Brick cutter for construction site and method for cutting bricks through brick cutter

A construction site and brick cutting machine technology, which is applied in the field of brick cutting machines for construction sites, can solve the problems of poor section shape and difficulty in cutting bricks, etc., and achieve the effects of good section quality, convenient cutting, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

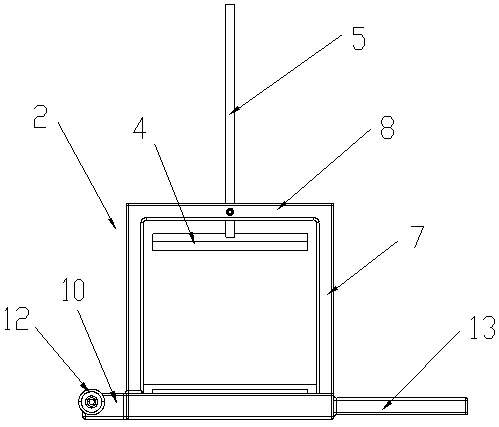

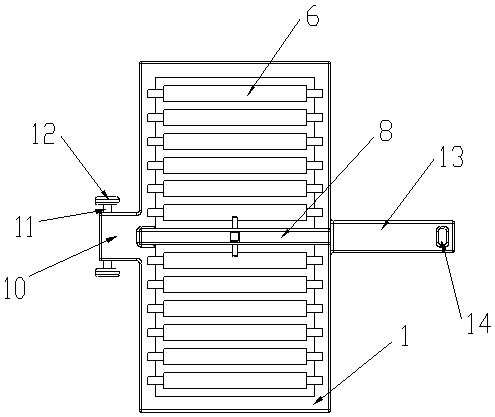

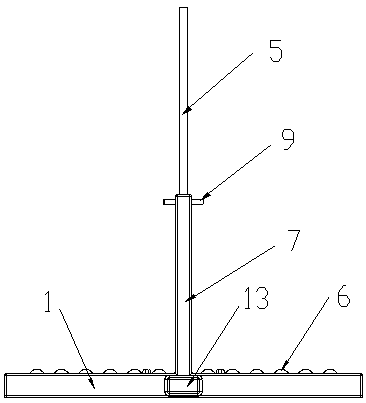

[0029] Such as Figure 1-Figure 4 The shown brick cutting machine for a construction site includes a base 1 for placing bricks, a support frame 2 arranged on the base 1, a lower cutter 3 and an upper cutter 4, and the lower cutter 3 is detachably installed on the base 1 and the edge of the lower cutter 3 is upward, the specific detachable installation method is to open an installation groove (not shown in the figure) on the base 1, and place the lower cutter 3 in the installation groove. For example, it is preferable to place fillers such as pieces of paper in the installation groove to make the installation of the lower cutter 3 and the base 1 more firm. The top of the support frame 2 is provided with a cutter mounting frame 5, and the blade mounting frame 5 5 and the supporting frame 2 form a vertical moving pair, so that the tool mounting frame 5 can move up and down on the title frame 2, so that the upper tool 4 can move in the vertical direction, and the upward movement o...

Embodiment 2

[0036] The technical solution of the present embodiment adopts the method for cutting bricks with the brick cutting machine described in the first embodiment, and the method of the present embodiment specifically includes the following seven steps:

[0037] Step 1, place the brick cutter for the ground on the level ground.

[0038] Step 2, insert the positioning pin 9 into the second through hole and the fixing hole, fix the tool mounting frame 5 and the horizontal support frame 8, and keep the distance between the lower tool 3 and the upper tool 4 greater than the thickness of the brick.

[0039] Step 3, place one end of the brick to be cut on the conveying roller 6 from the side of the brick cutter.

[0040] Step 4, forcefully push the bricks to the other side of the brick cutter until the part where the bricks need to be cut is located directly under the upper knife 4 .

[0041] Step 5, pull out the positioning pin 9 from the second through hole and the fixing hole.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com