Abnormal-shaped tooth star-shaped part forging method and die special for abnormal-shaped tooth star-shaped part forging method

A technology of special-shaped teeth and parts, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., which can solve the problems of affecting the mechanical properties and service life of products, metal streamline breakage, and large machining allowances To achieve the effect of ensuring the integrity of the metal fiber structure, improving the streamline and compactness, reducing the amount of mechanical processing and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

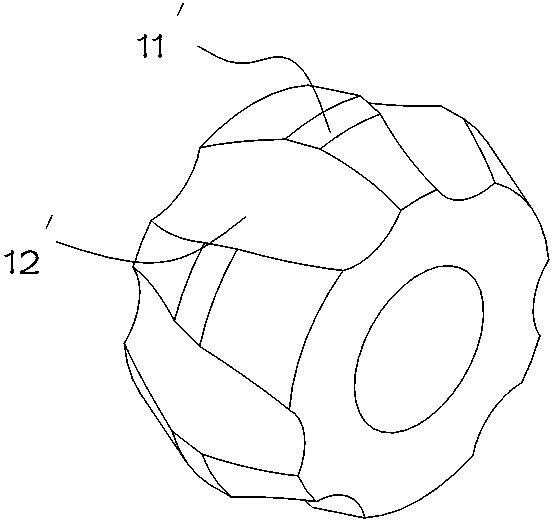

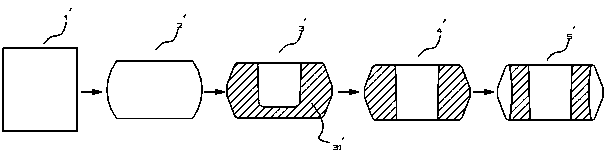

[0029] Such as image 3 As shown, a method for forging a special-shaped tooth star-shaped part includes the following steps:

[0030] The first step is to calculate the volume of the star-shaped part blank with machining allowance, and determine the volume of the forging blank according to this volume;

[0031] The second step is to obtain the forging blank by blanking according to the determined volume, and heat it to the forging temperature;

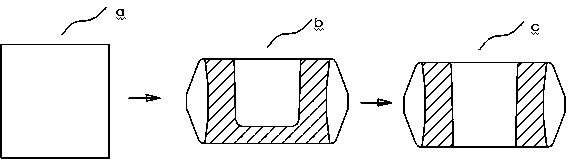

[0032] The third step is to put the heated forging blank into the pre-forged forging cavity with special-shaped teeth;

[0033] Step 4: Depress the upper punch to fill the forging cavity with the forging blank, forming a star-shaped part with special-shaped teeth outside the blind hole in the middle, and completing the pre-forging;

[0034] In the fifth step, the obtained pre-forging is taken out from the forging cavity and the blind hole in the middle is punched.

[0035] The forging method of the special-shaped tooth star-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com