Patents

Literature

47results about How to "Good cross section quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

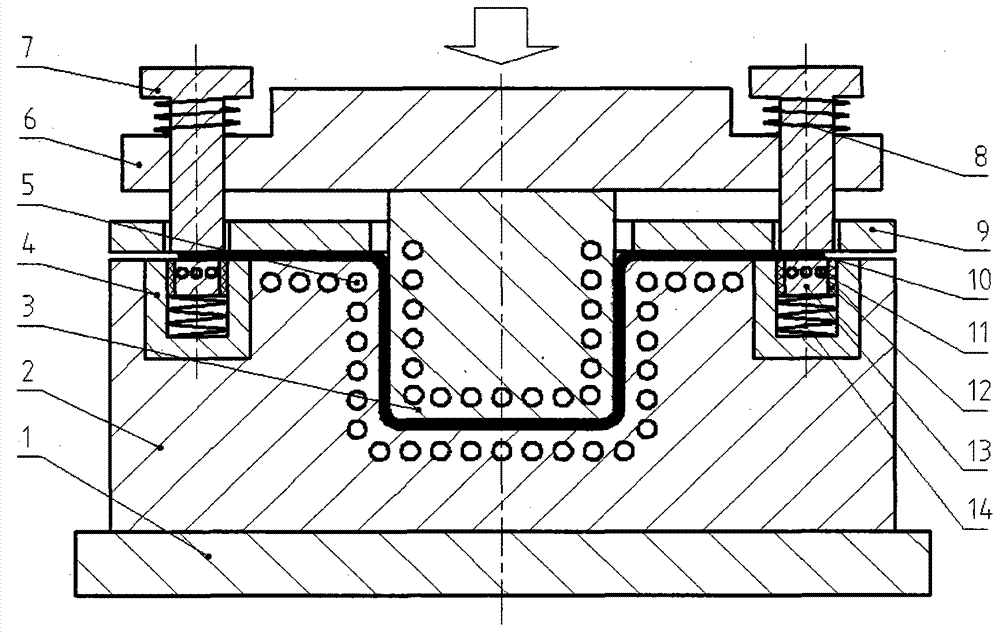

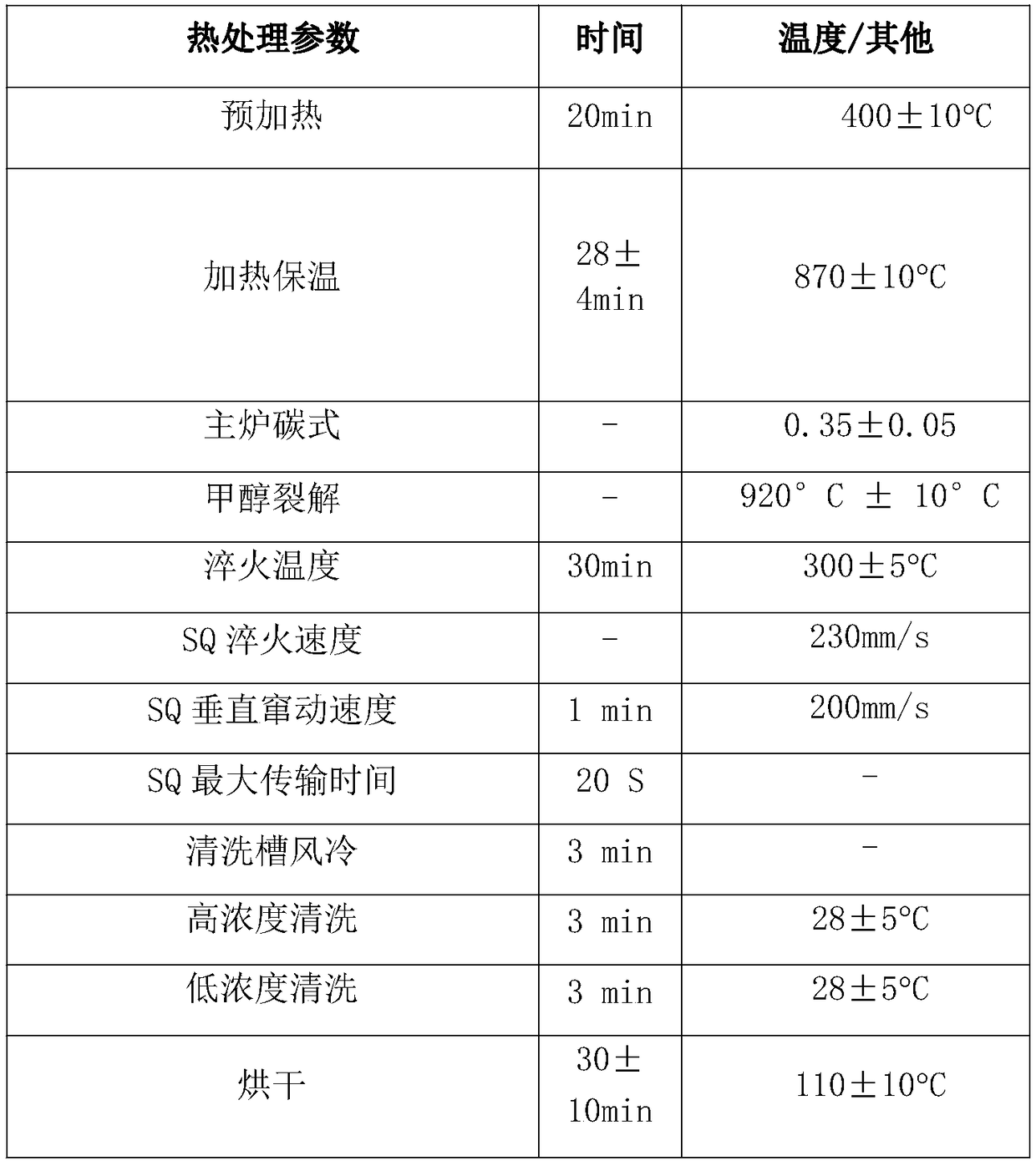

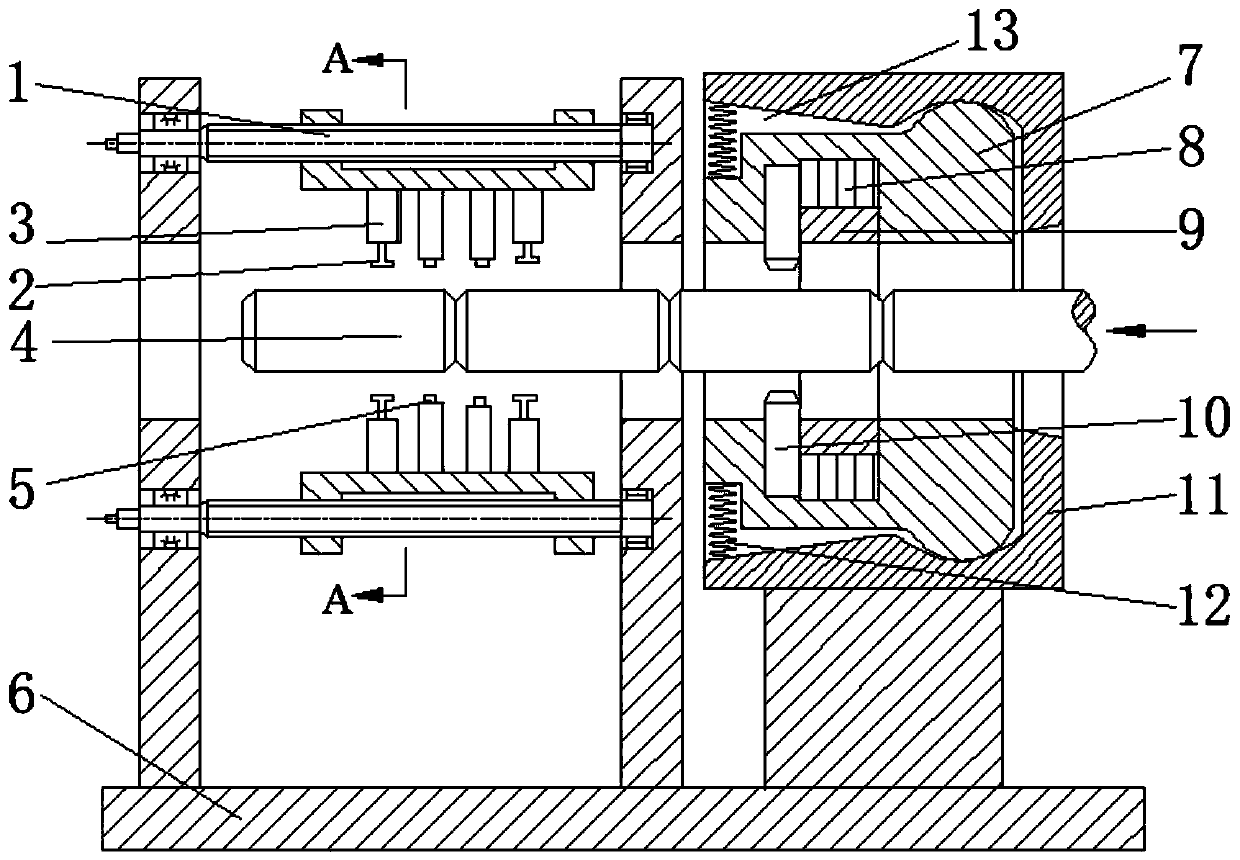

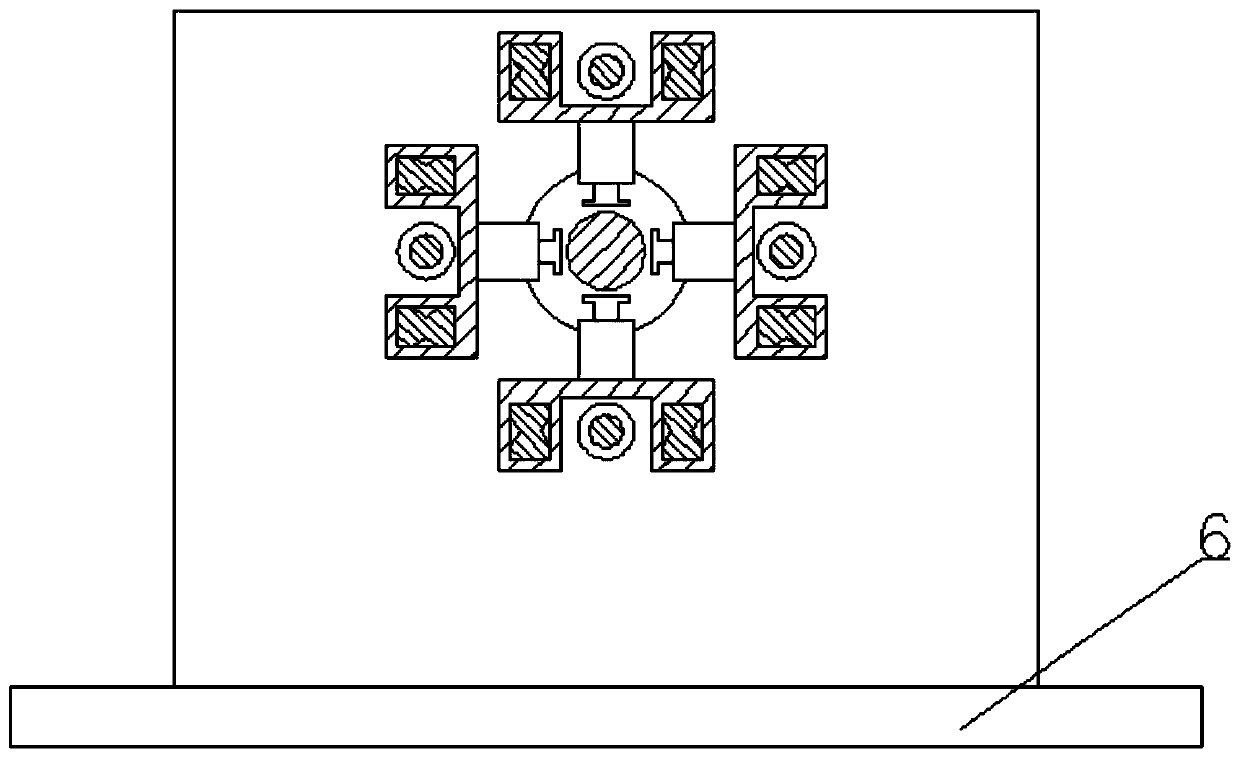

Hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel

The invention provides a hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel. By means of the composite mould, blanking is composited in a hot stamping process, and trimming and punching are performed on sheet metal at a temperature higher than a martensite formation temperature. The hot stamping and warm blanking composite forming technology comprises the following processes of putting the sheet metal of the ultrahigh-strength steel heated to achieve complete austenitizing into the composite mould, performing stamping forming and then performing cooling and quenching; heating sheet metal needing blanking locally, keeping a warm state, performing warm blanking after completion of forming, and performing cooling further in a pressure maintaining mode. The hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel effectively solves the problems of poor quality, low precision, high cost and long period of holes trimmed and punched in the later period of the ultrahigh-strength steel and has great practical significance in production practice.

Owner:JILIN UNIV

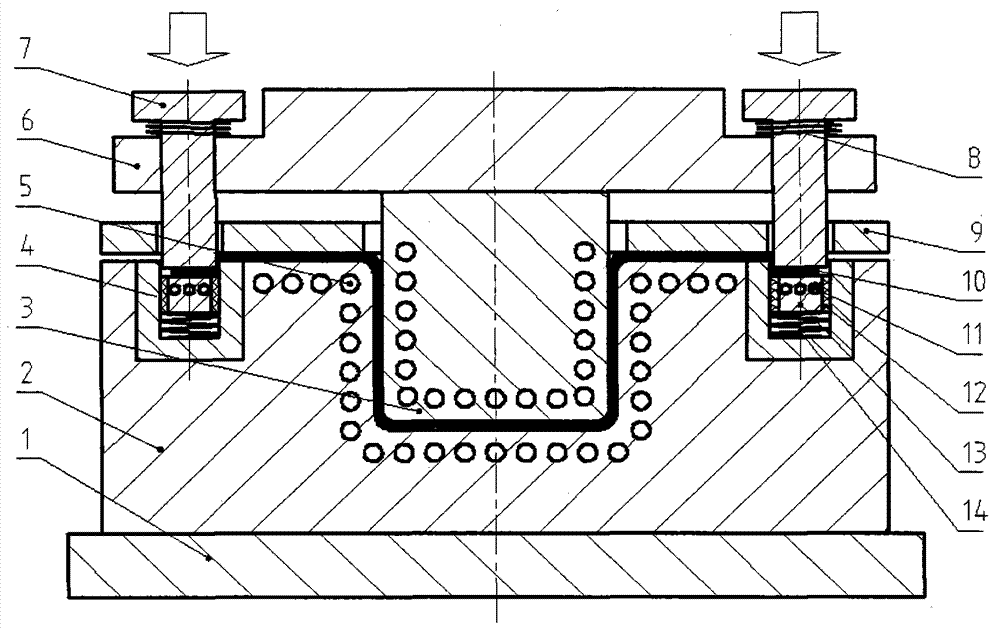

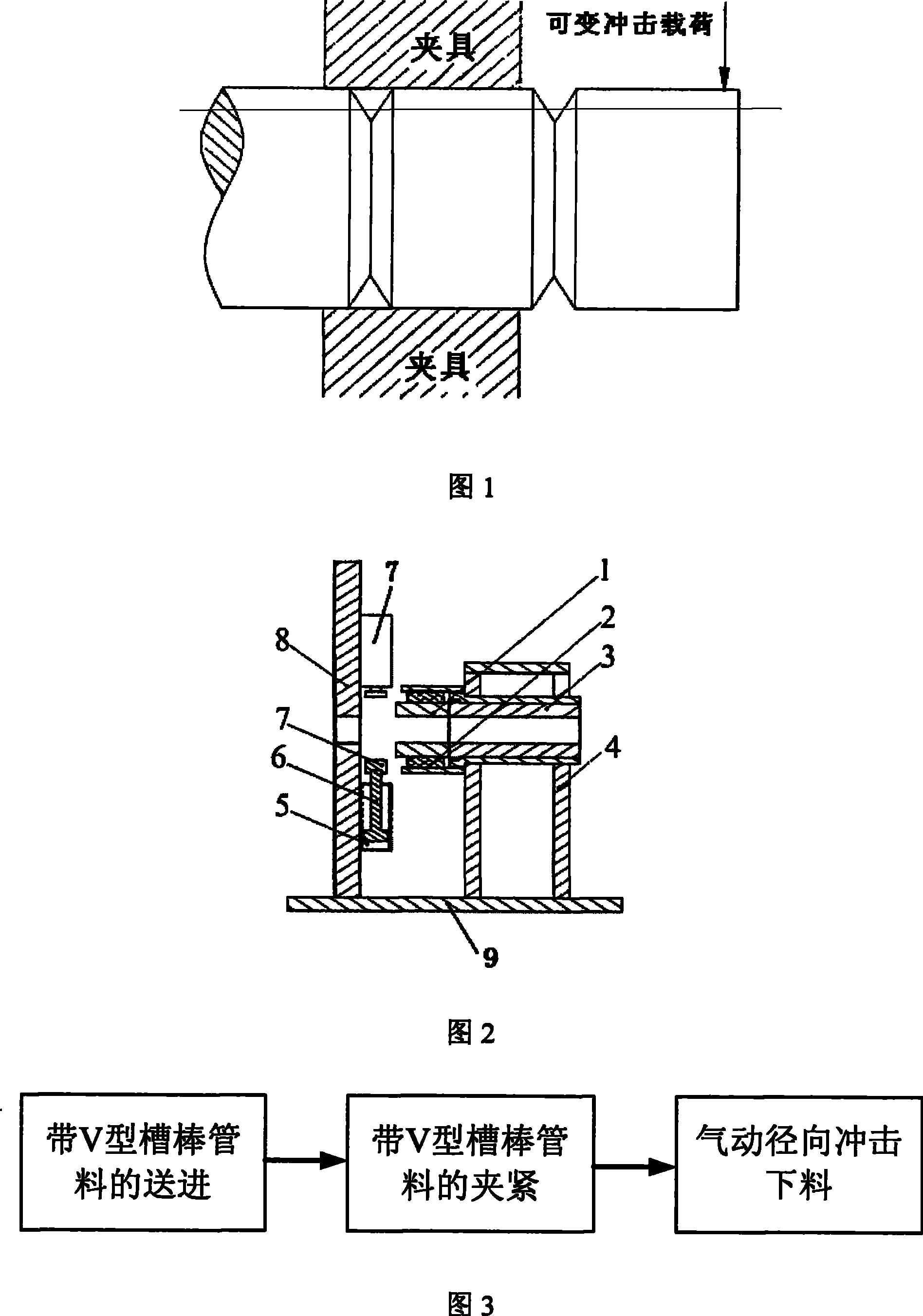

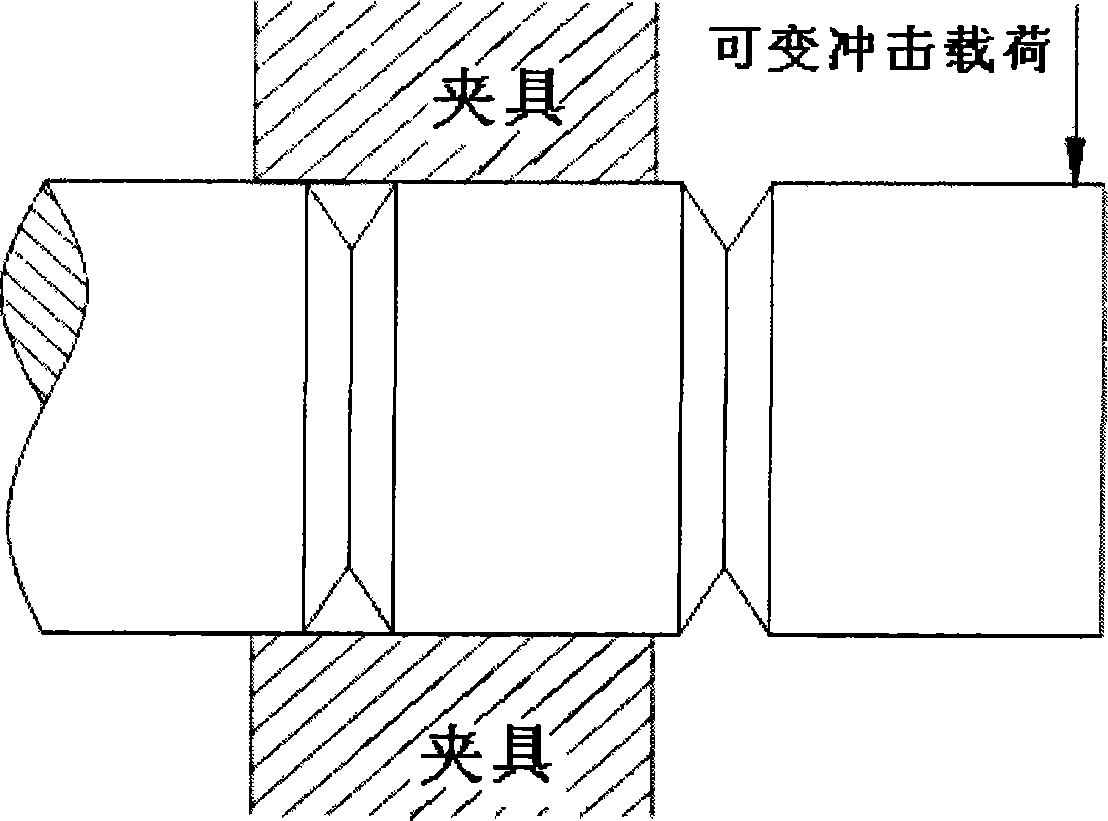

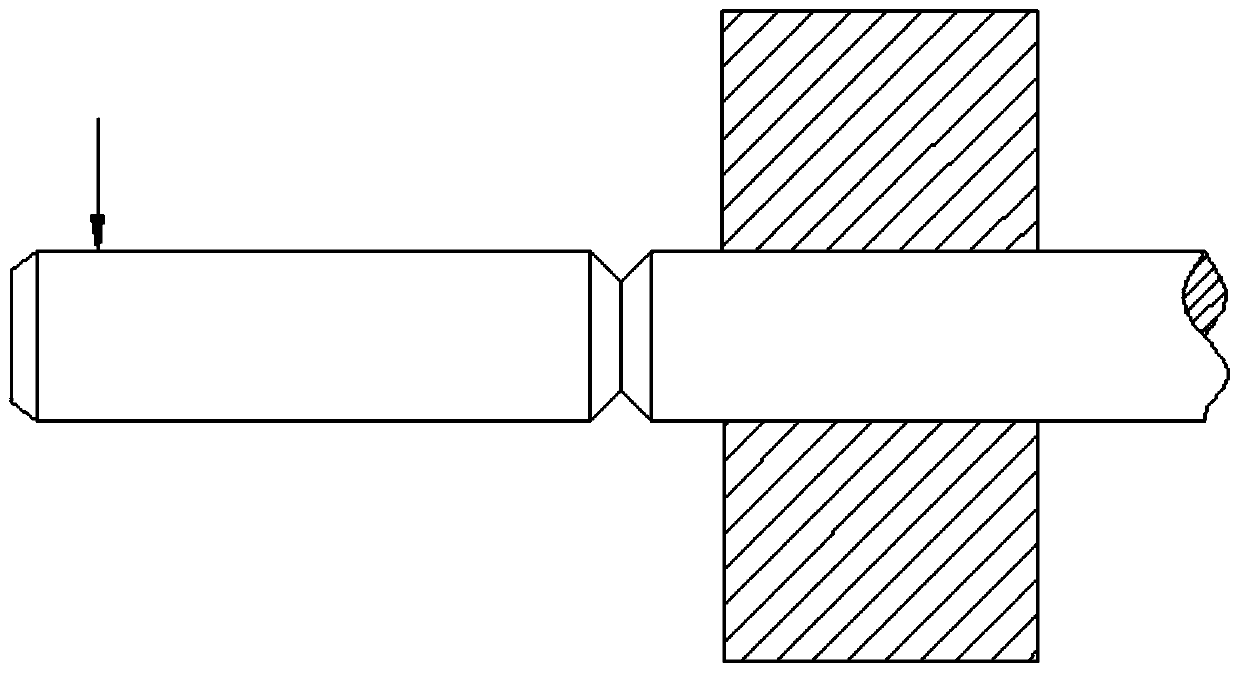

Bar stock pneumatic radial impact blanking method with high-efficiency and precision

The invention discloses a bar stock pneumatic radial impact high-efficiency precise blanking method. In the method, the bar stock is arranged on a pneumatic radial impact precise blanking device and the main working parts of the blanking device comprise a blanking sleeve, an elastic pad sleeve, a bar stock fixing sleeve, an impact cylinder, a piston and a blanking die. The impact cylinder works sequentially under the control of a control system and drives the blanking die to load the bar stock along the radial direction continuously; cracks are extended from the surface of the bar stock along the radial direction to the center of the circle by a fatigue breaking device of the bar stock, thus achieving the blanking and gaining good quality of the profile.

Owner:XI AN JIAOTONG UNIV

Cold-rolled fine-punched steel strip for automobile child seat locking device and preparation method thereof

The invention discloses a cold-rolled fine-punched steel strip for an automobile child seat locking device. The cold-rolled fine-punched steel strip is made of 51CrV4, and comprises the following components by mass percentage: 0.50-0.55 of C, 0.15-0.35 of Si, 0.80-1.10 of Mn, less than or equal to 0.015 of P, less than or equal to 0.01 of S, 0.90-1.20 of Cr, 0.10-0.20 of V, and less than or equalto 0.035 of Al. Directed at the special processing technology and application requirements of the child seat locking device, the cold-rolled fine-punched steel strip provided by the invention rationally optimizes the chemical components of 51CrV4, and rationally controls the C, S, P, Si and other elements sensitive to hydrogen embrittlement.

Owner:SUZHOU XIANGLOU METAL PROD

Plane edge-pressing and semi-fine blanking device and method

The invention relates to a plane edge-pressing and semi-fine blanking device and a method. The device is provided with a plane pressure plate and a concave die, when a workpiece is punched, the plane pressure plate needs to enable edge-pressing force to press on the outer edge of a profile of the workpiece on a workpiece blank, and the edge-pressing force can generate great friction force betweenthe surface of the workpiece blank and the plane pressure plate and between the surface of the workpiece blank and the concave die, so as to prevent the material of the workpiece blank from flowing out of the profile of the workpiece. The device is matched with punching force, three-dimensional pressure stress is generated in the material of the workpiece blank in an extrusion zone, and plastic flow is generated, so as to enable the numerical values of the pressure stress in the three-dimensional directions to tend to be consistent, enable the material of the workpiece blank in the profile ofthe workpiece to be in the hydrostatic pressure state and have a maximal plastic deformation range, reduce a region for generating tensile stress in a shearing deformation zone and prevent the emergence of cracks on the surface of a cross section of the workpiece. By using the plane edge-pressing and semi-fine blanking device and the method, an ordinary punch can be used, the processing of a die is simple, a pressurization region on the workpiece blank can not cause damages, the processing cost is low, the quality of the workpiece is high, and the device and the method are convenient to popularize and apply in the punching industry.

Owner:CHONGQING UNIV OF TECH

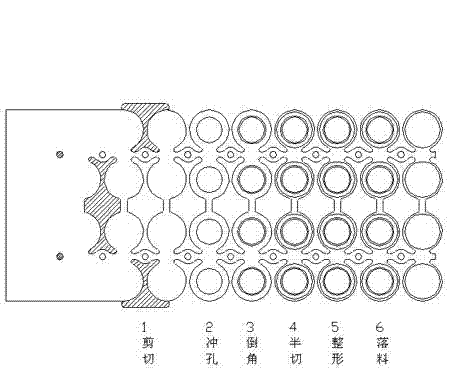

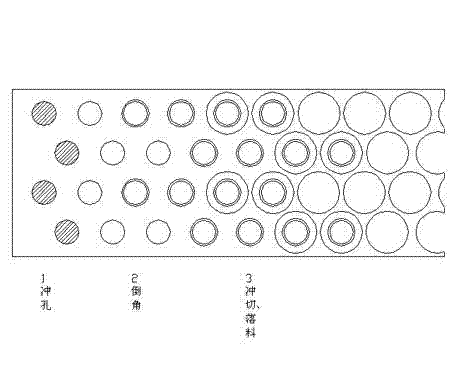

Symmetrical multi-cavity discharging technology

The invention relates to a symmetrical multi-cavity discharging technology. The working object of the discharging technology is a flat belt, and the formed products are flat annular columnar workpieces punched from the belt. A shearing step is increased before punching in the technology, namely the shape of each workpiece is previously sheared, and workpiece blanks are obtained, a gap is reserved between the two adjacent workpiece blanks in each column in the machining and advancing direction of the belt, and the belt can absorb micro expansion, so that alignment of the workpieces during machining with a mold is facilitated, the qualification rate is improved, and high section quality and flatness of the workpieces are obtained. Semi-cutting can be adopted when the outer edges of the workpieces are punched, so that the flatness of the surfaces of the workpieces is further improved; and a small quantity of connecting bands can be reserved only among the workpiece blanks during shearing, so that the expandable space of the workpiece blanks is increased, and the influence of stretching of the belt on the positions of the workpieces is further reduced.

Owner:FINEFORMING PRECSION ENG

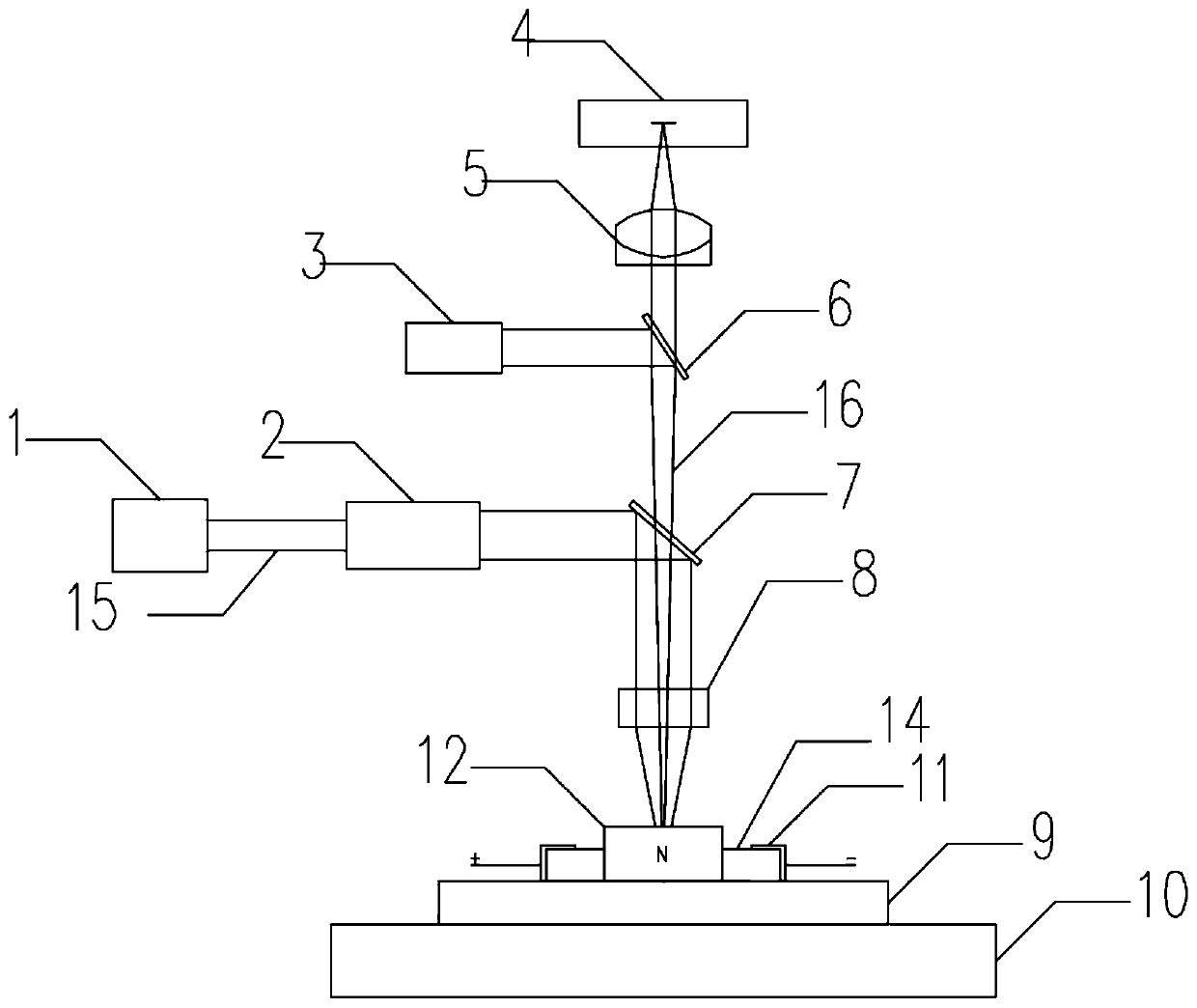

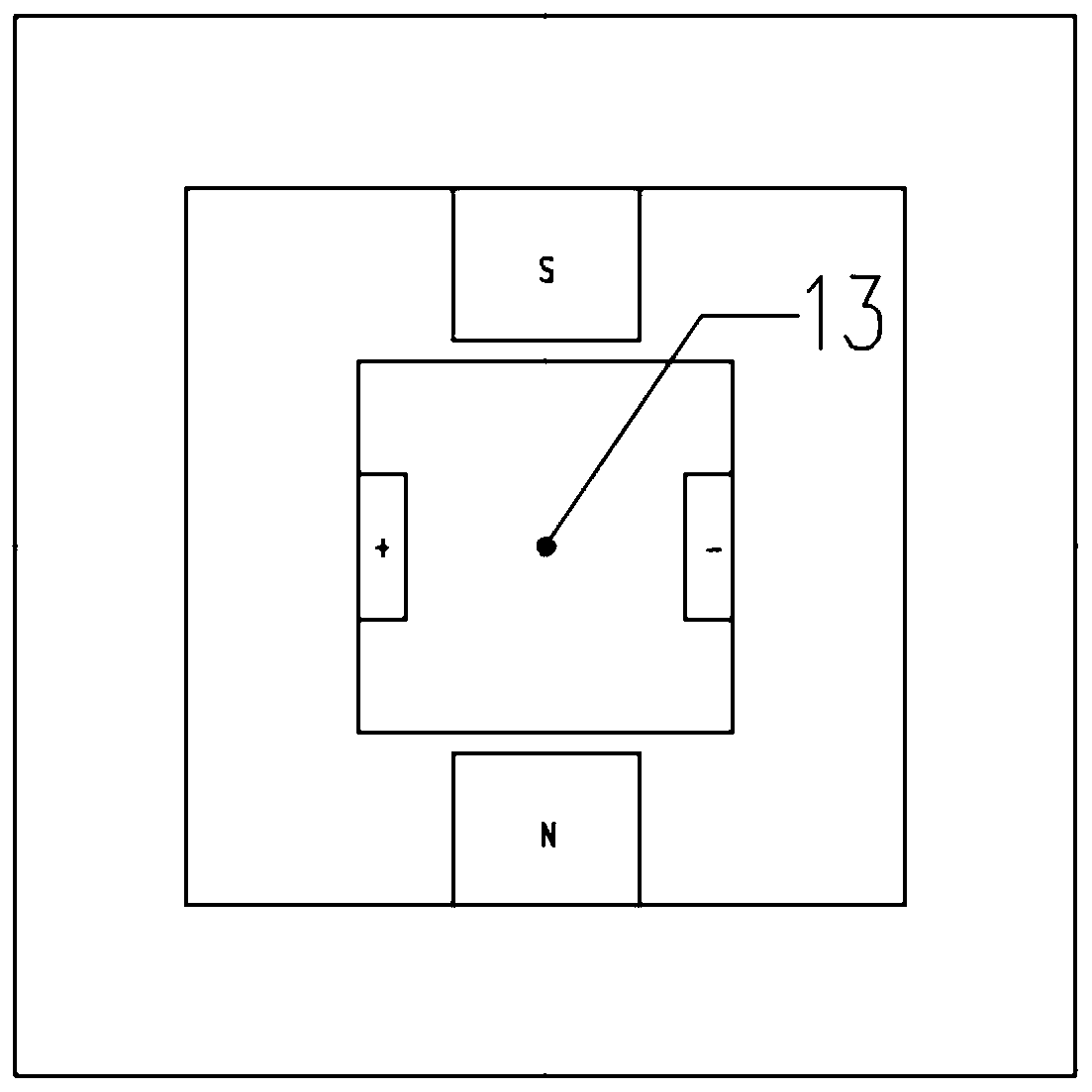

Laser cutting device and method for controlling plasma through electromagnetic field to regulate and control crack expansion

InactiveCN111055029AThe number of stealth cuts is reducedGood cross section qualityMetal working apparatusLaser beam welding apparatusLight beamEngineering

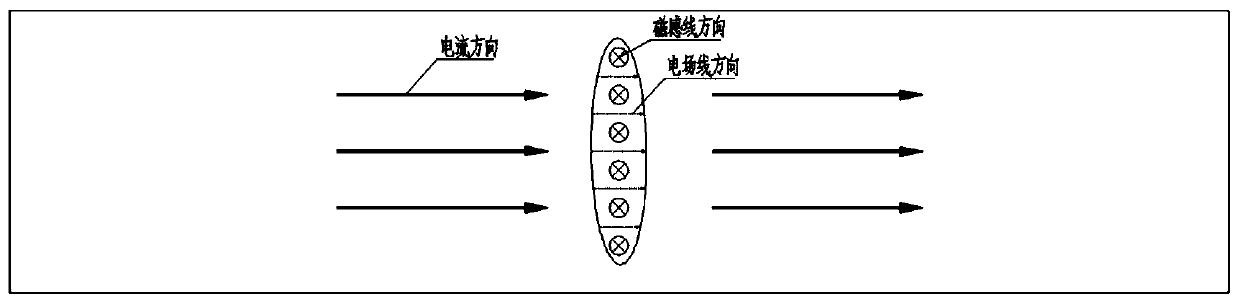

The invention discloses a laser cutting device and method for controlling plasma through an electromagnetic field to regulate and control crack expansion. The device comprises a multi-axis moving platform (9), an imaging system for obtaining surface images of a machining workpiece (14) on the multi-axis moving platform (9), a hidden cutting device used for generating laser beams (15) and an electromagnetic field generation device used for generating electric field force and magnetic field force applied to the plasma, wherein the laser beams (15) are gathered into the machining workpiece (14),and workpiece materials are gasified and ionized into the plasma. The plasma moves in an accelerating manner under the action of the electric field force and the magnetic field force, formed cracks are further impacted, and crack expansion is achieved. Through control over the space-time position and the field energy of the electromagnetic field, the purpose of ultra-fast laser hidden cutting on the basis that the electromagnetic field controls the plasma to regulate and control crack expansion is achieved. According to the laser cutting device and method, the ultra-fast laser hidden cutting quality is kept and improved, and meanwhile the bottleneck problem about the low hidden cutting efficiency is solved.

Owner:WUHAN UNIV

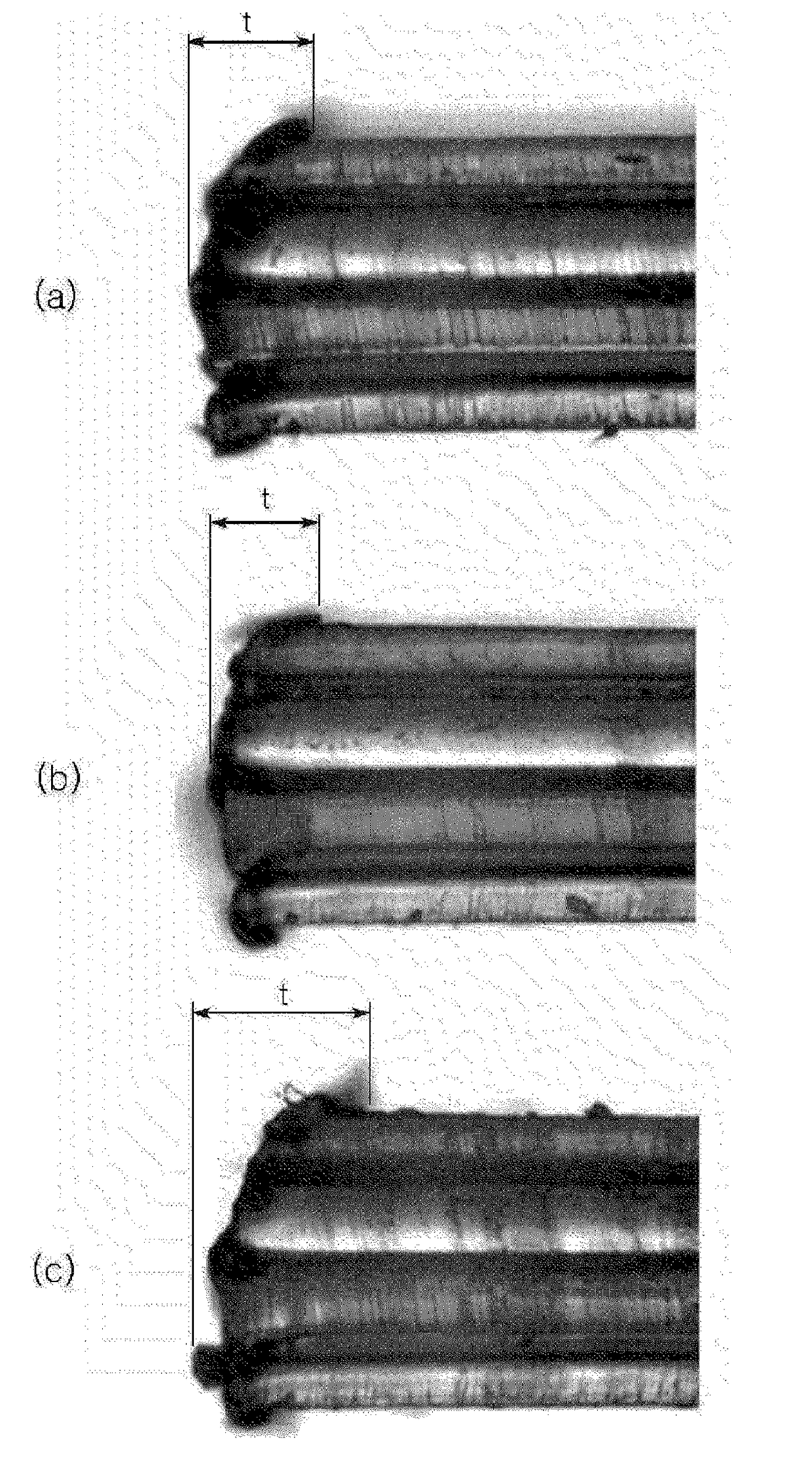

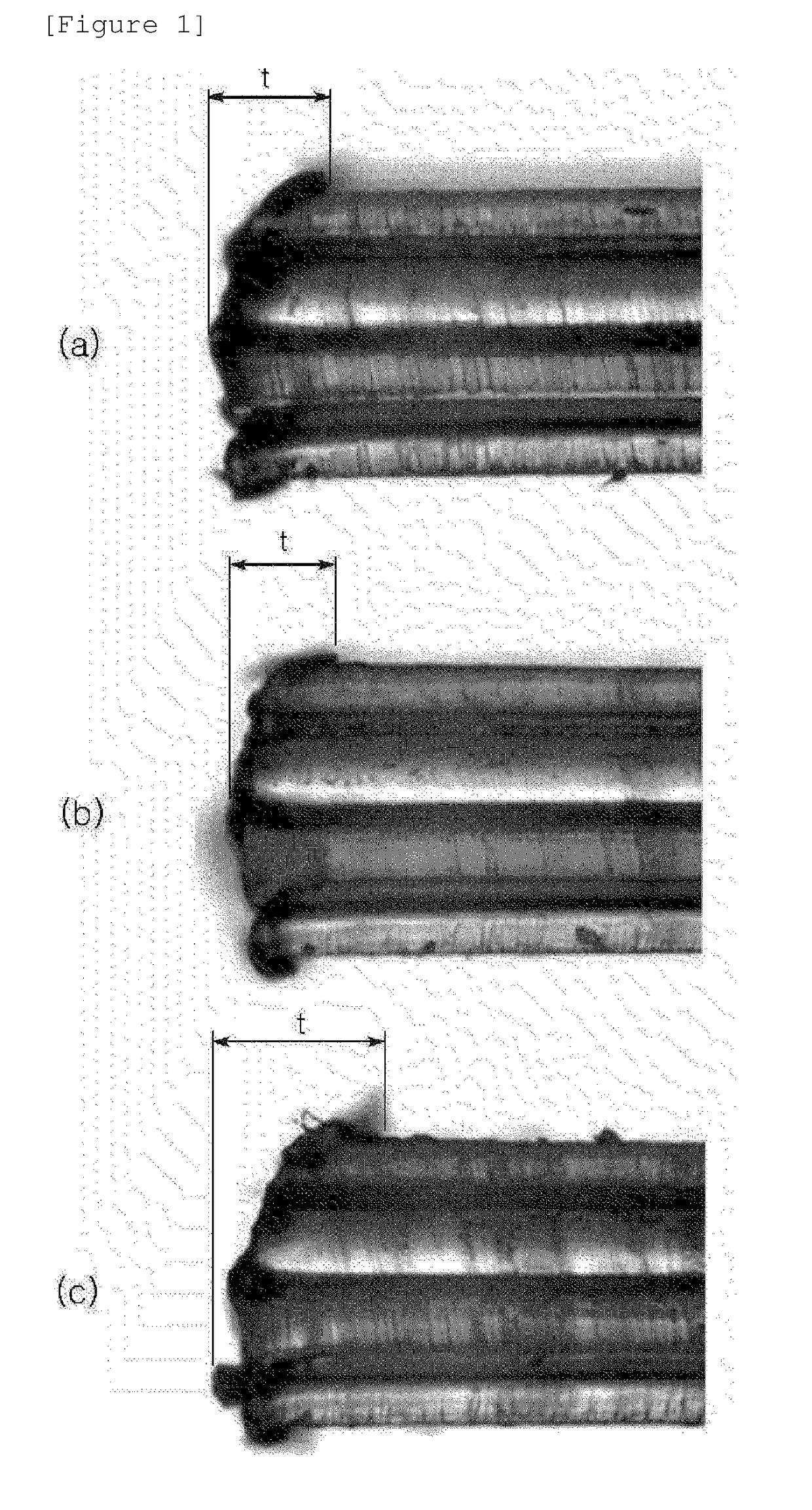

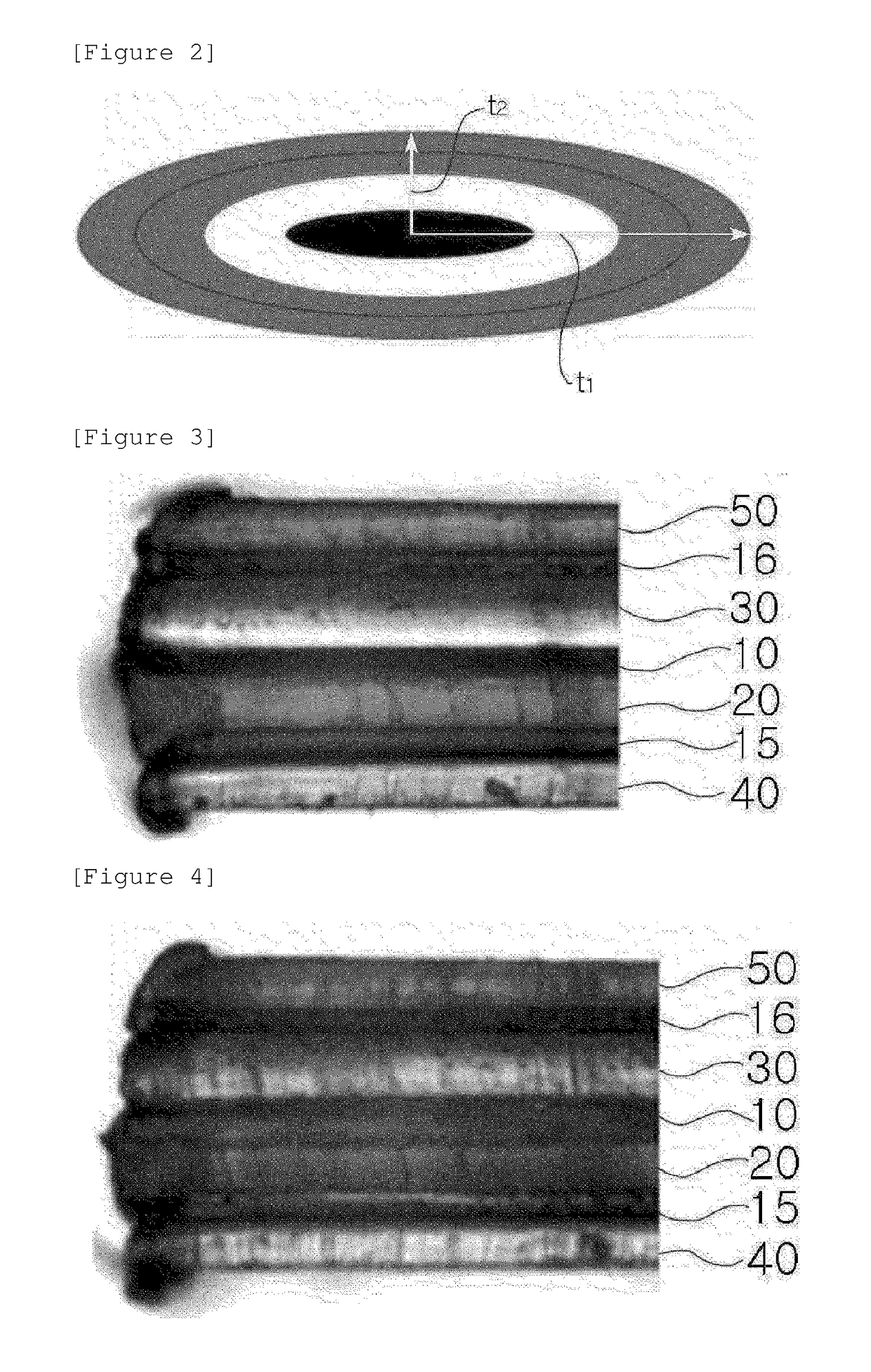

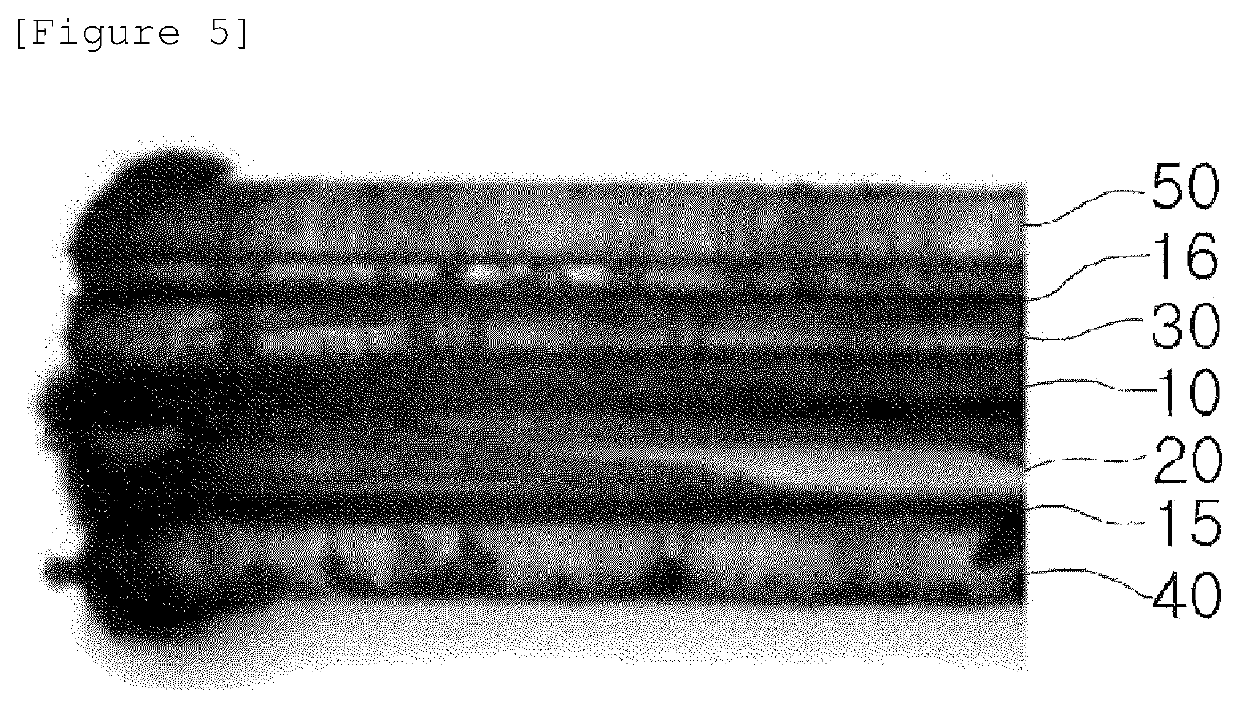

Method for cutting polarizing plate and polarizing plate cut using same

ActiveUS20170120389A1Excellent qualitySimplify cutting processWelding/soldering/cutting articlesMetal working apparatusPolarizerLong axis

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

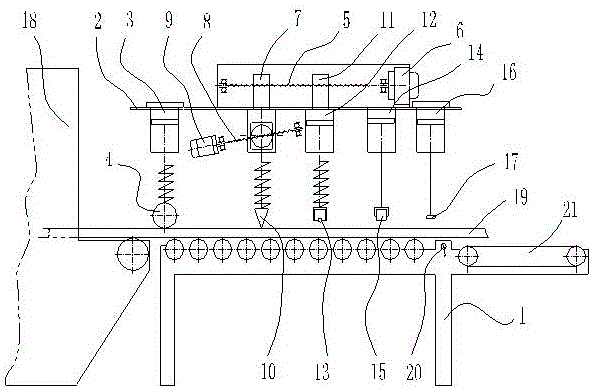

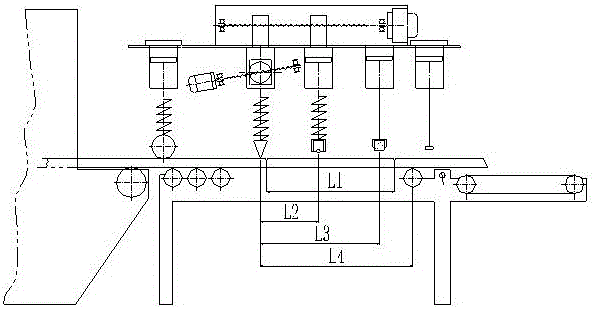

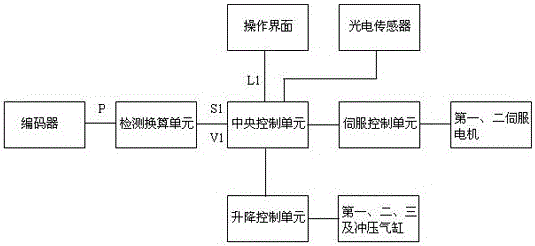

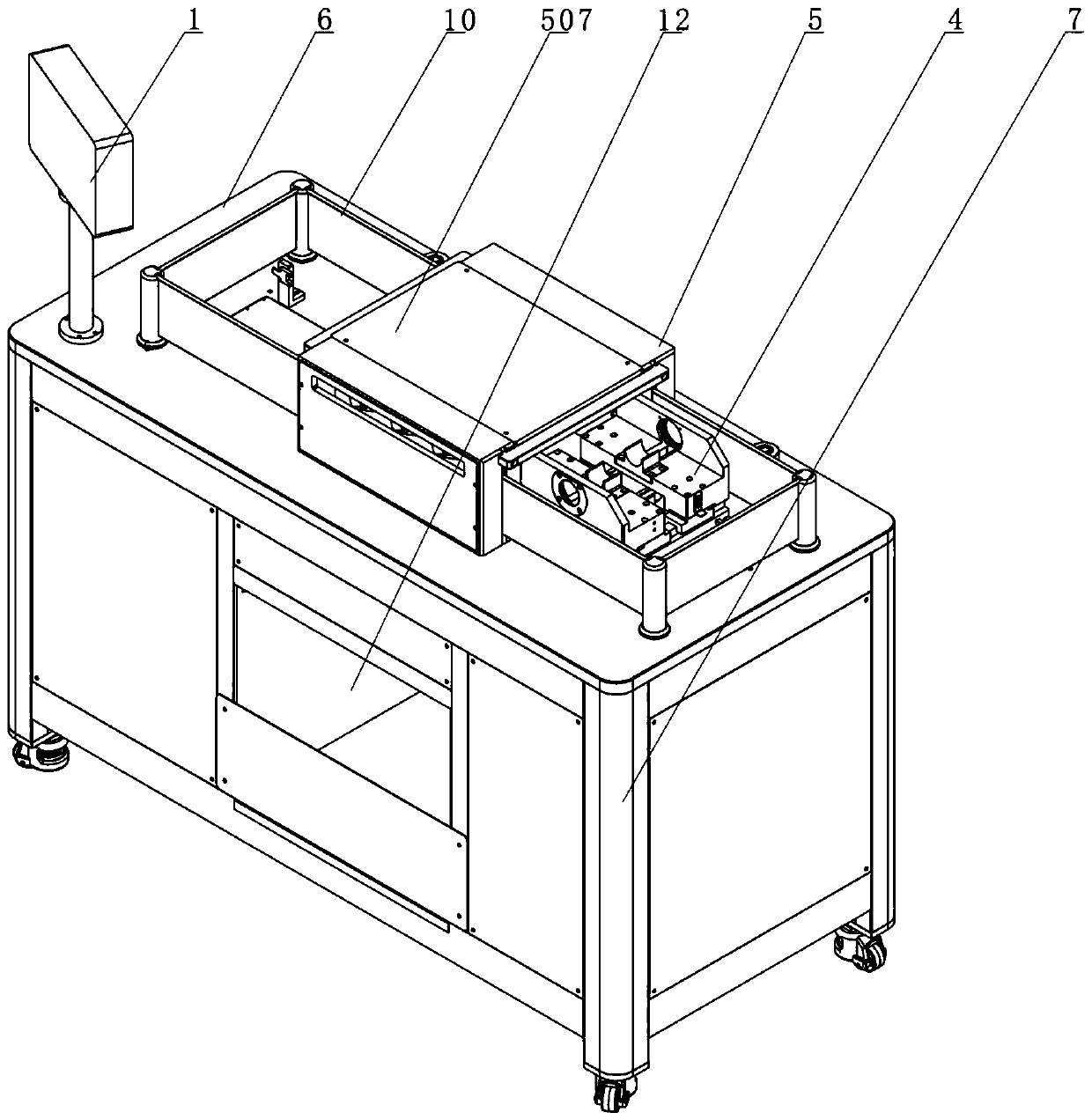

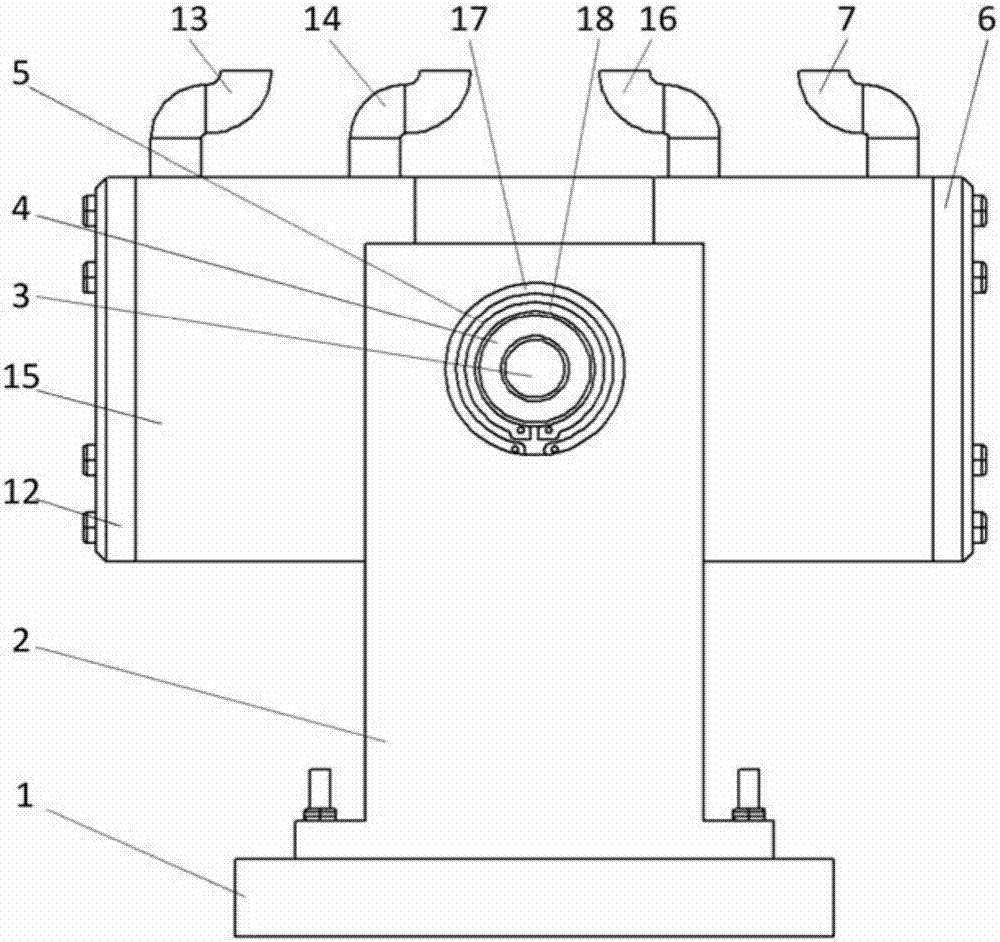

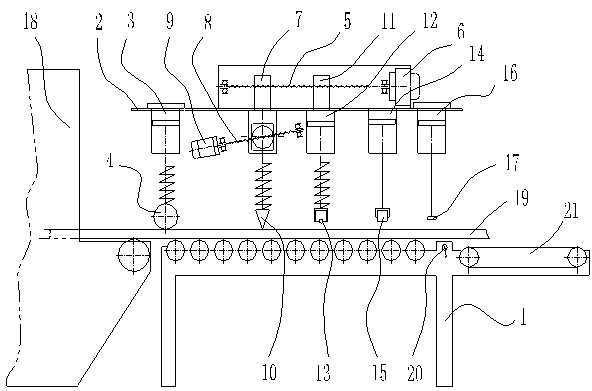

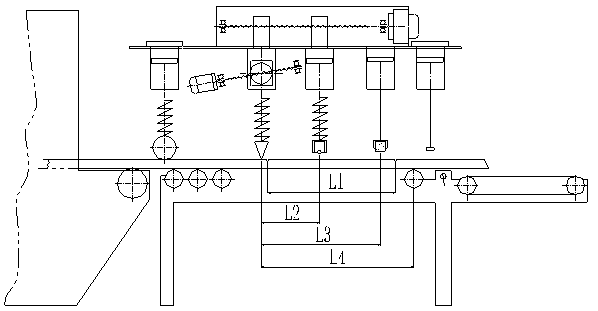

Automatic breaking device for optical glass plate material

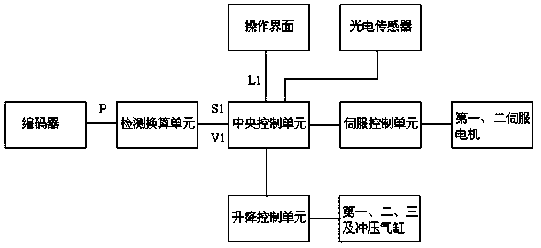

ActiveCN106277739AGood cross section qualityEasy to controlGlass transportation apparatusGlass severing apparatusBall screwOptical glass

The invention discloses an automatic breaking device for an optical glass plate material, and belongs to the technical field of optical glass production. The automatic breaking device mainly solves the problems that the labor intensity is high, the glass fracture surface quality is difficult to control and an existing breaking device is easy to damage glass and a clamping device in manpower breaking. The device comprises a transport mechanism, a detection mechanism, a longitudinal moving mechanism, a scribing mechanism, a heating mechanism, a cooling mechanism and a pressing and breaking mechanism, wherein the transport mechanism comprises a roller conveying platform and a belt conveyor; the detection mechanism comprises an encoder and a first cylinder; the longitudinal moving mechanism comprises longitudinal linear guide rails, a first ball screw and a first servo motor; the scribing mechanism comprises a second ball screw, a second servo motor, transverse linear guide rails and a diamond scribing knife; the heating mechanism comprises a heating rod and a second cylinder; the cooling mechanism comprises a sponge body and a third cylinder; and the pressing and breaking mechanism comprises a stamping cylinder and a pressing block. According to the automatic breaking device, automatic breaking of the optical glass plate material can be realized according to a set length, the fracture surface quality is good, and the breaking length is accurate.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

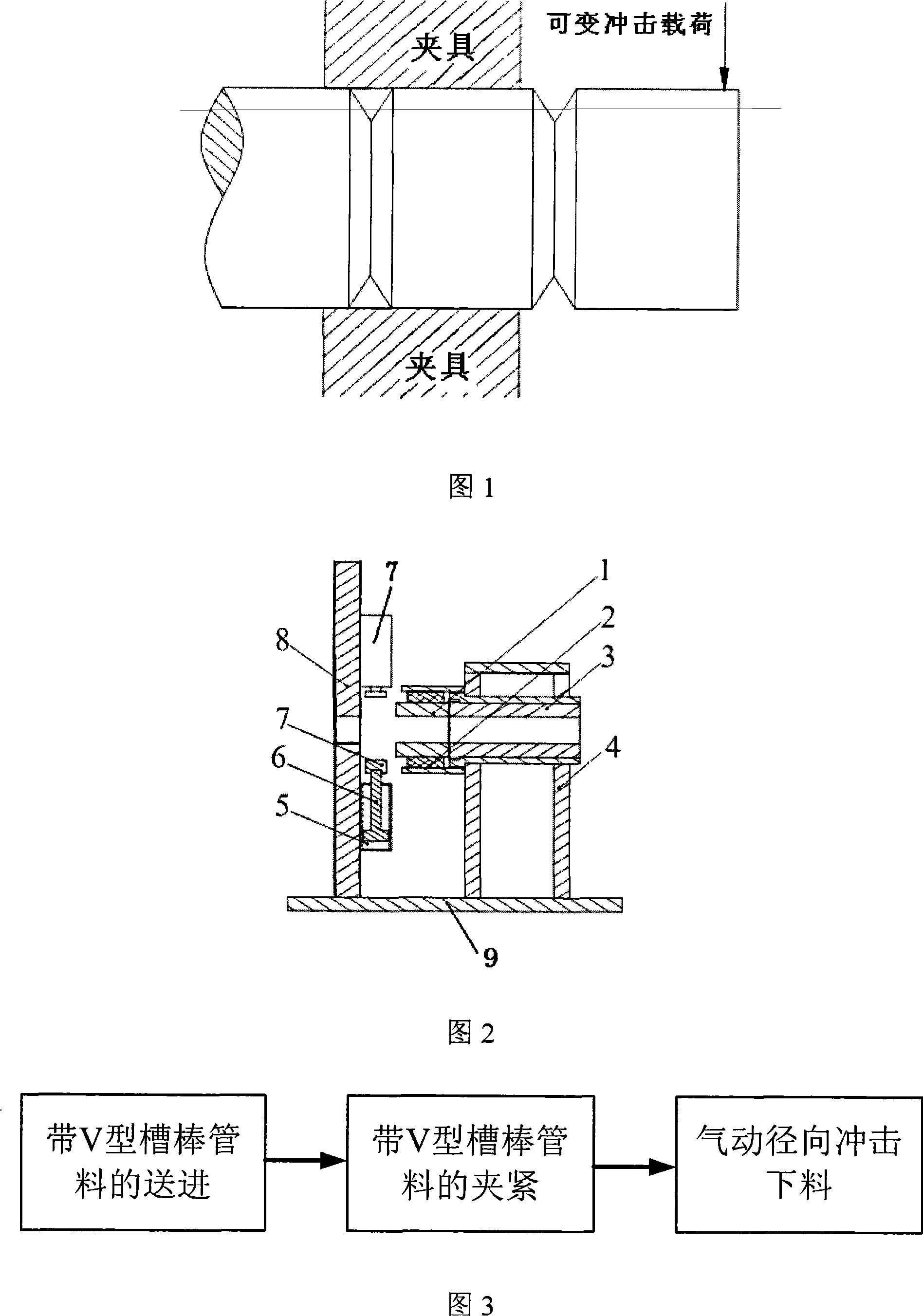

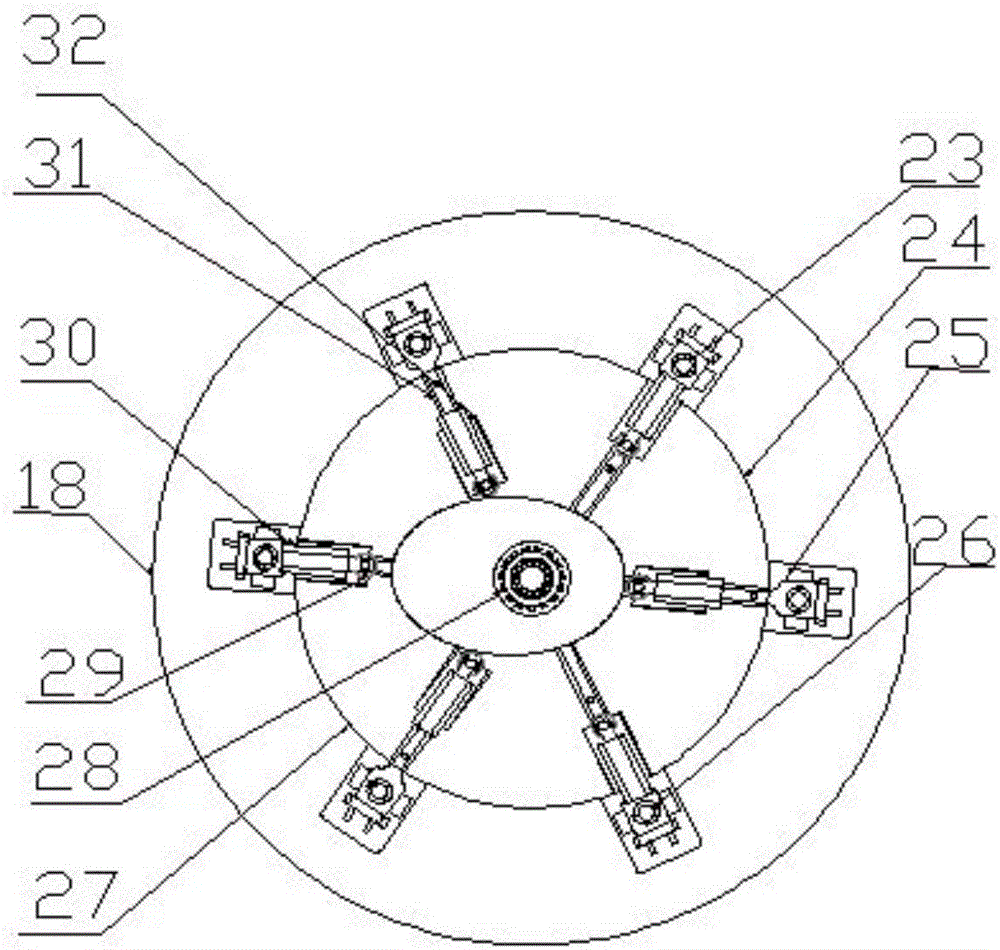

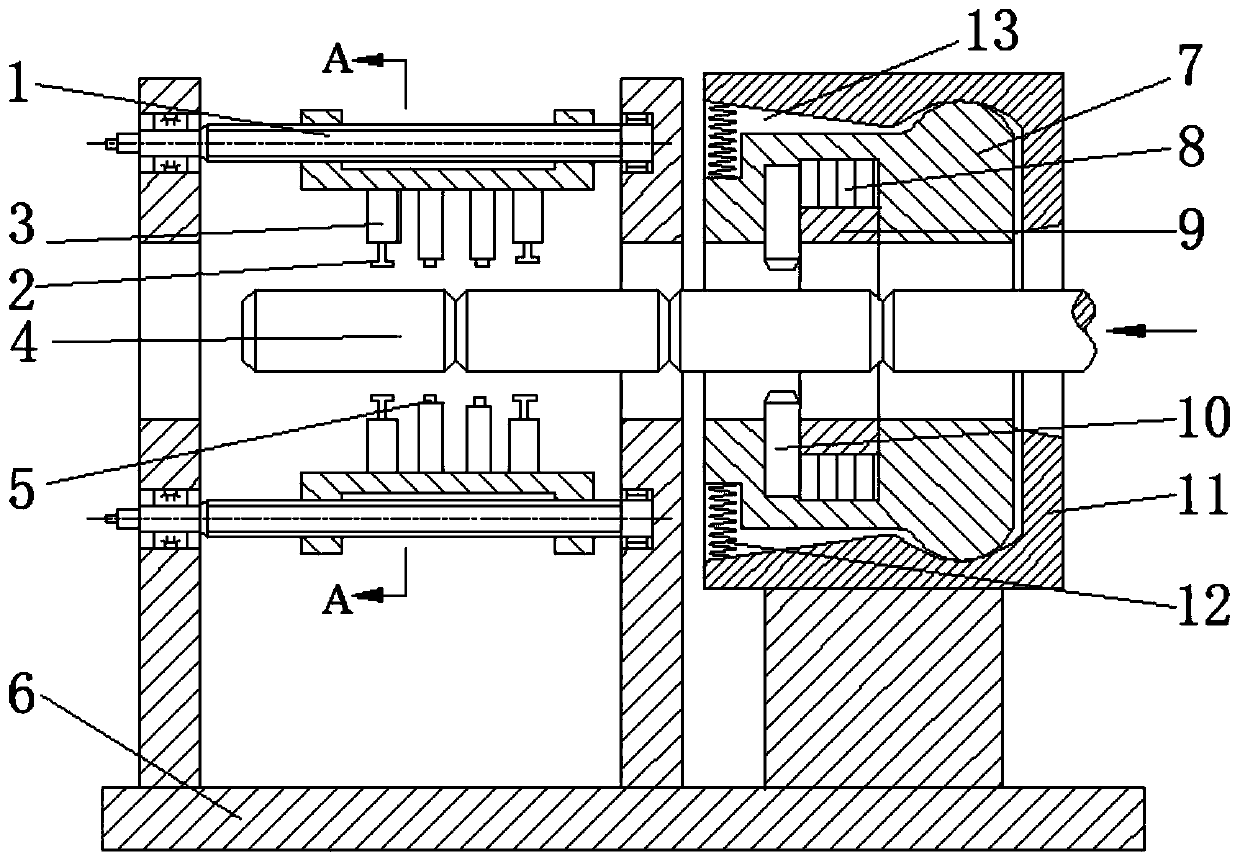

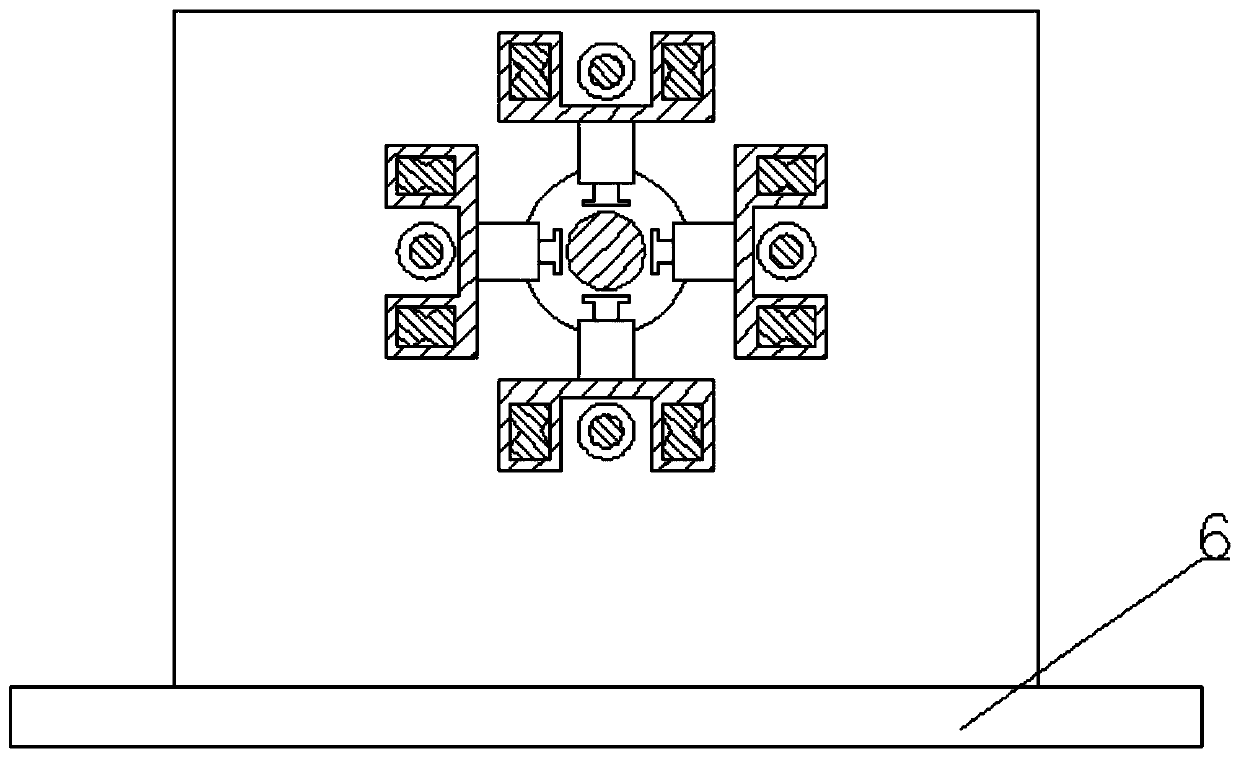

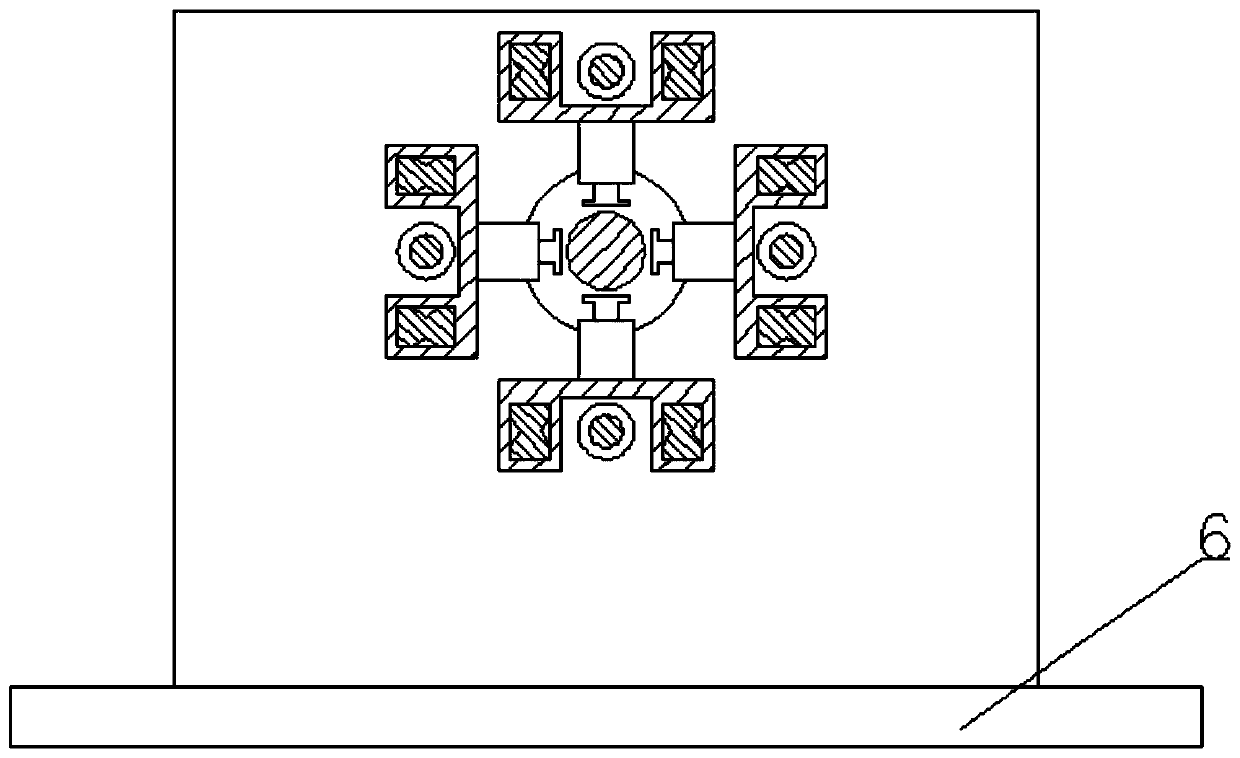

Radially-severing efficient and precise low-stress discharging method

The invention discloses a radially-severing efficient and precise low-stress discharging method, and belongs to the technical field of intelligent manufacturing. Four sets of discharging units symmetrically distributed in the circumferential direction of bars sequentially apply loads to the bars at intervals. Each set of discharging unit comprises discharging clamps arranged at the ends of a firsthydraulic oil cylinder and a second hydraulic oil cylinder, and thrust hammerheads fixed to the ends of piston rods of a third hydraulic oil cylinder and a fourth hydraulic oil cylinder. The discharging clamps and the thrust hammerheads are oppositely arranged, when the bars are severed, after the thrust hammerheads jack the bars, the discharging clamps apply loads to the two ends of V-shaped grooves of the bars simultaneously, the discharging clamps and the thrust hammerheads in the four sets of discharging units cooperate to generate alternating force at the positions of the V-shaped grooves, under the acting force, cracks are produced at the positions of the V-shaped grooves, it is guaranteed that the cracks circumferentially propagate along the sections of the sharp ends of the V-shaped grooves gradually towards circle centers, and the beneficial effects that the efficiency is high, the fatigue crack propagation region area is large, and the fracture surface quality is high are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

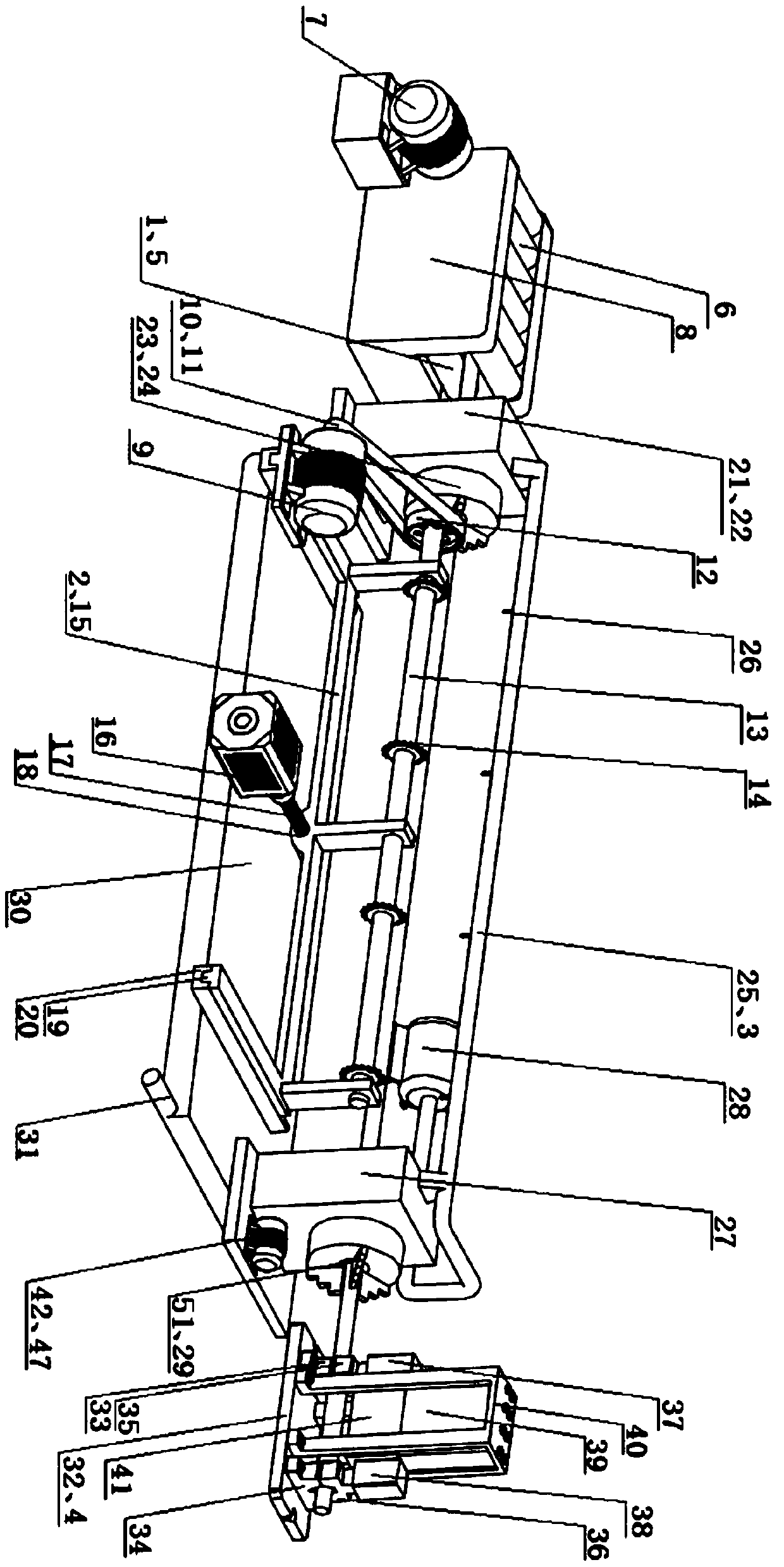

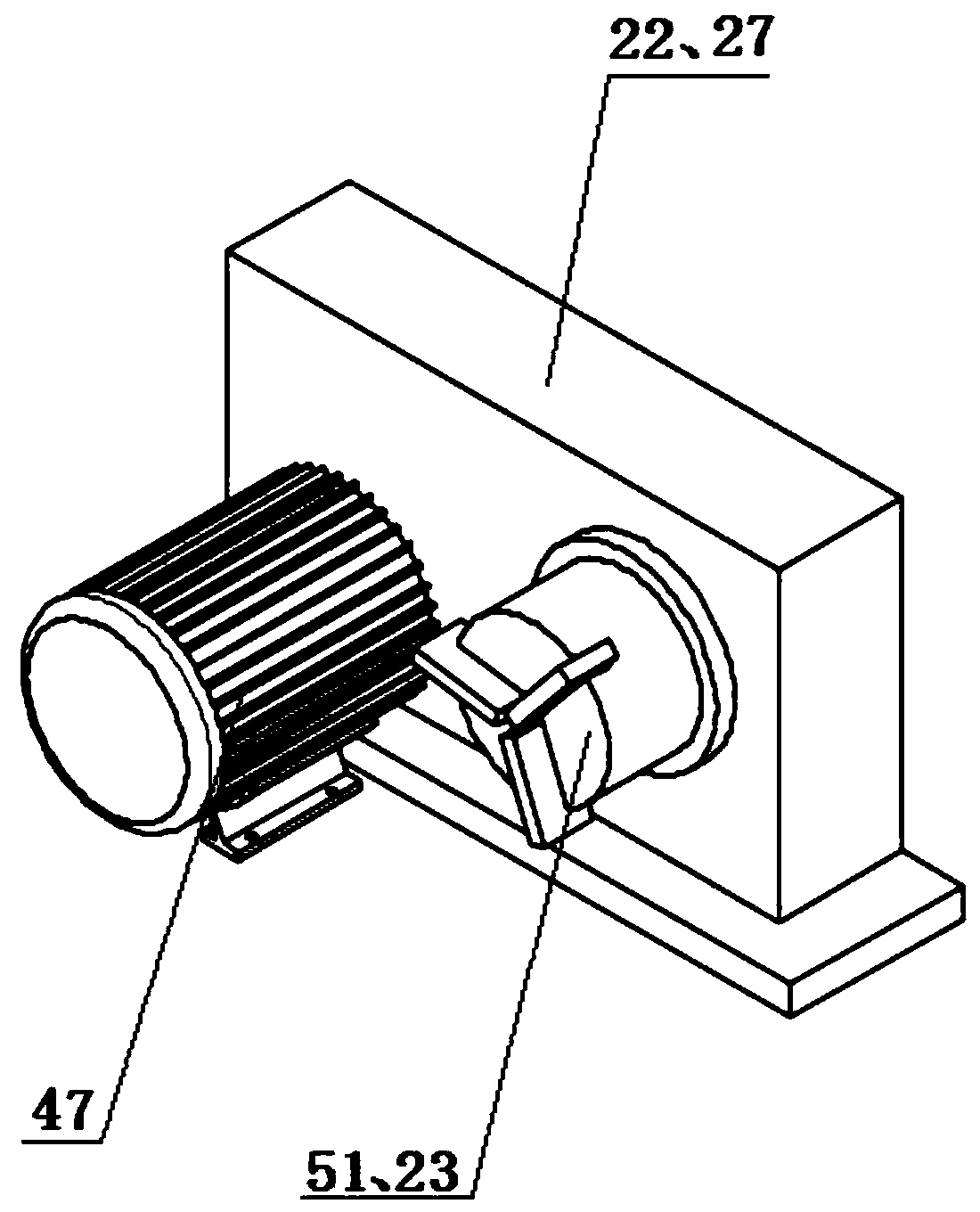

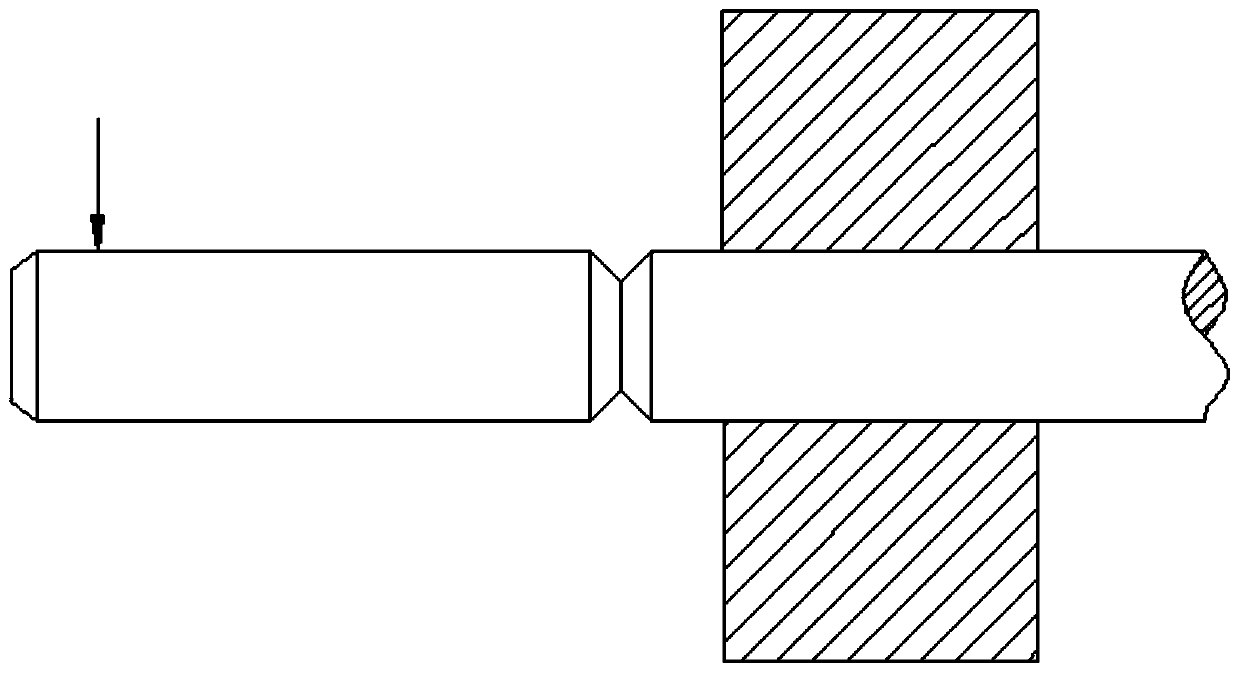

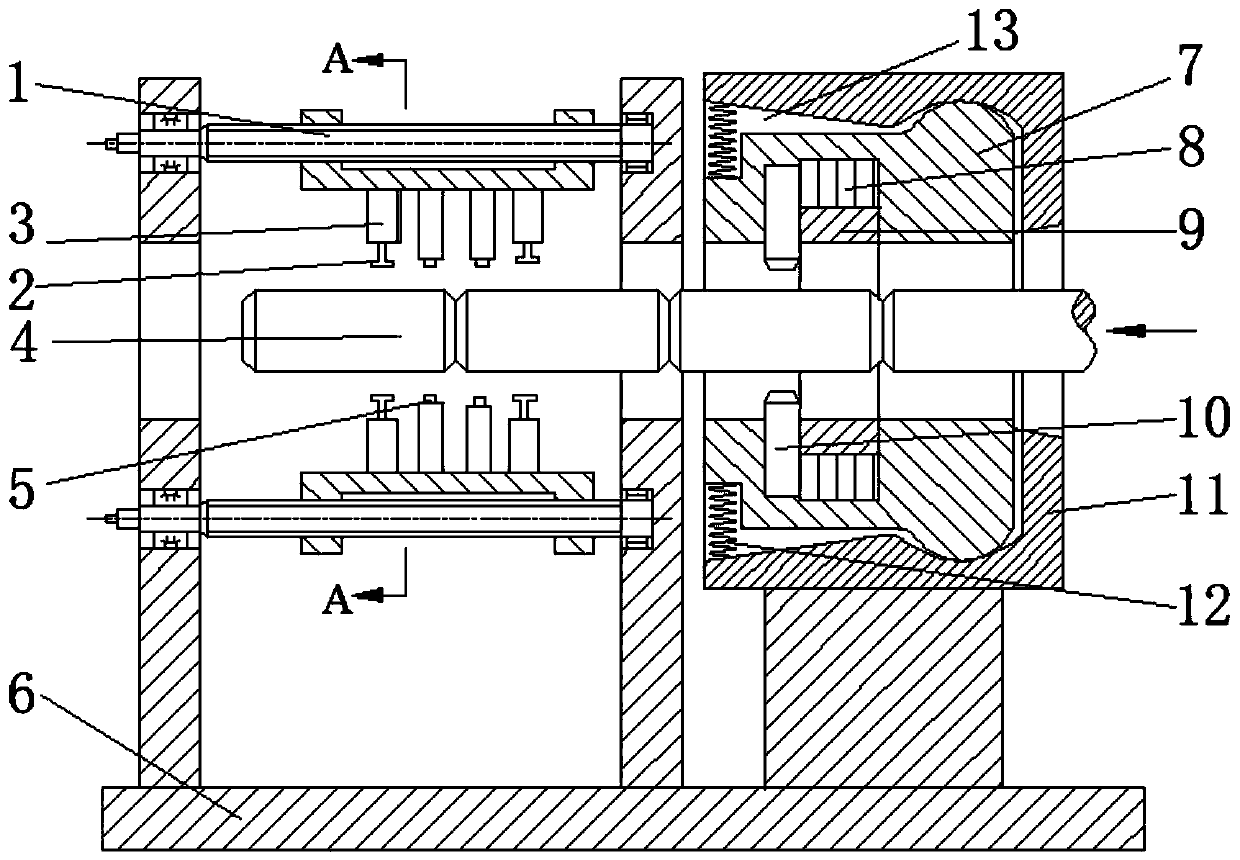

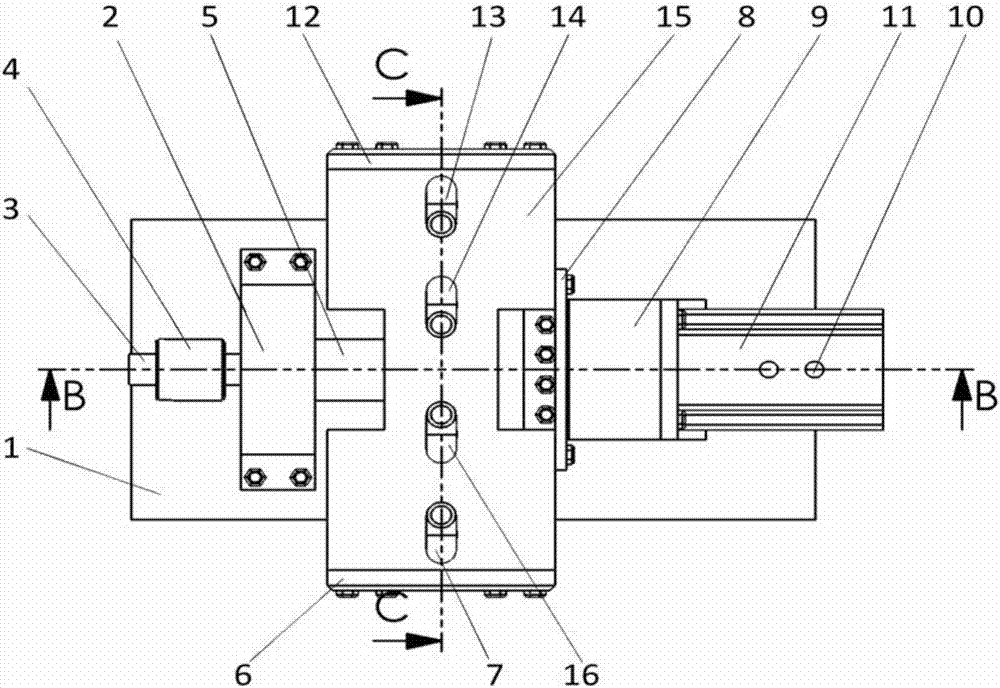

Metal bar material blanking device and blanking method

PendingCN110561124AEfficient and precise blankingImprove cutting efficiencyOther manufacturing equipments/toolsMilling equipment detailsWater flowEngineering

The invention discloses a metal bar material blanking device. The metal bar material blanking device comprises a feeding system, wherein a milling groove system is arranged on one side of the feedingsystem; the milling groove system is correspondingly connected with a clamping system and a cooling system; and a blanking system is arranged on one side of the milling groove system. The blanking method comprises the following steps of 1, feeding a metal bar material through a through hole a and a through hole b to the clamping system through the feeding system; a three-jaw chuck a and a three-jaw chuck b clamp and fix the metal bar material; 2, milling the metal bar material; 3, adjusting the position of a nozzle and the water flow speed, starting a water pump, and cooling the metal bar material; 4, loosening the three-jaw chuck a and the three-jaw chuck b, and moving the metal bar material to the blanking system through the feeding system; and 5, starting a clamping cylinder a and a clamping cylinder b to clamp and fix the metal bar material, starting an impact cylinder, and pushing a pressing block to strike the metal bar material, so that the metal bar material is disconnected.

Owner:XIAN AERONAUTICAL POLYTECHNIC INST

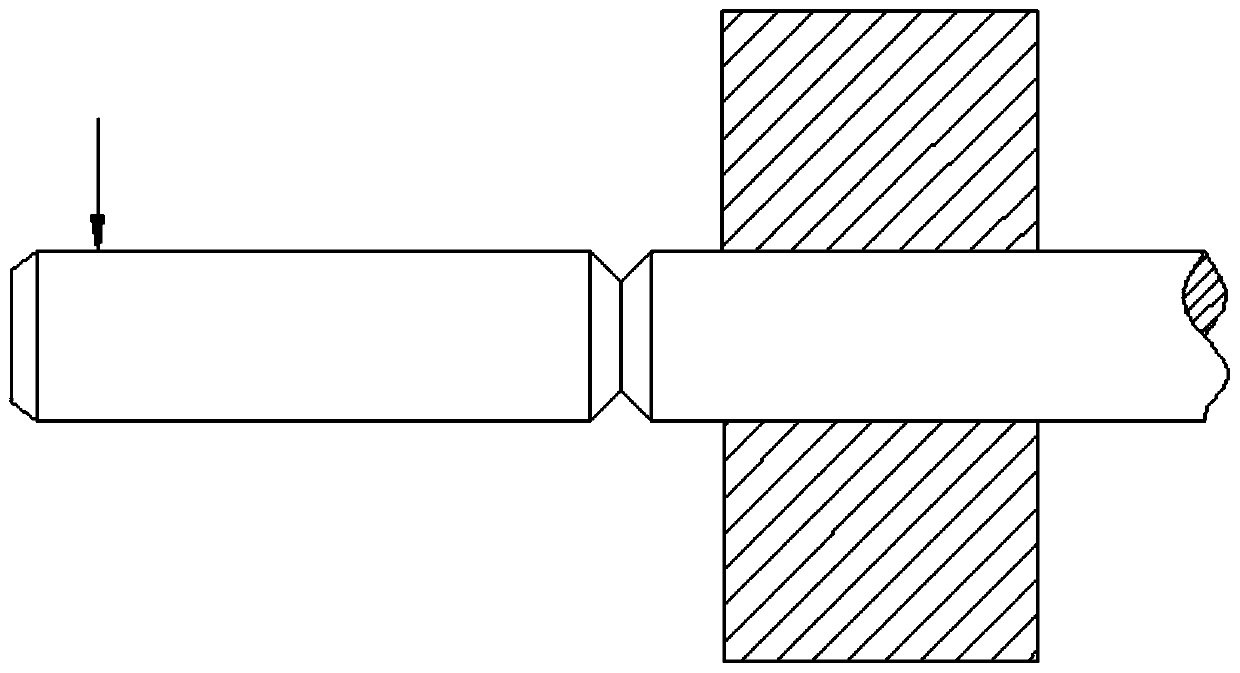

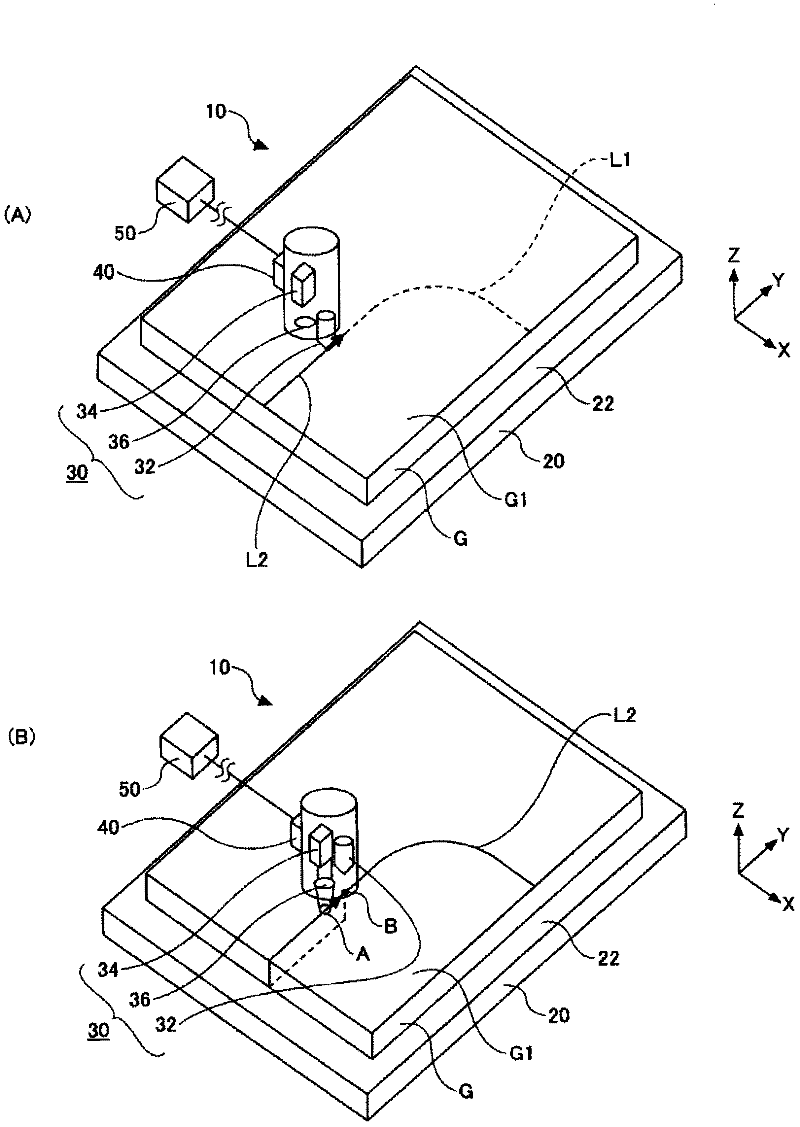

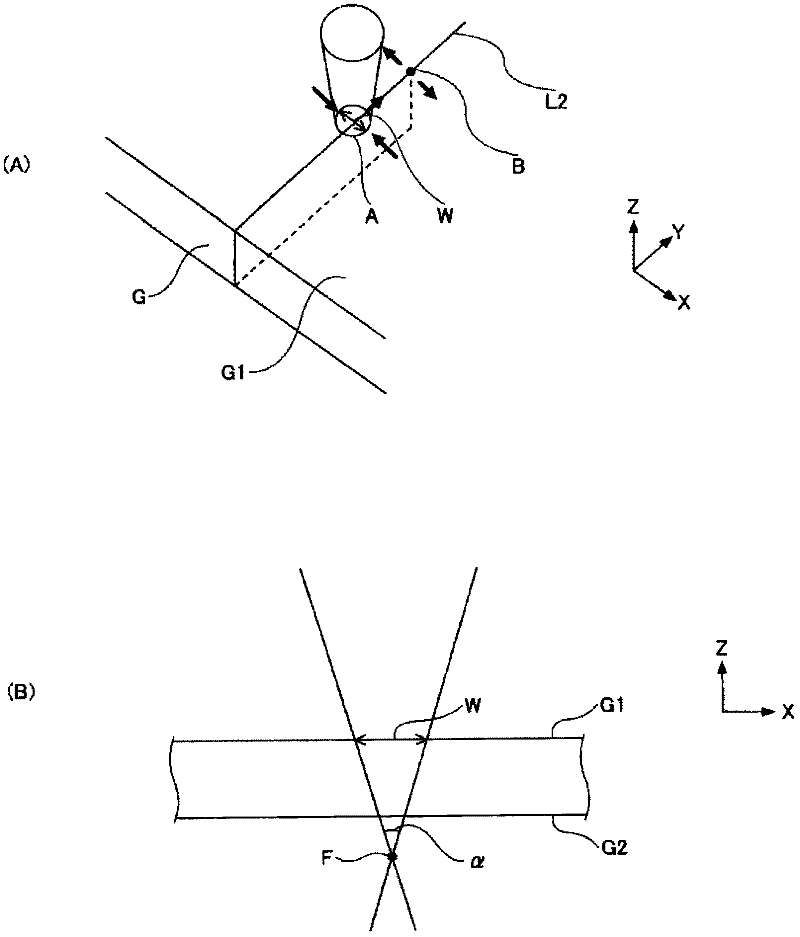

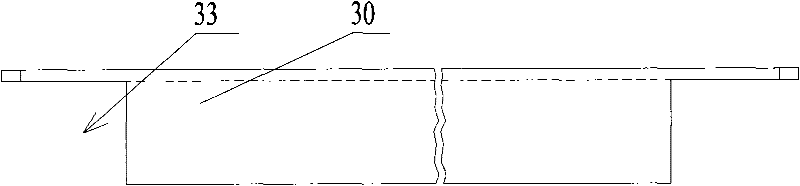

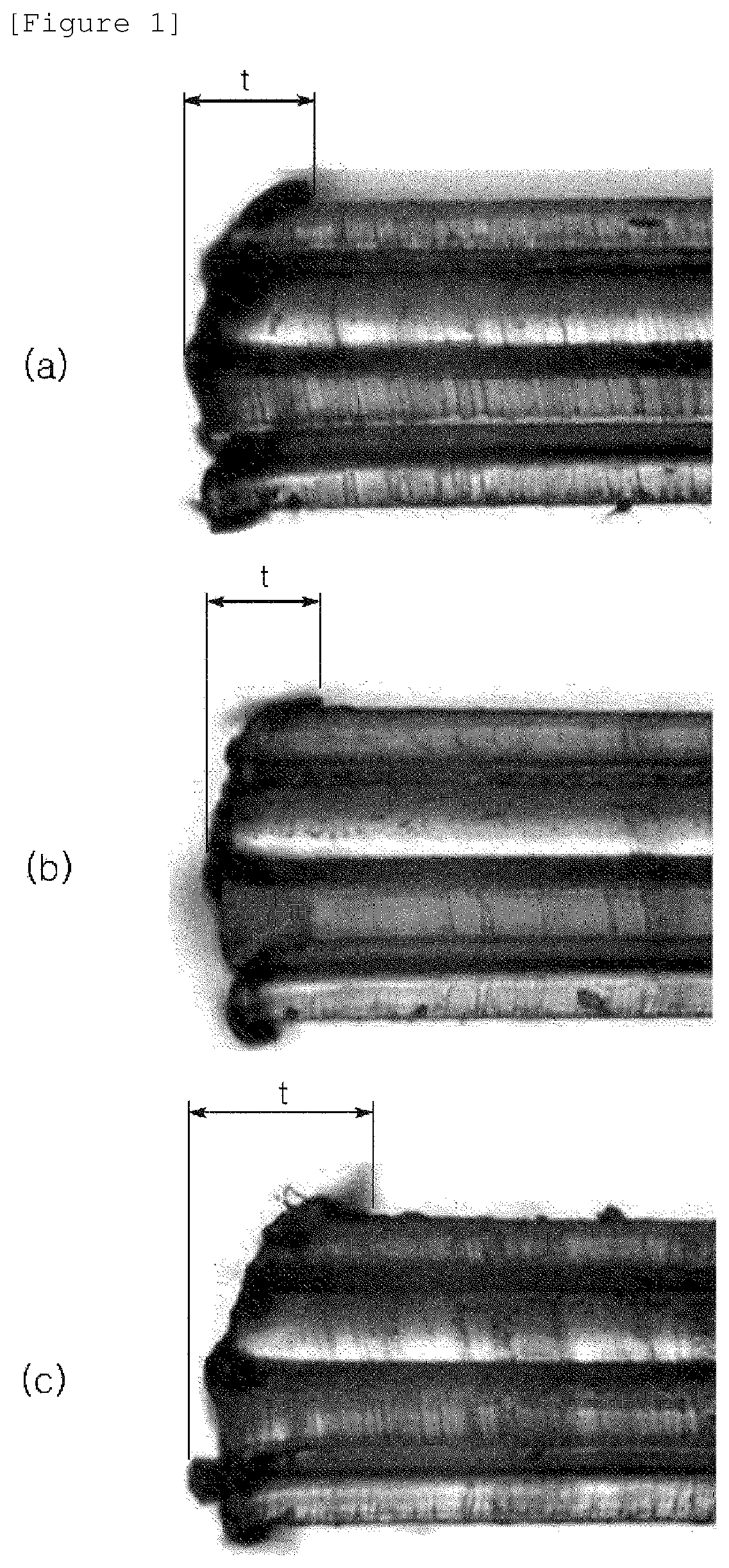

Method and device for cutting brittle material substrate, and window glass for vehicles

InactiveCN102264659AGood cross section qualityFine working devicesGlass severing apparatusLaser lightEngineering

A method of cutting a brittle-material plate is provided by which the brittle-material plate can be cut into a desired planar shape through automatic machine production without complicating the device. Also provided are a window glass for vehicles which is obtained by the cutting method and a device for cutting a brittle-material plate. The method of cutting a brittle-material plate comprises: a first step in which a scribe line (L2) is formed in a surface (G1) of a brittle-material plate (G); and a second step in which the position (A) where the surface (G1) of the brittle-material plate (G) is irradiated with laser light is relatively moved along the scribe line (L2) to cut the brittle-material plate (G) ahead of the irradiation position (A) with respect to the moving direction.

Owner:ASAHI GLASS CO LTD

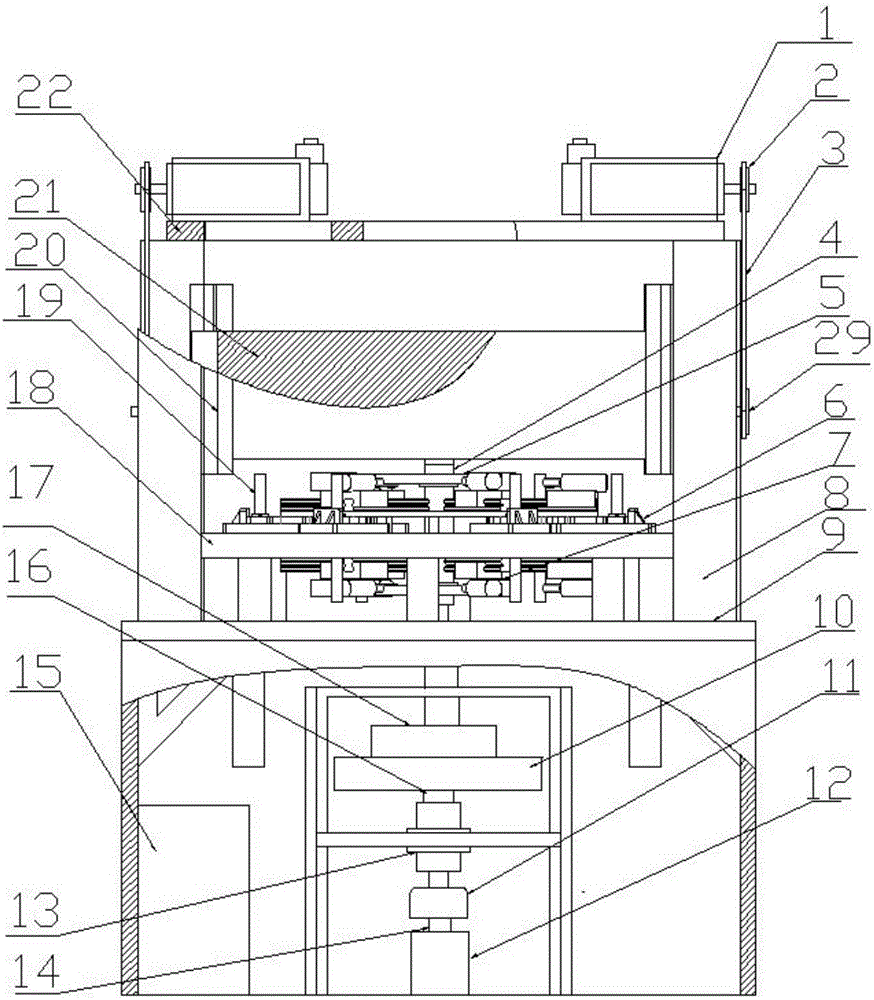

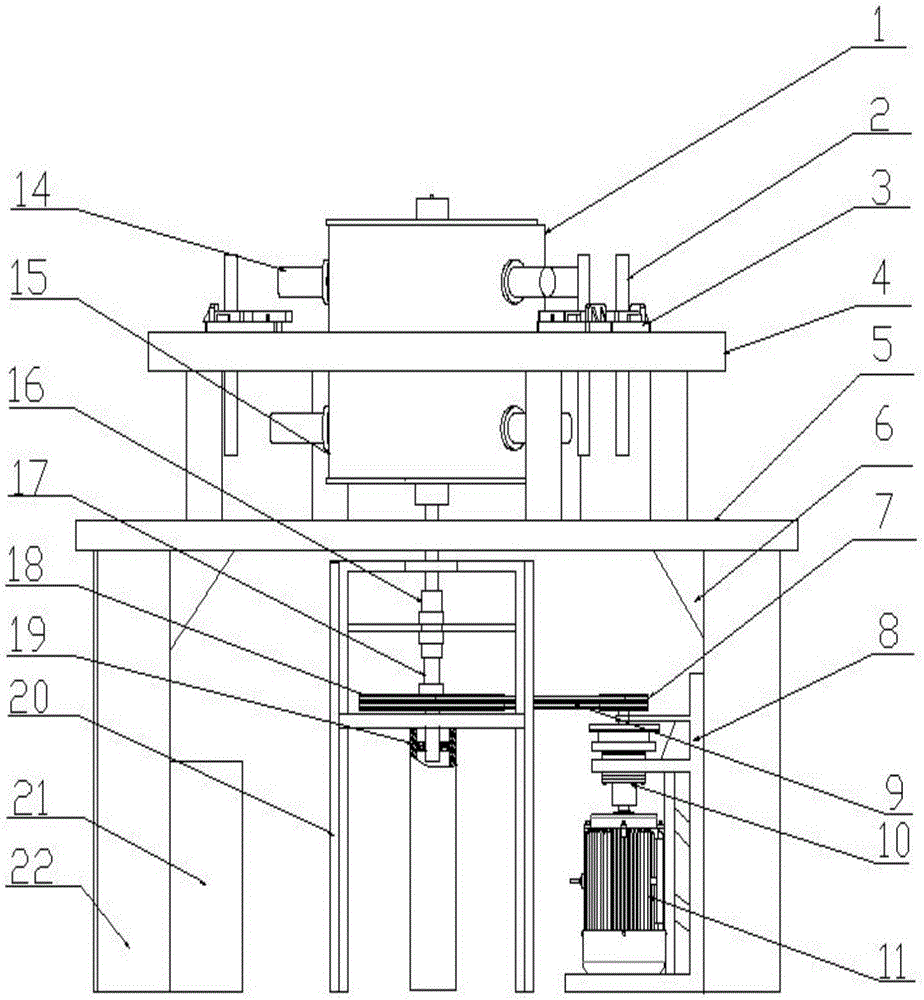

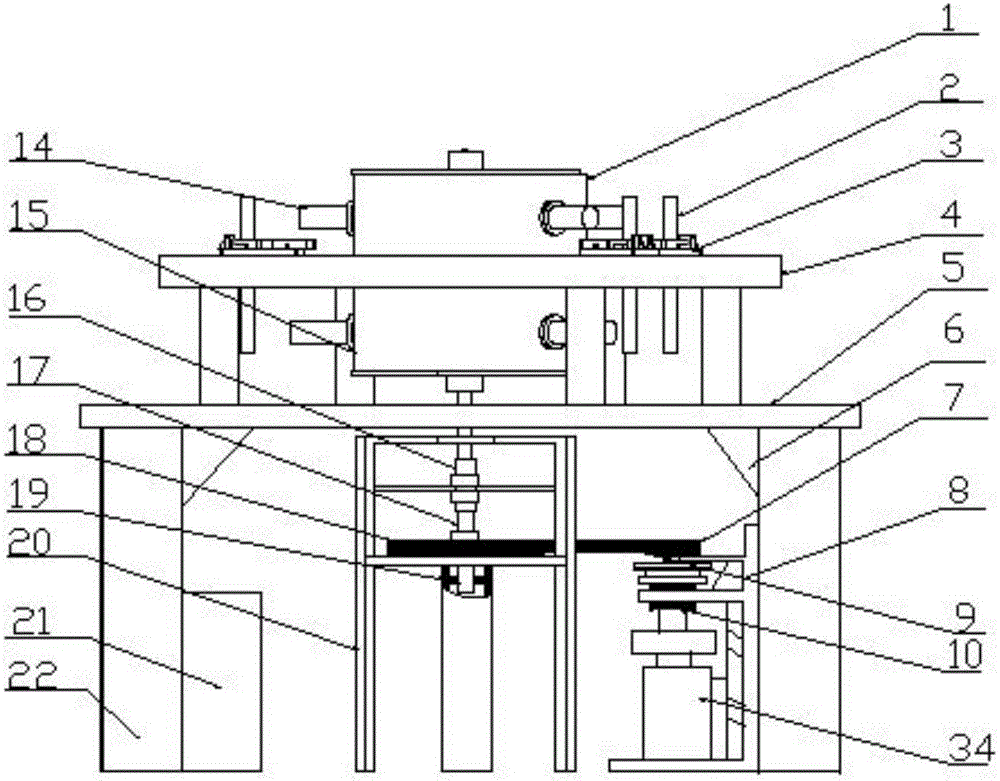

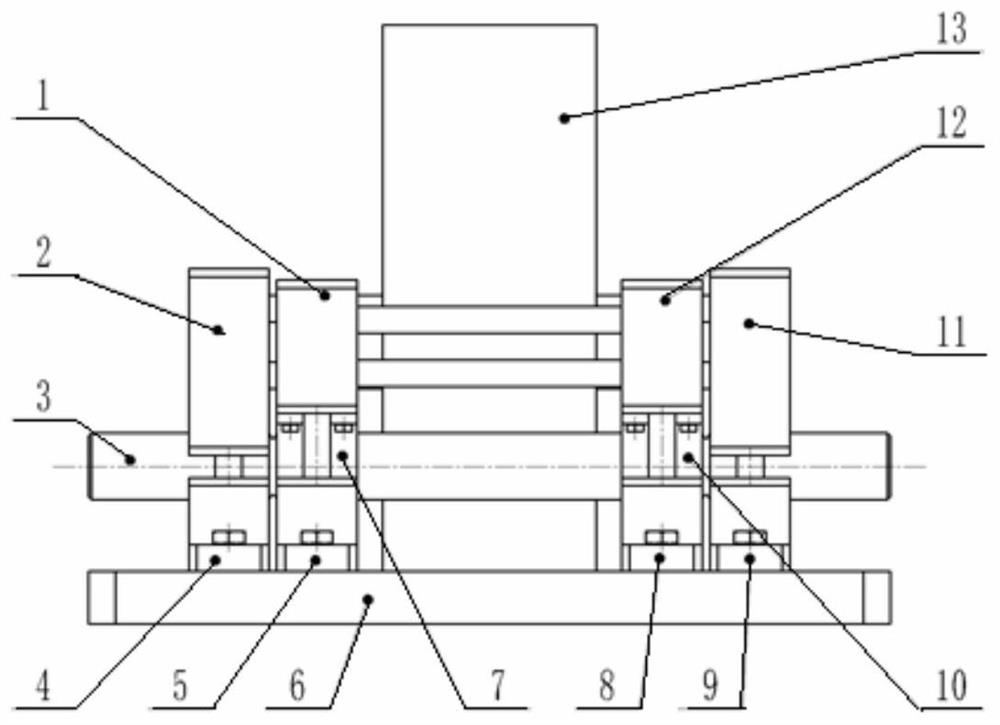

Radial cam loading and low-cycle fatigue splitting equipment for subdivision-type connecting rod fracture splitting

Radial cam loading and low-cycle fatigue splitting equipment for subdivision-type connecting rod fracture splitting comprises a base. The left side and the right side of the base are fixedly connected with four vertical columns. A cross beam is fixedly connected with the upper sides of the four vertical columns. Servo motors are bilaterally and symmetrically installed on the cross beam. The servo motors are connected with a cam plate lifting mechanism installed on the upper portion of a spline shaft. A motor decelerating power mechanism is connected with the lower portion of the spline shaft. The middle of the spline shaft is connected with a main working table. An upper end cam plate and a corresponding lower end cam plate of the main working table impact the upper end and the lower end of a core rod simultaneously, so that a connecting rod large head hole with a prefabricated fracture splitting groove is loaded repeatedly, and low-stress fatigue separating of the connecting rod large end and a connecting rod body is completed. The radial cam loading and low-cycle fatigue splitting equipment for subdivision-type connecting rod fracture splitting has the advantages of being environmentally friendly, energy saving, high in machining efficiency, wide in application range and good in fracture surface quality.

Owner:XI AN JIAOTONG UNIV

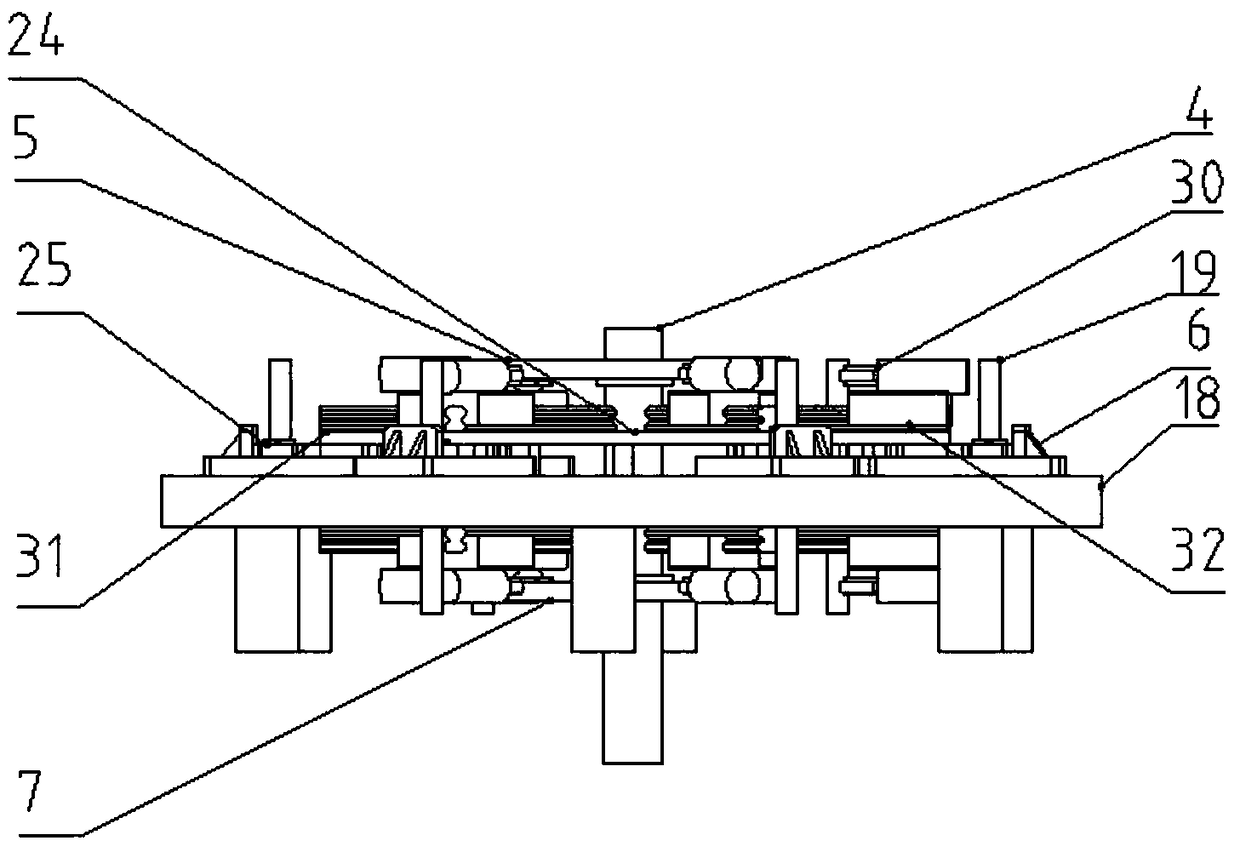

Radial breaking high-efficiency precise low-stress discharging machine

The invention discloses a radial breaking high-efficiency precise low-stress discharging machine, and belongs to the technical field of intelligent manufacturing. The radial breaking high-efficiency precise low-stress discharging machine comprises four groups of discharging units symmetrically distributed in the circumferential direction, each group of discharging units includes a first hydrauliccylinder, a second hydraulic cylinder, discharging fixtures disposed at the end parts of piston rods of the first hydraulic cylinder and the second hydraulic cylinder, a third hydraulic cylinder, a fourth hydraulic cylinder and thrust hammers separately fixed to the end parts of piston rods of the third hydraulic cylinder and the fourth hydraulic cylinder; the discharging fixtures and the thrust hammers are oppositely arranged; when a bar material is subjected to breaking, after the thrust hammers abut against the bar material, the discharging fixtures apply loads to both ends of a V-shaped groove of the bar material, and alternating force is generated at the V-shaped groove. Under the force, cracks are formed at the V-shaped groove, it is ensured that the cross section of the tip end of the V-shaped groove gradually expands toward the center of the circle in a circumference mode, and the quality and flatness of the cross section of the bar material are improved by changing the loadingmode of the bar material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Bar stock pneumatic radial impact blanking method with high-efficiency and precision

The invention discloses a bar stock pneumatic radial impact high-efficiency precise blanking method. In the method, the bar stock is arranged on a pneumatic radial impact precise blanking device and the main working parts of the blanking device comprise a blanking sleeve, an elastic pad sleeve, a bar stock fixing sleeve, an impact cylinder, a piston and a blanking die. The impact cylinder works sequentially under the control of a control system and drives the blanking die to load the bar stock along the radial direction continuously; cracks are extended from the surface of the bar stock alongthe radial direction to the center of the circle by a fatigue breaking device of the bar stock, thus achieving the blanking and gaining good quality of the profile.

Owner:XI AN JIAOTONG UNIV

A kind of glue sealing end surface cutting equipment

ActiveCN109093661BNice appearanceEasy to collectMetal working apparatusControl systemElectric machinery

The invention discloses glue sealing end face glue cutting equipment. The glue sealing end face glue cutting equipment comprises a control system, a motor, a machine frame, a workbench, a cutter assembly, a clamping mechanism and a transmission mechanism; the motor and the transmission mechanism are both installed on the machine frame; the workbench is installed on the machine frame and is locatedabove the transmission mechanism; a sliding groove is formed in the workbench; the sliding groove is covered with a sealing piece, and the workbench surface is free of a gap; the clamping mechanism is arranged on the workbench, and the lower end of the clamping mechanism penetrates through the workbench through the sliding groove to be connected with the transmission mechanism below the clampingmechanism; the sealing part on the sliding groove penetrates through the clamping mechanism; the cutter assembly is installed on the workbench and located on the two sides of the clamping mechanism; and the clamping mechanism is matched with the cutter assembly to work. The transmission mechanism is arranged below the workbench, and the sliding groove in the workbench is covered with the sealing strip, and then the sealing strip is tightly pressed against the workbench by combining the clamping mechanism, so that the overall matching enables the workbench of the glue sealing end face glue cutting equipment to be simple, the operation space is more sufficient, and the equipment is convenient to clean.

Owner:CHENGDU HEDA AUTOMATION EQUIP

Workpiece notch stamping device

InactiveCN101890451BImprove machining accuracyReduce labor intensityHigh volume manufacturingUltimate tensile strength

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Plane edge-pressing and semi-fine blanking device and method

Owner:CHONGQING UNIV OF TECH

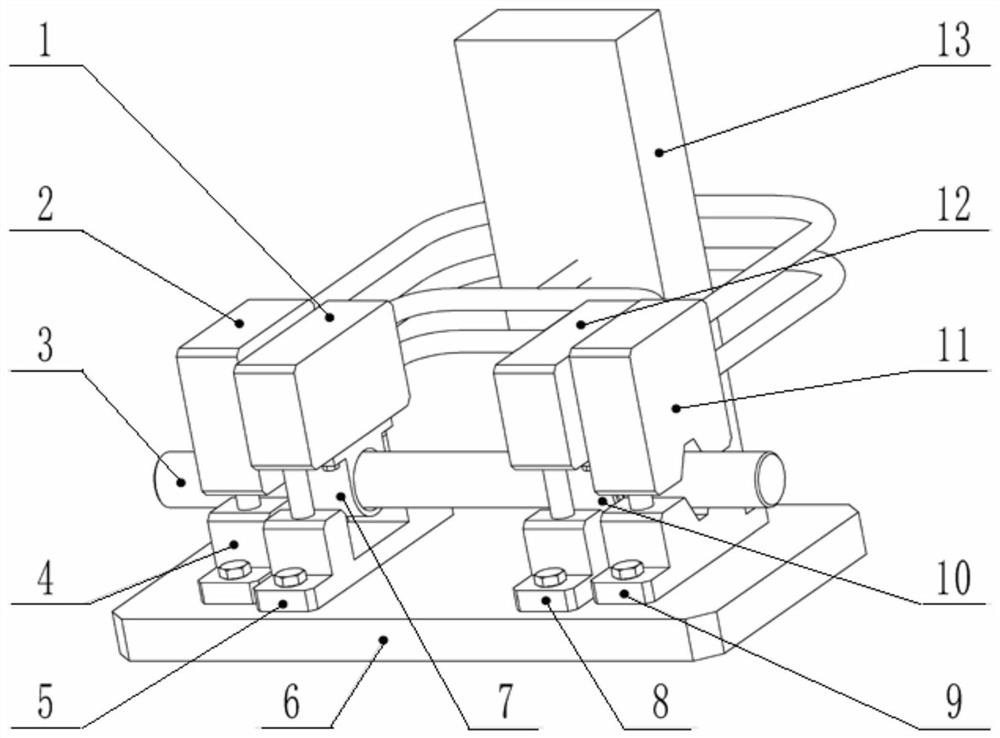

Five-star plunger loading and low cycle fatigue cracking equipment of split type connecting rod cracking

ActiveCN106826148AAvoid the problem of excessive loading speed at one timeNo obvious plastic deformationCouplingLow-cycle fatigue

The invention discloses five-star plunger loading and low cycle fatigue cracking equipment of split type connecting rod cracking. The five-star plunger loading and low cycle fatigue cracking equipment comprises a base. The base is connected with four upright columns; the upright columns are connected with a variable frequency motor through a motor bracket; and the control end of the variable frequency motor is connected with the output end of a control cabinet. An output shaft of the variable frequency motor is connected with a belt wheel shaft through a clutch, a small belt wheel, a narrow V belt and a large belt wheel. The lower end of the belt wheel shaft is movably connected with a supporting frame, and the upper end of the belt wheel shaft is connected with the bottom end of an eccentric shaft through a coupler. Five-star wheels are mounted on the eccentric part of the eccentric shaft and arranged in an upper plunger body and a lower plunger body, wherein the upper plunger body and the lower plunger body are symmetrically arranged on the upper side and the lower side of a placing platform of the base. Each edge of the five-star wheels is connected with a plunger, and the plungers are inserted in the upper end and the lower end of a mandrel of a connecting rod large head hole of a prefabricated V-shaped cracking groove in a butting mode and power is repeatedly loaded simultaneously. The efficiency of connecting rod cracking is greatly improved, and the cracking equipment has the advantages of environmental friendliness and energy saving, high machining efficiency, wide application range and good fracture surface quality.

Owner:XI AN JIAOTONG UNIV

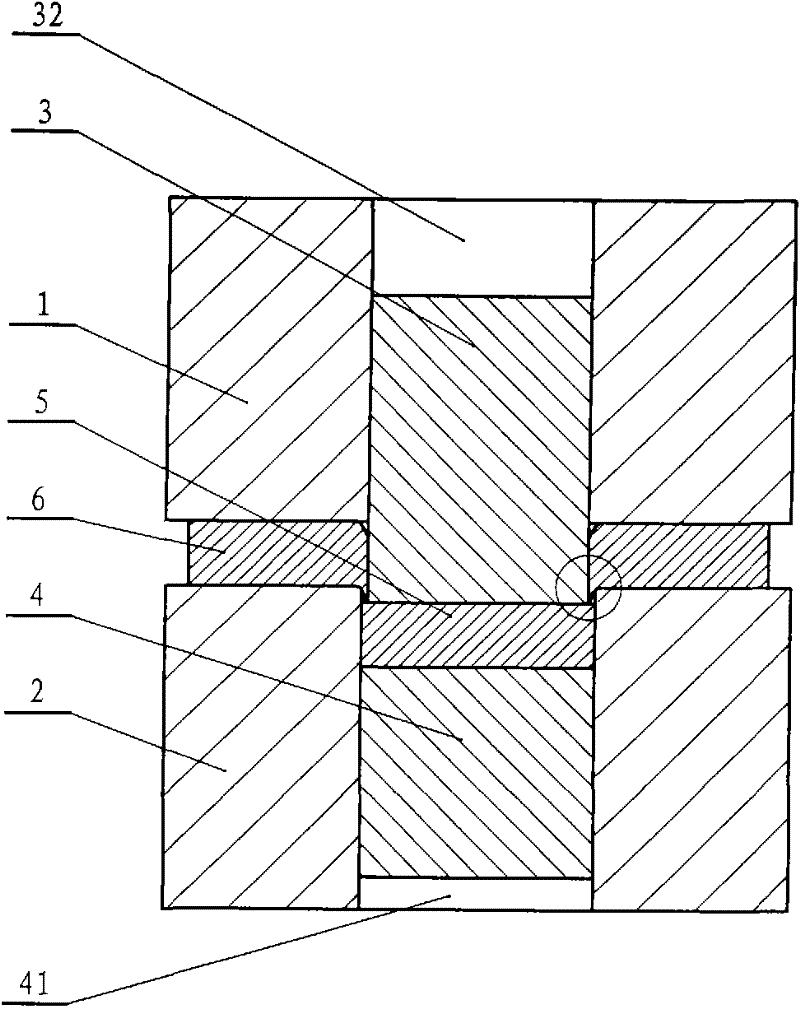

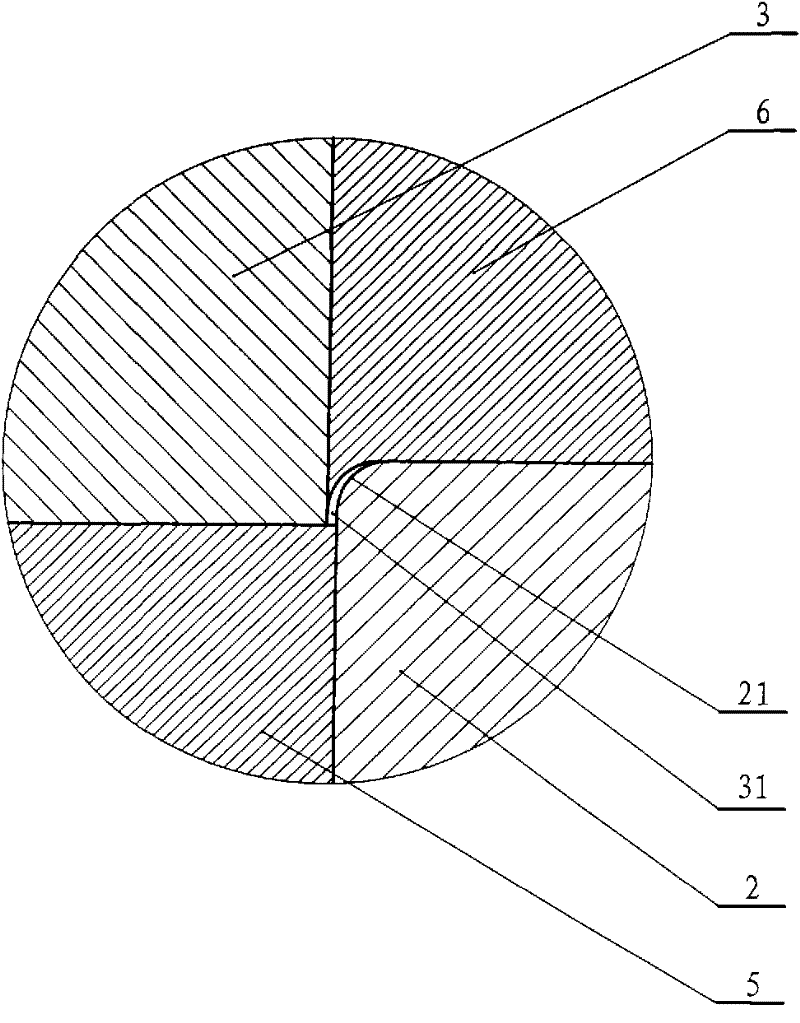

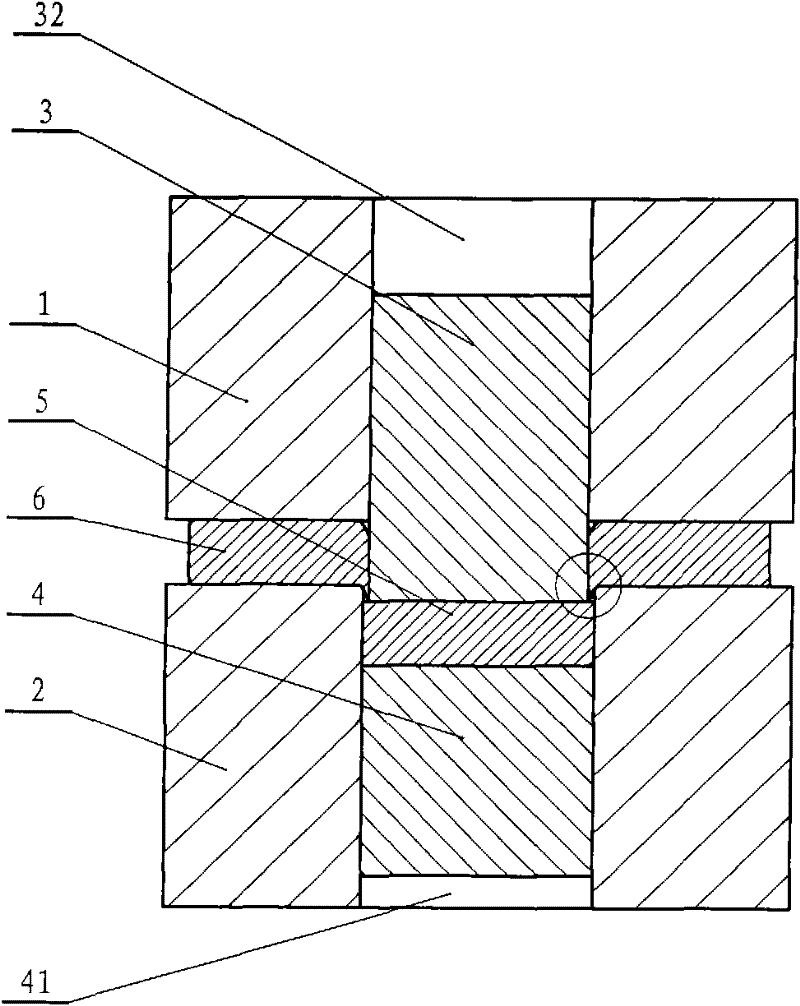

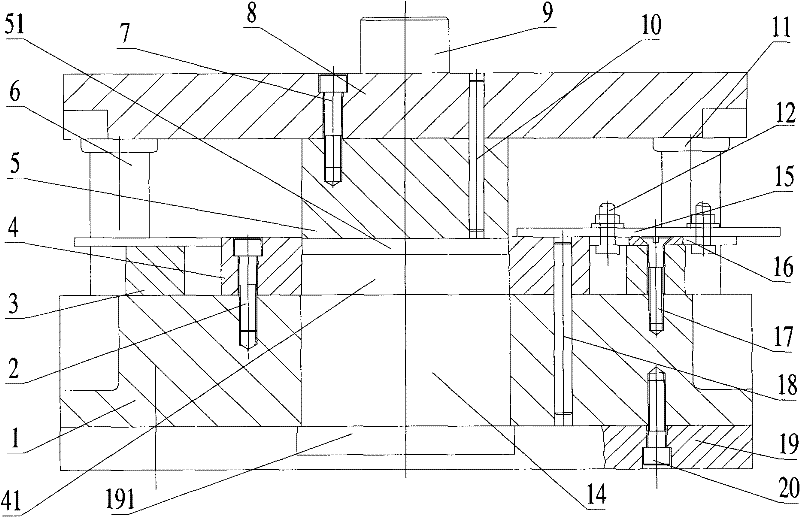

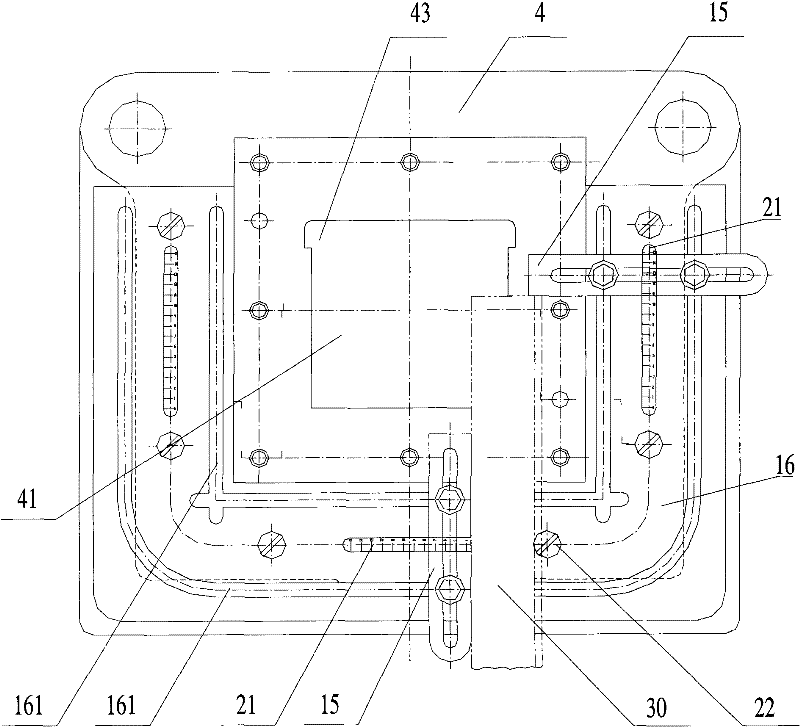

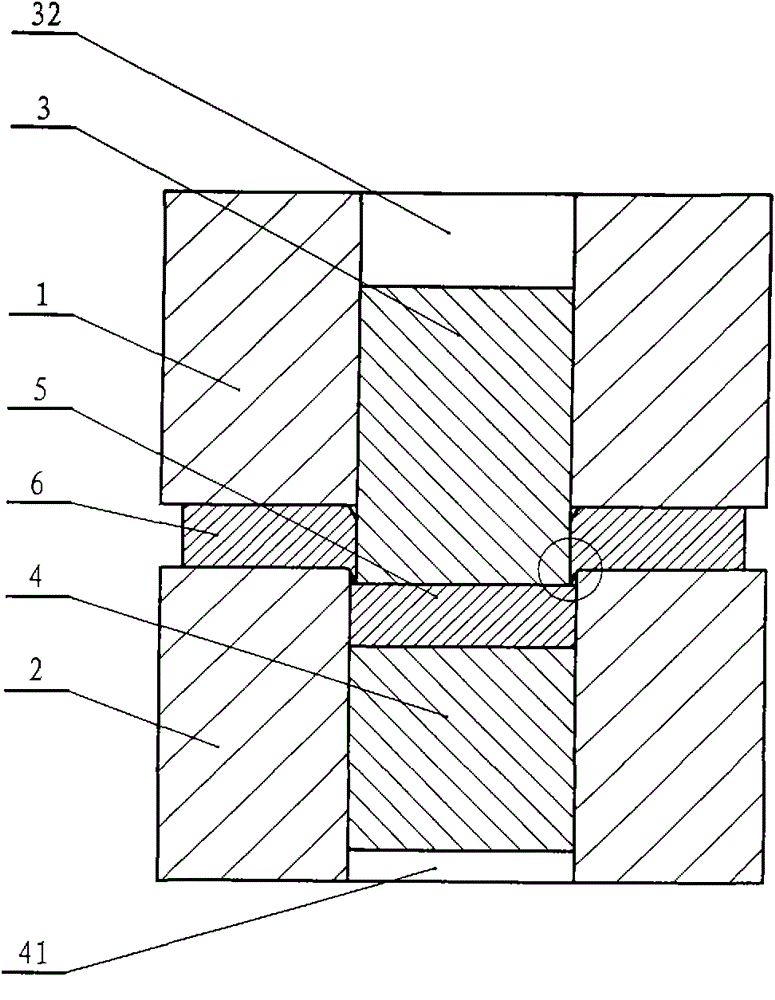

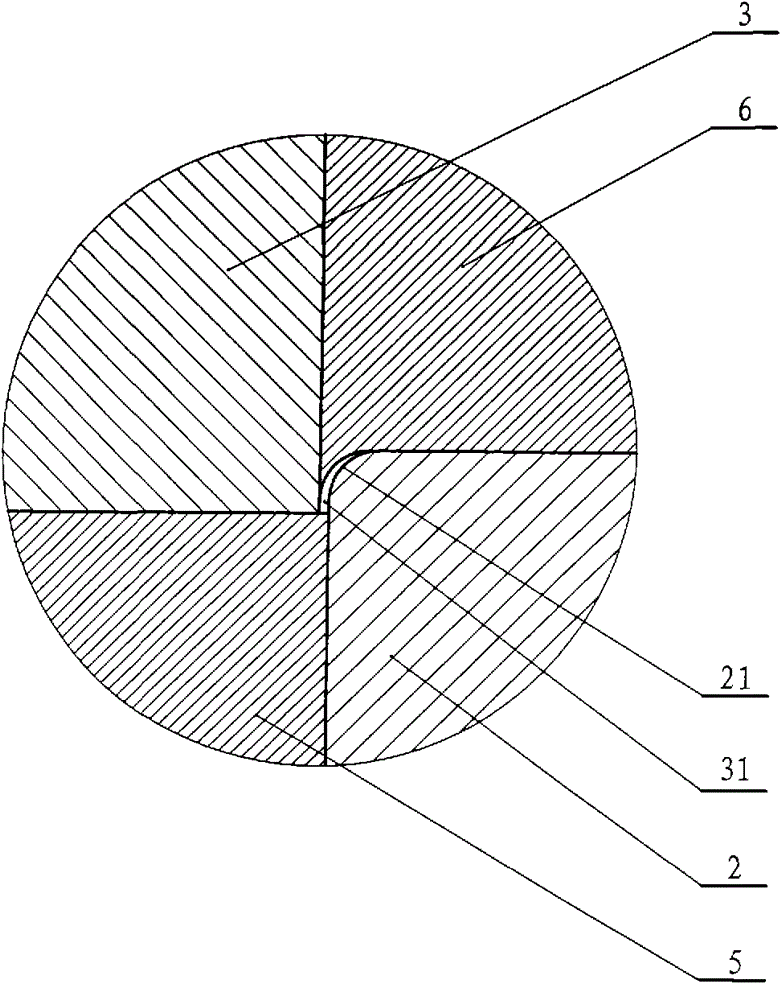

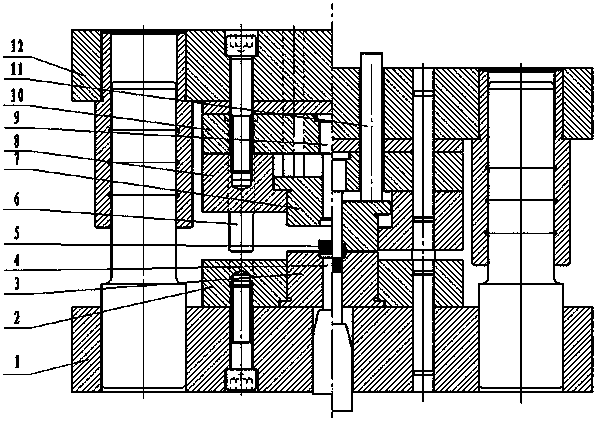

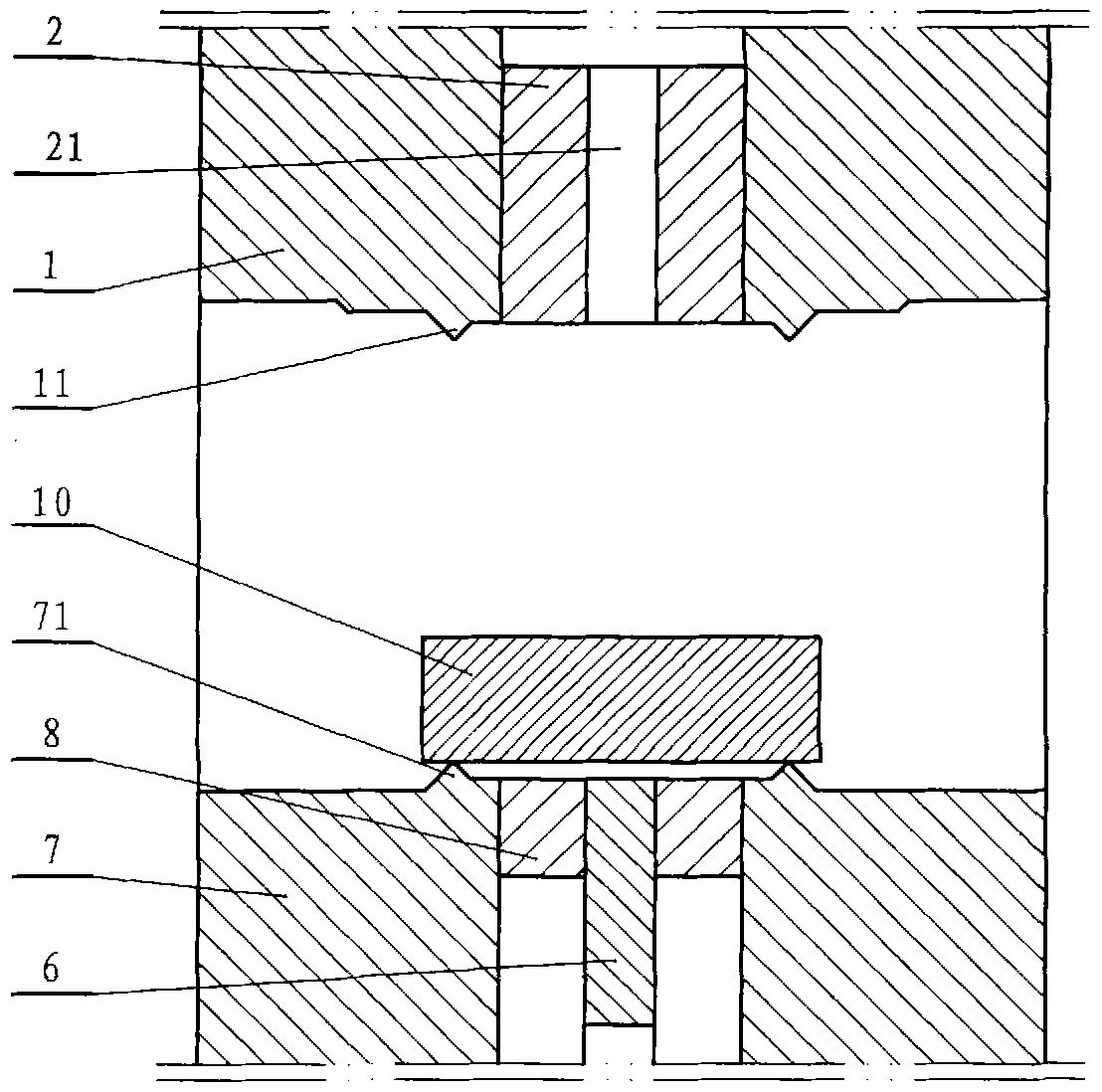

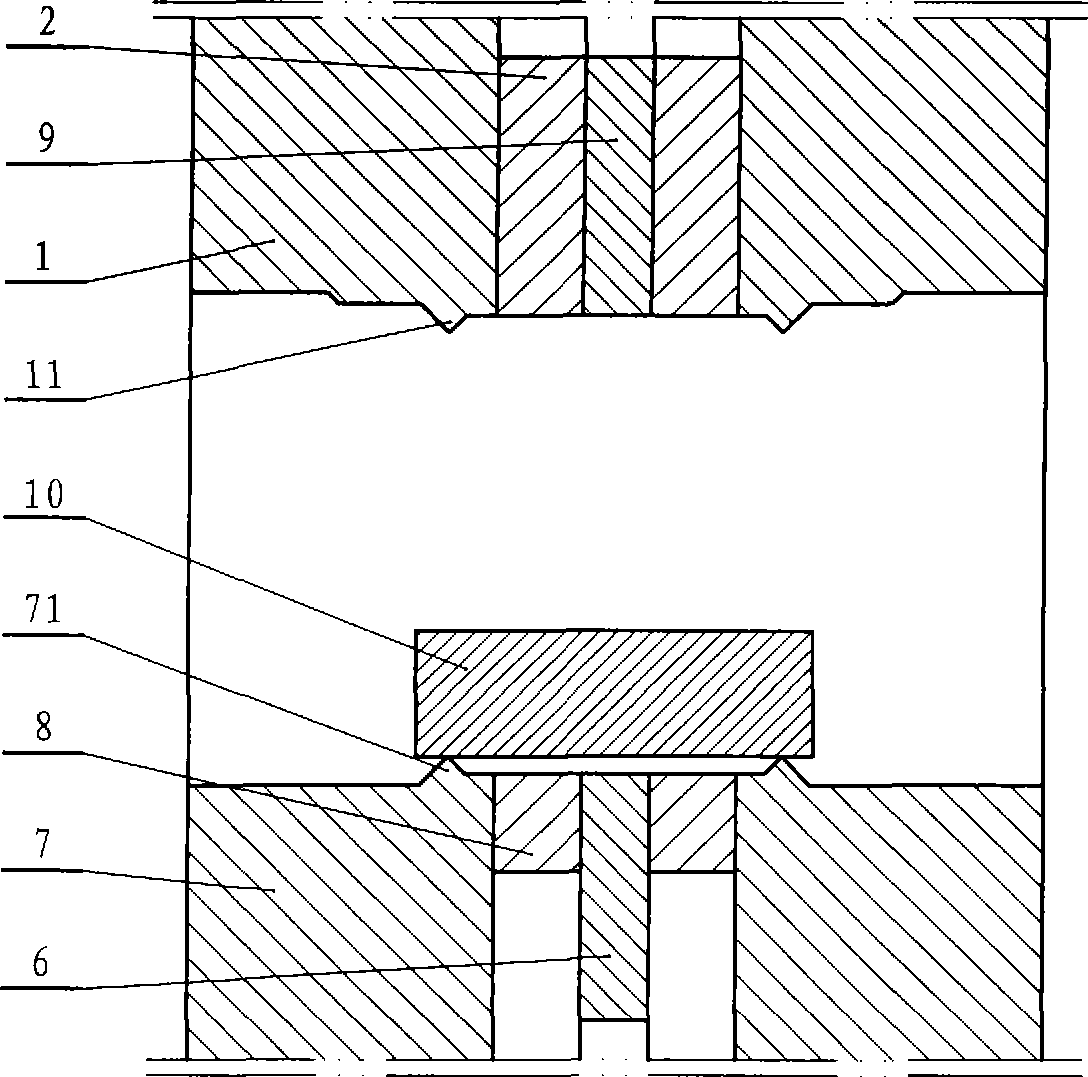

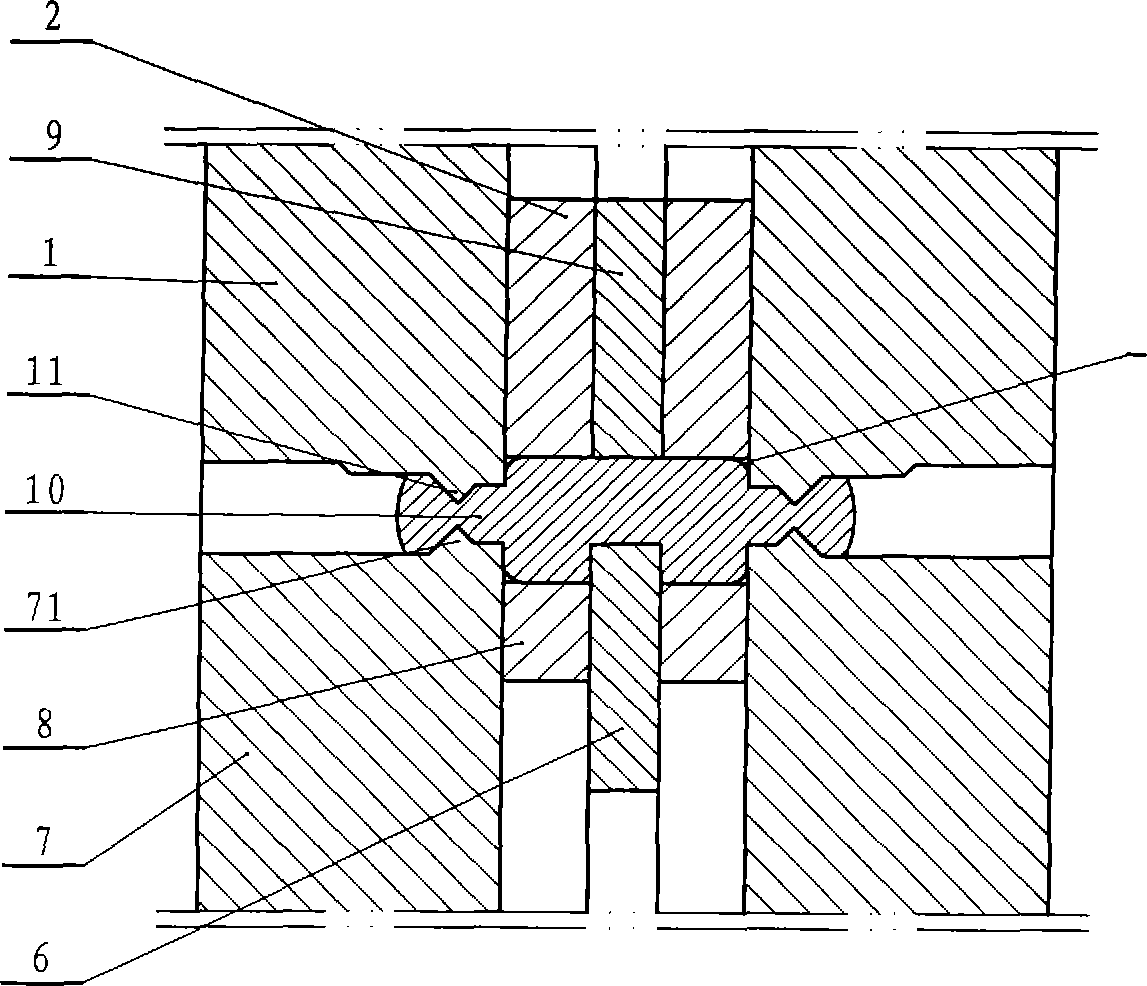

Closed extruding fine blanking die based on floating female die structure

The invention provides a closed extruding fine blanking die based on a floating female die structure. The die is provided with a floating auxiliary female die, can realize early extrusion closure and fine blanking required by a closed extruding fine blanking process, can meet the process requirement of keeping two subsequent forces constant in the process, a closing force is obtained from a fine blanking piston of equipment through a force transmission rod, and the closing force and an anti-jacking force are easy to adjust. The die can be used manufacturing parts with low plasticity and large thickness, ensures high section quality and dimensional accuracy, and is convenient to popularize and apply in the fine blanking process.

Owner:CHONGQING UNIV OF TECH

A high-efficiency and precise low-stress blanking method for radial breaking

The invention discloses a radially-severing efficient and precise low-stress discharging method, and belongs to the technical field of intelligent manufacturing. Four sets of discharging units symmetrically distributed in the circumferential direction of bars sequentially apply loads to the bars at intervals. Each set of discharging unit comprises discharging clamps arranged at the ends of a firsthydraulic oil cylinder and a second hydraulic oil cylinder, and thrust hammerheads fixed to the ends of piston rods of a third hydraulic oil cylinder and a fourth hydraulic oil cylinder. The discharging clamps and the thrust hammerheads are oppositely arranged, when the bars are severed, after the thrust hammerheads jack the bars, the discharging clamps apply loads to the two ends of V-shaped grooves of the bars simultaneously, the discharging clamps and the thrust hammerheads in the four sets of discharging units cooperate to generate alternating force at the positions of the V-shaped grooves, under the acting force, cracks are produced at the positions of the V-shaped grooves, it is guaranteed that the cracks circumferentially propagate along the sections of the sharp ends of the V-shaped grooves gradually towards circle centers, and the beneficial effects that the efficiency is high, the fatigue crack propagation region area is large, and the fracture surface quality is high are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

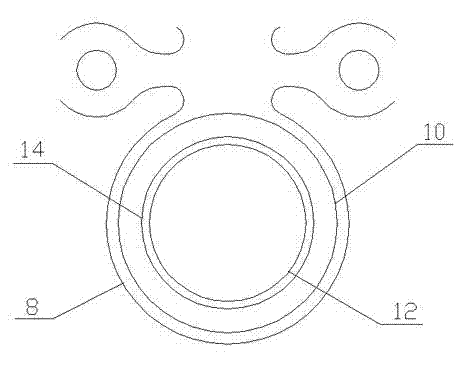

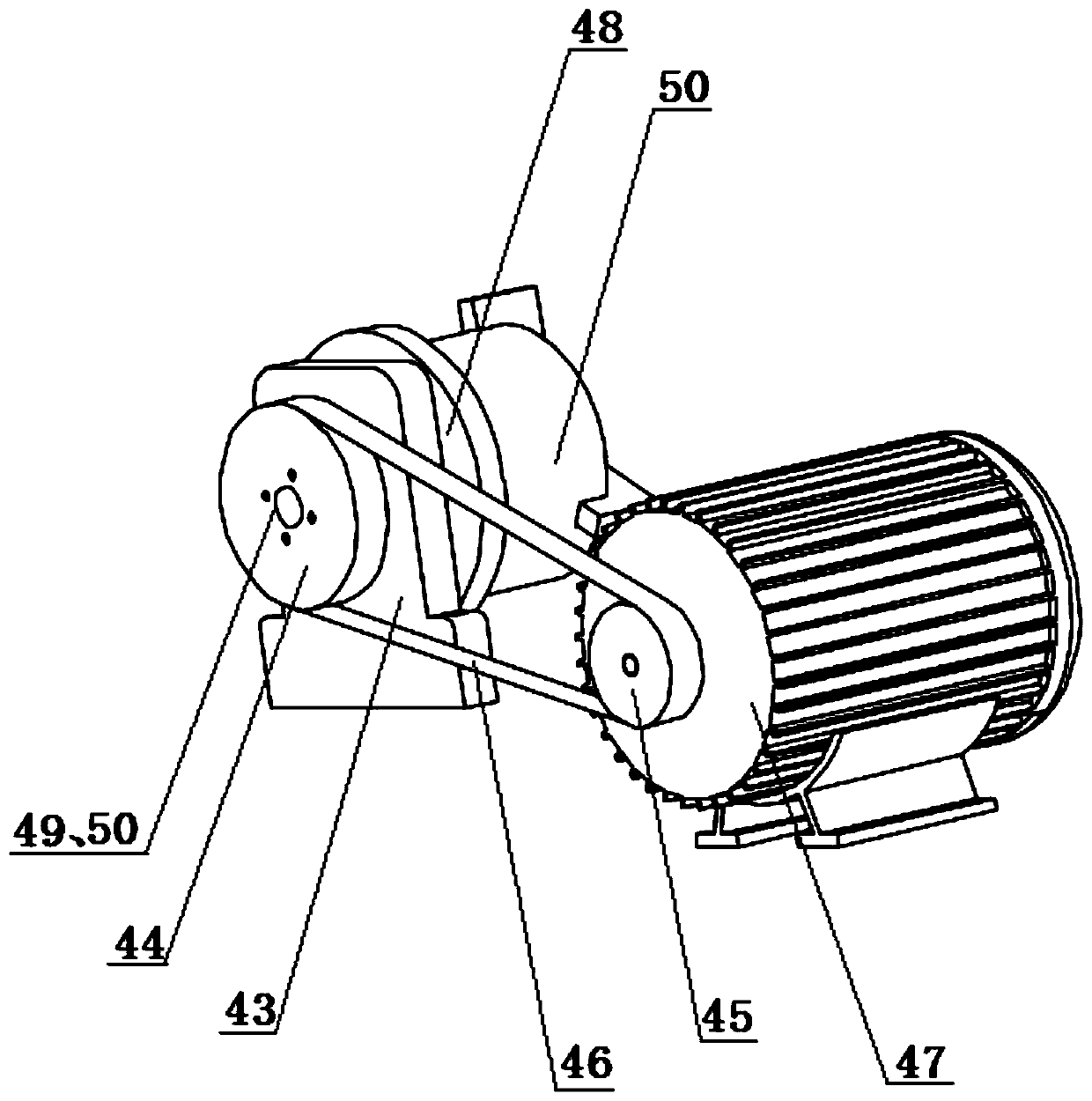

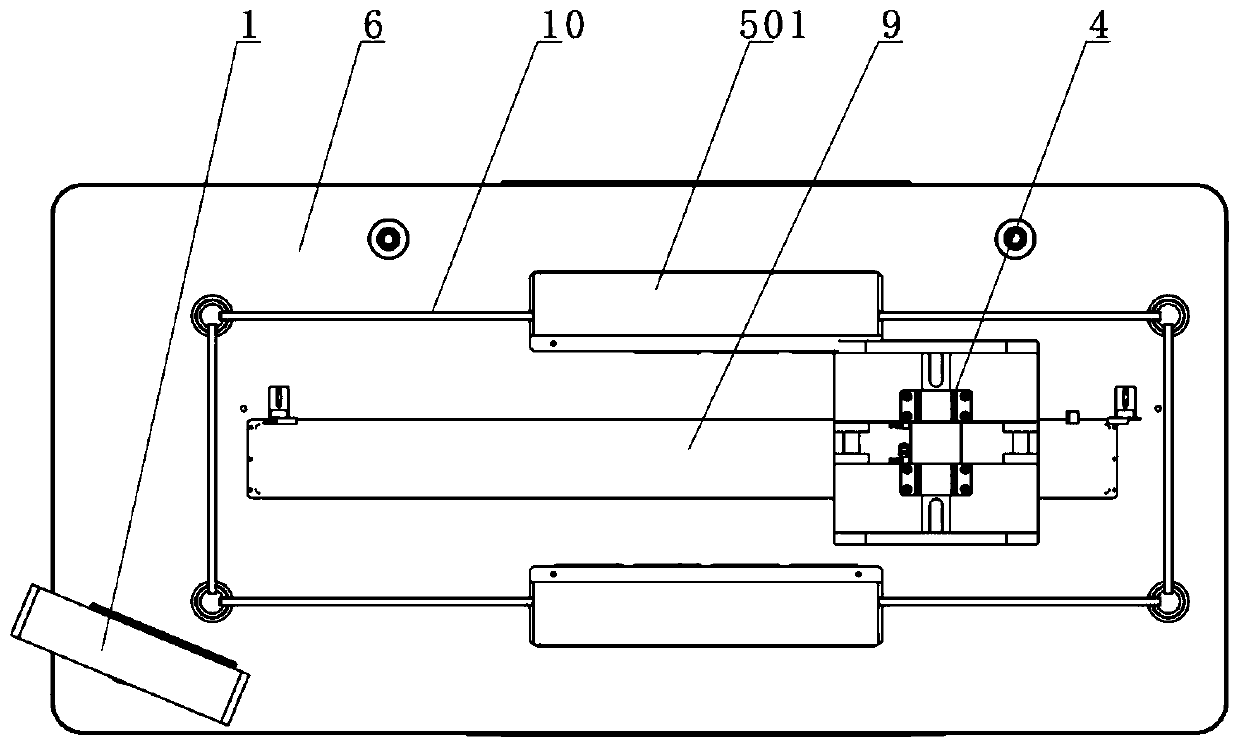

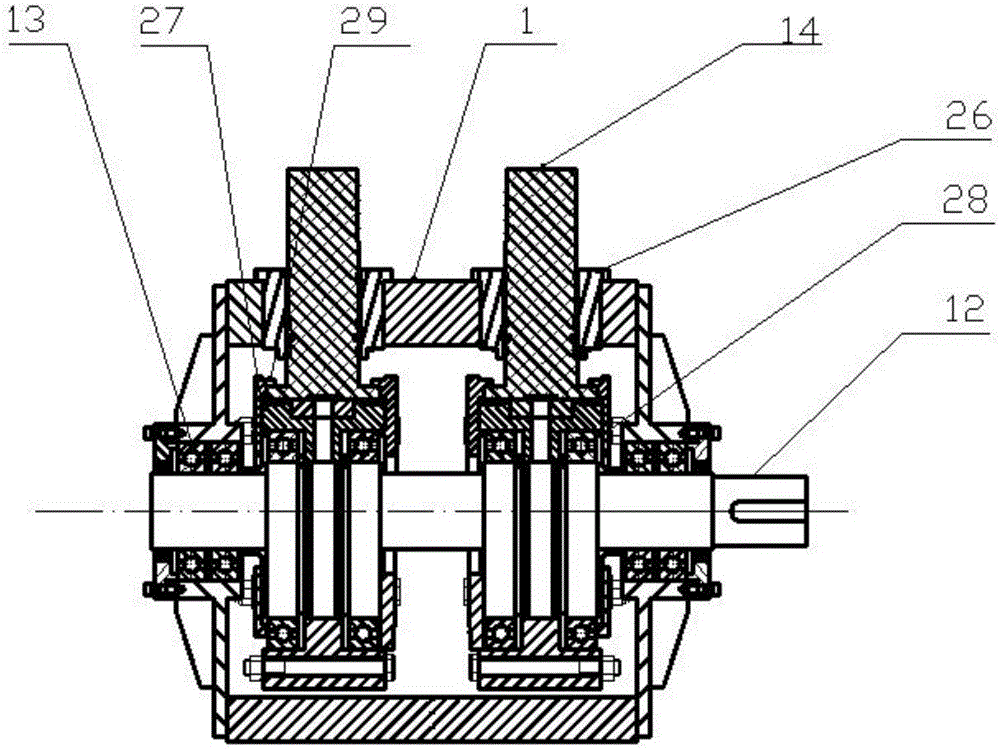

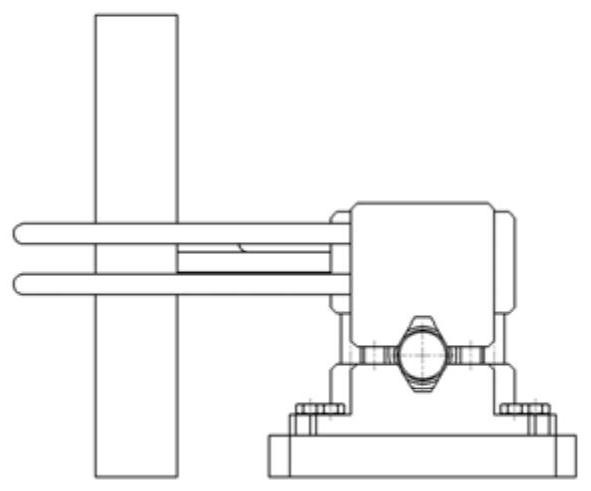

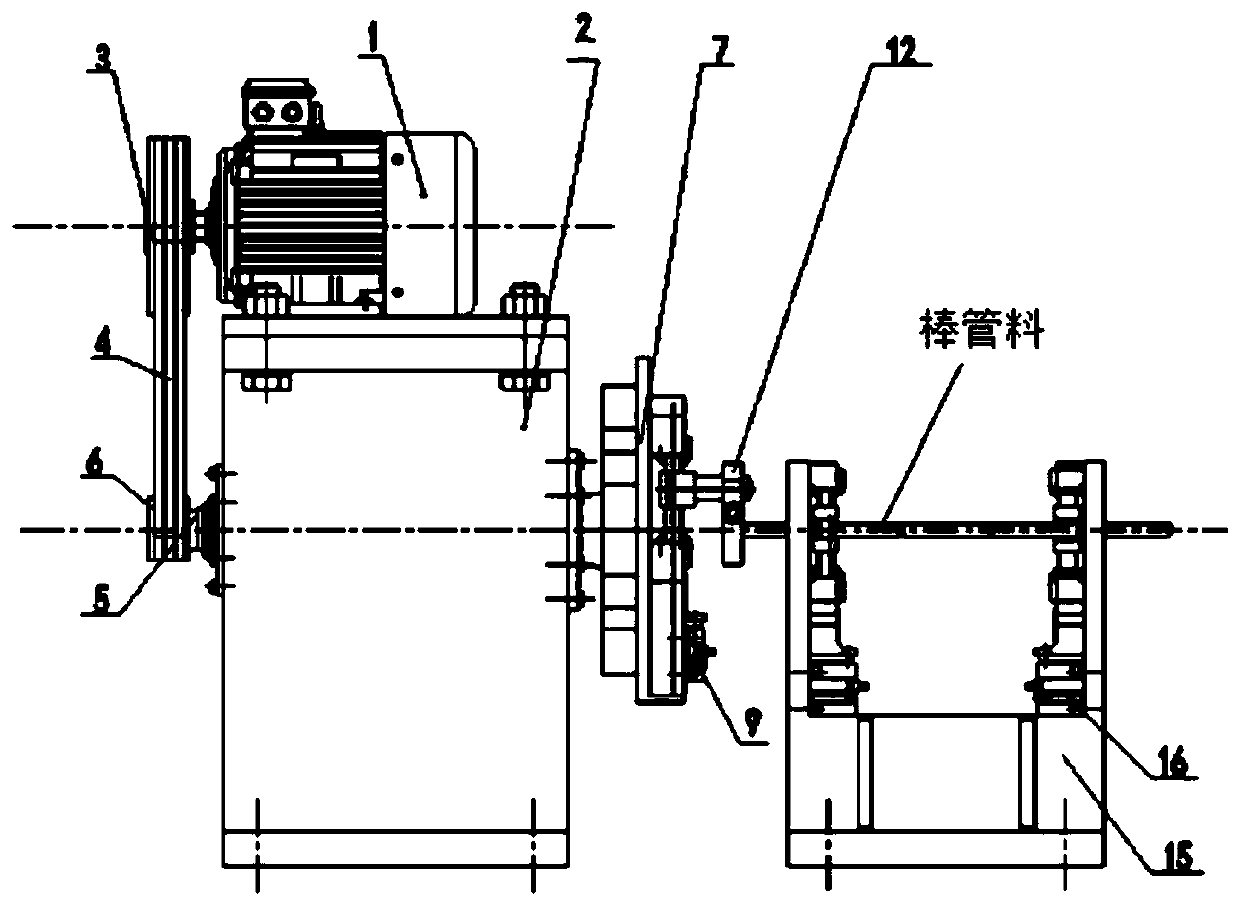

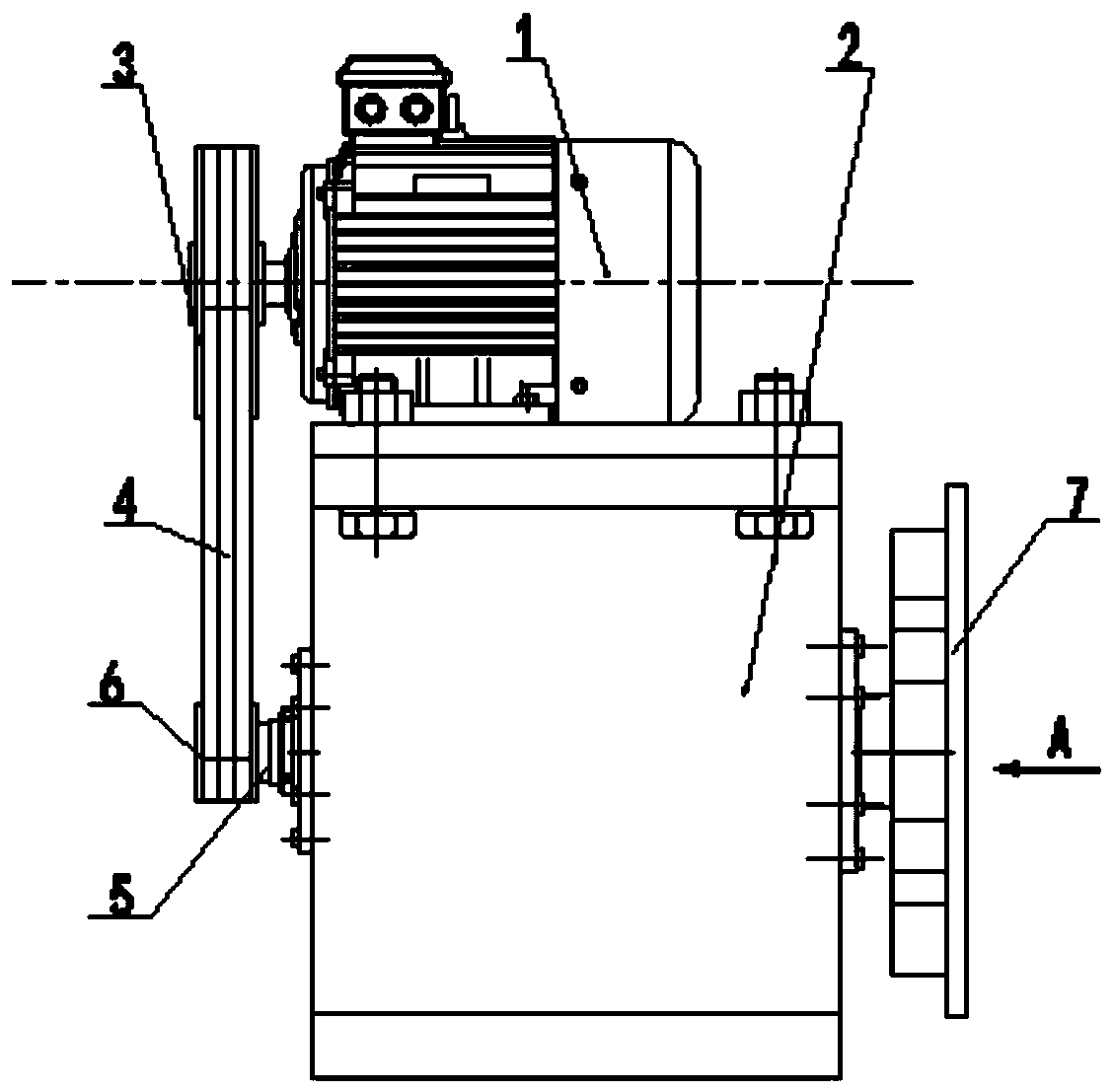

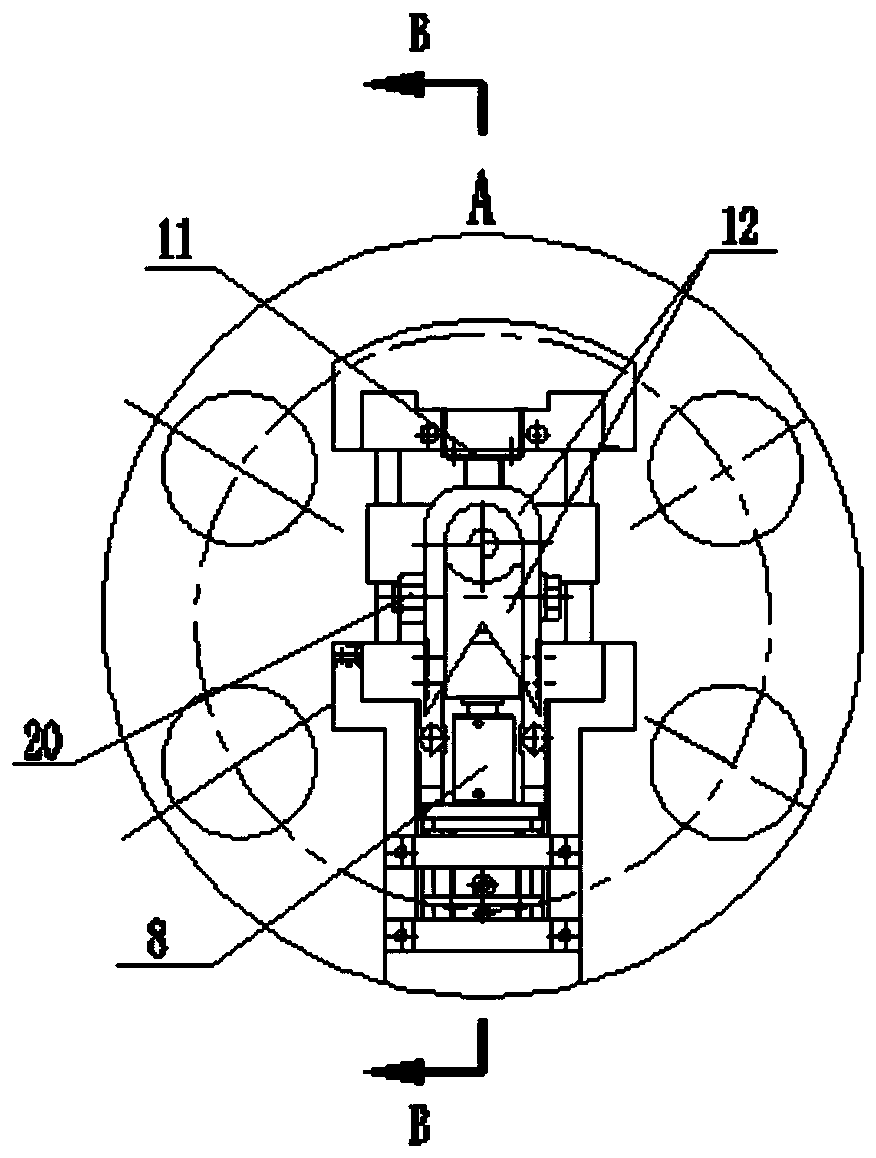

A pneumatic controllable radial impact metal rod pipe material precision cutting machine

InactiveCN105643000BHigh geometric accuracyGood cross section qualityNibbling shearing machinesBending momentImpact hammer

The invention relates to a pneumatic type controllable radial impact precision blanking machine for metal bar and tube materials. The pneumatic type controllable radial impact precision blanking machine comprises a metal bar and tube material clamping device, a power transmission device and a load application device. The metal bar and tube material clamping device comprises a bar and tube material sleeve used for fixing the metal bar and tube materials. The power transmission device comprises an alternating current servo motor and a revolving connecting plate driven by the alternating current servo motor. The load application device comprises a rotary cylinder which is connected to the revolving connecting plate and is of a symmetrical structure. The alternating current servo motor is used for driving the rotary cylinder of the symmetrical structure, so that loading is carried out in the circumferential direction of the metal bar and tube materials in a certain load sequence, and precision blanking of the metal bar and tube materials is finished under the cyclic action of bending moment loads. By adjusting the rotation angle and rotation speed of the alternating current servo motor and the air inlet and outlet sequence and air inlet amount of the rotary cylinder, an impact hammer in the rotary cylinder can accurately and rapidly apply constant amplitude impact loads to the specific loading position. The whole pneumatic type controllable radial impact precision blanking machine for the metal bar and tube materials has the advantages of being simple in structure, good in stability, high in controllability and the like.

Owner:XIAN UNIV OF SCI & TECH

A pneumatically controlled double-stage shear precision separation device

InactiveCN109530784BGood cross section qualityReduce plastic deformationTube shearing machinesNibbling shearing machinesEngineeringMechanical engineering

Owner:XIAN UNIV OF SCI & TECH

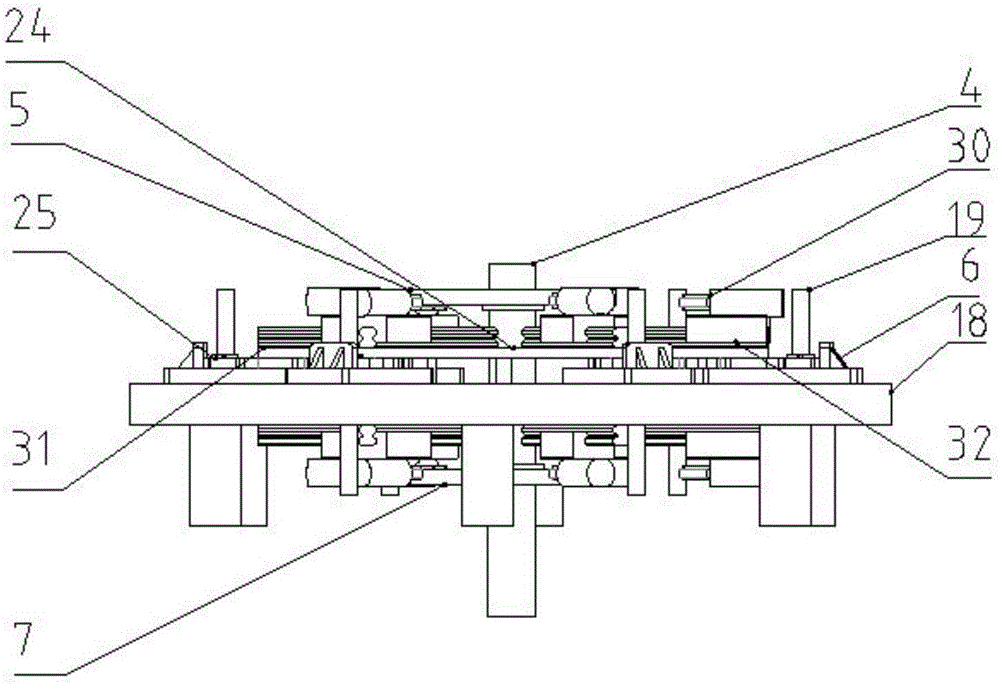

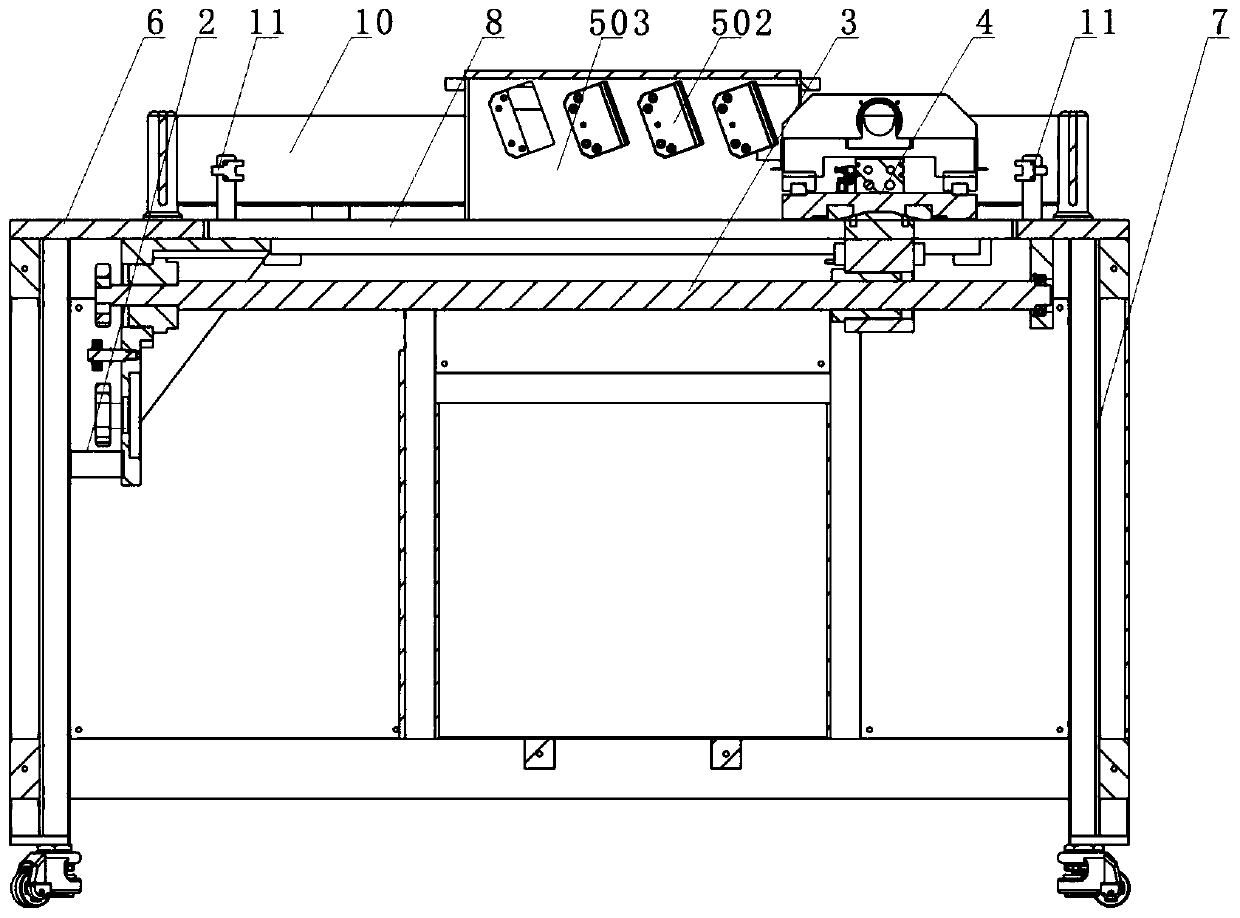

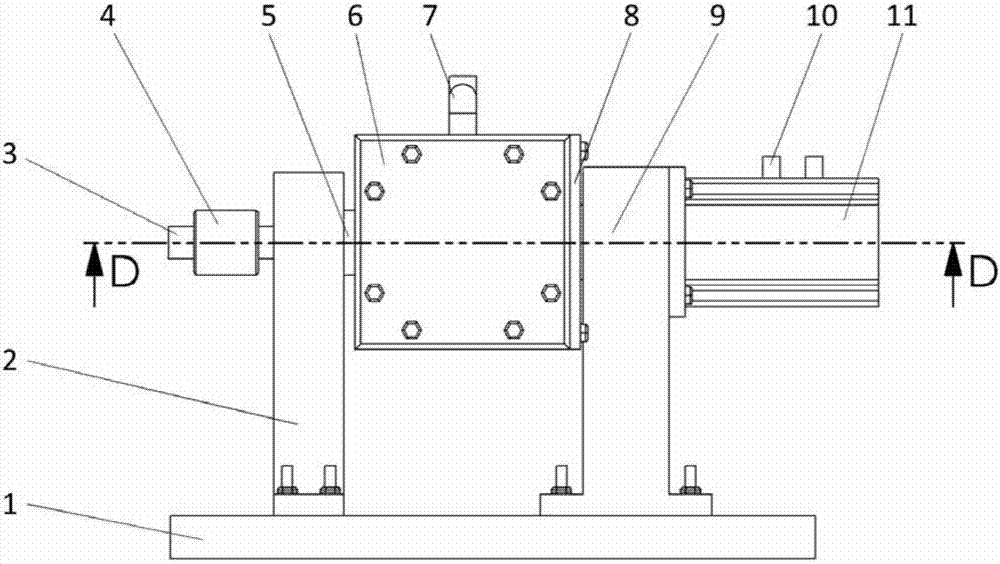

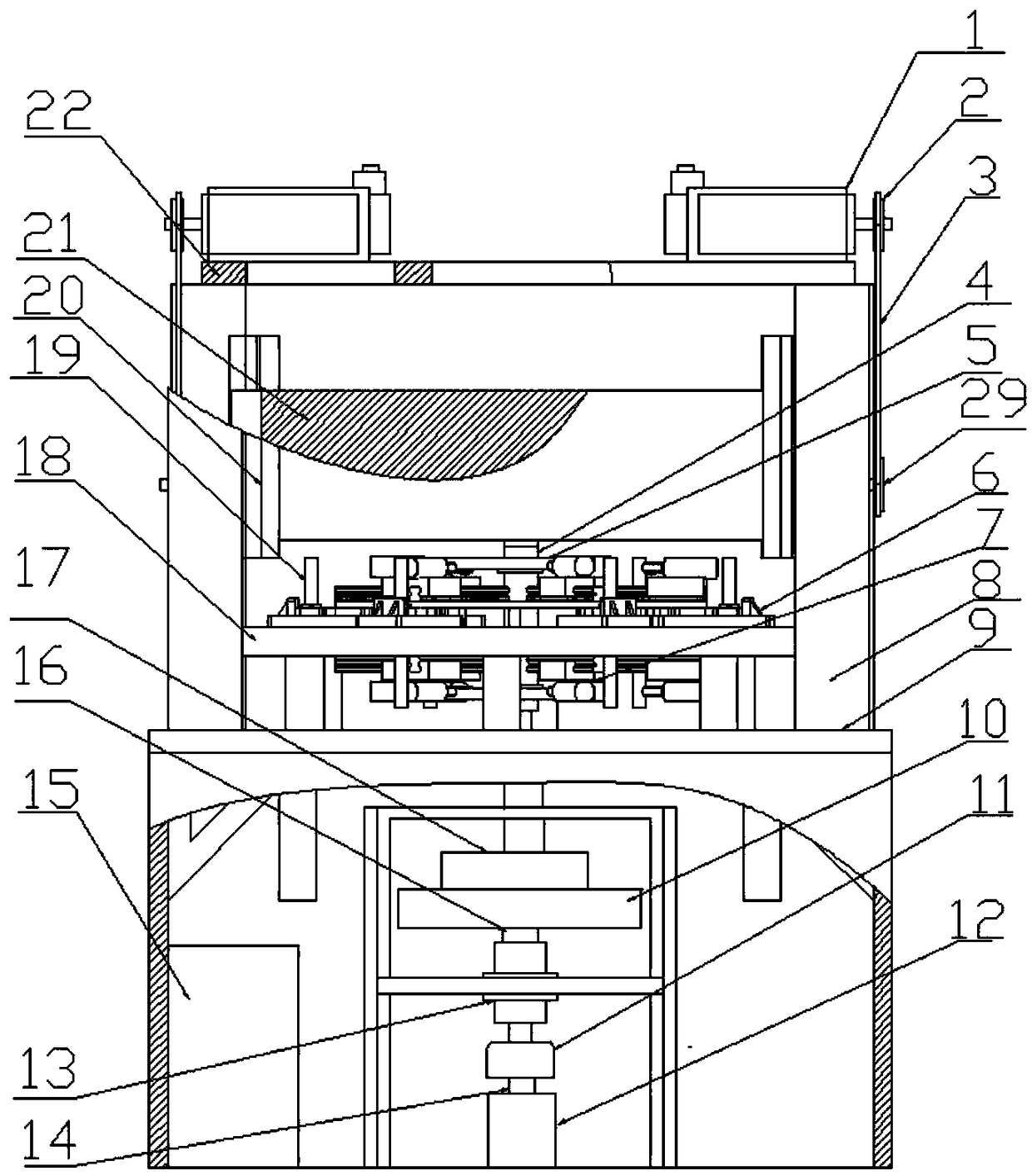

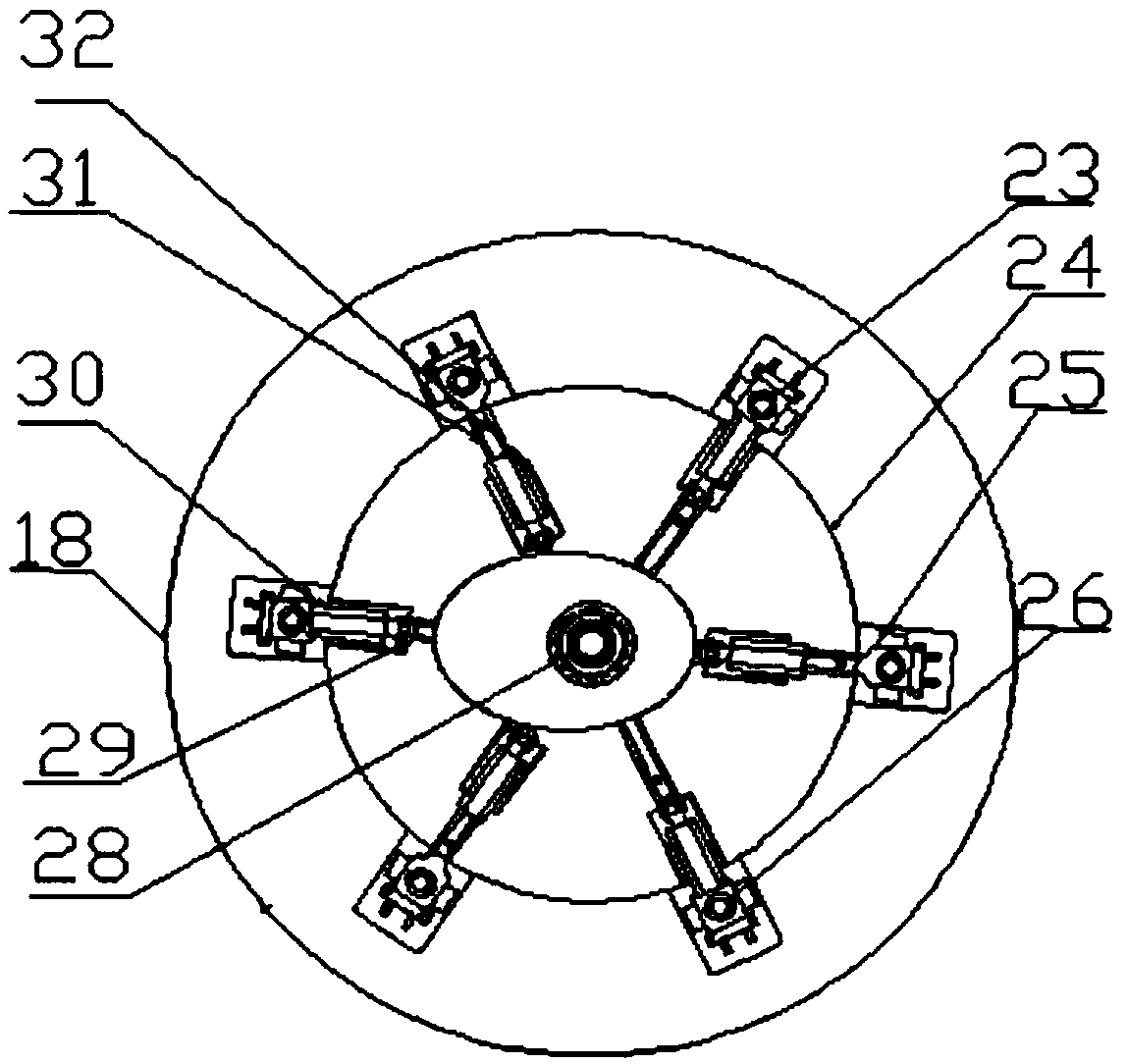

A Fatigue Fracture Blanking Machine for Circumferential Cyclic Loading of Workpieces with Unmoved Fatigue Loads

ActiveCN108043946BSatisfy the blanking requirementsGood cross section qualityMetal-working feeding devicesPositioning devicesFatigue loadingMotor drive

The invention discloses a fatigue break feeding machine for fixed workpiece fatigue load circumferential cyclic loading. A loading frequency regulating and controlling mechanism comprises a main shaftand a rotating chuck connected with the main shaft; a fatigue load loading mechanism comprises a first servo motor and a lead screw which are arranged on the rotating chuck, the first servo motor drives the lead screw to rotate, a nut is vertically installed on the lead screw, and a feeding die is movably installed on the nut; a workpiece clamping mechanism comprises a feeding opening and a discharging opening, the locations of the feeding opening and the discharging opening are separately provided with clamping assemblies, second servo motors of the clamping assemblies drive two-way lead screws to rotate, and each two-way lead screw is provided with two clamping pieces. A fatigue break principle is used, so that multiple fatigue crack sources are generated at the prefabricated stress gaps of rod and tube materials to enable the crack to quickly extend, and quick feeding of the rod and tube materials is achieved; and sections are kept smooth, end portions are free of deformation, wherein the fatigue load loading mechanism controls the displacement of the lead screws by the servo motors, and radial real-time adjustment of displacement amount is achieved.

Owner:XIAN UNIV OF TECH

Automatic down-cutting device for optical glass sheet

ActiveCN106277739BGood cross section qualityEasy to controlGlass transportation apparatusGlass severing apparatusBall screwEngineering

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Method for cutting polarizing plate and polarizing plate cut using same

ActiveUS10821553B2Good cross section qualityExcellent in appearance quality and optical characteristicPolarising elementsWelding/soldering/cutting articlesLight beamLaser cutting

A method of cutting a polarizing plate by using a laser, and a polarizing plate cut using the same. A beam shape of the laser is configured to have an elliptical shape and a major axis of the elliptical shape parallel to a cutting direction to provide excellent cross-sectional quality and improved productivity.

Owner:SHANJIN OPTOELECTRONICS (NANJING) CO LTD

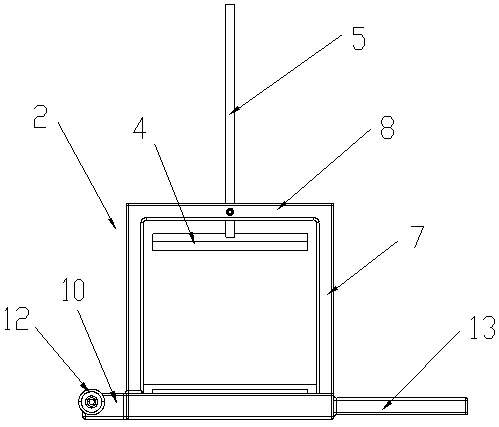

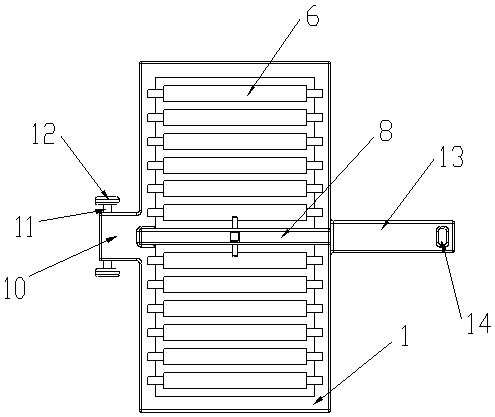

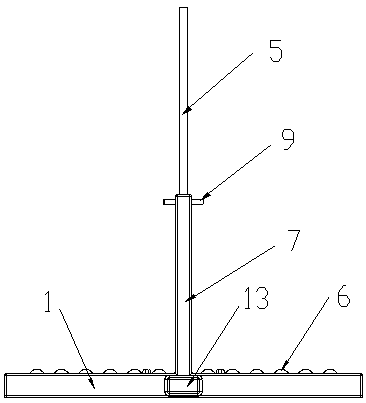

Brick cutter for construction site and method for cutting bricks through brick cutter

InactiveCN109421169AEasy to cutGood cross section qualityStone-like material working toolsBrickVertical plane

The invention discloses a brick cutter for a construction site and a method for cutting bricks through the brick cutter. The brick cutter comprises a base (1) used for containing the bricks, a supporting framework (2) arranged on the base (1), a lower tool (3) and an upper tool (4); the lower tool (3) is detachably installed on the base (1), and an edge of the lower tool (3) is upward; a tool mounting frame (5) is arranged on the top of the supporting framework (2) and forms a vertical movable pair with the supporting framework (2); the upper tool (4) is installed at the bottom of the tool mounting frame (5), and an edge of the upper tool (4) is downward; and the upper tool (4) and the lower tool (3) are parallel and located in the same vertical plane. The brick cutter has the beneficial effects that the brick cutter can conveniently cut the bricks, the quality of fracture surfaces of the cut bricks is good, and meanwhile, the brick cutter has the advantages of being simple in structure and convenient to operate.

Owner:南京舜力建设工程有限公司

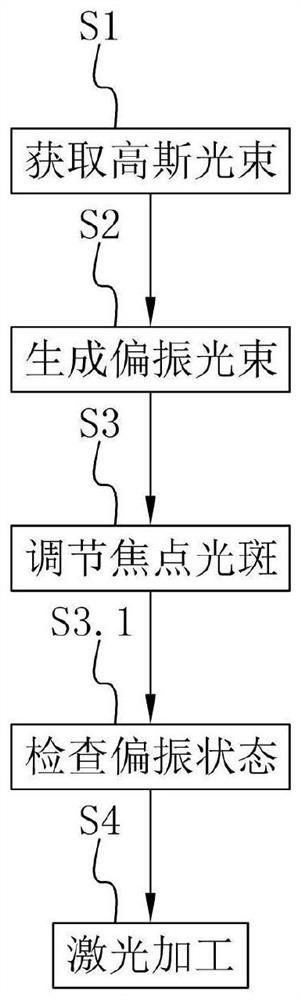

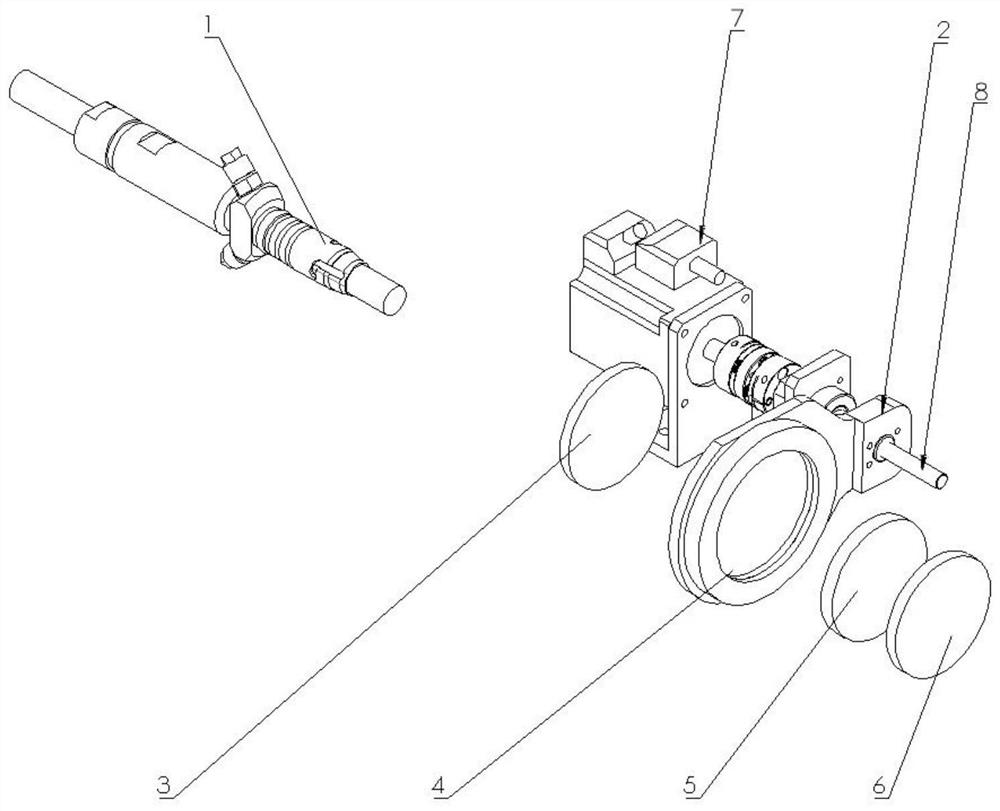

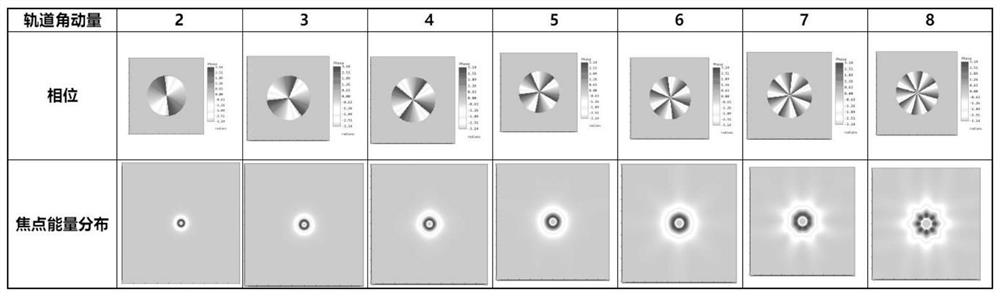

Laser processing method of vortex light beam

PendingCN114850660AImprove cutting efficiencyGood cross section qualityLaser beam welding apparatusLaser processingGaussian beam

According to the vortex beam laser processing method, laser processing equipment is adopted, and the laser processing equipment comprises a light source element, a collimating lens element, a vortex phase plate, an axicon and a Fourier lens. The light source element, the collimating lens element, the vortex phase plate, the axicon and the Fourier lens are sequentially arranged along the light beam propagation direction; the laser processing method for the vortex light velocity comprises the following steps of obtaining a Gaussian beam, generating a vortex beam, adjusting a focus spot and performing laser processing. The laser cutting device has the beneficial effects that laser cutting machining is conducted through the vortex light beams polarized in the radial direction and the angular direction, the cutting efficiency can be effectively improved, better section quality can be obtained, and the laser cutting device can be suitable for metal machining with the high depth ratio.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

A Punching Method for Improving Sectional Quality of Stamping Parts

ActiveCN107234164BGood cross section qualityReduce the overall heightShaping toolsPunchingEngineering

The invention relates to the technical field of metal stamping machining, in particular to a punching method for improving the sectional quality of a stamping part. The specific treatment steps include that before punching of the stamping part, the stamping position is determined; a high temperature and high pressure steam spraying gun is used for performing spraying treatment on a stamping position point, the work pressure of the high temperature and high pressure steam spraying gun is 350 bar, and the steam temperature is 150-160 DEG C; and after spraying treatment ends, punching is performed immediately, during punching, at the instant that the stamping part makes contact with a cutting edge, modifying coconut oil is fast sprayed onto the contact face of the punching face and the cutting edge, and liquid nitrogen is fast sprayed onto the contact face of the punching face and the cutting edge at the instant that the stamping part breaks away from the cutting edge. By means of the punching method for improving the sectional quality of the stamping part, the sectional quality of the stamping part obtained by means of final punching is good, the burr zone height is extremely small, the euphotic zone area is large and is 80% or above, and the fillet zone area is small.

Owner:青岛润众汽车配件有限公司

Opposite teeth extruding type fine-blanking die and fine-blanking method adopting same

InactiveCN102039346BConsistent valueEnsure a strong three-dimensional compressive stress stateShaping toolsPerforating toolsEngineeringContact line

Owner:CHONGQING UNIV OF TECH

Radial cam loading and low cycle fatigue cracking equipment for split connecting rod cracking

ActiveCN106826149BAvoid the problem of excessive loading speed at one timeNo obvious plastic deformationEngineeringCam

Radial cam loading and low-cycle fatigue splitting equipment for subdivision-type connecting rod fracture splitting comprises a base. The left side and the right side of the base are fixedly connected with four vertical columns. A cross beam is fixedly connected with the upper sides of the four vertical columns. Servo motors are bilaterally and symmetrically installed on the cross beam. The servo motors are connected with a cam plate lifting mechanism installed on the upper portion of a spline shaft. A motor decelerating power mechanism is connected with the lower portion of the spline shaft. The middle of the spline shaft is connected with a main working table. An upper end cam plate and a corresponding lower end cam plate of the main working table impact the upper end and the lower end of a core rod simultaneously, so that a connecting rod large head hole with a prefabricated fracture splitting groove is loaded repeatedly, and low-stress fatigue separating of the connecting rod large end and a connecting rod body is completed. The radial cam loading and low-cycle fatigue splitting equipment for subdivision-type connecting rod fracture splitting has the advantages of being environmentally friendly, energy saving, high in machining efficiency, wide in application range and good in fracture surface quality.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com