Patents

Literature

211 results about "Tooth cavity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

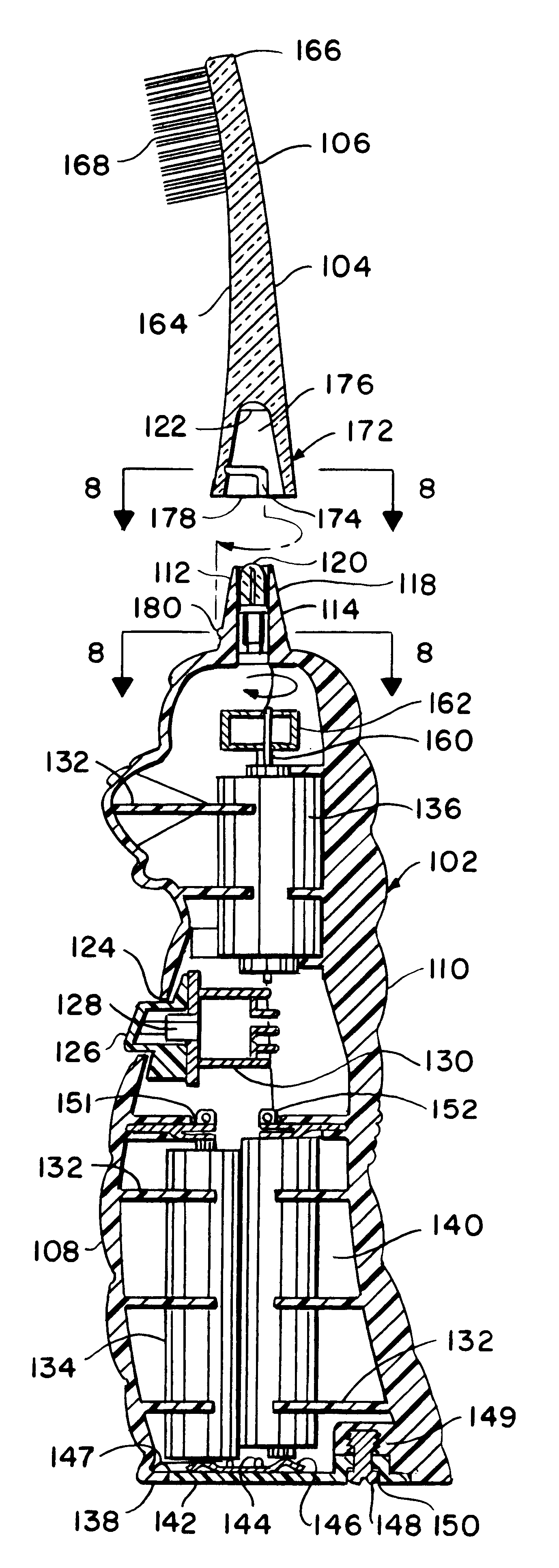

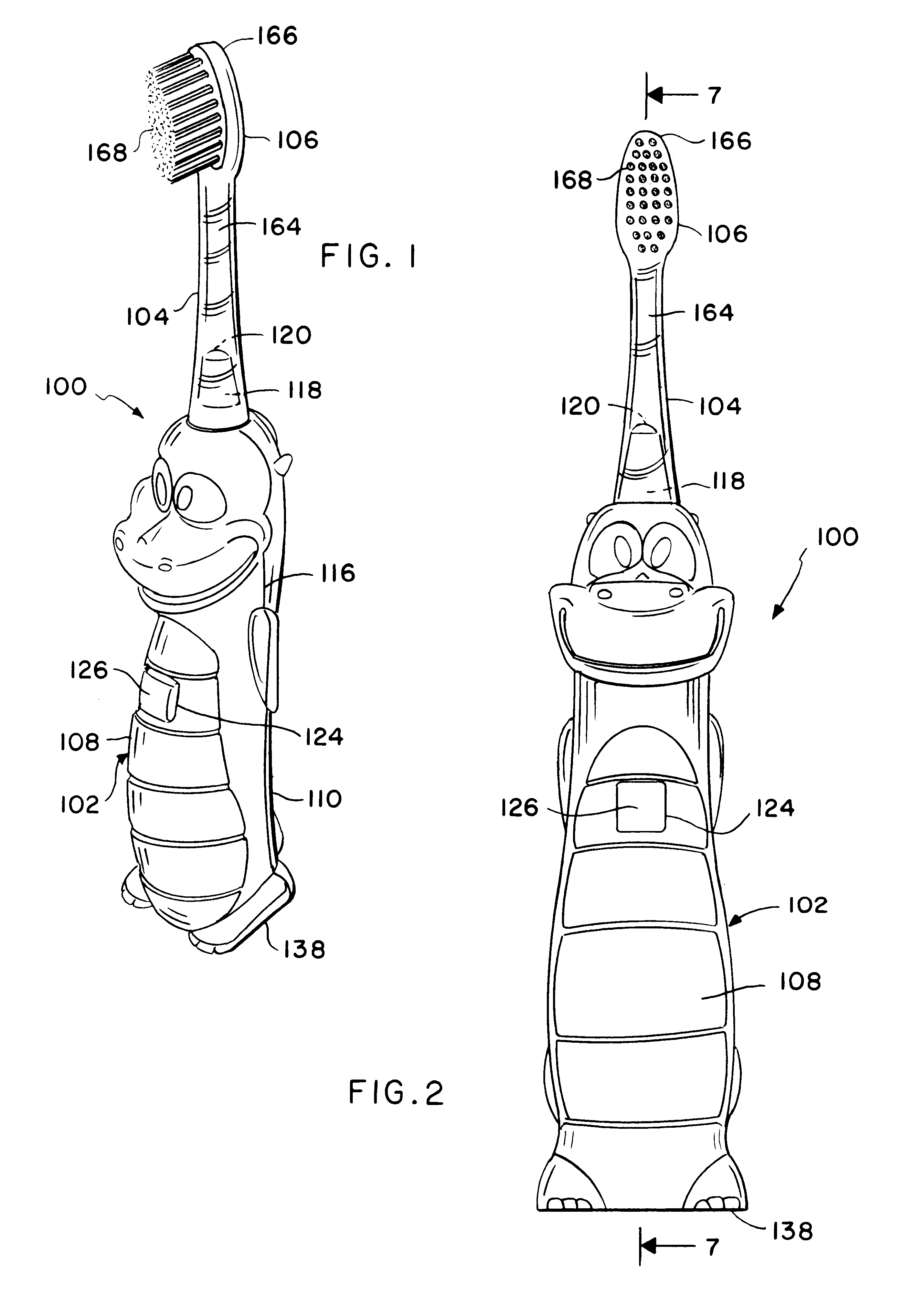

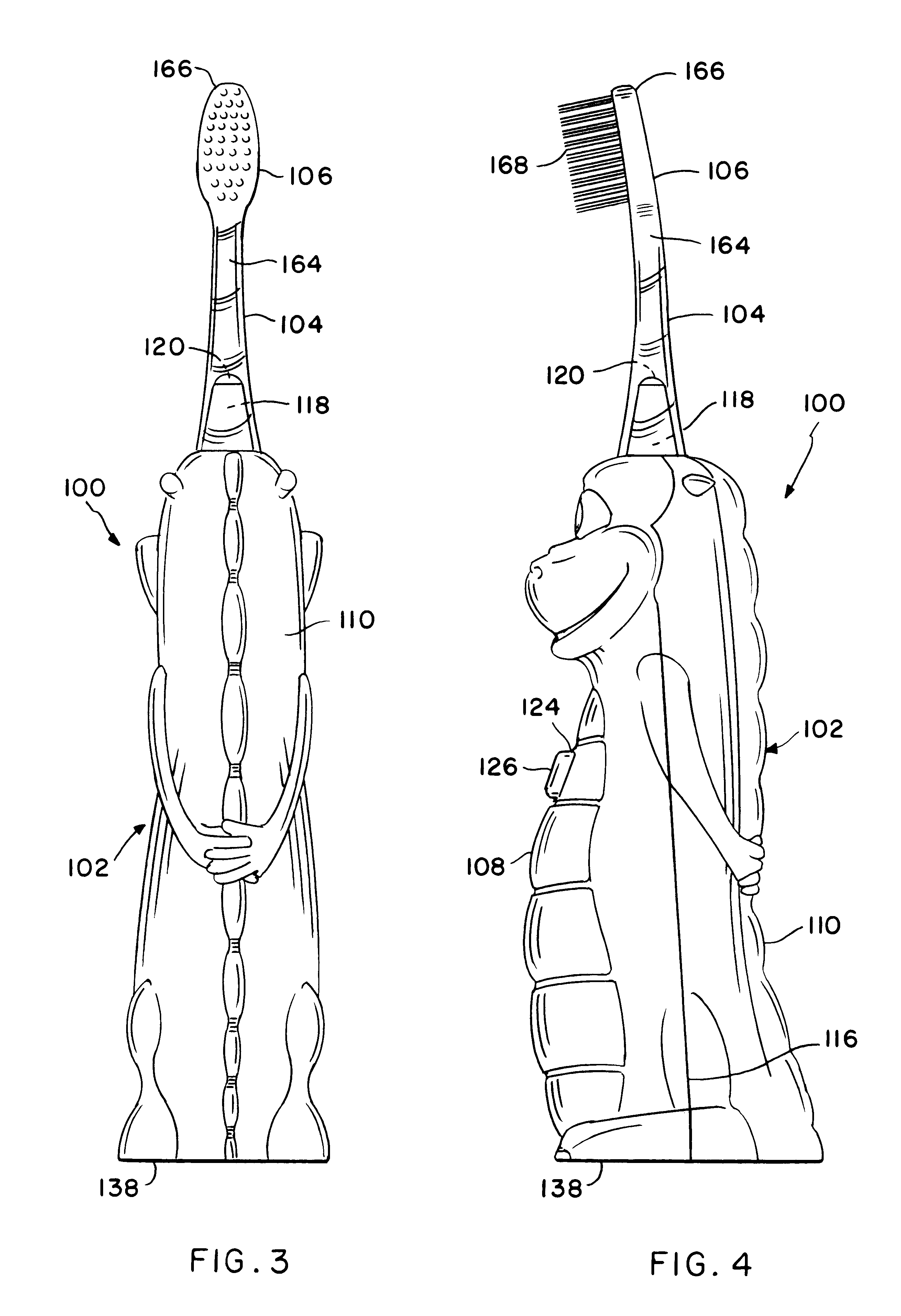

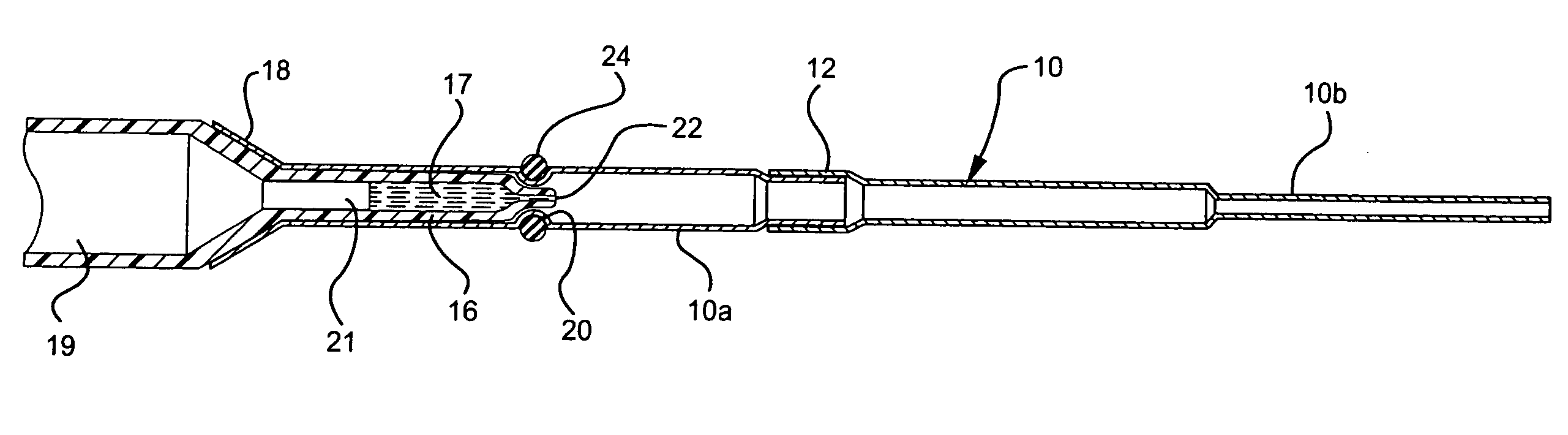

Light emitting electric toothbrush

A light emitting electric toothbrush and method therefore is disclosed which is intended for use by children, is comprised of a robust high-strength, plastic construction, and employs both light and vibration to assist in the development of suitable dental hygiene skills. In its most fundamental embodiment, the light emitting electric toothbrush comprises a construction including a handle having a bottom end and a top end and a toothbrush shaft mounted to the top end of the handle. The brush shaft is comprised of a plastic resin including a fluorescent colored light refractive additive for optimizing light transmission through the brush shaft. A high intensity light source is mounted within the top end of the handle for generating light and a domed-shaped optical lens is positioned over the high intensity light source for directing the generated light into the brush shaft. Finally, a switched electrical source is included for energizing the light source and the generated light therefrom creates a glowing illumination in the brush shaft for illuminating a dental cavity of a person during brushing of the teeth. In a preferred embodiment, the toothbrush also includes a vibrating motor mounted within the handle for causing the brush shaft to vibrate. The vibrating motor is also energized by the switched electrical source simultaneously with the light source.

Owner:ZEPHYR DESIGN

Dental composite restorative material and method of restroring a tooth

InactiveUS20030060532A1Highly packableCosmetic preparationsImpression capsMicrometerDental composite

A dental composite material includes a hardenable resin matrix and a filler component. The filler component includes (a) a first plurality of preferably glass particles having an average particle size of from about 1 to about 10 micrometers; (b) a second plurality of preferably glass particles having an average particle size of from about 0.1 to about 1 micrometers; and, (c) a plurality of filler particles having an average particle size of from about 0.01 to about 0.04 micrometers. A method according to the invention includes compacting a dental composite material into a prepared tooth cavity, wherein the material has a packability index above about 300 g / mm2.

Owner:DENTSPLY RES DEVMENT

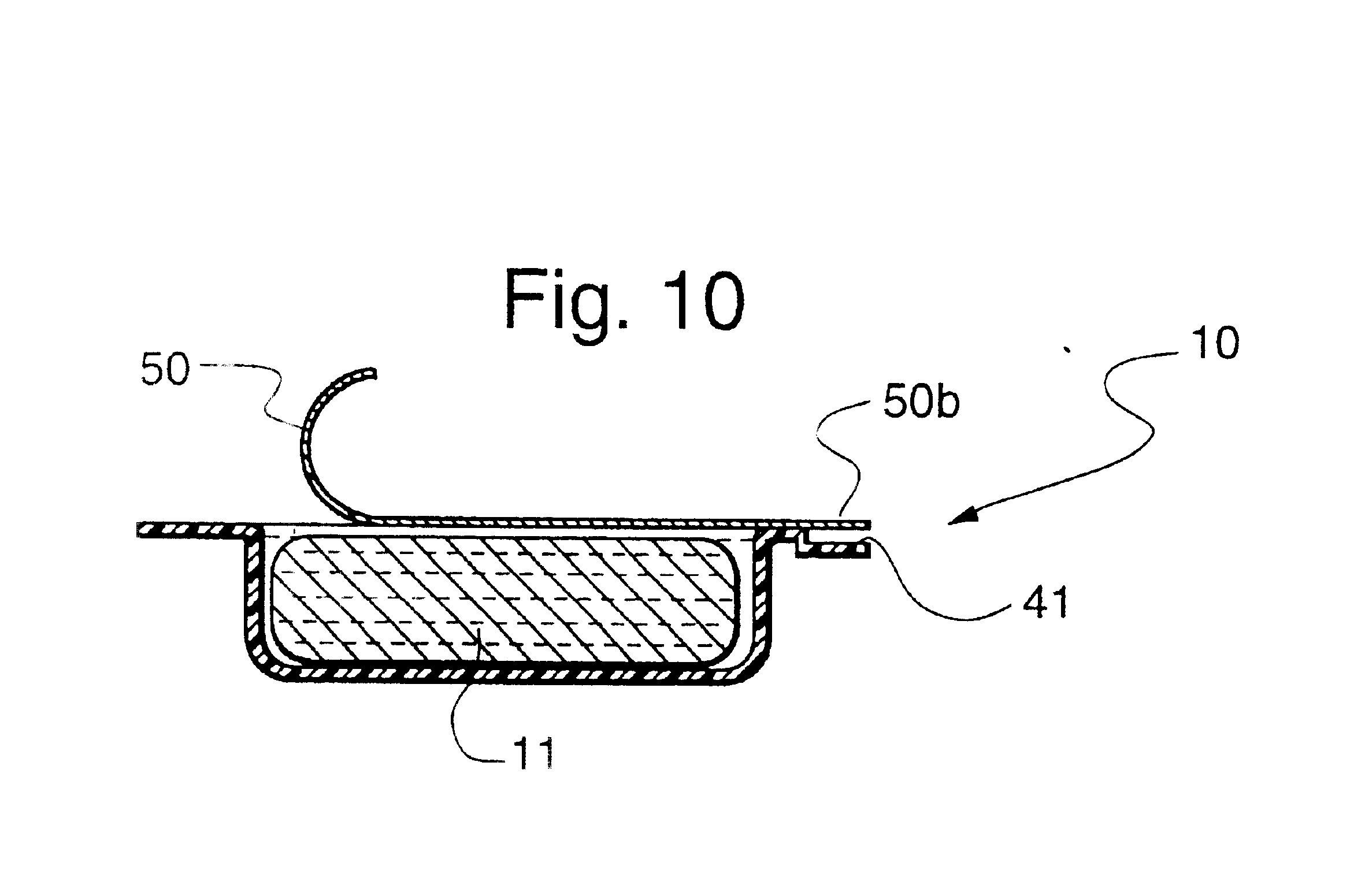

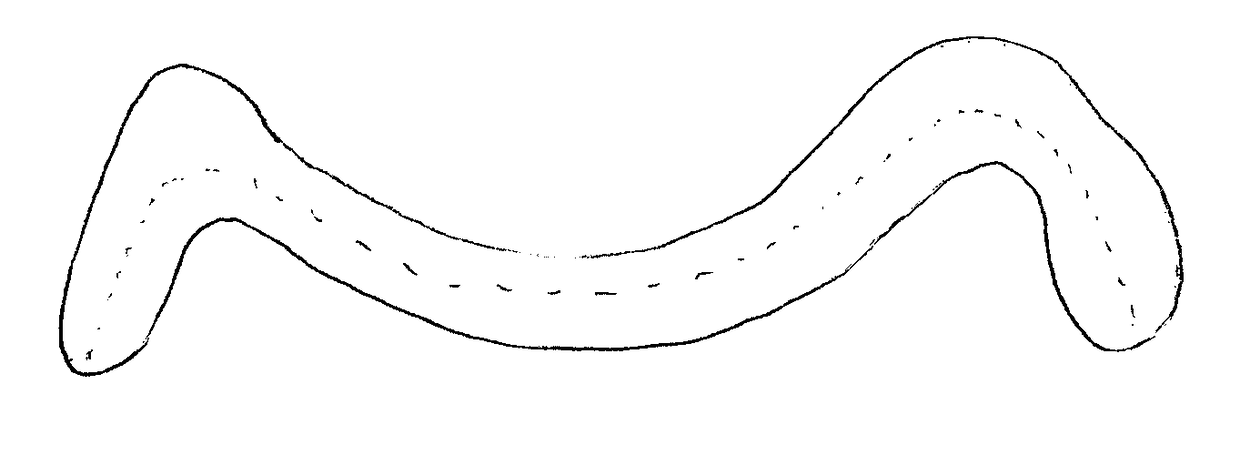

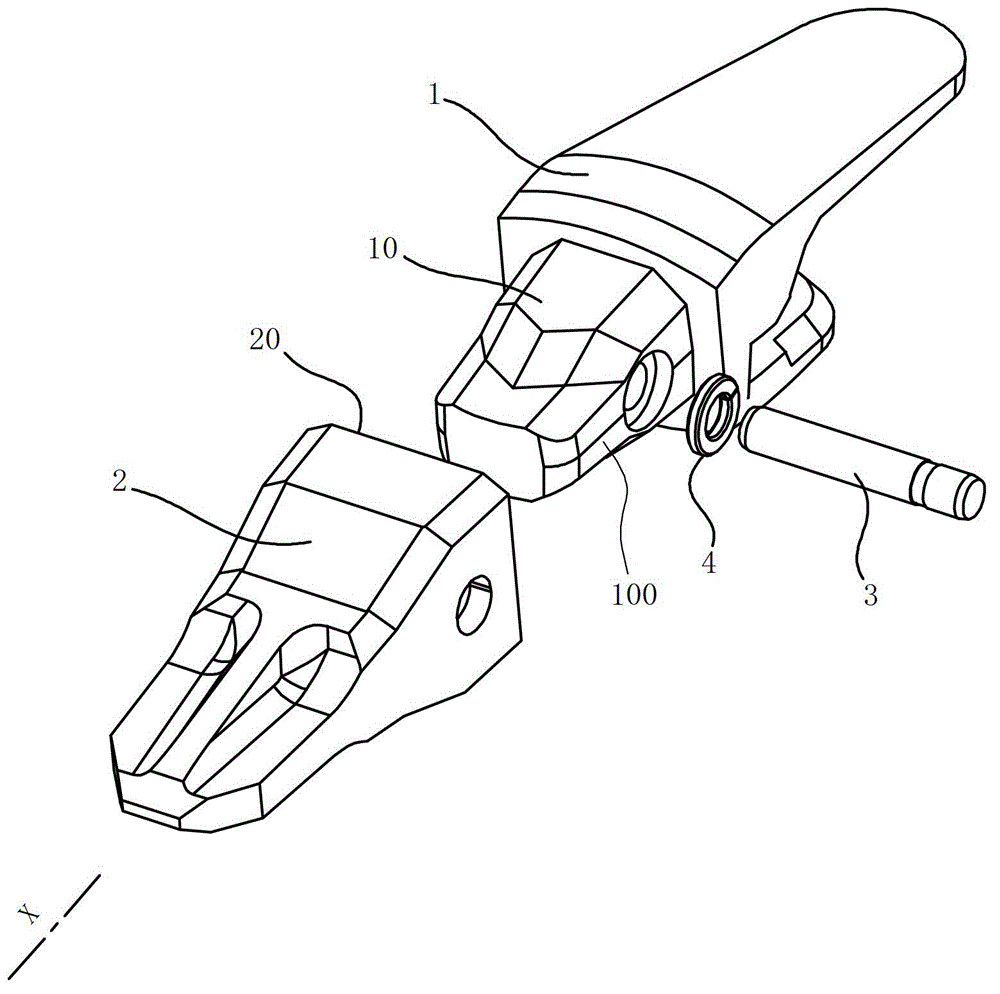

Connecting structure for trolley tine and tine holder

InactiveCN101153497AEmbedded connection is stable and firmFirmly connectedSoil-shifting machines/dredgersEngineeringCavity wall

A link structure between cutting teeth and a tooth holder comprises the cutting teeth, the tooth holder and pins. The tooth holder comprises a tooth holder head on the front part and a tooth holder connecting piece on the rear part, wherein, the tooth holder head on the front part is connected with the front cutting teeth, and the tooth holder connecting piece on the rear part is used for fixing the tooth holder onto the strickle of a bucket. The cutting teeth consists of a tooth tip part and a cutting teeth cavity, wherein, the cutting tooth cavity comprises a cutting tooth inner cavity and a cutting tooth outer cavity, and the tooth holder head is held by the cutting tooth inner cavity, is embedded into the cutting tooth inner cavity and is connected with the cutting tooth inner cavity through pins. The link structure is characterized in that: the elastic pins are arranged inside the pin holes of the tooth holder head, and pin locking holes are correspondingly arranged on the wall of the cutting tooth inner cavity or the extending part of the inner cavity wall to enable adaptation and connection between the elastic pins and the pin locking holes, thereby enabling detachable connection between the cutting teeth and the tooth holder. The link structure can easily fix the cutting teeth and the tooth holder together and enable easy replacement of the cutting teeth, thereby improving the operating efficiency of assembling and disassembling the cutting teeth, reducing the labor intensity of operators, and reducing use cost.

Owner:NINGBO ZHEDONG PRECISION CASTING

Three-dimensional fabricating material systems and methods for producing layered dental products

ActiveUS20170360534A1Highly shapeHigh wear resistanceAdditive manufacturing apparatusImpression capsFull denturesDental Product

This invention designs and builds multiple layers (two layers or more) of various dental devices, specifically denture base or denture, where printed multiple layered denture base with teeth cavities to receive artificial denture tooth materials to form final dental devices, such as partial and full dentures. It can also print denture teeth. This invention also designs and prints multiple layers (two layers or more) of denture base with artificial denture teeth to form final dental devices, such as partial and full dentures. A method for manufacturing a layered denture is provided. The invention provides a multiple layered denture base materials for printing a denture base. The invention also provides a multiple layered denture tooth materials for printing artificial denture teeth. Highly shape adjustable or shape memory polymer layer(s) may be used in these multiple layered denture base forms. Different layer of material has different mechanical and physical properties to meet different need, which provide added benefits to the patients, dental professional and dental laboratory.

Owner:DENTSPLY SIRONA INC

Dental composite restorative material and method of restoring a tooth

InactiveUS6353040B1Highly packableCosmetic preparationsImpression capsRestorative materialDental composite

A dental composite material includes a hardenable resin matrix and a filler component. The filler component includes (a) a first plurality of preferably glass particles having an average particle size of from about 1 to about 10 micrometers; (b) a second plurality of preferably glass particles having an average particle size of from about 0.1 to about 1 micrometers; and, (c) a plurality of filler particles having an average particle size of from about 0.01 to about 0.04 micrometers. A method according to the invention includes compacting a dental composite material into a prepared tooth cavity, wherein the material has a packability index above about 300 g / mm2.

Owner:DENTSPLY RES DEVMENT

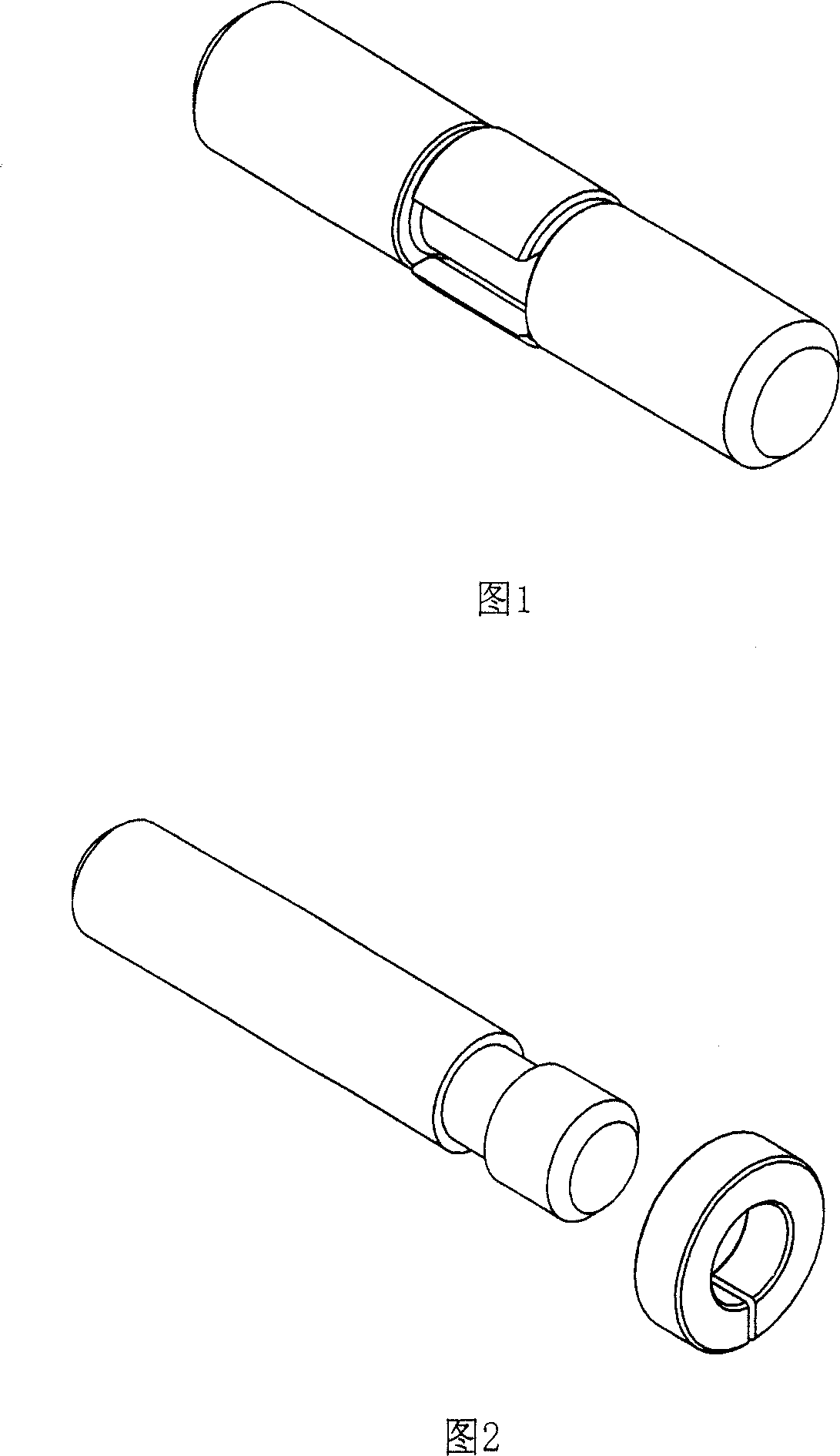

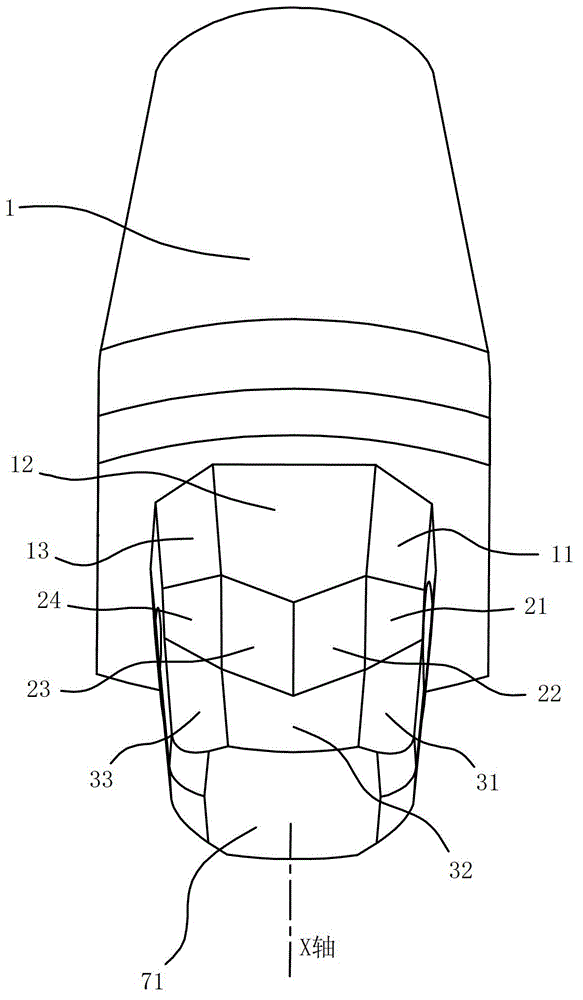

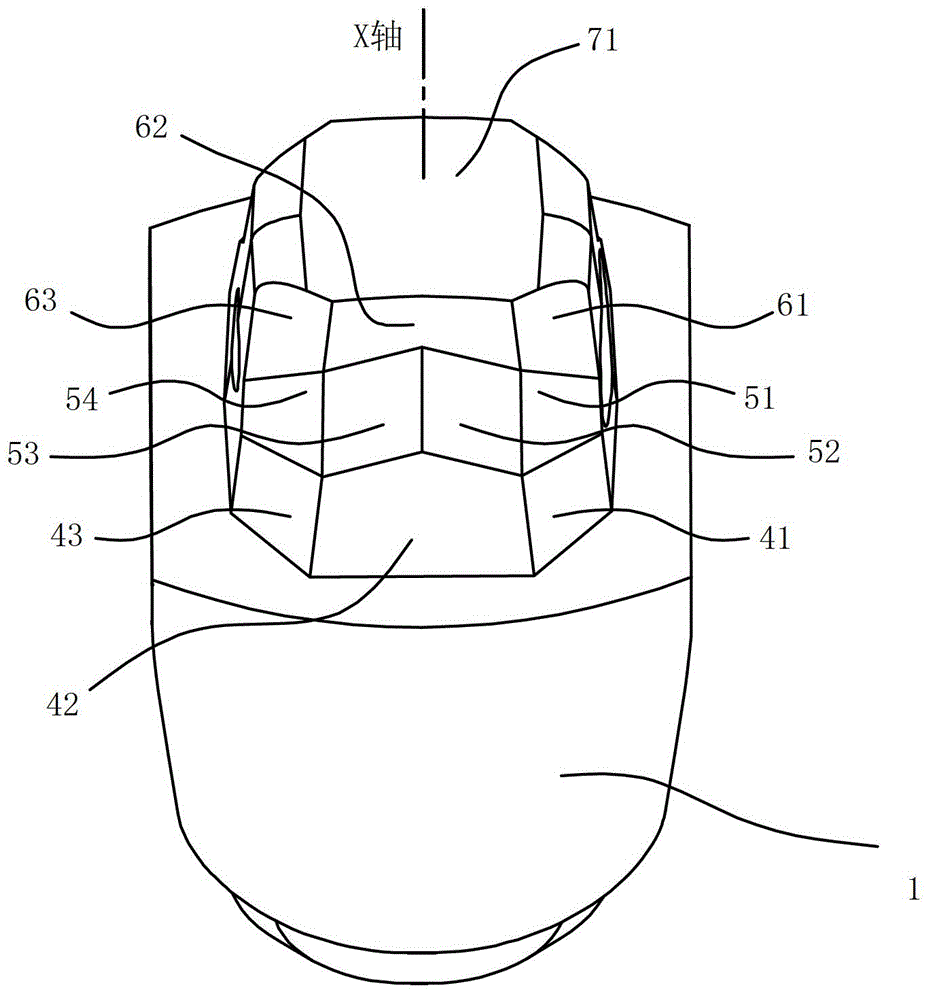

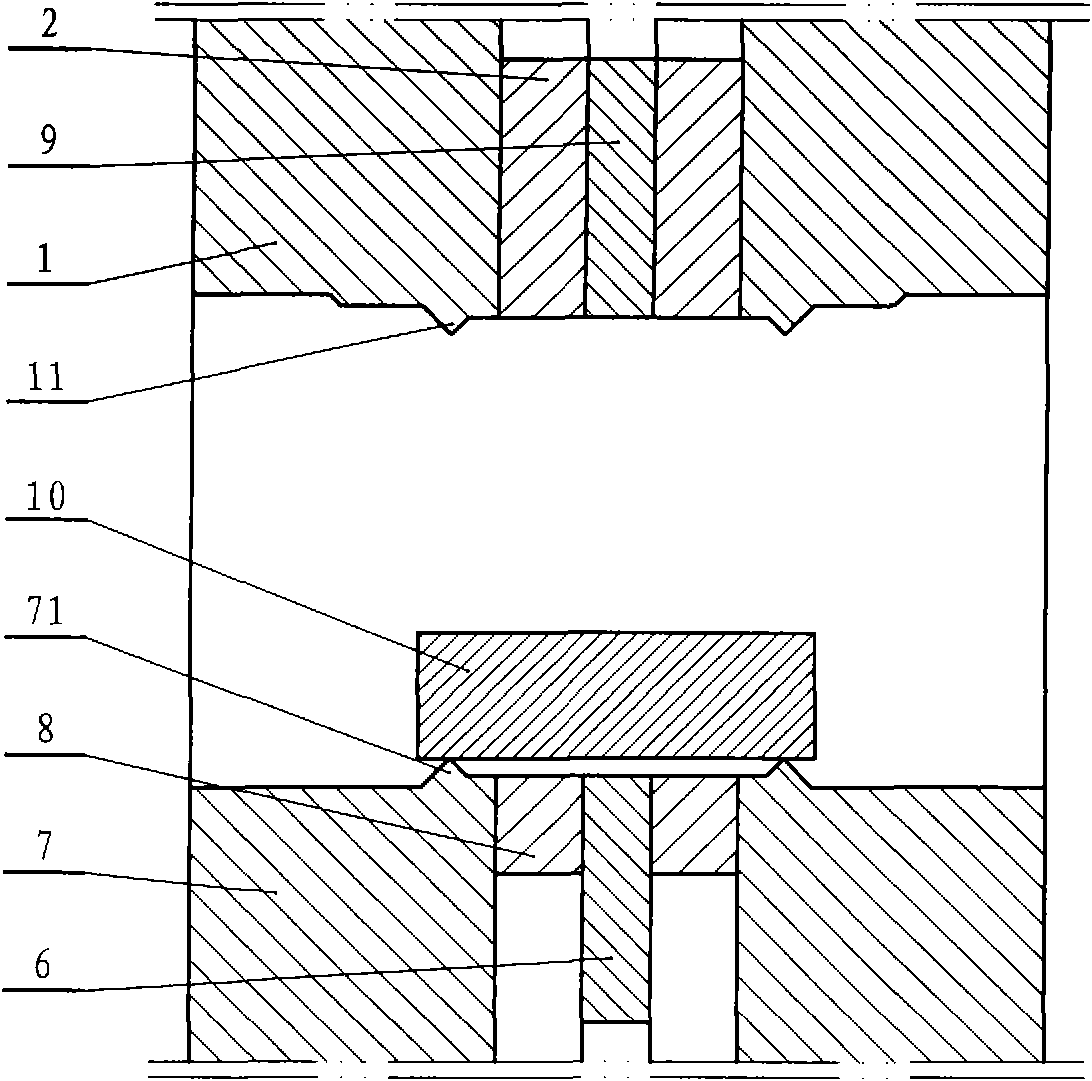

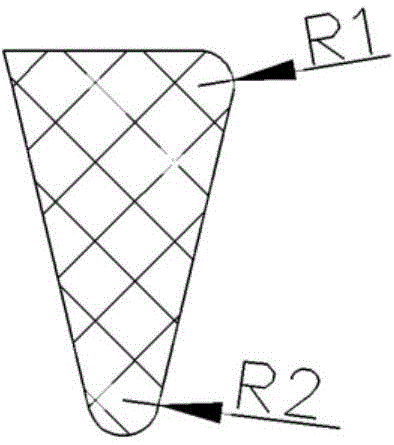

Stable bucket tooth, tooth seat and assembly for excavator

ActiveCN102864813AEven by forceImprove the forceSoil-shifting machines/dredgersEngineeringLarge size

The invention discloses a stable bucket tooth, a tooth seat and an assembly for a excavator. The assembly comprises the bucket tooth with a bucket tooth cavity, the tooth seat with a tooth seat head and a lock pin element, wherein the bucket tooth cavity of the bucket tooth is provided with an inner surface complementary with the outer surface of the tooth seat head, the front end of the tooth seat head is provided with a front end surface orthogonal with the center axial line of the tooth seat head, the upper part and the lower part of the tooth seat head are respectively provided with a first group of matching surfaces, transitional surfaces and a second group of matching surfaces from the front end surface, each group of matching surface and the transitional surface respectively comprise at least three matching surfaces in transverse and sequential ranging and symmetrical arrangement, a preset obtuse angle is formed between the adjacent matching surfaces, in addition, the matching surface positioned in the middle of each group of matching surfaces is parallel to the center axial line of the tooth seat head, and the matching surfaces at two sides are parallel to the center axial line or are slightly contracted from the back to the front in the center axial line direction. When the multidimensional complicated action effect is received, the stress is more uniform, higher stability can be maintained, meanwhile, the rejection ratio when the bucket tooth in the larger size is cast is favorably reduced so that the production cost is reduced, and the bucket tooth, the tooth seat and the assembly are particularly suitable for excavation and loading operation machinery in engineering machinery and mine machinery.

Owner:NINGBO HOPESUN NEW MATERIAL

Dental composite restorative material and method of restoring a tooth

A composite material is provided which, while having an unusually high filler content may be extruded from a dental syringe and remains easily adaptable in the dental cavity. When materials of the present invention are cured, dental restorations are provided which have unusually high surface hardness and yield strength, as well as a low volume shrinkage on curing. This is achieved by use of a mixture of filler particles with a specific size, size range, and size relationship. Such a combination of properties makes the material of the present invention particularly useful for restoring cavities in posterior teeth.

Owner:DENTSPLY DETREY GMBH

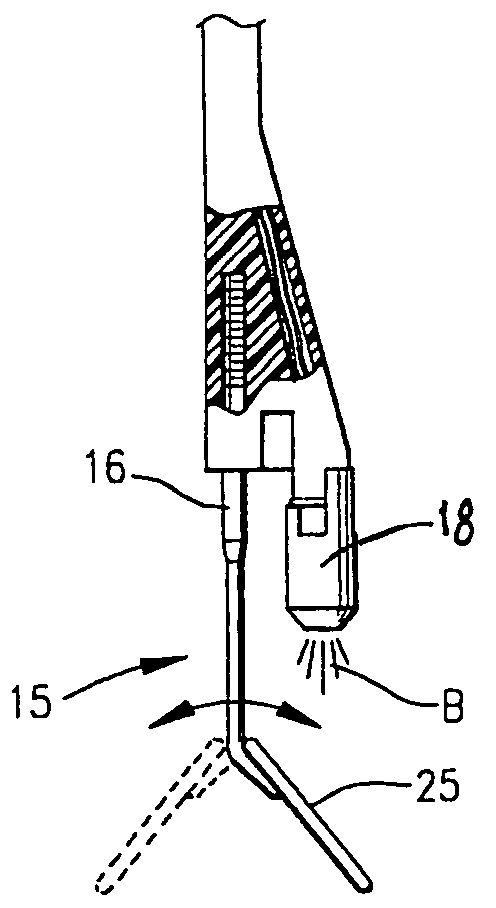

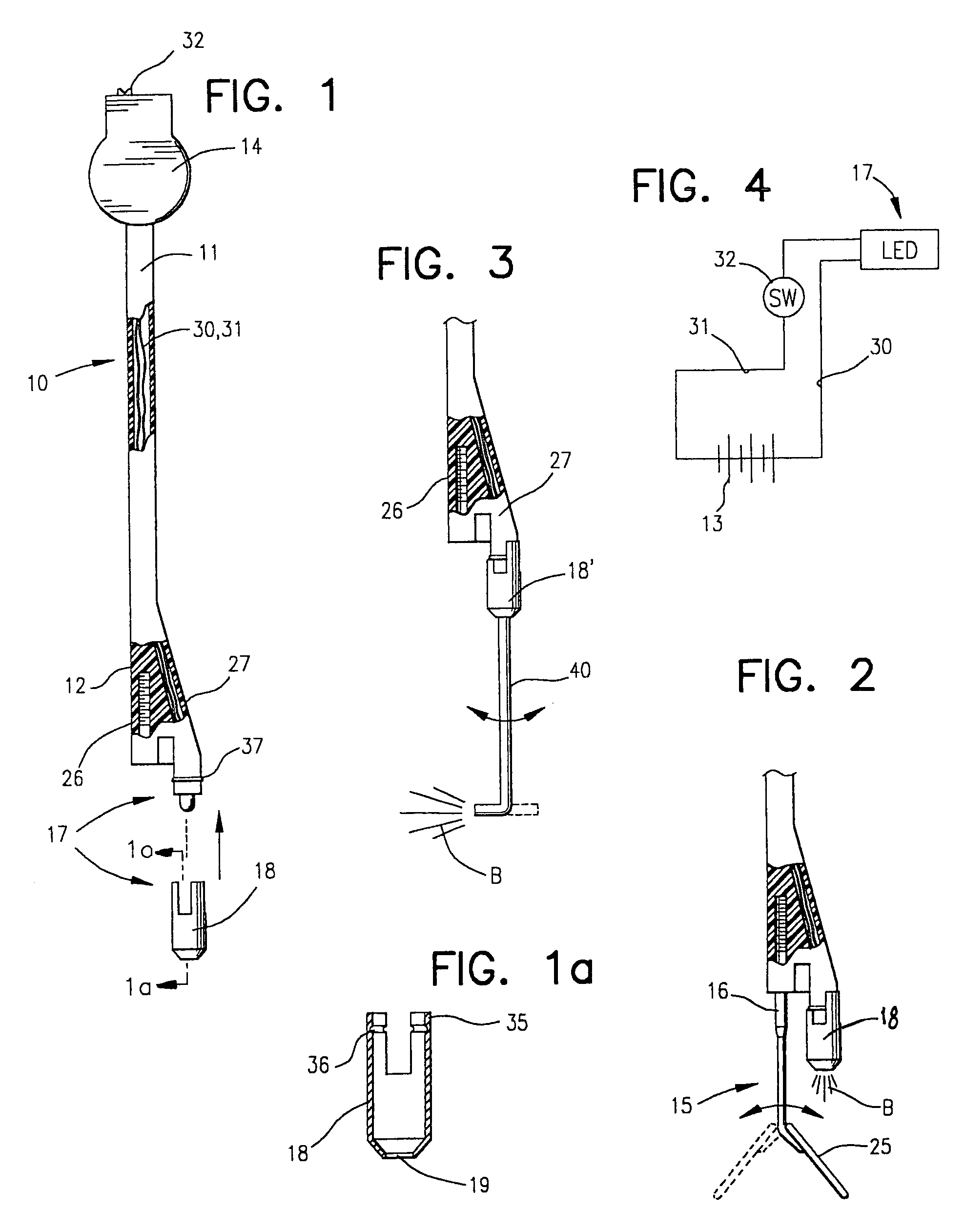

Dental handgrip

InactiveUS20080118887A1Easy to viewLow viscosityWheelchairs/patient conveyanceDental toolsMedicineFilling materials

A dental handgrip for delivering filling compound into a tooth cavity is described, the handgrip being provided with a connection device to which a container for the filling compound can be connected. In some embodiments, the handgrip comprises a light emission device via which radiation having a wavelength and radiant power for hardening of filling material can be provided. The dental handgrip can comprise a safety device to prevent a premature or inadvertent light emission onto the filling compound. In some embodiments, the handgrip comprises a fluid-operated feeding device for feeding the filling compound from the filling compound container. A vibration generator operable to cause vibrations in the filling compound and to assist in feeding of the compound can also be provided.

Owner:W&H DENTALWERK

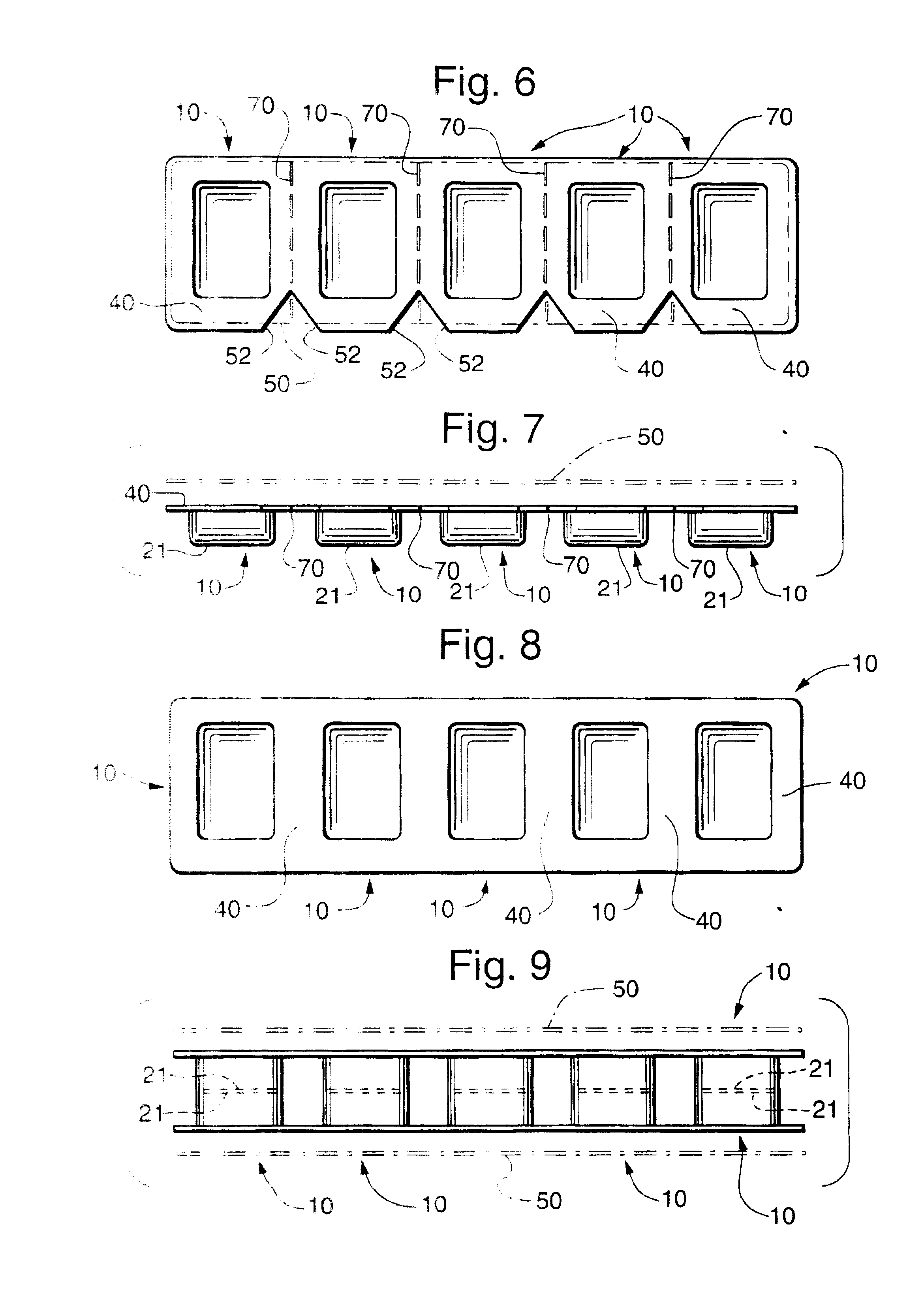

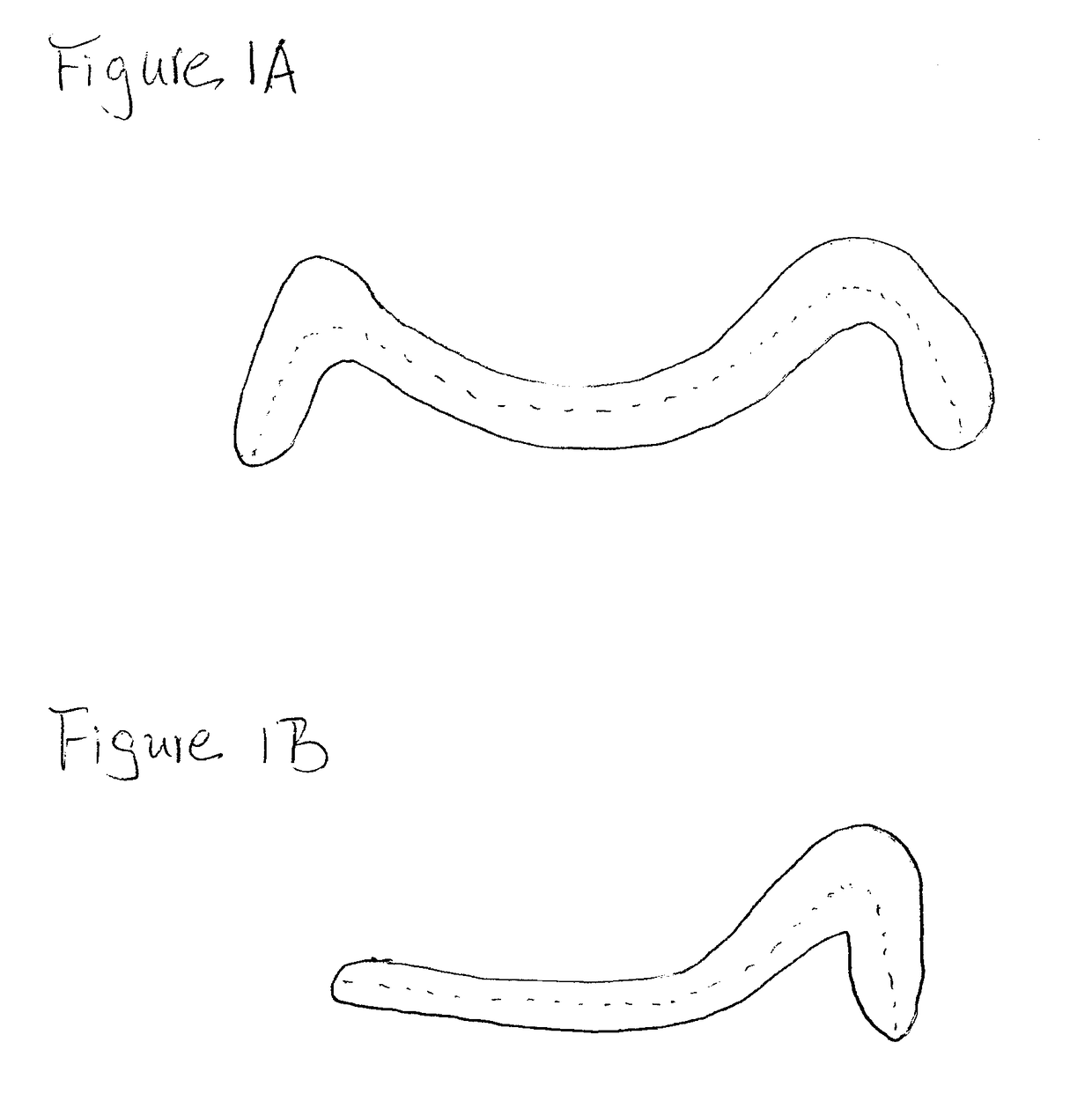

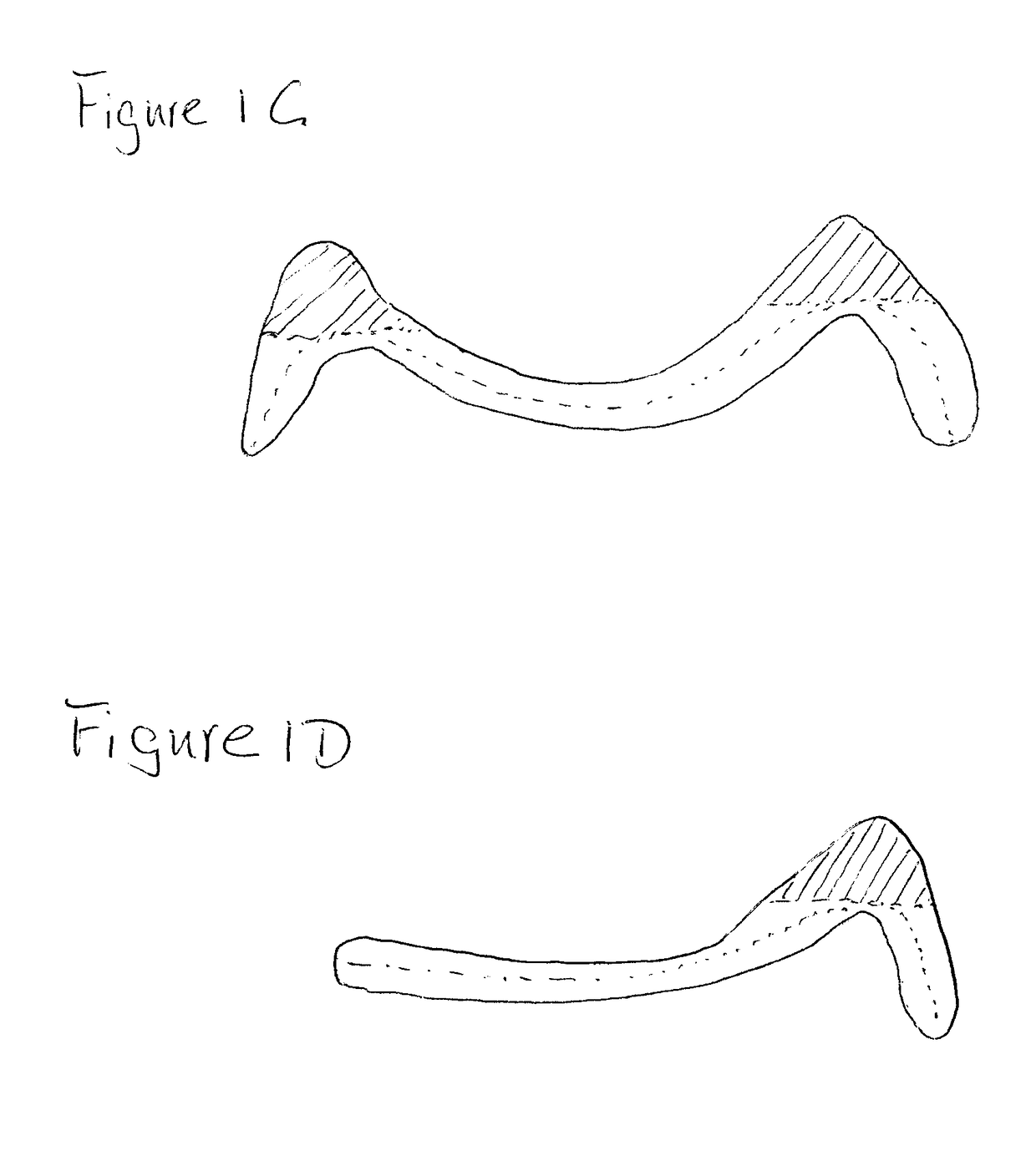

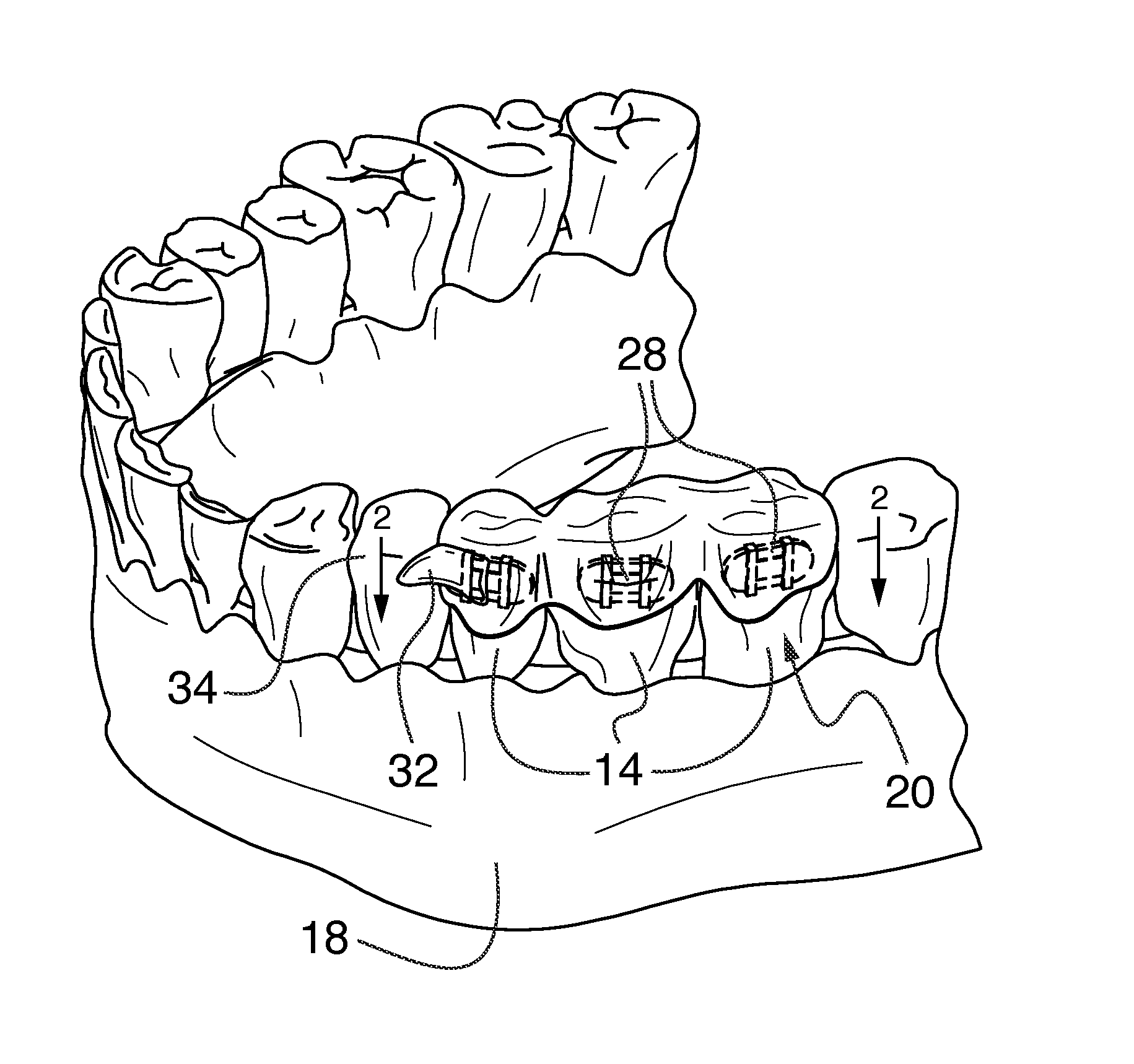

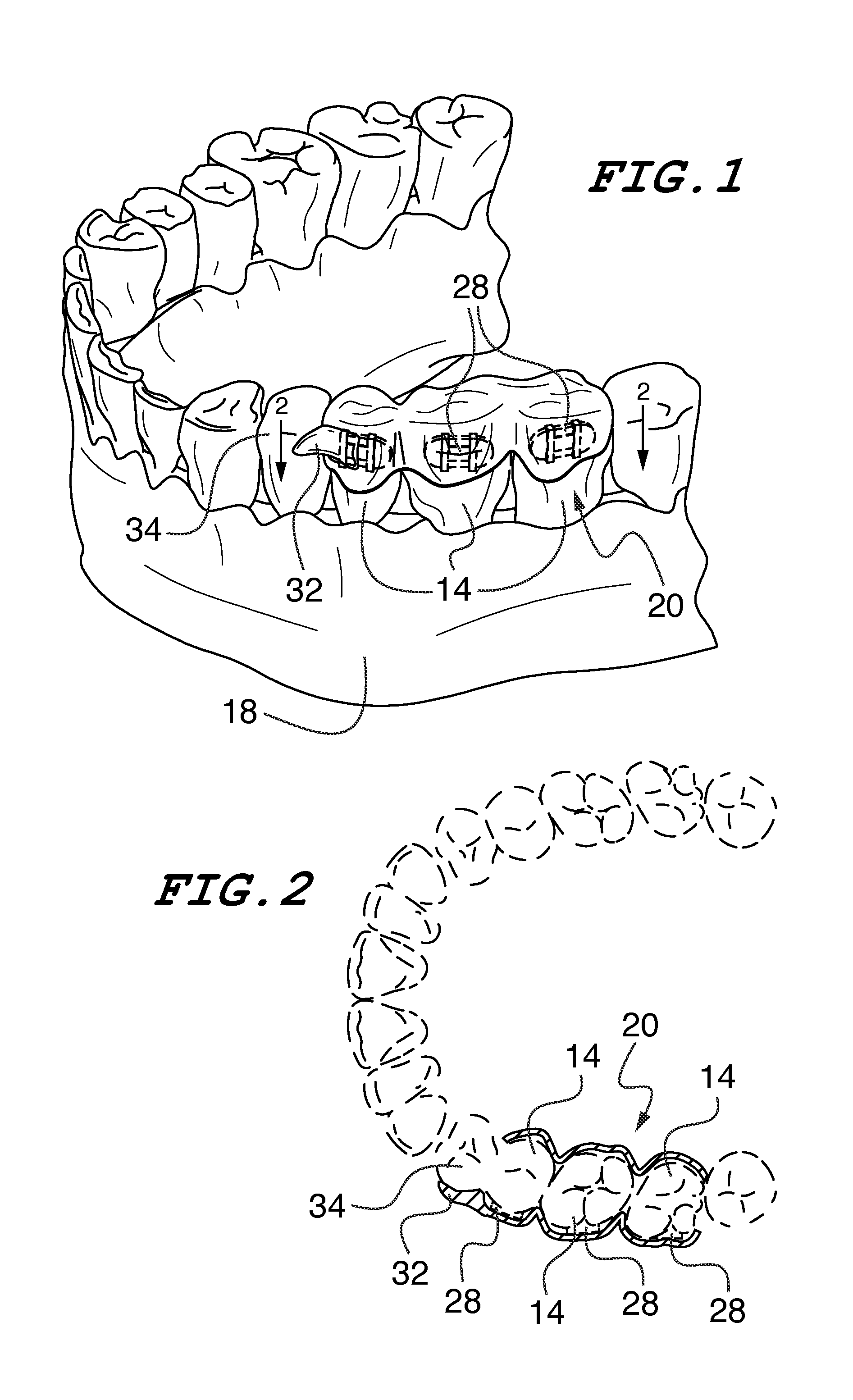

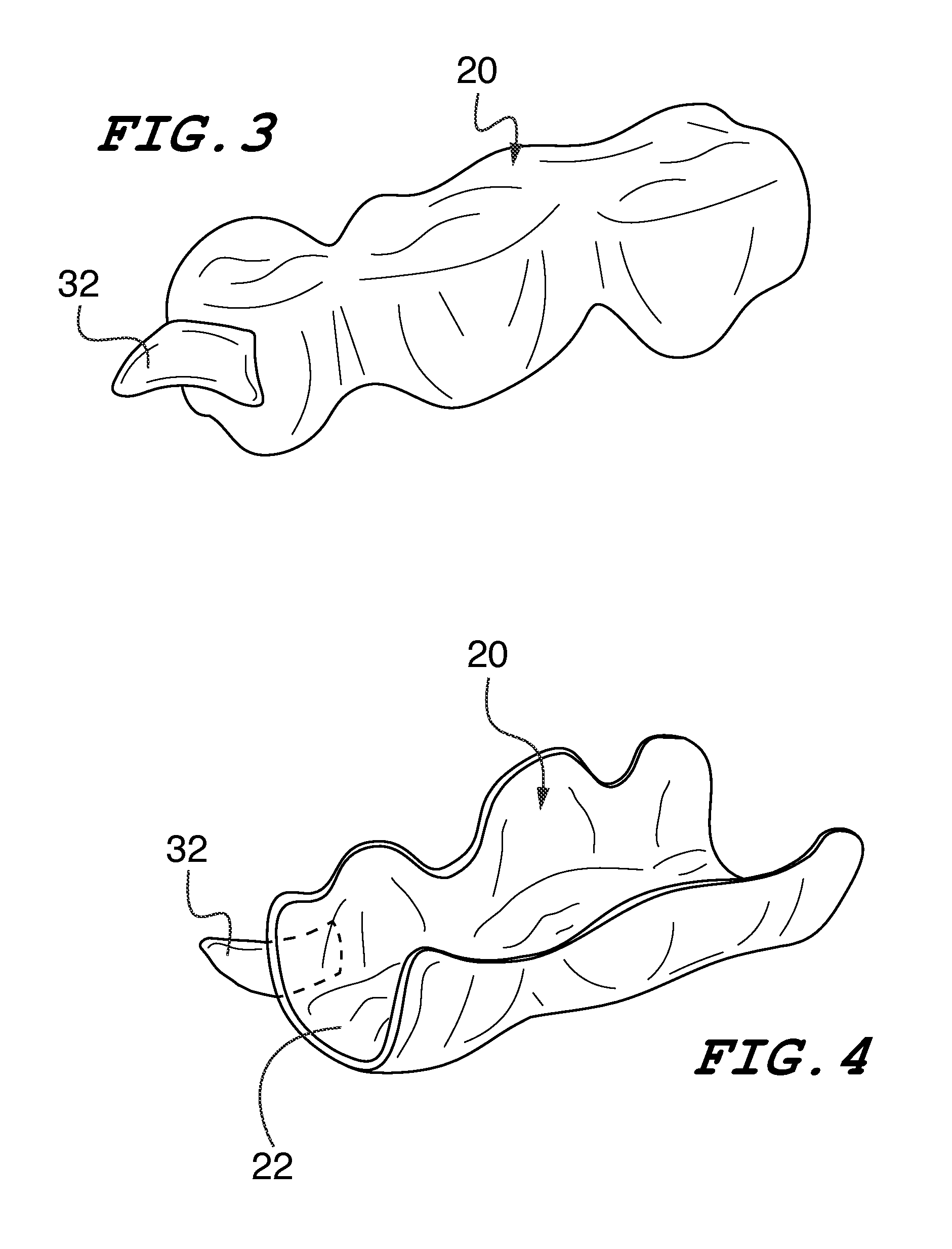

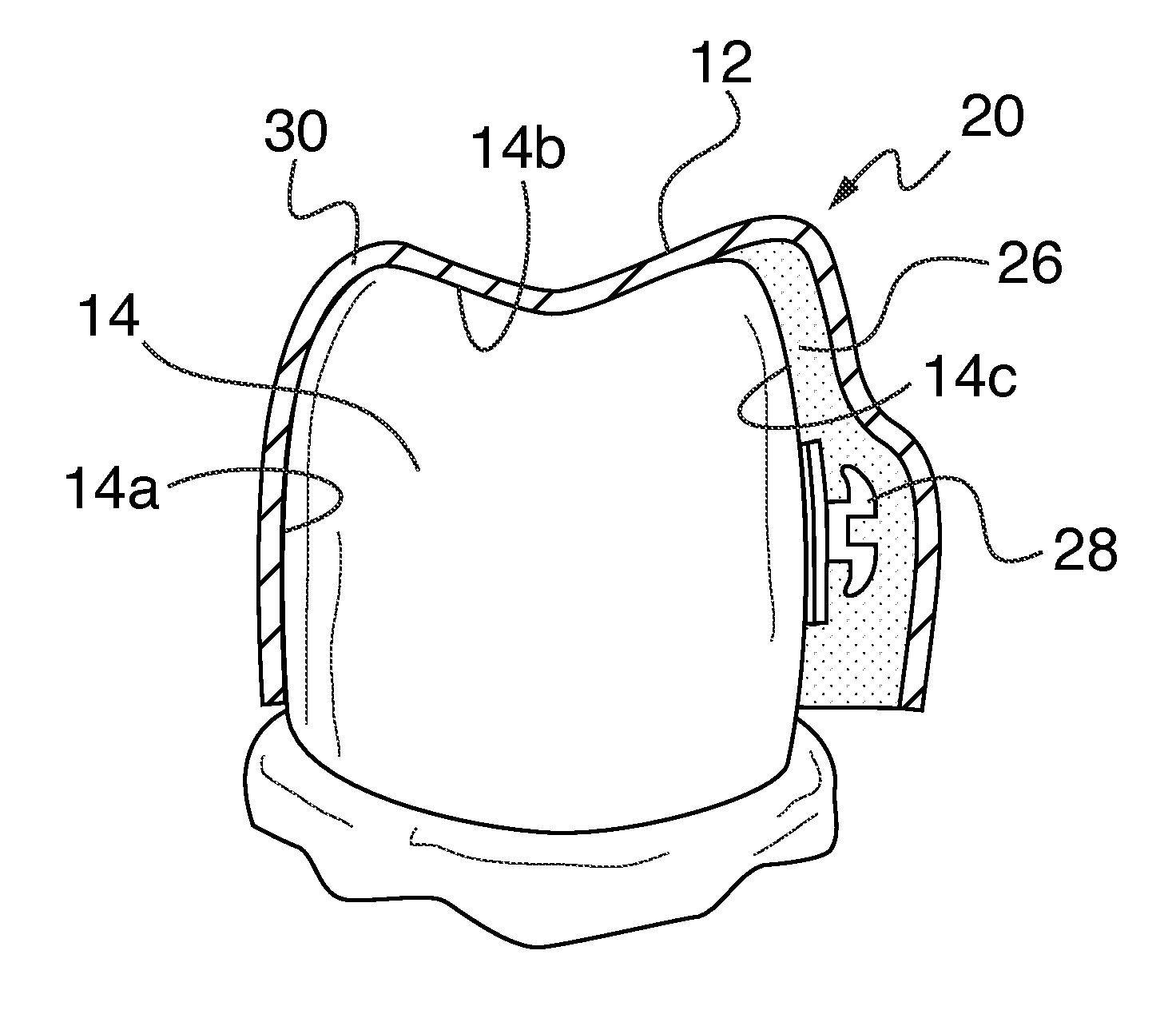

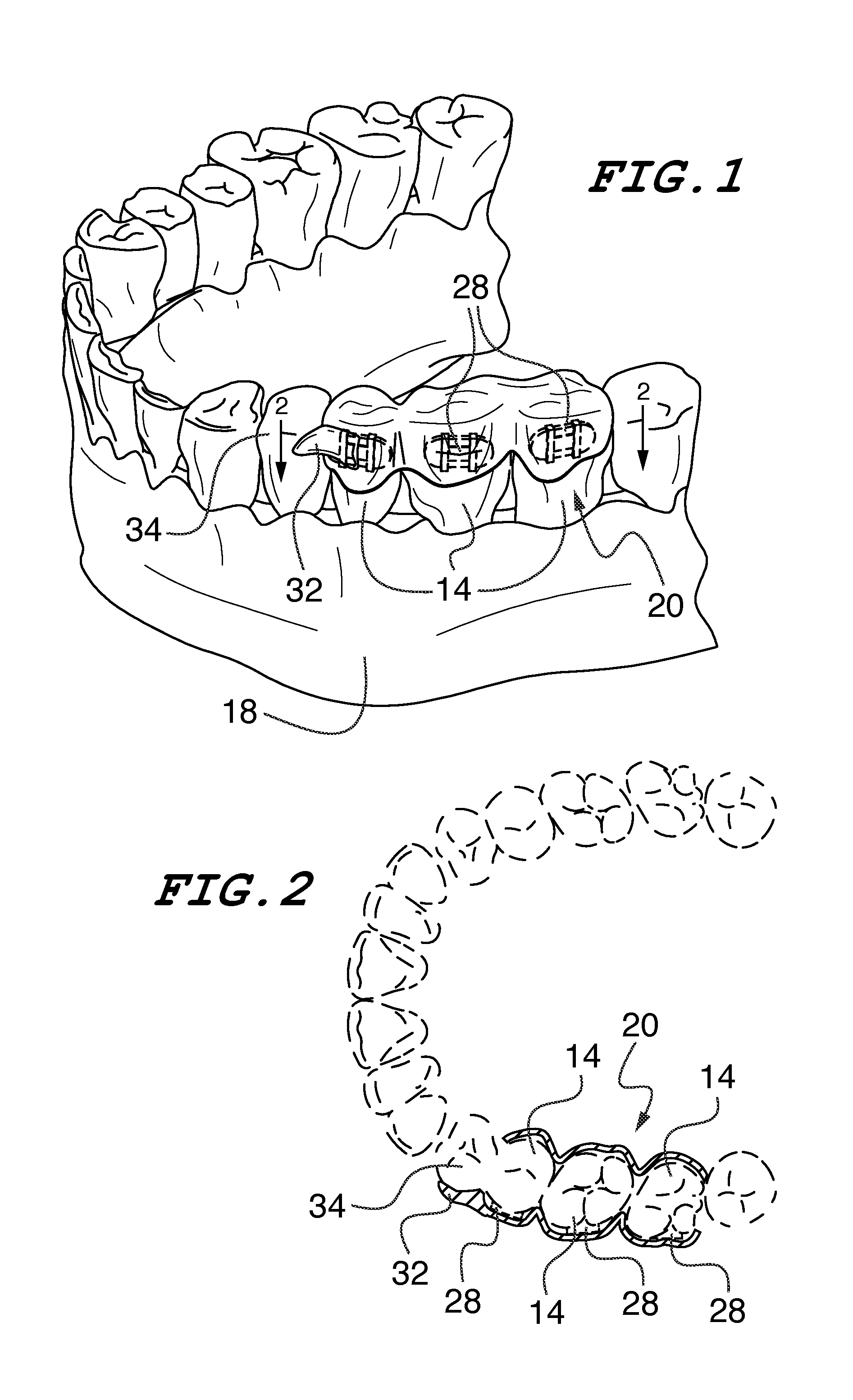

Orthodontic indirect bonding tray including stabilization features

A tray for use in bonding orthodontic appliances to selected teeth of a patient is disclosed. The tray includes an outer shell having wall sections extending over facial, lingual, and occlusal surfaces of the selected teeth to form a channel including tooth cavities having a configuration matching and arranged for receiving the selected teeth. A matrix is bonded to the inner surface of the outer shell and is contoured to complement the facial or lingual surface of the teeth. A stabilization member extends from the outer shell and includes an inside surface contoured to complement at least a portion of the facial surface of a tooth located adjacent the selected teeth. Orthodontic appliances are detachably connected to the matrix, wherein each appliance includes a base for bonding the appliance to a tooth.

Owner:CARRILLO GONZALEZ ROBERTO J +1

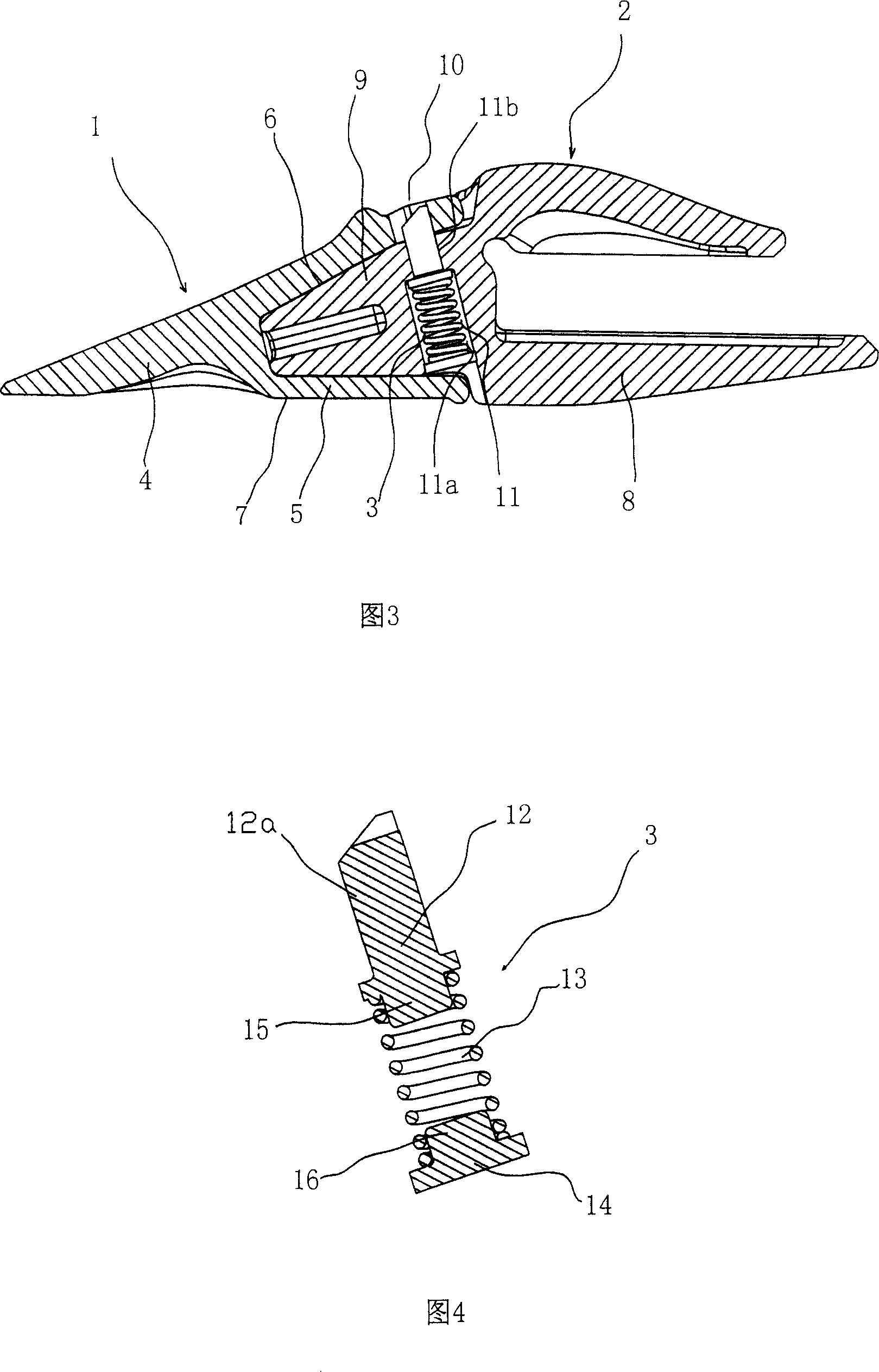

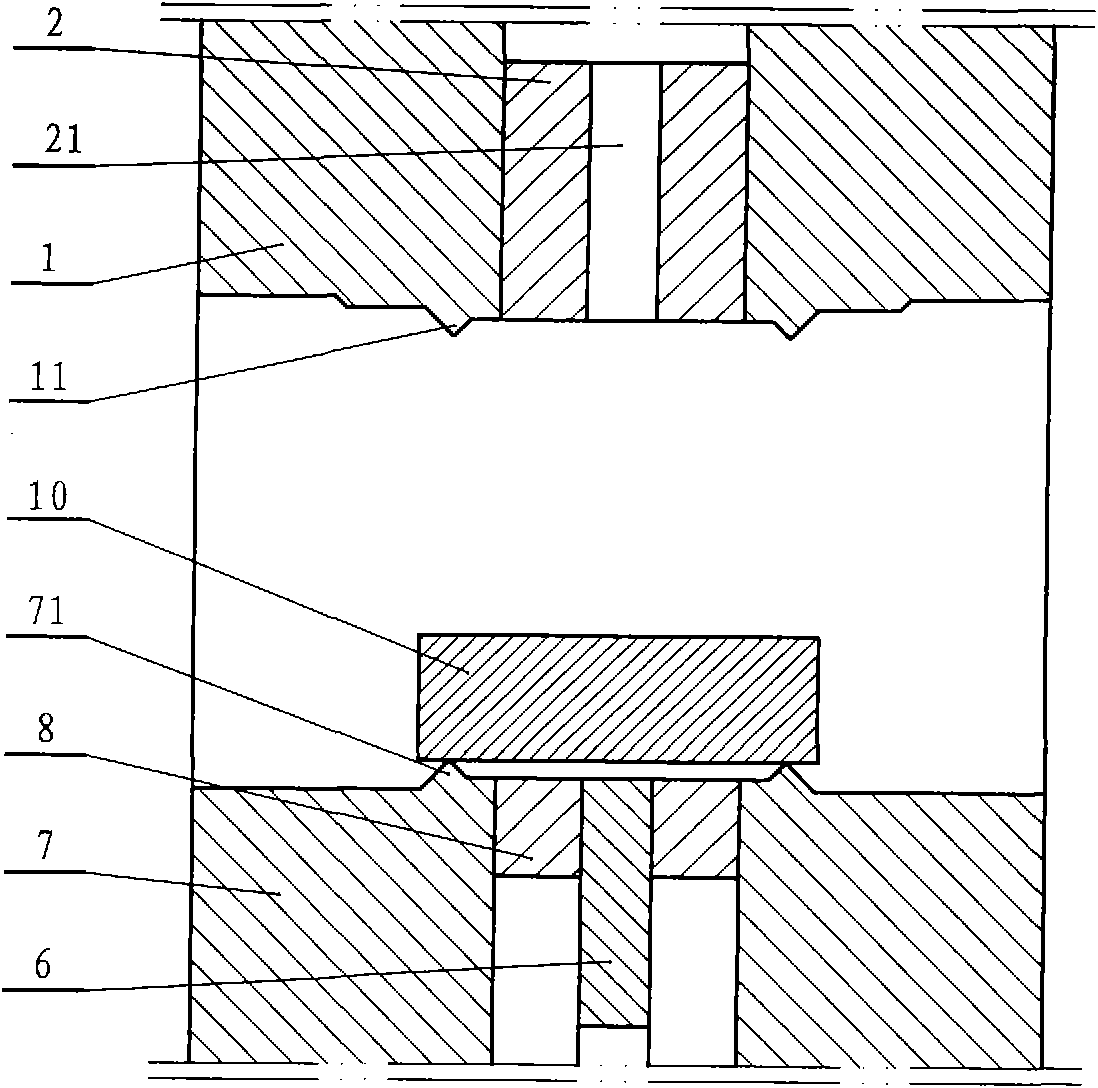

Opposite teeth extruding type fine-blanking die and fine-blanking method adopting same

InactiveCN102039346AConsistent valueEnsure a strong three-dimensional compressive stress stateShaping toolsPerforating toolsEngineeringContact line

The invention discloses an opposite teeth extruding type fine-blanking die and a fine-blanking method using the die. Opposite tooth-shaped plates and convex-concave dies are arranged on the upper side of an axial combining surface of the die; teeth cavity dies and anti-jacking plates are arranged on the lower side of the axial combining surface of the die; the opposite tooth-shaped plates and the teeth cavity dies are respectively provided with protruded annular gears, the section of the annular gear is of triangle tooth shape, and the contact lines of the annular gears and a blank are respectively arranged outside a blank upper workpiece outline and surround the outline of the workpiece. When a workpiece is blanked, an upper annular gear and a lower annular gear are respectively pressed into the workpiece to prevent a blank material from flowing in the horizontal direction, and the previous-period extrusion is carried out on the blank material so as to form a strong three dimension compressive stress inside the blank material, reduce the area of a tensile stress generated by the blank material in the blanking process, avoid the cracks, and eliminate sharp edges and burrs of the workpiece. By the invention, fine-blanked workpieces with good quality and high precision can be manufactured by utilizing a universal blanking device so as to promote the development of fine-blanking industry.

Owner:CHONGQING UNIV OF TECH

Photo-curing composition for tooth

InactiveCN101564357ANot easy to peel offReduce wear rateImpression capsDentistry preparationsSurface modificationPhoto curing

The invention relates to a photo-curing composition for tooth, with belongs to the field of preparation for dentistry. The object of the invention is to solve the problem that the abrasion resistance and obdurability of photo-curing dentistry compound resin material for filling tooth cavity is needed to be improved urgently. The composition provided by the invention comprises the following components, in mass percentages, nano inorganic powder treated by surface modification with silicone hydride coupling agent 20-85%; resin monomer such as bisphenol A glycidyl methacrylate 8%-70%; fluidifying agent such as triethylene glycol dimethacrylate 5%-25%; photoinitiator such as camphorquinon 0.25%-2%; coinitiator such as 2-(dimethylamino)ethyl methacrylate 0.5%-3%; the main point of the invention is the nano inorganic powder contains flaky alumina granules 10-80 wt.% based on its own weight. Flaky alumina granule component in the composition provided by the invention contributes to improve abrasion resistance and obdurability of photo-curing material.

Owner:中国人民解放军南京军区福州总医院四七六临床部

Orthodontic indirect bonding tray including stabilization features

A tray for use in bonding orthodontic appliances to selected teeth of a patient is disclosed. The tray includes an outer shell having wall sections extending over facial, lingual, and occlusal surfaces of the selected teeth to form a channel including tooth cavities having a configuration matching and arranged for receiving the selected teeth. A matrix is bonded to the inner surface of the outer shell and is contoured to complement the facial or lingual surface of the teeth. A stabilization member extends from the outer shell and includes an inside surface contoured to complement at least a portion of the facial surface of a tooth located adjacent the selected teeth. Orthodontic appliances are detachably connected to the matrix, wherein each appliance includes a base for bonding the appliance to a tooth.

Owner:CARRILLO GONZALEZ ROBERTO J +1

Oral cavity composition

ActiveUS20060171903A1High effect for preventionGood effectCosmetic preparationsGum massageO-Phosphoric AcidTreatment effect

The present invention provides an oral cavity composition with which brief treatment using the same yields a high effect for dental cavity prevention and an excellent dental hyperesthesia preventive and treatment effects, and a method of treatment using such a composition. The oral cavity composition according to the present invention contains a first composition (A) containing a fluoride ion-supplying compound, an inorganic phosphoric acid and a salt thereof, and a second composition (B) containing a calcium salt of organic acid, with an organic acid constituting said calcium salt of organic acid having a pKa value ranging from 3 to 11, or at least one pKa value ranging from 3 to 11 when said organic acid has plural pKa values, wherein said first composition (A) and said second composition (B) are discretely packed from each other so that said two compositions can be alternately used and then come to be mixed with each other at a tooth region when applied thereto.

Owner:KAO CORP

Convertible dental instrument

InactiveUS7066734B1Overcome disadvantagesFast transferEndoscopesDental toolsDental instrumentsDirect illumination

A self-contained and convertible dental instrument system includes both a lighted mirror and a direct illuminator. A hand piece has a handle section, including a battery in a housing, and a dual attachment section to receive a mirror and a light source. The illumination can be by reflection by said mirror or directly upon removal of the mirror from alignment with the light source. The handle and attachment sections preferably form a Y with the handle section reduced in size for balance and enhanced manipulation. The light source is an LED, is connected through wires in the hand piece to the battery and is controlled by a switch on the battery housing. A lens for the LED is attached by a snap-on adapter. For close contact illumination in the dental cavity, the lens includes a translucent rod, also attached by an adapter. The mirror and rod are rotatable for angular positioning to improve the illumination and the viewing.

Owner:COOPER IRA JEFFREY

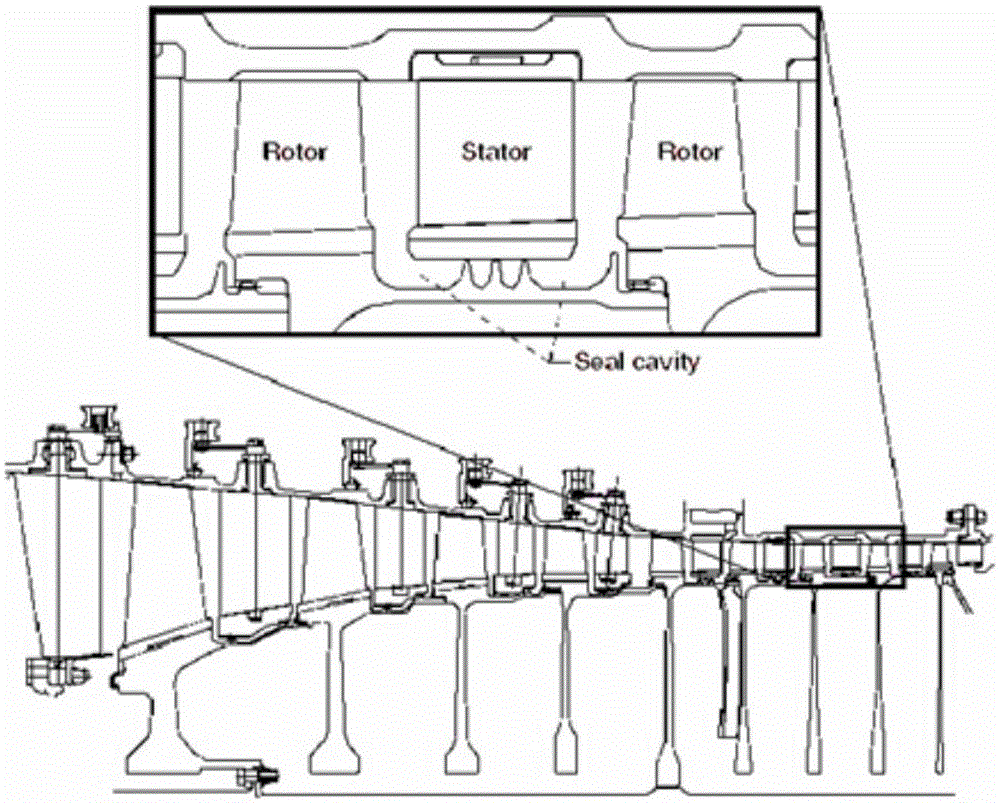

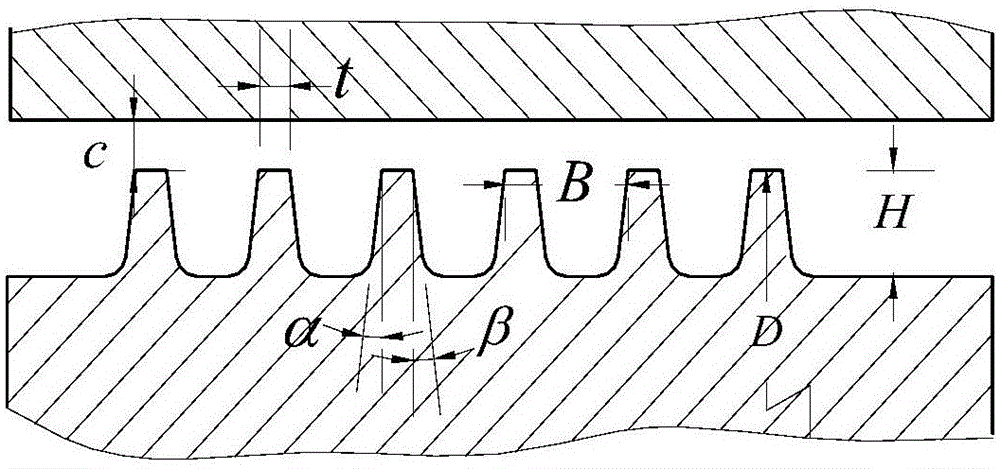

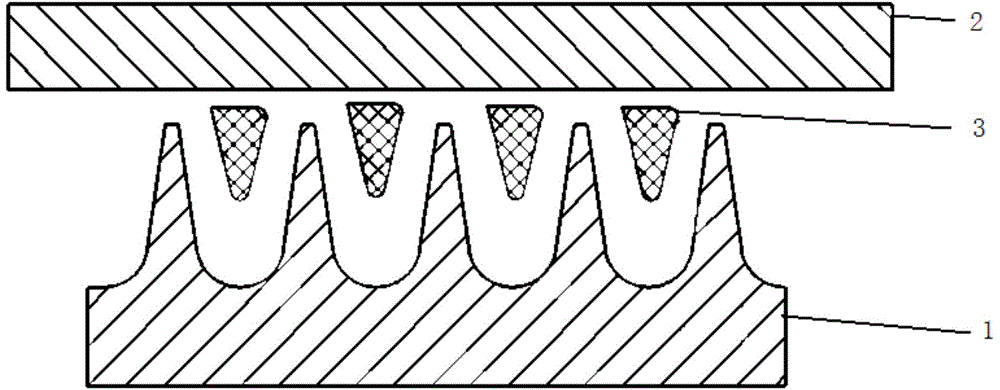

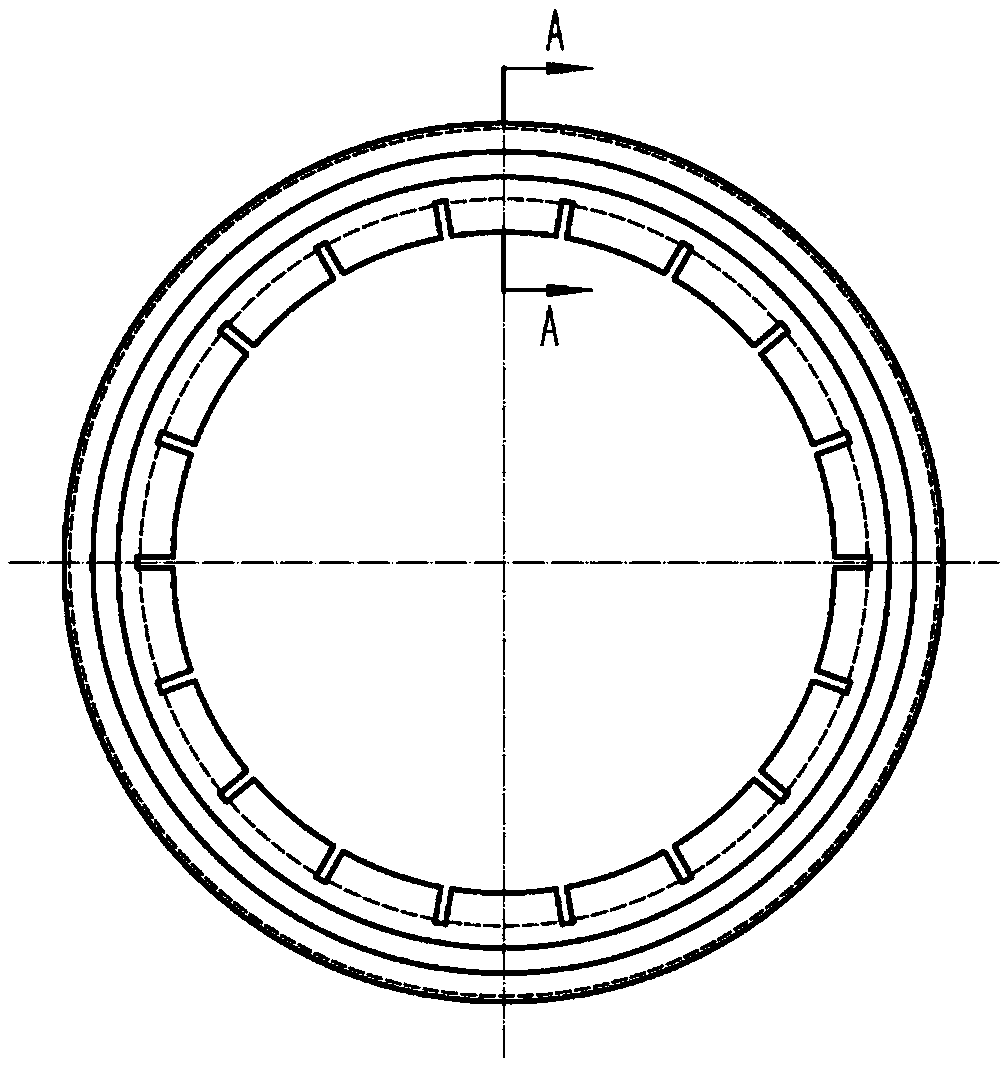

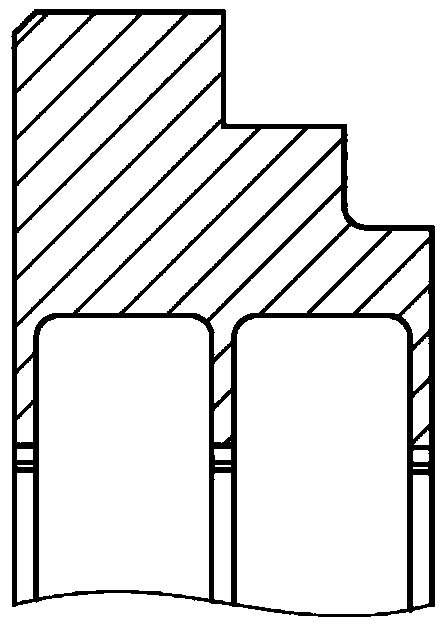

Aero-engine labyrinth seal structure with tooth cavity jet

InactiveCN105041479APromote fragmentationEnhanced kinetic energy dissipationGas turbine plantsLeakage preventionEngineeringLeakage flow

The invention relates to an aero-engine labyrinth seal structure with tooth cavity jet. The aero-engine labyrinth seal structure with the tooth cavity jet comprises a fluid inlet, a fluid outlet, a sealing bush, a rotating shaft and multiple levels of labyrinths which are distributed on the rotating shaft, labyrinth tooth cavities are formed between the adjacent two levels of the labyrinths, tooth cavity radial jet holes are formed in the bottoms of the labyrinth tooth cavities and evenly distributed at the bottoms of the cavities between the labyrinths in the circumferential direction, airflow is introduced from the interior of the rotating shaft to form radial jet, fracture of a tooth cavity large vortex structure is facilitated, kinetic energy dissipation of tooth cavity fluid is strengthened, and meanwhile extrusion is formed on tooth tip jet, flow area of the tooth tip jet is reduced, and the leakage rate is controlled. According to the aero-engine labyrinth seal structure with the tooth cavity jet, the tooth cavity jet is adopted, airflow dissipation inside the labyrinths can be effectively enhanced, and the overall leakage flow of the fluid is reduced. The aero-engine labyrinth seal structure with the tooth cavity jet is simple in structure and easy to implement and has good project application value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Antiseptic pharmaceutical composition for oral hygiene and the treatment of oral diseases of microbial origin

ActiveUS20120148506A1Promote healingReduces and prevents developmentCosmetic preparationsToilet preparationsOral diseaseEugenol

A polyantiseptic antimicrobial pharmaceutical composition for oral use, for the hygiene and treatment of oral diseases of bacterial, mycotic or viral etiology, for over-the-counter sale, without contraindications. The composition does not contain phenolic or, chlorophenolic compounds, and consists of a mixture of hydrogen peroxide, eugenol, natural camphor, zinc sulphate, sodium fluoride, xylitol, cetylpyridinium chloride and excipients. The formulation is used to deodorise, disinfect, astringe and soothe inflammation of the oral area, avoids the neoformation of bacterial plaque, prevents tooth cavities, inhibits the formation of dental tartar, improves the resistance of teeth to cavities, and treats and prevents oral aphthous ulcers.

Owner:INGALFARMA SPA

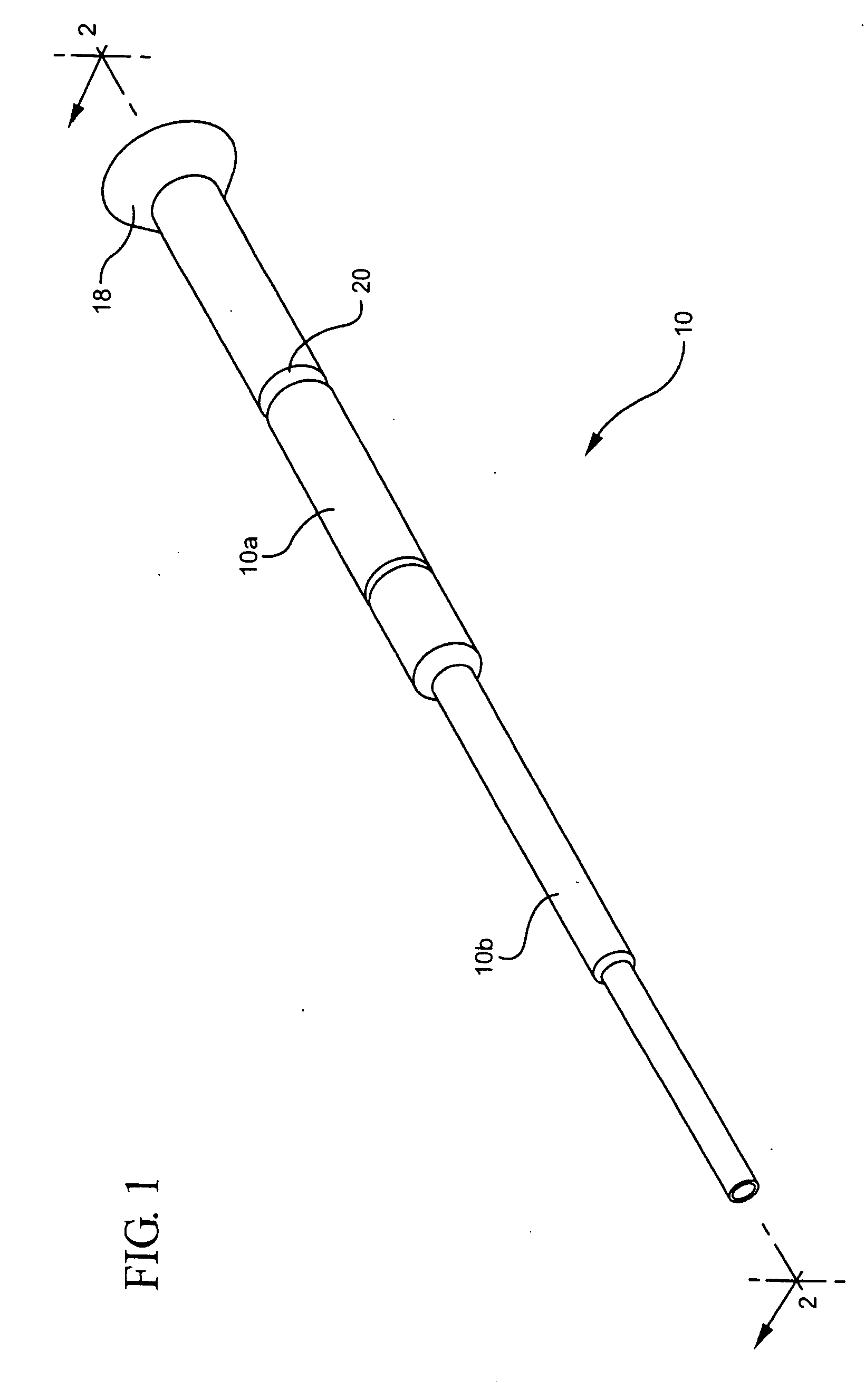

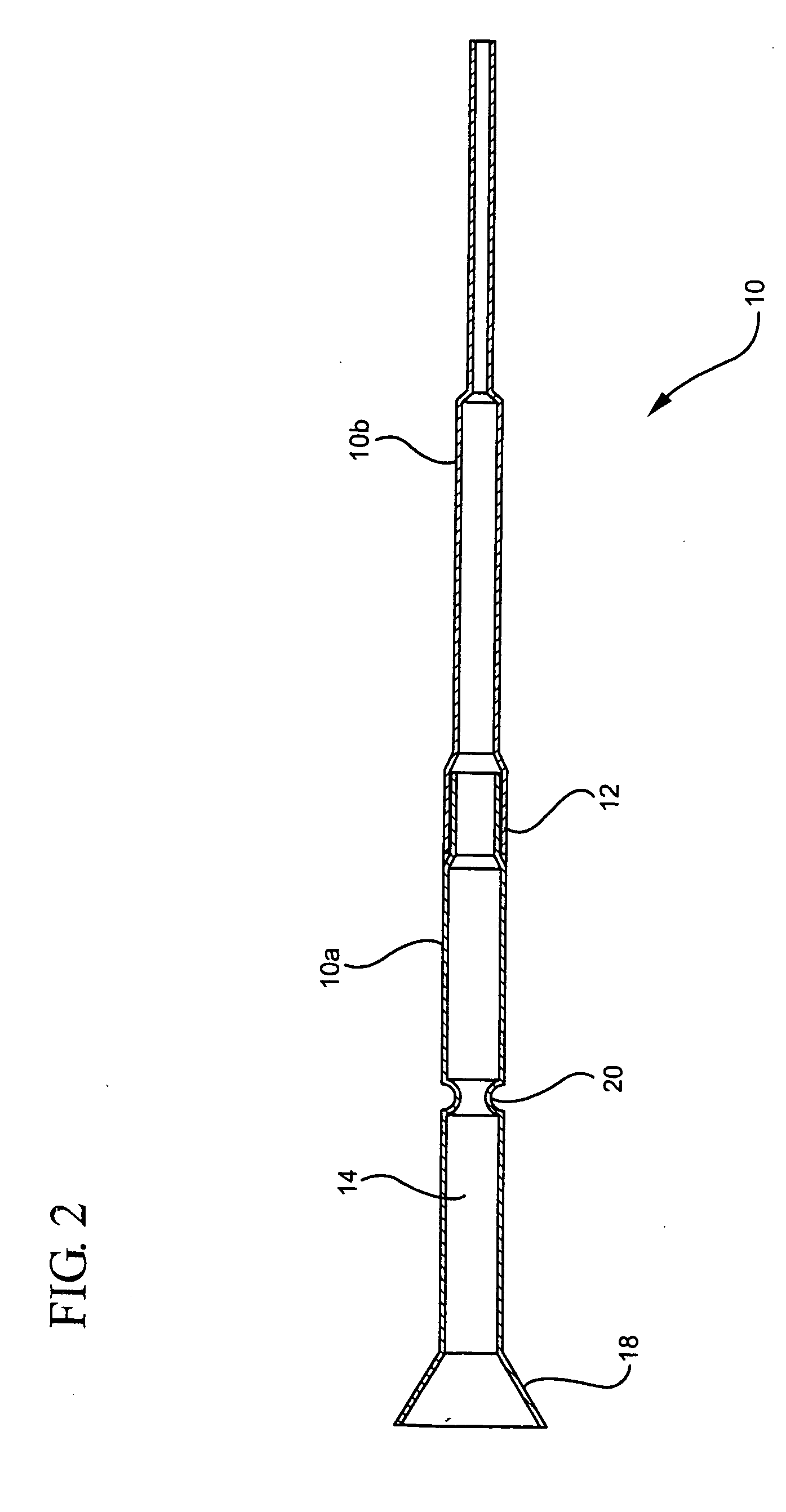

Hollow needle for obturating dental cavities

A two-part needle for a dental syringe in which the first part of the needle is attached to the syringe and has a larger cross0section than the other part, which is malleable, can be increased while the first part has a chamber for housing a cartridge with thermoplastic material therein that is caused to flow through the needle and into the dental cavity.

Owner:J MORITA USA

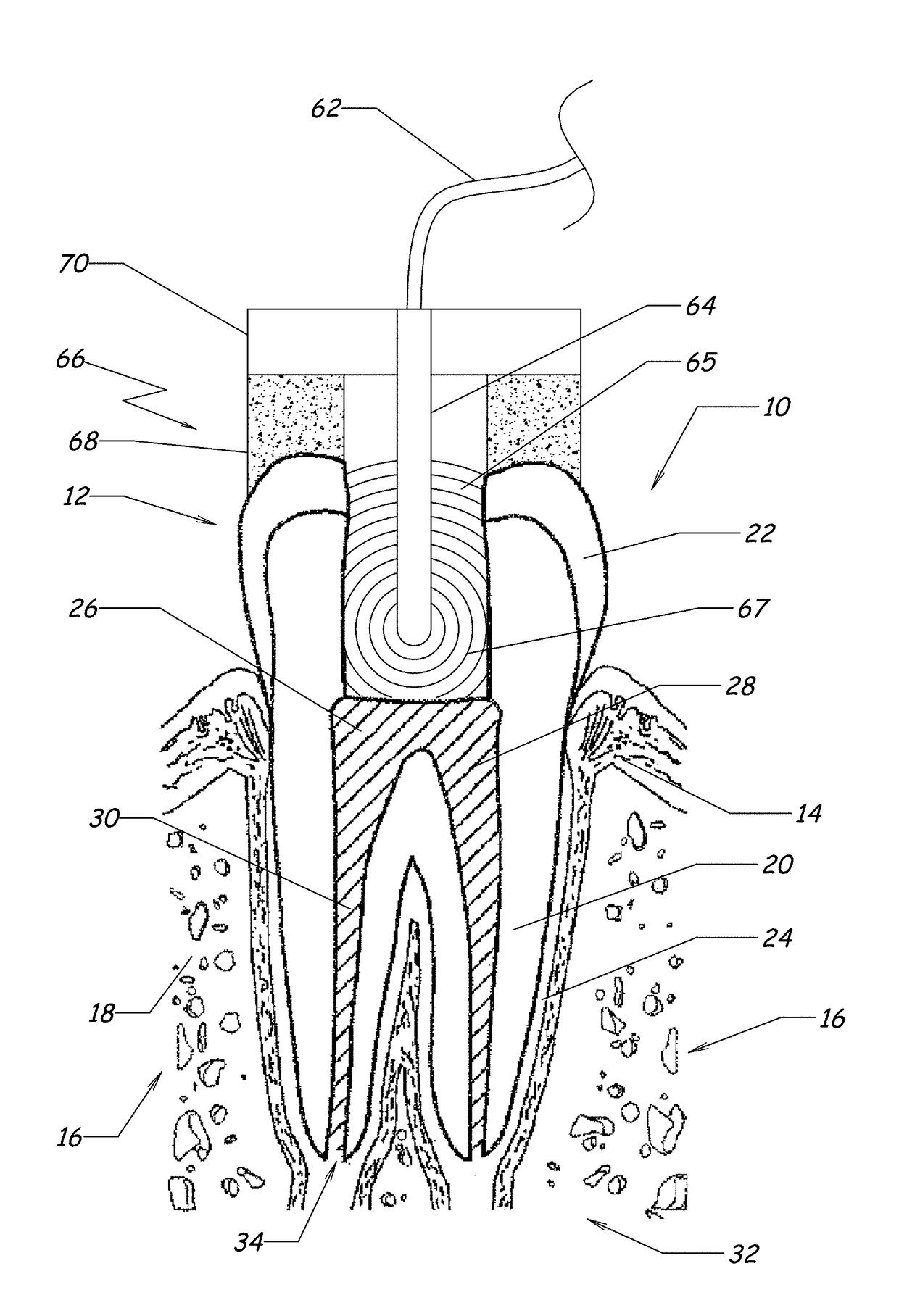

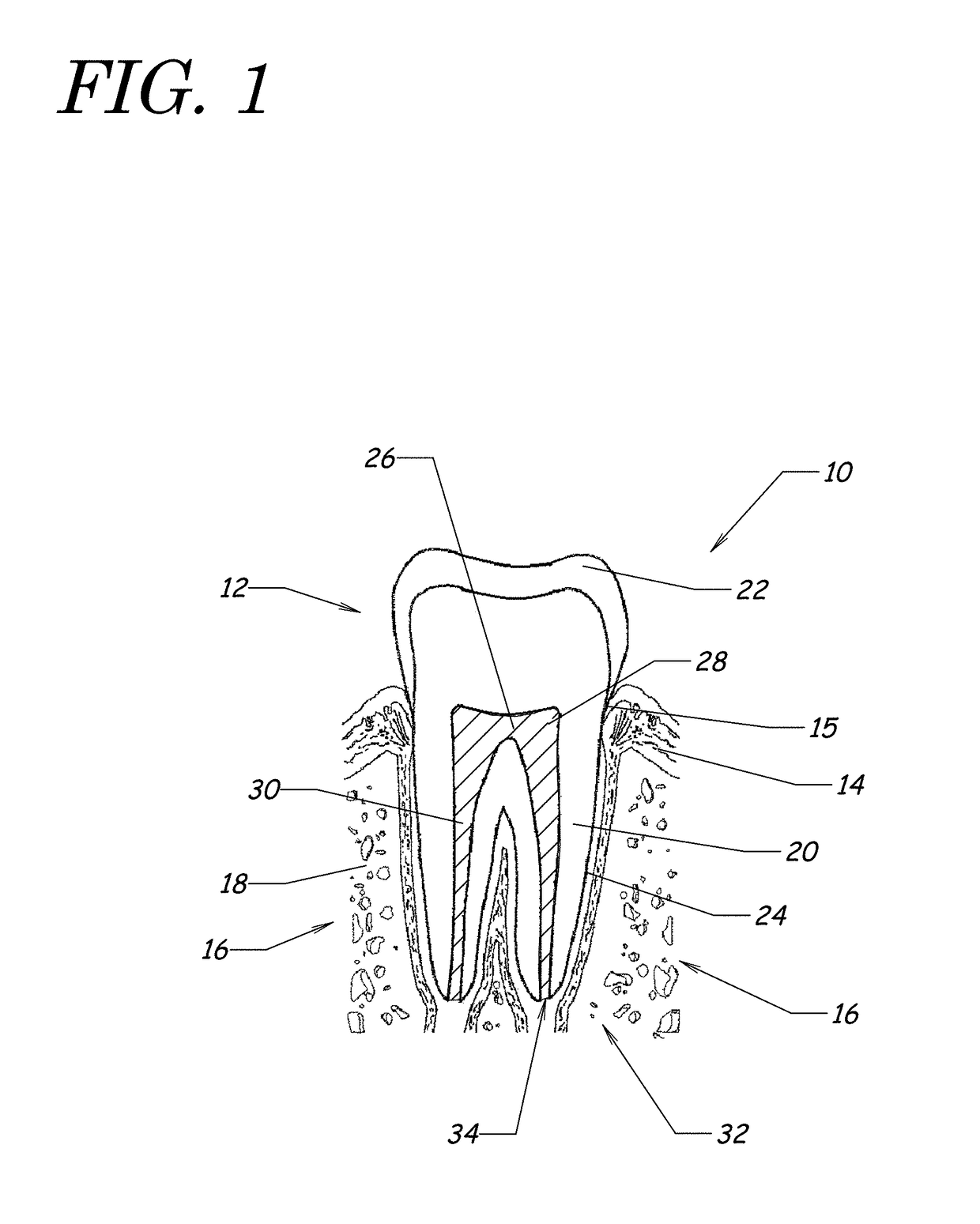

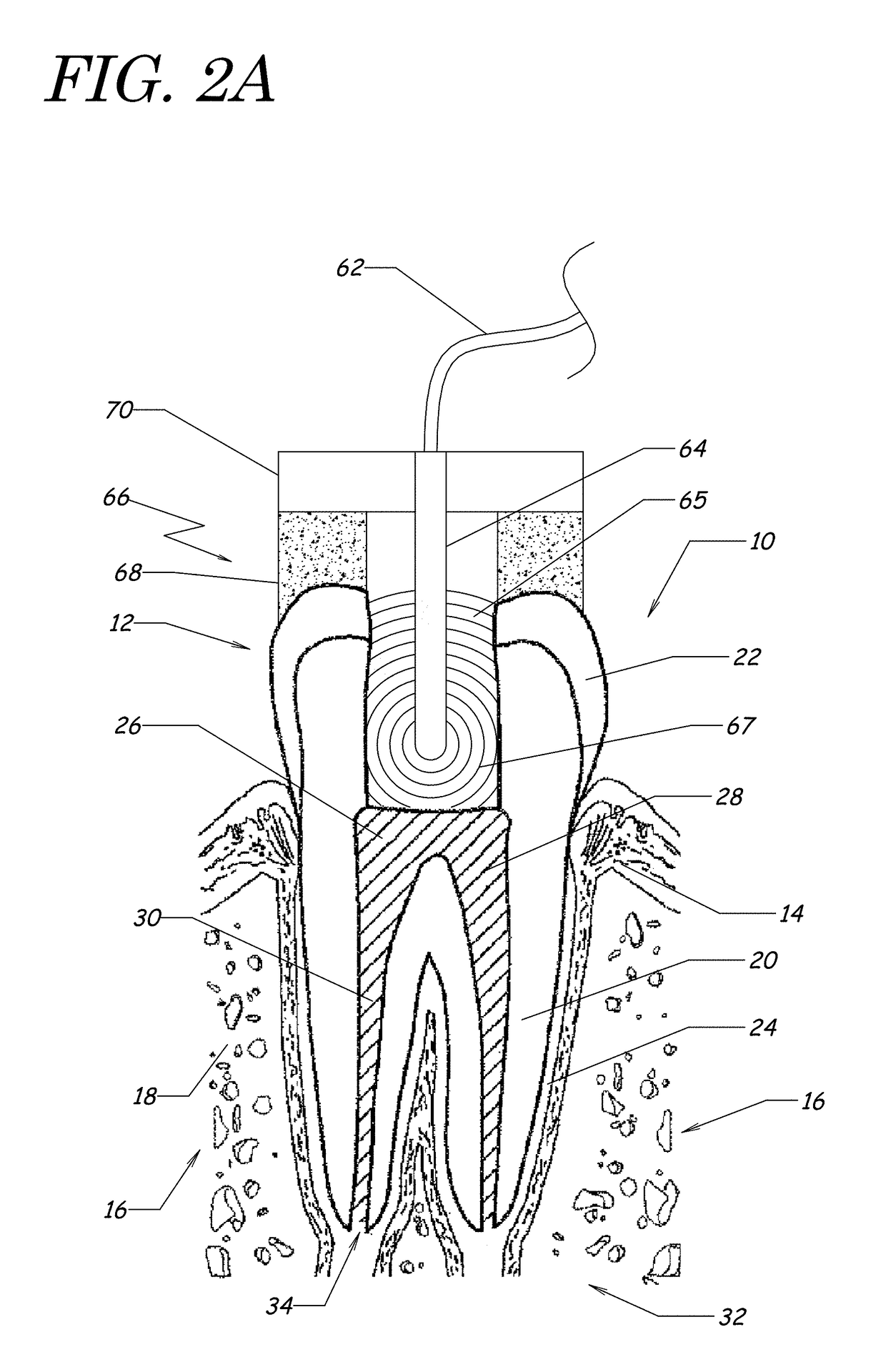

Apparatus, methods, and compositions for endodontic treatments

ActiveUS20180116761A1Easy to cleanBonding is loosenedCleaning using liquidsNerve needlesEndodontic therapyLiquid jet

Examples of apparatus, methods, and compositions for endodontic treatments are described. The apparatus can include a fluid platform configured to substantially retain fluid in a tooth chamber during treatment. The fluid platform can help maintain fluid circulation in the tooth chamber as fluid flows into and out of the tooth chamber. The apparatus can also include a pressure wave generator configured to generate acoustic waves that can be used for cleaning root canals and tooth surfaces in the tooth chamber. Examples of pressure wave generators include a liquid jet, an electromagnetic energy delivery device, and an ultrasonic device. The fluid can include antiseptic or antibacterial solutions to assist in tooth cleaning. The fluid may be degassed to have a reduced dissolved gas content (compared to non-degassed fluids used in endodontic treatments), which may improve the effectiveness of the pressure wave generation or the cleaning.

Owner:SONENDO

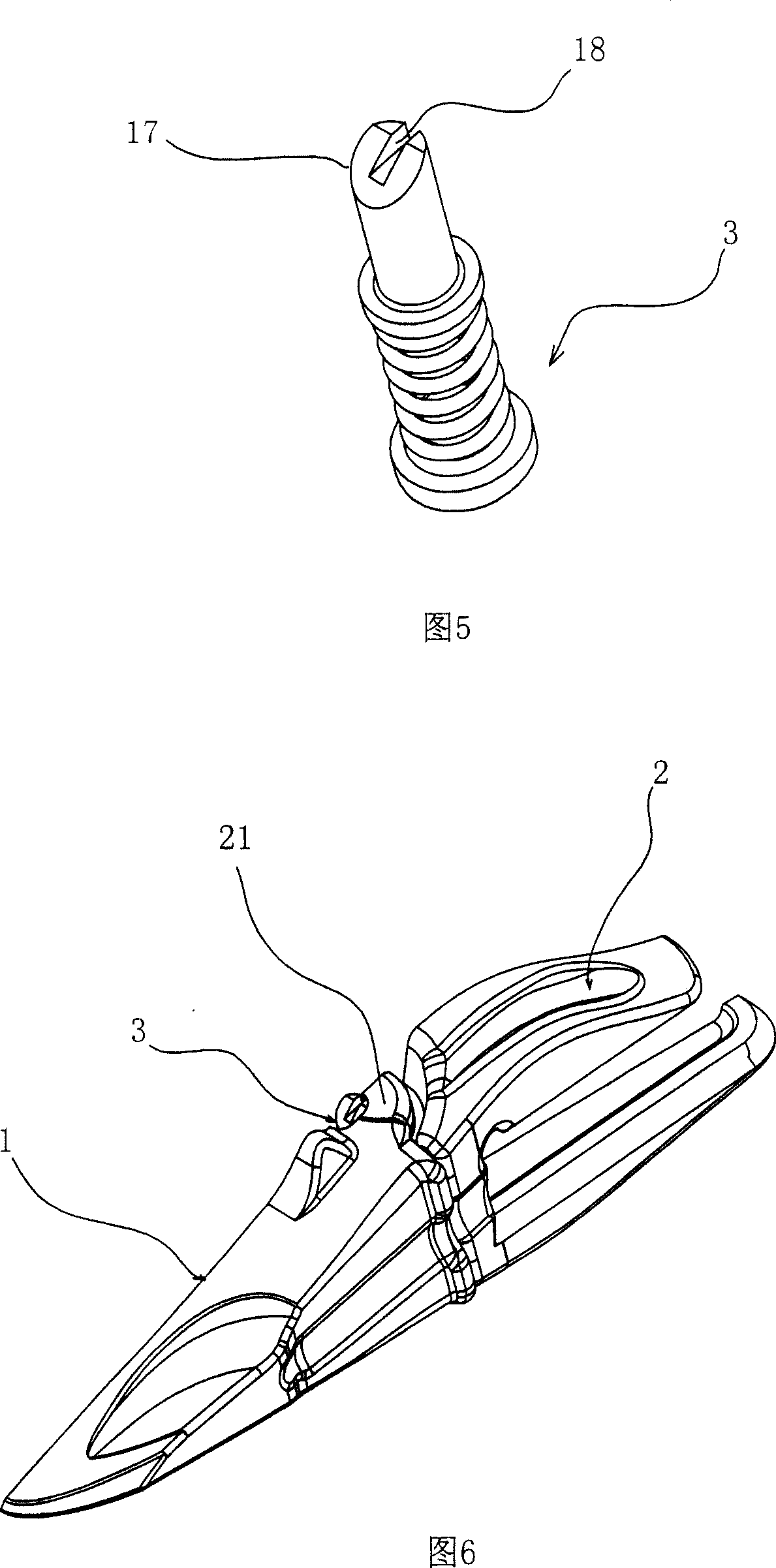

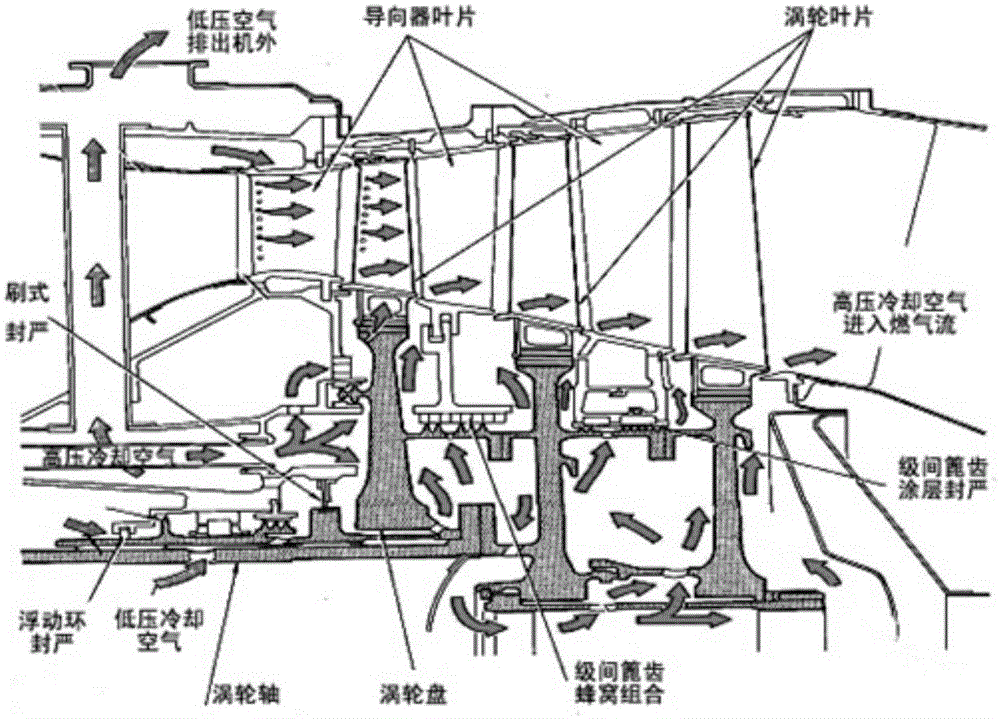

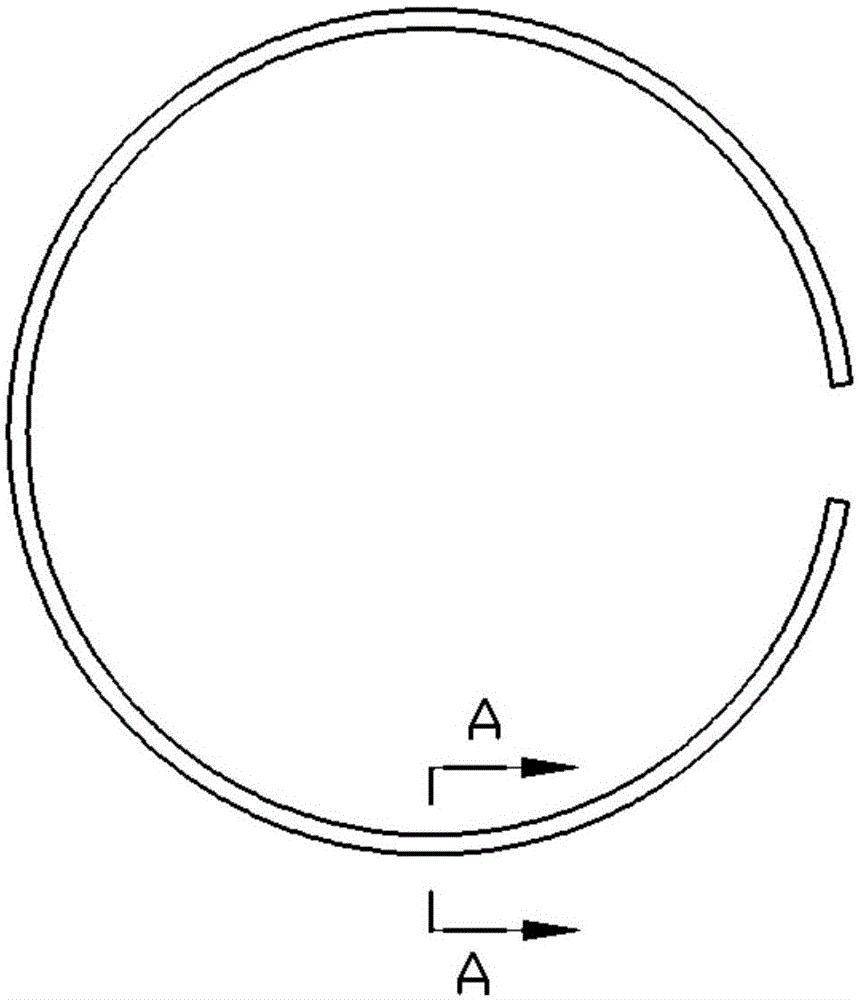

Comb tooth sealing structure

The invention relates to a sealing structure design technology, in particular to a comb tooth sealing structure, and solves the problem of high sealing leakage amount of a traditional comb tooth structure. The comb tooth sealing structure comprises a comb tooth and a bushing matched with each other, and a sealing ring arranged in a tooth cavity of the comb tooth and made of an elastic material; the sealing ring 3 can stop an airflow ejected from a tooth top gap to consume the speed of the airflow in the axial direction, so that the kinetic energy of the airflow cannot be totally transferred to the next tooth top gap, that is, the jet effect of the leaking airflow is eliminated; and the jet effect is a main factor of sealing leakage of the comb tooth, so that the leaking amount of the comb tooth sealing structure can be reduced.

Owner:AECC SHENYANG ENGINE RES INST

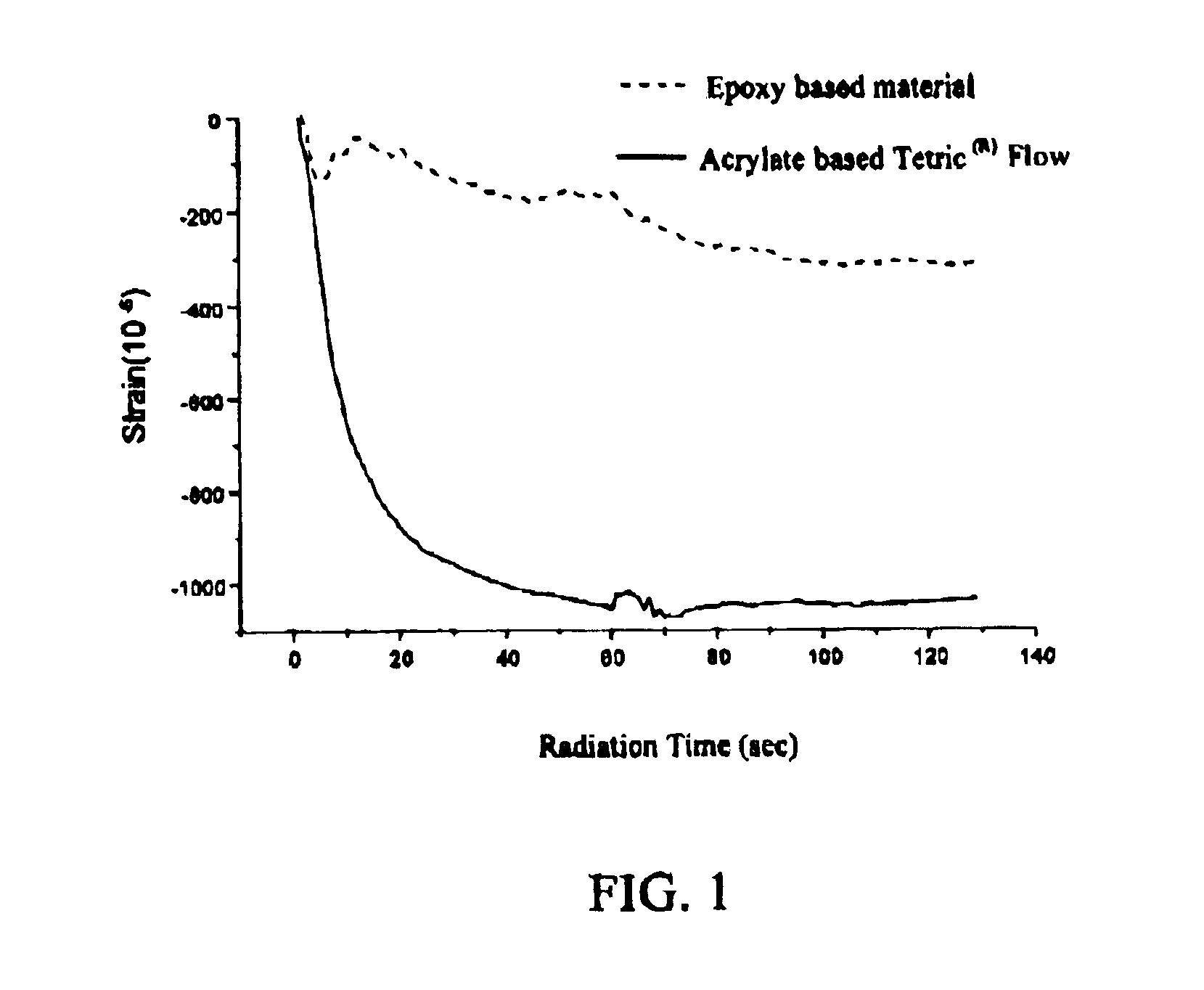

Tooth cavity restoration with nanocomposite of epoxy resin and nanoparticles

A method of restoring a tooth cavity is conducted by a direct or indirect method with a visible light curable nanocomposite of a dental restorative material with a low polymerization shrinkage, wherein the dental restorative material comprises an epoxy resin, inorganic oxide nano particles, a photoinitiator and a photosensitizer. The direct method involves the filling of the tooth cavity with the nanocomposite dental restorative material, stacking the nanocomposite dental restorative material in the tooth cavity, and curing with visible light followed by shaping and polishing. The indirect method involves making a mold of the tooth, casting the mold with the nanocomposite dental restorative material, curing with visible light followed by shaping and polishing, then removing the shaped and polished material and adhering it to the tooth cavity.

Owner:NAT TAIWAN UNIV

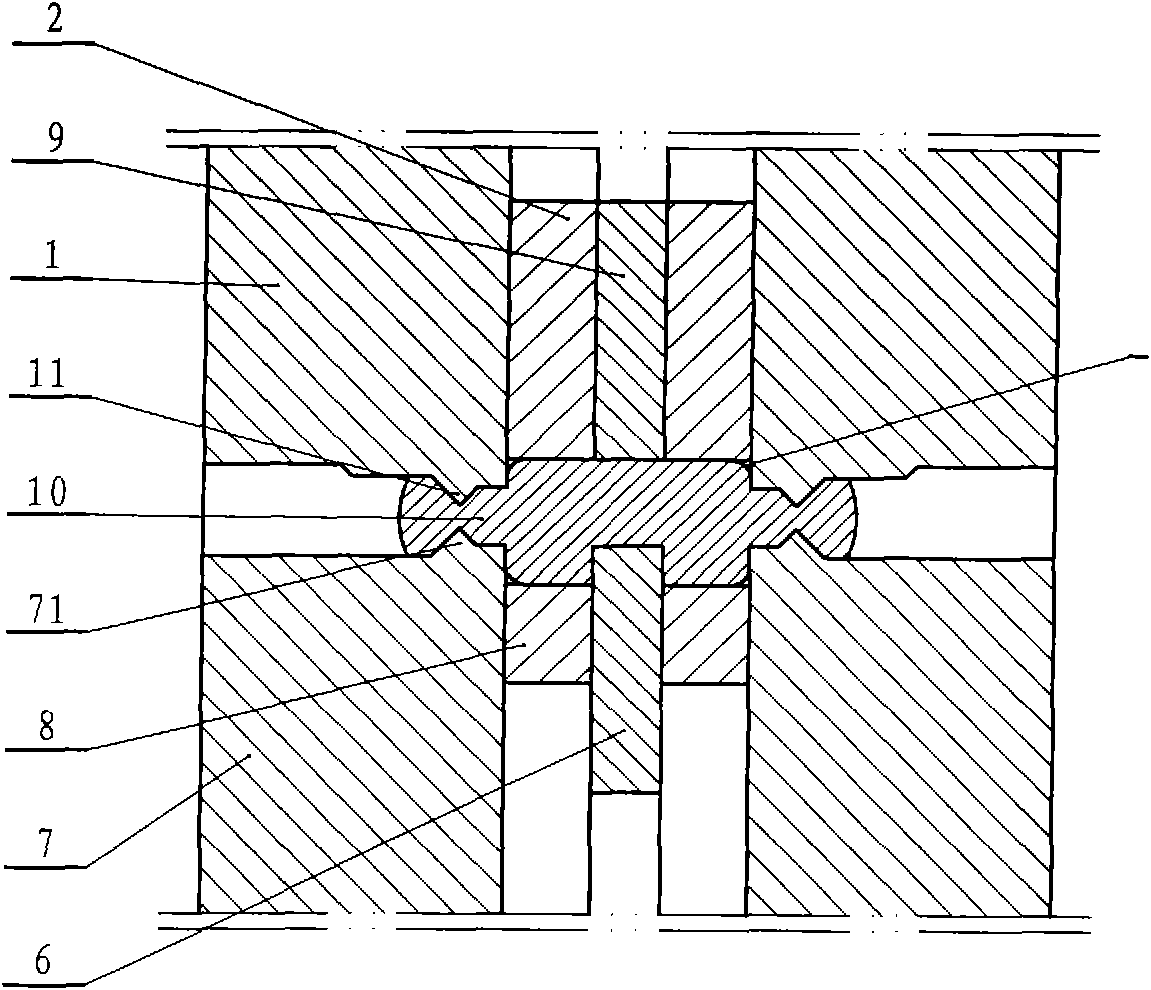

Manufacturing method of bucket tooth and applied mould thereof

The invention provides a manufacturing method of bucket tooth and an applied mould thereof. Liquid bucket tool material is poured into a material storage cavity, a core puller is utilized to push a tooth cavity core and a pin hole core into a bucket tooth mould cavity; an upper mould and a lower mould are closed, and pressure is maintained to be 3000-15000kN; the lower cylinder of a hydraulic cylinder drives a pressure head to push the liquid bucket tooth material in the material storage cavity to be filled with the bucket tooth mould cavity at the linear speed of 10-100m / s, pressure is increased to be 500-5000kN, and pressure is maintained until the material is completely solidified. The core puller is utilized to pull out the tooth cavity core and the pin hole core; the lower cylinder drives a material tray to push an ejector rod to eject the bucket tooth and residue material, heat treatment is carried out, thus obtaining the bucket tooth of the invention; the lower cylinder returns, the material tray pulls the ejector rod and the pressure head to be descended and reset, and next operating cycle is executed. Material utilization is 85-95%, strength is improved by 20-30% compared with a sand-cast bucket tooth, impact toughness is improved by 15-25%, energy consumption is reduced by 20-30%, cost is reduced by 15-30%, and hour output can reach 150 pieces. Qualified bucket tooth can be manufactured without a dead head or sand mould.

Owner:BEIJING JIAOTONG UNIV +1

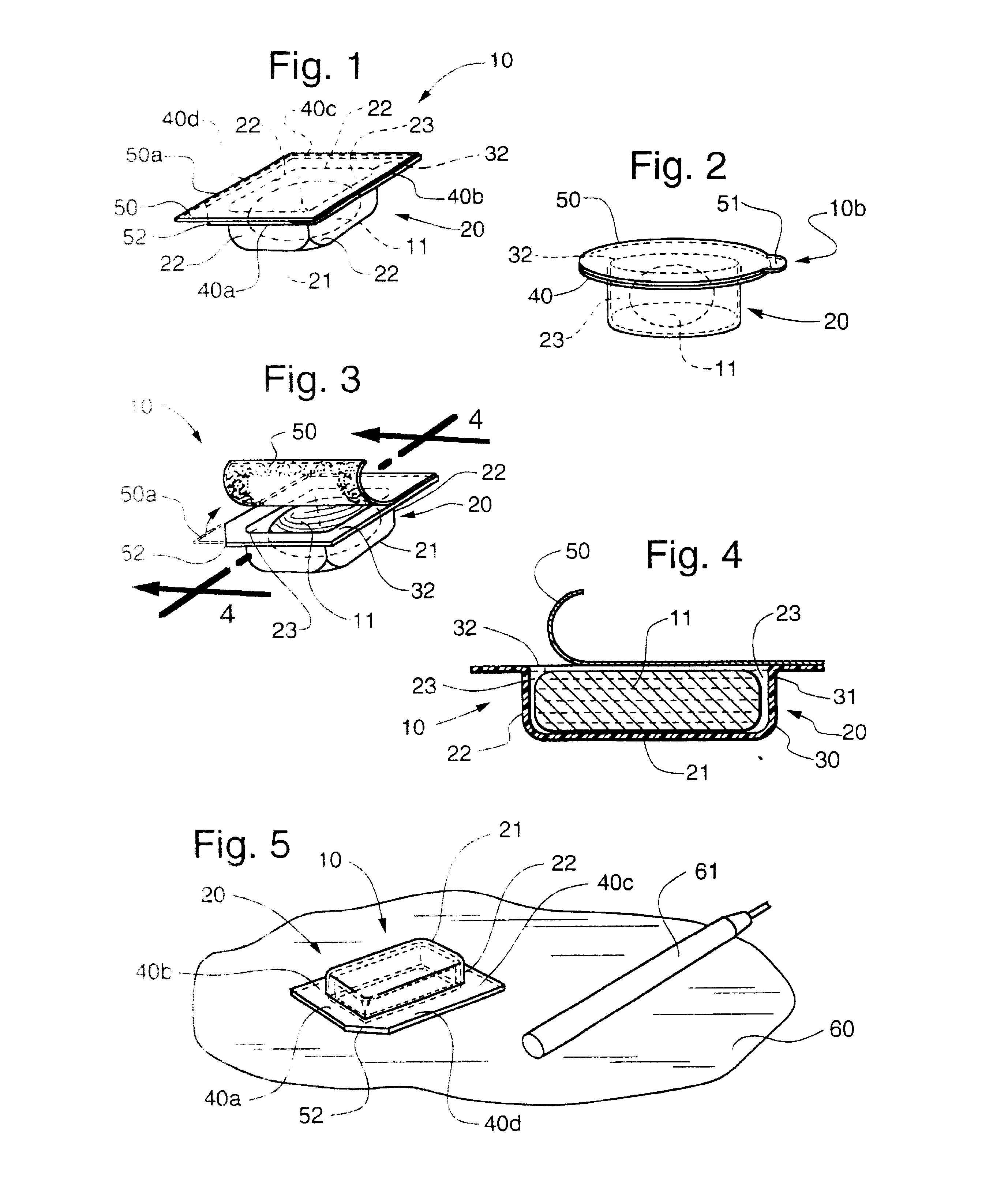

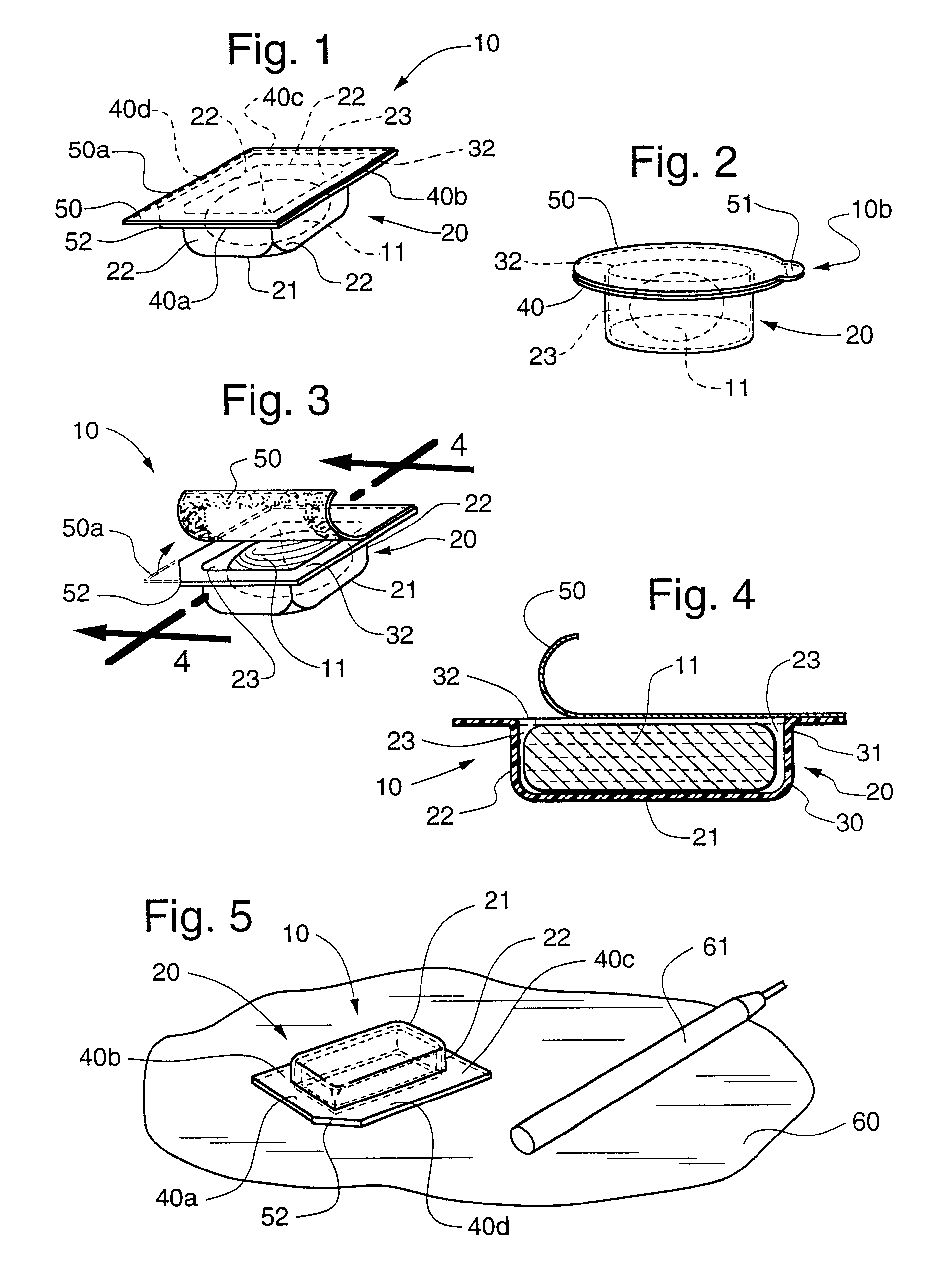

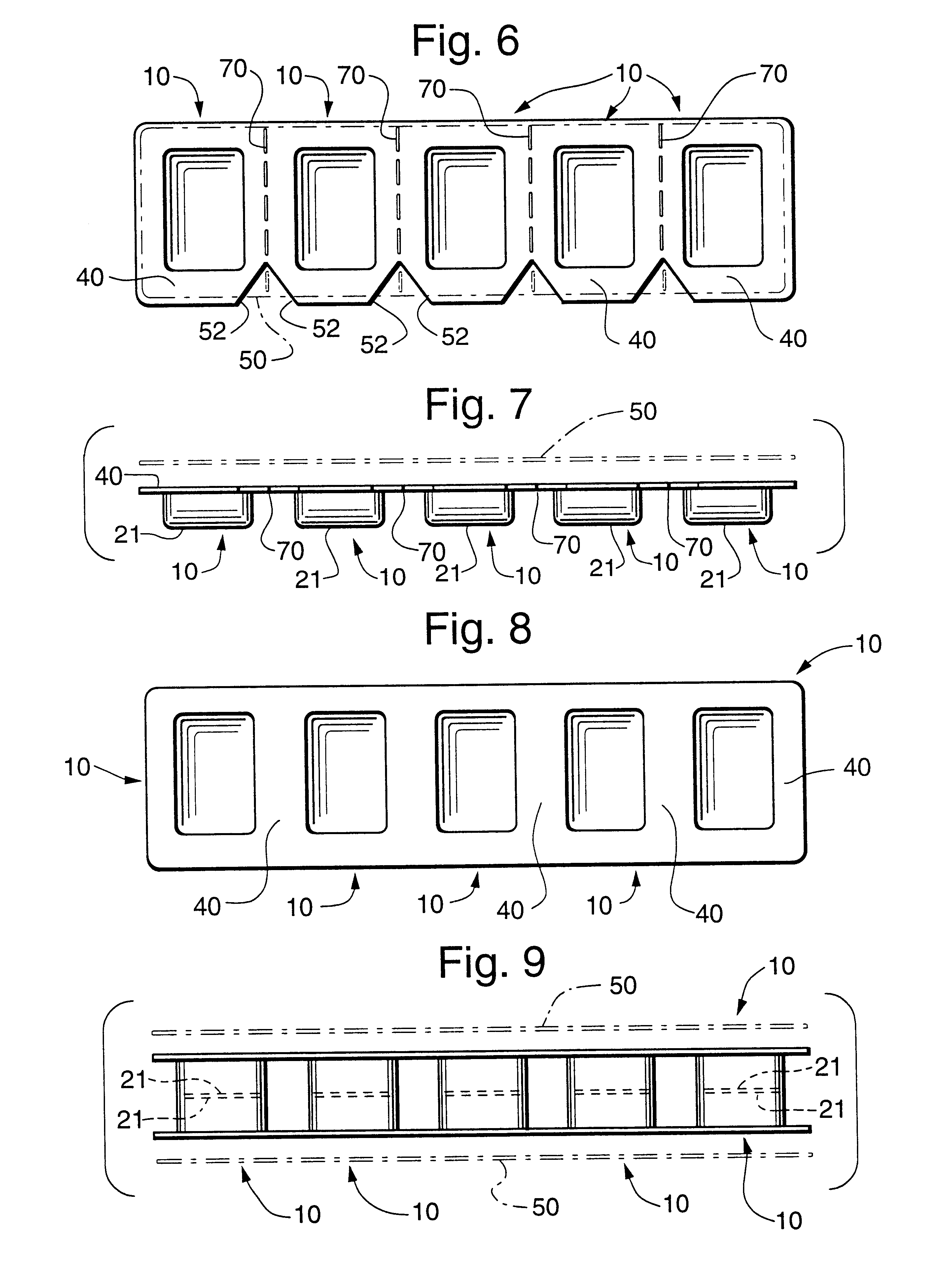

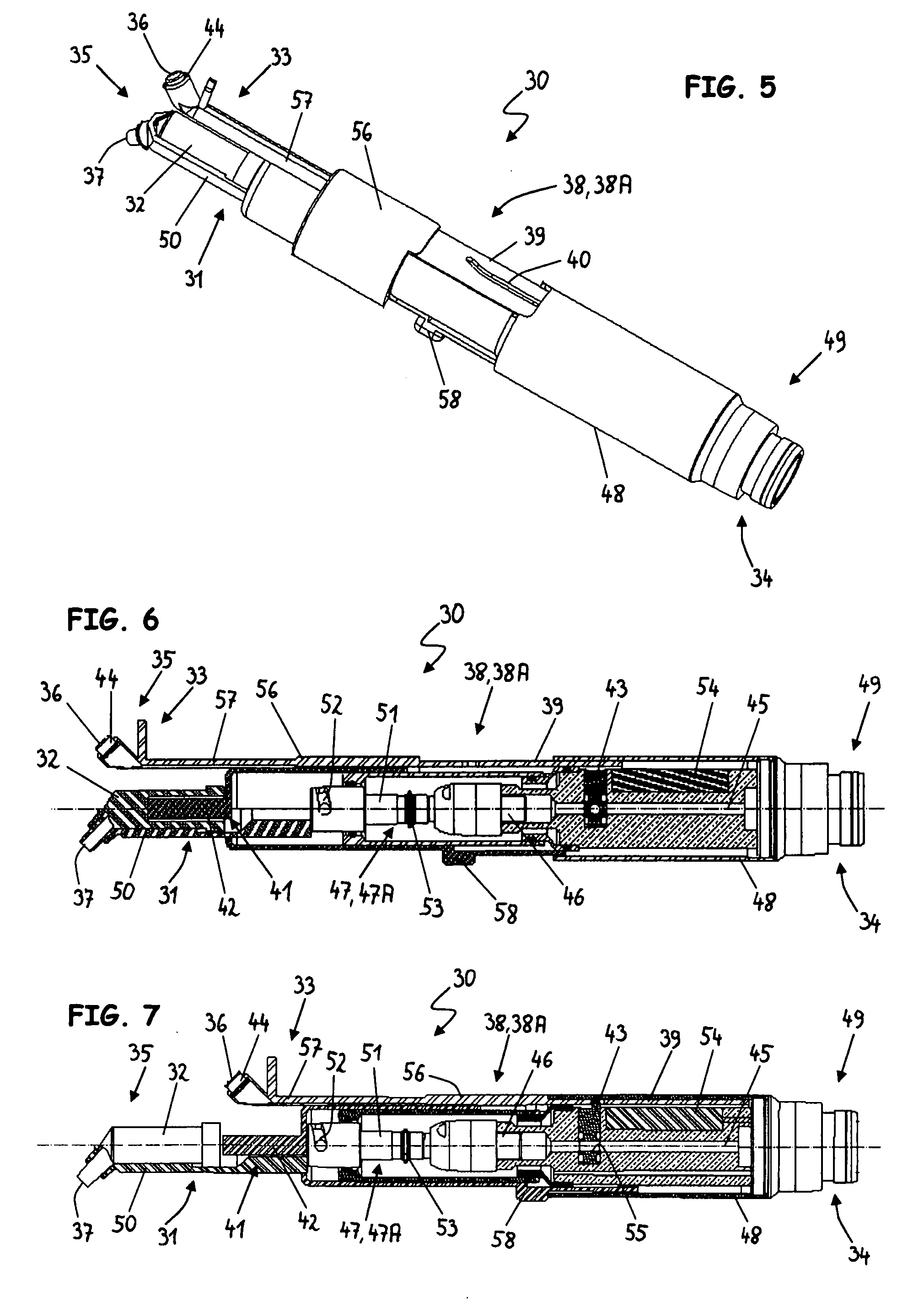

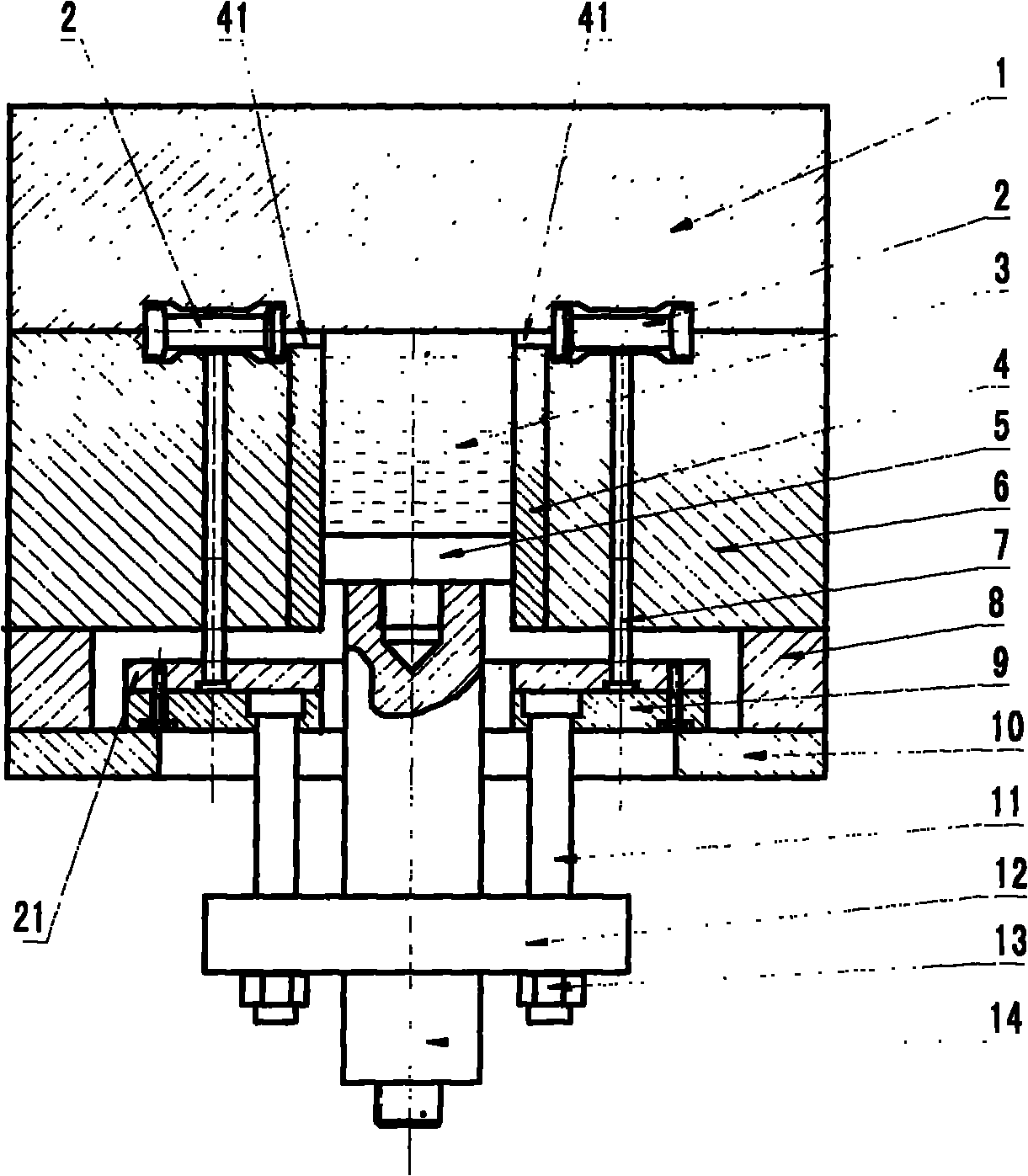

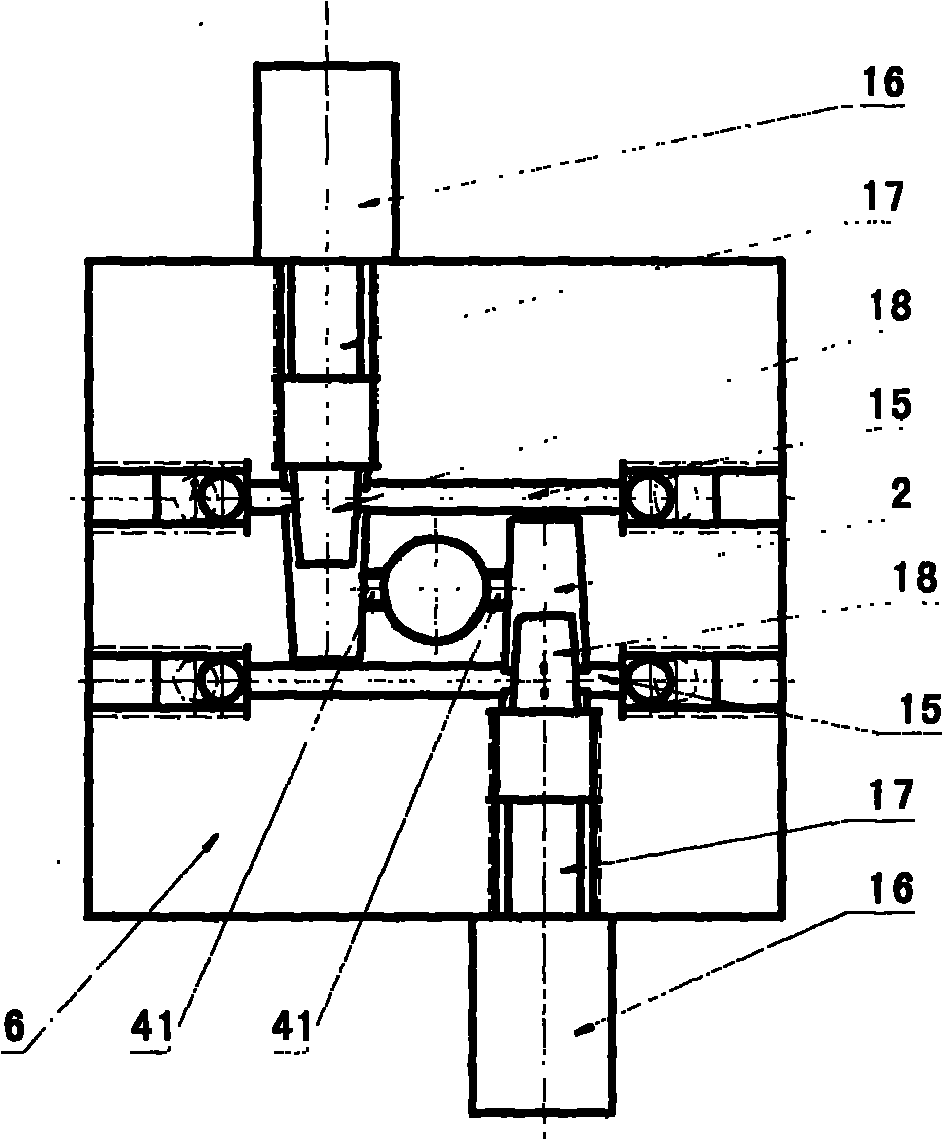

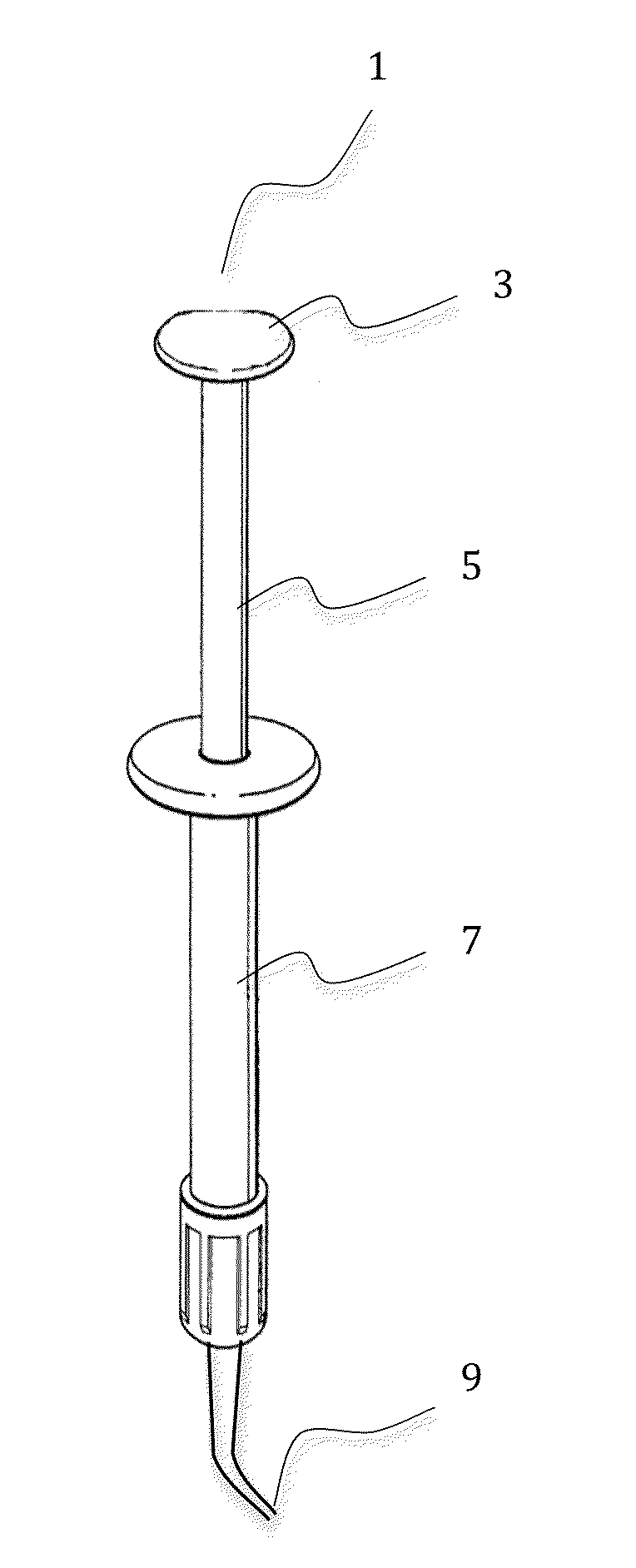

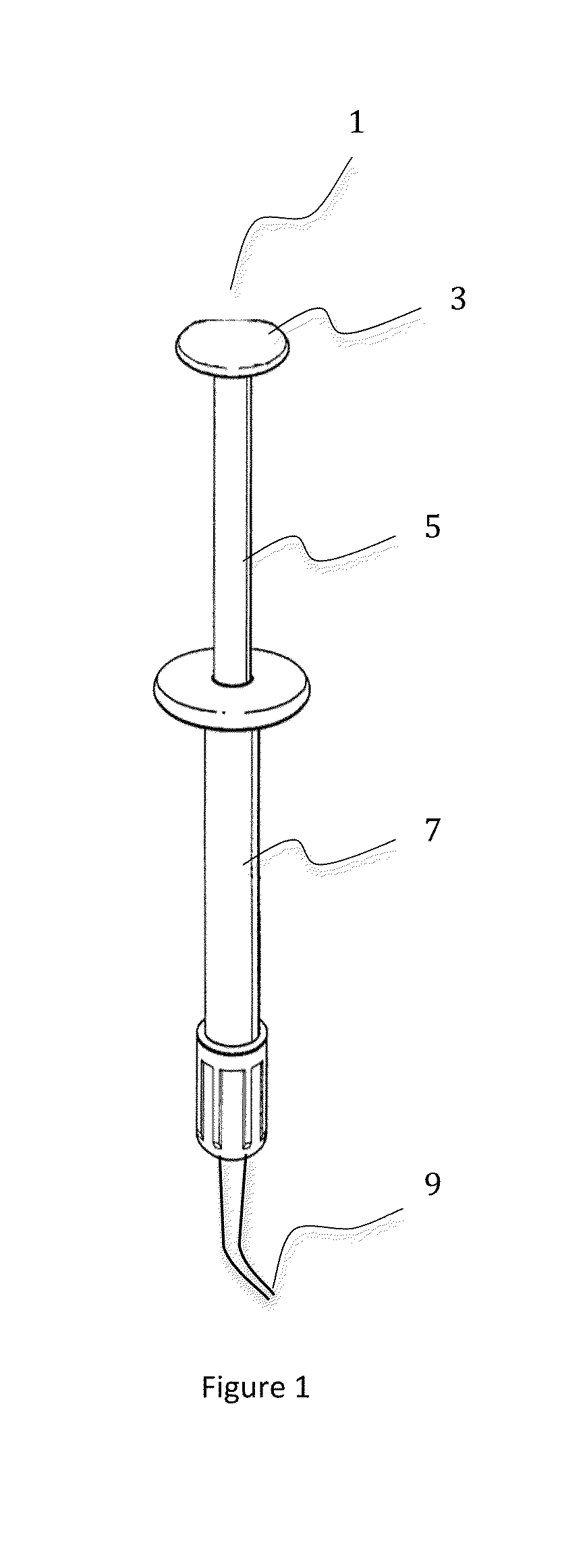

Delivery syringe for flowable dental compound

InactiveUS20110256501A1Improve carrying capacityDesirable flow characteristicAmalgam presses/mixersTeeth cappingFlowable CompositeEntrapment

The present invention provides a delivery syringe and a set of delivery syringes for flowable composite materials that overcome the difficulties associated with currently available composite delivery methods. Specifically, the present invention provides a flowable composite delivery syringe with a vibratory mechanism. The vibratory mechanism allows the composite material to contain a higher filler load and still have desirable flow characteristics. The higher filler load produces a stronger composite material with less shrinkage during the curing process. Additionally, the vibratory mechanism contained in the delivery syringe prevents air entrapment voids during the delivery of the composite material into the tooth cavity preparation.

Owner:LAMPERT CHRISTOPHER JAMES

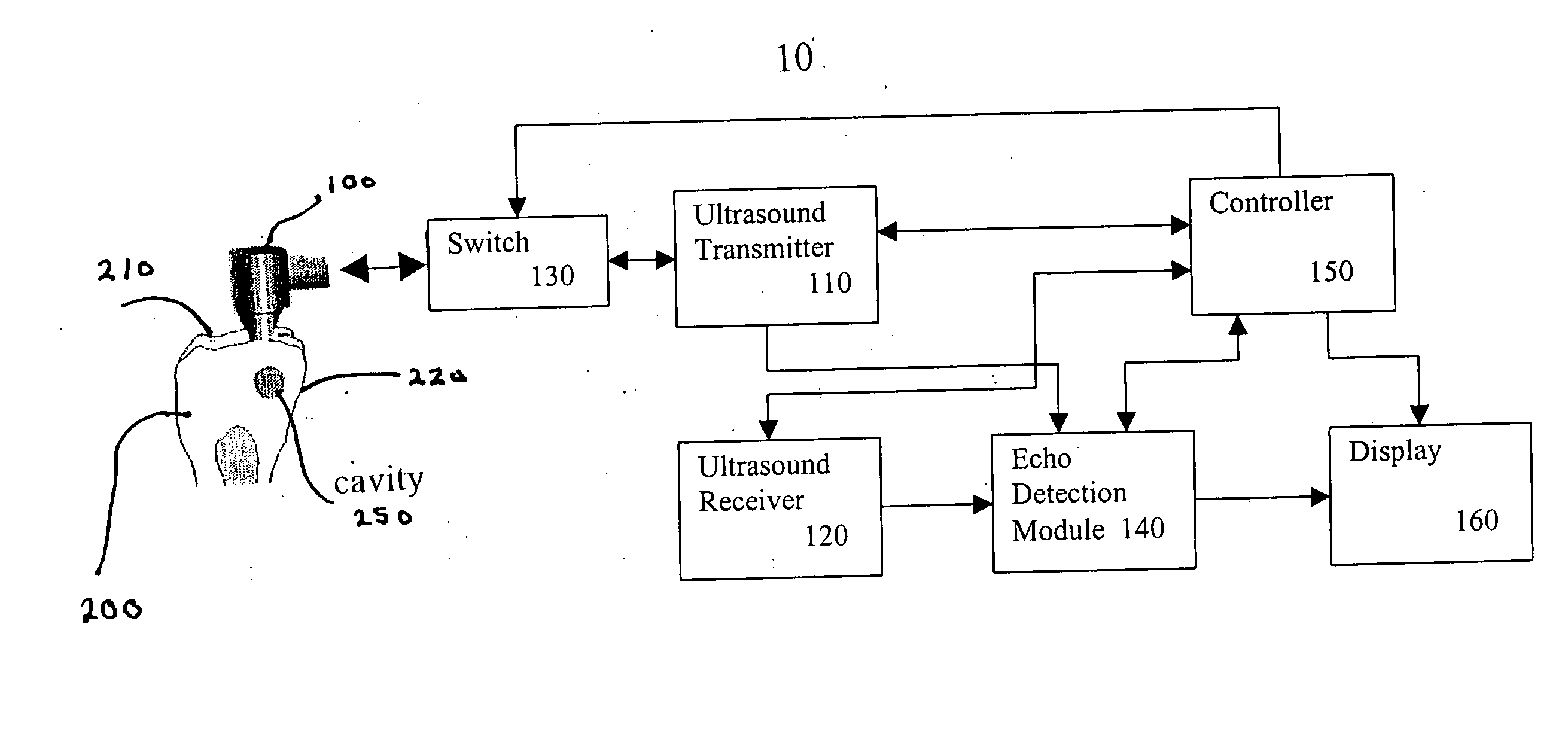

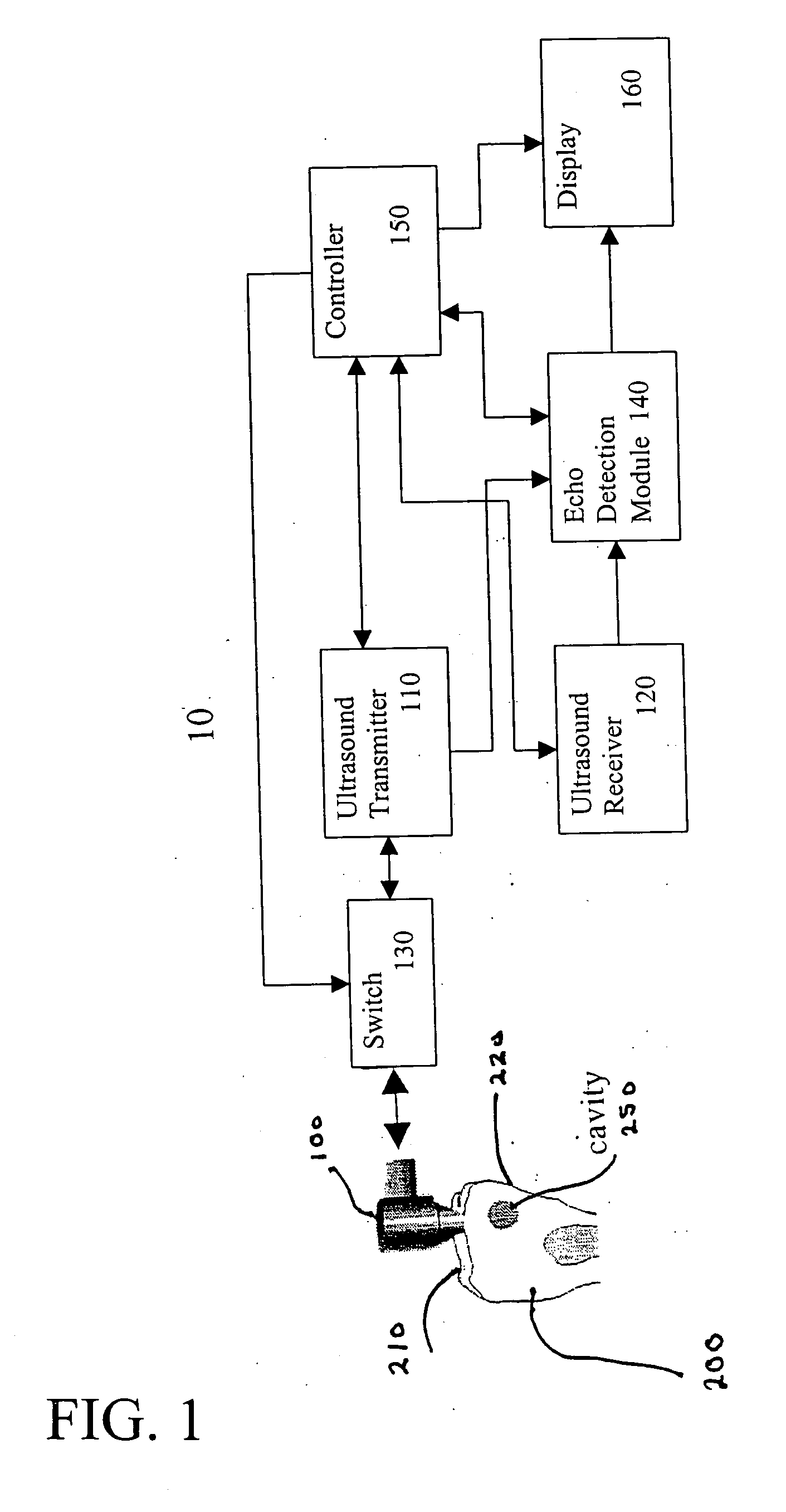

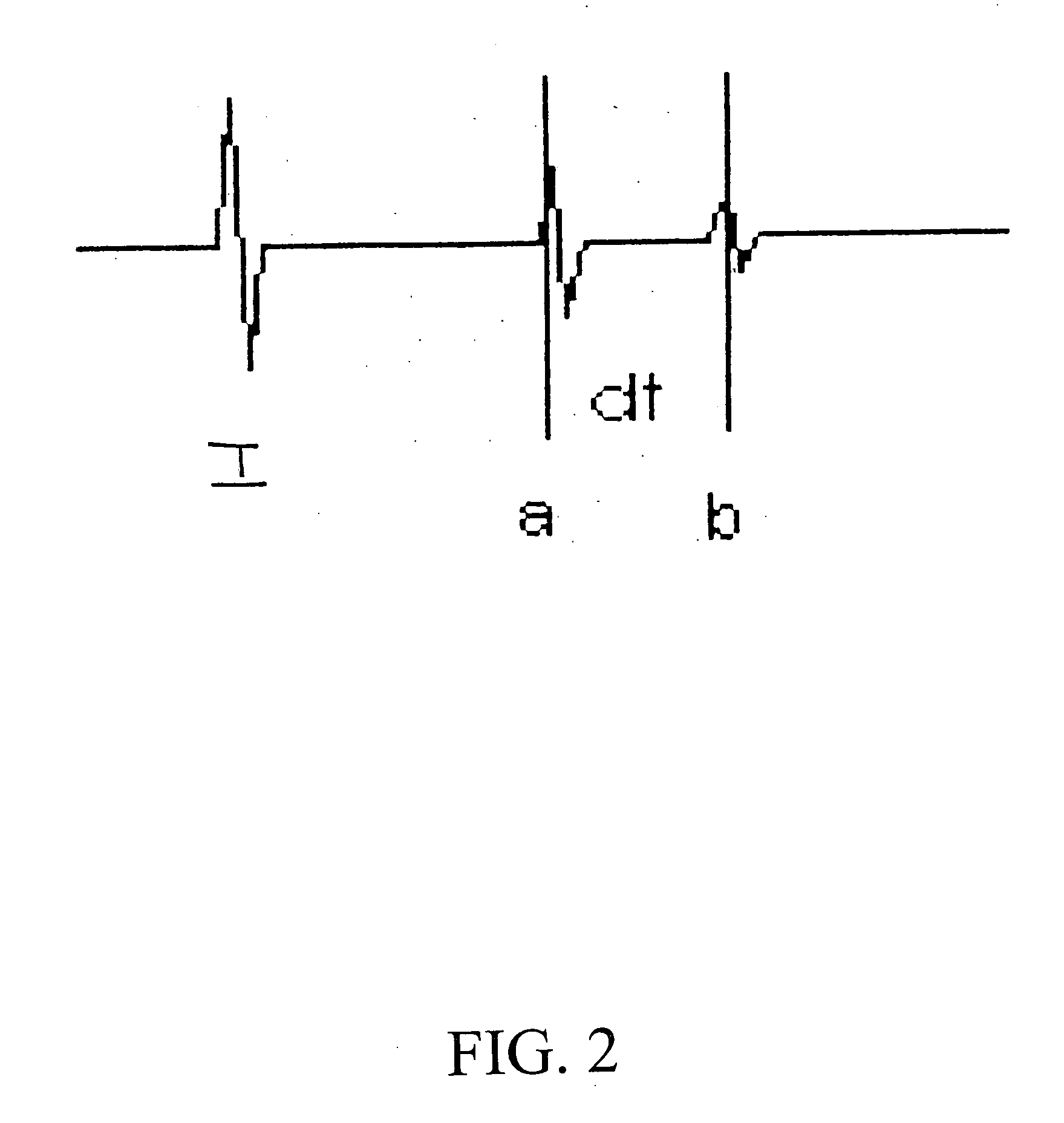

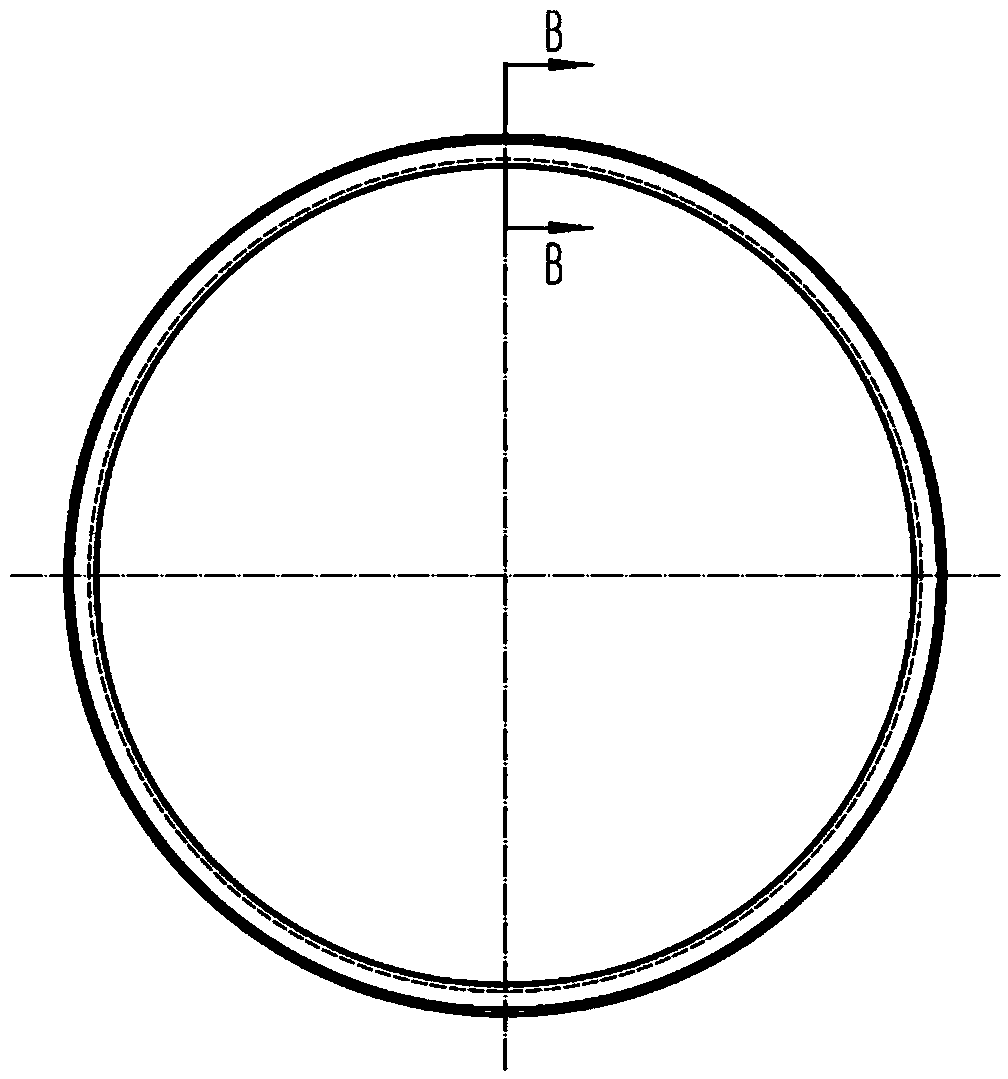

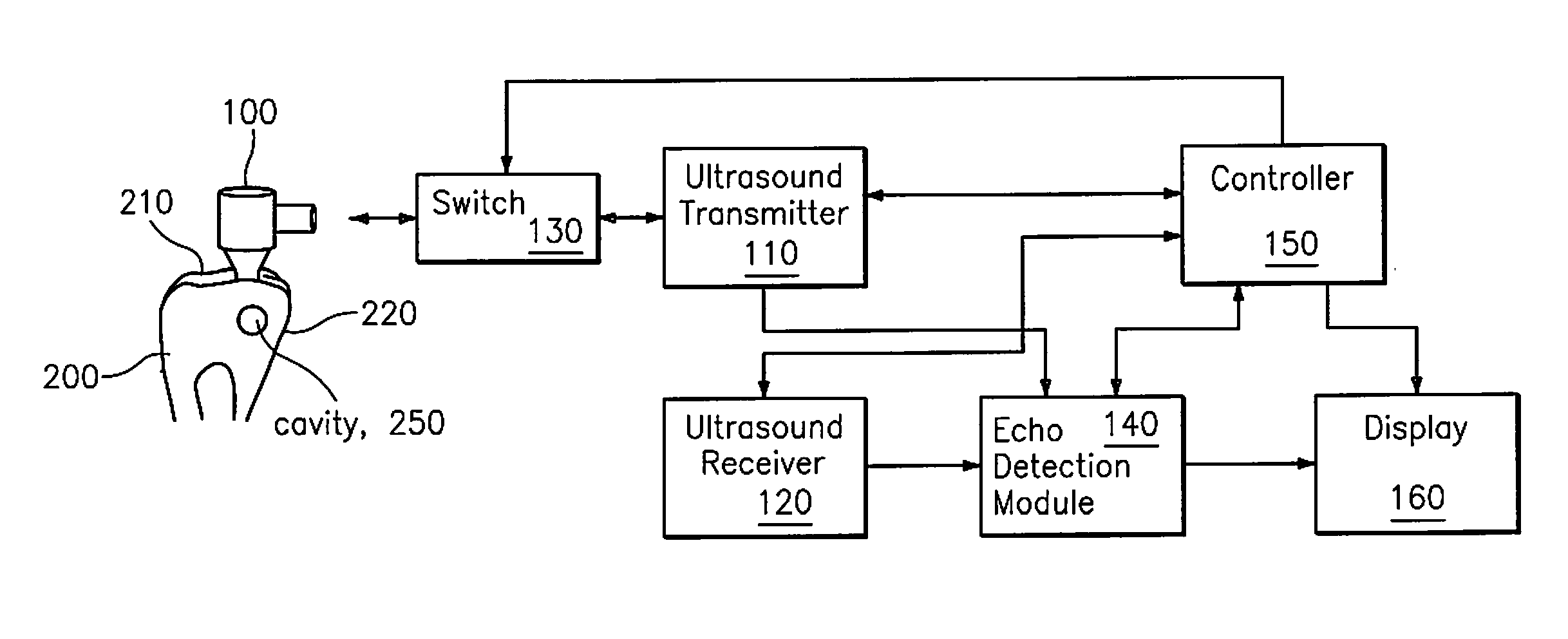

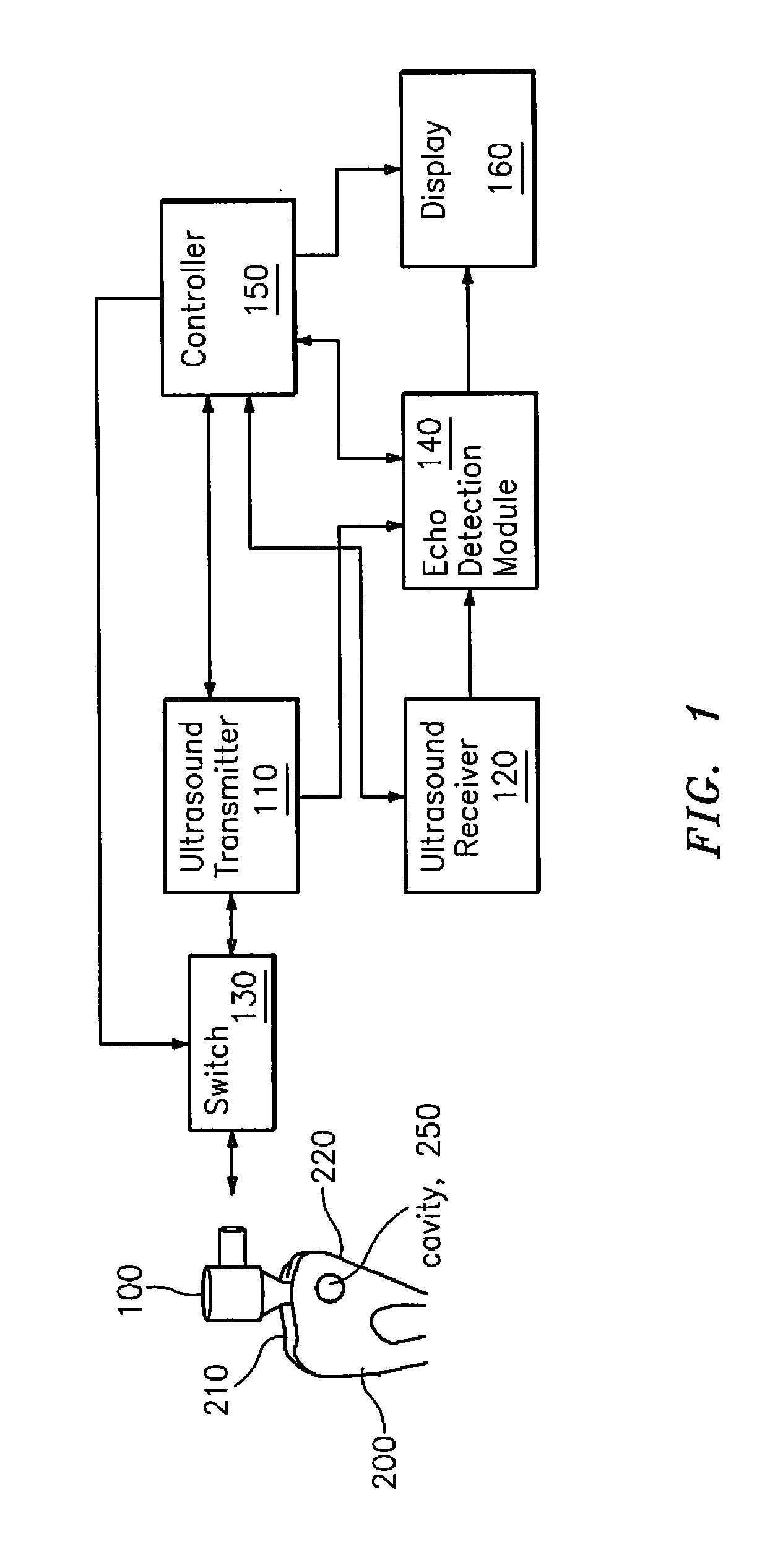

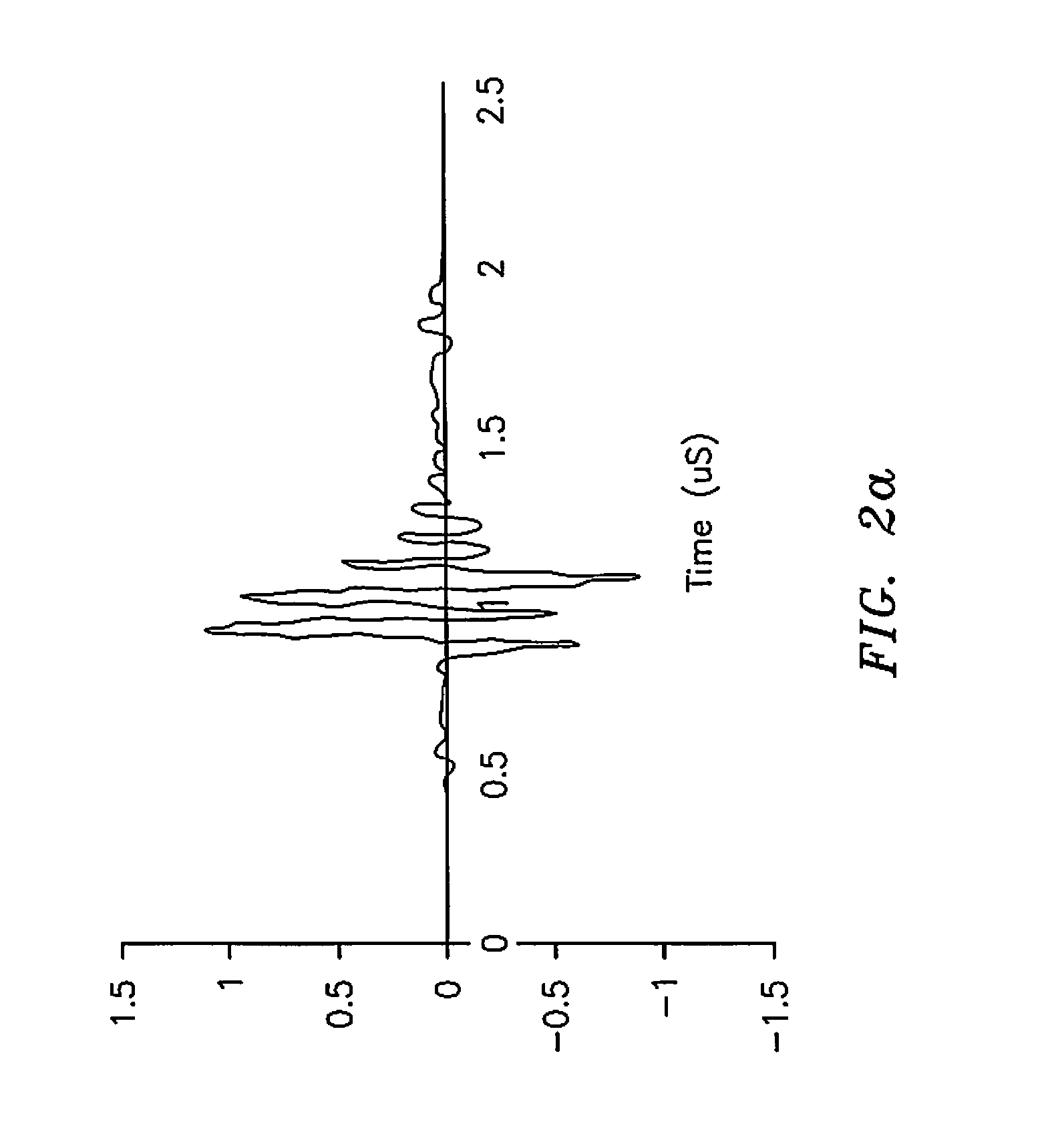

Portable ultrasonic device and method for diagnosis of dental caries

InactiveUS20070238996A1Effective informationUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsCementum cariesVisual perception

Provided is an apparatus and method for the detection of dental caries. The apparatus generates longitudinal ultrasound waves that may be applied to any accessible surface of a tooth. The reflected ultrasound pulse echoes are collected and correlated with the incident pulse. The ultrasound pulse echoes from the front and rear surface of a dental cavity may be distinguished from other echoes, and provided in visual display to inform as to the size and location of the cavity.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

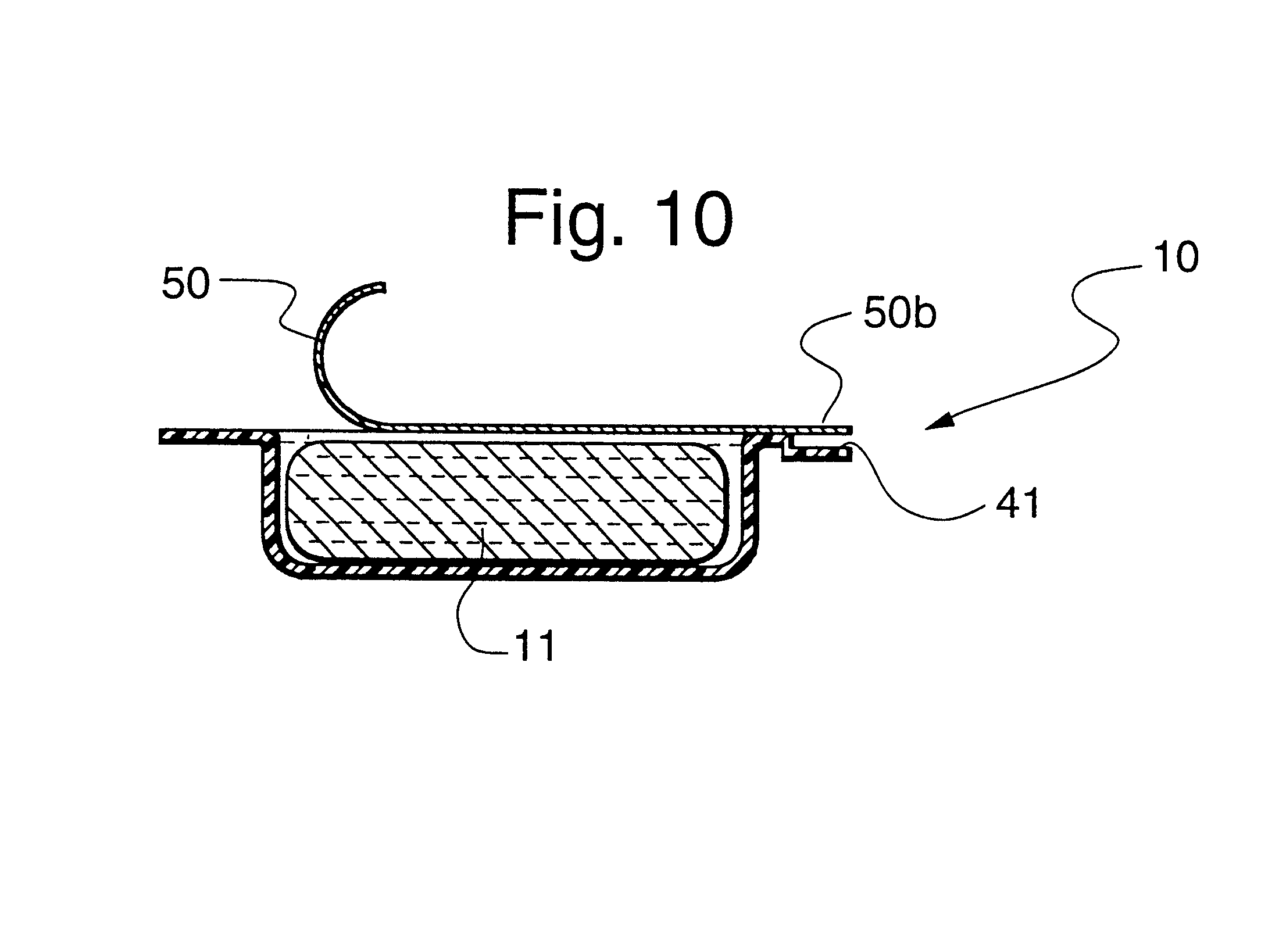

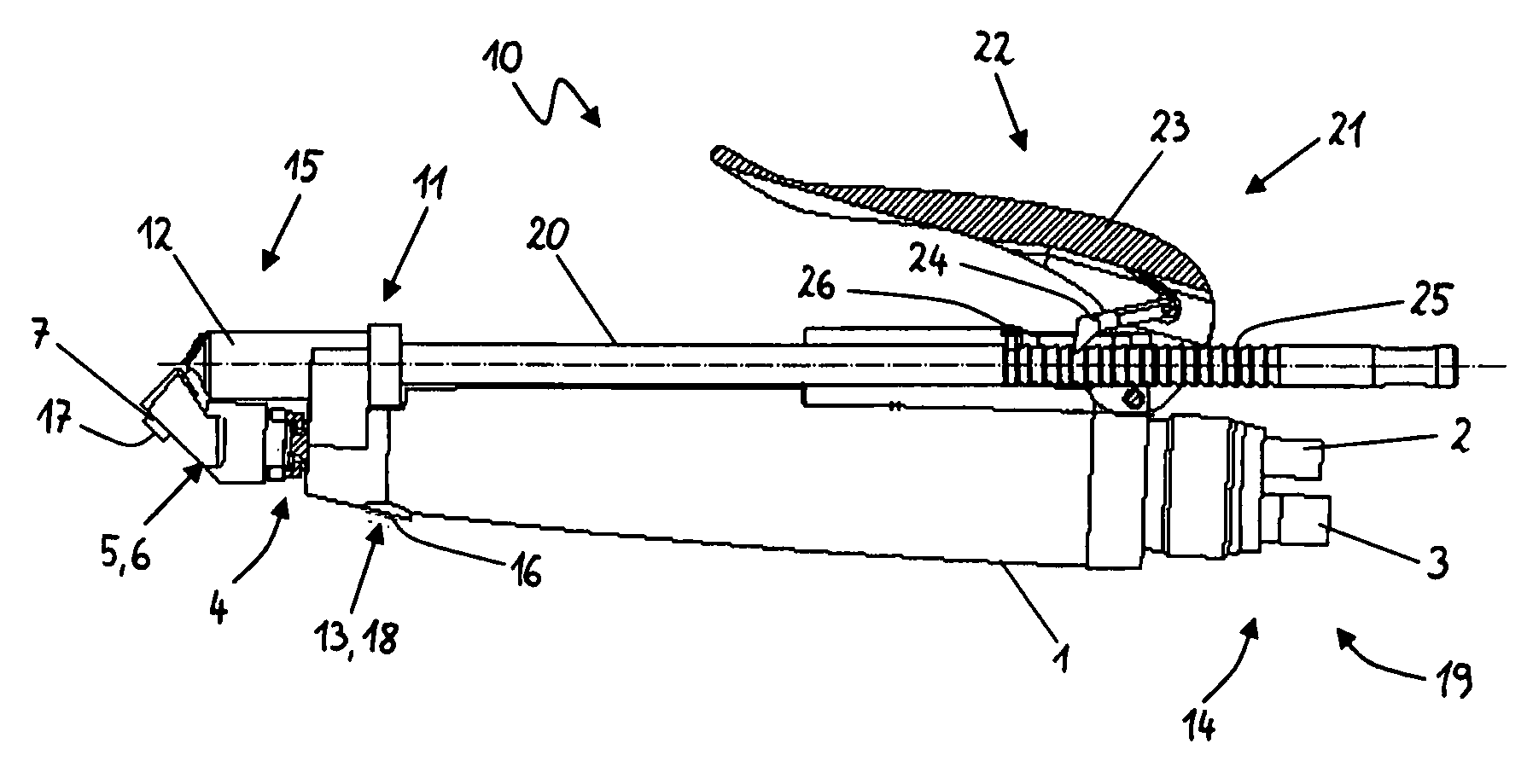

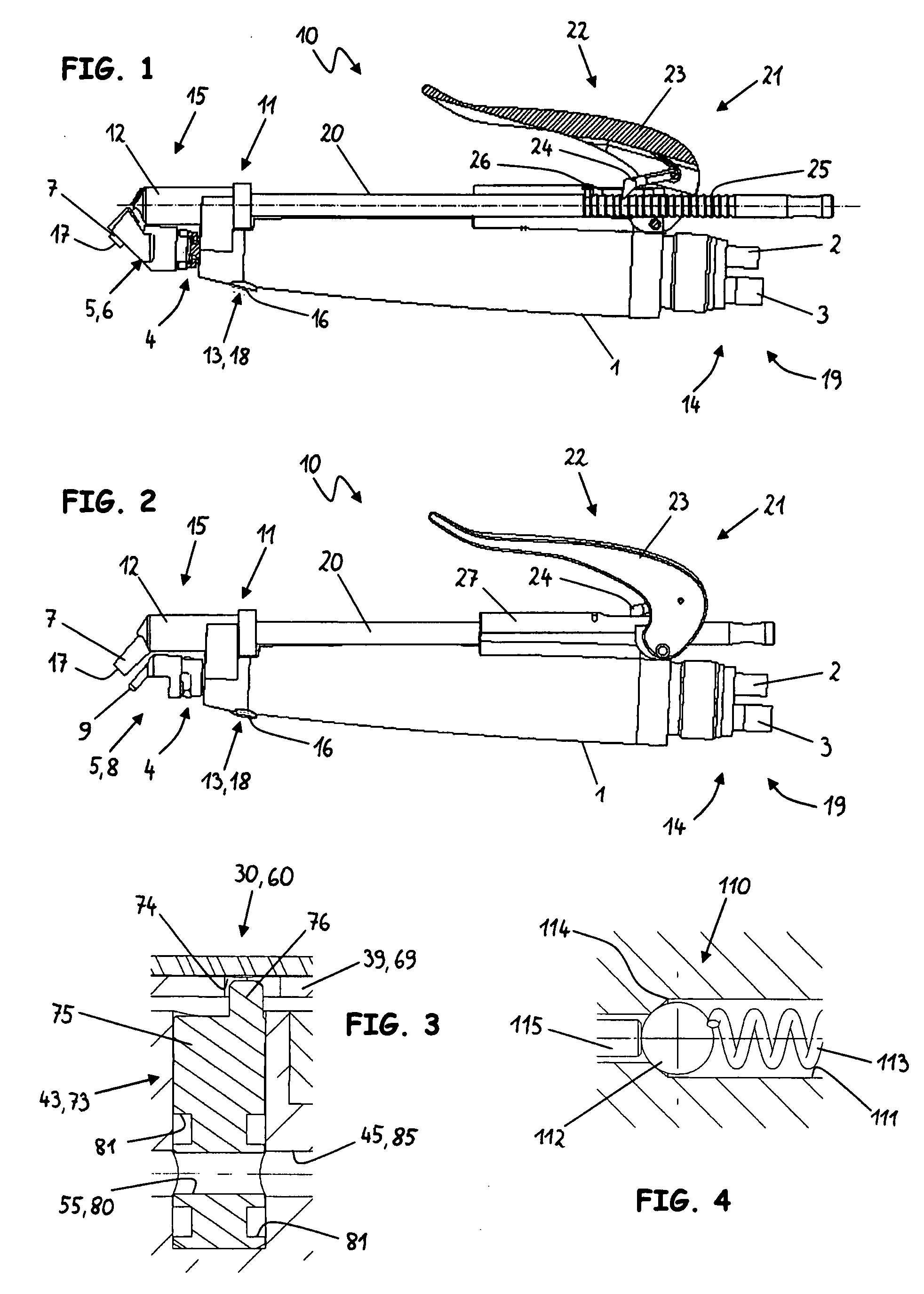

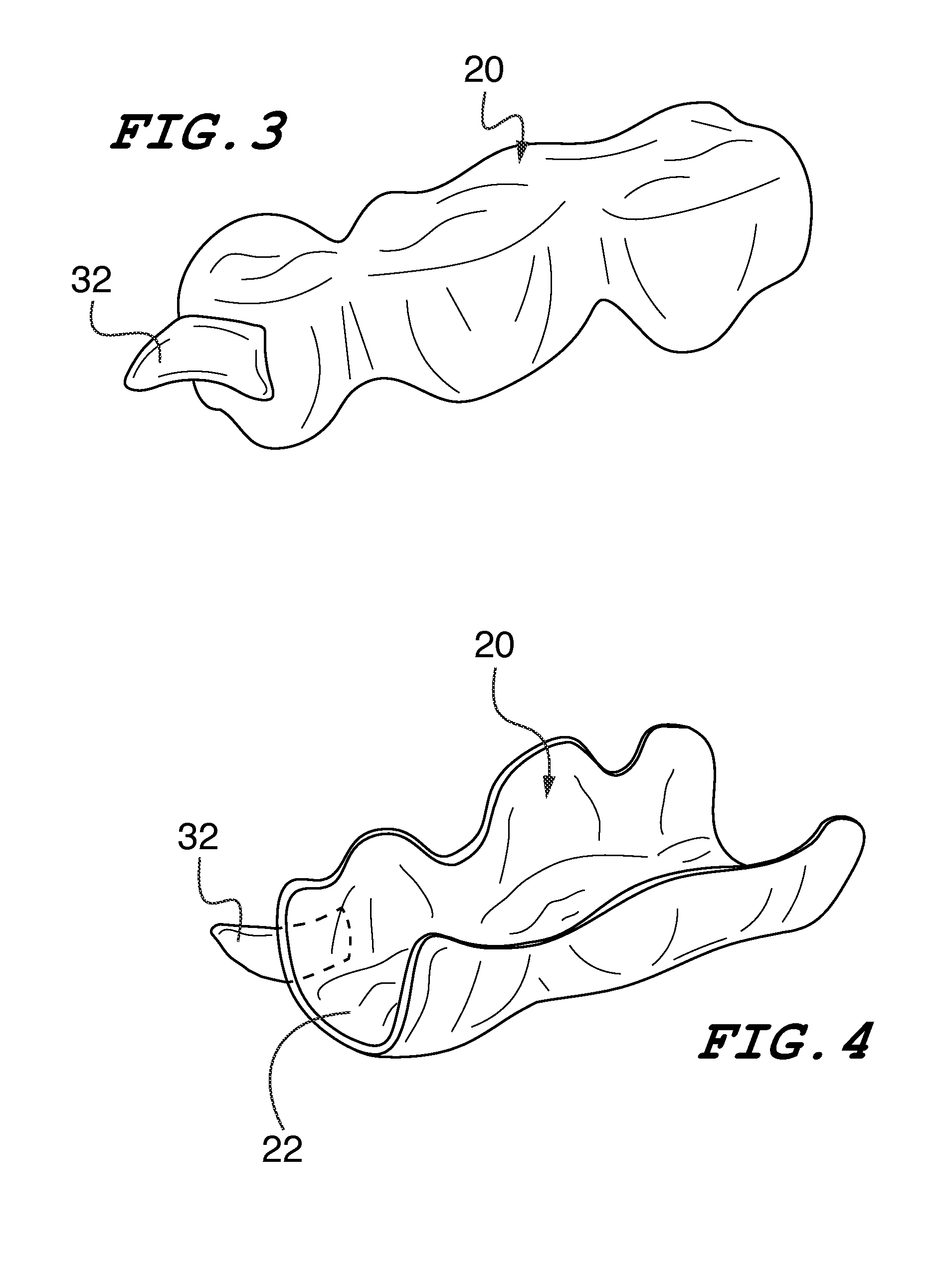

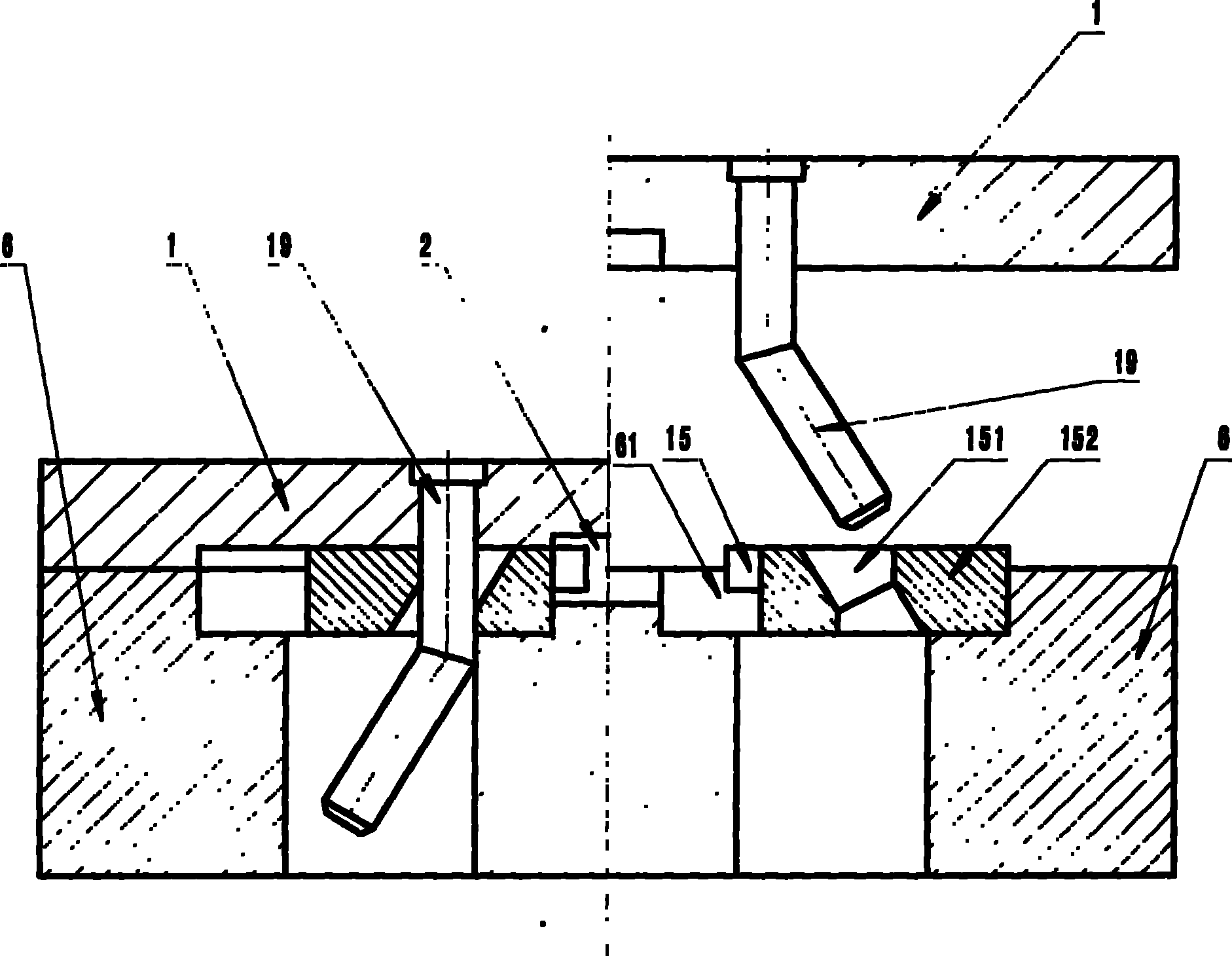

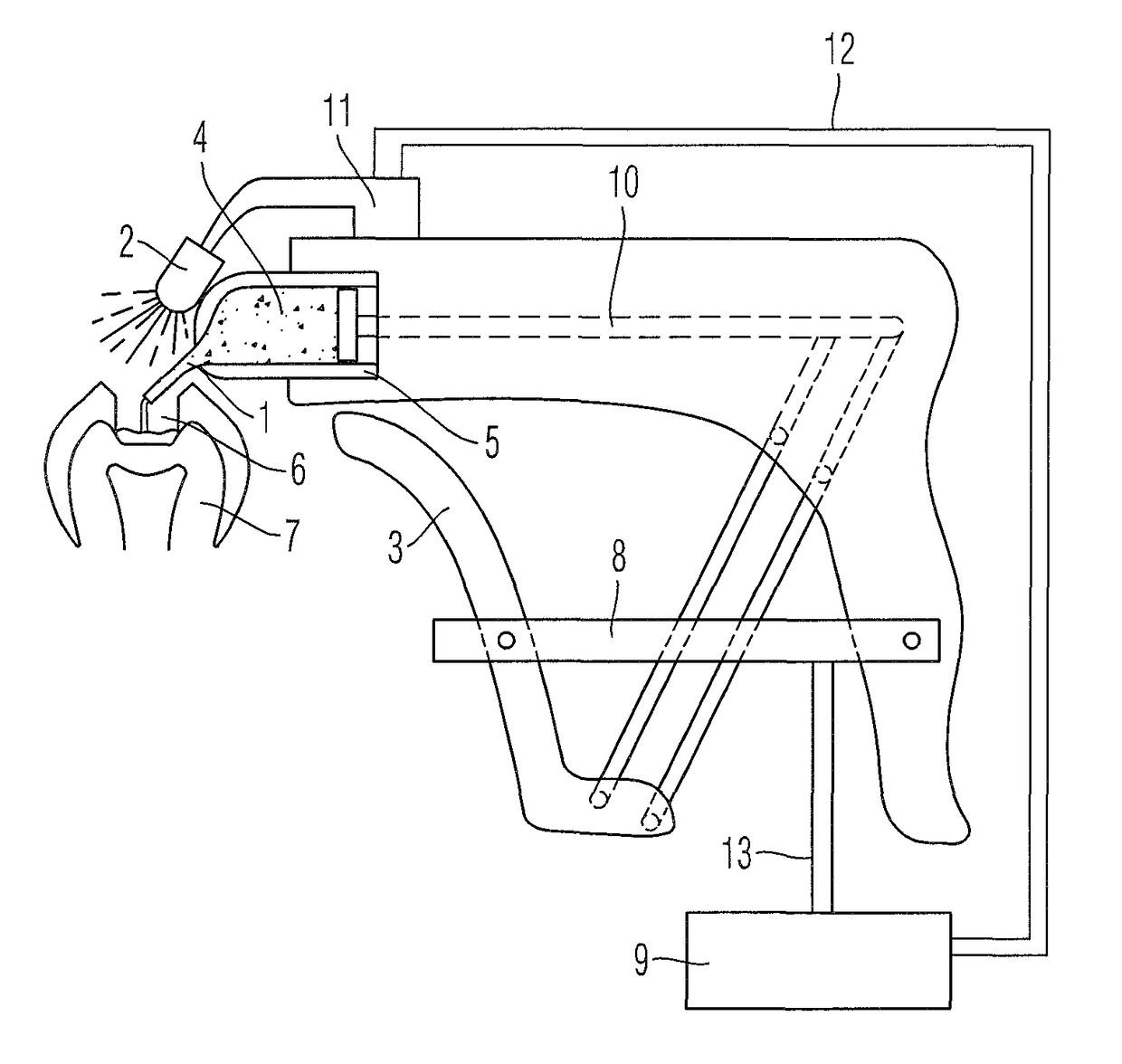

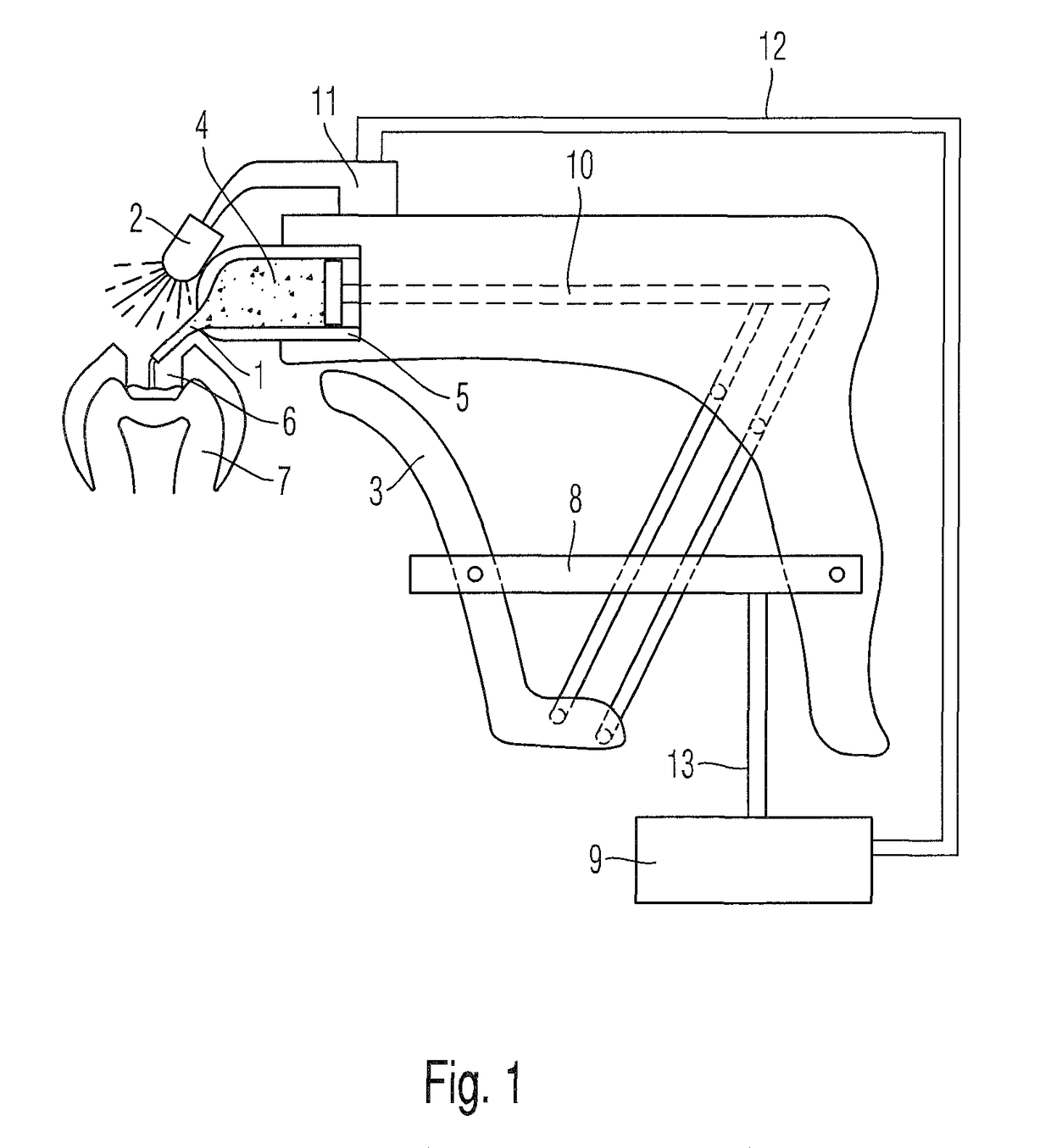

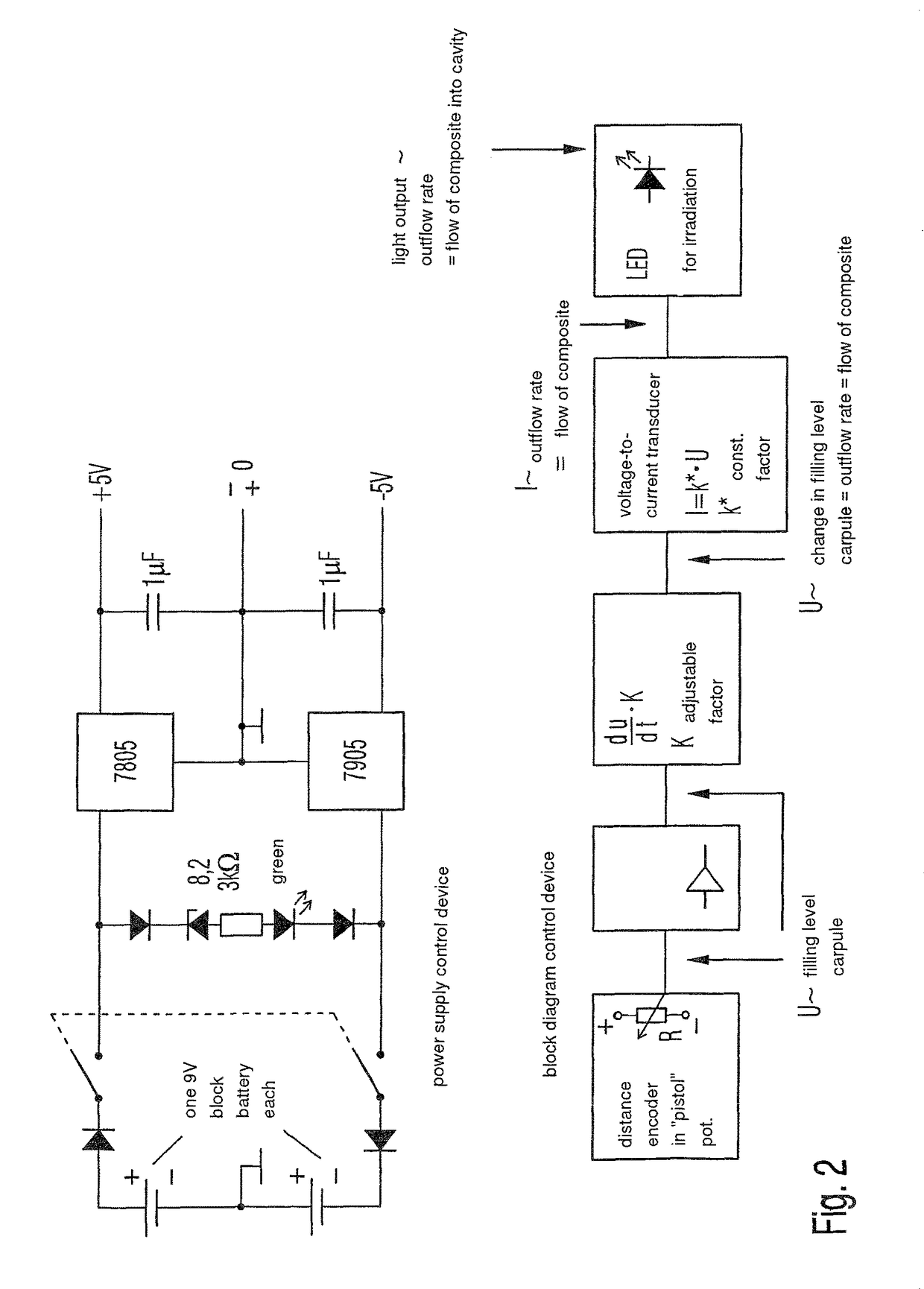

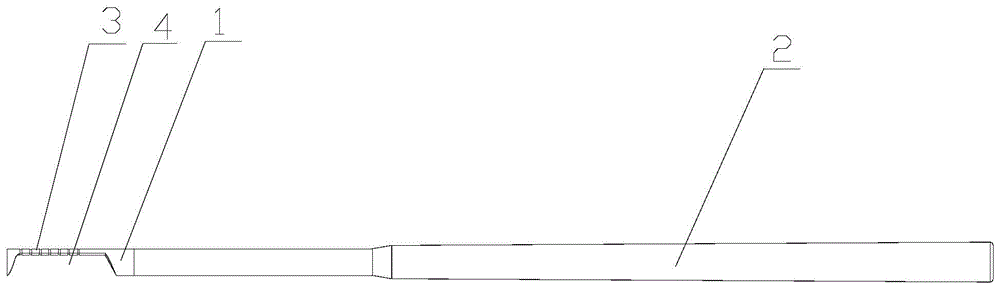

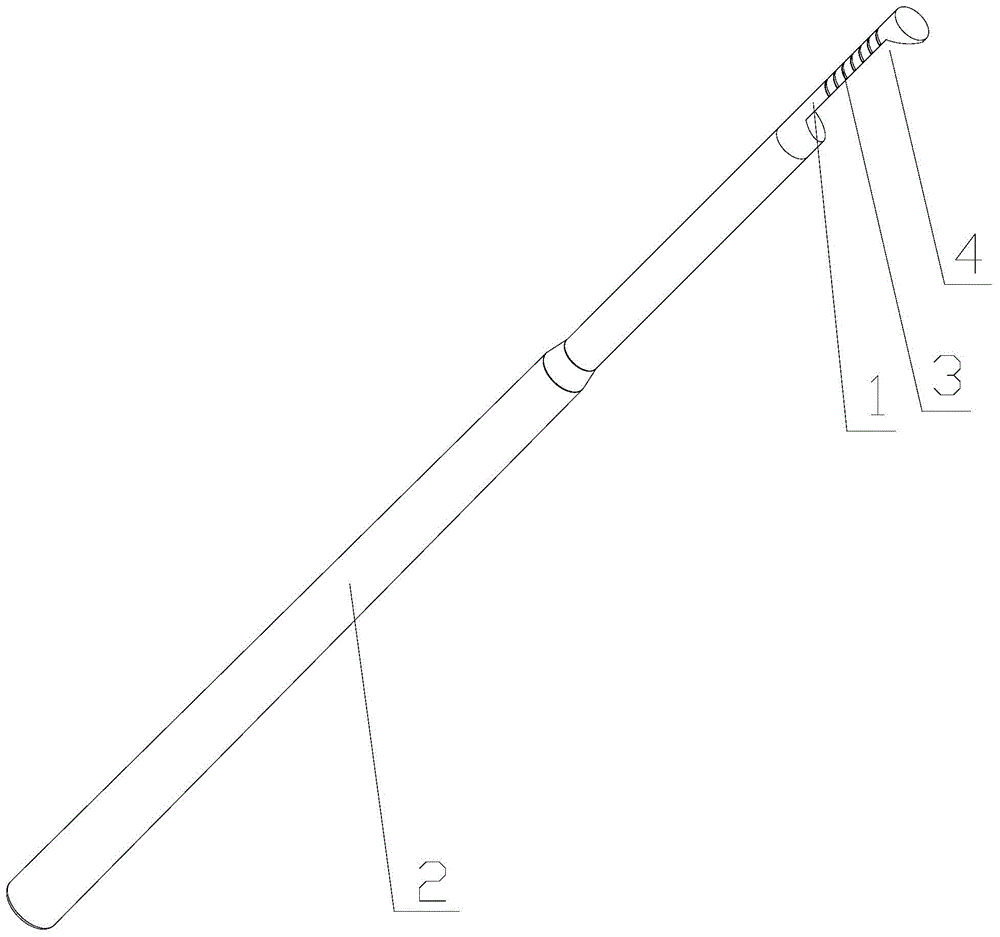

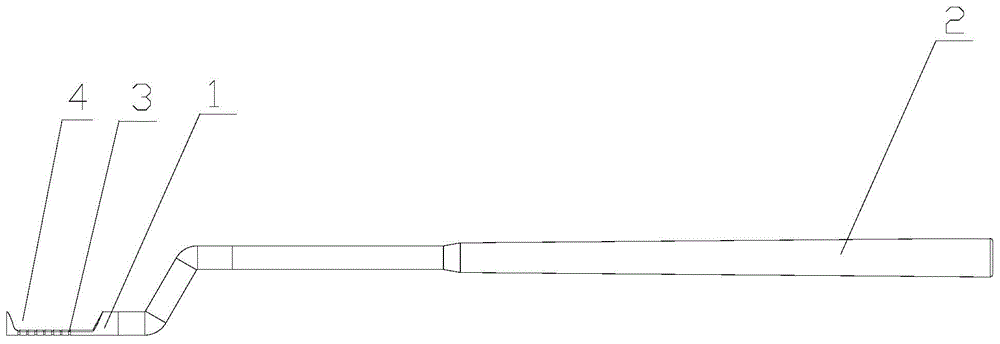

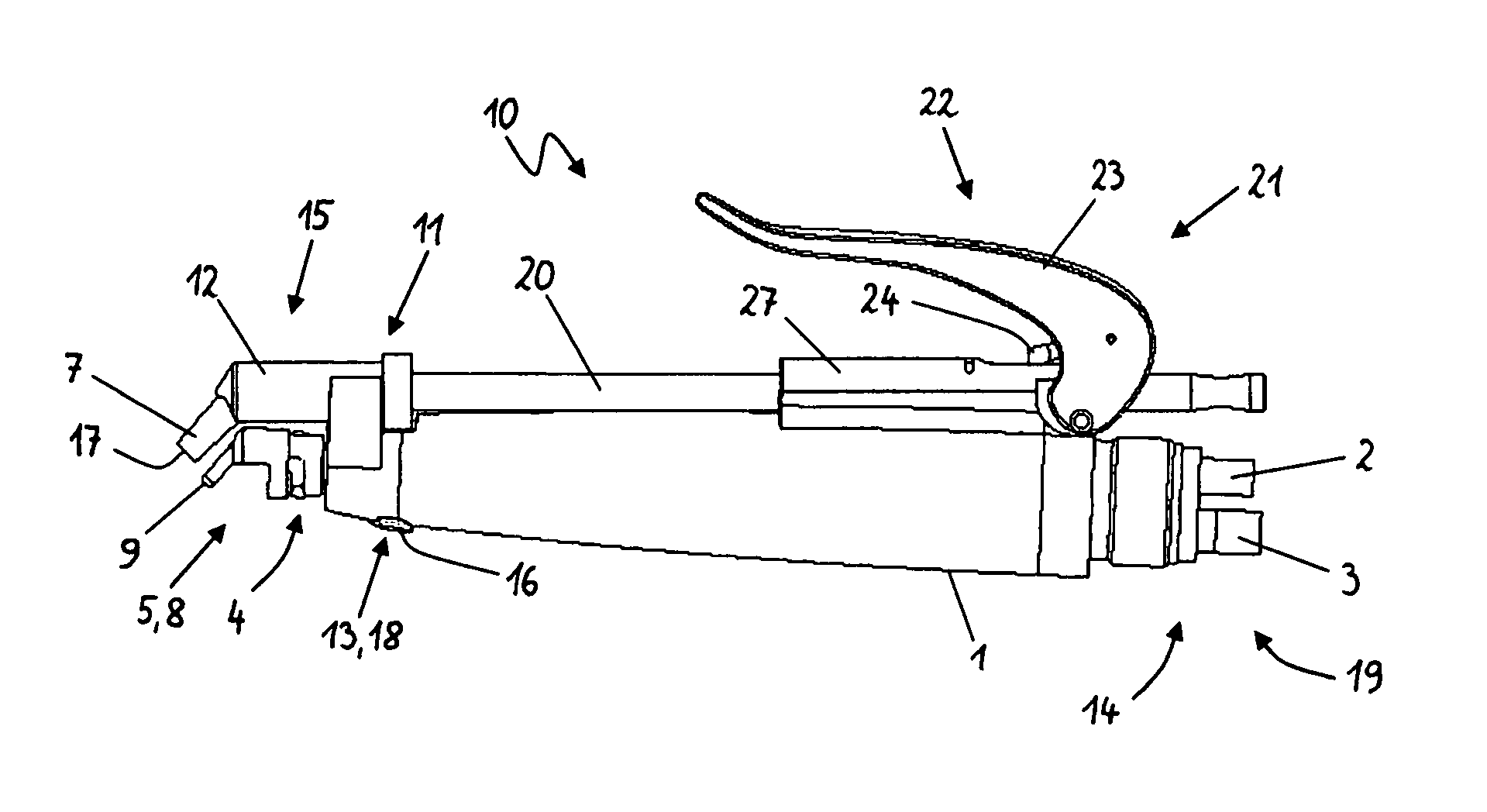

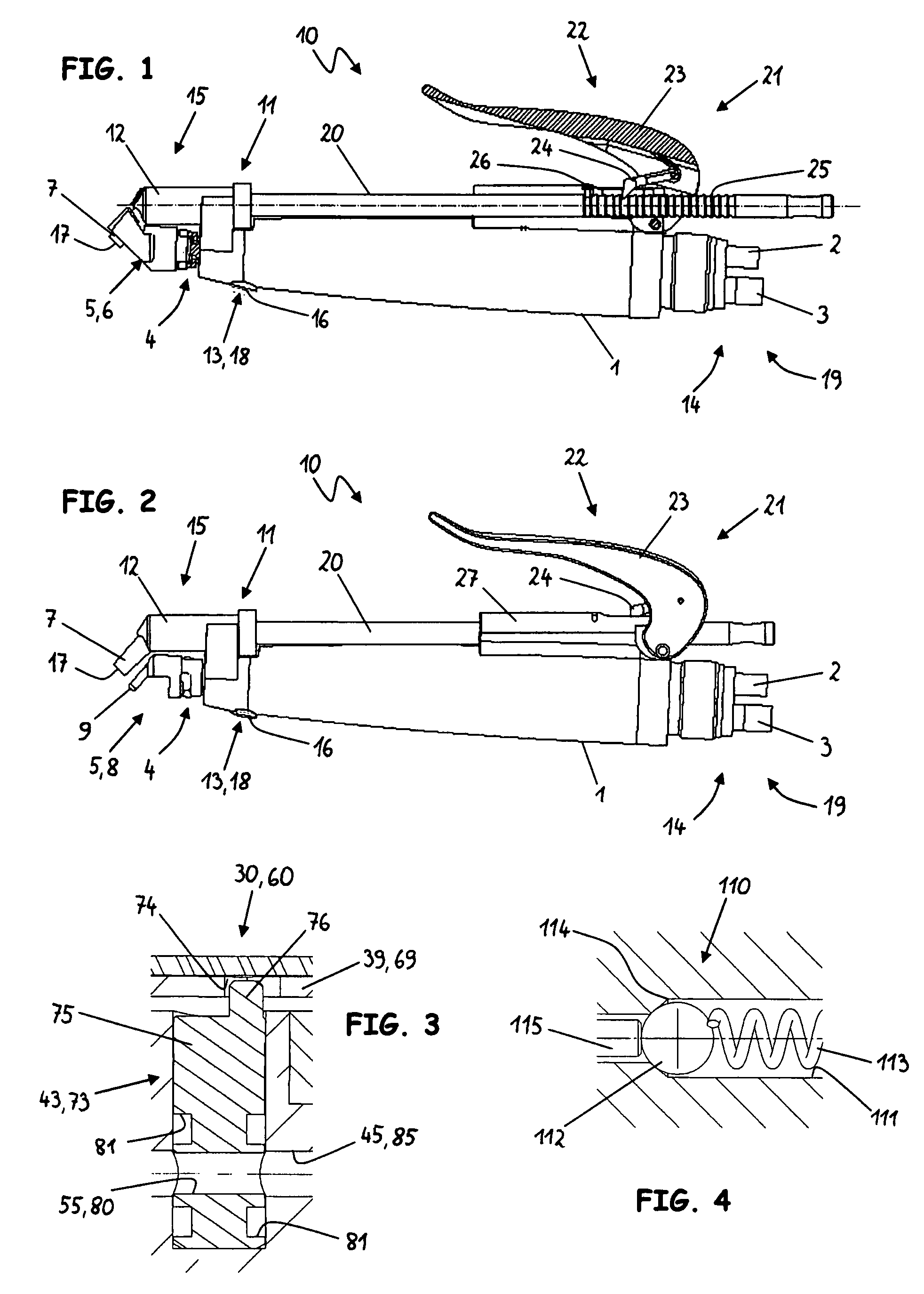

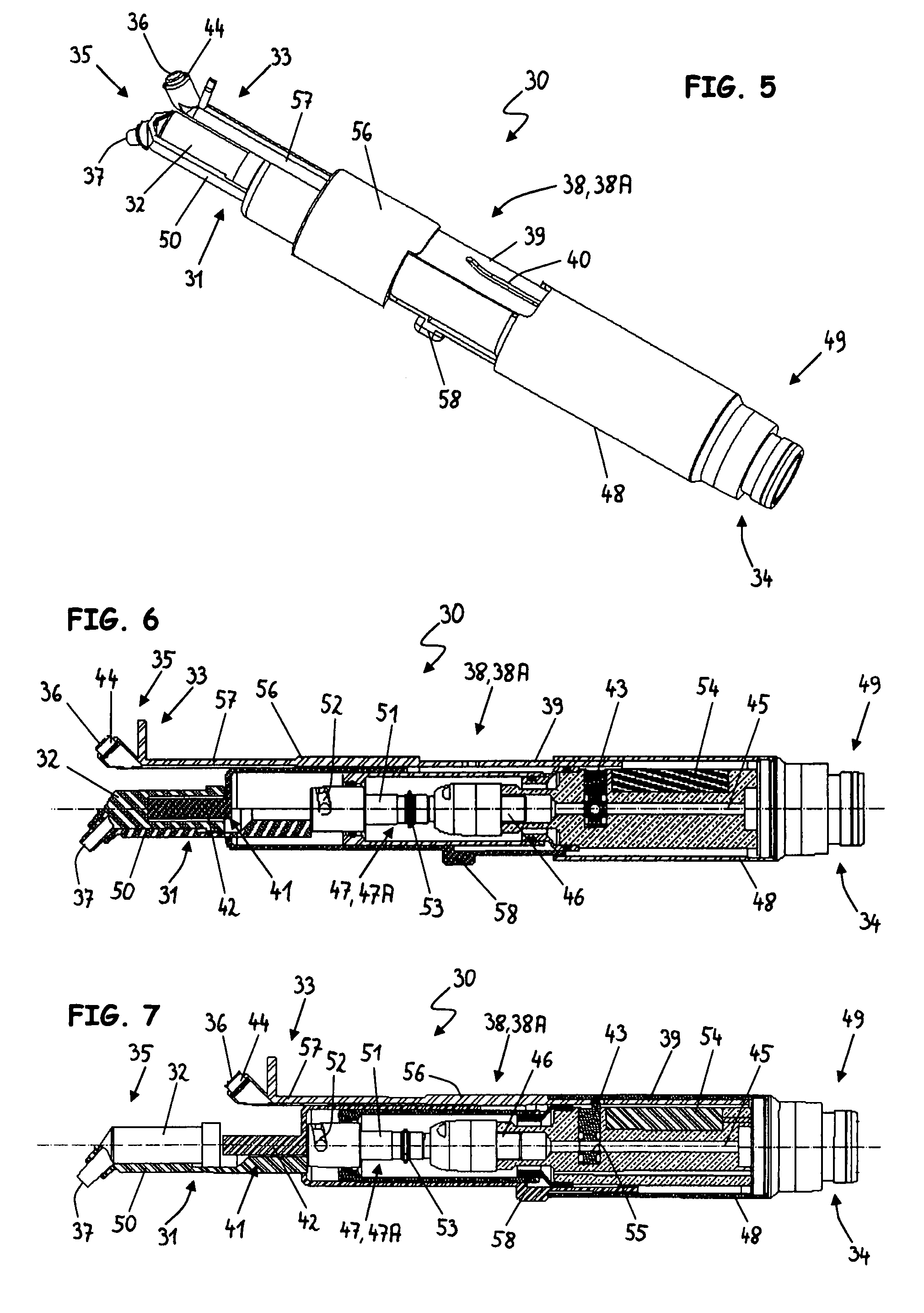

Device and method for the application of light-curing composites

InactiveUS9883931B2Save processing timePrevent gap formationTeeth fillingEndoscopesFilling materialsLight exposure

The present invention relates to a device and a method for the application of composites in tooth cavities. The device consists of a spray gun with integrated lighting for light-polymerizable composites, a measuring unit and a control unit. The composites are applied under controlled, precisely dosed exposure to polymerization light. According to the invention, the composite initially runs onto the walls of the cavity or onto previously introduced filling material and then, as a result of the light exposure, is transformed into the gel state. Thus, a large part of the polymerization shrinkage of the composite occurs while the composite is still plastically deformable so that any formation of gaps is compensated by the composite continuing to flow. It is only at this point in time that a sufficiently high dosage of light is applied for complete curing to occur.

Owner:PHILIPPS UNIV

Dental composite restorative material and method of restoring a tooth

A composite material is provided which, while having an unusually high filler content may be extruded from a dental syringe and remains easily adaptable in the dental cavity. When materials of the present invention are cured, dental restorations are provided which have unusually high surface hardness and yield strength, as well as a low volume shrinkage on curing. This is achieved by use of a mixture of filler particles with a specific size, size range, and size relationship. Such a combination of properties makes the material of the present invention particularly useful for restoring cavities in posterior teeth.

Owner:DENTSPLY DETREY GMBH

Bone chisel for interior lifting of maxillary sinus

The invention discloses a bone chisel for interior lifting of the maxillary sinus. The bone chisel comprises a working end and a handle, the working end is provided with a groove and used for stripping the sinus floor mucous membrane towards the periphery so that the maxillary sinus lifting range can be widened, the end face of the tail end of the working end is a plane, and the thickness of the tail end of the working end ranges from 0.3 mm to 1.5 mm. A cylindrical working end of a bone chisel in the prior art is changed into the half-cylindrical or incomplete-cylindrical working end by forming the groove in the working end; when the improved bone chisel is used for lifting of the maxillary sinus, the bone chisel can go deep into the maxillary sinus and then strip the sinus floor mucous membrane towards the periphery under the premise that an implant tooth cavity with the same diameter is prepared, the maxillary sinus bottom lifting range is widened, and therefore the lifting amplitude of the maxillary sinus is improved.

Owner:楚德国

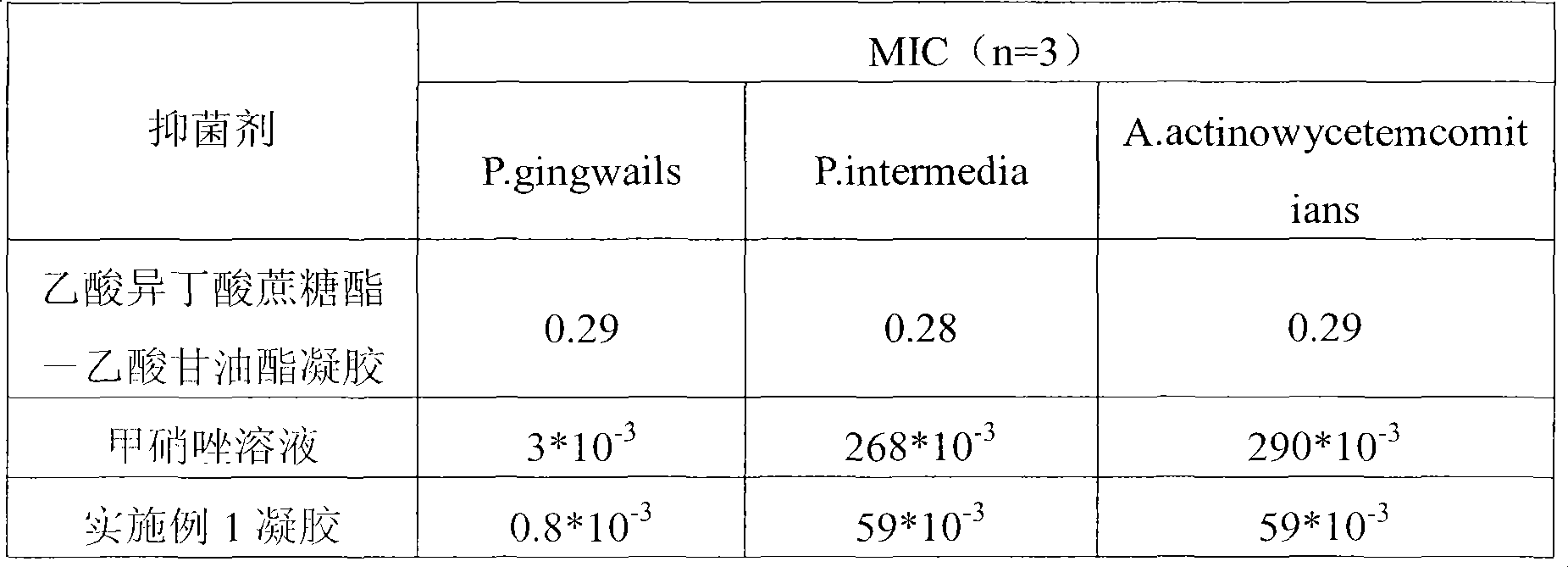

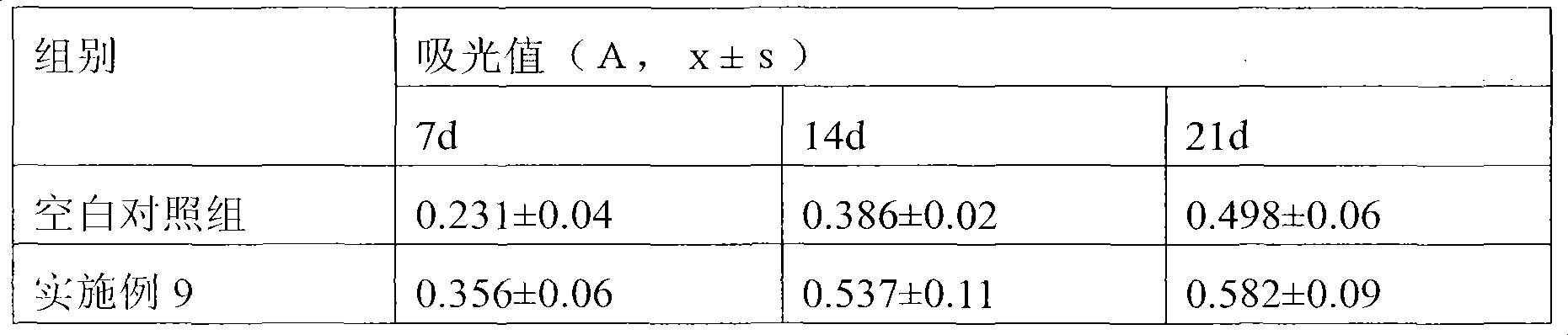

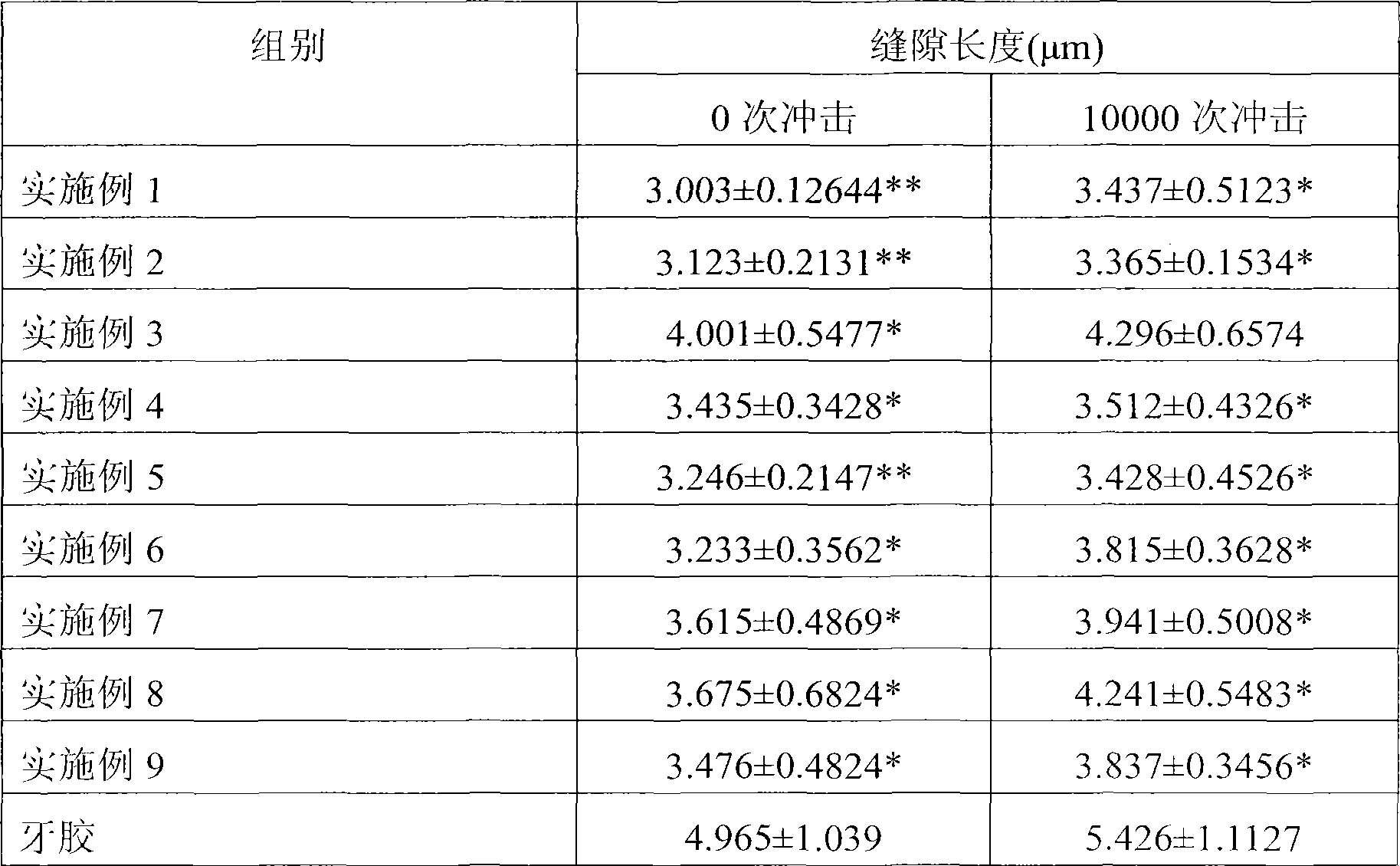

Sucrose acetate isobutyrate gel and application thereof

InactiveCN103830767AInduced formationEvenly distributedImpression capsSurgeryColloidal particleNew Bone Formations

The invention relates to a gel material which comprises 3-80 wt% of sucrose acetate isobutyrate colloidal particle, 0.1-30 wt% of pharmaceutical active component, 0-60 wt% of assistant and the balance of water. The gel material is applicable to promoting bone healing and new bone formation in tooth cavities after implementation of tooth extraction. The bone healing is wound healing after implementation of tooth extraction; and the new bone formation is new bone formation in a tooth implantation process. The gel material can also be used for temporary sealing after cavity preparation and during dental pulp disease treatment in the tooth disease treatment process.

Owner:韩冰

Dental handgrip

InactiveUS7857621B2Easy to useBlock compoundWheelchairs/patient conveyanceDental toolsFilling materialsLength wave

A dental handgrip for delivering filling compound into a tooth cavity is described, the handgrip being provided with a connection device to which a container for the filling compound can be connected. In some embodiments, the handgrip includes a light emission device via which radiation having a wavelength and radiant power for hardening of filling material can be provided. The dental handgrip can include a safety device to prevent a premature or inadvertent light emission onto the filling compound. In some embodiments, the handgrip includes a fluid-operated feeding device for feeding the filling compound from the filling compound container. A vibration generator operable to cause vibrations in the filling compound and to assist in feeding of the compound can also be provided.

Owner:W&H DENTALWERK

Self-centering sealing piece for achieving floating through gas pressure difference action and mounting method of self-centering sealing piece

A self-centering sealing piece for achieving floating through gas pressure difference action comprises a main sealing ring, circumferential spacers, a friction reducing ball and a ball retaining ring. The main sealing ring is of a labyrinth seal structure and is provided with at least two sealing teeth, sealing clearances formed between the sealing teeth and a rotor are not completely equal, and the low-pressure side sealing clearances are not larger than the high-pressure side sealing clearances. A labyrinth sealing cavity is divided into a plurality of tooth cavities through the circumferential spacers, so that the labyrinth sealing cavity is of a bag type structure. The ball retaining ring is matched with the main sealing ring. The main sealing ring is circumferentially provided with a plurality of radial slots, and the circumferential spacers are inserted into the radial slots in the radial direction. In the mounting process, it is guaranteed that the clearance between the attaching faces of a sealing cover and a sealing seat is as small as possible, and an auxiliary sealing ring is arranged between the matching faces of the sealing cover and a sealing piece body. The inner side of the auxiliary sealing ring is communicated with the high-pressure side, and the outer side of the auxiliary sealing ring is communicated with the low-pressure side. A rotating preventing pin is arranged between the sealing piece body and the sealing seat or the sealing cover. According to the self-centering sealing piece for achieving floating through gas pressure difference action, the advantages of traditional labyrinth sealing and floating sealing are integrated, and the defects of traditional labyrinth sealing and floating sealing are abandoned.

Owner:SHENYANG AEROSPACE UNIVERSITY

Portable ultrasonic device and algorithms for diagnosis of dental caries

InactiveUS20100152579A1Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsVisual perceptionRoot caries

Provided is an apparatus and method for the detection of dental caries. The apparatus generates longitudinal ultrasound waves that may be applied to any accessible surface of a tooth. The reflected ultrasound pulse echoes are collected and correlated with the incident pulse. The ultrasound pulse echoes from the front and rear surface of a dental cavity may be distinguished from other echoes, and provided in visual display to inform as to the size and location of the cavity.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com