Patents

Literature

143results about How to "Good anti-sag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

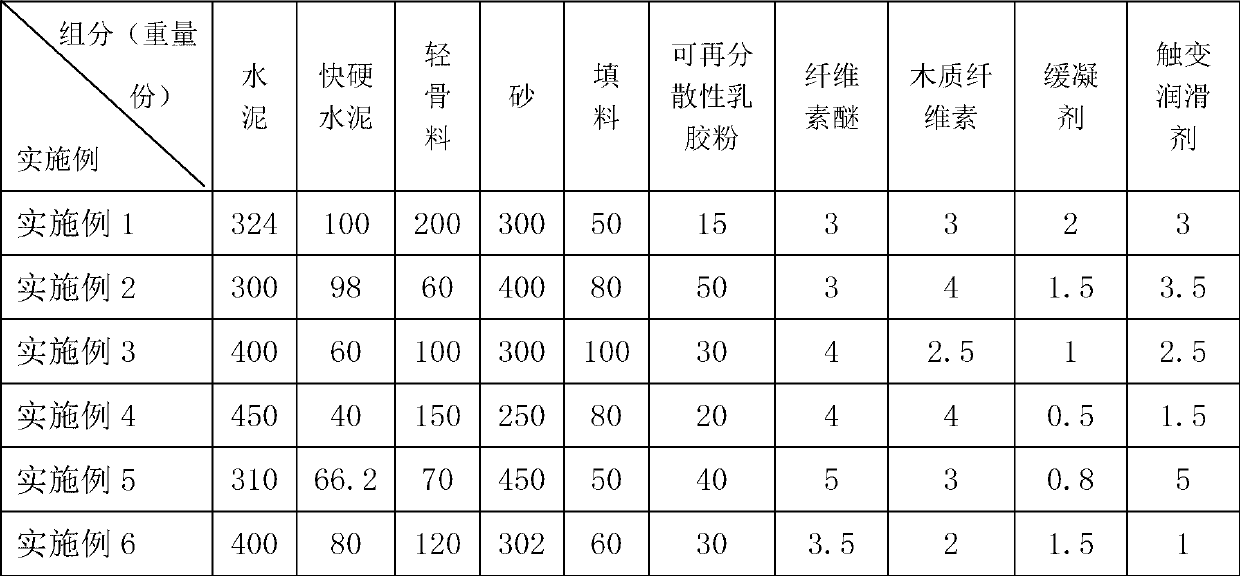

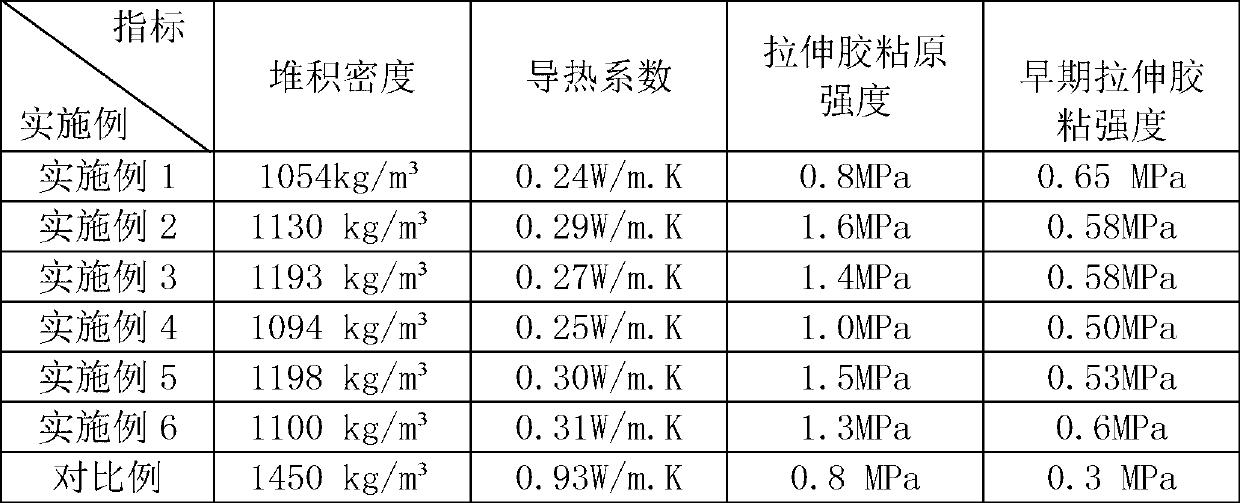

Binding mortar with light weight and high droop resistance and preparation and use methods

The invention provides binding mortar with light weight and high droop resistance, which consists of the following components in parts by weight: 300-450 parts of cement, 40-100 parts of rapid hardening cement, 60-200 parts of lightweight aggregate, 250-450 parts of sand, 50-100 parts of filling material, 15-50 parts of re-dispersible emulsion powder, 3-5 parts of cellulose ether, 2-4 parts of lignocellulose, 0.5-2 parts of retarder and 1-5 parts of thixotropic lubricant. The lightweight aggregates are glass microspheres, or hollow glass microspheres or ceramsite sand, of which the particle size is below 1.2mm and loose bulk density is below 0.8Kg / L. The invention has lower mortar density, good droop resistance, lower thermal conductivity and certain thermal insulation performance; the binding mortar can be hardened quickly, and the requirement of carrying out subsequent construction quickly is satisfied; the elastic modulus of the mortar is small, and deformation resistance is strong; and the mortar uses multiple polymer additives, and base materials have strong adaptability and strong binding performance.

Owner:深圳广田高科新材料有限公司

Novel high sealing property unsaturated polyester white primer, and preparation method thereof

The present invention discloses a novel high sealing property unsaturated polyester white primer, and a preparation method thereof. The unsaturated polyester white primer provided by the present invention comprises, by weight, 40-45% of unsaturated polyester PE resin, 0.2-0.3% of an antifoaming agent, 0.3-0.5% of a wetting dispersant, 0.2-0.3% of a polyacrylate leveling agent, 0.1-0.2% of an anti-green agent, 4-6% of organic bentonite pre-clotting slurry, 0.2-0.8% of fumed silica, 3-7% of zinc stearate, 3-9% of 1250 mesh pulvistalci, 7-11% of 800 mesh pulvistalci, 13-21% of ground calcium carbonate, 11-17% of rutile titanium dioxide, 2-5% of a nitrocellulose solution and 1-3% of n-butyl acetate. The unsaturated polyester PE primer provides especially good sealing property for the low density medium density fiberboard, wherein the low density medium density fiberboard is not subjected to a sealing treatment or is treated bad. In addition, the unsaturated polyester PE primer has characteristics of excellent caving resistance, excellent sagging resistance, short polishing time, good polishing property, strong interlayer adhesion, and can be applicable for the comprehensive primer solution schemes for different environments, various processes and plates.

Owner:恒昌涂料(惠阳)有限公司

A kind of anti-sagging thermal insulation mortar based on β-hemihydrate gypsum

The invention discloses an anti-sagging heat-insulation mortar based on beta-hemihydrated gypsum. The mortar comprises the following components in parts by weight: 100 parts of beta-hemihydrated gypsum, 5-30 parts of white cement, 60-100 parts of vitrified microsphere, 10-40 parts of quartz sand, 3-10 parts of re-dispersible latex powder, 0.1-0.5 part of cellulose ether, 0.1-0.5 part of poval, 0.05-0.3 part of citric acid, 0.05-0.5 part of polypropylene fiber, 0.05-0.3 part of starch ether, 0.05-0.3 of montmorillonite powder and 120-200 of water. According to the invention, the heat-insulation mortar has extremely good anti-sagging property and good anti-skating property through improvement of heat-insulation mortar components; and the heat-insulation mortar has good workability, thereby greatly improving the construction efficiency and bringing obvious progress for the field of modern building energy conservation materials.

Owner:NANJING CENGO ENERGY SAVING MATERIAL

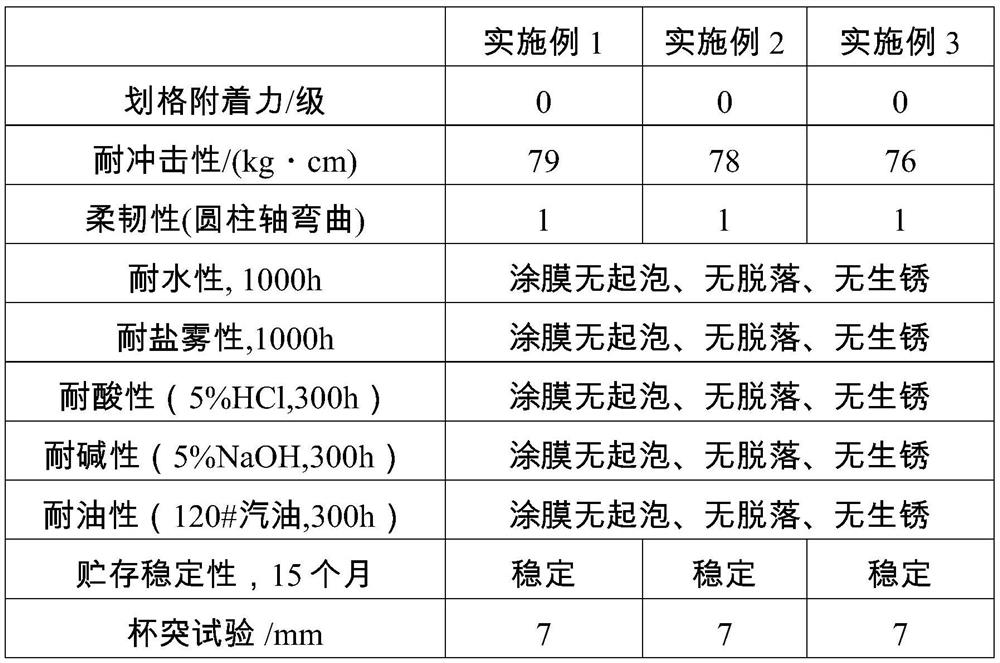

High-performance water-based two-component finish paint composition as well as preparation method and use thereof

InactiveCN108864918AHigh hardnessImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a high-performance water-based two-component finish paint composition, which is prepared finish paint and a curing agent, wherein the finish paint is prepared from the following components in parts by weight: 60-75 parts of water-based hydroxyl acrylic resin, 0.3-1.1 parts of a flatting agent, 0.3-1 part of an antifoaming agent, 1-4 parts of a dispersing agent, 2-30 parts of pigment, 5-15 parts of deionized water, 0-0.5 part of a pH regulating aid and 0-11.6 parts of other additives; the curing agent is prepared from the following components in parts by weight: 55-75 parts of isocyanate, 25-45 parts of a solvent and 0-1 part of a water removal agent. The finish paint composition provided by the invention has good construction performance and paint film property, andis lower in content of volatile organic compounds (VOCs), thus being used for finish paint for buses.

Owner:NIPPON PAINT CHINA

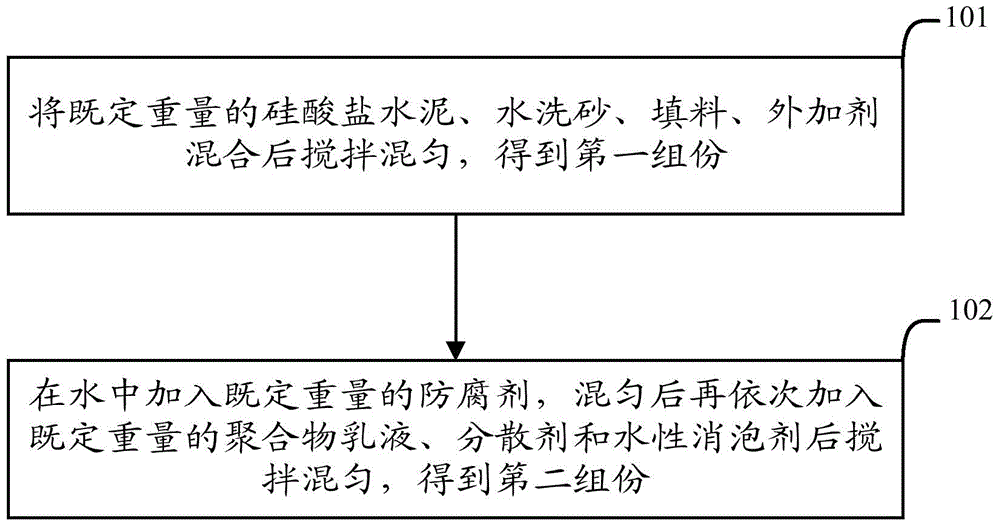

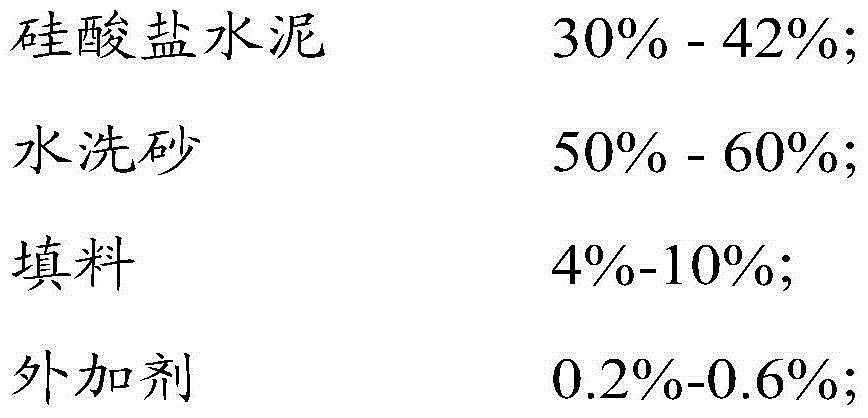

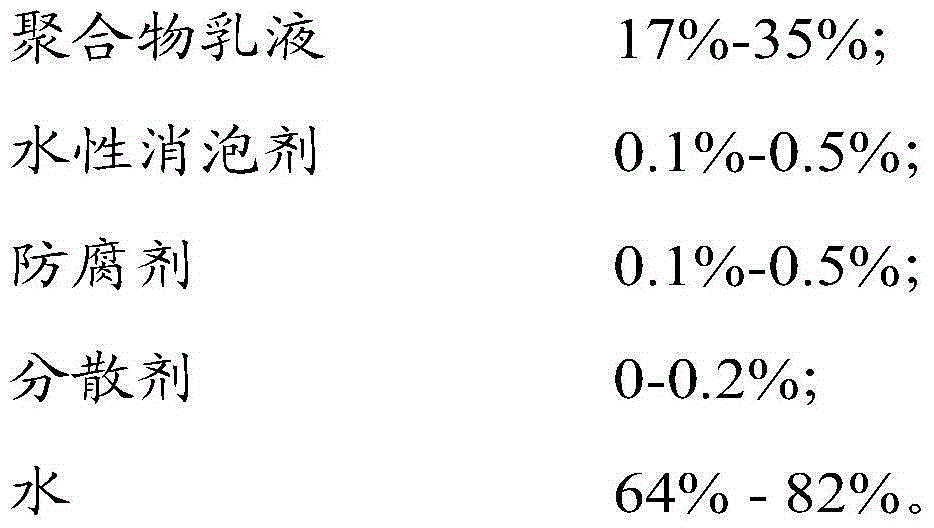

Adhesion agent as well as preparation method and application thereof

InactiveCN104446251APrevent peelingCounteract and absorb deformation stressWater basedMaterials science

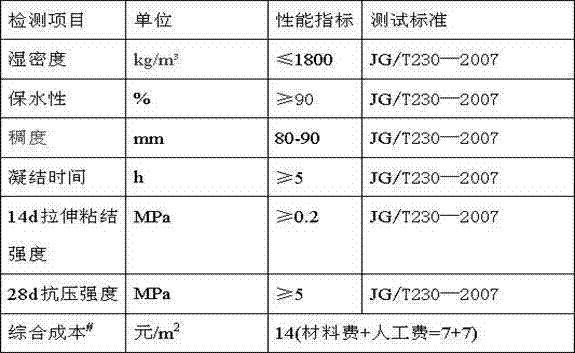

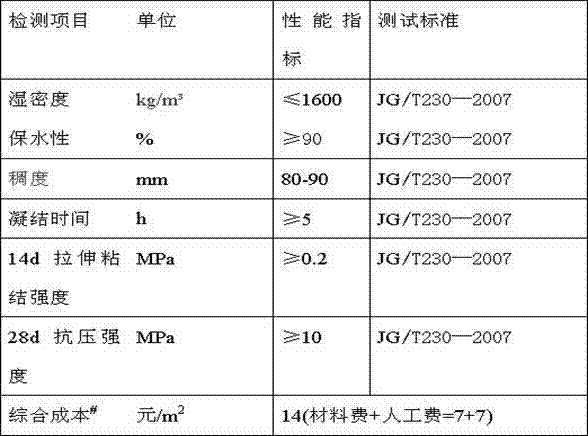

The invention provides an adhesion agent as well as a preparation method and application thereof, and relates to the technical field of building materials. Raw material components of the adhesion agent comprise a first component and a second component, wherein the first component comprises raw materials in percentage by weight: 30-42% of Portland cement, 50-60% of washed sand, 4-10% of stuffing and 0.2-0.6% of additives; the second component comprises raw materials in percentage by weight: 17-35% of polymer emulsion, 0.1-0.5% of water-based defoamer, 0.1-0.5% of corrosion remover, 0-0.2% of dispersing agents and 64-82% of water. The adhesion agent has the advantages of high adhesive strength, good water resistance, good heat resistance, good weather resistance, good vertical-flowing resistance, good anti-sliding performance, low cost and the like.

Owner:JIUZHU ENERGY SAVING TECH TIANJIN

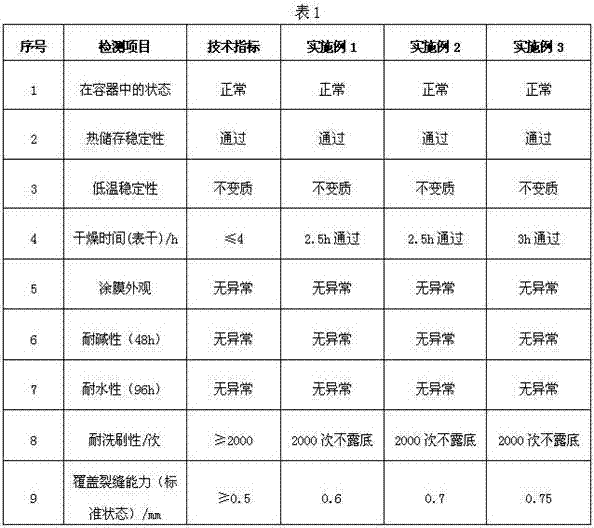

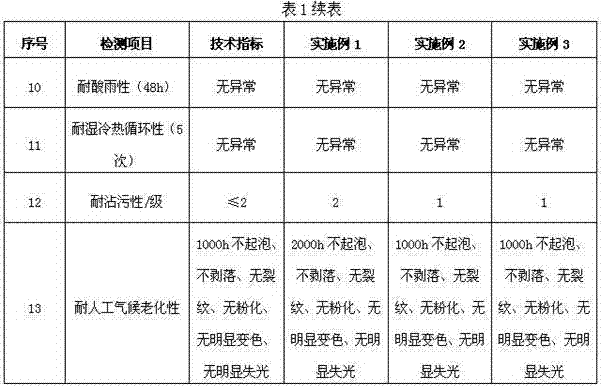

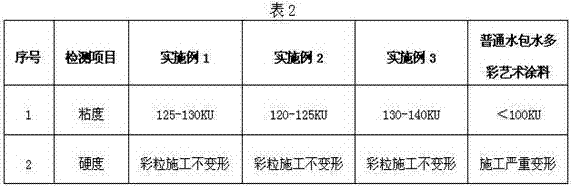

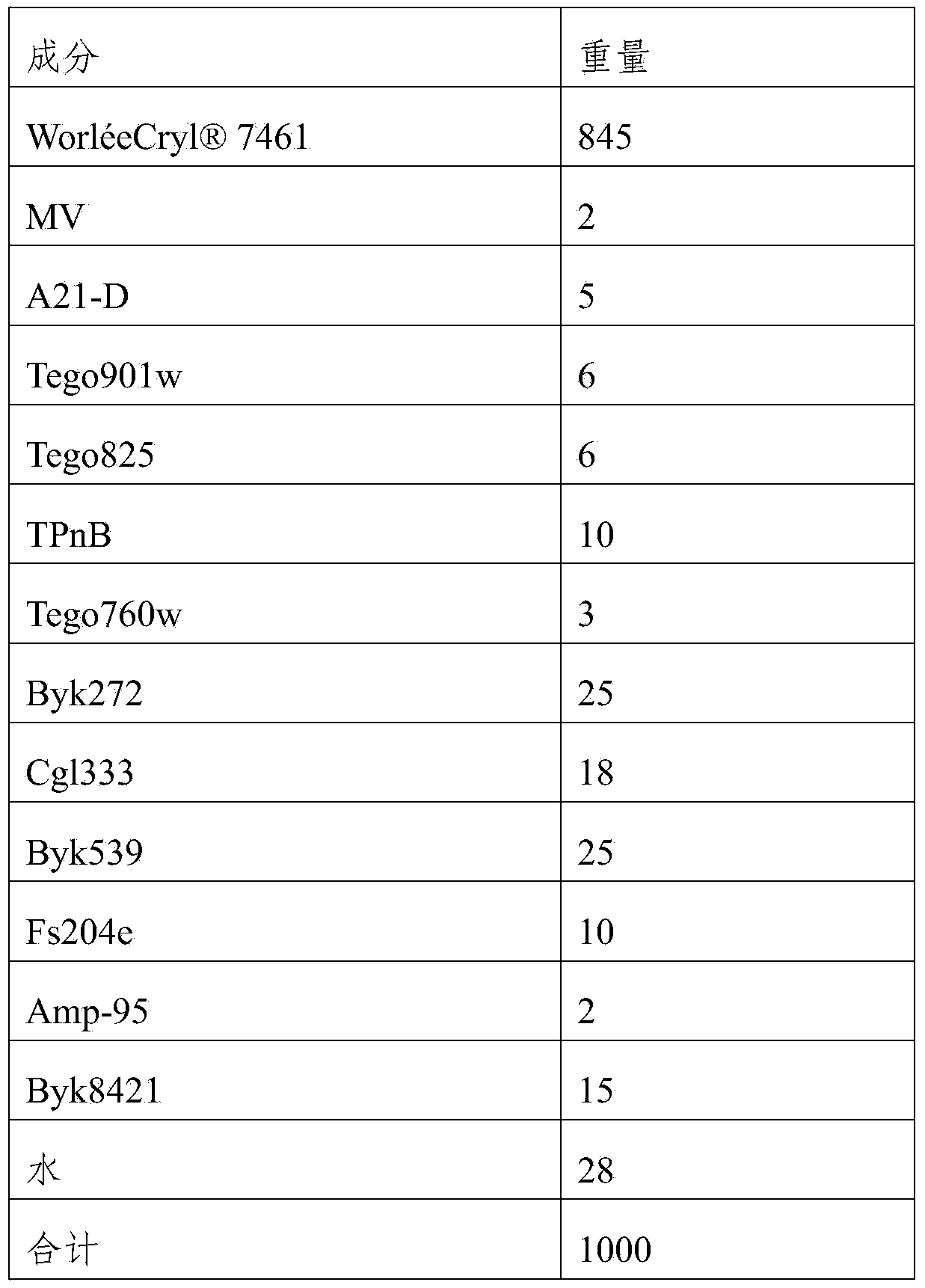

Water-in-water colorful art coating for brush coating and roller coating and preparation method thereof

InactiveCN106957578ARich construction methodsAppropriate areaAntifouling/underwater paintsPaints with biocidesEthyl(hydroxyethyl)celluloseFoaming agent

The invention discloses a water-in-water colorful art coating for brush coating and roller coating and a preparation method thereof. The weight ratio of protecting glue solution to basic paint to continuous phase is at 3:3:4; the protecting glue solution comprises the following components by weight percent: 96-97% of water and 3-4% of protecting glue powder; the basic paint comprises the following components: 22-25% of water, 0.3-0.4% of hydrophobic modified ethyl hydroxyethyl cellulose, 0.5-0.8% of modified bentonite, 0.15-0.25% of de-foaming agent, 0.1-0.15% of pH regulator, 0-0.1% of a wetting agent, 0-0.4% of a dispersing agent, 1-1.5% of an anti-freezing agent, 0-2% of titanium dioxide, 5-10% of a hardening agent, 2-2.3% of a coalescing agent, 60-65% of pure acrylic emulsion, 0.1-0.2% of bactericide and 2-3% of a protecting glue solution; the continuous phase comprises the following components: 80-85% of emulsion, 8.5-14% of water, 1-1.3% of an anti-freezing agent, 0.1-0.2% of bactericide, 4.3-5.1% of a coalescing agent and 0.15-0.2% of a de-foaming agent. The coating is suitable for brush coating and roller coating and the construction is various.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Water-based clear topcoat with high solid content and preparation method thereof

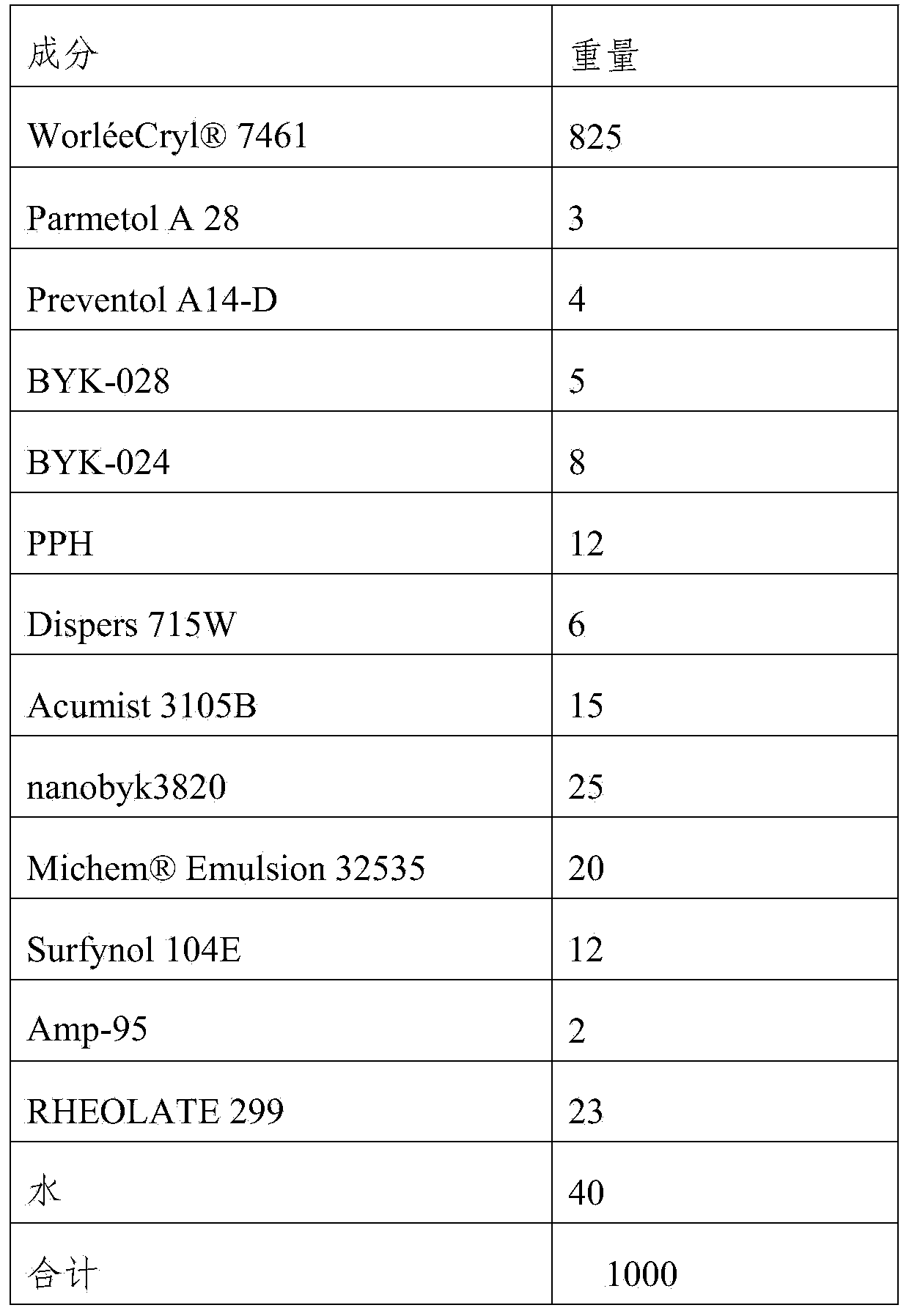

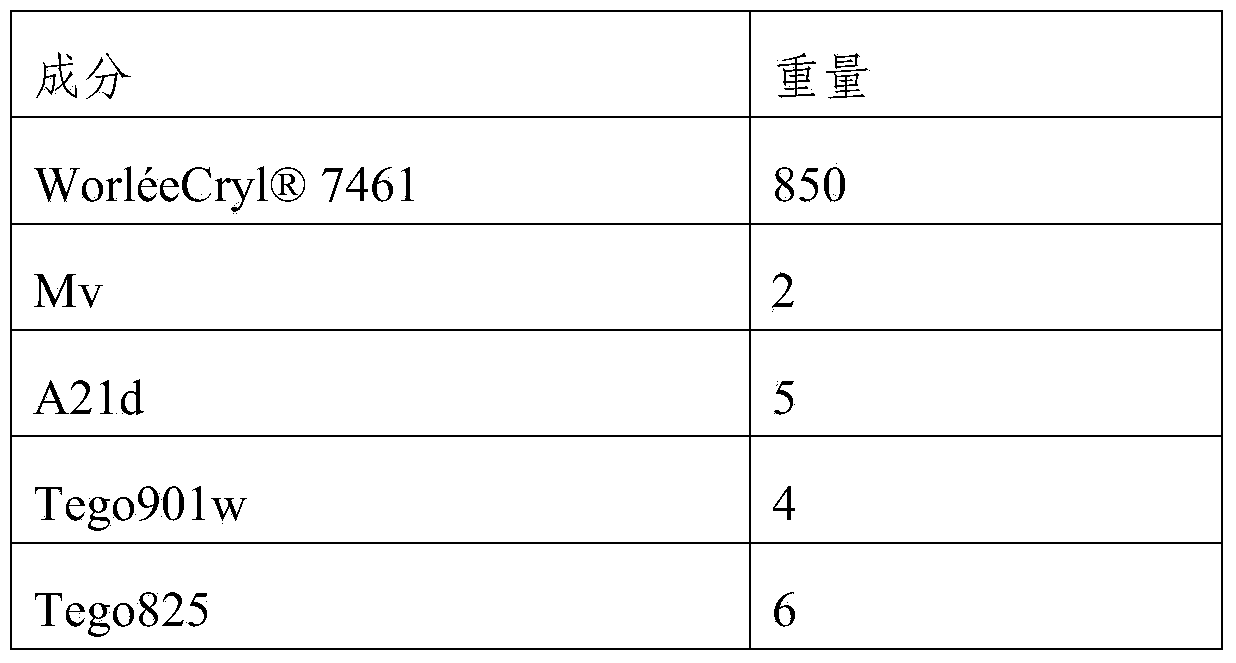

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

Automobile wear-resistant paint and preparation method thereof

ActiveCN104119737AGood anti-sag performanceImprove flame retardant performanceCoatingsWear resistantPlasticizer

The invention discloses an automobile wear-resistant paint and a preparation method thereof. The preparation method comprises the following steps: adding 100 parts by weight of PVC and 115 to 125 parts by weight of plasticizer into a reactor, evenly mixing; adding 1 to 6 parts by weight of silane coupling agent and 0.001 to 0.01 part of azodiisobutyronitrile into the reactor, increasing the stirring speed to evenly stir the mixture; adding 0.3 to 0.8 part by weight of organic fluorine surfactant and 2 to 8 parts of tackifier into the reactor, fully stirring until the added materials are evenly mixed; adding 250 to 300 parts of inorganic powder, increasing the stirring speed; and vacuumizing to remove the gas after the inorganic powder is evenly dispersed so as to obtain the automobile wear-resistant paint. The automobile wear-resistant paint has the excellent flame retardant performance, anticorrosion performance, and electric insulation performance, and high mechanical strength of polyvinyl chloride resin paint, and also has a very good anti-dropping and anti-sagging performance at the same time.

Owner:GUANGDONG TGPM AUTOMOTIVE IND GRP

Modified paint

A modified coating consists of acrylate 6-60wt%, water 10-60wt%, aggregate 12-50wt%, wetting disperser 0.01-5wt%, thickener 0.2-10wt%, film forming agent 0.1-10wt%, anti-bubbling agent 0.07-1.7wt%, anti-shrinking leveling agent 0.1-10wt%, fungicidal bactericide 0.02-4wt%, pH regulator 0.01-5wt%, propanediol 0.1-5wt%, pigment and dye. Particle diameter of mixed components is 0.1-1 nanometer. The process is carried out by proportioning the components. Its advantages include simple, non-toxic, good anti-aging and pollution preventive performances, and better air permeability.

Owner:闫俊杰 +1

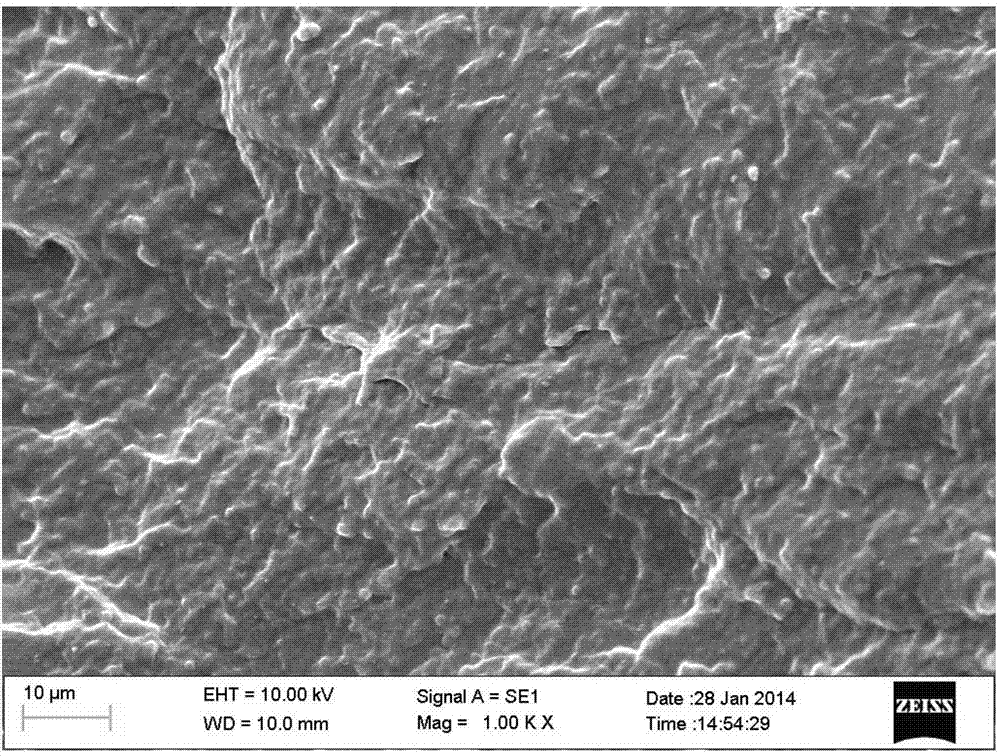

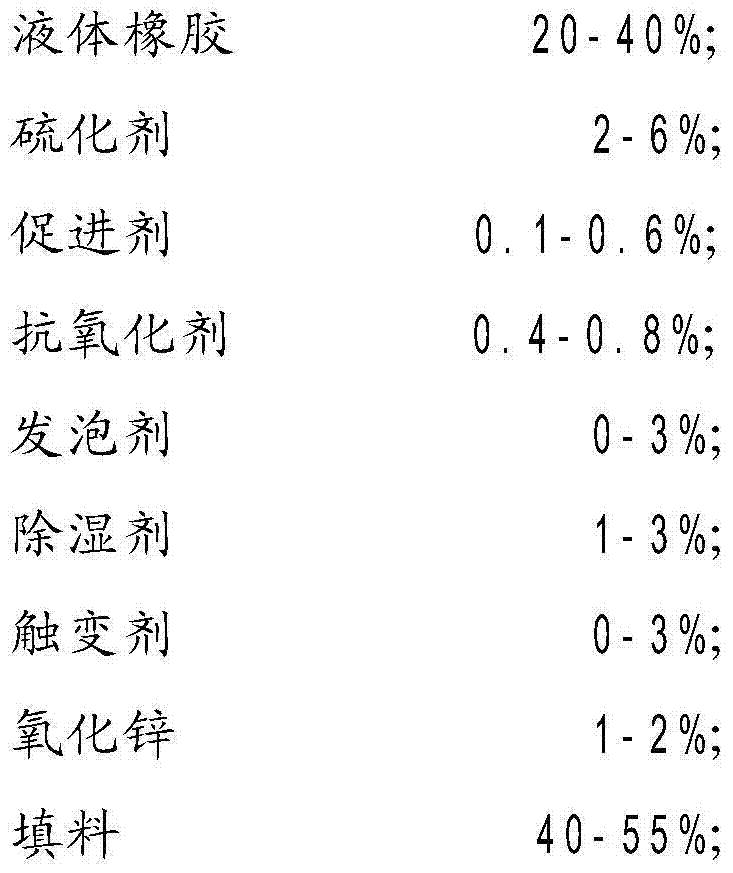

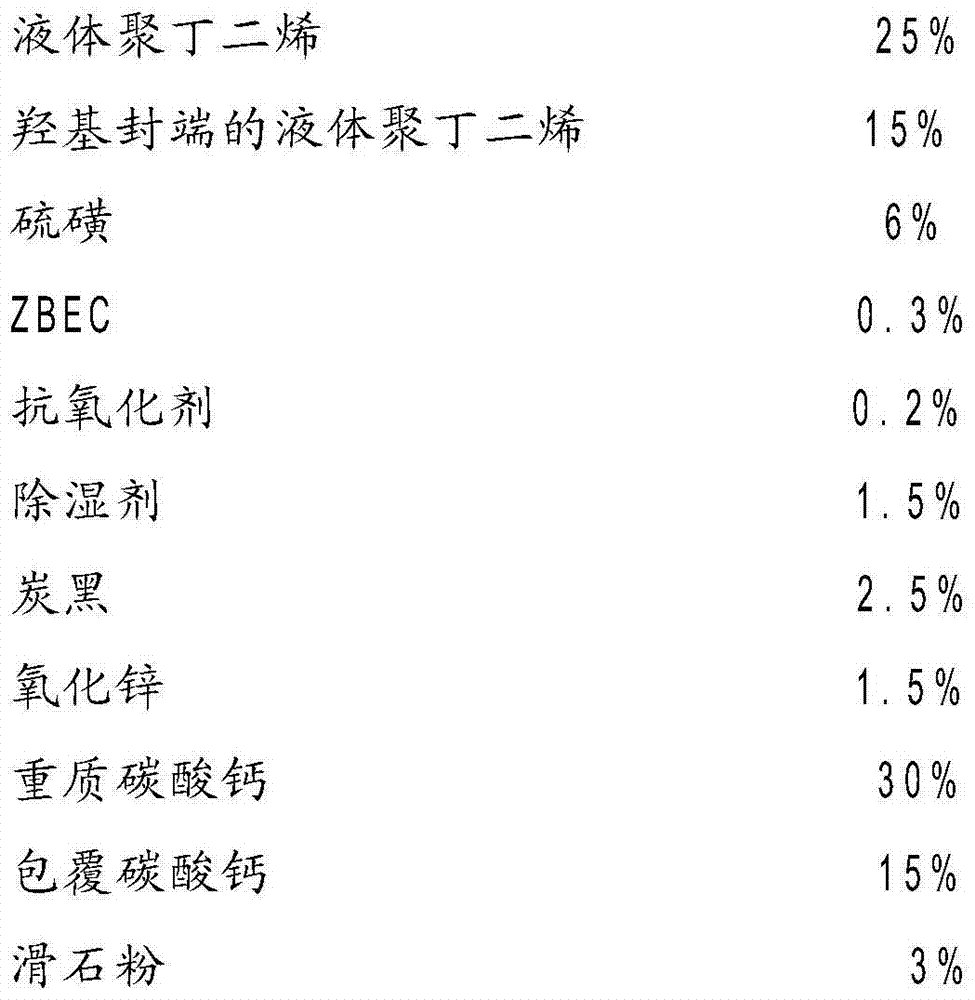

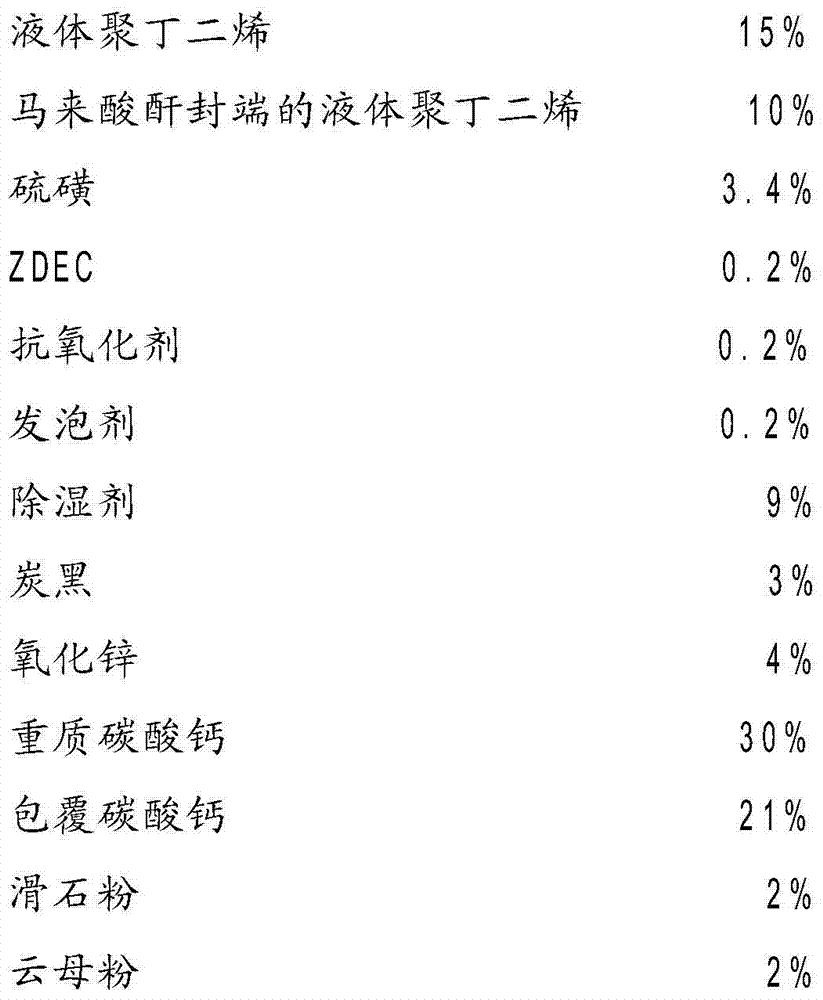

Rubber adhesive and preparation method thereof

ActiveCN103881615AExcellent anti-saggingHigh bonding strengthProductsNon-macromolecular adhesive additivesSteel platesChemistry

The invention discloses a rubber adhesive which comprises the following components in percentage by weight: 20-40 percent of liquid rubber, 2-6 percent of a vulcanizing agent, 0.1-0.6 percent of an accelerator, 0.4-0.8 percent of an antioxidant, 0-3 percent of a foaming agent, 1-3 percent of a dehumidifying agent, 0-3 percent of a thixotropic agent, 1-2 percent of zinc oxide and 40-55 percent of fillers, wherein the sum of the weight percentage of all the components is 100%. The invention also provides a preparation method of the rubber adhesive. The rubber adhesive disclosed by the invention has good status retention property and oil level steel plate stationarity when not cured, and a cured material has high intensity, good airtightness, shock absorptivity, noise reduction performance and the like, so the rubber adhesive can be widely applicable to adhesion and sealing of metal plates in automobile and engineering machinery industries.

Owner:依多科(常熟)汽车材料有限公司

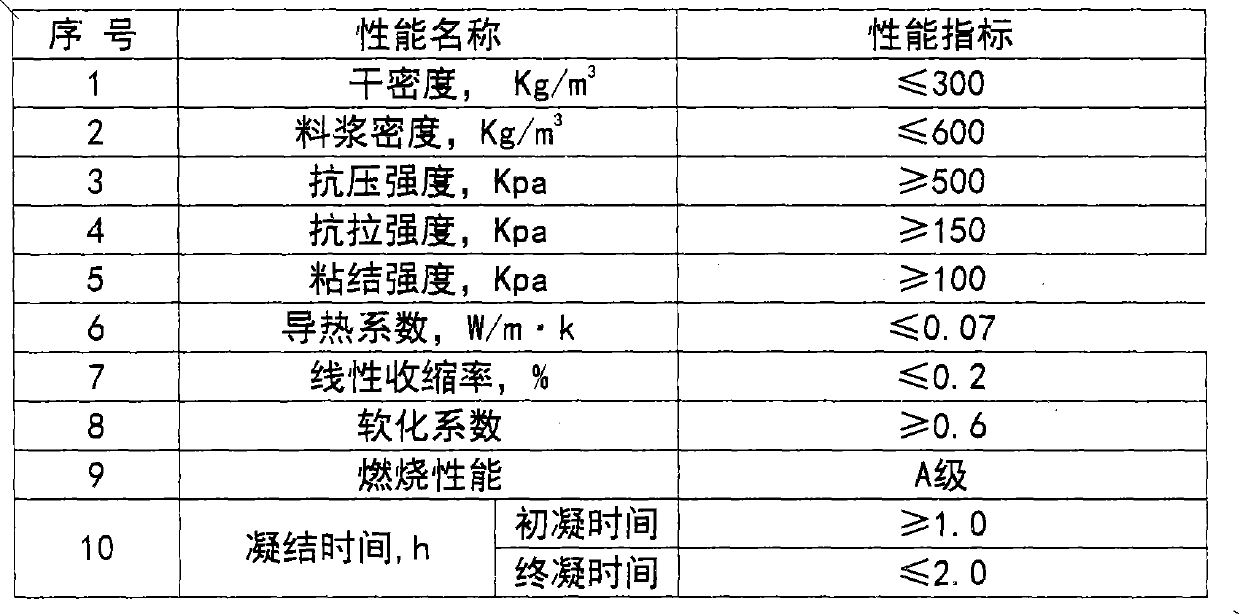

Composite silicate heat preservation mortar

The invention relates to the technical field of materials for construction industry, in particular to composite silicate heat preservation mortar. The invention adopts the following technical scheme that the mortar comprises the following raw materials in weight ratio: 45-65 percent of composite portland cement, 34-54 percent of glazed hollow bead, 0.5-2 percent of dispersible rubber powder, 0.1-0.6 percent of hydroxypropyl methyl cellulose, 0.5-1.2 percent of fiber and 0.1-0.4 percent of organic silicon waterproof powder. When in construction carried out by adopting the mortar produced by the technical scheme, an on-site construction mode can be adopted, and water is directly added to the mortar for stirring and then the mortar can be used. The stirred material can be directly constructed to a dry wall body; the construction performance is superior and the construction process is simple; and the construction efficiency can be greatly improved and the construction cost of a construction is reduced.

Owner:DONGGUAN HENGHE ENERGY SAVING TECH

Water-borne plastic paint and preparation method thereof

InactiveCN105885582AGood film formingImprove coalescenceFireproof paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to water-borne plastic paint and a preparation method thereof, and belongs to the technical field of paint processing. The water-borne plastic paint is prepared from the following components in a certain proportion: water-borne acrylic resin, water-borne epoxy resin, a coalescing agent, a water-borne color paste, hydroxyethyl cellulose, talc powder, a defoaming agent, a flatting agent, flame retardant, nano-silicon dioxide, dimethylethanolamine and deionized water. The paint film has strong adhesion, good glossiness and strong strength, has a certain flame retardant effect, and is safe and reliable.

Owner:杭州高思途实业有限公司

Thermal-insulation anti-cracking mortar and preparation method thereof

A thermal-insulation anti-cracking mortar is prepared from following raw materials, by weight, 20-30 parts of fly ash, 30-40 parts of carbide slag, 2-4 parts of salicylic acid, 7-10 parts of graphite powder, 10-14 parts of talcum powder, 2-3 parts of borax, 2-3 parts of wood fibers, 3-5 parts of polypropylene fiber, 2-3 parts of calcium formate, a proper amount of water, 20-25 parts of additives, 1-2 parts of a water repellent agent, 180-200 parts of cement and 300-330 parts of expanded perlite . The mortar is good in workability, flowability and water-retaining property, is easy to construct, is good in anti-sagging performance, is strong in thermal insulation, can be firmly adhered with wall body, is strong in anti-pressing property and tensile property and is good in anti-cracking performance due to the wood fibers and the polypropylene fibers. With the additives, the mortar is enhanced in anti-pressing and anti-folding strength and is improved in workability, the anti-sagging performance, thixotropism and an anti-settling performance.

Owner:尤明

Mechanized construction plastering mortar and preparation method thereof

The invention discloses mechanized construction plastering mortar and a preparation method thereof. The plastering mortar is formed by mixing powder, aggregate and water, and a mass ratio of the powder, the aggregate and the water is (200-300):(700-800):(160-250); the powder is formed by mixing portland cement clinker, plaster, granulated blast-furnace slag, coal ash, limestone powder and a chemical addition agent, and a mass ratio of the portland cement clinker, the plaster, the granulated blast-furnace slag, the coal ash, the limestone powder and the chemical addition agent is (100-300): (50-100): (50-200): (100-400): (100-400): (2-5). According to the invention, after the detection in a factory according to a quality requirement and the measuring packing, the powder and the aggregate are respectively sent to a construction site or a dedicated distributing bin for burdening, and the mechanized construction is performed; compared with dry-mixed mortar, the aggregate is not required to be dried, so that the drying cost and a part of transportation cost of the aggregate are reduced, and the material cost is substantially lowered; and simultaneously the advantages that the dry-mixed mortar quality can be controlled and the construction site environment is good are maintained.

Owner:郑州工大高新材料科技有限公司

Low-temperature repairing material for high-speed rail base concrete in severe cold region and application of low-temperature repairing material

The invention belongs to the technical field of construction materials, and particularly relates to a low-temperature repairing material for a high-speed rail base concrete in a severe cold region and application of the concrete low-temperature repairing material. The low-temperature repairing material comprises the following components: 425 ordinary Portland cement, 425 sulphoaluminate cement, 725 sulphoaluminate cement, a waterproof admixture, rubber powder, an aggregate, a water reducer, a construction improver, a water-retaining agent, an early strength agent, a nano multifunctional water repellent agent, and PP (polypropylene) fiber. The low-temperature repairing material for the high-speed rail base concrete in the severe cold region, provided by the invention, has a repairing construction time meeting a skylight time requirement of a high-speed rail, has compression strength after completion of hydration matching with that of the base concrete, is high in tensile bond strength with the base concrete, is slightly expanded and strong in anti-freezing circulation capability at -40 DEG C, can avoid secondary detachment, and well meets requirements on the low-temperature repairing material for the high-speed rail base concrete in the severe cold region.

Owner:郑州筑邦建材有限公司 +1

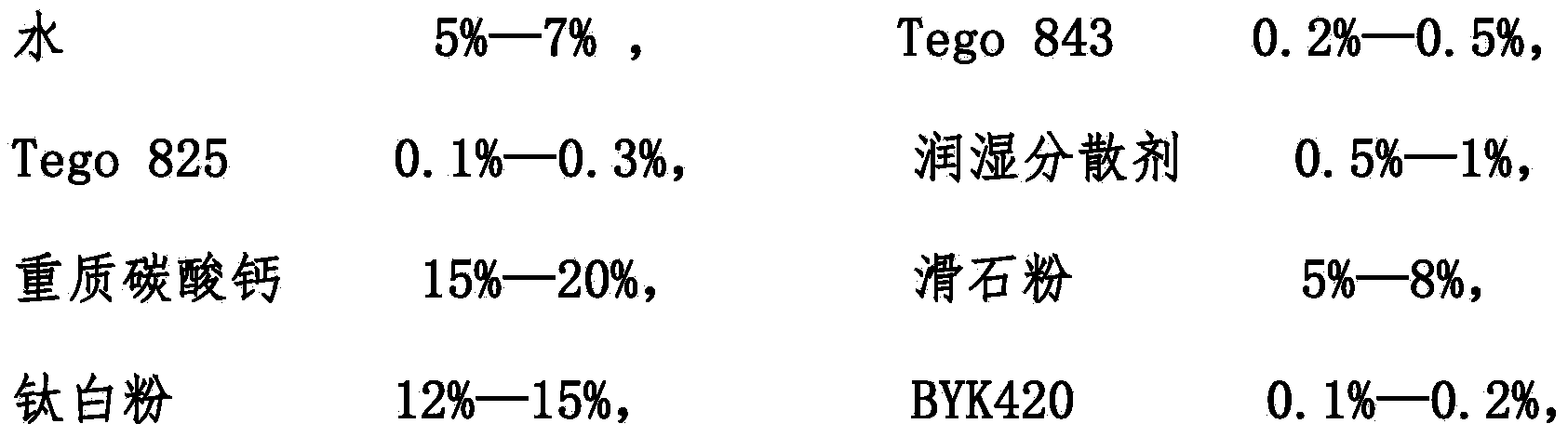

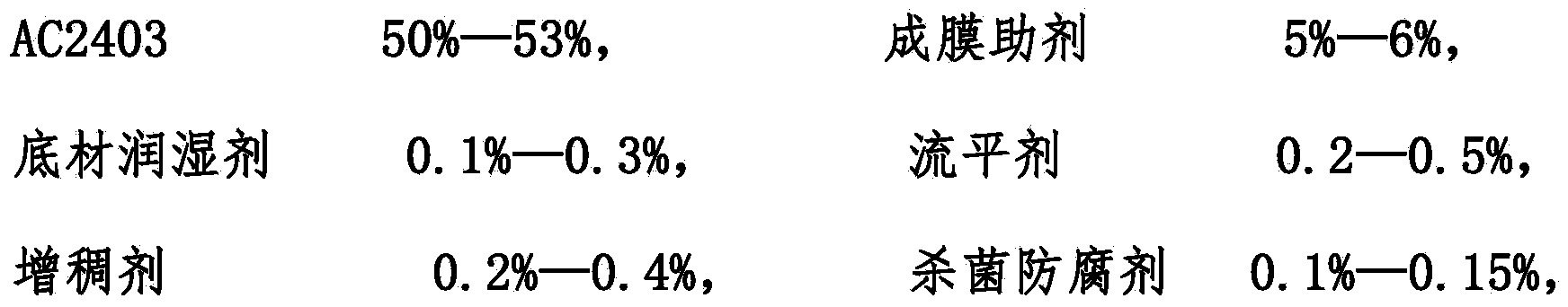

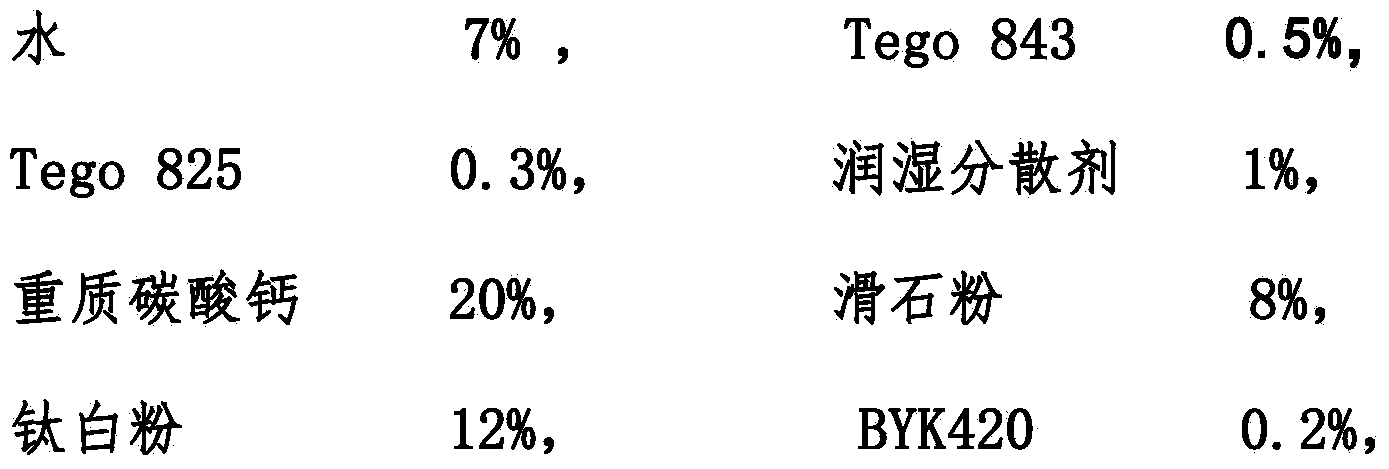

Single-component water-based dip-coating sealing white primer

The invention discloses a single-component water-based dip-coating sealing white primer prepared from a polyacrylic emulsion with a self-crosslinking two-phase core-shell structure. Examinations and trails prove that the single-component water-based dip-coating sealing white primer disclosed by the invention is good in sealing effect, the sagging resistance, defoaming speed, dilution and sinking prevention of the primer are superior to those of like products on the market, the substrate adhesive force and bleeding prevention of the primer are very good, the properties and environmental performance of the primer accord with GB / T23999-2009 and GB24410-2009, and the primer is particularly suitable for first dip-coating of wood wares.

Owner:GUANGDONG BADESE CHEM

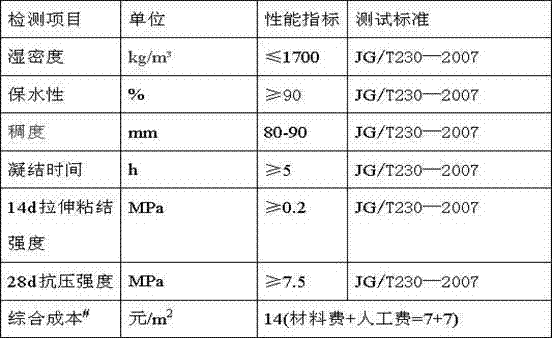

Plastering-free mechanically-sprayed putty powder, plastering-free mechanically-sprayed putty slurry as well as preparation method and application thereof

ActiveCN109439054AInhibition of ubiquitinationQuality assuranceFilling pastesBuilding constructionsFiberCrack resistance

The invention provides plastering-free mechanically-sprayed putty powder, plastering-free mechanically-sprayed putty slurry as well as a preparation method and application thereof. The plastering-freemechanically-sprayed putty powder is prepared from the following components in percentage by weight: 25.0-35.0% of an inorganic cementing material, 35.0-50.0% of aggregate, 10.0-30.0% of a filler, 1.0-3.0% of alkali-resistant additives, 3.0-5.0% of redispersible latex powder, 0.2-0.4% of hydroxypropyl methyl cellulose ether, 0.2-0.3% of anti-cracking fiber, 0.1-0.3% of a thixotropic agent, 0.05-0.15% of a water reducer and 0.01-0.05% of a water-repellent agent. The prepared plastering-free mechanically-sprayed putty has excellent bonding strength, cracking resistance, flexibility, water resistance, alkali resistance, efflorescence resistance and droop resistance, spraying constructability and scraping constructability, so that the construction efficiency is greatly improved, the construction period is shortened, and the labor cost is reduced.

Owner:ASIA PAINT SHANGHAI

Anti-cracking-shedding and strong-adhesion dry mixing plastering mortar

InactiveCN105294012AHigh bonding strengthImprove water retentionSolid waste managementPolymer scienceDry mixing

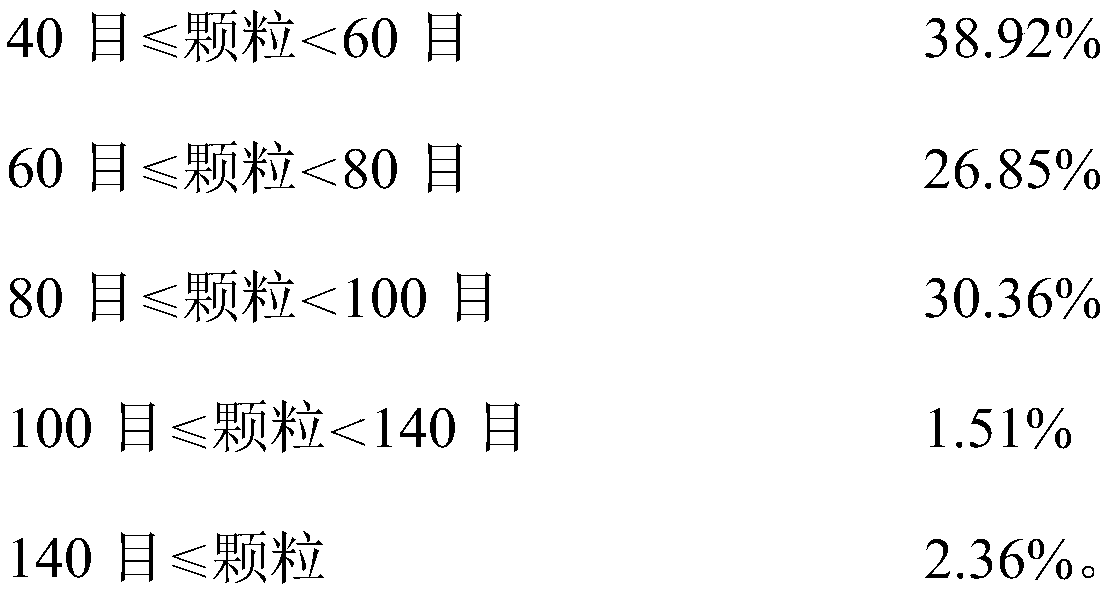

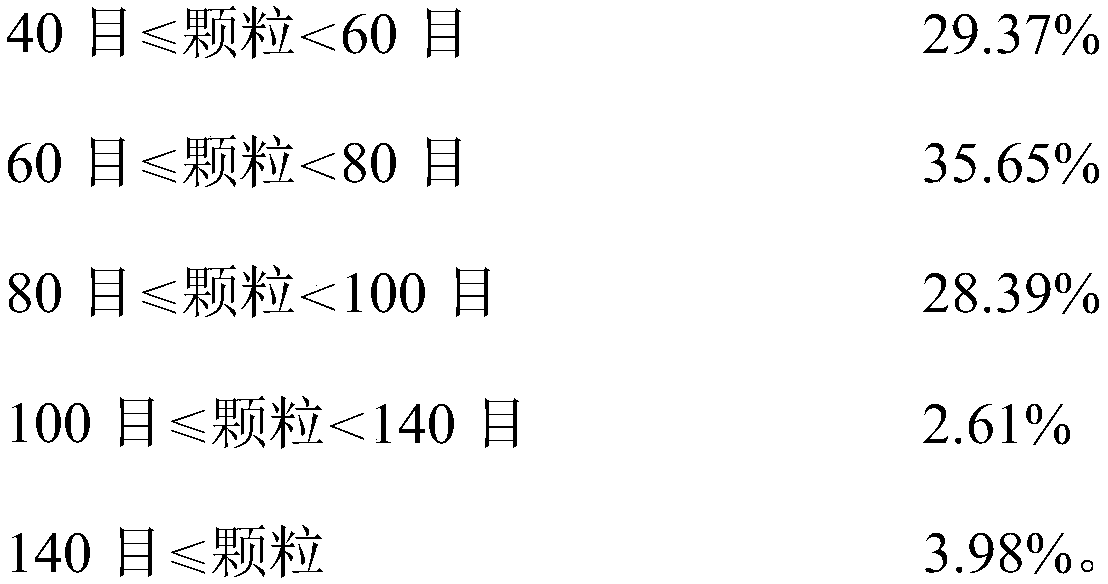

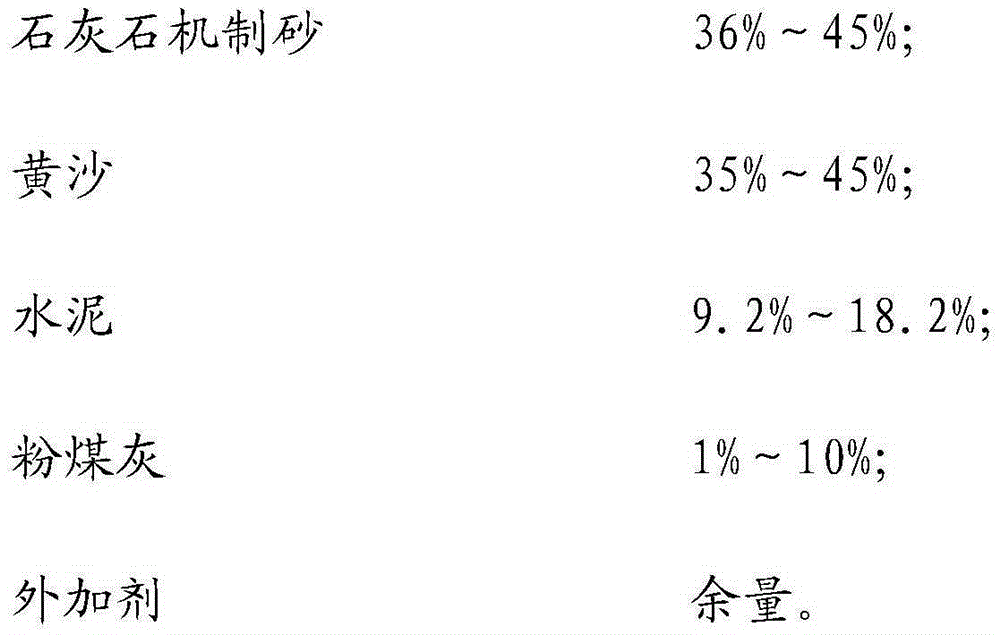

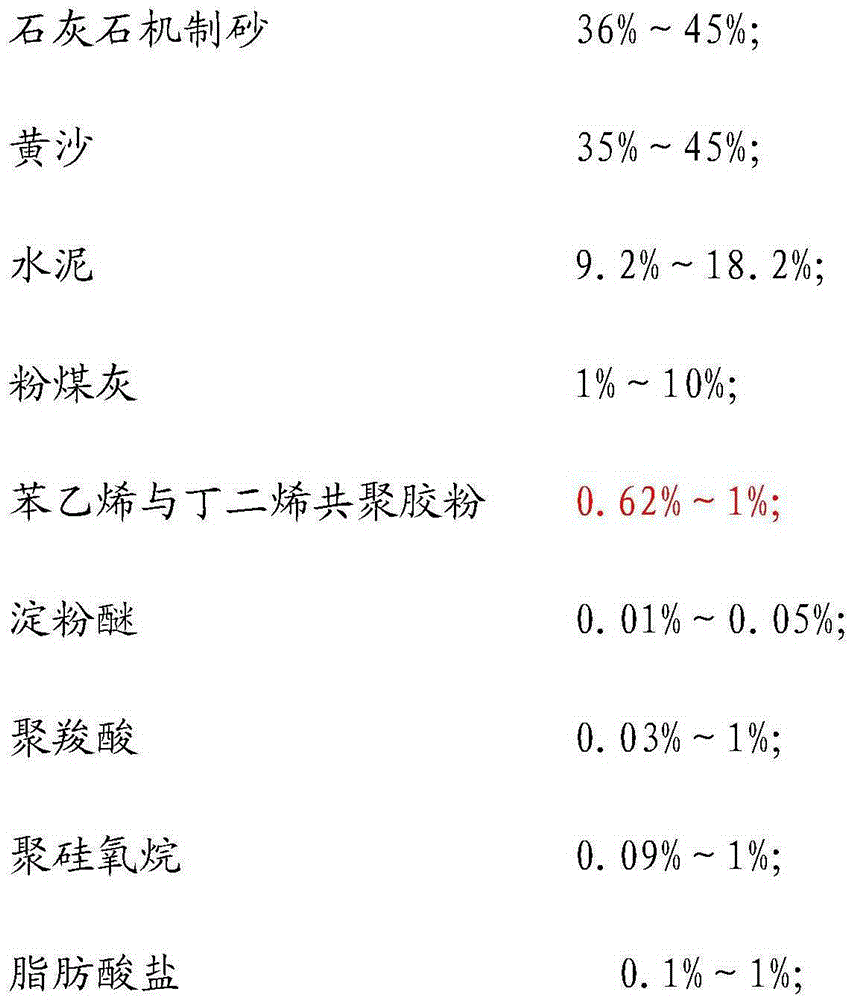

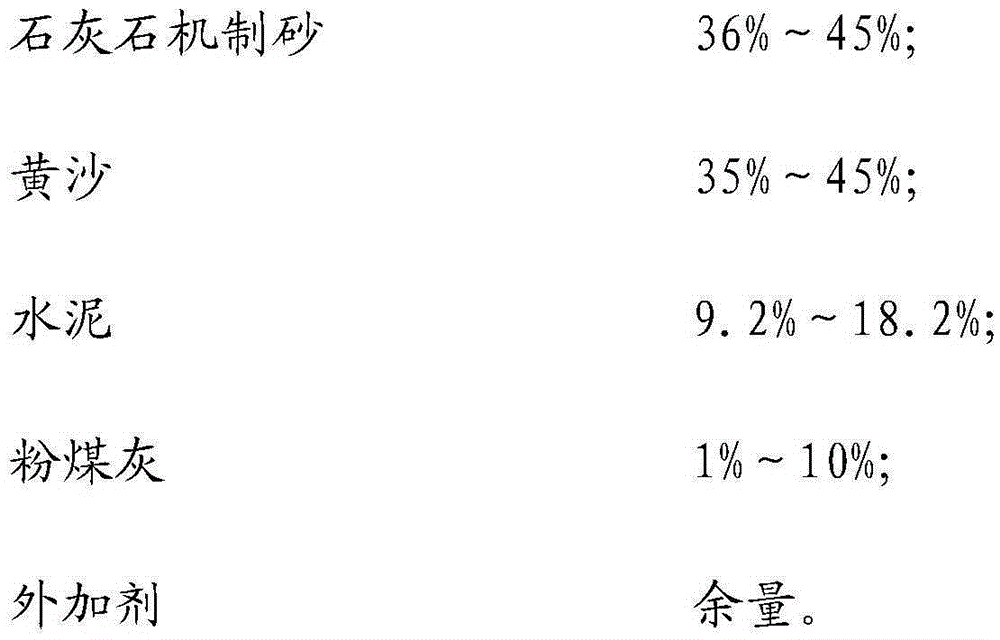

The invention relates to an anti-cracking-shedding and strong-adhesion dry mixing plastering mortar, which is characterized by comprising by mass: 36-45% of limestone machine-made sand, 35-45% of yellow sand, 9.2-18.2% of cement, 1-10% of fly ash, and the balance of an admixture, wherein the admixture comprises a modifier and a thickening agent, the modifier is a mixture of starch ether, polysiloxane and polycarboxylic acid, the thickening agent is styrene and butadiene copolymerization rubber powder, and a weight ratio of the styrene and butadiene copolymerization rubber powder to the starch ether to the polysiloxane to the polycarboxylic acid is 100:1.6:14.5:4.8.

Owner:浙江兆山建材科技有限公司

High-performance waterborne epoxy anticorrosive coating

InactiveCN111876052AIncrease the degree of cross-linkingImprove toughnessAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention provides high-performance water-based epoxy anticorrosive coating. The coating comprises a component A and a component B. The component A is prepared from the following components in parts by weight: 60-70 parts of waterborne epoxy resin emulsion, 5-8.5 parts of styrene-acrylic emulsion, 2-3.5 parts of a zinc oxide / graphene oxide composite material, 0.5-1.2 parts of cerium-doped nanotitanium dioxide, 1-2 parts of nano attapulgite, 3-5 parts of organic bentonite, 0.2-3 part of pigment, 0.3-0.5 part of a silane coupling agent, 2-3 parts of n-butyl alcohol, 0.3-0.6 part of a dispersing agent, 0.3-0.5 part of a defoamer, 0.2-0.4 part of a leveling agent and 18-25 part of deionized water. The component B is prepared from the following components in parts by weight: 30-35 parts ofpolyether amine, 3-5 parts of diethylenetriamine, 25-32 parts of wet sericite powder and 8-12 parts of talcum powder. The anticorrosive coating is environmentally friendly, all the raw materials arematched with one another, and the prepared coating is good in anticorrosive effect, excellent in mechanical property and high in adhesive force.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

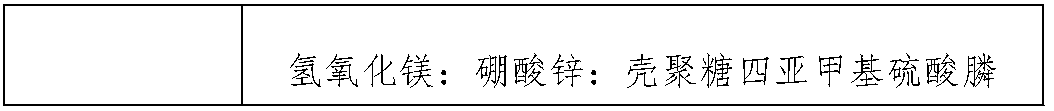

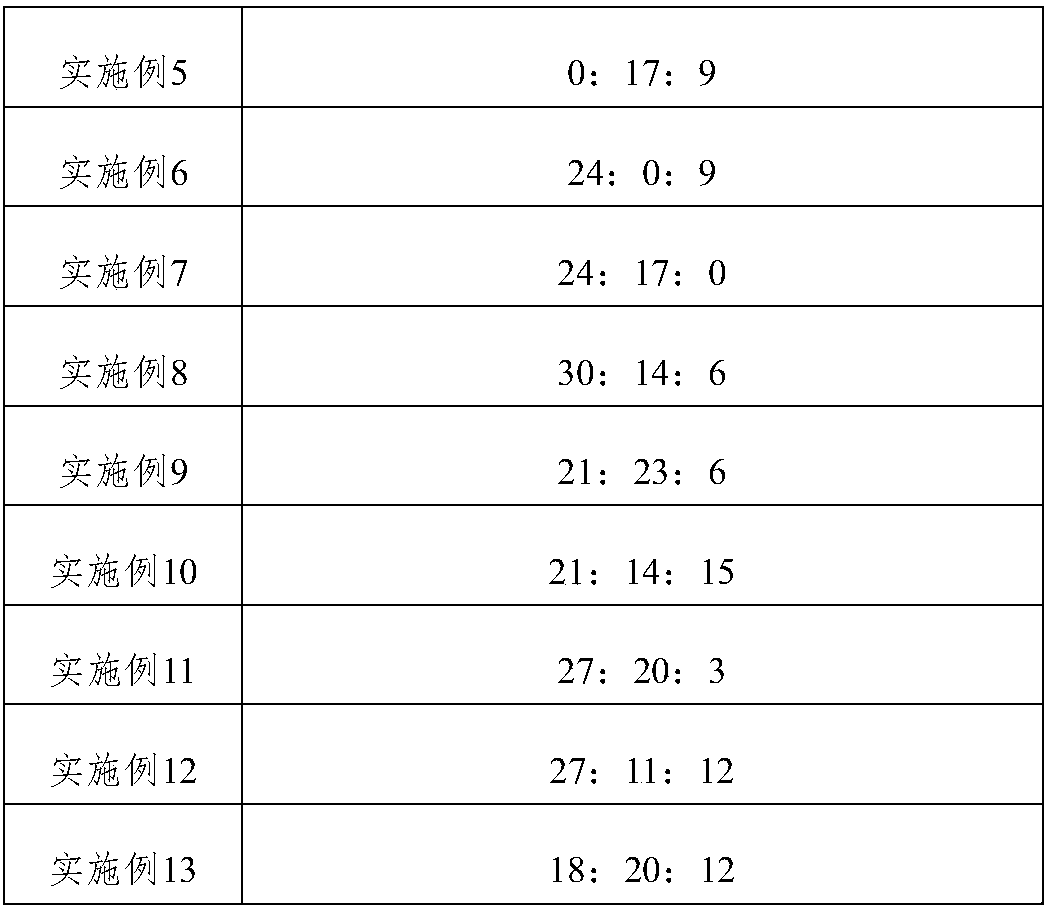

Fireproof type gypsum-based spraying material and preparation method thereof

The invention relates to the technical field of building materials and in particular relates to a fireproof type gypsum-based spraying material and a preparation method thereof. The fireproof type gypsum-based spraying material is prepared by grinding modified cellulose ether, a thixotropic lubricant, pearlite, a composite retarder, a flame retardant and a chlorine ion controlling agent until thegranularity is 0.6 to 1.0mm, and mixing powder with gypsum, sand and portland cement, so that the fireproof type gypsum-based spraying material provided by the invention has characteristics of convenience for working, water prevention and heat insulation, high temperature resistance, no hollowing, no cracking, strong binding power, good anti-sagging performance, bug and ant biting resistance, metal rusting prevention, greenness and environment protection and the like; furthermore, the flame retardant has the effect of keeping the average breaking strength of the gypsum-based spraying materialbeing 2.2MPa or more and the average compressive strength being 4.6MPa or more through a reasonable design and a dosage test of magnesium hydroxide, zinc borate and chitosan tetramethylene phosphine sulfate; the fireproof type gypsum-based spraying material keeps relatively good mechanical strength and also has the fireproof effect with the average fireproof degree of 560 DEG C or more.

Owner:深圳摩盾环保新材料有限公司

Preparation method of thickening water-retaining agent for building dry-mixed mortar and application thereof

The invention provides a preparation method of a thickening water-retaining agent for building dry-mixed mortar and an application thereof. The preparation method provided by the invention comprises the following steps of: (1) mixing a guar gum raw powder, a solvent and a surfactant to obtain a mixed solution; (2) adding a catalyst into the mixed solution obtained from Step(1), allowing nitrogen to enter, and carrying out an alkalization reaction at room temperature; (3) adding an etherifying agent for etherification while the pressure is 0.3-0.4 Mpa, the temperature is 40-90 DEG C but preferably 50-70 DEG C, and the etherification time is 2-5 hours but preferably 3-4 hours; (4) cooling to 25-40 DEG C, adding a neutralizer until the pH of the system is 6-8, and collecting the thickening water-retaining agent from the reaction product. The thickening water-retaining agent for building dry-mixed mortar is endowed with good water retention and working performance when applied in the building dry-mixed mortar. In addition, the price of the thickening water-retaining agent is obviously lower than that of cellulose ether. Thus, complete or part of replacement of cellulose ether by the thickening water-retaining agent makes the product formula cost to be obviously reduced.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Water-borne wood paint and preparation method of water-borne wood paint

InactiveCN102850886ASolve defects such as easy saggingSolve water problemsPolyurea/polyurethane coatingsAssociation typeDefoaming Agents

The invention provides water-borne wood paint, which comprises the following ingredients in percentage by weight: 10 to 20 parts of deionized water, 1 to 5 parts of propylene glycol, 1 to 3 parts of base association type thickening agents, 0.05 to 0.5 parts of dimethylethanolamine, 0.01 to 0.5 parts of non-silicone mineral oil system defoaming agents, 0.05 to 0.3 parts of water-borne carboxymethyl cellulose, 0.2 to 1.2 parts of ethanol, 60 to 80 parts of water-borne nanometer core-case crylic acid polymer dispersoid, 3 to 10 parts of water-borne fluorine-containing polyurethane nanometer dispersoid, 1 to 5 parts of alcohol ester twelve coalescing agents, 0.01 to 0.05 parts of fluorine flatting agents and 0.1 to 0.3 parts of anticorrosive and bacterium prevention agents. The water-borne wood paint has the advantages that the water-borne fluorine-containing polyurethane nanometer dispersoid is used as the core technology and is organically combined with water-borne auxiliaries such as the fluorine flatting agents, the problem that the wood surface cannot be easily moistened by the water-borne wood paint because the water surface tension is strong is solved, and the problems of poor paint film adhesion force, poor boiled water resistance and the like of the ordinary water-borne wood paint are solved. The invention also provides a preparation method of the water-borne wood paint at the same time.

Owner:WENZHOU BANGXUAN TECH

Normal-temperature rapid-reaction non-cured rubber asphalt waterproof coating and application thereof

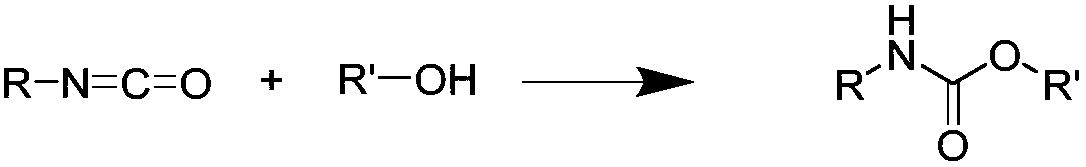

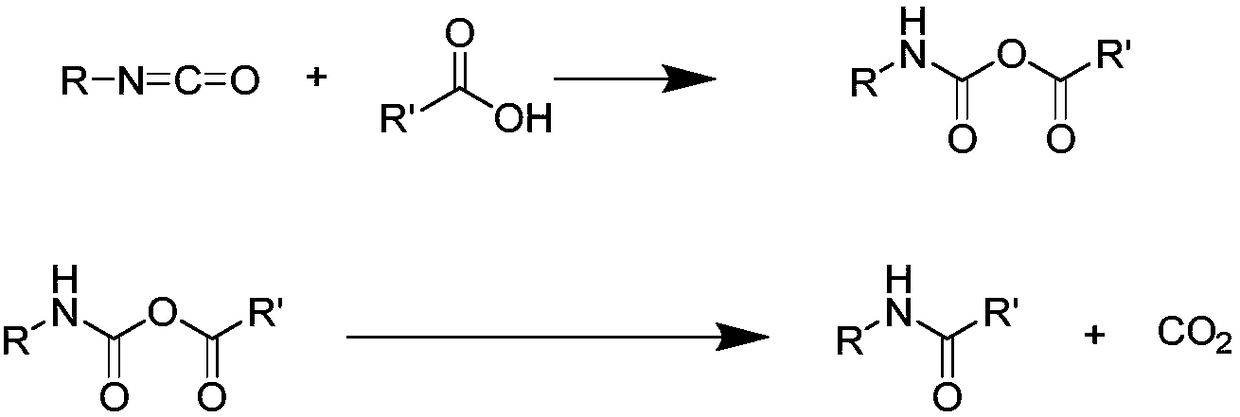

ActiveCN110016290AImprove adhesionHigh bonding strengthInksPolyurea/polyurethane coatingsBituminous waterproofingPolyol

The invention belongs to the technical field of waterproof coatings, and provides a normal-temperature rapid-reaction non-cured rubber asphalt waterproof coating. The coating comprises a component A and a component B; the component A is composed of the following components: 2-10 parts of an isocyanate, 10-30 parts of polyether polyol, 1-5 parts of 3-(2,3-epoxypropoxy)propylmethyldiethoxysilane, 0.5-3 parts of boron nitride, 0.1-1 part of sorbitol, 20-40 parts of petroleum asphalt, 10-20 parts of tackifying resin, 10-20 parts of aromatic oil, 10-20 parts of a plasticizer and 1-5 parts of surfactant; and the component B is composed of the following components: 2-30 parts of amino-terminated polyether, 1-5 parts of an amino chain extender, 20-50 parts of petroleum asphalt, 20-50 parts of aromatic oil, 1-5 parts of a surfactant, 1.3-3.5 parts of polyethyleneimine, 0.1-0.5 part of a catalyst and 0.5-2 parts of nano kaolin. The mass ratio of the component A to the component B is (1-3):1 during application. During using, the component A and the component B are mixed, and then scraping coating or spraying coating construction is carried out by using the mixture. According to the technicalscheme, the problem that a non-cured rubber asphalt waterproof coating in the prior art has poor adhesion and low peeling strength to a substrate is solved.

Owner:HEBEI YUYANGZELI WATERPROOF MATERIAL

Heat insulating material for flume and its preparation method

The invention relates to a heat insulating material used for an aqueduct and a preparation method thereof. The heat insulating material used for the aqueduct is characterized in that the material is made by mixing and stirring dry mixture and water, the mass ratio of the water to the dry mixture is between 1.1:1 and 1.2:1; the dry mixture consists of cement, vitrified hollow beads, sepiolite fiber, siliceous dust, cement-based capillary crystalline material, waste rubber powder, re-dispersible emulsion powder and hydroxypropyl methyl cellulose; and the mass percentage of the raw materials of the dry mixture are: 35 to 54.9 percent of the cement, 35 to 54.9 percent of the vitrified hollow beads, 2 to 8 percent of the sepiolite fiber, 3 to 6 percent of the siliceous dust, 1 to 4 percent of the cement-based capillary crystalline material, 3 to 6 percent of the waste rubber powder, 1 to 5 percent of the re-dispersible emulsion powder and 0.1 to 0.5 percent of the hydroxypropyl methyl cellulose. The heat insulating material has the characteristics of low water absorbing rate, high cohesional strength and compressive strength, good anti-cracking ability and good stability.

Owner:WUHAN UNIV OF TECH

Salt-freezing-resisting high-performance repairing mortar for repairing road concrete bridge

The invention relates to salt-freezing-resisting high-performance repairing mortar for repairing a road concrete bridge. The salt-freezing-resisting high-performance repairing mortar is prepared fromthe following raw materials: ordinary portland cement, granulated blast-furnace slag powder, fly ash, silicon ash, quartz sand, modified sulfonated melamine, redispersible latex powder, a de-foaming agent, starch ether and polyacrylonitrile fibers. The salt-freezing-resisting high-performance repairing mortar provided by the invention has the advantages that the salt-freezing-resisting high-performance polymer repairing mortar has relatively high durability and especially has extremely high salt freezing ablation resisting performance, freezing and thawing resisting performance and chloride ions penetration resisting performance.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST

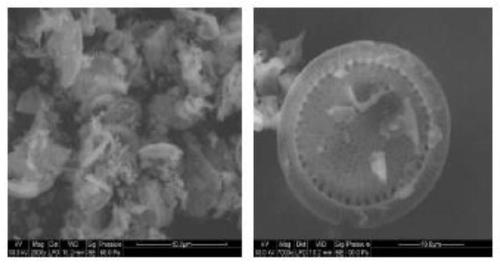

Diatom ooze decoration material and preparation method thereof

The invention discloses a diatom ooze decoration material. The diatom ooze decoration material is prepared from, by weight, 100-400 parts of diatomite, 10-70 parts of white cement, 150-400 parts of triple superphosphate, 150-400 parts of ash calcium powder, 80-250 parts of quartz sand, 2-10 parts of a thixotropic lubricant, 10-70 parts of dispersed latex powder and 650-850 parts of water and further optionally prepared from, by weight, 5-40 parts of titanium dioxide, 1-7 parts of a mildew preventive, 1-5 parts of starch ether, 0.1-2 parts of a dispersion agent, 2-10 parts of polyvinyl alcohol,2-6 parts of inorganic pigment, 3-15 parts of cellulose ether and 1-6 parts of wood fibers. The diatom ooze decoration material is a green, environment-friendly, healthy, breathable, waterproof and mould-proof diatom ooze decoration material and is wide in raw material source, low in cost, stable in performance and capable of being preserved for a long time.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

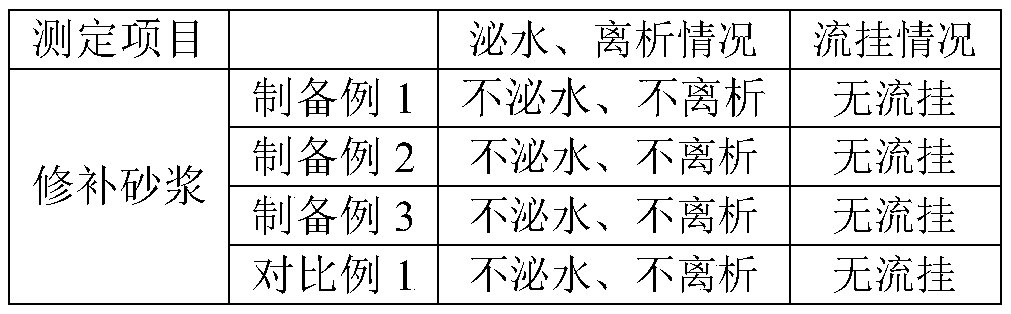

Construction process for large-area structure repair systems

The invention relates to a construction process for large-area structure repair systems, and the construction process comprises the following process steps: S1, treating a base layer of a wall body, ,specifically, chiseling off a loose part of the wall body, and cleaning the surface of the wall body; s2, performing interface treatment on the wall body, specifically, wetting the wall body, and coating the surface of the wall body with an interface agent to form an interface layer when the surface of the wall body is dry and the interior of the wall body is wet; s3, performing repairing treatment of the wall body, specifically, after the interface layer is dried, repairing and roughly leveling the wall body by adopting repairing mortar slurry to form a repairing layer; s4, performing plastering treatment of the wall, specifically, after the repairing layer is dried, plastering through plastering mortar slurry obtained by evenly mixing plastering mortar and water to form a plastering layer; and S5, performing plastering treatment of the wall body, specifically, after the plastering layer is dried, plastering through surface mortar slurry obtained by evenly mixing surface mortar and water to form a surface mortar layer. According to the invention, the large-area structure repair systems have the advantages of strong bonding strength and sagging resistance.

Owner:北京建工新型建材有限责任公司

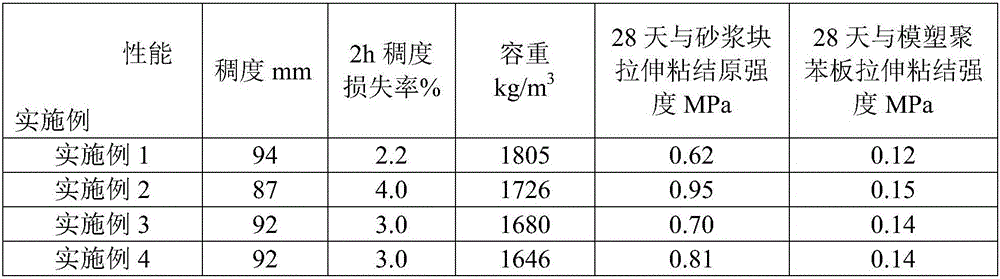

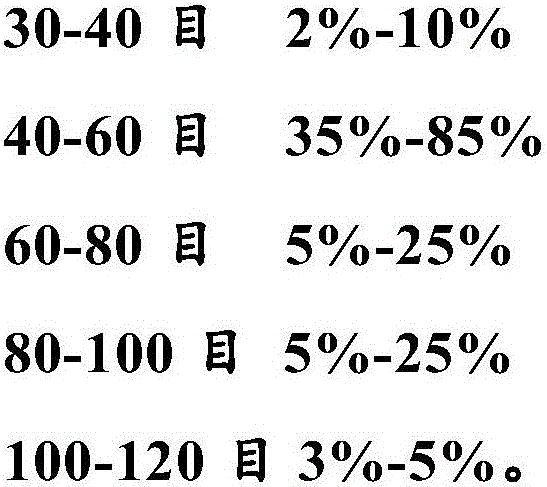

Machine sprayed mortar for thin plastering system

The invention provides machine sprayed mortar for a thin plastering system. The mortar comprises the components in percentages by weight: 20-30% of common silicate cement, 58.65-76.11% of 40-120-mesh river sand, 2-8% of filler, 1.83-3.15% of a water-retaining thickening material, 0-0.2% of a thixotropic agent, 0.05-0.15% of a water reducer and 0.01-0.05% of a water repellent, wherein the water-retaining thickening material is prepared by mixing 1.5-2.5% of redispersible latex powder, 0.2-0.4% of hydroxypropyl methyl cellulose, 0.03-0.05% of starch ether and 0.1-0.2% of anti-crack fibers. The components are uniformly mixed in a mixing device, and 18-22% by weight of water is added at a normal temperature and a normal pressure to stir slurry which can be used for mechanical construction of the thin plastering system, so that the construction efficiency is increased, the construction period is shortened, and the labor cost is lowered.

Owner:亚士创能科技(滁州)有限公司

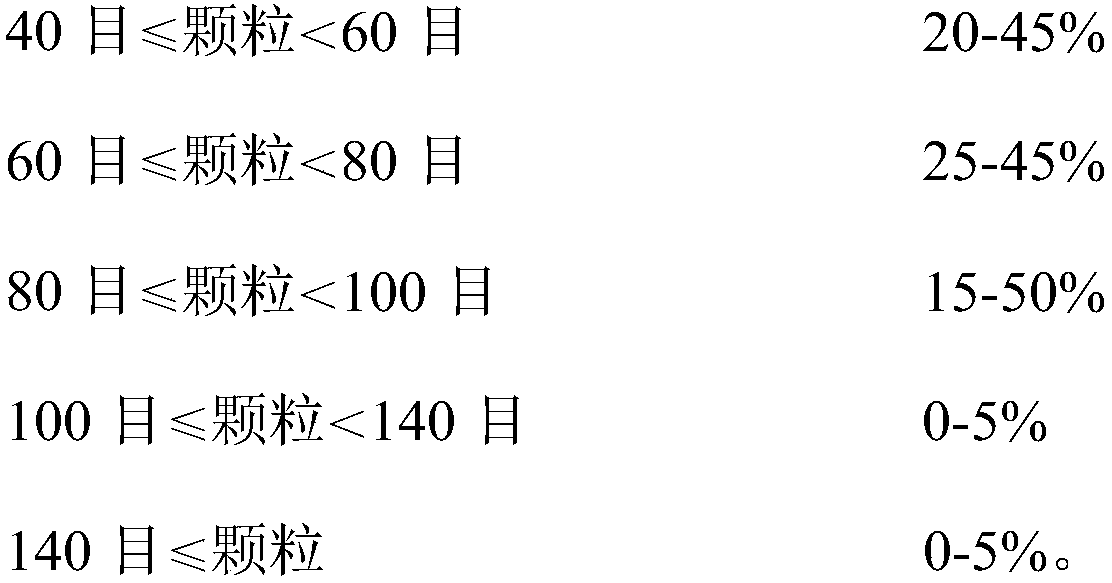

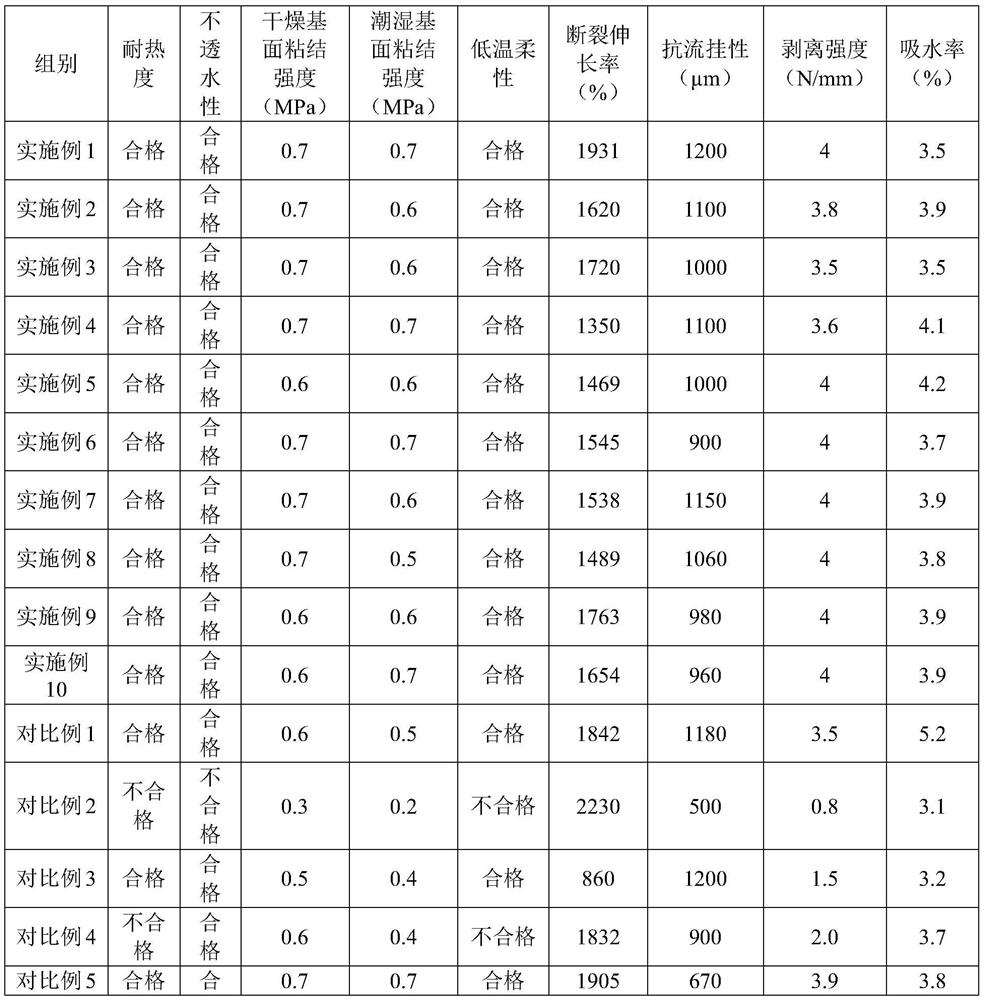

Special waterproof anti-slip coating for outer wall as well as preparation method and application of special waterproof anti-slip coating

PendingCN114163884AHas strong sticky and anti-skid characteristicsCoating safety and environmental protectionCoatingsUltimate tensile strengthPolymer emulsion

The invention provides a waterproof non-slip coating special for an outer wall and a preparation method and application thereof, and relates to the technical field of building materials, the coating comprises the following components: 21-27 parts of modified asphalt, 1-2 parts of an anionic slow-breaking emulsifier, 40-50 parts of an organosilicon modified polymer emulsion, 0.2-0.5 part of a thixotropic agent, 0.2-0.5 part of a rheological agent, 0.1-0.2 part of a defoaming agent, 0.2-0.5 part of a silane coupling agent and 20-25 parts of water. The prepared coating has high bonding strength, water resistance and anti-sliding performance, is excellent in anti-sagging performance, very high in ductility and high in base layer deformation adaptability, and can be compatible with multiple types of coiled materials.

Owner:河南蓝翎环科防水材料有限公司

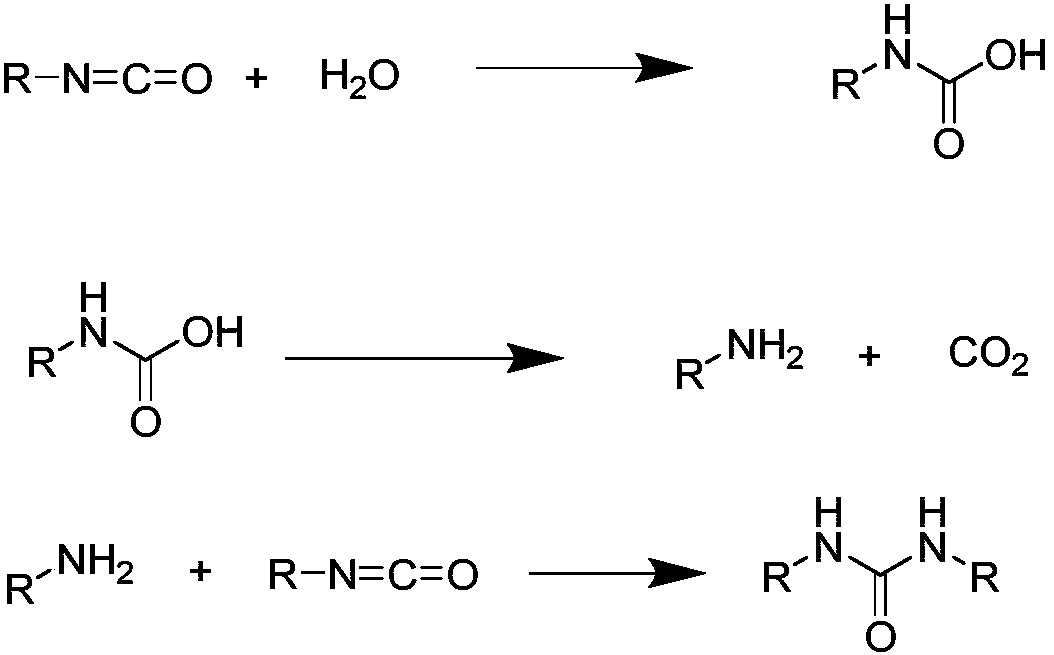

Preparation method of single-ingredient sag-resistant polyurethane waterproof paint

InactiveCN109321123ADelicate appearanceImprove tensile strength at breakPolyurea/polyurethane coatingsGas phaseFilling materials

The invention discloses a preparation method of single-ingredient sag-resistant polyurethane waterproof paint. The method comprises the following steps of (1) under inert gas protection, mixing dewatered polyether polyol and first isocyanate; performing reaction to obtain polyurethane prepolymers; (2) pre-mixing the polyurethane prepolymer with modified nanometer calcium carbonate, polyurea, modified nanometer gas phase silicon dioxide and filling materials which are respectively dewatered; then, adding the mixture into a first double-screw extrusion machine for mixing dispersion and extrusionto obtain a dispersed mixed material, wherein the polyurea is prepared from second isocyanate and diamine through reaction; (3) adding the dispersed mixed material into a second double-screw extrusion machine; sequentially adding solvents and auxiliary agents; performing mixed dispersion and extrusion to obtain the single-ingredient sag-resistance polyurethane waterproof paint. The vacuum pumpingis needed in step (2) and step (3). The problems of implosion, skinning, non-uniform dispersion and the like directly or indirectly caused by poor flowability in the prior art can be solved. The produced polyurethane waterproof paint can also have excellent sag resistance performance.

Owner:JIANGSU CANLON BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com