Patents

Literature

3062 results about "Abnormal shaped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

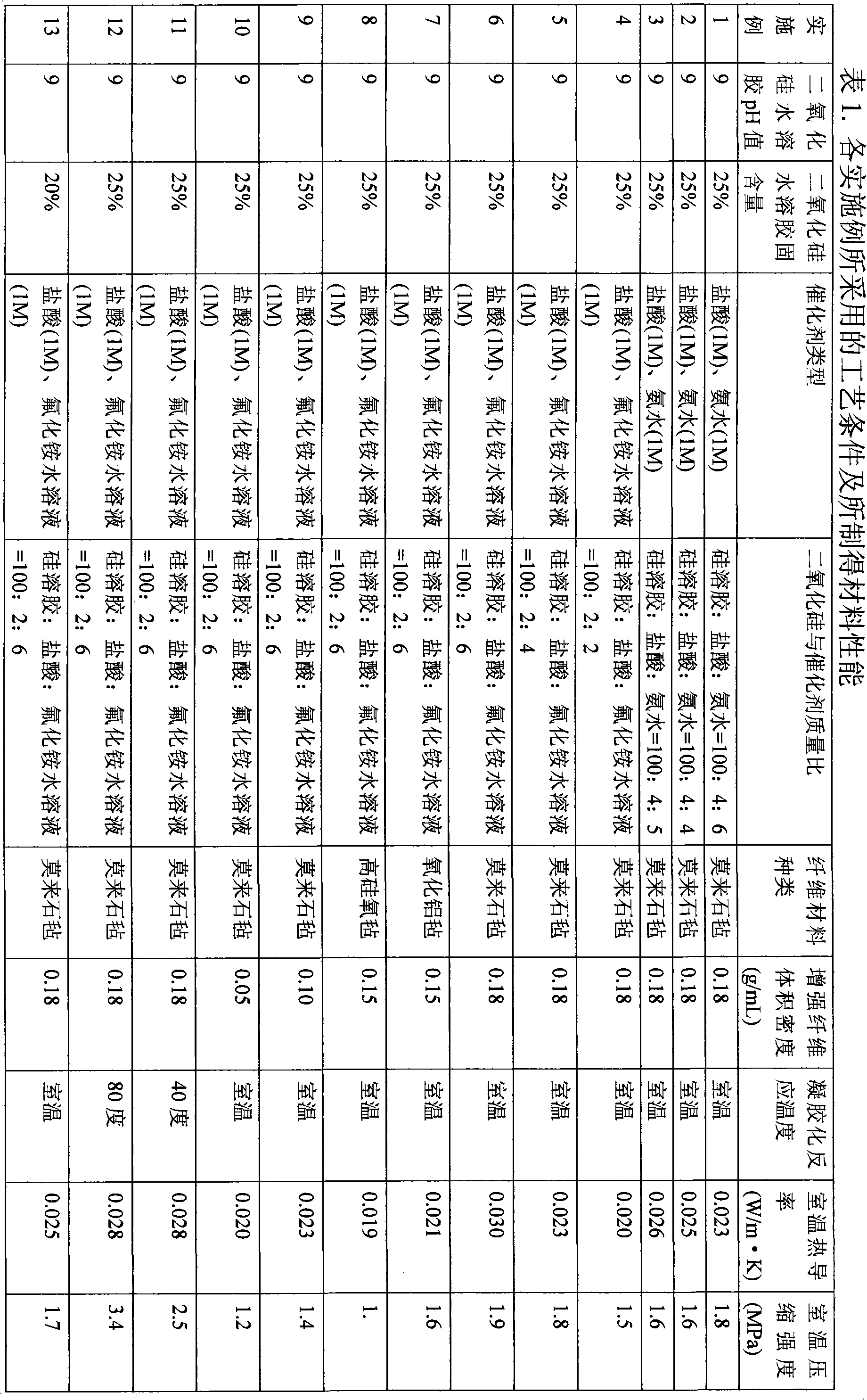

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

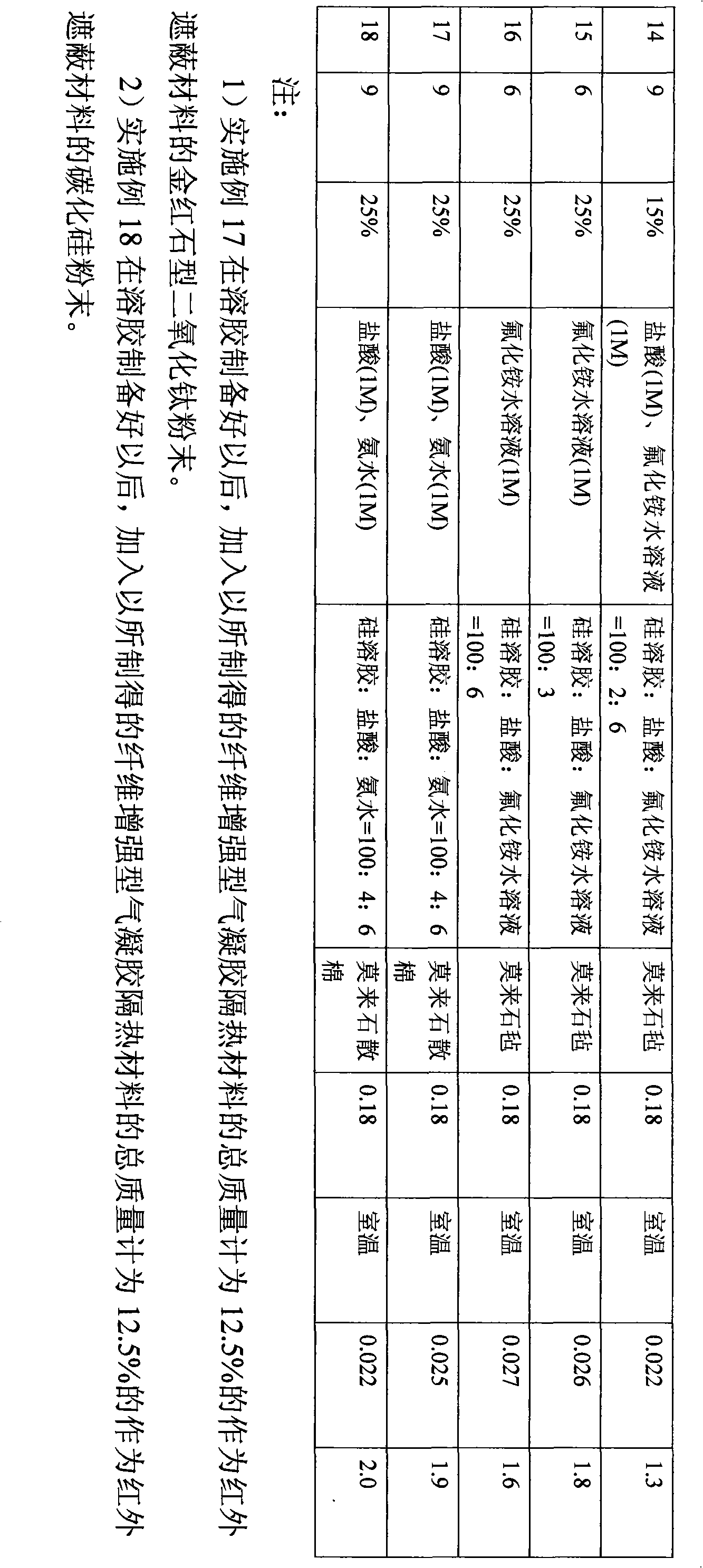

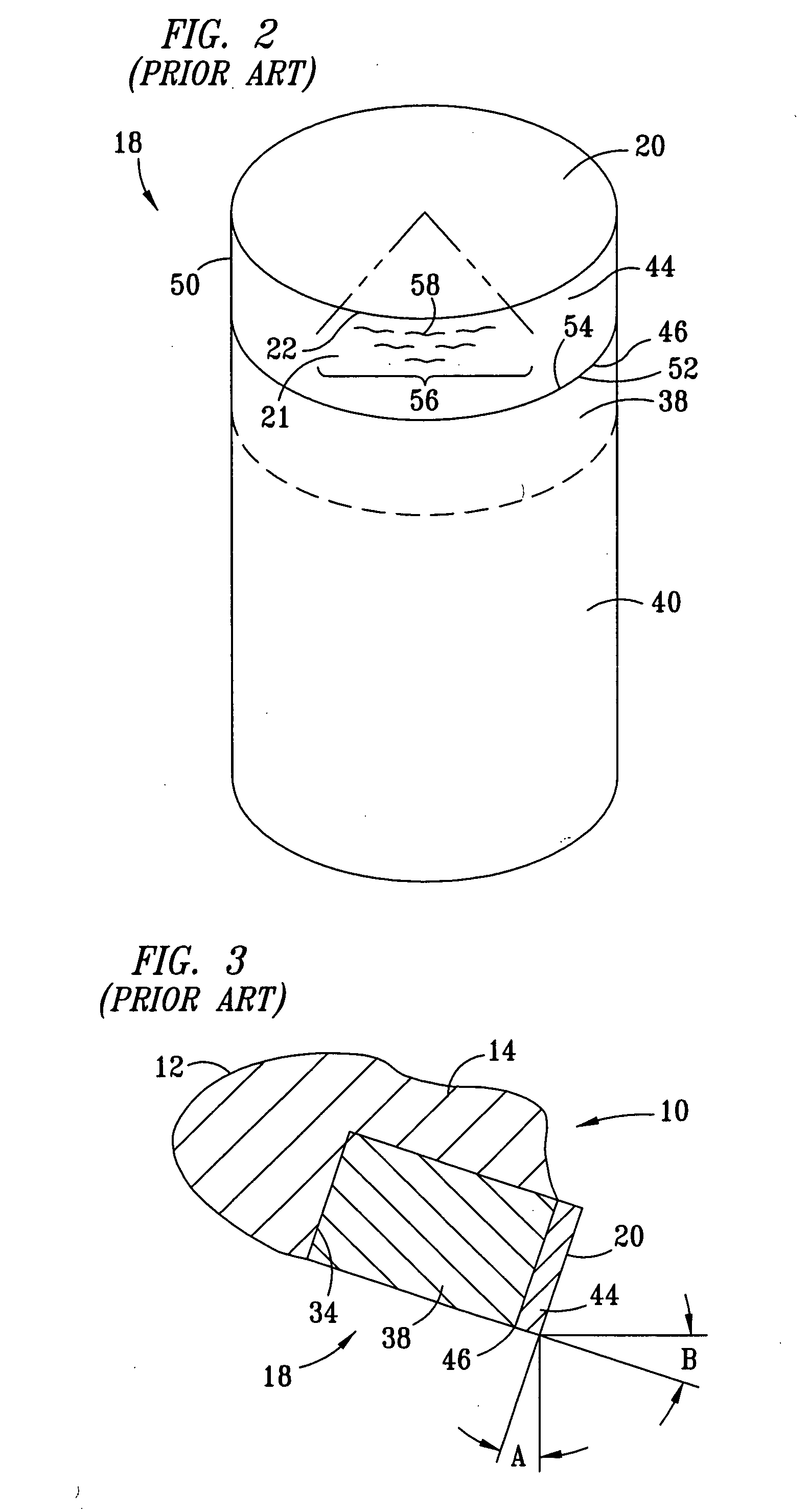

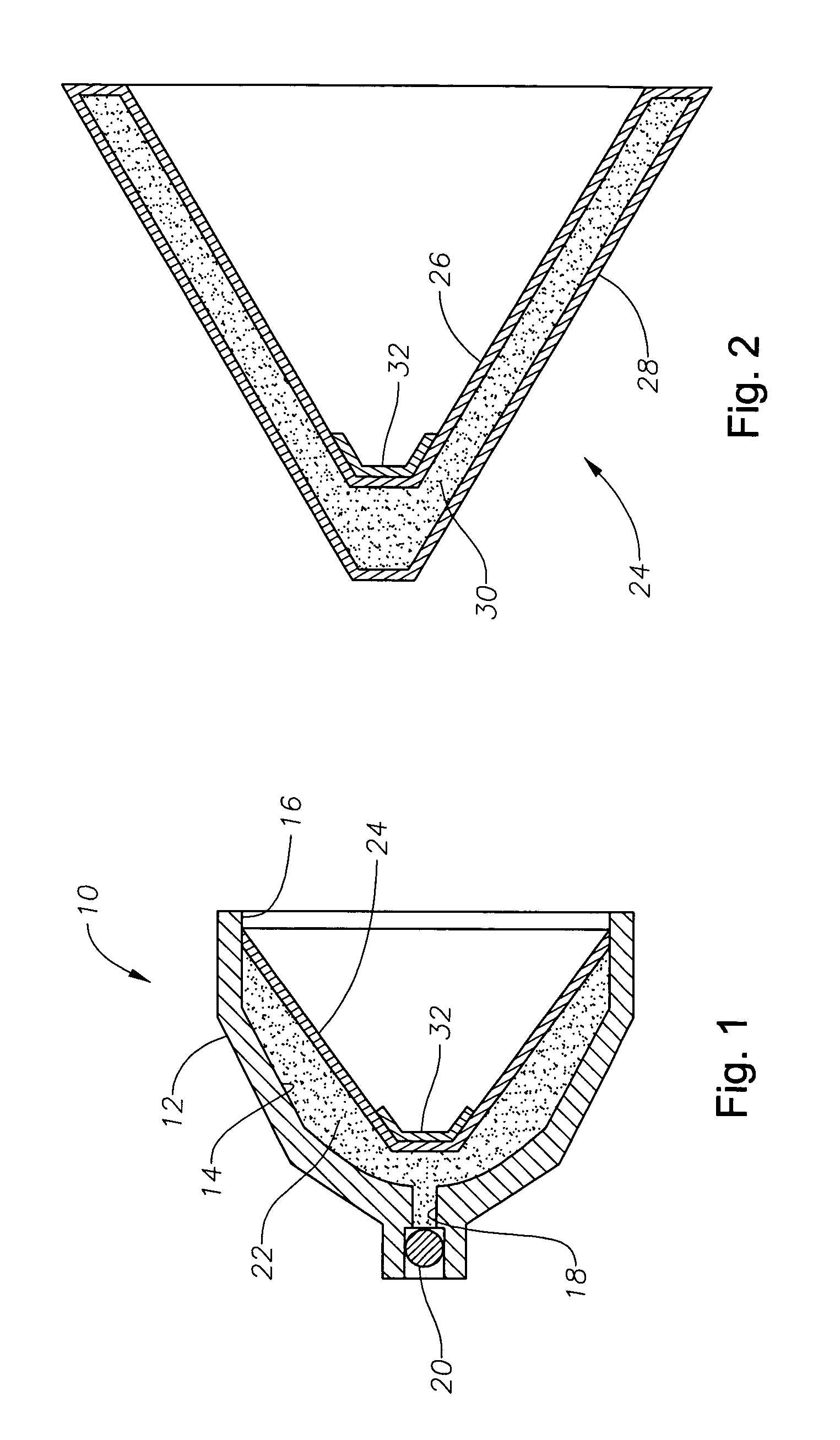

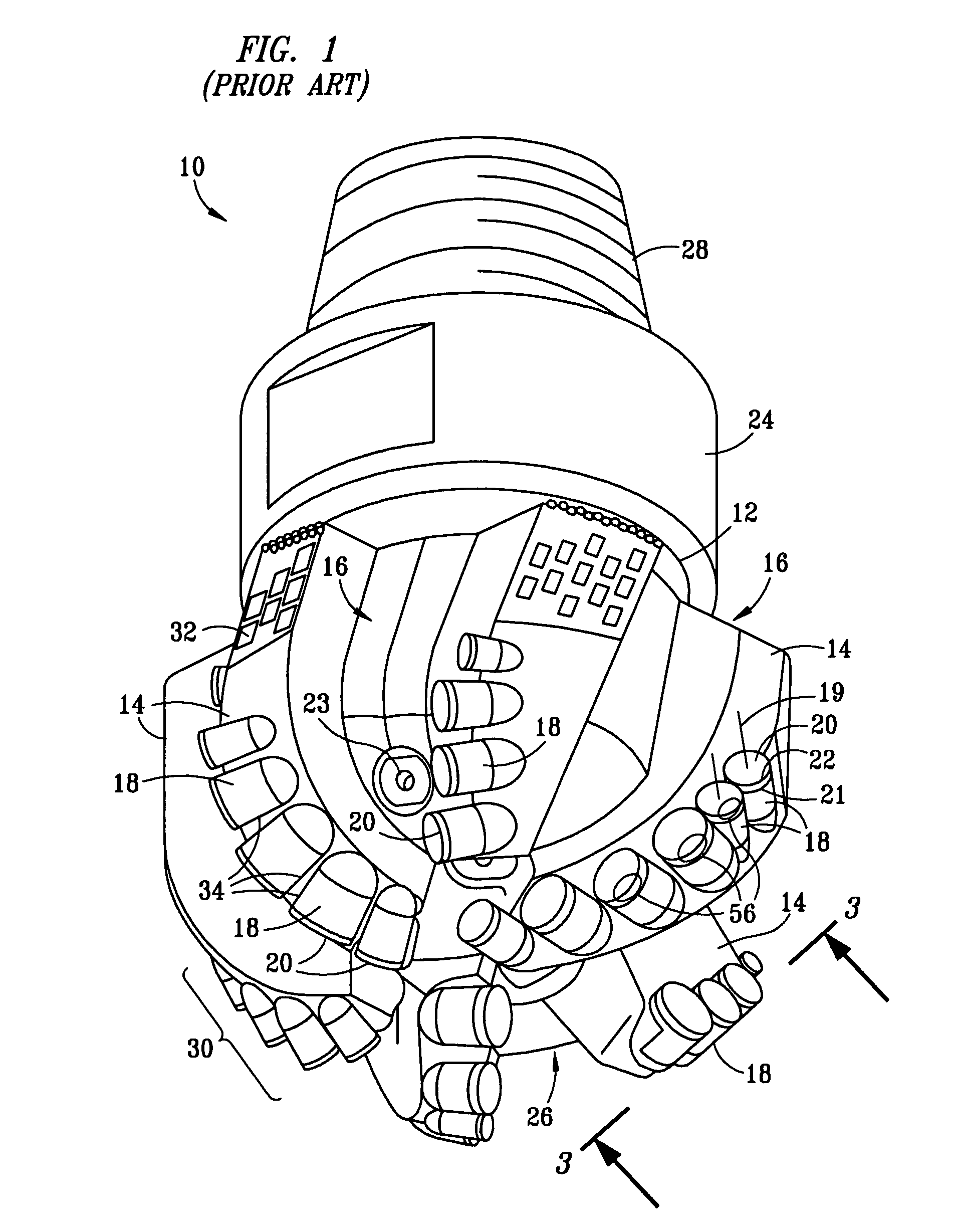

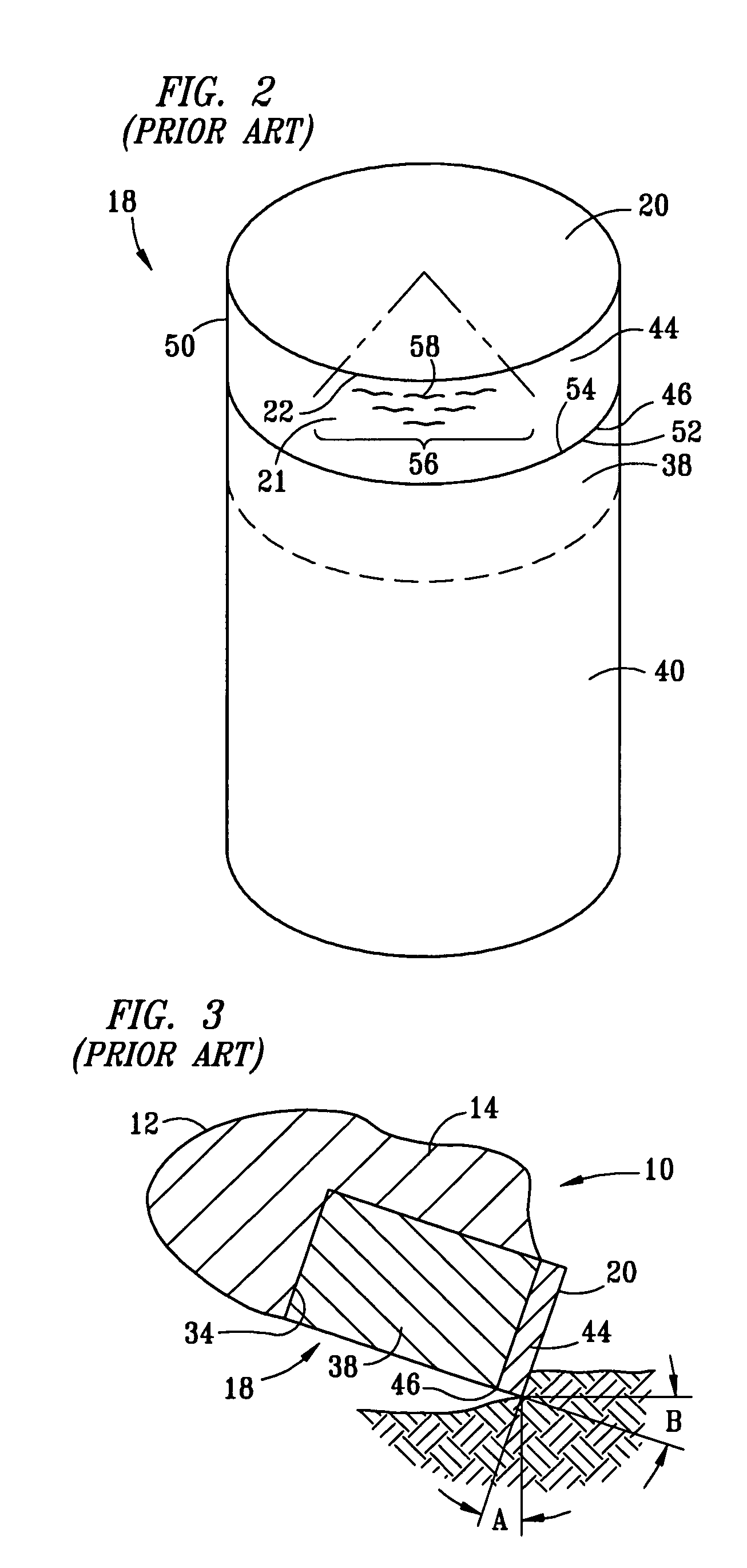

Shaped cutter surface

ActiveUS20050269139A1Reduce certain adverse consequenceSmooth curveDrill bitsConstructionsAbnormal shapedEngineering

A cutter for a drill bit used in a geological formation includes a shaped ultra hard working surface. The cutter with the shaped working surface is mounted on a drill bit to provide desired cutting characteristics. The shaped working surface provides varied cutting characteristics depending upon the shape, and the characteristics can vary depending upon the depth of the cut.

Owner:SMITH INT INC

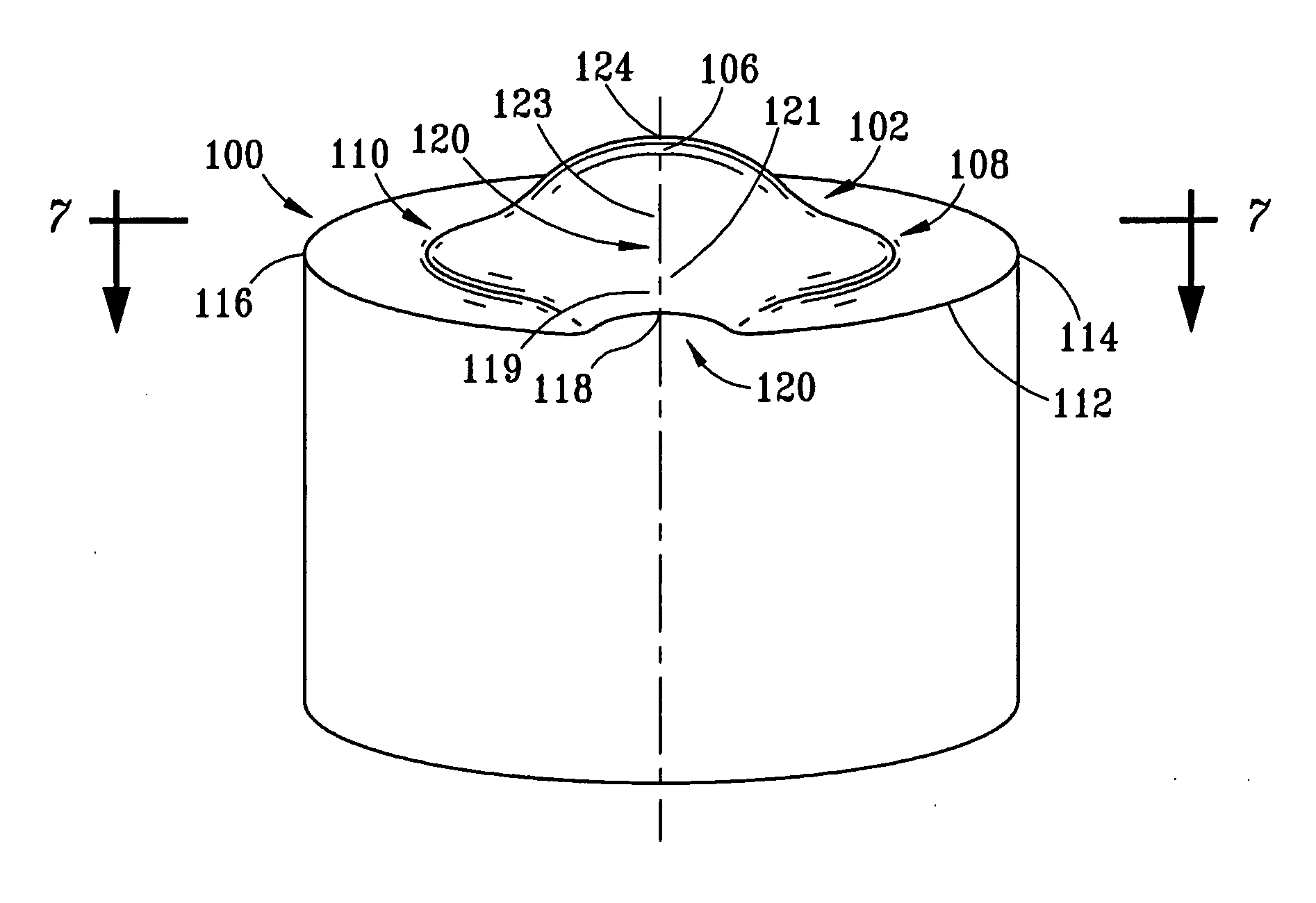

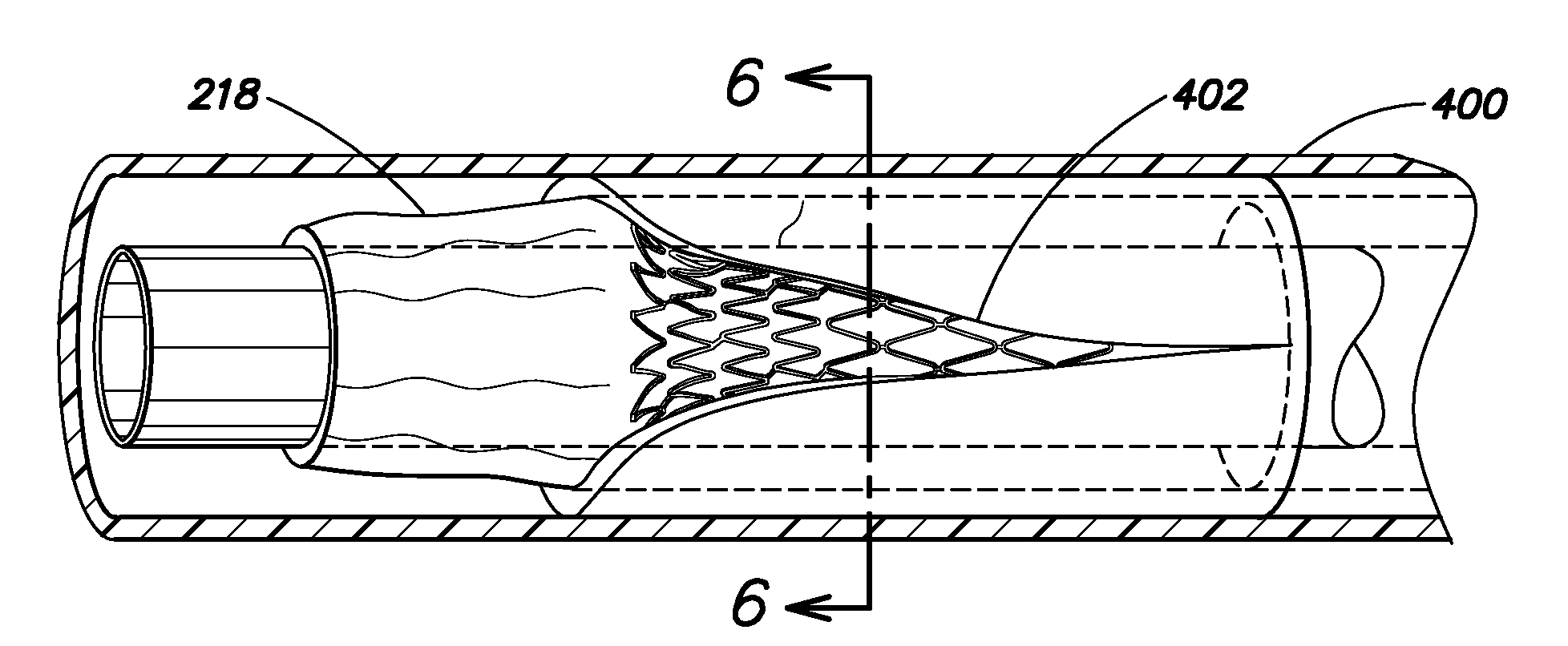

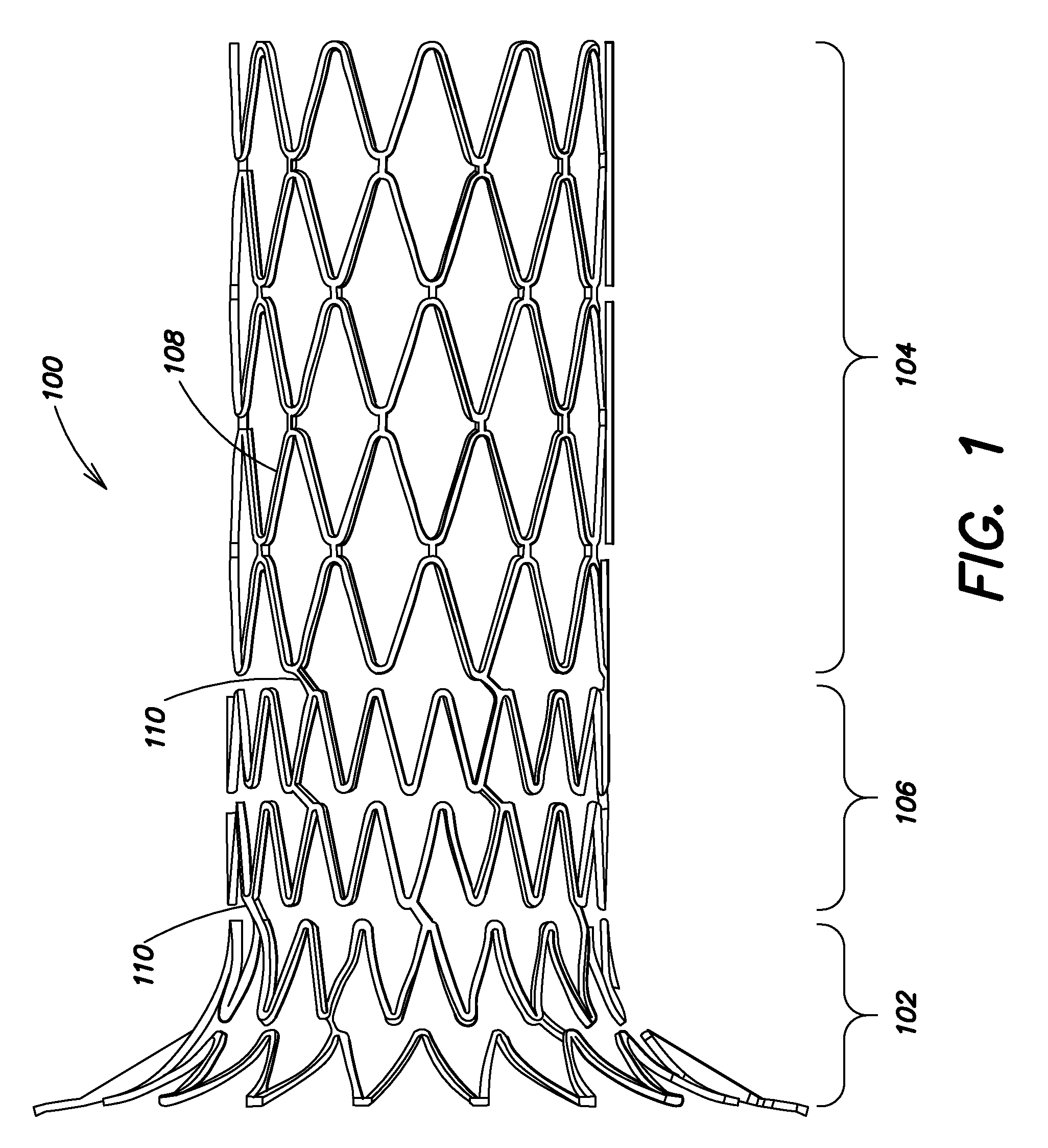

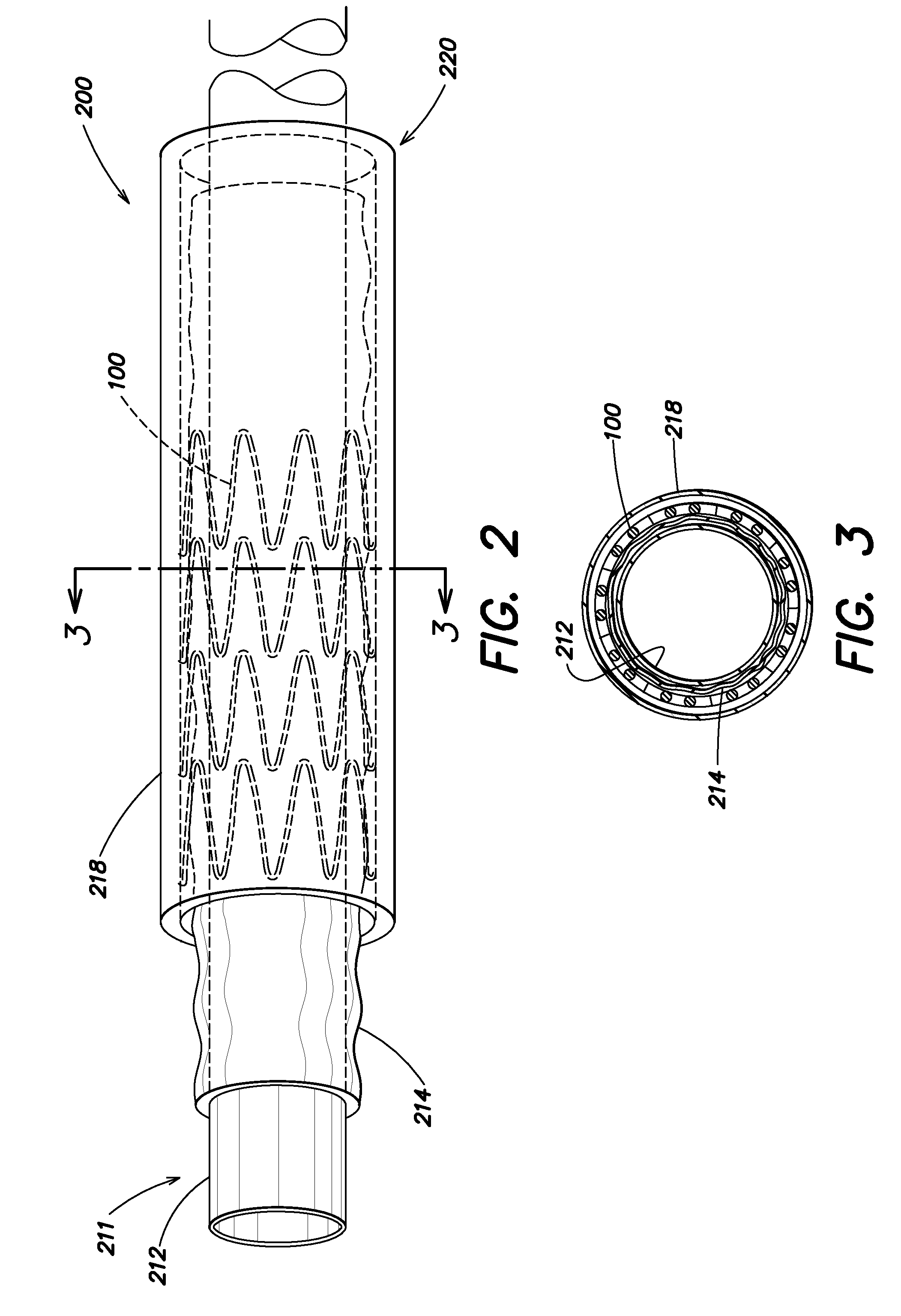

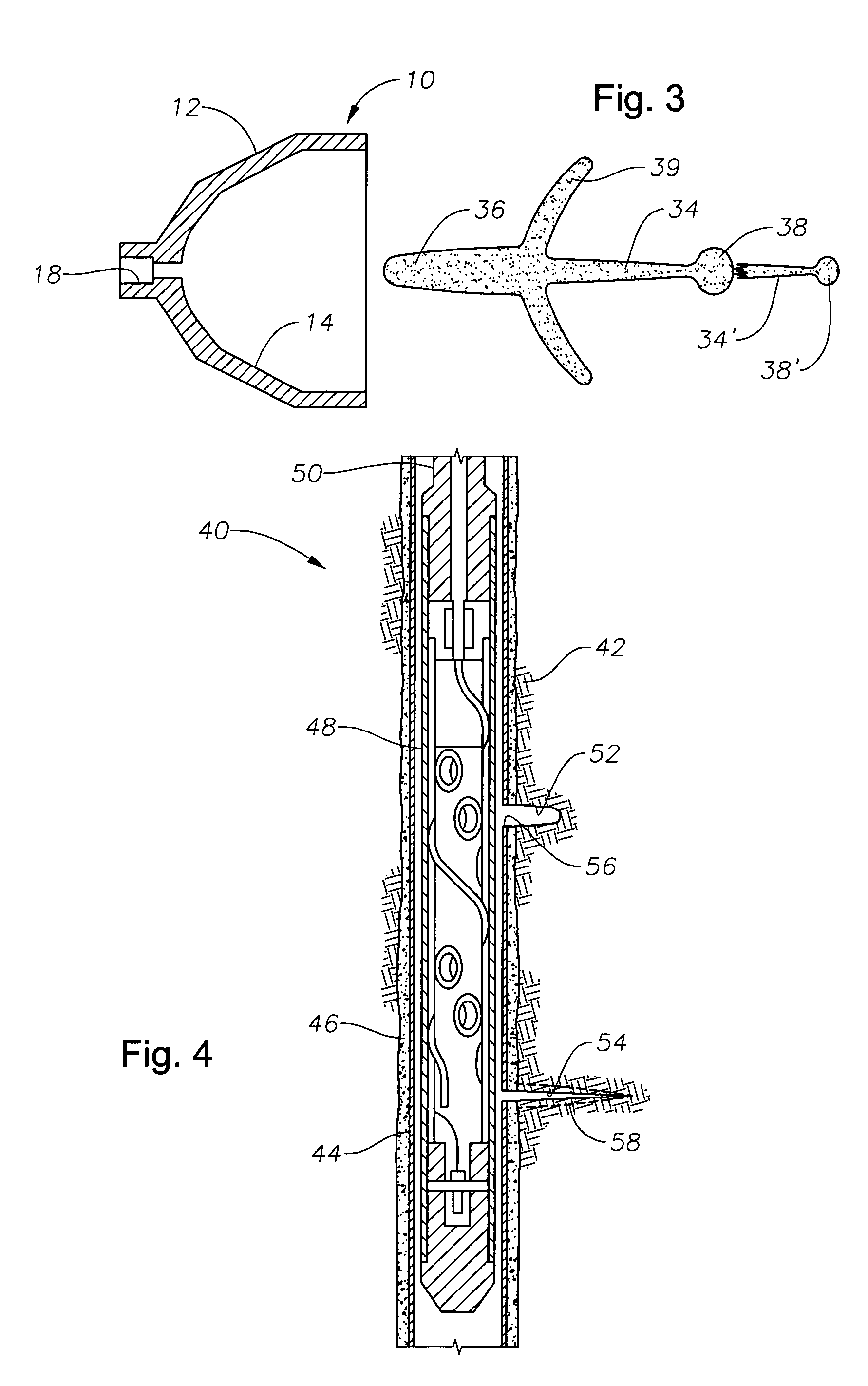

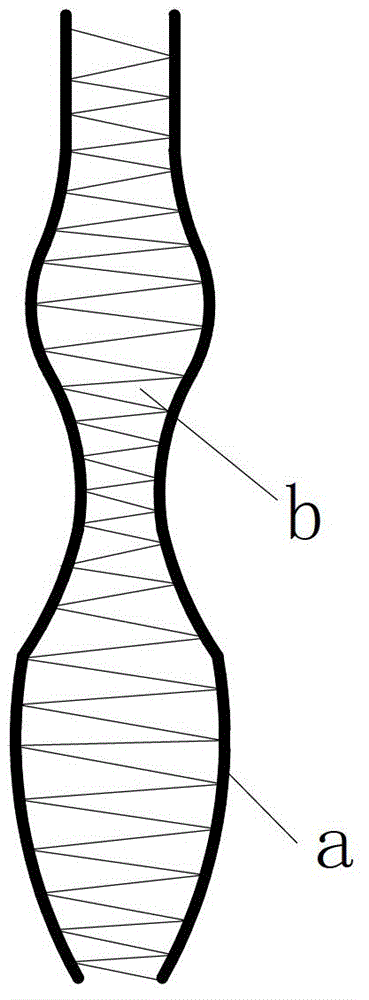

Delivery System With Profiled Sheath Having Balloon-Oriented Position

InactiveUS20090112159A1Minimize adverse effectsReduce morbidityStentsBalloon catheterInsertion stentAbnormal shaped

A delivery system for delivering a self-expanding medical device such as a stent. The delivery system includes a sheath profiled or shaped to reduce instances of interference between a distal edge of the sheath and a vessel or with any lesion or lesions that might be present in the vessel. The sheath is formed by modifying a cylinder of sheath material to include three portions and an initiation slit that controls the rupturing of the sheath to facilitate delivery of the medical device. The initiation slit is positioned on the delivery system with respect to a configuration of a balloon portion of the system.

Owner:CAPPELLA INC

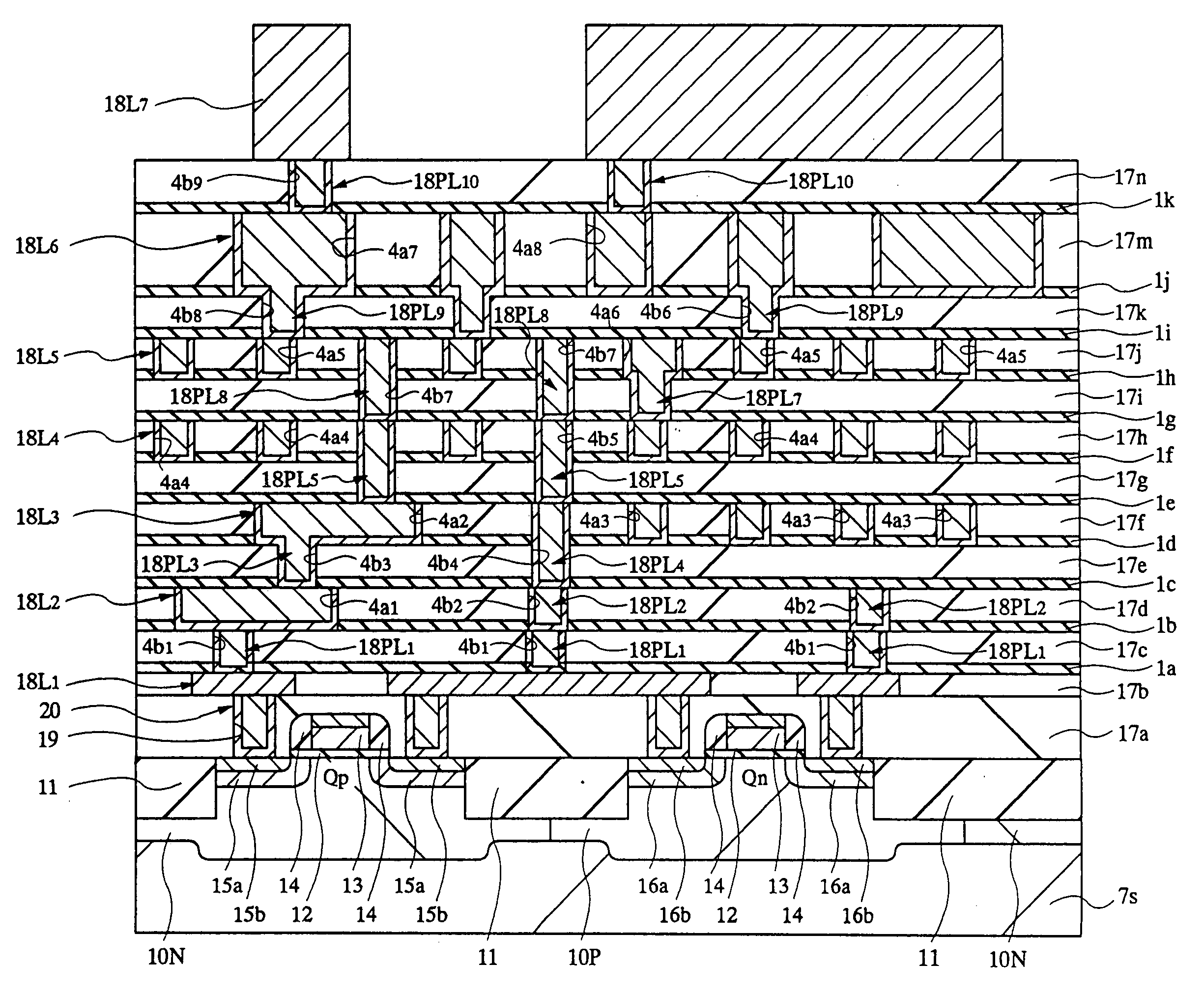

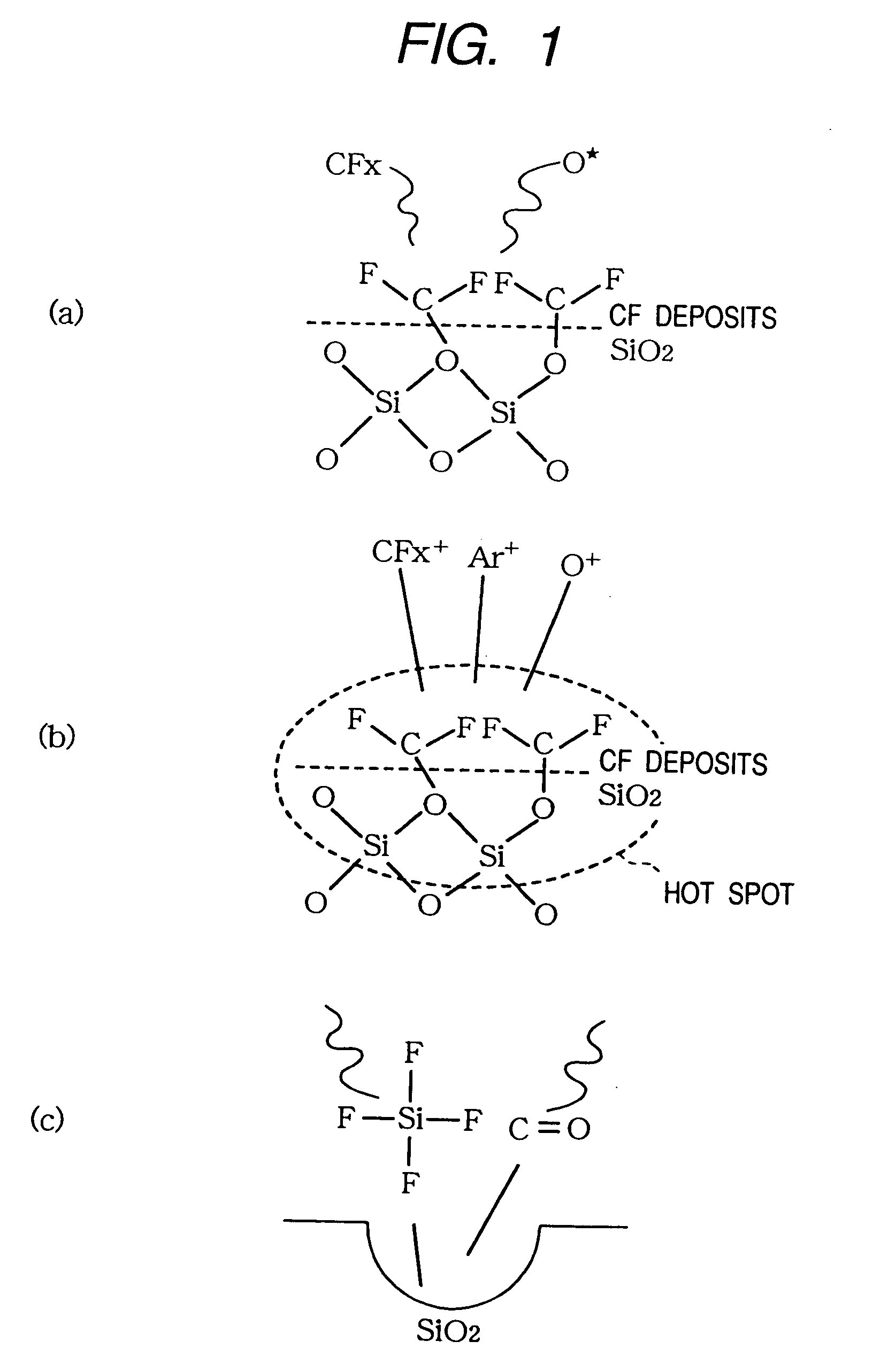

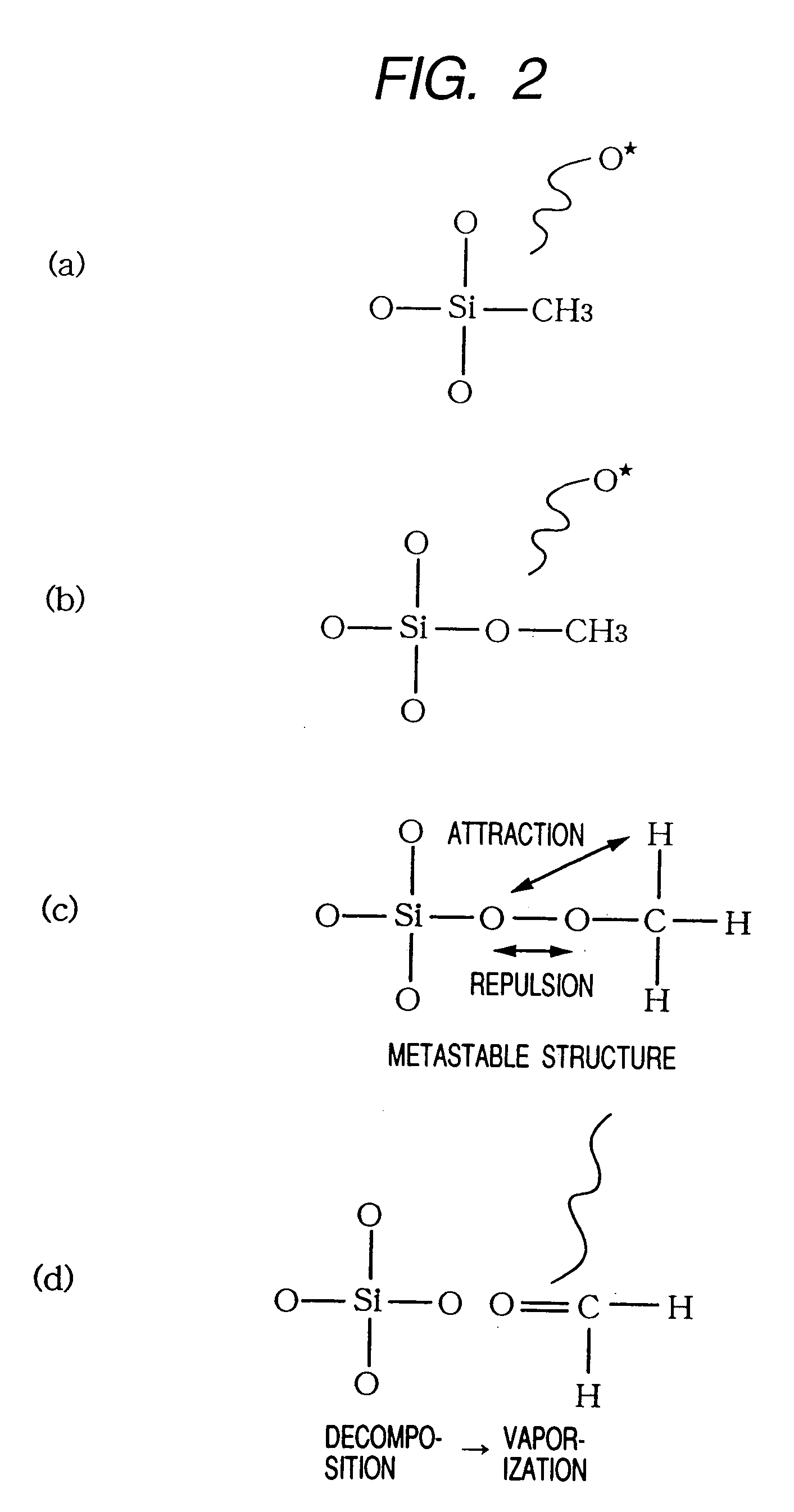

Method of manufacture of semiconductor integrated circuit

InactiveUS20050186801A1Improve etch selectivitySemiconductor/solid-state device detailsSolid-state devicesResistElectrical conductor

In a process for the manufacture of a semiconductor integrated circuit device having an inlaid interconnect structure by embedding a conductor film in a recess, such as a trench or hole, formed in an organic insulating film which constitutes an interlevel dielectric film and includes an organosiloxane as a main component, the recess, such as a trench or hole, is formed by subjecting the organic insulating film to plasma dry etching in a CF-based gas / N2 / Ar gas in order to suppress the formation of an abnormal shape on the bottom of the recess, upon formation of a photoresist film over the organic insulating film, followed by formation of the recess therein with the photoresist film as an etching mask.

Owner:RENESAS ELECTRONICS CORP

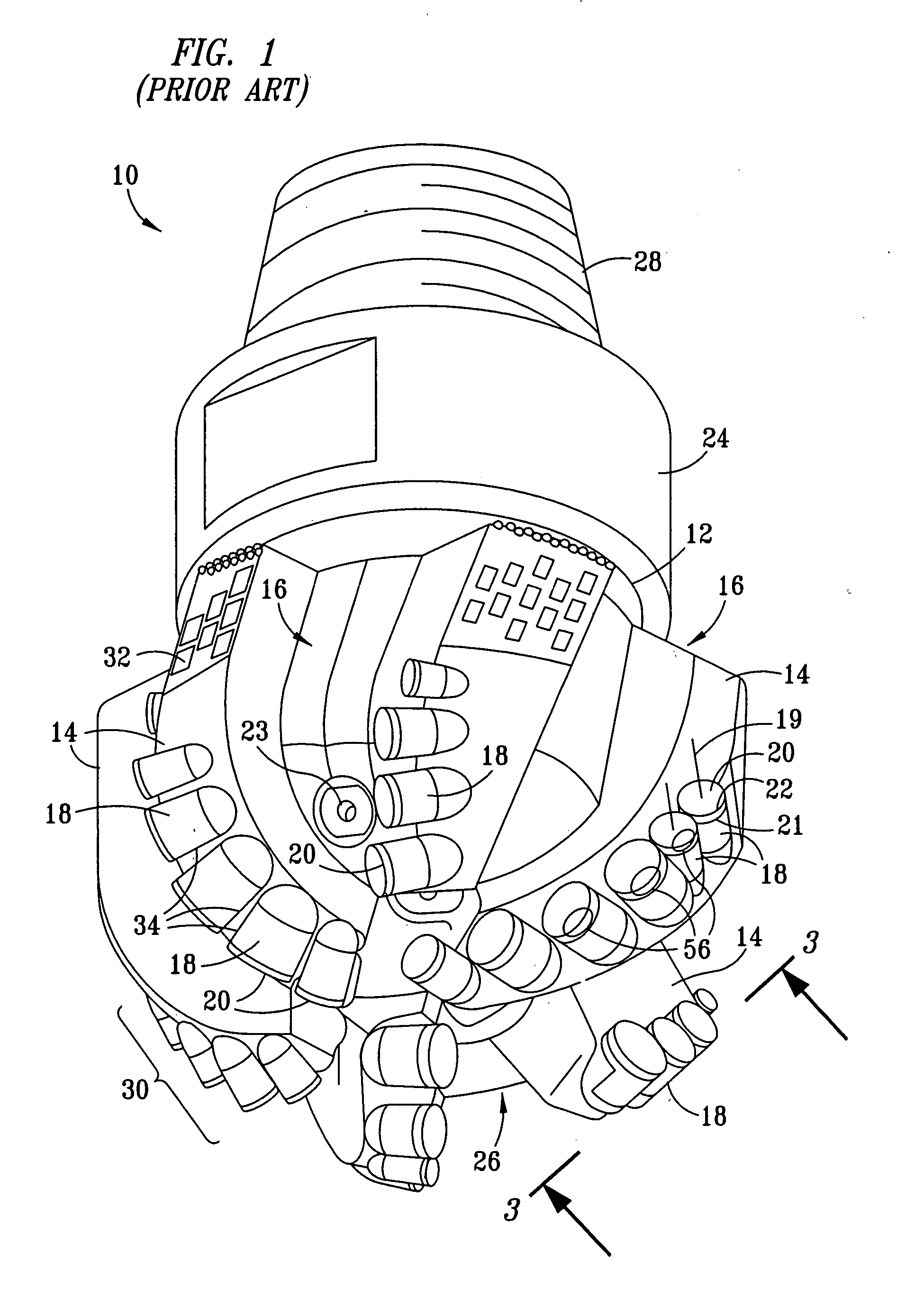

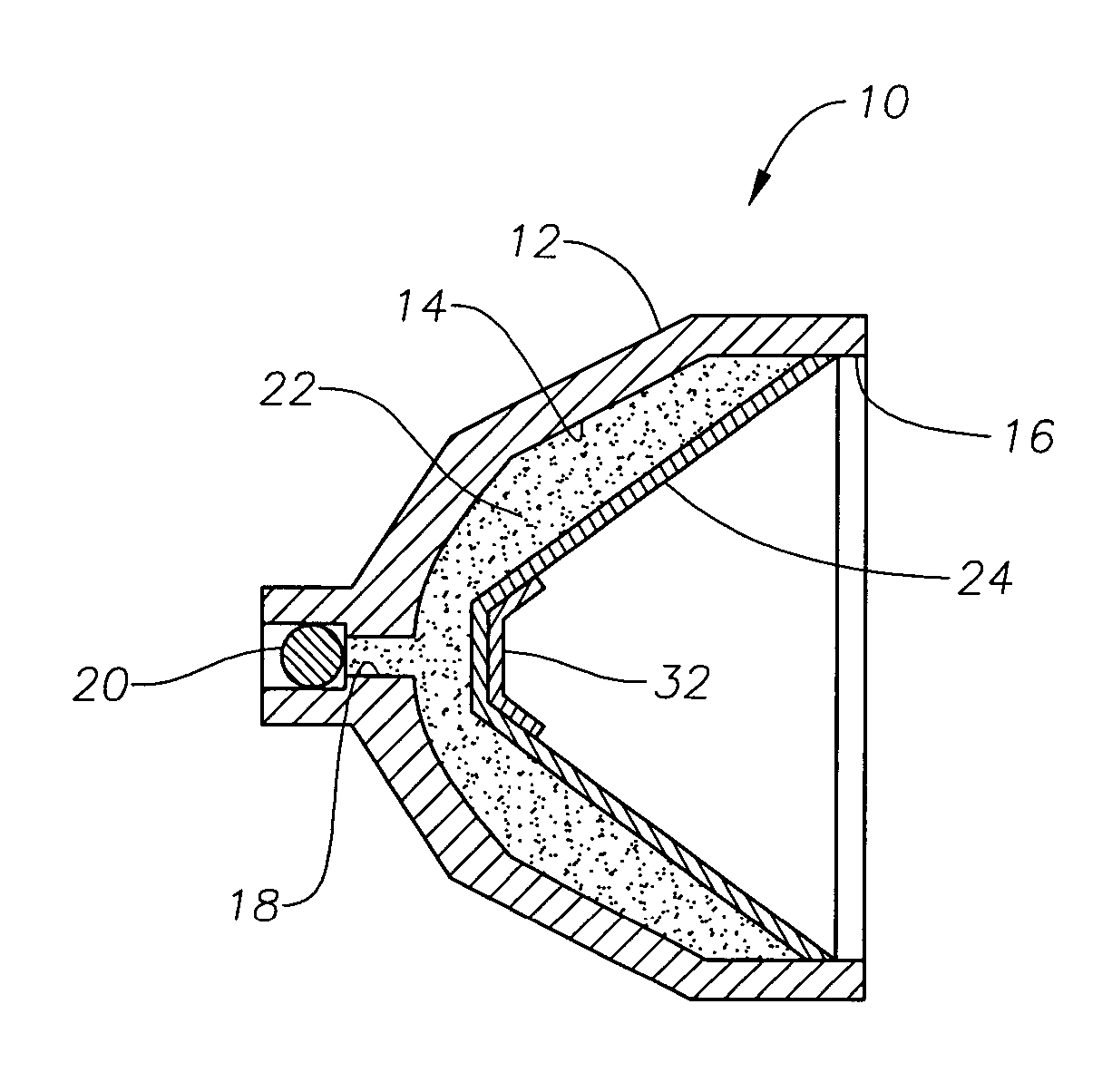

Apparatus and method for penetrating oilbearing sandy formations, reducing skin damage and reducing hydrocarbon viscosity

InactiveUS20050115448A1Excessive heatingMinimal damageExplosive chargesAmmunition projectilesPorosityPolyester

A shaped charge and a method of using such to provide for large and effective perforations in oil bearing sandy formations while causing minimal disturbance to the formation porosity is described. This shaped charge uses a low-density liner having a filler material that is enclosed by outer walls made, preferably, of plastic or polyester. The filler material is preferably a powdered metal or a granulated substance, which is left largely unconsolidated. The preferred filler material is aluminum powder, or aluminum particles, that are coated with an oxidizing substance, such as TEFLON®, permitting a secondary detonation reaction inside the formation following jet penetration. The filled liner is also provided with a metal cap to aid penetration of the gun scallops, the surrounding borehole casing and the cement sheath. The metal cap forms the leading portion of the jet, during detonation. The remaining portion of the jet is formed from the low-density filler material, thereby resulting in a more particulated jet. The jet results in less compression around the perforation tunnel and less skin damage to the proximal end of the perforation tunnel.

Owner:OWEN OIL TOOLS

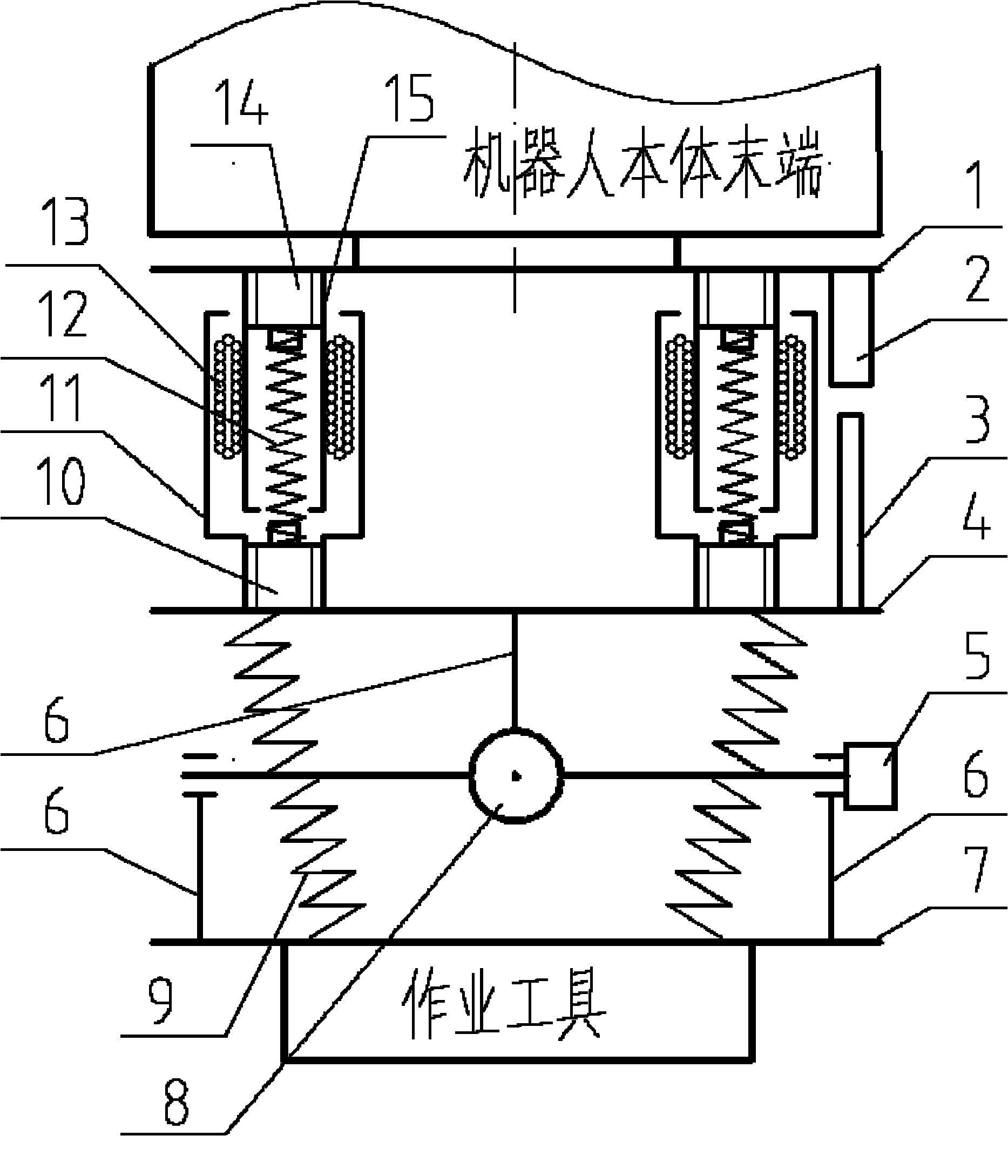

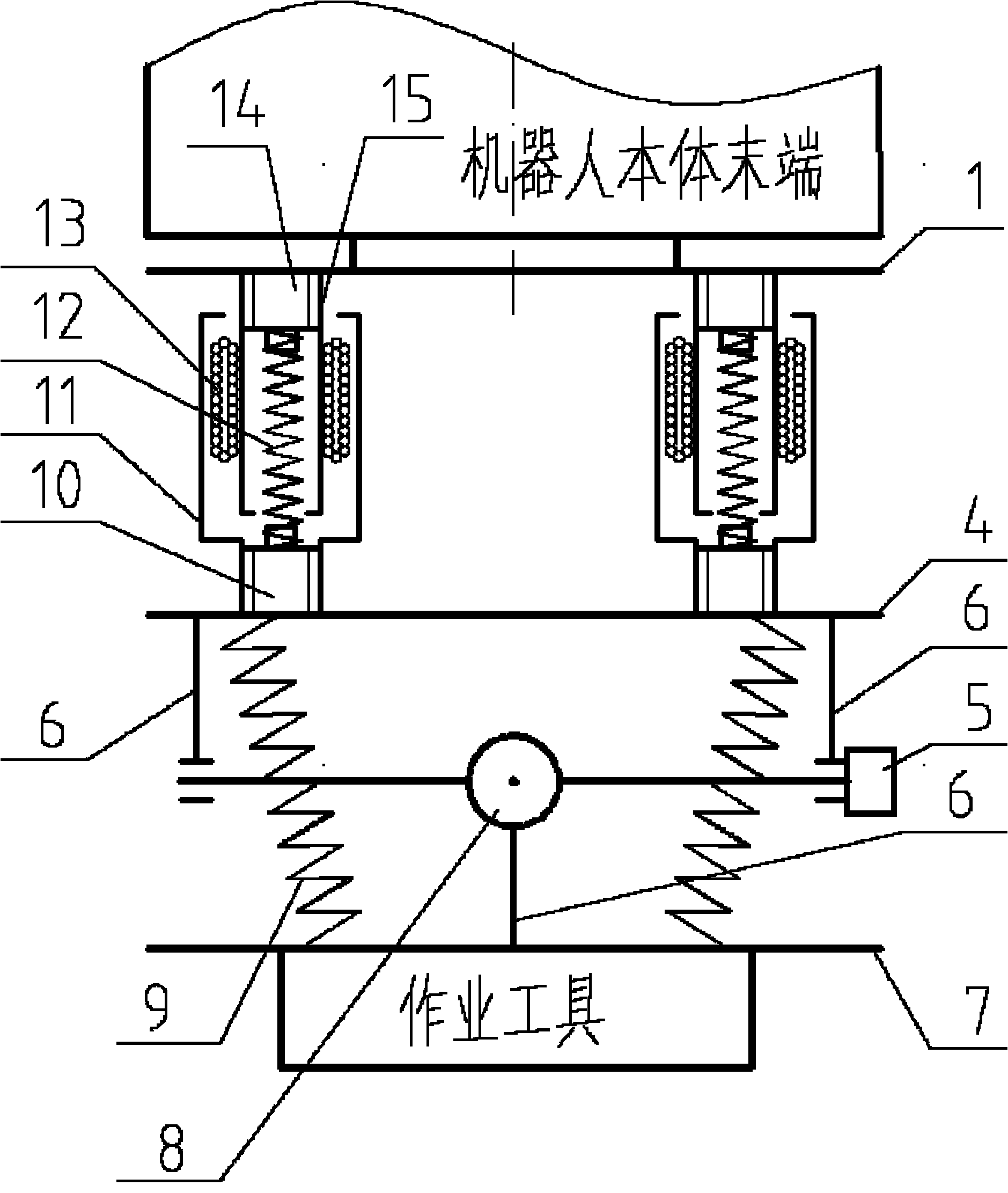

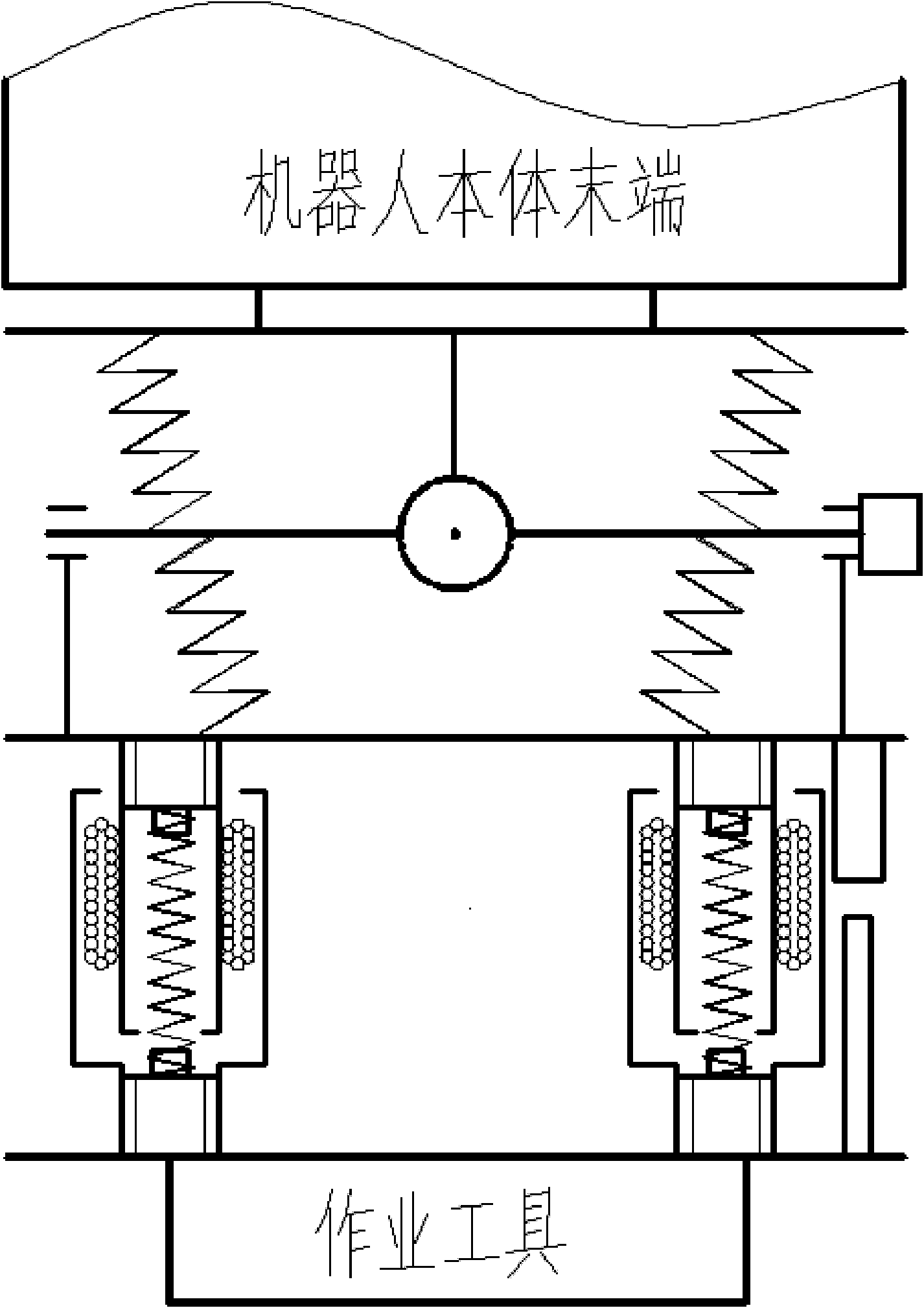

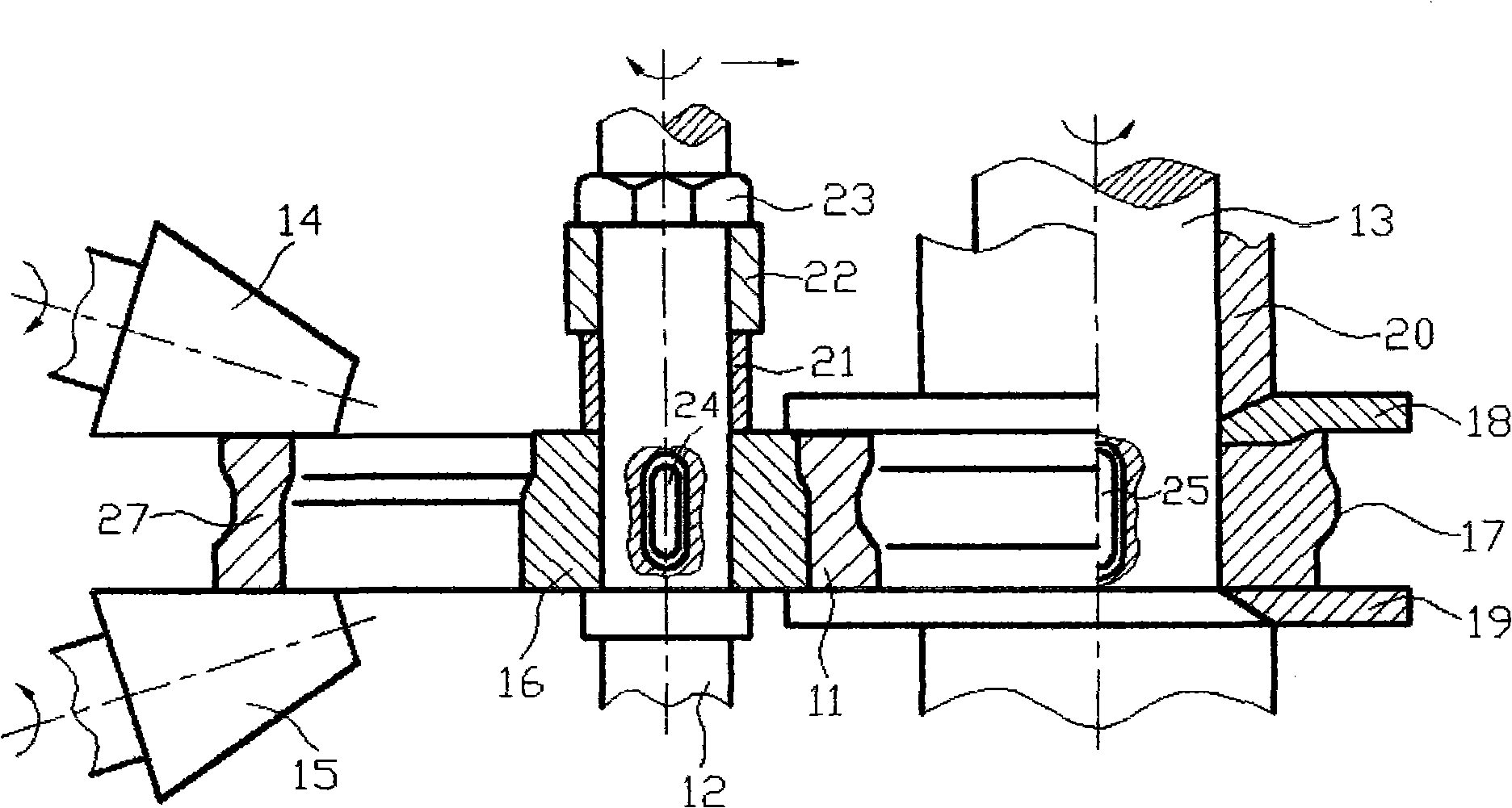

Flexible waist for robot

The invention relates to a flexible waist for a robot, which consists of a moving part, a swinging part, a displacement sensor and an angle sensor, wherein the moving part realizes the moving function in one direction, the swinging part realizes the swinging function in two directions, springs are arranged both in the moving part and the swinging part, the flexibility and the resetting function of the waist in the moving direction and the swinging direction can be realized through the elasticity of the springs, the contact state of operation objects can be identified through the information of a position sensor and the angle sensor arranged on the waist, and then, the position and the posture of the tail end of a robot body are regulated according to the information of the sensors, so the contact state of operation tools and the operation objects can be regulated, and the force / position mixed control can be realized. The invention has a simple structure, has flexibility, does not need the driving force, is applicable to operations such as grinding, polishing, hole insertion assembling, object outline reorganization and the like, and is particularly applicable to the grinding and polishing on curve surfaces in abnormal shapes.

Owner:HUAZHONG UNIV OF SCI & TECH

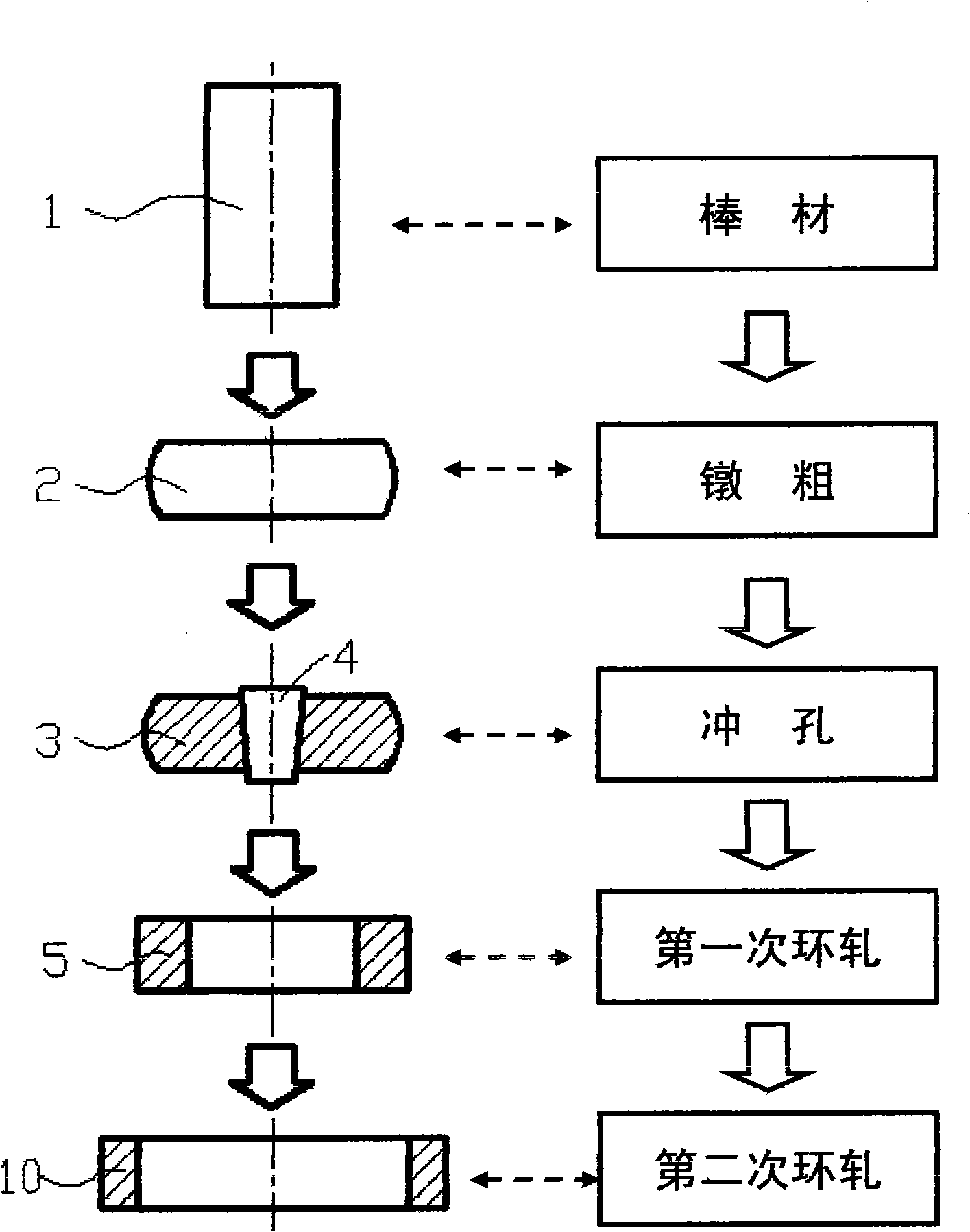

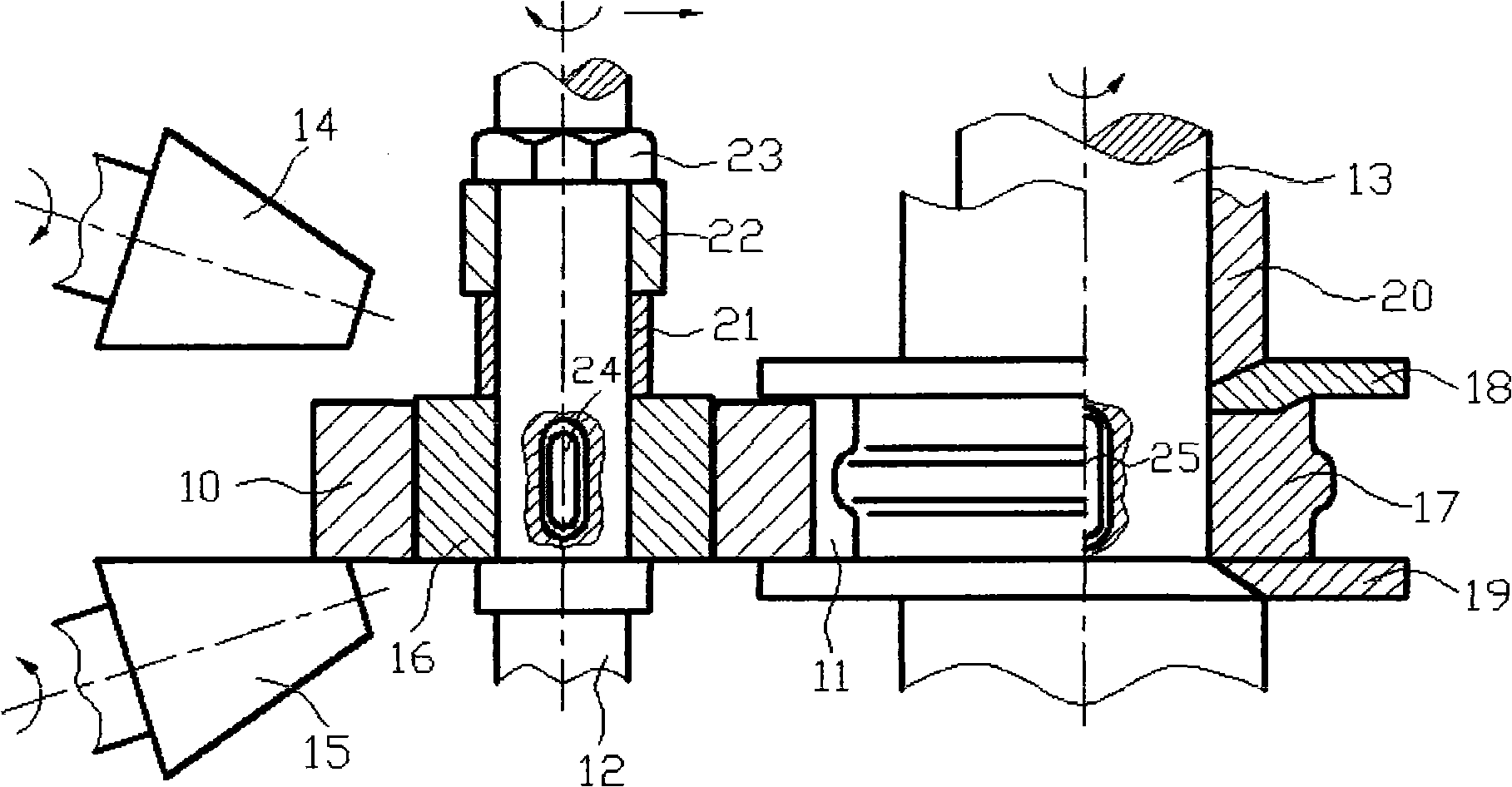

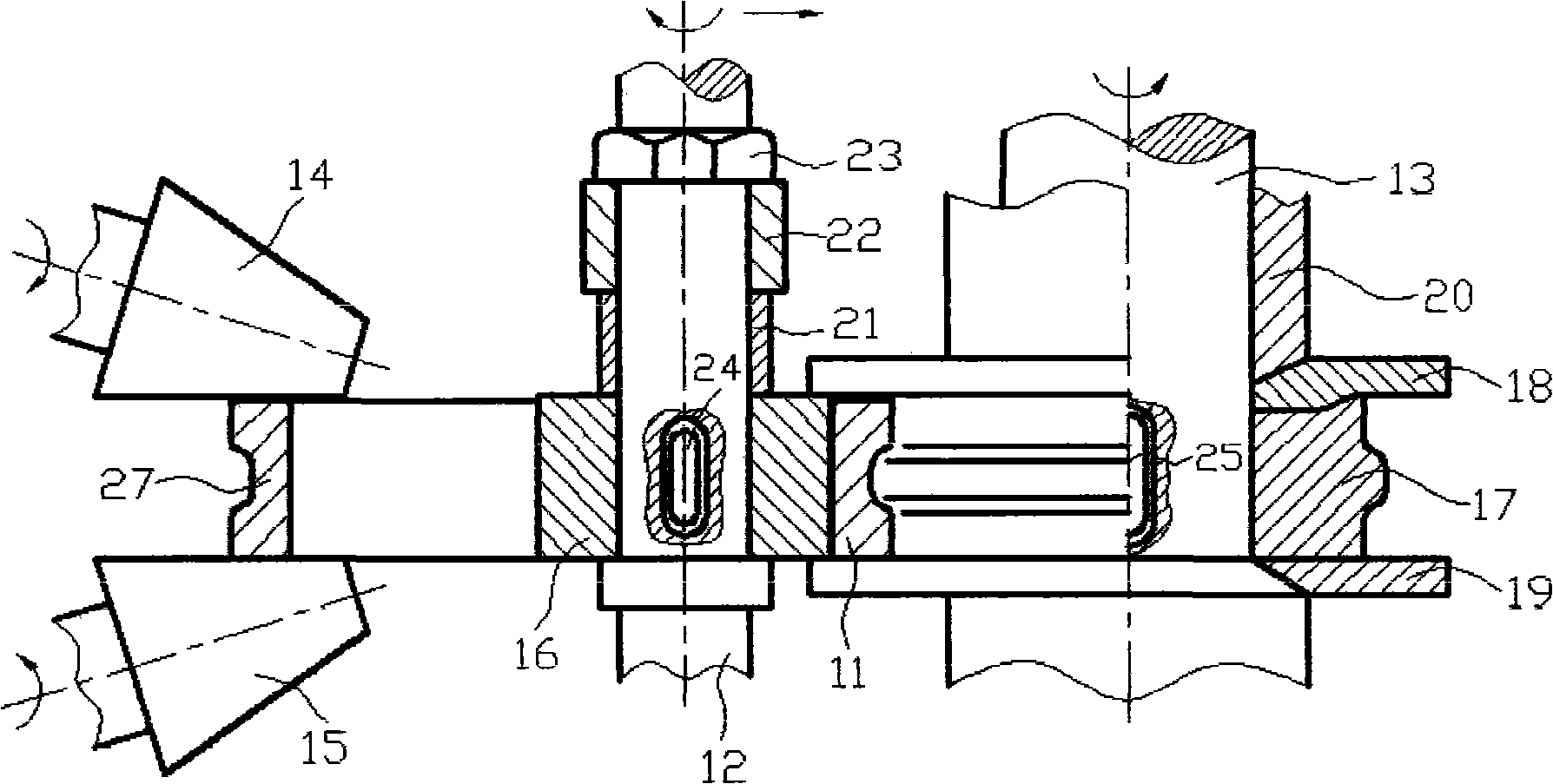

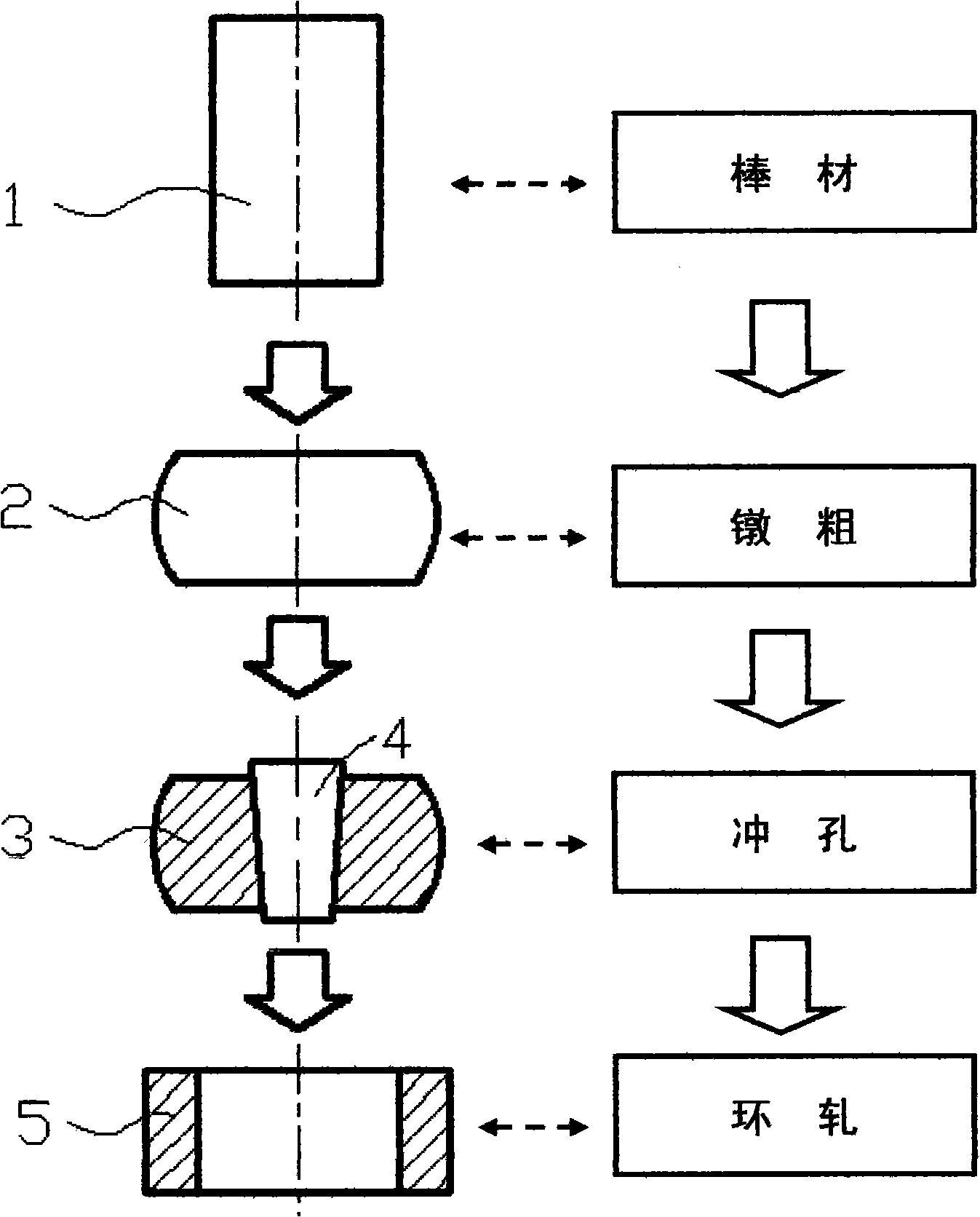

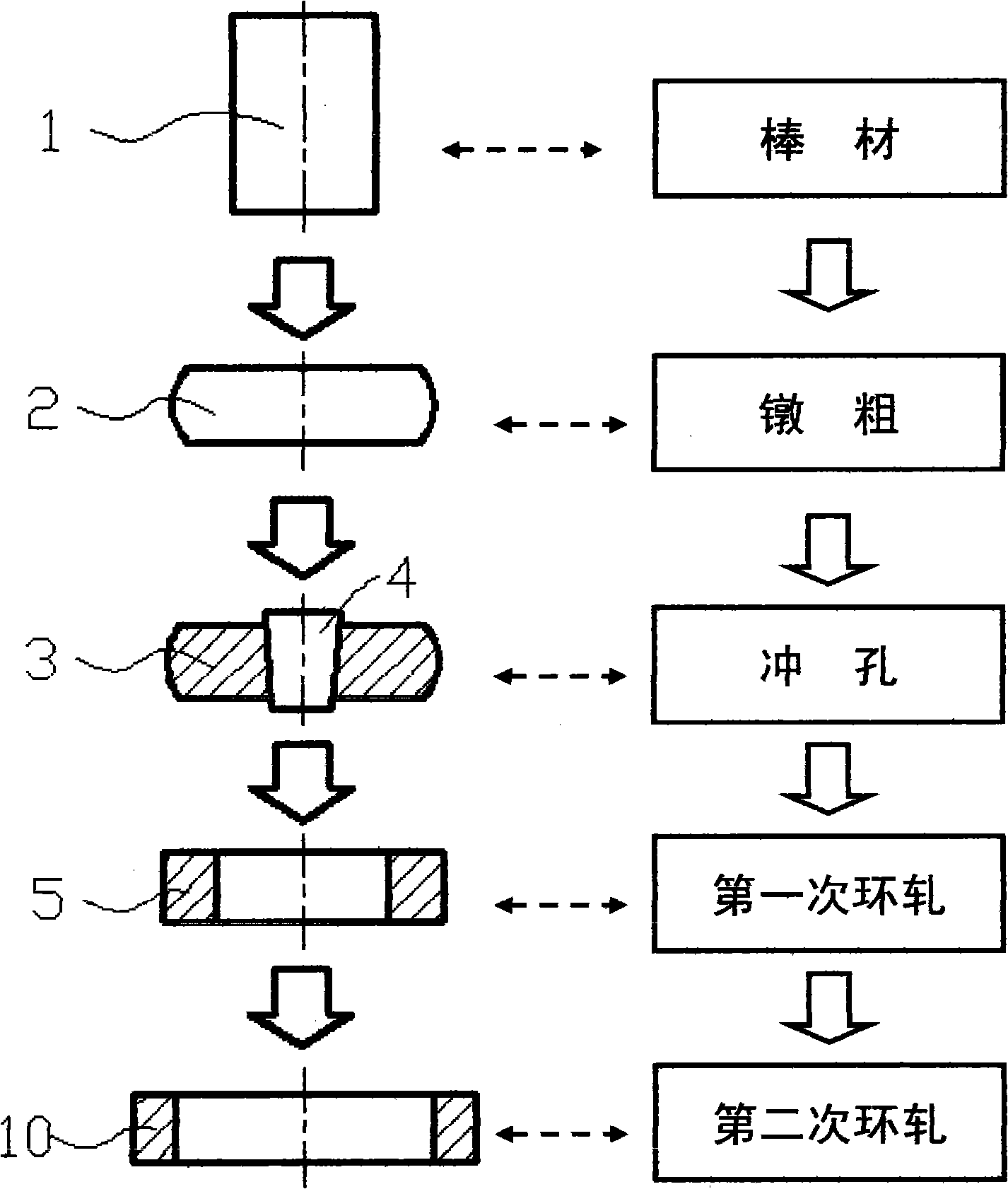

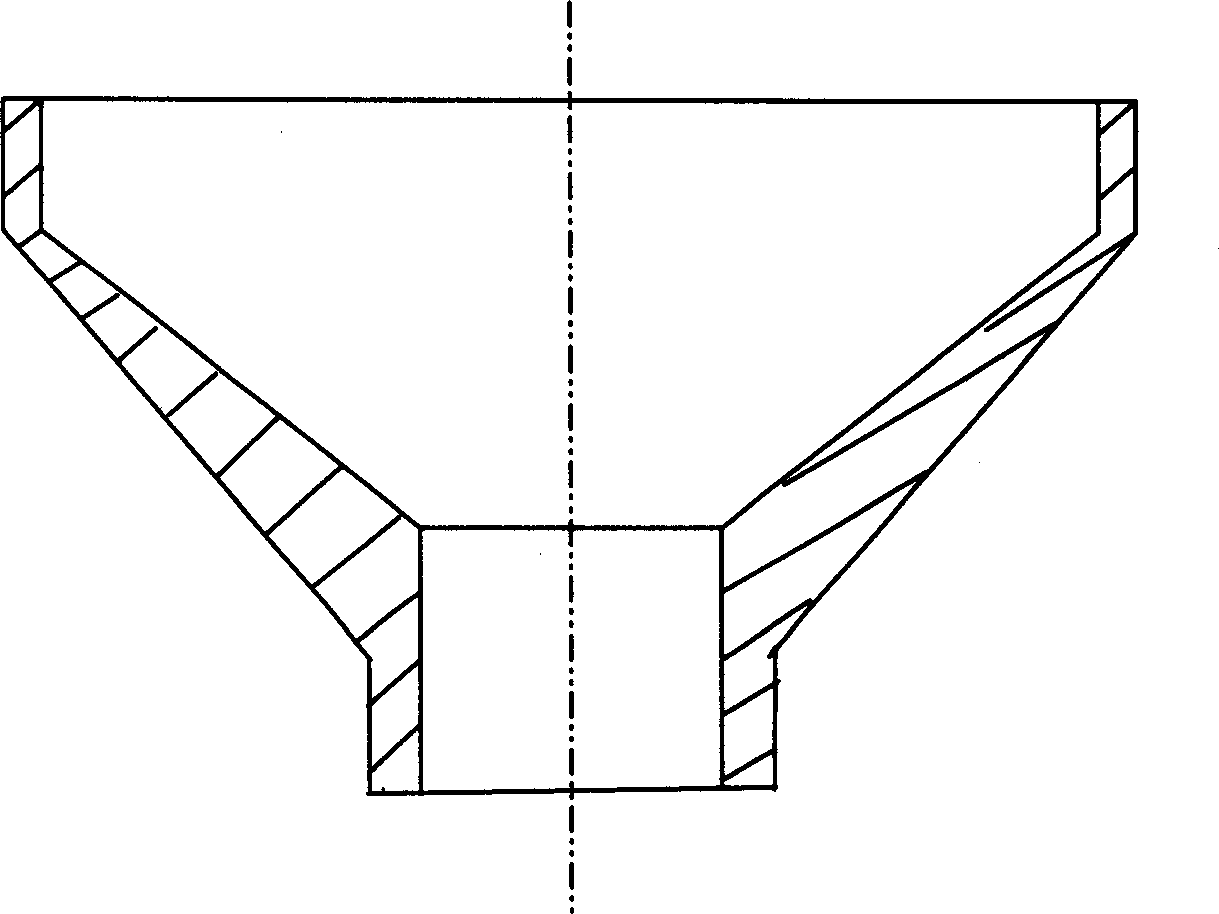

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for rolling and shaping aluminum alloy special-shaped ring forging

InactiveCN101279344AReduce manufacturing costHigh dimensional accuracyMetal rollingAbnormal shapedAero engine

The invention discloses a rolling and shaping method for an aluminum alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

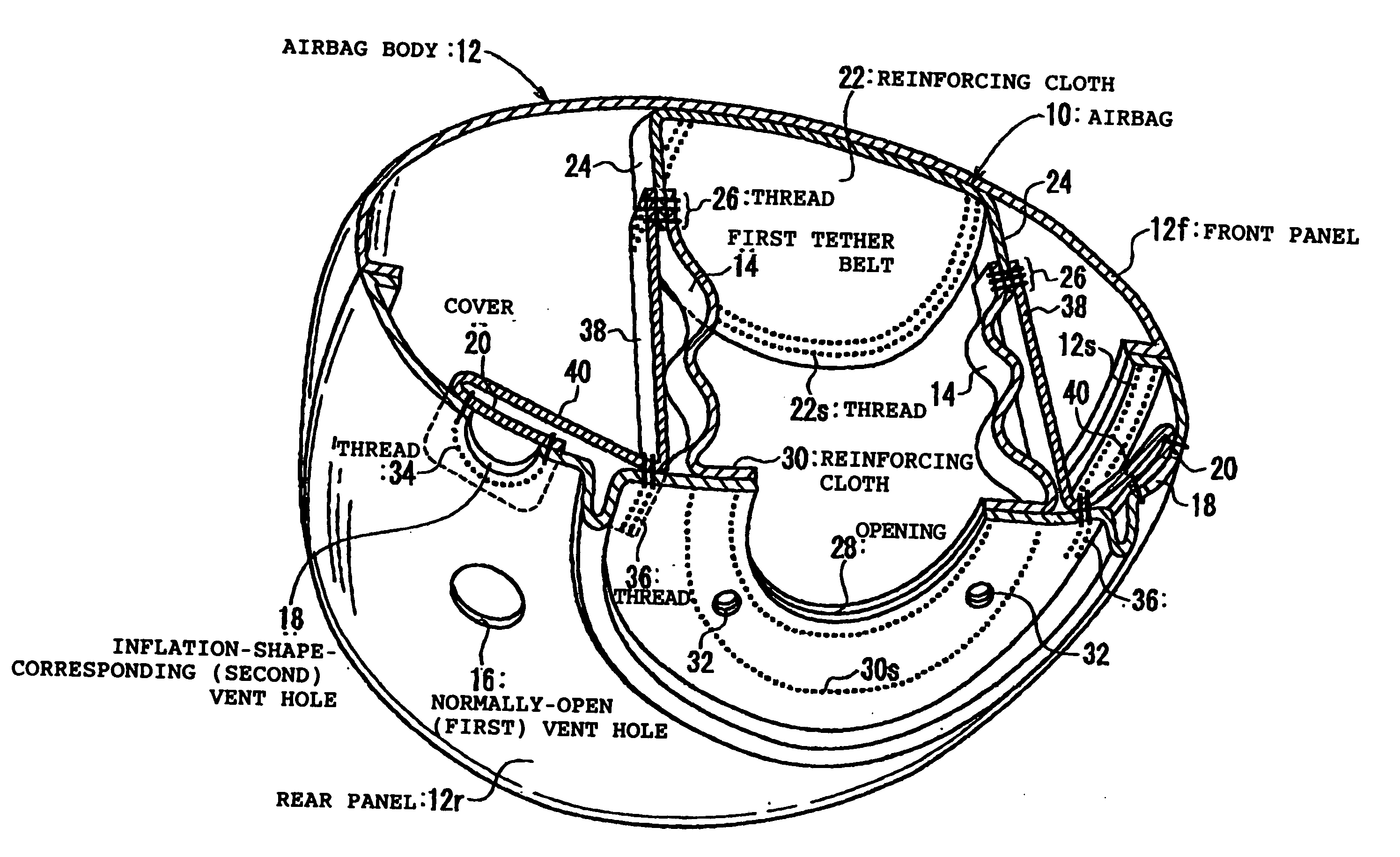

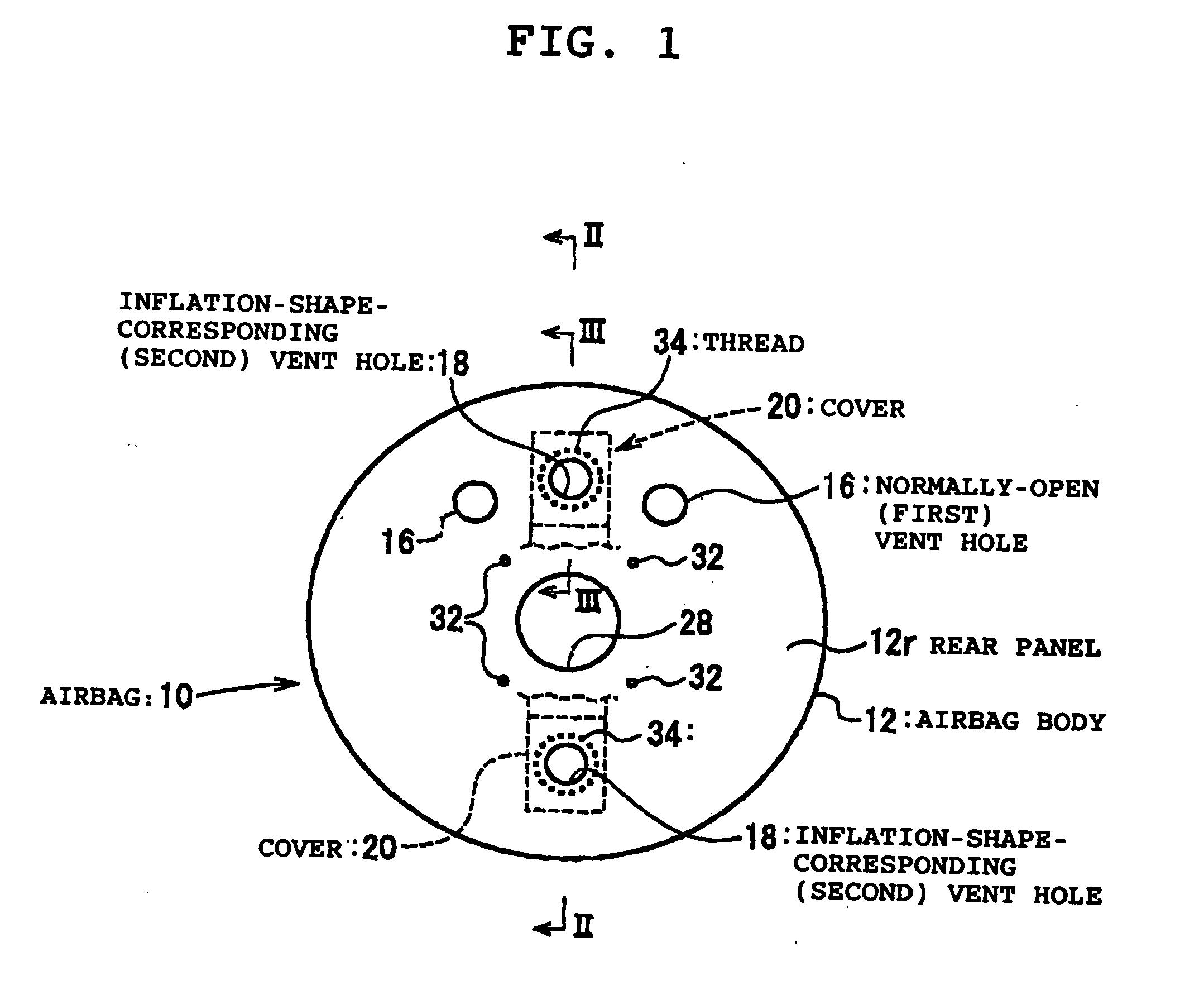

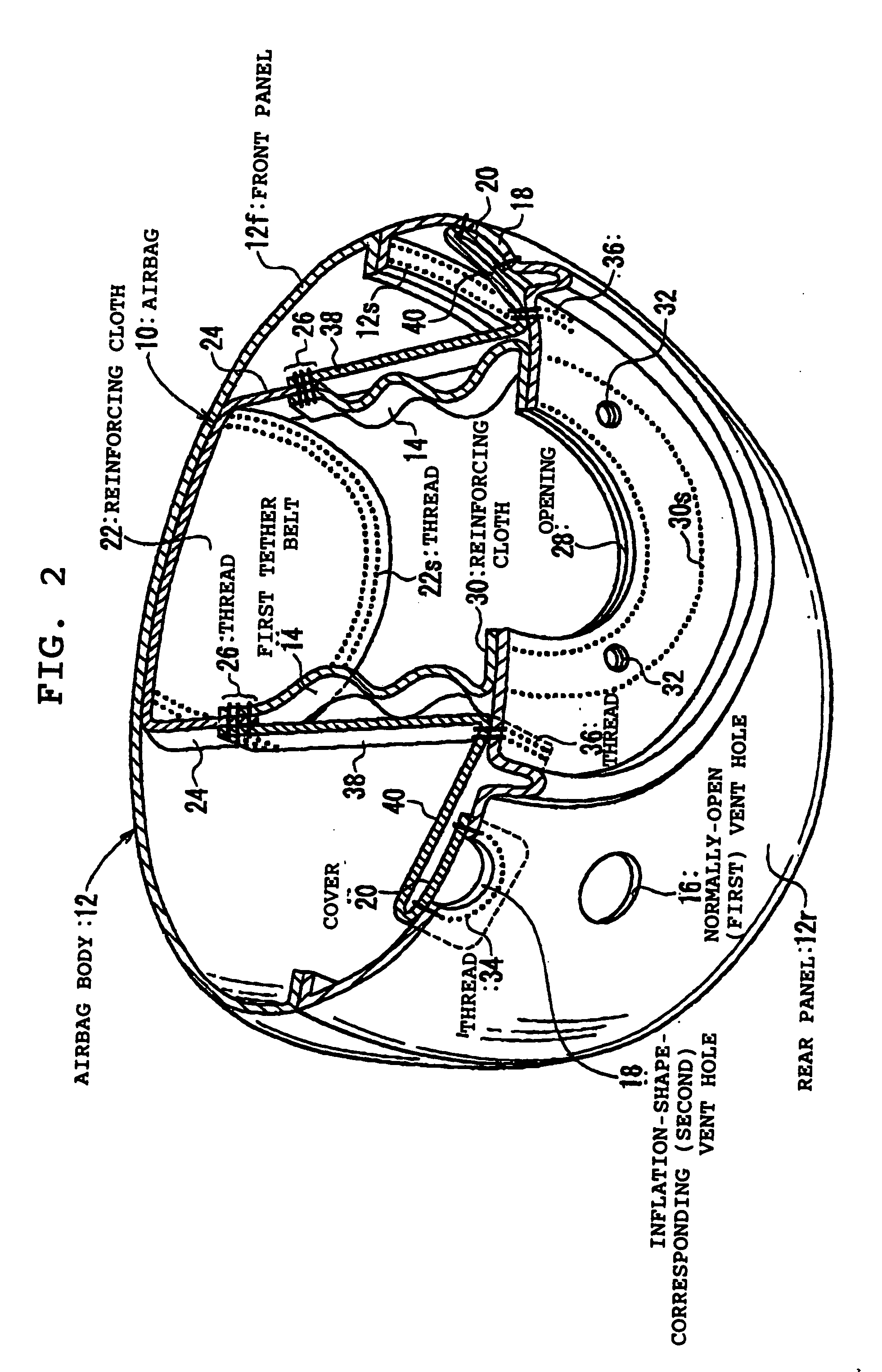

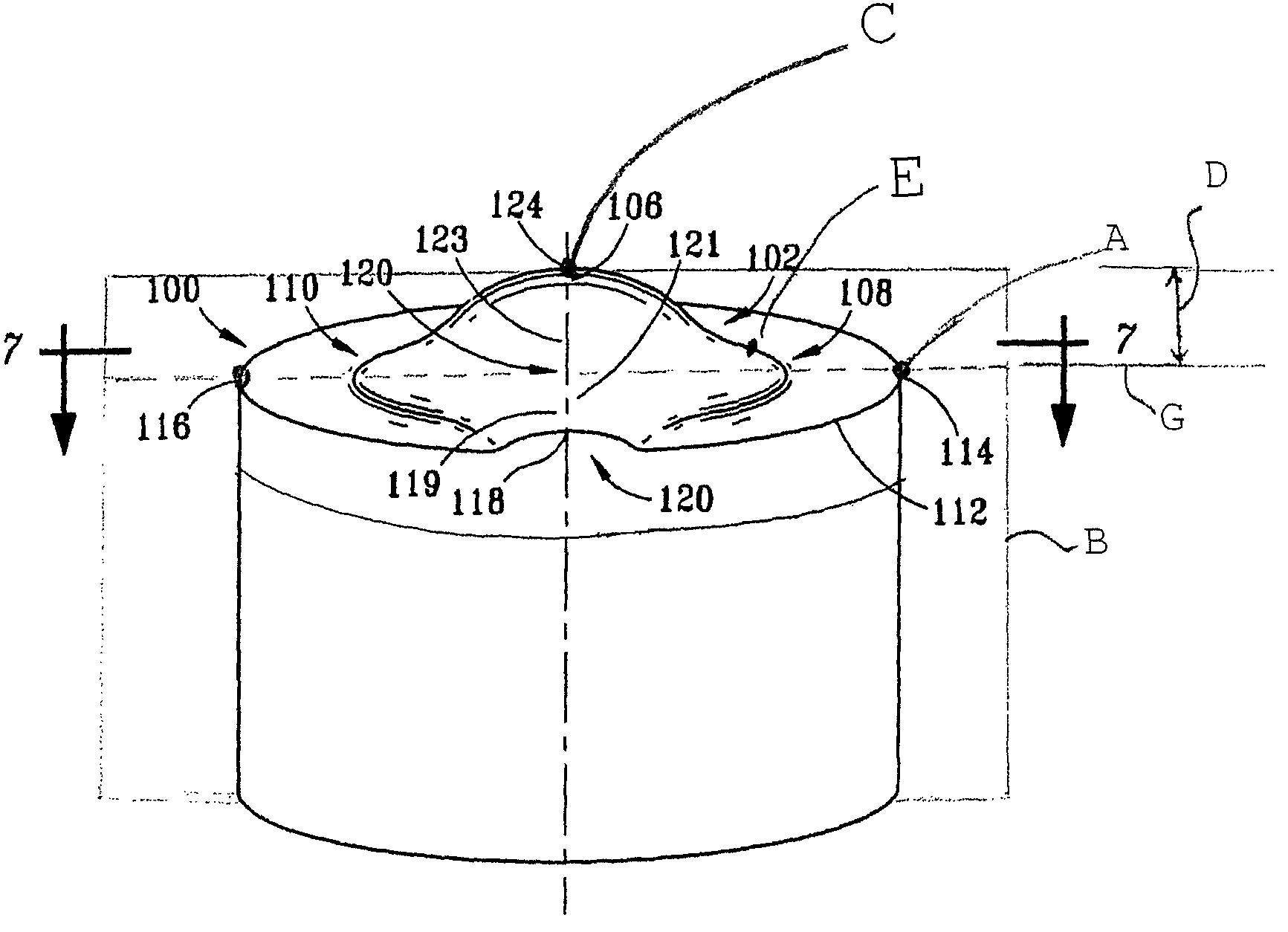

Airbag and airbag system

InactiveUS20050225065A1Reduce pressureIncrease volumePedestrian/occupant safety arrangementEngineeringAbnormal shapes

An airbag and an airbag system are disclosed. In one form, the airbag includes a first tether belt that connects a front panel and a rear panel together and becomes tense when the airbag inflates into a normal shape, a second tether belt that connects the front panel and the rear panel together and is shorter than the first tether belt and a third tether belt that connects the side rim and the center of the rear panel together. The airbag first inflates into a form in which the inflation toward the occupant and in the lateral direction is restrained by the second tether belt and the third tether belt. Thereafter, when the airbag inflates into a normal shape, both of the second tether belt and the third tether belt release the restraint; when the airbag inflates into an abnormal shape, only the third tether belt releases the restraint.

Owner:TAKATA CORPORATION

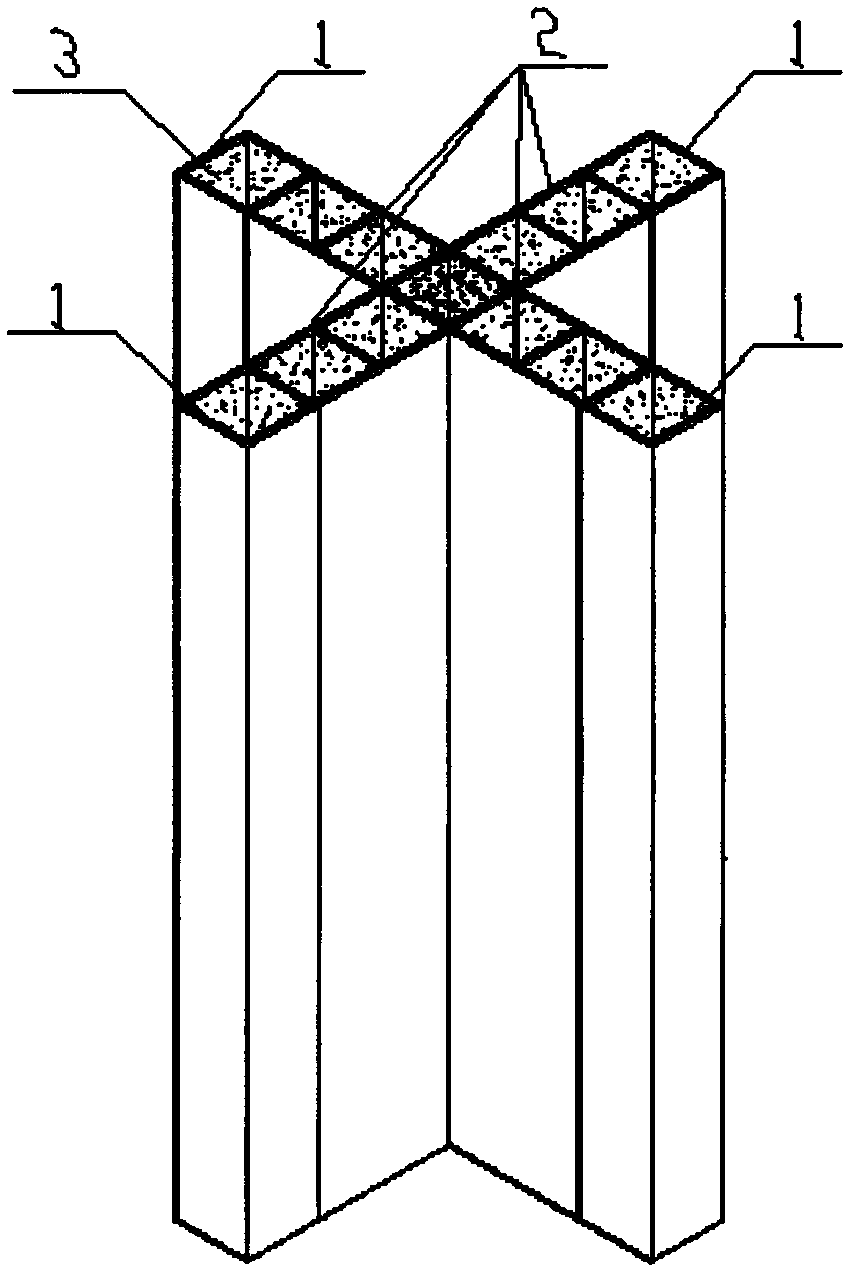

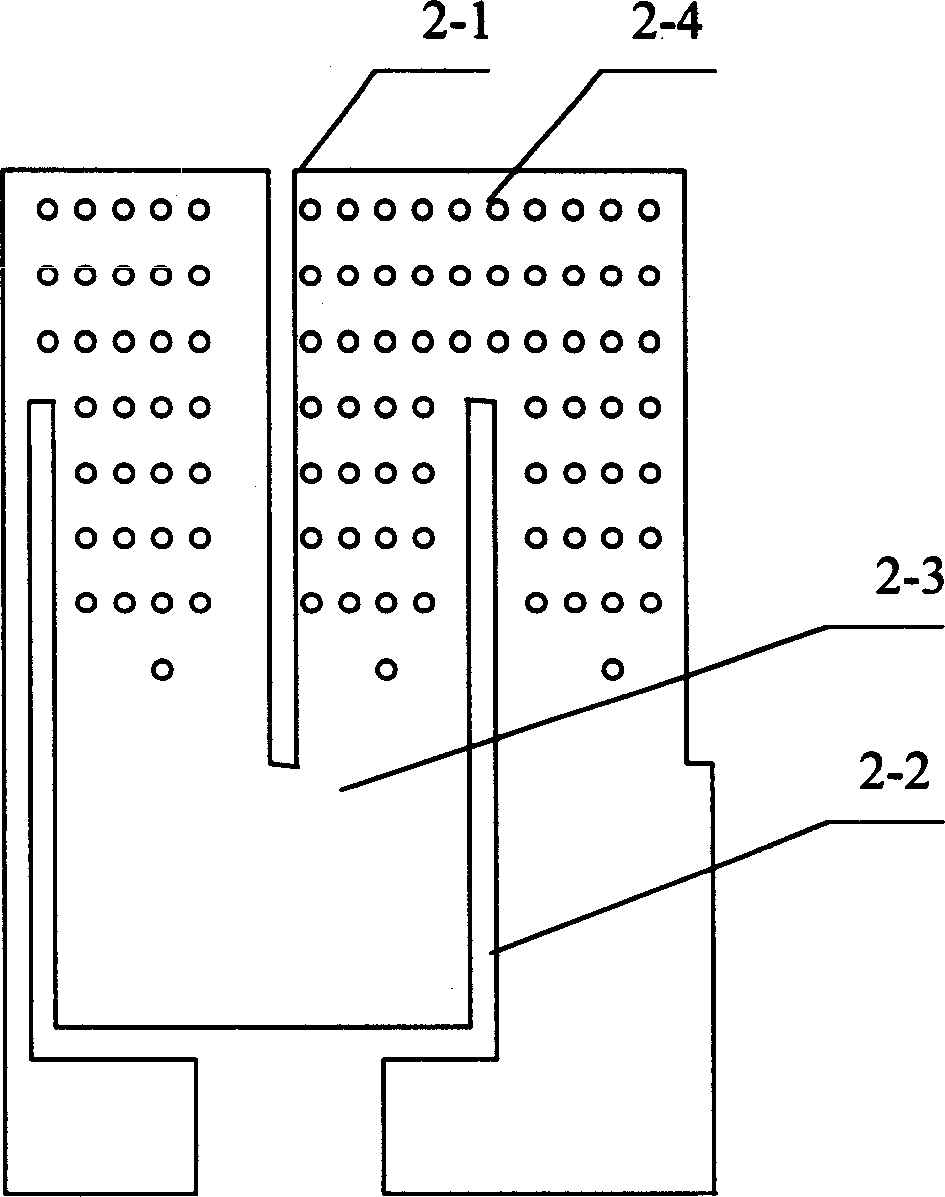

Steel tube-I beam combination steel tube concrete special-shaped columns and manufacture method thereof

InactiveCN102587577AOvercome deficienciesOvercoming the lack of restraint abilityStrutsBuilding material handlingSheet steelShock resistance

The invention relates to steel tube-I-beam combination steel tube concrete special-shaped columns, which comprises steel tubes, I-beams and concrete poured inside the special-shaped columns. The steel tubes and the I-beams are welded together to compose the special-shaped columns with different sections. The whole sections are separated through the steel tubes and the I-beams, then the concrete is filled in separation spaces of the steel tubes and the I-beams, the steel tubes can be made by welding or rolling, and the I-beams can be made by welding or rolling. The steel tube-I-beam combination steel tube concrete special-shaped columns have the advantages that inside corner steel tube walls and I-beam flange steel plates are communicated with each other so as to overcome the defect that force delivery of inside corner portions of other steel tube concrete special-shaped columns is unclear, and whole working capacity of steel tube concrete special-shaped columns is improved. The steel tubes are placed at the edges and at corner portions of the sections so as to improve restrain capacity of the special-shaped columns. The steel tubes and the I-beams separate the concrete of the special-shaped columns, width-to-thickness ratio of the steel plates is reduced, bearing capacity and shock-resistance are improved, production and assembly of the special-shaped columns are modularized, and simultaneously construction speed is fast.

Owner:TIANJIN UNIV

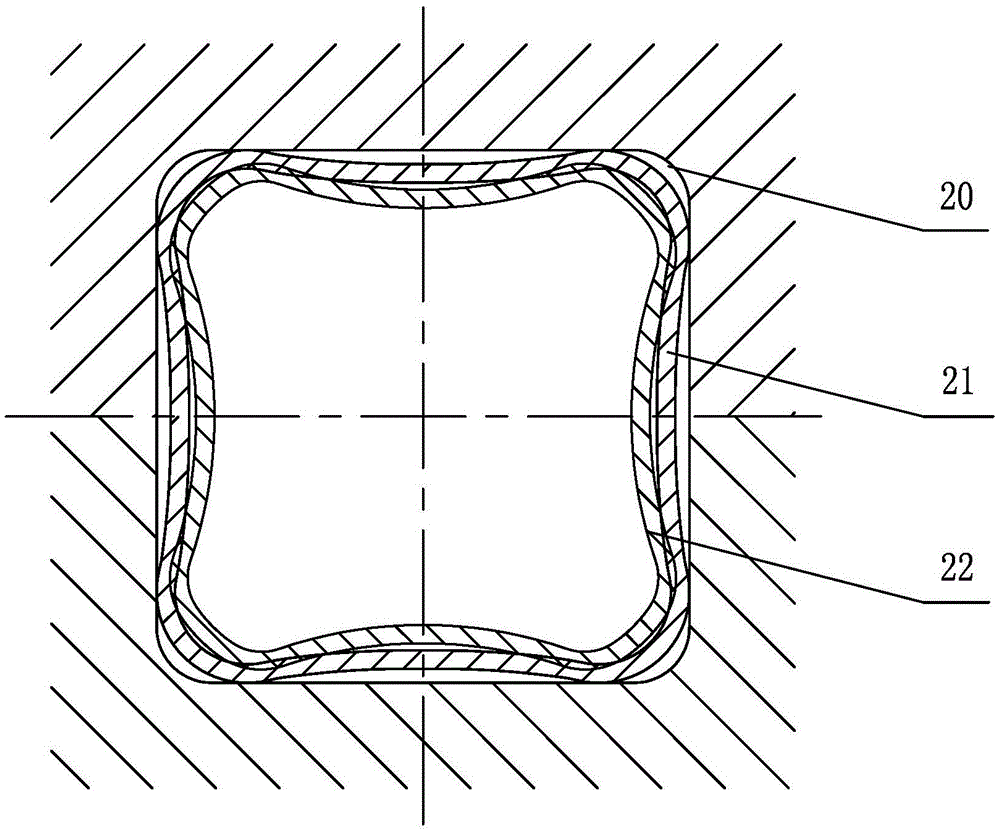

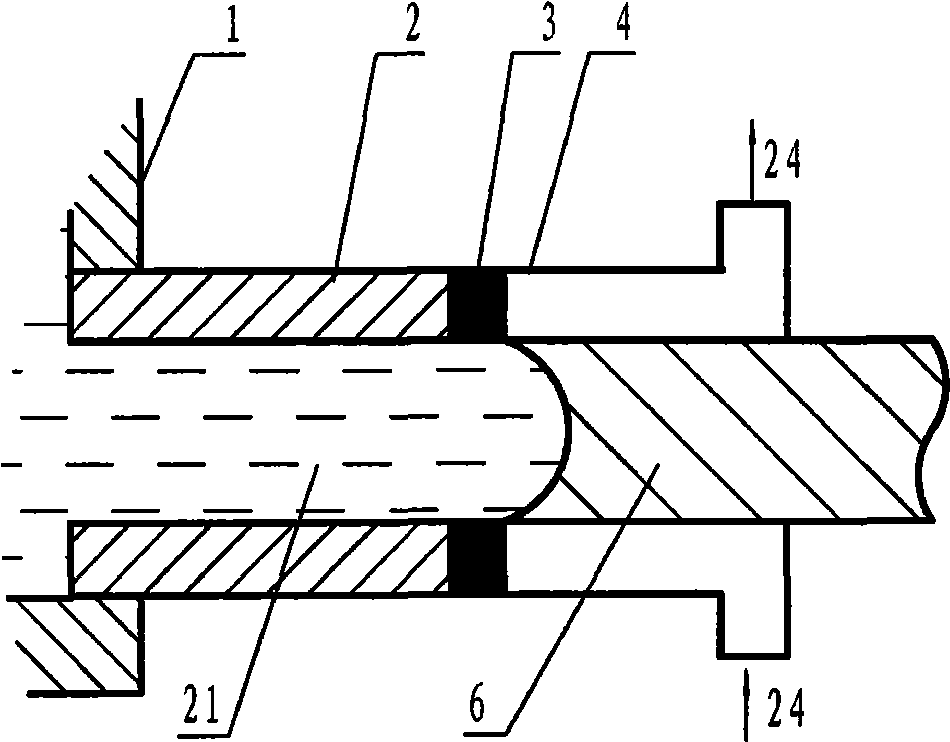

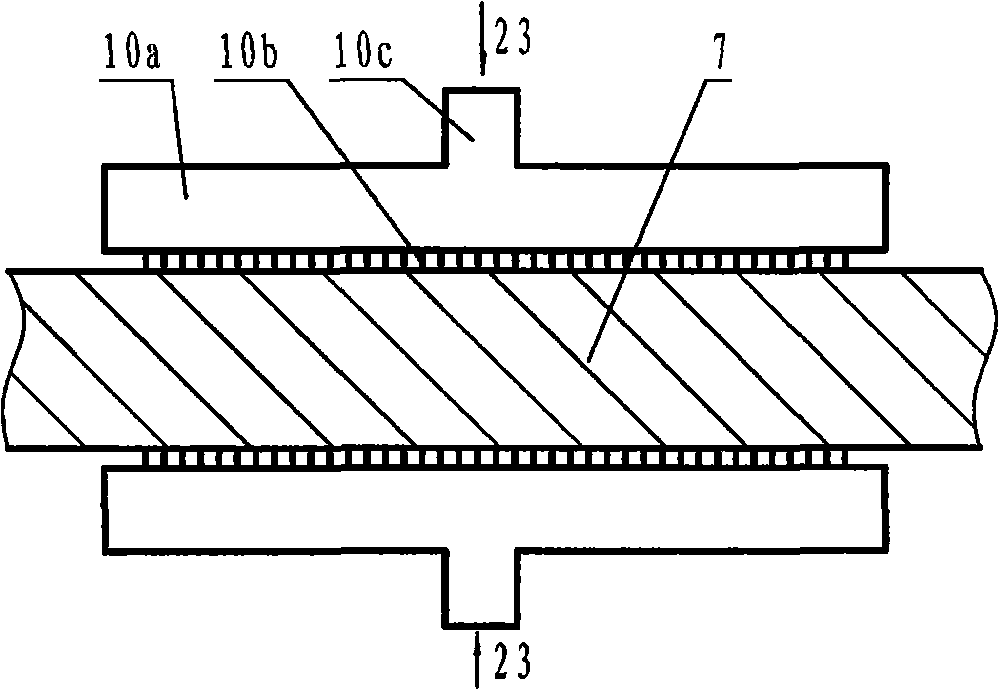

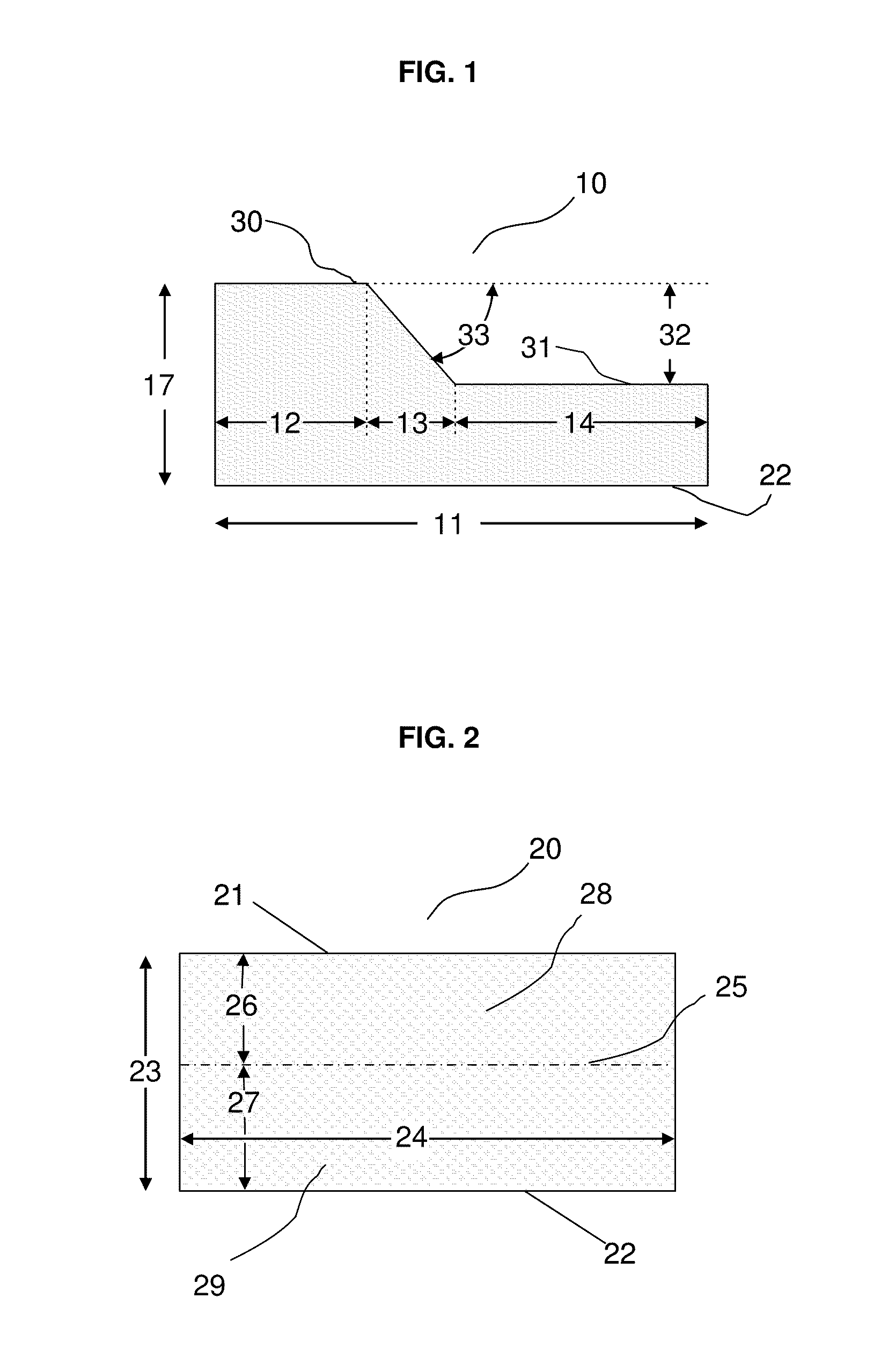

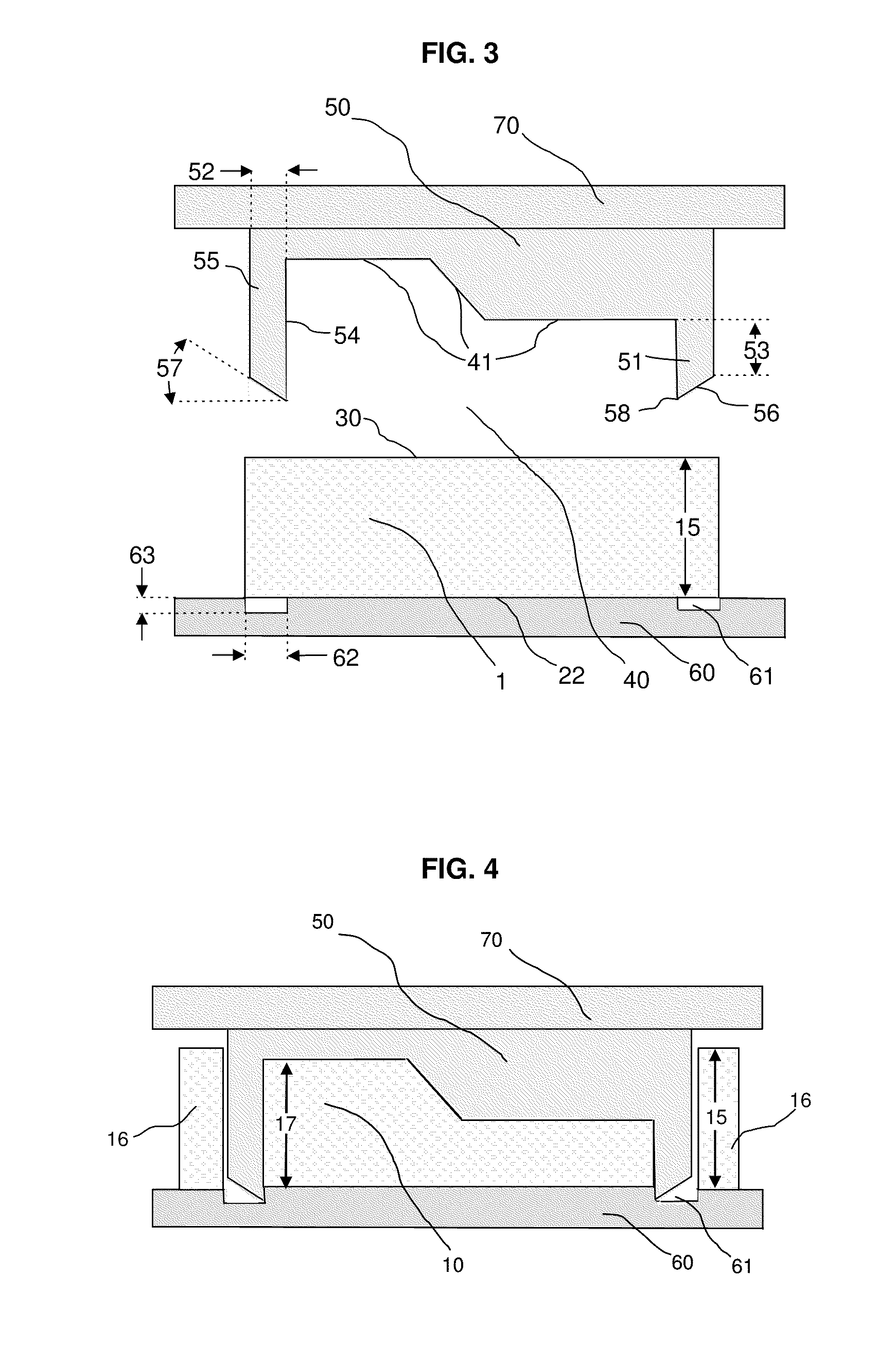

Charging pressing forming method for variable-cross-section special-shaped pipe

The invention discloses a charging pressing forming method for a variable-cross-section special-shaped pipe, and relates to a forming manufacturing method of a metal pipe. The problems that an existing low-internal-pressure forming technology only can form a pipe with the unchangeable section perimeter, and meanwhile, in the internal-high-pressure forming process of an advanced high-strength steel variable-cross-section pipe, the pressure is high, springback is large, and a mold is seriously worn are solved. The forming method comprises the steps that firstly, an upper expansion mold and a lower expansion mold are assembled on a pressure machine; secondly, the upper expansion mold descends to perform mold assembly, a pipe blank is subject to charging, and the pipe blank expands until the pipe blank is attached to the mold; thirdly, the internal pressure of the pipe blank is relieved; fourthly, an upper pressing block and a lower pressing mold are assembled on a pressure machine; fifthly, the upper pressing block descends to perform mold assembly; sixthly, under the joint action of mechanical pressure of the mold and hydraulic pressure of an inner cavity of a variable-cross-section round pipe, mold attaching is carried out, the variable-cross-section round pipe is formed into the variable-cross-section special-shaped pipe, and the forming process is finished; and seventhly, the internal pressure of the variable-cross-section special-shaped pipe is relieved, and the variable-cross-section special-shaped pipe is cut, so that the variable-cross-section special-shaped pipe meeting the design requirement is obtained. The method is used for forming the variable-cross-section special-shaped pipe.

Owner:HARBIN INST OF TECH

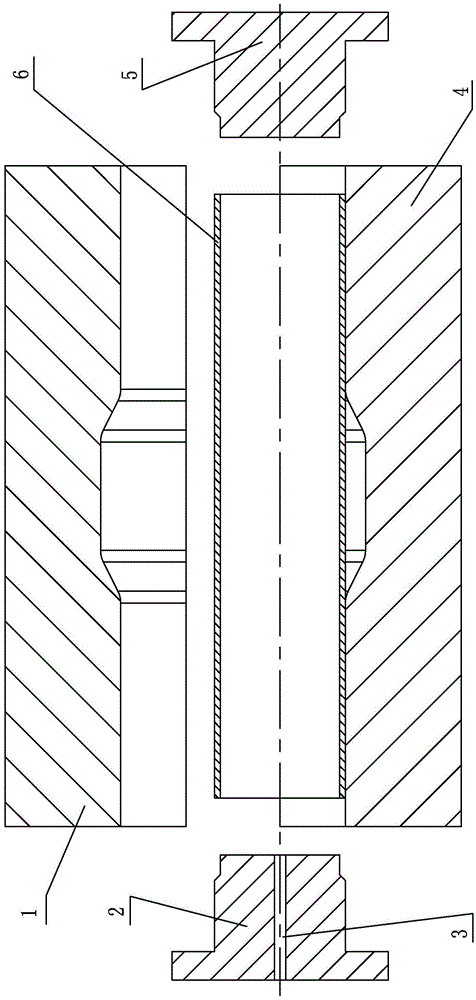

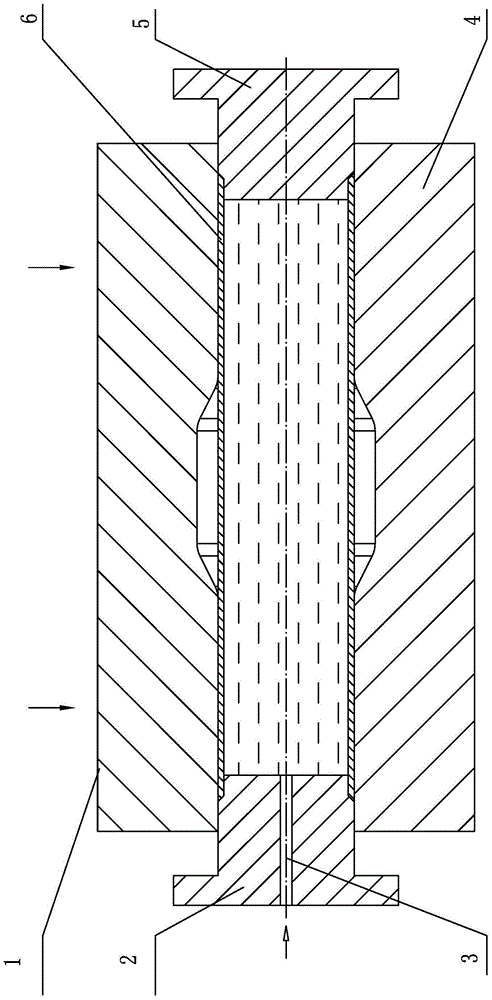

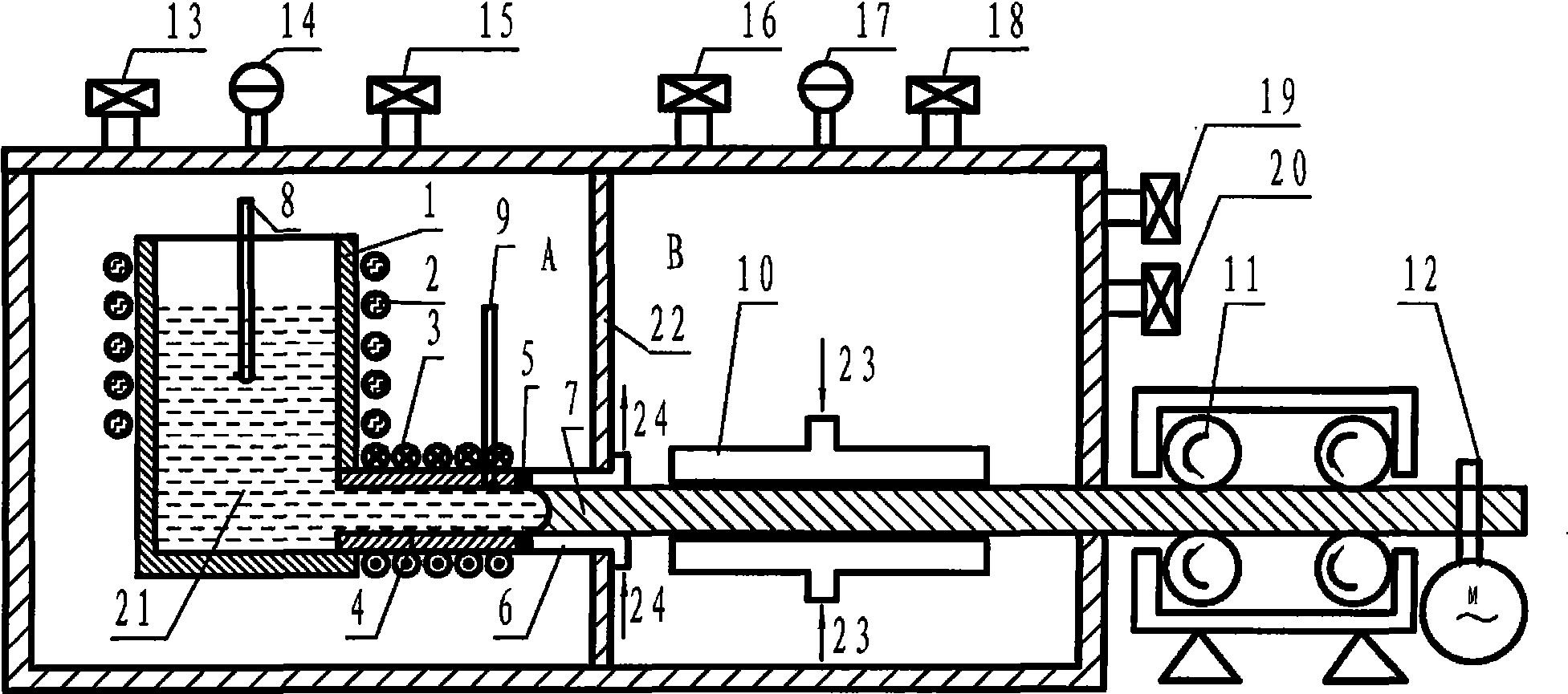

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

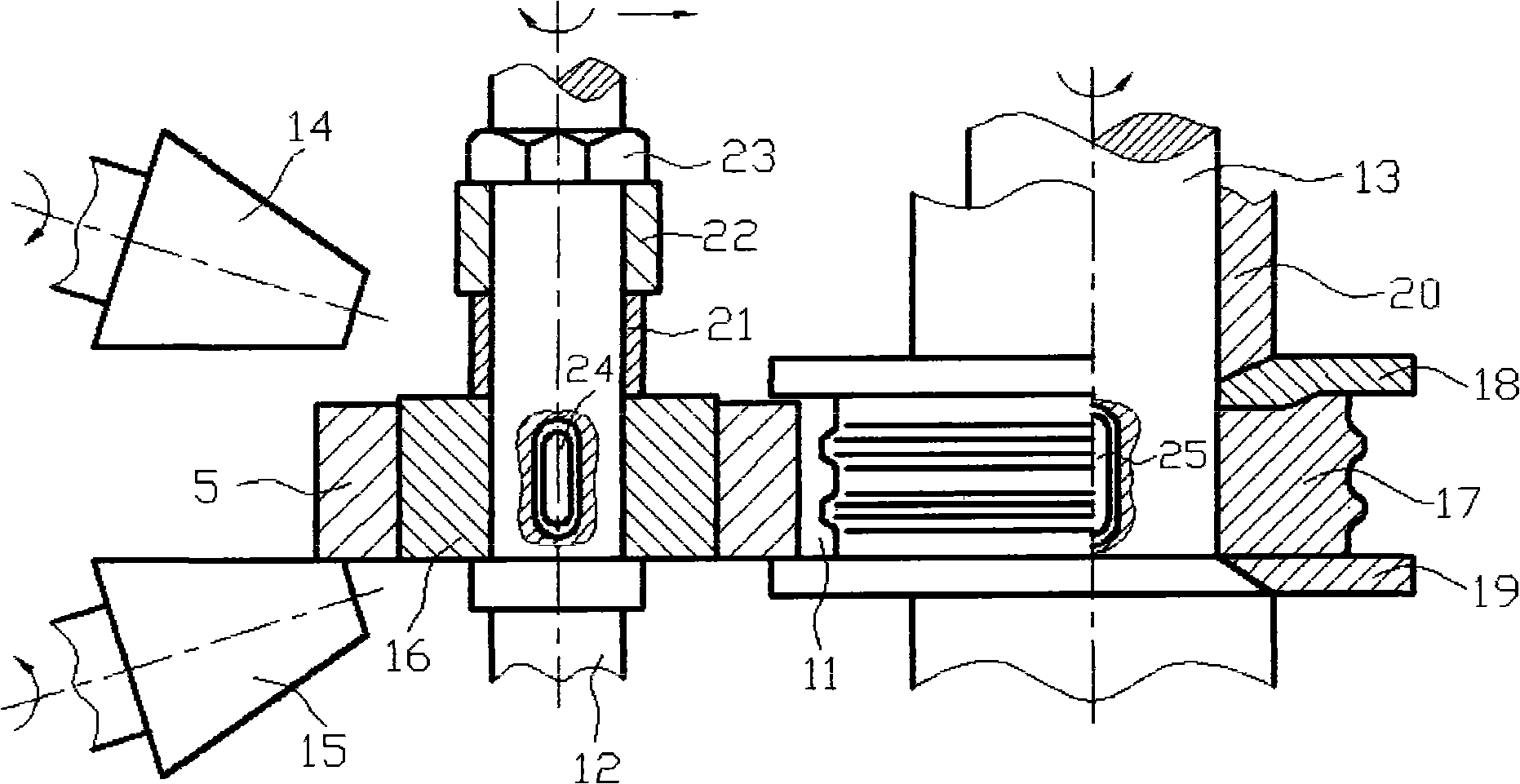

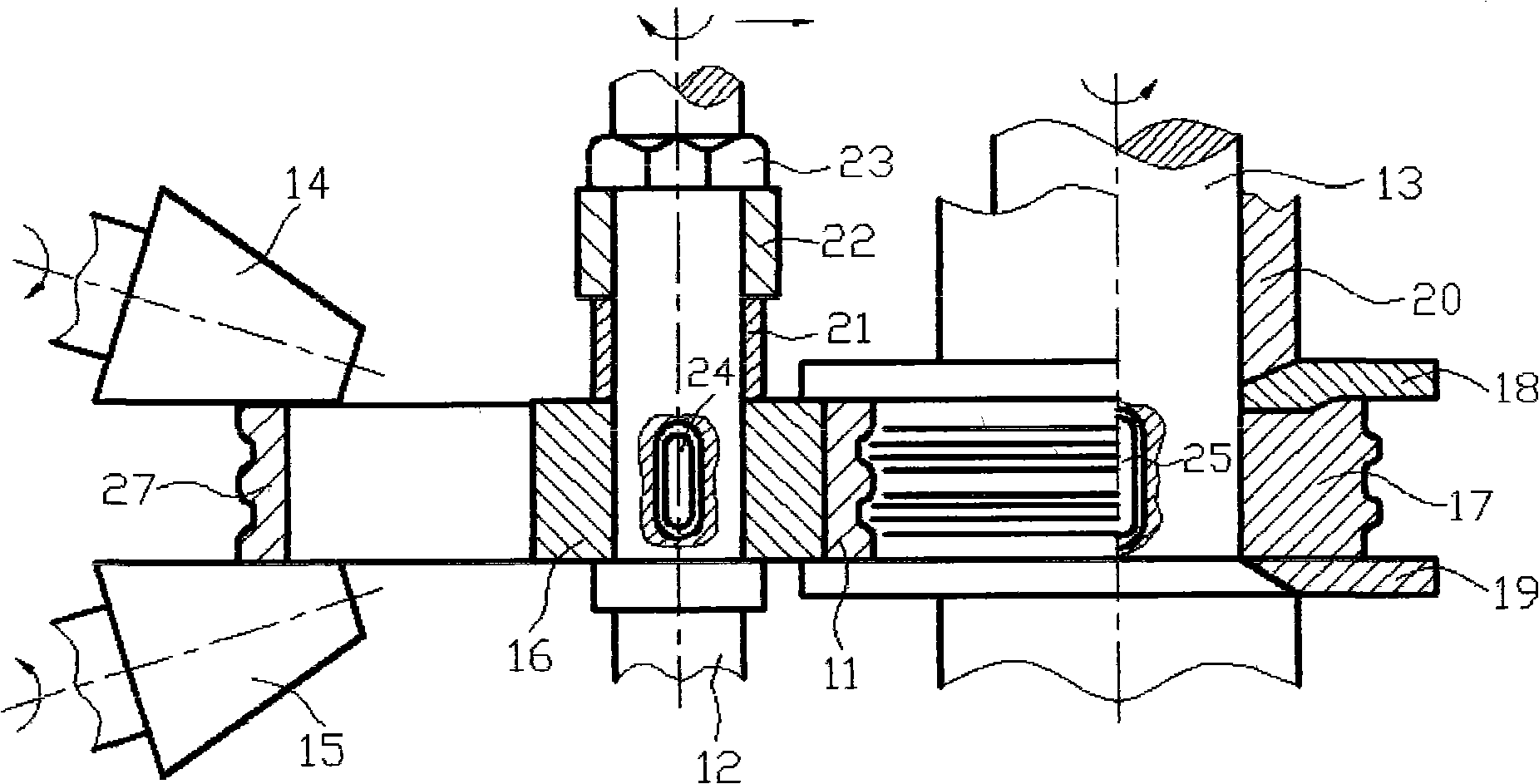

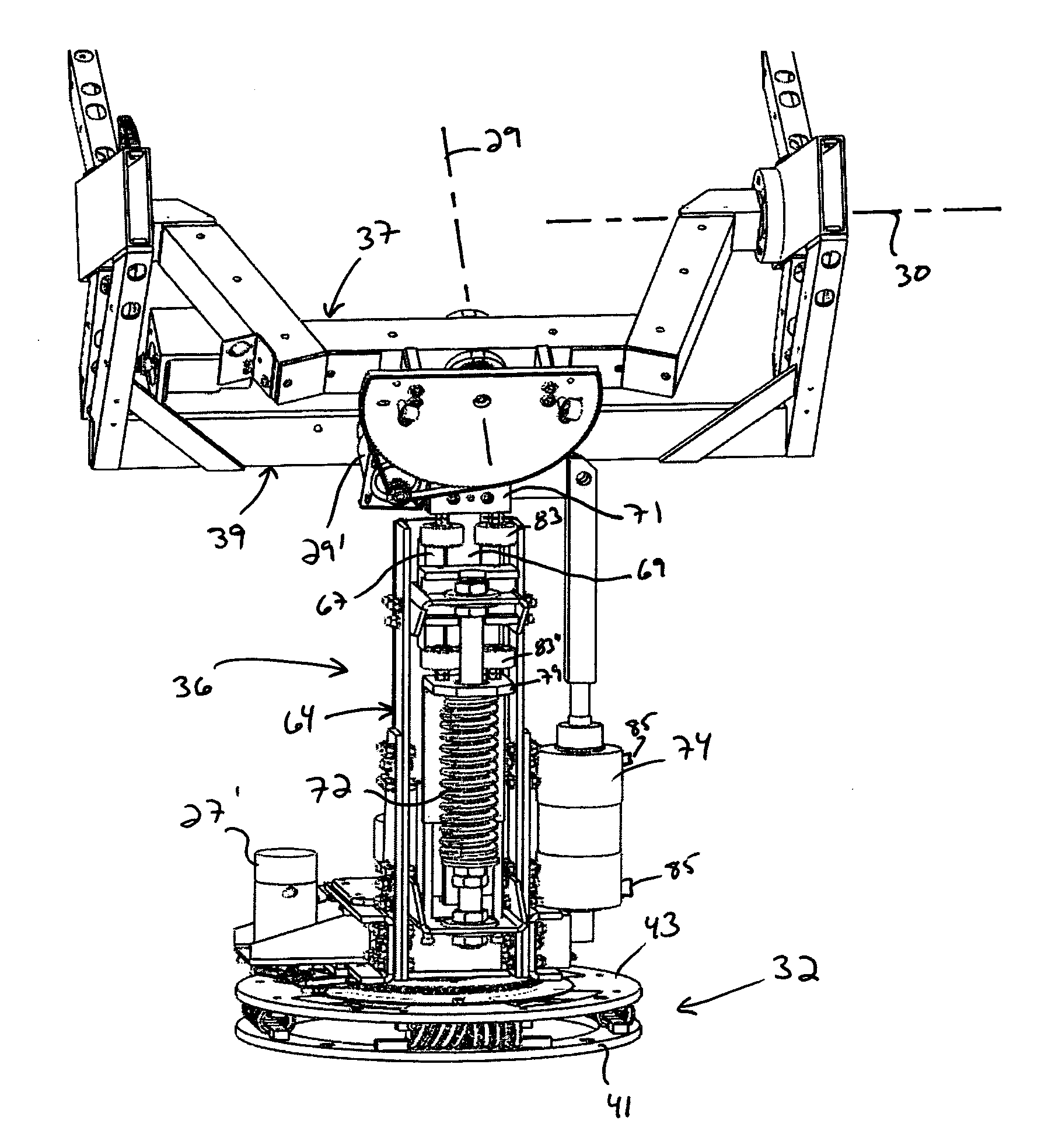

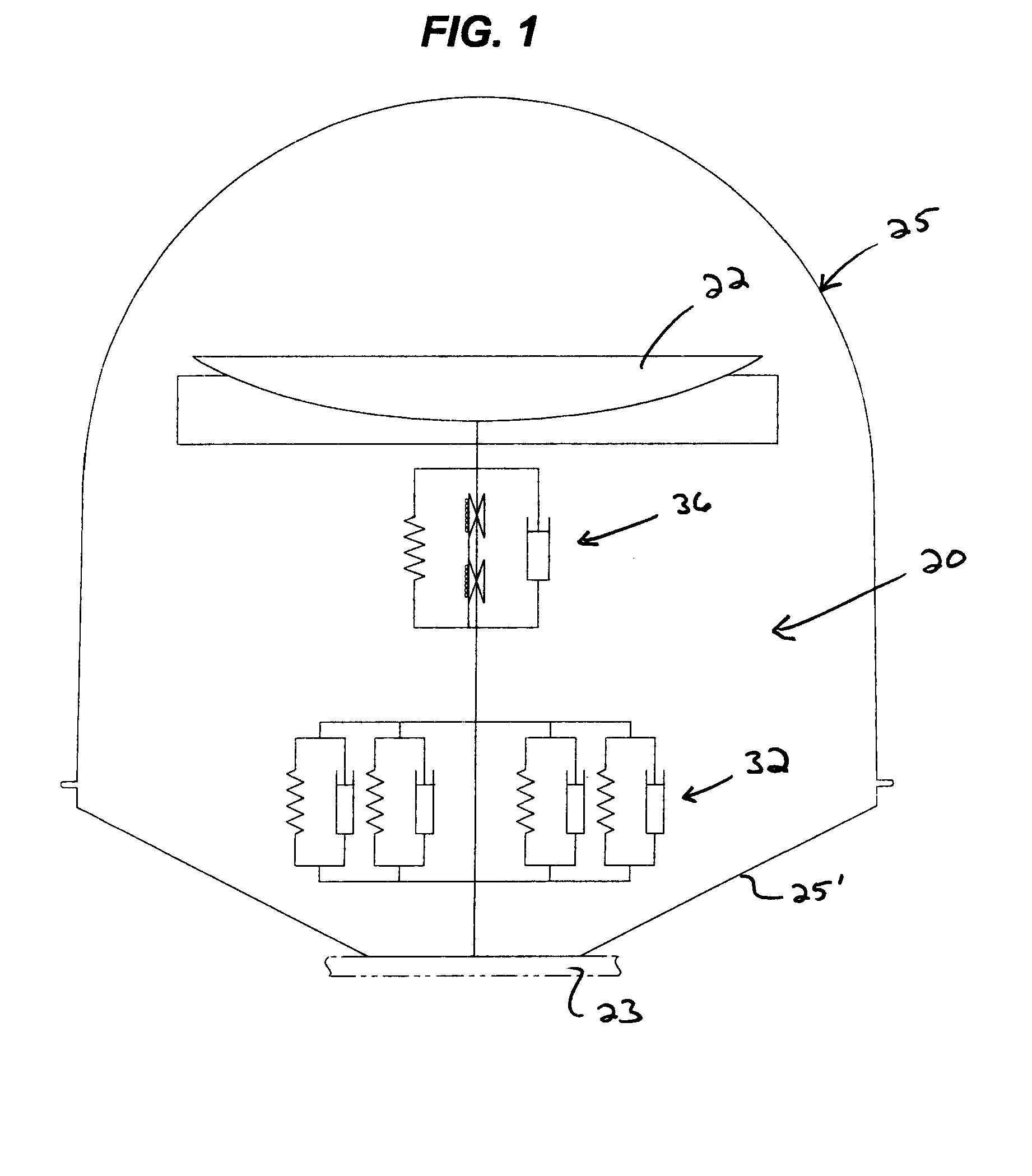

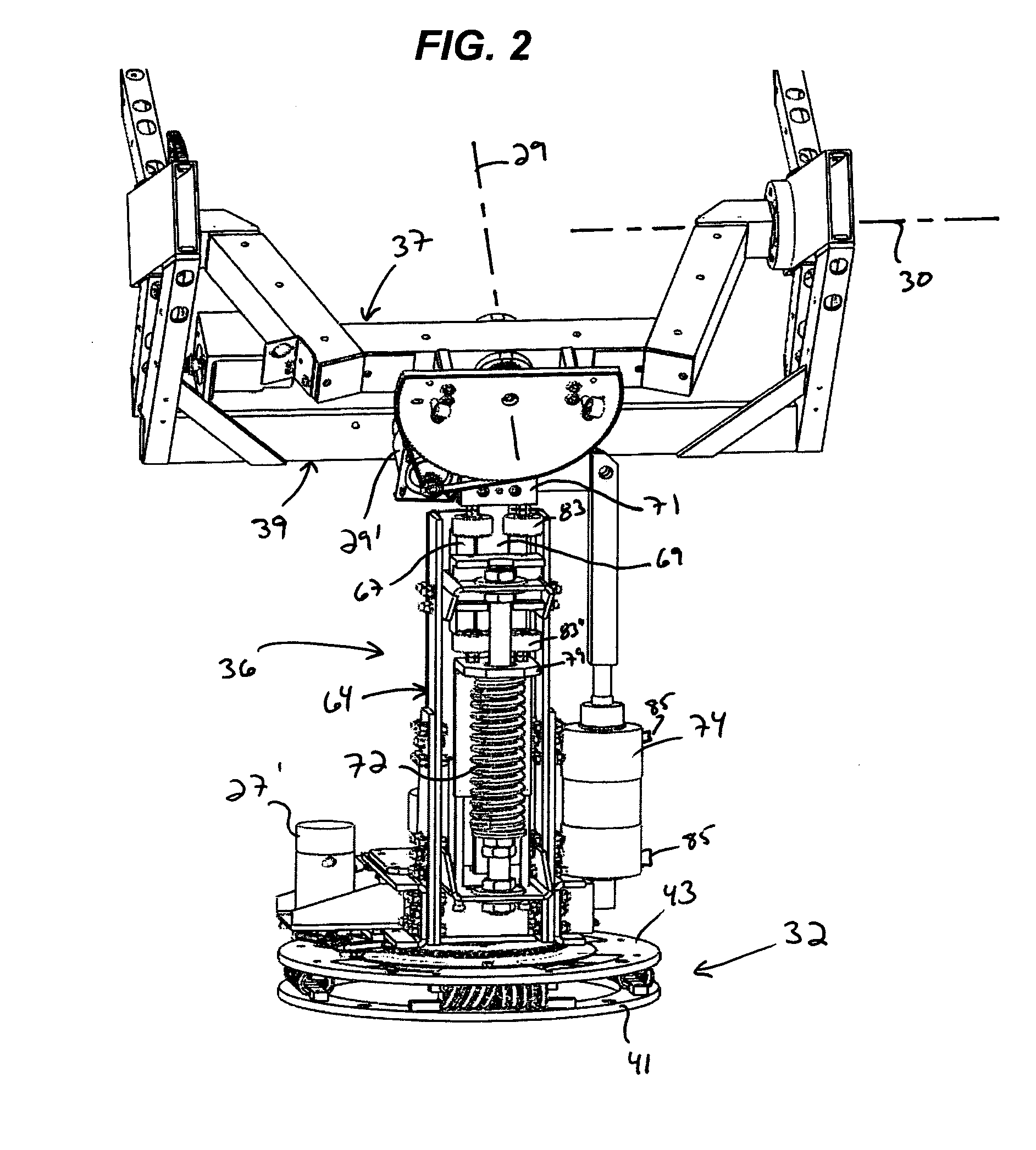

Pedestal for tracking antenna

ActiveUS20100149059A1Antenna supports/mountingsAntenna adaptation in movable bodiesEngineeringAbnormal shaped

A pedestal for tracking antenna includes a horizontal isolation assembly dimensioned and configured to isolate the support plate from horizontal vibration and shock of the base ring, a hub assembly including a support mounted on the horizontal isolation assembly rotatably supporting a rotating frame about a first azimuth axis, a vertical isolation assembly including an upright frame and a cross-level axis support slidably interconnected with a linear bearing assembly, the linear bearing assembly having a profiled rail slidably received within a complementary shaped bearing block, wherein the profiled rail can not twist axially relative to the bearing block, a cross-level frame pivotally mounted on the cross-level axis support about a second cross-level axis, and / or an elevation frame assembly supporting the tracking antenna and pivotally mounted on the cross-level frame about a third elevation axis.

Owner:SEA TEL INC D B A COBHAM SATCOM

Method for rolling and shaping nickel-based high-temperature alloy special-shaped ring forging

The invention discloses a rolling and shaping method for a nickel-based high temperature alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 60 to 65 percent so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 20 to 25 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 20 to 25 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

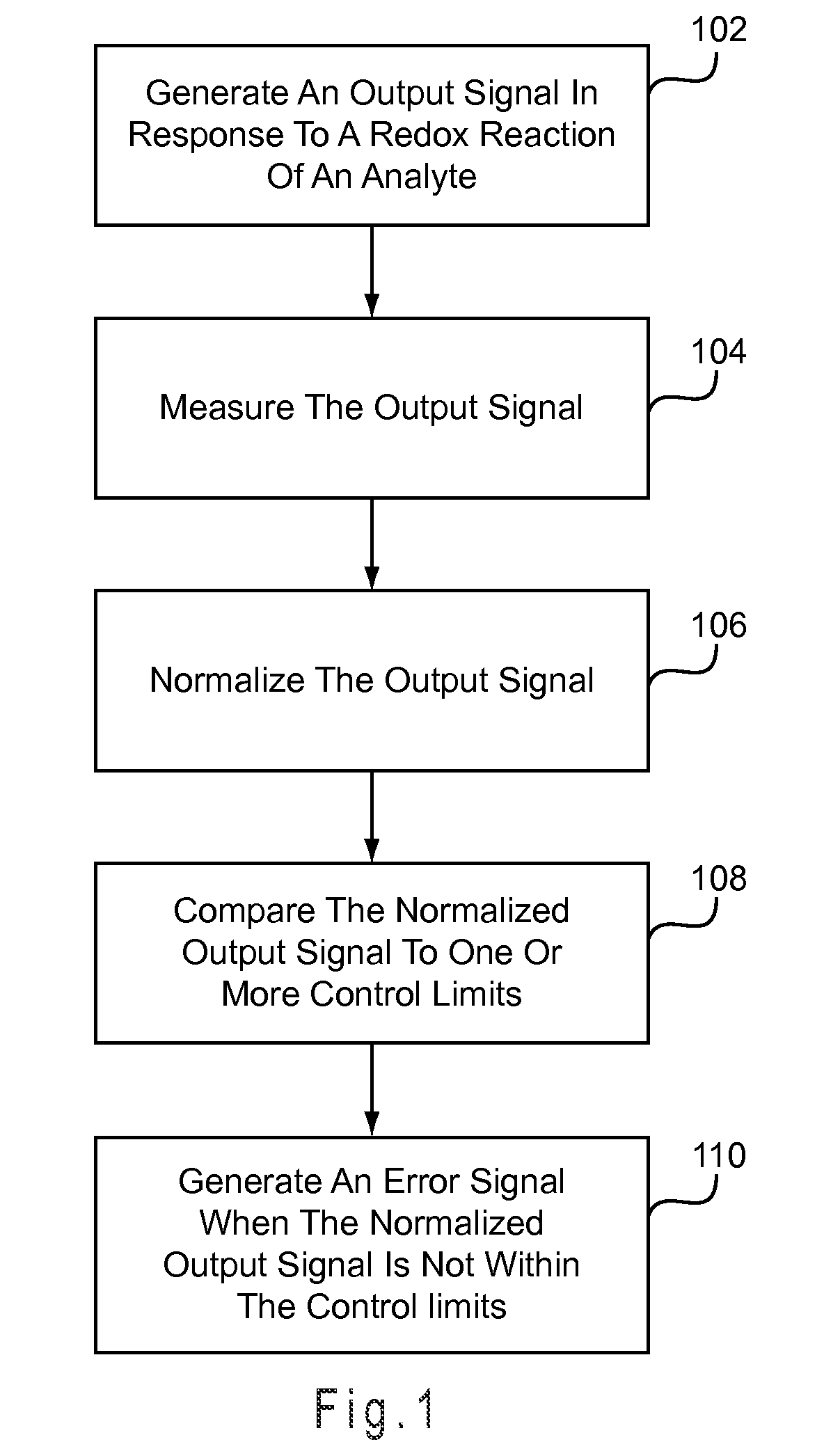

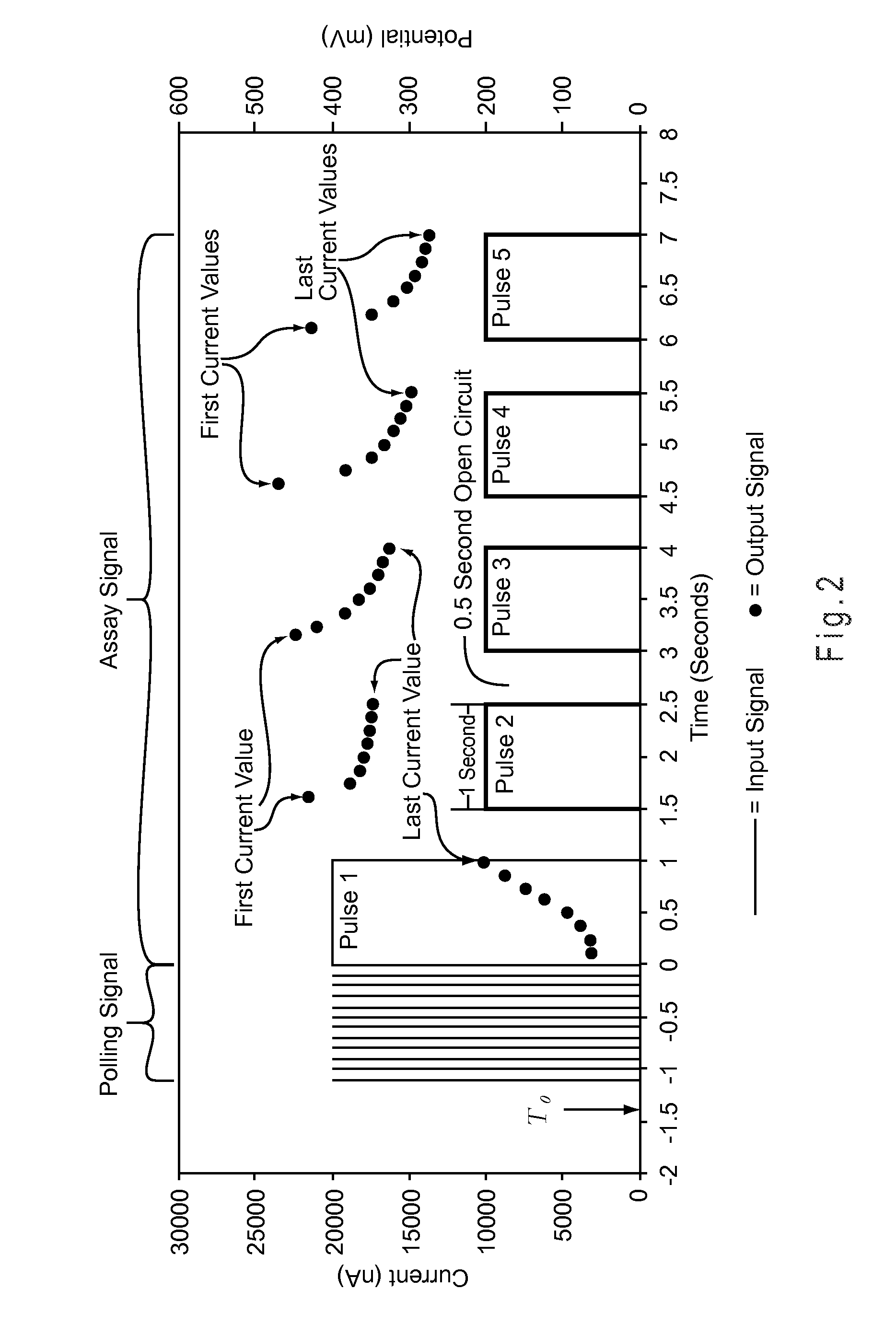

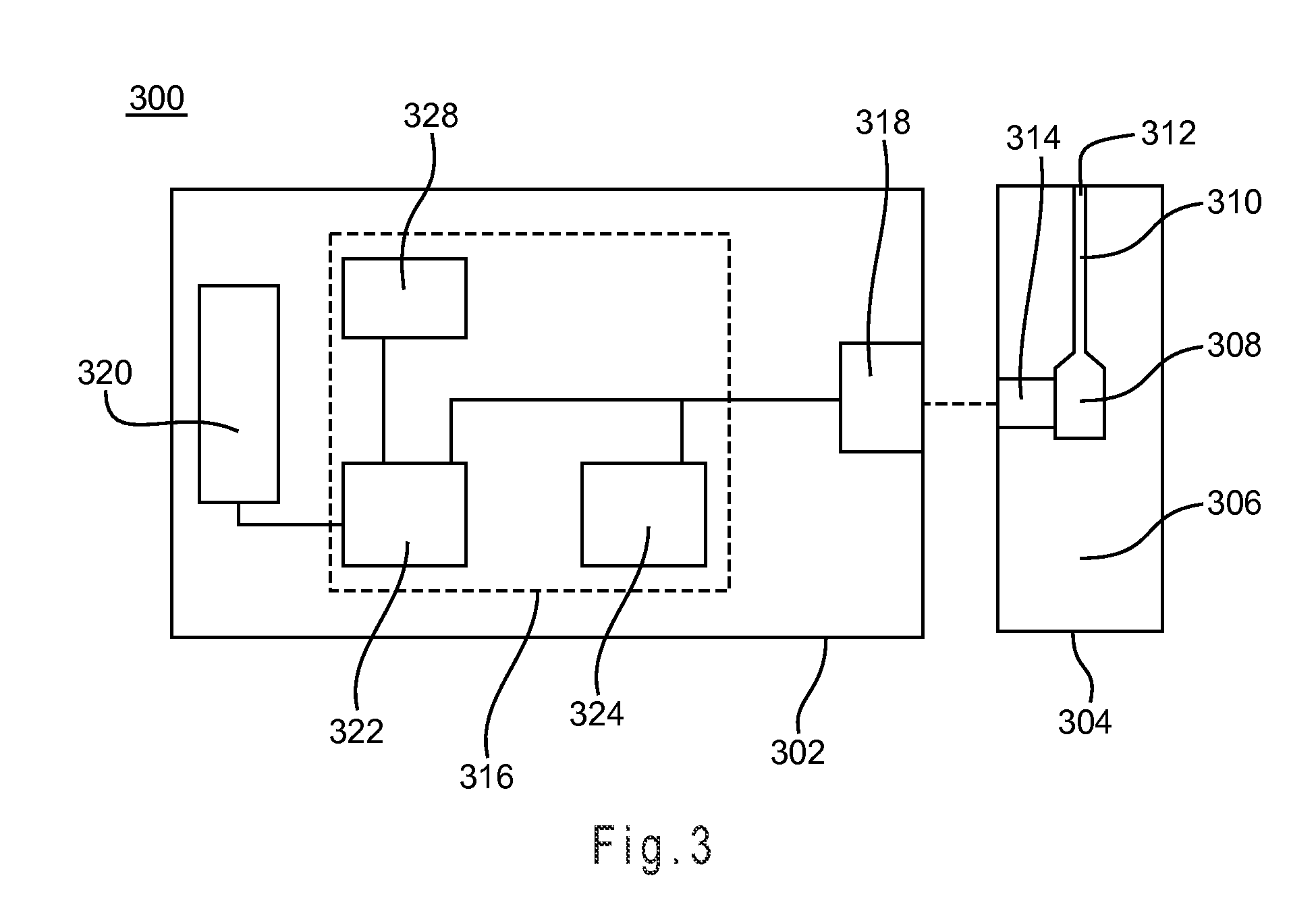

Abnormal Output Detection System For A Biosensor

ActiveUS20090099787A1Accurate and precise analysisMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalyteRedox

A biosensor has an abnormal output detection system that determines whether an output signal from the redox reaction of an analyte has a normal or abnormal shape or configuration. The abnormal output detection system improves the accuracy and precision of the biosensor in determining whether an output signal has a shape or configuration that may not provide an accurate and / or precise analysis of a biological fluid. The biosensor generates an output signal in response to the redox reaction of the analyte. The biosensor normalizes the output signal and compares the normalized output signal with one or more control limits. The biosensor may generate an error signal when the normalized output signal is not within the control limits.

Owner:ASCENSIA DIABETES CARE HLDG AG

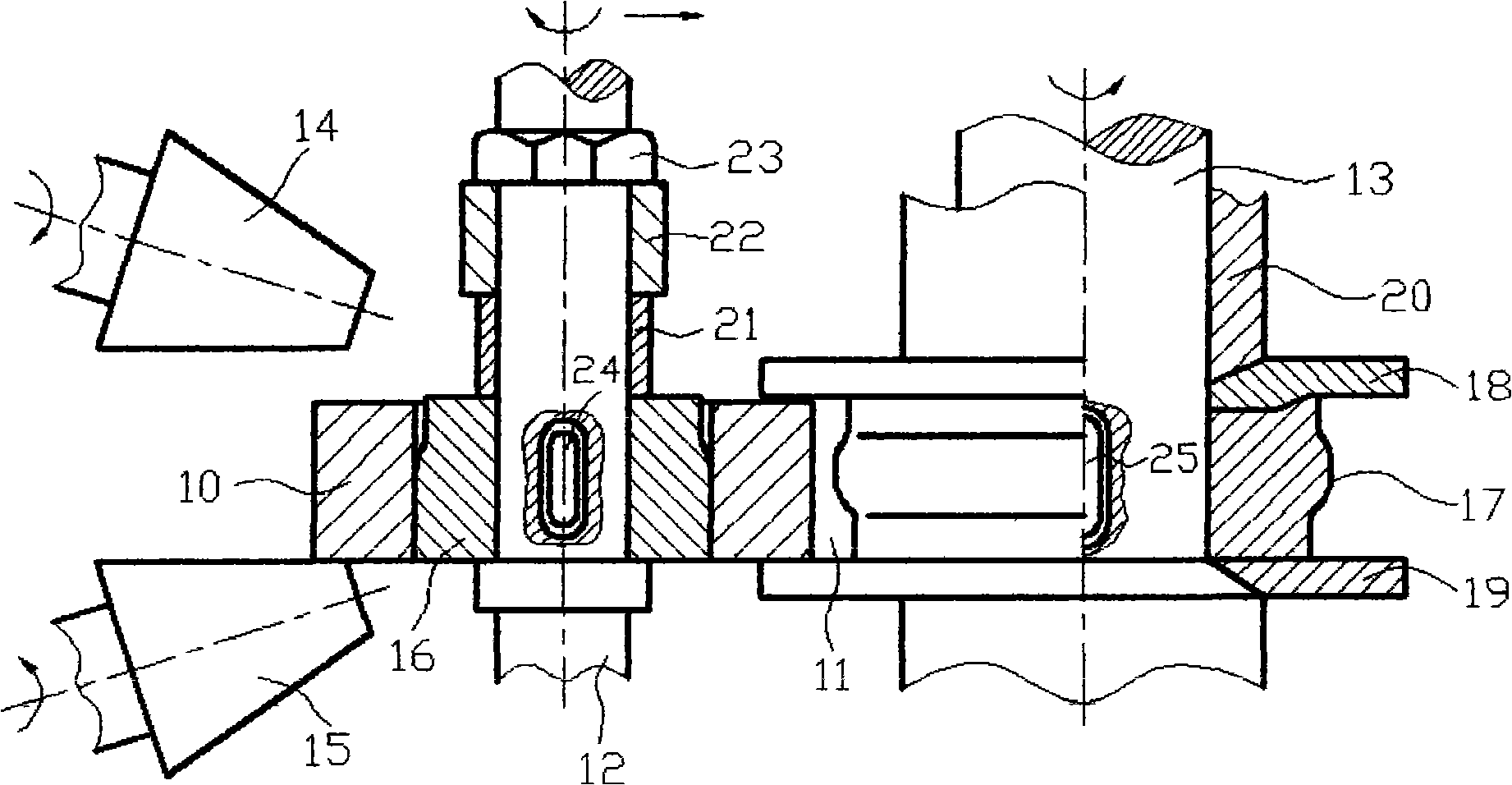

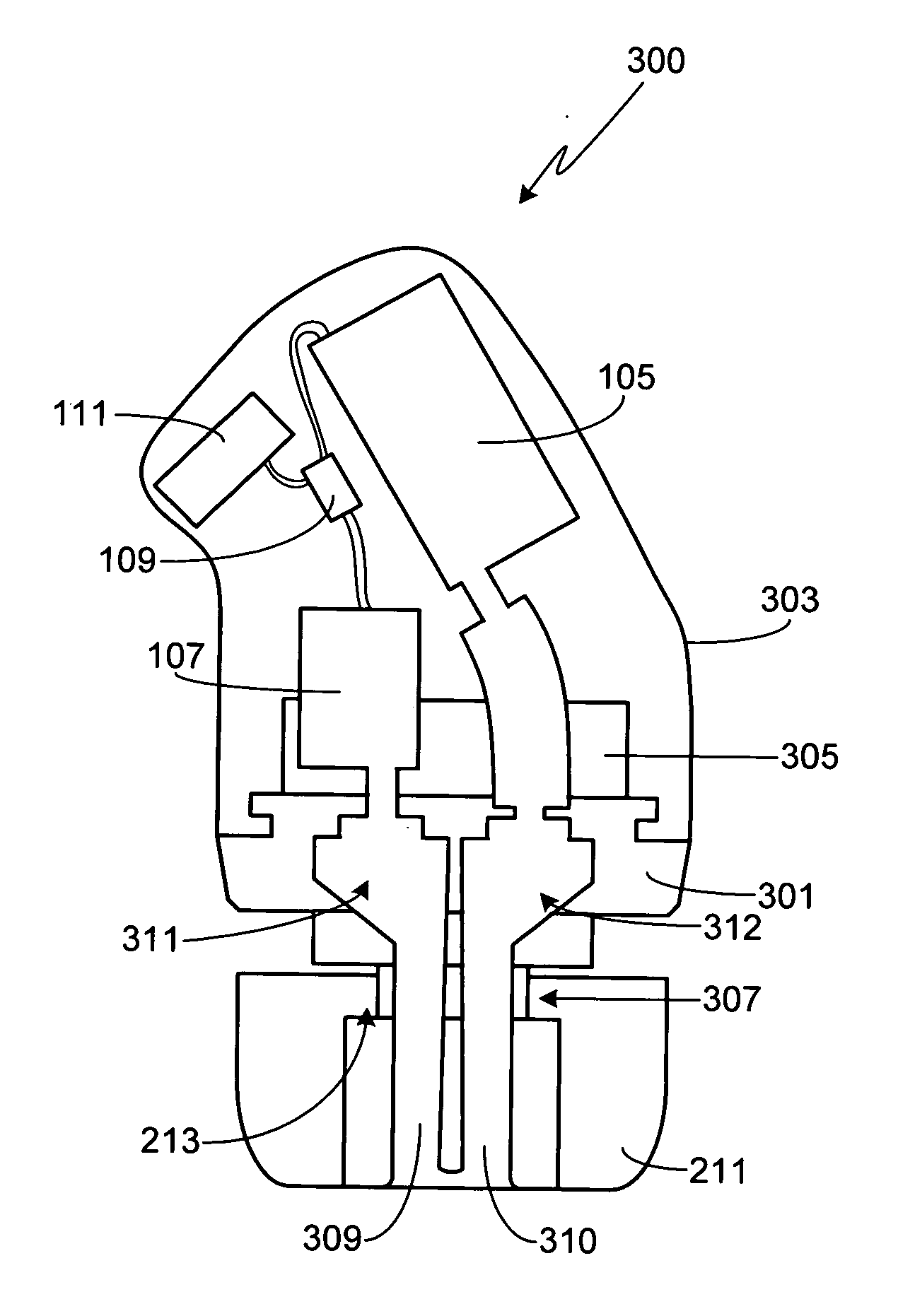

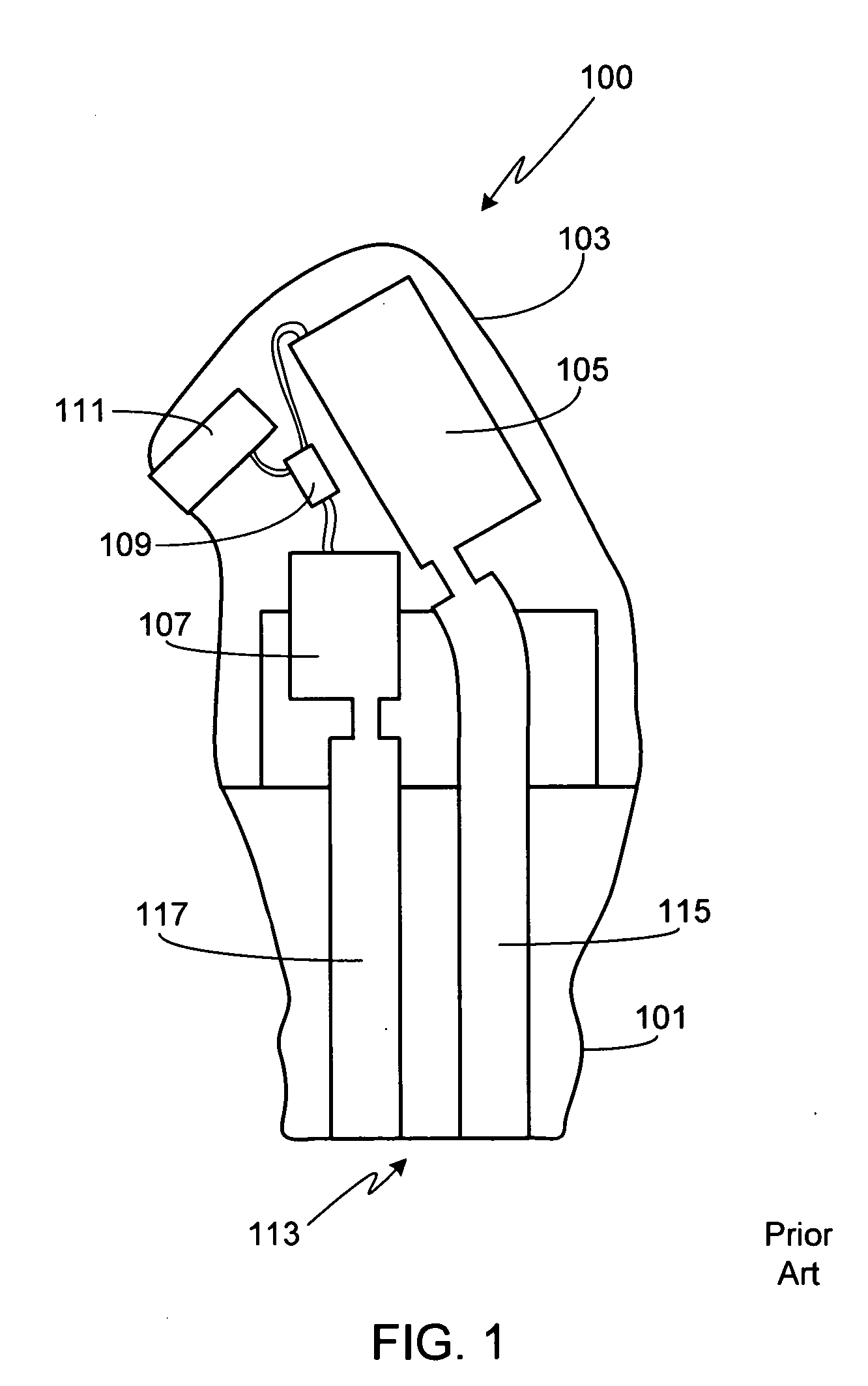

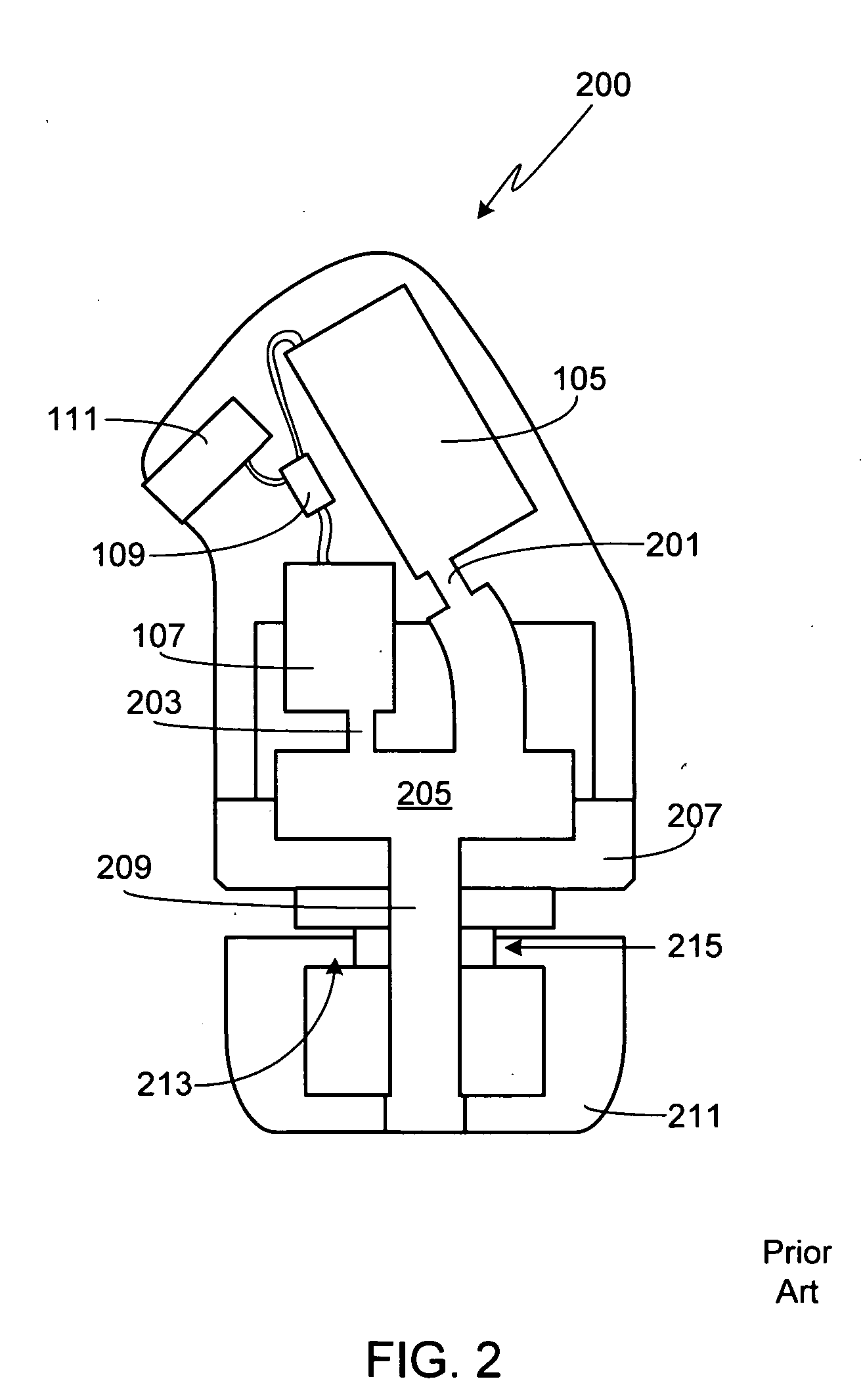

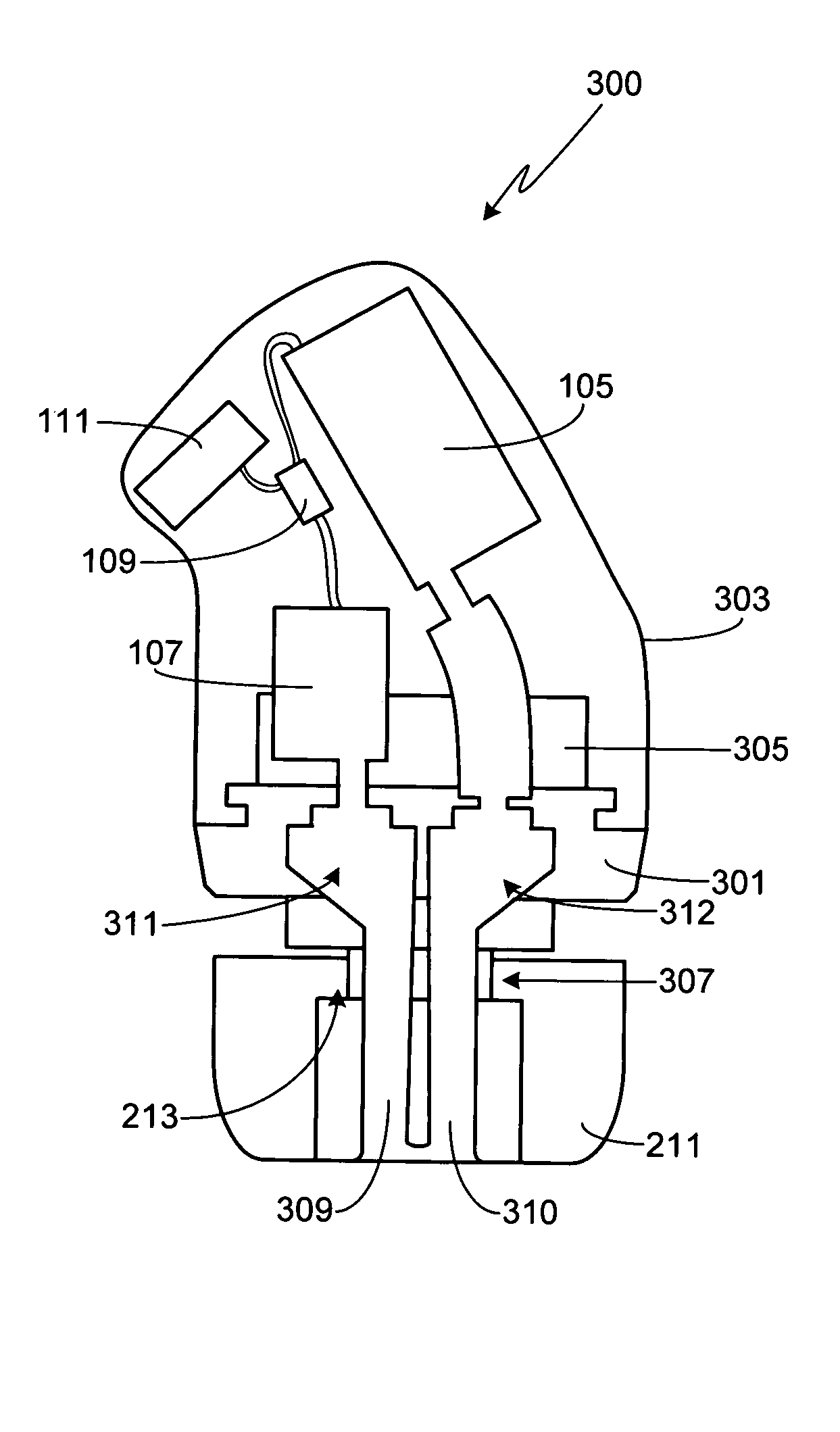

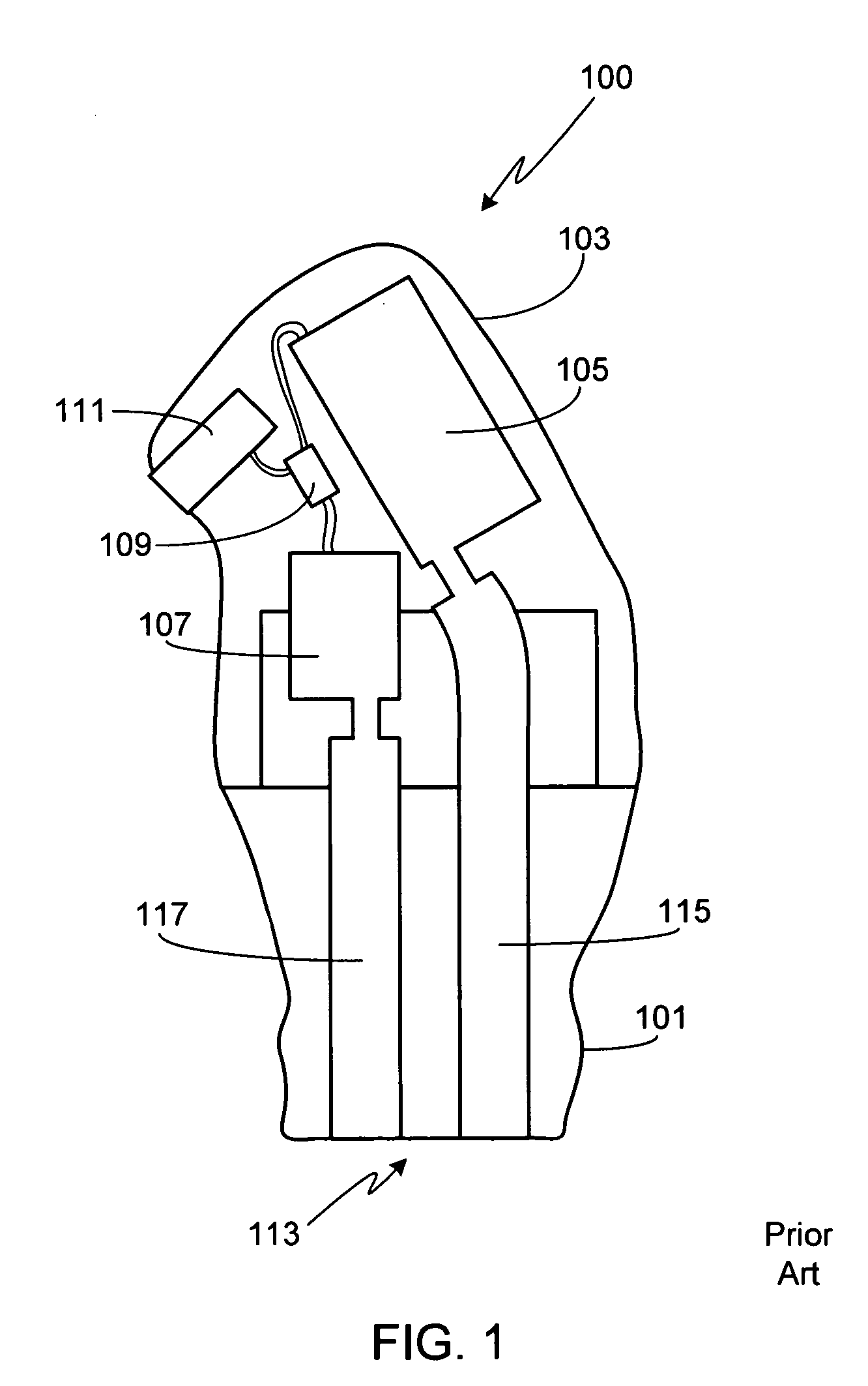

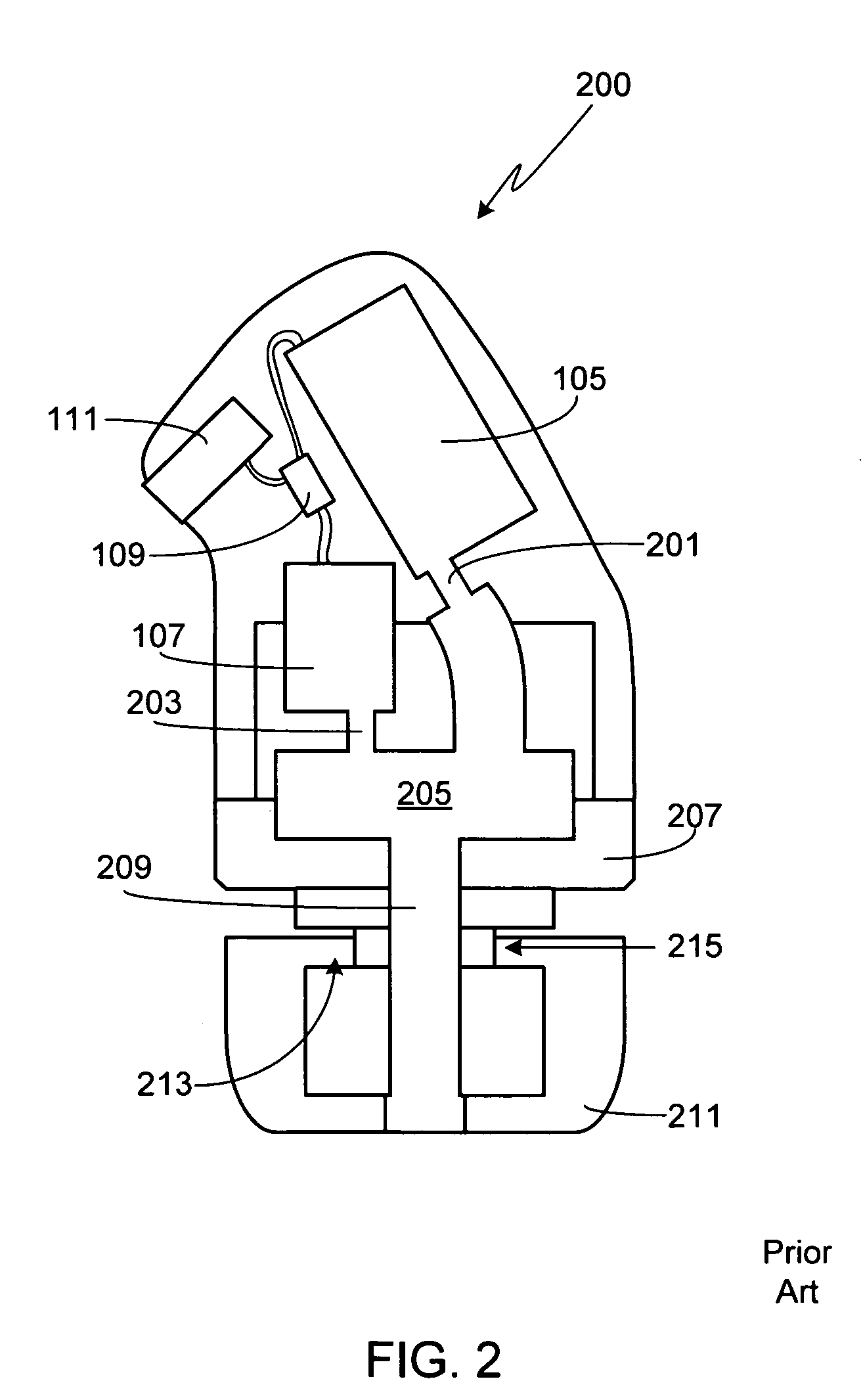

In-ear monitor with shaped dual bore

ActiveUS20060133631A1Easy to customizeDetails for specific frequency responseIntra aural earpiecesAcoustic transmissionEngineering

A multi-driver in-ear monitor for use with either a recorded or a live audio source is provided. If a pair of drivers is used, each driver has an individual sound delivery tube. If three drivers are used, the outputs from two of the drivers are merged into a single sound delivery tube while the output from the third driver is maintained in a separate, discrete sound tube. The sound delivery tubes remain separate throughout the end portion of the earpiece. The earpiece tip is configured to be fitted with any of a variety of sleeves (e.g., foam sleeves, flanged sleeves, etc.), thus allowing the in-ear monitor to be easily tailored to comfortably fit within any of a variety of ear canals. Due to the size constraints of such an earpiece, the sound delivery tubes include a transition region. Acoustic filters (i.e., dampers) can be interposed between one or both driver outputs and the earpiece output.

Owner:LOGITECH INT

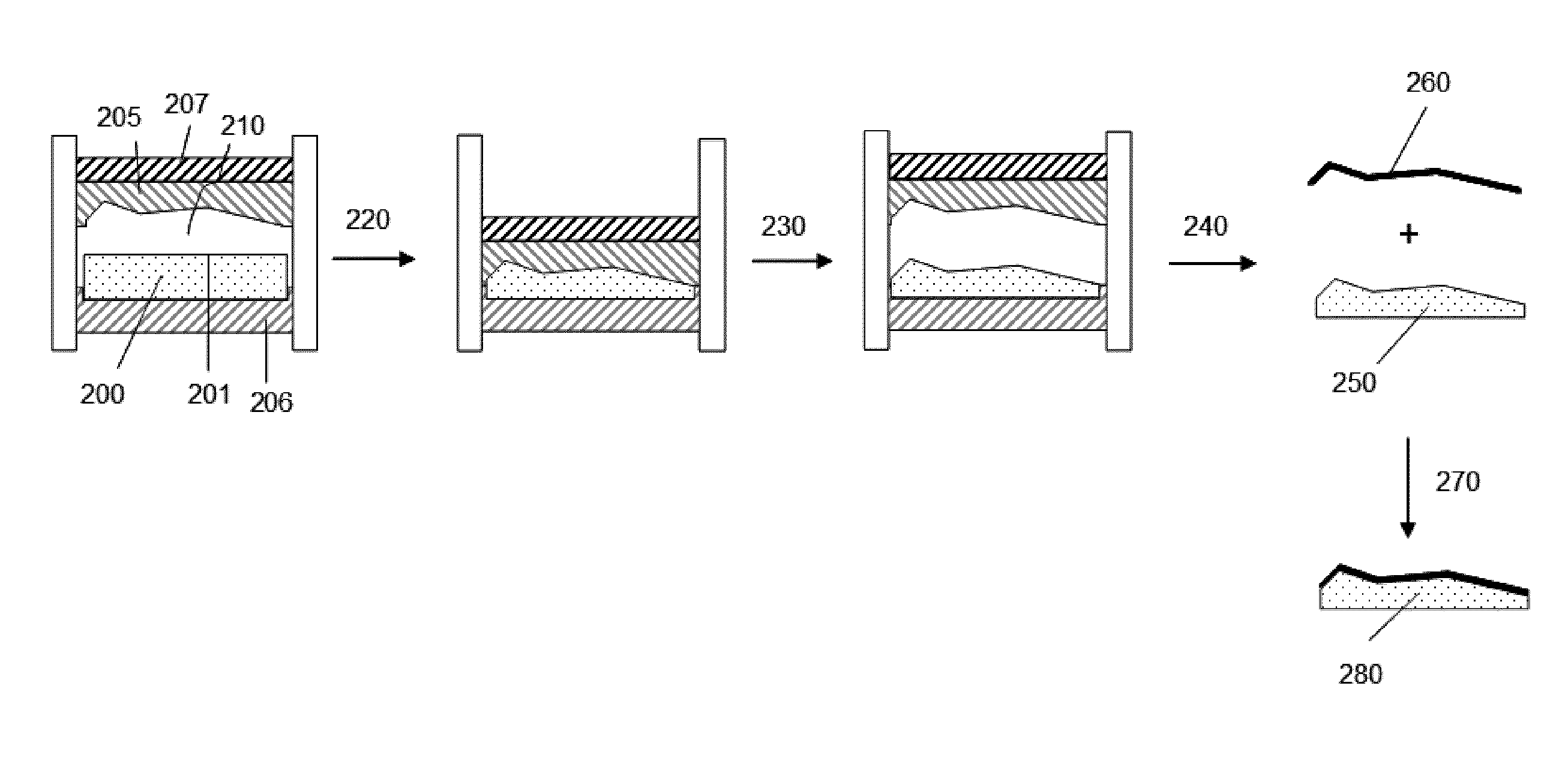

Shaped foam composite article

InactiveUS20110293914A1Simple and cost-effectiveLong cycle timeLaminationLamination apparatusCold formedPolymer science

The present invention is a method to manufacture shaped foam composite articles comprising a foam core and one or more skin and shaped foam composite articles made therefrom. Specifically, cold formed shaped foam articles having an upper and lower surface having a skin applied to one or both of the surfaces. Preferably the foam comprises a styrenic polymer foam and the skins may independently be mono-layered or multi-layered. The shaped foam article and the skin may be made from the same or different materials. In the case where there are more than one skin, the skins may comprise the same or different materials.

Owner:MAURER MYRON J +7

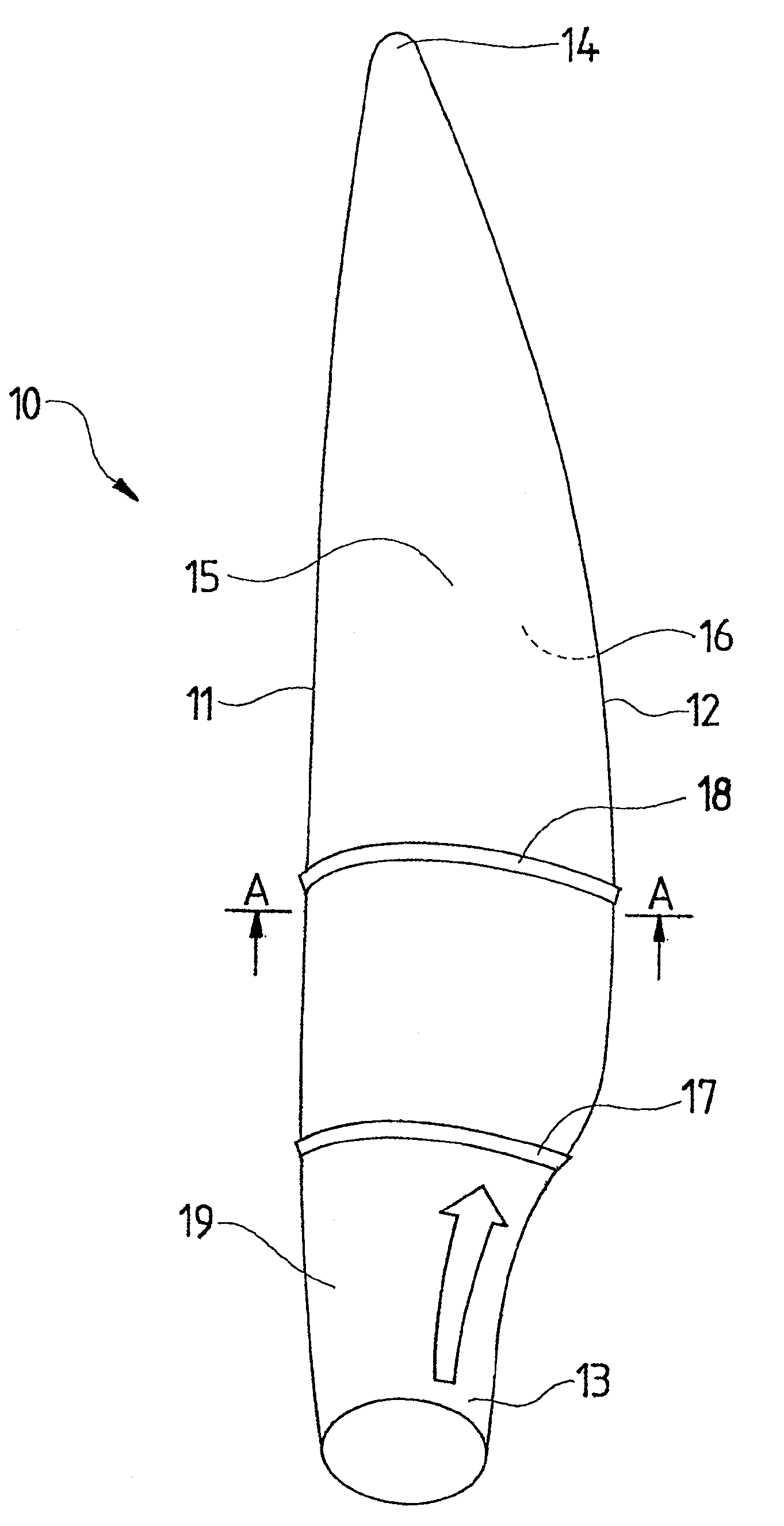

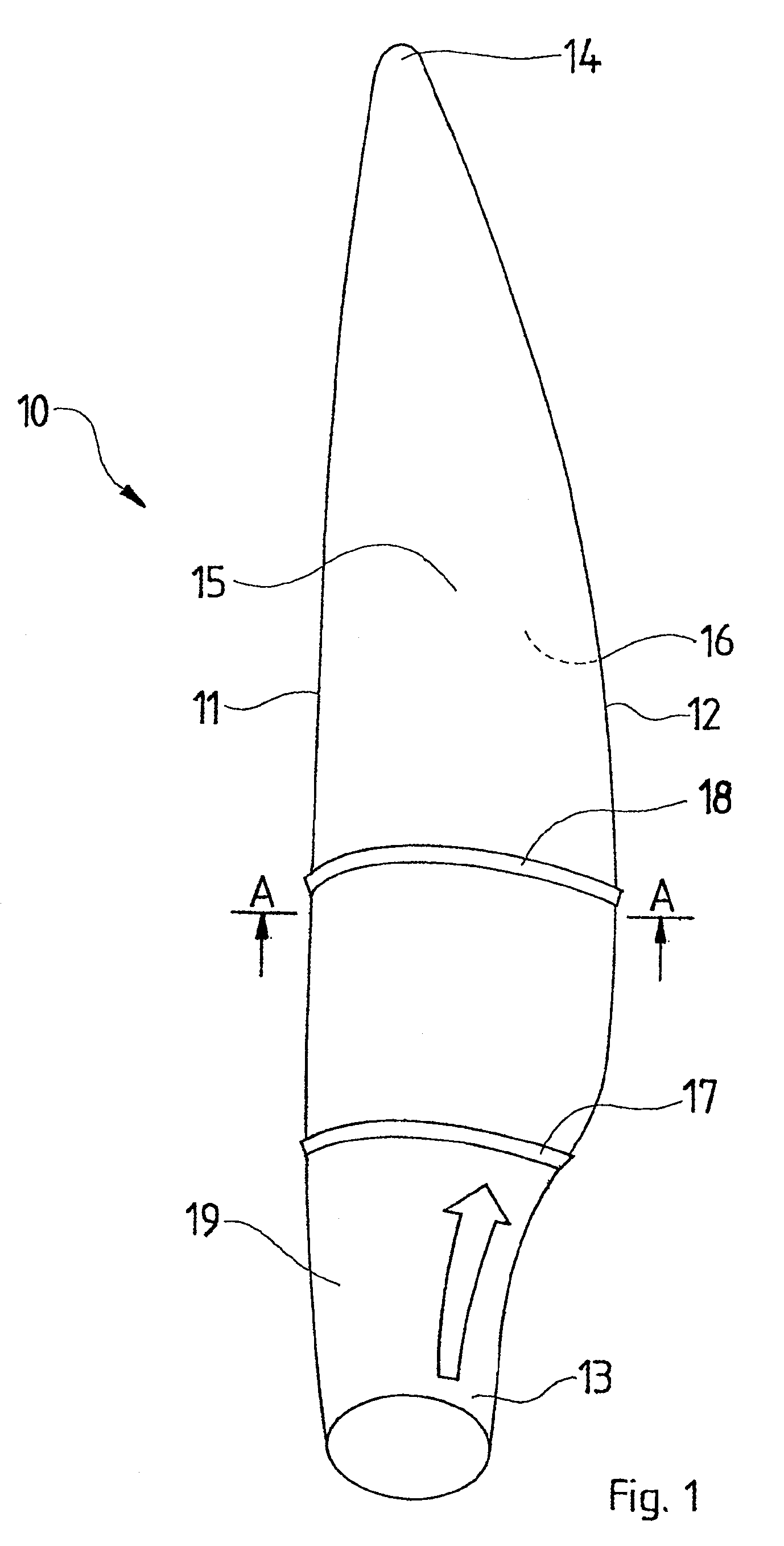

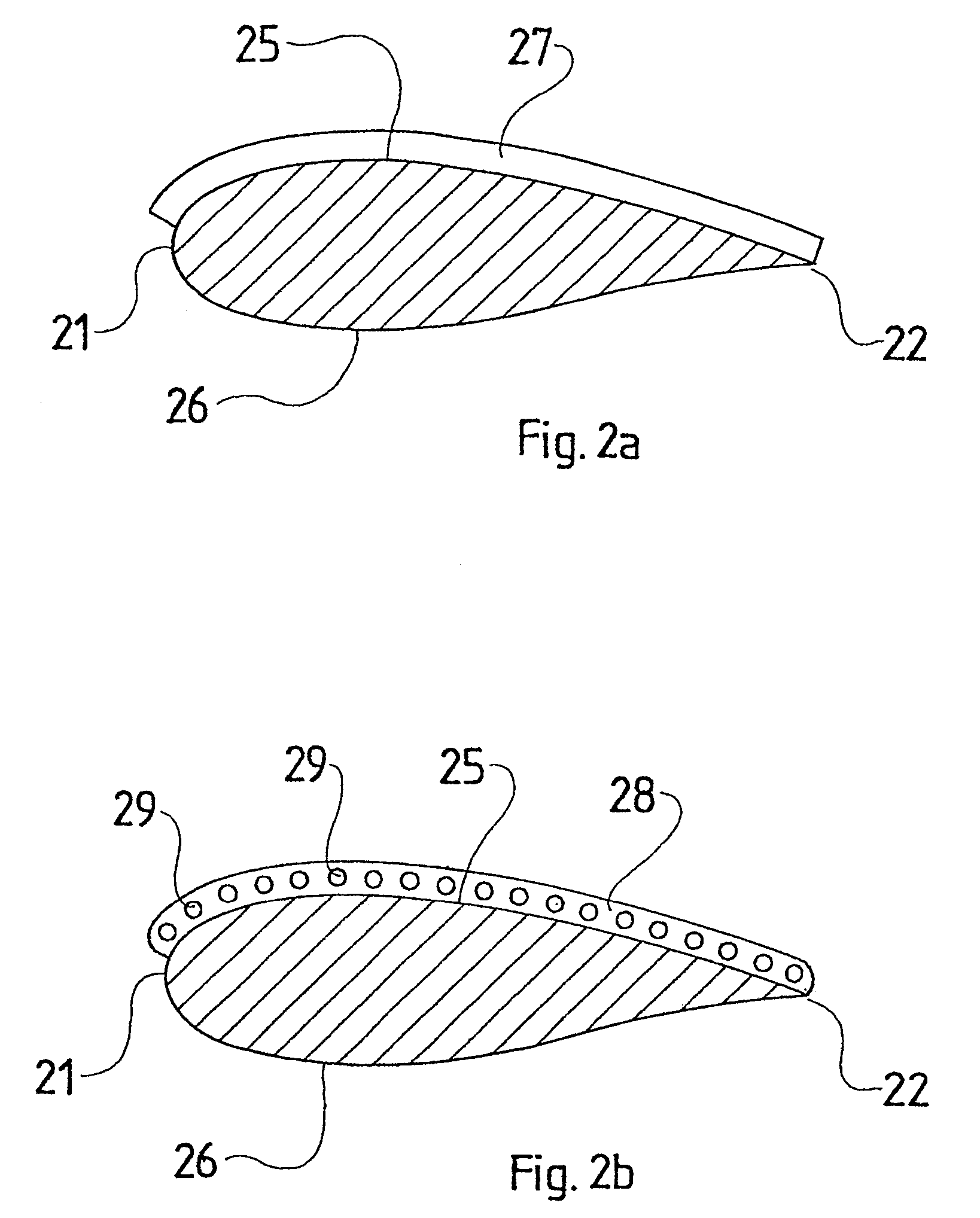

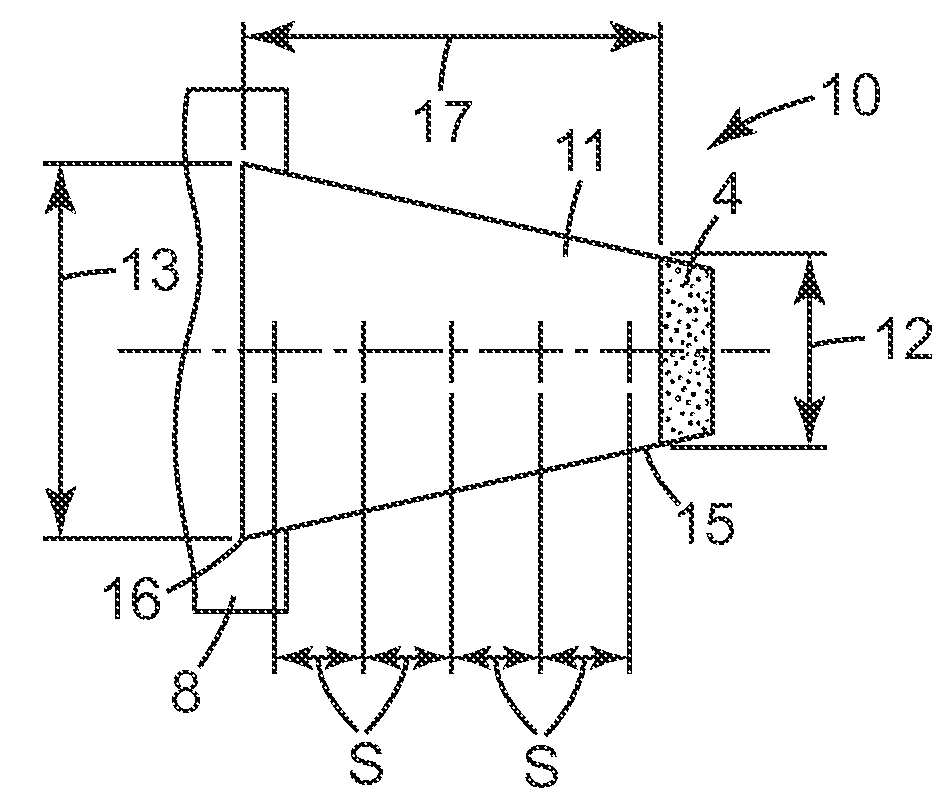

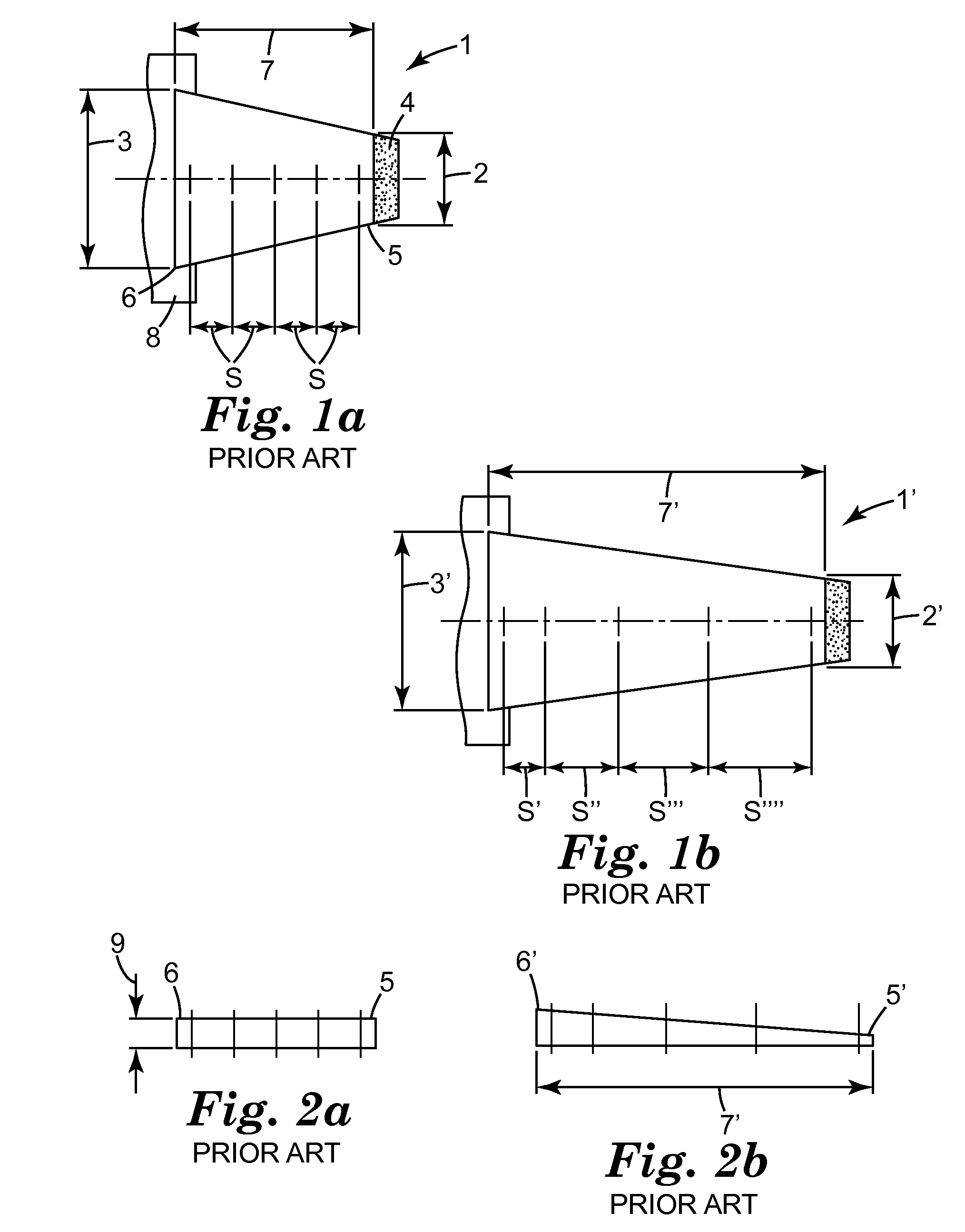

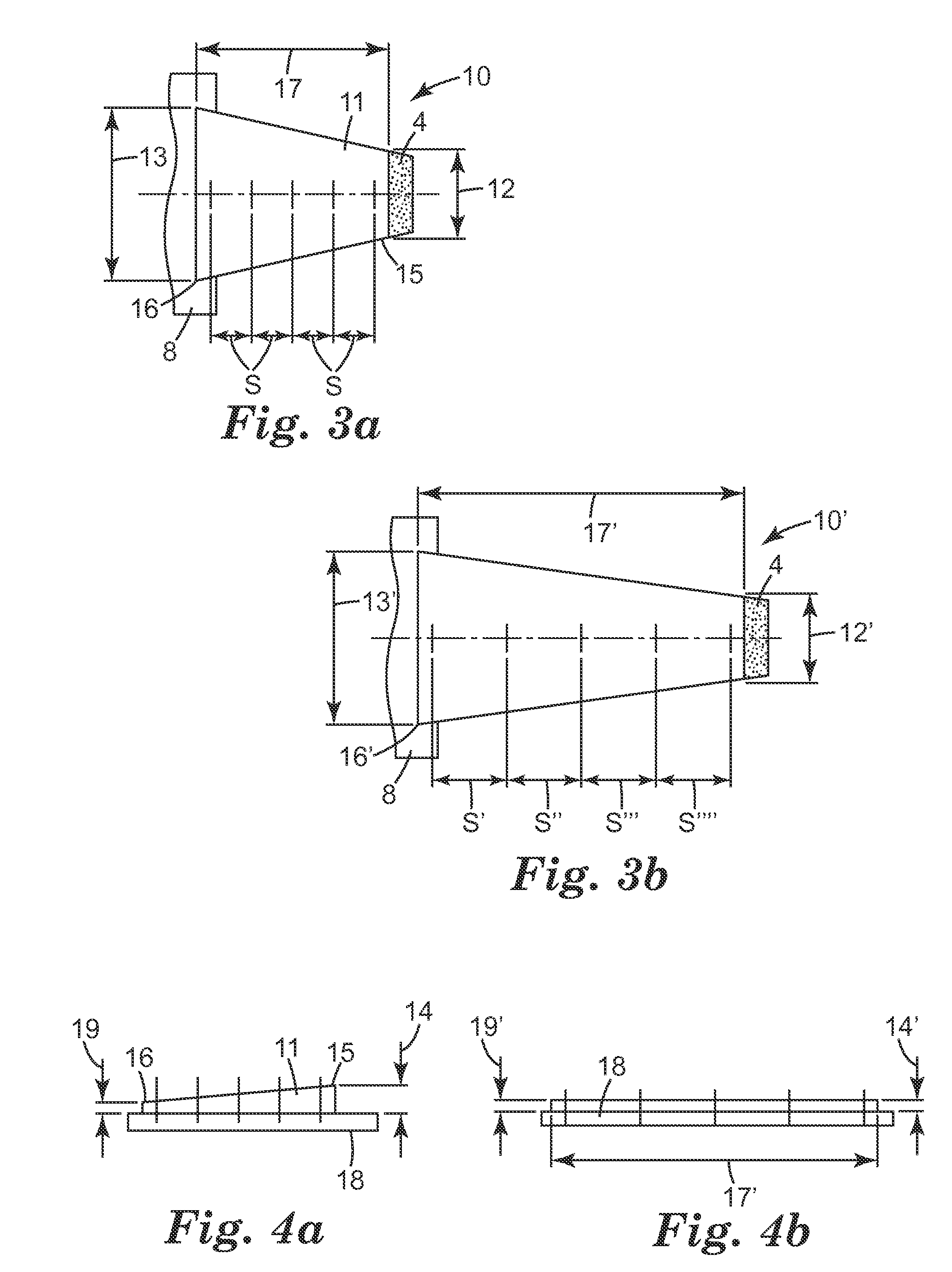

Rotor blade for a wind power station

A rotor blade for a wind power station includes a profiled member that is provided with a relative thickness which decreases towards the outside from a root to a tip of the blade. The profiled member has a leading edge and a trailing edge as well as a suction side and a pressure side while generating a negative pressure relative to the pressure side on the suction side when being flown against by moved air, the negative pressure resulting in buoyancy. The suction side of the rotor blade encompasses a device for optimizing flow around the profiled member. The device is provided with at least one planar element that extends substantially in the direction of flow, protrudes from the suction side, and is arranged in the zone of a transversal flow which runs from the root to the tip of the blade on the suction side of the profiled member.

Owner:SENVION GMBH

Shaped elastic tab laminates

Owner:3M INNOVATIVE PROPERTIES CO

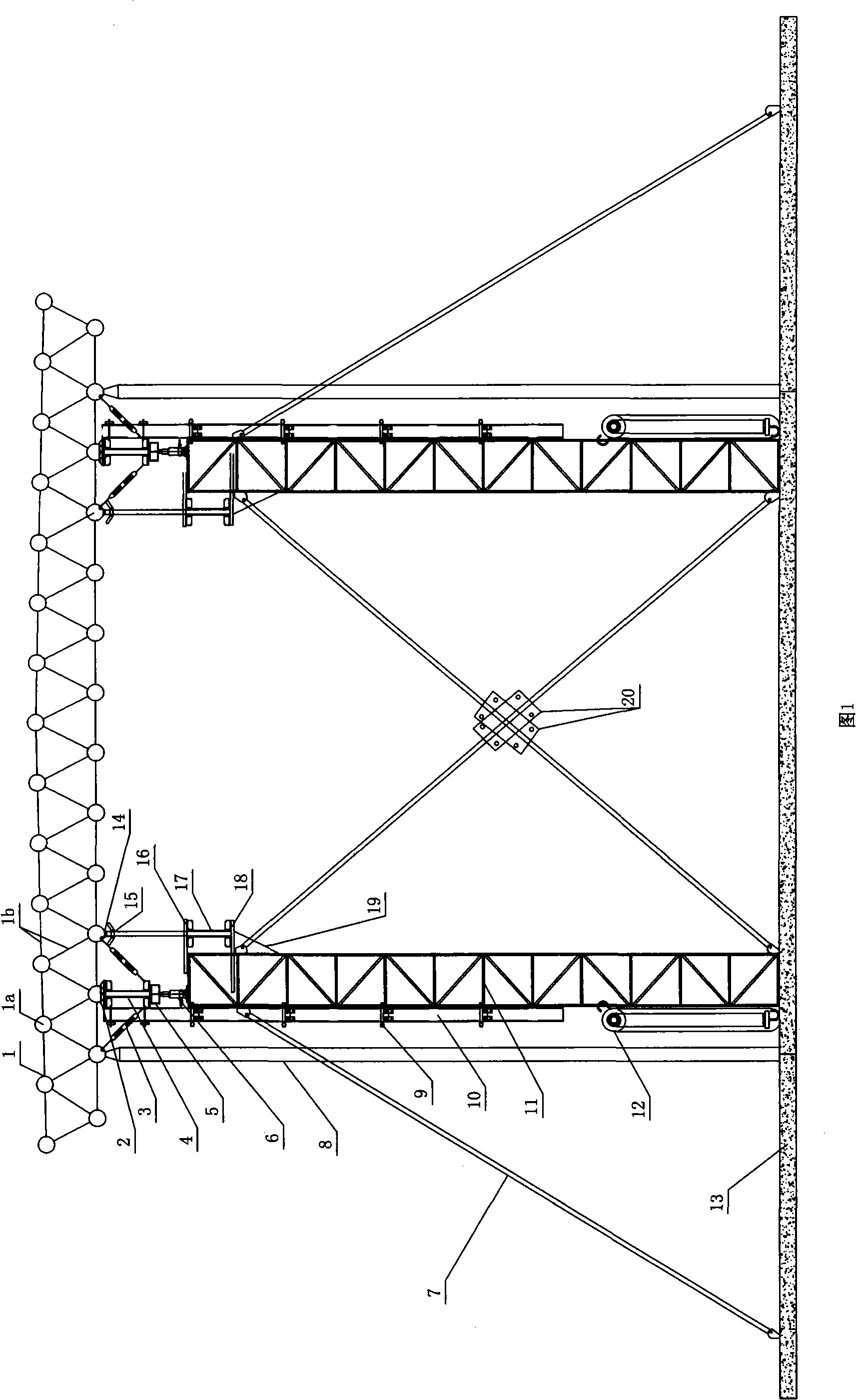

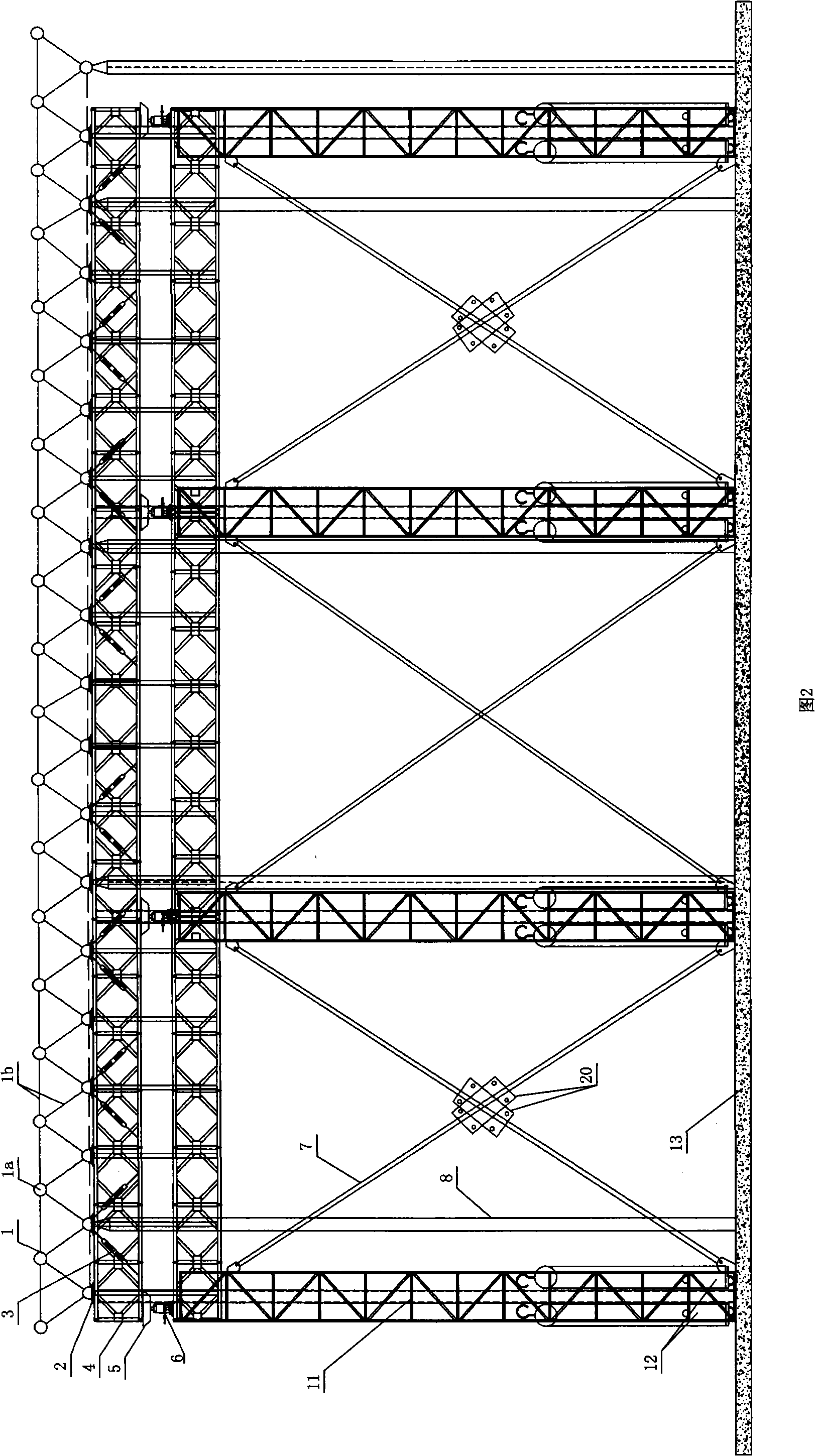

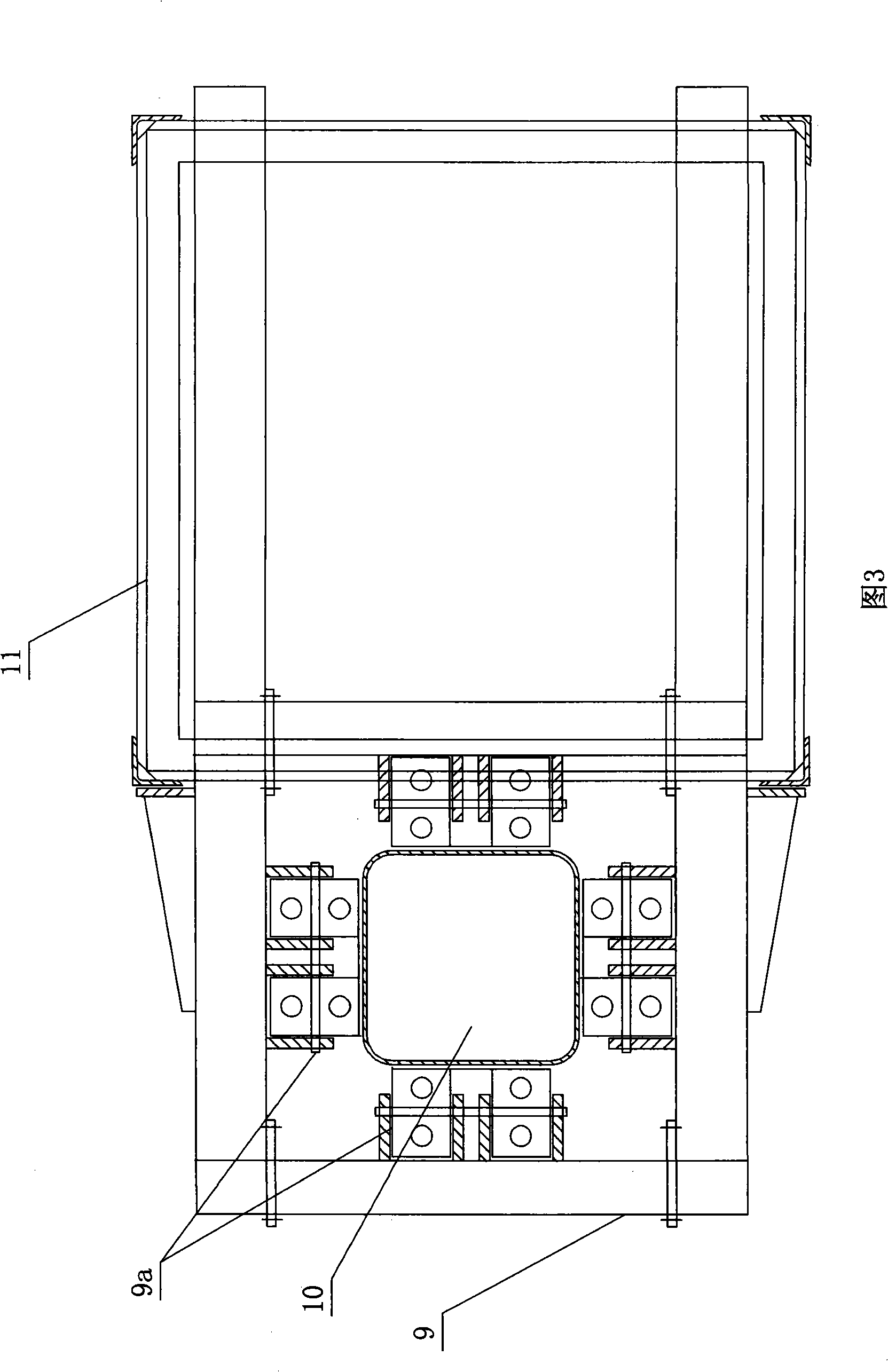

Network frame house cap integral lifting construction method

Disclosed is a construction method for lifting whole spatial grid roof structure, pertaining to the technical field of lifting a spatial grid roof structure. The spatial grid roof structure at which the method aims is composed of the connection of node spheres and tie bars; the whole spatial grid roof structure is supported and fixed by an upright column. The construction method is characterized by comprising the steps that: arranging a bearing upright column, connecting a lower girder, adjusting a radius rod, lifting an upper girder, installing a jack, arranging a bending- resistant lead, removing the original connection of the spatial grid roof structure, starting the jack to jack the whole spatial grid roof structure, padding the upper girder and jacking again, lengthening a connecting upright column and removing jacking facilities. The construction method adopts the combination of a hydraulic jack and girder multipoint supporting structure and directly jacks the whole spatial grid roof structure, which can shorten construction period, reduce construction amount as well as makes full use of the original structure; the construction method has components and equipment which are easy for manufacturing and convenient transportation and assembly, reduces project expenses, is fast and highly efficient, has low expense and is applicable to the heightening improvement of spatial grid roofs with various structures, such as circle, polygon, irregular odd shape, etc.

Owner:冯贵法

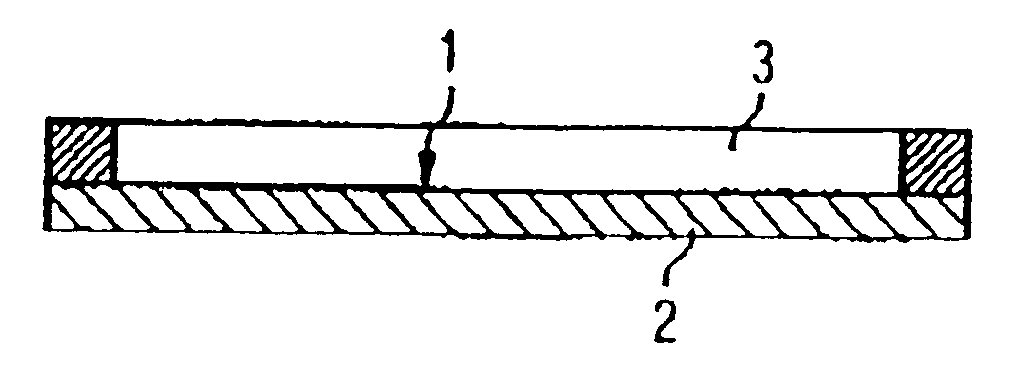

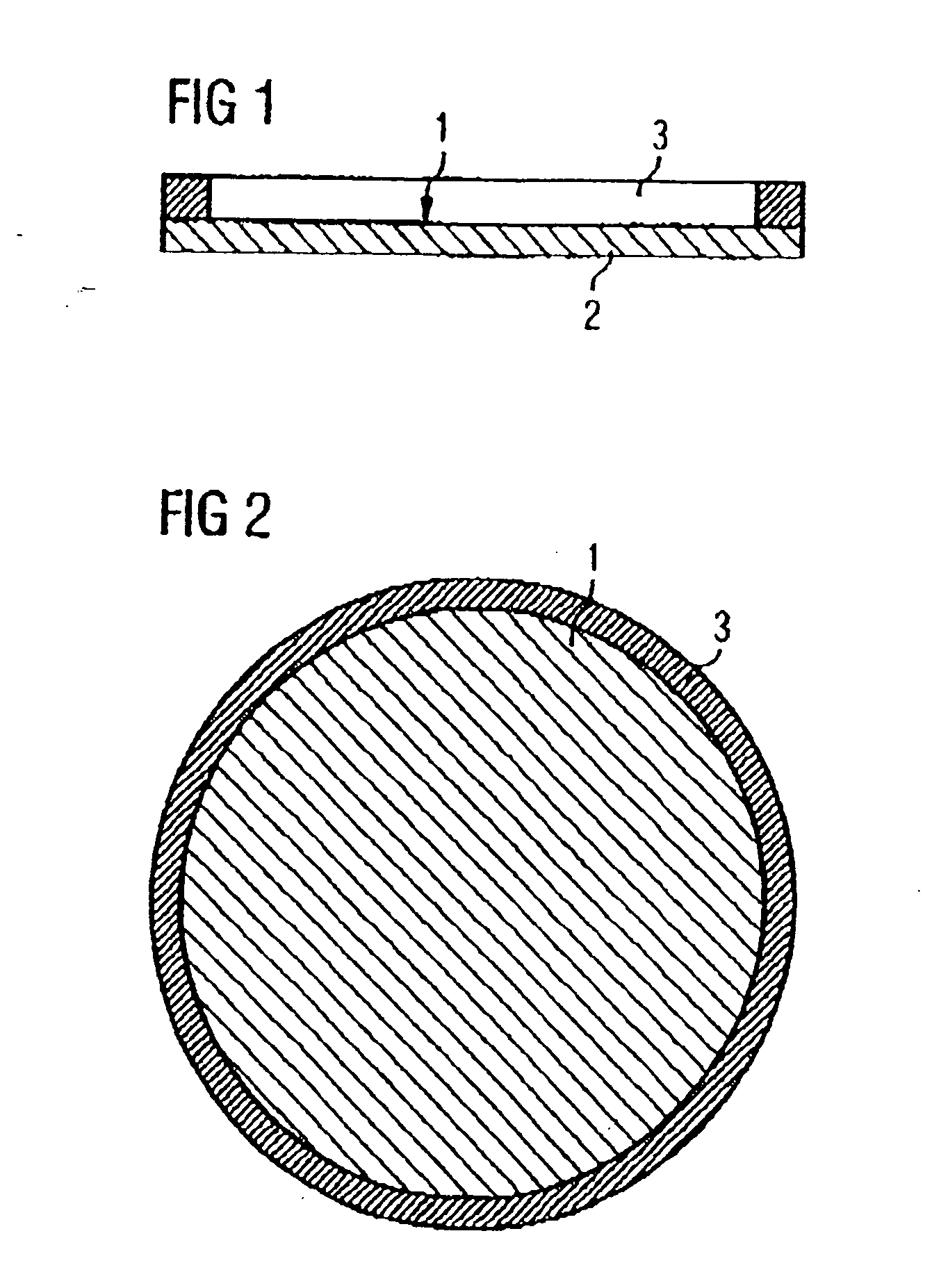

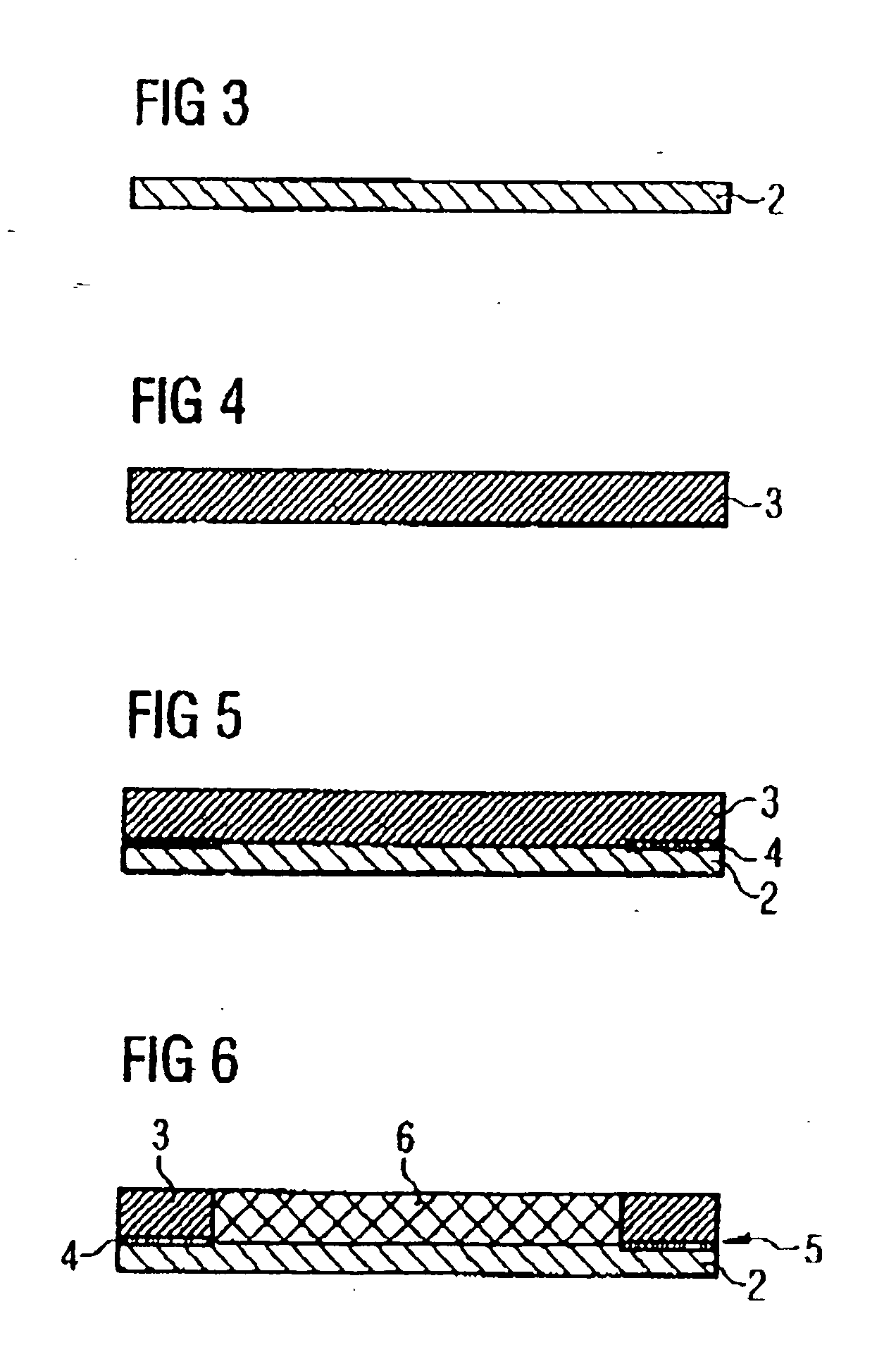

Wafer stabilization device and associated production method

InactiveUS20050236693A1Eliminate deformationFunction can be ensuredSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsAdhesive

A stabilization device and method for stabilizing a workpiece such as a thin film wafer is presented. The thin wafer is fixed and oriented in planar fashion. The stabilization device is realized by a profiled ring which is arranged on the periphery of the wafer and is intimately connected thereto. The stabilization device and wafer are connected via negative pressure or by means of an adhesive having high thermal stability. The wafer and device are formed from similar semiconductor materials and have the same outline contour. The stabilization device remains on the wafer during process steps in the course of production and processing of the wafer.

Owner:INFINEON TECH AG

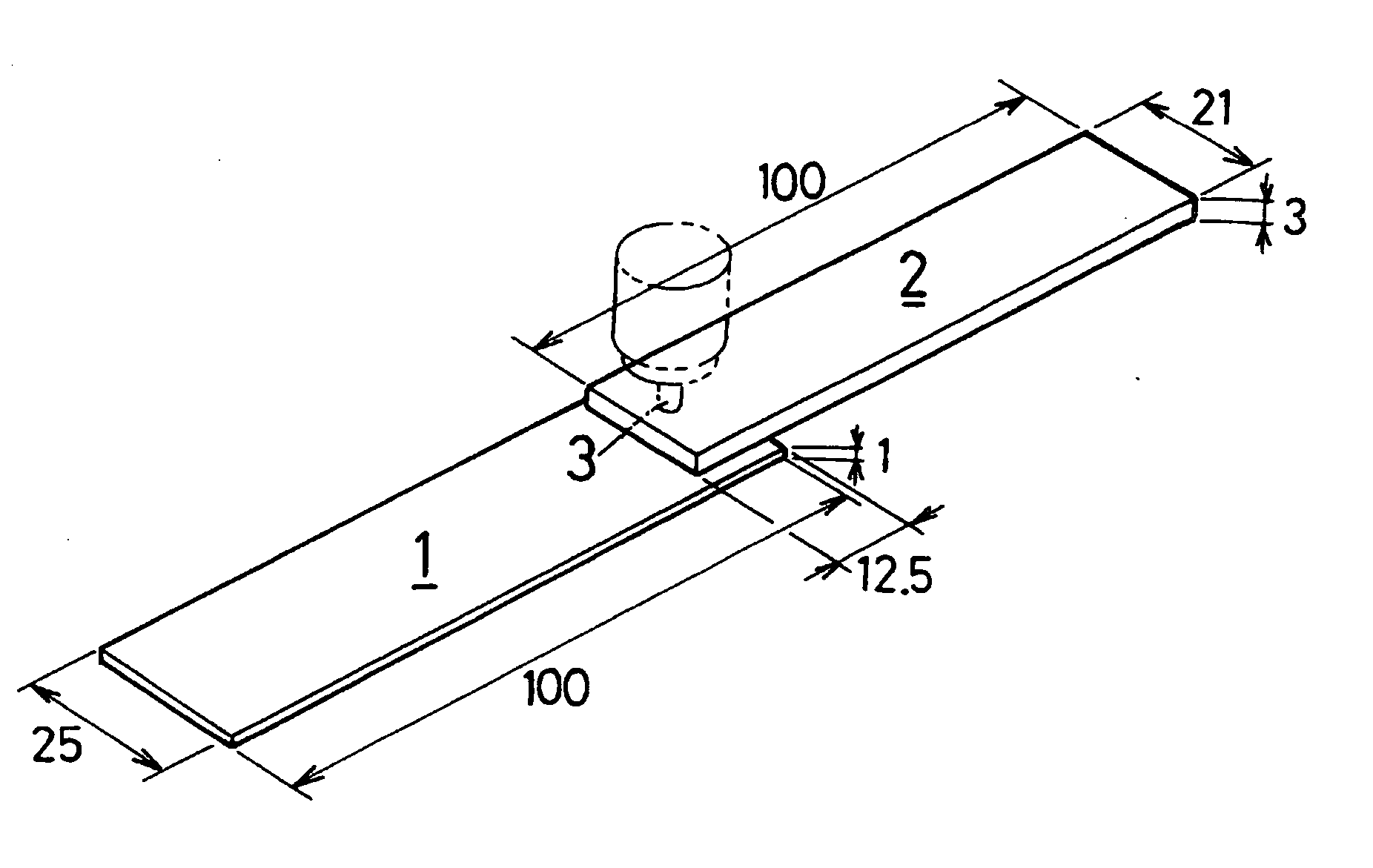

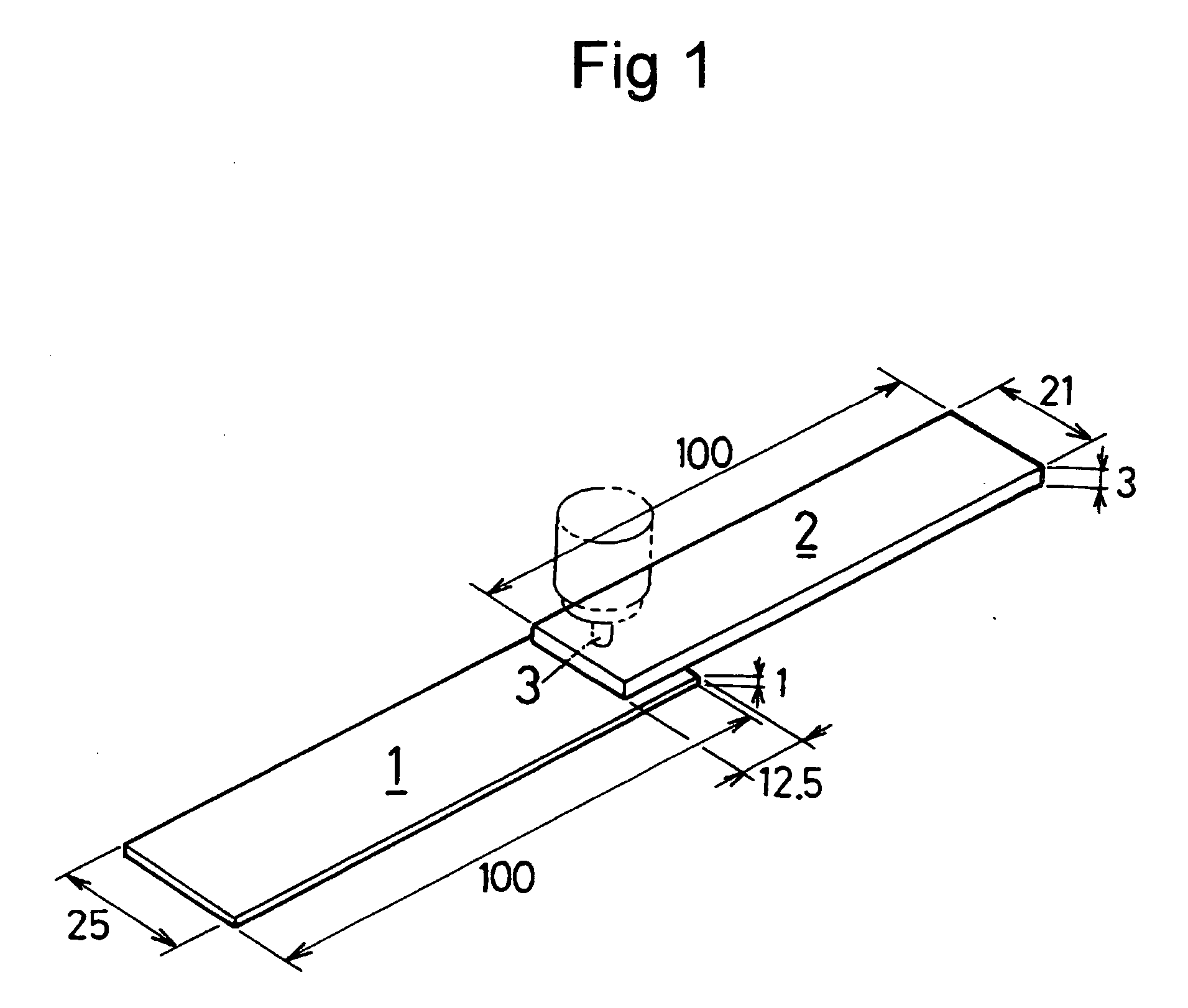

Composite article of aluminum alloy with resin and method for production thereof

ActiveUS20060127684A1Effective combinationExhibit some effectSynthetic resin layered productsPaper/cardboard layered productsHydrazine compoundElectrical devices

The present invention allows both the advantages of a metallic housing and those of a synthetic resin structure to be exhibited in electronic devices, home electrical devices, etc., and achieves high productivity and mass productivity and further enables a desired configuration and structure to be designed freely. As a pretreatment, a shaped aluminum alloy material is dipped in an aqueous solution of at least one selected from the group consisting of ammonia, hydrazine, and a water-soluble amine compound. A thermoplastic resin composition containing polyphenylene sulfide as a component is integrally bonded to the surface of the treated shaped aluminum alloy material by injection molding or other method. The molded article is a product made of the shaped aluminum alloy material and the thermoplastic resin composition containing PPS. Thus, the characteristic features of metal can be utilized in terms of mechanical strength and external appearance design. Moreover, a complicated configuration and structure can be formed inside the housing.

Owner:TAISEI PLAS CO LTD

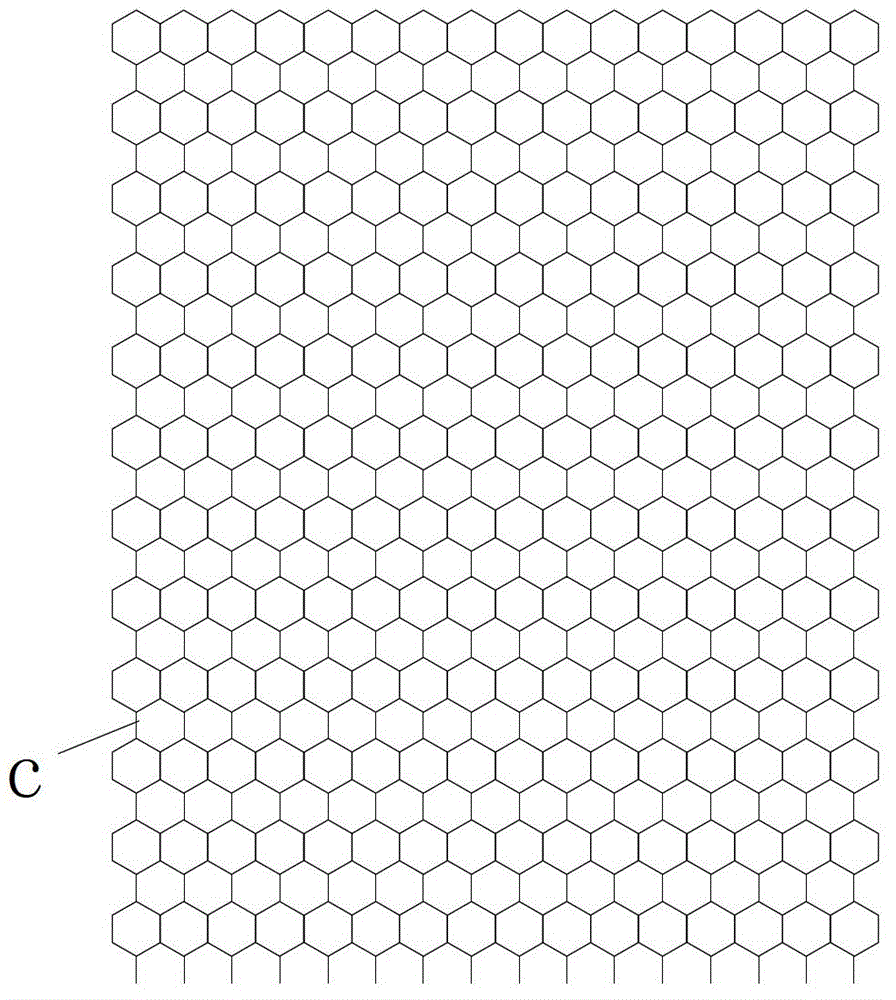

Special-shaped three-dimensional knitted fabric and manufacturing method thereof

The invention relates to a special-shaped three-dimensional knitted fabric and a manufacturing method thereof, which relate to the knitted fabric. The special-shaped three-dimensional knitted fabric with at least one of an upper surface and a lower surface being a concave-convex special-shaped curved face, and favorable air permeability, support performance and shearing resistance, and the manufacturing method thereof are provided. The special-shaped three-dimensional knitted fabric comprises an upper fabric layer, a middle fabric layer and a lower fabric layer, wherein the upper fabric layer or / and the lower fabric layer is / are provide with a concave-convex curved face(s) in a knitted longitudinal direction(s); and the middle fabric layer is formed by connecting yarns with flexural rigidity. According to a fabric structure and a texture requirement, required materials of the upper fabric layer, the required lower fabric layer and the middle fabric layer are selected; according to structural features of the fabric, the yarns are sewed on a guide bar; according to special-shaped structural features of the fabric, warp run-in of the fabric is set, and a distance between two needle beds can be adjusted in real time when the fabric is knitted in different horizontal lines according to variation in thicknesses of the different horizontal lines of the fabric; and a drawing device draws the knitted textile from the needle beds when knitting is carried out simultaneously.

Owner:福建福联精编有限公司

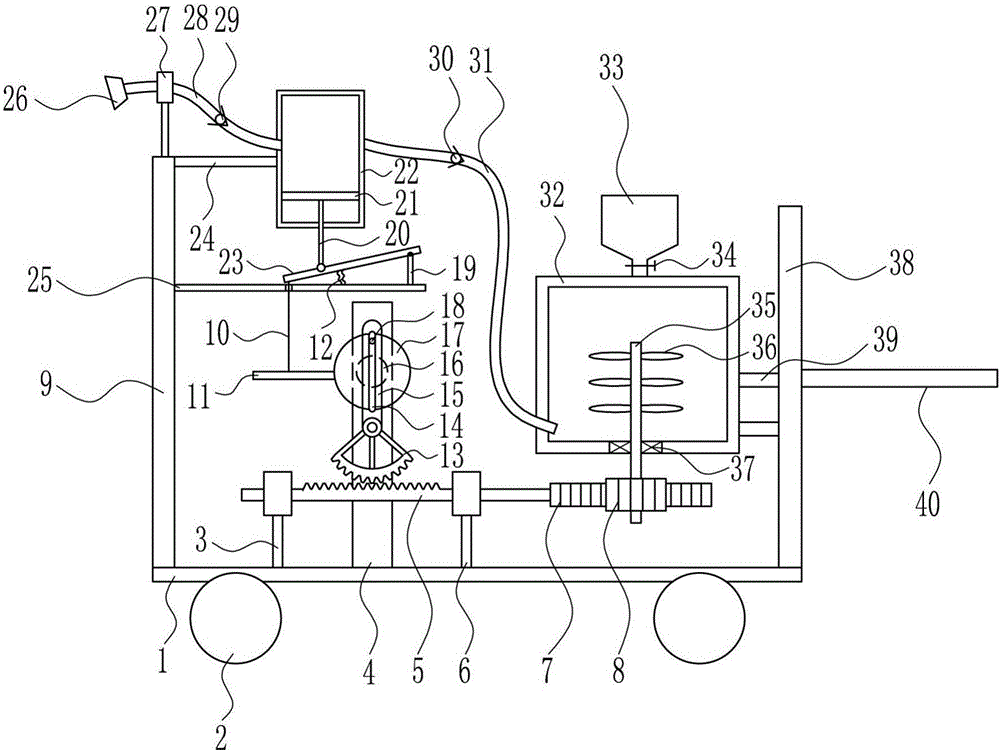

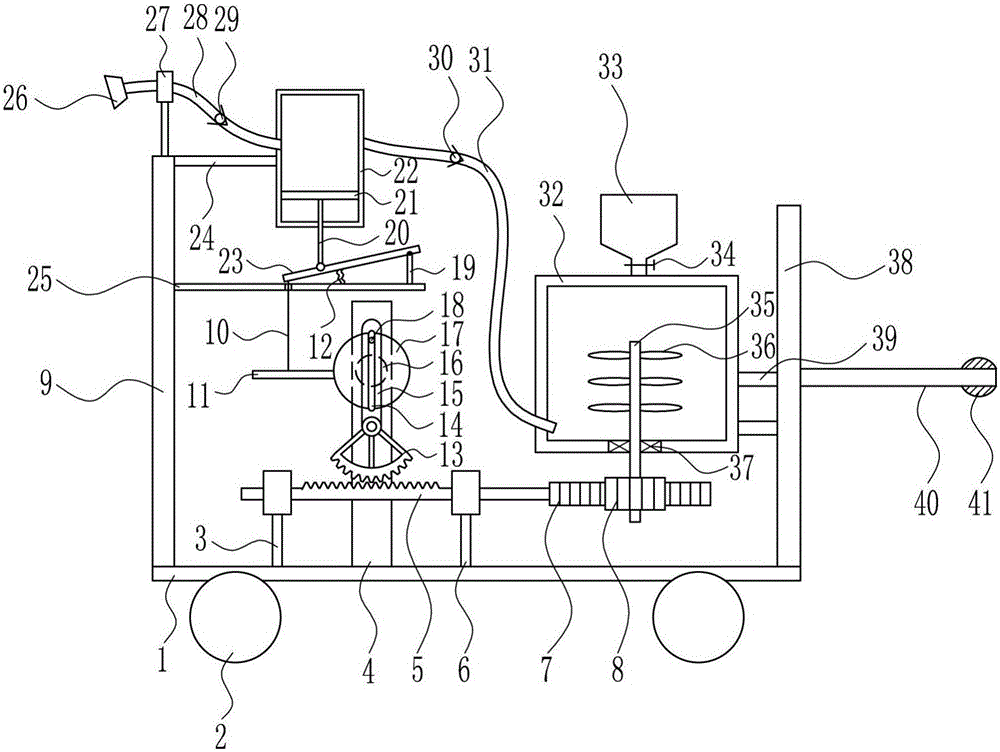

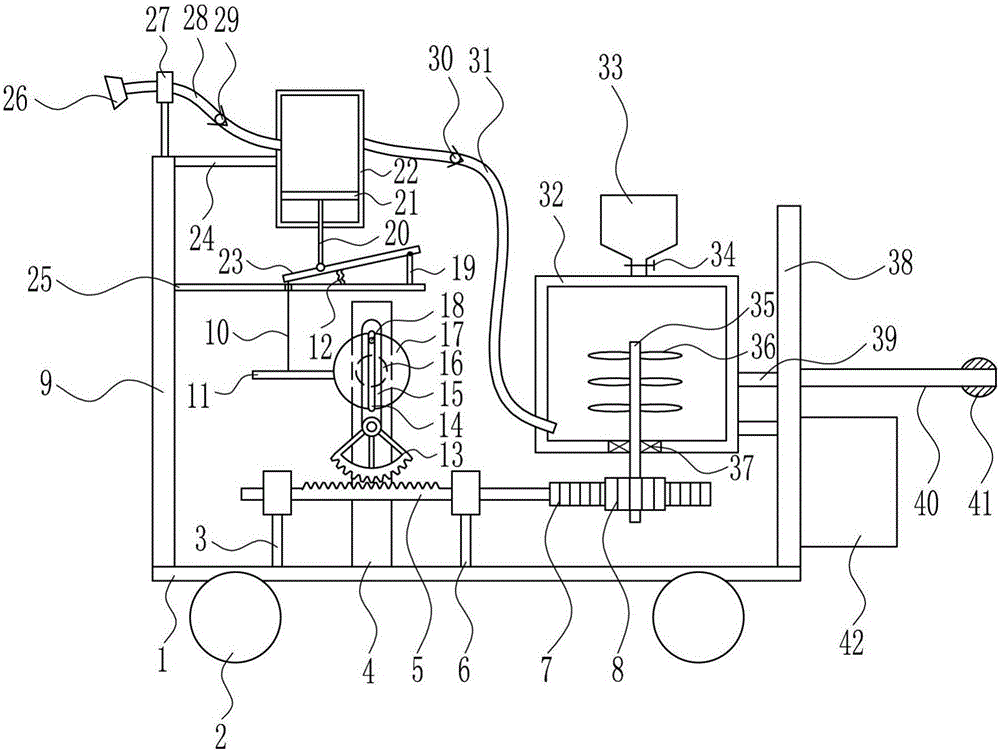

High-efficiency fertilizing device for planting forage grass in animal husbandry

ActiveCN106233914AEasy to useImprove fertilization efficiencyPressurised distribution of liquid fertiliserAgricultural scienceGear wheel

The invention relates to a fertilizing device for planting forage grass in the animal husbandry, in particular to a high-efficiency fertilizing device for planting forage grass in the animal husbandry. The invention aims at providing the high-efficiency fertilizing device for planting the forage grass in the animal husbandry, which is high in fertilizing efficiency and convenient in operation and is time-saving and labor-saving. In order to achieve the aim, the invention provides the high-efficiency fertilizing device for planting the forage grass in the animal husbandry. The high-efficiency fertilizing device comprises a bottom plate, wheels, a first guide sleeve, a bracket, a special-shaped rack, a second guide sleeve, a first rack, a first gear, a left frame, a drawing wire, a swinging rod, a spring, a sector-shaped gear, a connecting rod, a first motor, a rotary disc, a clamping block, a connecting rod, a first supporting rod, a piston, a cylinder body, an installing plate, a fixed rod, a fixed plate and a spraying nozzle and the like; the wheels are arranged at the bottom part of the bottom plate in a manner of bilateral symmetry. The fertilizing device provided by the invention has the advantages that the fertilizing efficiency is high, the operation is convenient, and the time and the labor are saved; the fertilizing device plays an important role all the time, not only has good fertilizing effect, but also improve the working efficiency.

Owner:TANGSHAN XINWANDA IND

Shaped cutter surface

ActiveUS7798257B2Reduce certain adverse consequenceSmooth curveDrill bitsConstructionsEngineeringAbnormal shaped

Owner:SMITH INT INC

In-ear monitor with shaped dual bore

ActiveUS7263195B2Easy to customizeDetails for specific frequency responseIntra aural earpiecesEngineeringHeadphones

A multi-driver in-ear monitor for use with either a recorded or a live audio source is provided. If a pair of drivers is used, each driver has an individual sound delivery tube. If three drivers are used, the outputs from two of the drivers are merged into a single sound delivery tube while the output from the third driver is maintained in a separate, discrete sound tube. The sound delivery tubes remain separate throughout the end portion of the earpiece. The earpiece tip is configured to be fitted with any of a variety of sleeves (e.g., foam sleeves, flanged sleeves, etc.), thus allowing the in-ear monitor to be easily tailored to comfortably fit within any of a variety of ear canals. Due to the size constraints of such an earpiece, the sound delivery tubes include a transition region. Acoustic filters (i.e., dampers) can be interposed between one or both driver outputs and the earpiece output.

Owner:LOGITECH INT

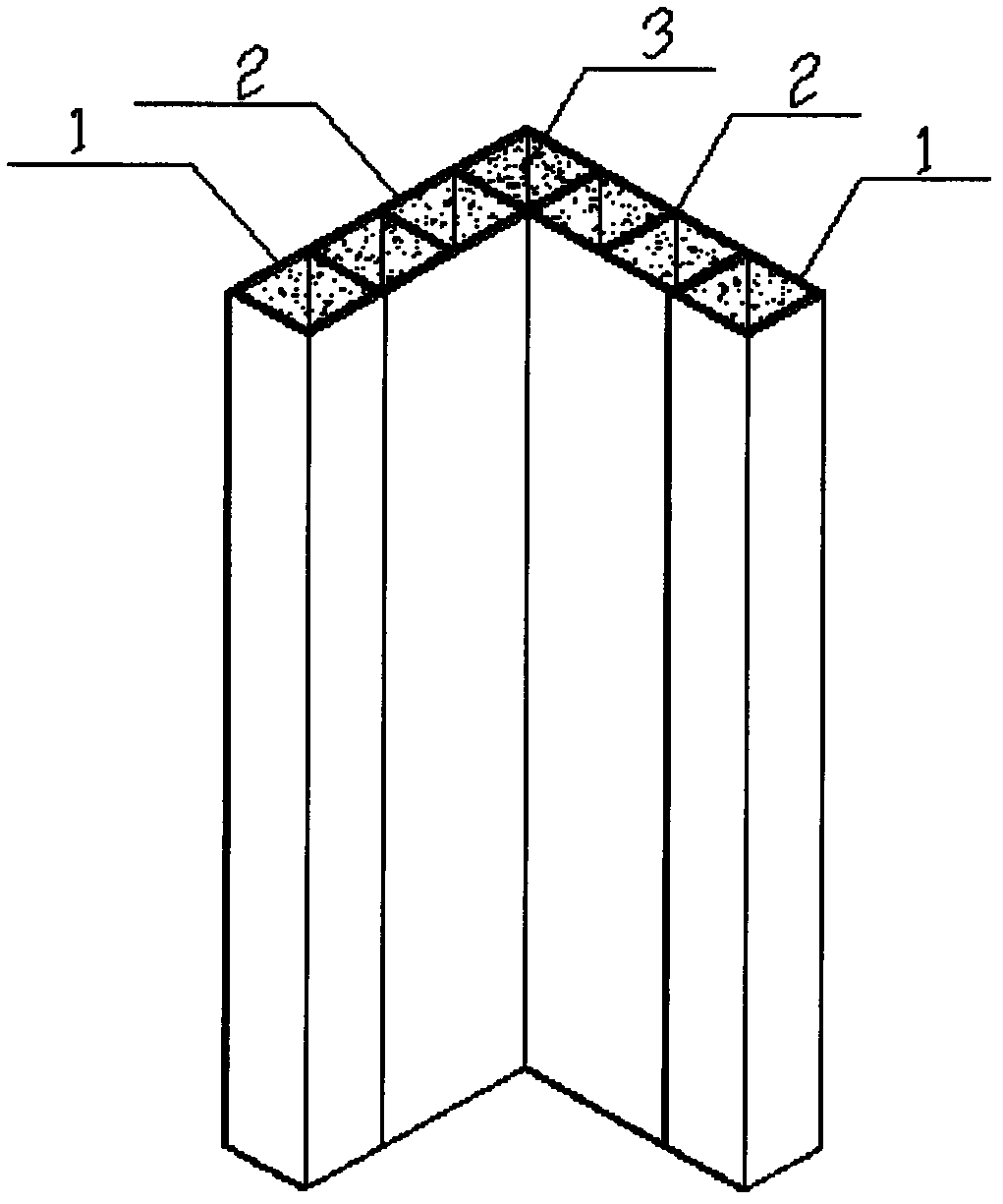

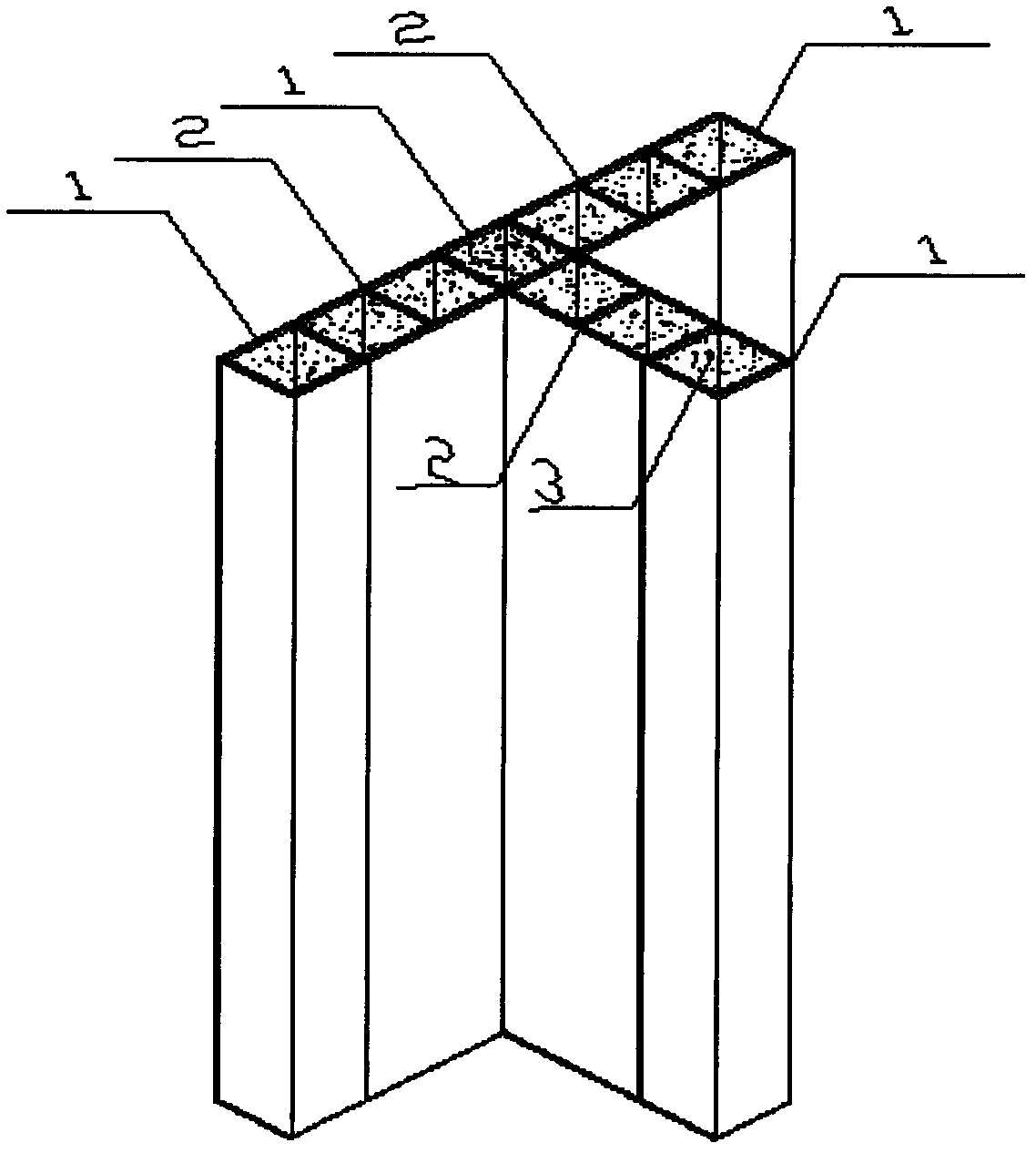

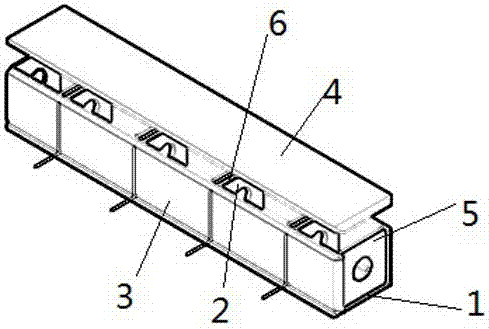

Abnormal shape box column and processing craft thereof

InactiveCN106884498ASimple structureGuaranteed sizeStrutsWelding apparatusEngineeringAbnormal shapes

The invention discloses an abnormal shape box column. The abnormal shape box column comprises a panel, partition plates, web plates and an upper flange plate, the partition plates are arranged on the panel, the web plates are arranged on the two sides of the partition plates and are fixedly connected with the panel, the upper flange plate is arranged at the upper parts of the two web plates, technical partition plates are arranged at the two ends of the panel, and the partition plates and the web plates are matched with the upper flange plate. According to the abnormal shape box column, the web plates are arranged on the panel to form a box body, the parathion plates are arranged in the box body, the upper flange plate is arranged at the upper part of the box body, and the technical partition plates are arranged at the two ends of the box body, so that the structure of the box column is improved, moreover, the size of the end part of the box body is effectively guaranteed, the processing of a large connector is facilitated on site, the supporting performance and the stability are also greatly improved, and the construction requirement is further better met.

Owner:JIANGSU HUNING STEEL MECHANISM

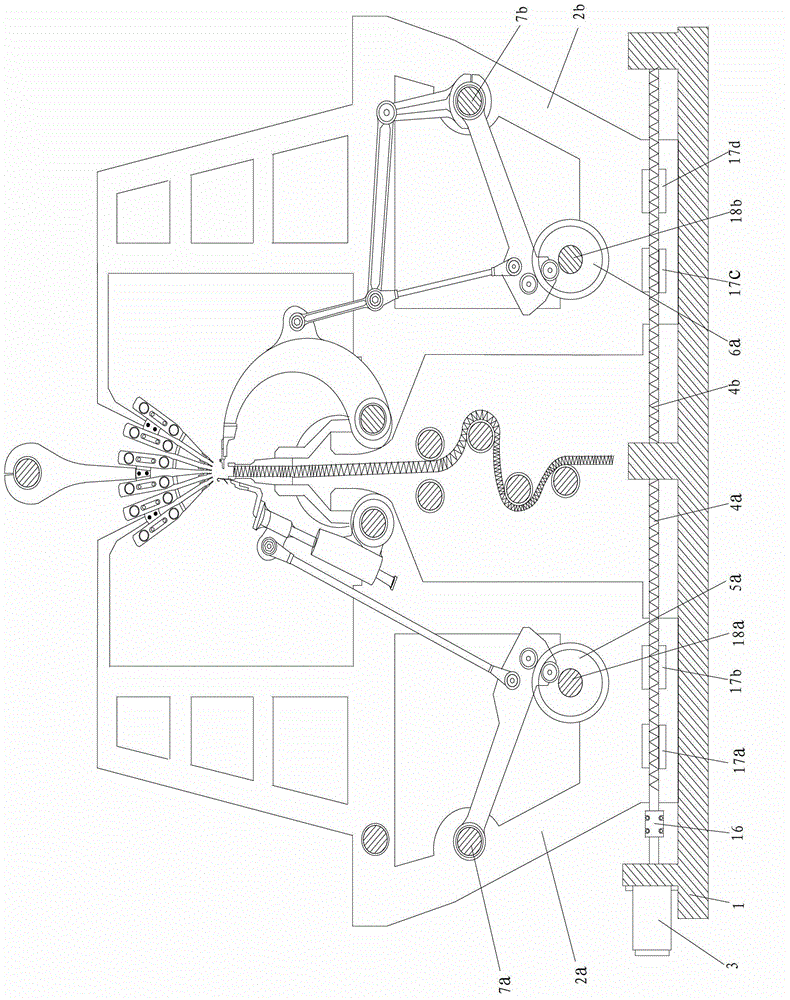

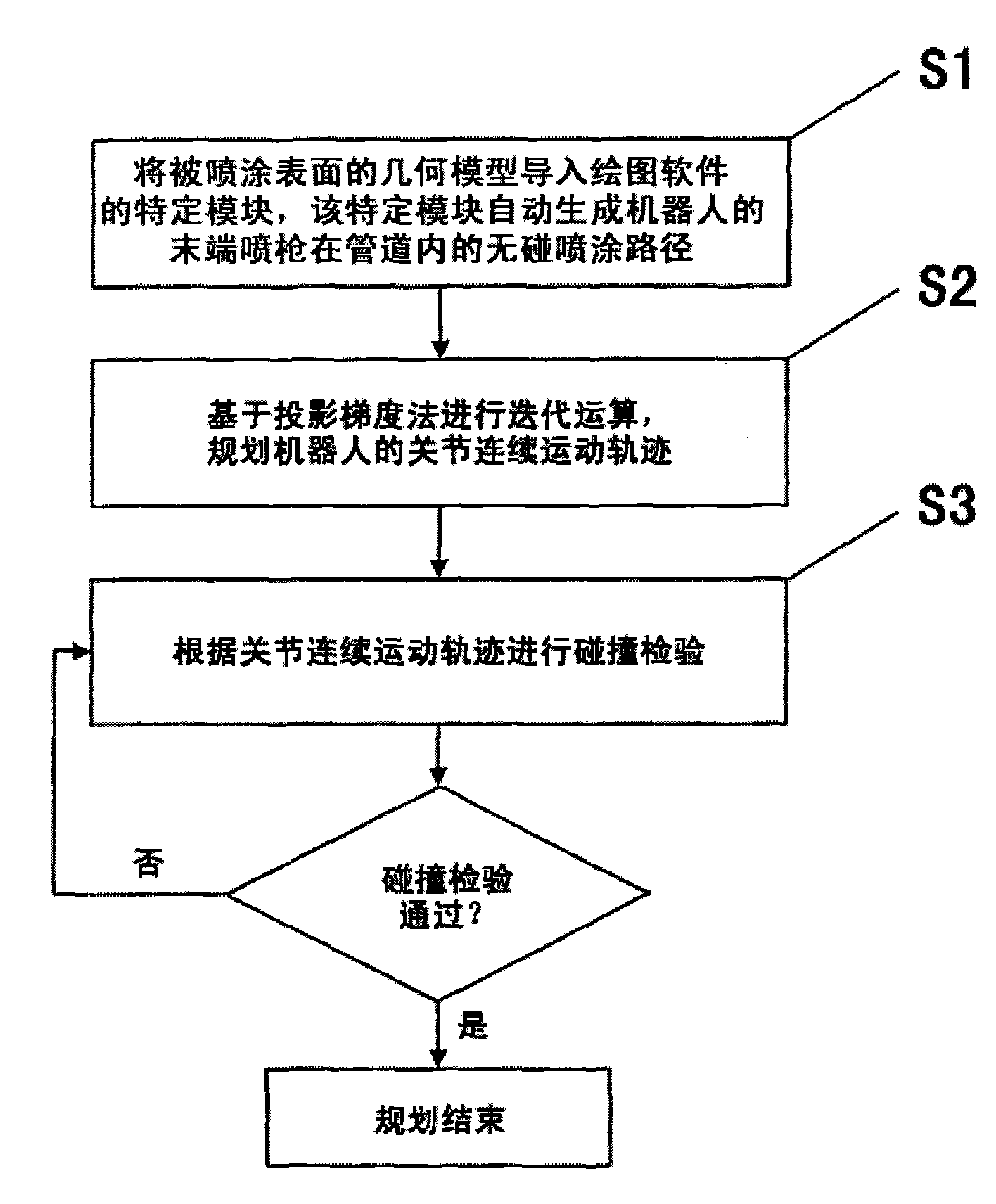

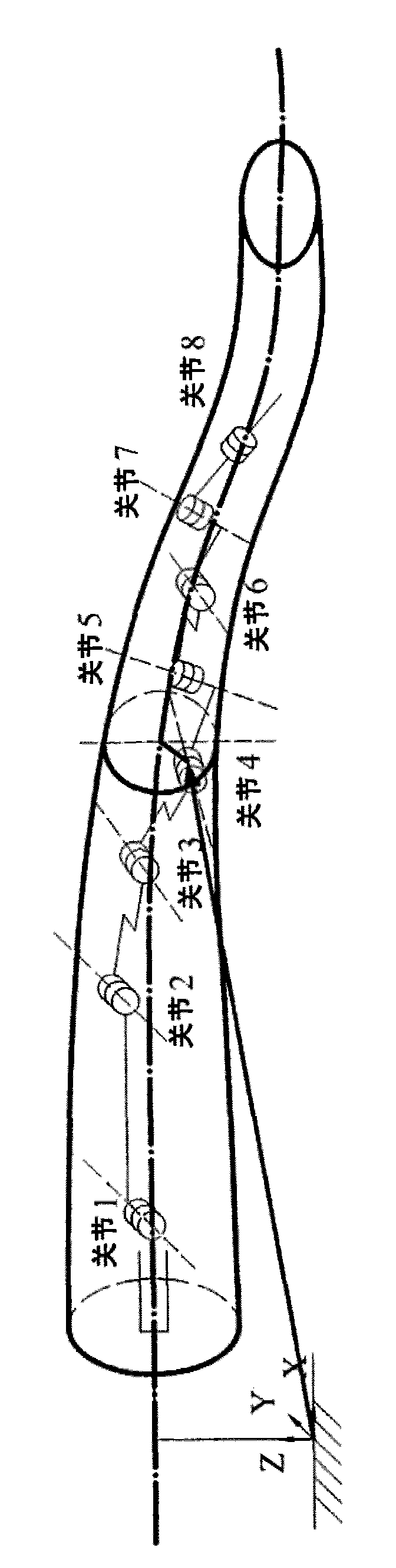

Pipeline spraying robot and operation track planning method thereof

InactiveCN101612734ASmall amount of calculationImprove spray qualityProgramme-controlled manipulatorSpraying apparatusAbnormal shapedEngineering

The invention discloses a pipeline spraying robot with multiple-redundant degree of freedom and an operation track planning method thereof. The method comprises the following steps: S1, a geometric mode of a sprayed surface is led into a specified module of a drawing software, the specified module automatically generates a no-touching spraying path of the spraying workpiece of the robot in the pipeline; S2, iterative operation is carried out based on a projection gradient method, and the continuous movement track of the joints of the robot is planned; S3, collision detection is carried out according to the continuous movement track of the joints, if colliding, the weighting coefficient of an optimization function is revised, and S2 is restarted to re-plan the continuous movement track of the joint; otherwise, planning ends. The method of the invention has small calculation amount, can ensure no wall collision occurs when the method is used for spraying the inner wall of a special-shaped long path after planning tracks, and has high spraying quality.

Owner:TSINGHUA UNIV +1

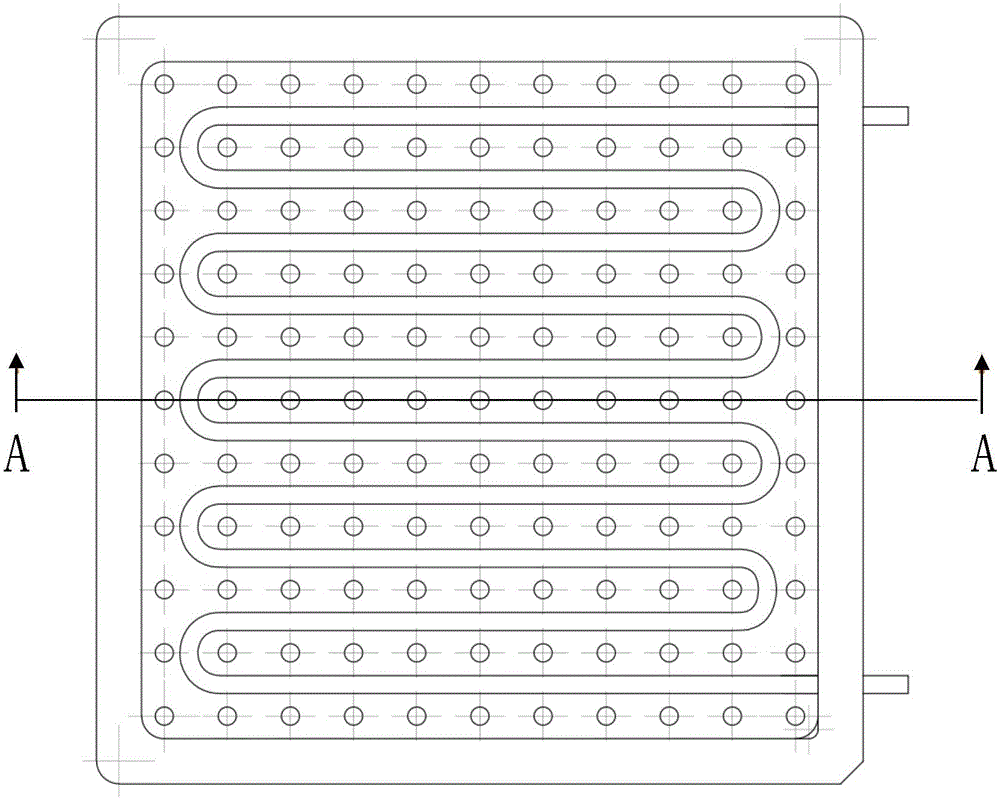

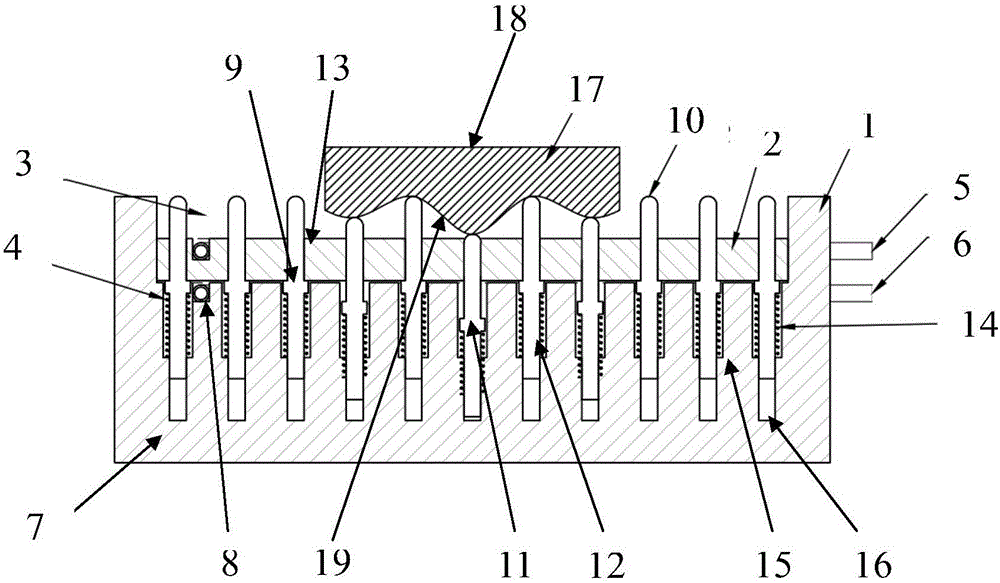

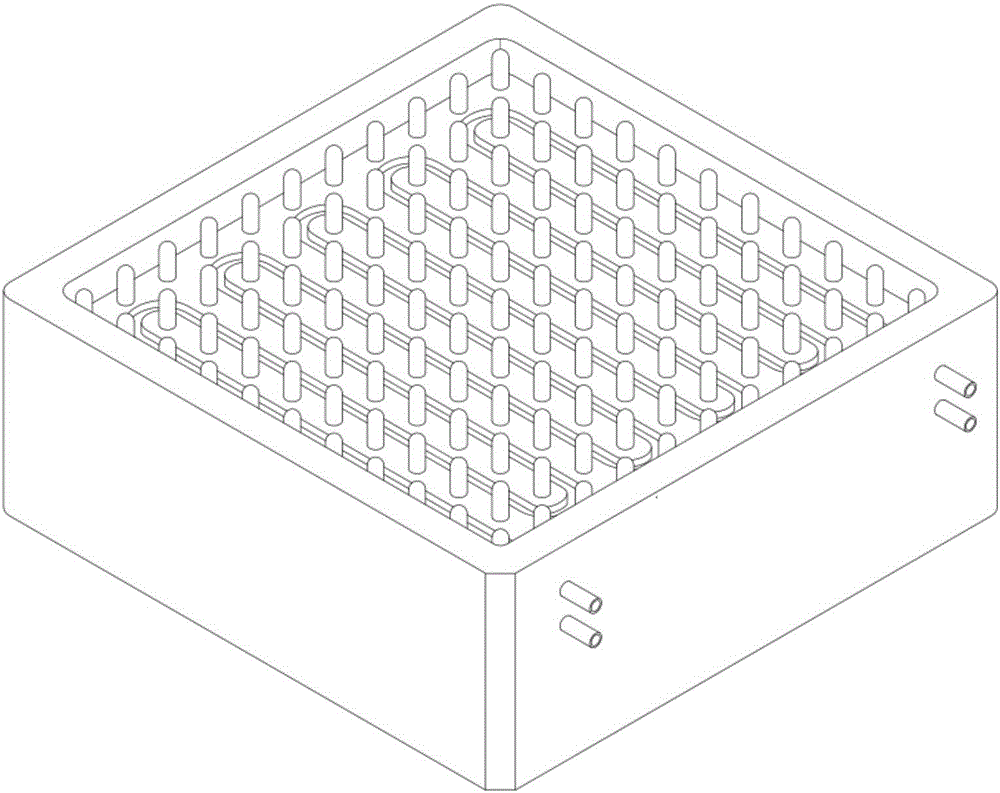

Shape Adjusting Tool

InactiveCN106334961ASimple designHigh speedPositioning apparatusMetal-working holdersNumerical controlProcess quality

The invention discloses a profile-followed adjustment frock, including main box, demarcation strip, upper cabin, lower cabin, upper-deck cabin cooling tube, lower cabin cooling tube, freezing liquid, cold-producing medium, floating thimble, centrehole, thimble spring, spring groove, pin bottom outlet, wherein floating thimble is each independently arranged, and each floating thimble can fluctuate under thimble spring and workpiece effect; Demarcation strip is divided into upper and lower two-layer main body case, upper and lower cabin cooling tube is respectively equipped with two sheaf spaces, it is filled with freezing liquid water, take arbitrary shape workpiece to be put in frock, be pressed downward floating thimble, profiling is formed by compression in workpiece shapes syringe needle with the shape, cooling tube is passed through cold-producing medium, sheaf space freezes up and down, and floating thimble positioning, workpiece are wrapped fixing positioning; Coordinate with Digit Control Machine Tool, gun turret milling machine, grinding machine, drilling machine, unstressed clamping and fast clamp are done to abnormal shape, yielding thin-walled, easy spring angle workpiece and minor items, it is ensured that work pieces process quality, precision and working (machining) efficiency.

Owner:NEUTRON SHANGHAI

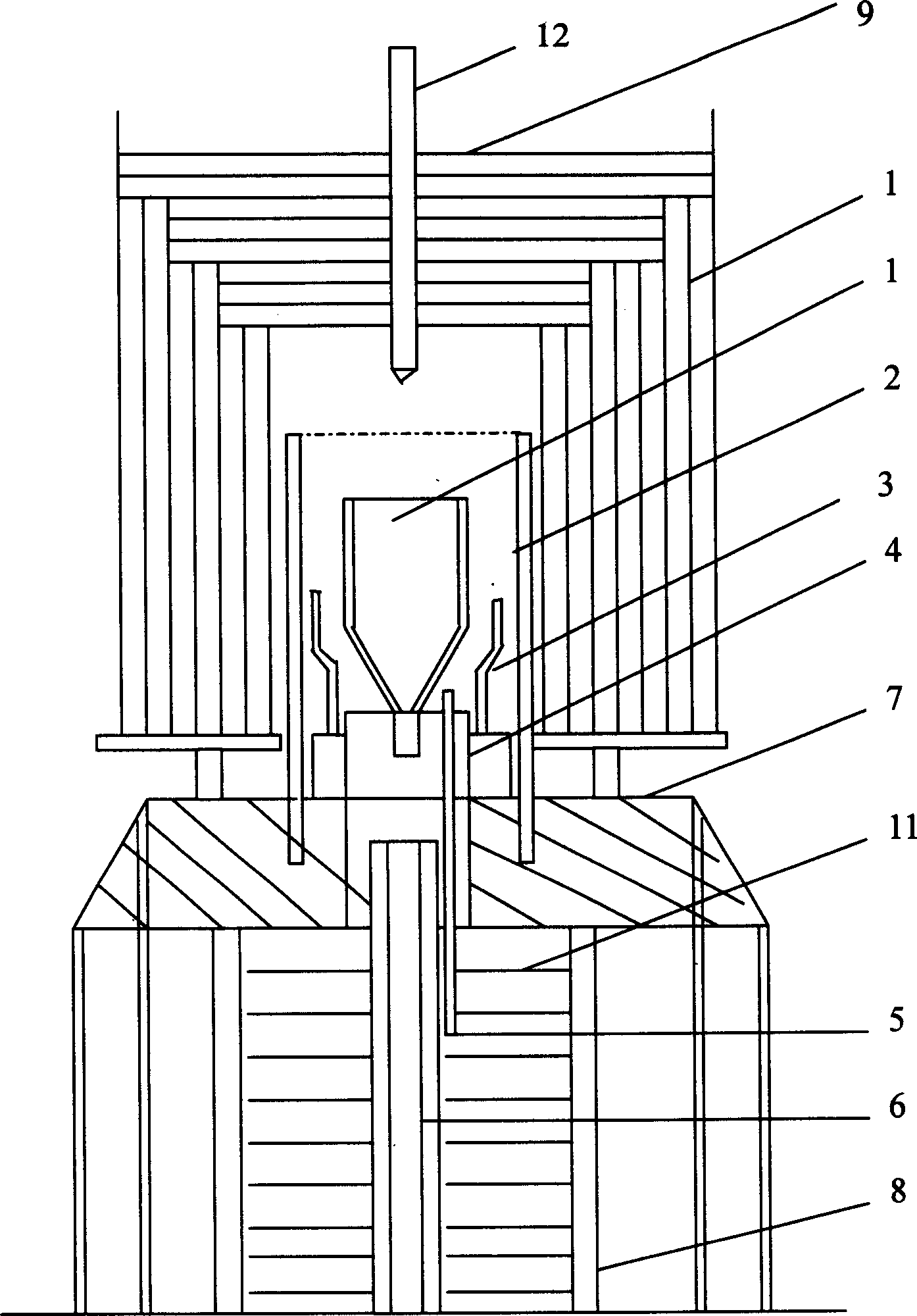

Growth apparatus for large-areaed crystal by temperature gradient technique and crystal growth method thereof

InactiveCN1485467AIn-situ annealingDynamic adjustment of temperature gradientFrom frozen solutionsEngineeringAbnormal shaped

A temperature-gradient device for growing crystals with large area and a method of growing crystals. The device comprises a bell-like vacuum resistance oven, cone crucible and a heater in the oven, the crucible at the center of the oven, the heater comprising main cylinder heater of graphite and auxiliary cone heater with an irregular shape, vacuum system, UPS regulated power supply, two sets of controllable silicon trigger circuits, two sets of temperature controllers. The device could adjust automatically temperature gradient in growing crystals.The invention could grow complete nonsplitingcrystals with the size of more than 5 inch.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com