Opposite teeth extruding type fine-blanking die and fine-blanking method adopting same

An extrusion and die technology, applied in the field of opposite-tooth extrusion fine-blanking dies, can solve the problems of increasing the three-dimensional compressive stress in the stamping deformation area, fine-blanking of low-plastic plates, and thick plates, and achieve large plastic deformation. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

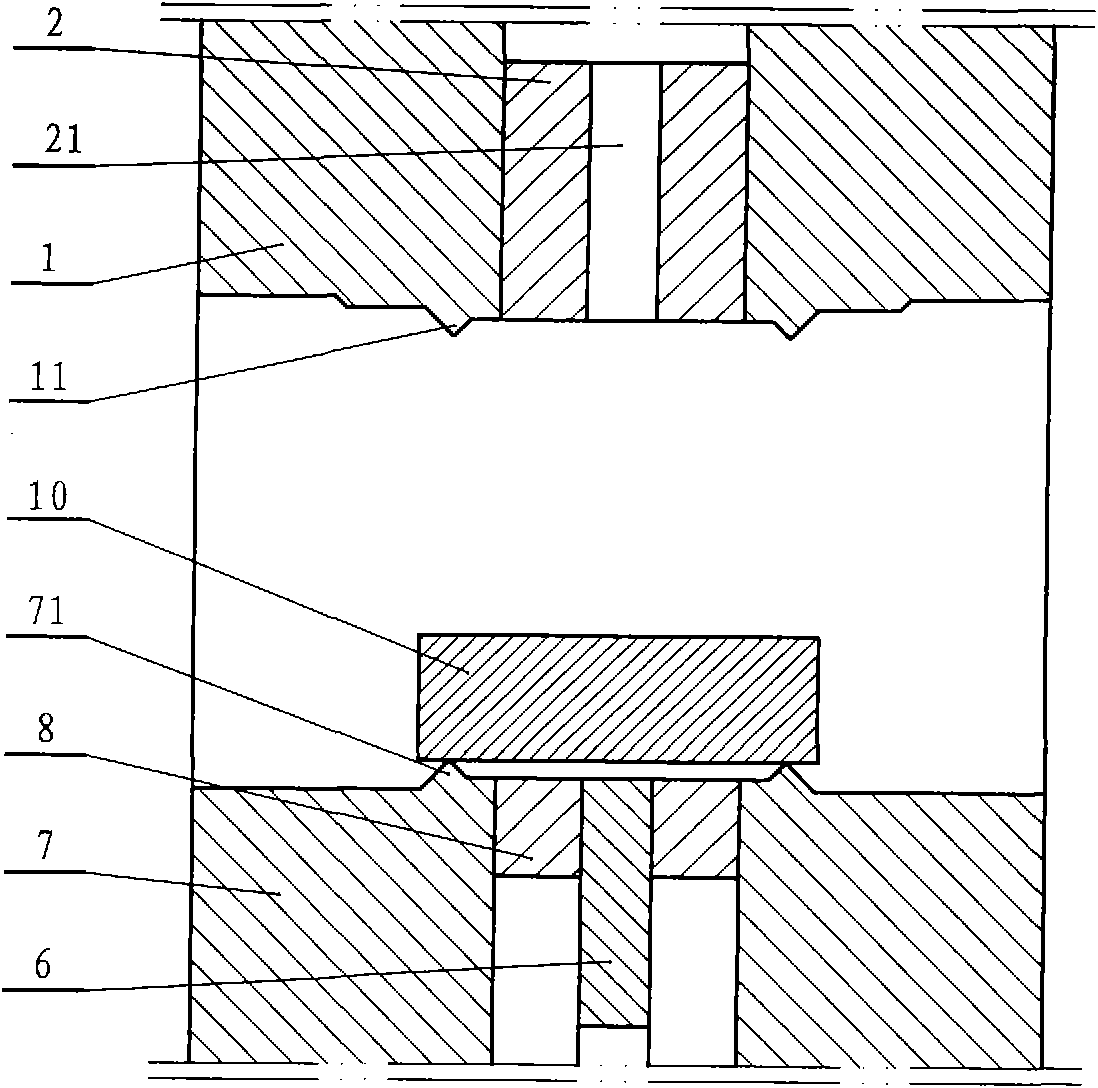

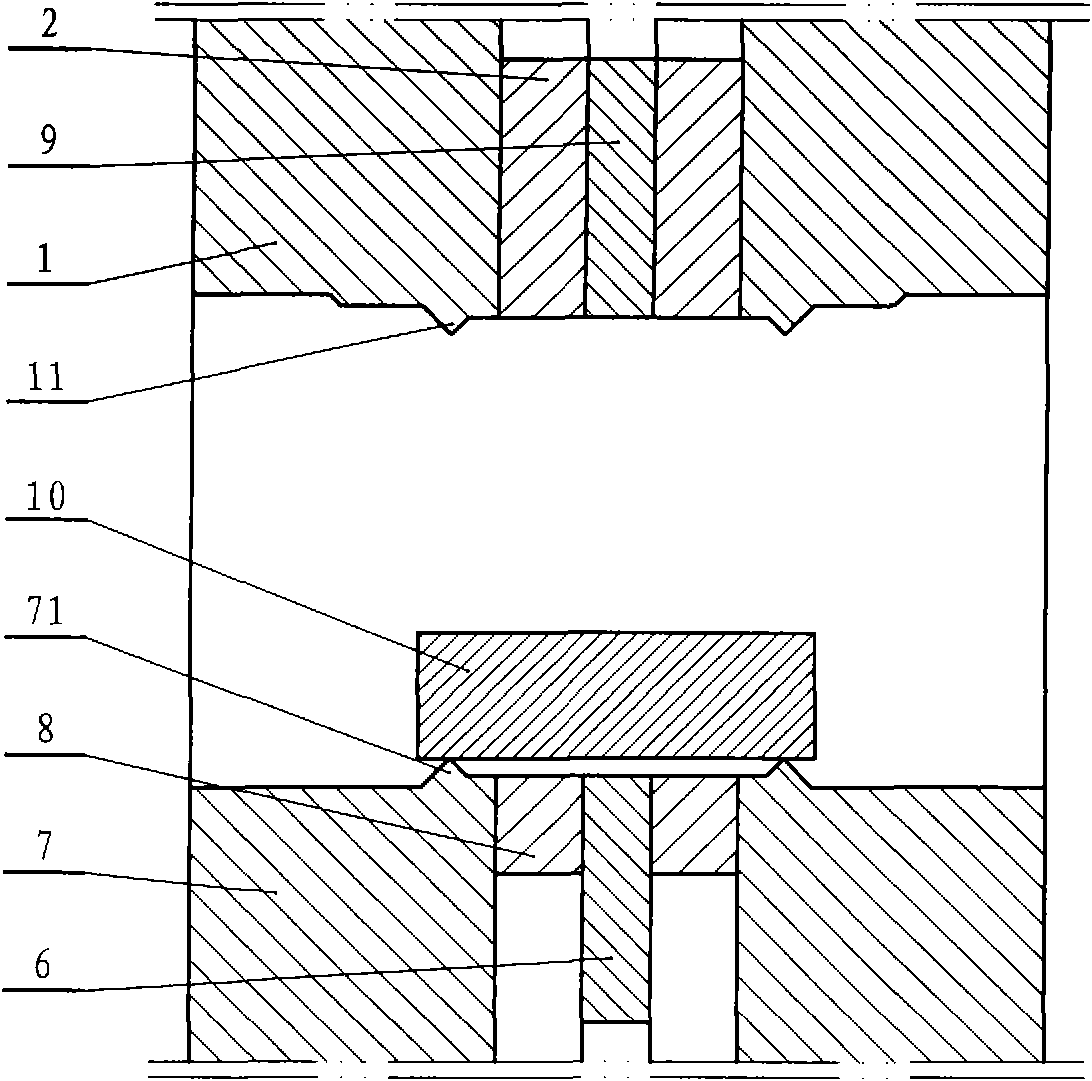

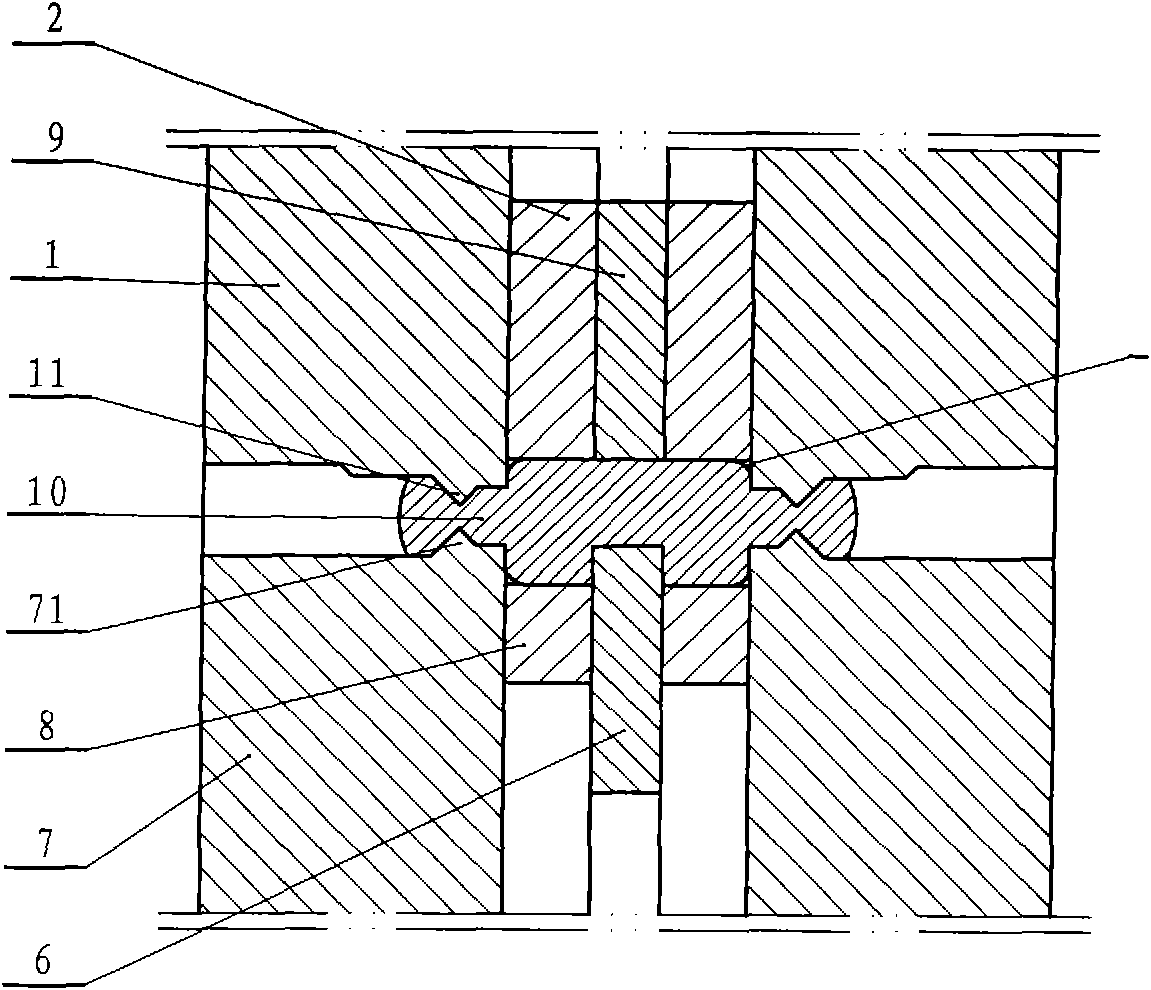

[0022] The opposed tooth extruding type fine blanking die of the present invention has the structure as attached figure 1 As shown, on the upper side of the axial joint surface of the mould, there is a slidingly fitted opposing tooth plate 1 and a convex and concave die 2, and the opposing tooth plate 1 is arranged around the convex and concave die 2, and on the lower side of the axial joint surface of the mold, a There is a toothed concave die 7 and an anti-top plate 8 that are slidingly fitted, and the toothed concave die 7 is arranged around the anti-top plate 8. The opposite tooth plate 1 and the toothed concave die 7 are respectively facing the two surfaces of the blank 10, and are respectively provided with convex The opposing gear plate ring gear 11 and the toothed die ring gear 71 form a pair of opposing teeth. The cross-sections of the two ring gears are both triangular tooth shapes, and the tooth tips of the triangular tooth shapes are respectively facing the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com