Dental repair material

a technology for dental repairs and materials, applied in the field of dental repair materials, can solve the problems of affecting affecting the healing effect of teeth, etc., and achieve the effect of improving the composition of dental repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Modified MTA

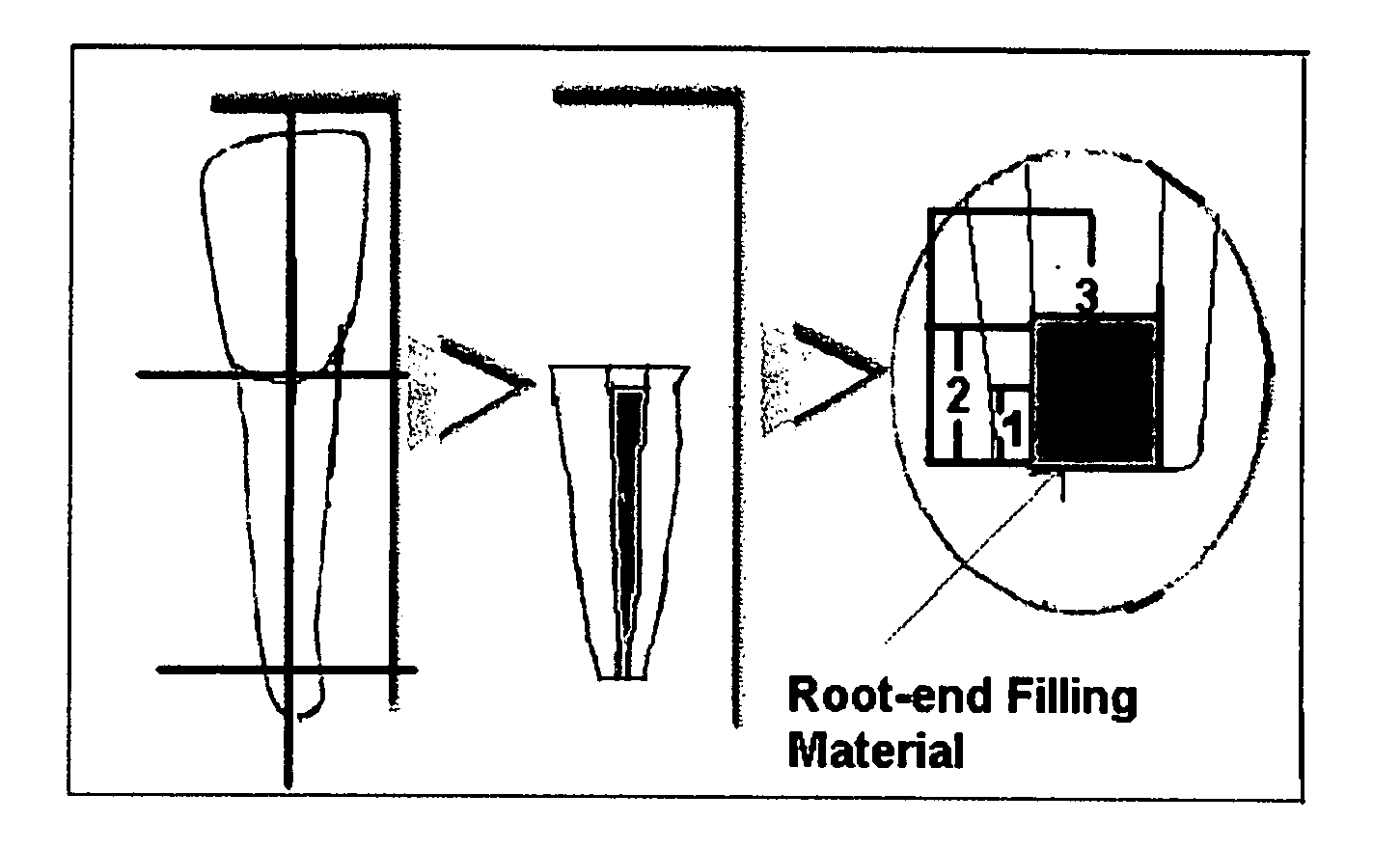

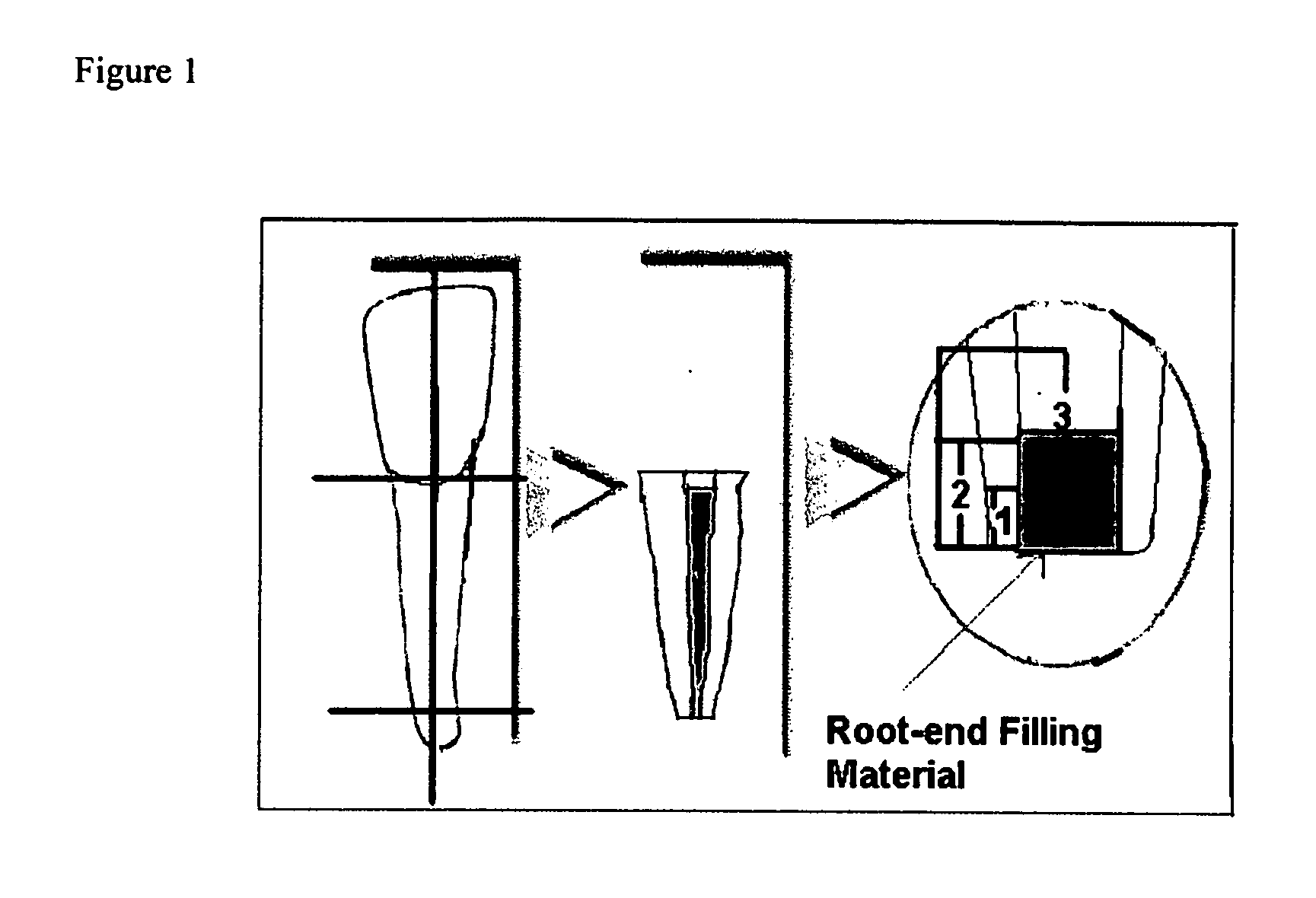

[0075] As of 2005, there have been some 150 articles published regarding Mineral Trioxide Aggregate's (MTA) composition, properties, biocompatibility, and indications for use. MTA has become the material of choice for an array of endodontic applications, including vital pulp therapy, apexification, perforation repair, as well as a root-end filling material. Any root-end filling material should have the ability to seal the root canal from bacterial and chemical invasion as well as be biocompatible, prevent periradicular tissue irritation, and ideally favor regeneration of the involved tissues to their prediseased status (1).

[0076] MTA has been demonstrated to meet many of the ideal properties of a root-end filling material as described by Gartner and Dom (2). MTA is different from other root-end filling materials currently in use, (Super-EBA, IRM, Amalgam, and composite resin-based materials). Both in vitro and in vivo studies have consistently demonstrated this materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

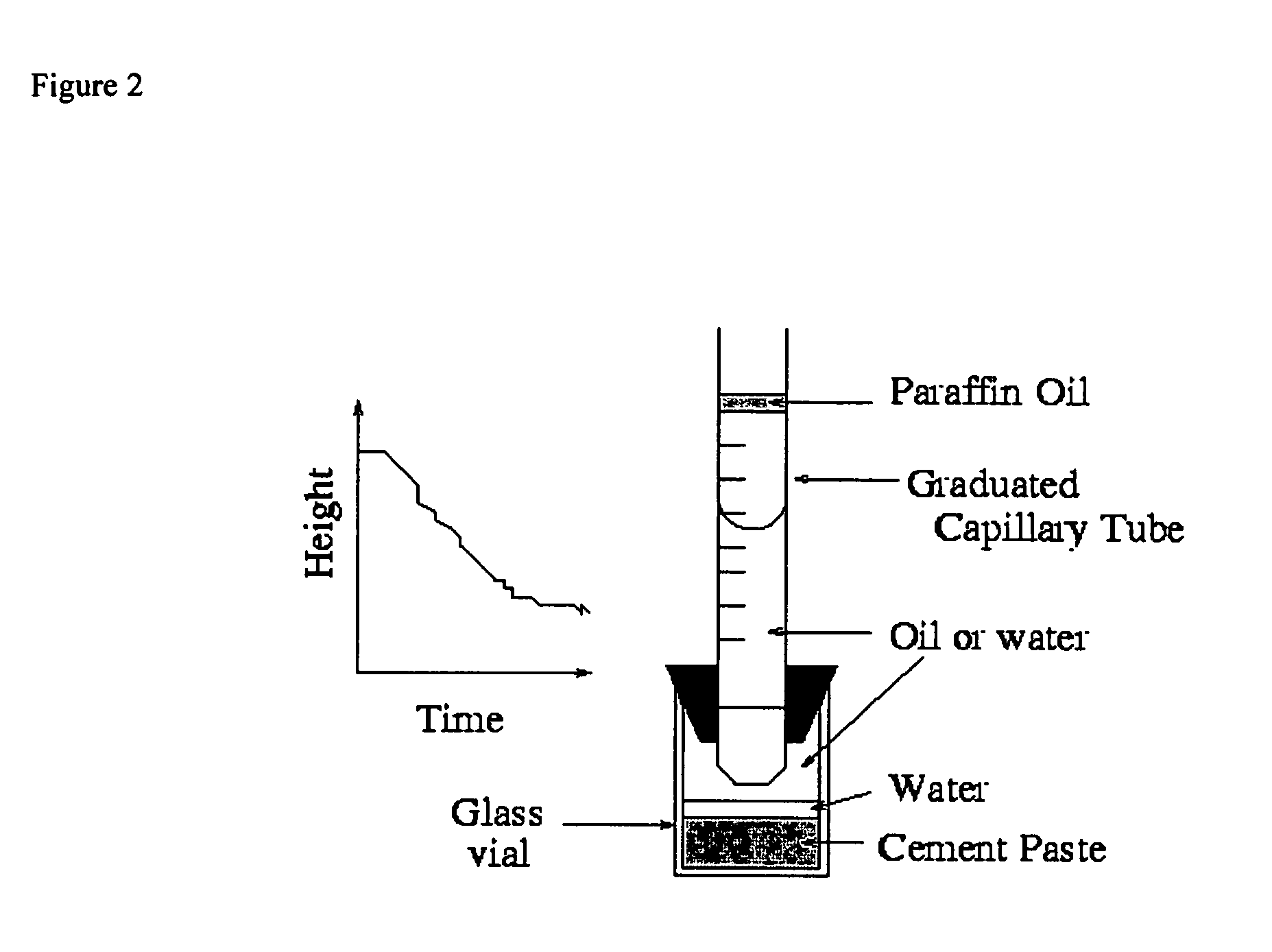

| chemical shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com