High-performance thermal insulation material and preparation method thereof

A technology of thermal insulation materials and fiber materials, which is applied in the field of fiber-reinforced airgel thermal insulation materials and its preparation, can solve the problems of easy oxidation and thermal insulation performance degradation, achieve low cost, avoid high cost, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] (1) Preparation of sol: add catalyst to silica hydrosol and mix to obtain sol;

[0076] (2) Sol dipping and gelling: immerse the fiber material in the sol, and gel at room temperature or under heating conditions to obtain a fiber-reinforced silica wet gel;

[0077] (3) Aging: aging at room temperature or under heating for 8 hours to 168 hours;

[0078] (4) Solvent replacement: put the aged fiber-reinforced wet gel material into an alcohol solvent or a ketone solvent, so that the water content is lower than 1%;

[0079] (5) Hydrophobization: put the fiber-reinforced wet gel that has completed the solvent replacement into an absolute ethanol solution containing 0.5% to 10% by volume of a hydrophobizing agent, and let it stand at room temperature for 1 to 24 hours; then put the wet gel Take it out and put it in absolute ethanol for solvent replacement; preferably, the solvent replacement in absolute ethanol is carried out twice, each time for 24 hours to 120 hours, if

[0...

Embodiment 1

[0099] Add an alkaline silica sol (pH 9) with a silica content (sometimes referred to as a solid content) of 25% to the container, add hydrochloric acid (1M) and ammonia water (1M) dropwise under stirring conditions, and the gel chemical reaction begins. Wherein, the mass ratio is: silica sol:hydrochloric acid:ammonia water=100:4:6. Mix well and continue stirring for 5 minutes.

[0100] The impregnated bulk density with the obtained sol is 0.18g / cm 3 mullite asbestos felt. The impregnation method is as follows: first put the mullite wool felt into the mold cavity, and slowly add the above-mentioned sol into the mold cavity to make the mullite wool felt absorb the sol. After the mullite fiber mat is soaked in the sol, close the mold. After gelling at room temperature, the mullite fiber mat-reinforced silica wet gel is obtained.

[0101] The gel was further aged for 1 day at room temperature. Then disassemble the mold, take out the wet gel, and put it into absolute ethanol...

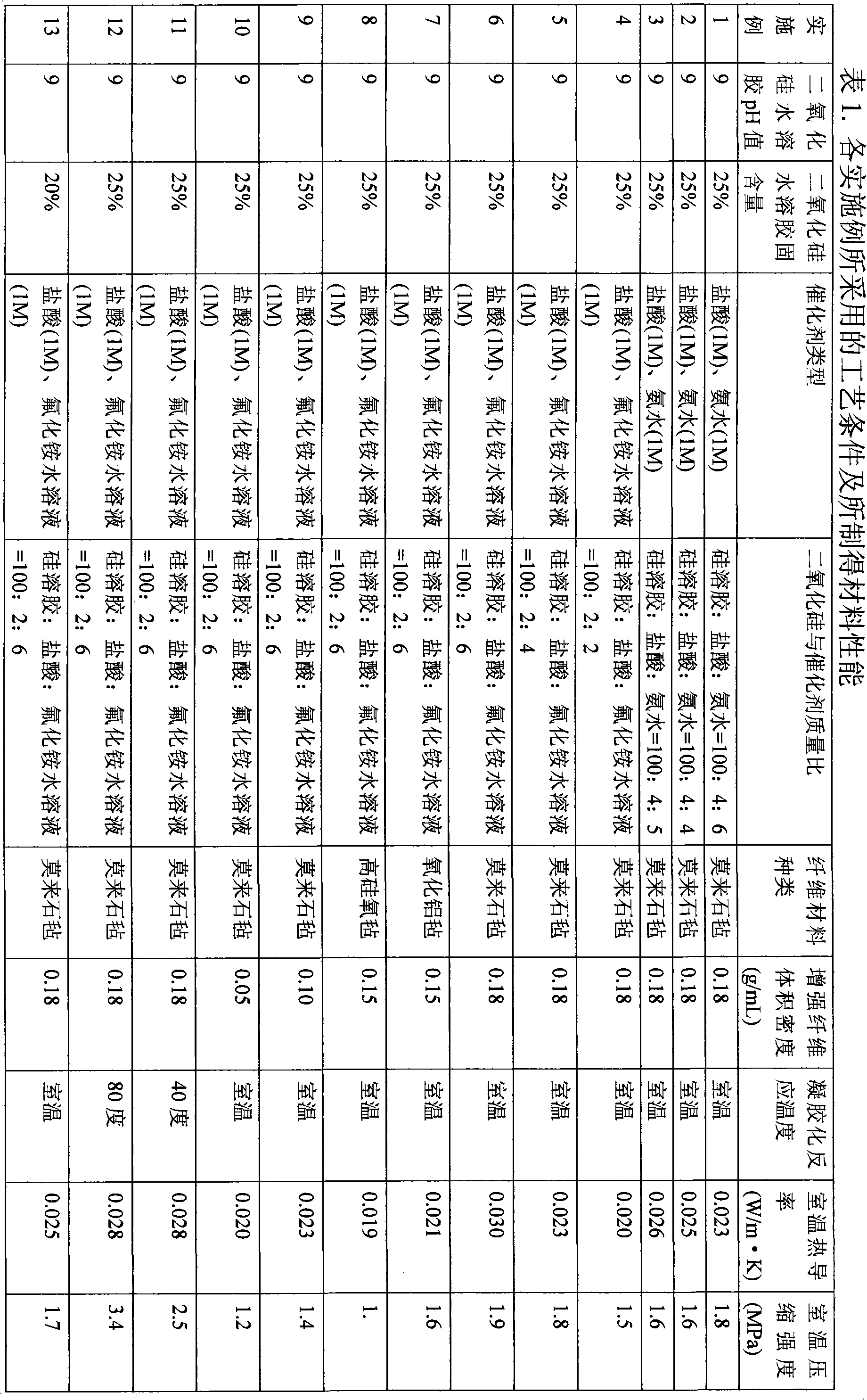

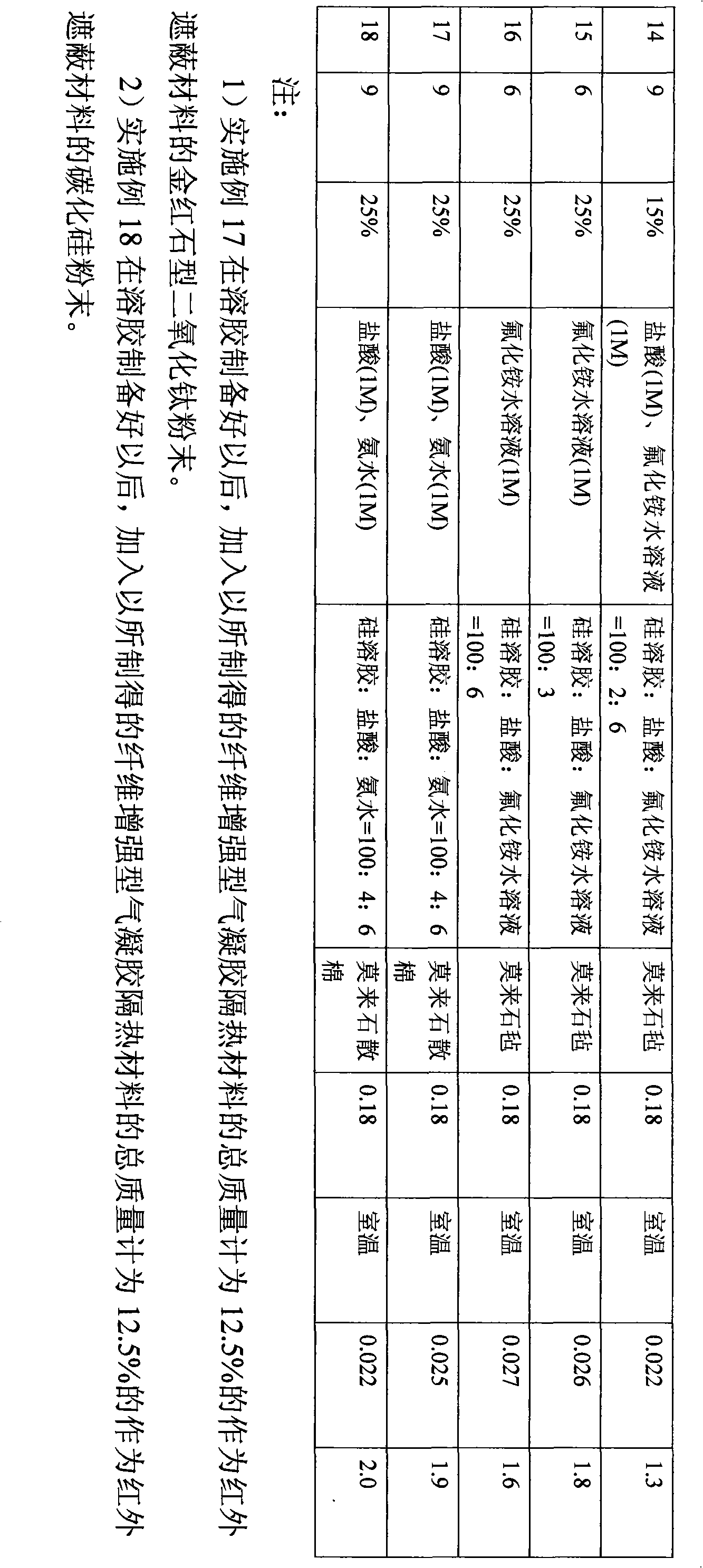

Embodiment 2~18

[0104] Except for the contents listed in Table 1, it was carried out in the same manner as in Example 1, and the properties of the obtained fiber-reinforced airgel thermal insulation material are shown in Table 1 below.

[0105]

[0106]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com