Patents

Literature

1082results about How to "Shorten the setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

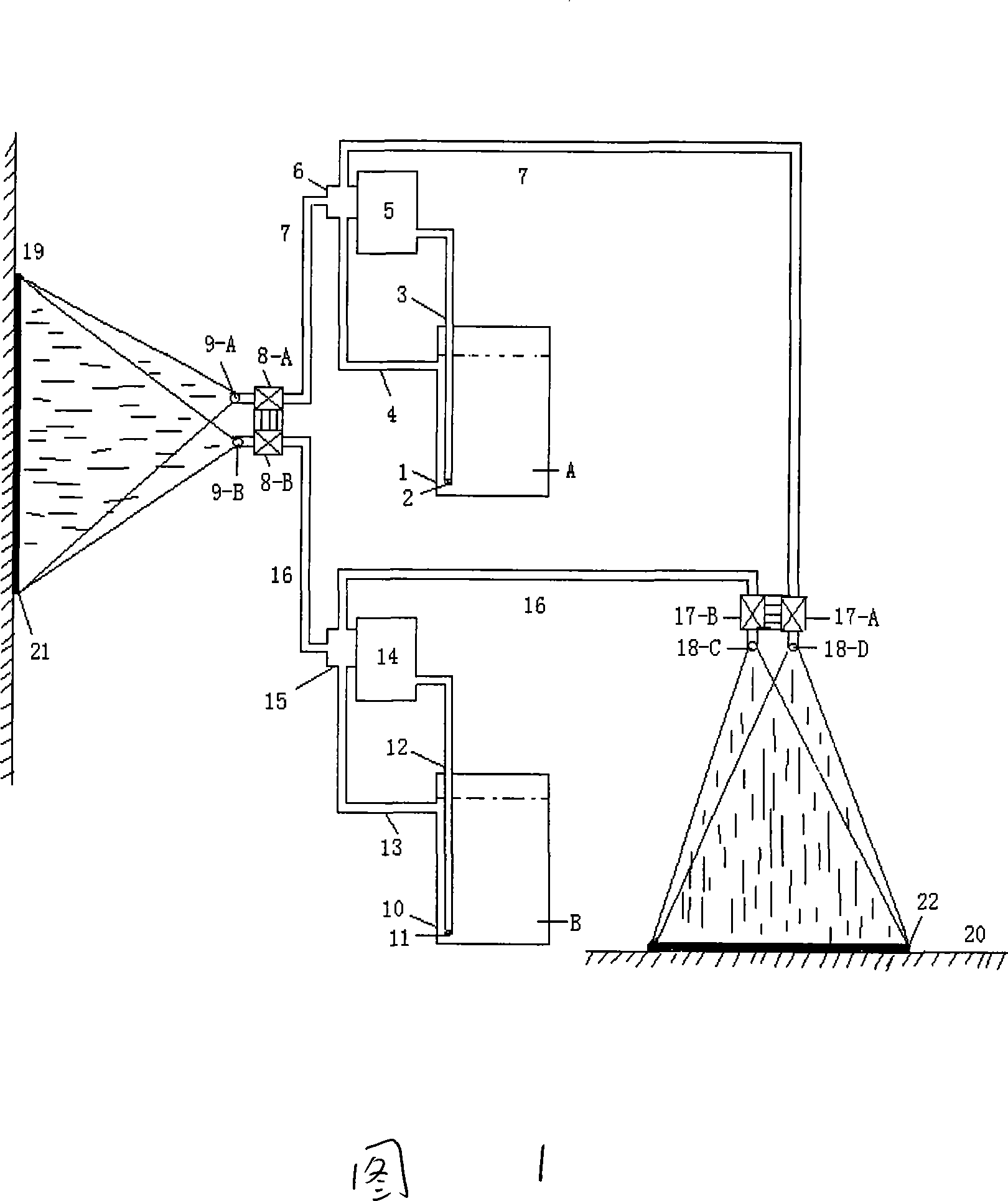

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

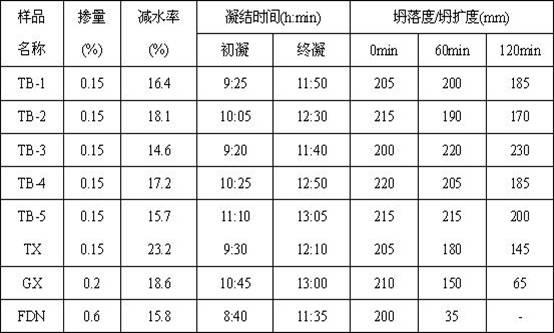

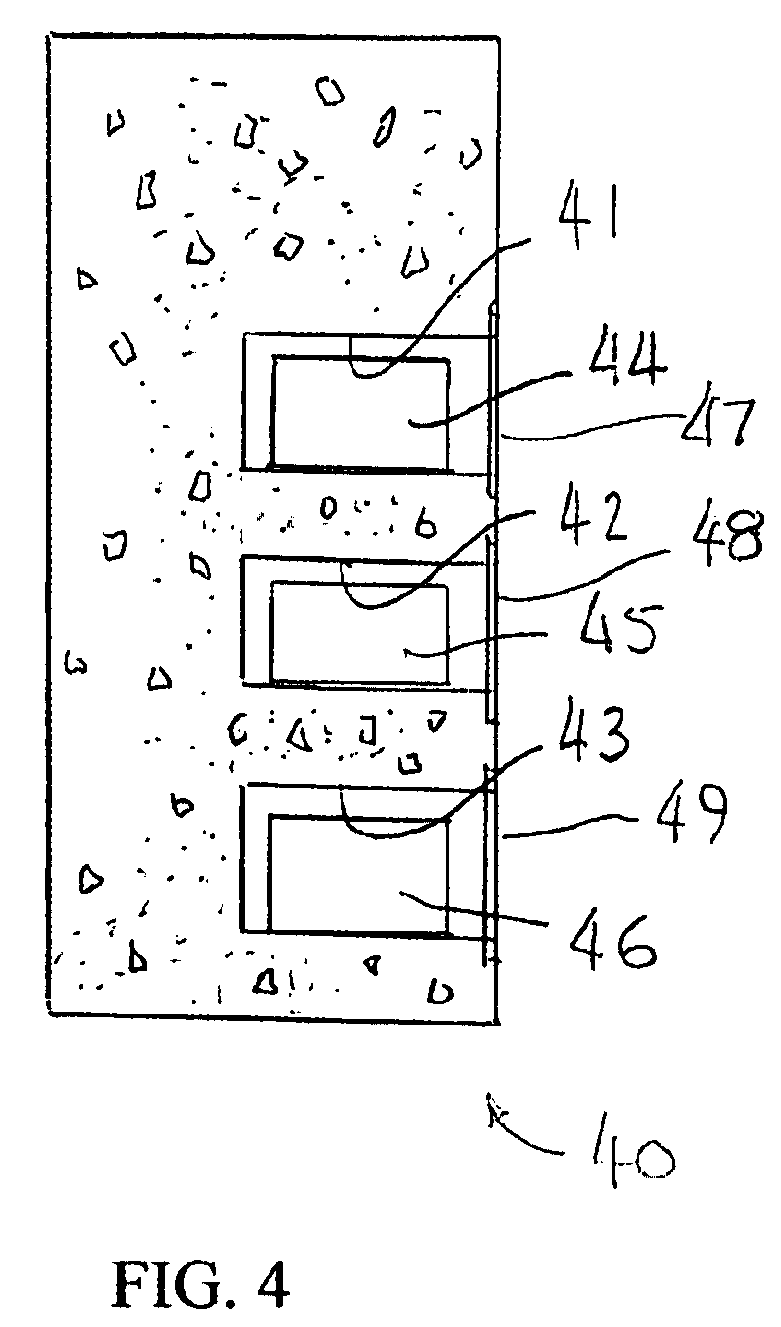

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

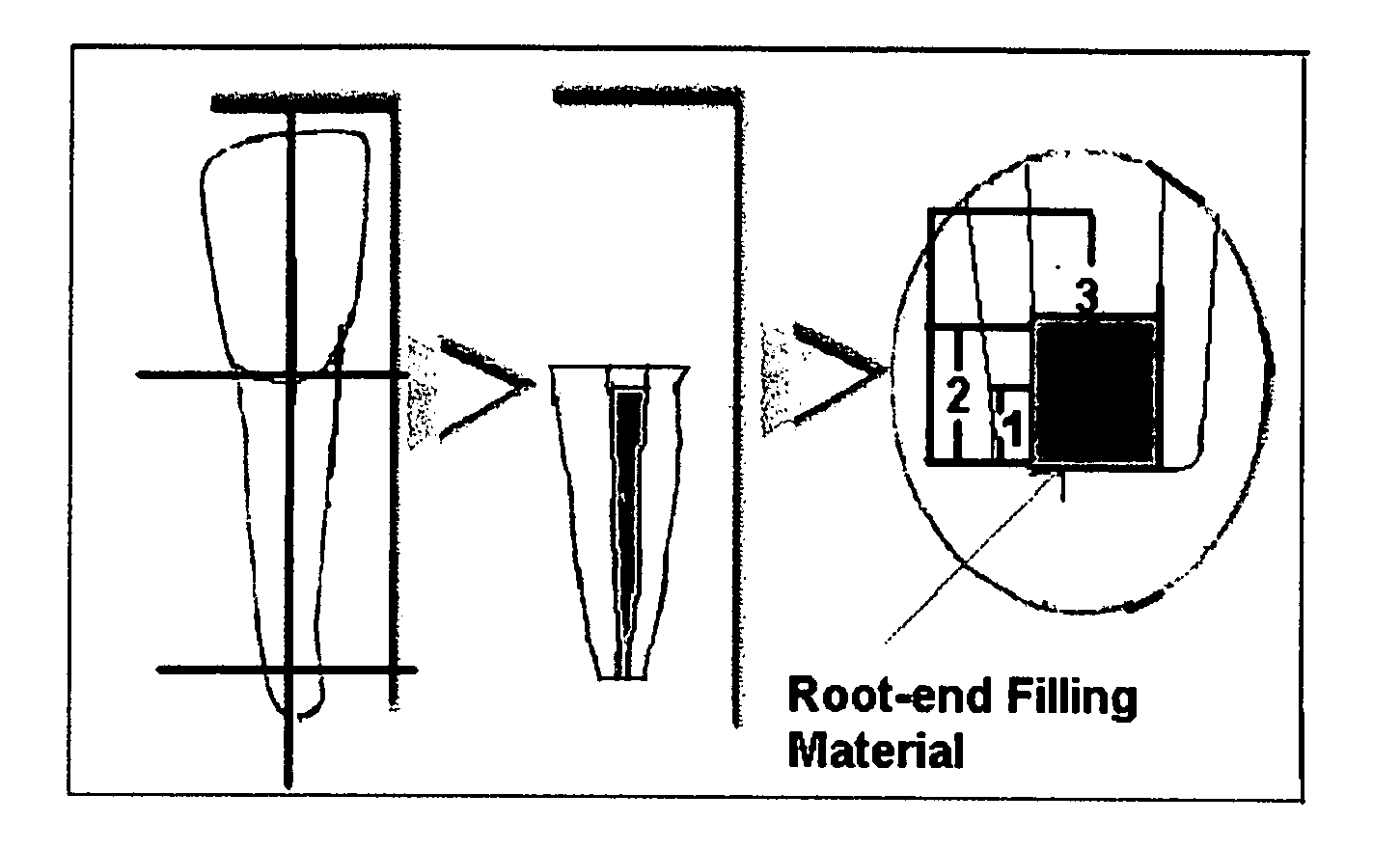

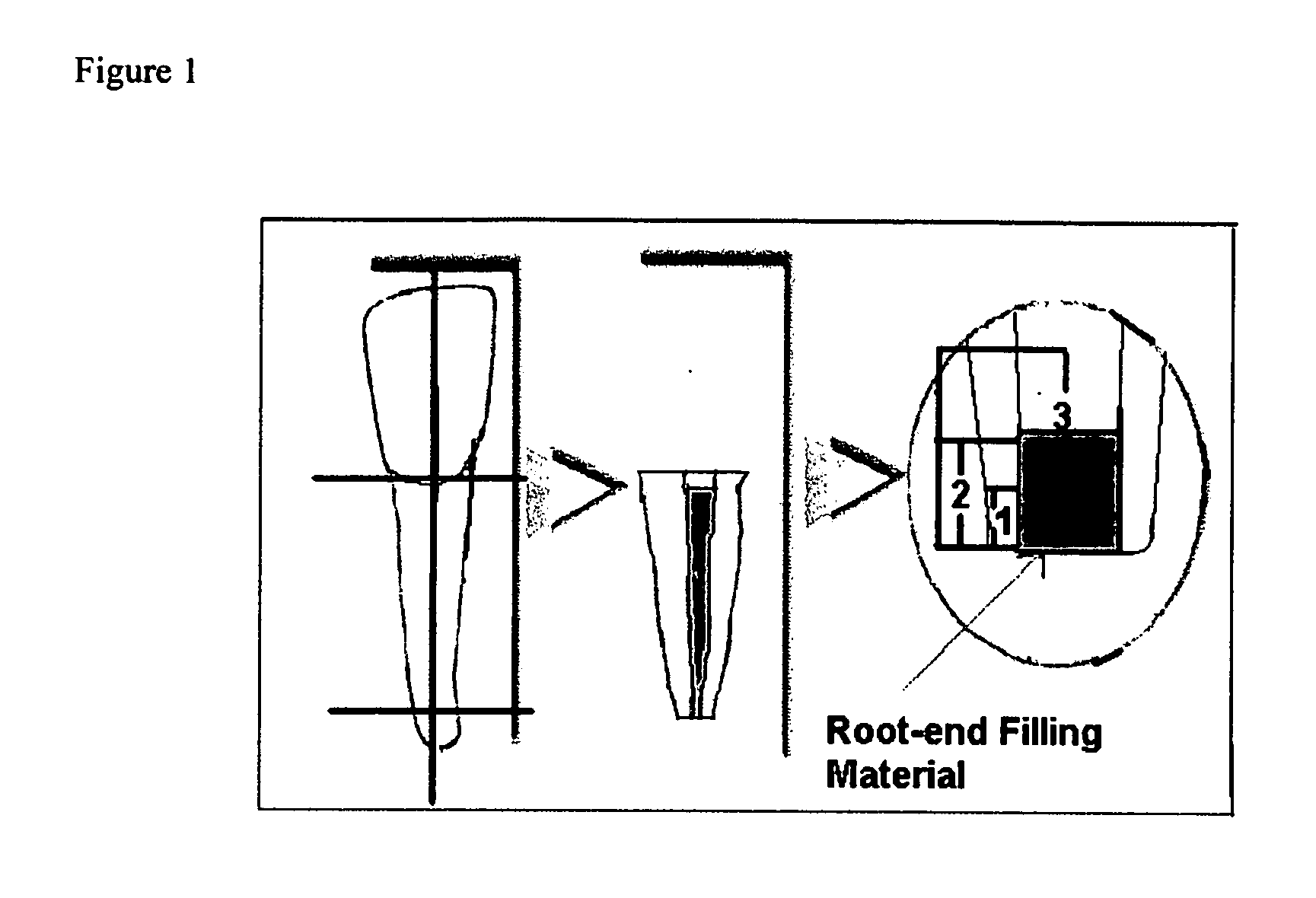

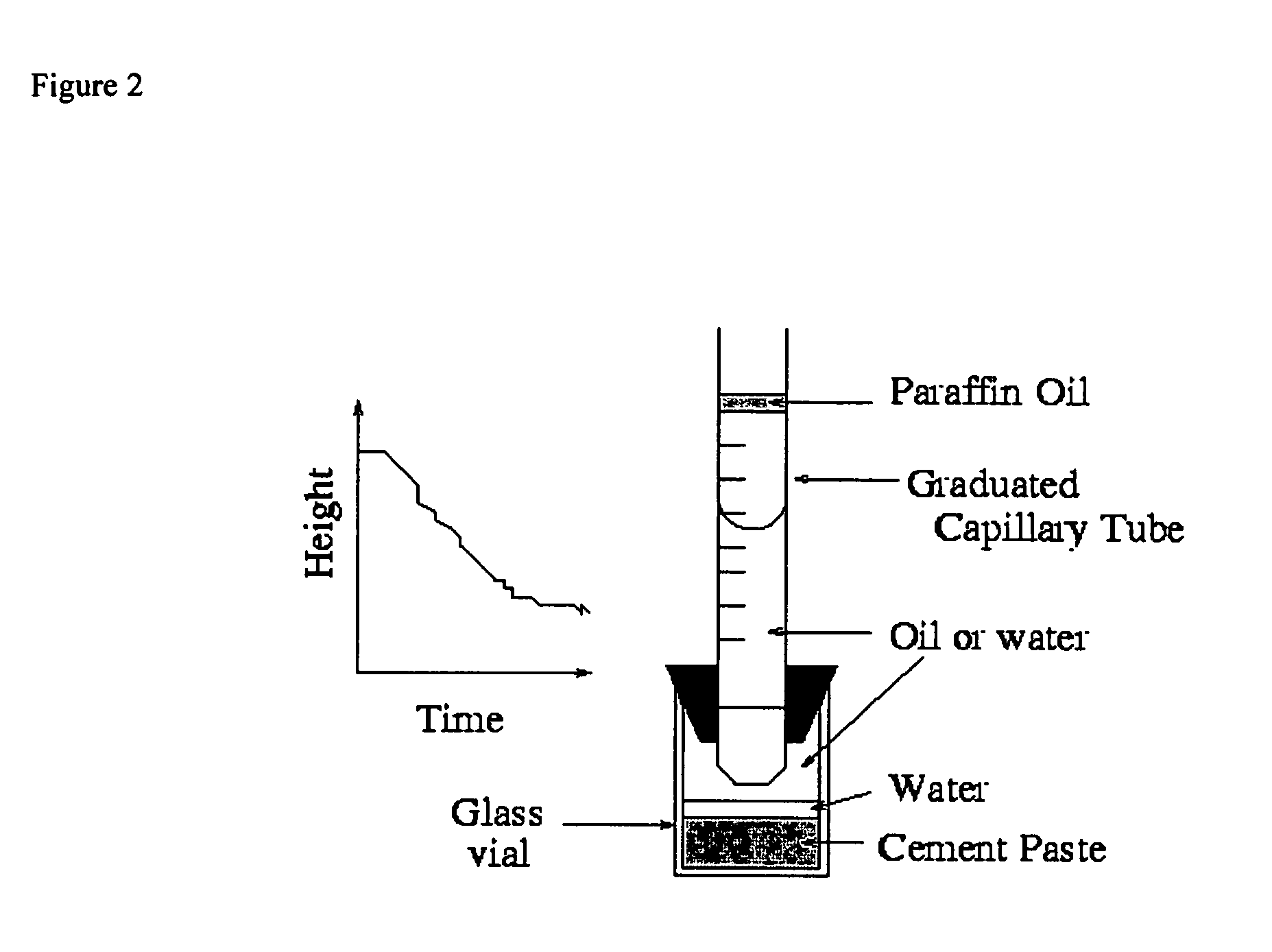

Dental repair material

InactiveUS20070009858A1Easy to operateEffective treatmentImpression capsDentistry preparationsRepair materialChloride

The invention is directed to an improved dental composition useful in the repair of cavities, apex repairs, root perforations and root canals. Disclosed is a dental composition and dental composition additive which have improved handling characteristics, for example improved viscosity and setting time. The addition of effective amounts of a modified cellulose and calcium chloride to available dental repair compounds, such as mineral trioxide compound, results in the improved dental composition without affecting the other characteristics of the dental repair compound.

Owner:SAINT LOUIS UNIVERSITY

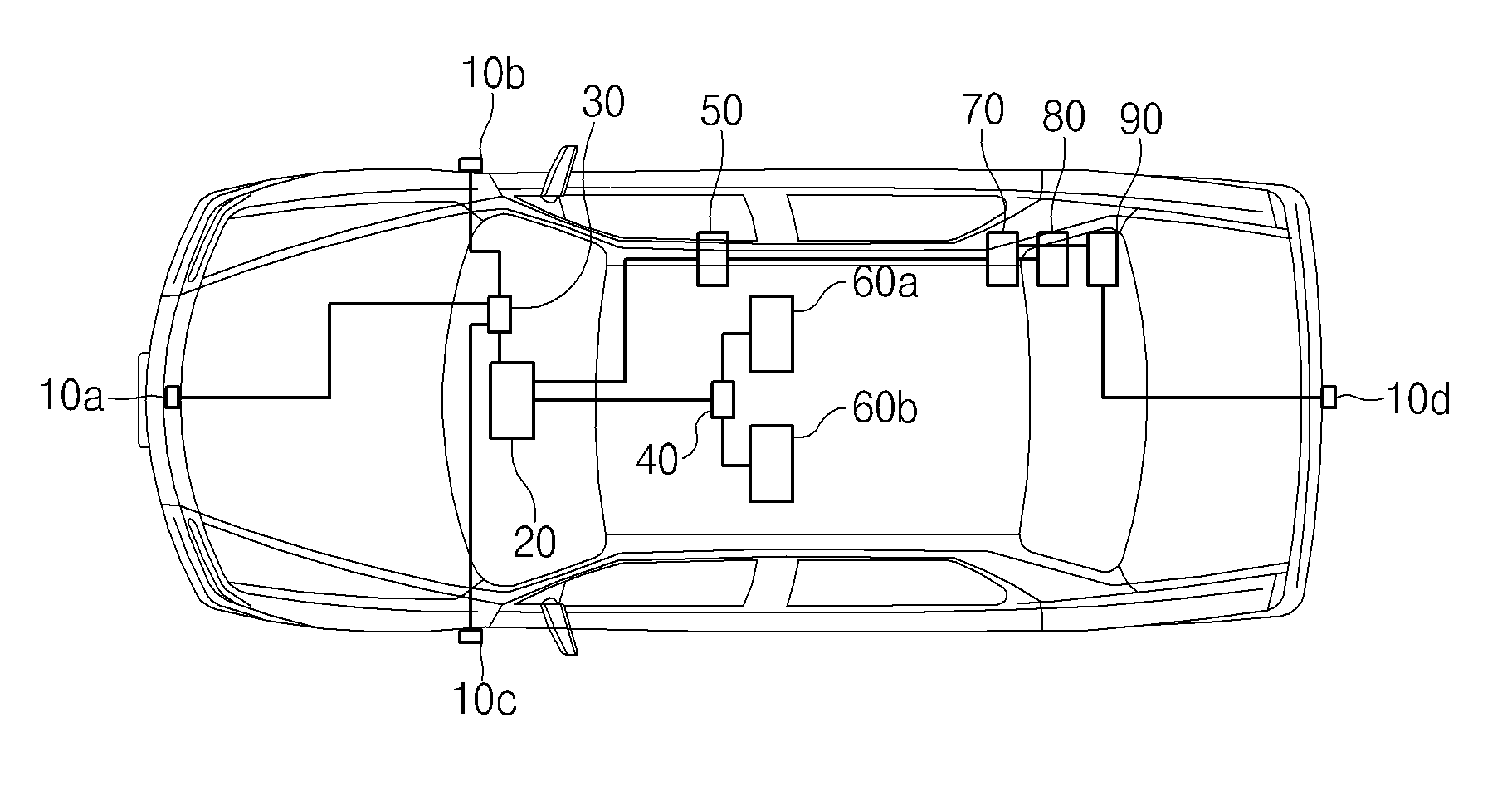

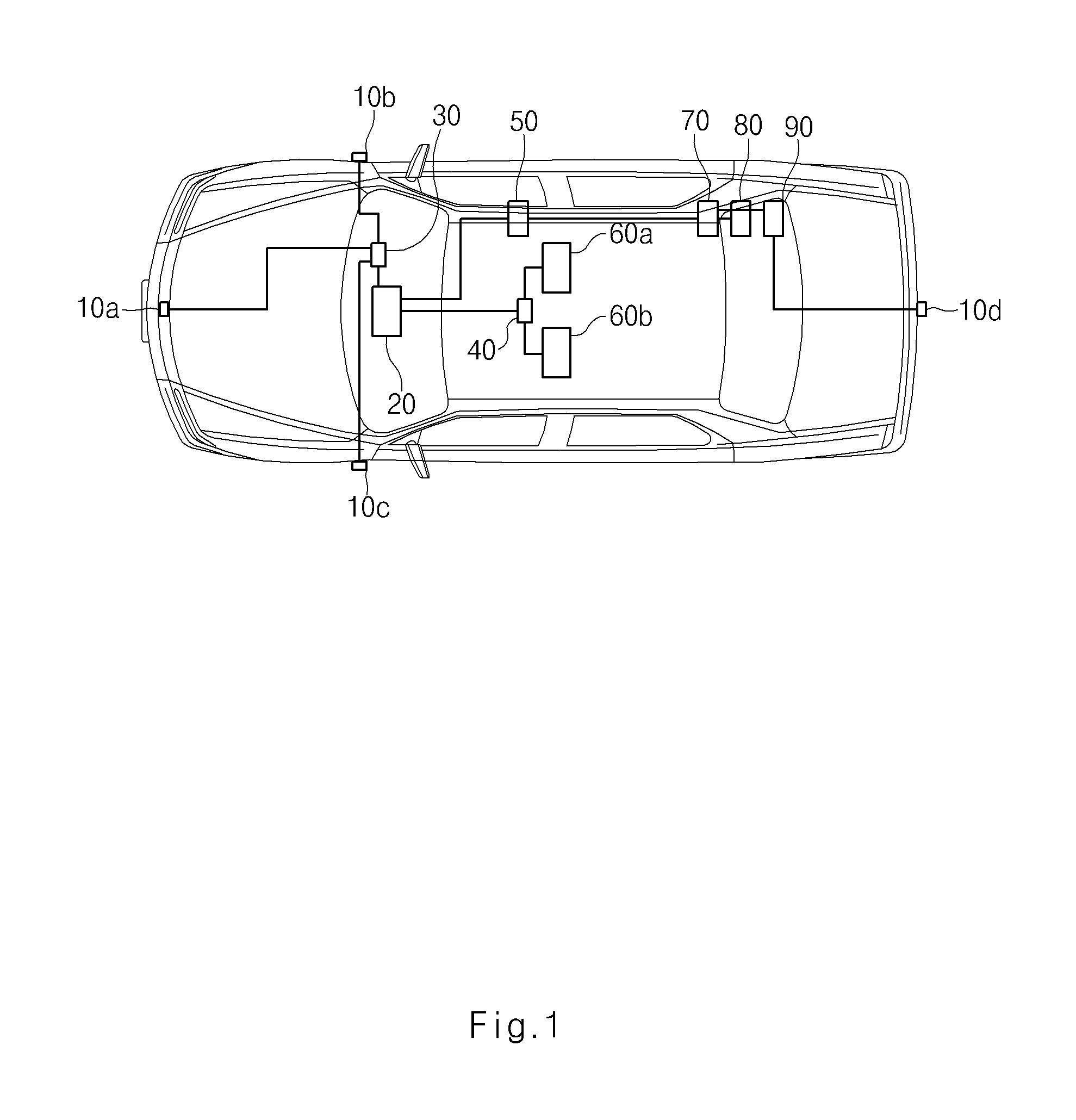

System and method for managing ethernet communication network for use in vehicle

ActiveUS20130159489A1Provide controlShorten the setting timeSubstation remote connection/disconnectionMultiple digital computer combinationsIn vehicleNormal mode

A system and method for managing a vehicle Ethernet communication network are disclosed. More specifically, each unit in a vehicle Ethernet communication network is configured to initially enter a power-on (PowerOn) mode when is applied to each unit of the vehicle to initialize operational programs. Once powered on, each unit enters a normal mode in which a node for each unit participates in a network to request the network. Subsequently, each unit enters a sleep indication (SleepInd) mode where other nodes are not requested even though the network has already been requested by the other nodes. A communication mode is then terminated at each unit and each unit enters a wait bus sleep (WaitBusSleep) mode in which all nodes connected to the network are no longer in communication and are waiting to switch to sleep mode. Finally, each unit is powered off to prevent communication between units in the network.

Owner:HYUNDAI MOTOR CO LTD

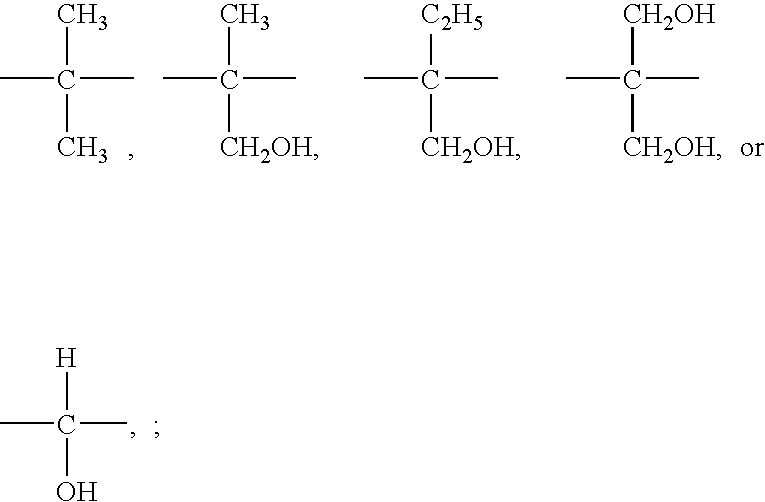

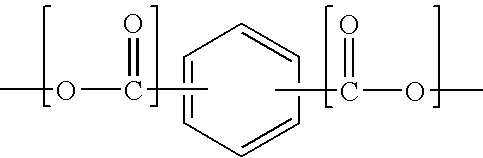

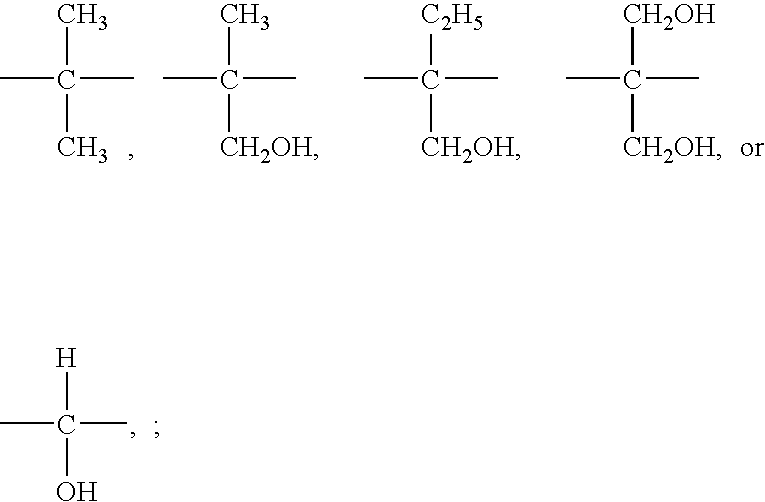

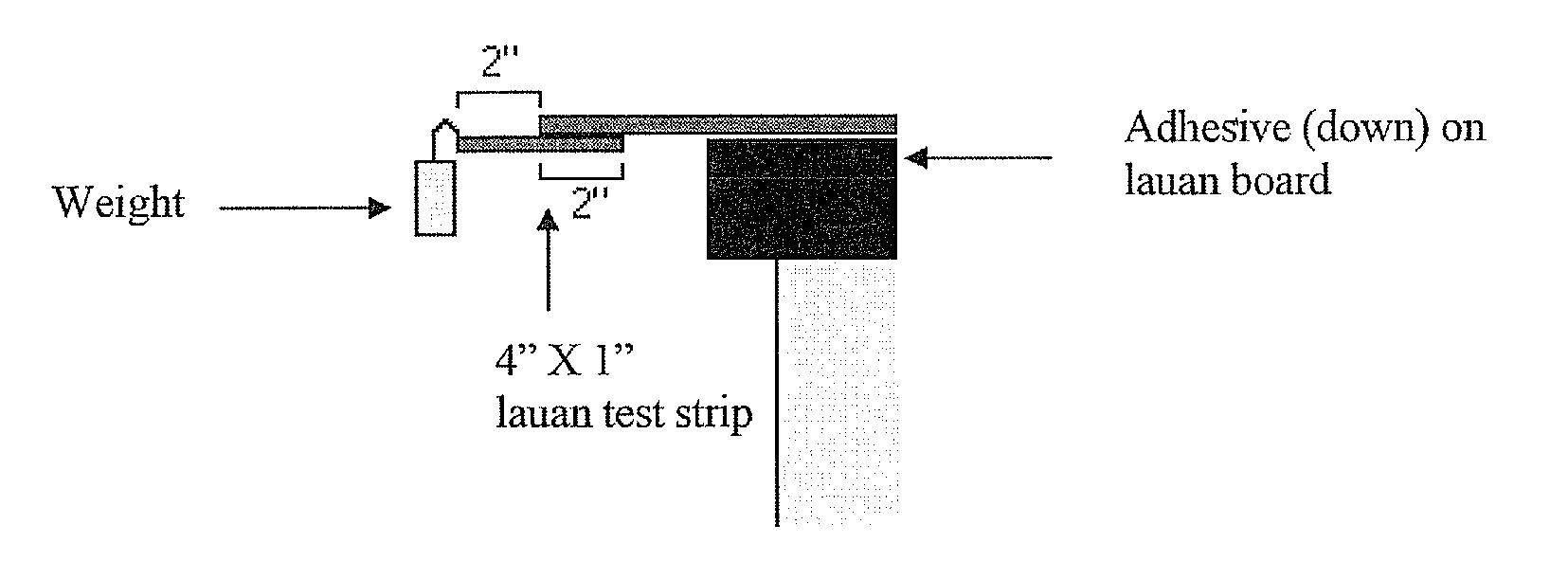

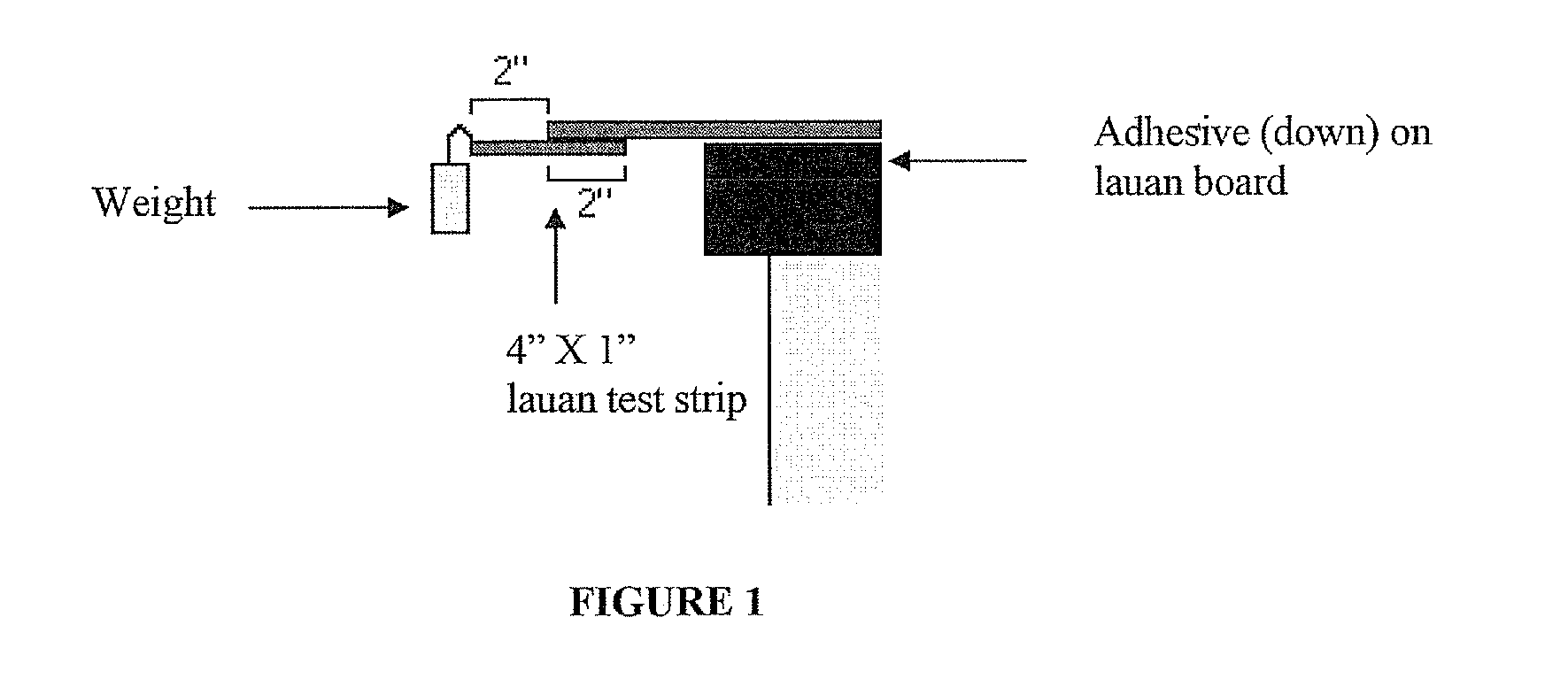

Polyester polyols for polyurethane adhesives

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phahalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:OBRIEN MICHAEL E

Geo-polymer recycled concrete and preparation method thereof

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

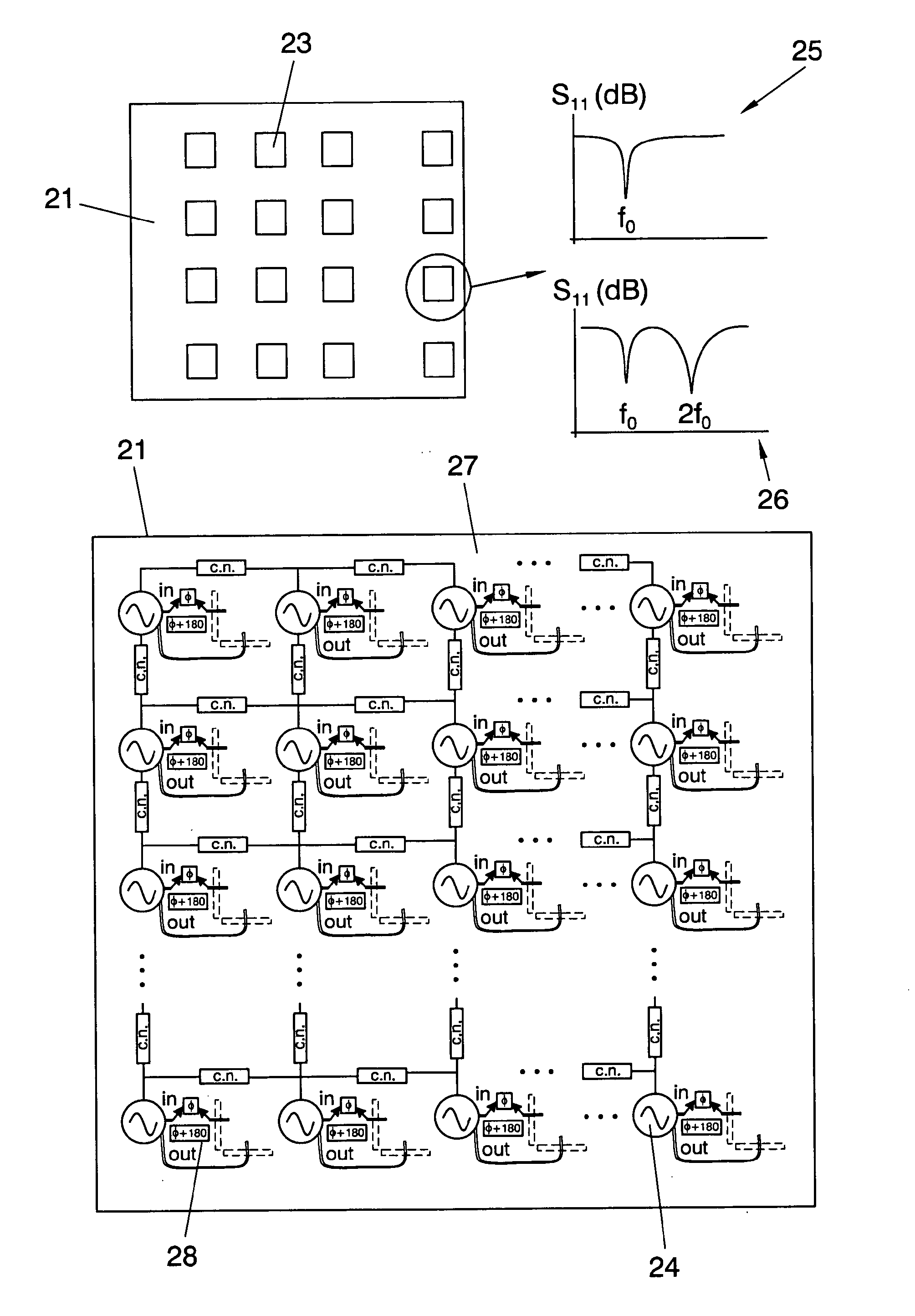

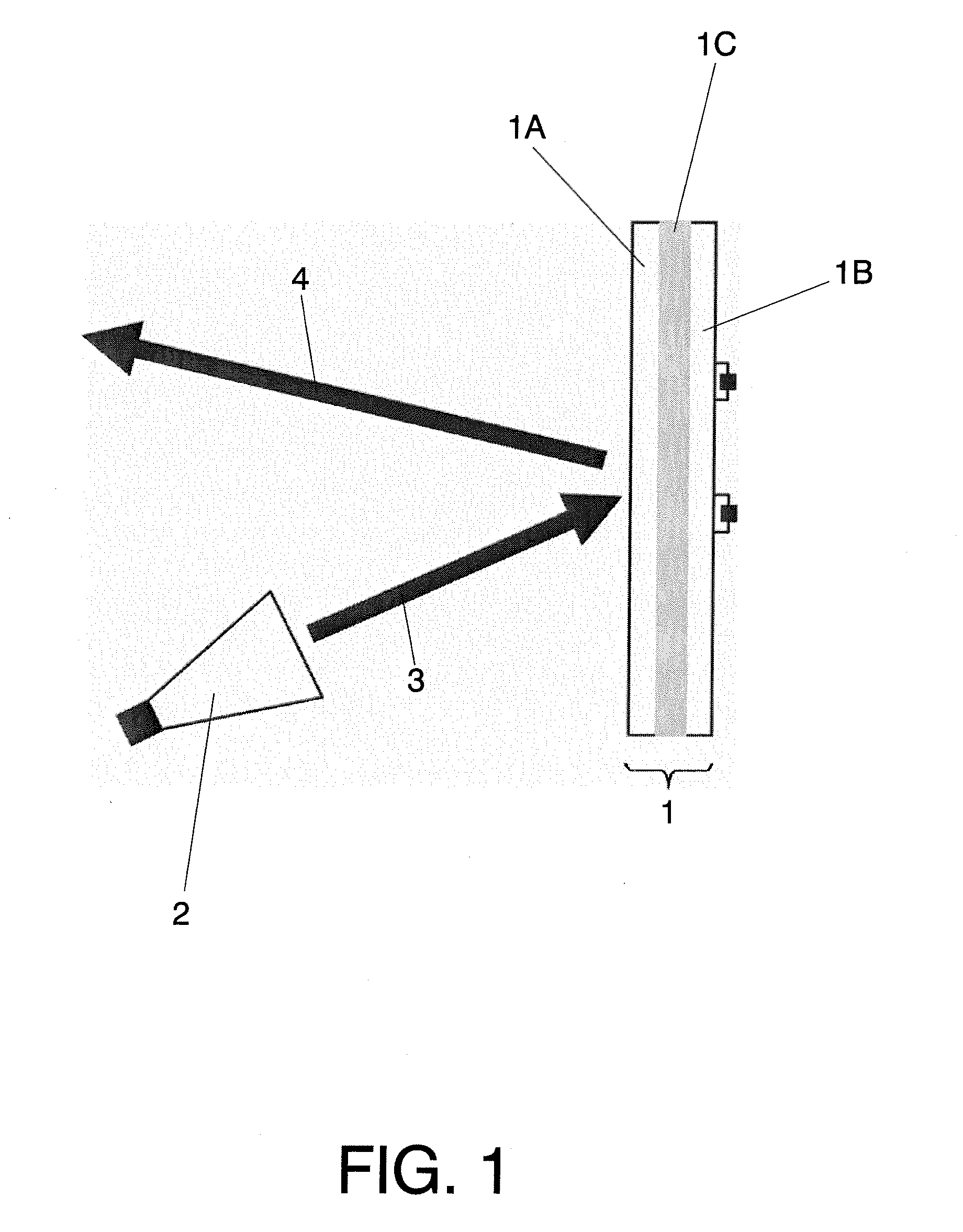

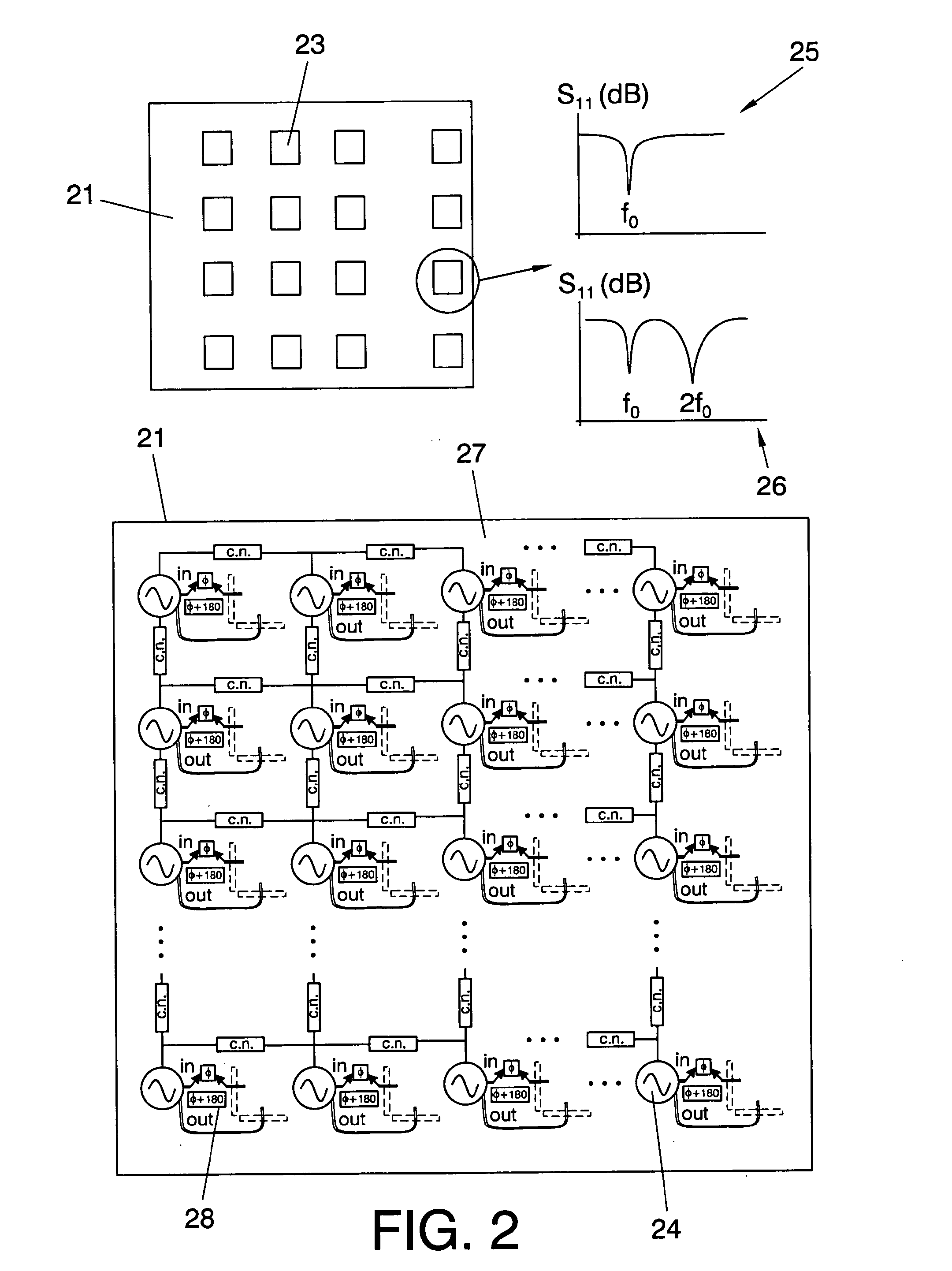

Reflectarray antenna system

InactiveUS20120162010A1Simple methodShorten the setting timeUnderwater structuresAntennasPhase variationRadiating element

The reflectarray includes a plurality of cells integrated in a PCB and externally illuminated by an input signal from a feeding source at a frequency fi, and an output signal is reflected, where each cell of the reflectarray is an AIA formed by a passive radiating element connected to an active circuit, which can be either an oscillator, or a push-push oscillator or a SOM, where the passive radiating circuit is placed on a reflective surface forming a side of the reflectarray and the active circuit is placed on the reverse side, the active circuit producing an output signal with a frequency related to the input frequency fi and the oscillation frequency fosc of said active circuit. This phase relationship is determined by an output phase variation, which is controlled by electronic means integrated in the reflectarray system, which allows an output phase variation interval even higher than 180°.

Owner:FUNDACIO PRIVADA CENT TECNOLOGIC DE TELECOMUNICACIONS DE CATALUNYA

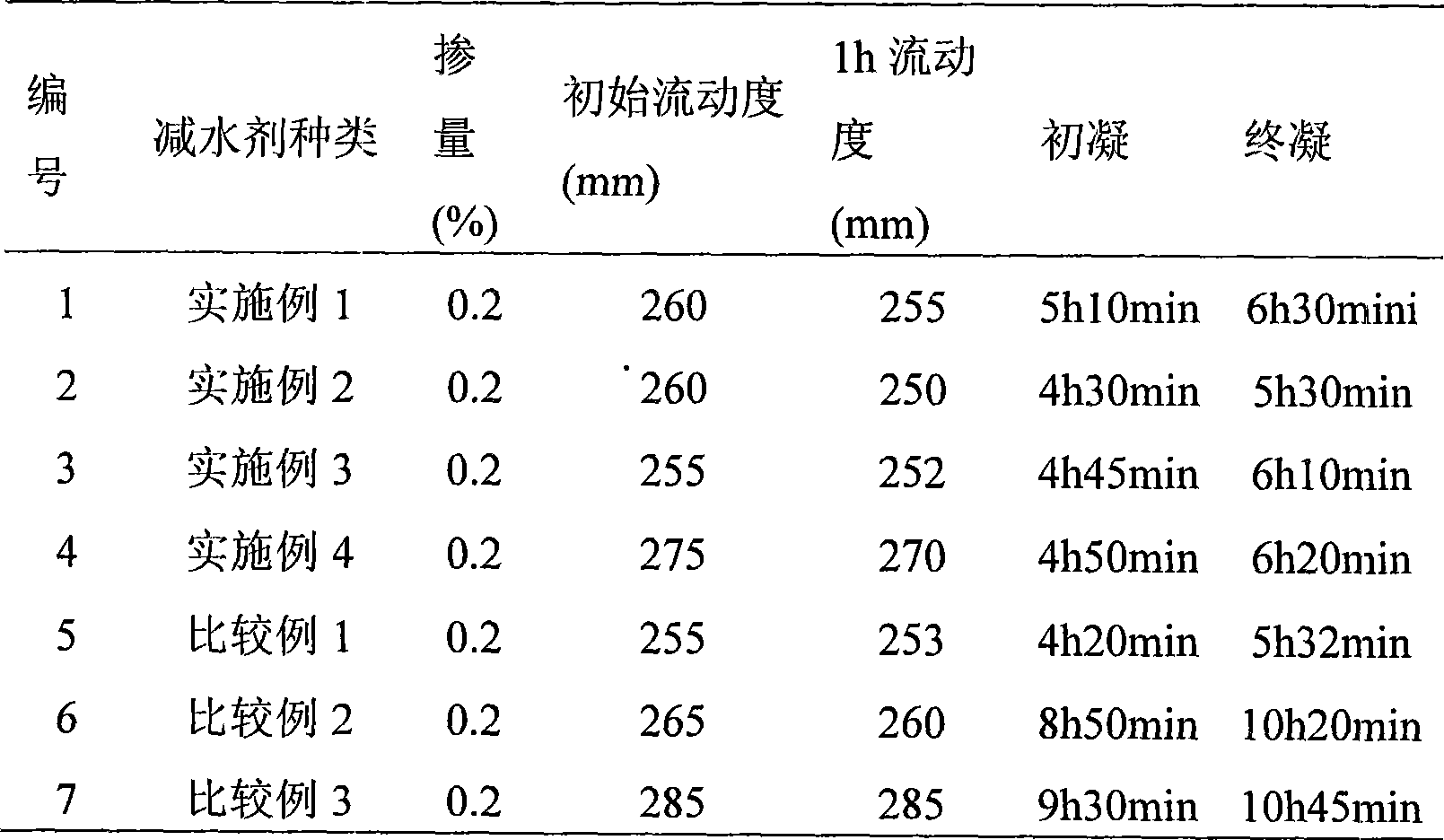

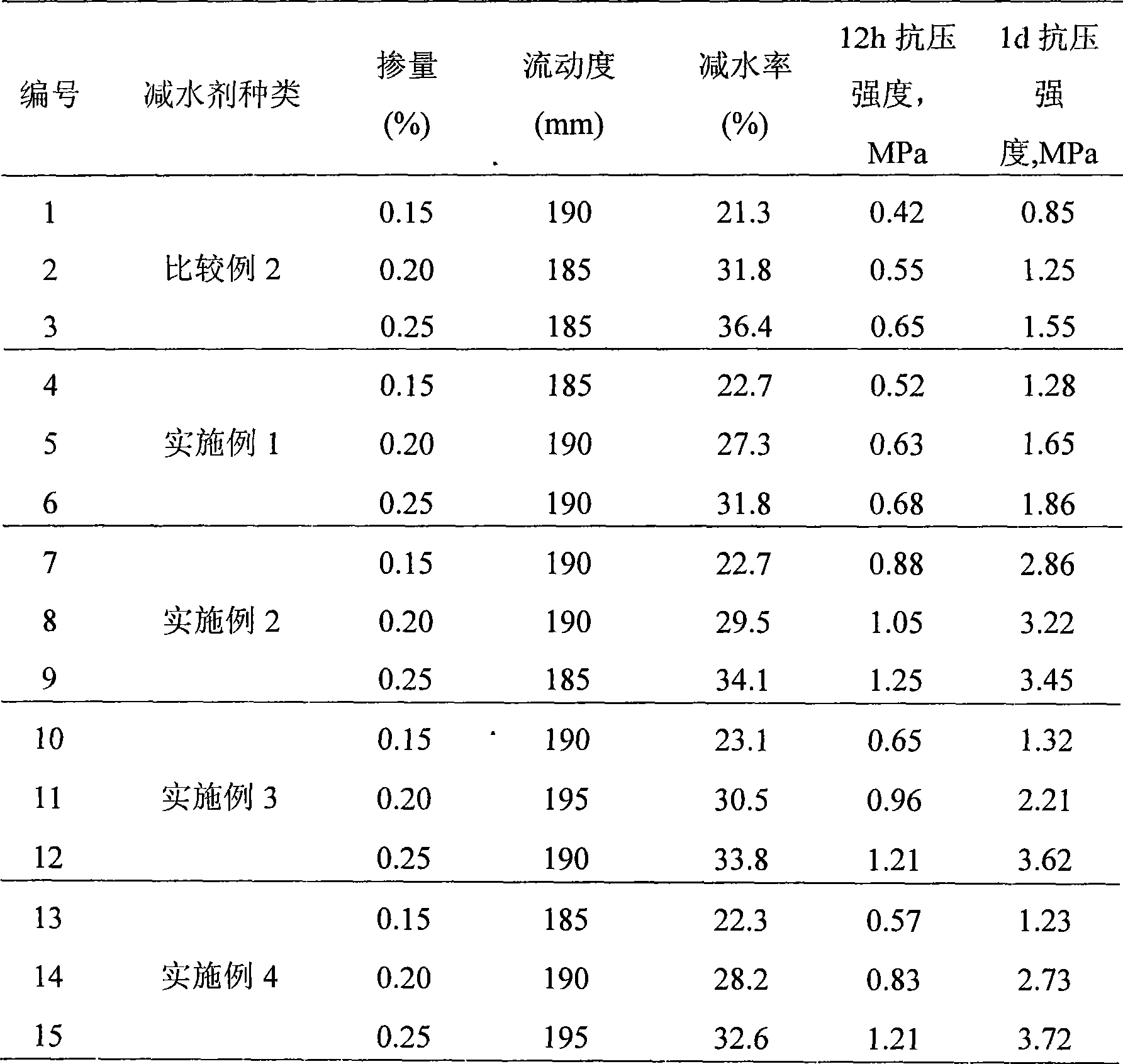

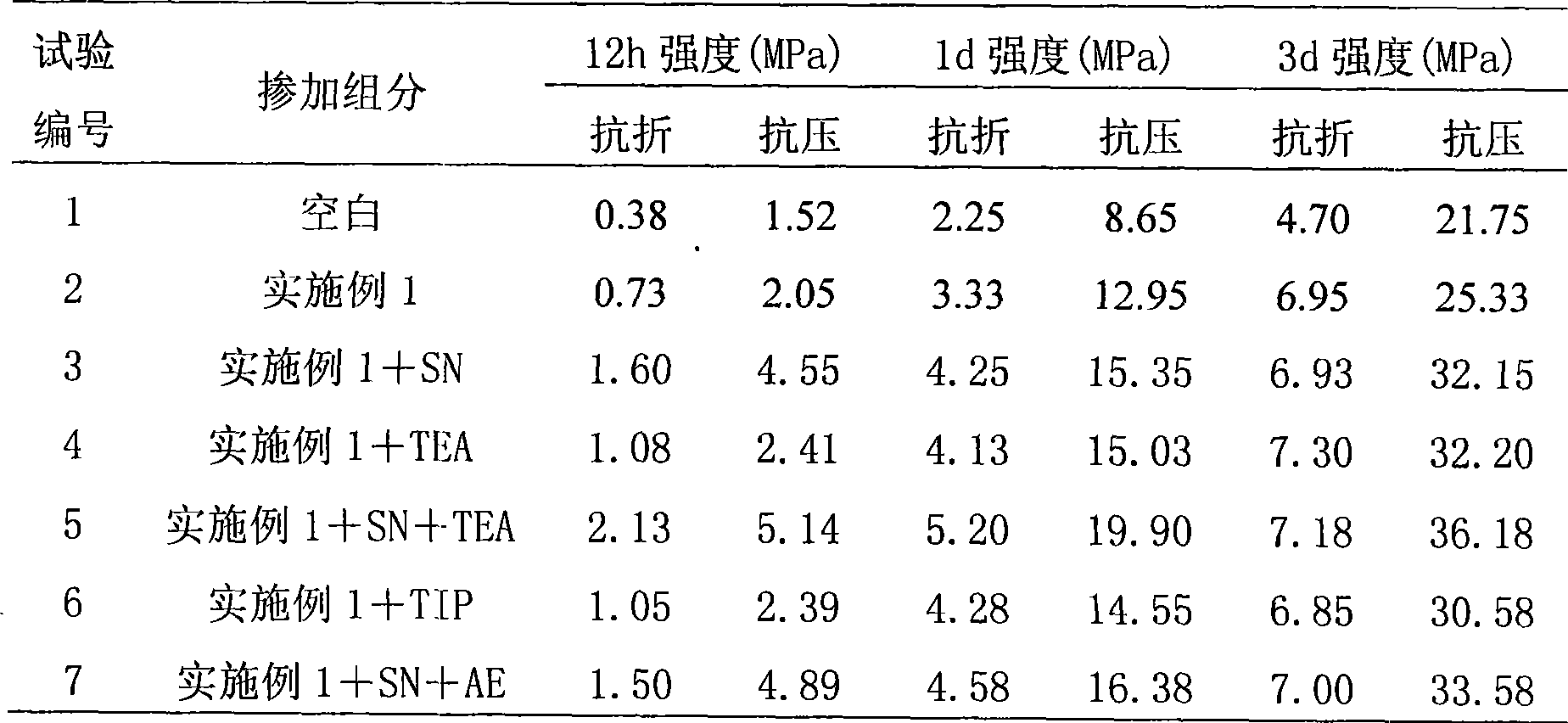

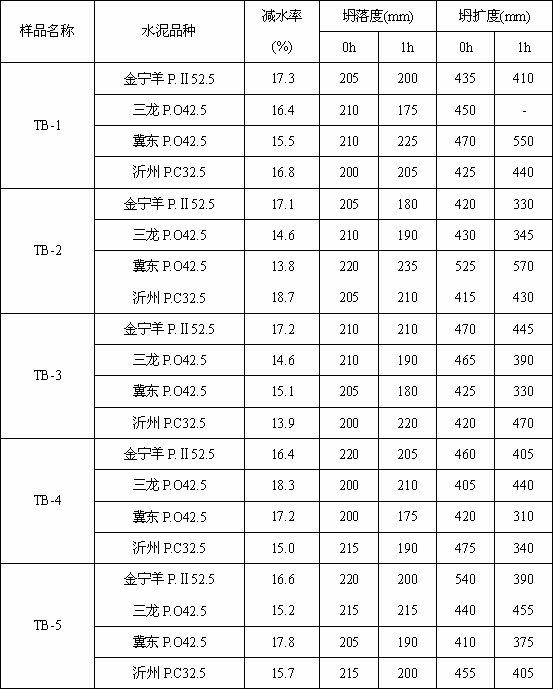

Preparation of polycarboxylic acid water reducing agent for prefabricated part

The invention discloses a preparation method for a polyocarboxy acid water reducing agent for precast units, which belongs to the field of water reducing agent. Under the action of a persulphate initiator, methoxypolyethylene glycol acrylate, acrylic acid, unsaturated sulfonic acid or a salt monomer b thereof, unsaturated amide or a salt monomer c thereof are copolymerized in an aqueous solution; a terminator is used to process the rest initiator of the reaction at a later polymerization stage; and finally alkaline solution is used for neutralization and the water reducing agent is obtained. The methoxypolyethylene glycol with high polymerization degree is introduced as a grafting side chain, thereby making the prepared water reducing agent effectively shorten the concrete coagulation time without reducing the concrete initial fluidity and improving the concrete compression strength. The early strength type polyocarboxy acid high performance water reducing agent can be widely applied to the construction of various concrete projects with a low temperature or early strength requirements, in particular to the low energy consumption production process of precast concrete units. The water reducing agent has wide generalization space.

Owner:HUIZHOU JIANKE IND

Foam cement insulation material for exterior wall and preparation method thereof

InactiveCN102942380AShorten the setting timeStrong synergistic effect is obviousCeramicwareSilica fumePortland cement

The invention belongs to the technical field of insulation material for building, and particularly relates to a foam cement insulation material for exterior wall and a preparation method thereof. The foam cement insulation material for exterior wall is prepared from raw materials comprising ordinary portland cement, sulphoaluminate cement, fly ash, silica fume, an expansive agent, a coagulating enhancer, a tackifier, a water-reducing agent, a waterproofing agent, a foaming agent, a foam stabilizer, fiber and water. The preparation method comprises the following steps: (1) first conducting dry mixing on ordinary portland cement, sulphoaluminate cement, fly ash, silica fume and the expansive agent, adding coagulating enhancer, tackifier, water-reducing agent, waterproofing agent, foam stabilizer, water and fiber, and stirring to obtain a slurry; and (2) adding the foaming agent in the slurry, and filling the foamed slurry into a mold. The foam cement insulation material for exterior wall has good fire resistance, long service life, good insulation property, light weight, high strength, low water absorption and good crack resistance.

Owner:刘巧玲

Method for preparing slump-retaining type polycarboxylic acid series high-performance water reducing agent in one step

The invention relates to a method for preparing a slump-retaining type polycarboxylic acid series high-performance water reducing agent in one step. The method comprises the following steps of: dissolving unsaturated polyoxyethylene ether into water, heating to 50 to 80 DEG C, adding oxidant solution and stirring uniformly; adding reducing agent solution and comonomer solution dropwise respectively to perform polymerization; preserving the heat and curing for 1 to 3 hours; and cooling to room temperature, adding an alkaline compound and adjusting the pH value to be 6.5 to 7 to obtain the slump-retaining type polycarboxylic acid series high-performance water reducing agent. In the method, unsaturated bond-containing allyl for hydrogen on terminated hydroxyl of the original unsaturated polyoxyethylene ether is substituted, so that the terminal group of alkoxy polyethylene glycol is changed from the original active hydroxyl into the conventional inert alkyl, byproducts of copolymerized products are greatly reduced, molecular weight distribution is narrowed, and the synthetized water reducing agent has a high water-reducing ratio and a high slump-retaining property.

Owner:NANJING RUIDI HIGH TECH

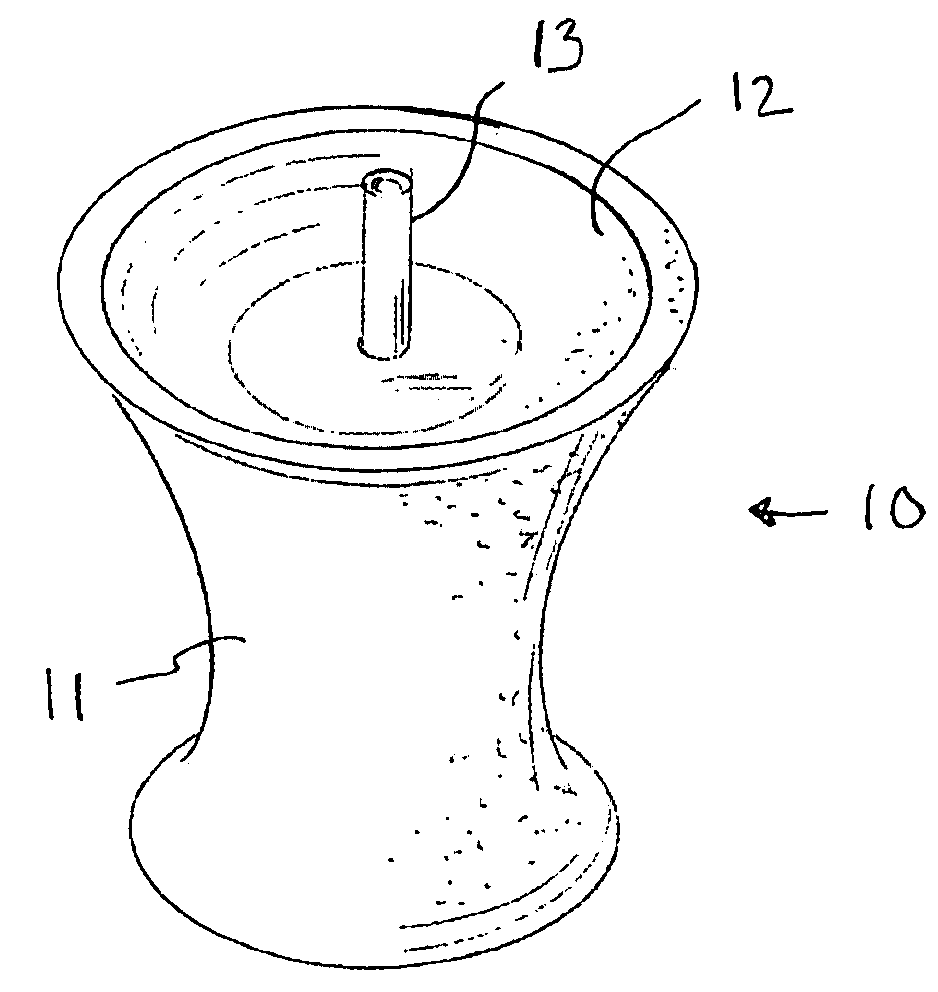

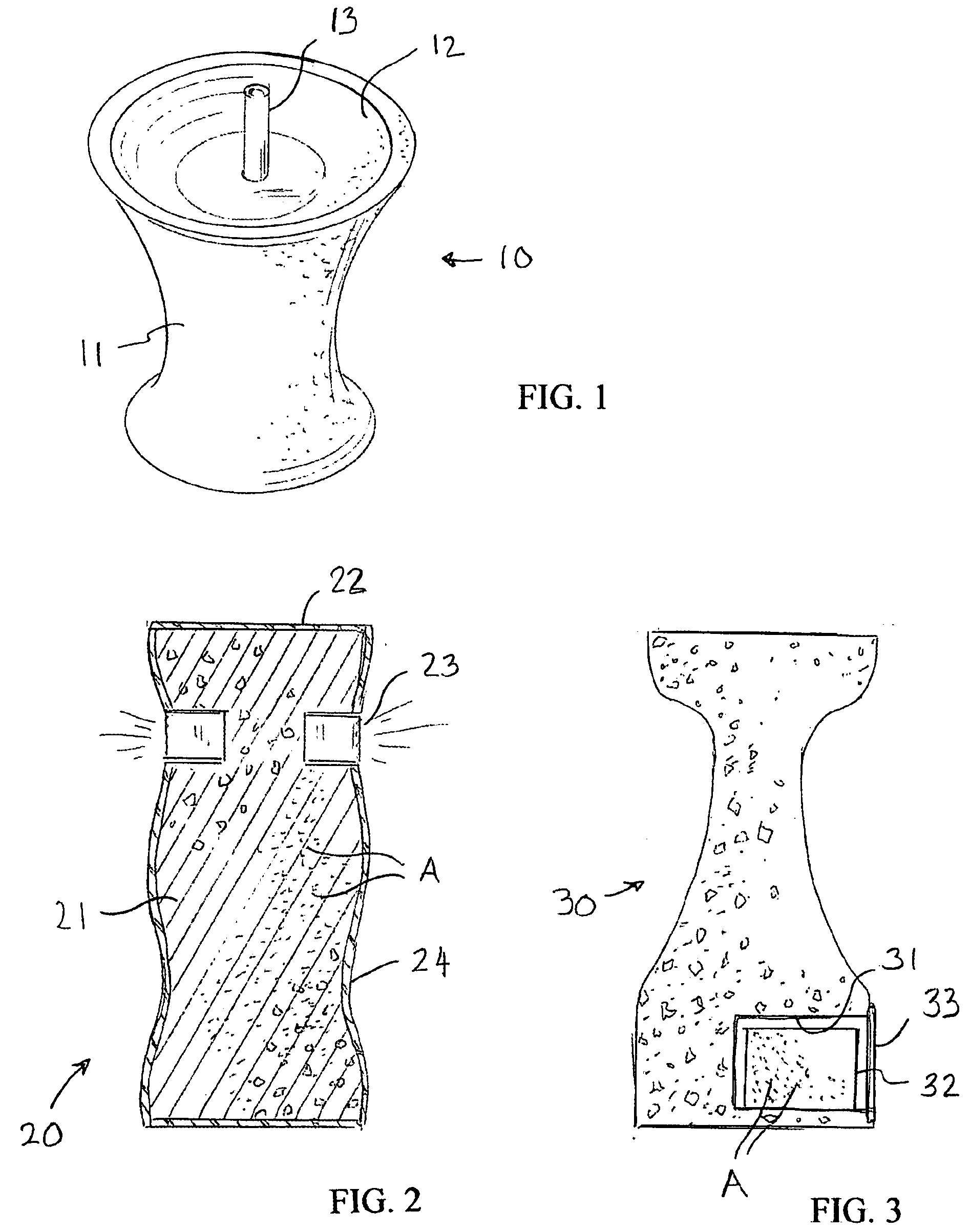

Memorial objects incorporating cremation ash

InactiveUS20090077779A1Enhance desired physicalGood chemical propertiesSolid waste managementUrnsMotion detectorGlass fiber

A memorial object cast in a mold and formed of a concrete mix having up to about 50% sand, up to about 25% aggregate, up to about 25% cement, and water. In one embodiment of the invention cremation ash is incorporated in the mix up to about 60% of the mix, with the percentage of at least one of the other ingredients, preferably sand and / or aggregate, being reduced corresponding to the amount of cremation ash added. In another embodiment, a cavity is formed in the object for receiving and holding a separate container holding cremation ashes. Various additives can be added to the mix, either alone or in combination, including an accelerator, an air entrainer, a plasticizer, and glass fibers. One or more of a motion detector, voice-activated recording, water effects and / or an illumination device can be mounted in the object.

Owner:ZIMMERMAN KURT +1

Polyester Polyols for Polyurethane Adhesives

InactiveUS20100126664A1Improve adhesionHigh bonding strengthPolyureas/polyurethane adhesivesLaminationPolyesterPolymer science

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phthalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:STEPAN COMPANY

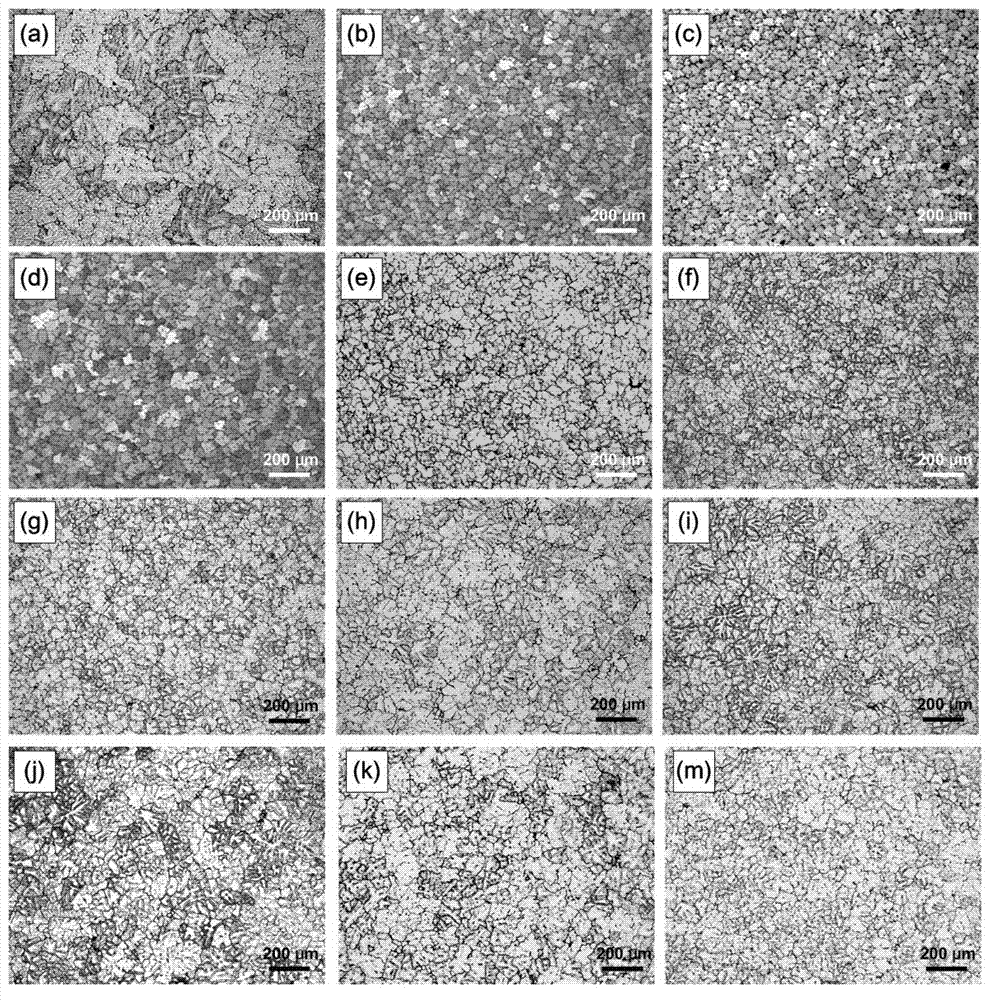

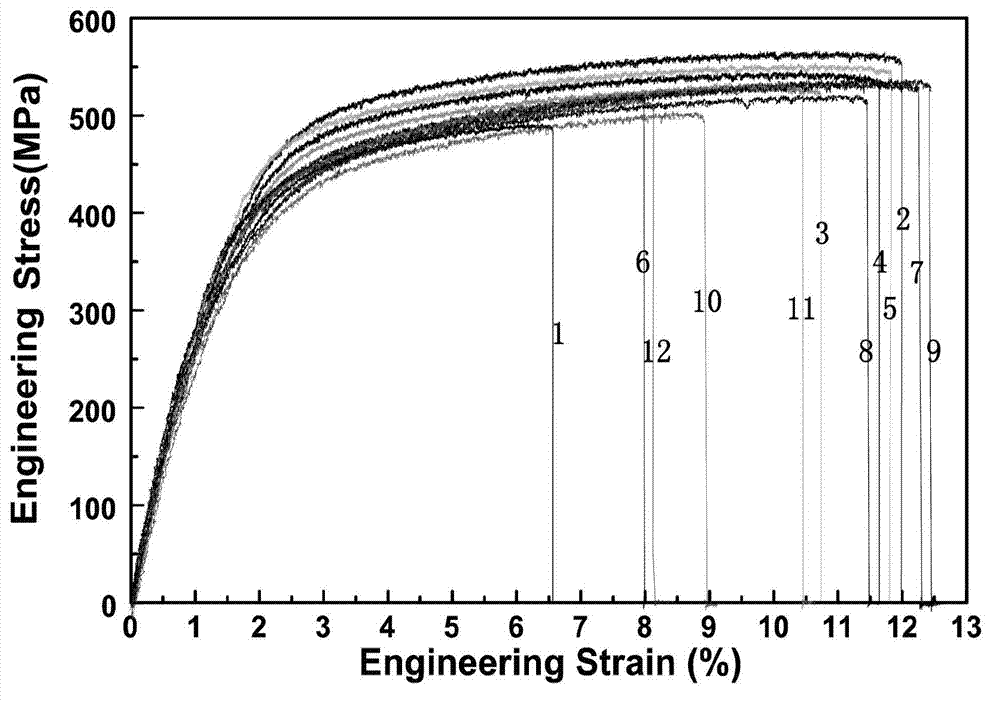

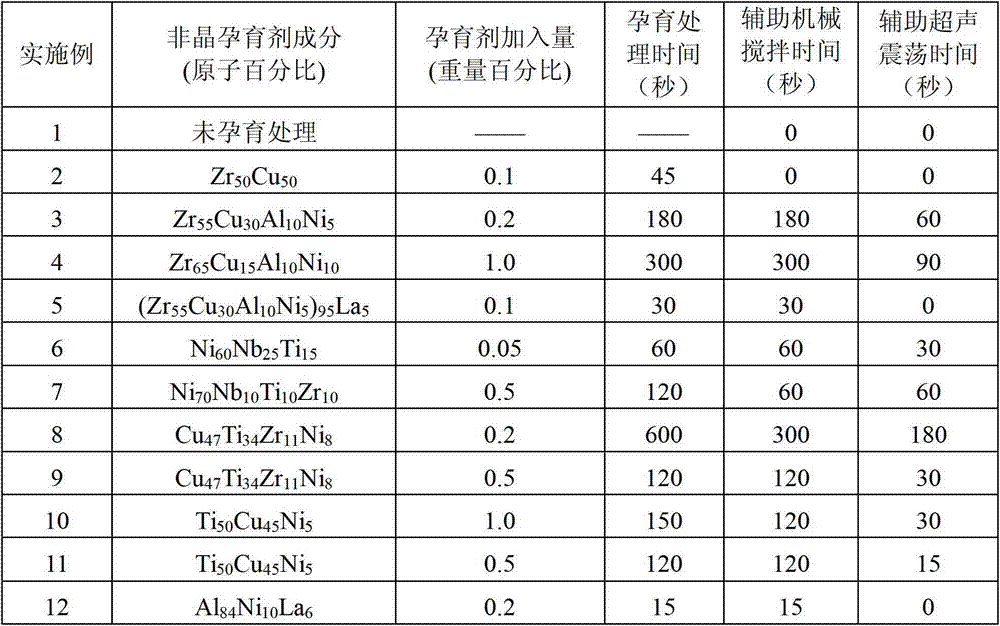

Amorphous alloy inoculation method for treating cast aluminum alloy

The invention relates to an amorphous alloy inoculation method for treating cast aluminum alloy. The amorphous alloy inoculation method for treating the cast aluminum alloy comprises preparation of inoculant and amorphous inoculation treatment. The technological parameter of the inoculation treatment is as follows: adding a prepared amorphous thin strip into aluminum melt before the aluminum is cast, the temperature of the aluminum melt is from 750 DEG C to 770 DEG C; the added amount of the amorphous inoculant is 0.05-1.0 wt.% of the weight of the aluminum; the treating time of inoculation is 15-600 seconds; an auxiliary machinery stirs for 0-300 seconds; and auxiliary ultrasound shocks for 0-180 seconds. The inoculant utilized by the amorphous alloy inoculation method is multivariate amorphous alloy including Zr series, Ni series, Cu series, Al series, Ti series and the like, precious metal is not contained, and cost is lower. The inoculant is in a thin-strip shape, can be dispersed in the melt uniformly and conveniently, the actual receiving ratio of modificator is high, tissue after refining is uniform, the time of modification treatment and alloy solidification are greatly shortened, and production efficiency is high. Moreover, the amorphous alloy inoculation method for treating cast aluminum alloy is applicable to large-batch continuous production of the amorphous alloy for a long time.

Owner:JILIN UNIV

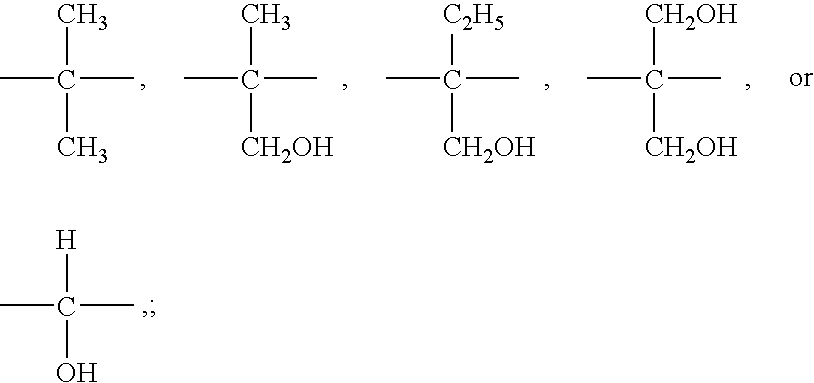

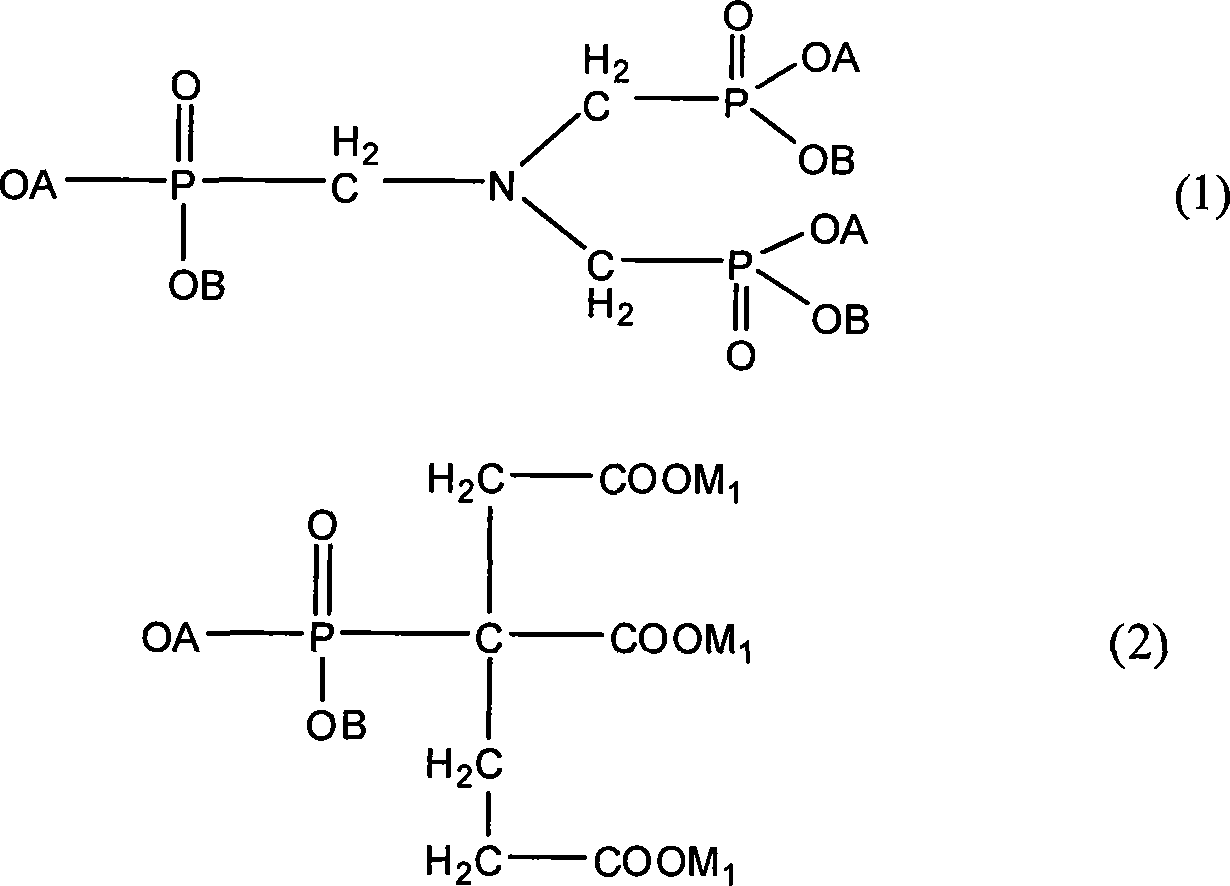

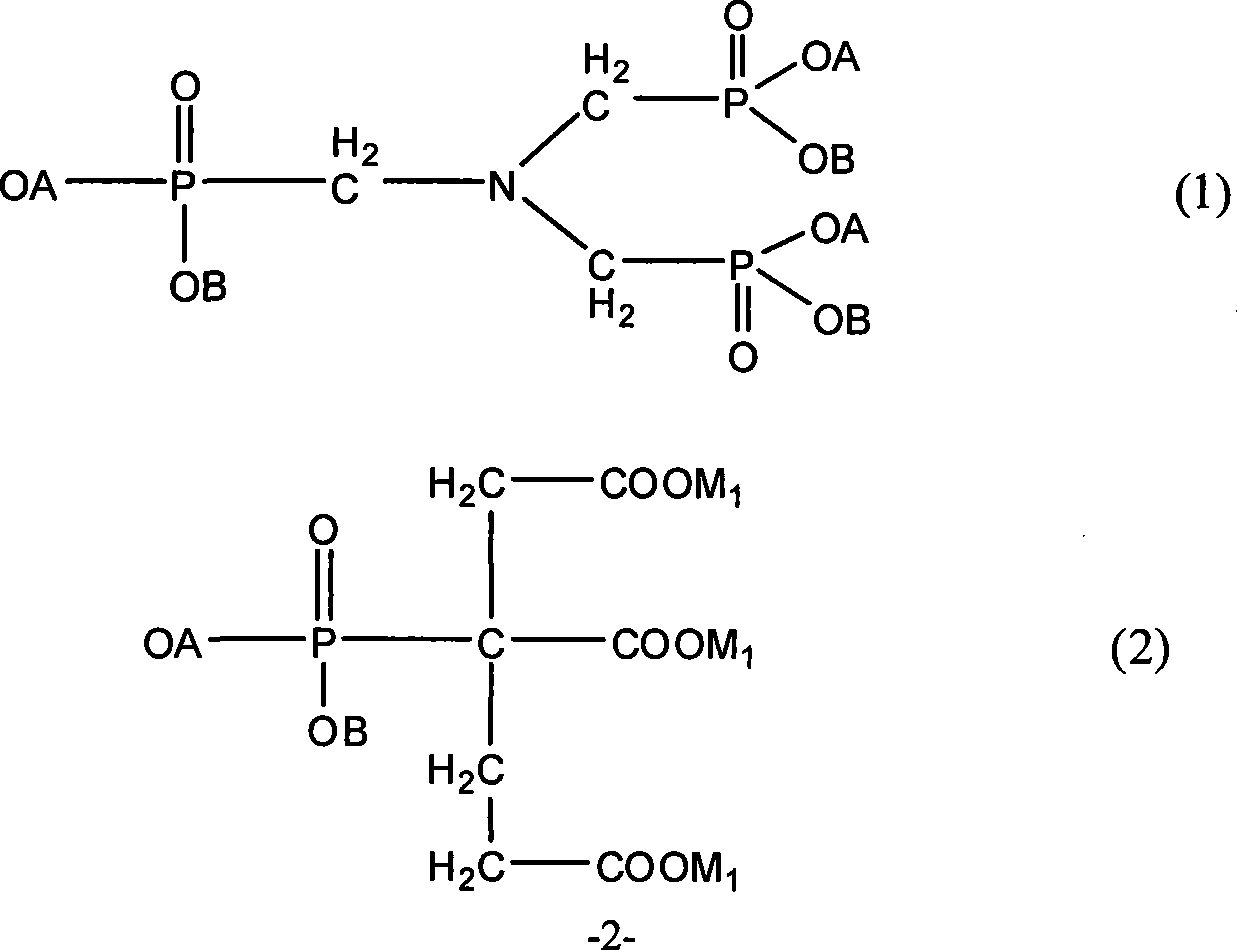

High-temperature retarders suitable for polycarboxylate concrete dehydragent and method for making same

The invention relates to a high-temperature retarder compatible with a polycarboxylate concrete water-reducer and a preparation method thereof. The high-temperature retarder is formulated by weight percentage from the following components: water-soluble organic phosphonic acid or its 20-30% of salt, 10-15% of carbohydrate retarding component, 5-10% of polyalcohol retarding component, 1-2% of alkyl glycoside non-ionic surfactant, and the balance is water. The preparation steps are as follows: 1) firstly add water into the reaction kettle, then put in organic phosphonic acid or its salt, and stir evenly; 2) open the jacket of the reaction kettle to circulate cooling water, and dropwise add alkali solution into the reaction kettle while stirring, Adjusting the pH value to 6-8; 3) Adding non-ionic sugar compounds, polyalcohol retarding components and alkyl glycoside non-ionic surfactants into the reaction kettle, stirring evenly to obtain the product. When the present invention is used in combination with the existing polycarboxylate concrete admixture, it can not only delay the setting time of concrete according to engineering needs, but also improve the fluidity loss of freshly mixed concrete even in high temperature environment in summer.

Owner:JIANGSU SOBUTE NEW MATERIALS

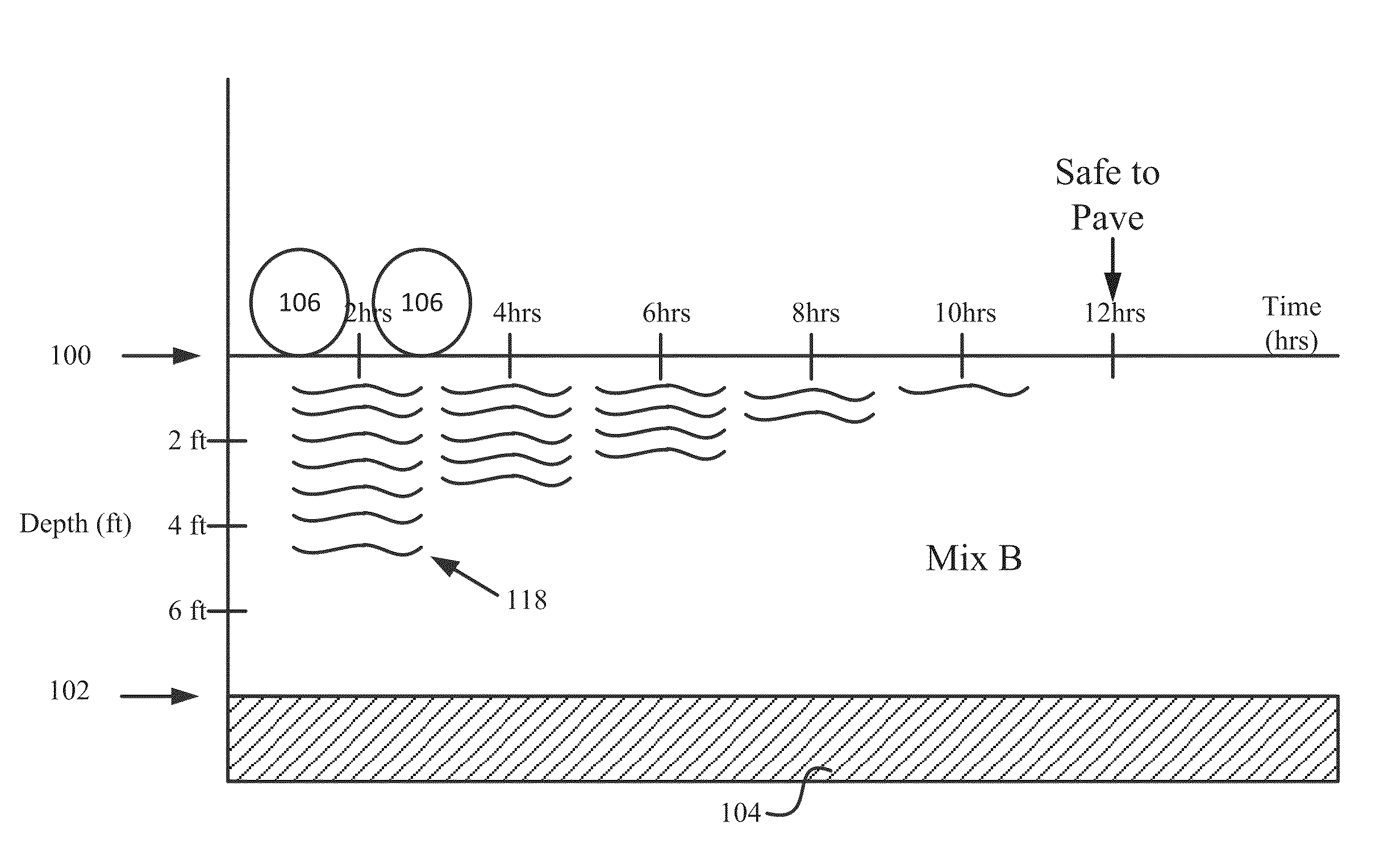

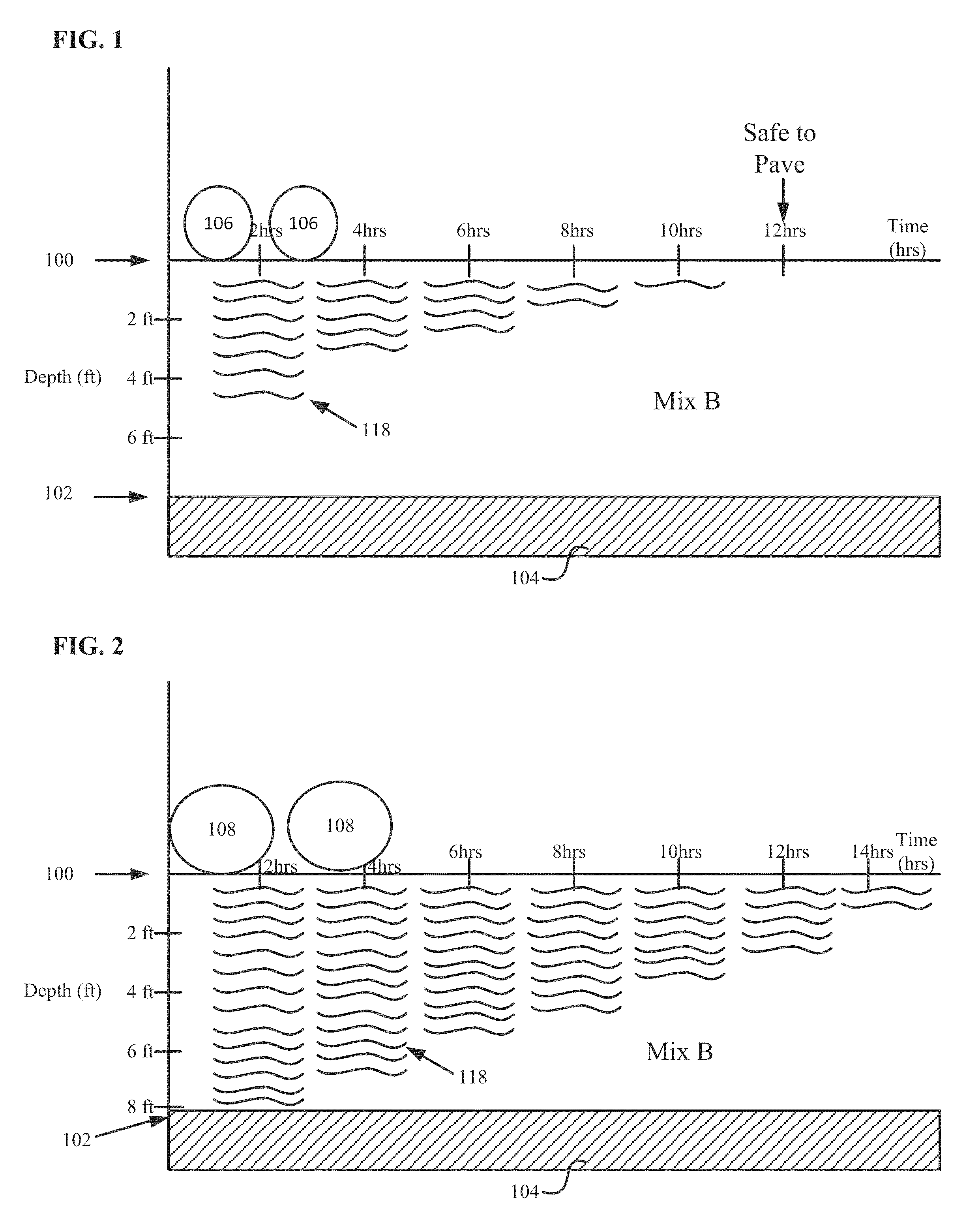

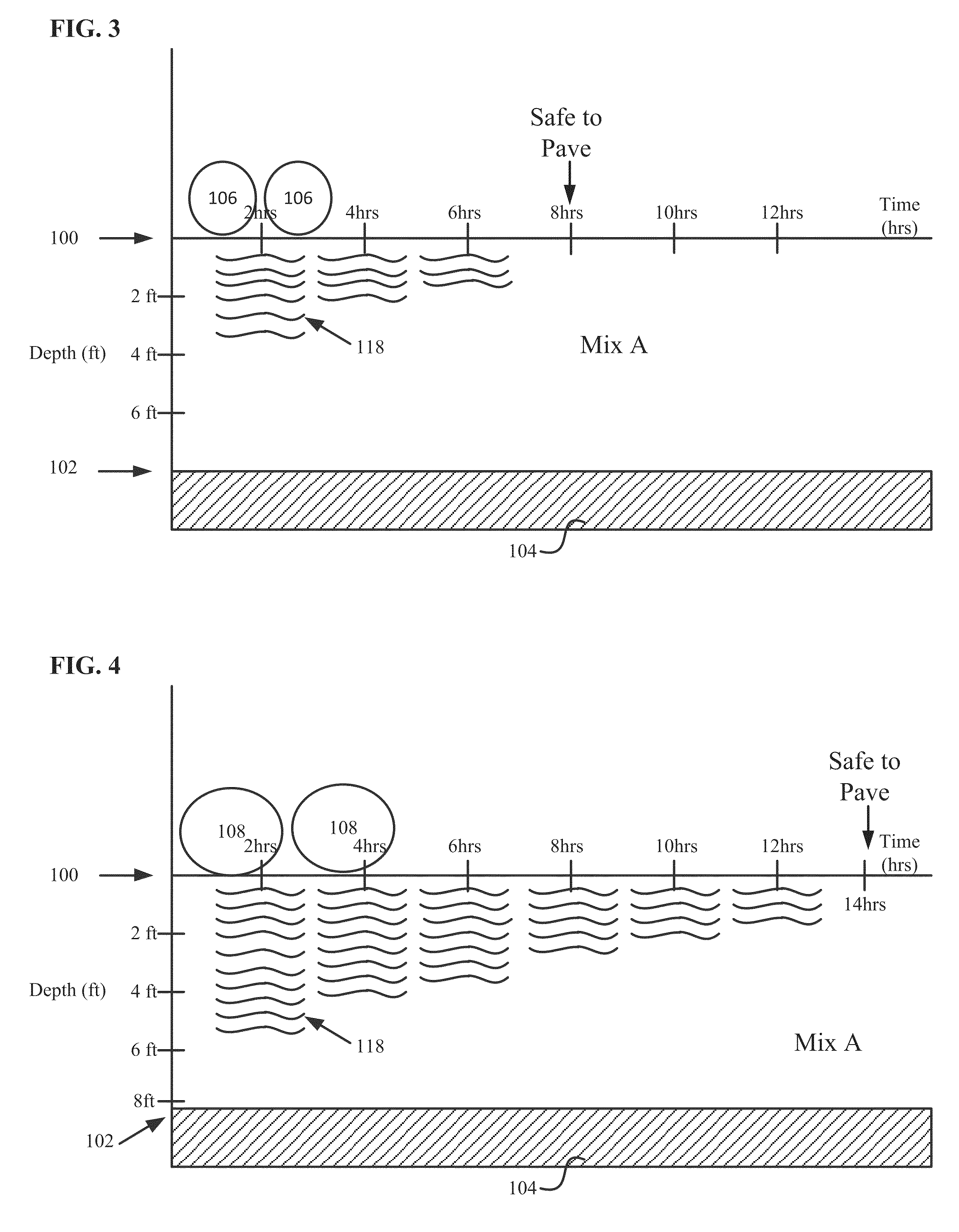

Foamed compositions for reducing freeze-thaw heave risk, and methods of utilizing and producing the same

ActiveUS8747547B1Flotation can be preventedAlleviates frost-heaveSolid waste managementPaving detailsFreezing thawingFly ash

A composition and method for reducing freeze-thaw heave risk over flash-filled voids are disclosed. A composition can include cementitious fly ash, water and cellular foam. The composition can optionally include a filler, e.g., Type F fly ash, or additional desired components. A method can include mixing the desired composition and applying the composition to a void. The method can optionally include determining the desired composition based on various factors.

Owner:EAGLE STRONG INVESTMENTS LLC

Zeolite-like lightweight heat preservation and sound insulation board and production method thereof

ActiveCN102167546ADelayed clotting timeStrong sound absorption effectCement productionPolystyreneZeolite

The invention provides a zeolite-like lightweight heat preservation and sound insulation board applied to a building outer wall, or wall filling of a nonbearing wall or a building top layer. The board comprises dry powder slurry and lightweight aggregate, wherein the dry powder slurry is a zeolite-like geopolymer formed by the excitation of a composite alkali excitant and comprises the following components in percentage by weight: 70-85 percent of coal ash, 5-15 percent of phosphorus slag, 8-20 percent of composite alkali excitant and 0.1-0.3 percent of anticracking fiber; the lightweight aggregate is EPS (Expandable Polystyrene) granules; and the charge ratio of the dry powder slurry to the lightweight aggregate is (89-95): (5-15). The zeolite-like lightweight heat preservation and soundinsulation board has low volume weight, high compression strength, favorable heat preservation and heat insulation properties and good sound absorption effect on various frequency bands of sound waves. The invention also provides a production method of the zeolite-like lightweight heat preservation and sound insulation board. The method has simple process conditions and is easy to realize.

Owner:广骏新材料科技股份有限公司

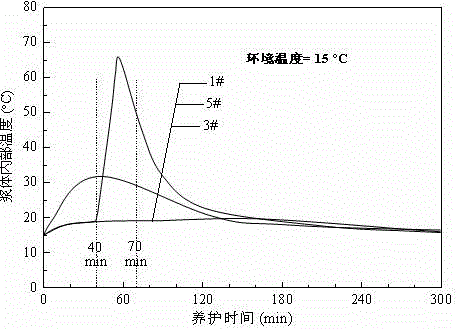

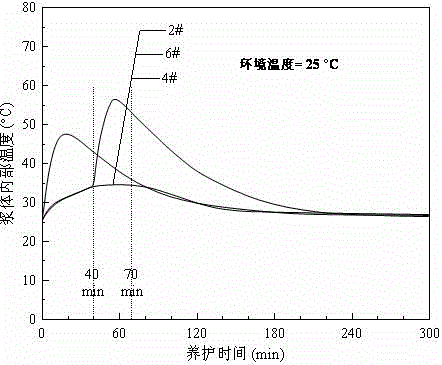

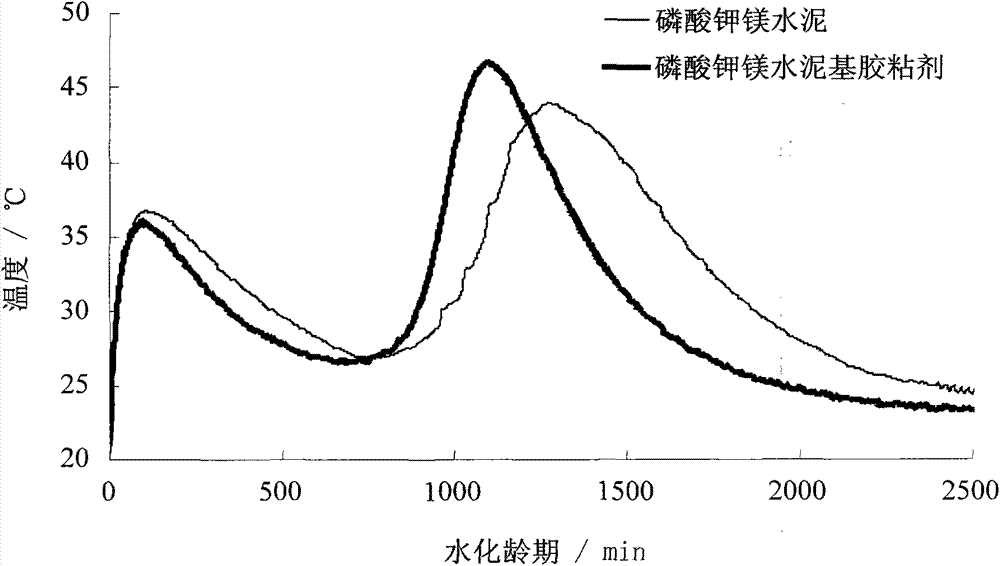

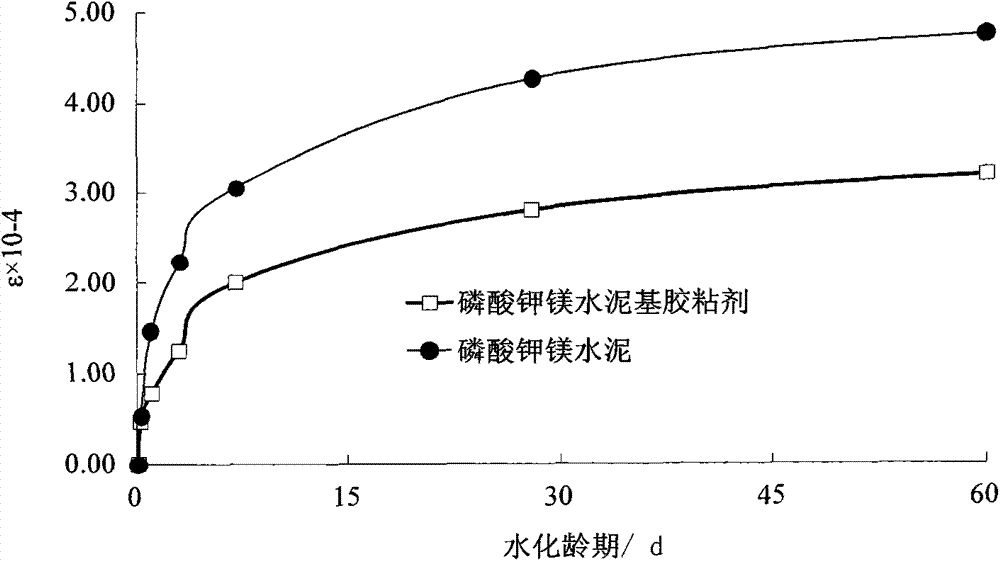

Method for controlling setting and hardening processes of magnesium phosphate cement

ActiveCN103332960APromotes hardening and early strength developmentLong term strength noMagnesium orthophosphateMagnesium phosphate

The invention relates to a method for controlling setting and hardening processes of magnesium phosphate cement. According to the method, the heat releasing speed of the magnesium phosphate cement is reduced by increasing addition of borax retarder to delay setting of magnesium phosphate cement mortar and adjust the setting time of the mortar within 20-150 minutes effectively, then a heat-transfer process between the mortar and an environment and the setting and hardening processes of the mortar are accelerated by increasing early environmental temperature of the mortar, and the early strength is form quickly and reaches 20-30MPa in an hour. The method solves the problem that the early strength of a magnesium phosphate cement system develops slowly due to the short setting time and a larger mixing amount of the borax retarder when the magnesium phosphate cement serves as a quick repairing material for a repairing project to some extent. Available test results indicate that the method can control the setting and hardening processes of the cement conveniently and effectively.

Owner:CHONGQING UNIV

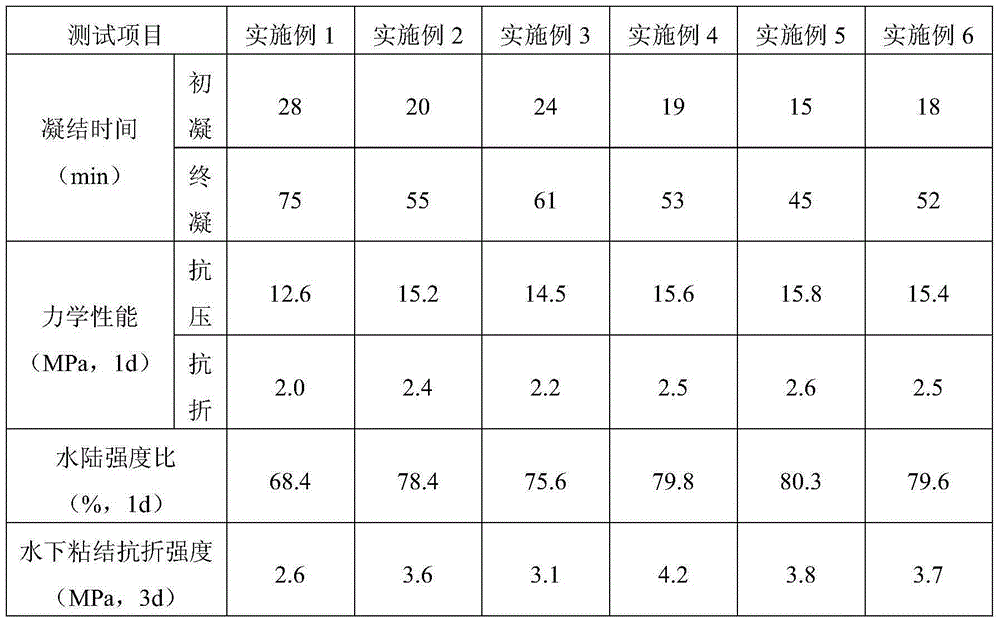

Epoxy resin emulsion modified cement-based patching material and preparation material thereof

The invention relates to an epoxy resin emulsion modified cement-based patching material and a preparation material thereof. The epoxy resin emulsion modified cement-based patching material is characterized by comprising the following raw materials in parts by weight: 100 parts of sulphate aluminum cement, 5 to 40 parts of epoxy resin emulsion, 5 to 20 parts of waterborne curing agent, 0.4 to 1.0 parts of accelerator, 2 to 10 parts of waterborne tackifier rosin resin emulsion, 0.2 to 1.0 parts of water reducer, 5 to 15 parts of silica fume, 40 to 60 parts of quartz powder and 10 to 30 parts of water. According to the epoxy resin emulsion modified cement-based patching material and the preparation material thereof disclosed by the invention, the sulphate aluminum cement and the accelerator are adopted so as to shorten the setting time of the patching material, therefore the underwater dispersion resistance of the patching material is improved; the mechanical property of the cement-based patching material and bonding strength between the cement-based patching material and a basement layer are improved by utilizing the epoxy resin emulsion; the prepared epoxy resin emulsion modified cement-based patching material has the characteristics of being short in setting time, high in underwater dispersion resistance, good in underwater bonding performance and the like, and can be used for concrete crack mending in underwater and humid environments.

Owner:WUHAN UNIV OF TECH

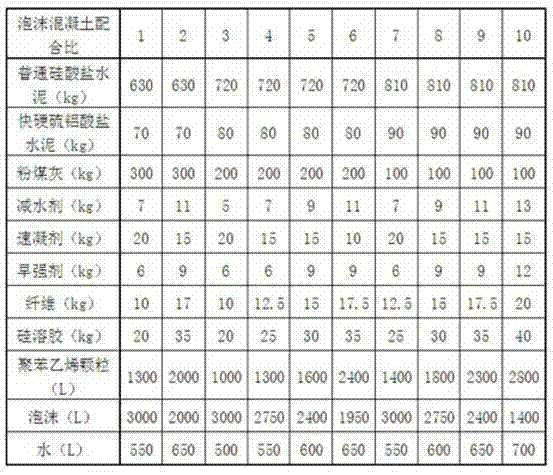

Foam concrete with large-dosage polystyrene particles and preparation method thereof

ActiveCN102503526AImprove thermal insulation performanceHigh electrical insulationCement mixing apparatusCeramicwareFoam concreteAluminate

The invention provides a foam concrete with large-dosage polystyrene particles and a preparation method thereof, which solve problems of water leakage and frost resistance of the foam concrete. The foam concrete comprises components in part as follows: 63-81 parts of ordinary portland cement, 63-81 parts of quick-hardening sulphoaluminate cement, 10-30 parts of coal ash, 0.5-1.3 parts of water reducing agent, 1-2 parts of accelerating agent, 0.6-1.2 parts of early strength agent, 1-2 parts of fiber, 2-4 parts of silica sol, and 50-70 parts of water. The percentage in volume (liter) of the polystyrene particles in added water is 200-400percent, and the percentage in volume (liter) of foam in the added water is 100-600percent. In the preparation process, the treated polystyrene particles stand for 10 min, and the foam can be added after standing uniformly-stirred cement slurry for 20 min. On the premise of ensuring the intensity, the foam cement disclosed by the invention has the advantages of higher heat preservation and heat-shielding performance, higher electric insulating performance, lower volume weight and lower water absorption. The problems of the water leakage and the frostresistance of the foam cement can be solved.

Owner:SHENYANG JIANZHU UNIVERSITY

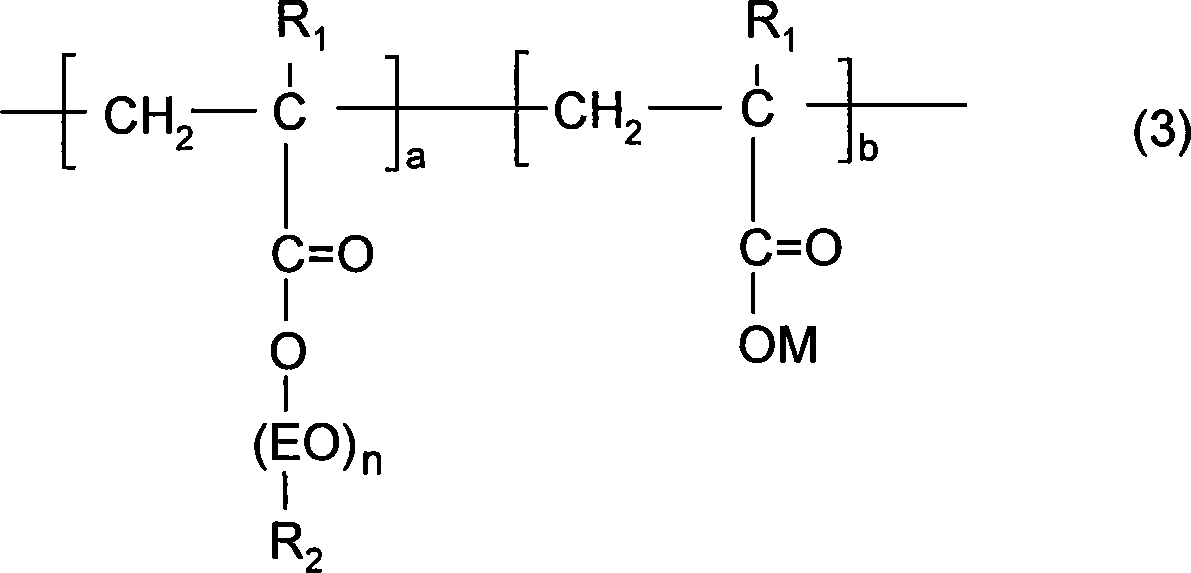

Preparation method for polycarboxylic acid high-performance water reducer

The invention discloses a preparation method of a poly-carboxylic acid water reducing agent with high performance, the water reducing agent is made in simple process with low mixing amount and high dispersive property. The technical proposal is as the follow: A) methacrylic acid and methoxy polyethylene glycol with a mole ratio of 1 to 1.2: 1 are put into a reactor with catalyst, polymerization inhibitor and water carrying agent being added to be mixed and heated to 100 to 150 DEG C and kept reacting within 8 to 12 hours to obtain polyoxyethylene methacrylate; B) water and initiator are added into the reactor, then a mixing solution containing sodium allylsulfonate, the polyoxyethylene methacrylate and the methacrylic acid is added drop by drop slowly into the reactor, wherein the weight proportion of the water and the mixing solution is 2: 1 to 1.2, the solution is mixed and heated to the temperature of 80 to 120 DEG C. Chain transfer agent is added after reaction of 4 to 6 hours and the adding drop by drop being finished, and the solution is discharged after being kept mixing with heat preserved for 1 to 2 hours, the poly-carboxylic acid water reducing agent with high performance is obtained.

Owner:JIANGSU CHEM RES INST

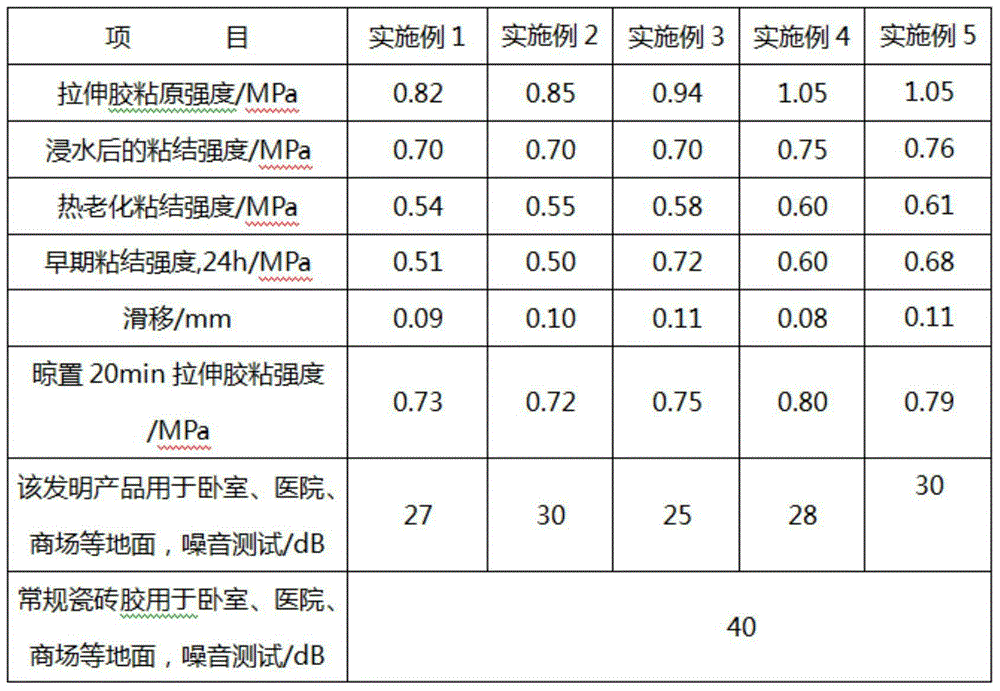

Cement-based adhesive

The invention discloses a cement-based adhesive which consists of an inorganic gel, elasticity modulus filler, sand and a dry-mixed mortar additive, wherein the mass percentages of the various components in the adhesive are as follows: 35-45% of inorganic gel, 15-30% of elasticity modulus filler, 17-47% of sand, 3-8% of dry-mixed mortar additive and the balance of water. The cement-based adhesive disclosed by the invention has the following beneficial effects that by adding the low elasticity modulus filler which has the advantages of good elasticity, shock-proofing, sound insulation and the like, the cement-based adhesive has the characteristics of shock absorbing, noise reduction and the like, so that a problem of noise generated from the collision of ceramic tiles in a public place is relieved; in addition, the cement-based adhesive provided by the invention also solves the problems of low compressive strength, low bonding strength and the like of the adhesive after the low-modulus filler is added; shearing strength on the interfaces of the ceramic tiles caused by heat expansion and cold contraction is reduced and the bonding durability of the ceramic tiles on the basis of shock absorbing and noise reduction is improved; therefore, the cement-based adhesive is quite high in promotional value.

Owner:北京天维宝辰化学产品有限公司

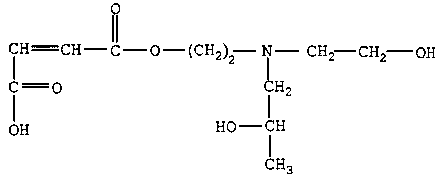

Early strength type polycarboxylate water reducer and preparation method thereof

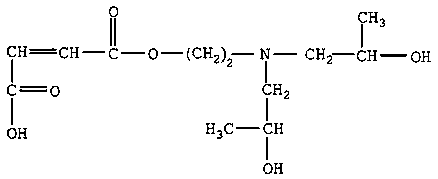

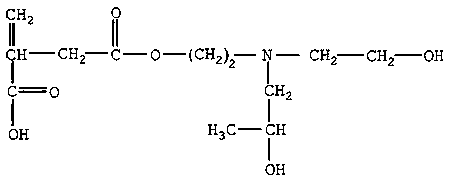

The invention discloses an early strength type polycarboxylate water reducer and a preparation method thereof. The early strength type polycarboxylate water reducer is prepared by performing free radical polymerization on unsaturated polyether, unsaturated carboxylic acid, hydramine-containing unsaturated ester and amide-containing unsaturated compounds in a redox system under the action of chaintransfer agent; the preparation process saves heat sources and accordingly is green and environmentally friendly. According to the prepared early strength type polycarboxylate water reducer, the long-chain unsaturated polyether can achieve certain enhancing effects on the early strength of cement and concrete components; the hydramine-containing unsaturated ester and the amide-containing unsaturated compounds serve as unsaturated early strength monomers, contained hydramine groups and amide groups can promote hydration of C3A (3CaO*Al2O3) to produce ettringite, thereby accelerating cement hydration, shortening the time of cement setting, improving the early strength and increasing the production efficiency of the cement and concrete components. Meanwhile, the carboxylic acid groups and theester groups inside the molecules of the early strength type polycarboxylate water reducer endow the early strength type polycarboxylate water reducer with good dispersibility and dispersion retentivity.

Owner:UNIV OF JINAN +1

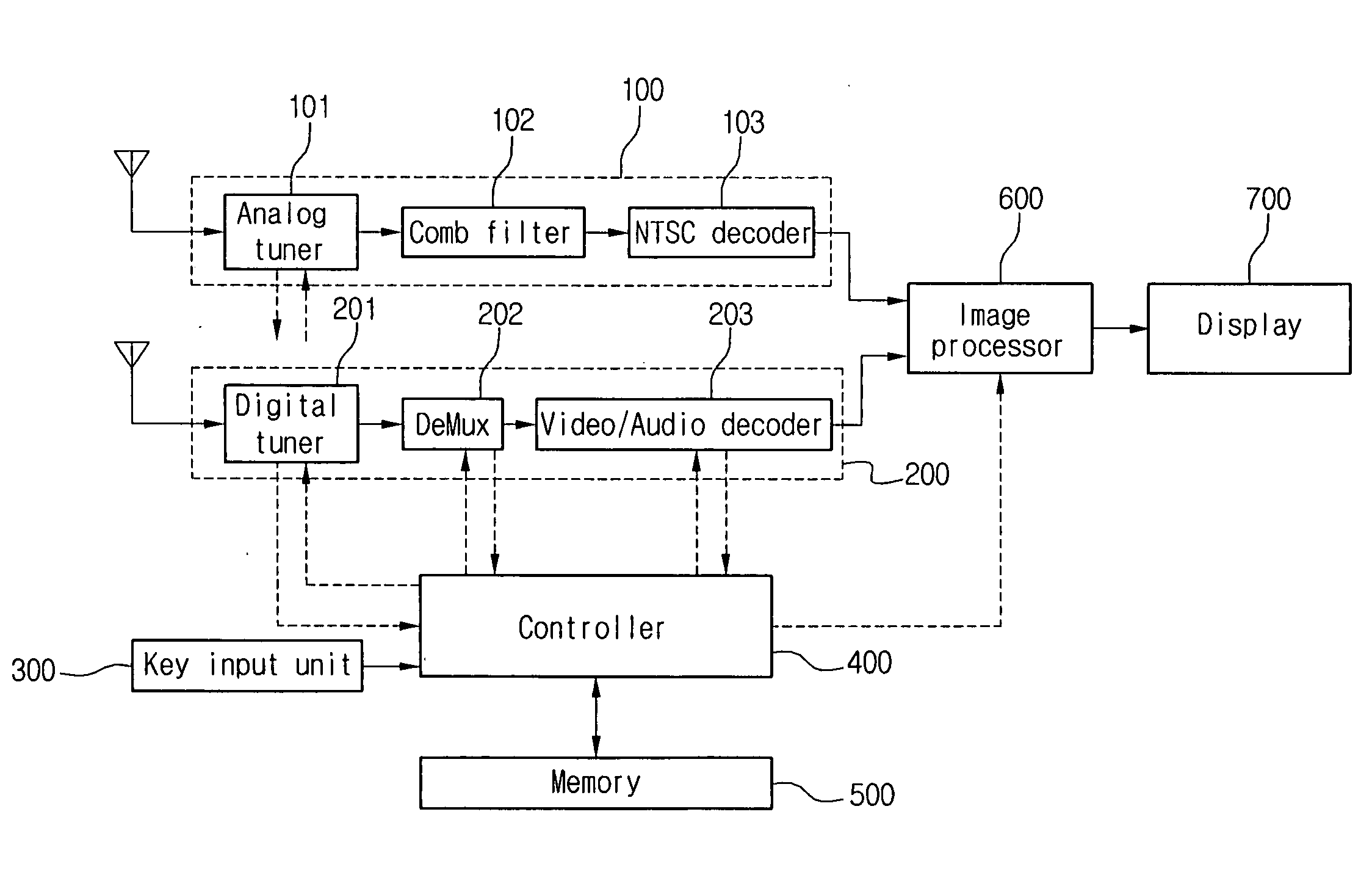

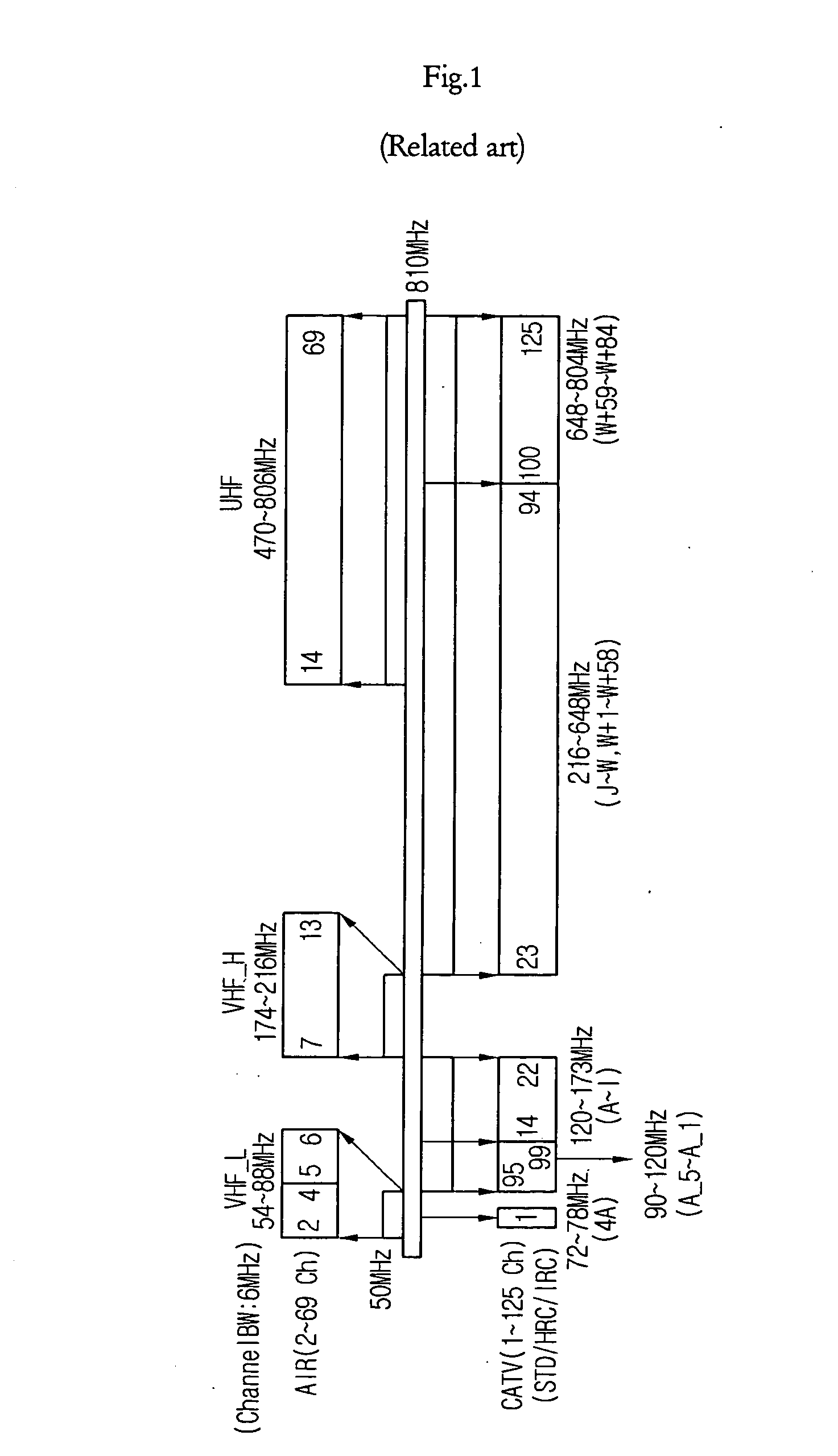

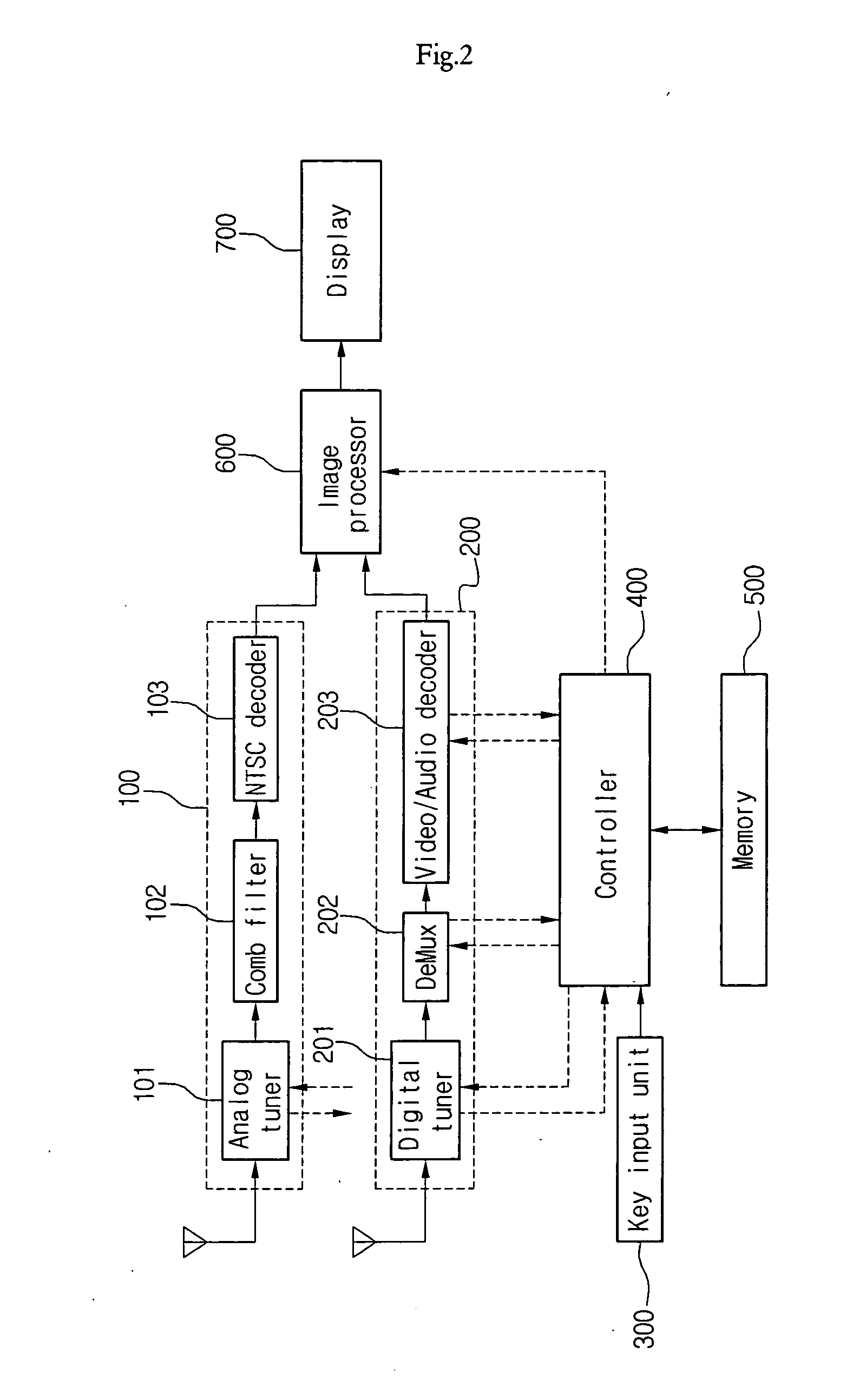

Digital TV and channel setting method thereof

ActiveUS20050036073A1Reduce digital broadcast channel setting timeShorten the setting timeTelevision system detailsTelevision system scanning detailsDigital tuningDigital television

An image display apparatus equipped with an analog tuner and a digital tuner includes a key input unit for enabling a user to input an automatic channel scan command and other requests; a controller for conducting channel scan in response to the automatic channel scan command inputted through the key input unit, the channel scan first being conducted on analog channels and then digital channels by using the analog tuner and the digital tuner, or first being conducted on digital channels and then analog channels by using the digital tuner and the analog tuner, wherein the comparison of the number of channels scanned first with a predetermined number of channels determines a channel scan method; and a memory for storing analog channels / digital channels being automatically scanned.

Owner:LG ELECTRONICS INC

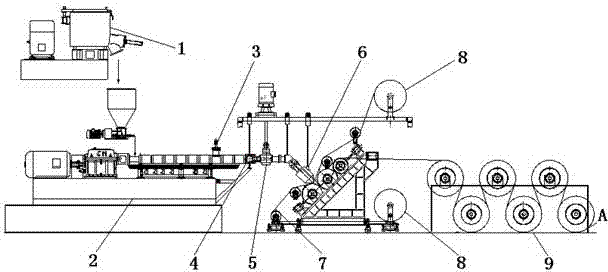

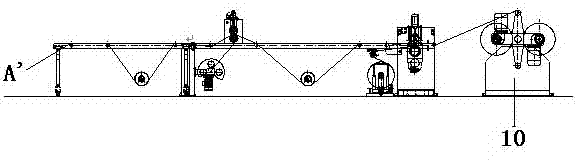

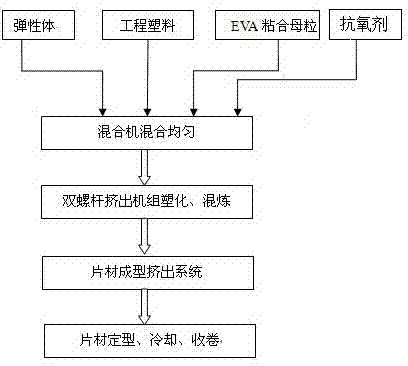

Shoe material hot-melt adhesive sheet and production process and equipment thereof

ActiveCN103613919AImprove physical performanceGood resilienceInsolesFlat articlesAntioxidantHot pressing

The invention discloses a shoe material hot-melt adhesive sheet. The shoe material hot-melt adhesive sheet comprises the following raw material components: 35-40% of elastomer, 45-50% of engineering plastic, 10-15% of EVA (ethylene vinyl acetate) binding masterbatch and 0.5-1.5% of antioxidant. A production process of the shoe material hot-melt adhesive sheet provided by the invention comprises the steps of mixing the elastomer, the EVA binder masterbatch, the engineering plastic and the antioxidant in a twin-screw extruder, pressurizing a melt by a melt pump, then enabling the melt to flow out of a T-shaped die head, hot-bonding double surfaces of polyester non-woven mesh fabric on the upper surface and lower surface of the melt of the sheet in a three-roller calendering machine, further calendering and shaping, cooling and shaping the sheet by a cooling roller cylinder after shaping, cutting edges, and then rolling or cutting according to a fixed size. The elastomer hot-melt adhesive sheet can be used for manufacturing finished products of shoe heads and back liners after being stamped by a mold, the shaped adhesive sheet finished products are placed into shoe inner liners and interlayers of shoe vamps for hot-pressing, binding and solidifying, and the production process flow is simplified and is suitable for mass production of an assembly line.

Owner:江苏诚盟装备股份有限公司

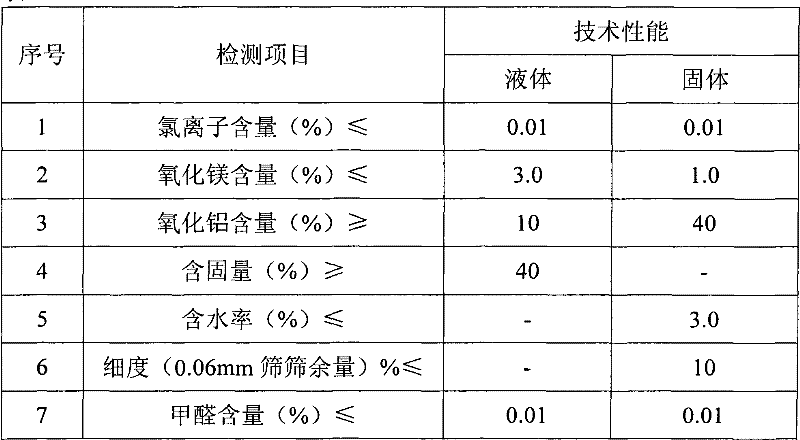

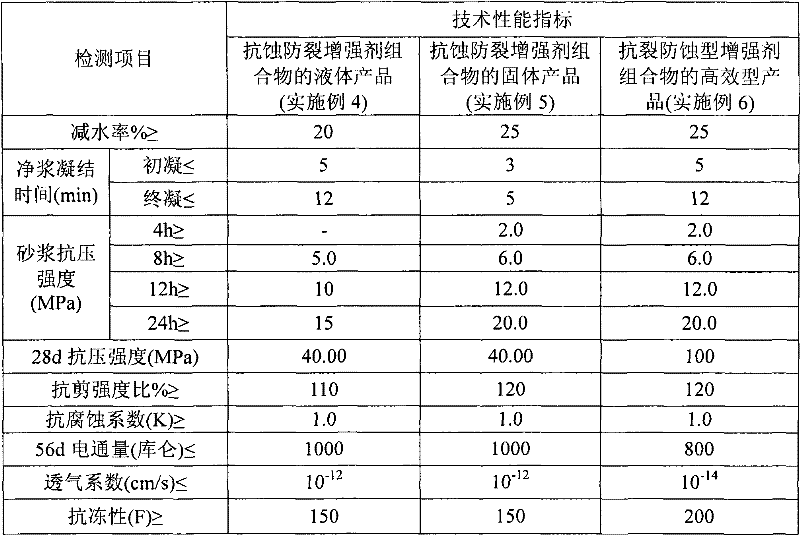

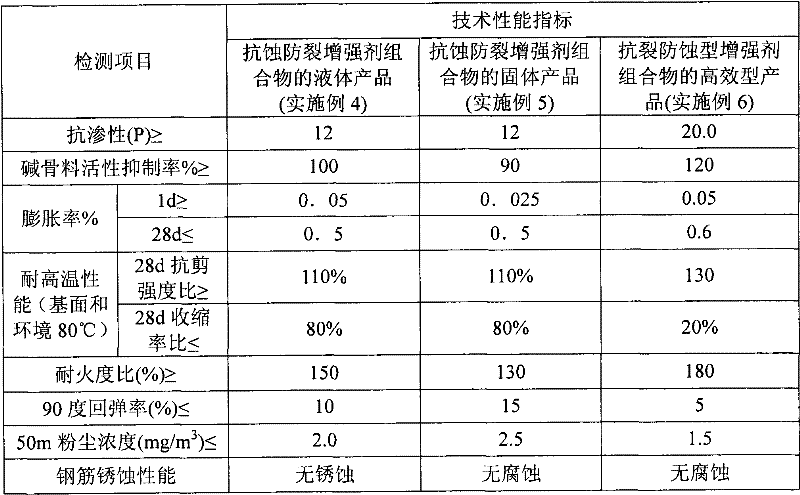

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

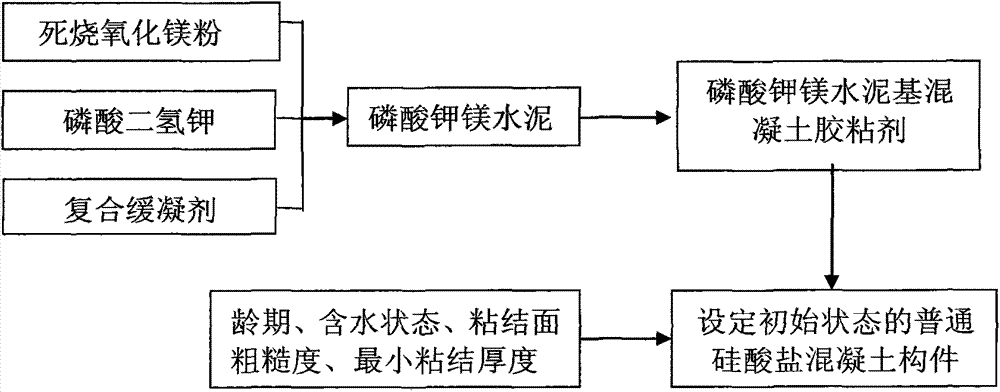

Magnesium potassium phosphate cement-based concrete adhesive and preparation method thereof

The invention discloses a magnesium potassium phosphate cement-based concrete adhesive and a preparation method thereof. The preparation method of the magnesium potassium phosphate cement-based concrete adhesive comprises the following steps: firstly, taking 50-70 parts by mass of dead-burned magnesia powder as an alkali component and 30-50 parts by mass of monopotassium phosphate as an acid component, and doping 6-10 parts by mass of complex retarder to prepare magnesium potassium phosphate cement, wherein the complex retarder is composed of sodium tetraborate, sodium phosphate dibasic dodecahydrate and inorganic chlorine salt in mass ratio of (2-4):(4-8):(2-5); secondly, preparing the magnesium potassium phosphate cement-based concrete adhesive by taking 5-15 parts by mass of limestone powder, 10-20 parts by mass of coal ash and 70-85 parts by mass of magnesium potassium phosphate cement. The complex retarder effectively delay condensation time of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement guarantees higher early strength, and the coal ash and limestone powder guarantee stable growth of strength and improve volume stability.

Owner:YANCHENG INST OF TECH +1

Carboxylic acid copolymer concrete slump retaining agent

The invention discloses a carboxylic acid copolymer concrete slump retaining agent. The slump retaining agent is a copolymer which has the molecular weight of between 10,000 and 100,000 and is synthesized by using modified polyester, unsaturated carboxylic acid and cross-linking agent and by adopting a redox system and an initiator; 30 percent liquid alkali is added into the copolymer at the temperature of 45 DEG C to neutralize the copolymer and the concentration of the neutralized solution is diluted to 45 percent by softened water, and the pH value of the mixed solution is controlled to be between 6.0 and 7.0. Compared with the prior art, the slump retaining agent is directly prepared by polymerization which is performed by using the modified polyester, the unsaturated carboxylic acid and the cross-linking agent and by adopting the redox system and the water soluble initiator, activated macro-monomers of esters are not required to be prepared, the process is simple and the reaction temperature is low. The slump retaining agent has a good plastic retaining effect on middle and low slump concrete or high slump concrete and does not prolong the setting time of the concrete. Meanwhile, the cross-linking agent contained in the structure has a slow-release effect under the action of a strongly alkaline cement environment and slowly releases dispersive low-molecular polymers, so the problem of slump loss of the concrete is effectively solved.

Owner:深圳市五山新材料股份有限公司

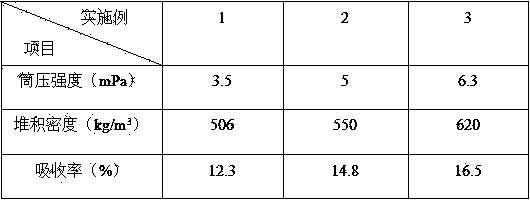

Sludge coal ash high-strength ceramsite and preparation method thereof

ActiveCN104261802AIn line with the principles of sustainable developmentRaise the ratioCeramic materials productionClaywaresSludgeExpanded clay aggregate

The invention discloses sludge coal ash high-strength ceramsite and a preparation method thereof. By using sludge and coal ash as main raw materials, the ceramsite is prepared by mixing, prilling and calcining by synergic match with an additive. The ceramsite is prepared from the following raw materials in parts by weight: 40-70 parts of sludge, 30-55 parts of coal ash, 0.5-1.5 parts of calcium sulphoaluminate, 0.5-1 part of phthalate, 1-3 parts of water glass and 0.5-1 part of a deodorant, wherein the water content of sludge is controlled within 35-50wt%. The sludge coal ash high-strength ceramsite is prepared by the following steps: mixing the materials; prilling; drying; calcining; and cooling. The ceramsite disclosed by the invention is economical, environment-friendly, efficient and energy-saving and scientific and reasonable in match of components of raw materials, and the prepared sludge coal ash high-strength ceramsite has the advantages of high cylinder compressive strength and high absorption.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

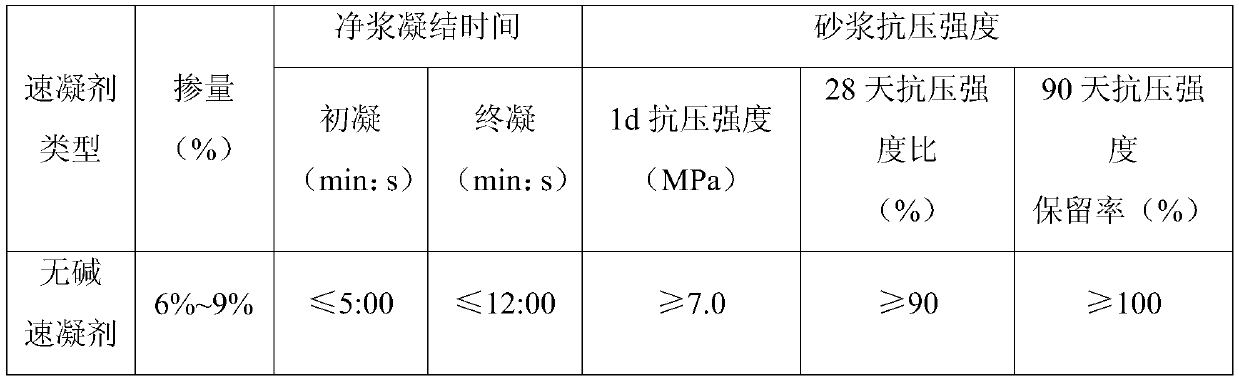

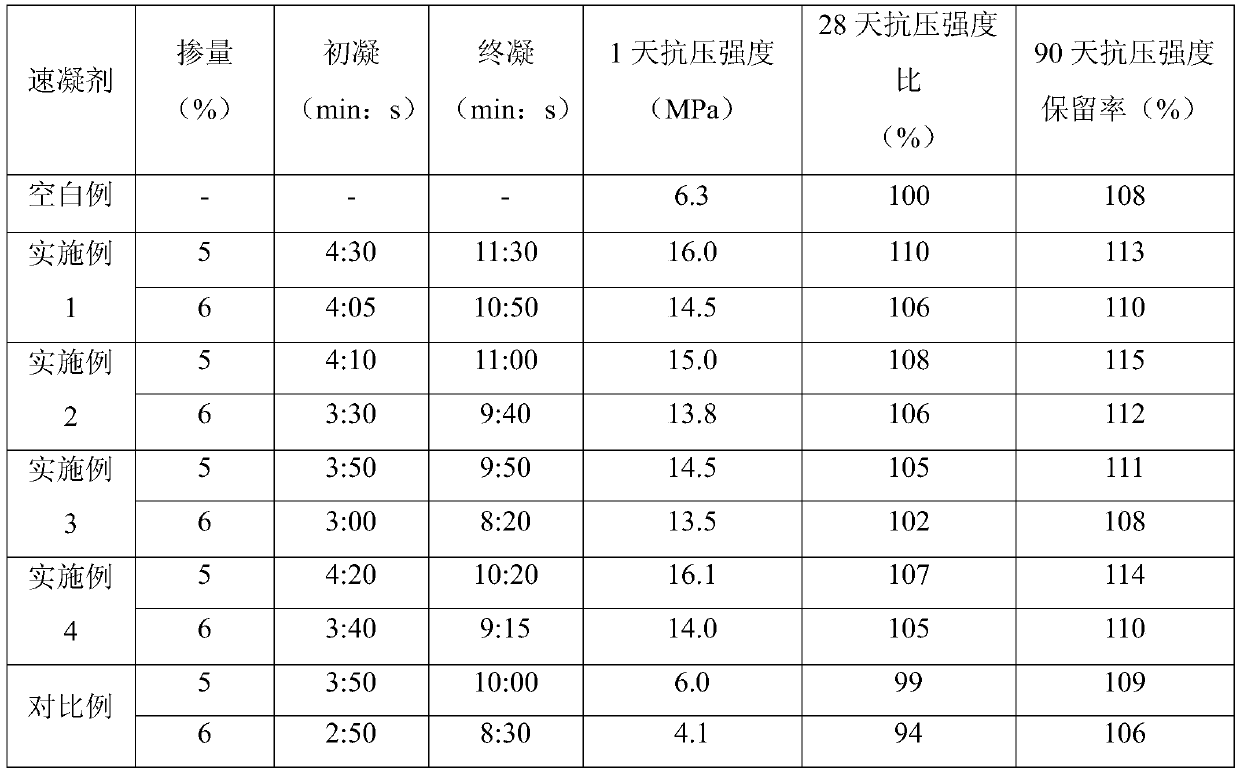

Low-dosage high-early-strength alkali-free liquid accelerator and preparation method thereof

The invention discloses a low-dosage high-early-strength alkali-free liquid accelerator and a preparation method thereof. The alkali-free liquid accelerator is prepared from the following raw materials: 1, an alkali-free liquid accelerator; 50%-60% of modified aluminum sulfate, 2%-4% of a fluorine-aluminum complex solution, 3%-6% of an organic cosolvent, 1%-2% of a pH regulator, 0.5%-1.5% of an inorganic stabilizer, 0.3%-0.5% of a viscosity regulator, 4%-6% of a composite early strength agent and the balance of water, wherein the sum of the mass percentages of the components is 100%. The invention also provides a preparation method of the alkali-free liquid accelerator. The preparation process of the alkali-free liquid accelerator is simple; hydrofluoric acid-free process, alkali-free, chlorine-free, rust-free steel bar, non-polluting environment. Meanwhile, when the mixing amount of the alkali-free liquid accelerator is 5%-6%, the technical requirements of GB / T35159-2017 on the alkali-free accelerator can be met, the one-day compressive strength is larger than or equal to 13.0 MPa, and the alkali-free liquid accelerator has the advantages of being low in mixing amount, good in stability, high in early strength and large in later strength retention rate.

Owner:刘翠芬

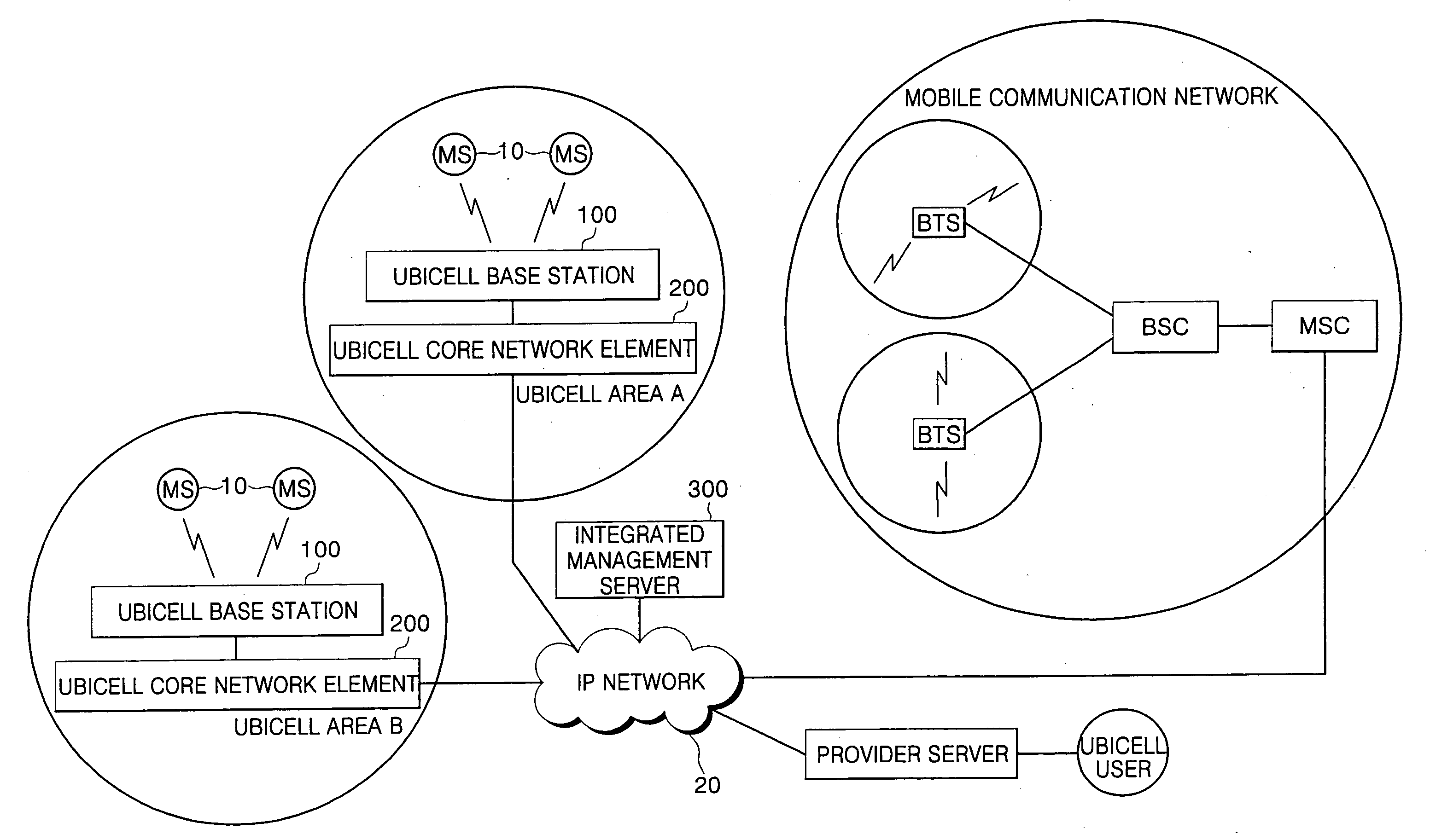

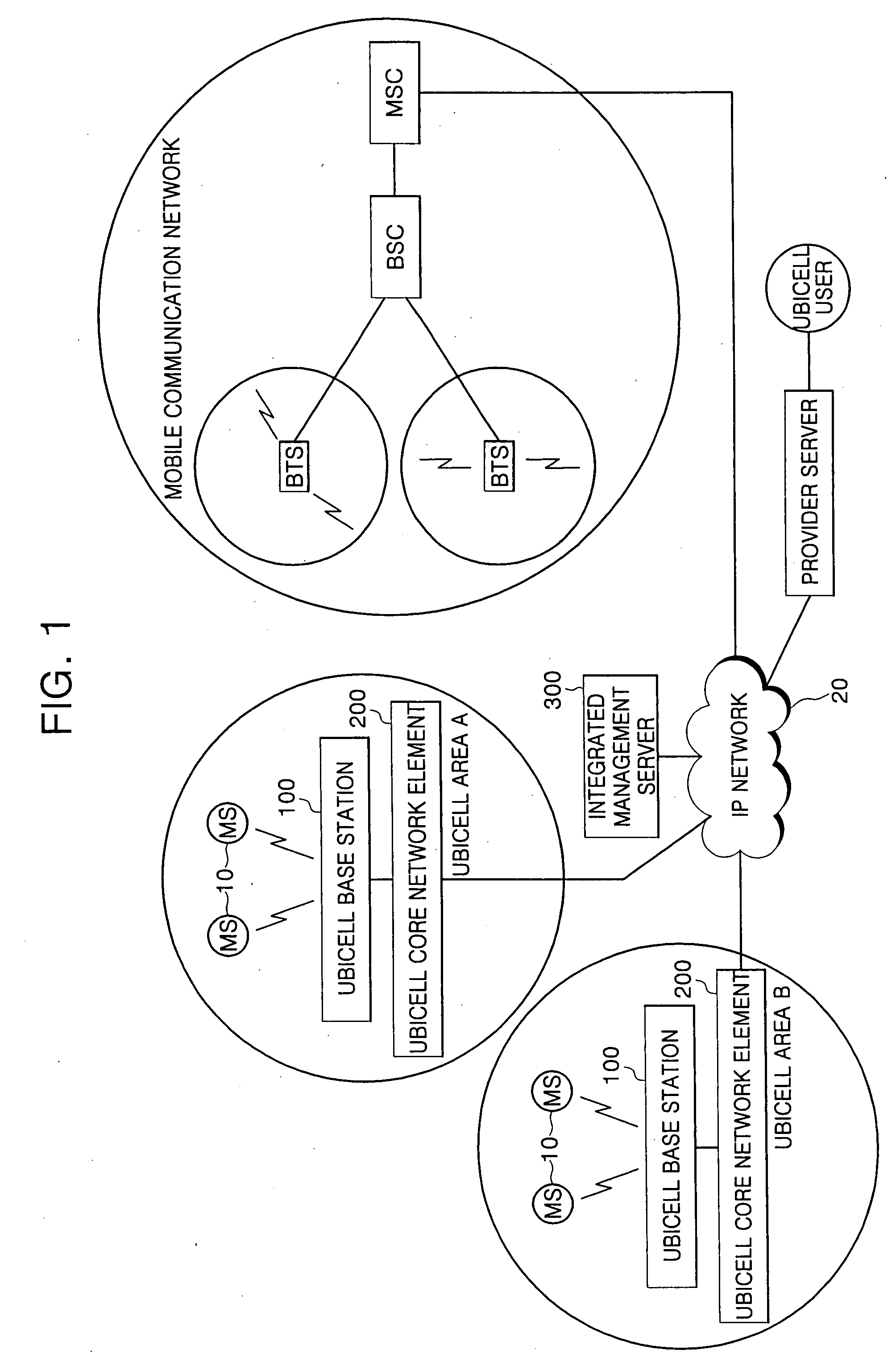

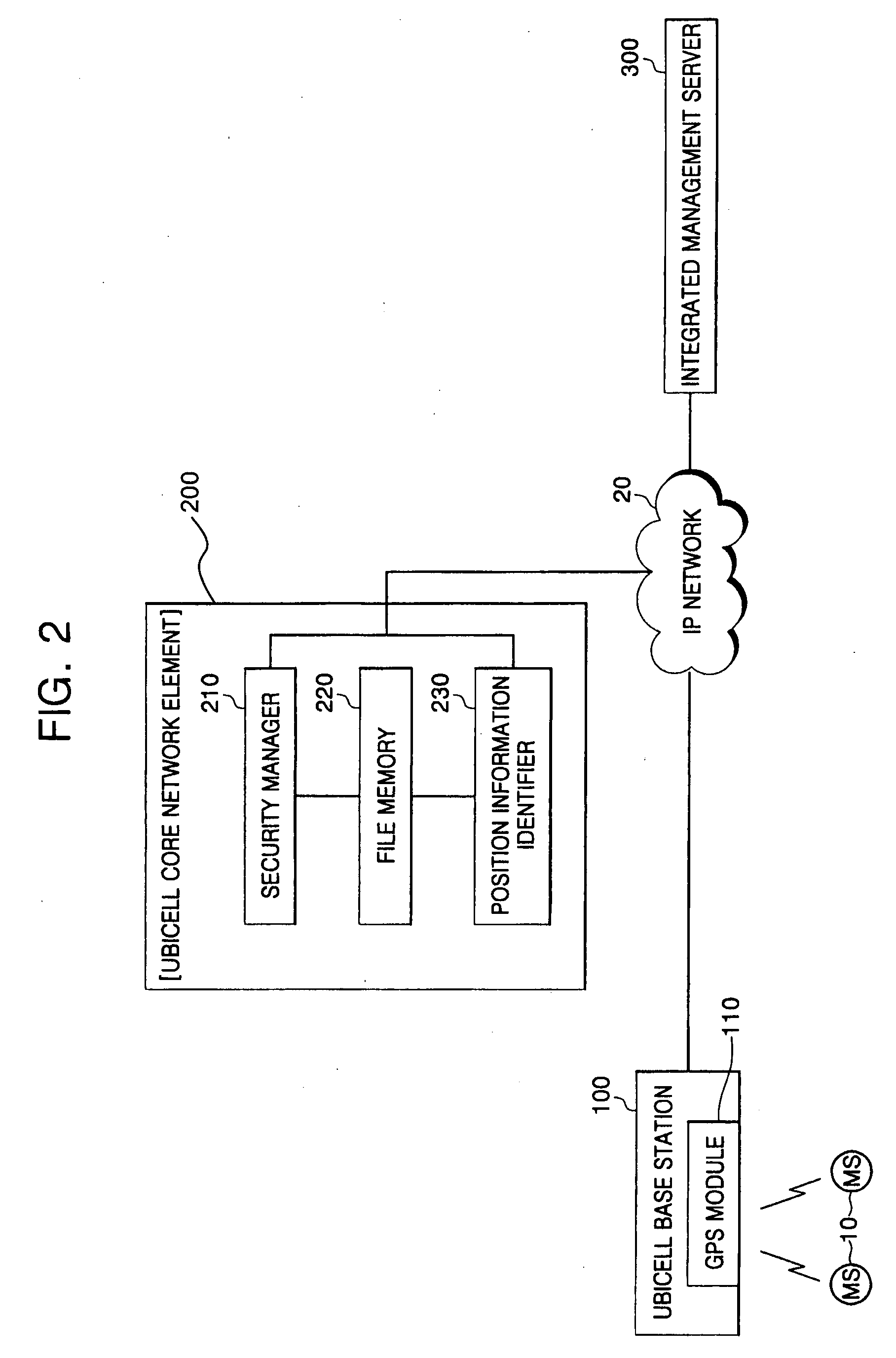

Automatic setup system and method of ubicell base station

InactiveUS20080139249A1Easy to set upShorten the setting timeSubstation equipmentRadio transmissionCore networkBase station

A Ubicell base station includes a Ubicell base station, one or more Ubicell core network elements, and an integrated management server. The Ubicell base identifies position information thereof using a GPS module, and at a time of setup, provides environment setting information including the position information thereof. Each Ubicell core network element, upon receiving environment setting information of an arbitrary Ubicell base station, generates an environment construction information file of the arbitrary Ubicell base station, registers the arbitrary Ubicell base station, and sends the environment construction information file to the arbitrary Ubicell base station. The integrated management server identifies the Ubicell core network element in a corresponding position based on the environment setting information, provided from the Ubicell base station, and provides the environment setting information of the Ubicell base station to the Ubicell core network element.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com