.3-0.6mm and a loose bulk density below 0.8Kg / L, the sand used is quartz sand with a particle size of 40-70 mesh, and the filler used is 200-400 mesh double fly powder, the redispersible latex powder used is vinyl acetate and ethylene copolymer powder (Vac / E), the cellulose ether used is hydroxypropyl methyl cellulose ether with a viscosity of 40,000, and the used The fiber length of the lignocellulose is 600 μm, the retarder used is citric acid, and the thixotropic lubricant used is 602 thixotropic lubricant produced by Lockwood Company.

[0058] In this embodiment, the light-weight and highly sag-resistant adhesive mortar is prepared ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com