Preparation method of thickening water-retaining agent for building dry-mixed mortar and application thereof

A technology of thickening water-retaining agent and dry-mixed mortar, which is applied in filling slurry and other directions, can solve the problems of high price and increased formula cost of mortar products, and achieve the effect of reducing formula cost, being easily soluble in water and reducing adhesiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

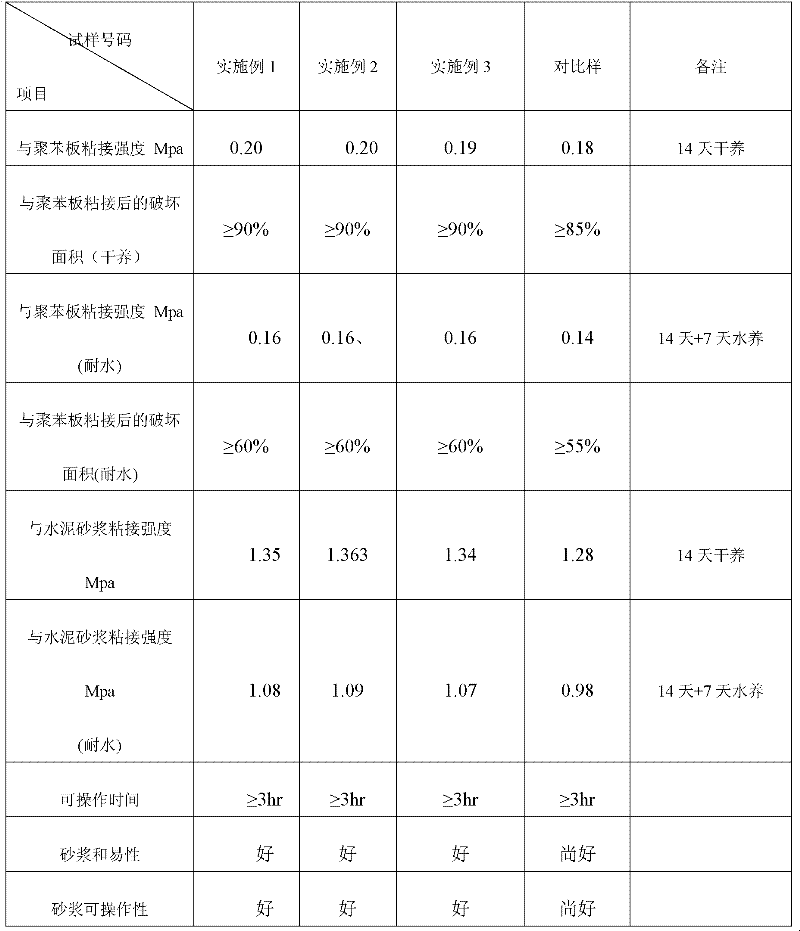

Examples

Embodiment 1

[0026] Add 200 parts of ethanol and 2 parts of cetyltrimethylammonium chloride into a 1000 ml reactor equipped with stirring, thermometer, feed port and reflux device, stir and mix, and add 100 parts of unpurified Guar collagen powder, nitrogen gas, after uniform dispersion, add 16 grams of sodium hydroxide aqueous solution (the weight concentration of sodium hydroxide solution is 32%), after basifying at room temperature for 2 hours, add methyl chloride, and then pressurize to 0.3M After pa, the temperature is raised to 50°C to react for 4 hours, the temperature is lowered, and the pH value is adjusted to about 7.0 with 10% hydrochloric acid. After the material is vacuum filtered, it is washed with ethanol / water (ethanol:water=9:1, volume ratio). Suction filtration, finally washing with absolute ethanol, suction filtration, the filter cake is dried in a vacuum at a temperature of 65°C, crushed, and passed through a 100-mesh net to obtain a finished product.

Embodiment 2

[0028] Add 400 parts of ethanol and 6 parts of cetyltrimethylammonium chloride into a 1000 ml reactor equipped with stirring, thermometer, feeding port and reflux device. After stirring and mixing uniformly, add 200 parts of untreated Purified guar collagen powder, ventilate nitrogen, and disperse uniformly, add 30 g of sodium hydroxide aqueous solution (the weight concentration of sodium hydroxide solution is 32%), basify at room temperature for 2 hours, add ethyl chloride, and then pressurize After reaching 0.4Mpa, the temperature is raised to 60°C for 3.5 hours, the temperature is lowered, the pH value is adjusted to about 7.0 with glacial acetic acid, and the material is vacuum filtered and washed with ethanol / water (ethanol:water=8:2, volume ratio) , Suction filtration, finally washing with absolute ethanol, suction filtration, the filter cake is dried in a vacuum at a temperature of 65°C, crushed, and passed through a 100-mesh net to obtain the finished product.

Embodiment 3

[0030] Add 150 parts of ethanol and 4 parts of cetyl trimethyl ammonium chloride into a 1000 ml reactor equipped with stirring, thermometer, feeding port and reflux device. After stirring and mixing uniformly, add 300 parts of untreated Purified guar collagen powder, ventilate nitrogen, and disperse uniformly, add 21 g of sodium hydroxide aqueous solution (the weight concentration of sodium hydroxide solution is 32%), basify at room temperature for 2 hours, add monochloropropane, and then pressurize After reaching 0.4Mpa, the temperature is raised to 70°C and reacted for 3 hours, the temperature is lowered, and the pH value is adjusted to about 7.0 with glacial acetic acid. After the material is vacuum filtered, it is washed with ethanol / water (ethanol:water=8:2, volume ratio) , Suction filtration, finally washing with absolute ethanol, suction filtration, the filter cake is dried in a vacuum at a temperature of 65 ℃, crushed, and the finished product is obtained after passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com