Patents

Literature

320 results about "Abnormal shapes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

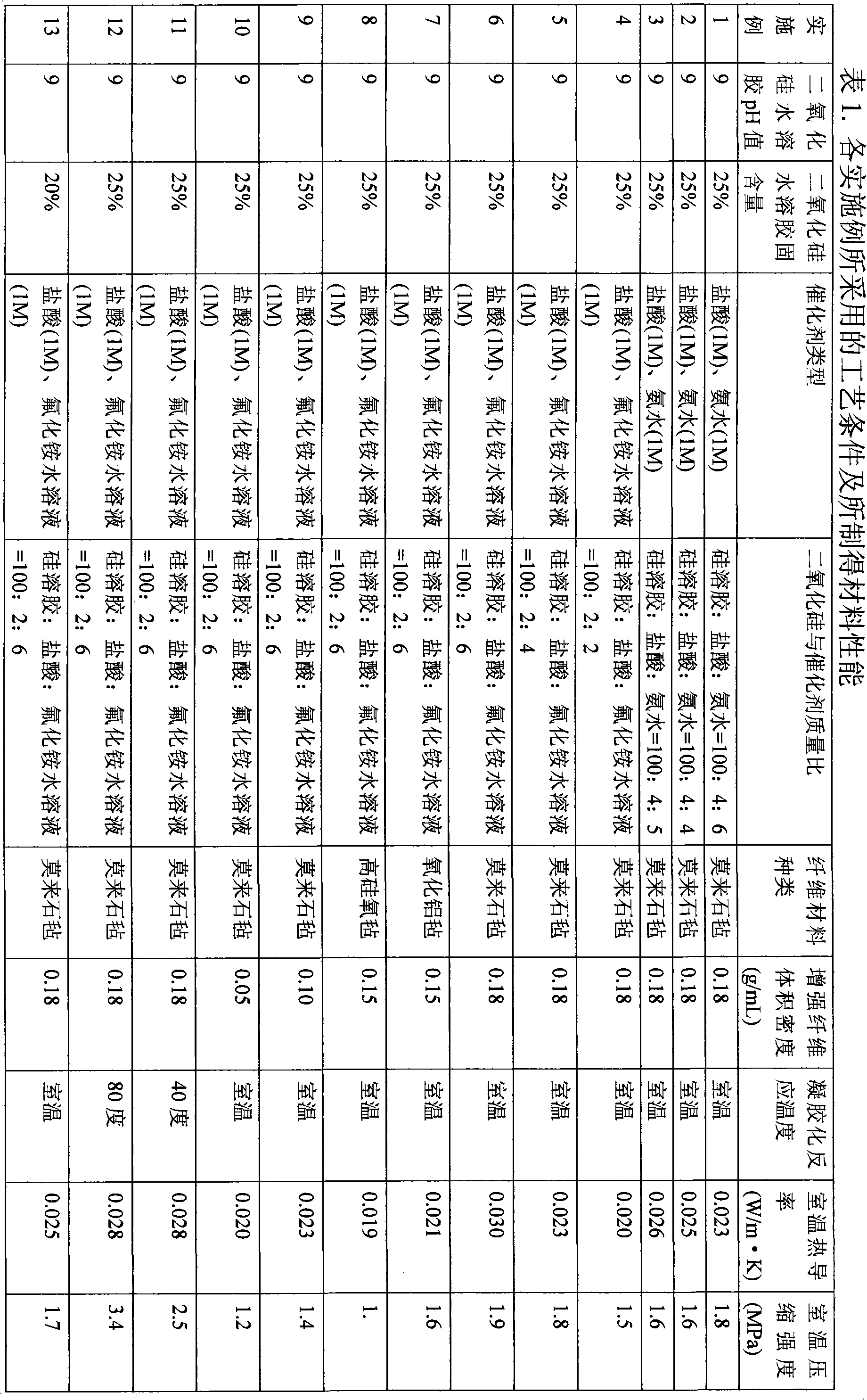

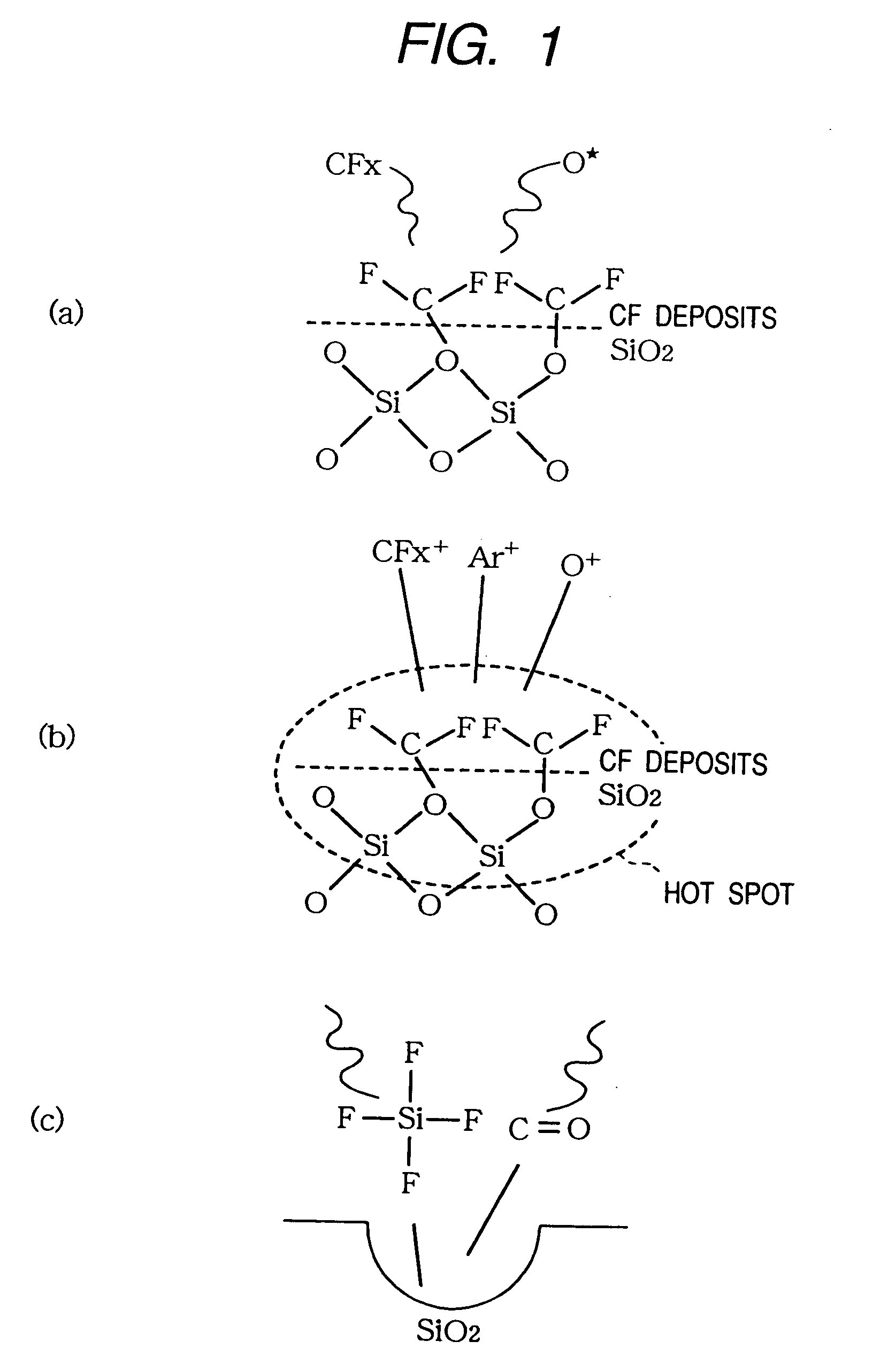

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

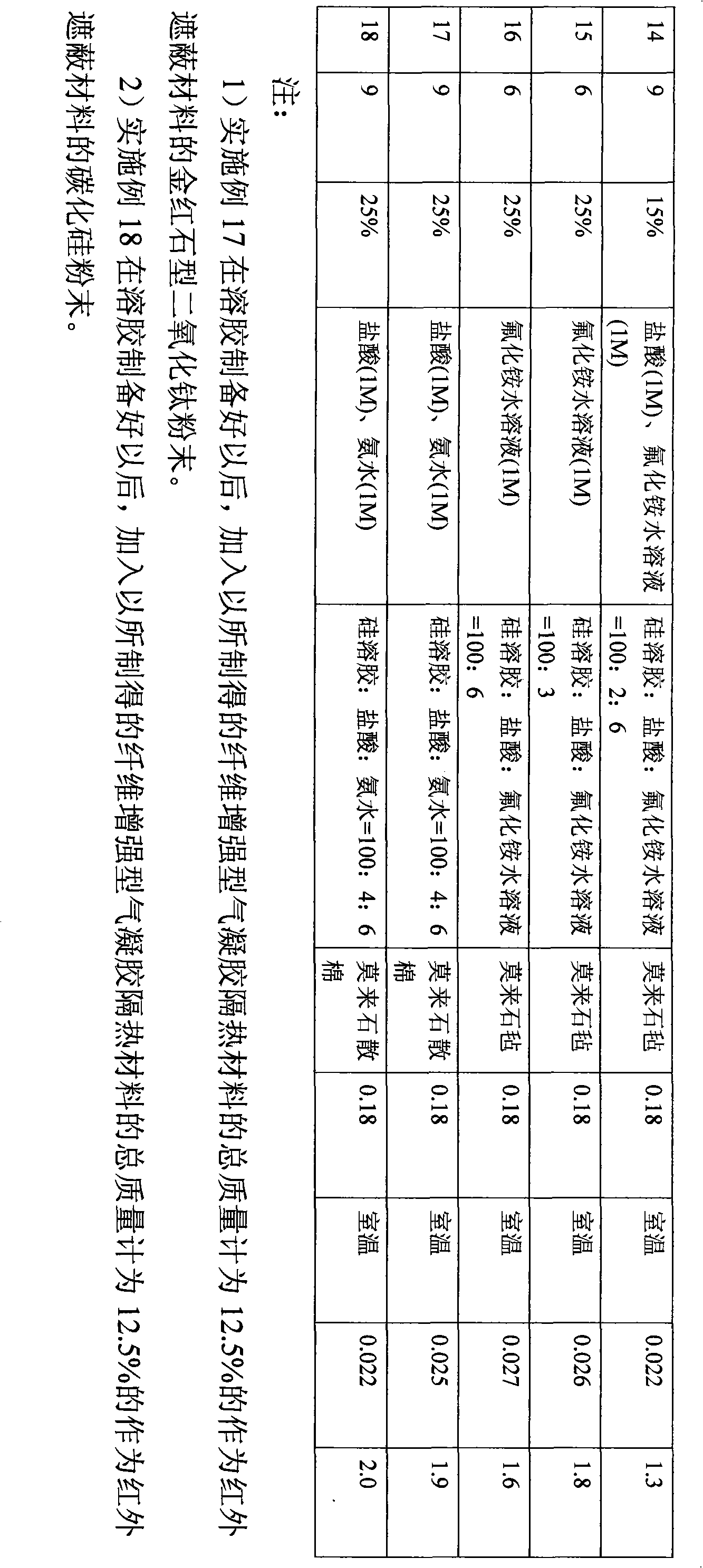

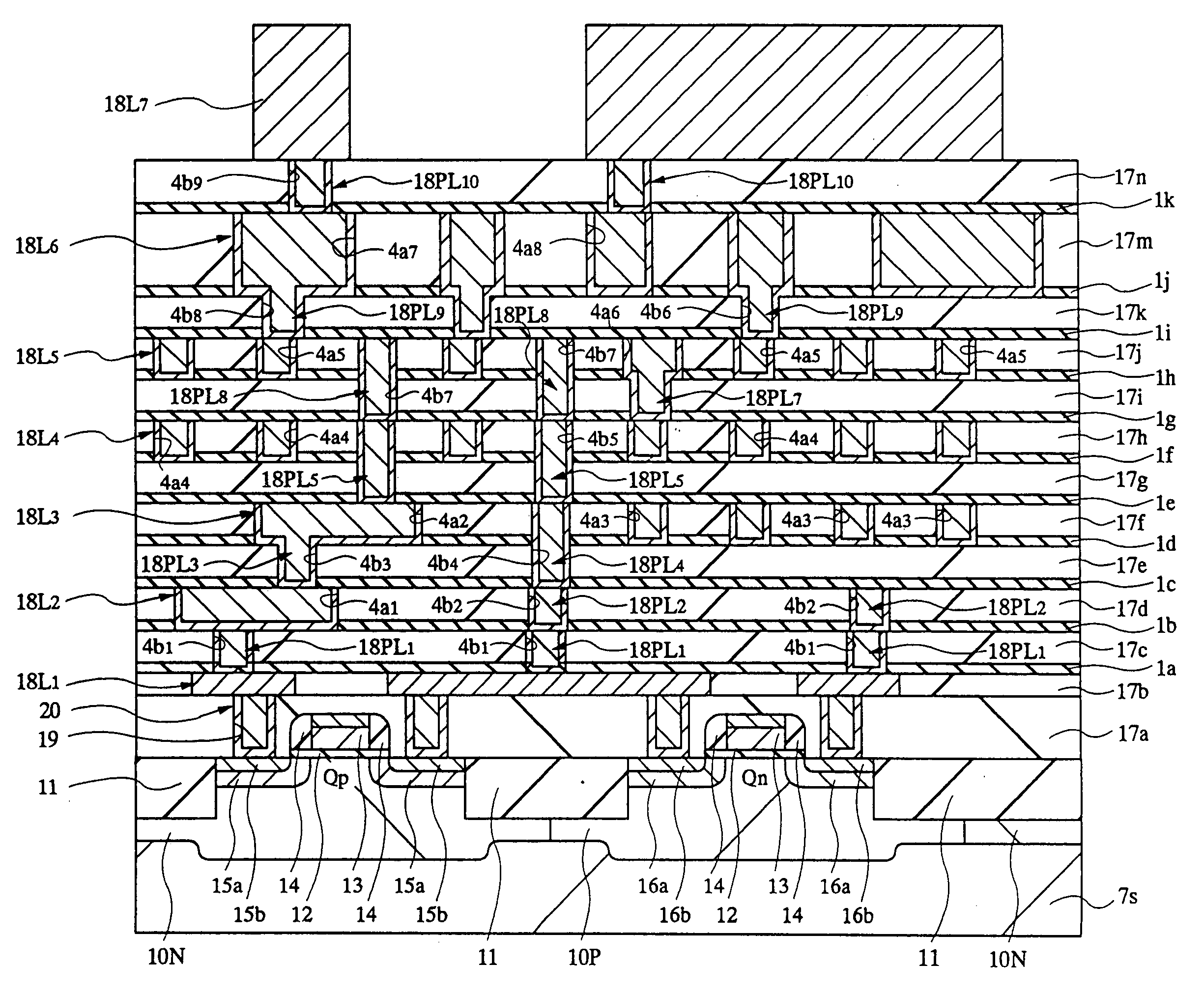

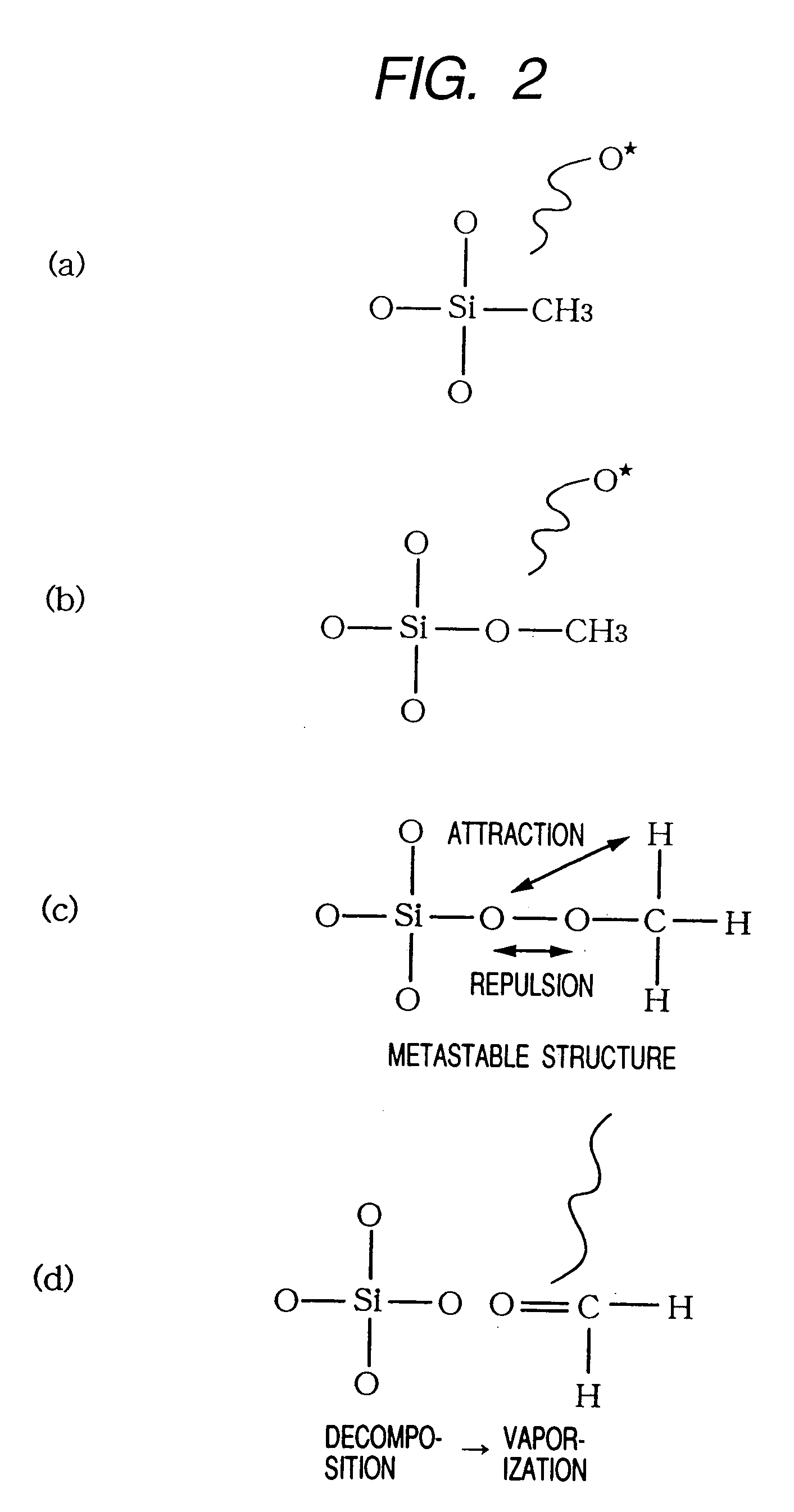

Method of manufacture of semiconductor integrated circuit

InactiveUS20050186801A1Improve etch selectivitySemiconductor/solid-state device detailsSolid-state devicesResistElectrical conductor

In a process for the manufacture of a semiconductor integrated circuit device having an inlaid interconnect structure by embedding a conductor film in a recess, such as a trench or hole, formed in an organic insulating film which constitutes an interlevel dielectric film and includes an organosiloxane as a main component, the recess, such as a trench or hole, is formed by subjecting the organic insulating film to plasma dry etching in a CF-based gas / N2 / Ar gas in order to suppress the formation of an abnormal shape on the bottom of the recess, upon formation of a photoresist film over the organic insulating film, followed by formation of the recess therein with the photoresist film as an etching mask.

Owner:RENESAS ELECTRONICS CORP

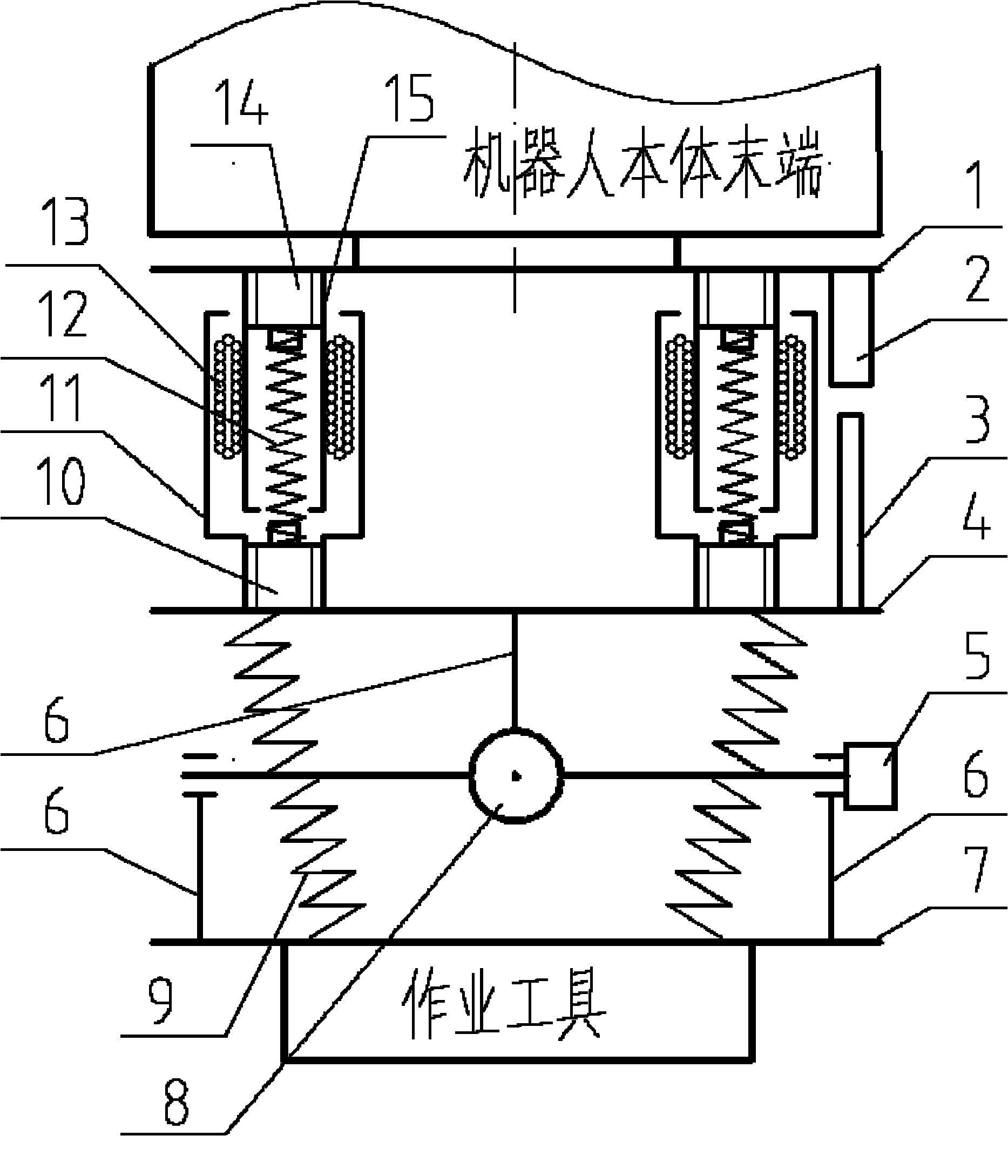

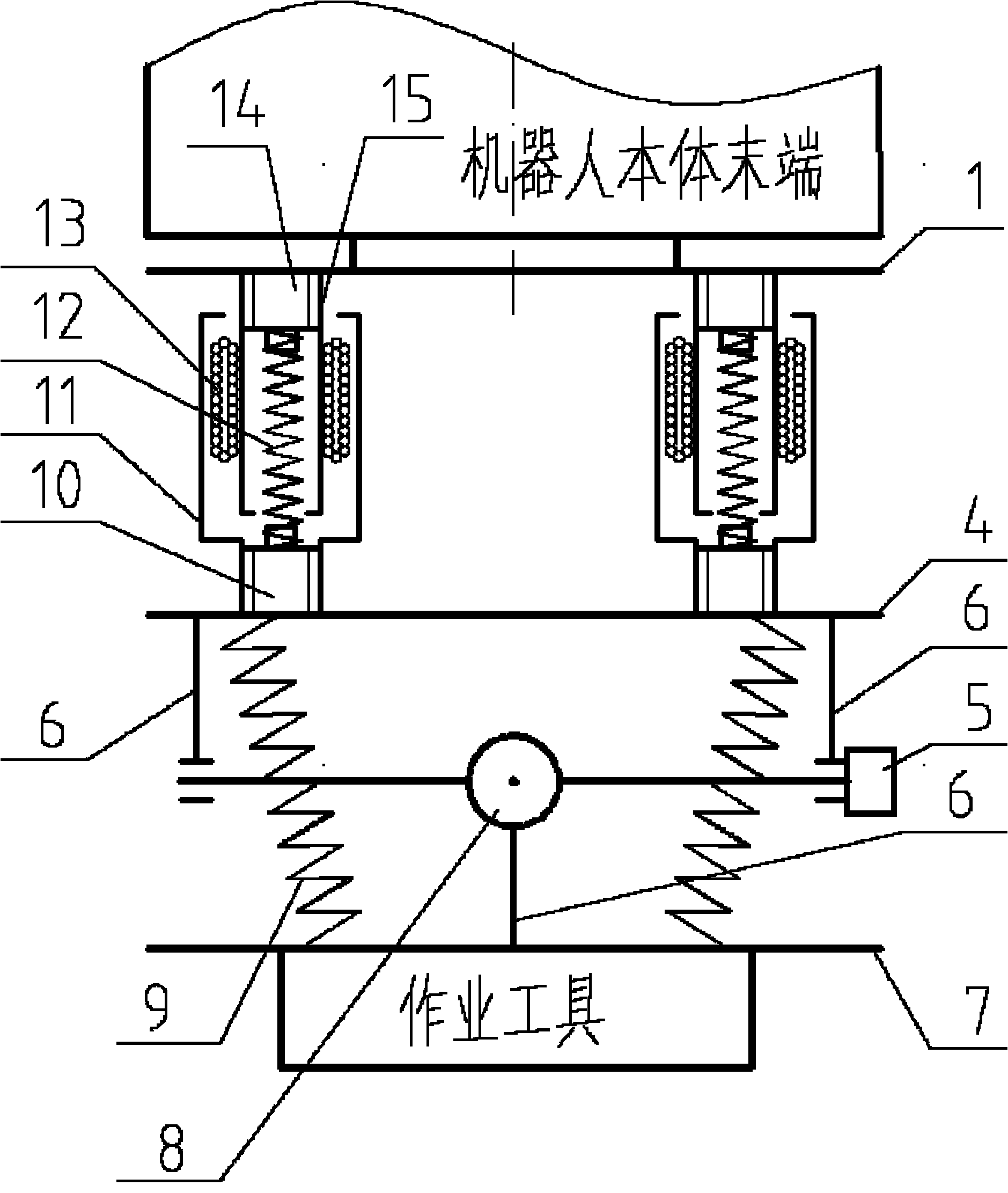

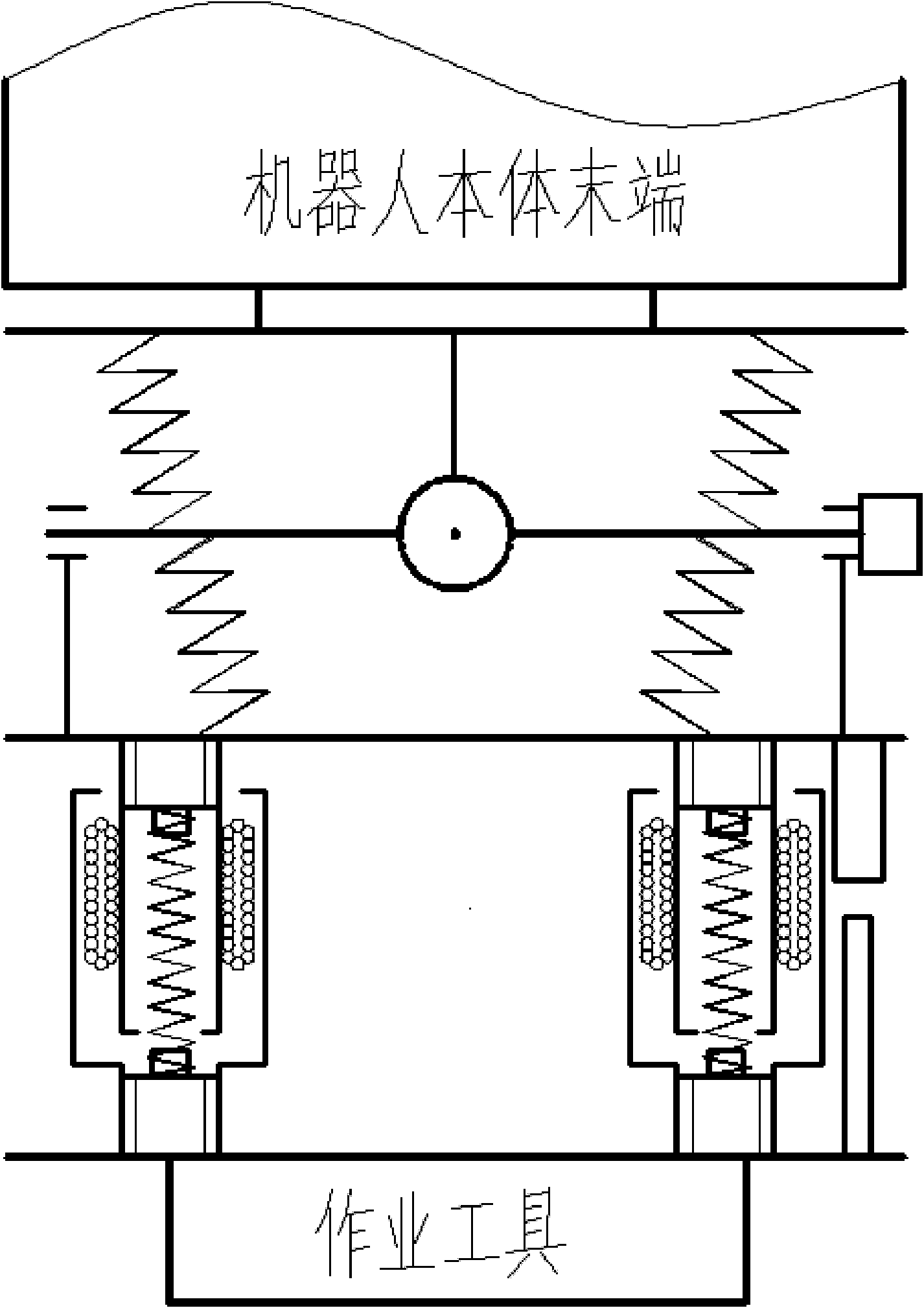

Flexible waist for robot

The invention relates to a flexible waist for a robot, which consists of a moving part, a swinging part, a displacement sensor and an angle sensor, wherein the moving part realizes the moving function in one direction, the swinging part realizes the swinging function in two directions, springs are arranged both in the moving part and the swinging part, the flexibility and the resetting function of the waist in the moving direction and the swinging direction can be realized through the elasticity of the springs, the contact state of operation objects can be identified through the information of a position sensor and the angle sensor arranged on the waist, and then, the position and the posture of the tail end of a robot body are regulated according to the information of the sensors, so the contact state of operation tools and the operation objects can be regulated, and the force / position mixed control can be realized. The invention has a simple structure, has flexibility, does not need the driving force, is applicable to operations such as grinding, polishing, hole insertion assembling, object outline reorganization and the like, and is particularly applicable to the grinding and polishing on curve surfaces in abnormal shapes.

Owner:HUAZHONG UNIV OF SCI & TECH

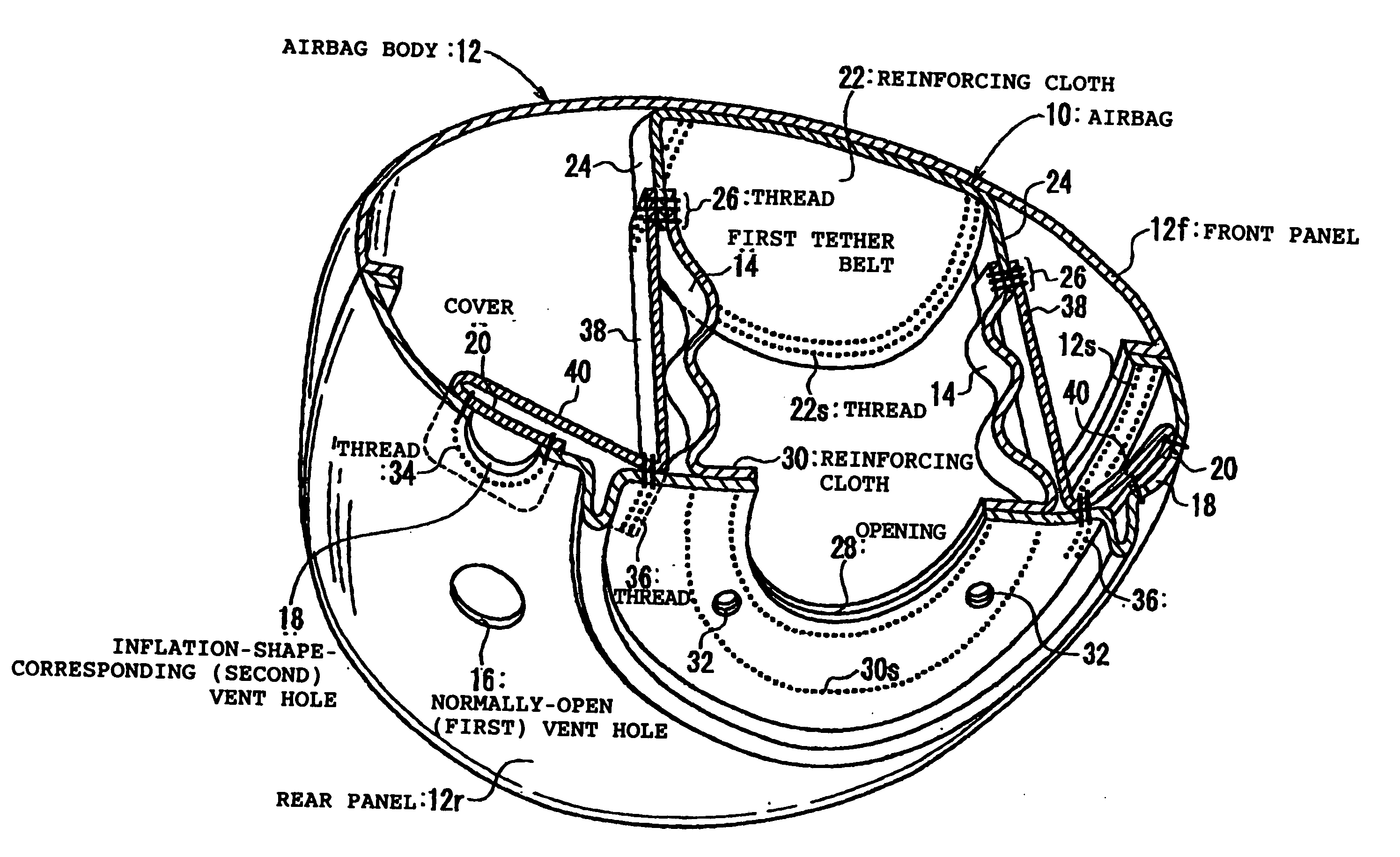

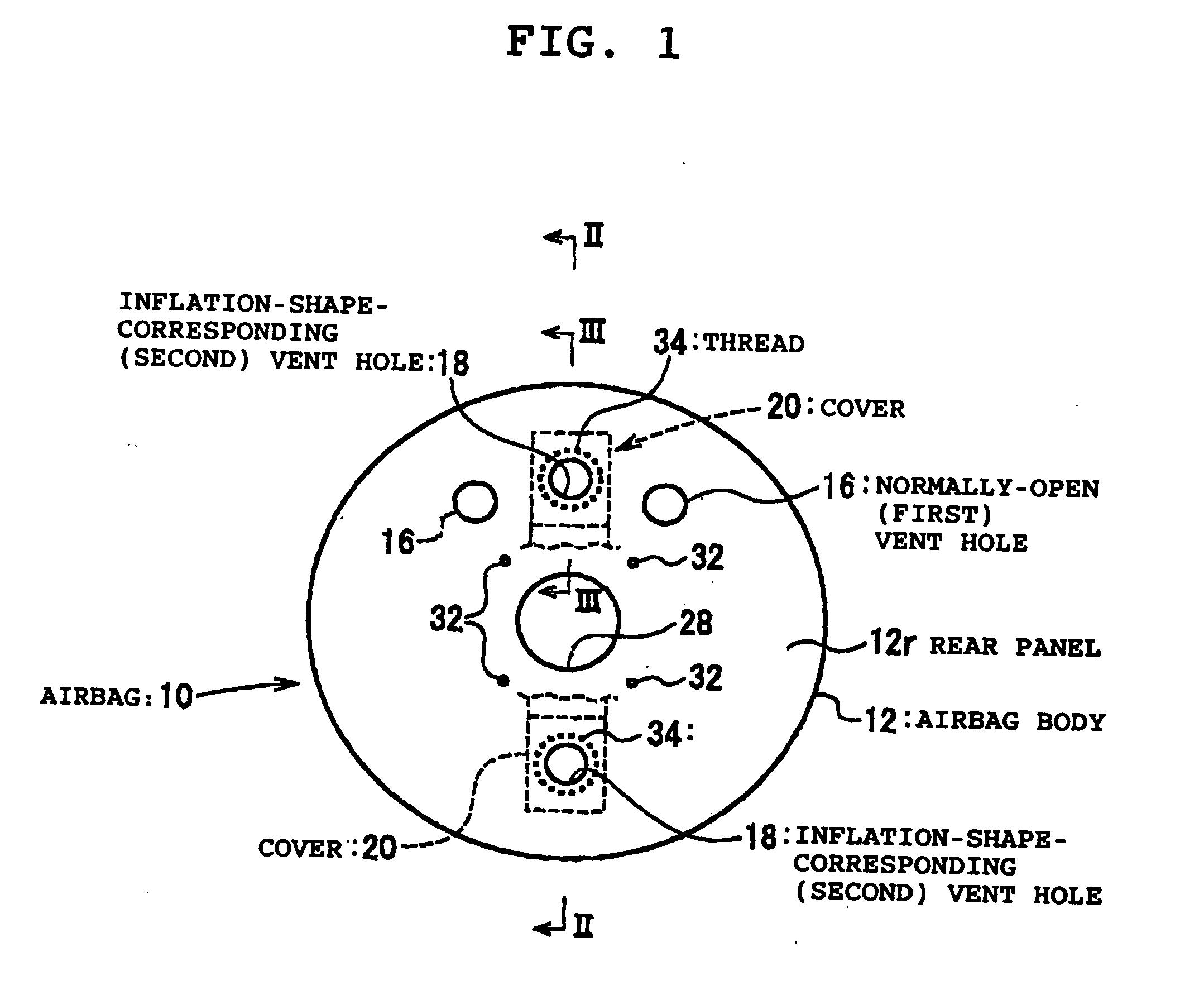

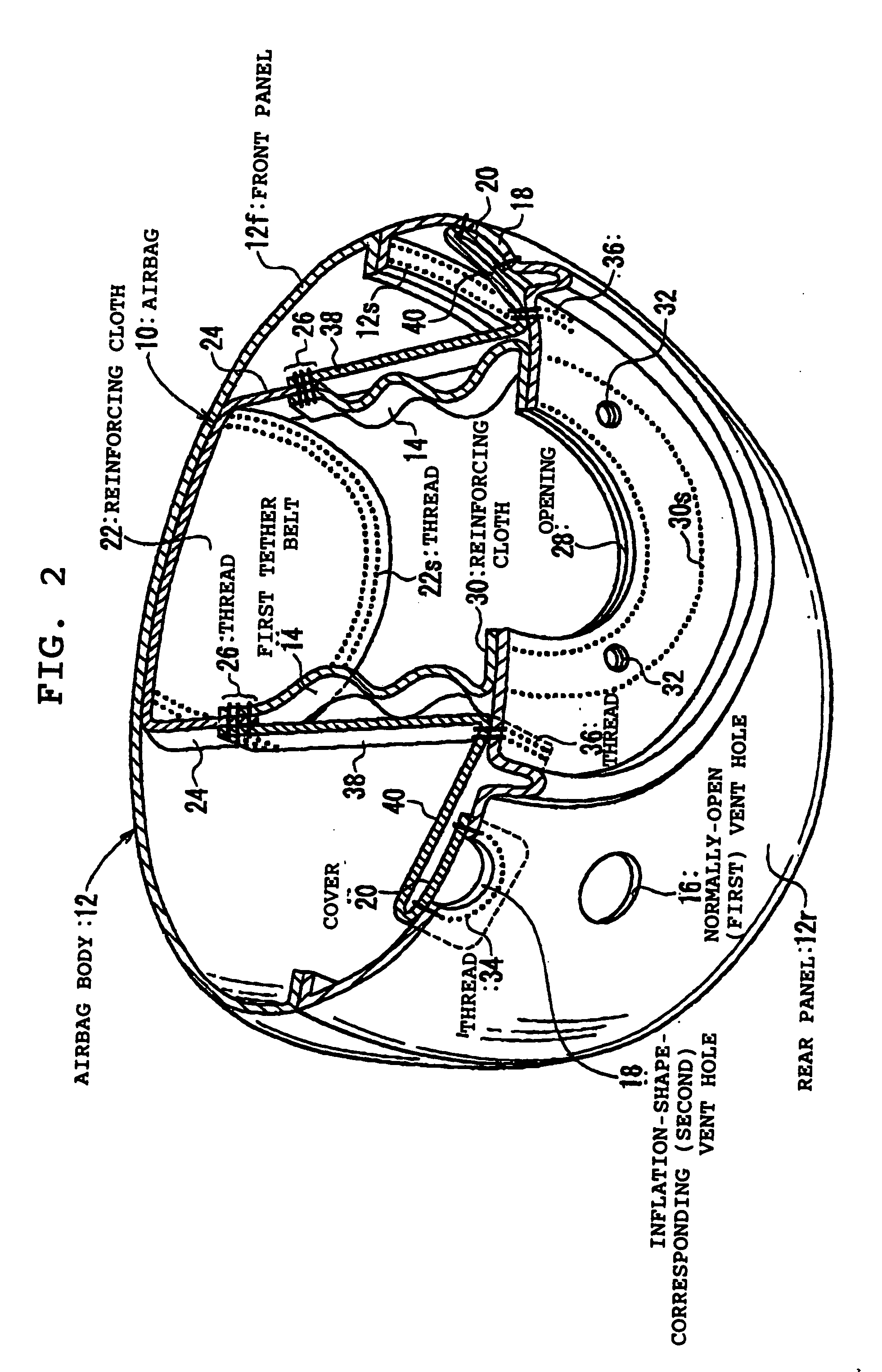

Airbag and airbag system

InactiveUS20050225065A1Reduce pressureIncrease volumePedestrian/occupant safety arrangementEngineeringAbnormal shapes

An airbag and an airbag system are disclosed. In one form, the airbag includes a first tether belt that connects a front panel and a rear panel together and becomes tense when the airbag inflates into a normal shape, a second tether belt that connects the front panel and the rear panel together and is shorter than the first tether belt and a third tether belt that connects the side rim and the center of the rear panel together. The airbag first inflates into a form in which the inflation toward the occupant and in the lateral direction is restrained by the second tether belt and the third tether belt. Thereafter, when the airbag inflates into a normal shape, both of the second tether belt and the third tether belt release the restraint; when the airbag inflates into an abnormal shape, only the third tether belt releases the restraint.

Owner:TAKATA CORPORATION

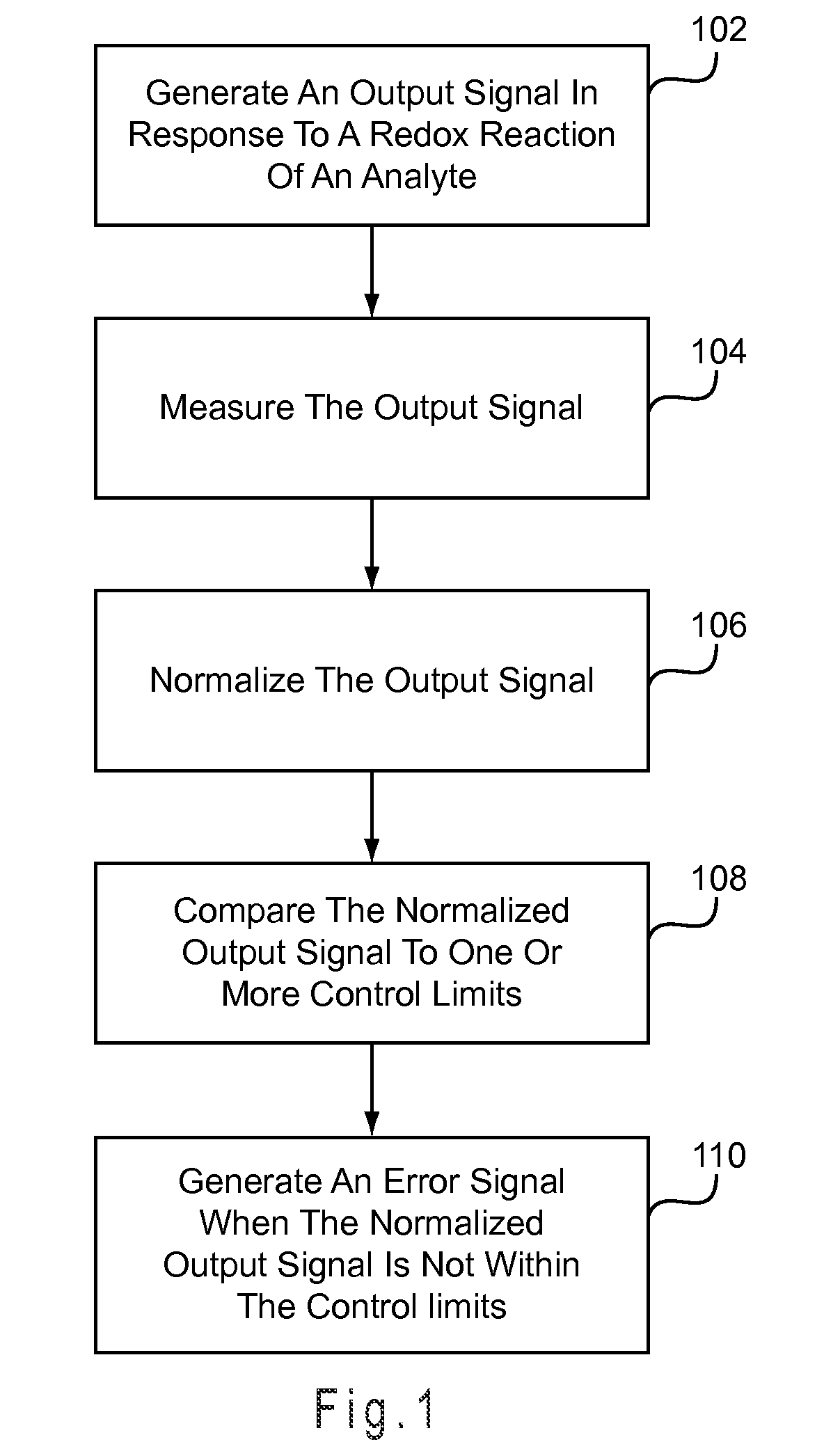

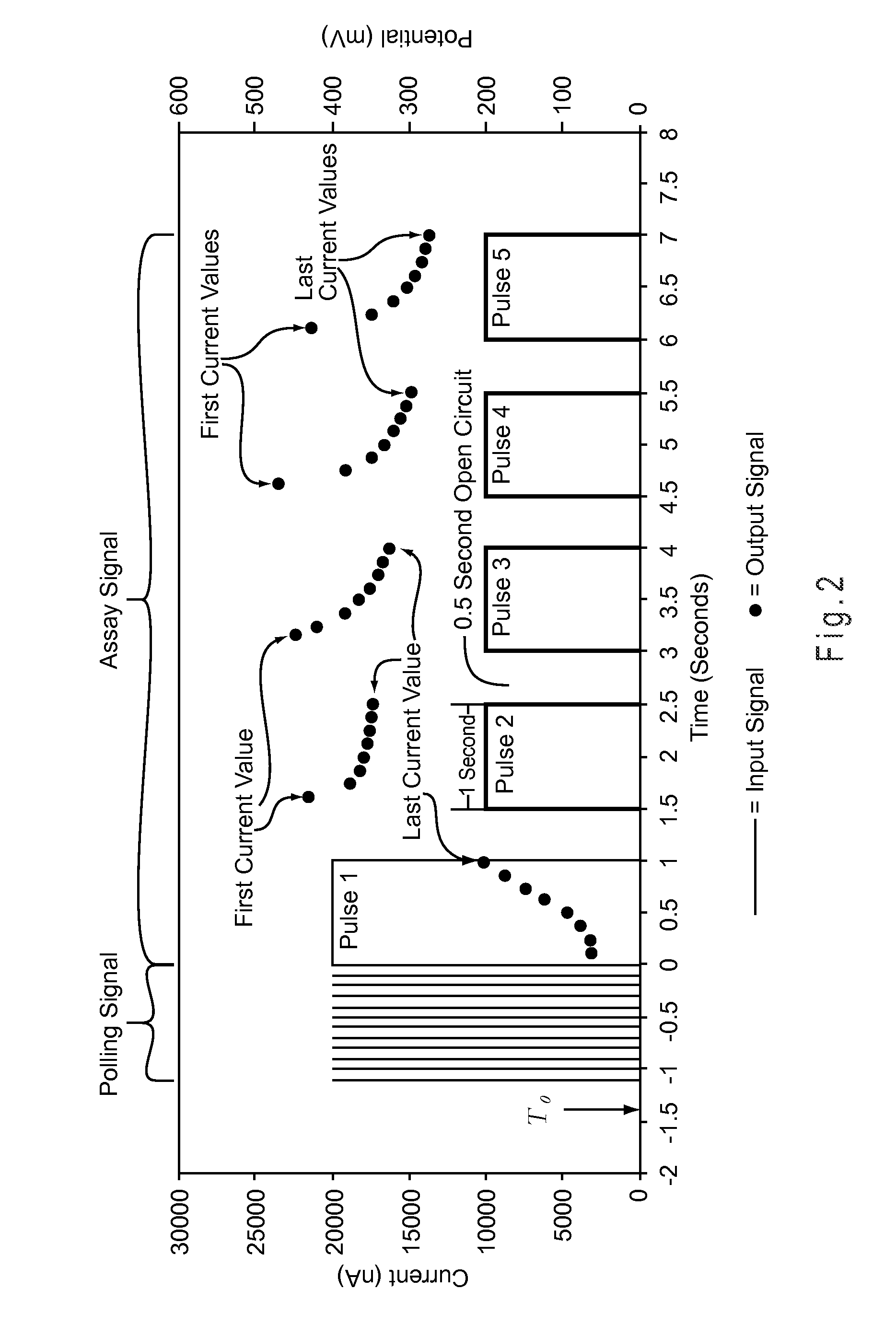

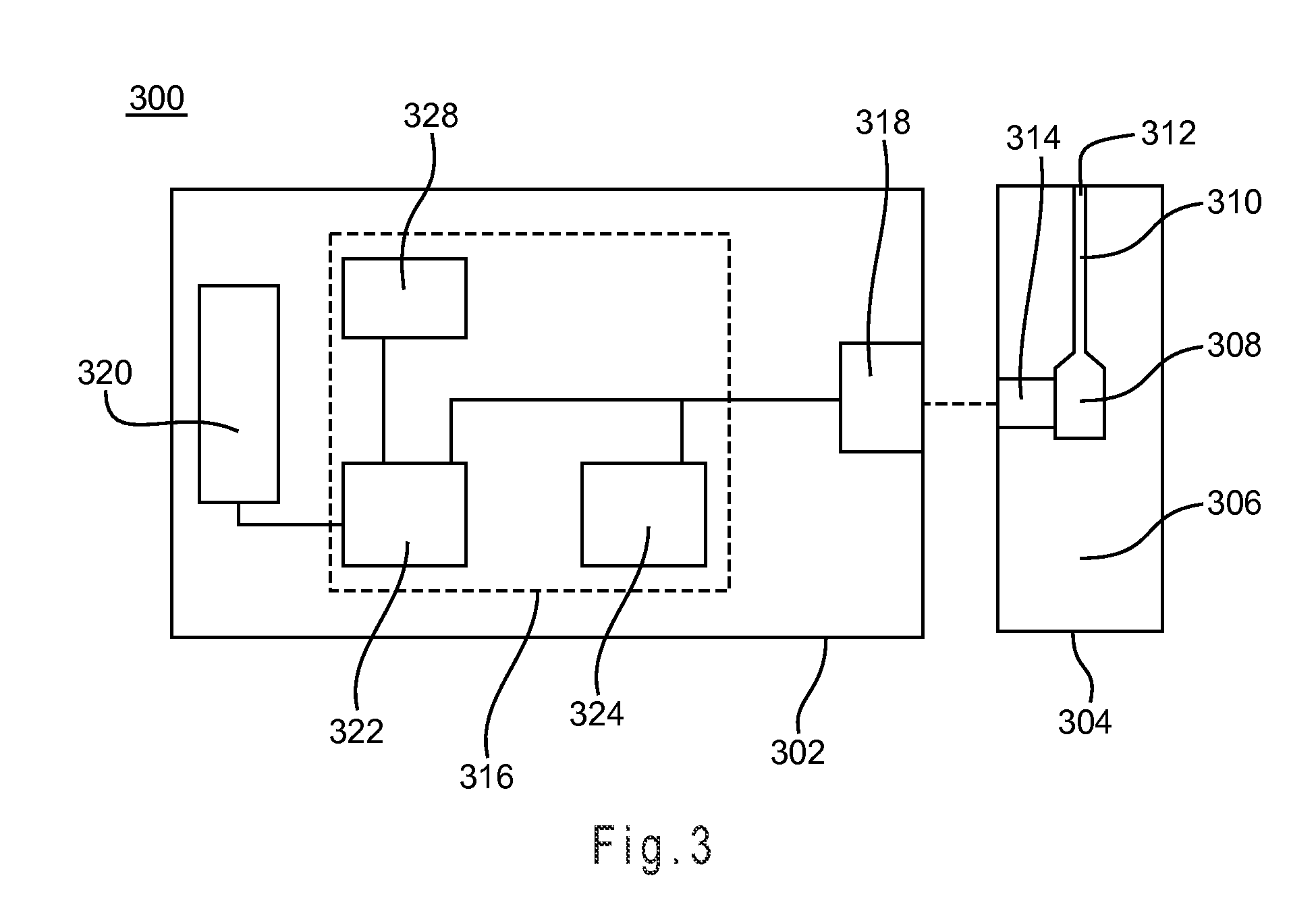

Abnormal Output Detection System For A Biosensor

ActiveUS20090099787A1Accurate and precise analysisMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalyteRedox

A biosensor has an abnormal output detection system that determines whether an output signal from the redox reaction of an analyte has a normal or abnormal shape or configuration. The abnormal output detection system improves the accuracy and precision of the biosensor in determining whether an output signal has a shape or configuration that may not provide an accurate and / or precise analysis of a biological fluid. The biosensor generates an output signal in response to the redox reaction of the analyte. The biosensor normalizes the output signal and compares the normalized output signal with one or more control limits. The biosensor may generate an error signal when the normalized output signal is not within the control limits.

Owner:ASCENSIA DIABETES CARE HLDG AG

Abnormal shape box column and processing craft thereof

InactiveCN106884498ASimple structureGuaranteed sizeStrutsWelding apparatusEngineeringAbnormal shapes

The invention discloses an abnormal shape box column. The abnormal shape box column comprises a panel, partition plates, web plates and an upper flange plate, the partition plates are arranged on the panel, the web plates are arranged on the two sides of the partition plates and are fixedly connected with the panel, the upper flange plate is arranged at the upper parts of the two web plates, technical partition plates are arranged at the two ends of the panel, and the partition plates and the web plates are matched with the upper flange plate. According to the abnormal shape box column, the web plates are arranged on the panel to form a box body, the parathion plates are arranged in the box body, the upper flange plate is arranged at the upper part of the box body, and the technical partition plates are arranged at the two ends of the box body, so that the structure of the box column is improved, moreover, the size of the end part of the box body is effectively guaranteed, the processing of a large connector is facilitated on site, the supporting performance and the stability are also greatly improved, and the construction requirement is further better met.

Owner:JIANGSU HUNING STEEL MECHANISM

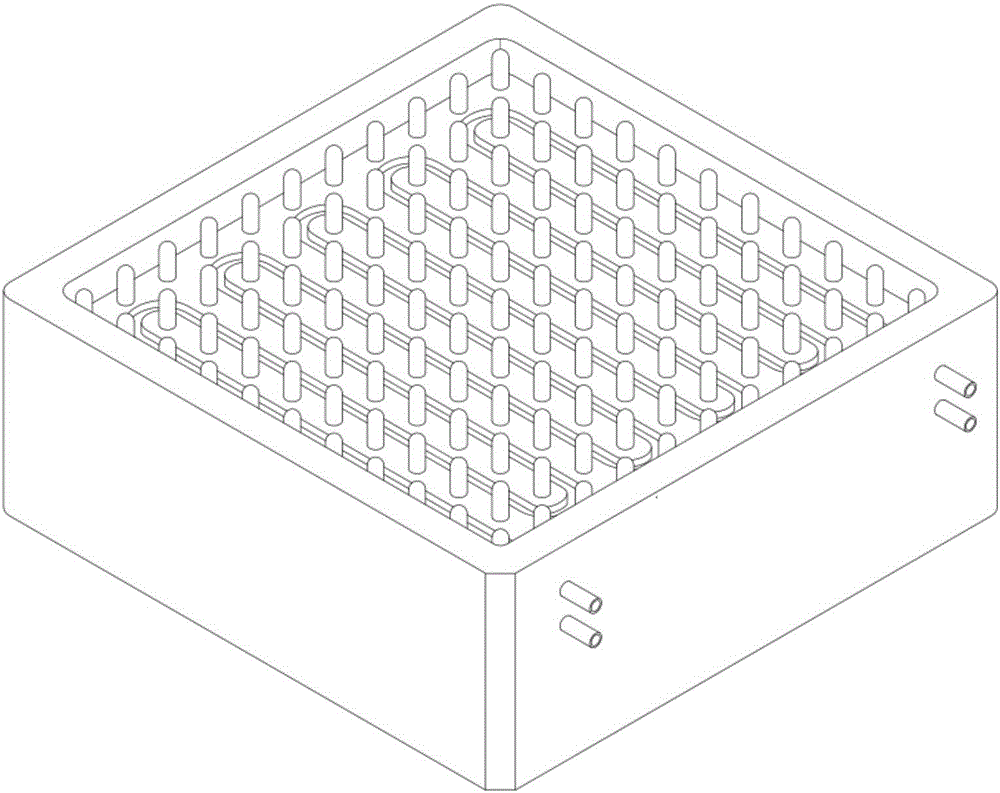

Shape Adjusting Tool

InactiveCN106334961ASimple designHigh speedPositioning apparatusMetal-working holdersNumerical controlProcess quality

The invention discloses a profile-followed adjustment frock, including main box, demarcation strip, upper cabin, lower cabin, upper-deck cabin cooling tube, lower cabin cooling tube, freezing liquid, cold-producing medium, floating thimble, centrehole, thimble spring, spring groove, pin bottom outlet, wherein floating thimble is each independently arranged, and each floating thimble can fluctuate under thimble spring and workpiece effect; Demarcation strip is divided into upper and lower two-layer main body case, upper and lower cabin cooling tube is respectively equipped with two sheaf spaces, it is filled with freezing liquid water, take arbitrary shape workpiece to be put in frock, be pressed downward floating thimble, profiling is formed by compression in workpiece shapes syringe needle with the shape, cooling tube is passed through cold-producing medium, sheaf space freezes up and down, and floating thimble positioning, workpiece are wrapped fixing positioning; Coordinate with Digit Control Machine Tool, gun turret milling machine, grinding machine, drilling machine, unstressed clamping and fast clamp are done to abnormal shape, yielding thin-walled, easy spring angle workpiece and minor items, it is ensured that work pieces process quality, precision and working (machining) efficiency.

Owner:NEUTRON SHANGHAI

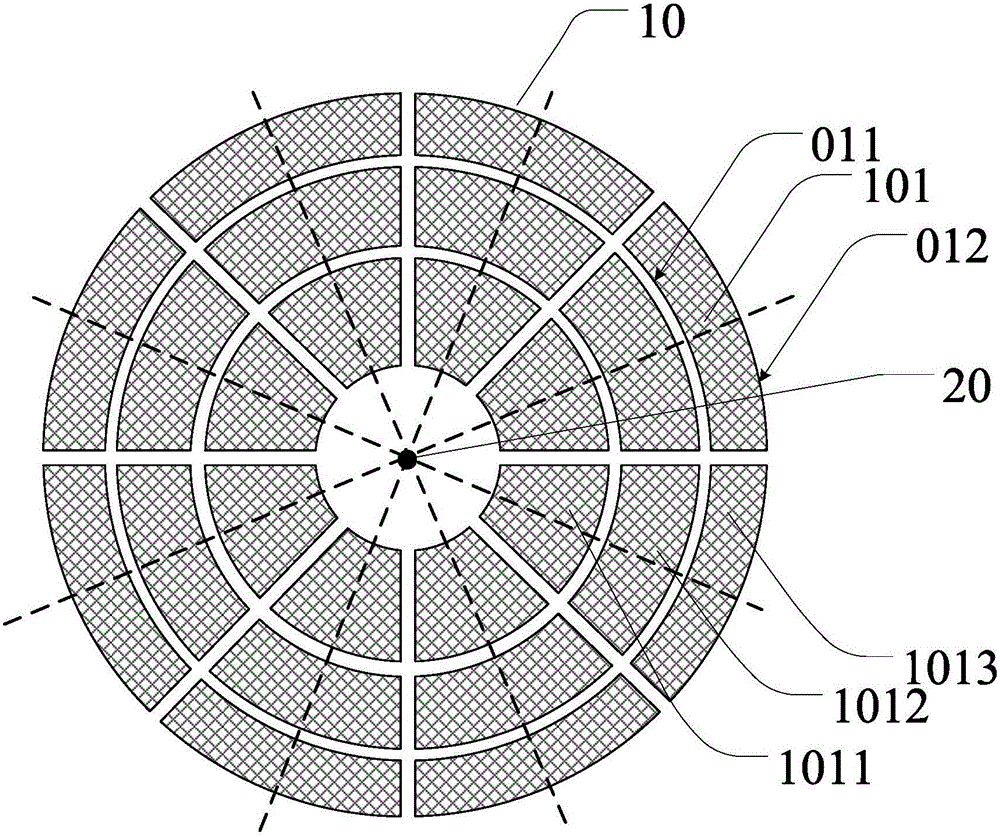

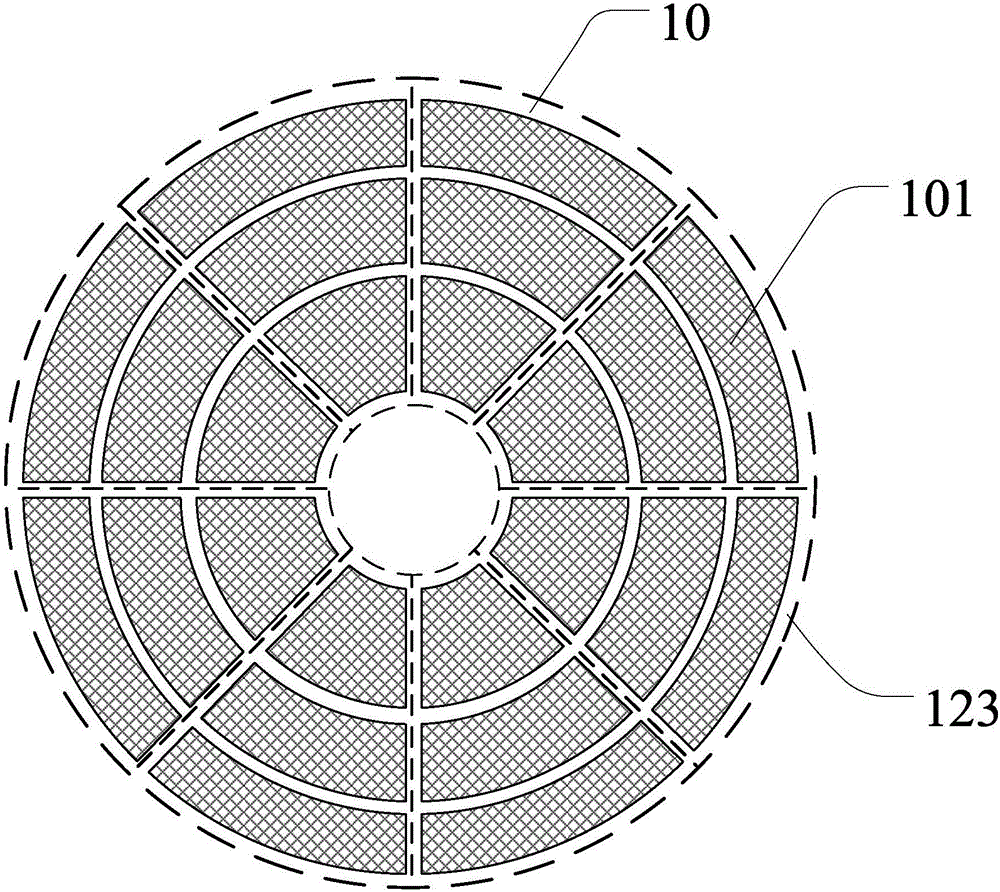

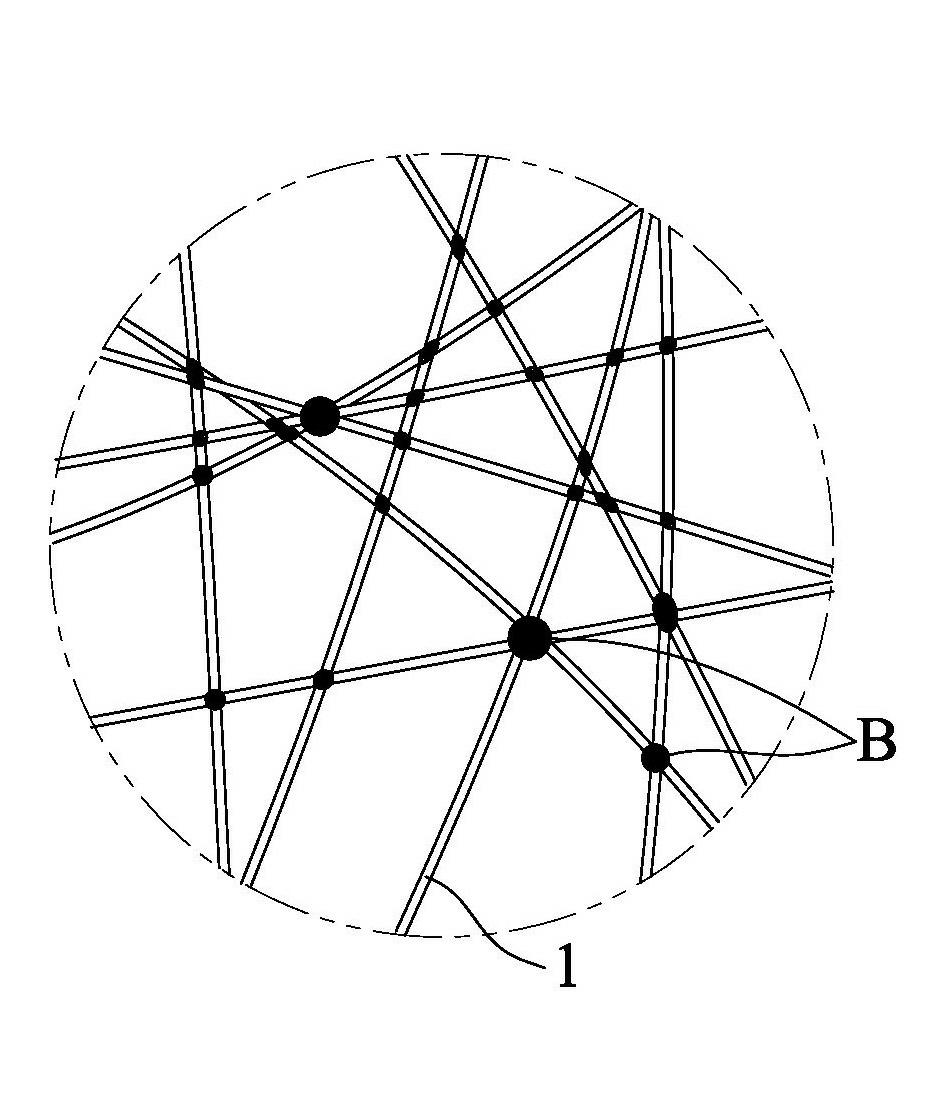

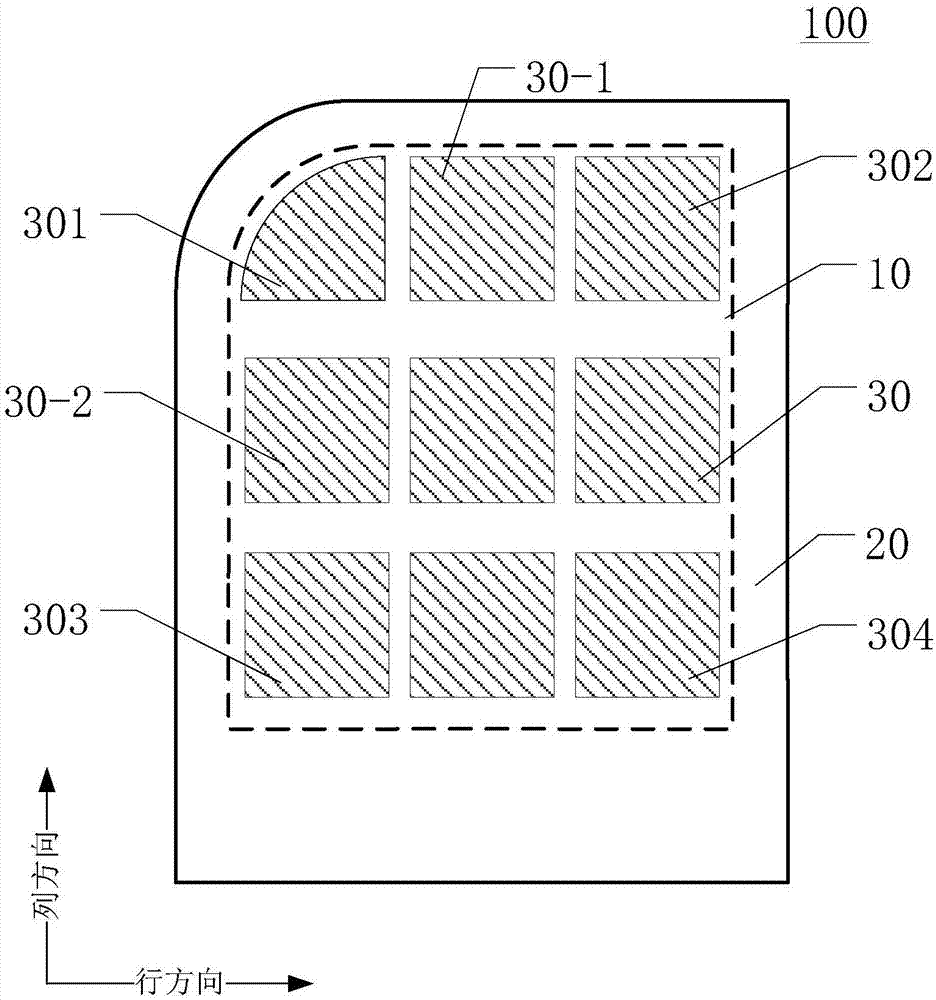

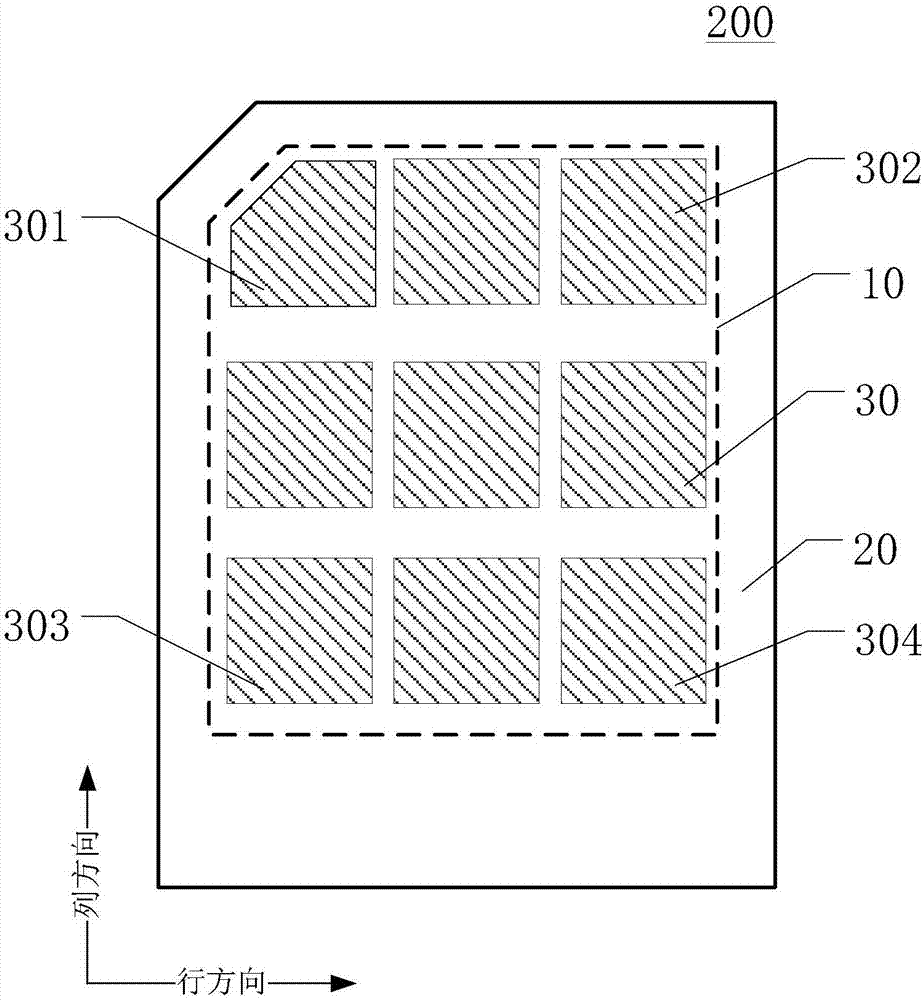

Touch electrode structure, touch screen and display device

ActiveCN105094495ANon-linear opticsInput/output processes for data processingDisplay deviceAbnormal shapes

The invention discloses a touch electrode structure, a touch screen and a display device. The touch electrode structure comprises at least one touch electrode assembly, wherein the at least one touch electrode assembly is arranged around a center; each touch electrode assembly comprises a plurality of touch electrodes; the plurality of touch electrodes in each touch electrode assembly are independently arranged from a position near the center to the position far away from the center; and the circumferential dimension of the end part, which is far away from the center, of each touch electrode is greater than the circumferential dimension of the end part, which is near the center, of each touch electrode. The touch electrode structure can be used for non-rectangular (abnormal-shape) touch screens, can effectively and completely cover the non-rectangular touch screens according to requirements and avoids the phenomena of inaccurate report points, poor linearity and the like caused by that the touch electrodes on the edge or the corner of the touch screen can not be completely covered.

Owner:BOE TECH GRP CO LTD +1

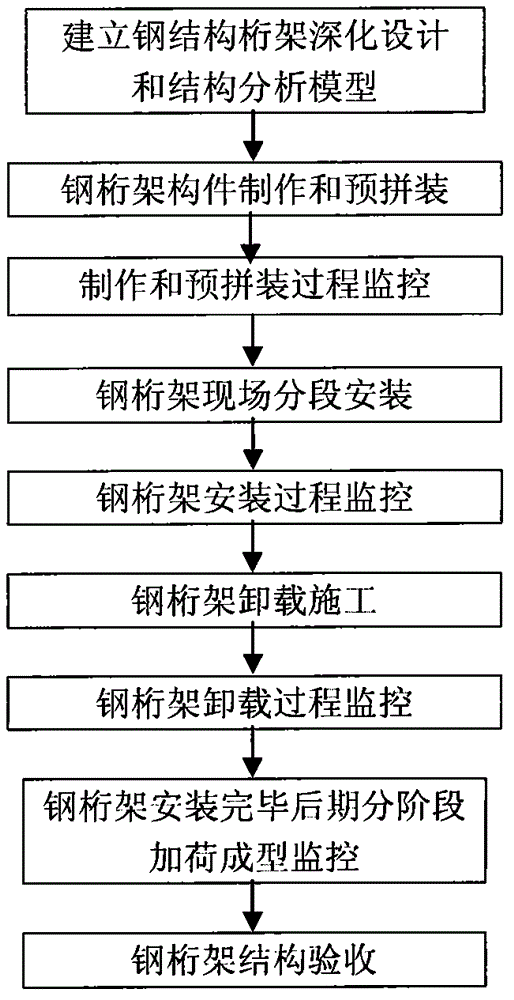

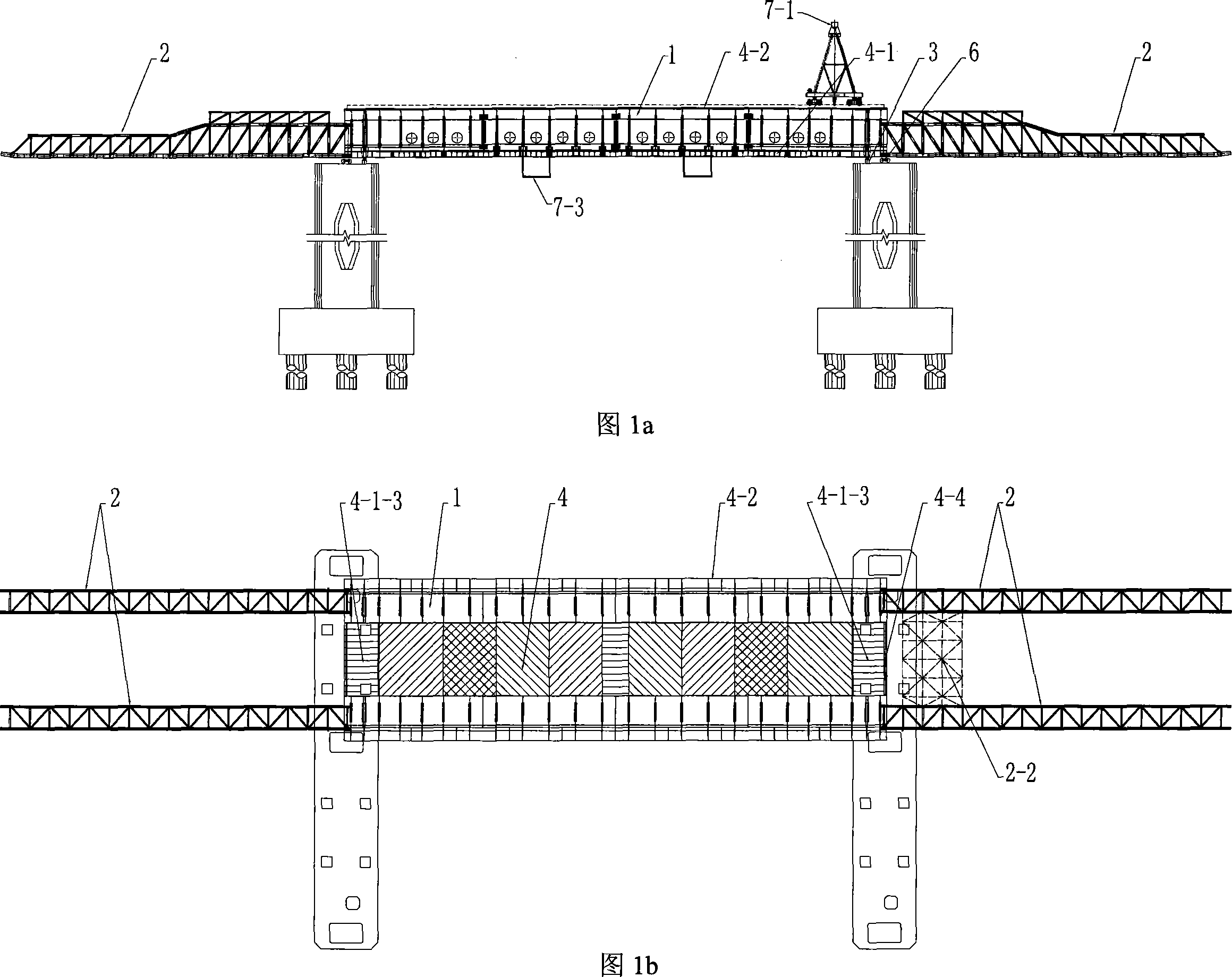

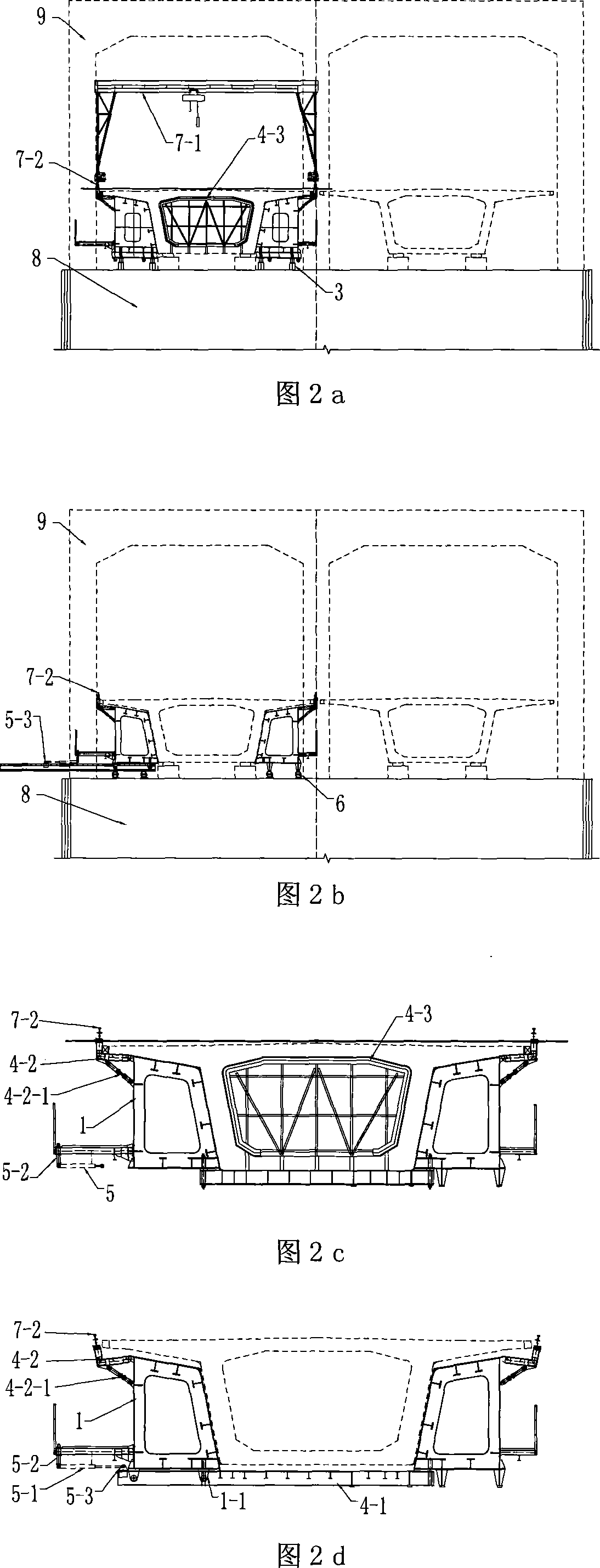

Method for installing abnormal-shaped extremely-large overhung steel truss under process monitoring construction

InactiveCN104631838AEasy to installEven by forceBuilding material handlingSupporting systemStructure analysis

The invention discloses a method for installing an abnormal-shaped extremely-large overhung steel truss under process monitoring construction. The installing method includes the steps that a steel structure truss deepening design and structure analysis model is built; steel truss parts are manufactured and pre-assembled, and the manufacturing process and the pre-assembling process are monitored; the steel truss is installed in site in a sectioned mode, and the steel truss installation process is monitored; unloading construction is carried out on the steel truss, and the steel truss unloading process is monitored; loading forming is monitored in the later period after the steel truss is installed in a staged mode; the structure of the steel truss is checked and accepted. The installation technology that a temporary supporting system and altitude spread assembling are combined is adopted, the large-span abnormal-shaped space lattice pipe truss is accurately installed, and the truss is evenly stressed and is not prone to deformation in the installation process. Heat accumulation, welding stress and welding deformation are prevented with the altitude spread roof-member method.

Owner:YONGSHENG CONSTR GRP

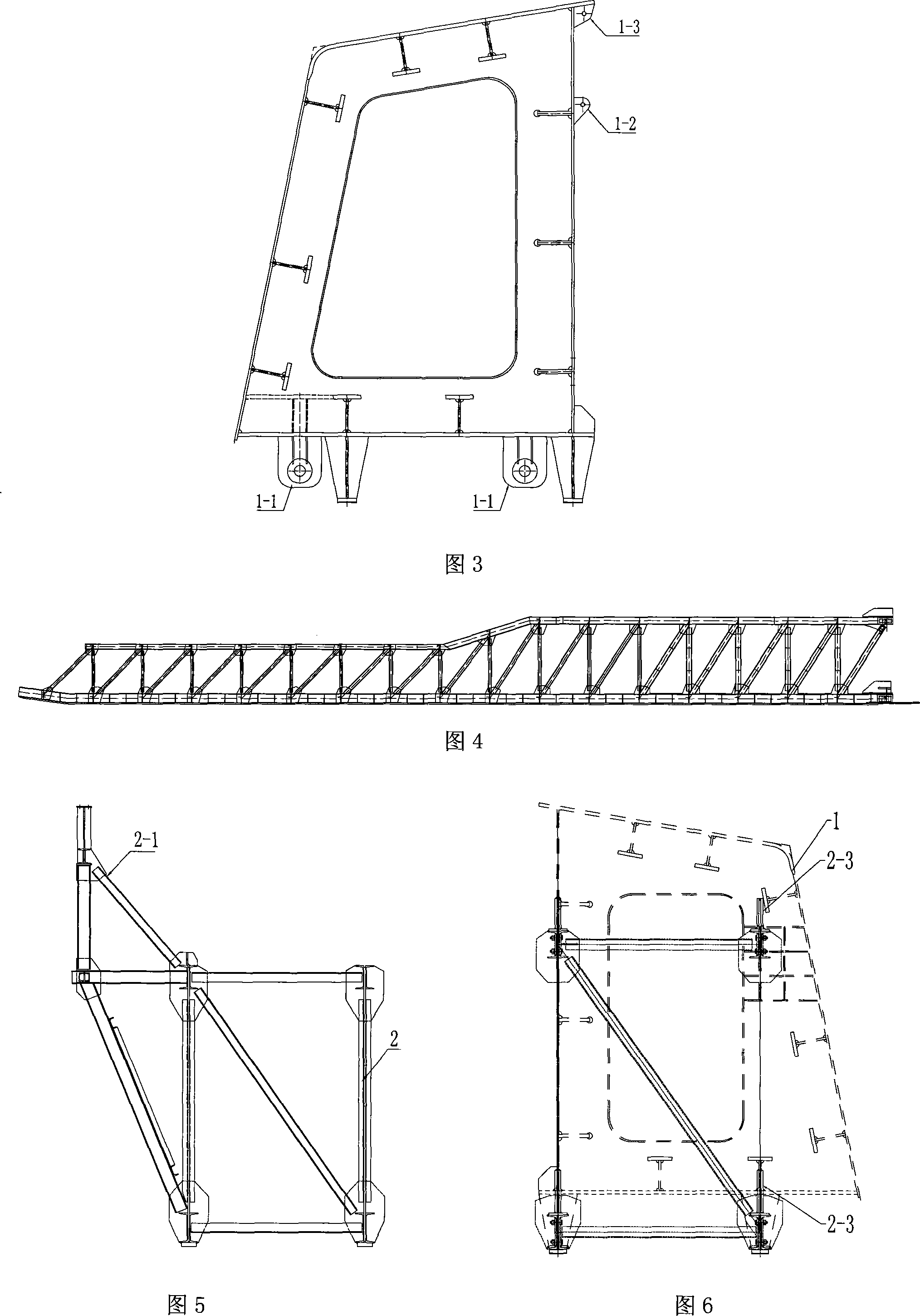

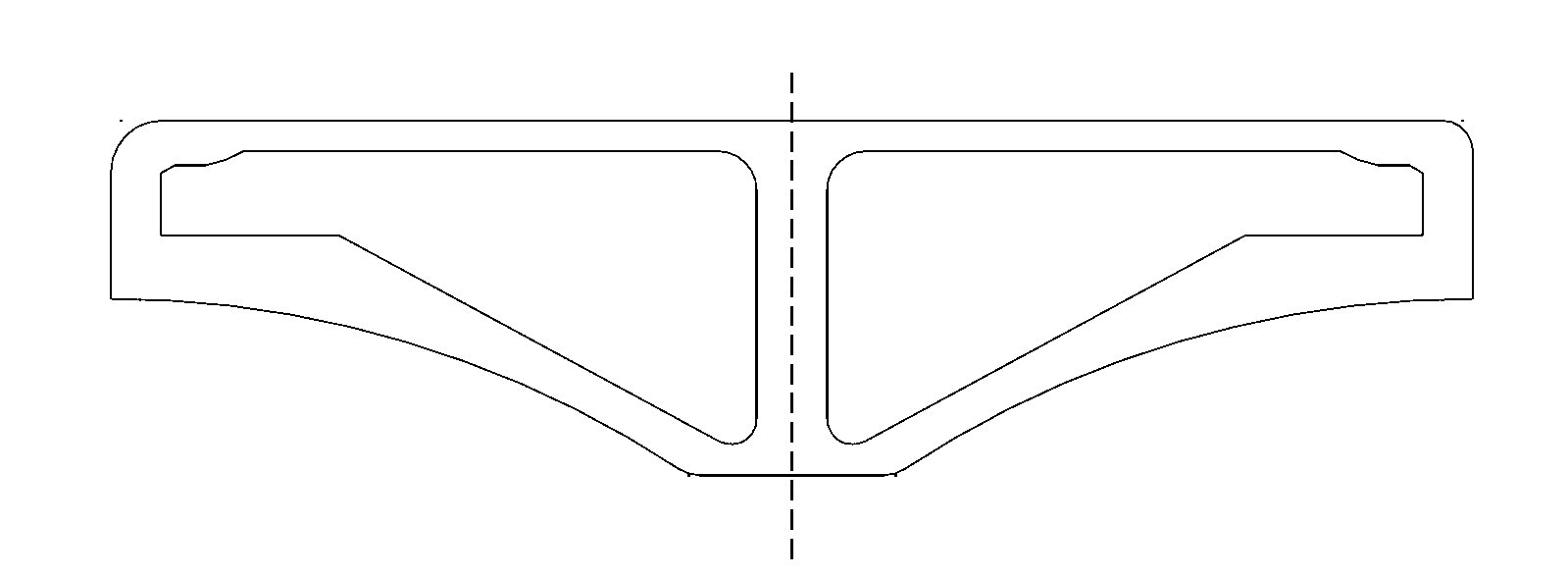

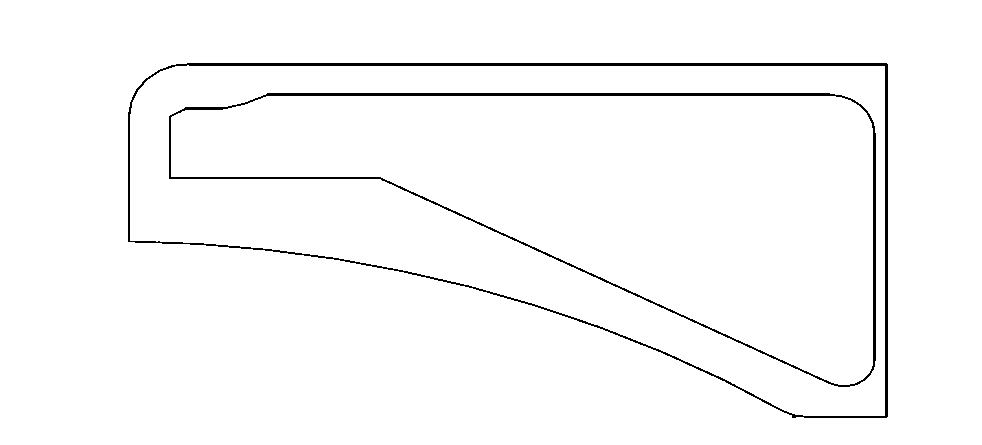

Abnormal shape steel case and orthotropic plate bottom formwork combined type moving die carrier framework and construction method thereof

ActiveCN101117791ALower the altitudeSolve the problem of running through holesBridge erection/assemblyBridge materialsPush and pullSelf locking

A heterotype steel box and an orthogonal heterology plate bottom mold combined moving mould base and a construction method are provided, the load bearing beam of the moving mould base is the beam of the heterotype steel box, and a top plate and an inner web plate are the outer mould of a concrete box beam; the bottom mold employs orthogonal heterology structure, high toughness and low height, through opening and closing by flat pushing at one side, and line feed is performed in the space between the concrete box beam and a pier shaft. The main beam of the moving mold base is directly supported at the pier top, with the self-locking hydraulic jacket to transmit the load and adjust the height, the transverse moving of the moving mold base is finished at the pier top, and therefore, a steel structure landing leg is not required. The longitudinal moving of the moving mold employs a steel strand and a continuous hydraulic jacket for pushing and pulling, power for the longitudinal moving is located at the front pier top, and removes the difficulty of the application of a bridge fabrication machine for a railway and a road bridge, is the construction equipment for the concrete box beam of the railway passenger line and used in the road bridge.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Method for preparing metal-ceramic composite material

The invention discloses a preparation method of metal-ceramics composite material which is obtained by combining the tape casting technique and the screen painting technique. The composite material has the advantages of good staying quality, high chemical durability and high shock resistance and overcomes the defect of low combing force among the layers of the current metal-ceramics laminar composite. The method can be used for preparing metal-ceramics composite materials in shapes of tablet, curved surface, pipe, stick and other abnormal shapes and can be used in cutters, thermocouple protecting sleeve, grinding tools, magnetic materials, heater elements, antifriction bearings and anticorrosion valves. The preparation method of the metal-ceramics composite material also has the advantages of simple preparation process, easy controlling, being easy to realize industrialization and good application prospect.

Owner:YANGZHOU FINE ELECTRON TECH

Self-compacting concrete

ActiveCN101805160AImprove compactnessSolid waste managementMixing operation control apparatusSuperplasticizerVolumetric Mass Density

The invention discloses a self-compacting concrete, which is characterized by comprising 100 parts of cement, 60-100 parts of coal ash, 20-50 parts of broken porcelain granula, 100-200 parts of broken stone, 1-5 parts of polycarboxylate superplasticizer, 0.001-0.08 part of tackifier, 0.001-0.1 part of defoamer, 280-360 parts of sand and 0.4-1 part of super plasticizer. Consequently, a structure with a complicated shape, thin walls and dense reinforcements can be cast and formed, a formwork can be prevented from being abraded by vibration, an agitator can be prevented from being abraded by the concrete, and thereby the construction speed and the sound restriction of the environment are improved, and the costs of labor, quality guarantee and those expended on other aspects are reduced; and meanwhile, the invention adopts a technology which uses waste porcelain instead of natural aggregate to produce the regeneration self-compacting concrete, and thereby the well meeting the currently proposed environmental-friendly and energy saving theme of a building system, haveing obvious environmental benefit, economic benefit and social benefit, particularly effectively increasing the compression strength, density, splitting tensile strength, rupture strength, elastic modulus and other indexes, and being applicable to continuous casting of dense type reinforcements and abnormal shape structures with large volume, large density and high span.

Owner:CENT SOUTH UNIV +1

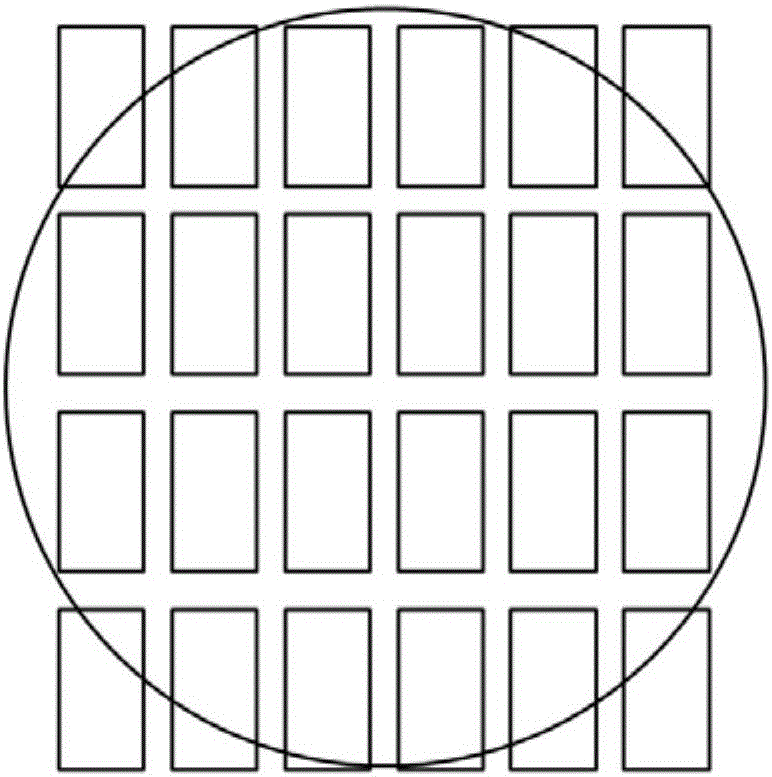

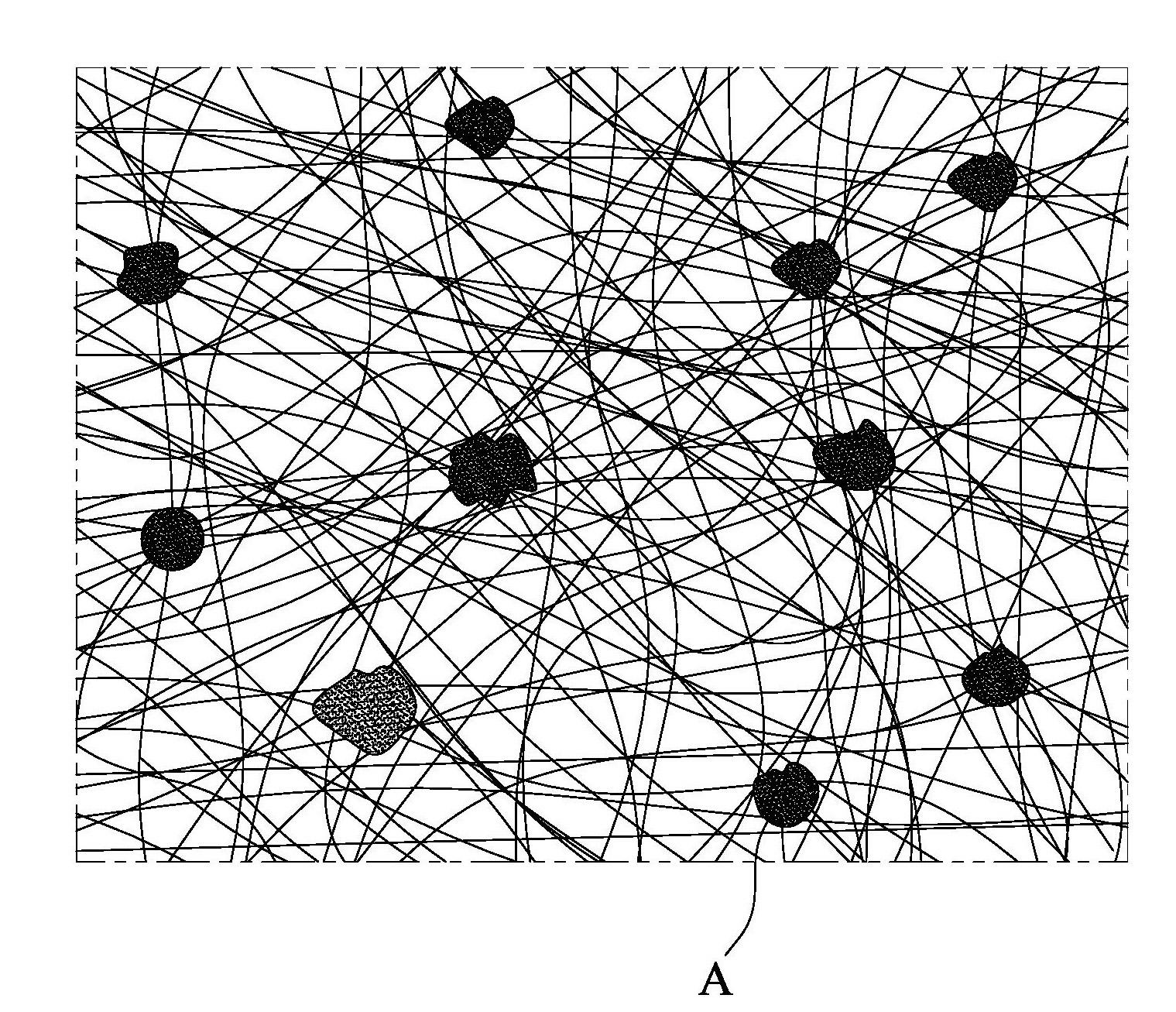

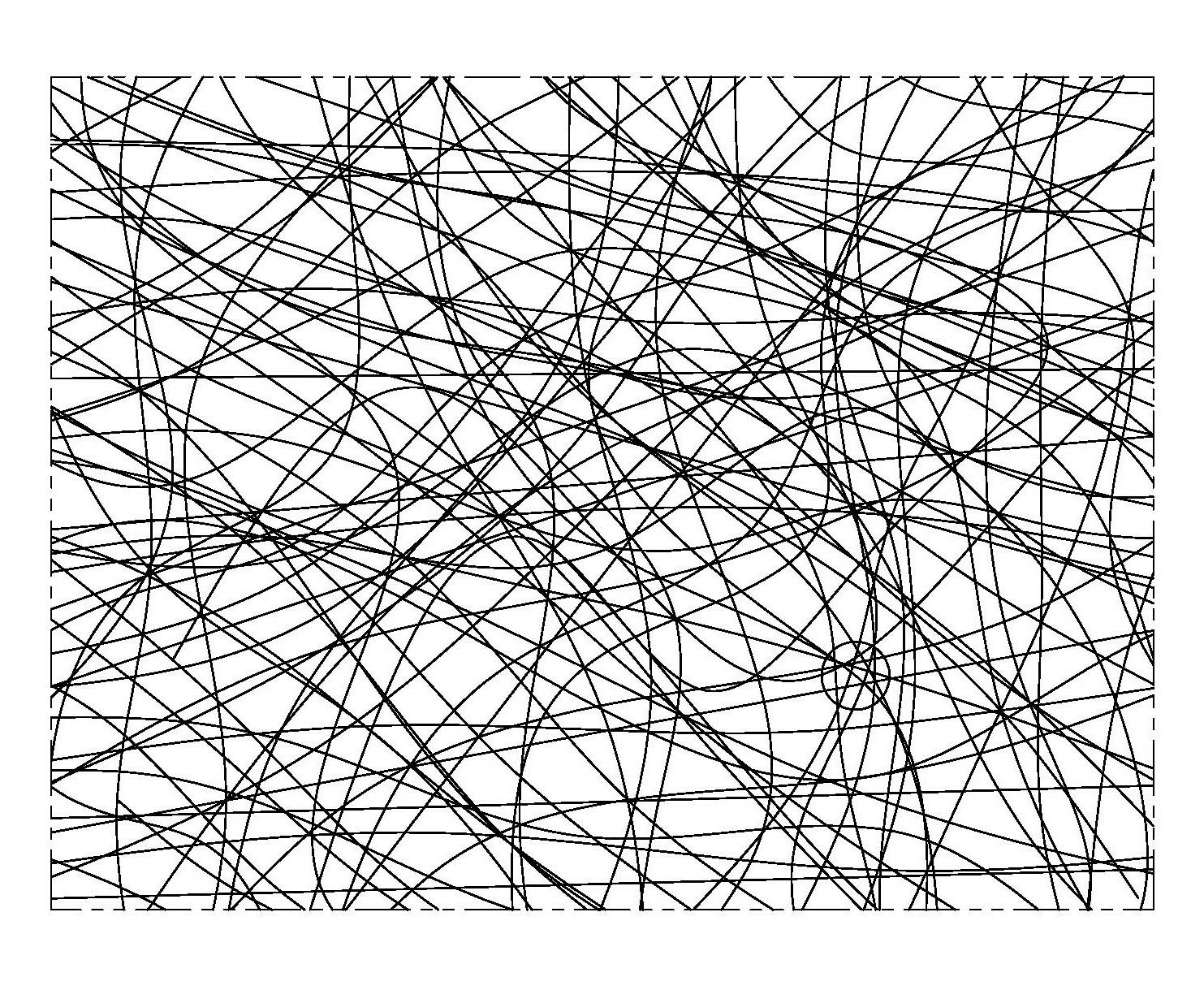

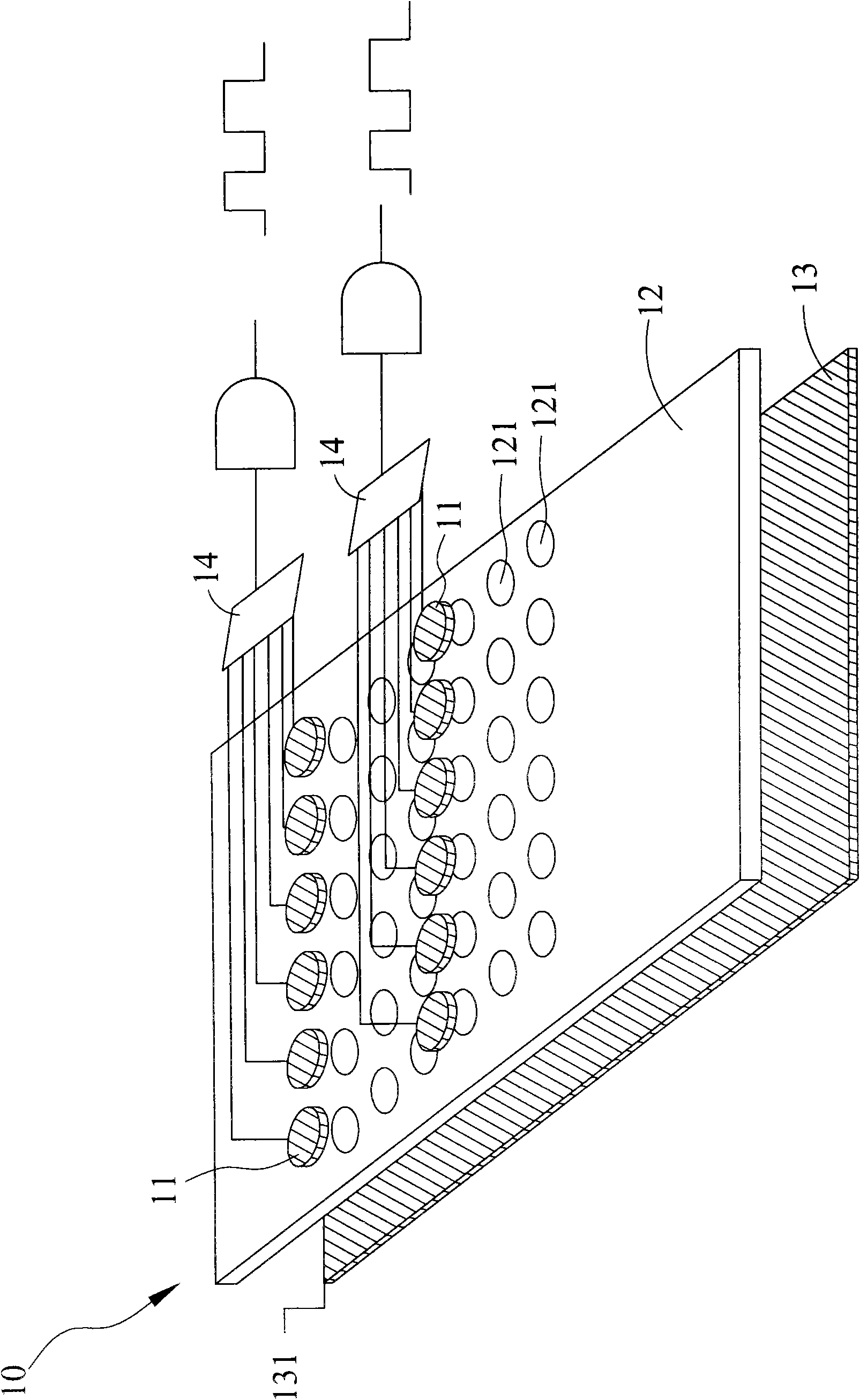

Abnormal-shape filament non-woven fabric and manufacture technology thereof

InactiveCN102560904AAvoid secondary pollutionReduce transportation linksFilament/thread formingNon-woven fabricsManufacturing cost reductionPolymer science

The invention provides an abnormal-shape filament non-woven fabric, wherein non-woven fabric coiled material consists of abnormal-shape fiber filaments, the length of each abnormal-shape fiber filament is more than or equal to 1000mm, the specific surface area of the abnormal-shape filament is more than 1.3 compared with that of the fiber with the same material, the equal denier and the circular cross section, the abnormal-shape fiber filaments consist of low-melting point thermoplastic high polymers and high-melting point thermoplastic high polymers, the low-melting point thermoplastic high polymers of which the melting point is less than 150 DEG C are arranged on the surface layers of the abnormal-shape fiber filaments, the abnormal-shape fiber filaments are glued with one another by the low-melting point thermoplastic high polymers arranged on the surface layers of the abnormal-shape fibers to form into the non-woven fabric coiled material, each gluing point among each abnormal-shape fiber is the surface layers of the low-melting point thermoplastic high polymers of two abnormal-shape fiber filaments contacted with each other, and the mean value of the area of each gluing point is less than 0.01 square millimeters. The non-woven fabric is fluffy and flexible, thereby being elastic; the transportation link is reduced, and the manufacture cost is reduced; and the non-woven fabric is quick in liquid absorption and good in flow guide effect.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

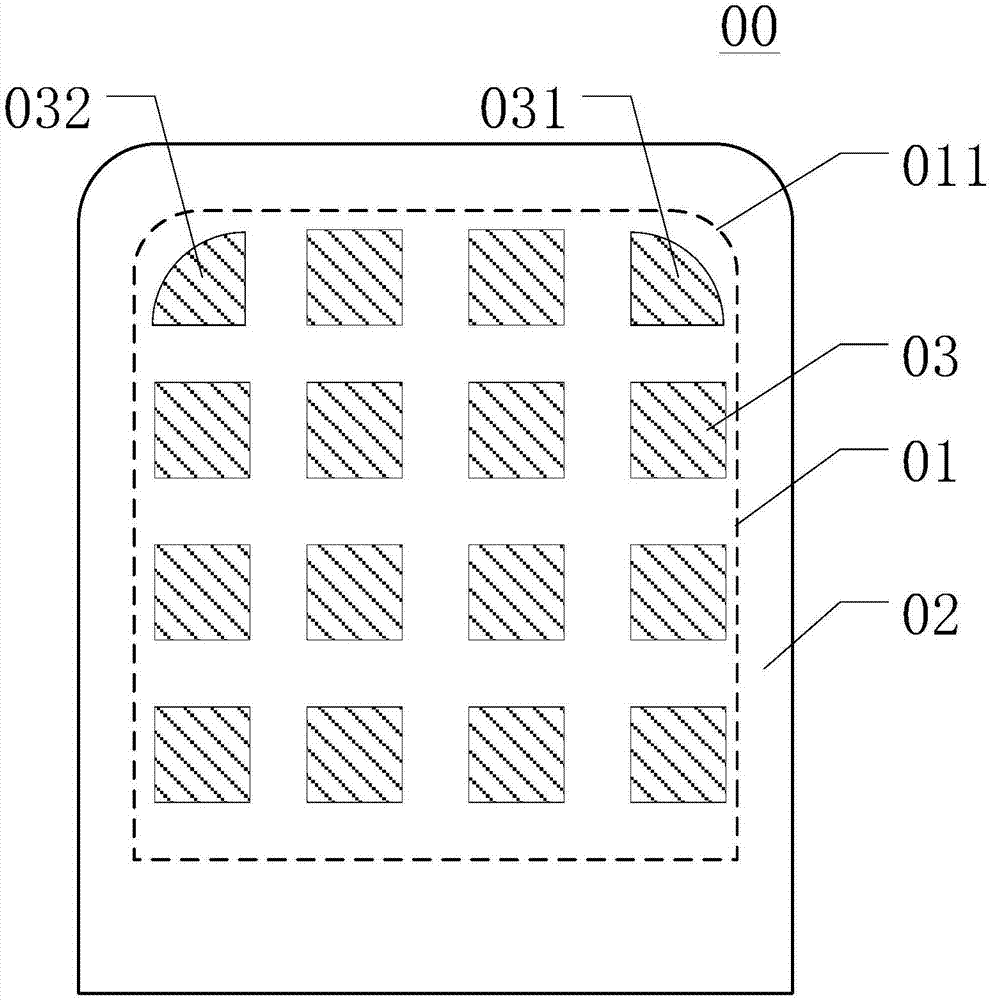

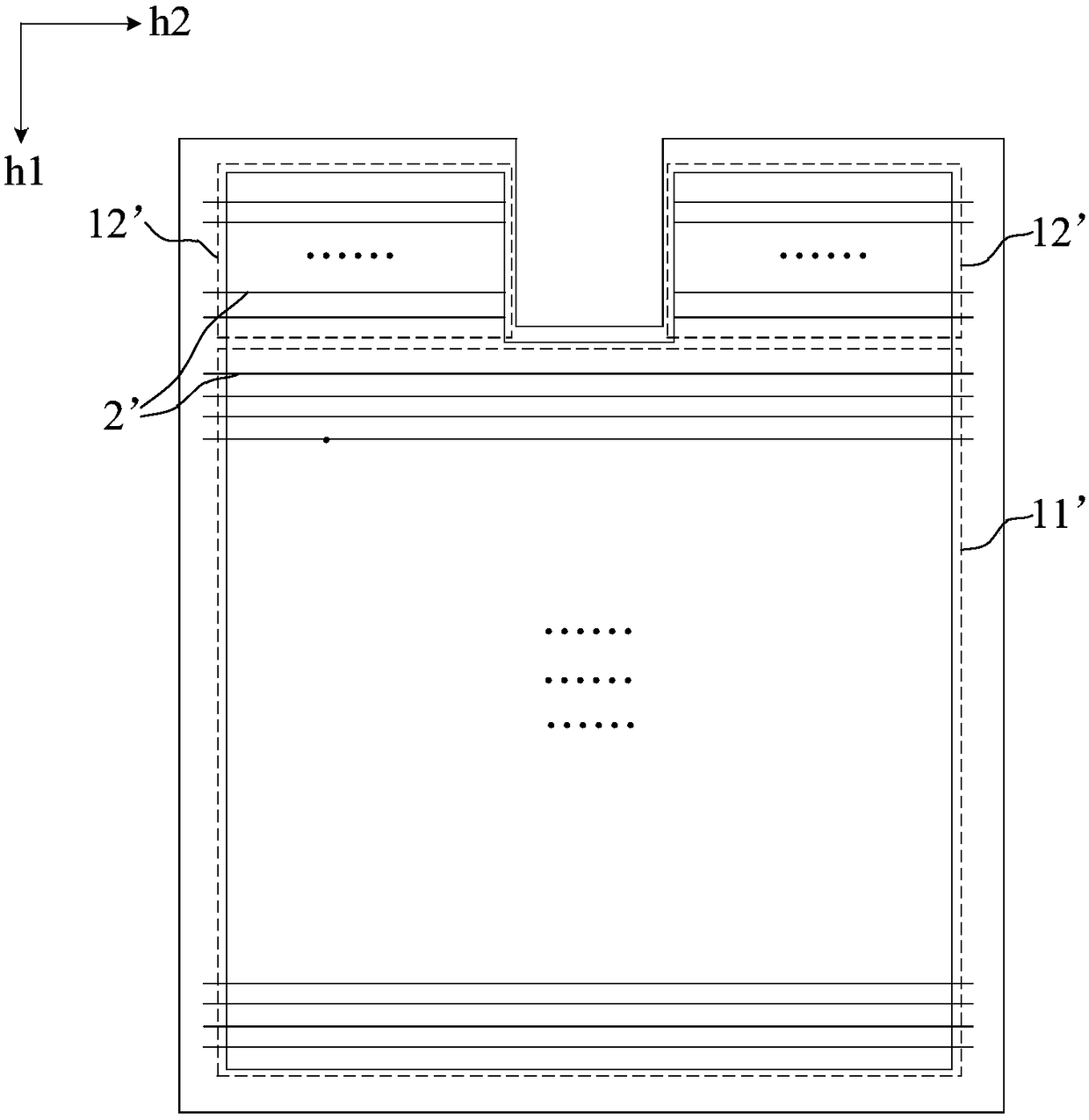

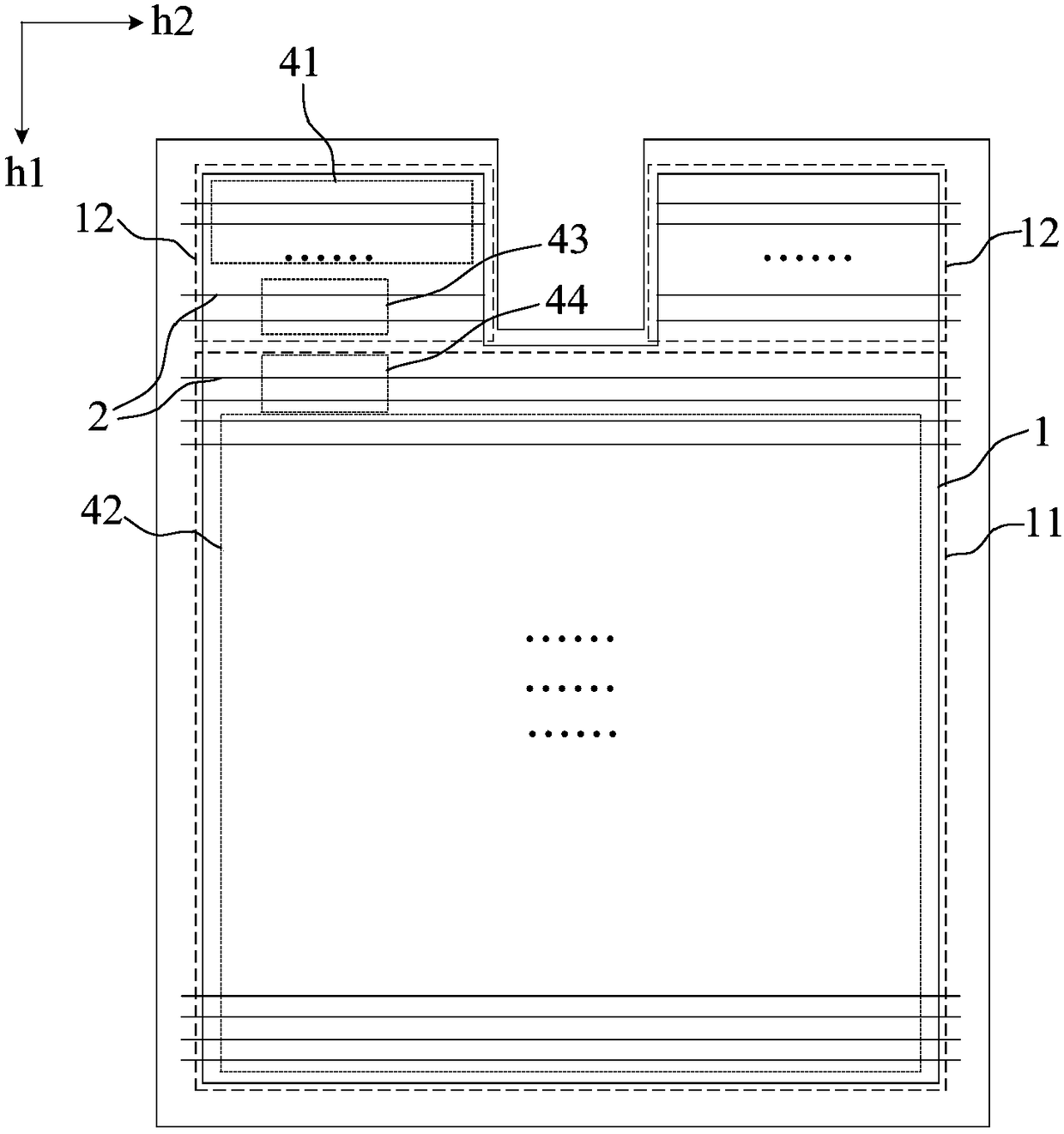

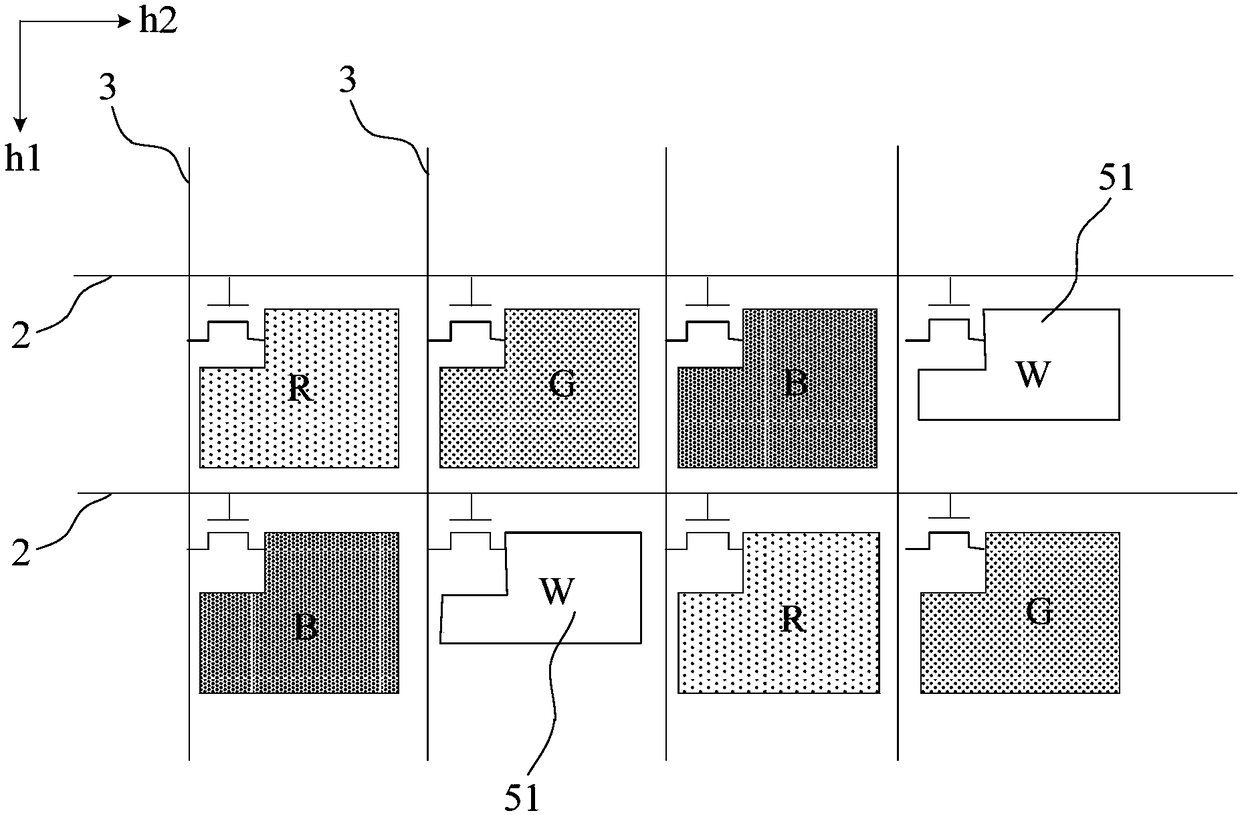

Abnormal-shape display panel and display device

ActiveCN107390920AMinimize variance in touch performanceImprove touch performanceInput/output processes for data processingDisplay deviceAbnormal shapes

The invention discloses an abnormal-shape display panel and a display device. The display panel comprises a display area and a non-display area, wherein the display area comprises multiple touch control electrode blocks, at least one abnormal-shape touch control electrode block exists, and the abnormal-shape touch control electrode block has a non-quadrilateral shape; in a line of touch control electrode blocks in which the abnormal-shape touch control electrode block is located, area values between the abnormal-shape touch control electrode block and a adjacent touch control electrode blocks form an arithmetic progression, wherein the common difference is x, and a is an integer and satisfies 2<=a<n; and / or in a row of touch control electrode blocks in which the abnormal-shape touch control electrode block is located, area values between the abnormal-shape touch control electrode block and b adjacent touch control electrode blocks form an arithmetic progression, wherein the common difference is y, and b is an integer and satisfies 2<=b<m. The abnormal-shape display panel and the display device provided by the invention have the advantages that touch control performance of the abnormal-shape display panel is improved, and users' experience is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

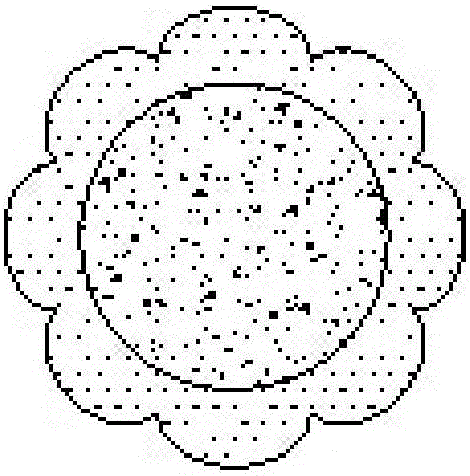

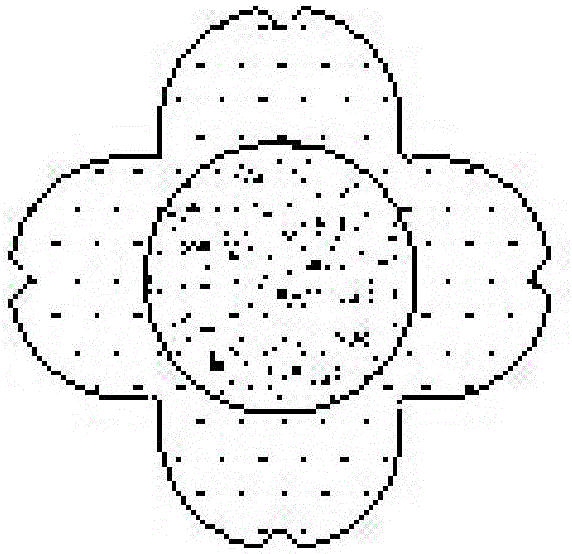

Multifunctional fiber with moisture absorption and perspiration, antibacterial and heating functions and preparation method of multifunctional fiber

ActiveCN106835348AIncrease surface areaImprove moisture wickingFilament/thread formingConjugated synthetic polymer artificial filamentsPerspirationAbnormal shapes

The invention discloses a multifunctional fiber with moisture absorption and perspiration, antibacterial and heating functions and a preparation method of the multifunctional fiber and belongs to the technical field of functional fiber materials. The multifunctional fiber disclosed by the invention comprises a multifunctional fiber body; the multifunctional fiber body is composed of a fiber skin layer and a fiber core layer; the section shape of the fiber body is of an abnormal structure that a plurality of convex abnormal-shape structures are uniformly and outward formed on the round circumference; the fiber skin layer is formed by bundling bacterium-inhibiting fiber monofilaments together in parallel; the fiber core layer is formed by bundling heating fiber monofilaments together in parallel. The fiber with moisture absorption and perspiration, antibacterial and heating functions is prepared through a melting spinning technology and can be used for the field of smart clothing.

Owner:WUHAN TEXTILE UNIV

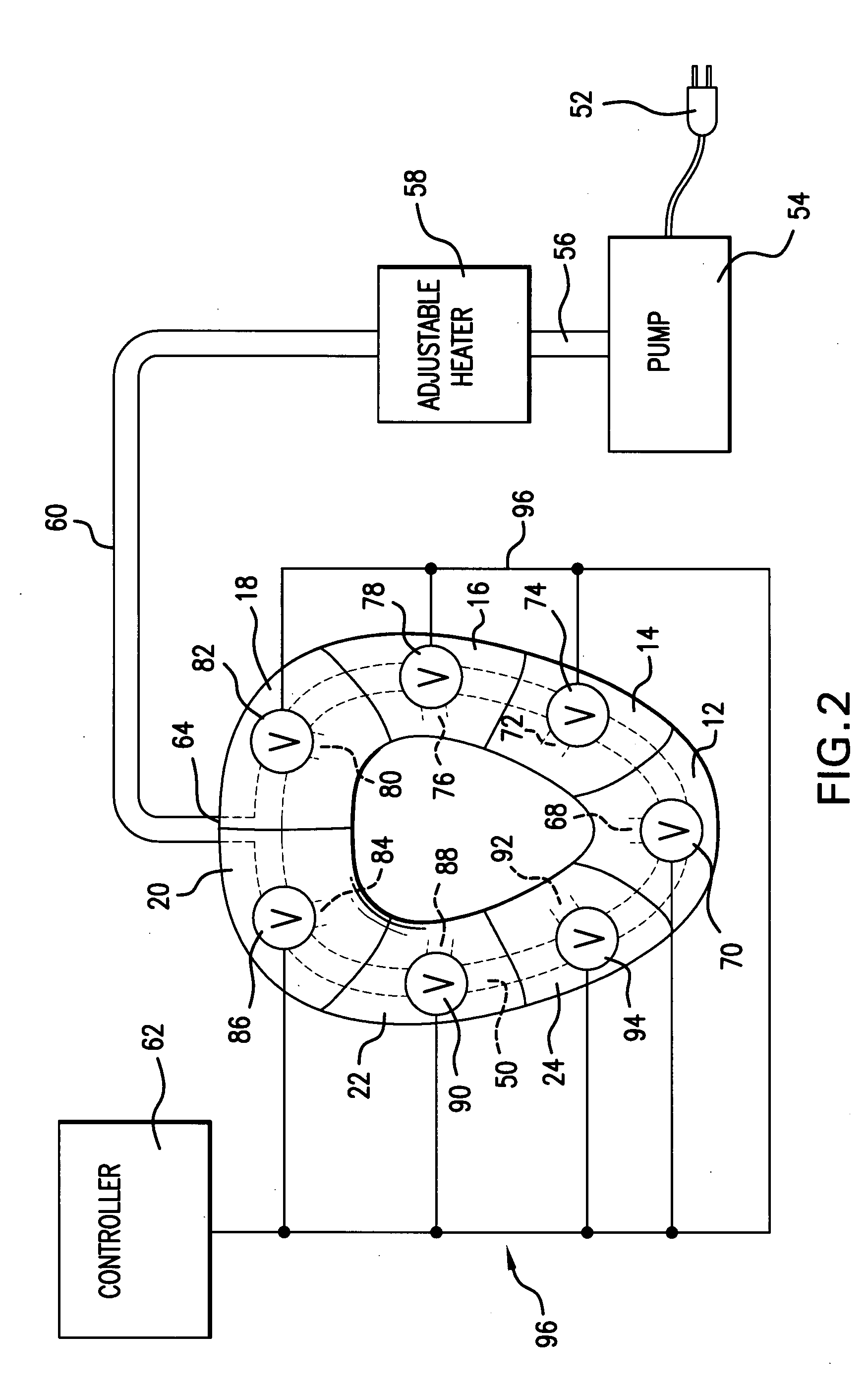

Dynamic infant head support

ActiveUS20090070938A1Effectively mitigating plagiocephalyOperating chairsOperating tablesAbnormal shapesEngineering

Owner:JESSICA JOY KELL

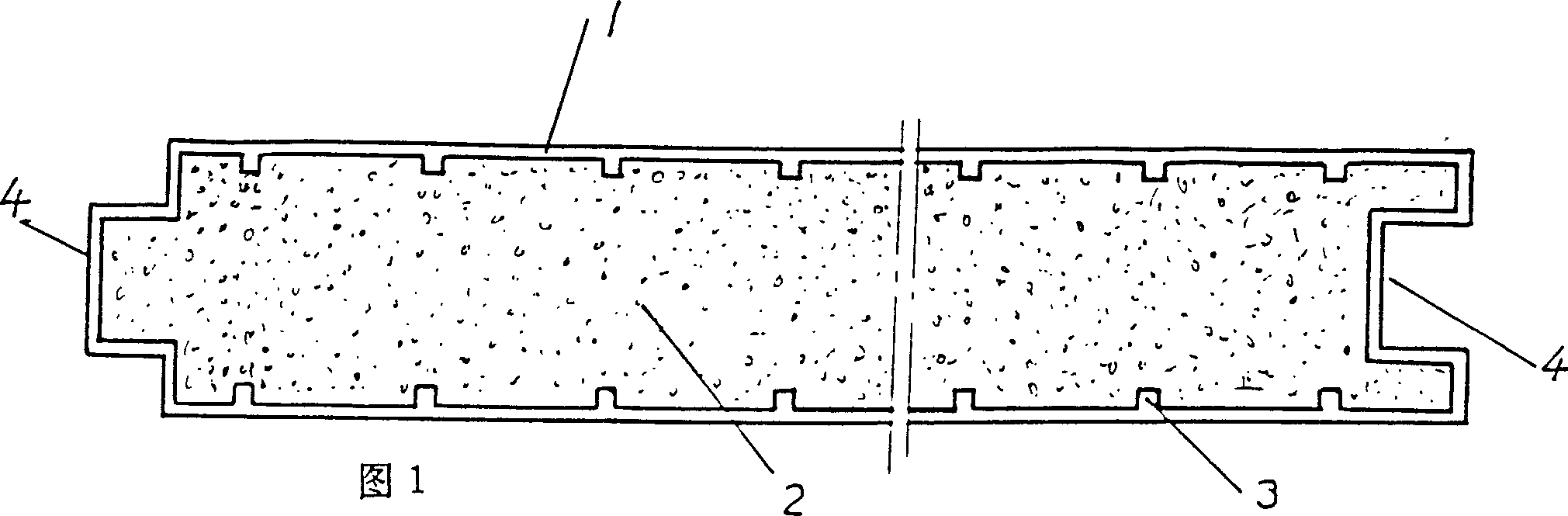

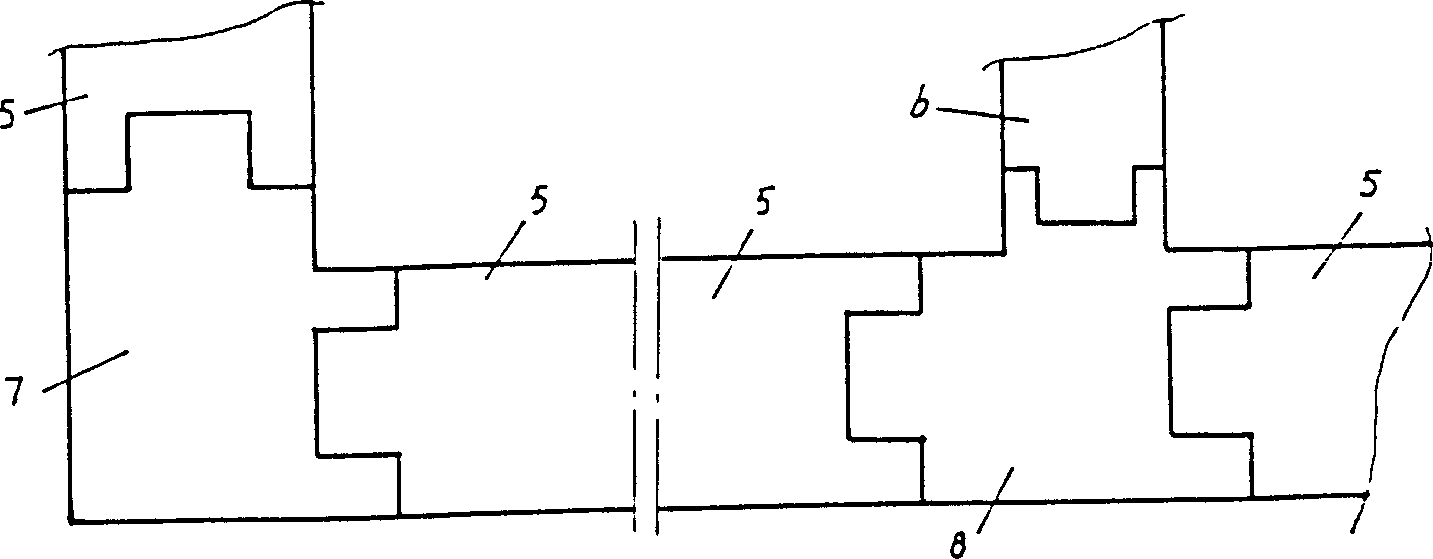

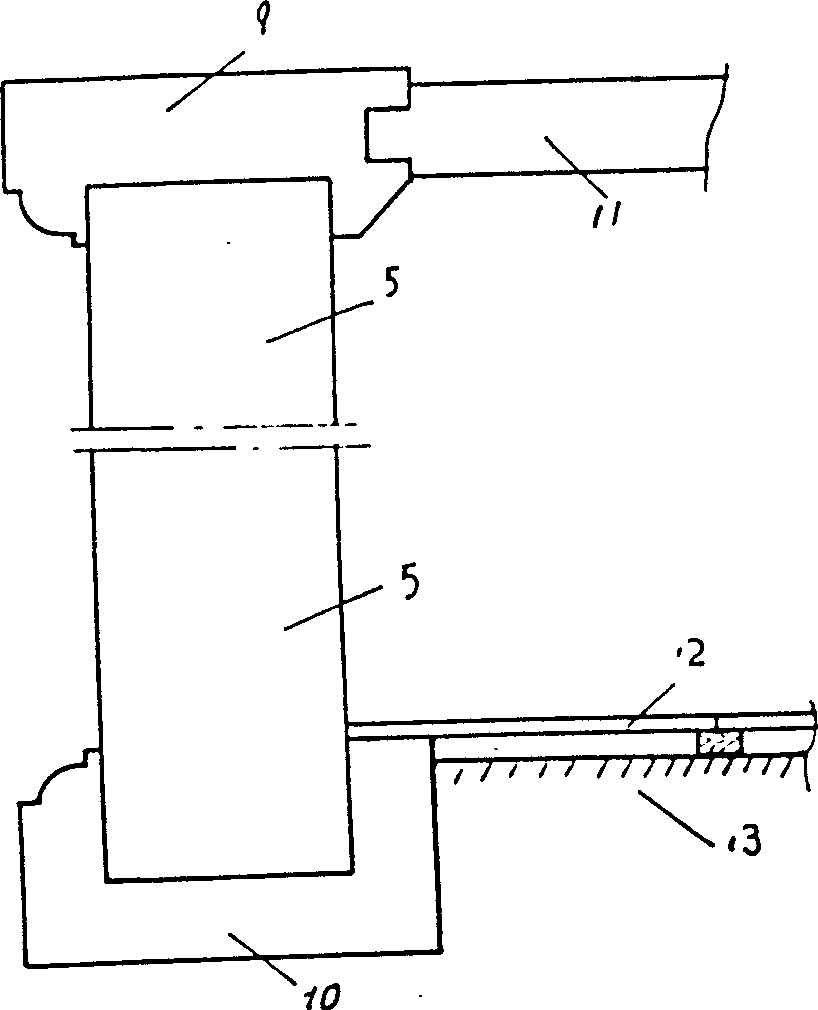

New type heat insulating plater, abnormal shape plate and its manufacturing method

A heat-insulating shaped plate for building is composed of the hollow plastic section with internal reinforcing ribs, and foam polyurethane plastics as filler which is filled in the said hollow plastic section. Its advantages are high strength, high resistance to corrosion, cold and fire, simple structure, low cost and long service life.

Owner:丛立亚

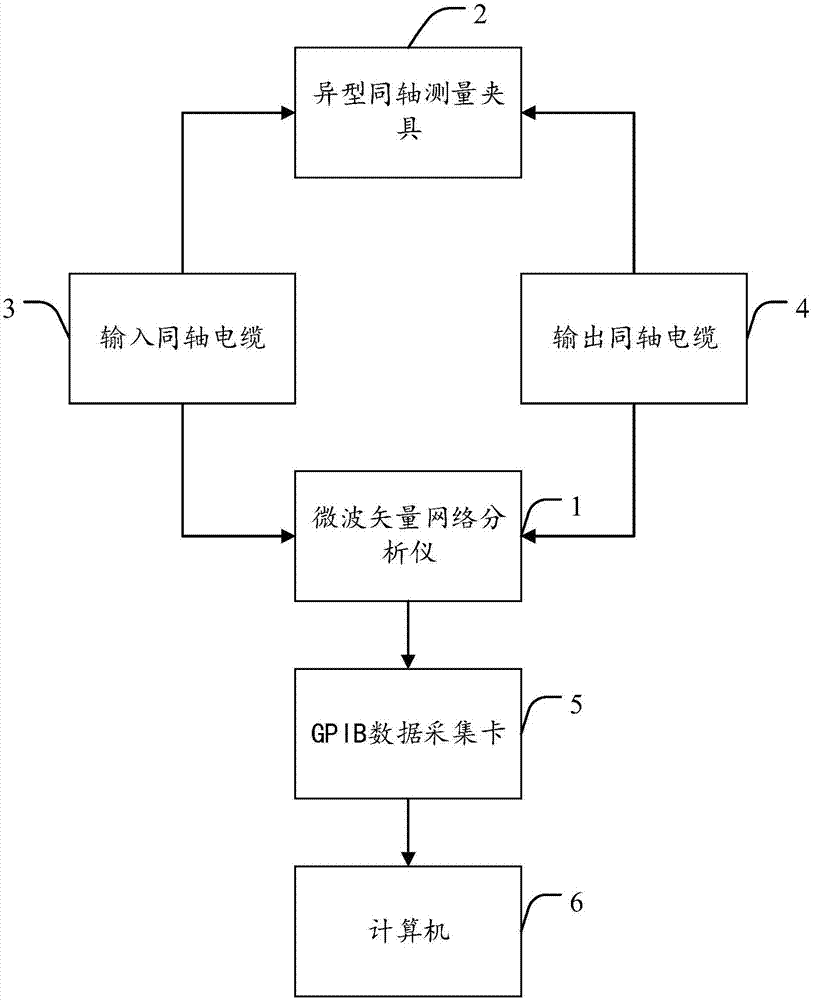

Measurement device and measurement method for dielectric material electromagnetic parameter

PendingCN107091847AHigh measurement accuracyImprove measurement efficiencyMaterial analysis using microwave meansGeneral purposeResonant cavity

The invention is suitable for the field of dielectric material measurement, and provides a measurement device and a measurement method for a dielectric material electromagnetic parameter. The measurement device for the dielectric material electromagnetic parameter comprises a microwave vector network analyzer, an abnormal-shape coaxial measurement fixture, an input coaxial cable, an output coaxial cable, a GPIB (General Purpose Interface Bus) data acquisition card and a computer, wherein the input coaxial cable and the output coaxial cable are respectively connected with two ends of the abnormal-shape coaxial measurement fixture; the GPIB data acquisition card is connected with the microwave vector network analyzer; the computer is connected with the GPIB data acquisition card. According to the measurement device and the measurement method for the dielectric material electromagnetic parameter in the embodiment of the invention, the abnormal-shape coaxial measurement fixture is arranged, a test box used for packaging a measurement sample is arranged in the abnormal-shape coaxial measurement fixture, the advantages of high measurement accuracy and wide transmission / reflection method measurement frequency band of a resonant cavity method are used, so that the measurement device for the dielectric material electromagnetic parameter has high accuracy and wide measurement frequency band, the microwave vector network analyzer and the computer are arranged to automatically analyze measurement data, and measurement speed is high.

Owner:XIAMEN UNIV

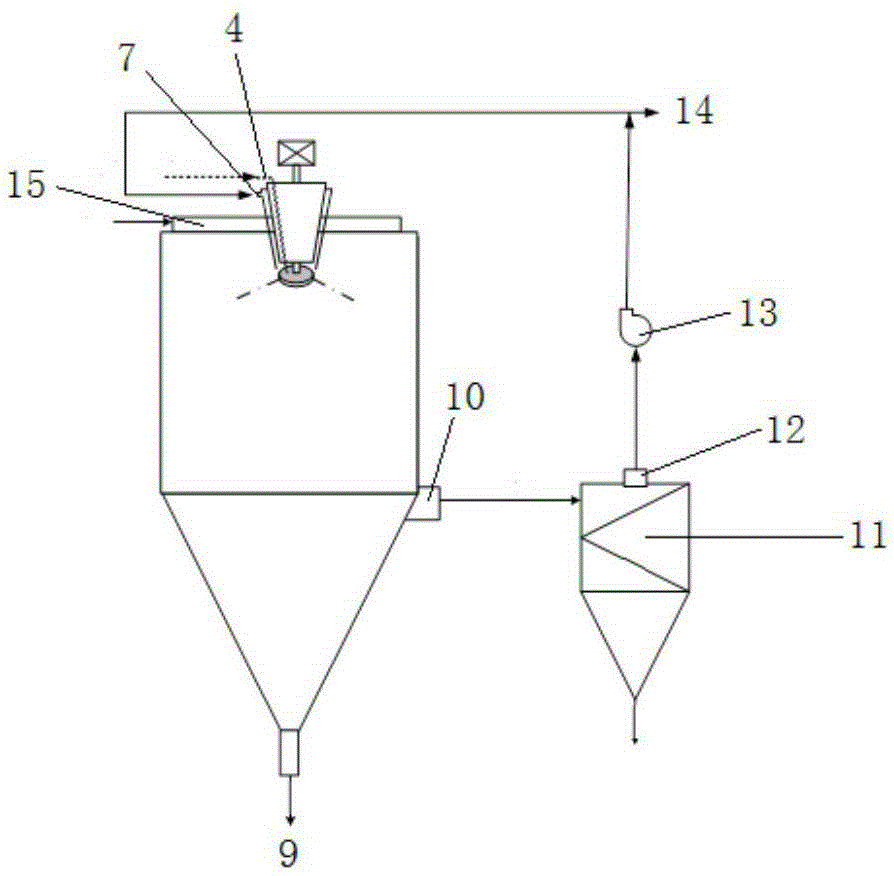

High-performance aerogel composite material, preparation method and equipment thereof

The invention provides a high-performance aerogel composite material, and a preparation method and equipment of the high-performance aerogel composite. The aerogel composite material comprises a silicon dioxide aerogel and a fiber material, wherein the silicon dioxide aerogel uses tetramethyl orthosilicate and water as raw materials and an alcohol solvent as a solvent to prepare a silica sol, and no gel catalyst is added in the silica sol. The equipment comprises a reaction part and a circulated cooling part. The method comprises the steps of preparing the sol, dipping glue, standing, gelatinizing, aging gel, dewatering, drying and the like. With the adoption of the method, materials with planar or abnormal shapes and multiple sizes can be conveniently and selectively prepared, the gelation time is controllable, no catalyst is needed, the kinds of raw materials are few, the operation is simple and convenient, and the environmental pollution is low. The material is excellent in heat-insulating property and has a wide application prospect in the fields of the civil industry, the space flight and aviation industry and the military industry.

Owner:海鹰空天材料研究院(苏州)有限责任公司

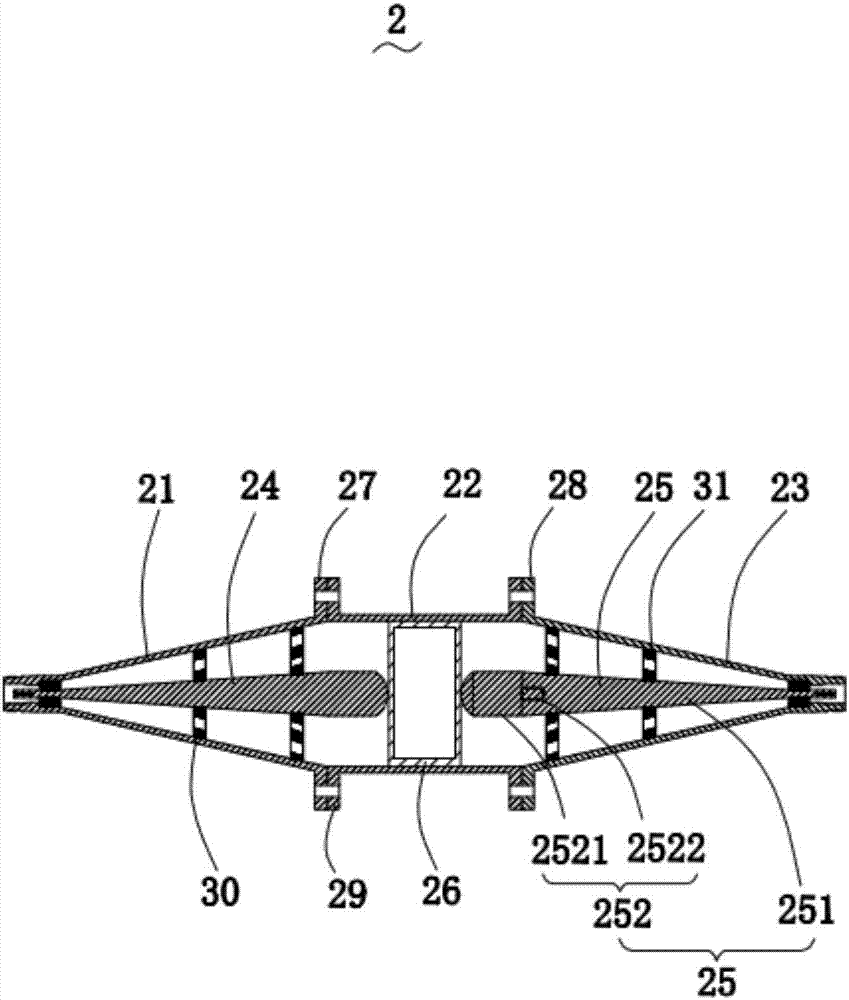

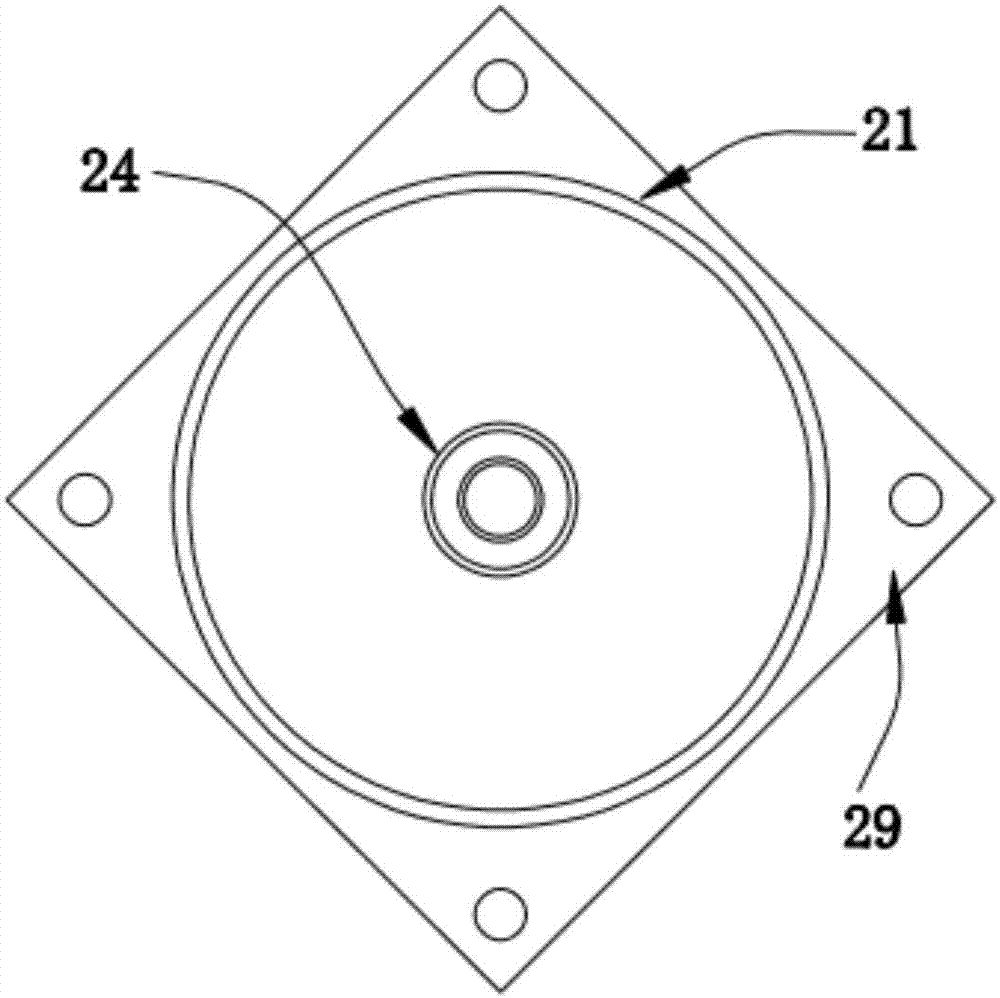

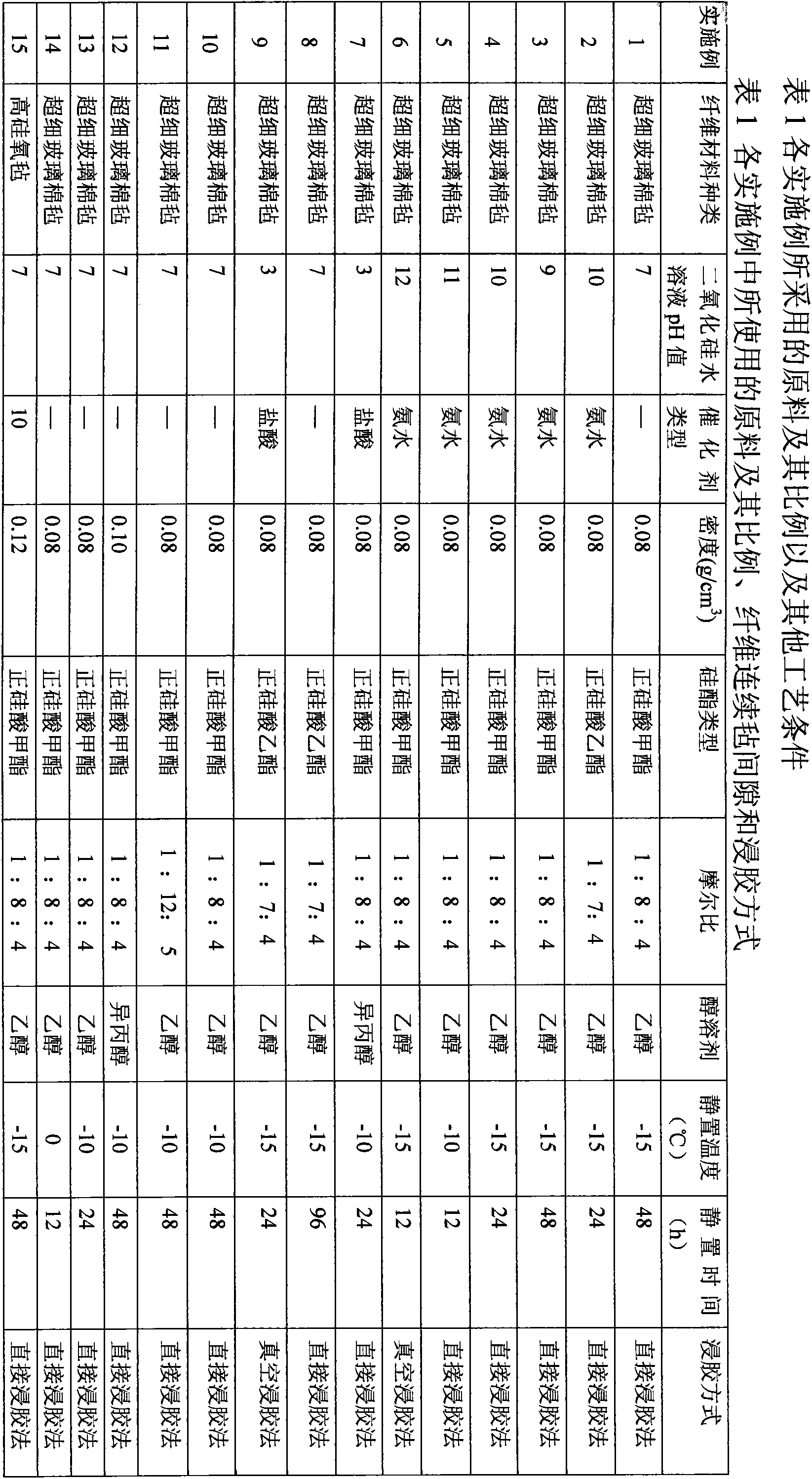

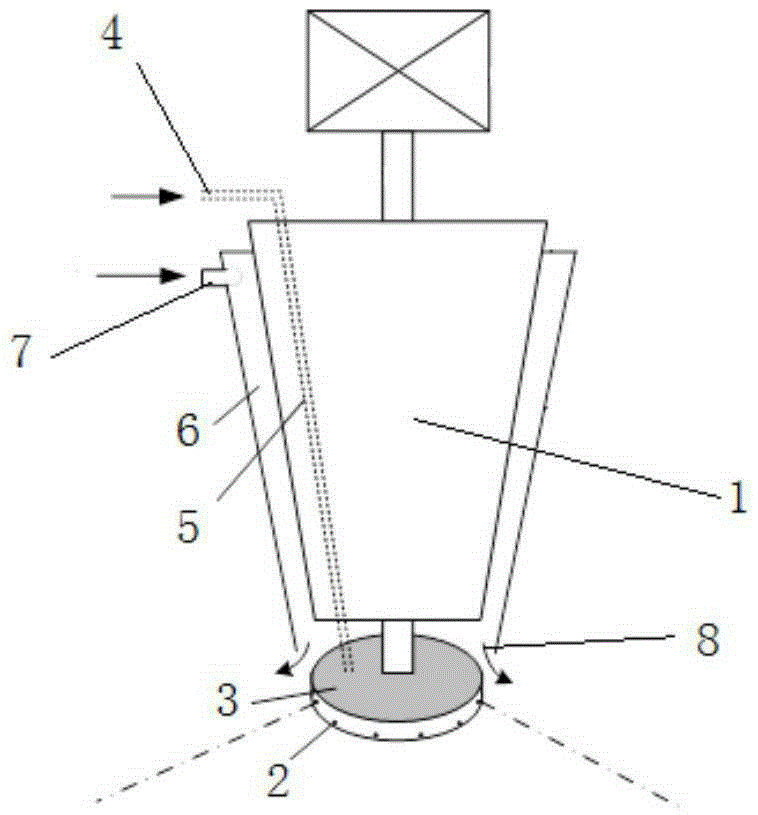

Centrifugal atomizing nozzle and spray dryer

InactiveCN106607197AReduce the chance of breakageAvoid direct contactSpray nozzlesEvaporation by sprayingNebulizerMicrosphere

The invention relates to the field of spray dryers and discloses a centrifugal atomizing nozzle and a spray dryer comprising the same. The centrifugal atomizing nozzle comprises a centrifugal atomizer and a protection wind guide pipe, wherein the centrifugal atomizer is internally provided with an atomizing disc which is used for spraying materials into fog drips and provided with atomizing holes, and a material guide pipe connected with the atomizing disc and a material inlet; and the protection wind guide pipe is provided with a protection wind inlet and a protection wind spraying opening. The protection wind guide pipe is arranged around the centrifugal atomizer, so that protection wind sprayed by the protection wind spraying opening surrounds the fog-drip-shaped materials sprayed by the atomizing holes. When spray drying is conducted by adopting the dryer comprising the centrifugal atomizing nozzle, the problems that microspheres are burst, abnormal shapes and fine powder are produced in the drying process can be solved, and the sphericity of obtained dried particles can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

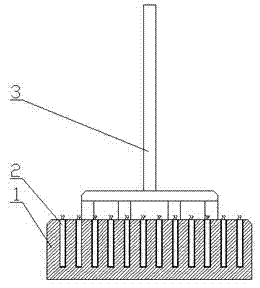

Preheating starting method for aluminium electrolysis cell

The invention relates to a preheating starting method for an aluminium electrolysis cell, and the preheating starting method comprises the following preheating starting processes: (1) drilling on the upper surface of a carbon or graphite electrode, and pre-embedding a heating element in the electrode; (2) heating a hearth by using a heating assembly according to a roasting curve; (3) after reaching a target temperature, adding a solid or liquid electrolyte until reaching a required electrolyte level, regulating the power of the heating assembly, and primarily building heat balance and inner hearth mold required by the electrolysis cell; (4) introducing direct current for electrolyzing a preheating electrode; and (5) gradually utilizing an electrode which normally operates to replace the preheating electrode carrying the heating element. The method disclosed by the invention can evenly heat; in the preheating process, an anode and the bus do not need flexible connection; a traditional cell of which the cathode is in an abnormal-shape structure can be effectively preheated, and an inert electrode aluminium electrolysis cell can be effectively preheated and started; and a stable electrolysis environment is built, current efficiency is improved, and the service life of the electrode is prolonged. The preheating electrode can be reused to lower electrolysis cell starting cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

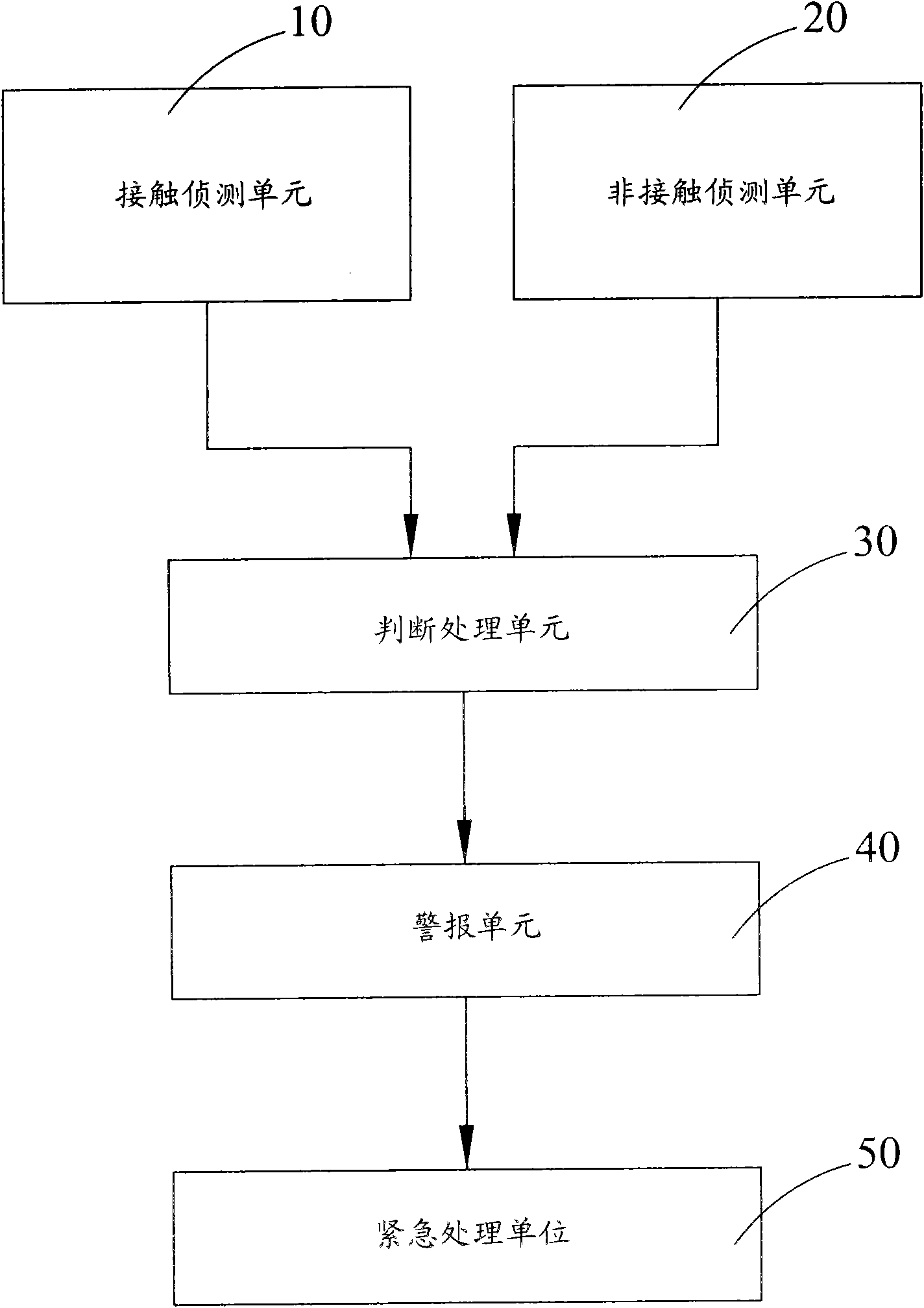

Falling warning system

The invention relates to a falling warning system. The system comprises a contact detection unit, a non-contact detection unit and a determination processing unit, which is respectively connected with the contact detection unit and the non-contact detection unit. With utilization of the contact detection unit and the non-contact detection unit, the determination processing unit respectively detects an object shape that is formed by contact distribution and an object life sign obtained by the non-contact detection; and when a non-contact detection signal reveals that the life sign of the object is abnormal and a contact detection signal reveals that the formed shape of the object is in an abnormal shape, it is determined that the object is in a falling state and a caution signal is emitted in order to make a request for assistance. According to the invention, a contact detection unit and a non-contact detection unit are arranged to respectively detect contact distribution and a life sign, so that possibility of misjudgment on falling is reduced.

Owner:CHINA MEDICAL UNIVERSITY(TW)

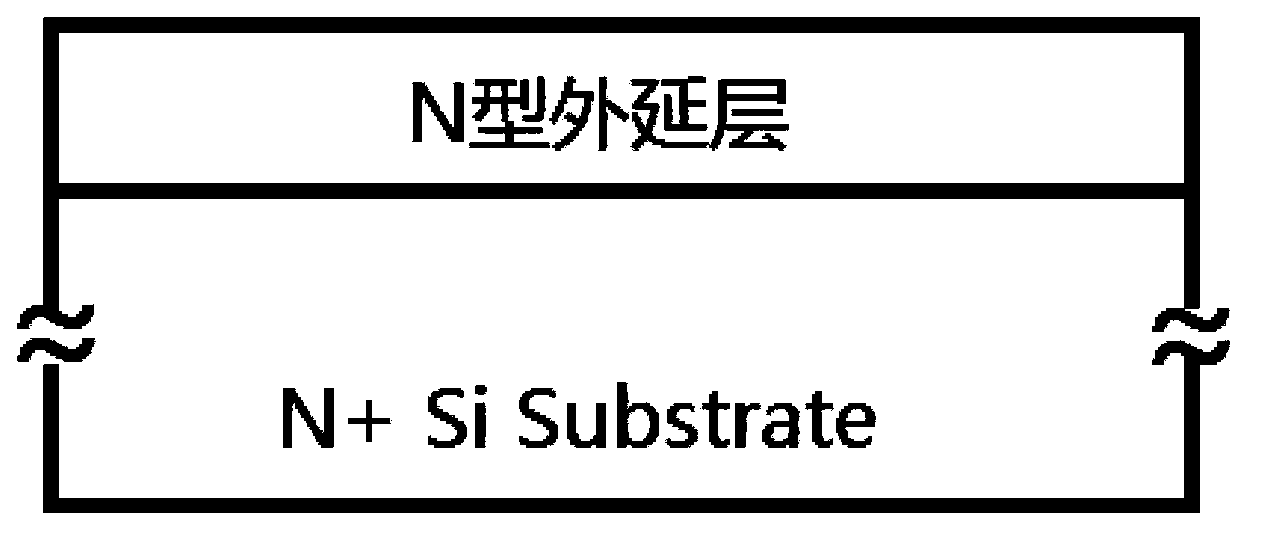

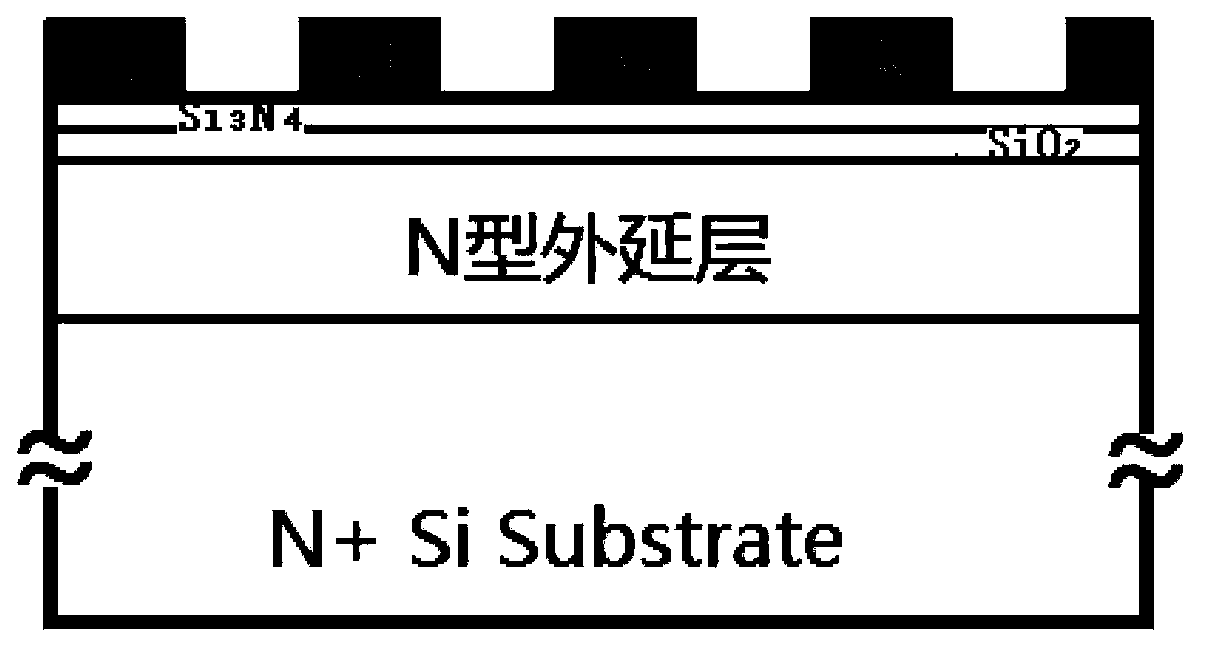

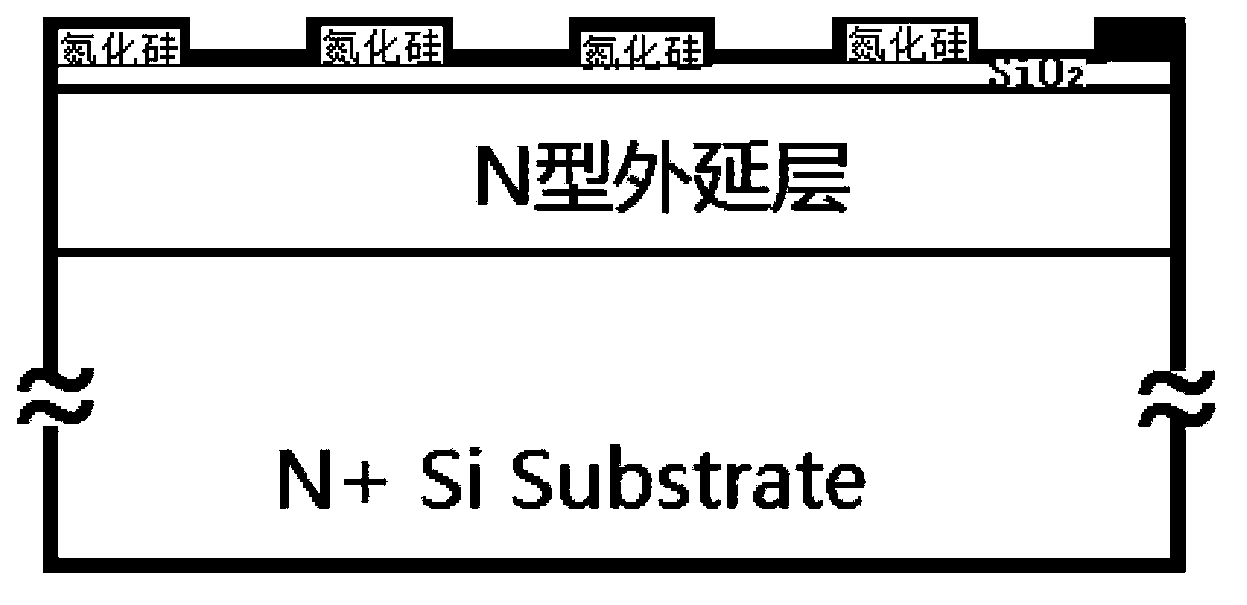

Method for manufacturing junction barrier schottky diode through selective oxidation of silicon

ActiveCN103681318AReduce the spreadOccupancy compensationSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierLOCOS

The invention discloses a method for manufacturing a junction barrier schottky diode through selective oxidation of silicon. As the formation of LOCOS (local oxidation of silicon) monox is adopted, the scope of diffusion of an injected foreign ion is effectively limited within an LOCOS monox area to effectively reduce the scope of lateral (horizontal) diffusion of a P area or an N area of a PN junction, a schottky interface occupied by the lateral diffusion of the P area or the N area is reduced, and the area of the schottky interface is sufficiently utilized. Moreover, the effectively schottky barrier interface is bent into a curve to increase the conductive area and compensate the area occupied by an abnormal-shape island, and the forward-direction electrifying function and the efficiency of the junction barrier schottky diode are improved.

Owner:桂林斯壮桂微电子有限责任公司

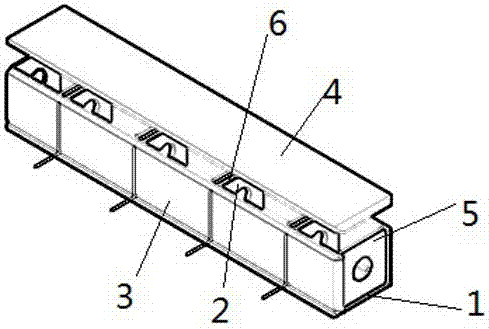

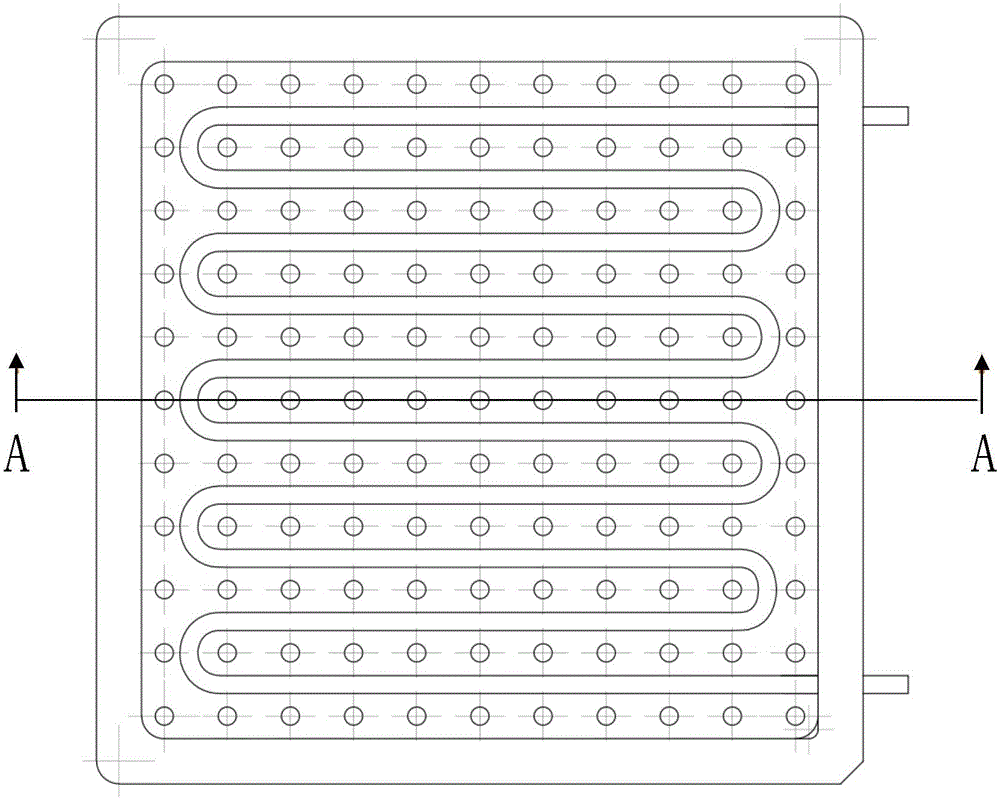

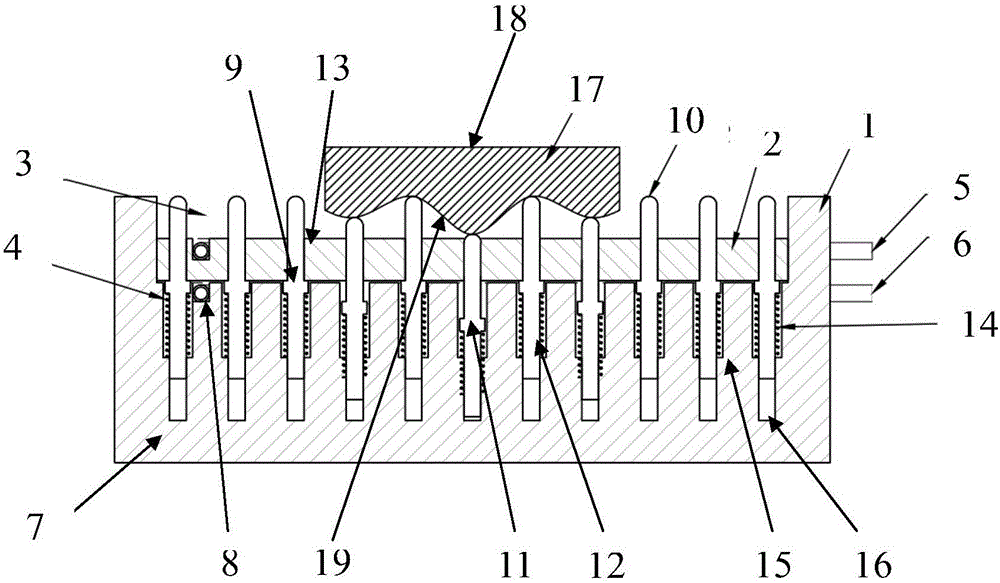

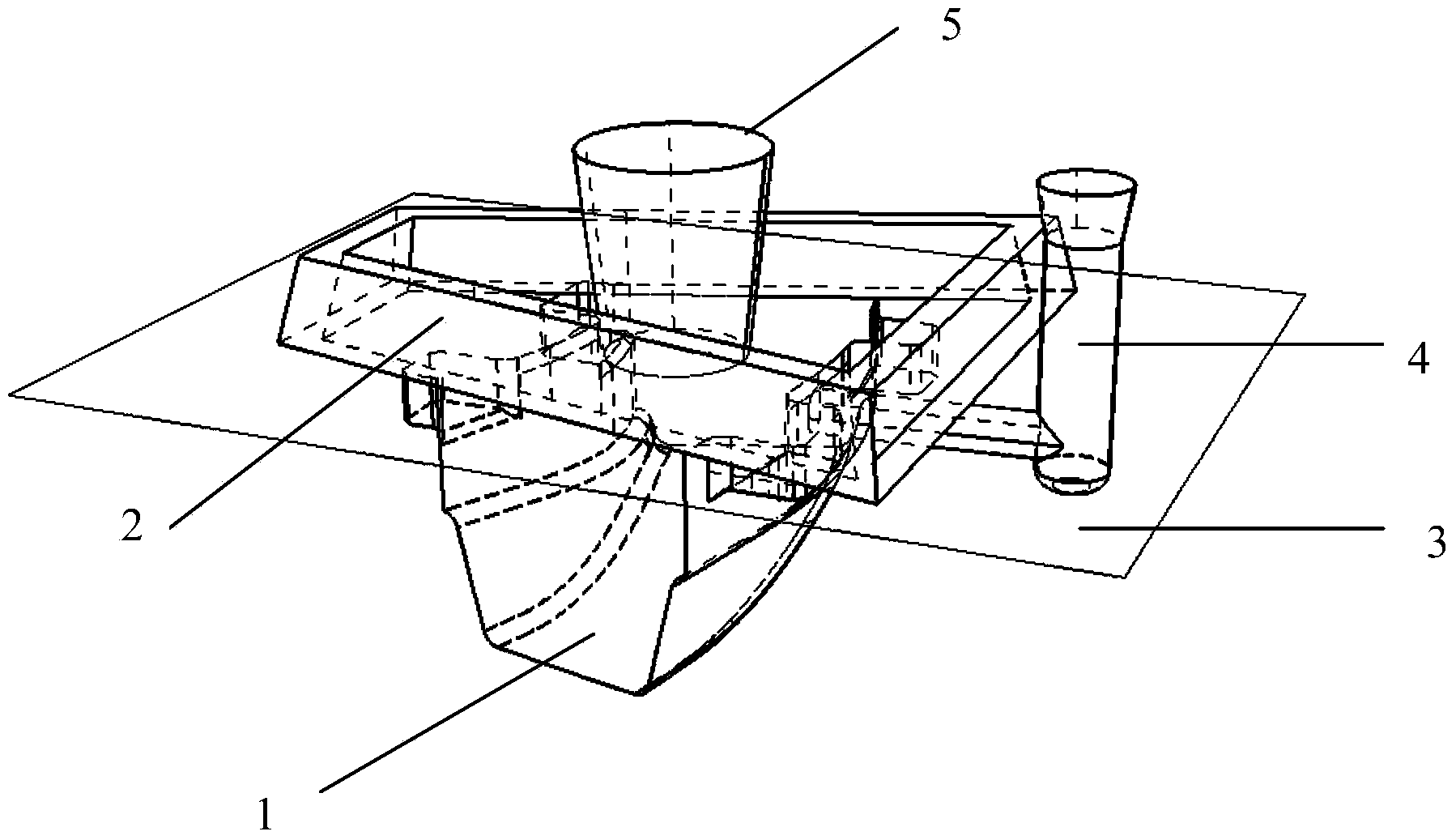

Non-pre-buried type abnormal-shaped bent water channel hot-work die and manufacturing method of non-pre-buried type abnormal-shaped bent water channel hot-work die

InactiveCN103522026AOvercoming cracks and leaksOvercome longevityShaping toolsFoundry mouldsWater channelHot work

The invention discloses a non-pre-buried type abnormal-shaped bent water channel hot-work die and a manufacturing method of the non-pre-buried type abnormal-shaped bent water channel hot-work die. The manufacturing method is characterized in that casting-state die workblank manufacturing is achieved by combining a ceramic core or a 3D printing core with a traditional sand casting method, and includes the steps of die workblank manufacturing, casting-state die workblank coarse machining and casting-state die workblank finish machining. The die workblank manufacturing includes the steps of manufacturing a cavity, an abnormal-shaped bent water channel core and a casting system, assembling the die, smelting steel, carrying out rapid casting, and carrying out cleaning, shot blasting, annealing, post-processing and flaw detection on the abnormal-shaped bent water channel core and a water collecting groove inlet-and-outlet core. The casting-state die workblank coarse machining includes the steps of casting-state die workblank profile coarse machining, quenching and tempering. The casting-state die workblank finish machining includes the steps of casting-state die workblank profile finish machining, casting-state die workblank matching face finish machining and profile PVD plating. The non-pre-buried type abnormal-shaped bent water channel hot-work die and the manufacturing method of the non-pre-buried type abnormal-shaped bent water channel hot-work die solve the problems that an abnormal-shaped bent water channel with optimized values cannot be achieved through a traditional mechanical drilling manner and the cooling rate of the traditional mechanical drilling manner is uneven, and have the advantages that the profile temperature is even, and the die machining cost is reduced.

Owner:DALIAN UNIV OF TECH

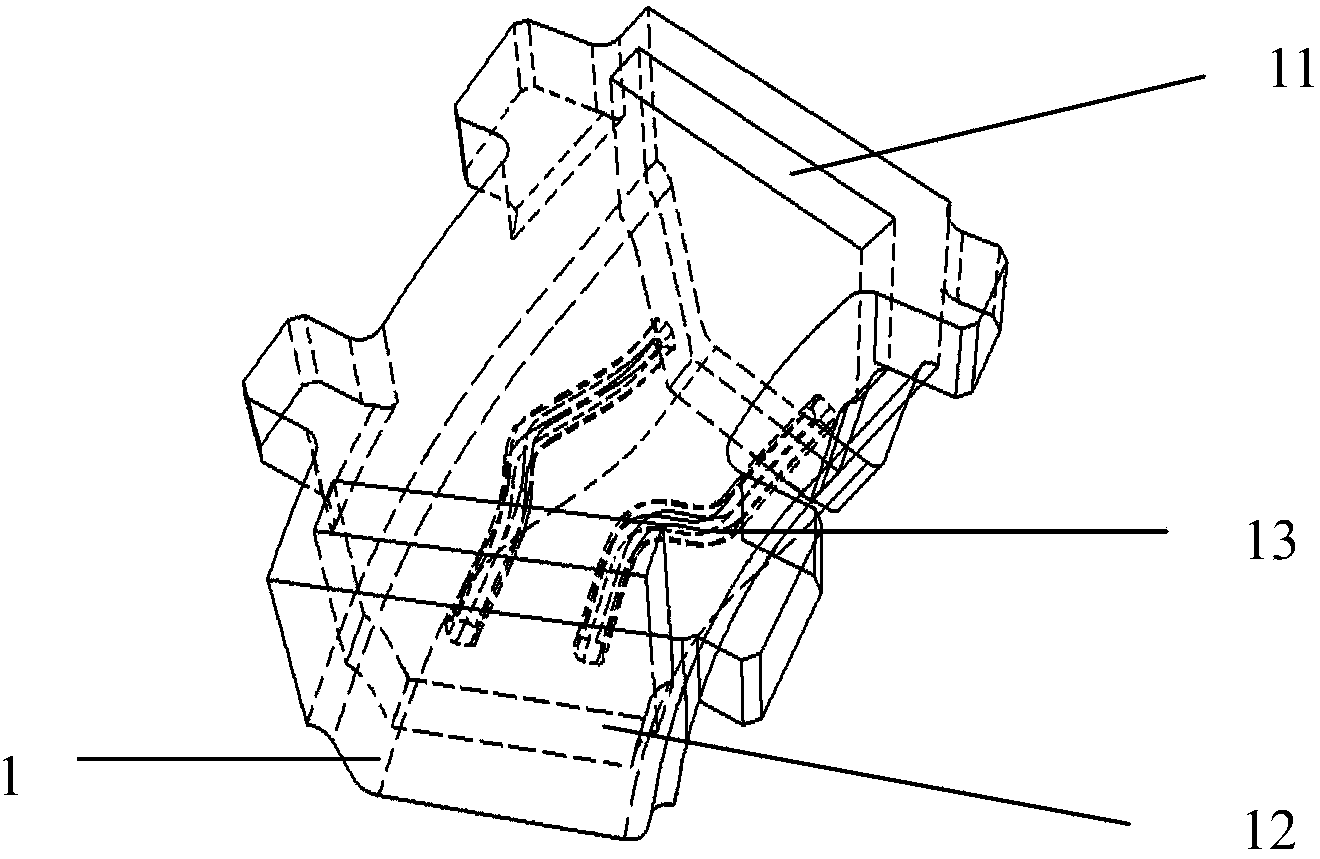

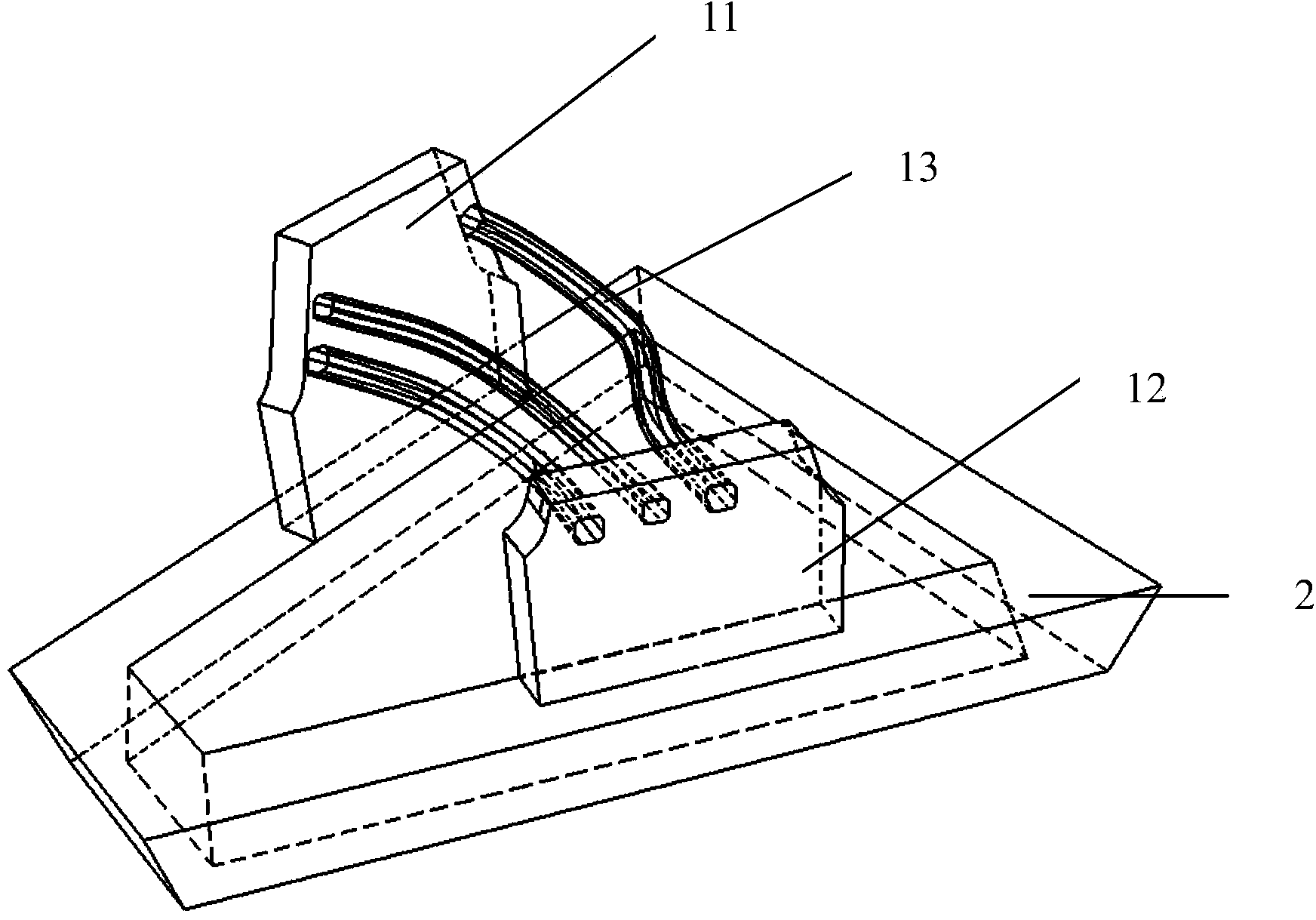

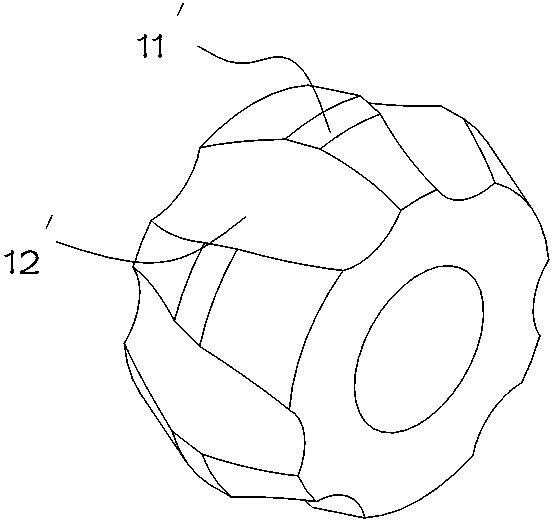

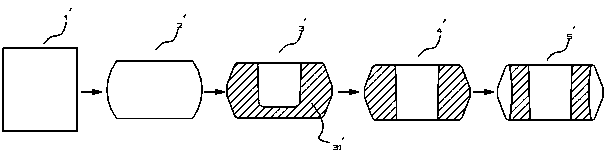

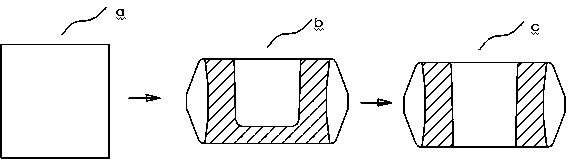

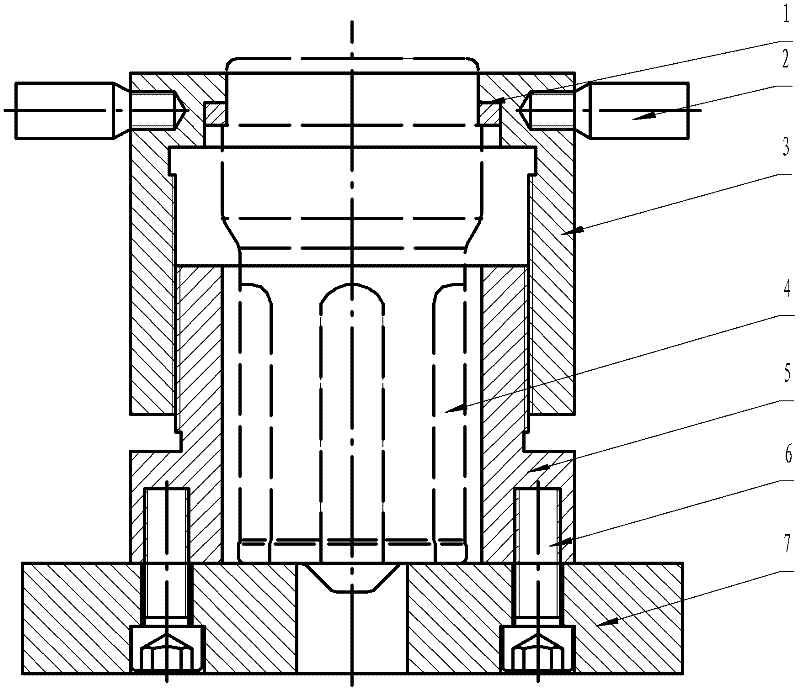

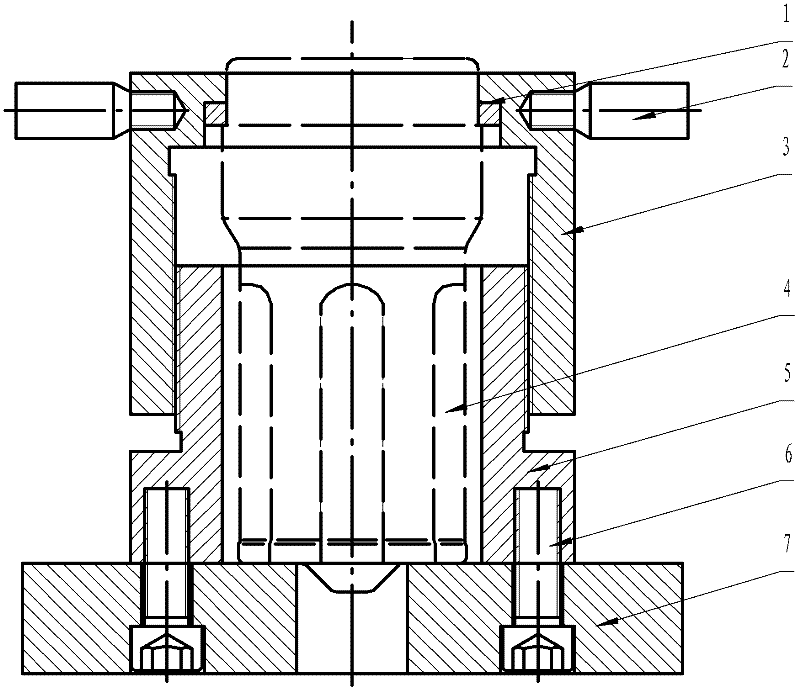

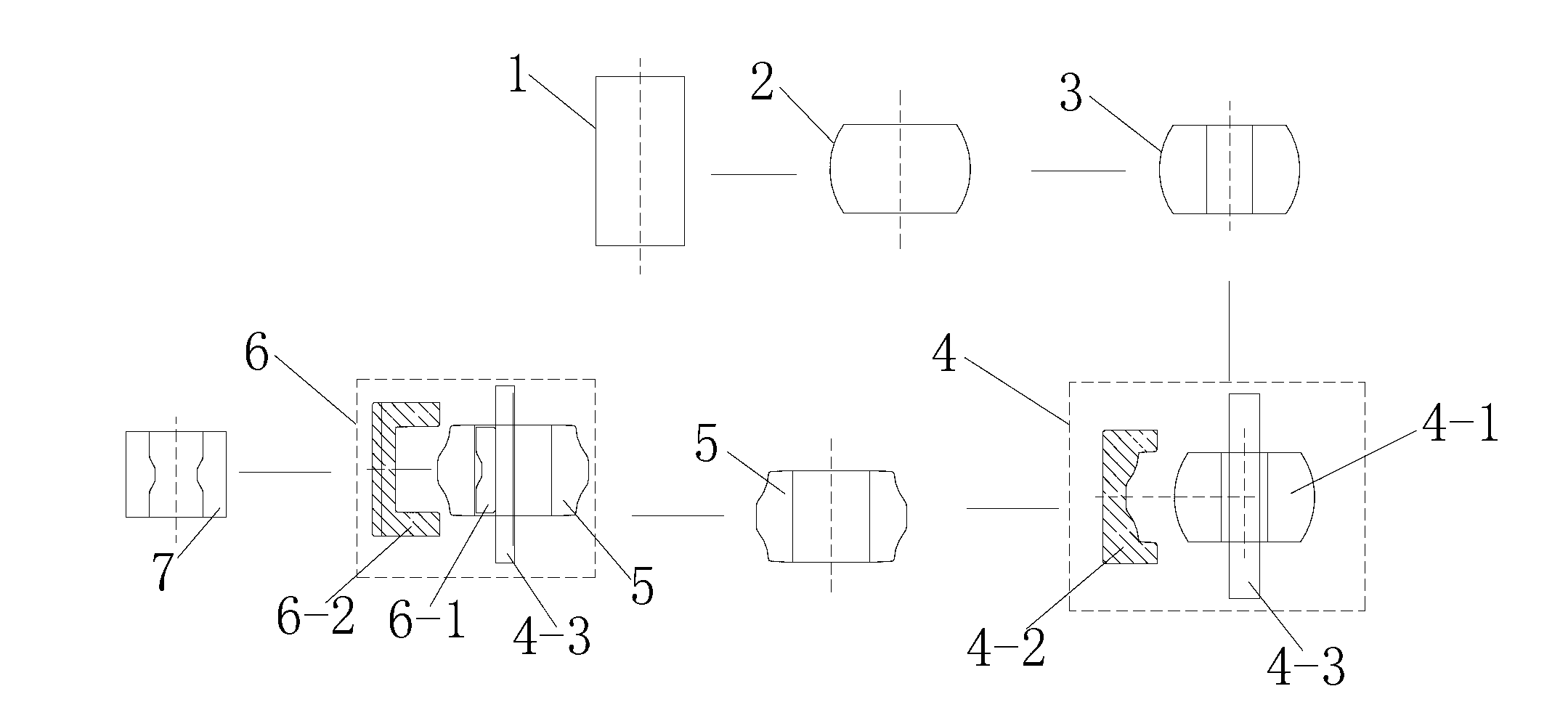

Abnormal-shaped tooth star-shaped part forging method and die special for abnormal-shaped tooth star-shaped part forging method

InactiveCN103990750AImprove streamlineImprove compactnessForging/hammering/pressing machinesPunchingAbnormal shapes

The invention discloses an abnormal-shaped tooth star-shaped part forging method and a die special for the abnormal-shaped tooth star-shaped part forging method. The abnormal-shaped tooth star-shaped part forging method includes the following steps: calculating the size of a workblank piece with the reserved working allowance, and determining the size of workblank materials of a forging piece according to the size; conducting blanking according to the determined size to obtain the workblank materials of the forging piece, and heating the workblank materials of the forged piece to be at the forging temperature; placing the heated workblank materials of the forged piece into a pre-forged forging cavity with abnormal-shaped teeth; pressing down an upper punching head to enable the forging cavity to be filled with the workblank materials of the forged piece to form a star-shaped part in the mode that the abnormal-shaped teeth are arranged outside a middle blind hole to complete pre-forged molding; taking out the obtained pre-forged piece from the forging cavity to punch the middle blind hole. By means of the abnormal-shaped tooth star-shaped part forging method, the forging time number is decreased, the follow-up mechanical cutting machining procedures and allowance are reduced, the manufacturing cost is reduced, the workblank piece with the abnormal-shaped teeth is directly formed in the three-direction pressing stress state, the filament line and the density degree of the forged piece are further improved, the mechanical property of the end product is effectively improved, and the service life of the end product is effectively prolonged.

Owner:张洪磊

Machining technology for inner race housing die abnormal-shaped punch

ActiveCN102335709AEven by forceAvoid breakingForging/hammering/pressing machinesNumerical controlAbnormal shapes

The invention provides a machining technology for an inner race housing die abnormal-shaped punch, which comprises the following specific steps of: sawing materials, roughly turning, milling into an abnormal shape by a machining center, carrying out heat treatment, finely turning, finely turning in a numerical-control mode, carrying out plane abrasion and electric spark, and grinding. The purposes of saving die materials and improving the die service life and the product quality are realized. In the plane abrasion technology, a plane abrasion fixture is designed to take the head plane of the punch which is finely turned in a numerical-control mode as a reference plane abrasion punch bottom so as to ensure that the depth of parallelism between the upper plane and the bottom plane of the punch is within 0.02mm. The plane abrasion working procedure guarantees the depth of parallelism between the upper plane and the bottom plane of the punch, so that the punch is evenly stressed and has small possibility of breaking, the punch service life is prolonged, and the product quality is improved.

Owner:JIANGSU SUNWAY PRECISION FORGING

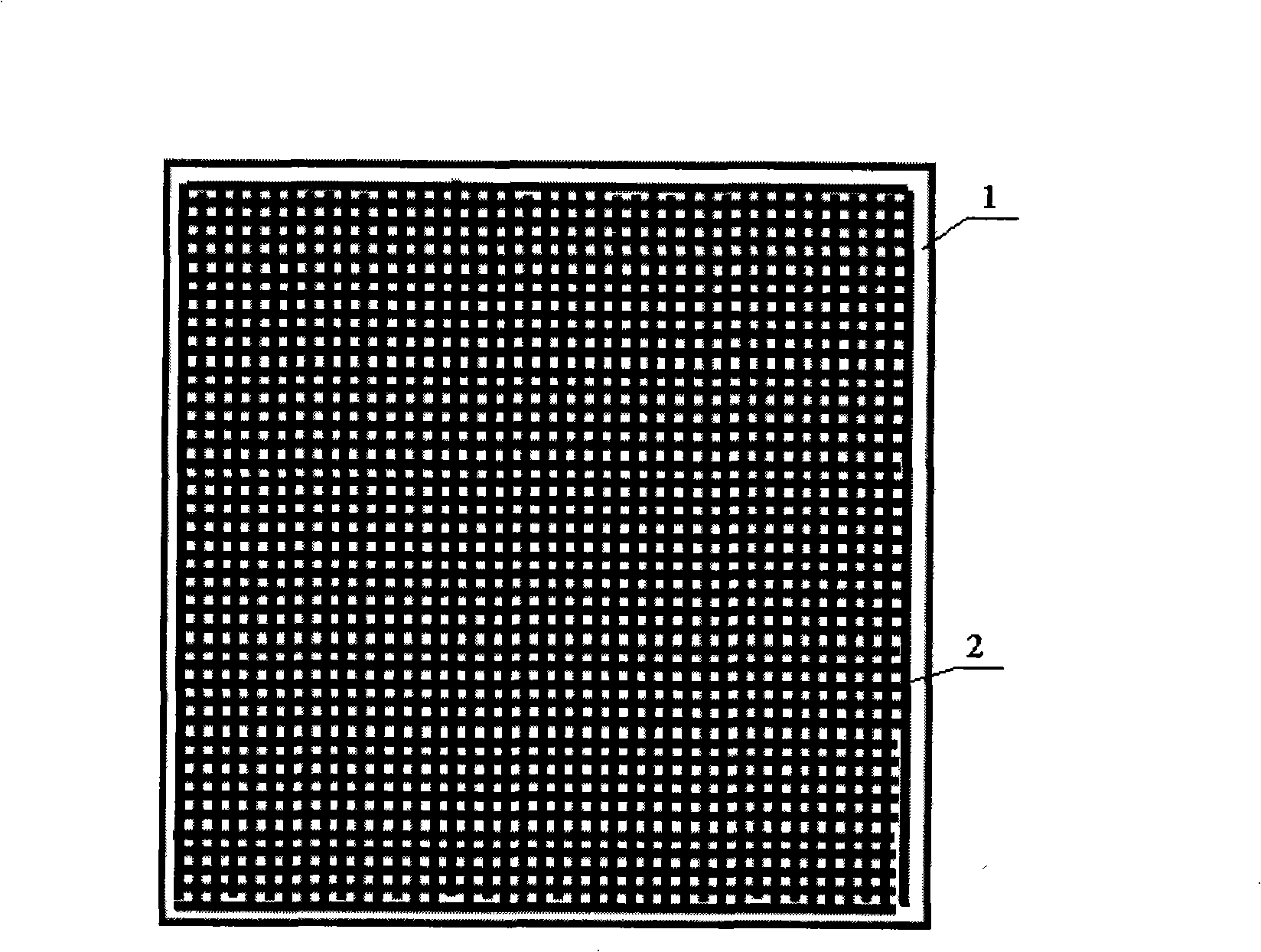

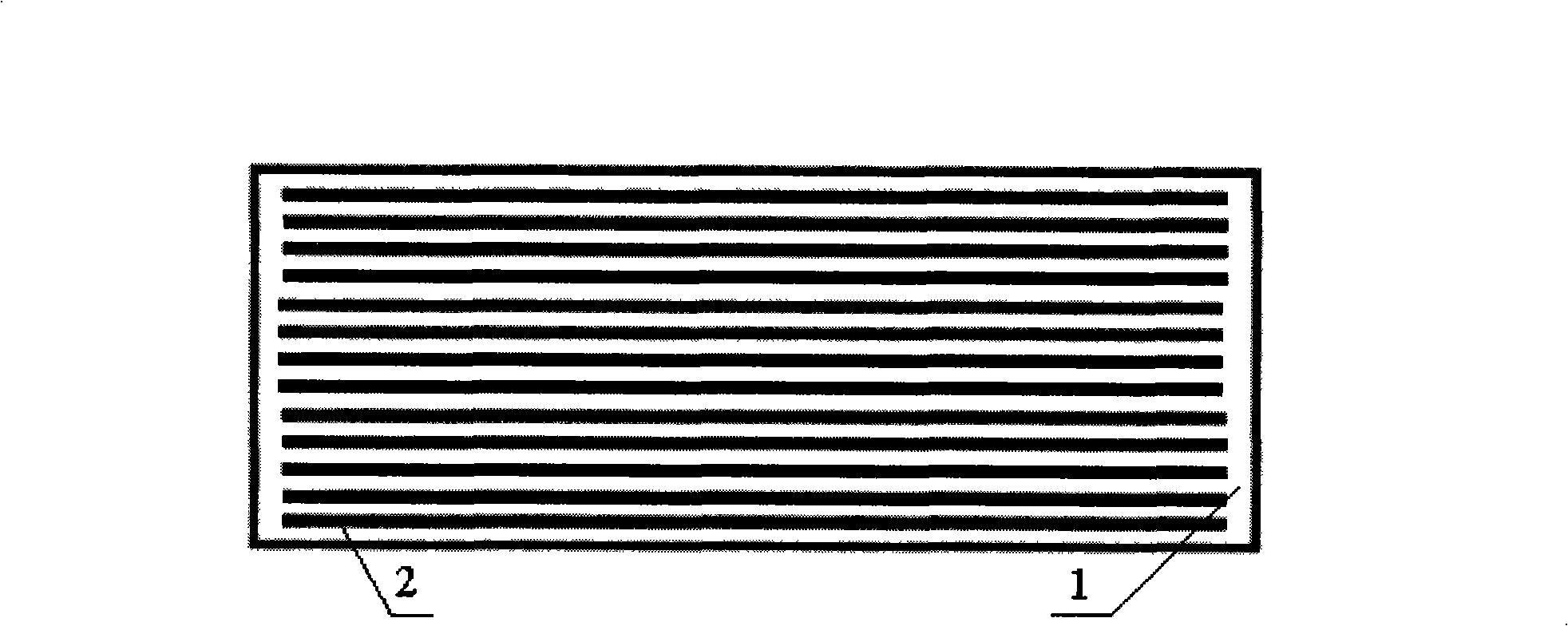

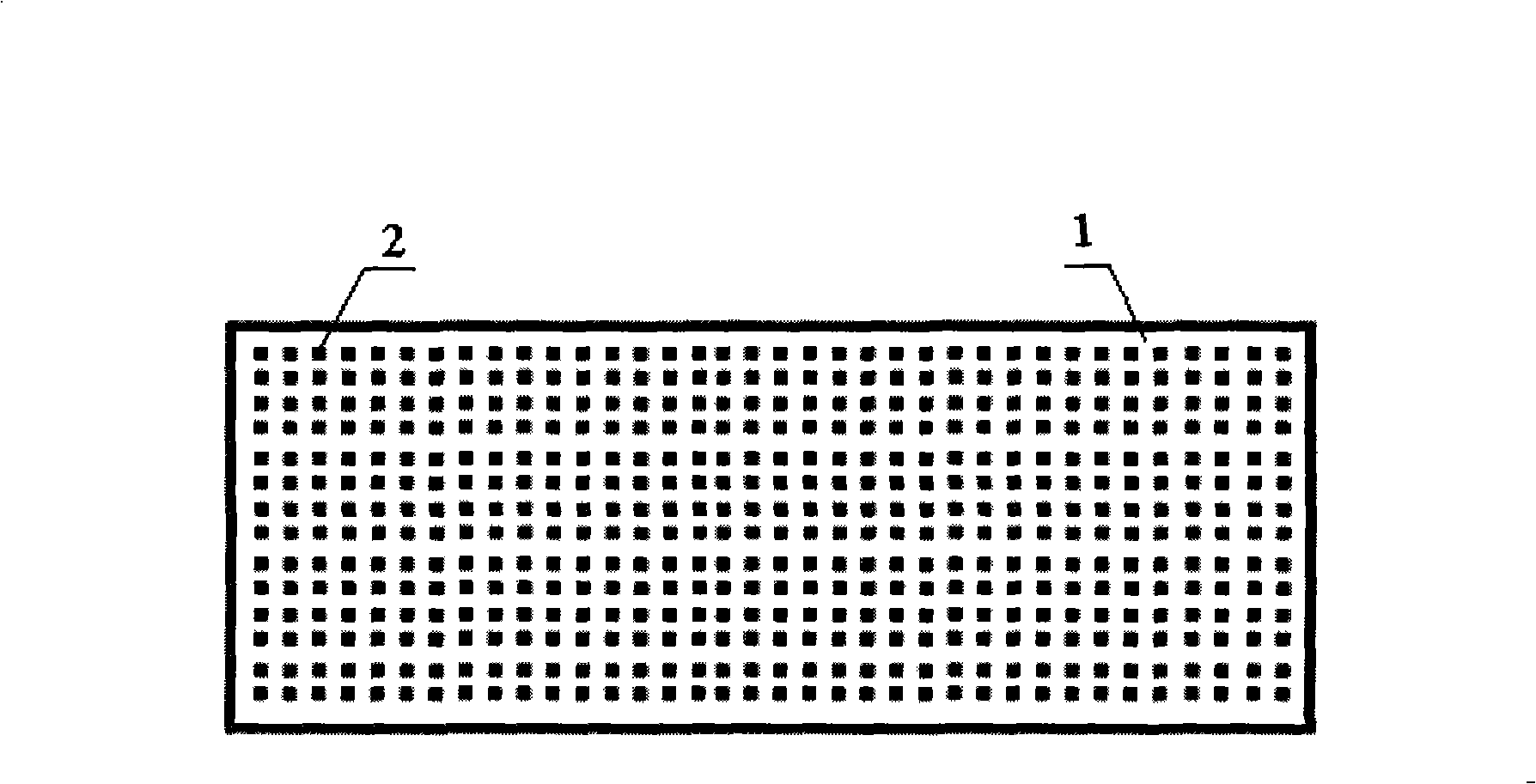

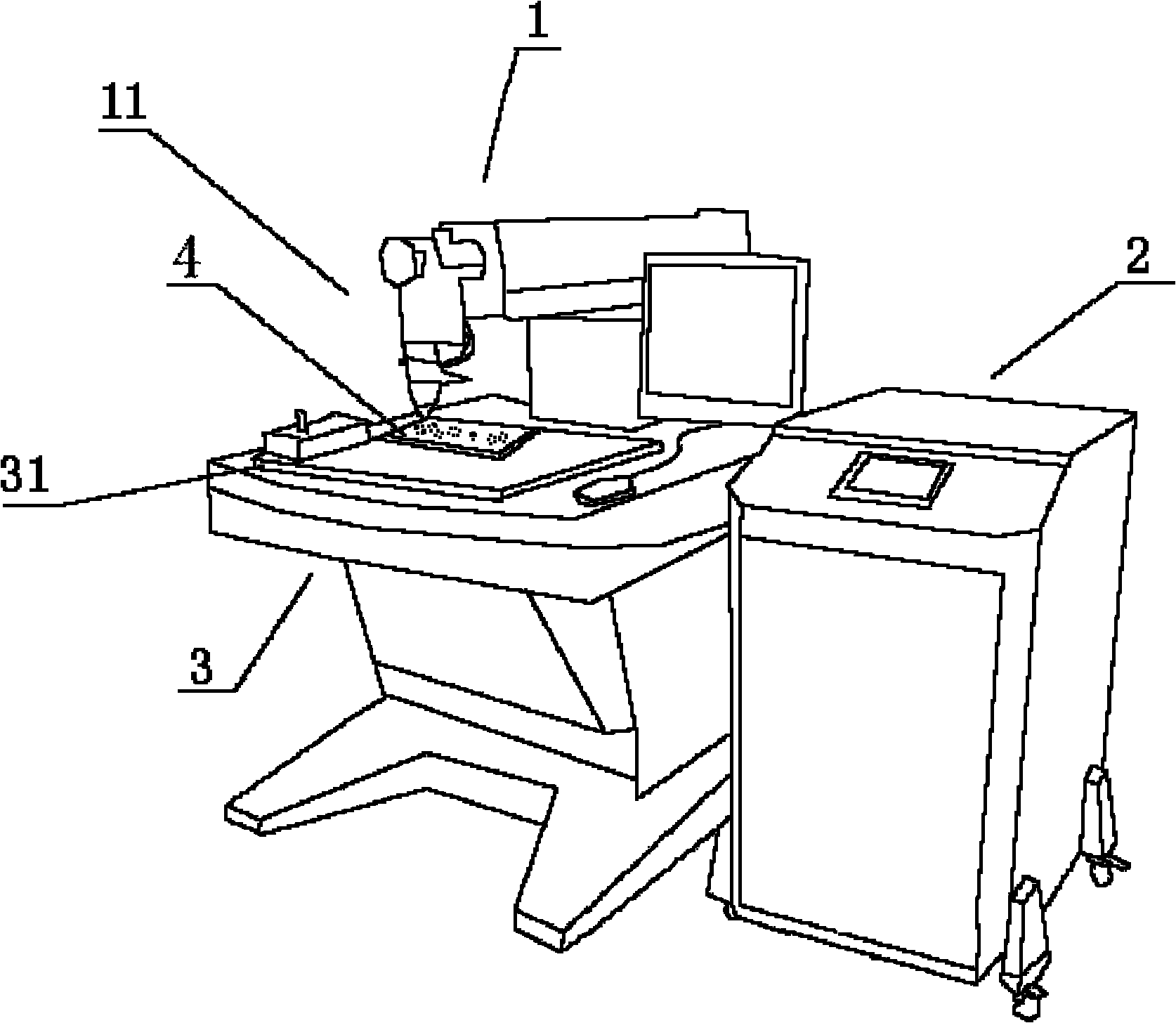

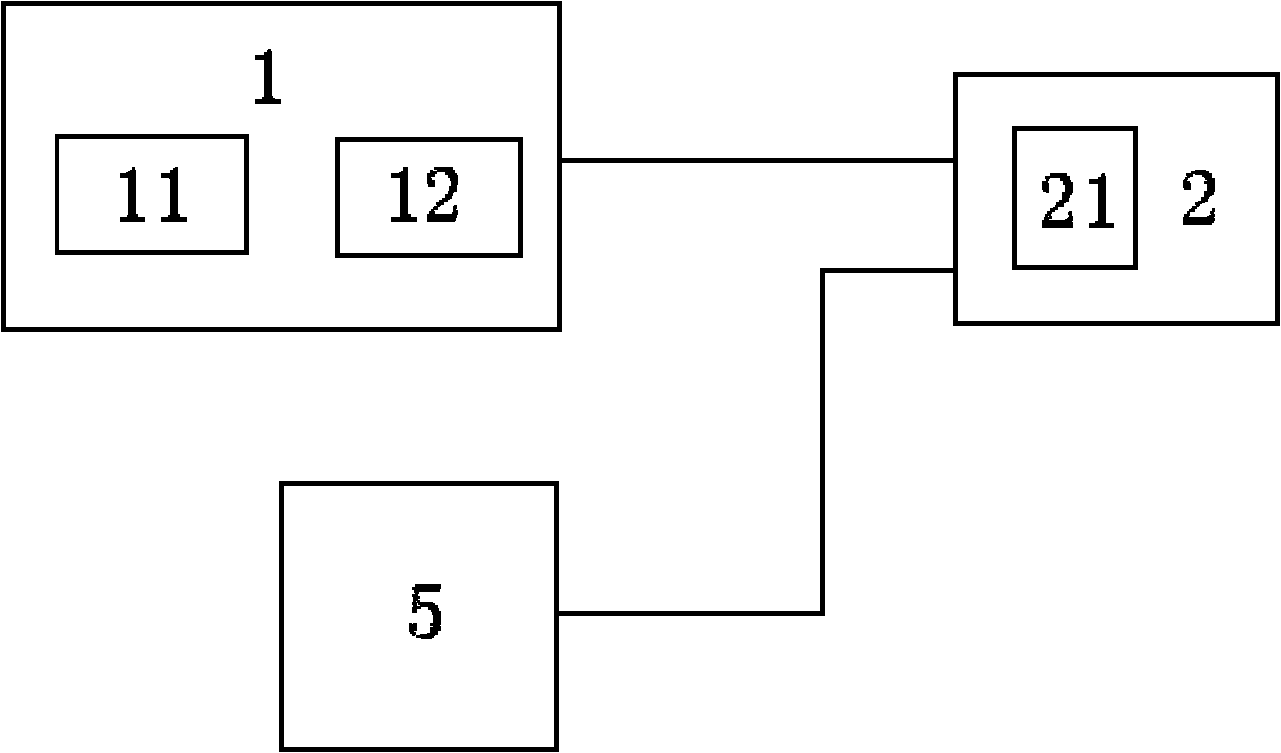

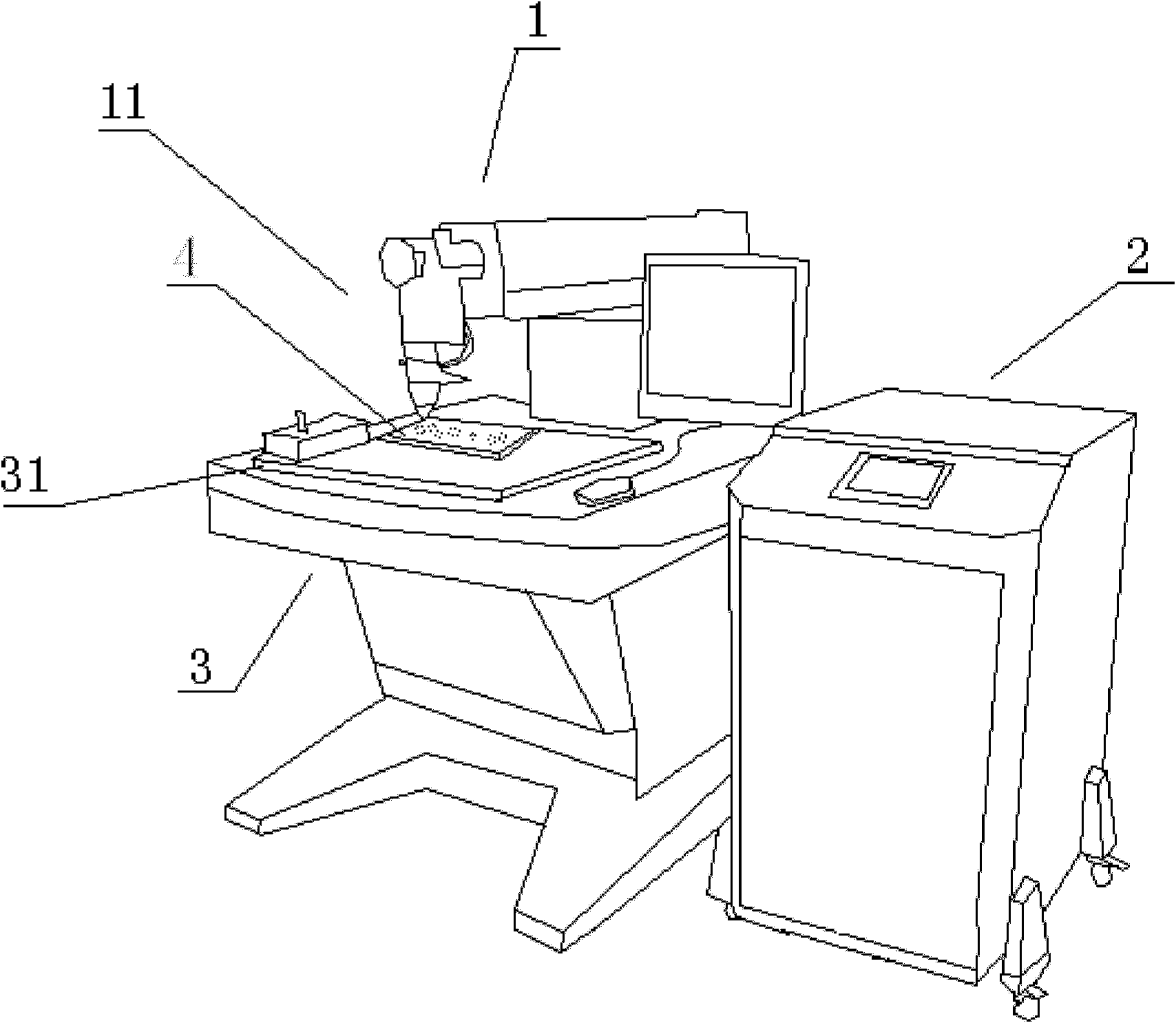

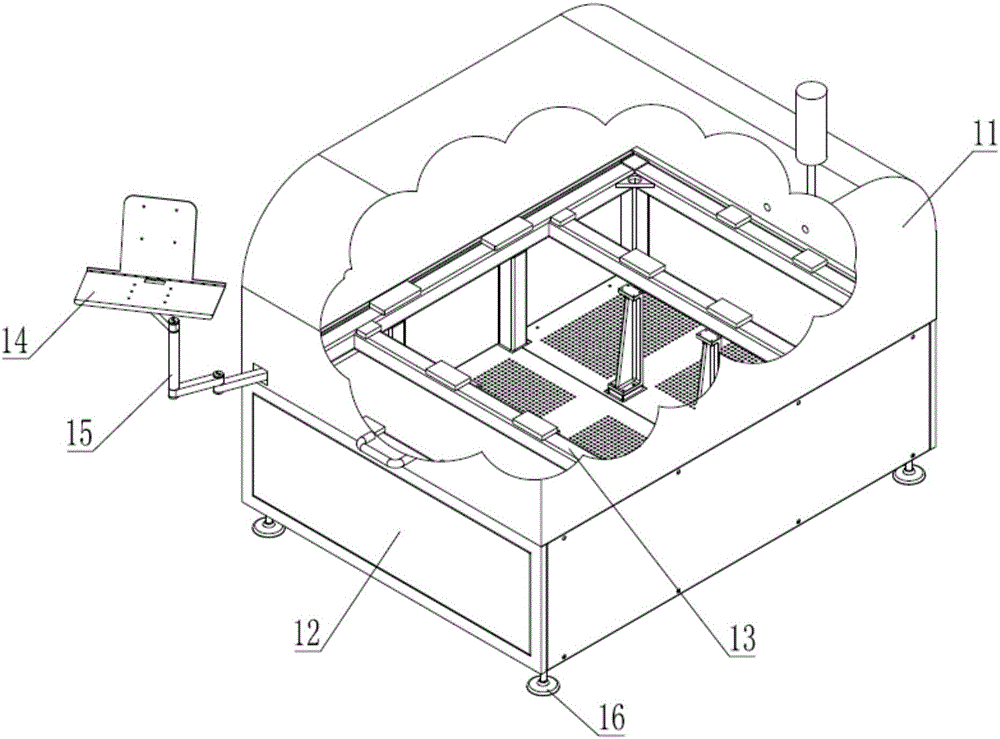

Laser type light guide plate carving equipment and using method thereof

InactiveCN102179628AIncrease productivityOptical light guidesLaser beam welding apparatusNumerical controlLight guide

The invention discloses laser type light guide plate carving equipment and a using method thereof, and relates to the field of production of optical parts. The laser type light guide plate carving equipment comprise a laser device system, a control system with a control function and an operating platform, wherein the laser device system comprises a laser device, a laser device control system and a vibration mirror which is used for adjusting the transmitting direction of laser; the vibration mirror is connected with a vibration mirror driving mechanism which is used for driving the vibration mirror to operate; the vibration mirror driving mechanism is controlled by the control system; an operating surface which is used for bearing a light guide plate to be machined is arranged on the operating platform, and is connected with an operating surface driving mechanism which is used for driving the operating surface to move; the operating surface driving mechanism is controlled by the control system; and the focusing position of the laser device is set inside or on the surface of the light guide plate, and a diffusion groove or a diffusion point is carved inside or on the surface of the light guide plate. In the invention, all molds are not needed; the equipment is suitable for manufacturing light guide plates of various dimensions, is completely operated by computer numerical control during machining, has high production efficiency, can be used for light guide plates in abnormal shapes and can be used for carving the inside or the surface of the light guide plate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Small abnormal-shape combined forging and ring-rolling process

The invention discloses a small abnormal-shape combined forging and ring-rolling process which comprises the following process steps of inspecting a blank, cutting and grinding a rounded corner, upsetting and punching, conducting reversed ring-rolling, conducting ring-rolling on an abnormal shape, reeling, cutting in a back-to-back manner, inspecting the process, treating thermally, inspecting hardness, testing performances, machining, and finally inspecting, marking and packaging. The small abnormal-shape combined forging and ring-rolling process has the beneficial effects that the small abnormal-shape combined forging and ring-rolling process is provided, the quantity of machining is small, the stock utilization is high, the production efficiency is high, the streamline of a material can be prevented from being damaged, the product percent of pass is high, and the process can also be used to manufacture a small abnormal-shaped forged ring.

Owner:江苏翔能科技发展有限公司

Display panel and display device

The embodiment of the invention provides a display panel and a display device, and relates to the technical field of displaying. A luminance difference between an abnormal-shape display area and a normal display area can be reduced. The display panel comprises a display area, and the display area comprises the normal display area and the abnormal-shape display area, the normal display area is adjacent to the abnormal-shape display area in the first direction, and the width of the abnormal-shape display area in the second direction is smaller than the width of the normal display area in the second direction; the display area comprises a plurality of sub pixels limited through crossing and insulation of a plurality of scanning lines and a plurality of data lines, the multiple scanning linesextend in the second direction and are arranged in the first direction, and the multiple data lines extend in the first direction and are arranged in the second direction; the abnormal-shape display area comprises a first area, the normal display area comprises a second area, the opening rate of first color sub pixels in the first area is smaller than the opening rate of first color sub pixels inthe second area.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

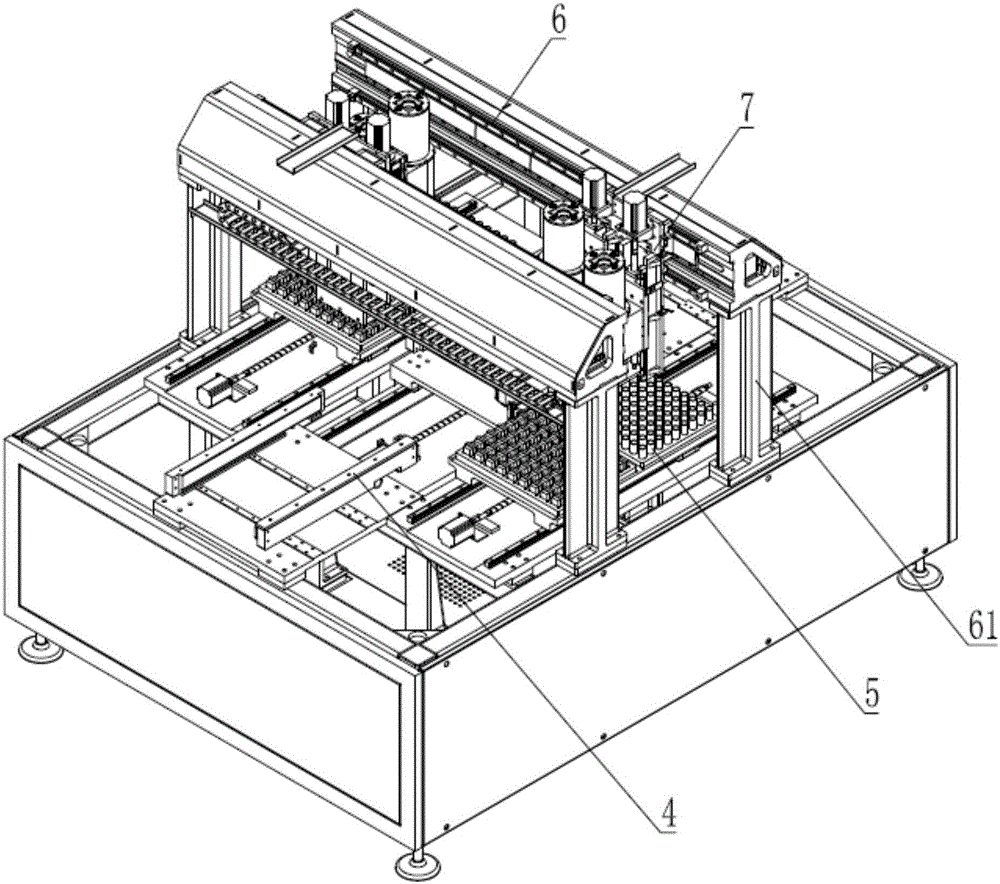

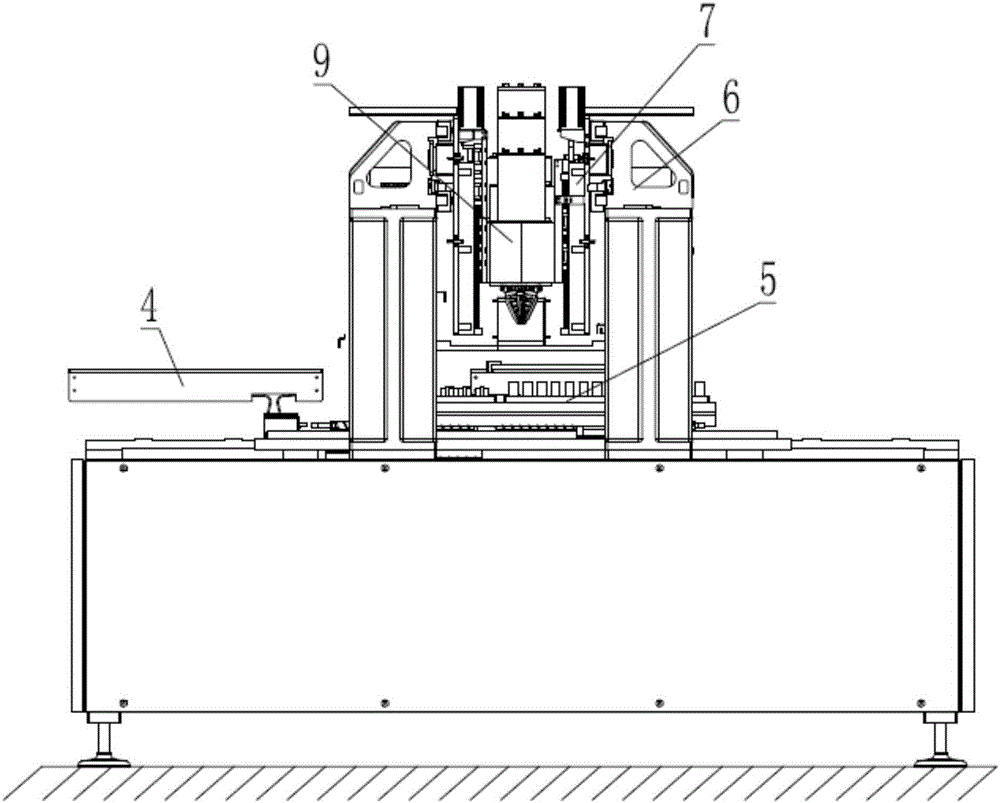

Abnormal shape part inserting machine

ActiveCN106852013ARealize automated productionImprove productivityPrinted circuit assemblingProduction rateControl system

The invention discloses an abnormal shape part inserting machine. A guide rail conveying system is used for conveying a PCB (printed circuit board) to the middle part inserting position; an electronic element charging system is used for conveying an electronic element to the specified position; a manipulator control system is used for obtaining the information of the electronic element according to the detection data of a vision detection system, and is moved onto the electronic element charging system to place and fetch the electronic element; the manipulator control system which has fetched the electronic element is used for adjusting a pin of the electronic element according to the PCB information detected by the vision detection system, is moved onto the PCB to insert the part, and then returns back, so as to complete one cycle. The abnormal shape part inserting machine has the advantages that the manipulator control system adopts a bionic manipulator, so that the high-precision positioning and flexible grabbing functions of the abnormal-shaped-contour electronic element are realized; by arranging a Y-axis movement system, the high-speed and high-accuracy movement is realized, the automatic production is realized, the productivity is improved, and the labor intensity of workers is decreased.

Owner:SHENZHEN GRANDSEED TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com